Page 1

Form S90-021 O (MAY 2007)

OPERATION - ADVANCED

File: SERVICE MANUAL - SECTION 90

Replaces: S90-021 O/JUN 2005

Dist: 3, 3a, 3b, 3c

OPERATION – ADVANCED

(SESSION LEVEL 1)

FRICK® QUANTUM™ LX

COMPRESSOR

CONTROL PANEL

Version 6.5x

Page 2

®

S90-021 O (MAY 07) FRICK

Page 2 OPERATION - ADAVNCED

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Table of Contents

OVERVIEW OF OPERATOR INTERFACE...............................................................................................................3

C

OMMON TERMINOLOGY ........................................................................................................................................3

PERATOR ACCESS...............................................................................................................................................3

O

Keys And Key Functions...............................................................................................................................4

MENU STRUCTURE .................................................................................................................................................5

OPERATING DISPLAY SCREENS...........................................................................................................................5

O

PERATING STATUS..................................................................................................................................................6

EQUENCING ............................................................................................................................................................9

S

START/STOP.............................................................................................................................................................9

SER DEFINED OPERATING STATUS ........................................................................................................................12

U

ODE SETUP..........................................................................................................................................................13

M

SAFETIES - HISTORY - CURRENT SAFETIES...............................................................................................................14

AFETIES - HISTORY - SAFETY HISTORY...................................................................................................................15

S

YSTEM STATUS -TRENDING - TRENDING SETUP ......................................................................................................16

S

S

YSTEM STATUS -TRENDING - REAL TIME TRENDING................................................................................................17

YSTEM STATUS -TRENDING - HISTORY TRENDING...................................................................................................18

S

YSTEM STATUS -TRENDING - REAL TIME DATA LOG................................................................................................19

S

SYSTEM STATUS -TRENDING - HISTORY DATA LOG...................................................................................................20

YSTEM STATUS - MAINTENANCE.............................................................................................................................21

S

YSTEM STATUS - EVENT LOG.................................................................................................................................22

S

SETPOINTS - CAPACITY CONTROL - MODE 1.............................................................................................................23

ETPOINTS -SEQUENCING - SYSTEM 1 SETUP ..........................................................................................................25

S

ETPOINTS -SCHEDULING........................................................................................................................................27

S

SETPOINTS -CONDENSER ........................................................................................................................................28

ETPOINTS -COMMUNICATIONS................................................................................................................................29

S

ETPOINTS - PANEL ................................................................................................................................................30

S

CALIBRATION 1........................................................................................................................................................31

ALIBRATION 2........................................................................................................................................................32

C

ONFIGURATION .....................................................................................................................................................33

C

COMPRESSOR...............................................................................................................................................33

NTERNET......................................................................................................................................................34

I

ECURITY .....................................................................................................................................................35

S

SESSION.................................................................................................................................................................36

ELP......................................................................................................................................................................37

H

SCREEN

BOUT....................................................................................................................................................................38

A

KEYS.....................................................................................................................................................37

To Change The Adjustable Setpoints.........................................................................................................37

MISCELLANEOUS SCREENS................................................................................................................................39

A

LPHA ....................................................................................................................................................................39

OPERATION OVERVIEW .......................................................................................................................................40

I

NITIAL SETUP PROCEDURE .....................................................................................................................................40

Compressor Start-Up Procedure ................................................................................................................40

Compressor Stopping Procedure................................................................................................................40

Setup For Automatic Control.......................................................................................................................40

Remote Control Of The Compressor ..........................................................................................................40

REMOTE CAPACITY CONTROL CHART..............................................................................................................41

WARNINGS/SHUTDOWNS MESSAGES...............................................................................................................42

INDEX ......................................................................................................................................................................52

Page 3

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 3

OVERVIEW OF OPERATOR INTERFACE

The compressor unit is controlled by a computer based

machine control system. The controller continuously

monitors the conditions and operation of the compressor

unit and the various subsystems. It also directs the

operation of components.

The panel user interface is designed to all ow an operator

to efficiently access and control the operation of the

compressor unit and subsystems. The control panel

screen is used to display graphic screens. By pressing a

key on the keypad, the labeled or described function is

recognized by the control processor.

The following information is presented to help the operator

interact with the graphic screens and the Quantum™

compressor control panel. This manual is intended to

describe all presently available features for the

compressors listed in Compressor Model Differences.

Reference this section for the differences of the

compressor models that will apply to the displayed data

and the setup and setpoint entry. If applicable is used

throughout this manual to indicate when something might

apply. This is because of the compressor model (see

Compressor Model Differences) or because this feature or

option was selected from a setup.

COMMON TERMINOLOGY

Shutdown - A critical safety limit has been reached or

exceeded and the compressor has been shutdown.

Warning - A Warning setpoint has been reached or

exceeded. The compressor will continue to run if running.

Manual - The device is being controlled from direct

commands or keys at the local controller.

Auto (Automatic) - The device is being controlled from

setpoints at the local controller.

Remote - The device is being controlled by a remote

controller.

OPERATOR ACCESS

Operator access to this system is through various screens.

A screen is the physical representation of data on the

display. Icons have been used to help an operator quickly

identify functions. An icon is a small, graphic symbol

representation. Each screen has a title area. The title is

descriptive of the screen. The current day; date and time,

is shown in this title area. The day of the week; Sunday

through Saturday (Sun. - Sat.) is displayed. The month of

the year from January to December (Jan. - Dec.) is

displayed. The day of the month from 1 to 31 and the year

from 0001 to 9999 are displayed. The time displayed is the

actual time in 24 hours (military) format. The hours,

minutes, and seconds are displayed. The labeled keys on

the panel keypad provide quick access to the operator's

needs. By pressing a labeled key on the keypad, the

corresponding function is recognized. Most of the screens

have screen keys that describe or show a function that is

recognized when the coinciding keypad key to the right of

the screen is pressed. The screen keys provide access to

other screens or commands. For easier viewing, related

information is separated into boxes. The setup and

setpoint entry is separated into logical control

components. Setup selection of features and options hav e

been provided to prevent the operator from unnecessary

viewing and entering of unused control settings. The

required control settings are clearly presented. To further

assist the operator, on-line help is provided. Some

selections appear faded to indicate that this feature is

unavailable. A feature can be unavailable because of

setup selections such as the compressor model. Some

selections appear faded to indicate that this feature might

be available in a future software release.

Page 4

®

8

9

5

6

3

0

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 4 OPERATION - ADAVNCED

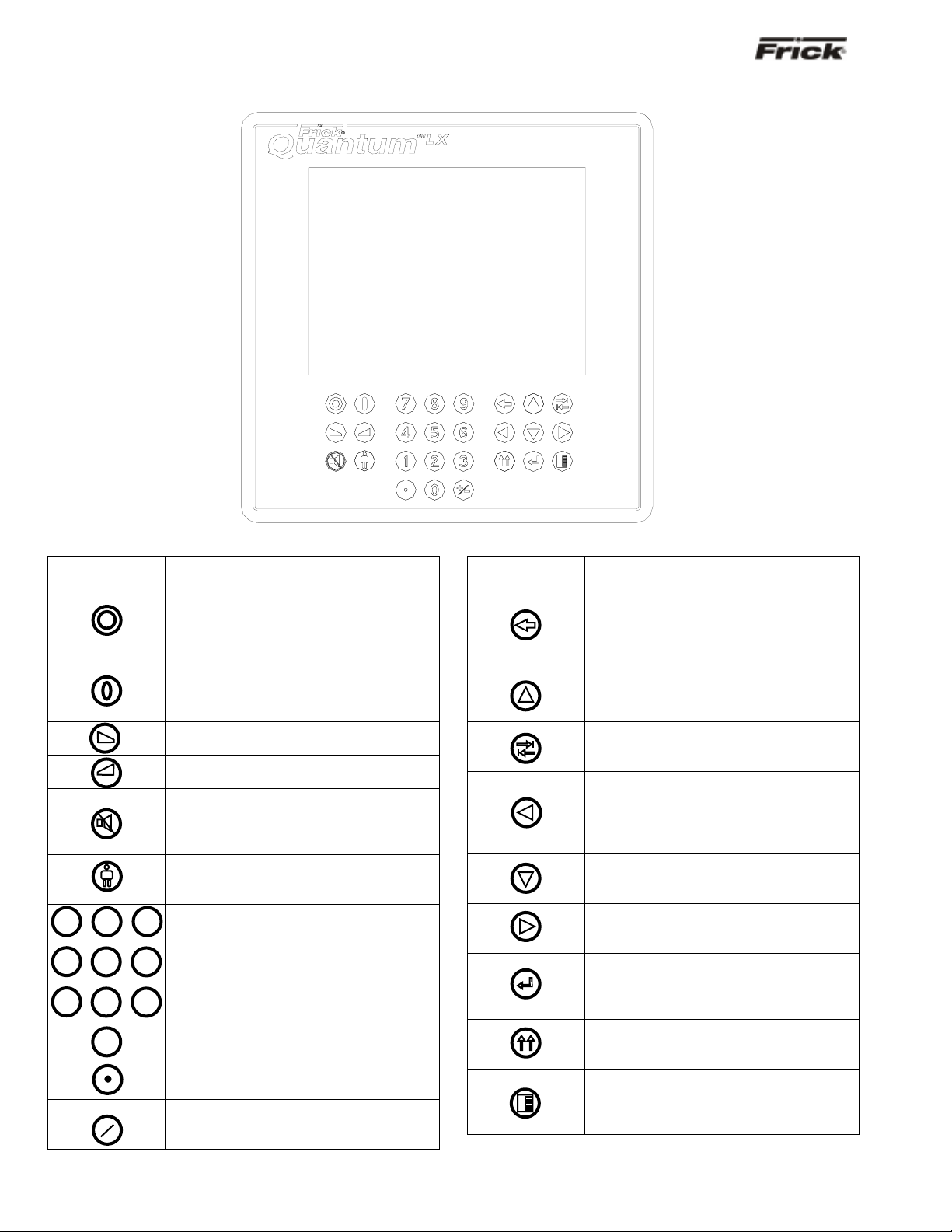

KEYS AND KEY FUNCTIONS

The following is a list of the labeled keypad keys and the actions that occur when they are pressed:

Key Function

[STOP] - When the compressor is

running in Manual Mode, pressing this

key immediately stops the compressor by

placing it into Stop Mode. The

compressor is stopped regardless of any

other conditions.

[START] - When in Manual Mode, this

key places the compressor unit into the

Start Mode for running.

[INCREASE

VALUE] - Increases

Capacity.

[DECREASE VALUE] - Decreases

Capacity.

[ALARM SILENCE] - Immediately

silences a sounding alarm and turns off

the alarm annunciation device that is

connected to this panel.

[MANUAL] - Changes the compressor

mode from its current mode to its

previous mode.

7

4

NUMERALS

[0] - [9] - The numerical

keys are used to enter a value in a data

1

2

field.

DECIMAL [.] - This key is used when

entering a decimal value in a data field.

[+/-] - When changing a value in a data

field, this key toggles the value between

negative and positive.

Key Function

[BACKSPACE] - Pressing this key will

cause the current location of the cursor to

backup one position per key depression.

When changing a value in a data field,

this key will delete the selected

character.

[UP ARROW] - Provides upward

navigation within the MAIN MENU

window.

[TAB] - When in the mode of changing

setpoints, pressing this key will cause the

cursor to jump to the next data entry field.

[LEFT ARROW] - When in the mode of

changing setpoints, this key is used to go

to the previous data entry field. When the

MAIN MENU is shown, pressing this key

will cancel the window.

[DOWN ARROW] - Provides downward

navigation within the MAIN MENU

window.

[RIGHT ARROW] - When in the mode of

changing a data entry field, this key is

used to go to the next character.

[ENTER] - When changing data in a data

entry field, this key will accept the

change. This key is also used to select

items on Menu Windows.

[SUBMIT] - After changing a setpoint

value, Use this key to enter (submit) the

change.

[MENU] - Shows the MAIN MENU

window. This window shows the main

selections for accessing information,

setup of options, and setpoint entry.

Page 5

®

g

g

y

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 5

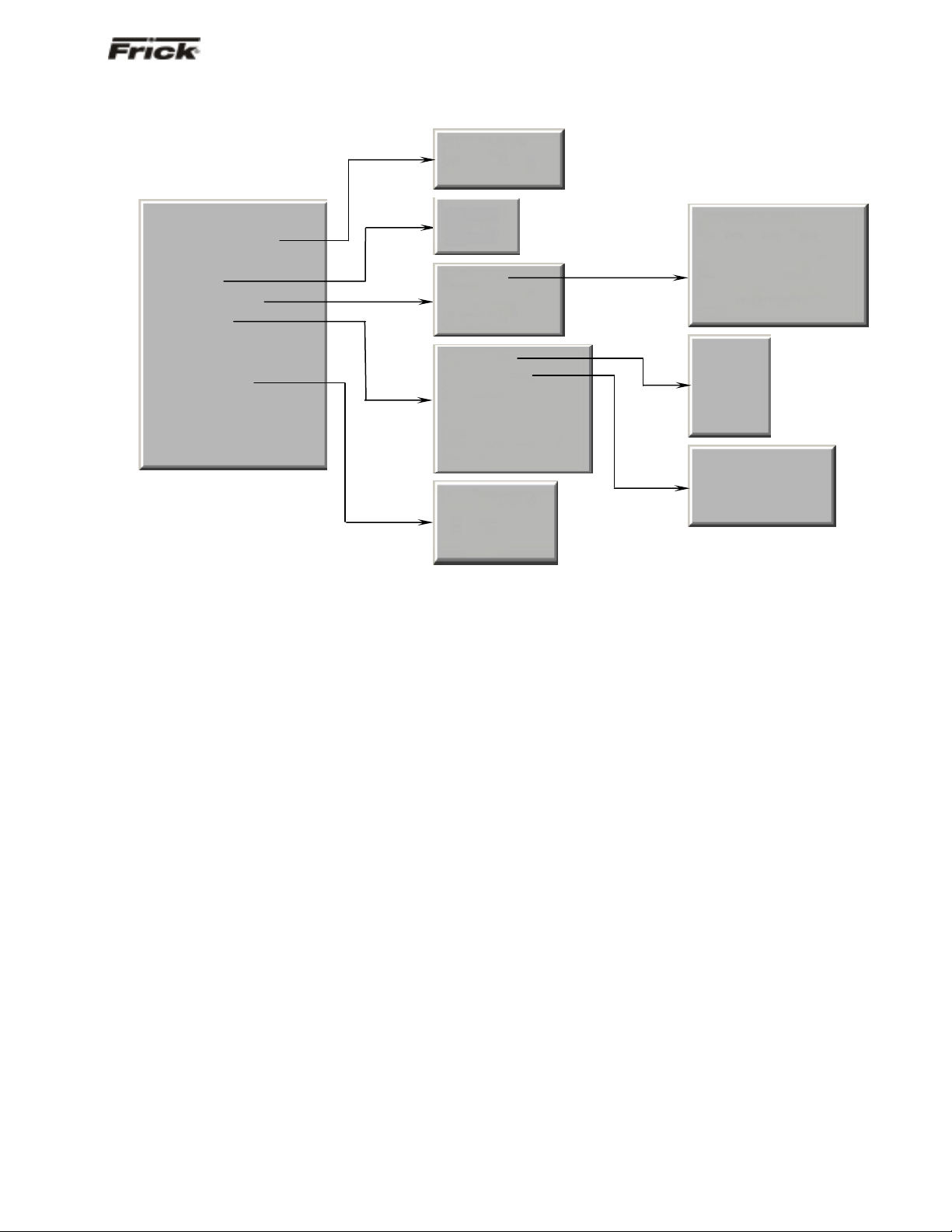

MENU STRUCTURE

Sequencing

User Defined

Home

Operating Values…

Modes

Safeties…

System Status…

Setpoints…

Calibration 1

Calibration 2

Configuration…

Session

Help

About

Current

History

Trending…

Maintenance

Event Lo

Capacity…

Sequencing…

Scheduling

Condenser

Communications

Panel

Compressor

Internet

Securit

The above graphic represents the menu structure, or tree,

of the Quantum™-LX screens. Use this tree when

accessing the various screens. When this document is

viewed electronically, passing the mouse pointer over

each of the above names, and then clicking on it, will take

Trending Setup

Real Time Trending

History Trending

Real Time Data Log

History Data Lo

Mode 1

Mode 2

Mode 3

Mode 4

System 1 Setup

System 2 Setup

System 3 Setup

you directly to the page with that screen. Please note that

this screen list is complete, and that certain screens may

not be available as shown here, depending upon the

enabled options.

Page 6

®

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 6 OPERATION - ADAVNCED

OPERATING DISPLAY SCREENS

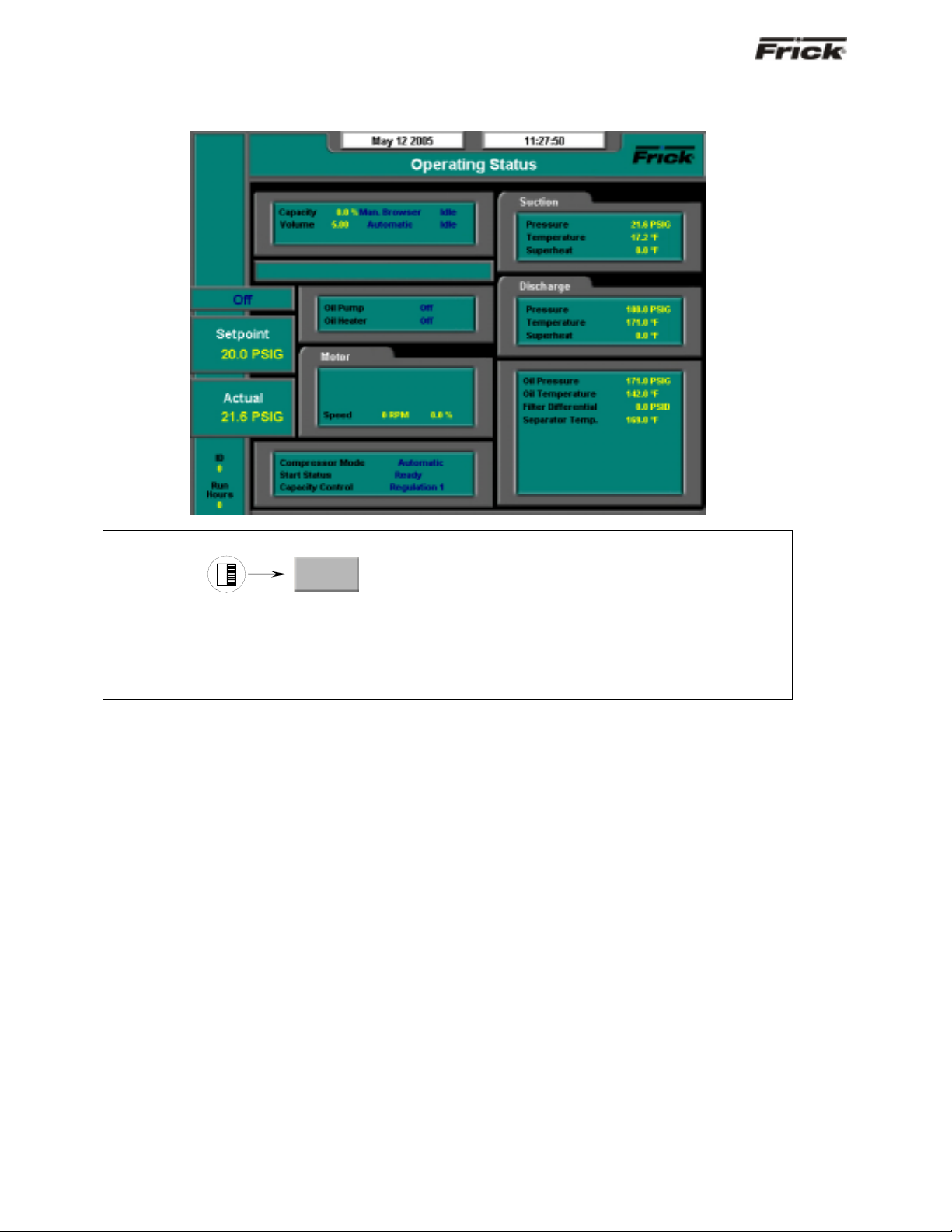

Operating Status

SCREEN NAME: Operating Status or Home.

ACCESSING:

Home

DESCRIPTION: This is the default screen. When power is applied, this screen will appear. Also called the

Home screen. The most important information about the compressor and the applicable subsystems

operation is displayed here. This screen is shown when power is first turned on and wh en a key is pressed

after the screen saver has turned off the backlight. The Operating Status screen is continuously updated

and provides a variety of information with regard to the current condition and performance of the compres sor

unit and subsystem.

The following information is shown on this screen:

DATE - The actual date will be displayed in this box.

The date must first be set correctly on the

Configuration screen. Once set, the date will be

automatically adjusted for at the end of each month,

much like the calendar feature of most modern

watches. The primary use of the date feature is to

provide a date stamp for Warnings and Shutdowns.

(See also TIME)

TIME - The actual time will be displayed in this box.

The time must first be set correctly on the

Configuration screen. The time will also need to be

adjusted for those locations which observe Daylight

Savings Time. The primary use of the time feature is

to provide a time stamp for Warnings and Shutdowns.

(See also Date)

SCREEN TITLE - This is the title for the screen that is

showing. Each screen will have a title. The

Quantum™ LX manuals will extensively refer to

screens by these names. When referred to in these

manuals, screen names will be shown in bold italic

print, such as Operating Status.

COMPRESSOR MODEL - This is actually a rotating

marquee. It will alternately display the model name of

the compressor (such as RWF) and will then rotate to

show Frick

®

.

COMPRESSOR RUN STATUS -

• Off

• Running

• Starting

• Stopping

• Stopping - High Capacity

• Stopping - Pumpdown

PROCESS SETPOINT VALUE - This is the control

setpoint maintained by the internal capacity control.

PROCESS ACTUAL VALUE - The actual reading of

the pressure or temperature that was chosen as the

compressor control setpoint.

ID - The value shown here is the number that has

been assigned to this particular unit on the

Communications Setup screen.

RUN HOURS – The value shown here is the total

number of hours that the compressor has been

actually running, since the last start.

Page 7

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 7

CAPACITY/VOLUME CONTROL BOX - Shows what

is presently controlling the Slide Valve and from what

source it was initiated. The following sources may be

shown:

Capacity:

• Manual

• Automatic

• Remote -- Communications

• Remote -- IO

• Remote -- 4-20 Input

• Remote -- Sequencing

VOLUME:

• Manual

• Automatic

WARNING/SHUTDOWNS STATUS BOX - The

Warning/Shutdowns Status is displayed in the

indented box below the Capacity/Volume status box.

This status box is blank with no message if there are

no warnings or shutdowns present.

One of the following messages could be shown:

WARNING - This message flashes when a

warning is present. A warning is a condition that

requires operator acknowledgement and allows

the compressor to continue to run if it is running.

SHUTDOWN - This message flashes when a

shutdown is present. A shutdown is a condition

that requires an operator to acknowledge it and

causes the compressor to shut down. If the

compressor cannot be stopped, it is minimally run

in a protected state.

A Warning or Shutdown message indicates a

Warning or Shutdown point has been

reached, or exceeded.

When a Shutdown occurs, the display

backlight will flash on and off to alert an

operator of the shutdown. This visual alarm

will help get the attention of the operator in a

noisy engine room environment where

audible alarms may not be heard. Pressing

any key on the keypad will clear the flashing

backlight.

OIL LUBRICATION DEVICE STATUS BOX - The

operating status is shown for the following devices:

Oil Pump - (If selected in the Configuration) –

The On or Off message is shown for the status of

the oil pump. The Manual or Auto message is

shown to indicate the position of the HAND-OFFAUTO switch. If dual pump control was enabled

in Configuration, the lead pump (either Oil Pump

1 or Oil Pump 2) is shown.

Oil Heater - The On or Off message is shown for

the status of the oil separator heater(s).

MOTOR STATUS BOX - The following items are

shown:

Motor Amps - The actual amps.

%FLA - The percentage of the drive motor full

load amperage rating that the motor is currently

using. % (FLA x SF)

Kilowatts - This is the estimated value of the

kilowatt usage of the compressor motor. It is

based on the calculation of Motor Amps * Volts *

2

3

/ 1000.

Recycle Delay - This message shows the

remaining time in minutes for Recycle Delay. If

the compressor has started and shuts down

within the recycle time delay setpoint period, the

Recycle Delay will prevent the compressor from

starting until the delay time expires. This time

delay is intended to prevent damage to the

compressor motor from successive restarts.

Note: The remaining recycle delay time can

be cleared from the Motor screen

COMPRESSOR STATUS BOX - Shows the present

operating status of the compressor and from what

source it has been initiated:

Compressor Mode - One of the following

messages is shown:

• Manual - A compressor manual start or

stop command was sent.

• Automatic - The compressor auto

command was sent. The compressor

starting and stopping is being controlled

from automatic cycling control setpoints

at the panel. The automatic cycling

control setpoints of the active capacity

control are used.

• Remote -- Communications - The

compressor remote communications

command was sent. The compressor

starting and stopping is through the

serial Com-2 channel.

• Remote -- IO - The compressor remote

I/O command was sent.

• Remote -- Sequencing - The

compressor remote sequencing

command was sent.

Note: If there is a shutdown in response to a

safety setting, a compressor in Remote or

Automatic mode is placed i nto Manual mode

requiring operator intervention.

Start Status - One of the following messages is

shown:

• Ready

• Start Inhibit In Shutdown

Page 8

®

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 8 OPERATION - ADAVNCED

• Start Inhibit In Recycle Delay

• Start Inhibit High Discharge Temp.

• Start Inhibit High Oil Temperature

• Start Inhibit Low Separator Temperature

• Start Inhibit Slide Valve Too High

• Start Inhibit Still In Prelube

• Start Inhibit High Suction Pressure

• Start Inhibit High Suction/Discharge

Differential Start Inhibit Permissive Start

• Start Inhibit Digital Auxiliaries

• Power Fail Restart

Capacity Control - One of the following

messages is shown:

• Regulation 1

• Regulation 2

• Regulation 3

• Regulation 4

SUCTION PRESSURE & TEMPERATURE BOX The following sensor information is displayed:

Suction Pressure - Is measured at the

compressor inlet and the value is displayed along

with the unit of measure.

Suction Temperature - Is measured at the

compressor inlet and the value is displayed along

with the unit of measure.

Superheat - The temperature of the gas at

saturation temperature for a given period of time.

DISCHARGE PRESSURE & TEMPERATURE BOX The following sensor information is displayed:

Discharge Pressure - Is measured at the

compressor outlet and the value is displayed

along with the unit of measure.

Discharge Temperature - Is measured at the

compressor outlet and the value is displayed

along with the unit of measure.

Superheat - Superheat is the term used to

describe the difference between the vapor point

(ie., the temperature at which the refrigerant

evaporates at a given pressure) and the actual

temperature of the refrigerant exiting the

evaporator coil.

OTHER PRESSURES AND TEMPERATURE BOX The following sensor information is displayed:

Oil Pressure - Is measured prior to entering the

compressor and the value is displayed along wit h

the unit of measure.

Oil Temperature - Is measured prior to entering

the compressor and the value is displayed along

with the unit of measure.

Filter Differential - If applicable, pressure drop

across the oil filter. The main oil injection oil filter

pressure drop value (differential) is displayed

along with the unit of measure.

Separator Temperature - The Oil Separator

Temperature value is displayed along with the

unit of measure.

Process Temperature - If applicable, the

Leaving Process Temperature value is displayed

along with the unit of measure.

Balance Piston - If applicable, the Balance

Piston pressure reading is displayed along with

the unit of measure. This reading is a

measurement of the presence at the Balance

Piston.

Page 9

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 9

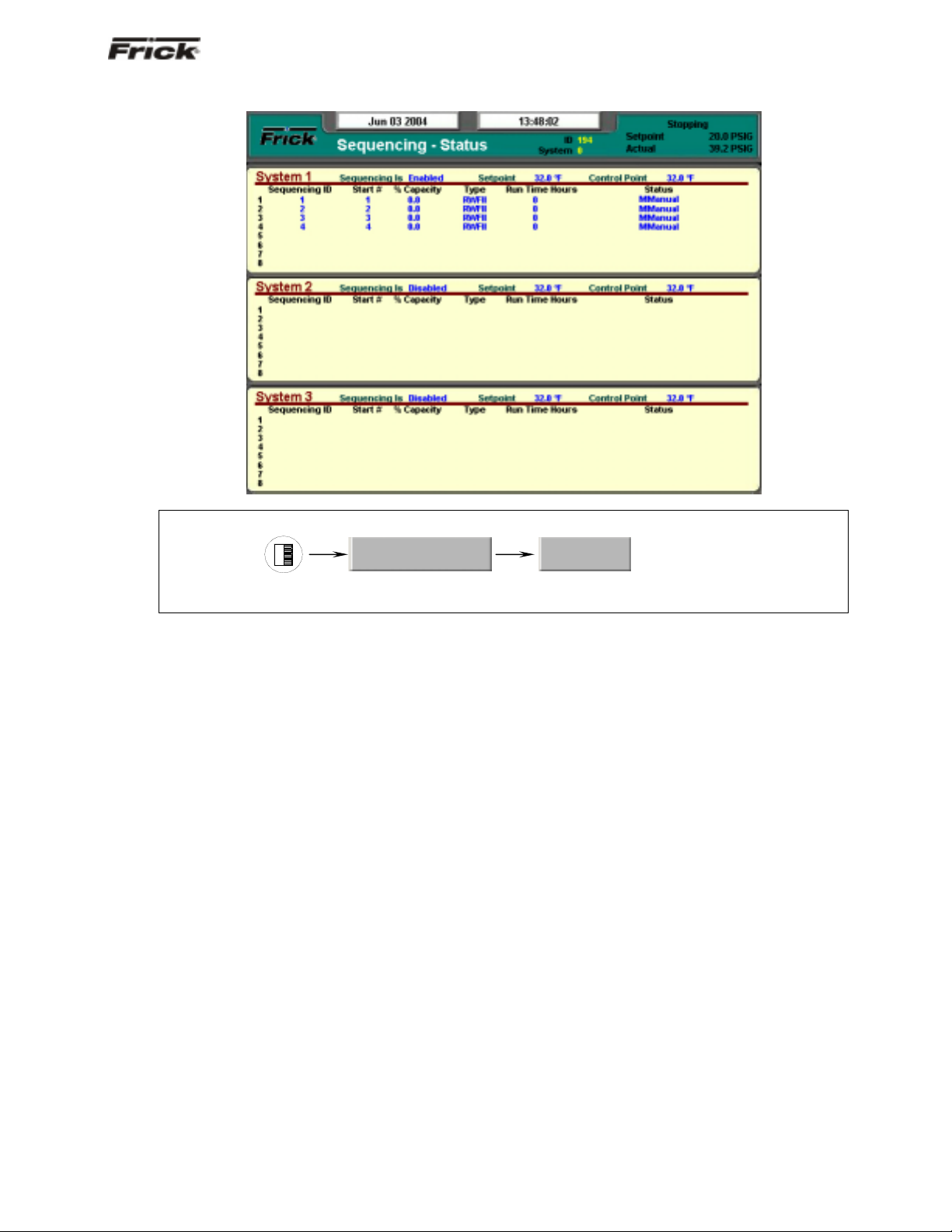

Sequencing

SCREEN NAME: Sequencing.

ACCESSING:

Operating Values…

DESCRIPTION: This screen will be available if Sequencing is enabled in Compressor configuration. This is

strictly a status screen, no values can be changed from here.

The following is a description of the Sequencing strategy:

Start/Stop

System Setup:

• Control Input – Suction Pressure

• Control Direction – Forward

• High Stage Link – Disabled

Start Procedure

Before starting a compressor, the master must

determine that all the running compressors are loaded

and that the Suction Pressure has risen to a point

where an additional compressor is needed.

First, the master checks that either no compressors

are running or all the running compressors average

90% capacity. If a running compressor is at less than

90% capacity but is in a Load Inhibit or Force Unload

condition, for the purposes of this calculation it is

assumed to be at 90% capacity.

If all the running compressors are loaded the master

next begins comparing its Suction Pressure to the

Autocycle Start setpoint. When the Suction Pressure

rises above the Start setpoint, the start timer is

initiated. If the start timer reaches the Autocycle Start

Delay setpoint time and the Suction Pressure has

remained above the Start setpoint for the entire time,

the master attempts to start an additional compressor.

If the Autocycle Start Delay setpoint is 0 minutes, the

Sequencing

master still waits 15 seconds before starting a

compressor.

To determine which compressor to start, the master

first sorts all the compressors in the system based on

their start number, low to high. If two compressors

have the same start number, the first one on the list

remains ahead of the second. Next, the master starts

at the top of the list and works down through list until

it finds a compressor that is available to run. To be

deemed available, a compressor must have good

sequencing communications and its Compressor

Mode and Capacity Mode must be set as Remote

Sequencing. In addition the compressor must be off,

and it cannot be in a Start Inhibit condition except for

the Start Inhibit Slide Value Too High condition. The

compressor with the lowest start number that also

meets these conditions is then sent a start command.

If no compressors are currently available to start, the

master will continue checking until one becomes

available or until the Suction Pressure drops below

the Start setpoint.

After a compressor has been sent a start command,

the master waits for that compressor to reach a

Running state. If 3 minutes passes and the

compressor has not yet begun to run, the master

sends it a stop command. This compressor is then

flagged as Unable to Start for 1 hour. After that time

the master may again try to restart the compressor if

additional capacity is needed. After a compressor

begins running or after one fails to start and is sent a

Page 10

®

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 10 OPERATION - ADAVNCED

stop command, the master can begin the process of

starting another compressor.

Stop Procedure

If the Suction Pressure drops to a point where one of

the running compressors is no longer needed, the

master will stop the last compressor in the sequence

list.

When the Suction Pressure drops below the

Autocycle Stop setpoint, the stop timer is initiated. If

the stop timer reaches the Autocycle Stop Delay

setpoint time and the Suction Pressure has remained

below the Stop setpoint for the entire time, the master

attempts to stop one of the running compressors. If

the Autocycle Stop Delay setpoint is 0 minutes, the

master still waits 15 seconds before stopping a

compressor.

To select the compressor to stop, the master also

sorts all the compressors in the system according to

their start number. Then the master starts at the

bottom of the list and works up, looking for a running

compressor that can be stopped. To be selected a

compressor must have good sequencing

communications and its Compressor Mode and

Capacity Mode must be set as Remote Sequencing.

In addition, the compressor’s run time must be greater

than the compressor’s Minimum Run Time setpoint. If

the Minimum Run Time setpoint is 0 minutes, a

compressor can also be stopped if it is still in Starting

mode. The compressor with the highest start number

that meets these conditions is sent a stop command.

If no compressors are currently available to stop, the

master will continue checking until one becomes

available or until the Suction Pressure rises above the

Stop setpoint.

After a compressor has been sent a stop command,

the master waits for that compressor to go to off. If 3

minutes passes and the compressor has not yet

turned off, the master then flags this compressor as

Unable to Stop for 1 hour. After that time the master

may again try to stop the compressor. After a

compressor goes to off or after one fails to stop within

3 minutes, the master can begin the process of

stopping another compressor.

Load/Unload

System Setup:

Control Input – Suction Pressure

Control Direction – Forward

High Stage Link – Disabled

Load Procedure

If the master compressor’s Suction Pressure is above

the Capacity Control setpoint, the master calculates

the increase in capacity that is required. The

calculation is as follows:

Difference = Suction Pressure – (Capacity

Control Setpoint + Upper Dead Band)

If the Difference is less than the Upper Proportional

Band:

Capacity Change = (Difference / Upper

Proportional Band) * Upper Cycle Time

If the Difference is greater than the Upper

Proportional Band:

Capacity Change = Upper Cycle Time

After the capacity increase has been calculated, the

master then finds the compressor whose capacity

should be changed. To make this determination, the

master sorts all the compressors based on their start

number. Beginning at the compressor with the lowest

start number, the master finds the first compressor on

the list that is running but is not at its maximum

capacity. A compressor is at maximum capacity if it is

at 100 percent capacity or if it is in a Load Inhibit or

Force Unload condition.

If the selected compressor is running the Quantum LX

software, the capacity increase is added to the

compressor’s current capacity. This new value is then

sent to the compressor as its Capacity Command,

and that compressor will try to increase its capacity to

match the Command value.

If the selected compressor is controlled by a Quantum

1-4 or a Plus panel, the capacity increase is

interpreted as the time period for a load pulse and is

sent to the compressor as a load command. The

slave compressor will then turn on its load output for

the given number of seconds.

Unload Procedure

If the master compressor’s Suction Pressure is below

the Capacity Control setpoint, the master calculates

the decrease in capacity that is required. The

calculation is as follows:

Difference = (Capacity Control Setpoint - Upper

Dead Band) – Suction Pressure

If the Difference is less than the Lower Proportional

Band:

Capacity Change = (Difference / Lower

Proportional Band) * Lower Cycle Time

If the Difference is greater than the Lower

Proportional Band:

Capacity Change = Lower Cycle Time

After the capacity decrease has been calculated, the

master then finds the compressor whose capacity

should be changed. To make this determination, the

master sorts all the compressors based on their start

number. Beginning at the compressor with the highest

start number, the master finds the last compressor on

the list that is running and whose capacity is above its

Minimum Capacity setpoint. If two compressors are

currently running at or below their Minimum Capacity

setpoints, the master will not allow any additional

Page 11

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 11

compressors to unload. This will allow the Suction

Pressure to continue to drop and will cause the

master to turn off one of the unloaded compressors. If

the master sees that only one compressor is running

in its system, it will continue to unload the compressor

down to the master’s Automatic Capacity Mode

Minimum Slide Valve Position setpoint.

If the selected compressor is running the Quantum LX

software, the capacity decrease is subtracted from the

compressor’s current capacity. This new value is then

sent to the compressor as its Capacity Command,

and that compressor will try to decrease its capacity

to match the Command value.

If the selected compressor is controlled by a Quantum

1-4 or a Plus panel, the capacity decrease is

interpreted as the time-period for an unload pulse and

is sent to the compressor as an unload command.

The slave compressor will then turn on its unload

output for the given number of seconds.

High Stage/Booster

The High Stage System Link setpoint is provided to

tie a system of Booster compressors to a system of

High Stage compressors. For example, if the Booster

compressors are setup on System #1 and the High

Stage Compressors are on System #2, the High

Stage System Link setpoint from System #1 would be

set as System 2.

When the Booster System’s master wants to start the

first Booster compressor, it first checks that a Booster

compressor is available to run and then sends a

signal to the High Stage System’s master telling it to

start a High Stage compressor. If all the High Stage

compressors are off, the High Stage System’s master

will start its first compressor, regardless of what the

High Stage Control Input is reading. When the

Booster System’s master observes that a High Stage

compressor is running, it will allow a Booster

compressor to start.

After the first High Stage compressor begins to run,

compressors in both systems will cycle on and off as

their Control Inputs move up and down. The only

stipulation to the control strategy is that one High

Stage compressor must always remain on as long as

at least one Booster compressor is running. If all the

Booster compressors turn off, the High Stage

compressor can then turn off as well.

Page 12

®

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 12 OPERATION - ADAVNCED

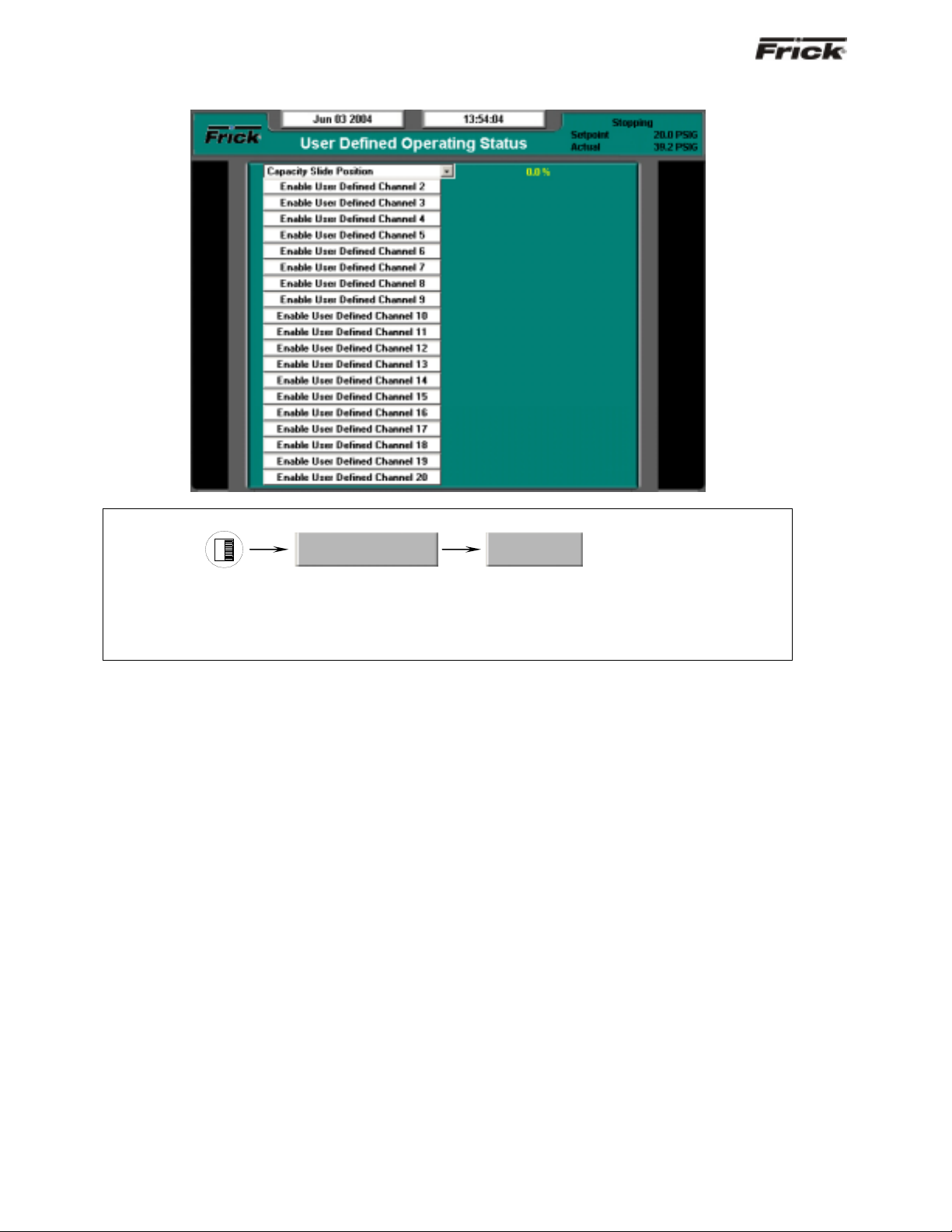

User Defined Operating Status

SCREEN NAME: User Defined Operating Status.

ACCESSING:

Operating Values…

DESCRIPTION: The purpose of this screen is to allow the user to assign additi onal analog channels to be

more readily viewable. Since the main Operating Status (Home) screen is capable of only showing a

limited number of pre-assigned analog values, it may be desirable for the user to have a method of viewin g

additional information that they can select, on a common screen. They may even select values that are

already being displayed on the Operating Status screen, as well as values that are not shown there.

As an example of how this screen works, assume that in

addition to the data that is shown on the Operating

Status screen, the user would like to monitor the Capacity

Slide Position, Suction Pressure and Motor Current.

Notice that both the Suction Pressure and the Motor

Current are already shown on the Operating Status

screen, but the user would also like to see Capacity Sli de

Position on the same screen as these other two. In order

to set this screen up this way, the user would highlight the

Enable User Defined Channel 1 (or whatever channel they

wish to use), by pressing the [Tab] key. Once the box is

highlighted, use the [Enter] key to cause the possible

settings for the channel to appear. Use the arrow keys to

scroll through the list. When the selection that you want to

use has been highlighted, press the [Enter] key to select

it. Once selected, a value will appear to the right of the list,

which corresponds to the analog value for that channel.

The following selections may be shown on this screen:

• Capacity slide position

• Volume slide position

• Suction pressure

• Discharge pressure

User Defined

• Oil pressure (Compressor)

• Main Oil Injection pressure

• Economizer pressure

• Filter pressure

• Intermediate pressure

• Balance piston pressure

• System discharge pressure

• Suction temperature

• Discharge temperature

• Oil temperature compressor

• Oil separator temperature

• Process/Brine temperature leaving

• Process/Brine temperature entering

• Motor Current

• RPM

• User defined analog inputs #1 - #20

• Compressor Vibration - Suction

• Compressor Vibration - Discharge

• Motor Vibration - Shaft Side

• Motor Vibration - Opposite Shaft Side

• None

Page 13

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 13

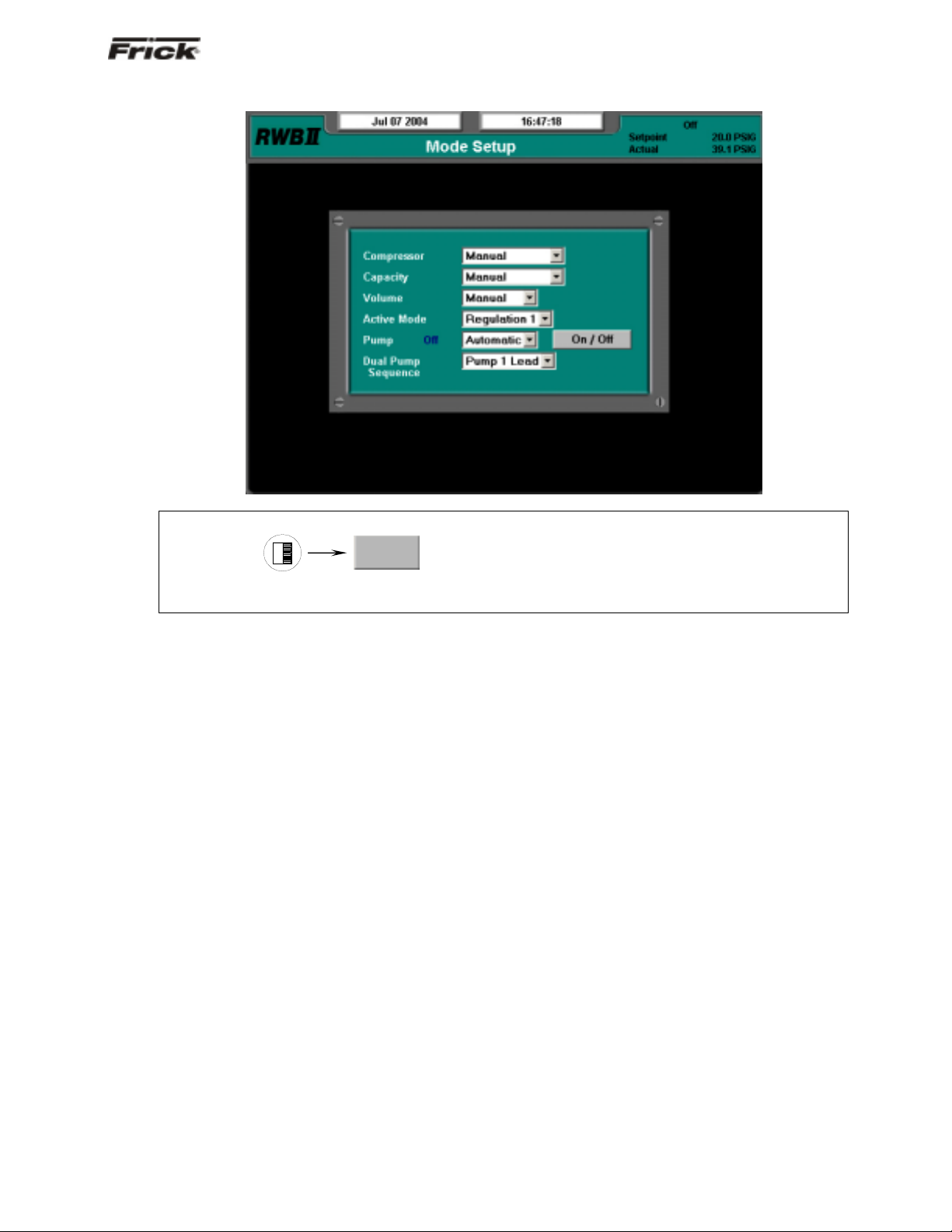

Mode Setup

SCREEN NAME: Mode Setup.

ACCESSING:

Mode

DESCRIPTION: The purpose of this screen is to allow the user to assign operational sta tes (such as m anu al

or automatic) to the various modes shown on the screen.

The following pull-down menus are shown here:

Compressor:

• Manual

• Automatic

• Remote -- Communications

• Remote -- IO

• Remote -- Sequencing

Capacity:

• Manual

• Automatic

• Remote -- Communications

• Remote -- IO

• Remote -- 4-20 Input

• Remote -- Sequencing

Volume:

• Manual

• Automatic

Active Mode:

• Regulation 1

• Regulation 2

• Regulation 3

• Regulation 4

Pump (if enabled):

A Pump On/Off indicator (blue text) is provided here

to alert the user as to the actual status of the Oil

Pump (if applicable). A drop down menu is also

provided, and there are two states that can be

selected for oil pump operation, they are:

• Manual

• Automatic

In Manual mode, the user has control over the

running of the pump. To run the pump, simply

observe the blue text indicator to ensure that the

pump is not already running, and if not, then press the

[On/Off] toggle button. The blue text indicator will

change from Off to On. To stop the pump, press the

toggle button again, and the pump indicator will

change to Off.

If the pump is set to Automatic mode, the Quantum™

LX software program is controlling the pump

operation. In this mode, if the toggle key is pressed,

the mode will be changed from Automatic to Manual

Mode, and the current state of the pump (digital

output 3) will toggle also.

Dual Pump Sequence (if enabled):

• Pump 1 Lead

• Pump 2 Lead

Page 14

®

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 14 OPERATION - ADAVNCED

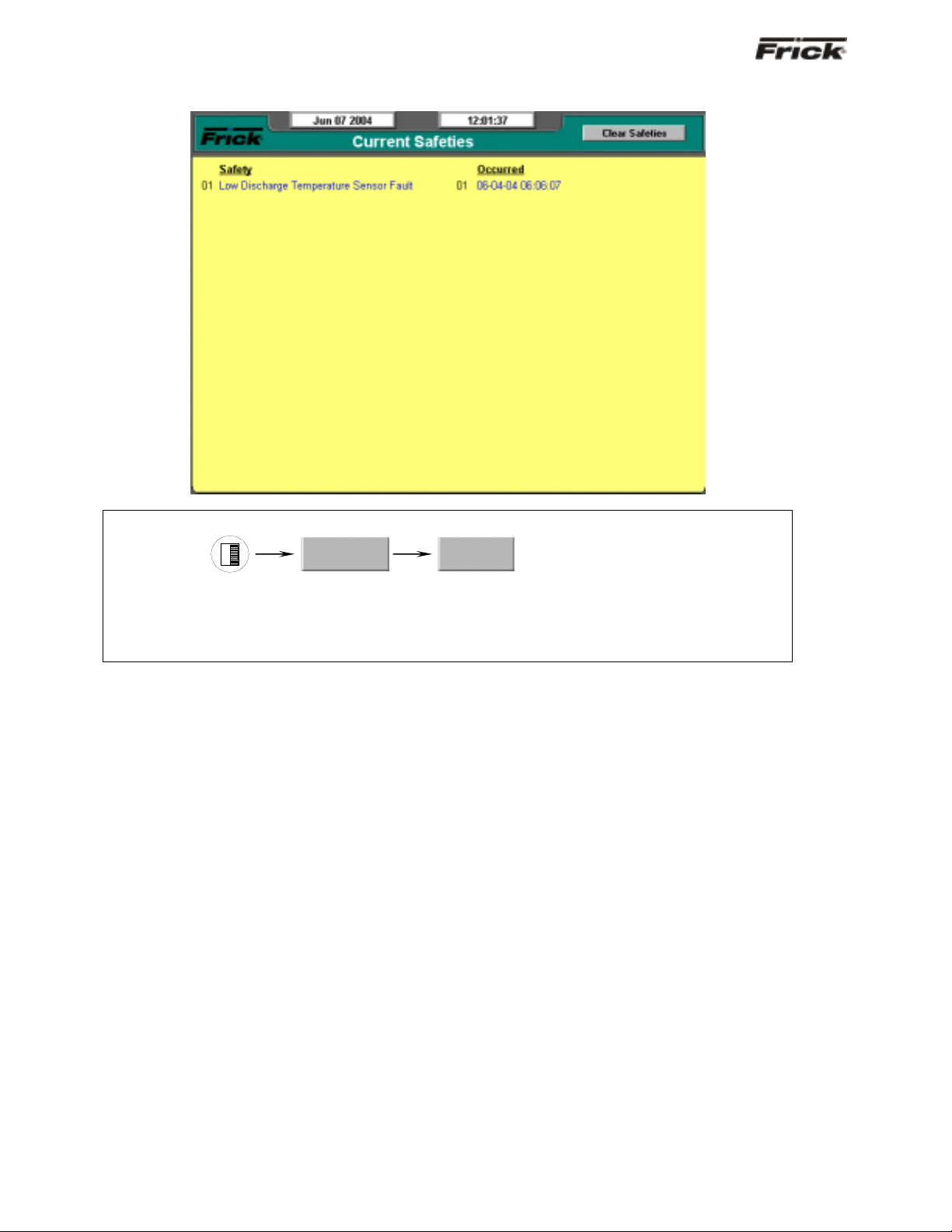

Safeties - History - Current Safeties

SCREEN NAME: Current Safeties.

ACCESSING:

Safeties…

DESCRIPTION: The Current Safeties screen shows the Warnings and Shutdowns that have recently

occurred (up to 50). When a warning or shutdown is triggered, a blue descriptive message shows on thi s

screen. The date and time of the warning or shutdown occurrence is shown to the right of its description.

The most recent message will appear on the top line of the screen with the oldest appearing at the bottom.

When a Warning or Shutdown is logged to this screen, it will also be logged to the Safety History screen.

The following Current Safeties screen key is provided:

[Clear Safeties] - Selecting this key will clear all

warnings and/or shutdowns from this screen. It also

de-energizes the Warning and Shutdown output

modules (digital outputs 23 and 24) to silence any

warning annunciation device. This will also place a

date/time stamp for the corresponding entry on the

Safety History screen showing that the particular

Warning or Shutdown was cleared. Clearing the entry

on the Current Safeties screen, will not clear it from

the Safety History screen.

To resume normal operation it will be necessary to go

through the following steps:

1. Correct the condition(s) causing the warning.

2. Press the [ALARM SILENCE] key. (This action

may precede correcting the condition(s) causing

the warning). Or, go to step 3.

3. To clear or reset the Warnings/Shutdowns

screen and turn off any warning annunciation

Current

device, from the screen, press the [Clear

Safeties] key. This will also clear the WARNING

or SHUTDOWN message from the Operating

Status screen.

4. If the conditions causing the warning have not

been corrected or a new fault has occurred, a

new WARNING or SHUTDOWN message will

appear. The Safety History screen keeps a

record of the warnings and shutdowns. This

information will help troubleshoot persistent

operational problems.

Refer to the Warnings/Shutdowns Message section for a

list of all the possible conditions.

When a Shutdown occurs, the screen backlight will flash

on and off to alert an operator of the shutdown. This visual

indication will help get the attention of the operator in a

noisy engine room environment where audible alarms may

not be heard. Pressing any key on the keypad will clear

the flashing backlight.

Page 15

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 15

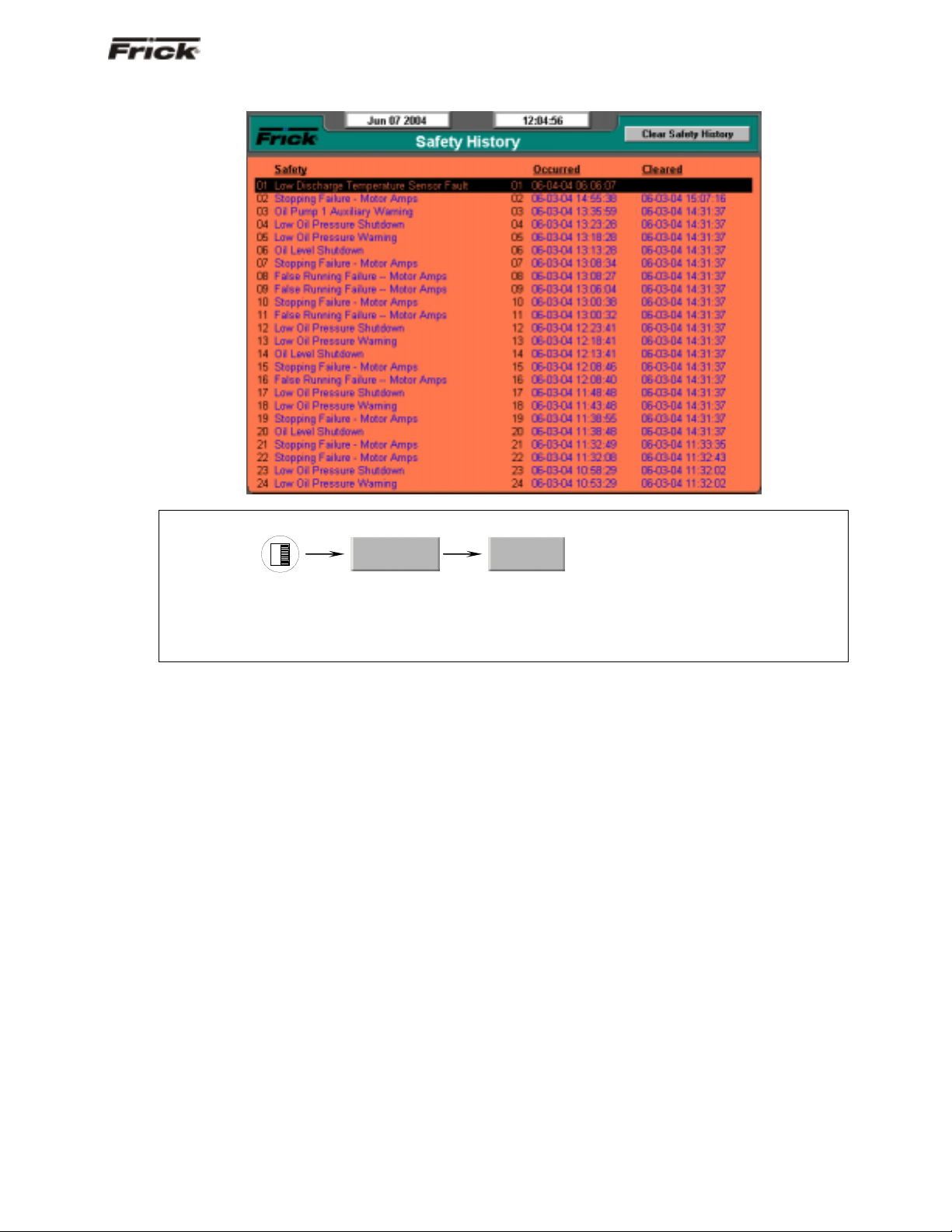

Safeties - History - Safety History

SCREEN NAME: Safety History.

ACCESSING:

Safeties…

History

DESCRIPTION: The Safety History screen shows the warnings and shutdowns that have recently occurred

(up to 50 maximum). When a warning or shutdown is triggered, a blue descriptive m essage shows on this

screen. The date and time of the warning or shutdown occurrence is shown to the right of its description,

followed by the date and time that the safety was cleared (if applicable, from the Current Safeties screen).

The most recent message will appear on the top line of the screen with the oldest appearing at the bottom.

Page 16

®

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 16 OPERATION - ADAVNCED

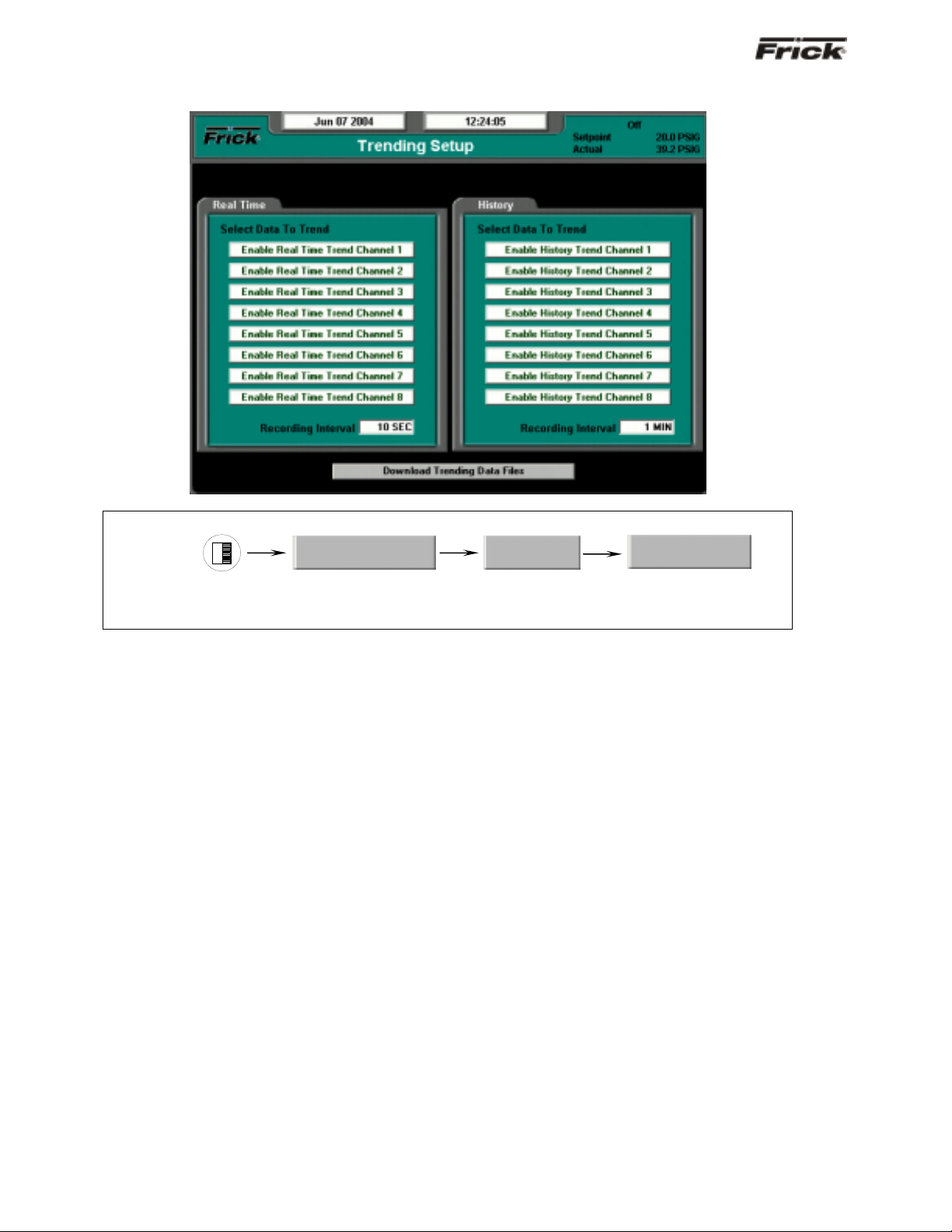

System Status -Trending - Trending Setup

SCREEN NAME: Trending Setup.

ACCESSING:

System Status…

DESCRIPTION: This is the Trending Setup screen. Up to eight channels can be monitored in real time

fashion (as the values are changing), and up to eig ht channels monitored as a history (l ong after they have

happened).

The following setpoints are provided:

Real Time Recording Interval – The time interval

that defines how often the trending data values are

recorded.

History Recording Interval – The time interval that

defines how often the trending data values are

recorded.

To program this screen with the data you wish to trend,

the user would highlight the Enable Real Time Trend

Channel 1 (or whatever channel they wish to use), by

pressing the [Tab] key. Once the box is highlighted, use

the [Enter] key to cause the possible settings for the

channel to appear. Use the arrow keys to scroll through

the list. When the selection that you want to use has been

highlighted, press the [Enter] key to select it. Once

selected, the value for this channel will be automatically

trended and shown on the Real Time Trending graph ( or

History Trending Graph), as well as on the Real Time

Trending Data Log (Or History Trending Data Log).

The following list is the selectable values that may be

shown on this screen:

• Capacity slide position

• Volume slide position

• Suction pressure

Trending…

Trending Setup

• Discharge pressure

• Oil pressure (Compressor)

• Main Oil Injection pressure

• Economizer pressure

• Filter pressure

• Intermediate pressure

• Balance piston pressure

• System discharge pressure

• Suction temperature

• Discharge temperature

• Oil temperature compressor

• Oil separator temperature

• Process/Brine temperature leaving

• Process/Brine temperature entering

• Motor Current

• RPM

• User defined analog inputs #1 - #20

• Compressor Vibration - Suction

• Compressor Vibration - Discharge

• Motor Vibration - Shaft Side

• Motor Vibration - Opposite Shaft Side

• None

The following screen command keys are provided:

Download Data Trending Files -

Page 17

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 17

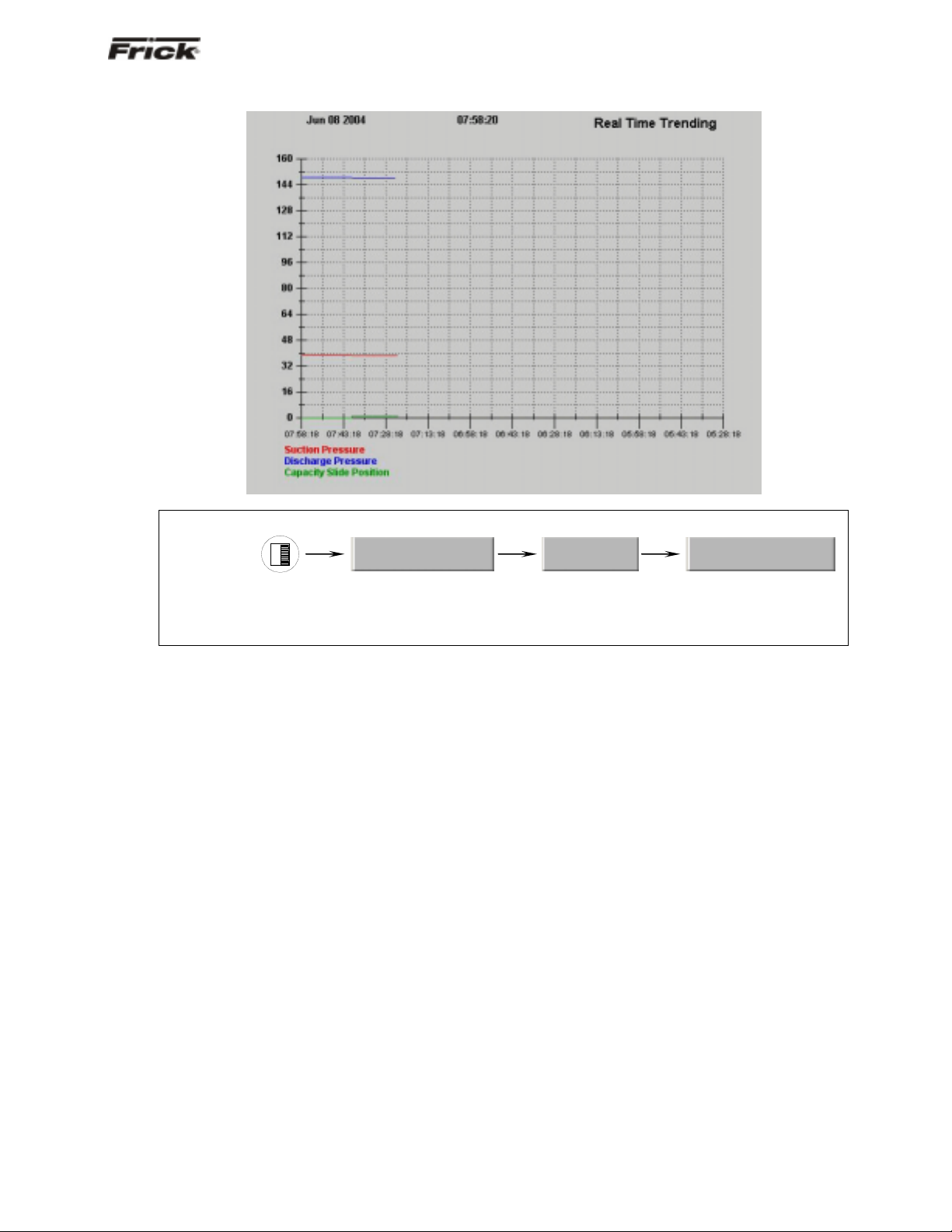

System Status -Trending - Real Time Trending

SCREEN NAME: Real Time Trending

ACCESSING:

System Status…

Trending…

Real Time Trending

DESCRIPTION: This is the Real Time Trending screen. This screen will display in a graphical chart format,

the data values as selected on the Real Time Trending Setup screen. Each of the possible eight selectable

channels will be shown at the bottom of the screen, each in a different color. The color data values displayed

in the chart, correspond to the matching color of the trending channels at the bottom of the screen.

Page 18

®

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 18 OPERATION - ADAVNCED

System Status -Trending - History Trending

SCREEN NAME: Real Time Trending

ACCESSING:

System Status…

Trending…

History Trending

DESCRIPTION: This is the History Trending screen. It is accessible from the Main Menu by pressing

System Status…, then Trending, and finally History Trending. This screen will display in a graphical chart

format, the data values as selected on the Real Time Trending Setup screen. Each of the possible eight

selectable channels will be shown at the bottom of the screen, each in a different color. The color data

values displayed in the chart, correspond to the matching color of the trending channels at the bottom of the

screen.

Page 19

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 19

System Status -Trending - Real Time Data Log

SCREEN NAME: Real Time Data Log.

ACCESSING:

System Status…

Trending…

Real Time Data Log

DESCRIPTION: This screen will display in a tabular format, the numerical data values as selected on the

Real Time Trending Setup screen. Each of the possible eight selectable channels will be shown at the

bottom of the screen, each in a different color. The color data values displayed in the chart, correspond to

the matching color of the trending channels at the bottom of the screen.

Page 20

®

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 20 OPERATION - ADAVNCED

System Status -Trending - History Data Log

SCREEN NAME: History Data Log.

ACCESSING:

System Status…

Trending…

History Data Log

DESCRIPTION: This screen will display in a tabular format, the numerical data values as selected on the

Real Time Trending Setup screen. Each of the possible eight selectable channels will be shown at the

bottom of the screen, each in a different color. The color data values displayed in the chart, correspond to

the matching color of the trending channels at the bottom of the screen.

Page 21

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 21

System Status - Maintenance

SCREEN NAME: Maintenance.

ACCESSING:

System Status…

DESCRIPTION: Using this screen, the user can view up to nine (9) pre-programmed maintenance

schedules, as well as eight (8) user definable maintenance schedules. Each of the user defined sch edules

may be custom named. This screen is based upon the Maintenance Schedule that is provided in the IOM

manual for the specific compressor package.

The usage of this screen is that the user can assign up to

seventeen different areas of compressor operation that

they would like to schedule routine maintenance for. As an

example, the above screen shows a row labeled as Oil

Analysis. The next column (Service Every) on the same

row has a value of 10000 Hrs. The last column (Next

Scheduled At) of this row has a value of 1000 Hrs. When

the compressor is running, this time value is being

clocked. After 1000 hours of compressor run time, a

message will be generated and placed on the Event Log

screen. This particular message will read Maintenance --

Oil Analysis. This is to notify the operator that it is time to

have the Oil checked. At this point, the operator should

notify the proper maintenance personnel that the

appropriate maintenance be performed. The user should

access the Event Screen on a regular basis (perhaps once

per week) to review the information provided there.

Once the message has been entered in the Event Log,

the values for the row will be automatically updated, with

new values as predetermined by an internal programmed

maintenance schedule, based upon the type of

compressor. The values for the Next Scheduled at column

are based upon the Compressor Run Time hours (shown

at the bottom of this screen).

At the bottom of the left most column is the user defined

Maintenance Required column. This is where custom

names may be entered for the various items that the user

would like to track.

Maintenance

Modifying numerical values

To modify any of the numerical boxes on this screen,

simply use the [Tab] key to scroll down the lists, or

the [Left Arrow] key to scroll up the lists. When the

box that you wish to change is highlighted, you may

enter the new value using the numerical keys, then

press the [Enter] key to accept the value.

Modifying Text (User Defined) Boxes

To modify any of the text boxes on this screen, simply

use the [Tab] key to scroll down the lists, or the [Left

Arrow] key to scroll up the lists. When the box that

you wish to change is highlighted, use the [Up Arrow]

key. A new screen (Alpha) showing a numerical

keypad will appear. Refer to the Alpha screen

description for information on entering text messages.

Press the [Enter] key to accept the text. The user

may type in a custom name up to 20 characters long.

The following additional information is provided on this

screen:

Run Hours - The value shown here are the total

number of hours that the compressor motor has

actually been in the running state. This value can b e

reset (or changed to any value from 0 to 1,000,000

Hours) from the Panel screen.

Page 22

®

S90-021 O (MAY 07) FRICK

Page 22 OPERATION - ADAVNCED

QUANTUM™ LX COMPRESSOR CONTROL PANEL

System Status - Event Log

SCREEN NAME: Event Log.

ACCESSING:

DESCRIPTION: This screen is used to log certain messages and events that are generated through normal

unit operation. Occurrences such as normal power up and power down sequences, as well as all

maintenance schedule messages (see the Maintenance screen for more information on these messages).

The messages that appear on this screen cannot be

cleared, they will be stored indefinitely. The user can use

System Status…

Event Log

the arrow keys on the keypad to scroll down through the

list.

Page 23

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 23

Setpoints - Capacity Control - Mode 1

SCREEN NAME: Capacity Control.

ACCESSING:

DESCRIPTION: The Mode 1 and Mode 2 screens are identical in appeara nce. All setpoints having to do

with Capacity Control, Autocylce, Regulation Safeties and Low Suction are found here.

CAPACITY CONTROL - The following setpoint boxes are

provided:

Setpoint - This setpoint is used to control the loading

and unloading of the compressor when the Slide

Valve Position is in the Automatic (AUTO) mode.

Proportional Band High - A band, measured in the

units of the Capacity Control setpoint, above the Dead

Band High, where proportional load control is used. If

the actual reading rises into this proportional band,

the load output will be pulsed as explained below in

the description about proportional band.

Proportional Band Low - A band, measur ed in the

units of the Capacity Control setpoint, below the Dead

Band Low, where proportional unload control is used.

If the actual reading falls into this proportional band,

the unload output will be pulsed as ex plaine d below i n

the description about proportional band.

A Note About Proportional Band: The

Proportional Band setpoint determines a range of

Capacity Control values where pulsed output is

used. Beyond the proportional band the output is

continuously energized. The length of time the

output will be pulsed on is proportional to the

distance the actual reading is from the Capacity

Control setpoint. The further the distance from

Setpoints…

Capacity…

Dead Band High - A band, measured in the units of

the Capacity Control setpoint, above the setpoint at

which the compressor will neither load nor unload.

Dead Band Low - A band, measured in the units of

the Capacity Control setpoint, below the setpoint at

which the compressor will neither load nor unload.

Cycle Time High - This setpoint determines the

amount of time in seconds that the load output is on

and off, when in the upper proportional band. Refer to

the above description about cycle time.

Cycle Time Low - This setpoint determines the

amount of time in seconds that the unload output is

on and off, when in the lower proportional band.

Refer to the above description about cycle time.

Mode1

setpoint, the longer the output is pulsed on and

the shorter the output is off. The closer the

distance to setpoint, the shorter the output is

pulsed on and the longer the output is off. If the

actual reading is midpoint from setpoint, the

output is on and off an equal amount of time.

A Note About Cycle Time: The Cycle Time

setpoint determines the amount of time the

output is on and off, when in the proportional

band. At the completion of the cycle time, the

Page 24

®

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 24 OPERATION - ADAVNCED

actual reading and necessary response is reevaluated. If a four-second period has been

selected, then the following will result:

Proportional

Distance

Actual Reading

Output

Pulsed On

(sec)

Output Off

(sec)

is From Setpoint

0 0 4

1/4 1 3

1/2 2 2

3/4 3 1

1 4 0

The following status indicator is provided:

Channel - Shows which analog channel is bein g

used to control this mode. The possible states of

this indicator are:

• Capacity slide position

• Volume slide position

• Suction pressure

• Discharge pressure

• Oil pressure (Compressor)

• Main Oil Injection pressure

• Economizer pressure

• Filter pressure

• Intermediate pressure

• Balance piston pressure

• System discharge pressure

• Suction temperature

• Discharge temperature

• Oil temperature compressor

• Oil separator temperature

• Process/Brine temperature leaving

• Process/Brine temperature entering

• Motor Current

• RPM

• User defined analog inputs #1 - #20

AUTOCYCLE - The following setpoint boxes are

provided:

Start - The compressor is st arted at this setpoint

when it is under automatic control.

Start Delay - The minimum time in minutes that

the actual Capacity Control value must equal or

exceed the start autocycle (automatic cycling)

setpoint before the compressor will start. This

timer helps prevent cycling a compressor on and

off due to short or sudden changes in load within

the refrigeration system.

Stop- The compressor is stopped at this setpoint

when it is under automatic control.

Stop Delay - The minimum time in minutes that

the actual Capacity Control value must equal or

exceed the stop autocycle (automatic cycling)

setpoint before the compressor will stop. This

timer helps prevent cycling a compressor on and

off due to short or sudden changes in load within

the refrigeration system.

REGULATION SAFETIES - The following setpoint

boxes are provided:

• Load Inhibit

• Force Unload

• Warning

• Warning Delay

• Shutdown

• Shutdown Delay

Each of the four Regulation Modes has a set of

Regulation Safeties and Low Suction Safeties.

Additionally, each also has a Control Channel and is

configured with a Control Direction of either Forward

or Reverse. The Regulation Safety Setpoints monitor

the Control Channel for their Regulation Mode.

If the Control Direction for a Regulation Mode is set

to Forward, its Regulation Safeties are activated as

the Control Channel’s value drops below the

Regulation Safety Setpoints.

Example:

Control Channel = Process Temperature

Control Direction = Forward

Regulation Safety Warning Setpoint = 35.0 F

Note: For the above conditions a Regulation

Warning will occur if the Process Temperature

drops below 35.0 F.

If the Control Direction for a Regulation Mode is set to

Reverse, its Regulation Safeties are activated as the

Control Channel’s value rises above the Regulation

Safety Setpoints.

Example:

Control Channel = Discharge Pressure

Control Direction = Reverse

Regulation Safety Load Inhibit Setpoint = 170.0

PSIG

Note: For the above conditions a Regulation

Load Inhibit condition will occur if the Discharge

Pressure rises above 170.0 PSIG.

If a Regulation Mode’s Control Channel is set to

Suction Pressure, and its Control Direction is set to

Forward, then both the Regulation Safeties and the

Low Suction Safeties are checking for the same

conditions. In this case, it is recommended that one

group of safeties be set lower than the other group so

that only one group will be actively monitoring the

channel. Otherwise, duplicate Warning and

Shutdown messages would be shown that could be

confusing.

LOW SUCTION - The following setpoint boxes are

provided:

• Load Inhibit

• Force Unload

• Warning

• Warning Delay

• Shutdown

• Shutdown Delay

Page 25

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 25

Setpoints -Sequencing - System 1 Setup

SCREEN NAME: Sequencing - System 1 Setup.

ACCESSING:

Setpoints…

DESCRIPTION: This screen will be available if Sequencing is enabled in Compressor configuration. The

screen shown here represents System 1. There are additionally a System 2 and a Sys tem 3 setup screen,

which are not discussed further here, as all three screens show the sa me layout, although they may get

setup using differently, using different capacity modes for example. Use these screens to setup all of the

necessary operating parameters for performing compressor sequenci ng. The information from these three

screens will be shown on the Sequencing Status screen.

The following pull-down menus and setpoint boxes are

shown here:

Sequencing - Use this menu to set the current

condition of System 1:

• Disabled - The compressors that are listed

on this screen will not run as part of the

sequencing scheme (System 1 will be

ignored).

• Enabled - The compressors that are listed

on this screen will run when called for as part

of the sequencing scheme (System 1 will be

included).

Setpoint - Use this setpoint box to set the value that

you wish all compressors within this System to

maintain.

Control Point - This is the actual value for the

capacity control (as measured from the Master

compressor). The master compressor is the unit with

the lowest number shown on the Start # list. It is to

this value that the compressors will attempt to

maintain. This is strictly a displayed value, and cannot

be changed here (it is based off of the Setpoint box

directly above it).

Sequencing…

System 1 Setup

Minimum Run Time - This is the minimum amount of

time that each compressor within this system will run,

when called upon to do so.

High Stage System Link - The High Stage System

Link setpoint is provided to tie a system of Booster

compressors to a system of High Stage compressors.

IP Address - Each compressor will have a different IP

Address. This value should be entered by the network

or LAN administrator, and will be shown here. Use the

last three digits of this number for setting the

Sequencing ID number for each compressor within

the system. For example, from the IP shown on this

screen, use 194 to enter into one of the eight

Sequencing ID boxes at the left of the screen. This

will identify which compressor is being communicated

to with sequencing instructions.

There are eight rows of setpoint boxes shown at the

bottom of this screen. These rows correspond to up to

eight different compressors, which combined will make up

this system. The user may program as few or as many of

these rows as their situation requires:

Sequencing ID - Enter the last three digits of the IP

Address here. This will identify each of the possible

eight compressors to the Master.

Page 26

®

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 26 OPERATION - ADAVNCED

Start # - Use the values of 1 - 8 here. The lowest

number will identify which compressor is to be the

Master. If the Master is for some reason turned off,

the next lowest numbered compressor will become

the Master, and so on.

Compressor Mode -

• Manual

• Automatic

• Remote Comm

• Remote IO

• Remote Seq.

Capacity Mode -

• Manual

• Automatic

• Remote Comm

• Remote 4-20

• Remote IO

Panel Type - Set this pull-down for the type of

controller on each of the associated compressors. If

the panel type is the Quantum / Plus version, then

use the Panel ID for these units as the Sequencing

ID. Ensure that the ID numbers are all different. The

two selections are:

• Quantum LX

• Quantum / Plus

Minimum Capacity -

Page 27

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 27

Setpoints -Scheduling

SCREEN NAME: Scheduling.

ACCESSING:

Setpoints…

DESCRIPTION: Scheduling allows the user to program up to four different operating schedules for each day

of the week. This can be a great way to save energy. At night or on weekends an d holidays, or even over

lunch periods when room doors are kept closed, or production is minimized, a higher temperature can be set

to reduce energy consumption.

This screen shows a time schedule. Up to four different

modes can be entered for each day of the week. The

Schedule is only effective if the compressor is in

automatic.

Notice that there are four columns of Hour/Minute entries,

each followed by a Regulation mode (1 - 4). Use the left

most column (on the row for the day of the week that you

wish to schedule) to enter the time of day that you would

like the compressor to switch form it’s normal operating

mode, into the scheduled mode. When that time of day

arrives, whatever mode the compressor WAS running in,

will be switched over to the scheduled (Regulation 1 -4)

mode. This mode will then be the active running mode,

and will continue to be the active mode until the time in the

following column is reached. If the time in the next colum n

is 00:00, it will be skipped.

The Schedule must be activated to switch the presently

active Regulation mode to the Scheduling regulation mode

at the assigned time. An entry of 00:00 will void the time

Scheduling

entry field. If setback is required at midnight (00:00) use

00:01.

The following drop down menu is provided:

Scheduling

• Enabled - The user programmed Schedule

will be followed.

• Disabled - The Quantum™ LX will ignore

any schedule that may have been set.

The following are descriptions of the setpoints:

Time Column - The time of day that you want to

switch to the Scheduled regulation setpoints of the

active capacity control.

Mode Column - Set this to the Regulation Mode (1 -

4) that you want to run at the assigned time.

Page 28

®

S90-021 O (MAY 07) FRICK

Page 28 OPERATION - ADAVNCED

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Setpoints -Condenser

SCREEN NAME: Condenser.

ACCESSING:

DESCRIPTION: If Condenser is enabled, this screen allows the end user to enter and view the basic

operating parameters related to condenser operation.

Setpoints…

Condenser

Page 29

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 29

Setpoints -Communications

SCREEN NAME: Communications configuration.

ACCESSING:

Setpoints…

DESCRIPTION: This screen is used to set the compressor ID number, and the parameters for each of the

three communications channels, as well as to show the status of the internal I/O board status.

The following setpoints are provided:

Compressor ID - A number that is used by an

external communications application, to converse to

individual compressors. On interconnected systems,

this number must be unique. Valid values are from 0 -

99.

Comm1 - (Setup parameter definitions for Comm1, 2,

and 3 are identical) Communications related

information for the communications ports:

Status - Shows the current communications

status of the port. The possible messages are:

• Off - No communications are currently

taking place. NOTE: A delay of 15

seconds or more of inactive

communications (time between valid

responses) will cause this message to

display.

• Active - Valid communications are

actively occurring.

• Failed - An invalid command was

received by the port. This could be due

to a bad checksum value, a wiring

issue, or hardware problem at either the

transmitting (host) or receiving

(Quantum™ LX) end.

Communications

Baud Rate - Allows for the following selections:

Data Bits - Allows for the following selections:

Stop Bits - Allows for the following selections:

Parity - Allows for the following selections:

RS-485 Connection - Allows for the following

selections:

Protocol - Allows for the following selections:

• 1200

• 2400

• 4800

• 9600

• 19200

• 38400

• 57600

• 115200

• 7

• 8

• 1

• 2

• None

• Even

• Odd

• No

• Yes

• None

• Frick

Page 30

®

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 30 OPERATION - ADAVNCED

• ModBus ASCII

• ModBus RTU

• AB DF1 Full Duplex

• AB DF1 Half Duplex

• DBS Motor Starter

• Vyper

Map File - Allows for the following selections:

• No

• Yes

I/O Comms - A status indicator is provided to show

the current state of the internal communications of the

I/O boards. The possible displayed states are:

• Off

• Active

• Failed

Select this key to detect all connected Analog and

Digital boards. If a board has been removed, a

communication error shutdown will be issued until this

key is selected. Reference the About screen to view

what has been detected.

Setpoints - Panel

SCREEN NAME: Panel configuration.

ACCESSING:

Setpoints…

DESCRIPTION: This screen is used to view and set basic compressor operational values.

The following information is provided:

Panel Temperature - The main processor board is

equipped with a temperature sensor. The panel has

an operational temperature range that should be

maintained. The operational temperature range is

documented in the specifications document.

Panel Heater - A Status message is showing the

current state of the Panel Heater:

• Off - Panel Heater is Off

• On - Panel Heater is On

Whether the Panel Heater is On or Off is determined

by the setting of the following two setpoints:

• On - If the sensor on the main processor

board detects that the temperature is less

than or equal to this setpoint, the Panel

Heater output is turned on.

Panel

• Off - If the sensor on the main processor

board detects that the temperature is greater

than or equal to this setpoint, the Panel

Heater output is turned off.

The following pull-down boxes are provided:

Permissive Start Remote Enable Output Run Hours PLC Interlock Input Module Capacity Mode Selection -

• Disabled

• Enabled

Page 31

®

FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-021 O (MAY 07)

OPERATION - ADVANCED Page 31

Calibration 1

SCREEN NAME: Calibration 1.

ACCESSING:

Calibration 1

DESCRIPTION: This screen is used to view and set calibration values.

This screen should be used anytime a sensor is found to

be out of calibration. The recommended practice for

adjusting the calibration reading is to first determine which

sensor(s) need to be calibrated. Once this is determined,

you must know the actual reading that the sensor should

be showing, This can be accomplished by comparing the

displayed reading shown here, with the actual value using

a separate measurement device, such as a Digital Volt

Meter, or temperature probe, etc. Determine the difference

between what the screen reading for the sensor is, and

what the reading of the separate device shows. As an

example, assume that the Suction Temperature on this

screen reads 120° F, but a separate device is showing a

reading of 123° F. Highlight the setpoint box for Suction

Temperature, and enter the value of 123. The new readin g

will now read 123, and should match your separate

reading.

The following fields are provided:

Pressure - The following sensor values are

displayed along with the unit of measure:

Suction Pressure - This value is measured at

the compressor inlet .

Discharge Pressure - This value is measured at

the compressor outlet.

Oil Pressure - This value is measured prior to

entering the compressor.

Filter (Differential) - If applicable, shows the

pressure drop across the oil filter. The main oil

injection oil filter pressure drop value (differential)

is displayed along with the unit of measure.

Balance Piston - If applicable, the Balance

Piston pressure reading is displayed along with

the unit of measure. This reading is a

measurement of the presence at the Balance

Piston.

Main Oil Injection -

Economizer -

System Discharge -

Temperature - The following sensor values are

displayed along with the unit of measure:

Suction Temperature - This value is measured

at the compressor inlet.

Discharge Temperature - This value is

measured at the compressor outlet.

Oil Temperature - This value is measured prior

to entering the compressor.

Separator Temp. - Oil Separator Temperature

value is displayed.

Process Leaving - If Process Temperature

Control Modes were enabled in Panel Setup, the

Leaving Process Temperature value is displayed.

Process Entering - If Process Temperature

Control Modes were enabled in Panel Setup, the

Leaving Process Temperature value is displayed.

Panel - This reading is measured on the

Quantum™ LX controller itself, and shows the

actual board temperature value.

Page 32

®

S90-021 O (MAY 07) FRICK

QUANTUM™ LX COMPRESSOR CONTROL PANEL

Page 32 OPERATION - ADAVNCED

Calibration 2

SCREEN NAME: Calibration 2.

ACCESSING:

Calibration 2

DESCRIPTION: This screen is used to view and set calibration values.

This screen should be used anytime a sensor is found to

be out of calibration. The recommended practice for

adjusting the calibration reading is to first determine which

sensor(s) need to be calibrated. Once this is determined,

you must know the actual reading that the sensor should

be showing, This can be accomplished by comparing the

displayed reading shown here, with the actual value using

a separate measurement device, such as a Digital Volt

Meter, or temperature probe, etc. Determine the difference

between what the screen reading for the sensor is, and