Friedrich Cp08n10 Owner's Manual

Room Air Conditioner

Service and Parts

Manual

ZQ08 - CP12 (05/06)

ZQ08C10 ZQ10C10 CP08C10 CP10C10 CP12C10

CONTENTS

1. PREFACE

1.1 SAFETY PRECAUTIONS................................2

1.2 INSULATION RESISTANCE TEST .................2

1.3 SPECIFICATIONS...........................................3

1.4 FEATURES......................................................4

1.5 CONTROL LOCATIONS .................................4

2.

DISASSEMBLY INSTRUCTIONS

2.1 MECHANICAL PARTS ....................................6

2.1.1 FRONT GRILLE .....................................6

2.1.2 CABINET ................................................6

2.1.3 CONTROL BOX .....................................6

2.2 AIR HANDLING PARTS ..................................7

2.2.1 AIR GUIDE AND TURBO FAN...............7

2.2.2 FAN ........................................................7

2.2.3 SHROUD ................................................8

2.3 ELECTRICAL PARTS......................................8

2.3.1 OVERLOAD PROTECTOR ....................8

2.3.2 COMPRESSOR......................................8

2.3.3 CAPACITOR...........................................9

2.3.4 POWER CORD ......................................9

2.3.5 MOTOR ................................................10

2.4 REFRIGERATION CYCLE ............................10

2.4.1 CONDENSER.......................................10

2.4.2 EVAPORATOR.....................................10

2.4.3 CAPILLARY TUBE ...............................11

3. TROUBLESHOOTING GUIDE

3.1 PIPING SYSTEM...........................................13

3.2 TROUBLESHOOTING GUIDE .....................14

1. PREFACE

This

SERVICE MANUAL provides various service information, including the mechanical and electrical

parts etc. This room air conditioner was manufactured and assembled under a strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 SAFETY PRECAUTIONS

1. When servicing, turn the unit Off and unplug the

power cord.

2. Observe the original lead dress.

.

If a short circuit is found, replace all parts which have

been overheated or damaged by the short circuit.

3. After servicing, make an insulation resistance test to

prevent the customer from being exposed to shock

hazards.

1.2

INSULATION RESISTANCE TEST

1. Unplug the power cord and connect a jumper between 2 pins

(black and white).

2. The grounding conductor (green or green and yellow) is to be

open.

3. Measure the resistance value with an ohm meter between the

jumpered lead and each exposed metallic part on the equipment at each working status.

4. The value should be over 1 MΩ.

—2—

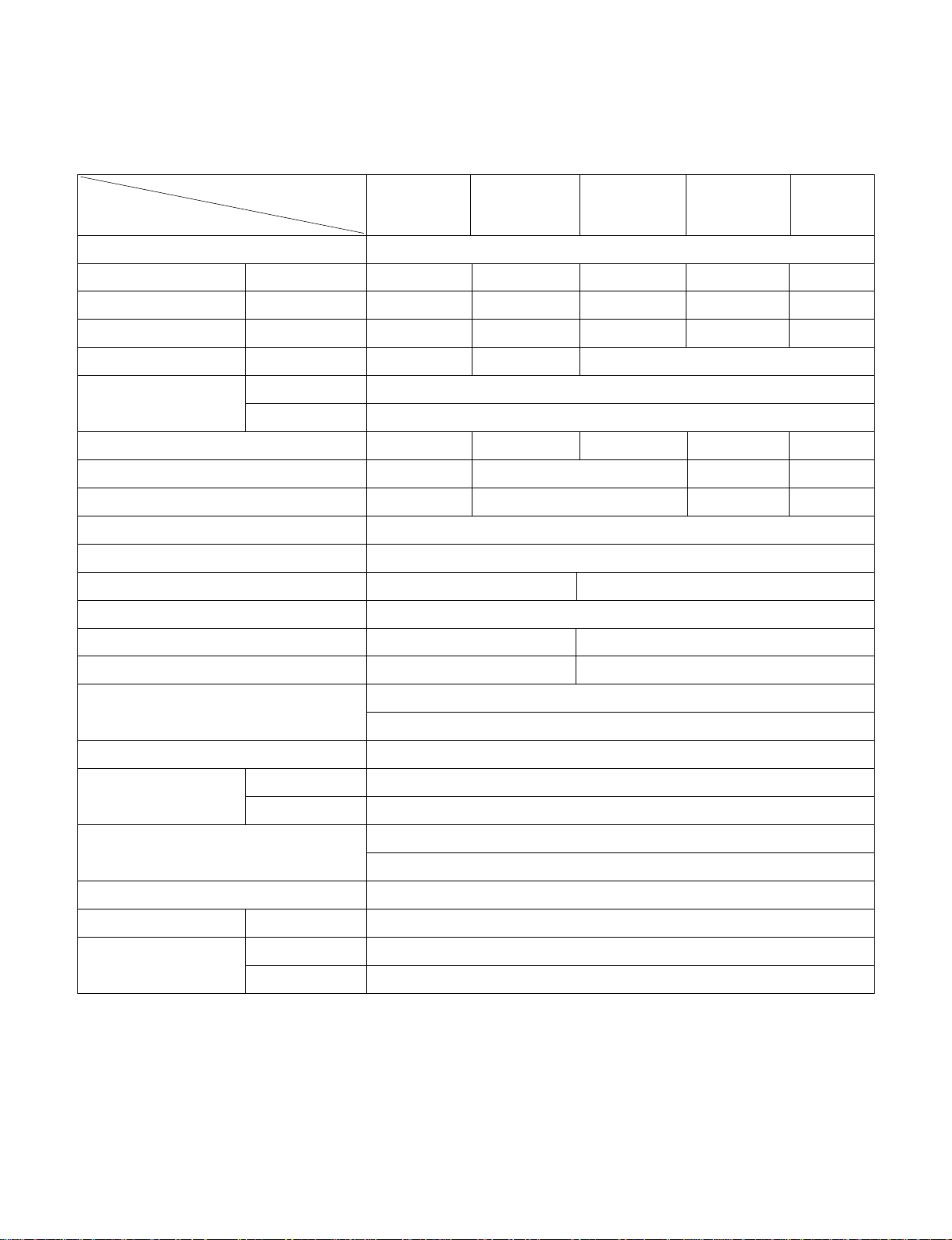

1.3 SPECIFICATIONS

1ø, 115V, 60HZ

ZQ08C 10,ZQ10C 10,C P 08C10,C P 10C10,C P 12C10

1.3.1 FOR

MODE LS

IT EMS

ZQ08C 10 ZQ10C 10 C P 08C10 C P 10C10

P O W ER S UP PLY

C O OLING C AP AC ITY (B tu/h)

INP UT (W )

7,800 9,800 7,800

800 1,000 730

R UNNING C UR R E NT (A)

E .E .R (B TU/W . h)

OP E R AT ING INDOOR (¡ C)

C O NDIT ION OUTDOOR (¡ C )

R E FR IGE R ANT (R -22) C HAR G E

E VAP OR ATO R

C O NDE NS E R

300g(10.6oz )

2 R OW 11S T AC KS

2 R OW 16S T AC KS

FAN, INDO OR

FAN, O UT DOOR

FAN S PE E DS , F AN/COOLING

FAN MOT OR

OP E R AT ION C ONT R OL

C P 12C10

10,000

920

7.6 9.4 6.6

9.7

9.8

8.5

10.8

11,800

1, 090

26.7(DB)* 19.4(WB)**

35(DB )* 23.9(WB )**

520g(18.3oz )

3 R O W 11S T AC KS

2 R O W 16S T AC KS (L )

420g(14.8oz )

525g(18.5oz )

2 R O W 10S T AC KS

2 R OW 17S T AC KS

510g(18.0oz )

3 R O W 12S T AC KS

2 R OW 17S T AC KS (L )

TUR B O FA N

P R OP E LL E R T YP E F AN WIT H S LING E R R ING

2/3 3/3

6 P OLE S

R OT AR Y S WIT CH

R E MOT E C ONT RO L L ER

10.1

R OO M T EMP . C ONT R O L

AIR DIR E C TIO N C O NT R O L

C O NS TR UC TIO N

C O MPR E S S OR

P R OT EC TOR

FAN MOT OR

P O W ER C OR D

DR AIN S YS TE M

NE T W EIGHT (lbs/kg)

OUTS IDE DIME NS IO N (inch)

(W xH xD) (mm)

* DB:Dry B ulb

**

WB : W et B ulb

THE R MOS TAT THE R MIS TOR

VE R TIC AL LOUV E R (R IG HT & LE FT )

HOR IZONT AL LOUV E R (UP & DOW N)

S LIDE IN-O UT C HAS S IS

OVE R LO AD P R O TE C TO R

INT E R NAL T H E R MAL P R OT EC TOR

(3 WIR E W ITH GR OUDING )

AT TAC HME NT P LUG (C OR D-C O NNE CTE D T YP E )

DR AIN P IPE O R S PL AS HE D BY F AN S LING E R

62/28

3

/32x 1329/

20

32

x 193/

8

510 x 354 x 490

—3—

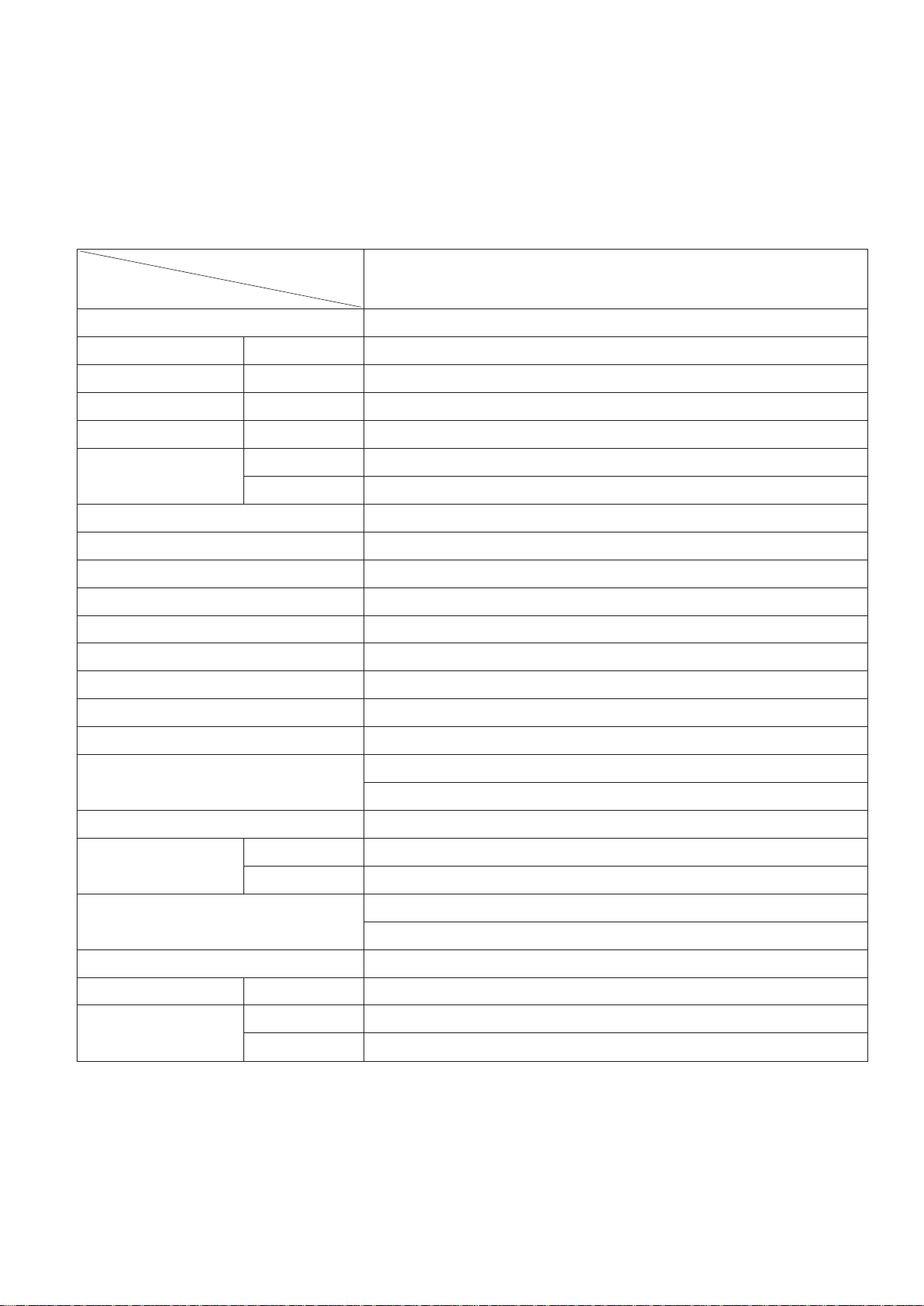

1.4 SPECIFICATIONS

1. .1F OR

1ø, 115V, 60HZ

4 ZQ08N10,

MO DE L S

IT E MS

P O W E R S U P P L Y

C O OL ING C AP AC IT Y (B tu/h)

INP UT (W)

R UNN ING C UR R E NT (A )

E .E .R (B T U/W.h)

OP E R AT ING INDOO R (¡ C )

C O NDIT ION OUTDOOR (¡ C )

R E FR IG E R ANT (R -22) C HAR G E

E VAP O R AT O R

C O NDE NS E R

F AN, INDOOR

F AN, OUT DOOR

F AN S P E E DS , F AN/CO O L ING

F AN MO T OR

OP E R AT ION C ONT R O L

R OOM T E MP . C ONT R OL

AIR DIR E C TIO N C ONTR OL

CP08N10

7,800

800

7.4

9.7

26.7(DB)* 19.4(WB )**

35(DB )* 23.9(WB )**

420g(14.8oz )

3 R OW 11S TAC K S

2 R OW 16S TAC K S (L)

TUR B O FAN

PR OP E LLE R TYP E F AN WITH S LING E R R IN G

3/3

6 POLE S

R E MOT E C ONT R O L L E R

THE R MIS TOR

VE R T IC AL LOUV E R (R IG HT & LE F T )

HOR IZONT AL LO UV E R (UP & DO W N )

C O NS T R UC TIO N

P R O T E CT OR

P O W E R C OR D

DR AIN S Y S T E M

NE T WE IG HT ( lbs /kg)

OUT S ID E DI ME NS ION (inch)

(W x H x D) (mm)

* DB:Dry B ulb

**

WB : W et B ulb

C O MP R E S S OR

F AN MO T OR

S LIDE IN -O UT C H AS S IS

OV E R LOAD P R O T E C T O R

INT E R NAL T HE R MAL P R O TE C T OR

(3 WIR E WIT H G R OUDING )

AT TAC H ME NT P L U G (C OR D-C ON NE C TE D T YP E )

DR AIN P IP E OR S P L A S HE D B Y F AN S LING E R

62/28

3

/32x 1329/32x 193/

20

510 x 354 x 490

8

1.4 FEATURES

• Designed for COOLING ONLY.

• Slide-out chassis for the simple

installation and service.

• Low air-intake, top cooled-air discharge.

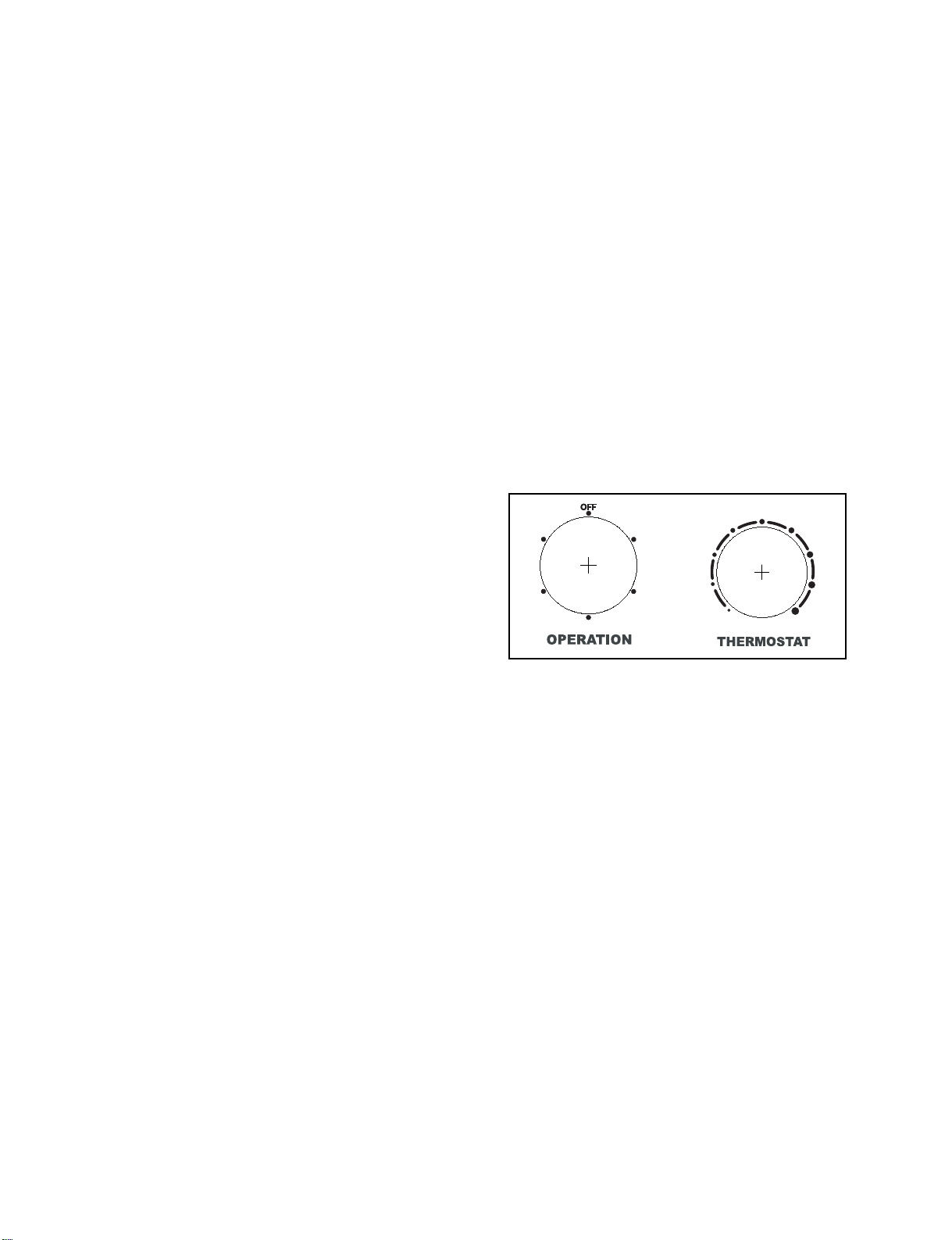

1.5 CONTROL LOCATIONS

• THERMOSTAT (Fig A)

Thermostat will control the temperature of

the discharge air. For a cooler setting, turn clockwise,

For a warmmer setting, turn counter clockwise.

CONTROLS -”ZQ”MODELSCONTROLS -”ZQ”MODELS

• OPERATION (Fig A)

adjustable thermostat

•

• Washable one-touch filter

• Compact size

OFF : Turns the air conditioner off.

MED FAN : Medium fan speed without cooling.

LOW FAN : Low fan speed without cooling.

HIGH COOL : Cooling with the high fan speed.

MED COOL : Cooling with the medium fan speed.

LOW COOL : Cooling with the low fan speed.

MED

MED

FAN

FAN

LOW

LOW

FAN

FAN

LOW COOLLOW COOL

HIGH

HIGH

COOL

COOL

MED

MED

COOL

COOL

Fig A

55

44

33

22

11

66

77

88

99

—4—

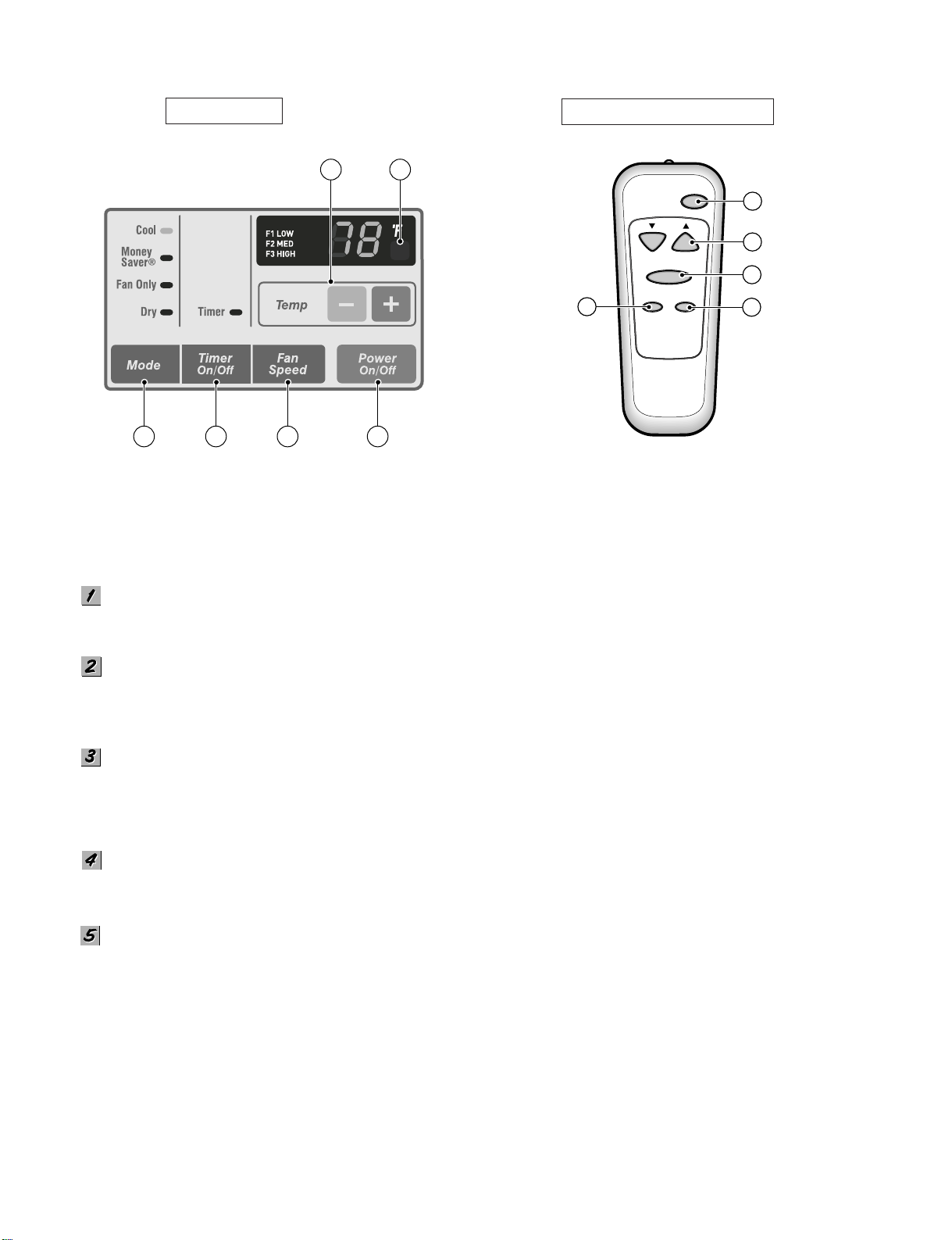

Precaution: The Remote Control unit will not function properly if strong light shines on the sensor window of the air

conditioner or if there are obstacles between the Remote Control unit and the air conditioner.

POWER BUTTON

To turn the air conditioner ON and OFF.

This button takes priority over any other buttons.

TEMPERATURE SETTING BUTTON

This button can control temperature of the room. The temperature can be adjusted within a range of 60 F to 86 F

by 1F,Select the lower number for lower temperature of the room.

OPERATION MODE SELECTION BUTTON

Push this button, it will shift operation between COOL, ENERGY SAVER, FAN and DRY modes.

-

Energy Saver: If Energy Save mode is selected, the fan stops when the compressor stops running

Approximately every 3 minutes the fan will turn on and check the room air to determine if cooling is needed.

FAN SPEED SELECTOR

Push this button, to shift fan speeds, as follows.

(Hi ➔ Low ➔ Med ➔ Hi ➔ Low ➔...)

ON/OFF TIMER BUTTON

ON - When the air conditioner is off, it can be set to automatically turn on.

DIS PLAY

1

2

453

6

Refer to Fig B&Fig C

OFF - When the airconditioner is on, it can be set to automatically turn off.

CONTROLS - "CP" MODELS

R E MOTE C ONT R OL

P owe r

1

Temp

2

Fa n S peed

5

Time r Mode

4

3

Fig B

Fig C

o

o

o

—5—

T

I

M

E

M

O

D

E

T

E

M

P

P

O

W

E

R

F

A

N

S

P

E

E

D

T

IM

E

M

O

D

E

T

E

M

P

P

O

W

E

R

F

A

N

S

P

EE

D

C

O

O

L

I

N

D

O

O

R

D

E

S

I

R

E

D

E

N

E

R

G

Y

S

A

V

E

R

A

I

R

P

U

R

Y

F

I

E

R

A

U

T

O

R

E

S

T

A

R

T

F

A

N

F

A

N

D

R

Y

H

E

A

T

DE

F

RO

S

T

T

I

M

E

M

O

D

E

T

E

M

P

P

O

W

E

R

F

A

N

S

P

E

E

D

C

O

O

L

IN

D

O

O

R

D

E

S

I

R

E

D

E

N

E

R

G

Y

S

A

V

E

R

A

IR

P

U

R

Y

F

I

E

R

A

U

T

O

R

E

S

T

A

R

T

F

A

N

F

A

N

D

R

YH

E

A

T

D

E

F

R

O

S

T

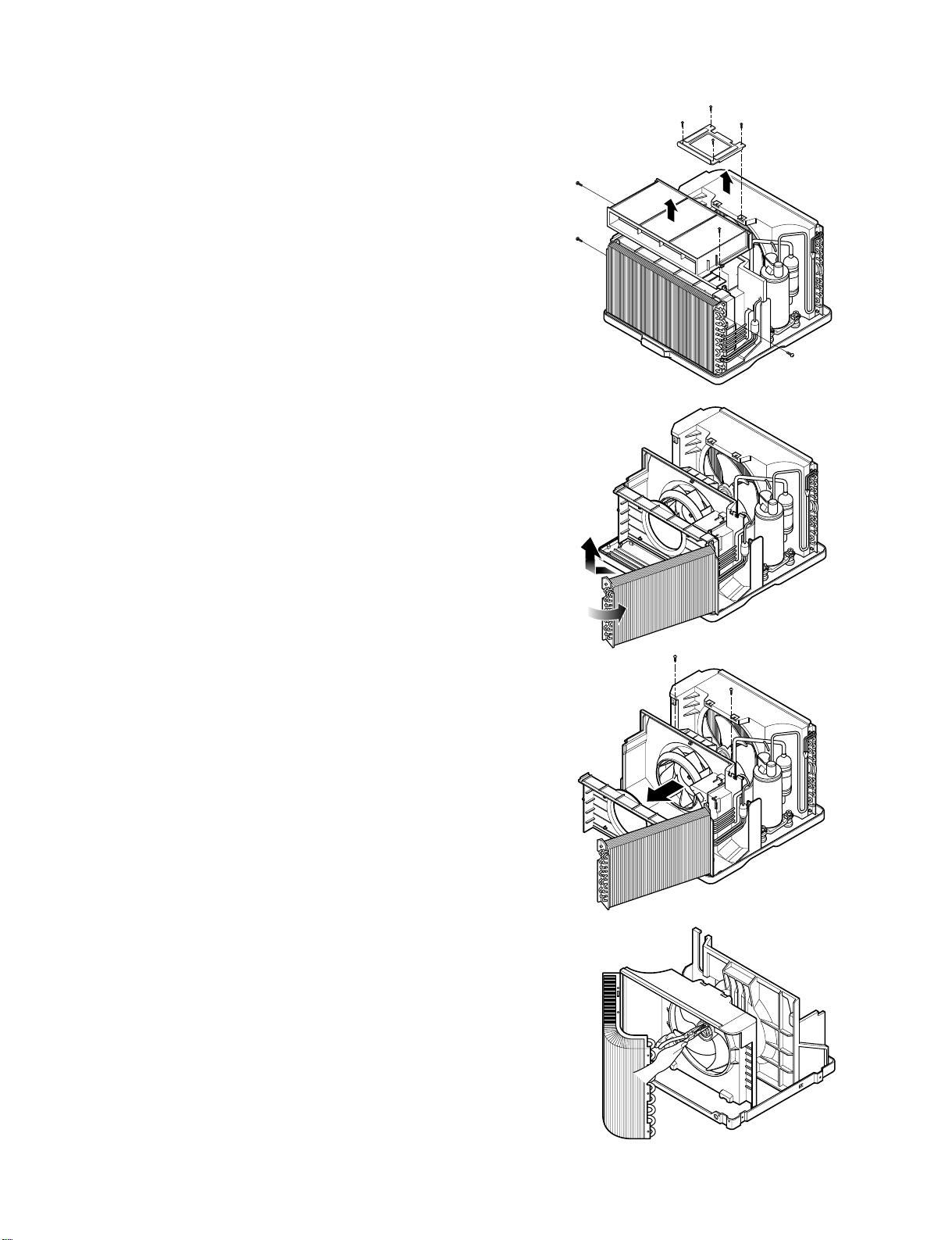

2. DISASSEMBLY INSTRUCTIONS

— Before servicing the unit,turn the unit OFF and disconnet the power cord.

2.1 MECHANICAL PARTS

2.1.1 FRONT GRILLE

1. Open the lnlet grille downward and remove the air

filter.

2. Remove the screw which fastens the front

grille.(See Figure 1)

3. Pull the front grille from the right side.

4. Remove the front grille.(There are 4 hooks.)

5. Re-install the components by referring to the

removal procedure, above.

2.1.2 CABINET

1. After removing the FRONT GRILLE, remove

the 2 screws which fasten the cabinet at both

sides.

2. Remove the 2 screws which fasten the cabinet at the

back.

3. Pull the base pan forward. (See Figure 2)

4. Remove the cabinet.

5. Re-install the components by referring to the

removal procedure, above.

Figure 1

2.1.3 CONTROL BOX

1. Remove the front grille. (Refer to section 2.1.1)

2. Remove the cabinet. (Refer to section 2.1.2)

3. Remove the 2 screws which fasten the power

cord.

4. Disconnect the grounding screw from the

evaporator channel.

5. Remove the 1 screw which fastens the control box

cover.

6. Remove the housing which connects PCB(the control panel ) (CP 08/10/12)

or connector(ZQ 08/10) and motor wire in the control box.

7. Remove the nut which fastens the terminal cover.

8. Remove the terminal cover.

9. Remove all the leads from the overload protector.

10. Discharge the capacitor by placing a 20,000

ohm resistor across the capacitor terminals.

11

. Raise the control box upward .

(See Figure 3)

12. Re-install the components by referring to the

removal procedure, above.

(Refer to the circuit diagram found on page 19 in

this manual and on the control box.)

Figure 2

Figure 3

—6—

2.2 AIR HANDLING PARTS

2.2.1 AIR GUIDE AND TURBO FAN

1. Remove the front grille. (Refer to section 2.1.1)

2. Remove the cabinet. (Refer to section 2.1.2)

3. Remove the control box. (Refer to section 2.1.3)

4. Remove the 4 screws which fasten the brace.

5. Remove the brace.

6. Remove the 2 screws which fasten the discharge air guide.

7. Remove the air guide upper.(See figure 4)

8. Remove the 2 screws which fasten the evaporator.

9. Move the evaporator forward pulling it upward

slightly. (See Figure 5)

10. Pull the hook out of orifice by pushing the tabs

and remove it. (See Figure 6)

11. Using pliers remove the clamp which

secures the turbo fan.

12. Remove the turbo fan.

13. Remove the 2 screws which fasten the air guide

to the base pan.

14. Move the air guide backward, and pull out from

the base pan.(Move the lower air guide carefully.)

15. Re-install the components by referring to the

removal procedure, above.

Figure 4

2.2.2 FAN

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the brace (Refer to section 2.2.1)

3. Remove the 5 screws which fasten the condenser.

4. Move the condenser to the left carefully.

5. Remove the clamp which secures the fan.

6. Remove the fan. (See Figure 7)

7. Re-install by referring to the removal procedure.

Figure 5

Figure 6

—7—

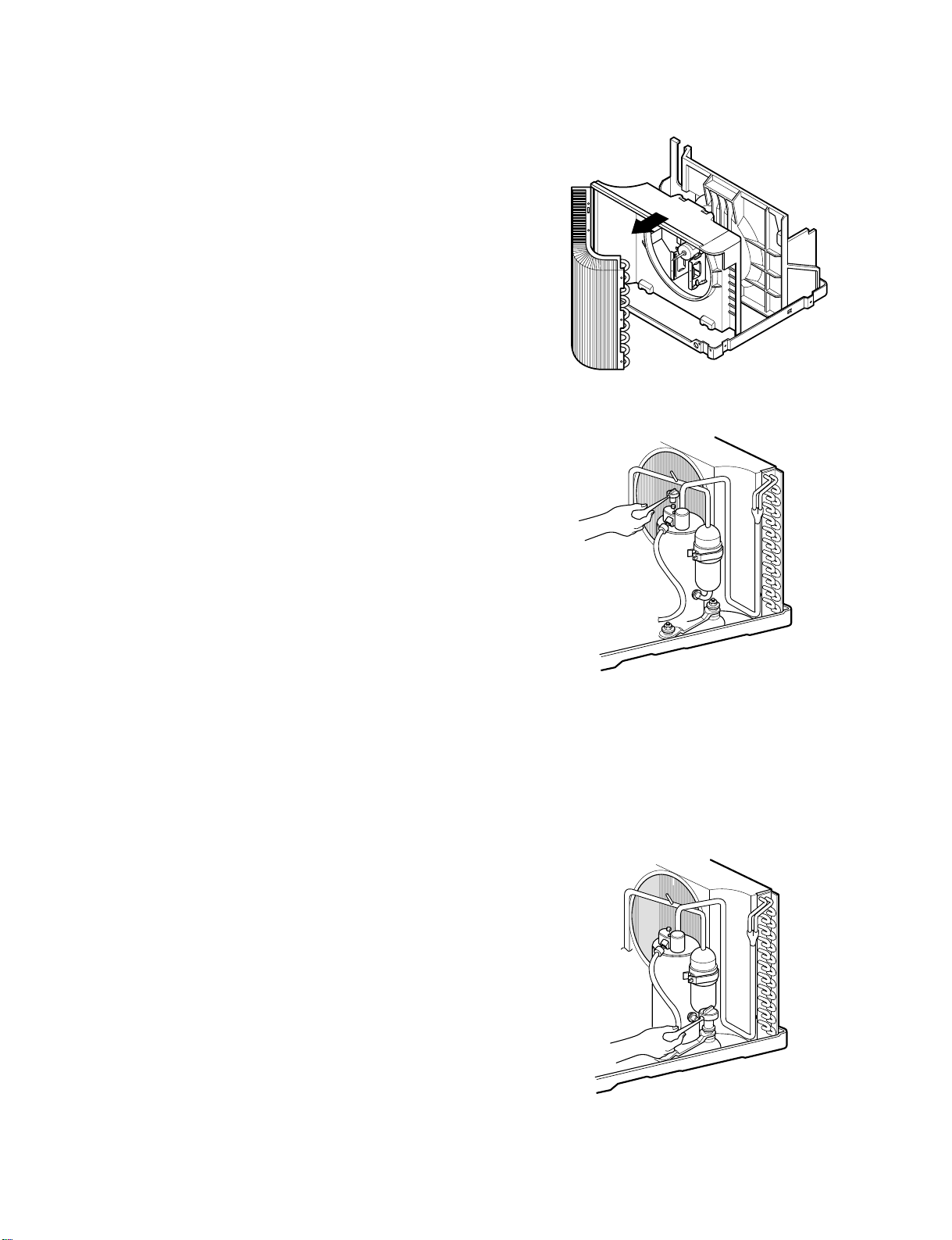

Figure 7

2.2.3 SHROUD

1. Remove the fan. (Refer to section 2.2.2)

2. Remove the shroud. (See Figure 8)

3. Re-install the components by referring to the

removal procedure, above.

2.3 ELECTRICAL PARTS

2.3.1 OVERLOAD PROTECTOR

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the nut which fastens the terminal cover.

3. Remove the terminal cover. (See Figure 9)

4. Remove all the leads from the overload protector.

5. Remove the overload protector.

6. Re-install the components by referring to the

removal procedure, above.

Figure 8

Figure 9

2.3.2 COMPRESSOR

1. Remove the cabinet. (Refer to section 2.1.2)

2. Discharge the refrigerant system using a Freon

Recovery System.

If there is no valve to attach the recovery system to,

install one (such as a WATCO A-1) before venting

the Freon

3. Remove the overload protector. (Refer to section

2.3.1)

4. After purging the unit completely, unbraze the

suction and discharge tubes at the compressor

connections.

5. Remove the 3 nuts and the 3 washers which

fasten the compressor.

6. Remove the compressor. (See Figure 10)

7. Re-install the components by referring to the

removal procedure, above.

TM

. Remove the valve when finished

TM

Figure 10

—8—

Loading...

Loading...