Wall-Mount

OutdoorWall-mounted Air Conditioners/ Heat Pumps

OES/ OHSSeries

Installation & Operation Manual

920-138-02 (3-04)

920-138-02(3-04)

TABLE OF CONTENTS

I. General Specifications

Model Number Identification Guide ............................................................. 3

Unit Dimensions ............................................................................ 3

II. Installation

Introduction ................................................................................ 4

Safety Considerations ........................................................................ 4

Indoor Air Requirements ...................................................................... 5

Filters ..................................................................................... 6

Outdoor Air System .......................................................................... 6

Condensate Drainage ........................................................................ 6

Mounting Preparations ....................................................................... 7

Mounting the Unit ......................................................................... 8-9

Rain Flashing Installation .................................................................... 10

Thermostat Wiring .......................................................................... 11

Line Voltage Electrical Wiring ................................................................. 11

Electrical Data Tables ..................................................................... 12-13

Standard Ventilation Package ................................................................. 14

Optional Ventilation Packages .............................................................. 15-17

III. Start Up

Sequence of Operation ...................................................................... 18

Defrost Cycle (Heat Pump models only) ........................................................ 18

Final Installation Checklist .................................................................... 18

IV. Service / Warranty

Service Hints .............................................................................. 18

Model Information Form ..................................................................... 19

Warranty Information ..................................................................... 20-21

Please read this manual thoroughly prior to equipment installation or operation. It is the installer's responsibility to properly apply

and install the equipment. Installation must be in conformance with the NFPA 70-2002 National Electric Code or current edition

and Universal Mechanical Code current edition and applicable local or national codes.

Remember, proper installation is not difficult but it is essential.

Inspect for Shipping Damage

You should inspect your shipment immediately for signs of external damage. Any damage found should be reported

(preferably in writing) to the last carrier to handle the shipment and a request for inspection by their agent made.

Any hidden damage should also be reported when the unit is unpacked.

920-138-02 (3-04)

I. GENERAL SPECIFICATIONS

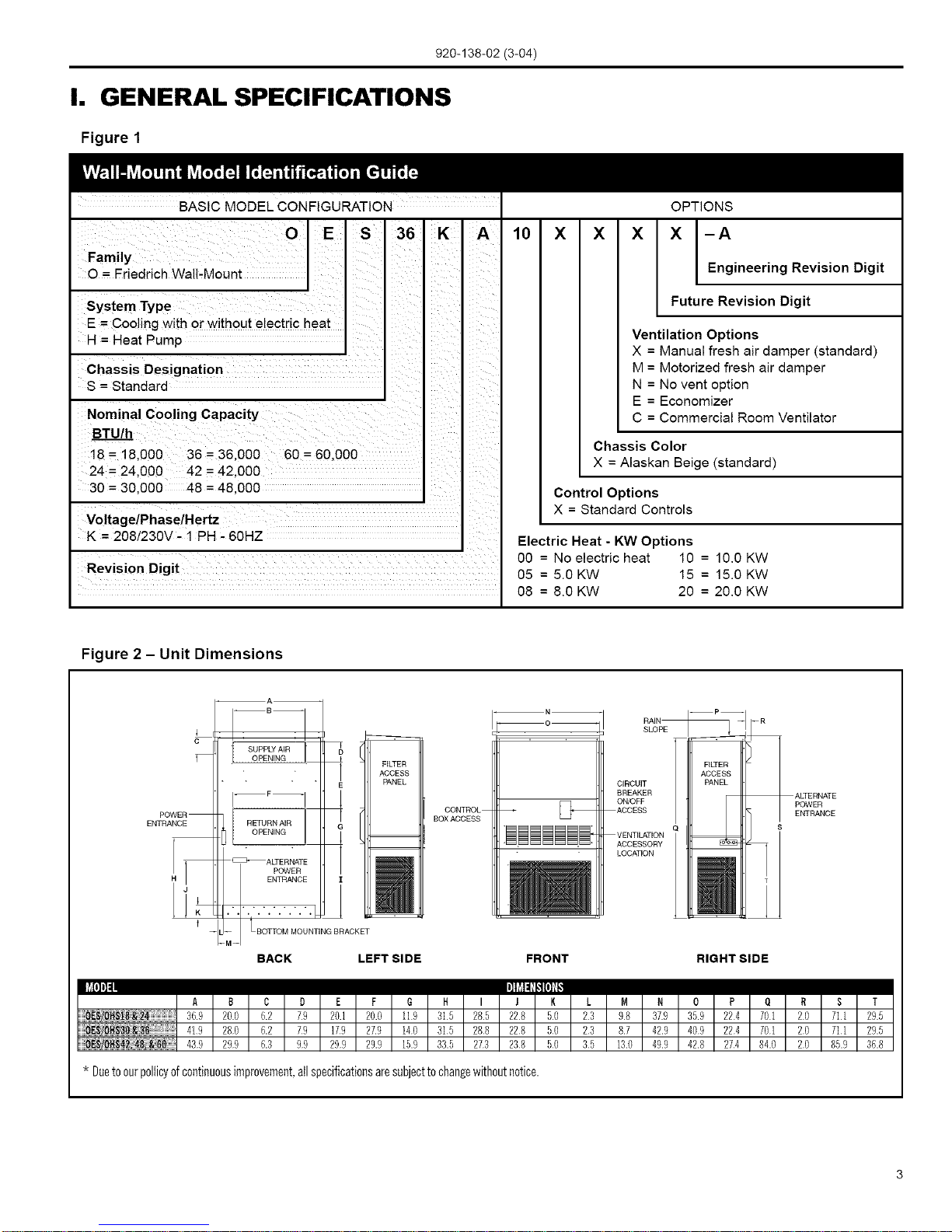

Figure 1

BASIC MODEL CONFIGURATION

O S

Family E

O = Friedrich Wall-Mount I

System Type

E = Cooling with or without electric heat

H = Heat Pump

Chassis Designation

S = Standard

Nominal Cooling Capacity

BTU/h

18 = 18.000 36 = 36.000 60 = 60.000

24 = 24.000 42 = 42.000

30 = 30.000 48 = 48.000

Voltage/Phase/Hertz

K = 208/230V - 1 PH - 60HZ

36 K

10 X X

OPTIONS

X X [-A

Engineering Revision Digit

Future Revision Digit

Ventilation Options

X = Manual fresh air damper (standard)

M = Motorized fresh air damper

N = No vent option

E = Economizer

C = Commercial Room Ventilator

Chassis Color

X = Alaskan Beige (standard)

Control Options

X = Standard Controls

Revision Digit

08 = 8.0 KW

Electric Heat - KW Options

00 = Noelectric heat 10 = 10.0 KW

05 = 5.0 KW 15 = 15.0 KW

20 = 20.0 KW

Figure 2 - Unit Dimensions

c

RAIN --P_ --R

SUPPLY AIR [

. OPENING .

]

FILTER

ACCESS

E PANEL

CONTROL

BOX ACCESS

FILTER

ACCESS

CIRCUIT PANEL

BREAKER

ON/OFF

ACCESS L

Q s

VENTILATION = =

ACCESSORY

LOCATION

_ T

.1

ALTERNATE

POWER

ENTRANCE

BACK LEFT SIDE FRONT RIGHT SIDE

lt'#l'], ']li'll_iiIPlil

A B C D E F G 14 I J K L M N 0 P O R S T

36.9 200 6.2 79 20.1 20.0 119 315 285 228 50 23 98 37.9 35.9 224 701 20 711 29.5

419 280 6.2 79 179 27.9 140 315 288 228 50 23 8.7 42.9 409 224 701 20 711 29.5

439 299 6.3 99 299 29.9 15.9 33.5 273 238 50 35 13.0 49.9 42.8 274 84.0 20 85.9 36.8

* Duetoourpolticyofcontinuousimprovement,allspecificationsaresubjecttochangewithoutnotice.

920-138-02 (3-04)

I _1, DANGER: Before installing or servicing system, always turn off main power to system. There may be more than one I(1) disconnect switch. Turn off auxiliary heater power if applicable. Electrical shock can cause personal injury or death.

I

II. INSTALLATION

Introduction

NOTE: Read the entire instruction manual before starting

the installation.

The OES/OHS series air conditioners and heat pumps are

ETL and c-ETL listed and are available inthe cooling/electric

heating sizes shown in Table 5 on page 13. This series of

units is designed for outside installation only.

The OES/OHS series air conditioners and heat pumps are

self-contained units. All components, including outdoor coil,

compressor, and refrigerant tubing, are located in a single

package. The units are already piped, charged, and wired.

Refer to Figure 2 on page 3 for basic unitdimensions.

The OES/OHS series air conditioners and heat pumps are

designed for installation invarious light commercial applications.

These instructions detail atypical method of installation. These

units can be installed with or without ductwork. Installed

flanges can be used for attaching ductwork or covered with a

decorative grille. OES/OHS series units come from the factory

with two 1"air filters installed. Simply bend tabs on filter rack

to accommodate 2" filters. Return filter grills are offered as

an accessory option. If a different or additional air filters are

required, they will need to be field-installed inthe duct system.

These units have 2" long duct flanges for connecting to the

field ducts.

Safety Considerations

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock, orother conditions which may cause personal injury or

property damage. Consult a qualified installer, service agency,

or your distributor or dealer for information and assistance.

The qualified installer or agency must use factory-authorized

parts or accessories when modifying this product. Refer to the

individual instructions packaged with the parts or accessories

when installing.

Follow all safety codes. Wear the proper attire, including

safety glasses and work gloves. Read these instructions

thoroughly and follow allwarnings or cautions attached to the

unit. Consult local building codes, the National Electric Code

(NEC), and the Installation Standards, Warm Air Heating

and Air Conditioning Systems ANSI/NFPA 90B for special

installation requirements.

Recognize safety information. This is the safety-alert symbol:

_, When you see this symbol on the unit or in instructions

and manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words areused with the safety-alert symbol.

DANGER identifies the most serious hazards which will result

insevere personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is

used to identify unsafe practices which would result in minor

personal injury or product and property damage. NOTE isused

to convey special or supplemental information or to repeat and

emphasize information previously provided.

General Recommendations

(Do's and Do Not's)

The installation of this unit must comply with all local and

national electrical and installation codes. Where local

regulations differ with these instructions, local codes must

apply.

• Do read the instructions completely before installation.

• Do take time to perform a quality installation.

• Supply and return airductwork must be properly sized

for this equipment. All ductwork should be insulated to

prevent condensation and water damage.

• Do tape and seal all ductjoints.

• Do check the indoor conditioned air duct system static

pressure losses. Itshould not exceed those listedfor

these units. Consult your dealer or distributor for more

information.

When designing indoor supply systems, do not reduce

air intake or discharge sizes.

Do insulate all conditioned air duct system

components.

Do locate thermostat on an interior wall.

Do check that condensate drain line drains freely.

Do provide minimum installation and service

clearances.

• Do follow all guidelines for indoor and outdoor air

system.

• Do not drill into unit (except for 2 in. flanges for ducted

return units). This could cause a refrigerant leak.

• Do not substitute any components without checking

with your dealer or distributor, lfyou do substitute, get

approval in writing. Substitutions without approval void

unitwarranty.

• Do not guess. Consult your dealer ordistributor if any

portion of the installation procedure is unclear.

920-138-02 (3-04)

Installer Qualifications

This equipment isintended to be installed by a qualified HVAC

specialist who is experienced and thoroughly knowledgable

in air conditioning unit installation and operation, high voltage

electrical systems, ductwork construction and airflow, and

thermostat installation. All instructions for this unit as well

as separate equipment should be read completely before

attempting installation.

Inspection

Remove shipping protection and pallet from unit and inspect

for damage. Be sure to check for concealed internal shipping

damage. Do not install a damaged unit. Damage should be

reported to the last motor carrier to handle the shipment and a

request (written is preferred) should be made foran inspection

by the carriers agent.

Supplies Needed for Installation

The following items are required to install unit:

• Seven-conductor thermostat cable for OHS series, and

5-conductor thermostat cable for OES series. (20 gage

wire minimum).

• Supplies to connect indoor air (conditioned air supply)

duct to unit.

• Supplies to connect power to the unit.

• Supplies to connect low-voltage thermostat to unit.

Service Clearance and Unit Location

A minimum of 30 in.service clearance must be allowed infront

of the unit, and a minimum of 20 in. on either side. Additional

clearance may be necessary. Most serviceable components

are accessible from the front of the unit with the front panels

removed.

INDOOR AIR REQUIREMENTS

The indoor air system is designed to operate at specified

airflow rates and external static pressures. The supply and

return air duct system pressure losses (including filter, louver/

grille and registers) must not exceed the listed external static

pressures for the indoor air system.

_, CAUTION: Failure toadhere to indoor air requirements as

listed in the following section will void the unit warranty.

Indoor Air (Conditioned Supply Air)

System

The unit may beapplied ineither afree return airconfiguration

or a ducted returnairconfiguration. The design and construction

of the indoor-air system must provide adequate airdistribution

to ensure comfort levelsthroughout the structure. All ductwork

must be properly sized for the designed air flow of the unit. All

duct work should be properly insulated to conserve energy and

prevent condensation damage. Where the duct runs through

unheated spaces, it should be insulated with at least one inch

of insulation. Insulation with a vapor barrier on the outside

should be used. Use flexible joints to connect the ductwork to

the unit to reduce noise transmission into the structure. See

Figure 2 for additional information.

Table 1 - Indoor Air System Data

Model

OE$18K/ OHS18K

OES24K/ OH$24K

OES30K/ OHS30K

OES36KtOHS36K

OES42KtOHS42K

OES48K/OHS48K

OES60KtOHS60K

MotorSpeed

Low

High

Low

High

Low

High

Low

High

0.1

840

840

1280

1370

1280

1370

1690

1895

1690

1895

2350

E.S.R

0.2

750

750

1140

1220

1140

1220

1645

1795

1645

1795

2200

(Wet Coil)

0.3

65O

65O

965

1060

985

1060

1550

1690

1550

1690

2060

0.4

440

440

808

885

808

885

1450

1565

1450

1565

1900

0.5

250

250

615

665

615

665

1300

1340

1300

1340

1730

Recommended

Airflow Range

585-720

720-880

900-1100

1015-1240

1260-1540

1395-1720

1800-2200

NOTE: italic font indicates performance is outside the required operating window.

920-138-02(3-04)

_, CAUTION: Ifreturn air ducting is not used, an adequately

sized metal return air grille is required. Velocity should not

exceed 500 FPM for return air grilles, and 400 FPM for filter

grilles. It is recommended that the proper Friedrich return air

grille kit be installed in applications where no return duct is

used.

FILTERS

Two replaceable air filters are supplied from the factory. The

filters are accessible through the access panels on the sides of

the unit (See Figure2) or from the inside of the building through

the return airgrille.

The combined pressure losses of the return and supply air

paths must not exceed the external static capabilities of the

system at the design airflow (See Table 1).

The factory-installed filter rails are designed to hold 1" or 2"

filters. When using 2" filters the filter rail divider tabs must be

folded flat (See Figure 3).

NOTE: Dirty filters are the most common cause of inadequate

heating and cooling performance

• Inspect filters monthly

• Replace disposable type filters before they become

clogged

• Use water and mild detergent to clean washable type

filters

NOTE: Most filters are marked with an arrow to indicate the

proper direction of air flow through the filter The arrow MUST

point in the direction of air flow

OUTDOOR AIR SYSTEM

As a completely self-contained system, OES/OHS series units

require an adequate supply of outdoor air to exchange heat

from the outdoor air coil. The outdoor air intake and discharge

openings are located on the front and sides of the unit.

_IL CAUTION: To ensure proper operation, the outdoor air

intake and discharge air paths must be free and unobstructed

for the first 20 inches. The two air paths must be unrestricted

to ensure that the intake and discharge air do not recirculate

(also called short-circuit).

CONDENSATE DRAINAGE

A plastic drain hose extends from the drain pan to the vent at

the bottom of the unit. This line can be attached to a suitable

drainage system. If this is done, the system must be vented

or open type to ensure proper drainage. Condensate water

can freeze in cold weather which could create hazardous

situations.

Figure 3 - Filter Rail Adjustment

BEND TAB TO i, LLO_&' FOR 2" FLTER

920-138-02 (3-04)

MOUNTING PREPARATIONS

Forming the Duct Flanges

To minimize the possibility of shipping damage, all units are

shipped with field formed duct flanges. These flanges must

all be formed into place prior to mounting the unit.

The perforated bend lines of the duct flanges provide

a location for field hand bending/forming to occur in a

repeatable manner. When forming the flanges, begin at the

upper most perforations and work from top to bottom. The

procedures for bending the duct flanges are as follows:

• Face the back side ofthe unit,which is the side that will

ultimately make contact with the mounting surface. (See

Figure 4.)

• Wearing protective gloves, grasp the center of the

metal flange with both hands and gradually bend

outward at approximately a 45 degree angle.

• Continue this process until the entire length of the

flange is bent to a 45 degree angle.

• Starting back in the center, grasp the flange with both

hands and complete the bend to 90 degrees along the

entire length. The flange should now be perpendicular

to the rear of the cabinet. (See Figure 5.)

• Repeat the above steps for each of the eight

perforated metal flanges on the rear of the cabinet.

When completed, there will be eight duct flanges that

are perpendicular to the rear of the cabinet. (See

Figure 5.)

_, CAUTION: Repeated bending of the flanges from

flat to the perpendicular position will eventually weaken

the sheet metal and ultimately cause failure of the metal

flanges.

Installing Sealing Gaskets

In order to ensure a proper air seal between unit and the

building, the factory-supplied sealing gaskets must be

applied. Failure to install the gaskets may result in air leaks

and poor unit performance.

• Facing the mounting side of the unit, retrieve the

sealing gaskets from the return air opening of the

unit.

• Next, apply a piece of the gasket vertically to both

the left and right side of the air openings as shown.

• With the remaining gasket, seal the top and bottom

of both the supply and return air opening as shown.

Gaskets may be cut with a utility knife or torn by hand to

the proper length.

Figure 4

Duct Flanges as Shipped

Left Side

Duct Flanges as Shipped

Figure 5

Formed Duct Flanges with Gaskets Installed

Formed Duct Flanges

Left Side

920-138-02 (3-04)

MOUNTING THE UNIT

Mounting Information

Two holes must be cut inthe wall for the supply and return air

openings. (See Figures 7 and 8)

On wood frame walls, the wall may need to be reinforced in

order to hold up to the weight of the unit.

Concrete block walls must be thoroughly inspected to insure

that they can handle the unit weight.

It is the installer's responsibility to insure that hardware used

for mountng of unit is correct for wall material.

New Installation

OES/OHS units are affixed to the wall by way of three

mounting brackets. The bottom bracket supports the majority

of the weight load, and the side brackets hold the unit in place

(See Figures 6 and 7).

Friedrich recommends a 1 inch clearance to combustible

material for the first 3 feet of duct attached to the outlet air

frame.

1. Locate and mark lag bolt locations and bottom

mounting bracket location. (See Figure 8)

2. Mount bottom mounting bracket.

3. Connect the side mounting brackets to the rear

corner posts of the unit. Brackets may be mounted

with flanges outward or inward. See Figure 6

for dimensions for new installation. Friedrich

recommends installing the brackets outward.

4. Connect the rain flashing to the back flange of the

unit top by using screws in the top panel. Top rain

flashing is shipped secured to the back of the unit.

(See Figure 9)

5. Position the unit in the opening and secure to the

wall with 5/16 inch lag bolts; use 7/8 inch diameter

flat washers on the lag bolts.

6. Secure the rain flashing to the exterior wall and caulk

across the entire length of the top. (See Figure 9)

7. On side by side installations, maintain a minimum

of 20 inches clearance on both sides to allow

access to heat strips and to allow proper airflow

out of the outdoor coil. Additional clearance may

be required to meet local or national codes.

Replacement Installation

Friedrich mounting brackets are removable and can be

mounted in two ways to ensure the bracket holes are in line

with the studs. (See Figure 6)

When doing a replacement project measure the space

between the studs, then look at the chart below, which gives

the space between mounting brackets for all chassis sizes.

Decide in which position the brackets should be mounted

to best match the stud spacing. If the unit is to be installed

with the brackets facing outwards, (Figure 6) first mount the

brackets onto the unit and then secure to the wall. If the unit

is to be installed with the brackets facing inwards (Figure

6), first mount brackets to the wall, then position the unit up

against the wall and secure brackets to the unit.

Figure 6

Mounting Options

Flange Outward

Flange Inward

MODEL

OES/OHSl8&24

OES/OHS30&36

OES/OHS42,48&60

Flanges Outward

Mount flanges to chassis first

Flanges Inward

Mount flanges to watt first

Flange outward

36.9

41.9

43.9

MODEL

OES/OHS18&24

OES/OHS30&36

OES/OHS42,48&60

Flange inward

33.9

38.9

40.8

Loading...

Loading...