Page 1

Installation

Instructions

Instrucciones

para la

instalad6n

Contents

SUBJECT PAGE

Pre-lnstallation Requirements .................................... 2

Electrical Requirements ........................................... 2

Exhaust System Requirements ............................ 2-3

Gas Supply Requirements ....................................... 3

Location of Your Dryer. ............................................ 4

Rough-In Dimensions ............................................. 5

Unpacking ................................................................ 5

Reversing Door Swing .............................................. 5

Electrical Installation ................................................ 6

Grounding Requirements ....................................... 6

Electrical Connections--3-wire .............................. 6

Electrical Connections--4-wire ........................... 6-7

Installation ................................................................ 7

Replacement Parts................................................... 7

Lint Blade Retaining Pin Location ........................... 7

Warranty. ................................................................... 8

Espanol ................................................................ 9-16

Requerimientos de instalacion preliminares .......... 9

Requerimientos electricos ....................................... 9

Requerimientos del sistema de escape ............ 9-10

Requerimientos del suministro de gas ............... 10

Ubicacion de su secadora ...................................... 11

Dimensiones para la instalacion .......................... 12

Desembalaje ........................................................... 12

Puerta reversible .................................................... 12

Instalacion electrica ............................................... 13

Requerimientos para la puesta a tierra ............... 13

Conexiones electricas - trifilares .......................... 13

Conexi6nes electricas - tetrafilares ................. 13-14

Instalaci6n .............................................................. 14

Piezas de recambio ................................................ 14

Garantia ................................................................. 15

Before beginning installation, carefully read these instructions. This

will simplify the installation and ensure the dryer is installed correctly

and safely. Leave these instructions near the Dryer after installation

for future reference.

NOTE: The electrical service to the Dryer must conform with local

codes and ordinances and the latest edition of the National Electrical

Code, ANSI/NFPA 70.

NOTE: The gas service to the Dryer must conform with local codes and

ordinances and the latest edition of the National Fuel Gas Code ANSI

Z223.1.

NOTE: The Dryer is designed under ANSI Z 21.S. 1 - for HOME USE only.

This Dryer is not recommended for commercial applications such as

restaurants or beauty salons, etc.

Antes de comenzar la instalaci6n, lea cuidadosamente estas

instrucciones. Esto simplificara la instalaci6n y aseg urara que la secadora

se instale correctamente y de manera segura. Despu_s de completar la

instalaci6n, coloque estas instrucciones cerca de la secadora para

referencia futura.

NO TA: La alimentacion el_ctrica para la secadora debera cumplir con los

c6digos y reg lamen tos locales y con la ultima edicion del C6digo Electrico

NacionaL

NO TA: La alimentacion de gas para la secadora debera cumplir con los

codigos y reglamen tos locales y con la ultima edicibn del C6digo National

para Gases Combustibles.

NO TA: La secadora esta clasificada para USO DOMES TICO solamente,

de acuerdo con la norma ANSI Z21.5. I o ANSI/UL 2158 - {las ultimas

edidbnes). Esta secadora no se recomienda para uso commercial tal

como en restaurantes, salones de belleza, etc.

For your safety the information in this manual must be followed

to minimize the risk of fire or explosion or to prevent property damage,

personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquid in the

vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

Do not try to Nght any appliance.

Do not touch any electrical switch; do not use any phone in your

building.

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor's phone. Follow

the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

Installations must be performed by a qualified or licensed contractor,

plumber, or gasfitter qualified or licensed by the state, province, or region

where this appliance is being installed.

este manual a fin de reducir a un minimo los riesgos de incendio o explosion

o para evitar danos materiales, lesiones personales o la muerte.

No almacene ni utilice gasolina u otros vapores y Nquidos inflamables en

la proximidad de este o de cualquier otro artefacto electrico.

QUE DEBE HACER S! PERCIBE OLOR A GAS

No trate de encender ningun artefacto electrico.

No toque ningun interruptor electrico; no use ningun telefono en su

edificio.

Haga salir atodos losocupantes de la habitacion, del edificio ydel lugar.

Llame a su proveedor de gas desde el telefono de un vecino. Siga las

instrucciones del proveedor de gas.

Si no Iogra comunicarse con su proveedor de gas, Ilame al

departamento de bomberos.

Lainstalacion y el servicio de mantenimiento debe de realizarlos un instalador

calificado, la agenda de servicios o el proveedor de gas.

Para su seguridad, siga las instrucciones contenidas en

Printed in U.S.A.

P/N 134589900A (0601)

Page 2

PRE-INSTALLA TION REQUIREMENTS

Tools and Materials Required for Installation:

1. Phillips head screwdriver.

2. Channel-lock adjustable pliers.

3. Carpenter's level.

4. Flat or straight blade screwdriver.

5. Duct tape.

6. Rigid or flexible metal 4 inch (10.2 cm) duct.

7. Vent hood.

8. Pipe thread sealer (Gas).

9. Plastic knife.

ELECTRICAL REQUIREMENTS

ELECTR/CDryer I

CIRCUIT- Individual 30 amp. branch circuit fused with 30 amp.

minimum time delay fuses or circuit breakers.

POWER SUPPLY - 3 wire, 240 volt, single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD KIT - The dryer MUST employ a 3-

conductor power supply cord NEMA 10-30 type SRDTrated at

240 volt AC minimum, 30 amp., with 3 open end spade lug

connectors with upturned ends or closed loop connectors and

marked for usewith clothes dryers. If being installed in a new

branch circuit installation, manufactured (mobile) home,

recreational vehicle or area which prohibits grounding through

the neutral conductor, the dryer MUST employ a4-conductor

power supply cord NEMA 14-30 type SRDTor ST (asrequired)

rated at 240 volt AC minimum, 30 amp., with 4 open end

spade lug connectors with upturned ends or closed loop

connectors and marked for use with clothes dryers. See

ELECTRICALCONNECTIONSFORA 4-WIRE SYSTEM.

OUTLET RECEPTACLE- NEMA 10-30R or 14-30R receptacle to

be located so the power supply cord is accessible when the

dryer isinthe installed position.

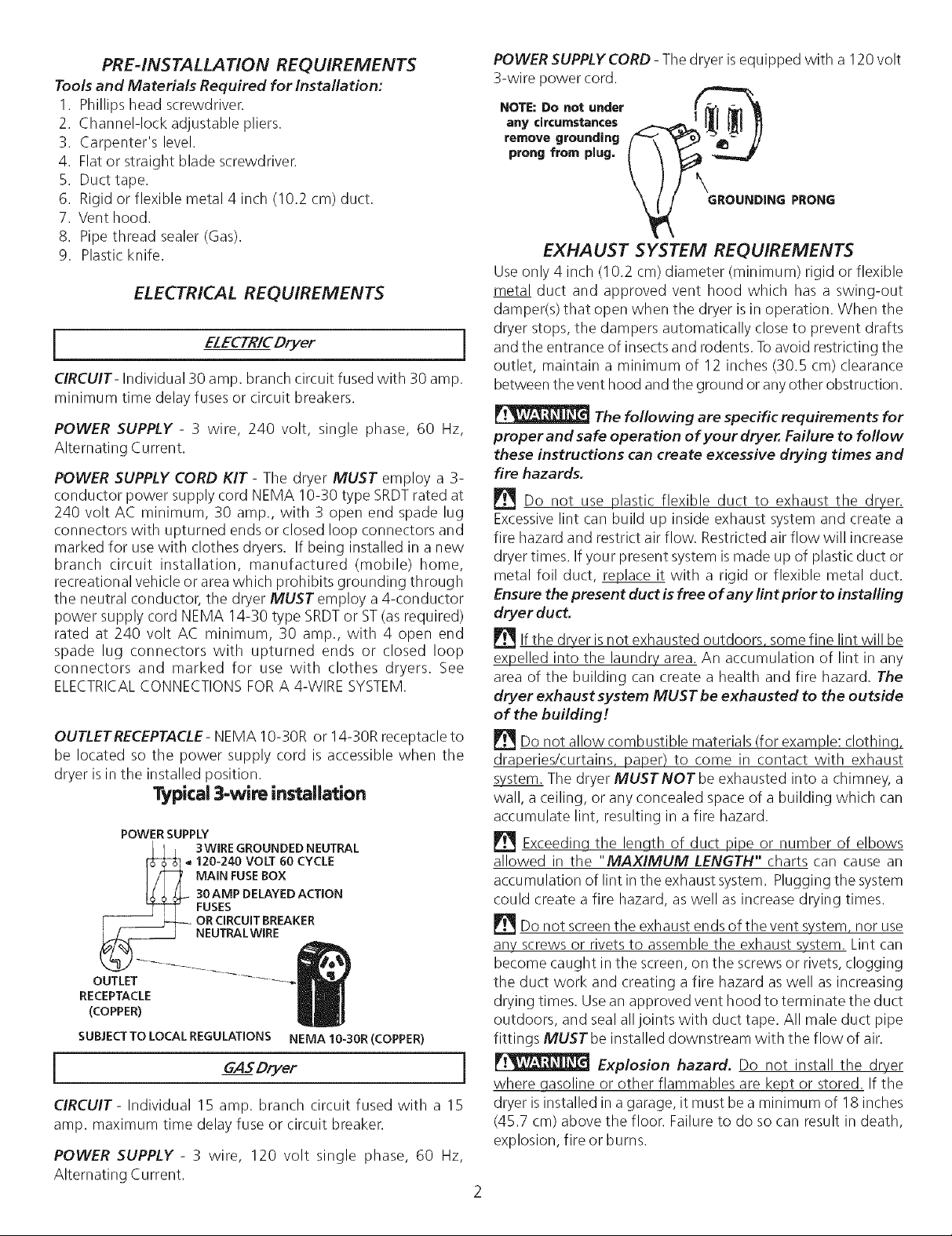

Typical 3-wire ins_ilation

POWER SUPPLY

I I E 3WIRE GROUNDED NEUTRAL

[$-_ 120-240 VOLT 60 CYCLE

I/4 MAI.FUSEBOX

j_ _ _ 30AMPDELAYEDACTION

FUSES

[ _ ORCIRCUITBREAKER

_ NEUTRALWIRE

OUTLET -- _

RECEPTACLE

(COPPER)

SUBJECTTO LOCALREGULATIONS NEMA 10-30R(COPPER)

GAS Dryer i

CIRCUIT- Individual 15 amp. branch circuit fused with a 15

amp. maximum time delay fuse or circuit breaker.

POWER SUPPLY - 3 wire, 120 volt single phase, 60 Hz,

Alternating Current.

POWER SUPPLYCORD - The dryer is equipped with a 120 volt

3-wire power cord.

NOTE: Do not under _'_ -_-,'_

any circumstances |

prong from plug.

remove grounding Q

_ GROUNDING PRONG

EXHAUST SYSTEM REQUIREMENTS

Useonly 4 inch (10.2 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation. When the

dryer stops, the dampers automatically close to prevent drafts

and the entrance of insectsand rodents. Toavoid restricting the

outlet, maintain a minimum of 12 inches (30.5 cm) clearance

between the vent hood and the ground or any other obstruction.

The following are specific requirements for

proper and safe operation of your dryer. Failure to follow

these instructions can create excessive drying times and

fire hazards.

Do not use plastic flexible duct to exhaust the dryer.

Excessivelint can build up inside exhaust system and create a

fire hazard and restrict air flow. Restricted air flow will increase

dryer times. If your present system ismade up of plastic duct or

metal foil duct, _lace it with a rigid or flexible metal duct.

Ensure the present duct is free of any lint prior to installing

dryer duct,

Ifthe dryer isnot exhausted outdoors some fine lint will be

expelled into the laundry area. An accumulation of lint in any

area of the building can create a health and fire hazard. The

dryer exhaust system MUST be exhausted to the outside

of the building!

Do not allow combustible materials (for example: clothing,

draperies/curtains, paper) to come in contact with exhaust

system. The dryer MUSTNOT beexhausted into a chimney, a

wall, a ceiling, or any concealed space of a building which can

accumulate lint, resulting in a fire hazard.

Exceeding the length of duct pipe or number of elbows

allowed in the "MAXIMUM LENGTH" charts can cause an

accumulation of lint inthe exhaust system. Plugging the system

could create a fire hazard, as well as increase drying times.

_Do not screenthe exhaust endsof the vent system, nor use

any screws or rivets to assemble the exhaust system. Lint can

become caught in the screen, on the screws or rivets, clogging

the duct work and creating a fire hazard as well as increasing

drying times. Use an approved vent hood to terminate the duct

outdoors, and seal all joints with duct tape. All male duct pipe

fittings MUST be installed downstream with the flow of air.

Explosion hazard. Do not install the dryer

where qasoline or other flammables are kept or stored. If the

dryer isinstalled in a garage, it must be a minimum of 18inches

(45.7 cm) above the floor. Failure to do so can result in death,

explosion, fire or burns.

Page 3

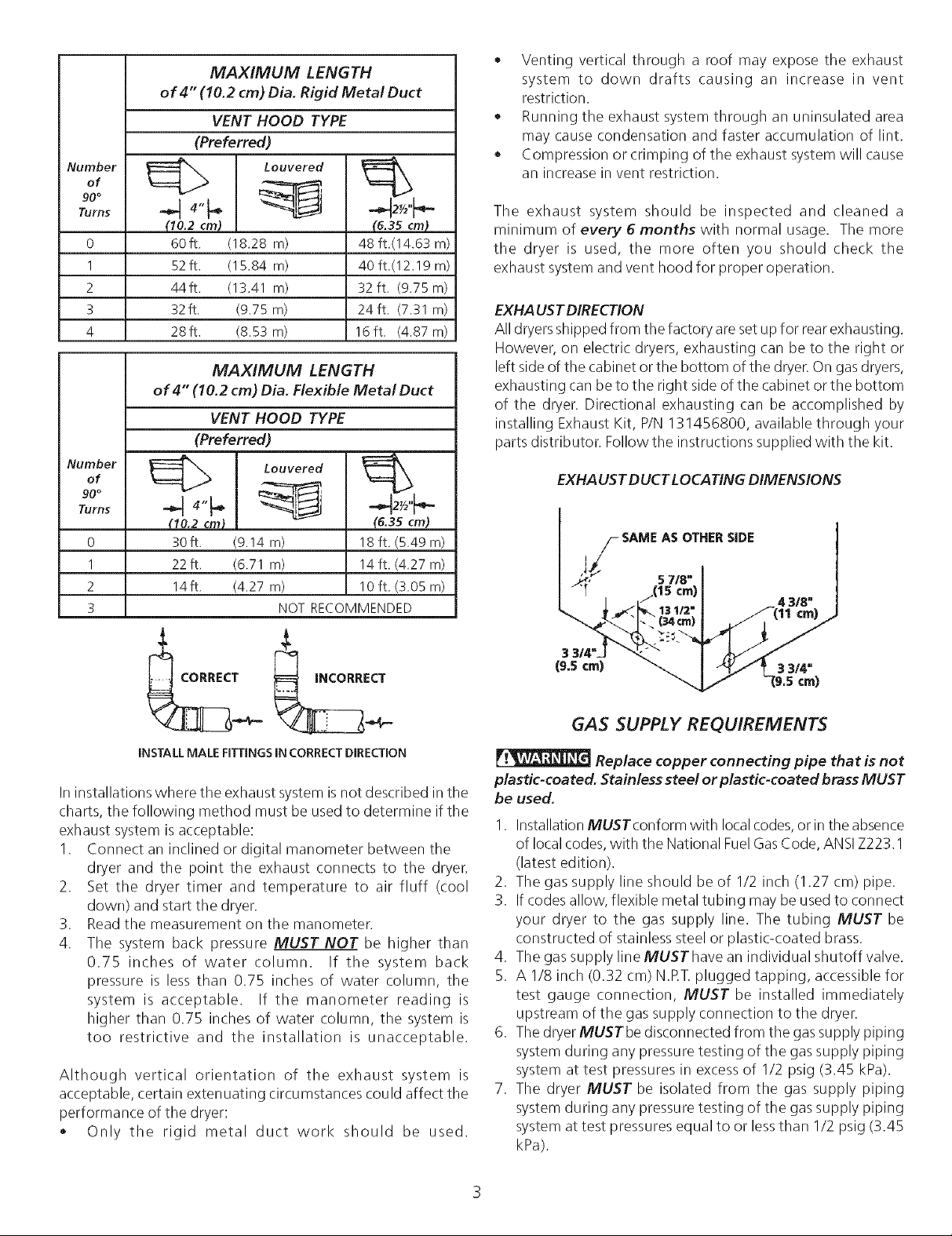

Number

of

90°

Turns

0

I

2

3

4

Number

of

90°

Turns

0

1

2

3

MAXIMUM LENGTH

of 4" (10.2 cm) Dia. Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

Louvered

(10.2 cm)

60ft,

52ft.

44 ft.

32ft.

28ft.

(18.28 rn)

(15.84 m)

(13.41 m)

(9.75 m)

(8.53 m)

(6.35 cm_

48 ft.(14.63 m)

40 ft.(12.19 m)

32 ft. (9.75 m)

24ft. (7.31 m)

16ft. (4.87 m)

MAXIMUM LENGTH

of 4" (10.2 cm) Dia. Flexible Metal Duct

VENT HOOD TYPE

(Preferred)

Louvered

(10.2 cm)

30ft.

22ft.

14ft.

(9.14

m) 18 ft. (5.49 m)

(6.71

m) 14ft. (4.27 m)

(4.27

m) 10ft. (3.05 m)

16.35cm)

NOT RECOMMENDED

Venting vertical through a roof may expose the exhaust

system to down drafts causing an increase in vent

restriction.

Running the exhaust system through an uninsulated area

may cause condensation and faster accumulation of lint.

Compression or crimping of the exhaust system will cause

an increase in vent restriction.

The exhaust system should be inspected and cleaned a

minimum of every 6 months with normal usage. The more

the dryer is used, the more often you should check the

exhaust system and vent hood for proper operation.

EXHAUSTDIRECTION

All dryers shipped from the factory are set up for rearexhausting.

However, on electric dryers, exhausting can be to the right or

left side of the cabinet or the bottom of the dryer.On gasdryers,

exhausting can be to the right side of the cabinet or the bottom

of the dryer. Directional exhausting can be accomplished by

installing Exhaust Kit, P/N 131456800, available through your

parts distributor. Follow the instructions supplied with the kit.

EXHAUST DUCT LOCATING DIMENSIONS

INSTALL MALE FITTINGS IN CORRECT DIRECTION

Ininstallations where the exhaust system isnot described in the

charts, the following method must be used to determine if the

exhaust system is acceptable:

1. Connect an inclined or digital manometer between the

dryer and the point the exhaust connects to the dryer.

2. Set the dryer timer and temperature to air fluff (cool

down) and start the dryer.

3. Read the measurement on the manometer.

4. The system back pressure MUST NOT be higher than

0.75 inches of water column. If the system back

pressure is less than 0.75 inches of water column, the

system is acceptable. If the manometer reading is

higher than 0.75 inches of water column, the system is

too restrictive and the installation is unacceptable.

Although vertical orientation of the exhaust system is

acceptable, certain extenuating circumstances could affect the

performance of the dryer:

• Only the rigid metal duct work should be used.

3

(9.5 cm)

GAS SUPPLY REQUIREMENTS

Replace copper connecting pipe that is not

plastic-coated. Stainless steel or plastic-coated brass MUST

be used.

I. Installation MUSTconform with localcodes,or in the absence

of local codes,with the National Fuel GasCode, ANSIZ223. I

(latest edition).

2. The gas supply line should be of 1/2 inch (1.27 cm) pipe.

3. If codes allow, flexible metal tubing may be used to connect

your dryer to the gas supply line. The tubing MUST be

constructed of stainless steel or plastic-coated brass.

4. The gas supply line MUST have an individual shutoff valve.

5. A 1/8 inch (0.32 cm) N.RT.plugged tapping, accessible for

test gauge connection, MUST be installed immediately

upstream of the gas supply connection to the dryer.

6. The dryerMUSTbe disconnected from the gassupply piping

system during any pressure testing of the gassupply piping

system at test pressures in excess of 1/2 psig (3.45 kPa).

7. The dryer MUST be isolated from the gas supply piping

system during any pressure testing of the gassupply piping

system at test pressures equal to or lessthan 1/2 psig (3.45

kPa).

Page 4

LOCATION OF YOUR DRYER

DO NOT INSTALL YOUR DRYER:

1. In an area exposed to dripping water or outside weather

conditions.

2. In an area where it will come in contact with curtains, drapes,

or anything that will obstruct the flow of combustion and

ventilation air.

3. On carpet. Floor MUST be solid with a maximum slope of 1

inch (2.54 cm).

INSTALLATION IN RECESSOR CLOSET

1. A dryer installed ina bedroom, bathroom, recessor closet,

MUSTbe exhausted outdoors.

2. No other fuel burning appliance shall be installed in the

same closet asthe Gas dryer.

3. Your dryer needsthe spacearound it for proper ventilation.

DO NOT INSTALL YOUR DRYER IN A CLOSET WITH A

SOLID DOOR.

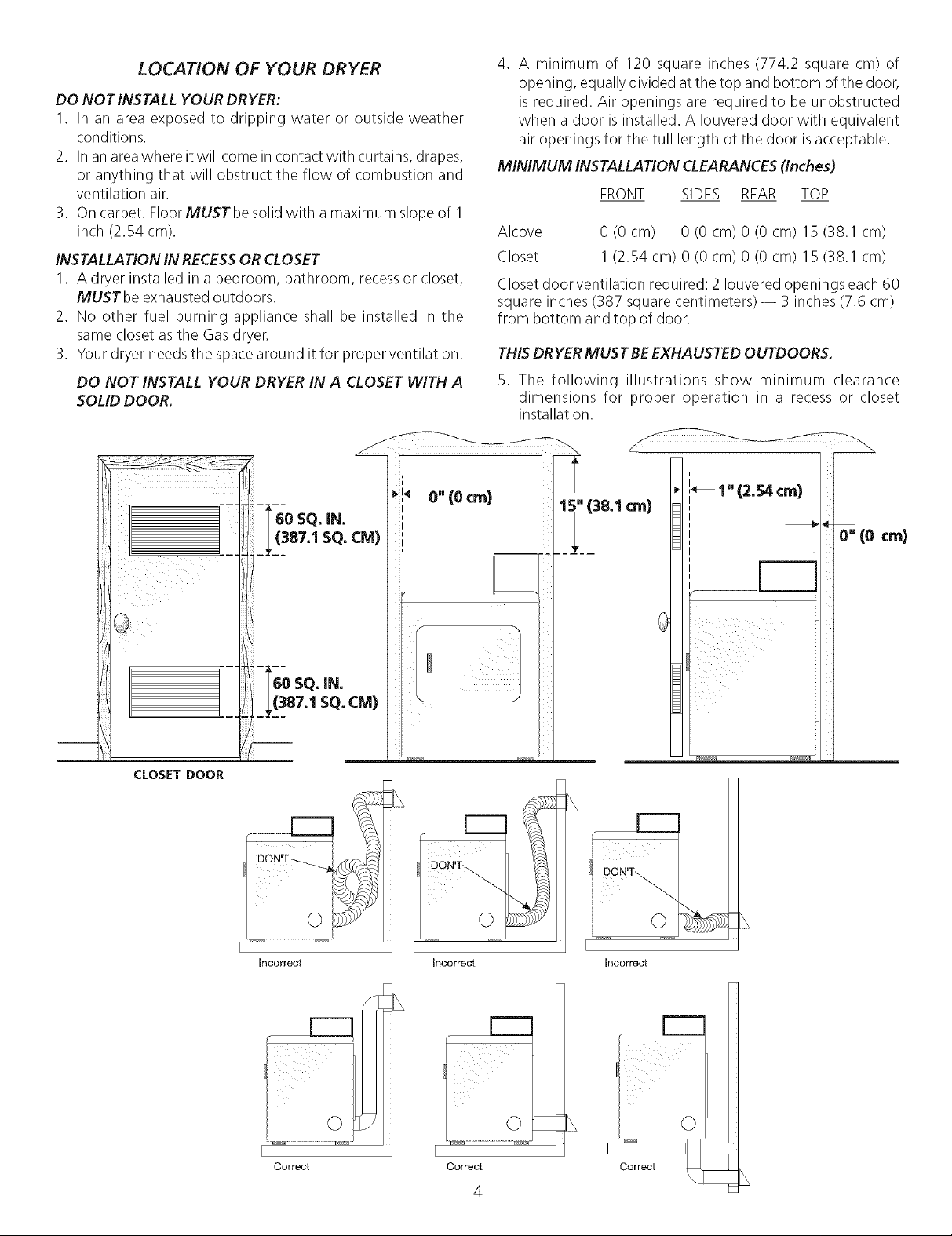

4. A minimum of 120 square inches (774.2 square cm) of

opening, equally divided at the top and bottom of the door,

is required. Air openings are required to be unobstructed

when a door is installed. A Iouvered door with equivalent

air openings for the full length of the door isacceptable.

MINIMUM INSTALLATION CLEARANCES (Inches)

FRONT SIDES REAR TOP

Alcove 0 (0 cm) 0 (0 cm) 0 (0 cm) 15 (38.1 cm)

Closet I (2.54 cm) 0 (0 cm) 0 (0 cm) 15 (38.1 cm)

Closet door ventilation required: 2 Iouvered openings each 60

square inches (387 square centimeters) -- 3 inches (7.6 cm)

from bottom and top of door.

THISDRYERMUST BE EXHAUSTED OUTDOORS.

5. The following illustrations show minimum clearance

dimensions for proper operation in a recess or closet

installation.

CLOS£T DOOR

incorrect

incorrect

¢m)_ '_ 1" (2 54 cm)

I

0" (0 cm)

r---

i _I__:i__ii

DON'T _

Q

incorrect

Correct

[:::::3

O

I

Correct

L

4

Page 5

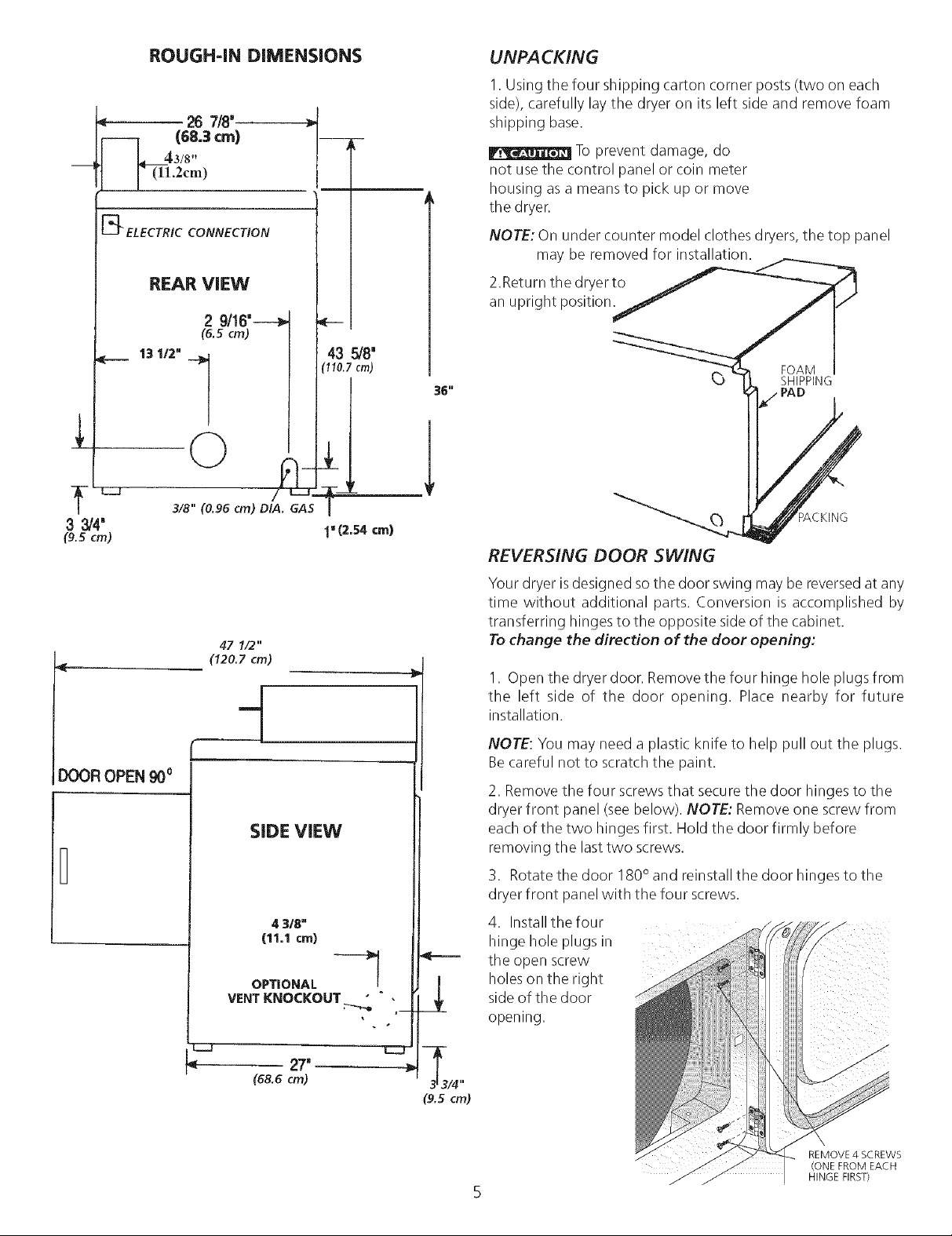

ROUGH=INDiMENSiONS

< 267/8'-------)

_d4 (68.3 cm)

3/8"

.2cm)

[_ ELECTRIC CONNECTION

UNPACKING

1. Using the four shipping carton corner posts (two on each

side), carefully lay the dryer on its left side and remove foam

shipping base.

To prevent damage, do

m

not use the control panel or coin meter

housing as a means to pick up or move

the dryer.

NOTE: On under counter model clothes dryers, the top panel

may be removed for installation.

3314"

(9. 5 cm)

<

REAR ViEW

2 9/16'---_

(6.Scm)

13 112"

3/8" (0.96 cm) DIA. GAS

47 1/2"

(120.7 cm)

43 5/8'

(110.7 cm)

1"(2.54crn)

36"

2.Return the dryer to

an upright position.

FOAM

SHIPPING

_, PAD

REVERSING DOOR SWING

Your dryer is designed so the door swing may be reversedat any

time without additional parts. Conversion is accomplished by

transferring hinges to the opposite side of the cabinet.

To change the direction of the door opening:

I. Open the dryer door. Remove the four hinge hole plugs from

the left side of the door opening. Place nearby for future

installation.

DOOR OPEN 90°

SiDE ViEW

4 3/8"

(11.1cm)

OPTIONAL --_

VENTKNOCKOUT;---,_,

< 27'

(68.6cm)

NOTE: You may need a plastic knife to help pull out the plugs.

Be careful not to scratch the paint.

2. Removethe four screws that secure the door hinges to the

dryer front panel (see below). NOTE: Remove one screw from

each of the two hinges first. Hold the door firmly before

removing the lasttwo screws.

3. Rotate the door 180° and reinstall the door hinges to the

dryer front panel with the four screws.

4. Install the four

hinge hole plugs in ..........

the open screw

holes on the right

side of the door

opening.

REMOVE 4 SCREWS

(ONE FROM EACH

HINGE FIRST)

5

Page 6

ELECTRICAL INSTALLATION

Before proceeding with electrical installation, install the dryer's

coin-metering system (when used) in accordance with the

separate instructions provided with the meter.

GREEN

SCREW SILVER

NEUTRAL

GROUND

WIRE

/TERMINAL

i

The following are specific requirements for proper

and safe electrical installation of your dryer Failure to follow

these instructions can create electrical shock and/or a fire hazard.

This appliance MUST be properly qrounded. Electrical

shock can result if the dryer is not properly grounded. Follow the

instructions in this manual for proper grounding.

extension cords are not designed to withstand the amounts of

electrical current this dryer utilizes and can melt, creating electrical

shock and/or fire hazard. Locatethe dryerwithin reach of the receptacle

for the length power cord to be purchased, allowing some slack in the

cord. Refer to the pre-installation requirements in this manual for the

proper power cord to be purchased.

A U.L listed strain relief must be installed onto power

cord. If the strain relief is not attached, the cord can be pulled out of

the dryer and can be cut by any movement of the cord, resulting in

electrical shock.

Do not usean aluminum wired receptacle with acopper

wired power cord and plug (or vice versa). A chemical reaction occurs

between copper and aluminum and can cause electrical shorts. The

proper wiring and receptacle is a copper wired power cord with

a copper wired receptacle.

NOTE: Dryers operating on 208 volt power supply will have longer

drying times than operating on 240 volt power supply.

i ELECTRIC Dryer }

F_I_I Improper connection of the equipment grounding

conductor can result in a risk of electrical shock. Check with a licensed

electrician if you are in doubt as to whether the appliance is properly

grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the event of a malfunction or

breakdown, grounding will reduce the risk of electrical shock by a

path of least resistance for electrical current.

2. If your dryer is equipped with a power supply cord having an

equipment-grounding conductor and a grounding plug, the plug

MUST be plugged into an appropriate, copper wired receptacle

that is properly installed and grounded in accordance with all

local codes and ordinances. If in doubt, call a licensed electrician.

Do not modify plug provided with the appliance.

For a permanently connected dryer:

1. The dryer MUST be connected to a grounded metal, permanent

wiring system; or an equipment grounding conductor must be

run with the circuit conductors and connected to the equipment-

grounding terminal or lead on the appliance.

ALL ELECTR/C Dryers

Do not use an extension cord with this dryer. Some

GROUNDING REQUIREMENTS

i

, HTENNUT

TO THESE

!ADS

REL EF

MOUNTING I

BRACKET POWER CORD

ELECTRICAL CONNECTIONS

FOR 3-WIRE SYSTEM

J

1.

Remove the screws securing the terminal block access cover and

the strain relief mounting bracket located on the back of the dryer

upper corner.

2. Install a U.L listed strain relief into the power cord entry hole of

the mounting bracket. Finger tighten the nut only at this time.

3. Thread a U.L listed 30 amp. power cord, NEMA 10-30 TypeSRDT,

through the strain relief.

4. Attach the power cord neutral (center wire) conductor to the silver

colored center terminal on the terminal block. Tighten the screw

securely.

5. Attach the remaining two power cord outer conductors to the

outer brass colored terminals on the terminal block. Tighten both

screws securely.

Pq'ql_2_l_:_l Do not make a sharp bend or crimp wiring/conductor

6. Reattach the strain relief mounting bracket to the back of the

dryer with two screws. Tighten screws securely.

7. Tighten the screws securing the cord restraint firmly against the

power cord.

8. Tighten the strain relief nut securely so that the strain relief does

not turn.

9. Reinstall the terminal block cover.

GREEN GROUND WIRE

GROUND _ SILVERTERMINAL

GROUND_-_ _

at connections.

ELECTR/C Dryer

GREENPOWER CORD

oi/_WHIT E TO THESEWIRE _ _,__yBLACK TIGHTEN NUT

i ALLGASDryers i

This dryer is equipped with a three-prong (grounding) plug for your

protection against shock hazard and should be plugged directly into

a properly grounded three-prong receptacle. Do not cut or remove

the grounding prong from this plug.

_ _- // NUT THREADS

/// RELIEF\_"Q,) // "_

/7/MOUN NG \ I/'//

, , c OW R

ELECTRICAL CONNECTIONS

FOR 4-WIRE SYSTEM

Page 7

ELECTRICAL CONNECTIONS

FOR 4-WIRE SYSTEM (Con't)

I ELECTR/CDryer 1

1, Remove the screws securing the terminal block access cover and

the strain relief mounting bracket located on the back of the dryer

upper corner.

2. Install a U.L listed strain relief in the entry hole of the mounting

bracket. Finger tighten the nut only at this time.

3. Remove the ground wire from the green ground screw located

above the terminal block.

4. Thread a U.L listed 30 amp power cord, NEMA 14-30 type ST or

SRDT through the strain relief.

(_ TYPICAL 4

CONDUCTOR BLACK 240V

RECEPTACLE

WHITE NEUTRAL

TYPICAL4 _,RED 240v

CONDUCTOR CORD "_,-

30 AMP NEMA 14-30 TYPE SRDT OR ST

5. Attach the green power cord ground wire to the cabinet with

the green ground screw.

6. Attach the white (neutral) power cord conductor from the power

cord and the neutral ground wire from the dryer harness

(removed from the ground screw in step 3) to the silver-colored

center terminal on the terminal block. Tighten the screw securely.

7. Attach the red and black power cord conductors to the outer

brass colored terminals on the terminal block.

Do not make a sharp bend or crimp wiring/conductor

at the connections.

8. Tighten the screws securing the cord restraint firmly against the

power cord.

9. Tighten the strain relief nut securely so the strain relief does not

turn.

10. Reinstall the terminal block access cover.

"_GREEN GROUND

INSTALLATION

1. GAS CONNECTION (Gas dryers only)

a. Remove the shipping cap from gas pipe at the rear of the

dryer.

NOTE: DO NOT connect the dryer to LP. gas service without

converting the gas valve. An L.R conversion kit must be

installed by a qualified gas technician.

2. Connect the exhaust duct to outside exhaust system. Use duct

tape to seal all joints.

3. With the dryer in its final position, adjust one or more of the legs

until the dryer is resting solid on all four legs. Place a level on top

of the dryer. THE DRYER MUST BE LEVEL AND RESTING SOLID

ON ALL FOUR LEGS.

4. Plug the power cord into a grounded outlet. NOTE: Check to

ensure the power isoff at circuit breaker/fuse box before plugging

the power cord into the outlet.

5. Turn on the power at the circuit breaker/fuse box.

Before operating the dryer, make sure the dryer area is

c/ear and free from combustible materials, gasoline, and other

flammable vapors. Also see that nothing (such as boxes, clothing,

etc.) obstructs the flow of combustion and ventilation air.

6. Run the dryer through a cycle check for proper operation.

NOTE: On gas dryers, before the burner will light, it is necessary

for the gas line to be bled of air. If the burner does not light

within 45 seconds the first time the dryer is turned on, the safety

switch will shut the burner off. If this happens, turn the timer to

"OFF" and wait 5 minutes before making another attempt to

light.

7. Place these instructions in a location near the dryer for future

reference.

NOTE: A wiring diagram is located inside the dryer.

REPLACEMENT PARTS

If replacements parts are needed for your dryer, contact the source

where you purchased your dryer, call 1-800-944-9044, or visit our

website, www.frigidaire.com, for the Frigidaire Company

Authorized Parts Distributor nearest you.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

Destroy the carton and plastic bags after the dryer is

unpacked. Children might use them for play. Cartons covered with

rugs, bedspreads, or plastic sheets can become airtight chambers

causing suffocation. Place all materials in a garbage container or

make materials inaccessible to children.

The instructions in this manual and all other literature

included with this dryer are not meant to cover every possible

condition and situation that may occur. Good safe practice and

caution MUSTbe applied when installing, operating and maintaining

any appliance.

Lint Blade Retaining Pin Location and Orientation

b. Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or approved pipe

from gas supply line to the 3/8 inch (0.96 cm) pipe located on

the back of the dryen Use a 1/2 inch to 3/8 inch (1.27 cm to

0.96 cm) reducer for a connection. Apply an approved thread

sealer that is resistant to the corrosive action of liquefied

gases on all pipe connections.

c. Open the shutoff valve in the gas supply line.

d. Test all connections by brushing on a soapy water solution.

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

Install the pins after the lint blade is installed.

7

Page 8

Your appliance is covered by a one year Iknited warranty. For one year from your original date of purchase, Electrolux will

pay all costs, except as set forth below, for repairing or replacing any parts of this appliance that prove to be defective in

materials or workmanship when such appliance is installed, used, and maintained in accordance with the provided instructions.

Exclusions

This warranty does not cover the following=

1. All labor costs on commercial laundry products.

2. Payment acceptance devices for commercial laundry products.

3. Products with odginal serial numbers that have been removed, altered or cannot be readily determined.

4. Normal wear and tear and gradual deterioration.

5. Product that has been transferred from its odginai owner to another party or removed outside the USA or Canada.

6. Rust on the interior or exterior of the unit.

7. Products purchased "as-is".

8. Food loss due to any refrigerator or freezer failures.

9. Damage caused at any time during shipment.

10. Service calls which do not involve malfunction or defects in materials or workmanship, or for appliances used other than in

accordance with the provided instructions.

11. Service calls to correct the installation of your appliance or to instruct you how to use your appliance.

12. Expenses for making the appliance accessible for servicing, such as removal of trim, cupboards, shelves, etc., which are not a part of

the appliance when it is shipped from the factory.

13. Service calls to replace appliance light bulbs, air filters, water filters, other consumables, or knobs, handles, or other cosmetic parts.

14. Surcharges including, but not limited to, any after hour, weekend, or holiday service calls, toils, ferry trip charges, or mileage

expense for service calls to remote areas, including the state of Alaska.

15. Damages to the finish of appliance and/or location that are incurred during installation, including but not limited to floors, cabinets,

walls, etc.

16. Damages caused by: services performed by unauthorized service companies; use of parts other than genuine Electrolux parts or parts

obtained from persons other than authorized service companies; or external causes such as abuse, misuse, inadequate power supply,

accidents, fires, or acts of God.

17. Labor costs after ninety (90) days from your original date of purchase incurred for product repair or replacement as provided herein

for appliances operated by a concessionaire or vendor in a trailer or other motorized vehicle or at varying locations.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR OR REPLACEMENT

AS PROVIDED HEREIN. CLAIMS BASED ON IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW, BUT NOT LESS THAN

ONE YEAR. ELECTROLUX SHALL NOT BE LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES SUCH AS PROPERTY DAMAGE

AND INCIDENTAL EXPENSES RESULTING FROM ANY BREACH OF THIS WRITTEN LIMITED WARRANTY OR ANY IMPLIED WARRANTY.

SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,

OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES, SO THESE LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO YOU.

THIS WRITTEN WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY ALSO HAVE OTHER RIGHTS THAT VARY FROM STATE

TO STATE.

If You Need Keep your receipt, delivery slip, or some other appropriate payment record to establish the warranty period should

Service service be required. If service is performed, it is in your best interest to obtain and keep all receipts. Service under

this warranty must be obtained by contacting Electrolux at the addresses or phone numbers below.

This warranty only applies in the USA and Canada. In the USA, your appliance is warranted by Electrolux Major Appliances North

America, a division of Electrolux Home Products, Inc. In Canada, your appliance is warranted by Electrolux Canada Corp. Electrolux

authorizes no person to change or add to any obligations under this warranty. Obligations for service and parts under this warranty must

be performed by Electrolux or an authorized service company. Product features or specifications as described or illustrated are subject

to change without notice.

USA

1.886.738.1640

Electrolux Major Appliances

North America

RO. Box 212378

Augusta, GA 30907

Electrolux

Electrolux Canada Corp.

5855 Terry Fox Way

Mississauga, Ontario, Canada

Canada

1.866.738.1640

L5V 3E4

Page 9

REOUERIMIENTOS DE INSTALA CION

PRELIMINARES

Herramientas y materiales necesarios para la instalaci6n:

1. Destornillador Phillips

2. Alicates universales

3. Nivel de carpintero

4. Destornillador para tornillo de cabeza plana o recta

5. Cinta para ductos

6. Ducto metalico rigido o flexible de 4"(10,2 cm)

7. Caperuza de salida

8. Sellador de tuberias (gas)

9. Un cuchillo de pl_istico

REQUERIMIENTOS ELECTRICOS

[ Secadoras ELLeCTR/CA, ]

ClRCUITO - Circuito derivado individual de 30 amperes, con

fusibles de 30 amp. del tipo de retardo minimo o disyuntores.

ALIMENTACIONELECTRICA - Corriente alterna, monoffisica, 60

Hz, 240 voltios; trifilar.

CORDON ELECTRICO - En la secadora se DEBE usar un cord6n

electrico trifilar NEMA 10-30 tipo SRDT para un voltaje nominal

minimo de 240 voltios CA, 30 amp, con 3 conectores de horquillas

con terminales abiertos y extremos dirigidos hacia arriba o

conectores de anillo cerrado y marcados para uso en secadoras

de ropa. Si siendo instalado en una nueva instalacibn del circuito

del rama, un vehiculo casero, recreacional (mbvil) manufacturado

o un _irea que prohiben el poner a tierra a traves del conductor

neutral, se DEBE utilizar un cordbn electrico tetrafilar NEMA 14-

30 tipo SRDT o ST (como sea necesario) para un voltaje nominal

minimo de 240 voltios CA, 30 amp con 4 conectores de horquillas

con terminales abiertos y extremos dirigidos hacia arriba o

conectores de anillo cerrado y marcados para uso en secadoras

de ropa. Ver CONEXIONES ELECTRICAS PARA SISTEMAS

TETRAFILARES.

TOMACORRIENTE - El tomacorriente NEMA 10-30R debe estar

ubicado de manera que elcord6n electrico Ilegue hasta el cuando

la secadora este instalada.

ALIMENTACIONELI_CTRICA

CAJA PRINCIPAL DE FUSIBLES CON CONDUCTOR NE UTRO

4 PUESTO A TIERRA, TRIRLAR, 120-240 VOLTIOS 60

CICLOS

FUSIBLES DE ACCION RETARDADA

DE 30 AMP O DISYDNTOR

-_ CONDUCTOR NEUTRO

TOMACORRIENTE _ _ _ _

(COBRE)

iNSTALACiON SUJETA A LOS

REGLAMENTOS LOCALES

NEMA I0-30R (COBRE)

NOTA:No saque por

espiga de puesta a

tierra del enchufe.

ning_n motivo la _k_

\ U ESP=eADEPUESTA

A TIERRA

REQUERIMIENTOS DEL SISTEMA DE ESCAPE

Utilice solamente ductos met_ilicos rigidoso flexibles de 4"

(10,2 cm) de di_imetro (minimo) y una caperuza de salida de uso

aprobado, con registros que giren hacia afuera que seabren cuando la

secadora se encuentra en funcionamiento. Cuando la secadora se

detiene, los registros se cierran autom_iticamente para evitar las

corrientes de airey laentrada de insectosy roedores. Paraevitar obstruir

la salida, mantenga una altura libre minima de 12"(30,5 cm) entre la

caperuza de salida y el piso o entre cualquier otra obstruccion.

Los siguientes requerimientos son

especificos para el funcionamiento correcto y seguro de su

secadora. El incumplimiento de estas instrucciones puede causar

prolongaci6n ex cesiva del tiempo de secado y riesgos de incendio.

_No useductos flexibles de pl_istico para el escape de la secadora.

Sepuede acumular un exceso de pelusasen el sistema de escape,treat

un riesgo y obstruir el flujo de aire. La restricci6n del flujo del aire

prolongar_i eltiempo de secado. Sisu sistema de escape actual tiene

ductos de plfistico o de laminas met_ilicasdelgadas, reempl_icelo con

un ducto metfilico rigido o flexible. Asegurese de que los ductos

existentes no tengan pelusas antes de instalar el ducto de la

secadora.

_Si el escape de la secadora no se diriqe al exterior, algunas pelusas

finas ser_qnsopladas hacia el recinto donde se efectua el lavado. La

acumulacion de pelusas en cualquier lugar de la construccion, puede

crear un peligro para la salud y un riesgo de incendio, iEIsistema de

escape de la secadora DEBEestar dirigido hacia el exterior de la

construcci6n!

_No permita que los materiales combustibles (por ejemplo: la ropa,

cortinas/cortinajes, papel) tengan contacto con los ductos. Elescape

de la secadora NO DEBE dirigirse hacia el interior de una chimenea,

hacia una pared, hacia el cielo raso o hacia cualquier otro espacio

reducido del edificio, donde puede ocurrir acumulaciOn de pelusas y

constituir un peligro de incendio.

_ Exceder la Iongitud del conducto rigido o los numeros de codos

permitidos en los diagramas "LARGO M,4XIMO" puede disminuir la

capacidad de exhaustacion del sistema. Obstruir el conducto puede

provocar peligro de incendio, asicomo aumentar el tiempo de secado.

_No coloque un filtro en elextremo del escapedel sistema niemplee

tornillos o remaches para ensamblar el sistema de escape. Laspelusas

podrian quedar atrapadas en los filtros, en los tornillos o en los

remaches, Io cual obstruiria el sistema de escape y crearia un riesgo de

incendio, asicomo tambien prolongaria eltiempo de secado. Useuna

caperuza de salida adecuada para el extremo del ducto que salga al

exterior de la vivienda y selle todas lasjuntas con cinta adhesiva para

ductos. Todos losaccesorios detuberia machos, DEBEN ser instalados

aguas abajo del flujo de aire.

[ ]

CIRCUITO - Circuito individual derivado de 15 amp, con fusibles

de 15 amp. de retardo m_iximo o disyuntor.

ALIMENTAClON ELECTRICA - Corriente alterna, monof_isica,

60 Hz, 120 voltios, trifilar.

CORDONELECTRICO- Lasecadoraest.1equipadacon un cord6n

electrico trifilar para 120 voltios.

Riesgo de explosi6n. Noinstale lasecadora

donde se guarda gasolina u otros materiales inflamables. Silasecadora

seinstala en un garage, ella debe estar por Io menos 18 pulgadas (45,7

cm) por encima del suelo. El incumplimiento puede resultar en la

muerte, explosion, incendio, o quemaduras.

9

Page 10

NQmero

de Codos

a 90 °

o

I

2

3

4

Numero

de Codos

a 90 °

LARGO MAXIMO

del Conducto Met&lico Rigido

de 4" (10,2 cm) de Diametro

TIPO DE CAPERUZA DE SALIDA

(Preferido)

Apersianada

-,-I4"t

(lo,2 cm)

60 pies (18,28 m)

52 pies (15,84 m)

44 pies (13,41 m)

32 pies (9,75 m)

28 pies (8,53m)

LARGO MAXIMO

del Conducto Metalico Flexible

de 4" (10,2 cm) de Diametro

TIPO DE CAPERUZA DE SALIDA

(Preferido)

Apersianada

(6.35 cm)

48 pies(14,63 m)

40 pies(12,19 m)

32 pies (9,75 m)

24 pies (7,31 m)

16 pies (4,87 m)

Elaislante que debe atravesa r el sistema puede causar condensaciOn

y disminuir asi la capacidad de exhaustaci6n del sistema.

o La capacidad de exhaustacion de un sistema de exhaustaci6n

comprimido o ondulado puede disminuirse.

Elsistema de exhaustacion debe de ser inspeccionado y limpiado por Io

menos cada 6 meses de uso normal. Cuanto mas la secadora esta uti-

lizada, mas debe verificar el buen funcionamiento del sistema de

exhaustacion y de la tapa del orificio de ventilacion.

UBICA CION DEL ESCAPE

Todas las secadoras vienen de fabrica equipadas con escape trasero.

Sin embargo, en las secadoras electricas, el escape puede hacerse al

lado derecho o izquierdo del gabinete o en la parte inferior de la secadora.

Enlas secadoras a gas, el escape del aire puede estar en el lado derecho

del gabinete o en la parte inferior de la secadora. El escape direccional

puede efectuarse instalando un Juego de Escape, P/N 131456800,

disponible atraves de su distribuidor de repuestos. Siga las instrucciones

que se suministran con el juego.

DIMENSIONES PARA LA UBICACION DEL DUCTO DE ESCAPE

(10,2 cm}

o

I

2

3

INSTALE LOS ACCESORIOS MACHOS EN LA DIRECCION CORRECTA

Para las instalaci6nes cuyas sistema de exhaustaci6n no se

encuentre en el diagrama, se puede utilizar el metodo a conti-

nuaciOn para determinar si el sistema de exhaustaciOn es apro-

piado.

1. Conecte un manOmetro a tubo inclinado o digital entre la

secadora y el union de exhaustaciOn de la secadora.

2. Ponga el contador de tiempo de la secadora y la temperatura

a aire frio (enfiriamiento), y la secadora en la posiciOn de

marcha.

3. Lea la medida indicada en el manOmetro.

4. La baja presiOn NO DEBE exceder 0.75 pulgada de la columna

de agua. Si la baja presiOn es inferior a 0.75" de la columna

deagua, elsistema esaceptable. Si la lectura indica una

presiOn superior a 0.75" de la columna de agua, la capacidad

del circuito es insuficiente y la instalaciOn es inaceptable.

Aungue un sistema vertical sea aceptable, algunas circunstancias

atenuantes pueden afectar el funcionamiento de la secadora:

• 5e debe utilizar solamente conductos metalicos rigidos.

e Una salida del sistema vertical en el techo, puede exponerle a un

corriente de aire descendente y disminuir asi su capacidad de

exhaustaci6n.

30 pies (9,14m)

22 pies (6,71 m)

14 pies (4,27 m)

NO RECOMENDADO

_'6.35cm_

18 pies (5,49 m)

14 pies (4,27 m)

10 pies (3,05 m)

REQUERIMIENTOS DEL SUMINISTRO DE GAS

Reemplace la tuberia de conexibn de cobre

que no est& recubrida con pl&stico. El laton inoxidable o recubrido

con plastico DEBE SERutilizado.

1. La instalacion DEBE hacerse cumplir con los codigos locales o en

ausencia de los mismos, de acuerdo con los estandares del National

Fuel Gas Code (Codigo Nacional para Gases Combustibles), ANSI

Z223.1 (la ultima edition).

2. Latuberia dealimentaciOn de gasdebeser de 1/2 pulgada (1,27 cm)

de diametro.

3. Si est_fi permitido por los cOdigos locales, se puede usar tubefia

de metal para conectar su secadora a la linea de suministro

de gas. La tuberia DEBE set fabricada de acero inoxidable o

cobre recubierto de pl_stico.

4. La tuberia de alimentaci6n de gas DEBEtener una Ilave de cierre

individual.

5. Una toma de 1/8 de pulgada (0,32 cm) N.RT. accesible para conexion

del manOmetro de prueba, DEBE ser instalada inmediatamente

aguas arriba de la conexion de la tuberia de alimentaciOn de gas a la

secadora.

6. La secadora DEBE ser desconectada del sistema de tuberias de

alimentaciOn de gas durante cualquier ensayo de presiOn del sistema

de tuberias de alimentaciOn de gas realizado a presiones de prueba

de mas de 1/2 Ibs/pulg. 2 (3,45 kPa).

7. La secadora DEBEaislarse del sistema de tuberias de alimentaci6n

de gas durante cualquier ensayo de presi6n del sistema de tuberias

de alimentacion de gas realizado en ensayos de presiOn iguales o

inferiores a 1/2 Ibs/pulg. 2 (3,45 kPa).

10

Page 11

UBICA CION DE SU SECADORA

NO INSTALE SU SECADORA:

1. Enun lugar donde puede haber goteos de agua o quede expuesta

a las inclemencias del tiempo.

2. En un _ireadonde pueda entrar en contacto con cortinas, cortinajes

o cualquier otra cosa que obstruya el flujo de combusti6n y

ventilaci6n de aire.

3. Sobre alfombras. Elpiso DEBEserfirme con un desnivel maximo de

1pulgada (2,54 cm).

/NSTALACION DENTRO DE UN NICHO 0 ARMARIO

1. Sila secadora es instalada en un dormitorio, cuarto de bano, nicbo

o armario, el tubo del escape DEBE set instalado hacia el exterior.

2. No sedebe instalar ningOn otto artefacto que queme combustible

en el mismo armario en que est,1instalada la secadora a Gas.

3. La secadora necesita espacio a su alrededor para una ventilaci6n

adecuada.

Se requiere como minimo una abertura de 120 pulgadas cuadra-

das (774,2 cm2), dividida equitativamente para la parte superior e

inferior de la puerta. Cuando se instala una puerta, es necesario

proveer aberturas para el aire. Una puerta apersianada con abertu-

ras para el aire en todo el largo de la puerta es aceptable.

DESPEJES MiNIMOS DE INSTALACION (Pulgadas)

PARTE PARTE PARTE

DELANTERA LADOS TRASERA SUPERIOR

Alcoba 0 (0 cm) 0 (0 cm) 0 (0 cm) 15 (38,1 cm)

Armario 1 (2,54 cm) 0 (0 cm) 0 (0 cm) 15 (38,1 cm)

Ventilaci6n requirida en la puerta del armario: dos aberturas rejilladas

cada 60 pulg. 2 (387 cm2) -- 3" (7,6 cm) desde la parte inferior y

superior de la puetra.

EL TUBO DEL ESCAPEDE LA SECADORA DEBE SER INSTALADO

HACIA ELEXTERIOR.

NO INSTALE LA SECADORA EN UN ARMARIO CON PUERTA

MA CIZA,

60 Pulgo2

{387,1 ¢m2)

PUERTA DEL ARMARmO

5. Lassiguientes ilustraciones muestran las dimensiones mfnimas de

espacio libre que debe existir para el buen funcionamiento de la

secadora cuando se instala en un nicho o en un armario.

NO

L

Correcto

sl

©

Incorrecto

L

11

Correcto

Incorrecto

Incorrecto

Page 12

MODELOS AUTONOMOS CON CONSOLA

SUPERIOR

DIMENSIONES PARA LA INSTALACI6N

_68.3cm_

m

L43/8"

[_ CONEXI6N EL_:CTRICA

26 7/8" 1

" (11.2cm)

DESEMBALAJE

1. Utilizando lascuatro esquineras de embarque de la caja de carton

(dos a cada lado), coloque cuidadosamente la secadora sobre el

costado izquierdo y saque la base de espuma de embarque.

_Para evitar danos, no use el panel de control como

un medio para levantar o mover la secadora.

NOTA: En los modelos de secadoras encastradas, el panel superior

puede set removido para la instalacion.

2. Vuelva la secadora a su posici6n vertical.

13 1/2" -_

(34,4 cm) [

3 3/4" (9,5 cm)

PUERTA

ABIERTAA90 °

B

2 9/16" (6,5 cm)

0

CONEXION DE LA

TUBERiA DE GAS

DE 3/8" (0,96cm)

VISTA POSTERIOR

47112"

(120,7 cm)_ 17(432)

44

(111.8ore)

36"

__ (91,5 cm)

1

1" (2,54 cm)

--1

PLACA DE

ESPUMA DE

_¢/ EMBARQUE

MPAQUE

PUERTA REVERSIBLE

Su secadora ha sido diser_ada para que la puerta pueda ser cambiada

de lado en cualquier momento sin necesidad de piezas adicionales.

La conversion se hace transfiriendo las bisagras al lado opuesto del

gabinete.

Como cambiar ladireccion de apertura de la puerta:

1. Abra lapuerta de la secadora. Quite loscuatro receptores del agujero

de la bisagra del lado izquierdo de la apertura de la puerta.

Coloquelos en un lugar cercano para futura instalaci6n. NOTA:

Puede que se necesite un cuchillo de pl_istico para poder sacar los

receptores. Tenga cuidado de no rayar la pintura.

2. Quite los cuatro tornillos que aseguranlas bisagras de la puerta al

panelfrontal de lasecadora (ver figura abajo). NOTA: Primero quite

untornillo decada una de lasbisagras. Mantenga la puerta sujetada

firmemente antes de quitar los dos 01timostornillos.

3. Gire la puerta 180° y vuelva a colocar las bisagras de la puerta en el

panel frontal con los cuatro tornillos.

4. Instale los cuatro receptores de los agujeros de las bisagras en los

agujeros abiertos en el lado derecho de la apertura de la puerta.

43/8"(11,1 cm) -----_

DISCO OPCl6NAL /

REMOVlBLE PARA-_....._

VENTILACl6N

27'

(68,6 cm)

VISTA LATERAL

.

i --

QUITE LOS CUATRO

TORNILLOS (PRIMERO QUITE

UNO DE CADA BISAGRA)

Page 13

INSTALA CION ELI_CTRICA

i TODAS/assecadorasELtCTRICAS i

Los siguientes requerimientos son

especificos para el funcionamiento correcto y seguro de su

secadora. El incumplimien to de estas instrucciones puede causar

p_r_a del tiempo de secado y riesgos de incendio.

_*_J__ Este artefacto DEBE ser puesto a tierra de

manera correcta. Sila secadora no est_qdebidamente puesta a tierra se

puede producir un choque electrico. Siga las instrucciones indicadas

en_puesta a tierra en forma correcta.

_lr! , By - _ • No use un cordon de extension con esta

secadora. Algunos cordones de extension no pueden soportar la

cantidad de corriente electrica que utiliza esta secadora y pueden

fundirse, creando un peligro de choque electricoy/o incendio. Ubique

la secadora de manera que el cordon electrico Ilegue hasta el

tomacorriente que se va a usar, dejando un poco de holgura para el

cordon. ConsultelosrequerimientosdeinstalaciOn preliminares

indicados en este manual para el cordon electrico que debe set

TORNILLO

VERDE DE

PUESTA A ,

TERRA

CABLE DE

PUESTA

ATIERRA

NEUTRAL

BORNE PLATEADO

ATORNILLE LA

TUERCA EN ESTAS

ROSCAS

Se debe instalar un anclaje aprobado por el U. L.

para el cordon electrico. Si no se utiliza un anclaje para sujetar el cordon

electrico, este puede salirse de la secadora y cortarse con cualquier

movimiento, resultando en un choque electrico.

No utilice un tomacorriente con cables de

aluminio con un cordon y un enchufe de cobre (o viceversa). Se produce

una reacciOn quimica entre el cobre y el aluminio que puede causar

cortaci rcu itos. El cableado y tomacorriente apropiado es un cord6n

electrico equipado con conductores de cobre con un tomacorriente

con conductores de cobre.

NOTA: Las secadoras que operan con un suministro de energia de 208

voltios usar_in m_is tiempo de secado que aquellas que operan con un

suministro de energia de 240 voltios.

REQUERIMIENTOS PARA LA PUESTA A TERRA

SecadorasELECTRICAS i

LaconexiOn indebida del conductor de puesta atierra

del equipo puede ocasionar un riesgo de choque electrico. Consulte

con un electricista profesional si tiene alguna duda respecto a la puesta

atierra correcta del artefacto.

Para una secadora puesta a tierra con cordon elOctrico:

1. La secadora DEBEser puesta a tierra. En caso de malfuncionamiento

o falla, la puesta a tierra reducira el riesgo de choque electrico

proporcionando un trayecto de menor resistencia a la corriente

elOctrica.

2. Si su secadora est,1 equipada con un cordon electrico que posee un

conductor de puesta a tierra del equipo y un enchufe de puesta a

tierra, dicho enchufe DEBE set conectado a un tomacorriente

adecuado, debidamente instalado y puesto a tierra de acuerdo con

todos los cOdigos y reglamentos locales. Si tiene alguna duda

consulte a un electricista profesional. No modifique el enchufe

propercionado la aplicaci6n.

Para una secadora conectada permanentemente:

1. La secadora DEBEserconectada a un sistema de cableado met_qlico

permanente, puesto a tierra; o se debe instalar un conductor de

puesta a tierra de equipo junto con los conductores del circuito y

conectarse al borne de puesta a tierra del equipo o al cable del

artefacto.

[ TODAS/assecadorasaGAS I

Esta secadora est,1 equipada con un enchufe de tres espigas (de puesta 2.

a tierra) para proteccion en contra de choques electricos y debe ser

conectada directamenta en un receptaculo para tres espigas el cual debe

estar puesto a tierra. No corte ni elimine la espiga de puesta a tierra de 3.

este enchufe. 13

SOPORTE DE

MONTAIE DEL

ANCLAJE DE

CABLE CORDON ELECTRICO

CONEXIONES ELECTRICAS PARA

UN SISTEMA TRIFILAR

Secadoras EL ECTR/CA S ]

1. Saque los tornillos que sujetan la cubierta de acceso del tablero de

bornes y el soporte de montaje del anclaje del cordon, situado en la

esquina superior de la parte trasera de la secadora.

2. Instale un anclaje de cable aprobado por el U.L, en el orificio de

entrada del cordon electrico en el soporte de montaje. Luego apriete

la tuerca con los dedos solamente.

3. Inserte un cordon el_ctrico de 30 amp, NEMA 10-30 Tipo SRDT,

aprobado por el U.L, a traves del anclaje de cable.

4. Conecte el conductor neutro del cordon electrico (cable central) al

borne central plateado del tablero de bornes. Apriete firmemente el

tornillo.

5. Conecte los dos conductores externos restantes del cordon electrico

a los homes bronceados externos del tablero de bornes. Apriete

firmemente los tornillos.

No doble en forma pronunciada ni engarce los

cables/conductores en las conexiones.

6. Coloque nuevamente el soporte de montaje del anclaje de cable en

la parte trasera de la secadora con dos tornillos. Apriete firmemente

los tornillos.

7. Apriete firmemente los tornillos del anclaje de cable contra el cordon

electrico.

8. Apriete la tuerca del anclaje de cable a fin de que el anclaje no gire.

9. Coloque nuevamente la cubierta del tablero de bornes.

CONEXIONES ELL'CTRICAS PARA UN SISTEMA

TETRAFILAR

Secadoras ELf'CTR/CAS i

Saque los tornillos que sujetan la cubierta de acceso del tablero de

bornes y el soporte de montaje del anclaje de cable situado en la

esquina superior en la parte trasera de la secadora.

Instale un anclaje de cable aprobado por el U.L, en el orificio de

entrada del cordon electrico en el soporte de montaje. Luego apriete

la tuerca con los dedos solamente.

Desconecte el cable de puesta a tierra neutral del tornillo verde de

puesta a tierra situado en la parte superior del tablero de bornes.

Page 14

TORNILLO VERDE

DE PUESTA

ATIERRA

CABLE DE

PUESTA A

IIERRA

NELrI1RAL-_

ROJO"

4. Inserte un cord6n electrico tetrafilar de 30 amp, NEMA 10-30

TipoST o SRDT, aprobado por el U.L, a traves del anclaje de cable.

TOMACORRIENTE

TETRAFILARTIPICO 240 V

_,#NEGRO

/_' NEUTRO

_ BLANCO

CORDON

ELIeCTRICO %v

CORDON ELECTRICO DE 30 AMP NEIVIA 14_l_l:il!O SRDT 0 ST

5. Conecte el cable verde de puesta a tierra del cordon electrico al

gabinete mediante el tornillo verde de puesta a tierra.

6. Conecte el conductor blanco (neutro) del cord6n electricoy el cable

de puesta a tierra neutro del mazo de cables de la secadora al borne

plateado central del tablero de bornes.

7. Conecte los conductores rojo y negro del cord6n el_ctrico a los

bornes bronceados externos del tablero de bornes.

los cables/conductores en las conexi6nes.

8. Apriete firmemente los tornillos del anclaje de cable contra el cord6n

el_ctrico.

9. Apriete la tuerca del anclaje de cable a fin de que el anclaje no gire.

10. Coloque nuevamente la cubierta del tablero de bornes.

TETRAFILAR TIPICO PUESTA A TIERRA

No doble en forma pronunciada ni engarce

_ 240v ROJO

lira

/NSTALAC/ON

CONEXION DEL GAS (Secadoras a gas solamente)

a. Saque la tapa de embarque de la tuberia de gas de la secadora

situada en la parte trasera.

NOTA:

NO conecte la secadora al suministro de propano, sin primero

instalar eljuegodeconversi6n a propano. EIjuegode

conversi6n a propano debe set instalado pot un t_cnico de

gas calificado.

2. Conecte el ducto de escape al sistema de escape exterior. Utilice

cinta para obturar todas las uniones.

3. Con la secadora en su posici6n definitiva, regule uno o ross tornillos

niveladores, hasta que la secadora repose firmemente sobre los

cuatro tornillos. Coloque un nivel sobre la parte superior de la

secadora. LA SECADORA DEBE ESTAR A NIVEL Y REPOSAR

SOLIDA Y FIRMEMENTE SOBRE LOS CUATRO TORNILLO5

NIVELADORES.

4. Conecte el cordon electrico a un tomacorriente puesto a tierra.

NOTA: Aseg0rese de que la corriente este desconectada en el

disyuntodcaja de fusibles, antes de conectar el cordon electrico en

el tomacorriente.

5. Conecte la corriente en el disyuntor/caja de fusibles.

Antes de poner en funcionamiento la secadora,

asegOresede que no haya materia/es combustib/es, gaso/ina y otr os

vapores inf/amab/es cerca de/a secadora. Ademas asegOrese de

que no haya nada (tal como cajas, ropas, etc.) que obstruya el flujo

de/aire de combusti6n y venti/ad6n.

6. Haga funcionar la secadora durante un ciclo completo para

comprobar su buen funcionamiento.

NOTA: En las secadoras a gas, antes de encender el quemador es

necesario purgar el aire de la tuberia del gas. Si el quemador no

enciende dentro de 45 segundos, cuando la secadora seenciende

pot primera vez, el interruptor de seguridad apagar_i el quemador.

Si esto sucede, gire el contador de tiempo a la posici6n "OFF"

(apagado) yespere 5 minutos antes de intentar encender lasecadora

nuevamente.

7. Conserve estas instrucciones cerca de la secadora para referencia

futura.

NOTA: Dentro de'l sobre seencuentra un diagrama del cableado.

PIEZAS DE RECAMBIO

Si necesita obtener piezas de recambio para su secadora, pongase en

contacto con el distribuidor donde compr6 su secadora, Ilame 1-800-

944-9044, o visitan nuestros website www.frigidaire.com, para la

Distribuidor Autorizada Company de las Piezas de Frigidaire m_is

cercana usted.

Cuando se reparan los controles, marque todos los

cables con etiquetas antes de desconectarlos. Cualquier error de

cableado puede causar una operacion inadecuada y peligrosa.

Aseg0rese de que la secadora funcione adecuadamente despues de

'_._ Destruya la caja de carton, las bolsas de pkistico

y la banda met_ilica despues de haber desempacado el centro de

lavanderia. Los niflos pueden ponerse a jugar con ellos. Las cajas de

carton cubiertas con alfombras, colchas o pedazos de pl_istico pueden

convertirse en c_imaras sin aire y causar asfixia. Elimine todos los

os en la basura o fuera del alcance de los ninos.

Las instrucciones inclu idas en este manual y en

el resto de la documentacion que se entrega con la secadora no pueden

cubrir todas las situaciones o condiciones posibles que puedan

presentarse. Por Io tanto, se DEBEN seguir practicas seguras y tener

cuidado cuando se instala cualquier artefacto domestico.

b. Conecte una tuberia semirigida de 1/2" (1,27 cm) D.I. o una

tuberia aprobada, desdela linea desuministro de gasa la tuberia

de 3/8" (0,96 cm) ubicada en la parte trasera dela secadora. Utilice

un reductor de 1/2" (1,27 cm) a 3/8" (0,96 cm) para laconexion.

Aplique un sellador de roscas de uso aprobado, resistente a la

corrosi6n de los gases licuados, en todas las uniones de la

tuberia.

c. Abra lawqlvula de cierre en la tuberia de suministro de gas.

d. Pruebe todas las conexiones aplicando con una escobilla una

solucion jabonosa. NUNCA UTILICE UNA LLAMA ABERTA

PARA DETECTAR FUGA5 DE GAS.

La Rejilla para peiusas prender con aifileres Posicion et

Orientacion

Instalar les alfileres despues de la rejilla para para pelusas

instalaciOn.

14

Page 15

Su electrodom6stico esta cubierto por una garantia limitada de un aho. Durante un aho a partir de la fecha original de

compra, Electrolux cubrira todos los costos de reparacion o reemplazo de cualquier pieza de este electrodom6stico que se

encuentren defectuosas en materiales o mano de obra cuando el electrodom_stico se instala, utiliza y mantiene de acuerdo

con las instrucciones proporcionadas.

Esta garantia no cubre Io siguiente:

1, Todos los costos de mano de obra en productos para lavado comerciak

2, Dispositivos de aceptaci6n de pago para productos para lavado comerciaL

3. Productos a los que se les quitaron o alteraron los n0meros de serie originales o que no pueden determinarse con facilidad.

4, Desgaste normal y deterioro gradual por el uso,

5. Productos que hayan sido transferidos del dueno original a un tercero o que no se encuentren en los EE.UU. o en Canada1.

6. Oxido en el interior o exterior de la unidad,

7, Los productos comprados "previamente usados o productos de muestra" no est_in cubiertos por esta garantia.

8, P_rdida de alimentos por fallas del refrigerador o congelador.

9_ Dafio provocado en cualquier momento durante el env[o_

10. Las Ilamadas de servicio que no involucren el funcionamiento defectuoso ni los defectos de materiales o de mano de obra, o para

electrodomesticos que no sean utilizados para uso normal del hogar o de acuerdo con las instrucciones proporcionadas.

11. Llamadas de servicio para corregir errores de instalaci6n del electrodom_stico o para instruirlo sobre el uso del mismo.

12. Gastos para facilitar el acceso al electrodomestico para el servicio, tales como la remoci6n de molduras, armarios, estantes, etc. que

no eran parte del electrodomestico cuando se envi6 de la flibrica.

13. Llamadas de servicio para reparar o reemplazar bombillas, filtros de aire, filtros de agua, otros consumibles, perillas, manijas u otras

piezas decorativas.

14. Costos adicionales que incluyen, sin limitarse, cualquier Ilamada de servicio fuera de las horas de oficina, durante los fines de

semana o dias feriados, peajes, pasajes de transporte o millaje/kilometraje para Ilamadas de servicio en _ireas remotas, incluyendo

el estado de Alaska.

15. Danos al acabado del electrodomestico o al hogar que hayan ocurrido durante la instalaci6n, incluyendo, sin limitarse, los armarios,

paredes, etc.

16. Dan6s causados por: servicio realizado por companias de servicio no autorizadas, el uso de piezas que no sean piezas genuinas

Electrolux o piezas obtenidas de personas que no pertenezcan a companias de servicio autorizado, o causas externas como abuso,

mal uso, suministro el_ctrico inadecuado, accidentes, incendios, hechos fortuitos or desastres naturales.

17 Costos de mano de obra despu6s de noventa (90) d[as de su fecha original de compra en los que se incurra para la reparaci6n o

el reemplazo del producto tal como se dispone en el presente para electrodom6sticos operados por un concesionario o proveedor

en un cami6n o en otro veh[culo motorizado o en distintos lugares

RENUNCIA DE RESPONSABILIDAD DE GARANTIAS IMPLICITAS; LIMITACION DE ACCIONES LEGALES

LA 0NICA Y EXCLUSIVA OPCION DEL CLIENTE BAJO ESTA GARANTfA LIMITADA ES LA REPARACION O REEMPLAZO DEL PRODUCTO

SEGON SE INDICA. LOS RECLAMOS BASADOS EN GARANT[AS IMPL[CITAS, INCLUYENDO LAS GARANTIAS DE COMERCIALIZACION O

APTITUD DEL PRODUCTO PARA UN PROPOSITO ESPEC/FICO, ESTAN LIMITADOS A UN ANO O AL PERtODO M[NIMO PERMITIDO POR LEY,

PERO NUNCA MENOS DE

UN ANO. ELECTROLUX NO SERA RESPONSABLE POR DANOS CONSECUENTES O INCIDENTALES COMO POR EJEMPLO DANOS A LA

PROPIEDAD Y GASTOS INCIDENTALES OCASIONADOS POR EL INCUMPLIMIENTO DE ESTA GARANT[A ESCRITA O DE CUALQUIER GARANT[A

IMPL/CITA. ALGUNOS ESTADOS Y PROVINCIAS NO PERMITEN LA EXCLUSION O LIMITACION DE DANOS INCIDENTALES O CONSECUENTES

O LIMITACIONES EN LA DURACION DE LAS GARANTiAS IMPL[CITAS, DE MANERA QUE PUEDE QUE ESTAS LIMITACIONES O EXCLUSIONES

NO SE APLIQUEN EN SU CASO. ESTA GARANT[A ESCRITA LE OTORGA DERECHOS LEGALES ESPEC[FICOS. ESO POSIBLE QUE TAMBI_N

TENGA OTROS DERECHOS QUE VAR[AN DE UN ESTADO A OTRO.

Exdusiones Si tiene

que solicitar servicio

tecnico

Esta garantia s61ose aplica en los Estados Unidos y Canada En los EE.UU., su electrodomestico est,1 garantizado por Electrolux Major

Appliances North America, una divisi6n de Electrolux Home Products, Inc. EnCanada1,su electrodomestico est,1garantizado por Electrolux

Canada Corp. Electrolux no autoriza a ninguna persona a cambiar o agregar ninguna obligaci6n bajo esta garantia. Nuestras obligaciones

de reparaci6n y piezas bajo esta garantia deben ser realizadas por Electrolux o compania de servicio autorizado. Lasespecificaciones o

caracteristicas del producto segun se describen o ilustran est_in sujetas a cambio sin previo aviso.

Guarde su recibo, el comprobante de entrega o cualquier otro registro de pago adecuado para establecer el

periodo de la garantia si Ilegara a requerir servicio. Si se realiza la reparaci6n, le conviene obtener y

conservar todos los recibos. El servicio realizado bajo esta garantia debe set obtenido a trav_s de Electrolux

utilizando las direcciones o n0meros que se indican abajo.

EE. UI/.

1.866.738.1640

Electrolux Major Appliances

North America

RO. Box 212378

Augusta, GA 30907

8] Electrolux

Canada

1.866.738.1640

Electrolux Canada Corp.

5855 Terry Fox Way

Mississauga, Ontario, Canada

L5V 3E4

Loading...

Loading...