Service & P arts Manual

WallMaster® Thru-the-Wall

M

P

r

e

w

o

P

72

Cool

n

®

a

F

Money Saver

e

d

o

M

d

e

e

p

S

ly

n

O

n

a

F

Clock

t

e

S

Start Time

r

e

im

T

r

u

o

H

Off

/

n

O

r

u

o

H

/

p

m

Stop Time

e

T

WM-Svc-Prts-07 (3-07)

WS08B10A-C

WS10B10A-C

WS14B10A-C

WS10B30A-C

WS13B30B-C

WS16B30A-C

WE10B33A-B

WE13B33B-B

WE16B33A-B

WY10B33A-B

WY13B33A-B

TABLE OF CONTENTS

Warranty .....................................................................................................................................................3

Routine Maintenance ................................................................................................................................4

Unit Identifi cation ......................................................................................................................................5

Performance Data .....................................................................................................................................6

Electrical Data ...........................................................................................................................................7

Functional Component Defi nitions .........................................................................................................8

Electronic Controls ...................................................................................................................................9

Rotary Controls .......................................................................................................................................10

Refrigeration Sequence of Operation ...................................................................................................11

Sealed Refrigeration Repairs ........................................................................................................... 12-13

Refrigerant Charging ..............................................................................................................................13

General Troubleshooting .................................................................................................................. 14-20

Wiring Diagrams ................................................................................................................................ 21-25

Parts Diagram ..........................................................................................................................................26

Parts Lists .......................................................................................................................................... 27-29

2

Friedrich Air Conditioning Company

£

P.O. Box 1540

San Antonio, TX 78295

210.357.4400

www.friedrich.com

WALLMASTER

THRU-THE-WALL AIR CONDITIONERS

LIMITED WARRANTY

FIRST YEAR

ANY PART: If any part supplied by FRIEDRICH fails because of a defect in workmanship or material within twelve months from

date of original purchase, FRIEDRICH will repair the product at no charge, provided room air conditioner is reasonably accessible

for service. Any additional labor cost for removing inaccessible units and/or charges for mileage related to travel by a Service

Agency that exceeds 25 miles one way will be the responsibility of the owner. This remedy is expressly agreed to be the exclusive

remedy within twelve months from the date of the original purchase.

SECOND THROUGH FIFTH YEAR

SEALED REFRIGERANT SYSTEM: If the Sealed Refrigeration System (defined for this purpose as the compressor, condenser

coil, evaporator coil, reversing valve, check valve, capillary, filter drier, and all interconnecting tubing) supplied by FRIEDRICH in

your Room Air Conditioner fails because of a defect in workmanship or material within sixty months from date of purchase,

FRIEDRICH will pay a labor allowance and parts necessary to repair the Sealed Refrigeration System; PROVIDED FRIEDRICH will

not pay the cost of diagnosis of the problem, removal, freight charges, and transportation of the air conditioner to and from the

Service Agency, and the reinstallation charges associated with repair of the Sealed Refrigeration System. All such cost will be the

sole responsibility of the owner. This remedy is expressly agreed to be the exclusive remedy within sixty months from the date of the

original purchase.

APPLICABILITY AND LIMITATIONS: This warranty is applicable only to units retained within the Fifty States of the U.S.A., District

of Columbia, and Canada. This warranty is not applicable to:

1. Air filters or fuses.

2. Products on which the model and serial numbers have been removed.

3. Products which have defects or damage which results from improper installation, wiring, electrical current

OBTAINING WARRANTY PERFORMANCE: Service will be provided by the FRIEDRICH Authorized Dealer or Service

Organization in your area. They are listed in the Yellow Pages. If assistance is required in obtaining warranty performance, write

to: Room Air Conditioner Service Manager, Friedrich Air Conditioning Co., P.O. Box 1540, San Antonio, TX 78295-1540.

LIMITATIONS: THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES. Anything in the warranty

notwithstanding, ANY IMPLIED WARRANTIES OF FITNESS FOR PARTICULAR PURPOSE AND/OR MERCHANTABILITY

SHALL BE LIMITED TO THE DURATION OF THIS EXPRESS WARRANTY. MANUFACTURER EXPRESSLY DISCLAIMS AND

EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGE FOR BREACH OF ANY EXPRESSED OR

IMPLIED WARRANTY.

NOTE: Some states do not allow limitations on how long an implied warranty lasts, or do not allow the limitation or exclusion of

consequential or incidental damages, so the foregoing exclusions and limitations may not apply to you.

OTHER: This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

PROOF OF PURCHASE: Owner must provide proof of purchase in order to receive any warranty related services.

All service calls for explaining the operation of this product will be the sole responsibility of the consumer.

All warranty service must be provided by an Authorized FRIEDRICH Service Agency, unless authorized by FRIEDRICH prior to

repairs being made.

characteristics, or maintenance; or caused by accident, misuse or abuse, fire, flood, alterations and/or misapplication

of the product and/or units installed in a corrosive atmosphere, default or delay in performance caused by war,

government restrictions or restraints, strikes, material shortages beyond the control of FRIEDRICH, or acts of God.

(10-04)

3

ROUTINE MAINTENANCE

NOTE: Un its are to be inspected and serviced by qualifi ed service personnel only.

Routine maintenance is required annually or semi-annually, depending upon annual usage.

1. Clean the unit air intake fi lter at least every 250 to 300 fan hours of operation or when the unit’s indicator light is on if

so equipped. Clean the fi lters with a mild detergent in warm water and allow to dry thoroughly before reinstalling.

2. The indoor coil ( evaporator coil), the outdoor coil (condenser coil) and base pan should be inspected periodically (yearly

or bi-yearly) and cleaned of all debris (lint, dirt, leaves, paper, etc. ). Clean the coils and base pan with a soft brush and

compressed air or vacuum. If using a pressure washer, be careful not to bend the aluminium fi n pack. Use a sweeping

up and down motion in the direction of the vertical aluminum fi n pack when pressure cleaning coils. Cover all electrical

components to protect them from water or spray. Allow the unit to dry thoroughly before reinstalling it in the sleeve.

NOTE: Do not use a caustic coil cleaning agent on coils or base pan. Use a biodegradable cleaning agent and degreaser.

Inspect the indoor blower housing, evaporator blade, condenser fan blade, and condenser shroud periodically (yearly or

bi-yearly) and clean of all debris (lint, dirt, mold, fungus, etc.) Clean the blower housing area and blower wheel with an

antibacterial / antifungal cleaner. Use a biodegradable cleaning agent and degreaser on condenser fan and condenser

shroud. Use warm or cold water when rinsing these items. Allow all items to dry thoroughly before reinstalling them.

3. Periodically (at least yearly or bi-yearly): inspect all control components, both electrical and mechanical, as well as the

power supply. Use proper testing instruments (voltmeter, ohmmeter, ammeter, wattmeter, etc.) to perform electr ical

tests. Use an air conditioning or refrigeration ther mometer to chec k room, outdoo r and coil operating temperatures.

Use a sling psychrometer to measure wet bulb temperatures indoors and outdoors.

4. Inspect the surrounding area (inside and outside) to ensure that the units’ clearances have not been compromised or

altered.

5. Inspect the sleeve and drain system periodically (at least yearly or bi-yearly) and clean of all obstructions and debris.

Clean both areas with an antibacterial and antifungal cleaner . Rinse both items thoroughly with water and ensure that

the drain outlets are operating correctly. Check the sealant around the sleeve and reseal areas as needed.

6. Clean the front cover when needed. Use a mild detergent. Wash and rinse with warm water. Allow it to dry thoroughly

before reinstalling it in the chassis.

4

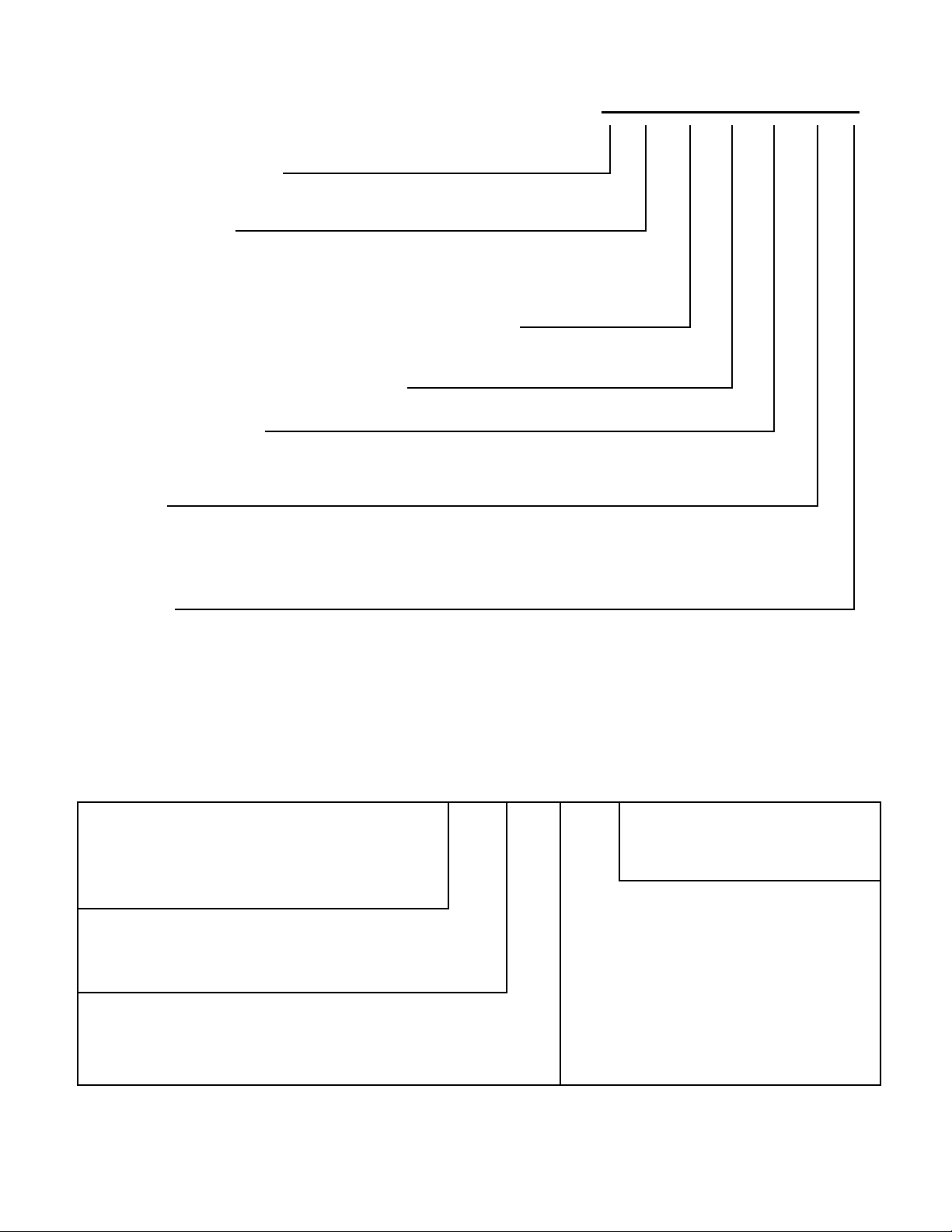

FRIEDRICH ROOM MODEL NUMBER CODE

W S 08 B 1 0 B

1st DIGIT - FUNCTION

W = Thru-The-Wall, WallMaster Series

2nd DIGIT - TYPE

S = Straight Cool

E = Electric Heat

Y = Heat Pump

3rd & 4th DIGITS - APPROXIMATE BTU/HR (Cooling)

Heating BTU/HR capacity listed in Specifi cations/Performance Data Section

5th DIGIT - ALPHABETICAL MODIFIER

6th DIGIT - VOLTAGE

1 = 115 Volts

3 = 230-208 Volts

7th DIGIT

0 = Straight Cool & Heat Pump Models

ELECTRIC HEAT MODELS

3 = 3 KW Heat Strip, Nominal

8th DIGIT

Major Change

RAC SERIAL NUMBER IDENTIFICATION GUIDE

Serial Number

Decade Manufactured

L=0 C=3 F=6 J=9

A=1 D=4 G=7

B=2 E=5 H=8

Year Manufactured

A=1 D=4 G=7 K=0

B=2 E=5 H=8

C=3 F=6 J=9

Month Manufactured

A=Jan D=Apr G=Jul K=Oct

B=Feb E=May H=Aug L=Nov

C=Mar F=Jun J=Sept M=Dec

L C G R 00001

Production Run Number

Product Line

R = RAC

P = PTAC

E = EAC

V = VPAK

H = Split

5

PERFORMANCE DATA

FUSE

BREAKER

OPERATING

PRESSURES ELECTRICAL RATINGS R-22 REF.

Amps

60 Hertz

RPM

Motor

CFM

Evap

OZ.

Charge in

Locked

Rotor Amps

Heat

Amps

Cool

Amps

Sub-

Cooling

Heat

Super

Lbs.

Net Weight

Room

Side Air

Circulation

Removal

Moisture

Pints/Hr.

EER

Ratio

Energy

Efficiency

Watts

Heating

Amps

Heating

Finished Hole

Thru-the-wall

Height Width

Outside

Minimum

Extension

Minimum

Extension

Into Room

with

Front

Depth

16 3/4" 27" 16 3/4" 23" 7 1/2" 9/16" 17 1/4" 27 1/4"

Model Height Width Depth

Sleeve Dimensions

WSC Sleeve

15 3/4" 26 1/2" 21" – – – – –

Chassis

Temp

Liquid

Temp

Suction

Temp

Discharge

TEMP.

DEG. F

CONDENSER

TEMP. DEG. F

EVAPORATOR

Temp .

Drop F. E(in) E (out) Suction Discharge

TEMP. DEG. F

EVAPORATOR AIR

* Rating Conditions: 80 degrees F, room air temp. & 50% relative humidity, with 95 degree F, outside air temp & 40% relative humidity

Calculate the heat loss of the space to be heated. As long as the heat loss does not exceed the resistance heating capacity rating of the unit, the heating performance will be satisfactory. Change-over

from heat pump operation to resistance operation on models indicated is automatic at a preset outside ambient temperature of approximately 35°F. If condensate disposal is desired, an optional drain

kit is available. DEFROST CONTROL: Initiated at 20°F (outdoor coil temperature) and terminated at 43°F (outdoor coil temperature). During defrost, the compressor stops and the electric heat starts,

then operates with the fan to maintain indoor comfort. Below 43°F, the unit remains in electric heat mode. During electric heat mode, the unit will achieve the following ratings: 11000/9100 BTU/h,

16.0/14.7 amps, and 3550/2950 watts. DEFROST DRAIN: Drain automatically opens at approximately 50°F in outdoor base pan for defrost condensate disposal.

Air

Discharge

WS08B10A 55 25 55 55 127 165 61 102 18 25 87 281 7.1 36.2 20.5 257 1100 15

WS10B10A 52 28 53 51 128 176 68 105 16 24 79 293 9.0 45.0 22.0 248 1100 15

WS14B10A 52 28 52 52 128 179 63 99 14 28 82 297 12.4 58.0 44.9 293 1300 15

WS10B30A 55 25 53 57 131 179 68 106 16 23 77 289 4.6 26.0 22.5 235 1100 15

WS13B30B 51 29 52 50 128 174 57 100 13 30 78 295 6.5 27.4 35.2 281 1300 15

WS16B30A 52 28 51 53 121 154 54 99 18 32 74 315 7.7 35.0 47.6 292 1421 15

WE10B33A 53 27 54 52 126 180 82 99 16 31 82 289 4.6 15.2 45.0 38.0 225 1074 20

WE13B33B 52 29 52 51 127 180 64 103 13 29 80 295 6.5 15.7 27.4 35.0 274 1318 20

WE16B33A 52 28 51 5 3 121 174 57 10 0 18 30 74 315 6.5 16.1 35.0 3 5.2 281 1305 20

WY10B33A 53 27 54 52 126 180 66 99 16 31 82 225 4.6 4 / 15.2 26.0 38.0 225 1074 20

WY13B33A 52 29 52 51 127 180 64 103 16 29 80 300 6.5 5.6 / 15.7 27.4 35.0 260 1200 20

Watts

Cooling

Wall

Outlet

Circuit Rating

Plug Face

Breaker

Appearance

(NEMA#)

125V - 15A 5 - 15P

250V - 15A 6 - 15P

or T-D Fuse

Model Numbers

WS08B10A, WS10B10A,

WS14B10A

250V - 20A 6 - 20P

WS10B30A, WS13B30A,

WS16B30A

WE10, WE13, WE16

WY10, WY13

Amps

Cooling

BTU/h Volts Rated

Heating

Capacity

BTU/h

Cooling

Capacity

Model #

WS08B10A 8000 — 115 6.8 762 — — 10.5 1.3 245 93

WS10B10A 10000 — 115 8.7 954 — — 10.5 2.4 245 103

WS14B10A 13500 — 115 12.0 1415 — — 9.5 3.3 295 112

WS10B30A 10000/10000 — 230/208 4.6/5.0 1005/996 — — 10.0/10.0 2.1 260 101

WS13B30B 12500/12000 — 230/208 6.3/6.7 1404/1379 — — 8.9/8.7 3.3 280 109

WS16B30A 15800/15000 — 230/208 7.8/8.5 1756/1705 — — 9.0/8.8 4.2 290 119

WE10B33A 10000/10000 11000/9100 230/208 4.6/5.0 1005/996 16.0/14.7 3550/2950 10.0/10.0 2.1 260 103

WE13B33B 12500/12000 11000/9100 230/208 6.3/6.7 1404/1379 16.0/14.7 3550/2950 8.9/8.7 3.3 280 111

WE16B33A 15800/15000 11000/9100 230/208 7.8/8.5 1756/1705 16.0/14.7 3550/2950 9.0/8.8 4.2 290 121

WY10B33A 10100/9800 8100/7800 230/208 4.6/4.8 1013/976 3.9/4.0 857/821 10.0/10.0 2.5 230 107

WY13B33A 12500/12100 10400/10000 230/208 6.4/6.8 1389/1352 5.4/5.7 1182/1136 9.0/9.0 3.2 280 116

Installation Information

6

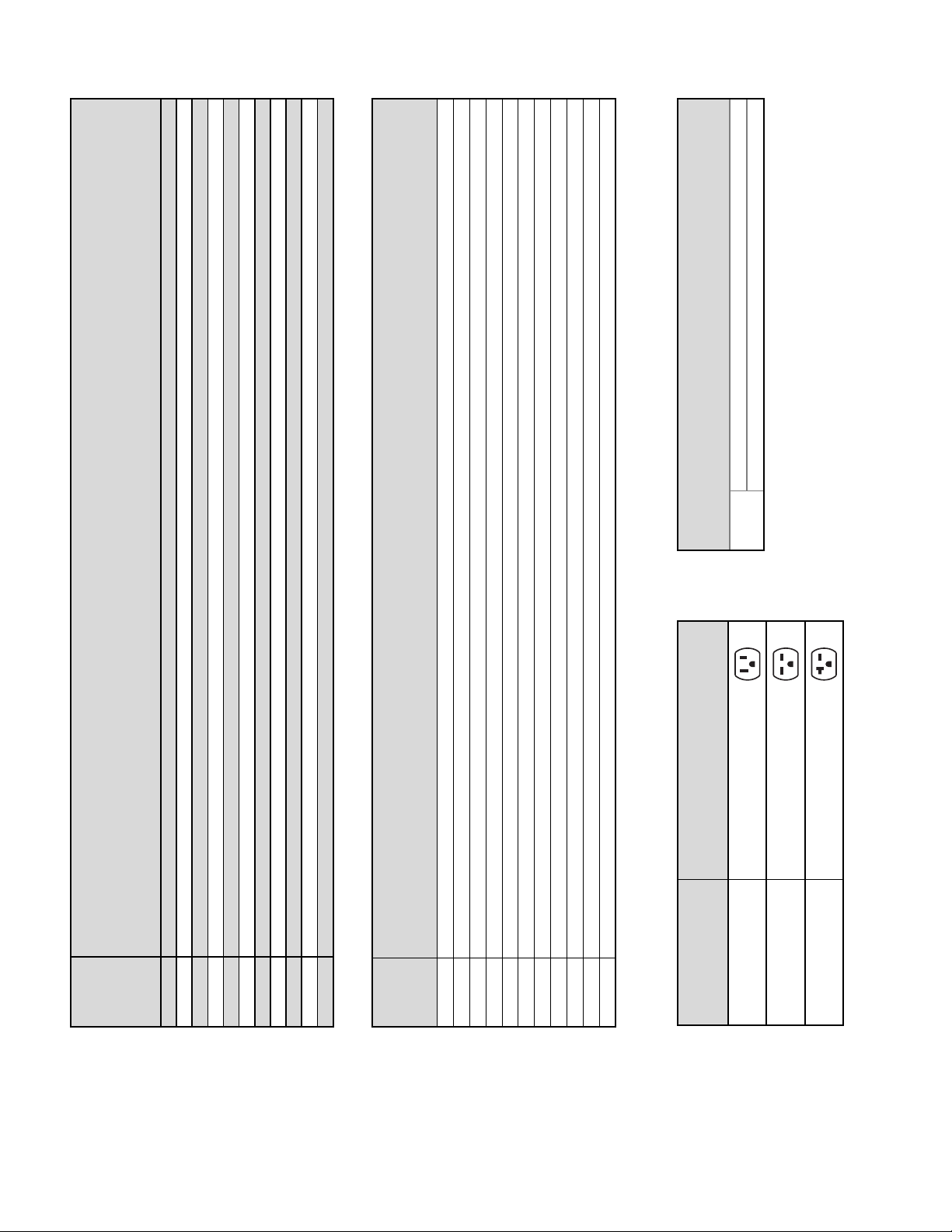

ELECTRICAL DATA

Wire Size Use ONLY wiring size recommended for

single outlet branch circuit.

Fuse/Circuit Use ONLY type and size fuse or HACR

Breaker circuit breaker indicated on unit’s rating

plate. Proper current protection to the unit

is the responsibility of the owner.

Grounding Unit MUST be grounded from branch

circuit through service cord to unit, or

through separate ground wire provided on

permanently connected units. Be sure that

branch circuit or general purpose outlet is

grounded.

Receptacle The fi eld supplied outlet must match plug on

service cord and be within reach of service

cord. Do NOT alter the service cord or plug.

Do NOT use an extension cord. Refer to

the table above for proper receptacle and

fuse type.

ELECTRIC SHOCK HAZARD.

T urn off electric power before service or installation.

All electrical connections and wiring MUST be

installed by a qualifi ed electrician and conform to the

National Electrical Co de and all local codes which

have jurisdiction.

Failure to do so can result in property damage,

personal injury and/or death.

The consumer - through the AHAM Room Air Conditioner Certifi cation Program - can be certain

that the AHAM Certifi cation Seal accurately states the unit’s cooling and heating capacity rating,

the amperes and the energy effi ciency ratio.

7

FUNCTIONAL COMPONENTS

A. Me c h anica l c o m p onents

Bellows condensate valve

T emperature-sensitive valve that opens up to drain off condensate water when the outside temperature falls below 40°F

and closes when the outside temperature reaches 58°F.

Plenum assembly

Diffuser with directional louvers used to direct the conditioned airfl ow.

Blower wheel

Attaches to the indoor side of the fan motor shaft and is used for distributing unconditioned, room side air though the heat

exchanger and delivering conditioned air into the room.

Slinger fan blade

Attaches to the outdoor side of the fan motor shaft and is used to move outside air through the condenser coil, while

slinging condensate water out of the base pan and onto the condenser coil, thus lowering the temperature and pressures

within the coil.

B. Electrical components

Thermostat

Used to maintain the specifi ed room side comfort level

System switch

Used to regulate the operation of the fan motor, the compressor or to turn the unit off. For troubleshooting, refer to the

wiring diagrams and schematics in the back of this service manual.

Capacitor

Reduces line current and steadies the voltage supply, while greatly improving the torque characteristics of the fan motor

and compressor motor.

MoneySaver® switch

When engaged, it sends the power supply to the fan motor through the thermostat, which allows for a cycle-fan operation.

Fan Motor

Dual-shafted fan motor operates the indoor blower wheel and the condenser fan blade simultaneously.

Solenoid

Used to energize the reversing valve on all heat pump units.

Heating elem en t

Electric resistance heater, available in 3.3, 4.0 or 5.2 kW on select T winT emp® models.

Heat anticip at or

Used to provide better thermostat and room air temperature control.

C. Hermetic components

Compressor

Motorized device used to compress refrigerant through the sealed system.

Reversing valve

A four-way switching device used on all heat pump models to change the fl ow of refrigerant to permit heating or cooling.

Check valve

A pressure-operated device used to direct the fl ow of refrigerant to the proper capillary tube, during either the heating or

cooli ng c ycle.

Capillary tube

A cylindrical meter device used to evenly distribute the fl ow of refrigerant to the heat exchangers (coils.)

8

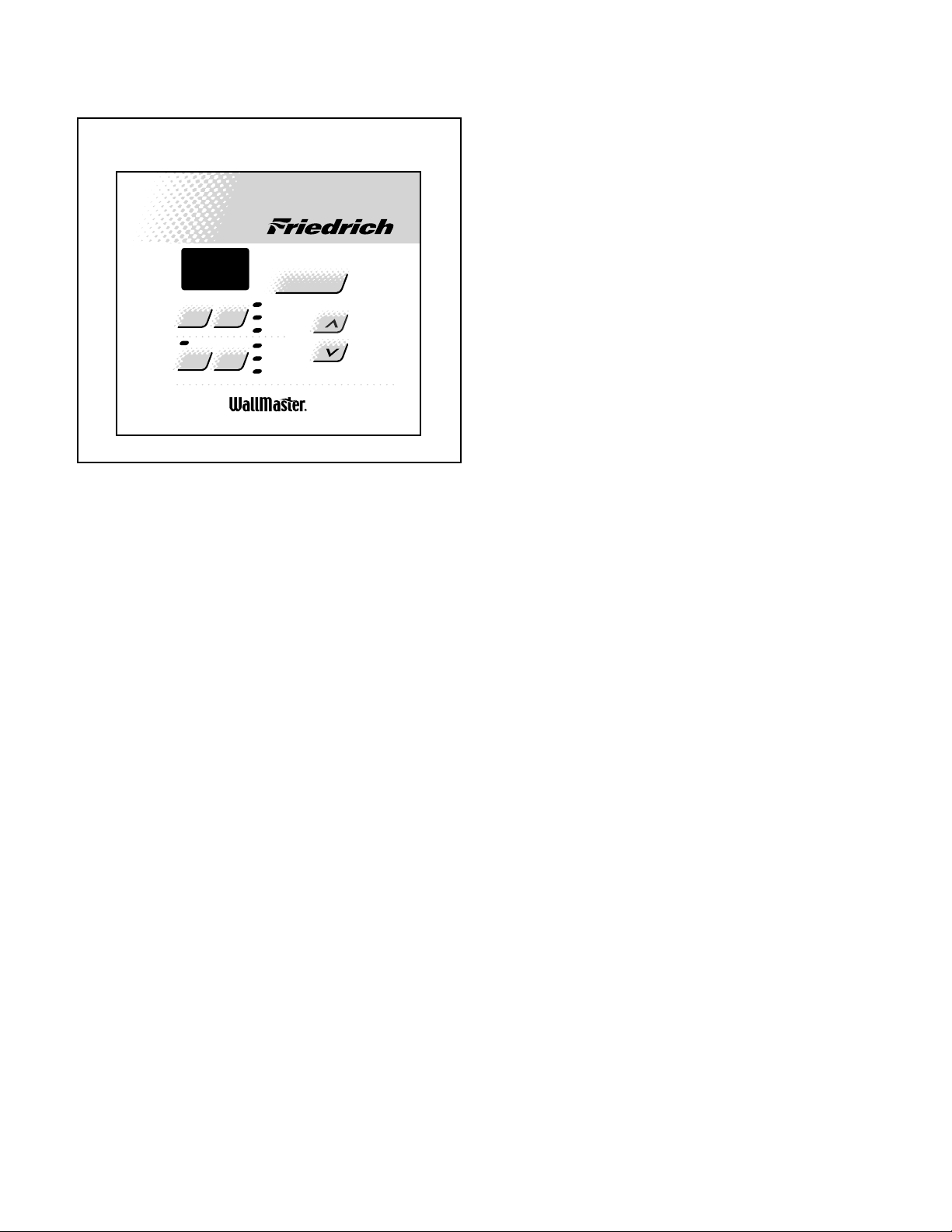

SYSTEM CONTROL PANEL

(“WS” Models)

Figure 6: System Control Panel

PM

Speed

Timer

On/Off

72

Fan

Mode

Hour

Set

Cool

MoneySaver

Fan Only

Clock

Start Time

Stop Time

Power

®

Tem p/H our

TESTING THE ELECTRONIC CONTROL

CHECKING ROOM TEMPERATURE

1. Check the room temperature at the electronic control

pad by pressing at the same time the “FAN SPEED”

button and the temperature “UP” button on XQ & WS

models.

2. The indoor temperature will display for 10 seconds.

Indoor temperature can be viewed in all modes,

including the TEST mode. The display can be changed

back to SET temperature by pressing any key, except

the ON/OFF button, or after 10seconds has elapsed.

ACTIVATING TEST MODE

Activate test mode by pressing at the same time the “MODE ”

button and the temperature “DOWN” button on XQ & WS

models. LEDs for Hour , Start, and Stop will blink 1bps while

Test Mode is active.

Test Mode has duration of 90 minutes. Test Mode

can be activated under any conditions, including O ff.

Test Mode is cancelled by pressing the On/Off button,

unplugging the unit, or when the 90 minutes is timed

out. All settings revert to the factory default settings of

Cool, 75 degrees F, Timer and Set Hour features are

nonfunctional.

Activating Err or C ode Mode ( Submode of Test Mode)

Unit must be in T est Mode to enter Error Code Mode

1. Activate Error Code Mode by pressing the “TIMER

ON/OFF” button on XQ & WS model s. LED for the

“TIMER ON/OFF” will fl ash 1bps while Error Code

Mode is active. Pressing the “TEMP/HR + ” button will

display 00. Consecutive presses will scroll through all

error codes logged. Press the “TEMP/HR - ” button

to see the reverse order of all error codes logged.

When the end of logged error codes is reached the

temperature set point will appear .

IMPORTANT

Error Codes are cleared from the lo g by exiting from Error

Code Mode. To exit on X Q & WS models, press Timer On/

Off but ton. Or unplug unit to exit Error Code Mo de. Plug

unit in after 5 seconds to resume normal operation of unit.

ERROR CODE LISTINGS

E1 SHORT CYCLE SITUATION: Defi ned as

compressor powered on before the three minute

time delay ten times in one hour. In vestigate and

correct short cycling problem.

E2 KEYBOARD STUCK ERROR: If key button(s)

are pressed continuously for twent y seconds or

more. If MODE key is stuck, unit will default to

cool. Exit Error Code M ode to see if error “ E2 ”

is no longer displayed and unit is functioning.

Replace board if “E2 ” still displays after exiting

Error Code Mode.

E3 FROST PROBE OPEN: Normal operation is

allowed. Ohm frost probe. Replace probe if ohm

value not read. If ohm value present replace

board.

E4 FROST PROBE SHORT: Normal operation

allowed. Replace probe.

E5 INDOOR PROBE OPEN: Control assumes

indoor ambient temperature is 90 degree F and

unit will operate. Ohm indoor probe. Replace

probe if ohm value not read.

E6 INDOOR PROBE SHORT: Control assumes

ambient temperature is 90 degree F and unit will

operate. Replace probe.

T est Mode overrides the three-minute lockout, all delays

for compressor and fan motor start / speed change, and

no delay when switching modes.

Te st Mode default settings are ON, Money Saver, 60

degrees F, and High fan speed.

NOTE: All Error Code displays for Frost & Indoor Probe

will allow unit to operate. Unit may or will ice up if faulty

components not replaced.

9

Loading...

Loading...