Page 1

Kuhl ® Series

Room Air Conditioners

Installation and Operation Manual

Q Chassis Models Using R-32 Refrigerant

Kühl

92000022_00

115-Volt:

THE EXPERTS IN ROOM AIR CONDITIONING

KCQ08B10A

Page 2

FRIEDRICH

AIR CONDITIONING CO.

SAN ANTONIO, TX

MODEL NUMBER

EQ08N11-A

SERIAL NUMBER

AALY00219

VOLTS

60 HZ/ 1PH

115

103 VOLT MIN.

COOLING:

BTU/HR

7500

EER

9.8

AMPS

6.9

HEATING:

BTU/HR

4000

EER

AMPS

11.2

MAX AMPS:

23.5 OZS.

DESIGN PRESSURES

600 PSIG HS

300 PSIG LS

U.S. PATENTS

D458, 229 S

5,634,346

IF CONNECTED TO

A FUSE PROTECTED

CIRCUIT, USE A 12 A

TIME DELAY FUSE

LISTED 183H

ROOM AIR

CONDITIONER

FRIEDRICH

AIR CONDITIONING CO.

SAN ANTONIO, TX

Assembled in Mexico

MODEL NUMBER

EQ08N11-A

SERIAL NUMBER

AALY00219

VOLTS

60 HZ/ 1PH

Model Nameplate Location

Register your Air Conditioner

Model information can be found on the name plate.

Please complete and mail the owner registration card furnished with this product, or register online at www.friedrich.

com.

For your future convenience, record the model information in

Section R, information for the owner.

A. IMPORTANT SAFETY AND GENERAL INFORMATION

A.1 Introduction ............................................................................. 3

A.2 • Safety Symbols ..................................................................... 3

A.3 • SAFETY WARNINGS

A.4 Unpacking Instructions .......................................................... 5

A.5 Importance of a Quality Installation ..................................... 6

A.6 Packing List ............................................................................. 7

B. SPECIFICATIONS

B.1 Product Data ............................................................................ 8

B.2 Model Identification Guide ..................................................... 8

B.3 Outdoor Use ............................................................................. 8

C. INSTALLATION OF THE UNIT

C.1 Pre-Installation Checkpoints ................................................. 9

C.2 Tools Required ........................................................................ 9

C.3. Choosing a Location .......................................................... 9

C.4 Window Installation ............................................................. 10

C.5 Thru-the Wall Installation .................................................... 13

C.6 Cord Routing Change ...........................................................16

C.7 Install Filter ........................................................................... 18

E. ELECTRICAL

E.1 Electrical Safety Information ......................................... 19

E.2 Testing the Power Cord .................................................19

J. STARTUP AND OPERATION

J.1 Final Inspection ..................................................................... 20

J.2 Airflow direction adjustment ............................................... 20

J.3 Control Panel Operation ....................................................... 21

J.4 Remote Control Operation ................................................... 35

J.5 Start-up...................................................................................35

L. WIFI

M. TROUBLESHOOTING

M.1. Troubleshooting Tips ...................................................... 36

P. Appendixes

P.1 Accessories and Options ................................................37

R . INFORMATION FOR THE OWNER

R.1 Room air conditioner unit performance test data sheet .... 38

R.2 Routine Maintenance ............................................................ 38

R.3 Warranty ................................................................................ 39

2

Page 3

A. IMPORTANT SAFETY AND GENERAL INFORMATION

SAFETY IS IMPORTANT

A.1 Introduction

This booklet contains the installation and operating instructions for your Air Conditioning unit. There are some precautions that should be taken

to ensure proper operation. Improper installation can result in unsatisfactory operation or dangerous conditions.

Read this booklet and any instructions packaged with separate equipment required to make up the system prior to installation. Give this booklet

to the owner and explain its provisions. The owner should retain this booklet for future reference.

A.2 • Safety Symbols

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages.

This is a safety Alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what will happen if the instructions are not followed.

All safety messages will follow the safety alert symbol with the word “WARNING” or “CAUTION”. These words mean:

WARNING

CAUTION

NOTICE

Indicates a hazard which, if not avoided, can result in severe personal injury or death and damage to product or other

property.

Indicates a hazard which, if not avoided, can result in personal injury and damage to product or other property.

Indicates property damage can occur if instructions are not followed.

This symbol indicates that this appliance uses a flammable refrigerant. If the refrigerant is leaked and is exposed to an

external ignition source, there is a risk of fire.

This symbol indicates that the Operation Manual should be read carefully.

This symbol indicates that service personnel should be handling this equipment with reference to the installation manual.

This symbol indicates that information is available such as the Installation and Operation manual, or the Service Manual.

3

Page 4

A. IMPORTANT SAFETY AND GENERAL INFORMATION

A.3 • Safety Warnings

The manufacturer’s warranty does not cover any damage or defect to the air conditioner caused by the attachment

WARNING

or use of any components, accessories or devices (other than those authorized by the manufacturer) into, onto or in conjunction with the air

conditioner. You should be aware that the use of unauthorized components, accessories or devices may adversely affect the operation of the

air conditioner and may also endanger life and property. The manufacturer disclaims any responsibility for such loss or injury resulting from

the use of such unauthorized components, accessories or devices.

WARNING

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by

a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

WARNING

Do not use above 2,000 meters(6,562 feet).

WARNING: Electrical Shock Hazard

Disconnect all power to the unit before starting maintenance. All electrical connections and wiring MUST be installed by a qualified

electrician and conform to the National Code and all local codes which have jurisdiction. Failure to do so can result in property

damage, severe electrical shock or death.

:

This appliance is not intended for use by persons (Including children) with reduced physical, sensory or mental

:

The maximum altitude for this appliance is 2,000 meters(6,562 feet).

:

WARNING: Read Installation Manual

Read this manual thoroughly prior to equipment installation or operation. It is the installer’s responsibility to properly apply

and install the equipment. Installation must be in conformance with the NFPA 70-2023 national electric code or current edition,

International Mechanic code 2021 or current edition, and any other local or national codes.

WARNING: Safety First

Do not remove, disable, or bypass this unit’s safety devices. Doing so may cause fire, injuries, or death.

WARNING: This Product uses R-32 Refrigerant

Do not use means to accelerate the defrosting process or to clean, other than those

recommended by the manufacturer.

The appliance shall be stored in a room without continuously operating ignition sources

(for example: open flames, an operating gas appliance or an operating electric heater.

Do not pierce or burn.

Be aware that refrigerants may not contain an odor.

WARNING: Refrigeration System under High pressure

Do not puncture, heat, expose to flame or incinerate. Only certified refrigeration technicians should service this

equipment. R32 systems operate at higher pressures than R22 equipment. Appropriate safe service and handling

practices must be used.

Refrigerant

Safety Group

A2L

CAUTION: Do Not Operate Equipment During Active Stages Of

Construction

To ensure proper operation, Friedrich requires that all equipment is not operated during active construction phases. This includes active stages

of completing framing, drywalling, spackling, sanding, painting, flooring, and moulding in the equipment’s designated conditioning space. The

use of this equipment during construction could result in premature failure of the components and/or system and is in violation of our standard

warranty guidelines. The operation of newly installed equipment during construction will accelerate the commencement and/or termination of

the warranty period.

Keep all air circulation and ventilation openings free from obstruction.

WARNING:

WARNING:

pulsation to the unit could result in damage to the refrigerant tubing.

4

The unit should not be in contact with any equipment that will transmit vibration to the unit. Any excessive vibration or

Page 5

A. IMPORTANT SAFETY AND GENERAL INFORMATION

A.4 Unpacking Instructions

STEP 1. Cut all 4 packing straps.

STEP 2. Slowly remove outer box, careful not to loosen decorative front.

STEP 3. Remove upper cover.

STEP 4. Remove 4 corner angles.

STEP 5. Remove base carton.

STEP 1

STRAPS x4

STEP 3

STEP 2

STEP 4

STEP 5

Figure A.4

5

Page 6

Upon receiving the unit, inspect it for any damage from shipment. Claims for damage, either shipping or concealed, should be filed immediately

for or detection of refrigerant leaks. A halide torch (or any other detector using a naked flame) shall not be used. The following leak detection

the case of FLAMMABLE REFRIGERANTS, the sensitivity may not be adequate, or may need re-calibration. (Detection equipment shall

A. IMPORTANT SAFETY AND GENERAL INFORMATION

A.5 Importance of a Quality Installation

Optimal system performance and longevity depend upon a quality and proper installation. Failure to properly install this unit could result in

undesirable operation and subsequent faults and potential failures.

Carefully follow all guidelines listed in the manual and industry best practices. Conform to all local code requirements. Contact your local

technical representative with any questions or concerns.

with the shipping company. IMPORTANT: Check the unit model number, Cooling size, electrical characteristics, and accessories to determine if

they are correct.

WARNING:

sharp edges, or any other adverse environmental effects. It is recommended that the cord is checked for any potential damage when filter

maintenance is performed. If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

WARNING:

install.

Contact a licenced repair person to perform a leak check on the unit.

WARNING:

methods are deemed acceptable for all refrigerant systems. Electronic leak detectors may be used to detect refrigerant leaks but, in

be calibrated in a refrigerant-free area.) Ensure that the detector is not a potential source of ignition and is suitable for the refrigerant used.

Leak detection equipment shall be set at a percentage of the LFL.

WARNING:

shall only be performed by trained service personnel. This includes:

Opening of any ventilated Any tubing or refrigerant circuit work

Opening of any sealed components

Enclosures beyond the hinged door for filter cleaning

Scan this QR code to be linked to the Friedrich professional support page

where you can locate the Service Manual.

Check the unit power cord and make sure the cord is protected from wear, corrosion, excessive pressure, vibration,

If the unit appears damaged,or if a refrigerant leak is suspected, do not

Under no circumstances shall potential sources of ignition be used in the searching

Service of this product (aside from filter maintenance)

6

Page 7

A. IMPORTANT SAFETY AND GENERAL INFORMATION

A.6 Packing List

A

C

E F G

Installation Hardware

ITEM

NO

A

Q KÜHL UNIT

B

Q SIDE CURTAINS (INCLUDES 8 PUSH PINS)

C

WINDOW SEAL GASKET

D

SHELL GASKET (ADHESIVE-BACK)

for replacement installations only

Carbon Filter

Remote Control

R1 Insulation Panel

DESCRIPTION QTY.

B

D

Installation Hardware

ITEM

NO

E

1

2

1

1

SCREW #8 x ½" (BLUE BAG)

F

SCREW #8 x 1 ¼" (GREY BAG)

SPARE PUSH PINS

G

DESCRIPTION QTY.

4

3

4

Figure A.6 (Packing List)

7

Page 8

B. SPECIFICATIONS

B.1 Product Data

The Kühl gives you a variety of options for control, programming, and scheduling

including wireless capabilities.

Wireless Programming and Control:

Friedrich Connect allows you to conveniently control, program, and monitor your air

conditioning unit remotely from a smartphone or computer.

Pre-Programmed Timer Options:

Your unit’s digital control comes equipped with a 24-hour timer.

24-Hour Timer

The 24-hour timer allows you to set 2 temperature changes at pre-set times or a

unit control panel.

Customizable Programming Options:

Customizable timers, with up to four temperature adjustments per day, can be set

using Friedrich Connect for one or multiple units.

See www.friedrich.com for complete details on Friedrich Connect.

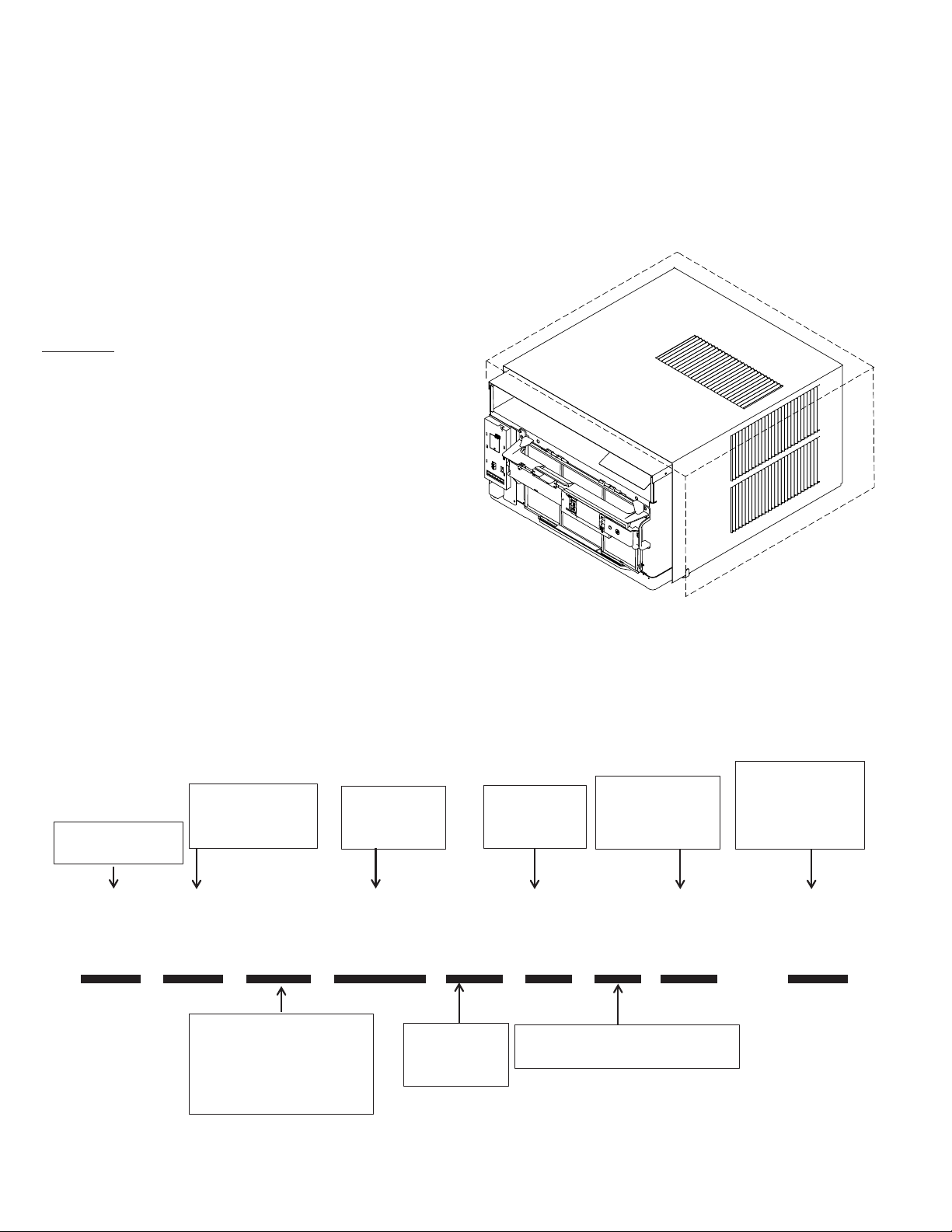

B.3 Outdoor Use

The only section of this air conditioner acceptable for outdoor use

is designated by the dotted area in the image below. To ensure the

protection of parts not acceptable for outdoor use please follow the

installation instructions as shown in this document. Please note that

junction and electrical boxes are not acceptable for outdoor use.

B.2 Model Identification Guide

Engineering Rev

Letter indicates an

engineering

modification to an

existing model

Model Type:

K - Kühl

Function:

C- Cool Only

H - Heat Pump

Approximate

Cooling

BTU/HR

Voltage

1- 115 Volts

3- 230 Volts

Marketing Suffix

Letter indicates

modification to

existing model

K H S 10 B 1 0 A - A

Application:

Q - Q

S - Small

M - Medium

L - Large

Major Model

Revision

Character

Heat Strip

0- Straight Cool & Heat Pump

8

Page 9

C. INSTALLATION OF THE UNIT

3

C.1 Pre-Installation Checkpoints

Before attempting any installation, carefully consider the

following points:

• Clearances and provision for servicing. Install this unit

in accordance with local and national standards. Any

and all work must be done by authorized personnel.

• IMPORTANT: Before you begin the actual installation

of your air conditioner, check your local electrical codes

and the information below. Your air conditioner must be

connected to a power source with the same alternating

current (A.C.) voltage and amperage as marked on the

name plate located on the chassis. Only A.C. can be used.

Direct Current (D.C.) cannot be used.

• CIRCUIT PROTECTION – Use on single outlet circuit only.

An overloaded circuit will invariably cause malfunction or

failure of an air conditioner; therefore, it is necessary that

the electrical protection is adequate. Due to momentary

high current demand when the air conditioner starts,

use a “TIME DELAY” fuse or a HACR type circuit breaker.

Consult your dealer or power company if in doubt.

• Refer to the electrical name plate located on the air

conditioner chassis (see Table E.1 to determine the

correct fuse or circuit breaker amperage for your model.

• The power cord has a plug with a grounding prong and a

matching receptacle is required.

C.2 Tools Required

WARNING

C.3. Choosing a Location

Installation Clearances

Improper installation of the Air Conditioner can cause poor performance and premature wear of the unit.

Ensure that the KUHL unit is installed with proper clearances as

described below.

Ensure no obstructions or enclosures are within clearances limits to

allow for proper airflow.

Ensure no open flames, or surfaces that will exceed 1200 degrees

fahrenheit are within clearances limits.

WARNING

Refigeration System

Under High Pressure

Do not puncture, heat, expose to flame or

incinerate.

Only certified refrigeration technicians should

service this equipment.

R410A and R32 systems operate at higher

pressures than R22 equipment.

Appropriate safe service and handling

practices must be used.

Only use gauge sets designed for use with

R410A or R32.

Do not use standard R22 gauge sets..

Clearances

Top and Bottom of Unit - One (1) foot

Sides of Unit - One (1) foot

Front of Unit - Three (3) feet

Rear of Unit - Three (3) feet

1. Power Drill

5/32

2.

” Drill Bit

3. Gloves

4. Carpenters Level

5/16

5.

” Wrench

1/4

6.

” Wrench

7. #2 Phillips Screw

Driver

8. Putty Knife or (wood

stir stick)

9. 1/4” Nut Driver

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong outlet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

4

1

2

5/16

5/16

1/4

Figure C.2 (Tools)

CAUTION

Moving Parts Hazard

Do not operate unit out of sleeve

or with front grille removed.

Do not place hands in blower

or fan blade areas.

Failure to do so can result

in serious injury

CAUTION

1/4

65

87

Excessive Weight Hazard

Use two or more people when

installing your air conditioner.

Failure to do so can result in

back or other injury.

9

Page 10

C. INSTALLATION OF THE UNIT

C.4 Window Installation

STEP 3. Once both curtains have been installed, slide hands underneath the

WARNING

Falling Object Hazard

Not following Installation Instructions

for mounting your air conditioner can

result in property damage, injury, or

death.

STEP 1. Fold down the sides of the carton bottom tray (see Figure C.4.1).

unit to lift and carry to the window, as shown in Figure C.5.3. Obtain

assistance as needed.

Figure C.4.1

STEP 2. Install side curtains (B in parts list) on both sides of the unit. Press

in the attached push pins (4 on each side) to secure curtains to the

sleeve (Figure 54).

Figure C.4.2

WARNING

Fire Hazard

A2L refrigerant is classified as mildly

flammable. Do not install unit next open flame

sources, or surfaces that will exceed

1200 degrees fahrenheit.

CAUTION

Excessive Weight Hazard

Use two or more people when installing your

air conditioner.

Failure to do so can result in back or other

injury.

NOTICE

For YOUR security and safety, YOU must

provide a means of preventing the upper

part of the window from opening.

10

Page 11

C.4 Window Installation (Continued)

SECTION A-A

STEP 4 Pull unit from sleeve, using the side handles located on either side of

the decorative front. Obtain assistance as needed. Place unit out of

the way on a secure, at surface (Figure C.4.4).

STEP 5 Place the sleeve in window with the bottom support rail up

against the back edge of the window sill. Center and close

window sash onto upper support rail. The unit should be

level or slightly tilted outside. Slope should be approximately

3/8” or 1/4 bubble on a level.

NOTE: Depending on the type of window, install the appropriate

security lock as recommended by manufacturer.

STEP 6 Extend side curtains to fill window. Secure outer top corner of

each curtain (left and right) to window jamb and/ or window

sash using supplied screws. Two sizes of screws (E and F

in parts list) and 2 different screw hole locations have been

provided to accommodate varying window types (See Figure

C.4.5).

C. INSTALLATION OF THE UNIT

If you desire a more permanent installation, you can secure your

curtains using both screw holes and your unit sleeve directly to the

lower window stool using the instruction Step 7 shown next. If you

choose the standard installation already covered in Steps 1 – 6, then

you can proceed to Step 8.

NOTE: When removing unit from sleeve and carrying or handling unit,

obtain assistance or help as necessary to support unit from bottom

(basepan), maintaining clearance from all obstacles.

STEP 7 Secure sleeve to window stool through screw hole in the bottom center of sill channel using 1 supplied 1 ¼" screw (F in parts list) (see Fig. C.4.5 Detail A).

In Step 6, the window curtains were secured using 1 supplied screw per curtain (2 screws total). For a more permanent application, you may secure

each curtain with an additional screw through the remaining screw hole, insuring each window curtain is secured to window jamb and sash with 2 screws

each (4 screws total). Two sizes of screws (E and F in parts list) have been provided to accommodate varying window types (see Figure C.4.5).

NOTE: Securing the curtains using both screw hole locations may not work in certain window types. For those applications, use only 1 screw per curtain and install

the appropriate security lock as recommended by window manufacturer.

SHELL SUPPORT CHANNEL

Figure C.4.4

WINDOW SASH

SECURE CURTAINS THROUGH

REMAINING HOLES USING

EITHER 1/2" SCREWS (ITEM E:

BLUE BAG) OR 1 1/4" SCREWS

(ITEM F: GREY BAG).

SECURE SILL CHANNEL TO

WINDOW STOOL USING (1) 1 1/4"

SCREW (ITEM F: GREY BAG).

WINDOW STOOL

SILL

CHANNEL

Figure C.4.5

A

A

SLEEVE

11

Page 12

C. INSTALLATION OF THE UNIT

C.4 Window Installation (Continued)

STEP 8 Inspect unit prior to inserting back into sleeve. Manually rotate fan to

see that it turns freely. Make sure electrical cord is positioned in the

front of unit and out of the way when inserting it back into the sleeve.

Insert unit back into sleeve by positioning onto bottom rails of sleeve

and pushing back into place. Obtain assistance as needed (see

Figure C.4.6).

Figure C.4.6

STEP 10 Plug in unit.

Now that installation is complete, your unit is ready to operate! Simply plug in

the power cord and follow the operation steps outlined in this manual or your

QuickStart Guide.

CIRCUIT PROTECTION - If the air conditioner is circuit protected by

a fuse, use a “TIME DELAY” fuse or HACR type circuit breaker due to

momentary high current demand when your air conditioner is started.

Before operating your unit, verify the ampere rating of the time-delay

fuse or circuit breaker which protects your unit. The ampere rating of

the time-delay fuse or circuit breaker shall be 15 amps.

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same conguration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong outlet.

Failure to follow these instructions can result

in death, re, or electrical shock.

CAUTION

Excessive Weight Hazard

Use two or more people when installing your

air conditioner.

Failure to do so can result in back or other

injury.

NOTE: WHEN REMOVING UNIT FROM SLEEVE AND CARRYING

OR HANDLING UNIT, OBTAIN ASSISTANCE OR HELP AS

NECESSARY TO SUPPORT UNIT FROM BOTTOM (BASEPAN),

MAINTAINING CLEARANCE FROM ALL OBSTACLES.

STEP 9. Cut the window seal gasket (C in parts list) to match the window width

and insert it between the window sashes as shown in Figure C.4.7.

EntryGard™ Security Lock

For additional safety, your unit is equipped with EntryGard™ protection, a feature

that helps prevents kick-in intrusions. To engage this feature, use 2 supplied 1/2"

screws (E in parts list) to secure decorative front cover to sleeve. See Figure

C.4.8 for screw hole locations.

12

Figure C.4.7

Figure C.4.8

Page 13

C. INSTALLATION OF THE UNIT

C.5 Thru-the Wall Installation

STEP 1. After removing the unit from shipping carton, slide chassis out of

sleeve. Hold the cabinet stationary. Then, use the hand grips on both

ends of the control unit support bracket to pull the chassis out of the

cabinet. (See gure C.5.1)

Figure C.5.1

WARNING

STEP 2. Remove shell channel from top of the sleeve (Figure C.5.2).

NOTE: Not applicable to heat pump models sold without quick mounting

sleeve.

Figure C.5.2

WARNING

Falling Object Hazard

Not following Installation Instructions

for mounting your air conditioner can

result in property damage, injury, or

death.

STEP 3. Layout - Cut and frame-in an opening in the desired wall area using

the illustration as a guide (Figure C.5.3).

STEP 4. Place the sleeve in the framed opening.

NOTE: Not applicable to heat pump models sold without qui ck mounting sleeve.

2" x 8" FRAME

FINISHED OPENING SIZE

Fire Hazard

A2L refrigerant is classified as mildly

flammable. Do not install unit next open flame

sources, or surfaces that will exceed

1200 degrees fahrenheit.

EXPANSION ANCHOR BOLT

MOLLY OR TOGGLE BOLT

CONCRETE BLOCK

CONSTRUCTION

FRAME CONSTRUCTION

Figure C.5.3

13

Page 14

C. INSTALLATION OF THE UNIT

C.5 Thru-the Wall Installation (Cont.)

STEP 5 Position the front edge to extend into the room 3/4" minimum at top

of sleeve and 1" minimum at bottom (Figure C.5.4).

STEP 6 Secure each side of the sleeve with supplied 1 ¼" screw

NOTE: Alternate fasteners which may be used for securing the unit sleeve

(F in parts list) or nails through the holes in the sides.

to a wall, including masonry walls, are not furnished (available at

local hardware stores).

FRONT EDGE OF LOUVERS

MUST ALWAYS BE OUTSIDE OF

EXTERIOR WALL SURFACE

3

/4" MINIMUM

SLEEVE FRONT

1" THICK LUMBER

1

1" MINIMUM

INSIDE WALL

EXTERIOR WALL

MAX. WALL THICKNESS

ALLOWED 8 1/2"

POSITION AND SECURE

SLEEVE DOWNWARD.

SLOPE OUTSIDE FOR

DRAINAGE.

/4" SLOPE DOWN.

1 1/2" SCREWS (F IN PARTS LIST) / 3 EA. SIDE

NAILS MAY BE USED IF DESIRED.

3

/4" MINIMUM FRONT

EDGE OF SLEEVE TO

INSIDE WALL SURFACE.

TRIM AROUND THE

SLEEVE WITH A

SUITABLE WOOD

MOULDING AND

FINISH TO SUIT.

CAULK ALL AROUND

SLEEVE ON OUTSIDE

TO INSURE A WEATHER

TIGHT SEAL.

STEP 7 Cut two pieces of standard 1" lumber (supplied by installer)

to the length and width required. Place in front and back of

bottom sill channel as shown in Figure C.5.4. Secure with

nails (supplied by installer).

STEP 8 Seal all holes in the sleeve with caulking compound (supplied

by installer).

MORTAR

Figure C.5.4

SOLID MASONRY

CONSTRUCTION

CAULK ALL SIDES

CABINET

NOTE: ELECTRICAL RECEPTACLE LOCATION

FROM POINT “X” MUST BE WITHIN A MAXIMUM

RADIUS OF 69" FOR 115V UNITS.

14

ELECTRICAL

RECEPTACLE

POINT “X”

Figure C.5.5

Page 15

C.5 Thru-the Wall Installation (Cont.)

C. INSTALLATION OF THE UNIT

STEP 9 Inspect unit prior to inserting back into sleeve. Manually rotate fan to

see that it turns freely. Make sure electrical cord is positioned in the

front of unit and out of the way when inserting it back into the sleeve.

Insert unit back into sleeve by positioning onto bottom rails of sleeve

and pushing back into place. Obtain assistance as needed (see

Figure C.5.6).

Figure C.5.6

STEP 10 Plug in unit.

Now that installation is complete, your unit is ready to operate! Simply plug in

the power cord and follow the operation steps outlined in this manual or your

QuickStart Guide.

EntryGard™ Security Lock

For additional safety, your unit is equipped with EntryGard™ protection, a feature

that helps prevents kick-in intrusions. To engage this feature, use 2 supplied 1/2"

screws (E in parts list) to secure decorative front cover to sleeve. See Figure

C.5.7 for screw hole locations.

WARNING

Falling Object Hazard

Not following Installation Instructions

for mounting your air conditioner can

result in property damage, injury, or

death.

CIRCUIT PROTECTION - If the air conditioner is circuit protected by

a fuse, use a "TIME DELAY” fuse or HACR type circuit breaker due to

momentary high current demand when your air conditioner is started.

Before operating your unit, verify the ampere rating of the time-delay

fuse or circuit breaker which protects your unit. The ampere rating of

the time-delay fuse or circuit breaker shall be 15 amps.

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same conguration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong outlet.

Failure to follow these instructions can result

in death, re, or electrical shock.

Figure C.5.7

15

Page 16

C. INSTALLATION OF THE UNIT

C.6 Cord Routing Change

Unplug unit.

Your Kühl Q unit will come with the power cord already installed and

routed to the left side of the unit.

WARNING

For convenience and optimum appearance the direction of the power

cord can be changed from left to right by following the procedure

below. Select the exit location on the left or right based on proximity

to the power outlet.

STEP 1. Remove the decorative front cover.

A. Open the decorative front cover. (See figure C.6.1)

B. Locate and disconnect electronic control power cable

harness. (See figure C.6.1)

C. Remove 4 screws attaching decorative front cover.

Save to reinstall later. (See figure C.6.2)

D. Remove decorative front cover. Store in a safe place to reinstall

later.

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong outlet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

Disconnect Plug

16

Figure C.6.1

STEP 2. Route the cord along bottom inside of the unit (see Figures C.6.4 and

C.6.5), under the lower left mounting screw embossments and exit the

cord through right side c ord opening (see Figure C.6.4) of the decorative

front cover. Decorative front cover will keep cord in place.

STEP 3. Reinstall the 4 screws removed earlier to secure decorative front cover

with cord exit ing to the front bottom of the unit (4 screws retained from

Step 1).

Remove Screws

Figure C.6.2

Page 17

C.6 Cord Routing Change

FACTORY SETTING WITH

LEFT-SIDE CORD PLACEMENT

Figure C.6.3 Figure C.6.5

C. INSTALLATION OF THE UNIT

CLOSE UP OF

CORD UNDER

LEFT MOUNTING

SCREW

EMBOSSMENT

NEW CORD ALIGNMENT FOR ROUTING CORD

EXIT TO THE RIGHT OF UNIT

Figure C.6.4

17

Page 18

C. INSTALLATION OF THE UNIT

ALIGN HOLES WITH

PROTRUSION

C.7 Install Filter

STEP 1. Swing the door open and remove the lter by grasping the lter grip

STEP 2. Slide the lter grip out from the lter as shown in Figure C.7.3.

NOTE: Make sure the front frame with the mesh lter is facing you.

STEP 3. If you already have a carbon lter installed remove the dirty lter by

Figure C.7.1

A

TOP TAB

FRONT

FRAME WITH

STANDARD

MESH FILTER

Figure C.7.4

and pushing the lter holder upward and outward. (See Figure C.7.2)

laying the lter down and swinging open the front frame as shown in

Figure C.7.4. Clean the front frame by washing the dirt from the lter.

Use a mild soap solution if necessary. Allow lter to dry.

Figure C.7.2

FILTER GRIP

FILTER

HANDLE

STEP 4. (Optional) Place the new carbon lter on the top of the back lter

frame. The carbon lter has been cut to the correct dimension and

should t within the frame as shown in Figure C.7.5.

NOTE: The carbon lter is not a reusable lter, and needs to be replaced every

three months for optimum efciency.

STEP 5. Slide the lter handle back on to hold the frames together

and slide the assembly into the unit as per the instructions

on the door.

NOTE: The lter handle slides into the frame in only one direction. If the tab

in the frame stops the handle from sliding in, slide the handle from the

other direction. DO NOT FORCE THE HANDLE INTO THE FRAME.

18

Figure C.7.3

FILTER GRIP

Figure C.7.5

Page 19

E. ELECTRICAL

E.1 Electrical Safety Information

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong outlet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

Make sure the wiring is adequate for your unit.

If you have fuses, they should be of the time delay type. Before you

install or relocate this unit, be sure that the amperage rating of the

circuit breaker or time delay fuse does not exceed the amp rating

listed in Table 1.

DO NOT use an extension cord.

The cord provided will carry the proper amount of electrical power

to the unit; an extension cord may not.

Make sure that the receptacle is compatible with the

air conditioner cord plug provided.

Proper grounding must be maintained at all times. Two prong

receptacles must be replaced with a grounded receptacle by a certified

electrician.

The grounded receptacle should meet all national and local codes

and ordinances. You must use the three prong plug furnished with

the air conditioner. Under no circumstances should you remove the

ground prong from the plug.

E.2 Testing the Power Cord

All Friedrich room air conditioners are shipped from the factory

with a Leakage Current Detection Interrupter (LCDI) equipped power

cord. The LCDI device on the end of the cord meets the UL and NEC

requirements for cord connected air conditioners.

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET (see Figure 1).

3. Press TEST, listen for click; the RESET button trips and pops out.

4. Press and release RESET (Listen for click; RESET button latches and

remains in). Check that the green LED light is on. The power cord is ready.

for use.

RESET

TEST

WARNING:

TEST BEFORE EACH USE.

TO TEST:

PRESS RESET BUTTON.

PLUG LCDI INTO POWER

RECEPTACLE.

PRESS TEST BUTTON, RESET

BUTTON SHOULD POP UP.

PRESS RESET BUTTON FOR USE.

DO NOT USE IF TEST IS FAILED.

GREEN LIGHT INDICATES

PROPER OPERATION

Table E.1

MODEL

KCQ08

CIRCUIT RATING

OR TIME DELAY

FUSE

AMP VOLT

15 125 5-15R

NEMA

REQUIRED

WALL

RECEPTACLE

NO.

Once plugged in, the unit will operate normally without the need to reset the

LCDI device. If the LCDI device fails to trip when tested or if the power supply

cord is damaged, it must be replaced with a new power supply cord from the

manufacturer.

NOTICE

Do not use the LCDI device as an ON/OFF switch.

Failure to adhere to this precaution may cause pre-

mature equipment malfunction.

19

Page 20

J. STARTUP AND OPERATION

J.1 Final Inspection

• Inspect and ensure that all components and accessories have been

installed properly and that they have not been damaged during the

installation progress.

• Check the condensate water drain(s) to ensure that they are

adequate for the removal of condensate water, and that they meet

the approval of the end user.

• Ensure that all installation instructions concerning clearances

around the unit have been adhered to. Check to ensure that the unit

air filter, indoor coil, and outdoor coil are free from any obstructions.

• Inspect the unit for any damage to the coils and tubing that could

cause a leak.

• Ensure that the circuit breaker(s) or fuse(s) and supply circuit wire

size have been sized correctly. If the unit was supplied with a power

supply cord, insure that it is stored properly.

• Ensure that the entire installation is in compliance with all applicable

national and local codes and ordinances having jurisdiction.

• Secure components and accessories, such as a decorative front

cover.

• Start the unit and check for proper operation of all components in

LEFT

AIRFLOW

LEVER

each mode of operation.

• Instruct the owner or operator of the units operation, and the

manufacturer’s Routine Maintenance.

NOTE: A log for recording the dates of maintenance and/ or service is

recommended.

J.2 Airflow direction adjustment

The airow path may be adjusted to distribute air independently from the left or right

side of the discharge opening. Each of the banks of louvers can be directed left,

right, up, or down in order to achieve the most optimum airow positioning.

To adjust airow direction, grab the lever in the center of the louver bank and move it

in the direction that you would like the air to be directed. Please note that it is normal

that airow may be stronger out of one side of the louvers than the other.

RIGHT

AIRFLOW

LEVER

20

Figure J.2.1

Page 21

J. STARTUP AND OPERATION

WI-FI OPERATING

- Clock (AM/PM)

FAN SPEED

Sets fan speed:

LOW, MED, HIGH,

OR MAX

(Actual settings are

model dependant)

FAN

Sets fan to either:

- Automatically cycle

- Continuously run

MODE

Cycles between

COOL, HEAT, FAN

ONLY or -AUTO(if equipped)

ON / OFF

J.3 Control Panel Operation

Power On – Press the button to turn on the air conditioner. The power button illuminates to indicate that the power is on. The backlight on the power switch will

automatically turn off after 20 seconds of inactivity.

Display – The display is a high efciency LCD with a built-in backlight. After 20 seconds of inactivity, the display switches off. Touching any button automatically changes

the display to full brightness.

There are three control push buttons on each side of the display.

Turns unit on/off

COOL HEAT FAN ONLY DISCONNECTED FROM

-AUTO Automatically switches

between cool & heat

POWER BOARD

CONTROL

LOCKED

STAT E

IR

RECEIVER

TEMPERATURE

UP

TEMPERATURE

DOWN

TIMER

shows on or off

FILTER

Check / clean

2 DIGIT DISPLAY

Shows Setting for:

- Set Point (Temperature)

Figure J.3.1

21

Page 22

J. STARTUP AND OPERATION

J.3 Control Panel Operation

SYSTEM - The MODE button allows you to sequentially select up to four modes

of operation:

AUTO Available on select models

COOL

HEAT Available on select models

FAN ONLY

AUTO FAN (No Cooling Demand)

When in AUTO mode, the fan only operates when the system has a demand to

cool or heat the room.

In the ON fan mode, the fan operates all the time. The system periodically cools

or heats the fan’s airow but the ow of air does not stop.

UP and DOWN Arrows - Pressing either an UP or DOWN button changes the

system’s setpoint (desired room temperature). These buttons are also used to

make system parameter changes later in this manual.

One press equals 1 degree of change in Fahrenheit mode. One press equals 0.5

degree change in Celsius mode.

TIMER

The timer can be engaged or disengaged from the control panel. This is done by

pressing or holding the UP and DOWN arrows simultaneously for three seconds.

OTHER FUNCTIONS

°F – °C Select

To switch from degrees Fahrenheit (F) to Celsius (C), press the MENU button

and enter the F-C sub-menu.

FAN SPEED - Depending on your model, the FAN SPEED button allows you to

toggle between three or four modes of operation: LOW, MEDIUM, HIGH and MAX.

Alerts

When the lter needs to be cleaned or replaced, the CHECK FILTER icon

displays.

The alert can be dismissed by pressing the FAN MODE and SPEED for 3

seconds.

Lock Control Panel

To lock/ unlock the front panel controls, navigate to the “LOCK” sub-menu found after clicking the MENU button. The lock requires a four digit pass code to lock/ unlock

the unit. This pass code will be required to enter the menu to unlock the unit. The

LOCK icon illuminates to indicate the locked status.

The LOCK icon disappears to indicate unlocked status.

External Control Status

The Wi-Fi icon illuminates to indicate that the system is receiving a Wi-Fi connection. The Wi-Fi icon also provides information about the signal strength.

ADVANCED FUNCTIONS

The functions mentioned in the following section may or may not be available depending on the air conditioner model.

Modify the TIMER Function

Navigate to the TIME menu to set the timer.

22

Page 23

J.3 Control Panel Operation

Accessing Sub-Menus

The MENU button accesses the sub-menu. See Figure J.3.3.

The arrow buttons navigate the 6 menu options See Figure J.3.4:

– LIM – LOCK

– TM – CnCT

– F-C – diAG

The RETURN button exits the menu. See Figure J.3.5.

Figure

J.3.3

J. STARTUP AND OPERATION

Figure

J.3.4

Figure

J.3.5

MENU RETURN

MENU

RETURN

MENU

RETURN

23

Page 24

J. STARTUP AND OPERATION

J.3 Control Panel Operation

Navigating Inside the Sub-Menus

The MENU button moves you forward through the sub-menu.

See Figure J.3.6.

The RETURN button moves you backward once inside the LIM and

TM menus. See Figure J.3.7.

Figure

J.3.6

Figure

J.3.7

MENU

MENU

RETURN

RETURN

24

Page 25

J.3 Control Panel Operation

The LIM Menu

This is the limit menu. See Figure J.3.8.

Upon entering the menu, the rst option will be to set the lower setpoint

limit using the arrow buttons. See Figure J.3.9.

Figure

J.3.8

Figure

J.3.9

J. STARTUP AND OPERATION

Then you can set the higher setpoint limit using the arrow buttons.

See Figure J.3.10.

Pressing the menu button completes the limit setting. See Figure J.3.11.

MENU RETURN

Figure

J.3.10

Figure

J.3.11

MENU RETURN

MENU RETURN

MENU

RETURN

25

Page 26

J. STARTUP AND OPERATION

J.3 Control Panel Operation

The TM Menu

This is the TM menu used to set a timer. See Figure J.3.12.

In the menu, you set the current time using the arrow buttons. See Figure J.3.13.

(Note: These two “set clock” steps will be skipped if the unit is already connected

to Wi-Fi.)

First, set the hour.

Figure

J.3.12

MENU RETURN

Figure

J.3.13

Using the button, you switch to the minutes and complete setting the

time. See Figure J.3.14.

You select your mode. Either cool, heat, or auto. Toggle these using the

arrow buttons. See Figure J.3.15. (Note: cooling-only models skip this

step.)

The process is the same for all three modes. Auto mode will be shown as

the example.

Figure

J.3.14

Figure

J.3.15

MENU RETURN

MENU RETURN

MENU

RETURN

26

Page 27

J.3 Control Panel Operation

The TM Menu continued

Auto mode selected. See Figure J.3.16.

Set the cool setpoint for your rst timer period using the arrow buttons.

The cooling mode timer only sets the cool setpoint. See Figure J.3.17.

Next, set the heat setpoint for your rst timer period. The heating mode

timer only sets the heat setpoint. See Figure J.3.18.

Figure

J.3.16

J. STARTUP AND OPERATION

Note: The auto mode timer sets both the cool and heat setpoint.

Set the time to start the rst timer period. See Figure J.3.19.

Figure

J.3.17

Figure

J.3.18

MENU

MENU

MENU

RETURN

RETURN

RETURN

Figure

J.3.19

MENU RETURN

27

Page 28

J. STARTUP AND OPERATION

J.3 Control Panel Operation

The TM Menu continued

Set the cool setpoint for the second scheduled timer. See Figure J.3.20.

Set the heat setpoint for the second timer.

Set the time to start the second timer period. See Figure J.3.21.

Press the button to complete the time timer setup.

See Figure J.3.22.

Figure

J.3.20

Figure

J.3.21

Figure

J.3.22

MENU

RETURN

MENU RETURN

MENU

RETURN

28

Page 29

J.3 Control Panel Operation

The F-C Menu

This menu is used to toggle between Fahrenheit and Celsius.

This is the Fahrenheit/ Celsius Menu. See Figure J.3.23

Using the arrow buttons on the right side switches it from Fahrenheit to

Celsius. See Figures J.3.24 and J.3.25.

Figure

J.3.23

J. STARTUP AND OPERATION

MENU RETURN

Figure

J.3.24

Figure

J.3.25

MENU RETURN

MENU RETURN

29

Page 30

J. STARTUP AND OPERATION

J.3 Control Panel Operation

The Lock Menu

This menu is used to lock the changing setting with a password.

This is LOCK on. See Figure J.3.28.

This is the Lock Menu. See Figure J.3.26.

The default is the off setting. Use the arrows to toggle between off and

on. See Figure J.3.27

Figure

J.3.26

MENU RETURN

Figure

J.3.27

Set the rst digit of the password using the arrow buttons. Use the button

to proceed to the next digit. See Figure J.3.29.

Figure

J.3.28

Figure

J.3.29

MENU RETURN

MENU RETURN

MENU RETURN

30

Page 31

J.3 Control Panel Operation

The Lock Menu continued

Set the second digit of the password using the same method.

See Figure J.3.30

J. STARTUP AND OPERATION

Set the fourth digit of the password using the same method.

See Figures J.3.32

Set the third digit of the password using the same method.

See Figure J.3.31

Figure

J.3.30

Figure

J.3.31

Press the button to complete the password process.

See Figure J.3.33

MENU RETURN

Figure

J.3.32

Figure

J.3.33

MENU RETURN

MENU

RETURN

MENU RETURN

31

Page 32

J. STARTUP AND OPERATION

J.3 Control Panel Operation

The Lock Menu continued

The ON on the right side of the display shows the lock function is

active. To go back into the menu, select the button again.

See Figure J.3.34

Enter the password in the same manner it was created. See Figure

J.3.35.

Figure

J.3.34

Entering the correct password will give the user access to all of the submenus. See Figure J.3.36

Accessing the lock menu will allow you to toggle lock OFF if needed.

See Figure J.3.37

Figure

J.3.35

Figure

J.3.36

Figure

J.3.37

MENU

RETURN

MENU RETURN

MENU RETURN

32

MENU RETURN

Page 33

J.3 Control Panel Operation

The CnCT Menu

This menu is used to turn on Wi-Fi connection.

This is the CnCT menu. Pressing the button will activate Wi-Fi.

See Figure J.3.38

The Wi-Fi symbol in the top right corner of the display shows Wi-Fi

connection is on. See Figure J.3.39

Figure

J.3.38

J. STARTUP AND OPERATION

Figure

J.3.39

MENU RETURN

MENU RETURN

33

Page 34

J. STARTUP AND OPERATION

J.3 Control Panel Operation

The diAG Menu

This menu is used to access the diagnostic codes. See Figure J.3.40.

Selecting this sub-menu shows the E that represents “Error.”

See Figure J.3.41

Toggle through the error codes using the arrow keys. See Figure J.3.42

Figure

J.3.40

MENU RETURN

Figure

J.3.41

Figure

J.3.42

MENU RETURN

MENU RETURN

34

Page 35

J. STARTUP AND OPERATION

J.4 Remote Control Operation

Remote Control - Refer to Figure J.4.1 during operation description.

Getting Started - Install two (2) AAA batteries in the battery

compartment located on the back of the unit.

Operation - The remote control should be within 25 feet of the air

conditioner for operation. Press the power button to turn the remote on.

The remote will automatically power off after 15 seconds if the buttons

are not being pressed. The remote must be on to control the unit.

POWER Button - Turns remote and unit on and off.

SYSTEM Button - Allows the user to sequentially select the following:

AUTO, COOL, HEAT, and FAN ONLY operations. When the button is

pressed, the display indicates which mode has been selected via a

display message. Note that when the heating function is not available,

the system will automatically skip the HEAT mode.

FAN MODE Button - Selects between automatic (AUTO FAN) or

CONTINUOUS operation. In the AUTO FAN mode, the fan only turns on

and off when the compressor operates or the heat function is enabled.

NOTE: AUTO FAN is not available in the FAN ONLY Mode, the display

indicates CONTINUOUS. In the CONTINUOUS mode, fan speed is

determined by your selection on the FAN SPEED button.

FAN SPEED Button - Used to sequentially select new fan speed, plus

AUTO operation. When the FAN SPEED button is pressed, the fan

speed icon (triangle)

changes to indicate the new speed level. Fan speed automatically varies

depending on the set temperature on the control panel and the actual

room temperature. For example, if there is a big difference between

your set temperature and the actual room temperature, the system

fan speed increases to HIGH. It remains at this speed until the

room temperature matches the set temperature.

UP and DOWN Arrows - Pressing either the UP or DOWN button

changes the desired room temperature. The factory preset lower

and upper limits are 60 °F (16 °C) and 99 °F (37 °C). These buttons are

also used to navigate between function options when using the User

Menu or Maintenance Mode.

Remote Effectiveness

Handheld Remote - Has an operating range of up to 25 ft. The infrared

remote control signal must have a clear path to transmit the command to the air

conditioning unit. The remote signal has some ability to “bounce” off of walls and

furniture similar to a television remote control. The diagram below shows the typical

operating range of the control in a standard room with 8 ft high ceilings.

J.5 Start-up

This is a warm weather appliance

Your air conditioner is designed to cool in warm weather when the

outside temperature is above 60 °F (15.6 °C) and below 115 °F (46.1 °C),

so it won’t cool a room if it is already cool outside. If you want to cool a

room in the spring or fall, select the FAN ONLY mode and set the Fresh

Air/ Exhaust air control to Fresh Air. This will bring in a supply of cooler

outside air.

Condensation is normal

Air conditioners actually pump the heat and humidity from your room

to the outside. Humidity becomes water, and your air conditioner

will use most of the water to keep the outside coil cool. If there is

excessive humidity, there may be excess water that will drip outside.

This is normal operation.

Frosting

This usually occurs because of insufficient airflow across the coils, a

dirty filter, cool damp weather, or all these. Set the SYSTEM mode to

FAN ONLY and the frost will disappear. Setting the thermostat a little

warmer will probably prevent the frosting from recurring.

Noises

All air conditioners make some noise. Friedrich units are designed to

operate as quietly as possible. An air conditioner mounted in a wall is

quieter than one mounted in a window. It is important to ensure that

the chassis seal gasket (Item 13) is properly installed (refer to the

Installation Instructions).

NOTICE

This unit is certified to operate in cooling mode under these maximum conditions. Any operation beyond these conditions may result

in intermittent operation.

Indoor temperature: 90 °F (45% relative humidity)

Outdoor temperature: 110 °F (25% relative humidity)

If unit is heat pump equipped, it is certified to operate in heating

mode under these maximum conditions. Any operation beyond these

conditions may result in intermittent operation.

Indoor temperature: 80 °F (humidity does not affect operation)

Outdoor temperature: 70 °F (60% relative humidity)

L.

WiFi

MODE

FAN

SPEED

This model is currently compatible with Friedrich Connect and

Alexa, but not Google Connect. Use a QR Reader on your phone to

scan this QR Code. It will take you to the Wifi Instructions page of

our website.

POWER

UP and

DOWN

ARROWS

FIgure J.4.1

35

Page 36

M. TROUBLESHOOTING

M.1. Troubleshooting Tips

COMPLAINT CAUSE SOLUTION

• The unit is turned to the off position, or the

thermostat is satised.

• The LCDI power cord is unplugged.

Unit does not operate.

Unit Trips Circuit Breaker or

Blows Fuses.

LCDI Power Cord Trips

(Reset Button Pops Out).

Unit Does Not Cool/ Heat Room

Sufciently, or Cycles On And Off

Too Frequently.

• The LCDI power cord has tripped (Reset

button has popped out).

• The circuit breaker has tripped or the

supply circuit fuse has blown.

• There has been a local power failure.

• Other appliances are being used on the

same circuit.

• An extension cord is being used.

• The circuit breaker or time-delay fuse is

not of the proper rating.

• The LCDI power cord can trip (Reset

button pops out) due to disturbances on

your power supply line.

• Electrical overload, overheating, or cord

pinching can trip (Reset button pops out)

the LCDI power cord.

NOTE: A damaged power supply cord must be replaced with a new power supply cord obtained from the product manu-

facturer and must not be repaired. The power cord must be replaced by trained service personnel.

• The return/ discharge air grille is blocked.

• Windows or doors to the outside are open. • Ensure that all windows and doors are closed.

• The temperature is not set at a cool

enough/ warm enough setting.

• The lter is dirty or obstructed. • Clean the lter, (see Routine Maintenance), or remove obstruction.

• The indoor coil or outdoor coil is dirty or

obstructed.

• There is excessive heat or moisture

(cooking, showers, etc.) in the room.

• The temperature of the room you are

trying to cool is extremely hot.

• Turn the unit to the on position and raise or lower temperature

setting (as appropriate) to call for operation.

• Plug into a properly grounded 3 prong receptacle. See “Electrical

Rating Tables” on Page 6 for the proper receptacle type for your

unit.

• Press and release RESET (Listen for click. Reset button latches

and remains in.) to resume operation.

• Reset the circuit breaker, or replace the fuse as applicable. If

the problem continues, contact a licensed electrician.

• The unit will resume normal operation once power has been

restored.

• The unit requires a dedicated outlet circuit, not shared with other

appliances.

• Do NOT use an extension cord with this or any other air condition-

er.

• Replace with a circuit breaker or time-delay fuse of the proper rat-

ing. See “Electrical Rating Tables” on Page 6 for the proper circuit

breaker/ fuse rating for your unit. If the problem continues, contact

a licensed electrician.

• Press and release RESET (Listen for click. Reset button latches

and remains in.) to resume normal operation.

• Once the problem has been determined and corrected, press

and release RESET (Listen for click. Reset button latches

and remains in.) to resume normal operation.

• Ensure that the return and/ or discharge air paths are not blocked

by curtains, blinds, furniture, etc.

• Adjust the Temperature control to a cooler or warmer setting as

necessary.

• Clean the coils, (see Routine Maintenance), or remove obstruction.

• Be sure to use exhaust vent fans while cooking or bathing and,

if possible, try not to use heat producing appliances during the

hottest part of the day.

• Allow additional time for the air conditioner to cool off a very hot

room.

36

Page 37

M.1. Troubleshooting Tips (Cont)

COMPLAINT CAUSE SOLUTION

• The outside temperature is below 60 °F

(16 °C).

• The digital control is set to fan cycling mode.

Unit Does Not Cool/ Heat Room

Sufciently, or Cycles On And Off

Too Frequently (continued).

Unit Runs Too Much.

• The air conditioner has insufcient cooling

capacity to match the heat gain of the room.

• The air conditioner has insufcient heating

capacity to match the heat loss of the room.

• This may be due to an excessive heat load

in the room.

• It may also be due to an improperly sized unit.

• This may be normal for higher efciency

(EER) air conditioners.

• You may notice that the discharge air

temperature of your new air conditioner

may not seem as cold as you may be

accustomed to from older units. This

does not; however, indicate a reduction

in the cooling capacity of the unit.

M. TROUBLESHOOTING

• Do not try to operate your air conditioner in the cooling mode

when the outside temperature is below 60 °F (16 °C). The unit will

not cool properly, and the unit may be damaged.

• Since the fan does not circulate the room air continuously at this

setting, the room air does not mix as well and hot (or cold) spots

may result. Using the continuous fan setting is recommended to

obtain optimum comfort levels.

• Check the cooling capacity of your unit to ensure it is properly

sized for the room in which it is installed. Room air conditioners are

not designed to cool multiple rooms.

• Check the heating capacity of your unit. Air conditioners are sized to

meet the cooling load, and heater size is then selected to meet the

heating load. In extreme northern climates, room air conditioners may

not be able to be used as a primary source of heat.

• If there are heat producing appliances in use in the room, or if the

room is heavily occupied, the unit will need to run longer to remove

the additional heat.

• Be sure to use exhaust vent fans while cooking or bathing and,

if possible, try not to use heat producing appliances during the

hottest part of the day.

• The use of higher efciency components in your new air

conditioner may result in the unit running longer than you feel

it should. This may be more apparent, if it replaced an older,

less efcient, model. The actual energy usage, however, will be

signicantly less when compared to older models.

• The energy efciency ratio (EER) and cooling capacity rating

(Btu/ h) listed on the unit’s rating plate are both agency certied.

P. Appendixes

P.1 Accessories and Options

DC-2 Drain Kit – Part No. 01900235

In some installations, excess condensate water caused by extremely humid

conditions, may result in an undesirable water drip such as on a patio or over an

entryway. MODEL DC-2 DRAIN KIT (Part No. 01900-235) can be installed to drain

excess condensation to an alternate location.

Carbon Filter Kits

The kits vary depending on the chassis size (small, medium, large). Each kit contains

three (3) lters.

KWCFS – Carbon lter kit for small chassis models.

KWCFM – Carbon lter kit for medium chassis models.

KWCFL – Carbon lter kit for large chassis models.

Decorative Color Front Panel Kits

The kits vary depending on the chassis size (small, medium, large).

KWBGE(S/ M/ L)A – S/ M/ L Decorative Front Cover in Classic Beige

KWBLK(S/ M/ L)A – S/ M/ L Decorative Front Cover in Black Onyx

KWBLU(S/ M/ L)A – S/ M/ L Decorative Front Cover in Cobalt Blue

KWPNK(S/ M/ L)A – S/ M/ L Decorative Front Cover in Pink Diamond

KWRED(S/ M/ L)A – S/ M/ L Decorative Front Cover in Deep Red

KWWHT(S/ M/ L)A – S/ M/ L Decorative Front Cover in Designer White

Window Installation Kits (Standard in Kühl Models without

Heat)

KWIKS – For all KES and KHS models.

KWIKM – For all KEM and KHM models.

KWIKL – For all KEL and KHL models.

See www.friedrich.com for additional accessories for your unit.

37

Page 38

R . INFORMATION FOR THE OWNER

Present the owner or operator of the equipment with the

Installation & Operation Manual, all accessory installation

instructions, and the name, address, and telephone number of the

Authorized Friedrich Warranty Service Company in the area for

future reference if necessary. Inspect the unit for any damage to

the coils and tubing that could cause a leak.

R.1 Room air conditioner unit performance test

data sheet

Job name________________________________

Tech’s name______________________________

Date_________

Air Conditioned

Area

100 - 150 5000 550 - 700 14000

150 - 250 6000 700 - 1000 18000

250 - 300 7000 1000 - 1200 21000

300 - 350 8000 1200 - 1400 23000

350 - 400 9000 1400 - 1500 24000

400 - 450 10000 1500 - 2000 30000

450 - 550 12000 2000 - 2500 34000

Cooling BTUs

Required

Air Conditioned

Area

Cooling BTUs

Required

Model#____________________serial #_____________________

Check the installation acceptable not acceptable

Yes no

Is a chasis gasket installed? _____ ____

Is the fresh / exhaust air vent open? _____ ____

Is a friedrich sleeve installed? _____ ____

Is a friedrich outdoor grille installed? _____ ____

Is maintenance being performed? _____ ____

Electrical

Line voltage (static) _____ volts

Start up voltage _____ volts

Amperage draw (cool) _____ amps

Amperage draw (heat) _____ amps

Compressor

Locked rotor amps _____ amps

Running amperage draw _____ amps

Indoor conditions

Indoor ambient temperature _____ f

Relative humidity (rh) indoor _____%

Discharge air temperature (indoor)(cool) _____f

Discharge air temperature (indoor)(heat) _____f

Return air temperature (indoor)(cool) _____f

Return air temperature (indoor) (heat) _____f

Outdoor temperature

Outdoor ambient temperature _____f

Rh outdoor relative humidity _____%

Discharge air temperature (outdoor)(cool) _____f

Discharge air temperature (outdoor)(heat) _____f

Intake air temperature (outdoor)(cool) _____f

Intake air temperature (outdoor)(heat) _____f

Cooling or heating area

Area w______ * l_______ = feet squared

For a general guide refer to sizing guide to the right

For exact load calculations consult manual j or m.

R.2 Routine Maintenance

Decorative Front

Use a damp (not wet) cloth when cleaning the control area to prevent

water from entering the unit, and possibly damaging

the electronic control.

The decorative front and the cabinet can be cleaned

with warm water and a mild liquid detergent. Do NOT use solvents

or hydrocarbon based cleaners such as acetone, naphtha, gasoline,

benzene, etc.

The indoor coil can be vacuumed with a dusting attachment if it appears

to be dirty. DO NOT BEND FINS. The outdoor coil can be gently sprayed

with a garden hose.

Air Filter

The air filter should be inspected weekly and cleaned if needed by

vacuuming with a dust attachment or by cleaning in the sink using

warm water and a mild dishwashing detergent. Dry the filter thoroughly

before reinstalling. Use caution, the coil surface can be sharp.

WARNING: Service of this product (aside from filter

maintenance) shall only be performed by trained service personnel.

Refer to the Service Manual for procedures on how to inspect and

maintain the interior of the unit and its components. A QR code is located

in section A.5 which will help you locate the service manual online.

Coils & Chassis

The indoor coil and outdoor coils and base pan should be inspected

periodically (annually or semi-annually) and cleaned of all debris (lint,

dirt, leaves, paper, etc.) as necessary. Under extreme conditions, more

frequent cleaning may be required.

Wall Sleeve

Inspect the inside of the wall sleeve and drain system periodically

(annually or semi-annually) and clean as required. Under extreme

conditions, more frequent cleaning may be necessary.

Blower Wheel / Housing / Condensor Fan / Shroud

Inspect the indoor blower and its housing, evaporator blade, condenser

fan blade and condenser shroud periodically (yearly or bi-yearly) and

clean of all debris (lint, dirt, mold, fungus, etc.).

38

Page 39

R.3 Warranty

R. INFORMATION FOR THE OWNER

39

Loading...

Loading...