Page 1

S90-555 M/OCT 2001

File: SERVICE MANUAL - SECTION 90

Replaces: NOTHING (New Manual)

Dist: 3, 3a, 3b, 3c

MAINTENANCE

FRICK QUANTUM™

CONDENSER/VESSEL

CONTROL PANEL

VERSION 2.1x

Page 2

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 2 MAINTENANCE

Table of Contents

Quantum™ Identification _____________________________________________________________ 4

Quantum™ 3 ___________________________________________________________________ 4

Quantum™ 4 ___________________________________________________________________ 4

Troubleshooting ____________________________________________________________________ 4

The Quantum™ Control Panel______________________________________________________ 4

General Information ___________________________________________________________ 4

What To Do Before Calling The Factory ___________________________________________ 5

What Should Occur When Powering Up The Panel __________________________________ 5

What If The “Home” Screen Is Not Shown __________________________________________ 5

Troubleshooting GCU Board Analog And Digital Problems ________________________________ 7

“About” Screen _______________________________________________________________ 7

Diagnosing A GCU Board Problem _______________________________________________ 7

Troubleshooting Digital Inputs And Outputs ______________________________________ 8

Troubleshooting Analog Inputs And Outputs _____________________________________ 9

Adding And Replacing Boards ______________________________________________________ 9

Quantum™ __________________________________________________________________ 9

GCU Boards _________________________________________________________________ 9

Display Replacement _________________________________________________________ 10

Troubleshooting A Problem That Appears Unexplainable ________________________________ 10

Jumper And Dipswitch Settings _______________________________________________________ 11

Digital Board (Optional) __________________________________________________________ 11

Digital I/O Board Communications Settings ________________________________________ 11

Digital I/O Board Dipswitch Settings (DP1) ________________________________________ 11

Condenser / Vessel (GCU) Board:__________________________________________________ 12

Communications Port Connections ______________________________________________ 12

Additional Communications Jumper Configurations _________________________________ 12

GCU Board Dipswitch Settings _________________________________________________ 12

Vessel GCU Board Analog I/O Jumper Settings _______________________________________ 13

Analog Output Configurations __________________________________________________ 14

Condenser GCU Board Analog I/O Jumper Settings ____________________________________ 14

Analog Output Configurations __________________________________________________ 16

Quantum™ 3 Main Processor Board ___________________________________________________ 17

Motherboard Jumpers ___________________________________________________________ 17

Communications Board Jumpers ___________________________________________________ 18

Com-1 ____________________________________________________________________ 18

Com-2 ____________________________________________________________________ 18

Com-3 ____________________________________________________________________ 18

Communications Wiring __________________________________________________________ 18

Quantum™ 4 Main Processor Board ___________________________________________________ 19

Motherboard Jumpers ___________________________________________________________ 19

Communications Board Jumpers ___________________________________________________ 20

Com-1 ____________________________________________________________________ 20

Com-2 ____________________________________________________________________ 20

Communications Wiring __________________________________________________________ 20

Drawing Reference Table ___________________________________________________________ 21

Quantum™ Panel DC Power Supply Diagram (Condor) _________________________________ 22

Quantum™ Panel DC Power Supply Diagram (Power-One) ______________________________ 22

Quantum™ Control Center Assembly _______________________________________________ 23

Vessel Control Center Assembly __________________________________________________ 285

Wiring Diagram – Vessel W/O MOA ________________________________________________

Wiring Diagram – Vessel With MOA ________________________________________________ 37

Condenser Control Center Assembly _______________________________________________ 43

Wiring Diagram – Condenser______________________________________________________ 53

Quantum™ 3 Communications Wiring Diagrams ______________________________________ 59

31

Page 3

MAINTENANCE Page 3

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

Rs-485 Communications ______________________________________________________ 59

Rs-422 Communications ______________________________________________________ 59

Rs-232 Communications ______________________________________________________ 59

Quantum™ 4 Communications Wiring Diagrams ______________________________________ 60

Rs-485 Communications ______________________________________________________ 60

Rs-422 Communications ______________________________________________________ 60

Rs-232 Communications ______________________________________________________ 60

Convenser/Vessel Recommended Spare Parts __________________________________________ 61

Quantum™ Control Panel ________________________________________________________ 61

Remote Panel _________________________________________________________________ 61

Display Assembly Component Replacement Guide ____________________________________ 61

QUANTUM™ PUBLICATIONS

S90-555 CS Frick Quantum™ Condenser/Vessel Control

S90-555 O Frick Quantum™ Condenser/Vessel Control

E90-555 SD Frick Quantum™ Condenser/Vessel Control

DANGER

!

Panel COMMUNICATIONS SETUP (setup

and wiring for data communication using

available protocols)

Panel OPERATION

Panel SETPOINT DATA SHEETS

Indicates an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

WARNING

!

CAUTION

!

NOTE: Indicates an operating procedure, practice, etc., or

portion thereof which is essential to highlight.

Indicates a potentially hazardous

situation or practice which, if not

avoided, will result in death or

serious injury.

Indicates a potentially hazardous

situation or practice which, if not

avoided, will result in damage to

equipment and/or minor injury.

Page 4

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 4 MAINTENANCE

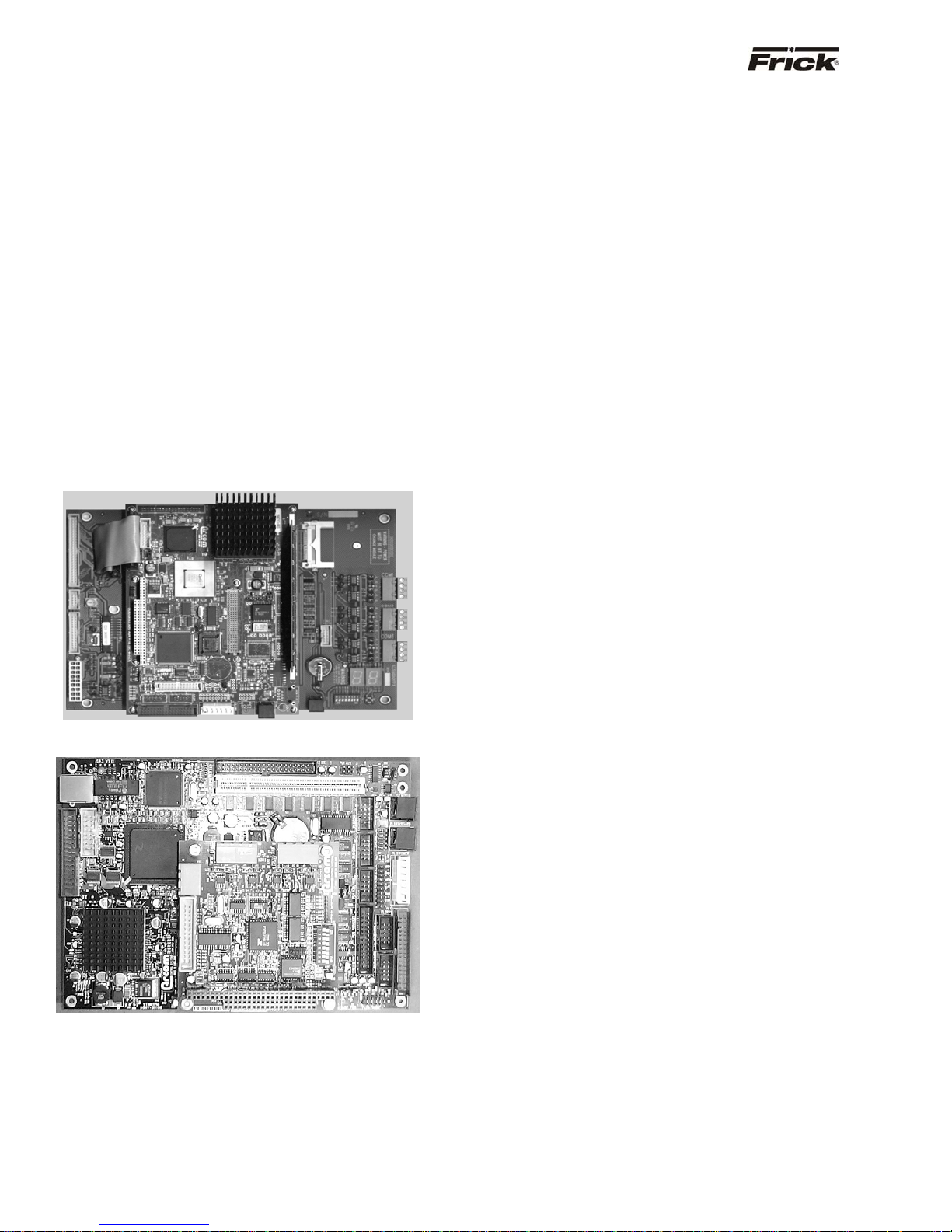

Quantum™ Identification

Frick Controls has over the years, strived to remain on the

cutting edge of microprocessor technology and

development. And because of the ever-increasing speed,

memory, features, and power of microprocessors, Frick

Controls will, from time to time, introduce the latest

advancement in microprocessor control technology.

Our microprocessor family has shared the name

Quantum™ over the past five years. There are currently

four controllers within this family. The first two of these

controllers (known as Quantum™ 1 and Quantum™ 2) are

no longer in production, and as such, will not be further

mentioned in this manual. The two current members in

production of the Quantum™ family are the Quantum™ 3,

and the Quantum™ 4. It is critical to the end user to be

able to identify the differences between these controllers.

Throughout this manual, the two different controllers will

be talked about for the most part as one (as they do

function the same). Where there is a difference between

these boards, as in jumpers or wiring, the different models

will be identified by name. This is why it is important for

you to be aware of which board you have.

Quantum™ 3

Quantum™ 4

TROUBLESHOOTING

THE QUANTUM™ CONTROL PANEL

This section contains information on troubleshooting and

making corrections to the boards and control circuits of the

Quantum™. Reference the drawings at the end of this

manual.

GENERAL INFORMATION:

The components within the control panel can be

inadvertently damaged by static electricity or

mishandling. Only qualified technicians should

directly handle these components.

1. DO NOT attempt to make corrections to the power

supply without shutting off power to the control

panel. Accidental shorts can irreparably damage

the processor boards or the display screen.

2. DO NOT HANDLE the panel boards when their

cables are disconnected without first attaching a

properly grounded wrist ground strap to prevent

static electrical discharge from your body.

Most problems encountered with the microprocessor and

control circuits will be the result of a wiring fault, a bl own

fuse, faulty I/O module or failure of a peripheral control

such as a solenoid coil or a pressure transducer. Faults in

the computer, while possible, are unlikely. If a fault

develops in the computer, the probability is that all

functions will cease and the display screen will go blank.

The control system consists of an AC (high voltage) sid e,

which can be either 120 volts, or 230 volts, and a DC (low

voltage) side. The AC side actuates solenoids, relays,

alarms, and other electromechanical functions. The DC

side operates the computer and it's various sensors.

When working within the panel, the AC high voltage

side, which can be either nominal 120 VAC or nominal

230 VAC, CAN CAUSE INJURY OR DEATH.

To troubleshoot the low-voltage side of the control circuits,

it is necessary to have the following tools:

1. Accurate digital multimeter*

2. Small wire stripper

3. Small screwdriver

4. Small snip nose pliers

5. Wrist Grounding strap*

6. Static free grounded work surface

Note: Proper panel voltage refers to the AC (high voltage) that has been supplied to the panel, which could

be either nominal 120 VAC or nominal 230 VAC

(Reference the Control Panel Power Specifications).

Some problems that are encountered involve

troubleshooting digital inputs and outputs.

The Digital I/O (Input/Output) board has six connectors

labeled P1 through P6. The input and output modules are

wired into a DIO connector plug. Position 3 provides 120

VAC power and position 4 is neutral.

The GCU Board has three digital inputs connectors,

labeled J7, J9, and J10. Each of these connectors has 16

pins. J10 is utilized for AC inputs, and use odd pin

numbers for 120 VAC signals, even pins for neutral. J9

and J10 are for AC outputs, and use even pins for 120

VAC hot, odd pins are for 120 VAC signals.

Page 5

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

MAINTENANCE Page 5

WHAT TO DO BEFORE CALLING THE FACTORY

The “Home” screen is shown.

When someone calls in to the factory with a Quantum™

related problem, many times there isn't enough

information provided. An example of this is the statement

that the Panel is not “booting” (the main processor board

is not starting). Unfortunately, this description is usually

vague and only means that there is nothing on the display.

A blank screen could be the result of many different

problems. Following is a list of possible reasons for no

display:

No power

Loose or Faulty Display Cable or Inverter Cable

Bad Display

Bad Backlight Inverter

Bad Backlight Fluorescent Tube

Faulty CPU Board

Wrong Combination of Display, Cable, Inverter,

or Software

Before calling the factory for assistance, review the

following information and try to discover what the problem

is, and resolve it.

WHAT SHOULD OCCUR WHEN POWERING UP

THE PANEL

The first thing that should be checked when

troubleshooting the Quantum™ is it’s powering up

sequence.

When powering up the Quantum™ the following sequence

of events are indicative of a properly working main

processor board:

Quantum™ 3

The LED’s for +5V, +12V, and –12V will turn

on solid. (Lower left corner of Main PCB)

LED KB will begin to blink. (Left side of Main

PCB)

Several initialization screens will appear

(these will look very similar to the way the

screen of a desktop computer appears when

it is booting.

The last of the initialization screens is the

“System Configuration” screen.

The screen will go blank for several seconds.

The “Home” screen is shown.

After the Quantum™ has properly powered up,

the following sequence of events is indicative of

proper communication to the GCU board:

The TX/RX LED’s near the white connector

will begin to blink.

The GCU board TX/RX lights should be

blinking.

Each GCU board should have the power

LED (next to the white connector) lighted

and the “Status” LED (next to the blue DIP

switch) should be blinking.

Quantum™ 4

Green PWR (Power) LED will turn on solid

(upper right corner of main PCB).

Red FLASH LED will begin to intermittently

during the Boot process. It will then go out

once the “Home” screen appears.

LED D8 (on the smaller board) will start to

blink at the rate of about once per second. It

will continue to blink after the Quantum™

has booted.

Once the screen displays “Loading…”, LED's

D4 , D5, D7 and D8 will be on solid.

The “Home” screen will appear.

After the Quantum™ has properly powered up,

the following sequence of events is indicative of

proper communication to the analog and digital

boards:

The TX/RX LED’s near the white connector

will begin to blink.

The GCU board TX/RX lights should be

blinking.

Each GCU board should have the power

LED (next to the white connector) lighted

and the “Status” LED (next to the blue DIP

WHAT IF THE “HOME” SCREEN IS NOT SHOWN

switch) should be blinking.

If the “Home” screen is not shown, check the following

items:

Quantum™ 3

1. If no LED’s are lighted, then check power AC

and DC.

2. Check if the lighting of the LED’s is occurring

as described in the “What Should Occur

When Powering Up The Panel” section.

If the powering up sequence continues

to repeat without displaying the “Home”

screen, then there is a booting problem.

3. Check if an error message is displayed when

booting.

Be sure to write down any error

4. Check that the software is OK:

messages that appear.

Is the correct software installed?

Did you just install new software?

If you need to clear the numerical

setpoint and calibration areas of

memory for any reason, clear the

memory as described in the S90-555

FSI publication. NOTE: This

information will be replaced by

factory default values, so any

setpoint and calibration data values

that need to be customized must be

reentered.

Page 6

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 6 MAINTENANCE

5. Check for bad connections.

6. Check the display. If the CPU board is

booting but you have no display, check the

following:

When working with the display, be

extremely cautious of the backlight

inverter board. This board is mounted

next to the display, and is used to

generate high voltage to drive the

displays fluorescent tube.

Check the LCD backlight tube. Look

very closely at the display to see if

anything is visible in the dark screen.

You will need good lighting and look for

any “ghost” type image. If it appears that

there is something on the screen but

very dark, the problem maybe the LCD

backlight tube. On the LG Philips, NEC

and Sharp displays this tube is field

replaceable. On the Samsung LCD

display, it is not available and the

display will have to be replaced. You

must take the display apart to identify

the display manufacturer.

Verify that both the display cable and

the inverter cable are firmly seated. It

may be necessary to remove the video

cable from the back of the LCD display

and reseat it to be sure it is connected

properly. Note: This is a small

connector and caution should be

observed so that it is not damaged

due to excessive force.

Check the backlight inverter connector

(P4). When the Quantum board is

mounted in the panel, this connector is

located at the middle left of the board.

The pins on the right side are odd

numbered, with pin P(1) at the bottom pin P(9) at the top. The pins on the left

side are even numbered, with pin P(2)

at the bottom - pin P(10) at the top. After

the Quantum has booted, pin P(3)

should measure +2.4Vdc, pins P(4) and

P(5) are DC grounds, and pins P(6) and

P(7) should measure +12Vdc. A bad

inverter will also cause a dark display.

Reference the “Display Assembly

Component Replacement Guide” at the

end of this manual, and check that the

LCD, LCD cable, and software versions

are matched correctly.

Quantum™ 4

1. If no LED’s are lighted, then check power AC

2. Check if the lighting of the LED’s is occurring

3. Check if an error message is displayed when

4. Check that the software is OK:

5. Check for bad connections.

6. Check the display. If the CPU board is

and DC.

as de-scribed in the “What Should Occur

When Powering Up The Panel” section.

If the powering up sequence continues

to repeat without displaying the “Home”

screen, then there is a booting problem.

booting.

Be sure to write down any error

messages that appear.

Is the correct software installed?

Did you just install new software?

If you need to clear the numerical

setpoint and calibration areas of

memory for any reason, clear the

memory as described in the S90-555

FSI publication. NOTE: This

information will be replaced by

factory default values, so any

setpoint and calibration data values

that need to be customized must be

reentered.

booting but you have no display, check the

following:

When working with the display, be

extremely cautious of the backlight

inverter board. This board is mounted

next to the display, and is used to

generate high voltage to drive the

displays fluorescent tube.

Check the LCD backlight tube. Look

very closely at the display to see if

anything is visible in the dark screen.

You will need good lighting and look for

any “ghost” type image. If it appears that

there is something on the screen but

very dark, the problem maybe the LCD

backlight tube. On the LG Philips, NEC

and Sharp displays this tube is field

replaceable. On the Samsung LCD

display, it is not available and the

display will have to be replaced. You

must take the display apart to identify

the display manufacturer.

Verify that both the display cable and

the inverter cable are firmly seated. It

may be necessary to remove the video

cable from the back of the LCD display

and reseat it to be sure it is connected

properly. Note: This is a small

connector and caution should be

observed so that it is not damaged

due to excessive force.

Reference the “Display Assembly

Component Replacement Guide” at the

end of this manual, and check that the

LCD, LCD cable, and software versions

are matched correctly.

Page 7

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

MAINTENANCE Page 7

TROUBLESHOOTING GCU BOARD ANALOG AND DIGITAL PROBLEMS

The information that follows in this section can help locate

problems that can occur with GCU Analog and Digital

input and output circuit boards.

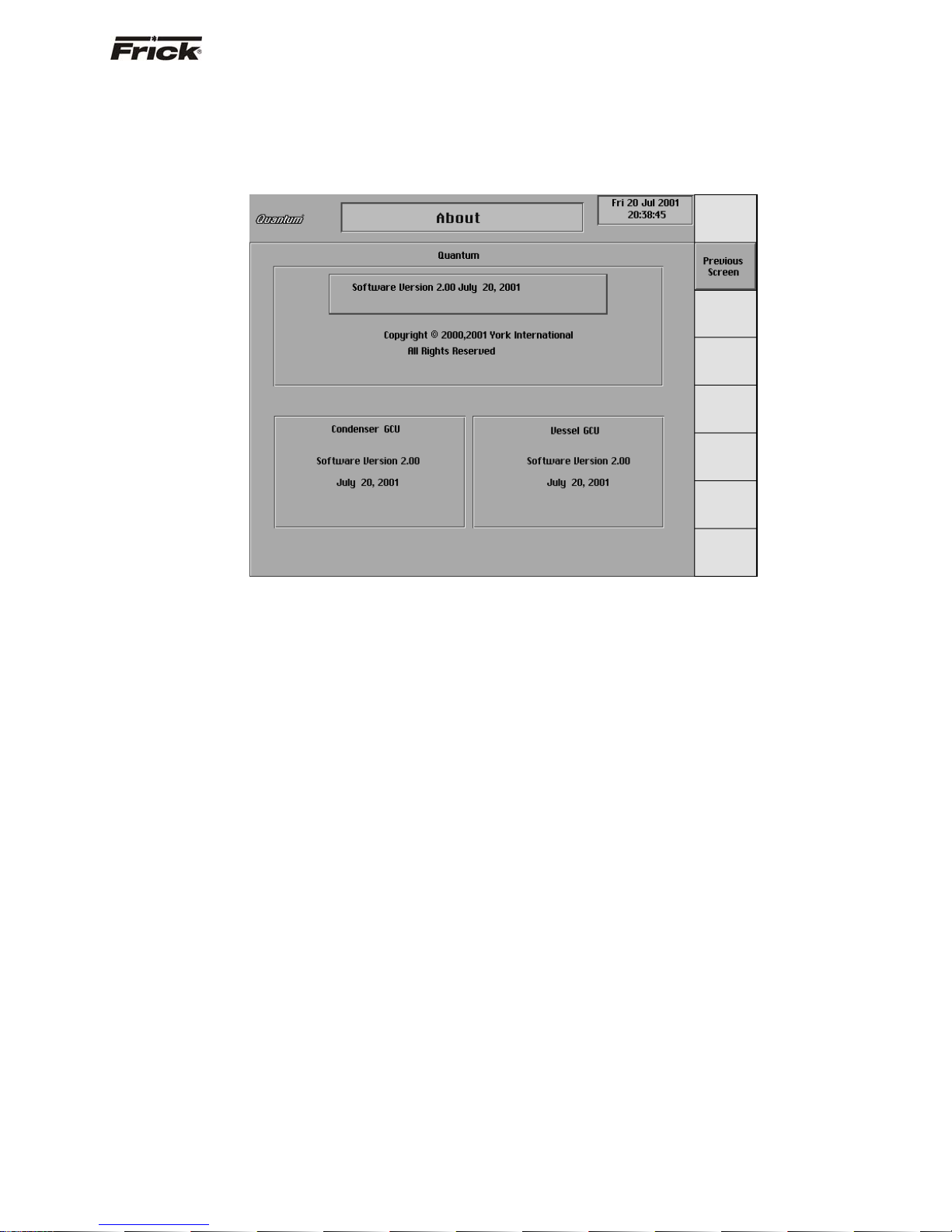

“About” Screen

The “About” screen shows any Condenser and Vessel

GCU board(s) that have been detected. If a board has lost

communications, the affected boards will continue to run

their internal programs.

Diagnosing a GCU Board Problem

The GCU Board (both Condenser and Vessel) have builtin features that help to troubleshoot faulty boards.

Following is a description of the built-in features:

1. The GCU Board has a “Status” LED indicator on

the board that blinks when the board’s software is

running.

If the “Status” LED is not blinking, check to

ensure that the EPROM is installed properly.

2. There are also 5 volt and 12 volt power LED's

that light when DC power is applied to the board.

If the either power LED is n ot lighted, check

the power harness for proper connectivity.

If the harness appears to be good, then

measure the voltages at the output of the DC

power supply.

3. The main indication of communications is the

RX/TX LED’s on the GCU board. These LED’s

should blink in response to the blinking of the

main processor board’s I/O communication

activity RX/TX LED’s. If the RX LED on the GCU

board is blinking but the board was not detected

on the “About” screen, or an I/O Comm failure

occurs, check the address of the board.

Reference the “JUMPER AND DIPSWITCH

SETTINGS” section later in this manual. This

section contains the dipswitch settings for

addressing all GCU Boards. When these

switches are properly set, the main

processor board is able to serially

communicate with each board and provide

data exchange.

Page 8

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 8 MAINTENANCE

“Condenser Service” - SCREEN - GCU Board Inputs and Outputs

“Vessel Service” - SCREEN - GCU Board Inputs and Outputs

Troubleshooting Digital Inputs and Outputs

The “Service Screen” (individual service screens are

available for both Condenser and Vessel) has been

provided to view the raw data from a GCU Board. There is

a separate screen for each of the GCU Boards that are

present. Digital values are shown as ON or OFF.

Checking the Digital Inputs and Outputs

Some problems that are encountered involve

troubleshooting the digital inputs and outputs. The Digital

I/O (Input / Output) boards have three Digital I/O (DIO)

board connectors labeled J7, J9 and J10. The input and

output modules are wired to a connector plug:

Input Module

On the input module, positions 1, 3, 5, 7, 9, 11,

13, and 15 provides neutral on the DIO

connectors. Positions 2, 4, 6, 8, 10, 12, 14, and

16 are signal connections. Input modules can

only occupy the eight positions adjacent to

connector J10.

Output Module

On the output module, positions 1, 3, 5, 7, 9, 11,

13, and 15 provides signal connections. Positions

2, 4, 6, 8, 10, 12, 14, and 16 are 120 volt AC on

the DIO connectors. Output modules can only

occupy the sixteen positions adjacent to

connectors J7 and J9. Notice also, that these

sixteen positions have fuses associated with

them.

Page 9

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

MAINTENANCE Page 9

An LED is associated with each I/O module and displays

the state of each module. A lighted LED represents an

Input that is “High” or an Output that is “On”.

If a properly configured GCU I/O is not responding

correctly, first look at the board on the appropriate

“Service Screen” (Condenser or Vessel) and check if the

module is on. If it is not on, check if the LED on the board

is also not lit. If the LED is not lit, then check the fuse. If

the fuse is OK, then check the module.

FUSE TESTING AND REPLACEMENT

1. Open the panel door.

2. Turn off circuit breaker 1CB.

3. Remove the questionable fuse.

4. Check the questionable fuse using a volt meter or

other reliable method. If the fuse is faulty, replace

the fuse with a new plug-type fuse (Part #

333Q0001326).

5. Turn on circuit breaker 1CB.

Input and Output Module Testing and

Replacement

1. Open the panel door.

2. Turn circuit breaker 1CB off.

3. Replace the questionable module.

4. Turn on circuit breaker 1CB.

5. If it is an output module, check for proper panel

voltage on the DIO connector plug. Check the

voltage between neutral the associated signal

position to the output module.

6. If it is an input module, check if the associated

LED is on when power is applied to the module.

Troubleshooting an Output

1. Make sure the LED associated with the output is

on when power is applied to the module.

2. If the LED is not on when it should be and there

is no operating condition preventing it, contact

the Frick Service Department.

3. If the LED is on when it should be, check for

proper panel voltage on the DIO connector plug.

Check the voltage between the neutral and the

associated position to the output module.

4. If the voltage is OK, check for proper panel

voltage between the associated position to the

output module on the DIO connector and the

associated position on the terminal strip.

5. If the voltage is OK, check the wiring external to

the panel.

6. If voltage is not OK, check the fuse.

7. If the fuse is OK then check the module.

8. If the module is OK, check for proper panel

voltage on the DIO connector plug between any

Troubleshooting an Input

odd numbered position (Hot) and neutral.

1. Ensure that the LED associated with the input is

on when power is applied to the module.

2. If the LED is on, and there is good in put voltage,

then the module is good.

3. If the LED is on and there is no input voltage,

replace the input module.

Troubleshooting Analog Inputs and Outputs

The “Service Screen” (both Condenser and Vessel) h ave

been provided to view the raw analog data from a GCU

Board. There is a separate screen for each of the GCU

Boards that are present. Analog values are converted from

binary to show volts. The error factor is .05 volts.

Checking Analog Inputs and Outputs

The GCU boards have numerous jumpers that must be

properly selected. There are eleven an alog input channels

that can be selected for 4-20ma, Resistance, 0-5Vdc, or

ICTD. All of these jumper settings are listed later in this

manual (Jumper and Dipswitch Settings Section). Besides

properly setting the hardware jumpers, each transducer

must be calibrated through the appropriate sensor

calibration screen. Improper setup of either the hard ware

or software will result in improper operation or range.

The most common fault associated with the reading of the

analog channels other than hardware or software setup

problems fall into one of the following categories: Sensor

fault, wiring problem, improper grounding of system.

An open wire, shorted wire, or faulty sensor will usually

give a reading at either the minimum, or maximum e nd of

the range scale. An erratic reading or a reading that

seems to float up and down is usually indicative of a

grounding problem. When a single transducer or cable is

shorted to earth (or system) ground, this can show up as a

whole assortment of problem channels. The easiest way

to find a short to earth problem is to disconnect all the

sensor plugs and ohm out each plug screw terminal to

earth for open (infinite) impedance. All sensors should

read open to earth.

ADDING AND REPLACING BOARDS

QUANTUM™

The procedure to replace the main board is outlined

below:

1. Shut off control power.

2. Remove the old board from the machine and the

new board from its packing and place both on an

anti-static surface.

3. Then install the modified replacement board in

the panel.

4. Verify that all jumpers are installed properly.

5. Follo w the directions in th e Factory Setup manu al

(S90-555 FSI) for the procedure to load a

program Flash Card.

The procedure to replace a GCU board is outlined below:

1. Shut off control power.

2. Remove the old board from the enclosure and

the new board from its packing and place bot h on

an anti-static surface.

3. Remove any required chip(s) from the defective

board and install them in the replacement board.

Align the notch at the end of the EPROM with the

notch in the socket.

Ensure that the GCU EPROM (installed into

GCU BOARDS

U22), has the proper label affixed to it. If the

GCU board being installed is to control a

vessel, then the EPROM label must be

printed with the words “GCU VESSEL”.

Likewise, if the GCU board is being installed

to control a condenser, then the EPROM

label must be printed with the words "GCU

Page 10

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 10 MAINTENANCE

CONDENSER". Additionally, the Version

number should match between all GCU

EPROMS, as well as the program version of

the Quantum (as shown on the

“About…”screen). As an example, if the

Quantum version is 2.11, then all GCU

boards must have version 2.11. The GCU

boards may have an additional digit in the

version number, such as 2.112. This final

digit is not critical with the compatibility of the

system.

4. Ensure that all jumpers, dip switches, I/O

modules and components are properly setup on

the new board as it was on the old board.

5. Install the modified replacement board in the

enclosure.

After replacing a GCU board, it will automatically be

detected after the Quantum power has been cycled off

then on. It will then be necessary to re-ente r all setpoints

and calibration data to the board. Refer to the Factory

Setup Instructions for more information (S90-555 FSI).

DISPLAY REPLACEMENT

1. Shut off control power.

2. Remove the defective display.

3. Install the new display.

TROUBLESHOOTING A PROBLEM THAT

When there is a problem that makes no sense due to

unexplainable things happening, then check the following:

APPEARS UNEXPLAINABLE

1. It is important to know if the unit ever worked

properly.

2. If the unit used to work properly, try to determine

when the problem first showed up.

3. It is important to know if the problem occurs

randomly, frequently, or all the time.

4. Check what the temperature is in the engine

room and at the panel. Is it very hot or very cold?

Make sure that the motor is not blowing

exhaust air on the control panel.

5. If it just started to act up, then check if there was

recently a severe lightning storm, fire, flood, or a

plant accident. If any of the following conditions

are possible, then check for it:

Has any liquid leaked into the panel or

conduit?

6. If it just started to act up, then check if anything

was recently changed in the system (i.e. software

or hardware.)

7. If it just started to act up, then check if any

service was recently done to the electrical

system?

8. If there is communication wiring connecting the

panel to another panel or device, then check the

following:

If the Quantum™ is unexplainably shutting

down, try disconnecting the communications

cable to see if the problem goes away.

Check if the communications cable shields

are tied to machine ground at only one

location.

Check that you are using the Frick

recommended communications cable. See

manual to match proper cable with type of

communications (i.e., RS-422, RS-232, RS485, or some other type of factory

communication bus system.)

9. If this is an older plant, has the plant wiring been

brought up to code?

10. Do you have power wiring mixed with control

wiring?

11. Do you have power wiring mixed with sensor

wiring?

12. Do you have power wiring mixed with

communications wiring?

13. Check that the pressure transducers are properly

grounded. The two types of transducers you may

have are as follows: an older type has an 8 to 10

inch 3-conductor pigtail coming out of the

transducer. This type will have the attaching

cable’s shield cut off and insulated at the

transducer end. The shield is then tied to a panel

ground terminal in the panel. The newer type has

the cable as an integral part of the housing and

has the shield crimped to the case at the

transducer end. This type of transducer has the

cable’s shield cut off and insulated in the control

panel.

14. Check that temperature transducers are properly

grounded. Temperature probes usually have t wo

short wires coming out of the sensor, and are tied

to a shielded cable at the thermal well head. The

shield is grounded at the temperature probe and

insulated at the panel end.

15. Check if one of the temperature probes has a

signal wire shorted to machine ground. To do

this, first pull the orange plug from the micro

board and then use an Ohmmeter and check

each white wire to machine ground and each

black wire to machine ground.

16. Ensure that all inductive loads (i.e. Coils,

Solenoids, or Relays, etc.) connected to the I/O

output modules have surge suppressers across

them, preferably at the devices and not at the

panel end.

17. If the control settings unexplainably change, it

may be a noise problem affecting the keypad’s

input circuit. Check if it works OK with the keypad

cable disconnected. If it works OK, then check

the grounding as described above. If the

grounding is OK, then replace the keypad.

18. Make sure that you have a continuous ground

back to the power source. The ground connection

must be aluminum or copper. A conduit ground

will not work

19. Make sure that there is no AC wiring lying next to

printed circuit boards.

20. Unexplainable auxiliary failures are usually

indicative of noise due to wiring problems (i.e.

incorrect earth grounds, mixed power and control

wiring, unsuppressed coils, etc)

Page 11

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

MAINTENANCE Page 11

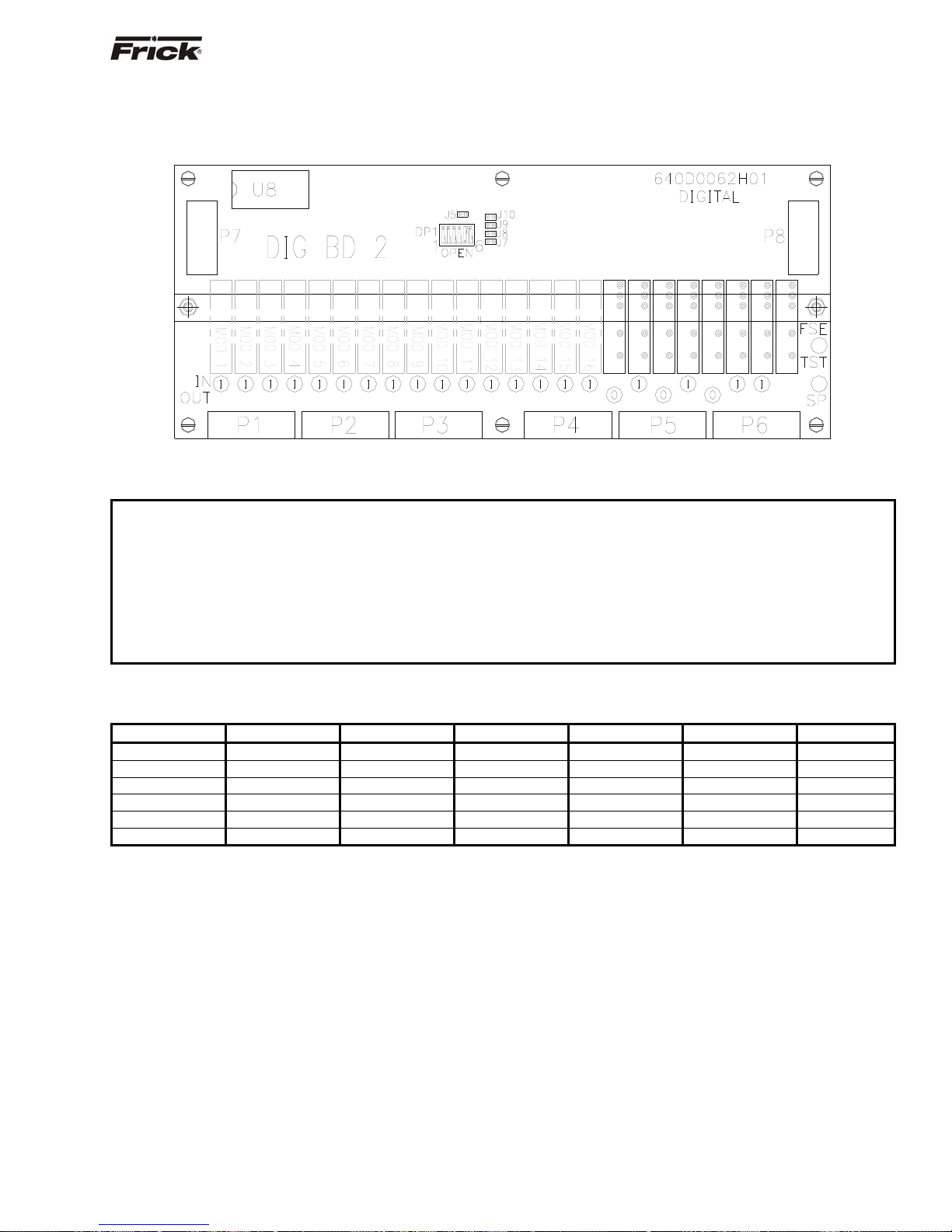

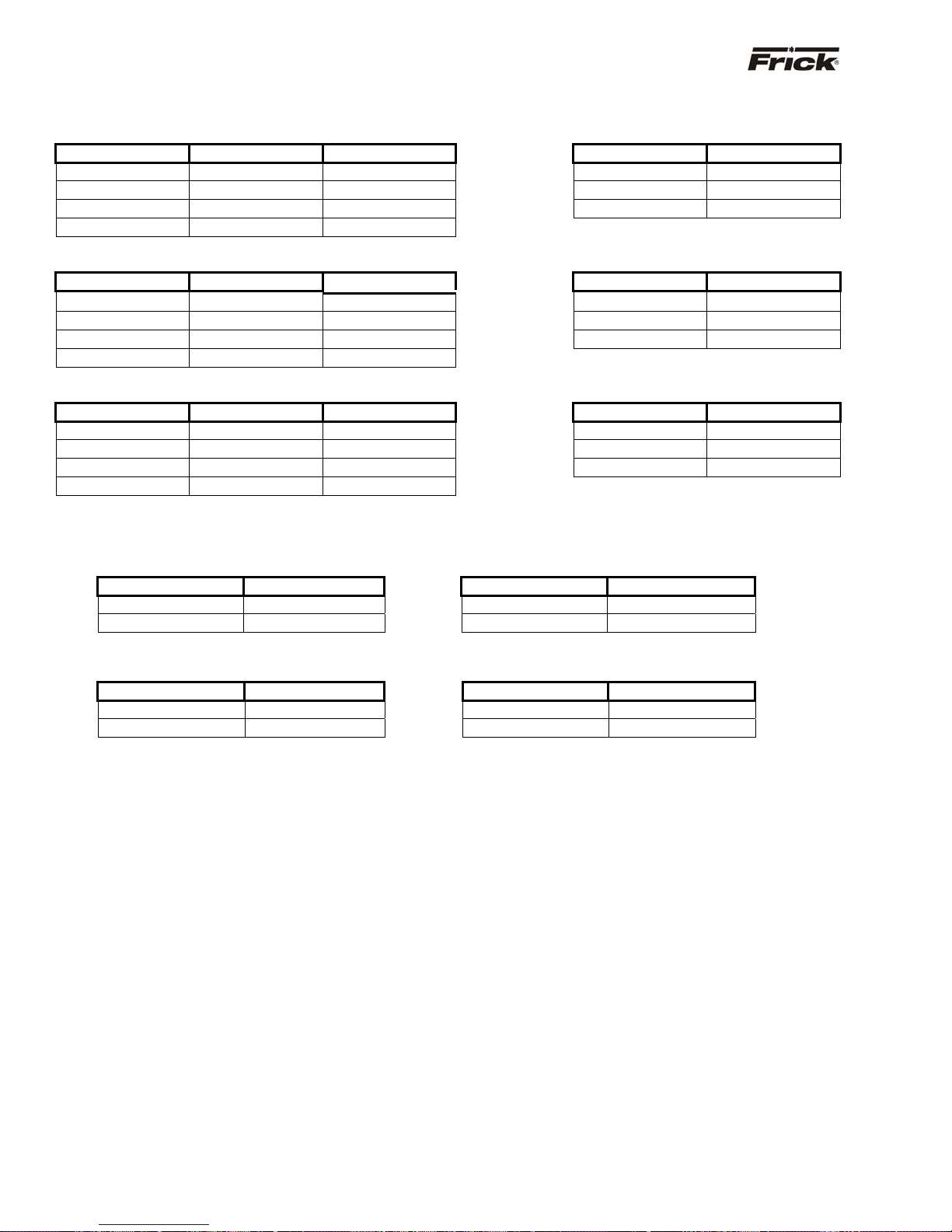

JUMPER AND DIPSWITCH SETTINGS

DIGITAL BOARD (Optional)

DIGITAL I/O BOARD COMMUNICATIONS SETTINGS

J5

J7

J8

J9

J10

In

out*

In

out*

In

out*

In

out*

In

out*

120 ohm long communications line termination.

No termination. (standard setting)

RS-422/485 transmit pull-up for long communications lines.

No pull-up. (standard setting)

RS-422 transmit pull-up for long communications lines.

No pull-up. (standard setting)

RS-422/485 receive pull-down for long communications lines.

No pull-down. (standard setting)

RS-422 receive pull-down for long communications lines.

No pull-down. (standard setting)

* = standard setting

DIGITAL I/O BOARD DIPSWITCH SETTINGS (DP1)

SW1 SW2 SW3 SW4 SW5 SW6

Board #1 on on on on off on

Board #2 off on on on off on

Board #3 on off on on off on

Board #4 off off on on off on

Board #5 on on off on off on

Board #6 off on off on off on

Page 12

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 12 MAINTENANCE

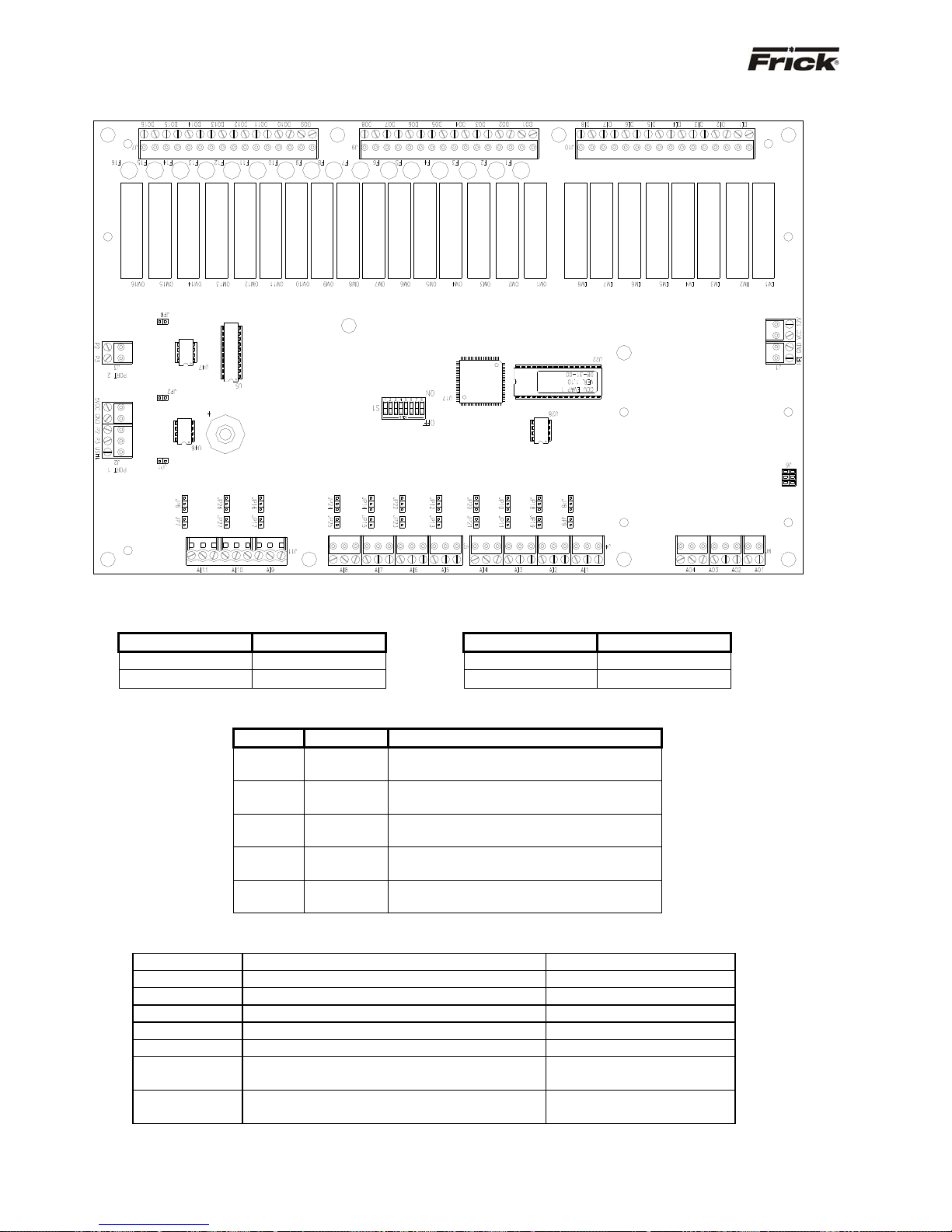

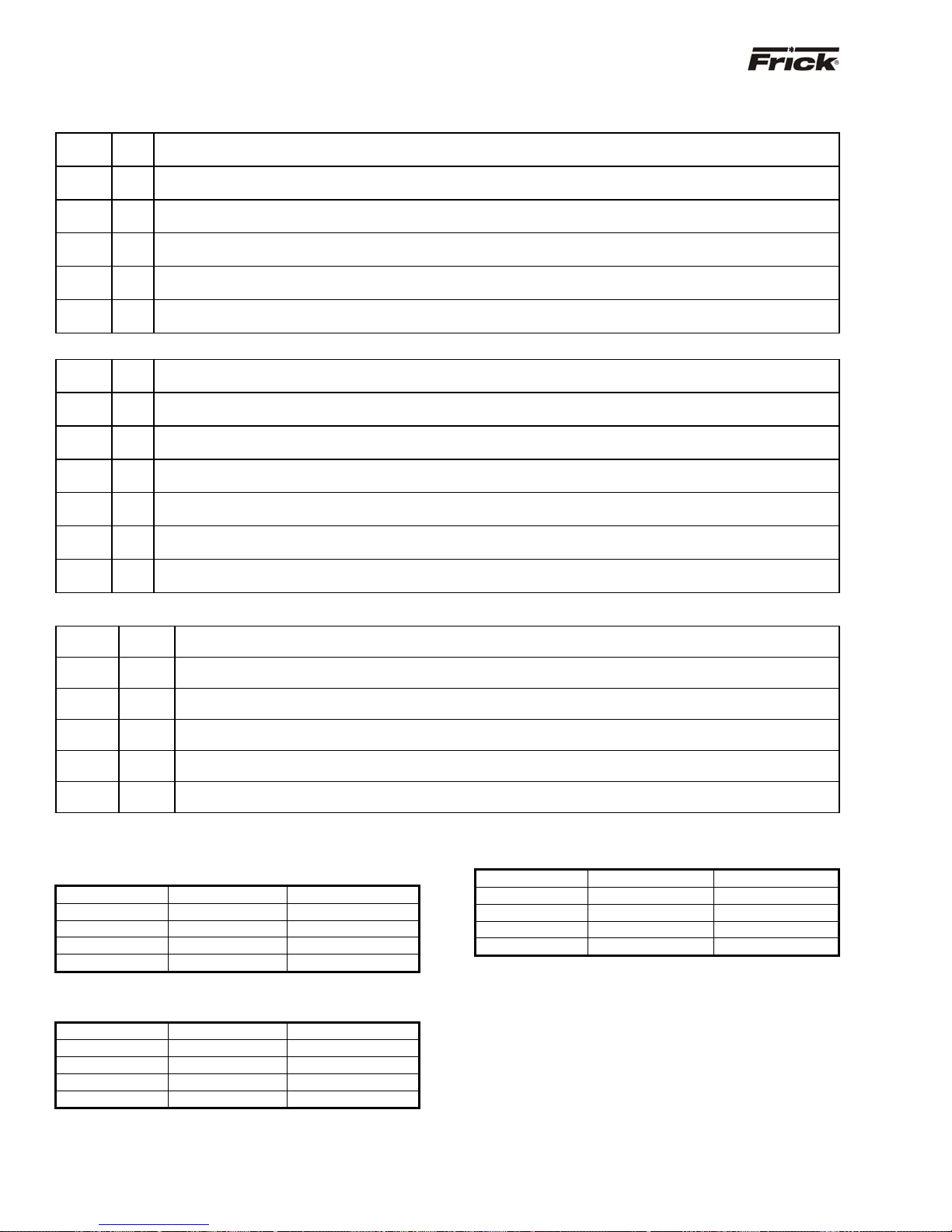

PICTORIAL DRAWING OF CONDENSER / VESSEL (GCU) BOARD:

Communications Port Connections

Comm. Port 1 Comm. Port 2

Connector Function Connector Function

J2-P2

J2-P3

Com-

Com+

J3-P2

J3-P3

Additional Communications Jumper Configurations

Com-

Com+

Jumper Setting Function

JP1

JP2

JP3

JP4

JP5

Installed

Removed

Installed

Removed

Installed

Removed

Installed

Removed

Installed

Removed

GCU Board Dipswitch Settings

Port 1 RS-485 pull-up resistor

No pull-up resistor (standard setting)

Port 1 RS-485 pull-down resistor

No pull-down resistor (standard setting)

Port 2 RS-485 pull-up resistor

No pull-up resistor (standard setting)

Port 2 RS-485 pull-down resistor

No pull-down resistor (standard setting)

PFI pull-up resistor (standard setting)

No pull-up resistor

Switch # 1 Not Used N/A

Switch # 2 Not Used N/A

Switch # 3 Not Used N/A

Switch # 4 Not Used N/A

Switch # 5 Not Used N/A

Switch # 6 Not Used N/A

Switch # 7 Baud Rate Selection

Switch # 8 Baud Rate Selection

off / open *

on / closed

off / open

on / closed *

* = standard setting

Page 13

V

A

V

A

V

A

A

V

A

V

A

A

A

MAINTENANCE Page 13

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

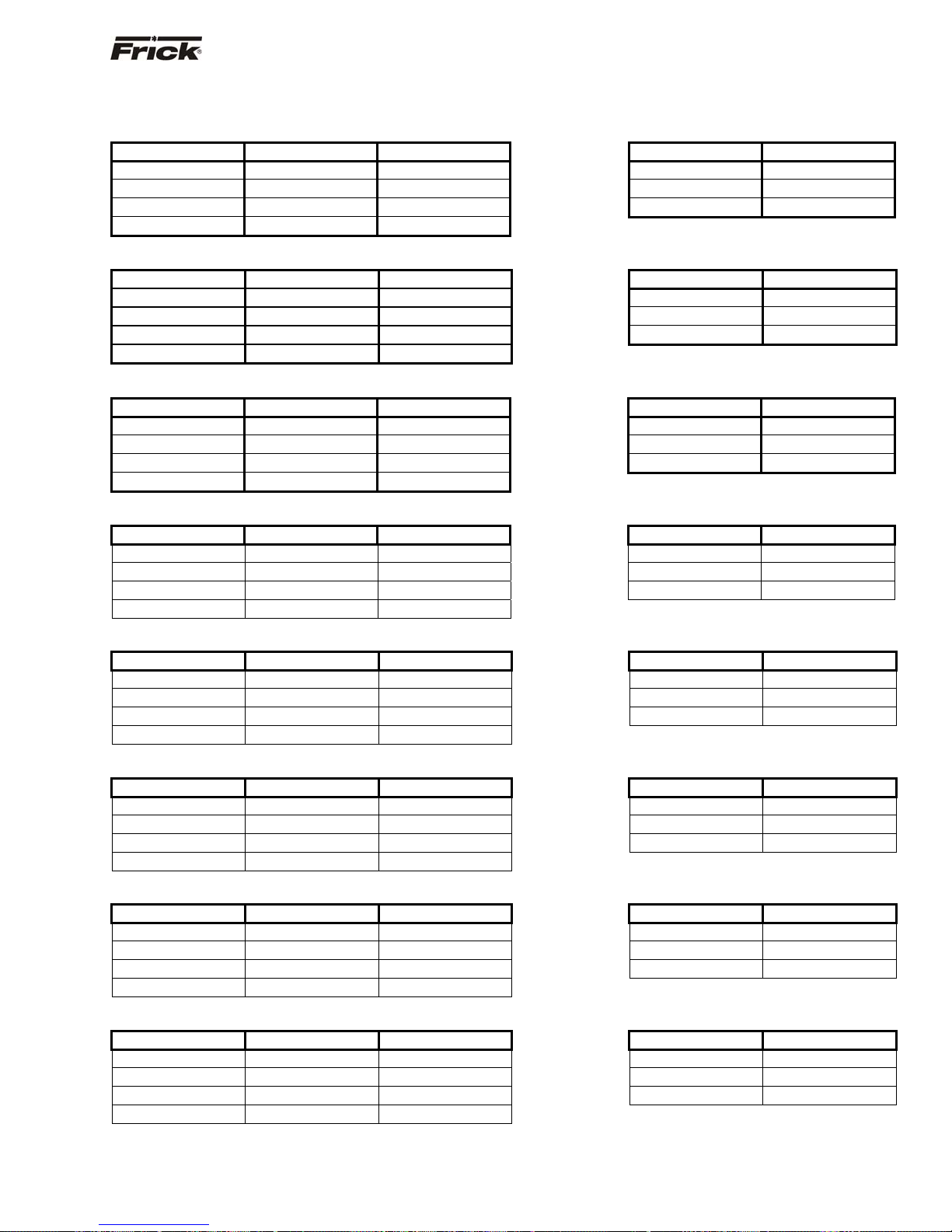

Vessel GCU Board Analog I/O Jumper Settings

Analog Input 1 -

Input Function JP8 JP9 Connector Function

0 – 5 VDC Out Out J4-10 +12 VDC

Resistance 1 - 2 Out J4-11 Input Signal

4 – 20 ma * Out * 1 – 2 * J4-12 GND

ICDT 2 - 3 Out

Analog Input 2 -

Input Function JP18 JP19 Connector Function

0 – 5 VDC Removed Removed J4-7 +12 VDC

Resistance 1 - 2 Removed J4-8 Input Signal

4 – 20 ma * Removed * 1 – 2 * J4-9 GND

ICDT 2 - 3 Removed

Analog Input 3 -

Input Function JP10 JP11 Connector Function

0 – 5 VDC Removed Removed J4-4 +12 VDC

Resistance 1 - 2 Removed J4-5 Input Signal

4 – 20 ma * Removed * 1 – 2 * J4-6 GND

ICDT 2 - 3 Removed

Analog Input 4 - Vessel Pressure #1

Input Function JP20 JP21 Connector Function

0 – 5 VDC * Removed * Removed * J4-1 +12 VDC

Resistance 1 - 2 Removed J4-2 Input Signal

4 – 20 ma Removed 1 – 2 J4-3 GND

ICDT 2 - 3 Removed

Analog Input 5 -

Input Function JP12 JP13 Connector Function

0 – 5 VDC * Removed * Removed * J5-10 +12 VDC

Resistance 1 - 2 Removed J5-11 Input Signal

4 – 20 ma Removed 1 – 2 J5-12 GND

ICDT 2 - 3 Removed

Analog Input 6 -

Input Function JP22 JP23 Connector Function

0 – 5 VDC * Removed * Removed * J5-7 +12 VDC

Resistance 1 - 2 Removed J5-8 Input Signal

4 – 20 ma Removed 1 – 2 J5-9 GND

ICDT 2 - 3 Removed

Analog Input 7 - Refrigeration Pump Pressure #1

Input Function JP14 JP15 Connector Function

0 – 5 VDC * Removed * Removed * J5-4 +12 VDC

Resistance 1 - 2 Removed J5-5 Input Signal

4 – 20 ma Removed 1 – 2 J5-6 GND

ICDT 2 - 3 Removed

Analog Input 8 - Refrigeration Pump Pressure #2

Input Function JP24 JP25 Connector Function

0 – 5 VDC * Removed * Removed * J5-1 +12 VDC

Resistance 1 - 2 Removed J5-2 Input Signal

4 – 20 ma Removed 1 – 2 J5-3 GND

ICDT 2 - 3 Removed

essel Level #1

essel Level #2

essel Level #3

essel Pressure #2

essel Pressure #3

nalog Input 1 Sensor Wiring

nalog Input 2 Sensor Wiring

nalog Input 3 Sensor Wiring

nalog Input 4 Sensor Wiring

nalog Input 5 Sensor Wiring

nalog Input 6 Sensor Wiring

nalog Input 7 Sensor Wiring

nalog Input 8 Sensor Wiring

Page 14

A

A

A

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 14 MAINTENANCE

Vessel GCU Board Analog I/O Jumper Settings (Continued)

Analog Input 9 - Refrigeration Pump Pressure #3

Input Function JP16 JP17 Connector Function

0 – 5 VDC * Removed * Removed * J11-7 +12 VDC

Resistance 1 - 2 Removed J11-8 Input Signal

4 – 20 ma Removed 1 – 2 J11-9 GND

ICDT 2 - 3 Removed

Analog Input 10 - Analog Auxiliary 1

Input Function JP26 JP27 Connector Function

0 – 5 VDC * Removed * Removed * J11-4 +12 VDC

Resistance 1 - 2 Removed J11-5 Input Signal

4 – 20 ma Removed 1 – 2 J11-6 GND

ICDT 2 - 3 Removed

Analog Input 11 - Analog Auxiliary 1

Input Function JP6 JP7 Connector Function

0 – 5 VDC * Removed * Removed * J11-1 +12 VDC

Resistance 1 - 2 Removed J11-2 Input Signal

4 – 20 ma Removed 1 – 2 J11-3 GND

ICDT 2 - 3 Removed

Analog Output Configurations

Analog Output 1 Sensor Wiring -

Analog Output 2 Sensor Wiring -

Vessel #1 Modulating Valve

Connector Function Connector Function

J8-8 Output Signal J8-6 Output Signal

J8-7 GND J8-5 GND

Analog Output 3 Sensor Wiring -

Analog Output 4 Sensor Wiring -

Vessel #2 Modulating Valve

Vessel #3 Modulating Valve

Connector Function Connector Function

J8-4 Output Signal J8-2 Output Signal

J8-3 GND J8-1 GND

nalog Input 9 Sensor Wiring

nalog Input 10 Sensor Wiring

nalog Input 11 Sensor Wiring

Future

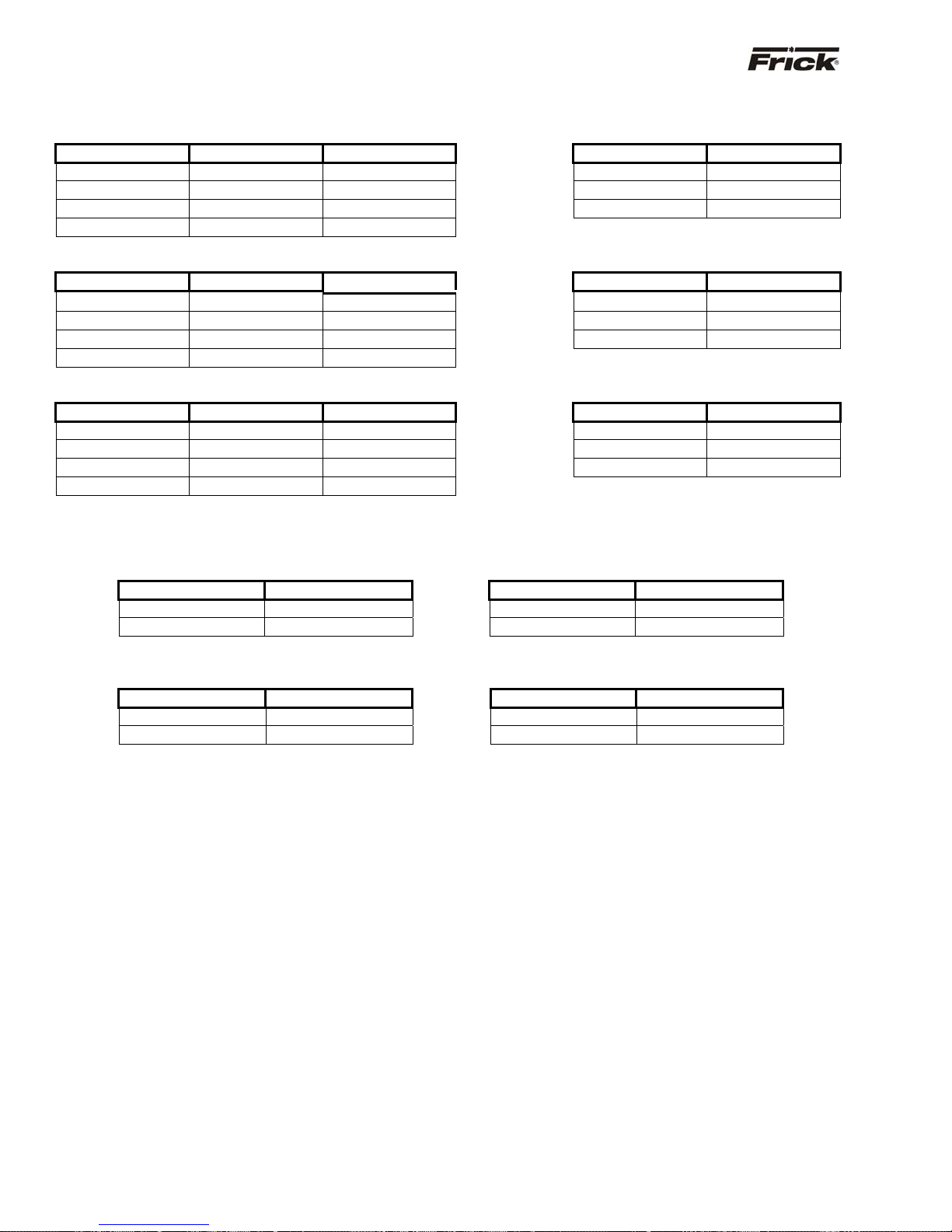

Condenser GCU Board Analog I/O Jumper Settings

Page 15

A

A

A

A

A

A

A

A

A

MAINTENANCE Page 15

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

nalog Input 1 - Condenser Pressure

Input Function JP8 JP9 Connector Function

0 – 5 VDC * Out * Out * J4-10 +12 VDC

Resistance 1 - 2 Out J4-11 Input Signal

4 – 20 ma Out 1 – 2 J4-12 GND

ICDT 2 - 3 Out

Analog Input 2 - Outside Air Temperature

Input Function JP18 JP19 Connector Function

0 – 5 VDC Removed Remov ed J4-7 +12 VDC

Resistance 1 - 2 Removed J4-8 Input Signal

4 – 20 ma Removed 1 – 2 J4-9 GND

ICDT * 2 - 3 * Removed *

Analog Input 3 - Outside Air Humidity

Input Function JP10 JP11 Connector Function

0 – 5 VDC Removed Removed J4-4 +12 VDC

Resistance 1 - 2 Removed J4-5 Input Signal

4 – 20 ma * Removed * 1 – 2 * J4-6 GND

ICDT 2 - 3 Removed

Analog Input 4 - Condenser Drain Temp. (Refrigerant)

Input Function JP20 JP21 Connector Function

0 – 5 VDC Removed Removed J4-1 +12 VDC

Resistance 1 - 2 Removed J4-2 Input Signal

4 – 20 ma Removed 1 – 2 J4-3 GND

ICDT * 2 - 3 * Removed *

Analog Input 5 - Future

Input Function JP12 JP13 Connector Function

0 – 5 VDC Removed Remov ed J5-10 +12 VDC

Resistance 1 - 2 Removed J5-11 Input Signal

4 – 20 ma * Removed * 1 – 2 * J5-12 GND

ICDT 2 - 3 Removed

Analog Input 6 - Future

Input Function JP22 JP23 Connector Function

0 – 5 VDC Removed Remov ed J5-7 +12 VDC

Resistance 1 - 2 Removed J5-8 Input Signal

4 – 20 ma * Removed * 1 – 2 * J5-9 GND

ICDT 2 - 3 Removed

Analog Input 7 - Future

Input Function JP14 JP15 Connector Function

0 – 5 VDC Removed Remov ed J5-4 +12 VDC

Resistance 1 - 2 Removed J5-5 Input Signal

4 – 20 ma * Removed * 1 – 2 * J5-6 GND

ICDT 2 - 3 Removed

Analog Input 8 - Future

Input Function JP24 JP25 Connector Function

0 – 5 VDC Removed Remov ed J5-1 +12 VDC

Resistance 1 - 2 Removed J5-2 Input Signal

4 – 20 ma * Removed * 1 – 2 * J5-3 GND

ICDT 2 - 3 Removed

nalog Input 1 Sensor Wiring

nalog Input 2 Sensor Wiring

nalog Input 3 Sensor Wiring

nalog Input 4 Sensor Wiring

nalog Input 5 Sensor Wiring

nalog Input 6 Sensor Wiring

nalog Input 7 Sensor Wiring

nalog Input 8 Sensor Wiring

Page 16

A

A

A

A

A

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 16 MAINTENANCE

Condenser GCU Board Analog I/O Jumper Settings (Continued)

Analog Input 9 - Future

Input Function JP16 JP17 Connector Function

0 – 5 VDC Removed Remov ed J11-7 +12 VDC

Resistance 1 - 2 Removed J11-8 Input Signal

4 – 20 ma * Removed * 1 – 2 * J11-9 GND

ICDT 2 - 3 Removed

Analog Input 10 - Future

Input Function JP26 JP27 Connector Function

0 – 5 VDC Removed Remov ed J11-4 +12 VDC

Resistance 1 - 2 Removed J11-5 Input Signal

4 – 20 ma * Removed * 1 – 2 * J11-6 GND

ICDT 2 - 3 Removed

Analog Input 11 - Future

Input Function JP6 JP7 Connector Function

0 – 5 VDC Removed Remov ed J11-1 +12 VDC

Resistance 1 - 2 Removed J11-2 Input Signal

4 – 20 ma * Removed * 1 – 2 * J11-3 GND

ICDT 2 - 3 Removed

Analog Output Configurations

Analog Output 1 Sensor Wiring -

Variable Fan 1

Connector Function Connector Function

J8-8 Output Signal J8-6 Output Signal

J8-7 GND J8-5 GND

Analog Output 3 Sensor Wiring -

Variable Fan 3

Connector Function Connector Function

J8-4 Output Signal J8-2 Output Signal

J8-3 GND J8-1 GND

nalog Output 2 Sensor Wiring -

Variable Fan 2

nalog Output 4 Sensor Wiring -

Variable Fan 4

nalog Input 9 Sensor Wiring

nalog Input 10 Sensor Wiring

nalog Input 11 Sensor Wiring

Page 17

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

MAINTENANCE Page 17

QUANTUM™ 3 MAIN PROCESSOR BOARD

Quantum™ 3 Motherboard Jumpers

LK1-1 LK1-2 COM3 IRQ Routing (DO NOT MODIFY)

A * A * RS-232 Interface Selected

A B Not Valid Combination

B A Not Valid Combination

B B Touchscreen Controller Interface Selected

LK2 COM3 IRQ Routing (DO NOT MODIFY)

A IRQ4

B * IRQ11

LK3 COM4 IRQ Routing (DO NOT MODIFY)

A IRQ3

B * IRQ10

LK4 RS-422 Termination (DO NOT MODIFY)

In * RS-422 Terminated

Out RS-422 Terminated

LK5 RS-485 Receiver (DO NOT MODIFY)

In RS-485 Receiver Enabled

Out * RS-485 Receiver Disabled

LK6 RS-485 Termination (DO NOT MODIFY)

In * RS-485 Terminated

Out RS-485 Not Terminated

* Standard Setting

LK7 Watc hdog Ti me r Enable

In Enabled

Out * Disabled

LK8 Watchdog timer Enable

In 2 second timeout

Out * 8 second timeout

LK9 Clear CMOS/Battery Disable (DO NOT MODIFY)

A Battery Backup Enabled

B * Battery Backup Disabled (CMOS RAM Clear ed)

LK10 LCD Backlight Voltage Supply Voltage

A +5V Backlight

B * +12V Backlight

LK11 LCD Panel Power Supply Voltage

A * +5V Supply (Samsung, NEC or Sharp Displays)

B +3.3V Supply (LG Phillips Display)

LK12 User Application Link (DO NOT MODIFY)

In * Bit 1 of 259H "Logic 1"

Out Bit 1 of 259H "Logic 0"

LK13 User Application Link (DO NOT MODIFY)

In * Bit 2 of 259H "Logic 1"

Out Bit 2 of 259H "Logic 0"

Page 18

(

g)

p

p

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 18 MAINTENANCE

Quantum™ 3 Communications Board Jumpers

COM-1 (Jumpers located adjacent to connector TB1)

In*

Link 1

Link 2

Link 3

Link 4

Link 5

Link 16

Pull down Rx- / Tx- (RS485) or Rx- (RS422) line to GND (0V) via a 10K resistor. (standard setting)

out

No pull down

in

Terminate Rx / Tx (RS485) or Rx (RS422) lines with a 120W resistor. (standard setting)

out*

No termination (standard setting)

in*

Pull up Rx+ / Tx+ (RS485) or Rx+ (RS422) line to VCC (5V) via a 10K resistor. (standard setting)

out

No termination.

in*

Pull down Tx- (RS422) line to GND (0V) via a 10K resistor. (standard setting)

out

No pull down.

in*

Pull up COM2 Tx+ (RS422) line to VCC (5V) via a 10K resistor. (standard setting)

out

No pull down.

A* B RS485 (standard setting)

RS422

COM-2 (Jumpers located adjacent to connector TB2)

In*

Link 6

Link 7

Link 8

Link 9

Link 10

Link 17

Link 19

Pull down Rx- / Tx- (RS485) or Rx- (RS422) line to GND (0V) via a 10K resistor. (standard setting)

out

No pull down

in

Terminate Rx / Tx (RS485) or Rx (RS422) lines with a 120W resistor. (standard setting)

out*

No termination (standard setting)

in*

Pull up Rx+ / Tx+ (RS485) or Rx+ (RS422) line to VCC (5V) via a 10K resistor. (standard setting)

out

No termination.

in*

Pull down Tx- (RS422) line to GND (0V) via a 10K resistor. (standard setting)

out

No pull down.

in*

Pull up COM2 Tx+ (RS422) line to VCC (5V) via a 10K resistor. (standard setting)

out

No pull down.

A* B RS485 (standard setting)

RS422

in*

Select RS422/RS485 comms mode. (standard setting)

out

Select RS232 comms mode.

COM-3 (Jumpers located adjacent to connector TB3)

In*

Link 11

Link 12

Link 13

Link 14

Link 15

Link 18

out

out*

out

out

out

Pull down Rx- / Tx- (RS485) or Rx- (RS422) line to GND (0V) via a 10K resistor. (standard setting)

No pull down

in

Terminate Rx / Tx (RS485) or Rx (RS422) lines with a 120W resistor. (standard setting)

No termination

in*

Pull up Rx+ / Tx+ (RS485) or Rx+ (RS422) line to VCC (5V) via a 10K resistor. (standard setting)

standard settin

No termination.

in*

Pull down Tx- (RS422) line to GND (0V) via a 10K resistor. (standard setting)

ull down.

No

in*

Pull up COM2 Tx+ (RS422) line to VCC (5V) via a 10K resistor. (standard setting)

No

ull down.

A* B RS485 (standard setting)

RS422

Quantum™ 3 Communications Wiring

TB1 - COM1 RS-485/422 (Used for Sequencing):

4-way screw terminal

Pin Signal (RS-422) Signal (RS-485)

4 COM1 TX+ 3 COM1 TX- 2 COM1 RX+ COM1 TX+ / RX+

1 COM1 RX- COM1 TX- / RX-

TB2 - COM2 RS-485/422 (Standard Communications):

4-way screw terminal

Pin Signal (RS-422) Signal (RS-485)

4 COM2 TX+ 3 COM2 TX- 2 COM2 RX+ COM2 TX+ / RX+

1 COM2 RX- COM2 TX- / RX-

TB3- COM3 RS-485/422: 4-way screw terminal

Pin Signal (RS-422) Signal (RS-485)

4 COM3 TX+ 3 COM3 TX- 2 COM3 RX+ COM3 TX+ / RX+

1 COM3 RX- COM3 TX- / RX-

Page 19

3

45670

2

A

T

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

MAINTENANCE Page 19

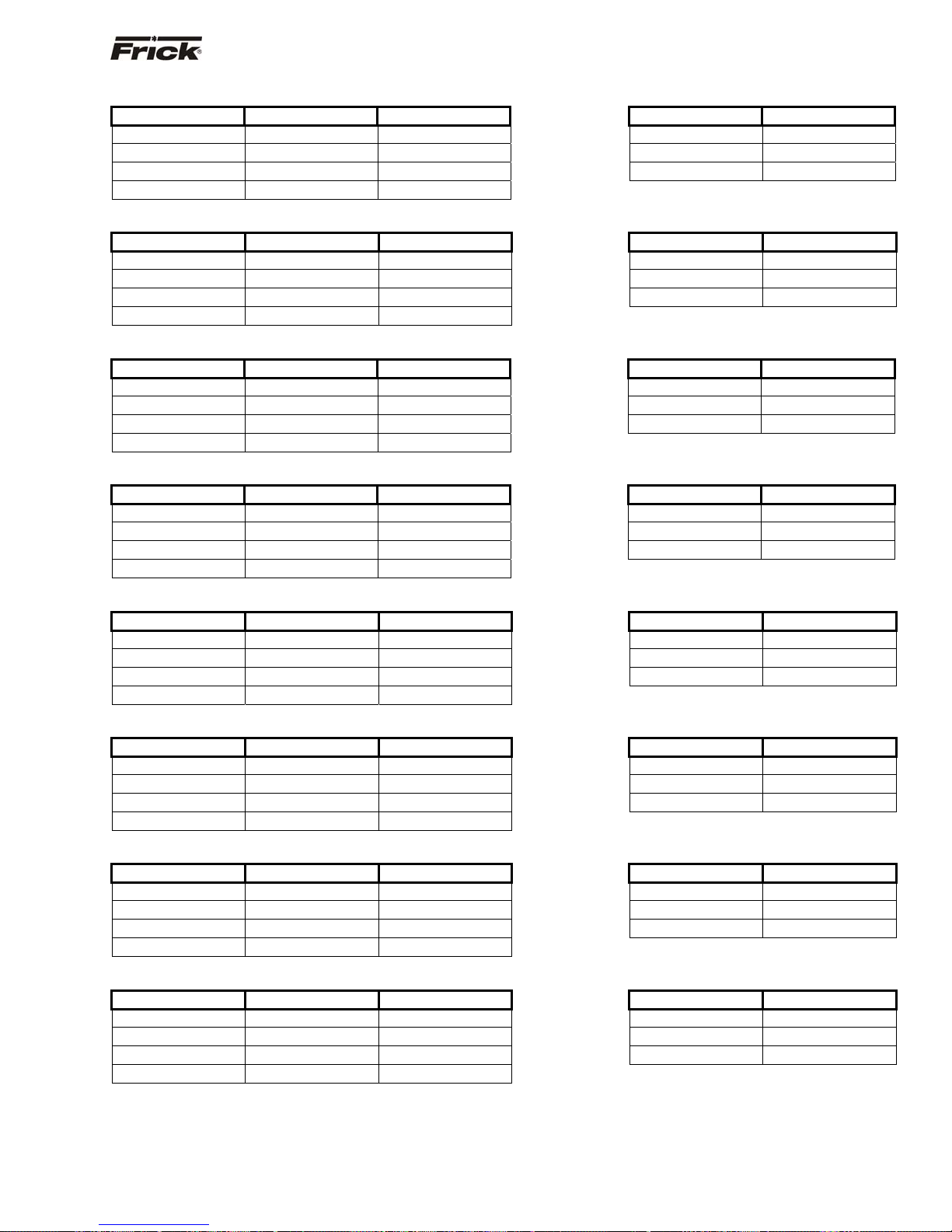

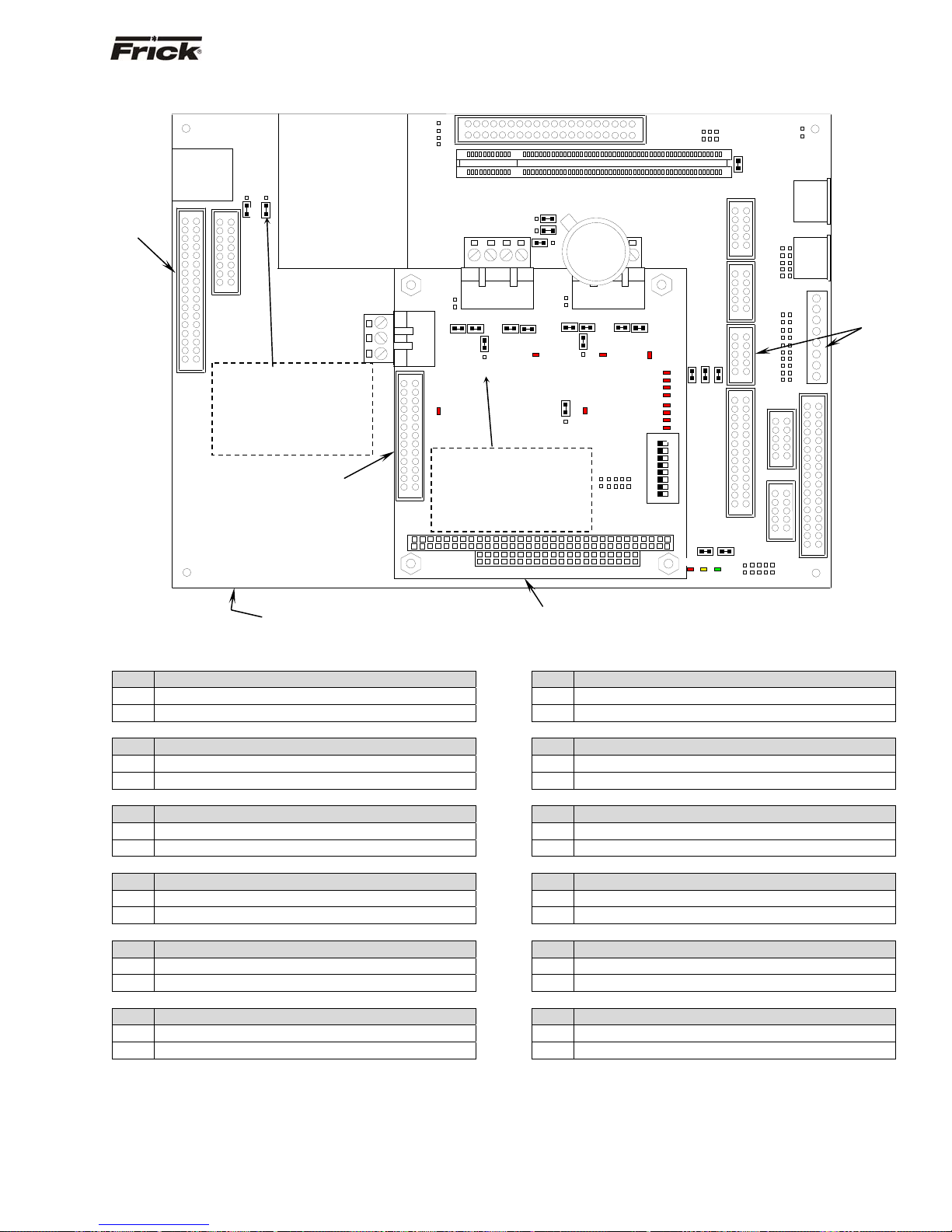

QUANTUM™ 4 MAIN PROCESSOR BOARD

LCD

Display &

Inverter

Cable

(Plugs into

PL15)

PL5

Flash Card

LK4

LK3

A

B

PL11

PL15

This assembly is shipped with LK4

set to "B" position for an LG Phillips

display (11.75" backplate).

If using a Samsung, NEC or Sharp

Display, set LK4 to position "A"

(12.75" backplate).

Socket

(Located

board)

Keypad Cable

plugs into PL1

Bottom board is the

Processor Board

under

COM-2

RS-232

PL3

TB3

PL1

PL3

Quantum 4 Motherboard Jumpers

LK1 Watchdog timer timeout selection

In 2 second timeout

Out * 8 second timeout

LK2 Watchdog timer Enable

In * Enabled

Out Disabled

LK3 Backlight Voltage

A +5V Backlight

B * +12V Backlight

LK4 LCD Panel Power Supply Voltage

A +5V Supply (Samsung, NEC or Sharp Displays)

B * +3.3V Supply (LG Phillips Display)

LK5 COM4 IRQ Routing (DO NOT MODIFY)

A IRQ3

B * IRQ10

LK6 COM3 IRQ Routing (DO NOT MODIFY)

A IRQ4

B * IRQ11

* Standard Setting

PL4

B

A

LK5

LK4LK3

LK17

LK6

LK7

B2

TB1

LK2

LK6LK5

B

A

D1

B

LK11

COM-2

RS-422

RS-485

LK1

D8

To set Comm-2 for RS-232

operation, set LK17 to "A" position.

To set Comm-2 for RS-422/485

operation, set LK17 to "B" position.

PL4

Communications Board

LK7 Clear CMOS / Battery Disable (DO NOT MODIFY)

A * Battery Backup Enabled

B Battery Backup Disabled (CMOS RAM Cleared)

LK8 RS-485 Receiver (DO NOT MODIFY)

In * RS-485 Receiver Enabled

Out RS-485 Receiver Disabled

LK9 RS-485 Termination (DO NOT MODIFY)

In * RS-485 Terminated

Out RS-485 Not Terminated

LK10 RS-422 Termination (DO NOT MODIFY)

In RS-422 Terminated

Out * RS-42 2 Terminated

LK11 User Application Link (DO NOT MODIFY)

In * Bit 1 of 259H "Logic 1"

Out Bit 1 of 259H "Logic 0"

LK12 User Application Link (DO NOT MODIFY)

In * Bit 2 of 259H "Logic 1"

Out Bit 2 of 259H "Logic 0"

LK7

B

A

LK16

LK8

D6

LK10LK9

D2

PL2

Top board is the

PL2

COM-1

RS-422

RS-485

PORT 80H

D3

D4

D5

D7

D8

D10

D11

D12

D13

1 2 3 4 5 6 7 8

SW1

PL1

PL24

PL8

PL13

PL18

PL19

LK1

PL7

PL9

PL12

PL17

Power - I/O

Comm.

Harness

(Plugs into

PL12 &

PL14)

LK2

PL6

PL10

PL14

LK8

LK10

1

LK9

O

PL16

LK12

LK11

PWR

FLASH

SUSP

Page 20

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 20 MAINTENANCE

Quantum™ 4 Communications Board Jumpers

Com-1 (TB1)

In

Link 2

Link 7

Link 8

Link 9

Link 10

Link 16

* = standard setting

Com-2 (TB2 - TB3)

Link 1

Link 3

Link 4

Link 5

Link 6

Link 11

Link 17

* = standard setting

TB1 - COM1 RS-485/422 (Used for Sequencing):

Pin Signal (RS-422) Signal (RS-485)

4 COM1 TX+ 3 COM1 TX- 2 COM1 RX+ COM1 TX+ / RX+

1 COM1 RX- COM1 TX- / RX-

TB2 - COM2 RS-485/422 (Standard Communications):

Pin Signal (RS-422) Signal (RS-485)

4 COM2 TX+ 3 COM2 TX- 2 COM2 RX+ COM2 TX+ / RX+

1 COM2 RX- COM2 TX- / RX-

Terminate COM1 Rx / Tx (RS-485) or COM1 Rx (RS-422) lines with a 120W resistor.

out*

No termination (standard setting)

In*

Pull down COM1 Rx- / Tx- (RS-485) or COM1 Rx- (RS-422) line to GND (0V) via a 10K res. (std. setting)

Out

No pull down

in*

Pull up COM1 Rx+ / Tx+ (RS-485) or COM1 Rx+ (RS-422) line to VCC (5V) via a 10K res.. (std. setting)

out

No termination.

in*

Pull down COM1 Tx- (RS-422) line to GND (0V) via a 10K resistor. (standard setting)

out

No pull down.

in*

Pull up COM1 Tx+ (RS-422) line to VCC (5V) via a 10K resistor. (standard setting)

out

No pull down.

A* B COM1 RS-485 (TB1) (standard setting)

COM1 RS-422 (TB1)

In

Terminate COM2 Rx / Tx (RS-485) or COM2 Rx (RS-422) lines with a 120W resistor.

out*

No termination (standard setting)

In*

Pull down COM2 Rx- / Tx- (RS-485) or COM2 Rx- (RS-422) line to GND (0V) via a 10K res. (std. setting)

Out

No pull down

in*

Pull up COM2 Rx+ / Tx+ (RS-485) or COM2 Rx+ (RS-422) line to VCC (5V) via a 10K res. (std. setting)

out

No termination.

in*

Pull down COM2 Tx- (RS-422) line to GND (0V) via a 10K resistor. (standard setting)

out

No pull down.

in*

Pull up COM2 Tx+ (RS-422) line to VCC (5V) via a 10K resistor. (standard setting)

out

No pull down.

A* B COM2 RS-485 (TB2) (standard setting)

COM2 RS-422 (TB2)

A

Select RS-232 comms mode for COM2 (TB3).

B*

Select RS-422/RS-485 comms mode for COM2 (TB2). (standard setting)

Quantum™ 4 Communications Wiring

TB3- COM2 RS-232 (Standard Communications):

4-way screw terminal

4-way screw terminal

3-way screw terminal

Pin Signal (RS-422)

3 Ground

2 RX

1 TX

Page 21

MAINTENANCE Page 21

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

DRAWING REFERENCE TABLE

DRAWING NAME DRAWING NUMBER

Quantum™ Panel DC Power Supply Diagram (Condor) N/A

Quantum™ Panel DC Power Supply Diagram (Power One) N/A

Quantum™ Control Center Assembly 649D4587

Vessel Control Center Assembly 640D0160

Wiring Diagram – Vessel W/O MOA 640D0158

Wiring Diagram – Vessel With MOA 640D0159

Condenser Control Center Assembly 640D0163

Wiring Diagram – Condenser 640D0161

Quantum™ 3 Communications Wiring Diagrams N/A

Quantum™ 4 Communications Wiring Diagrams N/A

The drawings that appear on the following pages are for reference purposes only, and are based upon the latest

revision available at the time of this printing.

Page 22

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 22 MAINTENANCE

QUANTUM™ PANEL DC POWER SUPPLY DIAGRAM (CONDOR)

7.25

Replacement Part # 640C0022G01

R51

13

J1

5

+5V ADJ

F1

3.15

1

INPUT: J1 INPUT: J2

AMP P/N: 640445-5

.312 CTR CONNECTOR, 3 CIRCUITS

Pin 1 AC GROUND PIN 1 OUTPUT #1

Pin 3 AC NEUTRAL PIN 2 OUTPUT #1

PIN 5 AC LINE PIN 3 OUTPUT #1

PIN 4 COMMON

OUTPUT 1 +5.1V PIN 5 COMMON

OUTPUT 2 +24V PIN 6 COMMON

OUTPUT 3 -12V PIN 7 COMMON

OUTPUT 4 12V PIN 8 OUTPUT #2

PIN 9 OUTPUT #2

MATING CONNECTORS: MOLEX

HOUSING CONTACT

INPUT 26-03-4050 08-52-0113

OUTPUT 26-03-4131 08-52-0113

J2

1

AMP P/N: 1-640445-3

.156 CTR CONNECTOR, 13 CIRCUITS

PIN 10 POWER FAIL

PIN 11 OUTPUT #3

PIN 12 COMMON

PIN 13 OUTPUT #4

4.50

QUANTUM™ PANEL D.C. POWER SUPPLY DIAGRAM (POWER-ONE)

(+12V) ADJ

(+5V) ADJ

Replacement Part # 640C0022G11

V2

V1

7

Pin 7 J1

Pin 3 TB1 Pin 1

3

TB2 Pin 1

1

1

POWER FAILURE

GND

NEUTRAL

HOT

V4 (+12)

V3 (-12V)

V2 (+12V)

GND

GND

V1 (+5V)

V1 (+5V)

GND

SIGNAL

TB1

Pin 1

Pin 3

TB2

Pin 1

Pin 7

J1

Page 23

MAINTENANCE Page 23

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

QUANTUM™ CONTROL CENTER ASSEMBLY (SHEET 1 OF 2)

Page 24

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 24 MAINTENANCE

QUANTUM™ CONTROL CENTER ASSEMBLY (SHEET 2 OF 2)

Page 25

MAINTENANCE Page 25

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

VESSEL CONTROL CENTER ASSEMBLY (Sheet 1 of 6)

Page 26

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 26 MAINTENANCE

VESSEL CONTROL CENTER ASSEMBLY (Sheet 2 of 6)

Page 27

MAINTENANCE Page 27

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

VESSEL CONTROL CENTER ASSEMBLY (Sheet 3 of 6)

Page 28

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 28 MAINTENANCE

VESSEL CONTROL CENTER ASSEMBLY (Sheet 4 of 6)

Page 29

MAINTENANCE Page 29

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

VESSEL CONTROL CENTER ASSEMBLY (Sheet 5 of 6)

Page 30

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 30 MAINTENANCE

VESSEL CONTROL CENTER ASSEMBLY (Sheet 6 of 6)

Page 31

MAINTENANCE Page 31

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

WIRING DIAGRAM – VESSEL W/O MOA (Sheet 1 of 6)

Page 32

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 32 MAINTENANCE

WIRING DIAGRAM – VESSEL W/O MOA (Sheet 2 of 6)

Page 33

MAINTENANCE Page 33

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

WIRING DIAGRAM – VESSEL W/O MOA (Sheet 3 of 6)

Page 34

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 34 MAINTENANCE

WIRING DIAGRAM – VESSEL W/O MOA (Sheet 4 of 6)

Page 35

MAINTENANCE Page 35

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

WIRING DIAGRAM – VESSEL W/O MOA (Sheet 5 of 6)

Page 36

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 36 MAINTENANCE

WIRING DIAGRAM – VESSEL W/O MOA (Sheet 6 of 6)

Page 37

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

MAINTENANCE Page 37

WIRING DIAGRAM – VESSEL WITH MOA (Sheet 1 of 6)

Page 38

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 38 MAINTENANCE

WIRING DIAGRAM – VESSEL WITH MOA (Sheet 2 of 6)

Page 39

MAINTENANCE Page 39

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

WIRING DIAGRAM – VESSEL WITH MOA (Sheet 3 of 6)

Page 40

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 40 MAINTENANCE

WIRING DIAGRAM – VESSEL WITH MOA (Sheet 4 of 6)

Page 41

MAINTENANCE Page 41

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

WIRING DIAGRAM – VESSEL WITH MOA (Sheet 5 of 6)

Page 42

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 42 MAINTENANCE

WIRING DIAGRAM – VESSEL WITH MOA (Sheet 6 of 6)

Page 43

MAINTENANCE Page 43

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

CONDENSER CONTROL CENTER ASSEMBLY (Sheet 1 of 10)

Page 44

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 44 MAINTENANCE

CONDENSER CONTROL CENTER ASSEMBLY (Sheet 2 of 10)

Page 45

MAINTENANCE Page 45

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

CONDENSER CONTROL CENTER ASSEMBLY (Sheet 3 of 10)

Page 46

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 46 MAINTENANCE

CONDENSER CONTROL CENTER ASSEMBLY (Sheet 4 of 10)

Page 47

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

MAINTENANCE Page 47

CONDENSER CONTROL CENTER ASSEMBLY (Sheet 5 of 10)

Page 48

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 48 MAINTENANCE

CONDENSER CONTROL CENTER ASSEMBLY (Sheet 6 of 10)

Page 49

MAINTENANCE Page 49

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

CONDENSER CONTROL CENTER ASSEMBLY (Sheet 7 of 10)

Page 50

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 50 MAINTENANCE

CONDENSER CONTROL CENTER ASSEMBLY (Sheet 8 of 10)

Page 51

MAINTENANCE Page 51

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

CONDENSER CONTROL CENTER ASSEMBLY (Sheet 9 of 10)

Page 52

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 52 MAINTENANCE

CONDENSER CONTROL CENTER ASSEMBLY (Sheet 10 of 10)

Page 53

MAINTENANCE Page 53

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

WIRING DIAGRAM – CONDENSER (Sheet 1 of 6)

Page 54

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 54 MAINTENANCE

WIRING DIAGRAM – CONDENSER (Sheet 2 of 6)

Page 55

MAINTENANCE Page 55

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

WIRING DIAGRAM – CONDENSER (Sheet 3 of 6)

Page 56

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 56 MAINTENANCE

WIRING DIAGRAM – CONDENSER (Sheet 4 of 6)

Page 57

MAINTENANCE Page 57

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

WIRING DIAGRAM – CONDENSER (Sheet 5 of 6)

Page 58

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 58 MAINTENANCE

WIRING DIAGRAM – CONDENSER (Sheet 6 of 6)

Page 59

(

)

V

To Customer

Remote

Computer / DCS

System

To Customer

Remote

Computer / DCS

System

Quantum

Controller

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

MAINTENANCE Page 59

QUANTUM™ 3 COMMUNICATIONS WIRING DIAGRAMS

TO CUSTOMER REMOTE COMPUTER/DCS

RS-485 COMMUNICATIONS

-RX/-TX

+RX/+TX

Belden #8761

#22 AWG or Equal

BLK

CLR

COM2

(TB2)

1

2

3

4

QUANTUM™ QUANTUM™

Belden #8761

#22 AWG or Equal

BLK

CLR

BLK

CLR

COM2

(TB2)

1

2

3

4

Belden #8761

#22 AWG or Equal

BLK

CLR

COM2

(TB2)

BLK

CLR

1

2

3

4

QUANTUM™

-RX/-TX

+RX/+TX

TO CUSTOMER REMOTE COMPUTER/DCS

-TX

+TX

-RX

+RX

Belden #8777

#22 AWG or Equal

BLK

GRN

Belden #8777

#22 AWG or Equal

BLK

RED

RS-422 COMMUNICATIONS

COM2

(TB2)

1

2

Belden #8777

#22 AWG or Equal

BLK

GRN

Belden #8777

#22 AWG or Equal

3

BLK

RED

4

QUANTUM™

COM2

(TB2)

BLK

GRN

BLK

RED

Belden #8777

#22 AWG or Equal

1

BLK

GRN

2

Belden #8777

#22 AWG or Equal

3

BLK

RED

4

QUANTUM™ QUANTUM™

COM2

TB2

BLK

GRN

BLK

RED

-RX

1

+RX

2

-TX

3

+TX

4

TO CONDENSER / VESSEL (GCU) BOARDS

-RX / -TX

+RX / +TX

BLK

RED

RS-232 COMMUNICATIONS

PORT 1

(J-2)

BLK

RED

P2

P3

BLK

RED

PORT 1

(J-2)

BLK

RED

P2

P3

CONDENSER

ESSEL PANEL

Page 60

(

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 60 MAINTENANCE

QUANTUM™ 4 COMMUNICATIONS WIRING DIAGRAMS

TO CUSTOMER REMOTE COMPUTER/DCS

RS-485 COMMUNICATIONS

To Customer

Remote

Computer / DCS

System

-RX/-TX

+RX/+TX

Belden #8761

#22 AWG or Equal

BLK

CLR

COM2

(TB2)

1

2

3

4

QUANTUM™ QUANTUM™ QUANTUM™

Belden #8761

#22 AWG or Equal

BLK

CLR

BLK

CLR

COM2

(TB2)

#22 AWG or Equal

1

BLK

2

CLR

3

4

Belden #8761

TO CUSTOMER REMOTE COMPUTER/DCS

RS-422 COMMUNICATIONS

COM2

(TB2)

BLK

GRN

BLK

RED

Belden #8777

#22 AWG or Equal

1

BLK

GRN

2

Belden #8777

#22 AWG or Equal

3

BLK

RED

4

QUANTUM™ QUANTUM™

To Customer

Remote

Computer / DCS

System

-TX

+TX

-RX

+RX

Belden #8777

#22 AWG or Equal

BLK

GRN

Belden #8777

#22 AWG or Equal

BLK

RED

COM2

(TB2)

1

2

3

4

QUANTUM™

Belden #8777

#22 AWG or Equal

BLK

GRN

Belden #8777

#22 AWG or Equal

BLK

RED

TO CONDENSER / VESSEL (GCU) BOARDS

RS-232 COMMUNICATIONS

Quantum

Controller

-RX / -TX

+RX / +TX

BLK

RED

BLK

RED

PORT 1

(J-2)

P2

P3

BLK

RED

CONDENSER

COM2

(TB2)

BLK

CLR

BLK

GRN

BLK

RED

BLK

RED

COM2

TB2)

PORT 1

(J-2)

1

-RX/-TX

2

+RX/+TX

3

4

1

2

3

4

P2

P3

VESSEL PANEL

-RX

+RX

-TX

+TX

Page 61

FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL S90-555 M

MAINTENANCE Page 61

CONVENSER/VESSEL RECOMMENDED SPARE PARTS

QUANTUM™ CONTROL PANEL

Part Number Description Spare-1 Spare-2 Spare-3

649D4824H01 Display cable (Quantum™ 4, see chart below) yes

649C1091G04 Main Pentium processor circuit board (Quantum™ 4) yes 1

649C1092G04 Main Pentium processor circuit board (Quantum™ 3) yes 1

649C1078H01 10.4"diag. LCD color VGA display assembly with backlight yes

649B0862H01 Wire Harness Adapter (Quantum™ 4) yes

649A0883H10 Circuit Breaker, 10A yes

640D0060H01 Keypad/overlay yes

640B0065H01 Display Cable (Quantum™ 3 & LG Phillips display, see chart below) yes

640B0049H01 AC Power Cable Harness for Quantum™ yes

640B0048H01 Power Cable Harness, I/O, DC, Condor yes

640B0045H01 Display Cable (Quantum™ 3 & Sharp display, see chart below) yes

640B0032H01 Back light (CCFT) inverter cable (Quantum™ 3) yes

640B0031H01 Keypad cable yes

640C0039H02 Cable Harness, Power yes

333Q0001637 DC Power Supply, Condor yes yes

333Q0001582 Inverter, for Sharp & LG Phillips yes

333Q0001418 Corcom RF Line Filter yes yes yes

333Q0001649 On/off power switch contact block yes yes

333Q0001764 On/off power switch yes yes

333Q0001786 Battery, 3V, Varta # CR2032

REMOTE PANEL

Part Number Description Spare-1 Spare-2 Spare-3

649B0776H01 HOA Switch Module, 120 v (Optional) yes

649A0883H03 Circuit Breaker, 3A (Optional w/Heater) yes

649A0883H10 Circuit Breaker, 10A yes

640D0117H01 Control, GCU Board yes

640D0062H01 Digital Input/output circuit board (Optional) yes

640C0056H01 Wire Harness, DC Power, Condor GSC25A Power Supply yes

640B0066H01 Wire Harness, Power & Comm. To Digital Board (Optional) yes

640B0060H01 DC Power Supply, Condor yes yes

640B0059H01 Wire harness , AC power yes

640C0049H01 Wire harness , DC power yes

333Q0001179 Heater, Flex, 150W, 120VAC, Built-in thermostat (Optional) yes

333Q0000116 Input Module 120 volt AC yes yes yes

111Q0281061 Output Module 120/240 volt AC yes yes yes

Note 1 – These processor boards are listed for reference. Each Quantum™ Control will have only one of these

boards. Order only the replacement board that is applicable to your controller, not both boards.

Spare-1 - Normal spare parts kept on hand. Operation can wait more than 24 hours to receive replacement parts.

Spare-2 - Additional spare parts kept on hand. Operation must have parts in less than 24 hours.

Spare-3 - Critical operation. Plant must have continuous operation.

DISPLAY ASSEMBLY COMPONENT REPLACEMENT GUIDE

MANUFACTURER

DESCRIPTION

SAMSUNG

NEC

(OBSOLETE)

10.4” TFT Display 333Q0001180 333Q0001494 333Q0001581 649C1078H01

Backlight Inverter

333Q0001582 (OR

333Q0001181)

333Q0001495 333Q0001582 333Q0001582

Cable - CPU to Display (Quantum™ 3) 640B0036H01 640B0043H01 640B0045H01 640B0065H01

Cable - CPU to Inverter (Quantum™ 3) 640B0032H01 640B0044H01 640B0032H01 640B0032H01

Cable - CPU to Display/Inverter (Quantum™ 4) 649D4824H01 SEE NOTE "A" 649D4824H01 649D4824H01

Replacement - Backlight Not Available 333Q0001587 333Q0001588 333Q0001785

Display Replacement Assy. 640C0021G01

NOTE : When upgrading from a Quantum™ 3 w ith an NEC Display, to the Quantum™ 4, the displa y will need to be upgraded also.

Order 640C0052G01 to replace the display. The LK4 jumper will need to be in the "A" position.

640C0021G01

Rev (A)

SHARP LG PHILIPS

(CURRENT)

640C0021G01

Rev (B)

640C0052G01

Page 62

S90-555 M FRICK QUANTUM™ CONDENSER/VESSEL CONTROL PANEL

Page 62 MAINTENANCE

YORK Refrigeration

100 CV Avenue, P.O. Box 997 Waynesboro, Pennsylvania USA 17268-0997

Phone: 717-762-2121

Printed in U.S.A.

Subject To Change Without Notice

Fax: 717-762-8624 www.frickcold.com

Loading...

Loading...