Page 1

All about the

Installation

of your Washer

TABLE OF CONTENTS

Important Safety Instructions ...........................2-3

Installation Requirements ................................4-6

Installation Instructions ................................... 7-9

Accessories ...................................................... 10

Français ........................................................... 11

Español ........................................................... 21

A00092401C (1306)

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Please read all instructions before using this washer.

Recognize safety symbols, words

and labels

Safety items throughout this manual are labeled with

a WARNING or CAUTION based on the risk type as

described below:

Defi nitions

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury

or death.

DANGER

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

injury.

WARNING

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

IMPORTANT

IMPORTANT indicates installation, operation or

maintenance information which is important but not

hazard-related.

Installation Checklist

Shipping Hardware

Foam shipping restraint (inside wash tub)

removed and stored

Foam shipping support (underneath tub inside

cabinet) removed and stored

Leveling

Washer is level, side-to-side and front-to-back

Cabinet is setting solid on all corners

Water Supply

Use only new hoses and verify rubber sealing

washers are installed

HOT supply is connected to HOT inlet and

COLD supply is connected to COLD inlet

HOT and COLD water supply turned on

No leaks present at water supply connections

or appliance inlet connections recheck in 24 hours

Drain

Stand pipe or wall drain height minimum 36”

Drain hose secured in place with cable tie

(shipped in drum)

Electrical Power

House power turned on

Washer plugged in

Final Checks

Installation Instructions

Guide

read thoroughly

Water enters drum when cycle starts with lid

lowered.

Registration card sent in

and

Use and Care

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

NOTE

The electrical service to the washer must conform with

local codes and ordinances and the latest edition of the

National Electrical Code, ANSI/NFPA 70, or in Canada,

the Canadian Electrical Code C22.1 part 1.

WARNING

For your safety the information in this manual must be

followed to minimize the risk of fi re or explosion or to

prevent property damage, personal injury or loss of life.

Do not store or use gasoline or other fl ammable vapors

and liquids in the vicinity of this or any other appliance.

FIRE HAZARD

WARNING

Destroy the carton and plastic bags after the washer is

unpacked. Children might use them for play . Cartons

covered with rugs, bedspreads, or plastic sheets can

become airtight chambers causing suffocation. Place

all materials in a garbage container or make materials

inaccessible to children.

SUFFOCATION HAZARD

CAUTION

To avoid back or other injury, have more than one

person move or lift the washer.

EXCESSIVE WEIGHT HAZARD

IMPORTANT

The instructions in this manual and all other literature

included with this washer are not meant to cover

every possible condition and situation that may occur.

Good safe practice and caution MUST be applied when

installing, operating and maintaining any appliance.

Maximum benefi ts and enjoyment are achieved

when all the Safety and Operating Instructions are

understood and practiced as a routine with your

laundering tasks.

Save these instructions for future reference.

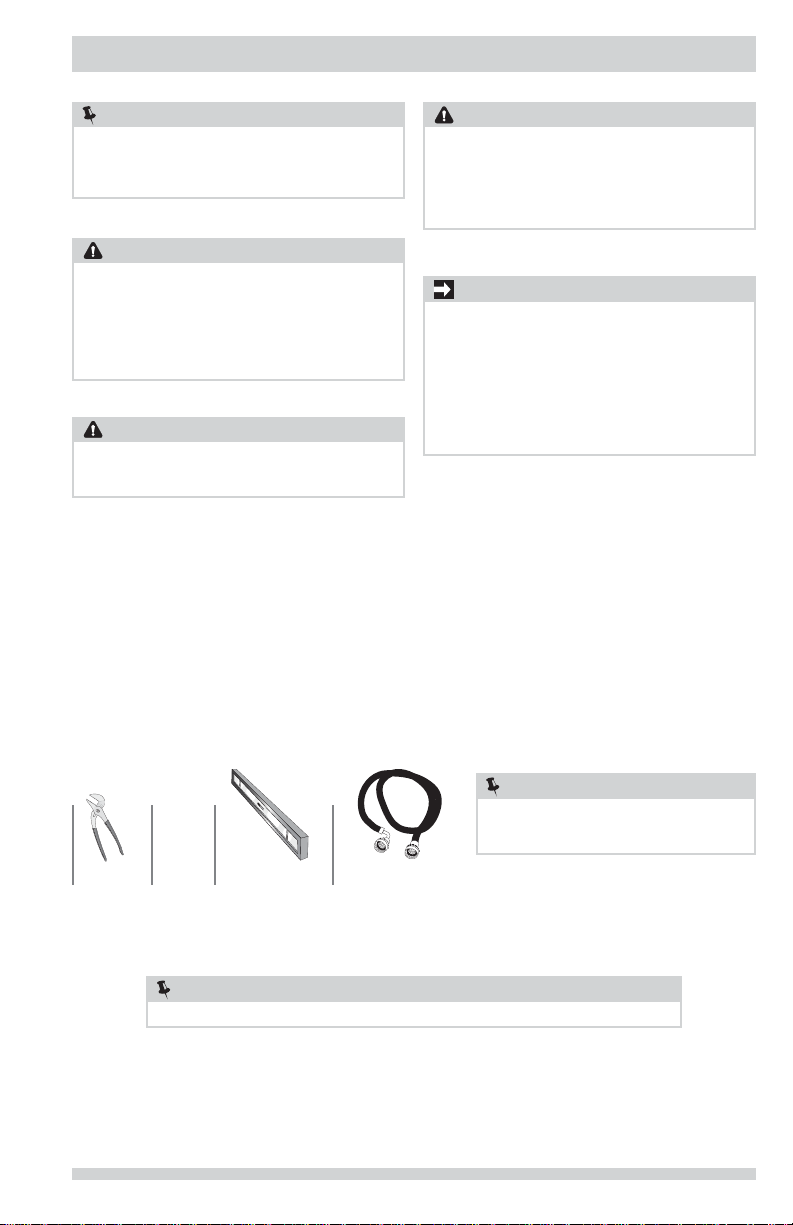

Tools and materials needed for installation:

AND

Adjustable

pliers

Carpenter’s level

NOTE

Before beginning installation, tip unit back and verify foam tub support has been removed.

Inlet hose (x2)

NOTE

Hoses are not included with washer purchase.

See “Accessories” section for various inlet

hose kits to fi t your specifi c installation.

3

Page 4

INSTALLATION REQUIREMENTS

Grounding type

ll receptacle

wer cord with

3-prong grgr

ounded plug

Do not,

under

y cir

cumstances,

cut,

removeve,

or b

ypass the

ounding pr

ong.

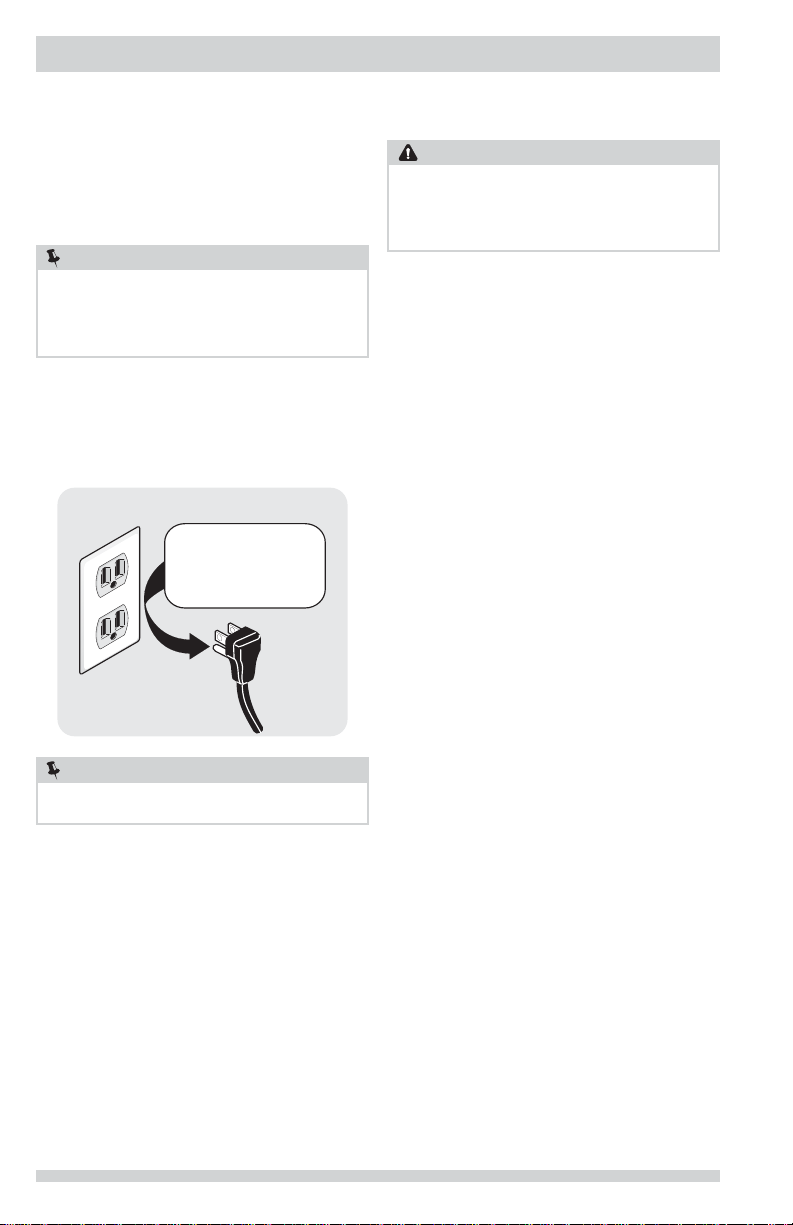

Electrical system requirements Ground requirements

CIRCUIT - Individual, properly polarized and grounded

15 amp. branch circuit fused with 15 amp. time delay

fuse or circuit breaker.

POWER SUPPLY - 2 wire, with ground, 120 volt single

phase, 60 Hz, Alternating Current.

NOTE

Because of potentially inconsistent voltage capabilities,

the use of this washer with power created by gas

powered generators, solar powered generators, wind

powered generators or any other generator other than

the local utility company is not recommended.

OUTLET RECEPTACLE - Properly grounded 3-prong

receptacle to be located so the power supply cord

is accessible when the washer is in an installed

position.

Grounding type

wawall receptacl

Do not,

under

anany cir

cumstances,

cut,

remo

or b

ypass th

grgrounding pr

ong.

WARNING

Improper connection of the equipment grounding

conductor can result in a risk of electrical shock. Check

with a licensed electrician if you are in doubt as to

whether the appliance is properly grounded.

1 The washer MUST be grounded. In the event of

2 Since your washer is equipped with a power supply

ELECTRICAL SHOCK HAZARD

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance

for electrical current.

cord having an equipment-grounding conductor

and a grounding plug, the plug MUST be plugged

into an appropriate, copper wired receptacle that is

properly installed and grounded in accordance with

all local codes and ordinances or in the absence of

local codes, with the National Electrical Codes, ANSI/

NFPA 70 (latest edition). If in doubt, call a licensed

electrician. DO NOT cut off or alter the grounding

prong on the power supply cord. In situations where

a two-slot receptacle is present, it is the owner’s

responsibility to have a licensed electrician replace

it with a properly grounded three prong grounding

type receptacle.

PoPower cord with

3-prong

ounded plug

NOTE

GFI (Ground Fault Interrupter) receptacle is not

required.

4

Water supply requirements

Hot and cold water faucets MUST be 3/4 inch with

threading for laundry hose connection. Water pressure

MUST be between 30 and 120 psi. Pressure difference

between hot and cold cannot be more than 10 psi. Your

water department can advise you of your water pressure.

Page 5

INSTALLATION REQUIREMENTS

Drain system requirements

1 Drain capable of eliminating 17 gals (64.3 L) per

minute.

2 A standpipe diameter of 1-1/4 in. (3.18 cm)

minimum.

3 The standpipe height above the fl oor should be:

Minimum height: 36 in. (91 cm)

Maximum height: 96 in. (244 cm)

96”

(244 cm)

max.

36”

(91 cm)

min.

NOTE

For installations requiring a longer drain hose, have

a qualifi ed technician install a longer drain hose

(according to your model number) available from an

authorized parts distributor. For drain systems in the

fl oor, install a syphon break kit available from your local

hardware store.

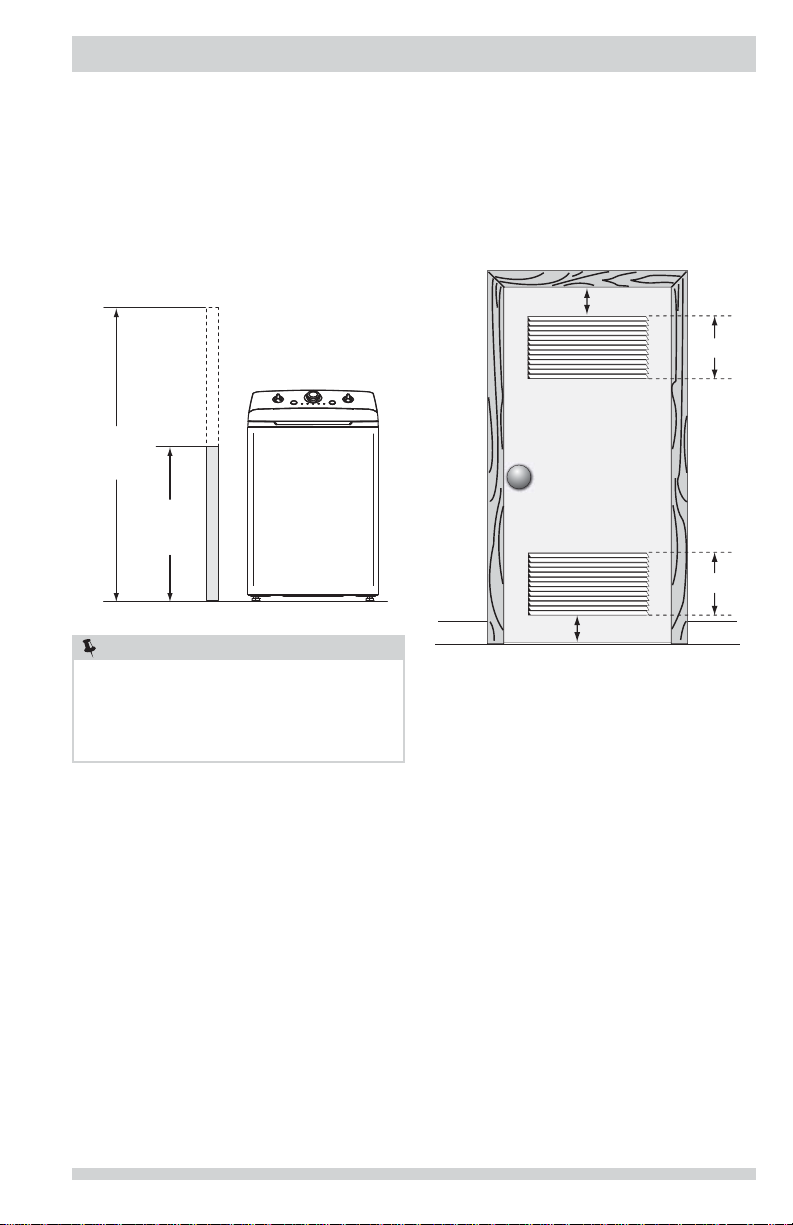

Installation in a Recess or Closet

If washer and dryer are installed in the same closet, door

ventilation is required: A minimum of 120 square inches

(774.2 cm²) of opening, equally divided at the top and

bottom of the door, is required. Louvered openings should

be located 3 inches (7.6 cm) from bottom and top of

door. Air openings are required to be unobstructed when

a door is installed. A louvered door with equivalent air

openings for the full length of the door is acceptable.

3”

(7.6cm)

60 sq. in.

(387.1cm²)

60 sq. in.

(387.1cm²)

3”

(7.6cm)

closet door

5

Page 6

INSTALLATION REQUIREMENTS

Clearance requirements

IMPORTANT

DO NOT INSTALL YOUR WASHER:

1 In an area exposed to dripping water or outside

weather conditions. The ambient temperature

should never be below 60° F (15.6° C) to

maximize detergent effectiveness.

2 In an area (garage or garage-type building)

where gasoline or other fl ammables (including

automobiles) are kept or stored.

3 On carpet. Floor MUST be solid with a maximum

slope of 1 inch (2.5 cm). To minimize vibration

or movement, reinforcement of the fl oor may be

necessary.

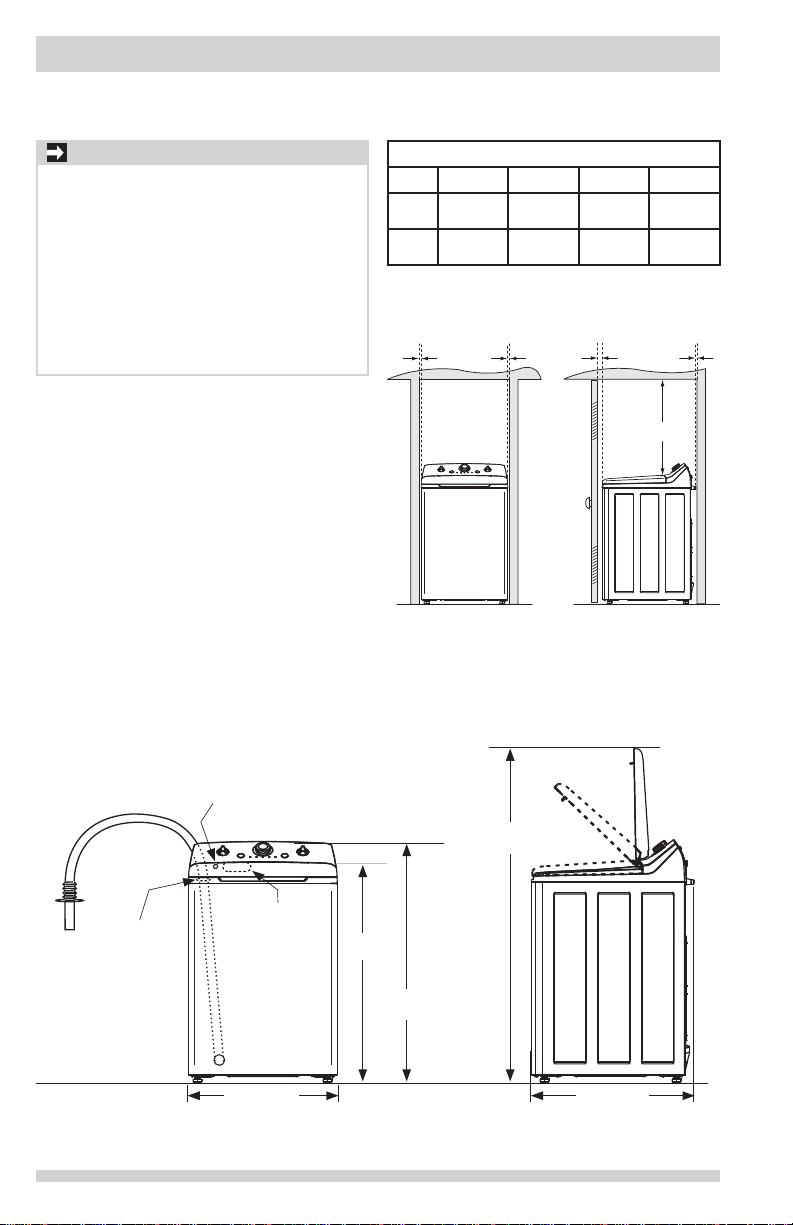

Washer Dimensions

MINIMUM INSTALLATION CLEARANCES - Inches (cm)

SIDES REAR TOP FRONT

Alcove

Closet

(0 cm)

(0 cm)

(0 cm)0”(0 cm)

0”

0”

(0 cm)

0”

(0 cm)

0”

0”

20.5”

(52 cm)

20.5”

(52 cm)1”(2.5 cm)

1”

(2.5 cm)

20.5”

(52 cm)

n/a

0”

(0 cm)

power cord attachment

location on rear of unit

drain hose

retainer on rear

2

of washer

1

Power supply cord length approximately 60 inches (152.5 cm).

2

Loose drain hose length beyond hose retainer approximately 61 inches (155 cm).

water supply

connection on

rear of washer

26.25” (67 cm)

1

38.5”

(98 cm)

(107 cm)

6

59” (150 cm)

to clear open lid

42”

28.75” (78 cm)

Page 7

INSTALLATION INSTRUCTIONS

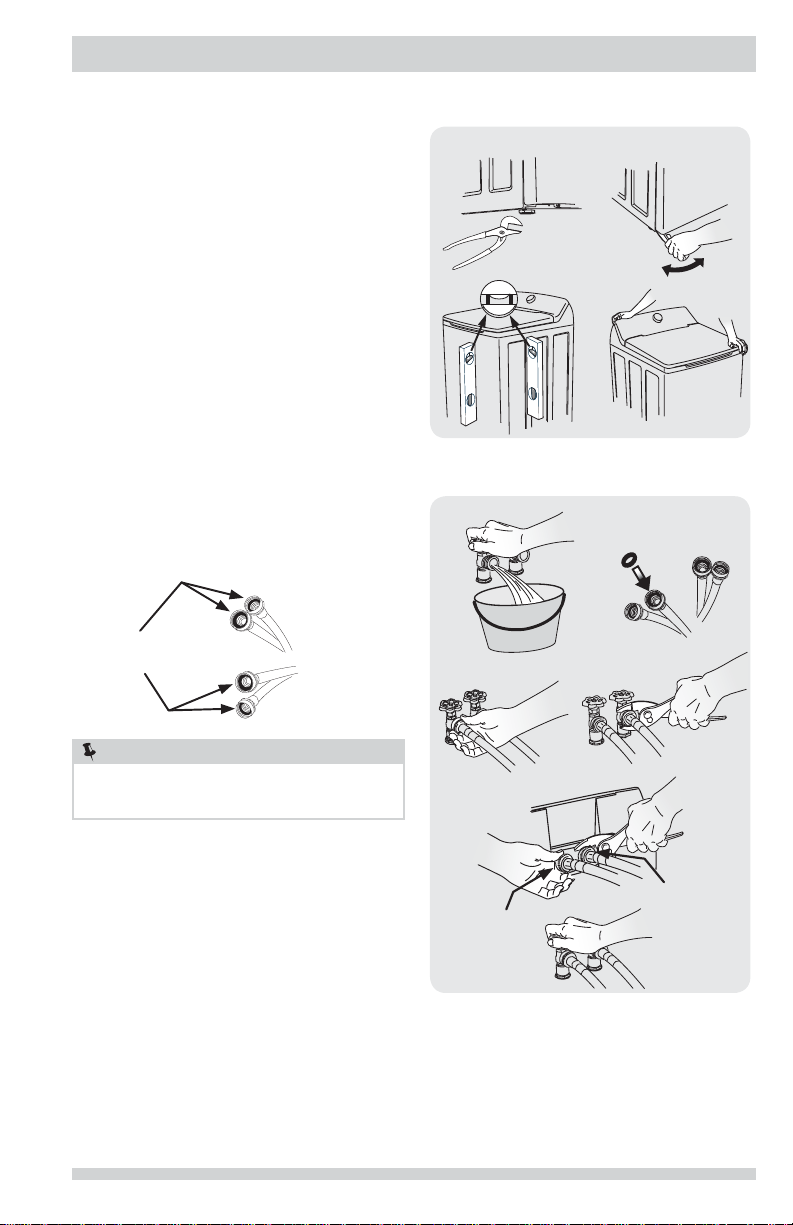

Leveling your washer

Excessive noise and vibration can be prevented by

properly leveling the washer.

1 With the washer within 4 feet (1 m) of its fi nal

location, use a carpenter’s level to level your

washer front-to-back and side-to-side. For front-toback leveling, place edge of the level fl ush to the

front panel. For side-to-side leveling place the edge

of the level fl ush to the side panel.

2 Use adjustable pliers to adjust the leveling legs so

the washer is level front-to-rear and side-to-side,

and stable corner-to-corner.

3 Press down on alternate corners and sides and feel

for the slightest movement. Adjust the appropriate

leg(s) so the washer sits solidly on the fl oor on

ALL four legs. Keep the leveling leg extension at a

minimum for best performance of the washer.

Connecting inlet water

1 Run some water from the hot and cold faucets

to fl ush the water lines and remove particles

that might clog the water valve screens and to

determine which faucet is hot and which is cold

supply.

a

c

a

b

raise

d

lower

b

RUBBER WASHERS

MUST BE PRESENT

USE ONLY

NEW HOSES

NOTE

Hoses are not included with washer purchase. See

“Accessories” section for various inlet hose kits to fi t

your specifi c installation.

2 Connect the HOT inlet hose to the HOT inlet

connection on the washer and the COLD inlet

hose to the COLD inlet connection on the washer.

Tighten by hand until snug. Then tighten each

supply connection another 2/3 turn with pliers.

Do not cross thread or over-tighten these

connections.

3 Connect the HOT inlet hose to the HOT water

supply and the COLD inlet hose to the COLD water

supply. Tighten by hand until snug. Then tighten

each supply connection another 2/3 turn with

pliers. Do not bend, kink or pinch water inlet

hoses.

4 Turn on the water and check for leaks.

e

BLUE

(COLD)

c

g

d

f

RED

(HOT)

7

Page 8

INSTALLATION INSTRUCTIONS

Connecting drain hose to washer

IMPORTANT

Inspect rubber fl ap on pump outlet. Ensure it is in

place and not folded under or torn.

1 With the spring clamp already installed, place

the drain hose elbow over the pump outlet at the

lower rear of the washer. Ensure the hose elbow is

completely and squarely seated to the pump outlet

before using pliers to move the spring clamp into

place.

DRAIN PUMP

OUTLET

SLIDE CLAMP

TO HERE

SPRING CLAMP

2 “Thread” the end of the drain hose up through

either of the outer, larger “D” ring retainers below

the top panel.

3 Locate the anti-siphon ring shipped with your

washer. Place it over the end of the drain hose and

slide it past the fi rst ring of “accordion” ribs.

8

ANTI-SIPHON

DISC

SLIDE DISC

TO HERE

DRAIN HOSE

RETAINER

Page 9

INSTALLATION INSTRUCTIONS

Grounding type

ll receptacle

wer cord with

3-prong grgr

ounded plug

Do not,

under

y cir

cumstances,

cut,

removeve,

or b

ypass the

ounding pr

ong.

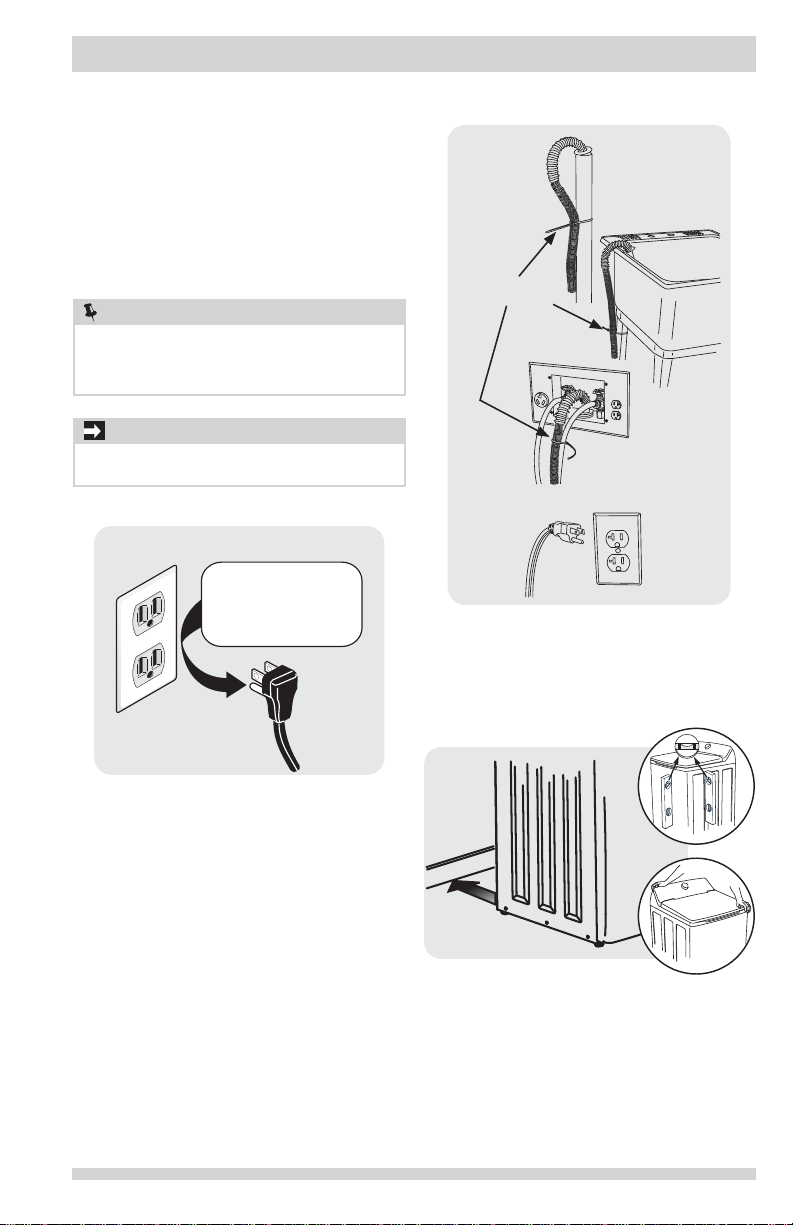

Connecting drain and electrical

1 Form a “U” shape on the end of the drain hose

with the hose pointed toward the drain. Place the

formed end in a laundry tub or a standpipe and

secure with a cable tie provided in the enclosure

package.

2 Place the hook end of the drain hose in the drain

opening. Secure the drain hose with the cable

tie (provided in the enclosure package) to the

standpipe, inlet hose, laundry tub, etc. so the hose

does not pull out from the force of the water.

NOTE

The standpipe inside diameter must be 1-1/4” (3.2 cm)

minimum. There must be an air gap around the drain

hose in the standpipe. A snug hose fi t can cause a

siphoning action.

IMPORTANT

Check to ensure the power is off at a circuit breaker/

fuse box before plugging the power cord into an outlet.

3 Plug the power cord into a grounded outlet.

Grounding type

wawall receptacl

Do not,

under

anany cir

cumstances,

cut,

remo

or b

ypass th

grgrounding pr

ong.

CABLE TIE

PoPower cord with

3-prong

4 Turn on the power at the circuit breaker/fuse box.

5 Carefully slide the washer to its fi nal position.

Recheck for level and rock corners for stability.

6 Read the

washer. It contains valuable and helpful information

that will save you time and money.

7 Run the washer through a complete cycle, checking

for water leaks and proper operation.

8 If you have any questions during initial operation,

please review the “Avoid Service Checklist” in your

Use & Care Guide before calling for service.

9 Place these instructions in a location near the

appliance for future reference.

Use & Care Guide

ounded plug

provided with the

9

Page 10

ACCESSORIES

MOBILE HOME INSTALLATION KIT

P/N 137067200

Installation in a mobile home requires the use of a

MOBILE HOME INSTALLATION KIT.

INLET HOSE KITS

Please call 866-233-8353 (in Canada, 800-265-8352)

to explore hose kit options that will meet your specifi c

installation needs.

UNIVERSAL APPLIANCE WRENCH

P/N 137019200

A UNIVERSAL APPLIANCE WRENCH is available to aid in

dryer/washer feet adjustment.

TOUCH UP PAINT PENS*

Classic White Touch Up Pen - P/N 5304468812

*Other colors may be available. Contact the source where you

purchased your washer.

Technical Sheet/Wiring Diagram:

NOTE

A wiring diagram and technical data sheet are located

inside the washer console.

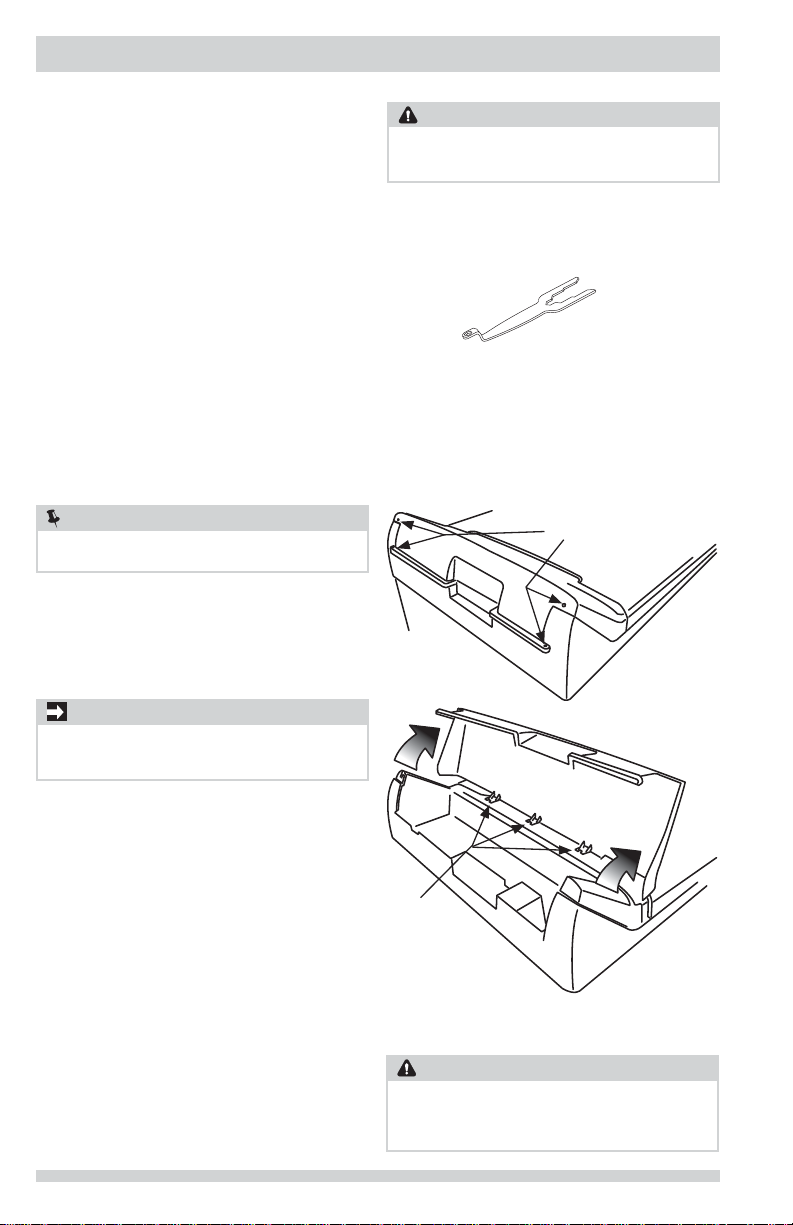

To remove the console faceplate follow the directions

below:

1. Disconnect washer from electrical source.

2. Remove four screws on back of the console housing.

3. Slowly rotate console forward on hinge tabs.

IMPORTANT

Internal parts of console are attached with wires to the

washer. Prevent machine damage. Do NOT pull console

away from washer.

4. When fi nished with repair, return sheet inside console

and ensure hinge tabs are inserted in top panel.

Gently rotate console back and reinsert all four screws.

CAUTION

Failure to use accessories manufactured by (or approved

by) the manufacturer could result in personal injury,

property damage or damage to the washer.

CONSOLE SCREWS

Replacement parts:

If replacements parts are needed for your washer, contact

the source where you purchased your washer or refer to

your

Use and Care Guide

for more information.

10

HINGE TABS

WARNING

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

ELECTRICAL SHOCK HAZARD

Page 11

Tout à propos de

Installation

de votre Laveuse

TABLE DES MATIÈRES

Mesures de sécurité importantes ...................12-13

Exigences d’installation .................................14-16

Instructions d’installation ..............................17-19

Accessoires ...................................................... 20

Page 12

MESURES DE SÉCURITÉ IMPORTANTES

AVERTISSEMENT

Veuillez lire ces instructions au complet avant d’utiliser

le laveuse.

Sachez reconnaître les symboles, les

avertissements et les étiquettes de

sécurité.

Les mesures de sécurité présentées dans ce guide sont

identifi ées par le mot AVERTISSEMENT ou ATTENTION

selon le type de risque présenté ci-dessous.

Défi nitions

Voici le symbole d’avertissement concernant la

sécurité. Il est utilisé pour vous avertir des risques de

blessures potentiels. Respectez tous les messages qui

suivent ce symbole afi n de prévenir les blessures ou la

mort.

DANGER

La mention DANGER indique un risque imminent qui

causera la mort ou de graves blessures, s’il n’est pas

évité.

AVERTISSEMENT

La mention AVERTISSEMENT indique une situation

potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait entraîner des blessures graves ou même la mort.

ATTENTION

La mention AT TENTION signale la présence d’une

situation potentiellement dangereuse susceptible de

causer des blessures mineures ou moyennement graves

si elle n’est pas évitée.

IMPORTANT

IMPORTANT - Cette mention précède des renseignements

importants relatifs à l’installation, au fonctionnement ou à

l’entretien. Toutef ois, ceux -ci n’impliquent aucune notion

de danger.

Liste de vérifi cation d’installation

Matériel d’expédition

Le bloc de retenue en mousse (situé dans la

cuve de lavage) a été enlevé et remisé

Le support d’expédition en mousse (sous

l’appareil) a été enlevé et remisé

Mise à niveau

La laveuse est au niveau latéralement et de

l’avant vers l’arrière

Les quatre coins de la caisse reposent

fermement sur le plancher

Alimentation en eau

Utilisez seulement les nouveaux tuyau

d’entrée d’eau et vérifi er que les rondelles en

caoutchouc sont en place.

Le tuyau d’entrée d’eau CHAUDE est raccordé

au robinet d’eau CHAUDE et le tuyau d’entrée

d’eau FROIDE est raccordé au robinet d’eau

FROIDE

Les robinets d’eau CHAUDE et d’eau FROIDE

sont ouverts

Les raccords d’alimentation en eau ou les

raccords d’arrivée d’eau de l’appareil ne

présentent aucune fuite refaites une vérifi cation 24 heures plus tard

Tuyau de vidange

La colonne montante ou le drain de mur est à

une hauteur d’au moins 91 cm (36 po)

Le tuyau de vidange est fi xé avec l’attache

(incluse dans la cuve)

Alimentation en électricité

Le système électrique de la maison est sous

tension

La laveuse est branchée

Vérifi cations fi nales

Vous avez lu entièrement les

d’installation

d’entretien

La porte se verrouille et l’eau entre dans la

cuve lorsqu’un cycle démarre

La carte d’enregistrement est envoyée

et le

Guide d’utilisation et

instructions

12

Page 13

MESURES DE SÉCURITÉ IMPORTANTES

REMARQUE

L’installation électrique de la laveuse doit être conforme

aux codes et aux règlements locaux ainsi qu’à la

toute dernière édition du National Electrical Code

(ANSI/NFPA 70), ou au Canada, au Code canadien de

l’électricité (C22.1, article 1).

AVERTISSEMENT

Détruisez le carton d’emballage et les sacs en plastique

après avoir déballé l’appareil. Les enfants pourraient

les utiliser pour jouer. Le carton recouvert de tapis, les

couvertures et les feuilles de plastique peuvent être

étanches à l’air et provoquer la suffocation. Déposez

tous les matériaux d’emballage dans un conteneur à

déchets ou faites en sorte que les enfants ne puissent

y avoir accès.

RISQUE D’ÉTOUFFEMENT

ATTENTION

Pour éviter les blessures au dos ou d’autres types de

blessure, demandez l’aide d’autres personnes pour

déplacer ou soulever la laveuse.

DANGER DE POIDS EXCESSIF

Conservez ces instructions pour vous

y reporter ultérieurement.

AVERTISSEMENT

Pour votre sécurité, l’information contenue dans ces

instructions doit être suivie afi n de réduire les risques

d’incendie ou d’explosion ou pour prévenir les dommages

matériels, les blessures ou la mort. Vous ne devez ni

entreposer, ni utiliser d’essence ou d’autres vapeurs ou

liquides infl ammables à proximité de cet appareil ou de

tout autre appareil électroménager.

RISQUE D’INCENDIE

IMPORTANT

Les instructions comprises dans ce guide et toute

autre documentation fournie avec cet appareil ne sont

pas conçues pour couvrir toutes les éventualités ou

situations qui pourraient survenir. Vous DEVEZ faire

preuve de bon sens et de prudence durant l’installation,

l’utilisation et l’entretien de tout appareil ménager.

Vous tirerez le maximum de votre appareil lorsque

toutes les instructions relatives à la sécurité et à son

fonctionnement auront été bien assimilées et mises en

pratique de façon routinière.

Outils et matériel nécessaires à l’installation :

ET

Pince

réglable

Niveau de charpentier

Tuyaux d’alimentation (x2)

REMARQUE

Avant de commencer l’installation unité de pointe, en arrière et vérifi er de support de cuve

en mousse a été éliminée.

REMARQUE

Les tuyaux ne sont pas inclus avec l’achat

laveuse. Voir la section «Accessoires» pour

divers trousse de tuyaux d’entrée qui pourrait

s’adapter à votre installation.

13

Page 14

EXIGENCES D’INSTALLATION

Prise murale avec

mise à la terre

à la terre de cette che.

Ne coupez pas, n'enlevez

pas et ne mettez pas hors

circuit la broche de mise

Cordon électrique muni

avec mise à la terre

d’une che à trois broches

Exigences des systèmes électriques Exigences relatives à la mise à la terre

CIRCUIT - Circuit indépendant de 15 ampères, polarisé

et mis à la terre, avec fusible temporisé ou

disjoncteur de 15 A.

ALIMENTATION ÉLECTRIQUE - Câble monophasé à deux

fi ls mis à la terre, 120 volts, 60 Hz; courant alternatif.

REMARQUE

Étant donné les variations de tension possibles, l’utilisation

de cette laveuse avec une source d’alimentation produite

par une génératrice à essence, solaire ou éolienne ou

par toute autre source d’alimentation différente de celle

fournie par les services publics n’est pas recommandée.

PRISE - Prise à trois alvéoles et mise à la terre située à

un endroit où il est possible de raccorder le cordon

d’alimentation de la laveuse une fois que cette

dernière est installée.

Prise murale avec

mise à la terre

Ne coupez pas, n'enlevez

pas et ne mettez pas hors

circuit la broche de mise

à la terre de cette che.

AVERTISSEMENT

RISQUE DE CHOC ÉLECTRIQUE

Un raccordement inadéquat du conducteur de terre de

l’équipement peut accroître les risques de choc électrique.

En cas de doute quant à la mise à la terre de l’appareil,

consultez un électricien qualifi é.

1 Cet appareil DOIT être mis à la terre. En cas de

mauvais fonctionnement ou de panne, la mise à

la terre diminue les risques de choc électrique en

fournissant au courant électrique une trajectoire de

moindre résistance.

2 Étant donné que votre laveuse est équipée d’un

cordon d’alimentation pourvu d’un conducteur de

mise à la terre et d’une fi che de mise à la terre, la

fi che DOIT être raccordée à une prise appropriée

(avec conducteurs en cuivre) correctement installée

et mise à la terre conformément aux codes et

règlements locaux ou, si aucun code local ne régit

ce type d’installation, à la plus récente édition du

National Electrical Code (ANSI/NFPA 70). En cas

de doute, faites appel à un électricien qualifi é. NE

COUPEZ PAS et NE MODIFIEZ PAS la broche de mise

à la terre du cordon d’alimentation. Si votre prise

murale n’est pourvue que de deux fentes, il incombe

au propriétaire de faire appel à un électricien qualifi é

pour la remplacer par une prise à trois alvéoles et

mise à la terre de façon adéquate.

Cordon électrique muni

d’une che à trois broches

avec mise à la terre

REMARQUE

Une prise GFI (disjoncteur de fuite de terre) n’est pas

nécessaire.

14

Exigences relatives à l’alimentation

en eau

Les robinets d’eau chaude et d’eau froide DOIVENT

être de 1,9 cm (3/4 po) et fi letés en fonction d’un

raccordement de tuyau de laveuse. La pression de l’eau

DOIT se situer entre 206,8 et 827,4 kPa (30 et 120 lb/

po²). La différence de pression entre l’eau chaude et

l’eau froide ne doit pas dépasser 68,9 kPa (10 lb/po²). Le

service des eaux de votre localité peut vous informer sur

la pression de votre alimentation en eau.

Page 15

EXIGENCES D’INSTALLATION

Exigences relatives au système

d’évacuation

1 Le drain doit pouvoir évacuer 64,3 L (17 gal) d’eau à

la minute.

2 Tuyau d’évacuation d’au moins 3,18 cm (1-1/4 po)

de diamètre.

3 Le tuyau d’évacuation doit être situé entre une

hauteur minimale de 91 cm (36 po) et une hauteur

maximale de 244 cm (96 po)

96”

(244 cm)

max.

36”

(91 cm)

min.

REMARQUE

Pour les installations exigeant un plus long tuyau

d’évacuation, demandez à un technicien qualifi é de

procéder à l’installation du tuyau conformément aux

spécifi cations du modèle de votre laveuse (un tuyau

plus long peut être acheté auprès d’un distributeur de

pièces autorisé). Pour les systèmes d’évacuation dans

le plancher, installez un ensemble de siphon (disponible

dans une quincaillerie de votre région).

Installation dans un Endroit en

Retrait ou une Armoire

Si la laveuse et la sécheuse sont installées dans le

même placard, une ventilation est requise dans la

porte : Une ouverture d’au moins 774,2 cm2 (120 po2),

divisée également au-dessus et au-dessous de la porte,

est requise. Les ouvertures à persiennes doivent être

situées à 7,6 cm (3 po) du haut et du bas de la porte.

Les ouvertures d’aération ne doivent pas être obstruées

lorsqu’une porte est installée. Une porte à persiennes

dont les ouvertures sur l’ensemble de la porte sont

équivalentes aux recommandations peut être utilisée.

3”

(7.6cm)

60 sq. in.

(387.1cm²)

60 sq. in.

(387.1cm²)

3”

(7.6cm)

Porte de placard

15

Page 16

EXIGENCES D’INSTALLATION

Exigences de dégagement

IMPORTANT

N’INSTALLEZ PAS VOTRE LAVEUSE :

1 À un endroit exposé aux écoulements d’eau

ou aux aléas des conditions météorologiques

extérieures. La température ambiante ne

devrait jamais tomber sous 15,6 °C (60 °F) afi n

d’optimiser l’effi cacité du détergent.

2 À un endroit (garage ou bâtiment similaire) où

de l’essence ou d’autres substances infl ammables

sont entreposées (incluant des automobiles).

3 Sur un tapis. Le plancher DOIT être solide et

présenter une pente inférieure à 2,5 cm (1 po).

Afi n d’éviter les vibrations et le déplacement de

l’appareil, il peut être nécessaire de renforcer le

plancher.

Dimensions de laveuse

DÉGAGEMENTS MINIMAUX - Centimètres (pouces)

CÔTÉS ARRIÈRE AVANT AVANT

Alcôve

Placard

(0 cm)

0 cm

(0 po)

0 cm

(0 po)

0”

0”

(0 cm)

0 cm

(0 po)

0 cm

(0 po)

52 cm

(20.5 po)

52 cm

(20.5 po)

1”

(2.5 cm)

20.5”

(52 cm)

s. o.

2.5 cm

(1 po)

(0 cm)

0”

cordon d’alimentation

à l’arrière de la laveuse

collier du tuyau de

vidange à l’arrière

de la laveuse

1

Longueur du cordon d’alimentation de la sécheuse à gaz, environ 152.5 cm (60 po).

2

Longueur du tuyau entre le collier et l’extrémité du tuyau, environ 155 cm (61 po).

2

raccord de

l’alimentation en

eau à l’arrière

de la laveuse

26.25” (67 cm)

1

38.5”

(98 cm)

42”

(107 cm)

16

59” (150 cm)

avec la couvercle

grande ouverte

28.75” (78 cm)

Page 17

INSTRUCTIONS D’INSTALLATION

Mise à niveau de votre appareil

Les bruits excessifs et les vibrations peuvent être évités

en mettant correctement la laveuse à niveau.

1 En plaçant la laveuse à 1 m (4 pi) de son

emplacement défi nitif, utilisez un niveau à bulle

pour mettre l’appareil à niveau de l’avant vers

l’arrière et latéralement. Pour mettre la laveuse

de l’avant vers l’arrière à niveau, bord la place du

niveau au ras du panneau frontal. Pour la mise à

niveau latérale, bord la place du niveau au ras du

panneau latérale.

2 Utilisez la clé universelle pour ajuster les pieds de

mise à niveau de façon à ce que la laveuse soit de

niveau d’avant en arrière et latéralement, et qu’elle

soit stable aux quatre coins.

3 Appuyez sur chaque coin et chaque côté pour

déterminer les endroits qui nécessitent un réglage.

Ajustez les pieds de mise à niveau appropriés de

manière à ce que la laveuse repose solidement

sur ses QUATRE pieds. Gardez les pieds de mise

à niveau le plus près possible de la laveuse afi n

d’optimiser le rendement de la laveuse.

a

c

b

soulever

d

abaisser

Branchement de l’entrée d’eau

1 Faites couler de l’eau chaude et froide des robinets

pour purger les tuyaux d’eau, pour éliminer

toute particule qui pourrait obstruer les grillages

des robinets, et pour déterminer quels robinets

fournissent l’eau chaude et l’eau froide.

LES RONDELLES

EN CAOUTCHOUC

DOIVENT ÊTRE

PRÉSENTES

UTILISEZ SEU-

LEMENT LES

NOUVEAUX

TUYAU D’EN-

TRÉE D’EAU

REMARQUE

Les tuyaux ne sont pas inclus avec l’achat laveuse. Voir

la section «Accessoires» pour divers trousse de tuyaux

d’entrée qui pourrait s’adapter à votre installation.

2 Raccordez le tuyau d’entrée d’eau CHAUDE au

raccord pour l’eau CHAUDE de la laveuse et le

tuyau d’entrée d’eau FROIDE au raccord pour l’eau

FROIDE de la laveuse. Serrez fermement à la main.

Avec des pinces, serrez chaque raccord de 2/3 de

tour. Ne faussez pas le fi letage et ne serrez

pas trop.

3 Branchez le tuyau d’entrée d’eau CHAUDE au

robinet d’eau CHAUDE, et le tuyau d’eau d’entrée

d’eau FROIDE au robinet d’eau FROIDE. Serrez

fermement à la main. Avec des pinces, serrez

chaque raccord de 2/3 de tour. Ne pliez pas,

n’entortillez pas et ne coincez pas les tuyaux

d’alimentation en eau.

4 Ouvrir les robinets et s’assurer qu’il n’y a pas de

fuite.

a

e

BLEU

(FROIDE)

b

c

g

d

(CHAUDE)

f

ROUGE

17

Page 18

INSTRUCTIONS D’INSTALLATION

Raccordement du boyau de vidange à la rondelle

IMPORTANT

Inspecter la bavette en caoutchouc sur l’orifi ce de

sortie de la pompe. S’assurer que celle-ci est en place

et qu’elle n’est pas pliée ou déchirée.

1 Avec le collier de serrage à ressort déjà installé,

placez le coude du tuyau de vidange sur le raccord

de sortie de la pompe sur le côté inférieur arrière

de la rondelle. S’assurer que le coude du boyau

est totalement et carrément assis à la sortie de

la pompe avant d’utiliser une paire de pince pour

mettre le collier de serrage à ressort en place.

SORTIE DE POMPE

DE VIDANGE

FAITES GLISSER

LE COLLIER ICI

COLLIER DE

SERRAGE À

RESSORT

2 « Fileter » l’extrémité du tuyau de vidange à travers

l’une ou l’autre des anneaux de retenue « D »

extérieurs, au-dessous du panneau supérieur.

3 Localiser l’anneau anti-siphon livré avec votre

lave-vaisselle. Placez-le sur l’extrémité du tuyau

de vidange et faites-le glisser au-delà du premier

anneau des nervures en « accordéon ».

18

DISQUE ANTI-

SIPHON

FAITES

GLISSER LE

DISQUE ICI

RETENUE DE BOYAU

DE VIDANGE

Page 19

INSTRUCTIONS D’INSTALLATION

Prise murale avec

mise à la terre

à la terre de cette che.

Ne coupez pas, n'enlevez

pas et ne mettez pas hors

circuit la broche de mise

Cordon électrique muni

avec mise à la terre

d’une che à trois broches

Branchement électrique et branchement du tuyau de vidange

1 Formez un U à l’extrémité du tuyau de vidange

avec le tuyau pointé vers la vidange. Placez

l’extrémité recourbée du tuyau de vidange dans

une cuve ou la conduite des eaux usées et fi xez-la

à l’aide d’un lien fourni dans le paquet.

2 Placez le côté du tuyau de vidange en forme de

crochet dans l’ouverture du tuyau d’évacuation.

Fixez le tuyau de vidange au moyen d’une attache

(incluse dans la trousse d’installation fournie) au

tuyau d’évacuation, au tuyau d’entrée, à la cuve à

lessive, etc. de façon à ce que le tuyau ne puisse

être arraché sous la force de l’eau.

REMARQUE

Le diamètre intérieur de la conduite verticale de

vidange doit être d’au moins 3,2 cm (1-1/4 po). Il doit

y avoir un brise-vide autour du tuyau de vidange de

la conduite verticale. Un tuyau au diamètre trop petit

peut entraîner un effet de siphonnage.

IMPORTANT

Assurez-vous que l’alimentation électrique est coupée au

disjoncteur ou au boîtier de fusibles avant de brancher le

cordon d’alimentation dans une prise électrique.

3 Branchez le cordon d’alimentation à la prise

électrique mise à la terre.

Prise murale avec

mise à la terre

Ne coupez pas, n'enlevez

pas et ne mettez pas hors

circuit la broche de mise

à la terre de cette che.

ATTACHE

Cordon électrique muni

d’une che à trois broches

avec mise à la terre

4 Ouvrez l’alimentation électrique au disjoncteur ou

au boîtier de fusibles.

5 Faites glisser soigneusement la laveuse à son

emplacement défi nitif. Vérifi ez à nouveau la stabilité

de l’appareil. Retirez et jetez le ruban de la porte.

6 Reportez-vous au Guide d’Utilisation et

d’Entretien fourni avec la laveuse. Il contient des

renseignements très utiles qui vous permettent

d’économiser temps et argent.

7 Faites faire un cycle complet à la laveuse. Vérifi ez

qu’il n’y a aucune fuite et que la laveuse fonctionne

correctement.

8 Pour toute question relative à l’utilisation initiale,

veuillez revoir la section intitulée « Liste de vérifi cation

avant service » de votre Guide d’utilisation et

d’entretien avant d’effectuer une demande de service.

9 Laissez ces instructions à proximité de l’appareil

pour vous y reporter ultérieurement.

19

Page 20

ACCESSOIRES

TROUSSE D’INSTALLATION DE MAISON MOBILE

PIÈCE N° 137067200

Toute installation dans une maison mobile nécessite

l’utilisation d’une TROUSSE D’INSTALLATION DE MAISON

MOBILE.

KITS TUYAUX D‘ALIMENTATION

S’il vous plaît appelez 866-233-8353 (au Canada, 800-

265-8352) pour explorer les options de tuyaux d’entrée

qui pourrait s’adapter à votre installation spécifi ques.

CLÉ D’APPAREIL UNIVERSELLE

PIÈCE N° 137019200

UNE CLÉ D’APPAREIL UNIVERSELLE est offerte pour

faciliter le réglage des pieds de sécheuse ou laveuse.

CRAYONS DE PEINTURE DE RETOUCHE*

Crayon de retouche Blanc - PIÈCE N° 5304468812

*Il se peut que d’autres couleurs soient disponibles.

Communiquez avec le marchand qui vous a vendu votre laveuse.

Fiche Technique/Schéma Électrique:

REMARQUE

Un schéma électrique et une fi che technique sont

situés à l’intérieur de la console de l’appareil.

Pour enlever la plaque avant de la console, suivez les

instructions ci-dessous :

1. Débranchez la laveuse de sa source d’alimentation en

électricité.

2. Retirer les quatre vis à l’arrière du boîtier de la console.

3. Faites pivoter lentement vers l’avant de la console sur

languettes de charnière.

ATTENTION

Tout défaut d’utiliser les accessoires fabriqués ou

certifi és par le fabricant pourrait entraîner des blessures,

des dommages aux biens ou à la laveuse.

VIS DE LA CONSOLE

IMPORTANT

Les composants internes de la console sont attachés

avec des fi ls de la laveuse. Éviter d’endommager la

machine. Ne tirez pas loin de la console rondelle.

4. Lorsque vous avez terminé avec la feuille de retour

de réparation, à l’intérieur de la console et s’assurer

languettes de charnière sont insérés dans le panneau

supérieur. Tournez doucement la console arrière et

remettre en place les quatre vis.

Pièces de rechange :

Si vous devez commander des pièces de rechange

pour votre laveuse, communiquez avec le marchand

qui vous a vendu votre appareil, ou reportez-vous

au guide d’utilisation et d’entretien pour obtenir plus

de détails.

20

LANGUETTES

DE CHARNIÈRE

AVERTISSEMENT

Étiquetez tous les fi ls avant de les débrancher pendant l’entretien

des commandes. Des erreurs de câblage pourraient nuire au bon

fonctionnement de l’appareil, et même être dangereuses. Vérifi ez

le bon fonctionnement de l’appareil après tout entretien.

RISQUE ÉLECTRIQUE

Page 21

Todo acerca del

Instalación

de su Lavadora

ÍNDICE

Instrucciones importantes de seguridad .........22-23

Requisitos de instalación ...............................24-26

Instrucciones de instalación ..........................27-29

Accesorios ....................................................... 30

Page 22

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

ADVERTENCIA

Lea todas las instrucciones antes de usar este lavadora.

Identifi cación de los símbolos,

palabras y avisos de seguridad

Las indicaciones de seguridad incluidas en este manual

aparecen precedidas de un aviso titulado “ADVERTENCIA”

o “PRECAUCIÓN”, de acuerdo con el nivel de riesgo.

Defi niciones

Este es el símbolo de alerta de seguridad. Se usa para

alertar sobre peligros potenciales de lesiones personales.

Obedezca todos los mensajes de seguridad que tengan este

símbolo para evitar posibles lesiones personales o la muerte.

PELIGRO

PELIGRO indica una situación de peligro inminente que,

si no se evita, podría causar lesiones graves o la muerte.

ADVERTENCIA

ADVERTENCIA indica una situación potencialmente

peligrosa que, si no se evita, podría causar lesiones

personales graves o la muerte.

PRECAUCIÓN

PRECAUCIÓN indica una situación potencialmente

peligrosa que, si no se evita, podría causar lesiones

personales leves o moderadas.

IMPORTANTE

IMPORTANTE indica información de instalación,

funcionamiento o mantenimiento que es importante,

pero que no está relacionada con la seguridad.

Lista de verifi cación de instalación

Ferretería de envío y transporte

Se retiró y guardó el perno (debajo del

electrodoméstico)

Se retiró y guardó el soporte de espuma de

empaque (dentro de la tina de lavado)

Nivelación

La lavadora está nivelada de lado a lado y de

adelante hacia atrás

La lavadora descansa fi rmemente sobre sus

cuatro esquinas

Suministro de agua

Utilice solamente las mangueras nuevas y

verifi qué que los empaques de hule estén

presentes.

Se conectó el suministro de agua CALIENTE a

la admisión de agua CALIENTE y el suministro

de agua FRÍA a la admisión de agua FRÍA

Se abrió el suministro de agua CALIENTE y

FRÍA

No hay escapes en las conexiones del

suministro de agua o en las conexiones de

admisión del electrodoméstico vuelva a verifi car a las 24 horas

Drenaje

Tubo vertical o drenaje de pared a una altura

mínima de 36” (91 cm)

Manguera de drenaje fi jada en su lugar con un

amarre para cables (empacado en el tambor)

Suministro eléctrico

El suministro eléctrico del hogar está activado

La lavadora está enchufada

Inspección fi nal

Lea bien las

Guía de Uso y Cuidado

La puerta se bloquea y el agua entra al tambor

cuando se inicia el ciclo.

Tarjeta de registro enviada

Instrucciones de Instalación

y la

22

Page 23

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

NOTA

La reparación eléctrica de la lavadora debe cumplimentar

los códigos y las ordenanzas locales y la última edición

del Código Eléctrico Nacional (National Electrical Code), el

ANSI/NFPA 70, o bien en Canadá, el CSA C22.1 del Código

Eléctrico de Canadá (Canadian Electrical Code) Parte 1.

ADVERTENCIA

Para su seguridad, debe seguir la información de esta

guía para minimizar el riesgo de incendio o explosión o

para evitar daños a la propiedad, lesiones personales

o incluso la muerte. No almacene ni utilice gasolina ni

otros líquidos o vapores infl amables cerca de este o de

cualquier otro electrodoméstico.

PELIGRO DE INCENDIO

ADVERTENCIA

Después de desembalar la lavadora, destruya los cartones

y las bolsas de plástico. Los niños podrían utilizarlos para

jugar. Los cartones cubiertos con alfombras, cubrecamas,

o láminas de plástico pueden convertirse en cámaras de

aire herméticamente cerradas y provocar asfi xia. Coloque

todos los materiales en un basurero o manténgalos fuera

del alcance de los niños.

PELIGRO DE ASFIXIA

PRECAUCIÓN

Para evitar lesiones en la espalda u otro tipo de lesiones,

procure levantar o mover la lavadora con la ayuda de

más de una persona.

PELIGRO DE EXCESO DE PESO

IMPORTANTE

Las instrucciones de esta guía y todo el material que

se incluye con esta lavadora no tienen como propósito

cubrir todas las condiciones y situaciones que puedan

presentarse. Cuando instale, opere o repare cualquier

artefacto DEBE tener cuidado y hacer uso de buenas

prácticas de seguridad.

Se obtienen mayores benefi cios y se disfruta más del

artefacto cuando se comprenden y se practican de

manera rutinaria todas las Instrucciones de Seguridad

y Funcionamiento al realizar las tareas de lavado.

Conserve estas instrucciones para referencia futura.

Herramientas y materiales necesarios para la instalación:

Y

Pinzas

ajustables

Nivel de carpintero

Mangueras de llenado (x2)

NOTA

Antes de comenzar la instalación, la unidad de punta hacia atrás y comprobar la

compatibilidad con bañera de espuma se ha eliminado.

NOTA

Las mangueras no están incluidos con la

compra de la lavadora. Vea la sección de

“Accesorios” para verifi car diferentes kits de

mangueras especifi cas para su instalación

23

Page 24

Tom

acorriente con

puesta a tierra

ninguna circunstancia.

No corte, retire ni

deshabilite la clavija de

conexión a tierra bajo

Cordón eléctrico de 3 clavijas

con puesta a tierra

REQUISITOS DE INSTALACIÓN

Requisitos del sistema eléctrico Requisitos de conexión a tierra

CIRCUITO - Circuito individual de bifurcación de 15 amp.,

correctamente polarizado y con conexión a tierra

con fusible de retardo de 15 amp. o con interruptor

automático.

SUMINISTRO ELÉCTRICO: corriente alterna de 2 cables,

con conexión a tierra, 120 voltios, monofásica, 60 Hz.

NOTA

Debido a posibles variaciones en el voltaje, no se

recomienda utilizar esta lavadora con electricidad

generada a partir de generadores a gas, solares,

eólicos ni de ninguna otra clase que no sean los

empleados por su empresa de electricidad local.

RECEPTÁCULO DEL TOMACORRIENTE - Receptáculo para

enchufes de 3 patas con conexión a tierra que debe

estar ubicado en un lugar que sea accesible para el

cable de alimentación eléctrica cuando la lavadora se

encuentre instalada.

Tom

acorriente con

puesta a tierr

No corte, retire ni

deshabilite la clavija de

conexión a tierra bajo

ninguna circunstancia.

ADVERTENCIA

PELIGRO DE DESCARGA ELÉCTRICA

Una conexión incorrecta del conductor de conexión

a tierra del equipo puede provocar un peligro de

descarga eléctrica. Si no está seguro de haber realizado

correctamente la conexión a tierra del artefacto, consulte

a un electricista autorizado.

1 La lavadora DEBE tener conexión a tierra. En el caso

de que la lavadora no funcione correctamente o se

descomponga, la conexión a tierra reduce el riesgo

de descarga eléctrica porque ofrece una trayectoria

de menor resistencia para la corriente eléctrica.

2 Debido a que la lavadora está equipada con un

cable de alimentación eléctrica que cuenta con un

conductor de conexión a tierra, el enchufe DEBE

estar conectado a un receptáculo adecuado con

cable de cobre correctamente instalado y con

conexión a tierra, de acuerdo con todos los códigos

y las ordenanzas locales o, ante la ausencia de

ordenanzas locales, con el Código Eléctrico Nacional

(National Electrical Codes), ANSI/NFPA 70 (última

edición). Ante cualquier duda, comuníquese con un

electricista autorizado. NO corte ni dañe la espiga de

conexión a tierra del cable de alimentación eléctrica.

En los casos en los que se dispone de un receptáculo

de dos ranuras, es responsabilidad del usuario pedir

a un electricista autorizado que lo cambie por un

receptáculo para enchufes de tres patas con una

adecuada conexión a tierra.

Cordón eléctrico de 3 clavijas

con puesta a tierra

NOTA

No es necesario conectar un tomacorriente con GFI

(interruptor de falla de conexión a tierra).

24

Requisitos de la entrada de agua

Los grifos de agua caliente y fría DEBEN estar a 1,9 cm

(3/4 pulgadas) con roscas para la conexión de la manguera

de lavado. La presión de agua DEBE ser de 30 a 120 psi.

La diferencia de presión entre el agua caliente y fría no

debe superar los 10 psi. El departamento hidráulico puede

asesorarlo con respecto a la presión de agua con la que

usted cuenta.

Page 25

REQUISITOS DE INSTALACIÓN

Requisitos del sistema de desagüe

1 Desagüe con capacidad para eliminar 64,3 l (17

galones) por minuto.

2 Un tubo vertical con un diámetro mínimo de 3,18 cm

(1-1/4 pulg.).

3 La altura del tubo vertical por encima del suelo debe

ser:

Altura mínima: 91 cm (36 pulgadas)

Altura máxima: 244 cm (96 pulgadas)

96”

(244 cm)

max.

36”

(91 cm)

min.

NOTA

Para las instalaciones que requieran un tubo de drenaje

más largo, pida a un técnico capacitado qui instale un

tubo más largo según el número de su modelo. Para

los systemas de drenaje el piso, instale un juego para

detener la acción de sifón. Ambos componentes están

disponible en los distribuidores autorizados de piezas

de repuesto.

Instalación en un Nicho o Armario

Si la lavadora y la secadora se instalan en el mismo

armario, será necesaria la ventilación en la puerta

de este: Se necesita un mínimo de 774,2 cm² (120

pulgadas²) de abertura, dividido en partes iguales en la

parte superior e inferior de la puerta. Las aberturas de

ventilación deben estar ubicadas a 7,6 cm (3 pulgadas)

de la parte superior e inferior de la puerta. Es necesario

que las aberturas de aire no estén obstruidas cuando

se instala una puerta. Se acepta una puerta que tenga

aberturas de ventilación distribuidas uniformemente en

toda la superfi cie.

3”

(7.6cm)

60 sq. in.

(387.1cm²)

60 sq. in.

(387.1cm²)

3”

(7.6cm)

puerta del armario

25

Page 26

REQUISITOS DE INSTALACIÓN

Requisitos de despeje

IMPORTANTE

NO INSTALE LA LAVADORA:

1 En una zona expuesta a la humedad o a las

condiciones climáticas externas. Para maximizar la

efi cacia del detergente, la temperatura ambiente

nunca debe ser menor a los 15,6° C (60° F).

2 En un área (garaje o construcción tipo garaje)

en la cual haya o se almacene gasolina u otros

productos infl amables (incluso automóviles).

3 Sobre una alfombra. El piso DEBE ser fi rme con una

pendiente máxima de 2,54 cm (1 pulgada). Para

reducir vibraciones o movimientos, puede que sea

necesario reforzar el piso.

Dimensiones de Lavadora

ESPACIOS MÍNIMOS PARA LA INSTALACIÓN: cm (pulgadas)

Hueco

Armario

0”

(0 cm)

LATERALES

0 cm

(0”)

0 cm

(0”)

0”

(0 cm)

PARTE

TRASERA

0 cm

(0”)

0 cm

(0”)

PARTE

SUPERIOR

52 cm

(20.5”)

52 cm

(20.5”)

1”

(2.5 cm)

PARTE

DELANTERA

n/d

2.5 cm

(1“)

(0 cm)

20.5”

(52 cm)

0”

cable eléctrico en la parte

trasera de la lavadora

abrazadera que

sujeta manguera de

llenado en parte tra-

sera de la lavadora

1

La longitud del cable de alimentación de la secadora a gas es de aproximadamente 152.5 cm (60 in).

2

Afl oje la longitud de la manguera de drenaje de la lavadora aproximadamente 155 cm (61 in).

2

1

conexión del sumi-

nistro de agua en la

parte trasera de la

lavadora

26.25” (67 cm)

38.5”

(98 cm)

42”

(107 cm)

59” (150 cm)

con la tapa abierta

26

28.75” (78 cm)

Page 27

INSTRUCCIONES DE INSTALACIÓN

Nivelación de la lavadora

Las vibraciones y el ruido excesivo se pueden evitar

nivelando la lavadora correctamente.

1 Con la lavadora a menos de 4 pies (1 m) de su

ubicación fi nal, utilice un nivel de carpintero para

nivelar todos los costados de la lavadora. Para nivelar

la unidad de adelante hacia atrás,

nivel al ras del panel frontal. Para nivelar la unidad de

lado a lado, coloque el borde del nivel al ras del panel

lateral.

2 Utilice la pinzas ajustables para ajustar las patas

niveladoras de modo que la lavadora esté nivelada

en relación con todos sus lados, atrás/adelante

y derecha/izquierda, y estabilizada en las cuatro

esquinas.

3 Presione hacia abajo las distintas esquinas y lados

para asegurarse de que no haya vibración alguna.

Ajuste las patas correspondientes de modo que la

lavadora descanse fi rmemente en el piso sobre las

CUATRO patas. Mantenga la extensión de las patas

niveladoras al mínimo para un mejor rendimiento de la

lavadora.

Conexión del suministro de agua de entrada

1 Haga correr un poco de agua de los grifos de agua

caliente y fría para enjuagar los caños de agua y

eliminar las partículas que puedan obstruir los fi ltros

de la llave de paso y para determinar cuál canilla

corresponde al suministro de agua caliente y cuál al

de agua fría.

coloque el borde del

a

c

a

b

levantar

d

bajar

b

ARANDELAS DE GOMA

DEBEN ESTAR PRESENTES

UTILICE SOLA-

MENTE LAS MAN-

GUERAS NUEVAS

NOTA

Las mangueras no están incluidos con la compra de la

lavadora. Vea la sección de “Accesorios” para verifi car

diferentes kits de mangueras especifi cas para su instalación.

2 Conecte la manguera de suministro de agua CALIENTE

a la conexión de admisión de agua CALIENTE de la

lavadora y la manguera de suministro de agua FRÍA a

la admisión de agua FRÍA de la lavadora. Ajústelas con

la mano hasta que queden fi rmes. Luego ajuste ambas

conexiones de suministro de agua 2/3 más de vuelta

con la pinza. No enrosque ni ajuste demasiado

estas conexiones.

3 Conecte la manguera de entrada de agua CALIENTE

al suministro de agua CALIENTE y la manguera de

entrada de agua FRÍA al suministro de agua FRÍA.

Ajústelas con la mano hasta que queden fi rmes. Luego

ajuste ambas conexiones de suministro de agua 2/3

más de vuelta con la pinza. No doble, tuerza o

presione las mangueras de admisión de agua.

4 Abra el grifo y verifi que que no haya fugas.

e

(FRÍA)

AZUL

c

g

d

(CALIENTE)

f

ROJO

27

Page 28

INSTRUCCIONES DE INSTALACIÓN

Conexión de la manguera de drenaje a la lavadora

IMPORTANTE

Inspeccione la pieza de goma en la salida de la bomba.

Asegúrese de que esté en el lugar correcto y que no

esté doblada hacia abajo ni rota.

1 Con la abrazadera con resorte ya instalada, coloque

el codo de la manguera de drenaje sobre la salida

de la bomba en la parte trasera de la lavadora.

Asegúrese de que el codo de la manguera esté

totalmente fi jado a la salida de la bomba y que

forme un ángulo recto antes de usar la pinza para

mover la abrazadera de resorte hasta su lugar.

SALIDA DE LA

BOMBA DE DRENAJE

DESLICE LA

ABRAZADERA

HASTA AQUÍ

ABRAZADERA

DE RESORTE

2 Tienda el extremo de la manguera de drenaje hacia

arriba y hágalo pasar por la argolla de retención

(la más grande) que se encuentra debajo del panel

superior.

3 Busque el anillo antisifón incluido junto con su

lavadora. Colóquelo alrededor del extremo de la

manguera de drenaje y deslícelo hasta pasar el

primer anillo de la manguera corrugada.

28

DISCO

ANTISIFÓN

DESLICE EL

DISCO HASTA

AQUÍ

ARGOLLA

DE RETENCIÓN

DE LA MANGUERA

DE DRENAJE

Page 29

INSTRUCCIONES DE INSTALACIÓN

Tom

acorriente con

puesta a tierra

ninguna circunstancia.

No corte, retire ni

deshabilite la clavija de

conexión a tierra bajo

Cordón eléctrico de 3 clavijas

con puesta a tierra

Conexión del desagüe y del suministro eléctrico

1 Forme una “U” en el extremo del tubo de drenaje

co el tubo señalando hacia el drenaje. Coloque el

extremo formado del tubo de drenaje en lavadero

o una tubería vertical y fíjelo con su sujetacables

incluido en el paquete.

2 Coloque el extremo con gancho de la manguera

de drenaje en la abertura de desagüe. Fije la

manguera de drenaje con el amarre para cables

(que viene en la caja) al tubo vertical, la manguera

de entrada, la tina del lavadero, etc. para que no se

salga por la fuerza del agua.

NOTA

El diámetro interior del tubo vertical debe ser de un

mínimo de 1-1/4” (3,2 cm). Debe haber un espacio de

aire alrededor de la manguera de desagüe en el tubo

vertical. Si la manguera está muy ajustada, se puede

producir un efecto sifón.

IMPORTANTE

Revise la caja del interruptor automático/fusibles para

asegurarse de que la electricidad esté desconectada antes

de conectar el cable de alimentación al tomacorriente.

3 Conecte el cable de alimentación a un

tomacorriente con conexión a tierra.

Tom

acorriente con

puesta a tierr

No corte, retire ni

deshabilite la clavija de

conexión a tierra bajo

ninguna circunstancia.

AMARRE

CABLES

PARA

Cordón eléctrico de 3 clavijas

con puesta a tierra

4 Conecte la electricidad desde la caja del interruptor

automático/fusibles.

5 Deslice la lavadora a su posición fi nal

cuidadosamente. Vuelva a verifi car que la lavadora

esté nivelada y estabilizada.

6 Consulte la Guía de uso y cuidado que se

proporciona con la lavadora. Dicha guía contiene

información útil y valiosa que le ahorrará tiempo y

dinero.

7 Haga funcionar la lavadora durante un ciclo

completo. Compruebe que no haya fugas de agua y

que funcione correctamente.

8 Si tiene alguna pregunta durante el funcionamiento

inicial, repase la “Lista de control para evitar el

servicio técnico” de su Guía de uso y cuidado antes

de llamar al servicio técnico.

9 Coloque estas instrucciones cerca de la lavadora

para referencia futura.

29

Page 30

ACCESORIOS

KIT DE INSTALACIÓN EN UNA CASA RODANTE

Pieza No.. 137067200

La instalación en una casa rodante requiere utilizar el KIT

DE INSTALACIÓN EN UNA CASA RODANTE.

KITS DE MANGUERAS LLENADO

Por favor llame al 866-233-8353 para explorar las

opciones de la manguera del kit que satisfagan sus

necesidades específi cas de instalación.

LLAVE UNIVERSAL PARA ELECTRODOMÉSTICOS

Pieza No. 137019200

También puede pedir una LLAVE UNIVERSAL PARA

ELECTRODOMÉSTICOS para ayudarlo a ajustar las patas

de las secadoras o lavadoras.

MARCADORES DE PINTURA DE RETOQUE*

Marcador de retoque de pintura blanca - Pieza Nº

5304468812

*Es posible que hayan otros colores disponibles. Póngase en

contacto con el distribuidor donde adquirió la lavadora.

PRECAUCIÓN

El no utilizar accesorios fabricados (o aprobados) por el

fabricante puede ocasionar lesiones personales, daños a

la propiedad o daños a la secadora.

Información Técnica/Diagrama de Cableado:

NOTA

Dentro de la consola de la lavadora, encontrará una hoja

de información técnica y un diagrama de cableado.

Para retirar la placa delantera de la consola, siga estas

instrucciones:

1. Desconecte la lavadora del suministro de electricidad.

2. Retire los cuatro tornillos de la parte posterior de la

carcasa de la consola.

3. Gire lentamente hacia delante en la consola lengüetas

de la bisagra.

IMPORTANTE

Las piezas internas de la consola están unidos con

alambres a la lavadora. Prevenir daños a la máquina.

NO tire consola lejos de la lavadora.

4. Cuando haya terminado con la reparación, vuelva hoja

dentro de la consola, asegúrese de que las lengüetas

de bisagra se insertan en el panel superior. Gire

suavemente la consola de nuevo y vuelva a insertar

los cuatro tornillos.

LENGÜETAS

DE LA BISAGRA

TORNILLOS DE LA CONSOLA

Piezas de repuesto:

Si su lavadora necesita piezas de repuesto,

comuníquese con el sitio donde la adquirió, o

consulte la

información.

Guía de uso y cuidado

para obtener más

30

ADVERTENCIA

Cuando se reparen los controles, rotule todos los cables antes

de desconectarlos. Los errores de cableado pueden producir

un funcionamiento incorrecto y peligroso. Verifi que que el

funcionamiento es correcto después de realizar las reparaciones.

PELIGRO DE DESCARGA ELÉCTRICA

Page 31

Page 32

Loading...

Loading...