Frick RWB II Plus Operation & Maintenance Manual

S70-200 OM/DEC 99

File: SERVICE MANUAL - Section 70

Replaces: S70-200 OM/MAR 99

Dist: 3, 3a, 3b, 3c

OPERATION - MAINTENANCE

MICROPROCESSOR CONTROL

S70-200 OM

Page 2

RWB II PLUS MICROPR OCESSOR CONTROL

OPERATION - MAINTENANCE

Contents

MICROPROCESSOR CONTROL PANEL ....................................................................................................................................3

KEYS AND KEY FUNCTIONS......................................................................................................................................................4

TO CHANGE THE ADJUSTABLE SETPOINTS: ...........................................................................................................................6

HOW TO DETERMINE ADJUSTABLE SETPOINTS: ...................................................................................................................7

TEMPERATURE-PRESSURE CONTROL PROGRAM (OPTION) .............................................................................................10

LEAD-LAG OPTION....................................................................................................................................................................12

COMMUNICA TIONS TROUBLESHOO TING ..............................................................................................................................13

HOW THE MICROPROCESSOR WORKS - SUMMARY -..........................................................................................................13

MULTIPLE COMPRESSOR SEQUENCING ...............................................................................................................................14

SUGGESTED PROGRAMMABLE CONTROLLER PROGRAM TO DECODE

MICROPROCESSOR OUTPUT DATA CODES ...................................................................................................................14

MICROPROCESSOR OUTPUT DATA CODE.............................................................................................................................15

MICROPROCESSOR TELECOMMUNICA TIONS .............................................................................................. ........................16

COMMUNICATIONS PROTOCOL SPECIFICATIONS:...............................................................................................................16

TROUBLESHOOTING THE RWB II PLUS MICROPROCESSOR..............................................................................................20

GENERAL INFORMATION .........................................................................................................................................................20

TROUBLESHOOTING FRICK SBC MICR OPR OCESSOR SYSTEM ........................................................................................20

TESTING MICRO-PANEL ALARMS/CUTOUTS .........................................................................................................................23

EPROM MEMORY I/C CHIP REPLACEMENT .............................................................................................. .............................25

SBC BOARD REPLACEMENT ...................................................................................................................................................25

MICROPROCESSOR DISPLAY REPLACEMENT......................................................................................................................25

OUTPUT FUSE REPLACEMENT...............................................................................................................................................25

SBC WIRING DIAGRAM.............................................................................................................................................................26

POINT-TO-POINT FIELD WIRING DIAGRAM ............................................................................................................................26

MICRO COMPONENT PLACEMENT DIA GRAM .......................................................................................................................27

RWB II PLUS TELECOMMUNICATIONS ...................................................................................................................................27

MICROPANEL ASSEMBLY WIRING DIAGRAMS.......................................................................................................................28

RECOMMENDED SPARE PARTS - CURRENT DESIGN ..........................................................................................................32

– Designates changes or new information on referenced pages. See page and topic for matching symbol.

RWB II PLUS MICROPR OCESSOR CONTROL

OPERATION

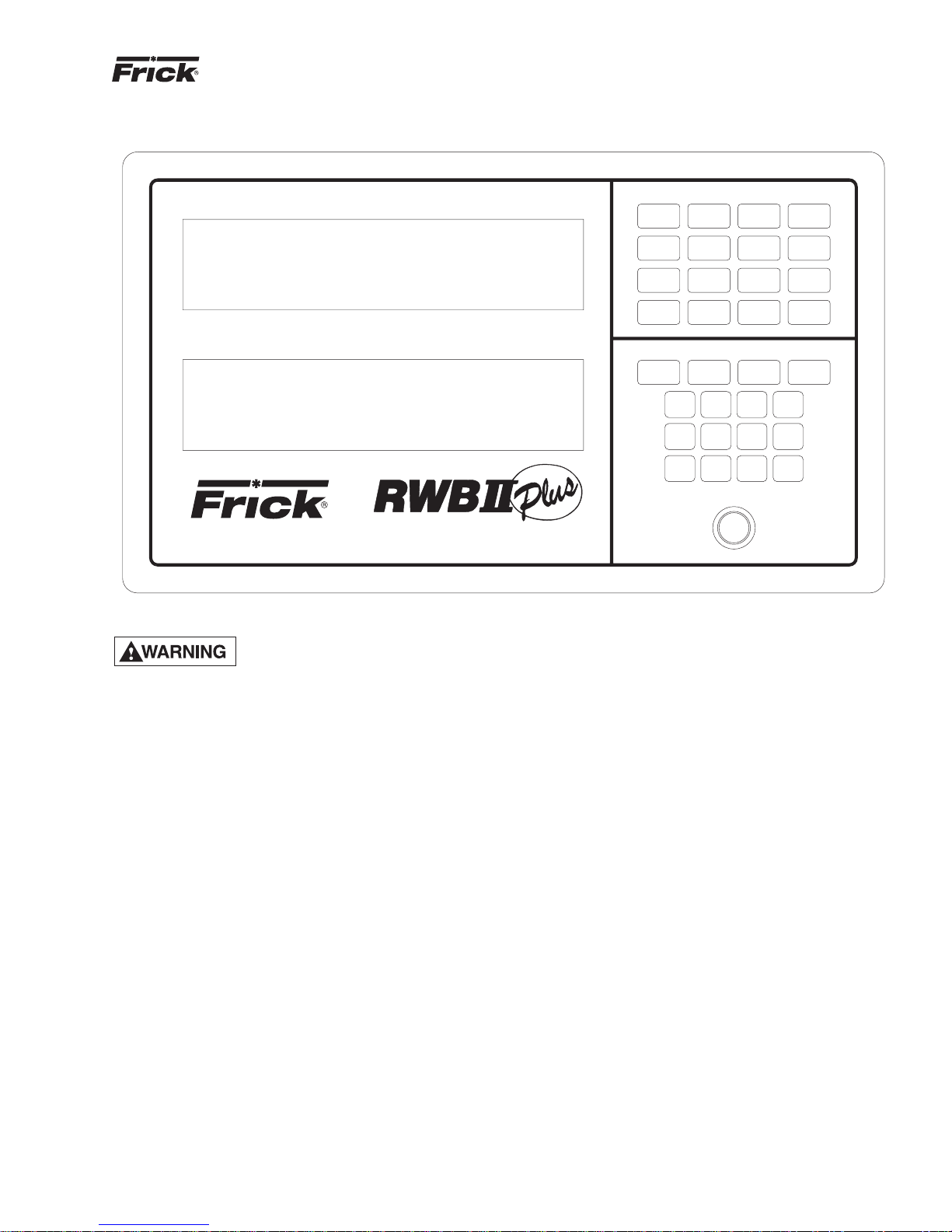

MICROPROCESSOR CONTROL PANEL

S70-200 OM

Page 3

The following must be read in addition to the Operation adn Start-up instructions in S70-200 IOM before attempting to start or operate the unit.

The RWB II PLUS compressor is controlled by a state-ofthe-art microprocessor control system. The microprocessor

continuously monitors the compressor unit’s condition and

operation. The microprocessor also directs instructions to

the various compressor unit subsystems.

The microprocessor has a membrane switch keyboard.

Pressing the keyboard in the area outlined as a ke y will cause

that function to be recognized by the microprocessor. The

keyboard has 32 membrane type keys.

In addition to the keyboard, there is an emergency stop b utton. Pushing the emergency stop will bypass the computer

and remove all power from the outputs.

RUN

STOP

FUNCTION

F1

F2

F3

F4

CLEAR

4

8

+/-

SLIDE STOP

AUTO

MANUAL

INCREASE

MANUAL

DECREASE

CHANGE

SLIDE VALVE

AUTO

REMOTE

MANUAL

LOAD

MANUAL

UNLOAD

SETPOINT ENTRY

STEP

1

2

5

6

9

*

EMERGENCY STOP

COMPRESSOR

REMOTE

START

ALARM

SILENCE

ENTER

3

7

0

This will shut down the compressor motor and all high voltage to the compressor auxiliary systems such as the oil

pump and liquid injection solenoid. THE EMERGENCY

STOP BUTT ON IS FOR EMERGENCY SHUTDOWN SITUA TIONS ONLY and MUST NOT BE USED TO ROUTINELY

SHUT OFF THE COMPRESSOR.

The microprocessor continuously monitors the state of the

battery which maintains setpoints and various other data. If

the battery voltage is low, the message “LOW BATTERY”

will flash in the lower right hand corner of the bottom display (see S70-200 IOM for description of battery backup).

The microprocessor hardware contains an output watchdog circuit. If the microprocessor should fail, this circuit will

disable (turn off) all outputs.

S70-200 OM

Page 4

RWB II PLUS MICROPR OCESSOR CONTROL

OPERATION

KEYS AND KEY FUNCTIONS

NOTE: The microprocessor will automatically return to

the main operating display after 60 seconds of keyboard nonactivity.

The [CHANGE] k ey rotates the dual displa y screen through

six display modes. The [CHANGE] key is also used to change

the status of various setpoints.

The [STEP] key steps or moves a set of flashing brackets

through the variable setpoints on the Adjustable setpoints

display, the Auto-cycle display, the Security display and the

Setback display. The setpoint enclosed within the flashing

brackets may be changed or updated. The [STEP] key is

also used when the annunciator display is selected to step

through the annunciator’s four information displays.

NOTE: The [ * ] key is used to step or move the flashing

brackets, described above, backwards.

The [ENTER] key is used to enter new setpoint limits.

The [CLEAR] ke y will reset an alarm or cutout indication on

the annunciator screen and will clear the microprocessor to

allow continued operation or restarting if all conditions have

returned to normal and no other control lockouts are in force.

The [NUMERIC KEYP AD] is used to introduce new setpoint

limits.

The [+/-] key is used to toggle between pounds per square

inch gauge (g) and inches of mercury (hg).

The [RUN], [STOP], and [REMOTE START] keys control

the starting and stopping of the compressor unit.

The [ALARM SILENCE] key will de-energize the alarm horn

output.

The [AUT O], [REMOTE], and [MANUAL] keys control the

operation of the compressor slide valve and mo v eab le slide

stop.

The [F1] function key will return the operator to the main

operating display. This function may be invoked at any time,

even during setpoint entry.

display mode. To change to a different display mode, press

the [CHANGE] k ey. The displa y modes in their order of rota-

tion are:

1. Operating display

2. Adjustable Setpoints display

3. Adjustable Setpoints display #2

4. Fixed Setpoints display

5. Annunciator display (4 pages)

6. Shutdown Record display

7. Freeze display

[F1] Operating display

[F2] Security display

[F3] Setback display

[F4] Auto Cycle display

NOTE: On initial powering of the microprocessor, and

any time power has been removed from the microprocessor, onl y the Operating, Setpoints, Ann unciator, and

Shutdown displays will display information. The freeze

display will appear as a dark screen. The Freeze display

will only be present after a compressor unit cutout and

power has not been interrupted to the microprocessor.

The cutout must be on a safety setpoint. When power is

lost to the micro, it will not show the freeze display.

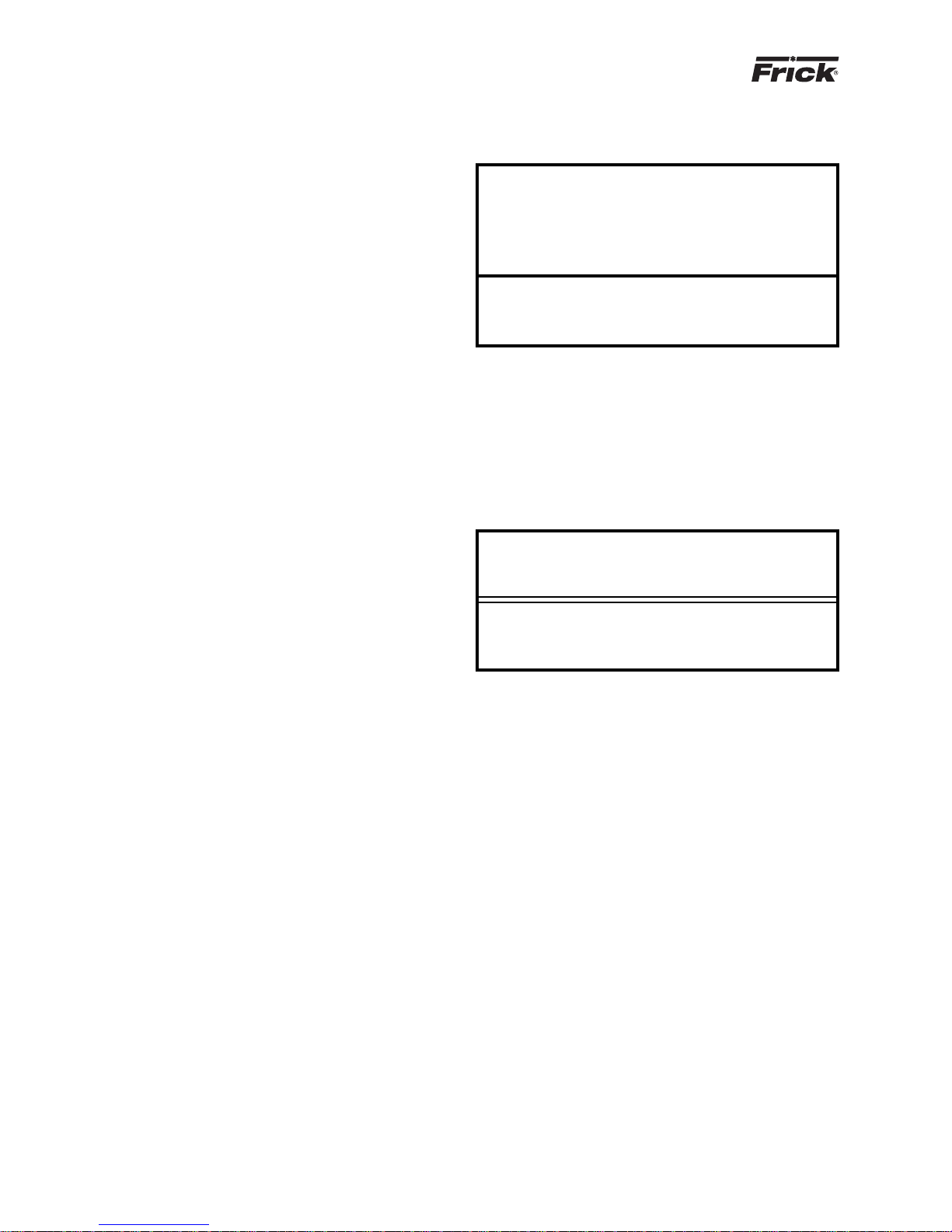

OPERATING DISPLAY *

OPERATING DISPLAY: Thu 10-01-87 15:33:36

Suction Disch Oil Filter Compressor

20.0 g 180 g 170 g 01PSID MAN Mode

+015 F 140 F 135 F RUNNING

V Ratio S V Pos Pump %FLA Sep 132 F

4.6 090% OFF 080% HTR off

Auto D Auto L FORCED UNLD ALARM

C.C.=20.0 g LOW-BATTERY

*Display for illustrative purposes only.

The Operating display is continuously updated and pro vides

a variety of information in regard to the current status of the

compressor’s condition and performance.

The information furnished by the Operating display is as follows:

The DAY, DATE, and TIME are displayed at the top right of

the display.

The [F2] function key will call up the Security display. NO TE:

Press the [F2] key , as prompted b y the displa y, to return

to the previously selected display.

The [F3] function k ey will call up the Setback displa y. NO TE:

To exit the Setback display, press the [F1] key as

prompted by the display.

The [F4] function key will call up the Auto Cycle display.

NOTE: T o exit the A uto Cycle displa y, press the [F1] key

as prompted by the display.

The [DISPLAY BACKLIGHT] key will toggle the dual LCD

display backlights on and off. A preset delay will shut off the

backlight after ten minutes elapsed time.

The microprocessor has two liquid crystal displays in an 8

line by 40 character format, for a total of 320 characters.

There are 9 different display modes. When power is first

applied to the control panel, the unit will be in the Operating

NOTE: To set day, date, and time; see TO CHANGE THE

ADJUSTABLE SETPOINTS.

SUCTION - Suction Pressure and Temperature are mea-

sured at the compressor inlet and are, respectively, displayed

in pounds per square inch gauge (g) or inches of mercury

(hg) and degrees Fahrenheit.

DISCH - Discharge Pressure and Temperature are measured at the compressor outlet and are, respectively, displayed

in pounds per square inch gauge (g) and degrees Fahrenheit.

OIL - Oil Pressure and Temperature are measured prior to

entering the compressor and are, respectively, displayed in

pounds per square inch gauge (g) and degrees Fahrenheit.

FIL TER - Pressure drop across the oil filter. On the model

676 only, the bear ing oil filter pressure drop is displayed.

The main oil injection feed filter pressure drop is shown on a

unit mounted gauge.

RWB II PLUS MICROPR OCESSOR CONTROL

OPERATION

S70-200 OM

Page 5

COMPRESSOR - Compressor displays the status of the

compressor unit. The mode of operation will be indicated as

either manual (MAN MODE) when the [RUN] key has been

pressed, automatic (AUTO MODE) when Auto Cycle has

been activated, remote (RMT MODE) when the [REMOTE]

key has been pressed, or off (OFF MODE).

V RATIO - Volume Ratio is the ratio selected by the microprocessor to provide the highest efficiency at any given suction and discharge pressure condition. Immediately below

this, an information space has been provided to indicate

whether V ratio is in the automatic (AUTO) or the manual

(MAN) mode. The microprocessor will control this function

only in the automatic mode. To the right of the mode indicator, two other messages may appear:

I - Indicates V Ratio increase.

D - Indicates V Ratio decrease.

SV POS - Slide valve position is display ed as a percentage.

This percentage reflects the mechanical position of the slide

valve and does not reflect the percentage of full load operation. Immediately below this information, space has been

provided to indicate whether SV Pos is in the automatic

(AUT O), manual (MAN), or remote (RMT) mode . The microprocessor will control this function in the automatic mode.

To the right of the mode indicator, two other messages may

appear:

L - Indicates Slide Valve loading.

U - Indicates Slide Valve unloading.

PUMP - Pump displays the current status of the oil pump.

The display will read ON or OFF whenev er the HAND-OFF-

-AUTO switch is selected to AUTO and the compressor is

running.

% FLA - Percent Full Load Amps displa ys the percentage of

the drive motor full load amperage rating that the motor is

currently using.

NOTE: Consult Motor Manufacturer for the recommended duration of the Recycle Delay.

If the [RUN] key is pushed while the

unit is in Recycle Delay, the compressor will start at the end of the

delay period.

C.C. - Capacity Control, located at the bottom left of the

display, indicates the current capacity control suction pressure setpoint in pounds per square inch gauge (g) or inches

of mercury (hg).

ADJUSTABLE SETPOINTS DISPLAY *

ADJUSTABLE SETPOINTS: ID=[33] [10-01-87]

Cap. Control---[20.0 g ] Thu [15:33:36]

Lo Suct Cutout-[12.0 g ] Baud----[ 2400]

Lo Suct Alarm--[16.0 g ]

Hi Disch Cutout-[225 g ] Aux1[Alarm][NO]

Hi Disch Alarm--[215 g ] Aux2[Shutd][NC]

M.L.C. Stop Load--[095%] CT Factor-[078]

M.L.C. Force Unld-[100%] Recy.Delay-[30]

The Adjustable Setpoints display lists the adjustable setpoints which define the limits of the compressor package

operation. When these limits are reached, or exceeded,

alarm or compressor shutdown will occur. The inf orma

an

tion fur-

nished by the Adjustable Setpoints display is as follows:

CAP CONTROL - The Capacity Control setpoint, reported

in pounds per square inch gauge (g) or inches of mercury

(hg), controls the loading and unloading of the compressor

when SV POS is in the automatic (AUTO) mode.

LO SUCT CUTOUT - The Low Suction Pressure Cutout, reported in pounds per square inch gauge (g) or inches of

mercury (hg), will shut down the compressor if the suction

pressure drops to this limit, or lower, f or 120 seconds or longer.

SEP - Separator displays the oil separator temperature in

degrees Fahrenheit.

HTR - Heater displays the condition of the oil separator

heater(s), indicating ON or OFF.

ALARM/CUTOUT - An Alarm or Cutout message indicates

an Alarm or Cutout setpoint has been reached, or exceeded.

Rotate the display mode to the Annunciator display for details. In the e vent of a cutout, rotate to the Freeze display for

further details.

FORCED UNLD - A Forced Unload message indicates that

the percentage of motor full load amps has exceeded the

maximum limit and the microprocessor is unloading the compressor until the percentage FLA falls back to normal limits.

RECYCLE DELAY - A Recycle Delay message indicates

that the compressor has started and has shut down within

the time delay set point period. The Recycle Delay will prevent the compressor from starting until the delay time expires and is intended to prevent damage to the compressor

motor from successive restarts. During Recycle Delay, the

microprocessor will alternatively flash “RECYCLE DELAY”

and the remaining delay time in minutes.

*Display for illustrative purposes only.

LO SUCT ALARM - The Low Suction Pressure Alarm, reported in pounds per square inch gauge (g) or inches of

mercury (hg), will trigger a prealarm if the suction pressure

drops to this limit, or lower.

HI DISCH CUTOUT - The High Discharge Pressure Cutout,

reported in pounds per square inch gauge (g), will shut down

the compressor if the discharge pressure equals, or exceeds,

this setpoint.

HI DISCH ALARM - The High Discharge Pressure Alarm,

reported in pounds per square inch gauge (g) will trigger a

pre-alarm if the discharge pressure equals, or exceeds, this

setpoint.

M.L.C. STOP LOAD - The Motor Load Control Stop Load,

reported as a percentage of the motor full load amps (FLA),

will prevent the compressor slide valve from loading when

the setpoint is equaled, or exceeded. NOTE: Consult mo-

tor nameplate for recommended setpoint.

M.L.C. FORCE UNLD - The motor Load Control Force Un-

load, reported as a percentage of the motor full load amps

(FLA), will force the compressor to unload until the motor

full load amps (FLA) fall within 1% of the setpoint, or lower.

NOTE: Consult motor nameplate f or recommended setpoint.

S70-200 OM

Page 6

RWB II PLUS MICROPR OCESSOR CONTROL

OPERATION

ID - The ID number is a programmable identification code

used in telecommunications to access a specific compressor.

DATE - The Date displays the current date in the following

format: Month - Day - Year.

DAY - Day will display the current day of the week.

TIME - The Time displays the current time in the following

format: Hours - Minutes - Seconds. The time is in 24:00:00

hour clock format.

BAUD - Shows the baud rate of the RS422 communication

ports 1 and 2. Both ports are configured as follows: word = 8

bit, parity = none or even, stop = 1 bit. The communications

ports are programmable from 300 to 19200 baud.

AUX 1 and A UX 2 - May be configured f or either an alarm or

shutdown and with either a normally closed (NC) or normally open (NO) contact.

CT FACTOR - The Current Transformer Factor records the

proper current transformer factor to match the compressor

motor FLA rating to the current transformer primary rating.

The CTF factor is programmable and its correct value is

determined by the following formula:

CTF =

1024 x FLA (Full Load Amps)

10 x CT (Current Transformer Primary Amps)

EXAMPLE: FLA = 230 Amps

CT = 300 (300:5)

CTF =

1024x 230 = 78 (Round to whole number)

10 x 300

RECY. DELAY - The Recycle Delay displays the current

recycle delay setpoint in minutes. NOTE: Consult motor

manufacturer for recommended setpoint.

ADJUSTABLE SETPOINTS PAGE 2 *

ADJUSTABLE SETPOINTS Page 2:

Start Diff Press--[100g]

Dead Band--[1.0#]

Prop. Band-[10 %]

Cycle Time-[10 sec]

Low % FLA--[020 %]

Dead Band - This is a + (plus) or - (minus) value above or

below the setpoint at which the compressor will neither load

nor unload. A dead band of 1 is the default value. It is

adjustable between .5 lbs. to 5 lbs. in increments of .5. The

“Step” key is used to select this setpoint; then press the

“Change” key to toggle through the selections.

Cycle Time - Cycle time is the amount of time between the

beginning of each load/unload response. Ten seconds is

the default value. “Cycle Time” is adjustable between 5 and

30 seconds in 5 second intervals. The “Step” key is used to

select a setpoint; then press the “Change” key to toggle

through the selections.

Low % FLA - This setpoint is used to determine if the coupling has broken. 20% is the default value. It is adjustable

from 0 to 100% FLA. Use the “Step” k ey to select a setpoint;

then enter the desired setpoint and press the “Enter” key.

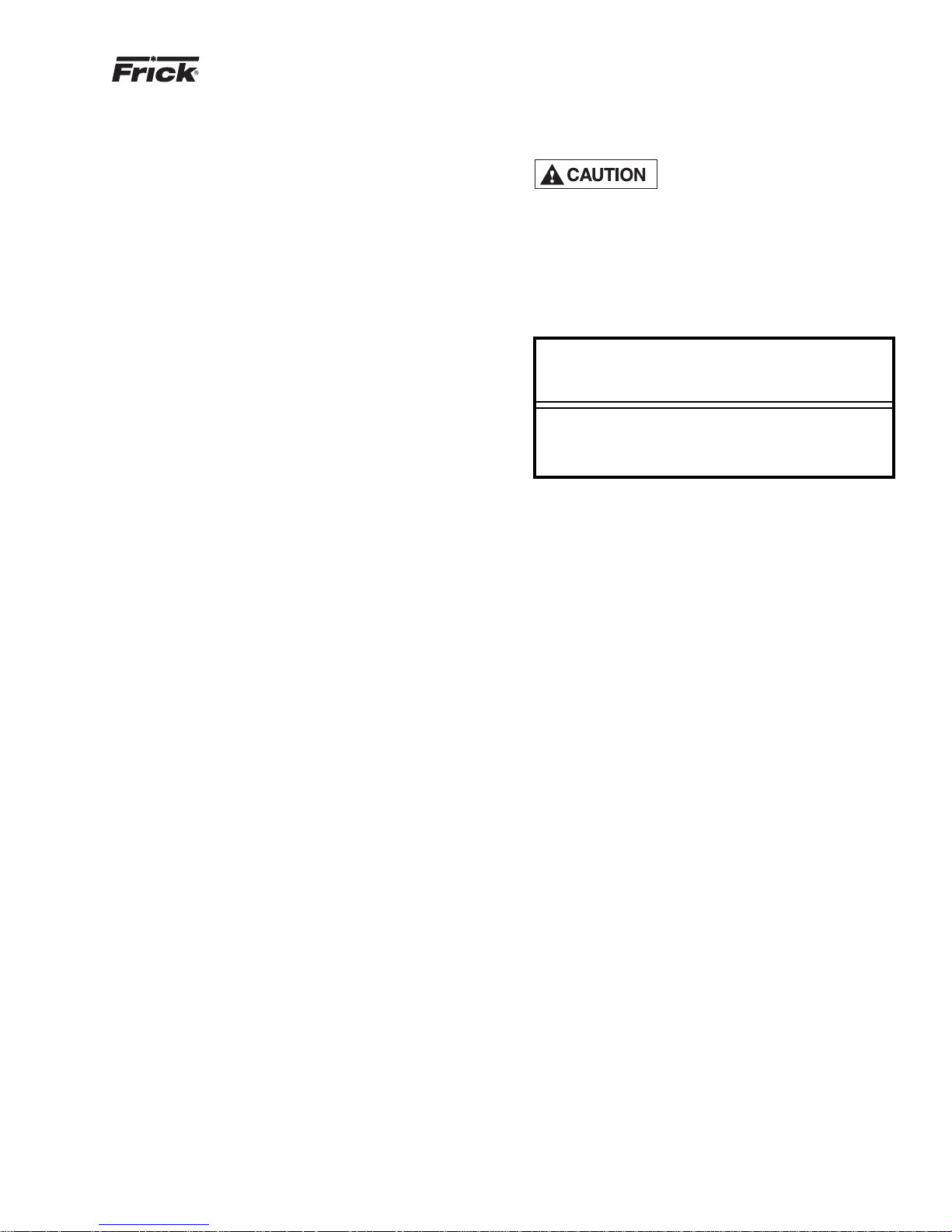

TO CHANGE THE ADJUSTABLE SETPOINTS:

Adjustable Setpoints are stored in RAM (random access

memory) and are easily changed in the field.

Adjustable Setpoints are lost if

power is interrupted and the battery

is not fully charged. To facilitate reentry, we suggest that a list of Adjustable Setpoints be

affixed to one end of the microprocessor cabinet for

reference. For your convenience, a blank Adjustable set-

points display which may be photocopied has been provided

(See page 10).

NOTE: The following procedure also applies to the c hanging of the Security, Setbac k, and A uto Cycle display setpoints.

1. Press the [CHANGE] key to rotate the display to the Ad-

justable Setpoints display.

2. Press the [STEP] key to move or step a set of flashing

brackets through the v arious setpoints. A setpoint is selected

for change or update when it is enclosed by the flashing

brackets.

NOTE: The DAY indicator, itself, will flash when selected

for change or update.

3. Having selected the setpoint to be changed, the [NU-

MERIC KEYPAD] may be used to enter the new setpoint.

NOTE: All digits must be entered, including zeros. For

example, (01.0).

NOTE: The D A Y, A UX 1, and A UX 2 setpoints, once selected,

are changed or updated by pressing the [CHANGE] key.

NOTE: Certain setpoints may be reported in either pounds

per square inch gauge (g) or inches of mercury (hg). To

toggle between (g) and (hg), having selected the setpoint,

press the [+/-] key to toggle between (g) and (hg).

4. In the event that an incorrect setpoint is keyed in all or

part, press the [CLEAR] key to restore the original setpoint.

Pressing the [CLEAR] key a second time will eliminate the

flashing brackets.

Proportional Band - This setpoint is used to determine the

amount of time the load/unload solenoid is energized, according to how far from the setpoint the actual control pressure is. The smaller the number, the longer a load/unload

signal will be sent. 10% is the def ault value . Selections are

2, 5, 10, 15, 20, or 25%. The “Step” ke y is used to select this

setpoint; then press the “Change” key to toggle through the

selections.

*Display for illustrative purposes only.

5. Having keyed the desired setpoint, press the [ENTER]

key. The new setpoint will be entered and the flashing brac kets will move or step to the next setpoint.

NOTE: A setpoint entry outside the parameters of the

Adjustable Setpoint display will be refused and the original Adjustable setpoint will be restored.

NOTE: To clear any time values [STEP] to the desired

setpoint, press [CHANGE] and then press [CLEAR].

RWB II PLUS MICROPR OCESSOR CONTROL

OPERATION

S70-200 OM

Page 7

HOW T O DETERMINE

ADJUSTABLE SETPOINTS:

Adjustable Setpoints should reflect values compatible with

normal system operation. Too high a Low Suction Pressure

Alarm setpoint may cause nuisance prealarms. Similarly,

cutout setpoints should not fall within what are considered

normal plant operation. As a rule of thumb, set the Low Suction Pressure Alarm 5 PSIG lower than the lowest normal

suction pressure. The Low Suction Pressure Cutout should

be 5 to 10 PSIG lower than the Low Suction Pressure Alarm

setpoint.

The High Discharge Pressure Cutout should be set at 90%

of the setting of the lowest high side relief valve. The High

Discharge

the Cutout.

The Capacity Control setpoint should be the equivalent of

the normal suction condition.

FIXED SETPOINTS: HIGH STAGE PRELUBE

OIL PUMP PGM/A

Hi Disch Cut----[212F]

Hi Disch Alarm--[194F] Liq Inj Con 113F

Hi Oil Temp Cut-[167F] Filter------[25]

Hi Oil Temp Alarm[158F]Oil Heater[113F]

Lo Oil Temp Cut--[49F] Lo Oil Cut-[030]

Lo Oil Temp Alarm[58F] Lo Oil Alrm[025]

The Fixed Setpoints display lists all fix ed setpoints, program

version, plus low oil alarm and low oil cutout setpoints. Fixed

Setpoints define the limits of acceptable compressor operation. Fixed Setpoints are factory determined, stored in programmed memory (PROM), and will remain in memory if

power to the microprocessor is interrupted.

HI DISCH CUT - The High Discharge Temperature Cutout,

reported in degrees Fahrenheit, will shut down the compressor if the discharge temperature equals or exceeds this

setpoint.

Pressure Alarm should be set 10 PSIG lower than

FIXED SETPOINTS DISPLAY *

PRELUBE, FULL LUBE, or CYCLING - Pump type will be

indicated.

PGM/ - Microprocessor Program version.

LIQ INJ CON - The Liquid Injection Control, reported in de-

grees Fahrenheit, will shut off the liquid refrigerant supply

to the compressor if the oil temperature equals or falls below this setpoint.

FILTER - The Oil Filter setpoint will trigger an alarm when

the differential pressure across the oil filter equals or exceeds 25 pounds per square inch (PSI) for 15 seconds, or

longer.

OIL HEA TER - The Oil Heater setpoint, reported in degrees

Fahrenheit, turns on the oil separator heater(s) when the oil

temperature equals or falls below this setpoint whenever

the compressor is NOT running.

Compressor Differential Cutout - The differential cutout

has been lowered from 55 lb to 25 lb. Cutout will occur after

five minutes. T o allo w operation at low differential pressures,

the micro will take the following steps:

A. Force unload the compressor to 50% and display an "F

Unload" when the oil pressure is within 10 lb of the main oil

injection port pressure and the slide valve position is greater

than 50%.

B. Prohibit the compressor from loading and display a "Ld

Inhib" message when the differential is within 15 lb of the

main oil injection port pressure.

Oil Pressure Alarm and cutout - Logic has been revised

to same logic as currently used on RXB/RXF. The new logic

is as follows:

Prelube and Cycling Oil Pump version when pump is not

running. Alarm will occur if oil pressure is 25 lb below discharge pressure or within 10 lb of suction pressure for 30

seconds. Cutout occurs if oil pressure is 30 lb below discharge pressure or if oil pressure is within 7 lb of suction

pressure for 10 seconds and alarm has already been set.

HI DISCH ALARM - The High Discharge T emperature Alarm,

reported in degrees Fahrenheit, will trigger a prealarm if the

discharge temperature equals or exceeds this setpoint.

HI OIL TEMP CUT - The High Oil Temperature Cutout, reported in degrees Fahrenheit, will shut down the compressor

if the oil temperature equals or exceeds this setpoint.

HI OIL TEMP ALARM - The High Oil Temperature Alarm,

reported in degrees Fahrenheit, will trigger a prealarm if the

oil temperature equals or exceeds this setpoint.

LOW OIL TEMP CUT - The Low Oil Temperature Cutout,

reported in degrees Fahrenheit, will shut down the compressor if the separator oil temperature equals or falls below this setpoint.

LOW OIL TEMP ALARM - The Low Oil Temperature Alarm,

reported in degrees Fahrenheit, will trigger a prealarm if the

separator oil temperature equals or falls below this setpoint.

HIGH STAGE or BOOSTER - Compressor application indicator.

Full Lube and Cycling Oil Pump version when oil pump is

running. Alarm occurs if oil pressure is within 10 lb of discharge pressure for 30 seconds. Cutout occurs when oil

pressure is within 5 lb of discharge pressure for 10 seconds

and oil pressure alarm has been set.

Cycling Oil Pump Control - The oil pump will cut off when

differential pressure between suction and discharge pressure is 55 lb or greater. Upon pump ter mination the above

cutout logic (pump not running) is utilized. Pump cut-in occurs when the differential pressure between suction and discharge is 45 lb or less. Oil pressure alarm and cutout logic

(pump running) begins after a 30 second delay which allows the oil pump to build pressure.

*Display for illustrative purposes only.

S70-200 OM

Page 8

RWB II PLUS MICROPR OCESSOR CONTROL

OPERATION

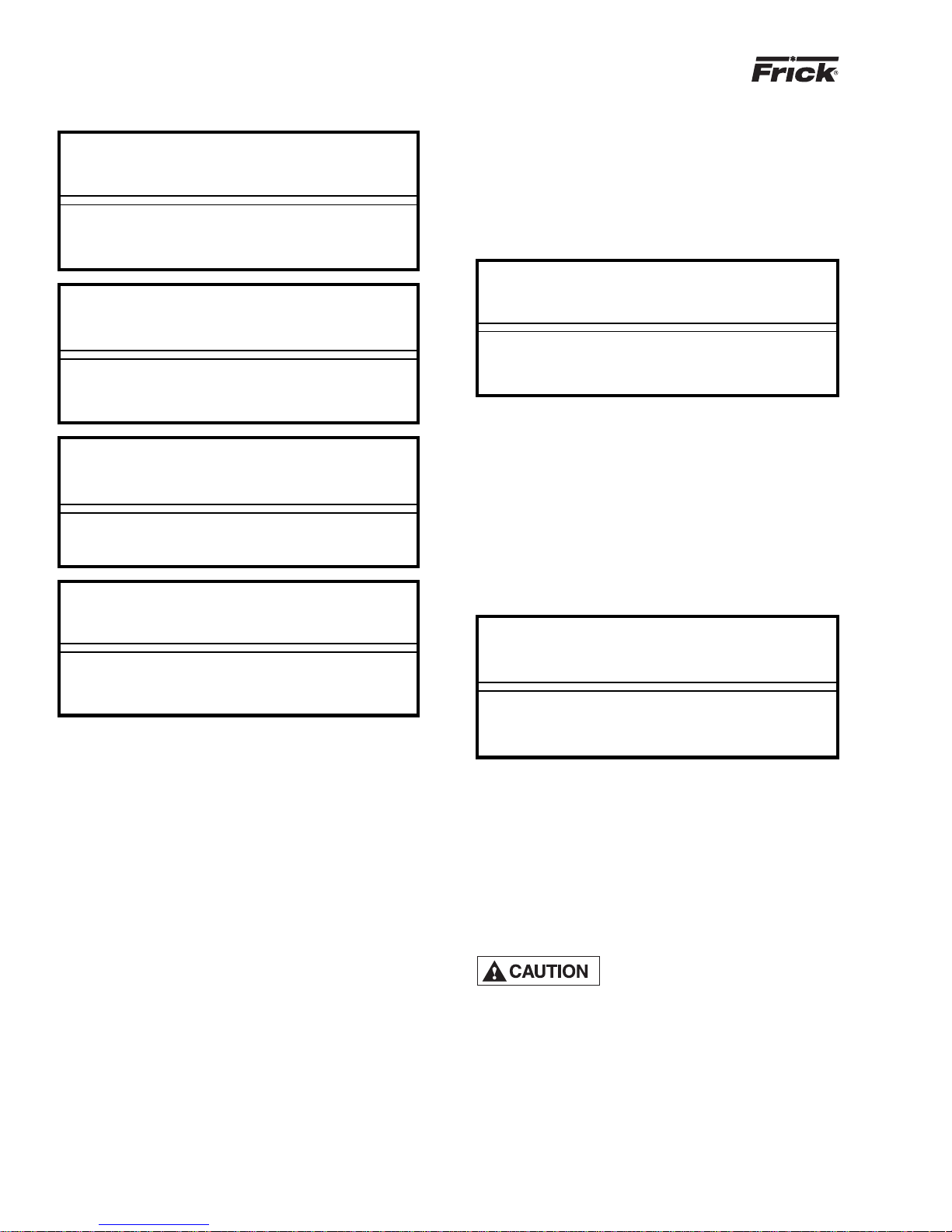

ANNUNCIATOR DISPLAY *

ANNUNCIATOR: PG-1 Thu 10-01-87 15:33:36

(Use STEP key to advance PAGE)

High Press. Cutout *********************

High Press. Alarm *********************

Low Press. Cutout *********************

Low Press. Alarm *********************

Oil Press. Cutout *********************

Oil Press. Alarm *********************

ANNUNCIATOR: PG-2 Thu 10-01-87 15:33:36

(Use STEP key to advance PAGE)

Hi Oil Temp Cutout *********************

Hi Oil Temp Alarm *********************

Low Temp Cutout *********************

Low Temp Alarm *********************

Disch. Temp Cutout *********************

Disch. Temp Alarm *********************

ANNUNCIATOR: PG-3 Thu 10-01-87 15:33:36

(Use STEP key to advance PAGE)

Comp. Auxiliary *********************

Pump Auxiliary *********************

Oil Level *********************

Comp. Differential *********************

Dirty Filter *********************

ANNUNCIATOR: PG-4 Thu 10-01-87 15:33:36

(Use STEP key to advance PAGE)

Aux. 1 (Alarm) *********************

Aux. 2 (Shutdown) *********************

Low Motor Amps

Sensor Fault

When a prealarm or cutout occurs, a flashing ALARM or

CUTOUT indicator will appear in the lower right hand cor-

ner of the Operating display. To determine the fault, rotate to

the Annunciator display by pressing the [CHANGE] key.

The Annunciator display lists all ke y operative points on f our

sequential displays. These displa ys can be rotated from page

#1 through page #4 by pressing the [STEP] key. When a

prealarm or cutout is triggered, the pertinent point will flash,

and the time of the occurrence will be recorded to the right

of the alarm. Prealarms are self-clearing. At this time the

alarm will stop flashing, but the time of the first occurrence

will still be recorded to the right of the alarm. Pressing the

[CLEAR] key while at the Annunciator display will clear all

alarms and/or cutouts.

In order to restore the Annunciator display and resume normal operation it will be necessary to go through the following steps:

1. Correct the conditions causing the alarm.

4. Press [F1] to call up the Operating display. If the condi-

tions causing the alarm have not been corrected or a new

fault has occurred, a new ALARM or CUT OUT message will

appear.

NOTE: Use of the Emergency Stop Button may trip one

or more alarm setpoints.

SHUTDOWN RECORD DISPLAY *

SHUTDOWN RECORD: Thu 10-01-87 15:33:36

(Use STEP key to advance PAGE)

Hi Oil Temp Cutout Wed 09-30-87 16:22:54

Comp Auxiliary Sat 08-22-87 09:47:02

Low Temp Cutout Thu 08-20-87 11:17:33

Pump Auxiliary Mon 08-17-87 18:53:11

Disch. Temp Cutout Tue 07-14-87 06:22:09

Oil Pres Cutout Fri 07-08-87 14:06:21

The Shutdown Record display keeps a record of the last six

shutdowns (cutouts). This information will help troubleshoot

persistent operational problems. The most recent cutout will

appear on the top line of the display with the oldest appearing

on the last or bottom line. When a cutout occurs, all inf ormation is moved down one line and the new cutout appears at

the top. When the displa y is full, the oldest record is dropped

off the display and is not retained in memory. The information presented is echoed from the Annunciator display; providing the type of cutout, the day, the date, and the time.

NOTE: This information will not be lost due to power

failure.

FREEZE DISPLAY *

FREEZE DISPLAY: Thu 10-01-87 15:33:36

Suction Disch Oil Filter Compressor

20.0 g 225 g 170 g 01PSID OFF Mode

+015 F 140 F 135 F RECYCLE

V Ratio S V Pos Pump %FLA Sep 132 F

4.6 090% OFF 080% HTR off

Auto Auto CUTOUT

C.C.=20.0 g

The Freeze displa y has the same appear ance and contains

the same information as the Operating display. (For a description of the information presented by the Freeze displa y,

refer to the Operating display.) The Freeze display freezes

the information of the Operating display A T THE MOMENT

OF A COMPRESSOR CUTOUT. The information on the

Freeze displa y can help the operator to identify the cause of

a fault which occurred when no one was present. The Freeze

display will retain the information generated by a cutout until a new cutout occurs or power is removed from the microprocessor.

Do not confuse the Freeze display

with the Operating display . In order

to avoid confusion remember that

the displayed information on the Operating display is

constantly being updated and changed. The Freeze display is fixed and FREEZE DISPLA Y appear s in the upper

left hand corner of the display.

2. Press the [ALARM SILENCE] key. (This action may pre-

cede correcting the conditions causing the alarm).

3. To clear or reset the Annunciator pages, press the

[CLEAR] key. This will also clear the ALARM or CUTOUT

indicator from the Operating display.

NOTE: The Freeze display will appear as a blank screen

when power is initially furnished to the unit, and it will

return to a blank screen anytime power is removed fr om

the microprocessor.

*Display for illustrative purposes only.

RWB II PLUS MICROPR OCESSOR CONTROL

OPERATION

S70-200 OM

Page 9

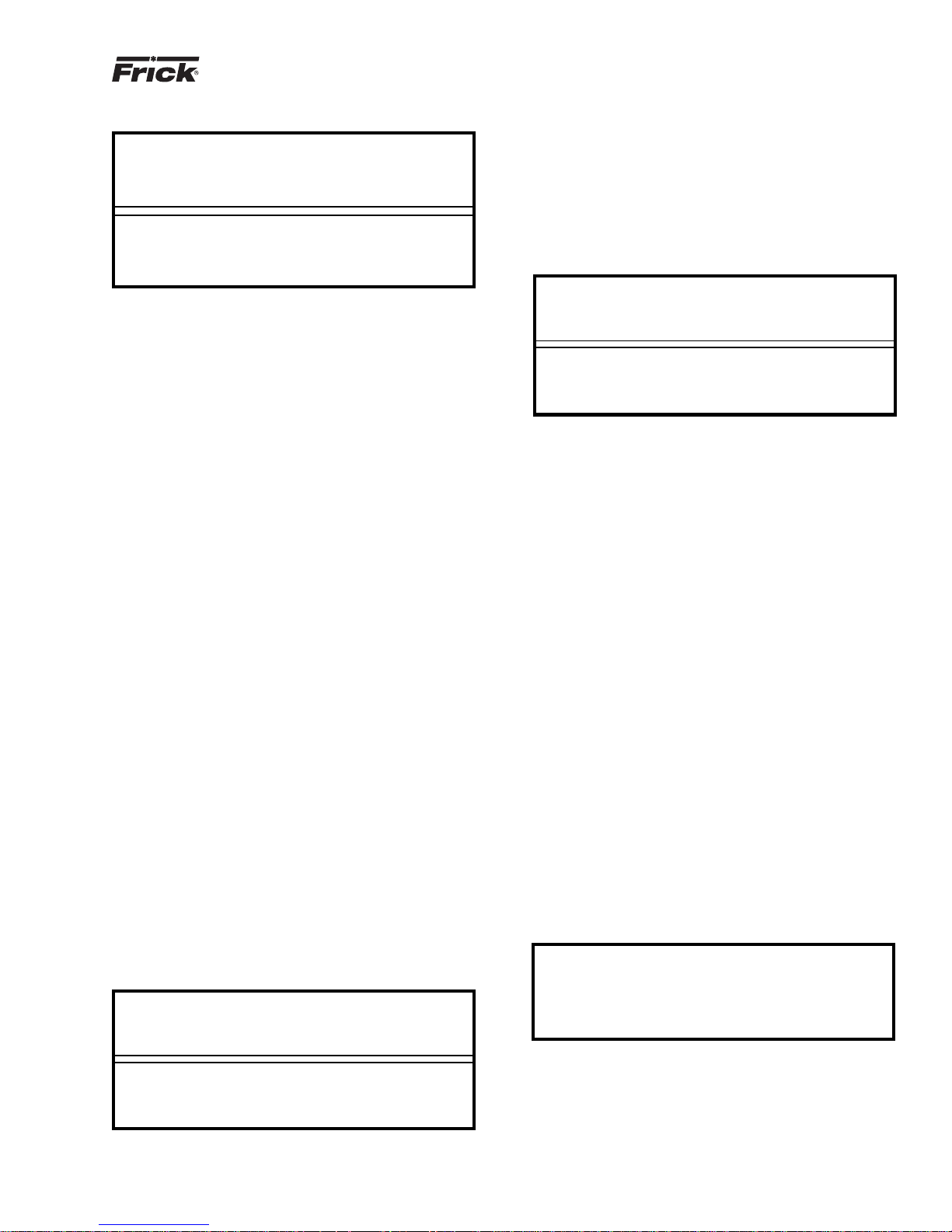

SECURITY DISPLAY *

SECURITY DISPLAY: Thu 10-01-87 15:33:36

Setpoints Access---[Enabled ] Keyboard

Enter Access Code---[*****]

Press F2 To Exit

The [F2] function key will call up the Security display. The

Security display allows the operator to either enable or disable the microprocessor’s keyboard and, thereby, prevent

unauthorized tampering with the various adjustable setpoints.

When enabled, the microprocessor ke yboard is fully operative and the security lockout is not in effect. When disabled,

the keyboard is rendered partially nonfunctional. All displa ys

will still be accessible through the keyboard. If any attempt

is made to enter new adjustable setpoints, ho w e v er, the microprocessor will default to the Security display.

TO ENABLE THE KEYBOARD, press the [STEP] key so

that the brackets beside Enter Access Code flash, key the

proper five digit access code, and press [ENTER]. The Setpoints Access will toggle from disabled to enabled and adjustable set point entry is now possible.

TO DISABLE THE KEYBOARD, press the [F2] function key

to call up the Security display. Press the [STEP] key until

the brackets beside Enter Access Code flash, k ey the proper

five digit access code, and press [ENTER]. Now, press the

[STEP] key until the brac kets beside Setpoints Access flash

and press the [CHANGE] key to toggle from enab led to disabled.

TO CHANGE THE ACCESS CODE, press the [F2] function

key to call up the Security display. Press the [STEP] key

until the brackets beside Enter Access Code flash, key the

proper five digit access code, and press [ENTER]. Now,

select the Enter Access Code a second time by pressing

the [STEP] key until the brackets beside Setpoints Access

flash, key in the new five digit access code, and press [EN-

TER].

NOTE: Power loss will not effect the Security display.

NOTE: IF NO ACCESS CODE WAS ENTERED AND THE

DISABLED COMMAND WAS SELECTED, THE ACCESS

CODE IS [00000].

LOST OR FORGOTTEN ACCESS CODE: Consult Frick

Company for assistance.

SETBACK DISPLAY *

SETBACK DISPLAY: Thu 10-01-87 15:33:36

Press F1 To Exit

Setback Setpoint-[05.0 g ] Active-[No ]

Start Stop Start Stop

Mon-[--:--]-[06:00] Fri-[16:00]-[--:--]

Tue-[--:--]-[--:--] Sat-[--:--]-[--:--]

Wed-[--:--]-[--:--] Sun-[--:--]-[--:--]

Thu-[--:--]-[--:--]

*Display for illustrative purposes only.

The [F3] function key will call up the Setback display. The

Setback feature enables automatic operation at two separate suction conditions on a preset time schedule. Having

entered the desired Setback setpoint, enter the start and

stop time or times, and select Active: (Yes) or (No).

NOTE: To change the Setback setpoints, refer to “TO

CHANGE THE ADJUST ABLE SETPOINTS”

AUTO CYCLE DISPLAY *

AUTO CYCLE Thu 10-01-87 16:33:36

DISPLAY: Press F1 To Exit

Suction Pressure--------[20.0 g ]

Compressor Start--------[20.0 g ]

Compressor Stop---------[18.0 hg]

Minimum Slide Valve-----[00%]

Auto Cycle Active-------[No ]

The Auto Cycle display provides for independently adjustable setpoints to turn the compressor on and off in response

to the suction pressure or as an adjustable setpoint to limit

the minimum slide valve position.

NOTE: To change the Auto Cycle setpoints, refer to

“TO CHANGE THE ADJUSTABLE SETPOINTS”

SUCTION PRESSURE - Constantly monitors and displays

the suction pressure in pounds per square inch gauge (g) or

inches of mercury (hg).

COMPRESSOR START - Compressor Start-up will bring

the compressor back on line when the suction pressure rises

to the displayed setpoint.

COMPRESSOR STOP - Compressor Stop will shut down

the unit if the suction pressure drops to or below the displayed setpoint limit. NOTE: This limit must be set higher

than Low Suction Pressure Cutout and the Low Suction Pressure Alarm setpoints.

MINIMUM SLIDE VALVE - Minimum Slide Valve Position,

shown as a percentage, will limit the slide valve position to

the displayed setpoint.

AUTO CYCLE ACTIVE - Indicates whether Auto Cycle is

active (YES) or not active (NO). Press the [CHANGE] key

while at this setpoint to change the status. Upon deactivation, the compressor will return to the previous mode of operation.

ANALOG OFFSET DISPLAY*

ANALOG OFFSET:

Suc Disch Oil Sep Filt Spare Econ

Temp +0 +0 +0 +0 +0.0

Pres +0.0 +0 +0 +0 +0

Channel 10 12 13

Press +0 +0 0

The Analog Offset Display is accessed by pressing +/- key.

All analog values can be offset + or - 3 to 9 units depending

on which value is being adjusted. Use the [STEP] key to

step to the desired setpoint. Press the [CHANGE] key to

change the value of the offset by 1. The actual analog value

will be displayed on the top line of the display. The “Econ”

and channels 10, 12, 13 are displayed but do not pertain to

the standard program.

S70-200 OM

Page 10

RWB II PLUS MICROPR OCESSOR CONTROL

OPERATION

Sensor Fault Failure - A “Sensor F ault” cutout was added

to the program to stop the compressor if a temperature or

pressure sensor is at its minimum or maximum limit for 5

seconds. The following channels and conditions will cause

this cutout:

O

F)

F)

O

F)

Channel 1 - Suction Temp Low or High (-67 to 113

Channel 2 - Low or High Discharge Temp (32 or 212OF)

Channel 3 - Low or High Oil Temp (0 or 180

O

Channel 4 - Low or High Separator Temp (0 or 180

Channel 6 - Low or High Oil Pressure (<0 g or 285 g)

Channel 8 -

Low or High Discharge Pressure (<0 g or 285 g)

Channel 9 - Low Suction Pressure (29 hg only)

Pulse Load Signal at 100% Slide Valve Position - This

new feature will stop loading the compressor when 100%

slide valve is display ed. The load signal will pulse for 2 seconds every minute when the slide valve is at 100% and the

pressure is above setpoint.

TEMPERA TURE-PRESSURE CONTROL

PROGRAM (OPTION)

NOTE: The following displays are provided only when

the Temperature-Pressure Control Program option has

been ordered with the RWB II Plus Rotary Screw Compressor Unit.

SETPOINTS DISPLAY PAGE 1 *

CONTROL - This setpoint is used to select either Pressure

Capacity Control or Temperature Capacity Control. NOTE:

There are only two setpoints, press f or pressure capacity control and temp for temperature capacity control.

CC - The capacity control setpoint is for normal operation,

not setback.

CUTOUT -This setpoint will stop the compressor if the suc-

tion pressure drops below the pressure setpoint for 90 seconds or if the CC Temperature drops below the temperature

setpoint. There is no time delay on the temperature cutout.

ALARM - An alarm will be activated if the suction pressure

drops below the pressure setpoint or if the CC Temperature

drops below the temperature setpoint. There is no time delay for either.

PB - The Proportional Band (PB) is used to determine the

amount of time the load/unload solenoid is energized, according to how far away from the setpoint the actual control

pressure or temperature is. The smaller the number , the more

load/unload will be sent. A PB of 10% is def ault. It is adjustable to 2, 5, 10, 15, 20, or 25 percent.

DB - The Dead Band (DB) is a + (plus) or - (minus) value

above or below the setpoint which the compressor will neither load nor unload. It is adjustable between .5 and 5.0

psig or degrees, in increments of .5 units.

SETPOINTS PAGE 1 Capacity Control=Press

C.C. CUTOUT ALARM PB DB CT

Press 25.3g 01.3g 05.3g 10 1.0 10

Temp +40.0F +32.0F +33.0F 10 0.5 10

offset-act

Sup Heat-Alarm-10F-no

Sep Cond-Alarm-10F-no

* Display for illustrative purposes only.

The Setpoints Display is accessed by pressing the

[CHANGE] key.

ADJUSTABLE SETPOINTS FORM

ADJUSTABLE SETPOINTS: ID = [ ] [ - - ]

Cap. Control ———[ ] Thu [ : : ]

Lo Suct Cutout ——[ ] Baud ———————[ ]

Lo Suct Alarm ———[ ]

Hi Disch Cutout ——[ ] Aux 1 [ ] [ ]

Hi Disch Alarm ——[ ] Aux 2 [ ] [ ]

CT - The Cycle Time (CT) setpoint is the amount of time

between the beginning of each load/unload response. It is

adjustable to 5, 10, 15, 20, 25, or 30 seconds.

Use the [STEP] key to step to the desired setpoint, then

press the [CHANGE] key to change the CC , PB, DB and CT

values. Enter the desire value for the remaining setpoints

and press [ENTER] when complete.

M.L.C. Stop Load —[ ] CT Factor ———[ ]

M.L.C. Force Unld —[ ] Recy. Delay ——[ ]

Photocopy and fill in applicable data for your unit. Retain for reference if reentry is required.

Loading...

Loading...