Page 1

Service Manual

Compact Programmable

CP-14-18-24-ServMan (04-09)

Models

2009

2008

Page 2

TECHNICAL SUPPORT

CONTACT INFORMATION

FRIEDRICH AIR CONDITIONING CO.

Post Ofce Box 1540 · San Antonio, Texas 78295-1540

4200 N. Pan Am Expressway · San Antonio, Texas 78218-5212

(210) 357-4400 · FAX (210) 357-4490

www.friedrich.com

Printed in the U.S.A.

Page 3

Table Of Contents

Important Safety Information ........................................................................................................................................ 2-4

Introduction ...................................................................................................................................................................... 4

Unit Identication ............................................................................................................................................................. 5

Electrical Data .............................................................................................................................................................. 6-7

Specications and Performance Data .......................................................................................................................... 8-9

Functional Components Denitions ............................................................................................................................... 10

Air Conditioner Use ........................................................................................................................................................ 10

How to Operate the Friedrich CP Room Air Conditioner ........................................................................................... 11-12

Refrigeration Sequence of Operation ............................................................................................................................. 13

Sealed Refrigeration System Repairs ....................................................................................................................... 14-17

Method of Charging/Repairs ........................................................................................................................................... 15

.

Metering Device ...............................................................................................................................................................18

Compressor Checks ...................................................................................................................................................18-22

Routine Maintenance ................................................................................................................................................. 23-24

Troubleshooting ......................................................................................................................................................... 25-28

Wiring Diagrams for 2009 Models .................................................................................................................................. 29

Wiring Diagrams for 2008 Models .................................................................................................................................. 30

Parts for 2009 Models ............................................................................................................................................... 31-34

Parts for 2008 Models ............................................................................................................................................... 35-37

Warranty ......................................................................................................................................................................... 38

1

Page 4

IMPORTANT SAFETY INFORMATION

The information contained in this manual is intended for use by a qualied service technician who is familiar

with the safety procedures required for installation and repair, and who is equipped with the proper tools and

test instruments required to service this product.

Installation or repairs made by unqualied persons can result in subjecting the unqualied person making

such repairs as well as the persons being served by the equipment to hazards resulting in injury or electrical

shock which can be serious or even fatal.

Safety warnings have been placed throughout this manual to alert you to potential hazards that may be

encountered. If you install or perform service on equipment, it is your responsibility to read and obey these

warnings to guard against any bodily injury or property damage which may result to you or others.

We have provided many important safety messages in this manual and on your appliance. Always read

and obey all safety messages.

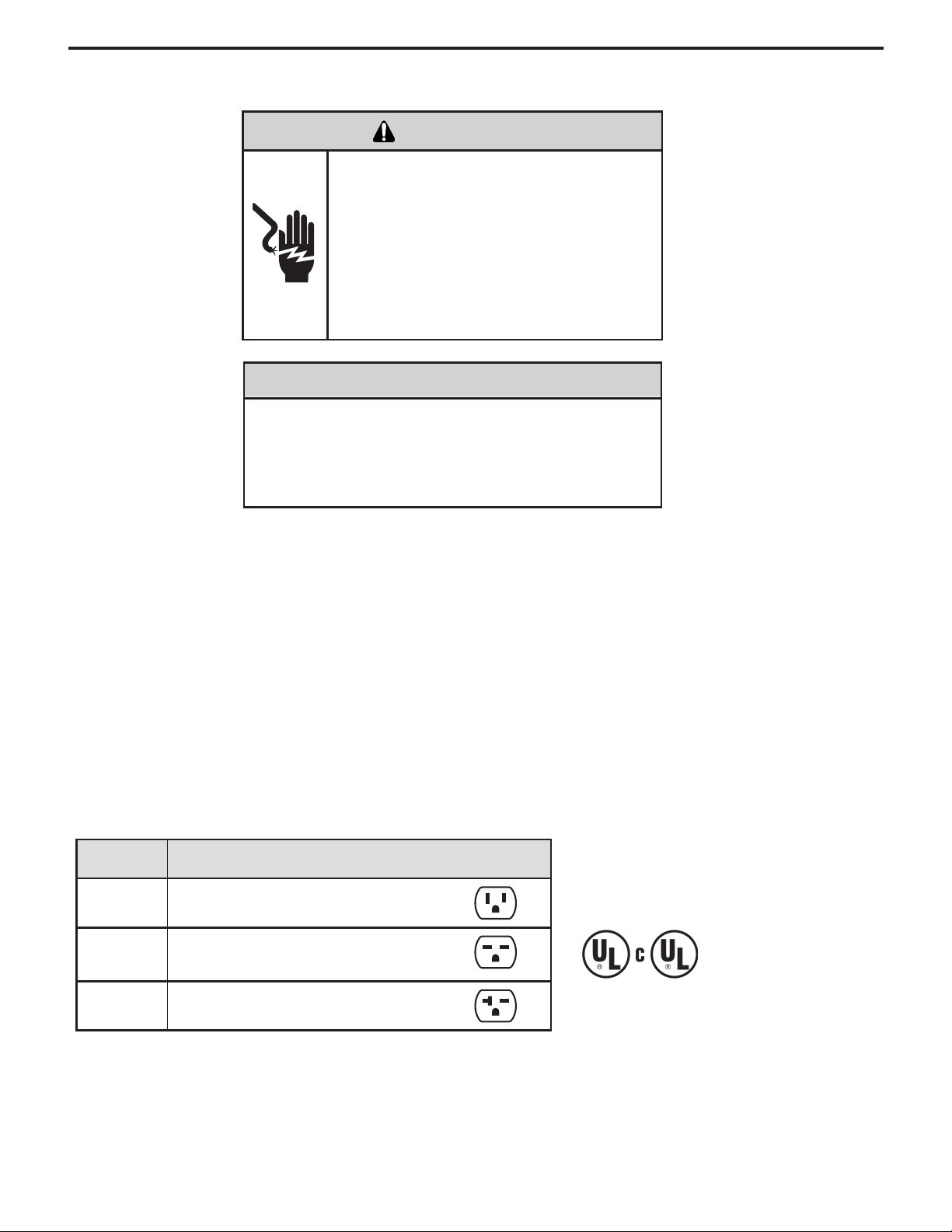

WARNING

CAUTION

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury,

and tell you what will happen if the instructions are not followed.

NOTICE

Your safety and the safety of others are very important.

This is a safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING”

or “CAUTION”. These words mean:

You can be killed or seriously injured if you do not follow instructions.

You can receive minor or moderate injury if you do not follow instructions.

A message to alert you of potential property damage will have the

word “NOTICE”. Potential property damage can occur if instructions

are not followed.

PERSONAL INJURY OR DEATH HAZARDS

ELECTRICAL HAZARDS:

Unplug and/or disconnect all electrical power to the unit before performing inspections, •

maintenance, or service.

Make sure to follow proper lockout/tag out procedures.•

Always work in the company of a qualied assistant if possible. •

Capacitors, even when disconnected from the electrical power source, retain an electrical charge •

potential capable of causing electric shock or electrocution.

Handle, discharge, and test capacitors according to safe, established, standards, and approved •

procedures.

Extreme care, proper judgment, and safety procedures must be exercised if it becomes necessary •

to test or troubleshoot equipment with the power on to the unit.

2

Page 5

Do not spray or pour water on the return air grille, discharge air grille, evaporator coil, control panel, •

and sleeve on the room side of the air conditioning unit while cleaning.

Electrical component malfunction caused by water could result in electric shock or other electrically •

unsafe conditions when the power is restored and the unit is turned on, even after the exterior is dry.

Never operate the A/C unit with wet hands.•

Use air conditioner on a single dedicated circuit within the specied amperage rating. •

Use on a properly grounded outlet only.•

Do not remove ground prong of plug.•

Do not cut or modify the power supply cord.•

Do not use extension cords with the unit.•

Follow all safety precautions and use proper and adequate protective safety aids such as: gloves, •

goggles, clothing, adequately insulated tools, and testing equipment etc.

Failure to follow proper safety procedures and/or these warnings can result in serious injury or death. •

REFRIGERATION SYSTEM HAZARDS:

Use approved standard refrigerant recovering procedures and equipment to relieve pressure before •

opening system for repair.

Do not allow liquid refrigerant to contact skin. Direct contact with liquid refrigerant can result in minor •

to moderate injury.

Be extremely careful when using an oxy-acetylene torch. Direct contact with the torch’s ame or hot •

surfaces can cause serious burns.

Make sure to protect personal and surrounding property with re proof materials.•

Have a re extinguisher at hand while using a torch.•

Provide adequate ventilation to vent off toxic fumes, and work with a qualied assistant whenever •

possible.

Always use a pressure regulator when using dry nitrogen to test the sealed refrigeration system for •

leaks, ushing etc.

Make sure to follow all safety precautions and to use proper protective safety aids such as: gloves, •

safety glasses, clothing etc.

Failure to follow proper safety procedures and/or these warnings can result in serious injury or death. •

MECHANICAL HAZARDS:

Extreme care, proper judgment and all safety procedures must be followed when testing, •

troubleshooting, handling, or working around unit with moving and/or rotating parts.

Be careful when, handling and working around exposed edges and corners of sleeve, chassis, and •

other unit components especially the sharp ns of the indoor and outdoor coils.

Use proper and adequate protective aids such as: gloves, clothing, safety glasses etc.•

Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.•

3

Page 6

PROPERTY DAMAGE HAZARDS

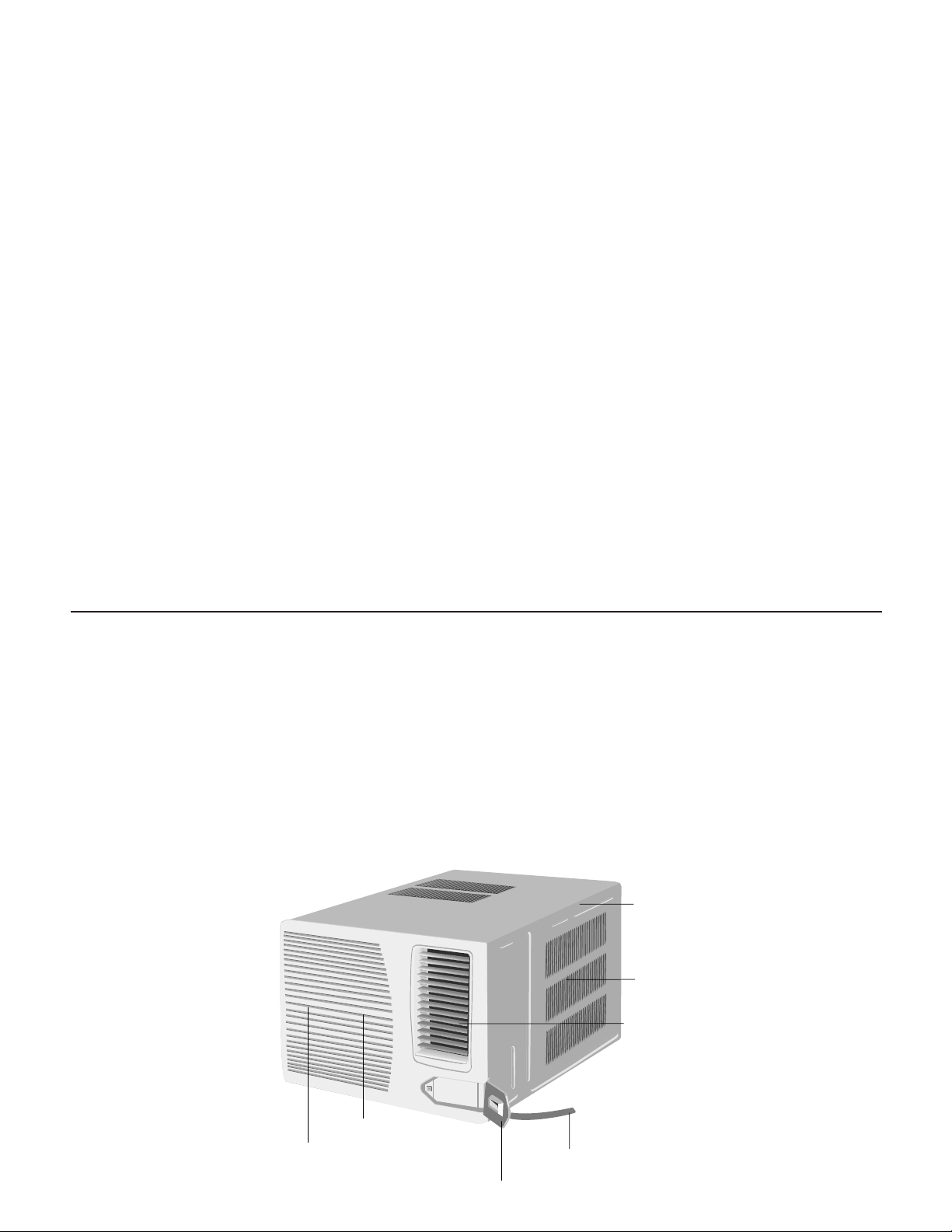

Cabinet

Airinlet louver

Front grille

Powercord

Control panelcover

Frontintakegrille

Airfilter

(behindfront intake grille)

FIRE DAMAGE HAZARDS:

Read the Installation/Operation Manual for this air conditioning unit prior to operating.•

Use air conditioner on a single dedicated circuit within the specied amperage rating. •

Connect to a properly grounded outlet only.•

Do not remove ground prong of plug.•

Do not cut or modify the power supply cord.•

Do not use extension cords with the unit.•

Failure to follow these instructions can result in re and minor to serious property damage.•

WATER DAMAGE HAZARDS:

Improper installation maintenance, or servicing of the air conditioner unit, or not following the above •

Safety Warnings can result in water damage to personal items or property.

Insure that the unit has a sufcient pitch to the outside to allow water to drain from the unit. •

Do not drill holes in the bottom of the drain pan or the underside of the unit. •

Failure to follow these instructions can result in result in damage to the unit and/or minor to serious •

property damage.

INTRODUCTION

This service manual is designed to be used in conjunction with the installation manuals provided with each unit.

This service manual was written to assist the professional HVAC service technician to quickly and accurately

diagnose and repair any malfunctions of this product.

This manual, therefore, will deal with all subjects in a general nature. (i.e. All text will pertain to all models).

IMPORTANT:

It will be necessary for you to accurately identify the unit you are

servicing, so you can be certain of a proper diagnosis and repair.

(See Unit Identication.)

4

Page 7

UNIT IDENTIFICATION

Model Number Code

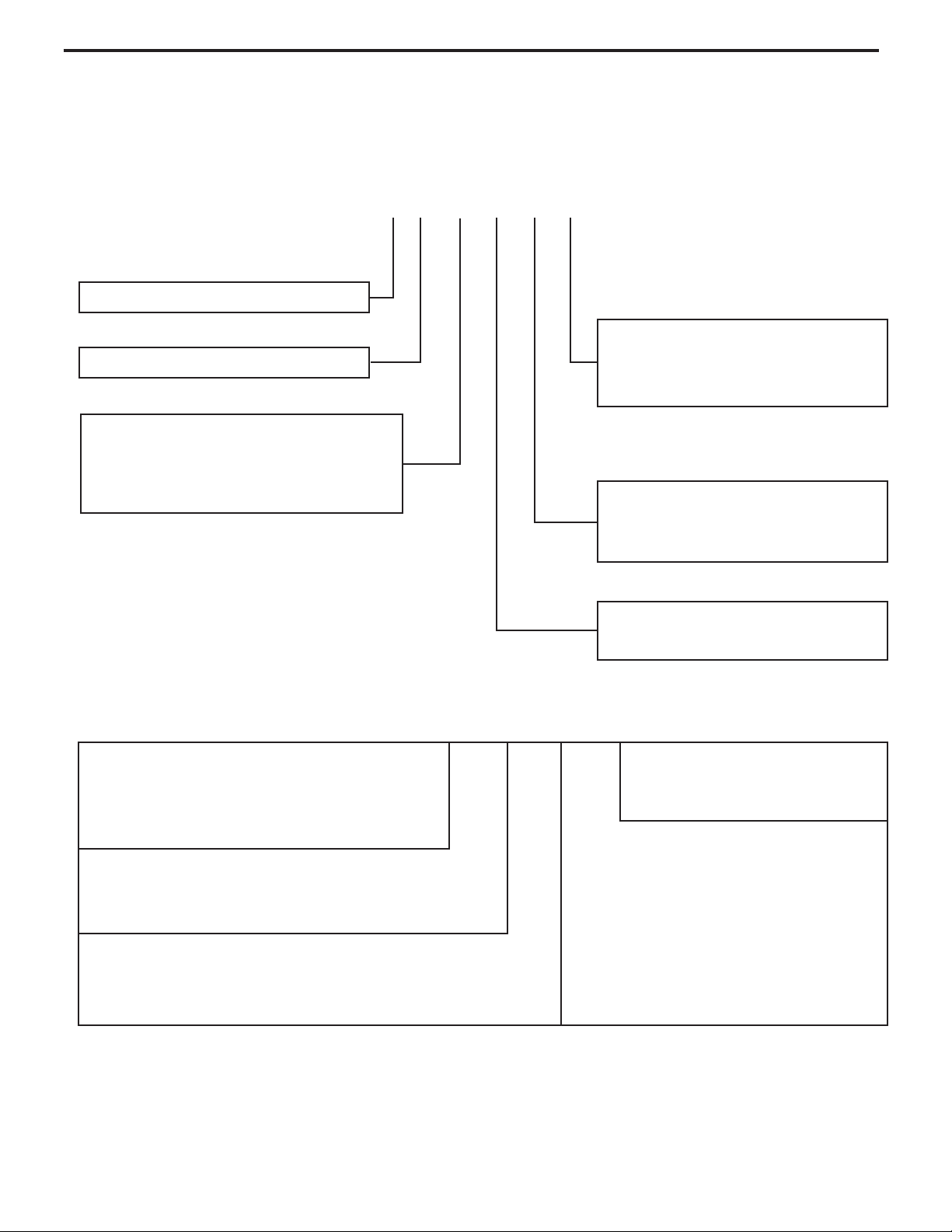

COMPACT

PROGRAMMABLE

3rd and 4th Digit - Approximate

BTU/HR (Cooling)

Heating BTU/Hr capacity listed in the

Specication/Performance Data Section

C P 08 E 1 0

7th Digit – Options

0 = Straight Cool &

Heat Pump Models

6th Digit – Voltage

1 = 115 Volts

3 = 230-208 Volts

RAC Serial Number Identication Guide

Serial Number

Decade Manufactured

L=0 C=3 F=6 J=9

A=1 D=4 G=7

B=2 E=5 H=8

Year Manufactured

A=1 D=4 G=7 K=0

B=2 E=5 H=8

C=3 F=6 J=9

Month Manufactured

A=Jan D=Apr G=Jul K=Oct

B=Feb E=May H=Aug L=Nov

C=Mar F=Jun J=Sept M=Dec

L H G K 00001

5th Digit

Alphabetical Modier

Production Run Number

Product Line

K = RAC

5

Page 8

ELECTRICAL DATA

Not following the above WARNING could result in re or

electically unsafe conditions which could cause moderate

or serious property damage.

Read, understand and follow the above warning.

WARNING

ELECTRIC SHOCK HAZARD

Turn off electric power before service or

installation.

All electrical connections and wiring MUST be

installed by a qualied electrician and conform to

the National Electrical Code and all local codes

which have jurisdiction.

Failure to do so can result in personal injury or

death.

NOTICE

FIRE HAZARD

Wire Size Use ONLY wiring size recommended for single outlet branch circuit.

Fuse/Circuit Breaker Use ONLY the correct HACR type and size fuse/circuit breaker. Read electrical ratings on unit’s

rating plate. Proper circuit protection is the responsibiity of the homeowner.

Grounding Unit MUST be grounded from branch circuit through service cord to unit, or through separate

ground wire provided on permanently connected units. Be sure that branch circuit or general

purpose outlet is grounded. Ground wire must be connected to ground screw located in lower

right corner of air conditioner when air conditioner is in cabinet. (CP 14, 18, 24)

Receptacle The eld supplied outlet must match plug on service cord and be within reach of service cord.

Do NOT alter the service cord or plug. Do NOT use an extension cord. Refer to the table above

for proper receptacle and fuse type.

Plug/Outlet/Circuit Rating

Model

CP14 125V - 15A 5 - 15P 6

CP18 250V - 15A 6 - 15P 4

Circuit Rating

Breaker or T-D Fuse

Plug Face

(NEMA#)

Power Cord

Length (ft.)

Wall Outlet

Appearance

CP24 250V - 20A 6 - 20P 4

6

Page 9

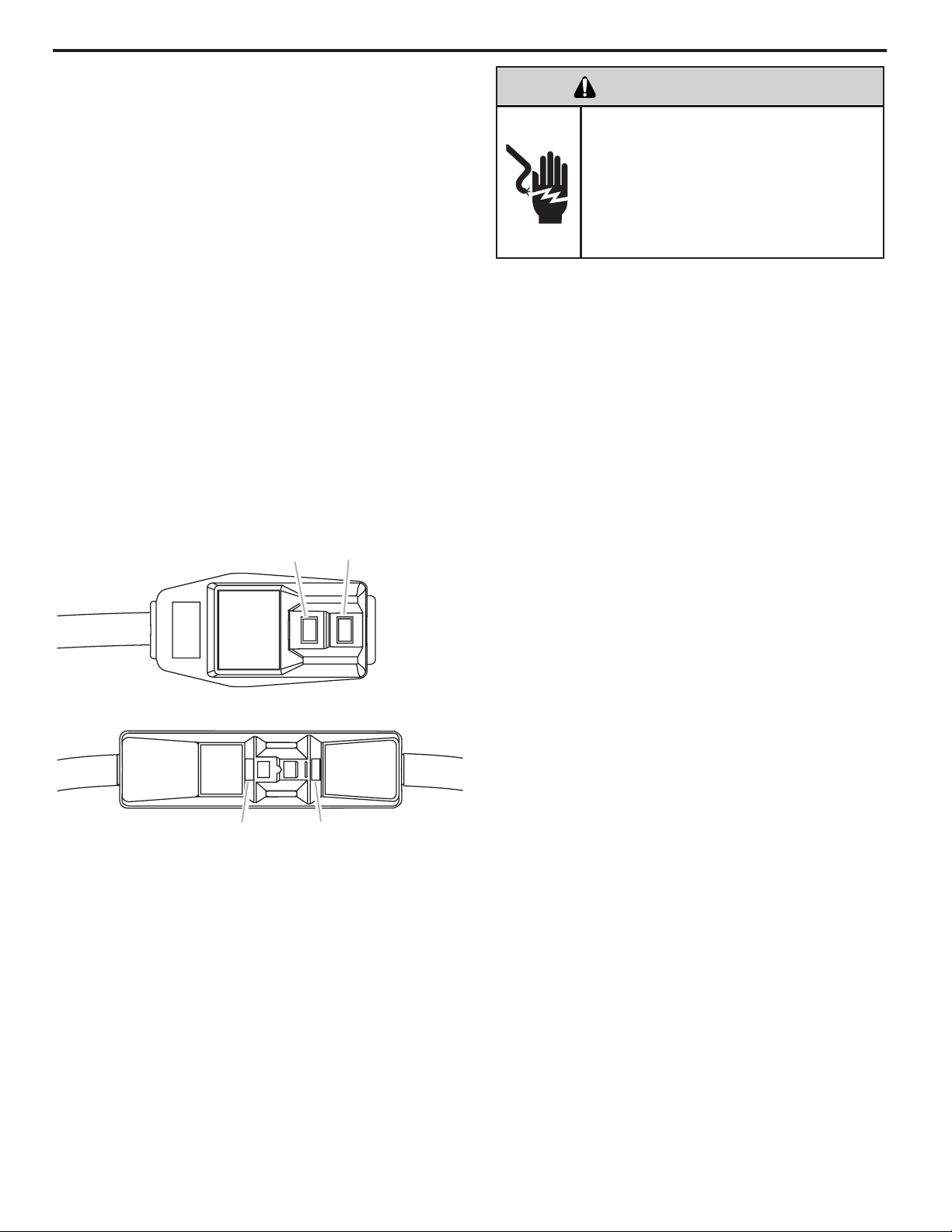

Recommended grounding method

This air conditioner must be grounded. This air conditioner

is equipped with a power supply cord having a grounded 3

prong plug. To minimize possible shock hazard, the cord

must be plugged into a mating, grounded 3 prong outlet,

grounded in accordance with all local codes and ordinances.

If a mating outlet is not available, it is the customer’s

responsibility to have a properly grounded 3 prong outlet

installed by a qualied electrical component installer.

It is the customer’s responsibility:

WARNING

ELECTRICAL SHOCK HAZARD

Plug into a grounded 3 prong outlet.

Do not remove powercord ground prong.

Do not use a plug adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, re, or electrical shock.

To contact a qualied electrical installer, and to assure

that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA

70 - latest edition, and all local codes and ordinances.

Copies of the standards listed may be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

Power Supply Cord

NOTE: Your unit’s device may differ from the ones shown.

B

TEST

B

A. Reset button

B. Test button

A

RESET

TEST

RESET

A

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET.

3. Press TEST (listen for click; Reset button will trip and

pop out).

4. Press and release RESET (listen for click; Reset butto

will latch and remain in). The power supply cord is ready

for operation.

NOTES:

The Reset button must be pushed in for proper

operation.

The power supply cord must be replaced if it fails to trip

when the test button is pressed or if it fails to reset.

Do not use the power supply cord as an off/on switch.

The power supply cord is designed as a protective

device.

A damaged power supply cord must be replaced with

a new power supply cord obtained from the product

manufacturer and must not be repaired.

The power supply cord contains no user serviceable

parts. Opening the tamper-resistant case voids all

warranty and performance claims.

This room air conditioner is equipped with a power supply

cord required by UL. This power supply cord contains

state-of-the-art electronics that sense leakage current. If

the cord is crushed, the electronics detect leakage current

and power will be disconnected in a fraction of a second.

7

Page 10

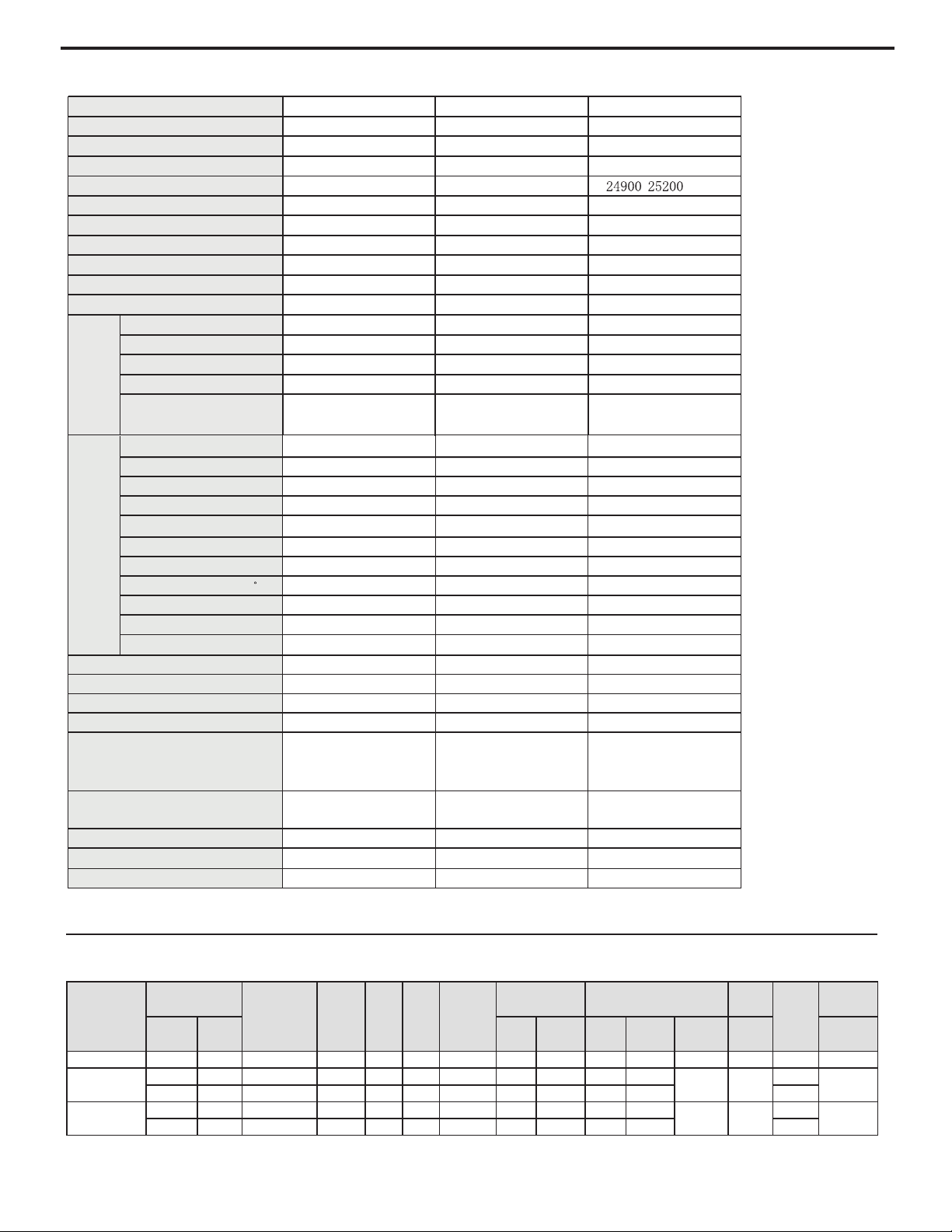

SPECIFICATIONS FOR 2009 MODELS

PERFORMANCE

DATA* Cooling

EVAP. AIR TEMP.

DEG. F

CONDENSER

TEMPERATURE

DEG. F

Discharge

Temp

Suction

Temp

Super

Heat

Sub-Cooling

OPERATING

PRESSURES

ELECTRICAL RATINGS R-22 REF.

Voltage

BREAKER

FUSE

Discharge

Air

Temp.

Drop F.

Suction Discharge

Amps

Cool

Amps

Heat

Locked

Rotor Amps

Charge in

OZ.

60 Hertz

Amps

CP14N10

59 21 118 173 56 41 54 78 267 12.1 / 58 26.5 115 15

CP18N30

58 22 119 173 66 52 55 77 269 8.3 /

38.9/42.4 27.9

230

15

802/5.8 962 775525 66 271 911 32 75

CP24N30

57 23 117 197 60 44 50 75 264 12.3 /

56A(230V) 33.5

230

20

802/1.31 462 570544 75 591 711 42 65

*Rating Conditions: 80 degrees F, room air temp. & 50% relative humidity, with 95 degree F, outside air temp & 40% relative humidity.

Compressor Type

Rotary Rotary Rotary

L.R.A. (A)

61 42 60

Compressor RLA(A)

11.5 11.2/10.7

Compressor Power Input(W)

1060

2310/2390

Overload Protector

InternalExternal Internal

Throttling Method

Capillary Capillary Capillary

Starting Method Capacitor Capacitor Capacitor

Working Temp Range (

F

)

50°-115° 50°-115° 50°-115°

Condenser

Aluminum fin-copper tube Aluminum fin-copper tube Aluminum fin-copper tube

Fan Type-Piece

Axial fan –1 Axial fan –1 Axial fan –1

F

an Diameter (inches)

15.59 15.59 15.59

900/780/730 1000/900/800 1060/970/820

205 297 320

1.78 1.29 1.39

15 7 7

300 300 300

150 150 150

17

½

X 26 X 27

⅝

17½ X 26 X 29

¾

17½ X 26 X 29

¾

121 141 165

R22/28.57 R22/32.10 R22/37.04

Outdoor

Side

Fan Motor Speed (rpm) (H/M/L)

Output of Fan Motor (W)

Fan Motor RLA(A)

Fan Motor Capacitor (uF)

Net

Weight

Refrigerant Charge (oz)

Permissible Excessive Operating

Pressure for the Discharge

Side(PSI)

Permissible Excessive Operating

Pressure for the Suction Side(PSI)

Dimension (W/H/D)

7.5

1606

CP14E10 CP18E30 CP24E30

COOLING

COOLING

COOLING

115V 208~230V 208~230V

60Hz 60Hz 60Hz

14700(Btu/h) 18000 /18450(Btu/h)

/ (Btu/h)

1370 1680/1730 2660/2690

1757W 2259W 3295W

17.61A 9.02A 15A

798/730/696 968/918/866 1002/950/866

5.28 5.92 9.93

10.8 10.8 / 10.8 9.4 / 9.4

Fan Type-Piece Centrifugal flow fan – 1 Centrifugal flow fan – 1 Centrifugal flow fan – 1

Diameter-Length (inch) 8.82 X 4.31 8.82 X 4.31 8.82 X 4.31

Evaporator Alum inum fin-copper tube Aluminum fin-copper tube Aluminum fin-copper tube

Pipe Diameter (inches)

.276 .276 .276

Coil length (l) x height (H) x

coil width (L)

422 X 381 X 25.4 422 X 381 X 25.4 422 X 381 X 25.4

Model

Function

Rated Voltage

Rated Input (W)

Rated Current (A)

Air Flow Volume

(CFM) (H/M/L)

Rated Frequency

Total Capacity (W/

Btu/h)

Power Input (W)

Indoor

Side

Dehumidifying Volume (pints/h)

EER

Performance Data

8

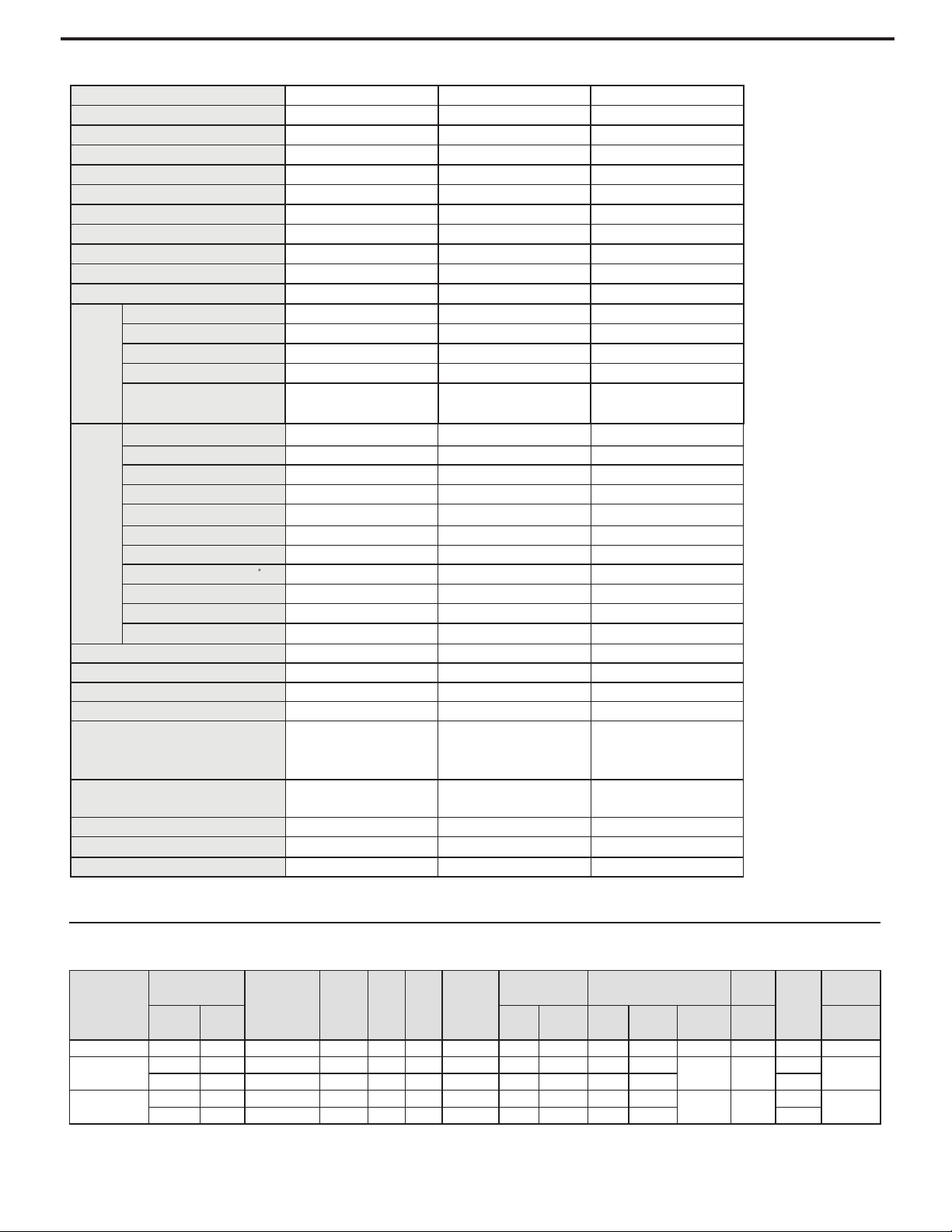

Page 11

PERFORMANCE

DATA* Cooling

EVAP. AIR TEMP.

DEG. F

CONDENSER

TEMPERATURE

DEG. F

Discharge

Temp

Suction

Temp

Super

Heat

Sub-Cooling

OPERATING

PRESSURES

ELECTRICAL RATINGS R-22 REF.

Voltage

BREAKER

FUSE

Discharge

Air

Temp.

Drop F.

Suction Discharge

Amps

Cool

Amps

Heat

Locked

Rotor Amps

Charge in

OZ.

60 Hertz

Amps

CP14N10

59 21 118 173 56 41 54 78 267 12.1 / 58 26.5 115 15

CP18N30

58 22 119 173 66 52 55 77 269 8.3 /

38.9/42.4 27.9

230

15

802/5.8 962 775525 66 271 911 32 75

CP24N30

57 23 117 197 60 44 50 75 264 12.3 /

56A(230V) 33.5

230

20

802/1.31 462 570544 75 591 711 42 65

*Rating Conditions: 80 degrees F, room air temp. & 50% relative humidity, with 95 degree F, outside air temp & 40% relative humidity.

Compressor Type

Rotary Rotary Rotary

L.R.A. (A)

58 42 56

Compressor RLA(A)

10.9 11.7/11.0

Compressor Power Input(W)

1182

2425/2480

Overload Protector

ExternalExternal Internal

Throttling Method

Capillary Capillary Capillary

Starting Method Capacitor Capacitor Capacitor

Working Temp Range (

F

)

50°-115° 50°-115° 50°-115°

Condenser

Aluminum fin-copper tube Aluminum fin-copper tube Aluminum fin-copper tube

Fan Type-Piece

Axial fan –1 Axial fan –1 Axial fan –1

F

an Diameter (inches)

15.59 15.59 15.59

900/780/730

900/780/730 1000/900/800

200 200 190

3 1.45 1.35

15 7 7

300 300 300

150 150 150

17

½

X 26 X 27

⅝

17½ X 26 X 27

⅝

17½ X 26 X 29

¾

121 141 165

R22/26.46 R22/27.87 R22/33.51

Outdoor

Side

Fan Motor Speed (rpm) (H/M/L)

Output of Fan Motor (W)

Fan Motor RLA(A)

Fan Motor Capacitor (uF)

Net

Weight

Refrigerant Charge (oz)

Permissible Excessive Operating

Pressure for the Discharge

Side(PSI)

Permissible Excessive Operating

Pressure for the Suction Side(PSI)

Dimension (W/H/D)

7.45

1700

CP14N10 CP18N30 CP24N30

COOLING

COOLING

COOLING

115V 230V/208V~ 230V/208V~

60Hz 60Hz 60Hz

14000(Btu/h) 18000 /17600(Btu/h) 23500/23100(Btu/h)

1430 1850/1810 2740/2710

1540W 2478W 3538W

15A 12.57A 18.09A

458.8 458.8 617.6

3.38 4.65 8.46

9.8 9.7 / 9.7 8.6 / 8.5

Fan Type-Piece Centrifugal flow fan – 1 Centrifugal flow fan – 1 Centrifugal flow fan – 1

Diameter-Length (inch) 7.93 X 4.31 7.93 X 4.31 8.82 X 4.31

Evaporator Alum inum fin-copper tube Aluminum fin-copper tube Aluminum fin-copper tube

Pipe Diameter (inches)

0.276 0.276 0.276

Coil length (l) x height (H) x

coil width (L)

16.61 X 15 X 1 16.61 X 15 X 1 16.61 X 15 X 1

Model

Function

Rated Voltage

Rated Input (W)

Rated Current (A)

Air Flow Volume

(CFM) (H/M/L)

Rated Frequency

Total Capacity (W/Btu/h)

Power Input (W)

Indoor

Side

Dehumidifying Volume (pints/h)

EER

SPECIFICATIONS FOR 2008 MODELS

Performance Data

9

Page 12

COMPONENT DEFINITIONS

A. Mechanical components

Vent door

Exhausts stale room air outside.

Plenum assembly

Diffuser with directional louvers used to direct the conditioned airow.

Blower wheel

Attaches to the indoor side of the fan motor shaft and is used for distributing unconditioned, room side air through

the heat exchanger and delivering conditioned air into the room.

Slinger fan blade

Attaches to the outdoor side of the fan motor shaft and is used to move outside air through the condenser coil, while

slinging condensate water out of the base pan and onto the condenser coil, thus lowering the temperature and

pressures within the coil.

B. Electrical components

Thermistor

A sensor that automatically responds to temperature changes.

Capacitor

Reduces line current and steadies the voltage supply, while greatly improving the torque characteristics of the fan

motor and compressor motor.

MoneySaver® switch

Used to regulate the operation of the fan motor and the compressor or to turn the unit off. For troubleshooting, refer

to the wiring diagrams and schematics in the back of this service manual.

Fan Motor

Dual-shafted fan motor operates the indoor blower wheel and the condenser fan blade simultaneously.

C. Hermetic components

Compressor

Motorized device used to compress refrigerant through the sealed system.

Capillary tube

A cylindrical meter device used to evenly distribute the ow of refrigerant to the heat exchangers (coils).

AIR CONDITIONER USE

Operating the air conditioner properly helps you to obtain

the best possible results.

This section explains proper air conditioner operation.

IMPORTANT:

If you turn off the air conditioner, wait at least 3 minutes

before turning it back on. This prevents the air conditioner

from blowing a fuse or tripping a circuit breaker.

Do not try to operate your air conditioner in the cool-

ing mode when outside temperature is below 65°F

(18°C). The inside evaporator coil will freeze up, and

the air conditioner will not operate properly.

NOTE: In the event of a power failure, your air conditioner will operate at the previous settings when the

power is restored.

10

Page 13

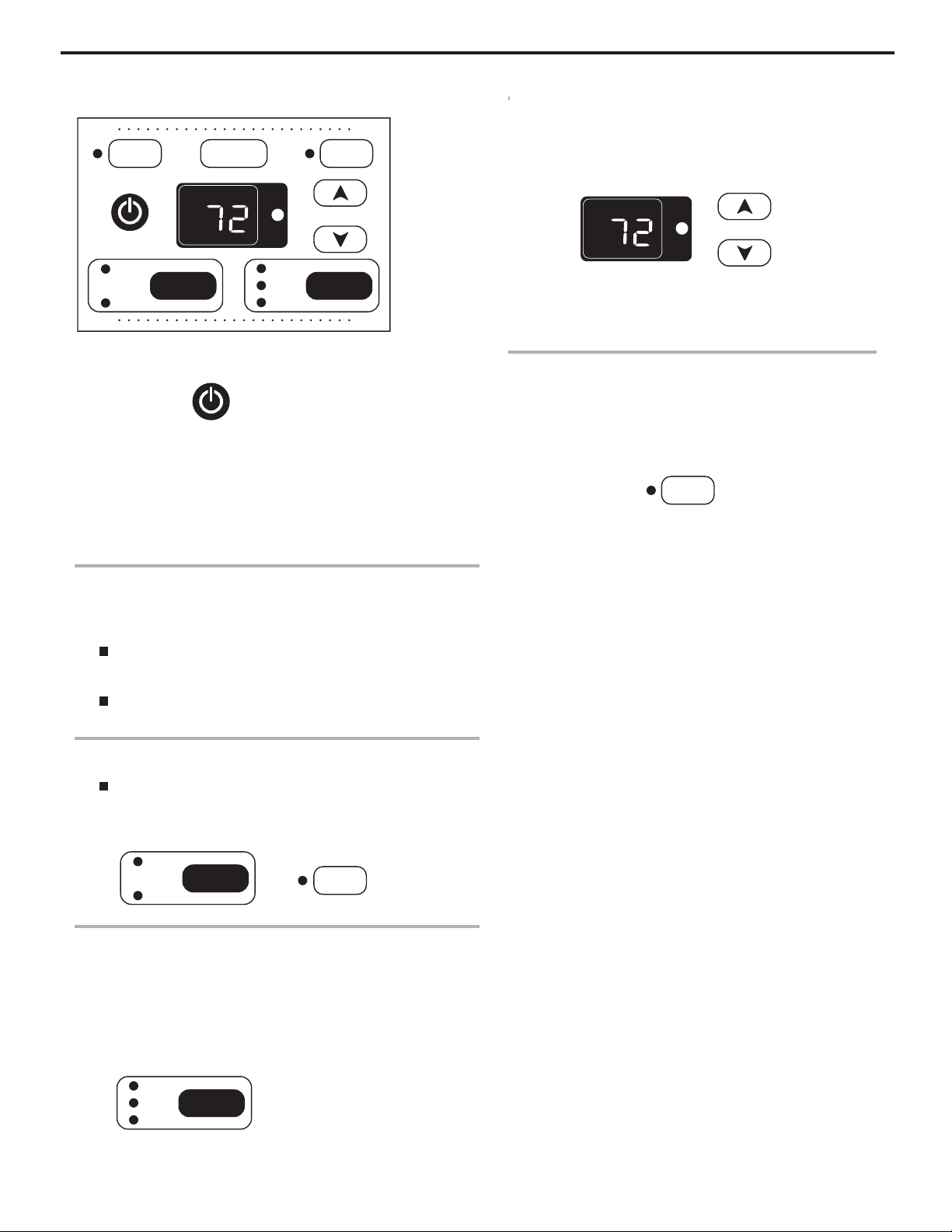

1. Press POWER to turn on air conditioner.

NOTE: When the unit is turned on, it will display the previous

settings for the Mode, Fan Speed and temperature.

2. Choose mode. See “Mode .”

3. Choose fan speed. See “ Fan Speed.”

4. Choose temperature. See “Temperature.”

Mode

1. Press and hold MODE.

2.

Cool—Cools room. Press FAN SPEED to choose fan

speed. Then adjust the temperature by pressing the up or

down arrow buttons.

Fan—Operates the fan at High sp eed, without cooling.

The display shows “FO” (fan only).

Fan Speed

NOTE: The Fan Speed button will operate only when the Cool or

Power Saver mode ha s been selected.

1. Press and hold FAN SPEED until you see the indicator light

for the desired setting.

2. Choose High, Medium or Low.

Temperature

Press, or press and hold, the plus button to raise the

temperature 1º until it reaches 86ºF (30ºC).

Press, or press and hold, the minus button to lower the

temperature 1º until it reaches 64ºF (18ºC).

Timer Delay

To set the Timer for a 1- to 24-hour delay until the air

conditioner turns o (the air conditioner must be On):

1. Press TIMER. Indicator light will ash.

2. Press the plus or minus button to change the delay time from

1 to 24 hours.

3. Press TIMER or wait 10 seconds. Indicator light will remain

on.

To set the Timer delay for a 1- to 24-hour delay until the air

conditioner turns on, keeping previous settings:

1. Turn o air conditioner.

2. Press TIMER. Indicator light wi

ll ash.

3. Press the plus or minus button to change the delay time from

1 to 24 hours.

4. Press TIMER or wait 10 seconds. Indicator light will remain

on.

To set the Timer delay for a 1- to 24-hour delay until the air

conditioner turns on, changing previous settings:

1. Turn on air conditioner.

2. Adjust MODE to desired setting.

3. Adjust FAN SPEEDto High, Medium or Low.

4. Adjust temperature between 64ºF (18ºC) and 86ºF (30ºC).

5. Turn o air conditioner.

6. Press TIMER. Indicator light will ash.

7. Press the plus or minus button to change delay time from 1 to

24 hours.

8. Press TIMER or wait 10 seconds.

To clear Timer delay program

NOTE: Air conditioner can be either on or o.

Press and hold TIMER for 3 seconds. Indicator light will turn o.

To see the time remaining (in hours)

1. Press TIMER once after it has been set.

2. While the display is showing the remaining time, you can

press the plus or minus button to increase or decrease the

time.

POWER

Temp/Hour

Timer

Fan Speed

Fan Only

Cool

Money

Saver

®

High

Med

Low

0

F

Mode

Hr.

Auto Swing

Temp/Hour

0

F

Hr.

Timer

Money Saver — Turns fan to low speed when

room temperature reaches the temperature setting

on the thermostat.

Fan Only

Cool

Mode

Money

Saver

®

Fan Speed

High

Med

Low

POWER

Money Saver

®

Choose Cool or Fan mode

How to operate the Friedrich room air conditioner

11

Page 14

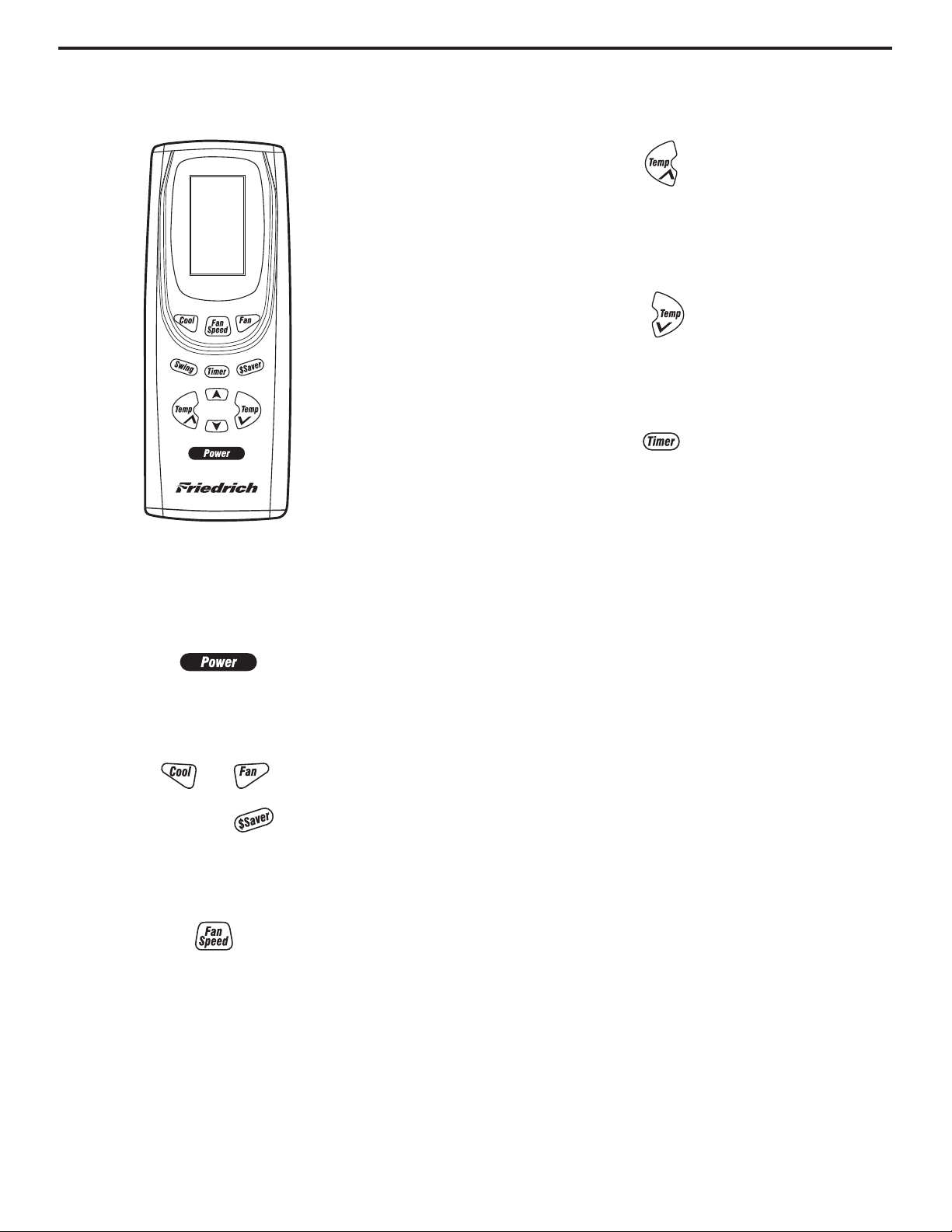

To operate air conditioner with remote control

NOTE: Remote control may vary in appearance.

NOTE: Two AAA batteries (included) power the remote control.

Replace batteries after 6 months of use, or when the remote

control starts to lose power.

To turn the air conditioner on or o:

Press POWER.

To select the mode:

To select the fan speed:

Press FAN SPEED for High, Medium or Low.

To raise the temperature:

Press the plus button to raise the temperature. Each time you

press or hold

the plus button, the temperature will go up 1º until it

reaches 86°F (30°C).

To lower the temperature:

Press the minus button to lower the temperature. Each time you

press or hold the minus butto n, the temperature will go down 1º

until it reaches 64°F (18°C).

To set Timer for a 1- to 24-hour delay before air conditioner

is turned o (air conditioner must be On):

1. Press TIMER. Indicator light on air conditioner control panel

will ash.

2. Press the plus or minus b

utton to change the delay time from

1 to 24 hours.

3. Press TIMER again or wait 10 seconds. Indicat or light on air

conditioner control panel will remain on.

To set Timer to turn on air conditioner, keeping previous

settings:

1. Turn o air conditioner.

2. Press TIMER. Indicator light on air conditioner control panel

will ash.

3. Press the plus or minus button to change delay time (1 to

24 hours).

4. Press TIMER again or wait 10 seconds. Indicat or light on air

conditioner control panel will remain on.

To set Timer to turn on air conditioner, changing the

previous settings:

1. Turn on air conditioner.

2. Adjust Mode to Cool, Fan Only, or Power Saver.

3. Adjust Fan Speed to High, Medium or Low.

4. Adjust temperature between 64°F (18ºC) and 86°F (30ºC).

5. Turn o air conditioner.

6. Press TIMER. Indicator light on air conditioner control panel

will ash.

7. Press the plus or minus button to change delay time (1 to

24 hours).

8. Press TIMER again or

wait 10 seconds. Indicator light on air

conditioner control panel will remain on.

Press COOL, FAN or $ SAVER

12

Page 15

REFRIGERATION SYSTEM SEQUENCE OF OPERATION

A good understanding of the basic operation of the

refrigeration system is essential for the service technician.

Without this understanding, accurate troubleshooting of

refrigeration system problems will be more difcult and time

consuming, if not (in some cases) entirely impossible. The

refrigeration system uses four basic principles (laws) in its

operation they are as follows:

1. “Heat always ows from a warmer body to a cooler

body.”

2. “Heat must be added to or removed from a substance

before a change in state can occur”

3. “Flow is always from a higher pressure area to a lower

pressure area.”

4. “The temperature at which a liquid or gas changes state

is dependent upon the pressure.”

The refrigeration cycle begins at the compressor. Starting

the compressor creates a low pressure in the suction line

which draws refrigerant gas (vapor) into the compressor.

The compressor then “compresses” this refrigerant, raising

its pressure and its (heat intensity) temperature.

The refrigerant leaves the compressor through the discharge

Line as a hot High pressure gas (vapor). The refrigerant

enters the condenser coil where it gives up some of its

heat. The condenser fan moving air across the coil’s nned

surface facilitates the transfer of heat from the refrigerant to

the relatively cooler outdoor air.

When a sufcient quantity of heat has been removed from

the refrigerant gas (vapor), the refrigerant will “condense”

(i.e. change to a liquid). Once the refrigerant has been

condensed (changed) to a liquid it is cooled even further by

the air that continues to ow across the condenser coil.

The RAC design determines at exactly what point (in the

condenser) the change of state (i.e. gas to a liquid) takes

place. In all cases, however, the refrigerant must be

totally condensed (changed) to a Liquid before leaving the

condenser coil.

The refrigerant leaves the condenser Coil through the liquid

line as a warm high pressure liquid. It next will pass through

the refrigerant drier (if so equipped). It is the function of the

drier to trap any moisture present in the system, contaminants,

and large particulate matter.

The liquid refrigerant next enters the metering device. The

metering device is a capillary tube. The purpose of the

metering device is to “meter” (i.e. control or measure) the

quantity of refrigerant entering the evaporator coil.

In the case of the capillary tube this is accomplished (by

design) through size (and length) of device, and the pressure

difference present across the device.

Since the evaporator coil is under a lower pressure (due to

the suction created by the compressor) than the liquid line,

the liquid refrigerant leaves the metering device entering the

evaporator coil. As it enters the evaporator coil, the larger

area and lower pressure allows the refrigerant to expand

and lower its temperature (heat intensity). This expansion is

often referred to as “boiling”. Since the unit’s blower is moving

indoor air across the nned surface of the evaporator coil,

the expanding refrigerant absorbs some of that heat. This

results in a lowering of the indoor air temperature, hence the

“cooling” effect.

The expansion and absorbing of heat cause the liquid

refrigerant to evaporate (i.e. change to a gas). Once the

refrigerant has been evaporated (changed to a gas), it is

heated even further by the air that continues to ow across

the evaporator coil.

The particular system design determines at exactly what

point (in the evaporator) the change of state (i.e. liquid to a

gas) takes place. In all cases, however, the refrigerant must

be totally evaporated (changed) to a gas before leaving the

evaporator coil.

The low pressure (suction) created by the compressor

causes the refrigerant to leave the evaporator through the

suction line as a cool low pressure vapor. The refrigerant then

returns to the compressor, where the cycle is repeated.

Suction

Line

Evaporator

Coil

Metering

Device

Refrigerant

Strainer

Discharge

Line

Condenser

Coil

Compressor

Refrigerant Drier

Liquid

Line

13

Page 16

SEALED REFRIGERATION SYSTEM REPAIRS

IMPORTANT

ANY SEALED SYSTEM REPAIRS TO COOL-ONLY MODELS REQUIRE THE INSTALLATION OF A LIQUID LINE DRIER.

ALSO, ANY SEALED SYSTEM REPAIRS TO HEAT PUMP MODELS REQUIRE THE INSTALLATION OF A SUCTION LINE DRIER.

EQUIPMENT REQUIRED:

1. Voltmeter

2. Ammeter

3. Ohmmeter

9. High Pressure Gauge - (0 - 400 lbs.)

10. Low Pressure Gauge - (30 - 150 lbs.)

11. Vacuum Gauge - (0 - 1000 microns)

4. E.P.A. Approved Refrigerant Recovery System

5. Vacuum Pump (capable of 200 microns or less

vacuum.)

6. Acetylene Welder

7. Electronic Halogen Leak Detector (G.E. Type H-6 or

equivalent.)

8. Accurate refrigerant charge measuring device such

as:

a. Balance Scales - 1/2 oz. accuracy

b. Charging Board - 1/2 oz. accuracy

WARNING

RISK OF ELECTRIC SHOCK

Unplug and/or disconnect all electrical power

to the unit before performing inspections,

maintenances or service.

Failure to do so could result in electric shock,

serious injury or death.

WARNING

HIGH PRESSURE HAZARD

Sealed Refrigeration System contains refrigerant

and oil under high pressure.

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with refrigerants.

Failure to follow these procedures could

result in serious injury or death.

Refrigerant Charging

NOTE: Because The RAC System Is A Sealed System,

Service Process Tubes Will Have To Be Installed. First

Install A Line Tap And Remove Refrigerant From System.

Make Necessary Sealed System Repairs And Vacuum

System. Crimp Process Tube Line And Solder End Shut.

Do Not Leave A Service Valve In The Sealed System.

14

EQUIPMENT MUST BE CAPABLE OF:

1. Recovery CFC’s as low as 5%.

2. Evacuation from both the high side and low side of the

system simultaneously.

3. Introducing refrigerant charge into high side of the

system.

4. Accurately weighing the refrigerant charge actually

introduced into the system.

5. Facilities for owing nitrogen through refrigeration tubing

during all brazing processes.

Proper refrigerant charge is essential to proper unit

operation. Operating a unit with an improper refrigerant

charge will result in reduced performance (capacity) and/or

efciency. Accordingly, the use of proper charging methods

during servicing will insure that the unit is functioning as

designed and that its compressor will not be damaged.

Too much refrigerant (overcharge) in the system is just as bad

(if not worse) than not enough refrigerant (undercharge). They

both can be the source of certain compressor failures if they

remain uncorrected for any period of time. Quite often, other

problems (such as low air ow across evaporator, etc.) are

misdiagnosed as refrigerant charge problems. The refrigerant

circuit diagnosis chart will assist you in properly diagnosing

these systems.

An overcharged unit will at times return liquid refrigerant

(slugging) back to the suction side of the compressor eventually

causing a mechanical failure within the compressor. This

mechanical failure can manifest itself as valve failure, bearing

failure, and/or other mechanical failure. The specic type of

failure will be inuenced by the amount of liquid being returned,

and the length of time the slugging continues.

Not enough refrigerant (undercharge) on the other hand, will

cause the temperature of the suction gas to increase to the point

where it does not provide sufcient cooling for the compressor

motor. When this occurs, the motor winding temperature will

increase causing the motor to overheat and possibly cycle open

the compressor overload protector. Continued overheating of

the motor windings and/or cycling of the overload will eventually

lead to compressor motor or overload failure.

Page 17

Method Of Charging / Repairs

The acceptable method for charging the RAC system is the

Weighed in Charge Method. The weighed in charge method is

applicable to all units. It is the preferred method to use, as it is

the most accurate.

The weighed in method should always be used whenever

a charge is removed from a unit such as for a leak repair,

compressor replacement, or when there is no refrigerant

charge left in the unit. To charge by this method, requires the

following steps:

1. Install a piercing valve to remove refrigerant from the

sealedsystem. (Piercing valve must be removed from the

system before recharging.)

2. Recover Refrigerant in accordance with EPA regulations.

WARNING

BURN HAZARD

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with a torch.

Failure to follow these procedures could

result in moderate or serious injury.

3. Install a process tube to sealed system.

CAUTION

FREEZE HAZARD

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with liquid refrigerant.

Failure to follow these procedures could

result in minor to moderate injury.

4. Make necessary repairs to system.

5. Evacuate system to 200 microns or less.

6. Weigh in refrigerant with the property quantity of R-22

refrigerant.

7. Start unit, and verify performance.

WARNING

BURN HAZARD

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with a torch.

Failure to follow these procedures could

result in moderate or serious injury.

8. Crimp the process tube and solder the end shut.

15

Page 18

WARNING

ELECTRIC SHOCK HAZARD

Turn off electric power before service or

installation.

WARNING

HIGH PRESSURE HAZARD

Sealed Refrigeration System contains refrigerant

and oil under high pressure.

Extreme care must be used, if it becomes

necessary to work on equipment with power

applied.

Failure to do so could result in serious injury or

death.

Undercharged Refrigerant Systems

An undercharged system will result in poor performance

(low pressures, etc.) in both the heating and cooling

cycle.

Whenever you service a unit with an undercharge of

refrigerant, always suspect a leak. The leak must be

repaired before charging the unit.

To check for an undercharged system, turn the unit on,

allow the compressor to run long enough to establish

working pressures in the system (15 to 20 minutes).

During the cooling cycle you can listen carefully at the exit

of the metering device into the evaporator; an intermittent

hissing and gurgling sound indicates a low refrigerant

charge. Intermittent frosting and thawing of the evaporator

is another indication of a low charge, however, frosting

and thawing can also be caused by insufcient air over

the evaporator.

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with refrigerants.

Failure to follow these procedures could

result in serious injury or death.

A check of the amperage drawn by the compressor

motor should show a lower reading. (Check the Unit

Specication.) After the unit has run 10 to 15 minutes,

check the gauge pressures. Gauges connected to system

with an undercharge will have low head pressures and

substantially low suction pressures.

Checks for an undercharged system can be made at

the compressor. If the compressor seems quieter than

normal, it is an indication of a low refrigerant charge.

Overcharged Refrigerant Systems

Compressor amps will be near normal or higher.

Noncondensables can also cause these symptoms. To

conrm, remove some of the charge, if conditions improve,

system may be overcharged. If conditions don’t improve,

Noncondensables are indicated.

Whenever an overcharged system is indicated, always

make sure that the problem is not caused by air ow

problems. Improper air ow over the evaporator coil may

indicate some of the same symptoms as an over charged

system.

An overcharge can cause the compressor to fail, since it

would be “slugged” with liquid refrigerant.

The charge for any system is critical. When the compressor

is noisy, suspect an overcharge, when you are sure that

the air quantity over the evaporator coil is correct. Icing

of the evaporator will not be encountered because the

refrigerant will boil later if at all. Gauges connected to

system will usually have higher head pressure (depending

upon amount of over charge). Suction pressure should be

slightly higher.

16

Page 19

Restricted Refrigerant System

Troubleshooting a restricted refrigerant system can be

difcult. The following procedures are the more common

problems and solutions to these problems. There are two

types of refrigerant restrictions: Partial restrictions and

complete restrictions.

A partial restriction allows some of the refrigerant to

circulate through the system.

With a complete restriction there is no circulation of

refrigerant in the system.

Restricted refrigerant systems display the same symptoms

as a “low-charge condition.”

When the unit is shut off, the gauges may equalize very

slowly.

Gauges connected to a completely restricted system will

run in a deep vacuum. When the unit is shut off, the gauges

will not equalize at all.

A quick check for either condition begins at the evaporator.

With a partial restriction, there may be gurgling sounds

at the metering device entrance to the evaporator. The

evaporator in a partial restriction could be partially frosted

or have an ice ball close to the entrance of the metering

device. Frost may continue on the suction line back to the

compressor.

Often a partial restriction of any type can be found by feel,

as there is a temperature difference from one side of the

restriction to the other.

With a complete restriction, there will be no sound at the

metering device entrance. An amperage check of the

compressor with a partial restriction may show normal

current when compared to the unit speci cation. With a

complete restriction the current drawn may be considerably

less than normal, as the compressor is running in a deep

vacuum (no load.) Much of the area of the condenser will

be relatively cool since most or all of the liquid refrigerant

will be stored there.

The following conditions are based primarily on a system

in the cooling mode.

17

Page 20

METERING DEVICE

Capillary Tube Systems

All units are equipped with capillary tube metering

devices.

Checking for restricted capillary tubes.

1. Connect pressure gauges to unit.

2. Start the unit in the cooling mode. If after a few minutes

of operation the pressures are normal, the check valve

and the cooling capillary are not restricted.

3. Switch the unit to the heating mode and observe

the gauge readings after a few minutes running time.

If the system pressure is lower than normal, the heating

capillary is restricted.

4. If the operating pressures are lower than normal in

both the heating and cooling mode, the cooling

capillary is restricted.

COMPRESSOR CHECKS

WARNING

ELECTRIC SHOCK HAZARD

Turn off electric power before service or

installation. Extreme care must be used, if it

becomes necessary to work on equipment with

power applied.

Failure to do so could result in serious injury or

death.

Locked Rotor Voltage (L.R.V.) Test

Locked rotor voltage (L.R.V.) is the actual voltage available

at the compressor under a stalled condition.

Single Phase Running and L.R.A. Test

NOTE: Consult the specication and performance section

for running amperage. The L.R.A. can also be found on the

rating plate.

Select the proper amperage scale and clamp the meter

probe around the wire to the “C” terminal of the compressor. Turn on the unit and read the running amperage on

the meter. If the compressor does not start, the reading

will indicate the locked rotor amperage (L.R.A.).

External Overload

The compressor is equipped with an external overload

which senses both motor amperage and winding temperature. High motor temperature or amperage heats the

overload causing it to open, breaking the common circuit

within the compressor.

Heat generated within the compressor shell, usually due

to recycling of the motor, is slow to dissipate. It may take

anywhere from a few minutes to several hours for the

overload to reset.

Checking the External Overload

WARNING

ELECTRIC SHOCK HAZARD

Turn off electric power before service or

installation. Extreme care must be used, if it

becomes necessary to work on equipment

with power applied.

Failure to do so could result in serious injury or

death.

Single Phase Connections

Disconnect power from unit. Using a voltmeter, attach one

lead of the meter to the run “R” terminal on the compressor

and the other lead to the common “C” terminal of the compressor. Restore power to unit.

Determine L.R.V.

Start the compressor with the volt meter attached; then stop

the unit. Attempt to restart the compressor within a couple

of seconds and immediately read the voltage on the meter.

The compressor under these conditions will not start and will

usually kick out on overload within a few seconds since the

pressures in the system will not have had time to equalize.

Voltage should be at or above minimum voltage of 197 VAC,

as specied on the rating plate. If less than minimum, check

for cause of inadequate power supply; i.e., incorrect wire

size, loose electrical connections, etc.

Amperage (L.R.A.) Test

The running amperage of the compressor is the most important of these readings. A running amperage higher than that

indicated in the performance data indicates that a problem

exists mechanically or electrically.

WARNING

BURN HAZARD

Certain unit components operate at

temperatures hot enough to cause burns.

Proper safety procedures must be followed,

and proper protective clothing must be

worn.

Failure to follow this warning could result

in moderate to serious injury.

With power off, remove the leads from compressor terminals. If the compressor is hot, allow the overload to cool

before starting check. Using an ohmmeter, test continuity across the terminals of the external overload. If you

do not have continuity; this indicates that the overload is

open and must be replaced.

18

Page 21

1. With no power to unit, remove the leads from the compressor terminals.

2. Using an ohmmeter, test continuity between terminals

C-S and C-R. If no continuity, the compressor overload

is open and the compressor must be replaced.

CHECKING THE INTERNAL OVERLOAD

INTERNAL OVERLOAD

Some model compressors are equipped with an internal

overload. The overload is embedded in the motor windings

to sense the winding temperature and/or current draw. The

overload is connected in series with the common motor

terminal.

Should the internal temperature and/or current draw become

excessive, the contacts in the overload will open, turning off

the compressor. The overload will automatically reset, but

may require several hours before the heat is dissipated.

Internal Overload

WARNING

ELECTRIC SHOCK HAZARD

Disconnect power to the unit before

servicing. Failure to follow this warning

could result in serious injury or death.

to “R”). The next highest resistance is from the start

to the common connections (“S” to “C”). The lowest

resistance is from the run to common. (“C” to “R”)

Before replacing a compressor, check to be sure it is

defective.

GROUND TEST

Use an ohmmeter set on its highest scale. Touch one

lead to the compressor body (clean point of contact

as a good connection is a must) and the other probe

in turn to each compressor terminal. If a reading is

obtained the compressor is grounded and must be

replaced.

Check the complete electrical system to the

compressor and compressor internal electrical

system, check to be certain that compressor is not

out on internal overload.

Complete evaluation of the system must be made

whenever you suspect the compressor is defective. If

the compressor has been operating for sometime, a

careful examination must be made to determine why

the compressor failed.

Single Phase Resistance Test

Remove the leads from the compressor terminals and set

the ohmmeter on the lowest scale (R x 1).

Touch the leads of the ohmmeter from terminals common

to start (“C” to “S”). Next, touch the leads of the ohmmeter

from terminals common to run (“C” to “R”).

Add values “C” to “S” and “C” to “R” together and

check resistance from start to run terminals (“S” to “R”).

Resistance “S” to “R” should equal the total of “C” to “S”

and “C” to “R.”

In a single phase PSC compressor motor, the highest

value will be from the start to the run connections (“S”

Many compressor failures are caused by the following

conditions:

1. Improper air ow over the evaporator.

2. Overcharged refrigerant system causing liquid to

be returned to the compressor.

3. Restricted refrigerant system.

4. Lack of lubrication.

5. Liquid refrigerant returning to compressor causing

oil to be washed out of bearings.

6. Noncondensables such as air and moisture in

the system. Moisture is extremely destructive to a

refrigerant system.

19

Page 22

CAPACITORS CAPACITORS

WARNING

ELECTRIC SHOCK HAZARD

Turn off electric power before servicing.

Discharge capacitor with a 20,000 Ohm 2 Watt

resistor before handling.

Failure to do so may result in personal injury,

or death.

Many motor capacitors are internally fused. Shorting

the terminals will blow the fuse, ruining the capacitor.

A 20,000 ohm 2 watt resistor can be used to discharge

capacitors safely. Remove wires from capacitor and place

resistor across terminals. When checking a dual capacitor

with a capacitor analyzer or ohmmeter, both sides must

be tested.

Capacitor Check with Capacitor Analyzer

The capacitor analyzer will show whether the capacitor

is “open” or “shorted.” It will tell whether the capacitor

is within its micro farads rating and it will show whether

the capacitor is operating at the proper power-factor

percentage. The instrument will automatically discharge

the capacitor when the test switch is released.

Dual Rated Run Capacitor Hook-up

F

C

H

Capacitor Connections

The starting winding of a motor can be damaged by a

shorted and grounded running capacitor. This damage

usually can be avoided by proper connection of the

running capacitor terminals.

From the supply line on a typical 230 volt circuit, a 115 volt

potential exists from the “R” terminal to ground through a

possible short in the capacitor. However, from the “S” or

start terminal, a much higher potential, possibly as high as

400 volts, exists because of the counter EMF generated

in the start winding. Therefore, the possibility of capacitor

failure is much greater when the identied terminal is

connected to the “S” or start terminal. The identied

terminal should always be connected to the supply line, or

“R” terminal, never to the “S” terminal.

When connected properly, a shorted or grounded running

capacitor will result in a direct short to ground from the “R”

terminal and will blow the line fuse. The motor protector will

protect the main winding from excessive temperature.

20

Page 23

COMPRESSOR REPLACEMENT

Recommended procedure for compressor

replacement

WARNING

RISK OF ELECTRIC SHOCK

Unplug and/or disconnect all electrical power

to the unit before performing inspections,

maintenances or service.

Failure to do so could result in electric shock,

serious injury or death.

1. Be certain to perform all necessary electrical and

refrigeration tests to be sure the compressor is

actually defective before replacing.

WARNING

HIGH PRESSURE HAZARD

Sealed Refrigeration System contains refrigerant

and oil under high pressure.

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with refrigerants.

Failure to follow these procedures could

result in serious injury or death.

2. Recover all refrigerant from the system though

the process tubes. PROPER HANDLING OF

RECOVERED REFRIGERANT ACCORDING TO

EPA REGULATIONS IS REQUIRED. Do not use

gauge manifold for this purpose if there has been

a burnout. You will contaminate your manifold and

hoses. Use a Schrader valve adapter and copper

tubing for burnout failures.

WARNING

HIGH TEMPERATURES

Extreme care, proper judgment and all safety

procedures must be followed when testing,

troubleshooting, handling or working around

unit while in operation with high temperature

components. Wear protective safety aids

such as: gloves, clothing etc.

Failure to do so could result in serious burn

injury.

3. After all refrigerant has been recovered, disconnect

suction and discharge lines from the compressor and

remove compressor. Be certain to have both suction

and discharge process tubes open to atmosphere.

4. Carefully pour a small amount of oil from the suction

stub of the defective compressor into a clean

container.

5. Using an acid test kit (one shot or conventional kit), test

the oil for acid content according to the instructions

with the kit.

6. If any evidence of a burnout is found, no matter how

slight, the system will need to be cleaned up following

proper procedures.

7. Install the replacement compressor.

WARNING

EXPLOSION HAZARD

The use of nitrogen requires a pressure

regulator. Follow all safety procedures and

wear protective safety clothing etc.

Failure to follow proper safety procedures

result in serious injury or death.

8. Pressurize with a combination of R-22 and nitrogen

and leak test all connections with an electronic or

Halide leak detector. Recover refrigerant and repair

any leaks found.

Repeat Step 8 to insure no more leaks are present.

9. Evacuate the system with a good vacuum pump capable

of a nal vacuum of 300 microns or less. The system

should be evacuated through both liquid line and suction

line gauge ports. While the unit is being evacuated, seal

all openings on the defective compressor. Compressor

manufacturers will void warranties on units received not

properly sealed. Do not distort the manufacturers tube

connections.

CAUTION

FREEZE HAZARD

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with liquid refrigerant.

NOTICE

FIRE HAZARD

The use of a torch requires extreme care and proper

judgment. Follow all safety recommended precautions

and protect surrounding areas with re proof materials.

Have a re extinguisher readily available. Failure to follow

this notice could result in moderate to serious property

damage.

Failure to follow these procedures could

result in minor to moderate injury.

10. Recharge the system with the correct amount of

refrigerant. The proper refrigerant charge will be

found on the unit rating plate. The use of an accurate

measuring device, such as a charging cylinder,

electronic scales or similar device is necessary.

21

Page 24

SPECIAL PROCEDURE IN THE CASE OF MOTOR

COMPRESSOR BURNOUT

WARNING

ELECTRIC SHOCK HAZARD

Turn off electric power before service or

installation.

Failure to do so may result in personal injury,

or death.

WARNING

HIGH PRESSURE HAZARD

Sealed Refrigeration System contains refrigerant

and oil under high pressure.

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with refrigerants.

Failure to follow these procedures could

result in serious injury or death.

WARNING

EXPLOSION HAZARD

The use of nitrogen requires a pressure

regulator. Follow all safety procedures and

wear protective safety clothing etc.

Failure to follow proper safety procedures

result in serious injury or death.

1.

Recover all refrigerant and oil from the system.

Remove compressor, capillary tube and lter drier

2.

from the system.

3.

Flush evaporator condenser and all connecting

tubing with dry nitrogen or equivalent. Use approved

ushing agent to remove all contamination from

system. Inspect suction and discharge line for

carbon deposits. Remove and clean if necessary.

Ensure all acid is neutralized.

Reassemble the system, including new drier strainer

4.

and capillary tube.

5.

Proceed with step 9-10 above. (see page #22).

ROTARY COMPRESSOR SPECIAL TROUBLESHOOTING

AND SERVICE

Basically, troubleshooting and servicing rotary compressors is the same as on the reciprocating compressor with

only one main exception:

NEVER, under any circumstances, charge a rotary compressor through the LOW side. Doing so would cause

permanent damage to the new compressor.

22

Page 25

ROUTINE MAINTENANCE

WARNING

ELECTRIC SHOCK HAZARD

Turn off electric power before inspections,

maintenances, or service.

Extreme care must be used, if it becomes

necessary to work on equipment with power

applied.

Failure to do so could result in serious injury

or death.

AIR FILTER

Clean the unit air intake lter at least every 300 to 350 hours of operation. Clean the lters with a mild detergent in

warm water and allow to dry thoroughly before reinstalling.

COILS AND BASE PAN

Units are to be inspected and serviced by qualied service

personnel only. Use proper protection on surrounding

property. Failure to follow this notice could result in

moderate or serious property damage.

WARNING

EXCESSIVE WEIGHT HAZARD

Use two people to lift or carry the unit, and wear

proper protective clothing.

Failure to do so may result in personal injury.

Do not use a caustic coil cleaning agent on coils or base

pan. Use a biodegradable cleaning agent and degreaser,

to prevent damage to the coil and/or base pan.

NOTICE

NOTICE

WARNING

CUT/SEVER HAZARD

Be careful with the sharp edges and corners.

Wear protective clothing and gloves, etc.

Failure to do so could result in serious injury.

The indoor coil (evaporator coil), the outdoor coil (condenser coil) and base pan should be inspected periodically

(yearly or bi-yearly) and cleaned of all debris (lint, dirt, leaves, paper, etc.). Clean the coils and base pan with a soft

brush and compressed air or vacuum. If using a pressure washer, be careful not to bend the aluminium n pack. Use

a sweeping up and down motion in the direction of the vertical aluminum n pack when pressure cleaning coils. Cover

all electrical components to protect them from water or spray. Allow the unit to dry thoroughly before reinstalling it in

the sleeve.

BLOWER WHEEL / HOUSING / CONDENSER FAN / SHROUD

Inspect the indoor blower housing, evaporator blade, condenser fan blade and condenser shroud periodically (yearly or

bi-yearly) and clean of all debris (lint, dirt, mold, fungus, etc.). Clean the blower housing area and blower wheel with an

antibacterial / antifungal cleaner. Use a biodegradable cleaning agent and degreaser on condenser fan and condenser

shroud. Use warm or cold water when rinsing these items. Allow all items to dry thoroughly before reinstalling them.

ELECTRONIC / ELECTRICAL / MECHANICAL

Periodically (at least yearly or bi-yearly): inspect all control components: electronic, electrical and mechanical, as well

as the power supply. Use proper testing instruments (voltmeter, ohmmeter, ammeter, wattmeter, etc.) to perform electrical tests. Use an air conditioning or refrigeration thermometer to check room, outdoor and coil operating temperatures. Use a sling psychrometer to measure wet bulb temperatures indoors and outdoors.

Inspect the surrounding area (inside and outside) to ensure that the unit’s clearances have not been compromised or

altered.

23

Page 26

Cabinet

Airinlet louver

Front grille

Powercord

Control panelcover

Frontintakegrille

Airfilter

(behindfront intake gril le)

ROUTINE MAINTENANCE (Continued)

NOTICE

Do not drill holes in the bottom of the drain pan or the

underside of the unit. Not following this notice could

result in damage to the unit or condensate water leaking

inappropriately which could cause water damage to

surrounding property.

SLEEVE / DRAIN

Inspect the sleeve and drain system periodically (at least yearly or bi-yearly) and clean of all obstructions and

debris. Clean both areas with an antibacterial and antifungal cleaner. Rinse both items thoroughly with water and

ensure that the drain outlets are operating correctly. Check the sealant around the sleeve and reseal areas as

needed.

FRONT COVER

Clean the front cover when needed. Use a mild detergent. Wash and rinse with warm water. Allow it to dry

thoroughly before reinstalling it in the chassis.

24

Page 27

COOLING ONLY ROOM AIR CONDITIONERS: TROUBLESHOOTING TIPS

noitcA esuaC elbissoP melborP

Compressor

does not run

Low voltage

Check voltage at compressor. 115V & 230V

units will operate at 10% voltage variance

T-stat not set cold enough or

inoperative

Set t-stat to coldest position. Test t-stat & replace if inoperative

Compressor hums but cuts off on

overload

Hard start compressor. Direct test compressor.

If compressor starts, add starting components

Open or shorted compressor

windings

Check for continuity & resistance

Open overload Test overload protector & replace if inoperative

Open capacitor Test capacitor & replace if inoperative

Inoperative system switch

Test for continuity in all positions. Replace if

inoperative

Broken, loose or incorrect wiring

Refer to appropriate wiring diagrams to check

wiring

noitcA esuaC elbissoP melborP

Fan motor

does not run

Inoperative system switch Test switch & replace if inoperative

Broken, loose or incorrect wiring Refer to applicable wiring diagram

Open capacitor Test capacitor & replace if inoperative

Fan speed switch open Test switch & replace if inoperative

Inoperative fan motor

Test fan motor & replace if inoperative (be sure

internal overload has had time to reset)

noitcA esuaC elbissoP melborP

Does not cool or

only cools slightly

Undersized unit Refer to industry standard sizing chart

T-stat open or inoperative

Set to coldest position. Test t-stat & replace if

necessary

Dirty fi launaM s’renwO ni dednemmocer sa naelC retl

Dirty or restricted condenser or

evaporator coil

Use pressure wash or biodegradable cleaning

agent to clean

Poor air circulation Adjust discharge louvers. Use high fan speed

Fresh air or exhaust air door open

on applicable models

Close doors. Instruct customer on use of this

feature

Low capacity - undercharge Check for leak & make repair

Compressor not pumping properly

Check amperage draw against nameplate. If

not conclusive, make pressure test

25

Page 28

COOLING ONLY ROOM AIR CONDITIONERS: TROUBLESHOOTING TIPS

noitcA esuaC elbissoP melborP

Unit does not run

Fuse blown or circuit tripped

Replace fuse, reset breaker. If repeats, check

fuse or breaker size. Check for shorts in unit

wiring & components

Power cord not plugged in Plug it in

System switch in “OFF” position Set switch correctly

Inoperative system switch or open

control board

Test for continuity

Loose or disconnected wiring at

switch, control board or other com-

ponents

Check wiring & connections. Reconnect per

wiring diagram

noitcA esuaC elbissoP melborP

Evaporator coil

freezes up

Dirty fi launaM s’renwO ni dednemmocer sa naelC retl

Restricted airfl ow

Check for dirty or obstructed coil. Use

pressure wash or biodegradable cleaning

agent to clean

Inoperative t-stat or thermistors Test for continuity

Short of refrigerant De-ice coil & check for leak

Inoperative fan motor Test fan motor & replace if inoperative

Partially restricted capillary tube

De-ice coil. Check temp. differential (delta T)

across coil. Touch test coil return bends for

same temp. Test for low running current

noitcA esuaC elbissoP melborP

Compressor runs

continually & does

not cycle off

Excessive heat load

Unit undersized. Test cooling performance &

replace with larger unit if needed

Restriction in line

Check for partially iced coil & check

temperature split across coil

Refrigerant leak

Check for oil at silver soldered connections.

Check for partially iced coil. Check split across

coil. Check for low running amperage

T-stat contacts stuck

Check operation of t-stat. Replace if contacts

remain closed.

T-stat incorrectly wired Refer to appropriate wiring diagram

Thermistor shorted Replace thermistor or electronic control board

noitcA esuaC elbissoP melborP

T-stat does not

turn unit off

T-stat contacts stuck

Disconnect power to unit. Remove cover

of t-stat & check if contacts are stuck. If so,

replace t-stat

T-stat set at coldest point

Turn to higher temp. setting to see if unit

cycles off

Incorrect wiring Refer to appropriate wiring diagrams

Unit undersized for area to be

cooled

Refer to industry standard sizing chart

Defective thermistor Replace thermistor or electronic control board

26

Page 29

COOLING ONLY ROOM AIR CONDITIONERS: TROUBLESHOOTING TIPS

noitcA esuaC elbissoP melborP

Compressor runs

for short periods

only. Cycles on

overload

T-stat does not

turn unit on

Overload inoperative. Opens too

soon

Compressor restarted before

system pressures equalized

Low or

Incorrect wiring Refer to appropriate wiring diagram

Shorted or incorrect capacitor

Restricted or low air

condenser coil or evaporator coil

Compressor running abnormally

hot

Loss of charge in t-stat bulb

Loose or broken parts in t-stat Check as above

Incorrect wiring Refer to appropriate wiring diagram

Defective thermistor Replace thermistor or electronic control board

uctuating voltage

ow through

Check operation of unit. Replace overload if

system operation is satisfactory

Allow a minimum of 2 minutes to allow

pressures to equalize before attempting to

restart. Instruct customer of waiting period

Check voltage with unit operating. Check for

other appliances on circuit. Air conditioner

should be in separate circuit for proper voltage

& fused separately

Check by substituting a known good capacitor

of correct rating

Check for proper fan speed or blocked

coils

Check for kinked discharge line or restricted

condenser. Check amperage

noitcA esuaC elbissoP melborP

Place jumper across t-stat terminals to check if

unit operates. If unit operates, replace t-stat.

Noisy operation

Water leaks into

the room

noitcA esuaC elbissoP melborP

Poorly installed

Fan blade striking chassis Reposition - adjust motor mount

Compressor vibrating

Improperly mounted or loose

cabinet parts

Evaporator drain pan over

Condensation forming on base pan

Poor installation resulting in rain

entering the room

Condensation on discharge grille

louvers

Chassis gasket not installed Install gasket, per Installation manual

Downward slope of unit is too

steep inward

owing Clean obstructed drain trough

Refer to Installation Manual for proper

installation

Check that compressor grommets have not

deteriorated. Check that compressor mounting

parts are not missing

Check assembly & parts for looseness,

rubbing & rattling

noitcA esuaC elbissoP melborP

Evaporator drain pan broken or cracked.

Reseal or replace. No chassis gasket installed.

Install chassis gasket

Check installation instructions. Reseal as

required

Dirty evaporator coil. Use pressure wash

or biodegradable cleaning agent to clean.

Environmental phenomena: point supply

louvers upward

Refer to installation manual for proper

installation

27

Page 30

COOLING ONLY ROOM AIR CONDITIONERS: TROUBLESHOOTING TIPS

noitcA esuaC elbissoP melborP

Water “spitting”

into room

Sublimation:

When unconditioned saturated,

outside air mixes with conditioned

air, condensation forms on the

cooler surfaces

Ensure that foam gaskets are installed in

between window panes & in between the

unit & the sleeve. Also, ensure that fresh

air/exhaust vents (on applicable models) are in

the closed position & are in tact

Downward pitch of installation is

too steep towards back of unit

Follow installation instructions to ensure that

downward pitch of installed unit is no less than

1/4” & no more than 3/8”

Restricted coil or dirty fi lter

Clean & advise customer of periodic cleaning

& maintenance needs of entire unit

noitcA esuaC elbissoP melborP

Excessive

moisture

Insuffi cient air circulation thru area

to be air conditioned

Adjust louvers for best possible air circulation

noitisop ”revaSyenoM“ ni etarepO tinu dezisrevO

Inadequate vapor barrier in building

structure, particularly fl oors

Advise customer

noitcA esuaC elbissoP melborP

T-stat or

thermistor

short cycles

Defective thermistor Replace thermistor or electronic control board

T-stat differential too narrow Replace t-stat

Plenum gasket not sealing,

allowing discharge air to short

cycle t-stat

Check gasket. Reposition or replace as

needed

Restricted coil or dirty fi lter

Clean & advise customer of periodic cleaning

& maintenance needs of entire unit

noitcA esuaC elbissoP melborP

Prolonged off

cycles (automatic

operation)

Heat anticipator (resistor) wire

disconnected at t-stat or system

switch

Refer to appropriate wiring diagram

Heat anticipator (resistor) shorted or

open

Disconnect plus from outlet. Remove resistor

from bracket. Insert plug & depress “COOL”

& “FAN AUTOMATIC” buttons. Place t-stat to

warmest setting. Feel resistor for temperature.

If no heat, replace resistor

Partial loss of charge in t-stat bulb

causing a wide differential

Replace t-stat

Defective thermistor Replace thermistor or electronic control board

noitcA esuaC elbissoP melborP

Outside water

leaks

Evaporator drain pan cracked or

obstructed

Repair, clean or replace as required

Water in compressor area

Detach shroud from pan & coil. Clean &

remove old sealer. Reseal, reinstall & check

Obstructed condenser coil

Use pressure wash or biodegradable cleaning

agent to clean