Frigidaire FGMC2765PB Wiring Diagram

IMPORTANT

DO NOT REMOVE THIS BAG

OR DESTROY THE CONTENTS

WIRING DIAGRAMS AND SERVICE

INFORMATION ENCLOSED

REPLACE CONTENTS IN BAG

Resistance (ohms)

1000 ± 4.0

1091 ± 5.3

1453 ± 8.9

1654 ± 10.8

1852 ± 13.5

2047 ± 15.8

2237 ± 18.5

2697 ± 24.4

Open circuit/infinite resistance

RTD SCALE

Temperature °F (°C)

32 ± 1.9 (0 ± 1.0)

75 ± 2.5 (24 ± 1.3)

250 ± 4.4 (121 ± 2.4)

350 ± 5.4 (177 ± 3.0)

450 ± 6.9 (232 ± 3.8)

550 ± 8.2 (288 ± 4.5)

650 ± 9.6 (343 ± 5.3)

900 ± 13.6 (482 ±7.5)

Probe circuit to case ground

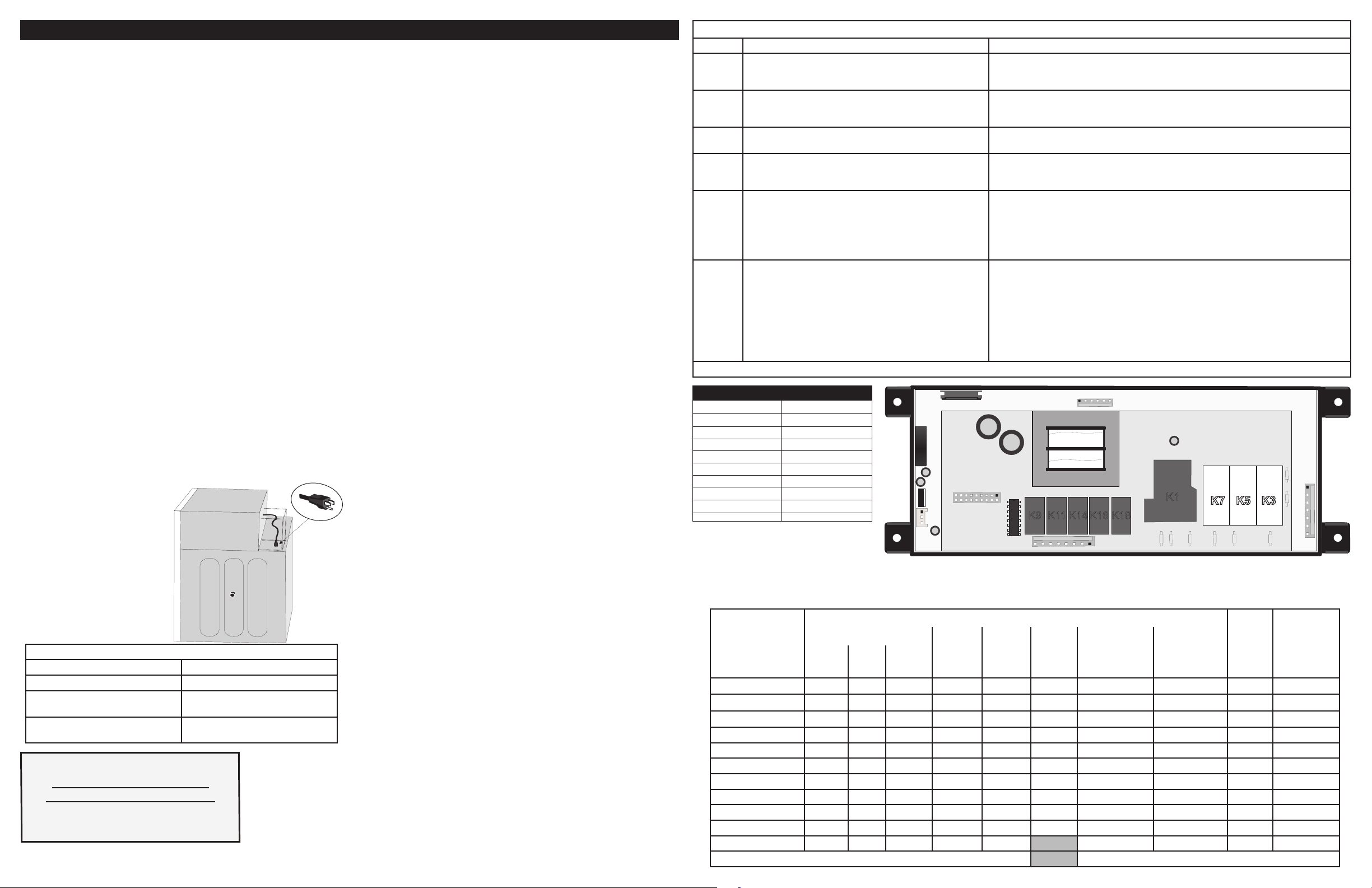

SERVICE DATA SHEET - Microwave Combination Unit with ES525/530 Electronic Oven Control

NOTICE: This service data sheet is intended for use by persons having electrical

and mechanical training and a level of knowledge of these subjects generally

considered acceptable in the appliance repair trade. The manufacturer cannot

be responsible, nor assume any liability, for injury or damage of any kind arising

from the use of this data sheet.

IMPORTANT NOTE: This unit includes an EOC (electronic oven control). This

board is not eld-repairable.

Safe Servicing Practices

To avoid the possibility of personal injury and/or property damage, it is important

that safe servicing practices be observed. The following are some, but not all,

examples of safe practices.

1. Do not attempt a product repair if you have any doubts as to your ability to

complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance, remove power cord from electric

outlet, trip circuit breaker to Off, or remove fuse.

3. Never interfere with the proper installation of any safety device.

4. Use only replacement parts specied for this appliance. Substitutions may

not comply with safety standards set for home appliances.

5. Grounding: The standard color coding for safety ground wires is green

or green with yellow stripes. Ground leads are not to be used as current

carrying conductors. It is extremely important that the service technician

reestablish all safety grounds prior to completion of service. Failure to do so

will create a potential hazard.

6. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp

edges, high-temperature components, and moving parts.

• All uninsulated electrical terminals, connectors, heaters, etc. are ade-

quately spaced away from all metal parts and panels.

• All safety grounds (both internal and external) are correctly and secure-

ly reassembled.

• All panels are properly and securely reassembled.

GROUNDING INSTRUCTIONS

This oven is equipped with a three prong grounding plug. It must be plugged into

the wall oven receptacle that is properly installed and grounded in accordance

with the National Electrical Code and local codes and ordinances.

In the event of an electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current.

WARNING: Improper use of the

grounding plug can result in a risk of

electric shock.

Electrical Requirements

The electrical requirements are a 120

volt 60 Hz, AC only, a branch circuit

protection fuse, 20 amp is provided in

series with the ac outlet on top of the

wall oven support.

*Note: Branch circuit fuse 20 amp

shall be replaced with class cc type.

Data Sheet Abbreviations and Terminology

DLB - Double Line Break EOC - Electronic Oven Control

LED - Light-Emitting Diode MDL - Motor Door Latch

PS - Power supply board (PS1, PS2,

etc)

TCO - Thermal cut out, also “thermo

disc” or “thermal limiter”

807574802 REV A (1607)

RTD - Resistance Temperature

Detector/Oven Probe

VSC - Variable Speed Control

DOOR SENSING AND PRIMARY INTERLOCK SWITCHES

The primary interlock switch is mounted in the lower position of the latch hook and

the door sensing switch in the secondary interlock system is mounted in the upper

position of the latch hook. They are activated by the latch heads on the door. When

the door is opened, the switches interrupt the power to all high voltage components.

A cook cycle cannot take place until the door is rmly closed thereby activating both

interlock switches. The secondary interlock system consists of the door sensing

switch and secondary interlock relay located on the control circuit board.

MONITOR SWITCH

The monitor switch is activated (the contacts opened) by the latch head on the door

while the door is closed. The switch is intended to render the oven inoperative, by

means of blowing the monitor fuse, when the contacts of the secondary interlock

relay (RY2) and primary interlock switch fail to open when the door is opened.

Functions:

1. When the door is opened, the monitor switch contact close (to the ON condition)

due to their being normally closed. At this time the secondary interlock relay

(RY2) and primary interlock switch are in the OFF condition (contacts open)

due to their being normally open contact switches.

2. As the door goes to a closed position, the monitor switch contacts are rst opened

and then the door sensing switch and the primary interlock switch contacts close.

(On opening the door, each of these switches operate inversely.)

3. If the door is opened, and the secondary interlock relay (RY2) and primary

interlock switch contacts fail to open, the monitor fuse blows simultaneously

with closing of the monitor switch contacts.

CAUTION: BEFORE REPLACING A BLOWN MONITOR FUSE TEST THE

DOOR SENSING SWITCH, SECONDARY INTERLOCK RELAY (RY2), RELAY

(RY1), PRIMARY INTERLOCK SWITCH AND MONITOR SWITCH FOR PROPER OPERATION. (REFER TO CHAPTER «TEST PROCEDURE»).

NOTE: MONITOR FUSE AND MONITOR SWITCH ARE REPLACED AS AN

ASSEMBLY.

CAVITY TEMPERATURE FUSE

The cavity temperature fuse located on the top of the oven cavity, is designed to

prevent damage to the oven by re. If the food load is overcooked, by either error

in cook time or defect in the control unit, the cavity temperature fuse will open.

Under normal operation, the cavity temperature fuse remains closed. However, when

abnormally high temperatures are reached within the oven cavity, the cavity temperature

fuse will open at 302OF(150OC) causing the oven to shut down.

NOTE: This is fuse. It does not reset.

MONITOR FUSE

1. The monitor fuse blows when the contacts (COM-NO) of the primary interlock

relay (RY2) and secondary interlock switch remain closed with the oven door

open and when the monitor switch closes.

2. If the wire harness or electrical components are short-circuited, this monitor

fuse blows to prevent an electric shock or re hazard.

MAGNETRON TEMPERATURE FUSE

The magnetron temperature fuse located near the magnetron is designed to prevent

damage to the magnetron if an over heated condition develops in the tube due to

cooling fan failure, obstructed air guide, dirty or blocked air intake, etc.

Under normal operation, the magnetron temperature fuse remains closed. However,

when abnormally high temperatures are reached within the magnetron, the magnetron temperature fuse will open at 302°F(150°C) causing the oven to shut down.

NOTE: This is a fuse. It does not reset.

Electronic Oven Control (EOC) Fault Code Descriptions

Code Condition / Cause Suggested Corrective Action

F10 Control has sensed a potential runaway oven condition,

control may have shorted relay, and/or RTD sensor probe

may have gone bad.

F11 Shorted Key: A key has been detected as pressed (for a

long period). Will be considered a shorted key alarm and

will terminate all oven activity.

F13 Control’s internal checksum may be corrupted. • Press CLEAR key. - Disconnect power, wait 10 seconds, and reapply power. If fault

F14 Misconnected at cables. No communication between oven

and controls.

F30

or

Open RTD sensor probe/ wiring problem. Note: EOC may

initially display an “F10,” thinking a runaway condition

exists.

F31

Shorted RTD sensor probe /wiring problem.

F90

to

Door motor mechanism failure.

F94

Note: Generally speaking, F1X implies a control failure, F3X an oven probe problem, and F9x a latch motor problem.

J3

J4

P1. L2 Out

P6

P3. L2 In

P5. L1 Input

P7. Broil Connector

P9. Bake Connector

P11. Convection Element Connector

P15. L1 Input

J3. Relay Outputs : Convection Fan, Motor Door

Latch, Oven Light, Cooling Fan. Power Input (L1

and Neutral).

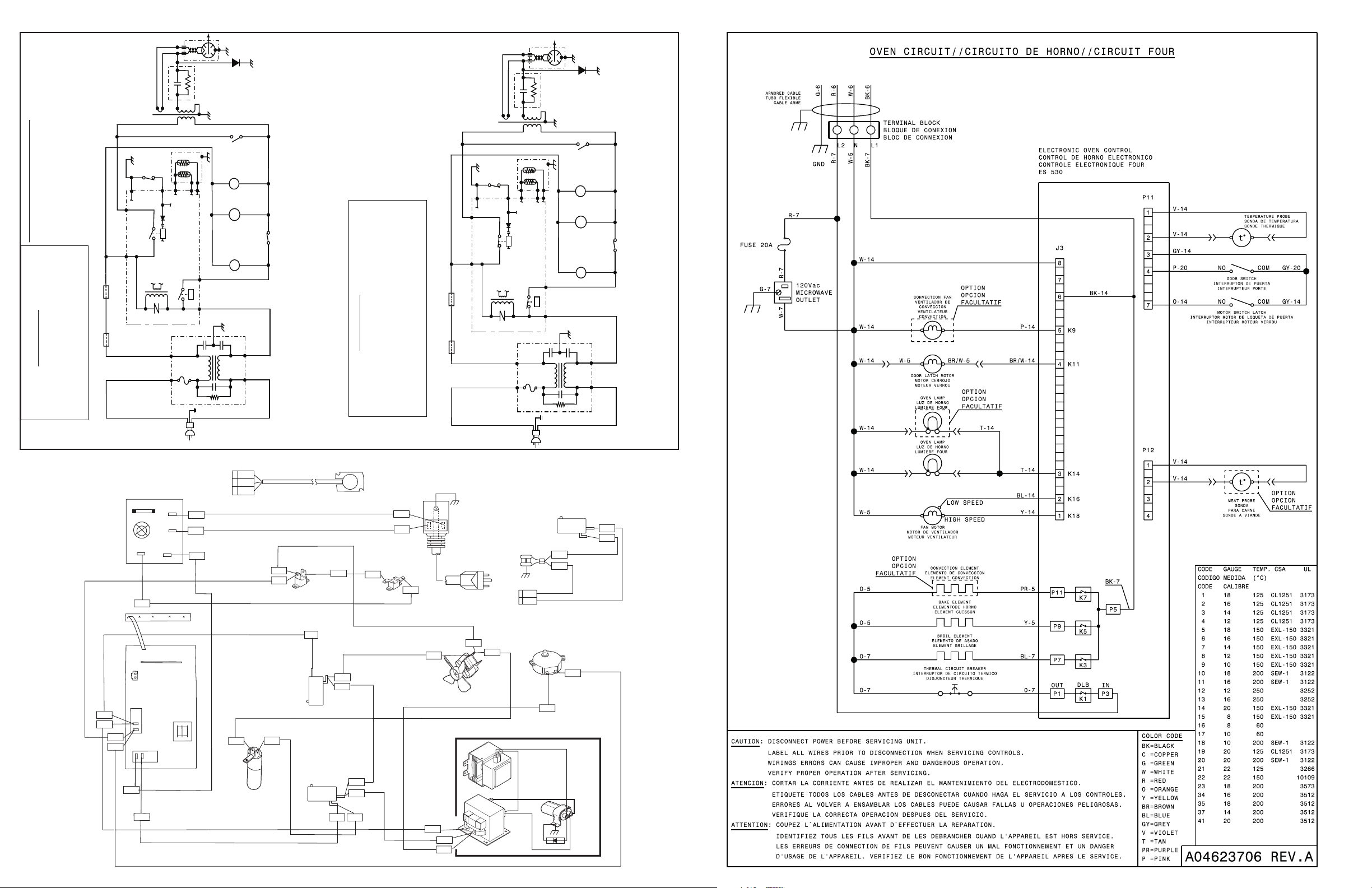

OVEN CIRCUIT

ANALYSIS

MATRIX

Preheat X X X X X X X

Bake X X X* X* X X X

Broil X X X X

Convection Bake X X X X X X X

Convection Roast X X X X X X X

Convection Broil X X X X X

Clean X X X X X

Locking / Unlocking X

Light X

Door Open X

Door Closed X

* Convection element and fan are used for the rst rise of temperature. Relay will operate in this condition only

ELEMENTS

Oven Light

J3-3

Check RTD sensor probe and replace, if necessary. If oven is overheating, disconnect

power. If oven continues to overheat when power is reapplied, replace the Electronic

Oven Control (EOC).

1. Press STOP key.

2. If the problem persists, replace the EOC.

returns upon power-up, replace EOC.

1. Disconnect power. Verify the at cable connection between the touch panel or

membrane and the EOC on P12 and P13.

2. If the problem persist, replace the EOC.

1. Check wiring in probe circuit for possible open or short condition.

2. Check RTD resistance at room temperature (compare to probe resistance chart). If

resistance does not match the chart, replace the RTD sensor probe.

3. Let the oven cool down and restart the function.

4. If the problem persists, replace the EOC.

1. Turn off power for 10 seconds, then turn on power. Test the door latch again (try to

start a Clean cycle).

2. If it fails, check wiring of Lock Motor, Lock Switch and Door Switch circuits.

3. Unplug the lock motor from the board and apply power (L1) directly to the Lock

Motor. If the motor does not rotate, replace Lock Motor Assembly.

4. Check Lock Switch for proper operation (do the contacts open and close, check

with ohmmeter). The Lock Motor may be powered as in above step to open and

close Lock Switch. If the Lock Switch is defective, replace Motor Lock Assembly.

5. If all above steps fail to correct situation, replace the EOC.

P2

P15

P11

K11 K14 K16 K18

K9

J3

K1

P3 P17

K7 K5 K3

P1

P11

P5

P9

P7

P11. Door switch, Motor Door Latch Switch and

Oven Probe Inputs.

On Relay Board On Display

Conv. Fan

J3-5

Door Motor

J3-4

Cooling Fan Low

Speed J3-2

Cooling Fan High

Speed J3-1

DLB L2

Out P1Bake P9 Broil P7 Conv. P11

Board

Door Switch

P11-4 / P11-3

Figure

SCHEMAT IC

CLOCK APPEARS ON DISPLA

ARIABLE COOKING CONTR

DOOR CLOSED

Note:* Indicates component

1.CIRCUITS SUBJECT

TERMINAL WITH PROJECTION OR OPPOSITE BL

MUST BE

POWER

1.CIRCUITS SUBJECT

TERMINAL WITH PROJECTION OR OPPOSITE BL

MUST BE

AIN MODELS USE

POWER TRANSFORMER

60Hz

NOTE: CONDITION OF OVEN

RED

Y

ORG

ORG

FUSE

TEMPERATURE

MAGNETRON

RED

FUSE

TEMPERATURE

CAVITY

2.

1. Door Closed

GENERAL TROUBLESHOOTING SCHEMATIC - MICROWAVE

MAGNETRON

HIGH

VOLTAGE

POWER

TRANSFORMER

HIGH

VOLTAGE

RED

RED

GRN

GRN

GRN

DOOR

SENSING

SWITCH

SENSOR

HUMIDITY

PNK

GRN

B2

COM.

RED

ORG

BRN

N.O.

B1

RED

BLK

F3

(RY2)

"TO LOAD"

"TO SOURCE"

F1

F2

CONTROL UNIT

SECONDARY

INTERLOCK

RELAY

COM.

(RY1)

OVEN

N.O.

C2

FUSE (20A)

MONITOR

GND

GRN

H

120VAC

60Hz

CAPACITOR

LAMP

R2

N

RECTIFIER

xx µF

WHT

WHT

N.C.

COM.

WHT

WHT

MONITOR

SWITCH

GRN

FAN

MOTOR

WHT

ORG

FM

ORG

TURN

TABLE

MOTOR

WHT

BRN

TTM

OVEN

LAMP

ORG

OL

RELAY

C3

C1

WHT

WHT

WHT

N.O.

PRIMARY

INTERLOCK

SWITCH

COM.

GRY

WHT

GRY

WHT

GRY

"TO SOURCE"

UE MARK ON LAMP SOCKET

TO CHANGE WITHOUT NOTICE.

CONNECTED TO NEUTRAL WIRE.

NOTES:

2.

NOISE

"TO LOAD"

FILTER

Figure O-1 Oven Schematic - Off Condition

SCHEMATIC

NOTE: CONDITION OF OVEN

TRANSFORMER TOP (FINISH LEAD) TERMINAL MUST BE CONNECTED TO THE NEUTRAL (WHT) WIRE.

4.

3. ONLY CERTAIN MODELS USE THE ABSOLUTE HUMIDITY SENSOR.

OL "HIGH"

2. COOKING TIME PROGRAMMED

1.

3. V

4. "START" PAD TOUCHED

GRN

GRN

DOOR

SENSING

GRN

B2

COM.

RED

RED

ORG

BRN

N.O.

ORG

ORG

FUSE

TEMPERATURE

MAGNETRON

RED

FUSE

TEMPERATURE

CAVITY

MAGNETRON

HIGH

VOLTAGE

POWER

TRANSFORMER

HIGH

VOLTAGE

RED

RED

SWITCH

SENSOR

HUMIDITY

PNK

B1

RED

BLK

F1

F2

F3

(RY2)

CONTROL UNIT

SECONDARY

INTERLOCK

RELAY

COM.

(RY1)

OVEN

N.O.

"TO LOAD"

C2

"TO SOURCE"

FUSE (20A)

MONITOR

GND

GRN

H

120VAC

CAPACITOR

LAMP

R2

N

RECTIFIER

xx µF

WHT

WHT

N.C.

COM.

WHT

WHT

MONITOR

SWITCH

FAN

MOTOR

WHT

ORG

FM

ORG

TURN

TABLE

MOTOR

WHT

BRN

TTM

OVEN

LAMP

ORG

OL

WHT

WHT

N.O.

PRIMARY

INTERLOCK

SWITCH

COM.

GRY

WHT

GRY

O-2 Oven Schematic - Cooking Condition

WHT

RELAY

GRY

"TO SOURCE"

UE MARK ON LAMP SOCKET

THE ABSOLUTE HUMIDITY SENSOR.

TOP (FINISH LEAD) TERMINAL MUST BE CONNECTED TO THE NEUTRAL (WHT) WIRE.

TO CHANGE WITHOUT NOTICE.

CONNECTED TO NEUTRAL WIRE.

4.

NOTES:

3. ONLY CERT

2.

WHT

NOISE

"TO LOAD"

FILTER

C3

C1

GENERAL TROUBLESHOOTING SCHEMATIC - OVEN

RED

RED

GRO

NRB

GRY

CN-F

AH SENSOR

BLK

1

RED

2

3

WHT

WHT

BLK

GRY

ORG

ORG

OVEN LAMP

AND SOCKET

MAGNETRON TEMP FUSE

GRY

RED

B-NC

1 2

RY2

N.O.

.O.N

WHT

COM.

COM.

)TINU REWOP(

YRADNOCES

KCOLRETN

I

YALER

T1

ORG

1YR

N.C.

RED

MONITOR

PRIMARY

SWITCH

RED

WHT

WHT

COM.

SWITCH

WHT

NO

WHT

COM.

GRY

WHT

WHT

H

N

NOTE:

The grounding conductor of

BLK

CAVITY TEMP. FUSE

RED

RED

the power supply cord has

been grounded by power

supply cord fixing screw.

The screw must always be

kept tight.

POWER SUPPLY

CORD 120V 60Hz

NOTE:

The neutral (WHT/GRY) wire must

be connected to the terminal with

"N" mark on the power supply

cord.

WHT

FAN MOTOR

MAGNETRON

RED

WHT

WHT

DOOR

SENSING

SWITCH

ORG

ORG

to Oven cavity

2

1

CN-B

GRN

PNK

GRN

GRN

TURNTABLE

MOTOR

WHT

HIGH VOLTAGE COMPONENTS

HIGH VOLTAGE

WIRE A

POWER

TRANSFORMER

H.V. RECTIFIER

COM.

BRN

HIGH

VOLTAGE

CAPACITOR

N.O.

PNK

GRN

Loading...

Loading...