Frick Quantum ACUair Service Manual

S90-500 O/JUL 2002

File: SERVICE MANUAL - SECTION 90

Replaces: S90-500 O/APR-2001

Dist: 3, 3a, 3b, 3c

OPERATION

FRICK® QUANTUM™

®

ACUair

CONTROL PANEL

Version 2.1x

S90-500 O FRICK® QUANTUM™ ACUair® CONTROL PANEL

Page 2 OPERATION

Table of Contents

OVERVIEW OF OPERATOR INTERFACE ...............................................................................................................3

OPERATOR ACCESS......................................................................................................................................... 3

Keys And Key Functions ............................................................................................................................... 4

Keypad Keys........................................................................................................................................... 4

Screen Keys ........................................................................................................................................... 5

To Change Setpoints........................................................................................................................ 5

INITIAL SETUP PROCEDURE............................................................................................................................ 6

GRAPHIC SCREENS.................................................................................................................................................6

“AIR HANDLING UNIT OVERVIEW” SCREEN ................................................................................................... 6

Screen Key Set ............................................................................................................................................. 7

UNIT SELECTED - "OPERATING STATUS" SCREEN ......................................................................................8

Air Handling Unit Data Box............................................................................................................................ 8

Alarm Status Box........................................................................................................................................... 8

Demand Output Box...................................................................................................................................... 8

Analog Readings Box.................................................................................................................................... 9

Operator Selection Keys ............................................................................................................................... 9

UNIT SELECTED - "OPERATING STATUS - 2" SCREEN ................................................................................. 9

ACUair® Input Status Box............................................................................................................................. 9

ACUair® Output Status Box.......................................................................................................................... 9

Sensor Indication......................................................................................................................................... 11

Defrost Status Box ...................................................................................................................................... 11

UNIT SELECTED - "MAIN MENU" SCREEN .................................................................................................... 11

Screen Key Set ........................................................................................................................................... 11

MAIN MENU SELECTION

"Alarms/Shutdowns" Screen................................................................................................................................... 11

"Alarms/Shutdowns History" Screen .............................................................................................................. 11

Main Menu Selection - "Control Setup" (1) Screen ............................................................................................. 12

Main Menu Selection - "Control Setup" (2) Screen ............................................................................................. 13

CONTROL SETUP

“Cooling Control Setup” Screen .................................................................................................................. 14

"Heating Control Setup" Screen .................................................................................................................. 15

“Exhaust Control Setup” Screen.................................................................................................................. 16

“Damper Control Setpoint” Screen .............................................................................................................. 17

“Heat Profile Control” Screen................................................................................................................ 18

“Safety Setpoints” Screen ........................................................................................................................... 18

ANALOG CALIBRATION

"Main Menu" Screen.................................................................................................................................... 18

"Analog Calibration" Screen.................................................................................................................. 19

"Pressure Calibration" Screen ..............................................................................................................20

"Temperature Calibration" Screen ........................................................................................................ 21

"Other Calibration" Screen.................................................................................................................... 22

PANEL SETUP

“Panel Setup” Screen .................................................................................................................................. 23

SECURITY SETUP SCREEN............................................................................................................................ 25

PANEL STATUS

"Real Time Trending" Screen...................................................................................................................... 26

"Real Time Trending" Screen – Data Log View .................................................................................... 27

"Real Time Trending" Screen – Trending View ....................................................................................28

"History Trending" Screen ........................................................................................................................... 29

ALARMS/SHUTDOWNS MESSAGES ....................................................................................................................30

INDEX ......................................................................................................................................................................31

FRICK® QUANTUM™ ACUair® CONTROL PANEL S90-500 O

g

OPERATION Page 3

Warnin

!

The Quantum™ has the capability of being modified by the user/owner in order to obtain different performance

characteristics. Any modification to the standard default settings may have a severe negative impact on the

operation and performance of the equipment. Any modification to these control settings is the sole responsibility of

the user/owner and Frick® disclaims any liability for the consequences of these modifications. It is possible that the

modification of these settings may cause improper operation and performance that results in property damage,

personal injury or death. It is the responsibility of the user/owner to evaluate and assess the consequences of their

actions prior to modifying the controls for this unit.

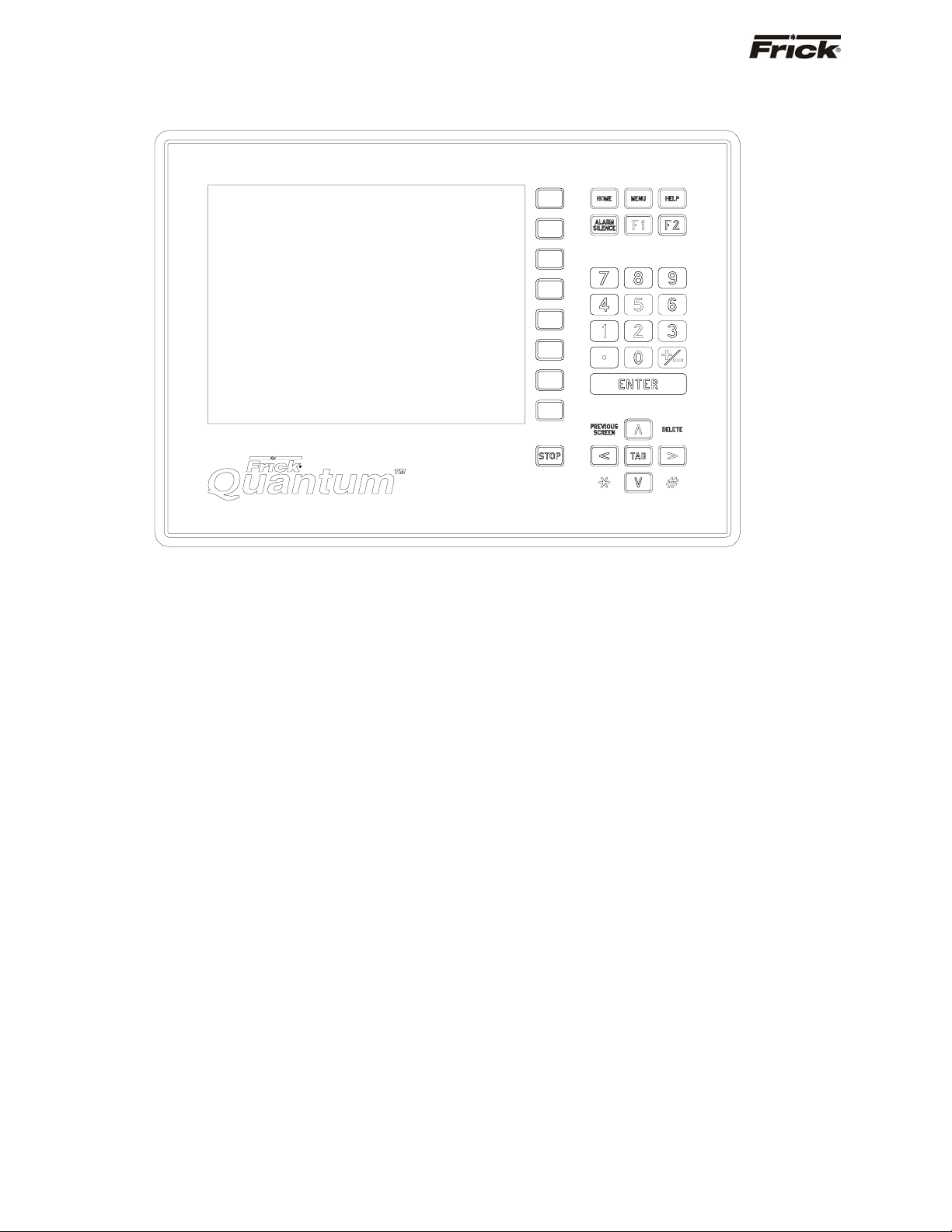

OVERVIEW OF OPERATOR INTERFACE

The panel user interface has been designed to allow an

operator to efficiently access and control the operation of

the units. The control panel screen is used for graphic

displays. By pressing a key on the keypad, the labeled or

described function is recognized by the control processor.

The following information is presented to help the operator

interact with the graphic screens and the Quantum™

ACUair® control panel. This manual is intended to

describe all presently available features.

OPERATOR ACCESS

Operator access to this system is through various

screens. A screen is the physical representation of data

on the display. Icons have been used to help an operator

quickly identify functions. An icon is a small graphic

symbol representation. Each screen has a title area. The

title is descriptive of the screen. The current date and time

is shown in this title area. The day of the week, Sunday

(Sun.) through Saturday (Sat.) is displayed. The month of

the year from January (Jan.) to December (Dec.) is

displayed. The day of the month from 1 to 31 and the year

from 0001 to 9999 is displayed. The time displayed is the

current time in 24 hours (military) format. The hours,

minutes and seconds are displayed. The labeled keys on

the panel keypad provide quick access to the operator's

needs. By pressing a labeled key on the keypad, the

corresponding function is recognized. Most of the screens

have screen keys that describe or show a function that is

recognized when the coinciding key found at the right of

the display screen is pressed. The screen keys provide

access to other screens or commands. For easier

viewing, related information is separated into boxes. The

setup and setpoint entry is separated into logical control

components. Setup selection of features and options has

been provided to prevent the operator from unnecessary

viewing and entering of unused control settings. The

required control settings are clearly presented. To further

assist the operator, an on-line help is provided.

Sometimes selections appear differently to indicate that

the feature is unavailable.

S90-500 O FRICK® QUANTUM™ ACUair® CONTROL PANEL

Page 4 OPERATION

KEYS AND KEY FUNCTIONS

KEYPAD KEYS

Following is a list of the labeled keypad keys and the

actions that occur when they are pressed:

[HOME] – If an operator is logged on to an individual unit

and the “Operating Status” screen is not presently

showing, then this unit’s “Operating Status” screen is

shown when this key is pressed. Otherwise, the “Air

Handling Unit Overview” screen is shown. All the pertinent

readings and operational status of a unit is shown on the

“Operating Status” screen. An overview of the most

important information about all the units is shown on the

“Air Handling Unit Overview” screen.

[MENU] - Shows the "Main Menu" screen. This screen

has the main selections for an individual unit, allowing

access to information, setup of options, and setpoint

entry.

[HELP] - Displays the on-line "HELP". Information is

shown for the operation of the ACUair

[F1] - A function key that is only active when a screen

indicates it as a selection key. Its function is dependent on

what the screen indicates will occur.

[F2] - A function key that is only active when a screen

indicates it as a selection key. Its function is dependent on

what the screen indicates will occur.

NUMERALS [0] - [9] - The numerical keys are used to

enter a value in a data field.

®

control panel.

DECIMAL [.] - The decimal point is used when entering a

decimal value in a data field.

[+/-] - When changing a value in a data field, this key will

toggle the value between negative and positive.

[ENTER] - When changing data in a data entry field, this

key will input the change.

[PREVIOUS SCREEN] - Shows the screen that was

viewed previously to the current screen. Also is used to

return to the previous set of screen keys when accessing

different sets of screen key selections on the same

screen.

[DELETE] - When changing a value in a data field, this

key will delete the selected character.

Up Arrow [Ù]- When in the mode of changing setpoints,

this arrow is used to go to the previous data entry field.

Down Arrow [Ú]- When in the mode of changing setpoints,

this arrow is used to go to the next data entry field.

Right Arrow [>]- When in the mode of changing setpoints,

this arrow is used to go to the next data entry field. When

in the mode of changing a data entry field, this arrow is

used to go to the next character.

Left Arrow [<]- When in the mode of changing setpoints,

this arrow is used to go to the previous data entry field.

When in the mode of changing data entry field, this arrow

is used to go to the previous character.

FRICK® QUANTUM™ ACUair® CONTROL PANEL S90-500 O

g

OPERATION Page 5

SCREEN KEYS

Most of the screens have screen keys that are graphically

depicted. They describe or show a function that is

recognized when the coinciding keypad key to the right of

the screen is pressed. A set of screen command keys

have a title area to describe the command control.

Following are descriptions of the commonly used screen

keys:

[Change Setpoints] - When on a screen that has

adjustable setpoint values, this positions the cursor at

the first data entry field. (See “To Change Setpoints”

for more information.)

[OK] - Available when in the mode of changing

setpoints, this accepts all data changes. Available as

a response to a message, this approves continuing.

[CANCEL] - Available when in the mode of changing

setpoints, this rejects all data changes. Available as a

response to a message, this disapproves continuing.

Arrows - Available when in the changing setpoints

mode, they function the same as the panel keypad

arrows.

[Increase Value] - Available when in the changing

setpoints mode, this increases the selected setpoint

by one unit each time it is pressed.

[Decrease Value] - Available when in the changing

setpoints mode, this decreases the selected setpoint

by one unit each time it is pressed.

[Up One] - Scrolls the data on the screen to show the

previous line of data.

[Down One] - Scrolls the data on the screen to show

the next line of data.

[Page Up] - Scrolls the data on the screen to show

the previous page of data.

[Page Down] - Scrolls the data on the screen to

show the next page of data.

[Goto Start] – Scrolls the data on the screen to show

the most recent data.

[Goto End] - Scrolls the data on the screen to show

the oldest data.

[More…] - Available when the selections are on more

than one screen. Used to go to the next selections.

[…Back] - Available when the selections are on more

than one screen. Used to go back to the previous

selections.

[Enable] - Available to place the indicated control

setpoints or option into usage.

[Disable] - Available to remove the usage of the

indicated control setpoints or option.

TO CHANGE SETPOINTS

Warnin

!

The Quantum™ has the capability of being modified

by the user/owner in order to obtain different

performance characteristics. Any modification to the

standard default settings may have a severe negative

impact on the operation and performance of the

equipment. Any modification to these control settings

is the sole responsibility of the user/owner and Frick

disclaims any liability for the consequences of these

modifications. It is possible that the modification of

these settings will cause improper operation and

performance that results in property damage,

personal injury or death. It is the responsibility of the

user/owner to evaluate and assess the consequences

of their actions prior to modifying the controls for this

unit.

The setpoints define the operation and limits of the air

units. Adjustable setpoints are setpoints that an operator

can easily change in the field. These setpoints are stored

in EPROM (non-volatile memory).

NOTE: Adjustable Setpoints are not lost after power is

interrupted. However, we suggest that a list of Adjustable

Setpoints be recorded and stored safely to facilitate

reentry, in case there is a need to return to the original

settings.

1. From an adjustable setpoint screen, select the

[Change Setpoints] key. This positions the

cursor at the first data entry field. The data entry

field that is selected is identifiable by the black

background and white text.

2. Use the arrow keys to move the cursor to the

data entry field to be modified.

3. Having selected the setpoint to be changed, the

numerical keys and the decimal key may be used

to enter the new setpoint. Typing a new value will

completely erase the old value.

4. To remove a typing mistake, the left and right

arrow key can be used to position the cursor to

the left of the mistake and then press the

[DELETE] key to erase it.

5. Press the [ENTER] key to input the new data in

the data entry field and to move to the next data

entry field.

6. If the value is out of bounds, an error message

box displays the proper range of values. Press

the [OK] key to acknowledge the error message.

Re-enter the correct value.

7. When finished making any changes to the data

on an adjustable setpoint display press the [OK]

key to accept all changes or press the

[CANCEL] key to ignore all changes.

®

S90-500 O FRICK® QUANTUM™ ACUair® CONTROL PANEL

Page 6 OPERATION

INITIAL SETUP PROCEDURE

1. “Panel Setup” is performed first. “Panel Setup” is

used to setup panel features and options that later

can be changed by an operator. Features such as the

panel time, and screen color are changed here.

2. “Unit Board Setup” is performed next. “Unit Board

Setup” is used to setup the customer specific control

features and options to be used by a unit controller

board. This setup should not need to be changed by

operators. “Unit Board Setup” is intended to be

GRAPHIC SCREENS

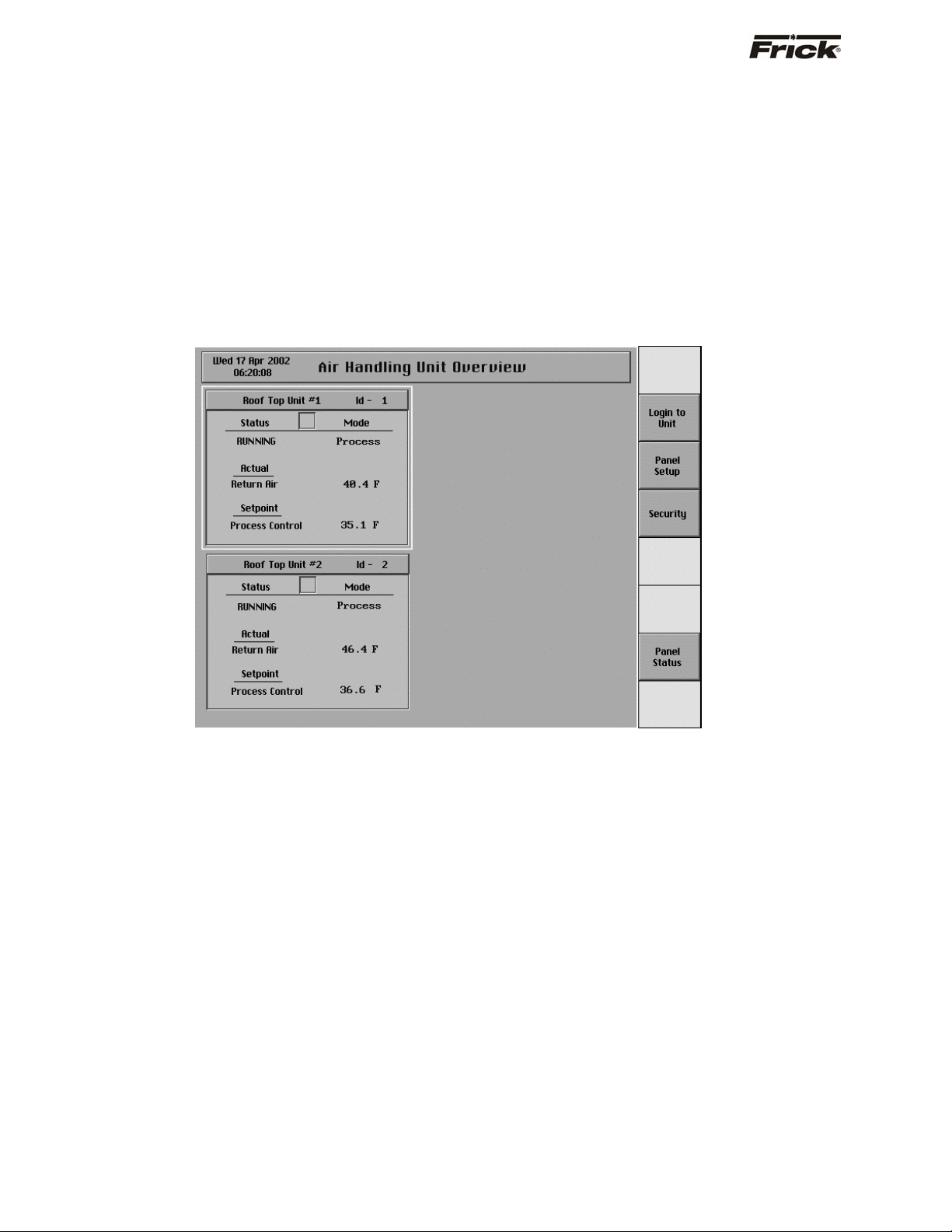

“AIR HANDLING UNIT OVERVIEW” SCREEN

accessed and performed only by a Factory

Representative or Distributor.

3. Calibrate the control devices.

4. From Control Setup enter and setup the control

settings.

5. From Security Setup, establish the desired access

rights of the operators.

The panel now provides quick access to the most

important information and controls of the units and their

subsystems.

Also called the "Home" screen. This screen shows an

overview of the most important information about the

units. This screen is shown when power is first turned on

and when a key is pressed after the screen saver has

turned off the backlight. The "Air Handling Unit Overview"

screen is continuously updated and provides the current

status of each unit's condition and performance.

The following information is shown on this screen:

· ID - The identification number of the unit

displayed.

· Name - The identification name that describes

the unit that is displayed.

· Status – The present operation status of the unit.

· Mode - The present mode of the unit, either

Cleanup or Process.

· Actual - The current reading of the present

analog control value.

· Setpoint - The setpoint that is currently being

maintained.

Several types of failures and alarms are also

indicated on this screen. If a unit stops

communicating with the Quantum™, the information

specific to that unit is shown in red text. After

communications with the unit has been restored, the

text color will return to black. In addition, a list of the

units that have previously been communicating with

the Quantum™ is saved even when powered off. If a

unit in that list does not respond to the Quantum™

during the starting sequence, the words “Not Found”

are displayed in red in place of that unit’s name.

Once a proper connection with the unit is made,

logging in to the unit will replace the words “Not

Found” with the unit’s name. Finally, when a unit is in

an alarm condition, a red circle flashes in the small

box between "Status" and "Mode" until the alarm is

cleared.

FRICK® QUANTUM™ ACUair® CONTROL PANEL S90-500 O

OPERATION Page 7

“AIR HANDLING UNIT OVERVIEW” SCREEN –

SCREEN KEY SET

Following are the screen key selections for the "Air

Handling Unit Overview" screen:

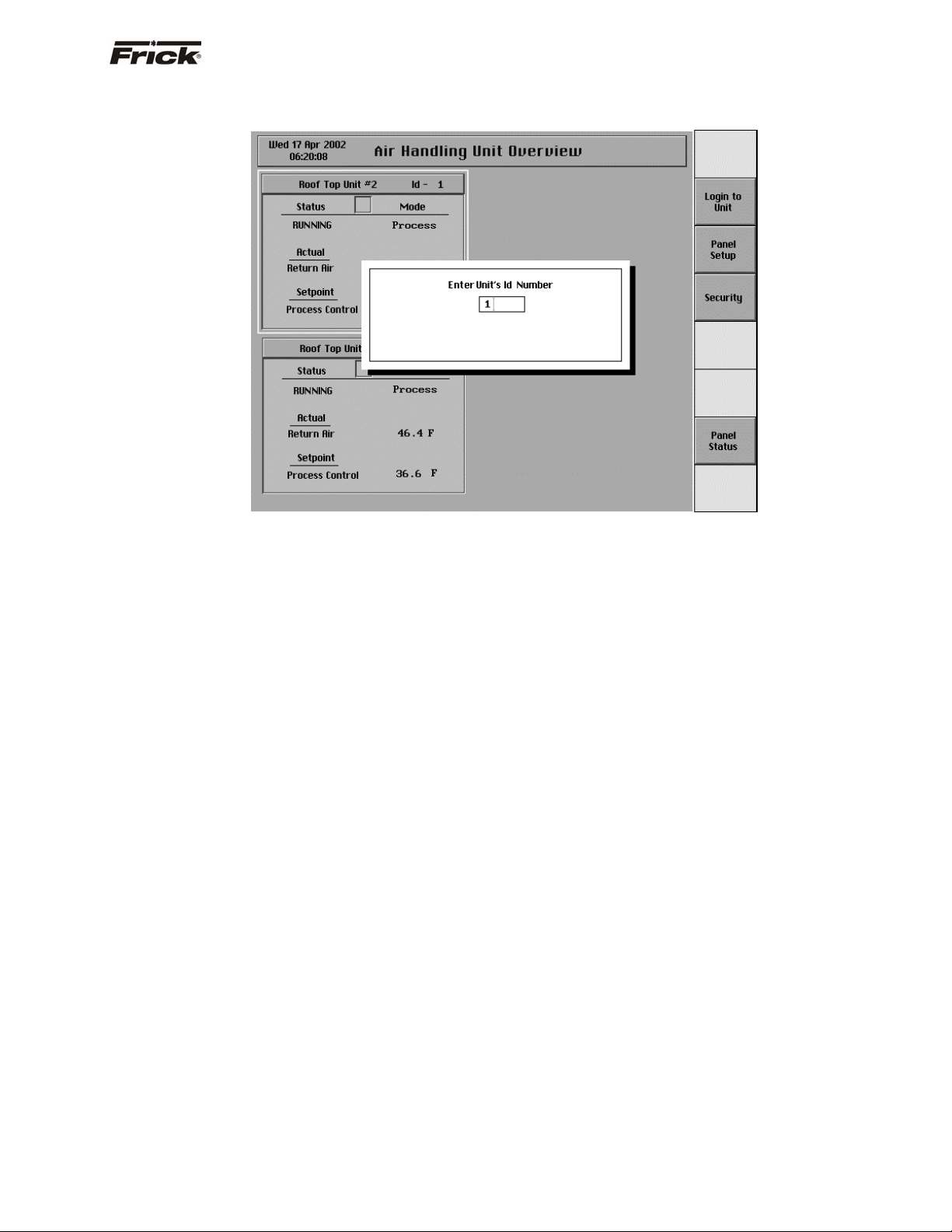

· [Login to Unit] - Shows a selection box for the

Unit ID. After a valid ID is entered, the “Operating

Status” screen for that unit is displayed.

· [Panel Setup] - Shows the "Panel Setup"

screen. This screen has the following menu

items for setup:

· Change Current Time and Date

· Temperature Units

· Change Communications

· Selectable Options

· Screen Setup

· [Security] - Shows the current security privilege

level and whether setpoints can be changed from

the keypad. Security can be changed on this

screen.

· [Panel Status] – Shows the Quantum™ control

panel internal temperature, as well as the Panel

Control status (manual or remote). This screen

also shows the last time the Quantum™ panel

was powered up and powered down.

S90-500 O FRICK® QUANTUM™ ACUair® CONTROL PANEL

y

Page 8 OPERATION

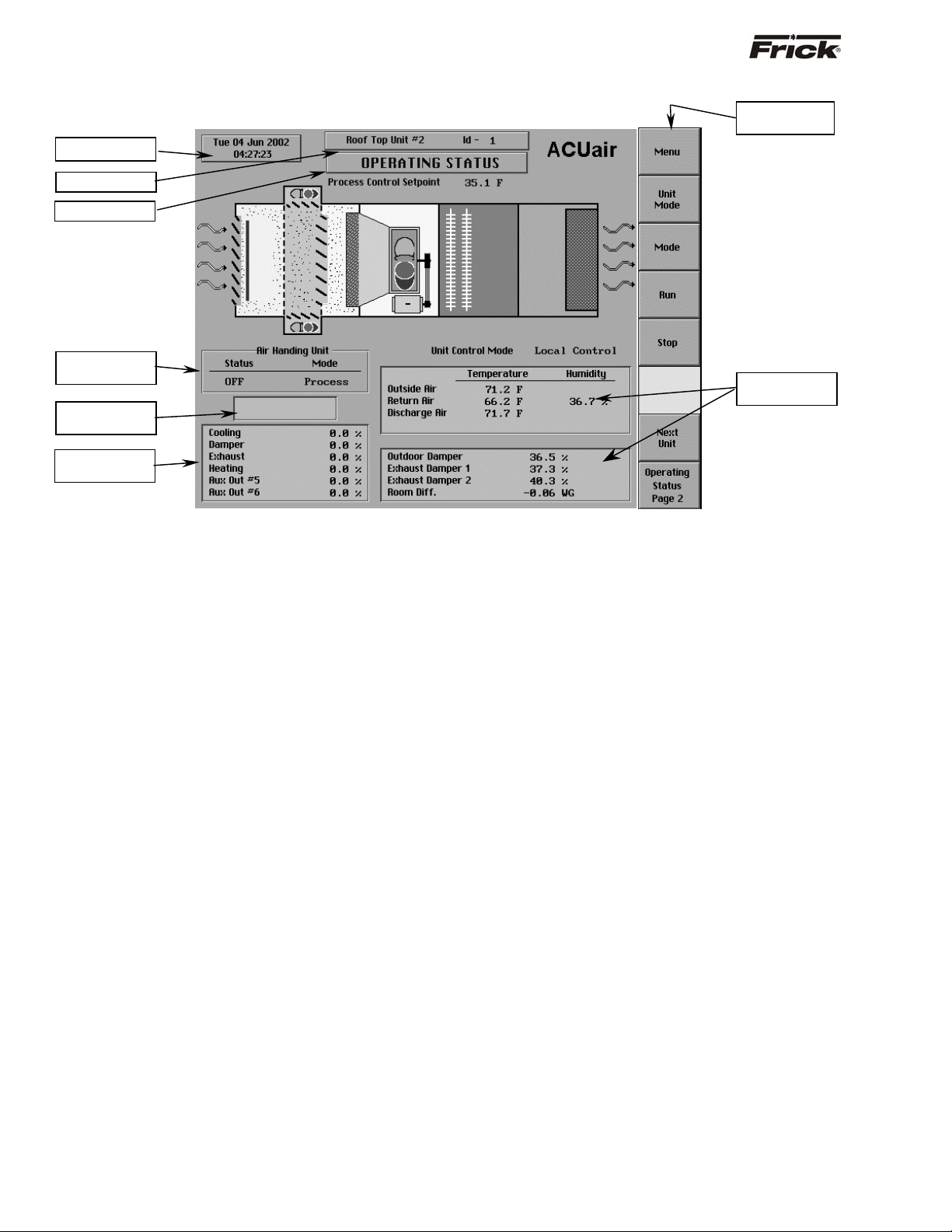

UNIT SELECTED - "OPERATING STATUS" SCREEN

Date and Time

Unit Name

Screen Title

Air Handling

Unit Data Box

Alarm Status

Box

Demand Output

Box

The most important information about the unit is displayed

here. In the middle of the screen is a diagram of an

ACUair® unit that shows the current state of the unit. The

supply fan and both exhaust fans spin, a flame is

displayed when the burner is on, and the cooling coils are

colored blue when they are open and white when they are

closed. The outside air dampers, the return air dampers,

and both exhaust dampers are drawn to match the state

of the dampers on the ACUair® unit.

Above this diagram, the Process Control Setpoint is

displayed. This setpoint is maintained when the unit is in

Process Mode. To the right of this setpoint, the word

"Economizer" is displayed when the Economizer

conditions are met. Below the diagram, the Unit Control

Mode is displayed. When in Local Control Mode the unit is

controlled from the Quantum™ Interface panel. When it is

set to Remote Control mode the unit can be turned on and

off and toggled between Process and Cleanup at the unit

itself.

The following information is shown on the left side of this

screen:

AIR HANDLING UNIT DATA BOX:

Shows the present operating status of the unit:

· Status - One of the following messages is

shown:

· Off

· Running

· Starting - The unit has turned on but air flow

has not been detected.

· Mode - One of the following messages is shown:

· Process – The unit is maintaining optimum

air conditions for processing product.

· Cleanup - The unit is modifying air

conditions to support the cleanup procedure.

Operator

Selection Ke

Analog

Readings Box

s

ALARM STATUS BOX:

The alarm status is displayed in the indented box

below the air handling unit data box. The status box

is blank with no message if there are no alarms

present.

The following message could be shown:

· ALARM - This message flashes when an alarm

is present. An alarm is a condition that requires

an operator to acknowledge it and allows the unit

to continue its operation.

· SHUTDOWN - This message flashes when the

unit is in a shutdown condition. During a

shutdown situation, the unit remains off until an

operator acknowledges the shutdown and

restarts the unit.

An Alarm message indicates an Alarm point has been

reached or exceeded. Select the [Alarms/Shutdown]

key from the "Main Menu" screen for details. For

additional shutdown information, select the

[Alarms/Shutdown] key from the "Main Menu"

screen and then the “Alarms/Shutdowns History”

screen.

DEMAND OUTPUT BOX:

The bottom box on the left side of the screen holds

the demand control values. These values range from

0 - 100% and are the results of PID calculations.

Larger percentages indicate that input readings have

moved away from setpoint and increased air

modification is necessary.

The following demand values are shown:

· Cooling

· Damper

· Exhaust

· Heating

· Aux. Output #5

· Aux. Output #6

FRICK® QUANTUM™ ACUair® CONTROL PANEL S90-500 O

OPERATION Page 9

ANALOG READINGS BOX:

The following analog input readings are possible.

They are shown if they were enabled during the

board setup.

· Outside Air Temperature

· Room/Return Air Temperature

· Discharge Air Temperature

· Coil Air Temperature

· Humidity

· Outdoor Damper

· Exhaust Damper 1

· Exhaust Damper 2

· Room Differential

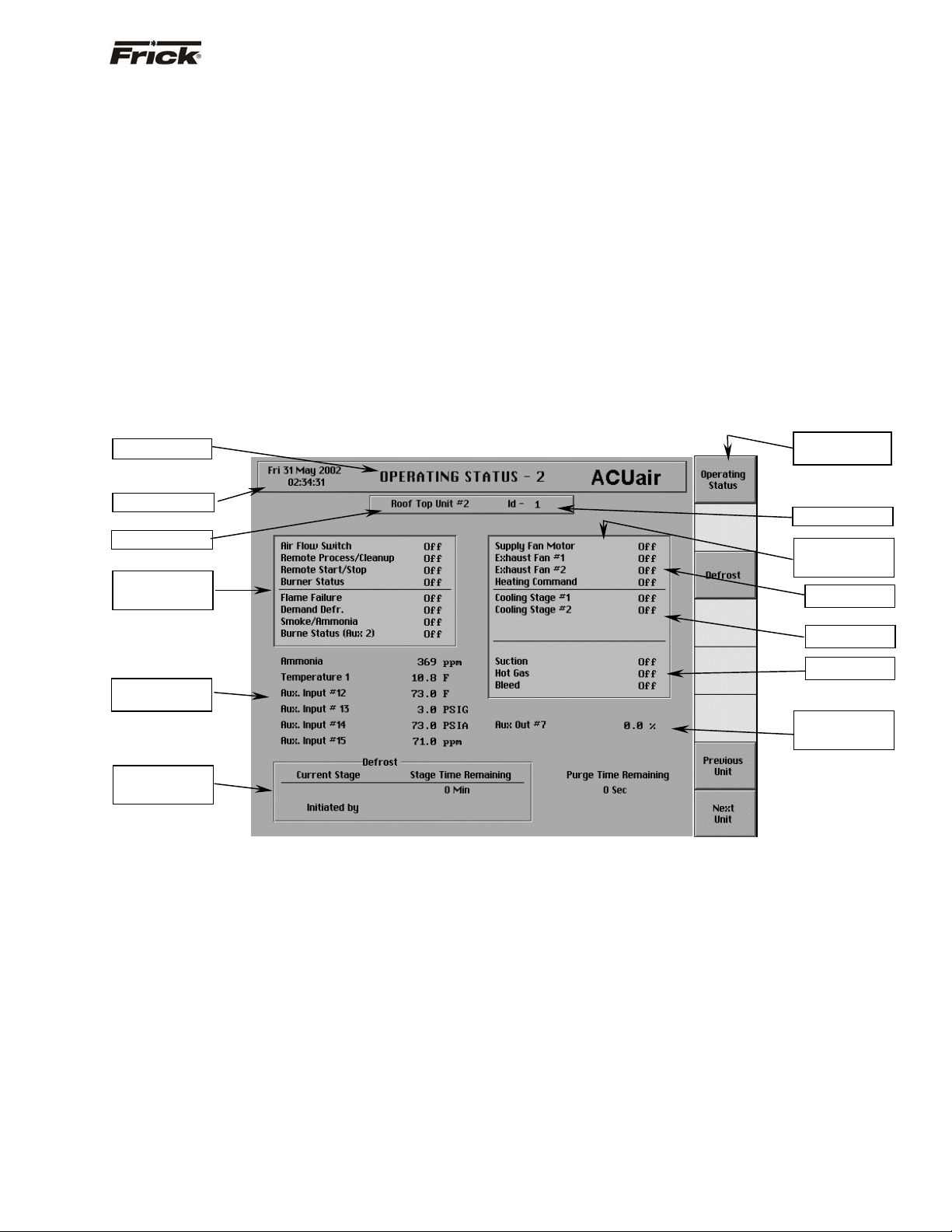

UNIT SELECTED - "OPERATING STATUS - 2" SCREEN

Screen Title

Date and Time

Unit Name

ACUair® Input

Status Box

OPERATOR SELECTION KEYS

Following are the screen key selections for the

"Operating Status" screen:

· [Menu] – Shows the “Main Menu” screen for the

selected Unit.

· [Unit Mode] – The following control mode can be

selected:

· [Remote] – The unit is turned on and off and

set to either Process or Cleanup Mode

through digital inputs. The unit can be

returned to local mode by pressing the

"Mode", "Run" or "Stop" buttons.

· [Mode] – Toggles the unit between Process and

Cleanup Mode.

· [Run] - Starts the unit if it is currently stopped.

· [Stop] - Turns the unit off.

· [Operating Status Page 2] - Shows the

“Operating Status - 2” screen.

Operator

Selection Keys

Unit ID

ACUair Output

Status Box:

First Block

Sensor

Indication

Defrost Status

Box

The Operating Status – page 2, displays additional

information that cannot be shown on the first Operating

Status screen. Along the left side of the page is the Input

Status Box while on the right side of the page is the

Output Status Box. Below these boxes, the current

Ammonia reading and other sensor values may be

displayed if they are enabled.

ACUair® INPUT STATUS BOX:

The present operating status of the digital inputs is shown.

One of the following messages is displayed:

· On – The input is energized or turned on.

· Off - The input is de-energized or turned off.

The following inputs are shown in the first block (if they

were enabled during the board setup).

Second Block

Third Block

Additional

Analog Outputs

· Remote Start/Stop

· Burner Status

The following inputs are shown in the second block (if

they were enabled during the board setup).

· Flame Failure

· Demand Defrost

· Smoke/Ammonia

· Burner Status (Aux. 2)

ACUair® OUTPUT STATUS BOX:

The present operating status of the digital outputs is

shown. One of the following messages is displayed:

· On – The output is energized or turned on

· Off - The output is de-energized or turned off.

· Air Flow Switch

· Remote Process/Cleanup

FRICK® QUANTUM™ ACUair® CONTROL PANEL S90-500 O

OPERATION Page 10

The following outputs are shown in the first block (if they

were enabled during the board setup):

· Supply Fan Motor

· Exhaust Fan #1

· Exhaust Fan #2

· Burner Command

The following outputs are shown in the second block (if

they were enabled during the board setup):

· Cooling Stage #1

· Cooling Stage #2

· Cooling Stage #3

· Cooling Stage #4

The following outputs are shown in the third block (if they

were enabled during the board setup):

· Preheat Command

UNIT SELECTED - "MAIN MENU" SCREEN

· Suction

· Hot Gas

· Bleed

The following outputs are shown in the Additional Analog

Outputs block (if they were enabled during the board

setup):

· Aux. Output #7

· Aux. Output #8

SENSOR INDICATION:

The current values of all the analog inputs that have been

selected and installed are shown.

DEFROST STATUS BOX:

If Defrost has been enabled, the current status of the

Defrost cycle is shown.

SCREEN KEY SET

The "Main Menu" screen provides a selection of screen

keys to guide the operator through all the screens. The

following are descriptions of each screen selection and a

listing of further selections:

· [Operating Status] - Shows the "Operating

Status" screen.

· [Alarms/Shutdowns] - Shows the Alarms /

Shutdowns" screen which shows in red text the

current Failures, and the Date, and Time of the

Failure. The following selections are available:

· [Clear Alarms]

· Alarms/Shutdowns History Screen

· [Control Setup] - Shows the "Control Setup"

menu screen. The following items are selections:

· [Cooling Control]

· [Heating Control]

· [Preheat Control]

· [Exhaust Control]

· [Damper Control]

· [Humidity Control]

· [Safety Setpoints]

· [Defrost]

· [Variable Fan]

· [Analog Aux. Input]

· [Analog Aux. Output]

· [Calibration] - Shows the "Analog calibration"

screen. From this screen, the following

calibrations can be selected:

· Change Temperature Probe Types, Ranges

and Offsets

· Calibrate Miscellaneous Sensors

FRICK® QUANTUM™ ACUair® CONTROL PANEL S90-500 O

OPERATION Page 11

MAIN MENU SELECTION - "ALARMS/SHUTDOWNS" SCREEN

The following are the "Alarms/Shutdowns" screen

selection keys:

· [Clear Alarms] - Selecting this key will clear all

alarms and/or shutdowns from this screen.

· [Alarms/Shutdown History] - A full screen of

failures is stored, along with the Last Fail

Date/Time of the failure. The stored data shows

on the "Alarms/Shutdowns History" screen. The

data is saved, even if there is a power outage.

To resume normal operation it will be necessary to go

through the following steps:

1. Correct the conditions causing the alarm.

MAIN MENU SELECTION - "ALARMS/SHUTDOWNS HISTORY" SCREEN

2. To clear or reset the "Alarms/Shutdowns" screen

and turn off any alarm annunciation device, from

the screen press the [Clear Alarms] key. This

will also clear the “ALARM” or “SHUTDOWN”

message from the "Operating Status" screen.

3. If the conditions causing the alarm have not been

corrected or a new fault has occurred, a new

“ALARM” or “SHUTDOWN” message will appear.

The Alarms/Shutdowns history screen keeps a

record of the alarms and shutdowns. This

information will help troubleshoot persistent

Refer to the "Alarms/Shutdowns Message" section for a

list of all the possible alarms.

operational problems.

Loading...

Loading...