Page 1

Service Manual

Low

Co

ol

Hig

h

Coo

l

Lo

w

H

eat

H

i

gh

Heat

MAX

COOL

MA

X

HE

AT

Fan

On

l

y

O

f

f

Allow 3 min.

betwe

e

n

r

es

ta

rt

s

!

M

one

y

Fan

T

i

m

erOp

e

r

at

i

on

Set Hr

.

S

to

p

Start

T

e

m

pe

ra

t

u

r

e

Fan

C

ool

O

n/O

P

o

w

er

Coo

le

r

Only Spee

d

S

ave

r

®

W

arm

er

Mon

ey

Fa

n

T

im

e

rO

p

e

r

a

t

i

o

n

S

e

tH

r

.

S

top

Sta

r

t

Tem

p

e

ratur

e

Fa

n

Cool

O

n

/Off

Powe

r

C

o

o

le

r

O

n

ly S

p

e

e

d

S

a

ver

®

Wa

r

m

e

r

Models

2009

Room Air Conditioners

RAC-ServMan (04-09)

2008

Page 2

TECHNICAL SUPPORT

CONTACT INFORMATION

FRIEDRICH AIR CONDITIONING CO.

Post Ofce Box 1540 · San Antonio, Texas 78295-1540

4200 N. Pan Am Expressway · San Antonio, Texas 78218-5212

(210) 357-4400 · FAX (210) 357-4490

www.friedrich.com

Printed in the U.S.A.

Page 3

Table Of Contents

Important Safety Information ........................................................................................................................................ 2-4

Introduction ...................................................................................................................................................................... 5

Unit Identication ............................................................................................................................................................. 6

Chassis Specications for 2009, 2008 Models ............................................................................................................... 7

Installation Information/Sleeve Dimensions .................................................................................................................... 8

Performance Data ........................................................................................................................................................... 9

Electrical Data ............................................................................................................................................................... 10

Before Operating the Unit .............................................................................................................................................. 11

How to Operate the QM Programmable ........................................................................................................................ 12

How to Use the QM Programmable Remote Control ..................................................................................................... 13

How to Operate the XQ .................................................................................................................................................. 14

How to Use the XQ Remote Control .............................................................................................................................. 15

How to Operate the QM and Twintemp .................................................................................................................... 16-17

Testing the Electronic Control and Error Code Listings .............................................................................................17-18

Testing the Rotary Control Switches ..........................................................................................................................19-20

Functional Component Denition ................................................................................................................................... 20

Components Testing ...................................................................................................................................................21-24

Defrost Thermostat Operation ........................................................................................................................................ 24

Electronic Control Sequence of Operation ..................................................................................................................... 25

Refrigeration Sequence of Operation ............................................................................................................................. 26

Sealed Refrigeration System Repairs ....................................................................................................................... 27-30

Hermetics Components Check ...................................................................................................................................... 31

Reversing Valve Description/Operation ......................................................................................................................... 32

Testing the Coil .............................................................................................................................................................. 33

Checking the Reversing Valve .................................................................................................................................. 33-34

Compressor Checks .................................................................................................................................................. 35-36

Compressor Replacement ......................................................................................................................................... 37-38

Routine Maintenance ................................................................................................................................................. 39-40

Troubleshooting ......................................................................................................................................................... 41-48

Wiring Diagrams ........................................................................................................................................................ 49-58

Instructions for using Cooling Load Estimate Form ........................................................................................................ 58

Cooling Load Estimate Form .......................................................................................................................................... 60

Heat Load Form ......................................................................................................................................................... 61-62

Warranty .......................................................................................................................................................................... 63

1

Page 4

IMPORTANT SAFETY INFORMATION

The information contained in this manual is intended for use by a qualied service technician who is familiar

with the safety procedures required for installation and repair, and who is equipped with the proper tools and

test instruments required to service this product.

Installation or repairs made by unqualied persons can result in subjecting the unqualied person making

such repairs as well as the persons being served by the equipment to hazards resulting in injury or electrical

shock which can be serious or even fatal.

Safety warnings have been placed throughout this manual to alert you to potential hazards that may be

encountered. If you install or perform service on equipment, it is your responsibility to read and obey these

warnings to guard against any bodily injury or property damage which may result to you or others.

We have provided many important safety messages in this manual and on your appliance. Always read

and obey all safety messages.

WARNING

CAUTION

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury,

and tell you what will happen if the instructions are not followed.

NOTICE

Your safety and the safety of others are very important.

This is a Safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING”

or “CAUTION”. These words mean:

You can be killed or seriously injured if you do not follow instructions.

You can receive minor or moderate injury if you do not follow instructions.

A message to alert you of potential property damage will have the

word “NOTICE”. Potential property damage can occur if instructions

are not followed.

PERSONAL INJURY OR DEATH HAZARDS

ELECTRICAL HAZARDS:

Unplug and/or disconnect all electrical power to the unit before performing inspections, •

maintenance, or service.

Make sure to follow proper lockout/tag out procedures.•

Always work in the company of a qualied assistant if possible. •

Capacitors, even when disconnected from the electrical power source, retain an electrical charge •

potential capable of causing electric shock or electrocution.

Handle, discharge, and test capacitors according to safe, established, standards, and approved •

procedures.

Extreme care, proper judgment, and safety procedures must be exercised if it becomes necessary •

to test or troubleshoot equipment with the power on to the unit.

2

Page 5

Do not spray or pour water on the return air grille, discharge air grille, evaporator coil, control panel, •

and sleeve on the room side of the air conditioning unit while cleaning.

Electrical component malfunction caused by water could result in electric shock or other electrically •

unsafe conditions when the power is restored and the unit is turned on, even after the exterior is dry.

Never operate the A/C unit with wet hands.•

Use air conditioner on a single dedicated circuit within the specied amperage rating. •

Use on a properly grounded outlet only.•

Do not remove ground prong of plug.•

Do not cut or modify the power supply cord.•

Do not use extension cords with the unit.•

Follow all safety precautions and use proper and adequate protective safety aids such as: gloves, •

goggles, clothing, adequately insulated tools, and testing equipment etc.

Failure to follow proper safety procedures and/or these warnings can result in serious injury or death. •

REFRIGERATION SYSTEM HAZARDS:

Use approved standard refrigerant recovering procedures and equipment to relieve pressure before •

opening system for repair.

Do not allow liquid refrigerant to contact skin. Direct contact with liquid refrigerant can result in minor •

to moderate injury.

Be extremely careful when using an oxy-acetylene torch. Direct contact with the torch’s ame or hot •

surfaces can cause serious burns.

Make sure to protect personal and surrounding property with re proof materials.•

Have a re extinguisher at hand while using a torch.•

Provide adequate ventilation to vent off toxic fumes, and work with a qualied assistant whenever •

possible.

Always use a pressure regulator when using dry nitrogen to test the sealed refrigeration system for •

leaks, ushing etc.

Make sure to follow all safety precautions and to use proper protective safety aids such as: gloves, •

safety glasses, clothing etc.

Failure to follow proper safety procedures and/or these warnings can result in serious injury or death. •

MECHANICAL HAZARDS:

Extreme care, proper judgment and all safety procedures must be followed when testing, •

troubleshooting, handling, or working around unit with moving and/or rotating parts.

Be careful when, handling and working around exposed edges and corners of sleeve, chassis, and •

other unit components especially the sharp ns of the indoor and outdoor coils.

Use proper and adequate protective aids such as: gloves, clothing, safety glasses etc.•

Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.•

3

Page 6

PROPERTY DAMAGE HAZARDS

FIRE DAMAGE HAZARDS:

Read the Installation/Operation Manual for this air conditioning unit prior to operating.•

Use air conditioner on a single dedicated circuit within the specied amperage rating. •

Connect to a properly grounded outlet only.•

Do not remove ground prong of plug.•

Do not cut or modify the power supply cord.•

Do not use extension cords with the unit.•

Failure to follow these instructions can result in re and minor to serious property damage.•

WATER DAMAGE HAZARDS:

Improper installation maintenance, or servicing of the air conditioner unit, or not following the above •

Safety Warnings can result in water damage to personal items or property.

Insure that the unit has a sufcient pitch to the outside to allow water to drain from the unit. •

Do not drill holes in the bottom of the drain pan or the underside of the unit. •

Failure to follow these instructions can result in result in damage to the unit and/or minor to serious •

property damage.

4

Page 7

INTRODUCTION

This service manual is designed to be used in conjunction with the installation manuals provided with each air conditioning

system component.

This service manual was written to assist the professional RAC service technician to quickly and accurately diagnose

and repair malfunctions.

This manual will deal with subjects in a general nature. (i.e. all text will not pertain to all models).

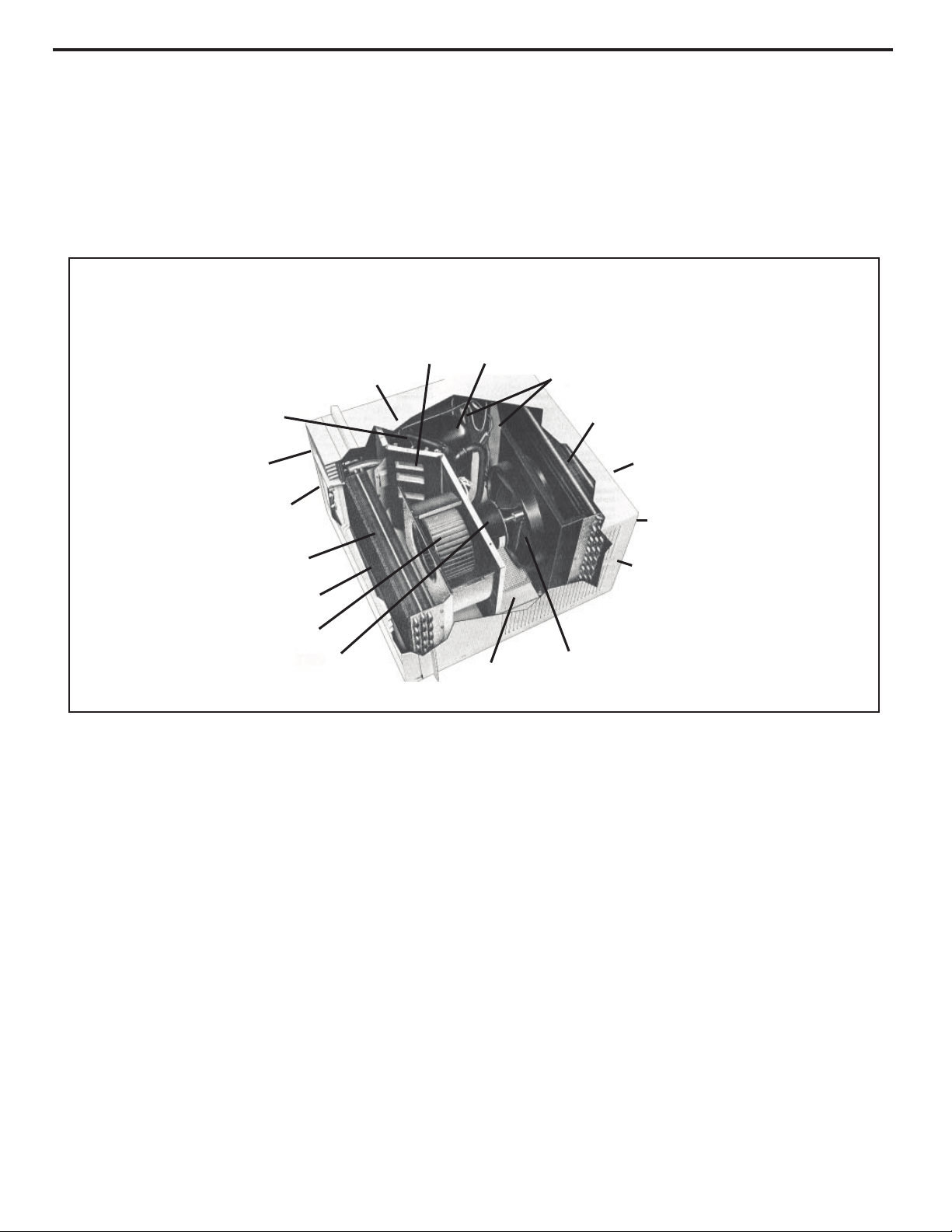

TYPICAL UNIT COMPONENTS

Fresh Air

Capillary Tube

Reversing Valve

(some models)

Front Cover

System Switches

Evaporator Coil

Return Air Grille/Filter

Blower Wheel

Blower Motor

IMPORTANT: It will be necessary for you to accurately identify the unit you are servicing, so you can be certain of a

proper diagnosis and repair (See Unit Identication on page 6).

Compressor

Liquid Filter Driers

Condenser Coil

Discharge Air

Outdoor Grille

Sleeve

Condenser Fan Blade

Basepan

5

Page 8

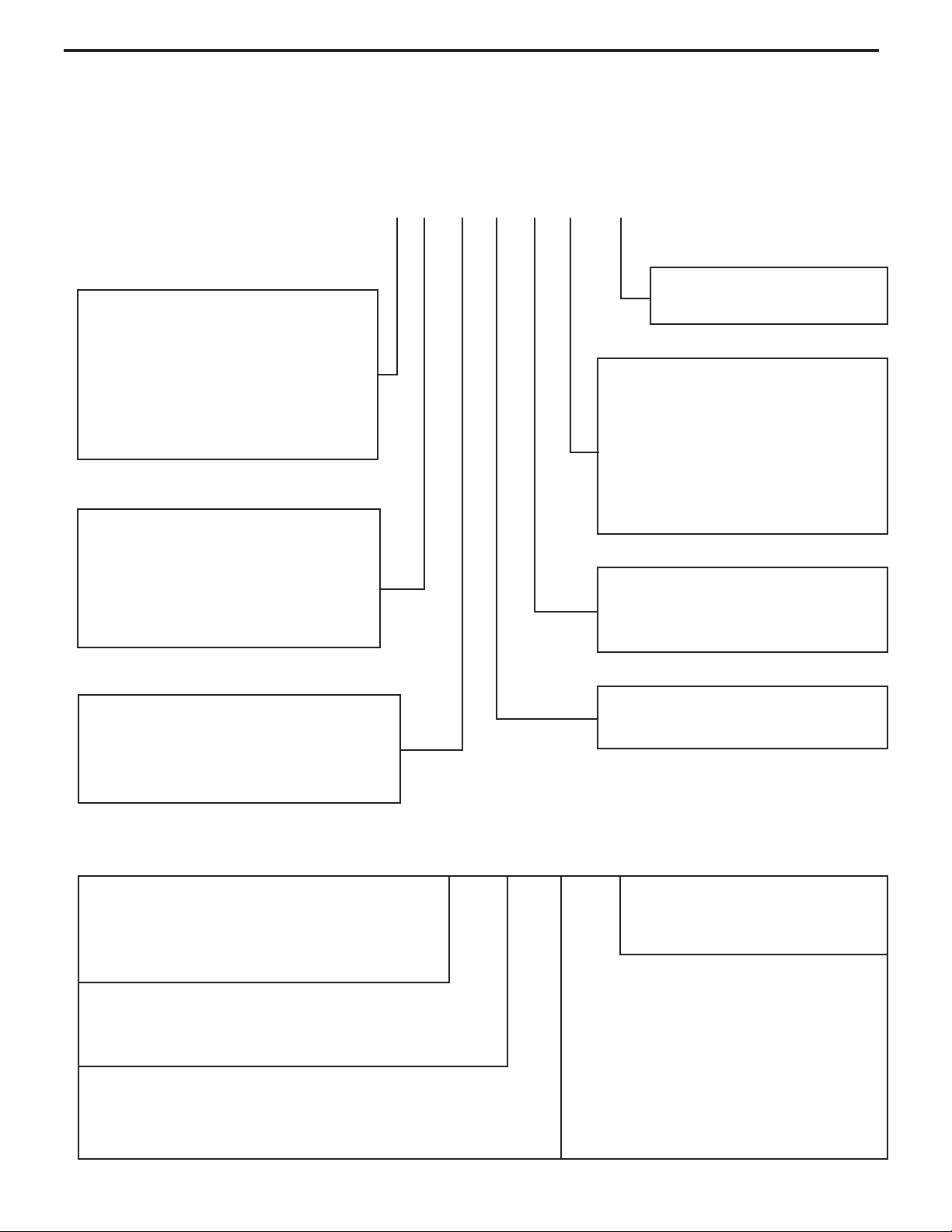

UNIT IDENTIFICATION

1st Digit – Function

S = Straight Cool, Value Series

Y = Heat Pump

E = Electric Heat

K = Straight Cool

R = Straight Cool

X = Straight Cool

Model Number Code

S S 08 L 1 0 E

8th Digit – Engineering

Major change

7th Digit – Options

0 = Straight Cool &

Heat Pump Models

1 = 1 KW Heat Strip, Nominal

3 = 3 KW Heat Strip, Nominal

4 = 4 KW Heat Strip, Nominal

5 = 5 KW Heat Strip, Nominal

2nd Digit

Q = Q-Star

S = Small Chassis

M = Medium Chassis

L = Large Chassis

H = HazardGard

3rd and 4th Digit - Approximate

BTU/HR in 1000s (Cooling)

Heating BTU/Hr capacity listed in the

Specication/Performance Data Section

RAC Serial Number Identication Guide

Serial Number

Decade Manufactured

L=0 C=3 F=6 J=9

A=1 D=4 G=7

B=2 E=5 H=8

L H G R 00001

6th Digit – Voltage

1 = 115 Volts

3 = 230-208 Volts

5th Digit

Alphabetical Modier

Production Run Number

Year Manufactured

A=1 D=4 G=7 K=0

B=2 E=5 H=8

C=3 F=6 J=9

Month Manufactured

A=Jan D=Apr G=Jul K=Oct

B=Feb E=May H=Aug L=Nov

C=Mar F=Jun J=Sept M=Dec

6

Product Line

R = RAC

Page 9

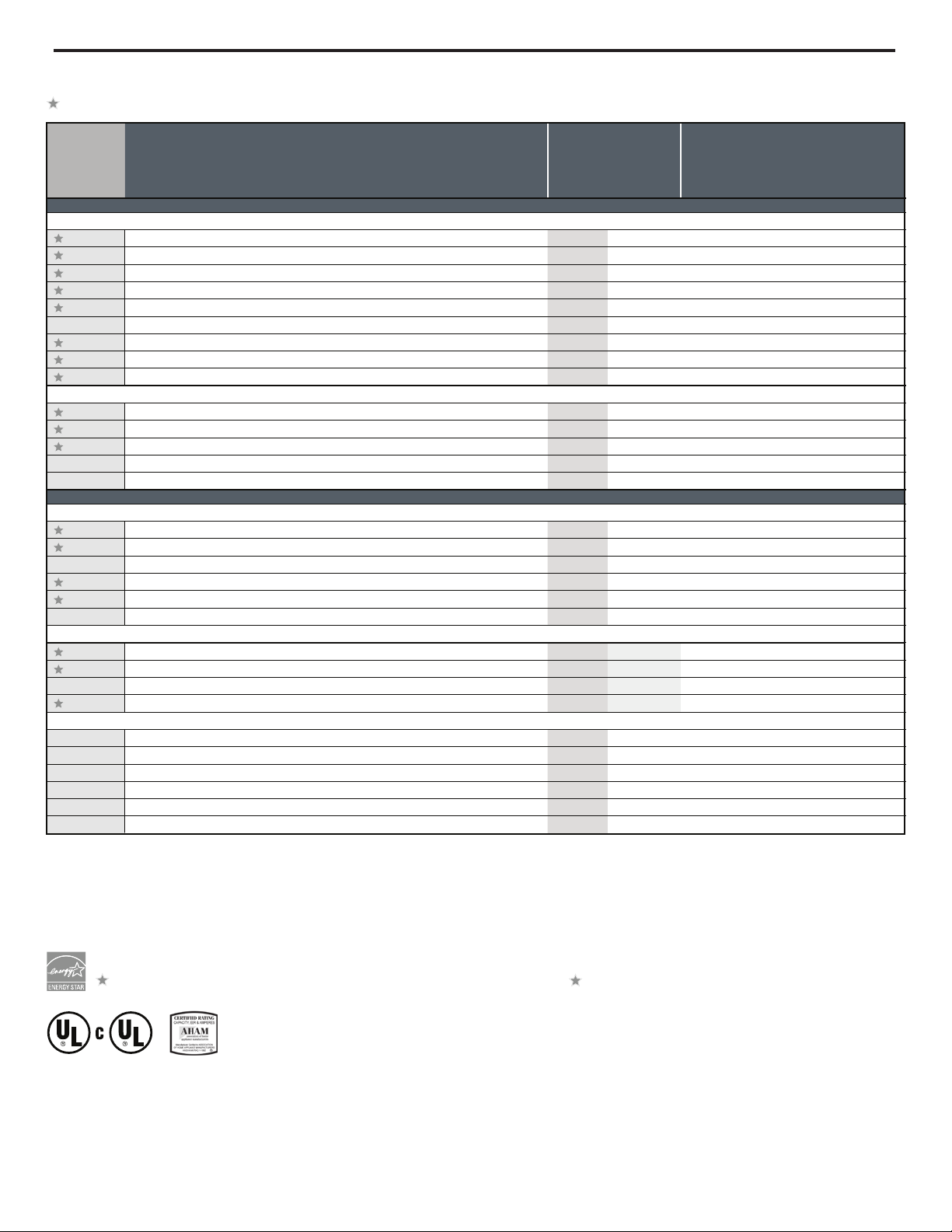

The consumer- through the AHAM Room Air Conditioner Certification Program- can be certain that the AHAM Certification Seal accurately

states the unit’s cooling and heating capacity rating, the amperes and the energy efficiency ratio.

As an ENERGY STAR

®

partner, Friedrich Air Conditioning Co. has determined that the selected ENERGY STAR

®

( ) models meet the ENERGY STAR

®

guidelines for energy efficiency.

* Sleeve dimensions listed on opposite page.

** Operates on 115 volt and is not equipped with supplemental heat. Will not provide heat at temperatures below 40°F.

Friedrich room air conditioners are designed to operate in outdoor temperatures from 50°

F to 115° F.

TwinTemp Heat Pump heating information

(shown in red) indicates heat pump heating per formance. TwinTemp Electric Heat heating information (shown in red) indicates electric heat strip performance.

For TwinTemp Heat Pump electric heating performance refer to corresponding TwinTemp Electric Heat model.

Due to continuing research in new energy-saving technology, specifications are subject to change without notice.

ENERGY STAR® Models

Cooling

Capacity

BTU/h

Heating

Capacity

Rated

Electrical Characteristics (60 Hertz)

Energy

Efficiency

Ratio

EER

Coefficient

Of

Performance

COP

Moisture

Removal

Pints/Hr.

Room Side

Air Circulation

CFM Sleeve*

Weight

Lbs.

Ship/Net Model

Volts

Rated

Cooling

Amps

Cooling

Watts

Heating

Amps

Heating

Watts

ULTRA PREMIUM LINE

QU IET MAS TER Pr og ram mabl e

SS08L10 8400 — 115 6.6 737 — — 11.4 1.6 265 S 114/108

SS10L10 10400 — 115 7.5 867 — — 12.0 2.5 260 S 121/115

SS12L10 11800 — 115 9.0 1000 — — 11.8 2.5 350 S 120/114

SS14L

10 14000 — 115 12.0 1305 — — 10.7 3.5 377 S 134/128

SS12L30 12100/11900 — 230/208 4.8/5.0 1052/1017 — — 11.5/11.7 2.9 320 S 120/114

SS16L30 16200/15900 — 230/208 7.4/8.0 1653/1656 — — 9.8/9.6 4.7 360 S 125/119

SM18L30A 17500/17300 — 230/208 7.2/7.7 1620/1570 — — 10.8/10.8 4.5 375 M 169/163

SM21L30 20600/20200 — 230/208 9.4/10.1 2081/2020 — — 9.9/10.0 6.0 425 M 160/154

SM24L30 23500/23000 — 230/208 11.2/12.1 2479/2421 — — 9.5/9.5 7.0 400 M

160/154

XS TAR

XQ05L10A 5500 — 115 5.0 500 — — 11.0 1.2 200 Q 76/70

XQ06L10A 6300 — 115 4.9 548 — — 11.5 1.4 175 Q 76/70

XQ08L10A 8000 — 115 6.8 741 — — 10.8 1.9 175 Q 83/77

XQ10L10A 10000 — 115 9.0 1000 — — 10.0 3.2 180 Q 89/83

XQ12L10A 11700 — 115 11.0 1198 — — 9.8 3.2 200 Q 89/83

PREMIUM LINE

QU IET MAS TER

KS12L10 11600 — 115 9.0 1055 — — 11.0 2.5 356 S 120/114

KS15L10 14500 — 115 12.0 1343 — — 10.8 3.5 377 S 134/128

KM18L30 17800/17600 — 230/208 8.1/8.8 1780/1760 — — 10.0/10.0 4.4 400 M 167/161

KM24L30 23500/23000 — 230/208 11.2/12.1 2479/2421 — — 9.5/9.5 7.0 400 M 160/154

SL28L3

0 28000/27700 — 230/208 13.0/14.2 2947/2916 — — 9.5/9.5 8.8 600 L 207/201

SL36L30A 36000/35700 — 230/208 18.0/19.6 4235/4200 — — 8.5/8.5 11.0 725 L 226/220

TW INTEM P He at Pu mp

YS09L10** 9200 7400 115 7.4 767 6.9 733 12.0 3.0 1.7 300 S 117/113

YS13L33 12700/12500 11000/10500 230/208 5.1/5.6 1149/1131 5.3/5.8 1185/1167 11.0/11.0 2.5/2.6 3.5 325 S 121/117

YM18L34 18000/18000 16800/16400 230/208 8.5/9.5 1895/1895 8.5/9.0 1867/1822 9.5/9.5 2.8/2.9 4.7 400 M 170/166

YL24L35 24000/24000 22000/21600 230/208 10.9/12.0 2400/2400 11.0/12.0 2444/2400 10.0/10.0 2.7/2.8 7.0 600 L 202/198

TW INTEM P El ec tri c He at

EQ08L11A 7700 4000 115 6.5 733 11.2 1290 10.5 1.9 175 Q 80/76

ES12L33 12100/11900 10700/8900 230/208 4.8/5.0 1052/1017 16.0/14.7 3500/2900 11.5/11.7 2.9 320 S 115/111

ES16L33 16200/15900 10700/8900 230/208 7.4/8.0 1653/1656 16.0/14.7 3500/2900 9.8/9.6 4.7 360 S 120/116

EM18L34 17800/17600 13000/10600 230/208 8.1/8.8 1780/1760 19.5/17.0 4200/3500 10.0/10.0 4.4 400 M 164/160

EM24L34 23500/23000 13000/10600 230/208 11.2/12.1 2479/2421 19.5/17.0 4200/3500

9.5/9.5 7.0 400 M 160/154

EL36L35A 36000/35700 17300/14300 230/208 18.0/19.6 4235/4200 24.0/22.4 5500/4650 8.5/8.5 11.0 725 L 224/220

CHASSIS SPECIFICATIONS FOR 2009, 2008 MODELS

7

Page 10

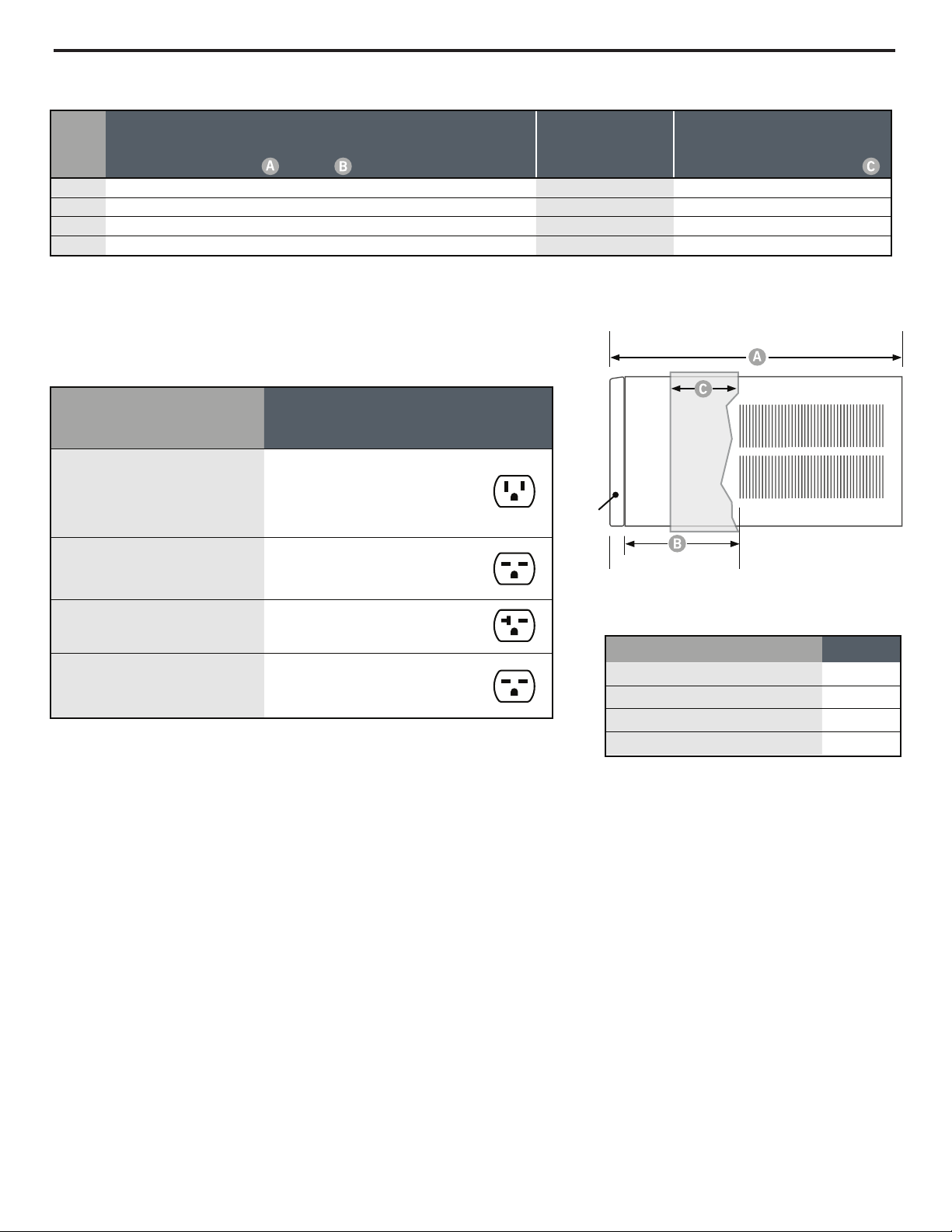

* Minimum extensions when mounted in a window.

** Minimum widths achieved using one side curtain assembly as opposed to both in a standard installation.

† Sleeve P1 does not have thru-the-wall hole dimensions, as these units are fixed chassis and should not be installed thru-the-wall.

NOTE: S,M and L sleeves may be installed in window with no side kits if properly installed.

Sleeve Height Width

Depth

with Front

Shell Depth to

Louvers

Minimum

Extension

Into Room*

Minimum

Extension

Outside*

Window Width

Thru-the-wall Installation

Finished Hole

Minimum** Maximum Height Width Max. Depth

Q 14" 19 ¾" 21 3∕8" 8 ½" 5 ½" 10 ¾"

22" 42" 14 ¼" 20" 8 ½”

S 15

15

∕16" 25 15∕16" 27 3∕8" 8 ¾" 3 1∕16" 16 15∕16" 27 3∕8" 42" 16 3∕16" 26 3∕16" 7 3∕8"

M 17

15

∕16" 25 15∕16" 27 3∕8" 8 ¾" 3 1∕16" 16 15∕16" 27 3∕8" 42" 18 3∕16" 26 3∕16" 7 3∕8”

L 20

3

∕16" 28" 33 5∕8" 16 ½" 3 3∕16" 18 15∕16" 29 7∕8" 42" 20 3∕8" 28 ¼" 15 1∕8"

TWINTEMP® models include accessories for thru-the-wall

installation only. Window mounting requires use of optional

accessory kit as listed above.

Window Mounting Kits

TwinTemp Model Kit No.

EQ08L11A WIKQ

ES12L33, ES16L33, YS09L10 and YS13L33. WIKS

EM18L34, YM18L34 and EM24L34. WIKM

EL36L35A and YL24L35. WIKL

Model

Circuit Rating

Breaker or

T-D Fuse

Plug Face

(NEMA#)

Power Cord

Length (ft.)

Wall Outlet

Appearance

All XQ MODELS.

KS12L10 and KS15L10. SS08L10, SS10L10,

SS12L10 and SS14L10. EQ08L11A.

YS09L10.

125V - 15A 5 - 15P 6

KM18L30.

SS12L30, SS16L30, SM18L30A and

SM21L30.

250V - 15A 6 - 15P 4

KM24L30. SM24L30 and SL28L30.

ES12L33 and ES16L33. YS13L33.

250V - 20A 6 - 20P 4

SL36L30A. EM18L34, EM24L34 and

EL36L35A. YM18L34 and YL24L35.

250V - 30A 6 - 30P 4

(B)

(A)

(C)

Front

SIDE VIEW

INSTALLATION INFORMATION / SLEEVE DIMENSIONS

Circuit Rating / Breaker

8

Page 11

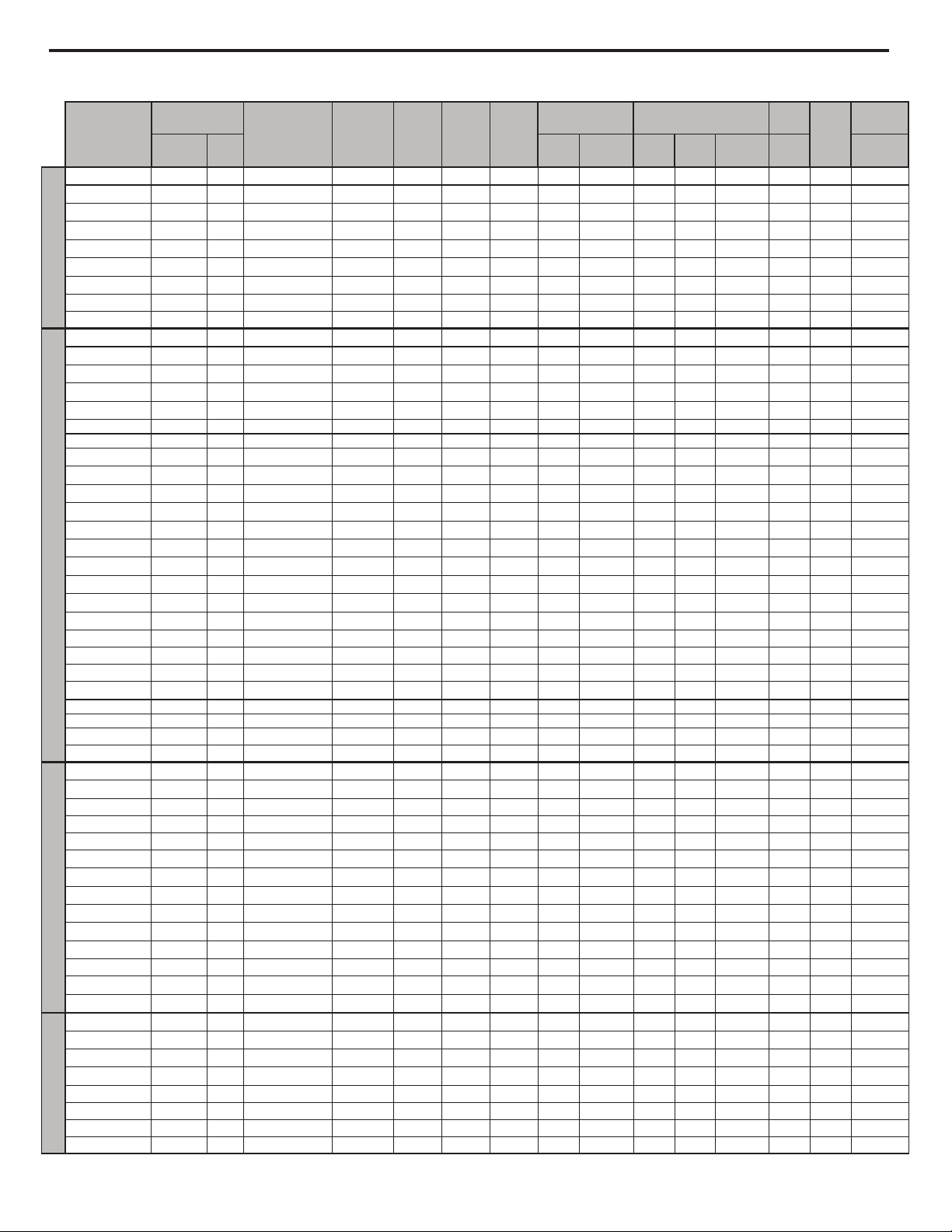

PERFORMANCE DATA FOR 2009, 2008 MODELS

COOLING

PERFORMANCE DATA*

XQ05L10A-C 56 24 119 151 58 13 20 89 255 4.9 28.0 21.4 11 5 15

XQ06L10A-C 55 26 121 157 65 13 27 87 261 5.0 24.0 21.0 11 5 15

XQ08L10A-B 52 29 128 167 60 13 33 81 283 6.8 36.2 22.1 11 5 15

XQ08L10A-E 52 29 125 161 49 13 24 81 280 6.7 36.2 19.8 11 5 15

XQ10L10A-C 50 31 130 176 65 20 29 75 287 9.2 44.0 19.2 11 5 15

Q-Chassis

XQ12L10A-B 51 29 126 166 51 6 30 75 271 11.0 56.0 31.0 11 5 15

XQ12L10A-C 51 29 126 166 51 6 30 75 271 11.0 56.0 31.0 115 15

EQ08L11A-B 52 29 124 173 69 21 29 82 283 6.5 10.7 36.2 20.0 11 5 15

EQ08L11A-E 52 29 125 161 49 13 24 81 280 6.7 10.7 36.2 19.8 11 5 15

SS08L10-E 56 24 116 157 68 16 18 86 250-260 6.6 36.2 27.0 115 15

SS08L10-F 56 24 11 6 157 68 16 18 86 250-260 6.6 36.2 27.0 11 5 15

SS08L10-G 53 24 116 157 57 13 23 85 250-260 6.5 36.2 27.0 115 15

SS10L10-D 57 23 117 166 65 16 23 82 243 7.5 42.0 26.0 11 5 15

SS10L10-E 57 23 117 166 65 16 23 82 243 7.5 42.0 26.0 11 5 15

KS12L10-E 52 28 122 170 60 12 26 83 266 9.0 44.0 30.0 11 5 15

KS12L10-F 52 28 122 170 60 12 26 83 266 9.0 44.0 30.0 115 15

SS12L10-E 53 27 124 169 62 13 30 82 266 9.3 44.0 32.0 11 5 15

SS12L10-F 53 27 124 169 62 13 30 82 266 9.3 44.0 32.0 115 15

KS15L10-C 51 30 125 182 62 16 29 77 278 12.2 61.0 29.0 115 15

KS15L10-D 51 30 125 182 62 16 29 77 278 12.2 61.0 29.0 115 15

SS14L10-D 53 27 125 184 62 15 27 78 268 12.3 61.0 29.2 115 15

SS14L10-E 53 27 125 184 62 15 27 78 268 12.3 61.0 29.2 115 15

S-Chassis

SS12L30-E 58 22 122 174 66 17 28 84 261 4.7 21.0 31.0 208 / 230 15

SS12L30-F 58 22 122 174 66 17 28 84 261 4.7 21.0 31.0 208 / 230 15

SS16L30-D 50 31 130 176 53 8 35 77 279

SS16L30-E 50 31 130 176 53 8 35 77 279 7.9 35.0 32.1 208 / 230 15

ES12L33-D 58 22 122 174 66 17 28 84 261 4.7 15.1 21.0 31.0 208 / 230 20

ES12L33-E 58 22 122 174 66 17 28 84 261 4.7 15.1 21.0 31.0 208 / 230 20

ES16L33-C 49 32 130 179 50 8 34 75 279 7.4 15.1 35.0 32.0 208 / 230 20

ES16L33-D 49 32 130 179 50 8 34 75 279 7.4 15.1 35.0 32.0 208 / 230 20

YS09L10-F 64 16 116 164 71 20 19 87 249 7.4 7.0 44.0 28.0 11 5 15

YS09L10-G 64 16 116 164 71 20 19 87 249 7.4 7.0 44.0 28.0 11 5 15

YS13L33-D 51 29 122 172 65 18 30 80 269 5.5/5.1 5.7/5.3 24.0 32.0 1 20

YS13L33-E 51 29 122 172 65 18 30 80 269 5.5/5.1 5.7/5.3 24.0 32.0 1 20

KM24L30-C 50 31 132 187 56 14 37 70 287 11.2 68.0 53.0 208 / 230 20

KM24L30-D 50 31 132 187 56 14 37 70 287 11.2 68.0 53.0 208 / 230 20

YM18L34-D 61 19 126 187 67 24 28 73 280 9.2/8.75 8.8/8.3 41.0 43.0 208/230 30

YM18L34-E 61 19 126 187 67 24 28 73 280 9.2/8.75 8.8/8.3 41.0 43.0 208/230 30

EM18L34-C 49 31 125 175 63 21 31 72 271 8.1 18.9 42.0 39.5 208 / 230 15

KM18L30-C 49 31 125 175 63 21 31 72 271 8.1 42.0 39.5 208 / 230 15

KM18L30-D 49 31 125 175 63 21 31 72 271 8.1 42.0 39.5 208 / 230 15

SM18L30A-D 54 26 121 171 61 13 25 81 262 7.7/7.1 37.0 45.0 208/230 15

M-Chassis

SM18L30A-E 54 26 121 171 61 13 25 81 262 7.7/7.1 37.0 45.0 208/230 15

SM21L30-E 48 32 125 173 52 13 25 75 278 9.6/9.3 43.0 43.0 208/230 15

SM21L30-F 48 32 125 173 52 13 25 75 278 9.6/9.3 43.0 43.0 208/230 15

EM24L34-B 50 31 132 187 56 14 37 70 287 11.2 25.0 68.0 53.0 208 / 230 30

SM24L30-C 50 31 132 187 56 14 37 70 287 11.2 68.0 53.0 208 / 230 20

SM24L30-D 50 31 132 187 56 14 37 70 287 11.2 68.0 53.0 208 / 230 20

SL28L30-D 53 28 128 172 56 13 29 73 259 13.0 68.0 50.1 208 / 230 20

SL28L30-E 53 28 128 172 56 13 29 73 259 13.0 68.0 50.1 208 / 230 20

SL36L30A-D 49 31 133 192 53

SL36L30A-E 49 31 133 192 53 12 37 70 287 17.2 91.0 57.6 208 / 230 30

EL36L35A-D 49 32 133 194 53 13 38 70 302 18.0 25.0 91.0 60.0 208 / 230 30

L-Chassis

EL36L35A-E 49 32 133 194 53 13 38 70 302 18.0 25.0 91.0 60.0 208 / 230 30

YL24L35-E 52 28 124 175 65 22 29 74 268 11.9/11.1 11.7/11.0 68.0 73.0 208/230 30

YL24L35-F

EVAP. AIR TEMP. DEG. F

Discharge Air

Temp.

Drop F.

52 28 124 175 65 22 29 74 268 11.9/11.1 11.7/11.0 68.0 73.0 208/230 30

CONDENSER

TEMPERATURE DEG. F

Discharge Temp Suction Temp Super Heat Sub-Cooling

12 37 70 287 17.2 91.0 57.6 208 / 230 30

OPERATING PRESSURES ELECTRICAL RATINGS R-22 REF.

Suction Discharge Amps Cool Amps Heat

7.9 35.0 32.1 208 / 230 15

Locked Rotor

Amps

Charge in

OZ.

BREAKER FUSE

Voltage

60 Hertz Amps

*Rating Conditions: 80 degrees F, room air temp. & 50% relative humidity, with 95 degree F, outside air temp & 40% relative humidity, all systems use R22.

9

Page 12

ELECTRICAL DATA

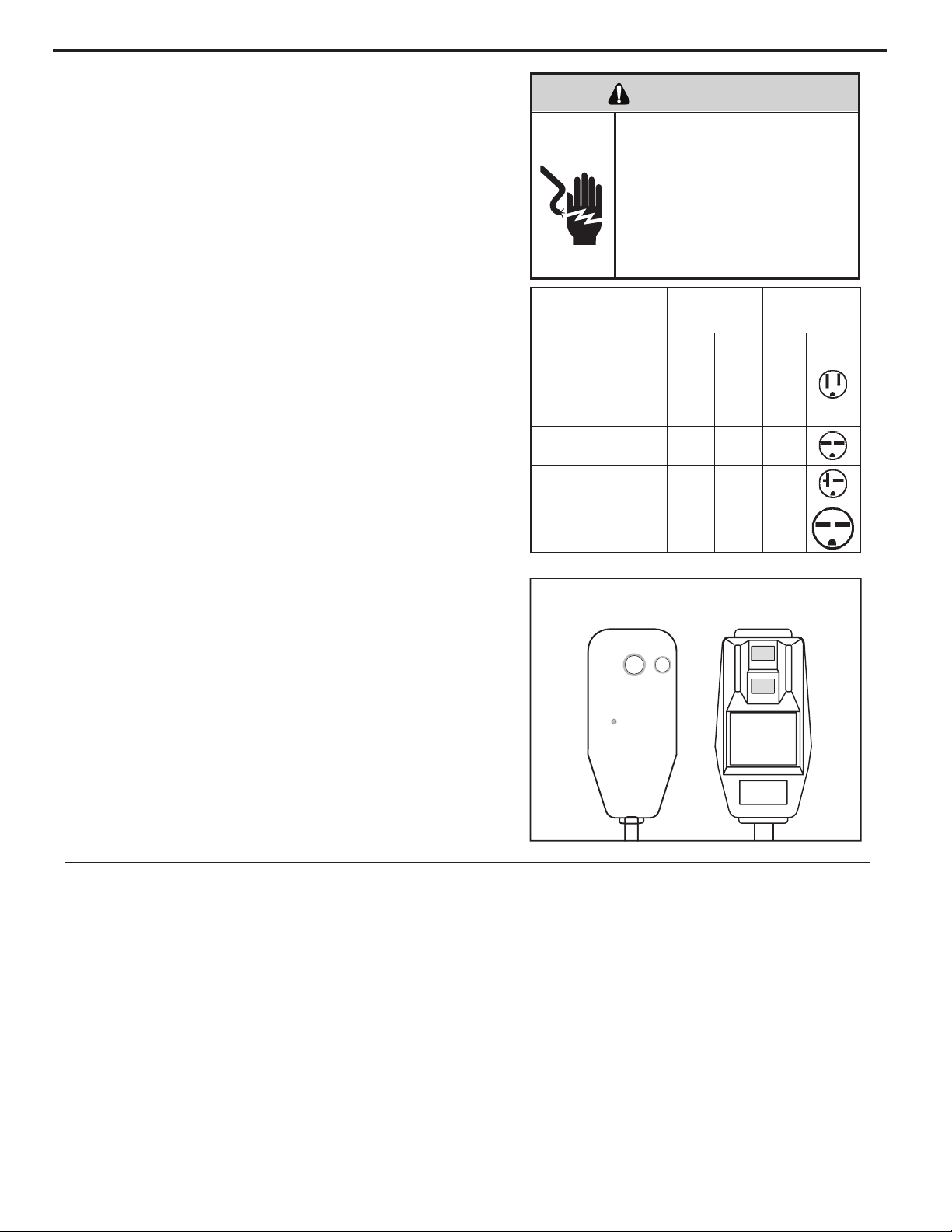

Not following the above WARNING could result in re or

electically unsafe conditions which could cause moderate

or serious property damage.

Read, understand and follow the above warning.

WARNING

ELECTRIC SHOCK HAZARD

Turn off electric power before service or

installation.

All electrical connections and wiring MUST be

installed by a qualied electrician and conform to

the National Electrical Code and all local codes

which have jurisdiction.

Failure to do so can result in personal injury or

death.

NOTICE

FIRE HAZARD

Wire Size Use ONLY wiring size recommended for single outlet branch circuit.

Fuse/Circuit Breaker Use ONLY the correct HACR type and size fuse/circuit breaker. Read electrical ratings on unit’s

rating plate. Proper circuit protection is the responsibiity of the homeowner.

Grounding Unit MUST be grounded from branch circuit through service cord to unit, or through separate

ground wire provided on permanently connected units. Be sure that branch circuit or general

purpose outlet is grounded.

Receptacle The eld supplied outlet must match plug on service cord and be within reach of service cord.

Do NOT alter the service cord or plug. Do NOT use an extension cord. Refer to the table above

for proper receptacle and fuse type.

The consumer - through the AHAM Room Air Conditioner Certication Program - can

be certain that the AHAM Certication Seal accurately states the unit’s cooling and

heating capacity rating, the amperes and the energy efciency ratio.

*HACR: Heating Air Conditioning and Refrigeration

10

Page 13

Keep the filter clean

Make sure that your air conditioner is always in top performing condition

.ylralugerretlifehtgninaelcyb

Provide good air flow

Make sure the airflow to and from the unit is clear. Your air conditioner puts the

conditioned air out at the top of the unit, and takes in unconditioned air at the

bottom. Airflow is critical to good operation. It is just as important on the outside

.dekcolbtonsiroiretxetinuehtdnuorawolfriaehttahtgnidliubehtfo

Unit placement

If your air conditioner can be placed in a window or wall that is shaded by a tree

rosepardgnisU.yltneiciffeeromneveetarepolliwtinueht,gnidliubre hto naro

blinds on the sunny side of the dwelling will also add to your unit’s efficiency.

Insulation

Good insulation will be a big help in maintaining desirable comfort levels.

Doors should have weather stripping. Be sure to caulk around doors and

windows.

Proper installation of seal gasket

Make sure the seal gasket has been installed properly to minimize noise

and improve effi ciency. If the seal gasket has not been installed, please

refer to Step 14 of the

installation instructions.

Also, if you switch from Cool mode to Fan Only, and switch back to

COOL mode, there is a three minute delay before the compressor comes

back on.

For the best cooling performance and highest energy efficiency

WARNING: Before operating your unit

Make sure the wiring is adequate for your unit.

If you have fuses, they should be of the time delay type. Before you install

rekaerbtiucricehtfognitaregarepmaehttahteruseb,tinusihtetac olerro

or time delay fuse does not exceed the amp rating listed in Figure 1.

DO NOT use an extension cord.

The cord provided will carry the proper amount of electrical power to the

.tonlliwdrocnois netxena;tinu

Make sure that the receptacle is compatible with

the air conditioner cord plug provided.

This insures proper grounding. If you have a two prong receptacle you

will need to have it replaced with a grounded receptacle by a certifi ed

electrician. The grounded receptacle should meet all national and local

codes and ordinances. Under no circumstances should you remove the

ground prong from the plug. You must use the three prong plug furnished

with the air conditioner.

Test the power cord

All Friedrich room air conditioners are shipped from the factory with a

Leakage Current Detection Interrupter (LCDI) equipped power cord. The

LCDI device meets the UL and NEC requirements for cord connected air

conditioners.

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET (See Figure 2).

3. Press TEST (listen for click; Reset button trips and pops out).

4. Press and release RESET (listen for click; Reset button latches and

remains in). The power supply cord is ready for operation.

NOTE: LCDI d

evice is not intended to be used as a switch.

Once plugged in the unit will operate normally without the need to reset

the LCDI device.

If the device fails to trip when tested or if the power supply cord is

damaged it must be replaced with a new supply cord from the manufacturer. We recommend you contact our Technical Assistance Line at

(800) 541-6645 ext. 845. To expedite service, please have your model

and serial number available.

MODEL

CIRCUIT RATING

OR TIME DELAY

FUSE

REQUIRED WALL

RECEPTACLE

AMP VOLT

NEMA

NO.

SS08 • SS10 • SS12 • SS14

XQ06 • XQ08 • XQ10 • XQ12

EQ08

KS12 • KS15 • YS09 • XQ05

15 125 5-15R

SS12 • SS16 • SM18

SM21 • KM18

15 250 6 -15R

SM24 • SL28 • KM24

YS13 • ES12 • ES16

20 250 6-20R

SL36 • YM18 • YL24

EM18 • EM24 • EL36

30 250 6-30R

Figure 1

Figure 2

TEST

RESET

WARNING

TEST BEFORE EACH USE

1. PRESS RESET BUTTON

2. PLUG LDCI INTO POWER

RECEPTACLE

3. PRESS TEST BUTTON,

RESET BUTTON SHOULD

POP UP

4. PRESS TEST BUTTON,

FOR USE

DO NOT USE IF ABOVE TEST

FAILS

WHEN GREEN LIGHT IS ON

IT IS WORKING PROPERLY

RESET

TEST

NOTE: Your LCDI device will resemble one of these illustrations.

WARNING

ELECTRICAL SHOCK HAZARD

Make sure your electrical receptacle has the same

configuration as your air conditioner’s plug. If

different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong outlet.

Failure to follow these instructions can result in

electrical shock, serious injury or death.

11

Page 14

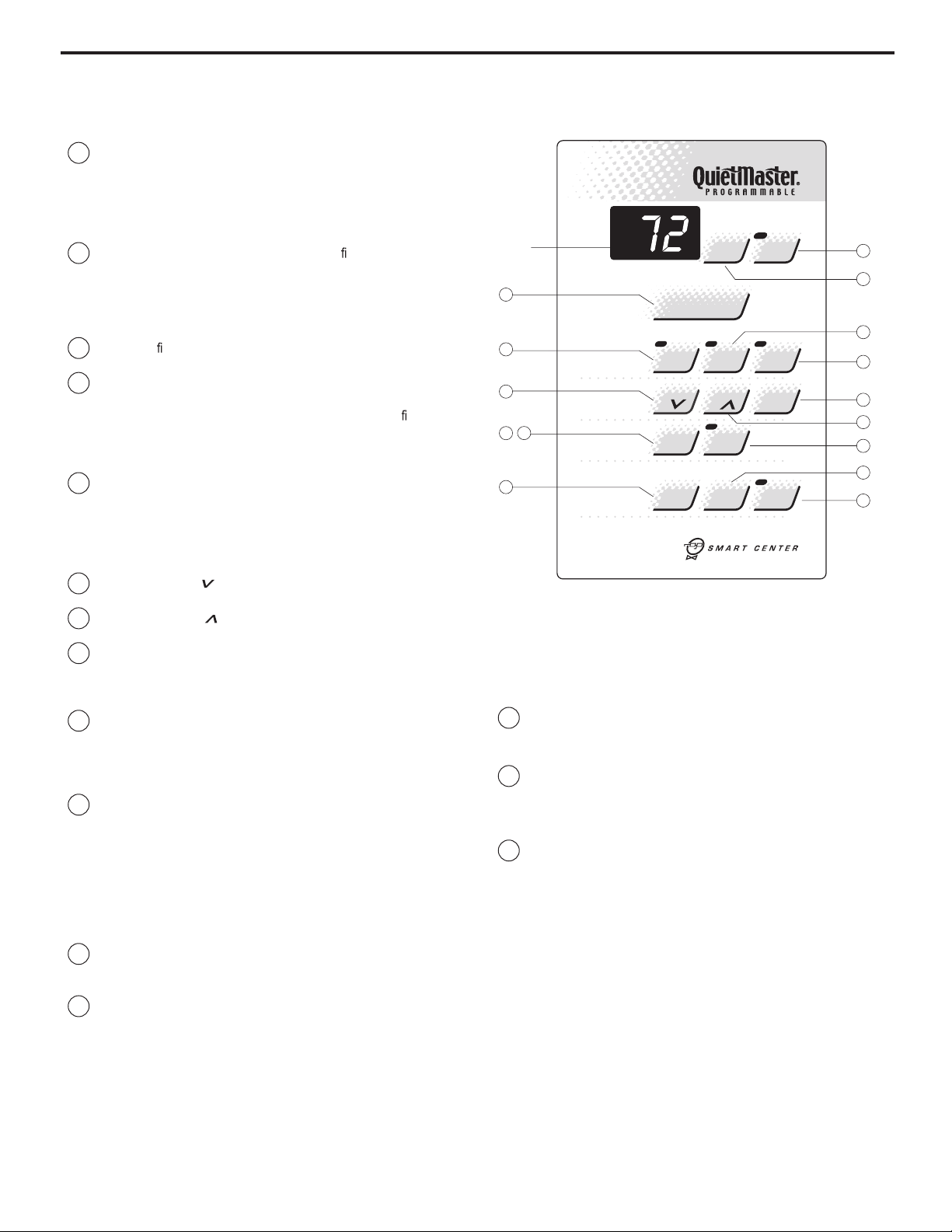

A/C

Stop

Mode

Temp

Fan

Timer

O

F

/

O

C

A/C

Start

Timer

On/O

1-4

Speed

Smart

Fan

Check

Filter

Set

Hour

Power

Cool

Money

Saver

®

PM

Fan

Only

Press to reset

13

DISPLAY

8

5

4

2

15

10

7

11

9

6

3

1

14

12

Figure 3

To start unit

1

If your air conditioner is installed and plugged intoaproper re-

hcuoT.ogotydaersiti,elc at pec Power button once. The unit will

automatically be in Cool mode with the temperature set at 75°F

(24°C) and the fan speed at F1, the sleep setting. There is a 3minute delay before the compressor will turn on. (See "Automatic

Component Protection" on this page).

2

Should the Check Filter light turn on when you rst turn on the unit,

touch Check Filter to turn off the light. Check Filter light will come

Clean filter..esufosruoh052ret fano

Touch Check Filter to reset.

To set mode of operation

3

When you rst turn on the unit, it will be in the Cool mode (light on),

with constant fan.

4

Touch MoneySaver®(light on) toactivate the MoneySaver®feature.

This cycles the fan with the compressor so that the fan does not

.noit ac

i dim uh edsevorpmidnaygrenesevassihT.emitehtllanur

(MoneySaver

®

will also run the fan to sample the return airtempera-

ture if the off cycle is too long). Or you may prefer constant fan for

more air movement. To return to constant fan, touch Cool.

5

TouchFan Only (light on) if you wantonly the fan to run. Youmay want

to use thisfeature in conjunctionwith the Fresh Air / Exhaust lever to

bring outside air intoaroom, or to exhauststale air. (See page 7, "Fresh

Air and ExhaustControl"for more information.)

To adjust temperature [60°F (16°C) to 90°F (32°C)]

6

COOLER – Touch and hold untilthe display shows thedesired

room temperature.

7

WARMER– Touch and holduntil the display showsthe desired

room temperature.

8

FAHRENHEIT / CELSIUS – Touch ºF/ºC toshow thetemperature

in Celsius, touch again to show Fahrenheit.

To adjust fan speed

9

Touch 1-4 Speed to see current setting. Touch again to change

deepswolsi2F,)GNITTESPEELS(gnit testsewolehtsi1F.deeps

(LOW), F3 is medium speed (MED), F4 is high speed (HIGH).

To activate smart fan

10

Touch Smart Fan (light on). Smart Fan will adjust the fan speed

,elpmaxeroF.leveltrofmocderisedehtniatniamotyl lac i tam ot ua

do ir epdednetxenarofnepoeraemohruoynisroodedistuoehtfi

of time, or more people enteraroom, Smart Fan may adjust to a

higher fan speed to compensate for the increased heat load. This

keeps you from having to adjust the fan speed on your own. Smart

Fan cannot be activated in the Fan Only mode.

To deactivate smart fan

11

Touch 1-4 Speed, and select your desired fan speed.

To set hour clock

12

Press Set Hour once to see the current clock setting. Continue

pressing the button until the hour closest to the actual time appears

in the display.

MAKE SURE YOU SET A.M. AND P.M. PROPERLY.Alight will appear in

the upper left corner of the display when the hour is P.M.

NOTE: Minutes will NOT show on display.

To set the timer

NOTE: .snoitcnufremittesotgni tpmet taerofebkcolcruoHteS

You can set the A/C Start and A/C Stop ruohenofomum i nimaremit

apa

rt and a maximum of 23 hours apart.

13

TIMER STOP - Press the A/C Stop button and continue pressing

until the hour you want the unit to shut off appears in the display

(A.M. or P.M.). The stop time for cooling will then be set.

14

START TIME - Press A/C Start to view the current start time for

cooling. Continue pressing until the hour you want the unit to start

appears in the display (A.M. or P.M.). The start time for cooling will

then be set.

15

Press the Timer On/ Off button once to activate (light on) the timer

functio

n. Touch Timer On/ Off again (light off) to cancel the timer

-esneebevahsemitffodnanoehtecnO.er

is edosuoyfinoitcnuf

lected, they will remain in memory, and cycle daily until changed.

NOTE: eht,de tpur ret nisirewoprodeggulpnusitinufI Set Hour button

ehtrotes erebtsum Timer On/ Off functions will not work.

Automatic component protection

.noitcetorPtnen op moCcitamotuAhtiwdeppiuqesitinuruoY

Toprotect thecompressor ofthe unit,there isathree minutetime delay if you

turn the unit off or if power is interrupted. The fan will not be affected.

How to operate the Friedrich room air conditioner

(QuietMaster Programmable)

12

Page 15

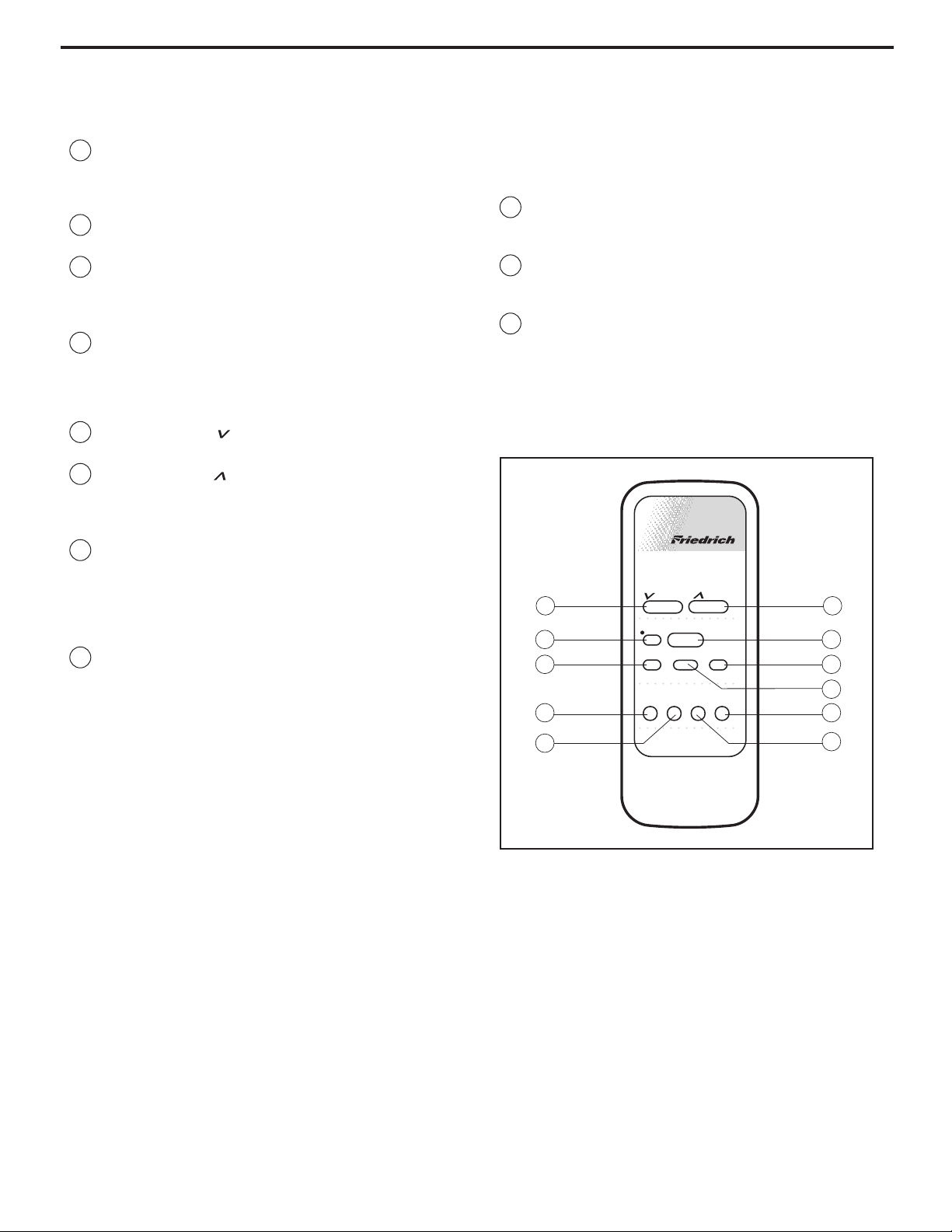

*

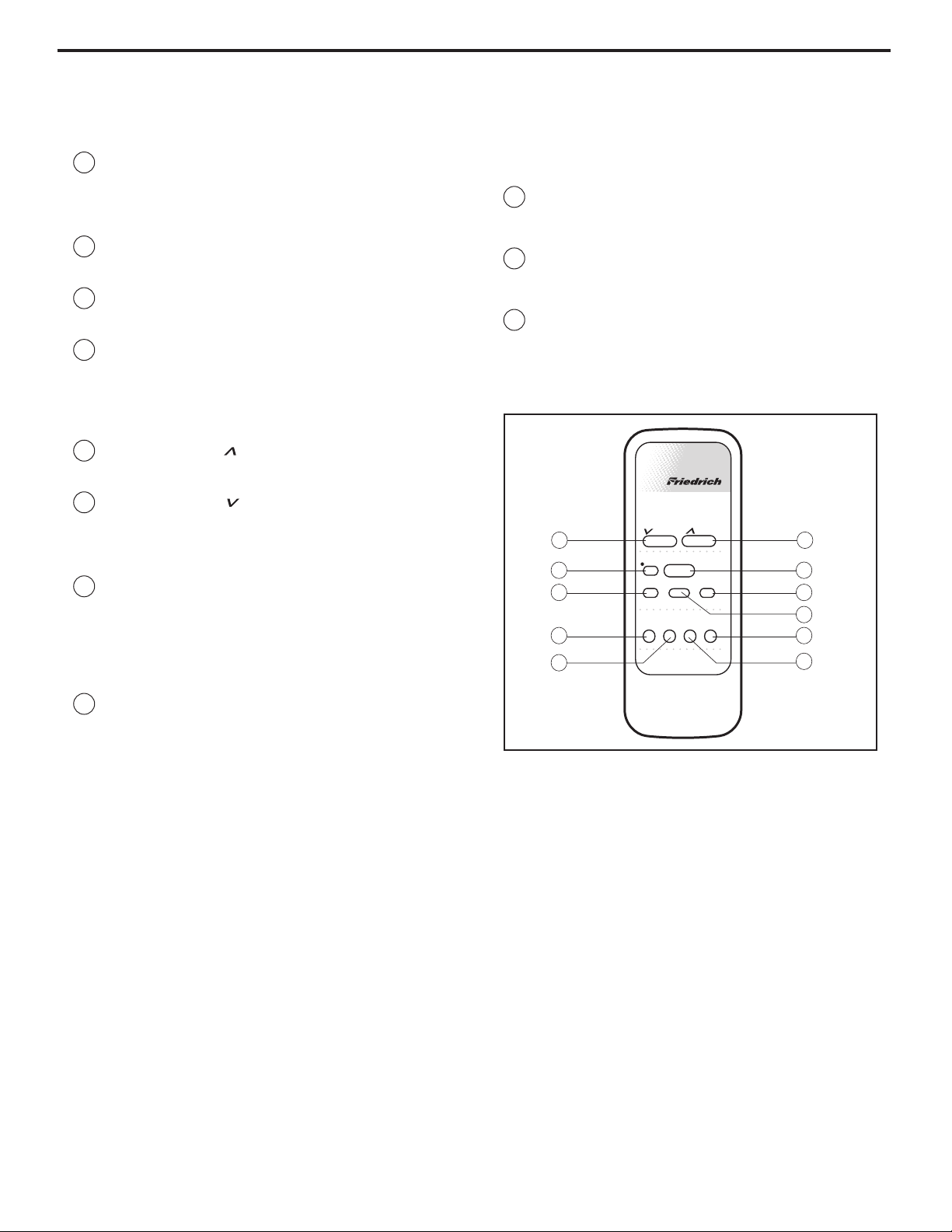

A Friedrich RC1 wireless remote control can be used to operate all

QuietMaster

®

Programmable models.

Figure 4

To start unit

1

POWER - Press the Power button once. The unit will automatically

turn on in the mode and fan speed it was last left on.

To set mode of operation

2

COOL - Press the Cool button toautomatically switch the operating

mode to COOL.

3

FANONLY - Press the Fan Only button ifyou want to run the fan only.

You may want to use this feature in conjunction with the Fresh Air/

Exhaust if you want to bring outside air into the room, or exhaust stale

air.

4

MoneySaver®- Press the MoneySaver®button to activate the

MoneySaver

®

feature. This cycles the fan with the compressor so

that the fan does not run all the time.

To adjust temperature

5

COOLER - Press the Cooler button to raise the temperature

setting.

6

WARMER - Press the Warmer button to lower the temperature

setting.

To adjust fan speed

7

FAN SPEED - Press the Fan Speed button to see the current set-

ting. Press again to change the fan speed. F1 is the lowest setting

(SLEEP SETTING), F2 is low speed (LOW), F3 is medium (MED),

and F4 is high (HIGH).

To set the hour clock

8

SET HOUR CLOCK- Press SetHour once to see the currentclock set-

ting. Continue pressing the button until you arrive at the current time.

MAKE SURE YOU SET THE A.M. AND P.M. PROPERLY. (NOTE:

MINUTESARE NOT SHOWN ON THEDI

SPLAY.)Alight will appear in

the upper leftcorner ofthe display when the hour is P.M.

How to use the remote control

*

(QuietMaster Programmable)

To set the timer

NOTE: Set the hour clock before attempting to set timer functions. You

can set the timer On/Off a minimum of one hour apart, and a maximum

of 23 hours apart.

9

TIMER START - Press Start to view the current start time for cool-

ing. Continue pressing the Start button until you arrive at the start

time you desire. The start time for cooling will then be set.

10

TIMER STOP - Press the Stop button. Continue pressing the Stop

button until you arrive at the stop time you desire. The stop time for

cooling will then be set.

11

TIMER ON/OFF - Press the On/off button once toactivate (light on)

or deactivate (light off) the timer. Once the Start and Stop times

have beenselected, they will remain in memory, and cycle dailyuntil

changed.

NOTE: If theunit isunplugged orthe poweris interrupted,the HOUR

CLOCK must be reset or the Tim

er On/off functions will not work.

Money

Fan

Timer Operation

Set Hr.

Stop

Start

Temperature

Fan

Cool

On/O

Power

Cooler

Only Speed Saver

®

Warmer

8

10

7

11

9

43

1

2

56

13

Page 16

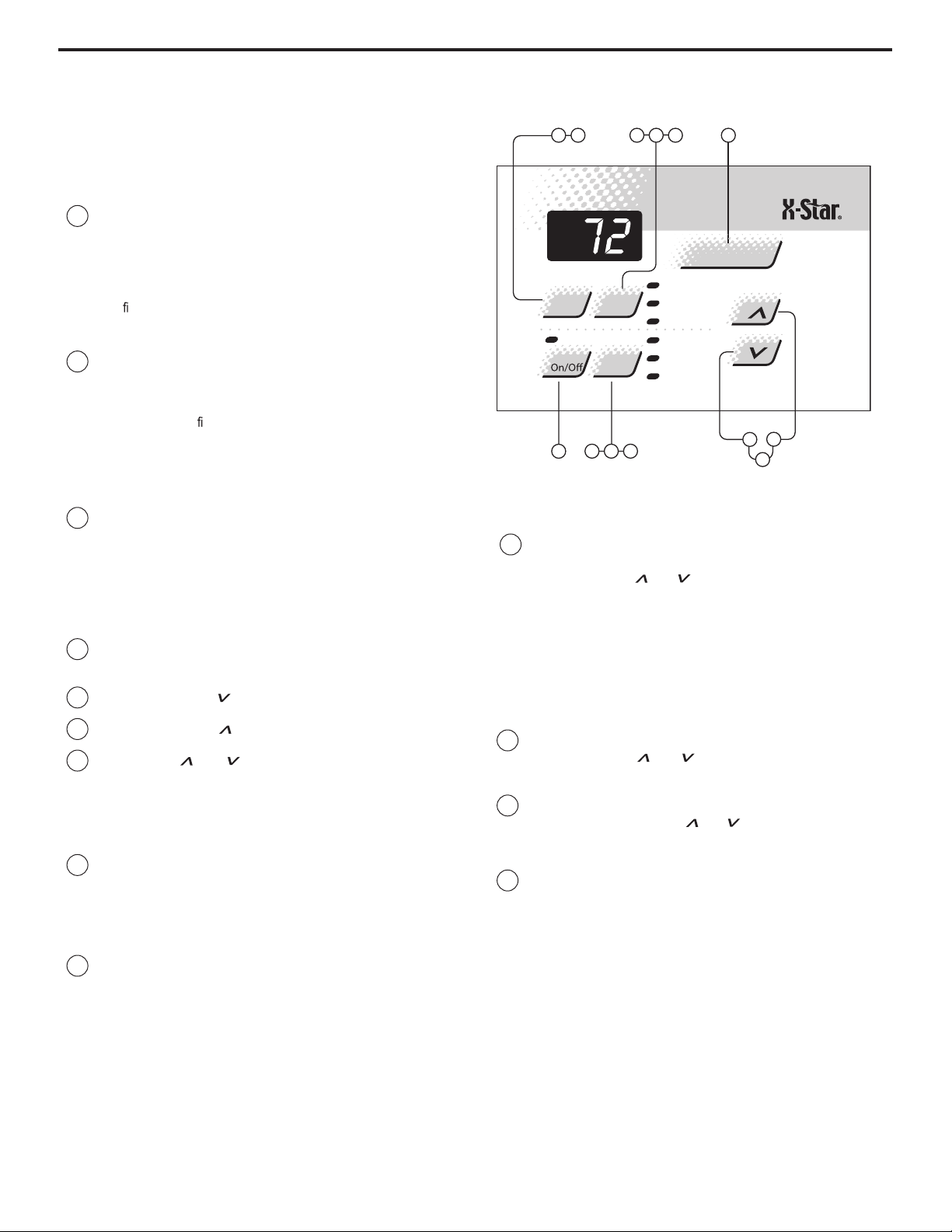

To startunit

siti,elc at pec erreporpaotnideggulpdnadellatsnisirenoitidnocriaruoyfI

ready togo.The first timethe unitis started, thecompressorwilldelay for three

minutes.See AutomaticComponentProtectiononthe followingpage.

1

Touchthe Power button once.The unitwill automaticallybein Cool

mode with the temperature setat75°F (24°C) andthe fanspeed at

F1, thesleep setting.

To setmodeofoperation

When you rstturnthe uniton, it will be in the Cool mode (lighton),with

constant fan.

2

Touchthe Mode button once to activatethe MoneySaver®(lighton).

MoneySaver

®

ros serp mocehthtiwnafehtselcyctahterutaefasi

so that thefan does notrun allthe time.Thissaves energy and

eromrofnaftnats nocreferpyamuoyrO.noit ac

i dim uh edsevorpmi

ehthcuot,naftnatsnocotnruterot(tnem evomria Mode button two

more times).

In order to runthe fanbyitself, do thefollowing:

3

Continuing fromMoneySaver®mode (lighton), touchthe Modebutton

once to activate the FANONLY feature(lighton).

The FANONLY settingwillcirculate air in the roomwithout thecom-

pressorcomingon.

To adjusttemperature

4

Usethe Mode button to select eitherthe COOL or MoneySaver

®

function

5

COOLER – Touch the button to lower theroomair temperature.

6

WARMER – Touch the button to raisethe roomair temperature.

7

Pressboth the and ehthctiwsotemitemasehttasnottub

temperature readoutfrom Fahrenheit(°F)toCelsius(°C).

Repeat step 7 to switch from °C back to °F.

To adjust fan speed

8

TouchtheFanSpeedbutton to seethe currentsetting. To uchit again

to changespeed. F1isthe lowest setting(SLEEPSETTING/LOW),

F2 is MEDIUM,and F3 is HIGH.

To activate Smart Fan

9

Thereisafourth option,SF, when selectingthe fanspeed.Thisis

the SMARTFAN function.SMART FA NDOESNOT OPERAT EIN

CONJUCTION WITH THEFAN ONLY MODE.

SmartFan will adjustthe fanspeed automaticallyto maintain the

desiredcomfort level. Forexample,ifthe outsidedoors in your home

are opened foranextended period of time,ormorepeople entera

room,Smart Fanmay adjusttoahigherfan speedtocompensate

forthe increasedheatload. This keepsyou from having to adjustthe

fanspeed on your own.

Howtooperate the Friedrich room airconditioner (XQmodels)

PM

Temp/Hour

Cool

Money Saver

®

Fan Only

Clock

Start Time

Stop Time

Power

Fan

Speed

Mode

Timer

Set

Hour

10 11 12

13

7

3 4

5

6

18 9 2

Figure 5

To setthe hour clock

10

Touchthe SetHour button to seethe currentsetting (clock light

comeson).The numberthatis displayed is the approximatetime

(hour only).Use the

and

buttonstochange thesettings.BE

SURETO SETA.M.AND P. M. ACCORDINGLY. (P.M.isindicated

by ared lightinthe upperleftcornerofthe display).

To setthe timer

NOTE: Setthe HOUR CLOCK before attempting to settimer functions.

Youcan setthe ST ART and STOP timesaminimumofone hour apart,and

amaximumoftwenty-three hours apart.

11

Aftersetting thetime, press the Set Hour button once (Start light

comeson).Use the

and buttonsto selectthe time that the

unit will START.

12

After selectingthe START time,press the SetHour button oncemore

(Stoplight comeson).Use the

and buttonsto select the time

that the unitwill STOP.After selecting the stoppingtime, pressthe

Set Hour button once.

13

Pressthe TimerOn/Off button (light turnson) to activate thetimer

function. To deactivate this function, press the TimerOn/Of f button

once again (lightturns off).Oncethe on andoff timeshavebeen

selected,theywillremaininmemory and cycle dailyuntil changed.

NOTE: If the unitisunplugged or thepower is interrupted,the HOUR

mustbereset or the TimerOn/Off will notfunctionwhendesired.

Automatic componentprotection

Your unit is equipped with Automatic Component Protection. To protectthe

compressorofthe unit, thereisathree minutestart delayifyou turn theunit

offorifpoweris interrupted.The fanoperation will notbeaffected. Also,ifyou

switch from Cool mode to Fan Only,and switch back to Cool mode,there

is athree minute delaybeforethe compressor comesbackon.

14

Page 17

To set the timer

NOTE: You can set the START and STOP timesaminimum of one hour

apart, andamaximum of 23 hours apart.

9

TIMER START - Press Start .gniloocrofemittratstnerrucehtweivot

Continue pressing the Start button until you arrive at the start time

you desire. The start time for cooling will then be set.

10

TIMER STOP - Press the Stop button. Continue pressing the Stop

button until you arrive at the stop time you desire. The stop time for

cooling will then be set.

11

TIMER ON / OFF - Press the On/Off button to activate (light on) or

deactivate (light off) the timer. Once the on and off times have been

selected, they will remain in memory and cycle daily until changed.

NOTE: If the unit is unplugged or the power is interrupted, the Set Hr.

function must be reset or the On/Off function will not work.

How to use the remote control

To start unit

1

POWER - Press the Power button once. The unit will automatically

start in the mode and fan speed it was last left on.

To set mode of operation

2

COOL - Press the Cool button to automatically switch the operating

mode to COOL.

3

FAN ONLY - Press the Fan Only button if you want to run the fan

only.

4

MoneySaver®- Press the MoneySaver®button to activate the

MoneySaver

®

feature. This feature cycles the fan with the compres-

sor so that the fan does not run all the time.

To adjust temperature setting

5

WARMER - Press the Warmer button to raise the temperature

setting.

6

COOLER - Press the Cooler button to lower the temperature

setting.

To adjust fan speed

7

FAN SPEED - Press the Fan Speed button to see the current set-

ting. Press again to change the fan speed. F1 is the lowest setting

(SLEEP / LOW), F2 is MEDIUM, F3 is HIGH, and SF is the SMART

FAN setting.

To set the hour clock

8

SET HOUR CLOCK - Press Set Hr. once to see the current clock

setting. Continue pressing the button until you arrive at the current

time (Hour only). Minutes are not shown on the display. Make sure

that the A.M. / P.M. setting is correct.

Money

Fan

Timer Operation

Set Hr.

Stop

Start

Temperature

Fan

Cool

On/O

Power

Cooler

Only Speed Saver

®

Warmer

8

10

7

11

9

43

12

56

Figure 6

Additional RC1 wireless remote controls can be purchased from your Friedrich dealer.

(XQ models)

15

Page 18

Allow3min. between restarts

SPEED

Sleep

Setting

Low

Cool

Medium

Cool

High

Cool

Fan

Only

O

MIN MAX

Money Saver

®

Yes No

Allow 3 min. between restarts

Money Saver

®

MAX

COOL

MAX

HEAT

Low

Cool

Med

Cool

High

Cool

Low

Heat

Med

Heat

High

Heat

Fan

Only

O

Yes No

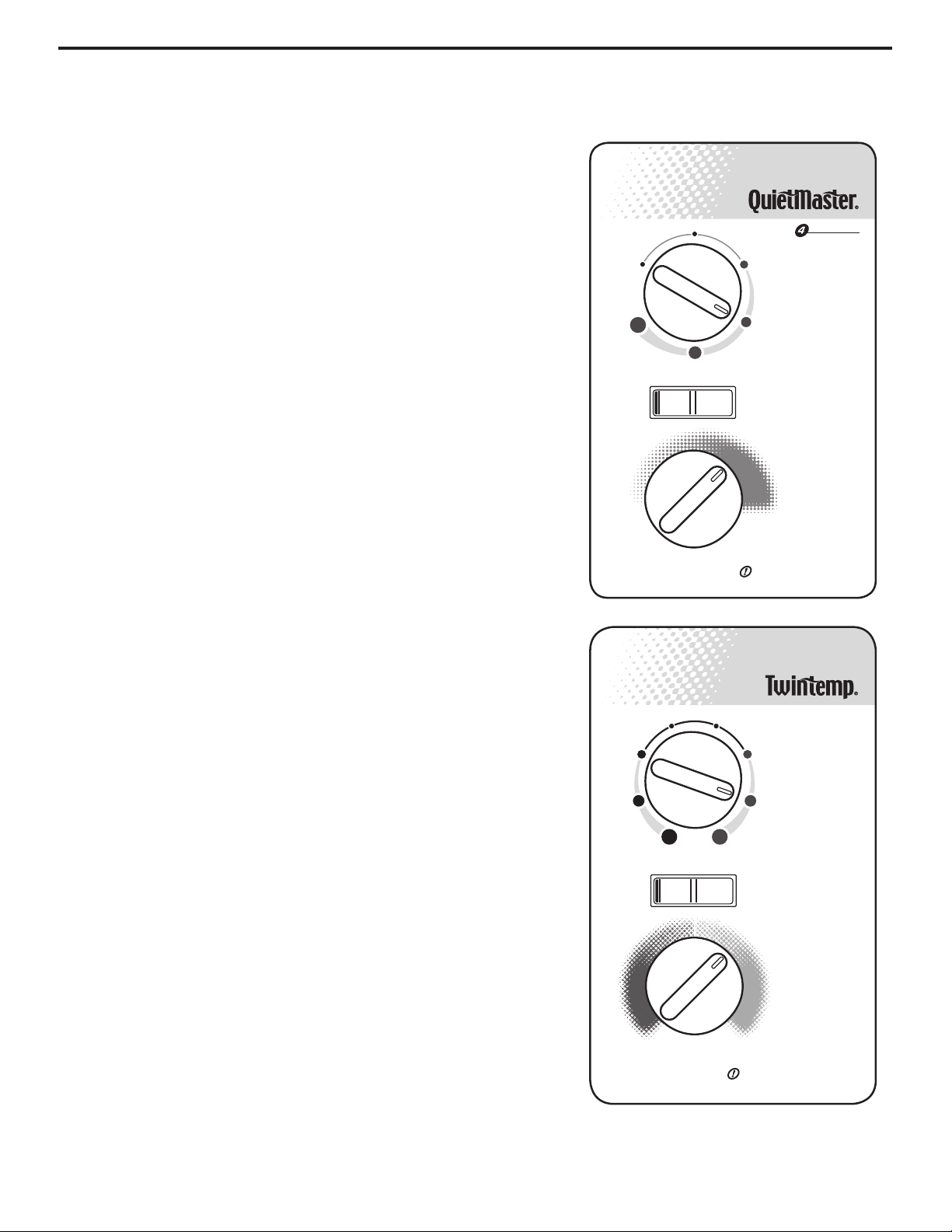

To start unit

If your air conditioner is installed and plugged into a properly grounded

.eta repootydaersiti,elc atpec er

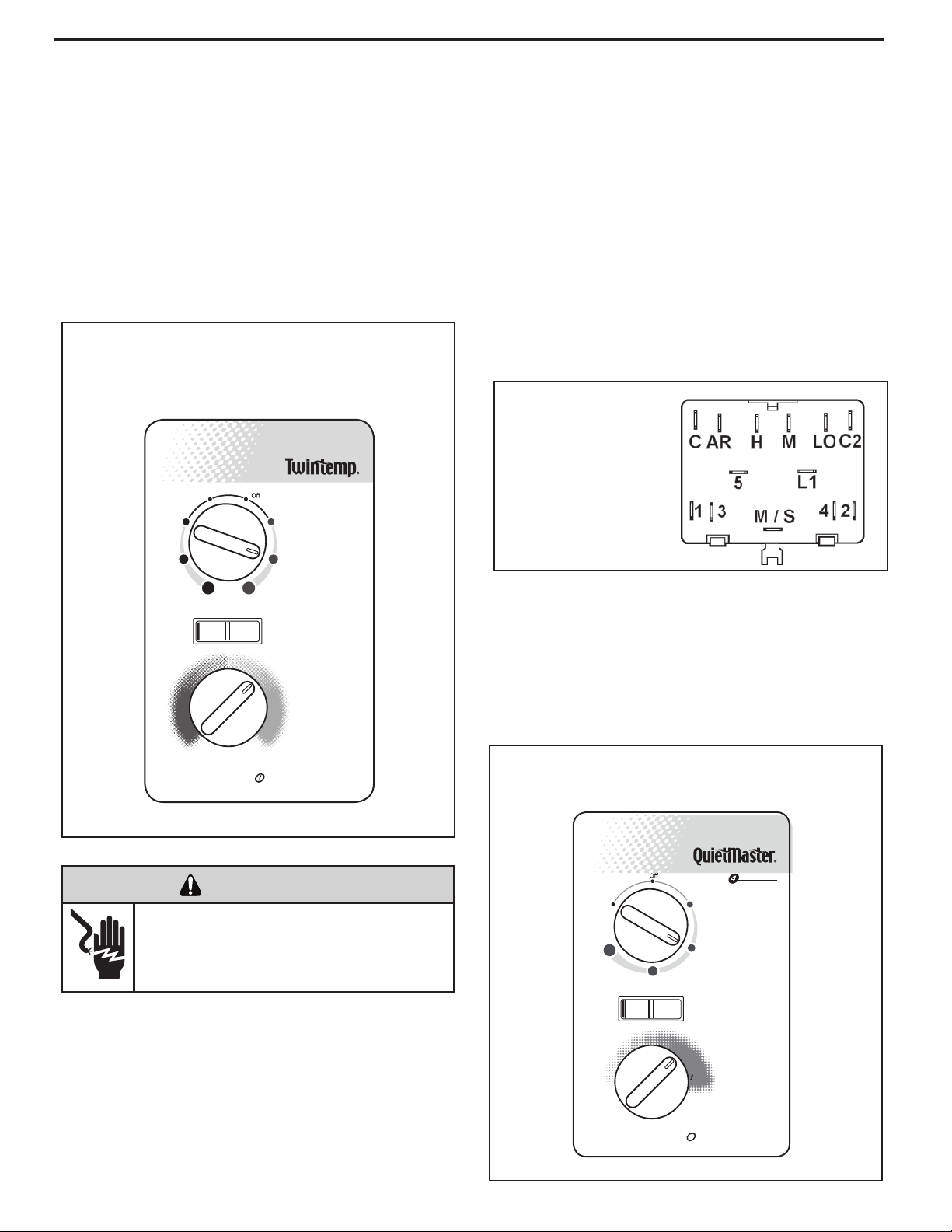

Mode control (QuietMaster)

The upper dial (Figure 7) allows you to select cooling at four different

speeds, as well as Fan Only (Models SL28 and SL36 only have three

cooling speeds.).

Off - to turn the unit off.

High Cool - for quick cooling.

Medium Cool .erutarepmetderis edaniatniamot-

Low Cool - when cooling demand is low.

Sleep Setting - for nighttime use, or when cooling demand is low.

Fan Only - to circulate air in the room without the compressor coming on.

The Fan Only setting can also be used with the Exhaust evomerotgnittesria

stale air or smoke from the room; or it can be used with the Fresh Air setting

to bring outside air into the room. This is especially useful in the spring and fall

ehT.yras se cenebtonyamgniloocne

hw Fresh Air and Exhaust controls

ehtsilortnocsihtfonoitis opretnecehT.aeraegrahcsidriareppuehtniera

normal, or closed position, which recirculates air for maximum performance

e.domgniloocehtni

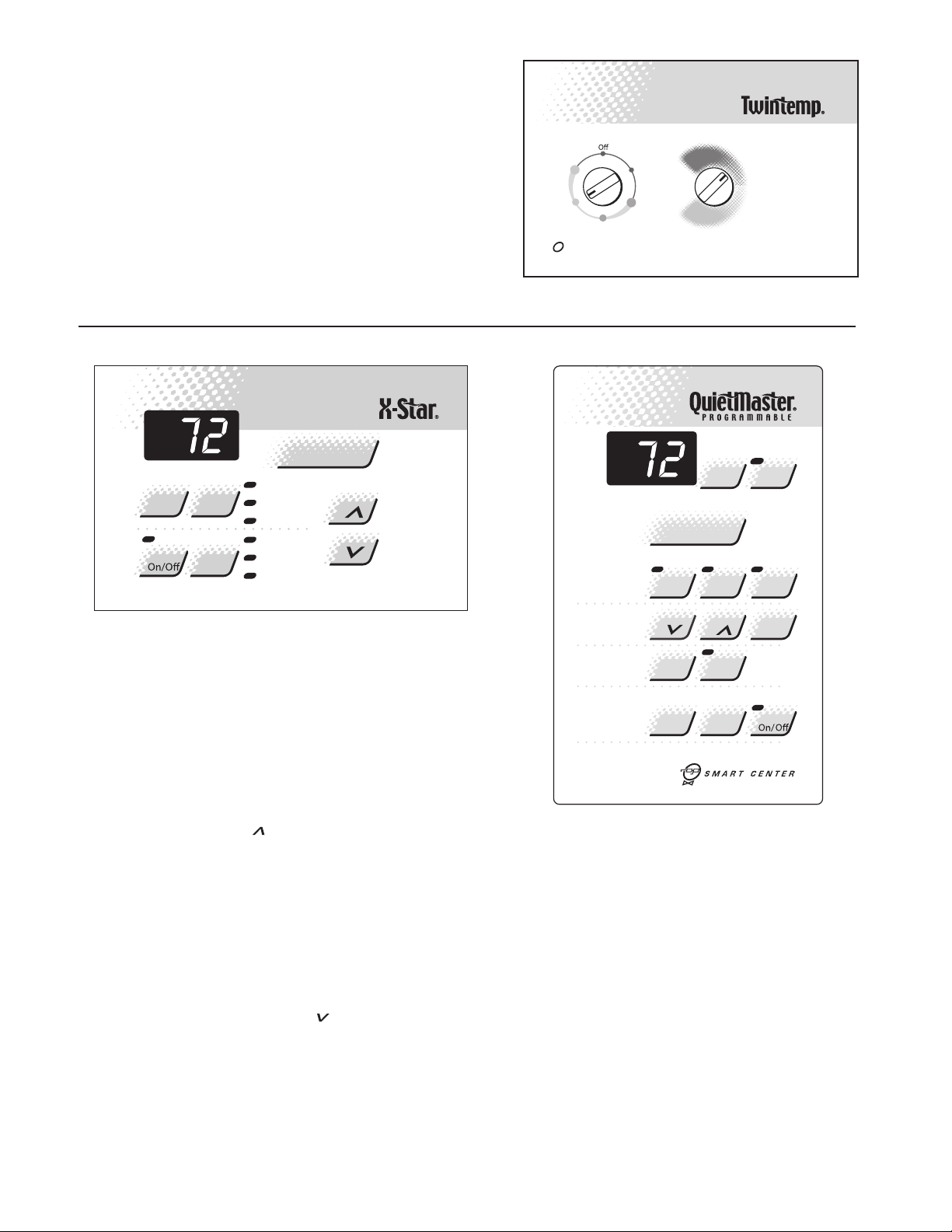

Mode control (Twintemp)

,sdeepstnereffideerhttagnitaehrognilooctcelesotuoyswollalaidsihT

as well as Fan Only (Figure 8).

Off - to turn the unit off.

High Cool or High Heat .esnops erkciuqrof-

Medium Cool or Medium Heat .erutare

pmetderis edaniatniamot-

Low Cool or Low Heat - for nighttime use, or when demand is low.

Fan Only - to circulate air in the room without the compressor coming on.

The Fan Only ehthtiwdesueboslanacgnittes Exhaust otgnittesria

ehthtiwdesuebnactiro,moorehtmo

rfekomsroriaelatsevom er Fresh

Air dnagnirpsehtniyllaicep se,moorehtotniriaedistuognirbotgnittes

.yras se cent’nsig

niloocnehwllaf

The Fresh Air and Exhaust a.eraegrahcsidriarep puehtnieraslortnoc

ro,lamronehtsilortnocsihtfonoitisopretnecehT

ehtniecnam rofrepmumixamrofriasetaluc ric er

hcihw,noitis opdesolc

.edomgnilooc

NOTE: ehtnehwtae

hehtgnitav itcatsrfinehwrodonaecitonyamuoY

yamtahtffogninrubtsudoteudsisihT.nosemoctnem e letaehcirtcele

.l

amrons

isihT.rem musehtgnirudliocehtnodere htagevah

Temperature control

esiw kcolctinruT.tatsomrehtehtsilenaplortnocehtnolaidmottobehT

for cooler temperature and counterclockwise for warmer.

Money Saver® switch

This rocker switch can be depressed to either Yes or No. In the Yes position

ros serp mocdnanafehthtoB.noitarepolac imonocetsomehtteglliwuoy

ataerutarep metdetcelesehtgniniatniam,re hteg otffodnanoelc yclliw

gniloocehtniyltneic fifeeromyt

idim uhehtgnicud erdnale veltnats nocerom

gnitaehr

ogniloocnisitinuehtnehweta re poylnolliwlortnocsihT.edom

mode. In the No sitinuehtsagnolsayltnatsnocnurlliwnafeht,noitisop

.edomgnitaehrogniloocehtni

NOTE: The YS09 is a 115 volt model and does not provide adequate heat

.snoitac ilp paetamilcmrawrofdengisedsitcu dorpsihT.)C°3(F°73woleb

How to operate the Friedrich room air con di tion er

(QuietMaster / Twintemp models)

Figure 7

Figure 8

16

Page 19

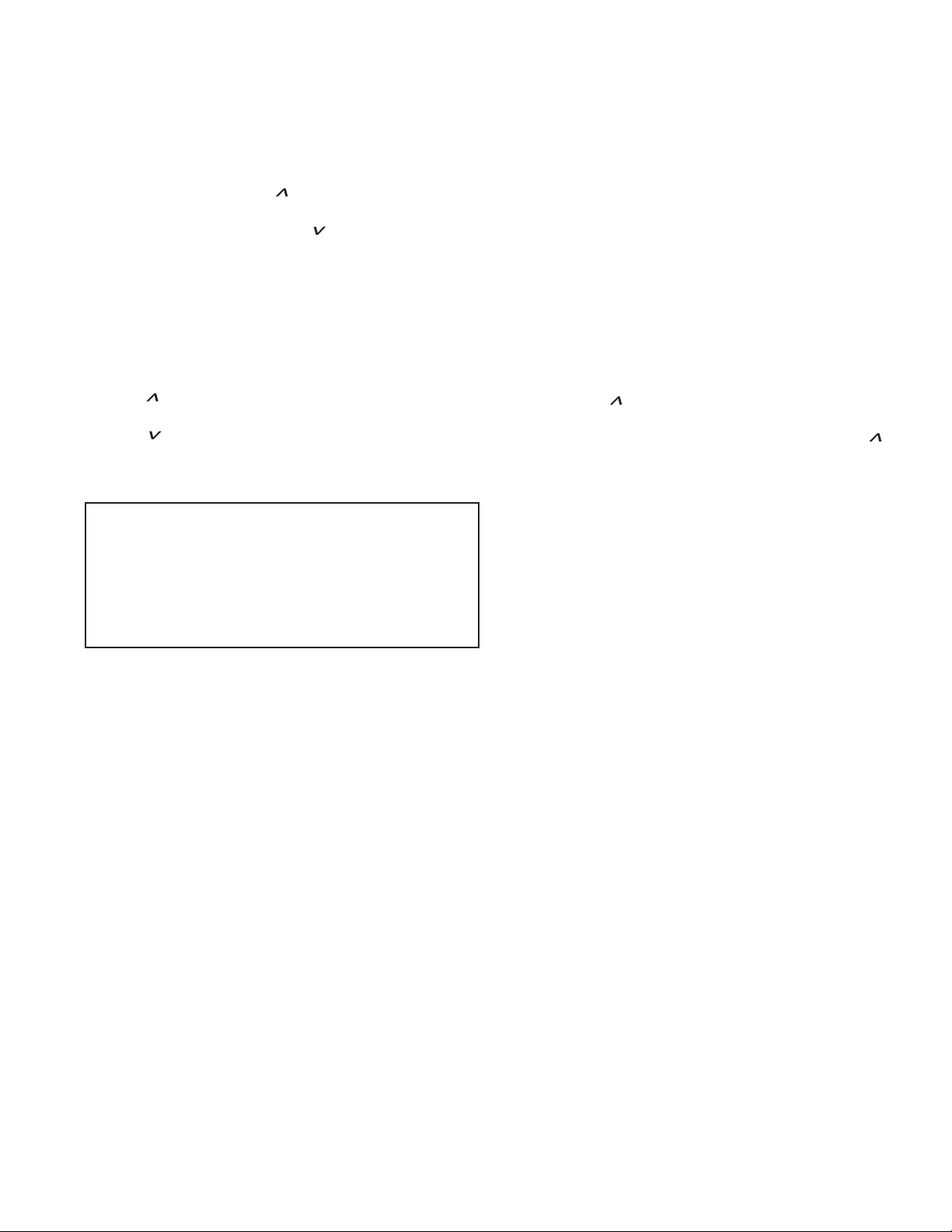

EQ08 models

Function Control

The left knob is a six position control that allows you to

select heat or cool in either low speed or high speed. Plus

you can select fan only if you wish.

High

Heat

Fan

Only

MAX

HEAT

Function Control

The right hand knob is the thermostat - turn it clockwise for

cooler, counter-clockwise for warmer (See Figure 9).

PM

Power

Set

Cool

Money Saver

Fan Only

Clock

Start Time

Stop Time

®

Te mp/Hour

Fan

Speed

Timer

Mode

Hour

FIGURE 10

TESTING THE ELECTRONIC CONTROL

BOARDS FOR QME & XQ MODELS

Checking Room Temperature:

1. Check the room temperature at the electronic control

pad by pressing the “FAN SPEED” button and the

temperature “UP” button at the same time on XQ models.

Low

Heat

Allow3 m in. between restar ts

!

FIGURE 9

Mode

Temp

Fan

Timer

High

Cool

Low

Cool

PM

MAX

COOL

Set

Hour

Check

Filter

Press to reset

Power

Cool

1- 4

Speed

A/C

Stop

Money

Saver

Smart

Fan

A/C

Start

Fan

®

Only

O

O

F

C

/

Timer

2. Check the room temperature at the electronic control

pad by pressing at the same time the “FAN SPEED”

button and the “TEMP ” button on QME models.

The indoor temperature will display for 10 seconds. Indoor

temperature can be viewed in all modes, including the

TEST mode. The display can be changed back to SET

temperature by pressing any key, except the ON/OFF

button, or after 10 seconds has elapsed.

Activating Test Mode:

Activate test mode by pressing at the same time the

“MODE” button and the “TEMP ” button on XQ

models. LEDs for Hour, Start, and Stop will blink 1 bps

while Test Mode is active.

Activate test mode by pressing at the same time the

“MONEY SAVER” button and the “CHECK FILTER”

button on QME models. LED for the Filter Alert will blink

1 bps while Test Mode is active.

FIGURE 11

Test Mode has duration of 90 minutes. Test Mode

can be activated under any conditions, including

Off. Test Mode is cancelled by pressing the On/Off

button, unplugging the unit, or when the 90 minutes

is timed out. All settings revert to the factory default

settings of Cool, 75 degrees F, Timer and Set Hour

features are nonfunctional.

Test Mode overrides the three-minute lockout, all

delays for compressor and fan motor start / speed

change, and no delay when switching modes.

Test Mode default settings are ON, Money Saver,

60 degrees F, and High fan speed.

17

Page 20

Activating Error Code Mode: (Submode of Test Mode)

Unit must be in Test Mode to enter Error Code Mode

1. Activate Error Code Mode by pressing the “TIMER ON/

OFF” button on XQ models. LED for the “TIMER ON/

OFF” will ash 1 bps while Error Code Mode is active.

Pressing the “TEMP/HR ” button will display 00.

Consecutive presses will scroll through all error codes

logged. Press the “TEMP/HR ” button to see the

reverse order of all error codes logged. When the end of

logged error codes is reached the temperature set point

will appear.

Activate Error Code Mode by pressing at the same time

the “A/C START” button and the “ON/OFF” button on

QME models. LED for the “TIMER ON/OFF” will ash

1 bps while Error Code Mode is active. Pressing the

“TEMP ” button will display 00. Consecutive presses

will scroll through all error codes logged. Press the

“TEMP ” button to see the reverse order of all error

codes logged. When the end of logged error codes is

reached the temperature set point will appear.

IMPORTANT: Error Codes are cleared from the log by

exiting from Error Code Mode. To exit on XQ models,

press Timer On/Off button. To exit QME models,

press A/C Start and On/Off buttons. Or unplug unit to

exit Error Code Mode. Plug unit in after 5 seconds to

resume normal operation of unit.

TESTING THE ELECTRONIC CONTROL

ERROR CODE LISTINGS

E1 SHORT CYCLE SITUATION: Dened as (compressor

powered on before the three minute time delay ten times in

one hour. Investigate and correct short cycling problem.

E2 KEYBOARD STUCK ERROR: If key button(s) are

pressed continuously for twenty seconds or more. If MODE

key is stuck, unit will default to cool. Exit Error Code

Mode to see if error “E2” is no longer displayed and unit is

functioning. Replace board if “E2” still displays after exiting

Error Code Mode.

E6 INDOOR PROBE SHORT: Control assumes

ambient temperature is 90 degree F and unit will

operate. Replace probe.

NOTE: All Error Code displays for Frost & Indoor Probe

will allow unit to operate. Unit may or will ice up if faulty

components not replaced.

FROST PROBE SENSOR: disables compressor at 35

degrees F.

INDOOR PROBE SENSOR: Control range is 60

degrees F to 90 degrees F +/- 2 degrees F.

Indoor temperature will be displayed by pressing:

(QME units) The Fan Speed button and the

Temperature button.

(XQ units) The Fan Speed button and the “TEMP “

button.

The indoor temperature will be displayed for 10

seconds. The display will change back to the Set Point

temperature by pressing any key button except for the

On/Off button. The indoor temperature can be viewed

in all modes, including test mode.

Check Filter: The Check Filter indicator turns on after

the fan motor has been operating for 250 hours. The

Check Filter indicator is reset by pressing the Check

Filter button one time only. Power failures will not reset

the 250 hour timer. All time elapsed is stored in memory

and resumes counting after power is restored.

Keep Alive: The electronic control has a memory to

retain all functions and status as set up by the user in

the event of a power failure. Once power is restored

to the unit there is a two second delay before the fan

comes on and approximately three minutes delay

before the compressor is activated, providing that the

mode was set for cooling and the set point temperature

has not been met in the room.

18

E3 FROST PROBE OPEN: Normal operation is allowed.

Ohm frost probe. Replace probe if ohm value not read. If

ohm value is present replace board.

E4 FROST PROBE SHORT: Normal operation allowed.

Replace probe.

E5 INDOOR PROBE OPEN: Control assumes indoor

ambient temperature is 90 degree F and unit will operate.

Ohm indoor probe. Replace probe if ohm value not read.

Page 21

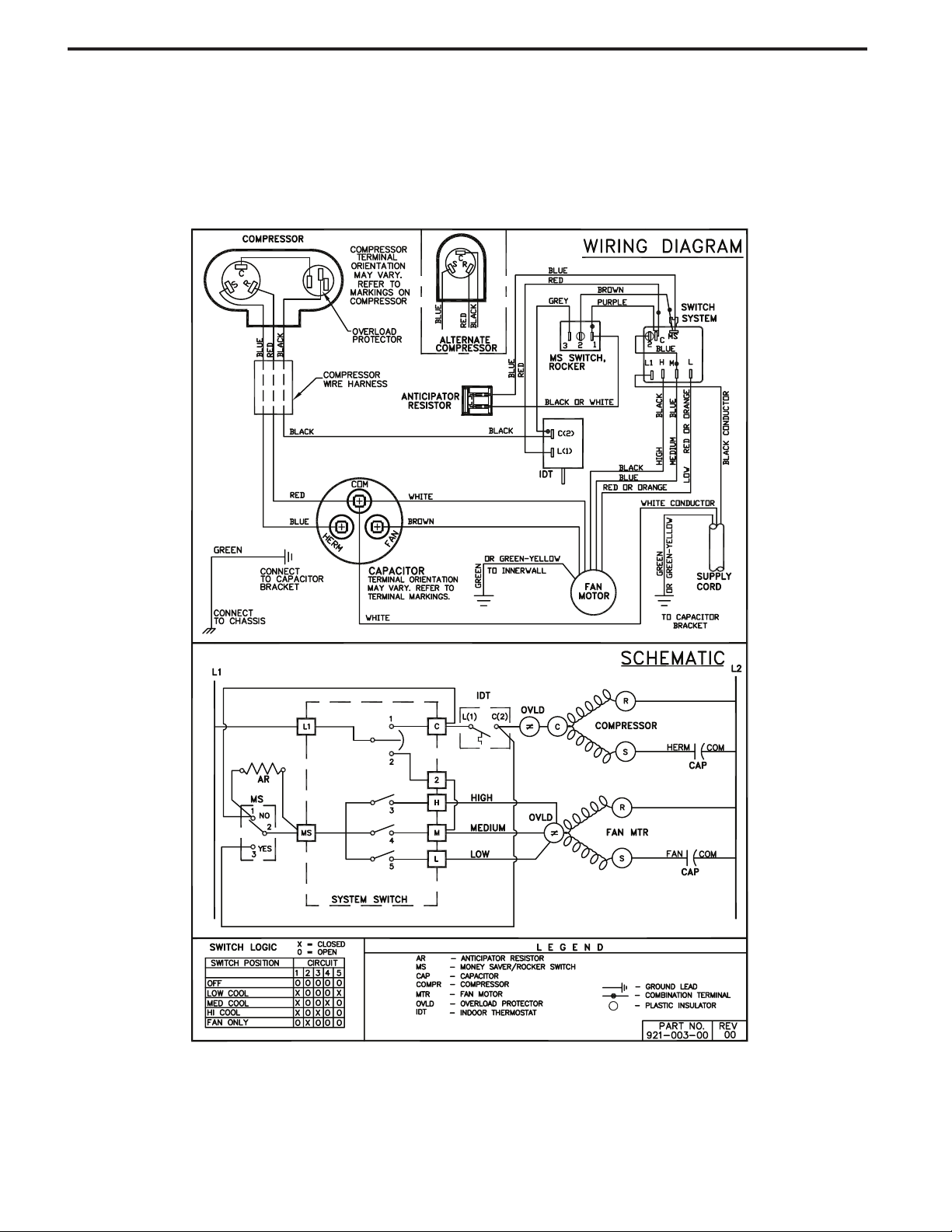

TESTING THE ROTARY CONTROL SWITCHES

Allow 3 min. between restarts

Money Saver

®

MAX

COOL

MAX

HEAT

Low

Cool

Med

Cool

High

Cool

Low

Heat

Med

Heat

High

Heat

Fan

Only

YesNo

Allow3min. betweenrestarts

SPEED

Sleep

Setting

Low

Cool

Medium

Cool

High

Cool

Fan

Only

MINMAX

MoneySaver

®

YesNo

(Heat Pump & Electric Heat Models)

(See Figure 12)

An e ight position control switch i s used t o regulate the

operation of the fan motor and compressor. The compressor

can be operated with the fan operating at low, medium or

high speed in the cooling or heating mode. The fan motor

can also be operated independently on medium speed. See

switch section as indicated on decorative control panel.

NOTE: Heat pump models with electric heat - in the heat

position, heating element only will be energized when

outdoor temperature is below t he operating range o f the

heat pump.

12

Figure

System Control Panel

Heat Pump & Electric Heat Models

(YS, ES, YM, EM, YL & EL)

3. “ Med Cool” Position - between terminals “C” and “3”,

“C2” and “2”, “M” and “M/S”, “AR” and “5”.

4. “ Hi Cool” Position - between terminals “C” and “3”, “C2”

and “2”, “H” and “M/S”, “AR” and “5”.

5. “ Hi Heat” Position - between terminals “C” and “1”, “C2”

and “4”, “H” and “M/S”, “AR” and “5”.

6. “ Med Heat” Position - between terminals “C” and “1”,

“C2” and “4”, “M” and “M/S”, “AR” and “5”.

7. “ Lo Cool” Position - between terminals “C” and “1”, “C2”

and “4”, “LO” and “M/S”, “AR” and “5”.

8. “ Fan Only” Position - between terminals “L1” and “M”.

13

Figure

System Control Switc

(Heat Pump / Electric

Heat Model

s

h

WARNING

SYSTEM CONTROL SWITCH - TEST

Disconnect leads from control switch. Turn control to position

being tested. There must be continuity as follows:

1. “ Off” Position - no continuity between terminals.

ELECTRIC SHOCK HAZARD

Disconnect power to the unit before

servicing. Failure to follow this warning

could result in serious injury or death.

(See Figure 13)

KS, KM, SL Models

(See Figure 14)

A six position control switch is used to regulate the operation

of the fan motor and compressor. The compressor can be

operated w ith the fan operating at l ow, medium o r high

speed. The fan motor can also be operated independently

on m edium speed. See switch s ection a s indicated on

decorative control panel.

Figure

System Control Panel (KS, KM, SL)

14

2. “ Lo Cool” Position - between terminals “C” and “3”, “C2”

and “2”, “LO” and “M/S”, “AR” and “5”.

19

Page 22

MECHANICAL COMPONENTS

Bellows condensate valve Temperature-sensitive valve

that opens up to drain off condensate water when the outside

temperature falls below 40°F and closes when the outside

temperature reaches 58°F.

Vent door Allows introduction of fresh air into the room

and/or exhausts stale room air outside (on select models.)

Plenum assembly Diffuser with directional louvers used

to direct the conditioned airfl ow.

Blower wheel Attaches to the indoor side of the fan motor

shaft and is used for distributing unconditioned, room side

air though the

heat exchanger and delivering conditioned

air into the room.

Slinger fan blade Attaches to the outdoor side of the fan

motor shaft and is used to move outside air through the

condenser coil, while slinging condensate water out of the

base pan and onto the condenser coil, thus lowering the

temperature and pressures within the coil.

ELECTRICAL COMPONENTS

Thermostat Used to maintain the specifi ed room side

comfort level

System switch Used to regulate the operation of the fan

motor, the compressor or to turn the unit off. For trou

bleshooting, refer to the wiring diagrams and schematics in the back

of this service manual.

Capacitor Reduces line current and steadies the voltage

supply, while greatly improving the torque characteristics of

the fan motor and compressor motor.

MoneySaver

Defrost thermostat (Heatpumps only)

®

switch When engaged, it sends the power

A dual purpose

supply to the fan motor through the thermostat, which allows

control that acts as an outdoor thermostat and defrost

control.

Smart Fan

Automatically adjusts the fan speed to main-

tain the desired room temp.

for a cycle-fan operation.

Fan Motor Dual-shafted fan motor operates the indoor

blower wheel and the condenser fan blade simultaneously.

Solenoid Used to energize the reversing valve on all heat

pump units.

Heating element Electric resistance heater, available in 3.3,

4.0 or 5.2 kW on select TwinTemp

®

models.

Heat anticipator Used to provide better thermostat and

room air temperature control.

HERMETIC COMPONENTS

Compressor Motorized device used to compress refrigerant

through the sealed system.

Reversing valve A four-way switching device used on all

heat pump models to change the fl ow of refrigerant to permit

heating or cooling.

Check valve A pressure-operated device used to direct the

fl ow of refrigerant to the proper capillary tube, during either

the heating or cooling cycle.

Capillary tube A cylindrical meter device used to evenly distribute the fl ow of refrigerant to the heat exchangers (coils.)

FUNCTIONAL COMPONENT DEFINITIONS

SYSTEM CONTROL SWITCH - TEST (See Figure 15)

Disconnect leads from control switch. There must be

continuity as follows:

1. “Off” Position - no continuity between terminals.

2. “Lo Cool” Position - between terminals “L1” and “C,” “LO”

and “MS.”

3. “Med Cool” Position - between terminals “L1” and “C,” “M”

and “MS.”

4. “Hi Cool” Position - between terminals “L1” and “C,” “H”

and “MS.”

5. “Fan Only” Position - between terminals “L1” and “2.”

Figure 15

System Control Switch

“EQ08” SYSTEM CONTROL SWITCH – TEST

(See Figure 16)

Turn knob to phase of switch to be tested. There must be

continuity as follows:

1. “Fan Only” Position – between terminals “MS” and “H”

2. “Hi Cool” Position – between terminals “L1” and “C” and

“MS” and “H”

3. “Low Cool” Position – between terminals “L1” and “C”

and “MS” and “LO”

4. “Low Heat” Position – between terminals “L2” and “2”

and “MS” and “LO”

5. “Hi Heat” Position – between terminals “L2” and “2” and

“MS” and “H”

L1

MS

2

H

LO

C

L2

B1

Figure 16

System Control Switch

(EQ Models)

20

Page 23

COMPONENTS TESTING

TEST:

1. Remove leads from thermostat.

2. Turn thermostat knob clockwise to its coldest

position.

3. Test for continuity between the two terminals. Contacts

should be closed.

4. Turn thermostat knob counterclockwise to its warmest

position.

5. Test for continuity - contacts should be open.

NOTE: The thermostat must be within the temperature

range listed to open and close.

To maintain the comfort level desired, a cross ambient type

thermostat is used. The thermostat has a range from 60°

±2°F to 92° ±3°F. The thermos

tat bulb is positioned in front

of the evaporator coil to sense the return air temperature.

Thermostat malfunction or erratic operation is covered in

the troubleshooting section of this manual.

THERMOSTAT - Models ES, YS, EM, YM, EL, YL

A cross ambient thermostat is used on all heat pump and

electric heat units. In addition to cycling the unit in a heating

or cooling operation, the thermostat will terminate the

cooling cycle in the event ice forms on the evaporator coil,

in this case the thermostat functions as a de-ice control. A

resistor (anticipator) is positioned within a plastic block to

supply a small amount of heat to the bulb area to prevent

long “off cycles” in the “Cool-Fan Auto” (MoneySaver)

position. A current feedback through the fan motor windings

during “off cycle” completes the circuit to the resistor.

THERMOSTAT (“EQ08” Models)

(See Figure 17)

This thermostat is single pole-double throw, cross ambient

with a range of 60° to 92°F and a differential of ±2°F. Terminal

“2” is common.

Figure 17

Thermostat

(EQ Model)

Figure 18

Thermostat

In the heating cycle, the heat anticipator is energized to

supply a small amount of heat during the “on” cycle. This

will open the contacts in the thermostat prematurely to

maintain a closer differential between the “cut in” and “cut

out” temperature. The heat anticipator is energized in the

heating mode regardless of whether fan is placed in the

automatic (MoneySaver) or constant run position.

RANGE: Thermostat Properties

60°F (±2°) to 92°F (±2°)

TEST:

Cooling/Heating Models: Remove wires from thermostat

and check continuity between terminal “2

” (common) and

“3” for cooling. Check between terminals “2” (common)

and “1” for heating. Also check that contacts in thermostat

open after placing in either position. NOTE: Temperature

must be within range listed to check thermostat. Refer to

the troubleshooting section in this manual for additional

information on thermostat testing.

THERMOSTAT ADJUSTMENT

No attempt should be made to adjust thermostat. Due

to the sensitivity of the internal mechanism and the

sophisticated equipment required to check the calibration,

it is suggested that the thermostat be replaced rather than

calibrated. Thermostat bulb must be straight to insure

proper performance.

THERMOSTAT BULB LOCATION

The position of the bulb is important in order for the

thermostat to function properly. The bulb of the thermostat

should be located approximately 45° to a maximum of 60°

from horizontal. Also, do not allow the thermostat bulb to

touch the evaporator coil. (See Figures 17 and 18)

Thermostat sensor holder 020

to be positioned between the

4th and 5th and 6th and 7th

rows of tubes from the bottom

of the coil at dimension shown

Figure 19

Thermostat Bulb Location

(EQ Model)

WARNING

ELECTRIC SHOCK HAZARD

Disconnect power to the unit before

servicing. Failure to follow this warning

could result in serious injury or death.

21

Page 24

COMPONENTS TESTING (Continued)

DEFROST THERMOSTAT (Heat Pump Models Only)

(See Figure 21)

This thermostat is single pole - double throw with contacts

between terminals “2” and “3” closing on temperature rise

and contacts between terminals “2” and “1” closing on

temperature fall. When the contacts between terminals “2”

and “1” make, power is supplied to the heater element.

This control is dual purpose control that acts as an outdoor

thermostat and defrost control.

When the sensing bulb, attached to the outdoor coil,

senses enough icing on the outdoor coil, it will interrupt

power to the compressor and supply power to the heating

element until the coil temperature reaches above 43°, then

the heater will shut off and the unit will resume operating in

the reverse cycle mode.

When the outdoor coil temperature drops below 20°, the

unit will operate in electric heat mode continuously until the

outdoor coil temperature rises above 43°.

The fan motor will not turn off when defrost occurs, and the

4-way valve will not reverse.

Figure 21

Defrost Thermostat

(Heat Pump Models)

DEFROST BULB LOCATION (Heat Pump Models

Only) (See Figure 22)

The defrost control bulb must be mounted securely and in

the correct location to operate properly.

RESISTOR: Heat Anticipator (See Figure 20)

Failure of the resistor will cause prolonged “off” and “on”

cycles of the unit. When replacing a resistor, be sure and use

the exact replacement. Resistor ratings are as follows:

115 Volt - 5,000 ohms 3 watt

230 Volt - 20,000 ohms 3 watt

Figure 20

Resistor

Slide the bulb

end of the

thermostat

defrost under

the retainer as

shown

Retainer

Figure 22

Defrost Thermostat Bulb

Location (All Heat Pump Models)

ELECTRIC SHOCK HAZARD

WARNING

Disconnect power to the unit before

servicing. Failure to follow this warning

could result in serious injury or death.

22

Page 25

FAN MOTOR - TEST

1. Determine that capacitor is serviceable.

2. Disconnect fan motor wires from fan speed switch or

system switch.

3. Apply “live” test cord probes on black wire and common

terminal of capacitor. Motor should run at high speed.

4. Apply “live” test cord probes on red wire and common

terminal of capacitor. Motor should run at low speed.

5. Apply “live” test cord probes on each of the remaining

wires from the speed switch or system switch to test

intermediate speeds. If the control is in the “MoneySaver”

mode and the thermostat calls for cooling, the fan will

start - then stop after approximately 2 minutes; then the

fan and compressor will start together approximately 2

minutes later.

Figure 23

Fan Motor

FAN MOTOR

A single phase permanent split capacitor motor is used to drive

the evaporator blower and condenser fan. A self-resetting

overload is located inside the motor to protect against high

temperature and high amperage conditions. (See Figure 23)

ELECTRIC SHOCK HAZARD

WARNING

Disconnect power to the unit before

servicing. Failure to follow this warning

could result in serious injury or death.

COMPONENTS TESTING (Continued)

Many motor capacitors are internally fused. Shorting the

terminals will blow the fuse, ruining the capacitor. A 20,000

ohm 2 watt resistor can be used to discharge capacitors

safely. Remove wires from capacitor and place resistor

across terminals. When checking a dual capacitor with

a capacitor analyzer or ohmmeter, both sides must be

tested.

Capacitor Check with Capacitor Analyzer

The capacitor analyzer will show whether the capacitor is

“open” or “shorted.” It will tell whether the capacitor is within

its micro farads rating and it will show whether the capacitor

is operating at the proper power-factor percentage. The

instrument will automatically discharge the capacitor when

the test switch is released.

Capacitor Connections

The starting winding of a motor can be damaged by a

shorted and grounded running capacitor. This damage

usually can be avoided by proper connection of the running

capacitor terminals.

From the supply line on a typical 230 volt circuit, a 115 volt

potential exists from the “R” terminal to ground through a

possible short in the capacitor. However, from the “S” or

start terminal, a much higher potential, possibly as high as

400 volts, exists because of the counter EMF generated

in the start winding. Therefore, the possibility of capacitor

failure is much greater when the identied terminal is

connected to the “S” or start terminal. The identied

terminal should always be connected to the supply line, or

“R” terminal, never to the “S” terminal.

When connected properly, a shorted or grounded running

capacitor will result in a direct short to ground from the “R”

terminal and will blow the line fuse. The motor protector

will protect the main winding from excessive temperature.

CAPACITORS

23

ELECTRIC SHOCK HAZARD

Turn off electric power before servicing.

Discharge capacitor with a 20,000 Ohm 2 Watt

resistor before handling.

Failure to do so may result in personal injury,

or death.

WARNING

Dual Rated Run Capacitor Hook-up

FIGURE 24

Page 26

COMPONENTS TESTING (Continued)

HEATING ELEMENT (See Figure 25)

All heat pumps and electric heat models are equipped with

a heating element with the exception of models starting

with YS09. The “YS” and “ES” models are equipped with a

3.3 KW element. The “YM” and “EM” models are equipped

with a 4.0 KW element. The “YL” and “EL” models are

equipped with a 5.2 KW element. The EQ08 has a 1.15

KW element.

Figure 25

Heating Element