Page 1

INCREDIBLE!

AMERICA'S BEST AIR CONDITIONER

12.2 EER

PTAC

PRODUCT PROFILE

PACKAGED TERMINAL AIR CONDITIONERS AND HEAT PUMPS

®

WallMaster

7,000 / 9,000 / 12,000 / 15,000 Btu/h

The All-new Friedrich

WallMaster

®

is a perfect fit

for:

New construction in hotels/

motels, medical facilities, assisted

living centers, apartments/condos,

office suites, dormitories and

remodels.

The New WallMaster

into existing 16" x 42" sleeves

more easily than other

manufacturer's PTACs.

®

retrofits

Standard Features

! Ultrahigh efficiency. Up to 12.2 EER.

! Unique component mounting and isolation

provide ultraquiet operation and vibration

dampening.

! Large well spaced control panel with

universal markings and non-removable

controls

! Attractive front cover and tamper resistant

contoured discharge grille blend with any

decor.

! Quiet and efficient rotary compressor

mounted on vibration isolators, with internal

high temperature overload protection.

! Built-in damper allows up to 70 CFM of

fresh air.

! Convenient top-mounted return air filters.

! Available in heat pump or electric heat.

! Front cover fastens to chassis with

thumbscrews hidden from user.

! Emergency heat compressor override

switch on all heat pumps.

! Single, totally enclosed "clam shell" motor

design protects against premature failure.

! Optional seacoast protection for harsh

coastal environments.

! Complete line of accessories.

! Remote thermostat control units are

available.

! Units are rated in accordance with ARI

Standard 310/380.

! Manufactured in the U.S.A.

Page 2

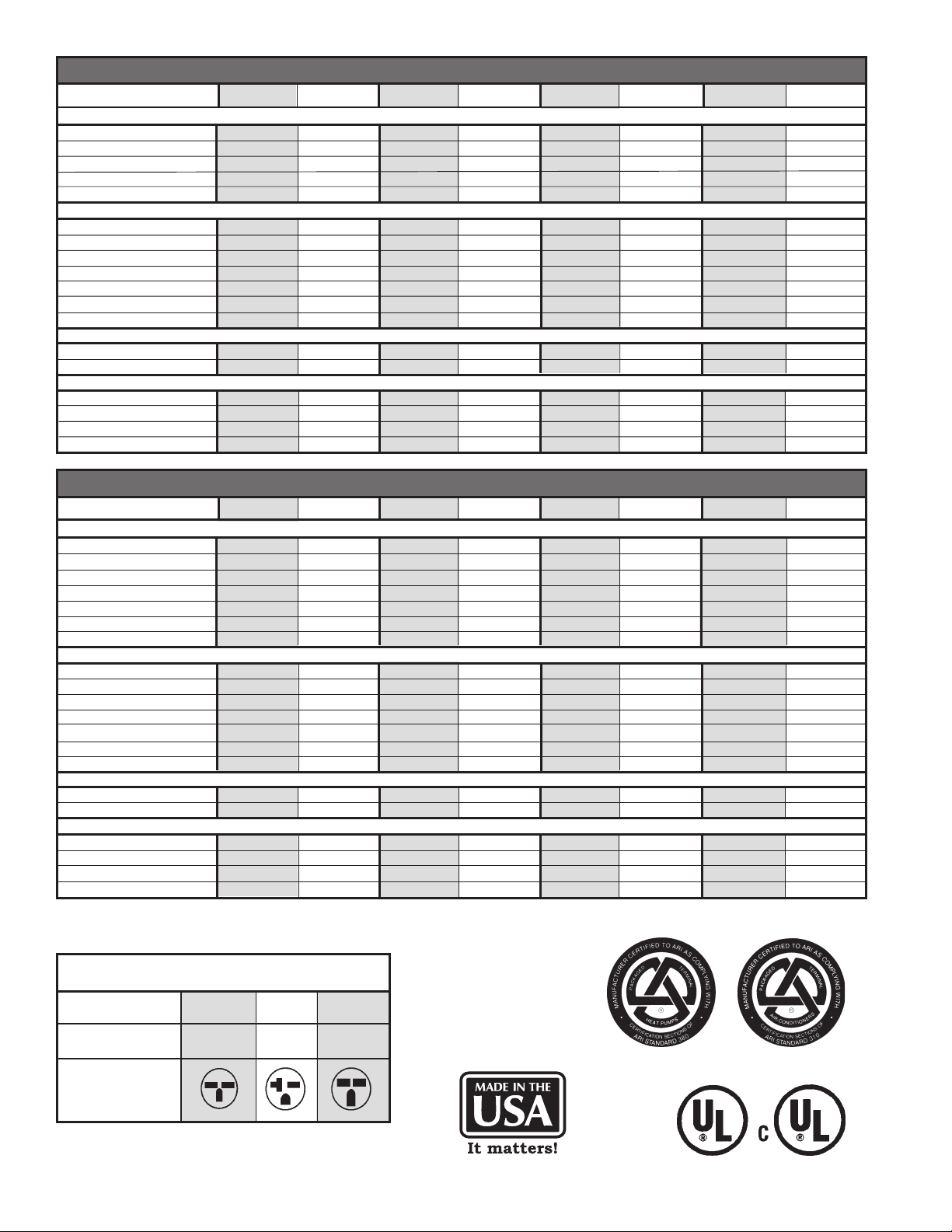

PE Series Chassis Specifications

MODELS: PE07K PE07R PE09K PE09R PE12K PE12R PE15K PE15R

PERFORMANCE DATA:

Cooling Btuh.

Cooling Power (W)

EER

Dehumidification (Pts/h)

Sensible Heat Ratio

ELECTRICAL DATA:

Voltage (1 Ph, 60Hz)

Voltage Range

Current (Amps) (A)

Power Factor

Amps L.R

Amps F.L.

Horsepower

AIRFLOW DATA:

Indoor CFM

Vent CFM

PHYSICAL DATA:

Dimensions (HxWxD) (In.)

Net Weight

Shipping Weight

R-22 Charge

7500/7300

615/598

12.2

2.1

0.76

230/208

253-198

3.0

0.9

18

3

1/15

250

60

16x42x13.75

105

123

27

7500

615

12.2

2.1

0.76

265

292-239

3.0

0.9

18

3

1/15

250

60

16x42x13.75

105

123

27

9200/9000

814/796

11.3

2.7

0.75

230/208

253-198

3.9

0.9

22.2

3.9

1/12

300

60

16x42x13.75

112

130

32

9200

814

11.3

2.7

0.75

265

292-239

3.9

0.9

22.2

3.9

1/12

300

60

16x42x13.75

112

130

32

12000/11800

1091/1073

11.0

3.8

0.72

230/208

253-198

5.1

0.9

26.3

5.1

1/10

325

70

16x42x13.75

120

138

31

12000

1091

11.0

3.8

0.72

265

292-239

5.1

0.9

26.3

5.1

1/10

325

70

16x42x13.75

120

138

31

15000/14800

1579/1578

9.5

5.5

0.72

230/208

253-198

6.6

0.9

38

6.8

1/10

350

70

16x42x13.75

125

143

34

15000

1579

9.5

5.5

0.72

265

292-239

6.6

0.9

38

6.8

1/10

350

70

16x42x13.75

125

143

34

PH Series Chassis Specifications

MODELS: PH07K PH07R PH09K PH09R PH12K PH12R PH15K PH15R

PERFORMANCE DATA:

Cooling Btuh.

Cooling Power (W)

EER

Heating Btuh

COP

Dehumidification (Pts/h)

Sensible Heat Ratio

ELECTRICAL DATA:

Voltage (1 Ph, 60Hz)

Voltage Range

Current (Amps) (A)

Power Factor

Amps L.R

Amps F.L.

Horsepower

AIRFLOW DATA:

Indoor CFM

Vent CFM

PHYSICAL DATA:

Dimensions (HxWxD)(In.)

Net Weight

Shipping Weight

R-22 Charge

7200/7000

595/579

12.1

6400/6200

3.3

2.1

0.76

230/208

253-198

3.0

0.9

18

3

1/15

250

60

16x42x13.75

105

123

27

7200

595

12.1

6400

3.3

2.1

0.76

265

292-239

3.0

0.9

18

3

1/15

250

60

16x42x13.75

105

123

27

9100/8900

805/788

11.3

8100/7900

3.2

2.7

0.75

230/208

253-198

3.9

0.9

22.2

3.9

1/12

300

60

16x42x13.75

112

130

30

9100

805

11.3

8100

3.2

2.7

0.75

265

292-239

3.9

0.9

22.2

3.9

1/12

300

60

16x42x13.75

112

130

30

12000/11800

1121/1103

10.7

10800/10600

3.1

3.8

0.72

230/208

253-198

5.1

0.9

26.3

5.1

1/10

325

70

16x42x13.75

120

138

28

12000

1121

10.7

10800

3.1

3.8

0.72

265

292-239

5.1

0.9

26.3

5.1

1/10

325

70

16x42x13.75

120

138

28

14700/14500

1581/1559

9.3

13500/13300

2.8

5.5

0.72

230/208

253-198

6.6

0.9

38

6.8

1/10

350

70

16x42x13.75

125

143

41

14700

1581

9.3

13500

2.8

5.5

0.72

265

292-239

6.6

0.9

38

6.8

1/10

350

70

16x42x13.75

125

143

41

250 V Receptacles and Fuse Types

AMPS 15 20 30

HEATER SIZE 0, 2.5 kW 3.4 kW 5.0 kW

RECEPTACLE

2

Page 3

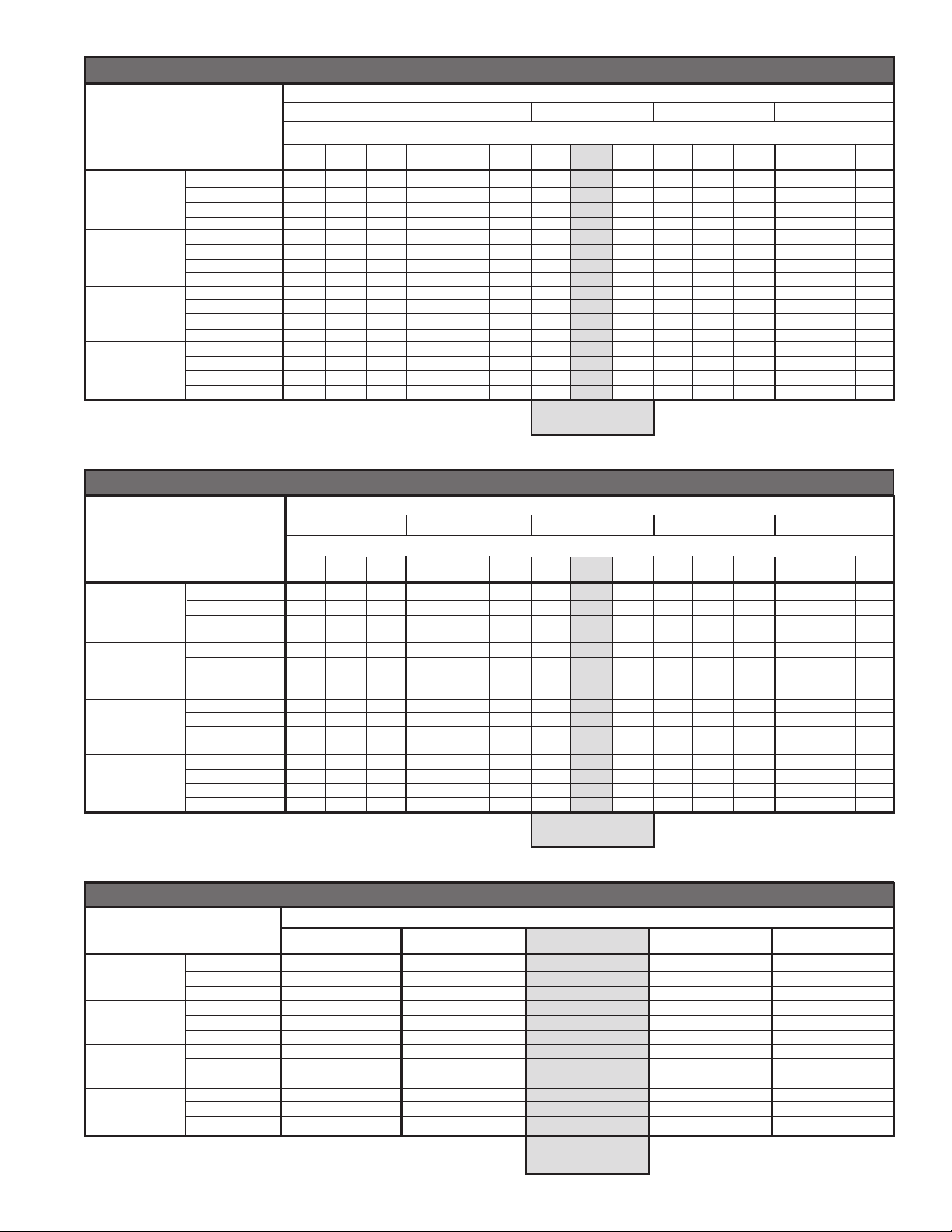

Extended Cooling Performance, PE07/09/12/15

Outdoor Dry Bulb Temp. (°F at 40% R.H.)

75 85 95 105 115

Indoor Wet Bulb Temp. (

72 67 62 72 67 62 72 67 62 72 67 62 72 67 62

PE07

PE09

PE12

PE15

Btuh

Watts

Amps

SHR

Btuh

Watts

Amps

SHR

Btuh

Watts

Amps

SHR

Btuh

Watts

Amps

SHR

8820 8483 7853 8400 7920 7305 8070 7500 6638 7560 6713 5918 6728 5790 5115

502 510 515 547 552 559 615 615 615 665 664 666 725 725 728

2.5 2.5 2.5 2.7 2.7 2.7 3 3.00 3 3.2 3.2 3.2 3.5 3.5 3.5

0.52 0.71 0.95 0.53 0.73 0.97 0.53 0.76 0.98 0.55 0.8 0.98 0.57 0.86 0.97

10819 10405 9632 10304 9715 8961 9899 9200 8142 9274 8234 7259 8252 7102 6274

664 675 682 724 731 740 814 814 814 880 879 882 960 960 964

3.2 3.2 3.3 3.5 3.5 3.5 3.9 3.90 3.9 4.2 4.2 4.2 4.6 4.6 4.6

0.51 0.70 0.94 0.52 0.72 0.96 0.53 0.75 0.96 0.54 0.79 0.97 0.57 0.84 0.96

14112 13572 12564 13440 12672 11688 12912 12000 10620 12096 10740 9468 10764 9264 8184

915 929 939 997 1007 1019 1121 1091 1121 1212 1211 1214 1322 1322 1327

4.2 4.2 4.3 4.5 4.6 4.6 5.1 5.10 5.1 5.5 5.5 5.5 6 6 6

0.49 0.67 0.9 0.5 0.7 0.92 0.51 0.72 0.92 0.52 0.76 0.93 0.54 0.81 0.92

17640 16965 15705 16800 15840 14610 16140 15000 13275 15120 13425 11835 13455 11580 10230

1288 1309 1323 1404 1418 1435 1579 1579 1579 1707 1705 1710 1862 1862 1870

5.5 5.5 5.6 5.9 5.9 5.9 6.6 6.60 6.6 7.1 7.1 7.1 7.7 7.7 7.8

0.51 0.70 0.94 0.52 0.72 0.96 0.53 0.72 0.96 0.54 0.79 0.97 0.57 0.84 0.96

Extended Cooling Performance, PH07/09/12/15

Outdoor Dry Bulb Temp. (°F at 40% R.H.)

75 85 95 105 115

Indoor Wet Bulb Temp. (°F at 80°F D.B.)

72 67 62 72 67 62 72 67 62 72 67 62 72 67 62

PH07

PH09

PH12

PH15

Btuh

Watts

Amps

SHR

Btuh

Watts

Amps

SHR

Btuh

Watts

Amps

SHR

Btuh

Watts

Amps

SHR

8820 8483 7853 8400 7920 7305 8070 7200 6638 7560 6713 5918 6728 5790 5115

502 510 515 547 552 559 615 595 615 665 664 666 725 725 728

2.5 2.5 2.5 2.7 2.7 2.7 3 3.00 3 3.2 3.2 3.2 3.5 3.5 3.5

0.52 0.71 0.95 0.53 0.73 0.97 0.53 0.76 0.98 0.55 0.8 0.98 0.57 0.86 0.97

10819 10405 9632 10304 9715 8961 9899 9100 8142 9274 8234 7259 8252 7102 6274

657 667 675 716 723 732 805 805 805 870 869 872 949 949 953

3.2 3.2 3.3 3.5 3.5 3.5 3.9 3.90 3.9 4.2 4.2 4.2 4.6 4.6 4.6

0.51 0.7 0.94 0.52 0.72 0.96 0.53 0.75 0.96 0.54 0.79 0.97 0.57 0.84 0.96

14112 13572 12564 13440 12672 11688 12912 12000 10620 12096 10740 9468 10764 9264 8184

915 929 939 997 1007 1019 1121 1121 1121 1212 1211 1214 1322 1322 1327

4.2 4.2 4.3 4.5 4.6 4.6 5.1 5.10 5.1 5.5 5.5 5.5 6 6 6

0.49 0.67 0.9 0.5 0.7 0.92 0.51 0.72 0.92 0.52 0.76 0.93 0.54 0.81 0.92

17640 16965 15705 16800 15840 14610 16140 14700 13275 15120 13425 11835 13455 11580 10230

1288 1309 1323 1404 1418 1435 1579 1581 1579 1707 1705 1710 1862 1862 1870

5.5 5.5 5.6 5.9 5.9 5.9 6.6 6.6 6.6 7.1 7.1 7.1 7.7 7.7 7.8

0.51 0.70 0.94 0.52 0.72 0.96 0.53 0.72 0.96 0.54 0.79 0.97 0.57 0.84 0.96

°F at 80°F D.B.)

RATING POINT

ARI 310/380

RATING POINT

ARI 310/380

Extended Heating Performance

37 42 47 52 57

PH07

PH09

PH12

PH15

Btuh

Watts

Amps

Btuh

Watts

Amps

Btuh

Watts

Amps

Btuh

Watts

Amps

5366 5663 6400 7053 7789

536 545 568 577 610

2.5 2.6 2.6 2.7 2.8

6005 6399 8100 8647 9245

666 676 742 747 757

3.1 3.1 3.2 3.2 3.3

7799 8611 10800 11383 12349

893 927 1021 1051 1085

3.8 3.9 4.3 4.5 4.7

10688 11013 13500 14769 16180

1301 1318 1413 1497 1564

5.3 5.4 5.8 6.1 6.3

Outdoor Dry Bulb Temp. (°F)

RATING POINT

ARI 310/380

3

Page 4

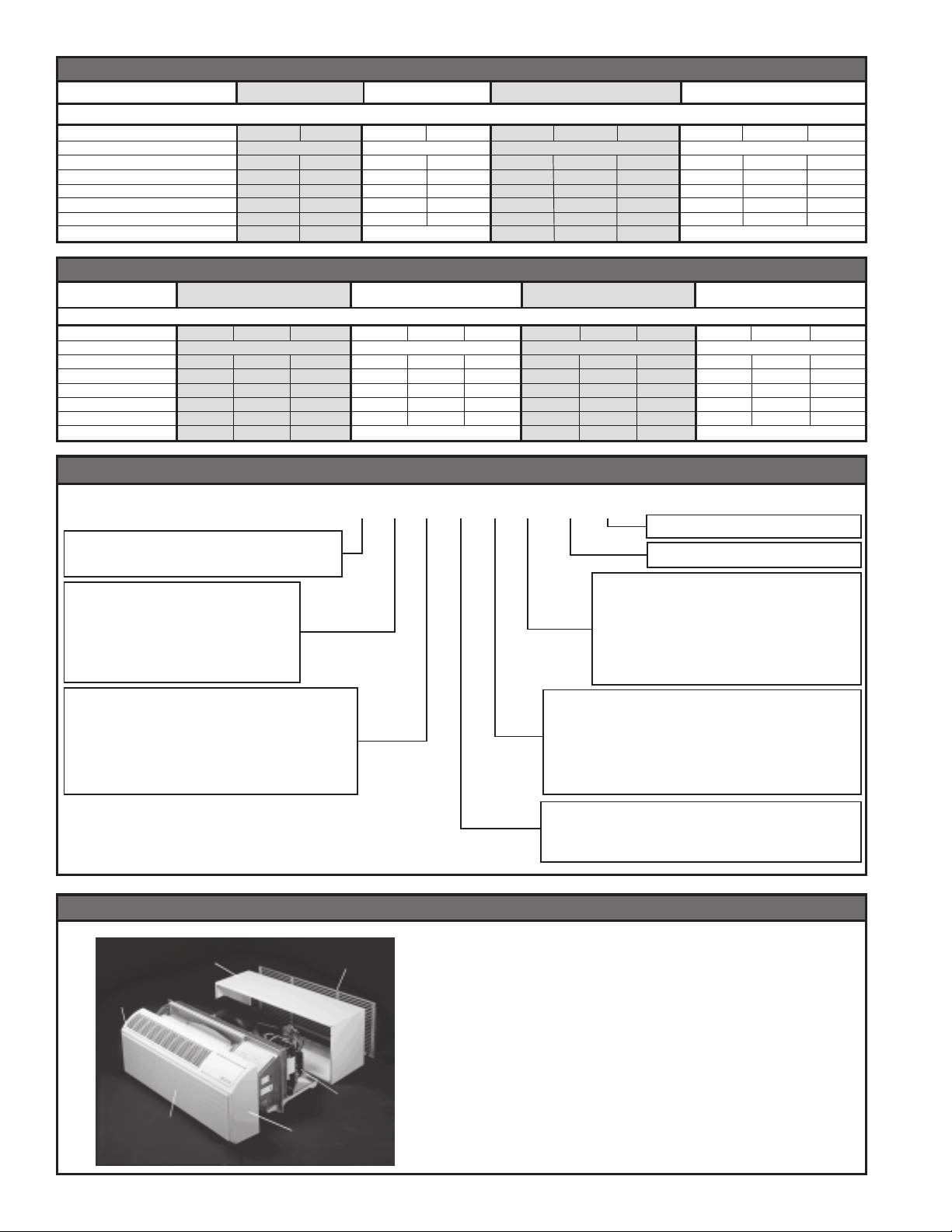

Electric Heat Data, PE/PH 07/09K/R

MODELS: PE/PH07K PE/PH07R PE/PH09K PE/PH09R

PERFORMANCE DATA:

Heater Watts

Voltage

Heating Btuh

Heating Power (Watts)

Heating Current (Amps)

Minimum Circuit Ampacity

Branch Circuit Fuse (Amps)

Nema Plug Face

2500/2050

8500/7000

2600/2150

11.4/10.4

14.1

15

6-15

3400/2780

230/208 265

11600/9500

3500/2880

15.3/13.9

19

20

6-20

2500

8500

2590

9.8

12.2

15

N/A

3400

11600

3490

13.2

16.4

20

2500/2050

8500/7000

2600/2150

11.4/10.4

14.1

15

6-15

3400/2780

230/208

11600/9500

3500/2880

15.3/13.9

19

20

6-20

5000/4090

17000/13900

5210/4300

22.3/20.3

27.8

30

6-30

2500

8500

2590

9.8

12.2

15

3400

265

11600

3490

13.2

16.4

20

N/A

Electric Heat Data, PE/PH 12/15K/R

MODELS: PE/PH12K PE/PH12R PE/PH15K PE/PH15R

ELECTRIC HEAT DATA:

Heating Current (Amps)

Minimum Circuit Ampacity

Branch Circuit Fuse (Amps)

WallMaster

Heater Watts

Voltage

Heating Btuh

Heating Power (Watts)

Nema Plug Face

14.1

15

6-15

3400/2780

230/208

11600/9500

3500/2880

15.3/13.9

6-20

2500/2050

8500/7000

2600/2150

11.4/10.4

®

PTAC/PTHP Model Identification Guide

19

20

5000/4090

17000/13900

5210/4300

22.3/20.3

27.8

30

6-30

2500

8500

2590

9.8

12.2

15

3400

265

11600

3490

13.2

16.4

20

N/A

5000

17000

5210

19.5

24.2

30

2500/2050

8500/7000

2600/2150

11.4/10.4

14.1

15

6-15

3400/2780

230/208

11600/9500

3500/2880

15.3/13.9

19

20

6-20

5000/4090

17000/13900

5210/4300

22.3/20.3

27.8

30

6-30

2500

8500

2590

9.8

12.2

15

3400

265

11600

3490

13.2

16.4

20

N/A

5000

17000

5210

19.5

24.2

30

5000

17000

5210

19.5

24.2

30

PH07K

Series

P = Packaged Terminal Unit

System

X = Accessory

E = Cooling with or

without electric heat

H = Heat Pump with

Auxiliary Heat

Nominal Cooling Capacity

07 = 7,000 Btuh

09 = 9,000 Btuh

12 = 12,000 Btuh

15 = 15,000 Btuh

Typical Unit Components and Dimensions

Wall

Filters

Return

Air Grille

Outdoor

Chassis

Front

Cover

3S A

PXWS Wall

Sleeve

Dimensions:

16" H x 42" W

x 13¾" D

1

Engineering Digit

Design Series

Options

S = Standard

R = Remote Thermostat

C = Seacoast Protection

X = Remote Thermostat and

Seacoast Protection

Nominal Heater Size

(@ 230V or 265V)

0 = No Heater

2 = 2.5 KW

3 = 3.4 KW

5 = 5.0 KW

Voltage

K = 230/208V - 1Ph. - 60 Hz.

R = 265V - 1Ph. - 60 Hz.

Front Cover

Dimensions:

16" H x 42" W x 7½" D

Cut-Out Dimensions:

16¼" x 42¼"

4

Page 5

Typical Wall Sleeve Installation (PXWS)

Lintel Used To Support

Masonry Walls

10" Maximum

Electrical

Receptacle

Main Studs

Jack

Stud

LINTEL

Mounting

Screw Holes

42¼"

Minimum

Wall Opening

13 ¾"

Lintel InstallationLintel Installation

Lintel Installation

Lintel InstallationLintel Installation

No holes are permitted in the top or bottom of

the sleeve. (Exception: PXDR10 Drain Kit)

Electrical Receptacle

16¼"

50"Max

Insulation

Smooth side of clip on Room side

Note the use of a lintel under the first course

of bricks above the wall sleeve. Do not use

the wall sleeve as a lintel. The mounting

screw holes shown are to be made by the

installer.

Extended Wall Sleeve Installation and Sealant Locations (PXWE)

Wall Sleeve Extension, 42" X 16"

Frame, 20 gauge minimum,

painted or aluminum

Width of Wall

Condensate Drip

Panel (Field Supplied)

Wall Sleeve

Outside Edge

Insulation

Air

Baffles

Four

Condensate

Notches

Sealant inside (4) bottom

corners

IMPORTANT NOTE: The

silicone bead MUST

extend 3" up the side of

the two flanges to

prevent condensate

from leaking.

5

Page 6

Internal Drain Kit Location and Installation (PXDR10)

Primary Area:

Condensation from the

chassis collects in the

sleeve in this area. The

Primary Area is the

preferred installation

location.

Foam Gasket

Mounting Plate

Screw

Wall Sleeve

Bottom

Tube

Screw

PXDR10 DRAIN KIT

1/2" O.D. Tube

Gasket

Mounting Plate

External Drain

When using an external drain system, the

condensate is removed through either of two

drain holes on the back of the wall sleeve. Select

the drain hole which best meets your drainage

situation and install the drain kit. Seal off the

other with a cover plate.

Place the drain tube through the gasket and the

mounting plate with the flange toward the wall

sleeve.

Attach the drain tube assembly to one of the

two drain holes at the rear of the wall sleeve.

The large flange on the mounting plate is

positioned at the bottom of the sleeve facing

toward the sleeve. When the drain tube is

positioned at the desired angle, tighten the

screws.

Back

of wall

sleeve

Foam Gasket

Overflow

Slots

1/2" O.D. Tube

Mounting

Plate

Foam Gasket

Cover Plate

Architectural Louver Installation (PXAA)

CAUTION:

Bodily injury can be caused by louvers falling from a

building during installation. It is recommended that a

safety line be attached to the louver and an anchor

point inside the building during installation.

6

Installation

1. Screw a threaded metal stud into each of

the holes at the four corners of the louver.

2. From inside the building, grasp the louver at

the vertical supports and maneuver the

louver through the wall sleeve. Pull towards

you until the threaded studs are inserted into

the four holes of the wall sleeve.

3. While holding the louver with one hand, start

washers and nuts on each of the four studs.

Tighten the nuts securely.

Page 7

WallMaster® PTAC/PTHP Engineering Specifications

All units shall be factory assembled, piped, wired and fully charged with R-22. All units shall be certified in accordance with

ARI Standard 310 for air conditioners and ARI Standard 380 for heat pumps. Units shall be UL listed and carry a UL label.

All units shall be factory run-tested to check operation and be Friedrich WallMaster® or equivalent.

The basic unit shall not exceed 16" high x 42" wide. Overall depth of the unit from the rear of the Friedrich wall sleeve to the

front of the decorative front cover shall not exceed 21¼". The unit shall be designed so that room intrusion may be as little

as 7¼". Installations in walls deeper than 13 ¼" may be accomplished with the use of a wall sleeve extension (PXWE). Unit

shall draw in ambient air through both sides of an outdoor architectural louver or grille measuring 42" wide x 16" high and

shall exhaust heated air out the middle portion of the louver. The architectural louver and wall sleeve shall be designed so

that the louver may be installed from the inside of the building.

REFRIGERATION SYSTEM - The refrigeration system shall consist of a hermetically sealed rotary compressor that is

externally mounted on vibration isolators no smaller than 1 ¾" dia. X 1 ½" high; condenser and evaporator coils constructed

of copper tubes and aluminum plate fins; and capillaries as expansion devices. Unit shall have a fan slinger ring to increase

efficiency and condensate disposal and have a drain pan capable of retaining 1½ gallons of condensate. A tertiary condensate

removal system shall also be incorporated for back up and shall overflow through the wall sleeve and to the outside of the

building as a safeguard against damage to the interior room.

AIR HANDLING SECTION - The evaporator and condenser fans shall be driven by a single, totally enclosed, ball bearing,

permanently lubricated split capacitor, "clam-shell" style fan motor. Airflow shall be directed into the room by a single,

injection molded, high-impact polystyrene discharge grille. The grill shall have openings no larger than 3/8" high x 3" wide

to prevent personal injury or damage to the PTAC unit, and will be reversible to allow air to be directed upward or outward as

determined by the installer.

The chassis shall have a built-in damper capable of providing at least 60 CFM of fresh air into the conditioned area. A fine

mesh screen shall filter the incoming fresh air. There must be a provision for locking the damper closed to ensure a proper

seal.

CONTROLS - Covered controls shall be accessible in a compartment at least 9" wide with the controls no deeper than 1¼" in

the opening to facilitate easy operation of the unit. Controls shall include dual rotary knobs for setting of the thermostat and

for mode control. The knobs will be tamper proof to prohibit the removal of knobs by the user and shall feature a temperaturelimiting device adjustable by the owner. The control panel shall be clearly marked and easy to read. Universal symbols shall

be used with markings no smaller than 12-point type. The chassis may be ordered with the option of remote thermostat

control.

Other controls accessible without removal of the chassis shall include fan cycle switch, fresh air vent control and emergency

heat override switch (heat pump only).

GENERAL CONSTRUCTION - The wall sleeve shall be constructed of 18 gauge G90 zinc-coated steel. It shall be prepared

by a process where it is zinc phosphate pretreated and sealed with a chromate rinse, then powder coated for maximum

coverage and protection. The sleeve shall be shipped with a protective weatherboard and a structural center support, and be

insulated for thermal efficiency. The grille or louver shall be shipped separately and made from stamped or extruded

anodized aluminum. All louvers shall be in the horizontal plane.

The front panel shall lock to the chassis by means of two factory-supplied thumbscrews to prevent tampering. The front

panel will feature a contoured discharge with no sharp corners. The air filters shall be reusable and be accessible without

removal of the front cover.

All 265V units shall possess an integral, over-current time-delay protective device.

The unit shall have a plastic fan, fan shroud and drain pan for corrosion protection and to help prevent rust on the side of the

building below the outdoor louver.

A complete line of accessories shall be available from Friedrich to equip the PTAC for a multitude of applications.

Friedrich Installation/Start-Up Specialists shall be available to answer questions regarding proper installation practices and

in some cases for on-site start-up inspections.

7

Page 8

Friedrich PTAC Accessories

New Construction Accessories

MODEL NUMBER DESCRIPTION PHOTO

WALL SLEEVE G-90 zinc coated steel is prepared

in an eleven-step process, then powder coated for

maximum coverage and protection. The wall

PXWS

sleeve is insulated for thermal efficiency. 16" High

x 42" Wide x 13¾" Deep.

PXWS

PXGA

PXAA

PXDB

PXSC

PXDR10

PXWE

GRILLE Standard, stamped aluminum, anodized

to resist chalking and oxidation.

ARCHITECTURAL GRILLES Consist of heavygauge 6063-T5 aluminum alloy:

– Clear, extruded aluminum

– Dark bronze acrylic enamel

– Also available in custom colors.

CONDENSATE DRAIN KIT Attaches to the bottom

of the wall sleeve for internal draining of condensate

or to the rear wall sleeve flange for external draining.

Recommended on all units to remove excess

condensate. Packaged in quantities of ten.

DEEP WALL SLEEVE EXTENSION A four inch

deep anodized aluminum extension that attaches

to the outside of the wall sleeve when

greater than thirteen inches thick (11¾

the wall is

" when a

subbase is used, 12¼" when a lateral duct is used).

PXDB

PXDR10

PXWE

DECORATIVE SUBBASE Provides unit support

for walls less than six inches thick. Includes leveling

legs, side filler panels and mounting brackets for

PXSB

electrical accessories. Accepts circuit breaker,

power disconnect switch, or conduit kit.

PXSB

CONDUIT KIT WITH JUNCTION BOX Hard wire

conduit kit with junction box for 208/230V and 256V

PXCJ

units (subbase not required). Kit includes a means

of quick disconnect for easy removal of the chassis.

*Required for 265V installations.

PXCJ

8

Page 9

New Construction Accessories (Continued)

MODEL NUMBER DESCRIPTION PHOTO

DESK CONTROL KIT A field installed kit which

PXDC

RT1

allows the unit to be turned on or off from a remote

central station via a 24V interface. This kit is

compatable with all chassis models.

DIGITAL REMOTE THERMOSTAT A Honeywell

wall mounted remote thermostat. Compatable only

with "RT" suffix chassis.

Additional Accessories

MODEL NUMBER DESCRIPTION PHOTO

SLEEVE EXTENSION RETROFIT KIT G-90 zinc

coated steel, 2¼" sleeve extension attached to the

PXSE

PXDA

room side of the sleeve to allow for the installation

of a P-Series Friedrich PTAC in a T-Series sleeve.

PXSE

LATERAL DUCT ADAPTER Attaches to the PTAC/

PTHP unit and provides a transition to direct up to

35% of the total CFM to a secondary room, either

left or right of the unit. Kit includes duct plenum

with discharge grille and internal baffle, adapter and

end cap.

PXDC

RT1

PXDE

PXFT

Chassis Options

SS

S

SS

RR

R

RR

CC

C

CC

LATERAL DUCT EXTENSION A three foot

insulated plenum that attaches to the left or right

side of the duct adapter. The extension can be cut

to length by the installer. Maximum allowable

straight extension is fifteen feet.

REPLACEMENT FILTER PACK These are original

equipment return air filters. They are reusable and

can be cleaned by vacuuming, washing, or blowing

out, and are sold in convenient ten packs. (Two

filters per chassis).

DESCRIPTIONITEM

STANDARD UNIT Standard PTAC/PCHP chassis. Can be 230/208V or 265V, electric

or heat pump.

REMOTE THERMOSTAT Chassis option necessary for wall mounted thermostat

control of the unit.

SEACOAST PROTECTION Additional protection for PTAC/PTHP units in a coastal or

corrosive environment. The entire outdoor coil is submerged in a specially formulated

enamel coating, then oven-cured for a tough, corrosion-resistant finish.

PXDA

PXFT

9

Page 10

Friedrich WallMaster® P-Series

Packaged Terminal Air Conditioners

Limited Warranty

FRIEDRICH AIR CONDITIONING CO.

Post Office Box 1540 · San Antonio, Texas 78295-1540

(210) 357-4400 · FAX (210) 357-4480

SAVE THIS CERTIFICATE. It gives you specific rights, you may also have other rights which may vary from state to state and province to

province.

In the event that your unit needs servicing, contact your nearest authorized service center. If you do not know the nearest service center, ask

the company that installed your unit or contact us - see address and telephone number above.

When requesting service: please have the

Unless specified otherwise herein, the following applies:

LIMITED WARRANTY - FIRST YEAR (Eighteen (18) Months from the original date of purchase or twelve (12) months from

installation). Any defect in the unit’s material or workmanship will be repaired or replaced free of charge by our authorized service center

during the normal working hours; and

LIMITED WARRANTY - SECOND THROUGH FIFTH YEAR (Sixty-six (66) months from the date of purchase) ON THE SEALED REFRIGERATION SYSTEM. Any part of the sealed refrigeration system on the P-series that is defective in material or workmanship will be repaired or

replaced free of charge (excluding freight charges) by our authorized service center during normal working hours. The sealed refrigeration

system consists of the compressor, metering device, evaporator, condenser, reversing valve, check valve, and the interconnecting tubing.

These warranties apply only while the unit remains at the original site and only to units installed inside the continental United

States, Alaska, Hawaii, Puerto Rico and Canada. The warranty applies only if the unit is installed and operated in accordance

with the printed instructions and in compliance with applicable local installation and building codes and good trade practices.

For international warranty information, contact the Friedrich Air Conditioning Company - International Division.

Reasonable proof must be presented to establish the original purchase date, otherwise the beginning date of this certificate will be considered

to be our shipment date plus sixty days. Replacement parts can be new or remanufactured. Replacement parts and labor are only warranted

for any unused portion of the unit’s warranty.

We will not be responsible for and the user will pay for:

1. Service calls to:

A) Instruct on unit operation. B) Replace house fuses or correct house wiring. C) Clean or replace air filters. D) Remove

the unit from inaccessible locations. E) Correct improper installations.

model and serial number from your unit readily available.

PACKAGED TERMINAL AIR CONDITIONERS AND HEAT PUMPS

2. Parts or labor provided by anyone other than an authorized service center.

3. Damage caused by:

A) Accident, abuse, negligence, misuse, riot, fire, flood, or acts of God. B) Operating the unit where there is a corrosive atmosphere containing chlorine, fluorine, or any damaging chemicals (other than in a normal residential environment). C) Unauthorized

alteration or repair of the unit, which in turn affects its stability or performance. D) Failing to provide proper maintenance and

service. E) Using other than a "Seacoast Protected" unit in a coastal environment. F) Using an incorrect power source. G) Faulty

installation or application of the unit.

We shall not be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure

of this unit. We have not made and do not make any representation or warranty of fitness for a particular use or purpose and

there is no implied condition of fitness for a particular use or purpose. We make no expressed warranties except as stated in

this certificate. No one is authorized to change this certificate or to create for us any other obligation or liability in connection

with this unit. Any implied warranties shall last for one year after the original purchase date. Some states and provinces do

not allow limitations on how long an implied warranty or condition lasts, so the above limitations or exclusions may not apply

to you. The provisions of this warranty are in addition to and not a modification of or subtraction from the statutory warranties and other rights and remedies provided by law.

In case of any questions regarding the provisions of this warranty, the English version will govern.

Revised 8/01

10

Page 11

WALLMASTER® P-SERIES

PACKAGED TERMINAL AIR CONDITIONERS

Purchaser: P.O. # Date:

Project: Location:

Engineer: Architect:

Submitted By: For Approval: For Reference:

ITEM PLAN DESIGNATION QUANTITY COOLING BTU/H VOLTAGE FRIEDRICH MODEL

ACCESSORIES

PXWS

PXWE

PXGA

PXAA

PXDB

PXSC

RT1

Wall Sleeve

Deep Wall Extension

Standard Outdoor Louver

Architectural Louver, clear

Architectural Louver, dark bronze

Architectural Louver, color matched

Electronic Digital Remote Wall

Mounted Thermostat

Qty

Qty

Qty

Qty

Qty

Qty

Qty

PXDR10

PXSB

PXDS

PXCJ

PXSE

PXDA

PXDE

PXDC

Condensate Drain Kit (pkg/10)

Subbase

Power Disconnect Switch

Conduit Kit w/Junction Box

T-Series Sleeve Adapter

Lateral Duct Adapter

Lateral Duct Extension

Desk Control Relay

Qty

Qty

Qty

Qty

Qty

Qty

Qty

Qty

NOTES:

FEATURES

" Ultraquiet operation

" Super high energy efficiency, up to 12.2 EER

" Easy to use controls feature tamper-proof knobs

" Built-in fresh air damper provides up to 70 CFM

" Two cooling and heating speeds plus fan-only setting

" Front cover fastens to chassis easily with thumbscrews hidden

from user

" Thermostat limiter switch

" Emergency heat switch (heat pump models)

" Easy access, easy-to-clean filter

" Made in the U.S.A.

" UL Listed and ARI Certified

DIMENSIONS

Wall Sleeve Overall Depth

Width Height Depth Sleeve with Front

42" 16" 13¾" 21¼"

Wall Opening - 42¼" wide x 16¼" high

11

Page 12

Multiple solutions.

One trusted name.

Post Office Box 1540 · San Antonio, Texas 78295-1540

4200 N. Pan Am Expressway · San Antonio, Texas 78218-5212

(210) 357-4400 · FAX (210) 357-4480 www.friedrich.com Printed in the U.S.A

12

Friedrich Air Conditioning Co.

PTACBW02 (04/02)

.

Loading...

Loading...