Page 1

Product Profile

All models use

environmentally

friendly R-410A

refrigerant.

R-410A

Packaged Terminal Air Conditioners

COOL ONLY | HEAT PUMPS | ELECTRIC HEAT

Over 40 standard features

Exceptional energy efciency

Diamonblue anticorrosion treatment

Digital temperature display

Rated quietest by hotel guests

One touch operation

Quiet start/stop fan delay

Internal diagnostic program

www.friedrich.com

Remote control operation

Remote thermostat operation

Desk control ready

Ultraquiet air system

Antimicrobial air lters

Fits most ptac sleeves

5 Year limited warranty

Ships individually palletized

Q UA L IT Y

Page 2

Digital Control Features

Digital temperature

reaDout

one-touch

operation

remote control

operation

inDiviDual moDe

& Fan control

Buttons

Quiet start/stop

Fan Del ay

remote thermostat

operation

Room temperature is digitally monitored, providing for more precise control than conventional systems.

The large, easy-to-read LED display can show either set-point or actual room temperature as selected

by owner.

When the unit is powered off, the unit can be returned directly to heating or cooling mode by pressing the

‘Heat’ or ‘Cool’ buttons without the confusing power up sequence of some controls. One-touch control

takes guesswork out of unit control, delivering a more enjoyable experience and eliminating front-desk

calls.

All 2008 “D” model and later PTAC units can be controlled by a wireless hand held remote control. The

remote control places all of the controls of the PTAC unit conveniently in the palm of your guest’s hands.

The remote can operate from distances up to 25 feet away. The remote is sold seperately as accessory

PDXRC.

By having separate control buttons and indicators for both fan and mode settings, the Friedrich digital

control eliminates the confusion of previous digital PTACs. The accurate temperature setting provides

greater guest comfort than other systems.

The fan start and stop delays prevent abrupt changes in room acoustics due to the compressor energiz-

ing or stopping immediately. Upon call for cooling or heating, the unit fan will run for ve seconds prior to

energizing the compressor. Also, the fan off delay allows for “free cooling” by utilizing the already cool

indoor coil to its maximum capacity by running for 30 seconds after the compressor.

Some applications require the use of a wall-mounted thermostat. All new Friedrich PTACs may be

switched from unit control to remote thermostat control easily without the need to order a special model

or accessory kit.

internal Diagnostic

program

service error coDe

storage

constant comFort

room monitoring

electronic

temper ature

limiting

room Freeze

protection

The new Friedrich digital PTAC features a self diagnostic program that can alert maintenance to compo-

nent failures or operating problems. The internal diagnostic program saves properties valuable time when

diagnosing running problems.

The self diagnosis program will also store error codes in memory if certain conditions occur and correct

themselves such as extreme high or low operating conditions or activation of the room freeze protection

feature. Storing error codes can help properties determine if the unit faced obscure conditions or if an

error occurred and corrected itself.

The on-board processor monitors time between demand cycles (heat or cool) and will cycle the fan every

9 minutes to sample the room condition and determine if the desired conditions are met. This allows the

room to have similar benets to a remote mounted thermostat without the complication or cost of a wall-

mounted thermostat.

By limiting the operating range, the prop er ty can save energy by eliminating “max cool” or “max heat” situ ations common with older uncontrolled systems. The new electronic control allows owners to set operating ranges for both heating and cooling independently of one another.

When the PTAC senses that the indoor room temperature has fallen to 40°F, the unit will cycle on the

fan (high) and the electric strip heat to raise the room temperature to 46

feature works regardless of the mode selected and can be turned off. The control will also store the Room

Freeze cycle in the service code memory for retrieval at a later date. This feature ensures that unoccupied

rooms do not reach freezing levels where damage can occur to plumbing and xtures.

°

F, and then cycle off again. This

ranDom compressor

restart

2

Multiple compressors starting at once can often cause electrical overloads and premature unit failure.

The random restart delay eliminates multiple units from starting at once following a power outage or initial

power up. The compressor delay will range from 180 to 240 seconds.

Page 3

General Product Features

DiamonBlue

corrosion

protection

Digital DeFrost

thermostat

instant heat

heat pump moDe

even heat monitoring

Fan cycle

control

emergency

heat overriDe

Desk control

reaDy

inDoor coil

Frost sensor

Diamonblue corrosion protection comes standard on all models. Diamonblue protects the outdoor coil

against deterioration, and extends the life of the unit.

The new Friedrich PTAC uses a digital thermostat to accurately monitor the outdoor coil conditions to al-

low the heat pump to run whenever conditions are correct. Running the PTAC in heat pump mode saves

energy and reduces operating costs. The digital thermostat allows maximization of heat pump run time.

Heat pump models will automatically run the electric heater to quickly bring the room up to temperature

when initially energized, then return to heat pump mode. This ensures that the room is brought up to

temperature quickly without the usual delay associated with heat pump units.

The digital control monitors indoor conditions to ensure that the room temperature is within ve degrees

of the setpoint. If necessary, the unit will cycle the electric heat to maintain the temperature. This feature

ensures guest comfort by delivering the heating benets of an electric heater while maintaining the ef-

ciency benets of a heat pump.

The owner may choose between fan cycling or fan continuous mode based on property preference.

(Note: Even heat monitoring and quiet start /stop fan delay only operate in fan cycle mode) Fan continuous mode constantly circulates the air while the unit is ‘ON’. Fan cycle will conserve energy by only

operating the fan while the compressor or electric heater is operating.

In the event of a compressor failure in heat pump mode, the compressor may be locked out to provide

heat through the resistance heater. This feature ensures that even in the unlikely event of a compressor

failure, the room temperature can be maintained until the compressor can be serviced.

All Friedrich digital PTACs have low voltage terminals ready to connect a desk control energy manage-

ment system. Controlling the unit from a remote location like the front desk can reduce energy usage and

requires no additional accessories on the PTAC unit.

The frost sensor protects the compressor from damage in the event that airow is reduced or low outdoor

temperatures cause the indoor coil to freeze. When the indoor coil reaches 30°F, the compressor is

disabled and the fan continues to operate based on demand. Once the coil temperature returns to 45°F,

the compressor returns to operation.

ultraQuiet

air system

high eFFiciency

single motor

rotary compressor

auxiliary Fan reaDy

aluminum enDplates

top-mounteD

antimicroBial

air Filters

FiltereD Fresh

air intake

r-410a reFriger ant

Friedrich PD series units feature an indoor fan system design that reduces sound levels without lowering

airow or preventing proper air circulation.

The Friedrich PTAC has been engineered so that all functional systems are optimized so that they work

together to deliver the highest possible performance.

Friedrich’s single-motor design allows for enhanced outdoor airow and simplies the unit design without the need for redundant components.

High efciency rotary compressors are used on all Friedrich PTACs to maximize durability and ef-

ci ency.

The Friedrich PTAC features a 24V AC terminal for connection to an auxiliary fan that may be used to

transfer air to adjoining rooms. Auxiliar y fans can provide conditioning to multiple rooms without the

need for multiple PTAC units.

All Friedrich PTACs are built with .04" endplates made from aluminum as opposed to steel. The end-

plates are typically the most susceptible area for corrosion and aluminum is far more resistant to corro-

sion than even-coated steel.

All Friedrich PTAC return air lters feature an antimicrobial element that has proven to prevent mold and

bacterial growth in laboratory testing. PDXFT replacement lter kits feature the same antimicrobial agent.

All lters are washable, reusable and easily accessed from the top of the unit without the removal of the

front cover.

Friedrich PTAC units are capable of introducing up to 70 CFM of outside air into the conditioned space.

The outdoor air passes through a washable mesh lter to prevent debris from entering the airstream.

Friedrich PTAC units use environmentally-friendly refrigerant.

3

Page 4

Chassis Specications

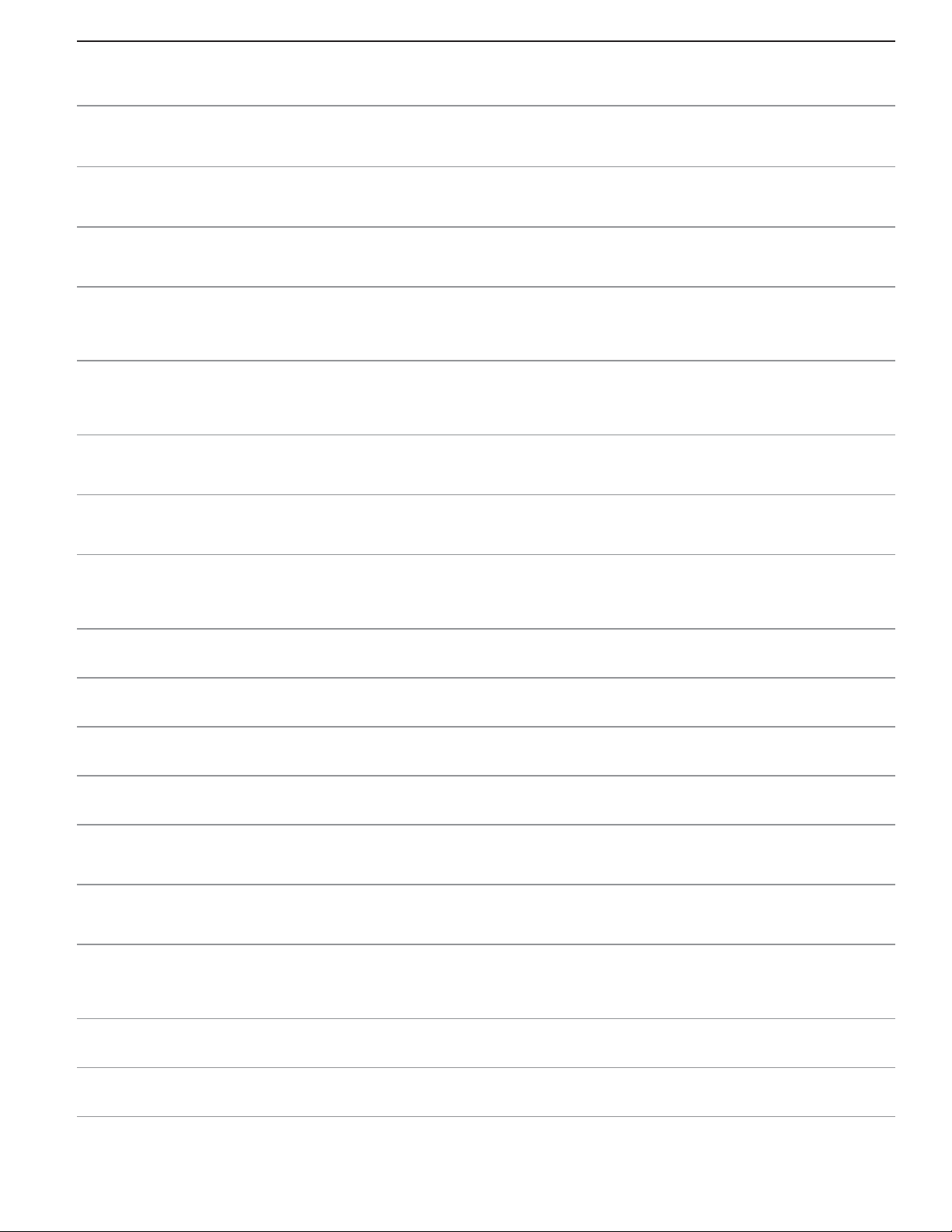

PDE SERIES CHASSIS SPECIFICATIONS

MODEL PDE07K PDE07R PDE09K PDE09R PDE12K PDE12R PDE15K PDE15R

PERFORMANCE DATA:

COOLING BTUh 7500/7300 7500 9000/8800 9000 11500/11300 11500 14000/13800 14000

POWER (WATTS) 647/629 658 789/772 818 1127/1108 1139 1505/1484 1505

EER 11.6 11.4 11.4 11.0 10.2 10.1 9.3 9.3

DEHUMIDIFICATION (pints/hr) 1.7 1.6 3.4 3.3 2.9 2.8 3.8 3.8

SENSIBLE HEAT RATIO 0.77 0.76 0.71 0.79 0.71 0.72 0.68 0.68

ELECTRICAL DATA:

VOLTAGE (1 PHASE, 60 Hz) 230/208 265 230/208 265 230/208 265 230/208 265

VOLT RANGE 253-198 292-239 253-198 292-239 253-198 292-239 253-198 292-239

CURRENT (AMPS) 3.3/3.4 2.9 3.6/3.9 3.3 5.5/5.8 4.6 7.0/7.4 6.4

POWER FACTOR 0.98 0.95 0.97 0.94 0.98 0.97 0.95 0.95

AMPS L.R. 13.0 15.0 19.8 16.8 27.0 23.0 32.0 27.0

AMPS F.L. 2.9 2.6 3.7 3.2 5.0 4.0 6.3 5.6

HORSEPOWER 0.625 0.625 0.75 0.75 1.0 1.0 1.1 1.1

AIRFLOW DATA:

INDOOR CFM, HIGH 220 245 220 210 325 315 310 340

INDOOR CFM, LOW 200 200 200 200 260 260 280 280

VENT CFM 60 60 60 60 70 70 70 70

PHYSICAL DATA:

DIMENSIONS 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5

NET WEIGHT 105 105 112 112 120 120 125 125

SHIPPING WEIGHT 125 125 132 132 140 140 145 145

R-410A CHARGE (oz) 42 35 36 35 33 35 48 42

PDH SERIES CHASSIS SPECIFICATIONS

MODEL PDH07K PDH07R PDH09K PDH09R PDH12K PDH12R PDH15K PDH15R

PERFORMANCE DATA:

COOLING BTUh 7300/7100 7200 8500/8300 8500 11500/11300 12000 14000/13800 14000

POWER (WATTS) cool 658/640 649 787/769 810 1173/1153 1237 1522/1500 1522

EER 11.1 11.1 10.8 10.5 9.8 9.7 9.2 9.2

REVERSE HEATING BTUh 6400 6300 8000 7700 10500 10500 12800 12800

POWER (WATTS) HEAT 625 615 781 752 1025 1025 1250 1250

COP 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3

DEHUMIDIFICATION (pints/hr) 1.3 1.3 1.9 2.1 2.8 2.9 3.6 3.7

SENSIBLE HEAT RATIO 0.78 0.78 0.73 0.71 0.72 0.72 0.7 0.72

ELECTRICAL DATA:

VOLTAGE (1 PHASE, 60 Hz) 230/208 265 230/208 265 230/208 265 230/208 265

VOLT RANGE 253-198 292-239 253-198 292-239 253-198 292-239 253-198 292-239

CURRENT (AMPS) 3.2/3.3 2.8 3.6/3.9 3.3 5.4/5.7 5.2 6.7/7.3 6.3

REVERSE HEAT. Amps 2.7/2.8 2.6 4.3/4.5 3.0 4.4/4.7 4.4 6.2/6.5 5.6

POWER FACTOR 0.98 0.97 0.97 0.95 0.97 0.97 0.96 0.95

AMPS L.R. 13.0 15.0 19.8 16.8 27.00 23.0 32.0 27.0

AMPS F.L. 2.9 2.6 3.7 3.2 5.0 4.5 6.3 5.6

HORSEPOWER 0.625 0.625 0.75 0.75 1.0 1.0 1.1 1.1

AIRFLOW DATA:

INDOOR CFM, HIGH 210 240 220 210 320 310 315 330

INDOOR CFM, LOW 200 200 200 200 260 260 280 280

VENT CFM 60 60 60 60 70 70 70 70

PHYSICAL DATA:

DIMENSIONS 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5

NET WEIGHT 105 105 112 112 120 120 125 125

SHIPPING WEIGHT 125 125 132 132 140 140 145 145

R-410A CHARGE (oz) 37 37

37 33 41 40 39 42

250 V Receptacles and Fuse Types

AMPS 15 20 30

HEATER SIZE 0, 2.5 kW 3.4 kW 5.0 kW

RECEPTACLE

4

Page 5

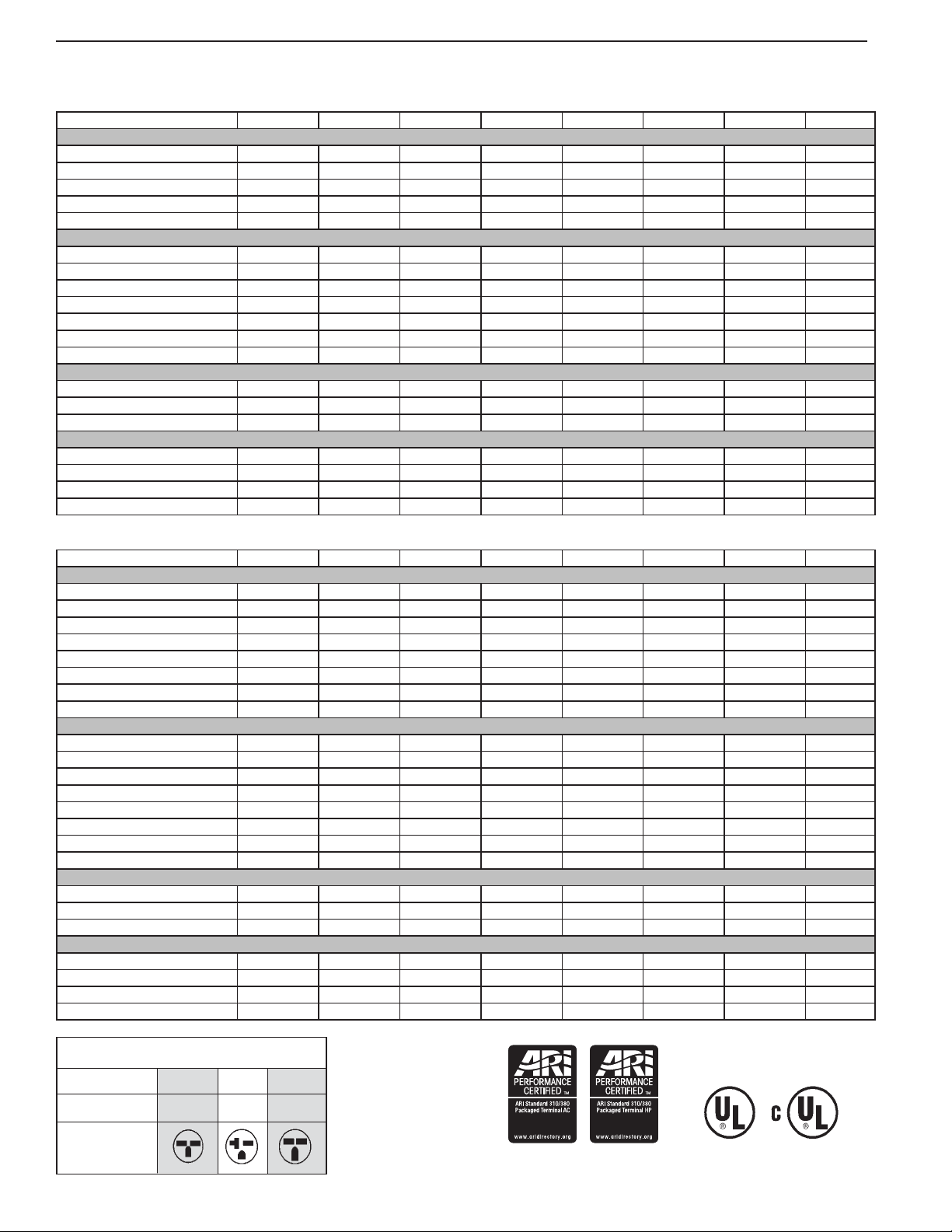

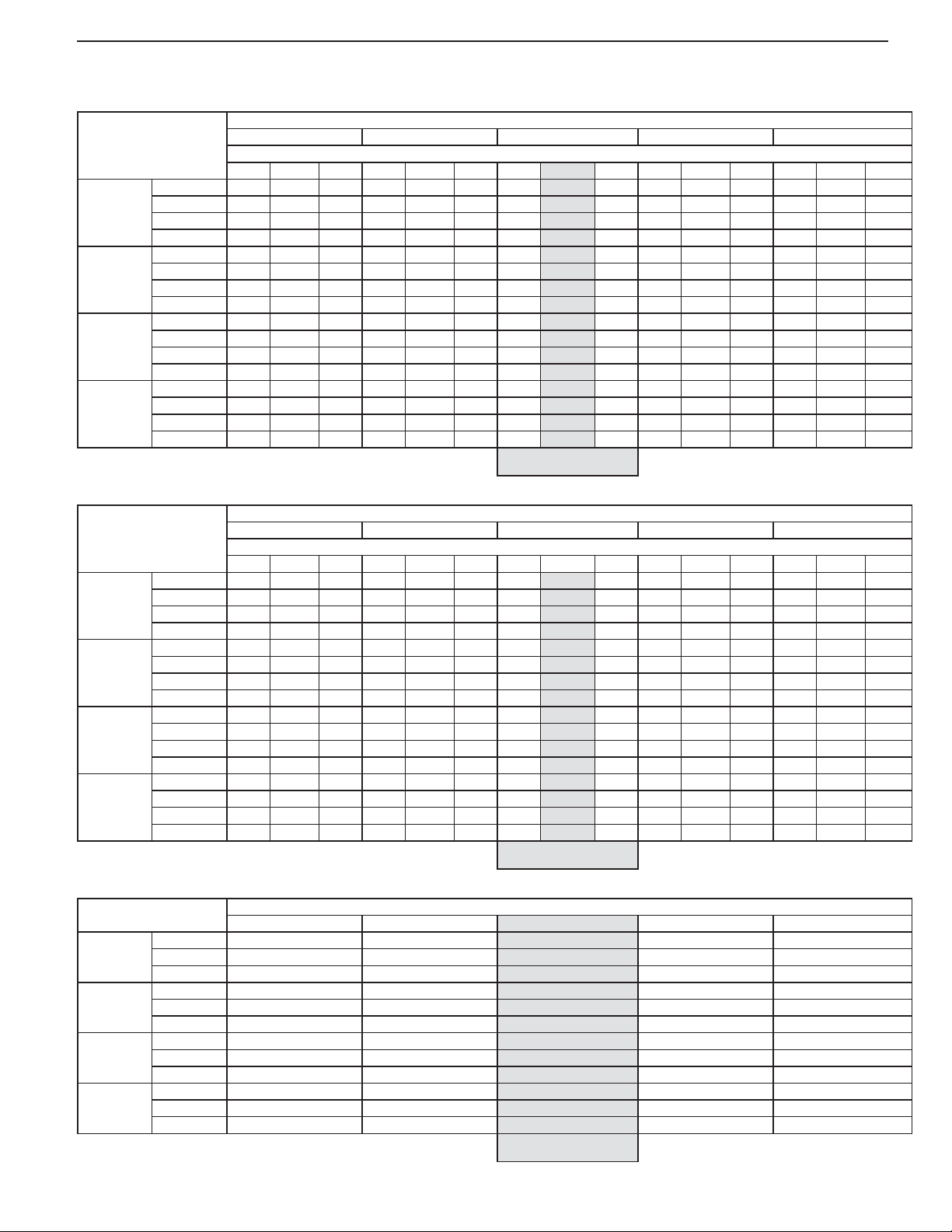

Cooling & Heating Performance

PDE 230V - EXTENDED COOLING PERFORMANCE

75 85 95 105 110

72 67 62 72 67 62 72 67 62 72 67 62 72 67 62

BTUh 8820 8483 7853 8400 7920 7305 8070 7500 6638 7560 6713 5918 6728 5790 5115

PDE07

PDE09

PDE12

PDE15

PDH 230V - EXTENDED COOLING PERFORMANCE

PDH07

PDH09

PDH12

PDH15

EXTENDED HEATING PERFORMANCE

PDH07

PDH09

PDH12

PDH15

WATTS 528 536 542 575 581 588 647 647 647 699 699 701 763 763 766

AMPS 2.7 2.7 2.8 2.9 3.0 3.0 3.3 3.30 3.3 3.6 3.6 3.6 3.9 3.9 3.9

SHR 0.53 0.72 0.96 0.54 0.74 0.98 0.54 0.77 0.99 0.55 0.81 0.99 0.58 0.87 0.99

BTUh 10584 10179 9423 10080 9504 8766 9684 9000 7965 9072 8055 7101 8073 6948 6138

WATTS 644 654 661 701 709 717 789 789 789 853 852 854 930 930 934

AMPS 3.0 3.0 3.0 3.2 3.2 3.2 3.6 3.60 3.6 3.9 3.9 3.9 4.2 4.2 4.2

SHR 0.49 0.66 0.89 0.5 0.69 0.91 0.5 0.71 0.91 0.51 0.75 0.92 0.54 0.8 0.91

BTUh 13524 13007 12041 12880 12144 11201 12374 11500 10178 11592 10293 9074 10316 8878 7843

WATTS 920 934 944 1002 1012 1024 1127 1127 1127 1218 1217 1221 1329 1329 1334

AMPS 4.6 4.6 4.6 4.9 4.9 5.0 5.5 5.50 5.5 5.9 5.9 5.9 6.5 6.5 6.5

SHR 0.49 0.66 0.89 0.5 0.69 0.91 0.5 0.71 0.91 0.51 0.75 0.92 0.54 0.8 0.91

BTUh 16464 15834 14658 15680 14784 13636 15064 14000 12390 14112 12530 11046 12558 10808 9548

WATTS 1228 1248 1261 1338 1351 1368 1505 1505 1505 1627 1625 1630 1774 1774 1782

AMPS 5.8 5.8 5.9 6.2 6.3 6.3 7.0 7.00 7.0 7.5 7.5 7.6 8.2 8.2 8.2

SHR 0.47 0.63 0.85 0.48 0.66 0.87 0.48 0.68 0.87 0.49 0.72 0.88 0.51 0.77 0.87

75 85 95 105 110

72 67 62 72 67 62 72 62 72 67 62 72 67 62

BTUh 8585 8256 7643 8176 7709 7110 7855 7300 6461 7358 6534 5760 6548 5636 4979

WATTS 537 545 551 585 591 598 658 658 658 711 711 713 776 776 779

AMPS 2.6 2.7 2.7 2.9 2.9 2.9 3.2 3.20 3.2 3.4 3.4 3.5 3.8 3.8 3.8

SHR 0.53 0.73 0.98 0.55 0.75 1.00 0.55 0.78 1.00 0.56 0.82 1.01 0.59 0.88 1.00

BTUh 9996 9614 8900 9520 8976 8279 9146 8500 7523 8568 7608 6707 7625 6562 5797

WATTS 642 652 660 700 707 715 787 787

AMPS 3.0 3.0 3.0 3.2 3.2 3.2 3.6 3.60 3.6 3.9 3.9 3.9 4.2 4.2 4.2

SHR 0.5 0.68 0.91 0.51 0.71 0.93 0.51 0.73 0.94 0.53 0.77 0.94 0.55 0.82 0.93

BTUh 13524 13007 12041 12880 12144 11201 12374 11500 10178 11592 10293 9074 10316 8878 7843

WATTS 957 972 983 1043 1053 1066 1173 1173 1173 1268 1267 1270 1383 1383 1389

AMPS 4.5 4.5 4.5 4.8 4.8 4.9 5.4 5.40 5.4 5.8 5.8 5.8 6.3 6.3 6.4

SHR 0.49 0.67 0.9 0.5 0.7 0.92 0.51 0.72 0.92 0.52 0.76 0.93 0.54 0.81 0.92

BTUh 16464 15834 14658 15680 14784 13636 15064 14000 12390 14112 12530 11046 12558 10808 9548

WATTS 1242 1262 1275 1353 1367 1383 1522 1522 1522 1645 1644 1648 1794 1794 1802

AMPS 5.5 5.6 5.6 6.0 6.0 6.0 6.7 6.7 6.7 7.2 7.2 7.2 7.9 7.9 7.9

SHR 0.48 0.65 0.88 0.49 0.68 0.89 0.49 0.70 0.90 0.50 0.74 0.90 0.53 0.79 0.9

37 42 47 52 57

BTUh 5333 5628 6400 7009 7741

WATTS 589 600 625 635 671

AMPS 2.6 2.8 2.75 2.9 3

BTUh 5930 6320 8000 8540 9130

WATTS 701 712 781 786 797

AMPS 3.8 3.8 3.9 3.9 4

BTUh 7582 8372 10500 11067 12006

WATTS 896 931 1025 1055 1089

AMPS 4.2 4.3 4.7 4.9 5.1

BTUh 10134 10442 12800 14003 15341

WATTS 1151 1166 1250 1324 1384

AMPS 5.7 5.8 6.3 6.6 6.9

OUTDOOR DRY BULB TEMP. (DEGREES F AT 40% R.H.)

INDOOR WET BULB TEMP. (DEGREES F AT 80 F D.B.)

RATING POINT

ARI 310/380

OUTDOOR DRY BULB TEMP. (DEGREES F AT 40% R.H.)

INDOOR WET BULB TEMP. (DEGREES F AT 80 F D.B.)

787 851 850 852 928 928 932

RATING POINT

ARI 310/380

OUTDOOR DRY BULB TEMP. (DEGREES F)

RATING POINT

ARI 310/380

5

Page 6

Cooling & Heating Performance

PDE 265V - Extended Cooling Performance

75 85 95 105 110

72 67 62 72 67 62 72 67 62 72 67 62 72 67 62

BTUh 8820 8483 7853 8400 7920 7305 8070 7500 6638 7560 6713 5918 6728 5790 5115

PDE07

PDE09

PDE12

PDE15

PDH 265V - Extended Cooling Performance

WATTS 537 545 551 585 591 598 658 658 658 711 711 713 776 776 779

AMPS 2.4 2.4 2.4 2.6 2.6 2.6 2.9 2.90 2.9 3.1 3.1 3.1 3.4 3.4 3.4

SHR 0.52 0.71 0.95 0.53 0.73 0.97 0.53 0.76 0.98 0.55 0.8 0.98 0.57 0.86 0.97

BTUh 10584 10179 9423 10080 9504 8766 9684 9000 7965 9072 8055 7101 8073 6948 6138

WATTS 667 678 685 727 735 744 818 818 818 884 883 886 964 964 969

AMPS 2.7 2.7 2.8 2.9 3.0 3.0 3.3 3.30 3.3 3.6 3.6 3.6 3.9 3.9 3.9

SHR 0.54 0.74 0.99 0.55 0.76 1.01 0.56 0.79 1.01 0.57 0.83 1.02 0.6 0.89 1.01

BTUh 13524 13007 12041 12880 12144 11201 12374 11500 10178 11592 10293 9074 10316 8878 7843

WATTS 929 944 954 1013 1023 1035 1139 1139 1139 1231 1230 1234 1343 1343 1349

AMPS 3.8 3.8 3.9 4.1 4.1 4.1 4.6 4.60 4.6 4.9 4.9 5.0 5.4 5.4 5.4

SHR 0.49 0.67 0.90 0.50 0.70 0.92 0.51 0.72 0.92 0.52 0.76 0.93 0.54 0.81 0.92

BTUh 16464 15834 14658 15680 14784 13636 15064 14000 12390 14112 12530 11046 12558 10808 9548

WATTS 1228 1248 1261 1338 1351 1368 1505 1505 1505 1627 1625 1630 1774 1774 1782

AMPS 5.3 5.3 5.4 5.7 5.7 5.8 6.4 6.40 6.4 6.9 6.9 6.9 7.5 7.5 7.5

SHR 0.47 0.63 0.85 0.48 0.66 0.87 0.48 0.68 0.87 0.49 0.72 0.88 0.51 0.77 0.87

OUTDOOR DRY BULB TEMP. (DEGREES F AT 40% R.H.)

INDOOR WET BULB TEMP. (DEGREES F AT 80 F D.B.)

RATING POINT

ARI 310/380

75 85 95 105 110

72 67 62 72 67 62 72 67 62 72 67 62 72 67 62

BTUh 8467 8143 7538 8064 7603 7013 7747 7200 6372 7258 6444 5681 6458 5558 4910

PDH07

PDH09

PDH12

PDH15

WATTS 530 538 544 577 583 590 649 649 649 702 701 703 765 765 768

AMPS 2.3 2.3 2.4 2.5 2.5 2.5 2.8 2.80 2.8 3.0 3.0 3.0 3.3 3.3 3.3

SHR 0.53 0.73 0.98 0.55 0.75 1.00 0.55 0.78 1.00 0.56 0.82 1.01 0.59 0.88 1.00

BTUh 9996 9614 8900 9520 8976 8279 9146 8500 7523 8568 7608 6707 7625 6562 5797

WATTS 661 671 679 720 727 736 810 810 810

AMPS 2.7 2.7 2.8 2.9 3.0 3.0 3.3 3.30 3.3 3.6 3.6 3.6 3.9 3.9 3.9

SHR 0.49 0.66 0.89 0.5 0.69 0.91 0.5 0.71 0.91 0.51 0.75 0.92 0.54 0.8 0.91

BTUh 14112 13572 12564 13440 12672 11688 12912 12000 10620 12096 10740 9468 10764 9264 8184

WATTS 1009 1025 1037 1100 1111 1124 1237 1237 1237 1337 1336 1340 1458 1458 1465

AMPS 4.3 4.3 4.4 4.6 4.7 4.7 5.2 5.20 5.2 5.6 5.6 5.6 6.1 6.1 6.1

SHR 0.49 0.67 0.90 0.50 0.70 0.92 0.51 0.72 0.92 0.52 0.76 0.93 0.54 0.81 0.92

BTUh 16464 15834 14658 15680 14784 13636 15064 14000 12390 14112 12530 11046 12558 10808 9548

WATTS 1242 1262 1275 1353 1367 1383 1522 1522 1522 1645 1644 1648 1794 1794 1802

AMPS 5.2 5.2 5.3 5.6 5.6 5.7 6.3 6.3 6.3 6.8 6.8 6.8 7.4 7.4 7.4

SHR 0.49 0.67 0.90 0.50 0.70 0.92 0.51 0.72 0.92 0.52 0.76 0.93 0.54 0.81 0.92

Extended Heating Performance

37 42 47 52 57

BTUh 5250 5540 6300 6900 7620

PDH07

PDH09

PDH12

PDH15

6

WATTS 580 590 615 625 660

AMPS 2.5 2.6 2.6 2.7 2.8

BTUh 5708 6083 7700 8220 8788

WATTS 675 686 752 757 767

AMPS 2.9 2.9 3.0 3.0 3.1

BTUh 7582 8372 10500 11067 12006

WATTS 896 931 1025 1055 1089

AMPS 3.9 4 4.4 4.6 4.8

BTUh 10134 10442 12800 14003 15341

WATTS 1151 1166 1250 1324 1384

AMPS 5.1 5.2 5.6 5.9 6.1

OUTDOOR DRY BULB TEMP. (DEGREES F AT 40% R.H.)

INDOOR WET BULB TEMP. (DEGREES F AT 80 F D.B.)

876 875 877 955 955 959

RATING POINT

ARI 310/380

OUTDOOR DRY BULB TEMP. (DEGREES F)

RATING POINT

ARI 310/380

Page 7

Electric Heat Data

Electric Heat Data

PDE/PDH07K PDE/PDH07R

Heater WATTS 2500/2050 3400/2780 2500 3400

Voltage 230/208 265

Heating BTUh 8500/7000 11600/9500 8500 11600

Heating current (AMPS) 11.4/10.4 15.3/13.9 9.8 13.2

Minimum circuit ampacity 14.1 19.0 12.2 16.4

Brance circuit fuse (AMPS) 15 20 15 20

Electric Heat Data

PDE/PDH09K PDE/PDH09R

Heater WATTS 0 Kw 2500/2050 3400/2780 5000/4090 2500 3400 5000

Voltage 230/208 265

Heating BTUh 0 8500/7000 11600/9500 17000/13900 8500 11600 17000

Heating current (AMPS) 0 11.4/10.4 15.3/13.9 22.3/20.3 9.8 13.2 19.5

Minimum circuit ampacity 5.2 14.1 19 27.8 12.2 16.4 24.2

Brance circuit fuse (AMPS) 15 15 20 30 15 20 30

Electric Heat Data

PDE/PDH12K PDE/PDH12R

Heater WATTS 0 Kw 2500/2050 3400/2780 5000/4090 2500 3400 5000

Voltage 230/208 265

Heating BTUh 0 8500/7000 11600/9500 17000/13900 8500 11600 17000

Heating current (AMPS) 0 11.4/10.4 15.3/13.9 22.3/20.3 9.8 13.2 19.5

Minimum circuit ampacity 7.9 14.1 19 27.8 12.2 16.4 24.2

Brance circuit fuse (AMPS) 15 15 20 30 15 20 30

Electric Heat Data

PDE/PDH15K PDE/PDH15R

Heater WATTS 0 Kw 2500/2050 3400/2780 5000/4090 2500 3400 5000

Voltage 230/208 265

Heating BTUh 0 8500/7000 11600/9500 17000/13900 8500 11600 17000

Heating current (AMPS) 0 11.4/10.4 15.3/13.9 22.3/20.3 9.8 13.2 19.5

Minimum circuit ampacity 8.5 14.1 19 27.8 12.2 16.4 24.2

Brance circuit fuse (AMPS) 15 15 20 30 15 20 30

Due to continuing research in new energy-saving technology, specif ications

are subject to change without notice.

7

Page 8

Model Identication / Components / Dimensions

PTAC/PTHP Model Identication Guide

PD H 07 K 3 S E A

Series

PD = Friedrich Digital PTAC

System

X = Accessory

E = Cooling with or without electric heat

H = Heat Pump with Auxiliary Heat

NOMINAL CAPACITY

07 = 7,000 Btuh

09 = 9,000 Btuh

VO LTAG E

K = 230/208V - 1 Ph. - 60 Hz.

R = 265V - 1 Ph. - 60 Hz.

12 = 12,000 Btuh

15 = 15,000 Btuh

Typical Unit Components and Dimensions

Wall Sleeve

Filters

Engineering Digit

Design Series

Note: All PTAC models with a C design series

or later come standard with Diamonblue

seacoast protection and digital controls.

Chassis

S = Standard

Nominal Heater Size (@ 230V or 265V)

0 = No Heater (only on PDE09 K, PDE12K AND PDE15K)

2 = 2.5 KW * 3 = 3.4 KW 5 = 5.0 KW**

* 2.5 kw only available on 7000, 9 000, and 12000 BTU models

** 5.0 kw only available on 12000 and 15000 BTU models

Outdoor Louver

PDXWS Wall Sleeve Dimensions:

16" H x 42" W x 13 ¾" D

Return Air Grille

Front Cover Dimensions:

16" H x 42" W x 7 ½" D

Cut-Out Dimensions:

16 ¼" x 42 ¼"

Chassis

Front Cover

8

Page 9

Cooling Only, Electric Heat, Heat Pump

All models use

environmentally

friendly R-410A

refrigerant.

R-410A

PURCHASER P.O. # DATE

PROJECT LOCATION

ENGINEER ARCHITECT

SUBMITTED BY FOR APPROVAL FOR REFERENCE

ITEM PLAN DESIGNATION QUANTITY COOLING BTU/H VOLTAGE FRIEDRICH MODEL

Accessories

PTAC

PDXWS Wall Sleeve Qty

PXWE Deep Wall Extension Qty

PXGA Standard Outdoor Louver Qty

PXAA Architectural Louver, clear Qty

PXBG Architectural Louver, beige Qty

PXSC Architectural Louver, color matched Qty

RT4 Digital Thermostat Qty

RT5 Digital Thermostat Qty

PDXRT Remote Thermostat Escutcheon Kit Qty

Features

• Electronictemperaturelimiting

• Constantcomfortroom

monitoring

• Deskcontrolready

• Auxiliaryfanready

• Remotethermostatoperation

• “InstantHeat”heatpumpmode

• Remotecontroloperation

• Evenheatmonitoring

• Randomcompressorrestart

• Highefficiency

• Roomfreezeprotection

• Filteredfreshairintake

• Fancyclecontrol

• Electronicdefrostcontrol

• Shipsindividuallypalletized

• Singlemotordesign

• Serviceerrorcodestorage

• Top-mountedantimicrobialair

filters

• Emergencyheatoverride

• Durabledesign

• Powdercoatpaintprocess

• Aluminumendplates

• Indoorcoilfrostsensor

• DiamonblueTechnology

advancedcorrosion

protection

PDXRC Remote Control Qty

PXDR10 Condensate Drain Kit (pkg/10) Qty

PXSB Sub Base Qty

PXSE T-Series Sleeve Adapter Qty

PXCJ Conduit Kit w/Junction Box Qty

PDXDA Lateral Duct Adapter Qty

PDXDE Lateral Duct Extension Qty

PXPC15/20/30 Sub Base Power Cord Kit Qty

PTAC_SUBMITTAL_10

Standa rd on all model S.

This adv anced corro sion protec tion treatm ent protec ts the

outdoo r coil against d eteriora tion and exte nds the life of

the unit e specially in h arsh coasta l environmen ts.

optional

remote

9

Page 10

Installation

Typical Wall Sleeve Installation (PDXWS)

Lintel Used To Support

Masonry Walls

10" Maximum

42 ¼"

Minimum

Wall Opening

16 ¼"

Electrical

Receptacle

50"Max

Insulation

Electrical

Receptacle

Main Studs

Jack Stud

13 ¾"

LINTEL

Mounting

Screw Holes

No holes are permitted in the top or bottom

of the sleeve. (Exception: PXDR10 Drain

Kit)

Extended Wall Sleeve Installation and Sealant Locations (PXWE)

Wall Sleeve Extension, 42" x 16" Frame,

20-gauge minimum, painted or aluminum

Smooth side of clip on Room side

Note the use of a lintel under the rst course

of bricks above the wall sleeve. Do not use

the wall sleeve as a lintel. The mounting

screw holes shown are to be made by the

installer.

Note: All 230/208V units are manufactured

with a 60" power cord. The receptacle locations above must be followed to ensure

proper connections.

10

Width of Wall

Wall Sleeve

Condensate Drip

Panel (Field Supplied)

Outside

Edge

Bafes

2

9 1/

Condensate

Air

Four

Notches

Sealant inside (4) bottom

corners

IMPORTANT NOTE:

The silicone bead MUST

extend 3" up the side

of the two anges to

prevent condensate from

leaking.

Page 11

Accessory Installation

Internal Drain Kit Location and Installation (PXDR10)

Wall Sleeve

Bottom

Foam Gasket

Mounting Plate

Tube

Screw

Screw

PRIMARY AREA:

Condensation from the

chassis collects in the sleeve

in this area.

The Primar y Area is the

preferred installation location.

PXDR10 DRAIN KIT

1/2" O.D. Tube

Gasket

Mounting Plate

External Drain

When using an external drain system, the

condensate is removed through either of two

drain holes on the back of the wall sleeve.

Select the drain hole which best meets your

drainage situation and install the drain kit. Seal

off the other with a cover plate.

Place the drain tube through the gasket and

the mounting plate with the ange toward the

wall sleeve.

Attach the drain tube assembly to one of the

two drain holes at the rear of the wall sleeve.

The large ange on the mounting plate is

positioned at the bottom of the sleeve facing

toward the sleeve. When the drain tube is

positioned at the desired angle, tighten the

screws.

Back of

wall sleeve

Foam Gasket

Overow Slots

1/2" O.D. Tube

Mounting Plate

Foam Gasket

Cover Plate

Architectural Louver Installation (PXAA)

CAUTION

Bodily injury can be caused by louvers

falling from a building during installation. It is

recommended that a safety line be attached

to the louver and an anchor point inside the

building during installation.

INSTA LL ATION

1. Screw a threaded metal stud into each of the

holes at the four corners of the louver.

2. From inside the building, grasp the louver

at the vertical supports and maneuver the

louver through the wall sleeve. Pull towards

you until the threaded studs are inserted into

the four holes of the wall sleeve.

3. While holding the louver with one hand, start

washers and nuts on each of the four studs.

Tighten the nuts securely.

11

Page 12

HVAC Engineering Specications

Digital Packaged Terminal Air Conditioners & Heat Pumps

Cooling: 7,100 – 14,000 Btuh

Heating: 7,000 – 13,900 Btuh (Heat Pump)

8,500 – 17,000 Btuh (Electric Heat)

Friedrich Models: PDE – Cooling with or without electric heat

PDH – Heat Pump with electric heat

All units shall be factor y assembled, piped, wired and fully charged

with R-410A. All units shall be cer tied in accordance with ARI

Standard 310 for air conditioners and ARI standard 380 for heat

pumps. Units shall be UL listed and carry a UL label. All units shall

be factory run-tested to check operation and be manufactured by

Friedrich or equivalent.

The basic unit shall not exceed 16" high x 42" wide. Overall depth

of the unit from the rear of the Friedrich wall sleeve to the front of

the decorative front cover shall not exceed 21 ¼". The unit shall be

de si gned so th at ro om int ru sion may be as little as 7 ½". Ins talla tions

in walls deeper than 13 ¼" may be accomplished with the use of a

wa ll sle eve exte nsion (PX WE ). Un it sh all d raw i n ambi ent a ir th rough

both sides of an outdoor architectural louver or grille measuring 42"

wide x 16" high and shall exhaust air out middle portion of the louver.

The architectural louver and wall sleeve shall be designed so that the

louver may be installed from the inside of the building.

REFRIGERATION SYSTEM – The refrigeration system shall be

hermetically sealed and consist of a rotary compressor that is externally mounted on vibration isolators no smaller than 1 ¾" dia. x 1 ½"

high; condenser and evaporator coils constructed of copper tubes

and alum in um plate ns; and capillaries as expansion devices. Unit

shall have a fan slinger ring to increase efciency and condensate

disposal and have a drain pan capable of retaining 1 ½ gallons of

condensate. A tertiary condensate removal system shall also be

incorporated for back up and shall overow through the wall sleeve

and to the outside of the building as a safeguard against damage

to the interior room.

AIR HANDLING SECTION – The evaporator and condenser

fans shall be directly driven by a single, totally enclosed, ball

bearing, permanently lubricated split capacitor, “clam-shell" style

fan motor. Airow shall be directed into the room by a single,

injection molded, high-impact polystyrene discharge grille. The

grille shall have openings no larger than

prevent personal injury or damage to the PTAC unit, and will

be reversible to allow air to be directed upward or outward as

determined by the installer.

The chas si s sh all h ave a bui lt-in d ampe r capa ble of prov idin g at l east

60 CFM of fresh air into the conditioned area. A ne mesh screen

shall lter the inc oming fresh air. There must be a provision for lock-

ing the damper closed to ensure a proper seal.

CONTROLS – Covered controls shall be accessible in a compartment at least 9" wide with the controls no deeper than 1 ¼" in the

opening to facilitate easy operation of the unit.

3

/8" high x 3" wide to

The unit must have the following energy saving and convenience

features built-in:

• Quiet start/stop fan delay

• Room freeze protection

• Random compressor restart

• Electronic temperature limiting

• Wireless remote control ready

• Internal diagnostics

The PTAC must also offer the ability to be controlled by a remote

wall-mounted thermostat without additional accessories. Low voltage inputs will include: C (common), R (24V power), Y (cooling), GL

(fan low), GH (fan high), W (heat) and B (reversing valve on PDH

heat pumps only).

The PTAC unit must also be able to be controlled by an optional hand

held wireless remote control. The remote control shall be capable

of all basic control functions of the PTAC including: power on/off,

cooling, heating, fan speed and temperature setting.

Other controls accessible without removal of the chassis shall include

fan cycle switch, fresh air vent control and emergency heat override

switch (heat pump only).

GENERAL CONSTRUCTION – T he wa ll sle eve shall be cons tr ucte d

of 18-gauge Galvanized zinc-coated steel. It shall be prepared by

a process where it is zinc phosphate pretreated and sealed with a

chr oma te r ins e, t hen pow der coated w ith a po lye ste r n ish and oven

cured for durability. The sleeve shall be shipped with a protective

weatherboard and a structural center support, and be insulated for

sound absorption and thermal efciency. The grille or louver shall be

shipped separately and made from stamped or extruded anodized

aluminum. All louvers shall be in the horizontal plane.

The front panel shall lock to the chassis by means of two factory-

supplied thumbscrews to prevent tampering. The front panel will

feature a contoured discharge with no sharp corners. The air lters

shall be reusable and be accessible without removal of the front

cover. The lters will feature an antimicrobial coating to prevent

mold and bacterial growth.

All 265V units shall possess an integral, over-current time-delay

protective device.

CORROSION PROTECTION – The unit shall have a corrosionresistant fan, fan shroud and drain pan for corrosion protection and

to prevent rust on the side of the building below the outdoor louver.

The unit shall feature corrosion resistant materials and nishes to help

prevent deterioration. The outdoor coil shall have Diamonblue cor-

rosion protection consisting of hydrophilic coated ns to prolong the

life of the coil in all applications including seacoast environments.

WARRANTY – The warranty is one year on all parts and 5 years on

the sealed system including compressor, indoor and outdoor coils

and refrigerant tubing.

• Service code storage

• Constant comfort room monitoring

• Instant heat heat pump mode

• Desk control terminals

• Indoor coil frost sensor

• Auxiliary fan control

The unit controls shall feature an LED readout that can display

either room temperature or setpoint temperature. The unit shall

receive input from the SMART CENTER

push buttons labeled: ‘Cool’, ‘Heat’, ‘High Fan’, ‘Low Fan’,

and ‘Power’. When 'Off', the unit may be put directly into cooling

or heating mode by pressing the ‘Cool’ or ‘Heat’ button.

®

control panel through

’, ‘ ’

12

Page 13

Accessories

New Construction Accessories

WALL SLEEVE Galvanized zinc coated steel is prepared in an 11-step

PDXWS

process, then powder coated with a polyester nish and cured in an oven

for exceptional durability. The wall sleeve is insulated for sound absorption

and thermal efciency. 16" High x 42" Wide x 13 ¾" Deep.

PXGA

PXAA

PXBG

PXSC

PXDR10

PXWE

PXSB

GRILLE Standard, stamped aluminium, anodized to resist chalking and

oxidation.

ARCHITECTURAL GRILLES Consist of heavy-gauge 6063-T5 aluminum

alloy:

PXAA– Clear, extruded aluminum

PXBG– Beige acrylic enamel

PXSC– Also available in custom colors.

CONDENSATE DRAIN KIT Attaches to the bottom of the wall sleeve for

internal draining of condensate or to the rear wall sleeve ange for external

draining. Recommended on all units to remove excess condensate. Packaged in quantities of ten.

DEEP WALL SLEEVE EXTENSION A four-inch deep anodized aluminium

extension that attaches to the outside of the wall sleeve when the wall is

greater than 11 inches thick (9 ½" when a subbase is used, 10 inches when

a lateral duct is used). Up to three extensions my be used together.

DECORATIVE SUBBASE Provides unit support for walls less than six

inches thick. Includes leveling legs, side ller panels and mounting brackets

for electrical accessories. Accepts circuit breaker, power disconnect switch,

or conduit kit.

PXAA

RT4

RT5

PDXRT

PDXRC

DIGITAL REMOTE WALL THERMOSTAT Single stage thermostat used on

PTAC units. Hard wired with single speed fan. Direct replacement for RT2.

DIGITAL REMOTE WALL THERMOSTAT Sin gle s tage t hermos tat fe atur es

high/low fan speed switch. Thermostat is hard wired and can be battery

powered or unit powered. Features backlit display and multiple conguration

modes. For use on PD-series Friedrich PTACs and Vert-I-Paks.

REMOTE THERMOSTAT ESCUTCHEON KIT This kit co nt ains ten e scutc heons that can be placed over the factory control buttons when a remote wall

mounted thermostat is used. The escutcheon directs the guest to the wall

thermostat for operation and retains the LED window to display error codes

and diagnostic information.

WIRELESS HAND HELD REMOTE CONTROL This kit contains one

remote control that can be used to operate any 2008 “D” model PTAC or

newer. The remote control can be used to control all user functions of the

PTAC unit including: power on/off, cool/heat/fan mode selection, fan speed

and temperature setpoint. Each kit contains one remote control and a ller

panel for use when the control door is removed.

13

Page 14

Additional Accessories

SLEEVE EXTENSION RETROFIT KIT Galvanized zinc coated

PXSE

PDXDA

steel, 2.4" sleeve extension attached to the room side of the sleeve

to allow for the installation of a PD-Series Friedrich PTAC in a TSeries sleeve.

LATERAL DUCT ADAPTER Attaches to the PTAC/PTHP unit and

provides a transition to direct up to 35% of the total CFM to a secondary

room, either left or right of the unit. Kit includes duct plenum with

discharge grille and internal bafe, adapter and end cap.

PDXDE

PXCJ

PXPC

15/20/30

LATERAL DUCT EXTENSION A thre e- foot insu lat ed pl enum t hat

attaches to the left or right side of the duct adapter. The extension

can be cut to length by the inst aller. Maximum allowable straight

extension is 15 feet.

CONDUIT KIT WITH JUNCTION BOX Hard wire conduit kit with

junction box for 208/230V and 265V units (subbase not required).

Kit includes a means of quick disconnect for easy removal of the

chassis. *Required for 265V installations.

POWER CORD RETROFIT Replaces LCDI power cord on 230V

models when unit is used with a subbase. PXPC15 is used with

15 amp 2.5 kW units. PXPC20 is used with 20 amp 3.4 kW units.

PXPC30 is used with 30 amp 5.0 kW units.

PDXDA

PXPC30

14

Page 15

15

Page 16

Friedrich Air Conditioning Company

P.O. Box 1540

San Antonio, TX 78295

210.357.4400

www.friedrich.com

PD-SERIES

PACKAGED TERMINAL AIR CONDITIONERS

LIMITED WARRANTY

SAVE THIS CERTIFICATE. It gives you specic rights. You may also have other rights which may vary from state to state and province to province.

In the event that your unit needs servicing, contact your nearest authorized service center. If you do not know the nearest service center, ask the company

that installed your unit or contact us - see address and telephone number above. To obtain service and/or warranty parts replacement, you must notify an

authorized FRIEDRICH Air Conditioning Co. service center, distributor, dealer, or contractor of any defect within the applicable warranty period.

When requesting service: please have the model and serial number from your unit readily available.

Unless specied otherwise herein, the following applies:

FRIEDRICH PACKAGED TERMINAL AIR CONDITIONERS AND HEAT PUMPS

LIMITED WARRANTY - FIRST YEAR (Twelve (12) months from the date of installation). Any part found to be defective in the material or workmanship

will be repaired or replaced free of charge by our authorized service center during the normal working hours; and

LIMITED WARRANTY - SECOND THROUGH FIFTH YEAR (Sixty (60) months from the date of installation). ON THE SEALED REFRIGERATION

SYSTEM. Any part of the sealed refrigeration system that is defective in material or workmanship will be repaired or replaced free of charge (excluding

freight charges) by our authorized service center during normal working hours. The sealed refrigeration system consists of the compressor, metering device,

evaporator, condenser, reversing valve, check valve, and the interconnecting tubing.

These warranties apply only while the unit remains at the original site and only to units installed inside the continental United States, Alaska,

Hawaii, Puerto Rico, Mexico and Canada. The warranty applies only if the unit is installed and operated in accordance with the printed instructions

and in compliance with applicable local installation and building codes and good trade practices. For international warranty information, contact

the Friedrich Air Conditioning Company - International Division.

Any defective part to be replaced must be made available to FRIEDRICH in exchange for the replacement part. Reasonable proof must be presented to

establish the date of install, otherwise the beginning date of this certicate will be considered to be our shipment date plus sixty days. Replacement parts can

be new or remanufactured. Replacement parts and labor are only warranted for any unused portion of the unit’s warranty.

We will not be responsible for and the user will pay for:

1. Service calls to:

A) Instruct on unit operation. B) Replace house fuses or correct house wiring. C) Clean or replace air lters. D) Remove the unit from its installed

location when not accessible for service required. E) Correct improper installations.

2. Parts or labor provided by anyone other than an authorized service center.

3. Damage caused by:

A) Accident, abuse, negligence, misuse, riot, re, ood, or acts of God. B) Operating the unit where there is a corrosive atmosphere containing

chlorine, uorine, or any damaging chemicals (other than in a normal residential environment). C) Unauthorized alteration or repair of the unit, which

in turn affects its stability or performance. D) Failing to provide proper maintenance and service. E) Using an incorrect power source. F) Faulty

installation or application of the unit.

We shall not be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of this unit. We have

not made and do not make any representation or warranty of tness for a particular use or purpose and there is no implied condition of tness for

a particular use or purpose. We make no expressed warranties except as stated in this certicate. No one is authorized to change this certicate

or to create for us any other obligation or liability in connection with this unit. Any implied warranties shall last for one year after the original

purchase date. Some states and provinces do not allow limitations on how long an implied warranty or condition lasts, so the above limitations or exclusions

may not apply to you. The provisions of this warranty are in addition to and not a modication of or subtraction from the statutory warranties and other rights

and remedies provided by law.

Performance of Friedrich’s Warranty obligation is limited to one of the following methods:

1. Repair of the unit

2. A refund to the customer for the prorated value of the unit based upon the remaining warranty period of the unit.

The method of fulllment of the warranty obligation is at the sole discretion of Friedrich Air Conditioning.

Providing a replacement unit of equal value3.

In case of any questions regarding the provisions of this warranty, the English version will govern.

PTAC-PP-10

(10-09)

Loading...

Loading...