Page 1

Room Air Conditioners

AUTO F

AN

SC

ONTINUOU

AUTO

F

C

SYSTEM

FAN MODE

POWER

FAN SPEED

SCHEDULE

Standard Chassis Models

Installation and Operation Manual

Kühl

Kühl +

Electric Heat

Kühl +

Heat Pump

93001015_00

115-Volt:

230-Volt:

115-Volt:

230-Volt:

KCS08, KCS10, KCS12, KCS14

KCS12, KCS16, KCM18, KCM21, KCM24

KCL22, KCL24, KCL28, KCL36

KHS10

KES12, KES16, KH12, KEM18

KHM18, KHM24, KEL36, KHL24

Page 2

Thank you for your decision to purchase the Friedrich High Efciency Air Conditioner. Your new Friedrich has been carefully engineered and manufactured to

give you many years of dependable, efcient operation, maintaining a comfortable temperature and humidity level. Many extra features have been built into

your unit to assure quiet operation, the greatest circulation of cool, dry air, and the most economic operation.

THANK YOU, on behalf of our entire company,

for making such a wise purchase.

AIR CONDITIONING CO.

SAN ANTONIO, TEXAS

ASSEMBLED IN MEXICO

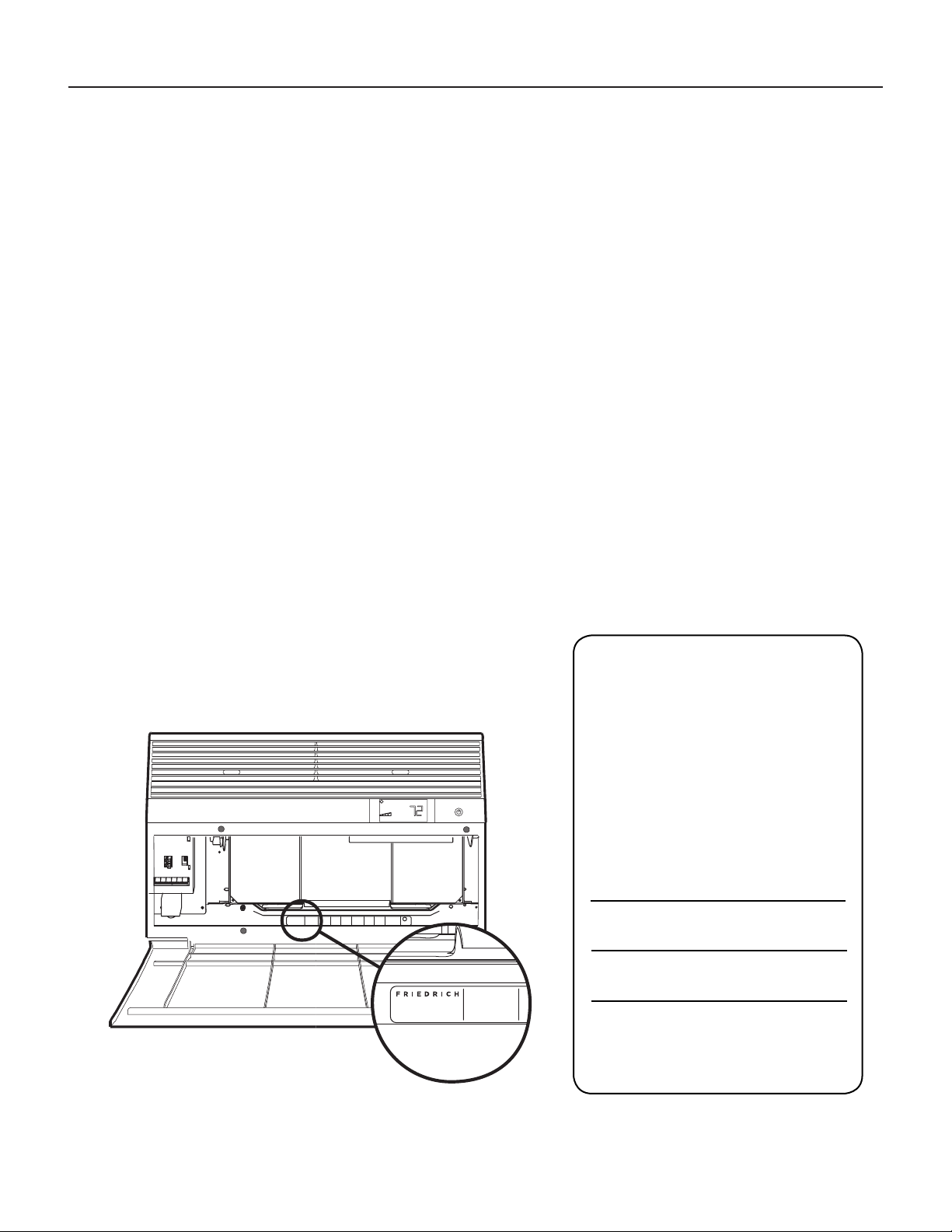

Register your air conditioner

Model information can be found on the name plate

behind the front cover.

Please complete and mail the owner registration

card furnished with this product, or register online

at www.friedrich.com.

For your future convenience, record the model

information here.

MODEL NUMBER

VOLTS 115

COOLING

HEATING

REFRIGERANT

XXXXXXXXX

XXXXXXXXXX

FUSE PROTECTED

U

YS10M10A

60 HZ / 1 PH

BTH/HR 6500

BTH/HR 6500

SERIAL NUMBER

LICY00008

30.1 OZ R410A

VOLTS MIN 108

EER 12.0

EER 10.4

AMPS 8.0

AMPS 7.0

600 PSIG HS

XXXXXXXXX

CIRCUITS USE 15A

300 PSIG LS

XXXXXXXXXX

TIME DELAY FUSE

XXXXXXXXXX

L

X XX

XXXXX

XXXXXXXXXX

AIR CONDITIONING CO.

SAN ANTONIO, TEXAS

ASSEMBLED IN MEXICO

MODEL NUMBER

YS10M10A

SERIAL NUMBER

LICY00008

MODEL NUMBER

SERIAL NUMBER

PURCHASE DATE

2 3

Page 3

Table of Contents

Safety Precautions ...................................................................................... 4

Unpacking Instructions .................................................................................. 5

WARNING: Before Operating Your Unit ..................................................................... 6

Standard Filter Cleaning / Installation Instructions ........................................................... 7

Premium Carbon Filter Installation Instructions .............................................................. 8

Control Panel Operation .................................................................................. 9

New Kühl Control Options ................................................................................ 22

Wi-Fi Set-Up Instructions ................................................................................ 23

Control Panel Operation Instructions ....................................................................... 24

Remote Control Operation ................................................................................ 25

Remote Effectiveness .................................................................................... 25

Airow Selection and Adjustment .......................................................................... 26

Installation Instructions .................................................................................. 27

Installation Hardware and Accessory Details ................................................................. 28

Standard Window Installation ............................................................................. 29

Cord Routing Change .................................................................................... 38

Thru-the-Wall Installation ................................................................................ 40

Final Inspection & Start-up Checklist ...................................................................... 44

Routine Maintenance .................................................................................... 45

Service and Assistance .................................................................................. 45

Available Accessories .................................................................................... 45

Troubleshooting Tips .................................................................................... 46

Warranty .............................................................................................. 48

Performance Installation & Test Method Addendum .......................................................... 49

Page 4

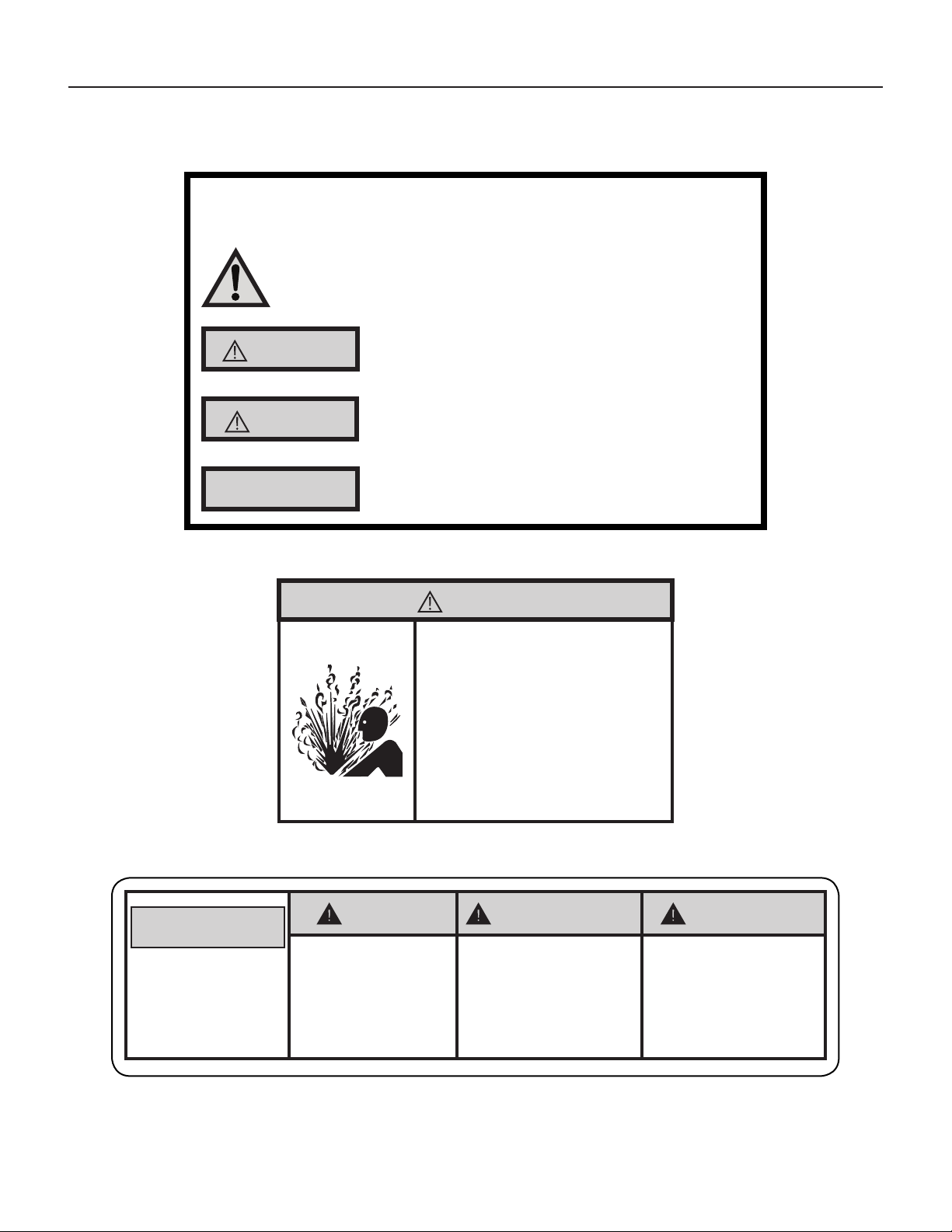

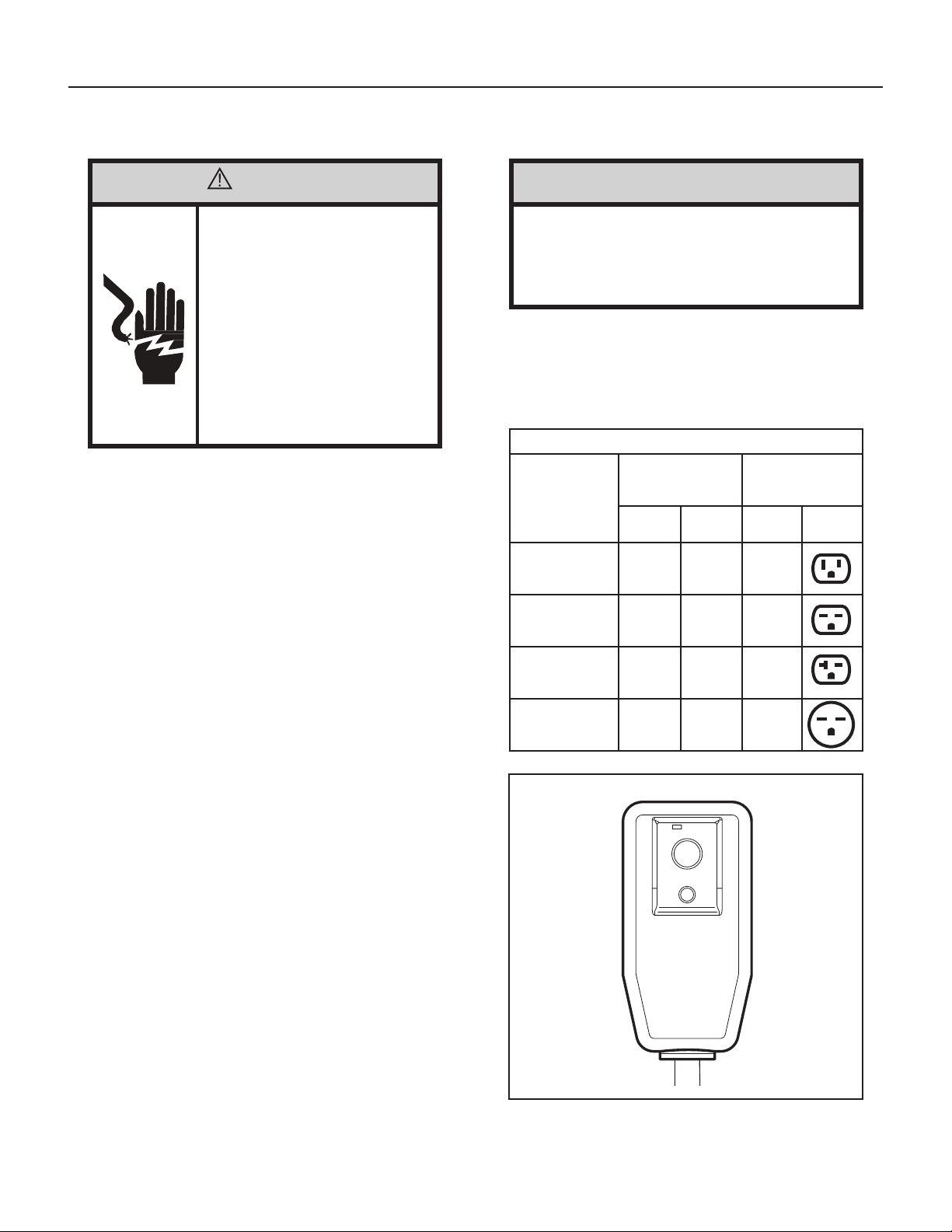

Safety Precautions

Your safety and the safety of others is very

WARNING

CAUTION

NOTICE

We have provided many important safety messages in this manual and on your

important.

appliance. Always read and obey all safety messages.

This is a safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING”

or “CAUTION”. These words mean:

Indicates a hazard which, if not avoided, can result in severe personal injury or

death and damage to product or other property.

Indicates a hazard which, if not avoided, can result in personal injury and damage to

product or other property.

All safety messages will tell you what the potential hazard is, tell you how to

reduce the chance of injury, and tell you what will happen if the instructions are

not followed.

Indicates property damage can occur if instructions are not followed.

THINK

SAFETY

FIRST

WARNING

Refrigeration system

under high pressure

Do not puncture, heat, expose to ame or incinerate.

Only certied refrigeration technicians should service

this equipment.

R410A systems operate at higher pressures than R22

equipment. Appropriate safe service and handling

practices must be used.

Only use gauge sets designed for use with R410A.

Do not use standard R22 gauge sets.

WARNING AVERTISSEMENT ADVERTENCIA

Do not remove, disable or

bypass this unit’s safety

devices. Doing so may cause

re, Doing so may cause re,

injuries, or death.

Ne pas supprime, désactiver ou

contourner cette l´unité des

dispositifs de sécurité, faire vous

risqueriez de provoquer le feu, les

blessures ou la mort.

No eliminar, desactivar o pasar

por alto los dispositivos de

seguridad de la unidad. Si lo hace

podría producirse fuego, lesiones

o muerte.

4 5

Page 5

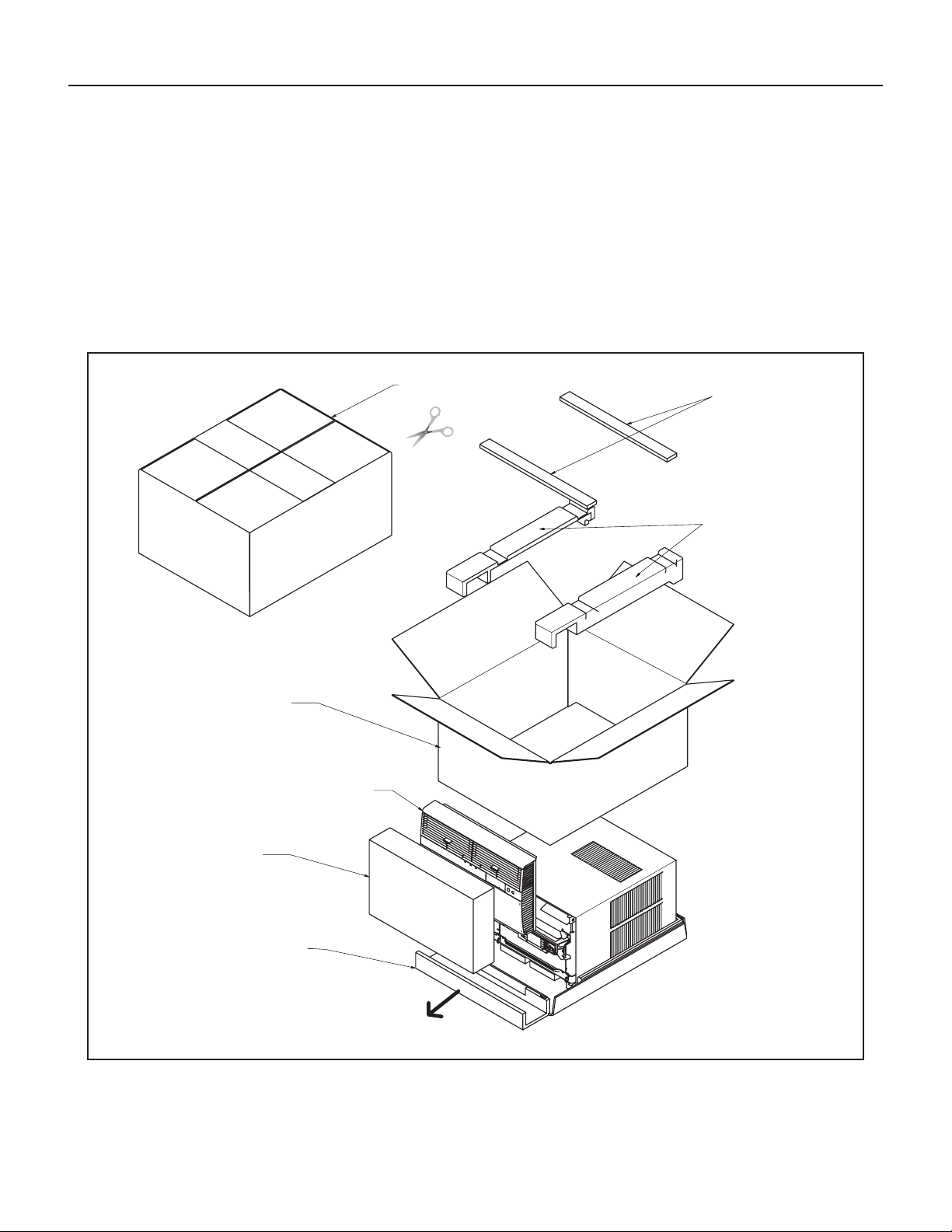

Unpacking Instructions

STEP 1. Cut all 4 packing straps.

STEP 2. Remove wooden shipping bar dividers.

STEP 3. Remove top foam pads.

STEP 4. Slowly remove outer box, careful not to loosen decorative front.

STEP 1

STRAPS x4

STEP 5. Slide the front forward.

STEP 6. Carefully lift decorative front box from foam front support.

STEP 7. Remove decorative front and set safely aside.

STEP 2

STEP 3

STEP 6

STEP 4

STEP 7

STEP 5

Page 6

WARNING: Before Operating Your Unit

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same conguration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong outlet.

Failure to follow these instructions can result

in death, re, or electrical shock.

Make sure the wiring is adequate for your unit.

If you have fuses, they should be of the time delay type. Before you

install or relocate this unit, be sure that the amperage rating of the

circuit breaker or time delay fuse does not exceed the amp rating

listed in Table 1.

DO NOT use an extension cord.

The cord provided will carry the proper amount of electrical power to

the unit; an extension cord may not.

Make sure that the receptacle is compatible with the air

conditioner cord plug provided.

Proper grounding must be maintained at all times. Two prong receptacles

must be replaced with a grounded receptacle by a certied electrician.

The grounded receptacle should meet all national and local codes

and ordinances. You must use the three prong plug furnished with

the air conditioner. Under no circumstances should you remove the

ground prong from the plug.

NOTICE

Do not use the LCDI device as an ON/OFF switch.

Failure to adhere to this precaution may cause

premature equipment malfunction.

Once plugged in, the unit will operate normally without the need to

reset the LCDI device. If the LCDI device fails to trip when tested

or if the power supply cord is damaged, it must be replaced with a

new power supply cord from the manufacturer. Contact our Technical

Assistance Line at (800) 541-6645. To expedite service, please have

your model number available.

Table 1

MODEL

KCS08, KCS10

KCS12, KCS14

KHS10

KCS12, KCS16

KCM18, KCM21

KCL22

KCM24, KCL28

KES12, KES16

KHS12, KCL24

KCL36, KEM18

KEM24, KEL36

KHM18, KHL24

Figure 1

CIRCUIT RATING

OR TIME DELAY

FUSE

AMP VO LT

15 125 5-15R

15 250 6-15R

20 250 6-20R

30 250 6-30R

REQUIRED

WALL

RECEPTACLE

NEMA

NO.

RESET

Test the power cord.

All Friedrich room air conditioners are shipped from the factory with

a Leakage Current Detection Interrupter (LCDI) equipped power

cord. The LCDI device on the end of the cord meets the UL and NEC

requirements for cord connected air conditioners.

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET (see Figure 1).

3. Press TEST, listen for click; the RESET button trips and pops out.

4. Press and release RESET (Listen for click; RESET button latches and

remains in). The power cord is ready for use.

TEST

WARNING:

TEST BEFORE EACH USE!

1. PRESS REST BUTTON.

2. PLUG LCDI INTO POWER

RECEPTACLE.

3. PRESS TEST BUTTON,

RESET BUTTON SHOULD

POP UP.

4. PRESS RESET BUTTON

FOR USE.

DO NOT USE IF ABOVE

TEST FAILS.

WHEN GREEN LIGHT

IS ON, IT IS WORKING

PROPERLY!

FRR072

6 7

Page 7

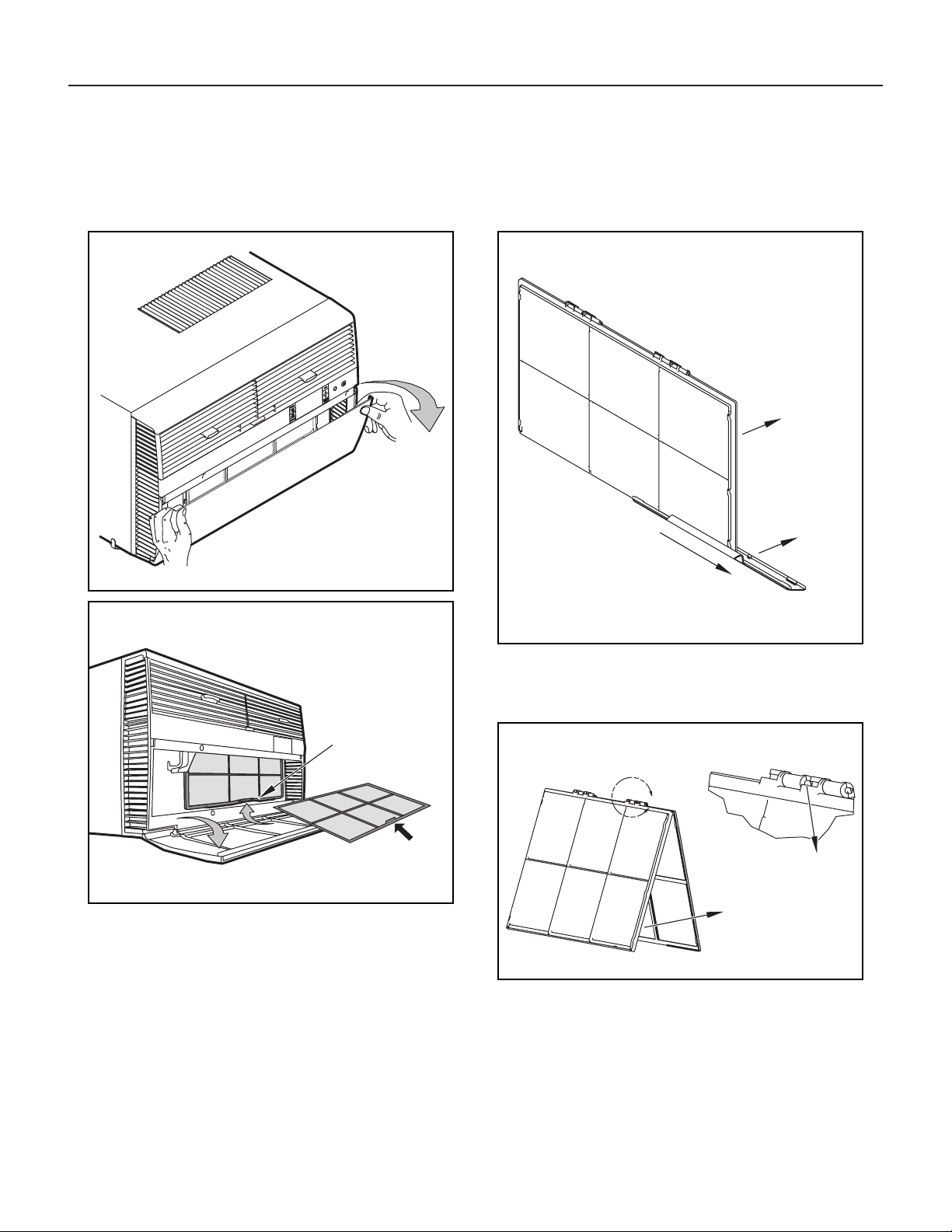

Standard Filter Cleaning / Installation Instructions

STEP 1. Swing the door open and remove the lter by grasping the lter

grip and pushing the lter holder upward and outward.

Figure 2

FRR071

Figure 3

STEP 2. Slide the lter grip out from the lter as shown in Figure 4.

NOTE: Make sure the front frame with the mesh lter is facing you.

Figure 4

FILTER

FILTER GRIP

FRR047

FILTER GRIP

HANDLE

FRR052

STEP 3. Swing the front frame open. Clean the front frame by washing

the dirt from the lter. Use a mild soap solution if necessary.

Allow lter to dry.

Figure 5

A

TOP TAB

FRONT

FRAME WITH

STANDARD

MESH FILTER

FRR048

STEP 4. Install the lter grip back into the lter by sliding it into the lter.

NOTE: The lter handle slides into the frame in only one direction. If the

tab in the frame stops the handle from sliding in, slide the handle

from the other direction. DO NOT FORCE THE HANDLE INTO

THE FRAME.

STEP 5. Install the lter back into the unit. Follow the instructions on the

inside of the front door.

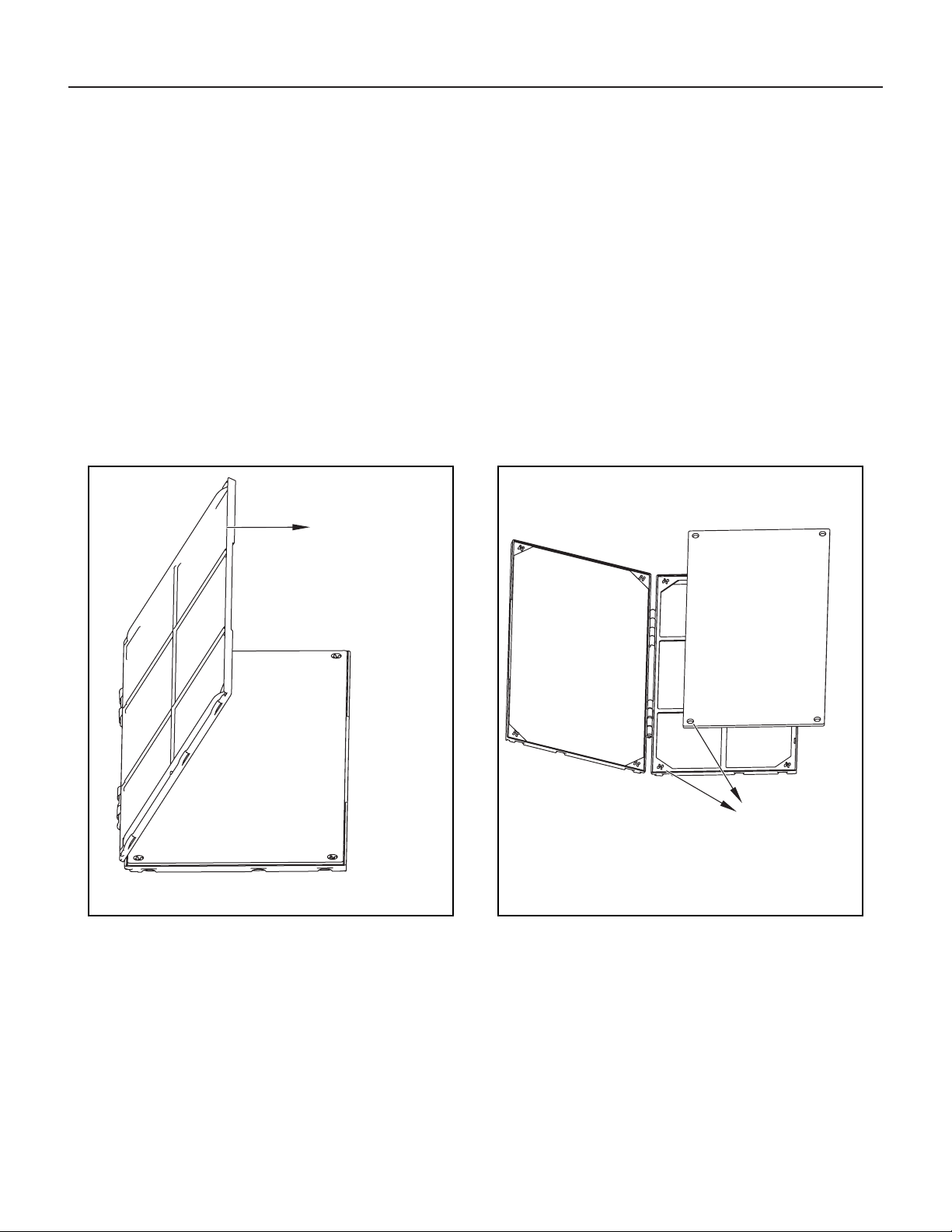

Page 8

FRAME WITH

ALIGN HOLES WITH

PROTRUSION

Premium Carbon Filter Installation Instructions

STEP 1. Remove the lter from the unit as per the instructions on the

inside of the lter door.

STEP 2. Hold the lter at the top and slide the grip out as shown in

Figure 4.

STEP 3. If you already have a carbon lter installed remove the dirty lter

by laying the lter down and swinging open the front frame as

shown in Figure 6.

NOTE: Make sure the frame with the mesh is facing toward you.

Figure 6

FRONT

MESH FILTER

STEP 4. Place the new carbon lter on the top of the back lter frame.

The carbon lter has been cut to the correct dimension and

should t within the frame as shown in Figure 7.

NOTE: The carbon lter is not a reusable lter, and needs to be replaced

every three months for optimum efciency.

STEP 5. Slide the lter handle back on to hold the frames together

and slide the assembly into the unit as per the instructions

on the door.

NOTE: The lter handle slides into the frame in only one direction. If the

tab in the frame stops the handle from sliding in, slide the handle

from the other direction. DO NOT FORCE THE HANDLE INTO

THE FRAME.

Figure 7

FRR050

FRR051

8 9

Page 9

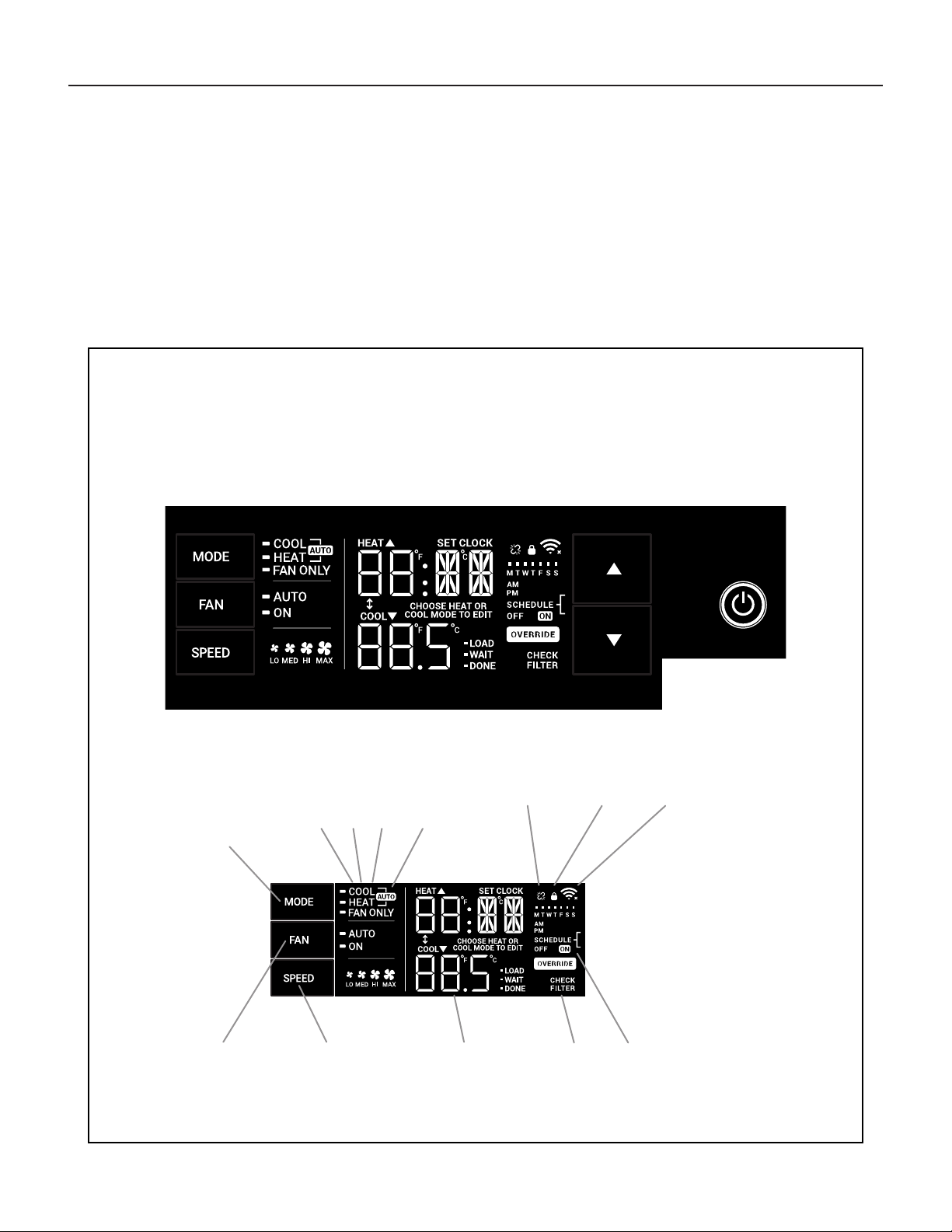

Control Panel Operation

MODE

CONTROL

WI-FI OPERATING

FA

Sets fan to either:

model dependant)

-

- Continuously run

DISCONNECTED

All of the control panel function buttons and mode icons can be viewed in Figure 8.

Power On – Press the button to turn on the air conditioner. The power button illuminates to indicate that the power is on. The backlight on the power switch

will automatically turn off after 20 seconds of inactivity. The remote control can also be used to turn power ON / OFF (see Remote Control).

Display – The display is a high efciency LCD with a built-in backlight. After 20 seconds of inactivity, the display switches off. Touching any button

automatically changes the display to full brightness.

There are three control push buttons on each side of the display.

Figure 8

SYSTEM

Cycles between

AUTO, HEAT,

COOL, or FAN

ONLY

(if equipped)

Figure 9

FAN MODE

Sets fan to either:

- Cycle automatically

- Run continuously

Cycles between

COOL, HEAT, FAN

ONLY or -AUTO(if equipped)

FAN SPEED

Sets fan speed:

LOW, MED,

HIGH or AUTO

(if equipped)

COOLHEATFAN ONLY

TEMPERATURE

Increment UP

TEMPERATURE

Increment DOWN

FROM POWER BOARD

-AUTO Automatically switches

between cool & heat

TIMER

Turns ON or OFF

LOCKED

IR WINDOW

Do not block

STATE

ON / OFF

Turns unit on/ off

N

Automatically cycle

FAN SPEED

Sets fan speed:

LOW, MED, HIGH, OR MAX

(Actual settings are

2 DIGIT DISPLAY

Shows Setting for: Check / clean

- Set Point (Temperature)

- Clock (AM/PM)

FILTER

TIMER

shows on or off

Page 10

Control Panel Operation

Accessing Sub-Menus

The leftmost MENU button accesses the sub-menu. See Figure 10.

The arrow buttons navigate the 6 menu options (See Figure 11):

– LIM – LOCK

– TM – CnCT

– F-C – diAG

The rightmost button exits the menu. See Figure 12.

Figure 10

MENU

Figure 11

Figure 12

MENU

MENU

10 11

Page 11

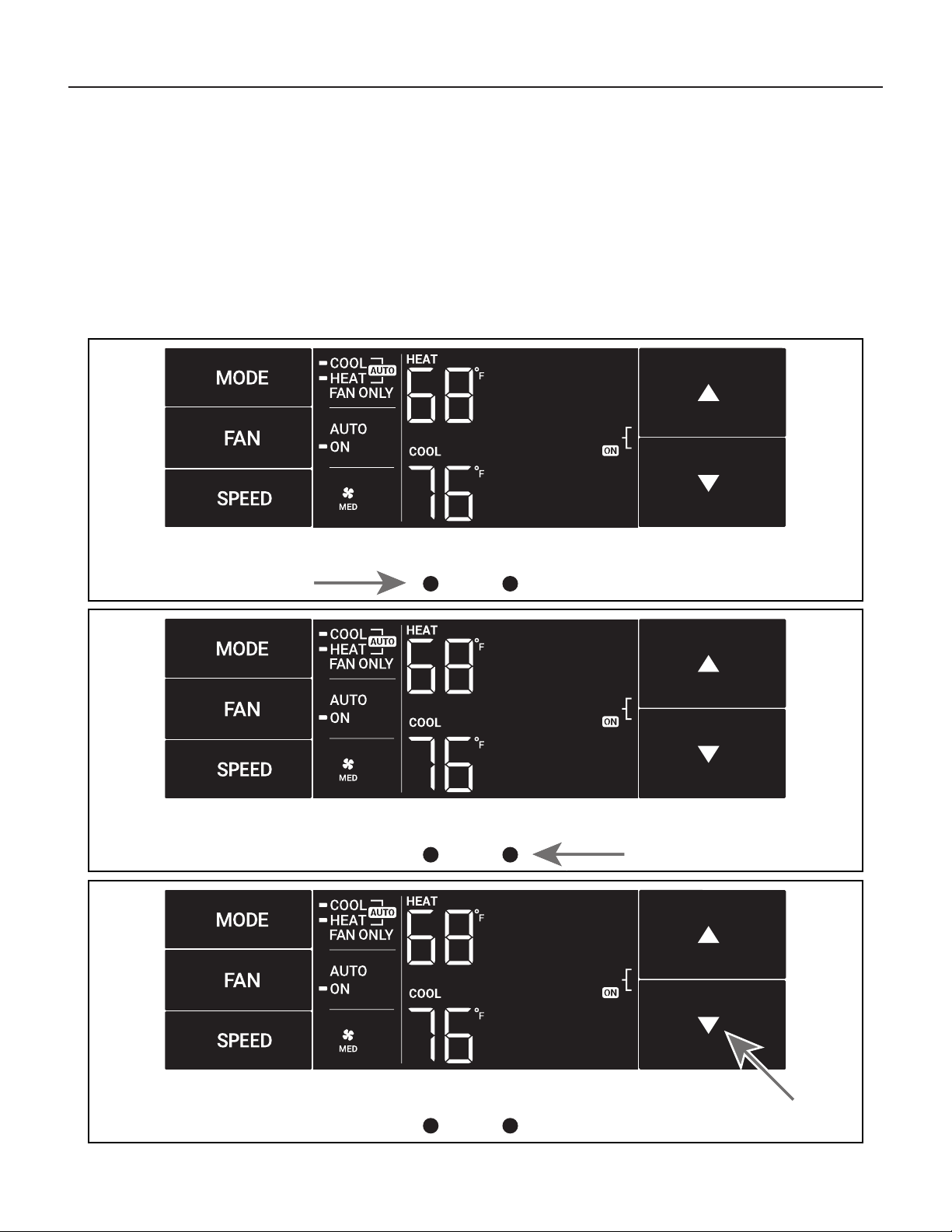

Control Panel Operation

Navigating Inside the Sub-Menus

The leftmost MENU button moves you forward through the sub-menu.

See Figure 13.

The rightmost button moves you backward once inside the LIM and TM

menus. See Figure 14.

Figure 13

MENU

Figure 14

MENU

Page 12

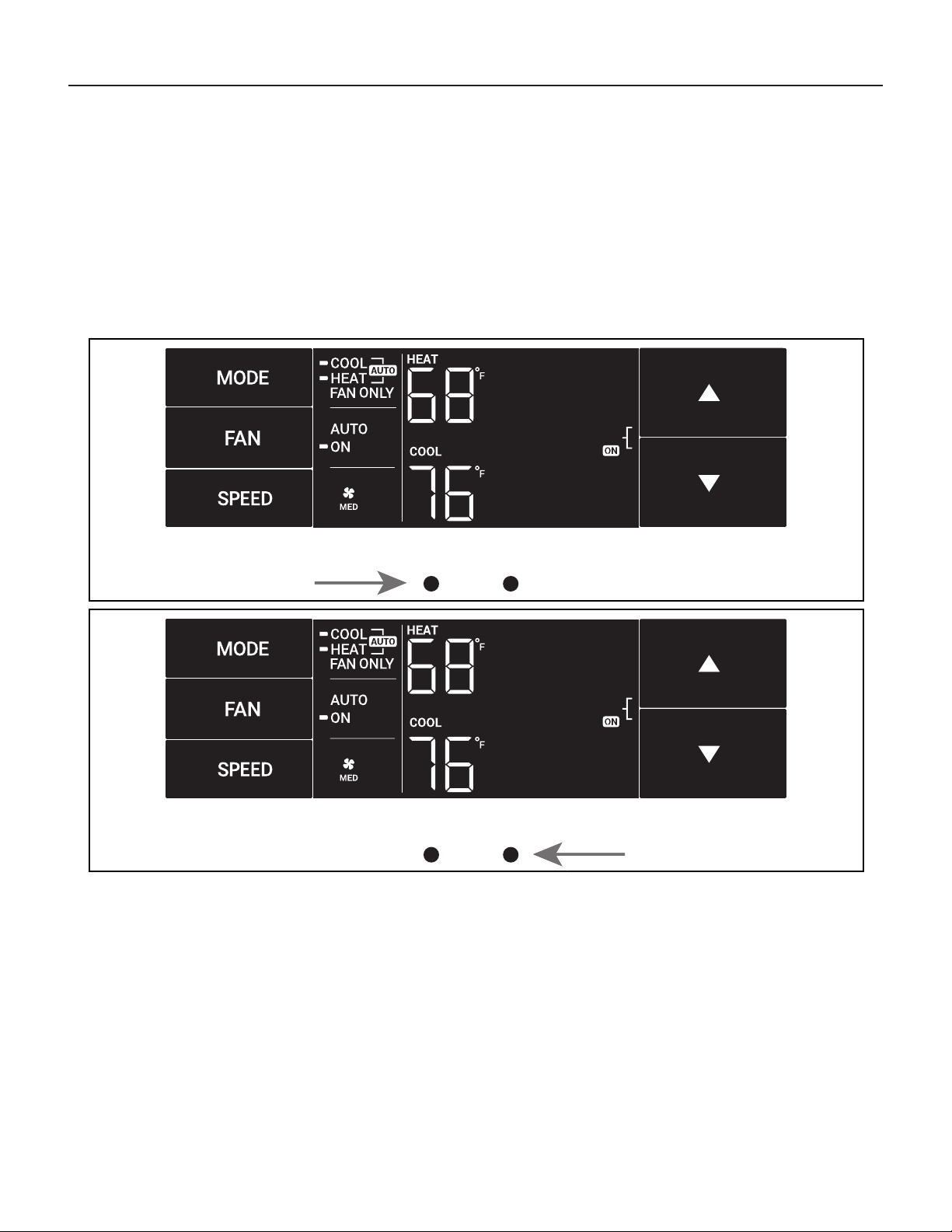

Control Panel Operation

The LIM Menu

This is the limit menu. See Figure 15.

Upon entering the menu, the rst option will be to set the lower setpoint

limit using the arrow buttons. See Figure 16.

Figure 15

MENU

Figure 16

Then you can set the higher setpoint limit using the arrow buttons.

See Figure 17.

Pressing the leftmost button completes the limit setting. See Figure 18.

MENU

Figure 17

MENU

Figure 18

MENU

12 13

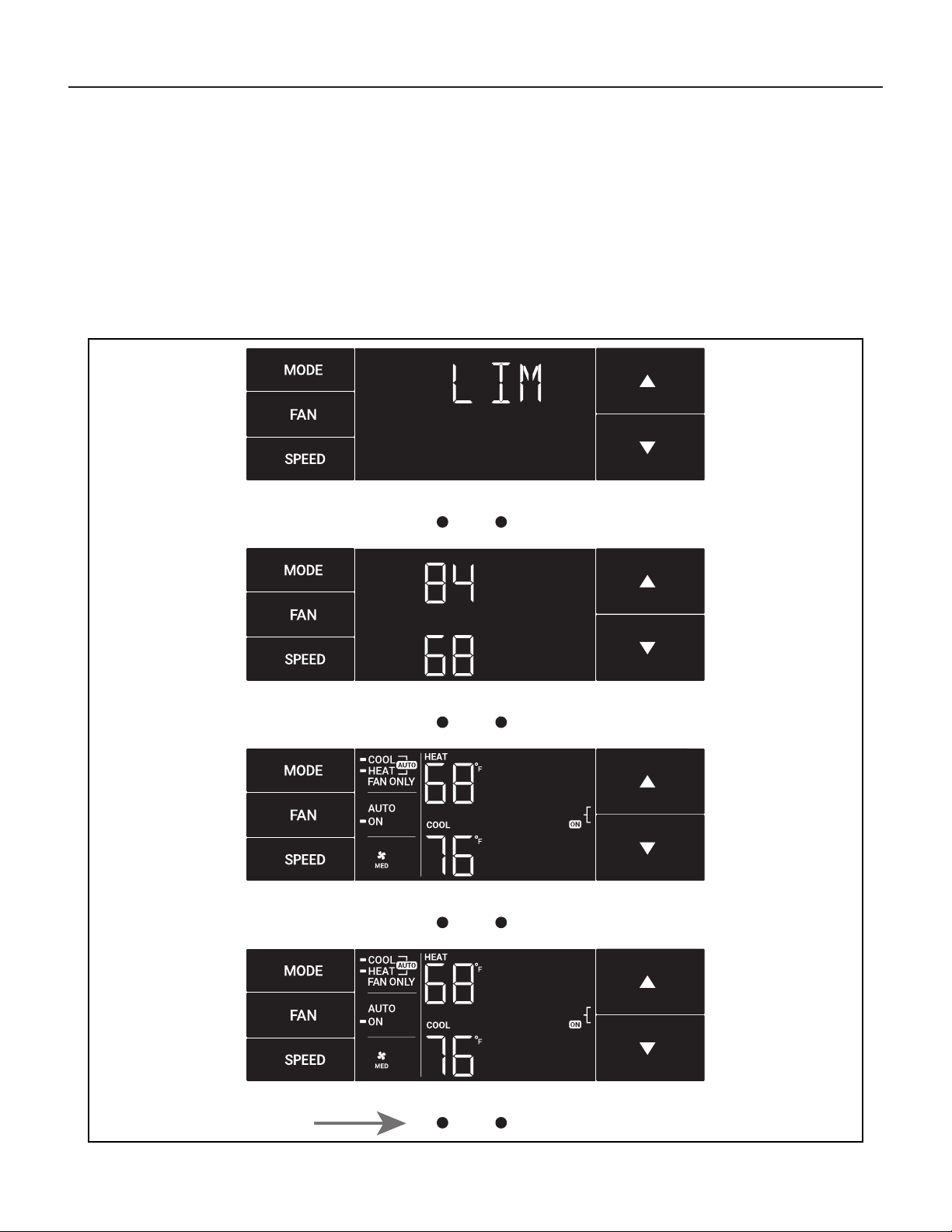

Page 13

Control Panel Operation

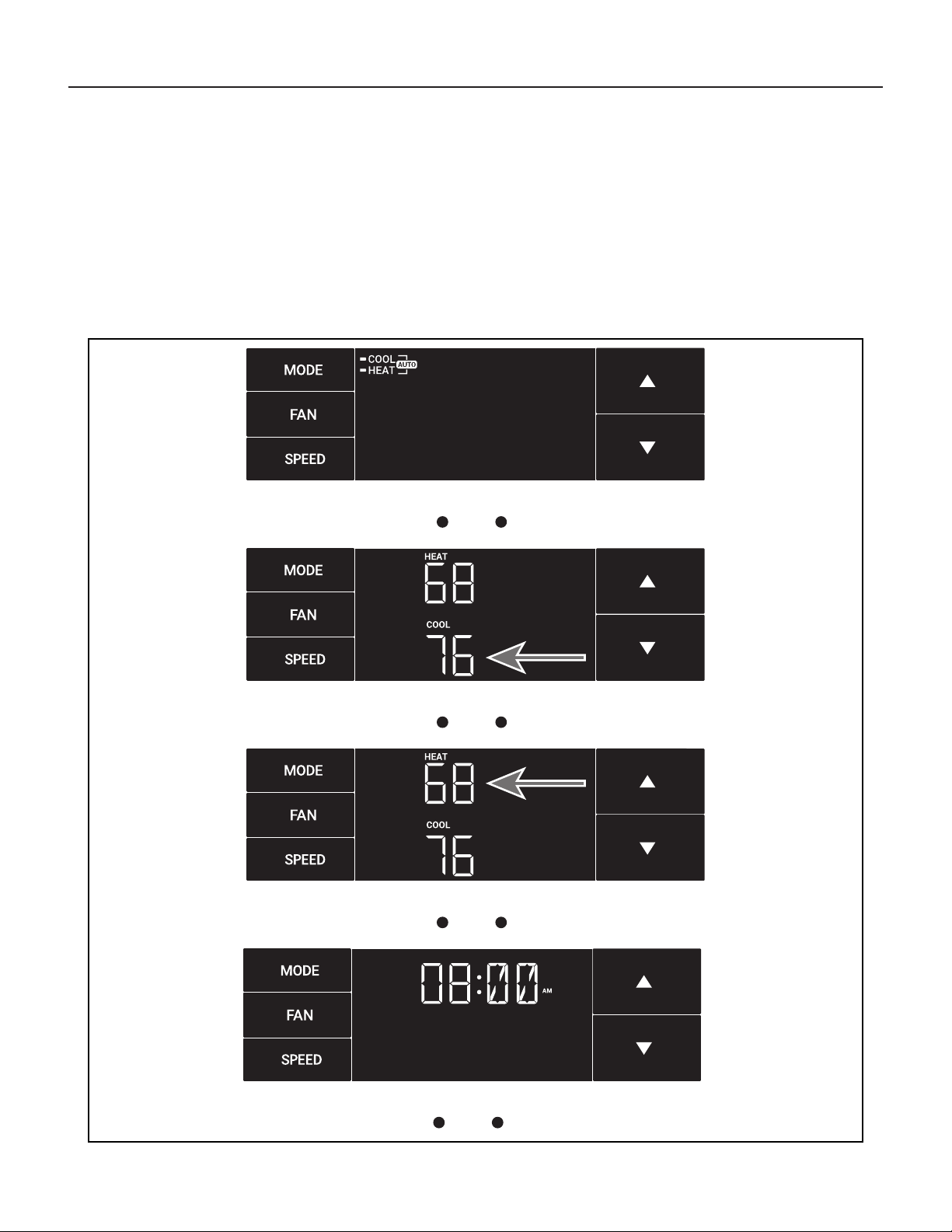

The TM Menu

This is the TM menu used to set a timer. See Figure 19.

In the menu, you set the current time using the arrow buttons. See Figure

20. (Note: These two “set clock” steps will be skipped if the unit is already

connected to Wi-Fi.)

Using the leftmost button, you switch to the minutes and complete setting

the time. See Figure 21.

You select your mode. Either cool, heat, or auto. Toggle these using the

arrow buttons. See Figure 22. (Note: cooling-only models skip this step.)

First, set the hour.

Figure 19

Figure 20

Figure 21

The process is the same for all three modes. Auto mode will be shown as

the example.

MENU

MENU

Figure 22

MENU

MENU

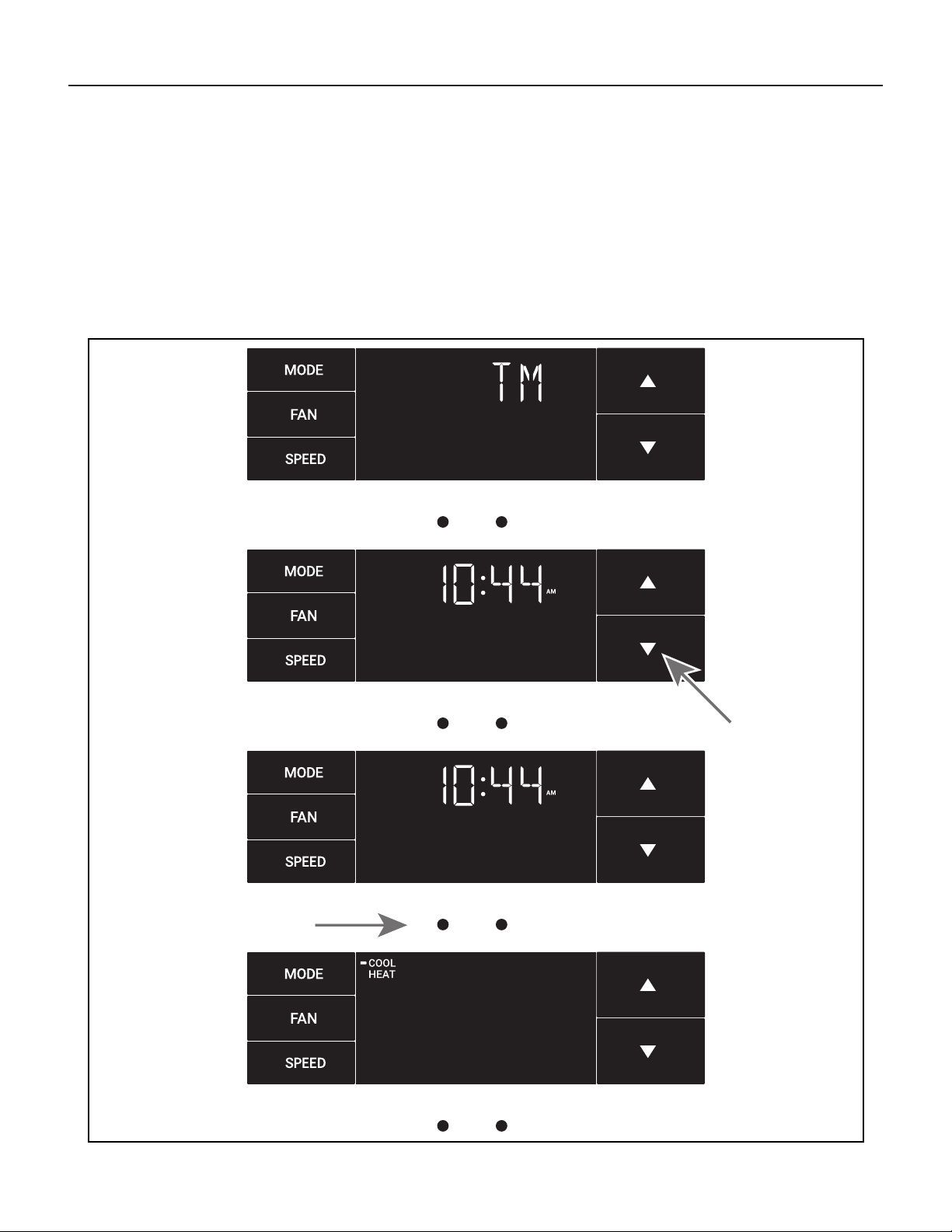

Page 14

Control Panel Operation

The TM Menu continued

Auto mode selected. See Figure 23.

Note: The auto mode timer sets both the cool and heat setpoint.

Set the cool setpoint for your rst timer period using the arrow buttons.

The cooling mode timer only sets the cool setpoint. See Figure 24.

Next, set the heat setpoint for your rst timer period. The heating mode

timer only sets the heat setpoint. See Figure 25.

Figure 23

MENU

Figure 24

Set the time to start the rst timer period. See Figure 26.

MENU

Figure 25

MENU

Figure 26

MENU

14 15

Page 15

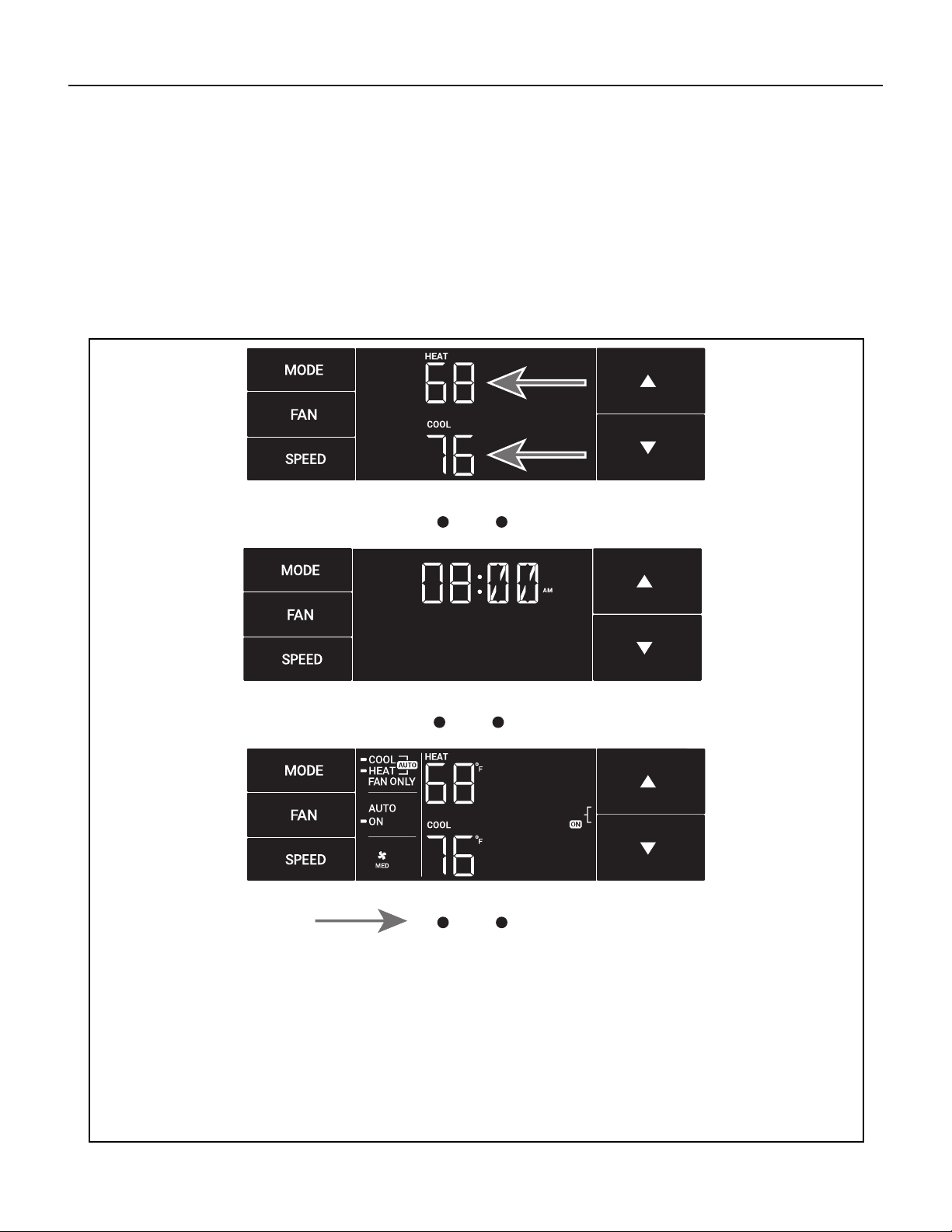

Control Panel Operation

The TM Menu continued

Set the cool setpoint for the second scheduled timer. See Figure 27.

Set the heat setpoint for the second timer.

Set the time to start the second timer period. See Figure 28.

Press the leftmost button to complete the time timer setup.

See Figure 29.

Figure 27

MENU

Figure 28

Figure 29

MENU

MENU

Page 16

Control Panel Operation

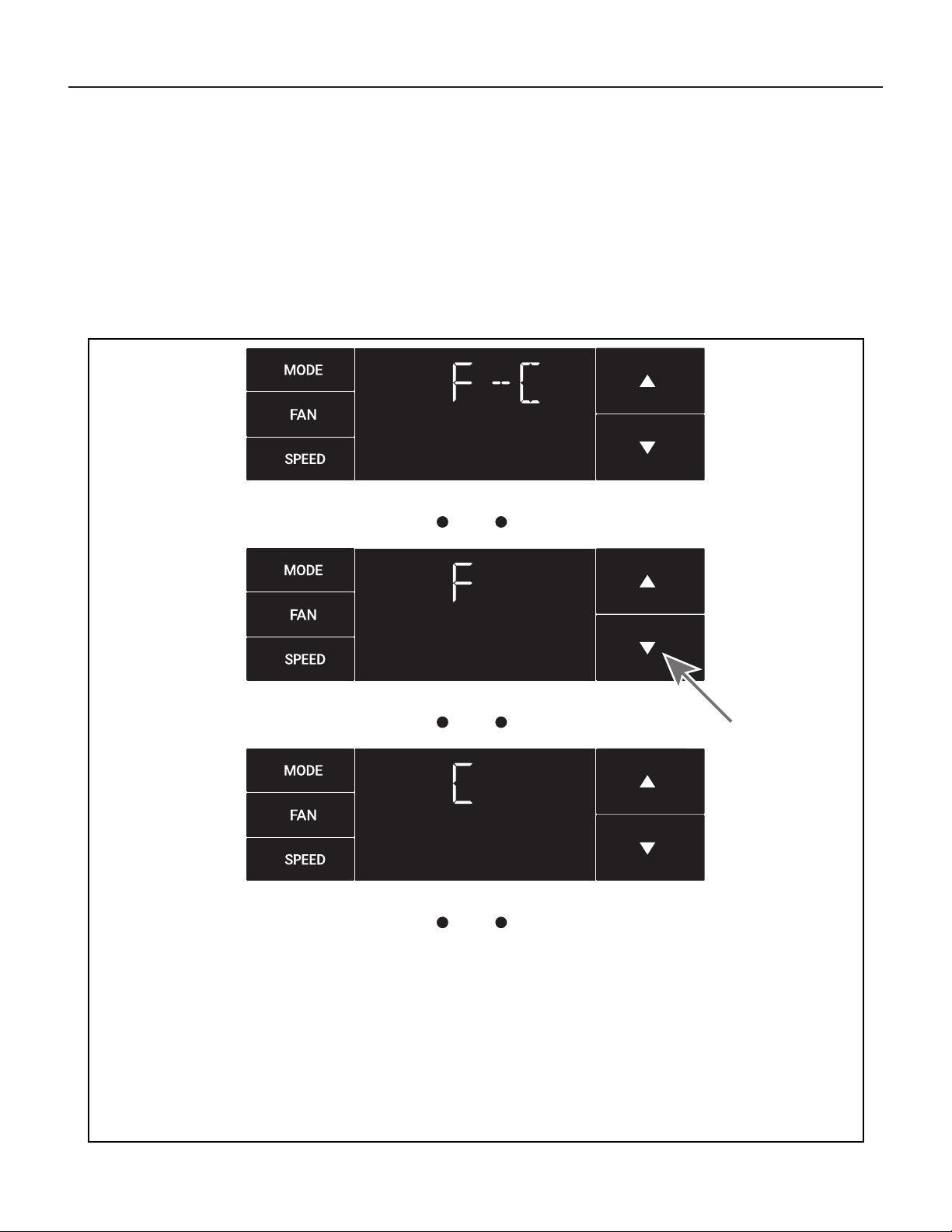

The F-C Menu

This menu is used to toggle between Fahrenheit and Celsius.

This is the Fahrenheit/ Celsius Menu. See Figure 30.

Using the arrow buttons on the right side switches it from Fahrenheit to

Celsius. See Figures 31 and 32.

Figure 30

MENU

Figure 31

MENU

Figure 32

MENU

16 17

Page 17

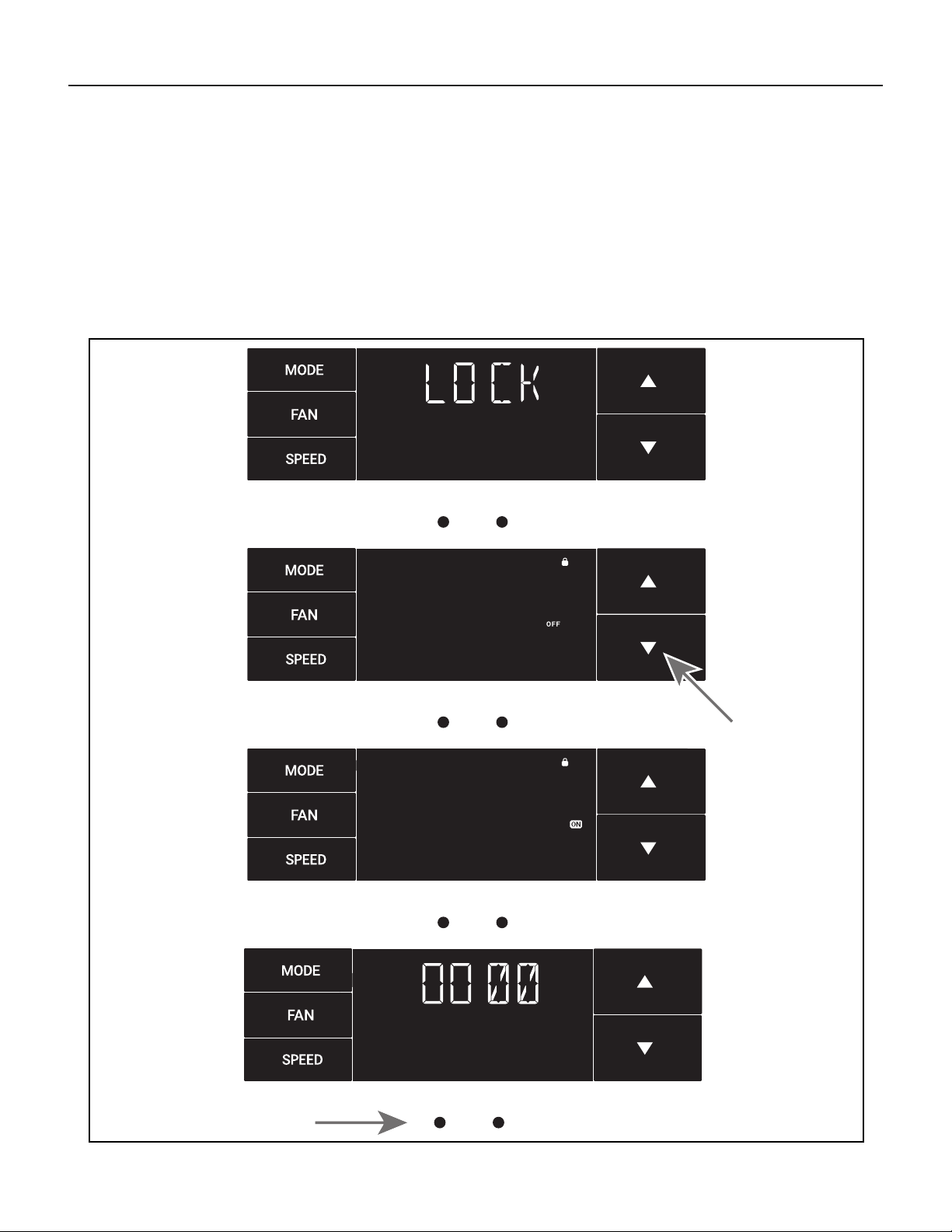

Control Panel Operation

The Lock Menu

This menu is used to lock the changing setting with a password.

This is LOCK on. See Figure 35.

This is the Lock Menu. See Figure 33.

The default is the off setting. Use the arrows to toggle between off and

on. See Figure 34.

Figure 33

MENU

Figure 34

Set the rst digit of the password using the arrow buttons. Use the leftmost button to proceed to the next digit. See Figure 36.

Figure 35

Figure 36

MENU

MENU

MENU

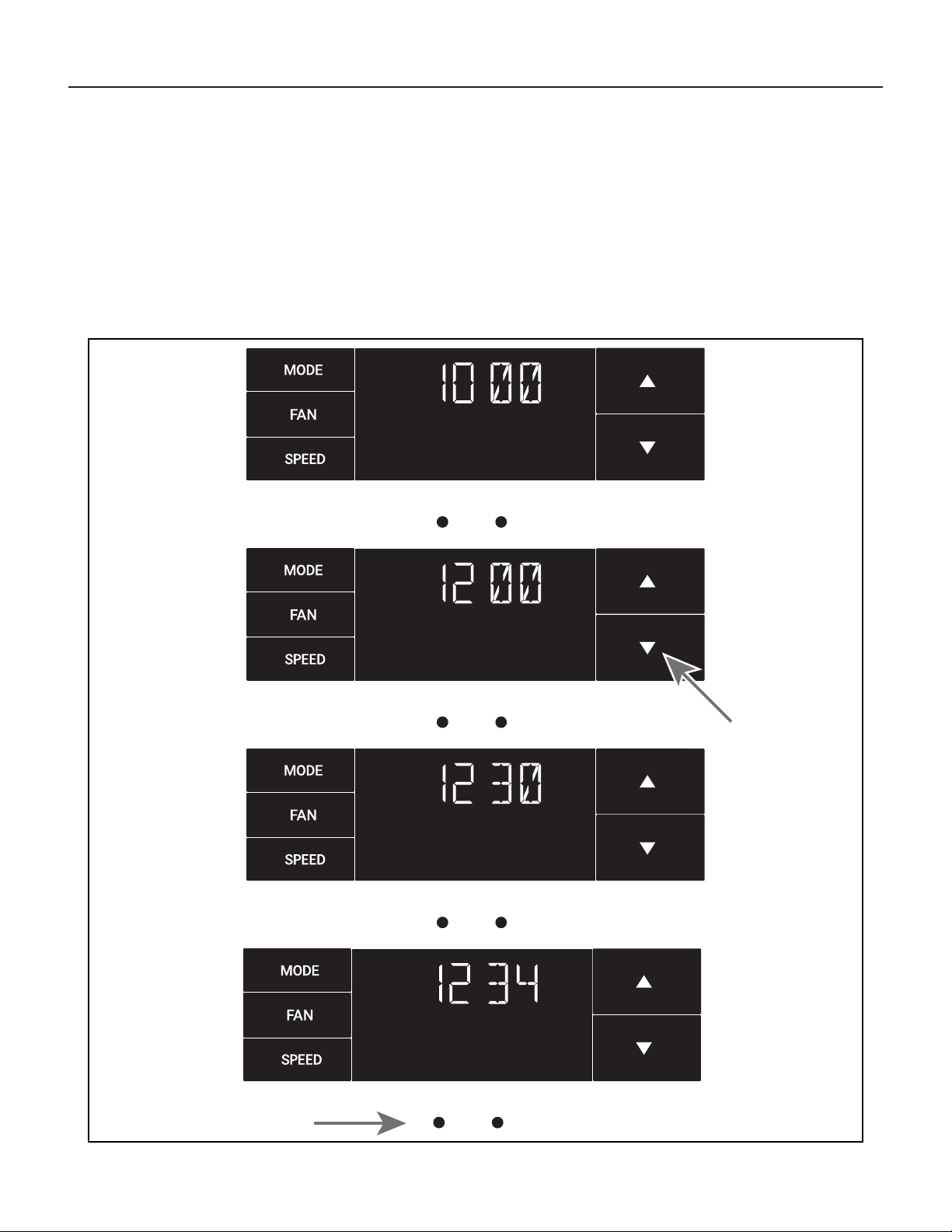

Page 18

Control Panel Operation

The Lock Menu continued

Set the second digit of the password using the same method.

See Figure 37.

Set the fourth digit of the password using the same method.

See Figures 39.

Set the third digit of the password using the same method.

See Figure 38.

Figure 37

Figure 38

Press the leftmost button to complete the password process.

See Figure 40.

MENU

MENU

Figure 39

MENU

Figure 40

MENU

18 19

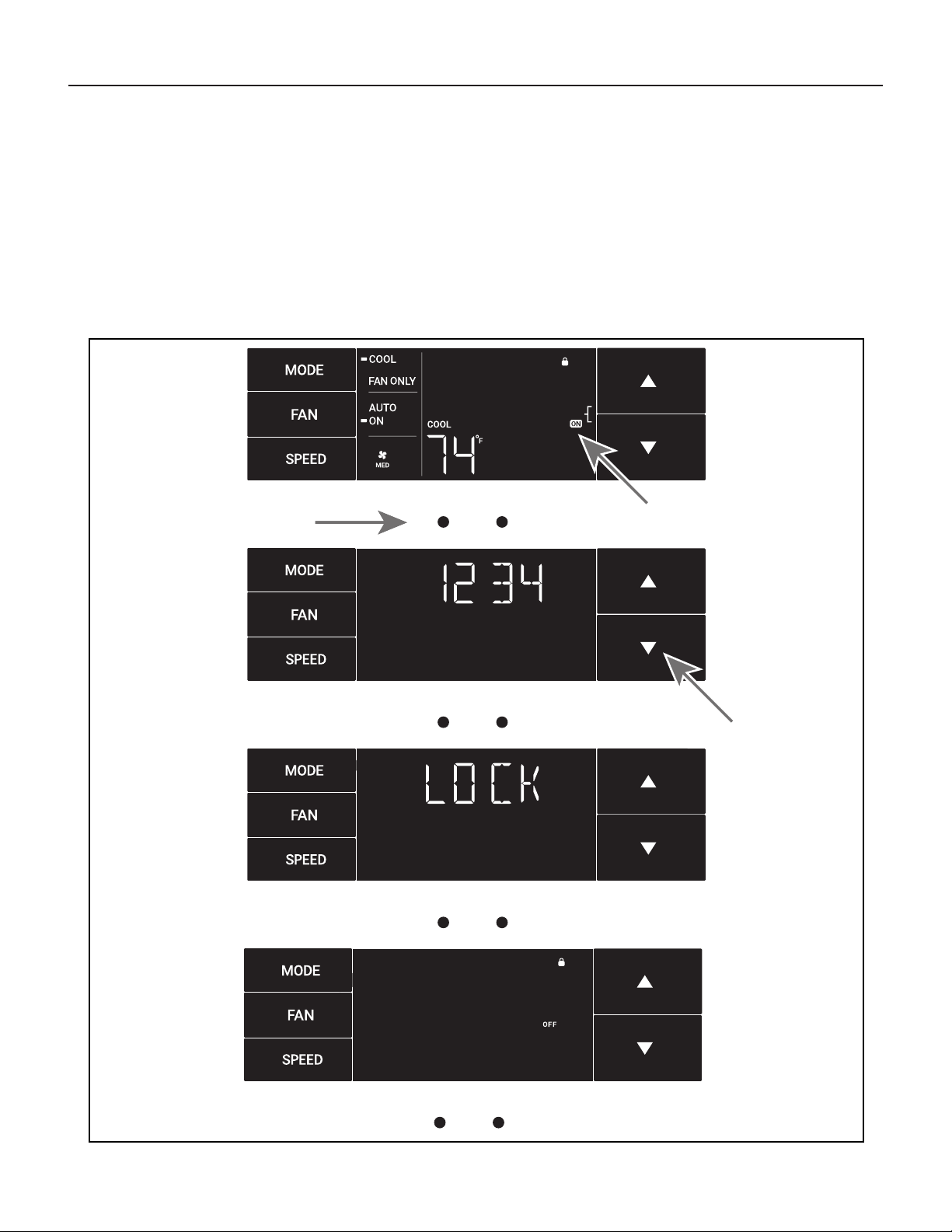

Page 19

Control Panel Operation

The Lock Menu continued

The ON on the right side of the display shows the lock function is

active. To go back into the menu, select the leftmost button again.

See Figure 41.

Enter the password in the same manner it was created. See Figure 42.

Figure 41

MENU

Figure 42

Entering the correct password will give the user access to all of the submenus. See Figure 43.

Accessing the lock menu will allow you to toggle lock OFF if needed.

See Figure 44.

Figure 43

Figure 44

MENU

MENU

MENU

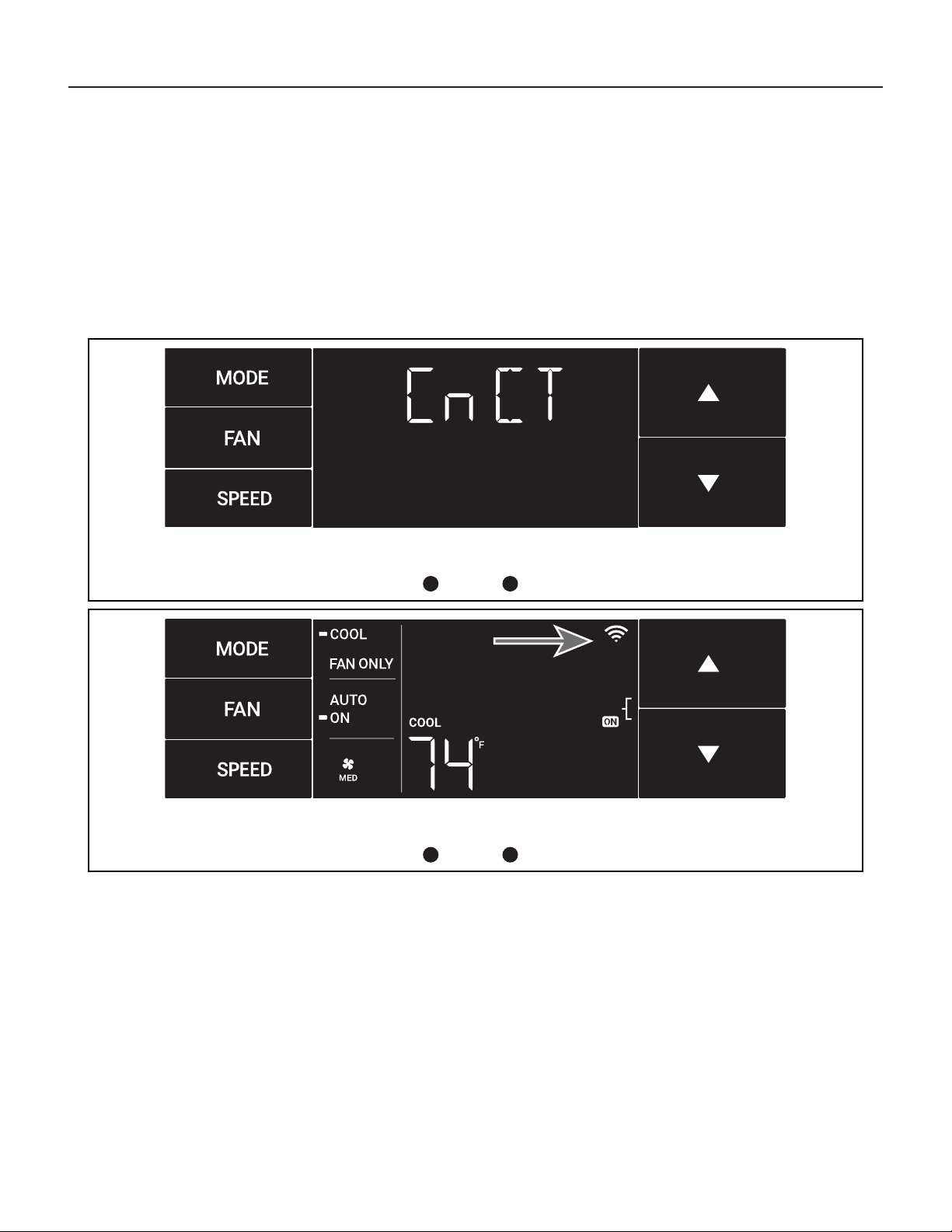

Page 20

Control Panel Operation

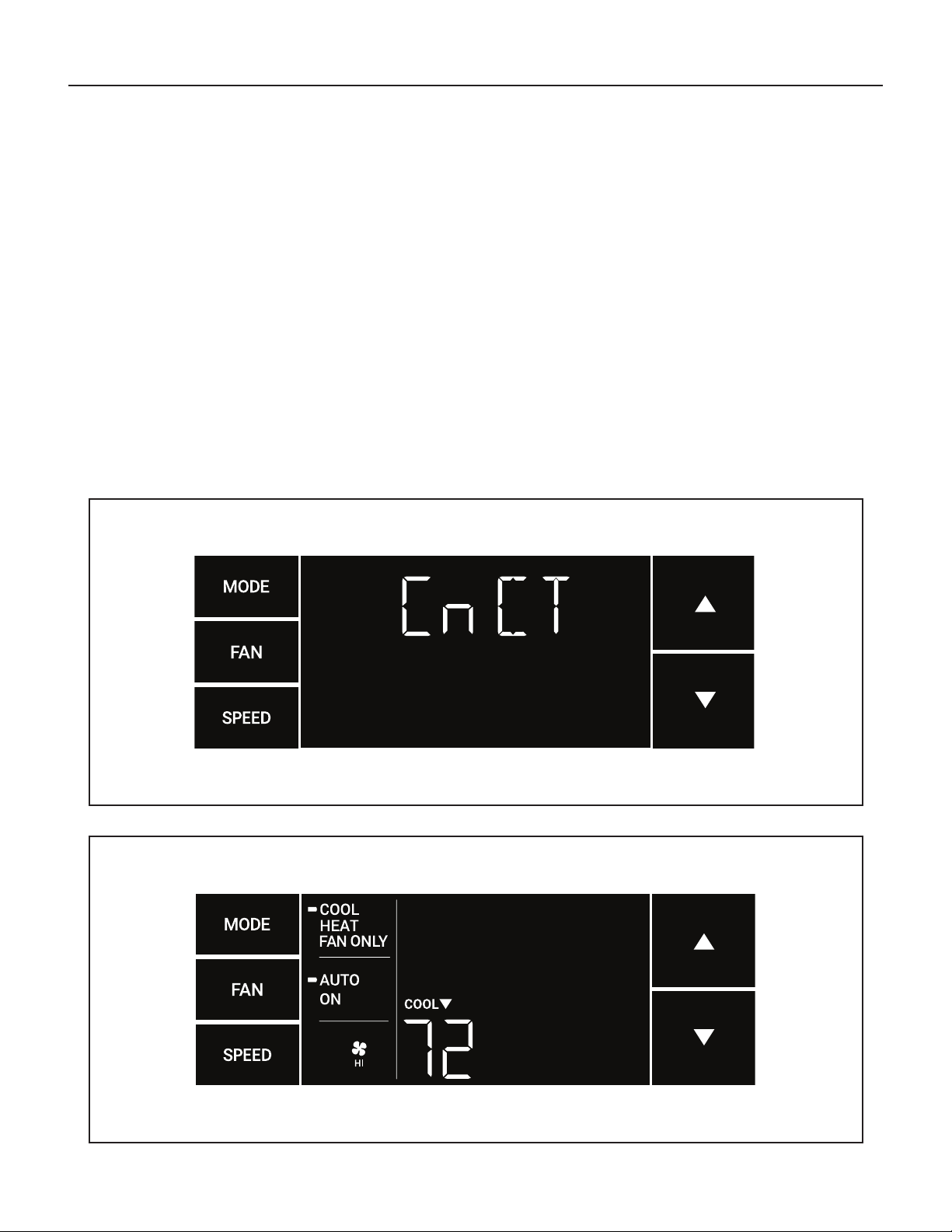

The CnCT Menu

This menu is used to turn on Wi-Fi connection.

This is the CnCT menu. Pressing the leftmost button will activate Wi-Fi.

See Figure 45.

The Wi-Fi symbol in the top right corner of the display shows Wi-Fi

connection is on. See Figure 46.

Figure 45

MENU

Figure 46

MENU

20 21

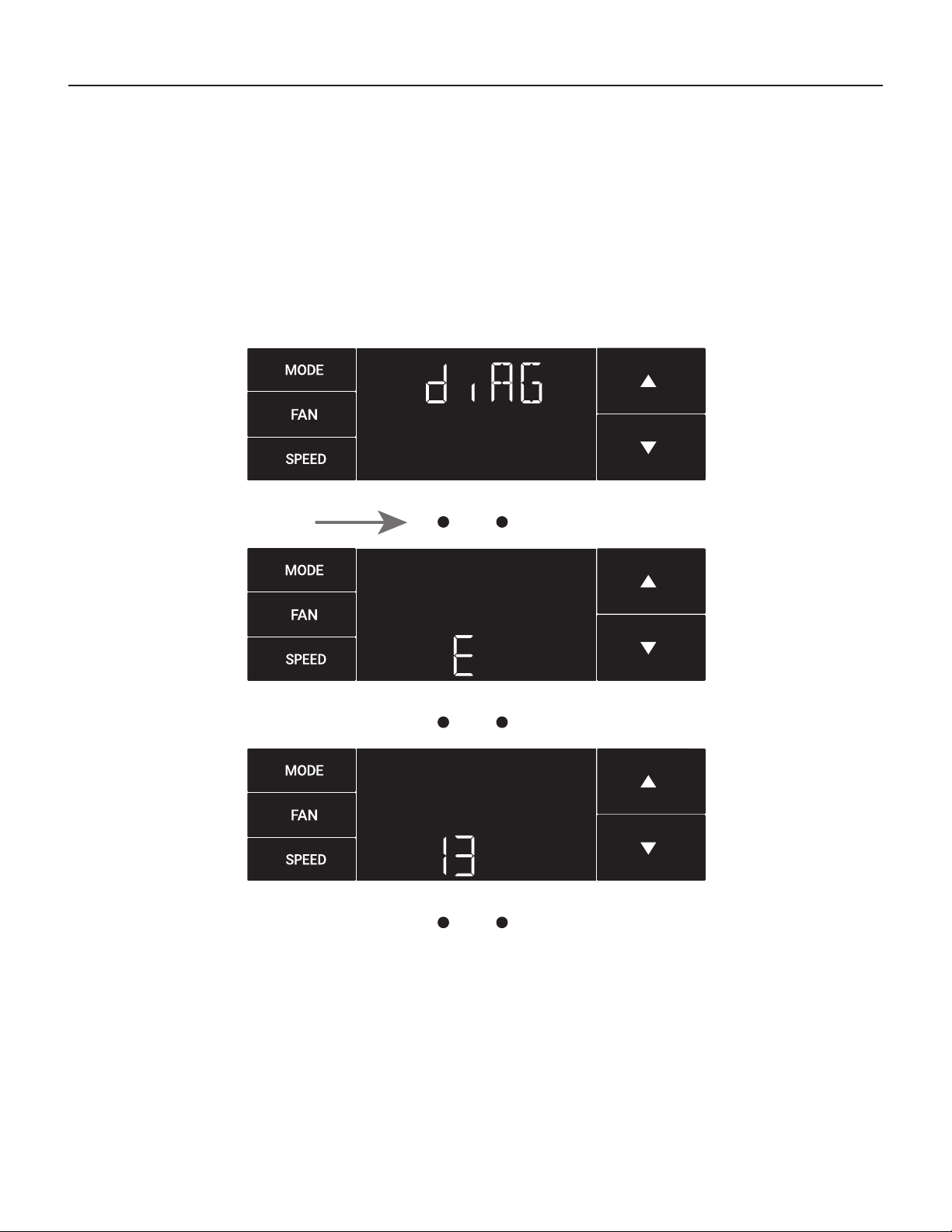

Page 21

Control Panel Operation

The diAG Menu

This menu is used to access the diagnostic codes. See Figure 47.

Selecting this sub-menu shows the E that represents “Error.”

See Figure 48.

Toggle through the error codes using the arrow keys. See Figure 49.

Figure 47

MENU

Figure 48

Figure 49

MENU

MENU

Page 22

New Kühl Control Options

The new Kühl gives you a variety of options for control, programming, and

scheduling including wireless capabilities.

Wireless Programming and Control:

Friedrich Connect allows you to conveniently control, program, and monitor

your air conditioning unit remotely from a smartphone or computer.

Pre-Programmed Timer Options:

Your unit’s digital control comes equipped with a 24-hour timer.

24-Hour Timer

The 24-hour timer allows you to set 2 temperature changes at pre-set times

or a unit control panel.

Customizable Programming Options:

Customizable timers, with up to four temperature adjustments per day, can

be set using Friedrich Connect for one or multiple units.

See www.friedrich.com for complete details on Friedrich Connect.

22 23

Page 23

Wi-Fi Set-Up Instructions

Accessing Sub-Menus:

Below are the set-up instructions for Wi-Fi to use your unit wirelessly.

Follow the instructions below:

STEP 1. Using a mobile device such as a smartphone or laptop, navigate

to www.FriedrichConnect.com.

STEP 2. Sign-in using your username and password.

STEP 3. Click the “Add Device” button.

STEP 4. Select the time zone the device is located in and click the “Next”

button.

STEP 5. To start the setup process click the menu button on the home

screen of your Kühl model.

Figure 50

STEP 6. Using the up and down arrows, navigate to the CnCT screen

(Figure 50).

STEP 7. Click the menu button, this will begin the setup process for your

Friedrich Connect enabled device.

STEP 8. Click the “Next” button on your mobile device.

STEP 9. Follow the on-screen steps to nish adding the device to

your account.

Figure 51

Page 24

Control Panel Operation Instructions

SYSTEM - The MODE button allows you to sequentially select up to four

modes of operation:

AUTO Available on select models

COOL

HEAT Available on select models

FAN ONLY

AUTO FAN (No Cooling Demand)

When in AUTO mode, the fan only operates when the system has a

demand to cool or heat the room.

In the ON fan mode, the fan operates all the time. The system periodically

cools or heats the fan’s airow but the ow of air does not stop.

UP and DOWN Arrows - Pressing either an UP or DOWN button changes

the system’s setpoint (desired room temperature). These buttons are also

used to make system parameter changes later in this manual.

One press equals 1 degree of change in Fahrenheit mode. One press

equals 0.5 degree change in Celsius mode.

TIMER

The timer can be engaged or disengaged from the control panel. This is

done by pressing or holding the UP and DOWN arrows simultaneously for

three seconds.

Alerts

When the lter needs to be cleaned or replaced, the CHECK FILTER

icon displays.

The alert can be dismissed by pressing the FAN MODE and TIME for

3 seconds.

Lock Control Panel

To lock/ unlock the front panel controls, navigate to the “LOCK” sub-menu

found after clicking the MENU button. The lock requires a four digit pass code

to lock/ unlock the unit. This pass code will be required to enter the menu to

unlock the unit. The LOCK icon illuminates to indicate the locked status.

The LOCK icon disappears to indicate unlocked status.

External Control Status

The Wi-Fi icon illuminates to indicate that the system is receiving a

Wi-Fi connection. The Wi-Fi icon also provides information about the

signal strength.

ADVANCED FUNCTIONS

The functions mentioned in the following section may or may not be available

depending on the air conditioner model.

Modify the TIMER Function

Navigate to the TIME menu to set the timer.

OTHER FUNCTIONS

°F – °C Select

To switch from degrees Fahrenheit (F) to Celsius (C), press the MENU

button and enter the F-C sub-menu.

FAN SPEED - Depending on your model, the FAN SPEED button allows

you to toggle between three or four modes of operation: LOW, MEDIUM,

HIGH and MAX.

24 25

Page 25

Remote Control Operation

Remote Control - Refer to Figure 52 during operation description.

Getting Started - Install two (2) AAA batteries in the battery compartment

located on the back of the unit.

Operation - The remote control should be within 25 feet of the air conditioner

for operation (refer to Figure 52 for effectiveness). Press the power button

to turn the remote on. The remote will automatically power off after 15

seconds if the buttons are not being pressed. The remote must be on to

control the unit.

POWER Button - Turns remote and unit on and off.

SYSTEM Button - Allows the user to sequentially select the following:

AUTO, COOL, HEAT, and FAN ONLY operations. When the button is

pressed, the display indicates which mode has been selected via a display

message. Note that when the heating function is not available, the system

will automatically skip the HEAT mode.

FAN MODE Button - Selects between automatic (AUTO FAN) or

CONTINUOUS operation. In the AUTO FAN mode, the fan only turns on

and off when the compressor operates or the heat function is enabled.

NOTE: AUTO FAN is not available in the FAN ONLY Mode, the display

indicates CONTINUOUS. In the CONTINUOUS mode, fan speed

is determined by your selection on the FAN SPEED button.

FAN SPEED Button - Used to sequentially select new fan speed,

plus AUTO operation. When the FAN SPEED button is pressed, the

fan speed icon (triangle) changes to indicate the new speed level. Fan

speed automatically varies depending on the set temperature on the

control panel and the actual room temperature. For example, if there

is a big difference between your set temperature and the actual room

temperature, the system fan speed increases to HIGH. It remains at

this speed until the room temperature matches the set temperature.

UP and DOWN Arrows - Pressing either the UP or DOWN button

changes the desired room temperature. The factory preset lower and

upper limits are 60 °F (16 °C) and 99 °F (37 °C). These buttons are also

used to navigate between function options when using the User Menu

or Maintenance Mode.

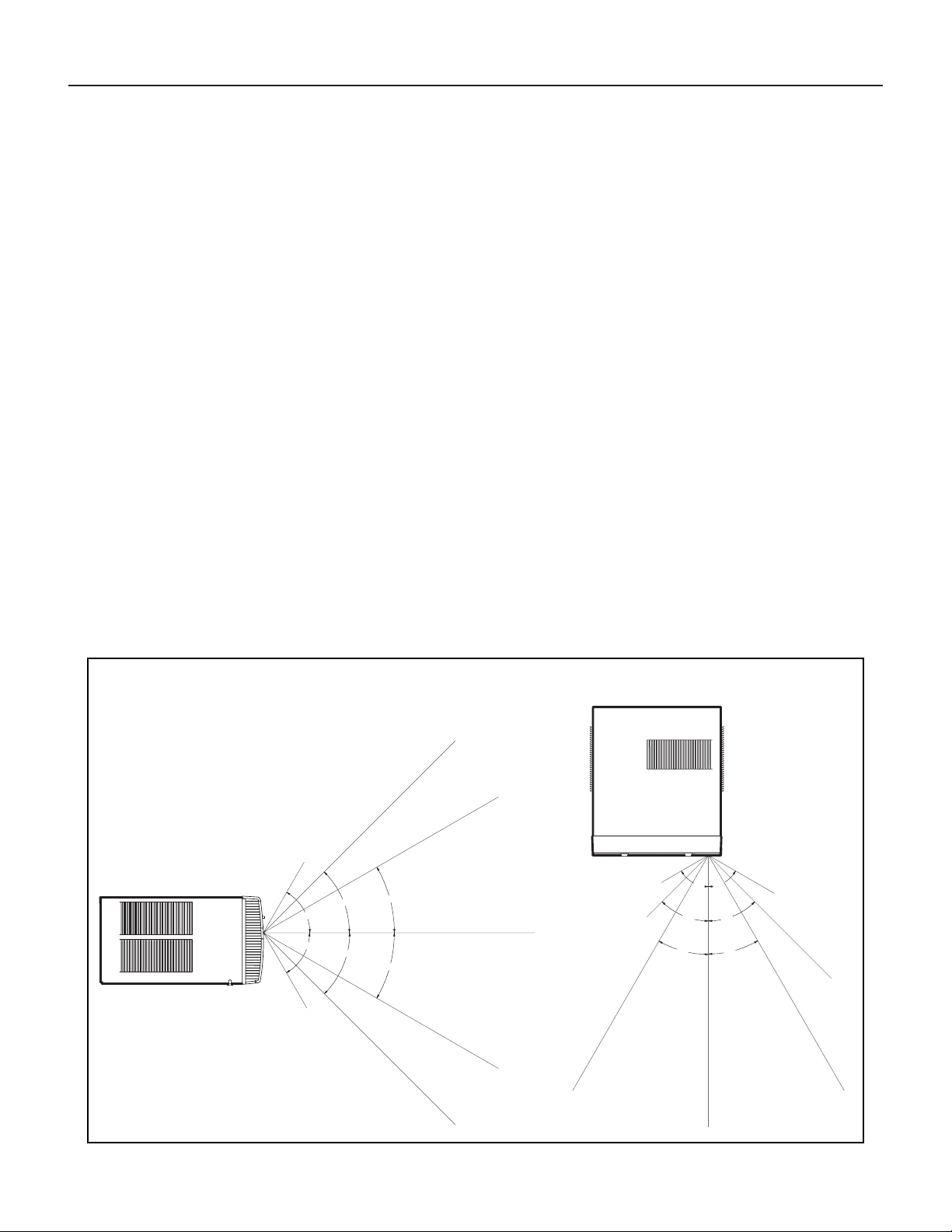

Remote Effectiveness

Handheld Remote - Has an operating range of up to 25 ft. The infrared

remote control signal must have a clear path to transmit the command to

the air conditioning unit. The remote signal has some ability to “bounce”

off of walls and furniture similar to a television remote control. The diagram

below shows the typical operating range of the control in a standard room

with 8 ft high ceilings.

Figure 52

SIDE VIEW

TOP VIEW

25ft

25ft

7.5ft

30°

45°

60°

60°

45°

30°

8ft

25ft

25ft

25ft

4ft

8ft

60°

60°

45°

45°

30°

30°

6ft

16ft

25ft

25ft

25ft

FRR080

Page 26

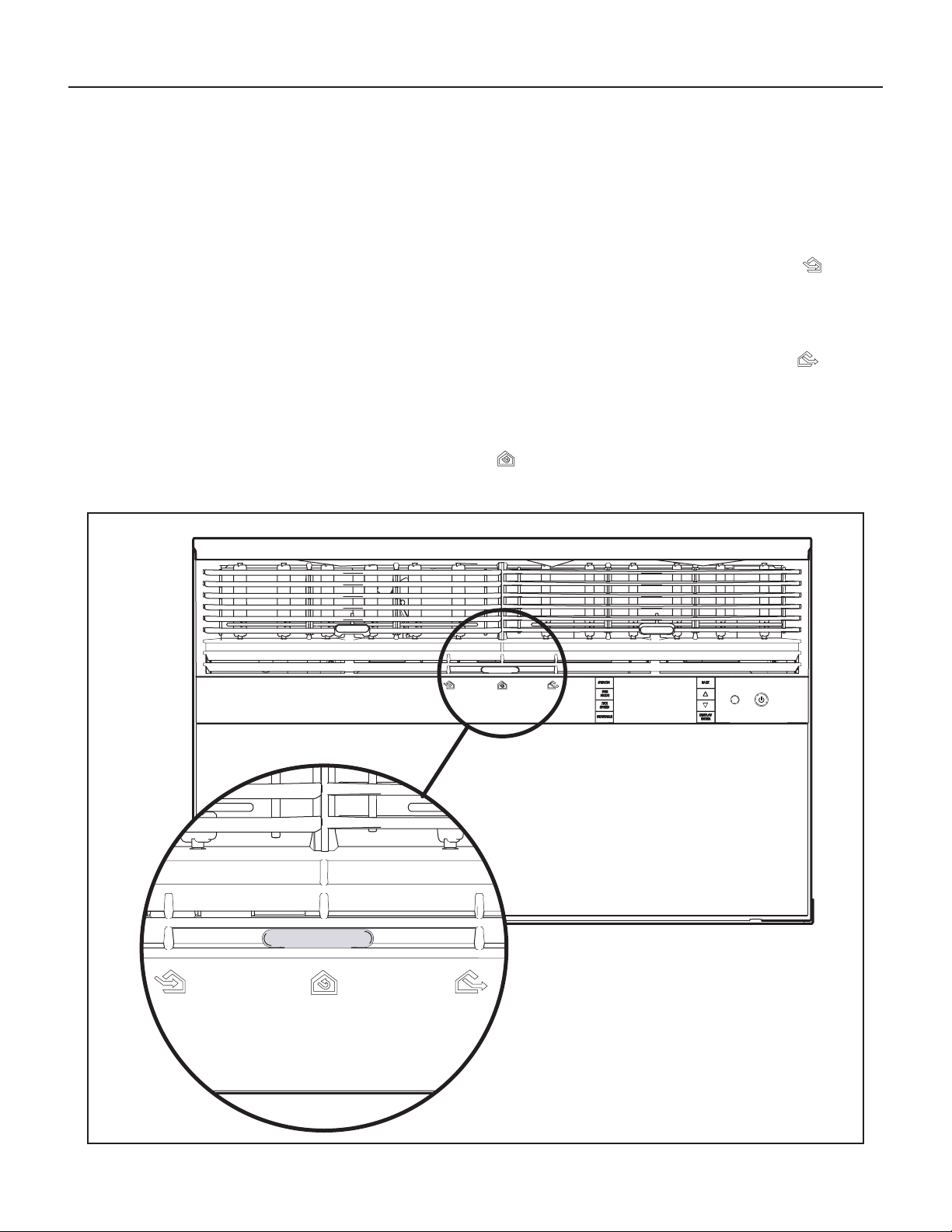

Airflow Selection and Adjustment

Airflow direction adjustment

The airow path may be adjusted to distribute air independently from the

left or right side of the discharge opening. Each of the banks of louvers can

be directed left, right, up, or down in order to achieve the most optimum

airow positioning.

To adjust airow direction, grab the lever in the center of the louver bank

and move it in the direction that you would like the air to be directed. Please

note that it is normal that airow may be stronger out of one side of the

louvers than the other.

Figure 53

Fresh air and exhaust control

Your air conditioner has the ability to bring fresh air into the room or exhaust

stale air out of the room. The control slide is found on the upper part of the

unit (see Figure 53).

TO BRING IN FRESH AIR – Move the lever to the Fresh Air position

which allows outside air to enter the room. This is useful in fall and spring

as a means of bringing in fresh outside air when using FAN ONLY. It can

also be used in the summer with the compressor in the Cooling Mode if

you wish.

TO EXHAUST INDOOR AIR – Move the lever to the Exhaust position.

This will allow stale air to be expelled to the outside of the dwelling. This

is especially handy in the spring or fall when indoor air tends to get stale,

or after a social gathering involving smokers, or to remove cooking odors.

BEST PERFORMANCE – Move the lever to the Re-Circulate Position.

This is the most efcient mode for cooling and heating.

FRR008

26 27

Page 27

Installation Instructions

READ THIS FIRST! Electrical Requirements

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same conguration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong outlet.

Failure to follow these instructions can result

in death, re, or electrical shock.

IMPORTANT: Before you begin the actual installation of your air

conditioner, check your local electrical codes and the information below.

Your air conditioner must be connected to a power source with the same

alternating current (A.C.) voltage and amperage as marked on the name

plate located on the chassis. Only A.C. can be used. Direct Current (D.C.)

cannot be used.

CIRCUIT PROTECTION – Use on single outlet circuit only. An overloaded

circuit will invariably cause malfunction or failure of an air conditioner;

therefore, it is necessary that the electrical protection is adequate. Due

to momentary high current demand when the air conditioner starts, use a

“TIME DELAY” fuse or a HACR type circuit breaker. Consult your dealer or

power company if in doubt.

Refer to the electrical name plate located on the air conditioner chassis

(see Page 2) to determine the correct fuse or circuit breaker amperage for

your model (see Table 1 on Page 6 for electrical receptacle types).

The power cord has a plug with a grounding prong and a matching

receptacle is required.

The following instructions are for standard chassis model groups

distinguished by the rst three letters of the model designations cabinet

sizes listed in Table 2.

Table 2

MODEL DESIGNATION CABINET SIZE (H x W x D)

SMALL CHASSIS –

KCS, KES, KHS

MEDIUM CHASSIS –

KCM, KEM, KHM

LARGE CHASSIS –

KCL, KEL, KHL

15 15⁄16" x 25 15⁄16" x 29"

(405 mm x 660 mm x 737 mm)

17 15⁄16" x 25 15⁄16" x 29"

(455 mm x 660 mm x 737 mm)

20 3⁄16" x 28" x 35 1⁄2"

(513 mm x 711 mm x 851 mm)

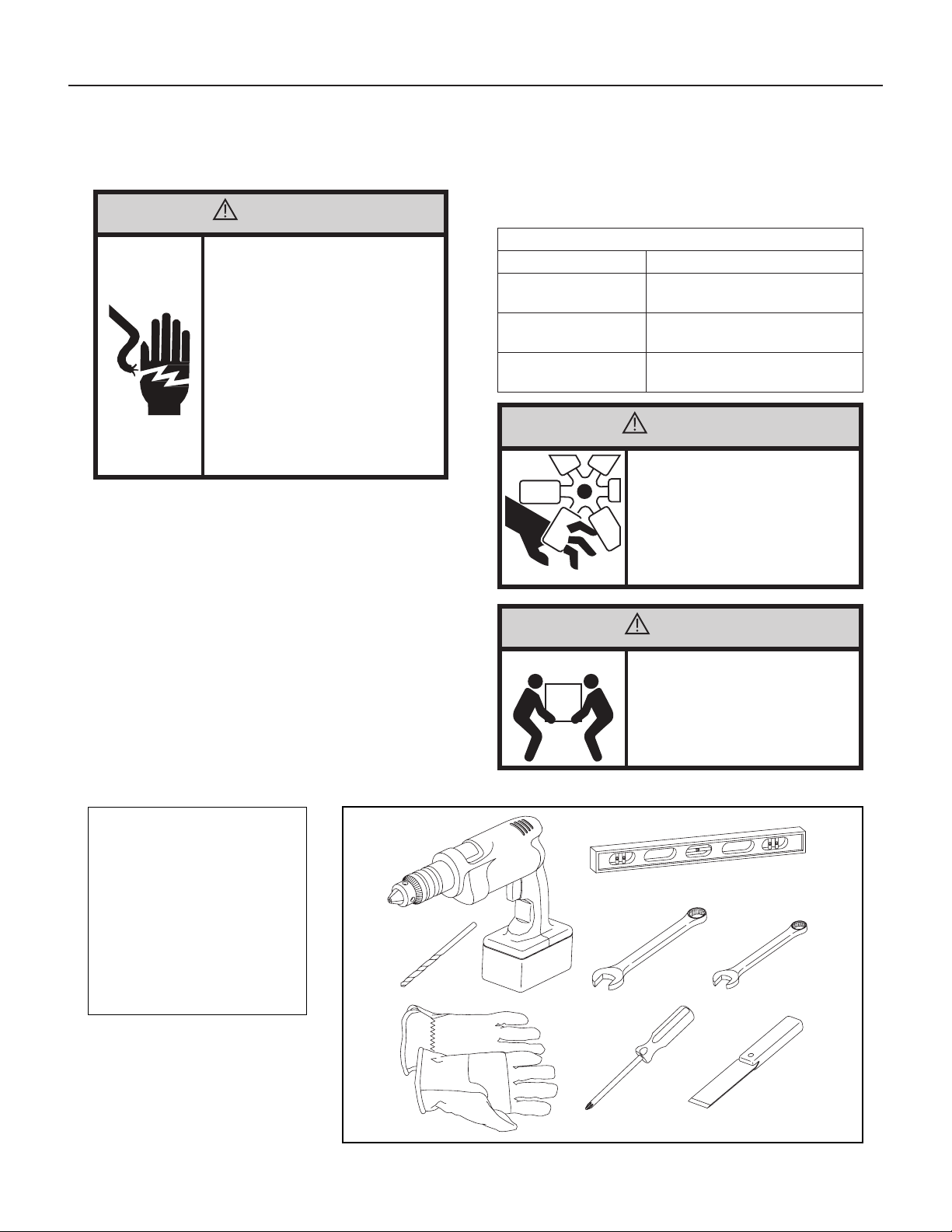

WARNING

MOVING PARTS HAZARDS

• Do not operate unit out of sleeve or

with front grille removed.

• Do not place hands in blower or fan

blade areas.

Failure to do so can result in serious injury.

CAUTION

Excessive Weight Hazard

Use two or more people when installing your

air conditioner.

Failure to do so can result in back or other

injury.

Recommended Tools

1. Power Drill

2. 5/32" Drill Bit

3. Gloves

4. Carpenters Level

5. 5/16" Wrench

6. 1/4" Wrench

7. #2 Phillips Screw Driver

8. Putty Knife or (wood stir stick)

4

1

2

3

ITEMS NOT TO SCALE

5/16

5/16

1/4

65

1/4

87

Page 28

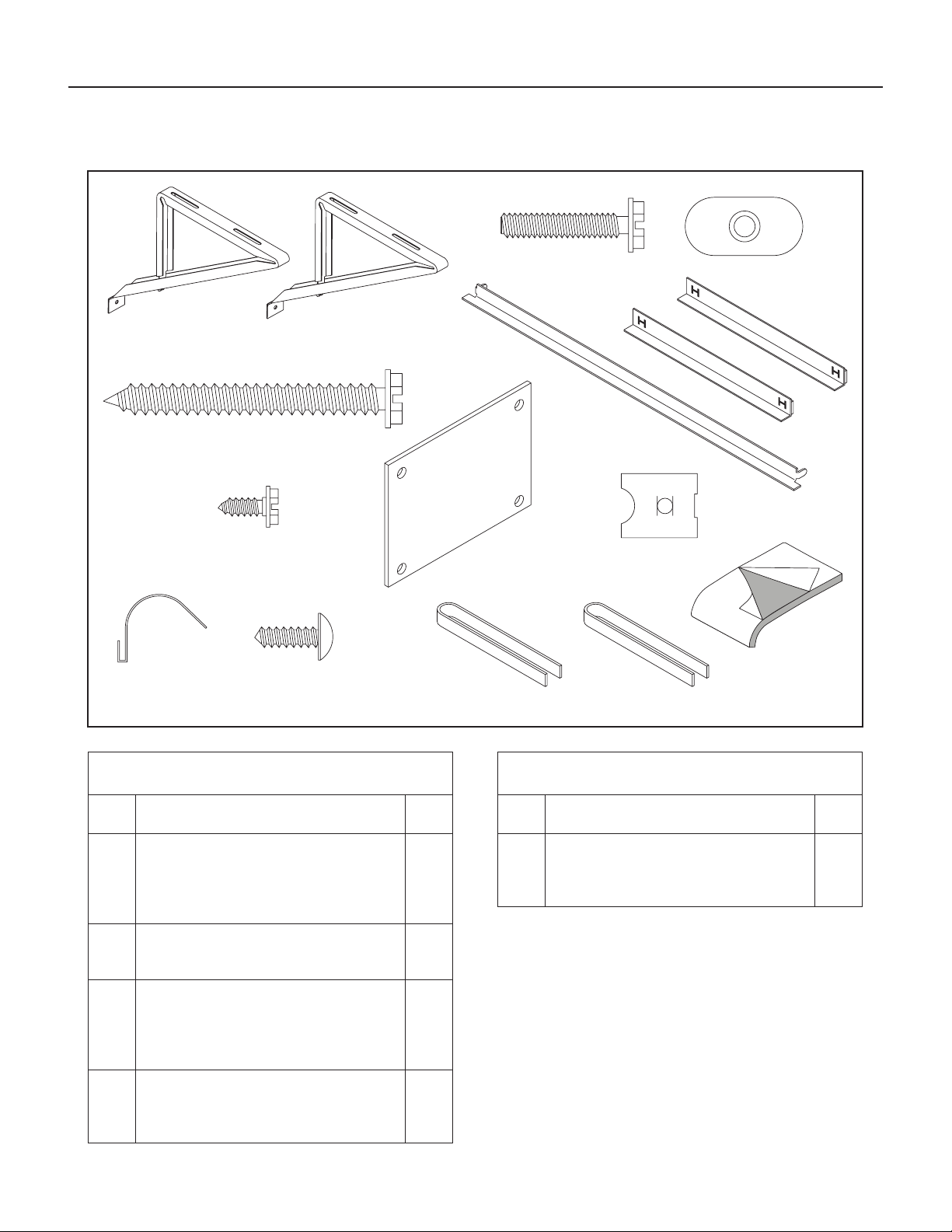

Installation Hardware and Accessory Details

ITEM 1

ITEM 4

ITEM 7

ITEM 10 ITEM 11

ITEM 2

ITEM 5

ITEM 8

ITEM 12 ITEM 13

ITEM 3

ITEM 6

ITEM 9

ITEM 14

Window Mount

Installation Hardware

ITEM

NO

WINGBOARD MOUNTING PARTS

8

WINGBOARD (MASONITE)

9

“J” TYPE SPEED NUT

10

WINGBOARD CLIP (SPRING STEEL)

11

SCREW, #8 x ½″ PHILLIPS TRUSS HD.

WINDOW SEALING

12

WINDOW SEAL GASKET (DARK FOAM)

13

CHASSIS SEAL GASKET (LIGHT FOAM)

SHELL MOUNTING PARTS

1

SUPPORT BRACKET

2

SCREW, 10-24 x 1″ HEX HEAD

3

10-24 FLAT WELD NUT

4

SCREW, SHEET METAL #12 x 2″

WINGBOARD ANGLE MOUNTING

5

WINGBOARD ANGLE, TOP

6

WINGBOARD ANGLE, SIDE

7

SCREW, SHEET METAL #8 x 3/8″

DESCRIPTION QTY.

ITEMS NOT TO SCALE

ITEM

NO

1

4

4

4

1

1

2

4

4

7

1

2

2

4

14

NOTE: Kühl + models do not come with window mounting

Thru-the-Wall

Installation Hardware

DESCRIPTION QTY.

MOUNTING PARTS

SCREW, SHEET METAL #12A x 2″

CHASSIS SEAL GASKET (LIGHT FOAM)

components. When mounting a cooling and heating

model, a window installation kit must be purchased

separately.

KWIKS – For all KES and KH models.

KWIKM – For all KEM and KHM models.

KWIKL – For all KEL and KHL models.

FRR009

7

1

28 29

Page 29

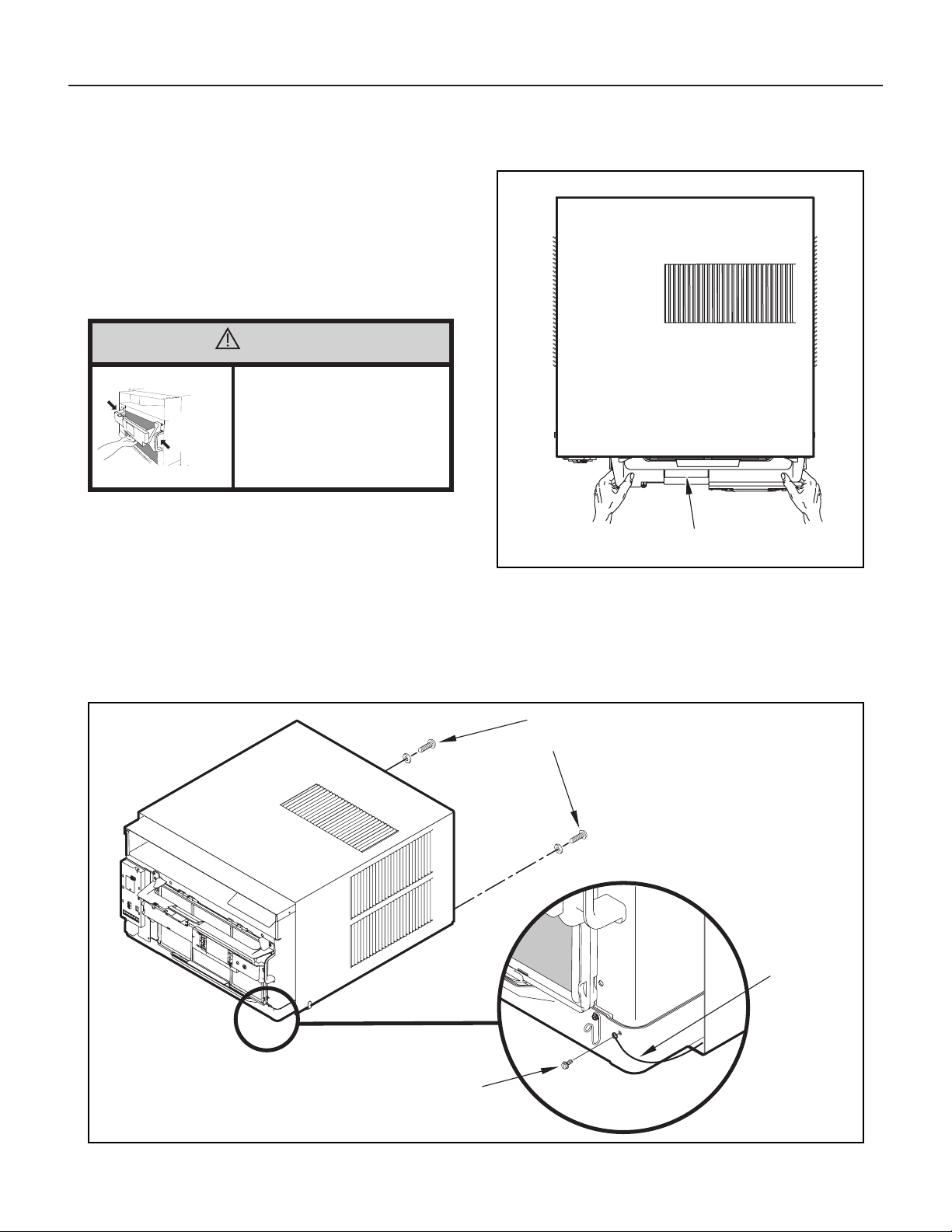

Standard Window Installation

NOTE: Hardware and accessories used during installation are shown

on Page 28. Each part will be referred as “Item No.”

STEP 1. Remove the chassis EntryGard™ retainer by removing the far

right screw (see Figure 54). Save this screw to reattach the

chassis retainer after installation (Step 12). Also, remove and

discard the two retainer screws and washer located at the rear

of the unit (see Figure 54).

CAUTION

Handle Use

Use Handle

Locations

(both sides)

STEP 2. Hold the cabinet stationary. Then, use the hand grips on both

ends of the control unit support bracket to pull the chassis out of

the cabinet (see Figure 55).

STEP 3. Remove the large white foam blocks used to restrain the

compressor during shipment (see Figure 56). Inspect base pan

for dislodged white foam blocks and remove. Do not remove

any other foam parts.

Use handle on both sides to

pull unit from sleeve.

Do not push, pull, or lift from

center of support.

Figure 55

CONTROL UNIT

SUPPORT BRACKET

STEP 4. Anchor the side angles (Item 6) by engaging the tabs of the

lower sill plate (see Figure 57, Detail B-2) with the loops of the

side angle. Engage the tabs of the top angle (Item 5) with the top

loops of the side angle (see Figure 57, Detail B-1). Install two (2)

screws (Item 7) to secure the top angle tabs and the side angle

to cabinet (see Figure 57, Detail B-1).

FRR012

Figure 54

RETAINER SCREWS

AND WASHERS

ENTRYGARD

RETAINER

WIRE

FAR RIGHT

SCREW

FRR011

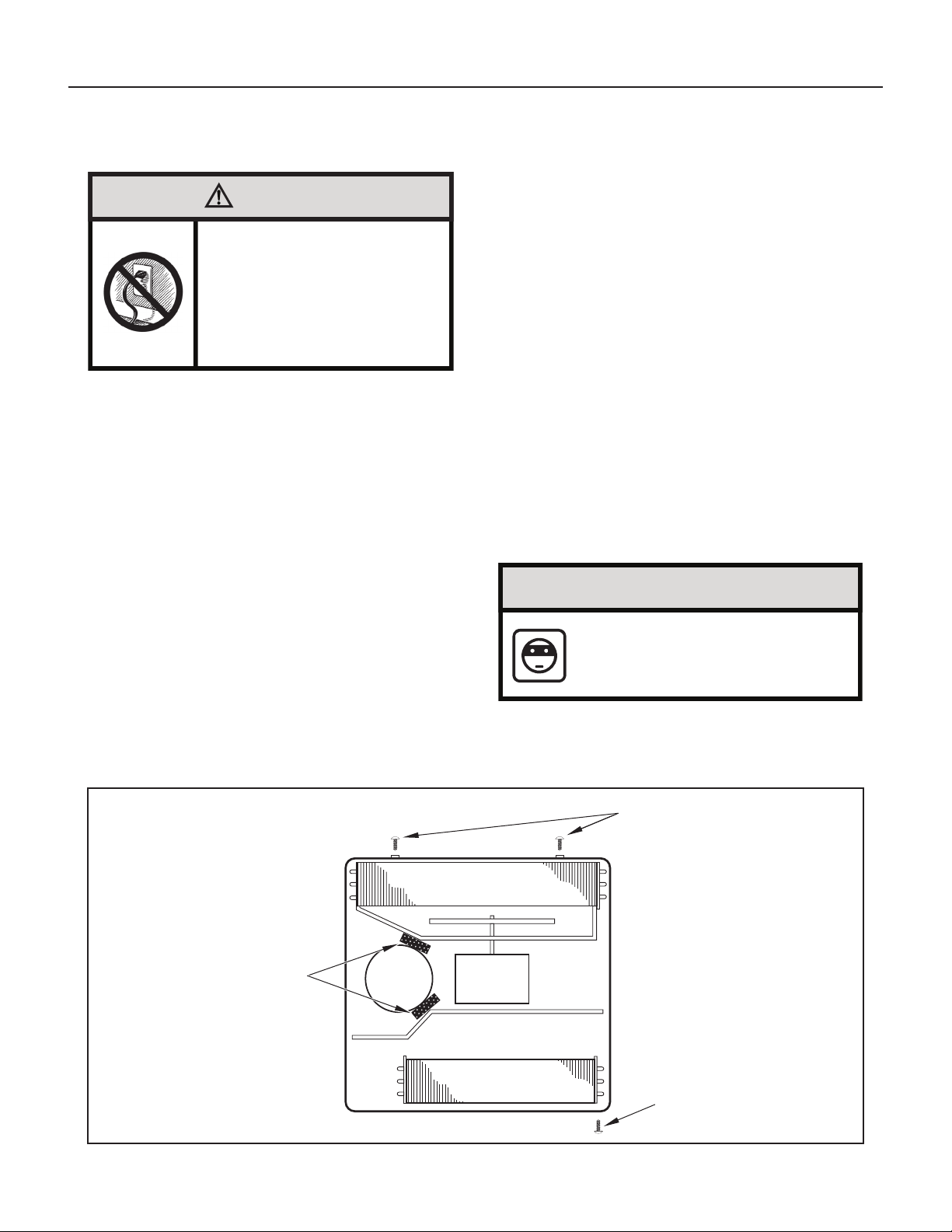

Page 30

Standard Window Installation continued

NOTE: DO NOT LEVEL the cabinet from front-to-back. Make sure

CAUTION

Remove Shipping Blocks

Prior to operating the unit remove

the foam shipping blocks.

Failure to do so may result in

damage to the unit which is not

covered by the manufacturer’s

warranty!

STEP 5. Check the window sill and frame to be sure they are in

good condition and functioning.

STEP 6. CABINET MOUNTING – Raise the lower window 1/4″ more than

the height of the cabinet. Carefully slide the cabinet through

the opening until the lower sill plate channel rests behind the

window sill and the top angle rests against the window (see

Figure 58). Center the cabinet within the opening. Drill three (3)

5

/32″ diameter pilot holes into window sill using the holes in the

cabinet sill plate as a guide. Install three (3) #12 x 2″ long screws

(Item 4) (see Figure 58).

Adjust the support brackets to provide an inside-to-outside slope for

excess condensation drainage (refer to Standard Window Installation,

Figures 59 through 61). Tighten all screws.

Alternate support method A: If you have a deep window sill which

prevents you from mounting the brackets as shown in Figure 61, try the

following: Using the elongated holes and different hole locations in the

cabinet, set the placement of the bracket to support the unit’s weight

(Figure 62). Tighten all screws.

Alternate support method B: If the window ledge gap is narrow, try the

following. Bend the bracket end tab at. Cut the bracket in two (2) places

as shown in Figure 63. Bend the short piece so it will be vertical when

installed. Adjust the placement as required. Tighten all screws.

STEP 8. Measure and cut the wingboard panels (t with about 1/8″

there is approximately a 3/8″ to 1/2″ slope (1/8 to 1/4 bubble

on level) toward the outside of the house.

clearance) from the supplied Masonite (Item 8) to t the space

between the window side channels and cabinet (Figure 64).

Make sure you include the depth of the window channel.

STEP 7. OUTSIDE SUPPORT MOUNTING – Refer to Figures 57

and 58. Assemble the support brackets (Item 1) to the

bottom of the cabinet with four (4) 10-24 1″ long screws

(Item 2) and four 10-24 flat nuts (Item 3). Adjust the support

brackets, using a combination of the elongated holes of the

bracket and different hole locations in the cabinet, to bring

the bottom support bracket pads in contact with the wall. A

1″ x 4″ or 2″ x 4″ SPACER SHOULD BE USED BETWEEN THE

WALL AND SUPPORT THE BRACKETS WHEN INSTALLED

ON ALUMINUM OR VINYL SIDING. Drill 5/32″ diameter pilot

holes and secure the brackets to the wall with two (2) 12A

x 2″ long screws (Item 4).

Figure 56

REMOVE AND DISCARD

FOAM BLOCKS

TOP VIEW OF UNIT

COMPRESSOR FAN MOTOR

NOTICE

For YOUR security and safety, YOU must

provide a means of preventing the upper

part of the window from opening.

STEP 9. To assemble the wingboard panels, push on the “J” type speed

nuts (Item 9) and spring steel clips (Item 10) (see Figure 65

on Page 35). Secure each panel with two (2) screws (Item 11).

Refer to Figure 66 on Page 36.

REMOVE AND DISCARD

SCREWS

BACK

RIGHT SIDELEFT SIDE

EVAPORATOR COIL

FRONT

REMOVE AND SAVE

SCREW FOR

RE-INSTALLATION

FRR045

30 31

Page 31

Standard Window Installation continued

Figure 57

CABINET

#8 x 3/8″ LONG SCREW

(ITEM 7) 2 REQUIRED

TOP ANGLE (ITEM 5)

TAB

DETAIL B-2

SIDE ANGLE

(ITEM 6)

2 REQUIRED

TAB

LOOP

SILL PLATE

TAB

Figure 58

DRILL (3) 5/32″ DIA.

PILOT HOLES AND

INSTALL (3) #12 x 2″

LONG SCREWS

CENTER

CABINET

IN WINDOW

SIDE TO SIDE

(ITEM 4)

DETAIL B-1

FRR013

TOP ANGLE

(ITEM 5)

PULL WINDOW

SASH DOWN

BEHIND TOP

ANGLE

SIDE ANGLE

(ITEM 6)

WINDOW SILL

LOCATE SILL PLATE GUIDE CHANNEL

JUST BACK OF WINDOW SILL

FRR014

Page 32

Standard Window Installation continued

Figure 59

SPACER SHOULD BE USED BETWEEN

WALL AND BRACKET WHEN INSTALLED

ON ALUMINUM OR VINYL SIDING.

3

/8″ SLOPE DOWN

#12 x 2″ SCREW

(ITEM 4)

SUPPORT BRACKET

(ITEM 1)

10-24 x FLAT WELD

NUT (ITEM 3)

#10-24 x 1″ HEX HEAD

SCREW (ITEM 2)

SUPPORT

BRACKET

(ITEM 1)

FRR015

Figure 60

3

/8″ SLOPE DOWN

CONDENSER

AIR OUTLET

CONDENSER

AIR INLETS

#10-24 SCREW

#10-24 FLAT WELD NUT

#12 x 2″ SHEET METAL

SCREW (ITEM 4)

SPACER SHOULD BE USED BETWEEN

WALL AND BRACKET WHEN INSTALLED

ON ALUMINUM OR VINYL SIDING.

FRR016

32 33

Page 33

Standard Window Installation continued

Figure 61

STONE LEDGE

FOR LEDGES

#12 x 2″ SHEET METAL

SCREW (ITEM 4)

SPACER

3

/8″ SLOPE DOWN

CONDENSER

AIR INLETS

#10-24 SCREW

#10-24 FLAT WELD NUT

FRR017

Figure 62

ALTERNATE METHOD A

SECURE THE LONGEST SIDE OF

THE BRACKET TO THE SHELL

ADJUST IN OR OUT TO REST

ON THE LEDGE

STONE LEDGE

3

/8″ SLOPE DOWN

#10-24 SCREW

STRAIGHTEN TAB TO LAY FLAT

ALONG THE BOTTOM RAIL OF

THE SHELL

#10-24 FLAT WELD NUT

FRR018

Page 34

Standard Window Installation continued

Figure 63

ALTERNATE METHOD B

3

/8″ SLOPE DOWN

#10-24 SCREW

#10-24 FLAT WELD NUT

STONE LEDGE

OUTSIDE WALL

DIMENSION “A”

CUT HERE

DISCARD

SHADED AREA

CUT TO FIT DIMENSION “A”

AND BEND DOWN TO FORM

A VERTICAL LEG.

A

FRR019

Figure 64

B

B

MEASURE DISTANCE “B” TO INSIDE

OF THE CHANNEL ON EACH SIDE.

CUT HERE AND DISCARD

CENTER WASTE MATERIAL

WINGBOARD

SUBTRACT 1/8″ FROM DIMENSION “B” AND

MEASURE FROM THE EDGE OF WINGBOARD

B

B

(ITEM 8), MARK, SCORE AND CUT WITH

APPROPRIATE CUTTING TOOL.

FRR020

34 35

Page 35

Standard Window Installation continued

WARNING

Falling Object Hazard

Not following Installation Instructions

for mounting your air conditioner can

result in property damage, injury, or

death.

STEP 10. INSTALL THE R1 INSULATION PANEL – To minimize air

leaks and ensure optimal insulation, install the included R1

insulation panel (14 in parts list) (see Figure 67A-C).

First, measure the width from one side of the cabinet/ sleeve

(covering the side angles where the wingboard was just secured)

to the end of the wingboard (see Figure 67A).

Next, cut the R1 insulation panel to the measured width and

remove protective cover, exposing adhesive on back panel

(see Figure 67B).

Last, evenly apply the adhesive side of the panel across the

entire height and width from side angle to wingboard panel

(see Figure 67C).

Repeat the steps above for the other wingboard panel.

STEP 11. INSTALL THE WINDOW SEALING GASKETS – Measure

and cut the dark foam window seal gasket (Item 12) and

install it between the upper glass panel and the top part of

the window sash (see Figure 67A).

CAUTION

Cut/Sever

Although great care has been

taken to minimize sharp edges

in the construction of your unit,

use gloves or other hand

protection when handling unit

Failure to do so can result in minor

to moderate personal injury.

STEP 12. Carefully team lift the chassis and set it into the cabinet. Slide

the chassis stopping approximately 3″ from full insertion. Insert

the chassis seal gasket (Item 13) one inch deep between the

chassis and the cabinet (see Figure 68) as shown on Page 37.

A paint stir stick or ruler might be helpful here. Begin inserting

the gasket at either bottom corner and go up the side, across the

top, and down the opposite side. Then push the chassis all the

way into the cabinet.

NOTE: If the chassis seal gasket is not installed or installed improperly,

the operation of the unit will be negatively affected. Operational

noise and outside noise will also amplied.

STEP 13. Reattach the EntryGard™ chassis and EntryGard™ retainer wire

with the same screw retained in Step 1 (see Figure 54).

Figure 65

“J” TYPE SPEED NUT

(ITEM #9) 2 REQUIRED

CUT

WINGBOARD

PANEL

CENTER THE HOLE IN THE

SPEED NUT OVER THE SLOT

IN THE WINGBOARD PANEL

SPRING STEEL CLIP

(ITEM 10) 2 REQUIRED

3″

CUT EDGE

ROTATED 90°

3″

SLIDE CLIP OVER CUT EDGE

OF WINGBOARD PANEL

FRR021

Page 36

Standard Window Installation continued

Figure 66

TOP OF CABINET

PLACE WINGBOARD PANEL IN WINDOW JAM

TO COMPRESS THE SPRINGS INSIDE THE

RUNNERS, AND SWING THE WINGBOARD

PANELS INTO PLACE AS INDICATED BY THE

DASHED LINES.

SECTION A-A

Figure 67

INSERT FOAM WINDOW

SEAL GASKET (ITEM 12)

WINDOW JAM

CLIP (ITEM 10)

A

B

A

A

C

SECURE THE SIDE WINGBOARD PANELS TO

THE SIDE ANGLES WITH FOUR (4) #8 x

SCREWS (ITEM 11), TWO ON EACH SIDE.

1

/2" LONG

SECTION B-B

FRR022

FRR023

36 37

Page 37

Standard Window Installation continued

OPTIONAL: The factory assembles the supply cord so that it exits the left

side of the unit at the bottom. At the consumer’s discretion, pull

the supply cord taut through the loops (refer to Cord Routing

Change, Figure 70) and route the cord down.

STEP 14. To attach and prevent damage to the front grille, align the cord

notch over the cord and center the fresh air lever, then align

and tighten the four (4) captive screws as indicated by the

arrows in Figure 69. Before closing the front panel, be sure

the lter is in place. Make sure curtains do not block the side

air intakes.

STEP 15. Refer to the Control Panel Operation section for instructions.

You are now to control the comfort level of the room.

Use Tool Provided

Please use the provided tool to attach the decorative front to the chassis.

Figure 69

USE HAND TOOLS

DO NOT

OVERTIGHTEN

B

LOCATION OF GRILLE

REMOVAL TOOL

FRR053

Figure 68

POWER CORD CLIP

NOTE: WHEN INSTALLING THE CHASSIS

SEAL GASKET, BEGIN AT EITHER BOTTOM

CORNER AND GO UP THE SIDE & ACROSS

THE TOP & DOWN THE OPPOSITE SIDE.

CHASSIS SEAL GASKET (ITEM 13)

FRR024

Page 38

Cord Routing Change

Unplug unit.

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong oulet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

For convenience and optimum appearance, the direction that the power

cord exits the unit may be changed from left to right by following the

procedure below. Select the exit location on the left or right based on

proximity to the power outlet.

Figure 70

ELECTRICAL

CONTROL

PANEL

STEP 16. Carefully pull out electrical control panel 1″, but not all the way.

Figure 72

1 INCH

FRR056

STEP 17. Pull electrical cord strain relief downward until free and rotate

90 degrees to the right.

Figure 73

NOTE:

DECORATIVE FRONT

REMOVAL USE TOOL PROVIDED.

(SEE FIGURE 69 FOR LOCATION OF TOOL)

Remove the 3 screws as shown from the electrical control panel.

Save to reinstall later.

Figure 71

ELECTRICAL CONTROL

PANEL SCREWS (3)

FRR054

FRR055

ELECTRICAL CORD

STRAIN RELIEF

STEP 18. Push electrical cord strain relief back upward into the electrical

control panel.

Figure 74

ENSURE THE ELECTRICAL CORD STRAIN RELIEF IS FLUSH

WITH THE TOP OF ELECTRICAL CONTROL PANEL.

90°

FRR057

FRR058

38 39

Page 39

Cord Routing Change continued

STEP 19. Carefully push electrical control panel back into chassis.

Figure 75

ELECTRICAL

CONTROL PANEL

FRR059

STEP 20. Reinstall the 3 screws removed earlier to secure electrical

control panel.

Figure 76

STEP 21. If running power cord to the right of the unit, install the cord into

the cord retainer clips along the bottom front of the unit.

Figure 77

CORD RETAINER

CLIPS

POWER

CORD

ELECTRICAL CONTROL PANEL SCREWS (3)

(RETAINED FROM STEP 1)

FRONT

GRILLE

FRR061

FRR060

Page 40

Thru-the-Wall Installation

WARNING

Falling Object Hazard

Not following Installation Instructions

for mounting your air conditioner can

result in property damage, injury, or

death.

A

The following instructions apply to wood, masonry, brick, concrete or cinder

block wall construction.

STEP 1. Follow Steps 1, 2, 3, and 4 of the “STANDARD WINDOW

INSTALLATION” instructions beginning on Page 29.

STEP 2. CABINET PREPARATION – Remove the sill plate from the

cabinet by removing two (2) nuts and screws (Figure 78).

Note that the chassis retainer is secured by a right side

nut and screw (Detail A, Figure 78). Bend the tabs of the

sill plate down into its channel at both ends of the plate or

cut them off (Detail B, Figure 78). Rotate the sill plate 180°

(end-to-end, Detail B, Figure 78) and reinstall. Reverse the

orientation of the nuts and screws, so that the head of the

screws are on the underside of cabinet facing up and the

nuts are on top (Detail C, Figure 78). Ensure that the chassis

retainer is reinstalled as shown in the detail.

NOTICE

The outside cabinet condenser air intake louvers

MUST NOT BE BLOCKED by extra thick walls.

STEP 3. WALL PREPARATION – The maximum wall thickness permissible

without special construction is determined by the model size to be

installed. Observe the maximum wall thickness shown in Figure 79.

Walls exceeding the maximum thickness shown in the chart should

be altered as shown in Figure 79.

B

Table 3

FINISHED

DIMENSION

A 16 3⁄16″ 18 3⁄16″ 20 3⁄8″

B 26 3⁄16″ 26 3⁄16″ 28 1⁄4″

NOTE: These dimensions are for nished opening size.

SMALL

CHASSIS

MEDIUM

CHASSIS

LARGE

CHASSIS

STEP 4. CHECKING WIRING AND PLUMBING – Check for wiring

and plumbing inside and outside of the wall to be sure none will

be damaged when the cabinet framework is being constructed.

STEP 5. OPENING CONSTRUCTION – Depending upon size of unit

to be installed, lay out the hole dimensions per Table 3. Cut

and frame-in the opening to nished dimensions. If the wall

construction is a typical frame, or 2″ x 4″ studding with brick or

stone veneers, locate the opening next to one of the studs. For

masonry, concrete, or cinder block walls, locate an opening for

your convenience (see Figures 80, 81, and 82).

40 41

Page 41

Thru-the-Wall Installation continued

Figure 78

CABINET

SILL PLATE

TURN SILL PLATE

END TO END

BEFORE AFTER

SCREW

(4 REQUIRED)

CABINET

NOTE: HOLES IN SILL

PLATE MOVED TO

BACK SIDE

DETAIL A

NUT

(4 REQUIRED)

DETAIL B

NOTE: SCREW AND NUT

BEND TABS DOWN

ORIENTATION NOW REVERSED.

NUT

(4 REQUIRED)

DETAIL C

SCREW

(4 REQUIRED)

Figure 79

A

MAXIMUM WALL THICKNESS

MODEL A

SMALL CHASSIS 7 3/8"

MEDIUM CHASSIS 7 3/8"

LARGE CHASSIS 15 1/8"

CONDITIONED AIR

INTAKE LOUVERS

TOP VIEW SHOWING BEVELED

SIDE FOR AIR INTAKE.

WALL BELOW UNIT MUST BE

BEVELED ALSO.

FRR026

TOP VIEW

CONDITIONED

ROOM SIDE AIR

2″ MINIMUM

BOTH SIDES

CONDENSER AIR

INTAKE LOUVERS

CONDENSER AIR OUTLET/

REJECTED HEATED AIR

NOTE: CONDENSER AIR INLETS AND OUTLETS

MUST BE UNOBSTRUCTED TO AVOID THE

RECIRCULATION OF REJECTED HEATED AIR.

FRR027

Page 42

Thru-the-Wall Installation continued

Figure 80

CABINET

CAULK ALL SIDES

INSIDE AND OUTSIDE

SHIM TO FILL IN VOID AT THE

TOP AND SIDE WITH WOOD

AS REQUIRED.

Figure 81

CAULK ALL SIDES

INSIDE AND OUTSIDE

CABINET

A

SHIM TO FILL IN VOID AT THE

TOP AND SIDE WITH WOOD

AS REQUIRED.

ELECTRICAL RECEPTACLE

ELECTRICAL RECEPTACLE

(SEE FIG. 81 FOR LOCATION NOTE)

Figure 82

MORTAR

CABINET

CAULK ALL SIDES

INSIDE AND OUTSIDE

POINT “X”

FRR028

ELECTRICAL

RECEPTACLE

FRR029

POINT “Y”

From Point “X” Small/ Medium Large

115V 69" N/A

230V 45" 45"

From Point “Y” Small/ Medium Large

115V 45" N/A

230V 21" 20"

FRR030

42 43

Page 43

Thru-the-Wall Installation continued

STEP 6. Slide the cabinet into the hole far enough to allow the guide-

channel of the sill plate to contact the inside wall surface

(Figure 83).

STEP 7. Drill three (3) 5/32″ diameter pilot holes (use the sill plate holes

as a guide) into the frame and install three (3) #12 x 2″ long

screws (Item 4) (Figure 83).

NOTE: Alternate fasteners are required when securing the sill plate

or support brackets to material other than wood (cinder block,

brick, masonry, or concrete). These items can be purchased at

your local hardware store.

EXPANSION ANCHOR BOLT

MOLLY OR TOGGLE BOLT

Figure 83

TRIM MOULDING

NOTE: DO NOT LEVEL the cabinet from front to back. Make sure

there is approximately 3/8″ to 1/2″ slope (1/8 to 1/4 bubble on

the level) toward the outside of the house.

STEP 8. Drill two (2) 5/32″ diameter pilot holes in each cabinet side at the

locations shown (Figure 83) and install four (4) #12 x 2″ screws

(Item 4). Provided that Step 5 (hole construction) provides

a sturdy mount with solid vertical studs, support brackets may

not be required. The installation must support the weight of the

unit plus an additional weight of 400 pounds on the rear of the

cabinet. If support brackets (Item 1) are available, they can be

installed as shown in Figure 83.

STEP 9. Complete the installation by following Steps 12 through 15 of

“STANDARD WINDOW INSTALLATION” instructions, starting

on Page 35.

CAULK ALL SIDES WEATHER TIGHT

INSIDE AND OUTSIDE

3

/8″ SLOPE DOWN

4″

SCREW #12 x 2″

LONG (USE 3)

(ITEM 4)

SILL PLATE GUIDE CHANNEL

INSIDE WALL SURFACE

3″

NOTE: SUPPORT BRACKET MAY BE OMITTED

FROM THRU-THE-WALL INSTALLATIONS IF

THE CABINET IS SECURED AS FOLLOWS:

DRILL TWO HOLES IN EACH SIDE AND

INSTALL 4 FASTENERS (2 EACH SIDE).

USE #12 x 2″ SCREWS, (ITEM 4).

TOGGLE BOLTS OR EXPANSION BOLTS

MAY BE REQUIRED.

CABINET

SUPPORT BRACKETS

SCREW #12 x 2″ LONG

DRILL 5/32″ DIA. PILOT HOLES.

FRR031

Page 44

Final Inspection & Start-up Checklist

♦ Inspect and ensure that all components and accessories have been

installed properly and that they have not been damaged during the

installation progress.

♦ Check the condensate water drain(s) to ensure that they are

adequate for the removal of condensate water, and that they meet

the approval of the end user.

♦ Ensure that all installation instructions concerning clearances around

the unit have been adhered to. Check to ensure that the unit air lter,

indoor coil, and outdoor coil are free from any obstructions.

♦ Ensure that the circuit breaker(s) or fuse(s) and supply circuit wire

size have been sized correctly. If the unit was supplied with a power

supply cord, insure that it is stored properly.

♦ Ensure that the entire installation is in compliance with all applicable

national and local codes and ordinances having jurisdiction.

♦ Secure components and accessories, such as a decorative front cover.

♦ Start the unit and check for proper operation of all components in

each mode of operation.

♦ Instruct the owner or operator of the units operation, and the

manufacturer’s Routine Maintenance.

NOTE: A log for recording the dates of maintenance and/ or service is

recommended.

♦ Present the owner or operator of the equipment with the Installation &

Operation Manual, all accessory installation instructions, and the name,

address, and telephone number of the Authorized Friedrich Warranty

Service Company in the area for future reference if necessary.

Heat pumps operate differently

If your unit is a “KH”, or heat pump model, there are some things that you

will want to be aware of. Some functions of a heat pump differ from your

unit when it is used for heating:

1. It is normal for ice to form on the outdoor coil of the heat pump.

Moisture in the outside air, passing over the coil when very

cold, will form ice.

2. If the outdoor temperature drops below 37 °F (3 °C), your heat

pump will automatically turn on the electric resistance heat.

When the temperature rises to 40 °F (4 °C), the compressor

will resume the heat pump operation. If your unit is a 115 volt

model (KHS10), it is designed for use in warmer climates and

does not have an electrical heat feature, and will not provide

adequate heat below 37 °F (2.8 °C).

Control Panel Battery Change Procedure

Remove the grille, by loosening four (4) captive screws (see Figure 84). In

the upper left corner, remove one (1) screw on the battery retaining door

(see Figure 85). Remove and replace the battery (CR2450). Reinstall

the battery retaining door. Align the grille guide pins then tighten the four

(4) captive screws. Before closing the grille panel door, check the lter.

Clean or replace it as necessary.

Figure 84

This is a warm weather appliance

Your air conditioner is designed to cool in warm weather when the outside

temperature is above 60 °F (15.6 °C) and below 115 °F (46.1 °C), so it won’t

cool a room if it is already cool outside. If you want to cool a room in the

spring or fall, select the FAN ONLY mode and set the Fresh Air/ Exhaust air

control to Fresh Air. This will bring in a supply of cooler outside air.

Condensation is normal

Air conditioners actually pump the heat and humidity from your room to the

outside. Humidity becomes water, and your air conditioner will use most of

the water to keep the outside coil cool. If there is excessive humidity, there

may be excess water that will drip outside. This is normal operation.

Frosting

This usually occurs because of insufcient airow across the coils, a dirty

lter, cool damp weather, or all these. Set the SYSTEM mode to FAN

ONLY and the frost will disappear. Setting the thermostat a little warmer

will probably prevent the frosting from recurring.

Noises

All air conditioners make some noise. Friedrich units are designed to

operate as quietly as possible. An air conditioner mounted in a wall is

quieter than one mounted in a window. It is important to ensure that the

chassis seal gasket (Item 13) is properly installed (refer to the Installation

Instructions).

Figure 85

USE HAND TOOLS

DO NOT OVERTIGHTEN

1. USE HAND TOOLS WHEN INSTALLING

AND REMOVING FRONT PANEL.

DO NOT OVERTIGHTEN SCREWS.

2. DISCONNECT POWER AND FOLLOW

ALL LABELED WARNINGS WHEN

FRONT PANEL IS REMOVED.

FRR010

44 45

Page 45

Routine Maintenance Service and Assistance

To ensure proper unit operation, the air lter should be cleaned at least

monthly, and more frequently if conditions warrant. The unit must be turned

off before the lter is cleaned.

To Remove, Wash and Replace Filter

Lower front panel (Figure 2). Use the handle on the lter to ex lter up and

out of retainer. Remove lter from unit (Figure 3). Clean the lter monthly or

more frequently if needed. Refer to the Accessories section for lter options.

Coils & Chassis

NOTE: Do not use a caustic cleaning agent on coils or base pan. Use a

biodegradable cleaning agent and degreaser. The use of harsh

cleaning materials may lead to deterioration of the aluminum

ns or the coil end plates.

The indoor coil and outdoor coils and base pan should be inspected

periodically (annually or semi-annually) and cleaned of all debris (lint,

dirt, leaves, paper, etc.) as necessary. Under extreme conditions, more

frequent cleaning may be required. Clean the coils and base pan with a

soft brush and compressed air or vacuum. A pressure washer may also be

used; however, you must be careful not to bend the aluminum n pack. Use

a sweeping up and down motion in the direction of the vertical aluminum n

pack when pressure cleaning coils.

NOTE: It is extremely important to insure that none of the electrical

and/ or electronic parts of the unit get wet. Be sure to cover all

electrical components to protect them from water or spray.

Decorative Front

Use a damp (not wet) cloth when cleaning the control area to prevent water

from entering the unit, and possibly damaging the electronic control.

The decorative front and the cabinet can be cleaned with warm water and a

mild liquid detergent. Do NOT use solvents or hydrocarbon based cleaners

such as acetone, naphtha, gasoline, benzene, etc.

The indoor coil can be vacuumed with a dusting attachment if it appears

to be dirty. DO NOT BEND FINS. The outdoor coil can be gently sprayed

with a hose if you can get to it. If not, you might call your dealer for a more

thorough cleaning when needed.

The air lter should be inspected weekly and cleaned if needed by

vacuuming with a dust attachment or by cleaning in the sink using warm

water and a mild dishwashing detergent. Dry the lter thoroughly before

reinstalling. Use caution, the coil surface can be sharp.

Fan Motor & Compressor

The fan motor & compressor are permanently lubricated and require no

additional lubrication.

Wall Sleeve

Inspect the inside of the wall sleeve and drain system periodically (annually

or semi-annually) and clean as required. Under extreme conditions, more

frequent cleaning may be necessary. Clean both of these areas with an

antibacterial and antifungal cleaner. Rinse both items thoroughly with water

and ensure that the drain outlets are operating correctly. Check the sealant

around the sleeve and reseal areas as needed.

Before calling for service, please check the “Troubleshooting Tips” section on

Pages 46 and 47. This may help you to nd the answer to your problem,

avoid unnecessary service calls, and save you the cost of a service call if

the problem is not due to the product itself. If you have checked the “Basic

Troubleshooting” section and still need help, it is available as follows:

You can nd the name of your local Authorized Service Provider by visiting our

website at www.friedrich.com.

If you require further assistance

You can call the Customer Support Call Center at 1-800-541-6645.

Before calling, please make sure that you have the complete model and serial

number, and date of purchase of your equipment available. By providing us

with this information, we will be better able to assist you.

Our specialists are able to assist you with:

♦ Specications and Features of our equipment.

♦ Referrals to dealers, and distributors.

♦ Use and Care Information.

♦ Recommended maintenance procedures.

♦ Installation information.

♦ Referrals to Authorized Service Providers and Parts depots.

Available Accessories

DC-2 Drain Kit – Part No. 01900235

In some installations, excess condensate water caused by extremely humid

conditions, may result in an undesirable water drip such as on a patio or over

an entryway. MODEL DC-2 DRAIN KIT (Part No. 01900-235) can be installed

to drain excess condensation to an alternate location.

Carbon Filter Kits

The kits vary depending on the chassis size (small, medium, large). Each kit

contains three (3) lters.

KWCFS – Carbon lter kit for small chassis models.

KWCFM – Carbon lter kit for medium chassis models.

KWCFL – Carbon lter kit for large chassis models.

FriedrichLink™ Adapter Accessory

KWIFI – FriedrichLink™ Adapter Accessory for wireless control and

additional programming options.

Decorative Color Front Panel Kits

The kits vary depending on the chassis size (small, medium, large).

KWBGE(S/ M/ L)A – S/ M/ L Decorative Front Cover in Classic Beige

KWBLK(S/ M/ L)A – S/ M/ L Decorative Front Cover in Black Onyx

KWBLU(S/ M/ L)A – S/ M/ L Decorative Front Cover in Cobalt Blue

KWPNK(S/ M/ L)A – S/ M/ L Decorative Front Cover in Pink Diamond

KWRED(S/ M/ L)A – S/ M/ L Decorative Front Cover in Deep Red

KWWHT(S/ M/ L)A – S/ M/ L Decorative Front Cover in Designer White

Window Installation Kits (Standard in Kühl Models without Heat)

KWIKS – For all KES and KHS models.

KWIKM – For all KEM and KHM models.

KWIKL – For all KEL and KHL models.

See www.friedrich.com for additional accessories for your unit.

Page 46

Troubleshooting Tips

COMPLAINT CAUSE SOLUTION

• The unit is turned to the off position, or the

thermostat is satised.

• The LCDI power cord is unplugged.

Unit does not operate.

Unit Trips Circuit Breaker or

Blows Fuses.

LCDI Power Cord Trips

(Reset Button Pops Out).

Unit Does Not Cool/ Heat Room

Sufciently, or Cycles On And Off

Too Frequently.

• The LCDI power cord has tripped (Reset

button has popped out).

• The circuit breaker has tripped or the

supply circuit fuse has blown.

• There has been a local power failure.

• Other appliances are being used on the

same circuit.

• An extension cord is being used.

• The circuit breaker or time-delay fuse is

not of the proper rating.

• The LCDI power cord can trip (Reset

button pops out) due to disturbances on

your power supply line.

• Electrical overload, overheating, or cord

pinching can trip (Reset button pops out)

the LCDI power cord.

NOTE: A damaged power supply cord must be replaced with a new power supply cord obtained from the

• The return/ discharge air grille is blocked.

• Windows or doors to the outside are open. • Ensure that all windows and doors are closed.

• The temperature is not set at a cool

enough/ warm enough setting.

• The lter is dirty or obstructed.

• The indoor coil or outdoor coil is dirty or

obstructed.

• There is excessive heat or moisture

(cooking, showers, etc.) in the room.

• The temperature of the room you are

trying to cool is extremely hot.

• Turn the unit to the on position and raise or lower

temperature setting (as appropriate) to call for

operation.

• Plug into a properly grounded 3 prong receptacle.

See “Electrical Rating Tables” on Page 6 for the

proper receptacle type for your unit.

• Press and release RESET (Listen for click. Reset

button latches and remains in.) to resume operation.

• Reset the circuit breaker, or replace the fuse as

applicable. If the problem continues, contact a

licensed electrician.

• The unit will resume normal operation once power

has been restored.

• The unit requires a dedicated outlet circuit, not shared

with other appliances.

• Do NOT use an extension cord with this or any other

air conditioner.

• Replace with a circuit breaker or time-delay fuse of

the proper rating. See “Electrical Rating Tables” on

Page 6 for the proper circuit breaker/ fuse rating for

your unit. If the problem continues, contact a licensed

electrician.

• Press and release RESET (Listen for click. Reset

button latches and remains in.) to resume normal

operation.

• Once the problem has been determined and

corrected, press and release RESET (Listen for

click. Reset button latches and remains in.) to

resume normal operation.

product manufacturer and must not be repaired.

• Ensure that the return and/ or discharge air paths are

not blocked by curtains, blinds, furniture, etc.

• Adjust the Temperature control to a cooler or warmer

setting as necessary.

• Clean the lter, (see Routine Maintenance), or

remove obstruction.

• Clean the coils, (see Routine Maintenance), or

remove obstruction.

• Be sure to use exhaust vent fans while cooking or

bathing and, if possible, try not to use heat producing

appliances during the hottest part of the day.

• Allow additional time for the air conditioner to cool off

a very hot room.

46 47

Page 47

Troubleshooting Tips continued

COMPLAINT CAUSE SOLUTION

• The outside temperature is below 60 °F

(16 °C).

• The digital control is set to fan cycling mode.

Unit Does Not Cool/ Heat Room

Sufciently, or Cycles On And Off

Too Frequently (continued).

Unit Runs Too Much.

• The air conditioner has insufcient cooling

capacity to match the heat gain of the room.

• The air conditioner has insufcient heating

capacity to match the heat loss of the room.

• This may be due to an excessive heat load

in the room.

• It may also be due to an improperly sized unit.

• This may be normal for higher efciency

(EER) air conditioners.

• You may notice that the discharge air

temperature of your new air conditioner

may not seem as cold as you may be

accustomed to from older units. This

does not; however, indicate a reduction

in the cooling capacity of the unit.

• Do not try to operate your air conditioner in the

cooling mode when the outside temperature is below

60 °F (16 °C). The unit will not cool properly, and the

unit may be damaged.

• Since the fan does not circulate the room air

continuously at this setting, the room air does not

mix as well and hot (or cold) spots may result. Using

the continuous fan setting is recommended to obtain

optimum comfort levels.

• Check the cooling capacity of your unit to ensure it

is properly sized for the room in which it is installed.

Room air conditioners are not designed to cool

multiple rooms.

• Check the heating capacity of your unit. Air conditioners

are sized to meet the cooling load, and heater size

is then selected to meet the heating load. In extreme

northern climates, room air conditioners may not be able

to be used as a primary source of heat.

• If there are heat producing appliances in use in the

room, or if the room is heavily occupied, the unit will

need to run longer to remove the additional heat.

• Be sure to use exhaust vent fans while cooking or

bathing and, if possible, try not to use heat producing

appliances during the hottest part of the day.

• The use of higher efciency components in your new

air conditioner may result in the unit running longer

than you feel it should. This may be more apparent, if

it replaced an older, less efcient, model. The actual

energy usage, however, will be signicantly less

when compared to older models.

• The energy efciency ratio (EER) and cooling

capacity rating (Btu/ h) listed on the unit’s rating

plate are both agency certied.

Page 48

Friedrich Air Conditioning Company

10001 Reunion Place, Suite 500

San Antonio, TX 78216

1-800-541-6645

www.friedrich.com

ROOM AIR CONDITIONERS

LIMITED WARRANTY

FIRST YEAR

ANY PART: If any part supplied by FRIEDRICH fails because of a defect in workmanship or material within twelve months from date of original purchase,

FRIEDRICH will repair the product at no charge, provided room air conditioner is reasonably accessible for service. Any additional labor cost for removing

inaccessible units and/or charges for mileage related to travel by a Service Agency that exceeds 25 miles one way will be the responsibility of the owner. This

remedy is expressly agreed to be the exclusive remedy within twelve months from the date of the original purchase.

SECOND THROUGH FIFTH YEAR

SEALED REFRIGERANT SYSTEM: If the Sealed Refrigeration System (dened for this purpose as the compressor, condenser coil, evaporator coil,

reversing valve, check valve, capillary, lter drier, and all interconnecting tubing) supplied by FRIEDRICH in your Room Air Conditioner fails because of

a defect in workmanship or material within sixty months from date of purchase, FRIEDRICH will pay a labor allowance and parts necessary to repair the

Sealed Refrigeration System; PROVIDED FRIEDRICH will not pay the cost of diagnosis of the problem, removal, freight charges, and transportation of the

air conditioner to and from the Service Agency, and the reinstallation charges associated with repair of the Sealed Refrigeration System. All such cost will be

the sole responsibility of the owner. This remedy is expressly agreed to be the exclusive remedy within sixty months from the date of the original purchase.

APPLICABILITY AND LIMITATIONS: This warranty is applicable only to units retained within the Fifty States of the U.S.A., District of Columbia, and Canada.

This warranty is not applicable to:

1. Air lters or fuses.

2. Products on which the model and serial numbers have been removed.

3. Products which have defects or damage which results from improper installation, wiring, electrical current characteristics, or maintenance; or caused by

accident, misuse or abuse, re, ood, alterations and/or misapplication of the product and/or units installed in a corrosive atmosphere, default or delay in

performance caused by war, government restrictions or restraints, strikes, material shortages beyond the control of FRIEDRICH, or acts of God.

OBTAINING WARRANTY PERFORMANCE: Service will be provided by the FRIEDRICH Authorized Dealer or Service Organization in your area. They are listed

in the Yellow Pages. If assistance is required in obtaining warranty performance, write to: Room Air Conditioner Service Manager, Friedrich Air Conditioning Co.

LIMITATIONS: THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES. Anything in the warranty notwithstanding, ANY IMPLIED WARRANTIES

OF FITNESS FOR PARTICULAR PURPOSE AND/OR MERCHANTABILITY SHALL BE LIMITED TO THE DURATION OF THIS EXPRESS WARRANTY.

MANUFACTURER EXPRESSLY DISCLAIMS AND EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGE FOR BREACH OF

ANY EXPRESSED OR IMPLIED WARRANTY.

NOTE: Some states do not allow limitations on how long an implied warranty lasts, or do not allow the limitation or exclusion of consequential or incidental

damages, so the foregoing exclusions and limitations may not apply to you.

OTHER: This warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

PROOF OF PURCHASE: Owner must provide proof of purchase in order to receive any warranty related services.

All service calls for explaining the operation of this product will be the sole responsibility of the consumer.