Page 1

Room Air Conditioners

Money

Fan

Timer Operati on

Set Hr.

Stop

Start

Temperature

Fan

Cool

On/Off

Power

Cooler

Only Speed Saver

®

Warmer

Standard Chassis Models

115-Volt: SS08, SS10, SS12, SS14

230-Volt: SS12, SS16, SM18, SM21, SM24

115-Volt: KS12, KS15

230-Volt: KM18, KM24

HEAVY DUT Y

115-Volt: YS09

230 -Volt: YS13, YM18, YM23, YL24, ES12, ES16, EM18, EM24, EL36

Register your air conditioner

230-Volt: SL28, SL36

Installation and Operation Manual

Model information can be found on the name

plate behind the front cover.

Ple ase compl ete and mail the ow n er

registration card furnished with this product,

or register online at www.friedrich.com (USA

only). For your future convenience, record the

model information here.

MODEL NUMBER

SERI AL NUMBER

PURCHASE DATE

920-198-00 (7-07)

Page 2

920-198-00

Congratulations!

You have purchased the very latest in room air conditioner technology. Your new Friedrich high efciency room air conditioner will give you many years of de-

pendable service. Many extra features have been built into your Friedrich air conditioner to assure quiet operation, the best circulation of cool, dry air, functional

controls, and the most economical operation.

Table of contents

Air Conditioner Operation

Before Operating Your Unit ...........................................................................................................................................................................................................3

For the best cooling performance and highest energy efciency ................................................................................................................................................3

How to operate your Friedrich room air conditioner .....................................................................................................................................................................4

QuietMaster Programmable models

To Start Unit .................................................................................................................................................................................................................................4

To Set Mode of Operation .............................................................................................................................................................................................................4

®

MoneySaver

To Adjust Temperature .................................................................................................................................................................................................................4

To Adjust Fan Speed .....................................................................................................................................................................................................................4

To Activate Smart Fan ...................................................................................................................................................................................................................4

To Set Hour Clock .........................................................................................................................................................................................................................4

To Set The Timer ........................................................................................................................................................................................................................... 4

Automatic Component Protection .................................................................................................................................................................................................4

How to Use the Remote Control ...................................................................................................................................................................................................5

Feature ................................................................................................................................................................................................................... 4

QuietMaster “K” & Heavy Duty Models / Twintemp

To Start Unit .................................................................................................................................................................................................................................6

To Set Mode of Operation .............................................................................................................................................................................................................6

To Adjust Temperature .................................................................................................................................................................................................................6

®

MoneySaver

Feature ...................................................................................................................................................................................................................6

Care & Maintenance / Fresh Air & Exhaust Control

Removing/Cleaning the Filter .......................................................................................................................................................................................................7

Fresh Air & Exhaust Control .........................................................................................................................................................................................................7

Air Conditioner Installation

Electrical Requirements/Cabinet Dimensions ..............................................................................................................................................................................8

Installation Hardware ....................................................................................................................................................................................................................9

Standard Sash Window Installations ..........................................................................................................................................................................................10

Through-the-wall Installations .....................................................................................................................................................................................................15

Troubleshooting Tips ................................................................................................................................................................................................................... 18

Accessories.................................................................................................................................................................................................................................18

Warranty .....................................................................................................................................................................................................................................19

2

Page 3

920-198-00

TEST

RESET

WARNING

TEST BEFORE EACH USE

1. PRESS RESET BUTTON

2. PLUG LDCI INTO POWER

RECEPTACLE

3. PRESS TEST BUTTON,

RESET BUTTON SHOULD

POP UP

4. PRESS TEST BUTTON,

FOR USE

DO NOT USE IF ABOVE TEST

FAILS

WHEN GREEN LIGHT IS ON

IT IS WORKING PROPERLY

RESET

TEST

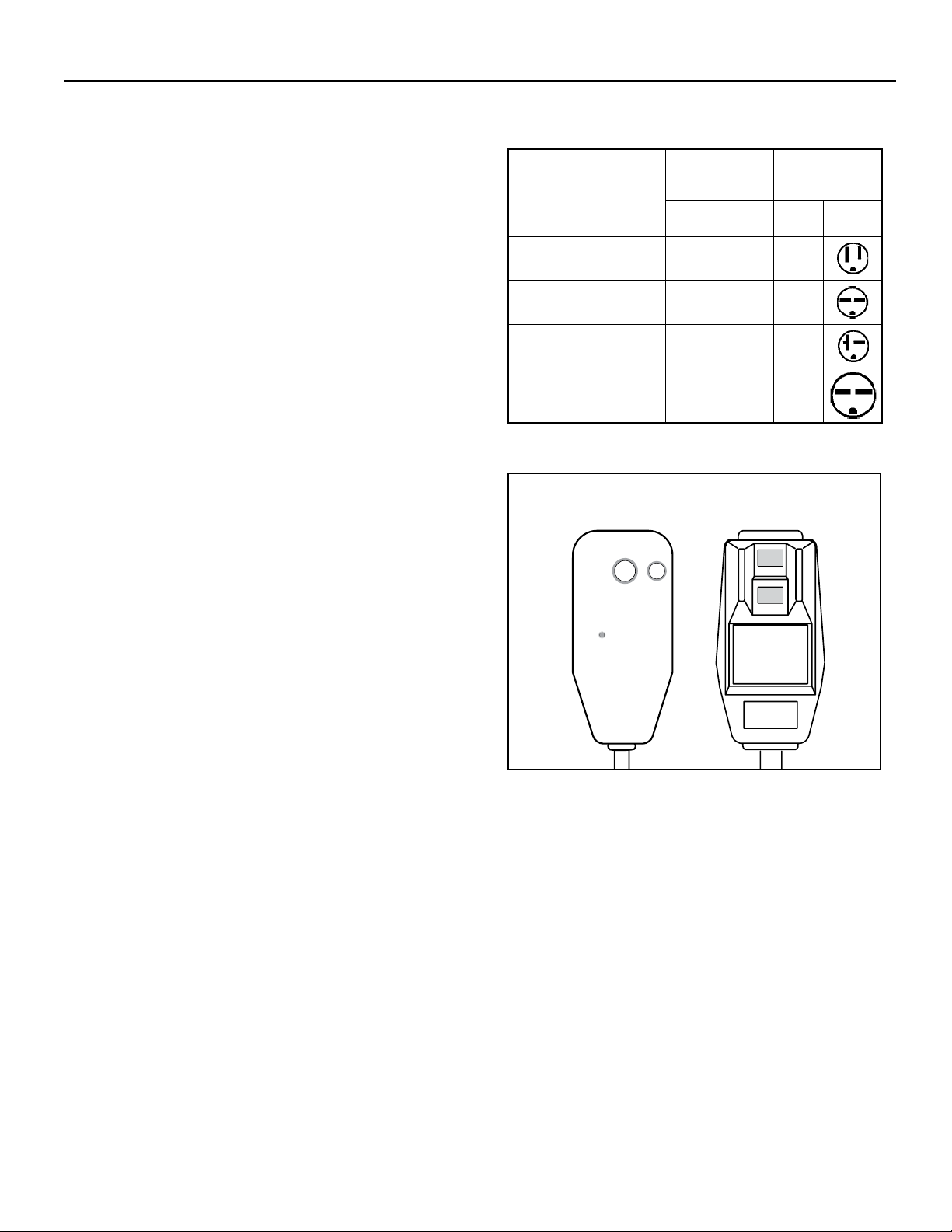

WARNING: Before operating your unit

Make sure the wiring is adequate for your unit.

If you have fuses, they should be of the time delay type. Before you install

or relocate this unit, be sure that the amperage rating of the circuit breaker

or time delay fuse does not exceed the amp rating listed in Figure 1.

DO NOT use an extension cord.

The cord provided will carry the proper amount of electrical power to the

unit; an extension cord will not.

Make sure that the receptacle is compatible with

the air conditioner cord plug provided.

This insures proper grounding. If you have a two prong receptacle you

will need to have it replaced with a grounded receptacle by a certied

electrician. The grounded receptacle should meet all national and local

codes and ordinances. Under no circumstances should you remove the

ground prong from the plug. You must use the three prong plug furnished

with the air conditioner.

Test the power cord

All Friedrich room air conditioners are shipped from the factory with a

Leakage Current Detection Interrupter (LCDI) equipped power cord. The

LCDI device meets the UL and NEC requirements for cord connected air

conditioners effective August 2004.

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET (See Figure 2).

3. Press TEST (listen for click; Reset button trips and pops out).

4. Press and release RESET (listen for click; Reset button latches and

remains in). The power supply cord is ready for operation.

NOTE: LCDI device is not intended to be used as a switch.

Once plugged in the unit will operate normally without the need to reset

the LCDI device.

If the device fails to trip when tested or if the power supply cord is

damaged it must be replaced with a new supply cord from the manufacturer. We recommend you contact our Technical Assistance Line at

(800) 541-6645 ext. 845. To expedite service, please have your model

and serial number available.

MODEL

SS08 • SS10 • SS12 • SS14

KS12 • KS15 • YS09

SS12 • SS16 • SM18

SM21 • KM18

SM24 • SL28 • KM24

YS13 • ES12 • ES16

SL36 • YM18 • YM23 • YL24

EM18 • EM24 • EL36

CIRCUIT RATING

OR TIME DELAY

FUSE

AMP VO LT

15 125 5-15R

15 250 6-15R

20 250 6-20R

30 250 6-30R

REQUIRED

RECEPTACLE

NEMA

NO.

Figure 1

NOTE: Your LCDI device will resemble one of these illustrations.

Figure 2

WALL

For the best cooling performance and highest energy efficiency

Keep the filter clean

Make sure that your air conditioner is always in top performing condition

by cleaning the filter regularly. Instructions for removing and cleaning the

filter can be found on page 7.

Provide good air flow

Make sure the airflow to and from the unit is clear. Your air conditioner puts the

conditioned air out at the top of the unit, and takes in unconditioned air at the

bottom. Airflow is critical to good operation. It is just as important on the outside

of the building that the airflow around the unit exterior is not blocked.

Unit placement

If your air conditioner can be placed in a window or wall that is shaded by a tree

or another building, the unit will operate even more efficiently. Using drapes or

blinds on the sunny side of the dwelling will also add to your unit’s efficiency.

Insulation

Good insulation will be a big help in maintaining desirable comfort levels.

Doors should have weather stripping. Be sure to caulk around doors and

windows.

Proper installation of seal gasket

Make sure the seal gasket has been installed properly to minimize noise

and improve efciency. If the seal gasket has not been installed, please

refer to Step 14 (page 13) of the installation instructions.

Also, if you switch from Cool mode to Fan Only, and switch back to

COOL mode, there is a three minute delay before the compressor comes

back on.

3

Page 4

920-198-00

A/C

Stop

Mode

Temp

Fan

Timer

O

F

/

O

C

A/C

Start

Timer

On/ Off

1- 4

Speed

Smart

Fan

Check

Filter

Set

Hour

Power

Cool

Money

Saver

®

PM

Fan

Only

Press to reset

13

DISPLAY

8

5

4

2

15

10

7

11

9

6

3

1

14

12

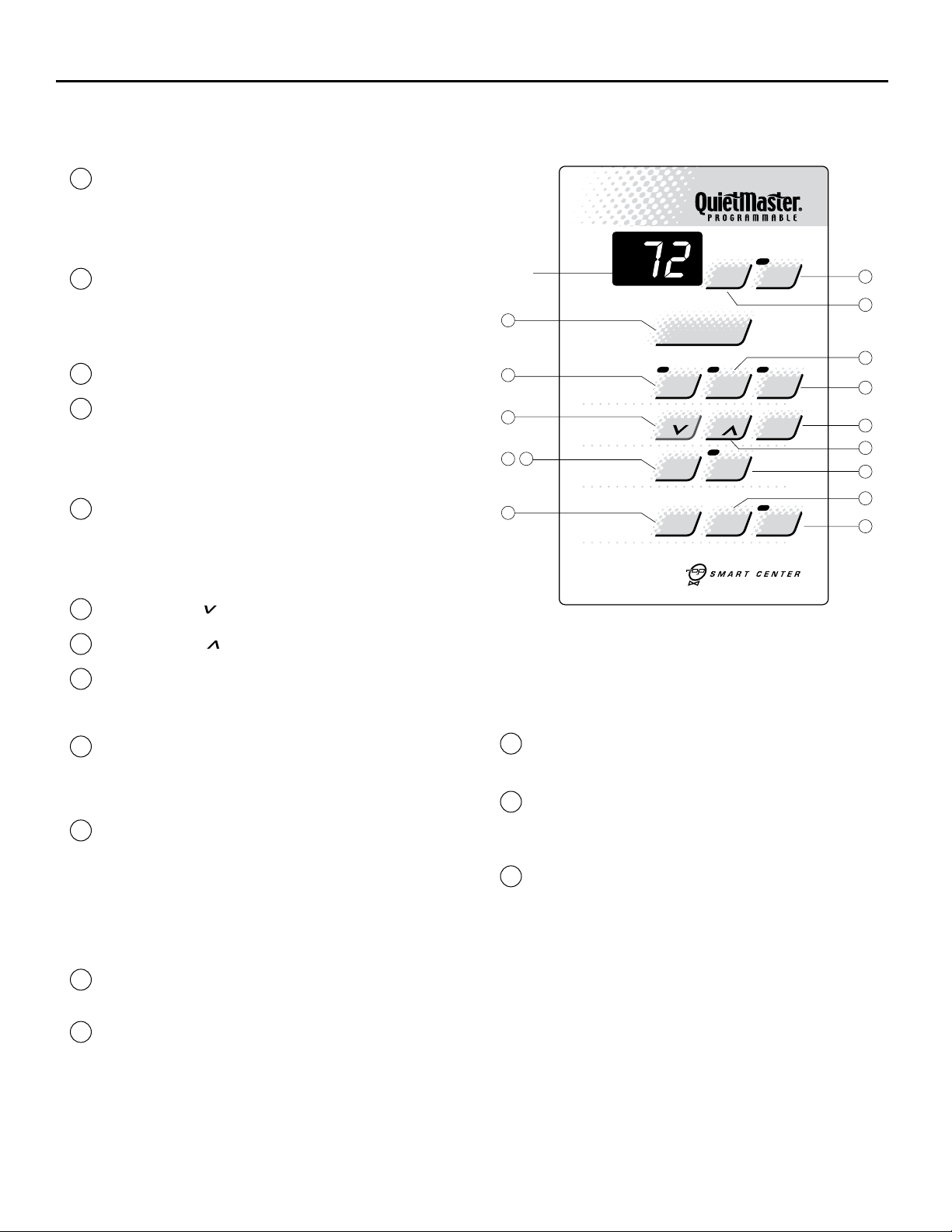

How to operate your Friedrich room air conditioner (QuietMaster Programmable)

To start unit

1

If your air conditioner is installed and plugged into a proper receptacle, it is ready to go. Touch Power button once. The unit will

automatically be in Cool mode with the temperature set at 75°F

(24°C) and the fan speed at F1, the sleep setting. There is a 3minute delay before the compressor will turn on. (See "Automatic

Component Protection" on this page).

2

Should the Check Filter light turn on when you rst turn on the unit,

touch Check Filter to turn off the light. Check Filter light will come

on after 250 hours of use. (See page 7 for lter cleaning instructions.)

Touch Check Filter to reset.

To set mode of operation

3

When you rst turn on the unit, it will be in the Cool mode (light on),

with constant fan.

Tou ch MoneySaver

4

This cycles the fan with the compressor so that the fan does not

run all the time. This saves energy and improves dehumidication.

(MoneySaver

ture if the off cycle is too long). Or you may prefer constant fan for

more air movement. To return to constant fan, touch Cool.

5

Touch Fan Only (light on) if you want only the fan to run. You may

want to use this feature in conjunction with the Fresh Air / Exhaust

lever to bring outside air into a room, or to exhaust stale air. (See

page 7, "Fresh Air and Exhaust Control" for more information.)

®

(l ight on) to acti vate the Mo ney Sav er® feature.

®

wi ll al so ru n the fan t o sam ple t he r etur n air temp era-

Figure 3

To adjust temperature [60°F (16°C) to 90°F (32°C)]

6

COOLER – Tou ch

room temperature.

WARMER – Touc h and hold until the display shows the desired

7

room temperature.

8

FAHRE NHEIT / CEL SIUS – Touc h º F / º C to show the temperature in Celsius, touch again to show Fahrenheit.

and hold until the display shows the desired

To adjust fan speed

9

Touch 1- 4 Speed to see current setting. Touch again to change

speed. F1 is the lowest setting (SLEEP SETTING), F2 is low speed

(LOW), F3 is medium speed (MED), F4 is high speed (HIGH).

To activate smart fan

Tou ch Smart Fan (light on). Smart Fan will adjust the fan speed

10

automatically to maintain the desired comfort level. For example,

if the outside doors in your home are open for an extended period

of time, or more people enter a room, Smart Fan may adjust to a

higher fan speed to compensate for the increased heat load. This

keeps you from having to adjust the fan speed on your own. Smart

Fan cannot be activated in the Fan Only mode.

To deactivate smart fan

Touch 1-4 Speed, and select your desired fan speed.

11

To set hour clock

Press Set Hour once to see the current clock setting. Continue

12

pressing the button until the hour closest to the actual time appears

in the display.

MAKE SURE YOU SET A.M. AND P.M. PROPERLY. A light will appear in

the upper left corner of the display when the hour is P.M.

NOTE: Minutes will NOT show on display.

4

To set the timer

NOTE: Set Hour clock before attempting to set timer functions.

You can set the A/C Start and A/C Stop timer a minimum of one hour

apart and a maximum of 23 hours apart.

TIMER STOP - Press the A/C Stop button and continue pressing

13

until the hour you want the unit to shut off appears in the display

(A.M. or P.M.). The stop time for cooling will then be set.

START TIME - Press A/C Start to view the current start time for

14

cooling. Continue pressing until the hour you want the unit to start

appears in the display (A.M. or P.M.). The start time for cooling will

then be set.

Press the Timer On/ Off button once to activate (light on) the timer

15

function. Touch Timer On/ Off again (light off) to cancel the timer

function if you so desire. Once the on and off times have been selected,

they will remain in memory, and cycle daily until changed.

NOTE: If unit is unplugged or power is interrupted, the Set Hour button

must be reset or the Timer On/ Off functions will not work.

Automatic component protection

Your unit is equipped with Automatic Component Protection.

To protect the compressor of the unit, there is a three minute time delay

if you turn the unit off or if power is interrupted. The fan will not be affected.

Page 5

920-198-00

Money

Fan

Timer Operation

Set Hr.

Stop

Start

Temperature

Fan

Cool

On/Off

Power

Cooler

Only Speed Saver

®

Warmer

8

10

7

11

9

43

1

2

56

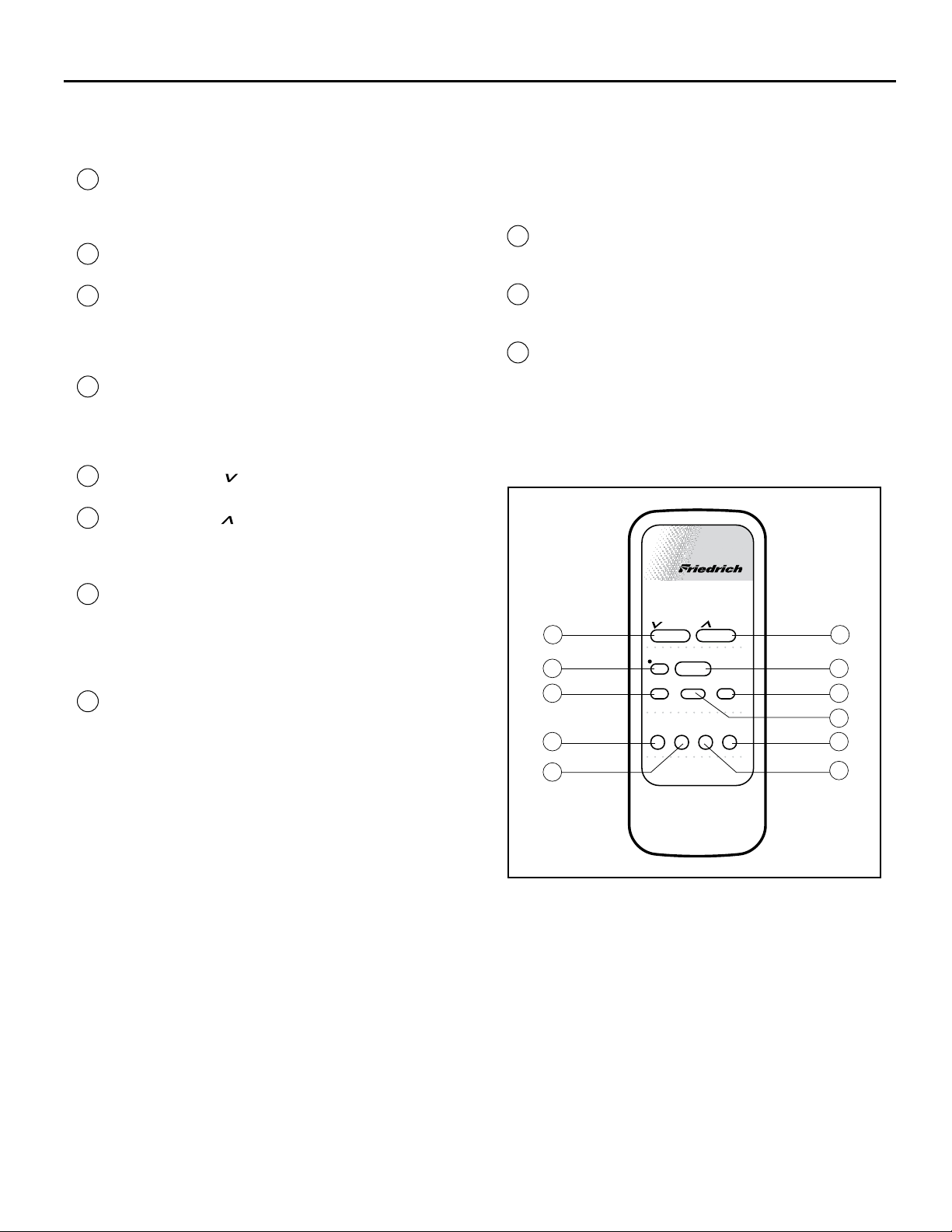

How to use the remote control* (QuietMaster Programmable)

To start unit

1

POWER - Press the Power button once. The unit will automatically

turn on in the mode and fan speed it was last left on.

To set mode of operation

2

CO OL - P ress the Cool button to automatically switch the operating

mode to COOL.

3

FAN ONLY - Press the Fan Only button if you want to run the fan only.

You may want to use this feature in conjunction with the Fresh Air/

Exhaust if you want to bring outside air into the room, or exhaust stale

air. (The FRESH AIR/ EXHAUST feature is located on the front of the

air conditioner near the top. See Figure 9 on page 7.)

4

MoneySaver

MoneySaver

®

- Press the MoneySaver

®

feature. This cycles the fan with the compressor so

®

button to activate the

that the fan does not run all the time.

To adjust temperature

5

COOLER - Press the

setting.

6

WARMER - Press the

setting.

Cooler button to raise the temperature

Warmer button to lower the temperature

To adjust fan speed

7

FAN SPEED - Press the Fan Speed button to see the current set-

ting. Press again to change the fan speed. F1 is the lowest setting

(SLEEP SETTING), F2 is low speed (LOW), F3 is medium (MED),

and F4 is high (HIGH).

To set the timer

NOTE: Set the hour clock before attempting to set timer functions. You

can set the timer On/Off a minimum of one hour apart, and a maximum

of 23 hours apart.

9

TIMER START - Press Start to view the current start time for cool-

ing. Continue pressing the Start button until you arrive at the start

time you desire. The start time for cooling will then be set.

TIMER STOP - Press the Stop button. Continue pressing the Stop

10

button until you arrive at the stop time you desire. The stop time for

cooling will then be set.

TIMER ON/OFF - Press the On/off button once to activate (light

11

on) or deactivate (light off) the timer. Once the Start and Stop times

have been selected, they will remain in memory, and cycle daily until

changed.

NOTE: If the unit is unplugged or the power is interrupted, the HOUR

CLOCK must be reset or the Timer On/off functions will not work.

Figure 4

To set the hour clock

8

SET HOUR CLOCK - Pre ss Set Hour o nc e to s ee t he c urre nt c loc k se t-

ting. Continue pressing the button until you arrive at the current time.

MAKE SURE YOU SET THE A.M. AND P.M. PROPERLY. (NOTE:

MINUTES ARE NOT SHOWN ON THE DISPLAY.) A light will appear in

the upper left corner of the display when the hour is P.M.

*

A Friedrich RC1 wireless remote control can be used to operate all

QuietMaster

Programmable models.

®

5

Page 6

920-198-00

Allow 3 min. bet ween restarts

S P E E D

Sleep

Setting

Low

Cool

Medium

Cool

High

Cool

Fan

Only

Off

MIN MAX

Money Saver

®

Yes No

Allow 3 min. between restarts

Money Saver

®

MAX

COOL

MAX

HEAT

Low

Cool

Med

Cool

High

Cool

Low

Heat

Med

Heat

High

Heat

Fan

Only

Off

Yes No

How to operate your Friedrich room air conditioner

(QuietMaster 'K' & Heavy Duty models / Twintemp models)

To start unit

If your air conditioner is installed and plugged into a properly grounded

receptacle, it is ready to operate.

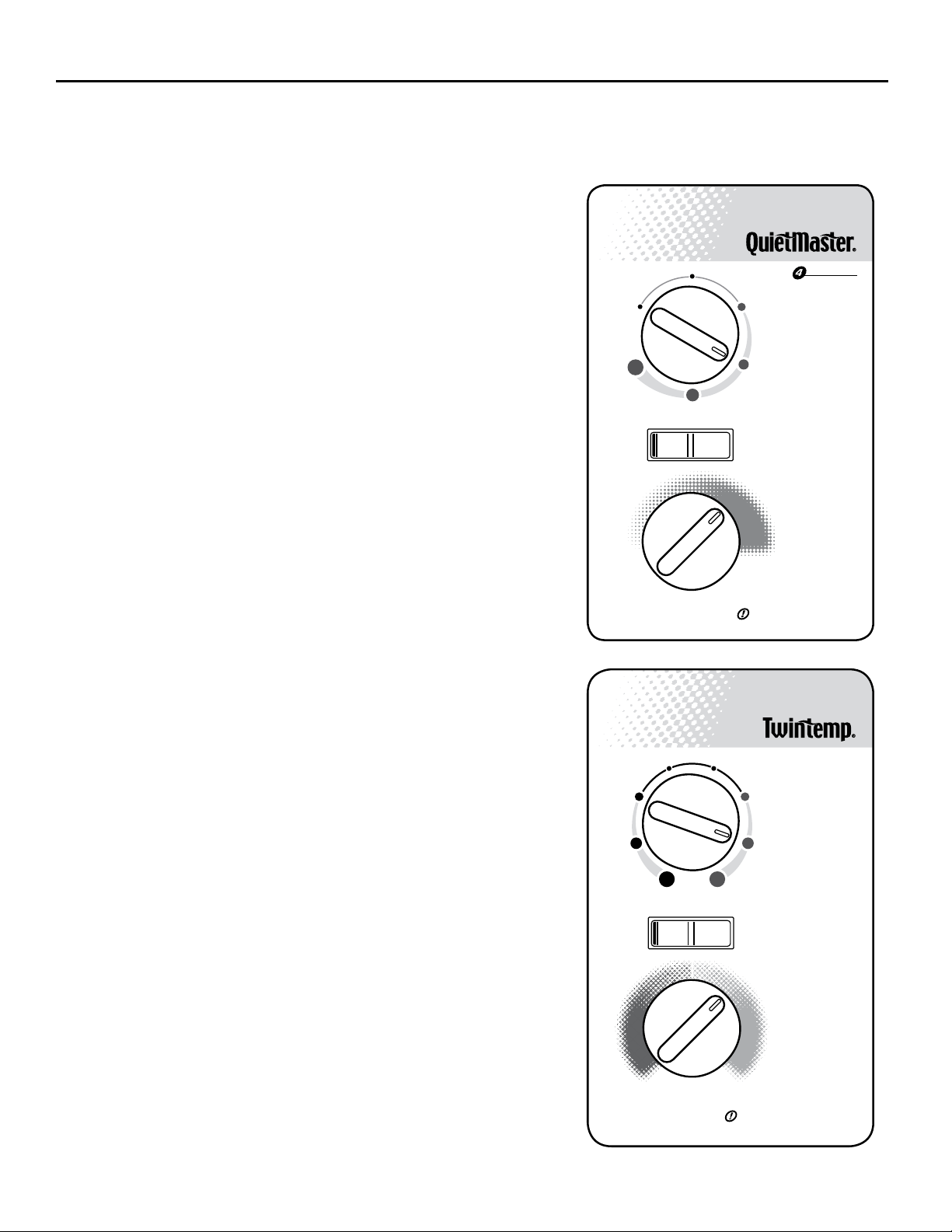

Mode control (QuietMaster ‘K’ and Heavy Duty)

The upper dial (Figure 5) allows you to select cooling at four different

speeds, as well as Fan Only (Models SL28 and SL36 only have three

cooling speeds.).

Off - to turn the unit off.

High Cool - for quick cooling.

Medium Cool - to maintain a desired temperature.

Low Cool - when cooling demand is low.

Sleep Setting - for nighttime use, or when cooling demand is low.

Fan Only - to circulate air in the room without the compressor coming on.

The Fan Only s et ti ng c an als o b e us ed wi th t he Exhaust air setting to remove

stale air or smoke from the room; or it can be used with the Fresh Air setting

to bring outside air into the room. This is especially useful in the spring and fall

when cooling may not be necessary. The Fresh Air and Exhaust controls

are in the upper air discharge area. The center position of this control is the

normal, or closed position, which recirculates air for maximum performance

in the cooling mode (See Figure 9).

Mode control (Twintemp)

This dial allows you to select cooling or heating at three different speeds,

as well as Fan Only (Figure 6).

Off - to turn the unit off.

High Cool or High Heat - for quick response.

Medium Cool or Medium Heat - to maintain a desired temperature.

Low Cool or Low Heat - for nighttime use, or when demand is low.

Fan Only - to circulate air in the room without the compressor coming on.

The Fan Only setting can also be used with the Exhaust air setting to

remove stale air or smoke from the room, or it can be used with the Fresh

Air setting to bring outside air into the room, especially in the spring and

fall when cooling isn’t necessary.

The Fresh Air and Exhaust controls are in the upper air discharge area

(see Figure 9, page 7). The center position of this control is the normal, or

closed position, which recirculates air for maximum performance in the

cooling mode.

NOTE: You may notice an odor when rst activating the heat when the

electric heat element comes on. This is due to dust burning off that may

have gathered on the coil during the summer. This is normal.

Temperature control

The bottom dial on the control panel is the thermostat. Turn it clockwise

for cooler temperature and counterclockwise for warmer.

Money Saver® switch

This rocker switch can be depressed to either Yes o r No. In the Yes position

you will get the most economical operation. Both the fan and compressor

will cycle on and off together, maintaining the selected temperature at a

more constant level and reducing the humidity more efciently in the cooling

mode. This control will only operate when the unit is in cooling or heating

mode. In the No position, the fan will run constantly as long as the unit is

in the cooling or heating mode.

NOTE: The YS09 is a 115 volt model and does not provide adequate heat

below 37°F (3°C). This product is designed for warm climate applications.

Figure 5

Figure 6

6

Page 7

920-198-00

DISCHA RGE AIR PL ENUM

SLOT

TA B

SLOT

TA B

NOTE 2

RETURN AIR GRILL E

NOTE 1

LATCHES

NOTE 3

NOTE 1

RETURN AIR GRILL E

NOTE 4

SIDE V IEW

LATCH

NOTE 3

Care and Maintenance / Fresh air and exhaust control

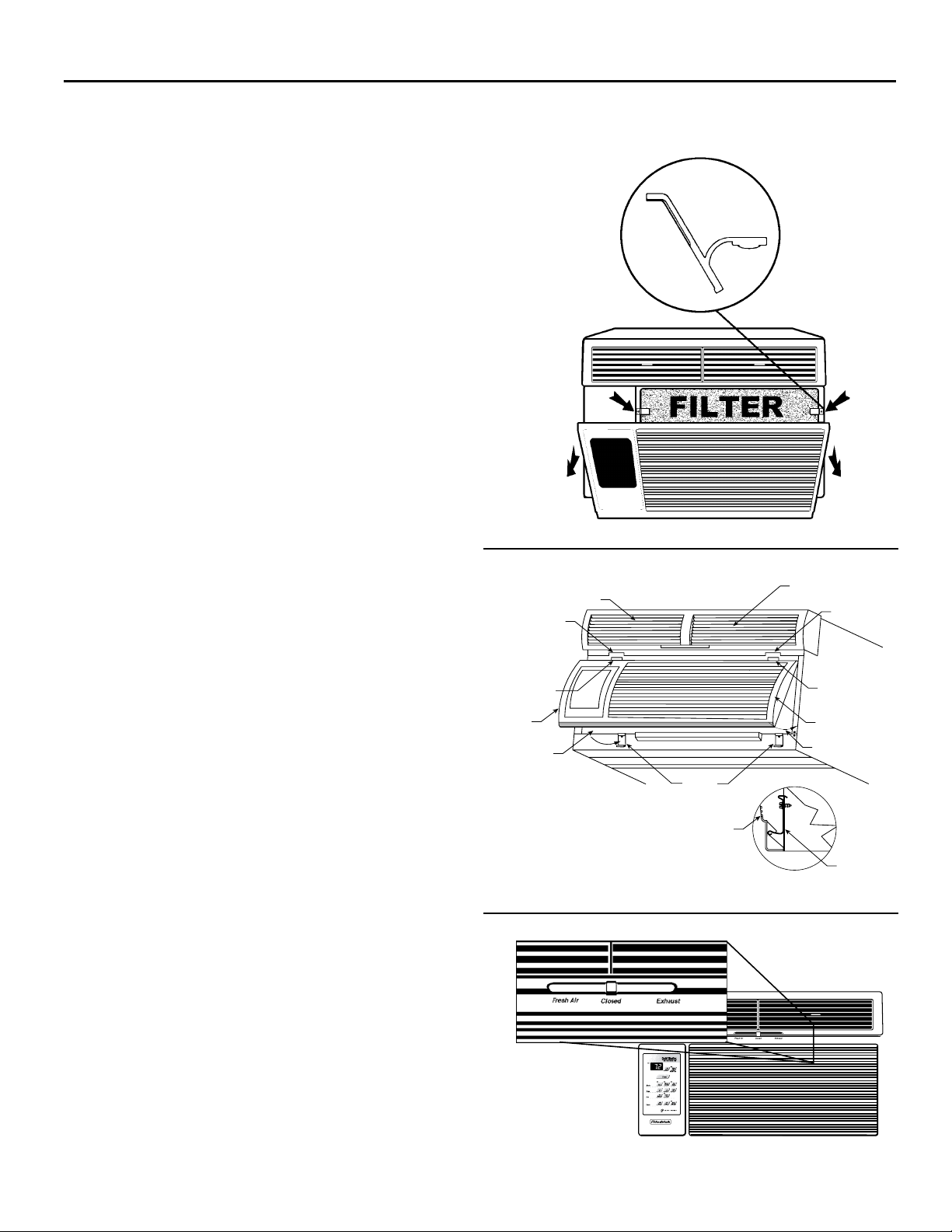

To remove, wash and replace filter and return air grille

Open the return air (RA) grille by grasping it at the top outside edges and

pulling towards you (See Figure 7). The RA grille will stay open until it is

detached or closed (it is easier to completely detach the grille before closing

it). To remove the RA grille, grasp it at the bottom and pull towards you.

The lter is held in place by two spring clips (See Figure 7). Push down on

the clips, grasp the lter and pull towards you to remove it for cleaning. Clean

with warm water and a mild detergent, rinse, dry completely and replace.

Use caution when removing the lter. The coil surface can be sharp.

If the RA grille has been removed, pick up the grille by supporting it from

both sides near the bottom (See Figure 8, Note 1). Lift return air grille and

insert the grille's tabs into the bottom slots of the discharge air plenum (See

Figure 8, Note 2). Snap the grille into place by pushing the grille up and onto

the unit's latches at the bottom (See Figure 8, Notes 3 and 4).

Fresh air and exhaust control

Your air conditioner has the ability to bring fresh air into the room or exhaust

stale air out of the room. The control lever is found on the upper part of

the unit (See Figure 9).

TO BRING IN FRESH AIR - Move the lever to the Fr esh A ir position which

allows outside air to enter the room. This is useful in fall and spring as a

means of bringing in fresh outside air when using Fan Only. It can also be

used in the summer with the compressor in the Cooling Mode if you wish.

Normally, for most efcient operation, cooling is accomplished with this

control in the middle or closed position.

TO EX HAU ST I ND OO R AI R - Mov e th e lev er t o th e Exhaust position. This

will allow stale air to be expelled to the outside of the dwelling. This is especially handy in the spring or fall when indoor air tends to get stale, or after a

social gathering involving smokers, or to remove odors after cooking.

Figure 7

Figure 8

Figure 9

7

Page 8

Installation Instructions

920-198-00

NOTE: This manual includes installation instructions for window mount and thru-the-wall mount methods. TwinTemp

®

heat/cool units are designed for

permanent thru-the-wall installation. Mounting the unit in a window will require a window mounting accessory kit, available through your Friedrich dealer.

Read This First! Electrical Requirements

I MP OR TAN T: Before you begin the actual installation of your air conditioner,

check local electrical codes and the information below.

Your air conditioner must be connected to a power supply with the same

A.C. voltage and hertz as marked on the data plate located on the chassis.

Only alternating current (A.C.), can be used. Direct Current (D.C.) cannot be

used. Refer to page 3 for the correct type of receptacle for your model.

CIRCUIT PROTECTION - USE ON SINGLE OUTLET CIRCUIT ONLY.

An overloaded circuit will invariably cause malfunction or failure of an air

conditioner, therefore, it is necessary that the electrical protection is adequate. Due to momentary high current demand when your air conditioner is

started, use a "TIME DELAY" fuse or a HACR type circuit breaker. Consult

your dealer or power company if in doubt.

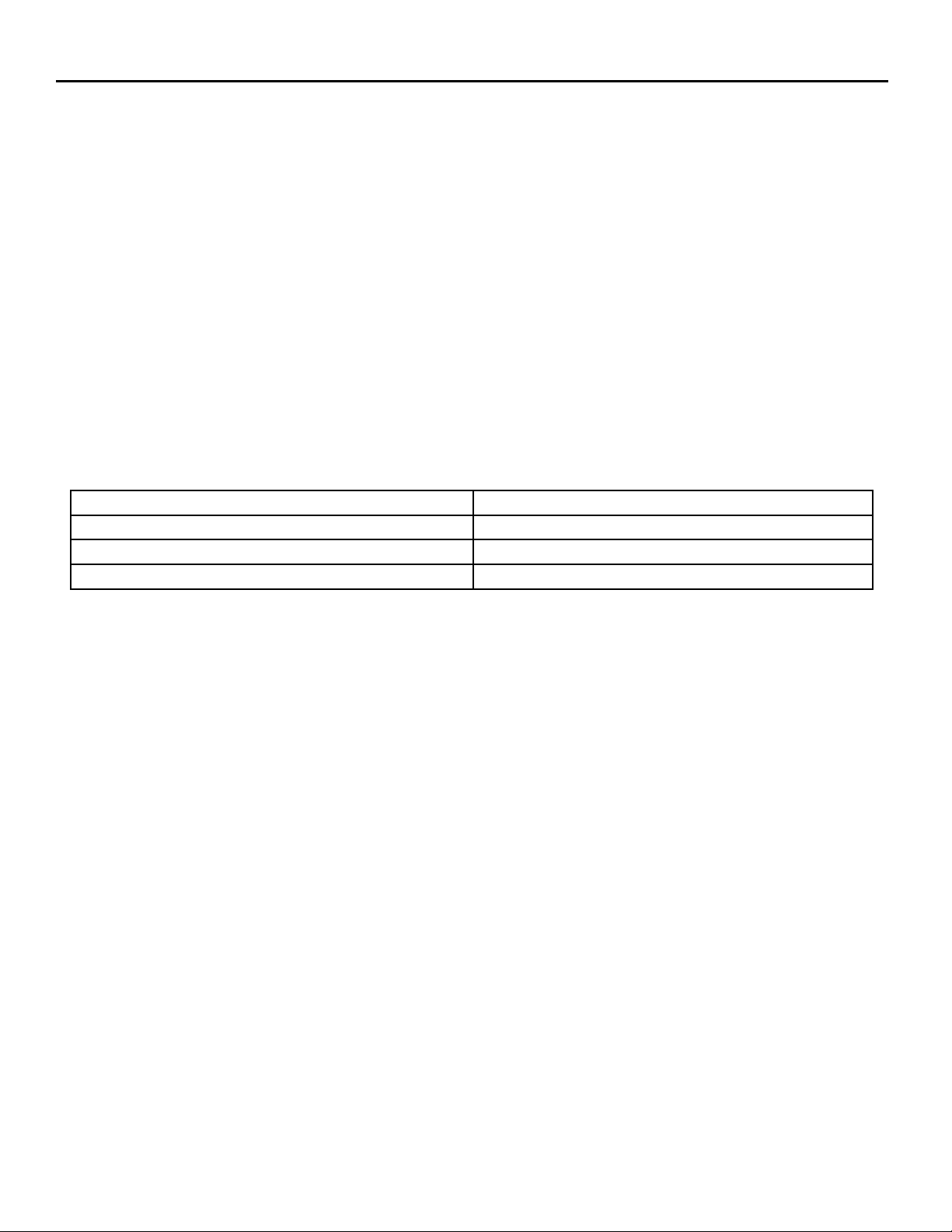

MODEL DESIGNATION CABINET SIZE (H x W x D)

SMALL CHASSIS - SS, ES, YS, KS 15

MEDIUM CHASSIS - SM, EM, YM, KM 17

LARGE CHASSIS - SL, EL, YL 20

Refer to the electrical data plate located on the air conditioner chassis to

determine the correct fuse or circuit breaker amperage for your model (See

Figure E on Page 16 for electrical receptacle location).

The power cord has a plug with a grounding prong of approved type and

a matching receptacle is required.

WARNING: NEVER CUT OR REMOVE THE GROUNDING PRONG

FROM THE PLUG. NEVER USE EXTENSION CORDS TO OPERATE

AN AIR CONDITIONER.

The following instructions are for standard chassis model groups distin-

guished by the rst two letters of the model designations and cabinet

sizes listed below.

15

⁄16" x 25 15⁄16" x 27 3⁄8" (405 mm x 660 mm x 695 mm)

15

⁄16" x 25 15⁄16" x 27 3⁄8" (455 mm x 660 mm x 695 mm)

3

⁄16" x 28" x 33 5⁄8" (513 mm x 711 mm x 854 mm)

8

Page 9

920-198-00

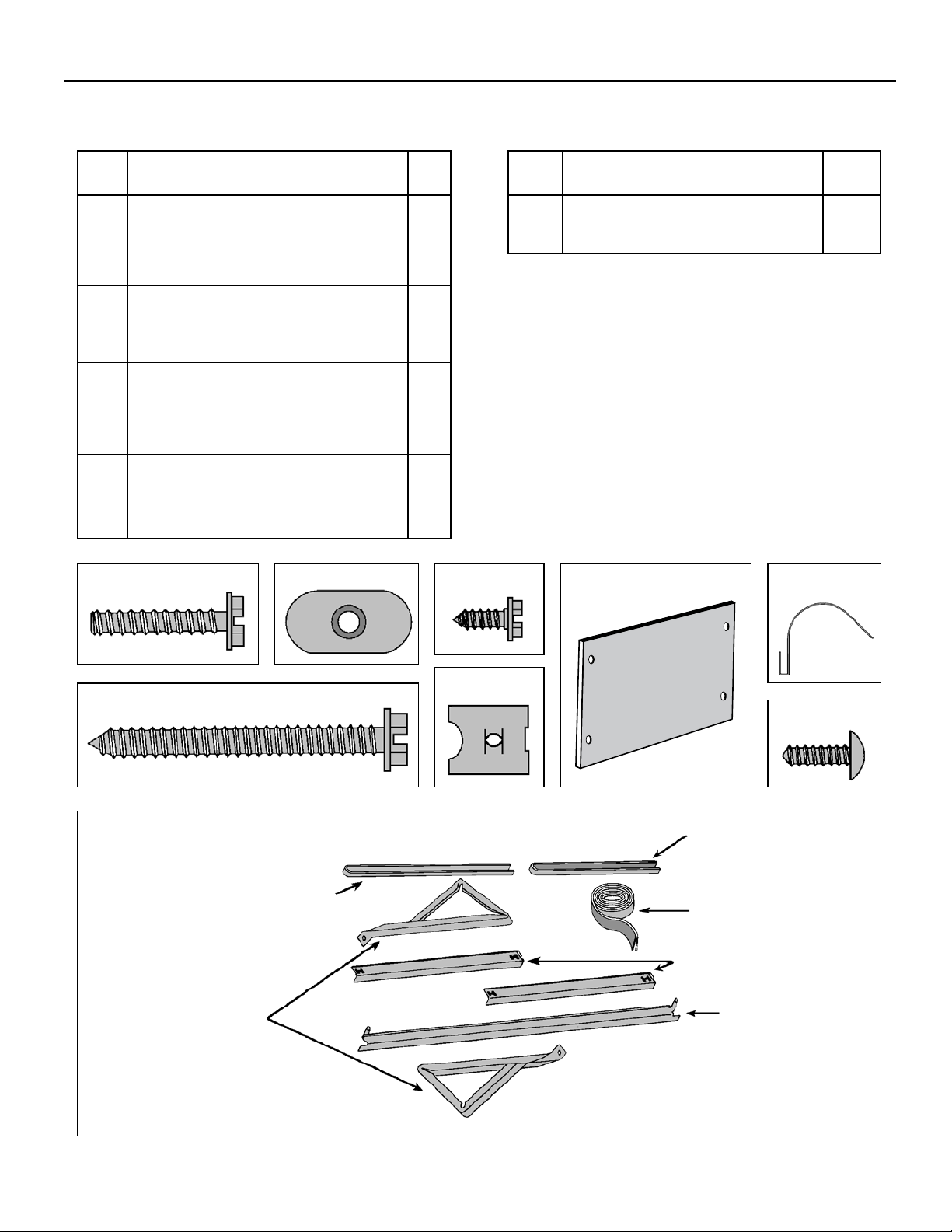

Window Mount

Installation Hardware

ITEM

NO.

DESCRIPTION

SHELL MOUNTING PARTS

1 SUPPORT BRACKET 2

2 SCREW, 10-24 x 1" HEX HEAD 4

3 10-24 FLAT WELD NUT 4

4 SCREW, SHEET METAL #12A x 2" 7

WINGBOARD ANGLE MOUNTING

5 WINGBOARD ANGLE, TOP 1

6 WINGBOARD ANGLE, SIDE 2

7 SCREW, SHEET METAL #8A x 3⁄8" 2

WINGBOARD MOUNTING PARTS

8 WINGBOARD (MASONITE) 1

9 "J" TYPE SPEED NUT 4

10 WINGBOARD CLIP (SPRING STEEL) 4

11 SCREW, #8A x ½" PHILLIPS TRUSS HD. 4

WINDOW SEALING

12 SEALING GASKET (VINYL) 1

13 WINDOW SEAL GASKET (DARK FOAM) 1

14 CHASSIS SEAL GASKET (LIGHT FOAM) 1

QTY.

Thru-the-wall

Installation Hardware

ITEM

NO.

MOUNTING PARTS

4 SCREW, SHEET METAL #12A x 2" 7

14 CHASSIS SEAL GASKET (LIGHT FOAM) 1

DESCRIPTION

QTY.

ITEM #2

ITEM #4

ACCESSORY DETAIL

ITEM #14

ITEM #1

ITEM #3

ITEM #7

ITEM #9

ITEM #8

ITEM #10

ITEM #11

ITEM #13

ITEM #12

ITEM #6

ITEM #5

NOT TO SCALE

9

Page 10

920-198-00

HAND PULL

FAR RIGHT

SCREW

CHASSIS

RETAINER

WIRE

PULL STRAP

Standard Sash Window Installations

STEP 1 Remove decorative plastic return air grille to a safe area away

from unit. The return air grille can be removed by pulling at the

sides on either the top or bottom.

STEP 2 Also remove the installation hardware to a safe area away from

the unit.

STEP 3 Remove the chassis retainer by removing the far right screw

in the basepan (see Figure A); save this screw to reattach the

chassis retainer after installation (Step 15). Also, remove and

discard the two retainer screws and black plastic washers

located at the rear of the unit.

STEP 4 While an assistant holds the cabinet stationary, use the hand pull at

the f ront of th e base pan, tog ethe r wit h the pull stra p (see Figure A)

to pull the chassis out of the cabinet. REMOVE THE LARGE WHITE

FOAM BLOCKS USED TO RESTRAIN THE COMPRESSOR

DURING SHIPMENT. Inspect basepan for dislodged white blocks,

and remove. Do not remove any other foam parts.

Figure A

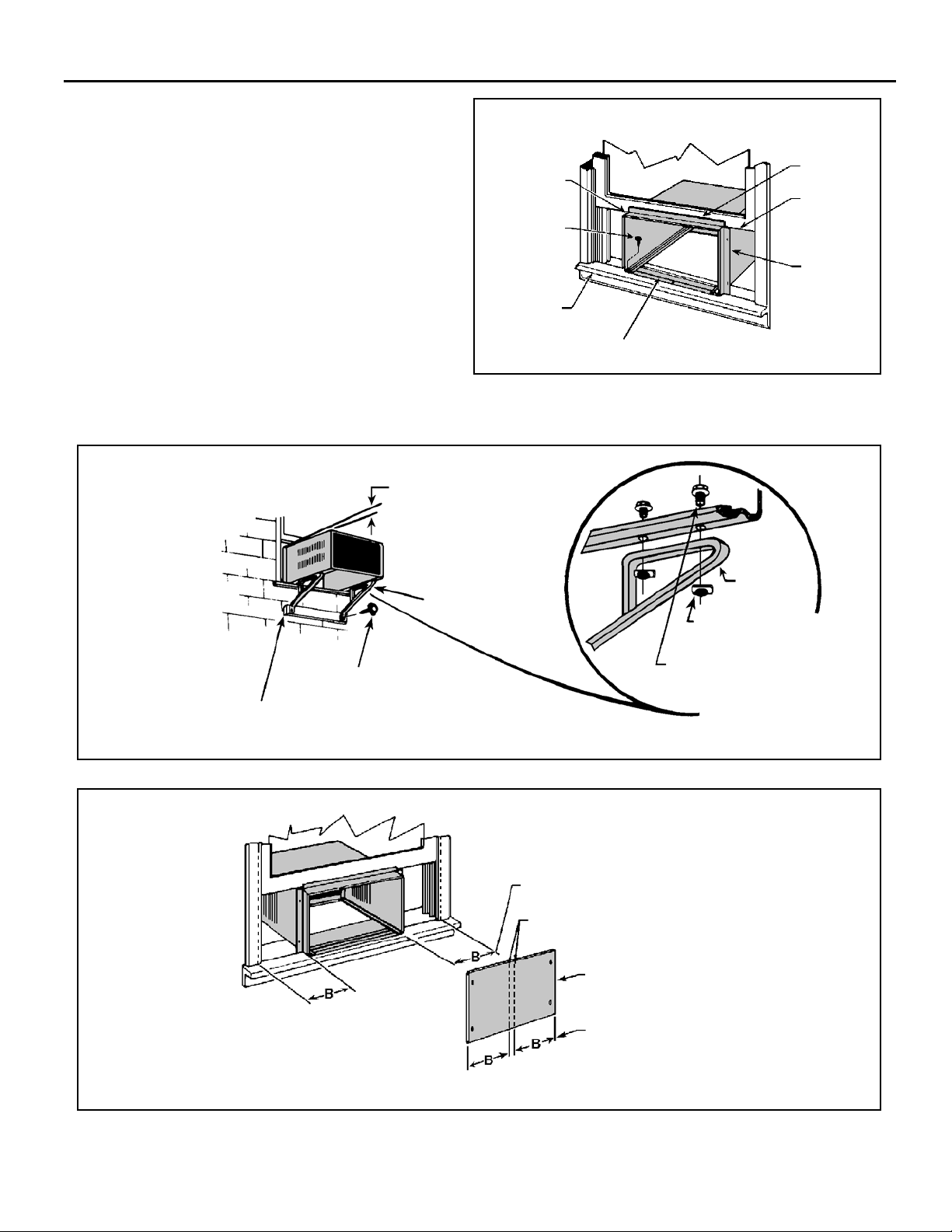

STEP 5 Anchor the side angles (Item #6) by engaging the tabs at each

end of the sill plate (see Figure B) with the bottom loops of the

side angle. Engage the tabs at each end of the top angle (Item

#5) with the top loops of the side angle (see Figure B). Install

two (2) screws (Item #7) to secure the top angle tabs and the

side angle to the cabinet (see Figure B).

STEP 6 Check the window sill and frame to be sure they are in good

condition and rmly anchored to the wall. Repair if necessary.

STEP 7 CABINET MOUNTING – Raise the lower sash window ¼"

more than the height of the cabinet. Carefully slide the cabinet

through the open window until the sill plate channel rests behind

the window sill and the top support rests against the window

(see Figure C.) Center side to side and drill three (3)

5

⁄32" dia.

pilot holes into the window sill using the holes in the cabinet sill

plate as a guide. Install three (3) #12A x 2" long screws (Item

#4, Figure C).

10

Figure B

CABINET

TOP ANGLE (ITEM #5)

SIDE ANGLE

(ITEM #6) 2

REQUIRED

SILL

PLATE TAB

8A x ⅜" LONG SCREW

(ITEM #7) 2 REQUIRED

DETAIL B-1

DETAIL B-2

TAB

LOOP

Page 11

920-198-00

STEP 8 OUTSIDE SUPPORT MOUNTING – Assemble the support

brackets (Item #1) to the bottom rails of the cabinet with four

(4) 10-24 1" long screws (Item #2) and four (4) 10-24 at nuts

(Item #3). Adjust the support brackets to bring the bottom pads

in contact with the wall surface. (A 1" x 4" or 2" x 4" SPACER

SHOULD BE USED BETWEEN THE WALL AND THE

SUPPORT BRACKETS WHEN INSTALLED ON ALUMINUM

OR VINYL SIDING). Drill

5

⁄32" dia. pilot holes and secure the

brackets to the wall with two (2) #12A x 2" long screws (Item

#4). Adjust the support brackets to provide an approximate 3/8"

down slope toward the outside for drainage. (See Figure D).

Tighten all screws.

NOTE: The discharge air, return air, condenser air inlets and

Figure C

CENTER

CABINET IN

WINDOW SIDE

TO SIDE.

DRILL (3)

PILOT HOLES

AND INSTALL

5

⁄32"

(3) #12A x

2" LONG

SCREWS

(ITEM #4)

WINDOW

SILL

TOP

SUPPORT

ANGLE

PULL

WINDOW

SASH DOWN

BEHIND TOP

SUPPORT

ANGLE

SIDE

SUPPORT

ANGLE

outlets must be unobstructed to avoid recirculation of rejected

heated air.

LOCATE SILL PLATE GUIDE CHANNEL

JUST BACK OF WINDOW SILL

The following illustrations show a standard frame construction installation as well as some suggested ways of adapting the support bracket to thick walls and

large stone ledges.

Figure D

⅜" DOWN SLOPE

#12A x 2" SCREW

(ITEM #4)

1" x 4" OR 2" x 4" SPACER SHOULD BE USED

BETWEEN WALL AND BRACKET WHEN INSTALLED

ON ALUMINUM, ASBESTOS OR VINYL SIDING

Figure E

NOTE: It is not necessary to cut the wingboard for

vertical height; only horizontal WIDTH Dimension “B”.

SUPPORT BRACKET

(ITEM #1)

MEASURE DISTANCE "B" TO INSIDE OF THE

CHANNEL ON EACH SIDE

CUT HERE AND DISCARD CENTER WASTE

MATERIAL.

SUPPORT

BRACKET

10 – 24 FLAT WELD

NUT (ITEM #3)

10 – 24 x 1" HEX HD.

SCREW (ITEM #2)

WINGBOARD

SUBTRACT ⅛" FROM DIMENSION "B" AND

MEASURE FROM THE EDGE OF THE WINGBOARD (ITEM # 8), MARK, SCORE AND CUT

WITH APPROPPRIATE CUTTING TOOL

11

Page 12

920-198-00

Figure 1A TYPICAL MOUNTING SCHEME

10 - 24 SCREW

10 - 24 FLAT NUT

SUPPLY AIR

RETURN AIR

#12A x 2" SHEET METAL

SCREW

1" x 4" OR 2" x 4" SPACER

BETWEEN WALL AND

BRACKET SHOULD BE

USED ON ALUMINUM,

ASBESTOS OR VINYL

SIDING.

⅜" SLOPE

DOWN

CONDENSER

AIR OUTLET

CONDENSER

AIR INLETS

Figure 2A MODIFIED MOUNTING SCHEME

⅜" SLOPE DOWN

CUT

HERE

DISCARD

SHADED AREA

CUT TO FIT DIMENSION "A"

AND BEND DOWN TO FORM A

VERTICAL LEG.

DIMENSION "A"

STONE LEDGE

OUTSIDE WALL

Figure 3A TYPICAL MOUNTING SCHEME Figure 4A REVERSE SUPPORT BRACKET SCHEME

STONE LEDGE

⅜" SLOPE

DOWN

STONE LEDGE

#12 x 2" SHEET

METAL SCREW

2" x 4" SPACER

STEP 9 CUT WINGBOARD PANELS – Measure and cut the wingboard

panels from the Masonite supplied (Item #8) to t the spaces between the side window channels and the sides of the cabinet. (See

Figure E).

NOTE: AFTER CUTTING THE PANELS, MAKE A TRIAL TEST TO SEE IF

THEY FIT THE SPACE WITH ABOUT

1

⁄8" CLEARANCE BEFORE

GOING TO STEP 10.

STEP 10 ASSEMBLE THE CLIPS TO THE WINGBOARD PANELS-

Assemble the "J" type speed nuts (Item 9) and spring steel clips

(Item 10) to the edges of the cut wingboard panels (See Figure F).

Figure F

WINGBOARD

STRAIGHTEN TAB TO LAY FLAT

ALONG THE BOTTOM RAIL OF

THE SHELL

SECURE THE LONGEST SIDE OF

THE BRACKET TO THE SHELL

ADJUST IN OR OUT TO REST

ON LEDGE

"J" TYPE SPEED NUT

(ITEM #9) 2 REQUIRED

CUT

PANEL

CENTER THE HOLE IN THE

SPEED NUT OVER THE SLOT IN

THE WINGBOARD PANEL

⅜" SLOPE

DOWN

SPRING STEEL

CLIP (ITEM #10) 2

REQUIRED

3"

CUT EDGE

3"

SLIDE CLIP OVER

CUT EDGE OF

WINGBOARD

PANEL

12

Page 13

920-198-00

TOP WINGBOARD ANGLE

LOWER WINDOW SASH

VINYL

WINDOW

GASKET

INSERT VINYL WINDOW SEAL

GASKET OVER TOP ANGLE

TO WINGBOARD (ITEM #12)

INSERT FOAM WINDOW

SEAL GASKET (ITEM # 13)

STEP 11 INSTALL THE SIDE WINGBOARD PANELS – Be sure the

cabinet has been secured to the window sill and that the outside support brackets have been installed as shown in Figure

D. Raise the window sash and install the right and left side

wingboard panels. (See Figure G).

STEP 12 INSTALL THE WINDOW SEALING GASKETS – Measure

and cut the vinyl window seal gasket (grey color, Item # 12) to

t the width of the window, and install as shown in Figure H.

Pull the window sash down behind the gasket. Measure and

cut the dark foam window seal gasket (Item #13) and install it

between the upper glass panel and the top part of the lower

sash. (See Figure H).

NOTE: FOR REASONS OF SECURITY AND SAFETY, THE

CUSTOMER MUST PROVIDE A MEANS OF PREVENTING

THE WINDOW FROM OPENING.

Figure G

STEP 13 When possible, caulk the outside of the installation with

industrial type caulking to prevent weather leaks.

STEP 14 INSTALL CHASSIS – After installing the shell, slide the chassis

into the shell stopping approximately 3" from full insertion. Stuff

the chassis seal gasket one inch deep between the chassis

and the shell (see Figure I ). Begin at either bottom corner and

go up the side, across the top, and down the opposite side. Then

push the chassis all the way into the shell for the remaining distance

so that the plastic front meets the front edge of the shell.

If chassis seal gasket is not installed, the operation of the unit

will be negatively affected. Operational noise and outside

noise will also be amplied.

STEP 15 Reattach the chassis retainer wire with the same screw as in

Step 3 (See Figure A).

Figure H

SECURE THE SIDE WINGBOARD PANELS TO

THE SIDE ANGLES WITH FOUR (4) #8 x ½" LONG

SCREWS (ITEM #11), TWO ON EACH SIDE.

TOP OF CABINET

PLACE WINGBOARD PANEL IN

WINDOW JAM TO COMPRESS THE

SPRINGS INSIDE THE RUNNERS,

AND SWING THE PANEL INTO PLACE

INDICATED BY THE DOTTED LINE.

WINDOW JAM

SECTION A - A

SECTION B - B

13

Page 14

920-198-00

AIR FILTER

RETURN AIR

GRILLE L ATCH

CORD

CLAMP

ADJACENT

SCREW HO LE

RETURN AIR

GRILLE L ATCH

CORD CLA MP

CHASSIS

SEAL

GASKET

FAR

LEFT

SCREW

ADJACENT

SCREW

HOLE

WHEN INSTALLING CHASSIS SEAL GASKET,

BEGIN AT EITHER BOTTOM CORNER AND

GO UP THE SIDE, ACROSS THE TOP, AND

DOWN THE OPPOSITE SIDE.

DISCHARGE

AIR PLENUM

SLOT

TA B

SLOT

TA B

NOTE 2

RETURN

AIR GRILLE

(NOTE 1)

LATCHES

NOTE 3

NOTE 1

RETURN

AIR

GRILLE

NOTE 4

SIDE VIEW

LATCH

NOTE 3

STEP 16 OPTIONAL: The factory assembles the supply cord so that

it exits the left side of the unit. At the consumer’s discretion,

the supply cord can be made to exit the right side of the unit.

To do this, remove the black rubber coated cord clamp from

under the far left screw (See Figure I). Replace this screw

back into the far left screw hole. Route the supply cord over

the top of the return air grille latches and reattach the clamp

to the adjacent screw hole (Figures I & J). Detach the right

side cord clamp, route the supply cord through it and reattach.

The supply cord should be pulled taut so as not to rest on the

return air grille latches.

Figure I

STEP 17 Be sure the lter is in place before installing the return air grille

(See Figure J), and that the electrical cord is properly routed

so not to interfere with the installation. (See Step 16.)

STEP 18 Pick up the grille by supporting it from both sides near the bottom

(See Figure K, Note 1.) Lift return air grille and insert the grille's

tabs into the bottom slots of the discharge plenum (See Figure K,

Note 2). Snap the grille into place by pushing the grille up and onto

the unit's latches at the bottom (See Figure K, Notes 3 and 4).

STEP 19 Refer to the Operating Instructions beginning on page 3.

Figure J

Figure K

14

Page 15

920-198-00

Through-the-wall Installations

The following instructions apply to wood, masonry, brick, concrete or cinder block wall construction

STEP 1 Follow steps 1, 2, 3 and 4 of the "STANDARD SASH WINDOW

INSTALLATION" instructions beginning on page 10.

STEP 2 CABINET PREPARATION – Remove the sill plate from the

cabinet by removing the two nuts and screws retaining the sill

plate. Note that the chassis retainer is secured by a right side

nut and screw (See Detail 1, Figure A.) Bend the tabs of the

sill plate down into its channel at both ends of the plate or cut

them off (See Detail 2, Figure A.) Turn the sill plate end to end,

180° and reinstall. Reverse the orientation of nuts and screws

so that the head of screw is on bottom of cabinet facing up and

nut is on top facing down (See Detail 3, Figure A.) Insure that

the chassis retainer is reinstalled as shown in the detail.

Figure A

CABINET

SILL

PLATE

TURN SILL PLATE

END TO END

BEFORE

SCREW

(2 REQUIRED)

DETAIL 1

NUT

(2 REQUIRED)

RETAINER, CHASSIS

THIS SIDE ONLY

DETAIL 2

STEP 3 WALL PREPARATION – The maximum wall thickness permis-

sible without special construction is determined by the model size

to be installed. THE OUTSIDE CABINET CONDENSER-AIRINTAKE-LOUVERS MUST NOT BE BLOCKED BY EXTENDING

INSIDE THE WALL AREA. Observe the maximum wall thickness

shown in the chart and diagram in Figure B.

SPECIAL INSTRUCTIONS FOR EXTRA THICK WALLS –

For installation in walls exceeding the maximum thickness shown

in the chart, the following suggested construction may apply.

AFTER

NUT

(2 REQUIRED)

NOTE: HOLES

MOVED TO

BACK SIDE

DETAIL 3

SCREW

(2 REQUIRED)

SCREW AND NUT

ORIENTATION NOW

REVERSED

BEND TABS DOWN

Figure B EXTRA THICK WALL CONSTRUCTION

MAXIMUM WALL THICKNESS

CONDENSER

AIR INTAKE

LOUVERS

TOP VIEW SHOWING

MODEL A

SMALL CHASSIS 7 ⅜"

MEDIUM CHASSIS 7 ⅜"

LARGE CHASSIS 15 ⅛"

BEVELED SIDES FOR

AIR INTAKE. WALL

BELOW UNIT MUST BE

BEVELED ALSO.

TOP VIEW

CONDITIONED ROOM SIDE AIR

CONDENSER AIR

OUTLET / REJECTED

HEATED AIR

2" MINIMUM

BOTH SIDES

CONDENSER AIR

INTAKE LOUVERS

NOTE: Condenser air inlets

and outlet must be unobstructed to avoid the recirculation of

rejected heated air.

15

Page 16

920-198-00

STEP 4 CHECKING WIRING AND PLUMBING: Check all wiring and

plumbing inside and outside of the wall to be sure none will be

broken where the hole is to be cut.

STEP 5 HOLE CONSTRUCTION: Depending upon size of unit to be

installed, lay out the hole dimensions per the chart below. Cut

and frame in hole to nished dimensions. Use 2" x 4" material for

framing and follow the suggested typical installations in Figure

C, D, or E.

NOTE: IF THE WALL CONSTRUCTION IS TYPICAL FRAME

OR 2 x 4 STUDDING WITH BRICK OR STONE VENEERS,

LOCATE THE HOLE NEXT TO ONE OF THE STUDS. FOR

MASONRY, CONCRETE OR CINDER BLOCK WALLS,

LOCATE HOLE FOR CONVENIENCE.

FINISHED

DIMENSION

A 16

B 26

SMALL

CHASSIS

3

⁄16" 18 3⁄16" 20 3⁄8"

3

⁄16" 26 3⁄16" 28 1⁄4"

MEDIUM

CHASSIS

LARGE

CHASSIS

NOTE: THESE DIMENSIONS ARE FOR FINISHED HOLE SIZE.

Figure D

BRICK VENEER CONSTRUCTION

SHIM VOID SPACES AT TOP AND

SIDES WITH WOOD AS REQUIRED

CAULK ALL SIDES

CABINET

ELECTRICAL RECEPTACLE

(SEE FIGURE E FOR

LOCATION NOTE)

Figure E

SOLID MASONRY CONSTRUCTION

Figure C

FRAME WALL CONSTRUCTION

CAULK ALL SIDES

CABINET

ELECTRICAL

RECEPTACLE

(SEE FIG. E FOR

LOCATION NOTE)

SHIM THE VOID

SPACE AT THE

TOP AND SIDES

WITH WOOD AS

REQUIRED

CAULK

ALL SIDES

CABINET

MORTAR

ELECTRICAL

RECEPTACLE

POINT "X"

NOTE: ELECTRICAL RECEPTACLE LOCATION FROM

POINT "X" MUST BE WITHIN A MAXIMUM RADIUS OF

69" FOR 115V UNITS AND 45" FOR 230V UNITS.

16

Page 17

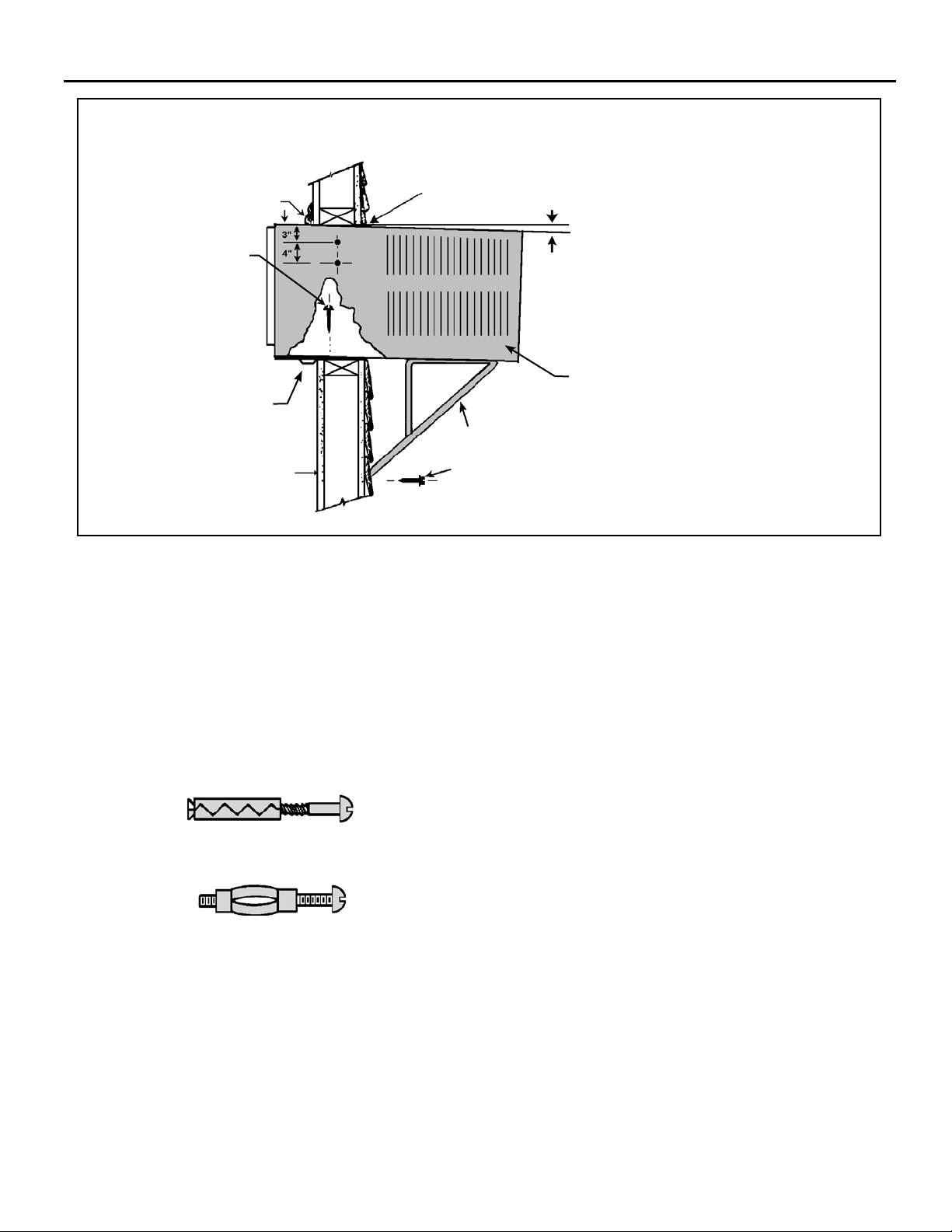

Figure F TYPICAL INSTALLATION

920-198-00

TRIM MOULDING

SCREW #12A x 2"

LONG (USE 3)

SILL PLATE GUIDE CHANNEL

INSIDE WALL SURFACE

CAULK ALL SIDES WEATHER TIGHT

STEP 6 Slide the cabinet into the hole far enough to allow the guide-

channel of the sill plate to contact the inside wall surface (See

Figure F).

STEP 7 Drill three (3)

5

⁄32" dia. pilot holes through holes in sill-plate

into framing and install three (3) #12A x 2" long screws (See

Figure F).

⅜" SLOPE DOWN

NOTE: SUPPORT BRACKETS MAY BE OMITTED

FROM THROUGH-THE-WALL INSTALLATIONS IF THE

CABINET IS SECURED AS FOLLOWS. DRILL 2 HOLES

IN EACH SIDE AND INSTALL 4 FASTENERS (2 EACH

SIDE). USE #12 x 2" SCREWS, TOGGLE BOLTS OR

EXPANSION ANCHOR BOLTS AS SHOWN IN STEP 7.

CABINET

SUPPORT BRACKETS (AVAILABLE AS OPTIONAL ACCESSORY)

SCREW #12 x 2" LONG, USE ONE EACH BRACKET.

5

DRILL

⁄32 DIA. PILOT HOLES.

STEP 8 Drill two (2)

5

⁄32" dia. pilot holes each cabinet side at the locations

shown (see Figure F) and install four (4) #12A x 2" screws (Item

# 4, page 9). Provided that Step 5 (hole construction) provides

a sturdy mount with solid vertical studs, no support brackets

are required. The installation must support the weight of the

unit plus an additional weight of 400 pounds on the rear of the

cabinet.

NOTE: ALTERNATE FASTENERS WHICH MAY BE USED FOR

SECURING THE SILL PLATE IN THE WALL AND THE SUPPORT

BRACKETS TO THE OUTSIDE WALL (NOT FURNISHED BUT

AVAILABLE AT LOCAL HARDWARE STORE).

EXPANSION ANCHOR BOLT

MOLLY OR TOGGLE BOLT

If support brackets are available, they can certainly be used for

through-the-wall installations as shown in Figure F.

If th e r el ia bi lit y of t he wa ll is i n q ue st io n, a wi nd ow in st al lat io n k it wh ic h

includes support brackets can be ordered (see Accessories).

STEP 9 If desired, trim around the cabinet on the room side with a suitable

frame moulding furnished by the installer (see Figure F).

STEP 10 Complete the installation by following steps 13 through 18 of SASH

WINDOW INSTALLATION INSTRUCTIONS, pages 13-14.

STEP 11 Refer to the OPERATION SECTION for instructions.

17

Page 18

Troubleshooting tips

Power failure

If you have a power failure, the unit's auto-restart feature will resume

operation in the selected mode prior to the power failure.

Won't cool?

If your air conditioner operates, but won’t cool; check to see if the controls

are properly set. Check the filter and clean thoroughly if needed. Check

to see if the vent door is closed. Check to see if the chassis seal gasket is

installed (refer to installation instructions).

Won't run?

Make sure the power cord is plugged in completely. Check for a bad fuse,

tripped breaker or tripped LCDI Device. Refer to page 3 for LCDI reset

instructions and to conrm proper fuse size.

For QuietMaster Programmable models only:

You can reset the circuit board by pressing the “Moneysaver” button and

the “Check Filter” button at the same time. The LED (small red light) for

the Check Filter will begin blinking. Once this occurs, turn the unit off by

pressing the On/Off button once and then unplug the unit. Finally, plug the

unit back in and turn it on by pressing the On/Off button once. All settings

revert back to the factory default settings.

This is a warm weather appliance

Your air conditioner is designed to cool in warm weather when the outside

temperature is above 60°F (16°C) and below 115°F (46°C), so it won't

cool a room if it is already cool outside.

spring or fall, touch

Fresh Air. This will bring in a supply of cooler outside air.

Fan Only and set the Fresh Air/Exhaust control to

Condensation is normal

Air conditioners actually pump the heat and humidity from your room to the

outside air. Humidity becomes water, and your air conditioner will use most

of the water to keep the outside coil cool. If there is excessive humidity, there

may be excess water that will drip outside. This is normal operation.

If you want to cool a room in the

920-198-00

Noises

All air conditioners make some noise. Friedrich QuietMaster® units are

designed to operate as quietly as possible. An air conditioner mounted in

a wall is quieter than one mounted in a window. It is important to ensure

that the chassis seal gasket is properly installed (refer to installation

instructions).

Cleaning your air conditioner

The decorative front and the cabinet can be cleaned with warm water and

a mild liquid detergent. The indoor coil can be vacuumed with a dusting

attachment if it appears to be dirty. The outdoor coil can be gently sprayed

with a hose if you can get to it. If not, you might call your dealer for a

more thorough cleaning when needed. The air lter should be inspected

weekly and cleaned if needed by vacuuming with a dust attachment or by

cleaning in the sink using warm water and a mild dishwashing detergent.

Dry the lter thoroughly before reinstalling. Use caution– the coil surface

can be sharp.

Heat pumps operate differently

If your unit is a "Y", or heat pump model, there are some things that you

will want to be aware of.

Some functions of a heat pump differ from your unit when it is used for

heating:

1. It is normal for ice to form on the outdoor coil of the heat pump.

Moisture in the outside air, passing over the coil when very cold,

will form ice.

2. If the outdoor temperature drops below 37°F (3°C), your heat pump

will automatically turn on the electric resistance heat. When the

temperature rises to 40°F (4°C), the compressor will resume the

heat pump operation. If your unit is a 115 volt model (YS09), it is

designed for use in warmer climates and has no electrical heat

feature, and will not provide adequate heat below 37°F (3°C).

Frosting

This usually occurs because of insufficient airflow across the coils, a dirty

filter, cool damp weather, or all of these. Set unit to Fan Only and the frost

will disappear. Setting the thermostat a little warmer will probably prevent

the frosting from recurring.

Available Accessories

DC Drain Kit - Part No. 01900235

In some installations, excess condensate water caused by extremely humid

conditions, may result in an undesirable water drip such as on a patio or

over an entryway. MODEL DC-2 DRAIN KIT (Part No. 01900-235) can be

installed to drain the excess condensate.

THESE ACCESSORIES CAN BE ORDERED FROM YOUR FRIEDRICH DEALER.

18

Window Installation Kits

TwinTemp or Heat/Cool room air conditioners are shipped without window

mounting hardware because they are seldom mounted in the window. For

those instances when these units are being mounted in a window, there

are window installation kits available. Depending upon the chassis size for

which an installation kit is desired, order:

• WIKS for Small Chassis (ES, YS models)

• WIKM for Medium Chassis (EM, YM models)

• WIKL for Large Chassis (EL, YL models)

Page 19

920-198-00

Friedrich Air Conditioning Company

P.O. Box 1540

San Antonio, TX 78295

210.357.4400

www.friedrich.com

ROOM AIR CONDITIONERS

LIMITED WARRANTY

FIRST YEAR

ANY PART: If any part supplied by FRIEDRICH fails because of a defect in workmanship or material within twelve months from

date of original purchase, FRIEDRICH will repair the product at no charge, provided room air conditioner is reasonably accessible

for service. Any additional labor cost for removing inaccessible units and/or charges for mileage related to travel by a Service

Agency that exceeds 25 miles one way will be the responsibility of the owner. This remedy is expressly agreed to be the exclusive

remedy within twelve months from the date of the original purchase.

SECOND THROUGH FIFTH YEAR

SEALED REFRIGERANT SYSTEM: If the Sealed Refrigeration System (defined for this purpose as the compressor, condenser

coil, evaporator coil, reversing valve, check valve, capillary, filter drier, and all interconnecting tubing) supplied by FRIEDRICH in

your Room Air Conditioner fails because of a defect in workmanship or material within sixty months from date of purchase,

FRIEDRICH will pay a labor allowance and parts necessary to repair the Sealed Refrigeration System; PROVIDED FRIEDRICH will

not pay the cost of diagnosis of the problem, removal, freight charges, and transportation of the air conditioner to and from the

Service Agency, and the reinstallation charges associated with repair of the Sealed Refrigeration System. All such cost will be the

sole responsibility of the owner. This remedy is expressly agreed to be the exclusive remedy within sixty months from the date of the

original purchase.

APPLICABILITY AND LIMITATIONS: This warranty is applicable only to units retained within the Fifty States of the U.S.A., District

of Columbia, and Canada. This warranty is not applicable to:

1. Air filters or fuses.

2. Products on which the model and serial numbers have been removed.

3. Products which have defects or damage which results from improper installation, wiring, electrical current

characteristics, or maintenance; or caused by accident, misuse or abuse, fire, flood, alterations and/or misapplication

of the product and/or units installed in a corrosive atmosphere, default or delay in performance caused by war,

government restrictions or restraints, strikes, material shortages beyond the control of FRIEDRICH, or acts of God.

OBTAINING WARRANTY PERFORMANCE: Service will be provided by the FRIEDRICH Authorized Dealer or Service

Organization in your area. They are listed in the Yellow Pages. If assistance is required in obtaining warranty performance, write

to: Room Air Conditioner Service Manager, Friedrich Air Conditioning Co., P.O. Box 1540, San Antonio, TX 78295-1540.

LIMITATIONS: THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES. Anything in the warranty

notwithstanding, ANY IMPLIED WARRANTIES OF FITNESS FOR PARTICULAR PURPOSE AND/OR MERCHANTABILITY

SHALL BE LIMITED TO THE DURATION OF THIS EXPRESS WARRANTY. MANUFACTURER EXPRESSLY DISCLAIMS AND

EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGE FOR BREACH OF ANY EXPRESSED OR

IMPLIED WARRANTY.

NOTE: Some states do not allow limitations on how long an implied warranty lasts, or do not allow the limitation or exclusion of

consequential or incidental damages, so the foregoing exclusions and limitations may not apply to you.

OTHER: This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

PROOF OF PURCHASE: Owner must provide proof of purchase in order to receive any warranty related services.

All service calls for explaining the operation of this product will be the sole responsibility of the consumer.

All warranty service must be provided by an Authorized FRIEDRICH Service Agency, unless authorized by FRIEDRICH prior to

repairs being made.

(9-04)

19

Page 20

920-198-00

¡Enhorabuena!

Acaba de comprar la tecnología más avanzada en unidades de aire acondicionado de tipo ventana. Su unidad de aire acondicionado de tipo ventana Friedrich

le dará muchos años de servicio de conanza. Este modelo incorpora muchas características para garantizar el funcionamiento silencioso, la mejor circulación

posible del aire frío, aire seco, controles funcionales y un funcionamiento económico.

Contenido

Funcionamiento del aire acondicionado

Antes de utilizar la unidad ..................................................................................................................................................................................................... 21

Para obtener el mejor rendimiento y el consumo más ecaz del aire acondicionado .........................................................................................................21

Funcionamiento del aire acondicionado Friedrich ................................................................................................................................................................ 22

Modelos QuietMaster programable

Puesta en marcha ................................................................................................................................................................................................................. 22

Conguración del modo de funcionamiento ..........................................................................................................................................................................22

Función MoneySaver

Ajuste de la temperatura ........................................................................................................................................................................................................ 22

Ajuste de la velocidad del ventilador .....................................................................................................................................................................................22

Puesta en marcha del ventilador inteligente ..........................................................................................................................................................................22

Programación del reloj ...........................................................................................................................................................................................................22

Programación del temporizador............................................................................................................................................................................................. 22

Protección automática de los componentes .......................................................................................................................................................................... 22

Uso del mando a distancia .................................................................................................................................................................................................... 23

®

........................................................................................................................................................................................................... 22

Modelos QuietMaster “K” y Heavy Duty / Twintemp

Puesta en marcha ................................................................................................................................................................................................................. 24

Conguración del modo de funcionamiento ..........................................................................................................................................................................24

Ajuste de la temperatura ....................................................................................................................................................................................................... 24

Función MoneySaver

Cuidado y mantenimiento / Aire fresco y control de la ventilación

Cómo quitar/limpiar el ltro ....................................................................................................................................................................................................25

Aire fresco y control de la ventilación ...................................................................................................................................................................................25

Instalación del aire acondicionado

Requisitos de electricidad/Medidas de la caja ......................................................................................................................................................................26

Material de instalación ...........................................................................................................................................................................................................27

Instalación estándar del marco corredizo de la ventana ....................................................................................................................................................... 28

Instalaciones de pared ........................................................................................................................................................................................................... 33

Consejos para solucionar problemas ....................................................................................................................................................................................36

Accesorios..............................................................................................................................................................................................................................36

Garantía .................................................................................................................................................................................................................................37

®

........................................................................................................................................................................................................... 24

20

Page 21

920-198-00

TEST

RESET

WARNING

TEST BEFORE EACH USE

1. PRESS RESET BUTTON

2. PLUG LDCI INTO POWER

RECEPTACLE

3. PRESS TEST BUTTON,

RESET BUTTON SHOULD

POP UP

4. PRESS TEST BUTTON,

FOR USE

DO NOT USE IF ABOVE TEST

FAILS

WHEN GREEN LIGHT IS ON

IT IS WORKING PROPERLY

RESET

TEST

ADVERTENCIA: Antes de utilizar la unidad

Asegúrese de que los cables sean apropiados.

Si tienen fusible, deben ser de relevo. Antes de instalar o mover la unidad de

sitio, asegúrese de que los amperios del interruptor automático y del fusible

de relevo no excedan el máximo de amperios indicados en la gura 1.

NO utilice un alargador.

El cable que se suministra transmite la energía eléctrica necesaria para

la unidad, y un alargador no lo haría.

Asegúrese de que el enchufe de pared sea compatible

con el enchufe del cable que se suministra.

Esto garantiza la toma de tierra apropiada. Si tiene un enchufe de pared

de dos clavijas, necesita que un electricista certicado lo cambie por un

enchufe de pared con toma de tierra. El enchufe con toma de tierra debe

cumplir con todos los códigos y requisitos nacionales y locales. Nunca quite

la clavija de toma de tierra de un enchufe. Debe utilizar el enchufe de tres

clavijas que se suministra con la unidad de aire acondicionado.

Pruebe el cable

Todas las unidades Friedrich de aire acondicionado vienen de fábrica con

un cable con interruptor de detección de fugas de corriente (LCDI, del inglés

Leakage Current Detection Interrupter), que cumple con los requisitos UL

y NEC para unidades de aire acondicionado con enchufe, vigente a partir

de agosto del 2004.

Para probar el cable de alimentación:

1. Conecte el cable de alimentación a un enchufe de tres clavijas

con toma de tierra.

2. Pulse el botón RESET (vea la gura 2).

3. Pulse el botón TEST (debe escuchar un clic; el botón RESET se

accionará y saltará).

4. Pulse y suelte RESET (debe escuchar un clic; el botón RESET se

anclará y quedará pulsado). El cable de alimentación ya está listo

para su uso.

NOTA: El dispositivo LCDI no se debe usar como interruptor.

Cuando enchufe la unidad funcionará normalmente sin tener que volver

a restablecerla.

Si el dispositivo no salta al probarlo, el cable está dañado y debe cambiarlo

por otro cable del fabricante. Recomendamos que se ponga en contacto

con nuestra Línea de asistencia técnica, llamando al (800) 541-6645,

extensión 845. Para que le atiendan más rápidamente, tenga a mano el

modelo y el número de serie.

MODELO

SS08 • SS10 • SS12

SS14 • KS12 • KS15

YS09

SS12 • SS16 • SM18

SM21 • KM18

SM24 • SL28 • KM24

YS13 • ES12 • ES16

SL36 • YM18 • YM23

YL24 • EM18 • EM24

EL36

CIRCUITO O

FUSIBLE

DE RELEVO:

AMP VOLT NÚM. NEMA

15 125 5-15R

15 250 6-15R

20 250 6-20R

30 250 6-30R

Figura 1

NOTA: Su dispositivo LCDI se parecerá a uno de éstos

Figura 2

ENCHUFE

DE PARED

Para obtener el mejor rendimiento y el consumo más eficaz del aire acondicionado

Mantenga limpio el filtro

Asegúrese de que su aire acondicionado funcione siempre al máximo lim-

piando el ltro regularmente. En la página 25 encontrará las instrucciones

sobre cómo quitar y limpiar el ltro.

Tenga buena ventilación

Asegúrese que la unidad tenga buena ventilación de entrada y salida. La

unidad manda el aire acondicionado a la parte de arriba y recibe el aire no

tratado por la parte de abajo. Para funcionar bien es necesario que tenga

buena ventilación. También es importante que la ventilación de la unidad

no esté bloqueada en la parte exterior del edicio.

Instalación de la unidad

Se puede instalar en una ventana o en una pared, a la sombra de un árbol o

de otro edicio para que funcione con mayor ecacia. También ayuda utilizar

cortinas en la parte soleada de la vivienda para aumentar su ecacia.

Aislamiento

Un buen aislamiento ayuda a mantener los niveles deseables de comodidad. Las puertas deben llevar burletes de aislamiento. Utilice sellador en

las juntas de las puertas y ventanas.

Correcta instalación de la junta de sello

Asegúrese de instalar correctamente la junta selladora para reducir el nivel

de ruido y mejorar la ecacia de la unidad. Si no está instalada, consulte

el paso 14 (página 31) de las instrucciones de instalación.

Además, si pasa de FRÍO (COOL) a VENTILADOR SÓLO (FAN ONLY), y otra

vez a FRÍO (COOL), el compresor tarda tres minutos en ponerse en marcha.

21

Page 22

A/C

Stop

Mode

Temp

Fan

Timer

O

F

/

O

C

A/C

Start

Timer

On/ Off

1- 4

Speed

Smart

Fan

Check

Filter

Set

Hour

Power

Cool

Money

Saver

®

PM

Fan

Only

Press to reset

13

DISPLAY

8

5

4

2

15

10

7

11

9

6

3

1

14

12

920-198-00

Funcionamiento del aire acondicionado Friedrich (Modelo QuietMaster programable)

Puesta en marcha

Si el aire está instalado y enchufado en el enchufe correcto, está

1

listo para ponerse en marcha. Pulse una vez el botón Power

(Encendido). La unidad se enciende automáticamente en Cool a

una temperatura de 24°C (75°F), a la velocidad F1 del ventilador

y en modo de noche. El compresor tarda tres minutos en ponerse

en marcha. (Vea “Protección automática de los componentes” en

esta página).

Si al poner en marcha la unidad por primera vez se enciende la luz

2

de Check Filter (Comprobar el ltro), pulse Check Filter para que

se apague la luz. La luz de Check Filter se enciende tras 250 horas

de uso (Consulte las instrucciones de limpieza del ltro en la página

25). Pulse Check Filter para restablecer.

Configuración del modo de funcionamiento

Al poner en marcha la unidad por primera vez, se enciende en Cool

3

(con la luz encendida) con ventilador constante.

Pulse MoneySaver ® (se enciende la luz) para activar la función de

4

MoneySaver®. De esta manera se pone en marcha el ventilador

con el compresor para que el ventilador no esté en funcionamiento

con stan te. Est a fun ción tamb ién a horra ene rgía y me jora la h umid icación. (MoneySaver® también pone en marcha el ventilador para

tomar una muestra de la temperatura del aire que expulsa cuando

el ciclo es demasiado largo). Si lo desea, puede dejar la unidad en

ventilador constante para que haya más movimiento del aire. Para

volver a ventilador constante, pulse Cool.

Pulse Fan Only (se enciende la luz) si sólo quiere que funcione el

5

ventilador. Puede utilizar esta función en combinación con Fresh

Air / Exhaust (AIRE FRESCO/VENTILACIÓN) para que entre aire

de fuera o para sacar el aire estancado de la habitación. (Para más

información consulte “Aire fresco y control de la ventilación”, en la

página 25.)

Para ajustar la temperatura [de 16°C (60 °F) a 32 °C (90° F )]

MÁS FRÍO – Pulse

6

temperatura deseada en la pantalla.

MÁS CALOR – Pulse

7

la temperatura deseada en la pantalla.

FAHRENHEIT / CELSIUS – Pulse

8

temperatura en grados Celsius o Fahrenheit.

Para ajustar la velocidad del ventilador

Pulse 1- 4 S pe ed (Velocidad 1-4) para ver el ajuste actual. Pulse otra

9

vez para cambiar la velocidad. F1 es la velocidad inferior (SLEEP

SETTING), F2 es velocidad baja (LOW), F3 es media (MED) y F4

es alta (HIGH).

Para activar el ventilador inteligente (Smart Fan)

Pulse Smart Fan (se e nci en de l a lu z). Sm ar t Fa n aj ust ar á au tom áti-

10

camente la velocidad del ventilador al nivel de comodidad deseado.

Por ejemplo, si las puertas de la casa están abiertas durante mucho

rato o hay mucha gente en la habitación, Smart Fan puede ajustar

la velocidad a una velocidad superior para compensar la subida de

la temperatura. Así no hace falta que usted ajuste la velocidad del

ventilador. No se puede activar Smart en el modo de Fan Only.

Para desactivar Smart Fan

Pulse 1-4 Speed y seleccione la velocidad que desee.

11

22

y mantenga pulsado hasta que aparezca la

y mantenga pulsado hasta que aparezca

y

ºF / ºC para mostrar la

Figura 3

Para programar el reloj

Pulse Set Hour (Hora) una vez para ver la hora. Siga pulsando el

12

botón hasta que aparezca en la pantalla la hora real.

ASEGÚRESE DE INDICAR CORRECTAMENTE A.M. O P.M.

Cuando es P.M. se enciende una luz en la esquina superior izquierda

de la pantalla.

NOTA: La pantalla NO muestra los minutos.

Para programar el temporizador

NOTA: Programe la hora antes de ajustar el temporizador.

Puede marcar la hora de encendido (A/C Start) y la hora de apagado

(A/C Stop) con una hora de diferencia como mínimo y veintitrés horas de

diferencia como máximo.

APAGADO - Pulse el botón A/C Stop y siga pulsando hasta que la hora

13

en que usted quiere que se apague la unidad aparezca en la pantalla

(A.M. o P.M.). Así se indica a qué hora quiere que deje de enfriar.

ENCENDIDO - Pulse A/C Start para ver a qué hora debe empezar

14

a enfriar. Siga pulsando hasta que aparezca en la pantalla la hora

en la que quiere que se encienda (A.M. o P.M.). Así se indica a qué

hora quiere que comience enfriar.

Pulse una vez el botón Timer On/ Off (Temporizador On/Off) para

15

activar el temporizador (se enciende la luz). Vuelva a pulsar Timer

On/ Off (se apaga la luz) para desactivarlo. Al seleccionar la hora

de inicio y de apagado, quedan programadas en la memoria para

cada día hasta que las vuelva a cambiar.

NOTA: Si se desconecta la unidad o se va la corriente, debe volver

a programar el botón Set Hour para que funcione el temporizador.

Protección automática de los componentes

La unidad dispone de protección automática de los componentes.

Para proteger el compresor de la caja hay tres minutos de retraso cuando

se apaga la caja o se corta la corriente. No afecta al ventilador.

Page 23

920-198-00

Money

Fan

Timer Operation

Set Hr.

Stop

Start

Temperature

Fan

Cool

On/Off

Power

Cooler

Only Speed Saver

®

Warmer

8

10

7

11

9

43

1

2

56

Cómo utilizar el mando a distancia* (Modelo QuietMaster programable)

Puesta en marcha

POWER - Pulse una vez el botón Power. La unidad se encenderá

1

automáticamente en el modo y velocidad del ventilador en que

estaba cuando se apagó.

Configuración del modo de funcionamiento

COOL - Pulse el botón Cool (Frío) para cambiar automáticamente

2

a COOL.

FAN ONLY - Pulse el botón Fan Only si sólo quiere que funcione el

3

ventilador. Puede utilizar esta función en combinación con FRESH

AIR / EXHAUST para que entre aire de fuera o para sacar el aire

estancado de la habitación. (Para más información consulte la gura

9 de la página 25).

®

MoneySaver

4

de MoneySaver®. De esta manera se pone en marcha el ventilador

- Pulse el botón MoneySaver® para activar la función

con el compresor para que el ventilador no esté en funcionamiento

constante.

Para ajustar la temperatura

COOLER - Pulse el botón Cooler para bajar la temperatura.

5

WARMER - Pulse el botón Warmer para subir la temperatura.

6

Para ajustar la velocidad del ventilador

FAN SPEED - Pulse el botón Fan Speed para ver el ajuste actual.

7

Pulse otra vez para cambiar la velocidad. F1 es la velocidad inferior

(SLEEP SETTING), F2 es velocidad baja (LOW), F3 es media (MED)

y F4 es alta (HIGH).

Para programar el temporizador

NOTA: Programe la hora antes de ajustar el temporizador. Puede marcar

la hora de encendido y apagado con una hora de diferencia como mínimo

y veintitrés horas de diferencia como máximo.

TIMER START - Pulse Start para ver a qué hora debe empezar a

9

enfriar. Siga pulsando hasta que aparezca en la pantalla la hora en

la que quiere que se encienda (A.M. o P.M.). Así se indica a qué

hora quiere que comience enfriar.

TIMER STOP - Pu lse el b otón S TOP y s iga pul san do has ta q ue l a hora

10

en que usted quiere que se apague la unidad aparezca en la pantalla

(A.M. o P.M.). Así se indica a qué hora quiere que deje de enfriar.

TIMER ON/OFF - Pulse una vez el botón On/Off para activar el

11

temporizador (se enciende la luz) o desactivarlo (se apaga la luz). Al

seleccionar el tiempo de inicio y de apagado, quedan programados