Page 1

Dishwasher

Installation

Instructions

\

INSTALLER: Leave Installation Instructions with owner.

OWNER: Read your dishwasher Use and Care Manual. It contains

important safety information for operating this appliance. It also has

many suggestions for getting the best results from your dishwasher.

Printed in U.S.A. 1544164B1

(1t/B1)

Read all instructions before Installing dishwasher.

For your safety, please read and observe all safety instructions.

This guide will help you anticipate drain, water, and electrical

connections, and help you select the best location for the dishwasher.

Tip Over Hazard

Do not use dishwasher until completely installed.

Do not push down on open door.

Failure to follow this warning can result in serious injury.

Parts You Will Need*

• Drain Hose Clamp, lV, _Diameter (included)

• Elbow, 90° with a 3/8"National Pipe Thread (not included)

• Strain Relief Bushing (not included)

• Wire Nuts, two (2) for 12-14 gauge wire (not included)

If required:

• "Y" Branch Tailpiece and

Connector Kit (See Step 4)

• Air Gap Kit (See Step 4)

• Fasteners for floor

anchoring (See Step 9)

Electric Shock Hazard

Disconnect electrical power at the fuse box or

circuit breaker box before beginning installation.

Failure to follow this warning could result in death

or serious injury.

• Exeminedishwasherandlocateconnections. SeeStep4.

• Locate dishwasher where there is easy access to drain, water,

and electrical lines. The best location is on either side of the

kitchen sink for access to existing plumbing and ease in

loading dishes. See Step 4.

Electrical, water, and drain connections are not the same for

all age, brands, or models of dishwashers. Check the location

and length of home utilities. See Step 4_

• A 15-20 amp, grounded, 120 volt AC only, electrical supply is

required. SeeSteps4and8.

• If dishwasher drain hose will be connected to a food disposer

for the first time, knock out plug located inside disposer inlet.

See Steps 4 and 6.

Kinked water or drain hoses can cause problems. See Step 6.

• Dishwashers need to be connected to a hot water supply with

enough water pressure to insure an adequate fill. See Steps 4

and 7.

• Each home installation differs. You will need additional parts

listed above to complete your installation. See Steps 4 and 7.

• Flush water line prior to making the final connection to

prevent clogging of dishwasher's filter screen. See Step 7.

• The dishwasher will look, sound, and perform best when

properly leveled. See Step5. (NOTE: If levelers are removed

during installation, make sure the floor is flat and free of any

obstruction.)

• Anchorthedishwashertocountertop. SeeStepB.

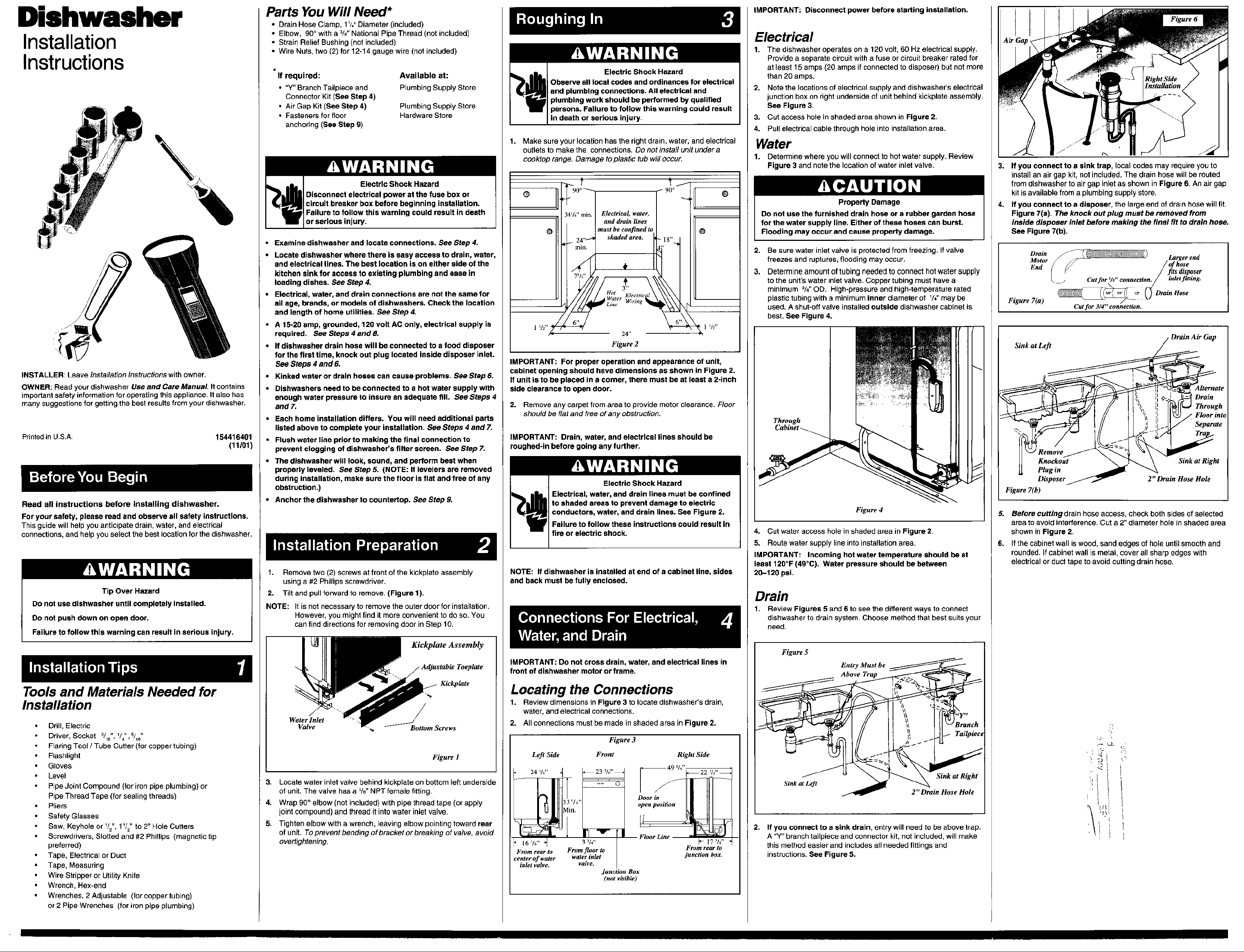

1. Remove two (2) screws at front of the kickplate assembly

using a #2 Phillips screwdriver•

2. Tilt and pull forward to remove. (Figure 1).

NOTE: It is not necessary to remove the outer door for installation.

However, you might find it more convenient to do so. You

can find directions for removing door in Step 10.

Available at:

Plumbing Supply Store

Plumbing Supply Store

Hardware Store

Kickplate Assembly

im

could result

ijury,

1. Make sure your location has the right drain, water, and electrical

outlets to make the connections. Do not install unit under a

cooktop range. Damage to plastic tub will occur.

t

%0L

@

Electrical, water,

and drain lines

must be confined to

shaded area.

6,,

24"

Figure 2

IMPORTANT: For proper operation and appearance of unit,

cabinet opening should have dimensions as shown in Figure 2.

If unit is to be placed in a corner, there must be at least a 2-inch

side clearance to open door.

2. Remove any carpet from area to provide motor clearance. Floor

should be flat and free of any obstruction.

IMPORTANT: Drain, water, and electrical lines should be

roughed-in before going any further.

Electric Shock Hazard

Electrical, water, and drain lines must be confined

to shaded areas to prevent damage to electric

conductors, water, and drain lines. See Figure 2.

Failure to follow these instructions could result In

fire or electric shock.

NOTE: If dishwasher is installed at end of a cabinet line, sides

and back must be fully enclosed.

IMPORTANT: Do not cross drain, water, and electrical lines in

front of dishwasher motor or frame.

0

IMPORTANT: Disconnect power before starting installation.

Electrical

1. The dishwasher operates on a 120 volt, 6B Hz electrical supply.

Provide a separate circuit with a fuse or circuit breaker rated for

at least 15 amps (20 arnps if connected to disposer) but not more

than 20 amps.

2. Note the locations of electrical supply and dishwasher's electrical

junction box on right underside of unit behind kickplate assembly.

See Figure 3

3. Cut access hole in shaded area shown in Figure 2,

4. Pull electrical cable through hole into installation area.

Water

1. Determine where you will connect to hot water supply. Review

Figure 3 and note the location of water inlet valve.

r!, Y I]i]iD] I

Property Damage

Do not use the furnished drain hose or a rubber garden hose

for the water supply line. Either of these hoses can burst.

Flooding may occur and cause property damage.

2.

Be sure water inlet valve is protected from freezing• Ifvalve

freezes and ruptures, flooding may occur.

3,

Determine amount of tubing needed to connect hot water supply

to the unit's water inlet valve. Copper tubing must have a

minimum 3/6"OD. High-pressure and high-temperature rated

plastic tubing with a minimum inner diameter of V4"may be

used. A shut-off valve installed outside dishwasher cabinet is

best. See Figure 4.

Figure 4

4. Cut water access hole in shaded area in Figure 2.

5. Route water supply line intoinstallation area.

IMPORTANT: Incoming hot water temperature should be at

least 120°F (49°C). Water pressure should be between

20-120 psi.

Drain

1. Review Figures 5 and 6 to see the different ways to connect

dishwasher to drain system. Choose method that best suits your

need.

Figure 5

Entry Must be

Above Trap

3. If you connect to a sink trap, local codes may require you to

installan air gap kit, not included. The drain hose will be routed

from dishwasher to air gap inlet as shown in Figure 6. An air gap

kitisavailable from a plumbing supply store.

4. If you connect to a disposer, the large end of drain hose willfit,

Figure 7(a). The knock out plug must be removed from

inside disposer inlet before making the final fit to drain hose.

See Figure 7(b).

Drain

Motor tr end

End those

I _ CutforS/s,,connection. inletfoting.

Figure 7(a)

Sink at Left

Knockout

//

Figure 7(b)

5. Before cutting drain hose access, check both sides of selected

area to avoid interference. Cut a 2" diameter hole inshaded area

shown in Figure 2.

6. Ifthe cabinet wall is wood, sand edges of hole until smooth and

rounded. If cabinet wall is metal, cover all sharp edges with

electrical or duct tape to avoid cutting drain hose.

Re_o_e

Plug in

Disposer

Cut for 3/4" connection.

J[rsdisposer

Drain Air Gap

I

Floor into

Separate

Sink at Right

2" Drain Hose Hole

Tools and Materials Needed for

Installation

Drill, Electric

Driver, Socket 3/16",V4",5/_s"

Flaring Tool / Tube Cutter (for copper tubing)

Flashlight

Gloves

Level

Pipe Joint Compound (for iron pipe plumbing) or

Pipe Thread Tape (for sealing threads)

Pliers

Safety Glasses

Saw, Keyhole or V2",1V2" to 2" Hole Cutters

Screwdrivers, Slotted and #2 Phillips (magnetic tip

preferred)

Tape, Electrical or Duct

Tape, Measuring

Wire Stripper or Utility Knife

Wrench, Hex-end

Wrenches, 2 Adjustable (for copper tubing)

or 2 Pipe Wrenches (for iron pipe plumbing)

Water Inlet

Valve BoSom Screws

Figure 1

3. Locate water inlet valve behind kickplate on bottom left underside

of unit. The valve has a 3/8"NPT female fitting.

4. Wrap 90° elbow (not included) with pipe thread tape (or apply

joint compound) and thread it into water inlet valve.

5. Tighten elbow with a wrench, leaving elbow pointing toward rear

of unit. To prevent bending of bracket or breaking of valve, avoid

overtightening.

Locating the Connections

1. Review dimensions in Figure 3 to locate dishwasher's drain,

water, and electrical connections.

2. All connections must be made in shaded area in Figure 2.

Figure 3

Left Side Front Right Side

49 1/4" --

_3_14'' • ,

I_* 24 V4"

16 _18'"

From rear to

cellter of w_er

inlet vai_e•

vlin, __

F_ Floor Line _ 17 _/4"

237/1" i Door in _. 22'h'_

From rear to

junction box.

Junction Box

(not risible)

Sink at Left

Sink at Right

2" Drain Hose Hole

If you connect to a sink drain, entry willneed to be above trap.

A "Y" branch tailpiece and connector kit, not included, willmake

this method easier and includes all needed fittings and

instructions. See Figure 5.

.j ,

I ,

i!

Page 2

t.

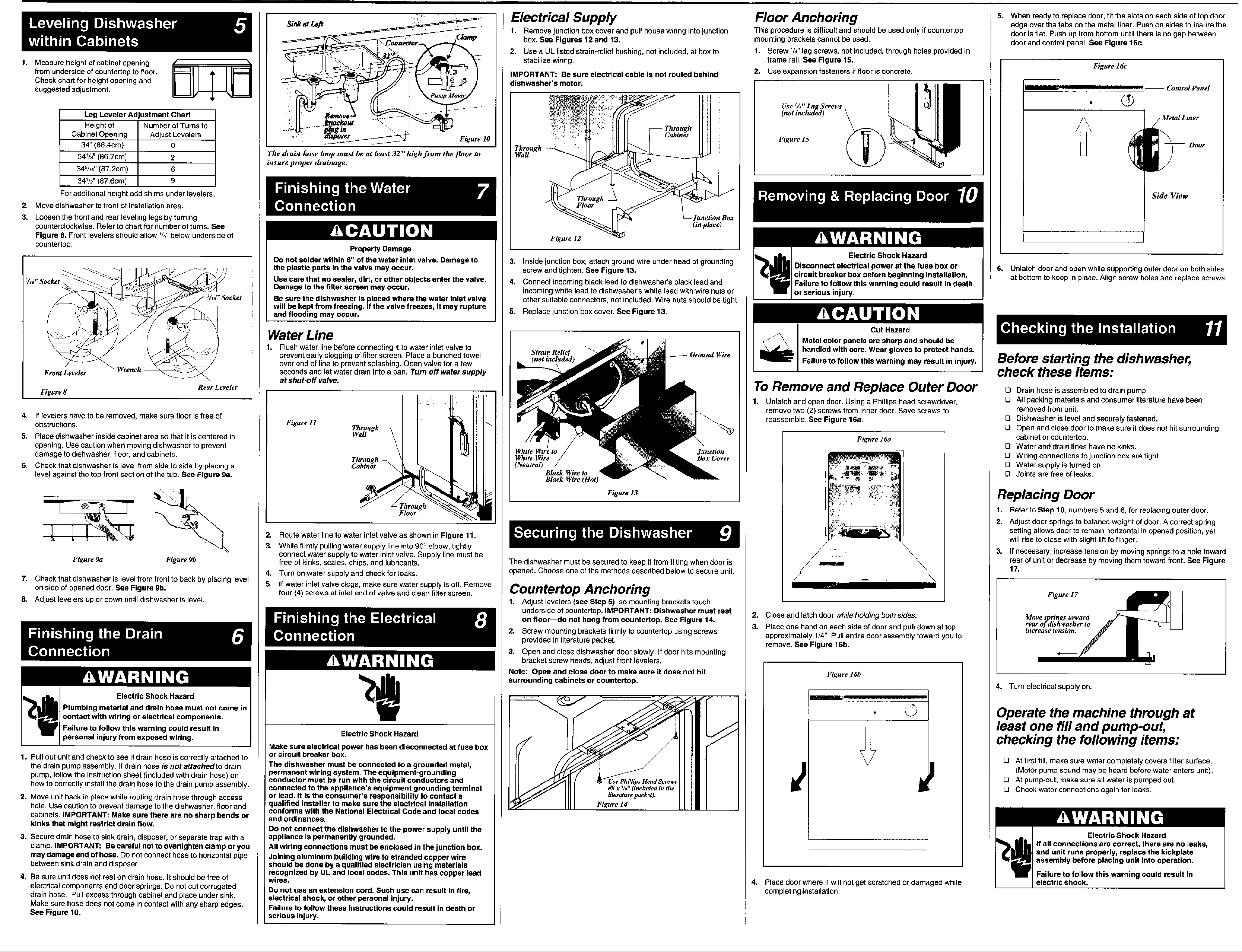

Measure height of cabinet opening

from underside of countertop to f_oor.

Check chart for height opening and

suggested adjustment.

Leg Leveler Adjustment Chart

Height of

Cabinet Opening

34" (86.4cm)

34V8" (86.7cm)

345/16"(87.2cm)

34V2" (87.6cm)

For additional height add shims under revelers.

2,

Move dishwasher to front of installation area.

3.

Loosen the front and rear leveling legs by turning

counterclockwise. Refer to chart for number of turns. See

Figure 8. Front levelers should allow V4'below underside of

countertop.

Number of Turns to

Adjust Levelers

0

2

6

9

' Figure 10

The drain hose loop must be at least 32" high from the floor to

insure proper drainage.

Property Damage

Do not solder within 6" of the water inlet valve. Damage to

the plastic parts in the valve may occur.

Use care that no sealer, dirt, or other objects enter the valve.

Damage to the filter screen may occur.

Be sure the dishwasher is placed where the water inlet valve

will be kept from freezing. If the valve freezes, it may rupture

and flooding may occur.

Electrical Supply

1. Remove junction box cover and pull house wiring into junction

box. See Figures 12 and 13.

2. Use a UL listed strain-relief bushing, not included, at box to

stabilize wiring•

IMPORTANT: Be sure electrical cable is not routed behind

dishwasher's motor.

Through •

Wall

Junction Box

(in place)

Figure 12

3. Inside junction box, attach ground wire under head of grounding

screw and tighten. See Figure 13.

4. Connect incoming black lead to dishwasher's black lead and

incoming white lead to dishwasher's white lead with wire nuts or

other suitable connectors, not included. Wire nuts should be tight.

5. Replace junction box cover. See Figure 13.

Floor Anchoring

This procedure is difficult and should be used only if counter[op

mounting brackets cannot be used•

1. Screw V4"lag screws, not included, through holes provided in

frame rail. See Figure 15.

2. Use expansion fasteners if floor is concrete•

Figure 15

Electric Shock Hazard

Disconnect electrical power at the fuse box or

circuit breaker box before beginning installation,

Failure to follow this warning could result in death

or serious injury.

5.

When ready to replace door, fit the slots on each side of top door

edge over the tabs on the metal liner. Push on sides to insure the

door is flat. Push up from bottom until there is no gap between

door and control panel. See Figure 16c.

Figure 16c

i i -- Control Panel

. @

Side View

6. Unlatch door and open while supporting outer door on both sides

at bottom to keep in place. Align screw holes and replace screws.

Front Leveler

Figure 8

4.

If teveJers have to be removed, make sure floor is free of

obstructions.

5.

Place dishwasher inside cabinet area so that it iscentered in

opening. Use caution when moving dishwasher to prevent

damage to dishwasher, floor, and cabinets.

6.

Check that dishwasher is level from side to side by placing a

level against the top front section of the tub. See Figure 9a.

Figure 9a Figure 9b

7. Check that dishwasher is level from front to back by placing level

on side of opened door. See Figure 9b.

8, Adjust levelers up or down until dishwasher is level.

Electric Shock Hazard

Plumbing material and drain hose must not come in

contact with wiring or electrical components.

Failure to follow this warning could result in

personal injury from exposed wiring.

1. Pull out unit and check to see if drain hose is correctly attached to

the drain pump assembly. If drain hose is not attachedto drain

pump, follow the instruction sheet (included with drain hose) on

how to correctly install the drain hose to the drain pump assembly.

2. Move unit back in place while routing drain hose through access

hole• Use caution to prevent damage to the dishwasher, floor and

cabinets. IMPORTANT: Make sure there are no sharp bends or

kinks that might restrict drain flow.

3. Secure drain hose to sink drain, disposer, or separate trap with a

clamp. IMPORTANT: Be careful not to overtighten clamp or you

may damage end of hose. Do not connect hose to horizontal pipe

between sink drain and disposer,

4. Be sure unit does not rest on drain hose• It should be free of

electrical components and door springs• Do not cut corrugated

drain hose. Pull excess through cabinet and place under sink.

Make sure hose does not come in contact with any sharp edges.

See Figure 10.

Rear Leveler

Water Line

1. Flush water line before connecting it to water inlet valve to

prevent early clogging of filter screen. Place a bunched towel

over end of line to prevent splashing. Open valve for a few

seconds and let water drain into a pan. Turn off water supply

at shut-off valve.

Figure 11

Wall

Through

Floor

2. Route water line to water inlet valve as shown in Figure 11.

3. While firmly pulling water supply line into 90° elbow, tightly

connect water supply to water inlet valve. Supply line must be

free of kinks, scales, chips, and lubricants.

4. Turn on water supply and check for leaks.

5. If water inlet valve clogs, make sure water supply is off. Remove

four (4) screws at inlet end of valve and clean filter screen.

Electric Shock Hazard

Make sure electrical power has been disconnected at fuse box

or circuit breaker box.

The dishwasher must be connected to a grounded metal,

lermanent wiring system. The equipment-grounding

conductor must be run with the circuit conductors and

connected to the appliance's equipment grounding terminal

or lead, It is the consumer's responsibility to contact a

qualified installer to make sure the electrical installation

conforms with the National Electrical Code and local codes

and ordinances,

Do not connect the dishwasher to the power supply until the

appliance is permanently grounded.

All wiring connections must be enclosed in the junction box.

Joining aluminum building wire to stranded copper wire

should be done by a qualified electrician using materials

recognized by UL and local codes. This unit has copper lead

wires.

Do not use an extension cord. Such use can result in fire,

electrical shock, or other personal injury.

Failure to follow these instructions could result in death or

serious injury.

Strain Relief

(not included)

White Wire to JunctMn

White Wire Box Cover

(Neutral)

Black Wire to

Black Wire (Hot)

Figure 13

The dishwasher must be secured to keep it from tilting when door is

opened. Choose one of the methods described below to secure unit.

Ground Wire

Countertop Anchoring

1. Adjust levelers (see Step 5) so mounting brackets touch

underside of countertop, IMPORTANT: Dishwasher must rest

on floor_o not hang from countertop. See Figure 14.

2. Screw mounting brackets firmly to countedop using screws

provided in literature packet.

3. Open and close dishwasher door slowly. If door hits mounting

bracket screw heads, adjust front levelers.

Note: Open and close door to make sure it does not hit

surrounding cabinets or countertop.

#8 x _/_" (included in the

[ite_qture pac'ke d.

Figure 14

Cut Hazard

Metal color panels are sharp and should be

handled with care. Wear gloves to protect hands.

Failure to follow this warning may result in injury,

To Remove and Replace Outer Door

1. Unlatch and open door. Using a Phillips head screwdriver,

remove two (2) screws from inner door• Save screws to

reassemble. See Figure 16a.

Figure 16a

2,

Close and latch door while holding both sides.

3.

Place one hand on each side of door and pull down at top

approximately 1/4". Pull entire door assembly toward you to

remove. See Figure 16b.

Figure 16b

©

II

4. Place door where it willnot get scratched or damaged while

completing installation.

Before starting the dishwasher,

check these items:

Drain hose isassembled to drain pump.

L3 All packing materials and consumer literature have been

removed from unit.

[3 Dishwasher is level and securely fastened.

Open and close door to make sure it does not hit surrounding

cabinet or countertop.

[3 Water and drain lines have no kinks.

[3 Wiring connections to junction box are fight.

[3 Water supply is turned on.

[3 Joints are free of teaks.

Replacing Door

f. Refer to Step 10, numbers 5 and 6, for replacing outer door.

2. Adjust door springs to balance weight of door, A correct spring

setting allows door to remain horizontal in opened position, yet

will rise to close with slight lift fo finger•

3. If necessary, increase tension by moving springs to a hole toward

rear of unit or decrease by moving them toward front. See Figure

17,

Figure 17

Move_ sp_srings toward

rear of dish washer to

increase tension.

4. Turn electrical supply on.

Operate the machine through at

least one fill and pump-out,

checking the following items:

[3 At first fill, make sure water completely covers filter surtace.

(Motor pump sound may be heard before water enters unit).

[3 At pump-out, make sure all water is pumped out.

[3 Check water connections again for leaks.

Electric Shock Hazard

If all connections are correct, there are no leaks,

and unit runs properly, replace the kickplate

assembly before placing unit into operation.

Failure to follow this warning could result In

electric shock.

Page 3

LavavajUlas

Instrucciones

de InstalaciEn

Art[culos Necesarios*

• Abrazadera para manguera de desag0e, 1 1/4" de diametro (se incluye)

• Code, 90° con una rosca de 3/8" (NPT) (no incluidos)

• Casquill0 para anclaje de cables (no incluidos)

• Tuercas para alambres, dos (2) pata alambre de 12 - 14 (no incluidos)

Si es necesario: Disponibles en:

• Bifurcaci6n de 45 ° y Juego Un almac6n de articulos de

de Conector (Ver Paso 4) plomefia

• JuegodeTubodeVentilaci6n Unalrnac_ndear_iculosde

(Ver Paso 4) plomeria

Riesgo de Cheque EI6ctrlco

Observe tedos los cddigos y reglamentos locales para las

conexlones eldctrlcas y de p¢omerta. Todo el trabaJo

el_ctrico y de plomerta dabs ser realizado per personae

cagflcadas. El Incumpffrclento de esta advertencia puede

resultar en una lesi6n grave o mortal.

IMPORTANTE: Desconecte la energ[a el6ctrlca antes de comenzar la

instalaci_n.

Summistro Eldctrico

1. El lavavajillas funciona con corriente el_ctrica de 120 voltios, 60 Hz.

Requiers un circuito separado con un fusible o disyuntor do per Io rnenos

15 amps. (20 amps. si se conecta con un tnturador de basura) pare de no

mds de 20 amps.

2. Observe las ubicaciones del suministro el_ctrico y de la caja de ercpalme

electrico del lavavajillas en el lade infenor derecho del lavavajillas detr_s

del conjunto de la placa inferior. Vet Flgura 3.

3. Corte el agujero de acceso en el _rea sombreada rcostrada en la Flgura 2.

4. Pass el cable el_ctrico a tray,s del agujero bacia el drea de instalaci6n.

Tubo de

\

INSTALADOR: Deje las Instrucciones de InstalaciEn con el propietario.

PROPIETARIO: Lea el Manual de Use y Cuidado del lavavajillas.

Contiene informaei6n ircportante sobre segundad para el funcionamiento de

este artefacto. Ademz_s tiene importantes sugersnctas para obtener los

mejores resuttados con su lavavajillas.

Impreso en Estados Unidos

154416401

(11/01)

• Sujetadores para Anclaje al

Unaferrete6a

Piso (Ver Paso 9)

Pellgro de Cheque El_ctrlco

Desconecte la corrlente eldctrica en la caja de fusibles o en

el disyuntor antes de corcenzar la instalacibn. El

Incum pllmlento de este advertencla puede resulter en una

leslbn grave o mortal.

Examine el lavavaJlllas y ublque las conexlones. Ver Paso 4.

Ubique el lavavajlllas donde haya f_cll acceso a la tuberla de desag0e,

del agua y aldctrlca. La me|or ublcacl6n es a cualquler lade del

fregadero de la coclna para tener acceso a la plomeria exlstente y

poder cargar los plates en el lavavajillas con facilidad. Vet Paso 4.

Las conexibn de la elect ricidad, del agua y del desagfle no son Iguales

para todas las marcas, rnodelos o el abe del lavavaJlgas. Verlflque la

ublcacl6n y el largo de las tuber(as del hogar, Ver Paso 4.

Es necesarlo sumlnlstro eldctrlco de 120 voltlos CA solamente,

puesto a tlerra con ampares de 15-20. VerPasos4y8.

Si la manguera de desagfie va a ser conecteda por prircera vez a un

trlturador de allmentos, saque el tep6n rercovlble sltuado dentro de la

admlsl6n del trlturador. Ver Pasos 4 y 6.

Las mangueras de desagQe o del agua que est_n dobladas o torcidas

pueden causar problercas. Ver Paso 6.

Los lavavajlllas (:leben conectarse a un suministro de agua callente

con presl_n de agua suflciente para asegurar un Ilenado adecuado.

Ver Pasos 4 y T,

La instalac;bn es diferente en cada hogar, Puede necesltar piezas

adicionales corco las Indicadas anteriormente para completar su

Instelaei6n. VerPasos4y7.

1. Aseg_rese de que la ubicaci6n seleccionada tiene los enchufes

correctos para la electricidad, el agua y el desag_e a fin de hacer las

conexiones correspondientes. No instate e/ lavavaj#/as debajo de/a

cubierta de una estufa. Se puede da_ar /a tina p/_stica.

_f

@ 90°_

el&tri¢a_ det agua

(_ i_s_alar_edentro

24"_' del(trea

mfn. sotr_reo_.

I Tuber_

del Cablea o

_agua eIdctric_°_

callent¢

1V_"._ 24"

6"

Figura 2

IMPORTANTE: Para funclonamlento y apariencia adecuada dellavavajillas,

la abertura del armarfo debe tener las dlmensiones qua sa muestran en la

Flgura 2. Sl el lavavaJlllas va a ser colocado en una esquina, debe haber

per Io menos un despeJe lateral de 2 pulgadas para abrlr la puella.

2. Saque cualquier alfombra del _rea para proporcionar despeje para eJ

motor. El piso debeser piano y lib[e de cualquier obstrucci6n.

IMPORTANTE: Las tuber(as de desag_e, del agua y el/actrlcas deben ser

instaladas antes de continuar con la Instelacl6n.

@

@

Suministro del Agua

1. Determine deride va a conectar el lavavajillas al suministro de agua

caliente. Examine la Flgura 3 y observe la ubicaciEn de la ,ave de

admisibn del agua.

PJll1:1[e][o]

Dafios Materiales

No use la manguera de desagge suministrada o una rcanguera de

goma del jardtn para la tuberta de suministro del agua. Cualquiera de

estas mangueras puede explotar. Se puede produclr inundacl6n y

causar dafios rcateriales.

2.

Aseg0rese de que la Ilave de admisi6n del agua este protegida contra

congelacibn. Si la llave se congela y se rompe, se puede producir una

inundaciOn.

3.

Determine el largo de tuberia que neeesitar& para conectar el surcinistro de

agua caliente a la ,ave de admisi_n del agua del lavavajillas. La tuberla de

cobre debe tarter un didmetro exterior minimo de 3/8". Se puede usar

tuberia de pldstico de alta presi6n y alta temperatura con un didmetro

Interior mlnimo de 1/4". Es major instalar la Ilave de cierre testa del

gabinete del lavavajillas. Ver Figura 4.

A trav_sdel

3. Si usted conecta a un colector de fregadero, los c6digos locales

pueden requerir qua ustad instals un juego de ventilacibn, no incluido.

La manguera de desag_e debeser guiada desde el lavavajillas a la

entrada del tube de ventilaci6n come se muestra en la FIgura 6. Se

dispone de un juego de tube de ventilaci6n en su alrcacdn de

surninistro de plomeria.

4. Si conecta a un triturador de alimento, el extreme rods grande de la

manguera de desagL_e calzard. Flgura 7(a). El tepdn removlble debe

ser sacado de dentro de la admlsl6n del trlturador de alimentes

antes de hacer la instalacidn final a la manguera de desagiJe. Ver

Flgura 7(b).

Extremo tatis

Extremo grande de la

del Motor

de

Desag_e

Figura 7(a)

Corte 114"

Tubo de

Lavarafillas a

la lzquierda

Oesagiie

alterno a

travt_s del

un

colector

Lea todas las instrucclones antes de Instelar el lavavaJlHas.

Para su seguridad, le pedlrcos leer y observar todas las Instrucciones de

seguridad. Estas instrucciones leayudar_n a verificarlas conexiones del agua,

el_ctricas y de desag0e ya seleccionar la major ubicaei6n para su lavavajillas.

Peligro de Inclinacibn

No use el lavavaJlllas hasta qua no estd completamente instalado.

No se apoye en la puerta abierta.

El Incumpllrclento de estas advertencias puede resultar en una lesl6n

grave.

Limpie la tuberia del agua antes de hacer la conext6n final para evlter

obstruccibn del filtro del lavavajillas. Ver Paso 7.

El lavavaJlgas se verd major, tendr_ meier sonido y realizard un major

trabajo si estlt debldamente nlvelado. Ver Paso 5. (NOTA: Sl las paras

nlveladoras son quitedas durante la instelaci6n, asegdrese de que el

plso est_ plane y libra de cualquier obst rucci_n.)

Sujete el lavavaJlllas a la mes6n. Ver Paso 9.

1. Saque los dos (2) tornillos en la parle delantera del conjunto de la placa

inferior usando un destornillador Phillips #2.

2. Incline y tire hacia adelante para sacar. (Flgura 1).

NOTA: No es necesario sacar la puerta exterior para la instalaei6n. Sin

embargo, puede que usted considers conveniente hacerlo. Las

instrucciones para saoar la puerta se indican en el Paso 10.

Conjunto de la Placa

Inferior

Plata de Proteccidn

Ajustable

Peligro de Cheque Eldctrico

El cableado el6ctrico, las tuberias del agua y de

desagQe ae deben ubicar dentro de las dreas

sombreadas a fin de evltar dafio a los conduetores

eldctrlcos, a las tubertas del agua y de desagiJe. Ver

Figura 2.

El incu mpllmiento de sstas instrucciones puede resultar

en un Incendlo o cheque ek._:trico.

NOTA: Si el lavavaJlllas va a set Instalado al final de la ilia de armarios,

deben cubrirse completamente los lades y la parte trasera,

IMPORTANTE: No cruce las tuberias de desagfie, del agua y el_ctrlcas en

frente del motor o del marco del lavavaJglas.

Ubicacidn de las Conexiones

Figttra 4

4. Corte el agujero de acceso del agua en el &rea sombreada indicada en

la Figura 2.

5. Pass la tuber/a de suministro del agua hacia el drea de instalaci6n.

IMPORTANTE: La temperatura del agua caliente de admisl6n debe ser por

Io menos de 120°F (49°C). La presl_n del agua debe ser entre 20-120 Ibld

pulg?.

Desagde

1. Examine las Flguras 5 y 6 para ver las diversas maneras de cone€tar el

lavavajillas al sisterca de desagL_e. Seleccione el mdtodo que major le

convenga.

Figura 5

La entrada debe

estar arriba del

coleetor

Lava vajillas a

del

Agujero de Acceso de 2"

la Derecha

Figura 7b

5. Antes de Collar el a¢ceso a la manguera de desagOa, revise ambos

lades del area seleccionada para evitar interferencia. Comteun

agulero de 2" de di_metro en el &rea sombreada mostrada en la

Pigura 2.

6. Si la pared del armario es de madera, lija los bordes del agujero hasta

qua queden suaves y redon_eados. Si la pared de_armario es de

metal, cubra lodes los bordes afilados con cinta eldctrica o cinta de

conductos para evitar qua secorte la manguera de desagEe.

Herramientas y Materiales

Necesarios para la Instalaci6n

• Taladro el6ctfico

Destornillador, Casquillos de 3/16", 1/4" y 5/16"

Abocinadora/Cortador de Tubes (para tubeda de cobra)

Linterna

Guantes

Nivel

Compuesto para Junta (para instalacibn de tubefla de hierro) o

Corcpuesto para Roscas de Tuberias {para sellar las roscas)

• Pinzas

• Lentes Protectores

• Sierra, Sierra de Punta o Cortadores de Agujeros de 1/2", 1 1/2" a 2"

• Destornilladores, Destornilladores Phillipsy dePunla Plana #2 (prefefi ble

con punta magn6tica)

• Cinta, El_ctrica o de conductos

• Cinta de Medir

• Pelacables o Cuchillo para todo use

• Llave hexagonal

• Llaves, 2 ajustabfes (para tuberia de cobra) o 2 Ilaves de tube (para

tuberia de hierro)

Vdlvula de Admislgn

del Agua ,_

Figura 1

3. Ubique la Ilave de admisi6n del agua detrds de la placa inferior en el

lade izquierdo inferior del lavavajillas. La ,ave de adrcisi6n tiene un

conector hembra NPT de 3/8".

4. Enrolls cinta para roscas en el code de 90° (no incluido) o (aplique

compuesto para juntas) y atornfllelo en Is ,ave de admisi6n del agua.

E. Apriete el code con una Ilave, dejdndolo dirigido hacia la parle trasera del

lavavajillas. A fin de evitar doblar el soporte o romper la /lave, no/o apriete

demasiado.

1. Examine las dimensionas on la Figura 3 para ubicar las conexiones del

desag0e, del agua y eldctricas dei lavavajillas.

2. Todas Fasconexiones deben quedar dentro del area sorcbreada indicada

en la Flgura 2.

Figara 3

Lado l_q_tierdo Parte Delantera Lode Derecho

49 'h"

_22 'h"

Puerta en posicidn

abierta

°

3%" _" 17a/4 ''

Desde la patte Desde Plpiso a Desde atrds a la

trasera hacia el la lla¢e de caja de empalme

centro de la admisi6n del

llave de agua. ia de

admisidn del empalme

agua. (no visible)

Bifurcaci6n

de 45 °

Laravajillas a

la lzquierda

Lavavajillas a

la Derecha ,

Agujero de A¢ceso de 2"

2.

Si usted conecta al desagne de un fregadero, la entrada deber&set

arribadel selector. Una bifurcacibn de 45° y un juegode conector,no

incluidos,facilitaran este m0todo e in¢luyetodoslosaecesorios

necesarios e instrucciones.Ver Figura 5.

Page 4

1. Mida la altura del armario desde el lade

interior del mes6n al piso. Consults la

Tibia pare la altura de la abertura y los

ajustes sugeridos.

Tibia de AJuste de las Pates Nlveladoras

Suministro EI6ctrico

1. Retire la tape de la caja de empalme y haga Ilegar el alambrado de la casa

ala caja de empalme. Vet Flguras 12 y 13.

2. Use un casquillo para anclaje de cables, aprobado per UL, no incluido, en

la caja pat estabilizar el alambrado.

IMPORTANTE: Asegdrese de que el cable eldctrico no est_ gulado per

detr&s del motor del lavavaJlgas.

Anclaje al Piso

Este procedimiento es diticil y debeser usado solamente si no se pueden _sar

los soportes de montaje al mes6n.

1. Atomille los tiratondos de 1/4", no ineluidos, a tray,s de los aguleros

provistos en el riei del bastidor. Ver Flgura 18.

2. Use sujetadores de expansi6n si el piso es de concrete.

Use tirafondos de

1/4" (no incluidos)\

\

5.

Cuandoest_ listopare volvera instalarlapuerta,coloquelasranuras

situadas en cada lade del borde superior de la puerta sabre las

leng0etasdolfortemetdlico. Empujeambosladespara asegurarse de

que la puertaestd plane. Empujedesde abajo hasta que no exista

espacioentre la puertay el panelde control.Ver Figure 16c.

Figura I6c

[I I_ii

Panel de

Control

Forte Met_lico

Alturade la I N0merodeVueltaspare I

AbertuladelArmario I AjustarlasPatasNive_adorasI

34" (86,4 cm) 0

34%" (86,7 cm) 2

345/_ " (87,2 cm) 6

34V2" (87,6 cm) 9

Para aitura adicional agregue laminillas debajo de las pates niveladoras.

2. Mueva el lavavajillas hacia la parle delantera de[ drea de instalaei6n.

3. Afloje las patas niveladoras delanteras y traseras gir_ndolas ala izquierda.

Consulte la tabla para el n0mero de vueltas. Ver Figure 8. Las patas

niveladoras deben dejar un despeje de 1/4" debajo de la parts interior del

mes6n.

Casquillode3/16"F.

\

• Casquillode3/16"

/

Pata Niveladora

Delantera

Pat, z Nivelodora Trasera

F_um 8

4. Si se hart sacado las pates niveladoras, aseg0rese de que el piso eat6

libra de obstrucciones.

5. Coloque el lavavajillas dentro del &rea del armape dejdndolo centrado en

la abertura. Tonga cuidado cuando mueva el lavavajillas para evitar dane

al lavavajillas, al piso y a los arTeries.

6. Verifique si el lavavajiflas est& nivelado de Jadea lade cofocando un nivel

contra la parte superior delantera de la tina. Ver Figure 9a.

\

Figura 10

El bucle de la manguera de drenaje debe estar a una distancia minima de

32" del suelo para asegurar un drenaje apropiado.

Defies Materlales

No suelde dentro de 6" de ta liars de admisi6n del ague. Se pueden

darer las plezas pldsticas de la liars det ague.

Tenga culdedo de qua no entren compuestos selladores, sucieded u

otros objetos a la ,ave. Puede defarse la mJllla filtradora.

Asegdrese de que el lavavaJlllas est_ colocado donde la gave de

admlsi6n del ague no ee congetard. SI la gave se congela, se puede

romper y se puede produclr una inundaci6n.

Tuberia del Agua

1. Limpie la tuberia del agua antes de contectarla ala nave de admisi6n

del agua pare evitar obstrucci6n de la rejilla filtradora. Coloque una

toalla tapando el extrerno de la tuberla pare evitar que salpique. Abra

la Ilave durante unos segundos y deje qua el agua se desagde en un

recipients. Cierre el sumlnlstro del ague en la liars de clerre.

F_u_ 11

A trav6s ?_ ; , •

de la pared

A tra_#s

A tray,s

de lo

pared

Caja de empalme

(en el lugar)

Figura 12

3. Dentro de la caja de empalme, instals el alambre de puesta a tierra, debajo

de la cabeza del tornillo de puesta a tierra y apriete. Ver Figure 13.

4. Conecte el conductor negro de entrada al conductor negro del lavavajillas

y el conductor blanco de entrada al conductor blanco del lavavajillas con

tuercas de alambre u arras conectores adecuados, no incluidos. Cas

tuercas de alambre deben ester bien apretadas.

5. Vuelva a colocar la tapa de la caja de empalme. Ver Figure 13.

Casquillo para

anclaje de

cables (no

puesta a tlerra

Alambre blanco at

abtmbre blanco

(neutro)

Al_tmbre negro

alalambre

negro(ca!tente) Figura l3

Cubierta de

la caja de

emgalme

Figura 15

Pellgro de Cheque Eldctrico

Desconecte la energia eldct rice en la caJa de fusibles o en

la caja del disyuntor antes de comeltzar la Instalacidn.

El iltcumpgmiento de esta advertencla puede resultar on

una lesl6n grave o mortal.

Peligro de Corfe

Los panelee de color metdlicos son otilados y deben ear

manlpulados con cuidado. Use guantes pare protegerse

la manes.

El iltcumpllmiento de esta adverfencla puede resultar en

una lesi6n.

Para Sacar y Volver a Colocar la

Puerta Exterior

1. Saque el pestillo y abra la pueda. Usando un destornillador de cabeza

Phillips saque los dos (2) tornillos de la puerta interior. Guards los

torniflos para reinstalarlos. Ver Figura 16a.

Figura 16a

Vista Lateral

6. Saque el pastille de ta puerta y abrala ala vez que sostiene la puerta

exterior enaThOS lades en la parts inferior para mantenerla en su lugar.

Alines los agujeros de los tornil_osy vuelva a colocar los torn,los.

Antes de poner en marcha el

lavavajillas, verifique Io siguiente:

La manguera de drenaje estfi fijada ala bomba de drenaje.

O Todos los materiales de empaque y los documentos del

consumidor hen side secedes del lavavajillas.

[_ El lavavajillas est,. nivelado y firmemente asegurado.

O Abra y cierre la puerta del lavavajillas para asegurarse de que no

golpee los arTeries adyacentes ni el mesbn.

[_ Las tuberias del ague y de desag0e no tienen torceduras.

Las conexiones del alambrado hacia la caja de empalme estdn

apretadas.

I..q El suministro del agua estd abierto.

[_ Las juntas no tienen escape.

Reinstalacidn de la Puerta

Figura 9a Figura 9b

7. Verifique si el lavavajillas estd nivelado desde el frente hacia atrds

colocando un nivel en el lade de la puerta abiella. Ver Figure 9b.

8. Ajuste las pates niveladoras hacia arriba o hacia apejo haste qua el

lavavajillas quede nivelado.

Peligro de Cheque Ell_ctrico

El material de plomer[a y la manguem de desagfie no

deb_n tenor eontaoto COlt e) alambrado o componentes

eldctrlcos.

El Ilteumpllmlento de esta advertencla puede resultar en

una lesl6n personal al tenor contacto con el alambrado

expuesto,

1. Extraer la unidad e inspeccionar para ver_ficarque la manguera de

drenaje est_ correctamente fijada al conjunto de la bomba de drenaje. En

case qua la manguera de drenaje no est& fijada a la bompe de drenaje.

seguir la hoja de instrucciones (incluida con la manguera de drenaje)

pare instalar correctamente fa manguera de drenaje al conjunto de la

bomba de drenaje.

2. Colocar nuevamente la unidad on su lugar al encaminar la manguera de

drenaje a travds del orificio de acceso. Tonga cuidado para no dafiar el

lavavajillas, el piso y los armasos. IMPORTANTE: Asegdrese de qua

no haya cuP/as afllades o torceduras que puedan restringir el flujo

del desag0e.

3. Asegura la manguera de desagpe en el desagpe del fregadere, del triturador

de alimentos o del colector separado con una abrazadera, IMPORTANTE:

Tonga culdado de no apretar demasiado la abrazadera puss se puede

dafter el extreme de la maltggera. No conecte la manguera a una tuberia

horizontal entre el desag0e del fregadaro y el triturador.

4. Aseg0rese de que el lavavajillas no quads sabre la manguera de desag0e.

Debe ester libra de componentes eldctricos y de los resodes de la puerta.

No carte la manguera de dasagpe corrugada. Tire el exceso de la manguera

a travds del armada y col6quelo debajo del fregadero. Aseg0rese de que [a

manguera no est_ en contacto con bordes afilados. Ver Figure 10.

del piso

2. Guie la tuberia del ague hacia la Ilave de admisi6n del ague come so

muestra en la Flgura 11.

3. Ala vez que tira firmemente la tuberia de suministro del agua hacia elcode

de 90%conecte firmemente el suministro de agua ala Ilave de admisi6n del

ague. La tuberia de suministro no debe tenor torceduras, escamas,

picaduras o lubrioantes.

4. Abra el suministro de ague y verifique si hay escapes.

6. Sila Ilave de admisi6n delagua se obstrdye asegL_rese dequa el suministro

de ague est_ eerrado. Saque los cuatro (4) tornillos del extreme de la

admisi6n de la Ilave y [impie la rejilla filtradora.

Peggro de Cheque Eldctrlco

Asegdrese de que la corriente el_ctrica haya aide desconactada en la

eaJa de fuslbles o en la caJa del dlsyuntor.

El lavavaJillas debe ester conectado a un sistema de alambrado metdltco

permanents puesto a tlerra o se puede Instalar un conductor de puesta

a tlarra del equlpo con los conductores de circuito y conectarse al

borne de puesfe atlerra del artefacto. Es la respensabilidad del clients

ponerse elt contacto con un Instalador calflcado pare asegurarse de

que la Instelacldn eldetrlca cumple con el Cbdigo EI6ctrico Nacional y

los c6digos y reglamentos locates.

No conecte el lavavaJlllas al sumlnlstro eldctrlco haste que el artefacfe

no est_ permanentemenfe puesto a tlerra.

Todas las conexlones del eabteado deport ester encerradas en la caJa

do empalme.

La unibn de alambre de alumlnlo al alambre de cobra dabs ser hecho

per un electrlclsta callflcado usando materlales aprobados per UL y per

los c6dlgos locales, Este lavavajillas tiene alambres conductores de

cobra.

No use un cord6n de extensl6n. El use de un cordbn de extensl6n

puede resulfer en un incendio, cheque eldctrlco o lesl6n personal.

El Ineumpllmlento de estas instrucciones puede resultar en una lesl6n

grave o mortat.

El lavavajillasdebe estar bien firme pare evitarque se inclinecuando se abre

lapuerta. Seleccioneunodelosm_todosquesedescribenacontinuaci6npara

sujetar el lavavajillas.

Anclaje al Mes6n

1. Ajuste los niveladores (ver Paso 5) de mode qua los soportes de montaje

toquen el lade interior del mesbn. IMPORTANTE: El levavaJglas debe

descaltsar en el plso--no depe colgar del mesdn. Ver Figure 14.

2.

Atornillefirmamentslos soportesde montaje en el mes6n usandolos

tornillos provistosen el paquetede losdocumentos.

3,

Abra y cierre lentamente la puerta del lavavajillas. Si la puerta golpea la

eabeza de los torniflos del seporte de montaje, ajuste las peta niveladoras

delanteras.

Note: Abra y clerre la puerta del lavavaJlllas pare asegurarse de que no

golpee los armarios adyacentes nl el meson.

Phillips #8 x 5/8"

(incloidos en et paquete

de los documentos).

l \

2,

Cierre y ponga el pestillo de la puerta ala vez qua sujeta ambos lades.

3.

Coloque una mane en cada lade de la pue6a y tire hacia abajo en la

parts de arriba aproximadamente 1/4". Tire todo el conjunto de la puerta

hacia usted pare sacado. Ver Figure 16b.

Figura 16b

4. Coloque la puerta en un lugar deride no se rayara ni dafiard mientras se

complete la instalaci6n.

1. Consults el Paso 10, n0meros 5 y 6, para volver a colocar la puerta

exterior.

2. Atuste los resortes de la pue6a pare equilibrar el peso de la pueda. Un

ajuste adeeuado del rosette permits qua la puerta permanezca horizontal

en la posici6n abierta, sin embargo se levantar_ para cerrarla con una

ligera presi6n hacia arriba con el dedo.

3. Si es necesario, aumente la tensi6n moviendo los resortes a un agujero

hacia atr&s del lavavajillas o disminuya la tensi6n moviOndolos hacia

adelante. Ver Figure 17.

Figura 17

Mue_a los resortes hacia

atrds del lavavajillas para

aumentar la tensi6n

4. Conecte la energta el_ctrica.

Haga funcionar la mdquina per Io

menos a travds de un Ilenado y

vactado vertficando los stgmentes

puntos:

[3 En el primerIlenadoaseg6rssede que el aguacubre

completamentela superficiedel filtro. {So puedeair el sonidodel

motorde la bomba antesde queelagua entre en el iavavajillas).

L.JDuranteel desag(_e,aseg0resede qua todael agua haya salido.

[3 Reviselas conexionesdel agua paraverifiearsi hayescapes.

Pellgro de Cheque EI6ctrlco

S) todas las conexiones estdlt correctas no hay escape y

eHavavajillas funcionard adecuadamente. Vuelvaa colocar

el conju nfe de la place Inferior antes de baser fultclonar et

levevajigas.

El Incumplimiento de esta advertencla puede resulfer en

un cheque eldctrico.

Loading...

Loading...