Frigidaire CFEB30S5DB2, CFEB30S5DB4, CFEB30S5DB6, CFEB30S5DB7, CFEB30S5DB8 Installation Guide

...Page 1

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUAUFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

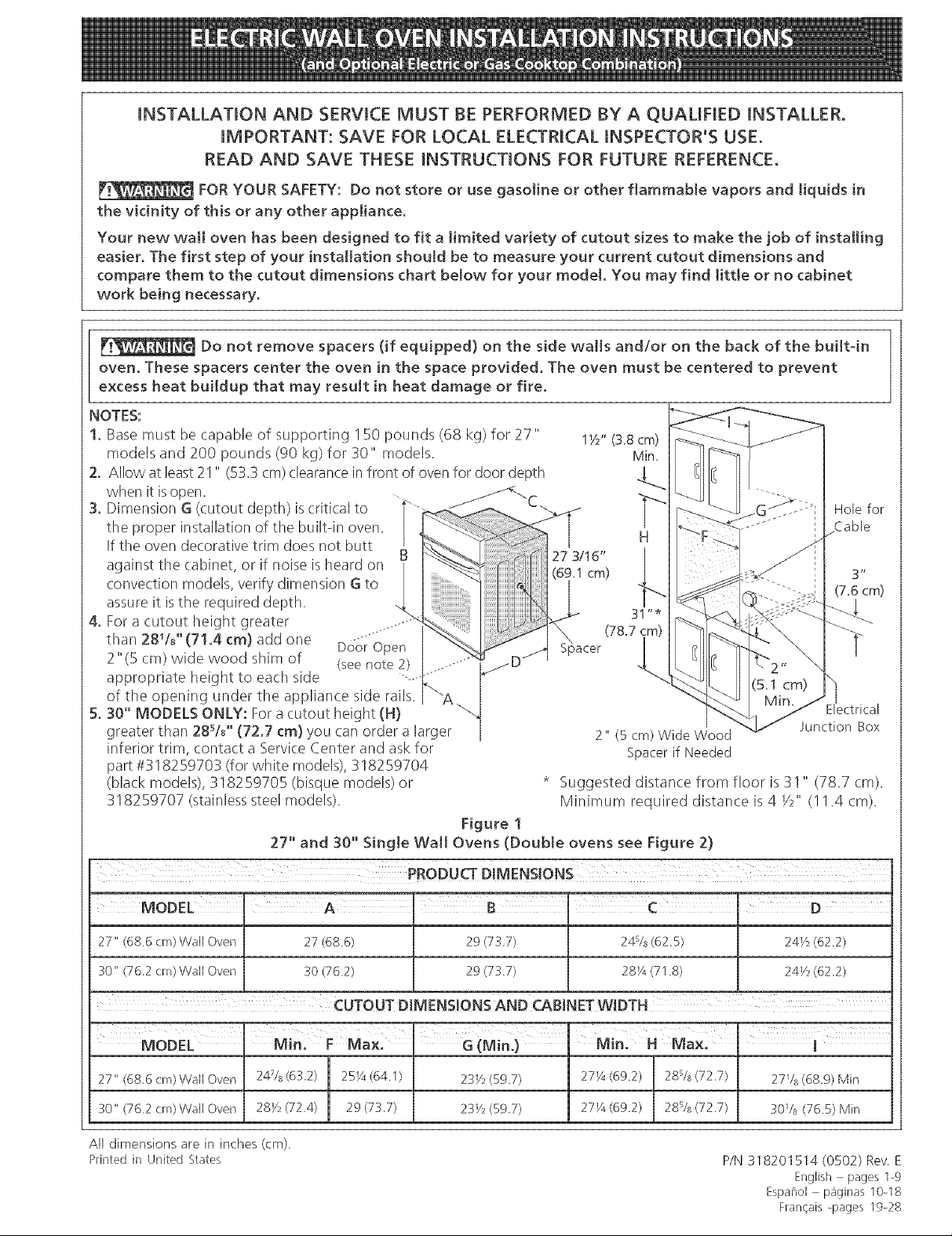

Your new wa[[ oven has been designed to fit a Jim[ted variety of cutout sizes to make the job of installing

easier, The first step of your installation should be to measure your current cutout dimensions and

compare them to the cutout dimensions chart below for your mode[, You may find little or no cabinet

work being necessary,

Do not remove spacers (if equipped) on the side walls and/or on the back of the bui[t4n

oven, These spacers center the oven in the space provided. The oven must be centered to prevent

excess heat buildup that may result in heat damage or fire,

1. Base must be capable of supporting 150 pounds (68 kg) for 27" 1Y2" (3.8 cm)[__

models and 200 pounds (90 kg) for 30" models. Min i

NOTES: __

2. Allow at least21 " (53.3 cm)clearancein front of oven for door depth _.

when it isopen.

the proper installation of the builtqn oven _-.__"_--_ ..... jCab e

If the oven decoratwe trim does not butt B " ' [

aga nst the cab net or fnose sheardon 3/16 [ [

- . ' . . . kb_._cm_ l #-_ 3"

convection models, verify dimension G to _ _ _ ........ _ _ _

. . " H i F...._ '

assure t sthe requ reddepth .. l "'[ _ (_": _=-_- _"_ _'''1

4. For a cutout height greater ......"__ <I ..... [_ _ _ _

.... _, _ / bpacer l _ [

2 (5cm)wldewoodshlmof (seenote2) ..... '" _f _D/ -_i _ [_ "_"_2" _

appropriate height to each side .....".... "--q>._ .... \

of the opening under the appliance side rails A "_ "' -]

,, - • M_n. Electrical

5. 30 MODELS ONLY: Fora cutout height (H) _ __n<

- - ,-.... kb./ cm2

greater than 28sA'' (72.7 cm) you can order a larger 2" (5 cm) Wide Wood _ Junction Box

inferior trim, contact a Service Center and ask for Spacer if Needed

part #318259703 (for white models), 318259704

(black models), 318259705 (bisque models) or * Suggested distance from floor is 31" (78.7 cm).

318259707 (stainlesssteel models). Minimum required distance is 4 Y2" (I 1.4 cm).

Figure 1

27" and 30" Single Wall Ovens (Double ovens see Figure 2)

PRODUCT DIMENSIONS

27" (686 cm)Wall Oven 27 (686)

30" (762 crn) Wall Oven 30 (762)

29 (737)

29 (737)

24sis (625) 24K, (622)

28¼ (71 8) 2@/2 (622)

MODEL Mira F Maxl' G(Min.} " Mira H Max.

27" (686 crn) Wall Oven 247s (632) 2%A (64.1) 23Y2 (597) 27Y4 (69.2) 28s/s (72.7)

30" (762 cm) Wall Oven 28Y_ (724) 29 (737) 23V2 (597) 271_ (69.2) 28s/s (72.7)

All dimensions are in inches (cm)

Printedin United States

i

27Vs (689) Min

30Vs (76.5) Min

P/N 318201514 (0502) Rev E

English - pages 1-9

Espai_o[ - p_ginas 10-18

Francais-pages 19-28

Page 2

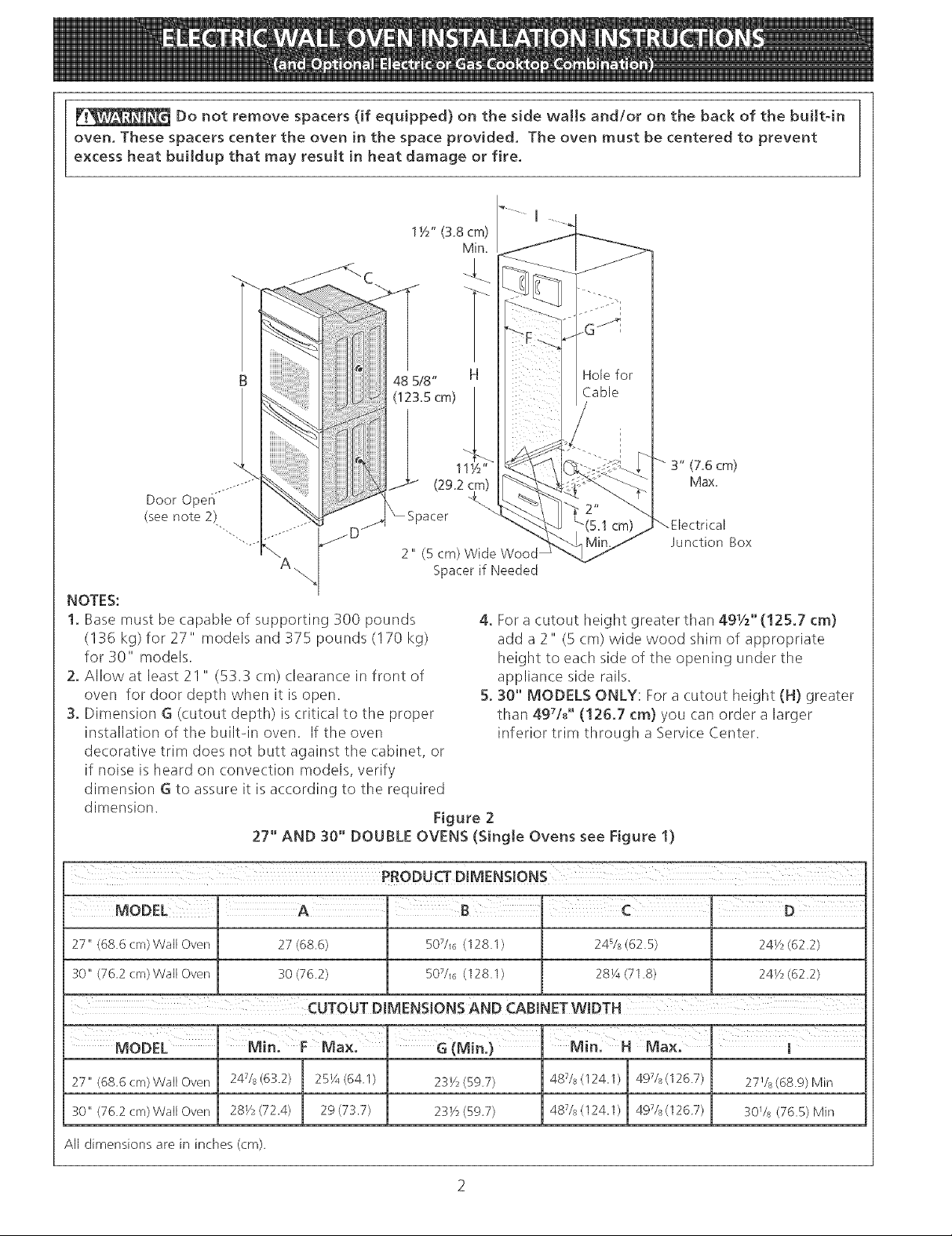

Do not remove spacers (if equipped) on the side wails and/or on the back of the built-in

oven, These spacers center the oven in the space provided, The oven must be centered to prevent

excess heat buildup that may result in heat damage or fire,

3" (7.6 cm)

Max,

2" (5 cm)Wide Wood

-. Spacerif Needed

NOTES:

1. Base must be capable of supporting 300 pounds

(136 kg) for 27" models and 375 pounds (170 kg)

for 30" models.

2. Allow at least 21 " (53.3 cm) clearance in front of

oven for door depth when it is open.

3. Dimension G (cutout depth) is critical to the proper

installation of the built-in oven. If the oven

decorative trim does not butt against the cabinet, or

if noise is heard on convection models, verify

dimension G to assure it is according to the required

dimension. Figure 2

27" AND 30" DOUBLE OVENS (Single Ovens see Figure 1)

27" (68 6 era)Wail Oven 27 (68.6) 1 507//6 (128.1) [ 24s/s (62.5) [ 24Y2 (62.2)

4. For a cutout height greater than 491/:,'' (!25.7 cm)

add a 2" (5 cm) wide wood shim of appropriate

height to ea(h side of the opening under the

appliance side rails.

5. 30" MODELS ONLY: Fora cutout height (H) greater

than 49Ud' (126.7 cm) you can order a larger

inferior trim through a Service Center.

Junction Box

3o"<762crNWa,Oven :30<76.2> _ SOTS6<12s.1> 2s_<71s> _ 24v_<62.2>

CUTOUT DIMENSIONS AND CABINET WIDTH

MODEL Max: GiM,n. J....Min: ]

30" (76 2 cm)Wail Oven J 281/,' (72.4) 29 (73.7) I 231/2(59 7) [ 48Vs (124.1)49Vs (126 7) I 30Vs (76.5) Mir_

A[[ dimensions are in inches (cm),

Page 3

Important Notes to the [nstammer

1. Read all instructions contained in these installation

instructions before installing the wall oven.

2. Remove all packing material from the oven

compartments before connecting the electrical supply

to the wall oven.

3. Observe all governing codes and ordinances.

4. Be sure to leavethese instructions with the consumer.

5. Oven door may be removed to facilitate installation.

6. THESE OVENS ARE NOT APPROVED FOR

STACKABLE OR S[DE-BY-S[DE [NSTALLAT[ON.

Important Note to the Consumer

Keep these instructions with your Owner's Guide for future

reference.

IMPORTANT SAFETY

[NSTRU S

Be sure your wall oven is installed and grounded

properJy by a qualified installer or service

technician.

• This wall oven must be eIectrka[Iy grounded in

accordance with iota[ codes or, in their absence,

with the Nationa[ EJectrica[ Code ANSJ/NFPA

No.70- tatest edition in United Sates, or with CSA

Standard C22.1, Canadian Electrical Code, Part 1, in

Canada.

Stepping, [eaning or sitting on the

door of this wall oven can resu[t in serious injuries

and can also cause damage to the wait oven.

Never use your wail oven for warming or heating

the room. Prolonged use of the wall oven without

adequate ventilation can be dangerous.

2. Electrical Requirements

This appliance must be supplied with the proper voltage

and frequency, and connected to an individual, properly

grounded branch circuit, protected by a circuit breaker or

fuse, having amperage as noted on the rating plate (the

rating plate is located on the side trim).

Observe all governing codes and local ordinances

1. A 3-wire or 4-wire single phase 120/240 or 120/208

Volt, 60 Hz AC only electrical supply is required on

a separate circuit fused on both sides of the line

(time-delay fuse or circuit breaker is recommended).

DO NOT fuse neutral. The fuse size must not exceed

the circuit rating of the appliance specified on the

nameplate. Only certain cooktop models may be

installed over certain builtqn electric oven models.

Approved cooktops and builtqn ovens are listed by

the MFG ID number (see the insert sheet included in

the literature package).

2. The single wall oven can consume up to 4000W at

240Vac; use a circuit breaker of 30 Amp with wire

gauge #8 AWG. The double wall oven can consume

up to 8000W at 240Vac; use a circuit breaker of 40

Amp with wire gauge #8 AWG.

NOTE: Wire sizes and connections must conform with

the fuse size and rating of the appliance in accordance

with the American National Electrical Code ANSI/NFPA

No. 70qatest edition, or with Canadian CSA Standard

C22.1, Canadian Electrical Code, Part 1, and local codes

and ordinances.

An extension cord should not be used

with this appliance. Such use may result in a fire,

electrical shock, or other persona[ injury. If you need

a longer power cord you can order for purchase a 10'

(3m) power cord kit #903056-9010 by calling the Service

Center.

The electrical power to the oven must

be shut off while Hne connections are being made.

Failure to do so could result [n serious injury or

death.

1. Carpentry

Refer to figure I or 2 for the dimensions applicable to

your appliance, and the space necessary to receive the

oven. The oven support surface may be solid plywood or

similar material, however the surface must be level from

side to side and from front to rear.

3. These appliances should be connected to the fused

disconnect (or circuit breaker) box through flexible

armored or nonmetallic: sheathed cable. The flexible

armored cable extending from the appliance should

be connected directly to the junction box. The

junction box should be located asshown in Figure 1

or Figure 2 and with as much slack as possible

remaining in the cable between the box and the

appliance, so it can be moved if servicing is ever

necessary.

4. A suitable strain relief must be provided to attach

the flexible armored cable to the junction box.

Page 4

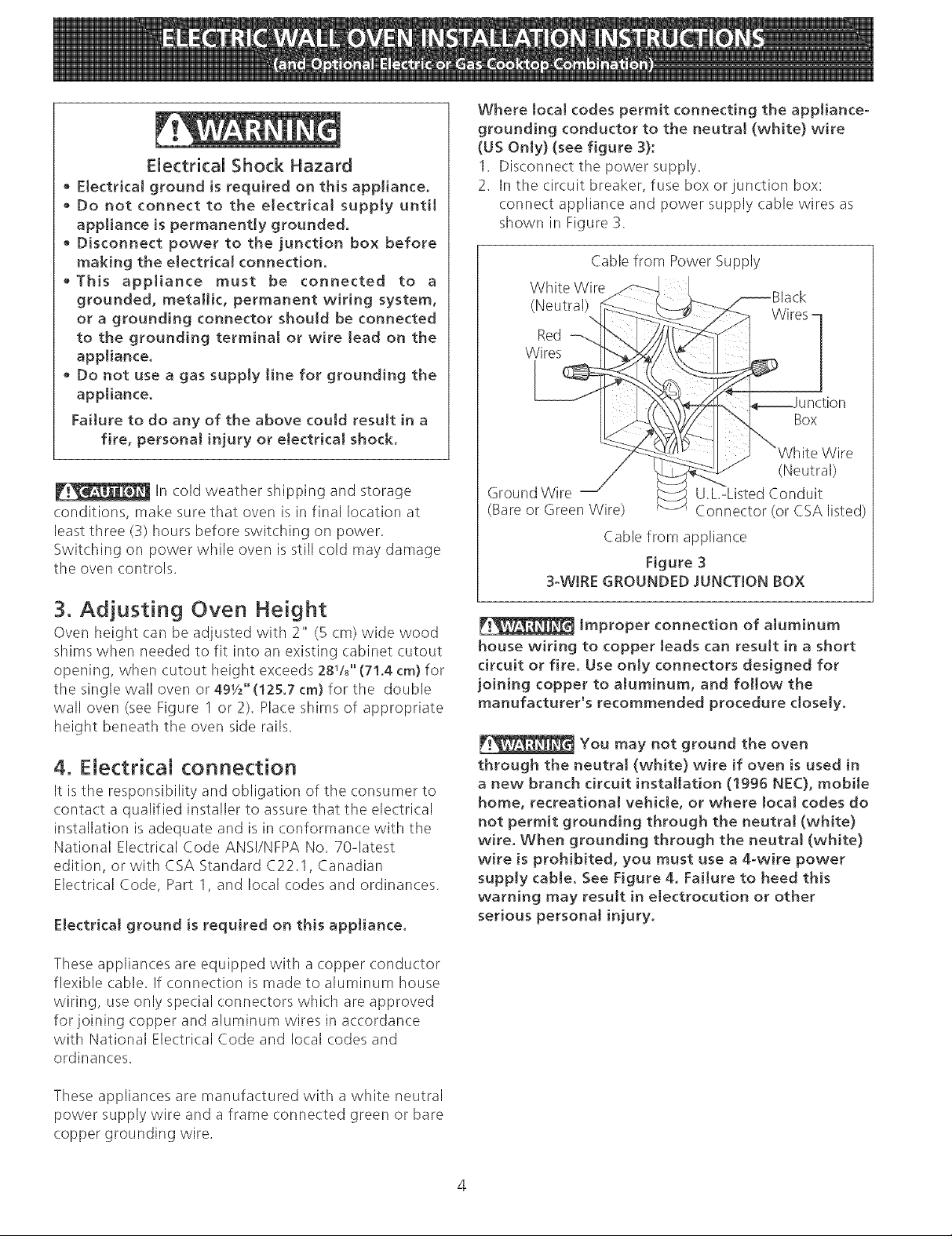

Electrical Shock Hazard

• E[ectrka[ ground [s required on this app!iance,

• Do not connect to the electrical supply until

appliance is permanently grounded,

• Disconnect power to the junction box before

making the eJectrkaJ connection,

• This appliance must be connected to a

grounded, metallic, permanent wiring system,

or a grounding connector should be connected

to the grounding terminal or wire lead on the

appliance.

• Do not use a gas supply line for grounding the

appliance.

Failure to do any of the above could result in a

fire, personal injury or electrical shock,

In cold weather shipping and storage

conditions, make sure that oven is in final location at

least three (3) hours before switching on power.

Switching on power while oven is still cold may damage

the oven controls.

Where local codes permit connecting the appliance-

grounding conductor to the neutra[ (white) wire

(US Only) (see figure 3):

1. Disconnect tile power supply.

2. In the circuit breaker, fuse box or junction box:

connect appliance and power supply cable wires as

shown in Figure 3.

Cable from Power Supply

White Wire

(Neutral)

%

Red

Wires

Wires [

Box

Wire

(Neutral)

Ground Wire U.L-Listed Conduit

(Bare or Green Wire) Connector (or CSA listed)

Cable from appliance

Figure 3

3-WIRE GROUNDED JUNCTION BOX

3. Adjusting Oven Height

Oven height can be adjusted with 2" (5 cm) wide wood

shims when needed to fit into an existing cabinet cutout

opening, when cutout height exceeds 28!/8" (71.4 cm) for

tile single wall oven or 491/2`'(125.7 cm) for the double

wall oven (see Figure 1 or 2). Place shims of appropriate

height beneath the oven side rails.

4. Electrical connection

It is the responsibility and obligation of the consumer to

contact a qualified installer to assure that the electrical

installation is adequate and is in conformance with the

National Electrical Code ANS!/NFPA No. 70qatest

edition, or with CSA Standard C22.1, Canadian

Electrical Code, Part 1, and local codes and ordinances.

Electrical ground is required on this appliance.

These appliances are equipped with a copper conductor

flexible cable. If connection is made to aluminum house

wiring, use only special connectors which are approved

forjoining copper and aluminum wires in accordance

with National Electrical Code and local codes and

ordinances.

__ Improper connection of aluminum

house wiring to copper leads can result in a short

circuit or fire. Use only connectors designed for

joining copper to aluminum, and follow the

manufacturer's recommended procedure dose[yo

You may not ground the oven

through the neutral (white) wire if oven is used in

a new branch circuit installation (1995 NEC), mobi[e

home, recreational vehicle, or where local codes do

not permit grounding through the neutra[ (white)

wire. When grounding through the neutra[ (white)

wire is prohibited, you must use a 4-wire power

supply cable. See Figure 4. Failure to heed this

warning may result in electrocution or other

serious personal injury.

These appliances are manufactured with a white neutral

power supply wire and a frame connected green or bare

copper grounding wire.

Page 5

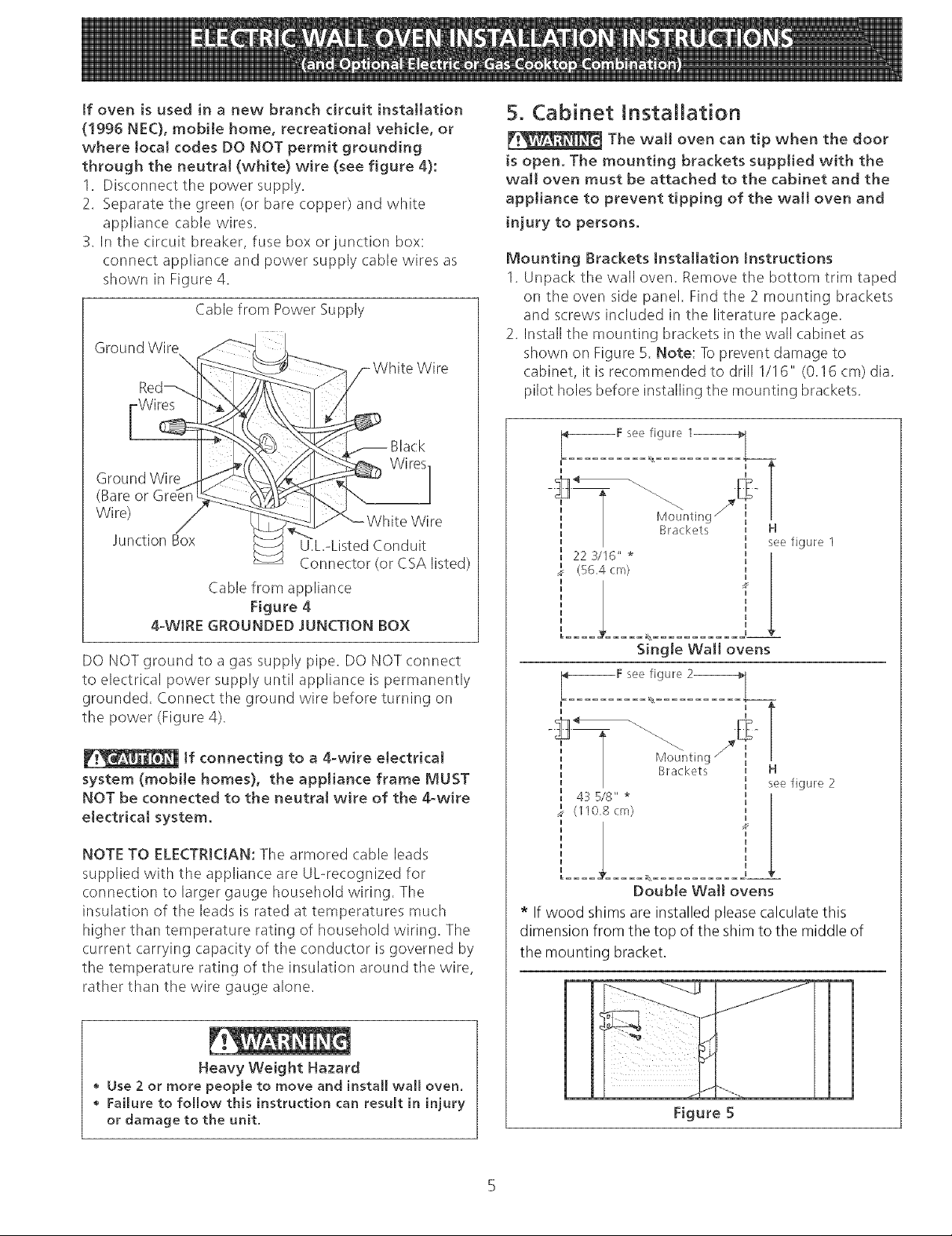

if oven is used in a new branch circuit installation

(!995 NEC), mobile home, recreational vehicle, or

where local codes DO NOT permit grounding

through the neutra! (white) wire (see figure 4):

1. Disconnect the power supply.

2. Separate the green (or bare copper) and white

appliance cable wires.

3. In the circuit breaker, fuse box or junction box:

connect appliance and power supply cable wires as

shown in Figure 4.

Cable from Power Supply

Ground Wire

Wire

Wires

Black

Ground Wire

(Bare or

Wire)

Junction Box

U.L.-Listed Conduit

Connector (or CSA listed)

Cable from appliance

Figure 4

4-WIRE GROUNDED JUNCTtON BOX

DO NOT ground to a gas supply pipe. DO NOTconnect

to electrical power supply until appliance is permanently

grounded. Connect the ground wire before turning on

the power (Figure 4).

5. Cabinet Installation

The wall oven can tip when the door

[s open. The mounting brackets supplied with the

wall oven must be attached to the cabinet and the

appliance to prevent tipping of the wall oven and

injury to persons.

Mounting Brackets Installation Instructions

1. Unpack the wall oven. Remove the bottom trim taped

on the oven side panel. Find the 2 mounting brackets

and screws included in the literature package.

2. Install the mounting brackets in the wall cabinet as

shown on Figure 5. Note: Toprevent damage to

cabinet, it is recommended to drill 1/16" (0.16 cm) dia.

pilot holes before installing the mounting brackets.

I XX

F see figure 1_

H

T

Mountinc

Brackets H

22 3/16" *

(56.4 cm)

Single Wall ovens

see figure 1

If connecting to a 4-wire electrical

system (mobile homes), the appliance frame MUST

NOT be connected to the neutrat wire of the 4-wire

electrical system.

NOTE TO ELECTRICIAN: The armored (:able leads

supplied with the appliance are UUrecognized for

connection to larger gauge household wiring. The

insulation of the leads is rated at temperatures much

higher than temperature rating of household wiring. The

current carrying capacity of the conductor is governed by

the temperature rating of the insulation around the wire,

rather than the wire gauge alone.

Heavy Weight Hazard

Use 2 or more people to move and install wall oven.

Failure to follow this instruction can result in injury

or damage to the unit.

Brackets

43 5/8" *

(110,8 cm)

H

see figure 2

Double Wail ovens

* If wood shims are installed please calculate this

dimension from the top of the shim to the middle of

the mounting bracket.

Figure 5

Page 6

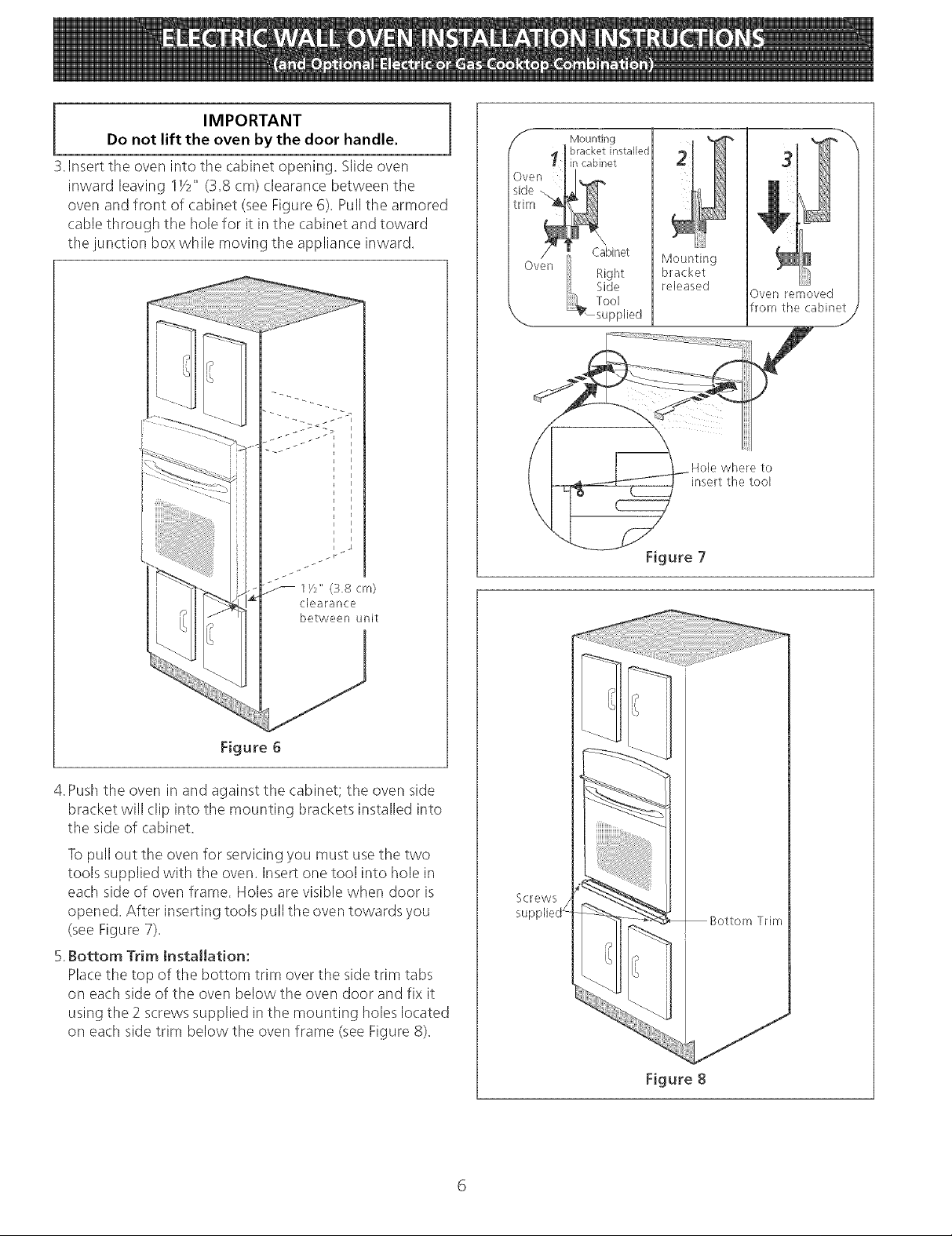

IMPORTANT

Do not lift the oven by the door handle.

3.Insert the oven into the cabinet opening, Slide oven

inward leaving IY2" (3,8 cm) clearance between the

oven and front of cabinet (seeFigure 6), Pull tile armored

cable through tile hole for it in tile cabinet and toward

tile junction box while moving the appliance inward.

S Mounting

Oven

side _,

trim _1

\--.. i_su pplied I

bracket installed

I I in cabinet

/_ Cabinet

Oven

Right

Side

Tool

Mounting

bracket

released

Hole where to

insert the tool

31

1

Oven removed

from the cabinet

J

1/_" (3.8 cm)

clearance

between unit

Figure 6

4.Push the oven in and against the cabinet; the oven side

bracket will clip into the mounting brackets installed into

the side of cabinet.

Topull out the oven for servicing you must use the two

tools supplied with the oven. Insert one tool into hole in

each side of oven frame. Holes are visible when door is

opened. After inserting tools pull the oven towards you

(see Figure 7),

5.Bottom Trim Installation:

Placethe top of the bottom trim over the side trim tabs

on each side of tile oven below the oven door and fix it

using the 2 screws supplied in tile mounting holes located

on each side trim below the oven frame (see Figure 8).

Figure 7

Screws

Figure 8

Page 7

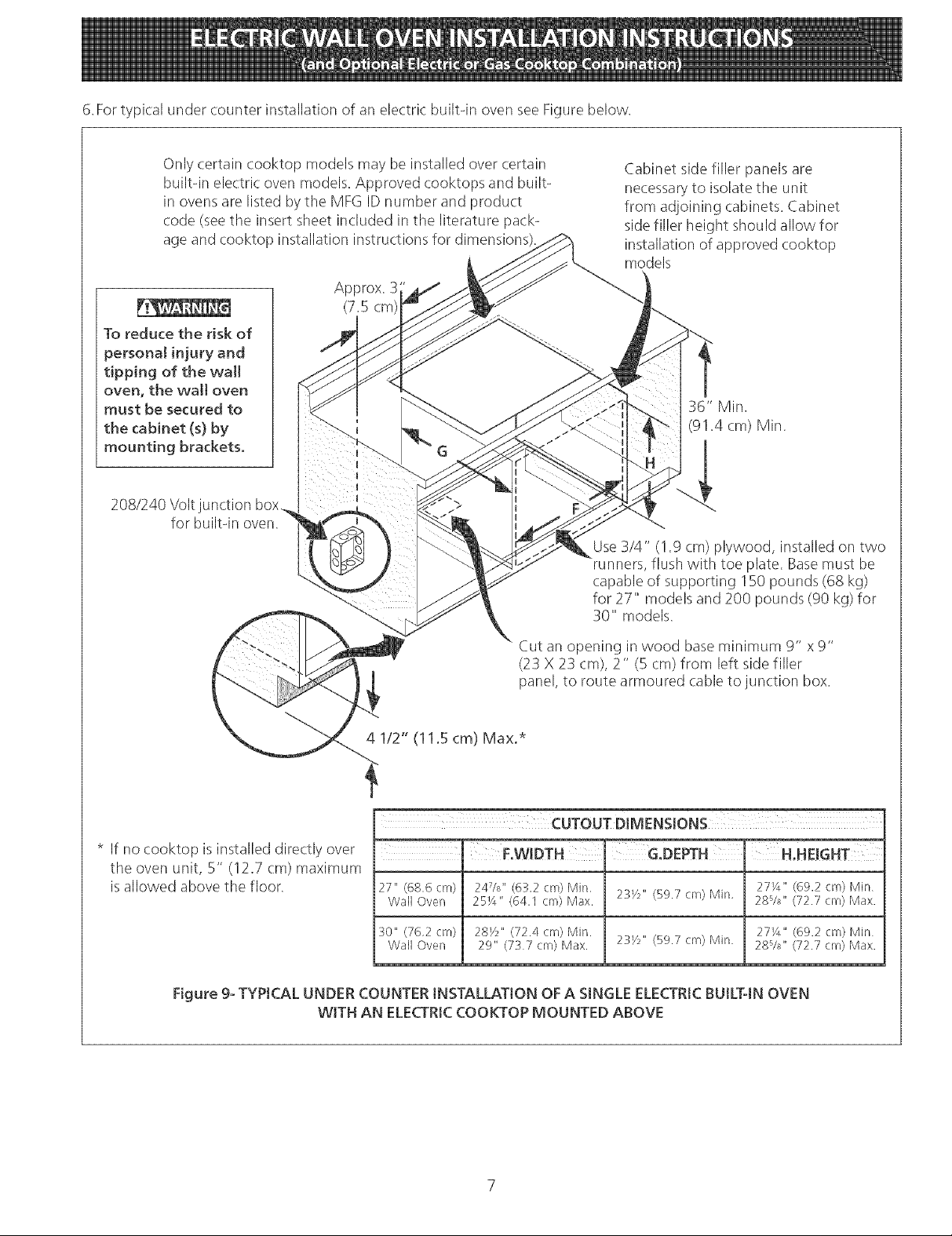

6.FortypicalundercounterinstallationofanelectricbuiltqnovenseeFigurebelow.

Onlycertaincooktopmodelsmaybeinstalledovercertain

builtqnele(tri(ovenmodels.Approvedcooktopsandbuilt-

inovensarelistedbytheMFGIDnumberandproduct

code(seetheinsertsheetincludedintheliteraturepack-

ageandcooktopinstallationinstructionsfordimensions

To reduce the risk of

personal injury and

tipping of the wa]l

oven, the walt oven

must be secured to

the cabinet (s) by

mounting brackets.

208/240 Volt junction box

for builtqn oven.

Cabinet side filler panels are

necessaryto isolate the unit

from adjoining cabinets. Cabinet

sidefiller height should allow for

installation of approved cooktop

models

Approx. 3

(7.5 cm)

36" Min.

(91.4 cm) Min.

4

Use3/4" (! .9 cm) plywood, installed on two

runners, flush with toe plate. Basemust be

capable of supporting 150 pounds (68 kg)

for 27" models and 200 pounds (90 kg) for

30" models.

* If no cooktop is installed directly over

the oven unit, 5" (12.7 cm) maximum

is allowed above the floor.

Figure 9- TYPICAL UNDER COUNTER INSTALLATION OFA SINGLEELECTRICBUILT-IN OVEN

WITH AN ELECTRICCOOKTOP MOUNTED ABOVE

Cut an opening in wood baseminimum 9" x9"

(23 X 23 cm), 2" (5 cm) from left side filler

panel, to route armoured cable to junction box.

4 1/2" (11.5 cm) Max.*

' F°WIDTH H,HDGHT

27" (68,6 cm) 24%" (63,2 cm) blin. 27X" (69.2 cm) Min

Wall Oven 25X" (64.1 cm) Max. 23Y2" (59.7 cm) Min, 28%" (72.7 cm) Max.

:10" (76,2 cm) 28Y2" (72.4 cm) Mir/. 27X" (69.2 cm) Min

Wall Oven 29" (737 cm) Max. 23_//' (59.7 cm) Min 28%" (72.7 cm) Max.

Page 8

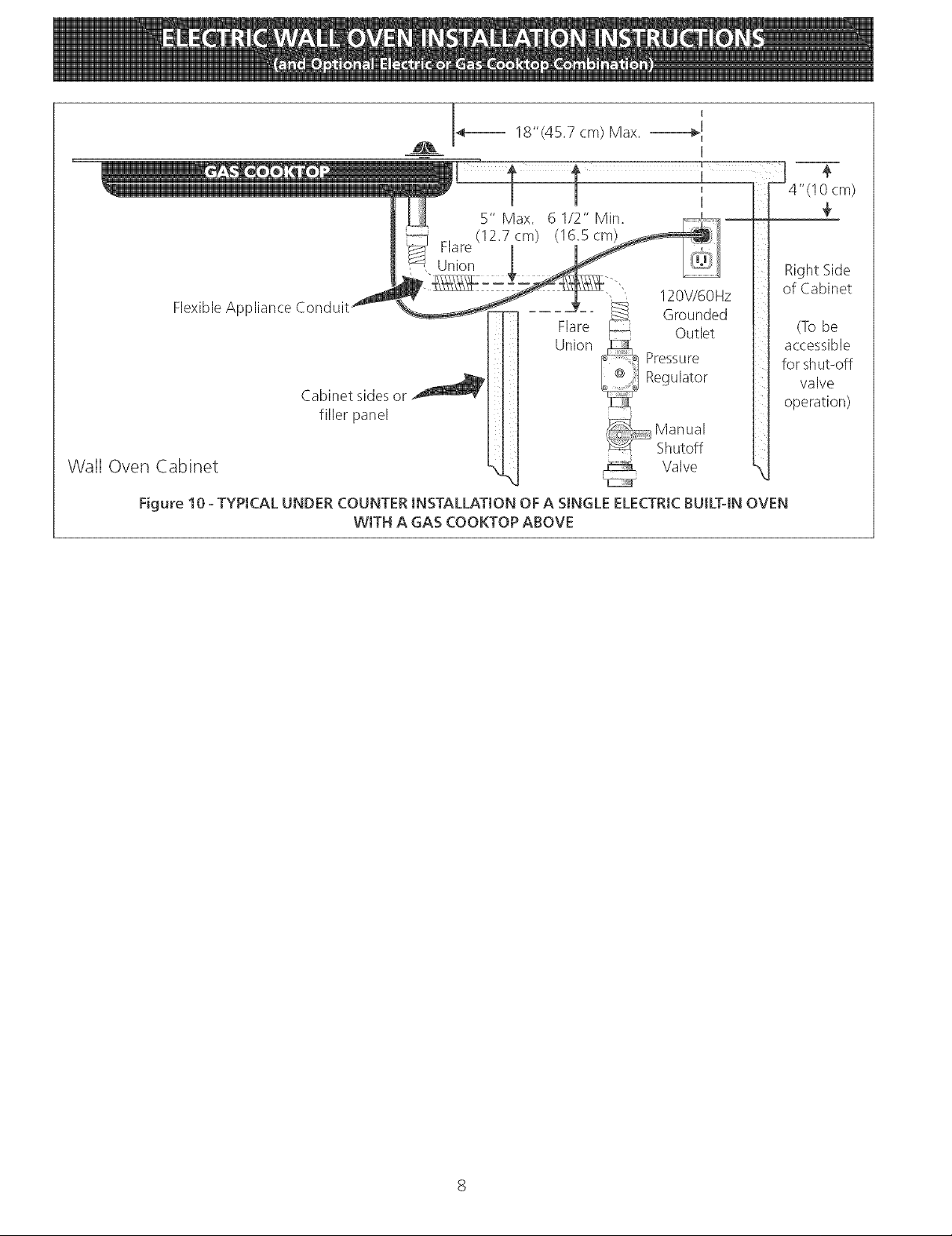

FlexibleApplianceConduit_

Wail Oven Cabinet

Figure 10 - TYPICAL UNDER COUNTER INSTALLATION OFA SINGLE ELECTRICBUILT-IN OVEN

__ 4---- 18"(4E7cm)Max.

fillerpanel

WITH A GAS COOKTOP ABOVE

Union

E

I1 Manual

Pressure

Regulator

Shutoff

Valve

cm)

Right Side

of Cabinet

(To be

accessible

for shut-off

valve

operation)

Page 9

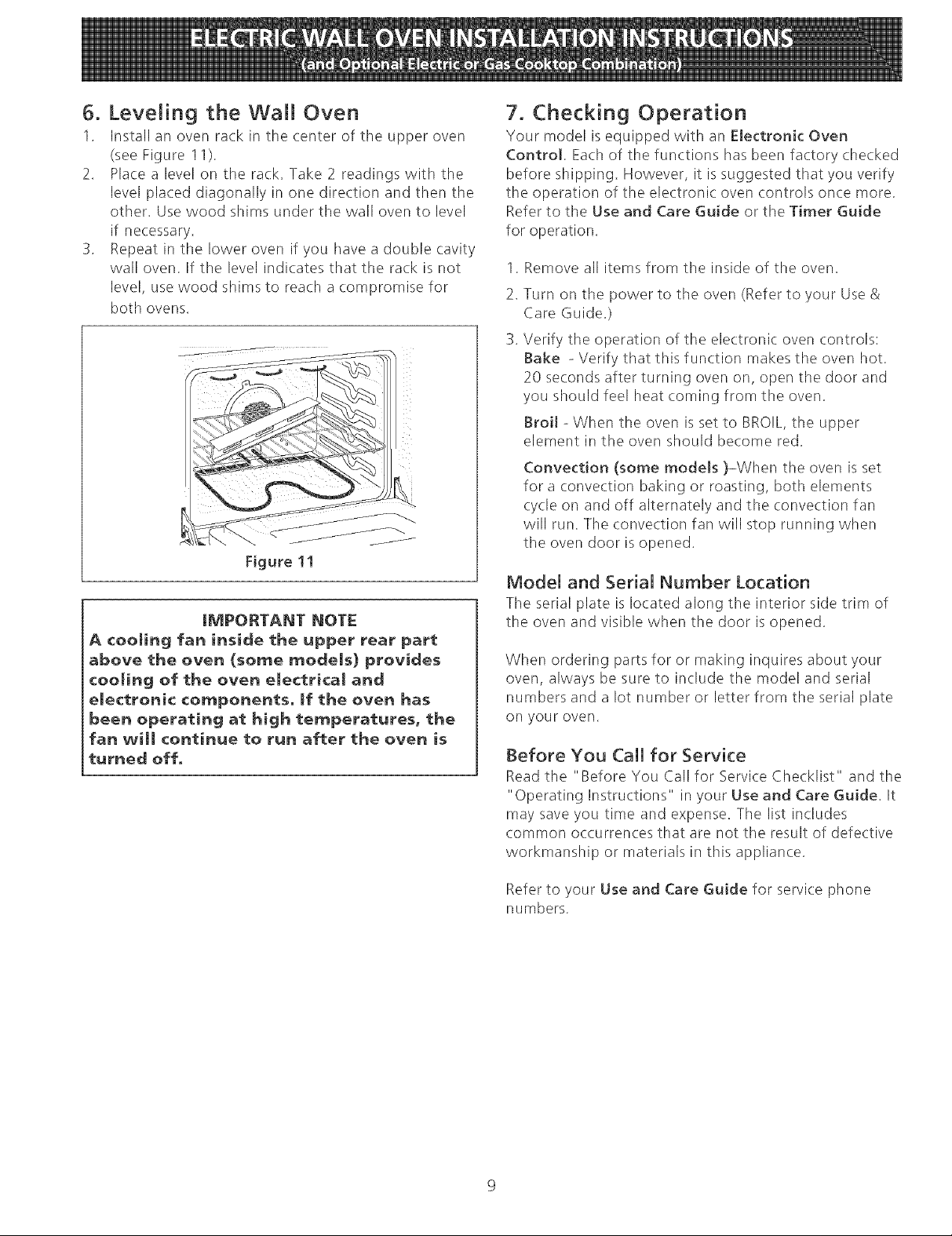

6. LeveJing the WaJJ Oven

1. Install an oven rack in the center of the upper oven

(see Figure 11).

2. Place a level on the ra(k. Take 2 readings with the

level placed diagonally in one direction and then the

other. Usewood shims under the wall oven to level

if necessary.

3. Repeat in the lower oven if you have a double cavity

wall oven. If the level indicates that tile ra(k is not

level, use wood shims to reach a compromise for

both ovens.

Figure 11

IMPORTANT NOTE

A ¢ooJing fan inside the upper rear part

above the oven (some modeJs) provides

¢ooJing of the oven eJectrical aria

eJectroni¢ components, If the oven has

been operating at high temperatures, the

fan will continue to run after the oven is

turned off,

7. Checking Operation

Your model is equipped with an EJectronic Oven

Control Ea(h of tile functions has been factory checked

before shipping. However, it is suggested that you verify

tile operation of the electronic oven controls once more.

Refer to the Use and Care Guide or the Timer Guide

for operation.

.

Remove all items from the inside of the oven.

2.

Turn on the power to tile oven (Refer to your Use &

Care Guide.)

Verify the operation of the electronic oven controls:

Bake - Verify that this function makes the oven hot.

20 seconds after turning oven on, open the door and

you should feel heat coming from the oven.

Broil - When the oven is set to BROIL,tile upper

element in tile oven should become red.

Convection (some models )-When the oven is set

for a convection baking or roasting, both elements

cycle on and off alternately and the convection fan

will run. The convection fan will stop running when

the oven door is opened.

Model and Serial Number Location

The serial plate is located along the interior side trim of

the oven and visible when tile door is opened.

When ordering parts for or making inquires about your

oven, always be sure to include tile model and serial

numbers and a lot number or letter from the serial plate

on your oven.

Before You Call for Service

Read the "Before You Call for Service Che(klist" and tile

"Operating Instructions" in your Use and Care Guide. It

may save you time and expense. Tile list includes

common occurrences that are not tile result of defective

workmanship or materials in this appliance.

Refer to your Use and Care Guide for service phone

numbers.

Page 10

LA iNSTALACiON Y EL SERViCiO DEBEN SER EFECTUADOS POR UN iNSTALADOR CALiFiCADO.

iMPORTANTE: GUARDE ESTAS iNSTRUCCiONES PARA USO DEL iNSPECTOR LOCAL DE

ELECTRiCiDAD. LEA Y GUARDE ESTAS iNSTRUCCiONES PARA REFERENCiA FUTURA.

PARA SU SEGURIDAD: No a[manece ni utHice gasolina u otros vapores y liquidos inflamables

en la pro×imidad de este o de cualquier otro artefacto.

El primer paso para su instaladbn debe de ser e[ de medir [as dimensiones de la apertura y compararlas con

las que se indican en el cuadro de dimensiones de[ hueco de la figura 1. Posib[emente encontrar_ que algQn

trabajo de carpinteria set& necesario.

No quite los separadores de los muros [atera[es o/y de [a parte posterior de[ homo

empotrado. Fstos espadadores centran e[ homo en e[ espado prov[sto. E[ homo debe estar centrado para

prevenir una concentraciOn excesiva de ca[or que podda resu[tar en da_os pot e[ caJor o un incendio.

NOTAS:

1. La base debe poder sostener 150 libras (68 kg) para los modelos 27"

y la base debe poder sostener 200 libras (90 kg) para los modelos 30".

2. Deie por Io menos 21" (53.3 (m) de espacio libre para la

profundidad de la puerta cuando esta abierta.

1S_" (3.8 cm)

Min.

3. La dimension G (profundidad del corte) esta

primordial para instalar correctamente C

el homo de pared. Si el adorno del

armazon del homo no topa contra el

?"

H

Orificio

para el

armario, o si es(u(he un ruido, verifique

si la dimension G est& en conform|dad

(.on la dimension requerida.

4. Paraun torte de una altura mayor que

281/8'' (71,4 cm) agregar una curia de

madera de 2" (5 cm) de ancho ..............

para Iograr la altura apropiada Puer{aAbierta

a cada lado del orificio ubicado (vea[a nora 2)

(69 1cm)

27 3/16" .._,..

31 "*

(787

Espaciador

debajo de los rieles laterales del accesorio.

5. MODELOS 30" SOLAMENTE: Para un corte \

de una altura (H} mayor que 28s/? ' (72.7 cm)

una moldura grande inferior puede set pedido

(.on su representante pide la parte #318259703

(para modelos blancos), 318259704 (modelos

negros), 318259705 (modelos bisque) o

318259707 (acero inoxidable modelos).

Figura !

Espaciador de Madera de de ernpalrne

(5 crn) de ancho, si es necesario

* Distancia sugerida desde el suelo es 31" (78.7 cm).

La distancia minima requerida es 4Y2" (I 1.4 cm).

Hornos simp[es de Pared de 27" y 30" (Para hornos dob[es, vet ta Figura 2)

elOtrica

DIM ENSIONES DELAPARATO

Homo de pared 27 (68.6) [ 27 (68.6) 29 (73.7) 24% (62 5) 24Y2 (62.2)

Horno de pared 30 (762) 1 30 (76.2) 29 (73.7) 28Y4 (71.8) 24V2 (62.2)

MODELO Ma×:I1 G(Mi":i. Ma×' 11

Horno de pared 27 (68.

Homo de pared 30 (76.2) 28V2 (72.4) 29 (73.7) 2312_(59.7) I 271A(69.2) 28% (727) 30% (765) Min

Todas lasdimensiones se dan en pulgadas (cm).

Imprimido en los Estados Unidos P/N 318201514 (0502) Rew E

6 247/8(63 2) 25 Y4(64 1)

> " 1 23122 (5g'7) 2"71_ (6g'2) 28%(727) I 27V_(68.g) Min

| i

English - pages I-9

Espat/ol - paginas I0-18

Francais - pages 19-28

Page 11

No quite los separadores de los muros [atera[es o/y de [a parte posterior de[ homo

empotrado. Estos espadadores centran e) homo en e) espado prov[sto. E[ homo debe estar centrado para

preven[r una concentration exces[va de ca[or que podda resu[tar en da_os pot e[ ca[or o un incend[o.

1_" (3.8cm)

i

B 48 5/8" H [ parael

_i_ (123.5 cm) Cable

......... /'t (29.2cm) [_L----__ Max

PuertaAbierta "_ _ ..... _3"_"--_/ _ 2"

(yea a nora 2) ...._ D_ Lspaciaqor _c_J _-(5 1 cm) _--

...... /- _..,o: 7 Caaeletricade

...... ;'_, _ Espac,ador de Madera de _"'_1 ,V_ ernpdme

A . v -

2" (5 cm) de ancho, si es

necesario

NOTES: 1 ,,

1. La base debe poder sostener 300 hbras (136 kg) para ". ..............

,os mode,os 27" y,a base debe poder sostener 375 '(tyf/_:j__lhagreagr2r,_miaa_X,m_,_er_laa)dre;a,_(_aZa _bda

. ) p g P P

hbras (!70 kg) para los modelos 30

- - • lado del orificio ubicado debajo de los rieles laterales

. 4 Paraun corte de una profundidad mayor que 49Y2

2. Deie pot Io menos 21 " (53.3 cm) de espacio libre del accesorio. ,,

paralaprofundidaddelapuertacuandoestaabierta. 5. IVIODELOS30 SOLAMENT, E:Parauncortedeuna

3. Ladimensi0nG(profundidaddelcorte) esta altura(H) mayorque497/s (126.Tcm) unamoldura

primordial para instalar correctamente el horno de grande inferior puede ser pedido con su

pared. Si el adorno del armazOn del homo no topa iepresentante.

(ontra el armario, o si escuche un ruido, verifique si

la dimension G esta en conforraidad con la dimension

requerida. ,, Figura 2

HORNOS DOBLES DE 27 Y 30 (Para homos simp[es, vet ta Figura 1}

Homo de pared 27 (686) 27 (686)

Horno de pared 30 (76.2) 30 (762)

50716 (128.1 ) 24% (62 5) 24Y2 (62 2)

50746 (128.1 ) 28¼ (71 8) 24Y_ (622)

MODELO I Minl F Max. I G(Min.) - Mira H Max. !

Homo de pared 27 (686) 247A (632) 251A (64.1)

Horno de pared 30 (76.2) 2@h(724) 29(737)

Todas las dimensiones se dan en pulgadas (cm).

23V2 (597) 48Vs (124 1)

23V2 (597) 487/s (124 1)

11

497/s (126 7) 271A (68 9) Min

497/s(126 7) 30Vs (76.5) Min

Page 12

Notas importantes para el instalador

1. Lea todas las instrucciones contenidas en este manual

antes de instalar el homo,

2. Saque todo el material usado en el embalaje del

compartimiento de! homo antes de conectar el

suministro electrico o de gas a la estufa.

3. Observe todos los c6digos y reglamentos pertinentes.

4. Deje estas instrucciones con el consumidor,

5. La puerta del homo se puede retirar para facilitar la

instalacion.

6. ESTE HORNO NO ESTA APROBADO PARA LA

INSTALACI6N APILABLE O DE LADe A LADe.

Nota importante al consumidor

Conserve estas instrucciones y e! manual del usuario para

referencia futura.

IMPORTANTES DE SEGURIDAD

Asegurese de que su homo de pared sea instalado

y puesto a tierra de forma apropiada per un

instalador calificado o per un t_cnico de servido.

• Este homo de pared debe ser el&ctricamente

puesto a tierra de acuerdo con los c6digos locales

o, en su ausenda, con el C6digo El&ctrico National

ANSt/NFPA No. 70-ultima edici6n en los Estados

Unidos, o el C6digo Electrico Canadiense CSA

Standard C22.1, Part 1, en Canad&.

__ Pisar, apoyarse, o sentarse sobre [a

puerta de este homo de pared puede causar serias

[esiones y da_os a[ homo de pared.

• Nunca use su homo de pared para calentar una

habitad6n. El use prolongado de la estufa sin la

ventilaci6n adecuada puede set peligroso.

La corriente etectrica a[ homo debe

estar apagada mientras se hacen [as conexiones de

[ineas. Si no seapaga, da_os series o [a muerte

podrian resultar.

1. Carpinteria

Consulte la Figura 1 o la figura 2 para conocer las dimen-

siones pertinentes al modelo de su homo y al espacio

necesario en el que poner el homo, La superficie donde se

va a apoyar e! homo debe de ser de madera

contrachapada sOlida u otro material similar y, sobre todo,

la superficie tiene que estar a nivel, de lade a lade, y de

atr3s hacia adelante.

2. Requisites Electricos

Este artefacto debe ser suministrado con e! voltaje y la

frecuencia adecuados, y conectado a un circuito

individual correctamente puesto a tierra, protegido per

un cortacircuito o un fusible con el amperio anotado en

la plata de calificaciOn (la plata se encuentra en el

armazOn del homo).

Cumpla con todos los c6digos en vigor y todos los re-

glamentos locales.

1. Para e! suministro electrico solamente se necesita

corriente con frecuencia de 60 Hz AC y fase 0nica de

120/208 o 120/240 voltios suministrada per cable de 3 o

de 4 alambres en un circuito separado con fusibles en

ambos lades de la linea (se recomienda un fusible de

tiempo retardado o un cortacircuito). NO ponga un

fusible en hilo neutro, El tamable de! fusible no tiene que

exceder la capacidad del circuito necesario para el

electrodomesticos y la cual se especifica en la placa.

S61o ciertos modelos de tapas de cocina se pueden

instalar sobre ciertos modelos de hornos electricos

empotrados, Las tapas de cocina y los homes empotra-

dos se mencionan per su n0mero de identificaci6n MFG

ID (ver la planilla que se incluye en el paquete de

literatura),

2. El horno simple de pared puede consumir un m_iximo de

4000W a 240Vat, Use un disyuntor de 30 amperes con

un cable #8 AWG, El homo doble de pared puede

consumir un m_iximo de 8000W a 240Vat, Use un

disyuntor de 40 amperes con un cable #8 AWG,

NOTA: El tamaFlo de los cables y de las conexiones debe

de estar en conformidad con el tamJ_o de! fusible y con la

capacidad del electrodomesticos y de acuerdo con el

COdigo Electrico Naciona! ANS!/NFPA No, 70 - 01tima

edici6n, o el C6digo Electrico Canadiense CSA Standard

C22.1, Part 1, y los c6digos y reglamentos locales.

No se debera usar extensiones para

enchufar este electrodomestico. Esto podrla causar

un incendio, cheque electrico u otro tipo de daffo

personal. Si usted necesita un cable mas largo, puede

ordernar un cable de 10" kit 903056-9010 Ilamando a!

centre de Partes y Servicion Sears al 1-888-SU-HOGAR sM.

3. Este electrodomestico debe conectarse a la caja de

fusibles (o de cortacircuito), per medio de un cable

blindado flexible o un cable con forro no met_ilico, El

cable blindado flexible que va desde e! electrodomestico

debe de estar conectado directamente a la caja de

empalme, La caja de empalme debe de estar Iocalizada

en e! lugar que se indica en la Figura 1 o 2, dejando

tanto exceso de cable come sea posible entre la caja y

el electrodomestico, de forma que asi el electrodomesti-

co se pueda mover f_icilmente, si fuera necesario para

hater una reparaci6n,

4. Se debe de usar un conector que reduzca la tirantez de

una forma adecuada para unir el cable blindado flexible

a la caja de empalme.

12

Page 13

Riesgo de choque el6ctrico

o Una puesta a tierra se require en este aparato.

o No 1o conecte a [a corriente el_ctrka hasta que

el aparato haya sido puesto a tierra.

, Desconecte [a corriente el_ctrka a [a ca]a de

empalmes antes de hater [a conexi6n etectrica.

Este aparato debe estar conectado con un

sistema de alambres puesto en tierra, met_[ico

y permanente o un conector de pueta a tierre

debe conectarse a[ terminal de puesta a tierra

o el alambre conductor en a[ aparato,

No utilke el suministro de gas para hacer Ja

puesta a tierra.

La faJta de cualquiera de [as instrucdones

mendonadas podria resultar en un incendio,

choque etectrko o lesiones personales.

En cuanto a las condiciones de despacho

y almacenamiento en el invierno, asegOrese de que el

homo Ilegue a su destino final como minimo tres (3)

horas antes de encenderlo. Si se enciende el homo

cuando alan esta ffio, se pueden dafiar los controles.

3. Ajuste de la altura del horno

La altura del homo se puede ajustar con cufias de madera

de 2" (5 cm) de ancho, donde sea necesario, para que

quepa en un gabinete o abertura existente, cuando la

altura del corte es superior a 281/? ' (71,4 cm) en el caso

del homo Oni(o de pared o 49W' (!25.7 cm) en el caso del

homo doble de pared (ver la Figura 1 6 2). Colocar las

cu_ias de altura apropiada debajo de los rieles laterales del

horno.

Donde los c6digos locales permitan conectar e[

conductor de puesta a tierra de[ e[_ctrodom_stico a[

neutral (blanco) (Solament en los Estados Unidos}

(yea figura 3}:

(Un cordon flexible o cable de 3 conductores debe de ser

reemplazado con un cordon flexible o cable de 4 conducto-

res donde la conexi6n del conductor a tierra al neutro esta

prohibida en las nuevas instalaciones (1996 NEC), las casas

sobre ruedas, los vehk:ulos de recreaci6n o otras areas

donde los c6digos locales no permiten la conexion a tierra

al neutro.)

1. Desconecte el suministro electrico.

2. Enel interruptor automatico, caja de fusibles o caja de

juntas; conectar el aparato y los cables residenciales

como se muestra en lafigura 3.

Cable desde el suministro de energla

Alambre

desnudo

negros

Alambre

rojos

ija de

empalmes

desnudo

Alambre verde

o desnudo

uni6n listado-UL

(o CSA)

Cable de la estufa

Figura 3 - CAJA DE EMPALMES

DE 3 ALAMBRES PUESTA A TtERRA

4. Conexi6n el@ctrica

El usuario tiene la responsabilidad personal y obligaci6n

de utilizar un instalador calificado, para asegurar que la

instalaci6n electrica est4 hacha de forma adecuada y

est4 conforme con e! C6digo Electrice Nacional ANS!/

NFPA No. 70-01tima edici6n en los Estados Unidos, o e!

C6digo Electrico Canadiense CSA Standard C22.1, Part

1, en Canada.

En este eJectrodomestico se necesita un cable de

toma a tierra.

Este electrodomestico viene equipado con un cable de

conexi6n de cobre. Si esto tuviera que conectarse a los

cables de aluminio de una casa, use solamente los

conectores especiales aprobados para empalmes de

cobre y aluminio, de acuerdo con el C6digo Electrico

Nacional y los reglamentos y c6digos locales,

Este electrodomestico se ha fabricado con un cable para

e! suministro de energia que tiene un alambre neutro de

color blanco y un alambre pelado de toma a tierra

conectado al armaz6n.

Una conexi6n incorrecta de[

alambrado de aluminio con los conductores de cobre

puede resuJtar en un cortacircuito o incendio. Use

so[amente los conectores dise_ados para juntar el

cobre con e[ aiuminio y siga exactamente et

procedimiento recomendado pot el fabdcante.

No se puede conectar a tierra et

homo a trav&s del cab[e neutral (blanco) si e[ homo

es usado en una instalaci6n de circuito de ramaJ

nuevo (!996 NEC), en una casa rodante, en un

vehkulo para recreaci6n o si los c6digos locales no

permiten ta conexi6n a tierra a trav6s de[ cabJe

neutral (blanco). Si est_ prohibida ta conexi6n a

t[erra a trav_s de[ cable neutral (b[anco}, se debe

usar un cable de a[[mentaci6n de 4 h[[os. Vet [a

Figura 4. Si no se observa esta advertenda, esto

puede resu[tar en e[ectrocuci6n o en otra [esi6n

personal grave.

13

Page 14

Si el horno se usa en una instalaci6n de circuito de

ramal nuevo (1996 NEC), en una casa rodante, en un

vehiculo para recreaci6n o si los c6digos locales NO

permiten la conexi6n a tierra a trav6s del cable

neutral (blanco) (ver figura 4):

1. Desconecte el suministro el6ctrico

2. Separe el alambre verde (o cobre desnudo) y el

alambre blanco del electrodomestico.

3. En el interruptor automatico, caja de fusibles o caja de

juntas: conectar el aparato y los cables residenciales

como se muestra en lafigura 4.

Cable desde el suministro de energia

Alambre

desnud°X'q_------..____-"-_--__ Alambre blanco

Alambre b. /

5. lnstalaci6n del Gabinete

El homo de pared puede incJinarse

cuando la puerta esta abierta. Los soportes de

montaje que vienen con et homo de pared deben de

estar ajustadas aJ armario y al aparato para evitar

que el homo de pared se incline y ocasione

quemaduras graves.

Instrucciones de instalaci6n de los soportes de

montaje

1. Desembalar el homo de pared. Extraer la guamici6n

inferior y los 2 tomillos unidos con cinta al panel lateral

del homo. Buscar las dos soportes de montaje y los

tomillos que se incluyen en el paquete de literatura.

2. Instate los soportes de montaje como en la figura 5. Nota:

Para prevenir cualquier tipo de daho al cabinete es

recomendable perforar agujeros corm un diametro de

1/16" (0,16cm) antes de instalar los soportes de montaje.

AlambreI" --Alambre

verdeo l____(\\/z: / L_ negros

. , / _ "-- Alambre blanco

Caja de _ "Conductor de uni6n

empalmes listado-UL (o CSA)

Cable de la estufa

Figura 4- CAJA DE EMPALMES

DE 4 ALAMBRES PUESTA A TIERRA

NO conecte el alambre puesto a tierra a una tuberia de

suministro de gas, NO conecte el suministro de energfa

electrica hasta que el electrodomestico haya sido

permanentemente puesto a tierra. Conecte el alarnbre de

puesto a tierra antes de enchufar por primera vez el

electrodomestico.

Si est_ conectado a un sistema

el_ctrico de 4 alambres, el armazbn del

electrodomestico NO TIENE QUE estar conectado al

aJambre neutro del sistema el_ctrico de 4 alambres.

NOTA AL ELECTRICISTA: Los conductores de cable

blindados provistos con este artefacto son aprobados por

UL para la conexiOn al alambrado de casa de un calibre

mayor, El aislamiento de los conductoresesta _ calificado

para temperaturas m_s altas que las del alambrado de

la casa. La capacidad de corriente del conductor esta_

gobernada por la calificaciOn de la temperatura de!

aislamiento alrededor del alambre en vez de solamente

e! calibre de! alambre.

_F veafigura

H

H

T

de

22:1/16" *

(56.4 cm)

Homo de pared simpte

_i;itiigura 2_

<H mj

H

yea figura 1

T

| Soportes de

/ montaje

43 5/8" *

(110 8 or'n)

Homo de pared dobte

* Si hay instaladas cufias de madera, calcular esta

dimensi6n desde la parte superior de lacuria hasta el

medio del soporte de montaje.

H

yea figure 2

Peligro de Peso Pesado

, Use 2 personas o m&s para mover e instalar el homo

de pared.

Si no ¢umpJe con esta instrucci6n, puede resuJtar

en Jesiones pesonaJes o daSos aJ homo de pared

Figura 5

14

Page 15

IMPORTANTE

No levante et homo pot la manija de la puerta.

3.1nsertar el horno en la abertura del gabinete. Deslizar el

homo hacia dentro dejando lY2" (3,8 cm) de espacio

libre entre el homo y la parte delantera del gabinete (ver

la Figura 6). Empujar el cable blindado a traves del

orifido del gabinete y hacia la caja de paso mientras se

desliza el accesorio hacia adentro.

Soporte de

Bracket1 instaadoene

del - / gabinete

horn_ _\

Homo Lateral

\ _incluida I

monta e

/_ inete

I_ derecho

_-_rra mienta

soporte de

montaje

liberado

Introduzca la

el electrodomestico en

el hoyo.

Figura 7

Horno retirado

del gabinete

que trae

I/2" (38 cm)

distanda entre la

unidad y el gabinete

Figura 6

4.Empujar el horno hacia adentro yen contra del gabinete;

la mensula lateral del homo enganchara en lossoportes

de montaje instalados en el costado del gabinete.

Rata extraer el homo en casode reparaci6n, usar lasdos

herramientas provistas con el horno. Insertar una

herramienta en el orificio a cada costado del marco del

homo. Los orificios sepueden vet cuando la puerta est&

abierta. Despues de insertar las herramientas, extraer el

homo hacia fuera (ver la Figura 7).

5.tnstalad6n de la Guamid6n Inferior:

Colocar la parte superior de la guarnici6n inferior sobre

las lengOetas laterales del homo, debajo de la puerta del

homo, y fijarlas usando los 2 tornillos provistos con los

orificios de montaje ubicados acada lado del marco del

homo (ver la Figura 8).

Tornillos

I

Suarnicion

Inferior

Figura 8

15

Page 16

6. Para una instalaci6n tfpica de un homo el6ctrico incorporado debajo del mostrado< ve_ise la figura 9.

$6!o ciertos modelos de tapas de cocina se pueden instalar

sobre ciertos modelos de hornos electricos empotrados, Las

tapas de cocina y los hornos empotrados se mencionan pot su

n0mero de identificaci6n MFG ID y c6digo de producto (vet la

planilla que se incluye en el paquete de literatura y las

instrucciones de instalaciOn de la cocina donde est3n detalladas

las dimensiones).

Approx. 3"

Para reducir eJ riesgo de

lesiones personates y

inclinad6n de! homo de

pared, 6ste debe

asegurarse a Jos

gabinetes mediante

soportes de montaje.

208/240 caja de empalme

para hornos de pared

(7.5cm)

Lospaneles de relleno laterales del

gabinete son necesarios para aislar

la unidad de los gabinetes

adyacentes. La altura del relleno

lateral del gabinete debe permitir

la instalacion de modelos de tapas

de cocina aprobados.

36" Min.

(91.4 cm) Min.

4

Instalecontrachapado de 314" (I .9 cm)

sobre dos correderas, nivelado con la parrilla

inferior. Labasedebe poder sostener 150

libras (68 kg) para los modelos 27"y 200

libras (90 kg) para losmodelos 30".

* Si no se instala ninguna tapa de

cocina directamente sobre la unidad

del homo, sepermite un espacio

m_ximo de 5" (I 2,7 cm) sobre el

piso.

Figura 9 - tNSTALAClON T[PtCA DEBA]O DE LA MESADA DE HORNO SIMPLE EMPOTRADO

Corte una abertura de 9" X 9"(23 cm X 23 cm)

(minimo) en el fondo del contrachapado, a 2" (5

cm) del lado izquierdo del panel Ilenador, para

poder encaminar el cable a la caja de empalme.

4 1/2" (11.5 cm) Max.*

DIMENSIONES DE ABERTURA

F.ANCHURA iG. PROFUNDtDAD H. ALTURA

27" (68.6 ¢:m) 247_¢' (63.2 cm) Mir/, 23Y2" (59.7 era) Min. 27Y4" (69.2 cm) Min.

Homo de pared 25¼" (64.1 cm) Max 28s/8''(727cm) Max

30" (76.2 cm) 28Y/' (72,4 cm) Min. 23Y/' (59.7 cm) Min. 27Y4" (69.2 cm) Min.

Homo de pared 29" (7:<7 cm) Max 28s/s'' (727 cm) Max

CON TAPA DECOClNA MONTADA

16

Page 17

Gabinete deI homo de pared

Figura 10 - tNSTALACtON TJPICA PARA UNA ESTUFA DE GAS ENCIMA

DEUN HORNO DE PAREDtNSTALADO DEBAJO DELMOSTRADOR

gabinete o panel

Ilenador

m18"(45.7 cm) Max. ----_I

1

Valvula

de cierre

manual

4"(!0 cm)

Lado

derecho del

gabinete

(para tener

acceso a la

valvula de

cierre

manual)

17

Page 18

6. Asegurese de que el horno de

pared esta a nivel

1. Instale una rejilla al centro del horno superior (yea la

Figura 11).

2. Ponga un nivel pot encima de la reiilla. Lea2 veces, una

vez (:on el nivel a la posici6n de lado a lado, y otra vez

de atras hacia adelante. Utilice trozo de madera o cu-

¢_aspot debajo del homo de pared para nivelar, si sea

necesario.

3. Vuelve a empezar en el homo inferior. Si el nivel mues-

tra que la rejilla no esta a nivel, utilice trozo de madera

o cufias para componer ambos hornos.

Figura 11

IMPORTANTE

Un ventilador ubicado dentro de la parte

trasera superior arriSa del homo (en

algunos modelos) permite la refrigeraci6n

de los ¢omponentes el_ctricos y

electr6nicos de enfriamiento. $i el homo

ha estado funcionando a altas

temperaturas0 el ventilador seguir&

funcionando despu_s de apagar el homo.

7. Verificaci6n del funcionamiento

Su modelo esta equipado con un Control Electr6nico de

Horno. Cada una de las funciones ha sido controlada en

fabrica antes del despacho. Sin embargo, le sugerimos

verificar elfuncionamiento de los controles electr6nicos

una vez mas. Consulte la Guia de Uso y Cuidado o la

Guia del controles para vet elfuncionamiento del homo.

1. Extraer todos los elementos de la parte interior del

homo.

2. Encender el homo (Consular la Guia de Uso y Cuidado.)

3. Verificar el funcionamiento de los controles electr6nicos

del homo:

Hornear - Verificar que estafunci6n caliente el homo.

Veinte minutos despu6s de encender el homo, abrir la

puerta y vet si se siente que el calor emana desde su

interior.

Asar- Cuando se pone el homo para asar, el

elemento de arriba del homo debe de ponerse rojo.

Convecci6n (aJgunos modelos) - Cuando se configu ra

el homo para horneado o asado pot convecci6n, losdos

elementos se encienden y apagan en forma alterna y se

enciende el ventilador. Elventilador de convecci6n

dejar_ de funcionar cuando seabre la puerta del horno

durante el horneado o asado pot conveccion.

Ubicacion del numero de modelo y de serie

La placa con el numero de serie esta ubicada en la

guarnici6n interior lateral del homo y se puede vet cuando

se abre la puerta.

Cuando haga pedidos de repuestos o solicite informacion

con respecto a su homo, est6 siempre seguro de incluir

el n0mero de modelo y de serie y el n0mero o letra del

lore de la placa de serie de su horno.

Antes de llamar al servicio

Lea la secci6n Lista de Control de Averlas en su Manual

delUsuario. Estolepodraahorrartiempoygastos. Esta

lista incluye ocurrencias comunes que no son el resultado

de defectos de materiales o fabricacion de este

artefacto.

Lea la garantia y la informaci6n sobre el servicio en su

Manual de! Usuario para obtener el nOmero de

telefono gratuito.

18

Page 19

L3NSTALLATION ET L'ENTRIETIEN DOIVENT I_TRE IEFFECTUI_SPAR UN INSTALLATFUR QUALINI_.

iMPORTANT : CONSERVEZ POUR L'INSPECTEUR D'[_LECTRICIT[_ LOCAL.

USEZ ET CONSERVEZ CES INSTRUCTIONS POUR R[':'FI_RENCESULT[_RIEURES.

__ POUR VOTRE SI_CURJTI_: N'entreposez pas ou n'utiiisez pas d'essence ou d'autres produits

inflammables _ proximit6 de cet apparei[ ou de tout autre apparei[ _[ectrom6nager.

Votre nouveau four encastr_ a _t6 con_u pour s'ajuster &diff_rentes dimensions de d_coupage et en

faciliter I'installation. La premiere _tape de votre installation cons[ste & mesurer [es dimensions du

d6coupage actue[ et, & [es comparer au tableau de dimensions de d6coupage d-dessous. Vous d6couvrirez

peut-6tre que peu ou pas de modification sera n6cessaire.

[F_ N'en[evez pas [es entretoises sur [es patois [at_ra[es et!ou & ['arriere du four. Ces entretoises

centrent[efourdans['espacefourni. Lefourdoit_trecentr_pourpr6venir uneaccumu[ationexcessivede

cha[eur pouvant causer un feu ou des dommages,

NOTE:

l. La Base doit pouvoir supporter 150 Ibs (68 kg) pour [es modeles 27"

et 200 Ibs (90 kg) pour les modeles 30"

2.AIIouez au moins 21 " (533 cm) d'espace a I'avant du four pour permettre

I'ouverture complete de la porte du four

3. La dimensionG(profondeurdudecoupage) _ C,

est critique pour une bonne installation du

four Sila moulureinf6rieuredufour ne

vient pas s'accoter contre I'armoire, ou si

un bruit se fait entendre sur [es modeles

convection, v6rifiez la dimension G pour

vous assurer qu'elle est correcte_

4. Si la hauteur de decoupage est plus grande .--

que 281/8" (71.4 cm), ajoutez ............

une entretoise de bois de 2" Porte ouverte

(5cm) de largeur et de hauteur (voir note 2)

appropri6e de chaque c616 de

I'ouverture sous ['appareiL

5. MOD_:LES 30" SEULEMENT: Si [a hauteur de d6cou

(H) est plus grande que 288/8" (72.7 cm), vous pouvez

commander une mouJure inf6rieure plus large en

contactant un Centre de service et demandant Ja piece

#318259703 (pour les mod@les bJancs), 318259704 (pour

[es modules noirs), 318259705 (pour [es modeles biscuits) *

ou 318259707 (pour [es mode[es en acier inoxydable)

Figure 1

Fours encastr6s simp[es 27" et 30" (Pour tes fours encastr6s doubles voir ta figure 2)

DIMENSIONS DE L'APPARE[L

1_'5"(3.8 cm)

IVlin

Ouverture

?"

pourla

sortie du

H

27 3/I 6" |

(691 cm)

,<

3! "*

(78=7

Botte de

Entretoise de bois de 2"

(5 cm) de largeur si n6cessaire

La distance suggeree du plancher est 31 " (78_7 cm)

La distance minimale requise est 4V2" (11,4 cm)_

jonction

_MODELE _,lin: F Ma×i G(Minl)Mi- H Ma×' _

Four encastre 27" (6 . " ) " • • 231/2 (597) 27V_ (692) 28s/8 (727) 27% (68.9) Min

8 6 cm 247/8 (63 2) 25V4 (64 1)

ourer, a re 0/TB cm/128v /724/29/73 /I 127 2 / g2/28 ,8/ 2 /I30' sITB.% ,n

Toutes [es dimensions sont en pouces (cm)

Imprimeaux Etats-Unis

P/N 318201514 (0502) Rev

English - pages 1-9

Espaflo[ - pBginas 10-18

Francais - pages 19-28

Page 20

N'enJevez pas tes entretoises sur Jes patois tat_rales et/ou _ J'arri_re du four, Ces

entretoises centrent Je four dans J'espace fourni, Le four doit _tre centr_ })our pr_venir une

accumuJation excessive de chaleur pouvant causer un feu ou des dommages,

_GYl

Ouverture

pour la

sortie du

c_ble

i

_.

Porte ou,derte

_..-

(volt note 2)

_j_D Entretoise de bois de

_'_ si n6cessaire

2" (5 cm) de largeur

NOTES:

1.La Basedoit pouvoir supporter 300 Ibs (136 kg) pour

les modeles 27" et 375 Ibs pour les modeles 30".

2.AIIouez au moins 21" (53.3 cm) d'espace a I'avant

du four pour perrnettre I'ouverture complete de la

porte du four.

3.La dimension 6 (profondeur du d6coupage) est

critique pour une bonne installation du four. Si la

moulure inferieure du four ne vient pas s'accoter

contre I'armoire, ou si un bruit se fait entendre sur

les modeles a conve(tion, verifiez la dimension 6

pour vous assurer qu'elle est correcte. Figure 2

Fours encastr_s doubles 27" et 30" (Pour tes fours encastr_s simpJes voir ta figure 1)

DIMENSIONS DE L APPAREIL

3" (7.6 cm)

Max,

de jonction

4. Si la hauteur de decoupage est plus grande que

491/2"(!25.7 cm), ajoutez une entretoise de bois de

2" (5 cm) de largeur et de hauteur appropri6e de

chaque c6t6 de I'ouverture sous I'appareil.

5. MODELES 30" SEULEMENT: Si la hauteur de

decoupage (N) est plus grande que 497/8" (126.7

cm), vous pouvez commander une moulure

inferieure plus large en contactant un Centre de

service.

B I :c | D

Fours encastres 27" (68.6 cm) 27 (68.6) 507//6 (128.1) 24/s (625) / 24Y_ (62.2)

Fours encastres 30" (76.2 cm) 30 (76.2) 507/16 (128.1) 28¼ (71.8) _ 24Y2 (62.2)

Min:,

Foursencastres30" (76.2cm) 28Y_(724) I 29(73 7) I 23Y2(597) I 48%(124 1)! 497/s(126.7) 30% (76 5)Min

Toutes les dimensions sont en pouces (cm)

2O

Page 21

1. Liseztouteslesinstructionscontenuesdanscefeuillet

avantd'installationdefourencastre.

2. Enleveztoutlemat6rield'emballagedufouravantde

procederauraccordementelectrique.

3. Observeztouslescodesetreglementsapplicables.

4. Assurez-vousdehissercesinstructionsau

consommateur.

5. Laportedufourpeut6treenlev6epourfaciliter

I'installation.

5. CEFOURN'ESTPASHOMOLOGUlePOURUNE

INSTALLATIONCOTEoAoC6TEOUSUPERPOSleE.

ConservezcesinstructionsavecvotreManueld'utilisation

etd'entretienpourref6rencesfutures.

DIRECTIVES IMPORTANTES

DESECU E

• Assurez-vous que votre four encastr_ est insta[[_

et mis & Ja terre conform_ment par un installateur

ou un techniden de service quaHfi_o

• Ce four encastr_ doit _tre mis _ [a terre

conform_ment aux codes [ocaux d'_[ectricit_ ou,

en [eurs absences, en conformit_ avec le National

EJectrical Code ANSI/NFA No. 70, derni_re _dition

aux Etats-Unis, ou avec la norme ACNOR C22.1,

Pattie 1, au Canada.

Grlmper, vous appuyer ou vous

asseoir sur [a porte de ce four encastr_ peut

entra_ner des blessures graves et peut auss[ causer

des dommages au four encastr_.

N'utlllsez jamals votre four encastr_ pour chauffer

ou r_chauffer [a piece. L'utilisation prolongee du four

encastre sansventilation adequate peut 6tre

dangereuse.

1[faut couper ['a[imentation

_[ectdque durant [e montage des connexions

_[ectriques. A d_faut de ce faire i[ peut en r_suJter

des b[essures graves ou [a mort.

1.Travaux de menuiserie

Reportez-vous a lafigure I ou a la figure 2 pour etablir

quelles sont les dimensions applicables a votre modele,

ainsi que I'espace necessaire pour recevoir I'appareil. La

surface qui supporte I'appareil dolt _tre en contre-

plaque solide ou tout autre mat6riau du m_me type. II

faut vous assurer que la surface est de niveau d'un c6t6

I'autre et de I'avant a I'arrDre.

2. Exigences lectriques

Ces appareils doivent 6tre branch6s sur une alimentation

possedant la tension et lafr6quence appropriees et

connect6 a un seul circuit correctement mis a la terre et

prot6ge par un disjoncteur ou un fusible correspondant

I'intensite indiqu_e sur la plaque signaletique (la plaque

signal_tique est situee sur le chassis du four).

Observez tous [es r_glements et [es codes [ocaux

app[icab[es,

I. Un cable decirique a 3 ou 4 fils de 120/240 ou 120/208

Volt monophas_, 60 Hz CA est requis sur un circuit

separe muni d'un fusible sur chaque fil conducteur

(fusible temporis6 ou disjoncteur recommande). NE

RELIEZpas de fusible au neutre. Lacapacite du fusible

ne doit pasexceder la capacite nominale du circuit de

I'appareil specifiee sur la plaque signal6tique. Seulement

certains modeles de tables de cuisson peuvent 6tre

insta%s au-dessus de certains modeles de fours

encastr6s. Lesmodeles approuv6s pour 6tre combin6s

sont identifi6s a I'aide d'un numero MGF ID (Consultez

la feuille qui setrouve dans I'enveloppe de litterature).

2. Lesfours encastres simples peuvent consommer

jusqu'a 4000W a 240 Vac; utiliser un circuit de

30Amp avec un fil #8 AWG de grosseur. Lesfours

encastres doubles peuvent consommer iusqu'a

8000W a 240 Vac; utiliser un circuit de 40Amp avec

un fil #8 AWG de grosseur.

NOTE: Lecalibre des fils et leurs connexions doivent _tre

conformes a la capacite des fusibles eta la capacite

nominale de I'appareil, selon le National Electrical Code

ANSI/NFPA No. 70, dernDre _dition, ou selon la norme

ACNOR C22,1, Pattie 1, du Code canadien de I'dectricite

et lescodes et les reglements Iocaux.

N'utilisez pas de rallonge _lectrique

avec ces appareils. Son uti[isation peut causer un

feu, un choc _[ectrique ou des blessures corporel[es.

Si vous avez besoin d'un cable arme plus long, vous

pouvez commander et acheter le kit Cable arme de I0'

(3 m) (#903056-9010) en t_lephonant au centre de

service.

3. II faut brancher ces appareils au panneau de

distributions en utilisant des cables flexibles a gaine

metallique ou non metallique. On doit brancher

directement a la boite de ionction le cable gaine

flexible de I'appareil. IIfaut disposer la boite de

jonction tel qu'illustre a la Figure 1ou 2 en laissant

autant de lache que possible dans le cable entre la

boite et I'appareil, pour en faciliter le deplacement si

I'entretien s'avere necessaire.

4. Une attache de protection s_curitaire doit retenir le

cable arme flexible a la boite de jonction.

21

Page 22

Risque de choc _[ectrique

La raise _ [a terre de cet apparei[ est

obJigatoffe.

• Ne branchez pas ['apparei[ au circuit _[ectrique

tant qu'i[ ne sera pas mis _ [a terre

correctement et en permanence_

• Coupez ['aHmentation _ [a bo_te de ionction

avant de faire les raccords _[ectriques°

• Cet apparei[ doit _tre connect_ _ un circuit

permanent _[ectr[que, m_ta[[[que et mis g [a

terre, ou g un connecteur de raise g [a terre qui

doit _tre branch_ & [a borne ou au fi[ de raise &

[a terre de ['appare[L

• N'ut[l[sez pas un tuyau d'a[[mentat[on de gaz

pour [a raise _ [a terre de ['appareiL

S[ vous ne respectez pas toutes [es instructions

pr_c(_dentes, un feu, des b[essures corporelles

ou un choc _[ectrique peuvent en r_su[ter.

Par temps froid, pour proteger la

commande du four, il faut attendre au moins trois (3) heures

la temperature de la piece avant de mettre I'appareil sous

tension. Ceci evitera toute possibilite d'endommager la

commande du four lots de la mise sous tension.

3. Reglage de la hauteur du four

encastre

Lorsque requis, ce four peut _tre ajuste en hauteur avec une

entretoise en bois d'une largeur de 2" (5 cm) pour en

permettre I'installation dans le decoupage existant d'une

armoire, si la hauteur du decoupage excede la

dimension 28118'' (71.4 cm) pour un four encastre simple ou

491/z'' (125.7 cm) pour un four encastre double (voir la figure

1 ou 2). Placez I'entretoise de hauteur appropriee de chaque

cGte de I'ouverture sous I'appareil.

4. Connexions lectriques

Le consommateur est responsable et dolt communiquer

avec un installateur qualifie pour s'assurer que I'installation

electrique est adequate et conforme avec le National

Electrical Code ANS!/NFPA No. 70-derniere edition, ou avec

la norme ACNOR C22.1, partie 1, du code canadien de

I'electricite, et les codes et reglements Iocaux.

La raise a [a terre de ces appareiJs est obligatoire.

Ces appareils sont munis d'un cable conducteur en cuivre

flexible. Si la connexion est fake a un filage residentie! en

aluminium, utilisez seulement des connecteurs speciaux

approuves pour le raccord de fils en cuivre et & des fils en

aluminium conformes au National Electrical Code et aux

codes et ordonnances !ocaux.

Si [es codes [ocaux permettent [a connexion du fil de

raise a [a terre du ch&ssis au neutre (b{anc) (aux [etats_

Unis seulement) (voir figure 3):

1. Coupez I'alimentation a la bo?te dejonction.

2. Darts la boite de jonction:

Raccordez les fils de I'appareil _ ceux du circuit

electrique tel que montre a la figure 3.

Cable d'alimentation

Fil denude

Fils rouc

noirs

]

de

jonction

Filblanc

Fild6nud6 Connecteur

ou vert homologue- U.L

Cable de I'appareil

Figure 3- BOJTE DE JONCTION A 3 FILS MISE A LA TERRE

[[!_ La connexion inappropriee du circuit

r_sidentie[ en aJuminium a des fiJs en cuivre peut

entrainer un court-circuit ou un feu, N'utiJisez que des

connecteurs con_us pour ioindre des fils de cuivre

ceux d'aiuminium, en suivant bien attentivement Jes

directives recommandees par Jefabricant.

[r_ Mise a la terre du ch&ssis au neutre.

Si I'apparei[ est utilise darts une maison mobile, un

nouveau branchement (1996 NEC), un vehicuJe

r_cr_atif ou si Jes codes [ocaux n'autorisent pas Ja

connexion du conducteur de raise g [a terre du ch&ssis

au neutre. Lorsque les codes n'autorisent pas la

connexion du conducteur de raise a [a terre du chassis

au neutre, vous devez utiliser un c_ble _ 4 fils, Voir [a

figure 4, Si vous ne suivez pas cet avertissement vous

vous exposer a un electrocution ou a d'autres

bJessures serieuses.

(ou ACNOR)

Ces appareils sont fabriques avec un fil d'alimentation

neutre blanc et un fil denude en cuivre de mise a la terre

connecte au chassis.

22

Page 23

Si I'appareil est utilise darts une maison mobile, un

nouveau branchement (1996 NEC), un vehkule

r_cr_atif ou si les codes Iocaux N'AUTORISENT PAS la

connexion du conducteur de raise a ia terre du chassis

au neutre (voir le figure 4):

1. Coupez I'alimentation a la bo_te de jonction,

2. Separez le fil blanc du fil denude en cuivre de raise _] la

terre du c2_bled'alimentation de I'appareil.

3. Dans la boite de jonction:

Raccordez les fils de I'appareil _] ceux du circuit

electrique tel que montre _] la figure 4.

Cable d'alimentation

blanc

Fils

rouges

L

Fildenud6

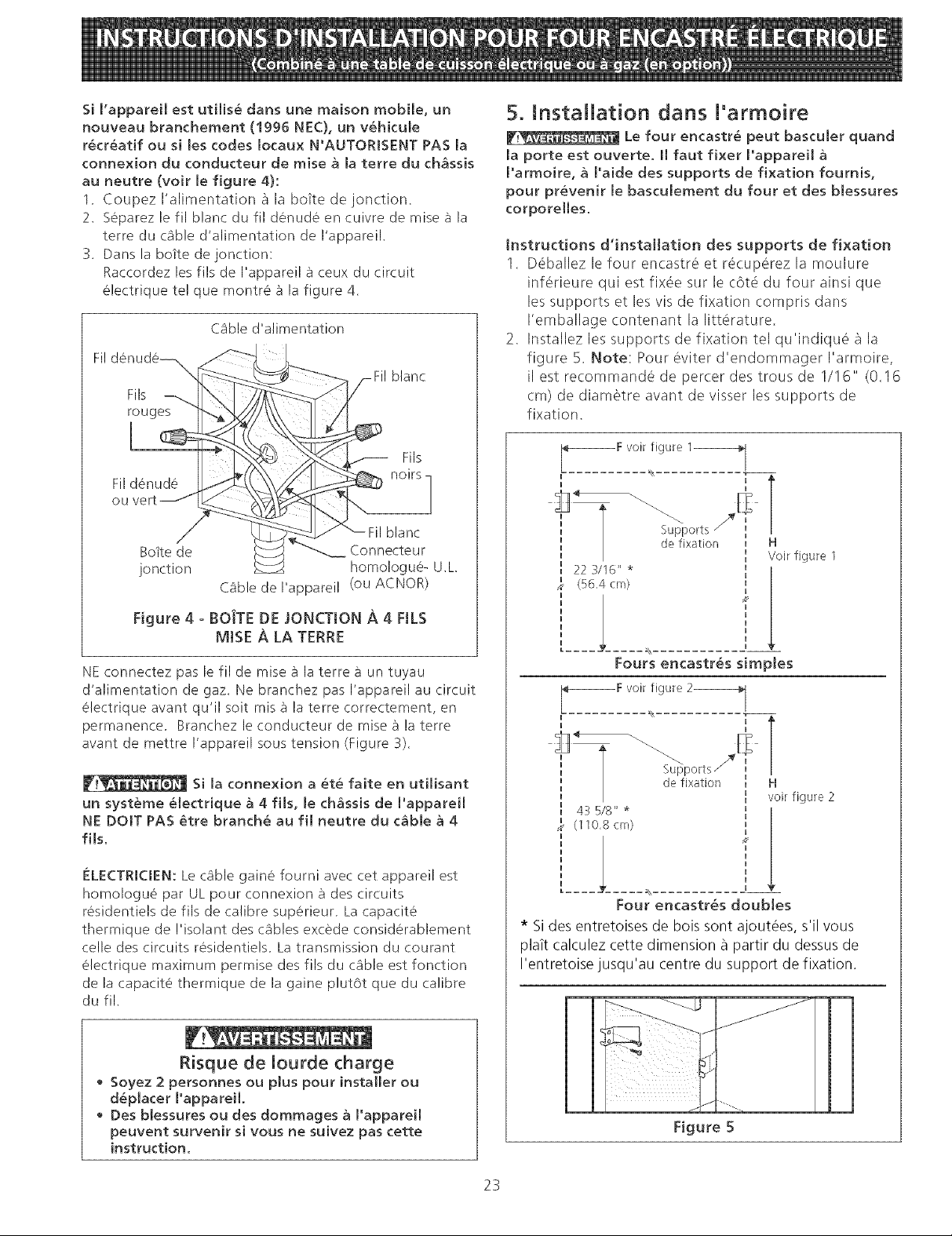

5. Installation darts i'armoire

Le four encastr_ peut basculer quand

la porte est ouverte. II faut fixer I'appareil

I'armoire, & I'aide des supports de fixation fournis,

pour prevenir le basculement du four et des blessures

corporelies.

Instructions d'instaHation des supports de fixation

1. D6ballez le four encastre et recup6rez la moulure

in%rieure qui est fixee sur le c6t6 du four ainsi que

les supports et les vis de fixation compris dans

I'emballage contenant la litterature.

2. Installez les supports de fixation tel qu'indique a la

figure 5. Note: Pour eviter d'endommager I'armoire,

il est recommande de percer des trous de 1/16" (0.16

cm) de diametre avant de visser les supports de

fixation.

Filblanc

Boite de Connecteur

jonction homologue- U.L

Cable de I'appareil (ou ACNOR)

Figure 4 - BOJTE DE JONCTION A 4 FtLS

MtSE A LA TERRE

NE connectez pas le fil de mise _] la terre ;] un tuyau

d'alimentation de gaz. Ne branchez pas I'appareil au circuit

electrique avant qu'il soit mis _] la terre correctement, en

permanence, Branchezleconducteurde mise_]laterre

avant de mettre I'appareil sous tension (Figure 3).

Si la connexion a ete faite en utilisant

un syst_me electrique a 4 fils, ie chassis de i'appareii

NE DOlT PAS _tre branche au fii neutre du c_ble a 4

fiis.

IeLECTRIClEN: Le cable gaine foumi avec cet appareil est

homologue par UL pour connexion _]des circuits

residentiels de fils de calibre superieur, La capacite

thermique de !'isolant des cables excede considerablement

celle des circuits residentiels, La transmission du courant

electrique maximum permise des fils du cable est fonction

de la capacite thermique de la gaine plutOt que du calibre

du fil.

Supports

defixation H

22 3/16" *

Fours encastr_s stmptes

F voir figure 2_

xq

Voir figure 1

T

Supports

de fixation

43 5/8" *

(110,8 cm)

Four encastr_s doubles

* Sides entretoises de bois sont ajout_es, s'il vous

plalt calculez cette dimension b partir du dessusde

I'entretoise jusqu'au centre du support de fixation.

H

voir figure 2

Risque de lourde charge

o Soyez 2 personnes ou plus pour installer ou

dep[acer ['appareil.

o Des blessures ou des dommages _ I'appareil

peuvent survenir si vous ne suivez pas cette

instruction.

[/........

Figure 5

23

Page 24

IMPORTANT

Ne soulevez pas le four encastr_ par la

poign&e de la porte.

3.

Inserez I'unit6 dans le d6coupage de I'armoire.

Glissez I'unit6 vers I'int6rieur en laissant un espace de

lY2" (3.8 cm) entre le four et le devant de I'armoire

(volt figure 6). Tout en glissant I'appareil vers

I'interieur, tirez le cable gain6 a travers le trou du

plancher de I'armoire et vers la bo_te de onction.

S

Moulure

lat_rale

du four

encastr_

Support de

fixation instaIB

'armoire.

Armoire

Outil fourn

Support de

fixation

d6gage

_Trou o@ins@er

I'outil,

Figure 7

31

Four encast@ reti@

de I'armoire

Espace d'environ

lye" (38 cm)

Figure 5

,

Poussez I'appareil a I'int6rieur contre I'armoire, les

supports anti-bascules situes sur le (6te de I'appareil

sefixeront derriere ceux qui viennent d'6tre instalBs

au cabinet.

Pour retirer le four du cabinet pour I'entretien,

inserez les outils fournis avec I'appareil dans les

ouvertures situ6s sur les c6t6s du chassis et visible

Iorsque la porte est ouverte (voir la figure 7).

5. Installation de la mouture inf_rieure:

Placez le haut de la moulure inferieure par dessus les

petites languettes de chaque c6t6 du four encastre,

sous la porte. Vissez la moulure dans les trous situes

de (haque (6t6 de I'appareil en utilisant les vis

fournies avec la moulure (voir la figure 8).

Vis

Figure 8

24

Page 25

6. L'installationtypiqued'unfourencast@electriquesouslecomptoirestp@sent@alafigure9.

Seulementcertainsmodelesdetablesdecuissonpeuvent6tre

instalBsau-dessusdecertainsmod¢lesdefoursencast@s.Les

modelesapprouvespour6trecombinBssontidentifiesaI'aided'un

numBroMGFIDetd'un(:odedeproduit(Consultezlafeuillequise

trouvedansI'enveloppedelitteratureainsiquelefeuillet

d'instructionsd'installationdelatabledecuissonpourles

dimensions).

F_

Pour r4d@re ies

rbques de blessures

et pour ernp_cher le

four encastre de

basc@er. Utilisez les

supports de fixation

pour retenir le four

encastr4 5 I'armoire.

208/240 Volt Boite de

pour le four encast@

Approx. 3"

(7.5_.m)

I

I

II faut fermer les c6tes de I'habitacle par

des panneaux de bois pour isoler

I'apparei! des armoires de chaque c6te, La

hauteur de ces panneaux doit faire en

sorte que I'installation des mo@les de

tables de cuisson au dessus soit possible.

36" Min.

(91.4 cm) Min.

Utilisez un contre-plaque de :W'

(1.9 cm) d'@aisseur monte sur deux

solives et _ egalite avec le coup-de-pied.

La Base doit pouvoir supporter 150 Ibs

(68 kg) pour les mo@les 27" et 200 Ibs

(90 kg) pour les mo@les 30" .

Decoupez une ouverture de 9" X 9" (23 cm X 23

cm), a 2" (5 cm) du cBte gauche du plancher pour

la sortie du c_ible arm6 de I'appareil vers la boite

de jorlctiorl.

41/2"(11.5 cm) Max.

F. LARGEUR G.PROFONDEUR H,HAUTEUR

Fourerlcastr_ 24%" (632 cm) Min, 27Y4"(69.2 cm) Min.

27" (68,6cm) 25Y4"(64.I cm) Max. 23Y2"(59.7 cm) Min. 28%" (72.7 cm) Max.

Fourencastr6 28Y2" (72.4 cm) Min. 27Y4"(69.2cm) Min.

30" (76,2cm) 29" (73,7 cm)Max. 23Y2"(59.7 cm) Min. 28%" (72.7 cm) Max.

Figure 9 - INSTALLATION TYPIQUE D'UN FOUR ENCASTRI_ SIMPLE SOUS LE COMPTOtR

AVEC UNE TABLE DE CUtSSON I_LECTRtQUEOU A GAZ tNSTALLleE PAR-DESSUS

25

Page 26

Conduit _]gaz

Armoire o@lefour est instalB

Figure 10 - INSTALLATION TYPIQUE D'UNE TABLE DE CUtSSON A GAZ MONTI_E AU DESSUS

D'UN FOUR ENCASTRI_ I_LECTRtQUEMONTI_ SOUS LE COMPTOtR

C6tes de I'armoire

ou panneau de

fermeture

5" Max, 6 1/2" Min,

(12.7cm) (16.5cm

evase

Baccord

6vase

Prise

120V/60Hz

mise a la terre

Regulateur

de pression

Robinet de

fermeture

manuel

#

4"(10 cm)

C6te droit de

I'armoire

(Acces facile

pour fermer

la robinet)

26

Page 27

7. MBe a niveau du four encastr

1. Installez une grille au centre du four superieur.

2. D6posezun niveaua bulle sur la grille (voir lafigure 11).

Prenez2 lecturesen pla_antle niveauendiagonaledans

une direction, puisdartsI'autre direction. Utilisezdes

entretoisesdebois sous lefour encastrepour nivelersi

necessaire.

3. Sivousavez un four encastredouble, repetezles m6mes

6tapesdans lefour inferieur. Si le niveau_ bulle indique

que la grille n'est pas _]niveau,utilisezdesentretoisesde

boie pour trouver un ajustement ad6quat pour lesdeux

fours.

f

Figure 11

@OTE IMPORTANTE

Ume soufflerie s[_tu_e dams la pattie interne

sup_r_eure & _'arr_r÷ de _'appareH permet

de garder l÷s composaHtes _÷ctr_ques et

_l÷ctron_ques _Hternes froideso I_ ÷st done

possible gu÷ _a souffler_÷ continue de

fonction_er m6me apr6s I'arr_t de

_'appareH, ÷t ce, j_sq_'8 ¢e q_e les

co_posa_tes aieHt refro_d_,

5. V rification du fonctionnement

Si votre appareil possede une commande _lectronique

de four. Toutes les fonctions qu'elle contr61e ont ete

verifiees en usine pour leur bon fonctionnement avant

que I'appareil soit expedie. Cependant, nous vous

suggerons de v_rifier le fonctionnement de la

commande electrique a nouveau. Reportez-vous a votre

Manuel d'utilisation et d'entretien ou au feuillet

minuterie pour le r_glage de la commande electronique.

1.Retirez tousles items du four avant de proc6der a la

v6rification.

2.Mettez I'appareil sous tension.

3.Ve'rifiez les operations de la commande electronique:

Cuisson-Verifier que Iorsque le four est en fonction

cuisson, I'el_ment de cuisson chauffe. 20 secondes

apr_s avoir programm_ le four en mode cuisson, si en

ouvrant la porte vous sentez de la chaleur s'echapper du

four, c'est qu'il fonctionne.

Grillage-L'el_ment du haut rougit Iorsque le four est

regle pour le mode grillage.

Convection (certains mod_les)-Si le four est regl_

pour la cuisson ou le r6tissage par convection, les deux

elements cyclent et le ventilateur convection situ_

I'arriere tourne. Le ventilateur convection arr_te Iorsque

I'on ouvre la porte du four

Emplacement du num_ro de module et de

s_rie

La plaque signaletique est situee sur le c6te int_rieur de

la moulure laterale.

Pour toute commande de pieces ou demande de

renseignement au sujet de votre appareil, assurez-vous

d'inclure le numero de modele et de serie, ainsi que le

num6ro ou lettre de lot de la plaque signaletique de

votre four.

Avant d'appeler meservice d'entretien

R_viser la liste de verifications preventives et les

instructions d'op_ration dans votre Manuel d'utilisation

et d'entretien. Vous sauverez probablement du temps et

de I'argent. La liste contient les incidents ordinaires ne

resultant pas de defectuosites dans le materiel ou la

fabri(ation de cet appareil.

Pour obtenir nos adresse et numero de t_lephone sans

frais, ref_rez-vous a votre Manuel d'utilisation et

d'entretien.

27

Page 28

Notes

28

Loading...

Loading...