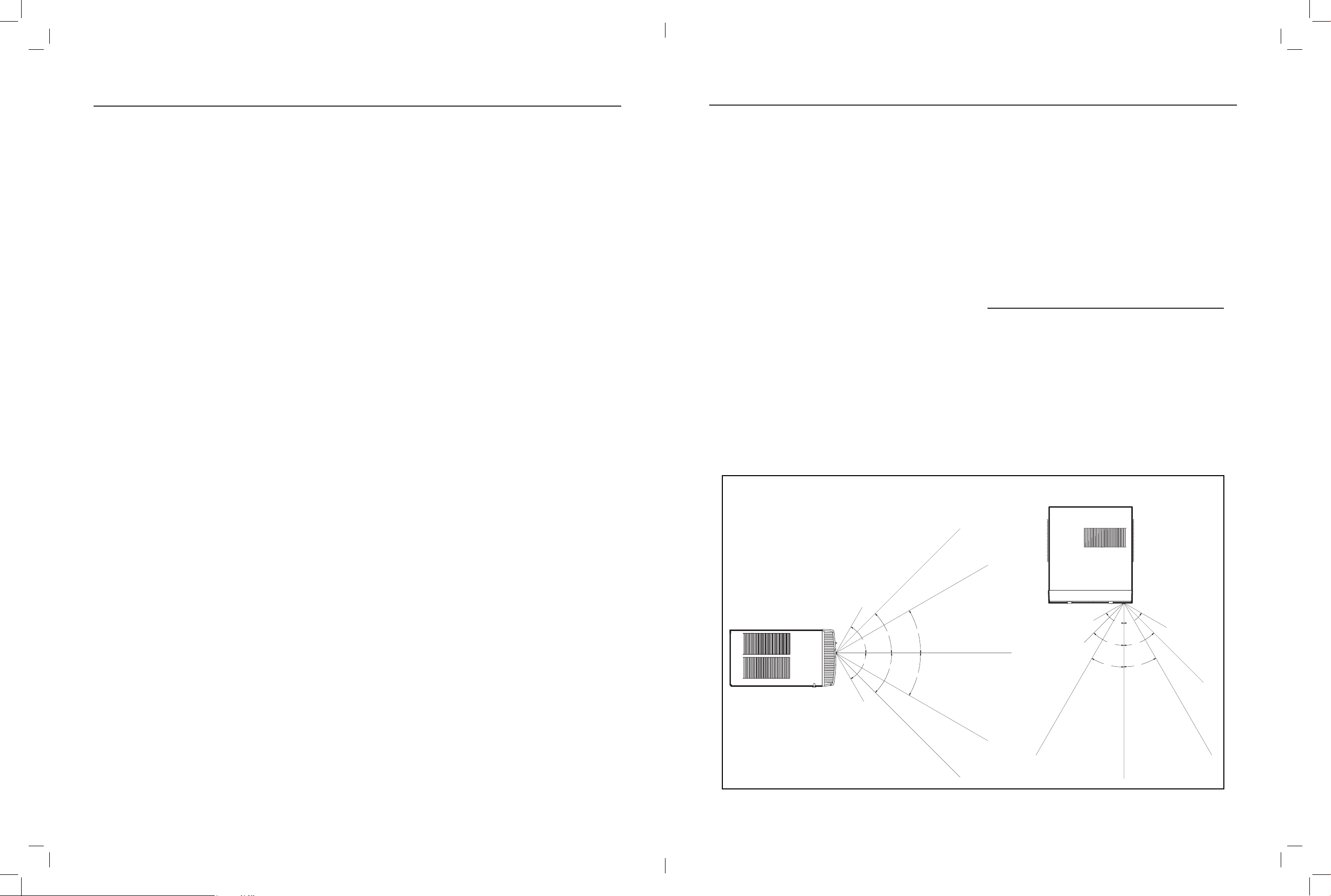

Thru-the-Wall Conditioners

Air Conditioners and Heat Pumps

Installation and Operation Manual

WallMaster

93001017_00

®

115-Volt:

230-Volt:

WCT08, WCT10, WCT12

WCT10, WCT12, WCT16, WET10, WET12,

WET16, WHT12

Thank you for your decision to purchase the Friedrich High Efciency Air Conditioner. Your new Friedrich has been carefully engineered and manufactured to

give you many years of dependable, efcient operation, maintaining a comfortable temperature and humidity level. Many extra features have been built into

your unit to assure quiet operation, the greatest circulation of cool, dry air, and the most economic operation.

THANK YOU, on behalf of our entire company,

for making such a wise purchase.

Table of Contents

Safety Precautions ...................................................................................... 4

WARNING: Before Operating Your Unit ..................................................................... 5

Standard Filter Cleaning / Installation Instructions ........................................................... 6

Control Panel Operation .................................................................................. 7

New WallMaster Control Options .......................................................................... 20

Wi-Fi Set-Up Instructions ................................................................................ 21

Control Panel Operation Instructions ....................................................................... 22

Remote Control Operation ................................................................................ 23

Remote Effectiveness .................................................................................... 23

Airow Selection and Adjustment .......................................................................... 23

Installation Instructions .................................................................................. 24

Installation Instructions for WSE Sleeve .................................................................... 25

WallMaster Chassis Installation Instructions ................................................................ 27

Troubleshooting Tips .................................................................................... 29

Warranty .............................................................................................. 31

AIR CONDITIONING CO.

SAN ANTONIO, TEXAS

ASSEMBLED IN MEXICO

Register your air conditioner

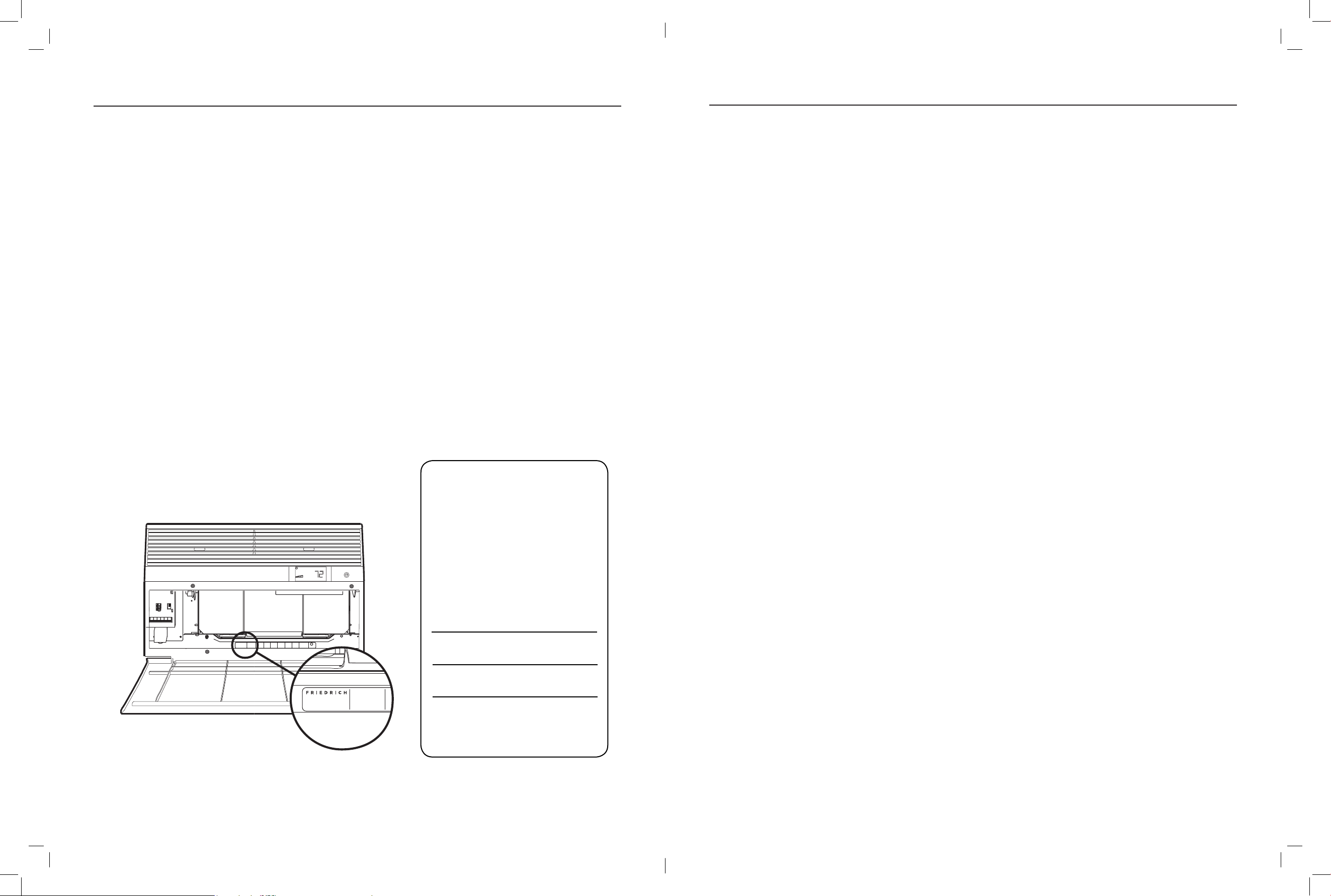

Model information can be found on the name plate

behind the front cover.

Please complete and mail the owner registration

card furnished with this product, or register online

at www.friedrich.com.

For your future convenience, record the model

information here.

MODEL NUMBER

VOLTS 115

COOLING

HEATING

REFRIGERANT

XXXXXXXXX

XXXXXXXXXX

FUSE PROTECTED

U

YS10M10A

60 HZ / 1 PH

BTH/HR 6500

BTH/HR 6500

SERIAL NUMBER

LICY00008

30.1 OZ R410A

VOLTS MIN 108

EER 12.0

EER 10.4

AMPS 8.0

AMPS 7.0

600 PSIG HS

XXXXXXXXX

CIRCUITS USE 15A

300 PSIG LS

XXXXXXXXXX

TIME DELAY FUSE

XXXXXXXXXX

L

X XX

XXXXX

XXXXXXXXXX

AIR CONDITIONING CO.

SAN ANTONIO, TEXAS

ASSEMBLED IN MEXICO

MODEL NUMBER

YS10M10A

SERIAL NUMBER

LICY00008

MODEL NUMBER

SERIAL NUMBER

PURCHASE DATE

2 3

Safety Precautions

WARNING: Before Operating Your Unit

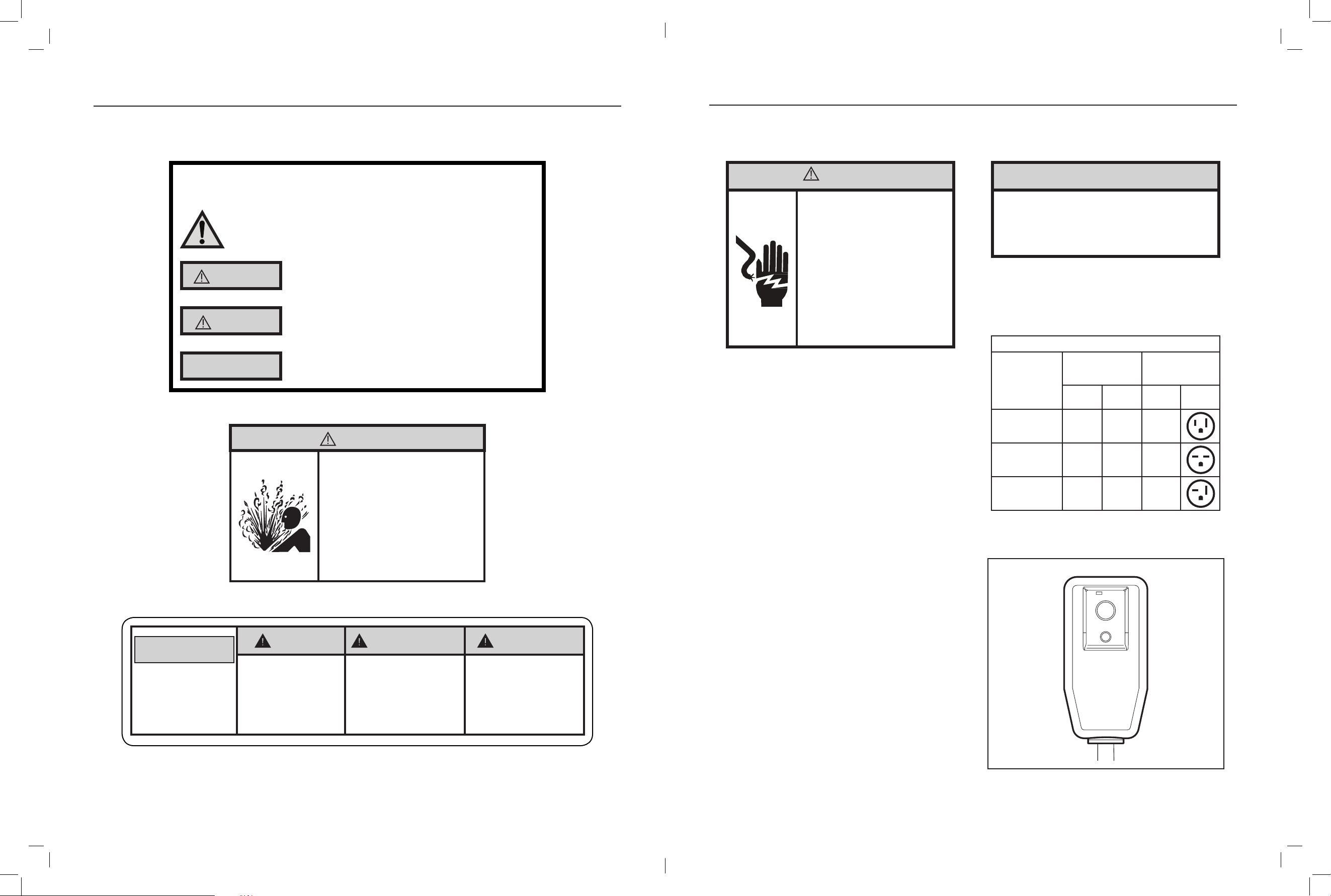

Your safety and the safety of others is very

important.

We have provided many important safety messages in this manual and on your

appliance. Always read and obey all safety messages.

This is a safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING”

WARNING

CAUTION

NOTICE

or “CAUTION”. These words mean:

Indicates a hazard which, if not avoided, can result in severe personal injury or

death and damage to product or other property.

Indicates a hazard which, if not avoided, can result in personal injury and damage to

product or other property.

All safety messages will tell you what the potential hazard is, tell you how to

reduce the chance of injury, and tell you what will happen if the instructions are

not followed.

Indicates property damage can occur if instructions are not followed.

WARNING

Refrigeration system

under high pressure

Do not puncture, heat, expose to ame or incinerate.

Only certied refrigeration technicians should service

this equipment.

R410A systems operate at higher pressures than R22

equipment. Appropriate safe service and handling

practices must be used.

Only use gauge sets designed for use with R410A.

Do not use standard R22 gauge sets.

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same conguration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong outlet.

Failure to follow these instructions can result

in death, re, or electrical shock.

Make sure the wiring is adequate for your unit.

If you have fuses, they should be of the time delay type. Before you install

or relocate this unit, be sure that the amperage rating of the circuit breaker

or time delay fuse does not exceed the amp rating listed in Table 1.

DO NOT use an extension cord.

The cord provided will carry the proper amount of electrical power to the

unit; an extension cord may not.

Make sure that the receptacle is compatible with the air

conditioner cord plug provided.

Proper grounding must be maintained at all times. Two prong receptacles

must be replaced with a grounded receptacle by a certied electrician.

The grounded receptacle should meet all national and local codes and

ordinances. You must use the three prong plug furnished with the air

conditioner. Under no circumstances should you remove the ground

prong from the plug.

NOTICE

Do not use the LCDI device as an ON/OFF switch.

Failure to adhere to this precaution may cause

premature equipment malfunction.

Once plugged in, the unit will operate normally without the need to reset

the LCDI device. If the LCDI device fails to trip when tested or if the

power supply cord is damaged, it must be replaced with a new power

supply cord from the manufacturer. Contact our Technical Assistance

Line at (800) 541-6645. To expedite service, please have your model

number available.

Table 1

CIRCUIT RATING

OR TIME DELAY

MODEL

WCT08, WCT10,

WCT12 15 125 5-15P

WCT10, WCT12,

WCT16 15 250 6-15P

WET10, WET12,

WET16, WHT12 20 250 6-20P

Figure 1

FUSE

AMP VO LT

REQUIRED

WALL

RECEPTACLE

NEMA

NO.

THINK

SAFETY

FIRST

WARNING AVERTISSEMENT ADVERTENCIA

Do not remove, disable or

bypass this unit’s safety

devices. Doing so may cause

re, Doing so may cause re,

injuries, or death.

Ne pas supprime, désactiver ou

contourner cette l´unité des

dispositifs de sécurité, faire vous

risqueriez de provoquer le feu, les

blessures ou la mort.

No eliminar, desactivar o pasar

por alto los dispositivos de

seguridad de la unidad. Si lo hace

podría producirse fuego, lesiones

o muerte.

Test the power cord.

All Friedrich room air conditioners are shipped from the factory with a

Leakage Current Detection Interrupter (LCDI) equipped power cord. The

LCDI device on the end of the cord meets the UL and NEC requirements

for cord connected air conditioners.

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET (see Figure 1).

3. Press TEST, listen for click; the RESET button trips and pops out.

4. Press and release RESET (Listen for click; RESET button latches and

remains in). The power cord is ready for use.

RESET

TEST

WARNING:

TEST BEFORE EACH USE!

1. PRESS REST BUTTON.

2. PLUG LCDI INTO POWER

RECEPTACLE.

3. PRESS TEST BUTTON,

RESET BUTTON SHOULD

POP UP.

4. PRESS RESET BUTTON

FOR USE.

DO NOT USE IF ABOVE

TEST FAILS.

WHEN GREEN LIGHT

IS ON, IT IS WORKING

PROPERLY!

FRR072

4 5

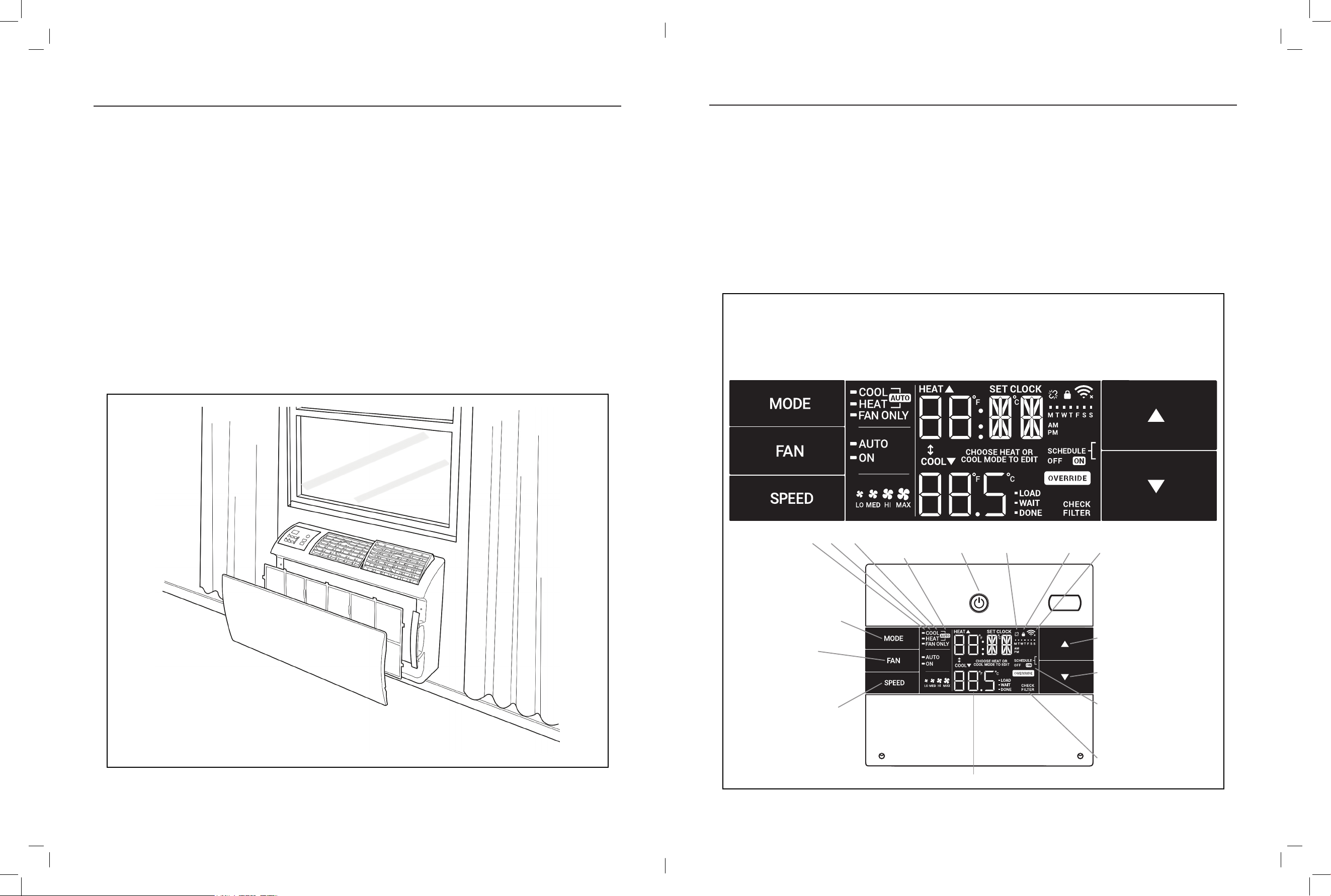

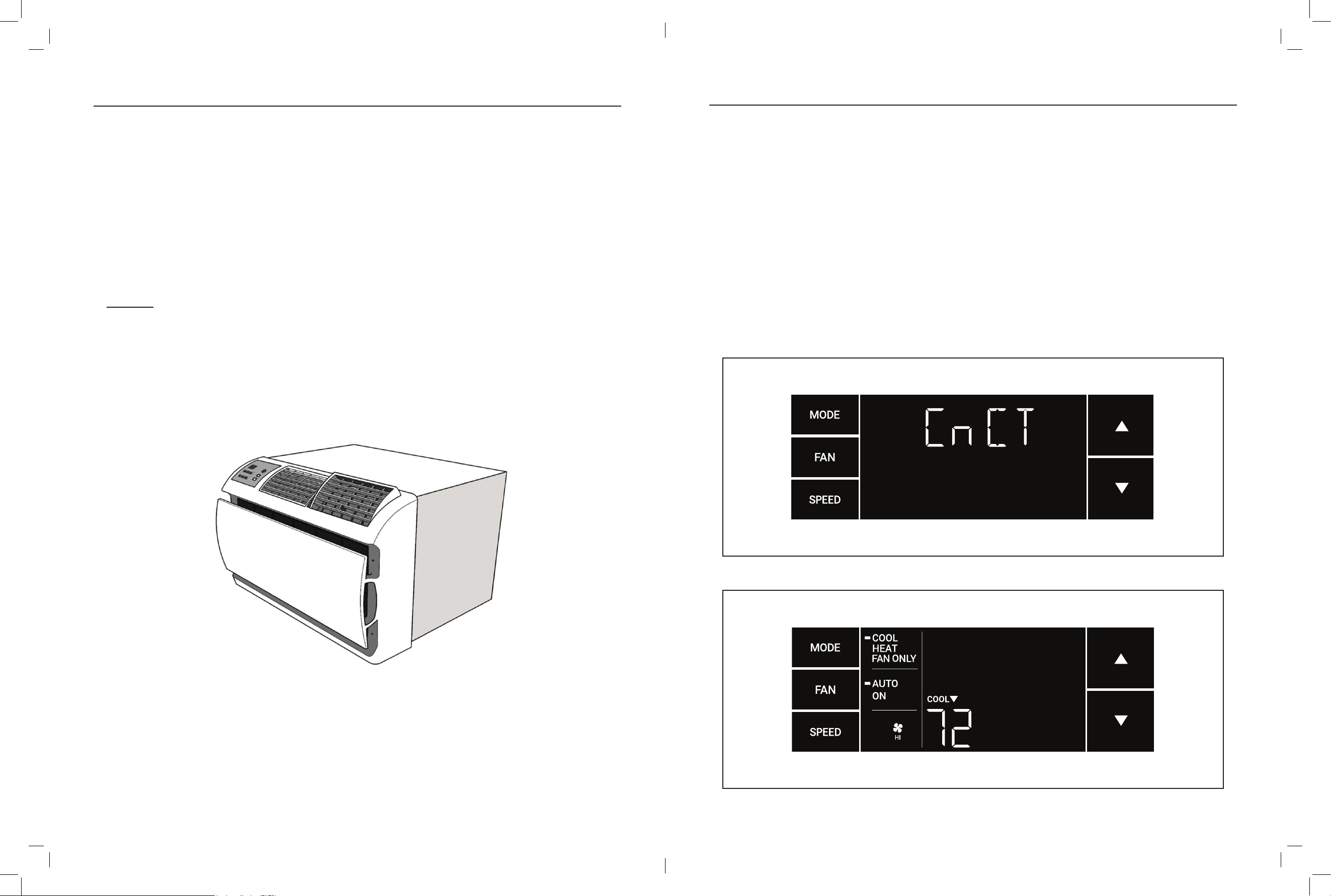

Standard Filter Cleaning / Installation Instructions

MODE

Cycles between

COOL, HEAT, FAN

ONLY or -AUTO(if equipped)

ON / OFF

-AUTO-

CONTROL

2 DIGIT DISPLAY

WI-FI OPERATING

FAN SPEED

Sets fan speed:

LOW, MED, HIGH,

OR MAX

(Actual settings are

model dependant)

FAN

Sets fan to either:

- Automatically cycle

- Continuously run

COOL HEAT FAN ONLY DISCONNECTED

Control Panel Operation

HOW TO CLEAN YOUR AIR FILTER

Your Friedrich room air conditioner is equipped with a permanent/ washable mesh air lter. The lter serves to remove dust, pollen, and other impurities

from the air.

CHECK FILTER LIGHT

Your Friedrich room air conditioner is equipped with a check lter light that will illuminate after *45 – 60 days of fan operation.

To reset the CHECK FILTER reminder press the CHECK FILTER button. (While the reminder is set for 45 – 60 days of operation, we recommend checking

the lter every 30 days for optimal performance.)

*Actual timer is set for 1000 hours of fan cycle operation.

FILTER ACCESS

Remove the FRONT PANEL. Using the handles, pull panel out until it is released from the two retaining snaps. Place the cover aside carefully. Remove the

lter by pulling it from the handles releasing it from the slots on the frame. Wash the lter with water to remove all dust and then rinse, remove water excess

and let it dry – do not twist – then replace the lter by inserting each tab in their respective slot.

Replace the FRONT PANEL by positioning one of the sides in the snaps of the handle rst and then the other side, make sure that both snaps are correctly

aligned and the logo is in the right position.

Figure 2

All of the control panel function buttons and mode icons can be viewed in Figure 3.

Power On – Press the button to turn on the air conditioner. The power button illuminates to indicate that the power is on. The backlight on the power switch

will automatically turn off after 20 seconds of inactivity. The remote control can also be used to turn power ON / OFF (See Remote Control).

Display – The display is a high efciency LCD with a built-in backlight. After 20 seconds of inactivity, the display switches off. Touching any button

automatically changes the display to full brightness.

There are three control push buttons on each side of the display.

Figure 3

SYSTEM

Cycles between

AUTO, HEAT,

COOL, or FAN

ONLY

(if equipped)

FAN MODE

Sets fan to either:

- Cycle automatically

- Run continuously

FAN SPEED

Sets fan speed:

LOW, MED,

HIGH or AUTO

(if equipped)

TEMPERATURE

Increment UP

TEMPERATURE

Increment DOWN

TIMER

Turns ON or OFF

IR WINDOW

Do not block

ON / OFF

Turns unit on/ off

6 7

FRR071

Figure 4

Automatically switches

between cool & heat

Turns unit on/off

FROM POWER BOARD

LOCKED

STATE

TEMPERATURE

UP

TEMPERATURE

DOWN

TIMER

shows on or off

FILTER

Check / clean

Control Panel Operation

Control Panel Operation

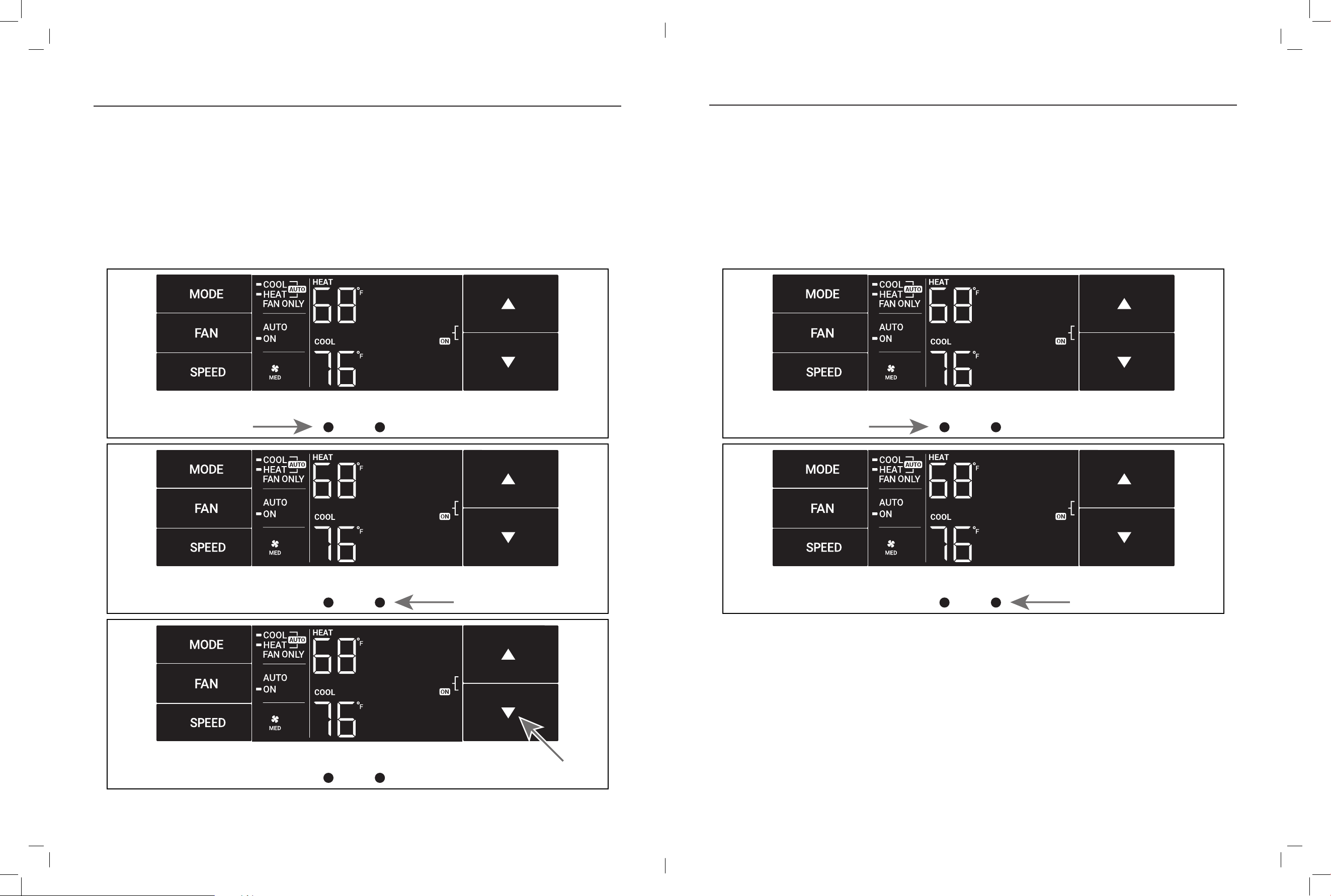

Accessing Sub-Menus

The leftmost MENU button accesses the sub-menu. See Figure 5.

The arrow buttons navigate the 6 menu options (See Figure 6):

– LIM – LOCK

– TM – CnCT

– F-C – diAG

The rightmost button exits the menu. See Figure 7.

Figure 5

MENU

Figure 6

Navigating Inside the Sub-Menus

The leftmost MENU button moves you forward through the sub-menu.

See Figure 8.

The rightmost button moves you backward once inside the LIM and TM

menus. See Figure 9.

Figure 8

MENU

Figure 9

MENU

Figure 7

MENU

MENU

8 9

Control Panel OperationControl Panel Operation

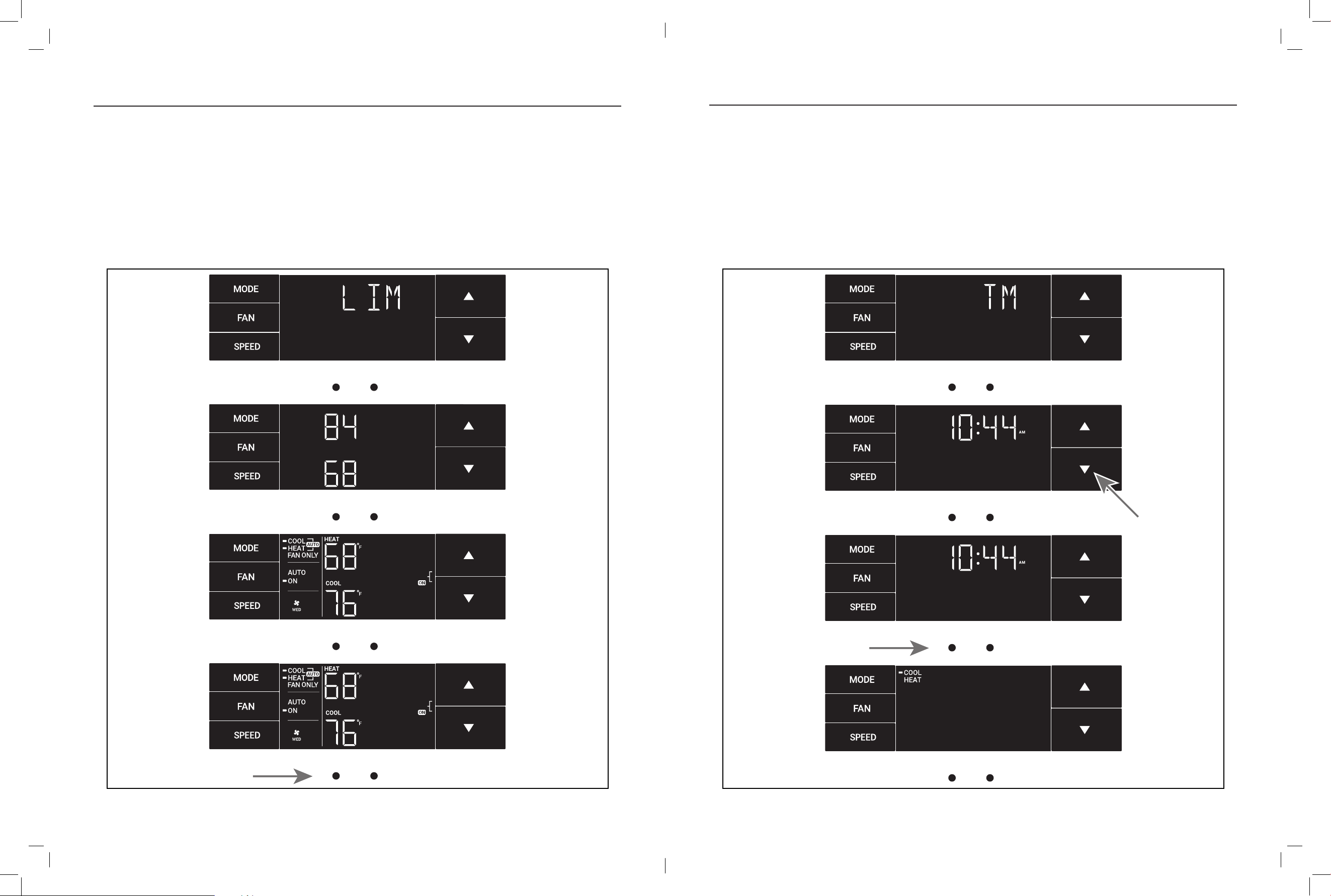

The LIM Menu

This is the limit menu. See Figure 10.

Upon entering the menu, the rst option will be to set the lower setpoint

limit using the arrow buttons. See Figure 11.

Figure 10

MENU

Figure 11

Then you can set the higher setpoint limit using the arrow buttons.

See Figure 12.

Pressing the leftmost button completes the limit setting. See Figure 13.

The TM Menu

This is the TM menu used to set a timer. See Figure 14.

In the menu, you set the current time using the arrow buttons. See Figure

15. (Note: These two “set clock” steps will be skipped if the unit is already

connected to Wi-Fi.)

First, set the hour.

Figure 14

MENU

Figure 15

Using the leftmost button, you switch to the minutes and complete setting

the time. See Figure 16.

You select your mode. Either cool, heat, or auto. Toggle these using the

arrow buttons. See Figure 17. (Note: cooling-only models skip this step.)

The process is the same for all three modes. Auto mode will be shown as

the example.

Figure 12

Figure 13

MENU

Figure 16

MENU

Figure 17

MENU

MENU

MENU

MENU

10 11

Control Panel Operation

Control Panel Operation

The TM Menu continued

Auto mode selected. See Figure 18.

Set the cool setpoint for your rst timer period using the arrow buttons.

The cooling mode timer only sets the cool setpoint. See Figure 19.

Next, set the heat setpoint for your rst timer period. The heating mode

timer only sets the heat setpoint. See Figure 20.

Figure 18

MENU

Figure 19

Note: The auto mode timer sets both the cool and heat setpoint.

Set the time to start the rst timer period. See Figure 21.

The TM Menu continued

Set the cool setpoint for the second scheduled timer. See Figure 22.

Set the heat setpoint for the second timer.

Set the time to start the second timer period. See Figure 23.

Press the leftmost button to complete the time timer setup.

See Figure 24.

Figure 22

MENU

Figure 23

Figure 20

Figure 21

MENU

Figure 24

MENU

MENU

MENU

MENU

12 13

Control Panel Operation

Control Panel Operation

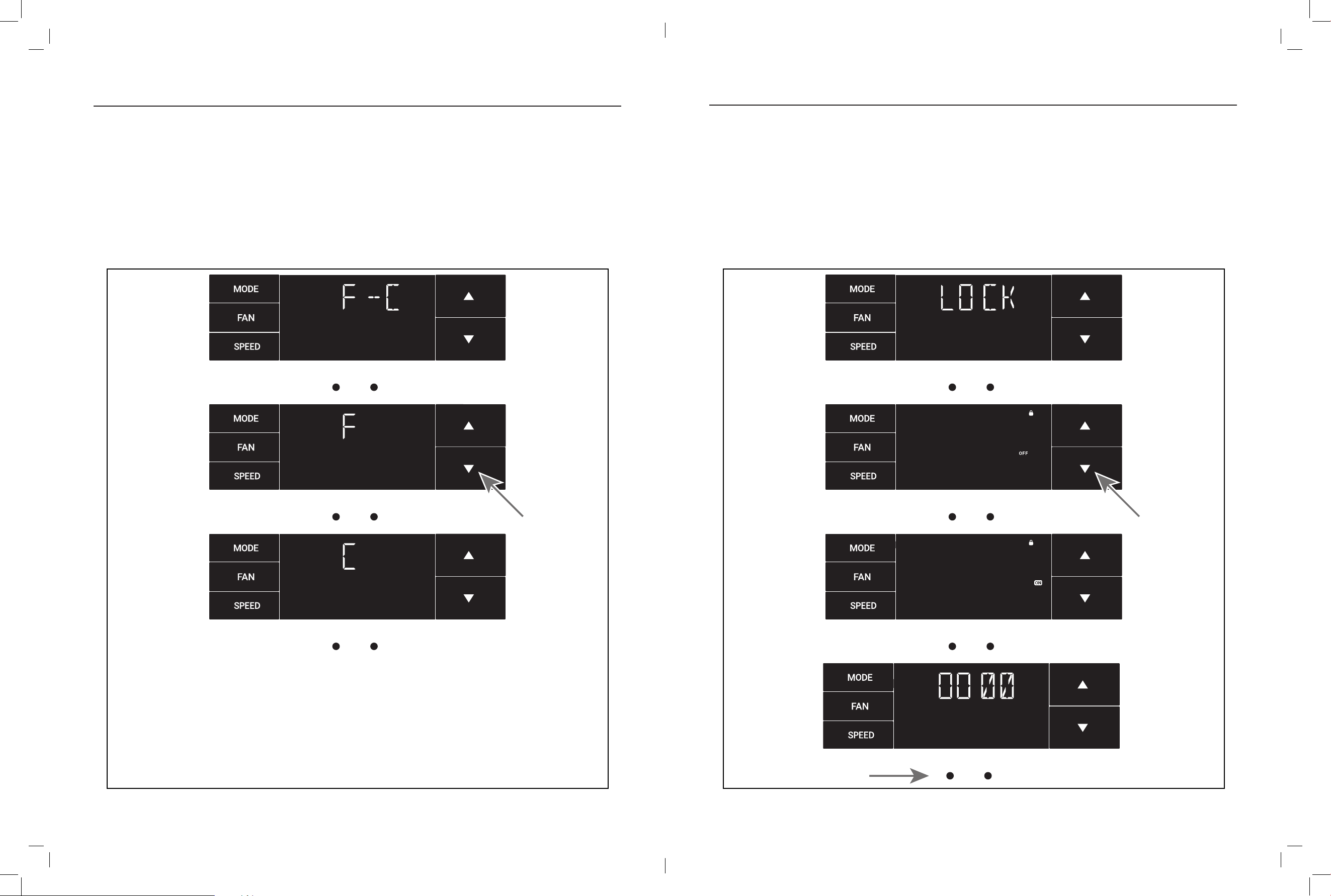

The F-C Menu

This menu is used to toggle between Fahrenheit and Celsius.

This is the Fahrenheit/ Celsius Menu. See Figure 25.

Using the arrow buttons on the right side switches it from Fahrenheit to

Celsius. See Figures 26 and 27.

Figure 25

MENU

Figure 26

The Lock Menu

This menu is used to lock the changing setting with a password.

This is the Lock Menu. See Figure 28.

The default is the off setting. Use the arrows to toggle between off and

on. See Figure 29.

Figure 28

MENU

Figure 29

This is LOCK on. See Figure 30.

Set the rst digit of the password using the arrow buttons. Use the leftmost button to proceed to the next digit. See Figure 31.

Figure 27

MENU

Figure 30

MENU

Figure 31

MENU

MENU

MENU

14 15

Control Panel Operation

Control Panel Operation

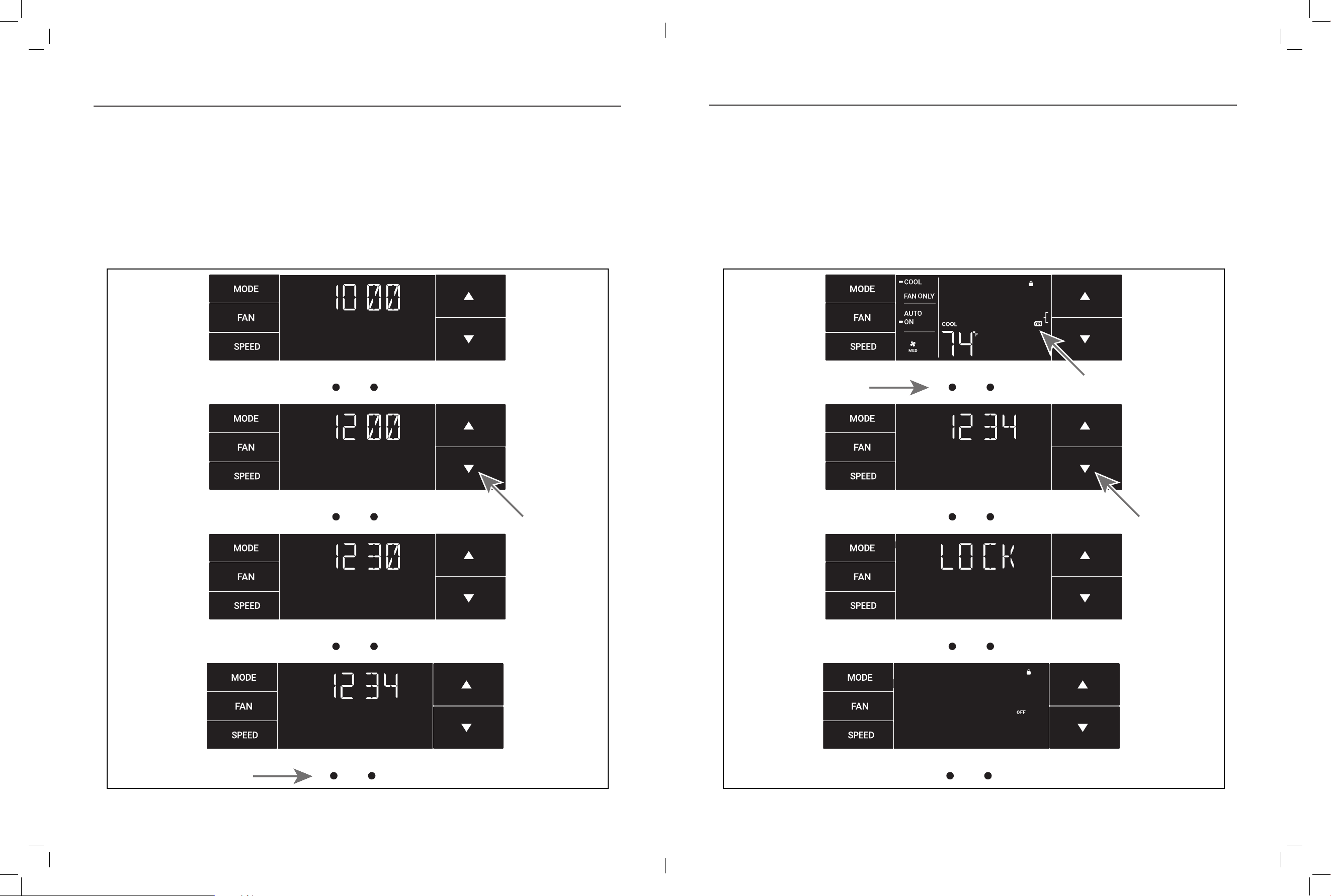

The Lock Menu continued

Set the second digit of the password using the same method.

See Figure 32.

Set the third digit of the password using the same method.

See Figure 33.

Figure 32

Figure 33

MENU

Set the fourth digit of the password using the same method.

See Figures 34.

Press the leftmost button to complete the password process.

See Figure 35.

The Lock Menu continued

The ON on the right side of the display shows the lock function is

active. To go back into the menu, select the leftmost button again.

See Figure 36.

Enter the password in the same manner it was created. See Figure 37.

Figure 36

MENU

Figure 37

Entering the correct password will give the user access to all of the submenus. See Figure 38.

Accessing the lock menu will allow you to toggle lock OFF if needed.

See Figure 39.

Figure 34

Figure 35

MENU

Figure 38

MENU

Figure 39

MENU

MENU

MENU

MENU

16 17

Control Panel Operation

Control Panel Operation

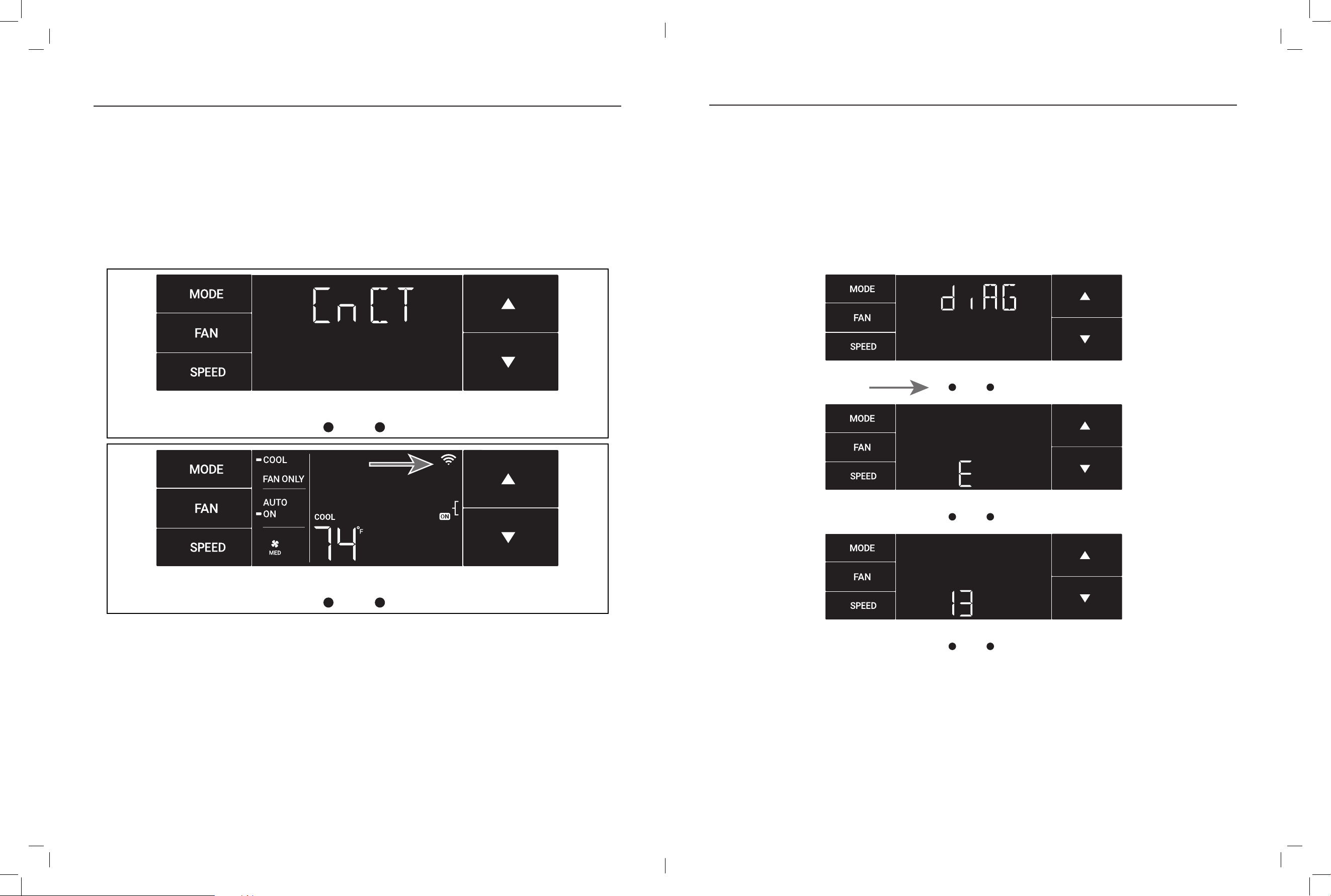

The CnCT Menu

This menu is used to turn on Wi-Fi connection.

This is the CnCT menu. Pressing the leftmost button will activate Wi-Fi.

See Figure 40.

The Wi-Fi symbol in the top right corner of the display shows Wi-Fi

connection is on. See Figure 41.

Figure 40

MENU

Figure 41

The diAG Menu

This menu is used to access the diagnostic codes. See Figure 42.

Selecting this sub-menu shows the E that represents “Error.”

See Figure 43.

Toggle through the error codes using the arrow keys. See Figure 44.

Figure 42

MENU

Figure 43

MENU

Figure 44

MENU

MENU

18 19

New WallMaster® Control Options Wi-Fi Set-Up Instructions

The new WallMaster gives you a variety of options for control, programming,

and scheduling including wireless capabilities.

Wireless Programming and Control:

Friedrich Connect allows you to conveniently control, program, and monitor

your air conditioning unit remotely from a smartphone or computer.

Pre-Programmed Scheduling Options:

Your unit’s digital control comes equipped with a 24-hour timer.

24-Hour Timer

The 24-hour timer allows you to set 2 temperature changes at pre-set times

or a unit control panel.

Customizable Programming Options:

Customizable timers, with up to four temperature adjustments per day, can

be set using Friedrich Connect for one or multiple units.

See www.friedrich.com for complete details on Friedrich Connect.

Below are the set-up instructions for Wi-Fi to use your unit wirelessly.

Follow the instructions below:

STEP 1. Using a mobile device such as a smartphone or laptop, navigate

to www.FriedrichConnect.com.

STEP 2. Sign-in using your username and password.

STEP 3. Click the “Add Device” button.

STEP 4. Select the time zone the device is located in and click the “Next”

button.

STEP 5. To start the setup process click the menu button on the home

screen of your WallMaster model.

Figure 45

STEP 6. Using the up and down arrows, navigate to the CnCT screen

(Figure 45).

STEP 7. Click the menu button, this will begin the setup process for your

Friedrich Connect enabled device.

STEP 8. Click the “Next” button on your mobile device.

STEP 9. Follow the on-screen steps to nish adding the device to

your account.

Figure 46

20 21

Control Panel Operation Instructions

Remote Control Operation

SYSTEM - The MODE button allows you to sequentially select up to four

modes of operation:

AUTO Available on select models

COOL

HEAT Available on select models

FAN ONLY

AUTO FAN (No Cooling Demand)

When in AUTO mode, the fan only operates when the system has a

demand to cool or heat the room.

In the ON fan mode, the fan operates all the time. The system periodically

cools or heats the fan’s airow but the ow of air does not stop.

UP and DOWN Arrows - Pressing either an UP or DOWN button changes

the system’s setpoint (desired room temperature). These buttons are also

used to make system parameter changes later in this manual.

One press equals 1 degree of change in Fahrenheit mode. One press

equals 0.5 degree change in Celsius mode.

TIMER

The timer can be engaged or disengaged from the control panel. This is

done by pressing or holding the UP and DOWN arrows simultaneously for

three seconds.

Alerts

When the lter needs to be cleaned or replaced, the CHECK FILTER

icon displays.

The alert can be dismissed by pressing the FAN MODE and TIME for

3 seconds.

Lock Control Panel

To lock/ unlock the front panel controls, navigate to the “LOCK” sub-menu

found after clicking the MENU button. The lock requires a four digit pass code

to lock/ unlock the unit. This pass code will be required to enter the menu to

unlock the unit. The LOCK icon illuminates to indicate the locked status.

The LOCK icon disappears to indicate unlocked status.

External Control Status

The Wi-Fi icon illuminates to indicate that the system is receiving a WiFi connection. The Wi-Fi icon also provides information about the signal

strength.

ADVANCED FUNCTIONS

The functions mentioned in the following section may or may not be available

depending on the air conditioner model.

Modify the TIMER Function

Navigate to the TIME menu to set the timer.

Remote Control - Refer to Figure 47 during operation description.

Getting Started - Install two (2) AAA batteries in the battery compartment

located on the back of the unit.

Operation - The remote control should be within 25 feet of the air conditioner

for operation. (Refer to Figure 47 for effectiveness). Press the power button

to turn the remote on. The remote will automatically power off after 15

seconds if the buttons are not being pressed. The remote must be on to

control the unit.

POWER Button - Turns remote and unit on and off.

SYSTEM Button - Allows the user to sequentially select the following:

AUTO, COOL, HEAT, and FAN ONLY operations. When the button is

pressed, the display indicates which mode has been selected via a display

message. Note that when the heating function is not available, the system

will automatically skip the HEAT mode.

FAN MODE Button - Selects between automatic (AUTO FAN) or

CONTINUOUS operation. In the AUTO FAN mode, the fan only turns on

and off when the compressor operates or the heat function is enabled.

NOTE: AUTO FAN is not available in the FAN ONLY Mode, the display

indicates CONTINUOUS. In the CONTINUOUS mode, fan speed

is determined by your selection on the FAN SPEED button.

FAN SPEED Button - Used to sequentially select new fan speed,

plus AUTO operation. When the FAN SPEED button is pressed, the

fan speed icon (triangle) changes to indicate the new speed level. Fan

speed automatically varies depending on the set temperature on the

control panel and the actual room temperature. For example, if there

is a big difference between your set temperature and the actual room

temperature, the system fan speed increases to HIGH. It remains at

this speed until the room temperature matches the set temperature.

Figure 47

UP and DOWN Arrows - Pressing either the UP or DOWN button

changes the desired room temperature. The factory preset lower and

upper limits are 60 °F (16 °C) and 99 °F (37 °C). These buttons are also

used to navigate between function options when using the User Menu

or Maintenance Mode.

Remote Effectiveness

Handheld Remote - Has an operating range of up to 25 ft. The infrared

remote control signal must have a clear path to transmit the command to

the air conditioning unit. The remote signal has some ability to “bounce”

off of walls and furniture similar to a television remote control. The diagram

below shows the typical operating range of the control in a standard room

with 8 ft high ceilings.

Airflow Selection and Adjustment

Airflow direction adjustment

The airow path may be adjusted to distribute air independently from the

left or right side of the discharge opening. Each of the banks of louvers can

be directed left, right, up, or down in order to achieve the most optimum

airow positioning.

To adjust airow direction, grab the lever in the center of the louver bank

and move it in the direction that you would like the air to be directed. Please

note that it is normal that airow may be stronger out of one side of the

louvers than the other.

TOP VIEW

OTHER FUNCTIONS

25ft

°F – °C Select

To switch from degrees Fahrenheit (F) to Celsius (C), press the MENU

button and enter the F-C sub-menu.

25ft

FAN SPEED - Depending on your model, the FAN SPEED button allows

you to toggle between three or four modes of operation: LOW, MEDIUM,

HIGH and MAX.

SIDE VIEW

7.5ft

30°

45°

60°

60°

45°

30°

8ft

25ft

25ft

25ft

25ft

4ft

8ft

60°

60°

45°

45°

30°

30°

25ft

6ft

16ft

25ft

FRR080

22 23

Installation Instructions

READ THIS FIRST! Electrical Requirements

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same conguration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong outlet.

Failure to follow these instructions can result

in death, re, or electrical shock.

IMPORTANT: Before you begin the actual installation of your air

conditioner, check your local electrical codes and the information below.

Your air conditioner must be connected to a power source with the same

alternating current (A.C.) voltage and amperage as marked on the name

plate located on the chassis. Only A.C. can be used. Direct Current (D.C.)

cannot be used.

CIRCUIT PROTECTION – Use on single outlet circuit only. An overloaded

circuit will invariably cause malfunction or failure of an air conditioner;

therefore, it is necessary that the electrical protection is adequate. Due

to momentary high current demand when the air conditioner starts, use a

“TIME DELAY” fuse or a HACR type circuit breaker. Consult your dealer or

power company if in doubt.

Refer to the electrical name plate located on the air conditioner chassis

(see Page 2) to determine the correct fuse or circuit breaker amperage for

your model (see Table 1 on Page 5 for electrical receptacle types).

The power cord has a plug with a grounding prong and a matching

receptacle is required.

WARNING

MOVING PARTS HAZARDS

• Do not operate unit out of sleeve or

with front grille removed.

• Do not place hands in blower or fan

blade areas.

Failure to do so can result in serious injury.

CAUTION

Excessive Weight Hazard

Use two or more people when installing your

air conditioner.

Failure to do so can result in back or other

injury.

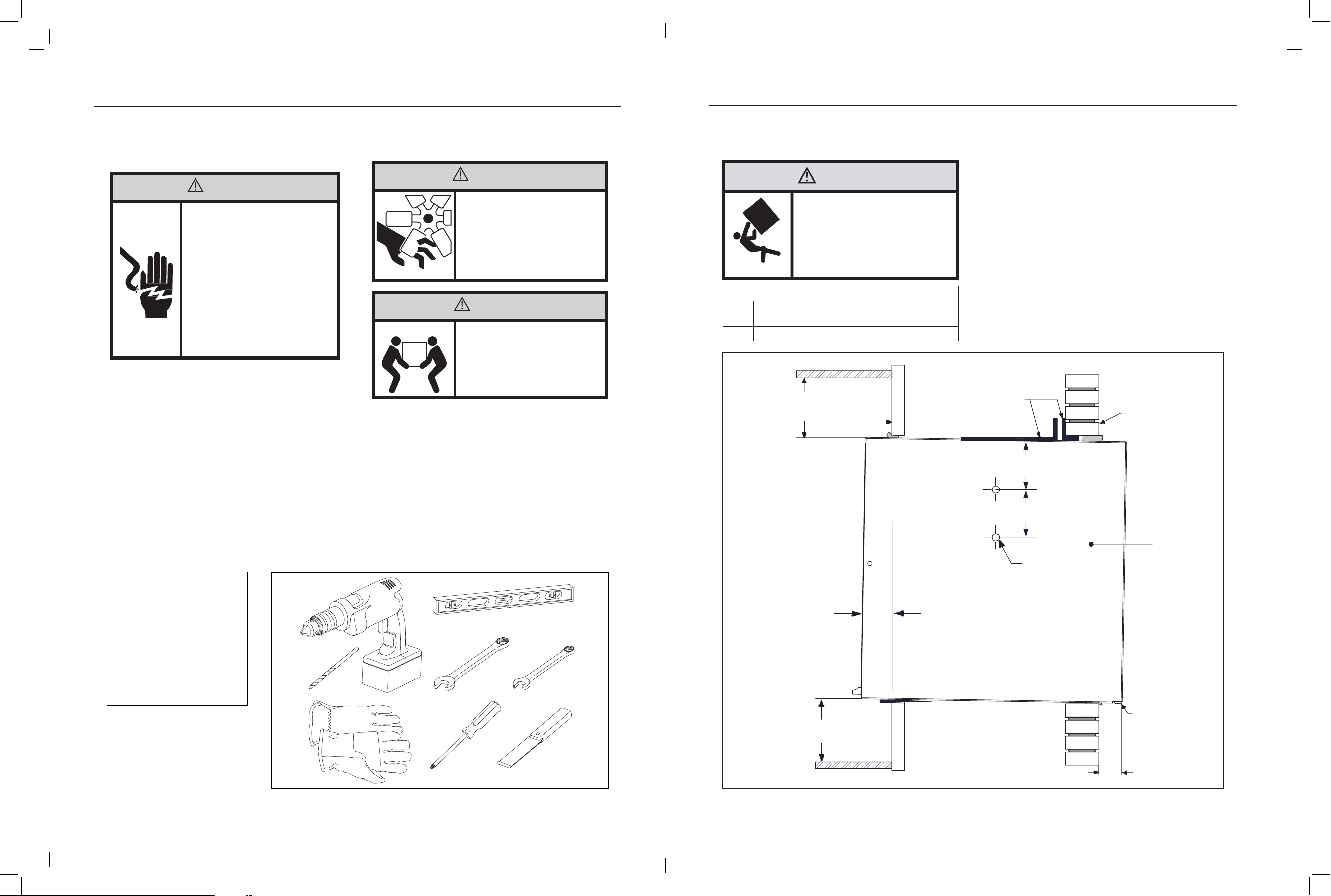

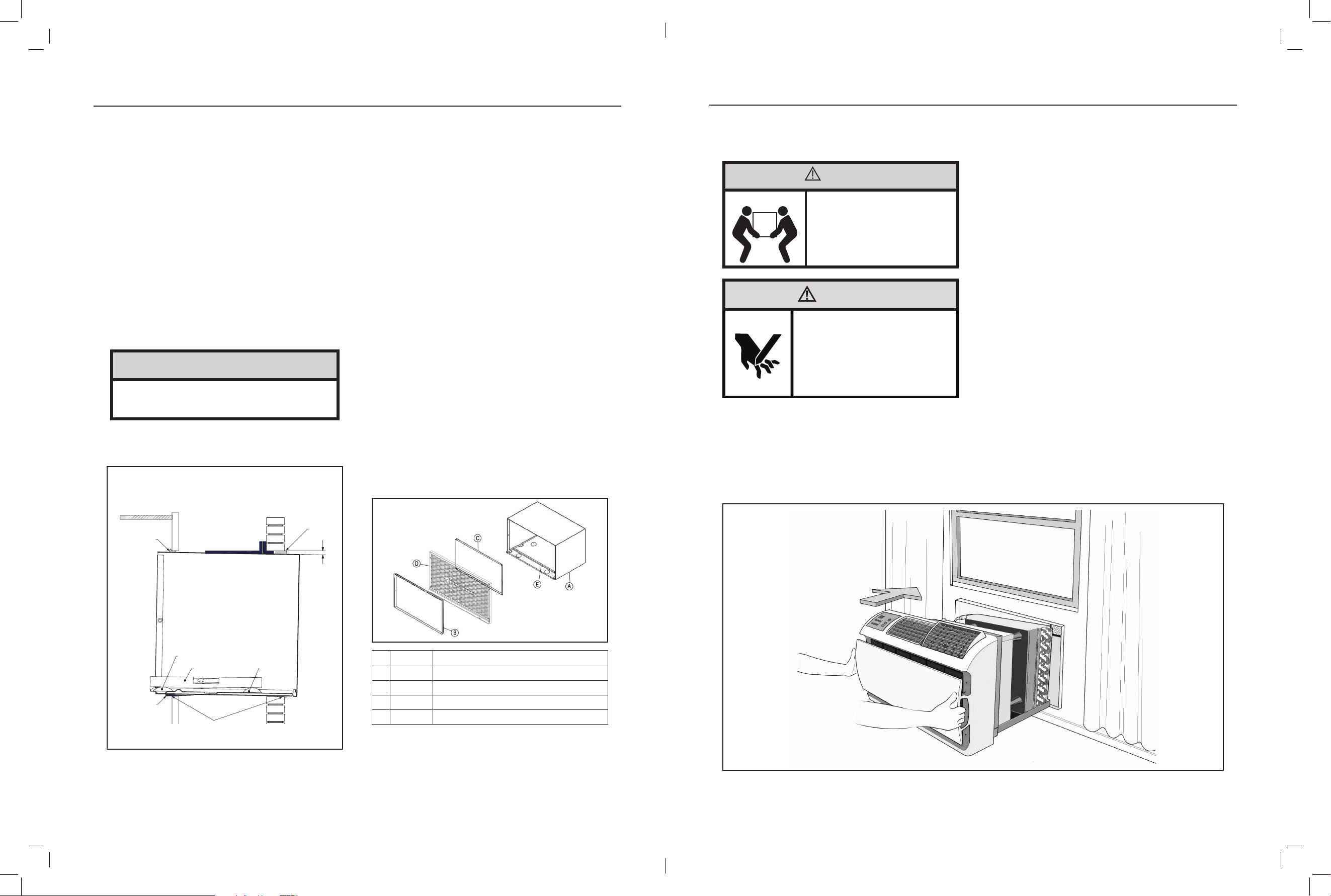

Installation Instructions for WSE Sleeve

(WSE Sleeve Accessory Sold Separately)

Wall Preparation

WARNING

STEP 1. The wall opening required for a WSE SLEEVE is 17 ¼″ high by

Falling Object Hazard

Not following Installation Instructions

for mounting your air conditioner can

result in property damage, injury, or

death.

Mounting Hardware

ITEM

NO

1 SCREW, #12A x 2″ 7

Figure 48

24″ MINIMUM REQUIRED FROM

TOP OF UNIT TO CEILING

1″ MINIMUM SPACING REQUIRED

ON ALL SIDES OF UNIT

7

/8″ MINIMUM BEYOND

INSIDE WALL

DESCRIPTION QTY.

INSIDE

WALL

STEP 2. LINTELS must be used in opening of brick veneer and masonry

A. Masonry walls to support the material above the WSE SLEEVE.

B. Adjustable SUBBASE (SB) or other unit support must be

SIDE VIEW

LINTELS

27 ¼″ wide.

walls to support the material above the WSE SLEEVE. The

following considerations should also be given:

provided for panel wall type construction and for walls less

than 8″ thick.

5″ (127 mm)

5″ (127 mm)

WALL MOUNT

SCREW LOCATIONS

OUTSIDE WALL

WSE SLEEVE

Recommended Tools

1. Power Drill

2. 5/32" Drill Bit

3. Gloves

4. Carpenters Level

5. 5/16" Wrench

6. 1/4" Wrench

7. #2 Phillips Screw Driver

8. Putty Knife or (wood stir stick)

1

2

3

ITEMS NOT TO SCALE

5/16

24 25

4

5/16

1/4

65

1/4

1″ MINIMUM

3 1/2″ FOR SUBBASE

5 1/2″ MAXIMUM FOR SUBBASE

87

DRAIN EXTENSION

9

/16″ MINIMUM BEYOND

OUTSIDE WALL

FRR011

Installation Instructions for WSE Sleeve continued

Installation Requirements

STEP 1. The WSE sleeve should be positioned so that the drain

extension extends a minimum of 9/16″ beyond the outside wall

(see Figure 48).

STEP 2. The WSE sleeve must extend a minimum of 7/8″ beyond the

inside wall.

STEP 3. The WSE sleeve must be installed level side to side.

STEP 4. The WSE sleeve must also be installed with a downward tilt

toward the outside of the building. If a level is placed so that

it rests on the front and back unit rest as shown in Figure 49, a

properly installed unit provides a 3/8″ slope to the outside of the

building.

NOTICE

Sleeve projections and leveling precautions must be

observed to prevent the entry of water into the room.

Figure 49

Sleeve Requirements

STEP 1. After unpacking the WSE sleeve from the carton, remove the

indoor weather panel. Place the WSE sleeve in the wall opening

following the instructions given in the Installation Requirements.

Attach the sleeve to the inside wall by driving two #12A x 2″

screws in each side of the sleeve (see Figure 50). Shim at the

top of the sleeve, midway between the sides. Drive one #12A

x 2″ screw in the top of the sleeve. If the wall opening is not

framed with wood, use expansion anchor bolts or molly (toggle)

bolts (not provided).

STEP 2. Once the sleeve has been installed, check the level again to be

sure the 3/8″ downward slope is maintained.

NOTE: If necessary, apply shims below the chassis and inside

the sleeve front unit rest, to ensure a 3/8″ downward slope front

to back.

STEP 3. Caulk the perimeter of the entire opening on the inside and the

outside between the sleeve and the wall.

STEP 4. The indoor weather panel removed in Step 1 above must be

remounted back in place if masonry work is to be done and/ or if

the “WallMaster”chassis is to be installed at a later date.

How to cover inner weather panel holes

Two beige plugs are included in the plastic bag taped to the WallMaster

chassis. These plugs may be used to cover the two holes left after removing

the indoor weather panel.

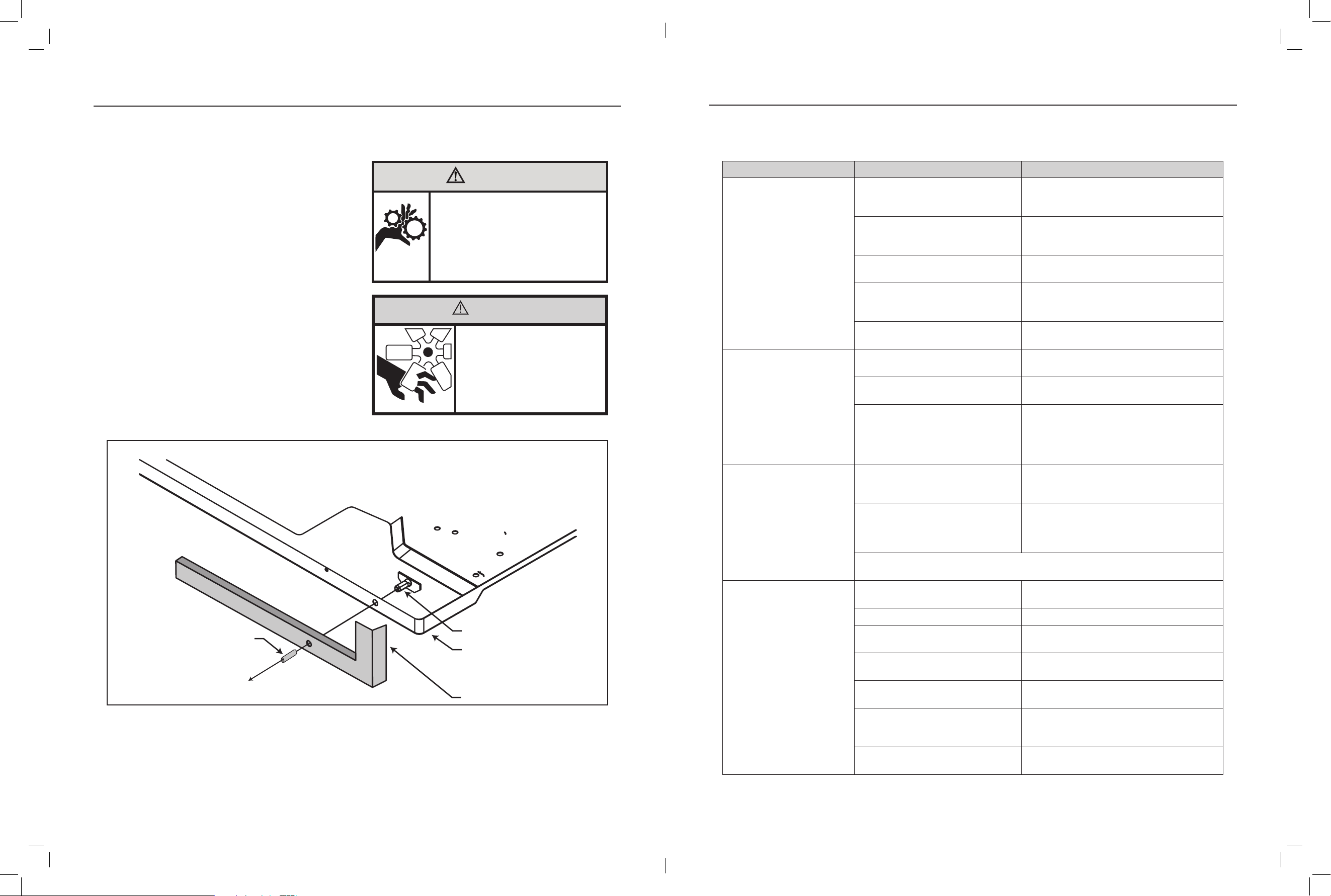

WallMaster Chassis Installation Instructions

for WCT, WET and WHT models

STEP 1. Check the sleeve to be certain it has been correctly installed

CAUTION

Excessive Weight Hazard

Use two or more people when installing your

air conditioner.

Failure to do so can result in back or other

injury.

CAUTION

Cut/Sever

Although great care has been

taken to minimize sharp edges

in the construction of your unit,

use gloves or other hand

protection when handling unit

Failure to do so can result in minor

to moderate personal injury.

A. Check the anchor screw. There should be four (4) in the WSE

B. Determine if the sleeve has a downward slope of 3/8″ to the

C. Check to be sure the sleeve has been sealed around all

STEP 3. Check the electrical receptacle to see that it conforms to the

STEP 3. Remove the chassis from the shipping carton. Lift the chassis

NOTE: Chassis comes with pre-installed seal gasket.

in the wall. Remove the front panel on the WSE SLEEVE.

Remove the rear WEATHER PANEL. Reverse grille. Place

lower edge into sleeve tab (Friedrich logo facing out). Align

slots with the screw holes. Secure grille with screws.

SLEEVE (two in each side).

outside. See Page 26 for further details.

edges with an industrial type caulking on both the outside

and inside to prevent rain entry.

requirements for the chassis model to be installed. See Page 5

for the receptacle requirements.

by the basepan and slide it into the front of the sleeve. (Obtain

assistance as needed.) Push the chassis all the way into the

sleeve, using the plastic front handles, so that the front panel

meets the front edge of the shell.

CAULK

(AS NEEDED)

FRONT

OF UNIT

SHIM TO

PROPER

SPACING

FRONT

UNIT

REST

LEVEL

CAULK

(AS NEEDED)

BACK

UNIT

REST

CAULK

(AS NEEDED)

3

/8″

SLOPE

BACK

OF UNIT

Figure 50

WSE SLEEVE

A

B 61603200 INDOOR WEATHER PANEL (METAL)

C 61603304 OUTDOOR WEATHER PANEL (PAINTED METAL)

D 61603012 ASSY GRILLE WSE SLEEVE

E 61578101 GASKET (ATTACHED TO SLEEVE)

Figure 51

26 27

WallMaster Chassis Installation Instructions

for WCT, WET and WHT models

Troubleshooting Tips

Condensate Removal

If you desire to drain condensate from the basepan during unit

operation, this unit is provided with a drain nipple that can be attached

to the basepan. You must provide a 3/8″ outside diameter thin-wall

plastic or copper tube which will attach to the drain nipple.

Follow the instructions below:

STEP 1. Find the drain rubber plug on the rear of the basepan and

remove it (see Figure 52).

STEP 2. Remove the knockout in the lower right side of the rear grille.

Slide the chassis into the WSE SLEEVE so that the drain nipple

extends through the knockout.

STEP 3. Slide the tubing over the drain nipple. If the chassis must be

removed from the sleeve for service, remove the clamped drain

hose before sliding the chassis out of the sleeve.

Alternate Drain Kits

Figure 52

WARNING

MOVING OBJECT HAZARD

Replace all panels before operating your air

conditioner.

Failure to do so can result in severe personal

injury or death and damage to product or other

property.

WARNING

MOVING PARTS HAZARDS

• Do not operate unit out of sleeve or

with front grille removed.

• Do not place hands in blower or fan

blade areas.

Failure to do so can result in serious injury.

Unit does not operate.

Unit Trips Circuit Breaker or

Blows Fuses.

LCDI Power Cord Trips

(Reset Button Pops Out).

COMPLAINT CAUSE SOLUTION

• The unit is turned to the off position, or the

thermostat is satised.

• Turn the unit to the on position and raise or lower

temperature setting (as appropriate) to call for

operation.

• Plug into a properly grounded 3 prong receptacle.

• The LCDI power cord is unplugged.

• The LCDI power cord has tripped (Reset

button has popped out).

• The circuit breaker has tripped or the

supply circuit fuse has blown.

• There has been a local power failure.

• Other appliances are being used on the

same circuit.

• An extension cord is being used.

See “Electrical Rating Tables” on Page 5 for the

proper receptacle type for your unit.

• Press and release RESET (Listen for click. Reset

button latches and remains in.) to resume operation.

• Reset the circuit breaker, or replace the fuse as

applicable. If the problem continues, contact a

licensed electrician.

• The unit will resume normal operation once power

has been restored.

• The unit requires a dedicated outlet circuit, not shared

with other appliances.

• Do NOT use an extension cord with this or any other

air conditioner.

• Replace with a circuit breaker or time-delay fuse of

• The circuit breaker or time-delay fuse is

not of the proper rating.

• The LCDI power cord can trip (Reset

button pops out) due to disturbances on

your power supply line.

• Electrical overload, overheating, or cord

pinching can trip (Reset button pops out)

the LCDI power cord.

NOTE: A damaged power supply cord must be replaced with a new power supply cord obtained from the

product manufacturer and must not be repaired.

• The return/ discharge air grille is blocked.

the proper rating. See “Electrical Rating Tables” on

Page 5 for the proper circuit breaker/ fuse rating for

your unit. If the problem continues, contact a licensed

electrician.

• Press and release RESET (Listen for click. Reset

button latches and remains in.) to resume normal

operation.

• Once the problem has been determined and

corrected, press and release RESET (Listen for

click. Reset button latches and remains in.) to

resume normal operation.

• Ensure that the return and/ or discharge air paths are

not blocked by curtains, blinds, furniture, etc.

• Windows or doors to the outside are open. • Ensure that all windows and doors are closed.

DRAIN

HOSE

DK (Drain Kit)

In the event that the outdoor temperature drops below 37 °F, any water

that remains in the chassis basepan is drained into the sleeve pan

on WET and WHT models to prevent freezing. (NOTE: In the cooling

mode of the WCT, WET and WHT models, condensate overow is

possible in very humid climates). For these particular instances, an

optional drain kit (Accessory #DK) is available for water removal.

IDK (Drain Kit)

New construction allowing for condensate drain systems built

within the walls can use the Friedrich Interior Drain Kit (Accessory

#IDK). This kit is designed for installation in the bottom of the sleeve

below the condensate bellows valve (heat/ cool models only).

DRAIN

NIPPLE

BASEPAN

SLEEVE

Unit Does Not Cool/ Heat Room

Sufciently, or Cycles On And Off

Too Frequently.

• The temperature is not set at a cool

enough/ warm enough setting.

• The lter is dirty or obstructed.

• The indoor coil or outdoor coil is dirty or

obstructed.

• There is excessive heat or moisture

(cooking, showers, etc.) in the room.

• The temperature of the room you are

trying to cool is extremely hot.

• Adjust the Temperature control to a cooler or warmer

setting as necessary.

• Clean the lter, (See Routine Maintenance), or

remove obstruction.

• Clean the coils, (See Routine Maintenance), or

remove obstruction.

• Be sure to use exhaust vent fans while cooking or

bathing and, if possible, try not to use heat producing

appliances during the hottest part of the day.

• Allow additional time for the air conditioner to cool off

a very hot room.

28 29

Troubleshooting Tips continued

COMPLAINT CAUSE SOLUTION

• The outside temperature is below 60 °F

(16 °C).

• The digital control is set to fan cycling mode.

Unit Does Not Cool/ Heat Room

Sufciently, or Cycles On And Off

Too Frequently (continued).

Unit Runs Too Much.

• The air conditioner has insufcient cooling

capacity to match the heat gain of the room.

• The air conditioner has insufcient heating

capacity to match the heat loss of the room.

• This may be due to an excessive heat load

in the room.

• It may also be due to an improperly sized unit.

• This may be normal for higher efciency

(EER) air conditioners.

• You may notice that the discharge air

temperature of your new air conditioner

may not seem as cold as you may be

accustomed to from older units. This

does not; however, indicate a reduction

in the cooling capacity of the unit.

• Do not try to operate your air conditioner in the

cooling mode when the outside temperature is below

60 °F (16 °C). The unit will not cool properly, and the

unit may be damaged.

• Since the fan does not circulate the room air

continuously at this setting, the room air does not

mix as well and hot (or cold) spots may result. Using

the continuous fan setting is recommended to obtain

optimum comfort levels.

• Check the cooling capacity of your unit to ensure it

is properly sized for the room in which it is installed.

Room air conditioners are not designed to cool

multiple rooms.

• Check the heating capacity of your unit. Air conditioners

are sized to meet the cooling load, and heater size

is then selected to meet the heating load. In extreme

northern climates, room air conditioners may not be able

to be used as a primary source of heat.

• If there are heat producing appliances in use in the

room, or if the room is heavily occupied, the unit will

need to run longer to remove the additional heat.

• Be sure to use exhaust vent fans while cooking or

bathing and, if possible, try not to use heat producing

appliances during the hottest part of the day.

• The use of higher efciency components in your new

air conditioner may result in the unit running longer

than you feel it should. This may be more apparent, if

it replaced an older, less efcient, model. The actual

energy usage, however, will be signicantly less

when compared to older models.

• The energy efciency ratio (EER) and cooling

capacity rating (Btu/ h) listed on the unit’s rating

plate are both agency certied.

Friedrich Air Conditioning Company

10001 Reunion Place, Suite 500

San Antonio, TX 78216

1-800-541-6645

www.friedrich.com

WALLMASTER® THRU-THE-WALL AIR CONDITIONERS

LIMITED WARRANTY

FIRST YEAR

ANY PART: If any part supplied by FRIEDRICH fails because of a defect in workmanship or material within twelve months from date of original purchase,

FRIEDRICH will repair the product at no charge, provided room air conditioner is reasonably accessible for service. Any additional labor cost for removing

inaccessible units and/or charges for mileage related to travel by a Service Agency that exceeds 25 miles one way will be the responsibility of the owner. This

remedy is expressly agreed to be the exclusive remedy within twelve months from the date of the original purchase.

SECOND THROUGH FIFTH YEAR

SEALED REFRIGERANT SYSTEM: If the Sealed Refrigeration System (dened for this purpose as the compressor, condenser coil, evaporator coil,

reversing valve, check valve, capillary, lter drier, and all interconnecting tubing) supplied by FRIEDRICH in your Room Air Conditioner fails because of

a defect in workmanship or material within sixty months from date of purchase, FRIEDRICH will pay a labor allowance and parts necessary to repair the

Sealed Refrigeration System; PROVIDED FRIEDRICH will not pay the cost of diagnosis of the problem, removal, freight charges, and transportation of the

air conditioner to and from the Service Agency, and the reinstallation charges associated with repair of the Sealed Refrigeration System. All such cost will be

the sole responsibility of the owner. This remedy is expressly agreed to be the exclusive remedy within sixty months from the date of the original purchase.

APPLICABILITY AND LIMITATIONS: This warranty is applicable only to units retained within the Fifty States of the U.S.A., District of Columbia, and Canada.

This warranty is not applicable to:

1. Air lters or fuses.

2. Products on which the model and serial numbers have been removed.

3. Products which have defects or damage which results from improper installation, wiring, electrical current characteristics, or maintenance; or caused by

accident, misuse or abuse, re, ood, alterations and/or misapplication of the product and/or units installed in a corrosive atmosphere, default or delay in

performance caused by war, government restrictions or restraints, strikes, material shortages beyond the control of FRIEDRICH, or acts of God.

OBTAINING WARRANTY PERFORMANCE: Service will be provided by the FRIEDRICH Authorized Dealer or Service Organization in your area. They are listed

in the Yellow Pages. If assistance is required in obtaining warranty performance, write to: Room Air Conditioner Service Manager, Friedrich Air Conditioning Co.

LIMITATIONS: THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES. Anything in the warranty notwithstanding, ANY IMPLIED WARRANTIES

OF FITNESS FOR PARTICULAR PURPOSE AND/OR MERCHANTABILITY SHALL BE LIMITED TO THE DURATION OF THIS EXPRESS WARRANTY.

MANUFACTURER EXPRESSLY DISCLAIMS AND EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGE FOR BREACH OF

ANY EXPRESSED OR IMPLIED WARRANTY.

NOTE: Some states do not allow limitations on how long an implied warranty lasts, or do not allow the limitation or exclusion of consequential or incidental

damages, so the foregoing exclusions and limitations may not apply to you.

OTHER: This warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

PROOF OF PURCHASE: Owner must provide proof of purchase in order to receive any warranty related services.

All service calls for explaining the operation of this product will be the sole responsibility of the consumer.

All warranty service must be provided by an Authorized FRIEDRICH Service Agency, unless authorized by FRIEDRICH prior to repairs being made.

30 31

Loading...

Loading...