Frigidaire FAS12P2ABJW, FAC09P2ABJW, FAC12P2ABJW, FAS18C2ABJW, FAS24P2ABJW Instruction Manual

...

FRIGIDAIR

INSTRUCTIONS MANUAL

SPL|T TYPE ROOM AIR CONDITIONER

ATTENTION

Please read this manual completely

before operating your room air conditioner.

Welcome to the world of

simple handling and no worries.

Thank you for choosing Frigidaire. This manual contains all of the information

required to guarantee your safety and the appropriate use of your air

conditioner.

Please read all of the instructions before using the air conditioner and keep this

manual for future reference.

We know you will enjoy your new air conditioner and thank you for choosing

our product. We hope you will consider us for future purchase.

Environmental advices

The packaging material used is

recyclable; we recommend that you

separate plastic, paper and cardboard

and give them to recyoling companies.

According to WEEE (Waste of Electrical

and Electronic Equipment) guidelines,

waste from electrical and electronic

devices should be collected separately, If

you need to dispose of this appliance in

the future, do NOT throw it away with the

rest of your domestic garbage. Instead,

please take the appliance to the nearest

WEEE collection point, where available.

Contents

01, Welcome ........................................................................................... 01

02. Environmental advices .......................................................................... 01

03. Contents ................................................................................................... 02

04. Safety precautions ..................................................................... 04

05. installation:

5.1 Choosing the installation site ....................................................... 08

5.2 Parts list ......................................................................................... 10

5.3 Indoor unit installation ................................................... 12

5.4 Outdoor unit installation .............................................................. 17

5,5 Refrigerant piping connection ........................................................ 19

5.6 Electrical work ..................................................................... 21

5,7 Purga de aire ............................................................................. 26

5.8 Electrical safety, ................................................................... 29

5.7 Gas leak check ............................................................................... 29

5.8 Test running ............................................................................. 30

06, Operation:

6.1 Preparing the device for operation .............................. 31

6.2 Product description ........................................................... 32

6.3 Remote control ................................................................... 34

- Remote control operation

- Remote control specifications

- Remote control battery

- When should the batteries be replaced

- To replace batteries

- Remote control instructions

6.4 Remote control description .................................................... 36

- On/Off

- Temp. increase

- Temp, decrease

- Swing

Clock

- Turbo

- Mode

- Fan speed

- Sleep

- Timer

- Cancel

- LED (screen)

6.5 LCD display indicators .................................................................. 38

6.6 How the air conditioner works ................................... 39

- Automatic operation

-Cool/heatandfanonlyoperation

- Dryoperation

-Airflowdirectionadjustment

-Sleepmode

-Timeroperation

-Optimal operation

6,7 How to use the indoor unit...................................................... 43

- Adjusting air flow direction

- Adjusting the vertical air flow direction (up/down)

- To set the horizontal air flow direction (left/right)

- To automatically swing the air flow direction (up/down)

6.8 Manual operation ........................................................................ 45

07. Maintenance .................................................................................... 46

08. Operation tips .......................................................................................... 48

09. Solution for problems .............................................................................. 50

I0. Technical specifications ..................................................................... 51

Attention

The air conditioner that you have bought may be slightly different from the

one illustrated in this manual. Please refer to the information related to the

model you have.

This air conditioner is for domestic use only. It is not reccomended for

commercial or industrial use.

The air conditioner you have may carry a different plug than the one

illustrated in this manual, The plug that comes with the product fo]Iows the

electrical specification of the country where it is sold.

Safety precautions

To prevent iniury to the user or other people and property damage, the

following instructions must be followed.

Incorrect operation due to ignon_ng of instructions may cause harm or damage.

The seriousness is classified by the following indications.

1. Connect with the power properly.

Otherwise, it may cause electric

shock or fire due to excess heat

generation.

2. Do not modify power cord length

or share the outlet with other

appliances. It may cause electric

shock or fire due to heat

generation.

3, Always ensure effective earthing,

No earthing may cause electric

shock.

4. Disconnect the power if strange

sounds, smell, or smoke comes

from it, tt may cause fire and

electric shock,

5. Keep firearms away. It may cause

fire.

6, Do not operate or stop the unit by

switching on or off the power, tt

may cause electric shock or fire

due to heat generation,

7, Do not operate with wet hands or

in damp environment. It may

cause electric shock,

8. Do not allow water to run into

electric parts. It may cause failure

of machine or electric shock.

9. Do not drink water drained from air

conditioner.Itcontains

contaminantsandcouldmakeyou

sick,

10.Donotusethepowercordcloseto

heatingappliances.Itmaycause

fireandelectricshock.

11.Do not damage or use an

unspecified power cord. It may

cause electric shock or fire.

12.Do not direct airflow at room

occupants only. This could damage

your health.

1&Always install circuit breaker and a

dedicated power circuit. No

installation may cause fire and

electric shock,

14.Do not open the unit during

operation. It may cause electric

shock.

15.Do not use the power cord near

flammable gas or combustibles,

such as gasoline, benzene, thinner,

etc. It may cause an explosion or

fire.

I &Ventilate room before operating air

conditioner if there is a gas leakage

from another appliance, It may

cause explosion, fire and, burns.

17.Do not disassemble or modify unit.

It may cause failure and electric

shock.

18.When the air filter is to be removed,

do not touch the metat parts of the

unit, It may cause an injury.

19,Do not clean the air conditioner

with water. Water may enter the

unit and degrade the insulation. It

may cause an electric shock,

\,...J

20.Ventilate the room well when used

together with a stove, etc. An

oxygen shortage may occur.

21.When the unit is to be cleaned,

switch off, and turn off the circuit

breaker. Do not clean unit when

power is on as it may cause fire

and electric shock, it may cause

an iniury.

22.Do not put a children, pet or house

plant where it will be exposed to

direct air flow. This could injure the

pet or plant.

23.Do not use for special purposes.

Do not use this air conditioner to

preserve precision devices, food,

pets, plants, and art objects. It

may cause deterioration of quality,

etc.

24.Stop operation and close the

window in storm or hurricane.

Operation with windows opened

may cause wetting of indoor and

soaking of household furniture.

25.Turn off the main power switch

when not using the unit for a long

time. It may cause failure of

product or fire.

26.Do not use strong detergent such

as wax or thinner. Use a soft cloth

for cleaning. Appearance may be

deteriorated due to change of

product color or scratching of its

surface.

27.Ensure that the installation bracket

of the outdoor appliance is not

damaged due to prolonged

exposure. If bracket is damaged,

there is concern of damage due to

®

falling of unit.

28.Always insert the filters securely.

Clean filter once every two weeks,

Operation without filters may cause

failure.

29.Do not place heavy object on the

power cord and take care so that

the cord is not compressed. There

is danger of fire or electric shock.

30.Do not place obstacles around air-

inlets or inside of air-outlet. It may

cause failure of appliance or

accident.

Choosing the Installation Site

Precautions for Installation

installation at the following sites may cause problems. If you must inevitably

install the unit at one of these sites, please consult your local distributor

beforehand:

1. Site with machine oil.

2. Sites with a high concentration of salinity, such as coastal areas.

3. Sites with sulfuric gas, such as hot water springs.

4. Sites with high frequency equipment, such as wireless equipment, welding

machines and medical installations.

5. Sites with flammable gases or volatile material.

6. Sites with special environmental conditions.

7. Laundry rooms.

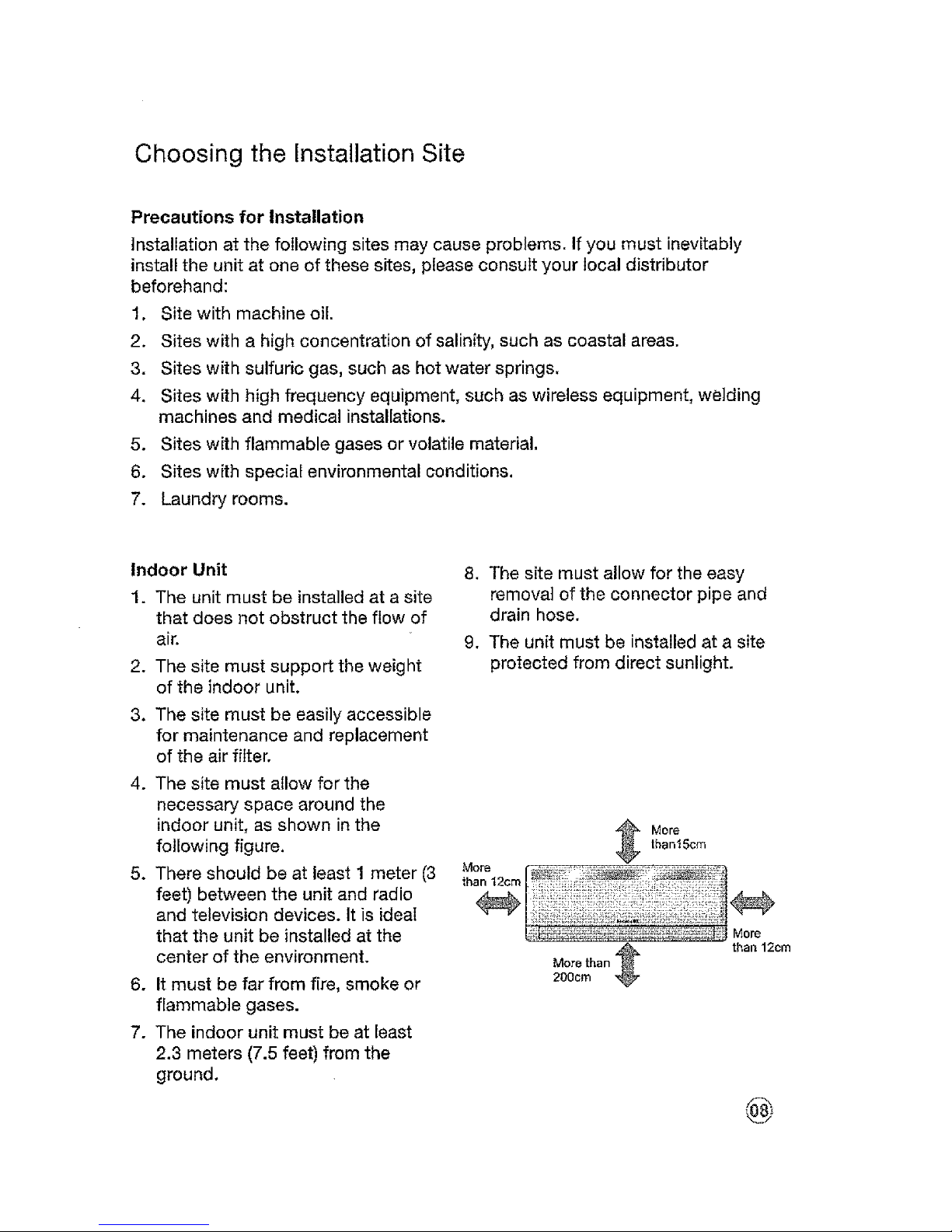

Indoor Unit

1. The unit must be installed at a site

that does not obstruct the flow of

air.

2. The site must support the weight

of the indoor unit.

3. The site must be easily accessible

for maintenance and replacement

of the air filter.

4. The site must allow for the

necessary space around the

indoor unit, as shown in the

following figure.

5. There should be at least 1 meter (3

feet) between the unit and radio

and television devices. It is idea[

that the unit be installed at the

center of the environment.

6. It must be far from fire, smoke or

flammable gases.

7. The indoor unit must be at least

2.3 meters (7.5 feet) from the

ground.

8. The site must allow for the easy

removal of the connector pipe and

drain hose.

9. The unit must be installed at a site

protected from direct sunlight.

More

thantScm

More than

200cm

than 12cm

@

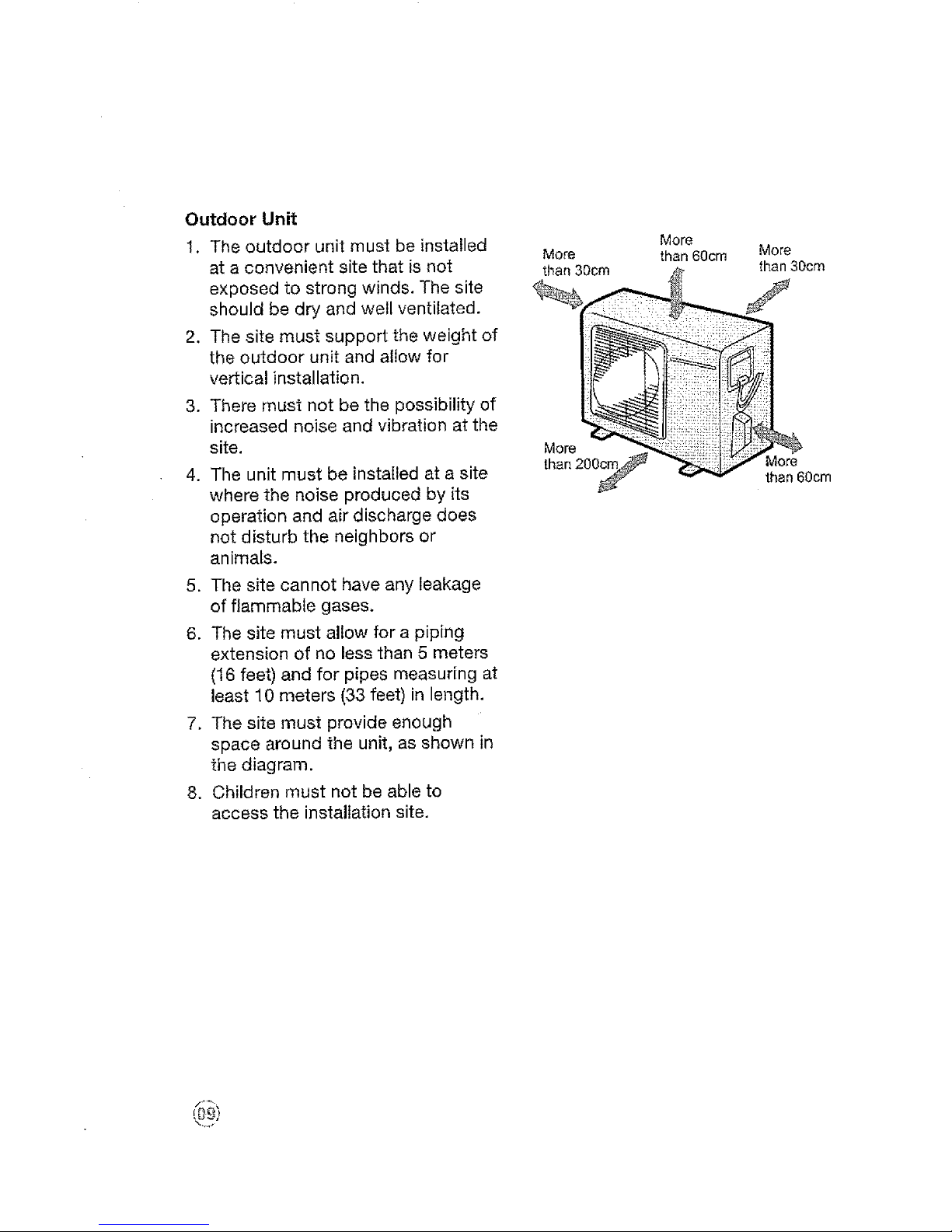

Outdoor Unit

1, The outdoor unit must be installed

at a convenient site that is not

exposed to strong winds. The site

should be dry and well ventilated.

2. The site must support the weight of

the outdoor unit and allow for

vertical installation.

3. There must not be the possibility of

increased noise and vibration at the

site.

4. The unit must be installed at a site

where the noise produced by its

operation and air discharge does

not disturb the neighbors or

animals.

5. The site cannot have any leakage

of flammable gases.

6. The site must allow for a piping

extension of no less than 5 meters

(16 feet) and for pipes measuring at

least 10 meters (33 feet) in length.

7, The site must provide enough

space around the unit, as shown in

the diagram.

8. Children must not be able to

access the installation site.

More

than 30cm

Mor_

than 200 S

More

than60cm More

than30cm

f

t??il !i

More

then 60cm

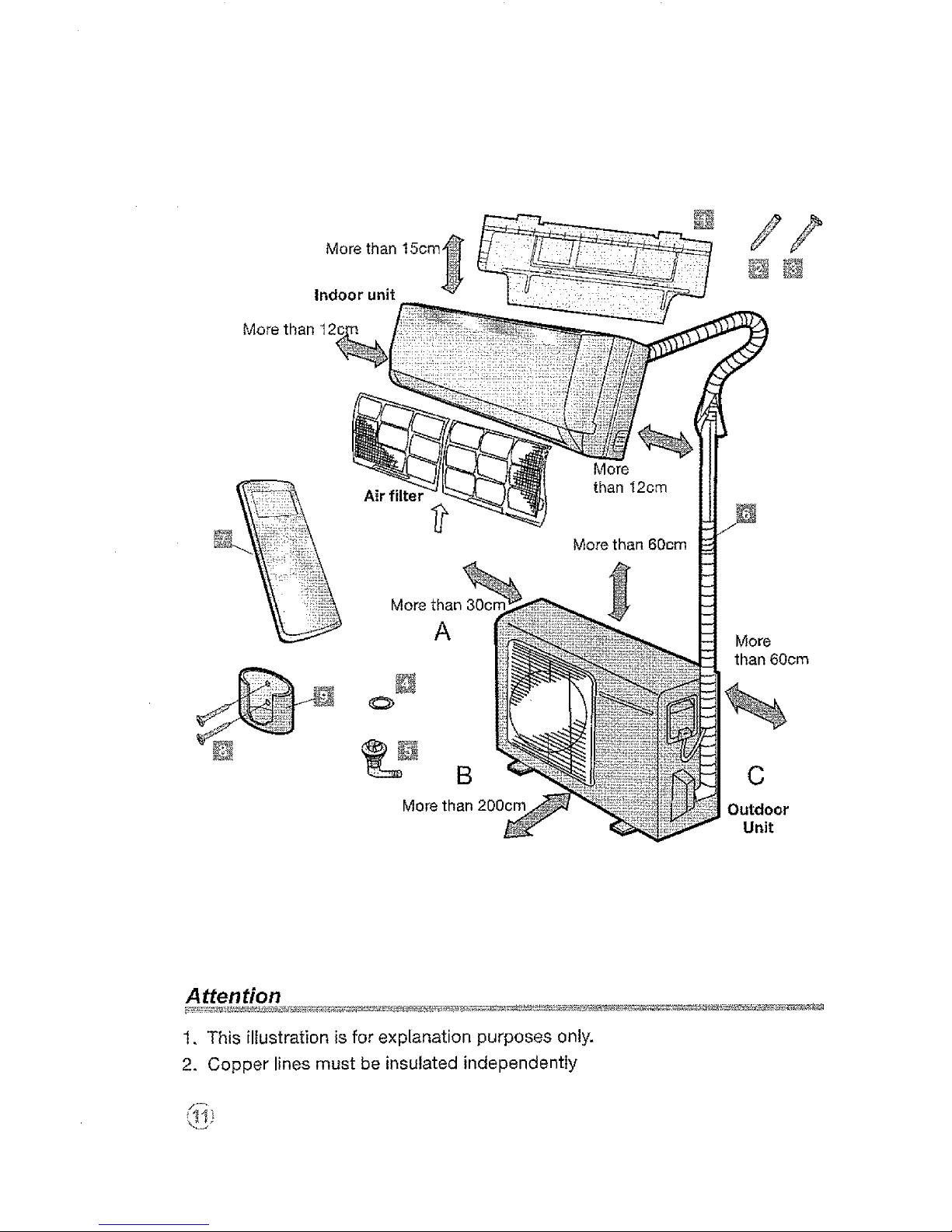

Parts list

Endoor unit

@ @

Outdoor unit

L!oj

More than

Air filte

More than

A

@

More than 60cm

More

than 60cm

B C

More than 200cm Outdoor

Unit

Attention

1. This illustration is for explanation purposes only.

2. Copper lines must be insulated independently

\_..J

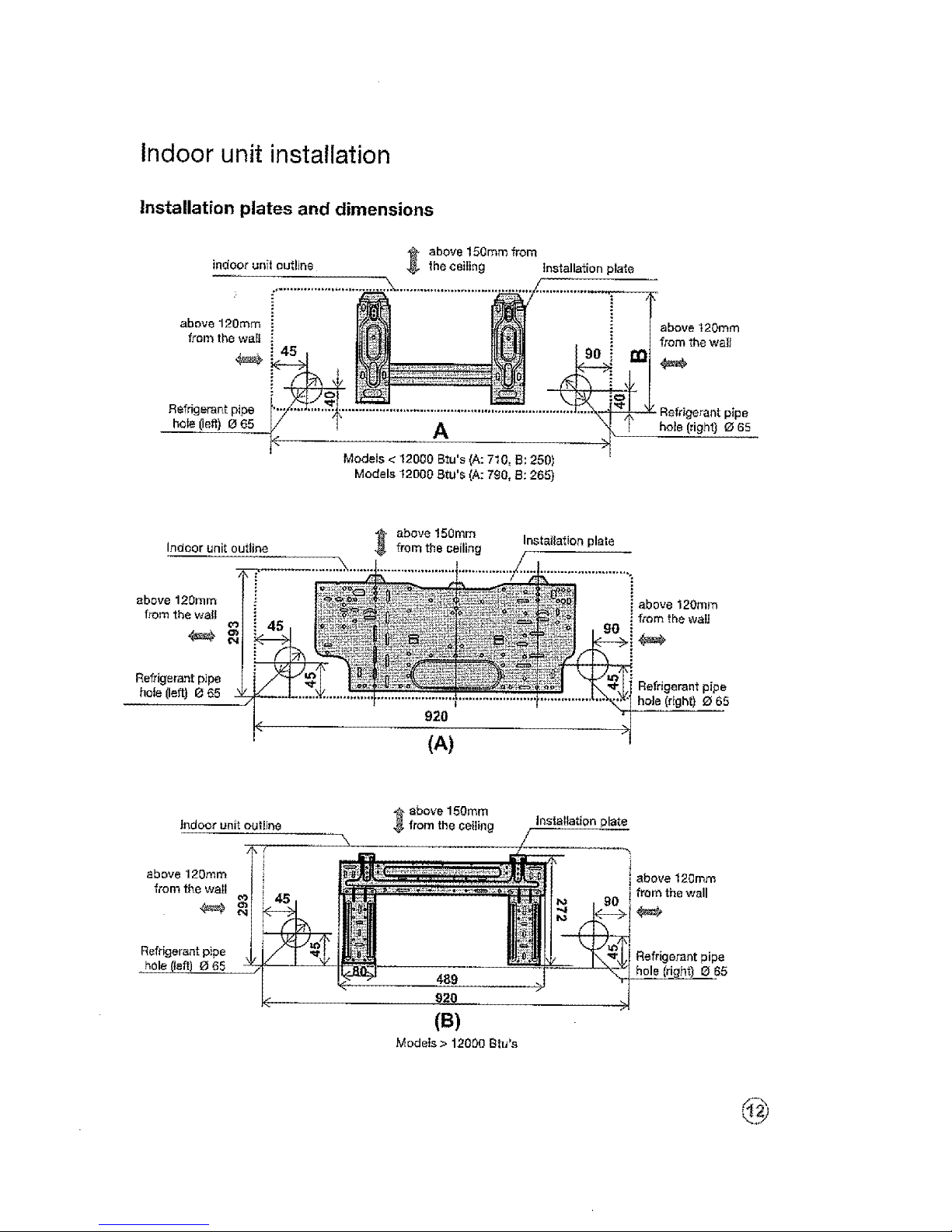

Indoor unit installation

Installation plates and dimensions

indoor unfl outline

above 150mm from

the ceiling Installation plate

above 120ram

from the wal!

Refri.gerae.t pipe

bole (left) O 65

i 45

A

Models < 12000 Btu's (A: 710, B: 250)

Models t2D00 Btu's (A: 790, 8: 265)

above 120ram

from the wall

pipe

hole (right) _ 65

Indoor unit outline

above 120ram

from the walt

Refrigerant p]pe

hole (left) 0 65

above 150ram

920

(A)

above 120ram

from the waU

4_F

Refrigerant pipe

hole (right) 0 65

l_doo_ unit out{i_

above 120mm

from the wail

Refrigerant p_pe

hole

_ above 150ram

from the ceiling

Installation plate

i above 120ram

i from the wall

£efrigeraht pipe

8 65

(B)

Models > 12000 Btu's

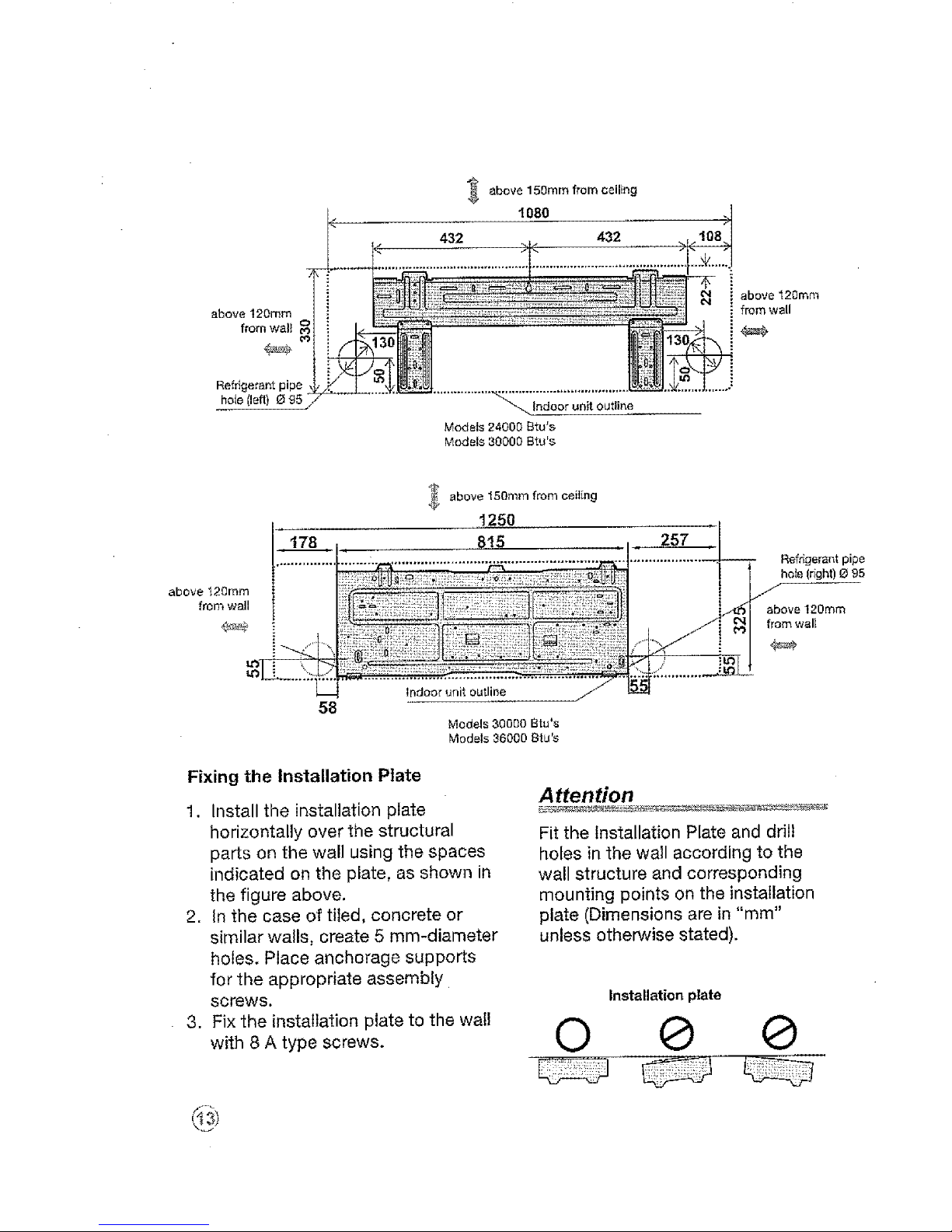

above120ram

fromwall

Refrigerant pipe

hole (left) O g5

above 150ram from

ceiling

1080

432 432

Indoor unit outline

Models 24000 Btu's

Models 30000 Btu's

above 120ram

from wall

above 120ram

from wall

above "E5Omm from ceiling

1250

815 . 257

Refrigerant pipe

hoIe (right) e 95

j--

above120mm

from wall

58

Indoor unit outline

Models 30000 Btu's

Models 36000 Btu's

Fixing the Installation Plate

1. Install the installation plate

horizontally over the structural

parts on the wall using the spaces

indicated on the plate, as shown in

the figure above.

2. In the case of tiled, concrete or

similar walls, create 5 mm-diameter

holes. Place anchorage supports

for the appropriate assembly

screws.

3. Fix the installation plate to the wall

with 8 A type screws.

Attention

Fit the installation Plate and drill

holes in the wall according to the

wall structure and corresponding

mounting points on the installation

plate (Dimensions are in "mm"

unless otherwise stated).

Installation plate

0 @ @

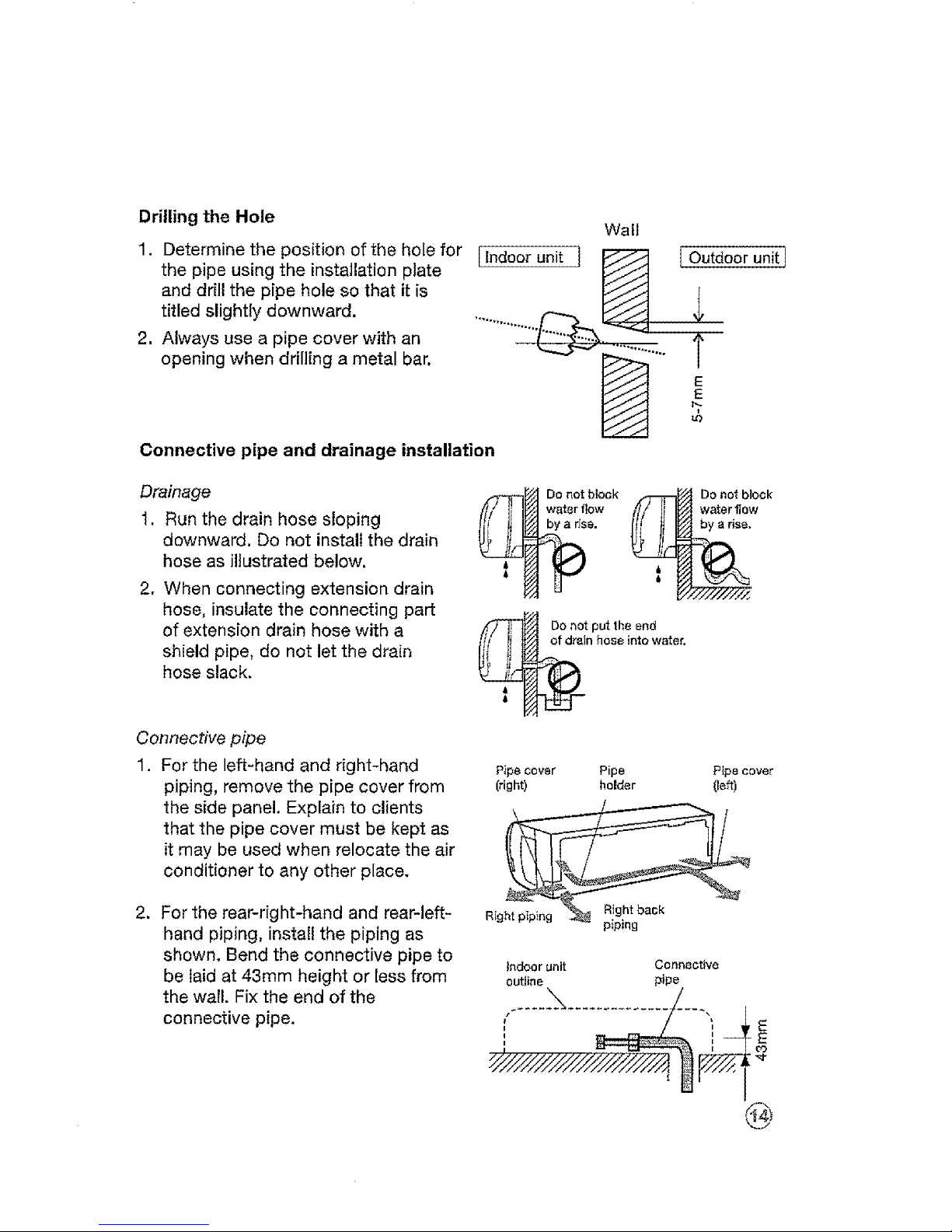

Drilling the Hole

Wall

1. Determine the position of the hole for [Indoor unit i _

the pipe using the installation plate

and drill the pipe hole so that it is

titled slightly downward .............. iii"_._... _.

2, Always use a pipe cover with an 1"

opening when drilling a metal bar. ....

E

E

Connective pipe and drainage installation

[ Outdoor unit I

Drainage

1, Run the drain hose sloping

downward. Do not install the drain

hose as illustrated below,

2. When connecting extension drain

hose, insulate the connecting part

of extension drain hose with a

shield pipe, do not let the drain

hose slack.

Do not put the end

of drain hose into water.

Connective pipe

1. For the left-hand and right-hand

piping, remove the pipe cover from

the side panel. Explain to clients

that the pipe cover must be kept as

it may be used when relocate the air

conditioner to any other place.

P_pe cover Pipe Pipe cover

(right) holder (left)

2. For the rear-right-hand and rear-left-

hand piping, install the piping as

shown. Bend the connective pipe to

be laid at 43mm height or less from

the wall. Fix the end of the

connective pipe.

Right piping Right back

piping

Indoor unit Connective

outline pipe

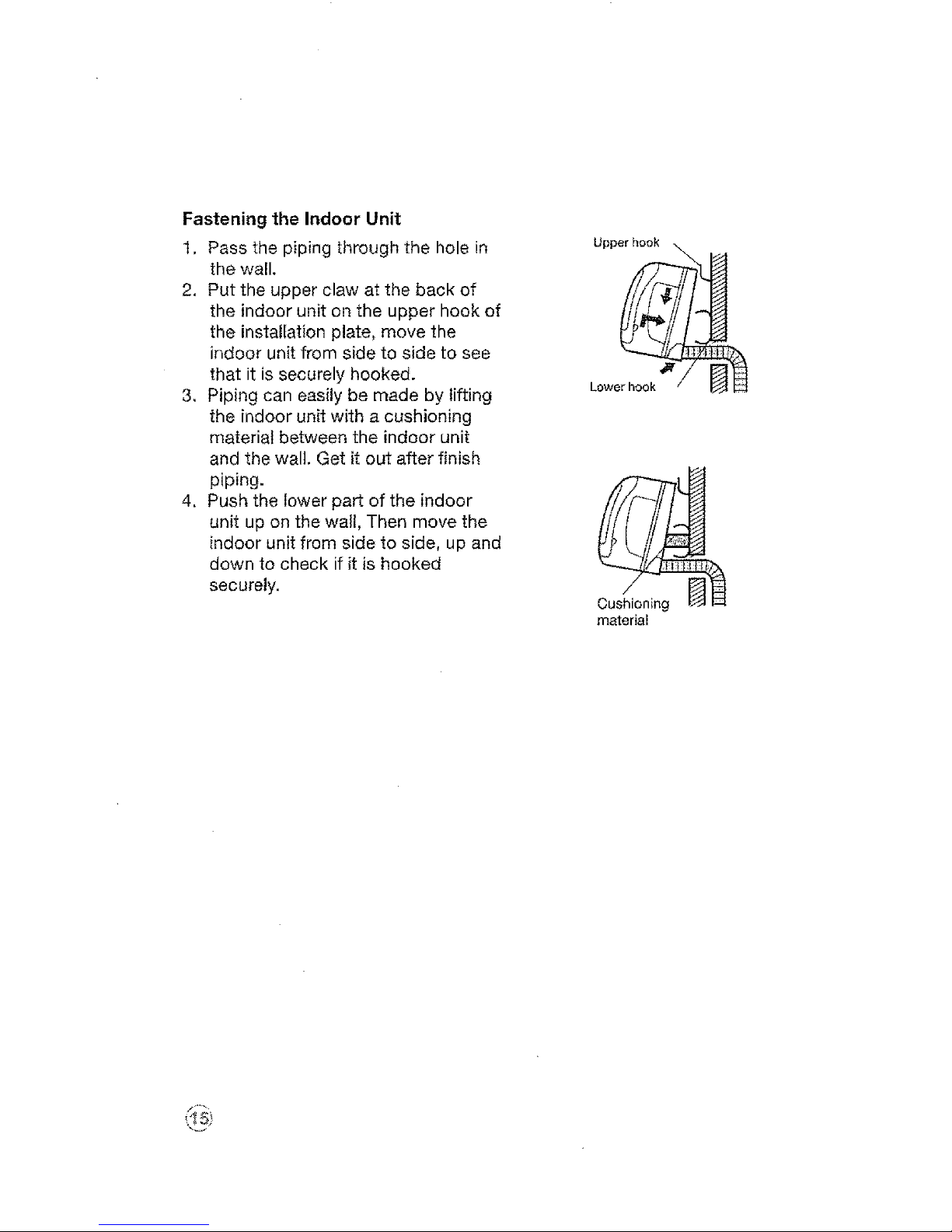

Fastening the Indoor Unit

1. Pass the piping through the hole in

the wall.

2. Put the upper claw at the back of

the indoor unit on the upper hook of

the insta

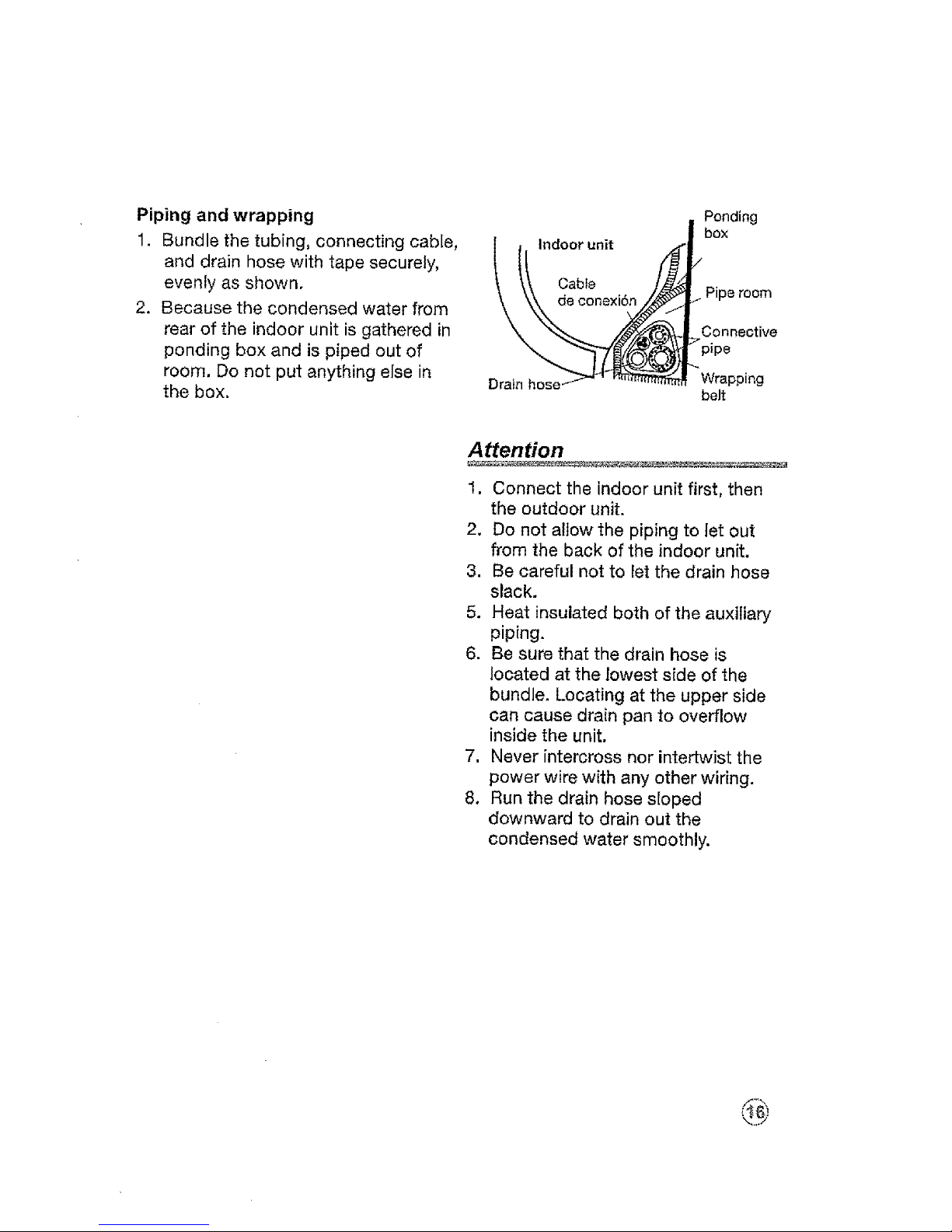

Piping and wrapping

1. Bundle the tubing, connecting cable,

and drain hose with tape securely,

evenly as shown.

2. Because the condensed water from

rear of the indoor unit is gathered in

ponding box and is piped out of

room. Do not put anything else in

the box.

l . Indoor unit

Ponding

box

Pipe room

Connective

_pipe

_Wrapping

belt

Attention

1. Connect the indoor unit first, then

the outdoor unit.

2. Do not allow the piping to let out

from the back of the indoor unit.

3. Be careful not to let the drain hose

slack.

5. Heat insulated both of the auxiliary

piping.

6. Be sure that the drain hose is

located at the lowest side of the

bundle. Locating at the upper side

can cause drain pan to overflow

inside the unit.

7. Never intercross nor intertwist the

power wire with any other wiring.

8. Run the drain hose sloped

downward to drain out the

condensed water smoothly.

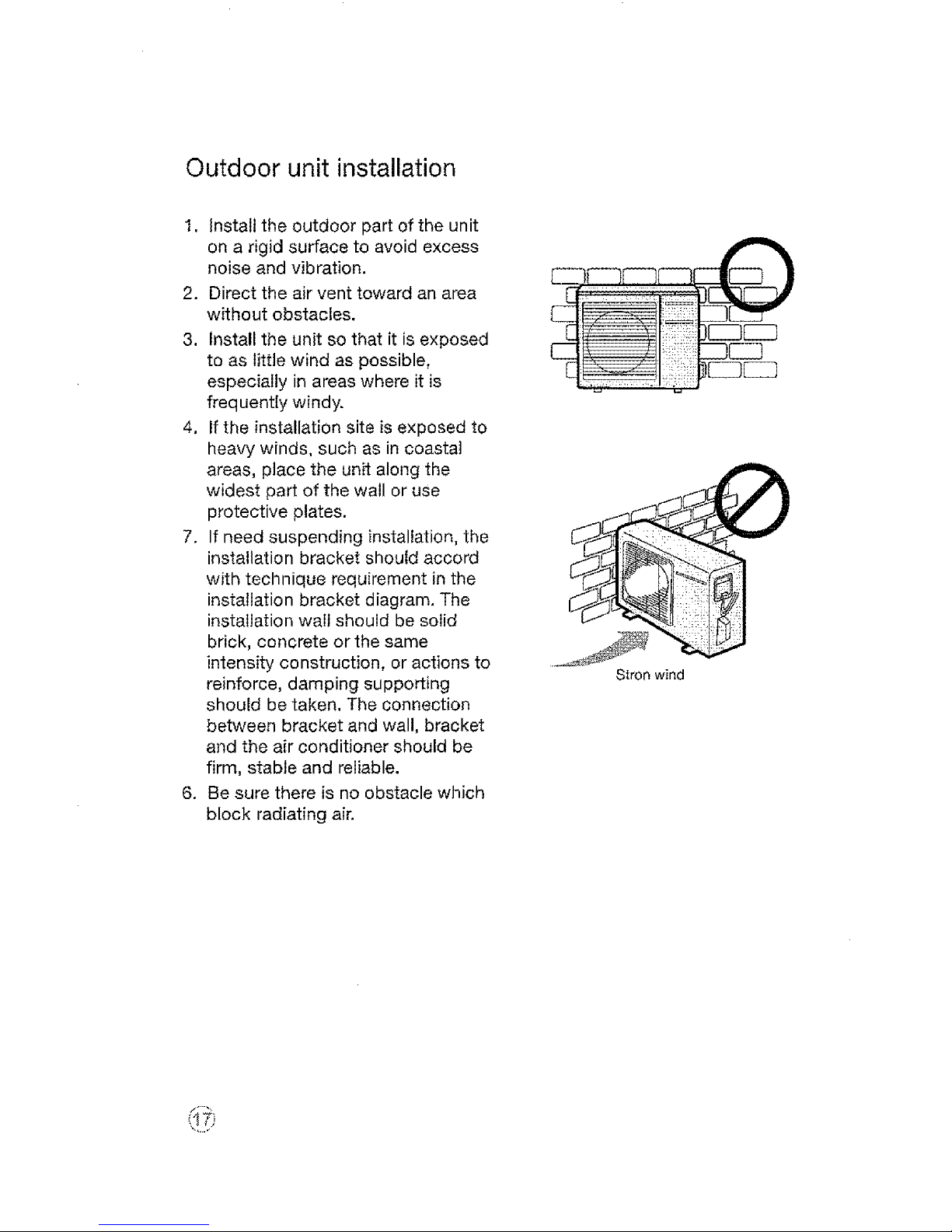

Outdoor unit installation

1. Install the outdoor part of the unit

on a rigid surface to avoid excess

noise and vibration.

2. Direct the air vent toward an area

without obstacles,

3. Install the unit so that it is exposed

to as little wind as possible,

especially in areas where it is

frequentiy windy.

4, If the installation site is exposed to

heavy winds, such as in coastal

areas, place the unit along the

widest part of the wall or use

protective plates.

7. If need suspending installation, the

installation bracket should accord

with technique requirement in the

installation bracket diagram. The

installation wait should be solid

brick, concrete or the same

intensity construction, or actions to

reinforce, damping supporting

should be taken. The connection

between bracket and wall, bracket

and the air conditioner should be

firm, stable and reliable.

6. Be sure there is no obstacle which

block radiating air.

Stron wind

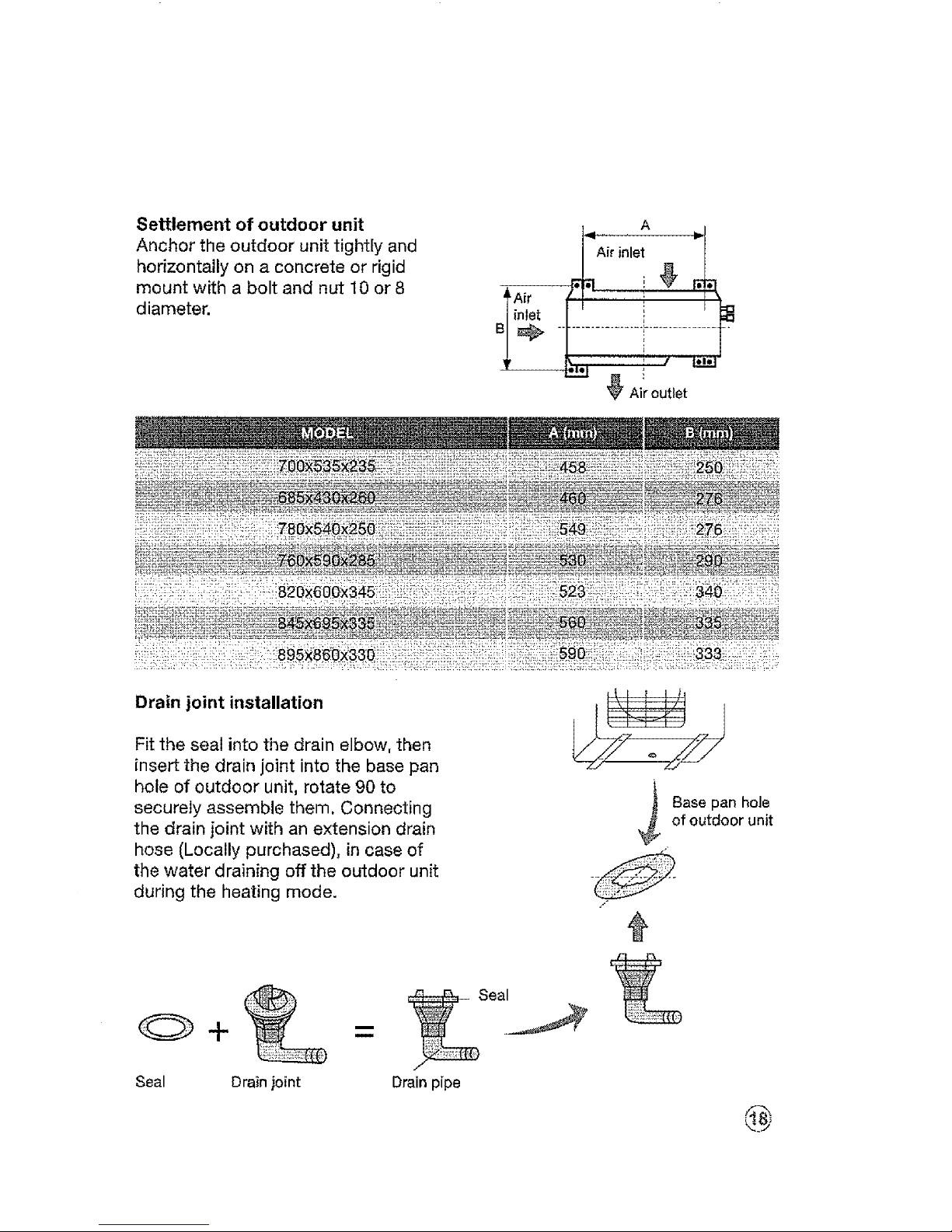

Settlement of outdoor unit

Anchor the outdoor unit tightly and

horizontally on a concrete or rigid

mount with a bolt and nut I0 or 8

diameter,

A,r,n,et0

Air 'i'

i%

Drain joint installation

Fit the seal into the drain elbow, then

insert the drain joint into the base pan

hole of outdoor unit, rotate 90 to

securely assemble them, Connecting

the drain joint with an extension drain

hose (Locally purchased), in case of

the water draining off the outdoor unit

during the heating mode.

/*

Seal Drain joint Drain pipe

Base pan hole

of outdoor unit

@

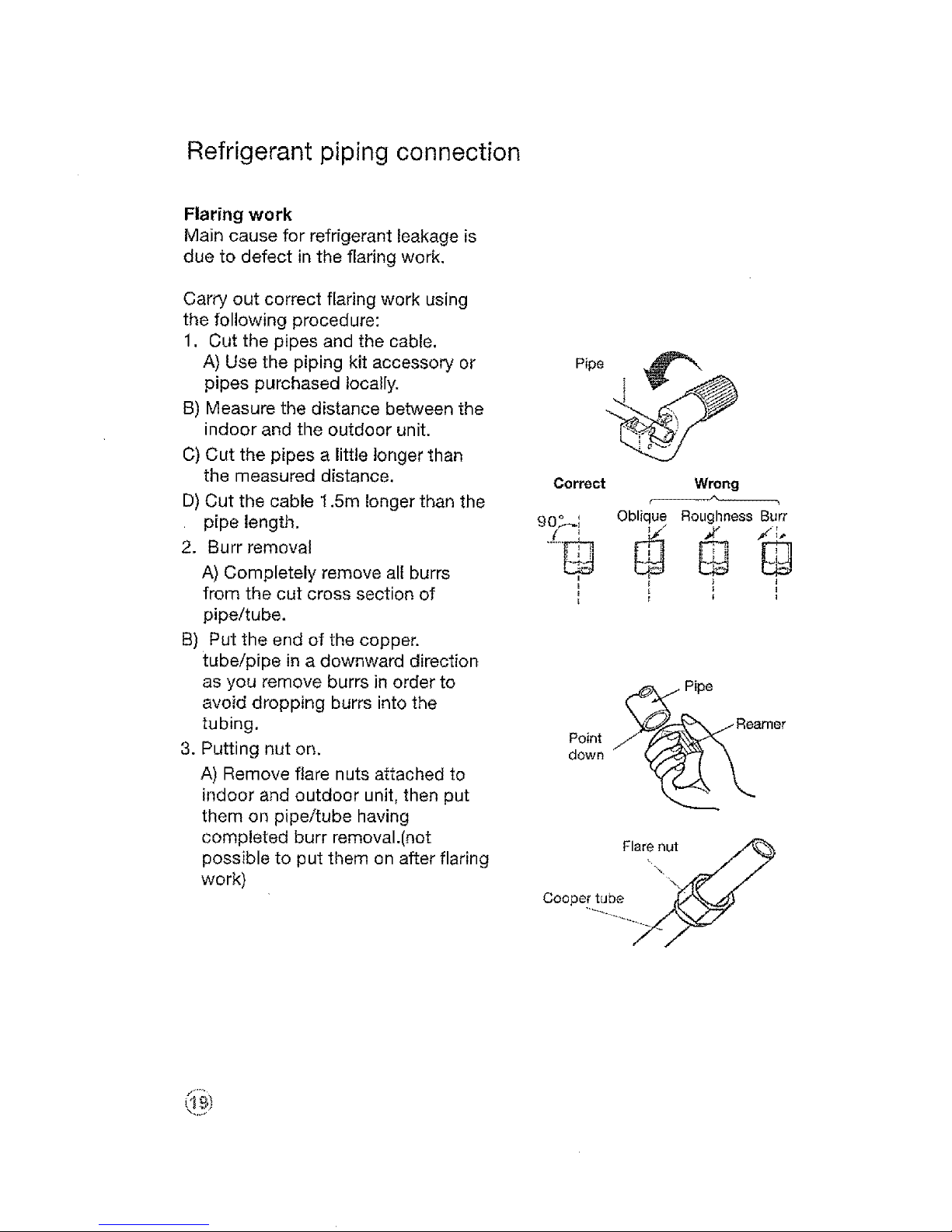

Refrigerant piping connection

Flaring work

Main cause for refrigerant leakage is

due to defect in the flaring work,

Carry out correct flaring work using

the following procedure:

1. Cut the pipes and the cable,

A) Use the piping kit accessory or

pipes purchased locally.

B) Measure the distance between the

indoor and the outdoor unit.

C) Cut the pipes a little longer than

the measured distance.

D) Cut the cable 1.5m longer than the

pipe length.

2, Burr removal

A) Completely remove all burrs

from the cut cross section of

pipe/tube,

B) Put the end of the copper.

tube/pipe in a downward direction

as you remove burrs in order to

avoid dropping burrs into the

tubing,

3. Putting nut on,

A) Remove flare nuts attached to

indoor and outdoor unit, then put

them on pipe/tube having

completed burr removal.(not

possible to put them on after flaring

work)

Correct Wrong

90,%_'_ Oblique Roughness Burr

i

_,,._ Pipe

down

Flare nut

\.

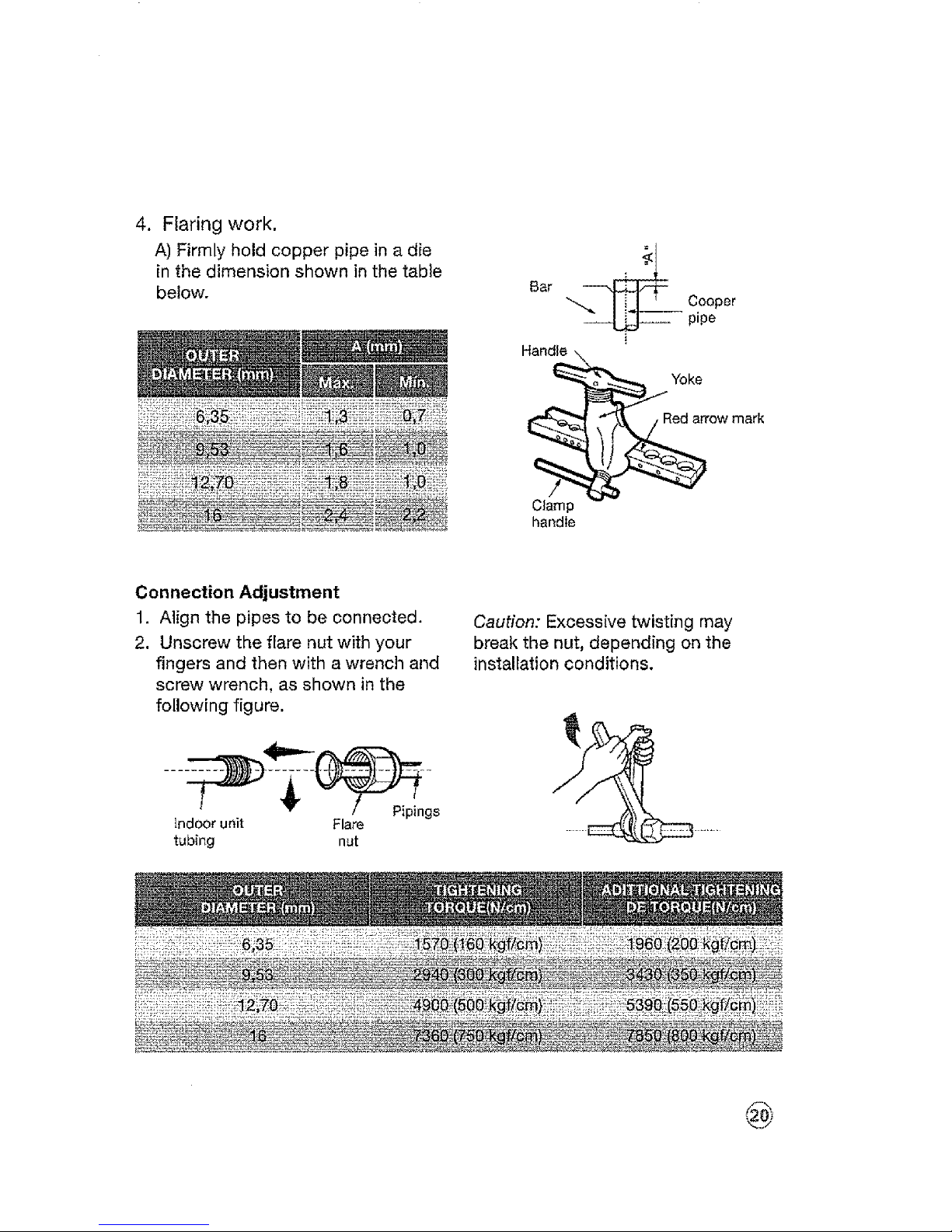

4.

Flaring work.

A) Firmly hold copper pipe in a die

in the dimension shown in the table

below.

Bar

Cooper

-- pipe

Clamp

handle

Connection Adjustment

1. Align the pipes to be connected.

2. Unscrew the flare nut with your

fingers and then with awrench and

screw wrench, as shown in the

following figure.

indoor unit Flare

tubing nut

Caution: Excessive twisting may

break the nut, depending on the

installation conditions.

@

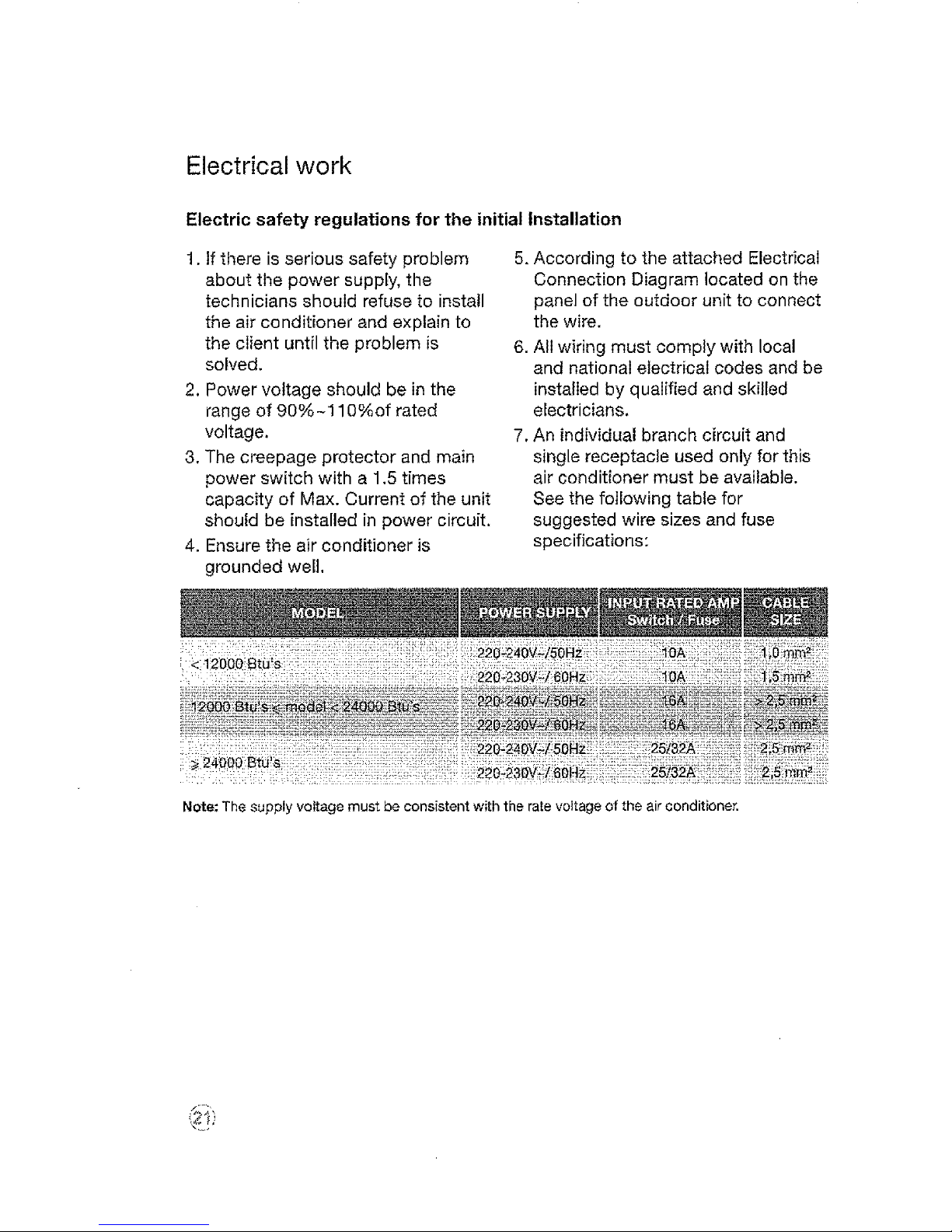

Electrical work

Electric safety regulations for the initial Installation

1. if there is serious safety problem

about the power supply, the

technicians should refuse to install

the air conditioner and explain to

the client until the problem is

solved.

2. Power voltage should be in the

range of 90%-110%of rated

voltage.

3. The creepage protector and main

power switch with a 1.5 times

capacity of Max. Current of the unit

should be installed in power circuit.

4. Ensure the air conditioner is

grounded well,

5. According to the attached Electrical

Connection Diagram located on the

panel of the outdoor unit to connect

the wire.

6. All wiring must comply with local

and national electrical codes and be

installed by qualified and skilled

electricians.

7. An individual branch circuit and

single receptacle used only for this

air conditioner must be available.

See the following table for

suggested wire sizes and fuse

specifications:

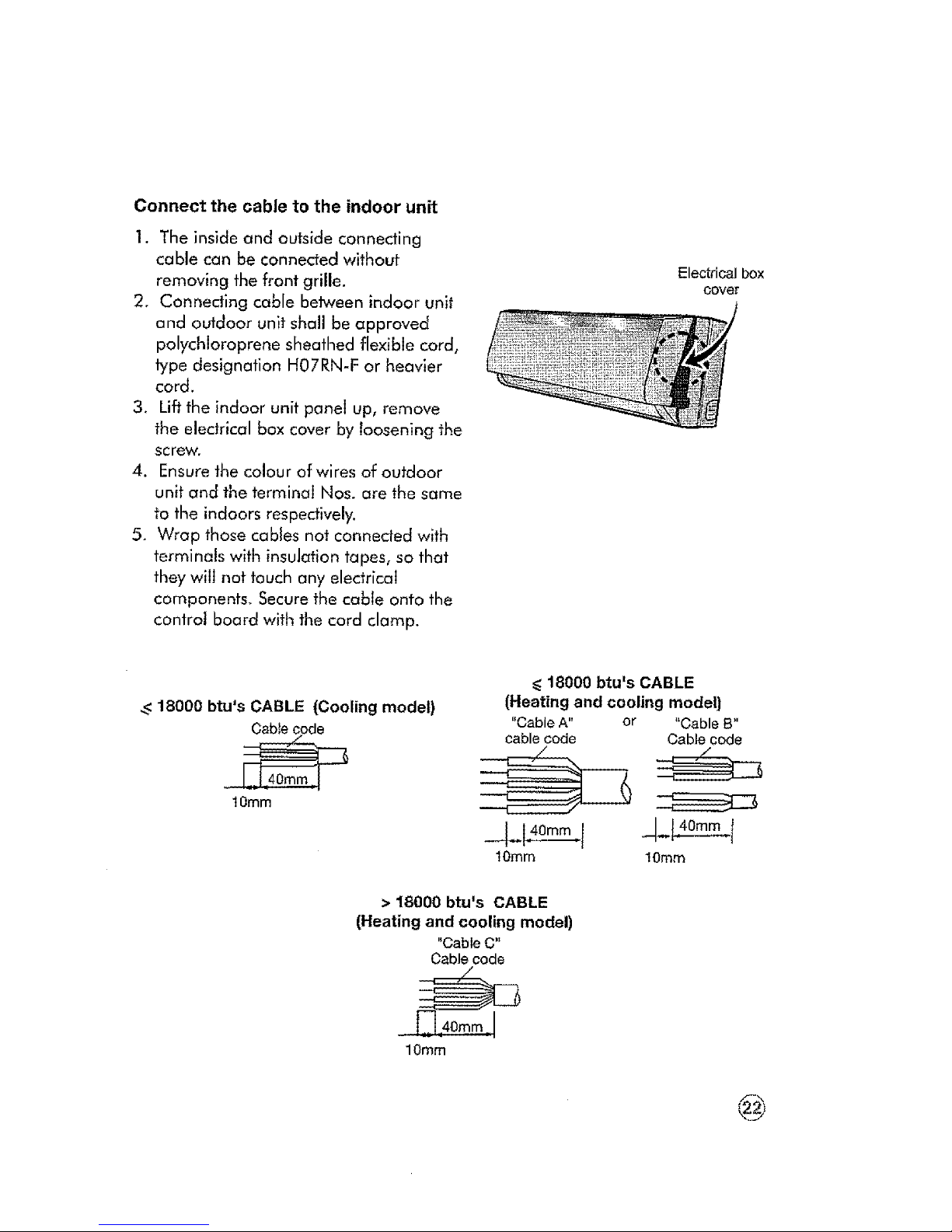

Connect the cable to the indoor unit

1. The inside and ou|side connecting

cable can be connected without

removing the front grille.

2. Conneding cable between indoor unit

and outdoor unit shall be approved

polychloroprene sheathed flexible cord,

type designation H07RN-F or heavier

cord.

3. Liftthe indoor unit panel up, remove

the electrical box cover by loosening the

screw.

4. Ensure the colour of wires of outdoor

unit and the terminal Nos. are the same

fo the indoors respectively.

5. Wrap those cables not conneded with

terminals with insulation tapes, so that

they will not touch any electrical

companents. Securethe cable onto the

control board with the card clamp.

Electrical box

cover

_<18000 btu's CABLE (Cooling model)

Cable code

1Omm

_<18000 btu's CABLE

(Heating and cooling model)

"Cable A" or "Cable B"

cable code Cable code

10mrn 10ram

> 18000 btu's CABLE

(Heating and cooling model)

"Cable C"

Cable code

10ram

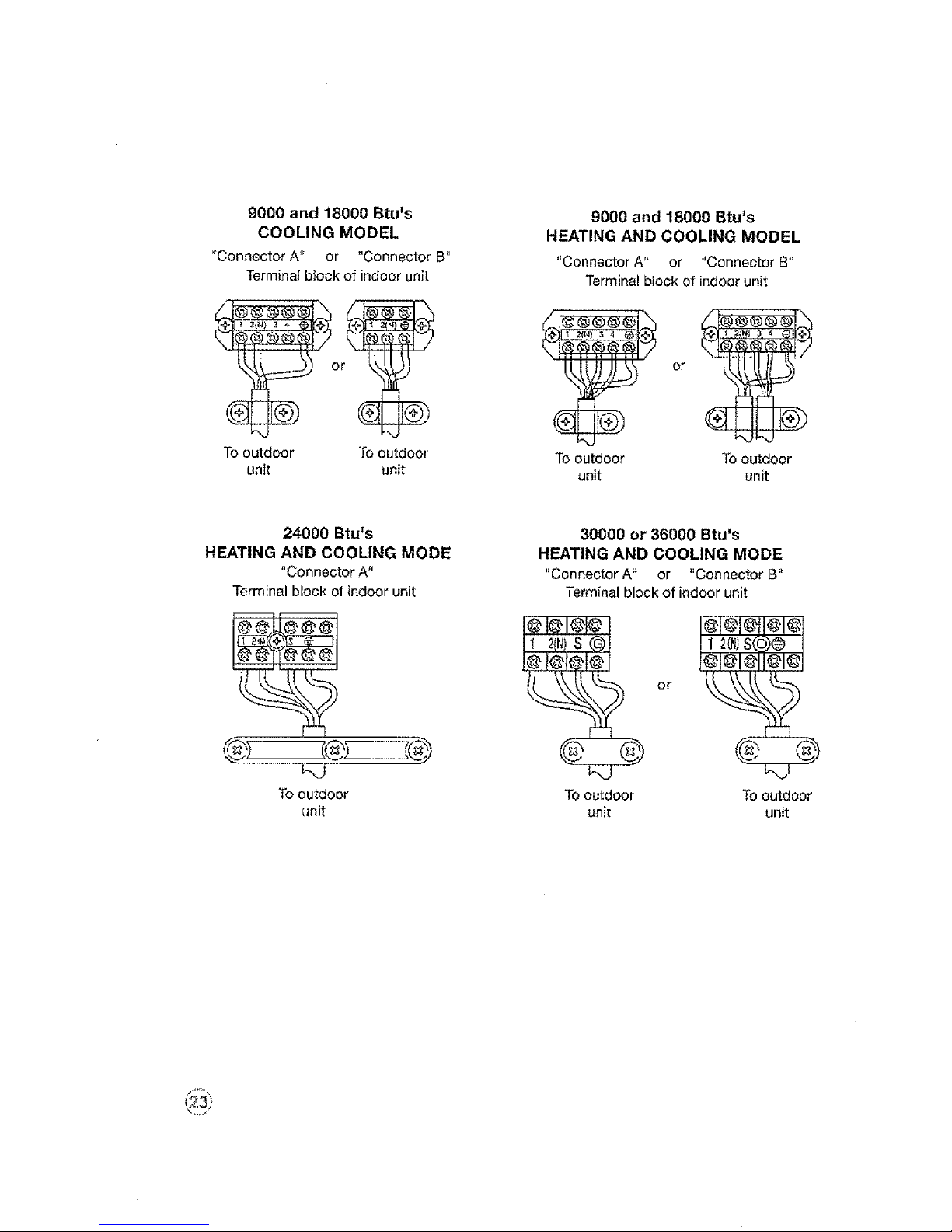

9000 and 18000 Btums

COOLING MODEL

"Connector A'_ or "Connector B"

Terminat block of indoor unit

To outdoor To outdoor

unit unit

9000 and 18000 Btu's

HEATING AND COOLING MODEL

"Connector A" or "Connector B"

Terminal block of indoorunit

To outdoor To outdoor

unit unit

24000 Btu's 30000 or 36000 Btu's

HEATING AND COOLING MODE HEATING AND COOLING MODE

"Connector A" "Connector A '_ or "Connector B"

Terminal block ofindoor unit Terminal block of indoor unit

or I

To outdoor To outdoor To outdoor

unit unit unit

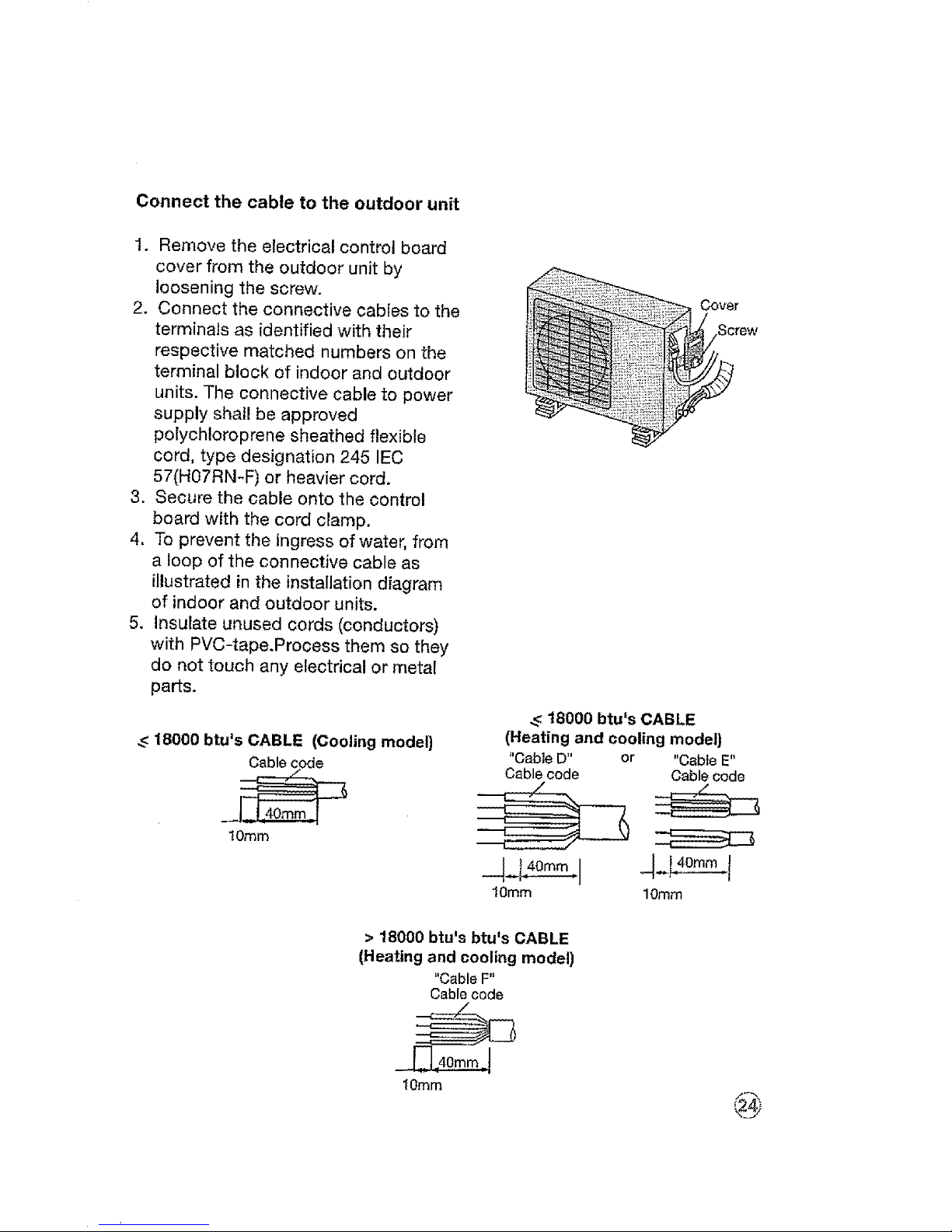

Connect the cable to the outdoor unit

1. Remove the electrical control board

cover from the outdoor unit by

loosening the screw.

2. Connect the connective cables to the

terminals as identified with their

respective matched numbers on the

terminal block of indoor and outdoor

units. The connective cable to power

supply shall be approved

polychloroprene sheathed flexible

cord, type designation 245 IEC

57(H07RN-F) or heavier cord.

3. Secure the cable onto the control

board with the cord clamp,

4. To prevent the ingress of water, from

a loop of the connective cable as

illustrated in the installation diagram

of indoor and outdoor units.

5. Insulate unused cords (conductors)

with PVC-tape.Process them so they

do not touch any electrical or metal

parts.

_<18000 btu's CABLE (Cooling model)

Cablecode

!0turn

Cover

;crew

_<18000 btu's CABLE

(Heating and cooling model)

+'CableD" or "Cable E"

Cable code Cable code

10ram 10ram

> 18000 btu's btu's CABLE

(Heating and cooling model)

"Cable F"

Cable code

10turn

@

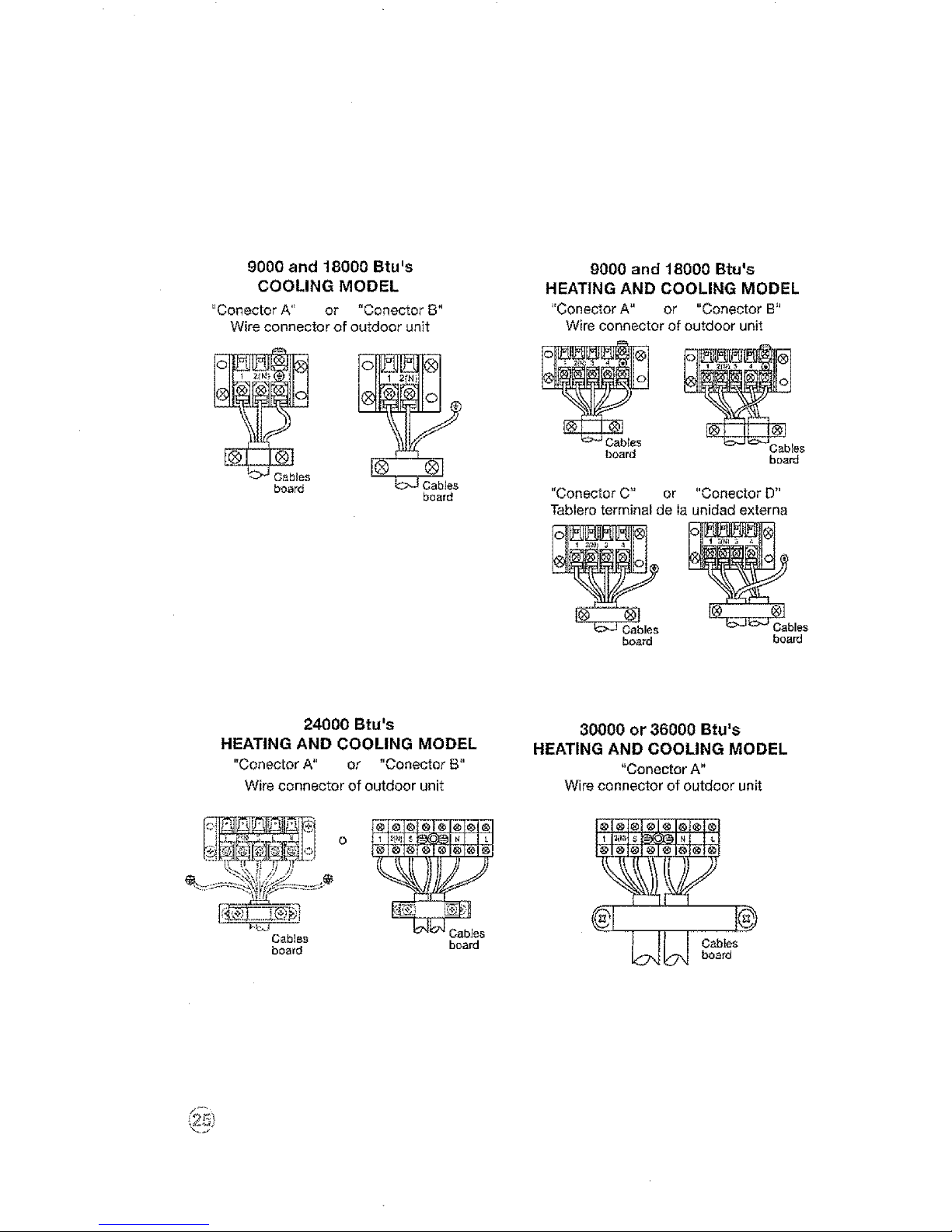

9000 and 18000 Btu's

COOLING MODEL

"Conector A" or "Conector B"

Wire connector of outdoor unit

c_ ©

board

board

9000 and 18000 Btu's

HEATING AND COOLING MODEL

"Conector A" or "Conector B"

Wire connector of outdoor unit

board board

"Conector C" or "Conector D"

Tablero terminal de Ia unidad externa

N

board board

24000 Btu's

HEATING AND COOLING MODEL

"Conector A" or "Conector B"

Wire connector of outdoor unit

W__I ,o,o_°,o,o,o,°,,,

Cables board

board

30000 or 36000 Btu's

HEATING AND COOLING MODEL

"(]onector A"

Wire connector of outdoor unit

UW

board

Caution

After the confirmation of the above conditions, prepare the wiring as follows:

1. Never fail to have an individual power circuit specifically for the air

conditioner. As for the method of wiring, be guided by the circuit diagram

posted on the inside of control cover,

2. The screw which fasten the wiring in the casing of electrical fittings are

liable to come loose from vibrations to which the unit is subjected during

the course of transportation, Check them and make sure that they are all

tightly fastened. (if they are loose, it could cause burn-out of the wires.)

3. Specification of power source.

4. Confirm that electricat capacity is sufficient.

5. See to that the starting voltage is maintained at more than 90 percent of the

rated voltage marked on the name plate.

6. Confirm that the cable thickness is as specified in the power source

specification.

7. Always install an earth leakage circuit breaker in a wet or moist area.

8. The following would be caused by voltage drop, Vibration of a magnetic

switch, which will damage the contact point, fuse breaking, disturbance of

the normal function of the overload.

9. The means for disconnection from a power supply shall be incorporated in

the fixed wiring and have an air gap contact separation of at least 3mm in

each active (phase) conductors.

Air purging

Air and moisture in the refrigerant system have undesirable effects as

indicated below:

1, Pressure in the system rises.

2. Operating current rises.

3. Cooling or heating efficiency

drops.

4. Moisture in the refrigerant circuit

may freeze and block capillary

tubing.

5. Water may lead to corrosion of

parts in the refrigeration system.

6, Therefore, the indoor unit and

tubing between the indoor and

outdoor unit must be leak tested

and evacuated to remove any

noncondensables and moisture

from the system.

Air purging with vacuum pump

1. Check that each tube(both liquid and gas side tubes) between the indoor

and outdoor units have been properly connected and all wiring for the test

run has been completed. Remove the service valve caps from both the gas

and the liquid side on the outdoor unit, Note that both the liquid and the gas

side service valves on the outdoor unit are kept closed at this stage.

2. When relocate the unit to another place, perform evacuation using vacuum

pump.

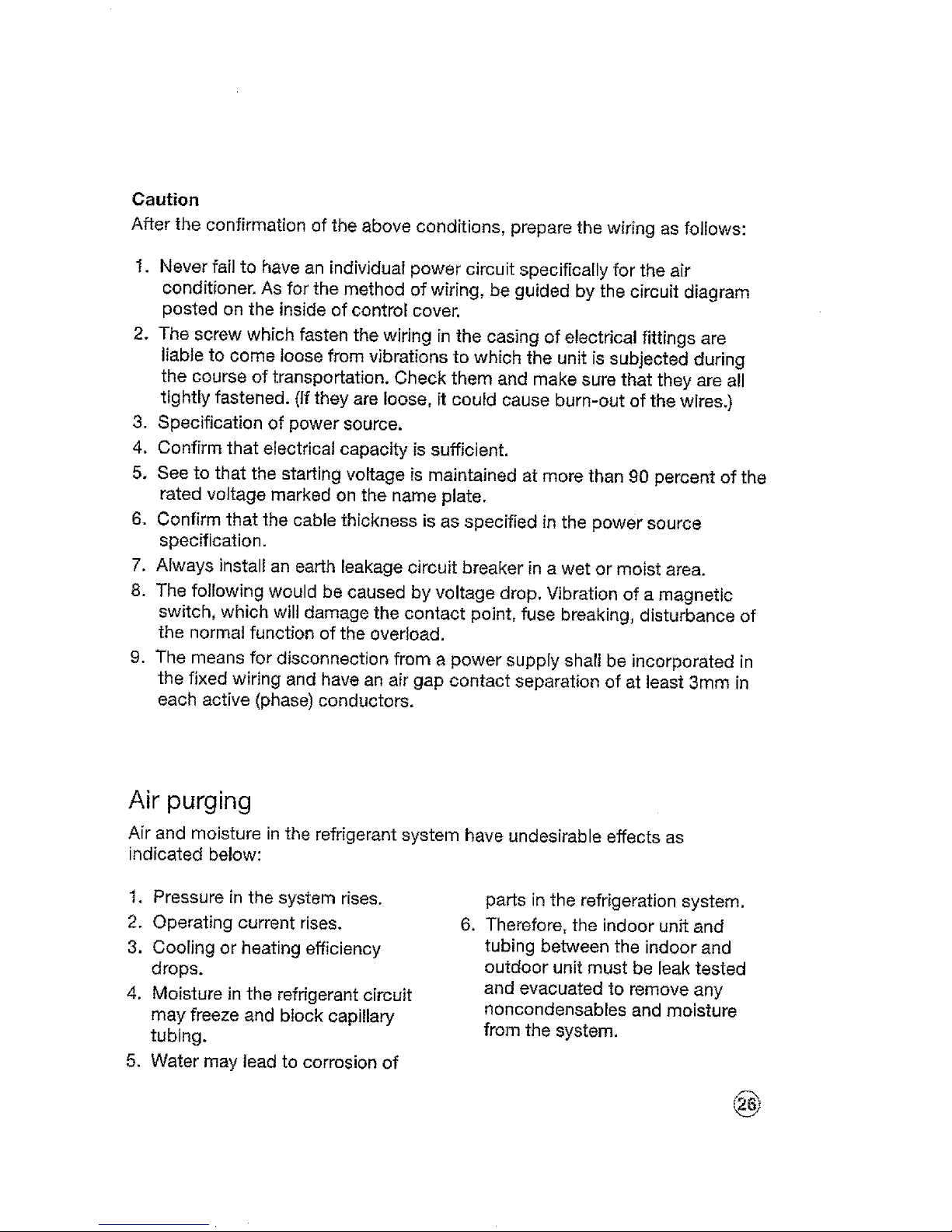

3, Pipe length and refrigerant amount:

Caution in handling the packed valve

t. Open the valve stem untie it hits against the stopper. Do not try to open it

further.

2. Securely tighten the valve stem cap with a spanner or the like. Valve stem

cap tightening torque (See Tightening torque table in page 19).

Refrigerant

Outdoorunit Indoorunit

A Gas _

-- _ mL* i

\

Packed valve Half unfon

Valve body

Flare nut

Stopper

/ Cap

Valw stem

@

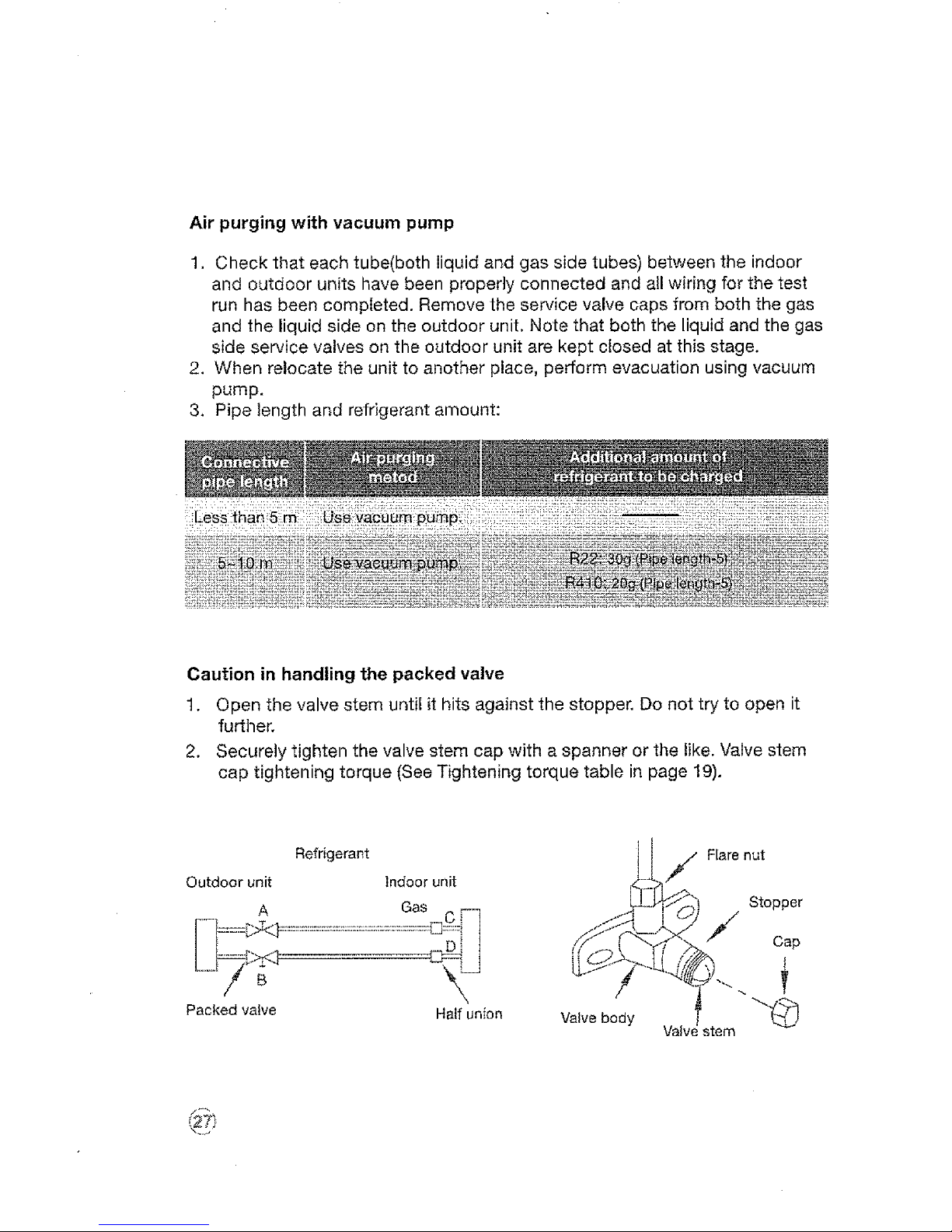

When using the vacuum pump

For method of using a manifold valve, refer to its operation manual.

I. Completely tighten the flare nuts,

A, B, C, D, connect the manifold

valve charge hose to a charge port

of the low-pressure valve on the

gas pipe side.

2, Connect the charge hose

connection to the vacuum pump,

3. Fully open the handle Lo of the

manifold valve,

4. Operate the vacuum pump to

evacuate. After starting evacuation,

slightly loose the flare nut of the Lo

valve on the gas pipe side and

check that the air is entering

(Operation noise of the vacuum

pump changes and a compound

meter indicates 0 instead of minus)

5. After the evacuation is complete,

fully close the handle Lo of the

manifold valve and stop the

operation of the vacuum pump,

Make evacuation for I5 minutes or

more and oheck that the compound

meter indicates -76cmHg (-Ix10

Pa),

6, Turn the stem of the packed valve

B about 45o counterclockwise for

6-7 seconds after the gas coming

out, then tighten the flare nut again,

Make sure the pressure display in

the pressure indicator is a little

higher than the atmosphere

pressure,

7. Remove the charge hose from the

Low pressure charge hose.

8. Fully open the packed valve stems

B and A.

9, Securely tighten the cap of the

packed valve,

Indoor unit

Outdoor unit

Charge hose

Har_dieLo

Handle Hi

_. Charge hose

'vacuum pump

@

Electrical safety

Perform the electric safe check after completing installation:

1. Insulated resistance: The insulated resistance must be more than 2M_.

2. Grounding work: After finishing grounding work, measure the grounding

resistance by visual detection and grounding resistance tester. Make sure the

grounding resistance is less than 4_.

3. Electrical leakage check (performing during test running): During test

operation after finishing installation, the serviceman can use the electroprobe

and mu[timeter to perform the electrical leakage check. Turn off the unit

immediately if leakage happens. Check and find out the solution ways till the

unit operate properly.

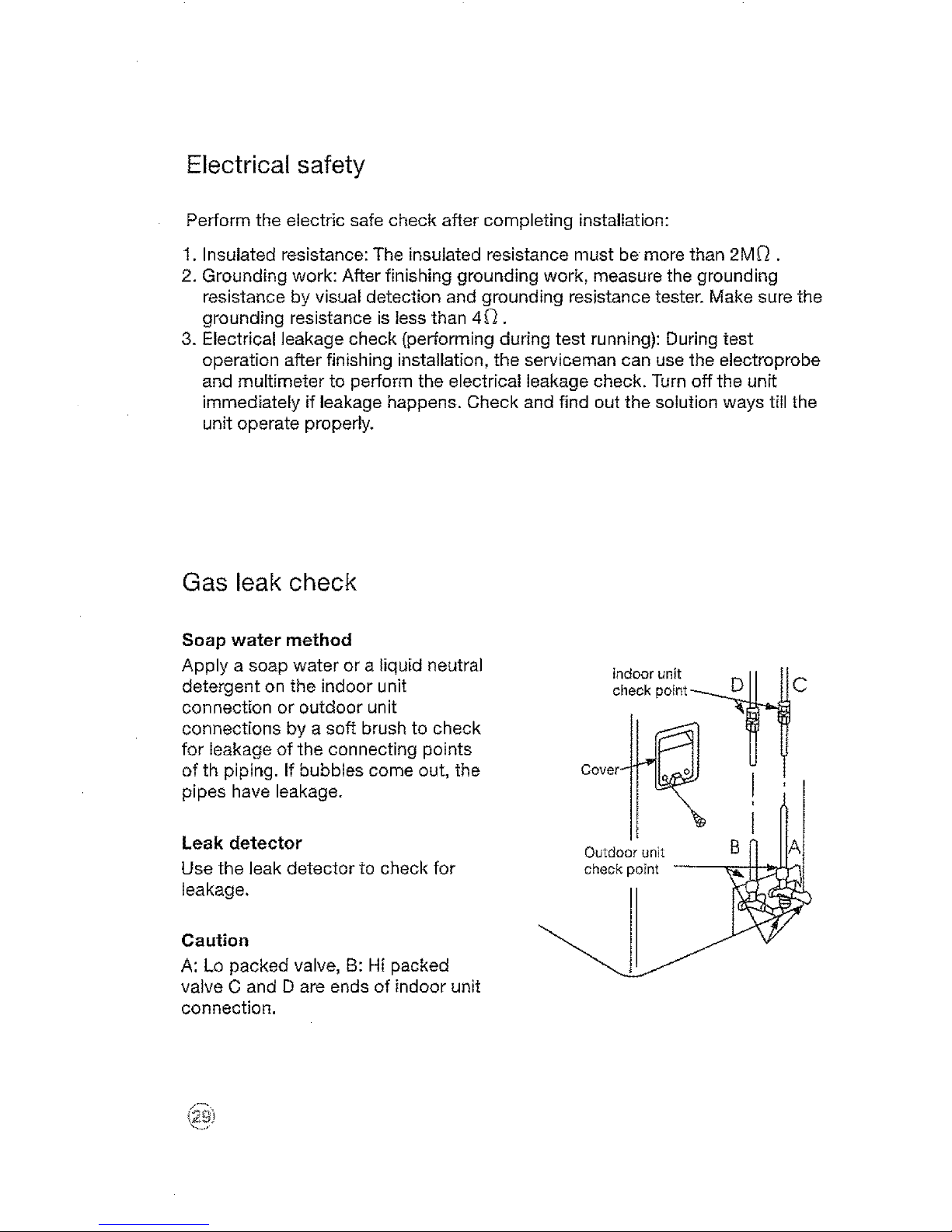

Gas leak check

Soap water method

Apply a soap water or a liquid neutral

detergent on the indoor unit

connection or outdoor unit

connections by a soft brush to check

for leakage of the connecting points

of th piping. If bubbles come out, the

pipes have leakage.

Leak detector

Use the leak detector to check for

leakage,

Caution

A: Lo packed valve, B: Hi packed

valve C and D are ends of indoor unit

connection.

indoor unit

check point _.._

Cover__

Outdoor unit B

check point ........... -_J._

Test running

Perform test operation after completing gas leak check at the flare nut

connections and electrical safety check,

1. Connect the power, press the ON/OFF button on the remote controller to

turn the unit on.

2. Use the MODE button to select COOL, HEAT, AUTO and FAN to check if all

the functions works well.

3. When the ambient temperature is too low(lower than 17°C), the unit cannot

be controlled by the remote controller to run at cooling mode, manual

operation can be taken. Manual operation is used only when the remote

controller is disable or maintenance necessary'.

_,_ [ Auto/CooiO

- Manual control button

Manual co

u.oo

Auto o I

Cool ® I

®

Preparing the device for operation

1. Contact a specialist to install the device.

2. Guarantee that the unit is appropriately fastened and complies with all of the

aforementioned safety norms.

3. Before operating the air conditioner, ensure that the air filter is installed

correctly.

4. If the unit has been out of use for a long period of time, it is recommended

that the air filter be cleaned before use. During continuous use, clean the air

filter every two weeks.

5. This air conditioner was designed for use under the following conditions:

::::Room Temperature: i:i::i

* (-5°C~43°C cooling only)

Attention

If air conditioner is used outside of the above conditions, certain safety

protection features may come into operation and cause the unit to function

abnormally.

Room relative humidity less than 80%. If the air conditioner operates in excess of

this figure, the surface of the air conditioner may attract condensation. Please

sets the vertical air flow louver to its maximum angle (vertically to the floor), and

set HIGH fan mode.

Optimum performance will be achieved within these operating temperature.

(3"t_

Product description

Front panel frame

Front panel

Air filter

(inside front panel)

Horizontal airflow grille

Vertical airflow grille

• _ Temperature sensor

(inside front panel)

Panel

Infra-red signal receiver

Drain hose connector and

refrigerant gas connector

Remote control

Connector cable

Detection valve

Drain hose and refrigerant

connecting pipe

Air iniet

#

Indoor

Air outlet

Air inlet

Attention

All the pictures in this manual are for

explanation purpose only. They may be

slightly different from the air conditioner

you purchased.

Air outlet

Outdoor unit

Display panel

(indoor unit)

_ AUTO indicator; This indicator

illuminates when the air conditioner

is in AUTO operation.

_ DEFROST indicator (For Cooling

& Heating models only): This

indicator illuminateswhen the air

conditioner starts defrosting

automatically or when the warm air

control feature is activated in

heating operation.

FAN**: The indicator will flash

when is in Fan mode only.

**Note: Only for models with

Cooling only and > 18,000 Btu's

INFRA-RED SIGNAL RECEIVER

_ DIGITAL SCREEN: Show the

present adjustments to

temperature when air conditioner is

operating.

OPERATION indicator: This

indicator flashes after power is on

and illuminates when the unit is in

operation.

TIMER indicator: This indicator

illuminates when TIMER is set

O N/O FE

Attention

The description in the control is based

on a typical model. The functions are

the same in your air conditioner, even if

there are some differences in the

appearance.

Remote control

Remote control operation

t. Operation mode: Cool, Heat (Only for the

models with cool/heat), DRY, FAN, and

AUTO (Automatic).

2. Timer 24 hrs.

3, Internal temperature range selection: 17°

- 30o.

4. LCD

5. Night light operation mode.

*(with 3 V,it reaches t 1 m)

A ttention

1. The air conditioner will not operate when curtains, doors our other materials

block the signals between the remote control and the indoor unit.

2. Avoid spilling any liquid in the remote control. Do not expose to sunlight or

any heat source.

3. If the infrared signal receiver inthe indoor unit is exposed to sunlight, the

air conditioner unit might not work properly. Use curtains or shades to

avoid having sunlight directly to the receiver.

4. If other electrical equipment react to the signals sent by the remote control,

change the position or consult with you local sales department.

Remote control battery

Touse the remote control, it is

necessary to install two (R03/Ir03x2)

alkaline AAA batteries.

When should the batteries be

replaced

1. When there is not a "beep"

anymore from the indoor unit when

using the control remote or the

signal light indicator does not lit.

2. The indoor unit does not respond

to the remote control commands to

activate the programs.

conditioner emits a "beep" that

indicates that a command has been

received and transmitted in the

indoor unit.

3. When selecting the function of

timer, the remote control sends

(automatically) a signal to the indoor

unit at the specific moment. If the

control remote is left in a position

that the signal is blocked, a 15

minute delay can be produced.

To replace batteries

1. Slide out the battery compartment

cover (located in the back part of

the remote control).

2. install the two AAA batteries in the

compartment (indicated in the

drawing located inside the

compartment).

3. Slide in the cover.

4. If the remote control is not

operated for long period of times,

batteries should be discarded.

Remote control instructions

1. The signal reach distance of the

remote control to the receiver that

is inside the main unit of the air

conditioner is 8 meters. Any

obstruction placed between the

receiver and the remote control can

cause interference, limiting the

capacity of the programming.

2. Any time that a button is pressed

in the remote control, the air

Attention

1. When replacing batteries, do not

use old batteries or a different type

battery. This may cause the remote

control to malfunction.

2. If you do not use the remote

controller for several weeks remove

the batteries. Otherwise battery

leakage may damage the remote

controller,

3. The average battery life under

normal use is about 6 months,

4. Replace the batteries when there is

no answering beep from the indoor

unit or if the Transmission indicator

light fails to light.

Remote control description

ON/OFF: Push this button to start

the unit operation. Push the button

again to stop the unit operation,

TEMP_: Press the button to

increase the indoor temperature

setting.

TEMPV: Press the button to

decrease the indoor temperature

setting.

SWING: Push this button, the louver

would swing up and down

automatically. Push again to stop it.

CLOCK: is used to select the time.

TURBO*: Press this button on

cooling/heating** mode to go into

powerful cooling (heating)operation.

Press againto cancel it,

*Note 1: Only for some models.

**Note 2: For models with PTC only.

MODE: Each time you push the

button, a mode is selected in a

sequence that goes from AUTO,

COOL, DRY, HEAT*, and FAN, as

the following figure indicates:

AUTO_.COOLi_DRYI_ HEAT* I_ FAN

t J

FAN SPEED: This button is used for

setting Fan Speed in the sequence

that goes from AUTO, LOW, MED to

HIGH, then back to Auto.

AUTO 1_ LOW I_ MED I_ ALTA

Attention

* Note: Only for heating and cooling

models.

_ SLEEP; This button is used to

start or stop the sleep function

and/or to start the block function.

Also, press this button once and

the unit starts operating in sleep

mode which keeps the room

temperature comfortable and

helps in the consumption of

energy. To start the block function

press this button for 3 seconds;

and it will start leaving the

configuration and it won't accept

in operation except for the present

block function.

_ TIMER: Is used to select the

turning on time and turning off

time of the air conditioner.

_ CANCEL:

1. If the timer is TIMER ON/TIMER

OFF and the function has been

configured, press "cancel" and

it will cancel the timer program

and turn off the unit.

2. If the timer is "TIMER OFF"

only mode, press the button

"Cancel" and it will cancel the

timer program and turn the unit

off.

Note: This function, works only

when some function of timer is

activated, tn the contrary, nothing

will happen when the button is

pressed.

LED (screen): Press this button

to erase the digits that are shown

in the screen of the air conditioner.

Press again to activate,

@

LCD display indicators

Auto air speed

Air speed indicator

®

Turbo*

Sleep

ON/OFF indicator: This

indicator lit and flash once the

remote control sends the signal

to the indoor unit.

Auto mode

Cool mode

Dry mode

Heat mode

Fan mode

Auto clean*

AUTO

CLEAN

2H _ Temperature display

Block

t Horizontal airflow (up/down)*

Vertical airflow(left/right)*

_n Timer set

f,J ,"U U

Attention

All the items are shown in the screen to have a clear and precise explanation.

But only the actual function items will be shown in the visualization panel.

*During the actual operation, this indicator will not be shown in the panel of the

indoor unit.

How the air conditioner works

Automatic operation

When the Air Conditioner is ready for use, switch on the power and the

OPERATION indicator lamp on the display panel of the indoor unit starts

flashing.

I. Use the MODE .select button to select AUTO.

2. Push the TEMP button to set the desired room temperature. The most

comfortable temperature setting are between 21°C o to 28°C.

3. Push the ON/OFF button to start the air conditioner. The OPERATION lamp

on the display panel of the indoor unit lights. The

operating mode is AUTO FAN SPEED is automatically set and there are no

indicators shown on the display panel of the remote controller.

4. Push the ON/OFF button again to stop the unit operation.

Attention

1. When you set the air conditioner in AUTO mode, it will automatically select cooling,

heating(cooling/heating models only), or fan only operation depending on what

temperature you have selected and the room temperature.

2. The air conditioner will control room temperature automatically round the

temperature point set by you.

3. If the AUTO mode is uncomfortable, you can select desired conditions manually.

COOL / HEAT and FAN ONLY operation

1. if the AUTO mode is not comfortable, you may manually override the settings

by using COOL, HEAT* or FAN** ONLY modes.

2, Push the TEMP button to set the desired room temperature. When in COOL

mode, the most comfortable settings are 21°C or above. When in HEAT

mode, the most comfortable settings are 28 C or b elow.

3. Push the FAN SPEED to select the FAN mode of AUTO, HIGH, MED or LOW.

4. Push the ON/OFF button, the operation lamp lights and the air conditioner

start to operate as your settings. Push the ON/OFF button again to stop this

unit operation.

* Nota: Only for heating and cooling models

"*Note: The FAN ONLY mode can not be used to control the temperature.

While in this mode, only steps 1,3 and 4 may be performed.

DRYoperation

Thedrymodewillautomaticallyselect

thedryingoperationbasedonthe

differencebetweentheset

temperatureandtheactualroom

temperature,

Thetemperatureisregulatedwhile

dehumidifyingbyrepeatingturningon

andoffofthecoolingoperationorfan

only,ThefanspeedisLOW.

1.PushtheMODEbuttontoselect

DRY,

2. PushtheTEMPbuttontosetthe

desiredtemperaturefrom21°Cto

28°C.

3. PushtheON/OFFbutton,the

operationlamplightsandtheair

conditionerstarttooperateinthe

DRYmode,FANSPEEDisLow,

PushtheON/OFFbuttonagainto

stopthisunitoperation.

Attention

Due to the difference of the set

temperature of the unit and the

actual indoor temperature, the Air

Conditioner when in DRY mode will

automatically operate many times

without running the COOL and FAN

mode.

# # o

Set temperature

DRY Function

Air flow direction adjustment

Use SWING to adjust the airflow direction up and down,

1. When swing is pressed the horizontal louver moves up and down

automatically. Press again to stop operation

Attention

if the louver oscillates or moves in a position that could affect the cooling or

heating ofthe air conditioner the direction of the oscillation/movement would

alter automatically.

SLEEP mode

Press the sleep button to activate the

sleep mode. To deactivate, press the

button again.

Cool only mode:

• The indoor unit fan operates at a

low velocity.

• After and hour of operation, the

adjusted temperature will increase

1° C. After, the unit keeps

operating 2°C above the adjusted

temperature.

In heating mode (some models):

• The indoor unit fan operates at a

low velocity.

• After and hour of operation, the

adjusted temperature will decrease

1° C. After, the unit keeps

operating 2° C below the adjusted

temperature.

Attention

Sleep function is only availaib[e in the

Coot/Heat and AUTO mode.

+l J--J S,°o

Ee

SLEEP FUNCTION (Cooling mode)

oo

I

I

SLEEP FUNCTION (Heating mode)

TIMER Operation

TIMER button can set the auto-on time of the unit.

To set the starting time

1. Push the TIMER ON button, then the remote controller shows TIMER ON,

the last set time for the starting operation and the signal "h" will be shown on

the DIGITAL DISPLAY area. You are now ready to reset the time to START the

operation.

2, Push the TIMER ON button again to set desired unit start time,

3. After setting the TIMER ON ,there will be a one-half second delay before the

remote controller transmits the signal to the air conditioner. Then, after

approximately another 2 seconds, the signal "h"disappears and the set

temperature will re-appear on the digital display.

To set the stopping time

1. Push the TIMER OFF button and the remote controller will show TIMER OFF,

the last set time for the stopping operation and the signal "h"wilt be shown

on the DIGITAL DISPLAY area. You are now ready to reset the time of the

STOP operation,

2. Push the TIMER OFF button again to set the time you want to stop the

operation.

3. After setting the TIMER OFF ,there will be a one-half second delay before the

remote controller transmits the signal to the air conditioner. Then, after

approximately another 2 seconds, the signal "h" disappears and the set

temperature will re-appear on the digital display.

Exernples:

ON ON

6h 6h

(T_mp On) (Te r_p Off)

ON ON ONN

....oFLJ

= ,, . = ,,.....>

12h 14h 20h 23h

('rempOf0 (TeTepOn) (Temp On) {Temp Off)

Optimal operation

To achieve optimal performance, please note the following:

1. Adjust the air flow direction correctly so that it is not directed on people.

2. Adjust the temperature to achieve the highest comfort level. Do not adjust

the unit to excessive temperature levels.

3. Close doors and windows on COOL or HEAT modes, or performance may be

reduced.

4. Use TIMER ON button on the remote controller to select a time you want to

start your air conditioner.

5. Do not put any object near air inlet or air outlet, as the efficiency of the air

conditioner may be reduced and the air conditioner may stop running.

6. Clean the air filter periodically, otherwise cooling or heating performance may

be reduced.

7. Do not operate unit with horizontal louvre in closed position.

@

How to use the indoor unit

Adjusting air flow direction

Adjust the air flow direction properly

otherwise, it might cause discomfort

or cause uneven room temperatures.

Adjust the horizontal louver using the

remote controller. Adjust the vertical

louver manually.

Adjusting the vertical air flow

direction (up - down)

The air conditioner automatically

adjusts the vertical air flow direction in

accordance with the operating mode.

To set the horizontal air flow

direction (left! right)

Adjust the vertical louver manually

using the lever on the left or right side

of the vertical louver arm (Depending

on model). Take care not to catch

fingers on the fan, horizontal louver or

to damage vertical louvers. When the

air conditioner is in operation and the

horizontal louver is in a specific

position, move the lever at left (or

right, depending on model) end of the

air outlet to the desired position.

To automatically swing the air flow

direction (up/down)

Perform this function while the air

conditioner is in operation,

Press the SWING button on the

remote controller.

To stop the function, press the

SWING button again.

Press AIR DIRECTION button to lock

louver in desired position.

%

Lever

The AIR DIRECTION and SWING buttons

will be disabled when the air conditioner

is not in operation (including when the

TIMER ON is set).

Do not operate the air conditioner for

long periods with the air flow direction set

downward in cooling or dry mode.

Otherwise, condensation may occur on

the surface of the horizontal louver

causing moisture to drop on to the floor

or on furnishings.

Do not move the horizontal louver

manually. Always use the AIR DIRECTION

or SWING button. If you move this louver

manually, it may malfunction during

operation, If the louver malfunctions, stop

the airconditioner once and restart it.

When the air conditioner is started

immediately after it was stopped, the

horizontal louver might not move for

approximately 10 seconds.

Open angle of the horizontal louver

should not be set too small, as COOLING

or HEATING performance may be

impaired due to too restricted air flow

area.

Do not operate unit with horizontal louver

in closed position.

When the air conditioner is connected to

power (initia_power), the horizontal louver

may generate a sound for 10 seconds,

this is a normal operation.

Manual operation (without remote control)

Manual operation can be used

temporarily in case you can not find

the remote controller or its batteries

are exhausted.

!. Open and lift the front panel up to

an angle until it remains fixed with

a clicking sound,

2. One press of the manual control

button will lead to the forced

AUTO operation.

3. Close the panel firmly to its

original position.

Attention

Once you push the manual button,

the operation mode is shifted in an

order as: AUTO, COOL, OFE

Push the button twice, the unit will

operate in forced COOL mode. This is

used for testing purposes only.

Third press will stop the operation and

turn off the air conditioner operation.

To restore the remote controller

operation, use the remote controller

directly.

@

Manual control

button /

Auto/Cool@

Maintenance

Cleaning the indoor unit and remote

controller

1. It is necessary to stop the air

conditioner and disconnect the power

supply before cleaning.

2, Use a dry cloth to wipe the indoor unit

and remote controller,

3, A cloth dampened with cold water

may be used on the indoor unit if it is

very dirty.

4. The front panel of the indoor unit can

be removed and cleaned with water.

Then wipe it with a dry cloth.

5. Do not use a chemically treated cloth

or duster to clean the unit.

6. Do not use benzine, thinner, polishing

powder, or similar solvents for

cleaning. These may cause the plastic

surface to crack or deform.

Cleaning the air filter

A clogged air filter reduces the cooling

efficiency of this unit. Please clean the

filter once every 2 weeks,

1. Lift the indoor unit panel up to an angle

until it stops with a clicking sound.2.

Take hold of the handle of the air filter

and lift it up slightly to take it out from

the filter holder, then pull it

downwards.

3. Remove the air filter (Fresh air filter +

support) of the unit.

4. Remove fresh air filter from frame

support.

5. Clean the fresh air filter at least once a

month, and replace every 4 to 5

months. Use a vacuum cleaner, then

dry.

6. Clean the support frame using a

4b

Air filter

Air filter

vacuum cleaner or water, After, dry

for a couple of hours or until dry.

7. Insert the fresh air filter in its original

place.

8. insert the high part of the air filter

(fresh air filter + Support frame)

again in the unit keeping in mind

that the outside border (right and

left) are lined up correctly, now

place the whole filter in the initial

position,

Support

Fresh frame

air filte_

Fresh

air filter

Fig.1 Fig.2

Support

frame

Fresh _\

air flits

Fig.3 - "\\ _"_

Suppo_

frame

Maintenance

Ifyou plan to idle the unit for a long time, perform the following:

1. Operate the fan for about half a day to dry the inside of the unit.

2. Stop the air conditioner and disconnect power. Remove the batteries from

the remote controller.

3. The outdoor unit requires periodic maintenance and cleaning. Do not

attempt to do this yourself. Contact your dealer or servicer.

Checks before operation

1. Check that the wiring is not broken off or disconnected.

2, Check that the air filter is installed

3. Check if the air outlet or inlet is blocked after the air conditioner has not

been used for a long time.

Operation tips

The following events may occur during normal operation.

Protection of the air conditioner,

Compressor protection

The compressor can't restart for 3 minutes after it stops.

Anti-cold air (Co..o!ingand heating models only)

The unit is designed not to blow cold air on HEAT mode, when the indoor heat

exchanger is in one of the following three situations and the set temperature

has not been reached.

1. When heating has just starting.

2. Defrosting.

3. Low temperature heating.

Defrosting (Cooling and heatinq models on[v)

Frost may be generated on the outdoor unit during heat cycle when outdoor

temperature is low and humidity is high resulting in lower heating efficiency of

the air conditioner. During this condition air conditioner wilt stop heating

operation and start defrosting automatically.

The time to defrost may vary from 4 to 10 minutes according to the outdoor

temperature and the amount of frost buildup on the outdoor unit.

The indoor or outdoor fan stop running when defrosting (Cooling and heating

models only).

A white mist coming out from the indoor unit

A white mist may generate due to a large temperature difference between air

inlet and air outlet on COOL mode in an indoor environment that has a high

relative humidity.

A white mist may generate due to moisture generated from defrosting process

when the air conditioner restarts in HEAT mode operation after defrosting.

Low noise of the air conditioner

You may hear a low hissing sound when the compressor is running or has just

stopped running.

This sound is the sound of the refrigerant flowing or coming to a stop.

You can also hear a low "squeak" sound when the compressor is running or

has just stopped running. This is caused by heat expansion and cold

contraction of the plastic parts in the unit when the temperature is changing.

A noise may be heard due to louver restoring to its original position when

power is first turned on.

Dust is blown out from the indoor unit.

This is a normal condition when the air conditioner has not been used for a long

time or during first use of the unit.

_Y

Apeculiarsmellcomesoutfromtheindoorunit.

Thisiscausedbytheindoorunitgivingoffsmellspermeatedfrombuilding

material,fromfurniture,orsmoke.

TheairconditionerturnstoFANonlymodefromCOOLorHEAT(For

coolingandheatingmodelsonly)mode.

Whenindoortemperaturereachesthetemperaturesettingonairconditioner,the

compressorwillstopautomatically,andtheairconditionerturnstoFANonly

mode.Thecompressorwillstartagainwhentheindoortemperatureriseson

COOLmodeorfallsonHEATmode(Forcoolingandheatingmodelsoly)tothe

setpoint.

Drippingwatermaygenerateonthesurfaceoftheindoorunitwhencoolingina

highrelativelyhumidity(relativehumidityhigherthan80%).Adjustthehorizontal

louvertothemaximumairoutletpositionandselectHIGHfanspeed.

Heatingmode(Forcoolingandheatingmodelsonly)

Theairconditionerdrawsinheatfromtheoutdoorunitandreleasesitviathe

indoorunitduringheatingoperation.Whentheoutdoortemperaturefalls,heat

drawninbytheairconditionerdecreasesaccordingly.Atthesametime,heat

loadingoftheairconditionerincreasesduetolargerdifferencebetweenindoor

andoutdoortemperature.Ifa comfortable temperature can't be achieved by the

air conditioner, we suggest you use a supplementary heating device.

Auto-restart function

Power failure during operation will stop the unit completely.

For the unit without Auto-restart feature, when the power restores, the

OPERATION indicator on the indoor unit starts flashing. To restart the operation,

push the ON/OFF button on the remote controller. For the unit with Auto-restart

feature, when the power restores, the unit restarts automatically with all the

previous settings preserved by the memory function.

Lightning or a car wireless telephone operating nearby may cause the unit

to malfunction.

Disconnect the unit with power and then re-connect the unit with power again.

Push the ON/OFF button on the remote controller to restart operation.

Solutions for problems

If your air conditioner malfunctions, check the following information to find

solutions or probable causes of the failure. Do not try to repair the unit by

yourself, if these solutions do not solve the failures; call your local service repair

team.

Poor Equipment performance

1. The air outlet or inlet in the exterior part is obstructed,

2. The temperature in the exterior is high due to direct sunlight or another heat

source.

3. Heater or a cooking stove is being used in the same room.

4. Room is full of people.

5. The air filter is obstructed by dust or is dirty.

6. Inappropriate temperature adjustment,

7. Front part is obstructed.

8. The capacity of the equipment is not adequate for the size of the room.

9. Air conditioner was just turn on.

10,Windows or doors are open.

11.Motor protector has been activated.

The unit does not start

1. The plug is not connected to the outlet.

2. No electricity in the outlet.

3. The voltage is different.

4. Temperature is not adjusted properly.

5. burned fuse,

6. The remote control batteries need to be replaced.

7, wrong operation time.

Attention

Stop the air conditioner immediately if one of the following malfunctions occur

1. The operation indicator or other indicator flash(5times persecond) and the flashing is

not stop by disconnecting and connecting the unit,

2. Frequentchange of fuses and malfunctions in the switch circuit.

3. Water spills over the equipment,

4. Remotecontrol does not work,

5. Any other abnormal situation,

®

Technical specifications

COOLING MODELS

HEATING + COOLING MODELS

Notes

@

Notes

Notes

_!_ii_i!_i_i_!!_i!!_i!_!i_i_i_!!i_i_!i!!_i_i_!_!i!_!_!_iii_i_!_i_ii_!!_!i!_!_i_!i!_ii_iii!i!_ii_i_!_i_ii_i_!!_!!i_!_:_ii_ii_!i_i!_ii!_i!_i_ii!i_i!_!i_ii_i!_iii_!i!_i_

ii:_ii!iil}i_i:i_iiiiii_!iiii:iiii:i:ii_iiiii?ii_ili$i:ili_i!!i_¸_ii_ii_iiii_i_i_ii_!!_ii!_i_!ii_{ii{_i_i_!_{i_ii_ii_iiiii!!_iii_!ii_ii_!iiiiiii_i{i_i_ii_i_iiii!_i_i_i!_i_!iii_ii_i!_i_iiiiii_i_ii!_iiiiii_iiii_ii_iiii

"_i:_ _ii;__i_!,_i_ii:i_!}ii_iii_i_iiiii_!!ii!_!i_ii_i£,_iii_Z___ _ __i_ii_i_!iiKii_iii_i!_i_!_iiii_i

FRIGI D_! R _ii_,,_;_

FRIGIDAIR

ATENCION

Lea todas las instrucciones antes de

utilizar el aparato y guardelas para futuras

Bienvenido al mundo dei

manejo simple y sin preocupaciones

Gracias por elegir Frigidaire como marca para su acondicionador de aire.

Los acondicionador de aire Frigidaire han sido concebidos bajo altisimos

est&ndares t_cnicos. Poseen caracteristicas especiales desarrolladas para

ofrecer aun m,'_scomodidad al usuario.

Para que usted pueda disfrutar todos los recursos que su nuevo

acondicionador de aire ofrece, Frigidaire cre6 este manual. Con orientaciones

simples y pr&cticas usted conocera sus funciones y aprenderA ]a manera de

operar este aparato de modo adecuado y seguro.

Lea las instrucciones sobre instalaci6n y operaci6n antes de utilizar su

acondicionador de aire y gu&rdelas en un lugar seguro para futuras consultas.

Frigidaire una vez mAs fabrica Io mejor en Io que se refiere a

electrodomesticos.

Consejos ambientales

E! material deI embalaje es reciclable.

Procure separar pl&sticos, espuma flex,

papeI y cart6n y enviarlos alas

compaSias de recictaje.

De acuerdo con la directriz de la RAEE

(Residuos de Aparatos El6ctricos y

Electr6nicos), en ingles WEEE (Waste of

Electrical and Electronic Equipment), se

debe colectar y disponer de los residuos

de aparatos el6ctricos y etectr6nicos

separadamente. Si futuramente usted

necesita desechar este electrodom6stico,

NO Io haga echandolo con el resto de la

basura dom6stica. S[rvase enviar el

aparato a los puntos de colecta de RAEE

donde los haya disponibles.

Indice

01. Bienvenido ........................................................................................... 01

02. Consejos ambientales .......................................................................... 0I

03. indice ................................................................................................... 02

04. Precauciones de seguridad ..................................................................... 04

05, Instalaci6n:

5.1 Eligiendo el local de instalaci6n .................................................. 08

5.2 Lista de piezas ............................................................................ 10

5.3 instalaci6n de la unidad interna ................................................... 12

5.4 Instalaci6n de [a unidad externa .................................................. 17

5.5 Conexi6n de ta tuberia refrigerante .............................................. 19

5.6 Conexi6n ei6ctrica ..................................................................... 21

5.7 Purga de aire ............................................................................. 26

5.8 Seguridad el_ctrica .................................................................... 29

5.7 Control de fuga de gas............................................................... 29

5.8 Prueba de funcionamiento ......................................................... 30

06. Operaci6n:

6.1 Preparando el aparato para hacerlo funcionar. ............................. 31

6.2 Descripci6n del producto ........................................................... 32

6.3 Como funciona et control remoto ................................................ 34

- Caracteristicas del control rernoto

- Cargar el control remoto

- Se deber_ sustituir las pilas cuando:

- Para sustituir las pilas:

- Instrucciones de uso del control remoto

6,4 Descripci6n del control remoto .................................................... 36

- Encender/apagar

- Mas (Temperatura)

- Menos (Temperatura)

- Swing

- Clock

- Turbo

- Modo

- Vent. (velocidade deI ventilador)

- Dormir

- Temporizador

- Cancel

- LED (Pantalla)

6,5 Indicadores en la pantalla LCD................................................... 38

6.6 Como funciona el acondicionador de aire ................................... 39

- Operaci6n Auto (Autom_.tica)

- Operaci6n Auto (autom&tica)

@

- Operaciones Frio, Calor Y Solo Vent.

- Uso de la deshumidificaci6n - Seco (Dry)

- Ajuste de la direcci6n del flujo de aire

- Uso de Dormir

- Operaci6n del Temporizador (Timer)

- Funcionamiento 6ptimo

6.7 Como usar la unidad interna ...................................................... 43

- Ajuste la direcci6n de! flujo del aire

- Ajuste de la direcci6n del aire verticalmente (arriba/abajo)

- Para ajustar la direcci6n horizontal (izquierda/derecha)

- Para ajustar la direcci6n horizontal (izquierdaiderecha)

- Para operar la funci6n SWING (arriba/abajo)

6.8 Operacion manual (sin control remoto) ...................................... 45

07. Mantenimiento y cuidados .................................................................... 46

08. Consejos de operaci6n ......................................................................... 48

09. Guia para la soluci6n de problemas ...................................................... 50

10. Especificaciones tecnicas ...................................................................... 51

Atenci6n

1. El aparato que usted ha comprado puede set tigeramente diferente del que

se muestra en las figuras de este manual, la forma en general deber4 ser la

misma.

2. Este acondicionador de aire ha sido proyectado para uso domestico. No

se recomienda su uso para fines comerciales, industriales yio en

laboratorios.

3. El aparato que usted ha comprado puede tenet un enchufe diferente del

que se muestra en las figuras de este manual, siendo que el que viene en

el producto cumple la especificaci6n el6ctrica de su pals.

Precauciones de seguridad

Normas de seguridad

Las siguientes normas deberAn ser siempre respetadas para mayor seguridad:

° Aseg_rese de leer las siguientes advertencias antes de instalar el

acondicionador de aire.

• Aseg_rese de seguir todas las precauciones especificadas aqui, ya que

incluyen importantes terminos relativos a [a seguridad,

1. El acondicionador de aire debe

estar conectado a tierra. Si no Io

est& completamente puede haber

choques el6ctricos, No conecte eJ

cable tierra al tubo de conexi6n, a

la tuberia de agua, barra de Iuz,

tierra del telefono. Despu_s de la

instalaci6n, verifique que no haya

fugas.

2. Utilice los cables especificados

para conectar las unidades intema

y extema con seguridad y conecte

los cables firmemente alas

secciones de la placa de los

bornes para que las tensiones no

se apliquen a las secciones. La

conexi6n o co]ocaci6n incorrecta

podria originar fuego.

3. No haga funcionar ni detenga la

unidad enchuf&ndolo por el cable

de alimentaci6n o tirando del cable

de alimentaci6n. Desconecte el

cable de alimentaci6n sujet&ndolo

por el enchufe,

4. No modifique el cable de

alimentaci6n el@ctrica ni utilice et

mismo tomacorriente para

conectar otros electrodom@sticos.

Peligro de descarga el_ctrica o de

incendio causado pot producci6n

excesiva de cator.

5. Noda_eniutiliceuncablede

alimentaci6net6ctricano

especificadeparaelproducto.Si

elcabledealimentaci6nest&

da_ado,elfabricante,suagente

demantenimientoosimilar

personaautorizadadeber_

substituirloparaevitarelpeligro

queelcablerepresenta,

6. I',1ouseeltomacorrientesiesta

flojoodaSado.

7. Instalesiempreuninterruptor

autom_.ticoyuncircuitode

alimentaci6nexctusivoparael

aparato.

8. Nodirijaelflujodeaireenla

direcci6ndelosocupantesdela

habitaci6n,esdaSinoparaIa

salud.Potlosmisrnosmotivos,

tampocoexpongaplantaso

animalesalflujodirectodelaire.

9. Desenchufeelaparatocuandono

1ovayaausarporunlargoperiodo

detiempo,elac[3mulodesuciedad

podriacausarfuego.

10.Instaleuninterruptorfusibledela

capacidadnominalparaevitar

posibleschoquesel6ctricos,

11.Cuandovayaalimpiarlaunidad,

descon_cteladeltomacorrientey

desconectetambienelinterruptor

autom&tico,l',Jolimpielaunidad

mientrasest&conectadapues

existepeligrodecausarun

incendio,descargasel6ctricaso

accidentes.

12.Nolimpieelacondicionadorde

aimconagua,Elaguapodria

penetrarenlaunidadydeteriorar

suaislamiento,adem_sdepeligro

dedescargasel6ctricas.

13. No maneje el aparato con las

manos mojadas o en lugares

hQmedos.

14. Cierre las puertas y ventanas

mientras el acondicionador de aire

est& funcionando por mucho

tiempo. Si necesita ventilar la

habitaci6n, abra la puerta o la

ventana por poco tiempo,

solamente para permitir la entrada

de aire fresco,

15. No ponga aparatos fuentes de

calor expuestos a las salida de

aire de[ acondicionador de aire,

debido a peligro de incendio.

I6, No instale el acondicionador de

aire en lugares en los que haya

gases inflamables o combustibles

como gasolina, benceno,

solventes, etc.

17. No utitice el acondicionador de

aire para otros propuestos como

atmac@nde equipos de precisi6n,

comida, pintura, etc., que

requieren ciertas condiciones de

temperatura y humedad, pues su

calidad se puede ver afectada.

18. No coloque los dedos o otros

objetos en las reji]las del panel

frontal, pues el ventilador girando

a alta velocidad podria causar un

accidente.

19. Desconecte la alimentaci6n

el6ctrica a la unidad si escucha

algt_n ruido anormal o siesta

emite olores o humo. H_galo

\

tambien en caso de tormenta o de

condiciones clim&ticas adversas.

20. No beba el agua drenada del

acondicionador de aire, esta

contiene agentes contaminantes

que pueden resultar daSinos para

la salud.

21. Cuando vaya a reemplazar el filtro

de aire, no toque las partes de

metal del aparato.

22. Antes de hacer funcionar el

aparato haga ventilar la habitaci6n

si ha habido algSn escape de gas

de otro aparato. En presencia de

estufas e otros aparatos fuente de

calor, ventile bien el recinto.

23. No abra el aparato durante el

funcionamiento.

24. No ponga objetos pesados sobre

el cable de alimentaci6n el6ctrica

y asegQrese de no aplastarlo.

25. No desarme ni modifique el

aparato.

26. Tome cuidado al desempacar y

instafar la unidad.

27. AsegOrese de que no entre agua a

los componentes el6ctricos,

28. Mantenga cualquier arma de

fuego alejada del

electrodomestico.

29. Siempre compruebe la instalaci6n

de los filtros y limpielos a cada

dos semanas. Hacer funcionar el

aparato sin los filtros puede

ocasionar averias.

30. No ponga objetos cerca de las

entradas o en las satidas de aire,

_07_

Eligiendo el local de instalaci6n

Precauciones para la instalaci6n

La instalaciSn en los siguientes lugares podria causar problemas. Si es

inevitable realizarla en algunos de estos lugares, por favor consulte con su

distribuidor local Electrofueguina.

1. Un lugar Ileno de aceites de m_tquina.

2. Lugares con alta concentraci6n de salinidad, como en la costa.

3. Lugares donde haya gas sulfOrico como por ejemplo balnearios de aguas

termales.

4. Lugares donde hay m&quinas de atta frecuencia como equipos inalAmbricos,

m&quinas de soldaduras e instalaciones m_dicas.

5. Un lugar con gases inflamables o material vol_.til.

6. Un lugar con condiciones ambientates especiales.

7. Lavadero

Unidad interna

1. Un lugar que no obstacuJice el

_rea de entrada o salida del aire.

2. Un lugar que soporte el peso de la

unidad interna.

3. Un lugar de facil acceso para

realizar el manteniemiento y el

oambio del filtro de aire en su

aparato.

4, Un lugar que provea los espacios

requeridos alrededor de la unidad

intema como se muestra en el

gr&fico abajo.

5. Un tugar que tenga pot Io menos

mas de un metro de distancia con

respecto a un televisor,

instrumentos de radio. En el centro

del lugar es perfecto.

6, Un lugar alejado deI fuego, humo y

gases inflamables,

7. La unidad interna debe estar

instalada por 1omenos a 2.3

metros por encima del piso.

8. Lugares donde el tubo de

conexi6n y la manguera de

desague sean f_ciles de sacar.

9. Lugar que evite el contacto directo

con los rayos solares.

M_s

de 12cm

M_s

de 15crn

¢@

Mas

de 12cm

M_s

de 200cm

Atencion

Recomendamos que ta unidad internana

no reciba Iuzdirecta del sol. De Io

contrario, el sol hara que se desvanezca e]

gabinete de pl,_sticoy esto podr&afectar

su apariencia. Si es inevitable que Ialuz

de sol entre directamente en contacto con

la unidad intern& las precauciones para

que el producto no se desvanezca no se

estar&ntomando en cuenta.

Unidad externa

1, Un ]ugar que sea conveniente para

la instalaci6n y no esta expuesto a

vientos muy fuertes. Un lugar seco

y ventilado.

2. Un lugar que soporte el peso de la

unidad externa y pueda ser

sostenida en posici6n vertical.

3, Un lugar que no permita un

incremento en el niveI de ruido y

vibraci6n.

4, Un lugar en donde el ruido

producido por el funcionamiento y

descarga del aire no moleste a sus

vecinos o animales.

5. Un lugar sin fugas de gases

inflamables.

6. Un lugar que permita una elevacion

de las tuberias no menor de 5

metros y con una Iongitud de

tuberias de pot Io menos 10

metros.

7. Lugares en los que haya espacio

suficiente en tomo de esta unidad,

como se muestra en el diagram&

8. Un lugar en donde los ni_os no

tengan acceso,

M_s

de 30cm

M_s

de 200cm

Mas

de 60cm

M_s

de 30cm

f

M&s

de 60cm

Lista de piezas

Unidad tnterna

Unidad Externa

MAs de 15cm

Unidad Interna

M&s de 12cm

Filtro _i 3

de Aire

MEs 0cm

M4sde 200cm

M_s de 12cm

M_s de 60cm

Mas

de 60cm

C

Unidad

Externa

Atenci6n

1. lnstale ]a unidad interna a una altura de no menos de 2 m. Un recorrido

minimo de 4 a 5 men las tuberias, requeddo para minimizar lavibraci6n y

el ruido en exceso, Dos de las tres Direcciones (A, B o C en la gr_.fica)

deben estar sin ning_n tipo de bloqueo.

2. Esta ilustraci6n es solo con prop6sito explicativo. La forma de la placa de

instalaci6n puede variar dependiendo del modelo.

3. Las lineas de cobre deber&n ser aisladas independientemente.