SERVICE MANUAL

DEHUMIDIFIER

MODELS:

1 Speed 2 Speeds

FDH25J FDD40J

FDH30J FDD50J

FDD60J

P/N 5995334660 May 2000

TABLE OF CONTENTS

SAFE SERVICING PRACTICES - ALL APPLIANCES............ 3

INTRODUCTION

Uncrating ........................................................................................................................................... 4

Model & Serial Numbers .................................................................................................................. 4

Basic Operation and Initial Startup ................................................................................................. 4

Electrical Information ....................................................................................................................... 5

Compressor Information .................................................................................................................. 5

OPERATION & REPAIR INSTRUCTIONS

Bucket ................................................................................................................................................ 6

To Remove Bucket ..................................................................................................................... 6

To Remove Front Grille .................................................................................................................... 6

To Remove Top Cover ...................................................................................................................... 6

To Remove Wrapper ......................................................................................................................... 6

Control Assembly ............................................................................................................................. 7

To Remove Control Assembly................................................................................................... 7

To Remove Humidistat ............................................................................................................... 7

To Remove Full Bucket Pilot Light........................................................................................ 8

To Test Fan Speed Switch ......................................................................................................... 8

To Remove Fan Speed Switch .................................................................................................. 8

Bucket Switch ................................................................................................................................... 8

To Remove Float: ....................................................................................................................... 8

To Remove Bucket Switch ........................................................................................................ 8

To Test Bucket Switch ............................................................................................................... 9

Defrost Thermostat ........................................................................................................................... 9

To Remove Defrost Thermostat ................................................................................................ 9

To Test Defrost Thermostat ....................................................................................................... 9

Motor, Motor Bracket & Blower Wheel ........................................................................................... 9

To Remove Blower Assembly .............................................................................................. 9-10

To Test Motor ............................................................................................................................ 10

To Remove Casters......................................................................................................................... 10

Compressor ......................................................................................................................................11

Permanent Split Capacitor (PSC) Compressor ......................................................................11

Split Phase Compressor ...........................................................................................................11

To Test Compressor Motor .......................................................................................................11

Possible Causes of Compressor Overloading or Overheating ............................................ 11

Compressor Test Cord for PSC Compressor .........................................................................11

Compressor Test Cord for Split Phase Compressor ............................................................ 12

Running Capacitors ................................................................................................................. 12

To Test Capacitor...................................................................................................................... 12

Compressor Overload Protector ............................................................................................ 12

To Test Overload ...................................................................................................................... 12

To Test Relay (Split Phase Compressor)................................................................................ 12

To Replace Relay (Split Phase Compressor) ......................................................................... 12

1

REFRIGERANT SYSTEM SERVICE INSTRUCTIONS

Definitions ....................................................................................................................................... 13

Recovery ................................................................................................................................... 13

Recycling .................................................................................................................................. 13

Reclaim...................................................................................................................................... 13

Safety Warnings .............................................................................................................................. 13

Compressor Testing ................................................................................................................. 13

Charging Sealed Systems ....................................................................................................... 13

Soldering .................................................................................................................................... 13-14

Sealed System................................................................................................................................. 14

Sealed System Diagnosis

Undercharged System .............................................................................................................14

Overcharged System ............................................................................................................... 14

Pressure Equalizing (System Unloading) .............................................................................. 14

Refrigerant Leaks ................................................................................................................ 14-15

Component Replacement............................................................................................................... 15

Compressor Replacement ............................................................................................................. 15

To Flush The System ............................................................................................................... 15

To Use Refrigerant To Flush The System .............................................................................. 15

Installing a New Compressor ............................................................................................. 15-16

To Remove Evaporator or Capillary Tube .............................................................................. 16

To Remove Condenser ............................................................................................................ 16

Filter Dryer ................................................................................................................................ 16

Evacuating & Recharging .............................................................................................................. 16

Equipment Needed ................................................................................................................... 16

Installing Evacuation & Recharging Equipment ................................................................... 17

Evacuating System .................................................................................................................. 17

Charging The System .............................................................................................................. 17

Final Leak Test.......................................................................................................................... 17

WIRING DIAGRAMS - DATA SHEETS

Electrical Wiring Diagrams

Single Speed Fan - Models with Reciprocating Compressors ............................................ 18

Two Speed Fan - Models with Reciprocating Compressors ................................................ 19

Two Speed Fan - Models with Rotary Compressors............................................................. 20

Dehumidifier Rating Sheets

Models FDH25J & FDH30J....................................................................................................... 21

Model FDD40J........................................................................................................................... 22

Model FDD50J........................................................................................................................... 23

Model FDD60J........................................................................................................................... 24

2

SAFE SERVICING PRACTICES - ALL APPLIANCES

To avoid personal injury and/or property damage, it is important that Safe Servicing

Practices be observed. The following are some limited examples of safe practices:

1. DO NOT attempt a product repair if you have any doubts as to your ability to

complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance:

Remove the power cord from the electrical outlet, trip the circuit breaker to the

OFF position, or remove the fuse

Turn off the gas supply

Turn off the water supply

3. Never interfere with the proper operation of any safety device.

4. USE ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE.

SUBSTITUTIONS MAY DEFEAT COMPLIANCE WITH SAFETY STANDARDS

SET FOR HOME APPLIANCES.

5. GROUNDING: The standard color coding for safety ground wires is GREEN, or

GREEN with YELLOW STRIPES. Ground leads are not to be used as current

carrying conductors. It is EXTREMELY important that the service technician

reestablish all safety grounds prior to completion of service. Failure to do so will

create a hazard.

6. Prior to returning the product to service, ensure that:

All electrical connections are correct and secure

All electrical leads are properly dressed and secured away from sharp edges,

high-temperature components, and moving parts

All non-insulated electrical terminals, connectors, heaters, etc. are adequately

spaced away from all metal parts and panels

All safety grounds (both internal and external) are correctly and securely

connected

All panels are properly and securely reassembled

WARNING

This service manual is intended for use by persons having electrical and mechnical training and

a level of knowledge of these subjects generally considered acceptable in the appliance repair

trade. Frigidaire cannot be responsible, nor assume any liability, for injury or damage of any kind

arising from the use of this manual.

3

INTRODUCTION

This Service Manual may be used to service the following Dehumidifiers:

ledoMeziSlortnoCdeepSrosserpmoC

J52HDFtniP52deepS1gnitacorpiceResahPtilpS

J03HDFtniP03deepS1gnitacorpiceResahPtilpS

J04DDFtniP04oL-iH/deepS2gnitacorpiceResahPtilpS

J05DDFtniP05oL-iH/deepS2yratoRCSP *

J06DDFtniP06oL-iH/deepS2yratoRCSP *

* roticapaCtilpSyltnenamreP

Uncrating

Uncrating instructions are clearly printed on the shipping

carton. See figures 4a and 4b to remove the unit from the

carton.

Figure 4a

Figure 4b

Model & Serial Numbers

Model and Serial numbers are found on the Serial Plate

located on the Front Panel directly behind the Bucket.

Figure 4c

rosserpmoC

rotoM

Basic Operation and Initial Startup

The Dehumidifier consists of a small refrigeration system

and a fan. The fan moves the moisture-laden air over the

evaporator and condenser. The moisture from the air

condenses on the cold evaporator surface where it drips

into a bucket. A drain hose can be connected to the bucket.

The cool air then passes over the warm condenser, raising

its temperature. Since this air contains less moisture and

is warmer, its relative humidity is lower. This drier air is

expelled through the side grille and mixes with the room

air.

Place the Dehumidifier on a level surface with all four

casters resting firmly on a solid floor. Since the

dehumidifier draws in air through the front grille and

exhausts out the left side louvers, the unit may be

positioned against a wall, but care should be taken not to

obstruct this air flow with furniture, walls, etc. Maintain at

least 2 feet clearance at left side and front. Shut all doors

and windows to the area to be dehumidified.

For the first operation, turn the Humidity Control to the

MAX position. This aids moisture removal from

furnishings as well as room air. When you feel a desired

level of dryness has been reached, adjust the Humidity

Control to your particular comfort level.

Prior to emptying the bucket, turn the Dehumidifier OFF

and disconnect the power cord. This eliminates any

possibility of electrical shock if you spill water, and there

is a fault in the grounding system of the unit or your home

wiring. Ensure the area, the Dehumidifier, and you are

dry before reconnecting the power cord.

A light coating of frost on the coil is normal when the

Dehumidifier is first turned "ON". Under normal conditions,

it will disappear in 30 to 45 minutes. If it doesnt disappear,

shut if off, and wait for it to defrost before running again.

4

Electrical Information

The Dehumidifier must be plugged into a 115 Volt, 60 Hz, AC only electrical outlet. The circuit should be protected by

a 15 Amp circuit breaker or 15 amp time-delay type fuse.

CAUTION: If voltage varies by ±10% of 115 volts, performance of the Dehumidifier may be affected.

Operating the Dehumidifier with insufficient power can damage the compressor.

The Dehumidifier power cord is equipped with a three prong grounding plug. It must be plugged directly into a

properly grounded three prong receptacle. The receptacle must be installed in accordance with local codes and

ordinances. A power cord about 6 feet long permits locating a unit suitably in most homes without the use of an

extension cord. An extension cord can become a shock hazard if it rests on a damp floor or if water spills on it. Do not

use an extension cord or an adapter plug.

Compressor Information

There are two types of compressors used on Dehumidifiers:

gnitacorpiceRediS-woL

rosserpmoCnotsiP

roedis-wolhtiwsetareporosserpmocsihT

.llehsrosserpmocehtnihtiwerusserpnoitcus

nwardsirotaropaveehtmorfropavtnaregirfeR

erofebsgnidniwrotomehtloocotllehsehtotni

siropaverusserphgiH.desserpmocgnieb

.resnednocehtotniyltceriddegrahcsid

:ETON gnitacorpicernahtssecorpnoitaregirferehttratsotregnolekatsrosserpmocyratoR

yratoRediS-hgiH

rosserpmoC

tnaregirfererusserpwolswardrosserpmocsihT

ehtotniyltceridrotaropaveehtmorfropav

siropaverusserphgiH.rebmahcnoisserpmoc

tierehwllehsrosserpmocehtotnidegrahcsid

otnignissaperofebtaehrotomssecxepuskcip

.resnednoceht

ehtfoerutarepmetehtelihwtahtsinosaerehT.emitnwoddednetxenaretfasrosserpmoc

foepytrehtien,erutarepmettneibmaehtfonoitautculfehthtiwegnahcresnednocdnarotaropave

metsysehtnitnaregirferehtfollaecnis,dnA.ssamelbatserutarepmetaedivorpnacrosserpmoc

rosserpmocyrator"edis-hgih"eht,sdoirepeldidednetxegnirudllehsrosserpmocehtnisesnednoc

pmupdnatnaregirferehteziropavotrosserpmocdnarotomehtybdetarenegtaehnopusdneped

srewolylkciuqrosserpmocgnitacorpicer"edis-wol"eht,dnahrehtoehtnO.metsysehthguorhtti

.metsysehthguorhttipmupyletaidemmidnaretsafeziropavottignisuacdiuqilehtnoerusserpeht

CAUTION: Replacement compressors are charged with oil at the factory. Care should be exercized

when replacing a compressor to avoid spilling any oil.

Rotary compressor hold down nuts must be torqued to 50 in/lbs to prevent loosening.

The motor for the Rotary compressor is a Permanent Split Capacitor (PSC ) motor with Start and Run windings. A

capacitor is wired in series with the Start winding. When power is applied, the capacitor assists in bringing the compressor

motor to optimum speed.

The motor for the Reciprocating compressor is a Split Phase. This compressor has a Start and Run winding, with a

current activated relay or PTC (Positive Temperature Coefficient) relay. When power is applied to the Run winding (on

models with current relay), the high starting current pulls the relay armature up, closing contacts, and completing the

circuit to the Start winding. The motor starts and accelerates to a point where the current is reduced enough to allow

the relay to drop out and disconnect the circuit to the Start winding. This point occurs at about 80% of full speed. The

motor continues to accelerate to full speed on the Run winding alone. On models with PTC relay, current is applied to

both windings at the same time. This starts the compressor. As current flows through the relay to the Start winding, the

relay will increase in resistance . Within a fraction of a second, the resistance will climb high enough for the Start

winding to drop out.

5

OPERATION & REPAIR INSTRUCTIONS

Bucket

The bucket is mounted to the front of the chassis and is

located beneath the cooling coil to catch the condensate.

A float mounted on the bucket is used to activate a switch

to shut off the unit when the bucket is full of water.

If the unit is to be installed near a floor drain, a permanent

drain hose may be attached to the threaded hose

connection on the bucket. If you want water to flow directly

into the drain, place the hose connection of the bucket

directly over the drain. When using either method of

draining, a plastic membrane in the hose connection of

the bucket must be cut out in order to permit the water to

flow into the hose or drain. To return to bucket collection,

the hose connection may be closed with a standard

threaded cap.

To Remove Bucket

1. Disconnect dehumidifier from electrical supply.

2. Pull bucket toward you, releasing actuator from

float assembly. (See Figures 6a and 6b.)

3. Reverse procedure to complete repairs.

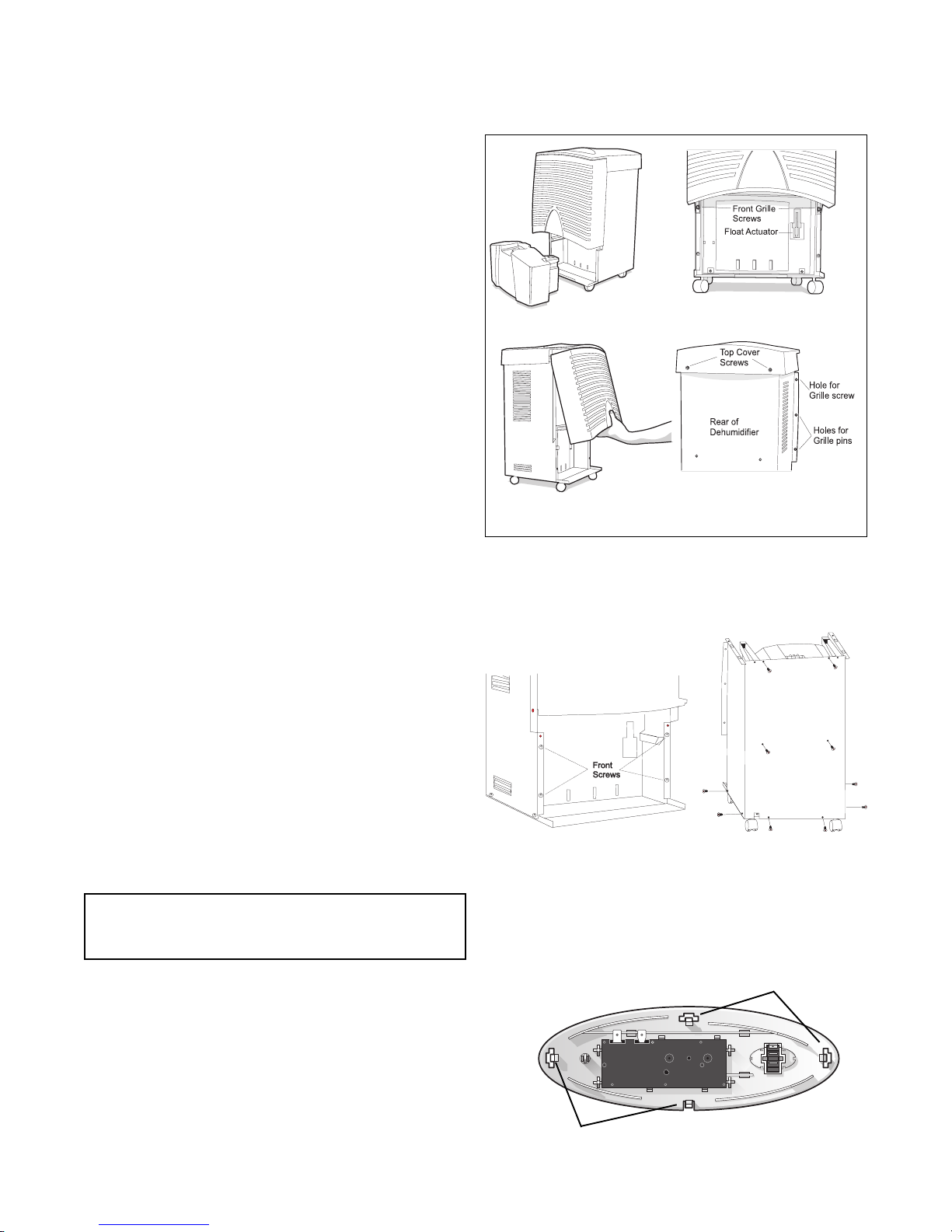

To Remove Front Grille

1. Disconnect dehumidifier from electrical supply.

2. Remove two screws at lower front of grille. (See

Figure 6b.) Note: Bucket must be removed to gain

access to these screws.

3. Remove two screws in upper holes in rear of

cabinet flange. (See Figure 6d.)

4. Pull grille toward you so the two pins on each side

of grille will pull free of holes in cabinet. (See

Figure 6c and 6d.)

5. Pull grille down to release from top cover.

6. Reverse procedure to reassemble.

To Remove Top Cover

1. Disconnect dehumidifier from electrical supply.

2. Remove front grille.

3. Remove two screws on rear of dehumidifier

holding top cover to cabinet. (See Figure 6d.)

4. Slide cover to rear to release tabs from flange.

NOTE: The Control Assembly is attached to the top

cover. This must be removed before the top cover

can be lifted up and off of the unit.

Figure 6a

Figure 6c

Figure 6b

Figure 6d

To Remove Wrapper

1. Disconnect dehumidifier from electrical supply.

2. Remove front grille and top cover.

3. Remove 14 screws from wrapper as shown in

Figures 6e and 6f.

Figure 6e Figure 6f

4. Grasp wrapper on its left and right sides, pulling

outward, then pull toward you and lift free of

dehumidifier.

5. Reverse procedure to reassemble.

5. To release the Control Assembly from the top cover,

press in on the four tabs, on the underside of the

top cover. (See Figure 6g.) Electrical wires are still

connected to assembly, so be careful.

6. Lift cover up and off.

6. Reverse procedure to reassemble.

Tabs

Tabs

Figure 6g

6

Control Assembly

The overlay of the Control Assembly for the two speed

models displays an Humidity Control Switch,

(humidification min. to max. range), Fan Speed Switch

(HI and LO), and a Bucket Full LED. (See Figure 7a1.)

On the single speed model, there is no Fan Speed Switch.

(See Figure 7a2.) A Humidistat cycles both the fan and

compressor ON or OFF to maintain humidity at the set

level. The humidity sensing element is a nylon film which

stretches with increased humidity and contracts with

decreased humidity. This action turns a switch in the

control ON and OFF to cycle the unit.

Figure 7a1

4. Disconnect two black wires and one red wire

connected to Fan Speed Switch. (Only on two

speed models.)

5. Remove control assembly.

6. Reverse procedure to reassemble.

To Remove Humidistat

1. Disconnect dehumidifier from electrical supply.

2. Remove control knob from front of control

assembly.

3. Disconnect three black wires connected to two

terminals on Humidistat.

4. Pull back on four tabs to release the humidistat.

(See Figure 7c.) Pull back on top tabs first, tilting

humidistat towards you, then pull back on bottom

tabs and pull humidistat free from assembly.

5. Reverse procedure to reassemble.

Figure 7a2

To Remove Control Assembly

1. Disconnect dehumidifier from electrical supply.

NOTE: See Figure 7b for location of electrical wires.

2. Disconnect one red and two white wires connected

to Bucket Full Light. (One of the white wires is

pigtailed to the red wire on one of the terminals.)

3. Disconnect two black wires connected to

Humidistat.

Figure 7c

Figure 7b

7

To Remove Full Bucket Pilot Light

1. Disconnect dehumidifier from electrical supply.

2. Disconnect three wires connected to two

terminals on pilot light. (See figure 7b.)

3. Using needle nose pliers, squeeze plastic tabs

against pilot light and push light through hole in

assembly. (See Figure 8a.)

Bucket Switch

The bucket switch is a Single Pole, Double Throw (SPDT)

device that shuts off the dehumidifier when the bucket is

full. The switch is activated by a float (see Figure 8c)

mounted inside the bucket. The switch is mounted to the

frame directly behind the bucket. (See Figure 8d.)

NOTE: This unit will not operate with the bucket

removed.

Figure 8a

To Test Fan Speed Switch (2 speed models only)

1. Disconnect dehumidifier from electrical supply.

2. Disconnect three wires connected to three

terminals on fan switch.

3. Using a multimeter on resistence scale, take

following readings: (See Figure 8b.)

With fan switch in HI:

Terminals 1 & 2 0 ohms

Terminals 1 & 3 max resistence

Terminals 2 & 3 max resistence

With fan switch in LO:

Terminals 1 & 2 max resistence

Terminals 1 & 3 0 ohms

Terminals 2 & 3 max resistence

Figure 8b

To Remove Fan Speed Switch (2 speed models only)

The Fan Speed Switch is very difficult to remove without

destroying it. Do not attempt to remove the switch unless

it is faulty. Then, it really doesnt matter if the switch is

damaged during removal. However, do be careful not to

damage the control assembly during removal. The new

switch will fit into place nicely once the faulty switch has

been removed.

Figure 8c

Figure 8d

To Remove Float:

1. Disconnect dehumidifier from electrical supply.

2. Remove bucket. (See procedure To Remove

Bucket on page 6.)

3. Drain any condensate

that may be in the

bucket.

4. Remove pin holding float

to bucket. (See Figure 6e.)

5. Remove float through top

access hole in bucket.

6. Reverse procedure to

reassemble.

Figure 8e

NOTE: When reinstalling float into bucket, ensure

the float is positioned so the tongue protrudes

through the front hole in the bucket. Then the pin is

inserted through the hole in the tongue and snapped

into the slot in the bucket.

To Remove Bucket Switch:

1. Disconnect dehumidifier from electrical supply.

2. Remove three electrical leads from terminals on

bucket switch.

3. Squeeze tabs together and push up on switch from

bottom. (See Figure 8f.)

Figure 8f

8

To Test Bucket Switch:

1. Test resistance between three terminals on switch.

(See Figura 9a.)

2. Using Multimeter on resistance scale, with switch in

AT REST position, resistance readings should be

as follows :

Common - Normally Open = Max. resistance

Common - Normally Closed = Zero resistance

With switch arm DEPRESSED, readings should be

as follows:

Common - Normally Open = Zero resistance

Common - Normally Closed = Max. resistance

3. Replace switch if readings are not within range.

Figure 9a

Defrost Thermostat

The defrost thermostat is mounted on the suction line close

to the compressor. When the ambient temperature drops

below 65°F, the evaporator coil temperature also drops

and frost begins to form on the evaporator surface. When

the suction line temperature reaches 37°F at the location

of the defrost thermostat, the thermostat opens the circuit

to the compressor. When the accumulated frost melts and

the suction line has warmed to 59°F, the defrost thermostat

closes, allowing the compressor to restart. The fan motor

will continue to run when thermostat is open.

To Remove Defrost Thermostat:

1. Disconnect dehumidifier from electrical supply.

NOTE: Refer to procedures on page 6 to remove

bucket, front grille, top cap and wrapper.

2. Remove bucket, front grille, top cap and wrapper.

3. Locate defrost thermostat just above compressor

on suction line.0

4. Disconnect two wire leads from thermostat.

5. Remove insulation from around Defrost Thermostat

so spring clip is exposed.

6. Press on spring clip with thumb and raise thermostat free from evaporator coil.(See Figure 9b.)

7. Reverse procedure to reassemble.

To Test Defrost Thermostat:

1. Using Multimeter on resistance scale, read

resistance of thermostat between the two leads. At

room temperature (above 60°F), resistance should

be zero (0), indicating the thermostat is closed.

2. To see if thermostat opens when temperature drops

to 37°F, bury thermostat in bucket of ice. With

multimeter still connected to two thermostat leads,

watch resistance scale to see if it goes to maximum

when temperature drops to 37°F. (Place

thermometer in ice bucket to monitor exact

temperature at which thermostat opens.)

3. Replace thermostat if readings are not within limits.

NOTE: When replacing the thermostat, make sure

the insulation is wrapped firmly around the

thermostat to prevent heat loss.

Motor, Motor Bracket and Blower Wheel

The shaded pole Fan Motor can be single or two speed,

depending on the model. The motor turns a Blower Wheel

(7 L x 2 W) rather than a fan blade.This motor does not

have a Start winding, but instead employs a shading coil

in the stator to produce starting torque in the proper

direction. When the motor speeds up, the shading coil

does not affect the motors operation.

The fan motor is permanently lubricated. However, some

motors have oil ports and should be oiled after two years

of service.

To Remove Blower Assembly

1. Disconnect dehumidifier from electrical supply.

NOTE: Refer to procedures on page 6 to remove

bucket, front grille, top cap and wrapper.

2. Remove bucket, front grille, top cap and wrapper.

3. Remove four screws from motor bracket. (See

Figure 9c.)

4. Pull blower assembly towards you and lift up and

out of unit. (See Figure 9d.)

Figure 9b

Figure 9c Figure 9d

9

5. Disconnect three wires going to the Control

Assembly.

6. Use a pair of pliers to remove compression clamp

holding blower wheel to motor shaft. (See Figures

10c and 10d.)

7. Pull blower wheel off of motor shaft and free from

blower assembly.

Figure 10c

To Remove Casters

1. Disconnect dehumidifier from electrical supply.

2. Lay humidifier on floor, front grille facing up.

3. Use a hammer and screwdriver to release locking

tabs securing casters to base. (See Figure 10c.)

4. Reverse procedure to reassemble.

Figure 10c

Figure 10d

8. Lift off styrofoam scroll chassis.

9. To remove motor from motor bracket, remove two

hex head nuts holding motor to bracket.

10. Reverse procedure to reassemble.

NOTE: When reassembling blower wheel to motor

shaft, make sure blower wheel is pressed onto shaft

as far as it will go.

To Test Motor

1. Using an ohmmeter, take resistance readings of

HI and LO speed windings. Readings should be as

follows:

LO Speed Red & White leads 45W ± 10%

HI Speed Black & White leads 30W ± 10%

2. If readings are not within limits, replace motor.

10

Compressor

There are two types of compressors used on

dehumidifiers:

1. Permanent Split Capacitor compressor (Rotary)

2. Split Phase compressor (Reciprocating)

Permanent Split Capacitor (PSC) Compressor

This compressor has a Start and Run winding with a

capacitor wired in series with the Start winding. When

power is applied, the capacitor assists in bringing the

compressor motor to optimum speed.

Split Phase Compressor

This compressor has a Start and Run winding. On models

equipped with a current activated relay, the relay is wired

in series with the Run winding. When power is applied to

the Run winding, The high starting current pulls the relay

armature up, closing contacts to complete the circuit to

the Start winding. The motor starts and accelerates to a

point where the current is reduced enough to allow the

relay to drop out and disconnect the circuit to the Start

winding. This point occurs at about 80% of full speed.

The motor continues to accelerate to full speed on the

Run winding alone. On models with PTC relay, current is

applied to both windings at the same time. This starts the

compressor. As current flows through the relay to the Start

winding, the relay will increase in resistance . Within a

fraction of a second, the resistance will climb high enough

for the Start winding to drop out.

CAUTION: Replacement compressors are charged

with oil at the factory. Care should be exercized when

replacing a compressor to avoid spilling any oil.

To Test Compressor Motor

WARNING: WHENEVER TESTING A

COMPRESSOR, EXTREME CAUTION SHOULD

BE USED TO PREVENT DAMAGING THE

TERMINALS. A COMPRESSOR WITH A

DAMAGED TERMINAL OR A GROUNDED

WINDING CAN EXPEL A TERMINAL FROM ITS

INSULATED HOUSING WHEN THE

COMPRESSOR IS ENERGIZED. IF THIS

HAPPENS, A MIXTURE OF REFRIGERANT AND

OIL WILL BE RELEASED THAT CAN BE IGNITED

BY AN EXTERNAL HEAT SOURCE (OPEN

FLAME, HEATER, ETC.). ALSO, IF THERE IS AIR

IN THE SYSTEM WHEN THIS HAPPENS, A

SPARK AT THE COMPRESSOR SHELL COULD

IGNITE THE REFRIGERANT AND OIL MIXTURE.

1. Disconnect dehumidifier from electrical supply.

2. Remove leads from compressor terminals.

3. Check for grounded windings by testing continuity

from each terminal to any copper tubing connected

directly to compressor. If continuity is indicated,

motor windings are grounded and compressor will

have to be replaced.

4. Check for open windings by checking continuity

from Start-to-Run terminals. If no continuity is

found, a winding is open and compressor must be

replaced.

Possible Causes of Compressor Overloading or

Overheating

1. Shorted winding. Recheck Start and Run windings.

2. Low voltage. With dehumidifier disconnected,

check voltage at electrical outlet. Voltage should be

of 115 VAC,+/- 10%.

3. Plug in dehumidifier and check voltage. If voltage is

not within +/- 10% of 115 VAC, compressor break

down or overheating may occur. Excessive voltage

drop during start-up or while running may be cause

of motor overload opening.

4. Defective run capacitor (if supplied). If compressor

will not start (or starts slowly), or compressor runs

but draws high current, test capacitor.

5. Dirty evaporator and/or condenser.

6. Insufficient air passing over condenser.

The compressor can also be operated on a test cord when

connected as illustrated below.

CAUTION: If compressor is a permanent split

capacitor type, use only a known good

electrolytic capacitor, rated for compressor

being tested. This running capacitor must be in

circuit while compressor is running.

Compressor Test Cord for PSC Compressor

NOTE: If compressor has a permanent split

capacitor (PSC) motor, running capacitor should be

tested first.

11

Compressor Test Cord for Split Phase

Compressor

Running Capacitors

Running capacitors are used on some compressor motors

to increase the efficiency of the motor by improving the

power factor.

Always replace running capacitors with capacitors of like

type and mF (microfarad) rating. Pay particular attention to

the voltage rating.

To Test Capacitor

WARNING: AN INTERNALLY SHORTED

CAPACITOR MAY EXPLODE IF ENERGIZED

DIRECTLY WITH LINE VOLTAGE. CHECK ONLY

WITH AN OHMMETER OR CAPACITOR TESTER.

AFTER TESTING, ALWAYS DISCHARGE

CAPACITOR WITH A 20,000W (OHM), 2 WATT

RESISTOR PLACED ACROSS THE TERMINALS.

1. Disconnect dehumidifier from electrical supply.

2. Remove wrapper.

3. Discharge capacitor.

NOTE: Best method of discharging capacitor is with

insulated copper wire in series with a 20,000 ohm,

2 watt resistor. Place this high resistance jumper

across capacitor terminals.

4. Disconnect capacitor wiring.

5. Connect ohmmeter across terminals of capacitor to

be checked:

a. If capacitor is good, needle should jump toward

zero ohms and quickly drop back to infinity.

b. If needle does not move, capacitor is open.

c. If needle reads constant value at near zero

ohms, capacitor is shorted.

d. If needle jumps toward zero and falls back to

constant high resistance value (not infinity),

capacitor has high resistance leak.

e. Check for ground from each terminal of capacitor

to bare metal of capacitor case. Resistance

should be infinite. If resistance is less than

infinite, capacitor is grounded.

Replace capacitor if it is open, shorted, grounded or has

a high resistance leak.

Compressor Overload Protector

An overload protector is attached to the compressor to

detect excessive heat or a current overload. If the overload

is actuated, it will shut off the current to the compressor

and automatically reset itself after a short cool down

period. The compressor will attempt to start after the cool

down period.

The overload is located under the terminal cover. To gain

access to the overload, disconnect the dehumidifier from

the electrical supply and remove the terminal cover.

To Test Overload

1. Disconnect dehumidifier from electrical supply.

2. Remove wrapper.

3. Remove terminal cover.

4. Disconnect all wiring to overload and check across

overload terminals with ohmmeter. (Overload

should be at room temperature when checked.)

Zero ohms (0W) should be indicated.

NOTE: Always replace terminal cover and gasket

to protect overload and compressor terminals from

moisture and corrosion.

To Test Relay (Split Phase Compressor)

1. Disconnect dehumidifier from electrical supply.

2. Remove relay and overload cover from

compressor.

3. Disconnect wire to relay and remove relay from

compressor terminals (pull straight off).

4. Check continuity of relay coil (refer to wiring

diagram for proper terminals to check across). If

relay coil checks OK, use compressor test cord to

test compressor.

5. If PTC relay is used, check resistance between L1

and Start winding. Resistance should be no more

than 4 ohms at room temperature.

To Replace Relay (Split Phase Compressor)

1. Disconnect humidifier from electrical supply.

2. Remove wrapper.

3. Remove relay cover from relay and overload.

4. Remove wire from relay and pull straight off.

5. Reverse procedures to reassemble.

12

REFRIGERATION SYSTEM & SERVICE

NOTICE: Instructions given here are furnished as a guide. Persons attempting to use these instructions to make

repairs to the sealed refrigeration system should have a working knowledge of refrigeration, previous training on

sealed system repair, and an EPA certification for servicing refrigeration systems.

IMPORTANT NOTICE

Effective July 1, 1992, the United States clean air act governs the disposal of refrigerants such as

R-22. Therefore, when discharging or purging the sealed system, use an EPA approved refrigerant

recovery system as outlined in the final rule on the protection of stratospheric ozone and refrigerant

recycling which was published in the Federal Register May 14, 1993.

NOTE: Frigidaire does not permit the use of recovered refrigerant in the servicing of our products for in-warranty

and out-of-warranty repairs or for products covered by service contracts. Therefore, only new refrigerant or

refrigerant that has been reclaimed back to new specifications by a refrigerant manufacturer is to be used.

DEFINITIONS

Recovery:

to remove refrigerant in any condition from a system and

store it in an external container without necessarily

testing or processing it in any way.

Recycling:

to clean refrigerant for reuse by oil separation and single

or multiple passes through devices, such as replaceable

core filter-driers, which reduce moisture, acidity and

particulate matter. This term usually applies to procedures implemented at the field job site or at a local

service shop.

Reclaim:

to reprocess refrigerant to new product specifications by

means which may include distillation. Will require chemical analysis of the refrigerant to determine that appropriate product specifications are met. This term usually

implies the use of processes or procedures available

only at a reprocessing or manufacturing facility.

SAFETY WARNINGS

Compressor Testing

Whenever testing a compressor, extreme caution should

be used to prevent damaging the terminals. A compressor with a damaged terminal or a grounded winding can

expel a terminal from its insulated housing when the

compressor is energized. If this happens, a mixture of

refrigerant and oil will be released that could be ignited

by an external heat source (open flame, heater, etc.).

Also, if there is air in the system when this happens, a

spark at the compressor shell could ignite the refrigerant

and oil mixture.

Charging Sealed Systems

Overcharging a refrigeration system with refrigerant can

be dangerous. If the overcharge is sufficient to immerse

the major parts of the motor and compressor in liquid

refrigerant, a situation has been created which, when

followed by a sequence of circumstances, can lead to

the compressor shell seam separating.

A hydraulic block then occurs, preventing the compressor from starting. This condition is known as locked

rotor. Electric current continues to flow through the

compressor motor windings which become, in effect,

electric resistance heaters. The heat produced begins

to vaporize the excess refrigerant liquid, causing a rapid

increase in system pressure. If the compressor

protective devices fail, the pressure within the system

may rise to extremes far in excess of the design limits.

Under these conditions, the weld seam around the

compressor shell can separate with explosive force,

spewing oil and refrigerant vapor which could ignite.

To eliminate this exceedingly rare but potential hazard,

never add refrigerant to a sealed system. If refrigerant

is required, evacuate the existing charge and recharge

with the correct measured amount of the refrigerant

specified for the system.

SOLDERING

WARNING: WEAR APPROVED SAFETY

GLASSES WHEN WORKING WITH OR ON

ANY PRESSURIZED SYSTEM OR

EQUIPMENT. HAVE AN APPROVED DRY TYPE

FIRE EXTINGUISHER HANDY WHEN USING

ANY TYPE OF GAS OPERATED TORCH.

1. All joints to be soldered must have proper fit.

Clearance between tubes to be soldered should be

from .001 to .006. It is not practical to actually

measure this; however, you do not want dry fit or

loose fit. Tubing joints should overlap about distance

of their diameter except for restrictor tubes, which

should be inserted 1.25

2. Clean all joint areas with fine steel wool or,

preferably, abrasive cloth, such as grit cloth No.

23 or Scotch-Brite.

13

3. Apply thin film of liquid flux recommended for silver

soldering to surfaces to be joined, and to surfaces

immediately adjacent to joint.

4. Align tubing so no stress is on joint. Do not move

tubing while solder is solidifying or leaks will result.

CAUTION: During application of heat, use

wet cloths to prevent heat from conducting to

areas other than soldered joint. Use a sheet

of metal as a heat deflector to keep flame

away from flammable materials and painted

surfaces.

5. Use torch of adequate capacity so joint can be

quickly heated with minimum of heat travel to

other points. Use good grade of silver solder.

6. Solder connections. If tubing is properly cleaned

and fluxed, solder will flow readily. Use only enough

solder to make a good bond.

7. Allow joint to cool, then wash exterior with water

to remove flux.

SEALED SYSTEM

The dehumidifying system is similiar to that of a room air

conditioner, except for size. The condenser and

evaporator are both fin and tube coils of copper tubing

with aluminum fins. Both coils are placed in the air

stream.

A capillary tube controls the refrigerant flow from the

condenser to the evaporator. The suction tube from the

evaporator outlet to the compressor is insulated to

prevent sweating.

NOTE: Check the performance of the dehumidifier

and electrical system before attempting to repair

the sealed system.

SEALED SYSTEM DIAGNOSIS

Undercharged System

Disconnect fan motor leads and start the unit. A slight,

uniform film of frost should form on the entire evaporator

within about 10 minutes. If it does not, the system is

possibly undercharged.

Overcharged System

Operate the unit for at least 30 minutes in a room

temperature of 75°F to 85°F. The top of the compressor

should be warm to the touch. This applies to a reciprocating compressor only. If it is cool or cold, the system

is possibly overcharged. On models eqipped with

Rotary compressors, check for frost or cold temperatures all the way to the top of the accumulator.

An overcharged system must be evacuated and

recharged. Purging off excess refrigerant is not legal or

practical, as there is no way of determining the amount

to purge.

Pressure Equalizing (System Unloading)

If an attempt is made to start the unit too soon after it has

stopped, the compressor may fail to start and will cycle

on the overload protector. This is caused by high head

pressure and low suction pressure. Allow the pressures

to equalize through the capillary tube. Pressure

equalizing (system unloading) will usually take 2 to 3

minutes.

Refrigerant Leaks

An undercharge of refrigerant is usually caused by a leak

in the system. Such leaks must be located, the

refrigerant recovered, and the leak repaired before

evacuating and recharging. Simply adding the refrigerant

or recharging will not permanently correct the problem

and may lead to a compressor burn out.

NOTE: Do not replace a component because the

system is undercharged unless a nonrepairable

leak is found within the system components.

If a leak cannot be readily found, the system should be

pressurized to at least 75 psig (gauge pressure). If

necessary, attach a ¼ line piercing valve to the compressor process tube and add enough refrigerant for

testing. (Only use the refrigerant specified on the serial

nameplate.)

NOTE: The line piercing valve (clamp-on type)

should be used for test purposes only. It must be

removed from system after it has served its purpose.

If an undercharged system is found, perform the

following:

Leak test unit.

Recover refrigerant.

Repair Leak.

Evacuate and recharge unit with proper amount of

refigeratant.

NOTE: Always leak test system after recharging.

Most leaks can be found with a Halide torch. However, for

very small leaks, it may be necessary to use an

Electronic Leak Detector, or the soap bubble method to

pinpoint the leaks.

CAUTION: Be sure the system has a positive

pressure before using the soap bubble method of

leak detecting. A vacuum within the system could

draw in moisture and contaminants.

After servicing a system, always leak test the entire

system, especially new joints before final recharging.

Clean off any soldering flux, if used, from the joints before

14

leak testing, as flux can seal off pinhole leaks that would

show up later.

COMPONENT REPLACEMENT

CAUTION: It is extremely important to verify

the type of refrigerant in a system before

starting any sealed system repair. Check

serial plate for the correct refrigerant type

and charge.

When replacing components, all copper joints must be

joined with silver solder or Sil-Fos.

CAUTION: Be careful not to damage adjacent

parts when using a torch on soldered joints. If

necessary, use a metal heat shield, or wrap a

wet cloth around the tubing to reduce heat

transfer.

COMPRESSOR REPLACEMENT

CAUTION: NEVER install a new compressor

without first checking for possible system

contamination.

CAUTION: The end of flushing hose of tank

regulator must be equipped with a hand

shut-off valve (Robinair No. 40380). Close

hand shut-off valve and adjust nitrogen regulator

to correct pressure before proceeding with

flushing procedure.

To Use Refrigerant To Flush The System:

CAUTION: Refrigerant used for flushing must

be captured in a recovery bag. Meter amount

of refrigerant used for flushing with your

charging cylinder. DO NOT OVERFILL THE

BAG.

1. Remove suction and discharge lines on compressor and

disconnect capillary tube from condenser. Connect process coupling to outlet and inlet tube of condenser.

2. Connect hose to outlet process coupling and

charging cylinder. Connect another hose to inlet

coupling and recovery bag.

3. Open charging cylinder and allow refrigerant to flow

through condenser until discharge into bag is clear.

4. Connect process fitting to compressor suction line.

Flush evaporator and capillary tube.

To check for contamination, obtain an oil sample from an

old compressor.

If oil has burned odor, but no color change or

residue follow instructions in section Installing A

New Compressor on page 14.

If oil has burned odor and shows contamination

(dark color) or feels gritty follow instructions in

next section, To Flush The System. Remove as

much contamination as possible from system

before installing new compressor.

To Flush The System

NOTE: The system should be flushed with dry

nitrogen. However, you must use R-22 if refrigerant

is used to flush system. This is the only refrigerant

that can be used to flush the system and it must be

recovered.

CAUTION: Use extreme care when using dry

nitrogen to flush systems. Pressure in nitrogen

cylinder could be as high as 2000 psi. Nitrogen

cylinder must be equipped with approved

pressure regulator and pressure relief valve.

Ensure that your hoses have adequate ratings

for pressure involved, and that all of your

equipment is in good condition.

NOTE: If unable to get refrigerant flow through

capillary tube, remove capillary tube from

evaporator and flush again.

5. If cap tube is blocked, replace cap tube.

6. Reassemble system.

Installing a New Compressor

All replacement compressors are shipped with rubber plugs in

the suction, discharge, and process tubes and contain the

correct oil charge and a holding charge of inert gas. Models with

Reciprocating Compressors have a low-side process tube

attached to the compressor shell. Models with Rotary

Compressors have a process tube on the high side of the

system soldered into the compressor discharge line

WARNING: DO NOT OPERATE COMPRESSOR

WHEN CHARGING LIQUID REFRIGERANT INTO

SYSTEM THROUGH ITS PROCESS TUBE.

Before installing the replacement compressor, remove the

discharge plug and check for the pop sound of the inert gas

leaving the compressor.

CAUTION: DO NOT use compressor if you do

not hear this sound.

A new compressor which is cold (e.g. after having been kept

in a cold service van) should be left to warm to the surrounding

temperature before the plugs on the compressor connections

are removed. This will help prevent condensation from forming

15

in the oil and the compressor. Also, avoid opening the system

when any of the components or lines are cold.

CAUTION: Release holding charge (release slowly

to avoid oil discharge) on new compressor to

ensure that there is no leak in seam or tubing. Then,

reinstall rubber plug.

1. Disconnect electrical supply to dehumidifier.

2. Remove bucket, front grille, top cap and wrapper.

3. Remove one screw at bottom of support of blower

motor assembly.

4. Bend all four tabs on top and bottom of condenser to

outside and pull blower assembly away from

condenser.

5. Recover refrigerant by using EPA approved

recovery system.

6. Remove leads from compressor motor terminals.

7. Remove mounting clips or bolts holding compressor to

base.

8. After refrigerant is completely recovered, cut

suction and discharge lines as close to compressor

as possible. Leave only enough tubing to pinch off and

seal defective compressor. Plug or tape any open

system tubing to avoid entrance of moisture and air

into system. Remove inoperable compressor and

transfer mounting parts to new compressor.

9. Install new compressor in exact same manner as

original compressor.

10.Reform suction and discharge lines to align with

new compressor. If they are too short, use additional

lengths of tubing. Joints should overlap 0.5 inch to

provide sufficient area for good solder joint. Clean

and mark area where tubing should be cut. Cut

tubing with tubing cutter. Work as quickly as possible to avoid letting moisture and air into system.

NOTE: If process tube is too short, silver solder four

inch piece of tubing onto process tube at this time.

11. Solder all connections according to soldering

procedure outlined on page 12.

12. Evacuate and charge system using recommended

procedure described under Evacuating and

Recharging on pages 15 to 16.

13. Reconnect compressor terminal leads.

14. Reassemble unit.

NOTE:On models equipped with Rotary Compressors, the process tube is on the high side of the

system. If you need access to the low pressure side

of the system, it is necessary to install a T in the

suction line and add a process tube to it.

To Remove Evaporator or Capillary Tube:

1. Disconnect dehumidifier from electrical supply.

2. Remove bucket, front grille, top cap and wrapper.

3. Recover refrigerant.

4. To replace capillary tube, unsweat tube from evaporator

and condenser. Remove and replace.

5. To replace evaporator, unsweat capillary tube and

suction line.

6. Remove top and center screws from left side of evaporator.

7. Swing evaporator out from right hand side of condenser.

To Remove Condenser:

1. Disconnect dehumidifier from electrical supply.

2. Remove bucket, front grille, top cap and wrapper.

3. Recover refrigerant.

4. Unsweat capillary tube and discharge line.

5. Remove three screws securing evaporator and

condenser from left side and one screw from bottom

right securing condenser.

6. Pull suction line forward far enough to allow evaporator

to bepulled out.

7. Remove one screw at bottom of support of blower motor

assembly.

8. Bend all four tabs on top and bottom of condenser to

outside and pull blower assembly away from condenser.

9. Lift condenser out and replace.

NOTE: Prior to reassembling condenser and evaporator, the gap aound right and left srew hole brackets

must be sealed with Permagum. See Figure 16a.

Gap

Screw Hole Brackets

Figure 16a

10.Reassemble in reverse order.

Filter Dryer

Dehumidifiers are not equipped with a filter dryer, but as

a servicer, if you feel you need a filter dryer in this system

after doing your repair, a filter dryer is available through

the Replacement Parts System.

EVACUATING AND RECHARGING

Equipment Needed:

Heated Dial-A-Charge charging cylinder

Standard 3-port manifold gauge set:

four charging hoses

Tee fitting with valve core stem removed

(Robinair No. 40396)

Hand shut-off valve (Robinair No.40380)

Two stage vacuum pump

Process tube adapter kit (Robinair No. 12458)

Tubing cutter

Pinch-off tool capable of making leak proof seal

Complete brazing torch set

Small 3-corner file

Grit cloth or Scotch-Brite

45% silver solder and flux or sil floss

16

Installing Evacuation and Recharging Equipment

1. Disconnect dehumidifier from electrical supply.

2. Install process tube adaptor on process tube leaving

as much tube as possible.

3. Attach refrigeration service gauge manifold to

system in following order:

Low-side (compound gauge) to process tube

Center port manifold hose before hand shut-off

valve to charging cylinder.

Center port manifold hose after hand shut-off

valve to vacuum pump.

Evacuating System

To achieve the required levels of evacuation, a properly

maintained two- stage vacuum pump in good condition is

required. It is absolutely essential to maintain your

vacuum pump according to the manufacturers

instructions including required oil changes at the

recommended intervals. Vacuum pump oil should a l w a y s

be changed after evacuating a contaminated system.

Vacuum pump performance should be checked

periodically with a micron gauge.

Charging The System

CAUTION: After charging the system with

liquid, be certain to wait at least 5 minutes

before starting the compressor to give the

refrigerant a chance to disperse throughout

the system. Otherwise, the compressor could

be damaged by attempting to pump

excessive quantities of liquid.

Preparing the Charging Cylinder:

1. Charging cylinder must have at least eight ounces

more refrigerant than required charge.

2. Plug in cylinder heater and bring pressure up to 30

pounds above gauge pressure at ambient

temperature. Maintain, but do not exceed, this 30

pound increase in gauge pressure during system

charging.

WARNING: DO NOT USE EXTERNAL HEAT

SOURCE ON CYLINDER OR EXCEED

MAXIMUM GAUGE PRESSURE ON

CHARGING SYSTEM.

1. Make certain that charging cylinder valve, hand

shut-off valve, and manifold gauge valves are closed.

2. Start vacuum pump.

3. Open hand shut-off valve and slowly open manifold

valve, turning counterclockwise, for two full rotations.

CAUTION: If high vacuum equipment is

used, just crack manifold valve for a few

minutes, then open slowly for two full turns,

counterclockwise. This will prevent the compressor oil from foaming and being drawn

into the vacuum pump.

4. Operate vacuum pump for minimum of 30 minutes

to attain minimum of 29.9 (500 micron) vacuum or

until vacuum of 500 microns is obtained..

5. Close hand shut-off valve to vacuum pump. Watch

compound gauge for several minutes. If reading rises,

there is leak in system, go to step 6. If no leak

is indicated, stop vacuum pump. System is now

ready for charging.

6. If leak is indicated, stop vacuum pump and

introduce small charge of refrigerant into system by

cracking valve on bottom of charging cylinder until

system is pressurized to 40 or 50 psig.

7. Leak test low-side. Close compound gauge.

Run compressor for few minutes and leak test highside. When leak is found, recapture refrigerant using

EPA approved recovery system, repair and go back

to step 1.

To Charge System:

1. Make certain that hand shut-off valve to vacuum

pump is closed.

2. Set charging cylinder scale to pressure indicated on

cylinder pressure gauge.

3. Observe refrigerant level in sight glass. Subtract

amount to be charged into system and note shut off

point.

4. Open charging cylinder valve slowly and allow proper

charge to enter system.

5. As soon as refrigerant in sight glass has gone down

to predetermined level, close charging cylinder valve.

WARNING: DISCONNECT THE CHARGING

CYLINDER HEATER AT THIS TIME TO

PREVENT THE CYLINDER PRESSURE FROM

EXCEEDING ITS MAXIMUM LIMITS.

6. Allow system to sit for five minutes.

7. Turn on dehumidifier compressor. Run compressor

for few minutes and monitor system pressures.

8. When satisfied that unit is operating correctly,

clamp process tube with pinchoff tool while unit is still

running.

9. Remove process tube adaptor and solder the process

tube closed.

11.Turn on unit. After few minutes, check process

tubes for refrigerant leaks.

FINAL LEAK TEST

1. With dehumidifier turned OFF, leak test all low-side

system components.

2. Turn unit ON and run until condenser is warm. Leak

test high-side system components.

17

WIRING DIAGRAMS - DATA SHEETS

ELECTRICAL WIRING DIAGRAM

Single Speed Fan - Models With Reciprocating Compressors

18

ELECTRICAL WIRING DIAGRAM

2 Speed Fan - Models With Reciprocating Compressors

19

ELECTRICAL WIRING DIAGRAM

2 Speed Fan - Models With Rotary Compressor

20

SGNITARREIFIDIMUHED

J03HDF/J52HDFsledoM

srH42/stniP 03/52

HWK/sretiL 0.1/48.

:ledoM Y2C06AMF

:#traP 207306723 :ARL 2.03

:daolrevO 35-ZZBFS897MT4 :N/P 218617E

:yaleRtratS 20-1500PRTM

:egrahCliO cc082

rotaropavE

:N/P )2202-E-CHD(018056723fotraP

:htgneL "83.01 :.D.O

:htoomS 4 :llaW ).ltuO&.lnI(610.

:devoorG 01 :epyT )LWniM8110.("C"

:hcnI/sniF .rvL51 :lairetaM .mulA2400.

:thgieHsniF "2.11

:oTtelnIylfrettuB eniLnoDI390./090.

.resnednocworelgnis

gnibuT

:N/PnoitcuS demroF104403723 :aiD

:N/PegrahcsiD demroF103403723 :aiD

:ssecorP 01H428A648 :aiD DO61/5

ycneuqerF ztreH06

egatloV CAV511

rosserpmoCgnusmaS

metsySriA

:gfMrotoMnaF PS:epyTnalliMcM

:#traP 904056723

:seloP 6 :emarF )21.5.aiD(24

:spmA 10.1 :sttaW 19 :roticapaC enoN

:leehWrewolB 100063723#"2x'7nergrohT

egarepmA 5.6

rotcaFrewoP 97.0

resnednoC

:N/P )2202-E-CHD(018056723fotraP

61/5

woR1.BT41L-.TAM

htiwstekcarbnommocemasehtnodetnuomsilioC

61/5

DO

4/1

DO

:aiD:N/PelgruG-itnA

:aiD:N/PnoitcuS-snarT

:htgneL "83.01 :.D.O

:htoomS 4 :llaW ).ltuO&.lnI(610.

:devoorG 01 :epyT )LlWniM8110.("C"

:hcnI/sniF 51 :.ltaM .mulA2400.

rotcirtseR

:epyT caigawoD.hciMreppoClanoitaNRFM/.BT.paC

:eziS eulB780.-"52x930.

:N/P )341211A(108363723

:oTtelnIylfrettuB enilnoDI552.-352.

:oTteltuOylfrettuB enilnoDI390.-090.

61/5

.mottobehttaebutdn2ehtni

:LTAM woR1.BT41

sireniartS.rotaropavehtiwtekcarbdnenommocsahlioC

slortnoC

:N/PtatsidimuH 102263723

:N/PlortnoCezeerF

stloV 511

:MPR 029

:yrDMFC 502

:ABDdnuoS

:thgieWtinU

iHdeepS

tnaregirfeR

seznuO5.6yletamixorppAtadegrahC22R

21

SGNITARREIFIDIMUHED

J04DDFledoM

srH42/stniP 04

HWK/sretiL 61.1

:ledoM )decudeRdnuoS(6863-1-351HSO

:#traP 817518E :ARL 43

:daolrevO )WDA-42-TSM(108617E

:yaleRCTP )100717E(104AE8

:egrahCliO cc053

rotaropavE

:N/P )A2202-E-EHD.BAL(108163723fotraP

:htgneL "83.01 :.D.O

:htoomS 4 :llaW ).ltuO&.lnI(610.

:devoorG 81 :epyT )LWniM8110.("C"

:hcnI/sniF 31 :lairetaM .mulA2400.

:thgieHsniF "8.8

:oTtelnIylfrettuB enilnoDI491./191

gnibuT

:N/PnoitcuS 106263723 :aiD

:N/PegrahcsiD 105163723 :aiD

:N/PelgruG-itnA 206153723 :aiD

:ssecorP 01H428A648 :aiD

:noitalusnInoitcuS )199(507446E)1(607448E

ycneuqerF ztreH06

egatloV CAV511

sttaW 086

rosserpmoCdlociremA

metsySriA

:gfMrotoMnaF PS:epyTnalliMcM

:#traP deepS1/deepS290/704056723

:seloP 6 :emarF )21.5.aiD(24

:spmA 10.1 :sttaW 19 :roticapaC enoN

:leehWrewolB 100063723#"2x'7nergrohT

egarepmA 5.7

rotcaFrewoP 86.

resnednoC

:N/P )3202-CHD.BAL(100163723fotraP

61/5

:ltaM woR2.BT22

:htgneL "83.01 :.D.O

:htoomS 4 :llaW ).ltuO&.lnI(610.

:devoorG 42 :epyT )LlWniM8110.("C"

:hcnI/sniF 51 :.ltaM .mulA2400.

:oTteltuOylfrettuB enilnoDI601.-201.

61/5

:LTAM woR2.BT82

"2.11=H.mottobehttaebutdn2ehtnisireniartS

rotcirtseR

61/5

DO

4/1

DO

61/3

DO

61/5

DO

:epyT caigawoD.hciMreppoClanoitaNRFM/.BT.paC

:eziS )151211A(990.-"72x940.

:N/P )demroF(102463723

slortnoC

:N/PtatsidimuH 102263723

:N/PlortnoCezeerF

stloV 511511

:MPR 008029

:yrDMFC 571502

:ABDdnuoS

:thgieWtinU

woLiHdeepS

tnaregirfeR

.zO0.8yletamixorppAtadegrahC22R

22

SGNITARREIFIDIMUHED

J05DDFledoM

srH42/stniP 05

HWK/sretiL 55.1

:ledoM A11HC690AQ

:#traP 701745A :ARL 62

:daolrevO )WDA-42-TSM(108617E

:yaleRCTP )277363A(683-47021ARM

:roticapaC 03 :DFM CAV073

:egrahCliO cc052

rotaropavE

:N/P )1202-E-EHD.BAL(104163723fotraP

:htgneL "83.01 :.D.O

:htoomS 4 :llaW ).ltuO&.lnI(610.

:devoorG 81 :epyT )LWniM8110.("C"

:hcnI/sniF 31 :lairetaM .mulA2400.

hgieHsniF "0.11:t

gnibuT

:N/PnoitcuS 102061723 :aiD

rosserpmoCratsdloG

8/3

:oTtelnIylfrettuB enilnoDI491./191

:N/PegrahcsiD 107363723 :aiD

:N/PelgruG-itnA 723 3 30615 :aiD

:N/PebuTssecorP 104061723 :aiD

:N/PnoitcuS-snarT 403101903 :aiD

sttaW 057

:ltaM woR2.BT22

8/3

61/5

61/3

ycneuqerF ztreH06

egatloV CAV511

DO

DO

DO

61/5

DO

61/5

DO

egarepmA 8.6

rotcaFrewoP 69.

metsySriA

:gfMrotoMnaF PS:epyTnalliMcM

:#traP deepS2704056723

:seloP 6 :emarF )21.5.aiD(24

:spmA 10.1 :sttaW 19 :roticapaC enoN

:leehWrewolB 100063723#"2x'7nergrohT

resnednoC

:N/P )3202-CHD.BAL(100163723fotraP

:htgneL "83.01 :.D.O

:htoomS 4 :llaW ).ltuO&.lnI(610.

:devoorG 42 :epyT )LlWniM8110.("C"

:hcnI/sniF 51 :.ltaM .mulA2400.

:oTteltuOylfrettuB enilnoDI111.-801.

61/5

rotcirtseR

:epyT caigawoD.hciMreppoClanoitaNRFM/.BT.paC

:eziS )611211A(601.-"04x450.

:N/P )demroF(109363723

:LTAM woR2.BT82

.mottobehttaebutdn2ehtnisireniartS

slortnoC

:N/PtatsidimuH 102263723

:N/PlortnoCezeerF

stloV 511511

:MPR 087029

:yrDMFC 561502

:ABDdnuoS

:thgieWtinU

woLiHdeepS

tnaregirfeR

.zO0.11yletamixorppAtadegrahC22R

23

SGNITARREIFIDIMUHED

J06DDF

srH42/stniP 06

HWK/sretiL 86.1

:ledoM B11HC690AQ

:#traP 701745A :ARL 62

:daolrevO )WDA-42-TSM(108617E

:yaleRCTP )277363A(683-47021ARM

:roticapaC 03 :DFM CAV073

:egrahCliO cc052

rotaropavE

:N/P )1202-E-EHD.BAL(104163723fotraP

:htgneL "83.01 :.D.O

:htoomS 4 :llaW ).ltuO&.lnI(610.

:devoorG 81 :epyT )LWniM8110.("C"

:hcnI/sniF 31 :lairetaM .mulA2400.

hgieHsniF "0.11:t

gnibuT

:N/PnoitcuS 102061723 :aiD

rosserpmoCratsdloG

8/3

:oTtelnIylfrettuB enilnoDI491./191

:N/PegrahcsiD 107363723 :aiD

:N/PelgruG-itnA 723 3 30615 :aiD

:N/PebuTssecorP 104061723 :aiD

:N/PnoitcuS-snarT 403101903 :aiD

sttaW 007

)yratoR(

:ltaM woR2.BT22

8/3

61/5

61/3

ycneuqerF ztreH06

egatloV CAV511

DO

DO

DO

61/5

DO

61/5

DO

egarepmA 3.6

rotcaFrewoP 79.

metsySriA

:gfMrotoMnaF PS:epyTnalliMcM

:#traP 804056723

:seloP 6 :emarF )21.5.aiD(24

:spmA 60.1 :sttaW 29 :roticapaC enoN

:leehWrewolB 100063723#"2x'7nergrohT

resnednoC

:N/P )4202-CHD.BAL(102363723fotraP

:htgneL "83.01 :.D.O

:htoomS 4 :llaW ).ltuO&.lnI(610.

devoorG 83: :epyT )LlWniM8110.("C"

:hcnI/sniF 51 :.ltaM .mulA2400.

:oTteltuOylfrettuB enilnoDI111.-801.

61/5

rotcirtseR

:epyT caigawoD.hciMreppoClanoitaNRFM/.BT.paC

:eziS )611211A(601.-"04x450.

:N/P )demroF(109363723

:LTAM woR3.BT24

.mottobehttaebutdn2ehtnisireniartS

slortnoC

:N/PtatsidimuH 102263723

:N/PlortnoCezeerF

stloV 511511

:MPR 087029

:yrDMFC 561502

:ABDdnuoS

:thgieWtinU

woLiHdeepS

tnaregirfeR

.zO0.11yletamixorppAtadegrahC22R

24

Loading...

Loading...