Page 1

0

F

hr

Fan

Speed

Timer

0n/0ff

Auto

Swing

CoolMoney

Fan

Saver

Only

®

Temp

Dry

Power

Mode

230

115

93011011

CP18

CP15

CP24

0

F

hr

Fan

Speed

Auto

Swing

Fan

CoolMoney

Saver

Only

®

Temp

Dry

Timer

Power

Mode

0n/0ff

Page 2

16

Satefy

18

Page 3

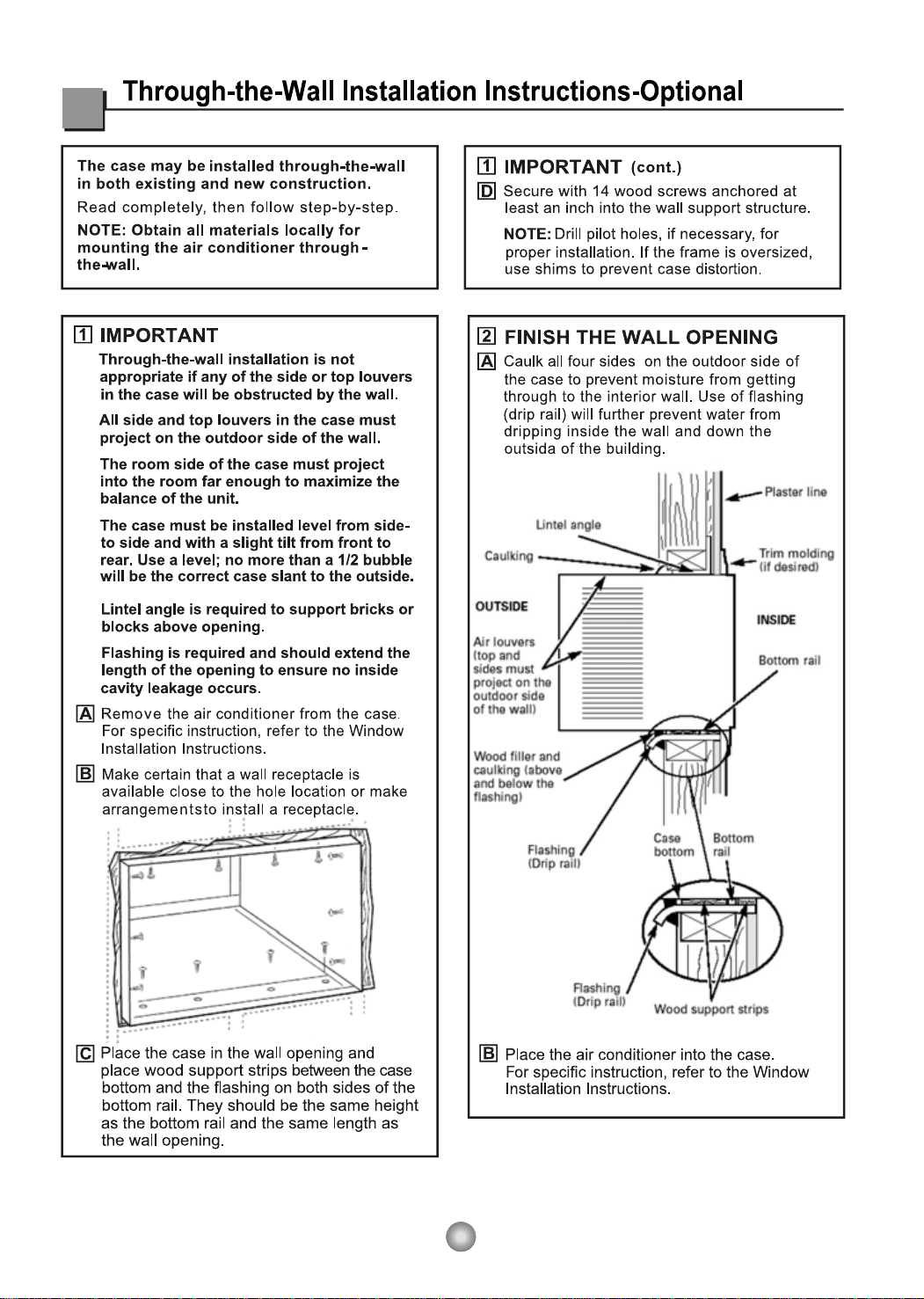

Page 4

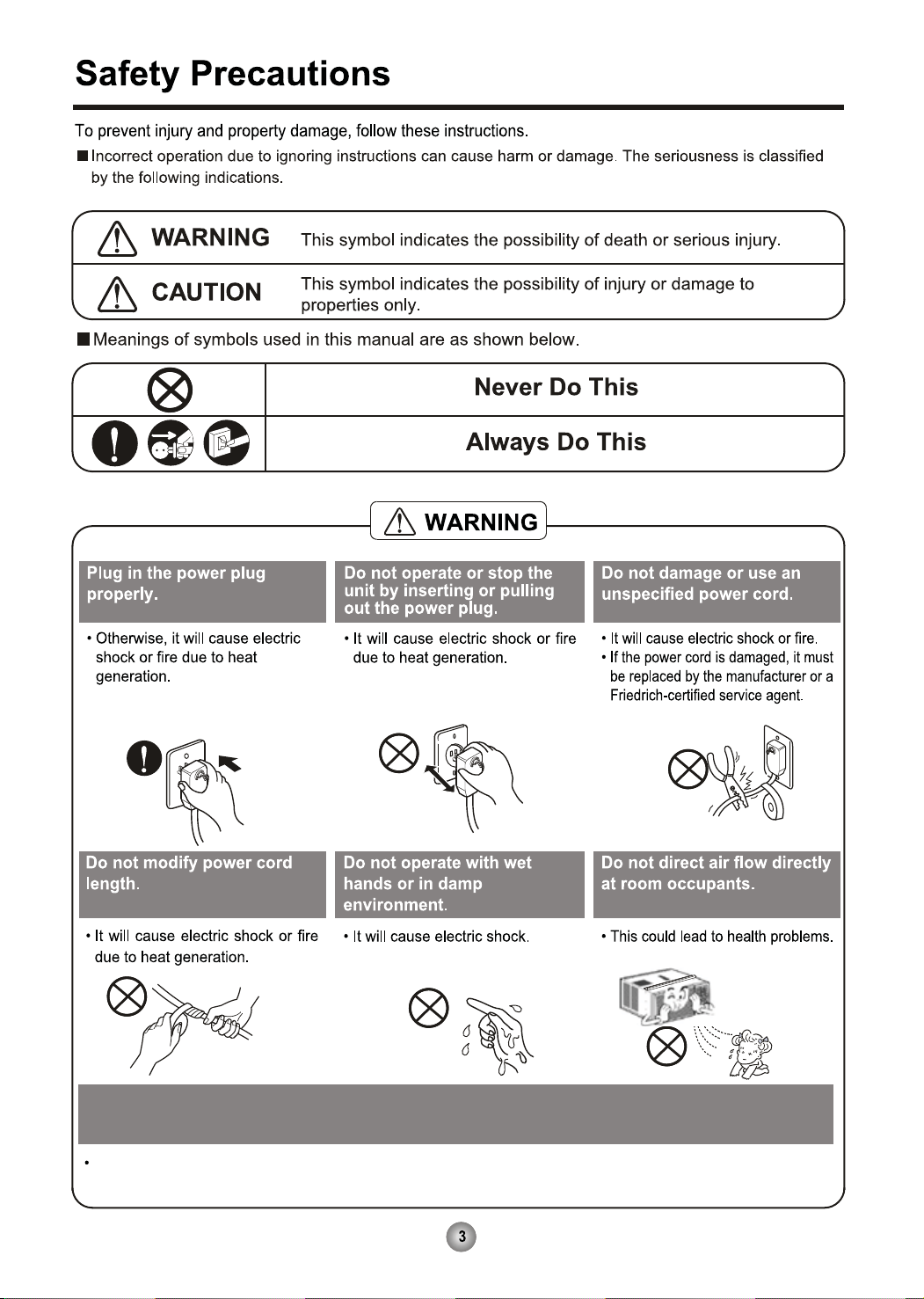

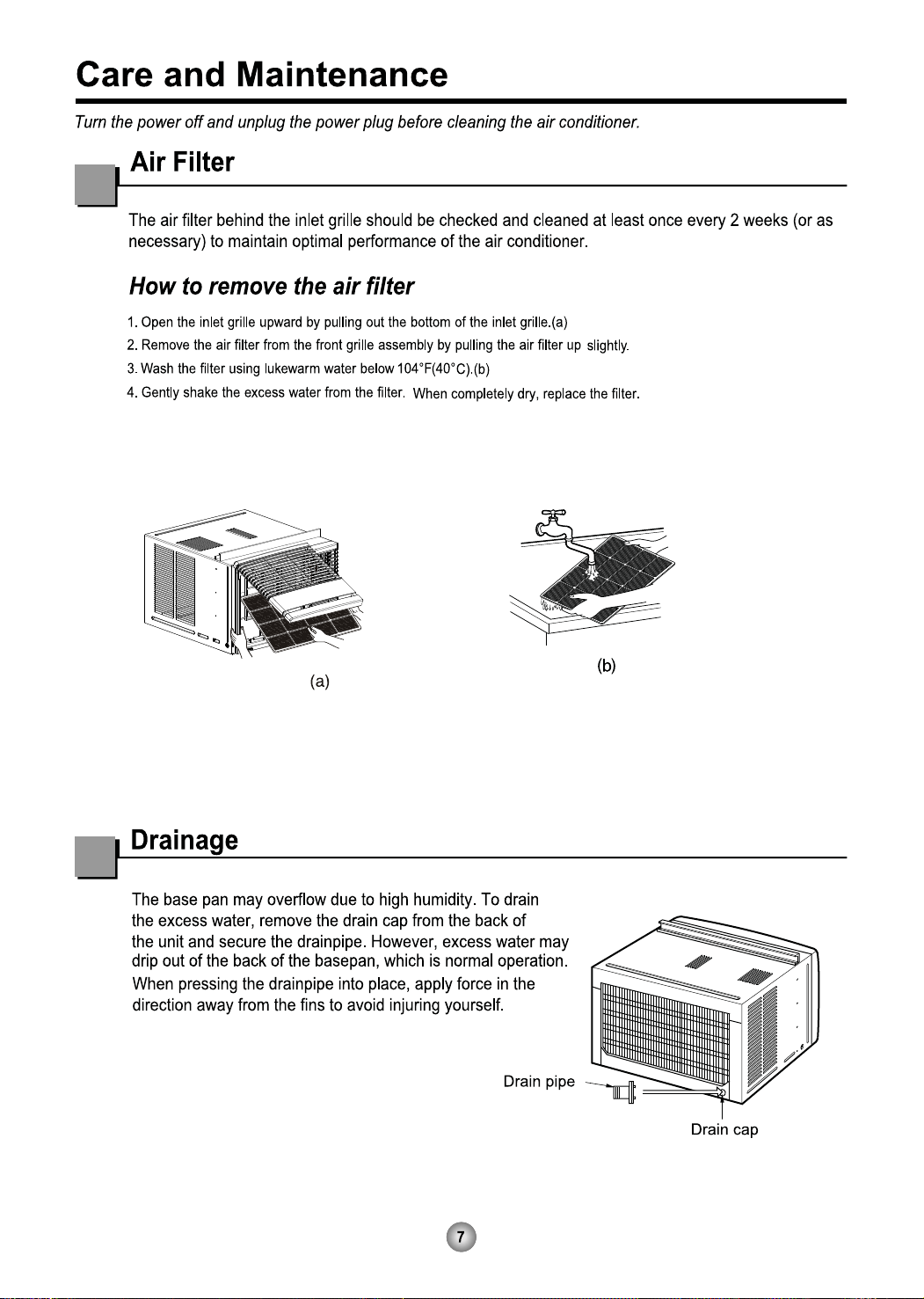

For inner cleaning, contact an Authorized Service Center or a dealer.

Do not use harsh detergent that causes corrosion or damage on the unit.

Harsh detergent may also cause failure of product, fire, or electronic shock.

Page 5

Page 6

6

7

8

6

7

3

5

2

4

5

3

1

2

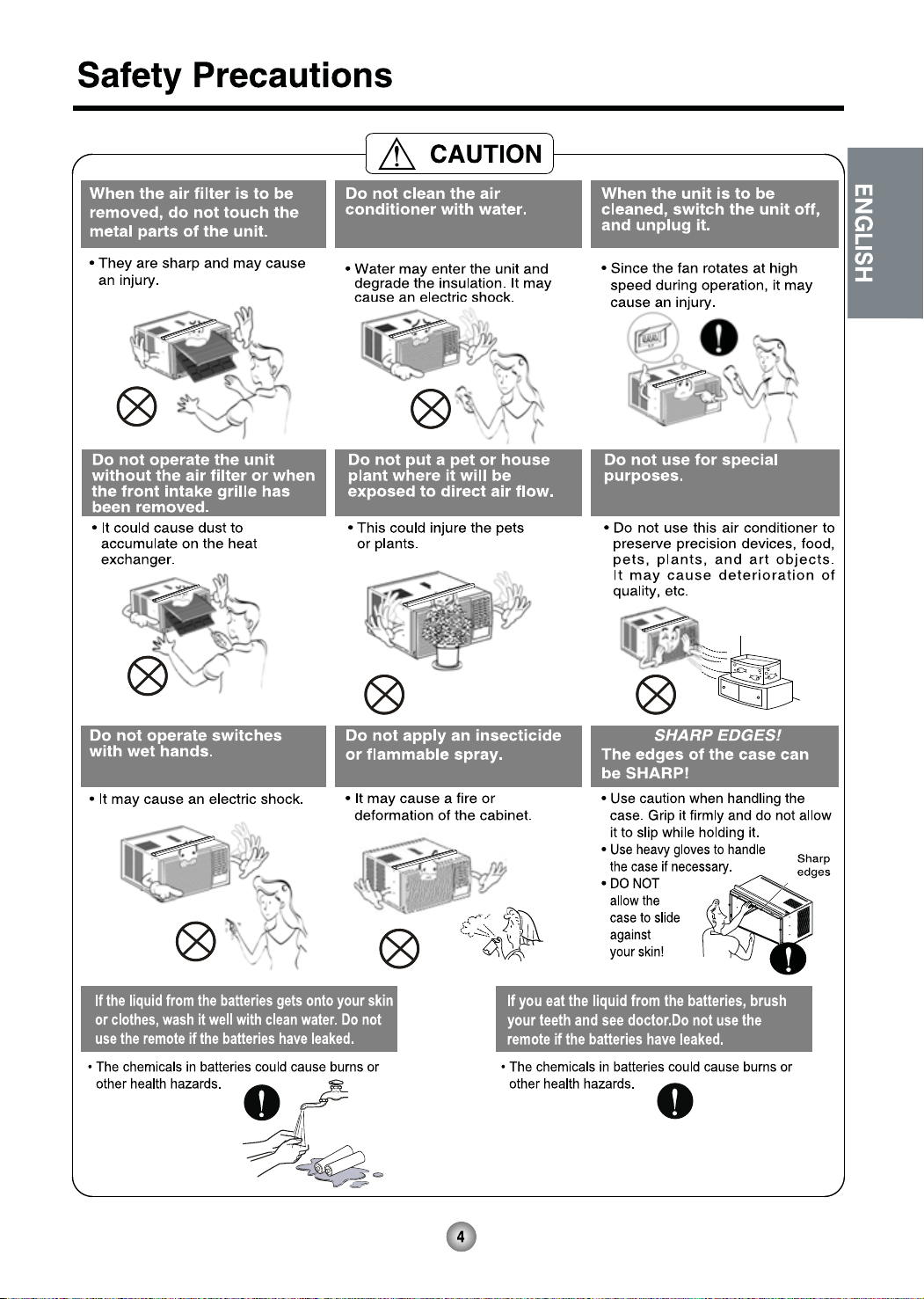

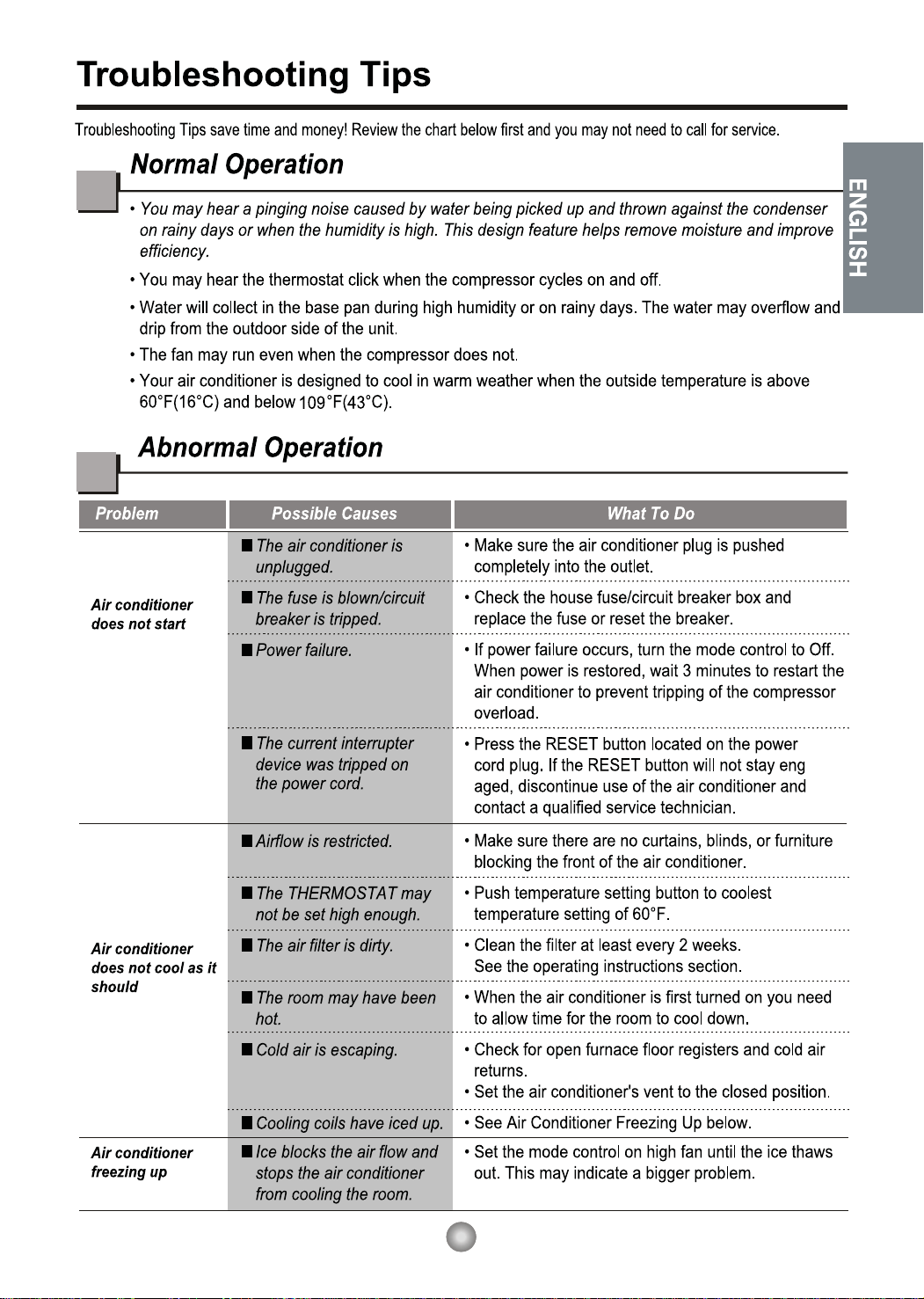

4. CHECK FILTER & FILTER RESET

Check Filter: Your ‘Check Filter’ LED will

light up after approximately 250 hours of

operation, notifying you that your filter needs

to be cleaned.

Filter Reset: press ‘Temp ∨∧’ together to

turn off ‘Check Filter’ light.

*Filter Reset must be done from unit control

panel, not remote control

MoneySaver: The fan will stop when the compressor

stops cooling. The fan will turn on approximately

every 3 minutes to sample to room air and determine

if more cooling is needed.

Cool: fan runs continually for normal cooling operation

Fan Only: Fan-only operation

*MoneySaver has it’s own button on your remote

control

*Timer Clear: On remote control, ‘Timer Clear’ button

will cancel the timer setting

8

6. OPERATION MODE SELECTOR

Push the ‘Mode’ button to rotate between

MoneySaver → Cool → Fan → Dry modes.

(select Dry mode for dry/dehumidifier

operation)

Page 7

Page 8

Page 9

Page 10

Page 11

41

18

41

8

26

Page 12

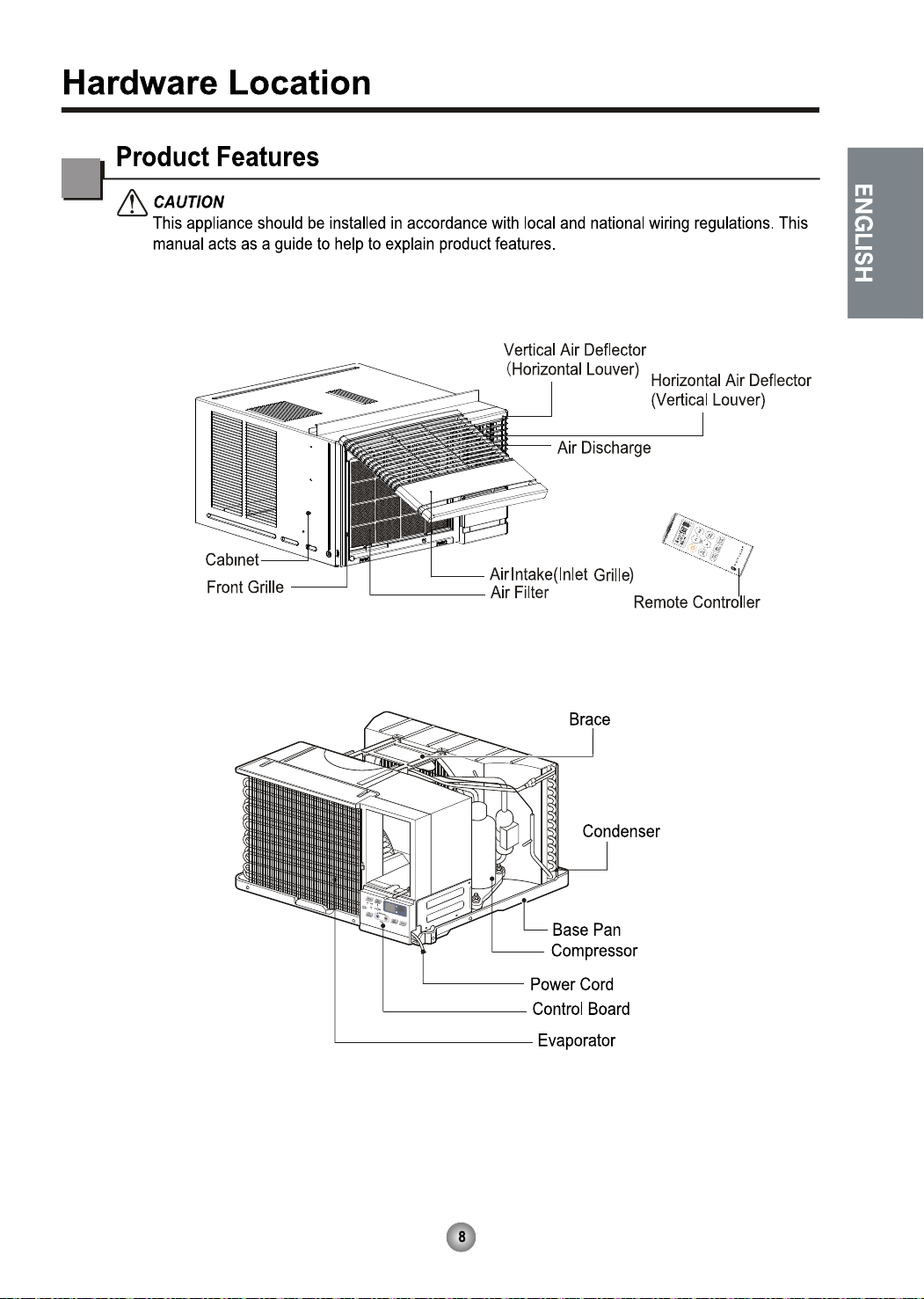

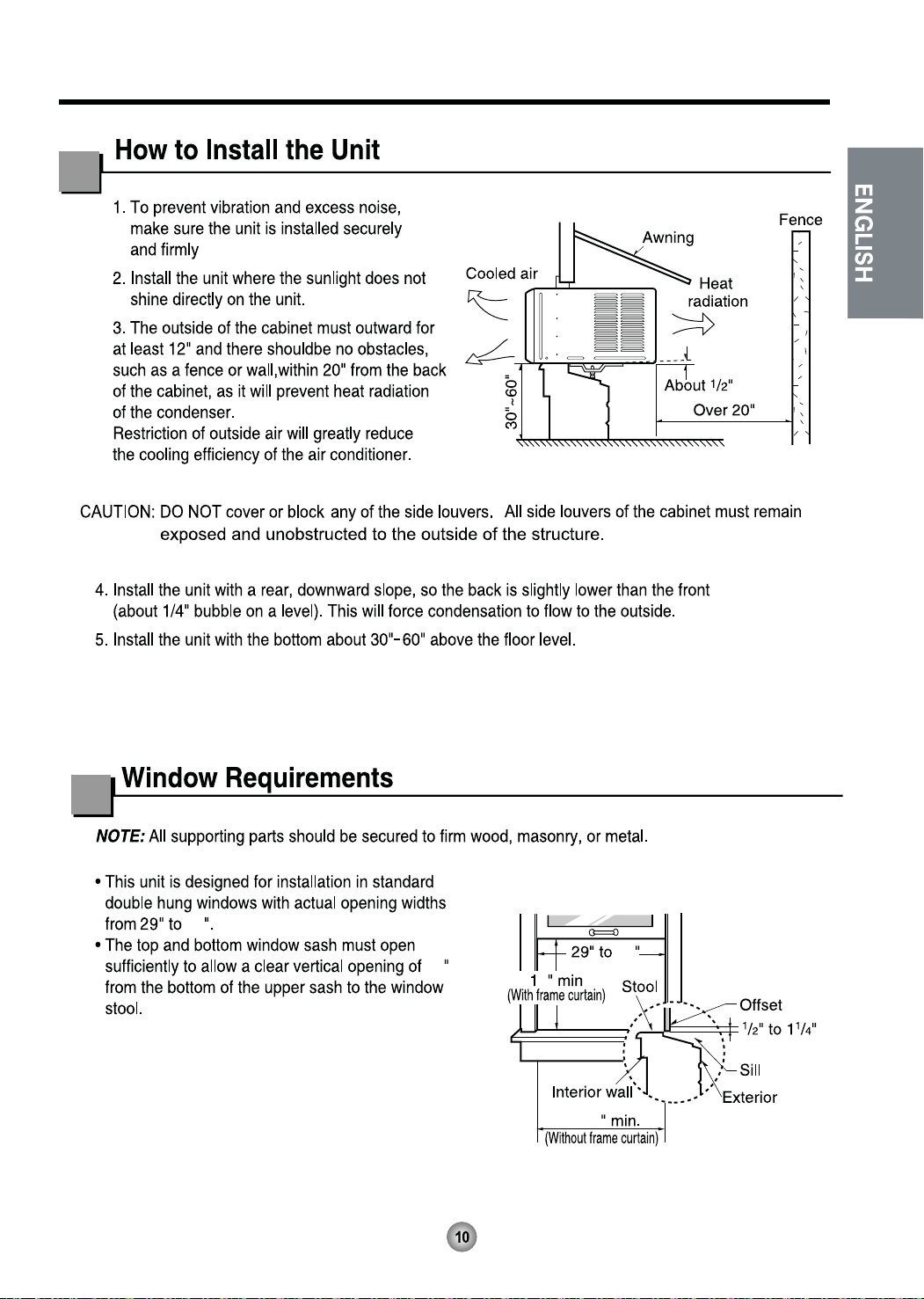

FOAMHEATPROOF

(2)

(Adhesive-Backed)

Left frame

curtain

Bottom guide(2)

Window locking

bracket

bracket

Sill

(2)

Support bracket(2)

Foam strip

(Plain-Back)

Foam-PE

(2)

(Adhesive-Backed)

Drain joint pipe

Right frame

curtain

Type A (11)

Type B (7)

Type C (5) Type D (2)

Carriage Bolt (2) Lock Nut (4)

Page 13

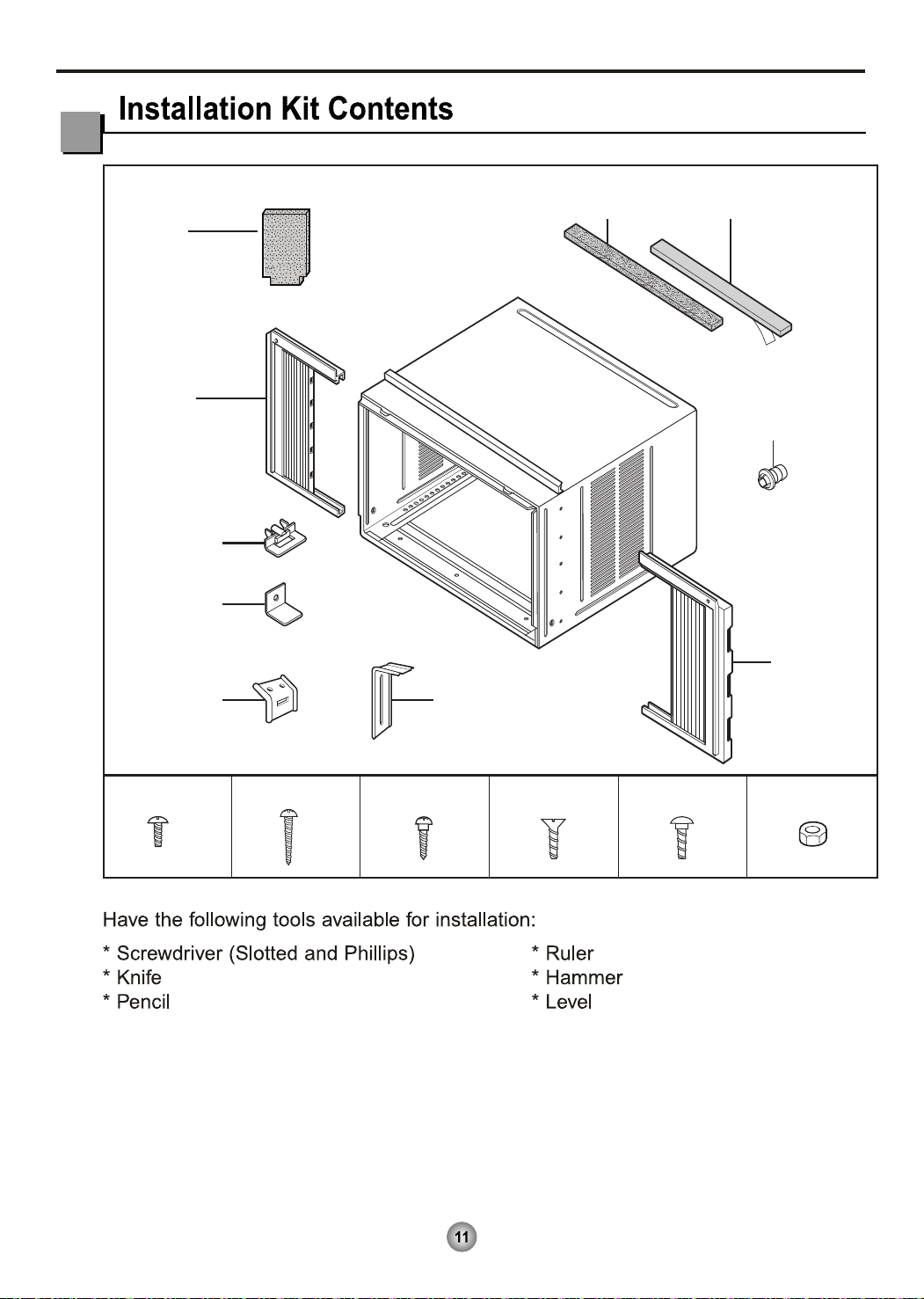

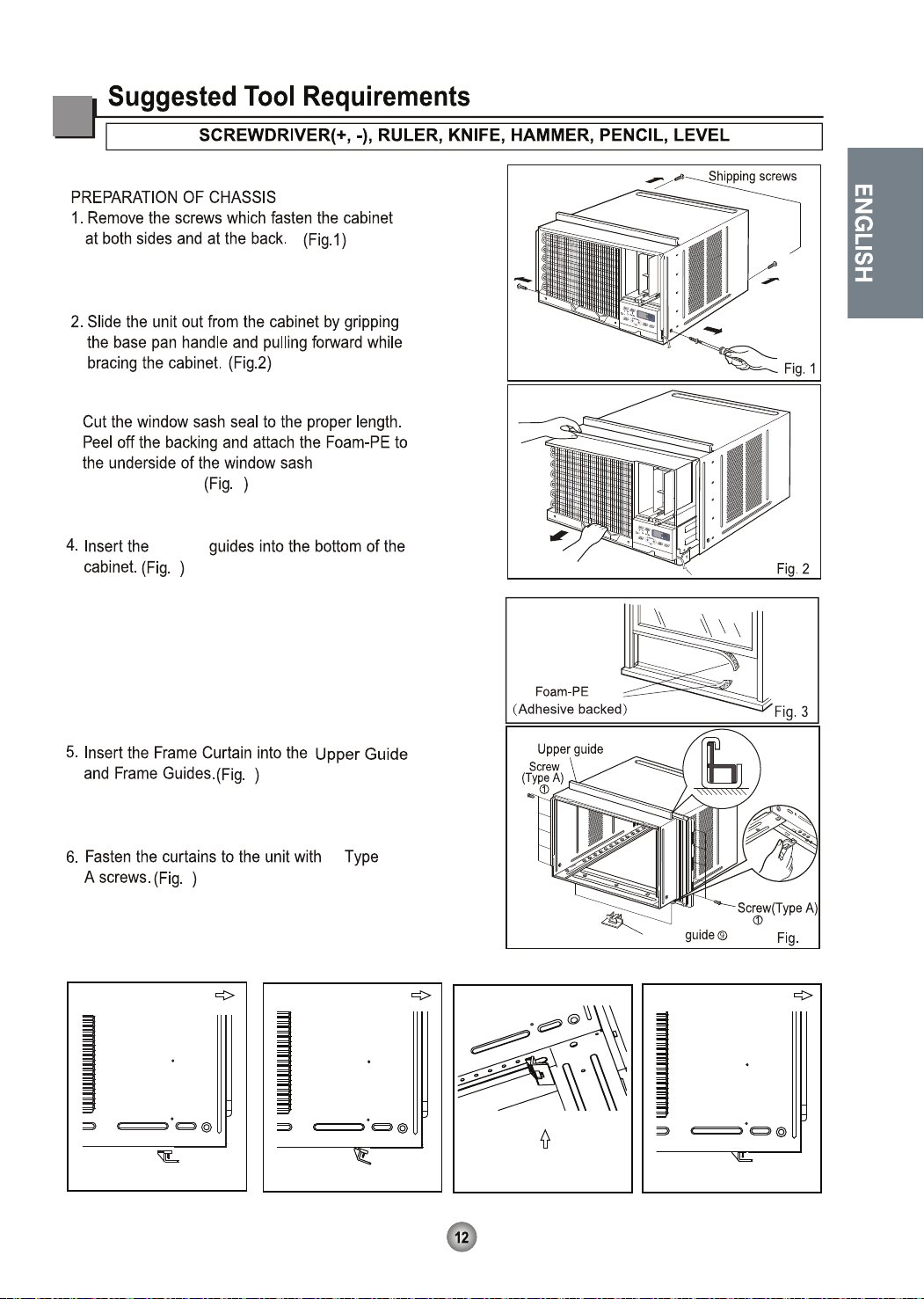

3.

and bottom

of window frame.

3

Bottom

4

4a. Make sure the pins on the bottom frame

guide are facing the back of the unit.(Fig.4-1)

4b. Align both pins to the slotted areas under

the cabinet.(Fig.4-2,Fig.4-3)

4c. Push upward fully to insert pins into slotted

areas and secure frame guide.(Fig.4-4)

4

4

10

Front

Bottom

Front Front

Bottom View

Fig.4-2Fig.4-1 Fig.4-3

Fig.4-4

4

Page 14

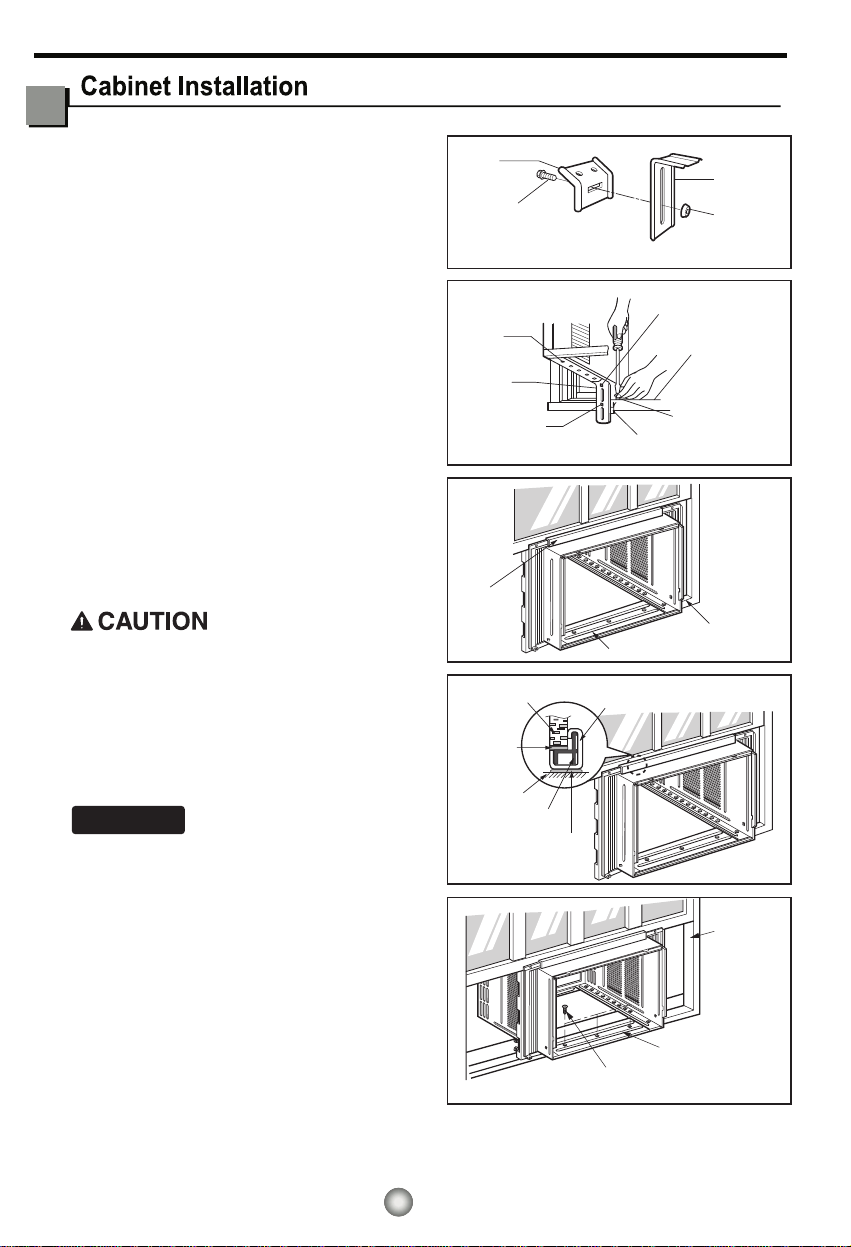

1. Open the window. Mark a line on the center of

NOTICE

the window stool between the side window stop

moldings.

Loosely attach the sill bracket to the support

bracket using the carriage bolt and the lock nut.

Sill

Bracket

Carriage

Bolt

(M-Screw)

Support

Bracket

Lock nut

Fig. 5

2. Attach the sill bracket to the window sill using

the screws (Type B).

Carefully place the cabinet on the window stool

and align the center mark on the bottom front

with the center line marked window stool.

3. Using the M-screw and the lock nut, attach the

support bracket to the cabinet track hole. Use

the first track hole after the sill bracket on the

outer edge of the window sill. Tighten the

carriage bolt and the lock nut. Be sure the

cabinet slants outward.

Do not drill a hole in the bottom pan. The unit is

designed to operate with approximately 1/2" of

water in bottom pan.

4. Pull the bottom window sash down behind the

Top retainer bar until they meet.

1. Do not pull the window sash down so tightly

that the movement of F

rame curtain is

restricted. Attach the cabinet to the window

stool by driving the screws (Type B) through

the cabinet into window stool.

2.The cabinet should be installed with a very

slight tilt downward toward the outside.

Cabinet

Track hole

Support

Bracket

Carriage bolt

and lock nut

Top

retainer

bar

Window sash

Foam-PE

Cabinet

Frame curtain

Top retainer bar

Foam-PE

Machine screw(Type D)

and lock nut

Outer edge

of window

sill

Screw(Type B)

Sill bracket

Front angle

Window stool

Fig. 6

Fig. 7

Fig. 8

Sash track

13

Screw(Type B)

Front Angle

Fig. 9

Page 15

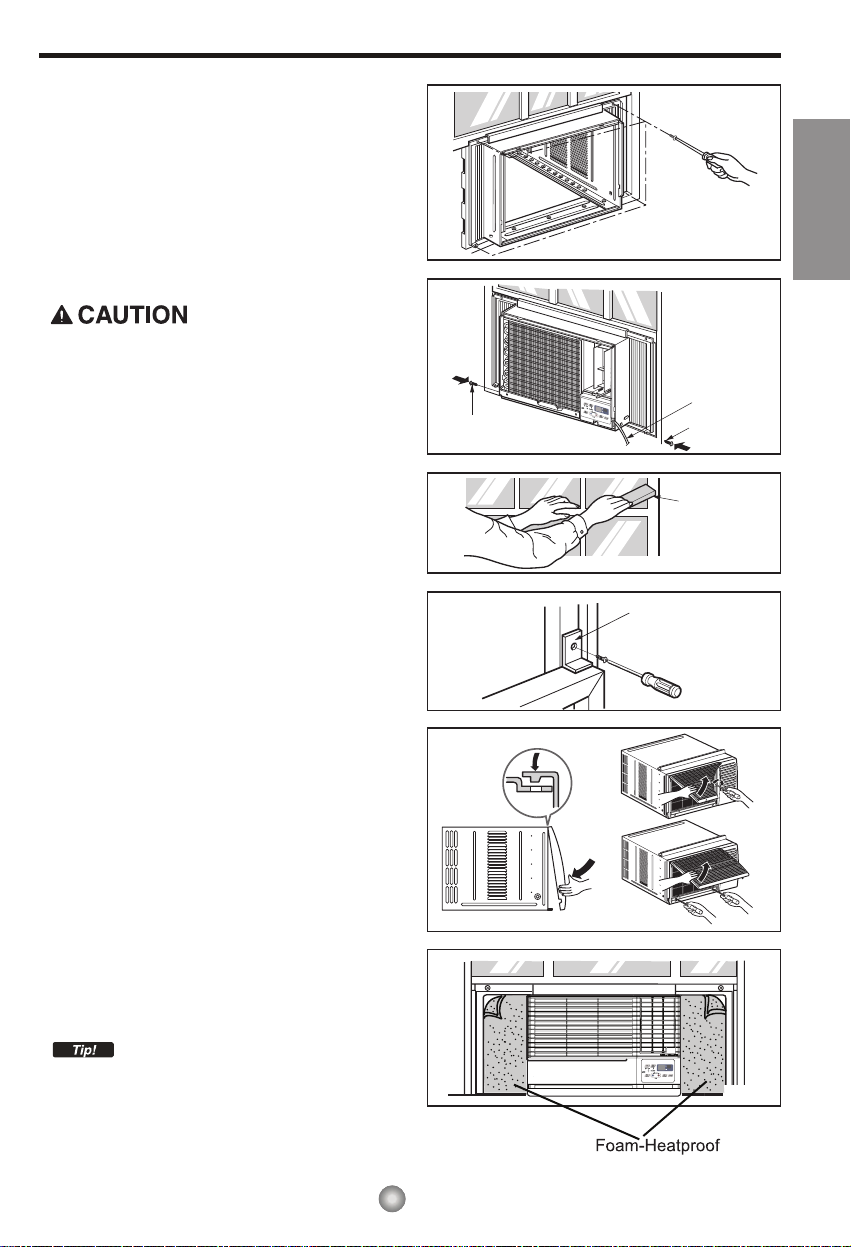

3.

Pull each Frame curtain fully to each window sash

track, and pull the bottom window sash down behind

the Top retainer bar until it meets.

4.

Attach each Frame curtain the window sash by

using screws (Type C.) (See Fig. 10)

5.

Slide the unit into the cabinet.(See Fig. 11)

For security purpose, reinstall screws(Type A) at

cabinet's sides.

Cut the Foam-strip to the proper length and insert

6.

between the upper window sash and the lower

window sash.(See Fig. 12)

7.

Attach the Window locking bracket with a screw

(Type C.) (See Fig. 13)

Screw

Screw(Type C)

Power Cord

Screw (Type A)

Foam-Strip

Window locking

bracket

ENGLISH

Fig. 10

Fig. 11

Fig. 12

Attach the front grille to the cabinet by inserting the

8.

tabs on the grille into the tabs on the front of the

cabinet. Push the grille in until it snaps into

place.(See Fig.14)

9.

Lift the inlet grille and secure it with a screw (Type

A) through the front grille.(See Fig. 14)

Cut the adhesive-backed Foam-Heatproofs

10.

to the Guide Panel size.

Remove the backing from the Foam-Heatproofs

and attach the Foam-Heatproofs

to Guide Panel.(See Fig. 15)

Foam-Heatproof improves

the cooling capability of the unit.

Window installation of room air conditioner is now

11.

completed. See ELECTRICAL DATA for attaching

power cord to electrical outlet.

Fig. 13

Fig. 14

Fig. 15

14

Page 16

15

Page 17

16

Page 18

10001 Reunion Place, Suite 500

San Antonio, TX 78216

800.541.6645

www.friedrich.com

date of original purchase, FRIEDRICH will repair the product at no charge, provided room air conditioner is reasonably accessible

for service. Any additional labor cost for removing inaccessible units and/or charges for mileage related to travel by a Service

Agency that exceeds 25 miles one way will be the responsibility of the owner. This remedy is expressly agreed to be the exclusive

remedy within twelve months from the date of the original purchase.

coil, evaporator coil, reversing valve, check valve, capillary, filter drier, and all interconnecting tubing) supplied by FRIEDRICH in

your Room Air Conditioner fails because of a defect in workmanship or material within sixty months from date of purchase,

FRIEDRICH will pay a labor allowance and parts necessary to repair the Sealed Refrigeration System;

not pay the cost of diagnosis of the problem, removal, freight charges, and transportation of the air conditioner to and from the

Service Agency, and the reinstallation charges associated with repair of the Sealed Refrigeration System. All such cost will be the

sole responsibility of the owner. This remedy is expressly agreed to be the exclusive remedy within sixty months from the date of the

original purchase.

of Columbia, and Canada. This warranty is not applicable to:

1. Air filters, fuses, batteries and the front grille removal tool.

2. Products on which the model and serial numbers have been removed.

3. Products which have defects or damage which results from improper installation, wiring, electrical current

to: Friedrich Air Conditioning Co.,ATTN:Warranty Registration,10001 Reunion Place,Ste.500,San Antonio,TX 78216.

If any part supplied by FRIEDRICH fails because of a defect in workmanship or material within twelve months from

If the Sealed Refrigeration System (defined for this purpose as the compressor, condenser

FRIEDRICH will

This warranty is applicable only to units retained within the Fifty States of the U.S.A., District

characteristics, or maintenance; or caused by accident, misuse or abuse, fire, flood, alterations and/or misapplication

of the product and/or units installed in a corrosive atmosphere, default or delay in performance caused by war,

government restrictions or restraints, strikes, material shortages beyond the control of FRIEDRICH, or acts of God.

Service will be provided by the

in your area. They are listed in the Yellow Pages. If assistance is required in obtaining warranty performance, write

1. Repair of the unit

2. A refund to the customer for the prorated value of the unit based upon the remaining warranty period of the unit.

consequential or incidental damages, so the foregoing exclusions and limitations may not apply to you.

All service calls for explaining the operation of this product will be the sole responsibility of the consumer.

All warranty service must be provided by an

repairs being made.

3. Providing a replacement unit of equal value

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the limitation or exclusion of

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Owner must provide proof of purchase in order to receive any warranty related services.

, unless authorized by FRIEDRICH prior to

17

(11-10)

Page 19

WARNING

1.Do not use means to accelerate the defrosting process or to clean, other than those recommended by the manufacturer.

2.The appliance shall be stored in a room without continuously operating ignition sources (for example: open flames, an

operating gas appliance or an operating electric heater).

3.Do not pierce or burn. Be aware that refrigerants may not contain an odor.

This unit contains flammable refrigerant and has special safety precautions not normally associated

with older units. Please follow all precautions and advisories.

1. Use caution while handling and prevent damage to unit.Do not put any holes into product for any

reason, this can cause damage to product and prevent unit from cooling.

2. Maintenance and cleaning of unit should be performedby trained personnel. Failure to properly

clean unit can result in damage to the refrigeration system and or the electrical system.

3. Make certain that all the air circulation/ventilation openings are free from obstruction.

4. Service should only be performed by technicains properly trained and certified in the use of flammable

refrigerants. Any service performed by unauthorized servicers/individuals will void all warranties.

5. When storing the appliance, do not put in a room with any open flame appliances, such as gas water

heaters or furnaces. Also keep away from electric heaters. Damaged units should be repaired before storage.

18

Page 20

Page 21

Power

Mode

Timer

0n/0ff

Fan

Speed

Temp

CoolMoney

Saver

®

Fan

Only

Dry

hr

Auto

Swing

0

F

hr

Fan

Speed

Timer

0n/0ff

Auto

Swing

CoolMoney

Fan

Saver

Only

®

Temp

Dry

Power

Mode

230

115

93011011

CP18

CP15

CP24

0

F

Page 22

16

17

Sécurité

18

Page 23

Page 24

Pour le nettoyage de l’intérieur, veuillez contacter un Centre de Service Agrée ou un concessionnaire.

N’utilisez pas de détergent puissants qui provoquent la corrosion ou endommagent l’unité.

Les détergents puissants peuvent aussi provoquer des pannes, des incendies ou des chocs électriques.

Page 25

Page 26

6

7

8

6

7

3

5

2

4

5

3

1

2

MoneySaver: Le ventilateur s'arrête lorsque le

compresseur s'arrête le refroidissement. Le

ventilateur s'allume environ toutes les 3 minutes

pour l'échantillonnage de l'air de la pièce et

déterminez si plus le refroidissement est nécessaire.

Cool : le ventilateur fonctionne en permanence pour

un refroidissement normal fonctionnement

Fan Only: seulement le ventilateur fonctionnement

* MoneySaver dispose de son propre bouton de votre

télécommande

4. CONTRÔLER LE FILTRE & RÉINITIALISATION

DU FILTRE

Check Filter: Votre ‘Check Filter' du filtre s'allume

après environ 250 heures de fonctionnement, vous

notifiant que votre filtre doit être nettoyé.

Filter Reset: appuyez sur la touche ‘Filter Reset'

pour désactiver 'Vérifier le filtre de lumière.

* Réinitialisation du filtre doit être effectuée à partir du

panneau de commande, et non pas de la télécommande

6. MODE DE FONCTIONNEMENT SELECTEUR

Appuyez sur ce bouton pour faire pivoter entre

8.

MoneySaver → Cool → Fan → Dry modes.

(Sélectionnez mode Dry sec/déshumidificateur

opération)

*Timer Clear: * Sur la télécommande, ‘Timer Clear' bouton

annuler le réglage de la minuterie.

Page 27

Page 28

Page 29

Page 30

Page 31

41

8

6

Page 32

Sommaire Kit d’Installation

Mousse à

protection calorifuge

(Enduit d’adhésif)

Rideau du

cadre gauche

Guide du bas (2)

Crochet de

fermeture de la fenêtre

Crochet de

l’appui (2)

(2)

Bande de mousse

(sous-couche simple)

Crochet de soutien (2)

Mousse-PE

(Enduit d’adhésif)

Tuyau d’évacuation joint

(2)

Rideau du

cadre droit

Type A (11)

Ayez les outils suivants à votre disposition au moment de l’installation

Tournevis (pour écrou à fentes et Phillips)

Couteau

Crayon

Type B (7)

Type C (5) Type D (2)

Règle

Marteau

Niveau à bulle d’air

carrosserie (2)

Boulon de Ecrou

autobloquant (4)

:

Page 33

3

Couper le sceau du sachet à la longueur appropriée.

Retirer l'endos et fixer le Foam-PE au dessous de la

fenêtre du sachet et du bas du cadre de la fenêtre.(Fig.3)

bas

4

4a. Assurez-vous que les broches sur le guide du cadre du

bas font face à l'arrière de l'appareil.(Fig.4-1)

4b. Alignez les deux broches dans les zones à fentes sous

l'armoire.(Fig.4-2,Fig.4-3)

4c. Poussez complètement vers le haut pour insérer les broches

dans les zones à fentes et fixez en place le guide du cadre.

(Fig.4-4)

4

6

4

BAS

Front

Front Front

Bottom View

Fig.4-2Fig.4-1 Fig.4-3

Fig.4-4

Page 34

1. Ouvrez la fenêtre,Faites un trait au centre du

ATTENTION

rebord de la fenêtre entre les moulures d’arrêt

de la fenêtre latérale.

Fixez moyennement le crochet de l’appui au

crochet de soutien en utilisant le boulon de

carrosserie et l’écrou autobloquant.

2. Fixez le crochet de l’appui à la fenêtre au

moyen des vis (Type B).

Placez doucement le boîtier sur le rebord de

la fenêtre et alignez le trait central de la face

inférieur sur la ligne centrale marquée du

rebord de la fenêtre.

3. Au moyen d’une M-vis et de l’écrou autobloquant,

fixez le crochet au trou du boitier.Utilisez le

premier trou après le crochet d’appui sur

le coté extérieur du rebord de la fenêtre.Resserrez

le boulon de carrosserie et l’écrou autobloquant.

Assurez-vous que le boîtier est incliné vers l’extérieur.

ATTENTION

Ne percez pas de trou sur le fond de la cuvette.

L’unité est conçue pour fonctionner avec

approximativement ½ d’eau dans le fond de

la cuvette.

4. Tirez le châssis de la fenêtre de fond vers

le bas derrière la bague d’arrêt Supérieure jusqu’à

ce qu’ils se rencontrent.

1. Ne tirez pas le châssis de la fenêtre si bas que

le mouvement du Rideau du cadre en soit

restreint.Fixez le boitier au rebord de la fenêtre en

passant les vis (Type B) à travers le boitier dans

le rebord de la fenêtre.

2.Le boitier doit être installé avec une très

légère inclinaison extérieure et vers le bas.

Crochet

de l’appui

Boulon de

Carrosserie

(M-vis)

Trou du

Boitier

Crochet

de Soutien

Boulon de Carrosserie

et Ecrou autobloquant

Bague

d’arrêt

supérieure

Châssis de la fenêtre

Mousse-PE

Boitier

Rideau du cadre

Bague d’arrêt Supérieure

Mousse-PE

Vis à Métaux (Type D)

et Ecrou autobloquant

Ecrou(Type B)

Crochet d’appui

Angle avant

Crochet

de Soutien

Ecrou

autobloquant

Fig. 5

Bord extérieur

du rebord de

la fenêtre

Fig. 6

Rebord de la fenêtre

Fig. 7

Fig. 8

Piste du châssis

Vis (Type B)

Angle Avant

Fig. 9

Page 35

3.

Tirez entièrement chaque Rideau du cadre à

châssis inférieure de la fenêtre vers le bas

derrière le bague d’arrêt Supérieure

jusqu’à ce qu’il se rencontre.

4.

Fixez chaque Rideau du cadre au châssis de

la fenêtre au moyen d’une vis (Type C).

(Voir Fig. 10)

5.

Faites glisser l’unité dans le boitier. (Voir Fig. 11)

ATTENTION

Pour des raisons de sécurité, réinstallez les vis

(Type A) sur les côtés du boitier.

Coupez une bande de mousse de longueur

6.

convenable et insérez-là entre le châssis

supérieur et le châssis inférieur de la fenêtre

(Voir Fig. 12)

Vis

Vis (Type C)

Fig. 10

Cordon d’alimentation

Vis (Type A)

Fig. 11

Bande de Mousse

ENGLISH

7.

Serrez le crochet de fermeture de la fenêtre

avec une vis (Type C.) (Voir Fig. 13)

Serrez la grille avant au boitier en insérant les

8.

anneaux sur la grille dans les anneaux à l’avant

du boitier.Poussez la grille jusqu’à ce qu’elle se

mette bien en place. (Voir Fig. 14)

9.

Soulevez la grille d’entrée d’air et sécurisez là

avec une vis (Type A) passée à travers la

grille avant. (Voir Fig. 14)

Couper la mousse à protection calorifuge et à endos

10.

collant selon les dimensions du panneau de guide.

Retirer l'endos de la mousse à protection calorifuge

et fixer la mousse à protection calorifuge aux

panneau de guide.

Conseil

L’installation du climatiseur de chambre sur la

11.

(Fig.15)

La mousse à protection calorifuge

améliore les capacités de

refroidissement de l'appareil.

fenêtre est à présent terminée.

Voir DONNEES ELECTRIQUES pour fixer le

cordon d’alimentation à la prise de courant.

Fig. 12

Crochet de fermeture

de la fenêtre

Fig. 13

Fig. 14

Fig. 15

Mousse à protection calorifuge

14

Page 36

15

Page 37

16

Page 38

Friedrich Air Conditioning Company

10001 Reunion Place, Suite 500

San Antonio, Tx 78216

www.friedrich.com

GARANTIE LIMITÉE

CLIMATISEURS INDIVIDUELS

PREMIÈRE ANNÉE

TOUTES LES PIÈCES - Si, dans les 12 mois suivant la date d’achat initial, une pièce fournie par FRIEDRICH devenait défectueuse en raison d’un

déf

aut de fabrication ou de matériau, FRIEDRICH réparera le produit gratuitement, dans la mesure où le climatiseur est raisonnablement acces-

si

ble pour la réparation. Tous les frais de main d’oeuvre additionnels pour la dépose d’un appareil difficilement accessible et/ou les frais de

déplacem

C

ent (kilométrage) encourus par le réparateur, au delà de 40 km (25 miles) dans une seule direction, sont la responsabilité du propriétaire.

ette comp

ensation est reconnue comme étant la seule compensation offerte dans les 12 mois qui suivent la date d’achat initial.

DEUXIÈME À CINQUIÈME ANNÉE

SYSTÈME FRIGORIFIQUE HERMÉTIQUE - Si le système frigorifique hermétique (comprenant, aux termes de cette garantie, le compresseur, le serpentin de

condenseur, le serpentin d’évaporateur, le robinet d’inversion, le clapet anti-retour, le tube capillaire, le déshydrateur-filtre et toute la tuyauterie interconnectée)

intégré par FRIEDRICH à votre climatiseur devenait défectueux en raison d’un défaut de fabrication ou de matériau dans les 60 mois à compter de la date

d’achat initial, FRIEDRICH allouera un dédommagement pour les frais de main d’oeuvre et les pièces nécessaires à la réparation du système frigorifique

hermétique. FRIEDRICH ne prendra pas en charge les frais de diagnostic, de dépose et de transport du climatiseur jusqu’au centre de réparation et retour, ni

les frais de réinstallation consécutifs à la réparation. Tous ces frais sont à la charge du propriétaire. Ce dédommagement est reconnu comme étant la seule

compensation offerte dans les 60 mois qui suivent la date d'achat initial.

CONDITIONS D’APPLICATION ET RESTRICTIONS - Cette garantie s’applique exclusivement aux appareils vendus au détail aux États-Unis, dans le District

de Columbia et au Canada. Cette garantie ne s’applique pas :

1. Aux filtres à air ni aux fusibles ;

2. Aux produits dont le numéro de modèle et le numéro de série ont été enlevés ;

3. Aux produits dont la défaillance ou les dommages résultent d’une mauvaise installation, d’un mauvais câblage, d’une tension d’alimentation inadaptée ou d’un mauvais entretien; ni lorsqu’ils sont causés par un accident, une utilisation erronée ou abusive, un incendie, une inondation, une

modification et/ou une erreur d’application du produit. La garantie

ni aux problèmes ou délais d’utilisation résultant d’actes de guerre, de restrictions ou de contraintes gouvernementales, de grèves, de pénuries de

matériau indépendantes du contrôle de FRIEDRICH, ou de catastrophes naturelles.

EXÉCUTION DE LA GARANTIE - Les réparations seront effectuées par un revendeur ou un centre de réparation agréés par FRIEDRICH et situés dans votre

région. Leurs coordonnées se trouvent dans les Pages Jaunes. Si vous avez besoin d’assistance pour obtenir une réparation sous garantie.

EXCLUSIONS - CETTE GARANTIE EST OFFERTE À L'EXCLUSION DE TOUTE AUTRE GARANTIE. Nonobstant les clauses cette garantie, TOUTE

GARANTIE IMPLICITE DE CONFORMITÉ POUR UN USAGE PARTICULIER ET/OU DE QUALITÉ MARCHANDE SERA LIMITÉE À LA DURÉE DE LA

PRÉSENTE GARANTIE EXPRESSE. LE FABRICANT DÉCLINE ET EXCLUT FORMELLEMENT TOUTE RESPONSABILITÉ POUR LES DOMMAGES ET

PRÉJUDICES INDIRECTS RELATIFS À L’INEXÉCUTION DE TOUTE GARANTIE EXPRESSE OU IMPLICITE.

La performance de l'obligation de Garantie de Friedrich est limitée à une des méthodes suivantes :

1. Réparation de l'unité

2. Un remboursement au client pour la valeur distribuée au prorata de l'unité basée sur la période restante de garantie de l'unité.

3. L'établissement d'une unité de remplacement de valeur égale

La méthode pour fulfuillment de l'obligation de garantie est à la discrétion unique de Friedrich.

REMARQUE - Certaines provinces n’autorisent pas de restriction sur la durée d’une garantie implicite ou n’autorisent pas de restriction ni d’exclusion des

dommages ou préjudices indirects. Il est donc possible que ces exclusions et restrictions ne s’appliquent pas à vous.

AUTRE - Cette garantie vous accorde des recours légaux spécifiques mais il est possible que vous bénéficiez d’autres droits selon votre province.

PREUVE D’ACHAT – Pour bénéficier des services offerts par la présente garantie, l’acquéreur devra fournir une preuve d’achat.

Tous les appels de service relatifs au fonctionnement de ce produit sont à la charge du consommateur.

Toute réparation sous garantie doit être effectuée par un centre de service agréé par FRIEDRICH, sauf autorisation expresse de FRIEDRICH au préalable.

ne s’applique pas non plus aux appareils installés dans une atmosphère corrosive,

17

Page 39

Sécurité

AVERTISSEMENT

1.Ne pas utiliser de moyens pour accélérer le processus de dégivrage

ou pour nettoyer, autres que ceux recommandés par le fabricant

2. L'appareil électroménager doit être entreposé dans une pièce sans sources d'allumage fonctionnant continuellement

(par example, des flammes nues, un appareil ménager au gaz en fonctionnement ou une fournaise électrique en fonctionnement)

3. Ne pas percer ou brûler. Soyez conscient que les réfrigérants peuvent ne pas avoir d'odeur

ATTENTION

Cet appareil contient un réfrigérant inflammable et vient avec des précautions de sécurité spéciales qui ne sont

pas normalement associées avec les appareils plus anciens. Veuillez suivre toutes les précautions et les

recommandations

1. Soyez prudent lors de la manipulation et éviter d'endommager l'appareil. Ne pas percer le produit pour quelque raison

que ce soit, cela peut endommager l'appareil et l'empêcher de refroidir.

2. L'entretien et le nettoyage de l'appareil doivent être effectués par du personnel formé. Omettre de nettoyer correctement

l'appareil peut aboutir en des dommages au système de réfrigération ou au système électrique.

3. Assurez-vous que toutes les ouvertures de circulation/ventilation sont exemptes d'obstacles.

4. L'entretien doit seulement être effectué par des techniciens adéquation formés et certifiés dans l'utilisation de

réfrigérants inflammables. Tout entretien effectué par des réparateurs/individus non autorisés annulera les garanties.

5. Lors de l'entreposage de l'appareil, ne pas le mettre dans une pièce avec tout autre appareil avec une flamme nue,

comme des chauffe-eaux à gaz ou des fournaises. Conserver loin de fournaises électriques. Les appareils endommagés

doivent être réparés avant leur entreposage.

18

Page 40

Page 41

0

F

hr

Fan

Speed

Timer

0n/0ff

Auto

Swing

CoolMoney

Fan

Saver

Only

®

Temp

Dry

Power

Mode

230

115

93011011

CP18

CP15

CP24

0

F

hr

Fan

Speed

Auto

Swing

Fan

CoolMoney

Saver

Only

®

Temp

Dry

Timer

Power

Mode

0n/0ff

Page 42

17

18

Seguridad

19

Page 43

Page 44

Para una limpieza interior, póngase en contacto con un Centro de Servicios Autorizado o un revendedor.

No utilice detergentes abrasivos que causan corrosión o dañan la unidad.

Los detergentes abrasivos pueden igualmente provocar un fallo del producto, un incendio o una

descarga electrónica.

Page 45

Page 46

6

7

8

6

7

3

5

2

4

5

3

1

2

6. OPERATION MODE SELECTOR / SELECCIÓN DE

FUNCIONES

Presione este botón para alternar entre las funciones de

MoneySaver → Cool → Fan → Dry (para obtener la función

de deshumidificación seleccione el modo dry)

MoneySaver: El ventilador se detiene cuando el compresor

deja de enfriar. El ventilador se enciende aproximadamente

cada 3 minutos para tomar muestras de aire ambiental y

determinar si se necesita más enfriamiento.

Cool: El ventilador gira continuamente para un enfriamiento

normal.

Fan Only: Únicamente el ventilador se encuentra encendido.

4. REVISION DE FILTRO Y RESETEO DEL

* MoneySaver tiene su propio botón en el control remoto.

INDCADOR DE REVISION

Revisión de filtro: La luz de ‘Check Filter’ LED se

iluminará después de aproximadamente 250 horas de

funcionamiento, lo cual indica que su filtro necesita ser

limpiado.

Reseteo del indicador de revisión: Presione el botón

‘Filter Reset’ para apagar la luz de ‘Check Filter’.

* El reseteo del indicador de revisión se deberá hacer desde

el panel de control de la unidad, no con el control remoto.

*Timer Clear: En el control remoto, el botón 'Timer Clear',

cancelará el ajuste del cronómetro

8.

Page 47

Page 48

Page 49

Page 50

Page 51

41

41

18

18

26

Page 52

Aislamiento

de espuma

(2)

(con adhesivo

en la parte trasera)

INFERIOR

(2)

(con adhesivo

en la parte trasera)

Page 53

Corte el sello del marco de la ventana guillotina a la longitud

adecuada. Despegue la parte posterior y adhiera la espuma

de polietileno a la parte inferior del marco de la ventana

guillotina y la parte inferior del marco de la ventana. FIG.3

inferior

4a. Asegúrese de que las clavijas de la guía del bastidor inferior

miren hacia la parte posterior de la unidad.(Fig.4-1)

4b. Alinee ambas clavijas en las áreas ranuradas debajo del

gabinete.(Fig.4-2,Fig.4-3)

4b. Levante completamente para insertar las clavijas en las

ranuras y asegurar la guía del bastidor.(Fig.4-4)

Front

INFERIOR

Front Front

Bottom View

Fig.4-2Fig.4-1 Fig.4-3

Fig.4-4

Page 54

1. Abra la ventana. Marque una línea en el centro

CONSEJO

de la repisa de la ventana entre las molduras de

tope de la ventana lateral.

Coloque sin apretar la ménsula del alféizar en la

ménsula de soporte utilizando el pemo y la

tuerca de segutidad.

MENSULA DEL

ALFEIZAR

BULÓN

MENSULA

DE SOPORTE

TUERCA DE

SEGURIDA

Fig. 5

2. Coloque la ménsula del alféizar en el alféizar de

la ventana utilizando los tornillos (Tipo B). Apriete

el perno y la tuerca de seguridad.

Repisa de la ventana y alinee la marca central en

el frente del fondo con la línea central marcada

en la repisa de la ventana.

3. Utilizando el tornillo M y la tuerca de seguridad,

coloque la ménsula de soporte en el orificio de la

guía del gabinete. Use el primer orificio de la guía

después de la ménsula del alfézar en el borde

exterior del alféizar de la ventana.

Apriete el perno y la tuerca de seguridad.

Asegúrese de que el gabinete esté inclinado

hacia afuera.

No perfore la charola del fondo.La unidad está

diseñada para operar con aproximadamente

1/2"

de agua en la charola del fondo.

1. No hale el marco de la ventana hacia abajo tan

apretado que se restrinja el movimiento de los

deslizadores. Sujete el gabinete a la repisa de

la ventana insstalando los tornillos (tipo A o B)

a través del gabinete en la repisa de la ventana.

2. El gabinete deberá ser instalado ligeramente

inclinado hacia abajo hacia el exterior.

ORIFICIO DE

CARRIL DE GABINETE

MENSULA

DE SOPORTE

BARRA

DE

RETENCION

SUPERIOR

MARCO DE LA

VENTANA

CINTA DE

ESPUMA

GABINETE

PARTE FRONTAL INTERIOR

PANEL

GUIA

CINTA DE

ESPUMA

TORNILLO PARA

METALES

(TIPO D)

TUERCA DE SEGURIDA

BORDE EXTERIOR

DEL ANTEPECHO

DE LA VENTANA

TORNILLO(TIPO B)

MENSULA

DEL ALFEIZAR

REPISA DE VENTANA

Fig. 6

Fig. 7

BARRA DE

RETENCION SUPERIOR

Fig. 8

Y

Parte Frontal Interior

TORNILLO(TIPO B)

Fig. 9

Page 55

Hale cada panel guía completamente a cada

3.

lado de la ventana y repita del paso 2.

Adjunte cada panel guía a cada lado de la

4.

ventana usando tornillos (Tipo C).

(Ver Fig.10)

Deslice el chasís dentro del gabinete.

5.

(Ver Fig.11)

Por razones de seguridad, re instale los tornillos

(Tipo A) en los lados del gabinete.

6.

Corte la tira de goma a la medida apropiada e

introdúzcala entre la parte superior e inferior de

la ventana. (Ver Fig. 12)

7.

Se debe instalar el asa antes de fijar el frente

decorativo. (Ver Fig. 13)

TORNILLO

TORNILLO

(TIPO C)

Fig. 10

CORDÓN DE

ALIMENTACIÓN

ELÉTRICA

TORNILLO

(TIPO A)

Fig. 11

TIRA DE GOMA

Fig. 12

ESPAÑOL

Instale la rejilla frontal en el cabinete

8.

insertando la lengüeta en la rejilla a la

lengüeta en el frente del cabinete. Empuje la

rejilla hasta que se cierre con sonido de golpe.

(Ver Fig. 14)

9.

Levante la rejilla de entrada y asegúrela con

un tornillo (tipo A) a través de la rejilla frontal.

(Ver Fig.14)

10.

Corte el aislamiento de espuma con adhesivo en

la parte trasera del tamaño del panel guía.

Retire la protección del adhesivo del aislamiento

de espuma y pegue el aislamiento en el panel guía.

(Ver Fig.15)

Sugerencia

El aislamiento de espuma

mejora la capacidad de

enfriamiento de la unidad.

11.

Ahora la instalación del aire acondicionado en

la ventana es completada. Vea los DATOS

ELECTRICOS para instalar el cable de

alimentación en la toma de corriente.

SOPORTE DE

CERRADURA

Aislamiento de espuma

Fig. 13

Fig. 14

Fig. 15

14

Page 56

15

Page 57

16

Page 58

17

Page 59

Friedrich Air Conditioning Company

10001 Reunion Place, Suite 500

San Antonio, Tx 78216

800.541.6645

www.friedrich.com

AIRE ACONDICIONADO DE HABITACIÓN

GARANTÍA LIMITADA

EL PRIMER AÑO

CUALQUIER PIEZA: Si cualquier pieza suministrada por FRIEDRICH falla debido a un defecto de fabricación o de material dentro de los doce meses a partir

de la fecha original de compra, FRIEDRICH reparara el producto sin costo adicional, siempre cuando el aire acondicionado de la habitación esté accesible

para servicio. El propietario será responsable de cualquier costo adicional de mano de obra para desinstalar unidades inaccesibles y/o cargos relacionados

con los viajes de una agencia de servicio que excede de 25 millas. Esta garantía sólo será válida 12 meses después de la fecha de compra original.

SEGUNDO A QUINTO AÑO

SISTEMA DE ENFRIAMIENTO: Si el sistema de enfriamiento (para este propósito se define como el compresor, serpentín de evaporador y del condensador,

válvula de retorno, válvula de retención,

de fabricación o de material dentro de los sesenta meses a partir de la fecha original de compra, FRIEDRICH pagará un subsidio de mano de obra y las partes

necesarias para reparar el sistema de enfriamiento, asumiendo que FRIEDRICH no pagará el costo del diagnóstico del problema, desinstalación, los gastos

de flete y transporte del aire acondicionado a la Agencia de Servicio, y los cargos asociados con la reparación y la reinstalación del sistema de refrigerante

sellado. Todos los gastos se harán de la exclusiva responsabilidad del propietario. Esta garantía sólo será válida 60 meses después de la fecha de compra

original.

APLICABILIDAD Y LIMITACIONES: Esta garantía sólo es aplicable a las unidades dentro de los cincuenta estados de los EE.UU., Distrito de Columbia

y Canadá.

Esta garantía no se aplica a:

1.

Filtros de aire o fusibles.

2. Productos en los que los números de modelo y de serie han quitado.

3.

Los productos que tienen defectos o daños que son debidos a una mala instalación, cableado, corriente eléctrica, o mantenimiento; accidente,

abuso, negligencia, mal uso, incendios, inundaciones, alteraciones, unidades instaladas en una atmósfera corrosiva, retraso en funcionamiento

debidos a la guerra, restricciones del gobierno, huelgas, provocados por

OBTENIENDO RESULTADOS DE LA GARANTIA: El servicio será suministrado por el distribuidor autorizado de servicio o la Organización de Servicio

de FRIEDRICH en su área. Se podrán encontrar en las Páginas Amarillas. Si se requiere asistencia con la garantía.

LIMITACIONES: ESTA GARANTÍA SE DA EN LUGAR DE CUALQUIER OTRA GARANTÍA Cualquier objeto incluido en esta garantía, CUALQUIER

GARANTÍA IMPLÍCITA PARA UN PROPÓSITO EN PARTICULAR Y/O MERCANTIL SERA LIMITADA POR LA DURACION DE ESTA GARANTIA. EL

FABRICANTE DECLARA EXPLICITAMENTE Y SE DESLINDA DE CUALQUIER RESPONSABILIDAD POR DAÑOS CONSECUENTES O INCIDENTALES POR INCUMPLIMIENTOS EN ACUERDOS DE CUALQUIER GARANTIA EXPLICITA O IMPLICITA.

La ejecución de la obligación de la garantía de Friedrich está limitada a cualquiera de los siguientes métodos:

1. Reparación de la unidad.

2. Reembolso al cliente por el valor prorrateado de la unidad basado en el período remanente de la garantía de la unidad.

3. Proveyendo el reemplazo de una unidad de igual valor.

El método de cumplimiento de la obligación de la garantía de Friedrich es a la sola discreción de Friedrich Air Conditioning.

AVISO: Algunos estados no permiten limitaciones en la duración de una garantía, o no permiten la limitación o exclusión de consecuenci as o

daños ind

OTROS:

COMPROBANTE DE COMPRA: El propietario debe entregar el comprobante de compra para poder recibir servicios de garantía .

Todas las llamadas de servicio para explicar el funcionamiento de este producto, será responsabilidad del consumidor.

La agencia de servicio autorizado de FRIEDRICH debe de dar servicio de garantía, o FRIEDRICH debe dar autorización antes que se haga la

reparación.

irectos o incidentales; por lo que las exclusiones y las limitaciones anteriores no se aplicaran a usted.

Esta garantía le da derechos legales específicos para que reciba servicios relacionados con la garantía.

capilar, filtro, secador, todas las tuberías de interconexión) suministrados por FRIEDRICH fallan debido a un defecto

la escasez de materiales fuera del control de FRIEDRICH, o actos de Dios

18

Page 60

Segoridad

ADVERTENCIA

1.No use medios que no sean los recomendados por el fabricante para acelerar el proceso de descongelación ni para limpiar el producto.

2.El aparato debe almacenarse en una habitación en donde no esté expuesto a fuentes de combustión en funcionamiento continuo

(por ejemplo: llamas expuestas, aparatos que funcionan a gas o calentadores eléctricos)

3.No perfore ni incinere el producto. Tenga en cuenta que es posible que los refrigerantes no tengan olor.

PRECAUCION

Esta unidad contiene un refrigerante inflamable y cuenta con precauciones de seguridad especiales que normalmente

no se asocian con modelos anteriores. Siga todos los consejos de seguridad y precauciones.

1. Tenga cuidado al manipular la unidad para evitar daños. No perfore el producto por ningún motivo;

si lo hace, puede dañar el producto e impedir que la unidad enfríe.

2. El mantenimiento y la limpieza de la unidad debe estar a cargo de personal capacitado. La falta de limpieza adecuada

de la unidad puede provocar daños en el sistema de refrigeración y/o el sistema eléctrico.

3. Asegúrese de que todas las aberturas de circulación/ventilación estén libres de obstrucciones.

4. El servicio debe estar a cargo únicamente de técnicos debidamente capacitados y certificados en el uso de refrigerantes inflamables.

Todo servicio realizado por personal no autorizado, o personas no autorizadas, anulará por completo las garantías.

5. Al almacenar el aparato, no lo coloque en una habitación donde esté expuesto a llamas abiertas,como hornos o calentadores de agua a gas.

Además,manténgalo alejado de calentadores eléctricos. Las unidades dañadas deben repararse antes de almacenarlas.

19

Page 61

Page 62

MFL69374602

93011011

Loading...

Loading...