Page 1

Room Air Conditioner

Service and Parts

Manual

CP05.Svc(05/06)

CP05C10

Page 2

—2—

CONTENTS

1. PREFACE ...................................................................................................................................................3

1.1 FEATURES.....................................................................................................................................................3

1.2 SPECIFICATIONS .........................................................................................................................................3

1.3 LOCATIONS OF CONTROLS .......................................................................................................................4

1.4 SAFETY PRECAUTIONS ..............................................................................................................................4

1.5 INSULATION RESISTANCE TEST ................................................................................................................4

2. DISASSEMBLY INSTRUCTIONS ................................................................................................5

2.1 MECHANICAL PARTS ..................................................................................................................................5

2.1.1 FRONT GRILLE ....................................................................................................................................5

2.1.2 CABINET................................................................................................................................................5

2.1.3 CONTROL BOARD................................................................................................................................5

2.2 AIR HANDLING PARTS ................................................................................................................................6

2.2.1 AIR GUIDE UPPER ..............................................................................................................................6

2.2.2 ORIFICE, TURBO FAN AND FAN .........................................................................................................6

2.2.3 MOTOR ..................................................................................................................................................7

2.2.4 AIR GUIDE.............................................................................................................................................7

2.3 ELECTRICAL PARTS ....................................................................................................................................7

2.3.1 OVERLOAD PROTECTOR ...................................................................................................................7

2.3.2 COMPRESSOR .....................................................................................................................................8

2.3.3 CAPACITOR ..........................................................................................................................................8

2.3.4 THERMOSTAT .......................................................................................................................................8

2.3.5 ROTARY SWITCH..................................................................................................................................8

2.3.6 POWER CORD .....................................................................................................................................9

2.4 REFRIGERANT CYCLE ................................................................................................................................9

2.4.1 CONDENSER .......................................................................................................................................9

2.4.2 EVAPORATOR ....................................................................................................................................10

2.4.3 CAPILLARY TUBE ..............................................................................................................................10

3. TROUBLESHOOTING GUIDE ....................................................................................................

3.1 OUTSIDE DIMENSIONS..............................................................................................................................12

3.2 PIPING SYSTEM........................................................................................................................................13

3.3 TROUBLESHOOTING GUIDE....................................................................................................................14

12

4. CIRCUIT DIAGRAM...........................................................................................................................19

5. EXPLODED VIEW..............................................................................................................................20

6. SERVICEPARTS LIST....................................................................................................................21

Page 3

1. PREFACE

CP05C10

This service manual provides various service information, including the mechanical and electrical parts, etc.

This room air conditioner was manufactured and assembled under a strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 FEATURES

• DESIGNED FOR COOLING ONLY

• BUILT-IN ADJUSTABLE THERMOSTAT

• WASHABLE ONE-TOUCH FILTER

• COMPACT SIZE

1.2 SPECIFICATIONS

MODELS

ITEMS

COOLING CAPACITY (BTU/h) 5,100

POWER SUPPLY (Phase, V, Hz)1ø, 115V, 60HZ

INPUT (W) 520

OPERATING CURRENT (AMP.) 4.4

REFRIGERANT CONTROL CAPILLARY TUBE

REFRIGERANT CHARGE (R-22) 330g (11.6 oz)

INSIDE FAN TURBO FAN

OUTSIDE FAN PROPELLER FAN WITH SLINGER RING

AIR DISCHARGE 2-WAY (RIGHT AND LEFT)

CHASSIS TOP-DOWN

PROTECTOR

TEMPERATURE CONTROL THERMISTOR

FAN MOTOR 6 POLES, 21W

• OVERLOAD PROTECTOR FOR COMPRESSOR

• INTERNAL PROTECTOR FOR FAN MOTOR

Page 4

—4—

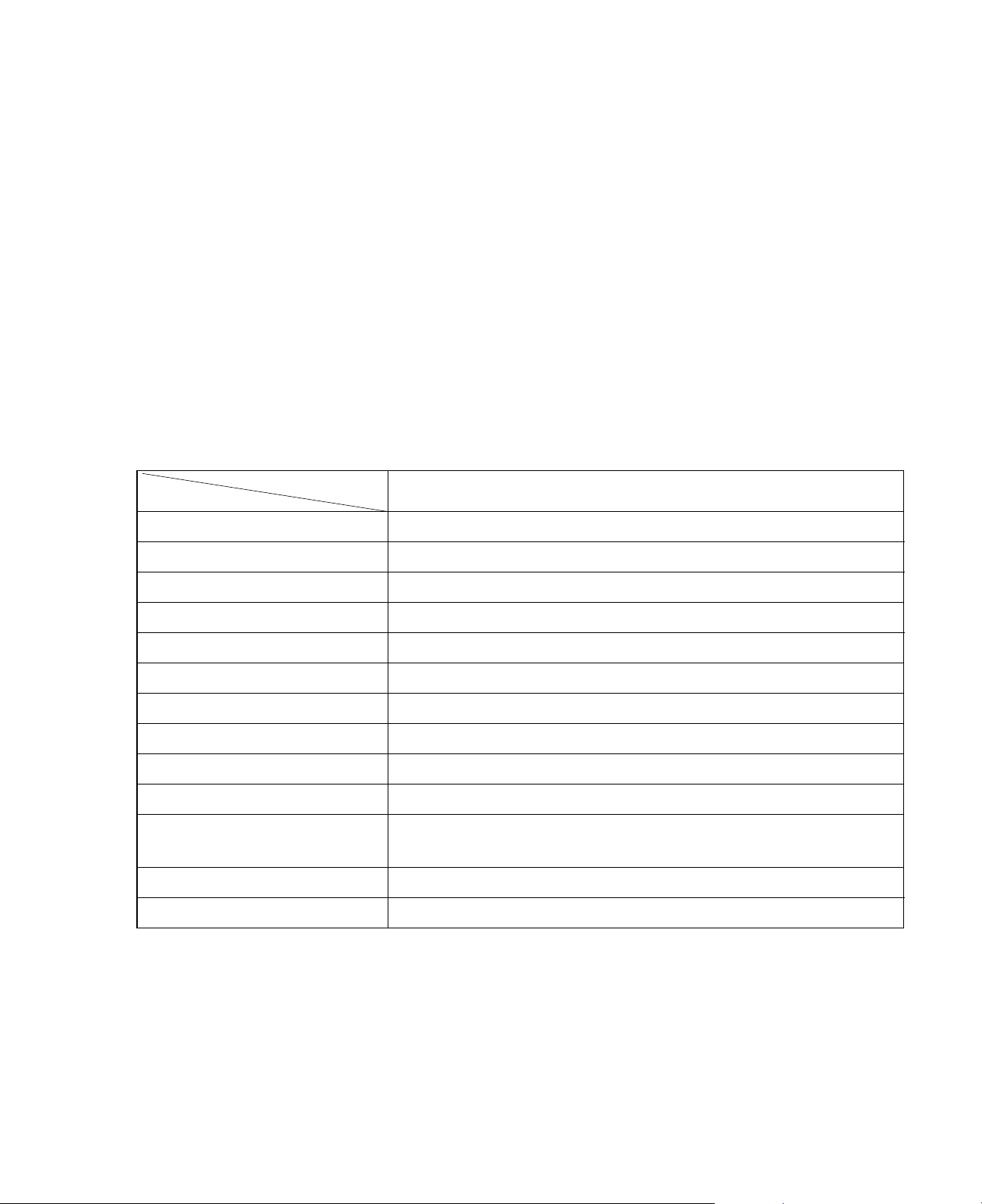

1.3 LOCATIONS OF CONTROLS

1

2

3

4

6

5

MONEY SAVER

2

The fan stops when the compressor stops cooling.

• Approximately every 3 minutes the fan will turn on and sample the room air to determine if

more cooling is needed.

TEMPERATURE SETTING

1

• These buttons control the temperature of the room.

The temperature can be set within a range of 60°F to 86°F, in increments of 1°F.

ON/OFF TIMER

4

ON–When the air conditioner is off, it can be set to automatically

come on in 1 to 12 hours from its previous setting. Each touch will increase the timer by 1

hour.

OFF–When the air conditioner is on, it can be set to automatically

turn off in 1 to 12 hours. Each touch will increase the timer by 1 hour. After the timer has been

on for 30 minutes, the temperature will automatically rise 2°F, and after another 30 minutes, it

will automatically rise 2°F again. The temperature will then stay the same until the timer goes

OFF.

To cancel the timer, press the TIMER pad until the display time disappears.

POWER

5

• To turn the unit ON, push the button. To turn the unit OFF, push the button again.

• This button takes priority over any other buttons.

• When you first turn it on, the unit is on the High cool mode and the temp. at 72°F

FAN SPEED

6

• Everytime you push this button it will rotate between the following fan speeds:

High (F3) → Low(F1) → Medium (F2) → High (F3)

Power

Temp

Fan Speed

Timer Mode

Money

Saver

5

1

6

34

2

OPERATION MODE SELECTOR

3

• Everytime you push this button, it will rotate between the COOL, FAN and DRY modes.

Page 5

—5—

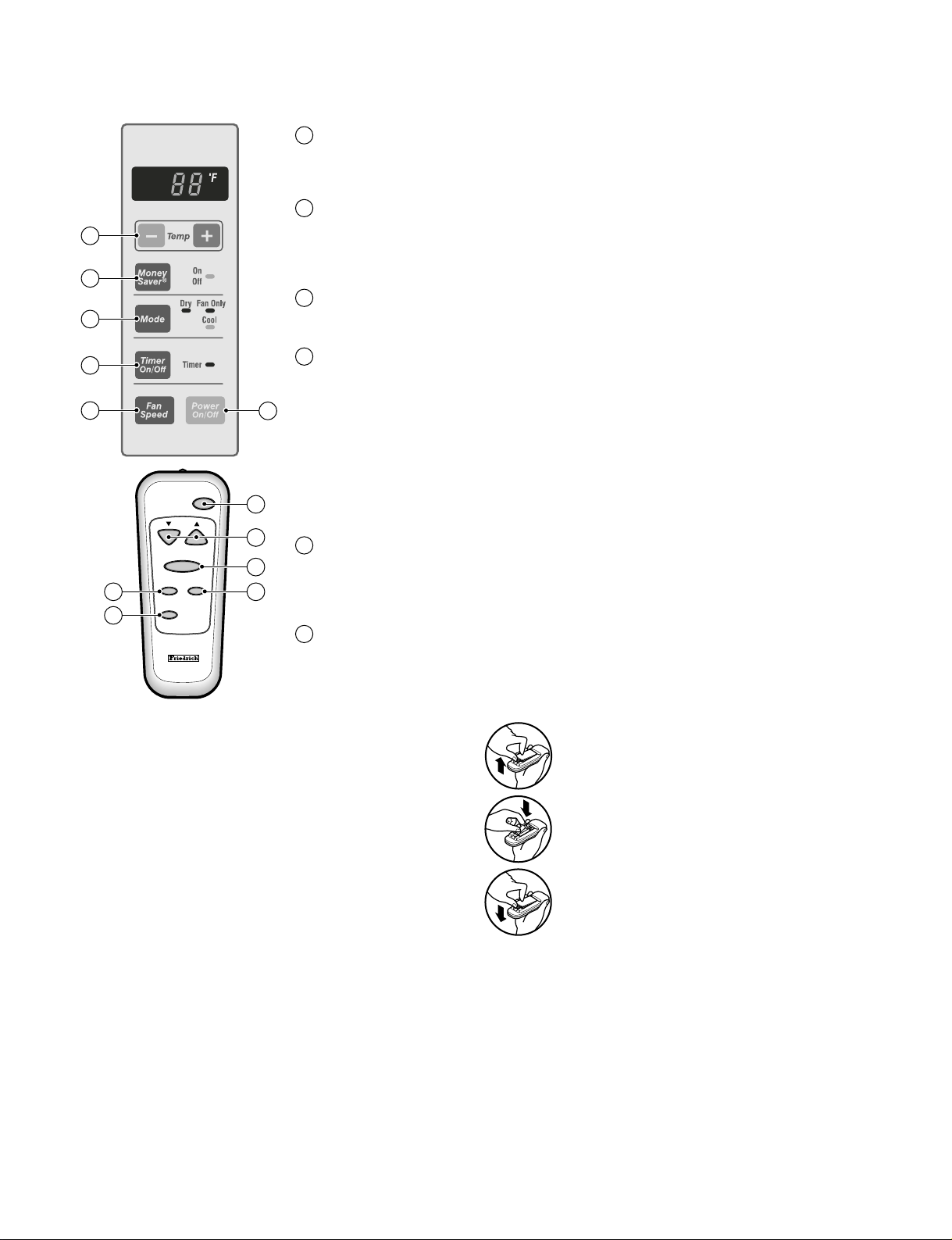

2. DISASSEMBLY INSTRUCTIONS

2.1 MECHANICAL PARTS

2.1.1 FRONT GRILLE

1. Pull the inlet grille forward.

2. Remove the screw securing the Front Grille. (Fig. 3)

3. Push the grille up from the bottom and pull the top of

the grille away from the case to lift the top tabs out of

their slots. (Fig. 4)

4. Carefully position the grille, bottom first, and snap back

into place.

5. Reposition the screw that secures the front grille

2.1.2 CABINET

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to section 2.1.1)

3. Remove 9 screws that secure the cabinet to the

base pan and condenser. (See Figure 3)

4. Lift the cabinet from the unit.

5. Re-install by referring to the procedures above.

2.1.3 CONTROL 2.1.3 CONTROL PANEL

2. Remove the front grille. (Refer to Section 2.1.1)

3. Remove the cabinet. (Refer to Section 2.1.2)

4. Remove 1 screws that secure the control board to

base pan and air guide. (See Figure 4)

5. Pull the control 5. Pull the control panel toward yourself.

the fan motor and compressor. (See Figure 5)

7. Re-install components by referring to procedures

above. (Refer to wiring diagram on page 23 in this

manual or inside control board.)

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

NOTE : Controls, wires, and capacitor are now

accessible for servicing. Discharge the

capacitor before servicing. See step

2.3.3 on page 8 for procedures.

Page 6

—6—

2.2 AIR HANDLING PARTS

2.2.1 AIR GUIDE UPPER

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to Section 2.1.1)

3. Remove the cabinet. (Refer to Section 2.1.2)

4. Remove the control panel.

(Refer to Section 2.1.3)

5. Remove 2 screws that secure the upper air guide

to air guide lower. (See Figure 6)

6. Lift upper air guide upward.

7. Re-install by referring to the procedures above.

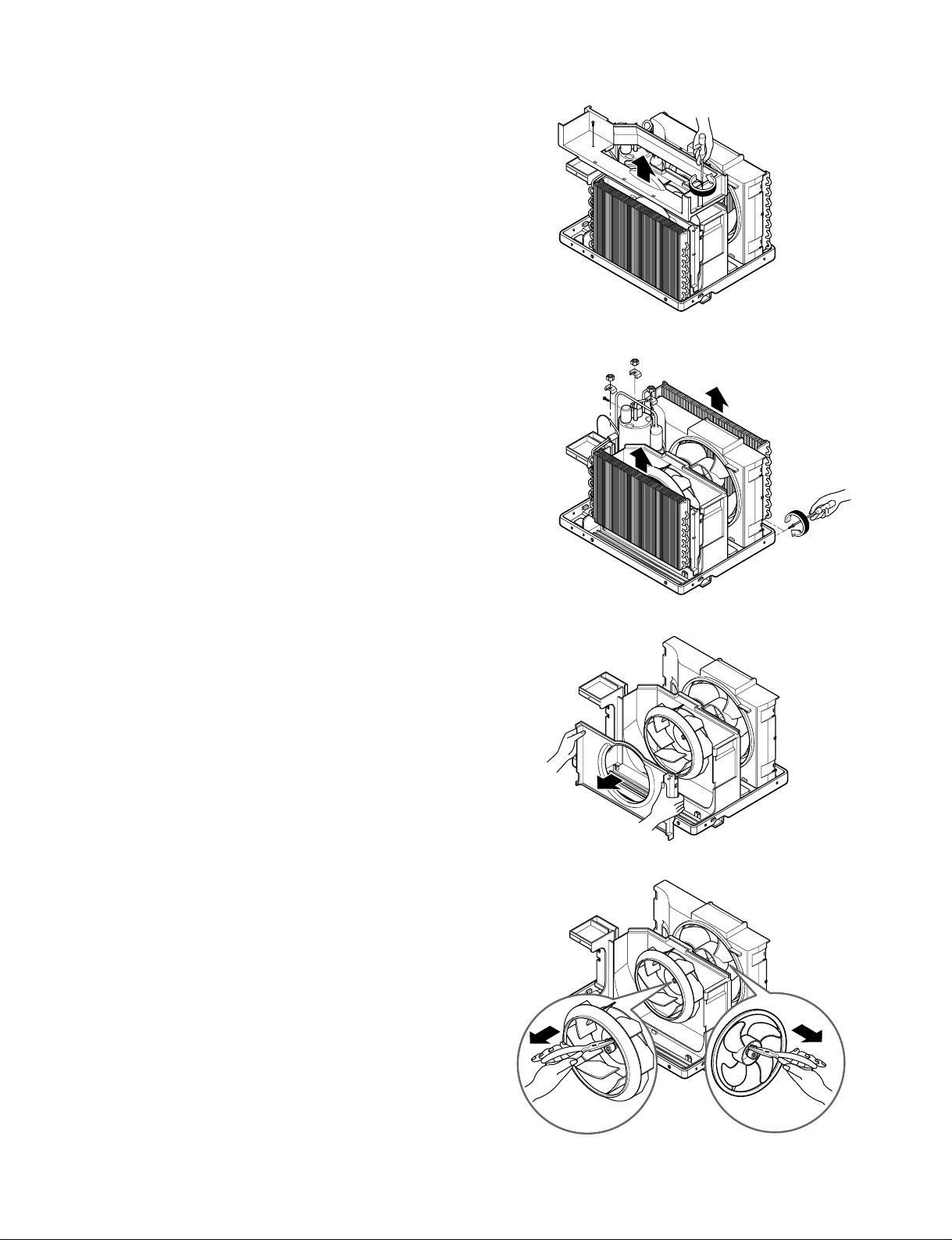

2.2.2 ORIFICE, TURBO FAN AND FAN

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to Section 2.1.1)

3. Remove the cabinet. (Refer to Section 2.1.2)

4. Remove the control board.

(Refer to Section 2.1.3)

5. Remove the air guide upper.

(Refer to Section 2.2.1)

6. Remove 2 screws that secure the base pan to

condenser. (See Figure 7)

7. Remove screw that secures the shroud to

channel of condenser.

8. Press the snap area of shroud with your thumbs.

This allows you to remove it from the condenser.

9. Lift the compressor upward with the evaporator

and condenser. (See Figure 7)

10. Remove the orfice by pushing the snap area of

the air guide blower. (See Figure 8)

11. Remove the clamp springs which are clamped to

the shaft of fan and turbo fan by hand plier. (See

Figure 9)

12. Pull the fan and turbo fan outward.

13. Remove the shroud.

14. Re-install by referring to the procedures above.

Figure 6

Figure 7

Figure 8

Figure 9

Page 7

—7—

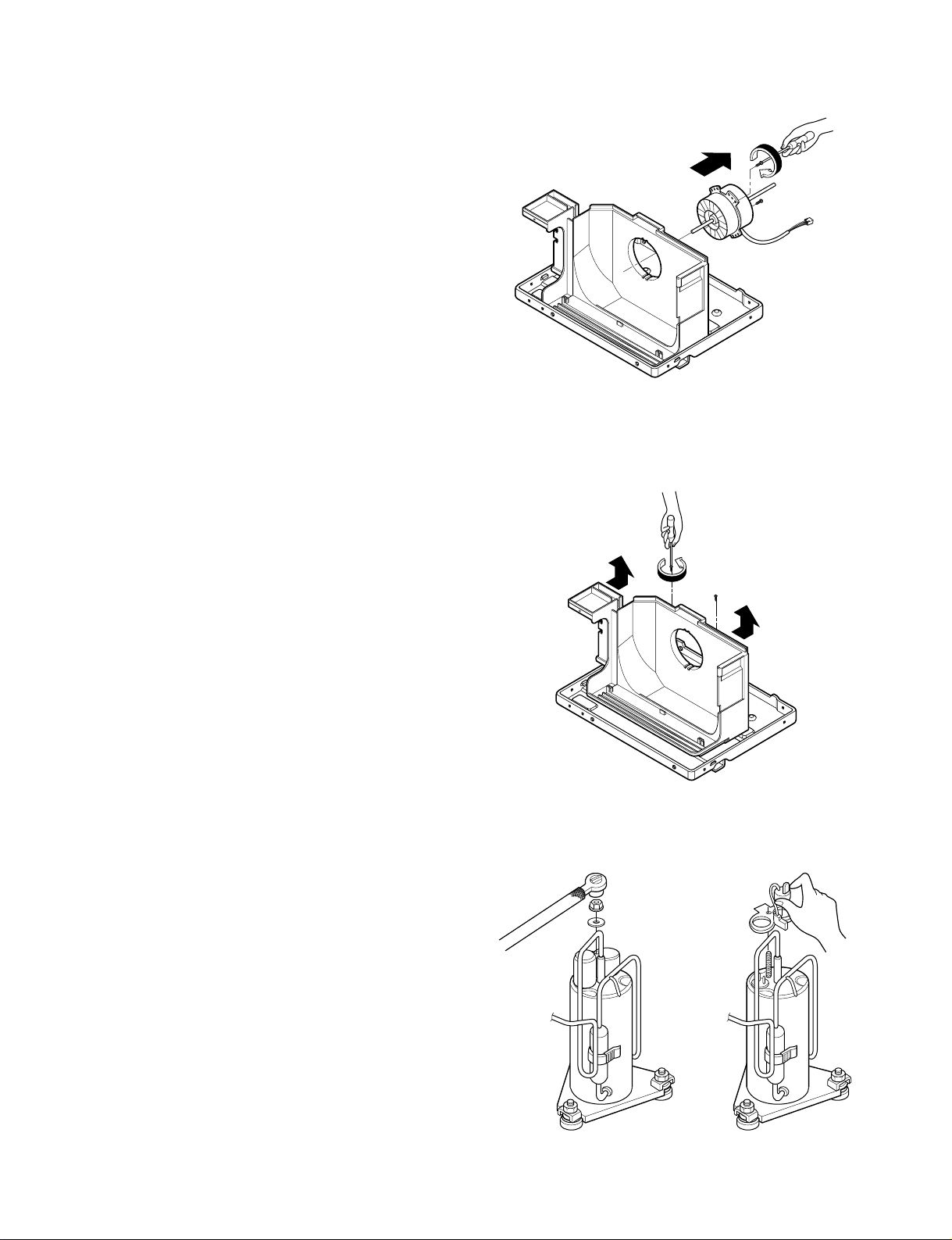

2.2.3 MOTOR

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to Section 2.1.1)

3. Remove the cabinet. (Refer to Section 2.1.2)

4. Remove the control panel.

(Refer to Section 2.1.3)

5. Remove the upper air guide.

(Refer to Section 2.2.1)

6.

Remove the compressor, turbo fan, fan and

shroud. (Refer to

Section

2.2.2)

7.

Remove 2 screws that secure the motor to the

motor mount . (See Figure 10)

8. Remove the motor.

9.

Re-install by referring to the procedures above.

2.2.4 AIR GUIDE

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to Section 2.1.1)

3. Remove the cabinet. (Refer to Section 2.1.2)

4. Remove the control panel.

(Refer to Section 2.1.3)

5. Remove the upper air guide .

(Refer to Section 2.2.1)

6.

Remove the compressor, turbo fan, fan and

shroud. (Refer to

Section

2.2.2)

7.

Remove the motor. (Refer to

Section

2.2.3)

8. Remove 2 screws that secure the air guide to the

base pan. (See Figure 11)

9. Push the air guide backward and lift it upward.

(See Figure 11)

10. Re-install by referring to the procedures above.

2.3 ELECTRICAL PARTS

2.3.1 OVERLOAD PROTECTOR

1. Remove the front grille and cabinet.

(Refer to Section 2.1)

2. Remove the nut which fastens the terminal cover.

3. Remove the terminal cover.

4. Remove all the leads from the overload protector.

5. Remove the overload protector.

6. Re-install the components by referring to the

removal procedure above.

(See Figure 12 and 13)

Figure 10

Figure 12

Figure 13

Figure 11

Page 8

—8—

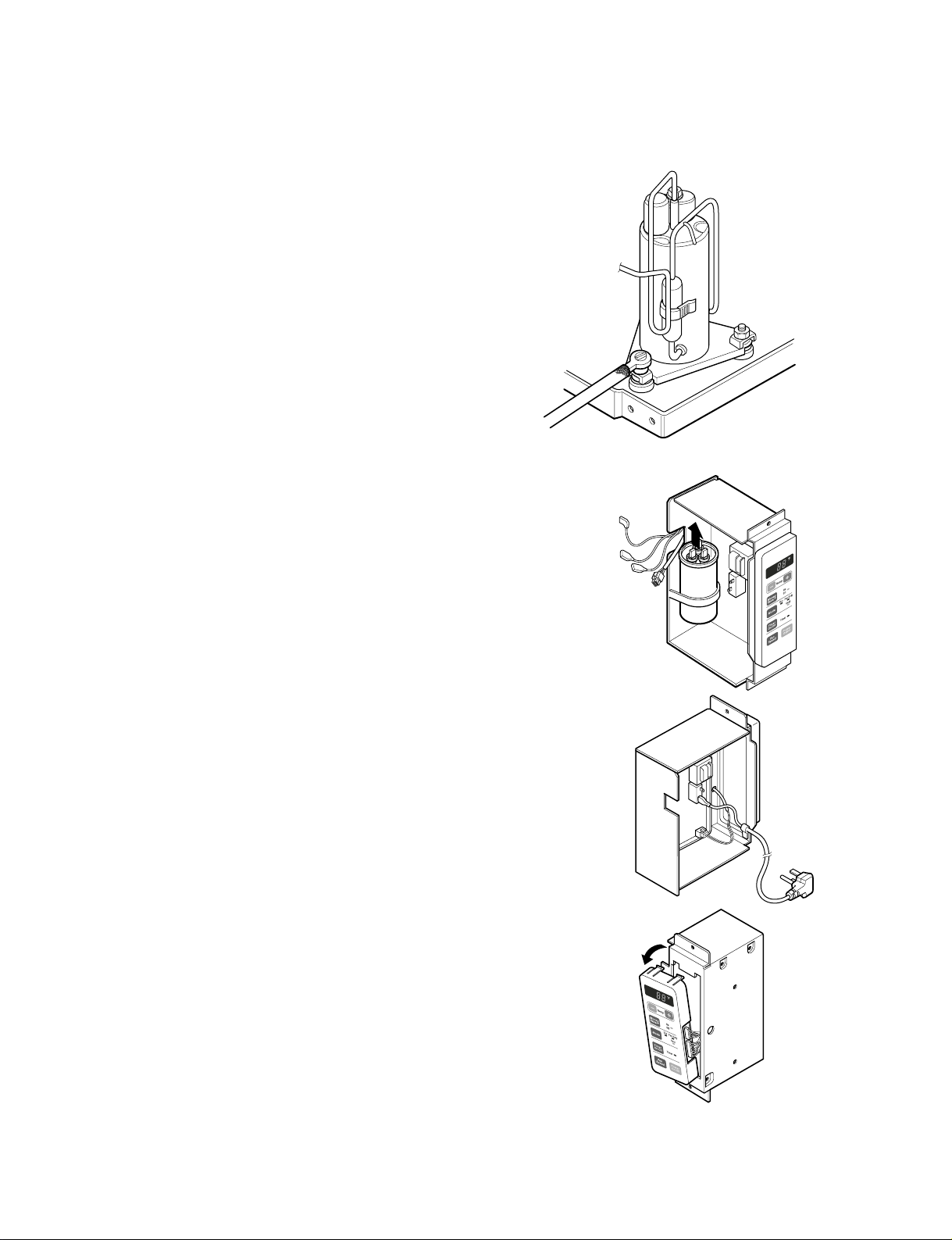

2.3.2 COMPRESSOR

1. Remove the front grille and cabinet.

(Refer to Section 2.1)

2. Discharge the refrigerant by using a refrigerant

recovery system.

3. Remove the overload protector.

(Refer to Section 2.3.1)

4. After discharging the unit completely, unbrace the

suction and discharge pipes at the compressor

connections.

5. Remove 3 nuts which fasten the compressor.

6. Remove the compressor.

7. Re-install by referring to the removal procedure

above. (See Figure 14)

2.3.3 CAPACITOR

1. Remove the cabinet. (Refer to Section 2.1.2)

2. Remove the control panel.

(Refer to Section 2.1.3)

3. Discharge the capacitor by placing a 20 KΩ

resistor across the capacitor terminals.

4. Remove the screw which fastens the capacitor

clamp.

5. Remove all the leads of capacitor terminals.

6. Re-install the components by referring to the

removal procedure above. (See Figure 15)

2.3.4 THERMISTOR

1. Remove the cabinet. (Refer to Section 2.1.2)

2. Remove the control panel.

(Refer to Section 2.1.3)

3. Disconnect the thermistor terminals from main

P.W.B assembly.

4. Remove the thermistor.

5. Re-install the components by referring to the

removal procedure above. (See Figure 16)

2.3.5 CONTROL BOARD

1. Remove the cabinet. (Refer to Section 2.1.2)

2. Remove the control panel.

(Refer to Section 2.1.3)

3. Pull the control board forward and pull out it.

4. Remove 2 lead wire terminals.

5. Re-install the components by referring to the

removal procedure above. (See Figure 17)

Figure 14

Figure 15

Figure 16

Figure 17

Page 9

—9—

2.3.6 POWER CORD

1. Disconnect the unit from source of power.

2. Remove the front grille. (Refer to Section 2.1.1)

3. Remove the cabinet. (Refer to Section 2.1.2)

4. Remove a screw that secures control panel to

base pan. (Refer to Section 2.1.3)

5. Pulls the control board toward you.

6. Disconnect the 2 receptacles and remove the

grounding screw.

7. Remove a screw securing the clip with cord to the

control panel.

8. Pull the power cord.

9. Re-install by referring to procedures above.

2.4 REFRIGERANT CYCLE

2.4.1 CONDENSER

1. Remove the cabinet. (Refer to Section 2.1.2)

2. Discharge the refrigerant by using a refrigerant

recovery system.

3. Remove the air guide. (Refer to Section 2.2.1)

4. Remove 2 screws which fasten the condenser.

5. After discharging the refrigerant completely,

unbraze the interconnecting tube at the

condenser connections.

6. Remove the condenser.

7. Re-install by referring to the procedures above.

Figure 18

Figure19

Page 10

2.4.2 EVAPORATOR

1. Remove the cabinet.

2. Discharge the refrigerant by using a refrigerant

recovery system.

3. Remove the upper air guide . (Refer to Section

2.2.1)

4. After discharging the refrigerant completely,

unbraze the interconnecting tube at the condenser

connections.

5. Remove the evaporator.

6. Re-install by referring to the procedures above.

2.4.3 CAPILLARY TUBE

1. Remove the cabinet.

2. Discharge the refrigerant by using a refrigerant

recovery system.

3. Remove the upper air guide. (Refer to Section

2.2.1)

4. After discharging the refrigerant completely,

unbraze the interconnecting tube of the capillary

tube.

5. Remove the capillary tube.

6. Re-install by referring to the procedures above.

NOTES

Replacement of the refrigeration cycle.

1. When replacing the refrigerating cycle, be sure to

discharge the refrigerant by using a refrigerant

recovery system.

2. After discharging the unit completely, remove the

desired components, and unbraze the pinch-off

tubes.

3. Solder service valves into the pinch-off tube ports,

leaving the valves open.

4. Solder the pinch-off tubes with service valves.

5. After completing the above procedures, the valve

must be removed .

6. Evacuate as follows:

6-1. Connect the vacuum pump, as illustrated in

figure 21A.

6-2. Start the vacuum pump. Slowly open manifold

valves A and B with two full turns counterclockwise and leave the valves closed.

The vacuum pump is now pulling through

valves A and B up to valve C by means of

manifold and the entire system.

CAUTION : If high vacuum equipment is used,

just crack valves A and B for a few minutes, then

open slowly with the two full turns counter-clock-

wise. This will keep oil from foaming and being

drawn into the vacuum pump.

6-3. Operate the vacuum pump for 20 to 30 min-

utes, until 600 micron vacuum is obtained.

Close valves A and B and observe vacuum

gauge for a few minutes.

A rise in pressure would indicate a possible

leak or moisture remaining in the system.

With valves A and B closed, stop the vacuum

pump.

6-4. Remove the hose from the vacuum pump and

place it on the charging cylinder. See figure

23B. Open valve C.

Discharge the line at the manifold connection.

6-5. The system is now ready for final charging.

7. Recharge as follows:

7-1. Rotary compressor systems are charged from

the high-side. If the total charge cannot be put

in the high-side, the balance will be put in the

suction line through the access valve which is

installed as the system is opened.

7-2. Connect the charging cylinder as shown in fig-

ure 21B. With valve C open, discharge the

hose at the manifold connection.

7-3. Open valve A and allow the proper charge to

enter the system. Valve B is still closed.

7-4. If more charge is required, the high-side will

not take it. Close valve A.

7-5. With the unit running, open valve B and add

the balance of the charge.

a. Do not add the liquid refrigerant to the low-

side.

b. Watch the low-side gauge, allow pressure to

rise to 30 lbs.

c. Turn off valve B and allow the pressure to

drop.

d. Repeat steps B and C until the balance of

the charge is in the system.

7-6. When the unit is operating correctly, use the

pinch-off tool with the unit still running and the

clamp on the pinch-off tube. Using a tube cutter, cut the pinch-off tube about 2 inches from

the pinch-off tool. Use sil-fos solder and solder

the pinch-off tube closed. Turn off the unit,

allow setting for a while and then test the leakage of the pinch-off connection.

—10—

Page 11

—11—

Equipment needed: Vacuum pump, charging cylinder, manifold gauge, brazing equipment, pinch-off tool capable

of making a vapor proof seal, leak detector, tubing cutter, hand tools to remove components and service valve.

B

A

B

A

B

A

COMPOUND GAUGE

SEE INSETS

BELOW

CAPILLARY TUBE

EVAPORATOR

(LOW PRESSURE SIDE)

COMPRESSOR

CONDENSER

(HIGH PRESSURE SIDE)

EXTERNAL VACUUM PUMP

LO HI

CHARGING CYLINDER

MANIFOLD

GAUGE

C

Figure 21A-Pulling Vacuum Figure 21B-Charging

Page 12

—12—

2.4.4 ELECTRICAL DATA

USE OF EXTENSION CORDS

Because of potential safety hazards, we strongly discourage the use of an extension cord. However, if you wish to use an extension

cord, use a CSA certified/UL-listed 3-wire (grounding) extension cord, rated 15A, 125V.

Do not under any

circumstances cut

or remove the

grounding prong

from the plug.

Line Cord Plug Use Wall Receptacle Power Supply

Power supply cord with

3-prong grounding plug

Standard 125V, 3-wire grounding

receptacle rated 15A, 125V AC

Use 15 AMP, time

delay fuse, or circuit

breaker.

3. TROUBLESHOOTING GUIDE

3.1 OUTSIDE DIMENSIONS (unit: mm [in])

370 (14 9/16")

312 (12 1/4")

370 (14 9/16")

312 (12 1/4")

29 (1

5

/32")

120 (4 3/4")

27.5 (1

3

/32")

346 (13

5

/8")

472 (18 9/16")

42 (1 21/32")

42 (1

21

/32")

155(6

3/32

")

12

(0.4

1/16

")

472 (18 9/16")

22.5(0.8

3/32

")

Page 13

—13—

3.2 PIPING SYSTEM

Following is a brief description of the important components and their function in what is called the refrigeration

system. Reference should be made to Figure 32 to follow the refrigerating cycle and the flow of the refrigerant in

the cooling cycle.

COOLED

AIR

HOT

DISCHARGED

AIR

MOTOR

COMPRESSOR

ROOM AIR HEAT LOAD

CAPILLARY TUBE

(LIQUID REFRIGERANT)

LIQUID OUTLET

VAPOR INLET

COMPLETE LIQUID

BOIL OFF POINT

SUCTION LINE

COOL LOW PRESSURE VAPOR

LIQUID

PRESSURE

DROP

DISCHARGE

LINE

NOT HIGH PRESSURE

VAPOR

OUTSIDE COOLING

AIR FOR REFRIGERANT

PASS THROUGH

EVAPORATOR COILS CONDENSER COILS

ROOM AIR CONDITIONER

CYCLE OF REFRIGERATION

HIGH PRESSURE VAPOR

LIQUID REFRIGERANT

LOW PRESSURE VAPOR

OIL

Figure 32

CONDENSER COILS

FAN

CAPILLARY

MOTOR

TUBE

TURBO FAN

EVAPORATOR

COILS

Page 14

—14—

3.3 TROUBLESHOOTING GUIDE

In general, possible trouble is classified in two kinds.

The one is called Starting Failure which is caused by an electrical defect. The other is Ineffective Air Con-

ditioning caused by a defect in the refrigeration circuit and improper application.

Unit is running but cooling is ineffective.

Ineffective Cooling

Satisfactory operation

with temperature

difference of inlet & outlet

air; 18~26°F.

Replacement of unit if

the unit is beyond repair.

Check outdoor coil

(heat exchanger) and

fan operation.

Check heat load

increase.

Check cold air

circulation for smooth

flow.

Check for gas leakage.

Clean condenser.

Not on dedicated circuit.

Check inside gas

pressure.

Adjust refrigerant

charge.

Malfunction of

compressor.

Replacement of

compressor.

Check for restriction in refri geration circuit.

Remove restriction in

refrigeration circuit.

Dirty indoor coil

(heat exchanger)

Repair gas leak.

Malfunction of fan.

Clogging air filter.

Obstruction at air outlet.

Remove obstruction.

Page 15

—15—

Fails to Start

Improper thermostat

setting

Loose terminal

connection

Improper wiring

Check voltage power source.

Drop of power voltage.

Capacitor check.

Replacement.

Check control switch

setting.

Compressor fails to

start.

Defect of compressor or

capacitor.

Replacement of compressor

(Motor damaged).

Irregular motor insulation (Ω)

Irregular motor resistance (Ω)

Check of circuit breaker

and fuse.

Gas leakage of feeler

bulb of thermostat.

Check control switch.

Fan fails to start.

Improper wiring.

Defect of fan motor or

capacitor.

Replacement of fan motor.

Regular but fails to start.

Replacement of compressor.

Irregular motor

resistance (Ω)

Irregular motor

insulation (Ω)

Page 16

COMPLAINT CAUSE REMEDY

Fan motor will not run. No power Check voltage at outlet. Correct if none.

Power supply cord Check voltage to electronic control board. If none,

check power supply cord. Replace cord if circuit is

open.

Wire disconnected or Connect wire. Refer to wiring diagram for

connection loose terminal identification. Repair or replace loose

terminal.

Capacitor (Discharge Test capacitor.

capacitor before testing.) Replace if not within ±10% of manufacturer's

rating. Replace if shorted, open, or damaged.

Will not rotate Fan blade hitting shroud or blower wheel hitting

scroll. Re-align assembly.

Units using slinger ring condenser fans must

have 1/4" inch clearance to the base.

If necessary, shim up the bottom of the fan motor

with mounting screw(s).

Check fan motor bearings; if motor shaft will not

rotate, replace the motor.

Fan motor runs. Revolves on overload Check voltage. See limits on this page.

If not within limits, call an electrician.

Test capacitor.

Check bearings. Does the fan blade rotate

freely?

If not, replace fan motor.

Pay attention to any change from high speed to

low speed. If the speed does not change,

replace the motor.

—16—

ROOM AIR CONDITIONER VOLTAGE LIMITS

NAME PLATE RATING MINIMUM MAXIMUM

115V ± 10% 103.5V 126.5V

Page 17

—17—

COMPLAINT CAUSE REMEDY

Fan motor noise. Fan blade If cracked, out of balance, or partially missing,

replace it.

Blower wheel If cracked, out of balance, or partially missing,

replace it.

Loose set screw Tighten it.

Worn bearings If knocking sounds continue when running

replace the motor. If the motor hums or

noise appears to be internal while running,

replace motor.

Compressor will not run, Voltage Check voltage. See the limits on the preceding

fan motor runs. page. If not within limits, call an electrician.

Wiring Check the wire connections; if loose, repair or

replace the terminal. If the wires are disconnected, refer to wiring diagram for identification,

and replace the wires. Check the wire connections;

If not according to the wiring diagram, correct

the connections.

Thermistor Check the TEMP control. If not at the lowest

number, set TEMP control to this setting.

Check the continuity of the thermistor. Replace

the control board if the circuit is open.

Capacitor (discharge Check the capacitor.

capacitor before Replace if not within ±10% of manufacturer’s

servicing.) rating, replace if shorted, open, or damaged.

Compressor Check the compressor for open circuit or

ground. If open or grounded, replace the

compressor.

Overload

Compressor cycles on Voltage Check the voltage. See the limits on the

overload. preceding page. If voltage is not within these limits,

Overload Check overload, if externally mounted.

Check the compressor overload if externally mounted.

Replace if open. (If the compressor temperature is

high, remove the overload, cool, and retest.)

call an electrician.

Replace if open. (If the compressor temperature

is high, remove the overload, cool, and retest.)

Page 18

—18—

COMPLAINT CAUSE REMEDY

Compressor cycles on Fan motor If not running, determine the cause. Replace if

overload. required.

Condenser air flow Remove the cabinet, inspect the interior surface

restriction of the condenser. If restricted, clean carefully

with a vacuum cleaner (do not damage fins) or

brush. Clean the interior base before

re-assembling.

Condenser fins If the condenser fins are closed over a large

(damaged) area on the coil surface, head pressures will

increase, causing the compressor to cycle.

Straighten the fins or replace the coil.

Capacitor Test the capacitor.

Wiring Check the terminals. If loose, repair or replace.

Refrigeration system Check the system for a restriction.

Insufficient cooling Air filter If restricted, clean or replace.

Unit undersized Determine if the unit is properly sized for the

area to be cooled.

Excessive noise Blower or fan Check the set screw, or clamp. If loose or miss-

ing, correct. If the blower or fan is hitting scroll

or barrier, rearrange the air handling parts.

Copper tubing Remove the cabinet and carefully rearrange the

tubing not to contact the cabinet,

compressor, shroud, and barrier.

Page 19

—19—

4. CIRCUIT DIAGRAM

WH(BL)

POWER INPUT

BK(BR)

(Ribbed) (Plain)

GN/YL

(GN)

GN/YL(GN)

THERMISTOR

BK BK

BLRDBL

RD

CN-TH1

YL YL

OR(BR) OR(BR)

OR

SYNC

MOTOR

RY-LO

RY-HI

CN-WORK

CN-SYNC CN-DISP

DISPLAY P.W.B ASM

RY-SYNC

250V/T2A

(115V/T2A)

TRANS

FORMER

ZNR

43

RY-COMP

MAIN P.W.B ASM

BK

BK

WH

BK

RD

BL BL

OLP

RD

MOTOR

CAPACITOR

F

R

S

COMP.

C

C

H

3854A20022K

WIRING DIAGRAM

RY-MID

FUSE

LOC

ATION

NO.

DESCRIPTION

1 POWER CORD ASSY

PART NO.

CP05C10

67300020

2 FAN MOTOR 67303026

3 COMPRESSOR 67301616

67300718

4 CAPACITOR

OVERLOAD PROTECTOR 67301405

5

Q'TY

PER SET

1

1

1

1

1

Page 20

—20—

5. EXPLODED VIEW

352390

130410

359012

W48602

354210

349480

352390-1

149980

559011

346811

554030

W48602

130910

550140

554160

567502

352115

552102

352111

352113

35211A

135313

135303

152302

135312

132111-2

132111-1

147582-1

147581

159900-1

269310

238310

W0CZZ

249950

268714

263230

137215

268712

267110

749740

Page 21

6. SERVICE PARTS LIST

• CP05C10

—21—

NOTE) *Please ensure GCSC since these parts may be changed depending upon the buyer's request.

(GCSC WEBSITE http://biz.LGservice.com)

R: Service Parts

N: Non Service Parts

LocNo FRIEDRICH DESCRIPTION

130410 67302921 Base Assy Single

130910 67303709 Cabinet Assy Single

135312 67306003 Grille Assy Front

135313 67304200 Grille Assy Inlet

14758

1 67304600 Link

147582-

149980 67303115 Shroud

152302 67304300 Filter (Mech)

238310 67500115 Escutcheon

269310 67300020 Power Cord Assy

349480 67307700 Remote Controller

352111 6730761

352115 67307612 PWB(PCB) Assy Main

35238

352390 67303026 Motor Assy Single

354210 67303410 Orifice

35211A 67302222 Tube Assy Suction

352113 67302306 Tube Assy Discharge

352115 6730202

352390-1 67302727 Air Guide Assy Upper

35239

550140 67301900 Isolator Comp

352111 67302120 Tube Assy Capillary

554160 67301616 Compressor

559011 67302613 Fan Assy Axial

359012 67302612 Fan Turbo

567502 67301405 O.L.P.

W0CZZ 67300718 Capacitor

1 67304501 Louver Vertical 2 ea.

0 67307806 Thermistor

0 67302734 Air Guide Assy Lower

CP05C10

1 PWB(PCB) Assy Display

1 Tube Assy Evaporator In

W48602 67302500 Clamp Spring

13211

1-1 67306310 Installation Kit w/Curtains L

13211

1-2 67306311 Installation Kit w/Curtains R

749740 67304005 Upper Guide Cabinet

Page 22

—22—

MEMO

Page 23

—23—

MEMO

Page 24

Post Office Box 1540 • 4200 N. Pan Am Expressway • San Antonio, Texas 78295-1540

• (210) 357-4400 • FAX (210) 357-4490

FRIEDRICH AIR CONDITIONING CO.

Visit our web site at www.friedrich.com

CP05.Svc (05/06)

Use Factory Certified Parts...

Loading...

Loading...