Page 1

S90-010 CS/APR 2008

File: SERVICE MANUAL - SECTION 90

Replaces: S90-010 CS/APR 04

Dist: 3, 3a, 3b, 3c

COMMUNICATIONS SETUP

FRICK® QUANTUM™

COMPRESSOR

CONTROL PANEL

VERSION 5.0x

Page 2

®

S90-010 CS (APR 08) FRICK

Page 2 COMMUNICATIONS SETUP

QUANTUM™ COMPRESSOR CONTROL PANEL

Table of Contents

QUANTUM™ IDENTIFICATION _______________________________________________________4

Setting Up the Quantum™ for Communication ________________________________________________ 4

Com-2 Pinouts for Quantum™ 3 ________________________________________________________ 4

Com-2 Pinouts for Quantum™ 4 ________________________________________________________ 4

RS-232 Communications _________________________________________________________________ 5

Quantum™ 3 _______________________________________________________________________ 5

Quantum™ 4 _______________________________________________________________________ 5

Converting an RS-232 Serial Port to RS-422 or RS-485 _________________________________________ 5

Change Communications_________________________________________________________________ 6

COMMUNICATIONS LOOPBACK TEST ________________________________________________7

Hardware Setup for RS-422 Testing ________________________________________________________ 7

Hardware Setup for RS-485 Testing ________________________________________________________ 7

Software Setup For The Communications Loopback Test________________________________________ 8

Performing the Communications Loopback test________________________________________________ 8

PROTOCOL DESCRIPTION__________________________________________________________9

Quantum™ Communications Protocols ______________________________________________________ 9

Checklist For Setting Up Communication _________________________________________________ 9

®

Protocols _______________________________________________________________________ 11

Frick

Quantum™ $ Protocol Specifications_______________________________________________________ 15

®

# Protocol Specifications ________________________________________________________ 11

Frick

Data Packet _______________________________________________________________________ 15

CONVERSION CHART FOR DECIMAL / HEXADECIMAL / ASCII ___________________________ 23

ALLEN-BRADLEY COMMUNICATION ________________________________________________24

SLC-500 - Suggested Setup _____________________________________________________________ 24

Channel Configuration _______________________________________________________________ 24

Read Message Setup Example ________________________________________________________ 25

Write Message Setup Example ________________________________________________________ 25

PLC-5/30 - Suggested Setup _____________________________________________________________ 25

Channel Configuration _______________________________________________________________ 25

Read Message Setup Example ________________________________________________________ 26

Allen-Bradley Programming Overview ______________________________________________________ 26

Channel Configuration _______________________________________________________________ 26

General Configuration __________________________________________________________________ 26

System Configuration___________________________________________________________________ 26

Message Sequence Logic _______________________________________________________________ 27

Message Read Logic ___________________________________________________________________ 27

Message Read Setup Screen _________________________________________________________ 28

Message Write Logic ___________________________________________________________________ 29

Message Write Setup Screen _________________________________________________________ 30

MODBUS Protocol ________________________________________________________________ 31

Port Configuration of The Master __________________________________________________________ 31

Data Packet __________________________________________________________________________ 31

The Query ___________________________________________________________________________ 32

The Response ________________________________________________________________________ 32

Data Field____________________________________________________________________________ 32

Error Checking ________________________________________________________________________ 32

ASCII Framing ________________________________________________________________________ 32

Query (Read) Example__________________________________________________________________ 33

Write Example ________________________________________________________________________ 34

Response Example ____________________________________________________________________ 36

Modbus Notes ________________________________________________________________________ 37

YORK ISN DATA ACCESS _________________________________________________________38

Page 3

®

FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 CS (APR 08)

COMMUNICATIONS SETUP Page 3

HYPERTERMINAL ________________________________________________________________41

Setting up Hyperterminal_________________________________________________________________41

Testing Communications_________________________________________________________________ 46

General Notes _________________________________________________________________________46

QUANTUM™ DATA TABLE _________________________________________________________48

Allen-Bradley and Modbus Data Access _____________________________________________________ 48

Modbus Addressing Note _____________________________________________________________48

ALARMS/SHUTDOWNS MESSAGE CODES ___________________________________________71

QUANTUM™ 3 MAIN BOARD HISTORY AND IDENTIFICATION ___________________________73

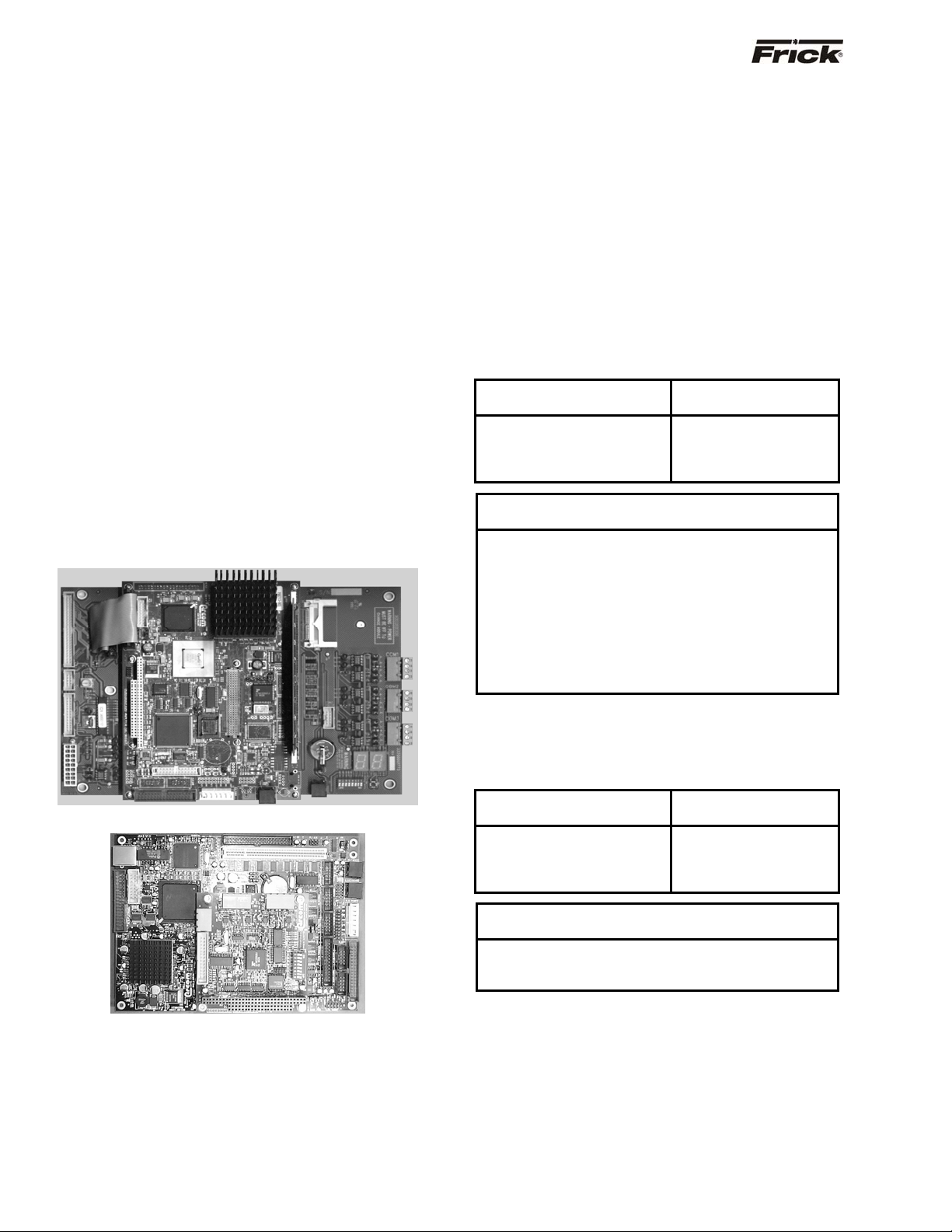

Quantum™ 3 Main Board Photo ___________________________________________________________73

Quantum™ 3 Communications Jumpers_____________________________________________________74

Communications Board Jumpers _______________________________________________________ 74

Com-1_________________________________________________________________________74

Com-2_________________________________________________________________________74

Communications WIRING_____________________________________________________________ 74

QUANTUM™ 4 MAIN BOARD HISTORY AND IDENTIFICATION ___________________________75

Quantum™ 4 Main Board Photo ___________________________________________________________75

Quantum™ 4 Communications Jumpers_____________________________________________________76

Communications Board Jumpers _______________________________________________________ 76

Com-1 (TB1)____________________________________________________________________76

Com-2 (TB2 - TB3)_______________________________________________________________76

Communications Wiring ______________________________________________________________76

COMMUNICATIONS WIRING DIAGRAMS _____________________________________________77

To Customer Remote Computer/Dcs _______________________________________________________77

RS-485 Communications _____________________________________________________________77

RS-422 Communications _____________________________________________________________77

Multicompressor Sequencing (Lead-Lag) ____________________________________________________77

RS-485 Communications _____________________________________________________________77

RS-422 Communications _____________________________________________________________77

CONNECTIONS __________________________________________________________________78

INDEX __________________________________________________________________________80

The Quantum™ has the capability of being modified by the user/owner in order to obtain different performance characteristics.

Any modification to the standard default settings may have a severe negative impact on the operation and performance of the

equipment. Any modification to these control settings is the sole responsibility of the user/owner and Frick

liability for the consequences of these modifications. It is possible that the modification of these settings may cause improper

operation and performance that results in property damage, personal injury or death. It is the responsibility of the user/owner

to evaluate and assess the consequences of their actions prior to modifying the controls for this unit.

WARNING

!

®

disclaims any

Page 4

®

S90-010 CS (APR 08) FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 4 COMMUNICATIONS SETUP

Frick

QUANTUM™ IDENTIFICATION

®

Controls has over the years, strived to remain on

the cutting edge of microprocessor technology and

development. Because of the ever-increasing speed,

memory, features, and power of microprocessors, Frick

®

Controls will continue to introduce the latest advancement

in microprocessor control technology.

Our microprocessor family has shared the name

Quantum™, over the past five years. There are currently

four controllers within this family. The first two of these

controllers (known as Quantum™ 1 and Quantum™ 2) are

no longer in production, and as such, will not be further

mentioned in this manual. The two current members in

production of the Quantum™ family are the Quantum™ 3,

and the Quantum™ 4. It is critical to the end user to be

able to identify the differences between these controllers.

Refer to the section in this manual entitled Quantum™ 3

Main Board History and Identification and Quantum™ 4

Main Board History and Identification for additional

information as to how to identify the particular Quantum™

controller that you have.

Throughout this manual, the two different controllers will

be talked about for the most part as one (as they do

function the same). Where there is a difference between

these boards, as in jumpers or wiring, the different models

will be identified by name. This is why it is important for

you to be aware of which Quantum™ board you have.

Quantum™ 3

Quantum™ 4

Setting Up the Quantum™ for

Data communication to and from the Quantum™ can be

through a modem, remote data communications terminal,

programmable controller, or master computer via either

RS-422, RS-232, or RS-485 connections to the

Quantum™ Com-2 port. Reference the Main Board

Communications section for the correct jumpering of RS422, RS-232, or RS-485. Also, reference the drawing of

the Quantum™ Main Board section to identify wiring

configurations for Com-2.

COM-2 PINOUTS FOR QUANTUM™ 3

Following is the RS-422, RS-485, and the RS-232 pin

descriptions for communications port 2 (also referred to as

Com-2 or Comm-2):

RS-422 Pinout

(4-Pin Connector)

1 - RX (Receive) 1 - RX / - TX

2 + RX (Receive) 2 + RX / + TX

3 - TX (Transmit)

4 + TX (Transmit)

1 Data Communication Device

2 Data Set Ready

3 Received Data

4 Request to Send

5 Transmit Data

6 Clear to Send

7 Data Terminal Ready

8 Ring Indicator

9 Ground

10 Not Used

COM-2 PINOUTS FOR QUANTUM™ 4

Following is the RS-422, RS-485, and the RS-232 pin

descriptions for communications port 2 (also referred to as

Com-2 or Comm-2):

RS-422 Pinout

(4-Pin Connector)

1 - RX (Receive) 1 - RX / - TX

2 + RX (Receive) 2 + RX / + TX

3 - TX (Transmit)

4 + TX (Transmit)

1 Transmit Data

2 Received Data

3 Ground

Communication

RS-485 Pinout

(4-Pin Connector)

RS-232 Pinout

(10-Pin Connector)

RS-485 Pinout

(4-Pin Connector)

RS-232 Pinout

(3-Pin Connector)

Page 5

®

j

(

FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 CS (APR 08)

COMMUNICATIONS SETUP Page 5

RS-232 Communications

Following is the pin connections showing how to wire a

standard 9-Pin RS-232 connector directly to the 10-Pin

RS-232 connector on the Quantum™ 3, and the 3-pin

connector on the Quantum™ 4:

QUANTUM™ 3

Reference the drawing of the main processor board for the

location and positioning of the 10-Pin RS-232 connector.

Following is the pin positions of the 10-Pin connector:

9-Pin

Connector

1

6

2

7

3

8

4

9

RXD RXD

TXD

COM COM

Quantum™ 3

10-Pin Connector

1 2

TXD

10

Note: The TX2 and RX2 are I/O communication activity

lamps on the Quantum™ Main Processor Board that can

be monitored to see if the Com-2 port is receiving (RX2)

and transmitting (TX2) data.

QUANTUM™ 4

Reference the drawing of the main processor board for the

location and positioning of the 3-Pin RS-232 connector.

Following is the pin positions of the 3-Pin connector:

9-Pin

Connector

1

6

2

7

3

8

4

9

5

RXD

TXD

COM

Quantum™ 4

3-Pin Connector

3

COM

TXD

1

Converting an RS-232 Serial Port to RS-422 or

In order to communicate to the Quantum™ controller via

RS-422 (or RS-485), you will need to convert the RS-232

signal from the source.

One converter that has proven to be effective is the Opto22 AC7A/B card. This card will allow the conversion from a

standard RS-232 signal to either RS-422 or RS-485. The

AC7A card is powered from a 115 VAC source, while the

AC7B card is powered from a 220 VAC source. They can

be used in a standalone panel along with an Allen Bradley

SLC 5/04 or along with an external modem. Keeping the

jumpers installed the same way they are received from the

factory, it is easy to wire for either RS-422 or RS-485.

RS-485

NOTE: Refer to the manual that comes with the AC7A/B

card for specific jumper information (as the configuration

shown is only a suggestion that has worked in most

applications).

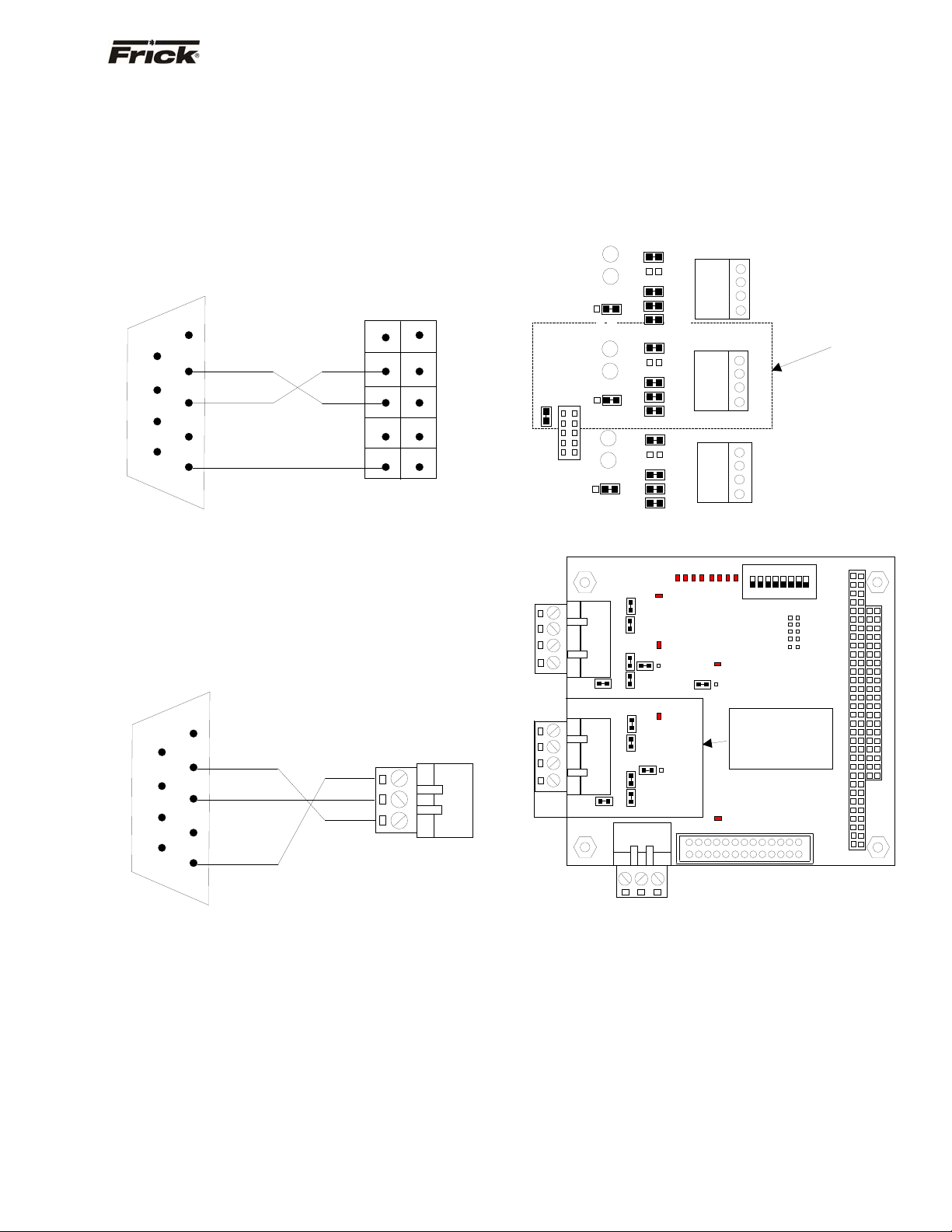

Once jumpers on the converter card have been verified,

you will need to verify the jumper settings of the

Quantum™ controller. Refer to the following diagrams for

the Quantum™ 3 and Quantum™ 4:

COM-2

RS-232

LK19

RX1

TX1

B

A

RX2

TX2

B

A

RX3

TX3

LK18

B

A

LK16

LK17

LK1

LK2

LK3

LK4

LK5

LK6

LK7

LK8

LK9

LK10

LK11

LK12

LK13

LK14

LK15

COM-1

RS-422/RS-485

1 2 3 4

COM-2

RS-422/RS-485

1 2 3 4

COM-3

Future Use)

1 2 3 4

Verify the

umpers in this

location.

Quantum™ 3

COM-1

RS-422

RS-485

COM-2

RS-422

RS-485

TB1

TB2

COM-2

RS-232

4 3 2 1

4 3 2 1

LK1

LK8 LK7

TB3

3 2 1

LK10 LK9

LK6 LK5

LK4 LK3

PORT

D5

D4

D7

D3

D2 D1

LK16

O

D8

D13

D11

D12

D10

D6

B

A

LK11

jumpers in this

B

A

LK17

D8

DIP

1 2 3 4 5 6 7 8

Verify the

location.

PL2

SW1

PL1

PL4

PL3

0

1

4 5 6

7

2

3

Quantum™ 4

NOTE: Some of these jumper settings may need to be

modified to ensure optimum communications

performance. Typically, the termination jumper should be

installed in the last Quantum™ in the communications

daisy chain only (Link 7 for the Quantum™ 3, Link 1 for

the Quantum™ 4).

Page 6

®

S90-010 CS (APR 08) FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 6 COMMUNICATIONS SETUP

After verifying both the Converter card and Quantum™

jumper settings, the interconnecting wiring must be done.

Be sure to use 4-conductor shielded communications

cable (two wires for transmit, two for receive). Refer to the

following diagrams for RS-422 and RS-485:

4-Pin

connector

1

2

3

4

Quantum

™

COM-2

-RX

+RX

-TX

+TX

Hard wire

TO-

TO+

FO-

FO+

RS-422 To RS-232

25-Pin Male

connector

2

3

7

AC7A

Converter

RXD

TXD

CTS

9-Pin Female

connector

RXD

2

TXD

3

RTS

5

RS-232

Computer

Port

RS-422

4-Pin

connector

1

2

3

4

Quantum

™ COM-2

-RX/-TX

+RX/+TX

Hard wire

TO-

TO+

FO-

FO+

RS-485

25-Pin Male

connector

2

3

7

AC7A

To RS-232

Converter

RXD

TXD

CTS

9-Pin Female

connector

RXD

2

TXD

3

RTS

5

RS-232

Computer

Port

RS-485

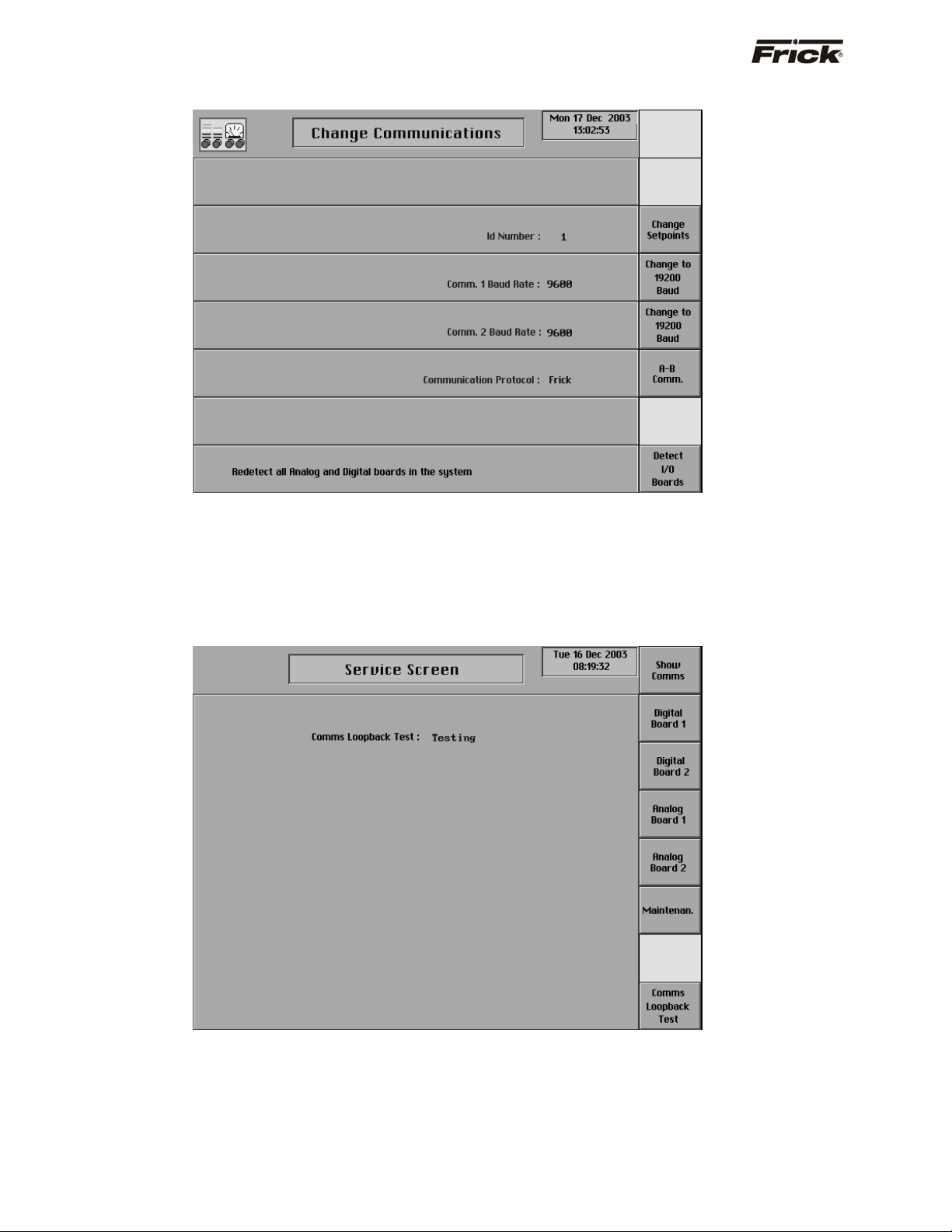

Change Communications

We have used both an Opto 22 AC7A/B and an Opto 22

AC422 adapter card. They can be wired to use either RS422 or RS-485.

Following is the pin connections showing how to wire a

DB9 connector on this adapter card to the Quantum™ for

RS-422 communication:

Quantum™ COM-2 DB9

1 5

2 4

3 9

4 8

Following is the pin connections showing how to wire for

RS-485 to the terminal connections on this adapter card

from the Quantum™:

Quantum™ Terminal

1 (-RX/-TX) FO-

2 (+RX/+TX) TO+

The card can be connected RS-232 to another device.

Following is the pin connections showing how to wire the

25-Pin RS-232 connector on this adapter card to a 9-Pin

connector of the SLC 5/04:

DB9 DB25

5 7

2 3

3 2

This screen is accessed by pressing the [Change

Comms.] key on the Panel Setup screen.

The following information is shown here:

• ID Number

• Comm. 2 Baud Rate

• Communication Protocol

• Comm. 1 Baud Rate

Page 7

®

T

T

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 CS (APR 08)

FRICK

COMMUNICATIONS SETUP Page 7

COMMUNICATIONS LOOPBACK TEST

With version 5.0x Quantum™ software, a method of

testing the onboard RS-422 and RS-485 communications

ports was developed. By utilizing a loopback test harness

(as shown below), the maintenance technician now has

the ability to locally test the Quantum™ communications

hardware and jumper configuration.

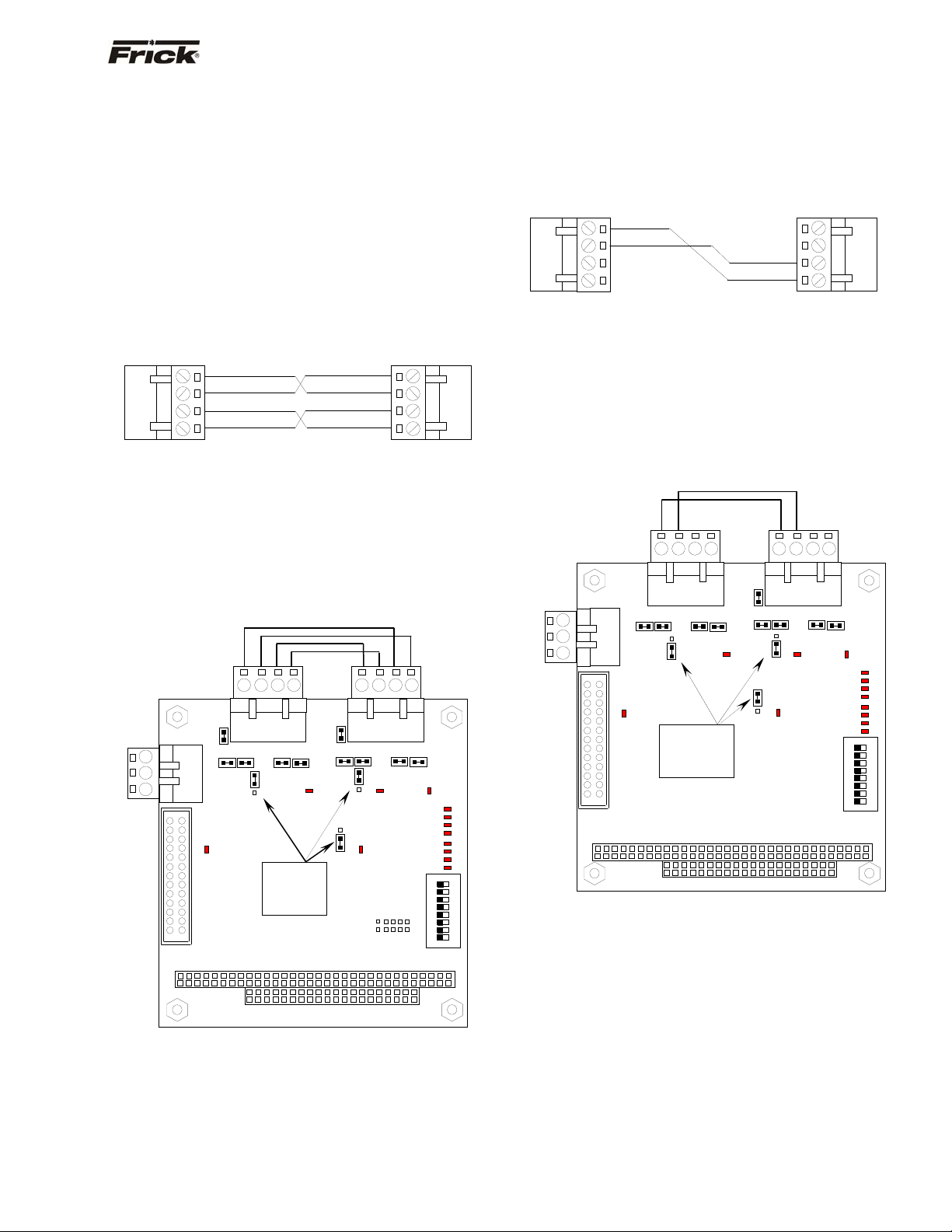

Hardware Setup for RS-422 Testing

To create the test harness for RS-422 communications

loopback testing, use the following example:

1

-

+RX

-TX

+TX

4

-

Set the Quantum™ 4 communications jumpers as follows:

• Set LK11 to position B

• Set LK16 to position A

• Set LK17 to position A

• Plug the RS-422 test harness (as shown above)

into the com ports at TB1 and TB2 as shown

here:

COM-2

RS232

3

2

1

TB3

1 2 3

LK1

RS-422/RS-485

LK4 LK3

COM-2

LK17

4

TB2

TB1

LK2

LK7

LK6 LK5

A

B

D8

Verify the

LK11

jumpers in

these

locations.

PL1

RS-422 Test Configuration

4-Pin Connector4-Pin Connector

+TX

-TX

+RX

-RX

1 2 3

COM-1

RS-422/RS-485

LK8

A

B

D2D1

LK16

B

A

D6

PL2

4

1

4

LK10LK9

D3

POR

0

D4

1

D5

2

D7

3

D8

4

D10

5

D11

6

D12

7

D13

1

ON

2

3

4

5

6

7

DIP

8

SW1

Hardware Setup for RS-485 Testing

To create the test harness for RS-422 communications

loopback testing, use the following example:

4-Pin Connector

1

-RX/-TX

4-Pin Connector

4

4

-

-RX/-TX

1

Set the Quantum™ 4 communications jumpers as follows:

• Set LK11 to position B

• Set LK16 to position B

• Set LK17 to position B

• Plug the RS-485 test harness (as shown above)

into the com ports at TB1 and TB2 as shown

here:

COM-2

RS232

3

2

1

PL1

TB3

LK1

LK3

D8

12 3

COM-2

RS-422/RS-485

LK4

A

B

LK17

Verify the

jumpers in

these

locations.

4

LK6 LK5

123

TB1 TB2

LK2

RS-422/RS-485

LK8 LK7

A

B

LK16

B

A

D6

LK11

COM-1

D2D1

PL2

4

LK10LK9

D3

POR

0

D4

1

D5

2

D7

3

D8

4

D10

5

D11

6

D12

7

D13

1

ON

2

3

4

5

6

7

DIP

8

SW1

RS-485 Test Configuration

Page 8

®

S90-010 CS (APR 08) FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 8 COMMUNICATIONS SETUP

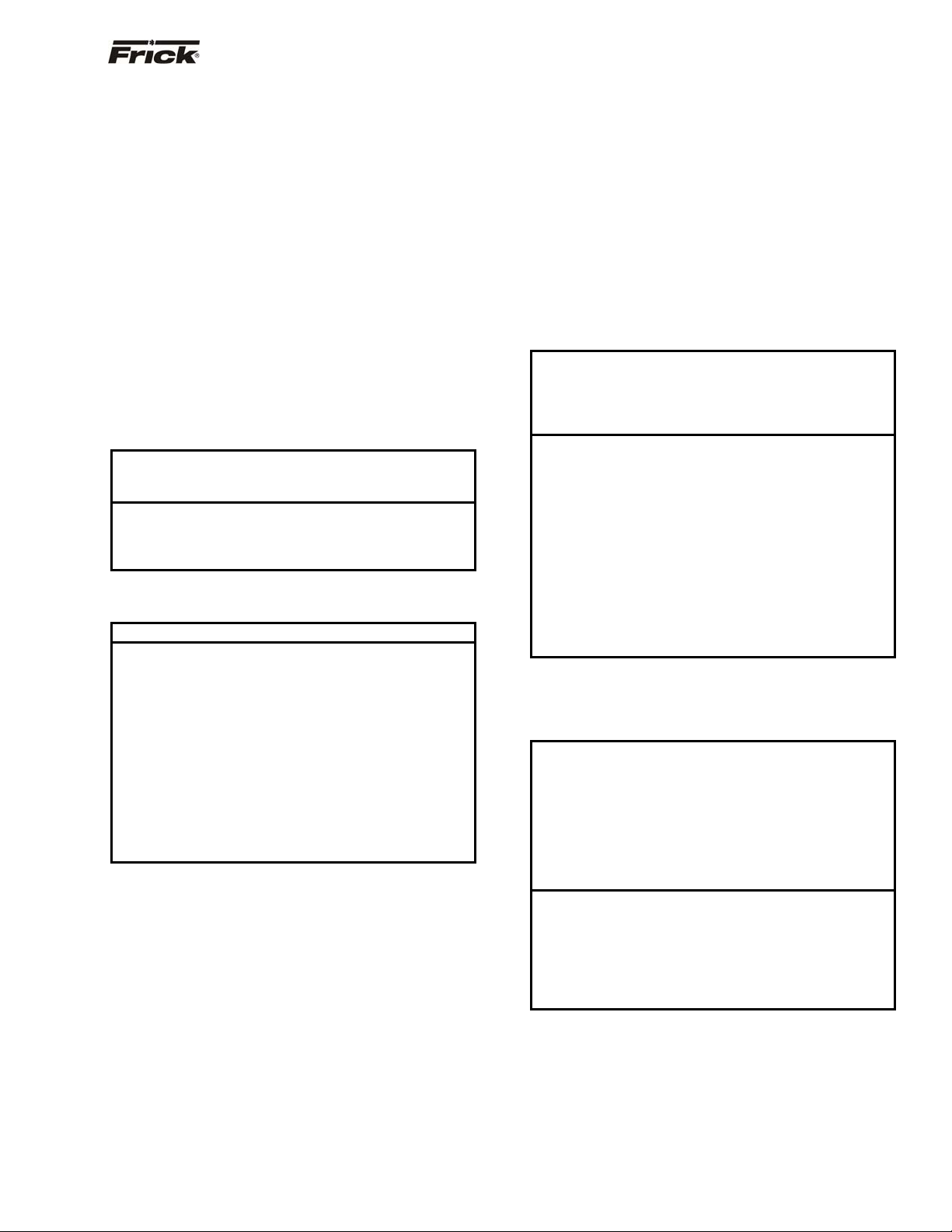

Software Setup For The Communications Loopback Test

On the Change Communications screen (shown above),

ensure that the settings are as follows:

• ID Number: 0 - 99 (does not matter)

• Comm 1 Baud Rate: (does not matter, but it must

be set the same as Comm 2 Baud Rate)

Performing the Communications Loopback test

• Comm 2 Baud Rate: (does not matter, but it must

be set the same as Comm 1 Baud Rate)

Communication Protocol: Frick® (must be Frick®)

Upon properly setting up the Change Communications

screen, access the Service Screen. The center of the

screen will initially appear blank. The bottom key on the

right side of this screen is the Comms Loopback Test key.

Pressing the key will initiate the test. The blank center of

the screen will be replaced by one of three word lines:

• Testing - This will appear as the test is running.

NOTE: The test occurs so quickly that It may be

possible that the word Testing will not appear if

the test passes.

• Passed - If the test passes, the word Passed will

appear.

• Failed - If the test does not pass, this will appear.

Page 9

®

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 CS (APR 08)

FRICK

COMMUNICATIONS SETUP Page 9

PROTOCOL DESCRIPTION

The use of communication protocols, permits data

transmission between devices. Protocol determines how

contact is established and how the query (question) and

response (answer) takes place. The information in a

message command requires an identity of the intended

receiver (ID #), what the receiver is to do (read or write to

a setpoint, etc.), data needed to perform an action (the

value of a setpoint to be changed), and a means of

checking for errors (checksum).

When using Com-2 for communication, check what

communication protocol, if any has been selected, from

the Panel Setup – Change Communications screen. For

example, [A-B Comm] should be selected when using

Allen-Bradley’s communication protocol. The baud rate of

Com-2 and the panel ID number are also changed from

this screen, and should coincide with the setup of the

other device.

Note: The data communication protocols are continuously

being expanded and improved. Therefore, you should

consult Frick

®

Controls for the exact details on your

particular unit(s) before developing system software to

interface with the panel.

Quantum™ Communications Protocols

The Quantum™ controller has the capability of

communicating to the outside world through four software

protocols:

• Frick

®

• Allen-Bradley DF-1 serial

• ModBus ASCII serial

• YORK ISN

Note: When using Modbus protocol, a [Comm. 2

Advanced] key will appear. Pressing this key will

allow the user to modify the number of Data and Stop

bits, as well as Parity. This only applies to Modbus.

Modbus cannot be changed from ASCII to RTU

however. Refer to the section on Modbus for further

information.

Checklist For Setting Up Communication

0191 Decide which Quantum™ protocol you

can communicate with and want to use.

0191 Setup your device’s communication port

for the Quantum™ protocol and select a baud

rate.

Protocols

0191 Next, setup the Quantum™ for the desired

communication protocol. Select the protocol from

the Panel Setup – Change Communications

screen. For example, [A-B Comm] should be

selected when using Allen-Bradley’s

communication protocol.

0191 Setup the baud rate of Com-2 to coincide

with the setup of the your device’s

communication port.

0191 Enter the Quantum™ ID. This will be used

to identify commands that are sent to it.

0191 Wire to the first panel via RS-232, RS-

422, or RS-485 connections to the Quantum™

Com-2 port.

• If you are communicating to more than one

panel, then you will not be able to use RS-

232. You can however, convert RS-232 to

either RS-422 or RS-485 with an adapter

card. Reference the Converting an RS-232

Serial Port to RS-422 or RS-485 section for

information about an adapter card.

Page 10

®

S90-010 CS (APR 08) FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 10 COMMUNICATIONS SETUP

• Reference the drawing of the Quantum™

Main Board in this manual to identify wiring

and jumpering locations for Com-2.

• Reference the Main Board Communications

Com-2 section in this manual for the correct

jumpering of RS-232, RS-422, or RS-485.

0191 Send a single command to read data from

this Quantum™ using its ID.

0191 Check if you received a data response at

your device.

0191 Troubleshooting when you don’t receive a

data response:

• Check if Com-2 on the Operating Status

screen is showing ACTIVE or OFF.

• ACTIVE is shown only when the Quantum™

understands it is receiving a properly

composed message to itself.

• Check that the RX2 I/O communication

activity lamp on the Quantum™ Main

Processor Board is blinking as it receives the

instruction from your device.

• A steady lit RX2 LED or one that isn’t

lighting, are signs of improper wiring.

• If the RX2 LED is properly blinking, then

check if the TX2 LED is blinking in response.

• If the TX2 is not blinking then check the

communication protocol setup at the panel,

the panel’s ID and the Com-2 baud rate

setting.

• If the TX2 is blinking, then check that the

Com-2 communication jumpers are correct.

• If you are sure that the wiring and

Quantum™ setup is correct, then select the

[Show Comms] key from the Service

Screen to see what is being received and

transmitted from Com-2.

Note: A useful tool for troubleshooting is Windows

HyperTerminal. Using HyperTerminal can help you

determine if you are wired OK. Reference the

HyperTerminal Setup section in this manual.

0191 If you properly receive data and you need

to communicate to more than one panel, then

setup and wire to another panel. Reference the

wiring diagram drawings in the back of this

manual. Send a single command to read data

from this Quantum™ using it’s ID and

troubleshoot as above, if necessary. To prevent

noise feedback which is possible when

communicating over a long distance, only the last

panel should have the termination for long

communications lines jumpered.

Page 11

®

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 CS (APR 08)

FRICK

COMMUNICATIONS SETUP Page 11

Frick® Protocols

All commands for Frick® protocols must be in ASCII to be

recognized (see the Conversion Chart For Decimal /

Hexadecimal / ASCII, located later in this manual). The

data should be setup as an 8 bit Word with no Parity, and

a Stop Bit. The commands can be in upper or lower case

letters. A compressor with an ID code of [00] is considered

disabled. ID codes from [01] through [99] are valid and

recognized by the microprocessor.

Frick® # Protocol Specifications

Frick® # protocol consists of commands that are available

for most other existing models of Frick control panels. The

®

Frick

# protocol does not utilize a checksum. It is better to

use Frick

communicating to Quantum™ panels.

®

Quantum™ ($) protocol when only

When there is more than one panel, a Quantum™ can be

wired from it’s Com-2 to another panels Com-2 or can be

wired from it’s Com-2 to Port 1 of a RWB, RDB, RXB or

RXF Micro Plus panel.

Frick® RWB, RDB, RXB, or RXF Panel Frick® #

Communications Port #1

RS-422 Pinout

9 - TX (Transmit)

8 + TX (Transmit)

5 - RX (Receive)

4 + RX (Receive)

The following is a complete list of available Frick® Protocol

# commands:

COMMAND CODE and DESCRIPTION

I = Returns compressor status information.

R = Compressor start control.

S = Compressor stop control.

V = Slide Valve/Slide stop control.

P = Return Pressures information.

A = Return full load amps information.

T = Return Temperatures information.

Q = Query setpoints data.

C = Enter Change setpoints mode.

MC = Change compressor mode.

MV = Change Slide Valve mode.

KF = Clear Failures.

KR = Clear remaining recycle delay time.

X = Return digital I/O status.

F = Return Failures.

All data is returned as integer values. If decimal positions

are assumed, then divide the data by the proper multiple

of 10 to get the actual value.

Temperature data, except for Suction Temperature, is

returned in the current temperature units as 3 characters

with no decimal position (i.e. 032 would represent 32

degrees Fahrenheit if the panel temperature units are in

Fahrenheit, or it would represent 32 degrees Celsius, if the

panel temperature units are in Celsius). Suction

Temperature is returned as 4 characters with a + or - as

the leading character (i.e. –010 would represent –10

degree).

Pressure data is usually returned in the current pressure

units. However, the Filter differential reading is always

returned in PSIA. When in PSIG or in PSIA, the pressure

data is returned as 3 characters with no decimal position.

However; in order to show the full transducer range, the

#IDPS command returns 4 characters with one decimal

position assumed. The #IDI, and #IDPA commands return

3 characters that assume one decimal position; therefore,

99.9 is the highest value that can be returned. When in

PSIG, suction pressure is returned in PSIA. When in Bar

and BarA, the pressure data is returned as 4 characters

with two decimal positions assumed. When in KpaA, the

pressure data is returned as 4 characters with no decimal

position.

The following is a detailed description of each command:

RETURN COMPRESSOR STATUS INFO: #01I

# Start of command sequence.

01 Compressor ID code.

I Return Status information command.

RETURNED ANSWER, ie: 090RRRN340

Character

Position

Description

of returned data

1, 2, 3 Slide Valve position.

4 Remote, Auto, Manual (Slide Valve)

5 Delay-recycle, Running, Off, Slide Valve

too high, Permissive Start not enabled,

d(I)fferential Pressure too high, s(T)opping,

au(X) not energized

6 Rem, M Keypad, Auto (Compressor mode)

7 Cutout (Shutdown), Alarm, Normal

8, 9, 10 Suction in PSIA.

(Carriage return, line feed.)

Note: The following control commands are for remote

control of a compressor. A compressor should be in both

remote compressor mode and remote Slide Valve or

capacity mode for remote control.

COMPRESSOR START CONTROL: #01R01

# Start command sequence.

01 Compressor ID code.

R Start compressor command.

01 ID code repeated for verification

NOTE: The compressor must be in the remote Start

mode for this command to be executed.

Returned answer: A01

Character

Position

Description

of returned data

1 Acknowledge of command sent.

2, 3 ID code of compressor.

(Carriage return, line feed.)

Page 12

®

S90-010 CS (APR 08) FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 12 COMMUNICATIONS SETUP

COMPRESSOR STOP CONTROL: #01S01

Returned in the current temperature units as 3

characters with no decimal position (i.e. 032 would

represent 32 # Start command sequence.

01 Compressor ID code.

S Stop compressor command.

01 ID code repeated for verification

NOTE: The compressor must be in the remote

Start mode for this command to be executed.

RETURNED ANSWER: A01

Character

Position

Description of returned data

1 Acknowledge of command sent.

2,3 ID code of compressor.

(Carriage return, line feed.)

SLIDE VALVE CONTROL COMMANDS: #01VLXX

#01VUXX

#01VS

# Start command sequence.

01 Compressor ID code.

V Slide Valve/Slide Stop command.

L Load Slide Valve command.

U Unload Slide Valve command.

XX = 00 Turns selected output off.

XX = 01 to 15 Turns selected output on for XX seconds.

S Return Slide Valve position value.

If the command was #01VL00, then the load Slide

Valve output on compressor #1 would be turned off. If

the command was #01VL05, then the load Slide Valve

output on compressor #1 would be turned on for 5

seconds, and would then automatically turn off. NOTE:

RETURN PRESSURES COMMAND: #01PX

# Start command sequence.

01 Compressor ID code.

P Return pressures command.

X = S Return suction Pressure (PSIA).

X = D Return discharge Pressure (g/hg).

X = O Return oil Pressure (g).

X = F Return filter differential Pressure.

X = A Return all pressures.

If the command was #01PS, then the micro-processor

would dump the suction Pressure.

Note: Don’t send CR or LF

RETURNED ANSWER:

XXX = 3 characters followed by a carriage return, line

feed.

If using the A command, the returned data would be:

XXXXXXXXXXXX = 12 characters followed by a

carriage return, line feed.

RETURN FULL LOAD AMPS COMMAND: #01A

# Start command sequence.

01 Compressor ID code.

A Return full load amps command.

If the command was #01A, then the microprocessor

would dump the full load amps value

RETURNED ANSWER:

XXX = 3 characters followed by a carriage return, line

feed.

RETURN TEMPERATURES COMMAND: #01TX

the Slide Valve must be in the remote mode for this

command to be executed. Time is not accrued, each

command restarts timer.

RETURNED ANSWER (for L or U commands): A01

Character

Position

Description

of returned data

1 Acknowledge of command sent.

2, 3 ID code of compressor.

(Carriage return, line feed.)

RETURNED ANSWER (for S command), i.e. 090

1,2,3 Slide Valve position.

RETURN SLIDE STOP POSITION COMMAND: #01VP

# Start command sequence.

01 Compressor ID code.

V Slide Valve/Slide Stop command.

P Return Slide Stop position value.

RETURNED ANSWER:

Character

Position

Description

of returned data

1 Acknowledge of command sent.

2, 3 ID code of compressor.

4, 5, 6 Slide Stop position, i.e. 025=2.5.

(Carriage return, line feed.)

# Start command sequence.

01 Compressor ID code.

T Return temperature command.

X = S Return Suction Temperature.

X = D Return Discharge Temperature.

X = O Return Oil Temperature.

X = P Return Separator Temperature.

X = A Return all temperatures as a string of data.

If the command was #01TS, then the microprocessor

would dump the Suction Temperature.

Note: Don’t send CR or LF

RETURNED ANSWER:

XXX = 3 characters followed by a carriage return, line

feed.

If using the A command, then the returned data would

be:

XXXXXXXXXXXX = 12 characters followed by a

carriage return, line feed.

NOTE: The S command will return four (4) characters: a +

or - and xxx, followed by a carriage return, and a line feed.

Page 13

®

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 CS (APR 08)

FRICK

COMMUNICATIONS SETUP Page 13

QUERY SETPOINTS DATA - #IDQ1 will return

Position # Byte(s) Setpoint (Name/Comment)

1 1 Always 0

2, 3, 4, 5 4 Capacity Control Setpoint,

3 chars followed by g or h

14, 15 2 Prop band

16, 17 2 Dead band

18, 19 2 Cycle time

20, 21, 22, 23 4 Future

24, 25, 26, 27 4 Future

28, 29, 30, 31 4 Future

32, 33 2 Future

34, 35 2 Future

36, 37 2 Future

38, 39, 40, 41 4 High Discharge Pressure

Shutdown

42, 43, 44, 45 4 High Discharge Press. Alarm

46 1 ID (tenths position byte)

47 1 ID (ones position byte)

48 1 ID Checksum of all data (pos.

1 to 47)

49 1 CR code 13

50 1 LF code 10

51 1 0 null terminator char.

QUERY SETPOINTS DATA - #IDQ2 will return

Position # Byte(s) Setpoint (Name/Comment)

1, 2, 3 3 Future

4, 5, 6 3 Future

7, 8, 9 3 MLC amps stop load

10, 11, 12 3 MLC amps force unload

13, 14, 15 3 CT factor

16, 17 2 Recycle delay (setpoint, not

time left)

18 1 Aux 1 0=alarm, 1=shutdown

19 1 Aux 1 0=NO, 1=NC

20 1 Aux 2 0=alarm, 1=shutdown

21 1 Aux 2 0=NO, 1=NC

22 1 Future

23, 24 2 Future

25 1 Future

26 1 Future

27, 28 2 Future

29 1 Future

30 1 ID (tenths position byte)

31 1 ID (ones position byte)

32 1 ID Checksum of all data

(pos. 1 to 47)

33 1 CR code 13

34 1 LF code 10

35 1 0 null terminator char.

QUERY SETPOINTS DATA - #IDQ3 will return

Position # Byte(s) Setpoint (Name/Comment)

1, 2, 3, 4 4 Spaces

5, 6, 7, 8 4 Future

9 1 Setback active 1=yes, 0=no

10, 11, 12, 13 4 Auto. cycling comp. start

14, 15, 16, 17 4 Auto. cycling comp. stop

18, 19 2 Future

20, 21 2 Future

22, 23 2 Autocycle min. Slide Valve

24 1 Autocycle active 0=no 1=yes

25, 26, 27, 28 4 Future

29, 30, 31, 32 4 Future

33, 34 2 Future

35, 36 2 Future

37, 38 2 Future

39 1 Future

40 1 ID (tenths position byte)

41 1 ID (ones position byte)

42 1 ID Chksum of data (pos 1-47)

43 1 CR code 13

44 1 LF code 10

45 1 0 null terminator char.

CHANGE SETPOINTS COMMAND: #01C

# Start command sequence.

01 Compressor ID code.

C Change setpoint command.

xx Which setpoint

xxx New value

y g or h for gauge or inches

The following is the complete list of setpoints that may

be changed while in the change setpoints command:

01xxxy Capacity Control Setpoint

(y deleted for KpaA & BarA ver.)

02xxxy Change Low Suction Shutdown Setpoint

(y deleted for KpaA & BarA ver.)

03xxxy Capacity Low Suction Alarm Setpoint

(y deleted for KpaA & BarA ver.)

04xxx Change High Press. Shutdown Setpoint

(xxxx is used for KpaA & BarA ver.)

05xxx Change High Press. Alarm Setpoint

(xxxx is used for KpaA & BarA ver.)

06xxx Change MLC Stop Load Setpoint

07xxx Change MLC Force Unload Setpoint

08xx Change Recycle Delay Setpoint

09xxx Change CTF Setpoint

10xx Proportional Band

11xx Dead Band

12xx Cycle Time

01 Compressor ID code

RETURNED ANSWER:

Axxxx The new setpoint which was sent followed by a

carriage return, line feed. BAD followed by the

ID, CR, LF if unsuccessful.

If the command was sent #01C01300g01, the capacity

control setpoint would be changed to 30.0g and the

returned answer is A300g followed by a carriage return,

line feed. If the command was sent #01C0711001, the

MLC force unload setpoint would be changed to 110%

and the returned answer is A110 followed by a carriage

return, line feed. If the command sent was

#01C0520002, the returned answer is BAD followed by

the ID number and a carriage return, line feed.

Page 14

®

S90-010 CS (APR 08) FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 14 COMMUNICATIONS SETUP

CHANGE COMPRESSOR MODE COMMAND:

#IDMCmID Change mode to m.

M or O = off A = Autocycle R = remote

Return message - A followed by the ID, CR, LF if

successful.

CHANGE SLIDE VALVE MODE COMMAND:

#IDMVmID Change Slide Valve mode.

to m. A = auto R = remote

Return message - A followed by the ID, CR, LF if

successful.

CLEAR FAILURE COMMAND:

#IDKFID Clear Fails

Return message - A followed by the ID, CR, LF if

successful.

CLEAR ANTIRECYCLE COMMAND:

#IDKRID Clear Recycle Delay

Return message - A followed by the ID, CR, LF if

successful.

RETURN FAILURE COMMAND:

#IDF Return Discrete Failure List Command:

Returns a 24 char data string followed by ID, CR, LF.

Position Alarm Description

1 High Discharge Pressure Shutdown

2 High Discharge Pressure Alarm

3 Low Suction Pressure Shutdown

4 Low Suction Pressure Alarm

5 Low Oil Pressure Shutdown and/or

Differential Oil Pressure Shutdown

6 Low Oil Pressure Alarm

7 High Oil Temperature Shutdown

8 High Oil Temperature Alarm

9 Low Oil Temperature Shutdown

10 Low Oil Temperature Alarm

11 High Discharge Temperature Shutdown

12 High Discharge Temperature Alarm

13 Compressor Aux. Fail- Shutdown

14 Pump Aux. Fail- Shutdown

15 Oil Level Shutdown

16 Unused - 0

17 High Oil Filter Pressure Alarm

18 Unused - 0

19 Auxiliary 1 Alarm/Shutdown

20 Auxiliary 2 Alarm/Shutdown

21 Low Motor Current - Shutdown

22 Sensor Fault

23 Unused - 0

24 Unused - 0

0 = safe 1 = alarm/shutdown

Page 15

®

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 CS (APR 08)

FRICK

COMMUNICATIONS SETUP Page 15

Quantum™ $ Protocol Specifications

Quantum™ ($) protocol commands have been added

specifically for the Quantum™. Unless otherwise shown, 9

characters are returned from the Quantum™ for a data

value. The data value includes two decimal fields and the

first character position is either; - if the value is negative,

or it is + if the value is positive. For example, if the data’s

value is 25.5; then the value +00002550 is sent. All

temperatures are in degree C and all pressures are in

PSIA. A mode such as Slide Valve mode is returned as an

integer value that represents the mode that it is in. For

example, a +00000000 is sent if it is in manual, or a

+00000100 is sent if it is in automatic, or a +00000200 is

sent if it is in remote. The value zero +00000000 is used to

represent an OFF status and a DISABLED option. The

value one +00000100, which is received as a 1, is used to

represent an ON status and an ENABLED option.

Setpoints are only changed if the value sent is within the

acceptable range. Reference the Frick

Control Panel Maintenance publication S90-010 M for the

setpoints default settings and ranges. The checksum is

the 2 byte hexadecimal sum of each character within the

command or returned answer excluding the command

type identifier, $. If the command’s checksum is replaced

with ??, the Quantum™ returns a response without using

checksum error checking on the received command (refer

to the Data Packet section for more information). If the

Quantum™ detects a checksum error, a N (Not

Acknowledged), the Compressor ID code, 02, Carriage

return, and Linefeed are returned.

This document will demonstrate how to communicate to the

Quantum™ panel using the tables that appear on the

following pages.

Data Packet

If you were interested in viewing the information that is

displayed on the Operating Status - Page 1 screen

(Home screen), you would want to refer to the table

entitled RETURN OPERATING STATUS Page 1 data:

$01D1 table on the next page.

The quickest and easiest way to demonstrate this protocol

is through Hyperterminal (see the section entitled

Hyperterminal later in this manual). After setting up

Hyperterminal and ensuring that all wiring and jumper

configurations are correct, type a $ symbol. This is the

character that will alert all of the Quantum™ panels on the

communications line that data is on its way. Following the $

symbol, type the ID code of the Quantum™ that you wish

to query (for instance 01 for the first Quantum™). After the

ID number, type a D1. The protocol code in the Quantum™

recognizes this portion of the data packet as a request for

the data that is displayed on the Operating Status - Page

1 screen.

Up to now you have typed the following information:

$01D1. The next thing that must be done is to enter a

checksum value. You may elect to type in a ?? as a

wildcard if you do not have the time to figure the correct

checksum, however, the information that is returned may or

may not always be reliable. The checksum will ensure

reliability.

®

Quantum™

To arrive at the checksum value for the command you have

just typed, you will need to convert each ASCII digit into

hexadecimal (do not include the $ symbol). For this

example, you will need to take the first digit 0, and referring

to the Conversion Chart at the end of this section, look

down the ASCII column until you find 0. You will notice that

the Hexadecimal equivalent for ASCII 0 is 30 hex. Repeat

the process of looking up each digit in the ASCII column,

and finding its equivalent in the Hexadecimal column, and

write each value down. When all four digits (01D1) have

been converted to hexadecimal, you will need to add the

four values together. Remember, the values are in

hexadecimal format, not decimal. If you are not familiar

with hexadecimal math, you may wish to utilize the

calculator that comes with Microsoft Windows. Look at the

following chart:

ASCII Value of

Data Packaet

Hexadecimal

Equivalent

0 30

1 31

D 44

1 31

Hex Total = D6

The answer that is arrived at from the previous chart is D6.

This will become the checksum for the data packet, and is

appended to the end of the data that has so far been typed

in.

NOTE: For any calculation that results in an answer of

more than two digits, use only the right most two digits, and

disregard all digits to the left.

The result should look like this:

$01D1D6

Press the [Enter] key. You should see an immediate

response. The format of this response should resemble

something (but not necessarily exactly) like:

A01+00006166+00008618+00008272+00002974+000154

15+00005314+00008501+00000000+00000000+0000000

0+00000341+00000231-00027249B6

Referring to the RETURN OPERATING STATUS Page 1

data: $01D1 table on the next page, we find that the first

line of the response, A01, indicates that an

Acknowledgement (A) was received from device 01 (01).

This is followed by +00006166 (Suction Pressure). The

plus (+) symbol indicates a positive value, followed by

00006166. Since there are two decimal positions assumed,

0006166 equals 61.66 PSIA. Using the +/- symbols as a

delimiter in the above example, each section of 8 digits can

be interpreted by comparing it with the Operating Status

table. The B6 value at the very end of the response is the

checksum value that the Quantum™ returned, not actual

data.

Page 16

®

S90-010 CS (APR 08) FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 16 COMMUNICATIONS SETUP

The following is a complete list of available $ command

types:

COMMAND CODE and DESCRIPTION

D1 = Operating Status Display Page 1.

D2 = Operating Status Display Page 2.

D3 = Operating Status Display Page 3.

D4 = Operating Status Display Page 4.

s0 = Suction Pressure Capacity Control Page 0.

s1 = Suction Pressure Capacity Control Page 1.

s2 = Suction Pressure Capacity Control Page 2.

p0 = Process Temperature Capacity Control Pg.0.

p1 = Process Temperature Capacity Control Pg.1.

p2 = Process Temperature Capacity Control Pg.2.

p3 = Process Temperature Capacity Control Pg.3.

d0 = Discharge Pressure Capacity Control Page 0.

d1 = Discharge Pressure Capacity Control Page 1.

d2 = Discharge Pressure Capacity Control Page 2.

d3 = User Selectable Control Page 3.

d4 = User Selectable Control Page 4.

d5 = User Selectable Control Page 5.

F1 = Alarms/Shutdowns Annunciation Page 1.

F2 = Alarms/Shutdowns Annunciation Page 2.

F3 = Alarms/Shutdowns Annunciation Page 3.

CT = Compressor Start.

CP = Compressor stop.

CL = Compressor load.

CU = Compressor unload.

MM = Compressor mode - Manual.

MA = Compressor mode - Autocycle.

MR = Compressor mode - Remote.

VA = Slide Valve mode - Automatic.

VR = Slide Valve mode – Remote.

S2 = Compressor sequence – activate

S3 = Compressor sequence – de-activate.

T1 = Read a value from the Table.

CS = Change a setpoint in the Table.

The following is a detailed description of each command:

RETURN OPERATING STATUS Page 1 data: $01D1

$ Start of command sequence.

01 Compressor ID code.

D1 Operating Status – Page 1 command.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Suction Pressure

13 Suction Temperature

22 Discharge Pressure

31 Discharge Temperature

40 Oil Pressure

49 Oil Temperature

58 Filter Differential

67 Motor Current

76 FLA%

85 Kilowatts

94 Slide Valve

103 Slide Stop

112 Process Temperature

121 CS (Checksum followed by Carriage

return, Line feed.)

RETURN OPERATING STATUS Page 2 data: $01D2

$ Start of command sequence.

01 Compressor ID code.

D2 Operating Status – Page 1 command.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Alarm Status

13 Shutdown Status

22 Running Status

31 Slide Valve Load

40 Slide Valve Unload

49 Slide Stop Increase

58 Slide Stop Decrease

67 Stop Load/Force Unload Code

76 Separator Temperature

85 Balance Piston Pressure

94 Process Variable

103 Compressor Mode

112 CS (Checksum followed by Carriage

RETURN OPERATING STATUS Page 3 data: $01D3

return, Line feed.)

$ Start of command sequence.

01 Compressor ID code.

D3 Operating Status – Page 1 command.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Communication Port 1 Code

13 Communication Port 2 Code

22 I/O Communication Port Code

31 Capacity Control Mode

40 Process Control

49 Oil Pump Mode

58 Oil Pump Code

67 Oil Heater Code

76 Process Setpoint

85 Slide Valve Mode

94 Slide Stop Mode

103 Runtime Hours

112 CS (Checksum followed by Carriage

return, Line feed.)

Page 17

®

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 CS (APR 08)

FRICK

COMMUNICATIONS SETUP Page 17

RETURN OPERATING STATUS Page 4 data: $01D4

$ Start of command sequence.

01 Compressor ID code.

D4 Operating Status – Page 1 command.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Date as 00/00/00

13 Time as hh:mm:ss

23 Remaining Recycle time as mm:ss

30 CS (Checksum followed by Carriage

return, Line feed.)

RETURN Suction Pressure Capacity Control

Mode 1 & 2 setpoints – Page 0: $01s0

$ Start of command sequence.

01 Compressor ID code.

s0 Suction Press. Cap. Control Page 0

command.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Suction Pressure Control Setpoint 1

13 Suction Press. Upper Prop. Band 1

22 Suction Press. Lower Prop. Band 1

31 Suction Press. Upper Dead Band 1

40 Suction Press. Lower Dead Band 1

49 Suction Press. Upper Cycle Time 1

58 Suction Press. Lower Cycle Time 1

67 Suction Press. Auto Start Setpoint 1

76 Suction Press. Auto Stop Setpoint 1

85 Suction Press. Auto Start delay 1

94 Suction Press. Auto Stop delay 1

103 CS (Checksum followed by Carriage

return, Line feed.)

RETURN Suction Pressure Capacity Control

Mode 1 & 2 setpoints – Page 1: $01s1

$ Start of command sequence.

01 Compressor ID code.

S1 Suction Press. Cap. Control Page 1

command.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Suction Pressure Control Setpoint 2

13 Suction Press. Upper Prop. Band 2

22 Suction Press. Lower Prop. Band 2

31 Suction Press. Upper Dead Band 2

40 Suction Press. Lower Dead Band 2

49 Suction Press. Upper Cycle Time 2

58 Suction Press. Lower Cycle Time 2

67 Suction Press. Auto Start Setpoint 2

76 Suction Press. Auto Stop Setpoint 2

85 Suction Press. Auto Start delay 2

94 Suction Press. Auto Stop delay 2

103 CS (Checksum followed by Carriage

return, Line feed.)

RETURN Suction Pressure Capacity Control

Mode 1 & 2 setpoints – Page 2: $01s2

$ Start of command sequence.

01 Compressor ID code.

S2 Suction Press. Cap. Control Page 2

command.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Suction Press. Stop Load 1

13 Suction Press. Force Unload 1

22 Suction Press. Low Alarm 1

31 Suction Press. Low Shutdown 1

40 Suction Press. Low Alarm delay 1

49 Suction Press. Low Shutdown delay 1

58 Suction Press. Stop Load 2

67 Suction Press. Force Unload 2

76 Suction Press. Low Alarm 2

85 Suction Press. Low Shutdown 2

94 Suction Press. Low Alarm delay 2

103 Suction Press. Low Shutdown delay 2

104 CS (Checksum followed by Carriage

return, Line feed.)

Page 18

®

S90-010 CS (APR 08) FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 18 COMMUNICATIONS SETUP

RETURN Process Temperature Capacity Control

Mode 1 & 2 setpoints – Page 0: $01p0

$ Start of command sequence.

01 Compressor ID code.

p0 Process Temperature Cap. Control Page 0

command.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Process Temperature Control 1

13 Process Temperature Upper Prop. Band 1

22 Process Temperature Lower Prop. Band 1

31 Process Temperature Upper Dead Band 1

40 Process Temperature Lower Dead Band 1

49 Process Temperature Upper Cycle Time 1

58 Process Temperature Lower Cycle Time 1

67 Process Temperature Auto Start Setpoint 1

76 Process Temperature Auto Stop Setpoint 1

85 Process Temperature Auto Start delay 1

94 Process Temperature Auto Stop delay 1

103 CS (Checksum followed by Carriage

return, Line feed.)

RETURN Process Temperature Capacity Control

Mode 1 & 2 setpoints – Page 1: $01p1

$ Start of command sequence.

01 Compressor ID code.

p1 Process Temperature Cap. Control Page 1

command.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Process Temperature Control 2

13 Process Temperature Upper Prop. Band 2

22 Process Temperature Lower Prop. Band 2

31 Process Temperature Upper Dead Band 2

40 Process Temperature Lower Dead Band 2

49 Process Temperature Upper Cycle Time 2

58 Process Temperature Lower Cycle Time 2

67 Process Temperature Auto Start Setpoint 2

76 Process Temperature Auto Stop Setpoint 2

85 Process Temperature Auto Start delay 2

94 Process Temperature Auto Stop delay 2

103 CS (Checksum followed by Carriage

return, Line feed.)

RETURN Process Temperature Capacity Control

Mode 1 & 2 setpoints – Page 2: $01p2

$ Start of command sequence.

01 Compressor ID code.

p2 Process Temperature Capacity Control

Page 2 command.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Process Temperature Stop Load 1

13 Process Temperature Force Unload 1

22 Process Temperature Low Alarm 1

31 Process Temperature Low Shutdown 1

40 Process Temperature Low Alarm delay 1

49 Process Temp. Low Shutdown delay 1

58 Process Temperature Stop Load 2

67 Process Temperature Force Unload 2

76 Process Temperature Low Alarm 2

85 Process Temperature Low Shutdown 2

94 Process Temperature Low Alarm Delay 2

103 Process Temp. Low Shutdown Delay 2

112 CS (Checksum followed by Carriage

return, Line feed.)

RETURN Process Temperature Capacity Control

Mode 1 & 2 setpoints – Page 3: $01p3

$ Start of command sequence.

01 Compressor ID code.

p3 Process Temperature Cap. Control Page 3

command.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Process Temp. Low Suction Stop Load 1

13 Process Temp. Low Suction Force Unload 1

22 Process Temp. Low Suction Alarm 1

31 Process Temp. Low Suction Shutdown 1

40 Process Temp. Low Suction Alarm delay 1

49 Process Temp. Low Suction Shutdown Dly 1

58 Process Temp. Low Suction Stop Load 2

67 Process Temp. Low Suction Force Unload 2

76 Process Temp. Low Suction Alarm 2

85 Process Temp. Low Suction Shutdown 2

94 Process Temp. Low Suction Alarm Delay 2

103 Process Temp. Low Suction Shutdown Dly 2

112 CS (Checksum followed by Carriage return,

Line feed.)

Page 19

®

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 CS (APR 08)

FRICK

COMMUNICATIONS SETUP Page 19

RETURN Discharge Pressure Capacity Control

Mode 1 & 2 setpoints – Page 0: $01d0

$ Start of command sequence.

01 Compressor ID code.

D0 Discharge Pressure Capacity Control

Page 0 command

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Description of returned data

Position

1 A Acknowledge

2 01 Compressor ID code.

4 Discharge Pressure Control 1

13 Discharge Pressure Upper Prop. Band 1

22 Discharge Pressure Lower Prop. Band 1

31 Discharge Pressure Upper Dead Band 1

40 Discharge Pressure Lower Dead Band 1

49 Discharge Pressure Upper Cycle Time 1

58 Discharge Pressure Lower Cycle Time 1

67 Discharge Pressure Auto Start Setpoint 1

76 Discharge Pressure Auto Stop Setpoint 1

85 Discharge Pressure Auto Start Delay 1

94 Discharge Pressure Auto Stop Delay 1

103 CS (Checksum followed by Carriage

return, Line feed.)

RETURN Discharge Pressure Capacity Control

Mode 1 & 2 setpoints – Page 1: $01d1

$ Start of command sequence.

01 Compressor ID code.

D1 Discharge Press. Cap. Control Page 1

command

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Discharge Pressure Control 2

13 Discharge Pressure Upper Prop. Band 2

22 Discharge Pressure Lower Prop. Band 2

31 Discharge Pressure Upper Dead Band 2

40 Discharge Pressure Lower Dead Band 2

49 Discharge Pressure Upper Cycle Time 2

58 Discharge Pressure Lower Cycle Time 2

67 Discharge Pressure Auto Start Setpoint 2

76 Discharge Pressure Auto Stop Setpoint 2

85 Discharge Pressure Auto Start delay 2

94 Discharge Pressure Auto Stop delay 2

103 CS (Checksum followed by Carriage

return, Line feed.)

RETURN Discharge Pressure Capacity Control

Mode 1 & 2 setpoints – Page 2: $01d2

$ Start of command sequence.

01 Compressor ID code.

D2 Discharge Pressure Capacity Control

Page 2 command

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Discharge Pressure Stop Load 1

13 Discharge Pressure Force Unload 1

22 Discharge Pressure Low Alarm 1

31 Discharge Pressure Low Shutdown 1

40 Discharge Pressure Low Alarm delay 1

49 Discharge Pressure Low Shutdown delay 1

58 Discharge Pressure Stop Load 2

67 Discharge Pressure Force Unload 2

76 Discharge Pressure Low Alarm 2

85 Discharge Pressure Low Shutdown 2

94 Discharge Pressure Low Alarm delay 2

103 Discharge Pressure Low Shutdown delay 2

112 CS (Checksum followed by Carriage

return, Line feed.)

RETURN Discharge Pressure Capacity Control

Mode 1 & 2 setpoints – Page 3: $01d3

$ Start of command sequence.

01 Compressor ID code.

D3 Discharge Press. Cap. Control Page 3

command

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 User Selectable Control 1

13 User Selectable Upper Prop. Band 1

22 User Selectable Lower Prop. Band 1

31 User Selectable Upper Dead Band 1

40 User Selectable Lower Dead Band 1

49 User Selectable Upper Cycle Time 1

58 User Selectable Lower Cycle Time 1

67 User Selectable Auto Start Setpoint 1

76 User Selectable Auto Stop Setpoint 1

85 User Selectable Auto Start Delay 1

94 User Selectable Auto Stop Delay 1

103 CS (Checksum followed by Carriage return

Line feed.)

Page 20

®

S90-010 CS (APR 08) FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 20 COMMUNICATIONS SETUP

RETURN Discharge Pressure Capacity Control

Mode 1 & 2 setpoints – Page 4: $01d4

$ Start of command sequence.

01 Compressor ID code.

d4 Discharge Pressure Capacity Control

Page 4 command

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 User Selectable Control 2

13 User Selectable Upper Prop. Band 2

22 User Selectable Lower Prop. Band 2

31 User Selectable Upper Dead Band 2

40 User Selectable Lower Dead Band 2

49 User Selectable Upper Cycle Time 2

58 User Selectable Lower Cycle Time 2

67 User Selectable Auto Start Setpoint 2

76 User Selectable Auto Stop Setpoint 2

85 User Selectable Auto Start delay 2

94 User Selectable Auto Stop delay 2

103 CS (Checksum followed by Carriage return,

Line feed.)

RETURN Discharge Pressure Capacity Control

Mode 1 & 2 setpoints – Page 5: $01d5

$ Start of command sequence.

01 Compressor ID code.

d5 Discharge Press. Cap. Control Page 5

command

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 User Selectable Stop Load 1

13 User Selectable Force Unload 1

22 User Selectable Low Alarm 1

31 User Selectable Low Shutdown 1

40 User Selectable Low Alarm delay 1

49 User Selectable Low Shutdown delay 1

58 User Selectable Stop Load 2

67 User Selectable Force Unload 2

76 User Selectable Low Alarm 2

85 User Selectable Low Shutdown 2

94 User Selectable Low Alarm Delay 2

103 User Selectable Low Shutdown Delay 2

112 CS (Checksum followed by Carriage return,

Line feed.)

RETURN Alarms & Shutdowns – Page 1 $01F1

$ Start of command sequence.

01 Compressor ID code.

F1 Failure Annunciation command Page 1.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Message Code 1

7 Date 1 as mm/dd/yy

15 Time 1 as hh:mm:ss

23 Space

24 Message Code 2

27 Date 2 as mm/dd/yy

35 Time 2 as hh:mm:ss

43 Space

44 Message Code 3

47 Date 3 as mm/dd/yy

55 Time 3 as hh:mm:ss

63 Space

64 Message Code 4

67 Date 4 as mm/dd/yy

75 Time 4 as hh:mm:ss

83 Space

84 Message Code 5

87 Date 5 as mm/dd/yy

95 Time 5 as hh:mm:ss

103 Space

104 Message Code 6

107 Date 6 as mm/dd/yy

115 Time 6 as hh:mm:ss

123 Space

124 CS (Checksum followed by Carriage return,

Line feed.)

Page 21

®

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 CS (APR 08)

FRICK

COMMUNICATIONS SETUP Page 21

RETURN Alarms & Shutdowns – Page 2 $01F2

$ Start of command sequence.

01 Compressor ID code.

F2 Failure Annunciation command Page 2.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Message Code 7

7 Date 7 as mm/dd/yy

15 Time 7 as hh:mm:ss

23 Space

24 Message Code 8

27 Date 8 as mm/dd/yy

35 Time 8 as hh:mm:ss

43 Space

44 Message Code 9

47 Date 9 as mm/dd/yy

55 Time 9 as hh:mm:ss

63 Space

64 Message Code 10

67 Date 10 as mm/dd/yy

75 Time 10 as hh:mm:ss

83 Space

84 Message Code 11

87 Date 11 as mm/dd/yy

95 Time 11 as hh:mm:ss

103 Space

104 Message Code 12

107 Date 12 as mm/dd/yy

115 Time 12 as hh:mm:ss

123 Space

124 CS (Checksum followed by Carriage return,

Line feed.)

RETURN Alarms & Shutdowns – Page 3 $01F3

$ Start of command sequence.

01 Compressor ID code.

F3 Failure Annunciation command Page 3.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Message Code 13

7 Date 13 as mm/dd/yy

15 Time 13 as hh:mm:ss

23 Space

24 Message Code 14

27 Date 14 as mm/dd/yy

35 Time 14 as hh:mm:ss

43 Space

44 Message Code 15

47 Date 15 as mm/dd/yy

55 Time 15 as hh:mm:ss

63 Space

64 Message Code 16

67 Date 16 as mm/dd/yy

75 Time 16 as hh:mm:ss

83 Space

84 Message Code 17

87 Date 17 as mm/dd/yy

95 Time 17 as hh:mm:ss

103 Space

104 Message Code 18

107 Date 18 as mm/dd/yy

115 Time 18 as hh:mm:ss

123 Space

124 CS (Checksum followed by Carriage

return, Line feed.)

Page 22

®

E

S90-010 CS (APR 08) FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 22 COMMUNICATIONS SETUP

RETURN DATA VALUE FROM TABLE $IDT1

$ Start of command sequence.

ID Compressor ID code.

T1 Return the value of a Table address.

0000 0000

0000 0000

0000 0000

0000 0000

0000 0000

0000 0000

0000 0000

0000 0000

®

Frick

Address(s) of data value in Table. Up

to 16 different addresses can be requested.

Example # 1: if requesting Suction

Temperature only, command would be (to

compressor ID of 1); $01T10128CSCR.

Example # 2: If requesting address 128

through 136, the command would be

$01T101280129013001310132013301340

1350136CSCR.

CS Checksum

CR Carriage Return

RETURNED ANSWER,

Starting

Character

Position

Description

of returned data

1 A Acknowledge

2 01 Compressor ID code.

4 Value(s) of requested data.

CS (Checksum followed by CR, LF)

The response to example # 1 above would

look like: A01+000018731F, the plus

symbol (+) indicates that the data value

returned is positive.

The response to example # 2 above would

look like:

A01+00001873+00004901+00002949+000

05652-0027249+00008211+00013354

CHANGE SETPOINT COMMAND: $IDCS

+00000656+0000288109

$ Start of command sequence.

ID Compressor ID code.

CS Change Table address’s setpoint value.

0000 Frick®’s Table address of the setpoint.

+/- Polarity indicator (for the new setpoint).

0000 0000 Value of the new setpoint. Decimal point

assumed to two places (0000 00.00)

CS Checksum

CR Carriage Return

RETURNED ANSWER, A followed by the ID,

and 1 CR, LF if successful.

and 0 CR, LF if unsuccessful.

CLEAR ALARMS COMMAND: $IDCA

followed by the CS, CR

RETURNED ANSWER, A followed by the ID,

CR, LF if successful.

NOTE: The following commands are for remote

control of a compressor. A compressor should be in

both remote compressor mode and remote Slide Valve

or capacity mode for remote control.

COMPRESSOR START COMMAND: $IDCT

followed by the CS, CR

RETURNED ANSWER, A followed by the ID,

CR, LF if successful.

COMPRESSOR STOP COMMAND: $IDCP

followed by the CS, CR

RETURNED ANSWER, A followed by the ID,

CR, LF if successful.

SLIDE VALVE CONTROL COMMANDS: $IDCLXX

$IDCUXX

$ Start command sequence.

ID Compressor ID code.

C Slide Valve/Slide Stop command.

L Load Slide Valve command.

U Unload Slide Valve command.

XX = 00 Turns selected output off.

XX=01 to 15 Turns selected output on for XX seconds.

If the command is $01CL00, then the load Slide Valve

output on compressor #1 would be turned off. If the

command is $01CL05, then the load Slide Valve output

on compressor #1 would be turned on for 5 seconds,

and would then automatically turn off. Time is not

accrued, each command restarts timer. NOTE: the

Slide Valve must be in the remote mode for this

command to be executed.

RETURNED ANSWER (for L or U commands): A01

Character

Position

Description of returned data

1 Acknowledge of command sent.

2,3 ID code of compressor. (CR, line feed.)

COMPRESSOR MODE - MANUAL COMMAND: $IDMM

followed by the CS, CR

RETURNED ANSWER, A followed by the ID,

CR, LF if successful.

COMPRESSOR MODE - AUTOCYCLE COMMAND:

$IDMA

followed by the CS, CR

RETURNED ANSWER, A followed by the ID,

CR, LF if successful.

COMPRESSOR MODE - REMOTE COMMAND: $IDMR

followed by the CS, CR

RETURNED ANSWER, A followed by the ID,

CR, LF if successful.

SLIDE VALVE MODE - AUTOMATIC COMMAND:

$IDVA

followed by the CS, CR

RETURNED ANSWER, A followed by the ID,

CR, LF if successful.

SLIDE VALVE MODE - REMOTE COMMAND: $IDVR

followed by the CS, CR

RETURNED ANSWER, A followed by the ID,

CR, LF if successful.

COMPRESSOR SEQUENCE - ACTIVATE

COMMAND: $IDS2

followed by the CS, CR

RETURNED ANSWER, A followed by the ID,

CR, LF if successful.

COMPRESSOR SEQUENCE – DE-ACTIVAT

COMMAND: $IDS3

followed by the CS, CR

RETURNED ANSWER, A followed by the ID,

CR, LF if successful.

Page 23

®

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 CS (APR 08)

FRICK

COMMUNICATIONS SETUP Page 23

CONVERSION CHART FOR DECIMAL / HEXADECIMAL / ASCII

Decimal

(DEC)

Hexadecimal

(HEX)

0 0 ctrl @ NUL 43 2B + 86 56 V

1 1 ctrl A SOH 44 2C , 87 57 W

2 2 ctrl B STX 45 2D - 88 58 X

3 3 ctrl C ETX 46 2E . 89 59 Y

4 4 ctrl D EOT 47 2F / 90 5A Z

5 5 ctrl E ENQ 48 30 0 91 5B [

6 6 ctrl F ACK 49 31 1 92 5C \

7 7 ctrl G BEL 50 32 2 93 5D ]

8 8 ctrl H BS 51 33 3 94 5E ^

9 9 ctrl I HT 52 34 4 95 5F _

10 A ctrl J LF 53 35 5 96 60 '

11 B ctrl K VT 54 36 6 97 61 a

12 C ctrl L FF 55 37 7 98 62 b

13 D ctrl M CR 56 38 8 99 63 c

14 E ctrl N SO 57 39 9 100 64 d

15 F ctrl O SI 58 3A : 101 65 e

16 10 ctrl P DLE 59 3B ; 102 66 f

17 11 ctrl Q DC1 60 3C < 103 67 g

18 12 ctrl R DC2 61 3D = 104 68 h

19 13 ctrl S DC3 62 3E > 105 69 i

20 14 ctrl T DC4 63 3F ? 106 6A j

21 15 ctrl U NAK 64 40 @ 107 6B k

22 16 ctrl V SYN 65 41 A 108 6C l

23 17 ctrl W ETB 66 42 B 109 6D m

24 18 ctrl X CAN 67 43 C 110 6E n

25 19 ctrl Y EM 68 44 D 111 6F o

26 1A ctrl Z SUB 69 45 E 112 70 p

27 1B ctrl [ ESC 70 46 F 113 71 q

28 1C ctrl \ FS 71 47 G 114 72 r

29 1D ctrl ] GS 72 48 H 115 73 s

30 1E ctrl ^ RS 73 49 I 116 74 t

31 1F ctrl _ US 74 4A J 117 75 u

32 20 SPACE 75 4B K 118 76 v

33 21 ! 76 4C L 119 77 w

34 22 " 77 4D M 120 78 x

35 23 # 78 4E N 121 79 y

36 24 $ 79 4F O 122 7A z

37 25 % 80 50 P 123 7B {

38 26 & 81 51 Q 124 7C |

39 27 ' 82 52 R 125 7D }

40 28 ( 83 53 S 126 7E

41 29 ) 84 54 T 127 7F DEL

42 2A * 85 55 U

ASCII Decimal

(DEC)

Hexadecimal

(HEX)

ASCII Decimal

(DEC)

Hexadecimal

(HEX)

ASCII

∼

Page 24

®

S90-010 CS (APR 08) FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 24 COMMUNICATIONS SETUP

ALLEN-BRADLEY COMMUNICATION

To provide for the reading and writing of data to

Quantum™ panels using Allen-Bradley communication,

the Quantum™ has an Allen-Bradley DF1 communication

driver that recognizes both half-duplex and full duplex SLC

500 protected typed logical read and write commands.

This is a Master / Slave multi-drop communication

method. The Quantum™ talks Allen-Bradley SLC protocol

and is programmed to resemble an Allen-Bradley SLC500

slave station. The customer’s PLC or DCS must be setup