Page 1

INSTALLATION INSTRUCTIONS

FOR "SC" MODELS

CASEMENT SASH WINDOW INSTALLATIONS.

These models will fit casement window openings as follows:

HEIGHT : 10-13/16" Minimum to 1 1-3/4" Maximum

WIDTH: 14-3/4" Minimum to 18-3/8" Maximum

STEP 1 Remove the unit from the shipping carton. Remove the tape holding the decorative front in place.

Remove the front and place it out of the way . Slide the unit out of the shell. As you slide the unit out,

you will notice a foam gasket between the chassis and the cabinet. Save the gasket for STEP 7.

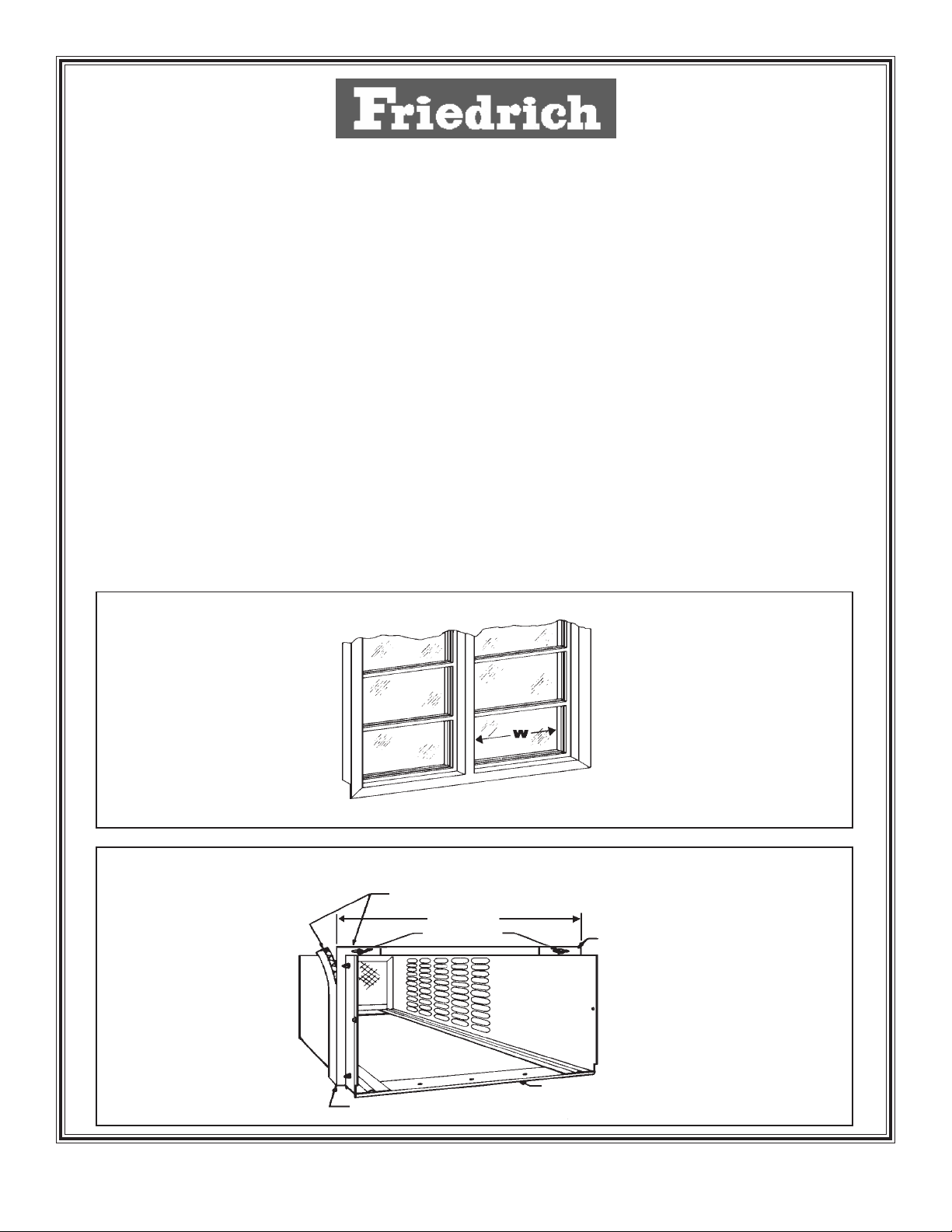

STEP 2 Remove the glass, putty and window crank, if necessary . Measure the horizontal width dimension “W”

or window frame opening (Figure 1). If dimension “W” is 16" (405 mm) or less, no adjustment of the

side bracket is necessary. If the dimension is more than 16" (405 mm) – loosen the two (2) acorn nuts

and slide the side brackets out. (Add one inch (25 mm) to the measured “W” dimension for this

adjustment.) Tighten the acorn nuts. (Figure 2).

FIGURE 1

FIGURE 2

ATTACH GASKETS TO BACKSIDE

OF THE BRACKETS AT THE TOP AND SIDES.

W+1"

ACORN NUT

SILL CHANNEL

SIDE BRACKET

SIDE BRACKET

RACINST4 (7/97) Page 1

Page 2

STEP 3 Remove the paper backing from the 36" (91 mm) strip of foam gasket (3/8" x 3/4"(10 mm x 19mm)) and attach

it to the back side of the top and side brackets (Figure 2). The edge of the gasket and brackets should be

flush. Press the gasket firmly in place.

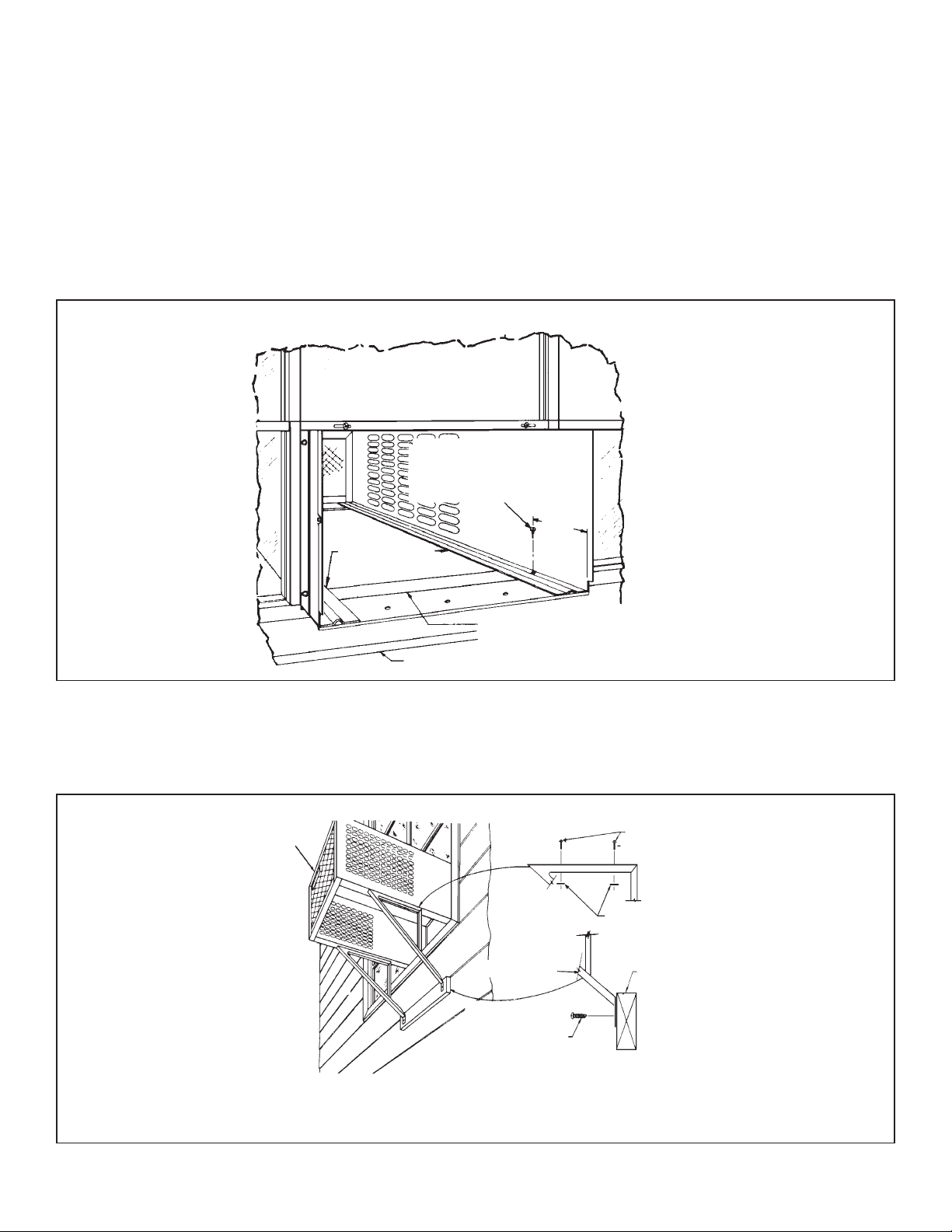

STEP 4 Slide the outer shell into the window opening as far as the sill channel will permit. The back side of the sill

channel must be in contact with the front side of the window frame (Figure 3). Drill two (2) 9/64" (3.6mm)

diameter pilot holes in the lower part of the window frame.

NOTE: Use the first empty hole in the bottom side rails of the shell, just back of the steel sill channel as a

guide. Secure the shell to the window channel with two (2) hex-head self-tapping screws 1-1/8"

(29 mm) long in the pilot holes. Part # 906-022-02 (Figure 3).

FIGURE 3

DRILL TWO 9/64" PILOT

HOLES IN THE WINDOW

AND INSTALL 2 SCREWS.

1-1/2"

(38 mm)

BOTTOM SIDE

RAIL

SILL CHANNEL NEXT TO WINDOW

FRAME.

WINDOW SILL

STEP 5 Position the support brackets as shown in Figure 4. Attach to the shell with four (4) truss-head 10-24 machine

screws and four (4) flat nuts. Secure the bottom of the support brackets to the wall with two (2) wood screws.

Check the shell to allow for a 1/4" (6 mm) downward slope towards the outside. If used on other than wood

construction, screw the support brackets to a piece of 2" x 4" material.

MACHINE SCREW 10-24 X 1"

FIGURE 4

NOTE: ADJUST THE

SUPPORT BRACKETS TO

PROVIDE A 1/4" (6 mm) DROP

OF THE SHELL TO THE

OUTSIDE FOR WATER

DRAINAGE. THIS VIEW

SHOWS THE SHELL

MOUNTED IN THE WINDOW.

THE SUPPORT BRACKETS

ARE ASSEMBLED THE SAME

FOR A THRU-THE-WALL

INSTALLATION.

SHELL

SUPPORT

BRACKET

SECURE THE

LOWER END OF THE

SUPPORT TO THE WALL

WITH TWO SHEET METAL

SCREWS 12A X 2" LONG

(PART #906-011-08) DRILL

5-32" PILOT HOLES.

(#906-067-00,4 REQ’D.)

FLAT NUT

910-026-00 (4 REQ’D.)

2" X 4" LUMBER (IF NEEDED)

Page 2 RACINST4 (7/97)

Page 3

STEP 6 If the installation is in the swing-out part of the window , be sure the window is locked closed, then slide the

chassis into the shell as far as it will go.

STEP 7 Reinstall the CHASSIS SEAL GASKET. Carefully "stuff" the gasket between the chassis and the cabinet

starting at either bottom corner and go up the side, across the top and down the opposite side. It is

IMPORTANT that this gasket be properly installed as it prevents air leakage around the chassis.

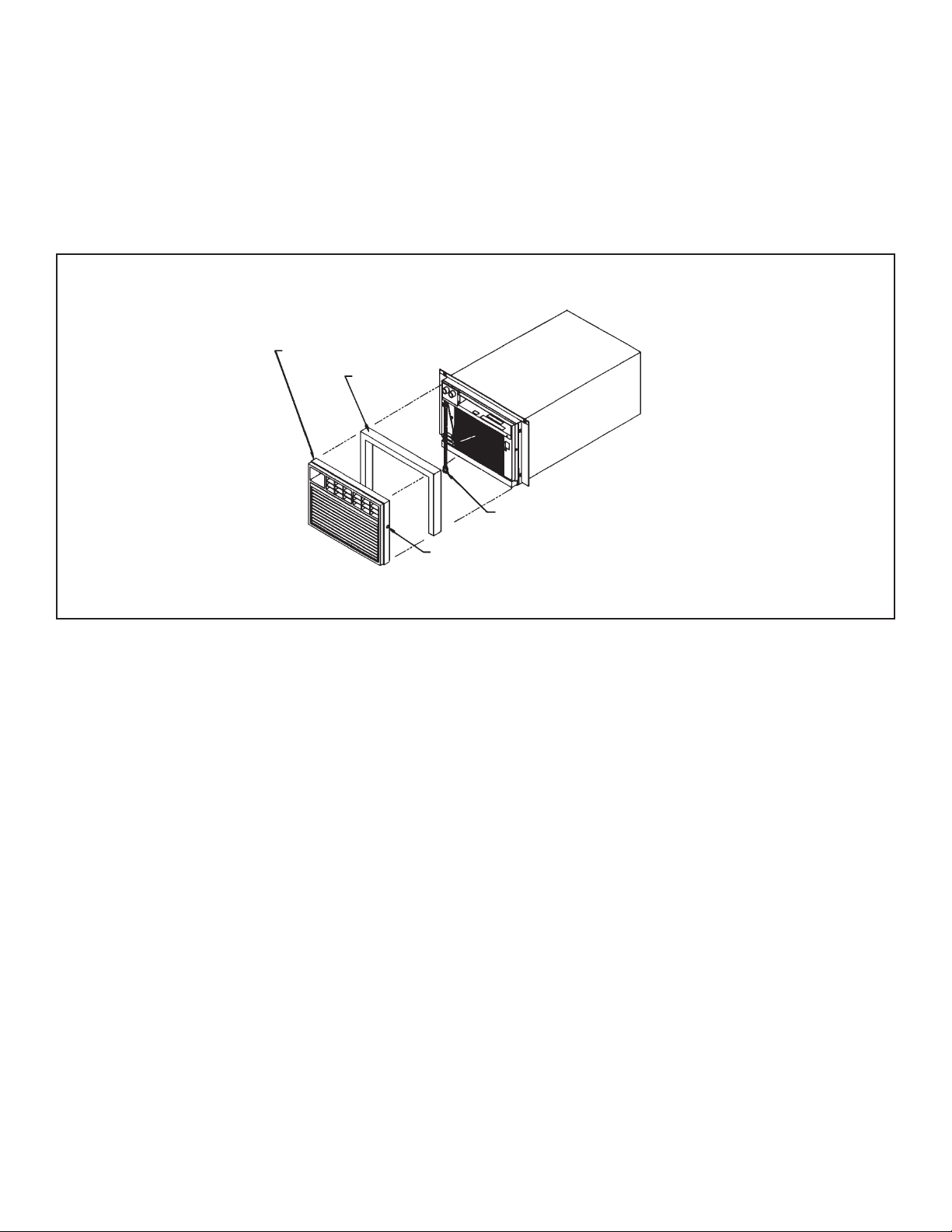

STEP 8 Place the filter in the pocket, in front of the coil, then install the decorative front over the edge of the shell and

secure it with two (2) number 10 x 1/2" slotted head screws, (Figure 5).

FIGURE 5

DECORATIVE FRONT

CHASSIS

SEAL

SERVICE CORD EXITS FROM A NOTCH IN THE BOTTOM

OF THE DECORATIVE FRONT

SLOTTED TRUSS–HEAD SCREW ON EACH SIDE OF THE

DECORATIVE FRONT

STEP 9 CIRCUIT PROTECTION – If the air conditioner is connected to a circuit protected by a fuse, use a “TIME-

DELA Y” fuse due to the momentary high current demand when the air conditioner is started. Before operating

your unit, verify the ampere rating of the time-delay fuse or circuit breaker which protects your unit. The

ampere rating of the time-delay fuse or circuit breaker must be 15 amps. Plug the service cord into the

electrical outlet (see warning note below). Refer to the Owner’s Manual for operating instructions.

WARNING: This appliance is equipped with a three-prong (grounding) plug for your protection against shock

hazards and should be plugged directly into a properly grounded three-prong receptacle.

Where a two-prong receptacle is encountered, it must be replaced with a properly grounded

three-prong receptacle in accordance with the National Electrical Code and local codes and

ordinances. The work should be done by a qualified electrician.

RACINST4 (7/97) Page 3

Page 4

THRU–THE–WALL INSTALLATIONS

Hardware included for installation:

2 - Support brackets

2 - No. 12A x 2" Sheet Metal Screws

4 - 10-24 x 1" Machine Screws

4 - 10-24 Flat Nuts

1 - 36" Strip Foam Gasket (Part # 604-673-32)

STEP 1 Remove the unit from the shipping carton. Remove the tape holding the decorative front in place. Remove the

front and place it out of the way. Slide the unit out of the shell. As you slide it out, you will notice a foam gasket

between the chassis and the cabinet. Save this gasket for STEP 6.

STEP 2 LAYOUT: Cut and frame-in an opening in the desired wall area, using Figure 6 as a guide. Remove two (2)

screws and relocate the sill plate back one inch to the next set of holes in the shell rail. Place the shell in the

wall opening with the front flange tight against the wall surface. Drill three (3) 3/32" (2.5 mm) diameter pilot

holes. Secure three (3) 1-1/4" long Phillips screws in the sill plate (Figure 7).

2 - 10BP x 1/2" Slotted Truss Head Screws

3 - 8A x 1 1/4" Phillips Head Screws

2 - 8-32 x 1-1/8" Hex Head Self-Tapping Screws

NOTE: This unit may be installed in walls up to 9"

thick (maximum).

FIGURE 6

FINISHED HOLE SIZE

2" x 8" FRAME

FINISHED HOLE

SIZE

FRAME CONSTRUCTION

CONCRETE BLOCK CONSTRUCTION

STEP 3 Attach the support brackets to the shell with screws and nuts furnished (See Figure 4 - Sash Window

Installations).

STEP 4 Secure the lower end of the support brackets to the wall. (See Figure 4 - Sash Window Installations.)

NOTE: If other than wood construction, use a piece of 2" x 4" lumber to attach support brackets. (See Figure

4 - Sash Window Installations.)

STEP 5 Caulk all around the shell on the outside to insure

a watertight seal. Slide the chassis into the shell

FIGURE 7

as far as it will go.

INTERIOR WALL SURFACE

STEP 6 Reinstall the CHASSIS SEAL GASKET . Carefully

SHELL

stuff the gasket between the chassis and the

cabinet, starting at either bottom corner and go up

the side, across the top and down the opposite

side. It is IMPORTANT that this gasket be

SCREW

(8A X 1-1/4"

properly installed as it prevents air leakage

around the chassis.

STEP 7 Complete the installation by following STEPS 8

and 9 of the Sash Window Installation

Instructions, Page 3.

Page 4 RACINST4 (7/97)

SILL CHANNEL RELOCATED 1" BACK TO THE

NEXT SET OF HOLES

Loading...

Loading...