Page 1

Installation Manual

Multizone: Ceiling Concealed- Low Static

ENGLISH

FRANÇAIS

ESPAÑOL

960-911-10

Page 2

• Do not cool excessively indoors. This may be harmful for your health and may consume more

electricity.

• Block sunlight with blinds or curtains while you are operating the air conditioner.

• Keep doors or windows closed tightly while you are operating the air conditioner.

• Adjust the direction of the air flow vertically or horizontally to circulate indoor air.

• Speed up the fan to cool or warm indoor air quickly, in a short period of time.

• Open windows regularly for ventilation as the indoor air quality may deteriorate if the air conditioner is used for many hours.

• Clean the air filter once every 2 weeks. Dust and impurities collected in the air filter may block the

air flow or weaken the cooling / dehumidifying functions.

For your records

Staple your receipt to this page in case you need it to prove the date of purchase or for warranty

purposes. Write the model number and the serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :

Here are some tips that will help you minimize the power consumption when you use the air

conditioner. You can use your air conditioner more efficiently by referring to the instructions

below:

TIPS FOR SAVING ENERGY

2

TIPS FOR SAVING ENERGY

Page 3

3

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE.

Always comply with the following precautions to avoid dangerous situations and ensure peak

performance of your product

WARNING

It can result in serious injury or death when the directions are ignored

CAUTION

It can result in minor injury or product damage when the directions are ignored

WARNING

• Installation or repairs made by unqualified persons can result in hazards to you and others.

• Installation of all field wiring and components MUST conform with local building codes or, in

the absence of local codes, with the National Electrical Code 70 and the National Building

Construction and Safety Code or Canadian Electrical code and National Building Code of

Canada.

• The information contained in the manual is intended for use by a qualified service technician

familiar with safety procedures and equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can result in equipment malfunction, property damage, personal injury and/or death.

Installation

• Always perform grounding. - Otherwise, it may cause electrical shock.

• For installation of the product, always contact the service center or a professional installation

agency. - Otherwise, it may cause a fire, electrical shock, explosion or injury.

• Securely attach the electrical part cover to the indoor unit and the service panel to the outdoor unit.

- If the electrical part cover of the indoor unit and the service panel of the outdoor unit are not

attached securely, it could result in a fire or electric shock due to dust, water, etc.

• Intall correct circuit breaker and switching board. - Otherwise, it can cause fire or electrical shock.

• Do not keep or use flammable gases or combustibles near the air conditioner. - Otherwise, it may

cause a fire or the failure of product.

• Ensure that an installation frame of the outdoor unit is not damaged due to use for a long time.

- It may cause injury or an accident.

• Do not disassemble or repair the product randomly. - It will cause a fire or electrical shock.

• Do not install the product at a place that there is concern of falling down. - Otherwise, it may result

in personal injury.

• Use caution when unpacking and installing. - Sharp edges may cause injury.

• Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air purge. Do not compress

air or Oxygen and Do not use Flammable gases. Otherwise, it may cause fire or explosion. There is

the risk of death, injury, fire or explosion.

• Consult your local dealer regarding what to do in case of refrigerant leakage.

When the air conditioner is to be installed in a small room, it is necessary to take proper measures

so that the amount of any leaked refrigerant does not exceed the concentration limit in the event of

a leakage. Otherwise, this may lead to an accident due to oxygen depletion.

• Ensure local building codes are followed when placing condenser. Unspecified installation work can

cause exidents like unit falling.

!

!

!

IMPORTANT SAFETY INSTRUCTIONS

ENGLISH

Page 4

• Make sure that a dedicated power supply circuit is provided for this unit and that all electrical work is

carried out by qualified personnel according to local laws and regulations and this installation manual.

An insufficient power supply capacity or improper electrical construction may lead to electric shocks or fire.

• Be sure to switch off the unit before touching any electrical parts.

• Make sure that all wiring is secured, the specified wires are used, and that there is no strain on the

terminal connections or wires.

• If refrigerant gas leaks during installation, ventilate the area immediately.

Toxic gas may be produced if the refrigerant gas comes into contact with fire.

• Don't put any materials in front of duct for air circulation.

Operation

• Unplug the unit if strange sounds, smell, or smoke comes from it. - Otherwise, it may cause electrical shock or a fire.

• Keep flames away. - Otherwise, it may cause a fire.

• Take the power plug out if necessary, holding the head of the plug and do not touch it with wet

hands. - Otherwise, it may cause a fire or electrical shock.

• Do not open the suction inlet of the indoor/outdoor unit during operation. it - Otherwise, it may

result in personal injury.

• Do not allow water to run into electrical parts. - Otherwise, it may cause the failure of machine or

electrical shock.

• Do not touch the edge of metal parts when removing the filter. - They are sharp and may cause

injury.

• Do not step on the indoor/outdoor unit and do not put anything on it. - It may cause an injury through

dropping of the unit or falling down.

• When the product is submerged into water, always contact the service center. - Otherwise, it may

cause a fire or electrical shock.

• Take care so that children may not step on the outdoor unit. - Otherwise, children may be seriously

injured due to falling down.

CAUTION

Installation

• Install the drain hose to ensure that drain can be securely done. - Otherwise, it may cause water

leakage.

• Install the product so that the noise or hot wind from the outdoor unit may not cause any damage to

the neighbors. - Otherwise, it may cause dispute with the neighbors.

• Always inspect gas leakage after the installation and repair of product. - Otherwise, it may cause the

failure of product.

• Keep level parallel in installing the product. - Otherwise, it may cause vibration or water leakage.

Operation

• Avoid excessive cooling and perform ventilation sometimes. - Otherwise, it may do harm to your

health.

• Use a soft cloth to clean. Do not use wax, thinner, or a strong detergent. - The appearance of the air

conditioner may deteriorate, change color, or develop surface flaws.

• Do not use an appliance for special purposes such as preserving animals vegetables, precision

machine, or art articles. - Otherwise, it may damage your properties.

• Do not place obstacles around the flow inlet or outlet. - Otherwise, it may cause the failure of appliance or an accident.

!

IMPORTANT SAFETY INSTRUCTIONS

4

Page 5

5

2 TIPS FOR SAVING

ENERGY

3 IMPORTANT SAFETY

INSTRUCTIONS

6 INSTALLATION PARTS

7 INSTALLATION

7 Selection of the best location

8 Ceiling dimension and hanging bolt

location

9 Indoor Unit Installation

10 Air Filter

11 Checking the Drainage

12 Indoor Unit Drain Piping

13 Flaring work

14 Plumbing materials and storage meth-

ods

16 Wiring Connection

16 Connection method of the connecting

cable(Example)

18 REMOTE CONTROLLER

INSTALLATION

20 Wired remote controller installation

21 OPTIONAL OPERATION

21 Installer Setting - Test Run Mode

22 Installer Setting - Setting Address of

Central Control

23 Installer Setting - Thermistor

24 Installer Setting - Group Setting

25 Installer Setting - Celsius / Fahrenheit

Switching

26 HOW TO SET E.S.P?

26 Installer Setting - E.S.P.

28 SELF-DIAGNOSIS FUNC-

TION

28 DIP SWITCH SETTING

TABLE OF CONTENTS

TABLE OF CONTENTS

ENGLISH

Page 6

6

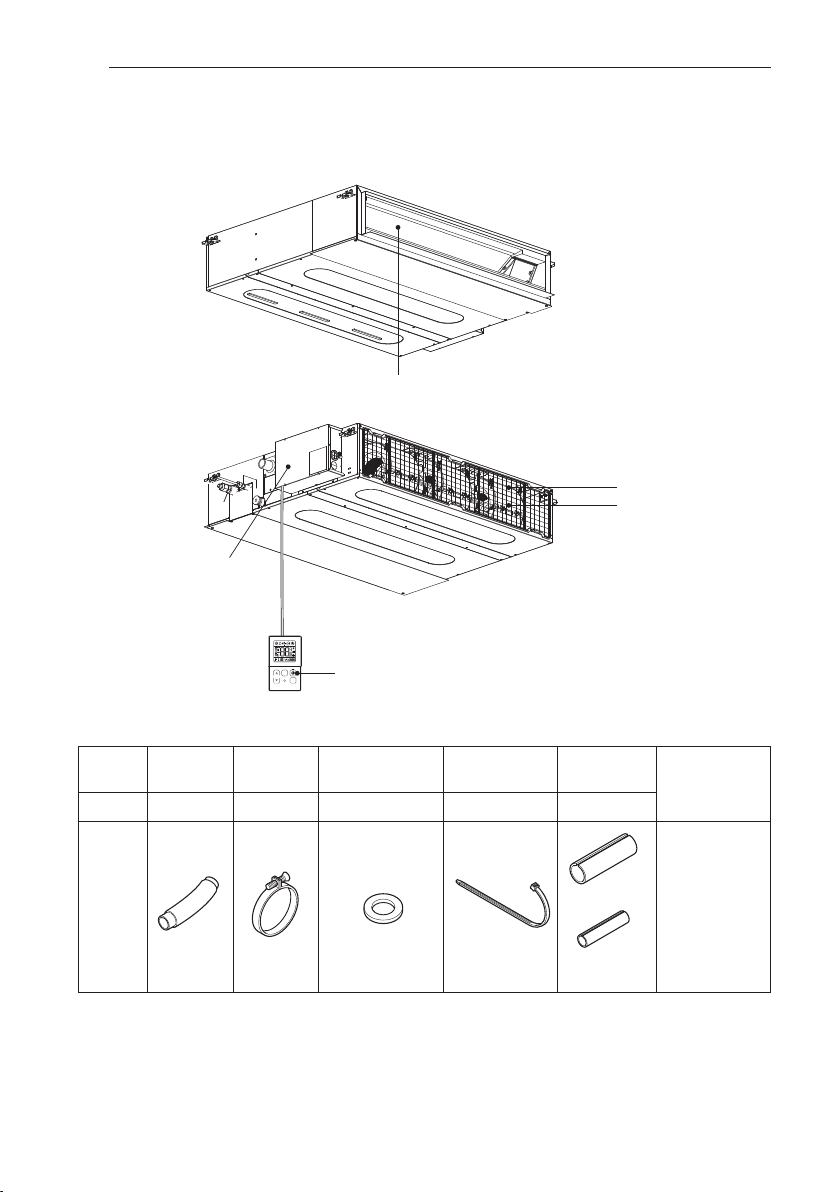

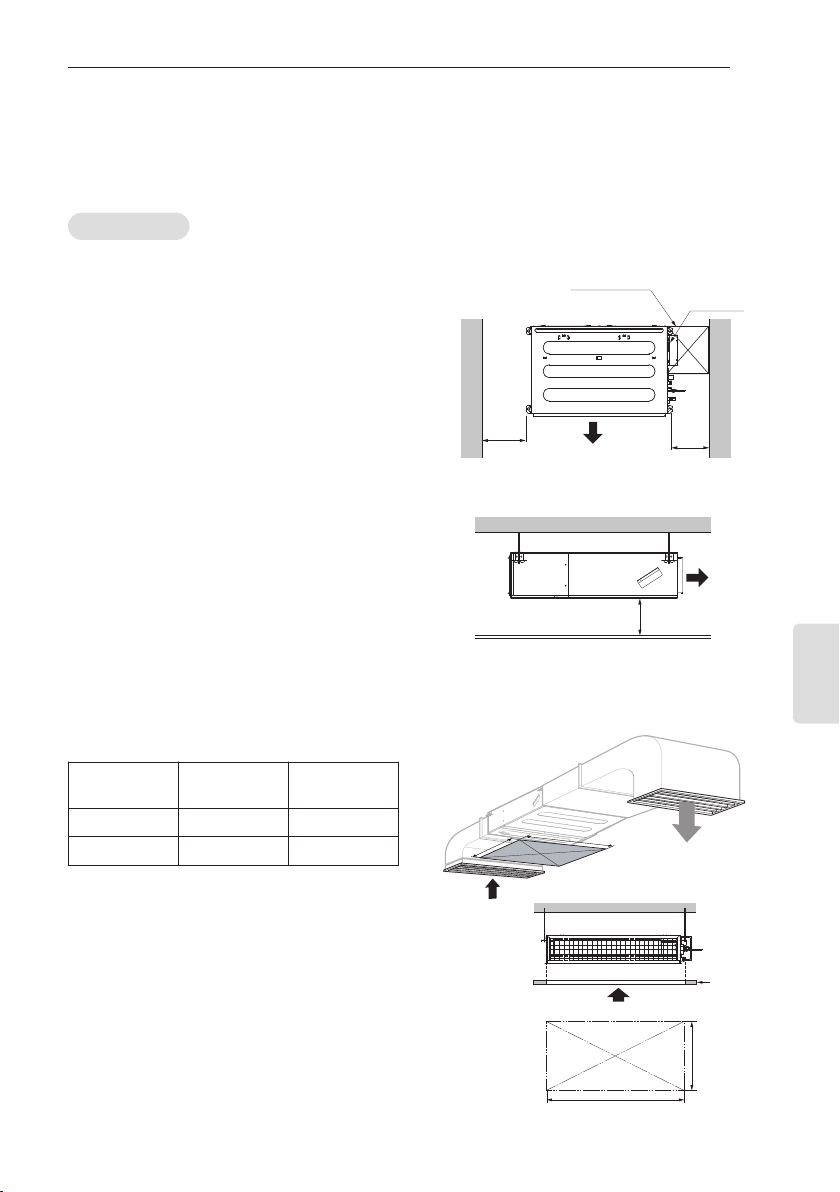

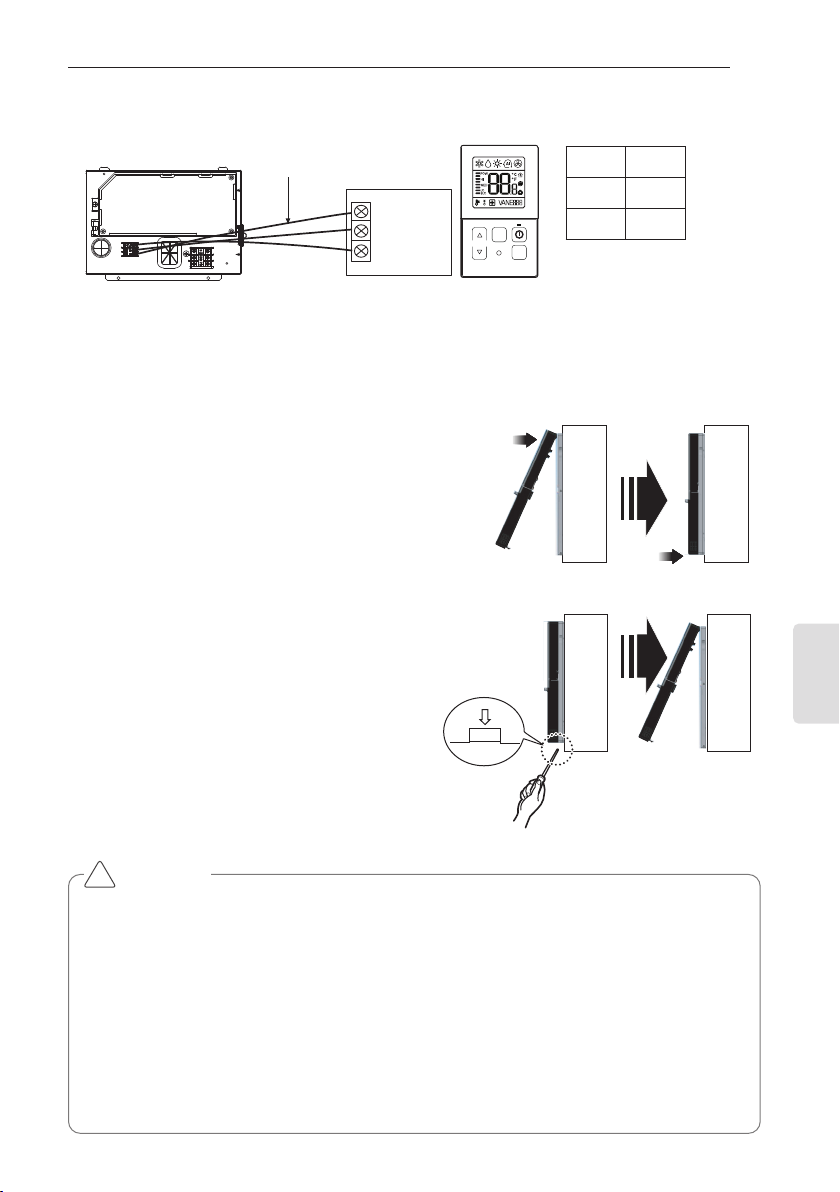

INSTALLATION PLACES

INSTALLATION PARTS

Air outlet vents

Air filters

Control box

Air intake vents

TEMP

FAN

SPEED

OPER

MODE

Wired Remote Controller

Name Drain hose

Clamp

metal

Washer for

hanging bracket

Clamp

(Tie Wrap)

Insulation for

fitting

Other

Quantity 1 EA 2 EA 8 EA 4 EA 1 set

Shape

• Owner's

manual

• Installation

manual

for gas pipe

for liquid

pipe

Page 7

7

ENGLISH

THE INDOOR UNIT INSTALLATION

Install the air conditioner in the location that

satisfies the following conditions.

- The place shall easily bear a load exceeding

four times the indoor unit’s weight.

- The place shall be able to inspect the unit as

the figure.

- The place where the unit shall be leveled.

- The place shall easily connect with the outdoor unit.

- The place where the unit is not affected by

an electrical noise.

- The place where air circulation in the room

will be good .

- There should not be any heat source or

steam near the unit

Confirm the positional relationship between

the unit and suspension bolts.

- Installation the ceiling opening to clean the

filter or service under the product.

[Unit:mm(inch)]

A(Min)

Ceiling

Service Space

A

B

B(Min)

H=20 (25/32)

or more

• Suitable dimension "H" is necessary to

get a slope to drain as shown in the figure

Side view [Unit: mm(inch)]

Air outlet

Inspection hole

600 x 600

(23-5/8 x 23-5/8)

Control box

600

(23-5/8)

600

(23-5/8)

Top view [Unit: mm(inch)]

Air outlet

Indoor unit

Capacity

(kBtu/h)

A B

9 800 (31-1/2) 800 (31-1/2)

12/18 800 (31-1/2) 1,000 (39-3/8)

Selection of the best location

INSTALLATION

Page 8

8

Ceiling dimension and hanging bolt location

Installation of Unit

Install the unit above the ceiling correctly.

- Apply a joint-canvas between the unit and

duct to absorb unnecessary vibration.

- Apply a filter Accessory at air return hole.

Unit:inch(mm)

C

E

G

D

F

I

A

J

B

H

Drainage hole

M10 Nut

M10 washer

X 4

X 4

M10 Nut

M10 washer

X 4

X 8

9 12/18

A

B

C

D

E

F

G

H

I

J

Capacity

(kBtu/h)

Dimension

POSITION OF SUSPENSION BOLT

- A place where the unit will be leveled and

that can support the weight of the unit.

- A place where the unit can withstand its

vibration.

- A place where service can be easily performed.

POSITION OF CONSOLE BOLT

h Install the unit leaning to a drainage hole

side as a figure for easy water drainage.

28-17/20 (733) 36-37/50 (933)

30-2/5 (772) 38-13/50 (972)

24-18/25 (628) 24-18/25 (628)

27-11/20 (700) 27-11/20 (700)

1-2/5 (36) 1-2/5 (36)

7-12/25 (190) 7-12/25 (190)

25/32 (20) 25/32 (20)

25-49/50 (660) 33-17/20 (860)

6-1/10 (155) 6-1/10 (155)

27-11/20 (700) 35-11/25 (900)

Page 9

9

ENGLISH

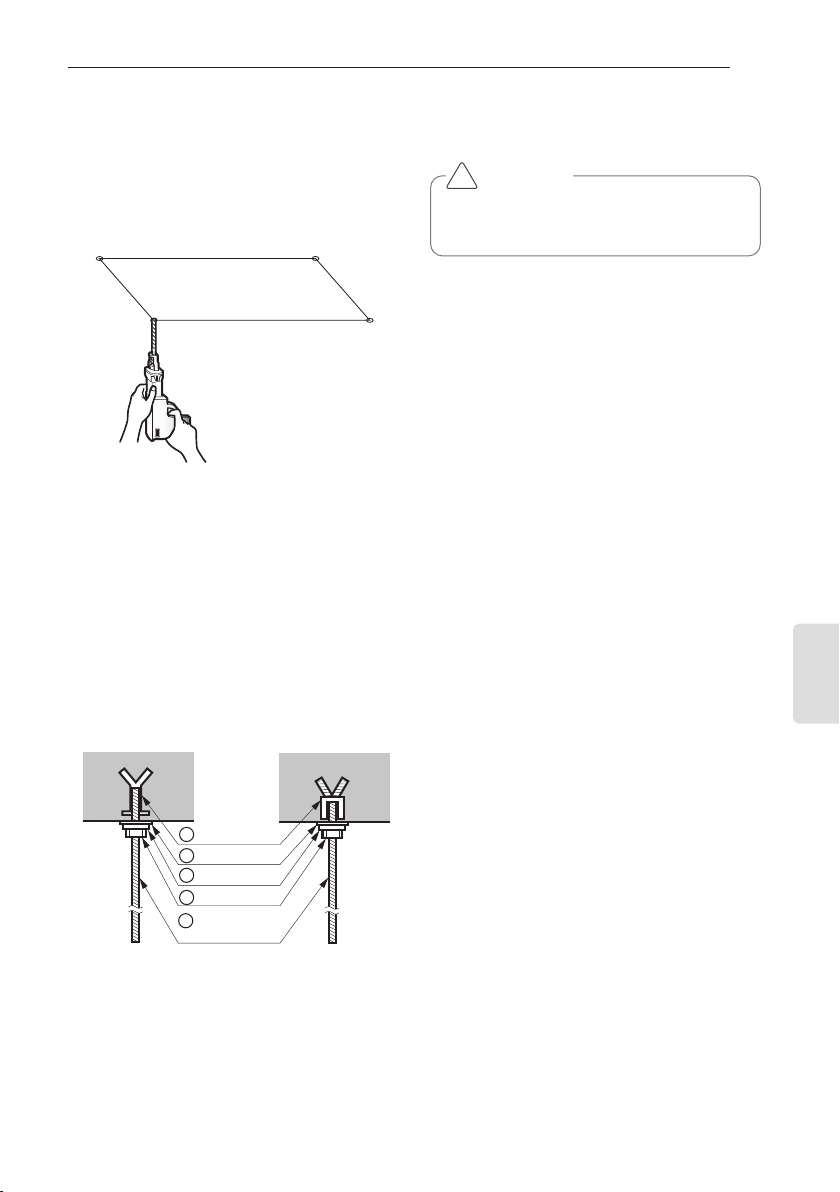

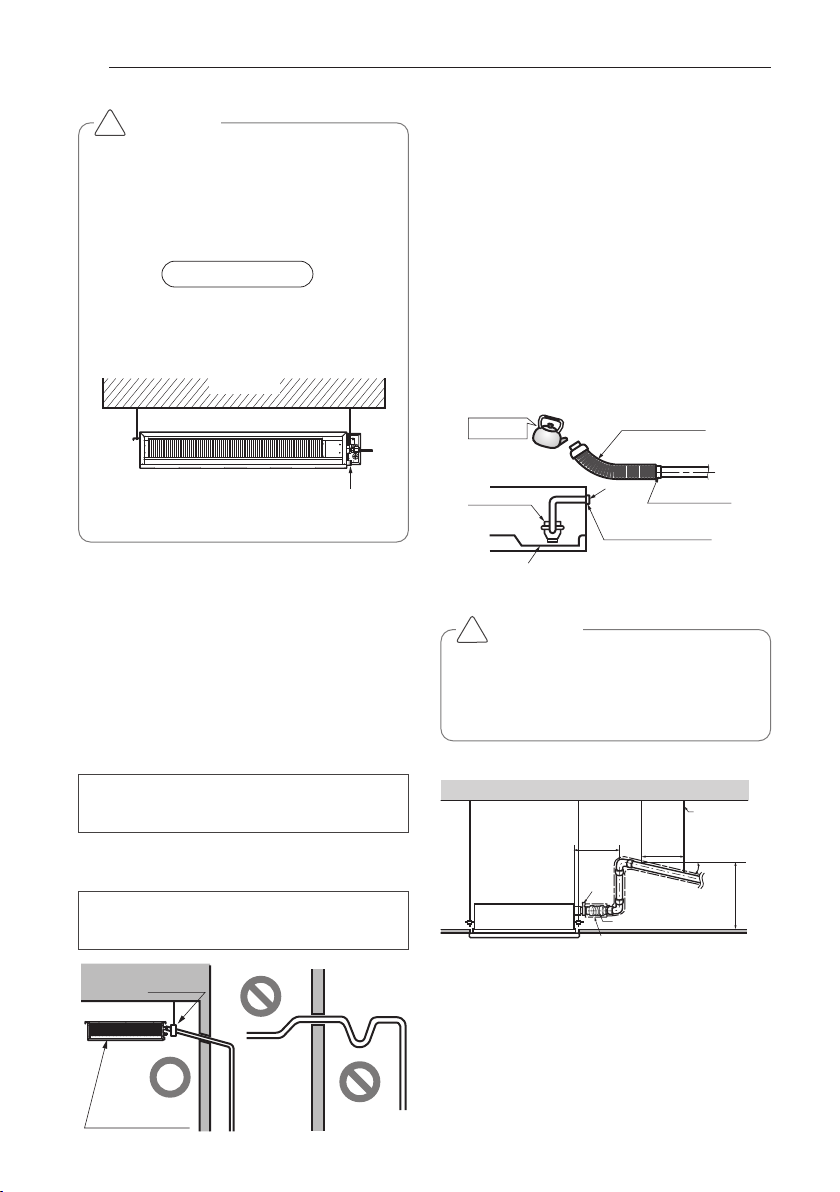

Indoor Unit Installation

1 Set anchor

Old building New building

2 Plate washer

3 Spring washer

4 Nut

5 Suspension

bolts

- Insert the set anchor and washer onto the

suspension bolts for locking the suspension

bolts on the ceiling.

- Mount the suspension bolts to the set

anchor firmly.

- Secure the installation plates onto the suspension bolts (adjust level roughly) using

nuts, washers and spring washers.

- Select and mark the position for fixing bolts.

- Drill the hole for set anchor on the face of

ceiling.

• Local supply

① Set anchor

② Plate washer - M10

③ Spring washer - M10

④ Nut - W3/8 or M10

⑤ Suspension bolt - W3/8 or M10

CAUTION

Tighten the nut and bolt to prevent unit

falling.

!

Page 10

10

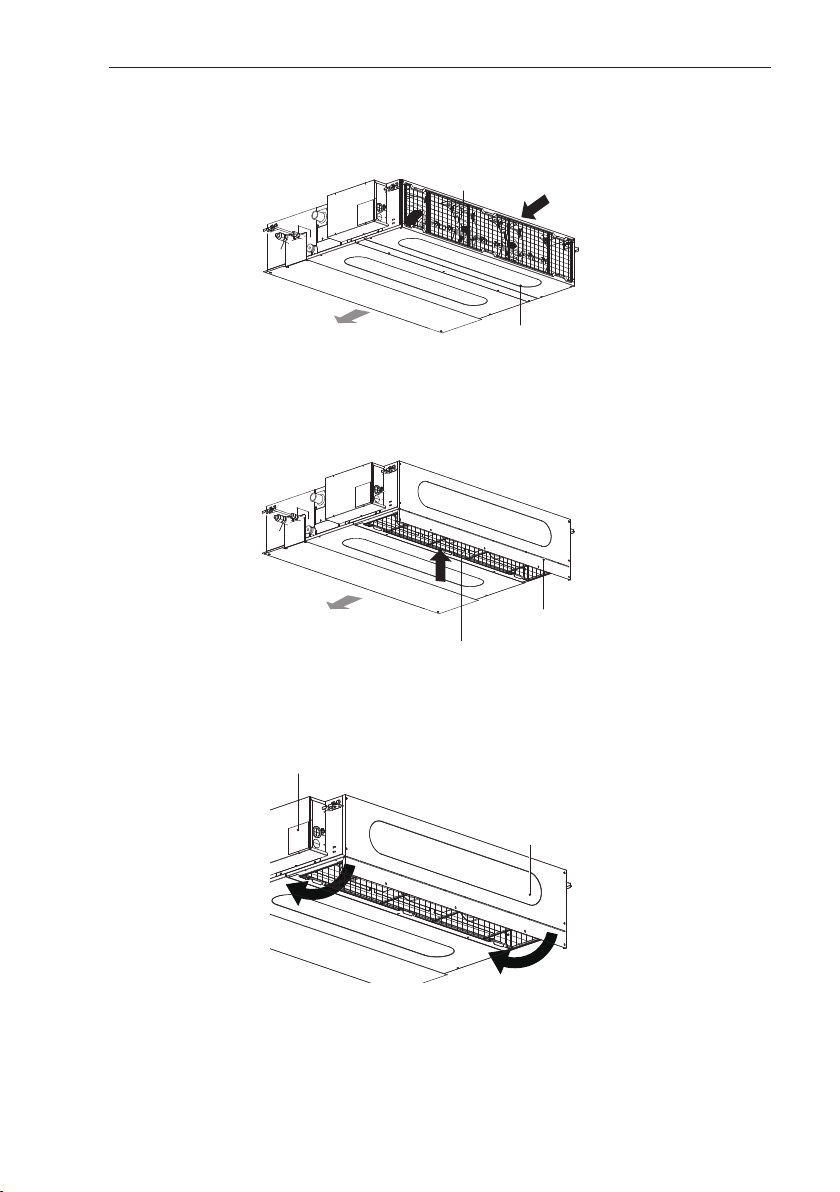

THE INDOOR UNIT INSTALLATION

Air Filter

Cabinet case

Panel Rear

Air outlet

Air Filter

Panel Rear

Air Filter

Air outlet

Panel Rear

Low static duct type in case of suction from back side.

Low static duct type in case of suction from bottom side.

In case of suction from bottom size, bend the Panel rear and screw with cabinet case.

Page 11

11

ENGLISH

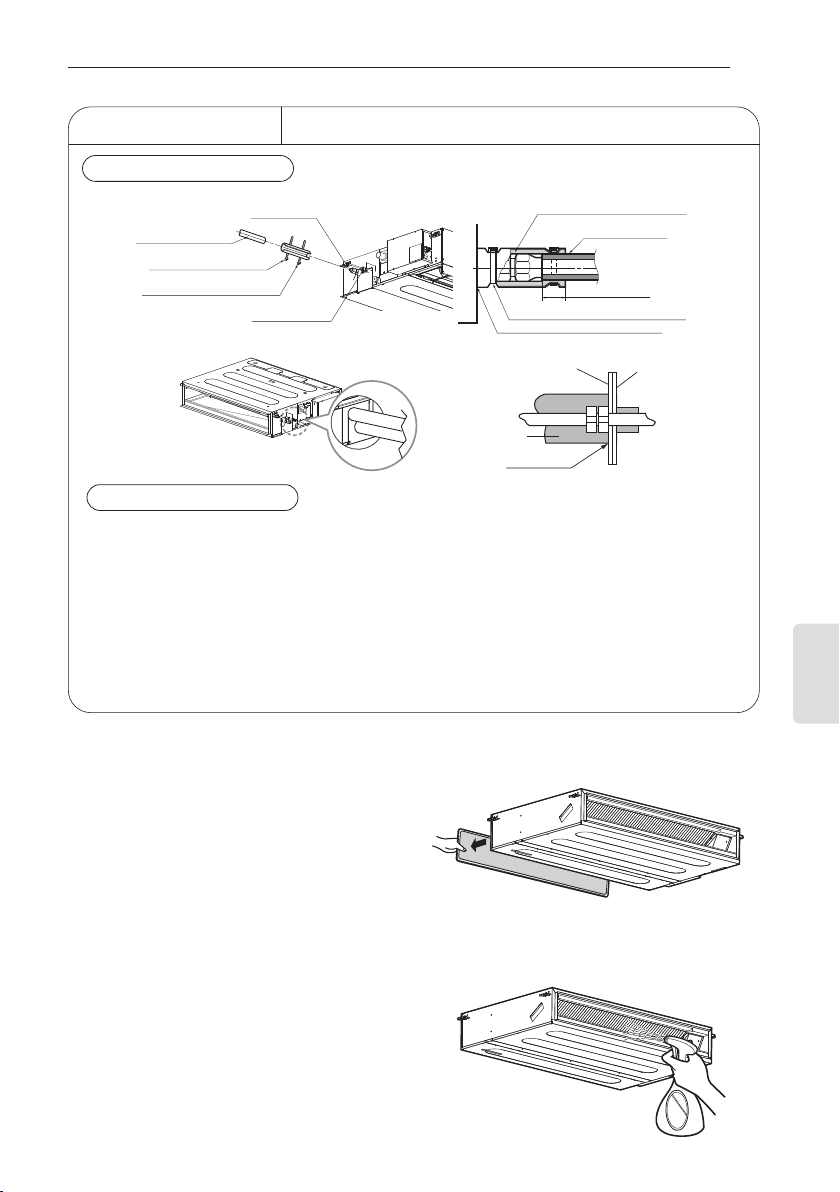

INSULATION, OTHERS

Insulate the joint and tubes completely.

All thermal insulation must comply with local requirement.

INDOOR UNIT

THERMAL INSULATION

After all workings are finished, check the working and operation.

• Air distribution ............. Is the air circulation good?

• Drain ............................ Is the drainage smoothly and no sweating?

• Gas leakage ................ Is the piping connection correctly?

• Wiring ......................... Is the wiring connection correctly?

• Lock-bolt ...................... Is the lock-bolt of compressor loosened?

• Insulation ..................... Is the unit fully insulated?

• Ground......................... Is the unit safely grounded?

TEST AND CHECK

Checking the Drainage

1 Remove the Air Filter.

2 Check the drainage.

- Spray one or two glasses of water upon the evaporator.

- Ensure that water flows down the drain hose of indoor unit without any leakage.

Refrigerant pipe and thermal

insulator(Local supply)

Hose clip for thermal insulator

Thermal insulator for refrigerant pipe

(Local supply)

(Local supply)

Union for gas pipe

Union for liquid pipe

Thermal insulator for refrigerant pipe

(Local supply)

Hose clip for thermal insulator(Local supply)

Make sure that there is no clearance here.

Insulation

No clearance

Thermal insulator for

piping(Local supply)

Overlap with thermal

insulator for piping.

Felt

Cabinet

Page 12

12

Indoor Unit Drain Piping

- Drain piping must have down-slope (1/50 to

1/100): be sure not to provide up-and-down

slope to prevent reversal flow.

- During drain piping connection, be careful

not to exert extra force on the drain port on

the indoor unit.

- The outside diameter of the drain connection

on the indoor unit is 32mm(1-1/4 inch).

- Be sure to execute heat insulation on the

drain piping.

Piping material: Polyvinyl chloride pipe

VP-25 and pipe fittings

Heat insulation material: Polyethylene

foam with thickness more than 8 mm.

Drain test

The air conditioner uses a drain pump to drain

water.

Use the following procedure to test the drain

pump operation:

- Connect the main drain pipe to the exterior

and leave it provisionally until the test comes

to an end.

- Feed water to the flexible drain hose and

check the piping for leakage.

- Be sure to check the drain pump for normal

operating and noise when electrical wiring is

complete.

- When the test is complete, connect the flexible drain hose to the drain port on the indoor

unit.

CAUTION

The supplied flexible drain hose should not

be curved, neither screwed. The curved or

screwed hose may cause a leakage of

water.

!

CAUTION

• Drain line must be angled down to ensure gravity drainage.

• Minimum thickness of the insulation for

the connecting pipe shall be 19mm(3/4

inch).

The unit must be horizontal or declined to

the drain hose connected when finished

installation.

!

1/50~1/100 slope

Hanger

distance

Hanger Bracket

Max 700mm

(27-11/20inch)

Flexible drain hose

Insulation

Metal

clamp

Max 300mm

(11-4/5inch)

1~15m

(3-7/25

~49-1/5ft)

Front of view

HAND OVER

Teach the customer the operation and mainte-

nance procedures, using the operation manual.

(air filter cleaning, temperature control, etc.)

Ceiling

Drain Pump use

Drainage

hole

Feed water

Drain Pump

Drain pan

Flexible drain hose

(accessory)

Main drain pipe

Drain

Glue the joint

port

Drain hose connection

Use the clip (accessory)

Pipe clamp

Indoor unit

Maintenance

drain port

Upward

routing

not allowed

Page 13

13

ENGLISH

Copper

tube

90

Slanted Uneven Rough

Pipe

Reamer

Point down

Flare nut

Copper tube

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Inclined

Inside is shining without scratches.

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Outside diameter A

mm inch mm inch

Ø6.35 1/4 1.1~1.3 0.04~0.05

Ø9.52 3/8 1.5~1.7 0.06~0.07

Ø12.7 1/2 1.6~1.8 0.06~0.07

Ø15.88 5/8 1.6~1.8 0.06~0.07

Ø19.05 3/4 1.9~2.1 0.07~0.08

Flaring work

Main cause of gas leakage is defect in flaring

work. Carry out correct flaring work in the following procedure.

1 Cut the pipes

- Use the accessory piping kit or the pipes

purchased locally.

- Measure the distance between the

indoor and the outdoor unit.

- Cut the pipes a little longer than measured distance.

- Cut the cable 1.5m(4.9ft) longer than the

pipe length.

2 Burrs removal

- Completely remove all burrs from the cut

cross section of pipe/tube.

- Put the end of the copper tube/pipe to

downward direction as you remove burrs

in order to avoid to let burrs drop in the

tubing.

3 Putting nut on

- Remove flare nuts attached to indoor and

outdoor units, than put them on

pipe/tube having completed burr removal.

(Not possible to put them on after flaring

work)

4 Flaring work

- Carry out flaring work using flaring tool as

shown below.

5 Check

- Compare the flared work with figure.

- If flare is noted to be defective, cut off

the flared section and do flaring work

again.

Firmly hold copper tube in a bar(or die) as

indicated dimension in the table above.

Page 14

14

Drying Cleanliness Airtight

Should be no moisture

inside

No dust inside.

There is no refrigerant

leakage

Items

Moisture

Dust

Leakage

Cause

failure

- Significant hydrolysis of

refrigerant oil

- Degradation of refrigerant

oil

- Poor insulation of the

compressor

- Do not cold and warm

- Clogging of EEV, Capillary

- Degradation of refrigerant

oil

- Poor insulation of the

compressor

- Do not cold and warm

- Clogging of EEV, Capillary

- Gas shortages

- Degradation of refrigerant

oil

- Poor insulation of the

compressor

- Do not cold and warm

Countermeasure

- No moisture in the pipe

- Until the connection is

completed, the plumbing

pipe entrance should be

strictly controlled.

- Stop plumbing at rainy

day.

- Pipe entrance should be

taken side or bottom.

- When removal burr after

cutting pipe, pipe entrance

should be taken down.

- Pipe entrance should be

fitted cap when pass

through the walls.

- No dust in the pipe.

- Until the connection is

completed, the plumbing

pipe entrance should be

strictly controlled.

- Pipe entrance should be

taken side or bottom.

- When removal burr after

cutting pipe, pipe entrance

should be taken down.

- Pipe entrance should be

fitted cap when pass

through the walls.

- Airtightness test should

be.

- Brazing operations to comply with standards.

- Flare to comply with standards.

- Flange connections to

comply with standards.

Plumbing materials and storage methods

Pipe must be able to obtain the specified thickness and should be used with low impurities.

Also when handling storage, pipe must be careful to prevent a fracture, deformity and wound.

Should not be mixed with contaminations such as dust, moisture.

Refrigerant piping on three principles

Page 15

15

ENGLISH

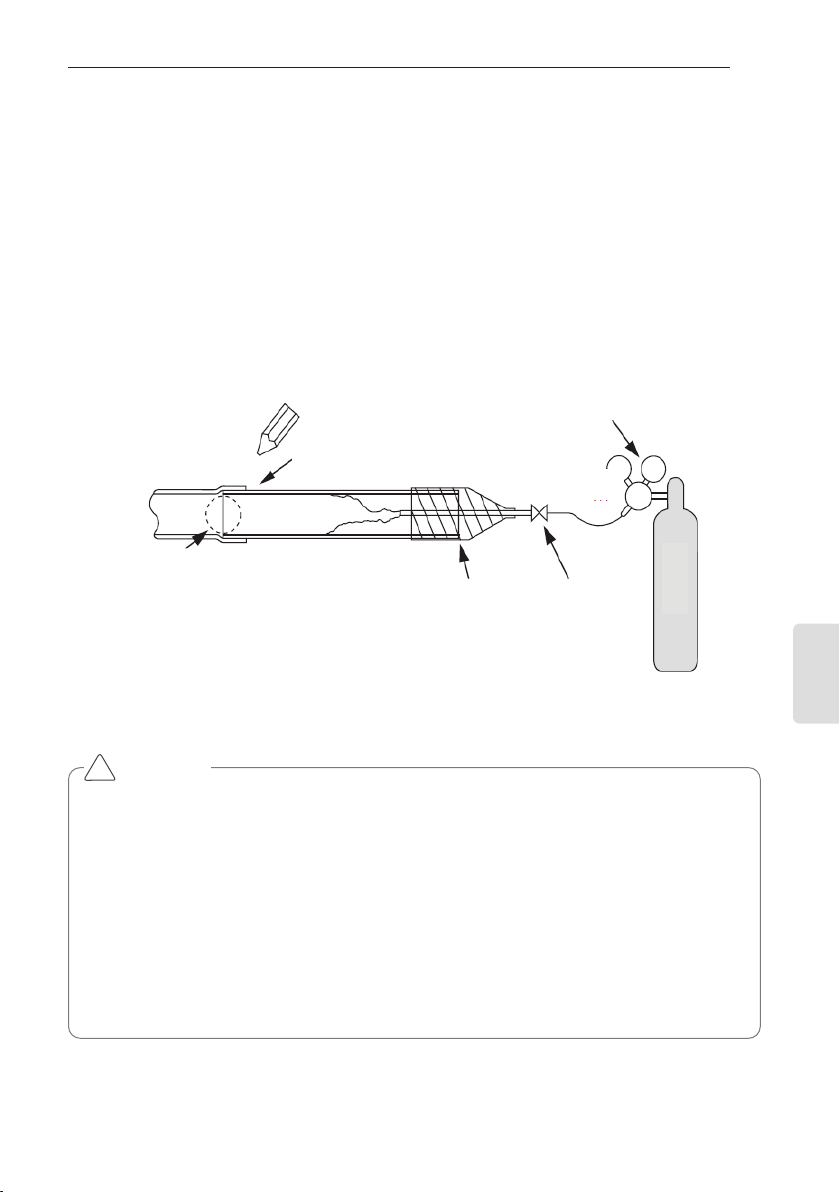

Nitrogen substitution method

Welding, as when heating without nitrogen substitution a large amount of the oxide film is

formed on the internal piping.

The oxide film is a caused by clogging EEV, Capillary, oil hole of accumulator and suction hole of

oil pump in compressor.

It prevents normal operation of the compressor.

In order to avoid this problem, Welding should be done after replacing air by nitrogen gas.

When welding plumbing pipe, the work is required.

◆How to work

CAUTION

1. Always use the nitrogen.(not use oxygen, carbon dioxide, and a Chevron gas):

Please use the following nitrogen pressure 0.02MPa

Oxygen --------- Promotes oxidative degradation of refrigerant oil.

Because it is flammable, it is strictly prohibited to use

Carbon dioxide --- Degrade the drying characteristics of gas

Chevron Gas ---- Toxic gas occurs when exposed to direct flame.

2. Always use a pressure reducing valve.

3. Please do not use commercially available antioxidant.

The residual material seems to be the oxide scale is observed.

In fact, due to the organic acids generated by oxidation of the alcohol contained

in the anti-oxidants, ants nest corrosion occurs. (causes of organic acid ’ alcohol

+ copper + water + temperature)

!

Regulator

Welding Point

Nitrogen gas

Pressure 0.02MPa less

Oxide scale

Note) should not block the outlet side.

When the internal pressure in pipe is abo

ve the atmospheric pressure, pinhole is o

ccurred and it is a leakage cause.

Taping

(Should not

contain air)

Auxiliary valve

Nitrogen

Page 16

16

- Remove the control box cover for electrical

connection between the indoor and outdoor

unit. (Remove screws ¿.)

- Open the control box cover and connect the

Remote controller cord and Indoor power

wires.

- Use the cord clamper to fix the cord.

Control box

1

1

1

Connection method of the

connecting cable(Example)

WARNING

Loose wiring may cause the terminal to

overheat or result in unit malfunction.

A fire hazzard may also exist.

Therefore, be sure all wiring is tightly

connected.

!

Wiring Connection

Conduit panel

Lock nut

Conduit

1(L1) 2(L2) 3

Power Supply

High Voltage

(208/230V)

Page 17

17

ENGLISH

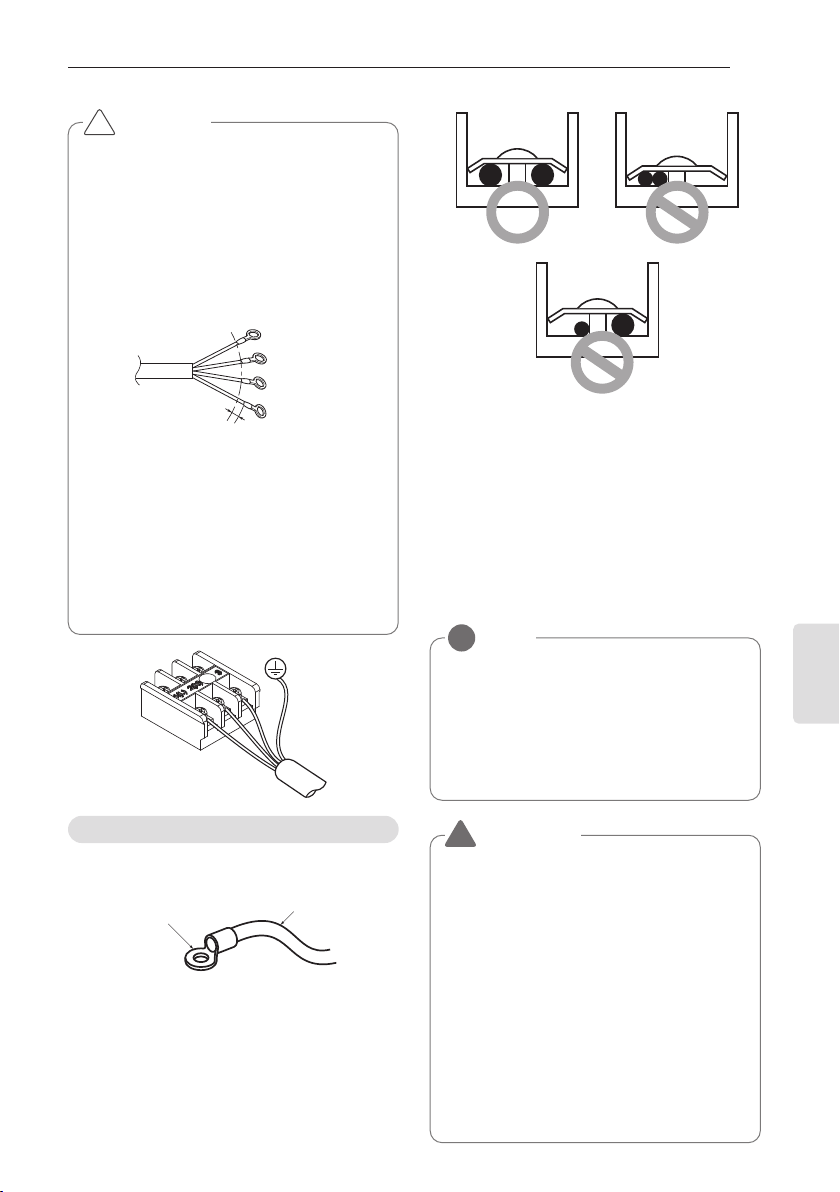

Precautions when laying power wiring

- For wiring, use the designated power wire and

connect firmly, then secure to prevent outside

pressure being exerted on the terminal block.

- Use an appropriate screwdriver for tightening

the terinal screws. A screwdriver with a small

head will strip the head and make proper

tighterning impossible.

- Over-tightening the terminal screws may break

them.

Use round pressure terminals for connections

to the power terminal block.

When none are available, follow the instructions below.

- Do not connect wiring of different thicknesses to the power terminal block. (Slack in the

power wiring may cause abnormal heat.)

- When connecting wiring which is the same

thickness, do as shown in the figure below.

Round pressure terminal

Power wire

CAUTION

The power connecting cable between

the outdoor and indoor units must comply with the following specifications:

NRTL Recognized (for example, UL or

ETL recognized and CSA certified).

AWG 14/4 is the minimum recommended wire size, however, the selected conductors must comply with local codes

and be suitable for installation in wet

locations.

If the supply cord is damaged, it must be

replaced by a special cord or assembly

available from the manufacturer of its

service agent. When the connection line

between the indoor unit and outdooor

unit and outdoor unit is over 1.57inch,

connect the telecommunication line and

power line separately.

!

NOTE

!

Use connection cable NRTL(UL, ETL, CAS…)

listed and stranded copper(4) THHN conductors, sunlight (UV) resistant ROHS compliant

PVC jacket 600V direct burial listed, approved

for wet conditions. Temperature rated for –

20°C(-4°F) to 90°C(194°F). And this cable

should be enclosed in conduit.

• Be sure to comply with local and national

codes while running the wire from the

indoor unit to the outdoor unit(size of wire

and wiring method, etc).

• Every wire must be connected firmly.

• No wire should be allowed to touch refrigerant tubing, the compressor or any moving parts.

• The communication wirings of air conditioner should be separate and isolated

from external device’s electric wiring

such as computers, elevator, radio &

Television broadcasting facilities, as well

as medical imaging offices.

WARNING

!

GN/YL

20mm

(25/32 inch)

Page 18

18

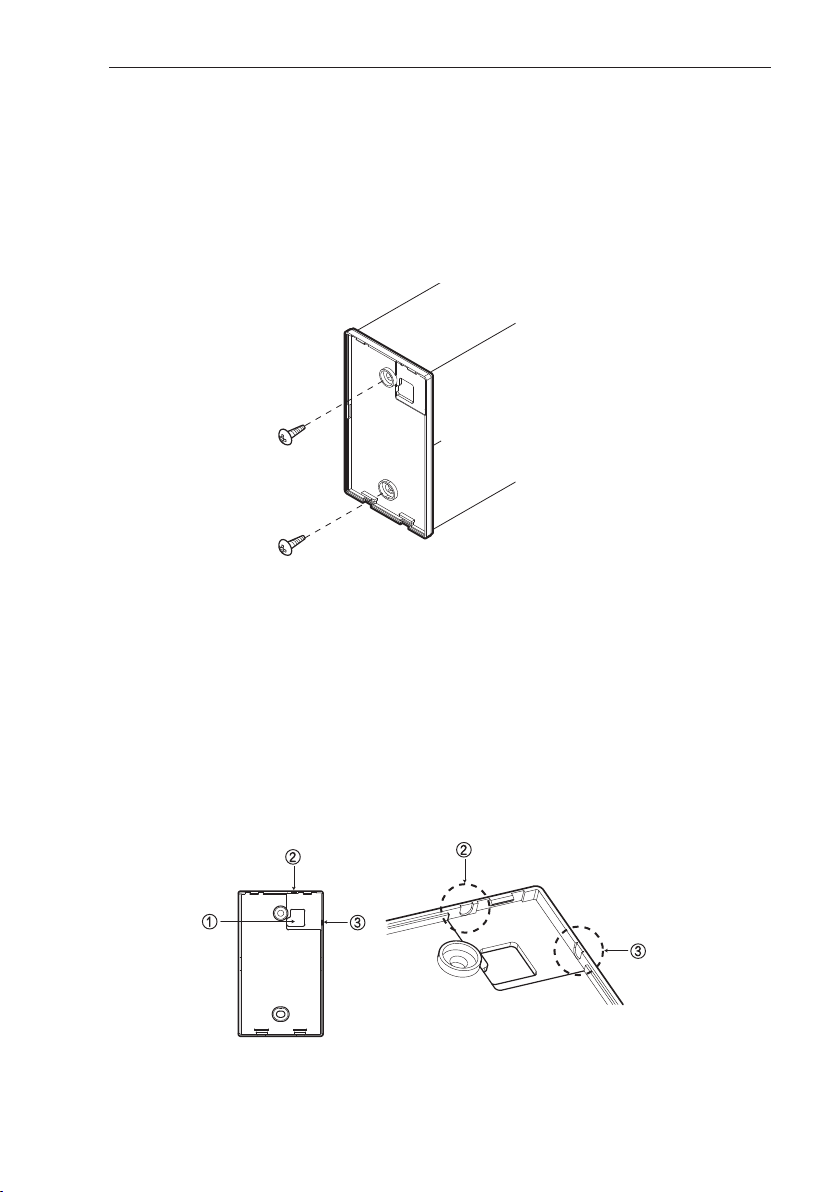

Please fix tightly using provided screw after placing remote controller setup

board on the place where you like to setup.

- Please set it up not to bend because poor setup could take place if setup board bends.

Please set up remote controller board fit to the reclamation box if there is a reclamation box.

Can set up Wired remote controller cable into three directions.

- Setup direction: the surface of wall reclamation, upper, right

- If setting up remote controller cable into upper and right side, please set up after removing

remote controller cable guide groove.

* Remove guide groove with long nose.

① Reclamation to the surface of the wall

② Upper part guide groove

③ Right part guide groove

<Wire guide grooves>

REMOTE CONTROLLER INSTALLATION

Page 19

19

ENGLISH

Please fix remote controller upper part

into the setup board attached to the surface of the wall, as the picture below, and

then, connect with setup board by pressing lower part.

- Please connect not to make a gap at the remote

controller and setup board’s upper and lower, right

and left part.

When separating remote controller from

setup board, as the picture below, after

inserting into the lower separating hole

using screw driver and then, spinning

clockwise, remote controller is separated.

- There are two separating holes. Please individually

separate one at a time.

- Please be careful not to damage the inside

components when separating.

Please connect indoor unit and remote controller using connection cable.

Please use extension cable if the distance between wired remote controller

and indoor unit is more than 10m(32-4/5ft).

Wall

Side

Wall

Side

Wall

Side

Wall

Side

<Connecting order>

<Separating order>

TEMP

FAN

SPEED

OPER

MODE

Remote

Controller

PCB

YELLOW RED

BLACK

Signal

12v

GND

Indoor Unit Side

Connecting Cable

CAUTION

When installing the wired remote controller, do not bury it in the wall.

(It can cause damage in the temperature sensor.)

Do not install the cable to be 50m or above.

(It can cause communication error.)

• When installing the extension cable, check the connecting direction of the connector of the

remote controller side and the product side for correct installation.

• If you install the extension cable in the opposite direction, the connector will not be connected.

• Specification of extension cable: 2547 1007 22# 2 core 3 shield 5 or above.

• Apply totally enclosed noncombustible conduit in case of local building code Requiring

plenum cable usage.

!

12V Red

Signal Yellow

GND Black

Page 20

20

Wired remote controller installation

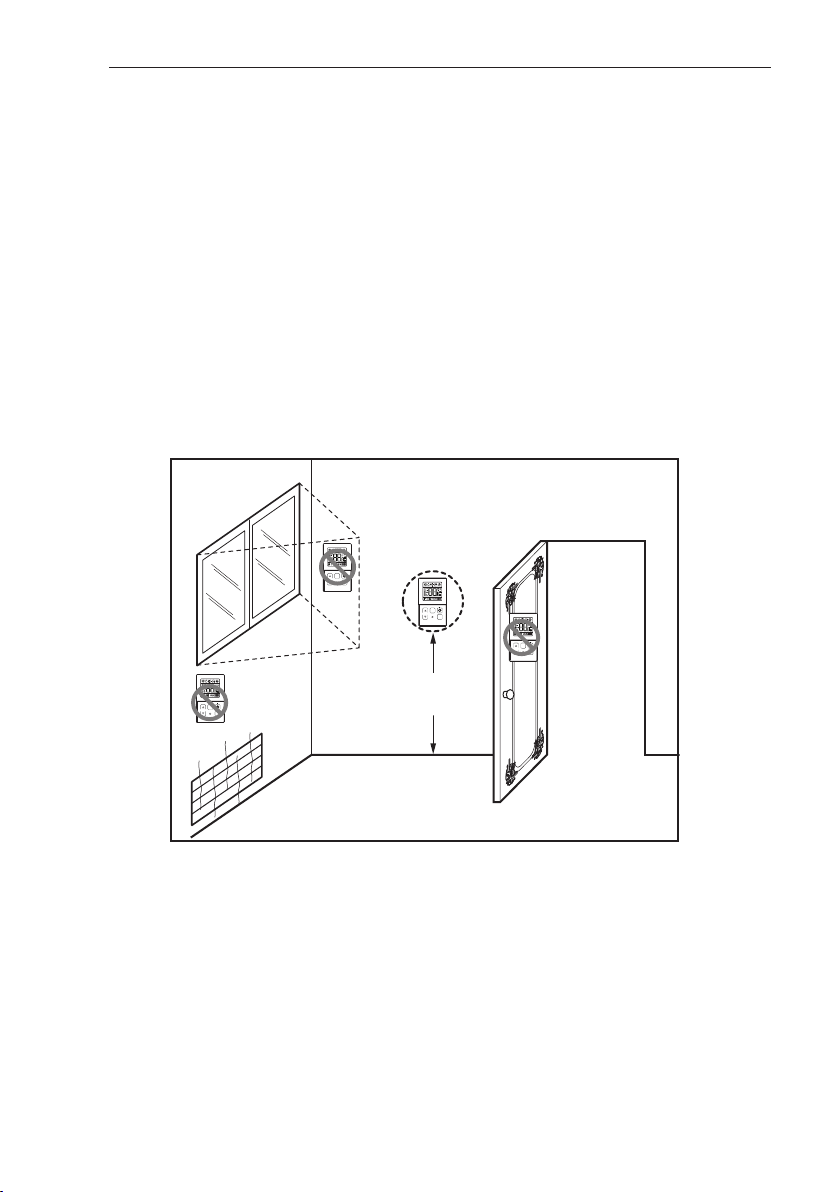

Since the room temperature sensor is in the remote controller, the remote controller box should

be installed in a place away from direct sunlight, high humidity and direct supply of cold air to

maintain proper space temperature. Install the remote controller about 5ft(1.5m) above the floor

in an area with good air circulation at an average temperature.

Do not install the remote controller where it can be affected by:

- Drafts, or dead spots behind doors and in corners.

- Hot or cold air from ducts.

- Radiant heat from sun or appliances.

- Concealed pipes and chimneys.

- Uncontrolled areas such as an outside wall behind the remote controller.

- This remote controller is equipped with LCD. display. For proper display of the remote controller

LCD's, the remote controller should be installed properly as shown in Fig.1.

(The standard height is 4~5 ft (1.2~1.5 m) from floor level.)

[Fig.1]

TEMP

no

FAN

SPEED

TEMP

OPER

MODE

no

FAN

SPEED

OPER

MODE

yes

FAN

SPEED

TEMP

OPER

MODE

5feet

(1.5meters)

TEMP

no

FAN

SPEED

OPER

MODE

Page 21

21

ENGLISH

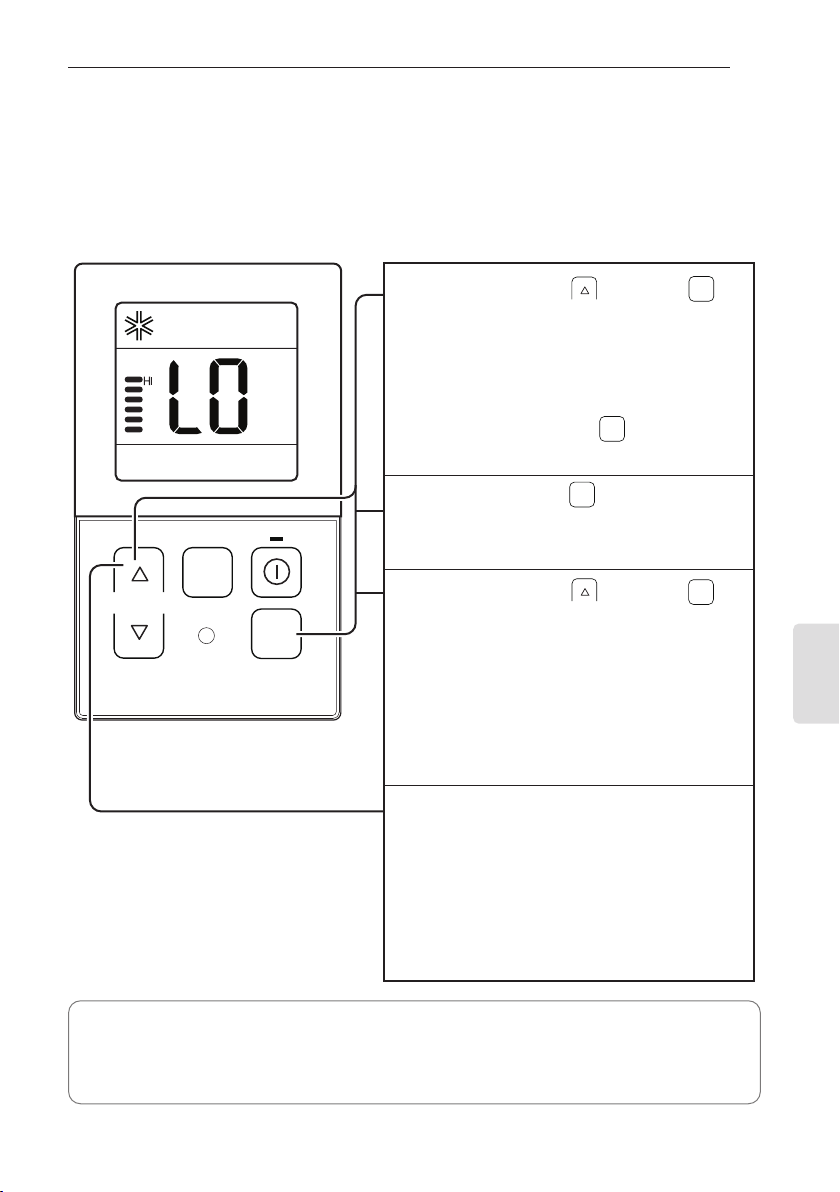

Installer Setting - Test Run Mode

After installing the product, you must run a Test Run mode.

For details related to this operation, refer to the product manual.

• What is the test run mode??

- This means the operation of the product under the cooling, strong wind, and Comp on

state without performing room temperature control in order to confirm the installed state

during the product installation.

OPTIONAL OPERATION

TEMP

FAN

SPEED

OPER

MODE

When pressing the button and

1

button simultaneously for more than 3

seconds, the system will be entered into

the installer setting mode.

- After entering into the installer setting

mode, select the test run mode code

value by pressing the button.

* Test run mode code value : 01

When pressing the button, the test

2

operation mode will be performed, and it is

displayed as shown in the left figure.

When pressing the button and

3

button simultaneously for more than 3

seconds after the setting has been

completed, the setting mode will be

released.

- If there isn’t any button input for more

than 25 seconds, the installer setting

mode will also be released.

When approx. 18 minutes are elapsed after

4

starting of the test oper-mode, the system

will be stopped automatically and converted

to the standby state.

- If any button is inputted during the test

run mode, the test run mode will be

forced to be relreased.

OPER

MODE

OPER

MODE

OPER

MODE

OPER

MODE

Page 22

22

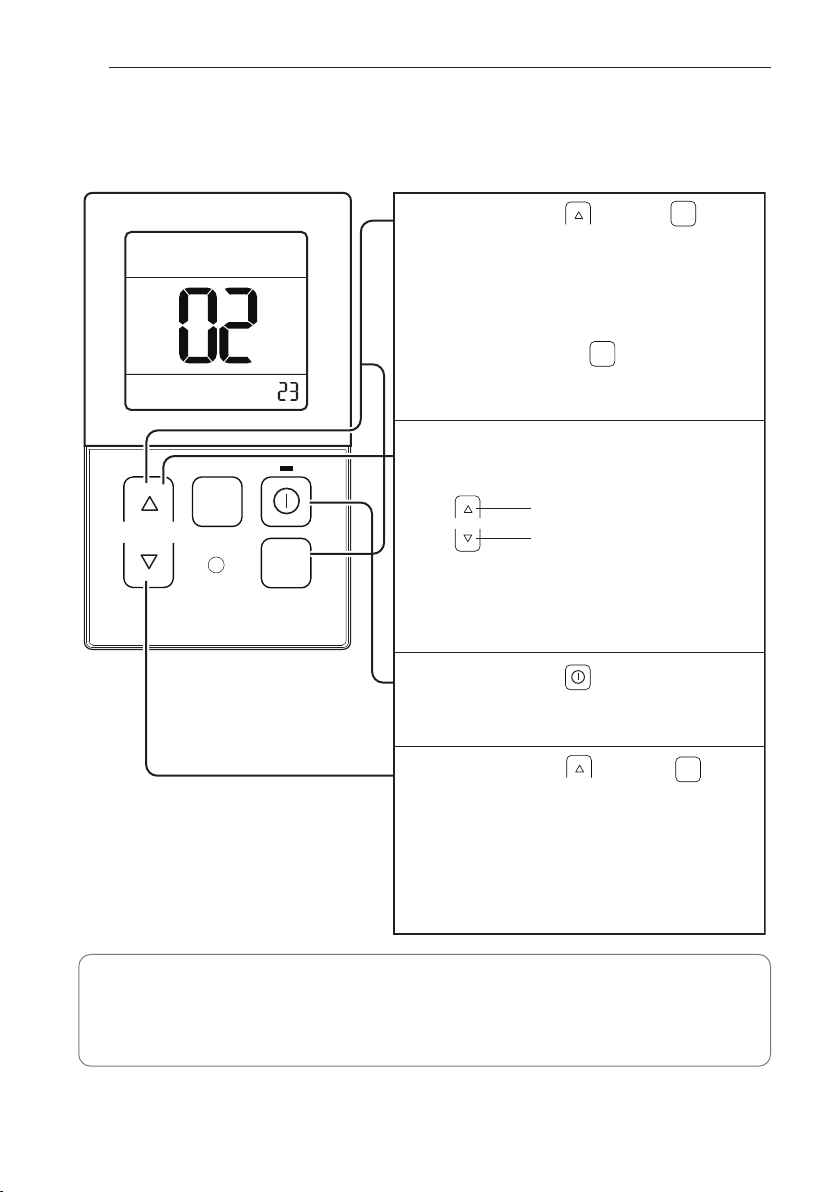

Installer Setting - Setting Address of Central Control

It's the function to use for connecting central control.

Please refer to central controller manual for the details.

* In the case when the lock is set up at the central controller, ‘HL’ will be indicated on the display

window of the wired remote controller and the indoor unit will not be controlled by the remote

controller.

• If you connect the indoor unit to the central controller, you should set the network address

of the indoor unit so that the central controller could recognize it.

• The center-control address is composed of the group number and the indoor-unit number.

Note : The remote controller displays 'HL' if central controller has locked the remote controller .

TEMP

FAN

SPEED

OPER

MODE

When pressing the button and button

1

simultaneously for more than 3 seconds, the

system will be entered into the installer setting

mode.

-

After entering into the installer setting mode,

select the central control address setting code

value by pressing the button.

* Setting address of central control code value

: 02

Set up the group nember and indoor unit with

2

the temperature adjustment(▲,▼) buttons.

TEMP

For example, when setting as

[ Group number=2 Indoor number=3 ]

it will be displayed as shown in the left figure.

When pressing the button, the system will

3

be set up with the address value which has

been established at present.

When pressing the button and

4

button simultaneously for more than 3 seconds

after the setting has been completed, the

setting mode will be released.

- If there isn’t any button input for more than

25 seconds, the installer setting mode will

also be released.

OPER

MODE

Group number

Indoor unit number

OPER

MODE

OPER

MODE

Page 23

23

ENGLISH

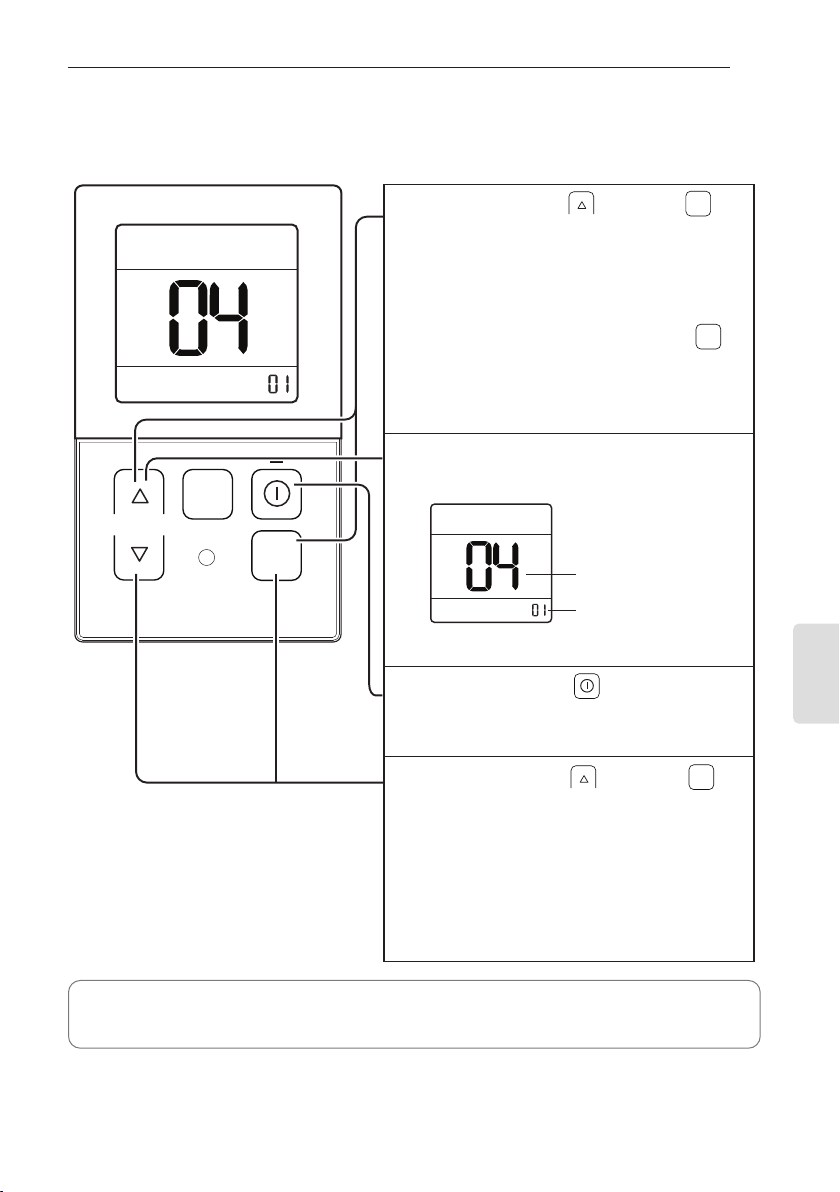

Installer Setting - Thermistor

This is the function to select the temperature sensor to judge the room temperature.

• As the characteristic of the ‘2TH’ function can be different in accordance with the products,

refer to the product instruction manual for its detail.

TEMP

FAN

SPEED

OPER

MODE

When pressing the button and

1

button simultaneously for more than 3

seconds, the system will be entered into

the installer setting mode.

- After entering into the installer setting

mode, select the thermistor sensor

setting code value by pressing the

button.

* Thermistor sensor selection code value

: 04

Select the desired setting value with the

2

temperature up(▲), down(▼) button.

Code value

Value

When pressing the button, currently

3

established thermistor sensor location will

be set up.

When pressing the button and

4

button simultaneously for more than 3

seconds after the setting has been

completed, the setting mode will be

released.

- If there isn’t any button input for more

than 25 seconds, the installer setting

mode will also be released.

OPER

MODE

OPER

MODE

*Setting value

01: Remote

controller

02: Indoor unit

03: 2TH

OPER

MODE

Page 24

24

TEMP

FAN

SPEED

OPER

MODE

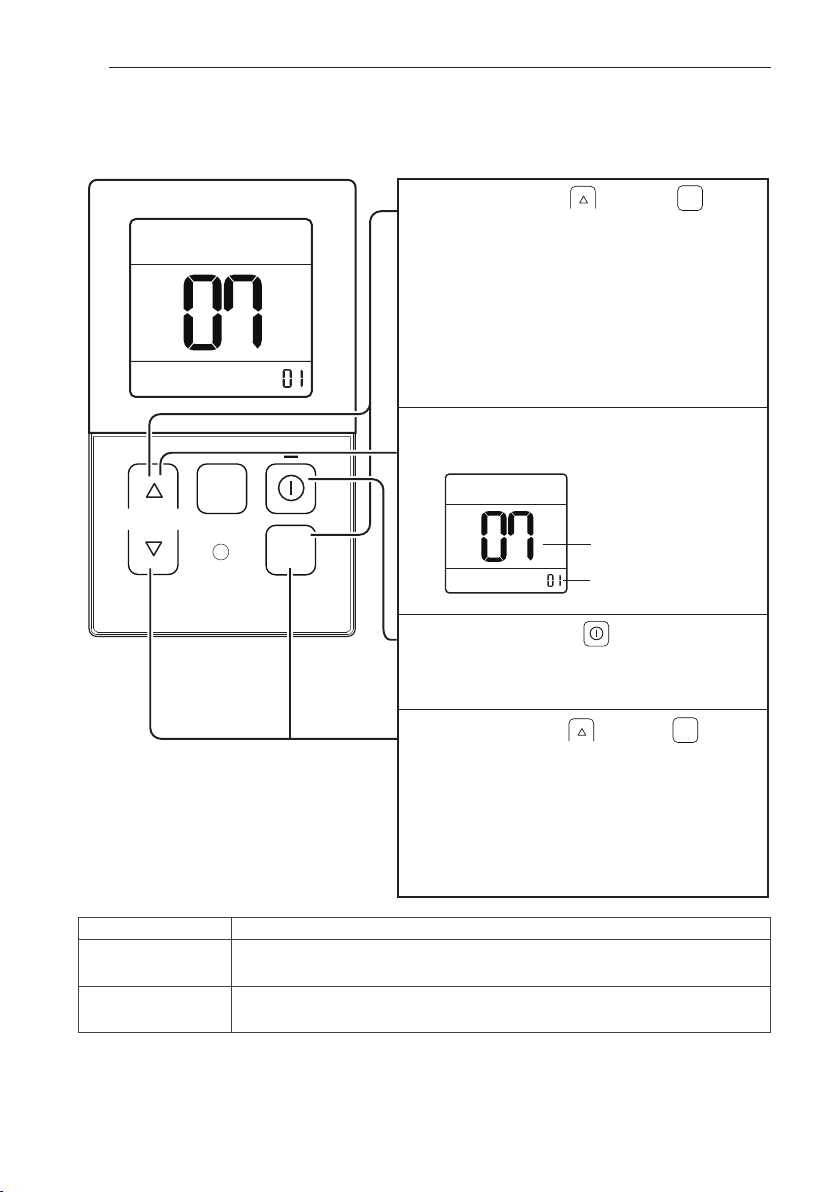

When pressing the button and button

simultaneously for more than 3 seconds, the

system will be entered into the installer setting

mode.

- After entering into the installer setting mode,

select the ceiling height setting code value by

pressing the oper-mode button.

* Remote controller master/slave setting code

value : 07

1

Select the desired setting value with the

temperature up(▲), down(▼) button.

2

When pressing the button, currently

established static pressure value will be set

up.

3

When pressing the button and button

simultaneously for more than 3 seconds after the

setting has been completed, the setting mode

will be released.

- If there isn’t any button input for more than 25

seconds, the installer setting mode will also be

released.

4

OPER

MODE

Code value

*Setting value

00:Slave

01:Master

OPER

MODE

Value

* Refer to the 'group control' part for details

- When controlling in groups, basic operation settings, airflow strength weak/medium/strong,

lock setting of the remote controller, time settings, and other functions may be restricted.

Remote controller Function

Master

Indoor unit operates based on master remote controller at group control.

(Master is set when delivering from the warehouse.)

Slave

Setup all remote controllers except one master remote controller to slave

at group control

Installer Setting - Group Setting

It is a function for settings in group control, or 2-remote controller control.

Page 25

25

ENGLISH

• Whenever press temp up(s), down(t) button in Fahrenheit mode, the temperature will

increase/drop 2 degrees.

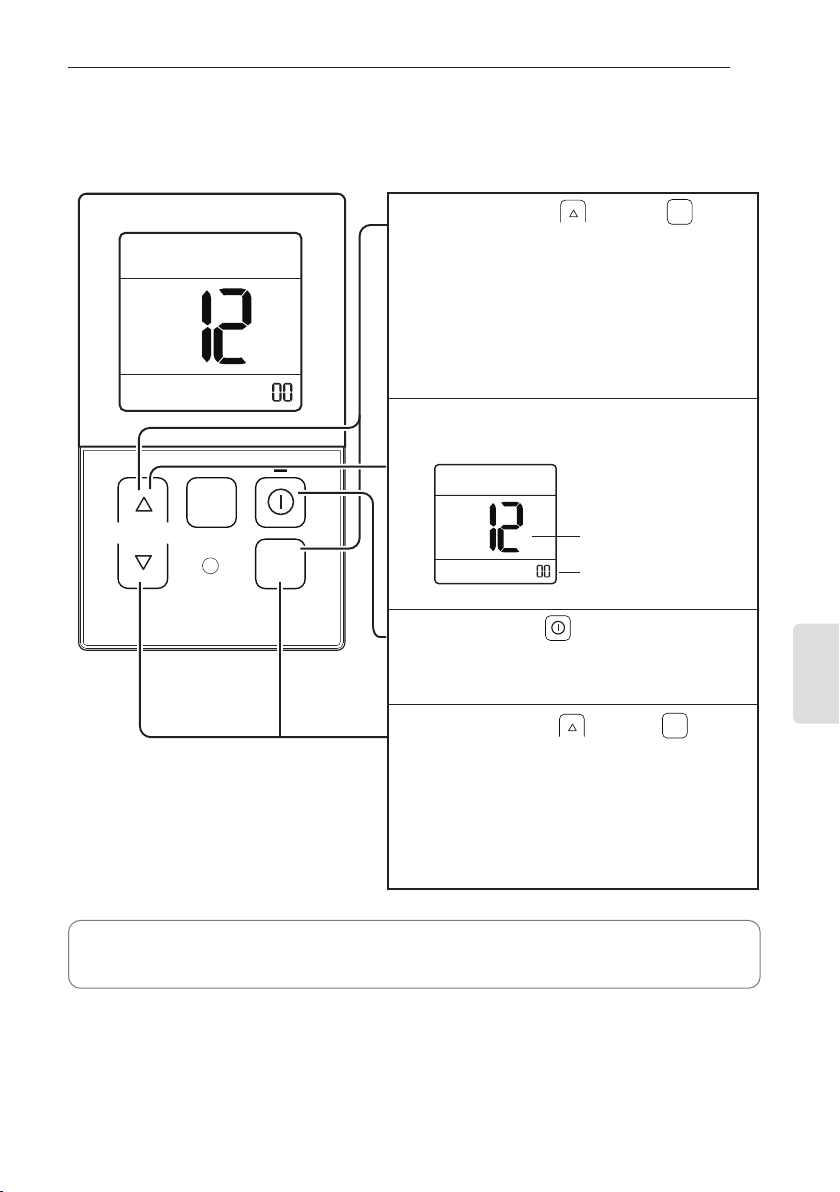

Installer Setting - Celsius / Fahrenheit Switching

This function is used for switching the display between Celsius and Fahrenheit.

(Optimized only for U.S.A)

TEMP

FAN

SPEED

OPER

MODE

When pressing the button and button

1

simultaneously for more than 3 seconds, the

system will be entered into the installer setting

mode.

- After entering into the installer setting mode,

select the ceiling height setting code value by

pressing the oper-mode button.

* Celsius/Fahrenheit setting code value : 12

Select the desired setting value with the

2

temperature up(▲), down(▼) button.

Code value

Value

When pressing button, currently

3

established celsius/Fahrenheit setting value

will be set up.

When pressing the button and button

4

simultaneously for more than 3 seconds after the

setting has been completed, the setting mode

will be released.

- If there isn’t any button input for more than 25

seconds, the installer setting mode will also be

released.

OPER

MODE

*Setting value

00:Celsius

01:Fahrenheit

OPER

MODE

Page 26

26

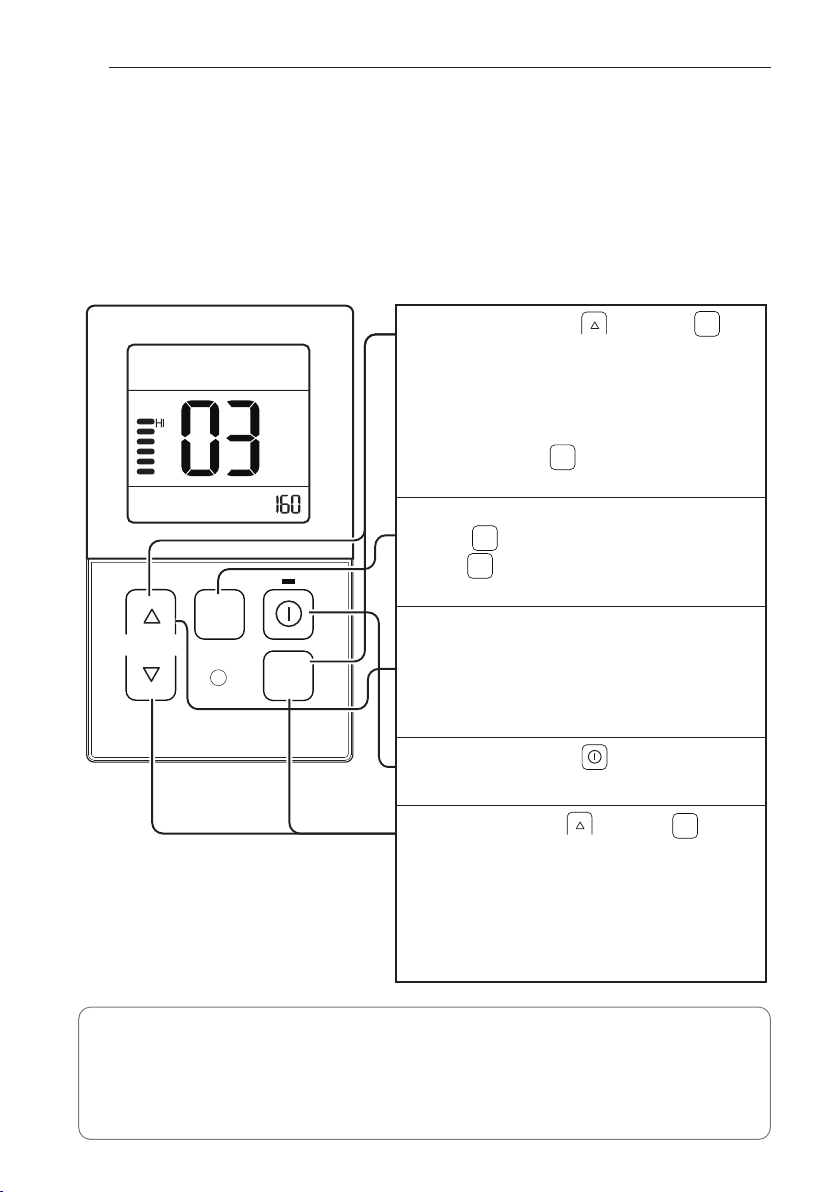

Installer Setting - E.S.P.

This is the function that decides the strength of the wind for each wind level and because this

function is to make the installation easier.

• If you set ESP incorrectly, the air conditioner may malfunction.

• This setting must be carried out by a certificated-technician.

• Precaution shall be taken not to alter the E.S.P value corresponded to each air flow section.

• E.S.P value can be varied according to the products.

• In the case of going to the next air flow rate stage by pressing the fan-speed button during

the setup of the E.S.P value, the E.S.P value of previous air flow rate will be maintained by

remembering the E.S.P value prior to the shift.

HOW TO SET E.S.P?

TEMP

FAN

SPEED

OPER

MODE

OPER

MODE

OPER

MODE

When pressing the button and

1

button simultaneously for more than 3

seconds, the system will be entered into

the installer setting mode.

- After entering into the installer setting

mode, select the E.S.P code value by

pressing the button.

* E.S.P code value : 03

Select the desired air flow rate with

2

3

4

5

FAN

SPEED

the button. Whenever pressing

FAN

the button, [SLo→Lo→Med→Hi→Po] will

SPEED

be indicated.

Select the desired air flow rate value with

the temperature up(▲), down(▼) button.

* E.S.P value range : 0~255

-

E.S.P value will be indicated at the upper

right section of the display window.

When pressing the button, currently

established E.S.P value will be set up.

When pressing the button and button

simultaneously for more than 3 seconds after the

setting has been completed, the setting mode

will be released.

- If there isn’t any button input for more

than 25 seconds, the installer setting

mode will also be released.

OPER

MODE

Page 27

27

ENGLISH

(Unit : CMM)

Capacity Step CFM

Static Pressure(mmAq(in.Aq))

0(0) 1(0.4) 2(0.08) 3(0.12) 4(0.16) 5(0.2)

Setting Value

9k

HIGH 318 98 103 108 116 123 130

MID 247 82 88 94 102 110 118

LOW 194 69 76 83 91 99 109

12k

HIGH 353 95 99 104 109 116 124

MID 300 86 91 96 101 108 116

LOW 247 78 82 87 93 100 108

18k

HIGH 530 123 125 129 134 141 145

MID 441 109 112 117 123 129 136

LOW 353 95 99 104 109 116 124

Page 28

28

Indoor PCBIndoor PCBIndoor PCB

3 Times 3 Times 3 Times

2 Sec.

LED02G

(GREEN)

2 Sec.

Function Description Setting Off Setting On Default

SW3 Group Control

Selection of Master or

Slave

Master Slave Off

SW4

Dry Contact

Mode

Selection of Dry Contact

Mode

Wired/Wireless remote

controller

Selection of Manual or

Auto operation Mode

Auto Off

SW5 Installation Fan continuous operation

Continuous operation

Removal

Working Off

DIP SWITCH SETTING

Indoor Unit Error

Ex) Error 03 (Remote controller error)

h Because remote controller turn off when occur ERROR in simultaneous operation system, it

should check LED blinks of outdoor in order to confirm error code.

h Repeatedly after LED1 is turned on and off as the Error code number of tens digit, LED2 is

turned on and off as the Error code number of single-digit.

Error Code Description LED 1(Red) LED 2(Green)

Indoor

status

01 Indoor Room sensor error 0 1time ◑ OFF

02 Indoor in-pipe sensor error 0 2times ◑ OFF

03 Remote controller error 0 3times ◑ OFF

04 Drain pump error 0 4times ◑ OFF

05 Communication error indoor and outdoor 0 5times ◑ OFF

06 Indoor out-pipe sensor error 0 6times ◑ OFF

09 EEPROM error (indoor) 0 9times ◑ OFF

10 BLDC motor fan lock (indoor) 1time ◑ 0 OFF

SELF-DIAGNOSIS FUNCTION

Page 29

Manuale d’installazione

TYPE : Climatiseur à conduit caché

dans le plafond - faible pression

statique

FRANÇAIS

Page 30

ASTUCES POUR ECONOMISER L’ENERGIE

2

ASTUCES POUR ECONOMISER L’ENERGIE

Nous vous donnons ici quelques astuces qui vous permettront de minimiser la consommation

d’énergie lorsque vous utilisez le climatiseur. Vous pouvez utiliser un climatiseur de manière plus

efficace en vous référant aux instructions ci-dessous.

• Evitez un refroidissement excessif des unités intérieures. Une telle application pourrait représenter un danger pour votre santé et entraîner une plus grande consommation de courant.

• Evitez d'exposer le climatiseur aux rayons solaires à l’aide des rideaux ou des persiennes lorsqu’il est en marche.

• Maintenez les portes et les fenêtres complètement fermées lorsque vous utilisez le climatiseur.

• Ajustez le sens du débit d’air verticalement ou horizontalement pour permettre la circulation

de l’air intérieur.

• Accélérez le ventilateur pour refroidir ou réchauffer rapidement l’air intérieur en peu de temps.

• Ouvrez régulièrement des fenêtres pour des besoins d’aération étant donné que la qualité de

l'air intérieur peut se détériorer si vous utilisez le climatiseur pendant plusieurs heures.

• Ouvrez régulièrement des fenêtres pour des besoins d’aération étant donné que la qualité de

l'air intérieur peut se détériorer si vous utilisez le climatiseur pendant plusieurs heures.

Pour vos archives

Agrafez votre reçu sur cette page dans le cas où vous en avez besoin pour prouver la date d’achat ou

pour des besoins de garantie. Ecrivez le numéro du modèle et le numéro de série ici:

Numéro du modèle:

Numéro de série:

Ces numéros sont disponibles sur l’étiquette de chaque côté du climatiseur.

Nom du distributeur:

Date d’achat:

Page 31

3

CONSIGNES DE SECURITE IMPORTANTES

LISEZ ENTIEREMENT LES INSTRUCTIONS AVANT D’UTILISER L’APPAREIL.

Respectez toujours les consignes suivantes pour éviter des situations dangereuses et garantir une

performance optimale de votre produit.

AVERTISSEMENT

Le non respect de ces consignes peut être fatal ou provoquer des blessures graves.

ATTENTION

Le non respect de ces consignes peut provoquer des blessures légères ou endommager le produit.

AVERTISSEMENT

• Les travaux d’installation ou de dépannage effectués par des personnes non qualifiées peuvent vous exposer

aux risques en même temps que les autres personnes.

• L’installation d’un câblage et des composantes sur site DOIVENT être conformes aux codes de construction locaux ou, en l'absence de codes locaux, au Code National d’Électricité 70 et au Code National de Sécurité et de

Construction de Bâtiment ou le code canadien de l’électricité et le Code national de construction du Canada.

• Les informations contenues dans ce manuel sont destinées à un technicien de maintenance qualifié qui maîtrise les consignes de sécurité et dispose d’outils et d’instruments de test appropriés.

• Le fait de ne pas lire attentivement et de ne pas respecter les instructions de ce manuel peut provoquer un

dysfonctionnement de l’équipement, des dégâts matériels, des blessures individuelles et/ou la mort.

Installation

• Mettez toujours à terre le produit. - Autrement, vous risquez de provoquer un choc électrique.

• Pour l'installation du produit, contactez toujours le centre après-vente ou un service d’installation professionnel. - Autrement, vous risquez de provoquer un incendie, un choc électrique, une explosion ou des blessures.

• Fixez correctement le couvercle de protection des pièces électriques à l’unité intérieure et le panneau de service à l’unité extérieure. - Si le couvercle de protection des pièces électriques de l’unité intérieure et le panneau de service de l’unité extérieure ne sont pas bien fixés, cela peut provoquer un incendie ou un choc

électrique dus à la poussière, à l’eau, etc.

• Installez toujours un interrupteur pour fuites d’air et un tableau électrique spécialisé. - Ne pas le faire peut provoquer un incendie ou un choc électrique.

• Ne rangez ni n’utilisez de gaz inflammable ni de combustibles près du climatiseur. - Autrement, vous risquez

de provoquer un incendie ou le mauvais fonctionnement de l’appareil.

• Assurez-vous que le cadre d’installation de l’unité extérieure ne soit pas endommagé à cause d’une utilisation

prolongée. - Cela peut provoquer des blessures ou un accident.

• Ne démontez ni ne réparez le produit en n’importe quel point. - Cela peut provoquer un incendie ou un choc

électrique.

• N'installez pas le produit dans un endroit d’où il puisse tomber. - Autrement, vous risquez de blesser quelqu’un.

• Soyez prudent pendant le déballage et l’installation. - Les bords aiguisés peuvent provoquer des blessures.

• Utilisez une pompe à vide ou un gaz Inerte (azote) lorsque vous faites des essais de fuite ou la purge

d’air. Ne compressez pas l'air ou l'oxygène et n'utilisez pas de gaz inflammable. Cela pourrait provoquer un incendie ou une explosion. Risque de décès, de blessure, d'incendie ou d'explosion.

• Consultez votre revendeur pour savoir quoi faire en cas de fuite du réfrigérant.

Lorsque le climatiseur est installé dans une petite pièce, il est nécessaire de prendre les mesures

appropriées afin que la quantité de réfrigérant en cas de fuite ne dépasse pas la limite de concentration. Autrement, il peut en découler un accident dû au manque d'oxygène.

!

!

!

CONSIGNES DE SECURITE IMPORTANTES

FRANÇAIS

Page 32

•

Procédez à l'installation comme spécifié en prenant en compte le risque de séisme.

Si vous ne le faites pas pendant l'installation, l'unité risque de tomber et de provoquer des accidents.

• Assurez-vous qu'un circuit d'alimentation distinct est fourni pour cette unité et que l'installation élec-

trique est effectuée par un technicien qualifié conformément aux lois et réglementations locales, ainsi

qu'au présent manuel d'installation.

Une alimentation de capacité insuffisante ou une mauvaise installation

électrique peuvent entraîner une décharge électrique ou un incendie.

• Veillez à éteindre l'unité avant de toucher des pièces électriques.

• Assurez-vous que l'intégralité du câblage est sécurisée, que les câbles spécifiés sont utilisés et que

les bornes de raccordement et les câbles ne subissent aucune contrainte.

• Si le gaz réfrigérant fuit pendant l'installation, ventilez immédiatement la pièce.

Du gaz toxique peut être produit si le gaz réfrigérant entre en contact avec une flamme.

Fonctionnement

• Débranchez l’unité si vous constatez la présence de bruits étranges, d’odeurs ou de fumée provenant de l’appareil. -

Autrement, vous risquez de provoquer un incendie ou un choc électrique.

• Évitez le contact avec des flammes. - Autrement, vous risquez de provoquer un incendie.

• A l’occasion, débranchez la fiche d’alimentation, en la prenant par la tête, et ne la touchez pas avec les mains

mouillées. - Autrement, vous risquez de provoquer un incendie ou un choc électrique.

• N’ouvrez pas l’ouverture d’aspiration de l’unité intérieure/extérieure en cours de fonctionnement. - Autrement, vous

risquez de provoquer un choc électrique ou un mauvais fonctionnement.

• Ne permettez pas que de l’eau entre en contact avec les pièces électriques. - Autrement, vous risquez de provoquer

le mauvais fonctionnement de l’appareil ou un choc électrique.

• Ne touchez jamais les pièces métalliques de l’unité lorsque vous retirez le filtre. - Elles sont aiguisées et peuvent pro-

voquer des blessures.

• Ne montez sur l’appareil ni n’y placez aucun objet. - Autrement, vous risquez de vous blesser en tombant de l’appareil.

• Contactez le service après-vente si le produit est submergé dans l’eau. - Autrement, vous risquez de causer un incen-

die ou un choc électrique.

• Veillez à ce que les enfants ne montent pas sur l’unité extérieure. - Autrement, ils risquent d’être sérieusement bles-

sés en tombant.

ATTENTION

Installation

• Installez le raccord de drainage de manière à assurer un drainage convenable. - Autrement, vous risquez de causer une

fuite d'eau.

• Installez le produit de sorte que vos voisins ne soient pas dérangés par le bruit ou par le vent chaud venant de l'unité

extérieure. - Autrement, vous risquez de susciter des querelles avec les voisins.

• Après l’installation ou la réparation du produit, veillez toujours à vérifier qu’il n’y ait pas de fuite de gaz.

- Autrement, vous risquez de causer le mauvais fonctionnement de l'appareil.

• Maintenez le niveau lors de l’installation du produit. - Autrement, vous risquez de provoquer des vibrations ou une

fuite d'eau.

Fonctionnement

• Évitez le refroidissement excessif et aérez parfois. - Autrement, vous risquez de nuire à votre santé.

• Utilisez un tissu doux pour nettoyer l’appareil. N'employez ni de cire, ni de diluant ni de détergent fort.

- Autrement, vous risquez de détériorer l’aspect de l’appareil, changer sa couleur ou provoquer des défauts sur sa surface.

• N'utilisez pas le produit à des buts particuliers, tels que la préservation d’animaux, de plantes, de dispositifs de préci-

sion ou d’objets d'art, etc. - Autrement, vous risquez d’endommager vos biens.

•

Ne placez pas d'obstacles autour de l'entrée ou de la sortie du flux d’air. - Autrement, vous risquez de provoquer le

mauvais fonctionnement de l’appareil ou un accident.

!

CONSIGNES DE SECURITE IMPORTANTES

4

Page 33

5

2 ASTUCES POUR ECO-

NOMISER L’ENERGIE

3 CONSIGNES DE SECURI-

TE IMPORTANTES

6 ELÉMENTS D'INSTALLA-

TION

7 INSTALLATION

7 Choix du meilleur emplacement

8 Dimension du plafond et emplacement

des fixations

9 Installation de i'unité interne

10 Filtre à air

11 Vérification du drainage

12 Conduits de drainage unité interne

13 Travail d’évasement

14 Tuyauterie matériels et stockage méto-

dos

16 Câblage

16 Méthode de raccordement du câble de

liaison (exemple)

18 INSTRUCTIONS D'INS-

TALLATION

20 Wired Inatallation télécommande

21 FONCTIONNEMENT

OPTIONNEL

21 Réglage d'installation – Mode test de

fonctionnement

22 Réglage d'installation - Configuration

de l'adresse du dispositif de régulation

centralisée

23 Réglage d'installation - Thermistance

24 Réglage d'installation - Configurazione

Gruppo

25 Réglage d'installation - Conversion

degrés Celsius (°C)/Fahrenheit (°F)

26 PARAMÈTRES DE L'INS-

TALLATEUR - E.S.P.

26 Réglage d'installation – E.S.P

28 FONCTION D’AUTO-DIA-

GNOSTIC

28 RÉGLAGES DU COMMU-

TATEUR DIP

TABLE DES MATIÈRES

TABLE DES MATIÈRES

FRANÇAIS

Page 34

6

ELÉMENTS D'INSTALLATION

Grilles de sortie d’air

Filtres à air

Boîtier de commande

Grilles d’entrée d’air

Commande à distance

Nom

Tuyauterie

souple de

vidange

Métal de

la bride

Rondelle pour

support de sus-

pension

Bride

(collier de ser-

rage)

Isolation

pour raccord

Autre

Quantité

1 DE CHAQUE 2 DE CHAQUE

8 DE CHAQUE 4 DE CHAQUE

1 jeu

Forme

• Manuel du

propriétaire

• Manuel d'installation

pour tuyau de gaz

pour tuyau à liquide

ELÉMENTS D'INSTALLATION

Page 35

7

FRANÇAIS

INSTALLATION

Installez le climatiseur dans un endroit qui

réponde aux conditions détaillées ci-dessous :

- Un endroit qui supporte sans difficulté un

poids excédant quatre fois celui de l’unité

intérieure.

- Un endroit qui permette l’inspection de l'unité comme montré dans la figure.

- Un endroit où l'unité soit placée de niveau.

- Un endroit qui permette de connecter les

deux unités intérieure et extérieure sans difficulté.

- Un endroit où le bruit électrique ne gêne pas

le fonctionnement de l’unité intérieure.

- Un endroit où la circulation de l’air soit convenable.

- Un endroit où l’unité se trouve éloignée des

sources de chaleur ou de vapeur.

Vérifiez le rapport de position entre l'unité et

les boulons de suspension.

- Installation de l’ouverture du plafond pour

nettoyage du filtre ou entretien sous le produit.

[Unité:mm(inch)]

A(Min)

Plafond

Espace pour le service

A

B

B(Min)

H=20 (25/32)

ou plus

• La hauteur "H" doit respecter la distance appropriée

de manière à obtenir une pente qui permette le

drainage, tel que montré dans la figure.

Vue latérale [Unité: mm(inch)]

Sortie d’air

Orifice d’inspection

600 x 600

(23-5/8 x 23-5/8)

Boîtier de

commande

600

(23-5/8)

600

(23-5/8)

Vue du haut [Unité: mm(inch)]

Sortie d’air

Unité intérieure

Capacité

(kBtu/h)

A B

9 800 (31-1/2) 800 (31-1/2)

12/18 800 (31-1/2) 1,000 (39-3/8)

Choix du meilleur emplacement

INSTALLATION

Page 36

8

INSTALLATION

Dimension du plafond et emplacement des fixations

Installation de l’unité

Installer l’unité correctement en haut du plafond.

-

Placer un joint de toile entre l’unité et les fixations pour amortir les vibrations indésirables.

- Placer un accessoire filtrant sur l’orifice de

retour d’air.

Unité:inch(mm)

C

E

G

D

A

J

B

Orifice de drainage

F

I

H

M10 écrou

M10 rondelle

X 4

X 4

M10 écrou

M10 rondelle

X 4

X 8

9 12/18

A

B

C

D

E

F

G

H

I

J

Capacité

(kBtu/h)

Dimension

POSITION DES ÉCROUS DE FIXATIONS

- La surface doit être à niveau et doit pouvoir

supporter le poids de l’unité.

- L’unité doit être montée dans un emplacement où elle devra résister aux vibrations

liées à son fonctionnement.

- Il faudra aménager un espace pour les opérations de maintenance/entretien

POSITION DES ÉCROUS DU BOITIER

h Pour un drainage efficace de l’eau, installez

l’unité en position légèrement oblique, l'orifice de drainage devant être le point le plus

bas par rapport au centre de gravité de l'unité.

28-17/20 (733) 36-37/50 (933)

30-2/5 (772) 38-13/50 (972)

24-18/25 (628) 24-18/25 (628)

27-11/20 (700) 27-11/20 (700)

1-2/5 (36) 1-2/5 (36)

7-12/25 (190) 7-12/25 (190)

25/32 (20) 25/32 (20)

25-49/50 (660) 33-17/20 (860)

6-1/10 (155) 6-1/10 (155)

27-11/20 (700) 35-11/25 (900)

Page 37

INSTALLATION

9

FRANÇAIS

1 Ancrage

Construction

ancienne

Construction

nouvelle

2 Rondelle plaque

3 Rondelle élastique

4 Ecrou

5 Boulon de

suspension

- Introduire l’ancrage et la rondelle sur les

boulons de suspension pour les bloquer au

plafond.

- Monter les boulons de suspension pour

ancrer solidement.

- Fixer les plaques d’installation sur les

boulons de suspension (régler le niveau) en

utilisant les écrous, les rondelles et les rondelles élastiques.

- Sélectionner et marquer la position de fixation des boulons.

- Faire un trou pour introduire les ancrages

sur le plafond.

• Fourniture locale

① Ancrage

② Rondelle plaque - M10

③ Rondelle élastique - M10

④ Ecrou - W3/8 ou M10

⑤ Boulon de suspension - W3/8 ou M10

ATTENTION

Serrer l’écrou et le boulon pour éviter la

chute du groupe.

!

Installation de i'unité interne

Page 38

10

INSTALLATION

Filtre à air

Panneau arrière

Boîtier de l'enceinte

Sortie d’air

Filtre à air

Panneau

arrière

Filtre à air

Sortie d’air

Panneau arrière

Climatiseur de type conduit à faible pression statique avec aspiration depuis la partie arrière.

Climatiseur de type conduit à faible pression statique avec aspiration depuis la partie inférieure.

En cas d'aspiration depuis le dessous, faites pivoter le panneau arrière et vissez-le au boîtier de

l'enceinte.

Page 39

INSTALLATION

11

FRANÇAIS

ISOLATION, AUTRES

Isolez complètement les joints et les conduits.

Toute isolation thermique doit respecter les régulations locales.

UNITÉ D’INTÉRIEUR

ISOLATION THERMIQUE

Une fois le travail terminé, contrôlez le bon fonctionnement de l’appareil.

• Distribution de l’air ...... La circulation de l’air est-elle correcte ?

• Drain ............................ Le drainage est-il régulier et y a-t-il des fuites ?

• Fuite de gaz ................. Les jointures sont elles correctes ?

• Raccord ....................... Les raccordements sont-ils corrects ?

• Serrage des écrous ..... Le serrage des écrous du compresseur présente t-il du jeu?

• Isolation ...................... L’appareil est-il entièrement isolé ?

• Mise à la terre ............. L’appareil a-t’il été mis à la terre ?

TEST ET VERIFICATION

1 Enlevez le filtre d’air.

2 Vérifiez le drainage.

- Arroser un ou deux verres d’eau sur l’évaporateur.

- Assurez-vous que l’eau coule dans le raccord de drainage sans fuites.

Vérification du drainage

Conduit réfrigérant et isolant

thermique (fourni)

Collier/Bague/fixation pour isolant

thermique (fourni)

Isolant thermique pour conduit

réfrigérant (fourni)

Raccord pour tuyau de gaz

Raccord pour conduit liquide

Isolation

Isolant thermique pour conduit réfrigérant

(fourni)ly)

Chevauchement/jonction avec

Collier/Bague/fixation pour isolant thermique (fourni)

Assurez vous qu’il n’y ait pas d’espace à cet endroit

Pas d’espace

isolant thermique pour canalisation.

Feutre

Isolant thermique pour

canalisation (fourni)

Coffre

Page 40

12

INSTALLATION

Orifice de drainage

de maintenance

Ce type de

parcours n’est

pas permis.

Serre-joint de tuyau

Unité intérieure

Conduits de drainage unité

interne

- La tuyauterie de drainage doit avoir une inclinaison

vers le bas (1/50 à 1/100) : pour éviter tout reflux,

assurez-vous qu’il n’y ait pas de remontées.

-

Pendant la connexion de la tuyauterie de drainage,

prenez garde à ne pas exercer une grande pression

sur l’orifice de drainage de l’unité intérieure.

- Le diamètre extérieur de la connexion de drainage

de l’unité intérieure est de 32mm(1-1/4 inch).

- Assurez-vous d’installer un isolant thermique pour

la tuyauterie de drainage.

Matériau de la tuyauterie: tuyau en PVC

VP-25 et tuyaux accessoires.

Matériau d'isolation thermique : Mousse de

polyéthylène de plus de 8 millimètres d’épaisseur.

Test de Vidange

Le climatiseur utilise une pompe de relevage

pour drainer l'eau.

Suivez le procédé ci-dessous pour tester le

fonctionnement de la pompe de relevage :

- Connectez le tuyau de drainage principal

vers l’extérieur et laissez-le provisoirement

jusqu'à la fin du test.

- Versez de l’eau dans le raccord de drainage

flexible et vérifiez qu’il n’y ait pas de fuites.

- Assurez-vous de vérifier le fonctionnement

normal de la pompe de drainage et l’absence

des bruits anormaux lorsque le câblage électrique est complet.

- Une fois que vous avez effectué le test,

reliez le raccord de drainage flexible à l'orifice de drainage sur l'unité intérieure.

ATTENTION

Le tuyau flexible de drainage.

La pliure ou le percement du tuyau.

!

ATTENTION

• L’installation en pente de l’unité intérieure est très importante pour le

drainage du climatiseur du type conduit.

•

L’épaisseur minimale de l’isolation pour le

tuyau de connexion devra être de

19mm(3/4 inch).

L’unité doit être horizontalement ou

inclinée vers le raccord de drainage à la fin

de l’installation.

!

suspension :

de 1/50 à 1/100

Distance du

crochet :

de 1 à

Pente du crochet de

700mm maximum

(27-11/20inch)

Tuyauterie de vidange flexible

Isolation

Bride

méta

-llique

300 mm

maximum

(11-4/5inch)

1~15m

(3-7/25

~49-1/5ft)

Vue du front

LIVRAISON

Montrez au client les procédures de fonction-

nement et d'entretien en ayant recours au

manuel d'utilisation (nettoyage du filtre d’air,

contrôle de température, etc.).

Plafond

Pompe de drainage utilisée

Trou de

drainage

Verser

de l’eau

Pompe de relevage

Bac de vidange

Raccord de drainage

flexible

Tuyau de

drainage principal

Orifice

Collez le joint

de

drainage

Connexion du raccord de drainage

Utilisez l'agrafe

Page 41

INSTALLATION

13

FRANÇAIS

Tuyau de

cuivre

90

Oblique Inégal Avec relief

Tuyau

Fraise

Point inférieur

Écrou évasé

Tuyau de cuivre

Barre

Tuyau de cuivre

Levier de la bride

Marque de la flèche rouge

Cone

Armature

Levier

Barre

"A"

Incliné

L'intérieur du tuyau est brillant et sans rayures

Polir tout rond

Même les prolongements

tous ronds

Surface

endommagée

Craqué Epaisseur

irrégulière

= Evasement incorrect =

Diamètre extérieur A

mm inch mm inch

Ø6.35 1/4 1.1~1.3 0.04~0.05

Ø9.52 3/8 1.5~1.7 0.06~0.07

Ø12.7 1/2 1.6~1.8 0.06~0.07

Ø15.88 5/8 1.6~1.8 0.06~0.07

Ø19.05 3/4 1.9~2.1 0.07~0.08

Travail d’évasement

La cause principale de fuites de gaz est un

travail d’évasement défectueux. Réalisez ce

travail correctement suivant cette procédure.

1 Coupez les tuyaux

- Utilisez le kit de tuyauterie accessoire ou

achetez les tuyaux sur place.

- Mesurez la distance entre l’unité

intérieure et l’unité extérieure.

- Coupez les tuyaux un peu plus longs que

la distance mesurée.

- Coupez le câble 1,5 m (5,0 pi) plus long

que la longueur des tuyaux.

2 Enlevez les rebords

- Enlevez complètement tous les rebords

de la section de coupe des

tuyaux/raccords.

- Lorsque vous enlevez les rebords, placez

le bout du tuyau/raccord de cuivre dans

une direction descendante pour éviter

que les rebords tombent à l’intérieur de

la tuyauterie.

3 Montage des écrous

- Retirez les écrous évasés de l’unité

intérieure et de l’unité extérieure, puis

placez-les autour des tuyaux/raccords

après avoir enlevé complètement les

rebords. (il n’est pas possible de les

installer après le travail d’évasement)

4 Travail d’évasement

- Réalisez le travail d’évasement à l’aide

d’un outil d’évasement tel qu’il est

illustré en bas.

5 Vérifiez

- Comparez votre travail d'évasement avec

la figure ci-dessous.

- Si vous notez que l'évasement est

défectueux, coupez la section évasée et

refaites l'évasement.

Soutenez fortement le tuyau de cuivre

avec une filière d’évasement suivant les

dimensions cités dans le tableau d’en bas.

Page 42

14

INSTALLATION

Séchage Propreté Hermétique

Il ne devrait pas y avoir

d'humidité à l'intérieure

Il ne devrait pas y avoir de

poussière à l'intérieure.

Il n'y a pas de fuite de

réfrigérant

Éléments

Humidité

Poussière

Fuite

Cause

d'échec

- Hydrolyse important de

l'huile de réfrigérant

- Dégradation de l'huile de

réfrigérant

- Mauvaise isolation du

compresseur

-

Ne pas refroidir et réchauffer

-

Bouchon de EEV, capillaire

- Dégradation de l'huile de

réfrigérant

- Mauvaise isolation du

compresseur

-

Ne pas refroidir et réchauffer

-

Bouchon de EEV, capillaire

- Manque d'essence

- Dégradation de l'huile de

réfrigérant

- Mauvaise isolation du

compresseur

-

Ne pas refroidir et réchauffer

Ressource

- Aucune humidité dans les

conduits

- Jusqu'à la finition de la connexion, l'entrée des conduits

de plomberie devrait être

strictement contrôlée.

- Cessez la plomberie lors de

jours pluvieux.

- L'entrée de conduit devrait être

prise de côté ou dessous.

- Lors du dégagement de conduit enterré, l'entrée de conduit

devrait aussi être éliminée.

- L'entrée de conduit doit être

munie d'un couvert lors du

passage à travers les murs.

- Aucune poussière dans

les conduits.

-

Jusqu'à la finition de la connexion, l'entrée des conduits

de plomberie devrait être

strictement contrôlée.

- L'entrée de conduit devrait être prise sur le côté

ou dessous.

- Lors du dégagement de

conduit enterré, l'entrée

de conduit devrait aussi

être éliminée.

-

L'entrée de conduit doit être

munie d'un couvert lors du

passage à travers les murs.

- Effectuer un test d'étanchéité d'air.

- Les opérations de brasage

doivent être conforme aux

normes.

- Exigence à se conformer

aux normes.

- Bride de sécurité conforme aux normes.

Tuyauterie matériels et stockage métodos

Les conduits doivent obtenir l’épaisseur spécifiée et devraient être utilisés avec un minimum

d'impureté. Lors de rangement, une attention spéciale des conduits est nécessaire pour éviter la

fracturation, déformation et coups. Ne devrait pas être mélangé avec les contaminents de poussière et humidité.

Trois principes de conduit réfrigérant

Page 43

15

FRANÇAIS

INSTALLATION

Méthode de substitution de l'Azote

La soudure, comme étant le chauffage sans substitution d'Azote, produit un film épais à l'intérieur des conduits.

Le film d'oxyde est une des causes de bouchon EEV, capillaire, trou d'huile dans l'accumulateur

et de trou d'aspiration d'huile de la pompe de compresseur.

Cela gêne les opérations normales du compresseur.

Pour éviter ce problème, la soudure devrait être réalisée après le remplacement de l'air pour le

gaz d'Azote.

Le travail est requis lors de la soudure.

◆Comment travailler

ATTENTION

1. Toujours utiliser l'Azote (ne pas utiliser d'oxygène, de dioxyde de carbone et

d'essence Chevron) : S.V.P. utilisez une pression pour l'Azote de 0,02MPa

Oxygène --------- Produit la dégradation par oxydation de l'huile de réfrigérant.

Il est strictement défendu l'utilisation due à sa nature inflammable

Dioxyde de Carbone --- Produit la dégradation de la caractéristique sèche du gaz

Gaz Chevron ---- Un gaz toxique est produit lorsqu'exposé aux flammes directes.

2. Utilisez toujours un détenteur régulateur de pression.

3. Ne pas utiliser un antioxydant commercial.

Le résidu observé semble être de l'oxydation.

En fait, les acides organiques produits par l'oxydation de l'alcool trouvé dans les

antioxydants occasionnant de la corrosion en nids de fourmis. (cause d'acide

organique → alcool + cuivre + eau + température)

!

Régulateur

Point de soudure

Gaz d'Azote

Pression 0,02MPa moins

Échelle d'Azote

Note) ne devrait pas bloquer le côté de sortie.

Lorsque la pression interne du conduit est

supérieure à la pression atmosphérique, un

trou miniature se produit et cause une fuite.

Pose de joints

(Ne devrait pas

contenir d'air)

Valve auxiliaire

Gaz d'Azote

Page 44

16

INSTALLATION

- Retirez le couvercle de la télécommande

pour effectuer le branchement entre l'unité

intérieure et l'unité extérieure. (Retirez les

vis ¿.)

- Ouvrez le couvercle du boîtier de contrôle et

connectez le câble de la télécommande et

les câbles d'alimentation internes.

- Fixez le cordon à l'aide du serre-fils.

Boîtier de

commande

1

1

1

Méthode de raccordement du

câble de liaison (exemple)

AVERTISSEMENT

Un raccordement desserré peut provoquer une surchauffe de la borne ou un

dysfonctionnement de l'unité.

Un risque d'incendie peut également survenir.

Par conséquent, assurez-vous que tous

les câbles sont correctement raccordés.

!

Câblage

Panneau des

conduits

Contre

-écrou

Conduit

1(L1) 2(L2) 3

Alimentation

Haute tension

(208/230V)

Page 45

INSTALLATION

17

FRANÇAIS

Précautions pour l’installation du

câblage d’alimentation

- Pour le câblage, utilisez les câbles d’alimentation appropriés et raccordez-les soigneusement. Veillez également à ce que la pression

extérieure ne puisse pas être exercée sur les

bornes d’alimentation.

- Utilisez un tournevis approprié pour serrer les

vis du bornier. Un tournevis doté d’une petite

tête risque d’arracher la partie supérieure de la

vis et rendre tout serrage impossible.

- Un serrage excessif des vis du bornier risque

de les altérer de manière irréversible.

Utilisez des cosses serties à anneau pour les

connexions au bornier de puissance.

En cas d’indisponibilité, suivez les instructions

ci-dessous.

- Ne connectez pas des câbles de diamètres

différents au bornier de puissance (un jeu

dans le câblage de puissance peut entrainer

un échauffement anormal).

- Lorsque vous connectez les câbles de

diamètre identique, procédez comme indiqué

dans la figure ci-dessous.

Cosse sertie à anneau

Câble d’alimentation

ATTENTION

Le câble d’alimentation entre l’unité intérieure

et extérieure doit être conforme aux spécifications suivantes: reconnu par le NRTL

(exemple, reconnu par UL ou ETL et certifié

par le CSA). AWG 14/4 représente la taille

minimum du câble recommandée, toutefois,

les conducteurs sélectionnés doivent être

conformes aux codes locaux et adaptés à une

installation dans les endroits humides.

Si le câble d’alimentation est endommagé, il

doit être remplacé par un câble spécial ou

d’assemblage fourni par le fabricant ou le

service d’assistance.

Si le ligne située entre l’unité intérieure et l’unité extérieure dépasse 1.57inch, raccordez la

ligne de communication et la ligne d’alimentation séparément.

!

REMARQUE

!

Utilisez le câble de branchement NRTL (UL, ETL,

CAS…) spécifié et les conducteurs THHN torsadés en cuivre, la gaine de 600V en fibre de polychlorure de vinyle répertoriée, conforme au

ROHS, résistant aux rayons ultraviolets (UV),

enterrée directement et approuvée pour une utilisation dans des conditions froides.

Température nominale pour –20°C (-4°F) jusqu’à

90°C (194°F). Ce câble doit être enveloppé dans

le conduit.

• Assurez-vous de respecter les codes

locaux pour le raccordement de l’unité

intérieure à l’unité extérieure (dimension

du câble et méthode de câblage, etc.).

• Tous les câbles doivent être solidement

raccordés.

• Aucun câble ne doit toucher la tuyauterie

de réfrigération, le compresseur ni

aucune pièce mobile.

• Les câbles de communication du climatiseur doivent être séparés et isolés du

circuit électrique des appareils externes

comme les ordinateurs, l’ascenseur, les

équipements de diffusion radio et télévision ainsi que des structures d'imagerie

médicale.

AVERTISSEMENT

!

V/J

20mm

(25/32 inch)

Page 46

18

INSTRUCTIONS D'INSTALLATION

Serrez fermement la vis fournie après avoir placé le boîtier d'installation du

dispositif de régulation à distance à l’emplacement souhaité.

- Installez-le de sorte à ce qu’il ne se torde pas car sinon cela pourrait entraîner une mauvaise

installation.

Installez le boîtier du dispositif de régulation à distance sur le boîtier d'encastrement, le cas

échéant.

Vous pouvez installer le câble du dispositif de régulation à distance fliaire

selon trois directions.

- Direction d'installation : vers la surface du mur, vers le haut, vers la droite

- Si vous installez le câble du dispositif de régulation à distance vers le haut et vers la droite,

veuillez le faire après avoir retiré la rainure guide de câble du dispositif de régulation à distance.

* Retirez la rainure guide avec la pince à long bec.

① Vers la surface du mur

② Rainure guide de la partie supérieure