Page 1

TECHNICAL

MANUAL

OPTIMA PT-VS-ST

TECHNICAL MANUAL

From Serial N° 18180100 till ...

Page 2

Revision table

TM Optima PT-VS-ST_en : ref NT1741

Date Revision Chapter Description

03/04/03 0 All index "a" création

20/08/07 1 Index "b" New EMC standard, spare parts up date

Page 3

1 Presentation...................................................................................................... 7

1.1 General presentation ............................................................................. 7

1.2 Operation diagram ................................................................................. 8

1.3 Precautions for use................................................................................ 9

1.4 Operation safety..................................................................................... 9

1.5 Technical characteristics ...................................................................... 9

1.5.1 Electrical details .........................................................................................................9

1.5.2 Electronic details ........................................................................................................ 9

1.5.3 Mechanical details...................................................................................................... 9

1.5.4 Conformity and norms .............................................................................................. 10

2 Description and operation ............................................................................. 11

2.1 Physical description ............................................................................ 11

2.1.1 Display board and front panel .................................................................................. 12

2.1.2 The CPU board ........................................................................................................ 14

2.1.3 The power supply board and battery........................................................................ 17

2.2 Operational description ....................................................................... 19

2.2.1 Tube check and maintenance sub-assembly ........................................................... 19

2.2.2 Pumping sub-assembly ............................................................................................ 19

2.2.3 External connection sub-assembly .......................................................................... 19

3 Description of the menus .............................................................................. 21

3.1 Parameter configuration menu ........................................................... 21

3.1.1 Access to the menu.................................................................................................. 23

3.1.2

3.1.3

3.1.4

SAV1, preventive maintenance configuration ....................................................... 24

SAV2, tube selection configuration ....................................................................... 24

SAV3, "Beep" ........................................................................................................ 25

3.2 Calibration menu.................................................................................. 27

3.3 After-Sales Service test menu............................................................. 29

4 Preventive maintenance ................................................................................ 31

4.1 Recommendations ............................................................................... 31

4.2 Maintenance schedule......................................................................... 31

4.2.1 Preventive maintenance........................................................................................... 31

4.2.2 Quality control .......................................................................................................... 31

4.3 Checks................................................................................................... 33

4.3.1 Accessing the tests .................................................................................................. 33

4.3.2 Visual check ............................................................................................................. 33

4.3.3 Operating period and maintenance date.................................................................. 34

4.3.4 Indicator lights test ................................................................................................... 34

4.3.5 Keyboard check ....................................................................................................... 35

4.3.6 Battery voltage check ............................................................................................... 35

4.3.7 Checking the last 10 alarms..................................................................................... 35

Optima_PT-VS-ST_enTDM.fm 3

Page 4

4.3.8 Checking the total operating period ......................................................................... 37

4.3.9 Checking the analogue sensor input........................................................................ 37

4.3.10 Checking the software version ................................................................................. 38

4.3.11 Checking the motor clamp (only Optima VS) .......................................................... 38

4.3.12 Checking the calibration values ............................................................................... 39

4.3.13 Checking the infusion motor..................................................................................... 39

4.3.14 Checking the last 10 events before a locking alarm or error .................................... 40

4.3.15 Checking the pressure alarm limit............................................................................ 40

4.3.16 Flow rate check ........................................................................................................ 41

4.3.17 Air detector check .................................................................................................... 41

4.3.18 Battery autonomy check........................................................................................... 41

4.3.19 Continuity test .......................................................................................................... 42

4.3.20 Contrast check ......................................................................................................... 42

4.3.21 Timestamp check ..................................................................................................... 42

4.3.22 Quality Control Certificate ........................................................................................ 43

4.4 Cleaning and disinfecting ................................................................... 45

4.5 Storage.................................................................................................. 46

5 Troubleshooting..............................................................................................47

5.1 Breakdown guide ................................................................................. 47

5.2 Error messages ................................................................................... 51

6 Intervention procedures................................................................................. 55

N∞1, Procedure: CPU board ....................................................................... 57

N∞2, Procedure: Display board .................................................................. 61

N∞3, Procedure: Pumping system ............................................................. 65

N∞4, Procedure: LCD display .................................................................... 69

N∞5, Procedure: Air detector board........................................................... 73

N∞6, Procedure: Pressure sensor.............................................................. 77

N∞7, Procedure: OCS clamp motor (if OCS is present) ........................... 81

N∞8, Procedure: Power supply board ....................................................... 85

N∞9, Procedure: Battery ............................................................................. 87

N∞10, Procedure: Front cover, base and angle bracket .......................... 89

7 Calibration .......................................................................................................93

7.1 Calibration procedure.......................................................................... 93

7.1.1 Access to the calibrations ........................................................................................ 93

7.1.2

7.1.3

7.1.4

EtAL.1 Door calibration....................................................................................... 94

EtAL.2 Calibration of the flow rate corrective coefficient .................................... 95

EtAL.9 Calibrating the upstream and downstream pressure sensors ................ 96

44 Optima_PT-VS-ST_enTDM.fm

Page 5

8 Spare parts catalogue.................................................................................... 99

8.1 Upper cover .......................................................................................... 99

8.2 Base..................................................................................................... 101

8.3 Optima pump angle bracket.............................................................. 103

Optima_PT-VS-ST_enTDM.fm 5

Page 6

66 Optima_PT-VS-ST_enTDM.fm

Page 7

1 Presentation

1.1 General presentation

The Optima pump is a new pump based on the same pumping mechanism as the MVP

pump. It is used for infusion of intravenous agents.

There are three types of the Optima pump:

PT: for standard PVC tubes with a drop detector.

VS: for standard PVC tubes. The drop detector is optional. The pump is equipped with an

automatic occlusion checking system (OCS).

ST: for silicon tubes equipped with a drop detector.

The Optima pump has its own control keyboard and distinct displays. It has an internal

battery which ensures a minimum autonomy of 4 hours for a flow rate of 125 ml/h.

A choice of easily accessible configurations enables optimal use of the functions according to

the needs of each department.

optima01_002b_en.fm 7

Presentation

Page 8

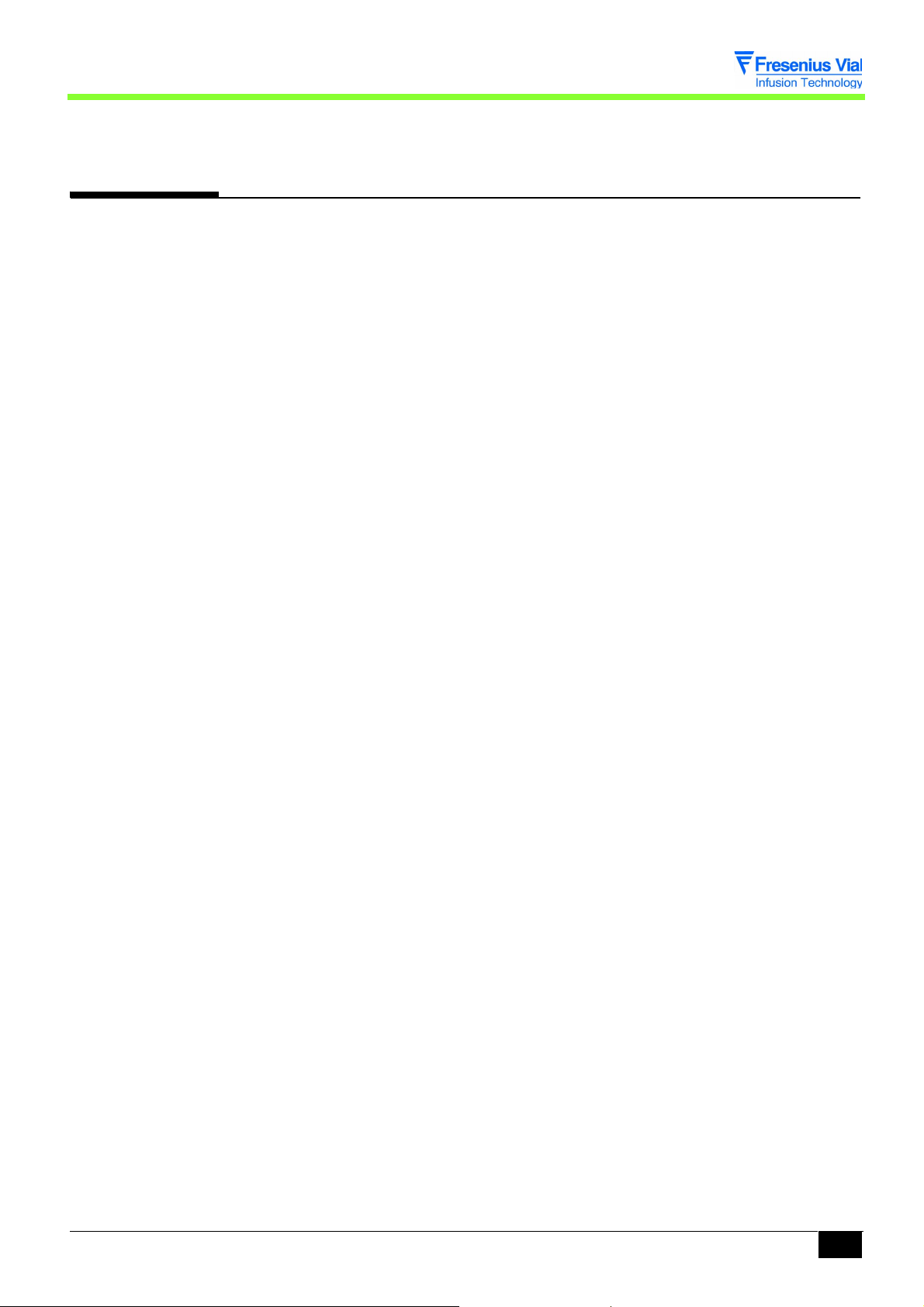

1.2 Operation diagram

Presentation

8 optima01_002b_en.fm

Page 9

1.3 Precautions for use

The symbol which appears on the device’s condensed user instructions recommends a

complete reading of the user instructions, in accordance with norm EN 60 601-1.

Fresenius Vial cannot, in any circumstances, be held responsible for any medical or other

problem due to incorrect use of the device.

Kindly consult the user manual for more details.

!

1.4 Operation safety

As soon as it is in operation, the device ensures permanent surveillance of its functions. Any

internal fault or any procedural anomaly is immediately detected. Nevertheless, abnormal

functioning of the device, without a defined cause, must always be brought to the attention of

the qualified staff in your establishment or our After-sales Service.

The Optima pump contains an internal battery which ensures normal functioning during a

mains power cut. In addition, two fuses protect the affected mains area.

1.5 Technical characteristics

1.5.1 Electrical details

! External power supply: 100 - 240 Vac.

! Max. consumption: 50 VA.

! Battery: 6 V - 2.7/ 3 Ah - NIMH.

! Fuse: 2 x 630 mA T IEC 127.

1.5.2 Electronic details

The Optima volumetric pump has 4 electronic boards:

! CPU board

! Display board

! Power supply board

! Air detector board

1.5.3 Mechanical details

! Dimensions: H x L x W: 135 x 175 x 145 mm.

! Weight: approx. 2.9 kg

optima01_002b_en.fm 9

Presentation

Page 10

1.5.4 Conformity and norms

0459

Safety of Electro

Medical

Equipements

EMC

(ElectroMagnetic

Compatibility)

Direct Courant Equipotentiality Fonctionnal earth.

Conform to the 93/42/EEC Medical Directive. IP31 Protection against

splashing liquid.

Conform to EN/IEC 60601-1 and EN/IEC 60601-2-24. Protection against

leakage current: CF

type.

Conform to EN/IEC 60601-1-2 (second index)

and EN/IEC 60601-2-24.

Detailed information concerning electromagnetic compatibility is available in the chapter

"Guidance and manufactureris declaration on EMC" of the User Manual.

Protection against

electric shocks: class I.

Presentation

10 optima01_002b_en.fm

Page 11

2 Description and operation

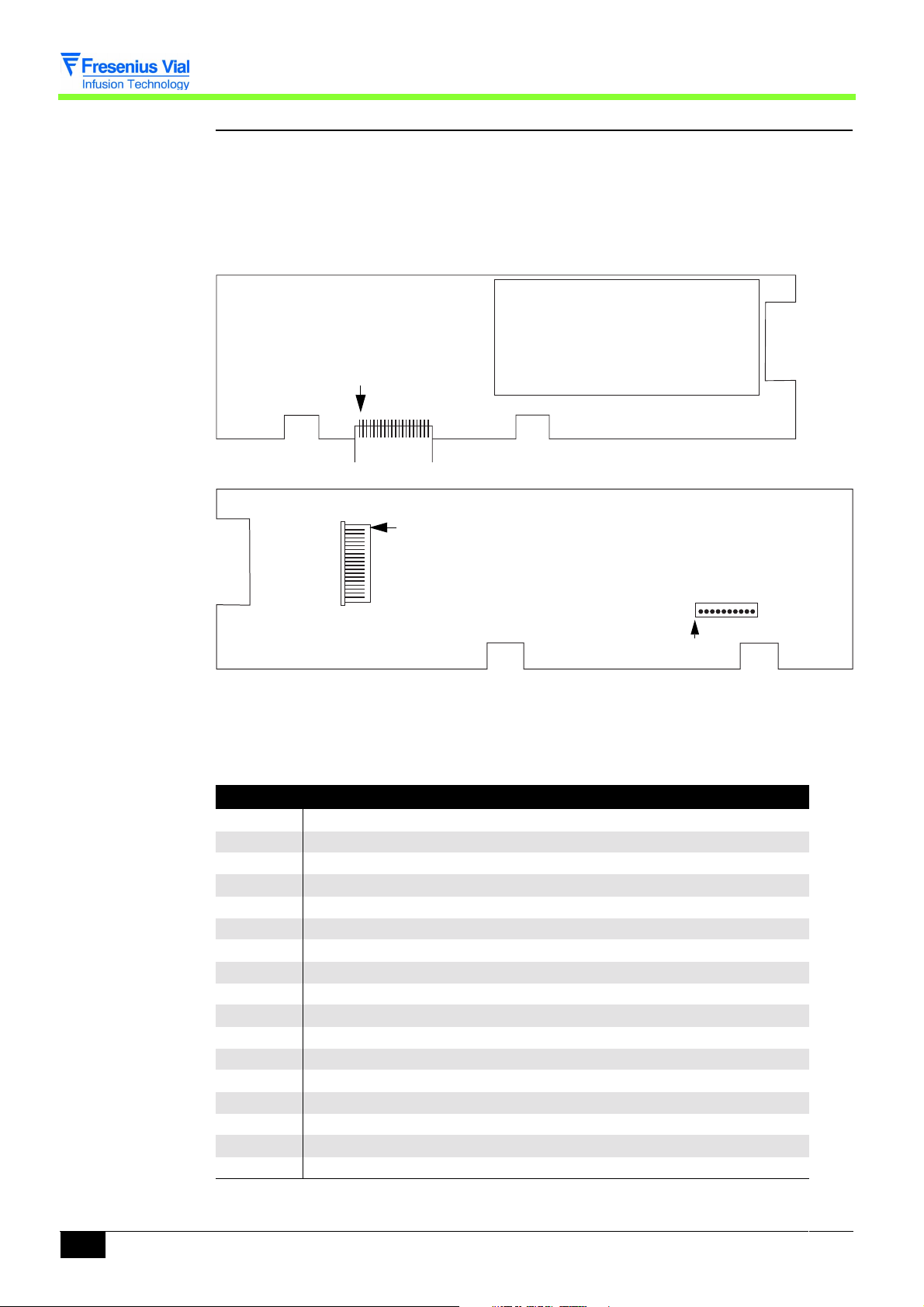

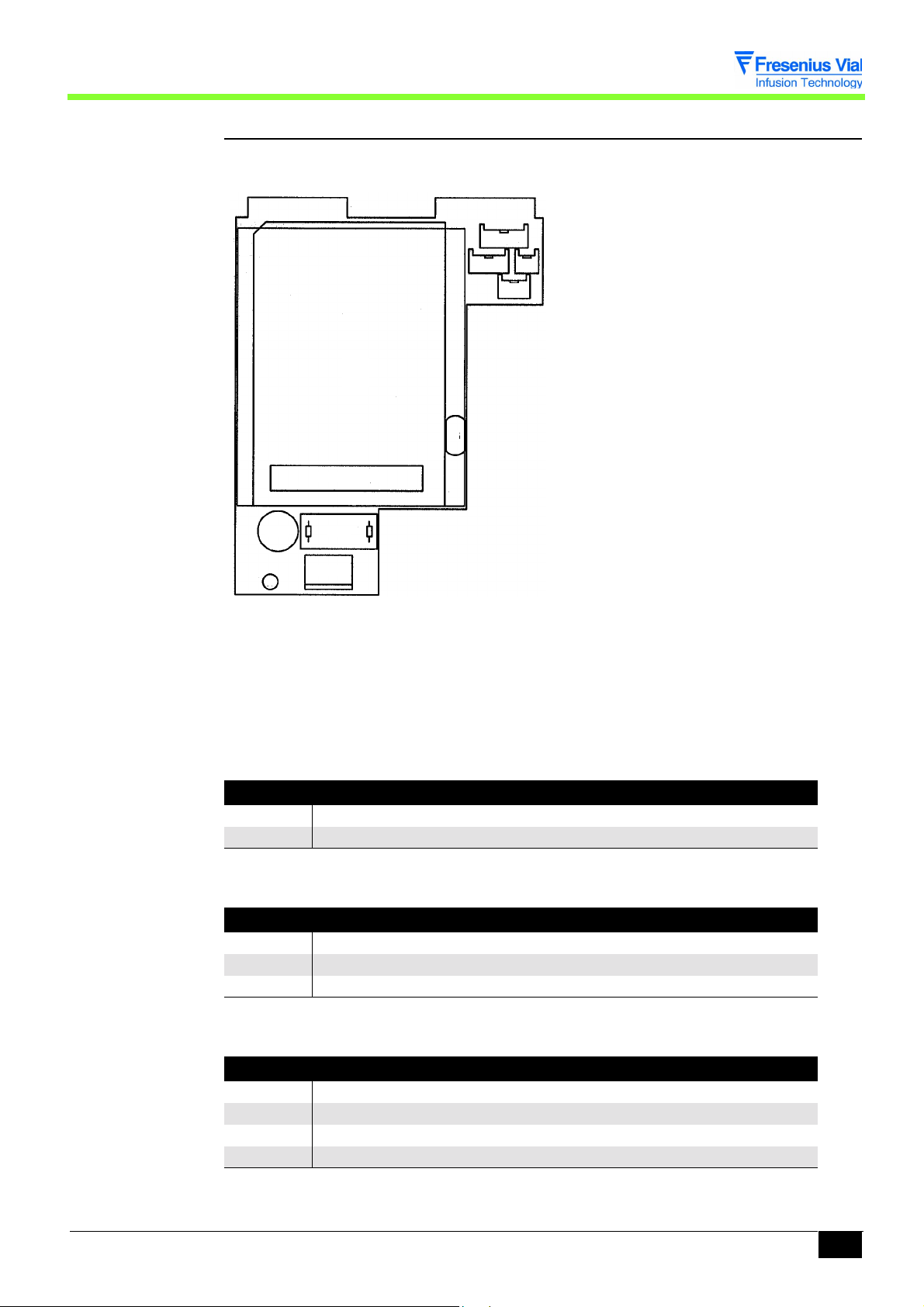

2.1 Physical description

Angle bracket

Control panel

Air bubble

Front cover

Door

Base

detector

The Optima pump is made out of a front cover, a base and an angle bracket.

! The front cover contains:

" a display board linked to the control panel,

" a CPU board,

" an air detector board,

" the OCS system if OCS is present.

! The base supports the door and contains:

" the pump body unit.

! The angle bracket contains:

" a power supply board,

" the battery.

optima02_002b_en.fm 11

Description and operation

Page 12

2.1.1 Display board and front panel

The display board is situated under the control panel and contains all the essential parts for

the man-machine interaction:

! keyboard,

! synoptic and control indicators,

! 7-segment displays,

! LCD screen.

Pin n°1

J1

Display board LCD screen side.

Pin n°1

J2

J3

Pin n°1

Display board component side

This board is connected to the various equipment by means of connectors:

J1 connector to CPU board

Pin Signal Description

1 5V Power supply

2 VBAT Battery voltage

3GND

4 MOSI-AFF Serial output

5GND

6 MISO-AFF Serial input

7GND

8 CLK-AFF Serial clock

9GND

10 CSLCD LCD selection

11 GND

12 CSAFCL Display selected

13 GND

14 A0AFF LCD address

15 GND

16 RESET/

17 GND

Description and operation

12 optima02_002b_en.fm

Page 13

J1 connector to CPU board

Pin Signal Description

18 TON/OFF ON/OFF Signal

19 VBAT Battery voltage

20 5V Power supply

J2 connector to LCD

Pin Signal Description

1 + led VBAT + back light

2 - led - back light

3+5V

4 /RESET /RESET

5VSS Gnd

6 LD7 Data’s writing

7 R/W Gnd - Writing selection

8 LD6 Data’s writing

9 A0AFF LCD address

10 LD5 Data’s writing

11 LD4 Data’s writing

12 LD3 Data’s writing

13 LD2 Data’s writing

14 LD1 Data’s writing

15 LD0 Data’s writing

16 Enable

17 LCDCS2 Chip select

18 /LCDCS1 Chip select

J3 connector to keyboard

Pin Signal Description

1 COL2 Keyboard interface column

2 COL1 Keyboard interface column

3 COL0 Keyboard interface column

4 Line 3 Keyboard interface

5 Line 2 Keyboard interface

6 Line1 Keyboard interface

7 Line 0 Keyboard interface

8 TON/OFF On/Off

9 CONTRÔLE

10 GND

optima02_002b_en.fm 13

Description and operation

Page 14

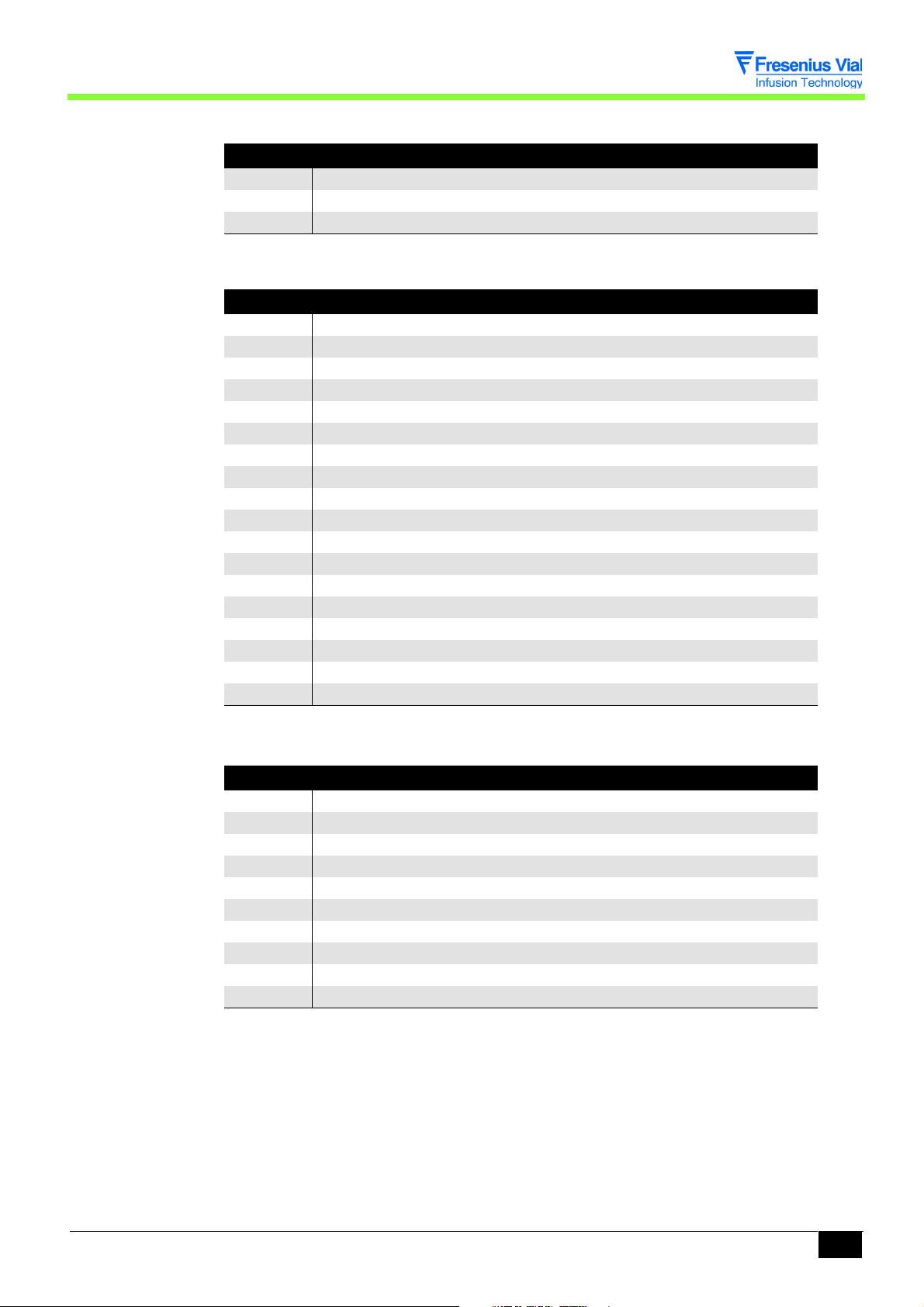

2.1.2 The CPU board

The CPU board contains a 80C32 micro-processor. It is connected to the display board by

means of the J1 connector.

J1 J2

J4

J3

Pin n°1

J7

J6

J10J9

J8

J11

J12

CPU board

Info: Pin 1 of connector J1 is opposite to that indicated by the CPU board screen printing.

J1 display board connector

Pin Signal Description

1 5V Power supply

2 VBAT Battery voltage

3GND

4 MOSI-AFFl Serial output

5GND

6 MISO-AFF Serial input

7GND

8 CLK-AFF Serial clock

9GND

10 CSLCD LCD selection

11 GND

12 CSAFCL Display selected

13 GND

14 A0AFF Address LCD

15 GND

16 RESET/

17 GND

18 GNDTON/OFF Signal ON/OFF

19 VBAT Battery voltage

20 5V Power supply

Description and operation

14 optima02_002b_en.fm

Page 15

J12 drip detector connector

Pin Signal Description

1 Pulse-drip Low signal yield

2 GND

3GND

4 CDLED-drip Control LED 5V/ 40 mA

J4 motor

Pin Description

1 +Reel A

2 - Reel A

3 +Reel B

4 - Reel B

J6 power supply

Pin Signal Description

1 ALIM SECT Power supply

2 GND

3 ALIM EXT Not used

J8 battery

Pin Signal Description

1 VBATNC + Battery

2 ANA-CTN Temperature sensor Output

3GND

4 VBATNP + Battery before thermal fuse

connector

connector

connector

J11 RS232 connector / Nurse call

Pin Signal Description

1 TxD-PC Data reception from PC

2 RTS-PC Request to send from PC

3 DTR-PC PC terminal ready

4 RXD-PC Transmission of data to PC

5GND

6 Nurse Call Normally open contact

7 Nurse Call Common contact

8 Nurse Call Normally closed contact

J10 D.C. motor

Pin Description

1 + DC motor

2 - DC motor

connector

Description and operation

optima02_002b_en.fm 15

Page 16

J2 sensors connector

Pin Signal Description

1GND

2 /PRES_CLAMP CLAMP presence

3 CD_CLAMP/ CLAMP detector power supply

4 +AMPLI_AM Input + ampli sensor upstream pressure

5 - ALIM_AM Upstream pressure sensor power supply return

6 - AMPLI_AM Input - ampli upstream pressure sensor

7 + ALIM_AM Upstream pressure sensor power supply

8 GND

9 - Hall effect sensor power supply

10 GND

11 ANA_HALL Hall effect sensor output

12 + AMPLI_AV Input + ampli downstream pressure sensor

13 - ALIM_AV Downstream pressure sensor power supply

return

14 - AMPLI_AV Input - ampli downstream pressure sensor

15 + ALIM_AV Downstream pressure sensor power supply

16 GND

17 ET OPTO State of sensor

18 GND

19 +5 V 5 V power supply

20 - Power supply sensor return

J9 air detector

Pin Description Description

1 /TST Sensor test

2 5V

3GND

4 /DETECT Air bubble detection

connector

Description and operation

16 optima02_002b_en.fm

Page 17

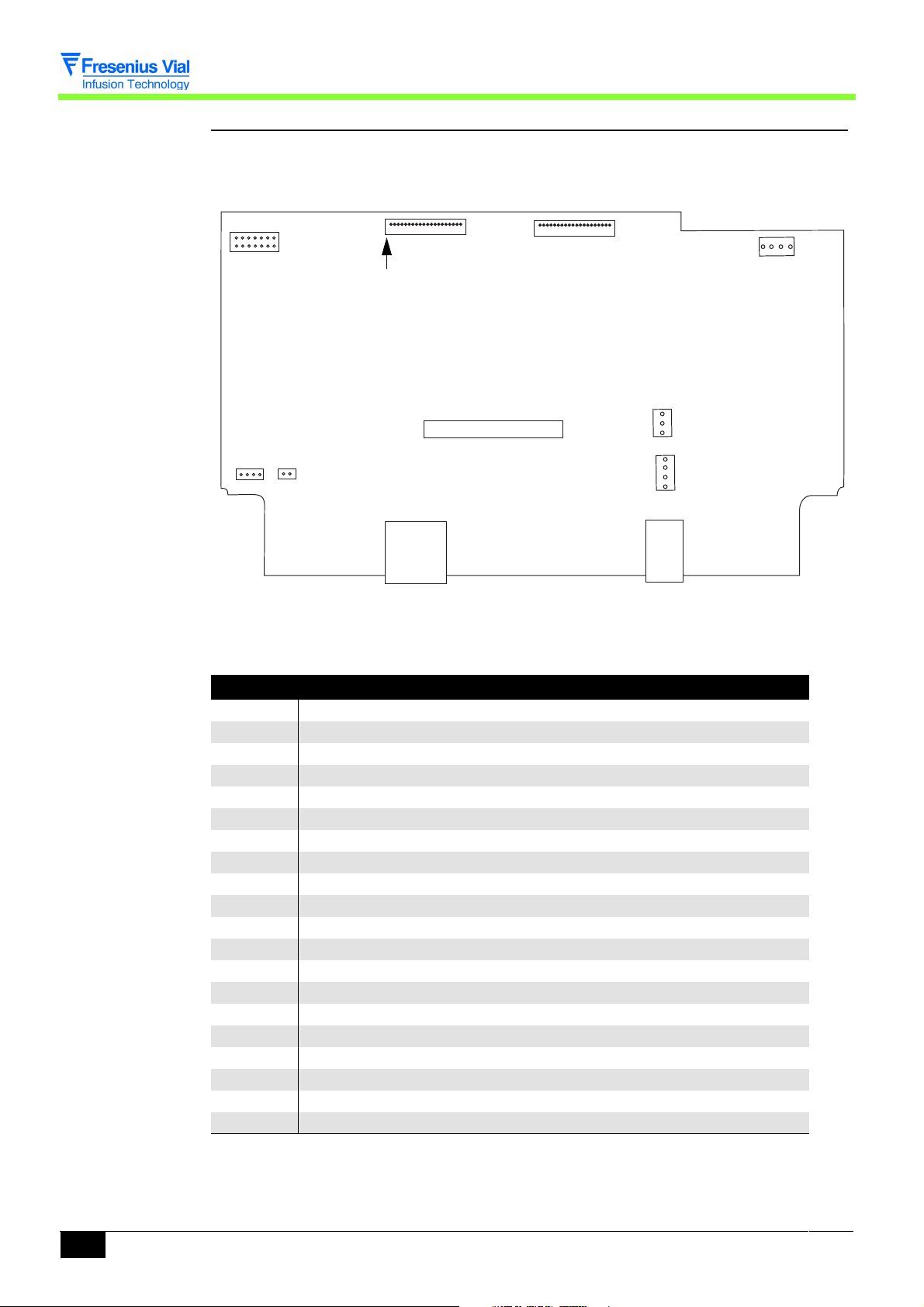

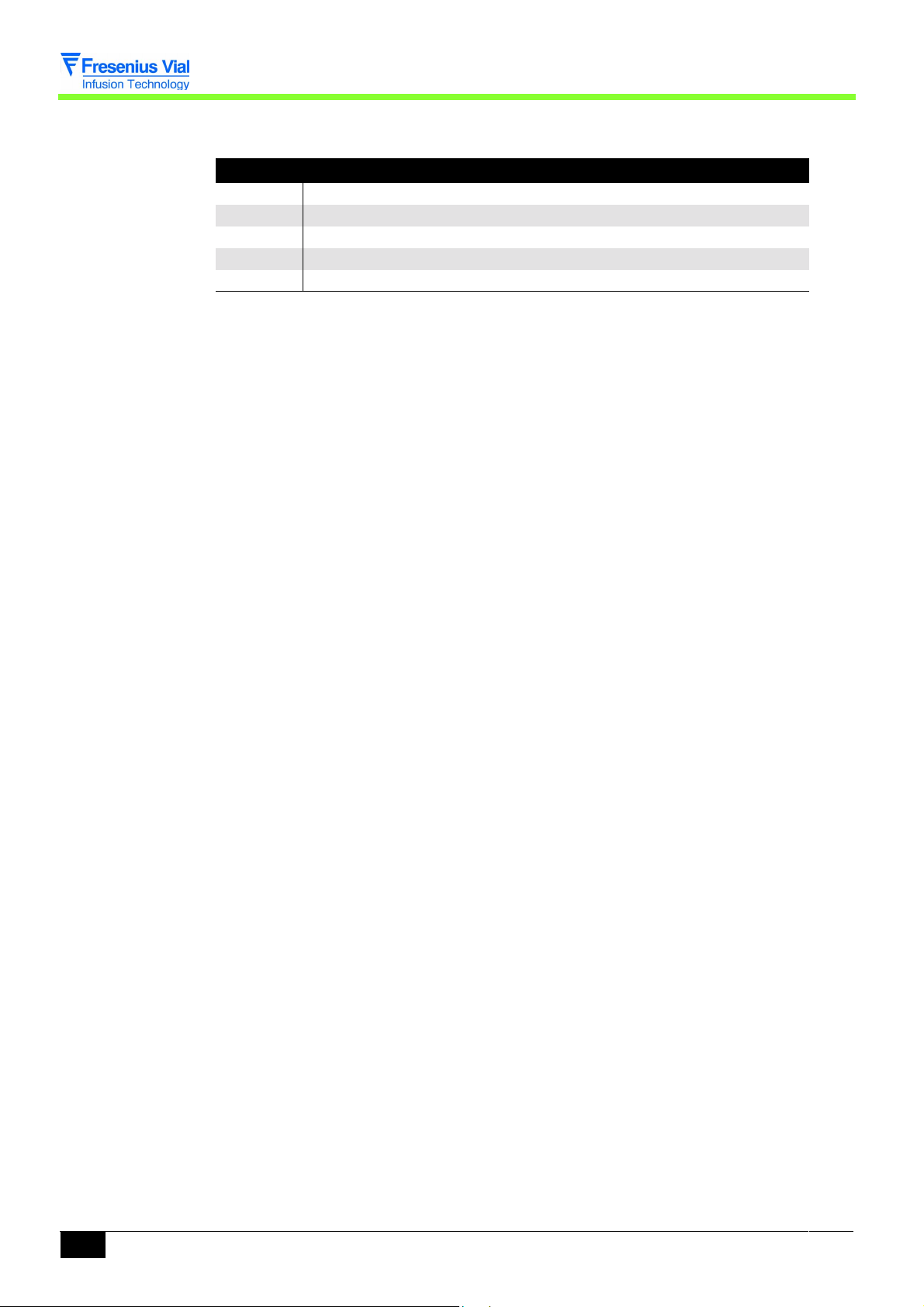

2.1.3 The power supply board and battery

The power supply board is positioned on the angle bracket. It supplies power to the electronic

unit from the 230 VAC network. It also ensures a battery charge of 2.7/3 Ah.

J6

J5

J4

J3

U1

U2

C3

Bars code

F2

J1

L1

J2

Power supply board

This board is connected to the various parts by means of connectors. F2 is time-delayed

fuses of 630 mAT.

J1 functional Earth connector

J2 Mains connector

Pin Description

1 PH Phase (100 - 240 Vac)

2 N Neutral (100 - 240 Vac)

J3 power supply output connector

Pin Description

1 9V Sect 9V output convertor AC/DC

2 GND

3 9V Ext 9V external power supply not used

J4 battery output connector to the CPU board

Pin Description

1+Vbat

2 +Thermal sensor

3GND

4 VBAT NP

optima02_002b_en.fm 17

Description and operation

Page 18

J6 battery input connector

Pin Description

1+ VBAT

2 VBAT NP

3 + Thermal sensor

4 - Thermal sensor

5GND

Description and operation

18 optima02_002b_en.fm

Page 19

2.2 Operational description

From an operational point of view, the Optima pump is made up of 3 sub-assemblies:

! a sub-assembly to maintain to check the correct positioning of the tube,

! a motorisation sub-assembly,

! an external connection sub-assembly.

2.2.1 Tube check and maintenance sub-assembly

The tube is positioned along the front part and held in place by the door.

The front part is equipped with four detection systems:

! a detector to check the closed /open position of the door,

! an ultra-sound detector to detect the presence of air bubbles in the tube.

! The pressure detection is ensured by two piezo-resistant sensors.

2.2.2 Pumping sub-assembly

The pumping sub-assembly contains the peristaltic pumping mechanism.

The mechanism is made up of a camshaft that creates a wave-like movement in a bank of 14

’fingers’. The displacement of these ’fingers’ is controlled by the CPU board, while turning it

displaces the liquid at the programmed flow rate.

The cam shaft is driven by a stepper-motor and a reduction gearbox assembly via a toothed

belt.

An optical disc attached to the end of the cam shaft controls its rotation.

2.2.3 External connection sub-assembly

The Optima contains two connectors located at the rear of the lower case:

! an RS 232 connector/Nurse call,

! a connector dedicated to the drip detector.

optima02_002b_en.fm 19

Description and operation

Page 20

Description and operation

20 optima02_002b_en.fm

Page 21

3 Description of the menus

3.1 Parameter configuration menu

The configuration menu adapts the Optima to the particular needs of each department. It

accesses the menus that customise the infusion parameters.

Fresenius Vial recommends the presence of its qualified staff, or a member of your Technical

Department, who will assist you in implementing the configuration procedures you wish to

select.

The configuration mode is activated by holding down the "MODE"

key when the device is switched on.

The following menus are displayed:

! User setting,

! Wards setting,

! Maintenance.

Each menu consists of sub-menus. The sub-menus can be accessed

by using the "START" key.

To access some of the sub-menus, you need to type in an access code. This code can be

defined and/or de-activated in the Service configuration mode. As long as the device is kept

switched on, the code does not need to be keyed in again.

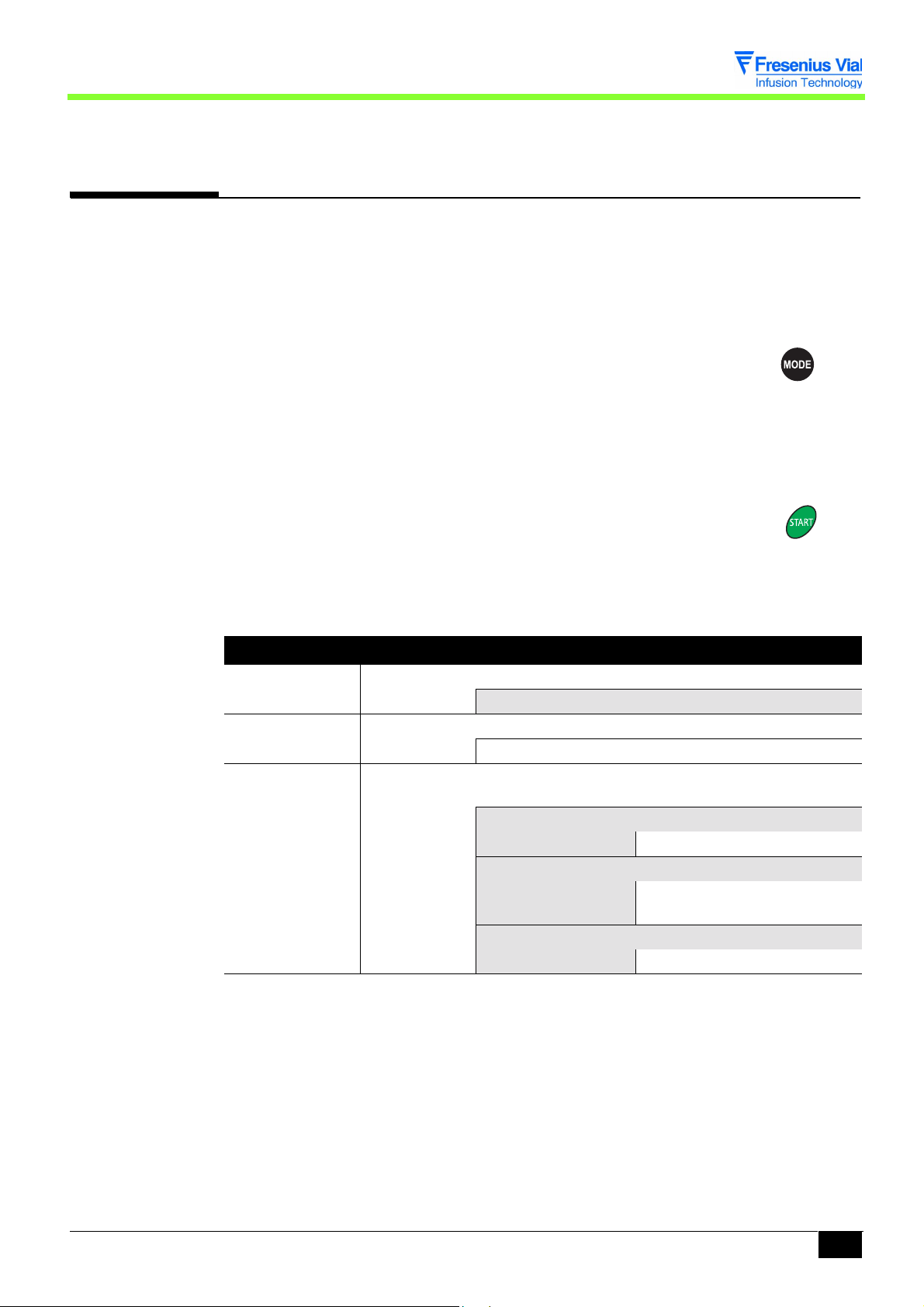

Main Menu Key in code Sub-menu Sub-menu

User setting Code XXXX

User setting menu

Wards setting Code 0200

Wards setting menu

Maintenance This code will be communicated at the end of the maintenance

technician training.

Te st

Maintenance tests menu

After-sales configuration

Maintenance configuration

menu

Calibration

Calibration menu

optima03.1_001b_en.fm 21

Description of the menus

Page 22

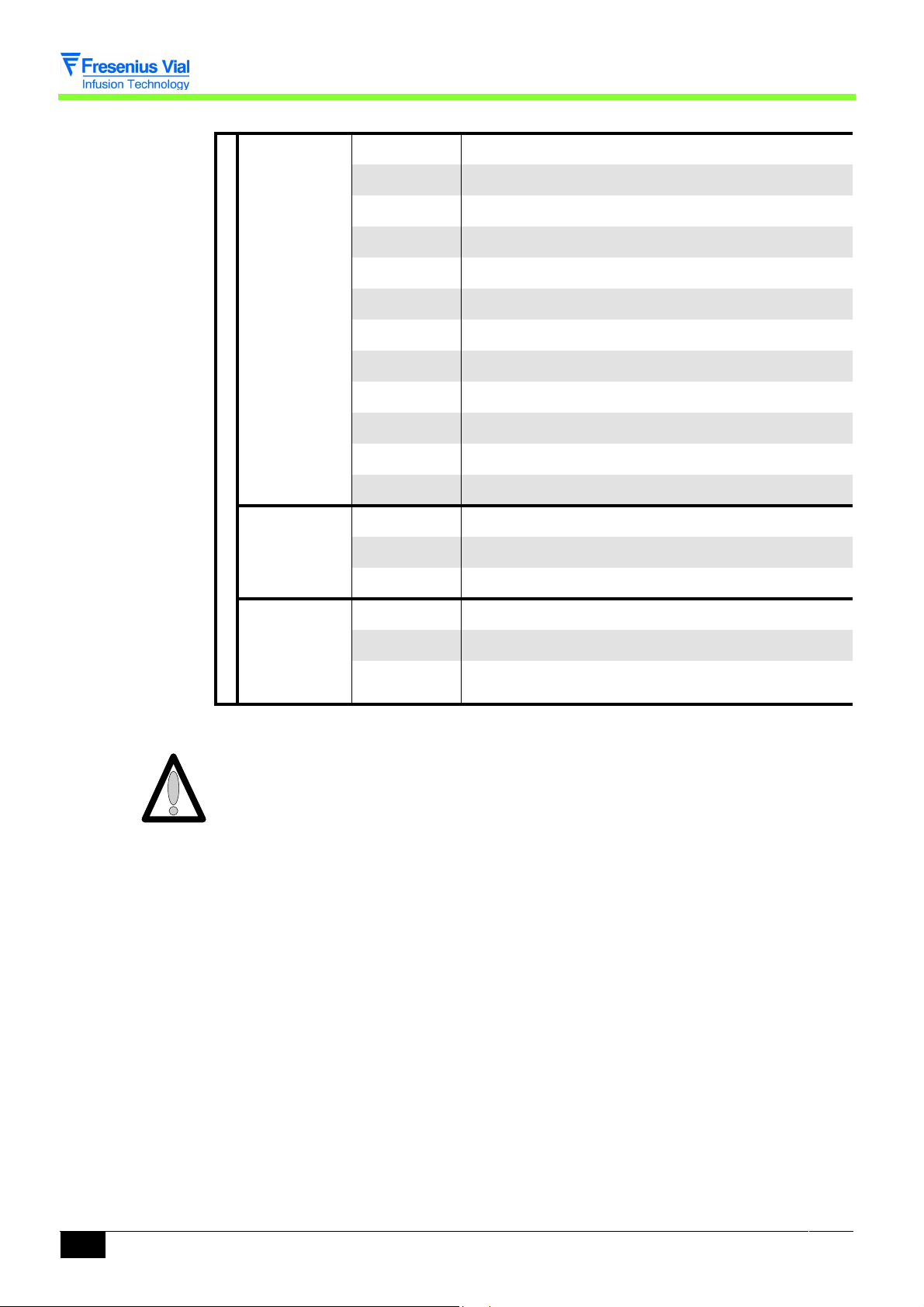

Te st

TEst.1

operating period and maintenance date

Maintenance

Configuration

Calibration

TEst.2

TEst.3

TEst.4

TEst.5

TEst.6

TEst.9

TEst.A

TEst.C

TEst.E

TEst.F

TEst.J

SAV.1

SAV.2

SAV.3

EtaL.1

LED, LCD screen, 7-segment display and buzzer test

keyboard test

display’s the battery voltage

display’s the last 10 alarms codes

display’s the total running time

display’s the analogue sensor values

display’s the software version

clamping motor test

display’s the calibration values

infusion motor test

display’s the code last 10 alarm codes before error

preventive maintenance

tube selection

Beep

door calibration

EtaL.2

EtaL.9

The maintenance menu is reserved for qualified staff only.

corrective infusion coefficient

upstream and downstream pressure sensors

calibration

Description of the menus

22 optima03.1_001b_en.fm

Page 23

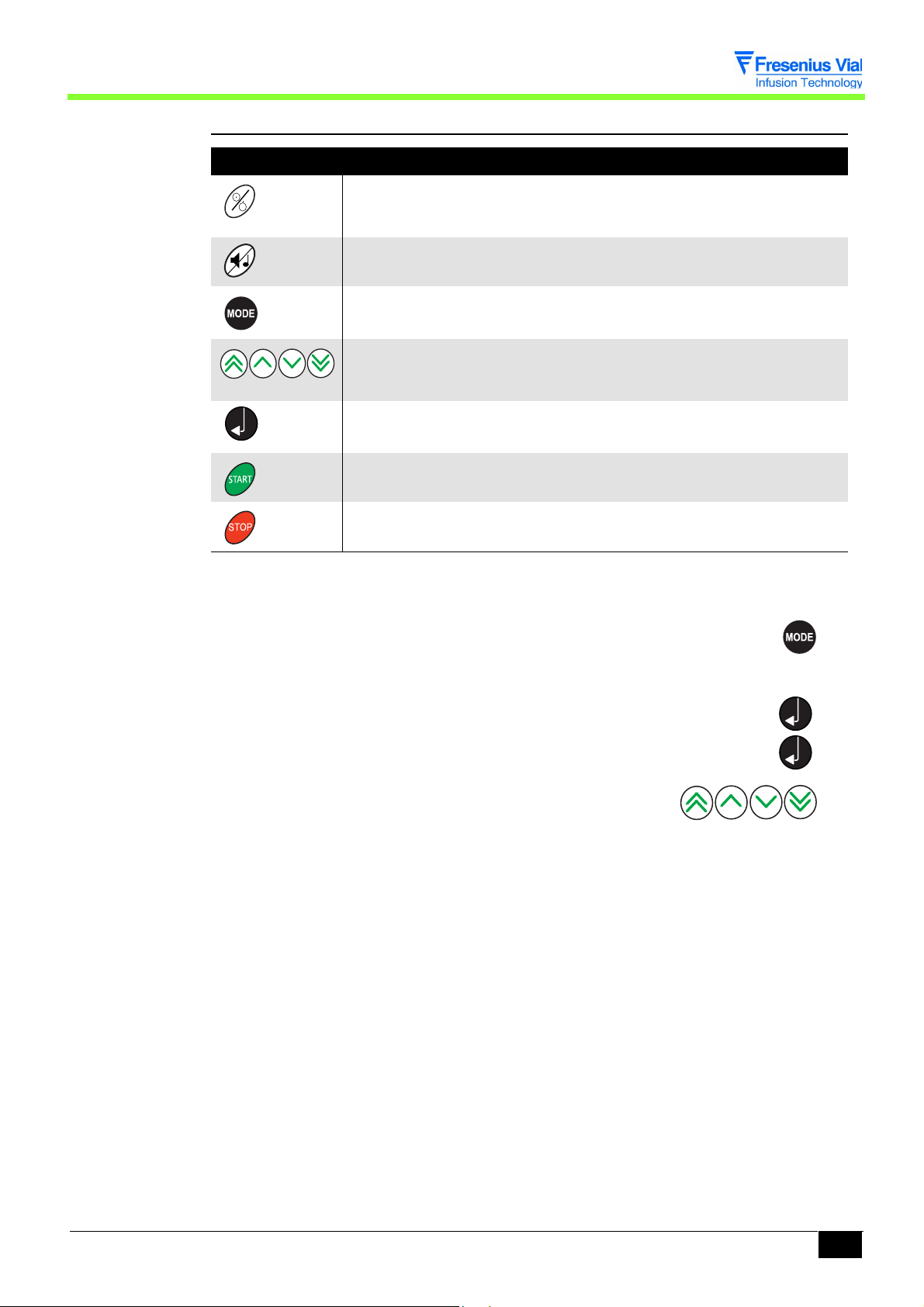

3.1.1 Access to the menu

Key Function

ON switches on the device.

OFF switches off the device and exits the configuration mode when

pressed for more than three seconds.

SILENCE ALARM

MODE accesses the configuration mode.

The selection keys scroll through the numbers and letters, the tenths,

units and tens values.

Activate or de-activate choices.

ENTER moves the cursor.

START validates a selection.

STOP cancels the current configuration.

Activate the After-Sales Service test menu.

! Keep the "MODE" button pressed, during the device

switch on.

" The various menus are displayed.

! Select the "Maintenance" menu and confirm.

! Type in the access code and confirm.

! Select "Sav" and confirm.

! Use the selection keys to scroll through the various tests on

the LCD display.

optima03.1_001b_en.fm 23

Description of the menus

Page 24

3.1.2 SAV1, preventive maintenance configuration

! SAV1, press "START".

" The running time since the last maintenance in hours and

the date are displayed on the LCD screen.

" To move the cursor use the enter key.

" Use the selection keys to modify a field.

" By validating once again, the new running time and date

are memorised and you may return to the After-sales

Service menu.

By pressing "STOP" you can cancel the modification and return to the Aftersales Service configuration menu.

You can exit the configuration mode at any time by pressing the "OFF" key.

3.1.3 SAV2, tube selection configuration

! SAV2, press "START".

" The list of available tubes is displayed on the LCD screen.

The tubes which have already been calibrated for pressure are marked with a "v".

" Select the tube using the keys.

" Press "START" to save the tube selection.

" When the device is switched on, the selected tube will

appear on the display unit.

By pressing "STOP", the modification is cancelled and you can return to the

After-sales Service configuration menu.

You can exit the configuration mode at any time by pressing the "OFF" key.

Description of the menus

24 optima03.1_001b_en.fm

Page 25

3.1.4 SAV3, "Beep"

This option is available on Optima pump equipped with software version 1.8e minimum.

!

SAV3, press "START".

! + 10 s. (not activated)

! + 0 s. (activated)

" Select your choice using the key.

# 10 s: the audible alarm "Beep" is triggered every 10

seconds.

# 0 s: the audible alarm "Beep" is triggered every 0

second.

" Press "START" to record your selection.

By pressing "STOP", the modification is cancelled and you can return to the

After-sales Service configuration menu.

You can exit the configuration mode at any time by pressing the "OFF" key.

optima03.1_001b_en.fm 25

Description of the menus

Page 26

Description of the menus

26 optima03.1_001b_en.fm

Page 27

Description of the menus

3.2 Calibration menu

The calibration menu is reserved for qualified staff only. Its access is protected by a

secret code. To find out about the operating mode for the various calibrations, refer

to the "Calibrations" chapter.

This menu enables manual calibration of:

!

ETAL.1: the door,

!

ETAL.2: the corrective coefficient for the infusion flow rate by tube type,

!

ETAL.9: the upstream and downstream pressure sensors.

optima03.3_001b_en.fm 27

Description of the menus

Page 28

Description of the menus

28 optima03.3_001b_en.fm

Page 29

Description of the menus

3.3 After-Sales Service test menu

The After-Sales Service test menu is reserved for qualified personnel. It enables a series of

checks that can be carried out on the Optima pump to confirm it is operating correctly. (See

chapter "Checks"). These must be carried out each time parts are replaced.

The After-Sales Service tests can also be carried out more quickly and simply from a PC

using our maintenance software. (Contact our After-Sales Service department.)

The Service test menu contains a series of 17 tests or checks:

!

tESt.1: operation period and maintenance date display

!

tESt.2: indicator lights test

!

tESt.3: keyboard test

!

tESt.4: battery voltage test

!

tESt.5: display’s the last 10 alarms codes

!

tESt.6: display’s the total operating period

!

tESt.9: display’s the analogue sensor values

!

tESt.A: display’s the software version

!

tESt.C: clamping motor test (only Optima VS)

!

tESt.E: display’s the calibration values

!

tESt.f: infusion motor test

!

tESt.J: display’s the last 10 alarm codes before error

A log of more than 760 time-stamped events can be consulted using our maintenance

software "VP Control". (Contact our After-Sales Service department.)

optima03.4_002b_en.fm 29

Description of the menus

Page 30

Description of the menus

30 optima03.4_002b_en.fm

Page 31

4 Preventive maintenance

4.1 Recommendations

The Optima pump can only be checked, serviced or repaired by Fresenius Vial or by a

certified and approved maintenance service. Any abnormal functioning of the pump must be

brought to the attention of your in-house qualified technical personnel or our After-Sales

Service.

Should you need to return the pump to our After-Sales Service, it should be cleaned,

disinfected and very carefully packaged, preferably in its original packaging, before being

sent.

For all information concerning the repair and use of the pump, kindly contact our After-Sales

Service or our Sales department.

Fresenius Vial is not liable for loss or damage to the pump during its transport to our AfterSales Service.

4.2 Maintenance schedule

4.2.1 Preventive maintenance

In order to maintain the pump’s performance, a Preventive Maintenance inspection

must be carried out every 3 years. This procedure, which includes changing the

battery, should be carried out by a qualified technician.

Any abnormal functioning or failure must be reported to the qualified technical staff in your

organisation or to our After-Sales Service. In these instances, the pump should not be used.

Important: If these maintenance procedures are not observed, the pump’s correct

operation will be impaired.

4.2.2 Quality control

At the request of the health organisation, a quality check will be carried out every 12

months.

A quality check (not included in the guarantee) consists of different inspection procedures as

defined in the pump’s Technical Manual. Only a qualified technician may perform the quality

check which must be performed using Fresenius-Vial software.

For more information, kindly contact our After-Sales Service.

At the end of the device life, return it to an organization competent in the

treatment of the electrical an electronic equipment waste. Remove the

battery from the device and return it to competent recycling organization.

optima04.1&2_001b_en.fm 31

Preventive maintenance

Page 32

Preventive maintenance

32 optima04.1&2_001b_en.fm

Page 33

Preventive maintenance

4.3 Checks

In order to ensure the preventive maintenance follow-up, a regular servicing inspection is

recommended every 12 months (see "Quality Control Certificate").

Recharge the battery during 16h before starting the checking procedure !

4.3.1 Accessing the tests

Keyboard description.

Key Function

ON switches on the device.

OFF switches off the device when pressed for over three seconds.

SILENCE ALARM

STOP, cancels the current test.

START validates a selection.

MODE accesses the test mode.

The selection keys scroll through the numbers and letters on the tenths,

units and tens values, and activate or de-activate the infusion menus.

ENTER validates your test selection or moves the cursor.

Activate the After-Sales Service test menu.

! Keep the "MODE" button pressed, during the device

switch on.

" The various menus are displayed.

! Select the "Maintenance" menu and confirm.

! Type in the access code and confirm.

! Select "Test" and confirm.

! Use the selection keys to scroll through the various tests on

the LCD display.

4.3.2 Visual check

Check the general aspect of the case and labels and check for shock impact damage.

optima04.3_002b_en.fm 33

Preventive maintenance

Page 34

4.3.3 Operating period and maintenance date

This test displays

the Optima’s

running time since

its last servicing

inspection. It also

displays and

modifies the "last"

servicing

inspection date.

When the servicing

inspection date is

modified, the

operating time is

resetted.

!

tESt.1, press "START".

" The operating time and the last service inspection date

are displayed on the LCD screen.

" If "Preventive test" flashes, service inspection is required.

" Press on the "Enter" key to select the date.

When reading this information, it is possible to modify

the day, month and year of the service inspection date using

the units and tens keys. This date will be stored in EEPROM

and the operating time is reseted to zero.

" When validating again, a new test can be selected.

This test checks

the correct

functioning of the

indicator lights, the

LCD screen

display, front panel

and buzzer.

You can interrupt the test at any time by pressing "STOP" and returning to

the test selection.

4.3.4 Indicator lights test

!

tEeSt.2, press "START".

" All the leds, 7-segment displays and the LCD lighten up.

" When validating again

# the leds and displays scroll across one by one from

left to right (leds display, 7 segment display by

segment and then by section of 8).

# An image scrolls across the LCD screen.

The test is OK if all the indicator lights have lit up and the buzzer has gone off.

You may interrupt the test at any time by pressing "STOP" and returning

to the test selection.

If the display is faulty, replace the display board (see "Display Board procedure).

Preventive maintenance

34 optima04.3_002b_en.fm

Page 35

4.3.5 Keyboard check

This test checks

that the keyboard

keys are

functioning

correctly.

This test displays

the mains or

battery voltage in

volts or in tenths of

volts.

!

tESt.3, press "START".

" The following screen appears:

" Press each key one by one,

# The keys that have been pressed appear as a

reverse video image on the LCD screen.

If two keys or more are held down simultaneously, "beep! beep! beep!" will be heard,

indicating an error.

You may exit the test at any time by pressing

"START" for more than 3 seconds, returning to the test selection.

4.3.6 Battery voltage check

!

tESt.4, press "START".

" The voltage is displayed in volts.

# If the Optima pump is running on battery, the LCD

screen displays, for example:

This test displays

in code form the

last ten alarms

which have been

triggered on the

Optima pump.

# If the Optima pump is running on the mains, the LCD

displays, for example:

" By confirming once again, a new test may be selected.

4.3.7 Checking the last 10 alarms

!

tESt.5, press "START".

" The code for the most recent alarm is displayed at the top

of the LCD screen.

" Press the selection keys to display the following codes

1xxx to 10xxx.

from

" By validating once again, a new test may be selected.

Preventive maintenance

optima04.3_002b_en.fm 35

Page 36

Alarm or error codes description:

Alarm Description

A10 Battery alarm

A12 End of infusion alarm

A16 Downstream occlusion alarm

A17 Air detection alarm

A18 Air volume alarm

A19 Upstream occlusion alarm

A20 Tube absence alarm

A21 Mobile clamp absence alarm.

A22 Door alarm

A23 Drip detector absence alarm

A24 Drip detector alarm: under flow

A25 Drip detector alarm: over flow

A26 Free flow

A27 Occlusion problem during auto-set

OFF Normal stop

FAIL Abnormal stop

Error Description

Er10 Internal RAM

Er20 External RAM

Er30 Check-sum Flash

Er40

Er50 Access Adc

Er60 Tube parameters

Er70 Motor frequency

Er80 Keyboard matrix (key press non functioning)

Er90 Check-sum Flash or software version µC secondary

Er01 Rotation (absence top turn)

Er11 Rotation (white or black too great)

Er21 Rotation (incorrect number of turns)

Er31 Automatic clamping motor

Er41 Rotation (presence top turn)

Er14 Period calculation parameters verification

Er24 Rotation direction verification

Er44 Incoherence quartz µC principal and µC secondary

Er54 Absence display board

Er74 Battery disconnection (3)

Er84 Battery charge (3) fault

Er94 Battery temperature fault

Er55 µC secondary access

Preventive maintenance

Er65 Absence LCD display back light

Access (E2prom) Eeprom

36 optima04.3_002b_en.fm

Page 37

Error Description

Er85 Restart µC secondary

Er16 Date and time in µC secondary verification

Er56 Association condition output/step number

Er17 Keyboard matrix (key press and columns inactive)

Er27 Keyboard check default (path not fine tuned)

Er37 ON/OFF key locked

Er47 Switching off impossible

Er28 Language file incompatible

4.3.8 Checking the total operating period

This test displays

the total period of

operation for the

Optima pump. The

value cannot be

modified manually.

!

tESt.6, press "START".

" The running time is displayed on the LCD screen.

" By confirming once again, a new test may be selected.

4.3.9 Checking the analogue sensor input

! tESt.9, press "START".

" The LCD screen displays:

# Upstream pressure, e.g.:

# Downstream pressure, e.g.:

# Door sensor, e.g.:

" By confirming once again, a new test may be selected.

If the value is out of limits, recalibrate the force sensor. (See "EtAL9 upstream and

downstream pressure sensors calibration").

optima04.3_002b_en.fm 37

Preventive maintenance

Page 38

4.3.10 Checking the software version

This test displays

the software

version and

revision numbers.

!

tESt.A, press "START".

" The LCD screen displays:

# the name of the Optima pump.

# the software version.

# the date.

" Press the tenths keys to continue the test.

" The LCD screen displays:

# the language versions.

" By confirming once again, a new test may be selected.

4.3.11 Checking the motor clamp (only Optima VS)

! tESt.C, press "START".

" The LCD screen displays:

# clamping

# unclamping

" Moving from clamping to unclamping occurs automatically

after confirming one of the two functions using the

selection keys.

" Press "START" to carry out the clamping or unclamping.

You may interrupt the test at any moment by pressing "STOP" and

returning to the test selection.

Preventive maintenance

38 optima04.3_002b_en.fm

Page 39

4.3.12 Checking the calibration values

This test displays

the calibration

values recorded in

the EEPROM.

!

tEStE, press "START".

" Move to another value using the keys.

Display Description

Por1

Por2

Por3

PaM1

PaM2

PaV1

PaV2

PaV3

! By confirming once again, a new test may be selected.

The value between brackets after the title is the number of calibrations carried out. The

display of the upstream and downstream pressure values is carried out according to the

number of active tubes.

Hall effect sensor, door closed without tube.

Hall effect sensor, door open.

Hall effect sensor, door closed with filled tube.

Upstream pressure, door open.

Upstream pressure, 0 mmHg, with filled tube.

Downstream pressure, door open.

Downstream pressure, 0 mmHG, with filled tube.

Downstream pressure, 750 mmHg, with filled tube.

This test starts the

motor without

activating any

infusion alarms.

4.3.13 Checking the infusion motor

!

tESt.F, press "START".

" Select an infusion flow rate (0.1 ml/h to 1000 ml/h) using

the keys.

" Press "START" to confirm the flow rate and start up the

motor.

If a motor rotation problem is detected, the LCD screen disappears and

Er01, Er11 or Er21 appears on the 7-segment display. By pressing

"STOP" you may exit the error and return to the test.

The test may be interrupted at any time by pressing the "STOP" key and

a new test may be selected.

optima04.3_002b_en.fm 39

Preventive maintenance

Page 40

4.3.14 Checking the last 10 events before a locking alarm or error

This test enables

the visualisation of

the codes for the

last 10 events that

have occurred

during operation of

the device before

the last locking

error.

!

teSt.J, press "START".

" The number of times the machine has been switched on

since the last locking error is displayed on the LCD

screen.

# "A" for an alarm. (See table

# "E" for an error. (See table

" By validating once again, a new test may be seleted.

teSt.5)

teSt.5)

4.3.15 Checking the pressure alarm limit

To carry out this operation, exit the test mode and press "OFF".

! Carry out the following assembly

1 m

Manom eter

Tap 3 ways

PUMP

Pocket

50cm

Container

! Press "ON".

" Position a tube in the device and lock the door inserting

the clamp.

" Position the manometer at the outlet of the tube.

" Select a flow rate of 125 ml/h.

" Adjust the pressure threshold to 750 mmHg.

# Let the tap run in a container.

# Start up the infusion and leave it running for 30

seconds.

# Position the tap to the manometer.

# Check that the alarm is triggered for a value of 1 bar ±

0.15 bar.

" Stop the infusion by pressing "STOP".

If the measured pressure value, depending to the limit selected is out of range, recalibrate

the pressure sensors. (See"

ETAL9 Calibration of the upstream and downstream

pressure sensors".)

Preventive maintenance

40 optima04.3_002b_en.fm

Page 41

4.3.16 Flow rate check

! Connect the Optima pump to the mains.

Before any flow rate test, run out an infusion of 20 ml to stabilise the flow rate.

To carry out this test, we recommend to use the IS Flow rate software available with

Fresenius Vial.

! Carry out a flow rate test according to the norm EN 60601-2-24.

! Check that the flow rate error lies between - 5% et + 5%.

If the discrepancy is too significant, refer to chapter 7 "Calibration / Calibration procedure

/

EtAL2 Calibrating the flow rate corrector coefficient".

4.3.17 Air detector check

To carry out this test, exit the test mode.

! Position a tube filled with water in the device.

! Press "ON".

" Select a flow rate of 100 ml/h.

" Press "START" to start up the infusion.

" Turn the drop chamber upside down to create an air

bubble of around 5 cm.

" Check that the alarm is triggered when the air bubble

crosses the detector.

The audio alarm can be stopped by pressing "SILENCE ALARM".

(Default running time is 2 minutes.).

4.3.18 Battery autonomy check

! Recharge the battery for at least 16 hours (100% capacity).

! Press "ON".

" Position a filled tube at a flow rate of 125 ml/h, then

confirm.

" Check the battery autonomy is at least 4 hours.

optima04.3_002b_en.fm 41

Preventive maintenance

Page 42

4.3.19 Continuity test

Use a multimeter.

To carry out this procedure, exit the test mode. Press "OFF.

! Using a calibrated multimeter in ohms, check the presence of an electrical resistance

greater than 10 MΩ between:

" between the phase and equipotential pin.

" between the neutral and equipotential pin.

4.3.20 Contrast check

To carry out this procedure, go to the "User configuration" menu.

" Key in the access code (if asked).

" Select "LCD contrast" and confirm.

" Check that the central portion of the screen is slightly

darker and adjust the contrast if necessary using the

selection keys.

" By pressing the confirm key, you can exit the test.

4.3.21 Timestamp check

To carry out this procedure, go to the "User configuration" menu.

" Key in the access code (if asked).

" Select "Time setting" and confirm.

" Check if the date and time are correct.

If necessary, adjust the date and time using the

selection keys and the ENTER key to move

from one figure to another.

" By pressing the confirm key you can exit the test.

Preventive maintenance

42 optima04.3_002b_en.fm

Page 43

Preventive maintenance

4.3.22 Quality Control Certificate

Use this table to summarise the results obtained from the various tests.

These tests can be done with a software dedicated to Optima.

Device type: Code: Device serial n°:

N° Procedure Obtained value

1 ! Check the general appearance of the case, labels, serial number and product

code.

2 ! Check the contrast.

If a fault is observed, refer to chapter ’Contrast Check’.

3 ! Check the clock. If an adjustment is needed, refer to chapter on datestamp

checking.

4

5

6

7

8

9

10 ! Check the drop detector (if the detector is present).

11 ! Check the air detector.

12 ! Check the downstream pressure.

! Display the operating period,

! Check the indicator lights, tESt.2.

! Check the keyboard,

! Display the total running time,

! Occlusion check, tESt.F

" Connect the water manometer to the tube outlet.

" Start up test F.

" Check that there is no motor error and that the maximum pressure is above

2 bar (1500 mmHg) for the version PT and ST,

above 1.6 bar for the version ST.

! Check clamping and unclamping,

" Confirm the two functions.

" Check for any absence of motor alarm.

" Start up an infusion.

" Check the (green) drop indicator lights up each time a drop appears in the drop

chamber.

" Disconnect the detector.

" Check if the drop alarm is activated.

" Create an air bubble in the tube of at least 5 cm long.

" Check the presence of the air bubble alarm (sound and visual) while the air

bubble is in the air bubble detector.

" Install a calibrated water manometer at the tube outlet.

" Adjust the pressure threshold to 750 mmHg.

" Start an infusion at 100 ml/h.

" Check that the downstream occlusion alarm is activated at 750 mmHh +/-125

(1 bar +/-0.15).

If there is a too great discrepancy, refer to chapter 7 "Calibration / Calibration

procedure /

sensors".

EtAL.9 calibrating the upstream and downstream pressure

tESt.3.

tESt.1and the maintenance date.

tESt.6.

tESt.C. (if OCS is present)

Conformity

Yes No

.

optfiche_002b_en.fm 43

Preventive maintenance

Page 44

N° Procedure Obtained value

13 ! Check the upstream pressure. (Only Optima VS)

" Start an infusion at 100 ml/h without drop detector.

" Clamp the tube between the drop chamber and the pump.

" Check that the upstream occlusion alarm is activated within 10 seconds.

" Unclamp.

" Check that the confirmation indicator lights up.

14 ! Check the clamp.

" Place a water pipe in the device.

" Close and open the door.

" Check that the clamp lock the tube.

# There should be no dripping at the tube outlet.

15 ! Check the battery operation.

" Disconnect the mains lead.

" Check the presence of the battery indicator.

" Reconnect the mains lead.

" Check if the battery indicator is switched off and that the mains indicator lights

up.

16 ! Check the flow rate.

Before any flow rate test, run an infusion of 20 ml to stabilise the flow rate.

Conformity

Yes No

" Carry out a flow rate check in accordance with the norm EN 60601-2-24.

" Check that the flow rate error is between - 5% and + 5%.

If there is too much discrepancy, refer to chapter 7 "Calibration / Calibration

procedure /

17 ! Check the battery autonomy.

" Start an infusion at 125 ml/h for 4 hours.

18 ! Carry out an electrical safety test according to norm EN 60601-1-2

EtAL.2 calibrating the flow rate corrector coefficient".

Name: Date: Visa:

Observations:

Preventive maintenance

44 optfiche_002b_en.fm

Page 45

Preventive maintenance

4.4 Cleaning and disinfecting

The pump form part of the patient's immediate environment. It is advisable to clean and

disinfect the device’s external surfaces of the device on a daily basis in order to protect

patient and staff.

! Disconnect the Base from its mains supply before cleaning.

! Do not place in an AUTOCLAVE nor IMMERSE the device, Do not let liquids enter the

device’s casing.

! If the device is placed in a high contamination risk unit, it is advisable to leave it in the room

during disinfecting, after having disinfected it with amoist cloth.

! Use a cloth soaked in DETERGENT-DISINFECTANT, previosly diluted with water if

required, to destroy micro organisms.

" Avoid abrasive scrubbing which could scratch the casing.

" Do not rinse or wipe the surfaces.

Do not use :

" ¨TRICHLOROETHYLENE-DICHLOROETHYLENE

" AMMONIA.

" AMMONIUM CHLORIDE

" CHLORINE AND AROMATIC HYDROCARBON.

" ETHYLENE DICHLORIDE-METHYLENE

" CHLORIDE-CETONE

These aggressive agents could damage the plastic parts and cause device malfunction.

Take car also with ALCOHOL based SPRAYS (20% -40% alcohol) .They lead to

tarnishing and small cracks in the plastic, and do not provide the neceeeary

cleaning prior to disinfection.

Disinfecting SPRAYS may be used, in accordance wih the manufacturer recommendation,

from a distance of 30 cm of the device, avoid the accumulation of the product in liquid form.

Avoid iodine-based solutions that may result in coloring some plastic parts permanently.

Please contact the appropriate service, responsible for cleaning and disinfecting products, in

your establishment for further details.

optima04.5&6_001b_en.fm 45

Preventive maintenance

Page 46

4.5 Storage

The device should be stored in a dry, cool place. In case of prolonged storage, the battery

should be disconnected via the battery access flap situated underneath the device.This

should be done by a qualified technician

! Storage conditions and carrying:

" Temperature: -10°C to 60°C / 14°F to 140°F.

" Atmospheric pressure: 500 hPa to 1060 hPa.

" Humidity: 10% to 90%, no condensation.

! Use conditions:

" Temperature: 5°C to 40°C / 41°F to 104°F.

" Atmospheric pressure: 700 hPa to 1060 hPa.

" Humidity: 20% to 90%, no condensation.

Fully recharge the battery before using the equipment to avoid any risks caused by micro

power cuts in the mains supply and to ensure maximum autonomy.

Preventive maintenance

46 optima04.5&6_001b_en.fm

Page 47

5 Troubleshooting

5.1 Breakdown guide

Message on

LCD display

Meaning Causes Action

Door open

alarm

Clamp

position

alarm

Set

insertion

alarm

OCS test

Alarm

! Hall affect sensor

detects that the door

is open

! The Optima does

not detect the

presence of the set

securing clamp

! Wrong position of

the set

! Occlusivity test

not successful. The

pumping mechanism

does not succeed to

increase the

pressure in the IV

set during the OCS

test

! Check set installation

! Check the presence of the

door magnet

! Calibration of the door sensor

! Replace the door sensor

! Check set installation

! Check the securing clamp

micro switch

! Replace it if necessary

! Check set installation

! Check the presence of the

door magnet

! Calibration of the door sensor

! Replace the door sensor

! Check set installation

! Check the door and carry on

a calibration if necessary

! Verify the good condition of

the membrane. Replace it if

necessary; refer to the

maintenance protocol : PM 0094

Air bubble

alarm

! Air volume

detected is higher

Than the limit

programmed

! Set is not

properly inserted in

the air detector

! Prime the line to remove the

air

! Check set installation on the

air detector Verify the air

adjustment of the air size

programmed

! Replace the air detector or

air bubble board

Troubleshooting

optima05.1_001a_en.fm 47

Page 48

Message on

LCD display

Meaning Causes Action

Drop alarm

(If drop

detector is

present)

! The container is

empty

! The rolling clamp

is closed

! Over-flow , under

flow, free flow

! The position of

the drip sensor

! Drop chamber is

full

! Drop detector is

disconnected while

the pump is

configured to be

used with

! The drip sensor

is connected and

disconnected

! Verify the volume remaining

on the container

! Verify if the roller clamp is

open

! Verify if the air inlet cap if

open when the pump is used

with a bottle

! Verify the positioning of the

drop detector

! Verify the volume of the liquid

in the drop chamber

! Verify the IV set position

! Verify the drip sensor is well

connected

! Verify the connector if it's

damaged

! Replace the drip sensor

Free flow

alarm

(in case of

use with

drip

sensor)

Upstream

occlusion

alarm

Downstrea

m pressure

alarm

! Over-flow

! Set not properly

positioned

! Upstream

pressure in line is

too low

! Empty container

! Check the roller

clamp

! Air inlet cap is

closed ( bottle

used)

! The pressure in

line exceeds the

limit programmed

! Check set installation

! Check drip sensor

positioning

! Check container

! Check roller clamp

! Check if the set is not

squeezed

! Check the container height

! Check the air inlet cap ( if

bottle used)

! Check the calibration values (

Test 9)

! Proceed to the calibration of

pressure

! Replace the force sensor

! Check the infusion line

! Check the correspondence

between the limit programmed

and detected

! Check the pressure sensor (

Test 9)

! Proceed to the calibration of

the force sensor

! Replace the force sensor

Troubleshooting

48 optima05.1_001a_en.fm

Page 49

Message on

LCD display

Meaning Causes Action

Air alarm

! The IV set is

present on the air

bubble detector but

not on the pumping

! Remove the IV set and reinstall it

! Carry on a calibration of the

door

mechanism

! The pump runs

over 24 hours, no air

bubble have

detected by the

sensor

Preventive maintenance

24/10/2003 passed

Battery

alarm

Preventive

maintenan

ce

! Low battery

voltage

! Preventive

maintenance date or

time is passed

requested

Problems Causes Action

Flow rate drift

! The installed set

doesn't correspond with

the set selected

! A mechanical part

which has a link with the

pumping mechanism or

the CPU board has been

changed without

calibrating the flow rate

correcting coefficient

! Check the set selection

! Measure the flow rate using a

reference set and calibrate the flow rate

correcting coefficient

! Connect the pump to the

mains power

! Check the charging voltage,

pump connected to the mains.

! Replace the battery

! Proceed to the complete

check up of the pump and

update the maintenance date or

time ( test 1)

Display defect:

LED's, 8 segments

display units

! Control transistors,

LED's and/or display

board connection are

defective

! Check the LED's and display (test 2)

! Check the good condition of the

display board

! Replace the LED's

! Check the connector which link CPU

and display boards

! Replace the display board

The device turns off

when it is

disconnected from

mains power

! The battery is

unplugged or the battery

cable is cut

! Battery is totally

! Check the battery connection

! Check the charging voltage

! Replace the battery

discharged

Mains LED's does

not switch ON

! Mains fuses out of

order

! Power supply out of

order

! Replace Check the mains fuses

! Replace the power supply board

! If the problem remains, replace the

CPU board

optima05.1_001a_en.fm 49

Troubleshooting

Page 50

Problems Causes Action

Battery alarm while

it has been

completely charged

Battery alarm

whereas the

Optima is

connected to the

mains

! Battery is totally

discharged

! Power supply or CPU

boards are faulty

! Check the charging voltage

! Replace the battery

! Check the charging voltage

! Check the power supply mains fuses

! Replace the power supply if

necessary.

! If the problem remains, replace the

CPU board and carry on a complete

configuration

The module MVP

turns ON or turns

OFF alone

Some keys from

keyboard out of

order

After a fall

Pump noisy

! Keyboard is defective

! CPU board is

defective

! Keyboard is defective ! Check the keyboard (test 3)

! Mechanical elements

damaged

! Power supply and

CPU wires are closed to

the motor (earth wire

also)

! Check the keyboard ( test 3)

! Replace the keyboard if necessary

! Check that there was no liquid

infiltration on the CPU board

! Replace the CPU board and carry

on a complete configuration of the

device

! Replace the keyboard if necessary

! Check that the mechanical

assembly and the cases are intact

! Fix the wires as it shown on the

technical manual

Troubleshooting

50 optima05.1_001a_en.fm

Page 51

Troubleshooting

5.2 Error messages

Error codes Meaning Action

Electronic and software command anomalies *

Er10

Internal RAM Anomaly

! Carry on a complete configuration of

the device via VP Control software

! Replace the CPU board and carry

on a complete configuration

Er20

Er30

Er40

Er50

Er60

Er70

Er80

External RAM Anomaly

EPROM Anomaly

EEPROM Anomaly

ADC Anomaly

Sets parameters anomaly

Motor frequency anomaly

Keyboard anomaly

! Check the ADC

! Replace the CPU board and carry

on a complete configuration

! Reconfigure the module MVP with

VP Control software

! Replace the CPU board and carry

on a complete configuration

! Check and replace the keyboard if

necessary

! Check that there is no liquid

presence inside the device which could

damage keyboard and the electronics

boards

! Replace the CPU board and carry

on a complete configuration

Er90

Er01

Er11

Er21

Er31

Er41

Software version

Stepper motor rotation error

Stepper motor rotation error

Stepper motor rotation error

OCS DC motor failure

Stepper motor rotation error

! Configuration of the device is

needed through with VP Control

! Replace the CPU board and carry

on a complete configuration

! Replace the motor

! Check the motor coupling

See PM 0094

! Replace the mechanical block

See PM 0094

! Check the motor clamp for OCS and

rubber O ring

! Put some grease on the clamp finger

threaded screw. Replace the rubber

O ring if necessary (p/n: 174256)

! Replace the OCS motor clamp

! Replace the motor

Troubleshooting

optima05.2_002a_en.fm 51

Page 52

Error codes Meaning Action

Er14

Motor period calculation

anomaly

! Reconfigure the device with VP

Control software

! Replace the CPU board and carry

on a complete configuration of the

device

Er24

Er44

Er54

Er74

Er84

Er94

Er55

Motor rotation direction

anomaly

Quartz frequency anomaly

Display board anomaly

Battery disconnected

Battery charging failure

Temperature fault

Access default to the

secondary µ processor

! Check the motor rotation sensor

! Replace the CPU board and carry

on a complete configuration of the

device

! Replace the quartz

! Replace the CPU board and carry

on a complete configuration of the

device

! Check the display board connection

and replace it if necessary

! Check the battery connection

! Check the charging voltage

! Ensure that the charging time is not

over 15 hours

! Replace the battery

! Replace the battery

! Replace the CPU board

! Carry on a complete configuration of

the device with VP Control software

! Replace the CPU board and Carry

on a complete configuration of the

device via VP Control software

Er65

Er85

Er16

Er56

Troubleshooting

52 optima05.2_002a_en.fm

Back light anomaly of LCD

display

Impossible to start the

secondary µ processor

! Date / time failure ! Check the date and the time clock

! Out put conditions / Step

number association default

! Replace the LCD

! Carry on a complete configuration of

the device with VP Control software

! Replace the CPU board and Carry

on a complete configuration of the

device via VP Control software

! Replace the CPU board and Carry

on a complete configuration of the

device via VP Control software

! Carry on a complete configuration of

the device with VP Control

Page 53

Error codes Meaning Action

Er17

Er27

Er37

Er47

Er28

! Keyboard matrices default ! Replace the keyboard

! Check that there is no liquid

presence inside the device which could

damage keyboard and electronics

boards

! Keyboard matrices default

! ON/OFF key locked

! OFF key out of order

(no way to switch OFF the

device)

! Language file

incompatible

! Replace the CPU board and carry

on a complete configuration of the

device via VP Control software

! Carry on a complete configuration of

the device via VP Control software

optima05.2_002a_en.fm 53

Troubleshooting

Page 54

Troubleshooting

54 optima05.2_002a_en.fm

Page 55

6 Intervention procedures

This chapter lists all the dismantling and re-assembling procedures.

optima06.0_001a_en.fm 55

Intervention procedures

Page 56

Intervention procedures

56 optima06.0_001a_en.fm

Page 57

Intervention procedures

N°1, Procedure: CPU board

Safety:

For safety reasons, the technician should not intervene while the device is in operation.

Material needed:

! 1 Posidriv Z1 screwdriver

! 1 anti-static bracelet

Maintenance level:

Level 2, specialist technician. (See biomedical technical training documentation.)

Procedure:

Access

! Pivot the Optima pump on the top of the front cover.

! Unscrew the 2 cruciform screws (marker 1), connecting the Optima angle bracket to the

base.

! Remove the angle bracket being careful not to pull out the connectors.

! Disconnect the J4 and J3 connectors, as well as the functional Earth.

! Return the Optima pump to its original position.

1

1

2

2

Allen key

! Using an Allen key, gently slide out the two screws located under the door.

! Remove the door.

! Unscrew the 4 cruciform screws (marker 2 on Fig. 1 and 2) connecting the front cover to

the base.

! Remove the front cover, being careful not to pull out the CPU board flat cable.

optima06.0_0010b_en.fm 57

Fig. 1

Intervention procedures

Page 58

! Disconnect the CPU board flat cable: J2 connector and J4 connector.

2

2

Fig. 2

Do not touch the electronic boards with your hands.

Dismantling

When working with electronic components, we recommend wearing an anti-static bracelet

connected to the earth and working on a foam anti-static mat.

! Disconnect the J6, J8, J9 and J10 connectors.

! Disconnect the J1 flat cable.

! Unscrew the 3 cruciform screws (marker 3) connecting the CPU board to the front cover.

3

J1

3

J9

J10

J6

J8

3

! Remove the board from its housing, being careful with the display board J3 flat cable.

! Remove the CPU board.

Intervention procedures

58 optima06.0_0010b_en.fm

Page 59

Re-assembling

Carry out the dismantling procedure in reverse order to re-assemble the unit.

When closing the pump, ensure that the 2 cables connecting the power supply board

and the CPU board are positioned above the motor. In addition, check that the earth

wire is next to the metal support.

Incorrect positioning of one of these cables could result in a noise being heard when

the pump is in operation.

! Positioning of the earth wire.

Correct

Incorrect

! Positioning of the wires connecting the power supply board and the CPU board.

Right

Wrong

Wrap an adhesive silicon cord around the CPU board J12 and J11 connectors.

optima06.0_0010b_en.fm 59

Intervention procedures

Page 60

! Perform a complete configuration for a new board using VP Control Maintenance

Software.

Each Optima pump has its own type of "display and CPU board"; it is important that you

do not mix up the different Optima pump references and that you order the one that

corresponds to your device.

! Carry out regular servicing checks. (See Quality Control Certificate.)

Intervention procedures

60 optima06.0_0010b_en.fm

Page 61

Intervention procedures

N°2, Procedure: Display board

Safety:

For safety reasons, the technician should not intervene while the device is in operation.

Material needed:

! 1 Posidriv Z1 screwdriver

! 1 anti-static bracelet

Maintenance level:

Level 2, specialist technician (see biomedical technical training documentation).

Procedure:

Access

! Pivot the Optima pump on the top of the front cover.

! Unscrew the 2 cruciform screws (marker 1) connecting the Optima pump angle bracket to

the base.

! Remove the angle bracket, being careful not to pull out the connectors.

! Disconnect the J4 and J3 connectors, as well as the functional Earth.

! Return the Optima pump back to its original position.

1

1

2

2

Allen key

! Using an Allen key, gently slide out the two screws located under the door.

! Remove the door.

! Unscrew the 4 cruciform screws (marker 2 on Fig. 1 and 2) connecting the front cover to

the base.

! Remove the front cover, being careful not to pull out the CPU board flat cable.

optima06.0_0020b_en.fm 61

Fig. 1

Intervention procedures

Page 62

! Disconnect the CPU board flat cable: J2 connector and J4 connector.

2

2

Fig. 2

Do not touch the electronic boards with your hands.

Dismantling

When working with electronic components, we recommend wearing an anti-static bracelet

connected to the earth and working on a foam anti-static mat.

! Disconnect the J1 connector connecting the display board to the CPU board.

! Disconnect the display board J3 connector.

! Unscrew the cruciform screw (marker 3) situated on the display board, connecting it to the

front cover.

! Remove the display board.

J3

J1

J2

3

Intervention procedures

62 optima06.0_0020b_en.fm

Page 63

Re-assembling

Each Optima pump has its own type of "display and CPU board"; it is important that you

do not mix up the different Optima pump references and that you order the one that

corresponds to your device.

Carry out the dismantling procedure in reverse order to re-assemble the new unit.

When fixing the display board, ensure that the plastic inserts are not tightened too much

or they will be damaged.

When positioning the front case, ensure that the sealing is perfectly positioned in its

housing after re-assembling.

When closing the pump, ensure that the 2 cables connecting the power supply board

and the CPU board are positioned above the motor. Also check that the earth wire is

next to the metal support.

Incorrect positioning of one of these cables could result in a noise being heard when

the pump is in operation. (See photo on procedure sheet n°1.)

! Carry out regular servicing checks. (See Quality Control Certificate.)

optima06.0_0020b_en.fm 63

Intervention procedures

Page 64

Intervention procedures

64 optima06.0_0020b_en.fm

Page 65

Intervention procedures

N°3, Procedure: Pumping system

Safety:

For safety reasons, the technician should not intervene while the device is in operation.

Material needed:

! 1 Posidriv Z1 screwdriver

! 1 anti-static bracelet

Maintenance level:

Level 2, specialist technician. (See biomedical technical training documentation.)

Procedure:

Access

! Pivot the Optima pump on the top of the front cover.

! Unscrew the 2 cruciform screws (marker 1), connecting the Optima pump angle bracket to

the base.

! Remove the angle bracket being careful not to pull out the connectors.

! Disconnect the J4 and J3 connectors, as well as the functional Earth.

! Return the Optima pump back to its original position.

1

1

2

2

Allen key

! Using an Allen key gently slide out the two screws located under the door from their

groove.

! Remove the door.

! Unscrew the 4 cruciform screws (marker 2 on Fig. 1 and 2) connecting the front cover to

the base.

! Remove the front cover, being careful not to pull out the CPU board flat cable.

optima06.0_0030b_en.fm 65

Fig.1

Intervention procedures

Page 66

! Disconnect the CPU board flat cable: J2 connector and J4 connector.

2

2

Fig.2

Do not touch the electronic boards with your hands.

Dismantling

When working with electronic components, we recommend wearing an anti-static bracelet

connected to the earth and working on a foam anti-static mat.

! Using a cutter, remove the label.

! Unscrew the 2 middle cruciform screws (marker 3) located under the label.

3

3

3

3

3

4

Intervention procedures

66 optima06.0_0030b_en.fm

! Unscrew the 2 cruciform screws (marker 4).

4

Page 67

! Unscrew the cruciform screw (marker 5), paying attention to the washer.

! Remove the pumping system.

5

Re-assembling

When replacing the mechanical bloc, it’s recommended to read the following instruction.

! If a good metal washer and a metal pulley are already mounted, let them in place.

old aluminium pulley with washer New aluminium pulley without washer

6

L

Check that there is no axial free play on the mechanical block cam shaft.

Carry out the dismantling procedure in reverse order to re-assemble the new unit.

When closing the pump ensure that the 2 cables connecting the power supply board

and the CPU board are positioned above the motor. In addition, check that the earth

wire is next to the metal support.

Incorrect positioning of one of these cables could result in a noise being heard when

the pump is in operation. (See photo in Procedure n°1.)

! Carry out regular servicing checks. (See Quality Control Certificate.)

optima06.0_0030b_en.fm 67

Intervention procedures

Page 68

Intervention procedures

68 optima06.0_0030b_en.fm

Page 69

Intervention procedures

N°4, Procedure: LCD display

Safety:

For safety reasons, the technician should not intervene while the device is in operation.

Material needed:

! 1 Posidriv Z1 screwdriver

! 1 anti-static bracelet

Maintenance level:

Level 2, specialist technician. (See biomedical technical training documentation.)

Procedure:

Access

! Pivot the Optima pump on the top of the front cover.

! Unscrew the 2 cruciform screws (marker 1), connecting the Optima pump angle bracket to

the base.

! Remove the angle bracket being careful not to pull out the connectors.

! Disconnect the J4 and J3 connectors, as well as the functional Earth.

! Return the Optima pump to its original position.

1

1

22

Allen key

! Using an Allen key, gently slide out the two screws situated under the door.

! Remove the door.

! Unscrew the 4 cruciform screws (marker 2 on Fig. 1 and 2) connecting the front cover to

the base.

! Remove the front cover, being careful not to pull out the CPU board flat cable.

optima06.0_0040b_en.fm 69

Fig. 1

Intervention procedures

Page 70

! Disconnect the CPU board flat cable: J2 connector and J4 connector.

2

2

Fig. 2

Do not touch the electronic boards with your hands.

Dismantling

When working with electronic components, we recommend wearing an anti-static bracelet

connected to the earth and working on a foam anti-static mat.

! Remove the display board. (See corresponding Procedure n°2.)

! Disconnect the J2 keyboard connector.

! Detach the LCD display.

! Remove the LCD display.

J2

Intervention procedures

70 optima06.0_0040b_en.fm

Page 71

Re-assembling

! Recover the self-adhesive block from the old LCD.

! Position the self-adhesive block on the LCD display, above the LCD display label.

! Position the LCD display on the display board.

! Press down the display on the display board so that the block adheres to the display

board.

Carry out the dismantling procedure in reverse order to re-assemble the new unit.

When closing the pump, ensure that the 2 cables connecting the power supply board

and the CPU board are positioned above the motor. In addition, check that the earth