Frigidaire FEX831FS0, FGX831FS0, GLET1031FS0, GLET1142FS0, GLGT1031FS0 Installation Guide

...Page 1

Installation Instructions

....'' ....... E e "trh:

Instructions d'installation

; o ............... . ..

Instrucciones para la instalaci6n

simplify the installation and ensure the laundry center is installed correctly

f

I

and safely. Leave these instructions near the laundry center after installation

for future reference.

NOTE; The electrical service to the laundry center must conform with local

codes and ordinances and the latest edition of the National Electrical Code,

ANSI/NFPA 70, or in Canada, the Canadian Electrical Code, CSA C22.1

NOTE: The gas service to the laundry center must conform with local codes

and ordinances and the latest edition of the National Fuel Gas Code AN_I

Z223. 1/NFPA 54, or in Canada, the Canadian Natural Gas and Propane

Installation Code, CSA B149. 1.

NOTE: The laundry center is designed under ANSI Z21.5.1 or ANSI/UL

2158- CAN/CSA C22.2 No. 112 (latest edition) for HOME USEonly. This

laundry center is not recommended for commercial applications such as

restaurants or beauty salons, etc.

\

Avant de commencer, lireattentivement lepresent document. Cela simplifiera

I'installation et assurera la posecorrecte et securitaire de la secheuse. Apres

I'installation, laisser ce document a proximite de la secheuse pour reference

future.

REM, a,ROUE "L'alim entation electriq ue de lasecheuse doit respecter lescodes

et ordonnances Iocaux ainsi que I'edition la plus recente du CodeANSVNFPA 70,

ou au Canada, le Code canadien d'elect ricite, ACNOR C22.1, partiel.

REM, a,ROUE : L'alimentation en gaz de la secheuse doit respecter les codes

et ordonnances Iocaux ainsi que I'edition laplus recente du Code ANSI Z223.1,

ou au Ca nada, le code CAN/AC G B149.12.

RE_,a, RO UE - Lasecbeuse est concue conformement au code ANSI Z 21.5.1

ou ANSI/UL 2158- CAN/AC G C22.2 No. 112 (l'edition la plus recente) pour un

USAGE DOMESTIQUE seulement. Cette secheuse n'est pas recommandee

pour utilisation commerciale, comme par exemple un restaurant ou un salon

de coiffure, etc. ........

Antes de comenzar la instalaci6n, lea cuidadosamente estas instrucciones. Esto

simplificar_la instalaci6n yasegurara que la secadora se instale correctamente

y de manera segura. Despu6s de completar la instalacion, coloque estas

instrucciones cerca de la secadora para referenda futura.

NOTA: Laalimentacion eK_drica para lasecadora deber_i cumplir con losc6digos

y reglamentos locales ycon la 01timaedici0n del C6digo Electrico Nacional, ANSI/

NFPA70 o en Canada1CSAC22.1 C6digo EI6ctdco Canadiense, Parte I.

NOTA: Laalimentaci6n degas para la secadora deber_ cumplir con los codigos

y regla mentos locales y con la 0kima edici6n del C6digo Nacional para Gases

Combustibles, ANSIZ223.1 o en Canada CAN/CGA B149.12.

NOTA: La secadora esta dasificada para USO DOMESTICO solamente, de

acuerdo con lanorma ANSI Z21.5.1 oANSI/UL 2158- CAN/CSA C22.2 No. 112

(las 0kimas edici6nes). Esta secadora no se recomienda para uso commercial

tal como en restaurantes, salones de belleza, etc.

r r r r

iii

11 (_1 1 [ [(}[

Printed in U.S.A. P/N134809200 (0610)

Page 2

Contents

SUBJECT PAGE

Pre-lnstallation Requirements .......................................... 2

Electrical Requirements ................................................... 2

Water Supply Requirements ........................................... 2

Drain Requirements .......................................................... 2

Exhaust System Requirements ...................................... 2-3

Gas Supply Requirements ................................................ 3

Location ............................................................................ 3

Mobile Home Installation .................................................. 3

Rough-In Dimensions ......................................................... 4

Unpacking ......................................................................... 4

Electrical Installation ......................................................... 5

Grounding Requirements .................................................. 5

3 & 4-Wire Connections ................................................. 5-6

installation ..................................................................... 6-7

Replacement Parts ........................................................... 7

PRE-INSTALLATION REQUIREMENTS

Tools and Materials Required for Installation:

1. Phillips head screwdriver.

2. Channel-lock adjustable pliers.

3. Carpenter's level.

4. Flat or straight blade screwdriver.

5. Duct tape.

6. Rigid or flexible metal 4 inch (10.16 cm) duct.

7. Vent hood.

8. Pipe thread sealer (Gas).

9. Ratchet with 3/8 inch (0.96 cm) socket.

For your safety the information in this manual must be

followed to minimize the risk of fire or explosion or to prevent property

damage, personal injury or loss of life.

- Do not store or use gasoline or other flammable vapors and

liquid in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

. Do not touch any electrical switch; do not use any phone in your

buikJing.

• Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor_ phone.

• Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be preformed by a qualified installer, service

agency or the gas supplier.

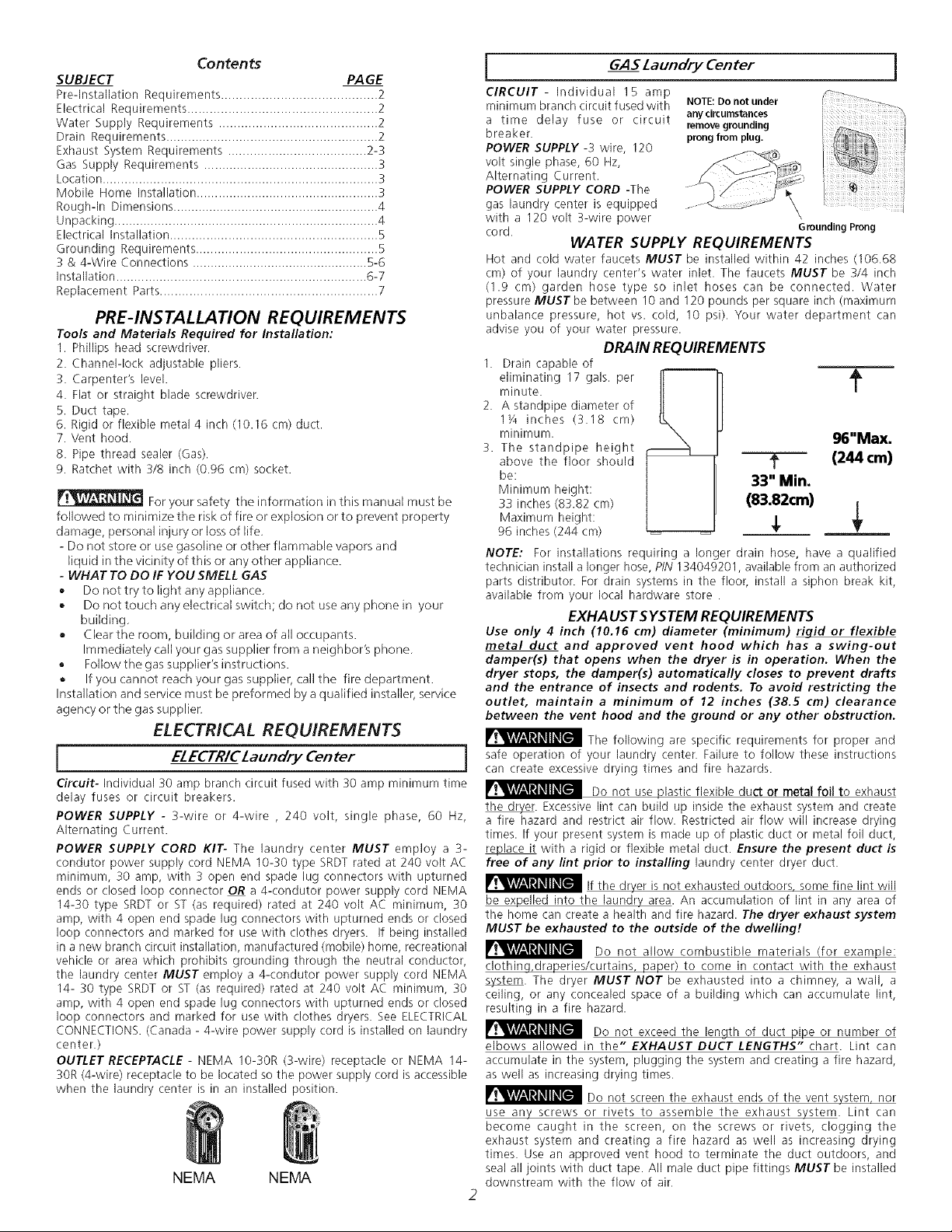

ELECTRICAL REQUIREMENTS

[ ELECrR/CLaundry Center ]

Circuit- Individual 30 amp branch circuit fused with 30 amp minimum time

delay fuses or circuit breakers.

POWER SUPPLY - 3-wire or 4-wire , 240 volt, single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD KIT- The laundry center MUST employ a 3-

condutor power supply cord NEMA 10-30 type SRDT rated at 240 volt AC

minimum, 30 amp, with 3 open end spade lug connectors with upturned

ends or closed loop connector OR a 4-condutor power supply cord NEMA

14-30 type SRDT or ST (as required) rated at 240 volt AC minimum, 30

amp, with 4 open end spade lug connectors with upturned ends or closed

loop connectors and marked for use with clothes dryers, if being installed

in a new branch circuit installation, manufactured (mobile) home, recreational

vehicle or area which prohibits grounding through the neutral conductor,

the laundry center MUST employ a 4-condutor power supply cord NEMA

14- 30 type SRDT or ST (as required) rated at 240 volt AC minimum, 30

amp, with 4 open end spade lug connectors with upturned ends or closed

loop connectors and marked for use with clothes dryers. See ELECTRICAL

CONNECTIONS. (Canada - 4-wire power supply cord is installed on laundry

center.)

OUTLET RECEPTACLE- NEMA 10-30R (3-wire) receptacle or NEMA 14-

30R (4-wire) receptacle to be located so the power supply cord is accessible

when the laundry center is in an installed position.

NEMA NEMA

I GASLaundry Center ]

CIRCUIT- Individual 15 amp

minimum branch circuit fused with NOTE:Donot under

a time delay fuse or circuit reroovegrounding

breaker. prongfromplug.

POWER SUPPLY -3 wire, 120

volt single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD -The

gas laundry center is equipped

with a 120 volt 3-wire power

cord. GroundingProng

anycircumstances

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within 42 inches (106.68

cm) of your laundry center's water inlet. The faucets MUST be 3/4 inch

(1.9 cm) garden hose type so inlet hoses can be connected. Water

pressure MUSTbe between 10 and 120 pounds per square inch (maximum

unbalance pressure, hot vs. cold, 10 psi). Your water department can

advise you of your water pressure.

DRAIN REQUIREMENTS

1. Drain capable of

eliminating 17 gaB. per

minute.

2. A standpipe diameter of

I_A inches (3.18 cm)

minimum.

3. The standpipe height

above the floor should

be:

Minimum height:

33 inches (83.82 cm)

Maximum height:

96 inches (244 cm)

NOTE: For installations requiring a longer drain hose, have a qualified

technician install a longer hose, PIN 134049201, available from an authorized

parts distributor. For drain systems in the floor, install a siphon break kit,

available from your local hardware store .

33" Min.

(83.82cm)

1'

96"Max.

(244 cm)

EXHAUST SYSTEM REQUIREMENTS

Use only 4 inch (10.16 cm) diameter (minimum) Hqid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that opens when the dryer is in operation. When the

dryer stops, the damper(s) automatically closes to prevent drafts

and the entrance of insects and rodents. To avoid restricting the

outlet, maintain a minimum of 12 inches (38.5 cm) clearance

between the vent hood and the ground or any other obstruction.

_The following are specific requirements for proper and

safe operation of your laundry center. Failure to follow these instructions

can create excessive drying times and fire hazards.

Do not use plastic flexible duct or metal foil to exhaust

the dryer. Excessive lint can build up inside the exhaust system and create

a fire hazard and restrict air flow. Restricted air flow will increase drying

times. If your present system is made up of plastic duct or metal foil duct,

_lace it with a rigid or flexible metal duct. Ensure the present duct is

free of any lint prior to installing laundry center dryer duct.

_lf the dryer is not exhausted outdoors some fine lint will

be expelled into the laundry area. An accumulation of lint in any area of

the home can create a health and fire hazard. The dryer exhaust system

MUST be exhausted to the outside of the dwelling!

Do not allow combustible materials (for example:

dothinq,draperies/curtains, paper) to come in contact with the exhaust

_stem. The dryer MUST NOT be exhausted into a chimney, a wall, a

ceiling, or any concealed space of a building which can accumulate lint,

resulting in a fire hazard.

elbows allowed in the" EXHAUST DUCT LENGTHS" chart. Lint can

accumulate in the system, plugging the system and creating a fire hazard,

as well as increasing drying times.

_Do not screen the exhaust ends of the vent system nor

use any screws or rivets to assemble the exhaust system. Lint can

become caught in the screen, on the screws or rivets, clogging the

exhaust system and creating a fire hazard as well as increasing drying

times. Use an approved vent hood to terminate the duct outdoors, and

seal all joints with duct tape. All male duct pipe fittings MUST be installed

downstream with the flow of air.

Do not exceed the length of duct pipe or number of

Page 3

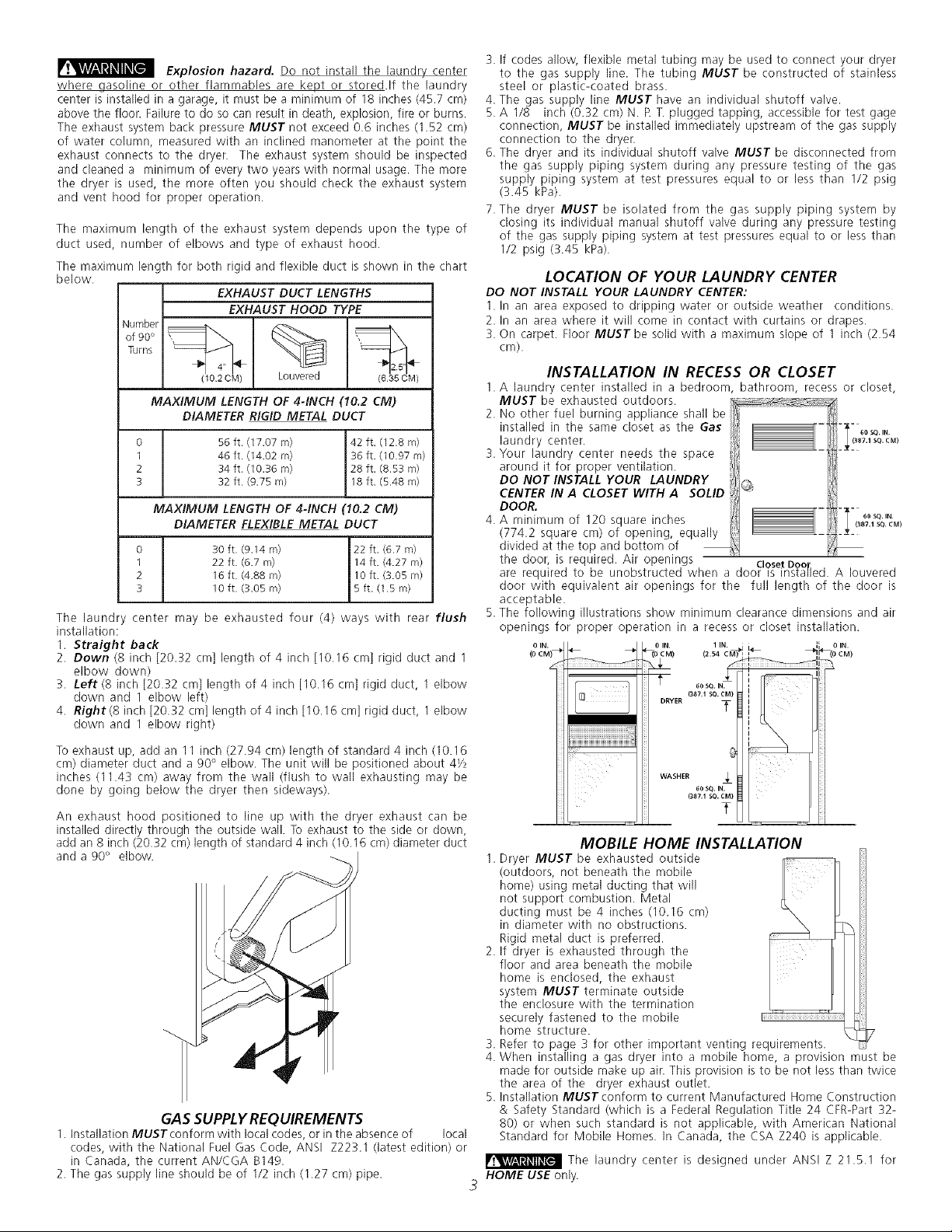

Explosion hazard. Do not install the laundry center

where gasoline or other flammables are kept or stored.if the laundry

center is installed in a garage, it must be a minimum of 18 inches (45.7 cm)

above the floor. Failure to do so can result in death, explosion, fire or burns.

The exhaust system back pressure MUST not exceed 0.6 inches (1.52 cm)

of water column, measured with an inclined manometer at the point the

exhaust connects to the dryer. The exhaust system should be inspected

and cleaned a minimum of every two years with normal usage. The more

the dryer is used, the more often you should check the exhaust system

and vent hood for proper operation.

The maximum length of the exhaust system depends upon the type of

duct used, number of elbows and type of exhaust hood.

The maximum length for both rigid and flexible duct is shown in the chart

below.

EXHAUST DUCT LENGTHS

EXHAUST HOOD TYPE

Number

Turns _

4_ 4_

(102 CM) Louvered (635 CM)

MAXIMUM LENGTH OF 4-INCH (10.2 CM)

DIAMETER RIGID METAL DUCT

0

1

2

3

56 ft. (17.07 m) 42 ft. (12.8 m)

46 ft. (14.02 m) 36 ft. (10.97 m)

34 ft. (10.36 m) 28 ft. (8.53 m)

32 ft. (9.75 m) 18 ft. (5.48 m)

MAXIMUM LENGTH OF 4-INCH (10.2 CM)

DIAMETER FLEXIBLE METAL DUCT

0

1

2

3

The laundry center may be exhausted four (4) ways with rear flush

installation:

30 ft. (9.14 m) 22 ft. (6.7 m)

22 ft. (6.7 m) 14 ft. (4.27 m)

16 ft. (4.88 m) 10 ft. (3.05 m)

10 ft. (3.05 m) 5 ft. (1.5 m)

1. Straight back

2. Down (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid duct and 1

elbow down)

3. Left (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid duct, 1 elbow

down and 1 elbow left)

4. Right(8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid duct, 1 elbow

down and 1 elbow right)

To exhaust up, add an 11 inch (27.94 cm) length of standard 4 inch (10.16

cm) diameter duct and a 90° elbow. The unit will be positioned about 4Y2

inches (11.43 cm) away from the wall (flush to wall exhausting may be

done by going below the dryer then sideways).

An exhaust hood positioned to line up with the dryer exhaust can be

installed directly through the outside wall. To exhaust to the side or down,

add an 8 inch (20.32 cm) length of standard 4 inch (10.16 cm) diameter duct

and a 90° elbow.

GASSUPPLYREQUIREMENTS

1. Installation MUST conform with local codes, or in the absence of local

codes, with the National Fuel Gas Code, ANSI Z223.1 (latest edition) or

in Canada, the current AN/CGA B149.

2. The gas supply line should be of 1/2 inch (1.27 cm) pipe.

3. If codes allow, flexible metal tubing may be used to connect your dryer

to the gas supply line. The tubing MUST be constructed of stainless

steel or plastic-coated brass.

4. The gas supply line MUST have an individual shutoff valve.

5. A 1/8 inch (0.32 cm) N. R T. plugged tapping, accessible for test gage

connection, MUST be installed immediately upstream of the gas supply

connection to the dryer.

6. The dryer and its individual shutoff valve MUST be disconnected from

the gas supply piping system during any pressure testing of the gas

supply piping system at test pressures equal to or less than 1/2 psig

(3.45 kPa).

7. The dryer MUST be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing

of the gas supply piping system at test pressures equal to or less than

1/2 psig (3.45 kPa).

LOCATION OF YOUR LAUNDRY CENTER

DO NOT INSTALL YOUR LAUNDRY CENTER:

1. In an area exposed to dripping water or outside weather conditions.

2. In an area where it will come in contact with curtains or drapes.

3. On carpet. Floor MUSTbe solid with a maximum slope of 1 inch (2.54

cm).

INSTALLATION IN RECESS OR CLOSET

1.

A laundry center installed in a bedroom bathroom, recess or closet,

MUST be exhausted outdoors. .............................................

2.

installed in the same closet as the Gas I _0so._..

laundry center. !_!7.1SO.CMI

No other fuel burning appliance shall be _rl_ ]

3.

Your laundry center needs the space

around it for proper ventilation. I[ll

DO NOT INSTALL YOUR LAUNDRY

CENTER IN A CLOSET WITH A SOLID

DOOR. _" I1: 3_ 60 SO. IN.

4.

A minimum of 120 square inches ))' 1_87_soCM)

(774.2 square cm) of opening, equally _L

divided at the top and bottom of

the door, is required. Air openings Coset Doo)"

are required to be unobstructed when a door is installed. A Iouvered

door with equivalent air openings for the full length of the door is

acceptable.

The following illustrations show minimum clearance dimensions and air

openings for proper operation in a recess or closet installation.

MOBILE HOME INSTALLATION

Dryer MUST be exhausted outside

(outdoors, not beneath the mobile

home) using metal ductinq that will

not support combustion. _letal

ducting must be 4 inches (10.16 cm)

in diameter with no obstructions.

Rigid metal duct is preferred.

If dryer is exhausted through the

floor and area beneath the mobile

home is enclosed, the exhaust

system MUST terminate outside

the enclosure with the termination

securely fastened to the mobile

home structure. 7

3. Refer to page 3 for other important venting requirements.

4. When installing a gas dryer into a mobile home, a provision must be

made for outside make up air. This provision is to be not less than twice

the area of the dryer exhaust outlet.

5. Installation MUST conform to current Manufactured Home Construction

& Safety Standard (which is a Federal Regulation Title 24 CFR-Part 32-

80) or when such standard is not applicable, with American National

Standard for Mobile Homes. in Canada, the CSA Z240 is applicable.

I_'!_giT/:11|lllllel The laundry center is designed under ANSI Z 21.5.1 for

HOME USE only.

3

...... /

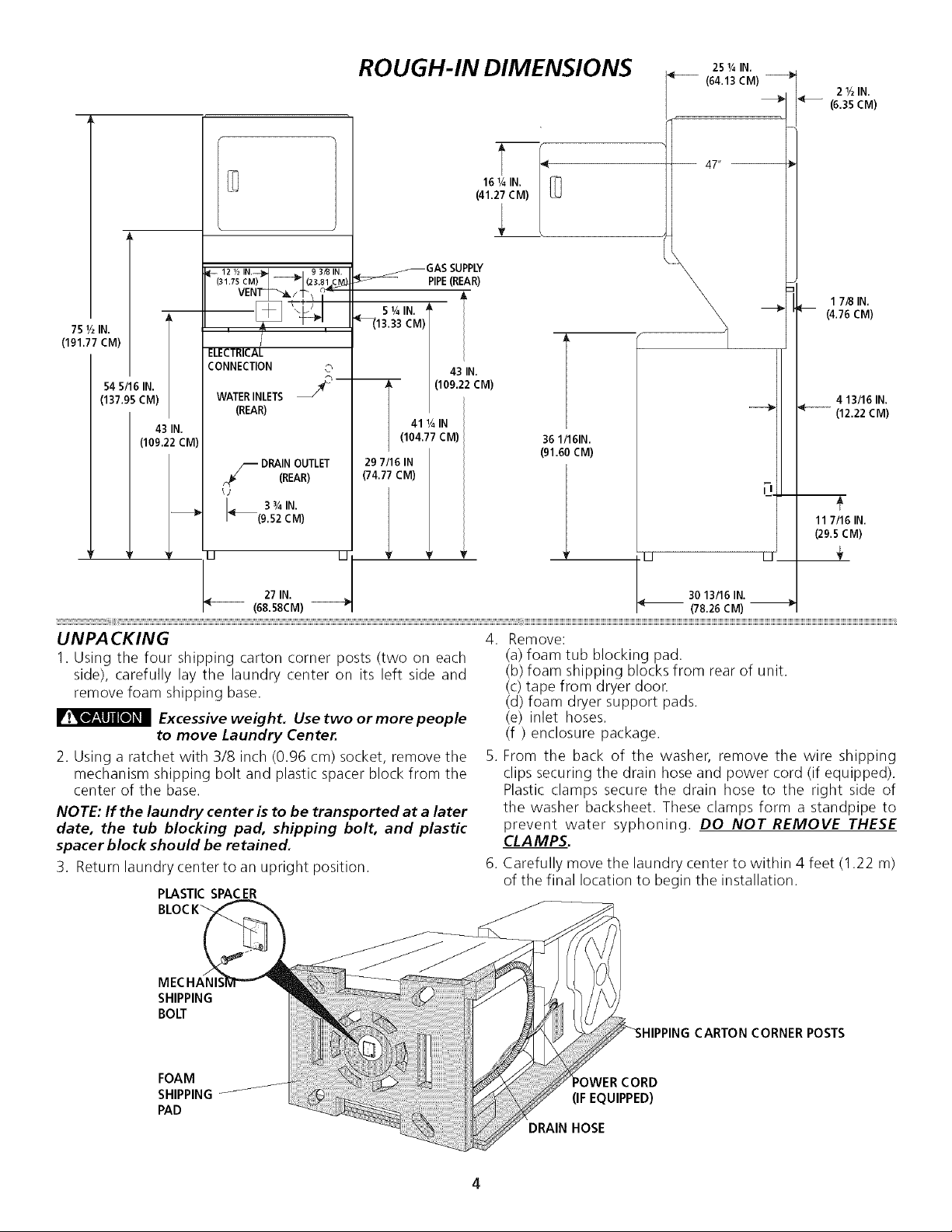

Page 4

75YzIN,

(191.77 CM)

54 5/16 IN.

(137.95 CM)

43 IN.

(109.22 CM)

CONNECTION ©

WATERINLETS _ --

(REAR)

._ DRAIN OUTLET

_J

_(9.52 CM)

(REAR)

3%1N.

ROUGH-IN DIMENSIONS

16¼ IN.

(41.27 CM)

_GAS SUPPLY

PIPE(REAR)

5 I/4 IN, _

_(13.33 CM) /

43 IN.

11::

I (104.77 CM)

29 7/16 IN

(74.77CM)

36 1/161N.

(91.60 CM)

25 ¼ IN.

(64.13 CM) --

47" --

\

2 YzIN.

(6.35 CM)

17/8 IN.

(4.76CM)

4 13/16 IN.

(12.22CM)

+

117/16 IN.

(29.5 CM)

II

27IN.

(68.58CM)

UNPACKING

1. Using the four shipping carton corner posts (two on each

side), carefully lay the laundry center on its left side and

remove foam shipping base.

Excessive weight. Use two or more people

to move Laundry Center.

2. Using a ratchet with 3/8 inch (0.96 cm) socket, remove the

mechanism shipping bolt and plastic spacer block from the

center of the base.

NOTE: If the laundry center isto be transported at a later

date, the tub blocking pad, shipping bolt, and plastic

spacer block should be retained.

3. Return laundry center to an upright position.

PLASTIC SPAC ER

MECHANIS

SHIPPING

BOLT

30 13/16 IN.

(78.26 CM)

4. Remove:

(a) foam tub blocking pad.

(b) foam shipping blocks from rear of unit.

(c) tape from dryer door.

(d) foam dryer support pads.

(e) inlet hoses.

(f) enclosure package.

5. From the back of the washer, remove the wire shipping

clips securing the drain hose and power cord (if equipped).

Plastic clamps secure the drain hose to the right side of

the washer backsheet. These clamps form a standpipe to

prevent water syphoning. DO NOT REMOVE THESE

CLAMPS.

.

Carefully move the laundry center to within 4 feet (1.22 m)

of the final location to begin the installation.

POSTS

FOAM

SHIPPING

PAD

(IF EQUIPPED)

DRAIN HOSE

Page 5

ELECTRICAL INSTALLATION

i ALL ELECTRICLaundry Centers ]

The following are specific requirements for

proper and safe electrical installation of your laundry center.

Failure to follow these instructions can create electrical shock

and/or afire hazard.

This appliance MUST be properly grounded.

Electrical shock can result if the laundry center is not properly

grounded. Follow the instructions in this manual for proper

grounding.

Do not use an extension cord with this

laundry center. Some extension cords are not designed to

withstand the amounts of electrical current this laundry center

utilizes and can melt, creating electrical shock and/or fire hazard.

Locate the laundry center within reach of the receptacle for the

length power cord to be purchased, allowing some slack in the

cord. Refer to the pre-installation requirements in this manual

for the proper power cord to be purchased.

A U.L approved strain relief must be installed

onto power cord. If the strain relief isnot attached, the cord can

be pulled out of the laundry center and can be cut by any

movement of the cord, resulting in electrical shock.

I Canadian ELECTRICLaundry Center j

_lmproper connection of the equipment

grounding conductor can result in a risk of electrical shock.

Check with a licensed electrician if you are in doubt as to

whether the appliance is properly grounded.

Fora grounded cord connected laundry center:

1. The laundry center MUST be grounded. In the event of

malfunction or breakdown, grounding will reduce the risk of

electrical shock by providing a path of least resistance for

the electrical current.

2. Since your laundry center is equipped with a power supply

cord having an equipment-grounding conductor and a

grounding plug, the plug MUST be plugged into an

appropriate outlet that isproperly installed and grounded in

accordance with all codes and ordinances. If in doubt, call

a licensed electrician.

ALL GAS Laundry Centers

1.The laundry center is equipped with a three-prong (grounding)

plug for your protection against shock hazard and should

be plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong from

the plug.

ELECTRICAL CONNECTIONS

FOR A 3-WIRE SYSTEM

1

with a copper Wired power cord and plug (or vice versa). A

chemical reaction occurs between copper and aluminum and

can cause electrical shorts. The proper wiring and receptacle 1.

is a copper wired power cord with a copper wired

receptacle OR aluminum wired power cord with an

aluminum wired receptacle. 2.

NOTE: Laundry centers operating on a 208 volt power supply

will have longer drying times than laundry centers operating on

a 240 volt power supply.

GROUNDING REQUIREMENTS

[ Non-CanadianELECTRlCLaundryCenter ]

grounding conductor can result in a risk of electrical shock.

Check with a licensed electrician if you are in doubt asto whether

the appliance is properly grounded.

For a qrounded, cord-connected laundry center:

1. The laundry center MUST be grounded. In the event of

malfunction or breakdown, grounding will reduce the risk of

electrical shock by a path of least resistance for electrical

current.

2. If your laundry center isequipped with a power supply cord

having an equipment-grounding conductor and agrounding

plug, the plug MUSTbe plugged into anappropriate, copper

wired receptacle that is properly installed and grounded in

accordance with all local codes and ordinances. If in doubt,

call a licensed electrician. Do not modify plug provided

with the appliance.

For a permanently connected laundry center:

The laundry center MUST be connected to a grounded metal,

permanent wiring system; or an equipment grounding conductor

MUST be run with the circuit conductors and connected to the

equipment-grounding terminal or lead on the appliance.

Do not use an aluminum wired receptacle i

4.

Improper connection of the equipment

5. Attach the remaining two power cord outer conductors to

6. Tighten the screws securing the cord restraint against the

7. Reinstall the terminal access cover.

NON-CANAD/AN ELECTR/CLaundry Center j

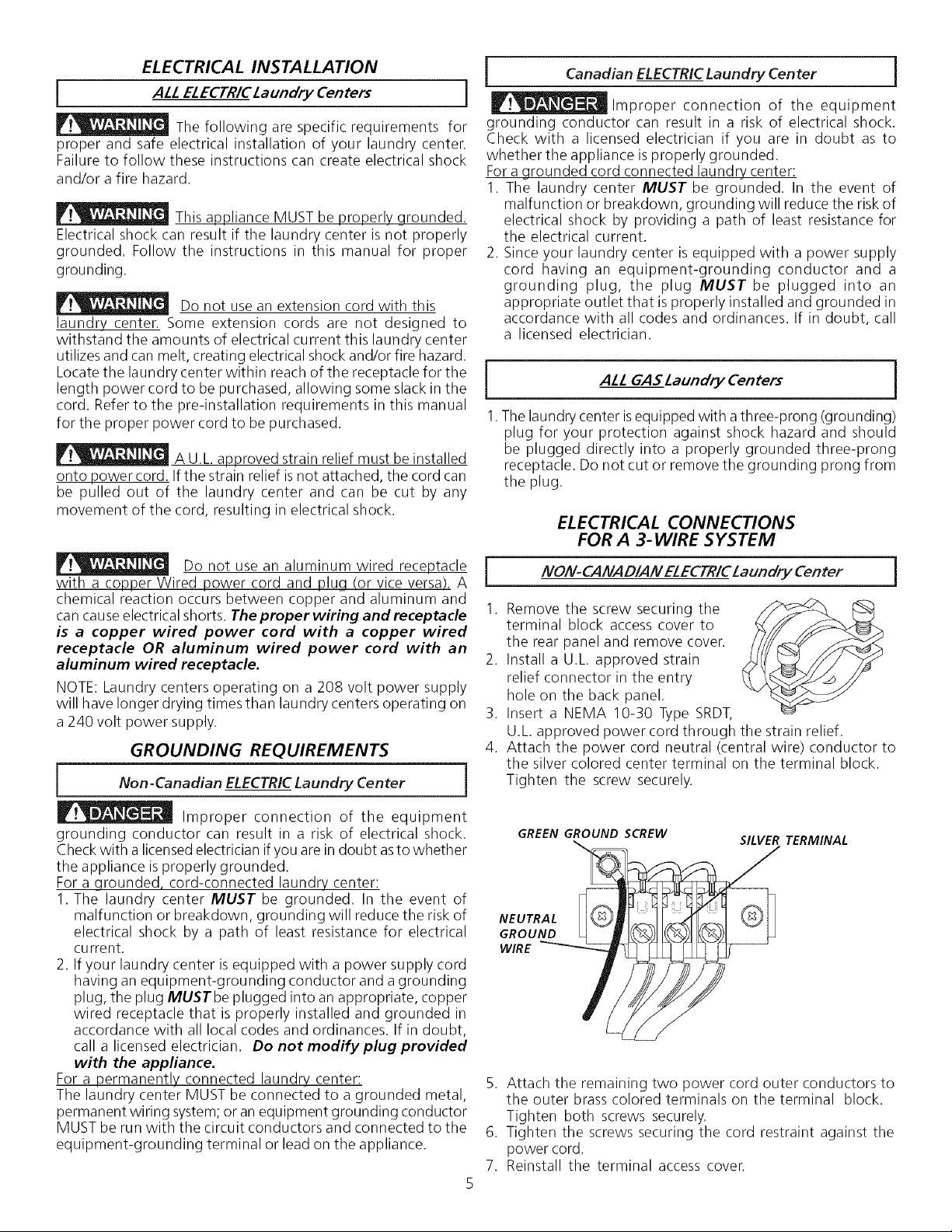

Remove the screw securing the

terminal block access cover to

the rear panel and remove cover.

Install a U.L approved strain

relief connector in the entry

hole on the back panel.

.

Insert a NEMA 10-30 Type SRDT,

U.L approved power cord through the strain relief.

Attach the power cord neutral (central wire) conductor to

the silver colored center terminal on the terminal block.

Tighten the screw securely.

GREEN GROUND SCREW

NEUTRAL

GROUND

WIRE

the outer brasscolored terminals on the terminal block.

Tighten both screws securely.

power cord.

SILVER TERMINAL

Page 6

ELECTRICAL CONNECTIONS

FOR A 4-WIRE SYSTEM

NON-CANADIAN ELECTRICLaundry Center

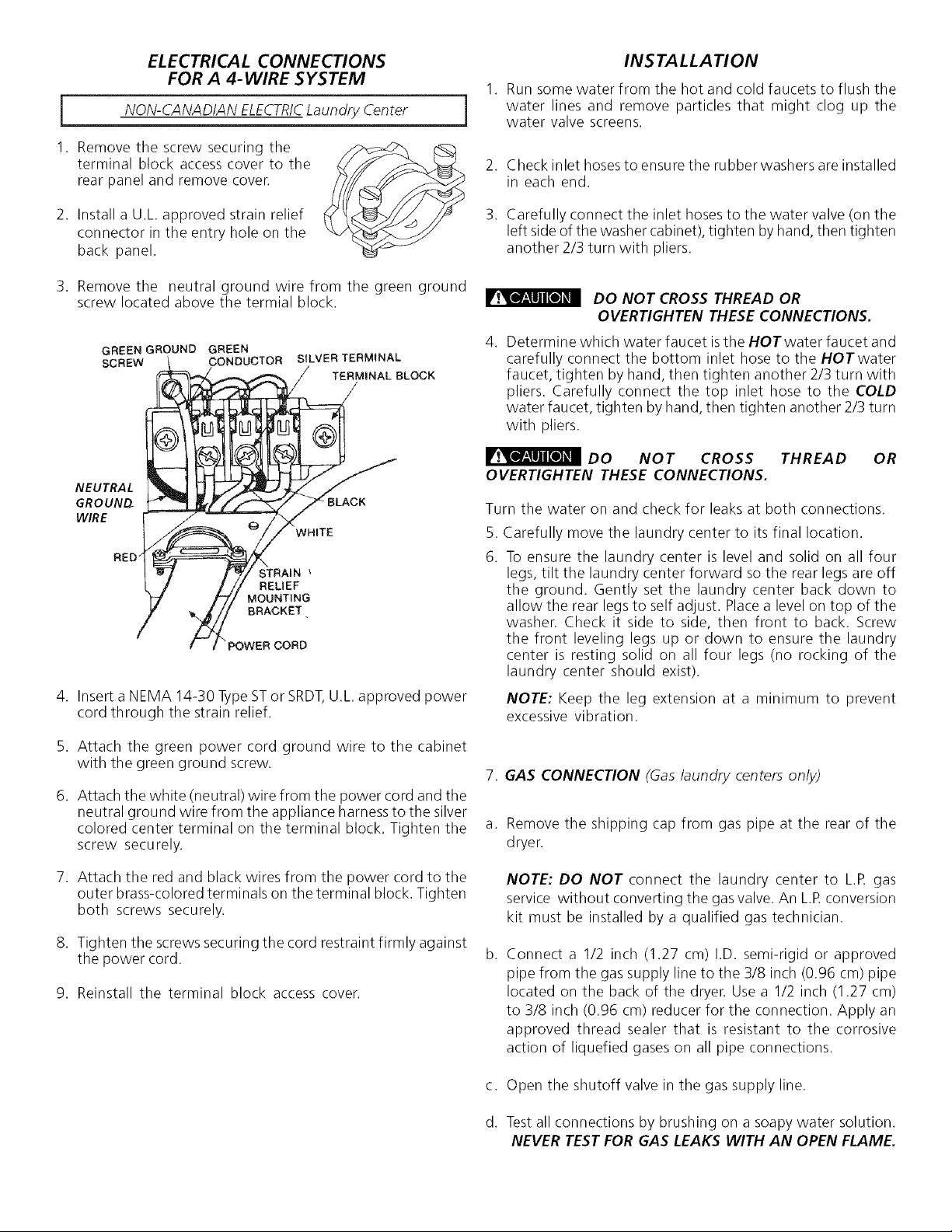

1. Remove the screw securing the

terminal block access cover to the

rear panel and remove cover.

INSTALLATION

Run some water from the hot and cold faucets to flush the

water lines and remove particles that might clog up the

]

water valve screens.

.

Check inlet hoses to ensure the rubber washers are installed

in each end.

2. Install a U.L approved strain relief

connector in the entry hole on the

back panel.

3. Remove the neutral ground wire from the green ground

screw located above the termial block.

4. Insert a NEMA 14-30 TypeSTor SRDT,U.L approved power

cord through the strain relief.

3.

Carefully connect the inlet hoses to the water valve (onthe

left side of the washer cabinet), tighten byhand, then tighten

another 2/3 turn with pliers.

DO NOT CROSS THREAD OR

OVERTIGHTEN THESE CONNECTIONS.

4. Determine which water faucet isthe HOTwater faucet and

carefully connect the bottom inlet hose to the HOTwater

faucet, tighten by hand, then tighten another 2/3 turn with

pliers. Carefully connect the top inlet hose to the COLD

water faucet, tighten by hand, then tighten another 2/3 turn

with pliers.

DO NOT CROSS THREAD OR

OVERTIGHTEN THESE CONNECTIONS.

Turn the water on and check for leaks at both connections.

.

Carefully move the laundry center to its final location.

6.

To ensure the laundry center is level and solid on all four

legs, tilt the laundry center forward so the rear legs are off

the ground. Gently set the laundry center back down to

allow the rear legs to self adjust. Placea level on top of the

washer. Check it side to side, then front to back. Screw

the front leveling legs up or down to ensure the laundry

center is resting solid on all four legs (no rocking of the

laundry center should exist).

NOTE: Keep the leg extension at a minimum to prevent

excessive vibration.

5. Attach the green power cord ground wire to the cabinet

with the green ground screw.

6. Attach the white (neutral) wire from the power cord and the

neutral ground wire from the appliance harnessto the silver

colored center terminal on the terminal block. Tighten the

screw securely.

7. Attach the red and black wires from the power cord to the

outer brass-colored terminals on the terminal block. Tighten

both screws securely.

8. Tighten the screws securing the cord restraint firmly against

the power cord.

9. Reinstall the terminal block access cover.

7. GAS CONNECTION (Gas laundry centers only)

a. Remove the shipping cap from gas pipe at the rear of the

dryer.

NOTE: DO NOT connect the laundry center to L.R gas

service without converting the gas valve. An LR conversion

kit must be installed by a qualified gas technician.

b.

Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or approved

pipe from the gas supply line to the 3/8 inch (0.96 cm) pipe

located on the back of the dryer. Use a 1/2 inch (1.27 cm)

to 3/8 inch (0.96 cm) reducer for the connection. Apply an

approved thread sealer that is resistant to the corrosive

action of liquefied gases on all pipe connections.

c. Open the shutoff valve in the gas supply line.

d. Test all connections by brushing on a soapy water solution.

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

Page 7

8. Form a " U " shape on the end of the drain hose with the

hose pointed toward the drain. Place the formed end in a

laundry tub or a standpipe and secure with a cable tie

provided in the enclosure package.

WATER WILL SYPHON FROM THE WASHER IF THE

ABOVE INSTRUCTIONS ARE NOT FOLLOWED.

C_ble

Tie

10. Connect the exhaust duct to outside duct work. Use duct

tape to seal all joints.

11. Plug the power cord into a grounded outlet.

NOTE: Check to ensure the power isoff at a circuit breaker/

fuse box before plugging the power cord into an outlet.

12. Turn on the power at a circuit breaker/fuse box.

_ Before operating the dryer, make sure

the dryer area is clear and free from combustible

materials, gasoline, and other flammable vapors. Also

see that nothing (suchasboxes, clothing, etc.) obstructs

the flow of combustion and ventilation air.

13. Reinstall the dryer front access panel.

14. Run the washer and dryer though a cycle. Check for proper

operation.

NOTE: On gas dryers, before the burner will light, it is

necessary for the gas line to be bled of air. If the burner

does not light within 45 seconds the first time the dryer

is turned on, the safety switch will shut the burner off.

If this happens, turn the timer to "OFF" and wait 5

minutes before making another attempt to light.

15. If your laundry center does not operate, please review the

"Avoid Service Checklist" located in your Owner's Guide

before calling for service.

16. Place these instructions in a location near the laundry

center for future reference.

NOTE: A wiring diagram is located behind the dryer front

access panel.

9. Remove the two (2) screws securing the dryer front access

panel to the dryer cabinet. Lift the panel until the tabs can

be disengaged from the cabinet. Removethe panel and set

aside.

Access

Panel

Screws

REPLACEMENT PARTS

If replacement parts are needed for your laundry center, contact

the source where you purchased your laundry center.

Destroy the carton, plastic bags, and metal

band after the laundry center isunpacked. Children might use

them for play. Cartons covered with rugs, bedspreads, or plastic

sheets can become airtight chambers causing suffocation.

Place all materials in a garbage container or make materials

inaccessible to children.

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

The instructions in this manual and all other

literature included with this laundry center are not meant to

cover every possible condition and situation that may occur.

Good safe practice and caution MUST be applied when

installing, operating and maintaining any appliance.

Maximum benefits and enjoyment are achieved when all

the Safety and Operating instructions areunderstood and

practiced asa routine with your laundry tasks.

Page 8

Table des mati_res

SUJET PAGE

Avant I'installation 8

Exigenceselectriques 8

Exigencesd'alimentation 8

Exigensesde vidange 8

Exigensesdu circuit d'evacuation 9

Exigensesd'alimentation engas 10

Emplacementdu combinelaveuse/secheus 10

Installation dartsunemaisonmobile 10

DimensionsdeI'emplacement 11

Deballage 11

Installation electrique 12

Exigencesde misea laterre 12

Connexionselectriques- 3ills et 4fils 13

Installation 13

Piecesderechange 14

d'une capacite minimale de 240 volts, courant alternatif, 30 A,

avec fiche en L a 4 broches pleines ou repliees conque pour le

branchement d'une secheuse. Se reporter a la section

BRANCHEMENT ELECTRIQUE D'UNE INSTALLATION A 4 FILS.

(Canada - Cordon d'alimentation a 4 fils branche a la secheuse.)

PRISE- Prise NEMA 10-30R situee de faqon ace que le cordon

d'alimentation electrique soit accessible une fois la secheuse en

place. (Canada - prise NEMA de 14-30R.)

AVANT L'INSTALLATION

Outils et materiel requis pour I'installation :

1. Tournevis a pointe cruciforme

2. Pinces multiprise

3. Niveau de menuisier

4. Tournevis _ pointe plate ou a lame droite

5. Ruban adhesif pour conduites

6. Conduite en metal rigide ou flexible de 10,2 cm (4 po)

7. Grille de sortie

8. Pate a joint pour conduites (modele a gaz)

9. Couteau a mastic en plastique

_!_ Pour votre s6curit& suivre lesdirectives donn6es dans

le pr6sent guide afin de minimiser les risques d'incendie, d'explosion, de

dommages materiels, de blessures et de mort.

Ne pas entreposer ni utiliser d'essence ou d'autres vapeurs ou

liquides inflammables a proximit6 de cette s6cheuse ou de tout autre

appareil dectrom6nager,

QUE FAIRE S'IL YA UNE ODEUR DE GAZ

• N'allumer aucun appareil dectrique.

• Ne toucher aucun commutateur dectrique; ne pas utiliser le

t61ephone dans I'immeuble.

• Faire sortir tousles occupants de la piece, de I'immeuble ou de la

zone avoisinante,

• Appeler lacompagnie de gaz imm6diate-ment en utilisant le

t616phone d'un voisin. Suivre les instructions de la compagnie

de gaz,

• S'il est impossible de joindre la compagnie de gaz, appeler les

pompiers.

L'installation et les r6parations doivent 6tre effectu6es par un technicien

qualifi6, un agent de service ou la compagnie de gaz,

INSTALLATION L'LECTRIQUE

Secheuses E'LECTRIOUES j

CIRCUIT - Derivation distincte de 30 A avec fusibles

retardement ou disjoncteurs d'au moins 30 A.

ALIMENTATION ELECTRIQUE - 3 fils, 240 volts, une phase,

60 Hz, courant alternatif. (Canada - 240 volts, une phase, 60 Hz,

courant alternatif.)

CORDON D'ALIMENTATION ELECTRIQUE - La secheuse DOlT

_tre reliee a un cordon d'alimentation electrique a 3 conducteurs

NEMA 10-30 de type SRDTd'une capacite minimale de 240 volts,

courant alternatif, 30 A, avec fiche en L a 3 broches pleines ou

repliees conque pour le branchement d'une secheuse. Si etant

installe dans une nouvelle installation de circuit de branche,

manufacturee(mobile)_ la maison, vehicule la recreationnel

ou secteur qui interdisent fondre par le conducteur neutre, elle

DOlT _tre reliee a un cordon d'alimentation electrique

4 conducteurs NEMA 14-30 de type SRDT ou ST (au besoin)

NEMA 10-30R NEMA 14-30R

i

CIRCUIT- Derivation distincte de 15 A minimum avec fusible

retardement ou disjoncteur.

ALIMENTATION E'LECTRIQUE - 3 fils, 120 volts, une phase, 60

Hz, courant alternatif.

CORDON D'ALIMENTATION - Le combine laveuse/secheuse _i

gaz est d'un cordon d'alimentation electrique a 3 fils de 120 volts.

Combin@ /aveuse/s@cheuse & _AZ

REMARQUE: II ne fau i [_l _l_ _

en aucun casretirer la

broche de raise b la

terre de la fiche.

\

BROCHEDEMISE

LA TERRE

EXIGENCES D'ALIMENTATION EN EA U

Lesrobinets d'eau chaude et d'eau chaude et d'eau froide DOIVENT

6ntre installes a moins de 42 pounces ( 106,68 cm ) de

I'arrivee d'eau du combine. Les robinets DOIVENTtre du type pour

boyau de jardin de 3/4 pounce (1,9 cm), de maniere

pouvoir raccader les boyaux d'arriv6e d'eau. Lapression d'eau

DOITse siteur entre 10 et 120 livres par pounce carre ( dese-

quilibre de pression maximale, eau chaude vs eau froide, 10

psi ). Le service d'aqueduc peut vous informer sur la pression

d'eau.

EXIGENCES DE VIDANGE

1. Le circit de vidange doit permettre d'evacuer 17 gallons _ la

minute.

2. Le diam_tre du tuyau de vidange doit _tre d'un minimum de

1 - 1/4 po (3,18 cm). _'

3.

La hauteur hors sol du JJ JJ

tuyau de vidange

dolt _tre :

Minimale:

33 po (83,82 cm)

Maximale:

96 po (244 cm)

NOTA: Si I'installation necessite un tuyau de vidange plus long,

demandez _ un technicien qualifie d'installer un boyau

de vindage plus long, P/N 131461201, disponsible chez

un distributeur autorise de pi_ces. Pour les circuits de

vidange au sol, installez un ensemble de siphon, se

procurer aupres d'une quincaillerie locale.

rC---------h

/

/

_M_,

(244cm)

i

Page 9

EVA CUATION DE L'AIR

Utiliser uniquement une conduite en metal rigide ou flexible de

10,2 cm (4 po) de diametre (minimum) ainsi qu'une grille de

sortie approuvee pourvue de clapets qui s'ouvrent Iorsque la

secheuse fonctionne. Quand la secheuse s'arrete, les clapets se

ferment automatiquement pour eviter lescourants d'air et I'entree

d'insectes ou de rongeurs. Afin de ne pas obstruer I'evacuation

de I'air, laisser une distance minimum de 30,5 cm (12 po) entre

la grille de sortie et le sol ou tout autre obstacle.

Les raises en garde qui suivent se

rapportent directement au fonctionnement correct et

securitaire de la secheuse. Toute derogation aces raises

en garde pourrait ralentir le s_chage et entrafner des

risques d'incendie.

ON' utiliser pas de conduit souple en plastique ou en metallique

pour evacuer I'air de la secheuse. Une quantite excessive de

charpie pourrait s'accumuler dans la conduite d'evacuation, ce

qui reduirait la circulation de I'air et presenterait un risque

d'incendie. Toute obstruction de la circulation de I'air ralentit le

sechage. Si la conduite existante est en plastique ou en papier

metallique, la _par uneconduiteen metal rigideou

flexible. S'assurer qu'il n'y a pas de charpie clans la conduite

existante avant d'installer la conduite de la secheuse.

O Si I'air n'etait pas repousse a I'exterieur de la maison de

petites particules de charpie se retrouveraient dans la piece ou

est installee la secheuse. Toute accumulation de charpie dans la

maison peut presenter des risques pour la sante et des risques

d'incendie. La conduite d'evacuation de la secheuse

DOIVENT se terminer a I'exterieur de la maison!

ONe laisser aucun materiau inflammable (comme des

vetements, des tentures, des rideaux ou du papier) entrer en

contact avec les conduits d'evacuation. L'air de la secheuse NE

DOITPAS etre evacue darts une cheminee, un mur, un plafond

ni tout espace ferme d'un b_itiment ou la charpie pourrait

s'accumuler et presenter un risque d'incendie.

O Augmenter la Iongueur du conduit rigide ou le nombre de

coudes permis au tableau _LONGUEUR MAXIMUM_ risque de

reduire la capacite d'evacuation du circuit. Obturer le circuit peut

creer un risque d'incendie et augmenter le temps de sechage.

ONe pas poser de qrillaqe sur I'ouverture exterieure des

conduites d'evacuation d'air ni utiliser des vis ou des rivets pour

assembler la conduite d'evacuation. De la charpie pourrait

s'emprisonner darts le grillage ou sur les vis ou les rivets et ainsi

engorger la conduite d'evacuation en plus de presenter un risque

d'incendie et de ralentir le sechage. Utiliser une grille de sortie

approuvee pour fermer I'ouverture exterieure et sceller tousles

joints _ I'aide d'un ruban adhesif pour conduites. L'extremite m_ile

de chaque composante de la conduite DOITetre installee en aval

par rapport a la circulation de I'air.

Risques d'explosion. Ne pas installer la

secheuse a un endroit ou I'on garde de la gazoline ou tout autre

produit inflammable. Si la secheuse est installee dans un garage,

elle doit etre a un minimum de 45,7 cm (18 po) au-dessus du

plancher. Toute derogation pourrait provoquer la mort, I'explosion,

I'encendie ou les br01ures.

1. La contre-pression du circuit d'evacuation ne DOlT pas

exceder 0.6 ponces (1,52 cm) de colonne d'eau, mesureeavec

un manometre a tube incline au point ou le conduit

d'evacuation est connecte secheuse.

2. II faut verifier et nettoyer le circuit d'evacuation au moins

tousles deux arts dans des conditions d'utilisation normale.

Plus la secheuse est utilisee frequemment, plus le circuit

et le registre d'evacuation doivent etre verifies pour assurer

un bon.

La Iongueur maximum du system d'evacuation depend du type de

conduit utilise, du nombre de coudes et du type de registre

d'evacuation. La Iongueur maximum de conduits rigides et

flexibles est indiquee dans le tableau suivant:

EXHAUSTDUCT LENGTHS

EXHAUSTHOOD TYPE

Turns _ "_

of 90 ° ',' _

(102 CM) Louvered (6.35 CM)

MAXIMUM LENGTHOF 4-INCH (10.2 CM)

DIAMETERRIGID METALDUCT

0

1

2

3

MAXIMUM LENGTH OF 4-INCH (10.2 CM)

o

1

2

3

56 ft. (17.07 m) 42 ft. (12.8 m)

46 ft. (14.02 m) 36 ft. (10.97 rn)

34 ft. (10.36 rn) 28 ft. (8.53 rn)

32 ft. (9.75 rn) 18 ft. (5.48 m)

DIAMETER FLEXIBLE METAL DUCT

30 ft. (9.14 rn) 22 ft. (6.7 m)

22 ft. (6.7 m) 14ft. (4.27 m)

16 ft. (4.88 rn) 10 ft. (3.05 m)

10 ft. (3.05 rn) 5 ft. (1.5 rn)

L'evacuation du combine laveuse/secheuse par un circuit

d'evacuation arriere peut sefaire de quatre (4) facons:

1. En ligne droite.

2. Vers le has (8 pounces (20,32 cm) de Iongueur pour un con-

duit de 4 pounces (10,16 cm) rigide & 1 coude vers le bas).

3. A gauche (8 pounces (20,32 cm) de Iongueur pour un con-

duit de 4 pounces (10,16 cm) rigide, 1 coude vers le bas & 1

coude a gauche).

4. A droite (8 pounces (20,32 cm) de Iongueur pour un conduit

de 4 pounces (10,16 cm) rigide, 1 coude vers les bas & 1

coude a droite).

Pour une evacuation vers la haut, ajoutez une Ionueur de 11

pounces (27,94 cm) de conduit standard de 4 pounces (10,16 cm) et

un coude de 90°. L'appareil se situera a une distance

d'environ 4-1/2 pontes (11,43 cm) du mur (une evacuation sans

degagement au mur peut se faire en passant sous la secheuse

puis sur les c6tes).

Un registre d'evacuation aligne directement avec lasortie d'evac-

uation de la secheuse peut _tre installe directement dans lemur

exterieur. Pour une evacuation vers le haut, ajoutez ue Iongueur

de 11 pounces (27,94 cm) de conduit standard de 4 pounces (10,16

cm) et un coude de 90°. L'appareil se situera _ une distance d'environ

4-1/2 pounces (11,43 cm) du mur ( une evacuation sans

degagememt au mur peut se faire en passant sous Is secheuse

puis sur lesc6tes). Pour evacuer sur le c6te ou vers le bas,ajoutez une

Iongueur de 8 pounces (20,32 cm) de conduit standard

de 4 pounces (10,16 cm) et un coude de 90°.

Page 10

ALIMENTATION EN GAZ

Remplacer le tuyau de raccordement en

cuivre non recouvert de plastique. I! FA UT utiliser du laiton

inoxydable ou recouvert de plastique.

1. L'installation DOITrespecter les codes Iocaux, ou s'il n'existe pas

de codes Iocaux, le code ANSI Z223.1 (l'edition la plus recente) ou

au Canada, le Code actuel CAN/CGA B149.

2. La conduite d'alimentation en gaz dolt mesurer 1,27 cm (1/2 po).

3. Si les codes le permettent, un tuyau en metal flexible peut _tre utilise

pour connecter la secheuse _ I'alimentation en gaz. Le tuyau DOlT

_tre fabriqu_ en acier inoxydable ou en cuivre avec un rev_tement

de plastique.

4. La conduite d'alimentation en gaz DOITcomporter un robinet

d'arr_t distinct.

5. Une prise de 0,32 cm (1/8 po) NPTaccessible pour lebranchement

d'un manometre DOlT _tre installee tout juste en amont du

branchement de la conduite d'alimentation en gaz sur la secheuse.

6. La secheuse DOlT _tre debranchee de la canalisation de gaz

pendant toute v_rification de pression de I'alimentation en gaz

des pressions qui depassent 3,45 kPa (1/2 Ib/po2).

7. La secheuse DOIT_tre isolee de la canalisation de gaz pendant

toute verification de pression de I'alimentation en gaz a des

pressions _gales ou inferieures _ 3,45 kPa (1/2 Ib/po2).

EMPLA CEMENTD UCOMBINEE LA VEUSE/SECHEUSE

NE PAS INSTALLER COMBINE LAVEUSE/ SECHEUSE :

1. Dans un endroit expose a un ecoulement d'eau ou aux conditions

atmospheriques.

2. Dans un endroit o0 elle serait en contact avec des rideaux, draperies

ou tout ce qui obstruera le flux d'air de combustion et de

ventilation.

3. Sur un tapis. Le plancher DOIT_tre fermeet presenter une pente

de 2,54 cm(1 po) au maximum.

Les illustrations qui suivent indiquent la dimension minimum

de degagement pour un fonctionnement adequat dans une

niche ou une armoire.

0 po

(0CM)_

60 po 2

(387.1 SQ. CM)

SECHEUSE T

LAVEUSE

6O

(387,1 SQ. CM)

T

INSTALLATION DANS UNE NIAISON NIOBIII E

1. L'evacuation de la secheuse DOITse faire _ I'exterieur (a

I'exterieur et non pas au-dessous de la maison mobile) a I'aide

de conduit en metal inflammable. Les conduits en metal

doivent avoir 4 pounces (10,16 cm) de diam_tre sans obstruc-

tions. Les conduits en metal rigide sont preferables.

2. Si I'evacuation de la secheuse se fait a travers le plancher et

que I'espace sous la maison mobile est ferme, le circuit

d'evacuation DOlT se terminer en dehors de I'espace ferme,

et la sortie bien fixee _ la structure de la mason mobile.

3. R_f_rez-vous a la page 3 pour de plus amples informations

sur les exigences de ventilation.

INSTALLATION DANS UNE ALCOVE OU UN PLACARD

1. Toute secheuse installee dans une chambre a coucher, une

salle de bain, une alc6ve ou un placard DOIT_tre reliee a une

conduite d'_vacuation d'air se terminant _ I'exterieur de la

maison.

2. Aucun autre appareil brOlant du combustible ne dolt _tre

installs dans le re&me placard que la secheuse au Gaz.

3. La secheuse a besoin d'un degagement suffisant pour

permettre la circulation de I'air.

NE PA S iNS TALLER LA SECHEUSE DA NS UN PLA CA RD PO URVU

D'UNEPORTE PLEINE.

4. Une ouverture minimum de 774,2 cm 2(120 po 2) repartie

_galement entre le haut et le bas de la porte est requise. Cette

ouverture ne dolt pas _tre obstruee Iorsque la porte est en place.

Une porte a volets dont les ouvertures totalisent la norme decrite

ci-dessus est acce _table.

60 SQ. IN.

387.1 SQ. CM)

60 SQ. IN.

(387.1SQ.CM)

PORTE DU ARMOIRE 10

4.

Lots de I'installation d'une secheuse a gaz dans une maison

mobile, il faut prevoir un apport d'air exterieun L'espace

prevoir dolt &tre superieur _ deux fois celui du conduit d'_vac

-cuation de la secheuse.

L'installation DOlT respecter les normes de la Manufactured

Home Construction and Safety,(r_glement federal titre 24CFR,

partie 32-80), ou en leur absence, les normes de la American

National Standard pour maisons mobiles. Lorsque L'installa-

tion se fait au Canada, elle dolt se conformer a la norme ACNO

RZ240.

Le combine est con_ue conformement a la

norme ANSI Z 21.5.1 pour un USAGE DOMESTIQUE seulement.

Page 11

Dimensions de l'emplacement _ 25lj.,,. _

(64.13CM)

47 _

\

2I/2IN.

(6.35 CM)

12 _/2 IN _ , 9 3/8 IN

(31.7scM)_- ---_"I (23.81c_

VEN_It'x _!

75 1/2IN,

(191,77 CM)

54 5/16 IN.

(137,95 CM)

43 IN.

(109,22 CM)

r _r

....................................................................................................................................................................................._jiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_jiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_jiiii........................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................i_

ONNEXCIONS I_LECTRIQUI:

ARRIVI_ES D'EA_ "dL_-

(ARRIIERE)

/_ VIDANGE

(ARRII_RE)

3%1N.

"_(9.52 CM)

u ii

27 IN.

(68.58CM)

5¼1N.

_13.33 CM)

-_( (109.22 CM)

29 7116 IN

(74,77 CM)

DL'BALLAGE

1. A I'aide des quatre encoignures d'expedition (deux de chaque

c6te) posez avec attention le combine sur le c6te gauche et

enlevez la base de caoutchouc mousse.

__ Poids excessif. Faites deplacer le Centre de

buanderie par deux personnes ou plus,

2. A I'aide de la cle et de la douille de 3/8 po. (0,96 cm) enlevez

le boulon d'expedition et I'entretoise en plastique du centre

de la base.

NOTA: Si le combin_ laveuse/secheuse doit _tre transporte

ulterieurement, il faut conserver le coussin de blocage de

la cuve, le boulon d'expedition et Pentretoise en plastique.

3. Replacez le combine laveuse/secheuse a la verticle.

ENTRETOISEEN

PLASTIQUE

COUSSINS D'EXPEDITION

TUYAUD'ALIMENTATION

EN GAZ (ARRII_RE)

43 IN.

41% IN

104,77 CM)

4. Enlevez:

5. A I'arri_re du combine, retirez les attaches m_talliques d'expe-

6. Avant d'entreprendre I'installation, deplacez precautionneuse

1718IN.

(4.76CM)

1

36 1/161N.

4 13/16 IN.

(12,22CM)

(91.60CM)

I

II

_30 13116 IN.

(78,26 CM)

(a) le coussin de blocage en mousse de la cuve.

(b) les coussins d'expedition en mousse a I'arri_re de

I'appareil

(c) le ruban adhesif de la porte de la s_cheuse.

(d) les supports en mousse de la secheuse.

(e) les tuyaux d'arrivee d'eau.

(f) I'emballage.

dition du boyau de vidange et du cordon d'alimentation (si

I'appareil en est muni). Des attaches en plastique fixent le

le boyau de vidange au c6te droit du combine. Ces attaches

forment une conduite verticale emp_chant I'effet de siphon.

N 'ENLEVEZ PAS CES ATTACHES.

-ment le combin_ a environ 4 pieds (1,22 m) de son em-

placement final.

117/16 IN.

(29.5CM)

D'EXPEDITION

BASE

D'EXPEDITION

ENMOUSSE

ENCOIGNURESD'EXPEDITION

(S!L'APPAREIL EN ESTMUNI)

BOYAU DE VIDANGE

11

Page 12

INSTALLATION L'LECTRIQUE

i ombin#/aveuse/s#cheusesEZECTR/OUES canadiennes i

TOUS combin_es/aveude/s_cheusesf'ZECTR/OUES ]

Les mises en garde qui suivent se

rapportent directement au branchement _lectrique correct et

securitaire de la s@cheuse. Toute derogation _ces mises en garde

pourrait entra_ner des risques choc electrique et d'incendie.

_Cet appareil DOITStre convenablement mis _la terre. SilecombinS

presenterait des risques choc electrique si elle n'etait pas

convenablement mise a laterre. Respecter les directives de mise _ la

terre contenues dans cette notice pour une raise _ la terre correcte.

P_Ne pas utiliser de cordon de rallonge avec ce combin& Certains

cordons de rallonge ne sont pas con_us pour supporter I'intensite du

courant qu'utilise cette combine; ils peuvent fondre et presenter un

risque choc electrique ou d'incendie. Placerla secheuse a portee de la

prise murale afin de dSterminer la Iongueur du cordon a acheter et

prevoir un certain jeu dans la Iongueur du cordon. Se reporter _ la

section <<AvantI'installation>> de cette notice pour savoir quel type de

cordon acheter.

I_1_ Un detendeur approuve par U.L doit Stre fixe au cordon

d'alimentation. Sile detendeur n'etait pas present, le cordon pourrait

Stre arrache de lacombine ou coups par tout type de mouvement, ce

qui presenterait un risque choc electrique.

ONe pas utiliser une prise a conducteurs en aluminium avec un

cordon ou une prisea conducteurs encuivre (hi I'inverse). Une reaction

chimique se produit entre le cuivre et I'aluminium qui pourrait causer

un court-circuit. II faut utiliser un cordon d'alimentation

conducteurs en cuivre avec une prise aconducteurs en cuivre.

_Le branchement inadequat du conducteur de mise

la terre pourrait presenter un risque choc Slectrique. En cas de doute

quant _ la mise _ la terre adequate de I'appareil, contacter un electricien

agreS.

Pour brancher et mettre _ la terre la secheuse _ I'aide d'un cordon

d'alimentation :

1. La secheuse doit Stre mise a la terre. En cas de mauvais

fonctionnement ou de panne, la mise _ la terre rSduit les risques

choc electrique en offrant un parcours de moindre resistance au

courant.

2. Puisque la secheuse est pourvue d'un cordon d'alimentation

electrique comportant un conducteur et une fiche de terre, la fiche

doit Stre branchee dans une prise murale a conducteur en cuivre

convenablement raccordee au reseau et mise a la terre

conformement a tous les codes et ordonnances Iocaux. En cas de

doute, contacter un electricien agre&

i OUS combines/aveuse/s_cheuses _ GAZ j

Pour votre protection contre les chocs Slectriques, la secheuse est

equipSe d'une fiche _trois bornes (raise _ la terre) et doit Stre branchee

directement dans une prise a 3 bornes correctement raise a la terre. Ne

pas couper ni enlever la fiche de raise & la terre de cette prise.

REMARQUE : Le delai sechage d'un combin_ laveuse/secheuse

qui fonctionnent avec une alimentation de 208 volts auront un

temps de s_chage plus long que celles qui utilisent une

alimentation de 240 volts.

MISE A LA TERRE

usLes_LECTRlOUESn°n-canadiennes I

ebranchement inadequat du conducteur de mise

la terre pourrait presenter un risque choc electrique. Encas de doute

quant a lamise alaterre adequate de I'appareil, contacter un electricien

agre&

Pour brancher et mettre _ la terre la secheuse a I'aide d'un cordon

d'alimentation :

1. Lascombine DOITStre mise_ la terre. En casde mauvais

fonctionnement ou de panne, la mise a la terre reduit les risques

choc electrique en offrant un parcours de moindre resistance au

courant.

2. Si la combine est pourvue d'un cordon d'alimentation electrique

comportant un conducteur et une fiche de terre, la fiche DOITStre

branchee dans une prise murale a conducteur en cuivre

convenablement raccordee au reseau et mise a la terre

conformSment a tous les codes et ordonnances Iocaux. En cas de

doute, contacter un electricien agre& Ne modifiezpas la prise

equipee d" appareil.

Pour brancher la secheuse en permanence :

La combine DOITStre branchee _ une installation metallique mise

la terre en permanence; sinon, un conducteur de mise a la terre

de I'appareil doit suivre les conducteurs du circuit et Stre branche

la borne ou _ la connexion de mise a la terre de I'appareil.

12

Page 13

BRANCHEMENT ELECTRIQUED'UNE

INSTALLATION A 3 FILS

/Von-canadien

[

1. Retirer les vis qui retiennent le couvercle

2. Poser un detendeur approuve par U.L. dansletrou du supporto0

3. Enfiler un cordon d'alimentation NEMA 10-30 approuve par U.L.

4. Fixer le conducteur neutre (conducteur central) du cordon

Combine/aveuse/s_cheuses EZECTR/OUES

du panneau de branchement ainsi que le

support de montage du detendeur situes

dans le coin superieur a I'arriere de la

secheuse.

s'insere le cordon d'alimentation. Serrer simplement I'_crou a la

main pour le moment.

de 30 Ade type SRDTdans le detendeur.

d'alimentation a la borne centrale argentee du panneau de

branchement. Serrer la visa fond.

BORNE

VlS DE MISE A LA ARGENTINE

FILDE

NEUTRE

1. Retirer les vis qui retiennent le couvercle

du panneau de branchement ainsi que le

support de montage du detendeur

situes dans le coin superieur a I'arri_re

de la secheuse.

2. Poser un detendeur approuve par U.L. dans le trou du support.

Serrer simplement I'ecrou a la main pour le moment.

3. Retirer le fil de terre de la vis de raise a la terre verte neutre situee

au-dessus du panneau de branchement.

4. Enfiler un cordon d'alimentation NEMA 10-30 approuve par U.L.

de 30 A de type SRDTdansle detendeur.

5. Fixer le fil de terre vert du cordon d'alimentation au bottier de la

secheuse a I'aide de la vis de raise _ la terre verte.

6. Fixer le conducteur blanc (neutre) du cordon d'alimentation ainsi

que le fil de terre neutre du bo_tier de la secheuse _ la borne

centrale argentee du bloc de branchement.

7. Fixer les conducteurs rouge et noir du cordon d'alimentation aux

bornes cuivrees exterieures du panneau de branchement.

8. Serrer _ fond les vis qui retiennent le dispositif de retenue du

cordon autour du cordon d'alimentation.

9. Reattacher le couvercle du panneau de branchement.

INSTALLATION

1. Faites couler de I'eau dans les robinets d'eau chaude et froide

pour purger les conduites d'eau et les debarrasser des partic-

ules pouvant obstruer le tamis du robinet d'eau.

2. Veifiez les boyaux d'arrivee d'eau pour assurer que les rondelles

en caoutchouc sont installees a chaque extr_mit&

3. Connectez soigneusement les boyaux d'arrivee au robinet d'eau

(a gaunch de I'appareil), serrez a la main, puis serrez 2/3 de

pinces.

5. Fixer les deux conducteurs restants du cordon d'alimentation aux

bornes cuivrees exterieures du panneau de branchement. Serrer

les deux visa fond.

6. Serrer a fond lesvis qui retiennent le dispositif de retenue du cordon

autour du cordon d'alimentation.

7. Reattacher le couvercle du panneau de branchement.

BRANCHEMENTELECTRIQUE D'UNE

INSTALLATION A 4 FILS

/Von-canadien

i

Combin_s /aveuse/s_cheuses EZECTRIOLIES

VIS DE MISE A LA -CONDUCTEURVERT BORNE

TERRE VERTE FIL DE TERRE _,RGENTIEE

FILDE

TERRE

NEUTRE

R_UGE

/

/ PANNEAU DE BRANCHEMENT

BLANC

SUPPORT DE

MONTAGEDU

DETENDEUR

NOIR

IL NE FA UT PA5 FA USSER LE FILETA GE

0 U TROP SERRER CES RA CCORDEMENTS.

4. Deplacez quel est le robinet d'eau CHAUD et branchez soig-

neusement le tuyau d'arrivee inferieur au robinet d'eau

CHAUDE serrez & la main puis serrez 2/3 de tour supplement-

aire a I'aide de pinces. Branchez soigneusement le tuyau

d'arrivee superieur au robinet d'eau FROIDE, serrez a la main

puis serrez 2/3 de tour supplementaire a I'aide de pinces.

IL NE FA UT PAS FA USSER LE FILETA GE

0 U TROP SERRER CES RA CCORDEMENTS.

Ouvrez I'eau et verifiez qu'il n y a aucune fuite dans les raccords.

5.

D_placez soigneusement la laveuse jusqu'_ son emplacement

definitif.

6.

Pour vous assurer que le combine est de niveau et repose

solidement sur ses quatre pieds, faites incliner le combine

vers I'avant de maniere _ soulever les pieds arrieres du

plancher. Replacez soigneusement le combin_ por que

les pieds arrieres se reglent d'eux m_mes. Placez un

niveau sur le dessus de la laveuse. Verifiez le niveau de

droite _ gauche et d'avant en arriere. Vissez ou devissez

les pieds de raise _ niveau avants pour assurer que le

combine repose solidement sur ses quatre pieds (le com-

bine ne doit aucunement osciller).

NOTA: La hauteur des pieds doit _tre fixee au minimum pour

eviter toute vibration excessive.

ORDON

D'AUMENTATK

Page 14

7. BRANCHEMENT DU GAZ (Combine a gaz seulement)

a. Retirer le couvercle qui recouvre le tuyau de gaz a I'arri_re de la

secheuse.

REMARQUE: NE PAS brancher la combine sur une alimentation

au propane sans avoir pose un necessaire de

conversion. Ce necessaire dolt _tre installe par un

technicien agre&

b,

Brancher un tuyau semi-rigide ou approuv_ de 1,27 cm

(1/2 po) de diam_tre interieur entre ia conduite d'alimentation

en gazet ie tuyau de 0,96 cm (3/8 po) situe sur i'arri_re de la

secheuse. Utiliser un r_ducteur de 1,27 cm-0,96 cm (1/2 po-

3/8 po) pour ie branchement. Appliquer un mastic de fermeture

pour filets approuve qui resiste a la corrosion qu'exercent ies

gaz liquefies sur tousies raccords de tuyaux.

c. Ouvrir le robinet d'arr_t de la conduite d'alimentation en gaz.

d. Verifier tousles branchements en versant de I'eau savonneuse

sur les joints. NE JAMAIS VERIFIER S'IL Y A DES FUITES A

L'AIDE D'UNE FLAMME VIVE.

8,

Repliez le boyau de vindage pour former un <U> a son extr_mit_

en direction de i'_vier ou du tuyau d'_gout, disposez le boyau

dans i'_vier ou le tuyau d'egout, et fixez-ie avec une attache de

cable fournie dans i'enveloppe jointe. L'EAU SERA SIPHON-

NEE DE L'APPAREIL SI LES INSTRUCTIONS PRECITeLES NE

SONT PAS PAS SUIVIES.

10. Reliez les conduits d'6vacuation d'air conduit d'6vacuation

extetieur. Utilisez un ruban adh6sif pour conduits pour

sceller lesjoints.

11. Brancher le cordon d'alimentation electrique dans une prise mise

a ia terre. REMARQUE : S'assurer que ie courant est coupe a ia boite

de fusibles ou de disjoncteurs avant de brancher le cordon

d'alimentation dans une prise.

12. Remettre le courant a la bofte de fusibles ou de disjoncteurs.

I ' " ' w ' Avant d'utiliser la combine, s'assurer que les

environs de/a secheuse sont exempts de tout materiau inf/ammab/e,

d' essenceet de toute autre vapeur inflammab/e. S'assurer ega/ement

qu'aucun objet (boOtes,v6tements, etc.) n'obstrue /acircu/ation de/'air

servant ala combustion et a la ventilation.

13.

Faire fonctionner la laveuse/secheuse sur un cycle complete

pour en v_rifier le fonctionnement.

REMARQUEt Darts ie cas des iaveuse/secheuses a gaz, ia

conduite dolt &tre videe de son air avant que ie br0ieur ne puisse

s'allumer. Si le brOleur ne s'aliume pas dans ies 45 secondes

qui suivent le premier demarrage, i'interrupteur de s0rete _teint

automatiquement le br0ieur. Si ceia se produit, remettre ia

minuterie a <<OFF>>et attendre 5 minutes avant de tenter une

nouvelle fois d'aliumer ie br0ieur.

14.

Si la combine ne fonctionne pas, passer en revue la section

de depannage incius dans le Guide de i'utilisateur avant

d'appeler un centre de service.

\

9,

Retirez les deux vis fixant le panneau d'acc_s avant de la

s_cheuse a la carrosserie de la s6cheuse. Soulevez le

panneau jusqu'a d_gagement des attaches. Retirez le

panneau et mettez-le c6t&

Access

Panel

Screws

15. Placer cette notice pres de la combine pour reference future.

REMARQUE: Un schema de cablage se trouve dans le panneau de

commande ou sous le couvercle de la secheuse.

PIECES DE RECHANGE

Pour obtenir des pi_ces de rechange pour la laveuse/secheuse,

contacter le magasin d'oO vient ia secheuse.

_,, • . w , Lorsdetouttravaild'entretienoudereparation

des commandes, etiqueter tous les cables avant de les debrancher.

Les erreurs de connexion de cable peuvent entra;ner un

fonctionnement incorrect et dangereux. Une fob la reparation ou

I'entretien termine, assurez-vous que I'appareil fonctionne

correctement.

Detruire le carton et les sacs en plastique apres

avoir debaiie ia combin& Des enfants risqueraient de s'en servir comme

jouet. Lescartons recouverts d'un tapis, d'un couvre-lit ou d'une feuille

de piastique peuvent former une chambre etanche et faire suffoquer

un enfant. Placer ie materiel d'emballage dans une poubelle ou les

mettre hors de portee des enfants.

T_ Lesdirectives qui figurent dans cette notice et

dans les autres documents qui accompagnent lasecheuse ne sauraient

couvrir toutes les circonstances et les situations possibles. IL FAUT

donc faire preuve de jugement et de prudence pendant I'installation,

I'utilisation et I'entretien de tout appareil _lectromenager.

14

Losque toutes les instructions sur la s6curit6 et le

fonctionnement sont bien comprises et qu'eiles sont

appliqu6es r6guli_rement, vous pouves profiter au

maximum des advantages de i'appareil.

Page 15

/ndice

MATER#A

Requerimientos de instalacion preliminares

Requerimientos electricos

Requerimientos del suministro de agua

Requerimientos de desagOe

Requerimientos del sistema de escape

Requerimientos del suministro de gas

Ubicacion

Instalacion en casasmOviles

Dimensiones para la instalacion

Desembalaje

Instalacion electrica

Requerimientos para la puesta a tierra

Conexi6nes el_ctricas - trifilares y tetrafilares

Instalacion

Repuestos

REQUERIM/ENTOS DE INSTALA CION

PREL#MINA RES

Herramientas y materiales necesarios para la instalacion:

1. Destornillador Phillips

2. Alicates universales

3. Nivel de carpintero

4. Destornillador para tornillo de cabeza plana o recta

5. Cinta para ductos

6. Ducto metalico rigido o flexible de 4"(10,2 cm)

7. Caperuza de salida

8. Sellador de tuberias (gas)

9. LLavede tubo de 3/8 de pulgada (0,96 cm).

Parasuseguridad, sigalasinstruccionescontenidas en

estemanualafin de reducira unminimo losriesgosde incendioo explosi6n

opara evitar dar]os materiales, lesionespersonaleso lamuerte.

Noalmaceneni utilicegasolinau otrosvaporesy Nquidosinfiamables

en laproximidad de6ste ode cualquier otro artefacto el6ctrico.

QUEDEBEHACERSIPERCIBEOLORA GAS

o Notrate de encender ningon artefacto el_ctrico.

• Notoque ningon interruptor el6ctrico; nouseningOntel(_fonoen

suedificio.

• Hagasalira todos losocupantes dela habitaci6n, del edificio ydel

lugar.

• Llamea suproveedor de gasdesdeeltel6fono de un vecino.Siga

las instruccionesdel proveedor degas.

• Sino Iogra comunicarsecon suproveedor de gas,Ilameal

departamento de bomberos.

LainstaJacibny eJserviciode mantenimiento debe de realizarJosun

instalador caNficado,laagenciade servicioso elproveedor de gas.

REQUERIMIENTOS ELL'CTRICOS

PAGINA

15

15

15

15

16

17

17

17

18

18

19

19

19-20

2O

2O

Ver CONEXIONES ELI_CTRICAS PARA SISTEMAS TETRAFILARES.

(Ca nad_i -un cord6n de suministro de energia de 4 alambres es instalado

en la secadora.)

TOMACORRIENTE- Eltomacorriente NEMA 10-30Rdebe estar ubicado

de manera que el cordon electrico Ilegue hasta el cuando lasecadora

este instalada. (Canada1- recept_iculo NEMA 14-30R.)

NEMA 10-30R NEMA 14-30R

I Centro de la vanderia a GAS I

ClRCUITO - Circuito individual derivado de 15 amp minimo, con

fusibles de retardo m_iximo o disyuntor.

ALIMENTACION ELECTRICA - Corriente alterna, monof_isica,

60 Hz, 120 voltios, trifilar.

CORDONELECTRICO - La secadora est,1 equipada con un cord6n

electrico trifilar pal

NOTA: No saque

por ning,_n motivo

la espiga de puesta

a tierra del enchufe,

Espiga

REQUERIMENTOS DE SUMINI5 lieu D_ A(JUA

LasIlaves del agua caliente y fria DEBERAN set instaladas a no

m_is de 42 pulgadas (106,68 cm) de la entrada de agua de su

centro de lavanderfa. La boca DEBE ser de 3/4 pulgada (1,9

cm) de di_imetro para que las mangueras de jardin puedan ser

conectadas. La presion de agua DEBE SER entre 10 y 1201bs./

pulg. 2(la maxima diferencia entre la presion no equilibrada del

agua caliente y frfa es 101bs./pulg.2) La compania de agua

potable puede informarle sobre le presi6n del agua.

[ Centro de/avanderia ELECTRICAS ]

CIRCUITO - Circuito derivado individual de 30 amperes, con fusibles

de 30 amp. del tipo de retardo minimo o disyuntores.

ALIMENTACIONELECTRICA - Corriente alterna, monof_qsica,60 Hz,

240 voltios; trifilar. (Canada1-240 voltios, monof_isico, 60 Hz,corrienta

alterna.)

CORDONELECTRICO - Enlasecadora seDEBEusar un cordon electrico

trifilar NEMA 10-30 tipo SRDTpara un voltaje nominal minimo de 240

voltios CA, 30 amp, con 3 conectores de horquillas con terminales

abiertosy extremos dirigidos haciaarriba o conectores de anillo cerrado

y marcados para uso en secadoras de ropa. Sisiendo instalado en una

nueva instalaciOn delcircuito delrama, unvehiculo casero, recreacional

(m6vil) manufacturado o un _ireaque prohiben el poner a tierra atrav_s

del conductor neutral, se DEBE utilizar un cordon electrico tetrafilar

NEMA 14-30tipo SRDToST(como seanecesario)para unvoltaje nominal

minimo de 240 voltios CA, 30 amp con 4 conectores de horquillas con

terminales abiertos y extremos dirigidos hacia arriba o conectores de

anillo cerrado y marcados para uso en secadoras de ropa.

REQUERIMINTOS DE DESAGUE

1. Capacidad para desaguar 17 galones por minuto,

2. Di_metrodelatomadeagua: 1-1/4 pulgadas (3,16) como

minimo.

3. Altura de la toma de

agua sobre el piso:

Altura minima: 1244cm)

33 pulgadas (83,82 cm)

Altura maxima: (83.82cm)

96 pulgadas (244 cm)

NOTA : Para las instalaciones que requieran un tubo de m_s

largo, pida a un tecnico capacitado que instale un tubo m_s largo,

P/N 131461201, disponsible en los disribuidores autorizados de

piezas de repuesto. Para los sistemas de drenaje en el piso, instale

un uego para detener laaccion de sifon, disponsible de una ferreteria

local.

15

/

g6"MaX,

Page 16

REQUERIMIENTOS DEL SISTEMA DE ESCAPE

Utilice solamente ductos met_ilicos, rigidoso flexibles de 4"

(10,2 cm) de di_imetro (minimo) y una caperuza de salida de uso

aprobado, con registros que giren hacia afuera que se abren cuando la

secadora se encuentra en funcionamiento. Cuando la secadora se

detiene, los registros se cierran autom_fticamente para evitar las

corrientes de airey la entrada de insectosy roedores. Para evita r obstruir

la salida, mantenga una altura libre minima de 12 "(30,5 cm) entre la

caperuza de salida y el piso o entre cualquier otra obstruccion.

Los siguientes requerimientos son

especificos para el funcionamiento correcto y seguro de su

secadora, El incumplimien to de estas instrucciones puede causar

prolongaci6n excesiva del tiempo de secado y riesgos de incendio.

I_No use carlo flexible de pkqstico ni papel metalizado para desagotar

la secadora.

Sepuede acumular un exceso de pelusas en el sistema de escape, crear

un riesgo y obstruir el flujo de aire. La restriccion del flujo del aire

prolongara el tiempo de secado. Si su sistema de escape actual tiene

ductos de pkqstico o de I_iminas metalicas delgadas, reempl_icelo con

un ducto met_flico rigido o flexible. Asegurese de que los ductos

existentes no tengan pelusas antes de instalar el ducto de la

secadora.

P_Si el escape de la secadora no se dirige al exterior, algunas pelusas

finas set,fin sopladas hacia el recinto donde se efectOa el lavado. La

acumulaci6n de pelusas en cualquier lugar de la casa, puede crear un

peligro para la salud y un riesgo de incendio, iEIsistema de escape de

la secaclora DEBE estar dirig ido hacia el exterior de la vivienda f

_No permita que los materiales combustibles (por ejemplo: la ropa.

cortinas/cortinajes, papel) tengan contacto con los ductos. El escape

de la secadora NO DEBE dirigirse hacia el interior de una chimenea,

hacia una pared, hacia el cielo raso o hacia cualquier otro espacio

reducido del edificio, donde puede ocurrir acumulacion de pelusas y

constituir un peligro de incendio.

_ Exceder la Iongitud del conducto rigido o los nOmeros de codos

permitidos en los diagramas "LARGO MAXlMO" puede disminuir la

capacidad de exhaustacion del sistema. Obstruir el conducto puede

provocar peligro de incendio, asi como aumentar el tiempo de secado.

_No coloque un filtro en el extremo del escape del sistema ni emplee

tornillos o remaches para ensamblar el sistema de escape. Las pelusas

podrian quedar atrapadas en los filtros, en los tornillos o en los

remaches, Io cual obstruiria el sistema de escape y crearia un riesgo de

incendio, asi como tambi_n prolongaria el tiempo de secado. Use una

caperuza de salida adecuada para el extremo del ducto que salga al

exterior de la vivienda y selle todas las juntas con cinta adhesiva para

ductos. Todos los accesorios de tuberia machos, DEBEN set instalados

aguas abajo del flujo de aire.

Riesgo de explosi6n. No instale la secadora

donde se quarda qasolina u otros materiales inflamables. Si la secadora

se instala en un garage, ella debe estar por Io menos 18 pulgadas (45,7

cm) por encima del suelo. El incumplimiento puede resultar en la

muerte, explosi6n, incendio, o quemaduras.

1. La constrapresion del sistema de escape NO DEBE exceder

0,6 pulgadas (1,52 cm) de columna de agua, medida con un

man6metro inclinado en la conexiOn del ducto de escape a

la secadora.

2. El sistema de escape debe set inspeccionado y limpiado

cada 2 anos como minimo, bajo condiciones de uso normal.

Mientras masse use la secadora, con mayor frecuencia

deben inspeccionarse el sistema de escape y la caperuza

de salida para verificar su buen funcionamiento.

El largo maximo sistema de escape depende del tipo de ducto

que se usa, del numero de codos y del tipo de caperuza de salida.

En la tabla se muestra el largo maximo tanto para ductos

flexibles como rigidos.

EXHAUST DUCT LENGTHS

EXHAUST HOOD TYPE

Turns _'_

of 90° __ J_

(102 CM) vered (6.u5 CM)

MAXIMUM LENGTH OF 4-INCH {10.2 CM)

DIAMETER RIGID METAL DUCT

0

1

2

3

56 ft. (17.07 m) 42 ft. (12.8 m)

46 ft. (14.02 m) 36 ft. (10.97 m)

34 ft. (10.36 m) 28 ft. (8.53 m)

32 ft. (9.75 m) 18 ft. (5.48 m)

MAXIMUM LENGTH OF 4=INCH (10.2 CM)

DIAMETER FLEXIBLE METAL DUCT

o

1

2

3

30 ft. (9.14 m) 22 ft. (6.7 m)

22 ft. (6.7 m) 14ft. (4.27 m)

16 ft. (4.88 m) 10 ft. (3.05 m)

10 ft. (3.05 rn) 5 ft. (1.5 rn)

5e puede colocar el ducto de escape de cuatro (4) maneras

distintas cuando el artefacto est_ instalado con el fondo paralelo

con la pared.

1. Derecho hacia arras.

2. Hacia abajo - ducto rigido, 8 pulgadas (20.32 cm) de Iongitud

y 4 pulgadas (10,16 cm) de diametro & 1 ducto acodado hacia

abajo.

3. Hacia la izquierda - ducto rigido, 8 pilgadas (20,32 cm) de

Iongitud y 4 pulgadas (10,16 cm) de diametro, 1 ducto aco-

dado hacia abajo y un ducto acodado hacia la derecha.

4. Hacia la derecha - ducto rigido, 8 pulgadas (20,32 cm) de

Iongitud y 4 pulgadas (10,16 cm) de diametro, 1 ducto aco-

dado hacia abajo y un ducto acodado hacia la derecha.

Para colocar el ducto de escape hacia arriba, anada un ducto

de 11 pulgadas (27,94 cm) de Iongitud y de 4 pulgadas (10,16

cm) de diametro y un ducto acodado de 90° . El artefacto debe

estar a aproximadamente 4 1/2 pulgadas (11,43 cm) de la pared

(Se puede colocar el ducto de escape paralelo con la pared por

colocarlo debajo de la secadora y dirigirlo hacia un lado).

Una caperuza de escape colocada en forma tal que se alinie

con el escape de la secadora, puede ser instalada directamente

a traves de la pared exterior. Para colocar el ducto de escape

hacia arriba, anada un ducto 11 pulgadas (27,94 cm) de Iongitud

y 4 pulgadas (10,16 cm) de diametro y un ducto acodado de 90 °.

El artefacto debe estar a aproximadamente 4 1/2 pulgadas (11,

43 cm) de la pared (se puede colocar el ducto de escape paralelo

con la pared colocandolo debajo

de la secadora y dirigido hacia un

lado). Para permitir el escape

lateral o inferior, agregue un ducto