Page 1

ROOM AIR

CONDITIONERS

USE, CARE, AND

INSTALLATION

MANUAL

Models

SH14

920-024-04 (10/01)

SH20

Page 2

TABLE OF CONTENTS

OPERATION AND CARE INSTRUCTIONS

PART 1 General Instructions............................................................. Page 3

PART 2 Filter Information .................................................................. Page 4

PART 3 Maintenance Checklist......................................................... Page 4

PART 4 Special Features ................................................................... Page 5

PART 5 Control Panel ........................................................................ Page 6

PART 6 Underwriters Laboratories................................................... Page 6

INSTALLATION INSTRUCTIONS

SECTION I Electrical Requirements....................................................... Page 7

SECTION II Unpacking the Unit ............................................................... Page 9

SECTION III Chassis Wiring and Preparation ......................................... Page 9

SECTION IV Shell Preparation .................................................................. Page 10

SECTION V Shell Installation ................................................................... Page 11

A. Sash Window................................................................... Page 11

B. Through the Wall ............................................................. Page 14

SECTION VI Chassis Installation .............................................................. Page 17

WARRANTY ......................................................................................................... Page 19

Spanish Translation............................................................................................ Page 21

French Translation.............................................................................................. Page 41

Page 2

Page 3

WELCOME TO YEARS OF ECONOMICAL COMFORT

WITH YOUR NEW FRIEDRICH HAZARDGARD

ROOM AIR CONDITIONER

PART 1 — GENERAL INSTRUCTIONS

Your new Friedrich has been carefully engineered and manufactured to give you many years of dependable,

efficient operation, maintaining a comfortable temperature and humidity level. Many extra features have been

built into your unit to assure quiet operation, the greatest circulation of cool, dry air, and the most economic

operation.

Here are some suggestions to help you use your new Friedrich most efficiently:

1. Carefully read and follow the installation instructions.

2. Your Friedrich HazardGard room air conditioner is electrically grounded for your safety. The power supply

must also be grounded and must be installed in accordance with NEC Article 501. The branch circuit rating is shown

on the nameplate for each model.

3. Make sure the unit is the right capacity for the area to be cooled. Too little capacity makes the unit work too hard,

using more electricity than needed and increasing wear. Too much capacity is also hard on the unit as it will cycle on

and off too rapidly, and cannot control humidity as well.

4. When you first turn on your Friedrich, set the thermostat to its coldest position to cool the room. When the

desired temperature is reached, turn the thermostat control toward the "warmer" position until you hear a click and the

compressor goes off. The thermostat will then cycle the compressor to maintain the selected temperature.

5. Clean the filter frequently (See General Maintenance).

6. Do not block the air flow to and from the unit. Make sure the louvers are directed to give even distribution of air

throughout the room. Caution: If air is directed into a restricted area such as behind a bed or into a corner, this may

cause the unit to cycle on and off rapidly, which could damage your unit.

7. A dirty filter or improperly set controls can affect the cooling ability of the unit.

8. If cooling is weak and you have verified that the filter is clean and the controls are properly set, the unit may be low

on refrigerant, and you should call your Friedrich service provider to check the unit.

9. Keep blinds, shades and drapes closed on the sunny side of the room being cooled.

10. Proper insulation helps your unit maintain the desired inside temperature.

11. Whenever possible, shade west-facing windows with awnings.

12. Keep window coverings away from the unit to provide free air flow.

Page 3

Page 4

PART 2 — FILTER INFORMATION

The filter in your Friedrich removes dust, pollen and other impurities from the air as they are drawn through the unit. The

filter is permanent and reusable, and has a germicidal treatment which is not affected by washing.

A clogged, dirty filter reduces the air flow through the unit and reduces its efficiency. You should check the filter every

seven to ten days, depending on the amount your unit is used. Clean the filter regularly.

Filter Retainer Clips

The filter can be removed for cleaning by opening the

front of the unit and releasing the filter from its retaining

clips.

PART 3 — MAINTENANCE CHECKLIST

WON’T COOL

If the unit operates, but doesn’t cool, check to see that the controls are properly set. Inspect the filter and

clean it thoroughly, if needed.

WON’T RUN

If the unit does not operate at all, check that the power supply connections are tight. Check for blown fuses or

tripped circuit breakers. Replace blown fuses with the proper size time-delay fuse. The nameplate on the unit

shows the proper fuse size. After restoring power, wait three minutes before restarting the unit.

INSIDE COIL FREEZES UP

Your Friedrich HazardGard is designed not to freeze with outdoor temperatures as low as 45°F (7°C). Freezing

should only occur when the outside air is damp and below 45°F (7°C). If the indoor coil should ice over while

cooling, set the thermostat to the warmest position until the ice on the coil is gone. Setting the thermostat to a

slightly warmer position will probably keep ice from forming on the coil. A dirty filter will contribute to icing.

CLEANING

The front grille of your Friedrich, as well as the complete cabinet may be cleaned with warm water and a mild

detergent. The coils and base pan should be cleaned periodically for the most efficient operation. We suggest you

call your Friedrich dealer for this service.

LUBRICATION

Fan motors are factory lubricated and sealed. No lubrication is required.

Page 4

Page 5

PART 4 — HAZARDGARD SPECIAL FEATURES

HAZARDGARD UNIT

SPECIAL FEATURES

! Permanent Split-Capacitor, totally

enclosed fan motor to assure efficient

operation even under adverse electrical

conditions. Motor has a special

stainless steel shaft to resist corrosion

and a hermetically sealed overload for

arc-free operation.

! High capacity compressor with internal

hermetically sealed overload.

! Solid-state printed circuit board

insulated against corrosion on

conductor paths. Contains transient

voltage suppressor to protect controls

against transient voltage spikes.

Provides solid state switches for arcfree operation.

! Copper tubing/aluminum fin coils.

! Galvanized steel cabinet and base pan,

all bonderized.

! Slide-out chassis for easy installation in

window or through–the–wall.

! Extra insulation inside, including

completely insulated plenum chamber

for quieter, more efficient cooling.

! Entire unit test run in environmental

chamber before crating.

! Eight–way air flow control for uniform

air circulation.

! Hot gas bypass low ambient control to

permit operation without freezing at

outdoor ambient temperatures as low

as 45°F (7°C).

! Environmentally sealed on-off switch

and gold plated contacts in thermostat

for corrosion resistance.

! Electrodeposited epoxy primer and

alkyd enamel, both oven-baked for an

attractive, long-lasting finish.

Friedrich Air Conditioning quality has been proven by more than twenty-five years of

successful experience from the Gulf of Mexico to the searing sands of the Arabian desert.

! Patented electronic control circuit.

! Condensate drain with exclusive

mosquito trap.

! 15 amp circuit with time-delay fuse

required. Accommodates direct wiring.

! Long lasting 3/8" (10 mm) thick air filter,

germicidally treated, easily removed for

cleaning.

Page 5

Page 6

PART 5 — CONTROL PANEL

FUNCTION CONTROL (POWER)

This switch is a double pole, single throw toggle

switch.

ON - Turns everything on.

OFF - Turns everything off.

TEMPERATURE CONTROL

The knob at the bottom is the thermostat which is a

cross ambient type used to maintain the desired

comfort level. The thermostat reacts only to a change

in temperature at the bulb location - turn the knob

clockwise to set cooler, counterclockwise for warmer.

PART 6 — EXCLUSIVE !

Friedrich leads again with the first UL Listed Room Air Conditioners designed to cool living

quarters and other enclosures situated in hazardous locations where specific volatile

flammable liquids or gases are handled or used with enclosed containers or systems.

Friedrich HazardGard

Code, Article 500 requirements for Class I, Division 2, Groups A, B, C, D Hazardous locations

and are the only air conditioners UL Listed for this application.

®

room air conditioners are designed to meet the National Electrical

THIS UNIT IS LISTED BY UNDERWRITERS LABORATORIES FOR USE IN

CLASS I, DIVISION 2, GROUPS A, B, C, D HAZARDOUS LOCATIONS.

Operating Temperature Code: T3B.

Page 6

Page 7

INST ALLA TION INSTRUCTIONS

Models SH14 and SH20

NOTE: THIS MANUAL INCLUDES INSTALLATION INSTRUCTIONS FOR BOTH WINDOW MOUNT AND THROUGH-

THE-WALL INSTALLATIONS

SECTION I: ELECTRICAL REQUIREMENTS

ALL FIELD WIRING MUST MEET THE REQUIREMENTS OF THE NATIONAL ELECTRICAL CODE (ANSI/NFPA 70)

ARTICLE 501.

THE FIELD-PROVIDED CIRCUIT PROTECTION DEVICE (HACR CIRCUIT BREAKER OR TIME DELAY FUSE) MUST

NOT EXCEED THE AMPACITY INDICATED ON THE PRODUCT NAMEPLATE.

IMPORTANT: Before you begin the actual installation of your air conditioner, check local electrical codes and the

information below.

Your air conditioner must be connected to a power supply with the same A.C. voltage and frequency (hertz) as marked on

the data plate located on the chassis. Only alternating current (A.C.), no direct current (D.C.), can be used.

An overloaded circuit will invariably cause malfunction or failure of the air conditioner; therefore, it is extremely important

that the electrical power is adequate. Consult your dealer or power company if in doubt.

The following instructions are for HAZARDGARD models and cabinet sizes listed below.

GROUPS CABINET SIZE (H x W x D)

SMALL CHASSIS SH14 15–15/16" x 25–15/16" x 27–3/8"

(405 mm x 660 mm x 695 mm)

MEDIUM CHASSIS SH20 17–15/16" x 25–15/16" x 27–3/8"

(455 mm x 660 mm x 695 mm)

Model Number Plug Type Circuit Rating

Time Delay Fuse

SH14 Junction Box 250V-15 Amp

SH20 Junction Box 250V-15 Amp

Page 7

Page 8

HAZARDGARD WINDOW MOUNT

INSTALLATION HARDWARE

ITEM DESCRIPTION QTY.

No.

SHELL MOUNTING PARTS

1 SUPPORT BRACKET 2

2 SCREW, 10 - 24 x 1" HEX HEAD 4

3 10 - 24 FLAT WELDNUT 4

4 SCREW, SHEET METAL #12A x 2" 7

WINGBOARD ANGLE MOUNTING

5 WINGBOARD ANGLE, TOP 1

6 WINGBOARD ANGLE, SIDE 2

7 SCREW, SHEET METAL #8A x 3/8" 2

WINGBOARD MOUNTING PARTS

8 WINGBOARD (MASONITE) - (NOT SHOWN) 1

9 "J" TYPE SPEED NUT 4

10 WINGBOARD CLIP

11 SCREW. #8A x 1/2" PHILLIPS TRUSS HD. 4

(SPRING STEEL) 4

ITEM # 2

ITEM # 3

WINDOW SEALING

12 SEALING GASKET (VINYL) 1

13 WINDOW SEAL GASKET (DARK FOAM) 1

14 CHASSIS SEAL GASKET (LIGHT FOAM) 1

ITEM # 7

ITEM # 9

ACCESSORY DETAIL

ITEM # 14

ITEM # 4

ITEM # 11

ITEM #10

ITEM # 13

ITEM # 12

Page 8

ITEM # 1

ITEM # 6

ITEM # 5

NOT TO SCALE

Page 9

SECTION II

UNPACKING THE UNIT

STEP 1. Remove decorative plastic return air grille to a safe area away from the unit.

STEP 2. Remove the installation hardware, wingboard and two (one light colored and one dark colored) gaskets from

beneath the unit, and place them in a safe area away from the unit.

STEP 3. Remove the chassis retainer by removing the far right screw in the basepan (see Figure A); save this screw to

reattach the chassis retainer after installation (Step 15). Also, remove and discard the two retainer

screws and plastic bushings located at the rear of the unit.

STEP 4. While an assistant holds the cabinet stationary, use the hand pull at the front of the base pan (see Figure A) to pull

the chassis out of the cabinet. Remove white foam blocks used to restrain the compressor during shipment.

Inspect basepan for dislodged white blocks, and remove. Do not remove any other foam.

FIGURE A

HAND PULL

CHASSIS WIRING AND PREPARATION

1 JUNCTION BOX FRIEDRICH PN: 613-893-00

2 MOUNTING LEGS RACO INC. PN: 5324-0

2 LEG SCREWS

2 HOLE COVERS

1 GROUND SCREW

BOX COVER FRIEDRICH PN: 613-892-00

GASKET RACO INC. PN: 5173-0

2 SCREWS

1 SHEET METAL SCREW

FAR RIGHT

SCREW

SECTION III

PROVIDED HARDWARE

CABINET

CABINET

STEP 3

HAND PULL

CHASSIS

RETAINER

STEP 1. Remove the junction box, cover and screw (above items) from the shipping position underneath the fan motor.

Install one junction box mounting leg in the upper left position facing the rear of the junction box.

STEP 2. Remove and discard the plastic b ushing from the conduit connector on the side panel of the control compartment.

Strip the black wires only, approximately 1/2 inch (13 mm).

STEP 3. Insert all wires (2 black, 1 green) into the box and thread the box onto the conduit connector until tight. Bac k of f

counter clockwise until the junction bo x is vertical with the mounting leg at the upper–right position facing the bo x

opening. Be sure that the shell can fit between this box and the chassis.

Page 9

Page 10

SECTION IV

SHELL (CABINET) PREPARATION:

It will be necessary to relocate the sill plate of the cabinet 2" back from its shipping position, and the shell guides 4" forward, to

the forward-most hole in the shell rail. Discard the chassis retainer wire disconnected in Section II, Step 3. The junction box

mounting leg from Section VI, Step 1, and the field-installed conduit will retain the chassis in the shell.

IF THIS INSTALLATION IS FOR A SASH WINDOW – With the wide flange and pilot holes of the sill plate forward, put the

screws/nuts in the rear holes of the sill plate and third shell hole from the front (the center of three square holes). Anchor the

side angles (Item #6) by engaging the tabs at each end of the sill plate with the bottom loops of the side angle. Engage the

tabs at each end of the top angle (Item #5) with the top loops of the side angle. Install tw o (2) screws (Item #7) to secure the

top angle tabs and the side angle to the rear-most holes in the side of the cabinet (See Figure B, below).

IF THIS INSTALLATION IS THROUGH A WALL – Turn the sill plate end to end so that the wide flange with pilot holes will

be over the wall header (towards the rear) and two inches from the front of the cabinet. Bend the tabs into the channel of the

sill plate, put the screws/nuts in the front holes of the sill plate and into the second shell hole from the front. Use one bolt on

each side to secure the sill plate to the cabinet. (See Figure C, below.)

FIGURE B

FIGURE C

Cabinet

Cabinet

BEFORE

Top Angle (Item #5)

Screw

(2 required)

Sill Plate Tab

AFTER

Side Angle

(Item #6) 2

required

8A x 3/8" long screw (Item #7) 2

required

Loop

Detail B-1

Detail B-2

Tab

Loop

Turn sill plate

end to end

Page 10

Sill Plate

Retainer, Chassis

(This side only)

DETAIL 2

Bend tabs down

NOTE: HOLES

MOVED TO BACK SIDE

Nut (2

required)

DETAIL 1

Position the sill plate into the

cabinet with the sill plate holes

to the back. Align the plate 2

inches from the front of the

cabinet and secure it with a nut

and bolt in each end.

Page 11

SECTION V — SHELL INSTALLATION

(A) SASH WINDOW INSTALLATIONS

SHELL (CABINET) INST ALLA TION – STANDARD SASH WINDOWS

STEP 1. Check the window sill and frame to be sure they are in good condition and firmly anchored to the wall. Repair if

necessary.

STEP 2. CABINET MOUNTING: Raise the lower window sash 1/4" more than the height of the cabinet. Carefully slide

the cabinet through the open window until the sill plate channel rests behind the window sill and the top support

angle rests against the window (See Figure D). Center the cabinet side to side and drill three (3) 5/32" dia. pilot

holes into the window sill using the holes in the cabinet sill plate as a guide. Install three (3) #12A x 2" long scre ws

(Item #4) (See Figure D).

FIGURE D

Top Support Angle

Center cabinet side to

side in window

Drill 3 5/32" pilot holes and install 3

#12A x 2" long screws (Item #4)

Pull window sash down behind

the top support angle

Side Support Angle

Window sill

Locate the sill plate guide channel

just back of the window sill.

FIGURE E

#12A x 2" Screw (Item #4)

A 1" x 4" or 2" x 4" spacer should be used between the

wall and bracket when installed on aluminum, asbestos

or vinyl siding.

3/8" (10 mm)

Down slope

Support

Bracket

Support

Bracket

(Item #1)

10 - 24 Flat Weldnut (Item #3)

10 - 24 x 1" Hex Head Screw (Item #2)

STEP 3. OUTSIDE SUPPORT MOUNTING: Assemble the support brackets (Item #1) to the bottom rails of the cabinet

with four (4) 10-24 1" long scre ws (Item #2) and f our (4) 10–24 flat nuts (Item #3). Adjust the support brac kets to

bring the bottom pads in contact with the wall surface. (See Figure E.)

A 1" x 4" or 2" x 4" SPACER SHOULD BE USED BETWEEN THE WALL AND THE SUPPORT BRACKETS WHEN

INST ALLED ON ALUMINUM OR VINYL SIDING). Drill 5/32" (4 mm) dia. pilot holes, and secure the brackets to the wall

with two (2) #12A x 2" long screws (Item #4). Adjust the support brack ets to provide an approximate 3/8" (10 mm) down

slope towards the outside f or drainage. Tighten all screws. (See Figure E).

Page 11

Page 12

The illustrations below show a standard frame construction installation as well as some suggested ways of

adapting the support bracket to thick walls and large stone ledges.

TYPICAL INSTALLATION SILL PLATE

Figure 1

Figure 3

10 - 24 Screw

10 - 24 Flat Nut

3/8" (10 mm)

Slope down

#12A x 2" Sheet metal screw

1" x 2" or 2" x 4" spacer between wall

and bracket should be used on

aluminum, asbestos or vinyl siding

Stone ledge

3/8" (10 mm)

Slope down

#12A x 2" Sheet metal

screw

2" x 4" Spacer

Figure 2

Cut

Here

Discard shaded area

Figure 4

3/8" (10 mm)

Slope down

Stone ledge

Outside wall

Cut to fit Dimension "A" and

bend down to for a vertical leg

Stone ledge

3/8" (10 mm) Slope down

Straighten tab to lay flat along

the bottom rail of the shell.

Secure the longest side of the

bracket to the shell.

Adjust in or out to rest on the ledge

STEP 4. CUT WINGBOARD PANELS: Measure and cut the wingboard panels from the supplied masonite (Item #8) to fit

the spaces between the side window channels and the sides of the cabinet (See Figure F).

NOTE: AFTER CUTTING PANELS, MAKE A TRIAL TEST TO SEE IF THEY FIT THE SPACE WITH ABOUT

1/8" CLEARANCE BEFORE GOING TO STEP 5.

FIGURE F

Measure distance "B" to the inside of

the channel on each side

Cut here and discard the center

waste material

Wingboard

Subtract 1/8" (3 mm) from

dimension "B" and measure

from the edge of the

wingboard (Item # 8), mark

and cut with a saw.

Page 12

Page 13

FIGURE G

"J" type speed nut (item #9)

2 required

Spring steel clip (item #10)

2 required

Cut wingboard panel

Center the hole in the speed

nut over the slot in the

wingboard panel

Cut edge

Slide clip over cut edge of wingboard panel.

STEP 5. ASSEMBLE CLIPS TO WINGBO ARD P ANELS: Assemble "J" type speed n uts (Item #9) and spring steel clips

(Item #10) to the edges of the cut wingboard panels (See Figure G).

FIGURE H

Secure the side wingboard panels to the

side angles with four (4) #8 x 1/2" long

screws (Item #11), two on each side.

Top of cabinet

Place wingboard panel in window jam to

compress the springs inside the runners, and

swing the panel into place indicated by the dotted

line.

Window jam

SECTION A - A

STEP 6. INSTALL SIDE WINGBOARD PANELS: Be sure that the cabinet has been secured to the window sill and the

outside support bra ckets have been installed as shown in Figures D and E on Page 11. Raise the window sash

and install the right and left side wingboard panels (See Figure H).

STEP 7. INSTALL WINDO W SEALING GASKETS: Measure and cut the vinyl window seal gask et (gre y color , Item #12)

to fit the width of the window and install as shown in Figure I. Pull the window sash down behind the gasket.

Measure and cut the dark foam window seal gasket (Item #13) and install it between the upper glass panel and

the top part of the lower sash (See Figure I).

FIGURE I

Vinyl window seal gasket Item #12)

Foam window seal gasket (Item # 13)

Lower window sash

Vinyl window seal gasket

Top wingboard angle

SECTION B - B

NOTE: FOR REASONS OF SECURITY AND SAFETY, THE CUSTOMER MUST PROVIDE A MEANS OF PREVENTING

THE WINDO W FROM OPENING.

STEP 8. When possible, caulk the outside of the installation with industrial type caulking to pre vent air and water leaks.

Page 13

Page 14

SECTION V — SHELL INSTALLATION

(B) THROUGH–THE–WALL INSTALLATIONS

WALL PREPARATION:

The maximum wall thickness permissible without special construction is determined by the model size to be installed. THE

OUTSIDE CABINET CONDENSER AIR INTAKE LOUVERS MUST NOT BE BLOCKED BY EXTENDING INSIDE THE

WALL AREA. Observe the maximum wall thickness shown as dimension "A" in Figure J.

SPECIAL INSTRUCTIONS FOR EXTRA THICK WALLS: For installation in walls exceeding the maximum thickness

shown as dimension A, the following suggested construction may apply. (See Figure J).

FIGURE J

15 1/8 " (384 mm)

Maximum wall thickness

Condenser

Air intake

Louvers

Top view showing beveled sides for

air intake. Wall below unit must

also be beveled to assure proper tilt

angle.

EXTRA THICK WALL CONSTRUCTION

2" (51 mm) minimum

Both sides

Condenser air

Intake louvers

STEP 1. CHECKING WIRING AND PLUMBING: Check all wiring and plumbing inside and outside the wall to be sure

none will be broken where the hole is to be cut.

STEP 2. HOLE CONSTRUCTION: Depending on the size of the unit to be installed, layout the hole dimensions in

accordance with the chart below (See Figure K). Cut and frame in the hole to the finished dimensions. Use

2" x 4" material for framing and follow the suggested typical installations in Figure L, M or N on Page 15.

NOTE: IF THE WALL CONSTRUCTION IS TYPICAL FRAME OR 2 X 4 STUDDING WITH BRICK OR STONE

VENEERS, LOCATE THE HOLE NEXT TO ONE OF THE STUDS. FOR MASONRY , CONCRETE OR CINDER BLOCK

WALLS, LOCATE THE HOLE FOR CONVENIENCE.

FIGURE K

HOLE SIZE REQUIREMENTS

FINISHED SMALL MEDIUM

DIMENSION CHASSIS CHASSIS

A 16-3/16" 18-3/16"

B 26-3/16" 26-3/16"

NOTE: THESE DIMENSIONS ARE FOR FINISHED HOLE SIZE

Page 14

Page 15

FIGURE L FRAME W ALL CONSTRUCTION

Caulk all sides

Weather cabinet

Shim the void space at the top and

sides with wood as required

FIGURE M BRICK VENEER CONSTRUCTION

Weather cabinet

Caulk all sides

FIGURE N SOLID MASONRY CONSTRUCTION

Caulk all sides

Cabinet

Shim void spaces at top and sides

with wood as required

Mortar

Page 15

Page 16

STEP 3. Slide the cabinet into the hole far enough to allow the guide-channel of the sill plate to contact the inside wall

surface (See Figure O).

STEP 4. Drill three (3) 5/32" dia. pilot holes through holes in sill-plate into the framing and install three (3) #12 x 2" long

screws (Item #4) (See Figure O).

FIGURE O TYPICAL INSTALLATION

Trim moulding

Screw #12A x 2" long

Use 3.

Sill plate

Guide channel

Inside wall

Surface

Caulk all sides air tight

3/8" (10 mm) slope down

Note: Support brackets may be omitted from

through-the-wall installations if the cabinet is

secured as follows. Drill 2 holes in each side

and install 4 fasteners (2 each side).

Use #12A x 2" (51 mm) screws, toggle bolts or

expansion anchor bolts as shown in Step 5.

Support brackets (Item 1) (See note above)

Screw #12 x 2" long, use one in each bracket.

Drill 5/23 (4 mm) dia. pilot holes.

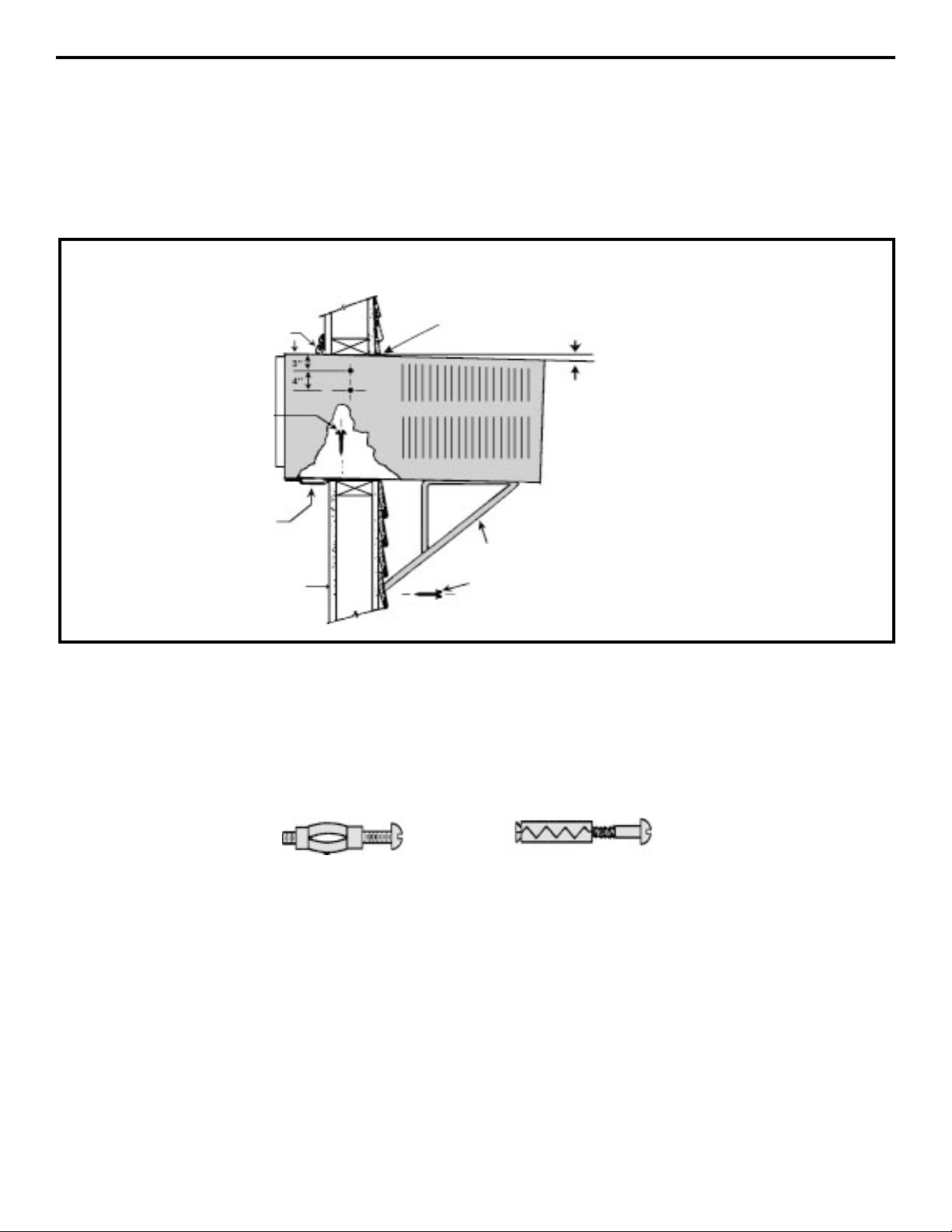

NOTE: ALTERNATE FASTENERS WHICH MAY BE USED FOR SECURING THE SILL PLATE IN THE W ALL, AND THE

SUPPORT BRACKETS TO THE OUTSIDE WALL ARE NOT FURNISHED, BUT ARE AVAILABLE AT A LOCAL

HARDWARE STORE.

MOLLY OR TOGGLE BOLT EXPANSION ANCHOR BOLT

STEP 5. Drill two (2) 5/32" (4 mm) dia. pilot holes in each side at the locations shown (Figure O) and install four (4) #12 x

2" screws (Item #4). If the hole construction in Step 2 provides a sturdy mount with solid v ertical studs, no support

brack ets are required. The installation must support the weight of the unit plus an additional weight of 400 pounds

(185 kg) on the rear of the cabinet. The support brack ets may be used for through-the-w all installations as sho wn

in Figure O, for additional support.

STEP 6. If desired, trim around the cabinet on the room side with a suitable frame molding furnished by the installer (See

Figure O).

Page 16

Page 17

SECTION VI

CHASSIS INSTALLATION

STEP 1. Slide the chassis into the cabinet stopping approximately 3" from full insertion. Stuff the chassis seal gasket (Item

#14) one inch deep between the chassis and the cabinet (See Figure P). Make sure that the gasket is behind

the conduit connector (furthest from you). Push the chassis into the shell the remaining distance so that the

plastic front shrouds the front edge of the shell. Fasten the junction box mounting foot to the shell with the sheet

metal screw .

NOTE: Field wiring must be provided to this junction box in accordance with NATIONAL ELECTRIC CODE

ARTICLE 501. Field and equipment grounds are to be terminated at the post in the junction box with

the green screw provided. Equipment power leads are to be connected with the field supply by means

of wire nuts (not provided). Install the gasket and cover plate onto the junction box.

FIGURE P

CHASSIS SEAL

GASKET

Page 17

Page 18

STEP 2. Be sure that the filter is in place then install the return air grille (See Figure Q). The top of the return air grille can

be butted against the bottom of the discharge plen um and then snapped at the bottom cupport clips, or the

bottom of the grille can be snapped into the grille clips and then engaged below the discharge plenum.

FIGURE Q

Discharge Air Plenum

DETAIL 2

Slot

Tab

Slot

Tab

Return Air Grille

DETAIL 1

DETAIL 1

DETAIL 3

Return air grille

Latches

Latch

DETAIL 4

Side view

(Cutaway)

STEP 3. You have completed your installation. Conduct a review of y our installation to insure that the unit is safely and

securely installed. Ref er to the "OPERATING GUIDE" section of this manual to test the operation of your unit.

WARNING: – EXPLOSION HAZARD –

SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

Page 18

CLASS I, DIVISION 2.

Page 19

FRIEDRICH AIR CONDITIONING CO. INC.

Post Office Box 1540 · San Antonio, Texas 78295-1540

(210) 357-4400 · FAX (210) 357-4480

FRIEDRICH HAZARDGARD

ROOM AIR CONDITIONERS

LIMITED WARRANTY

LIMITED ONE YEAR P ARTS WARRANTY

1. Limited warranty - One year . Friedrich warrants that it will provide a replacement for any part of this

HazardGard Room Air Conditioner found defective in material or workmanship for a period of one (1) year

from the date of original purchase.

2. Limited warranty - One year. The Friedrich warranty also covers the cost of labor for repairing any

compressor, condenser , evaporator or inter-connecting tubing found defective within the warranty period,

providing the unit is returned to an authorized Friedrich Repair Station located within the Continental

United States.

The Friedrich warranty does not cover:

(1) any charges for removal, transportation or reinstallation of the unit; (2) the cost of labor to

replace parts other than those described above; and (3) does not apply to any HazardGard

Room Air Conditioner that has been subject to (a) accident, misuse, flood, fire, or neglect; (b)

repairs or alterations outside of the Friedrich Authorized Dealer or Service Center so as to affect

adversely its performance and reliability; or (c) any repairs or servicing as a result of using parts

not sold or approved by Friedrich.

LIMITATIONS: This warranty is a LIMITED warranty. Anything in the warranty notwithstanding,

IMPLIED WARRANTIES FOR P ARTICULAR PURPOSE AND MERCHANT ABILITY SHALL BE LIMITED

TO THE DURA TION OF THE EXPRESS W ARRANTY. MANUF ACTURER EXPRESSLY DISCLAIMS

AND EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL OR INCIDENT AL DAMAGES FOR BREACH

OF ANY EXPRESS OR IMPLIED WARRANTY.

T o be assured of registered warranty protection in the event that field service contact and/or product recall

should ever become necessary, please complete your warranty registration card immediately , and mail

to: FRIEDRICH, CUSTOMER SERVICE DEPT., P .O. Box 1540, San Antonio, TX 78295.

In case of questions regarding the provisions of this warranty , the English version will govern.

W ARNING: – EXPLOSION HAZARD –

SUBSTITUTION OF COMPONENTS MA Y IMP AIR SUITABILITY FOR CLASS I, DIVISION 2.

Revised 8/01

Page 19

Page 20

FRIEDRICH HAZARDGARD ROOM AIR CONDITIONERS

FRIEDRICH AIR CONDITIONING CO. INC.

• Post Office Box 1540 • San Antonio , Texas 78295-1540

• 4200 N. Pan Am Expressway • San Antonio, Texas 78218-5212

• (210) 357-4400 • FAX (210) 357-4480

Visit us on the Internet at www.friedrich .com

Printed in the U.S.A.

Page 20

Page 21

UNIDADES DE AIRE

ACONDICIONADO

MANUAL DE USO

INSTALACIÓN Y

MANTENIMIENTO

Modelos

SH14

SH20

Page 21

Page 22

TABLA DE CONTENIDOS

INSTRUCCIONES PARA USO Y MANTENIMIENTO

PARTE 1 Instrucciones generales ............................................ página 23

PARTE 2 Información sobre el filtro......................................... página 24

PARTE 3 Lista de control para el mantenimiento ................... página 24

PARTE 4 Características especiales del HazardGard ............ página 25

PARTE 5 Pánel de control......................................................... página 26

PARTE 6 Underwriters Laboratories (Lista U.L.)..................... página 26

INSTRUCCIONES PARA LA INSTALACION

SECCION I Requerimientos eléctricos ........................................ página 27

SECCION II Desempaque de la unidad ........................................ página 29

SECCION III Preparación e instalación eléctrica del chasís ....... página 29

SECCION IV Preparación del armazón de la unidad (gabinete) .. página 30

SECCION V Instalación del armazón ............................................ página 31

A. Ventana de bastidor ............................................ página 31

B. A través de la pared ............................................ página 34

SECCION VI Instalación del chasís................................................ página 37

GARANTÍA ..................................................................................... página 39

Page 22

Page 23

BIENVENIDO A MUCHOS AÑOS DE COMODIDAD

Y ECONOMIA CON SU NUEVA UNIDAD DE AIRE

ACONDICIONADO FRIEDRICH HAZARDGARD

PARTE 1 — INSTRUCCIONES GENERALES

Su nueva unidad Friedrich se ha diseñado y fabricado cuidadosamente para brindarle muchos años de

funcionamiento confiable y eficiente para mantener un temperatura y el nivel de humedad cómodos. Se han

incluído muchas características adicionales en su unidad Friedrich para asegurarle un funcionamiento silencioso,

la mayor cantidad de circulación de aire frío y seco y un funcionamiento económico.

Estas son algunas sugerencias para ayudarle a utilizar su nueva unidad Friedrich con la mayor eficiencia:

1. Lea con cuidado y siga las instrucciones para la instalación.

2. Su unidad de aire acondicionado Friedrich HazardGard para cuartos se atierra eléctricamente y debe instalarse de

acuerdo con el Artículo 501 del NEC (National Electrical Code) de los Estados Unidos. La clasificación de resistencia

del circuito de la unidad aparece en la placa de identificación para cada uno de los modelos.

3. Asegúrese de que la unidad tiene la capacidad apropiada para el área que debe enfriar. Si la capacidad es

demasiado baja, la unidad debe trabajar demasiado y utiliza más electricidad de la necesaria y aumenta su desgaste.

Si la capacidad es demasiado alta, también le cuesta trabajo a la unidad, ya que se encenderá y apagará con

demasiada frecuencia y no podrá controlar la humedad tan bien.

4. Cuando usted enciende su unidad de aire acondicionado Friedrich por primera vez, debe colocar el

termostato en la temperatura más fría. Cuando llegue a la temperatura deseada, gire el control del termostato hacia

la posición "warmer" (más caliente) hasta cuando oiga un sonido metálico y el condensador se apague. El termostato

entonces hará el ciclo del condensador para mantener la temperatura que se haya seleccionado.

5. Limpie el filtro con frecuencia (Ver el mantenimiento general).

6. No obstruya el flujo de aire desde y hacia la unidad. Asegúrese que las rejillas para la regulación de ventilación

están dirigidas de tal forma que suministren una distribución pareja de aire por todo el cuarto. Atención: Si el aire se

dirige a una zona restringida como detrás de una cama o a una esquina de la habitación, esto puede hacer que la

unidad se encienda y se apague con rapidez, lo que puede perjudicarla.

7. Un filtro sucio o unos controles que no se hayan graduado bien, pueden tener un efecto nocivo sobre la

capacidad de enfriamiento de la unidad.

8. Si el enfriamiento es débil y usted ha verificado que el filtro está limpio y los controles se encuentran bien graduados,

la unidad puede estar baja de refrigerante y usted debe llamar a su representante de Friedrich para revisarla.

9. Mantenga las persianas, y las cortinas cerradas en el lado soleado del cuarto que debe enfriarse.

10. Un aislamiento adecuado le ayuda a su unidad a mantener la temperatura que usted desea dentro de la

habitación.

11. Cuando sea posible, coloque una tolda protectora contra el sol en las ventanas que dan hacia el occidente.

12. Mantenga las persianas y cortinas lejos de la unidad en la ventana para que haya un flujo de aire.

Page 23

Page 24

PARTE 2 — INFORMACION SOBRE EL FILTRO

El filtro de su unidad Friedrich elimina el polvo, polen y otras impurezas del aire a medida que el aire contiene. El filtro es

permanente y reutilizable y viene acondicionado con un tratamiento germicida (contra bacterias) que no se afecta cuando

se lava.

Un filtro sucio y obstruído reduce el flujo de aire a través de la unidad y reduce su eficiencia. Usted debe examinar el filtro

cada siete a diez días de acuerdo con la cantidad de uso de su unidad. Límpie el filtro periódicamente.

Ganchos de retencion del filtro

El filtro se puede sacar para limpiarlo abriendo la

parte de adelante de la unidad y quitando el filtro

de sus ganchos de retencion

PARTE 3 — LISTA DE CONTROL PARA EL MANTENIMIENTO

NO ENFRIA

Si la unidad funciona pero no enfría, asegúrese que los controles están en su debida posición. Examine el filtro y

límpielo cuidadosamente cuantas veces sea necesario.

NO FUNCIONA

Si la unidad no funciona en absoluto, asegúrese de que las conexiones de electricidad están ajustadas. Averigue si

los fusibles y los interruptores de circuito están funcionando. Reemplace los fusibles que se hayan quemado con

fusibles de acción retardada (time-delay) que sean apropiados. El tamaño adecuado de los fusibles se puede

encontrar en la placa de identificación de la unidad. Una vez haya restaurado el suministro de electricidad, espere

tres minutos antes de volver a encender la unidad.

EL SERPETIN INTERIOR SE CONGELA

Su Friedrich HazardGard se ha diseñado de tal forma que no debe congelarse en temperaturas exteriores hasta de

45 grados fahrenheit (7 grados centígrados). Debe congelarse solamente si el aire exterior es húmedo y la

temperatura es inferior a 45 grados fahrenheit (7 grados centígrados). Si comienza a congelarse el serpentín

interior cuando la unidad está enfriando, coloque el termostato en su posición más caliente hasta cuando el hielo

haya desaparecido. Mantener el termostato en una posición un poco más caliente evitará la formación de hielo en

el serpentín. Un filtro sucio contribuye a que haya congelación.

LIMPIEZA

Tanto la rejilla delantera de su unidad Friedrich como el gabinete se pueden limpiar con un detergente suave y agua

tibia. Los serpentines y la bandeja base deben limpiarse periódicamente para su mejor funcionamiento. Sugerimos

que usted llame a su distribuidor Friedrich para este servicio.

LUBRICACION

Los motores de los ventiladores vienen lubricados y sellados en la fábrica. No necesitan lubricación.

Page 24

Page 25

PARTE 4 — CARACTERISTICAS ESPECIALES DEL HAZARDGARD

Características especiales

de la unidad HazardGard

!!

! Motor de arranque doble permanente,

!!

motor del ventilador totalmente

sellado para asegurar un

funcionamiento eficiente aún durante

condiciones eléctricas adversas. El

motor tiene una vara de acero

inoxidable para evitar que haya

corrosión y un control de sobrecarga

herméticamente sellado para evitar

que hayan cortes del circuito.

!!

! Condensador de alta capacidad con

!!

un control interno de sobrecarga

sellado herméticamente.

!!

! Tablero electrónico impreso de

!!

circuitos aislado contra corrosión de

conductores. Supresor de cambios de

voltaje para proteger los controles en

contra cambios y recargas de voltaje.

Interruptores transistorizados para

evitar cortes de circuito.

!!

! Un control para la desviación de gas

!!

caliente en temperaturas bajas del

medio ambiente, para pemitir el

funcionamiento sin que se congele

cuando las temperaturas exteriores

ambientales son inferiores a 45

grados fahrenheit (7 grados

centígrados).

!!

! Serpentines en cobre con aletas de

!!

aluminio.

!!

!

El Gabinete en acero galvanizado y la

!!

andeja base se han tratado

químicamente (bonderizado).

!!

!

Chasís deslizable para instalación fácil

!!

en ventanas o a través de las paredes.

!!

! Aislamiento interior extra, incluyendo na

!!

cámara distribuidora de aire

completamente aislada para un

enfriamiento más eficiente y silencioso.

!!

! Prueba completa de la unidad en una

!!

cámara ambiental antes de empacarla.

!!

! Control de flujo de aire de ocho

!!

posiciones para garantizar la

uniformidad en la circulación de aire.

!!

! Circuito de control electrónico

!!

patentado.

!!

! Drenaje de condensación con una

!!

barrera exclusiva contra mosquitos.

!!

! Se requiere un circuito de 15 amperios

!!

con un fusible de acción retardada.

Acepta una instalación eléctrica directa.

!!

! Interruptor sellado para encender y

!!

apagar, con contactos en el

termostato bañados en oro para evitar

la corrosión.

!!

! Revestimiento galvanizado y

!!

esmaltado con alcaloides, los dos

horneados para dar un acabado

atractivo y de larga duración.

La calidad de las unidades de aire acondicionado Friedrich se

ha comprobado durante más de veinticinco años de

experiencia exitosa desde el Golfo de México hasta las arenas

tórridas de los desiertos árabes.

!!

! Filtro de aire de 3/8" (10 mm) de

!!

grueso, de larga duración, con

tratamiento germicida; se puede quitar

fácilmente para poderlo limpiar.

Page 25

Page 26

PARTE 5 — PANEL DE CONTROL

CONTROL DE ENCENDIDO

(ELECTRICIDAD)

El interruptor es bipolar (dos polos), con un interruptor de

palanca de movimiento sencillo.

ON (encendida) - enciende todo el sistema

OFF (apagada) - apaga todo el sistema

CONTROL DE LA TEMPERATURA

El control giratorio en la parte inferior es un termostato del

tipo de ambiente cruzado y se emplea para mantener un

nivel de comodidad deseado. El termostato reacciona

solamente a un cambio de temperatura cerca de la ubicación

del bombillo - gire el control de izquierda a la derecha para

un mayor enfriamiento y de derecha hacia la izquierda para

un ambiente menos frío.

PARTE 6 — ¡EXCLUSIVA!

Friedrich nuevamente lleva el liderazgo con la primera serie de aire acondicionados para

habitación en la Lista UL (Underwriters Laboratories), los cuales se han diseñado para enfriar

habitaciones y otros recintos ubicados en sitios peligrosos, en donde se manejan líquidos

inflamables, elementos explosivos y volátiles o se utilizan en recetáculos o sistemas

encerrados.

Los aparatos para habitación Friedrich HazardGard

los requisitos del Código Nacional de Electricidad (de los Estados Unidos), para la clase 1,

División 2, Grupos A, B, C, D de locales peligrosos y son los únicos aparatos de aire

acondicionado en la lista de Underwriters Laboratories (UL) para ese uso. ESTA UNIDAD SE

ENCUENTRA EN LA LISTA DE LOS UNDERWRITERS LABORATORIES (UL) PARA USE

EN LOS LOCALES PELIGROSOS CLASE 1, DIVISION 2, GRUPOS A, B, C, D. Codigo de

temperatura de funcionamiento: T3B.

®

se han diseñado para que cumplan con

Page 26

Page 27

INSTRUCCIONES P ARA INST ALACION

Modelos SH14 y SH20

NOTA: ESTE MANUAL INCLUYE LAS INSTRUCCIONES PARA LA INSTALACIÓN T ANTO DEL MODELO DE

MONTAJE EN LA VENTANA COMO PARA EL MODELO QUE SE INSTALA A TRAVÉS DE LAS PAREDES.

SECCION 1: REQUERIMIENTOS ELECTRICOS

TODA LA INSTALACION ELECTRICA DEBE CUMPLIR CON LOS REQUISITOS DEL CODIGO NACIONAL DE

ELECTRICIDAD (ANSI/NFPA 70) ARTICULO 501.

EL APARATO PARA PROTECCION DEL CIRCUITO QUE SE SUMINISTRA (INTERRUPTOR DE CIRCUIT O O FUSIBLE

DE ACCION RETARDADA) NO DEBE SER SUPERIOR AL AMPERAJE QUE APARECE EN LA PLACA DE

IDENTIFICACION DEL PRODUCTO.

IMPORTANTE: Antes de instalar su unidad de aire acondicionado, averigue los códigos locales de electricidad y lea la

información a continuación.

Su unidad de aire acondicionado debe conectarse al suministro de electricidad con el mismo voltaje A.C. y frecuencia

(hertz) que aparece en la placa de información que se encuentra en el chasís. Debe emplearse solamente corriente

alterna (A.C.) y nunca corriente directa (D.C.).

Un circuito sobrecargado inevitablemente hará que su aire acondicionado no funcione debidamente o que falle. Consulte

con su distribuidor o con la empresa de energía si tiene alguna duda.

Las instrucciones siguientes son para los modelos HAZARGARD y para los tamaños de gabinetes que se

detallan a continuación:

GRUPOS

CHASIS PEQUEÑO SH14

CHASÍS MEDIANO SH20

15-15/16" pulgada de altura x 25-15/16" pulgada de ancho x

27-3/8" pulgada de profundidad (405 mm x 660 mm x 695 mm).

17-15/16" pulgada de alto x 25-15/16" pulgada de ancho x

27-3/8" pulgada de profundidad (455 mm x 660 mm x 695 mm).

TAMAÑO DEL GABINETE

Número del modelo Tipo de enchufe Clasificación de resistencia del

circuito fusible de acción

retardada.

SH14 Caja de empalme 250 Voltios-15 Amperios

SH20 Caja de empalme 250 Voltios-15 Amperios

Page 27

Page 28

HERRAMIENTA PARA LA

INSTALACION DE LAS UNIDADES

PARA MONTAJE EN VENTANA

Número Descripción Cantidad

de item

HERRAMIENTA PARA MONTAJE

DE LA ARMAZON

1 Repisa de apoyo 2

2 Tornillo, 10-24 x 1" pulgada con cabeza hexagonal 4

3 10-24 tuerca plana 4

4 Tornillo para hoja metálica #12A x 2" pulgadas 7

MONTAJE PARA LOS

PANELES LATERALES

5 Conexión superior para los páneles laterales 1

6 Conexión lateral para los páneles laterales 2

7 Tornillo para hoja metálica #8A x 3/8" 2

HERRAMIENTA PARA INSTALACION

DE LOS PANELES LATERALES

8 Pánel lateral (en masonita) 1

9 Tuerca tipo J 4

10 Gancho para los páneles laterales

en resorte de acero 4

11 Tornillos #8A x 1/2" tipo phillips con

cabeza redonda 4

RELLENO PARA LA VENTANA

12 Empaque de relleno (en vinilo) 1

13 Empaque para sellar la ventana

(en espuma oscura) 1

14 Empaque para sellar el chasis (en espuma clara) 1

ELEMENTO 2

ELEMENTO 4

ELEMENTO 3

ELEMENTO

7

ELEMENTO 9

LISTA DE ACCESORIOS

ELEMENTO 14

ELEMENTO 1

ELEMENTO

11

ELEMENTO 10

ELEMENTO 13

ELEMENTO 12

ELEMENTO 6

ELEMENTO 5

(ESTA GRAFICA NO ESTA DIBUJADA A ESCALA)

Page 28

Page 29

SECCION II

DESEMPAQUE DE LA UNIDAD

PASO 1. Remueva la rejilla a plástica decorativa y manténgala en un sitio seguro separada de la unidad.

PASO 2. Remueva de la parte inferior de la unidad la herramienta de instalación, el pánel lateral y dos empaques o

arandelas (uno de color claro y el otro oscuro) y colóquelos en un sitio seguro lejos de la unidad.

PASO 3. Quite el alambre fijador del chasís sacando el tornillo interior derecho al f ondo de Ia base (Ver Figura A);

guarde este tornillo para volver a asegurar el fijador del chasis una v ez lo haya instalado (Paso 15). También

quite y deseche los dos tornillos de retención y los casquillos de plástico colocados detrás de la

unidad.

PASO 4. Mientras un a yudante sostiene el gabinete, utilice Ia manija para jalar Ia parte delantera de Ia base (Ver

Figura A) y saque el chasís fuera del gabinete. Deseche los bloques amortiguadores de espuma blanca

utilizados para retener el compresor durante envío. Examine la base y quite todos los bloques blancos

desalojados. No quite cualquiera otra espuma.

GABINETE

FIGURA A

TERCER PASO

MANIJA

MANIJA

TORNILLO INFERIOR

DERECHO

RETENEDOR DEL

CHASIS

SECCION III

PREPARACION Y INSTALACION ELECTRICA DEL CHASIS

HERRAMIENTA QUE SE SUMINISTRA

1 caja de empalme de conexión, Friedrich PN: 613-893-00

2 patas de montaje, Raco Inc. PN: 5324-0

2 tornillos de patas

2 tapas para huecos

1 tornillo de tierra

Cubierta de la caja, Friedrich PN: 613-892-00

Arandela, Raco Inc. PN: 5173-0

2 tornillos

1 Tornillos para hoja metálica

PASO 1. Saque la caja de empalme de conexión y el tornillo (los elementos anteriores) de la posición en que se han

colocado para el transporte por debajo del motor del ventilador. Instale una de las patas de montaje de la caja de

empalme de conexión en la posición superior izquierda frente a la parte de atrás de la caja de empalme de

conexión.

PASO 2. Saque y deshágase del cojinete plástico del conector del conducto en el pánel lateral del compartimento de los

controles. Pele los alambres negros solamente, aproximadamente 1/2 pulgada (13 mm).

PASO 3. Introduzca todos los cables (2 negros, 1 verde) en la caja e introduzcalos asegure la caja al conector del conducto

hasta que esté apretada. Devuélvala de derecha hacia izquierda hasta que la caja de emaplme de conexión

quede vertical con la pata de montaje en la posición superior derecha, de frente a la apertura de la caja. Asegúrese

de que la armazón cabe entre esta caja y el chasís.

Page 29

Page 30

SECCION IV

PREPARACION DEL ARMAZON (GABINETE):

Será necesario volver a ubicar la placa del borde del armazón del gabinete 2" pulgadas (50 mm) más atrás de la posición en que

se ha colocado para transportarse, y las guías de la armazón 4" pulgadas (100 mm) más adelante, hacia el hueco delantero en

el carril de la armazón. Retire el alambre de retención del chasís desconectado en la Sección II, Paso 3. La pata de montaje

de la caja de empalme de conexión de la Sección VI, Paso 1, y el conducto instalado en el campo retendrán el chasís en la

armazón.

SI ESTA INSTALACION ES PARA UNA VENTANA DE BASTIDOR - Con el reborde ancho y los huecos piloto de la placa

del antepecho hacia adelante, coloque los tornillos/tuercas en los huecos posteriores de la placa del antepecho y en el tercer

hueco de la armazón contado de adelante hacia atrás (el hueco en la mitad de tres huecos cuadrados para los modelos de

1995-1996). Fije los ángulos laterales (Elemento #6) apretando las lengüetas en cada extremo de la placa del antepecho y

asegurando de esta manera las presillas del ángulo lateral. Encaje las lengüetas en cada extremo del ángulo superior

(Elemento #5) con las presillas superiores del ángulo lateral. Instale dos (2) tornillos (Elemento #7) para asegurar las lengüetas

del ángulo superior y el ángulo lateral a los huecos traseros en la pared de la armazón (Vea la figura B, a continuación).

SI LA INSTALACION SE HACE A TRAVES DE LA PARED - Voltée la placa del antepecho de extremo a extremo (180

grados) para que el reborde ancho con los huecos piloto quede encima de la pared (hacia atrás) y a dos pulgadas de la parte

de adelante del gabinete. Doble las lengüetas para que entren por el canal de la placa del antepecho, coloque los tornillos/

tuercas en los huecos delanteros de la placa del antepecho y dentro del segundo hueco de la parte delantera del gabinete.

Utilice una tuerca en cada lado para asegurar la placa del antepecho al gabinete. (Vea la Figura C a continuación).

FIGURA B

FIGURA C

GABINETE

ANTEPECHO

VOLTEE EL

FILO DEL

ANTEPECHO

DE LADO A

LADO

GABINETE

ANTES

TORNILLOS, SE

REQUIEREN 2

RETENEDOR, CHASIS.

(SOLAMENTE ESTE

LADO)

DOBLE LAS LENGÜETAS

HACIA ABAJO

DETALLE 1

DETALLE 2

ANGULO SUPERIOR

(ELEMENTO #5)

NOTA: LOS

HUECOS SE HAN

MOVIDO A LA

PARTE LATERAL

POSTERIOR

TUERCAS, SE

REQUIEREN 2

ANGULOS

LATERALES

(ELEMENTO

#6) SE

REQUIEREN

2

PRESILLA DEL BORDE

DEL GABINETE

DESPUES

SE REQUIEREN DOS TORNILLOS

LARGOS DE 8A x 3/8" PULGADA

PRESILLA

DETALLE B-1

DETALLE B-2

Placa del antepecho volteada (los

huecos hacia la parte de atrás), y

colocados a dos pulgadas de la

parte delantera del gabinete.

Coloque las tuercas de la parte

superior empleando una tuerca/

tornillo en cada extremo de la

placa del antepecho. Bote el

alambre de retención del chasís.

LENGÜETA

PRESILLA

Page 30

Page 31

SECCION V — INSTALACION DEL ARMAZON

(A) INSTALACIONES EN VENTANAS DE BASTIDOR

INSTALACION DEL ARMAZON (GABINETE) - VENTANAS REGULARES DE BASTIDOR

PASO 1. Examine el antepecho y marco de la ventana y asegúrese que están en buenas condiciones y anclados firmemente

en la pared. Haga los arreglos que sean necesarios.

PASO 2. MONTAJE DEL GABINETE. Suba la ventana del antepecho inferior 1/4 de pulgada más arriba de la altura del

gabinete. Con cuidado introduzca el gabinete a través de la ventana abierta hasta que el canal de la placa del

antepecho descanse por detrás del antepecho de la ventana y que el ángulo superior de apo yo quede contra la

ventana (Vea Figura D ). Coloque el gabinete en el centro de lado a lado y taladre tres (3) huecos piloto de un

diámetro de 5/32" pulgada en el antepecho de la ventana, utilizando los huecos en la placa del antepecho del

gabinete como guía. Instale tres (3) tornillos largos #12A x 2" pulgadas (Elemento #4) (Vea Figura D.)

FIGURA D

CENTRE EL GABINETE A

CADA LADO DE LA VENTANA

TALADRE TRES (3) HUECOS PILOTO DE

5/32" PULGADA E INSTALE TRES (3)

LOCALICE EL CANAL GUIA DEL ANTEPECHO

DE LA VENTANA EN LA PARTE POSTERIOR

DEL ANTEPECHO DE LA MISMA

ANGULO DE SOPORTE

SUPERIOR

BAJE EL BASTIDOR DE LA

VENTANA DETRÁS DEL

ANGULO DE SOPORTE

SUPERIOR

ANGULO DE SOPORTE

LATERAL

TORNILLOS LARGOS #12A x 2" PULGADAS

(ELEMENTO #4)

FIGURA E

UN ESPACIADOR DE 1" x 4" PULGADAS O DE 2" x 4"

PULGADAS SE DEBE USAR ENTRE LA PARED Y LA

REPISA DE APOYO CUANDO SE INSTALAN EN PLACAS

DE CUBIERTA (SIDING) DE ALUMINIO, ASBESTOS O

VINILO.

DECLIVE HACIA EL EXTERIOR (ABAJO) DE 3/8"

PULGADA (10 mm)

REPISA DE

APOYO

(ELEMENTO #1)

TORNILLO #12A x 2"

PULGADES

(ELEMENTO #4)

REPISA DE APOYO

TUERCA PLANA (WELDNUT)

10-24 (ELEMENTO #3)

TORNILLO HEXAGONAL (1)

10-24 (ELEMENTO #2)

PASO 3. MONTAJE DE APOYO EXTERIOR: Ensamble las repisas de apo yo (soporte)(Elemento #1) a los rieles inferiores

del gabinete, utilizando cuatro (4) tornillos largos de 10-24 1" pulgadas (Elemento #2) y cuatro (4) tuercas planas

de 10-24 (Elemento #3). Ajuste las repisas de apo y o para que los cojinetes inferiores queden en contacto con la

superficie de la pared (Ver Figura E).

DEBE EMPLEARSE UN SEPARADOR DE MADERA DE 1" x 4" O DE 2" x 4" PULGADAS ENTRE LA PARED Y LAS

REPISAS CUANDO SE ESTE HACIENDO UNA INSTALACION EN PAREDES EXTERIORES DE VINILO O DE ALUMINIO.

T aladre huecos de 5/32" pulgada (4 mm) de diámetro y asegure las repisas a la pared con dos (2) tornillos lar gos de #12A x 2"

pulgadas (Elemento #4). Ajuste las repisas de apoyo para dar una inclinación de de aproximadamente

3/8" pulgada (10 mm) hacia abajo en la parte exterior, para que haya drenaje. Apriete todos los tornillos. (Vea la Figura

E).

Page 31

Page 32

Las ilustraciones a continuación muestran la instalación en marcos de construcción normal, así como también

algunas formas de adaptar la repisa de apoyo al espesor de las paredes y a los salientes de piedras grandes.

INSTALACION TIPICA DEL FILO DEL ANTEPECHO

FIGURA 1

FIGURA 3

TORNILLO DE 10-24

TUERCA PLANA DE

10-24

TORNILLO DE METAL

#12A x 2" PULGADAS

UN ESPACIADOR DE 1" x 4" PULGADAS

O DE 2" x 4" PULGADAS ENTRE LA

PARED Y LA ARANDELA DEBE USARSE

CON TABLAS DE FORRO (SIDING) DE

ALUMINIO, ASBESTO O VINILO.

SALIENTE

DE PIEDRA

DECLIVE HACIA

AFUERA DE 3/8

PULGADA (10 mm)

DECLIVE HACIA

ABAJO DE 3/8 DE

PULGADA (10 mm)

FIGURA 2

CORTE AQUI

RETIRE LA PARTE

OBSCURECIDA

FIGURA 4

DECLIVE HACIA

ABAJO DE 3/8

PULGADA

(10 mm)

SALIENTE DE PIEDRA

PARED EXTERIOR

CORTE PARA QUE SE ADAPTE A LA

DIMENSION "A" Y DOBLE HACIA

ABAJO, PARA FORMAR UNA PATA

VERTICAL

ASEGURE A LA ARMAZON EL

LADO MAS LARGO DE LA REPISA

DECLIVE

HACIA

ABAJO DE 3/8

DE PULGADA

(10 mm)

TORNILLO METALICO

#12A x 2" PULGADAS

ESPACIADOR DE 2" x 4"

PULGADAS

ENDERECE LA LENGÜETA PARA QUE

SE MANTENGA PLANA A LO LARGO

DEL ANTEPECHO DE LA ARMAZON.

AJUSTE HACIA ADENTRO O HACIA

AFUERA PARA QUE DESCANSE

SOBRE EL BORDE

PASO 4. CORTE DE LOS PANELES DE ALAS LATERALES: mida y corte los páneles de alas laterales de masonita

que se suministran (Elemento #8) para que se acomoden a los espacios entre los canales laterales de la v entana

y los lados del gabinete (Vea la Figura F).

NOTA: UNA VEZ HAYA CORTADO LOS PANELES, HAGA UN ENSAYO PARA VER SI SE AJUSTAN AL CAMPO

CON UN ESPACIO DE APROXIMADAMENTE 1/8" PULGADA (3 mm) ANTES DE CONTINU AR AL PASO 5.

FIGURA F

MIDA LA DISTANCIA "B" A LA PARTE INTERIOR

DEL CANAL EN CADA LADO.

CORTE AQUI Y DESHAGASE DEL MATERIAL DESECHABLE EN LA MITAD.

A LA LATERAL

Page 32

RESTE 1/8" (3 mm) DE PULGADA DE LA DIMENSION "B" Y

MIDA DEL BORDE DEL ALA LATERAL (ELEMENTO #8),

MARQUE Y CORTE CON UNA SIERRA.

Page 33

FIGURA G

TUERCA SPEED EN FORMA

DE J (ELEMENTO #9)

SE REQUIEREN 2 GANCHOS DE

RESORTE DE ACERO (ELEMENTO #10)

CORTE EL PANEL DE

ALAS LATERALES

HUECO CENTRAL DE LA

TUERCA SPEED SOBRE LA

RANURA DEL PANEL

CORTE EL BORDE

META EL GANCHO SOBRE EL

BORDE CORTADO DEL PANEL DE

ALAS LATERALES

PASO 5. INSTALE LOS GANCHOS DE LOS PANELES DE ALAS LATERALES: Ensamble las tuercas de tipo "J"

(Elemento #9) y los ganchos de resorte de acero (Elemento #10) a los bordes cortados de los paneles de alas

laterales (Vea Figura G).

FIGURA H

ASEGURE LOS PANELES DE

ALAS LATERALES A LOS

ANGULOS DE LOS LADOS CON

CUATRO (4) TORNILLOS

LARGOS #8A x 1/2 PULGADA

(ELEMENTO #11)

PARTE SUPERIOR DEL GABINETE

PONGA EL PANEL DE ALAS LATERALES EN EL

ANTEPECHO DE LA VENTANA PARA APRETAR

LOS RESORTES DENTRO DE LAS CORREDERAS

Y HAGA GIRAR EL PANEL HASTA EL SITIO

INDICADO POR LA LINEA DE PUNTOS

ANTEPECHO DE LA VENTANA

P ASO 6. INST ALE LOS PANELES DE ALAS LATERALES: Asegúrese de que el gabinete se encuentra bien apretado al

antepecho de la ventana y que las repisas de apoyo se han instalado de acuerdo a como se demuestra en las

figuras D y E en la página 31. Levante el bastidor de la ventana e instale los páneles de alas laterales de la

derecha y de la izquierda (Ver Figura H).

PASO 7. INST ALE LOS EMP A QUES DE AISLAMIENT O DE LA VENT ANA: Mida y corte el empaque de vinilo para aislar

(sellar) la ventana (Color gris, Elemento #12) para que se acomode al ancho de la v entana e instálelo de acuerdo

con la muestra en la figur a I. Baje el bastidor de la v entana por detrás del empaque . Mida y corte el empaque de

espuma oscura para sellar la ventana (Elemento #13) e instálelo entre el pánel superior de vidrio y la parte

superior del bastidor inferior. (Ver Figura I)

FIGURA I

ARANDELA DE ESPUMA PARA SELLAR LA VENTANA (ELEMENTO #13)

ARANDELA DE VINILO PARA SELLAR LA VENTANA (ELEMENTO #12)

MARCO DE LA VENTANA INFERIOR

ARANDELA DE VINILO PARA SELLAR LA VENTANA

ANGULO SUPERIOR DEL ALA

NOTA: POR RAZONES DE SEGURIDAD, EL CLIENTE DEBE UTILIZAR UN SISTEMA PARA PREVENIR QUE SE

PUEDA ABRIR LA VENTANA.

PASO 8. Cuando sea posible, ponga masilla para relleno en la parte ext erior de la instalación, empleando una masilla de

relleno tipo industrial, para prevenir que haya filtración de agua.

Page 33

Page 34

SECCION V — INSTALACION DE LA ARMAZON

(B) INSTALACIONES A TRAVES DE LA PARED

PREPARACION DE LA PARED:

El grueso máximo que se permite para la pared sin que se emplee una construcción especial se determina de acuerdo

con el tamaño del modelo que va a instalarse. LAS LAS REJILLAS DE ENTRADA DE AIRE EXTERIOR DEL

CONDENSADOR DEL GABINETE NO DEBEN SER OBSTACULIZADAS POR LA PARED. Fíjese en el grosor máximo

de la pared mostrado como la dimensión "A" en la Figura J.

INSTRUCCIONES ESPECIALES PARA PAREDES EXTRA GRUESAS. Para las instalaciones en paredes más anchas

de las que aparecen en la dimensión "A" sugerimos que se utilice la construcción de la Figura J. (Ver Figura J)

FIGURA J

MAXIMO GROSOR DE LA PARED: 15 1/8

PULGADAS (384 mm)

VISTA SUPERIOR QUE MUESTRA LOS LADOS

BISELADOS PARA LA ENTRADA DEL AIRE. LA

PARED DEBAJO DE LA UNIDAD DEBE SER

BISELADA TAMBIEN

CONSTRUCCION PARA PAREDES MAS GRUESAS

REJILLAS

PARA LA

ENTRADA DE

AIRE DEL

CONDENSADOR

2" (51 mm) MINIMO

A AMBOS LADOS

REJILLAS PARA

ENTRADA DEL AIRE DEL

CONDENSADOR

PASO 1. EXAMINE LAS CONEXIONES ELECTRICAS Y LA PLOMERIA: Cerciórese de la ubicación de todas las

conexiones eléctricas y de la plomería por dentro y por fuera de la pared, para asegurar que no se dañarán

donde usted va a perfor ar un hueco.

PASO 2. EXCA V A CION DEL HUECO: De acuerdo con el tamaño de la unidad que se va a instalar , calcule las dimensiones

del hueco de acuerdo con el gráfico a continuación (Vea la Figura K). Corte y enmarque el hueco de acuerdo con

las dimensiones establecidas. Utilice maderas de 2" x 4" pulgadas para el marco y siga las instrucciones de

instalación típicas que se sugieren en las Figuras L, M, o N de la página 35.

NOTA: SI LA CONSTRUCCION DE LA P ARED ES DE VIGAS DE MADERA TÍPICAS O ES DE 2 x 4, CON FORRO EN

LADRILLO O EN PIEDRA, UBIQ UE EL HUECO AL LADO DE UNA DE LAS VIGAS. P ARA CONSTRUCCIONES

DE LADRILLO, CONCRETO O LADRILLOS DE CENIZAS LOCALICE EL HUECO A SU CONVENIENCIA.

FIGURA K

REQUISITOS DE TAMAÑO DE LOS HUECOS

DIMENSION CHASIS CHASIS

TERMINADA PEQUEÑO MEDIANO

A 16-3/16" pulgada (411 mm) 18-3/16" pulgada (462 mm)

B 26-3/16" pulgada (665 mm) 26-3/16" pulgada (665 mm)

NOTA: ESTAS SON LAS DIMENSIONES DEL HUECO TERMINADO

Page 34

Page 35

FIGURA L

CONSTRUCCION EN EL MARCO DE LA PARED

PONGA MASILLA EN

TODOS LOS LADOS

GABINETE PROTECTOR

RELLENE CON MADERA LOS ESPACIOS

VACIOS EN LA PARTE DE ENCIMA Y A

LOS LADOS, SEGUN SE REQUIERA

FIGURA M

FIGURA N

CONSTRUCCION EN PAREDES DE LADRILLO

PONGA MASILLA EN

TODOS LOS LADOS

GABINETE

RELLENE CON MADERA LOS ESPACIOS

VACIOS EN LA PARTE DE ENCIMA Y A LOS

LADOS, SEGUN SE REQUIERA.

CONSTRUCCION EN ALBAÑILERIA SOLIDA

PONGA MASILLA EN

TODOS LOS LADOS

GABINETE

CEMENTO

Page 35

Page 36

PASO 3. Meta el gabinete en el hueco suficientemente como para permitir que el canal de guía de la placa del antepecho

haga contacto con la superficie interior de la pared (Ver Figura O).

PASO 4. Taladre tres (3) huecos piloto de un diámetro de 5/32" pulgada a través de los huecos de la placa del antepecho

en el marco e instale tres (3) tornillos largos #12 x 2" (Elemento #4) (Ver Figura O).

FIGURA O INSTALACION TIPICA

RELLENE CON MASILLA LA PARTE

MOLDE PARA REBORDE

(DECORATIVO)

USE TRES (3) TORNILLOS

LARGOS #12A x 2" PULGADAS

(51 mm)

CANAL GUIA DE LA PLACA

SUPERFICIE DE LA

PARED INTERIOR

SUPERIOR Y LOS LADOS

DECLIVE HACIA ABAJO DE

3/8 DE PULGADA (10 mm)

NOTA: EN LAS INSTALACIONES A TRAVES DE LA

PARED SE PUEDEN OMITIR LAS REPISAS DE

APOYO SI SE ASEGURA EL GABINETE DE LA

FORMA SIGUIENTE: PERFORE DOS HUECOS A

CADA LADO E INSTALE 4 GANCHOS (DOS A

CADA LADO). USE TORNILLOS #12A x 2"

PULGADAS (51 mm), TORNILLOS ARTICULADOS

O TORNILLOS CON ANCLA DE EXPANSION,

COMO SE MUESTRA EN EL PASO 5.

REPISAS DE APOYO (ELEMENTO #1)

(VER LA NOTA ANTERIOR)

USE UN (1) TORNILLO #12 x 2" PULGADAS

(51 mm) EN CADA REPISA. TALADRE HUECOS

PILOTO DE 5/23 PULGADA (4 mm)

NOTA: LOS SUJETADORES OPCIONALES QUE SE PUEDEN EMPLEAR PARA ASEGURAR LA PLACA DEL

ANTEPECHO A LA PARED Y LAS REPISAS DE APOYO A LAS PAREDES EXTERIORES NO SE

SUMINISTRAN PERO LOS PUEDE ENCUENTRAR EN CUALQUIER FERRETERIA.

TORNILLO ARTICULADO O MOLLY

TORNILLO DE ANCLA DE EXPANSION

PASO 5. Taladre dos (2) huecos piloto de 5/32" (4 mm) de diámetro a cada lado de los lugares que aparecen en la Figura

O e instale cuatro (4) tornillos #12 x 2" (Elemento #4). Si la construcción del hueco en el paso 2 da un montaje

fuerte con vigas verticales sólidas, no se necesitan repisas de apoy o . La instalación debe sostener el peso de la

unidad más un peso adicional de cuatrocientas (400) libras (185 kg) en la parte de atrás del gabinete. Las

repisas de apoyo pueden emplearse en instalaciones a través de la pared como se demues t ra en la Figura O,

para lograr un apo yo adicional.

PASO 6. Si se desea, se puede emplear una moldura de acabado alrededor del gabinete por el lado interior, el cual lo

debe suministrar la persona que haga la instalación (Vea la Figura O).

Page 36

Page 37

SECCION VI

INSTALACION DEL CHASIS

PASO 1. Introduzca el chasís en el gabinete dejando un espacio de aproximadamente tres pulgadas por fuera. Meta la

arandela de sello del chasís (Elemento #14) a una profundidad de 1" pulgada dentro del chasís y el gabinete

(V ea la Figura P). Asegúrese de que el empaque queda por detrás del conector del conducto (más alejado

de usted). Empuje el chasís hacia adentro de la armazón en la distancia que queda para que la tapa plástica

delantera recubra el borde delantero del armazón. Asegure la placa de montaje de la caja de empalme de

conexiones al armazón con un tornillo para hoja de metal.

NOTA: Usted debe suministrar la instalación eléctrica a esta caja de empalme de conexión de acuerdo con EL

ARTICULO 501 DEL CODIGO NACIONAL DE ELECTRICID AD (DE LOS ESTADOS UNIDOS). Los alambres

a tierra para el equipo deben terminarse en el poste, en la caja de empalme de conexión, con el tornillo ve

verde que se suministra. Los alambres de suministr o de electricidad para los equipos deben conectarse

con el suministro por medio de tuercas para alambre (no se suministran). Instale la arandela y la placa

de la cubierta en la caja de empalme de conexión.

FIGURA P

ARANDELA PARA SELLAR EL CHASIS

Page 37

Page 38

PASO 2. Asegúrese de que el filtro está en su lugar e instale la rejilla para retorno de aire. (Ver Figura Q). La parte

superior de la rejilla de retorno de aire se puede colocar contra la parte inferior del distribuidor de descargue de

aire y luego se puede enganchar con las presillas de apoyo, o la parte inferior de la rejilla se puede colocar con

las presillas de la rejilla y luego se puede conectar por debajo del distribuidor descargue.

FIGURA Q

Distribuidor para salida

del aire (Pleno)

Detalle 2

Ranura

Lengüeta

Ranura

Lengüeta

Detalle 1

Rejilla para retorno del aire

Detalle 1

Detalle 3

Rejilla para retorno

del aire

Presillas

Presilla

Detalle 4

Vista lateral (cortar)

PASO 3. Usted ha completado su instalación. Repase la instalación con el fin de garantizar que la unidad se ha instalado

de forma correcta y segura. Diríjase a la “GUIA DE FUNCIONAMIENTO” de este manual para comprobar el

funcionamiento de la unidad.

ADVERTENCIA — PELIGRO DE EXPLOSION

La substitución de componentes puede ocasionar que el aparato no sea aceptable

para el uso en las circunstancias previstas en la Clase 1, División 2.

Page 38

Page 39

FRIEDRICH AIR CONDITIONING CO. INC.

Post Office Box 1540 · San Antonio, Texas 78295-1540

(210) 357-4400 · FAX (210) 357-4480

UNIDADES DE AIRE ACONDICIONADO HAZARDGARD DE FRIEDRICH

GARANTÍA LIMIT ADA DE UN AÑO

1. Garantia limitada - un año. Friedrich garantiza que reemplazará cualquier parte de esta

unidad de Aire Acondicionado HazardGard para habitación que no funciona debido a un defecto

de manufactura o del material, dentro un año a partir de la fecha original de compra.

2. Garantia limitada - un año. La garantía de Friedrich cubre también los costos de mano de

obra para la reparación de cualquier condensador, evaporador o tubería de conexión que se encuentre

defectuoso dentro del período de la garantía, siempre y cuando la unidad se devuelva a un sitio de

reparación Friedrich ubicado dentro de los 48 Estados Unidos contiguos.

Esta garantía de Friedrich no cubre (1) ningún costo ocasionado por remover, transportar

o reinstalar la unidad; (2) el costo de la mano de obra para reemplazar partes distintas a

las descritas anteriormente; y (3) no cubre ninguna unidad de aire acondicionado

HazardGard para habitación que haya estado sometida a (a) accidentes, maltrato,

inhundaciones, incendios, o negligencia; (b) arreglos o alteraciones hechas fuera de un

centro de servicio o un distribuidor Friedrich, en forma tal que impacte adversamente su

debldo funcionamiento o confiabilidad; ni (c) reparaciones o servicio que sean

concecuencia del uso de partes no vendidas o aprobadas por Friedrich.

Esta garantía es una garantía limitada. No obstante, cualquier término de la garantía, DE

IDONEIDAD EXPRESA P ARA CUALQUIER PROPOSlTO P ARTICULAR Y/O PARA MERCADEO

SE LIMITARÁ A LA DURAClON CONCEDIDA POR ESTA GARANTIA EXPRESA. EL

FABRICANTE RENUNClA EXPRESAMENTE Y EXCLUYE CUALQUIER RESPONSABILIDAD

POR DAÑOS INCIDENTALES O CONSECUENClALES DETERMINADOS POR EL

ROMPIMIENTO DE CUALQUIER GARANTIA EXPRESA O IMPLIClT A.

Para obtener cumplimento de la garantia en caso de que el contacto de servicio local y/o si fuese

necesario que Friederich exija la devolución del aparato para corregir alguna falla, por

favor llene su tarjeta de registro de garantía de inmediato y envíela a: Friedrich, Customer Service

Department, Box 1540, San Antonio, TX 78295.

ADVERTENClA – PELIGRO DE EXPLOSION

La substitución de componentes puede ocasionar que el aparato no sea aceptable

para el uso en las circunstancias previstas en la Clase 1, División 2.

Page 39

Page 40

FRIEDRICH HAZARDGARD ROOM AIR CONDITIONERS

FRIEDRICH AIR CONDITIONING CO. INC.

• Post Office Box 1540 • San Antonio, T exas 78295-1540

• 4200 N. Pan Am Expressway • San Antonio, Texas 78218-5212

• (210) 357-4400 • FAX (210) 357-4480

Visit us on the Internet at www.friedrich .com

Printed in the U.S.A.

ROOM AIR

CONDITIONERS

Page 40

Page 41

®

HAZARDGARD

CLIMATISEURS

MANUEL

D’UTILISATION

D’ENTRETIEN ET

D’INSTALLATION

Modèles

SH14

SH20

Page 41

Page 42

TABLE DES MATIÈRES

INSTRUCTIONS D’UTILISATION ET D’ENTRETIEN

CHAPITRE 1 Instructions générales ....................................................... page 43

CHAPITRE 2 Renseignements sur le filtre ............................................. page 44

CHAPITRE 3 Dépannage .......................................................................... page 44

CHAPITRE 4 Caractéristiques spéciales ................................................ page 45

CHAPITRE 5 Panneau de commande ..................................................... pag e 46

CHAPITRE 6 Underwriters Laboratories................................................. page 46

INSTRUCTIONS D’INST ALLATION

SECTION I Alimentation électrique...................................................... page 47

SECTION II Déballage de l’appareil ...................................................... page 49

SECTION III Préparation et câblage du châssis ................................... page 49

SECTION IV Préparation de l’enveloppe................................................ page 50

SECTION V Installation de l’enveloppe................................................. page 51

A. Fenêtre à guillotine ................................................. page 51

B. Dans un mur ............................................................ page 54

SECTION VI Installation du châssis....................................................... page 57

GARANTIE .............................................................................................. page 59

Page 42

Page 43

BIENVENUE À DES ANNÉES DE

CONFORT ÉCONOMIQUE AVEC LE

CLIMATISEUR HAZARDGARD FRIEDRICH

CHAPITRE 1 — INTRUCTIONS GÉNÉRALES

Le climatiseur Friedrich a été développé et fabriqué avec soin pour donner de nombreuses années de service

fiable et efficace, et maintenir une température et un niveau d’humidité confortables. De nombreuses

caractéristiques supplémentaires ont été incorporées dans le climatiseur Friedrich pour assurer un

fonctionnement silencieux, une excellente circulation d’air frais et sec, et une utilisation économique.

V oici quelques sug gestions pour aider à utiliser le climatiseur Friedric h d’une manière plus efficace.

1. Il faut lire attentivement les instructions d’installation et les suivre.

2. Le climatiseur Friedrich HazardGar d est mis à la terre pour des raisons de sécurité. L’alimentation doit toujours

être mise à la terre et doit être installée conformément aux normes nationales et locales. La capacité du circuit est

montrée sur la plaque d’identification de chaque modèle.

3. Vérifier que l’appareil a une capacité suffisante pour le volume à refroidir. Quand la capacité est trop faible,

l’appareil travaille plus dur, utilise plus d’électricité et s’use plus rapidement. Quand la capacité est trop grande,

l’appareil se met en marche et s’arrête trop fréquemment et ne peut pas contrôler l’humidité aussi bien.

4. À la mise en marche de l’appareil, mettre le thermostat à la température la plus basse pour refroidir la pièce.

Quand la température désirée est atteinte, tourner le thermostat à une température plus élevée jusqu’au déclic d’arrêt

du compresseur. Le thermostat met en marche et arrête le compresseur pour maintenir la température désirée.

5. Nettoyer le filtre fréquemment (consulter l'entretien général).

6. Il ne faut pas bloquer la circulation d’air entrant et sortant de l’appareil. Il faut s’assurer que les bouches sont

dirigées pour distribuer l’air de manière uniforme dans toute la pièce. Attention - Si l’air est dirigé vers un endroit clos,

tel que derrière un lit ou dans un coin, ceci peut forcer le climatiseur à se mettre en marche et s’arrêter fréquemment,

ce qui peut l’endommager.

7. Un filtre sale ou des commandes mal réglées peuvent affecter le refroidissement par l’appareil.

8. Si le refroidissement est faible et si, après vérification, le filtre est propre, et si les commandes sont réglées

correctement, il est possible que le niveau de fluide frigorigène dans l’appareil est trop faible , au quel cas, il faut

appeler le technicien Friedrich pour vérifier l’appareil.

9. Maintenir les stores, les rideaux et les draperies fermés sur le côté ensoleillé de la pièce à refroidir.

10. Une isolation appropriée aide à maintenir la température désirée.

11. Dans la mesure du possible, utiliser des auvents pour créer de l’ombre sur les fenêtres exposées à l’ouest.

12. P our assurer une bonne circulation de l’air, les rideaux de la fenêtre ne doivent pas recouvrir l’appareil.

Page 43

Page 44

CHAPITRE 2 — RENSEIGNEMENTS SUR LE FILTRE