Page 1

Form 090.610-M (MAY 2016)

Please check www.johnsoncontrols.com/frick for the latest version of this publication.

MAINTENANCE

File: SERVICE MANUAL - Section 90

Replaces: 090.610 - M (DEC 2012)

Dist: 3, 3a, 3b, 3c

MAINTENANCE

FRICK® QUANTUM™

EVAPORATOR

CONTROL PANEL

Version 3.1x

Page 2

090.610-M (MAY 2016)

Page 2

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

TABLE OF CONTENTS

SECTION 1

INTRODUCTION TO THE QUANTUM™ EVAPORTOR CONTROL SYSTEM ................................................................3

SECTION 2

REMOTE PANEL.....................................................................................................................................................9

SECTION 3

Q5 CONTROLLER..................................................................................................................................................13

SECTION 4

Q4 CONTROLLER..................................................................................................................................................23

SECTION 5

DIGITAL BOARD..................................................................................................................................................29

SECTION 6

ANALOG BOARD..................................................................................................................................................35

SECTION 7

SERVICE SCREENS...............................................................................................................................................41

SECTION 8

TROUBLESHOOTING.............................................................................................................................................49

SECTION 9

EVAPORATOR CONTROL PANEL AND REMOTE PANEL DRAWINGS........................................................................51

SECTION 10

REPLACEMENT PARTS..........................................................................................................................................59

THE FOLLOWING PUBLICATIONS ARE AVAILABLE FROM THE JOHNSON CONTROLS® WEBSITE jci.com

090.612-O Frick® Quantum™ LX Evaporator Control Panel Operation

090.610-CS Frick® Quantum™ LX Evaporator Control Panel Communications Setup (setup and wiring for data communication using available protocols)

090.610-M Frick® Quantum™ LX Evaporator Control Panel Maintenance (repair and troubleshooting)

Page 3

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

090.610-M (MAY 2016)

SECTION 1

INTRODUCTION TO THE QUANTUM™ EVAPORATOR

CONTROL SYSTEM

Page 3

Page 4

090.610-M (MAY 2016)

Page 4

INTRODUCTION TO THE QUANTUM™ LX EVAPORATOR CONTROL SYSTEM

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

INTRODUCTION

The Quantum™ LX Evaporator system consists of two

major control components:

• The Quantum™ LX Evaporator Control Panel

• Evaporator Remote Panel(s)

With the Quantum™ LX Evaporator system version

3.0x and later, a single Evaporator Control Panel can

control up to ten remote panels with each remote capable of handling three Evaporator units, for a total

possible of thirty units. It is also capable of Ethernet

access, which can be viewed remotely through any

web browser, or the optional Frick™ Evaporator Operator Interface Panel.

The Frick® Quantum™ LX Evaporator control system

consists of ve major areas:

QUANTUM™ LX CONTROL PANEL ENCLOSURE

The Frick® Quantum™ LX Evaporator control

panel enclosure is congured to make it as

standard as possible. Since there are nearly

an innite number of possible congurations

and options, this manual will describe the

most common features and arrangements. It

is always best to refer to the wiring diagrams,

panel layouts, and operational documentation

that is included with each unit for exact details regarding equipment operation.

• Power Supply - Provides the necessary

operating voltages for the proper operation of all control components. Additional

information about the power supply can

be found later in this manual.

• Quantum™ Controller - Evaporator

panels are currently supplied with the Q5

control board, but numerous units with

the previous version known as the Q4

board also exist. This manual will include

information for both of these boards.

Both the Q4 and Q5 boards run a software program that communicates with

all Remote Panels, which in turn control the Digital and Analog boards within

those panels. This communication allows

the controller to read the status of all

the I/O boards, and display the data either on its own display, a Web Browser,

or the optional Standard Interface Panel.

The Quantum™ controller acts on this

data, and provides the necessary con-

trol information to the I/O boards to provide

the appropriate control of all input and output

signals, based upon the conguration of installed features and options of the Evaporator

package. Interaction to the outside world can

be achieved through industry-standard communications protocols. Additional information

is located under the Q4 (or Q5) CONTROLLER

section found later in this manual. The Quantum™ controller, when loaded with the operating system, is then known as the Quantum™

LX Evaporator system.

EVAPORATOR REMOTE PANEL

The Remote Panel contains the I/O that will control

up to three Evaporator units. Up to ten Remote

Panels may be connected to the Quantum™ LX

Control panel via RS-485 communications, for a

maximum total of thirty units.

• Power Supply - Provides the necessary operating voltages for the proper operation of all

control components. Additional information

about the power supply can be found later in

this manual.

• Digital Input / Output Boards - Digital (on/off)

signals are sent and received by these boards.

The output signals are used for energizing

solenoids, valves, contactors, relays, etc.,

and the input signals are used to sense the

condition of switches, relay contacts, auxiliary

contacts, etc. This board runs an independent

software program from the Quantum™ LX to

control devices, and communicates the status

of all devices back to the Quantum™ LX. Additional information about the Digital Boards

is located under the DIGITAL BOARD section

found later in this manual.

• Analog Input / Output Board - Analog (variable) signals are sent and received by this

board. The output signals are used for controlling damper motors, modulated valves,

etc., and the input signals are used to read

the values being sent from pressure transducers, temperature sensors, etc. This board runs

an independent software program from the

Quantum™ LX to control devices, and communicates the status of all devices back to

the Quantum™ LX. The analog board contains

24 analog inputs, and 8 analog outputs. Additional information about the Analog board

is located under the ANALOG BOARD section

found later in this manual.

Page 5

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

090.610-M (MAY 2016)

Page 5

GENERAL INFORMATION

The components within the control panel can be

inadvertently damaged by static electricity or mis-

handling. Only qualied technicians should directly

handle these components.

1. DO NOT attempt to make corrections to the

power supply without shutting off the power

to the control panel. Accidental shorts can

irreparably damage the processor boards or

the display screen.

2. DO NOT HANDLE the panel boards when their

cables are disconnected without rst attaching a properly grounded wrist ground strap to

prevent static electrical discharge from your

body.

Most problems encountered with the microprocessor

and control circuits will be the result of a wiring fault, a

blown fuse, faulty I/O module or failure of a peripheral

control such as a solenoid coil or a pressure transducer.

Faults in the computer, while possible, are unlikely. If a

fault develops in the computer, the probability is that

all functions will cease and the display screen will go

blank. The control system consists of an AC (high voltage) side, which can be either 120 volts, or 230 volts,

and a DC (low voltage) side. The AC side actuates solenoids, relays, alarms, and other electromechanical

functions. The DC side operates the computer and its

various sensors.

WHAT TO DO BEFORE CALLING THE FACTORY

Many times when a suspected Quantum™ problem is

called in to the factory, not enough information is provided for the service personnel to assist in solving the

problem. This is because the caller most likely is not

aware of the type of information that would be useful to factory personnel in helping to identify and correct the problem. An example of this is the statement

that the Quantum™ is not booting (the main processor

board is not starting). Unfortunately, this description is

usually vague and only means that there is nothing on

the display. A blank screen could be the result of many

different problems. The following is a list of possible

reasons for no display:

• No power

• Loose or Faulty Display Cable or Inverter Cable

• Bad Display

• Bad Backlight Inverter (on CCFT style displays)

• Bad Backlight Fluorescent Tube (on CCFT style

displays)

• Wrong Combination of Display, Cable, Inverter, or Software

• Faulty CPU Board

When working within the panel, the AC high voltage

side, which can be either nominal 120 VAC or nominal 230 VAC, CAN CAUSE INJURY OR DEATH.

To troubleshoot the low-voltage side of the control circuits, it is necessary to have the following tools:

1. Accurate digital multimeter (capable of reading to DC/AC, mA to the hundreds place)

2. Small wire stripper

3. Small screwdriver (with insulated shaft)

4. Small snip nose pliers

5. Wrist Grounding strap

6. Static free grounded work surface

Note: Proper panel voltage refers to the AC (high voltage) that has been supplied to the panel, which could

be either nominal 120 VAC or nominal 230 VAC.

Before calling the factory for assistance, review the information on the following pages and try to discover

and resolve your Quantum™ LX problem. The actual

cause of most problems is usually not with the Quantum™ board itself, but with something external. However, on the rare occasion that the problem has been

identied as being the Quantum™ board, use the following section as a guideline for replacing it.

Page 6

090.610-M (MAY 2016)

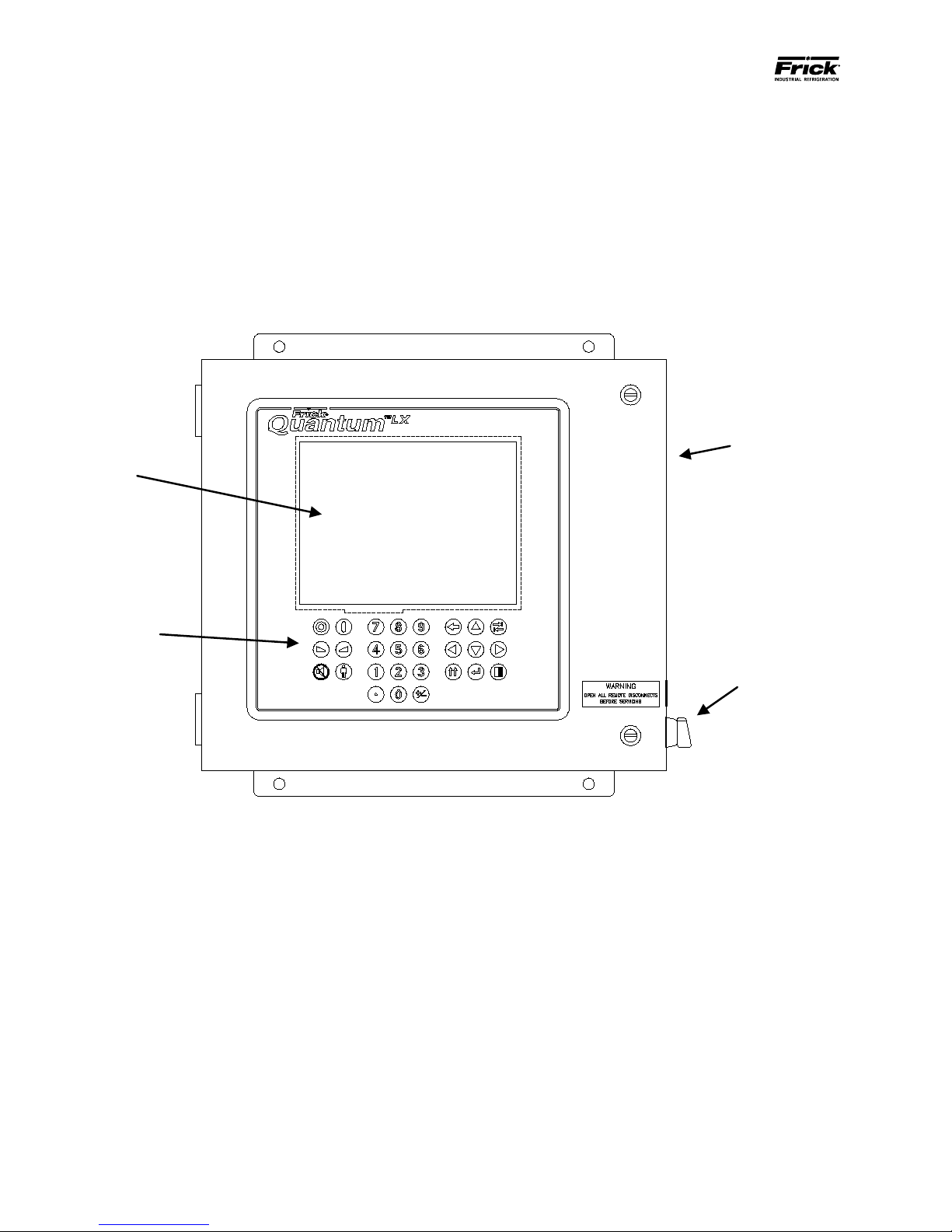

Enclosure

Display

Keypad

Control Power

Switch

Page 6

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

QUANTUM™ EVAPORATOR CONTROL PANEL

The following pictorial shows front the Control Panel portion of the unit, and will appear the same for both a Q4 or Q5 control,

and shows the following components:

• Enclosure

• Display

• Keypad

• Control Power Switch

Front of Enclosure

Page 7

QUANTUM™ LX EVAPORATOR CONTROL PANEL

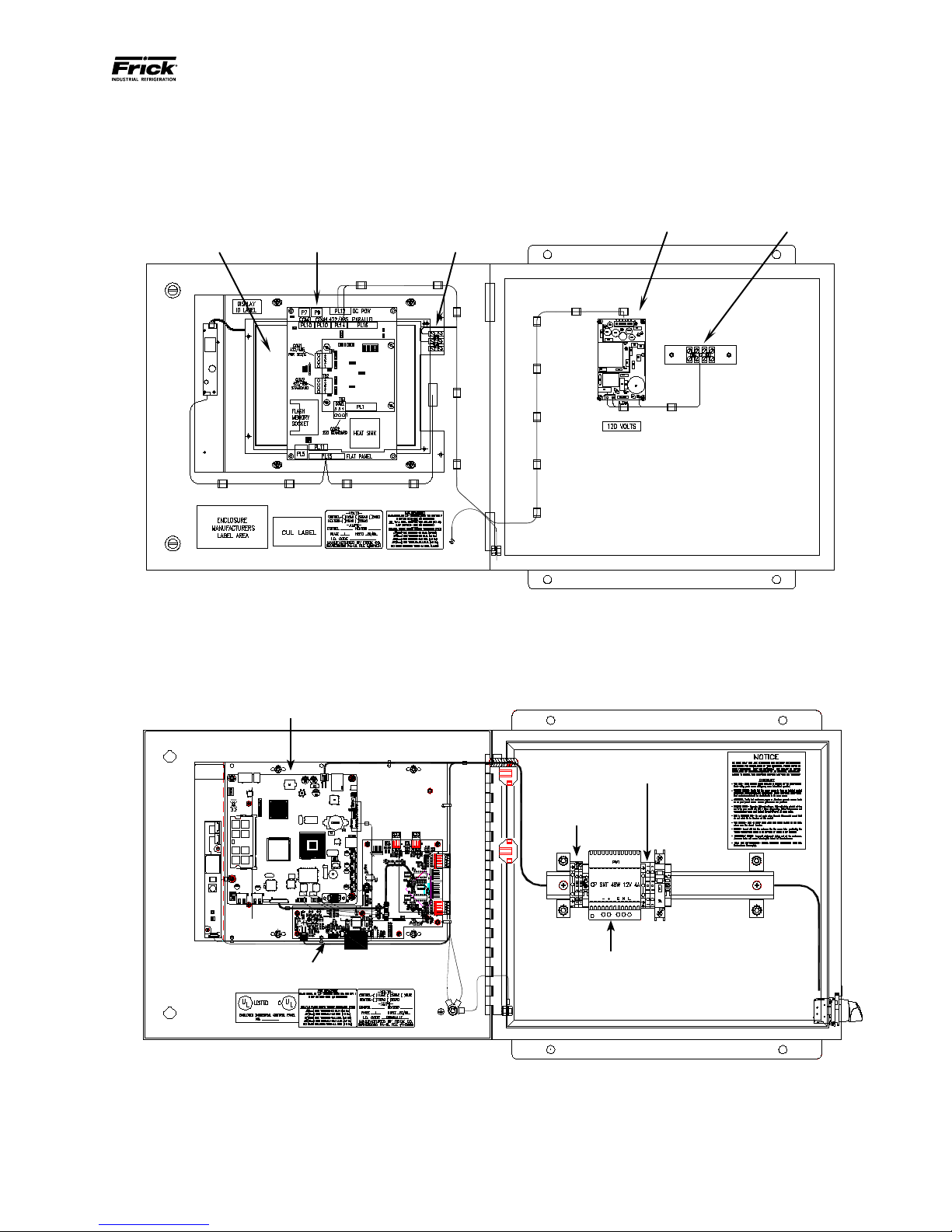

Power Supply

Communications

120 VAC Power

Rear of Display

Quantum™ LX

MAINTENANCE

090.610-M (MAY 2016)

Page 7

The inside of the panel will vary, depending on whether it is a Q4 or Q5 based controller. The following pictorial shows both versions:

Q4 Controller

Controller

Connection

Terminal Block

Q4 Panel

Q5 Controller

120 VAC Power

Connection

Communications

Terminals

Interface Board

Q5 Panel

Power Supply

Page 8

090.610-M (MAY 2016)

Page 8

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

NOTES:

Page 9

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

SECTION 2

REMOTE PANEL

090.610-M (MAY 2016)

Page 9

Page 10

090.610-M (MAY 2016)

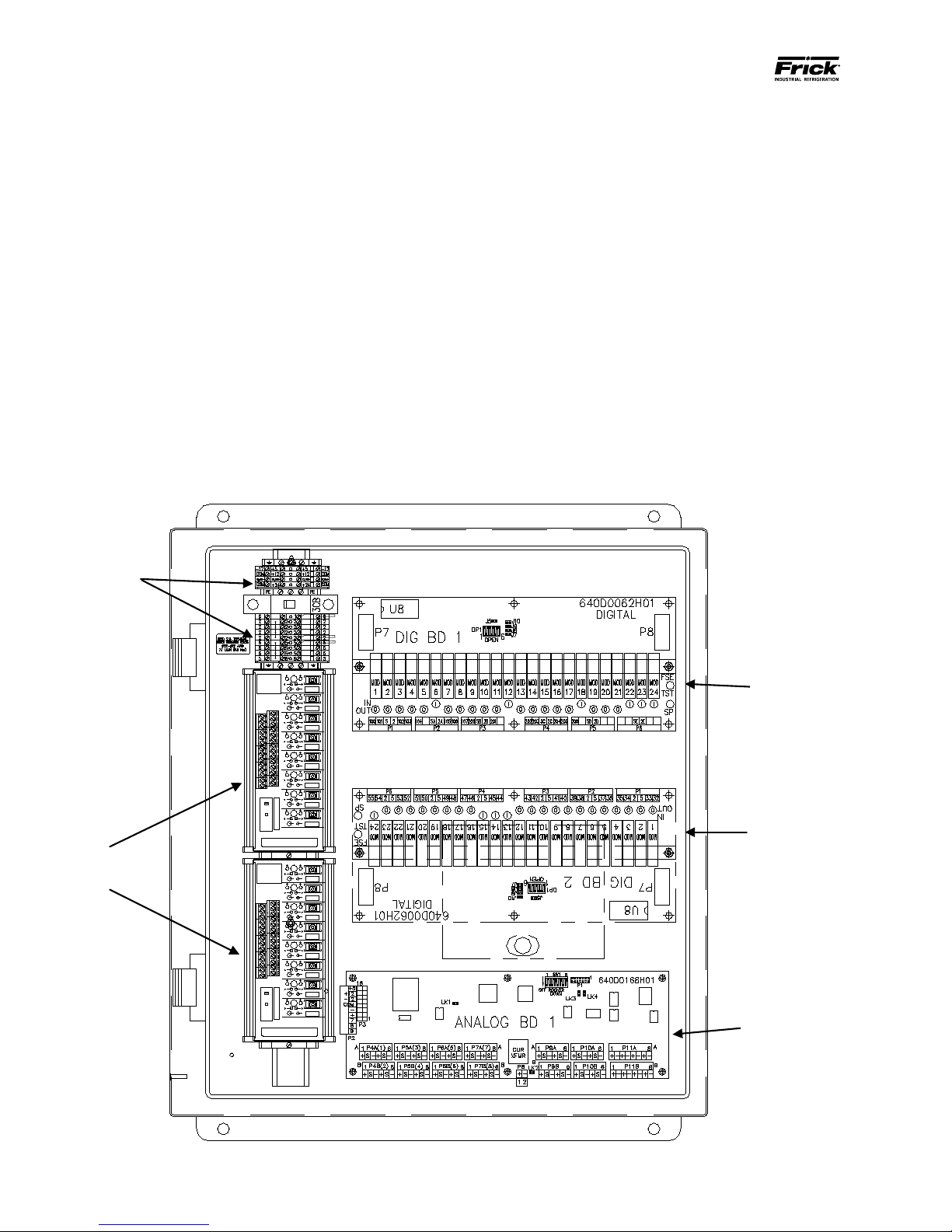

Field and panel

wiring

HOA

Modules

Analog

Board

Digital

Board

Optional

Digital Board

Page 10

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

THE EVAPORATOR REMOTE PANEL ENCLOSURE

DESCRIPTION

Both versions of the Evaporator control panel, Q4 and

Q5, utilize the same Remote panel. With the Quantum™

LX Evaporator system version 3.0x and later, a single

Quantum ™ Control Panel can control up to ten remote

panels with each remote capable of handling three

Evaporator units, for a total possible of thirty units. It is

also capable of Ethernet access, which can be viewed

remotely through any web browser, or the optional

®

Frick

Evaporator Operator Interface Panel.

The Frick® Quantum™ LX Remote panel enclosure

utilizes available space efciently. The panel is also

equipped with the necessary posts and hardware to

add options in the eld. Each Remote panel is congured with one Digital and one Analog board, and a

second Analog board may be present depending upon

installed options.

There are additionally two HOA (Hands Off Automatic)

boards installed, which allow for overriding the automatic function of the control by allowing the user to

manually operate outputs.

The DC power/communications harness in this panel

is color-coded. This will make wire identication much

easier. The coding is as follows:

• +5VDC - RED

• +12VDC - YELLOW

• -12VDC - PURPLE

• Common/Ground - BLACK

• +RX/TX - BLUE

• -RX/TX - BLUE w/WHITE stripe

Page 11

QUANTUM™ LX EVAPORATOR CONTROL PANEL

Power

AC Input

DC

Output

-12 RET RET +5 +5 +12

MAINTENANCE

POWER SUPPLY FOR THE REMOTE PANEL

090.610-M (MAY 2016)

Page 11

DESCRIPTION

CAUTION! Measuring the power supply voltages

require the control power to be energized. Extreme

care must be observed when taking any readings, as

120 VAC is present within the power supply.

The Remote panel power supply is mounted on the

inside at the top of the panel, as shown at the bottom

of this page. A three-pin connector provides 120 VAC

power to the supply, and a six-pin connector delivers

DC power out of the supply. These connections are of

a push-on multiple contact connector type. This power

supply is not adjustable.

EVAPORATOR REMOTE PANEL POWER

The Evaporator Remote Panel utilizes the +5 VDC, +12

VDC and – 12 VDC voltages from its power supply. To

perform measurements on the power supply voltages,

use a reliable, calibrated Digital Volt Meter (DVM). The

DVM should be accurate to 1/100 of a volt DC. Turn the

control power switch to ON.

Measure the voltages on the power supply at the DC

output connector as shown below.

Power supply is located at the inside top of the Remote Panel

Page 12

090.610-M (MAY 2016)

Page 12

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

Page 13

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

SECTION 3

Q5 CONTROLLER

090.610-M (MAY 2016)

Page 13

Page 14

090.610-M (MAY 2016)

Page 14

QUANTUM™ LX EVAPORATOR CONTROL PANEL

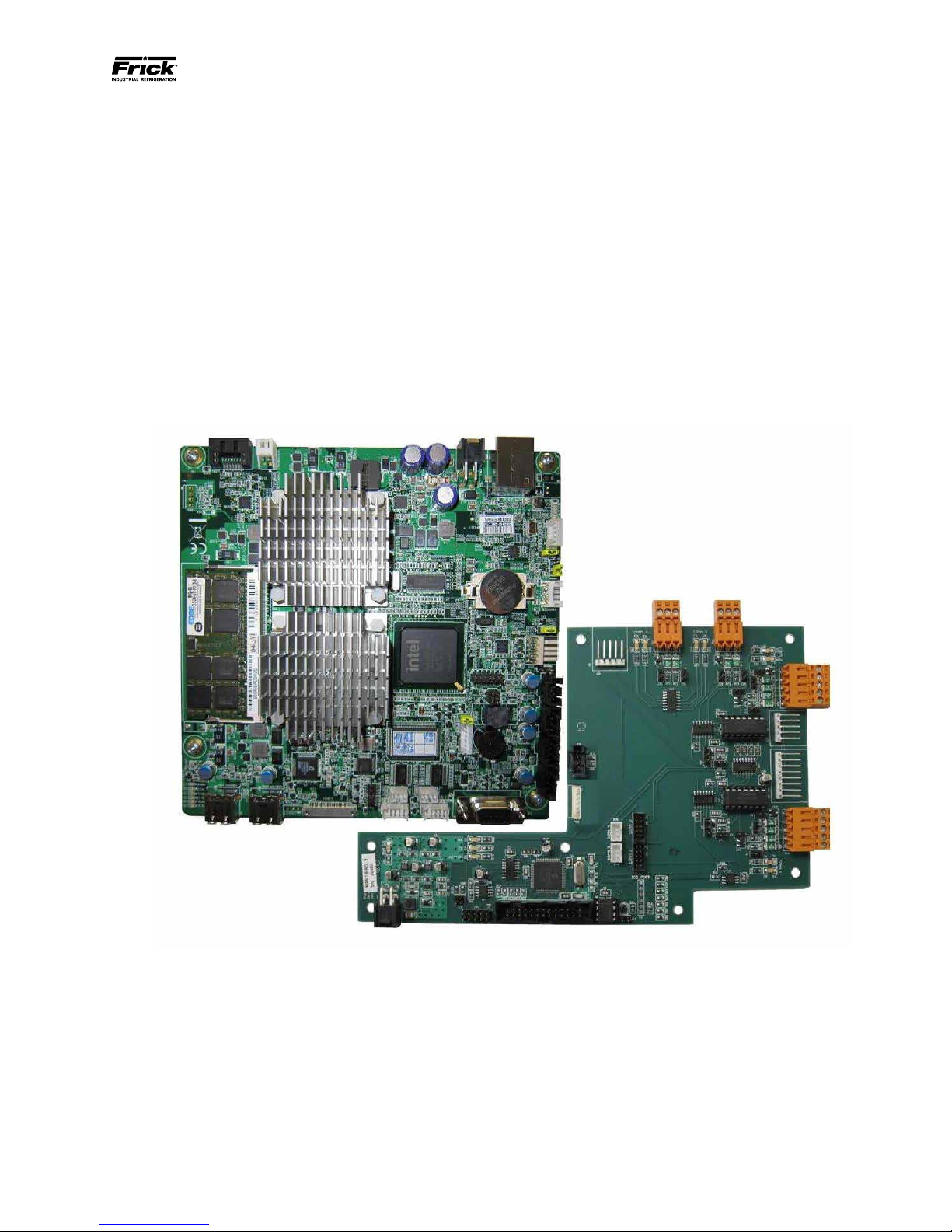

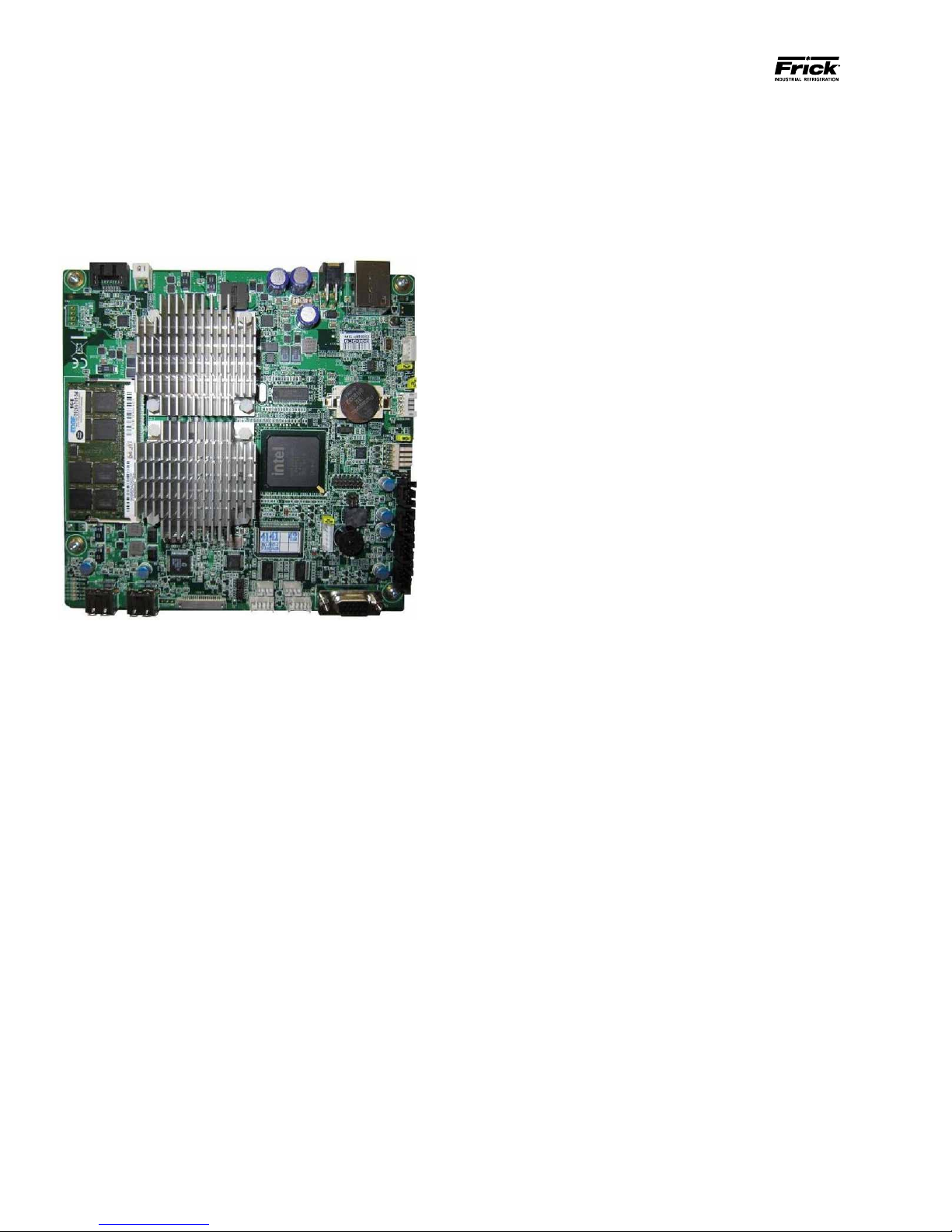

Q5 CONTROLLER BOARD

INTRODUCTION

Frick® Controls has released the latest version of the

Quantum ™ LX microprocessor board. This brand will

be referred to as the Q5. A photo of this board appears

here:

MAINTENANCE

• Just before fully booting, a Loading bar will

appear at the bottom of the screen, showing

the percent of load that has completed.

• The Operating Status screen will appear.

After the Q5 has properly powered up, the following

sequence of events is indicative of proper communication to the analog and digital boards:

• The Analog and Digital I/O boards TX/RX lights

should be blinking.

• Each I/O board should have the power LED

lighted and the Active LED should be blinking.

• The rst thing that should be checked when

troubleshooting the Q5 board is its powering

up sequence.

FEATURES

The Q5 board includes the following features:

• 6 total USB ports (2 are dedicated, 4 are available)

• 10/100/1000 Mbps Ethernet Connection

• 2 RS-422 ports

• 2 RS-485 ports

• External Video monitor connection

• LED indicators to verify proper operation of

various on board areas (power, communications, Ethernet connectivity, etc.)

• 2 GB RAM memory

• Battery to maintain date and time

WHAT SHOULD OCCUR WHEN APPLYING POWER

When powering up, the following sequence of events

are indicative of a properly working main processor

board:

• The six LED’s in the lower left corner should

turn on solid.

WHAT IF THE OPERATING STATUS SCREEN IS NOT

SHOWN

If the Operating Status screen is not shown, check the

following items:

1. If no LED’s are lit, then check AC and DC power. Refer to the Power Supply section.

2. Check if the lighting of the LED’s is occurring

as described in the What Should Occur When

Applying Powering section.

• If the powering up sequence continues to repeat without displaying the

Operating Status screen, then there

is a booting problem.

3. Check all plugged connectors for proper seating.

4. Check if an error message is displayed when

booting.

• Be sure to write down any error

messages exactly as they appear,

as well as the top line on the screen

where the message appears.

5. Check that the software is OK:

• Is the correct software installed?

• The on-board “buzzer” should “beep” once.

• The display should show several DOS (text)

style screens. A penguin image will appear

in the upper left corner of the screen as the

boot sequence progresses.

• Did you just install new software?

Page 15

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

090.610-M (MAY 2016)

Page 15

6. Check the display. If the Q5 board is booting

but you have no display, check the following:

• Check the backlight tube. Look very

closely at the display to see if anything is visible in the dark screen.

Using a beam type source of good

lighting, such as a ashlight, look for

any ghost type image. If it appears

that there is something on the screen

but very dark, the problem may be

with the backlight tube. There is

a sticker on the display mounting

plate, that will have a part number

that describes the type of display. If

there is no sticker, you must take the

display apart to identify the display

manufacturer.

• Verify that both the display cable and

the inverter cable are rmly seated.

It may be necessary to remove the

video cable from the back of the display and re-seat it to be sure it is

connected properly. Note: This is a

small connector and caution should

be observed so that it is not damaged due to excessive force.

To replace the battery, ensure that the Control Power

switch has been turned OFF.

Locate the Battery socket, as shown on the following

drawing:

Place your ngernail under the edge of the battery, and

gently lift up. The battery should release itself from the

socket easily. Take a new battery and place it into the

holder in the same orientation as the old battery (the

side with the writing must be facing out). Return the

Control Power switch back to ON.

Once the Q5 has rebooted, the correct Date and Time

must be set.

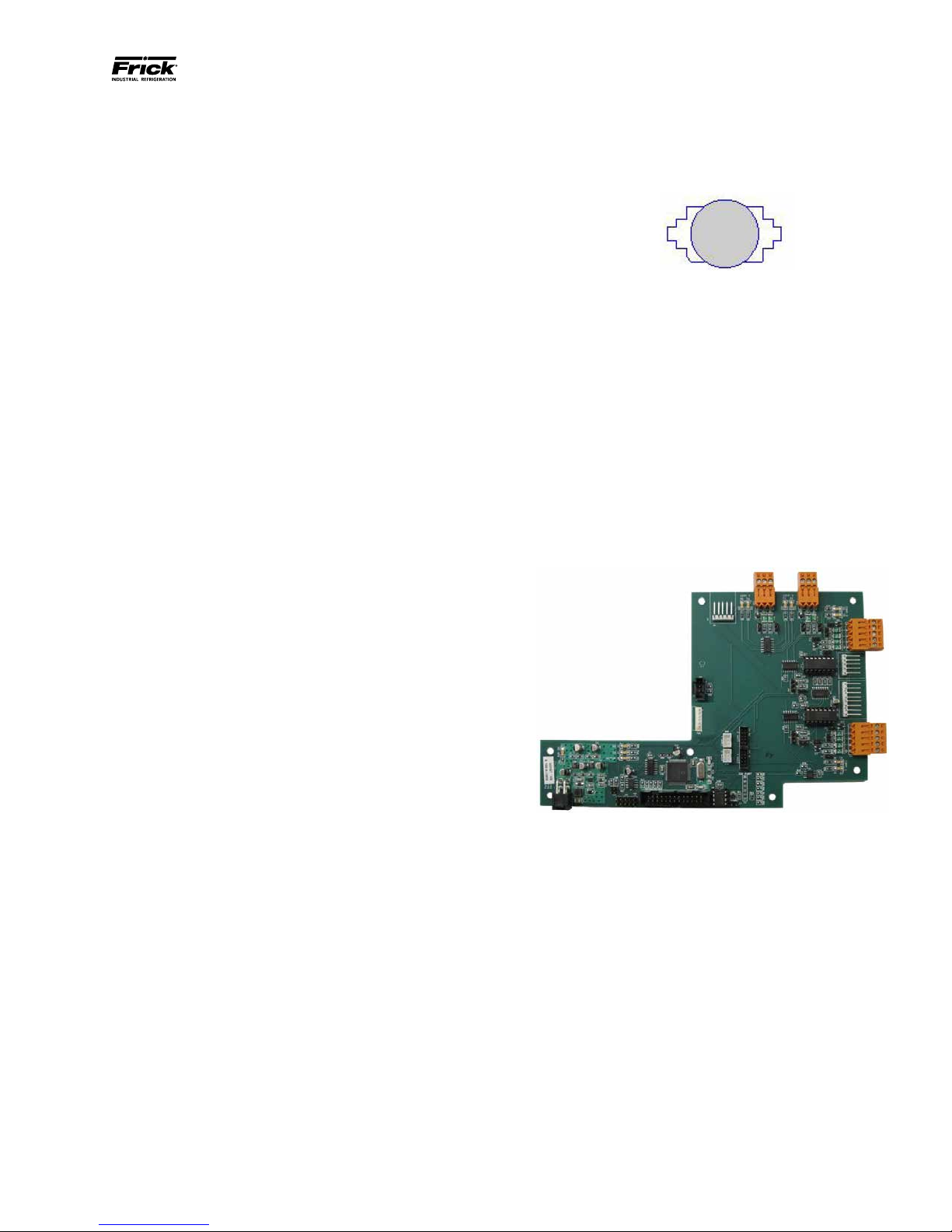

Q5 INTERFACE BOARD

An interface board has been developed by Frick controls allowing the user to interface exterior connections to the Q5. A photo of this interface board is

shown here:

• Refer to the Operator Interface section and check that the display, display cable, and software versions are

matched correctly.

BATTERY FUNCTION AND REPLACEMENT

The Q5 board utilizes a battery to maintain correct date

and time for the purpose of stamping warnings and

shutdowns with the date and time that they occurred.

If the date and time are not being maintained properly,

this may indicate that the battery is not functioning,

and should be replaced. The battery may be ordered

through Baltimore Parts (P/N 333Q0001786) or may be

purchased at most electronic shops (manufacturers P/N

CR-2032).

The battery is fully assessable, but is surrounded by

sensitive electronic components, so care should be

taken when changing.

Page 16

090.610-M (MAY 2016)

JLVDS2

POWER

LVDS1

CRT1

COM1

COM2

FUSE

DIMM1

CN_POWER1

USB

ETHERNET

CMOS1

Flash Card located

Page 16

QUANTUM™ LX EVAPORATOR CONTROL PANEL

Power Connector

MAINTENANCE

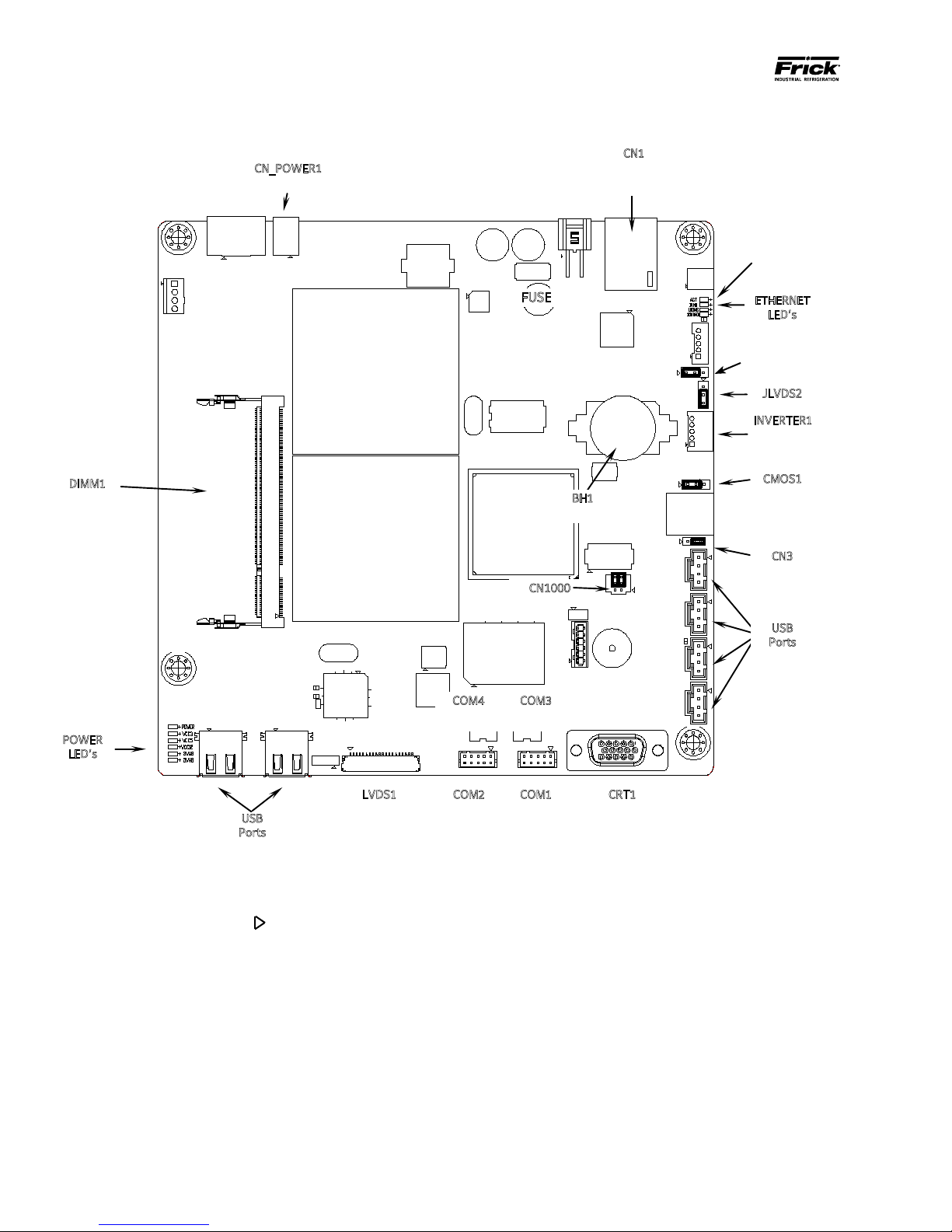

Q5 BOARD

BH1

Battery

CN1

Ethernet

Connector

under the board

here

LED’s

JLVDS3

(See Note 4

below)

JLVDS3

INVERTER1

Inverter

Connector

CN3

CN1000

Ports

LED’s

USB

Ports

NOTE 1: The triangle symbol ( )

COM4

RS-485

Video Connector

RS-232

denotes Pin 1 on connectors. Refer to the chart on the following page for jumper settings.

COM3

RS-485

RS-232

Video Monitor

NOTE 2: Do NOT remove the CN4 jumper. Removal of this jumper will cause the processor to not power up.

NOTE 3: Although the Q5 board is the main controller, most of customer connections will be to the Interface board, as

shown later.

NOTE 4: Ensure that this jumper is installed between pins 1 and 2 if a display is used that requires an inverter board. Install

the jumper between pins 2 and 3 for an LED display that does not use an inverter board. See also the jumper table on the

next page for JLVDS3.

Page 17

QUANTUM™ LX EVAPORATOR CONTROL PANEL

1 2 3

1 2 3

1 2 3

2

1

1

2

3

2

5

1

1

2

1

1 2 3

2

1

1 2 3

MAINTENANCE

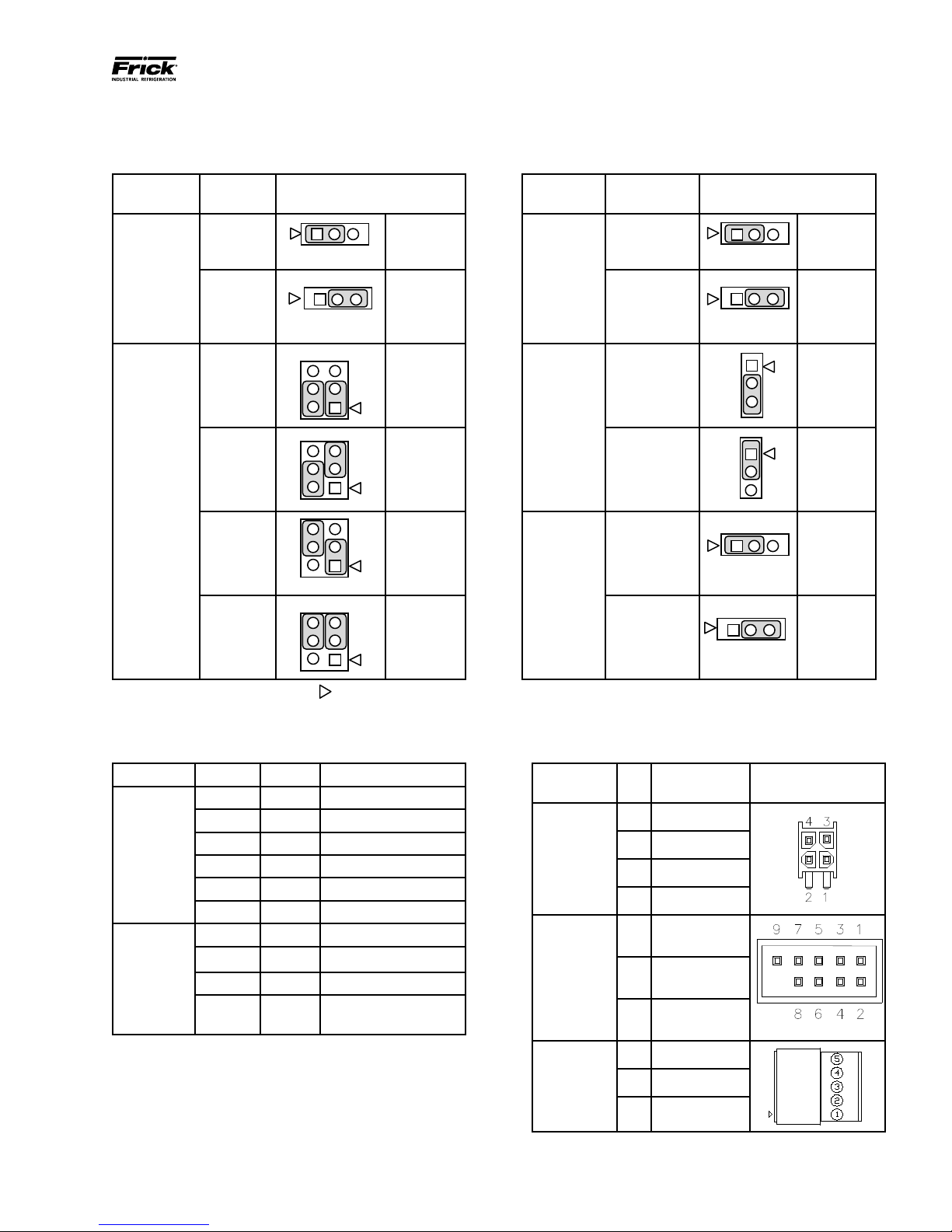

Q5 BOARD JUMPERS, LED’S AND CONNECTORS

JUMPER TABLE

090.610-M (MAY 2016)

Page 17

Jumper

Title

CMOS1

(CMOS

Clear)

CN1000

(LCD

Resolution

Selector)

Function Jumper Setting

Normal

(default)

Closed

Clear

CMOS

24-bit

800x600

24-bit

1024x768

18-bit

800x600

18-bit

640x480

(default)

1 2 3

6

4

6

4

6

4

2

6

4

Closed

1-3 Closed

5

3

2-4 Closed JLVDS2

3-5 Closed

3

2-4 Closed

5

1-3 Closed

3

4-6 Closed JLVDS3

3-5 Closed

5

3

4-6 Closed

1 - 2

2 - 3

&

&

&

&

Jumper

Title

CN3

(Touch

Panel Type

Selector)

(Backlight

Level Se-

lector)

(Backlight

Control

Mode)

Function Jumper Setting

5-Wire

Touch

Screen

8-Wire

Touch

Screen

(default)

0 – 5V

(default)

0 – 2.5V

3

Voltage

Mode - use

with inverter

(default)

PWM Mode

(Use for LED

display - no

inverter)

1-2 Closed

2-3 Closed

2-3 Closed

1-2 Closed

1-2 Closed

2-3 Closed

NOTE 1: The triangle symbol (

NOTE 2: Jumper CN4 is not shown on this chart, as it must always be installed.

LED DEFINITION TABLE

LED Title Label Color Function

LED1 Red 5VSB

LED2 Red 3VSB

Power

LED’s

LED3 Green VCC 12V

LED4 Green VCC 5V

LED5 Green VCC 3V

LED6 Blue Power On OK Status

1000MB Green Giga – LAN Speed

CN1000

(LCD

Resolution

Selector)

100MB Yellow 100MB - LAN Speed

10MB Red 10MB –LAN Speed

ACT

Green

(Blinks)

) denotes Pin 1 on connectors.

LINK Activity

CONNECTOR PINOUT TABLE

Connector

Pin Function

Title

1 Ground (GND)

CN_PWR1

2 Ground (GND)

(Power

Input)

3 VCC 12V

4 VCC 5V

COM1 &

2 Receive (RX)

COM2

(RS-232

3 Transmit (TX)

Communi-

cations)

COM3 &

5 Ground (GND)

1 -RX/TX

COM4

(RS-485

Communi-

cations)

2 +RX/TX

3 Ground (GND)

Page 18

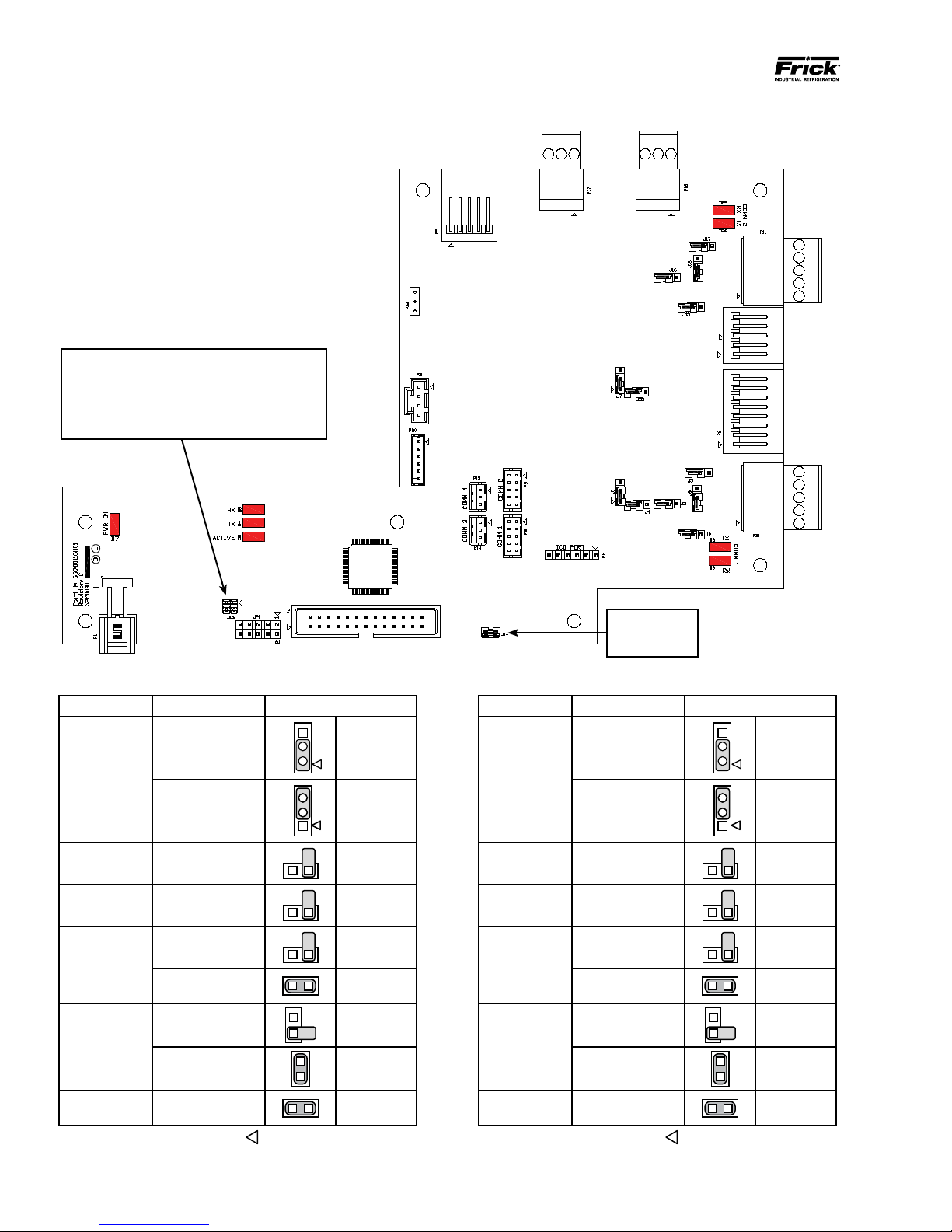

090.610-M (MAY 2016)

2

1

2

1

Page 18

Baud Rate Jumpers

J15 Not Installed = 19200 (Default)

J15 Pins 1-2 Installed = 38400

J15 Pins 3-4 Installed = 56K

J15 Pins 1-2 and 3-4 Installed = 115K

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

Q5 INTERFACE BOARD

COMM

4

COMM

3

COMM

2

COMM

1

COMM 1 JUMPER SETTINGS COMM 2 JUMPER SETTINGS

Jumper Title Function Jumper Setting

3

RS-422 (4-Wire)

Default

J1

RS-485

(2-Wire)

J2

J3

Pull Down

Default

Pull Up

Default

RS-422

J5

Default

RS-485

RS-422

Default

J6

RS-485 1 - 2 Closed

3

2

1

1 - 2 Closed

2 - 3 Closed

1 Pin Only

1 Pin Only

1 Pin Only

1 - 2 Closed

1 Pin Only

Do Not

Remove J14

Jumper Title Function Jumper Setting

3

3

2

1

1 - 2 Closed

2 - 3 Closed

1 Pin Only

1 Pin Only

1 Pin Only

1 - 2 Closed

1 Pin Only

J7

J13

J16

J17

J18

RS-422 (4-Wire)

Default

RS-485

(2-Wire)

Pull Down

Default

Pull Up

Default

RS-422

Default

RS-485

RS-422

Default

RS-485 1 - 2 Closed

J4

High Speed Target

Default

NOTE: The triangle symbol ( ) denotes Pin 1 on connectors.

1 - 2 Closed

J22

High Speed Target

Default

1 - 2 Closed

NOTE: The triangle symbol ( ) denotes Pin 1 on connectors.

Page 19

QUANTUM™ LX EVAPORATOR CONTROL PANEL

090.610-M (MAY 2016)

MAINTENANCE

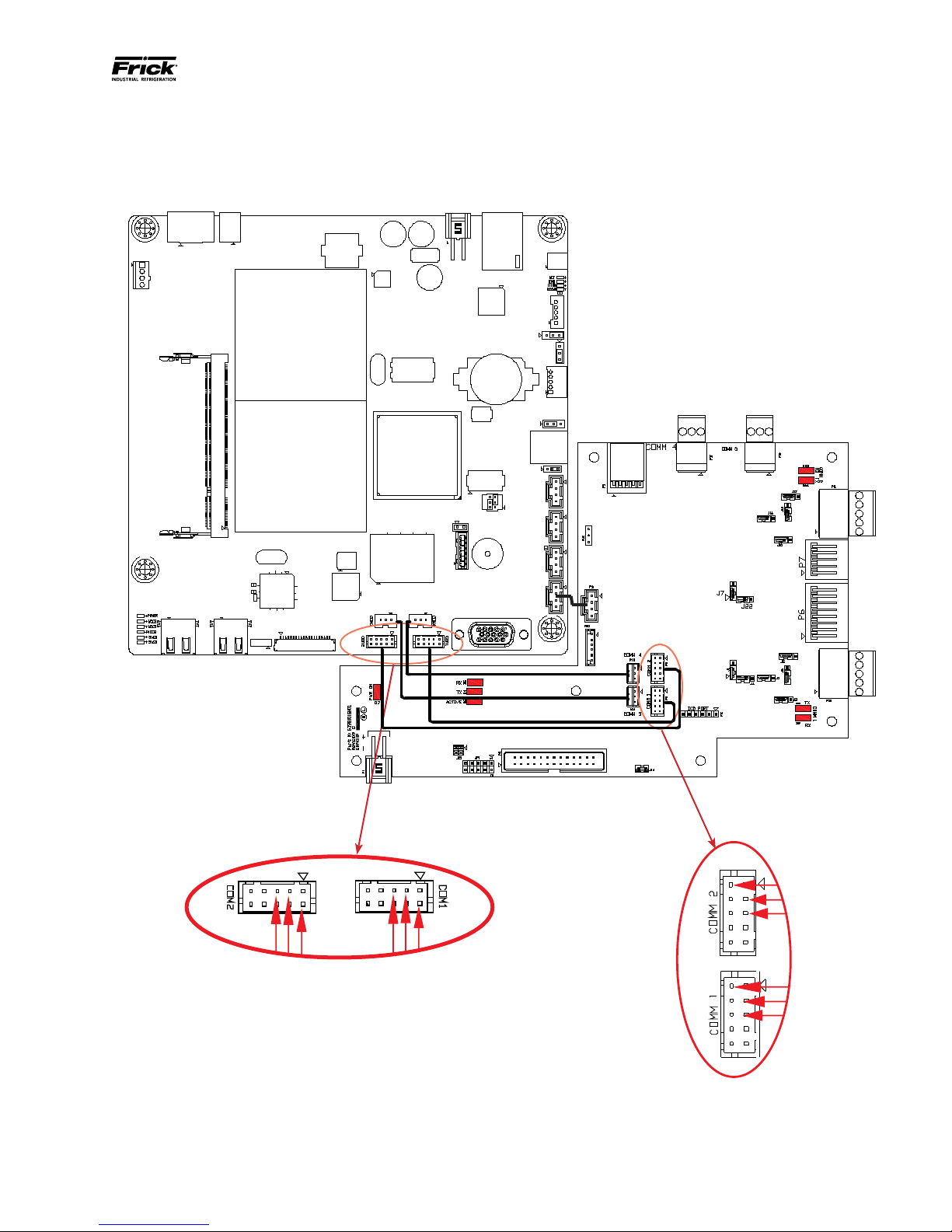

Q5 INTERCONNECTIONS

The pictorial below depicts the Q5 motherboard, and the necessary interconnects between it and the Interface

Page 19

If the harness for either

COMM1 or COMM2 is

ever removed for either

repair, replacement or

troubleshooting, ensure

that the pinout matches

as shown here when

plugging the ends back

in. All other Interconnec

tion harness ends share

the same pinout at both

ends.

-

Page 20

090.610-M (MAY 2016)

Page 20

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

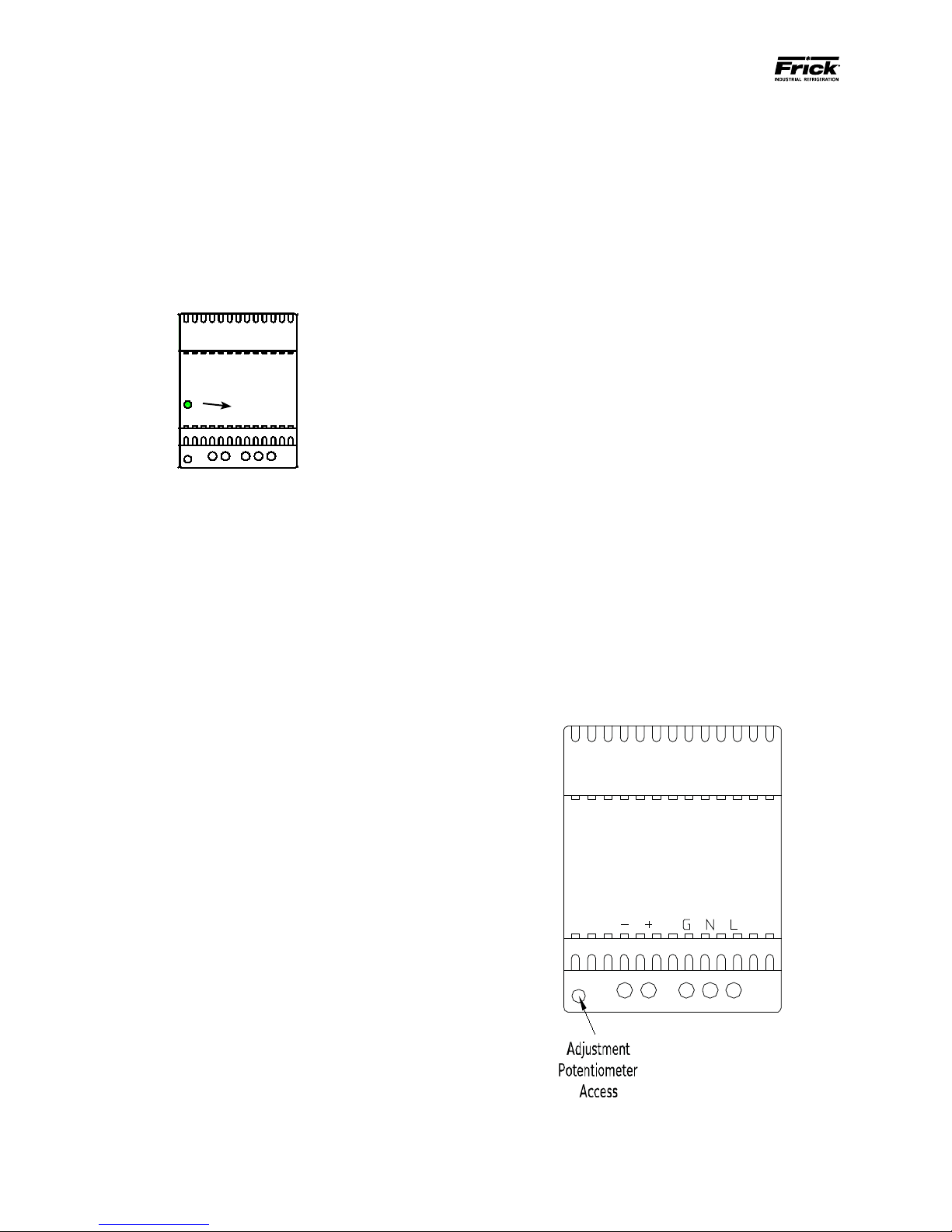

POWER SUPPLY (Q5)

DESCRIPTION

The power supply of the Q5 control panel consists a

single, 12 volt DC supply, and is located on the DIN rail

at the back of the enclosure.

The supply is adjustable and has an indicator to show

that it is powered. Refer to the following page for the

location for the adjustment.

Power ON

Indicator

12 Volt DCPower Supply

POWER DISTRIBUTION

12 Volt DC Power is distributed to the Q5 processor

board and Interface Board.

MEASURING VOLTAGES

CAUTION! Measuring and adjusting the power supply

voltage requires the control power switch to be energized. Extreme care must be observed when taking any

readings, as 120 or 230 VAC (depending on incoming

system voltage) will be present next to the DC voltage connector. Adjusting the supply requires the use

of a small Philips screwdriver inserted into the supply

to access an adjusting potentiometer. CAUTION: It is

possible for the screwdriver (and the person making the adjustment) to come into contact with potentially lethal voltages. Proper Personal Protective

Equipment (PPE) measures need to be observed.

• LED’s on the Q5 are lit, but nothing appears on

the display.

To perform measurements and adjustments on the

power supply voltage, use a reliable, calibrated Digital Volt Meter (DVM). The DVM should be accurate

to 1/100 of a volt DC. With the control power switch

turned ON, wait until the Operating Screen appears.

This is because the graphics required to create this

screen will draw more current than when the screen is

showing the normal POST (DOS) style messages during

a boot up. If the screen never appears however (possibly due to a voltage problem), you will need to proceed

regardless of what is or is not displayed.

In order to properly measure the DC power system, it

must be checked at the DC power supply.

ADJUSTMENT

Ensure that the meter is set to the proper range (DC,

0-50 V or equivalent), as well as observing proper wire

polarity. The power supply drawing shown on the following page applies to all three power supplies. The

adjustment access hole for each supply is located on

the lower left of the front of the supplies. If an adjustment is required, use a thin, Philips screwdriver, insert

the tip into the access hole for the appropriate voltage

potentiometer (refer to the diagram on the following

page for adjustment location). NOTE: Extreme care

must be used when adjusting the potentiometer.

Adjustment should only be performed by qualied

personnel. The use of a non-conductive device is

recommended.

All circuit boards within the Q5 control panel require

accurately adjusted DC voltages in order to function

properly. Periodic measurement and adjustment of the

DC power system is recommended for optimum system operation. Over time, it is possible for temperature, humidity, vibration and component age, to degrade the accuracy of these voltages. When any of the

DC voltages begin to stray from their optimum range,

mysterious problems can begin to arise.

Even with a perfectly adjusted supply, it is possible for

a potential drop in voltage at each connection point.

This drop normally is in the millivolt range, but under some conditions, the drop can be much greater (as

high as tenths of a volt). Some examples of problems

could be:

• Loss of or intermittent communications failures.

• Q5 reboots for no apparent reason.

+ -DCG N L

120 VAC

or

240 VAC

Page 21

QUANTUM™ LX EVAPORATOR CONTROL PANEL

+12 VDC Adjustment

Locate the DC power supply terminals. Place the

negative lead on - and the positive lead on +.

Verify that the DVM is displaying in the range of

+12.10 to +12.20.

If adjustment is required, locate the adjustment

access hole on the +12 VDC supply, as previously

shown. While watching the DVM, slowly rotate

the screwdriver blade clockwise to increase the

voltage or counter-clockwise to decrease until the

voltage is correctly adjusted.

POWER SUPPLY REPLACEMENT

If the power supply is found to be bad, or not capable

of acceptable adjustment, the failing supply will need

replacing. Refer to the Recommended Spare Parts list

for the appropriate part number.

MAINTENANCE

090.610-M (MAY 2016)

Page 21

Page 22

090.610-M (MAY 2016)

Page 22

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

Page 23

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

SECTION 4

Q4 CONTROLLER

090.610-M (MAY 2016)

Page 23

Page 24

090.610-M (MAY 2016)

Page 24

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

Q4 CONTROLLER BOARD

INTRODUCTION

Frick® Controls has strived to remain on the cutting

edge of microprocessor technology and development.

Because of the ever-increasing speed, memory features, and power of microprocessors, Frick® will continue to introduce the latest advancement in microprocessor control technology.

• The display should show several DOS (text)

style screens. A penguin image will appear

in the upper left corner of the screen as the

boot sequence progresses.

• Just before fully booting, a Loading bar will

appear at the bottom of the screen, showing

the percent of load that has completed.

• The Operating Status screen will appear.

After the Q4 has properly powered up, the following

sequence of events is indicative of proper communication to the analog and digital boards:

• The Analog and Digital I/O boards TX/RX

lights should be blinking.

• Each I/O board should have the power LED

lighted and the Active LED should be blinking.

WHAT IF THE OPERATING STATUS SCREEN IS NOT

SHOWN

If the Operating Status screen is not shown, check the

following items:

Q4 Board

WHAT SHOULD OCCUR WHEN APPLYING POWER

The rst thing that should be checked when troubleshooting the Q4 board is it’s powering up sequence.

When powering up the Q4, the following sequence of

events are indicative of a properly working main processor board:

• Green PWR (Power) LED will turn on solid.

• Red FLASH LED will ash several times early

in the boot sequence. It is normally not lit.

• LED D8 (on the smaller board) will start to

blink at the rate of about once-per-second. It

will continue to blink after the Q4 has booted.

The only time that this ashing rate is interrupted, is when a key is pressed on the keypad.

1. If no LED’s are lit, then check AC and DC power. Refer to the Power Supply section.

2. Check if the lighting of the LED’s is occurring

as described in the What Should Occur When

Applying Powering section.

• If the powering up sequence continues

to repeat without displaying the Operating Status screen, then there is a booting

problem.

3. Check for bad connections.

4. Check if an error message is displayed when

booting.

• Be sure to write down any error mes-

sages exactly as they appear.

5. Check that the software is OK:

• Is the correct software installed?

• Did you just install new software?

6. Remove Flashcard and reboot. This will cause

the Q4 to boot under a pre-LX operating

software. If it boots properly under this older

software, then trying re-booting from the

Flashcard again. If it doesn’t boot with the

card, then the Flashcard could be corrupted,

and needs to be replaced.

Page 25

QUANTUM™ LX EVAPORATOR CONTROL PANEL

Battery Release

MAINTENANCE

090.610-M (MAY 2016)

Page 25

7. Check the display. If the Q4 board is booting but

you have no display, check the following:

• Check the backlight tube. Look very closely

at the display to see if anything is visible in

the dark screen. Using a beam type source of

good lighting, such as a ashlight, look for any

ghost type image. If it appears that there is

something on the screen but very dark, the

problem may be with the backlight tube. On

the LG Philips, NEC and Sharp displays this

tube is eld replaceable. On the Samsung display it is not available and the display will have

to be replaced. There may be a sticker on the

display mounting plate. If there is, it will have

a part number that describes the type of display. If there is no sticker, you must take the

display apart to identify the display manufacturer.

• Verify that both the display cable and the in-

verter cable are rmly seated. These cables

both originate from the same connector on

the Q4. It may be necessary to remove the

video cable from the back of the display and

re-seat it to be sure it is connected properly.

Note: This is a small connector and caution

should be observed so that it is not damaged

due to excessive force.

BATTERY FUNCTION AND REPLACEMENT

The Q4 board utilizes a battery to maintain correct

date and time for the purpose of stamping warnings

and shutdowns with the date and time that they occurred. If the date and time are not being maintained

properly, it may indicate that the battery is not functioning, and should be replaced. The battery may be

ordered through Baltimore Parts (P/N 333Q0001786) or

may be purchased at most electronic shops (manufacturers P/N CR-2032).

The battery is partially covered by the communications

daughter board, and is located directly beneath the

COM1 port (it may be necessary to unplug any connector that is plugged into COM1 to fully access the

battery).

To replace the battery, ensure that the Control Power

switch has been turned OFF.

Locate the Battery Release Clip on the following drawing:

Clip

• Refer to the Operator Interface section and

check that the display, display cable, and software versions are matched correctly.

Battery

Battery

Holder

Simply push the clip away from the battery, to release

the battery from the holder. Remove the battery, observing the orientation. Take a new battery and place

it into the holder in the same orientation as the old

battery (the side with the writing must be facing out).

Reinstall the COM1 plug (if removed), and return the

Control Power switch back to ON.

Once the Q4 has rebooted, the correct Date and Time

must be set.

Page 26

090.610-M (MAY 2016)

Page 26

RS-422/485

RS-422/485

USB Connector

(Depending on board version,

USB could be located in either

of these two locations.

COM-3

(PL6)

RS-232

connector

COM-1

(TB1)

LK2

PL1

RS-422/485

connector

PL2

3.3 Volt

Battery

PL3

COM-2

COM-2

(TB2)

(TB2)

connector

connector

PL5

PL7

LK1

PL

Flash Card Socket

(located under

board)

LK4

A

LK3

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

Q4 BOARD

+5VDC

Power

PL

9

PL8

COM-1

4

3

2

1

TB1

A

B

LK

TB2

7

LK

LK

5

4

6

3

2

1

COM-2

COM-2

PL

B

11

PL

12

PL10 PL6

RS-

422

LK2

RS-

422

LK1

TB3

LK

10

LK

LK

LK

LK

LK

RET / GND

+12VDC

PL13

PL14

COM1

(TX)

COM1

(RX)

9

8

A B

7

COM2

(TX)

LK

6

LK

5

A

4

3

RS-232

2

3

PL

15

-RX/-TX (I/O Boards)

+RX/+TX (I/O Boards)

PL

17

PL

18

LK9

LK8

POR

T

80H

D4 D5 D7

D3

D2

LK16

D1

B

LK17

1

Baltimore Parts with LK4

set to B position for an

4

1

3

2

0

D11

D1

D9

0

COM2

(RX)

B A

KB

This assembly is

shipped from

LG Philips Display.

If using a Samsung,

NEC or Sharp

Display, set LK4

to position A.

LX panels use

the Sharp display.

PL

19

PL

24

LK12

P

PL16

5

6

7

ON

D13

D1

8

2

7

SW1

6

LK11

W

SU

FL

SP

AS

H

PL2

D6

LK11

PL4

D8

PL

PL1

3

Keypad

Cable

Communications Board

(small top board)

COM-2

(TB3)

RS-232

connector

Display

Cable

CAT-5 Ethernet

NOTE: There are duplicate numbers for the links on the processor (larger) board and the communications (smaller)

board. If you must make a change to a jumper (link), ensure that you modify the correct link.

Processor Board

(large botom board)

Controller Board Pictorial

Page 27

Processor Board Jumpers

2 second Watchdog timer timeout

LK1

LK2

LK3

LK4

LK5

LK6

LK7

LK8

LK9

LK10

LK11

LK12

* Standard Setting

in

8 second Watchdog timer timeout

out*

Watchdog timer Enabled

in*

Watchdog timer Disabled

out

+5V Backlight Voltage (not used)

A

+12V Backlight Voltage (all displays)

B *

+5V Supply (Samsung, NEC, Sharp)

A

+3.3V Supply (LG Philips & Sharp LED Display)

B *

COM4 IRQ3

A

COM4 IRQ10

B *

COM3 IRQ4

A

COM3 IRQ11

B *

Battery Backup Enabled

A *

Battery Backup Disabled (CMOS Cleared)

B

RS-485 Receiver Enabled

in*

RS-485 Receiver Disabled

out

RS-485 Terminated

in*

RS-485 Not Terminated

out

RS-422 Terminated

in

RS-422 Not Terminated

out*

Bit 1 of 259H “Logic 1” User Application Link

in*

Bit 1 of 259H “Logic 0” User Application Link

out

Bit 2 of 259H “Logic 1” User Application Link

in*

Bit 2 of 259H “Logic 0” User Application Link

out

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

Q4 BOARD SETTINGS

090.610-M (MAY 2016)

Page 27

Communications Board Jumpers

Com-1 (TB1)

in

LK2

LK7

LK8

LK9

LK10

LK16

* Standard Setting

Terminate COM1

out*

No termination

in

Pull down COM1

out*

No pull down

in

Pull up COM1

out*

No pull up

in

Pull down COM1

out*

No pull down

in

Pull up COM1

out*

No pull up

AB*COM1 RS-422 (TB1)

COM1 RS-485 (TB1)

Com-2 (TB2 - TB3)

LK1 in

LK3 in

LK4 in

LK5 in

LK6 in

LK11 A

LK17 A

* Standard Setting

Terminate COM2

out*

No termination

Pull down COM2

out*

No pull down

Pull up COM2

out*

No pull up

Pull down COM2

out*

No pull down

Pull up COM2

out*

No pull up

Select RS-232 for COM2 (TB2)

B*

Select RS-422/RS-485 for COM2 (TB3)

COM2 RS-422 (TB2)

B*

COM2 RS-485 (TB2)

RS-422/485

RS-422/485 (Rx-/Tx-)

RS-422/485 (Rx-/Tx+)

RS-422 (Tx-)

RS-422 (Tx+)

RS-422/485

RS-422/485 (Rx-/Tx-)

RS-422/485 (Rx-/Tx+)

RS-422 (Tx-)

RS-422 (Tx+)

Page 28

090.610-M (MAY 2016)

+5 VDC

Common

+12 VDC

+5V

RET

AC Input

DC

Output

RET RET +5 +12

Page 28

QUANTUM™ LX EVAPORATOR CONTROL PANEL

EVAPORATOR LX CONTROL PANEL POWER

SUPPLY

CAUTION! Measuring the power supply voltages

require the control power to be energized. Extreme

care must be observed when taking any readings, as

120 VAC is present within the power supply.

The Q4 controller utilizes only the +5 VDS and +12

VDC voltages from the power supply. To perform

measurements on the power supply voltages, use a

reliable, calibrated Digital Volt Meter (DVM). The DVM

should be accurate to 1/100 of a volt DC. Turn the

control power switch to ON.

MAINTENANCE

Q4 POWER SUPPLY

Measure the voltages on the power supply at the DC

output connector as shown below:

The following voltage range is considered to be acceptable:

• +5 VDC supply (+5.15 to +5.20 VDC)

• +12 VDC supply (+11.8 to +12.2 VDC)

If the voltages from the power supply are within the

acceptable ranges, then measure them at the Q4 control

board, as shown below:

If the voltages from the power supply are within the

acceptable ranges, then measure them at the last I/O

board in the daisychain, as shown below:

If any of the voltages measure outside of the acceptable

range, yet measured correctly at the power supply,

then a problem with the wiring harness should be

suspected and checked.

REPLACEMENT

If the power supply is found to be bad, or out of

adjustment, it will need replacing.

Page 29

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

SECTION 5

DIGITAL BOARD

090.610-M (MAY 2016)

Page 29

Page 30

090.610-M (MAY 2016)

+5V

RET

Page 30

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

DIGITAL BOARD

INFORMATION

The information that follows in this section can help

locate problems that can occur with Digital Input and

Output circuit boards, and their interaction with the

Q4/Q5 controller.

Therefore, any time that a connector is unplugged from

the daisy-chain, these voltages and signals cannot

continue through the daisy-chain to the next board.

Whenever a plug is not to be inserted into a board,

either for service or if not all boards are present, then

a shunting plug (refer to Replacement Parts list) must

be installed onto the open connector.

DIGITAL BOARD DESCRIPTION

The Digital Boards only require the +5 Vdc voltage

The Digital Board is actually a small microprocessor

board and programmed to control discrete outputs, or

accept discrete inputs, from external electrical devices.

Each Digital Board has the capability of 24 independent

channels or I/O (Input/Output). With the Quantum™

LX Evaporator Control, some of these I/O channels are

dedicated as to their function, through the operating

system (software), enabled options and external wiring.

Each channel that is used by the software will have a

module plugged into it. A yellow module indicates that

it is used for Inputs, a black module is used for Outputs.

The standard Quantum™ LX Evaporator Control can

have up to two Digital Boards (depending on options).

COMMUNICATIONS LED'S

The controller is in constant communication with all

Digital (and Analog) Boards. You will notice on each

Digital and Analog board, that there are a pair of LED’s

labeled as RX and TX. These letters represent Receive

(RX) and Transmit (TX). These LED’s should be ashing

at a high rate during normal operation. This indicates

that the Q5 (or Q4) control board, and the Digital Board

that you are looking at, are properly communicating

with each other.

• Reference the JUMPER AND DIPSWITCH

SETTINGS section later in this manual. This

section contains the dipswitch settings for

addressing the Digital I/O Boards. When

these switches are properly set, the Q5 (or

Q4) board is able to serially communicate

with each I/O board and provide control

signals and data exchange. If these switches

are not properly set, the result will be lost or

failed communications, or the wrong outputs

being energized, or the wrong inputs being

received.

CONNECTIONS TO THE QUANTUM™

The Frick® Evaporator control system utilizes up to two

Digital, and one Analog Boards. To connect all of these

boards together so that the Q4/Q5 can control them,

they must be interconnected with a wiring harness that

provides all of the necessary D.C. voltage requirements,

as well as the communications capabilities. Upon close

examination of this harness, you will notice that each

of the connectors have two rows of connections. The

wires that are inserted into the positions of one row,

are internally daisy-chained on each I/O board, to

continue the voltages and signals to the adjacent row.

and the Return (or common) for logic power. The

communications signals (RX & TX) are required by all

boards.

LOGIC VOLTAGE (POWER) LED

Located on the Digital Board is a Power LED. This LED

will be illuminated as long as the Control Power switch

is ON, and the proper voltage is present at the Remote

panel power supply. The power supply generates the

+5 VDC voltage, and passes it on through the PowerI/O harness. This LED does not indicate however

that the proper voltage is necessarily present at the

board, only that the voltage is enough to energize the

voltage sensing circuitry. If a voltage related problem is

suspected with regard to a Digital Board, the only way

to actually determine this is to read the voltage on a

Digital Voltage Meter (DVM). This may be accomplished

by locating the white power/communications connector

on the board. Notice that the Digital Board has one

of these connectors on both ends of the board. The

associated power/communications harness will only

be plugged into one of these connectors. Take the red

(positive) probe of the DVM and carefully insert the

end into the “+5V” lead, and the black (negative) probe

end into the “RET” (Return or Common) lead, as shown

below:

Set the DVM to read DC, and set the proper range.

The voltage reading must read a minimum of +5.0 Vdc.

The Power-I/O harness will have an associated voltage

drop at each board connection. As an example, if you

are reading the voltage at the rst I/O board in the

daisy-chain, and it reads 4.98 Vdc, you can be assured

that the voltage at the subsequent connections for

the remaining boards will be lower yet. The voltage

will need to be corrected for proper operation of the

system. The cause for a low voltage reading could be:

• The power supply may need adjustment (see

the section on power supplies).

Page 31

QUANTUM™ LX EVAPORATOR CONTROL PANEL

5 4 3

COM OUT VDC

2

1

90-140VAC

120 VAC

4

3

3-8 VDC

2

1

3A 280VAC

120 VAC Output

HOT

NEUTRAL

Position1

Position2

Position3

Position4

MAINTENANCE

090.610-M (MAY 2016)

Page 31

• The Power-I/O communications harness has a

problem (a new harness may be needed).

• A problem may exist with one of the I/O

boards (Digital or Analog).

• If the power LED is not lighted, check the cable

for proper connectivity. Note: Each board

provides the necessary connections to feed

all signals to the following connectors. If the

auxiliary Analog or Digital Board is not present

then a jumper plug (see Recommended Spare

Parts List) must be installed to daisychain the

signals.

The most common symptom that is be exhibited by a

low +5 Vdc voltage to the Digital Boards is an alarm

message that reads Digital Board Reset Shutdown.

ACTIVE LED

The Digital Board(s) have an Active LED indicator on the

board that blinks when the board’s software is running.

If the Active LED is not blinking, check to ensure that

the EPROM is installed properly. The EPROM is located

in chip slot U8, next to the power connector.

DIGITAL INPUTS

A Digital Input is the portion of the hardware that allows

devices such as limit switches, relay contacts, and

level switches, to interface with the Quantum™. The

software program within the Quantum™ is constantly

looking at these Input channels, via communications,

and based upon whether a control voltage is present or

not, will provide the necessary control for an associated

Output channel.

The following pictorial shows a side view of the 120

VAC Input module. The color of an Input module is

yellow:

DIGITAL OUTPUTS

A Digital Output is the portion of the hardware that

the Quantum™ is to control (energize). These devices

include solenoids, relay coils, and heaters to be

energized, based upon the logic within the Quantum™

LX software program.

The following pictorial shows a side view of the 120

VAC Output module. The color of an Output module

is black:

Although this Output module is labeled as 280 VAC on

the top, and on the side, it can be used on both 120 and

240 volt applications.

Never plug an Input module into a position designated

for an Output module.

You will notice that when a module is plugged into the

Digital Board, there is a fuse located directly adjacent

to the module. This fuse is of the plugable variety, and

must be plugged into the OUT position for an Output

module.

CHECKING THE DIGITAL INPUTS AND OUTPUTS

Some problems that may be encountered involve

troubleshooting the digital inputs and outputs. The

Digital I/O (Input / Output) Boards have six Digital I/O

(DIO) board connectors labeled P1 through P6. The Input

and Output modules are wired to a DIO connector plug.

Position 3 provides power and position 4 is a neutral on

the DIO connectors. Positions 1, 2, 5, and 6 are signal

connections, as shown below:

Never plug a 120 Volt Input module into a 240 Volt

system, and vice-versa. Never plug an Output module

into a position designated for an Input module.

You will notice that when a module is plugged into the

Digital board, there is a fuse located directly adjacent

to the module. This fuse is of the plugable variety,

and must be plugged into the IN position for an Input

module.

Signal

Signal

Signal

Signal

The Digital I/O board’s I/O modules are congured by

proper module selection, AC or DC, operating voltage,

input or output, and moving the fuse to the in or out

position. An LED is associated with each module and

displays the state of each module. A lit LED represents

an Input that is High, receiving a signal or an Output

that is On.

If a properly congured Digital I/O is not responding

correctly, rst look at the Digital Board on the Digital

I/O Screen and check if the module is on. If it is not on,

check if the LED on the Digital Board is also not lit. If

the LED is not lit, then check the fuse. If the fuse is OK,

then check the module.

Page 32

090.610-M (MAY 2016)

Page 32

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

FUSE TESTING AND REPLACEMENT

1. Power off the panel.

2. Open the panel door.

3. Remove the questionable fuse.

4. Place the questionable fuse into the fuse tester at

the one end of each Digital I/O Board (refer to the

Digital Board drawings at the end of this section

for exact fuse tester location).

5. Power on the panel.

6. Check the LED on the tester. If the LED is lit, the

fuse is OK.

7. Power off the panel.

8. If the fuse is faulty, check for external shorts on

the corresponding circuit, the replace the fuse

with a new plug-type fuse (refer to Recommended

Spare Parts list).

INPUT AND OUTPUT MODULE TESTING AND

REPLACEMENT

1. Power off the panel.

2. Open the panel door.

3. Replace the questionable module.

4. Power on the panel.

5. If it is an Output module, check for proper panel

voltage on the DIO connector plug. Check the

voltage between position 4 (neutral) and the

associated position to the Output module.

6. If it is an Input module, check if the associated LED

is on when power is applied to the module.

TROUBLESHOOTING AN OUTPUT

1. Make sure the LED associated with the Output is

on when power is applied to the module.

2. If the LED is not on when it should be and there is

no operating condition preventing it, contact the

®

Service Department.

Frick

3. If the LED is on when it should be, check for proper

panel voltage on the DIO connector plug. Check

the voltage between the position 4 (neutral) and

the associated position to the Output module.

4. If the voltage is OK, check for proper panel voltage

between the associated position to the Output

module on the DIO connector and the associated

position on the terminal strip.

5. If the voltage is OK, check the wiring external to

the panel.

6. If voltage is not OK, check the fuse.

7. If the fuse is OK then check the module.

8. If the module is OK, check for proper panel voltage

on the DIO connector plug between position 3

(Hot) and position 4 (neutral).

TROUBLESHOOTING AN INPUT

1. Make sure the LED associated with the Input is on

when power is applied to the module.

2. If the LED is on then the fuse and Input module are

good.

3. If the LED is on and there is no input voltage,

replace the Input module.

4. If the LED is not on when power is applied, check

the fuse.

5. If the fuse is good, replace the Input module.

6. If you are receiving an Alarm or Shutdown from

a digital input in which the adjacent LED indicator

light is on, check the Digital I/O screen to see if

that channel is turning on and off. If so, replace the

input module.

REPLACING A DEFECTIVE DIGITAL BOARD

The procedure to replace a Digital board is outlined

below:

1. Shut off control power.

2. Remove the old board from the machine and

the new board from its packing and place both

on an anti-static surface.

3. Remove any required chip(s) from the

defective board and install them in the

replacement board.

4. Check that all jumpers, dipswitches and

components are properly setup on the new

board using the old board as a reference (refer

to the Digital Settings tables near the end of

this section).

5. Install the modied replacement board in the

panel.

After replacing or installing a Digital Board and powering

on the control panel, select User Level 1 or higher, then

select the Setpoints Menu, then the Communications

Menu. On the Communications Screen is a button

labeled as [Redetect I/O Comms]. Clicking on the

[Redetect I/O Comms] button will cause the controller

to examine the internal I/O communications of the

panel, and initialize all connected boards If a board has

been removed, a communication error shutdown will

be issued until this key is selected. The About screen

will show what was detected.

Page 33

QUANTUM™ LX EVAPORATOR CONTROL PANEL

TEST FUSE HERE.

IF LAMP LIGHTS

SPARE FUSE

P8

D8

1

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

5A

F7

F8

F9

F10

F3

F2

F1

F4

F5

F6

F11

F12

F13

F15

F14

F17

F16

F18

F23

F22

F21

F24

F19

F20

BOARD REVISION L EVEL

BOARD PART NUMBER

Frick

SERIAL #

REVISION

PART # 640D0062H

PROGRAM EPROM

DIO

I/O COMMUNICATION

ACTIVITY LAMPS

D25

TX

D26

RX

D28

ACTIVE

MICROPROCESSOR

WATCHDOG LAMP

(BLINKS IF OK)

M7

D7

M8

M9

D9

M10

D10

M3

D3

M2

D2

M1

D1

M4

D4

M5

D5

M6

D6

M11

D11

M12

D12

M13

D13

M15

D15

M14

D14

M17

D17

M16

D16

M18

D18

M23

D23

M22

D22

M21

D21

M24

D24

M19

D19

M20

D20

1

AMP794068-1

POWER

ON

D29

+5 VOLTS

+12 VOLTS

-12 VOLTS

GND

-RX / -TX

+RX / +TX

BOARD DC POWER

I/O COMMUNICAT IONS

+5 DC

U8

P7

FUSE POSITION DETERMINES

INPUT OR OUTPUT

DIGITAL I/O BOARD

NOTE 1: ALL OUTPUTS ARE RATED FOR A

Liquid (Zone A)

Suction (Zone A)

HOT

NEUTRAL

Hot Gas (Zone A)

Bleed (Zone A)

Liquid (Zone C)

Suction (Zone C)

HOT

NEUTRAL

Hot Gas (Zone C)

Bleed (Zone C)

Aux. Output (Zone C)

Aux. Input (Zone A)

HOT

NEUTRAL

Aux. Input (Zone B)

Aux. Input (Zone C)

Fan (Zone C)

Defrost Initiate (Zone C)

HOT

NEUTRAL

Aux. Output (Zone A)

Aux. Output (Zone B)

Hot Gas (Zone B)

Bleed (Zone B)

HOT

NEUTRAL

Fan (Zone B)

Defrost Initiate (Zone B)

Fan (Zone A)

Defrost Initiate (Zone A)

HOT

NEUTRAL

Liquid (Zone B)

Suction (Zone B)

1

P5

1

P4

1

P2

1

P1 1 P3

1

P6

IN

OUT

IN

IN

OUT

IN

IN

OUT

OUT

IN

IN

OUT

IN

OUT

OUT

OUT

IN

IN

OUT

OUT

IN

IN

OUT

IN

OUT

OUT

IN

IN

OUT

IN

IN

OUT

IN

OUT

OUT

OUT

OUT

OUT

INSTALLED

FUSE

SPARE

FUSE

D27

FUSE TESTER

1

AMP794068-1

COMMUNICATION S JUMPERS

OPEN

DIPSWITCH SETTINGS S IGNIFY

DP1

J5

J7

J8

J9

J10

MAINTENANCE

DIGITAL I/O BOARD PICTORIAL

090.610-M (MAY 2016)

Page 33

INPU T MODULE

OUTPUT MODULE

FUSE

MAXIMUM 2 AMP LOAD.

OUT

IN

IN

OUT

OUTPUT MODULE

OUTPUT MODULE

OUTPUT MODULE

OUTPUT MODULE

OUTPUT MODULE

INPUT MOD ULE

OUTPUT MODULE

OUTPUT MODULE

OUTPUT MODULE

OUTPUT MODULE

OUTPUT MODULE

INPUT MOD ULE

OUTPUT MODULE

OUTPUT MODULE

OUTPUT MODULE

OUTPUT MODULE

OUTPUT MODULE

IN

INPU T MODULE

OUTPUT MODULE

OUT

OUT

IN

IN

IN

5A

OUTPUT MODULE

OUTPUT MODULE

INPUT MOD ULE

INPUT MOD ULE

INPUT MOD ULE

Page 34

090.610-M (MAY 2016)

Quantum™ LX

Control Board

Comm. 4

(Zones

1-15)

Comm. 3

(Zones

16-30)

I/O Group 1

Zones 16, 17, 18

Digital Board

Digital Board

Analog Board

I/O Group 2

Zones 19, 20, 21

Digital Board

Digital Board

Analog Board

I/O Group 3

Zones 22, 23, 24

Digital Board

Digital Board

Analog Board

I/O Group 4

Zones 25, 26, 27

Digital Board

Digital Board

Analog Board

I/O Group 5

Zones 28, 29, 30

Digital Board

Digital Board

Analog Board

I/O Group 1

Zones 1, 2, 3

Digital Board

Digital Board

Analog Board

I/O Group 2

Zones 4, 5, 6

Digital Board

Digital Board

Analog Board

I/O Group 3

Zones 7, 8, 9

Digital Board

Digital Board

Analog Board

I/O Group 4

Zones 10, 11, 12

Digital Board

Digital Board

Analog Board

I/O Group 5

Zones 13, 14, 15

Digital Board

Digital Board

Analog Board

Page 34

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

DIGITAL BOARD SETTINGS

COMMUNICATIONS SETTINGS

The following table is to be used when conguring the Quantum™ for external communications.

J5

J7

J8

J9

J10

in 120 ohm long communications line termination.

out* No termination.

in RS-422/485 transmit pull-up for long communications lines.

out* No pull-up.

in RS-422 transmit pull-up for long communications lines.

out* No pull-up.

in RS-422/485 receive pull-down for long communications lines.

out* No pull-down.

in RS-422 receive pull-down for long communications lines.

out* No pull-down.

* = standard setting

DIPSWITCH SETTINGS

The following table is to be used to set the digital board addresses. Refer to and study the diagram at the bottom of this page

to determine the correct board conguration.

Comm. 4 of Quantum™ (Zones 1-15) Comm. 3 of Quantum™ (Zones 16-30)

I/O

Group

1

2

3

Digital

Board #

SW1 SW2 SW3 SW4 SW5 SW6

1 On On On On Off On

6 Off On Off On Off On 6 Off On Off On Off On

2 Off On On On Off On

7 On Off Off On Off On 7 On Off Off On Off On

3 On Off On On Off On

8 Off Off Off On Off On 8 Off Off Off On Off On

4 4 Off Off On On Off On 4 4 Off Off On On Off On

9 On On On Off Off On 9 On On On Off Off On

5 5 On On Off On Off On 5 5 On On Off On Off On

10 Off On On Off Off On 10 Off On On Off Off On

I/O

Group

1

2

3

Digital

Board #

SW1 SW2 SW3 SW4 SW5 SW6

1 On On On On Off On

2 Off On On On Off On

3 On Off On On Off On

Page 35

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

SECTION 6

ANALOG BOARD

090.610-M (MAY 2016)

Page 35

Page 36

090.610-M (MAY 2016)

Page 36

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

ANALOG BOARD

OVERVIEW

The Frick® Quantum™ LX Evaporator control panel is

capable of reading external analog devices, such as

temperature probes and pressure sensors. It uses these

input signals for the purpose of monitoring and control.

As an example, if an external temperature sensor

begins to read a higher than expected temperature in

some area, the controller would sense this change, and

provide the necessary output control signal to remedy

the situation, or provide a warning. Unlike a digital

signal, which is typically either an on or off state, an

analog signal can assume a wide range of values, such

as a temperature probe’s reading a wide range of

temperatures.

The method used for receiving (and sending) these

signals, is the analog board. The analog devices are

wired directly to the board, and the on-board software/

hardware converts the electrical signals received from

these devices into data, which is then sent on to the

Q4 or Q5 control board via communications, and is

monitored by the control software.

GENERAL DESCRIPTION

This board features twenty-four input channels,

and eight output channels. The board channels are

congured through software, rather than using physical

jumpers. A more detailed description of the operation

of this board is provided in the sections that follow. A

drawing f this board is shown here:

ANALOG BOARD DESCRIPTION

The Analog Board is actually a small microprocessor board

and is programmed to control analog outputs, or accept

analog inputs, from external electrical devices. Each

enhanced board has the capability of 24 independent input

channels. With the Quantum™ Evaporator Control, these

I/O channels are dedicated through the software and

external wring, as to the function of each channel.

COMMUNICATIONS LED’S

The Quantum™ controller is in constant communication with

the Analog (and Digital) Board(s). You will notice on each

Analog and Digital board, that there is a pair of LED’s that

are labeled as RX and TX. These letters represent receive

(RX) and Transmit (TX). These LED’s should be ashing at

a high rate during normal operation. This indicates that the

Quantum™ LX, and the board that you are looking at, are

properly communicating with each other.

• Refer to the JUMPER AND DIPSWITCH SETTINGS

section later in this section. This section contains

the dipswitch settings for addressing the Analog

I/O Boards. When these switches are properly set,

the Quantum™ LX is able to serially communicate

with each I/O board and provide control signals and

data exchange. If these switches are not properly

set, the result can be one of the following:

• Lost or failed communications (displayed in

the Communications Status box on the Home

screen)

• The wrong analog input signals being received

• The wrong analog output signals being sent

from the board.

CONNECTIONS TO THE QUANTUM™

As stated earlier, the Quantum™ Evaporator control

system utilizes up to two Digital, and one Analog

Board. In order to connect all of these boards together

so that the Quantum™ can control them, they must

be interconnected with a wiring harness that provides

all of the necessary D.C. voltage requirements, as well

as the communications capabilities. A diagram of this

wiring harness can be found later in this manual (see

the Power I/O Wiring Harness drawing). This harness

has a 6-pin connector at one end that plugs into the

Quantum™. Another connector plugs into the power

supply. The remaining three connectors (16 pin) will

plug into each of the Digital and Analog Boards in the

system.

Upon close examination of this harness, you will

notice that each of the connectors have two rows

of connections. The wires that are inserted into the

positions of one row, are internally daisy-chained on

each I/O board, to continue the voltages and signals

to the adjacent row. Therefore, any time that a

connector is unplugged from the daisy-chain, these

voltages and signals cannot continue through to the

Page 37

QUANTUM™ LX EVAPORATOR CONTROL PANEL

+5V

RET

MAINTENANCE

090.610-M (MAY 2016)

Page 37

next board. Whenever a plug is not to be inserted onto

a board, either for servicing, or if not all boards are

present because of the options that are present, then a

shunting plug (refer to the Replacement Parts list) must

be installed onto the open connector.

The Analog Board requires the +5 Vdc for logic, the

-12 Vdc for internal voltage reference, and +12 Vdc for

external sensors (plus or +) and the Return (common or

-). The communications signals (RX & TX) are required

by all boards.

LOGIC VOLTAGE (POWER) LED’S

Located on the Analog Board are two power LED’s. The

rst of these is D1 LED (+5VDC), and will be illuminated

as long as the Control Power switch is ON, and the

proper voltage is present at Analog Board connector

P3. The power supply generates the +5 VDC voltage,

and passes it on through the Power-I/O harness. This

LED does not indicate however that the proper voltage

is necessarily present at the board, only that the voltage

is enough to energize the voltage sensing circuitry.

If a voltage related problem is suspected with regard to

the Analog Board, the best way to actually determine

this is to read the voltage on a DVM (Digital Volt Meter.

This may be accomplished by locating the white power

/ communications connector on the board. Notice that

the Analog Board has only one of these connectors.

The associated power / communications harness plugs

in to it. Take the red (positive) probe of the DVM and

carefully insert the end into the +5V lead, and the black

(negative) probe end into the RET (Return or Common)

lead, as shown below:

• If the power LED is not lighted, check the cable

for proper connectivity. Note: Each board

provides the necessary connections to feed

all signals to the following connectors. If the

auxiliary Analog or Digital Board is not present

then a jumper plug (Part # 640B0039H01)

must be installed to daisy-chain the signals.

The second power LED is D5 (+24Vdc). This +24Vdc

voltage is generated on the Analog Board from the

+5Vdc supply being fed from the Remote panel power

supply. If the +5Vdc is present as stated earlier, then

this LED will illuminate if the on-board +24Vdc supply

is functioning properly.

ACTIVE LED

The Analog Board has an Active LED indicator that

blinks when the board’s software is running.

If the Active LED is not blinking, it could be an

indication that the internal program is not running. Try

powering the Remote panel off, then back on to see if

the Active light starts blinking. If not, a new board may

be required.

ANALOG INPUTS

An Analog Input is the portion of the hardware that allows

devices such as temperature sensors and pressure

transducers, to interface with the Quantum™ The

software program within the Quantum™ is constantly

looking at these Input channels, via communications,

and based upon what the voltage or current level of

the channel is, will provide the necessary control for

an associated action.

Analog inputs arrive at the board on connectors P4

through P10. Each of these connectors can receive two

channels (for a total of twenty-four).

ANALOG OUTPUTS

An Analog Output is the portion of the hardware that

Set the DVM to read DC, and set the proper range. The

voltage reading must read a minimum of +4.98 Vdc.

The Power-I/O harness will have an associated voltage

drop at each board connection. As an example, if you

are reading the voltage at the rst I/O board in the

daisy-chain, and it reads 4.98 Vdc, you can be assured

that the voltage at the subsequent connections for

the remaining boards will be lower yet. The voltage

will need to be corrected for proper operation of the

system.

The cause for a low voltage reading could be:

• The Remote panel power supply may need

adjustment (see the section on power

supplies).

• The Power-I/O communications harness has a

problem (a new harness may be needed).

• A problem may exist with one of the I/O

boards (Digital or Analog).

the Quantum™ uses to provide control. These outputs

are dedicated for a 4-20 mA signal and cannot be

changed through the software conguration.

TROUBLESHOOTING THE ANALOG INPUTS AND

OUTPUTS

Some problems that may be encountered involve

troubleshooting the Analog inputs and outputs. The

Analog Board has twelve Analog I/O board connectors

labeled P4 through P10. The external Analog devices

are wired to a connector plug. Position 1 connects

to the plus (+) of the external device for channel 1,

position 2 connects to the signal (SIG) of the external

device for channel 1 and position 3 connects to ground

(GND) of the external device for channel 1. Position

4 connects to the plus (+) of the external device for

channel 2, position 5 connects to the signal (SIG) of the

external device for channel 2 and position 6 connects

Page 38

090.610-M (MAY 2016)

GND

Channel 2 +

Channel 1

Channel 1

Channel 2

Signal

GND

Page 38

QUANTUM™ LX EVAPORATOR CONTROL PANEL

MAINTENANCE

to ground (GND) of the external device for channel 2,

as shown below:

Signal

Each input channel is congurable through the

operating software. There are twenty-four analog

input channels that can be selected for 4-20 mA,

0-5 Vdc, ICTD, or RTD. Besides properly setting the

software conguration, each channel is setup through

software calibration for the proper transducer type and

range, and each transducer must be calibrated through

the appropriate sensor calibration screen. Improper