Page 1

S70-101 IOM/JAN 2000

File: SERVICE MANUAL - Section 70

Replaces: S70-101 IOM/APR 96

Dist: 3, 3a, 3b, 3c

Installation - Operation - Maintenance

ROTARY SCREW COMPRESSOR UNITS

WITH

MICROPROCESSOR CONTROL

ALL REFRIGERANTS

THIS MANUAL CONTAINS RIGGING, ASSEMBLY, START-UP, AND

MAINTENANCE INSTRUCTIONS. READ THOROUGHLY BEFORE

BEGINNING INSTALLATION. FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESUL T IN D AMAGE OR IMPR OPER OPERATION OF THE UNIT.

Page 2

RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

Page 2

INSTALLATION - OPERATION - MAINTENANCE

TABLE OF CONTENTS

GENERAL INFORMA TION

Preface..............................................................................3

Design Limitations ............................................................3

Job Inspection...................................................................3

Transit Damage Claims.....................................................3

Compressor/Unit Identification ..........................................3

INSTALLATION

Foundation ........................................................................4

Handling and Moving ........................................................4

Skid Removal....................................................................5

Motor Mounting .................................................................5

Compressor/Motor Coupling Installation ..........................5

Coupling Alignment Procedure .........................................6

Hot Alignment of Compressor/Motor ................................8

Checking Motor/Compressor Rotation .............................. 8

Holding Charge and Storage ............................................ 8

Compressor Oil .................................................................8

Oil Charge.........................................................................8

Oil Heater..........................................................................8

Liquid Injection Oil Cooling ...............................................9

Dual Dip Tube Method.......................................................9

Level Control Method........................................................9

Water-Cooled Oil Cooling ...............................................10

Thermosyphon Oil Cooling ............................................. 1 0

Economizer - High Stage ................................................ 12

Electrical .........................................................................13

Motor Starter Package ....................................................13

Current Transformers (CT) Ratios...................................14

Minimum Burden Ratings................................................14

Battery Backup ...............................................................14

OPERA TION

General Information ........................................................15

Microprocessor Control Panel .........................................15

Keys and Key Functions .................................................16

To Change The Adjustable Setpoints.............................. 1 8

How To Determine Adjustable Setpoints......................... 18

Temperature-Pressure Control Program.........................22

Lead-Lag (Option)...........................................................24

Communications Troubleshooting ...................................24

How The Microprocessor Works - Summary ..................25

Multiple Compressor Sequencing...................................26

Microprocessor Telecommunications ..............................27

Communications Protocol Specifications ....................... 2 7

RXB Compressor ............................................................30

Compressor Lubrication System..................................... 30

Full-Lube Oil System ......................................................30

Compressor Oil Separation System ...............................30

Compressor Hydraulic System ....................................... 31

Compressor Oil Cooling Systems...................................32

Single-Port Liquid Injection ............................................. 3 2

Dual-Port Liquid Injection ................................................ 3 3

Liquid Injection Adjustment Procedure ...........................33

Prestart Checklist............................................................34

Initial Start-up Procedure ................................................35

Normal Start-up Procedure ............................................. 35

Restarting Unit After Power Failure.................................35

MAINTENANCE

Normal Maintenance Operations ....................................36

Compressor Shutdown and Start-up ..............................36

General Instructions For Replacing

Compressor Unit Components....................................36

Suction Check Valv e Bypass Valve ................................. 36

Oil Filter, Single...............................................................36

Oil Filter, Dual ................................................................. 3 7

Strainer, Oil Return ......................................................... 37

Strainer, Oil Pump (Optional)..........................................37

Strainer, Liquid Injection ................................................. 37

Coalescer Filter Element ................................................3 8

Changing Oil ...................................................................38

Recommended Maintenance Program ...........................38

Vibration Analysis ........................................................... 39

Oil Quality and Analysis..................................................39

Motor Bearings ...............................................................39

Operating Log .................................................................39

Maintenance Schedule ................................................... 40

Troubleshooting Guide .................................................... 4 1

Abnormal Operation Analysis and Correction ................41

Troubleshooting The Microprocessor..............................42

EPROM Memory I/C Chip Replacement ........................45

SBC Board Replacement................................................45

Microprocessor Display Replacement ............................45

Output Fuse Replacement .............................................. 45

Pressure Transducers - Testing....................................... 45

Pressure Transducer Conversion Data ...........................45

Pressure Transducers - Replacement.............................46

Volumizer Potentiometer - Replace/Adjust .....................47

Temperature/Pressure Adjustment ................................. 47

Bare Compressor Mounting ............................................47

Troubleshooting The RXB PLUS:

Compressor.................................................................48

Oil Separator System ..................................................48

Hydraulic System ........................................................ 48

Full-Time Pump Systems ............................................49

Liquid Injection Oil Cooling .........................................49

Thermal Expansion Valves .............................................50

Temperature Control Valve..............................................51

Wiring Diagrams .............................................................52

P and I Diagrams ............................................................ 58

PROPER INSTALLA TION OF ELECTRONIC

EQUIPMENT ............................................................... 61

SPARE P AR TS LIST....................................................... 64

OPERA TING LOG .......................................................... 65

Page 3

RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

GENERAL INFORMATION

Page 3

PREFACE

This manual has been prepared to acquaint the owner and

serviceman with the INSTALLATION, OPERATION, and

MAINTENANCE procedures as recommended by Frick for

RXB PLUS Rotary Screw Compressor Units.

It is most important that these units be properly applied to

an adequately controlled refrigeration system. Your authorized Frick representative should be consulted for his expert guidance in this determination.

Proper performance and continued satisfaction with these

units is dependent upon:

CORRECT INSTALLATION

PROPER OPERATION

REGULAR, SYSTEMATIC MAINTENANCE

T o ensure correct installation and application, the equipment

must be properly selected and connected to a properly designed and installed system. The Engineering plans, piping

layouts, etc. must be detailed in accordance with the best

practices and local codes, such as those outlined in ASHRAE

literature.

A refrigeration compressor is a V APOR PUMP. To be certain

that it is not being subjected to liquid refrigerant carryover , it

is necessary that refrigerant controls are carefully selected

and in good operating condition; the piping is properly sized

and traps, if necessary, are correctly arranged; the suction

line has an accumulator or slugging protection; that load

surges are known and provisions made for control; operating cycles and defrosting periods are reasonable; and that

high side condensers are sized within system and compressor design limits.

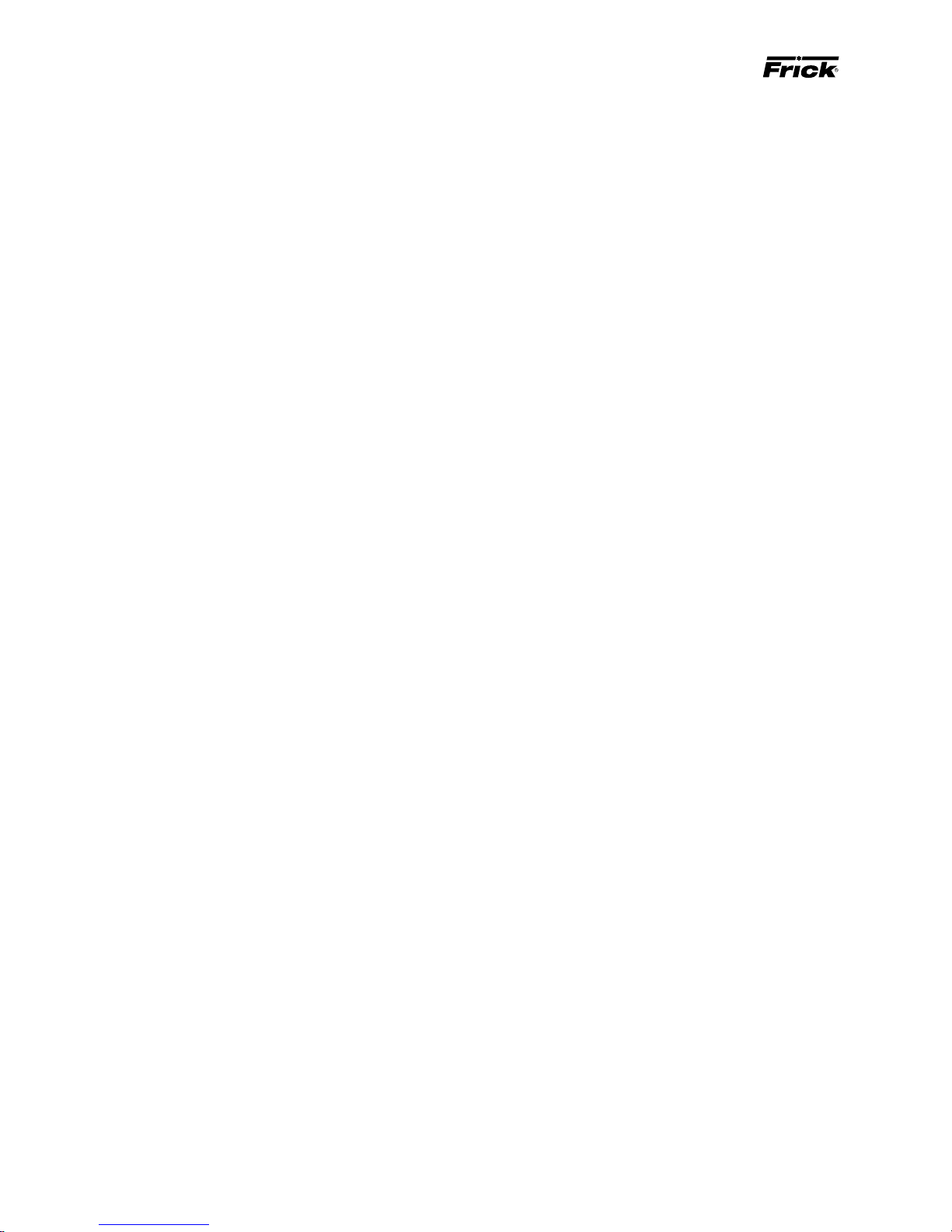

COMPRESSOR and UNIT IDENTIFICATION

Each compressor unit has 2 identification data plates. The

compressor data plate, containing compressor model and

serial number, is mounted on the compressor body . The unit

data plate, containing unit model, serial number, and Frick

sales order number, is mounted on the side of the motor

base.

NOTE: When inquiring about the compressor or unit, or

ordering repair parts, pro vide the MODEL, SERIAL, and

FRICK SALES ORDER NUMBERS from these data plates.

It is recommended that the entering vapor temperature to

the compressor be superheated to 10

ant saturation temperature. This ensures that all refrigerant

at the compressor suction is in the vapor state.

O

F above the refriger-

DESIGN LIMITATIONS

The compressor units are designed for operation within the

pressure and temperature limits as shown in Frick Pub.

E70-100 SED.

JOB INSPECTION

Immediately upon arrival examine all crates, boxes and exposed compressor and component surfaces for damage.

Unpack all items and check against shipping lists for any

possible shortage. Examine all items for damage in transit.

TRANSIT DAMAGE CLAIMS

All claims must be made by consignee. This is an ICC requirement. Request immediate inspection by the agent of

the carrier and be sure the proper claim forms are executed.

Report damage or shor tage claims immediately to Frick ,

Sales Administration Department, in Waynesboro, PA.

COMPRESSOR DATA PLATE

UNIT DATA PLATE

Page 4

Page 4

RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

INSTALLATION

FOUNDATION

Each RXB PLUS Rotary Screw Compressor Unit is shipped

mounted on a wood skid which must be removed prior to unit

installation. CA UTION: Allow space f or servicing both ends

of the unit. A minimum of 24 inches is recommended.

The first requirement of the compressor foundation is that it

must be able to support the weight of the compressor package including coolers, oil, and refrigerant charge. Screw

compressors are capable of converting large quantities of

shaft power into gas compression in a relatively small space

and a mass is required to effectively dampen these relatively high frequency vibrations.

Firmly anchoring the compressor package to a suitable foundation by proper application of grout and elimination of piping stress imposed on the compressor is the best insurance

for a trouble free installation. Use only the certified general

arrangement drawings from Frick to determine the mounting foot locations and to allow for recommended clearances

around the unit for ease of operation and servicing. Foundations must be in compliance with local building codes and

materials should be of industrial quality.

The floor should be a minimum of 6 inches of reinforced concrete and housekeeping pads are recommended. Anchor bolts

are required to firmly tie the unit to the floor. Once the unit is

rigged into place (See HANDLING and MOVING), the feet m ust

then be shimmed in order to level the unit. The shims should

be placed to position the feet roughly one inch above the housekeeping pad to allow room for grouting. An expansion-type

epoxy grout must be worked under all areas of the base with

no voids and be allowed to settle with a slight outw ard slope so

oil and water can run off of the base.

When installing on a steel base, the following guidelines should

be implemented to properly design the system base:

1. Use I-beams in the skid where the screw compressor will be

attached to the system base. They should run parallel to the

package feet and support the feet f or their full length.

2. The compressor unit f eet should be continuously welded to

the system base at all points of contact, or bolted.

3. The compressor unit should not be mounted on vibration

isolators in order to hold down package vibration le vels.

4. The customer’ s foundation f or the system base should fully

support the system base under all areas, but most certainly

under the I-beams that support the compressor package.

When installing on the upper floors of buildings, extra precautions should be taken to prevent normal package vibration from being transferred to the building structure. It may

be necessary to use rubber or spring isolators, or a combination of both, to prevent the transmission of compressor

vibration directly to the structure. Howe ver , this may increase

package vibration levels because the compressor is not in

contact with any damping mass. The mounting and support

of suction and discharge lines is also very important. Rubber or spring pipe supports may be required to avoid exciting the building structure at any pipe supports close to the

compressor package. It is best to emplo y a vibration expert

in the design of a proper mounting arrangement.

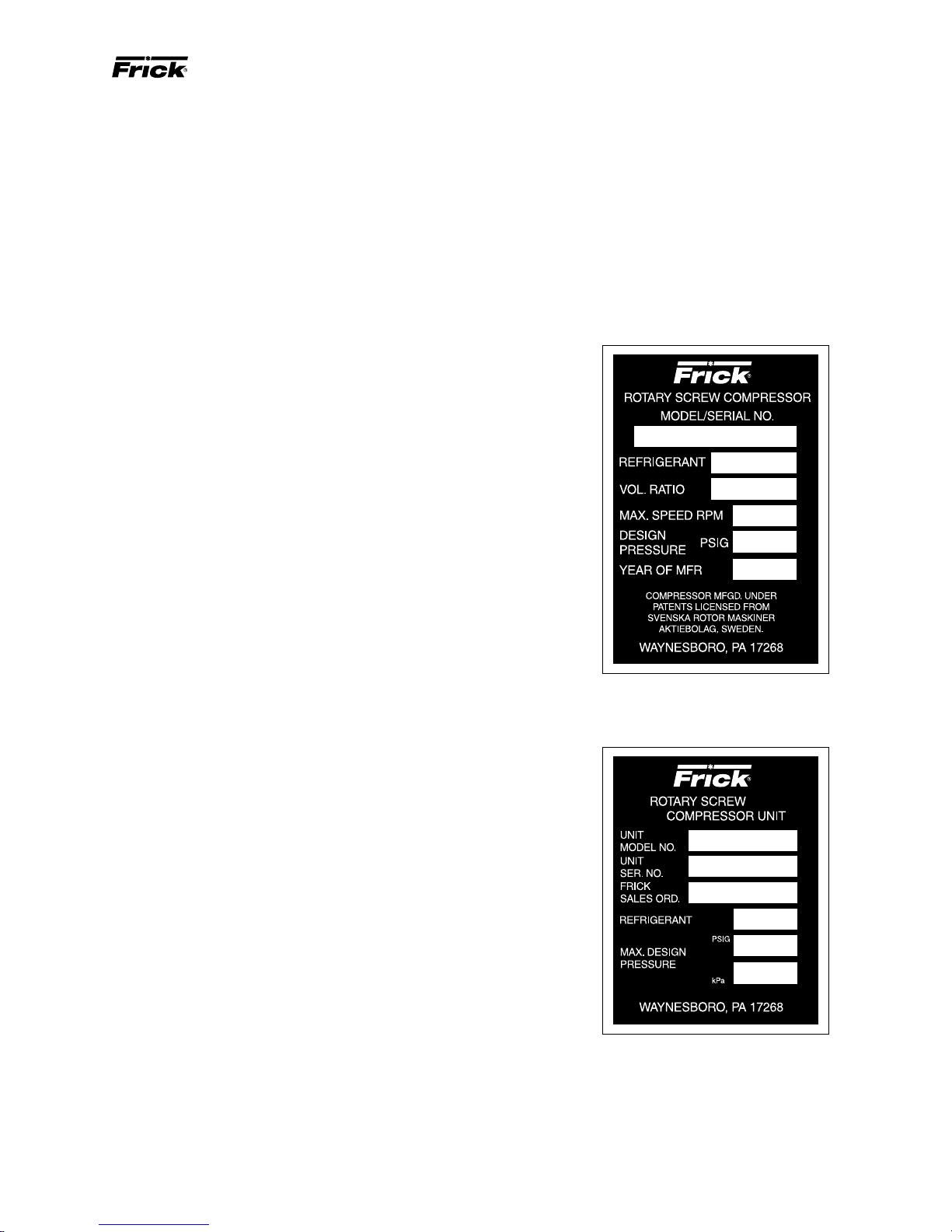

In any screw compressor installation, suction and discharge lines

should be supported in pipe hangers (preferably within 2 ft. of

vertical pipe run) so that the lines won’t move if disconnected

from the compressor. See table for Allowab le Flange Loads .

A licensed architect should be consulted to determine the

proper foundation requirements for any large engine or turbine drive.

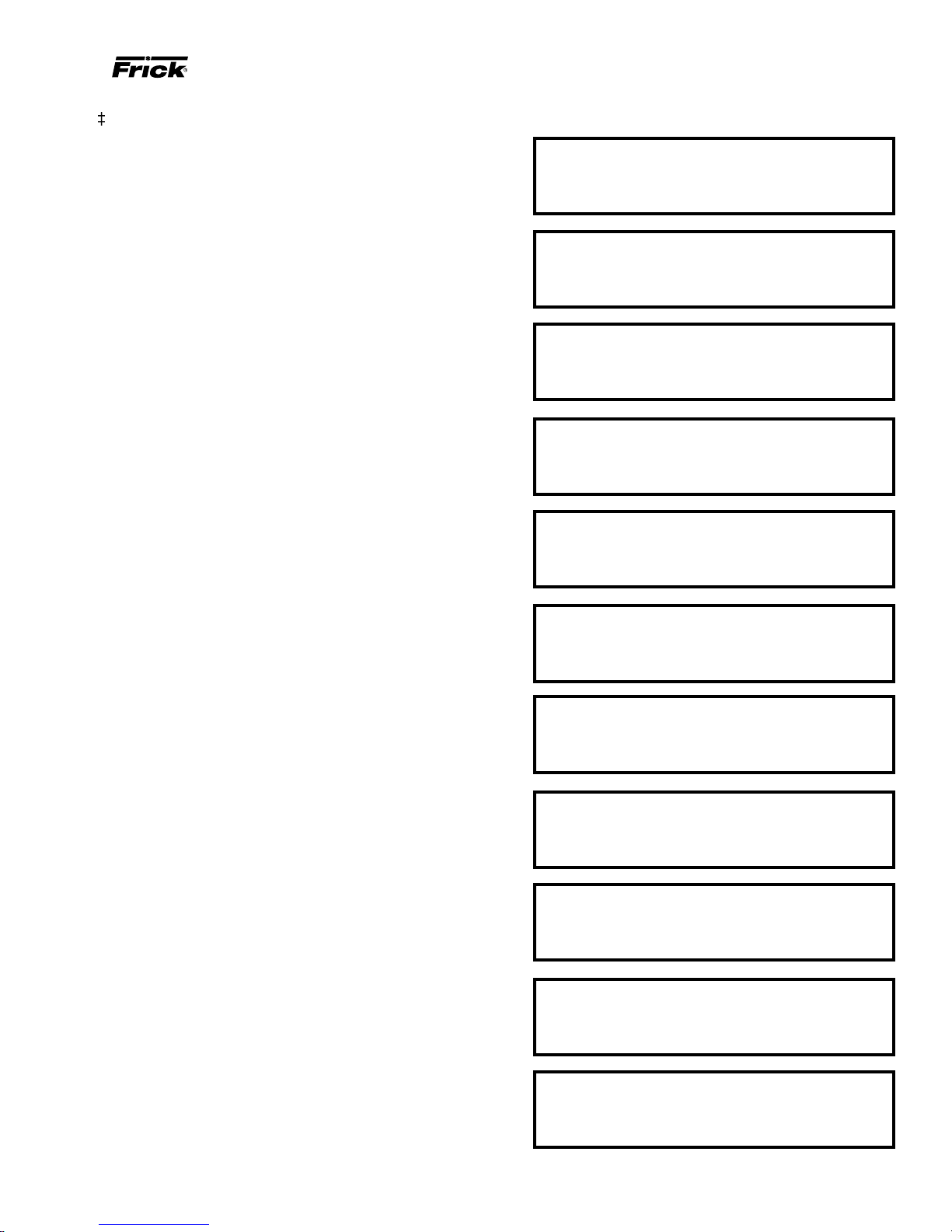

ALLOWABLE FLANGE LOADS

NOZ.

SIZE

NPS

(in.)

1

1.25

1.5

2

3

4

5

6

8

10

12

14

MOMENTS (ft-lbf) LOAD (lbf)

AXIAL VERT. AXIAL VERT. LAT.LA T.

M

R

25

25

50

100

250

400

425

1000

1500

1500

1500

2000

M

175

200

400

750

1000

1200

1500

1800

25

25

40

70

M

C

25

25

40

70

175

200

400

750

1000

1200

1500

1800

PVCV

L

50

50

100

150

225

300

400

650

1500

1500

1500

1700

50

50

75

125

250

400

450

650

900

1200

1500

2000

L

50

50

75

125

250

400

450

650

900

1200

1500

2000

When applying screw compressors at high pressures, the

customer must be prepared for package vibration and noise

higher than the values predicted for normal refrigeration duty .

Proper foundations and proper installation methods are vital; and ev en then, sound attenuation or noise curtains may

be required to reduce noise to desired levels.

For more detailed information on Screw Compressor F oundations, please request Frick publication S70-210 IB.

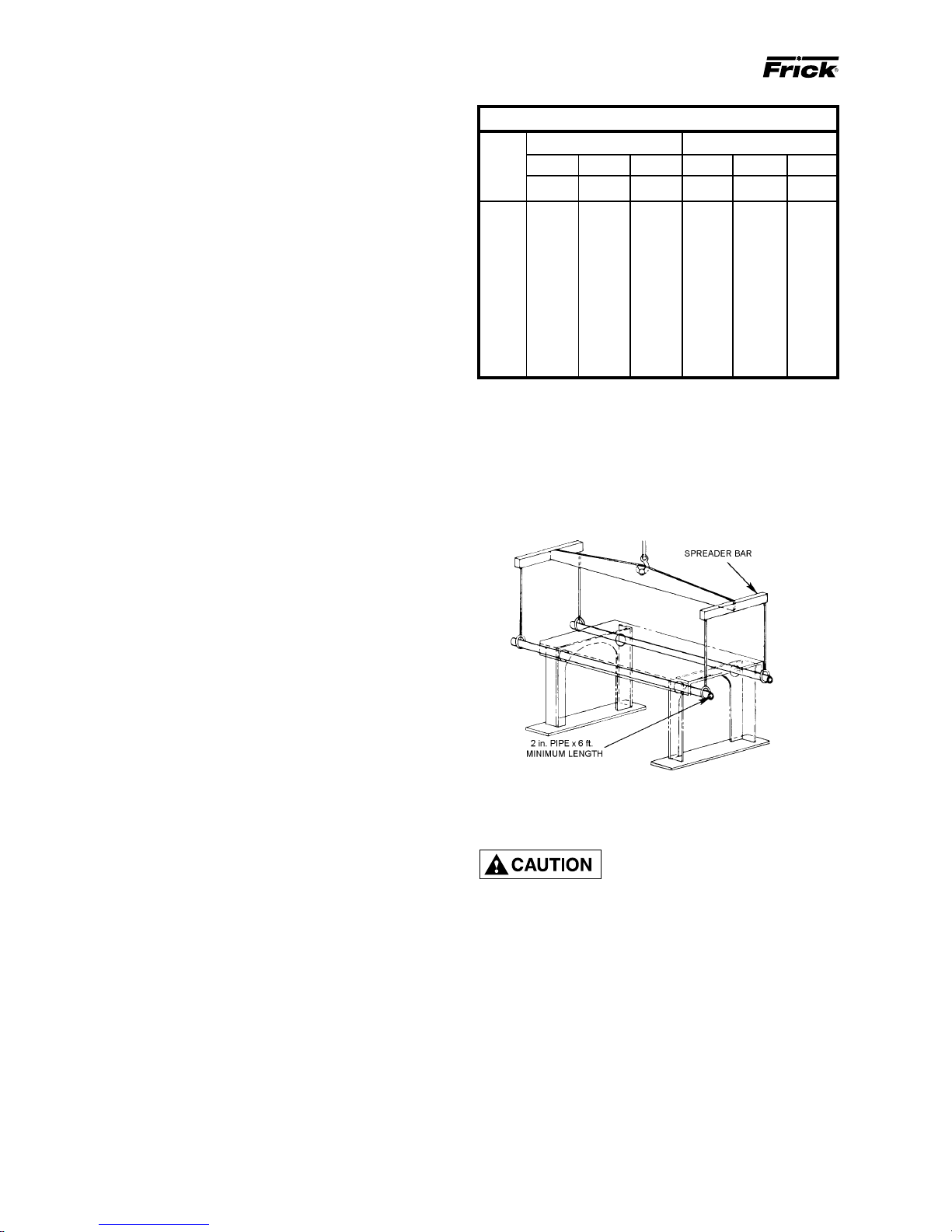

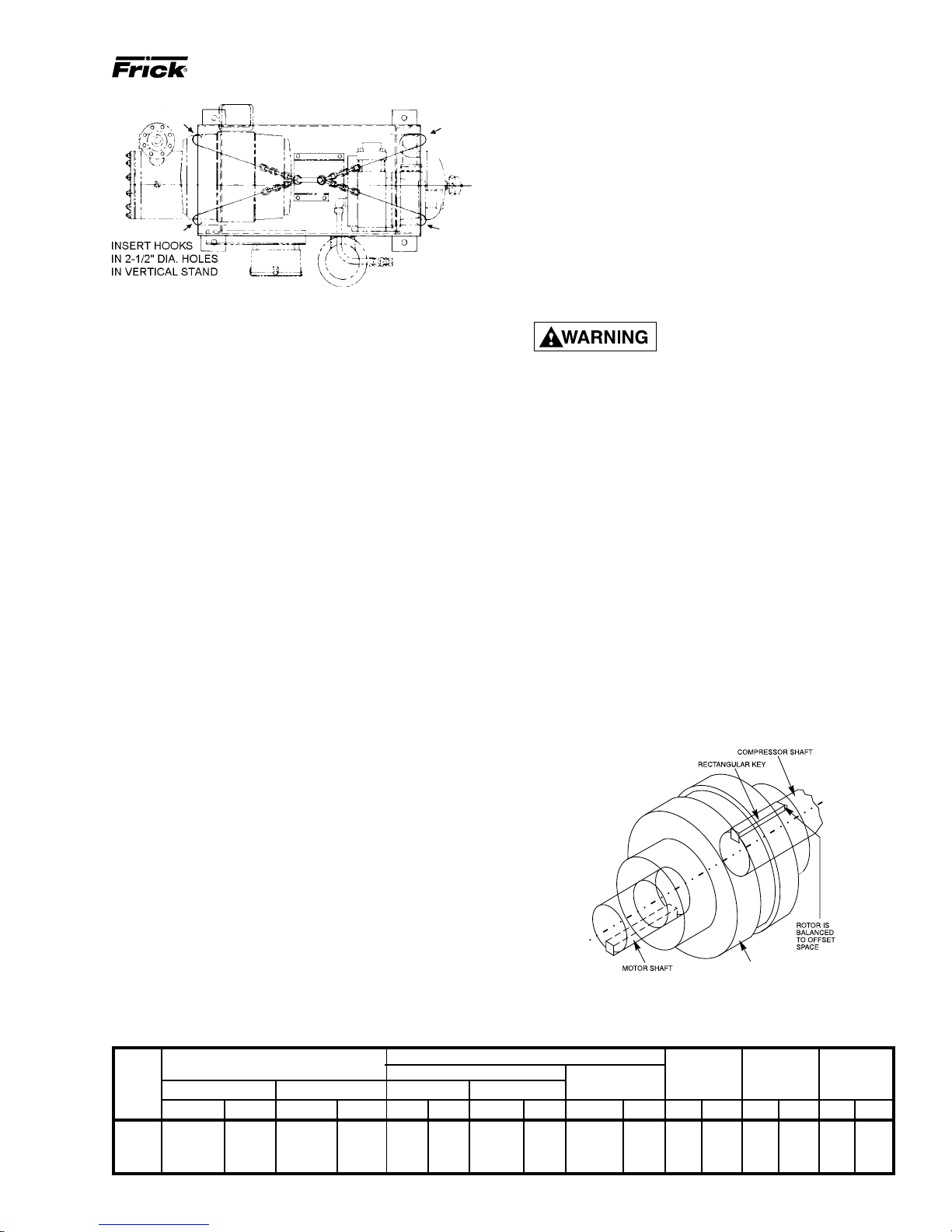

FIG. 1 - RECOMMENDED LIFTING METHOD

HANDLING AND MOVING

THIS UNIT MAY BE TOP HEAVY.

USE CARE WHILE HANDLING.

both the length and width of the package to prevent

bending of oil lines and damage to the package.

The unit can be moved with rigging, using a crane or forklift.

The recommended method is to insert lengths of 2" pipe

through the lifting holes in the vertical supports (see FIG. 1).

Alternatively, hooks may be used in rigging, inserting them

in the lifting holes (see FIG. 2).

Use CAUTION in locating the lifting ring. If no motor is

mounted, the lifting ring should be moved off center to the

compressor side of the unit because 60 percent of the weight

is toward the compressor end. If a motor is mounted, appropriate adjustment in the lifting point should be made to

compensate for motor weight. Adjustment of the lifting point

must also be made for any additions to the standard package, such as an external oil cooler, etc., as the center of

balance will be affected.

Spreader bars should be used on

Page 5

RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

INSTALLATION

FIG. 2 - ALTERNATIVE LIFTING METHOD

The unit can be moved with a forklift by forking under the

skid, or it can be skidded into place with pinch bars by pushing against the skid. NEVER MOVE THE UNIT BY PUSH-

ING OR FORKING AGAINST THE SEPARATOR SHELL

OR ITS MOUNTING SUPPORTS.

SKID REMOVAL

If the unit is rigged into place the skid can be removed by

taking off the nuts and bolts that are fastening the unit mounting supports to the skid before lowering the unit onto the

mounting surface.

If the unit is skidded into place, remove the cross members

from the skid and remove the nuts anchoring the unit to the

skid. Using a 5-ton jack under the separator, raise the unit at

the compressor end until it clears the two mounting bolts.

Spread the skid to clear the unit mounting support, then lower

the unit to the surface. Repeat procedure on opposite end.

MOTOR MOUNTING

The following procedure is required only when the motor is

mounted at the job site.

1. Thoroughly clean the motor feet and mounting pads of

grease, burrs, and other foreign matter to ensure firm seating of the motor.

Page 5

1. Inspect the shaft of the motor and compressor to ensure

that no nicks, grease, or foreign matter is present.

2. Inspect the bores in the coupling hubs to make sure that

they are free of burrs, dirt, and grit.

3. Check that the keys fit the hubs and shafts properly.

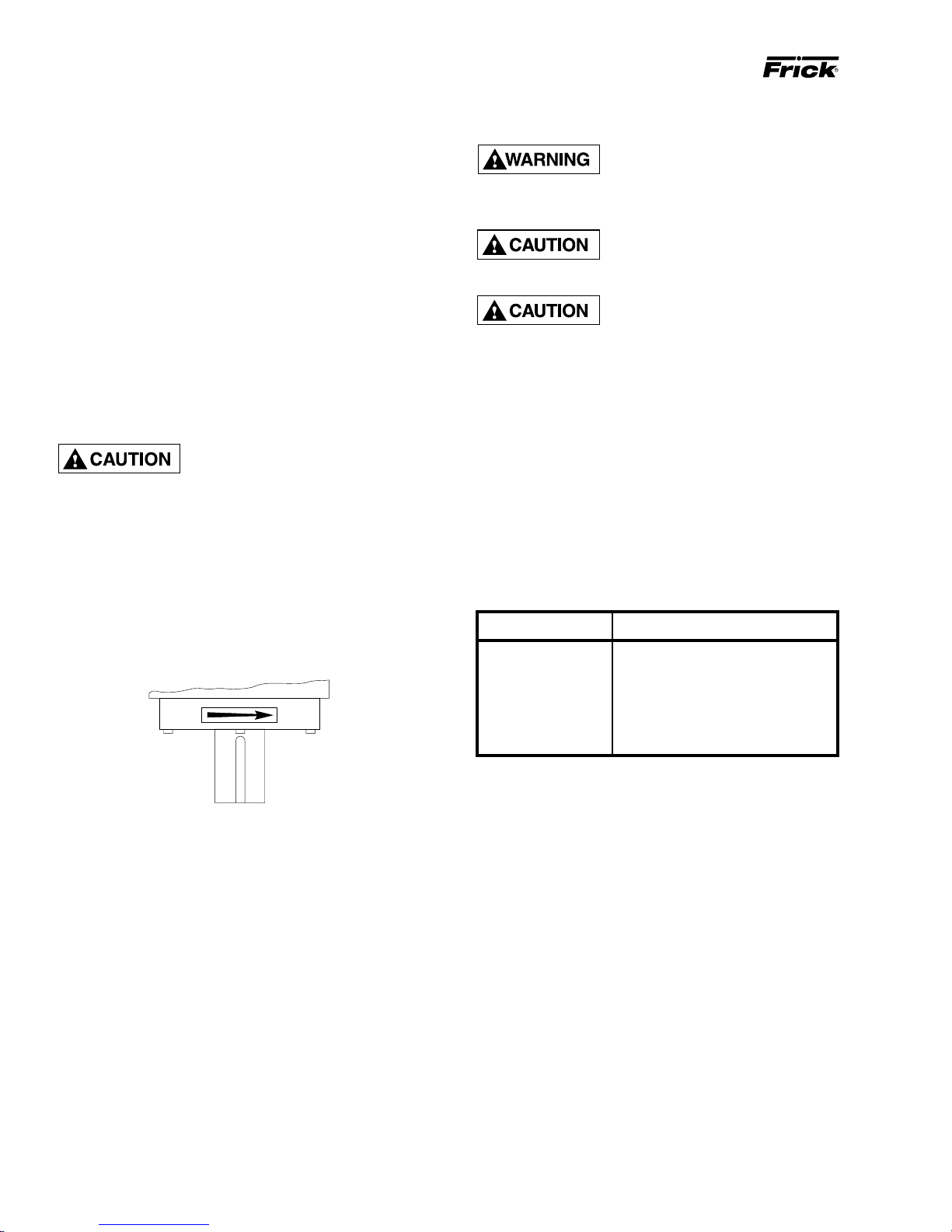

CH COUPLING – The T.B. Woods Elastomeric CH Coupling

is used in most applications. It consists of two drive hubs

and a loose, gear-type Hytrel Drive Spacer. The split hub is

clamped to the shaft by tightening the clamp screws. T orque

is transmitted from the motor through the elastomeric gear

which floats freely between the hubs. Install as follows:

IT IS MANDA T OR Y THA T THE COUPLING CENTER BE REMOVED

AND THE DIRECTION OF MOTOR

ROTATION BE CONFIRMED

BEFORE

RUNNING THE

COMPRESSOR. Proper rotation of the compressor shaft

is clockwise looking at the end of the compressor shaft.

FAILURE TO FOLLOW THIS STEP COULD RESULT IN

BACKWARD COMPRESSOR ROTATION WHICH CAN

CAUSE COMPRESSOR FAILURE OR EXPLOSION OF

THE SUCTION HOUSING.

1. Slide one hub onto each shaft as far as possible. It may

be necessary to use a screwdriver as a wedge in the slot to

open the bore before the hubs will slide onto the shafts.

2. Hold the elastomeric gear between the hubs and slide

both hubs onto the gear to fully engage the mating teeth.

Make sure that the keys on the compressor and motor halves

of the coupling are offset 180

O

(see FIG. 3). Center the gear

and hub assembly so there is equal engagement on both

shafts. Adjust the space between hubs as specified in the

CH Coupling Data Table below.

3. Torque the clamping bolts in both hubs to the torque value

given in the CH Data Table. DO NOT USE ANY LUBRI-

CANT ON THESE BOLTS.

4. Proceed to Coupling Alignment.

2. Attach the motor to the base using the bolts and motorraising blocks, if required. Bolt snugly through the base.

3. Weld the four kick bolts into place so that they are positioned to allow movement of the motor feet.

4. Now that the motor has been set, check that the shafts

are properly spaced for the coupling being used. Refer to

the coupling data table for the applicable dimension.

COMPRESSOR/MOTOR COUPLING

INSTALLATION

RXB PLUS units are arranged for direct motor drive and

require a flexible drive coupling to connect the compressor

to the motor. Before installing, perform the following:

FIG. 3 - COUPLING/SHAFT KEYS INSTALLATION

CH COUPLING DATA TABLE

19.0

25.4

25.4

31.8

COUPLING HUB

15/16

1-3/8

1-13/16

2-3/8

23.8

34.9

46.0

60.3

FACE SPACING

7/8

1-1/16

1-1/8

1-7/16

CH

COUP-

LING

SIZE in. mm mm mmin. in. mm in. in. mm in. mm ft-lb Nm ft-lb Nm

6

7

8

9C

BETWEEN SHAFT SPACING

MIN *

3

3

3-13/16

3-9/16

76.2

76.2

96.8

90.5

3-1/4

3-7/16

4

5-7/16

MAX

101.6

138.1

161.9

149.2

SHAFT ENGAGEMENT

MIN MAX

3/4

1

1

1-1/4

22.2

27.0

28.6

36.5

MAXIMUM

INDICATOR

.004

.004

.004

.004

TOTAL

READING

.104

.104

.104

.104

DRIVE COUPLING

CLAMP

BOLT

TORQUE

10

20

35

35

13.6

27.1

47.5

47.5

KEYWAY

SETSCREW

TORQUE

13

13

13

13

17.6

17.6

17.6

17.6

Page 6

RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

Page 6

INSTALLATION

COUPLING ALIGNMENT PROCEDURE

The life of the compressor shaft seal and bearings, as well

as the life of the motor bearings, is dependent upon proper

coupling alignment. Couplings may be aligned at the factory but realignment MUST ALWAYS be done on the job

site after the unit is securely mounted on its foundation. Initial alignment must be made prior to start-up and rechecked

after a few hours of operation. Final (HOT) field alignment

can only be made when the unit is at operating temperature. After final (HOT) alignment has been made and found

to be satisfactory for approximately one week, the motor

may be dowelled to maintain alignment.

NOTE: Frick recommends cold aligning the motor .005"

high. This cold misalignment compensates for thermal

growth when the unit is at operating temperature.

Use dial indicators to measure the angular and parallel shaft

misalignment. Coupling alignment is attained by alternately

measuring angular and parallel misalignment and repositioning the motor until the misalignment is within specified

tolerances. The following procedure is recommended.

MISALIGNMENT MUST NOT EXCEED .004" FOR ALL CH COUPLINGS.

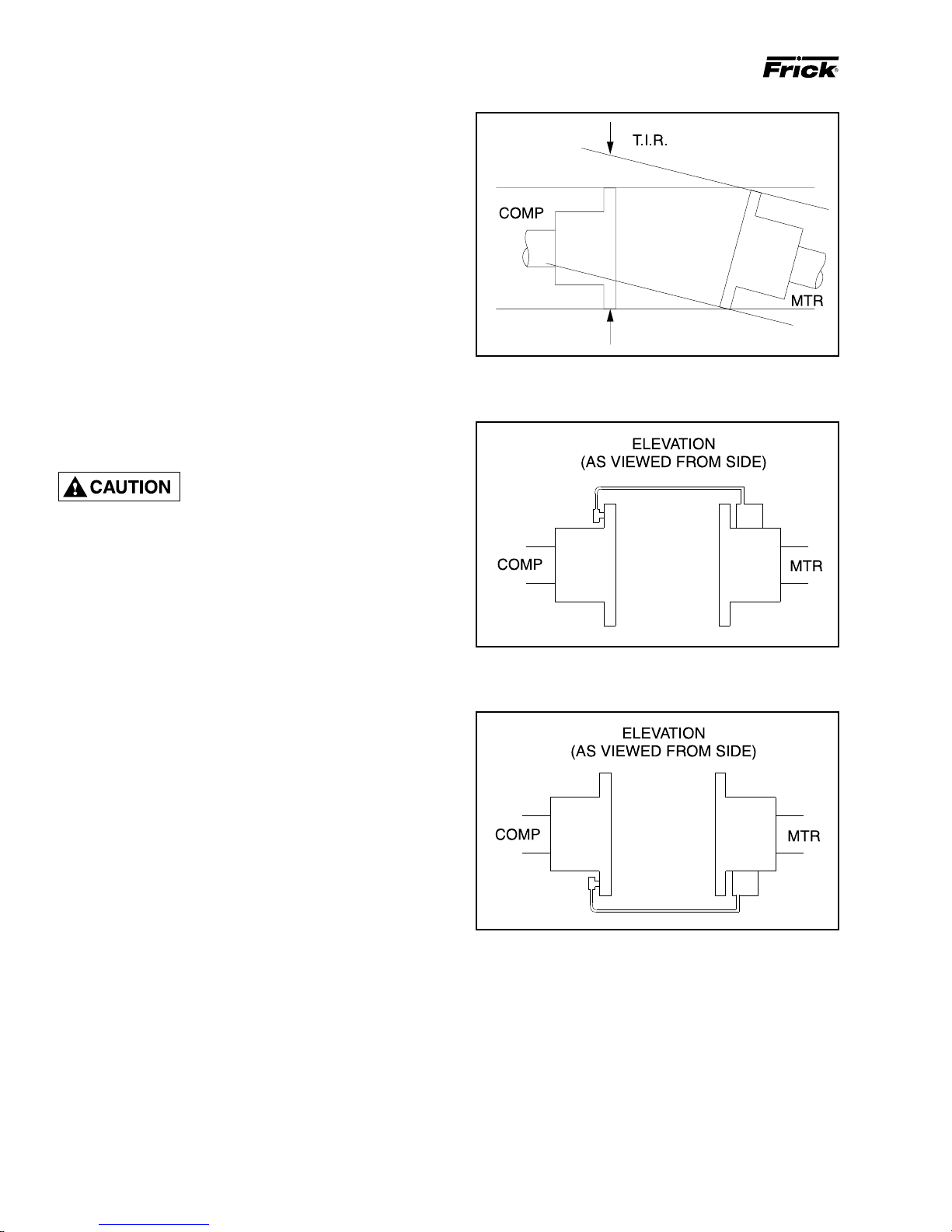

FIG. 1 - ANGULAR MISALIGNMENT

ANGULAR ALIGNMENT

1. To check angular alignment, as shown in Fig. 1., attach

dial indicator rigidly to the motor hub. Move indicator stem

so it is in contact with the outside face of compressor hub,

as shown in Fig. 2.

2. Rotate both coupling hubs several revolutions until they

seek their normal axial positions.

Check the dial indicator to be sure that the indicator stem is

slightly loaded so as to allow movement in both directions.

3. Set the dial indicator at zero when viewed at the 12 o’clock

position, as shown in Fig. 2.

O

4. Rotate both coupling hubs together 180

tion), as shown in Fig. 3. At this position the dial indicator

will show TOTAL angular misalignment.

NOTE: The use of a mirror is helpful in reading the indicator dial as coupling hubs are rotated.

5. Loosen motor anchor bolts and move or shim motor to

correct the angular misalignment.

After adjustments have been made for angular misalignment

retighten anchor bolts to prevent inaccurate readings. Repeat Steps 3 through 5 to check corrections. Further adjustments and checks shall be made for angular misalignment

until the total indicator reading is within the specified tolerance.

(6 o’clock posi-

FIG. 2 - DIAL INDICATOR ATTACHED (AT 12 O'CLOCK)

FIG. 3 - DIAL INDICATOR AT 6 O'CLOCK

Page 7

RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

INSTALLATION

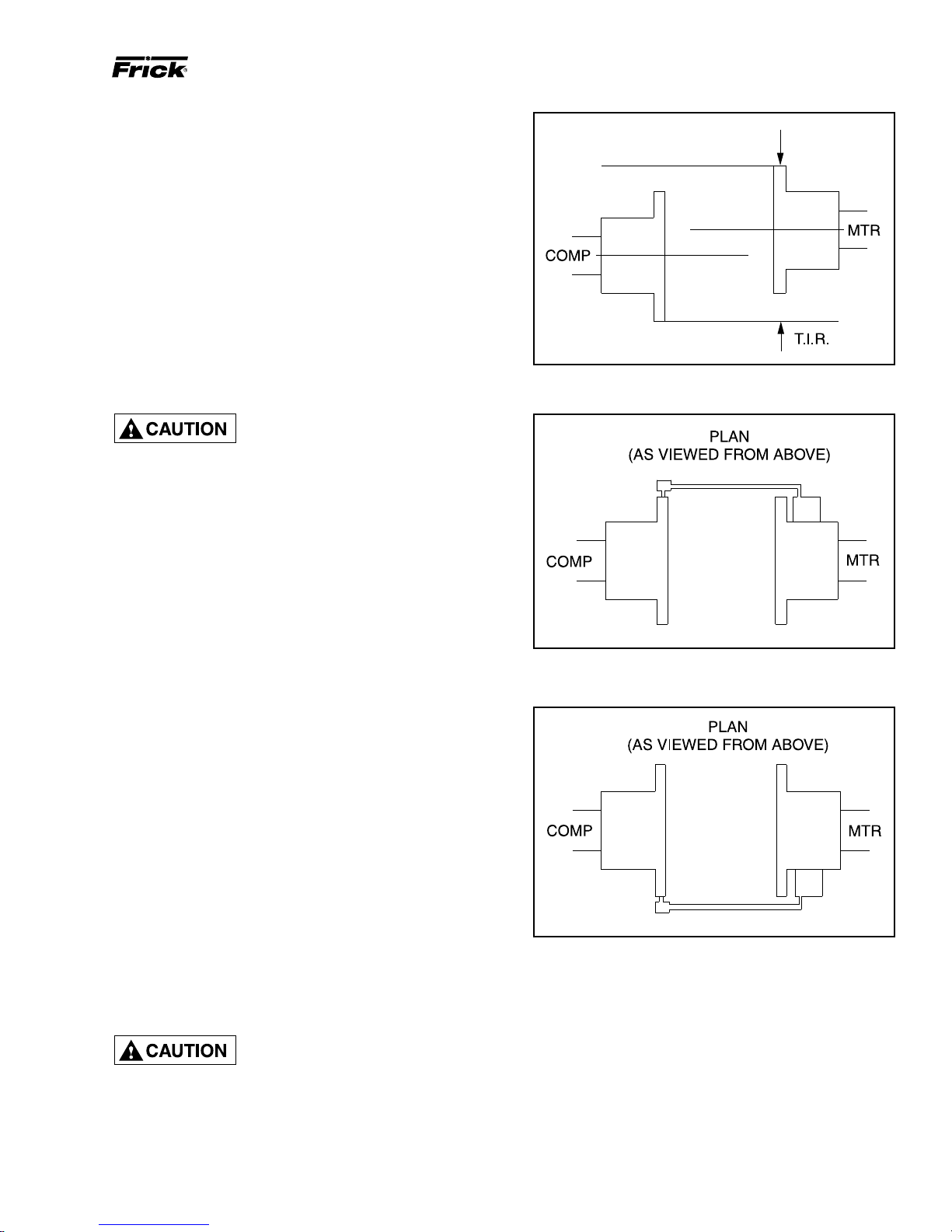

P ARALLEL ALIGNMENT

6. To check parallel alignment, as shown in Fig. 4, reposi-

tion dial indicator so the stem is in contact with the rim of the

compressor hub, as shown in Fig. 5.

Check the dial indicator to be sure that the indicator stem is

slightly loaded so as to allow movement in both directions.

7. Check parallel height misalignment by setting dial indicator at zero when viewed at the 12 o'clock position. Rotate

both coupling hubs together 180

position the dial indicator will show TWICE the amount of

parallel height misalignment.

8. Loosen motor anchor bolts and add or remove shims under

the four motor feet until parallel height misalignment is within

specified tolerance when anchor bolts are retightened.

CARE MUST BE USED WHEN

CORRECTING FOR PARALLEL

MISALIGNMENT TO ENSURE

THAT THE AXIAL SPACING AND ANGULAR MISALIGNMENT IS NOT SIGNIFICANTLY DISTURBED.

9. After the parallel height misalignment is within tolerance,

repeat Steps 1 through 5 until angular misalignment is within

specified tolerance.

O

(6 o'clock position). At this

Page 7

FIG. 4 - PARALLEL MISALIGNMENT

10. Check parallel lateral misalignment by positioning dial

indicator so the stem is in contact with the rim of the compressor hub at 3 o'clock, as shown in Fig. 6.

Set indicator at zero and rotate both coupling hubs together

O

(9 o'clock position), as shown in Fig. 5.

180

Adjust parallel lateral misalignment using the motor adjust-

ing screws until reading is within specified tolerance.

11. Recheck angular misalignment and realign if necessary .

12. Tighten motor anchor bolts and rotate both coupling hubs

together, checking the angular and parallel misalignment

through the full 360

O

travel at 90O increments. If dial read-

ings are in excess of specified tolerance, realign as required.

13. When the coupling hubs have been aligned to within

specified tolerance, a recording of the cold alignment must

be made for unit records and usage during hot alignment.

14. Bump the motor to check for correct compressor rotation. COMPRESSOR ROTATION IS CLOCKWISE WHEN

FACING COMPRESSOR SHAFT (see "CHECKING MOTOR/COMPRESSOR ROTATION", page 8). After verifica-

tion, install gear or disk drive spacer, as applicable.

15. Install the coupling guard before operating the compressor.

FIG. 5 - DIAL INDICATOR ATTACHED (AT 9 O'CLOCK)

FIG. 6 - DIAL INDICATOR AT 3 O'CLOCK

When installing drive spacer, make

sure that hub spacing is within lim-

its shown on the Coupling Data

T able applicable to the coupling being installed and that

the clamping bolt(s) are properly torqued.

Page 8

Page 8

RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

INSTALLATION

HOT ALIGNMENT OF COMPRESSOR/MOTOR

Hot alignments can only be made after the unit has operated for several hours and all components are at operating

temperatures.

Shut down the unit and quickly affix dial indicator to coupling motor hub, then take readings of both the face and rim

of the compressor hub. If these readings are within tolerance, record reading, attach coupling guard, and restart unit.

However, if the reading is not within limits, compare the hot

reading with the cold alignment and adjust for this difference; i.e. if the rim at 0

the motor rises .005" between its hot and cold state, .005"

of shims should be removed from under the motor.

After the initial hot alignment adjustment is made, restart

unit and bring to operating temperature. Shut down and recheck hot alignment. Repeat procedure unit hot alignment

is within specified tolerance.

O

and 180O readings indicates that

INSTALL COUPLING GUARD BEFORE OPERATING COMPRESSOR.

CHECKING MOTOR/COMPRESSOR

ROTATION

COMPRESSOR ROTATION IS CLOCKWISE WHEN FACING THE END OF THE COMPRESSOR SHAFT. Under NO

conditions should the motor rotation be checked with the

coupling center installed as damage to the compressor may

result.

COMPRESSOR

COMPRESSOR UNIT OIL

DO NOT MIX OILS of different

brands, manufacturers, or types.

Mixing of oils may cause excessive

oil foaming, nuisance oil le vel cutouts, oil pressure loss,

gas or oil leakage and catastrophic compressor failure.

Use of oils other than Frick Oil must

be approved in writing by Fric k engineering or warranty claim may be

denied.

Use of filter elements other than

Frick must be approved in writing

by Frick engineering or warranty

claim may be denied.

The oil charge shipped with the unit is the best suited lubricant for the conditions specified at the time of purchase. If

there is any doubt due to the refrigerant, operating pressures, or temperatures; refer to Frick Pub. E160-802 SPC

for guidance.

OIL CHARGE

The normal charging level is midway in the top sight glass

located midway along the oil separator shell. Normal operating level is between the top sight glass and bottom sight

glass. The following table gives the approximate oil charge

quantity.

TABLE - BASIC OIL CHARGE (Gal)

MODEL BASIC CHARGE* (GAL.)

12 10

15 10

19 14

24 14

30 17

39 17

50 21

HOLDING CHARGE AND STORAGE

Each compressor unit is pressure and leak tested at the

Frick factory and then thoroughly evacuated and charged

with dry nitrogen to ensure the integrity of the unit during

shipping and short term storage prior to installation.

NOTE: Care must be taken when entering the unit to

ensure that the nitrogen charge is safely released.

All units must be kept in a clean, dry location to prevent

corrosion damage. Reasonable consideration must be given

to proper care for the solid state components of the microprocessor. Unit which will be stored for more than two

months must have the nitrogen charge checked periodically.

* Add oil volume for external oil cooler, according to cooler

size selected: 6 x 5 TSOC - 4 gal.; 6 x 5 WCOC - 5 gal.; 8 x

5 TSOC - 6-1/2 gal.; and 8 x 5 WCOC - 8 gal.

Add oil by attaching the end of a suitable pressure type

hose to the oil charging valve, located on the top of the oil

separator on the compressor end of the separator. Using a

pressure-type pump and the recommended Frick oil, open

the charging valve and pump oil into the separator.

Oil distillers and similar equipment which act to trap oil must

be filled prior to unit operation to normal design outlet levels. The same pump used to charge the unit may be used

for filling these auxiliary oil reservoirs.

NOTE: The sight glass, located near the bottom of the

separator shell at the discharge end, should remain

empty when the unit is in operation. The presence of oil

in this end of the vessel during operation indicates liquid carryover or malfunction of the oil return.

OIL HEATER

Standard units are equipped with a 500 watt oil heater, providing sufficient heat to maintain the oil temperature for most

indoor applications during shutdown cycles to permit safe

Page 9

RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

INSTALLATION

Page 9

start-up. Should additional heating capacity be required

because of unusual environmental condition, contact Frick

Company. The heater is energized only when the unit is not

in operation.

DO NOT ENERGIZE THE HEATER

WHEN THERE IS NO OIL IN THE

UNIT, OTHERWISE THE HEATER

WILL BURN OUT. THE OIL HEA TER WILL BE ENERGIZED

WHENEVER 120 VOLT CONTROL POWER IS APPLIED

TO THE UNIT AND THE COMPRESSOR IS NOT RUNNING

UNLESS THE 10 AMP FUSE (1FU) IN THE CONTROL

PANEL IS REMOVED.

LIQUID INJECTION OIL COOLING

The liquid injection system provided on the unit is self-contained but requires the connection of the liquid line sized as

shown in the table and careful insertion of the expansion

valve bulb into the thermowell provided in the separ ator. High

pressure gas is connected through the regulator to the external por t on the liquid injection valve to control oil temperature. Refer to the liquid injection piping diagram.

NOTE: For booster applications, the high pressure gas

connection must be taken from a high side sour ce (highstage compressor discharge). This should be a minim um

3/8" line connected into the solenoid valve provided. This

gas is required by the expansion valve external port to

control oil temperature.

Where low compression ratios (low condensing pressures)

are anticipated, thermosyphon or water-cooled oil cooling

should be used. It is IMPERATIVE that an uninterrupted

supply of high pressure liquid refrigerant be provided to the

injection system at all times. Two items of EXTREME IM-

PORTANCE are the design of the receiver/liquid injection

supply and the size of the liquid line. It is recommended that

the receiver be oversized sufficiently to retain a 5 minute

supply of refrigerant for oil cooling. The evaporator supply

must be secondary to this consideration. Two methods of

accomplishing this are shown.

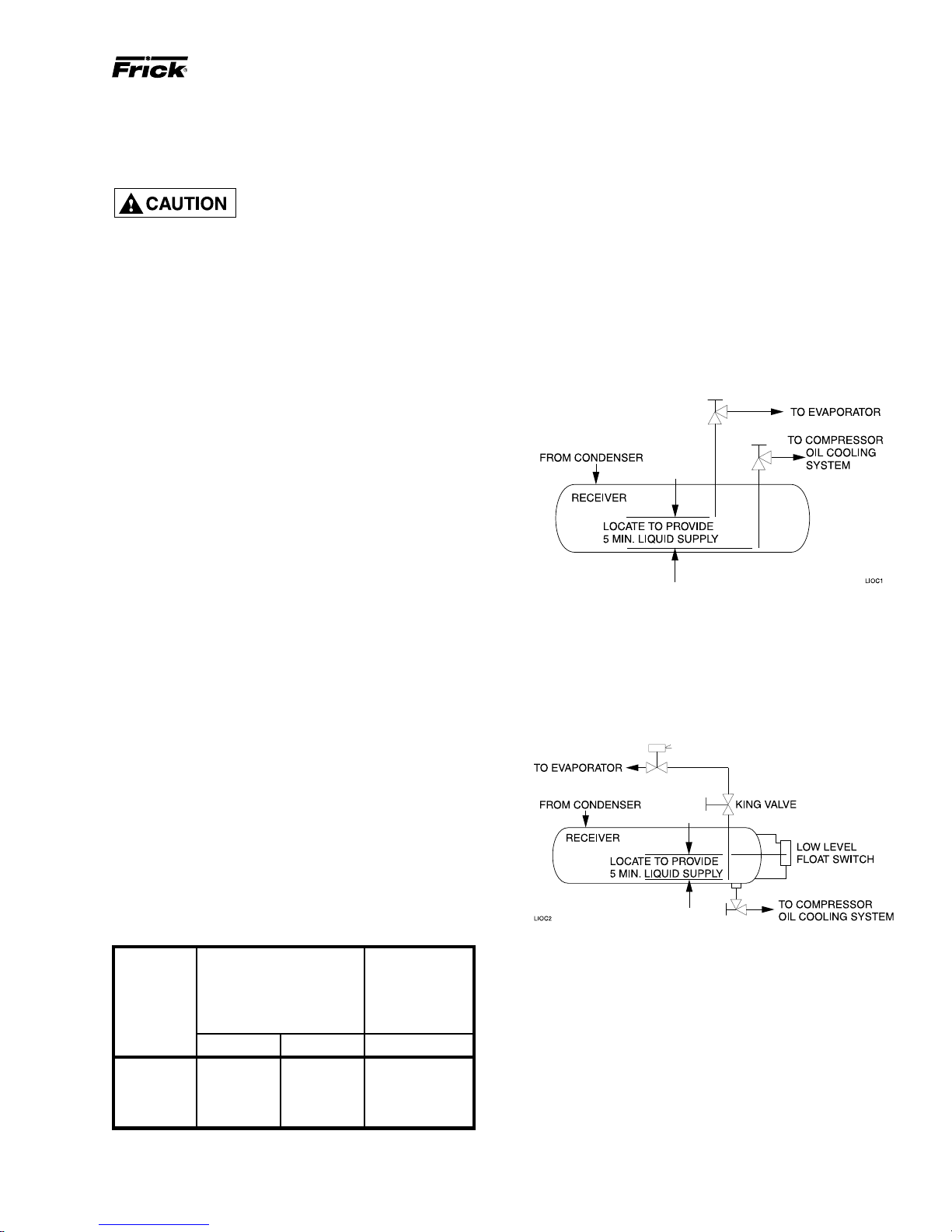

DUAL DIP TUBE METHOD

The dual dip tube method uses two dip tubes in the receiver. The liquid injection tube is below the evaporator tube to

ensure continued oil cooling when the receiver level is low.

High-stage compressor units may be supplied with singleport (low Vi) or dual-port (low Vi and high Vi), liquid injection

oil cooling. Single port will be furnished for low compression

ratio operation and dual port for high compression ratio operation. Booster compressor units use single-port, liquid injection oil cooling due to the typically lower compression

ratios.

The control system on high-stage units with dual-port, liquid

injection oil cooling switches the liquid refrigerant supply to

the high port when the compressor is operating at higher

compression ratios (3.5 Vi and above) for best efficiency.

The following table giv es the condensing temperature(s) with

the corresponding maximum evaporator temperature limit

for liquid injection usage and the minimum evaporator temperature for a single-port application.

TABLE - EVAPORATOR TEMPERATURE with

SINGLE-PORT LIQUID INJECTION

MAXIMUM MINIMUM *

EVAPORATOR EV AP TEMP

CONDENS- TEMPERATURE FOR FOR

ING LIQUID INJECTION SINGLE PORT

TEMP USAGE (LOW V i)

R-717 R-22 R-717 & R-22

75OF +10OF+5

85OF +25OF +15OF -17OF

95OF +35OF +25OF -11OF

105OF +40OF +35OF- 4

O

F -23OF

O

F

LEVEL CONTROL METHOD

The level control method utilizes a float level control on the

receiver to close a solenoid valve feeding the evaporator

when the liquid falls below that amount necessary for 5 minutes of liquid injection oil cooling.

* Dual Injection Kit will be shipped by Frick

below these temperatures.

Page 10

Page 10

RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

INSTALLATION

Liquid line sizes and the additional receiver volume (quantity of refrigerant required for 5 minutes of liquid injection oil

cooling) are given in the following table:

REF RXB RATE VOLUME

HIGH 19 1/2 – 15 .4

STAGE 24 1/2 – 20 .6

R-717 30 1/2 – 25 .7

HIGH 19 3/4 5/8 45 .6

STAGE 24 3/4 7/8 60 .8

R-22 30 3/4 7/8 75 1.0

BOOST- 19 1/2 – 3.5 .1

R-717 30 1/2 – 5.5 .2

BOOST- 19 3/4 1/2 9 .1

R-22 30 3/4 1/2 14.5 .2

MODEL PIPE TUBING (lb.) CU.FT.

12 1/2 – 10 .3

15 1/2 – 12.5 .4

39 1/2 – 30 8

50 3/4 – 40 1.1

12 3/4 5/8 30 .4

15 3/4 5/8 37.5 .5

39 3/4 7/8 95 1.3

50 1 1 125 1.7

12 1/2 – 2.1

15 1/2 – 2.5 .1

ER 24 1/2 – 4.5 .1

39 1/2 – 6.5 .2

50 1/2 –- 8.5 .3

12 3/4 1/2 6 .1

15 3/4 1/2 7 .1

ER 24 3/4 1/2 12 .2

39 3/4 1/2 18 .3

50 3/4 5/8 24 .3

LIQ. LINE SIZE* FLOW LIQUID

SCH 80 OD 5 MIN

* 100 ft. liquid line. For longer runs, increase line size ac-

cordingly.

NOTE: The water regulating valve shipped with the unit

will be sized to the specific flow for the unit.

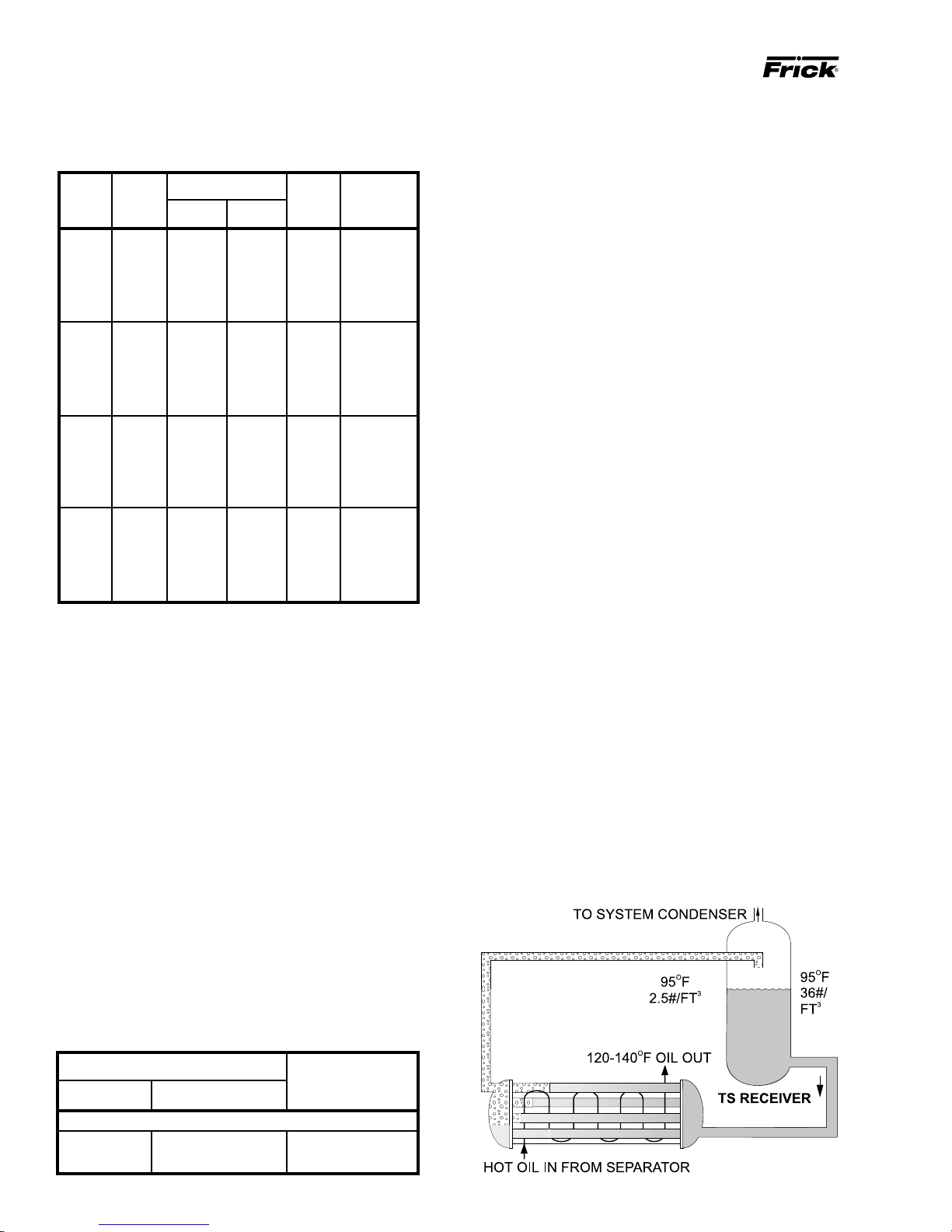

THERMOSYPHON OIL COOLING (OPTIONAL)

Thermosyphon oil cooling is an economical, effective method

for cooling oil on screw compressor units. Thermosyphon

cooling utilizes liquid refrigerant at condenser pressure and

temperature which is partially vaporized at the condenser

temperature in a shell and tube- or plate-type vessel cooling the oil to within 15

condensing pressure, is vented to the condenser inlet and

reliquified. This method is the most cost effective of all currently applied cooling systems since no compressor capacity is lost or compressor power penalties incurred. The vapor from the cooler need only be condensed, not compressed. Refrigerant flow to the cooler is automatic, driven

by the thermosyphon principle, and cooling flow increases

as the oil inlet temperature rises.

EQUIPMENT - The basic equipment required for a thermosyphon system consists of:

1. A source of liquid refrigerant at condensing pressure and

temperature located in close proximity to the unit to minimize piping pressure drop. The liquid le vel in the refrigerant

source must be 6 to 8 feet above the center of the oil cooler .

2. A shell and tube- or plate-type oil cooler with a 300 psi

minimum design working pressure on both the oil and refrigerant sides.

Due to the many variations in refrigeration system design

and physical layout, several systems for ensuring the above

criteria are possible.

O

F of that temperature. The vapor, at

WATER-COOLED OIL COOLING (OPTIONAL)

The shell and tube-type, water-cooled oil cooler is mounted

on the unit complete with all oil piping. The customer must

supply adequate water connections and install the two-way

water regulating valve. It is recommended that (local codes

permitting) the water regulator be installed on the water outlet

connection. Insert the water regulator valve bulb and well in

the chamber provided on the oil outlet connection. Determine the size of the water-cooled oil cooler supplied with

the unit, then refer to table for the water connection size

and water flow range (GPM). The water supply must be

sufficient to meet the required flow.

It is imperative that the condition of cooling water and closed

loop fluids be analyzed and maintained regularly and as

necessary to prevent corrosion of heat exchanger surfaces.

The oxygen content of river water and some other cooling

water sources will oxidize steel tubes and cause premature

failure. Careful attention to water treatment is essential to

ensure adequate life of steel cooler tubes if cooling tower

water is used. The condition of heat e xchanger tubes should

be checked semiannually to prevent hazard.

OIL COOLER DATA TABLE

SIZE - Inches APPROX

WATER FLOW

COOLER WATER CONN RANGE (GPM)

5 Foot Lengths

6" DIA. 1 NPT 10 – 23

8" DIA. 1-1/4 NPT 35 – 60

SYSTEM OPERATION - Liquid refrigerant fills the cooler

tube side up to the Thermosyphon receiver liquid level.

Water or hot oil (above the liquid temperature) flowing

through the cooler will cause some of the refrigerant to boil

and vaporize in the tubes. The vapor rises in the return line.

The density of the refrigerant liquid/vapor mixture in the return line is considerably less than the density of the liquid in

the supply line. This imbalance provides a differential pressure that sustains a flow condition to the oil cooler. This relationship involves:

1. Liquid height above the cooler.

2. Oil heat of rejection.

3. Cooler size and piping pressure drops.

Page 11

RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

INSTALLATION

Page 11

Current thermosyphon systems are using two-pass oil coolers and flow rates based on 4:1 overfeed.

The liquid/vapor returned from the cooler is separated in the

receiver. The vapor is vented to the condenser inlet and need

only be reliquified since it is still at condenser pressure.

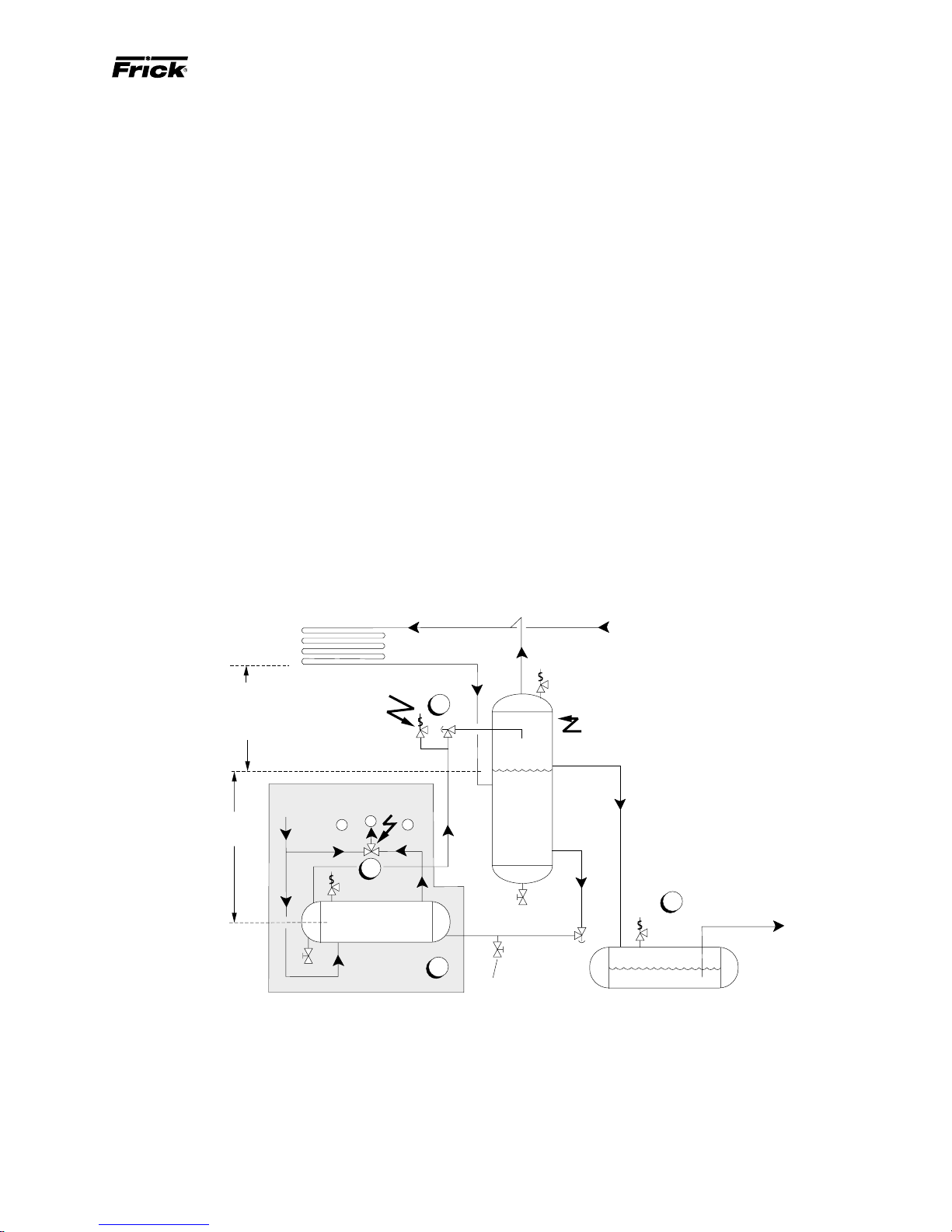

INSTALLATION - The shell and tube-type thermosyphon oil

cooler with oil-side piping and a thermostatically controlled

mixing valve (if ordered) are factory mounted and piped. The

customer must supply and install all piping and equipment

located outside of the shaded area on the piping diagram

with consideration given to the following:

1. The refrigerant source, thermosyphon or system receiver, should be in close pro ximity to the unit to minimize piping

pressure drop.

2. The liquid level in the refrigerant source must be 6 to 8

feet above the center of the oil cooler.

3. A safety valve should be installed if refrigerant isolation

valves are used for the oil cooler.

4. F rick recommends the installation of an angle v alve in the

piping before the thermosyphon oil cooler to balance the

thermosyphon system. Frick also recommends the installation of sight glasses at the TSOC inlet and outlet to aid in

troubleshooting. The factory-mounted, plate-type thermosyphon oil cooler requires a refrigerant-side drain valve

to be provided and installed by the customer.

TSOC AND WCOC OPTIONAL OIL SIDE SAFETY RELIEF

- Compressor units, which have valves in the oil piping to

isolate the oil cooler from the oil separator for servicing,

may have factory installed piping to relieve the shell side

(oil side) safety valve directly into the oil separ ator, as sho wn

in the P & I diagrams on pages 58 through 60.

This arrangement uses a special UV stamped safety valve

rated for liquid and vapor relief . The safety v alve is designed

for 500 psi DWP and is set to relieve at 75 psi delta P. The

safety valve piping contains flanged connections should the

valve require maintenance or replacement.

Extra caution should be used when servicing an oil separator with this arrangement. If the oil cooler is valved off

from an oil separator which has been evacuated for servicing, then the oil cooler could relieve into the separator vessel if the 75 psi delta p setpoint is exceeded.

Other units, which do not use this special safety valve arrangement, will have factory mounted safety valves on the

shell side of the oil cooler which the installing contractor

should pipe into house safety systems designated suitable

for oil relief.

The component and piping arrangement shown below is intended only to illustrate the operating principles of thermosyphon oil cooling. Other component la youts ma y be better suited

to a specific installation. Ref er to publication E70-900E for additional information on Thermosyphon Oil Cooling.

CONDENSER

STATIC HEAD

TO O VERCOME

CONDENSER

PRESSURE DROP

8 Ft.

Min.

TSOCA

SYSTEM

SAFETY

VALVE

OIL TEMP

CONTROLVALVE

A

B

HOT

COOL

2

OIL OUT

THERMOSYPHON

OIL COOLER

HOT OIL IN

VAPOR

3

THERMOSYPHON

RECEIVER

LIQUID

LEVEL

C

1

Refrigerant-side drain valve

required for plate-type

thermosyphon oil coolers.

LIQUID OVERFLOW

DRAIN TO RECEIVER

TO SYSTEM

4

EVAPORATOR

SYSTEM

RECEIVER

(Mounted below Thermosyphon

receiver le vel)

1. The thermosyphon oil cooler is supplied with the oil side piped to the compressor unit and stub ends supplied on the refrigerant side.

2. A three-way oil temperature control valve is required where condensing temperature is expected to go below 65

3. A refrigerant-side saf ety valv e is required in this location only when refrigerant isolation valv es are installed between the cooler

and thermosyphon receiver. If no valves are used between the cooler and TSOC receiver, the safety v alv e on the TSOC receiver

must be sized to handle the volume of both vessels. Then, the safety valve on the cooler vent (liquid refrigerant side) can be

eliminated.

4. The system receiver must be below the thermosyphon receiver in this arrangement.

O

F.

Page 12

Page 12

RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

INSTALLATION

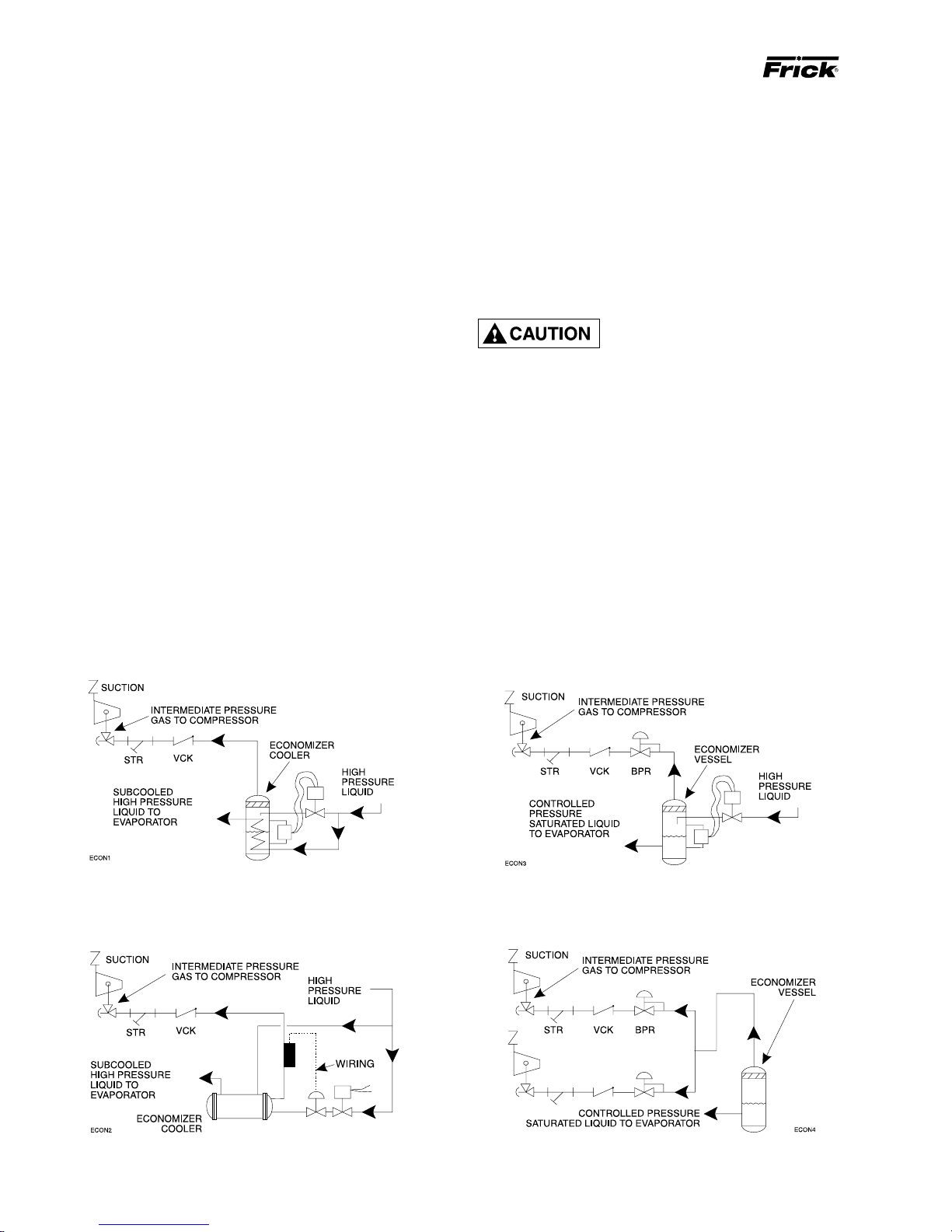

ECONOMIZER - HIGH STAGE (OPTIONAL)

The economizer option provides an increase in system capacity and efficiency by subcooling liquid from the condenser

through a heat exchanger or flash tank before it goes to the

evaporator. The subcooling is provided by flashing liquid in

the economizer cooler to an intermediate pressure level.The

intermediate pressure is provided by a port located part way

down the compression process on the screw compressor.

As the screw compressor unloads, the economizer port will

drop in pressure level, eventually being fully open to suction. Because of this, an output from the microprocessor is

generally used to turn off the supply of flashing liquid on a

shell and coil or DX economizer when the capacity falls below approximately 45%-60% capacity (85%-90% slide valve

position). This is done because the compressor will be more

efficient operating at a higher slide valve position with the

economizer turned off, than it will at a low slide valve position with the economizer turned on. Please note however

that shell and coil and DX economizers can be used at low

compressor capacities in cases where efficiency is not as

important as ensuring that the liquid supply is subcooled. In

such cases, the economizer liquid solenoid can be programmed to be left open whenever the compressor is running.

Due to the tendency of the port pressure to fall with decreasing compressor capacity, a back-pressure regulator

valve (BPR) is generally required on a flash economizer

system (FIG. 3) in order to maintain some preset pressure

difference between the subcooled liquid in the flash vessel

and the evaporators. If the back-pressure regulator valve is

not used on a flash economizer, it is possible that no pressure difference will exist to drive liquid from the flash v essel

to the evaporators, since the flash vessel will be at suction

pressure. In cases where wide swings in pressure are an-

ticipated in the flash economizer vessel, it may be necessary to add an outlet pressure regulator to the flash vessel

outlet to avoid overpressurizing the economizer port, which

could result in motor overload. Example: A system feeding

liquid to the flash vessel in batches.

The recommended economizer systems are shown below.

Notice that in all systems there should be a strainer (STR)

and a check valve (VCK) between the economizer vessel

and the economizer port on the compressor. The strainer

prevents dirt from passing into the compressor and the check

valve prevents oil from flowing from the compressor unit to

the economizer vessel during shutdown.

Other than the isolation valve

needed for strainer cleaning, it is

essential that the strainer be the

last device in the economizer line before the compressor. Also, piston-type check valves are recommended

for installation in the economizer line, as opposed to

disc-type check valves. The latter are more prone to gaspulsation-induced failure. The isolation and check valves and strainer should be located as closely as possible to the compressor, preferably within a few feet.

For refrigeration plants employing multiple compressors on

a common economizing vessel, regardless of economizer

type, each compressor must have a back-pressure regulating valve in order to balance the economizer load, or gas

flow, between compressors. The problem of balancing load

becomes most important when one or more compressors

run at partial load, exposing the economizer port to suction

pressure. In the case of a flash vessel, there is no need for

the redundancy of a back-pressure regulating valve on the

vessel and each of the multiple compressors. Omit the BPR

valve on the flash economizer vessel and use one on each

compressor, as shown in FIG. 4.

FIG. 1 - SHELL and COIL ECONOMIZER SYSTEM

FIG. 2 - DIRECT EXPANSION ECONOMIZER SYSTEM

FIG. 3- FLASH ECONOMIZER SYSTEM

FIG. 4 -MUL TIPLE COMPRESSOR ECONOMIZER SYSTEM

Page 13

RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

INSTALLATION

Page 13

ELECTRICAL

NOTE: Before proceeding with electrical installation, read

the instructions in the section “Proper Installation of

Electronic Equipment in an Industrial Environment”.

RXB PLUS units are supplied with a SBC (single-board computer) microprocessor control system. Care must be taken

that the controls are not exposed to physical damage during handling, storage, and installation. The microprocessor

enclosure cover must be kept tightly closed to prevent entry

of moisture and foreign matter.

Customer-control power connections are made at the BOTTOM of

the microprocessor enclosure.

Consult local ordinances before installation. Current

transformer wiring should be kept separate. Extreme

care should be taken that metal filings or other foreign

material is not left in the microprocessor enc losure. Use

seal-tight conduit fittings to prevent moisture entry into

the microprocessor enclosure. This is the ONL Y electrical enclosure that should be opened during installation

and it should be kept tightly closed whenever work is

not being performed in it.

1. The compressor motor starter of the specified HP and

voltage for the starting method specified (across-the-line,

autotransformer, wye-delta, or solid state).

NOTE: If starting methods other than across-the-line are

desired, a motor/compressor torque analysis must be

done to ensure that sufficient starting torque is available, particularly in booster applications. Contact FRICK

Company if assistance is required.

2. If specified, the starter package can be supplied as a

combination starter with circuit breaker disconnect. However, the motor overcurrent protection/disconnection device

can be supplied by others, usually as a part of an electrical

power distribution board.

3. A 2.0 KVA control power transformer (CPT), to supply

120 volt control power to the control system and separator

oil heaters, is included. If environmental conditions require

more than a 500 watt oil heater, an appropriately oversized

control transformer will be required.

4. One (1) normally open, compressor-motor-starter auxiliary contact and 1 normally open, oil-pump-motor-star ter

auxiliary contact (opt.) should be supplied and wired as

shown on the starter package wiring diagram. In addition,

the compressor and oil pump motor starter (opt.) coils and

the CPT secondaries should be wired as shown on starter

package wiring diagram.

NOTE: Customer ground required, see Micro Panel Assembly Wiring Diagram.

MOTOR STARTER PACKAGE

5. The compressor motor Current Transformer (CT) can be

installed on any one phase of the compressor leads. NOTE:

The CT must see all the current on any one phase; therefore in wye-delta applications, BOTH leads of any one

phase must pass through the CT.

6. Oil Pump Option: If the optional oil pump is specified, an

oil pump starter must be a component of the unit starter

package. The pump starter should be equipped with fuses

or, in the case where the compressor motor is a different

voltage from the oil pump motor, a circuit breaker disconnect suitable for separate power feed.

NOTE: Do not install a compressor HAND/OFF/AUTO

switch in the starter package as this would bypass the

compressor safety devices.

Motor starter and interlock wiring requirements are shown

in the wiring diagram, above. All the equipment shown is

supplied by the installer unless a starter package is purchased from Frick . Starter packages should consist of:

NOTE: When compressor motor voltage is different from

oil pump motor voltage, supply a cir cuit breaker disconnect for separate feed in lieu of fuses.

Page 14

Page 14

RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

INSTALLATION

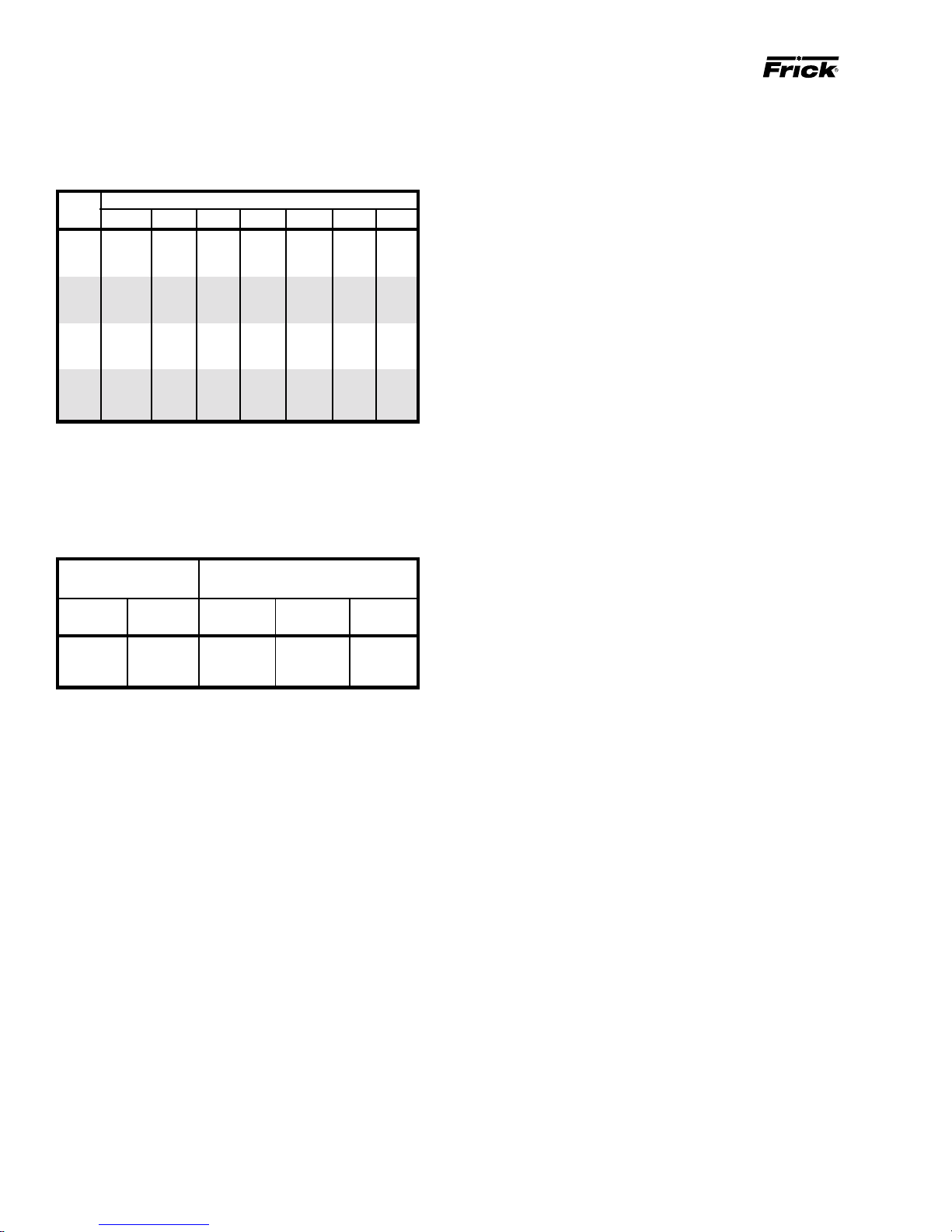

CURRENT TRANSFORMER (CT) RATIOS

The CT ratio for various motor sizes (with a 5 amp secondary) is given in the following table:

VOLTAGE

HP 200 230 380 460 575 2300 4160

20 100:5 100:5 100:5 100:5 100:5 - 25 100:5 100:5 100:5 100:5 100:5 - 30 200:5 100:5 100:5 100:5 100:5 - 40 200:5 200:5 100:5 100:5 100:5 - 50 200:5 200:5 100:5 100:5 100:5 - 60 300:5 200:5 200:5 100:5 100:5 - -

75 300:5 300:5 200:5 200:5 100:5 - 100 400:5 300:5 200:5 200:5 200:5 - 125 500:5 400:5 300:5 200:5 200:5 - 150 500:5 500:5 300:5 300:5 200:5 - 200 800:5 600:5 400:5 300:5 300:5 100:5 50:5

250 800:5 800:5 500:5 400:5 300:5 100:5 50:5

MINIMUM BURDEN RATINGS

The following table gives the minimum CT burden ratings.

This is a function of the distance between the motor starting

package and the compressor unit.

BA TTER Y B A CKUP

The battery backup prevents data loss during power interruption. It will maintain the adjustable setpoints stored in

RAM (Random Access Memory) for up to 1 year after power

loss. Expected battery life is 10 years. A trickle charge maintains the battery backup at peak charge when control voltage is present.

To prevent power loss, the battery backup is shipped disabled. To enable the batter y backup, a jumper pin located

near the top of the microprocessor circuit board (see illustration page 52) must be moved from OFF (pins 1-2) to ON

(pins 2-3).

NOTE: It is not necessary to disconnect the battery

backup during extended downtime.

BURDEN MAXIMUM DISTANCE FROM

RA TING FRICK P ANEL

USING # USING # USING #

ANSI VA 14 AWG 12 AWG 10 AWG

B-0.1 2.5 15 ft 25 ft 40 ft

B-0.2 5 35 ft 55 ft 88 ft

B-0.5 12.5 93 ft 148 ft 236 ft

In addition to the starter package interlocks shown on the

starter package diagram, the following optional interlocks

are on the typical RXB PLUS Screw Compressor unit with

the SBC Microprocessor Control System wiring diagram:

1. Remote LOAD, UNLO AD, and RUN interlocks in case the

customer desires to operate the unit from a remote control

device.

2. Alarm Horn output.

3. Control solenoid valve for the economizer option.

For customer control options, consult FRICK Company.

NOTE: The microprocessor will not operate without

EPROM chips installed. When EPROM chips are not installed, the microprocessor display will typically indicate two dark lines across both the upper and lower display screens.

Page 15

RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

OPERATION and START-UP INSTRUCTIONS

GENERAL INFORMATION

OPERATION

Page 15

The Frick RXB PLUS Rotary Screw Compressor Unit is an

integrated system consisting of six major subsystems:

1. Microprocessor Control Panel

2. Compressor

3. Compressor Lubrication System

4. Compressor Oil Separation System

5. Compressor Hydraulic System

6. Compressor Oil Cooling System

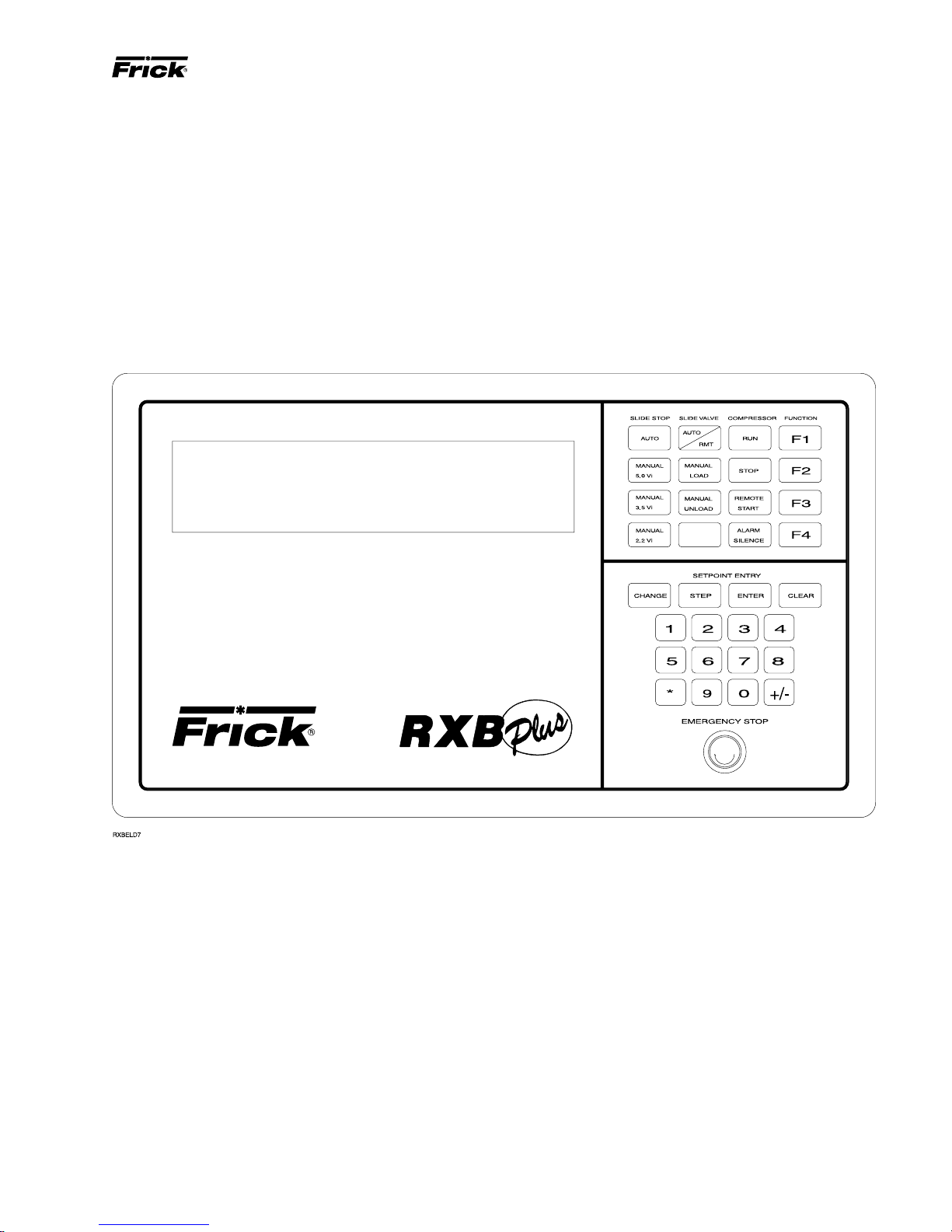

MICROPROCESSOR CONTROL PANEL

The information in this section of the manual provides the

logical step-by-step instructions to properly start up and operate the RXB PLUS Rotary Screw Compressor Unit.

THE FOLLOWING SUBSECTIONS MUST BE READ AND

UNDERSTOOD BEFORE ATTEMPTING TO START OR

OPERA TE THE UNIT.

The RXB PLUS compressor is controlled by a state-ofthe-art microprocessor control system. The microprocessor

continuously monitors the compressor unit’s condition and

operation. The microprocessor also directs instructions to

the various compressor unit subsystems.

The microprocessor has a membrane switch keyboard.

Pressing the keyboard in the area outlined as a key will cause

that function to be recognized by the microprocessor. The

keyboard has 32 membrane-type keys.

In addition to the keyboard, there is an emergency stop button. Pushing the emergency stop will bypass the computer

and remove all power from the outputs. This will shut down

the compressor motor and all high voltage to the compres-

sor auxiliary systems such as the oil pump and liquid injection solenoid. THE EMERGENCY STOP BUTTON IS FOR

EMERGENCY SHUTDOWN SITUATIONS ONLY and

MUST NOT BE USED TO ROUTINELY SHUT OFF THE

COMPRESSOR.

The microprocessor continuously monitors the state of the

battery which maintains setpoints and various other data. If

the battery voltage is low, the message “LOW BATT” will

flash in the lower right hand corner of the bottom display

(see page 14 for description of battery backup).

The microprocessor hardware contains an output watchdog circuit. If the microprocessor should fail, this circuit will

disable (turn off) all outputs.

Page 16

Page 16

RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

OPERATION

Revised 2/95

KEYS AND KEY FUNCTIONS

NOTE: The microprocessor will automatically return to

the main operating display after 60 seconds of keyboard nonactivity.

The [CHANGE] ke y rotates the dual display screen through

six display modes. The [CHANGE] key is also used to change

the status of various setpoints.

The [STEP] key steps or moves a set of flashing brackets

through the variable setpoints on the Adjustable setpoints

display, the Auto-cycle display, the Security display and the

Setback display. The setpoint enclosed within the flashing

brackets may be changed or updated. The [STEP] key is

also used when the Annunciator display is selected to step

through the annunciator’s four information displays.

NOTE: The [ * ] key is used to step or move the flashing

brackets, described above, backwards.

The [ENTER] key is used to enter new setpoint limits.

The [CLEAR] key will reset an alarm or cutout indication on

the annunciator screen and will clear the microprocessor to

allow continued operation or restarting if all conditions have

returned to normal and no other control lockouts are in force.

The [NUMERIC KEYPAD] is used to introduce new setpoint

limits.

The [+/-] key is used to toggle between pounds per square

inch gauge (g) and inches of mercury (hg).

1. Operating displays

2. Setpoints displays

3. Annunciator displays

4. Shutdown Record displays

5. Freeze displays

[F1] Operating display

[F2] Security display

[F3] Setback display

[F4] Auto Cycle display

NOTE: On initial powering of the microprocessor, and

any time power has been removed from the microprocessor, onl y the Operating, Setpoints, Ann unciator, and

Shutdown displays will display inf ormation. The Freeze

display will appear as a dark screen. The Freeze display

will only be present after a compressor unit cutout.

OPERATING DISPLAY *, Pages 1 and 2

OP.DISPLAY PAGE 1 Thu 03-01-89 15:33:36

Suction Disch Oil Compressor

14.3 hg 024 g 060 g Man Mode

O

F 135OF 135OF Running

-040

OP.DISPLAY PAGE 2 Thu 03-01-89 15:33:36

V Ratio S V Pos Pump %FLA Sep 132OF

2.2 070% on 096% HTR off

Auto Auto U

The [RUN], [STOP], and [REMOTE START] keys control

the starting and stopping of the compressor unit.

The [ALARM SILENCE] k ey will de-energize the alarm horn

output.

The [AUTO], [REMOTE], and [MANUAL] keys control the

operation of the compressor slide valve.

The [AUTO], [MANUAL 2.2], [MANUAL 3.5], and [MANUAL

5.0] keys control the operation of the compressor slide stop .

The [F1] function key will return the operator to the main

operating display. This function may be inv ok ed at any time,

even during setpoint entry.

The [F2] function ke y will call up the Security display. NOTE:

Press the [F2] key , as pr ompted b y the display, to return

to the previously selected display.

The [F3] function ke y will call up the Setback displa y . NOTE:

To exit the Setback display, press the [F1] key as

prompted by the display.

The [F4] function key will call up the Auto Cycle display.

NOTE: T o exit the A uto Cyc le display, press the [F1] key

as prompted by the display.

The microprocessor has two liquid crystal displays in an 8

line by 40 character format, for a total of 320 characters.

When power is first applied to the control panel, the unit will

be in the Operating display mode. To change to a different

display mode, press the [CHANGE] key. The display modes

in their order of rotation are:

OPERATING DISPLAY, P age 1

The Operating display is continuously updated and pro vides

a variety of information in regard to the current status of the

compressor’s condition and performance.

The information furnished by the Operating display is as follows:

The DAY, DATE, and TIME are displayed at the top right of

the display.

NOTE: To set day, date, and time, see TO CHANGE THE

ADJUSTABLE SETPOINTS.

SUCTION - Suction Pressure and Temperature are mea-

sured at the compressor inlet and are, respectively, displayed

in pounds per square inch gauge (g) or inches of mercury

(hg) and degrees Fahrenheit.

DISCH - Discharge Pressure and Temperature are measured at the compressor outlet and are, respectively, displayed

in pounds per square inch gauge (g) and degrees Fahrenheit.

OIL - Oil Pressure and Temperature are measured prior to

entering the compressor and are, respectively, displayed in

pounds per square inch gauge (g) and degrees Fahrenheit.

ALARM/CUTOUT - An Alarm or Cutout message indicates

an Alarm or Cutout setpoint has been reached, or exceeded.

Rotate the display mode to the Annunciator display for details. In the ev ent of a cutout, rotate to the F reez e displa y f or

further details.

*Display for illustrative purposes only.

COMPRESSOR - The compressor displa ys the status of the

compressor unit. The mode of operation will be indicated as

either manual (Man Mode) when the [RUN] key has been

Page 17

RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

OPERATION

pressed, automatic (AUTO MODE) when Auto Cycle has

been activated, remote (RMT MODE) when the [REMOTE]

key has been pressed, or off (OFF MODE).

RECYCLE DELAY - A Recycle Delay message indicates

that the compressor has started and has shut down within

the time delay setpoint period. The Recycle Delay will prevent the compressor from starting until the delay time expires and is intended to prevent damage to the compressor

motor from successive restarts. During Recycle Delay, the

microprocessor will alternatively flash “RECYCLE DELAY”

and the remaining delay time in minutes.

NOTE: Consult Motor Manufacturer for the recommended duration of the Recycle Delay.

Page 17

SETPOINTS PAGE 1B

Dead Band--[/./#]

Prop. Band--[/ / %]

Cycle Time--[/ / sec]

LOW % FLA---[/ / / %]

SETPOINTS PAGE 2 MLC Stop LD-[095%]

CT Factor-[078] MLC Force ULD[100%]

Aux1[Alarm] [NO] Hi Disch Cutout-[050 g ]

Aux2[Shutd] [NO] Hi Disch Alarm—[045 g ]

If the [RUN] key is pushed while

the unit is in Recycle Delay, the

compressor will start at the end of

the delay period.

OPERATING DISPLAY, P age 2

V RATIO - Volume Ratio is the ratio selected by the micro-

processor to provide the highest efficiency at any given suction and discharge pressure condition. Immediately below

this, an information space has been provided to indicate

whether V ratio is in the automatic (AUTO) or the manual

(MAN) mode.

SV POS - Slide valve position is display ed as a percentage.

This percentage reflects the mechanical position of the slide

valve and does not reflect the percentage of full load operation. Immediately below this information, space has been

provided to indicate whether SV Pos is in the automatic

(AUT O), manual (MAN), or remote (RMT) mode . The microprocessor will control this function in the automatic mode.

To the right of the mode indicator, two other messages may

appear:

L - Indicates Slide Valve loading.

U - Indicates Slide Valve unloading.

PUMP (Optional) - Pump displays the current status of the

oil pump. The display will read ON or OFF whenever the

HAND-OFF-AUT O switch is selected to A UT O and the compressor is running.

% FLA - Percent Full-Load Amps displays the percentage

of the drive motor, full-load amperage rating that the motor

is currently using.

SETPOINTS PAGE 3 HIGH STAGE RXB NP-22

Oil Heater----- [113F] Liq Inj Con-------[122F]

Hi Disch Cut -[212F] Hi Disch Alarm -[194F]

SETPOINTS PAGE 4

Hi Oil Temp Cutout --[167F] Alarm -- [158F]

Lo Oil Temp Cutout -- [49F] Alarm -- [58F]

Lo Oil Press. Cutout -- [005] Alarm -- [010]

The information furnished by these displays is as follows:

PB-[10% DB-[1.0 #]

SETPOINTS DISPLAY, Page 1A:

CAP CONTROL - The Capacity Control setpoint, reported

in pounds per square inch gauge (g) or inches of mercury

(hg), controls the loading and unloading of the compressor

when Capacity is in the automatic (AUTO) mode.

LO SUCT CUTOUT - The Low Suction Pressure Cutout,

reported in pounds per square inch gauge (g) or inches of

mercury (hg), will shut down the compressor if the suction

pressure drops to this limit or lower, f or 90 seconds or longer .

LO SUCT ALARM - The Low Suction Pressure Alarm, reported in pounds per square inch gauge (g) or inches of

mercury (hg), will trigger a prealarm if the suction pressure

drops to this limit or lower.

ID - The ID number is a prog rammable identification code

in telecommunications to access a specific compressor.

used

SEP - Separator displays the oil separator temperature in

degrees Fahrenheit.

HTR - Heater displays the condition of the oil separator

heater(s), indicating ON or OFF.

FORCED UNLD - A Forced Unload message indicates that

the percentage of motor, full-load amps has exceeded the

maximum limit and the microprocessor is unloading the compressor until the percentage FLA falls back to normal limits.

SETPOINTS DISPLAY *

SETPOINTS PAGE 1A ID=[33] [03-01-89]

Cap. Control-----[14.3 hg] Thu [15:33:36]

Lo Suct Cutout -[20.0 hg] Baud----[ 2400]

Lo Suct Alarm --[18.0 hg] Recy.Delay-[30]

*Display for illustrative purposes only.

DATE - The Date displays the current date in the following

format: Month - Day - Year.

DAY - Day will display the current day of the week.

TIME - The Time displays the current time in the following

format: Hours - Minutes - Seconds. The time is in 24:00:00

hour clock format.

BAUD - Shows the baud rate of the RS422 communication

port. Both ports are configured as follows: w ord = 8 bit, parity = none or even, stop = 1 bit. The communications port is

programmable from 300 to 19200 baud.

RECY. DELAY - The Recycle Delay displays the current

recycle delay setpoint in minutes. NOTE: Consult the mo-

tor manufacturer for recommended setpoint.

Page 18

Page 18

RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

OPERATION

SETPOINTS DISPLAY, P a ge 1B:

Dead Band - This is a + (plus) or - (minus) value above or

below the setpoint at which the compressor will neither load

nor unload. A dead band of 1 is the default value. It is adjustable between .5 lb to 5 lb in increments of .5. The [Step]

key is used to select this setpoint; then press the [Change]

key to toggle through the selections.

Proportional Band - This setpoint is used to determine the

amount of time the load/unload solenoid is energized, according to how far from the setpoint the actual control pressure is. The smaller the number, the longer a load/unload

signal will be sent; 10% is the default value. Selections are

2, 5, 10, 15, 20, or 25%. The [Step] k ey is used to select this

setpoint; then press the [Change] ke y to toggle through the

selections.

Cycle Time - Cycle time is the amount of time between the

beginning of each load/unload response. Ten seconds is

the default value. “Cycle Time” is adjustable between 5 and

30 seconds in 5 second intervals. The [Step] key is used to

select a setpoint; then press the [Change] key to toggle

through the selections.

Low % FLA - This setpoint is used to determine if the coupling has broken; 20% is the default value. It is adjustable

from 0 to 100% FLA. Use the [Step] ke y to select a setpoint;

then enter the desired setpoint and press the [Enter] key.

AUX 1 and A UX 2 - May be configured f or either an alarm or

shutdown and with either a normally closed (NC) or normally open (NO) contact.

TO CHANGE THE ADJUSTABLE SETPOINTS:

Adjustable Setpoints are stored in RAM (random access

memory) and are easily changed in the field.

Adjustable Setpoints are lost if

power is interrupted and the bat-

tery is not fully charged. To facilitate reentry, we suggest that a list of Adjustable

Setpoints be affixed to one end of the microprocessor

cabinet for reference.

NOTE: The following procedure also applies to the changing of the Security, Setback, and Auto Cycle display

setpoints.

1. Press the [CHANGE] key to rotate the display to the Ad-

justable Setpoints display.

2. Press the [STEP] key to move or step a set of flashing

brackets through the v arious setpoints. A setpoint is selected

for change or update when it is enclosed by the flashing

brackets.

NOTE: The DAY indicator, itself, will flash when selected

for change or update.

SETPOINTS DISPLAY, Page 2:

MLC STOP LD - The Motor Load Control Stop Load, re-

ported as a percentage of the motor, full-load amps (FLA),

will prevent the compressor capacity control pistons from

loading when the setpoint is equaled or exceeded. NOTE:

Consult motor manufacturer for recommended setpoint.

MLC FORCE ULD - The motor Load Control Force Unload,

reported as a percentage of the motor, full-load amps (FLA),

will force the compressor to unload until the motor, full-load

amps (FLA) fall within 1% of the setpoint or lower. NOTE:

Consult motor manufacturer for recommended setpoint.

HI DISCH CUTOUT - The High Discharge Pressure Cutout,

reported in pounds per square inch gauge (g), will shut down

the compressor if the discharge pressure equals or exceeds

this setpoint.

HI DISCH ALARM - The High Discharge Pressure Alarm,

reported in pounds per square inch gauge (g) will trigger a

prealarm if the discharge pressure equals or exceeds this

setpoint.

CT FACTOR - The Current Transformer Factor records the

proper current transformer factor to match the compressor

motor FLA rating to the current transformer primary rating.

The CTF factor is programmable and its correct value is

determined by the following formula:

CTF =

* See motor nameplate.

** See CT located in starter panel.

EXAMPLE: FLA = 230 Amps

CT = 300 (300:5)

CTF = = 78 (Round to whole number)

10x CT (Current Transformer Primary Amps **)

1024 x 230

10 x 300

1024 x FLA (Full Load Amps *)

3. Having selected the setpoint to be changed, the [NUMERIC KEYPAD] may be used to enter the new setpoint.

NOTE: All digits must be entered, including zeros. For

example, (01.0).

NOTE: The D A Y, AUX 1, and AUX 2 setpoints, once selected,

are changed or updated by pressing the [CHANGE] key.

NOTE: Certain setpoints may be reported in either pounds

per square inch gauge (g) or inches of mercury (hg). To

toggle between (g) and (hg), ha ving selected the setpoint,

press the [+/-] key to toggle between (g) and (hg).

4. In the event that an incorrect setpoint is keyed in com-

pletely or partially, press the [CLEAR] key to restore the

original setpoint. Pressing the [CLEAR] key a second time

will eliminate the flashing brackets.

5. Having keyed the desired setpoint, press the [ENTER]

key. The new setpoint will be entered and the flashing br ackets will move or step to the next setpoint.

NOTE: A setpoint entry outside the parameters of the

Adjustable Setpoint display will be refused and the original Adjustable setpoint will be restored.

NOTE: To clear any time values [STEP] to the desired

setpoint, press [CHANGE] and then press [CLEAR].

HOW T O DETERMINE

ADJUST ABLE SETPOINTS:

Adjustable Setpoints should reflect values compatible with

normal system operation. Too high a Low Suction Pressure

Alarm setpoint may cause nuisance prealarms. Similarly,

cutout setpoints should not fall within what are considered

normal plant operation. As a rule of thumb, set the Low Suction Pressure Alarm 5 PSIG lower than the lowest normal

suction pressure. The Low Suction Pressure Cutout should

be 5 to 10 PSIG lower than the Low Suction Pressure Alarm

setpoint.

Page 19

RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

The High Discharge Pressure Cutout should be set at 90%

of the setting of the lowest high side relief valve. The High

Discharge

the Cutout.

The Capacity Control setpoint should be the equivalent of

the normal suction condition.

Pressure Alarm should be set 10 PSIG lower than

OPERATION

FIXED SETPOINTS:

Fixed setpoints define the limits of acceptable compressor

operation. Fix ed Setpoints are factory determined, stored in

programmed memory (PROM), and will remain in memory if

power to the microprocessor is interrupted.

SETPOINTS DISPLAY, Page 3:

OIL HEA TER - The Oil Heater setpoint, reported in degrees

Fahrenheit, turns on the oil separator heater(s) when the oil

temperature equals or falls below this setpoint whenev er the

compressor is NOT running.

LIQ INJ CON - The Liquid Injection Control, reported in degrees Fahrenheit, will shut off the liquid refrigerant supply to

the compressor if the oil temperature equals or falls below

this setpoint.

HI DISCH CUT ported in degrees Fahrenheit, will shut down the compressor if

the discharge temperature equals or exceeds this setpoint.

HI DISCH ALARM - The High Discharge T emperature Alarm,

reported in degrees Fahrenheit, will trigger a prealarm if the

discharge temperature equals or exceeds this setpoint.