Friedrich SH20M30A Parts List

Cool Only

SH15M30*

SH20M30*

S

Service & Parts Manual

Room

2010-2011

2010 2011

Air Conditioners

R-410A

Cool Only

SH15M30*

SH20M30*

HG-ServMan (4-10)

93031400_00

Table Of Contents

Important Safety Information ..................................................................................................................... 2-4

Introduction ................................................................................................................................................... 4

Unit Identification .......................................................................................................................................... 5

Hazardgard Application ................................................................................................................................ 6

Performance Specifications and Installation Data ........................................................................................ 7

Electrical Data .............................................................................................................................................. 8

HazardGard Special Features ...................................................................................................................... 9

Component Definitions ............................................................................................................................... 10

Component Testing ................................................................................................................................ 11-12

R-410A Sealed System Repair Considerations .......................................................................................... 13

Sealed Refrigeration System Repairs ................................................................................................... 14-17

Refrigerant Charging ............................................................................................................................. 14-17

Compressor Checks .............................................................................................................................. 18-19

Compressor Replacement ..................................................................................................................... 19-20

Routine Maintenance ............................................................................................................................. 21-22

Performance Test Data Sheet ..................................................................................................................... 23

Troubleshooting ..................................................................................................................................... 24-26

Wiring Diagram and Schematic .................................................................................................................. 27

Warranty ..................................................................................................................................................... 28

'LVDVVHPEO\-30

3DUW/LVWLQJ1

T echnical Assistance ...................................................................................................................................

IMPORTANT SAFETY INFORMATION

The information contained in this manual is intended for use by a qualifi ed service technician who is familiar

with the safety procedures required for installation and repair, and who is equipped with the proper tools and

test instruments required to service this product.

Installation or repairs made by unqualifi ed persons can result in subjecting the unqualifi ed person making

such repairs as well as the persons being served by the equipment to hazards resulting in injury or electrical

shock which can be serious or even fatal.

Safety warnings have been placed throughout this manual to alert you to potential hazards that may be

encountered. If you install or perform service on equipment, it is your responsibility to read and obey these

warnings to guard against any bodily injury or property damage which may result to you or others.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read

and obey all safety messages.

This is a safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING”

or “CAUTION”. These words mean:

WARNING

CAUTION

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury,

and tell you what will happen if the instructions are not followed.

NOTICE

You can be killed or seriously injured if you do not follow instructions.

You can receive minor or moderate injury if you do not follow instructions.

A message to alert you of potential property damage will have the

word “NOTICE”. Potential property damage can occur if instructions

are not followed.

PERSONAL INJURY OR DEATH HAZARDS

ELECTRICAL

• Unplug and/or disconnect all electrical power to the unit before performing inspections,

maintenance, or service.

• Make sure to follow proper lockout/tag out procedures.

• Always work in the company of a qualifi ed assistant if possible.

HAZARDS:

• Capacitors, even when disconnected from the electrical power source, retain an electrical charge

potential capable of causing electric shock or electrocution.

• Handle, discharge, and test capacitors according to safe, established, standards, and approved

procedures.

• Extreme care, proper judgment, and safety procedures must be exercised if it becomes necessary

to test or troubleshoot equipment with the power on to the unit.

2

• Do not spray or pour water on the return air grille, discharge air grille, evaporator coil, control panel,

and sleeve on the room side of the air conditioning unit while cleaning.

• Electrical component malfunction caused by water could result in electric shock or other electrically

unsafe conditions when the power is restored and the unit is turned on, even after the exterior is dry.

• Never operate the A/C unit with wet hands.

• Use air conditioner on a single dedicated circuit within the specifi ed amperage rating.

• Use on a properly grounded circuit only.

• Do not use extension cords with the unit.

• Follow all safety precautions and use proper and adequate protective safety aids such as: gloves,

goggles, clothing, adequately insulated tools, and testing equipment etc.

• Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.

REFRIGERATION SYSTEM HAZARDS:

• Use approved standard refrigerant recovering procedures and equipment to relieve pressure before

opening system for repair

• Do not allow liquid refrigerant to contact skin. Direct contact with liquid refrigerant can result in minor

to moderate injury.

.

• Be extremely careful when using an oxy-acetylene torch. Direct contact with the torch’s fl ame or hot

surfaces can cause serious burns.

• Make sure to protect personal and surrounding property with fi re proof materials.

• Have a fi re extinguisher at hand while using a torch.

• Provide adequate ventilation to vent off toxic fumes, and work with a qualifi ed assistant whenever

possible.

• Always use a pressure regulator when using dry nitrogen to test the sealed refrigeration system for

leaks, fl ushing etc.

• Make sure to follow all safety precautions and to use proper protective safety aids such as: gloves,

safety glasses, clothing etc.

• Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.

MECHANICAL HAZARDS:

• Extreme care, proper judgment and all safety procedures must be followed when testing,

troubleshooting, handling, or working around unit with moving and/or rotating parts.

• Be careful when, handling and working around exposed edges and corners of sleeve, chassis, and

other unit components especially the sharp fi

ns of the indoor and outdoor coils.

• Use proper and adequate protective aids such as: gloves, clothing, safety glasses etc.

• Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.

3

PROPERTY DAMAGE HAZARDS

FIRE DAMAGE HAZARDS:

• Read the Installation/Operation Manual for this air conditioning unit prior to operating.

• Use air conditioner on a single dedicated circuit within the specifi ed amperage rating.

• Connect to a properly grounded circuit only.

• Do not use extension cords with the unit.

• Failure to follow these instructions can result in fi re and minor to serious property damage.

WATER DAMAGE HAZARDS:

• Improper installation maintenance, or servicing of the air conditioner unit, or not following the above

Safety W

• Insure that the unit has a suffi cient pitch to the outside to allow water to drain from the unit.

• Do not drill holes in the bottom of the drain pan or the underside of the unit.

• Failure to follow these instructions can result in result in damage to the unit and/or minor to serious

property damage.

arnings can result in water damage to personal items or property.

INTRODUCTION

This service manual is designed to be used in conjunction with the operation and installation manual provided

with each unit.

This service manual was written to assist the professional HVAC service technician to quickly and accurately

diagnose and repair any malfunctions of this product.

This manual, therefore, will deal with all subjects in a general nature. (i.e. All text will pertain to all models).

IMPORTANT:

It will be necessary for you to accurately identify the unit you are servicing, so

you can be certain of a proper diagnosis and repair

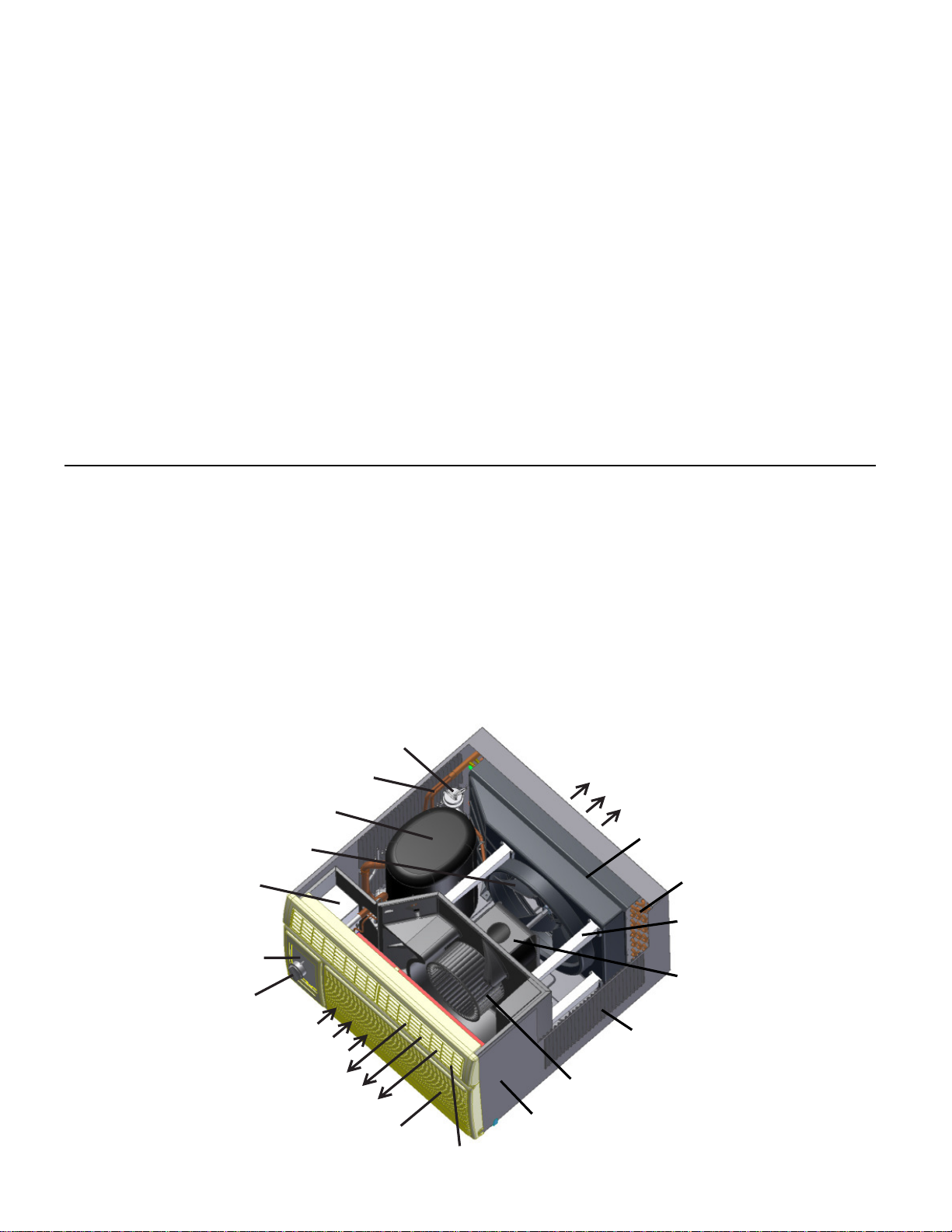

Bypass Valve

Capillary Tubes

Compressor

Fan Blade

Electrical

Compartment

On/Off Switch

Thermostat

Air Intake

Condenser

Air Discharge

. (See Unit Identifi cation.)

Condenser/Fan Blade

Shroud

Condenser Coil

Condenser

Shroud Brace

Fan/Blower

Motor

Condenser

Air Intake

Indoor Blower

Air Discharge

Front Cover

Air Discharge

Vents

4

Wheel

Sleeve

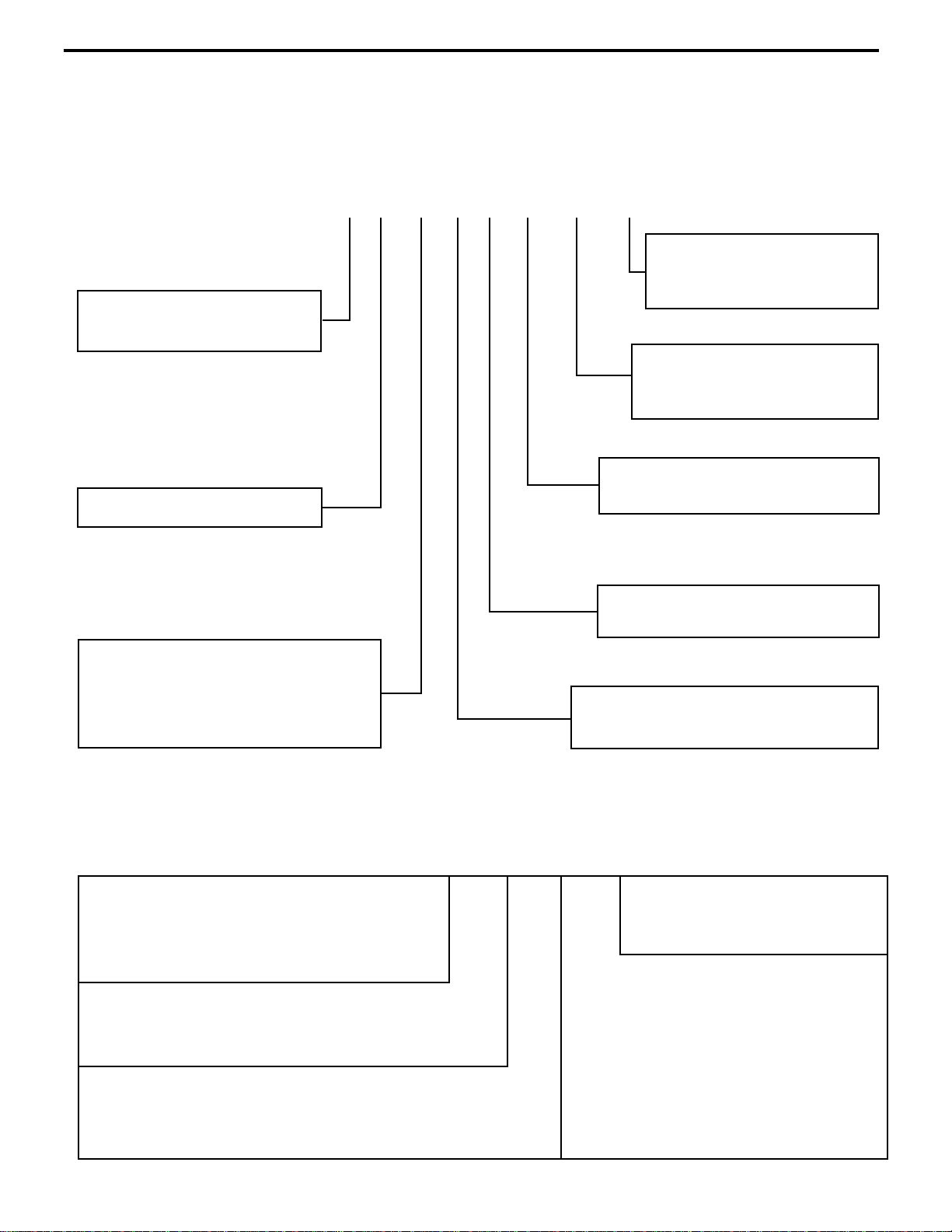

UNIT IDENTIFICATION

1st Digit – Function

S = Straight Cool, Value Series

H = HazardGard

Model Number Code

S H 15 M 3 0 A - A

8th Digit – Marketing Suffi x

Indicates Modifi cation

(Subject to change)

7th Digit – Options

0 = Straight Cool &

9th Digit – Engineering Suffi x

Indicates Modifi cation

(Subject to change)

3rd and 4th Digit - Approximate

BTU/HR (Cooling)

Heating BTU/Hr capacity listed in the

Specifi cation/Performance Data Section

RAC Serial Number Identifi

Serial Number

Decade Manufactured

L=0 C=3 F=6 J=9

A=1 D=4 G=7

B=2 E=5 H=8

Year Manufactured

A=1 D=4 G=7 K=0

B=2 E=5 H=8

C=3 F=6 J=9

6th Digit – Voltage

3 = 230-208 Volts

5th Digit - Model Series/Year Introduced

M=2010

cation Guide

A A A R 00001

Production Run Number

Product Line

R = RAC

Month Manufactured

A=Jan D=Apr G=Jul K=Oct

B=Feb E=May H=Aug L=Nov

C=Mar F=Jun J=Sept M=Dec

5

UL Listed for use in Class I, Division 2, Groups A, B, C

and D hazardous locations.

Hazardgard is specically designed to cool living qua

rters, storage areas

and other enclosures situated in hazardous locations, where specic volatile

ammable liquids or gases are handled or used within enclosed containers

or systems.

For more than 30 years, the Friedrich Hazardgard has endured some of the

toughest and most unforgiving operating conditions imaginable. Time-tested

in the eld where it counts, Hazardgard is trusted by professionals who have

to get the job done. Robust engineering with design details like 33% thicker

ns extend the life of the coil. Diamonblue

Technology, our anti-corrosive treatment,

provides added endurance and protection

in coastal or corrosive environments.

e

ch

Oshore oil rigs, on-shore oil company

ofces and reneries

Petrochemical sites and propane ll-up

stations

Paint and varnish storage or processing

plants

Grain alcohol processors or storage sites

Plant areas using strong solvents or

chemicals

Munitions plants or armories

PVC or plastics plants and processing

points

Recycling plants

Furniture renishing/stripping

workshops

Fertilizer plants

Ofce complexes where methane is a

by-product

Hazardous materials storage

Ideal applications

| HAZARDOUS DUT Y |

HAZARDGARD APPLICATION

6

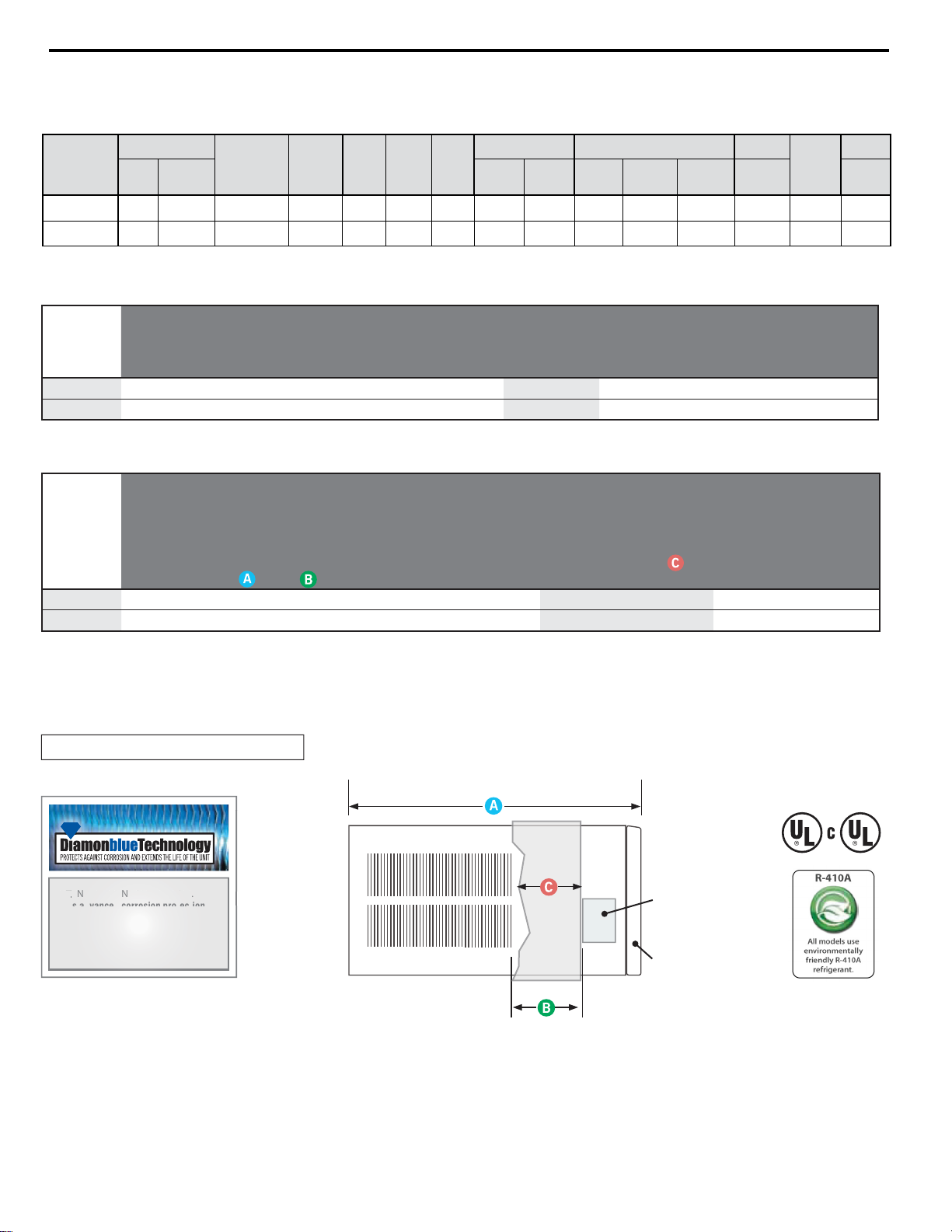

SPECIFICATIONS AND PERFORMANCE DATA

Due to continuing engineering research and technology, specL¿cations are subject to change without notice. Manufactured under U.S. Design Patent

DES 368, 306 decorative front; Utility Patent 5, 622, 058. MAXIMUM outdoor ambient operating temperature is 130°F. MAXIMUM TEMPERATURE

RATING FOR CL ASS I, DIVISION 2, GROUPS A ,B,C,D.

OPERATING TEMPERATURE CODE T3B

Specications

I

nstallation Information

Model

Cooling Capacity Electrical Characteristics (60 Hertz)

E

nergy

Efficiency

Ratio AHAM

Moisture

Removal

Air Direction

Controls

Room Side Air

Circulation

(BTU/Hr.- AHAM) Volts Rated Amps AHAM Watts EER

(Pints/ Hr.) CFM

SH15M30

*

1

4500/14000 230/208 6.9/7.4 1495/1443 9.7/9.7 6.0 8-way 375

SH20M30

*

19500/19000 230/208 9.1/10.0 2074/2021 9.4/9.4 4.0 8-way 375

Model

Dimensions

(

Inches)

Window Width

(Inches)

Thru-The-Wall

Finished Hole (Inches)

Circuit Rating

Breaker or

T - D Fuse

Weight

(Lbs.)

Height Width

Depth

Overall

Depth J Box

to Louvers

Minimum

Extension

Into Room

Minimum

Extension

Outside Min. Max. Height Width Max. Depth Volts - Amps Net Shipping

SH15M30

*

15

15

/

16 25

15

/

16 27

3

/

8 6 3

1

/

16 16

15

/

16 27

7

/

8 42 16

3

/

16 26

3

/

16 6 250V - 15A 156 168

SH20M30

*

17

15

/

16 25

15

/

16 27

3

/

8 6 3

1

/

16 16

15

/

16 27

7

/

8 42 18

3

/

16 26

3

/

16 6 250V - 15A 160 174

(A)

Front

SIDE VIEW

(A)

Junction

Box

Max.

Wall

Depth

S TANDA RD ON A LL M ODEL S .

This advanced corrosion pro tection

treatment protects the outdoor coil

against deterioration and extends

the life of the unit especially in harsh

coastal environments.

TAA

A

All models use

environmentally

friendly R-410A

refrigerant.

R-410A

Cooling Performance Data

EVAPORATOR AIR

TEMP. DEG. F

Discharge

Temp. Drop F. Suction Discharge Amps Cool Amps Heat

Air

SH15M30

SH15M30

Due to continuing research in new energy-saving technology, performance data and 8th and 9th character are subject to change without notice.

*

54 26 127 186 67 18 35 137 480 6.9 - 43 50 208 / 230 15

*

54 26 185 124 68 15 38 137 485 9.1 - 43 42.7 208 / 230 15

*

CONDENSER

TEMPERATURE

DEG. F

*

Discharge

Temp

Suction

Temp

Super

Heat

Sub-

Cooling

OPERATING

PRESSURES

ELECTRICAL RATINGS R-410A REF.

Locked Rotor

Amps

Charge in OZ.

Voltage

BREAKER

FUSE

60 Hertz

Amps

7

7

ELECTRICAL DATA

Not following the above WARNING could result in fi re or

electrically unsafe conditions which could cause moderate

or serious property damage.

Read, understand and follow the above warning.

WARNING

ELECTRIC SHOCK HAZARD

Turn off electric power before service or

installation.

All electrical connections and wiring MUST be

i

nstalled by a qualifi ed electrician and conform to

the National Electrical Code and all local codes

which have jurisdiction.

Failure to do so can result in personal injury or

death.

NOTICE

FIRE HAZARD

ELECTRICAL REQUIREMENTS

ALL FIELD WIRING MUST MEET THE REQUIREMENTS OF THE NATIONAL ELECTRICAL CODE (ANSI/NFPA 70)

ARTICLE 501.

THE FIELD-PROVIDED CIRCUIT PROTECTION DEVICE (HACR CIRCUIT BREAKER OR TIME DELAY FUSE)

MUST NOT EXCEED THE AMPACITY INDICATED ON THE PRODUCT NAMEPLATE.

IMPORTANT: Before you begin the actual installation of your air conditioner, check local electrical codes and the

information below.

Your air conditioner must be connected to a power supply with the same A.C. voltage and frequency (hertz) as marked

on the data plate located on the chassis. Only alternating current (A.C.), no direct current (D.C.), can be used.

An overloaded circuit will invariably cause malfunction or failure of the air conditioner therefore, it is extremely important

that the electrical power is adequate. Consult your power company if in doubt.

Model Number Connection Type

SH15 Junction Box 250V-15 Amp

Circuit Rating

Time Delay Fuse

SH20 Junction Box 250V-15 Amp

8

HAZARDGARD SPECIAL FEATURES

Permanent Split-Capacitor, totally enclosed fan motor

• •

to assure effi cient operation even under adverse

electrical conditions. Motor has a special stainless

steel shaft to resist corrosion and a hermetically sealed

overload for arc-free operation.

•

High capacity compressor with internal hermetically

sealed overload.

•

Solid-state relay contains transient voltage suppressor

to protect controls against transient voltage spikes.

Provides solid state switches for arc-free operation.

•

Hot gas bypass low ambient control to permit operation

without freezing at outdoor ambient temperatures as

low as 45°F (7°C).

•

Environmentally sealed on-off switch and gold plated

contacts in thermostat for corrosion resistance.

•

Electrodeposited epoxy primer and alkyd enamel, both

oven-baked for an attractive, long-lasting fi nish.

Copper tubing/aluminum fi n coils.

•

Galvanized steel cabinet and base pan, all bonderized.

•

Slide-out chassis for easy installation in window or

through–the–wall.

•

Extra insulation inside, including completely insulated

plenum chamber for quieter, more effi cient cooling.

•

Entire unit test run in environmental chamber before

crating.

•

Eight–way air fl ow control for uniform air circulation.

•

Condensate drain with exclusive mosquito trap.

•

15 amp circuit with time-delay fuse required.

Accommodates direct wiring.

Long lasting 3/8” (10mm) thick air fi lter, germicidally

•

treated, easily removed for cleaning.

Friedrich Air Conditioning quality has been proven by more than 25 years of successful experience from the Gulf

of Mexico to the searing sands of the Arabian desert.

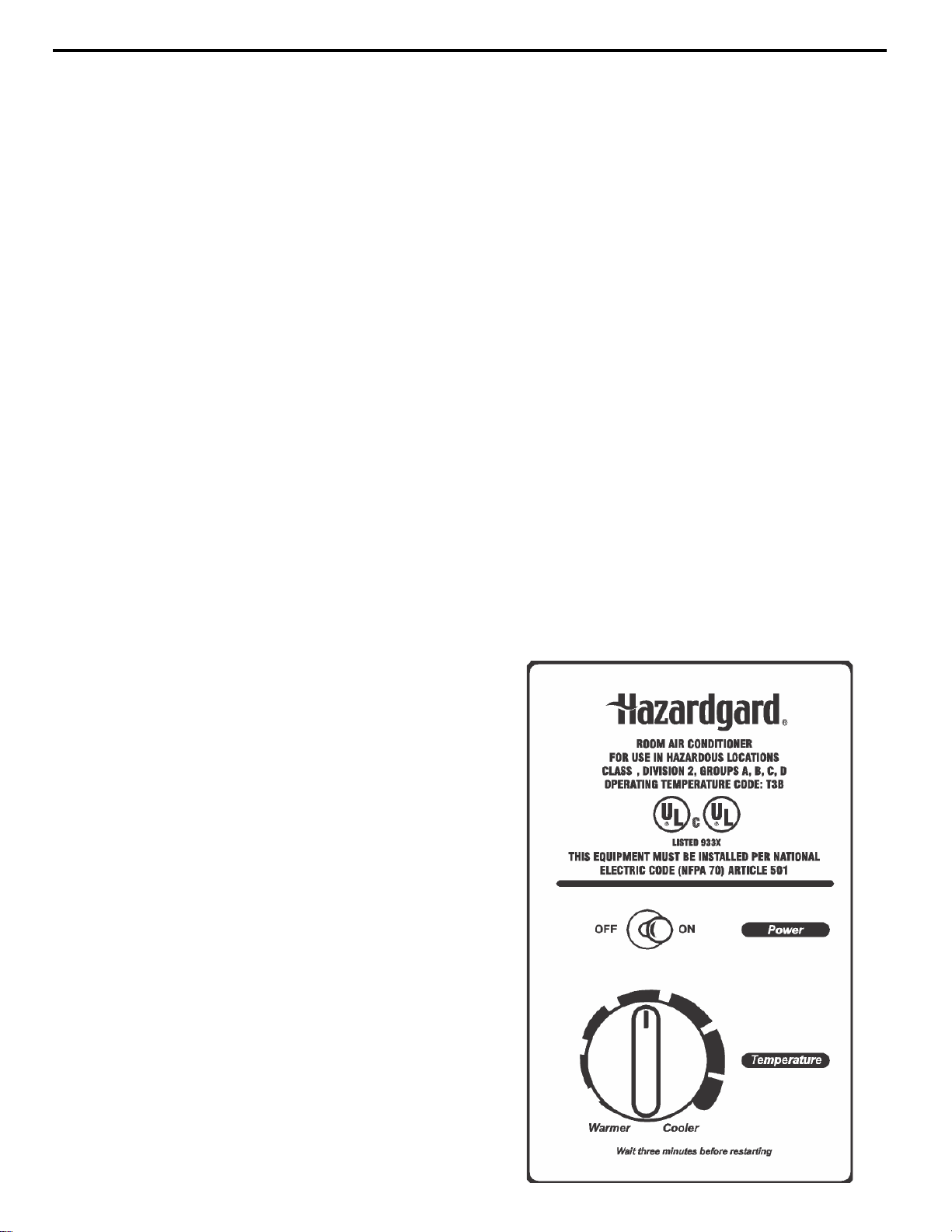

Control Panel

Function Control (Power)

This switch is a double pole, single throw toggle switch.

ON -

Turns everything on.

(Fan motor runs continuously)

OFF - Turns everything off.

Temperature Control

The knob at the bottom is the thermostat which is a cross

ambient

The thermostat reacts only to a change in temperature at

the bulb location - turn the knob clockwise to set cooler,

counterclockwise for warmer.

Ex

Friedrich leads with the fi rst UL Listed Room Air

Conditioners designed to cool living quarters and other

enclosures situated in hazardous locations where specifi c

volatile fl ammable liquids or gases are handled or used with

enclosed containers or systems. Friedrich Hazardgard

room air conditioners are designed to meet the National

Electrical Code, Article 500 requirements for Class

I, Division 2, Groups A, B, C, D Hazardous locations,

and are the only air conditioners UL Listed for this

application. THIS UNIT IS LISTED BY UNDERWRITERS

LABORATORIES FOR USE IN CLASS I, DIVISION

2,GROUPS A, B, C, D HAZARDOUS LOCATIONS.

Operating Temperature Code: T3B.

type used to maintain the desired comfort level.

clusive

9

COMPONENT DEFINITIONS

A. Mechanical components

Plenum assembly

Diffuser with directional louvers used to direct the conditioned airfl

Blower wheel

Attaches to the indoor side of the fan motor shaft and is used for distributing unconditioned, room side air through

the heat exchanger and delivering conditioned air into the room.

Slinger fan blade

Attaches to the outdoor side of the fan motor shaft and is used to move outside air through the condenser coil, while

slinging condensate water out of the base pan and onto the condenser coil, thus lowering the temperature and

pressures within the coil.

B. Electrical components

Thermostat Control

Used to maintain the specifi ed room side comfort level.

System Switch

Used to regulate the operation of the fan motor and the compressor or to turn the unit off. For troubleshooting, refer

to the wiring diagrams and schematics in the back of this service manual.

ow.

Solid State Relay

Used to energize the compressor and fan motor. Each unit has 2, 50 amp, 208/230 volt relays.

Capacitor

Reduces line current and steadies the voltage supply, while greatly improving the torque characteristics of the fan

motor and compressor motor

.

Fan Motor

Dual shafted fan motor operates the indoor blower wheel and the condenser fan blade simultaneously. (When unit

is turned on, the fan motor runs continuously).

C. Hermetic components

Compressor

Motorized device used to compress refrigerant through the sealed system.

Low ambient bypass (hot gas bypass) valve

Used for low ambient cooling operation, the valve is connected between the discharge line at the compressor and

the

suction process tube. It responds to suction pressure, whcih when reduced in the system, causes the valve to

open and bypass hot gas from the high pressure side to the low pressure side of the system. The valve is preset

to open when the suction pressure reaches 88 psig.

Capillary tube

A cylindrical metering device used to evenly distribute the fl ow of refrigerant to the heat exchanger (evaporator

coils).

10

Loading...

Loading...