Freescale Semiconductor

User Manual

Document Number:

MPC5604EEVB64UM

MPC5604EEVB64 Evaluation

board User Manual

For MPC5604E Evaluation/Validation

by: Pavel Bohacik

MSG Application Engineering

1 Introduction

The MPC5604EEVB64 Evaluation Board (EVB) is

based on the e200z0 Power Architecture®. This board is

shipped with the PPC5604EEMLH 64-pin LQFP MCU

populated to allow the evaluation of the full functionality

of this part.

This board is designed as a validation platform with the

maximum flexibility. Where possible it is also designed

for power and speed but the primary goal of this system

is to allow main usecases of this processor.

2 References

• MPC5604ERM Reference Manual

• MPC5604E Data Sheet

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 EVB Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

5 Default Jumper Summary Table . . . . . . . . . . . . . . . . . . 16

6 User Connector Descriptions. . . . . . . . . . . . . . . . . . . . . 18

7 Known Bugs List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

© Freescale Semiconductor, Inc., 2011. All rights reserved.

EVB Features

3 EVB Features

The following is a list of evaluation board features:

MPC5604E External Interfaces

• Video Encoder Wrapper connected to Omnivision connector

• Serial Audio Interface connected to the Audio connector

• Onboard Ethernet physical interface plus MII lite connector

• Crystal / clock

• JTAG

• One LIN and one UART interface selectable through Jumper setting

• One FlexCAN interface

• External Interrupts

• ADC connector

NOTE

Before the EVB is used or power is applied, please read the complete

document on how to correctly configure the board. Failure to correctly

configure the board may cause irreparable component, MCU or VB

damage.

4 Configuration

This section details the configuration of each of the EVB functional blocks.

Throughout this document, all of the default jumper and switch settings are clearly marked with “(D)” and

are shown in blue text. This should allow a more rapid return to the default state of the EVB if required.

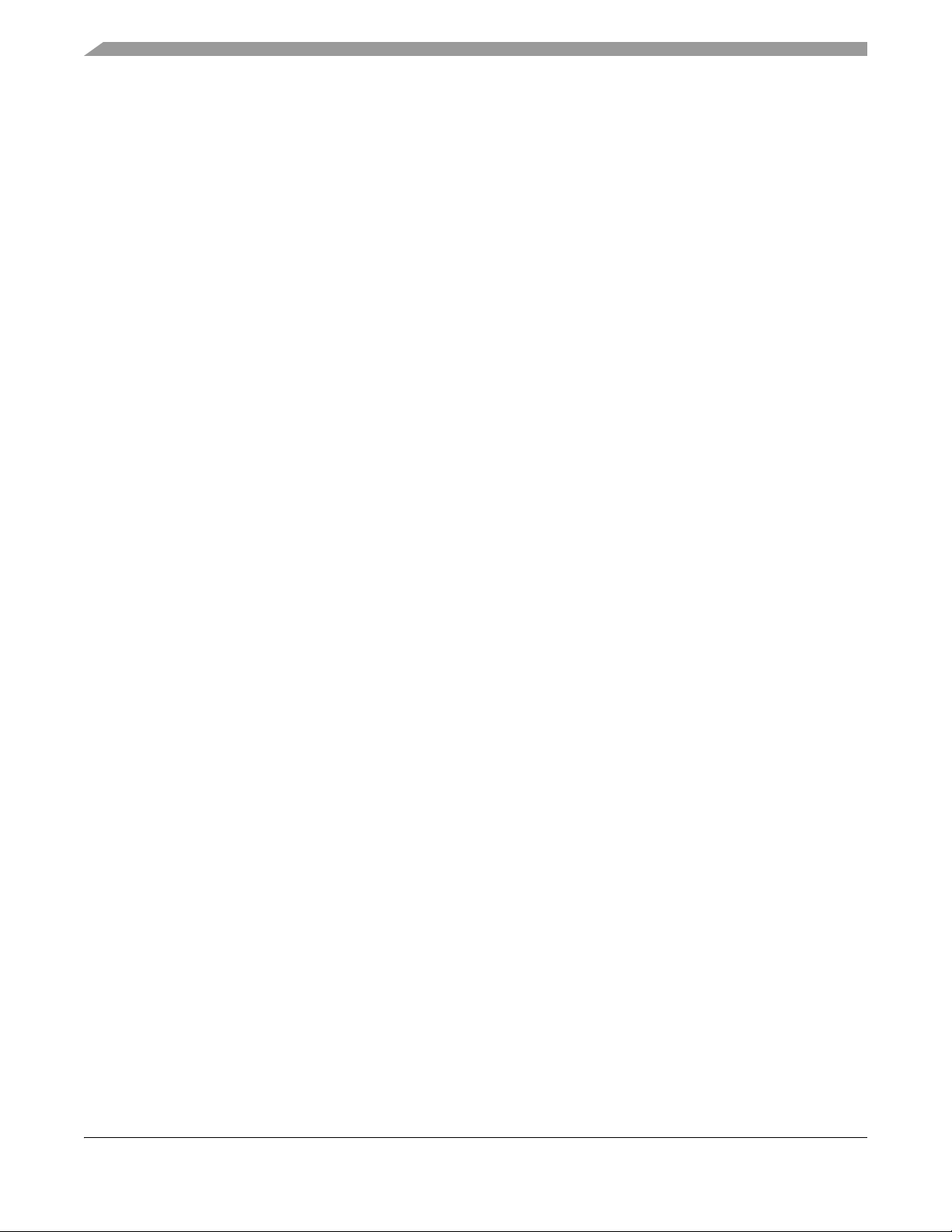

The EVB is designed with ease of use in mind and is segmented into functional blocks as shown below.

Detailed silkscreen legend is used throughout the board to identify all switches, jumpers and user

connectors.

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor2

Configuration

Figure 1. Evaluation board silkscreen legend

4.1 Processor

The MPC5604E processor is the fundamental control chip on the MPC5604EEVB64. This is a version 1

Power Architecture running at a maximum core speed of 64 MHz. The MPC5604EEVB64 allows you to

fully evaluate the feature set of the MPC5604E MCU. Refer to Section 3, “EVB Features to review the list

of board features.

4.2 Power

The EVB requires an external power supply voltage of 12V DC, minimum 1A. This allows the EVB to be

easily used in a vehicle if required. The single input voltage is regulated on-board using switching

regulators to provide the necessary EVB and MCU operating voltages of 5.0 V, 3.3 V and 1.2 V. For

flexibility there are two different power supply input connectors on the EVB as detailed below.

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 3

Configuration

4.3 Power supply Connectors

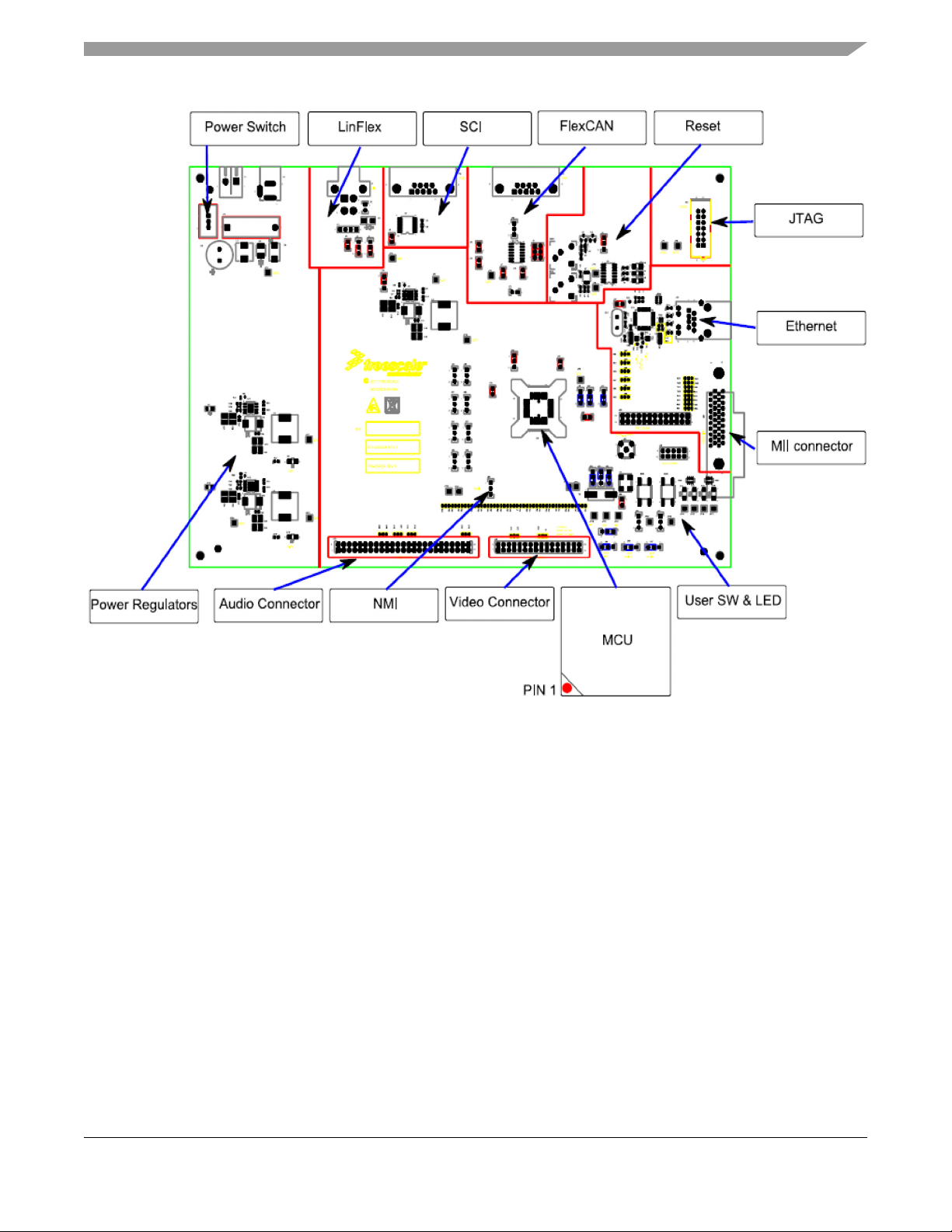

2.1 mm Barrel Connector – P4:

This connector should be used to connect the supplied wall-plug mains adapter.

NOTE

If a replacement or alternative adapter is used, care must be taken to ensure

that the 2.1 mm plug uses the correct polarization as shown in Figure 2.

Figure 2. 2.1 mm Power Connector

2-Way Lever Connector – P1:

This can be used to connect a bare wire lead to the EVB, typically from a laboratory power supply. The

polarization of the connectors is clearly marked on the bottom site of the EVB. Care must be taken to

ensure correct connection.

Figure 3. 2-Level Power Connector

4.4 Power Switch (SW1)

Side switch SW1 can be used to isolate power supply input from the EVB voltage regulators if required:

• Position 1 will turn the EVB OFF

• Position 3 will turn the EVB ON

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor4

Configuration

4.5 Power Status—LEDs and Fuse

When Power is applied to the EVB, the Green Power LEDs adjacent to 5 V and 3.3 V of the voltage reg-

ulators show the presence of the supply voltage.

Green LED D9 = 3.3 V for EVB supply

Green LED D16 = 5 V for EVB supply

If there is no power to the MCU it is possible that either power switch SW1 is in the “OFF” position or

that the fuse F1 has blown. The fuse will blow if power is applied to the EVB in reverse-bias, where a

protection diode ensures that the main fuse blows rather than causing damage to the EVB circuitry. If the

fuse has blown, check the bias of your power supply connection then replace fuse F1 with a 20 mm 2 A

fast blow fuse.

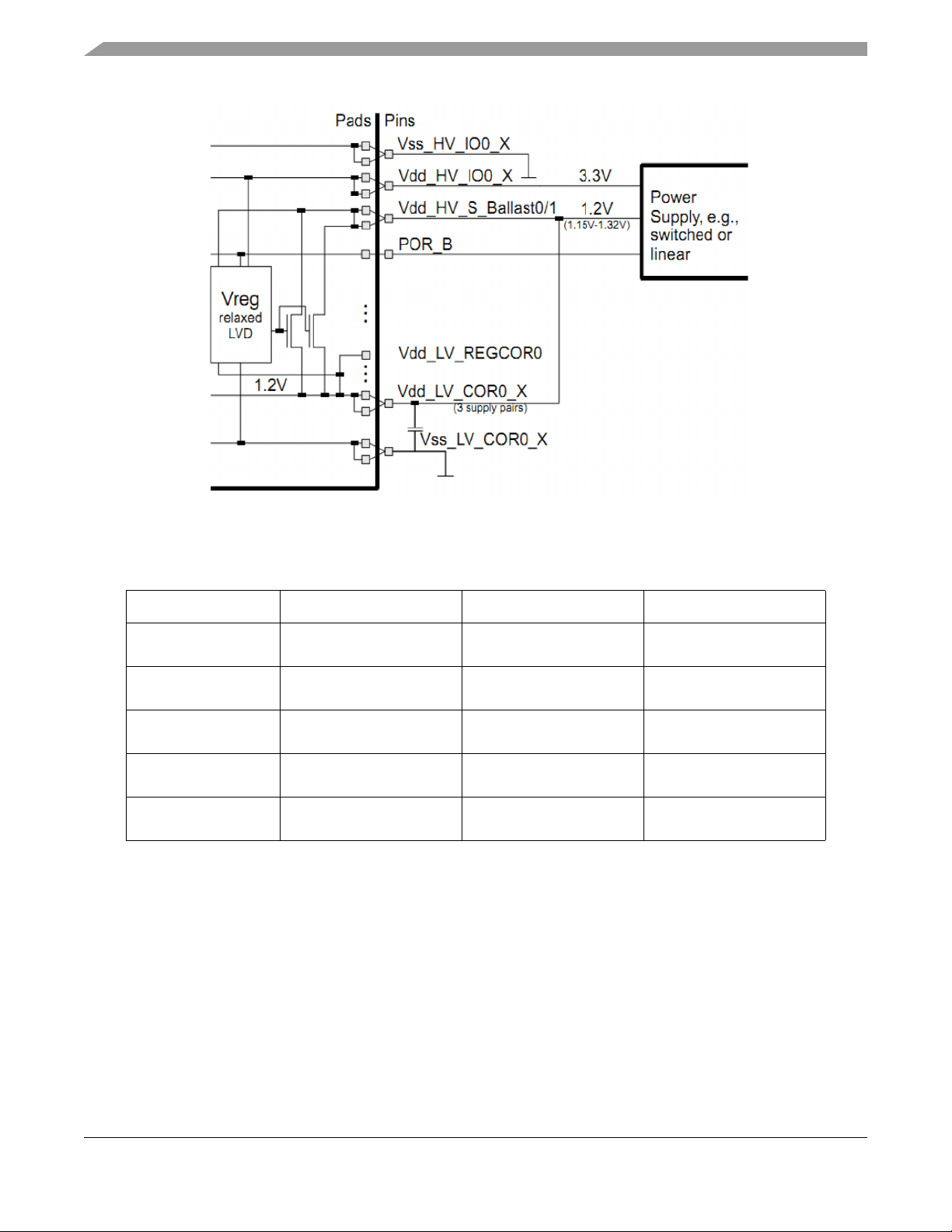

4.6 MCU supply routing and Jumpers (J16, J18, J19, J20, J23)

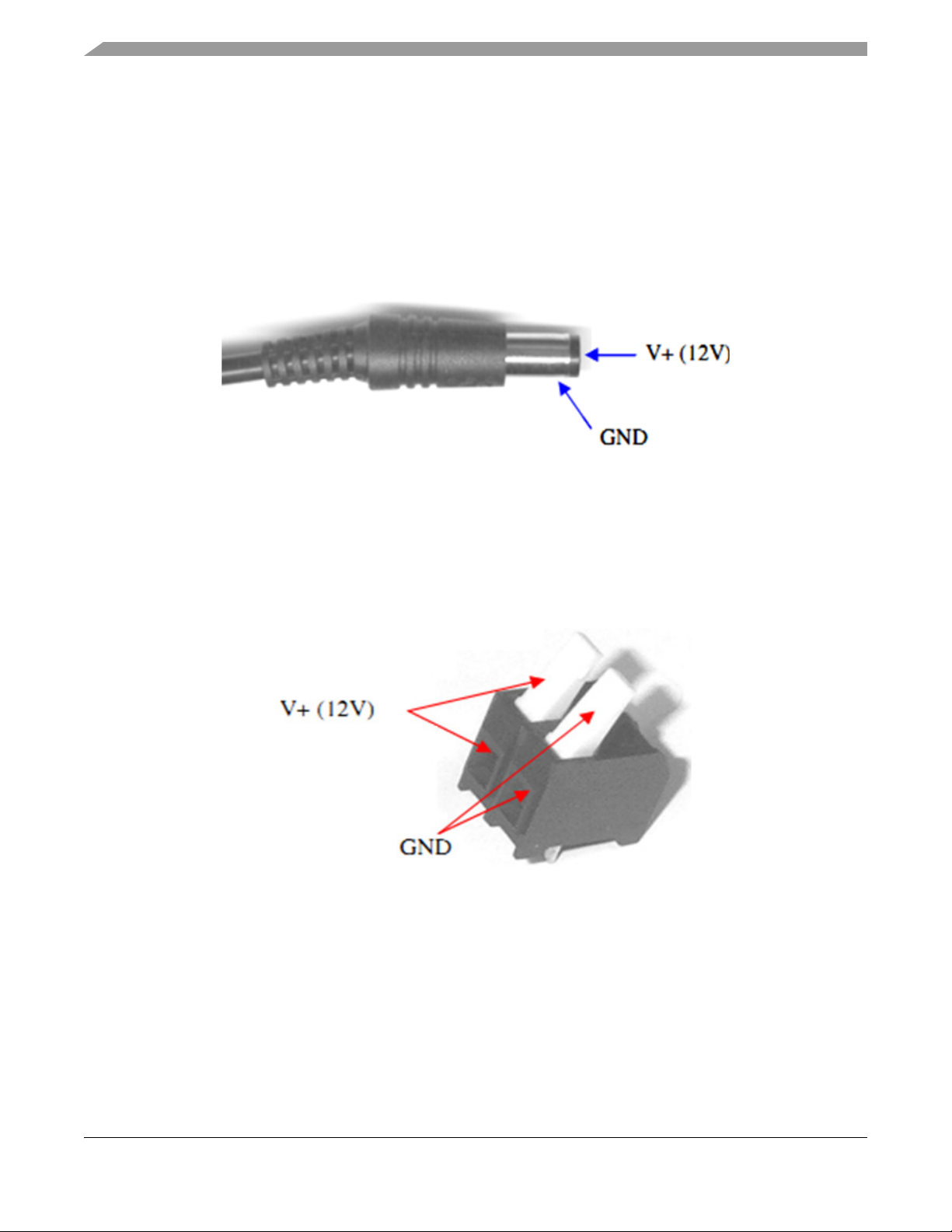

The EVB is designed to run the MCU at two supported regulation modes:

Internal regulation mode

In this mode the I/O supply, Ballast supply and ADC supply are at the same potential of typical 3.3 V

(+/- 10%). To reduce power dissipation on the chip, the possibilities of connecting the I/O supply with the

Ballast supply via a small resistor 2.5 is being explored. This will lead to the Ballast supply being lower

than the I/O supply.

Figure 4. Internal regulation mode

External regulation mode

In this mode, the Ballast supply is shorted to 1.2 V (+/-10%) generated from an external regulator. The I/O

supply and the MCU ADC supply continues to be at 3.3 V (+/-10%).

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 5

Configuration

Figure 5. External regulation mode

The FlexCAN circuity also has 5 V supplier to the transceiver.

Table 1. MCU Power Supply Jumpers – internal regulation mode

Power Domain Jumper Position Description

1.2 V J18

(VDD_LV)

3.3 V J19

(V_BALLAST_IN)

3.3 V J20

(V_BALLAST_IN_HDR)

3.3 V J16

(VDD_HV)

3.3 V J23

(VDD_HV_ADDR)

X This supplies VDD_LV

supply pins

1-2 This supplies

VDD_S_BALAST supply pin

2-3 (D) VDD_S_BALAST routed via

BALAST resistor

1-2 (D) This supplies VDD_HV

supply pins

1-2 (D) ADC reference voltage 3.3 V

The jumper configuration shown in Table 1, details the default state (D) of the EVB. In this configuration

all power is supplied from the regulators.

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor6

Table 2. MCU Power Supply Jumpers – external regulation mode

Power Domain Jumper Position Description

Configuration

1.2 V J18

(VDD_LV)

3.3 V J19

(V_BALLAST_IN)

3.3 V J20

(V_BALLAST_IN_HDR)

3.3 V J16

(VDD_HV)

3.3 V J23

(VDD_HV_ADR)

1-2 (D) This supplies VDD_LV

supply pins

2-3 (D) This supplies

VDD_S_BALAST supply

2-3 (D) VDD_S_BALAST routed via

BALAST resistor

1-2 (D) This supplies VDD_HV

supply pins

1-2 (D) ADC reference voltage 3.3 V

The jumper configuration shown in Table 2, details the default state (D) of the EVB. In this configuration

all power supplied from the regulators.

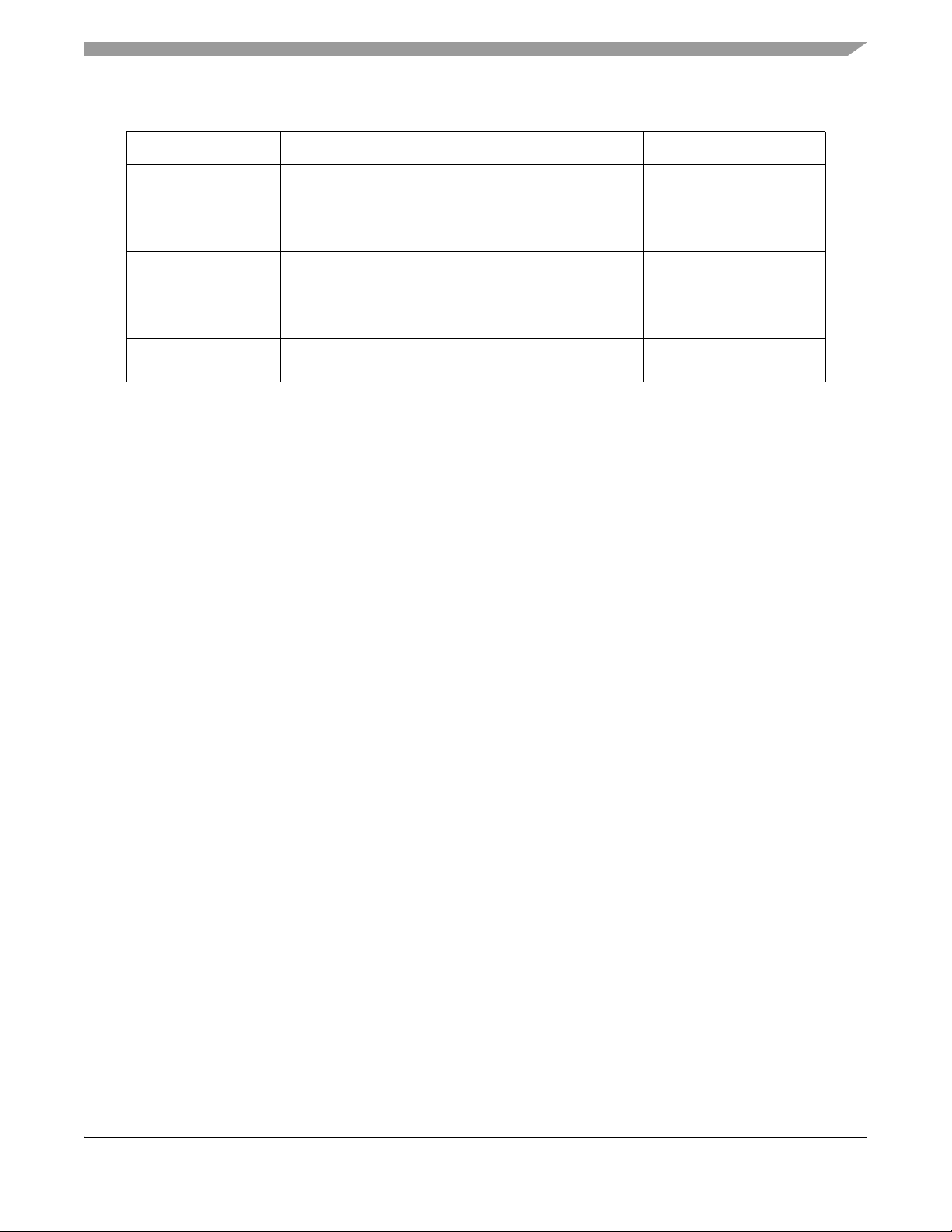

4.7 MCU clock control - Main Clock Selection (J30, J31, J32, J34)

EVB supports three possible MCU clock sources:

• The local 25 MHz oscillator circuit (Y2)

• An 8 MHz Oscillator module (Y1) on the EVB, driving the MCU EXTAL signal

• An external clock input to the EVB via the SMA connector, driving the MCU EXTAL signal

The clock circuity is shown in the diagram below. Please refer to the appropriate EVB schematic for

specific jumper numbers and circuity.

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 7

Configuration

Table 3. Table Clock source jumper selection (J30, J31, J32, J34)

Jumper Position PCB Legend Description

J34 (Y1 PWR) FITTED (D)

REMOVED

J32 (OSC SEL) 1-2

2-3 (D)

J30

Must Match J31

J31

Must Match J30

1-2

2-3 (D)

1-2 (D)

2-3

Figure 6. EVB Clock Selection

EXTAL-SMA

OSC-MOD

Y2

GND

EVB-EXTAL

Y2

EVB oscillator module Y1 is

powered

EVB oscillator module Y1 is

not powered

SMA external square wave

input

8 MHz Oscillator is routed

from Y1

MCU clock is Y2 XTALIN

GND

MCU clock is selected by

J68

MCU clock is Y2 XTALOUT

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor8

Configuration

NOTE

The MPC5604E clock circuity is 3.3 V based. Any external clock signal

driven into the SMA connector must have a maximum voltage of 3.3 V.

4.8 Reset Boot Configuration (J44, J46, J47)

The MPC5604E has 3 boot configuration jumpers (BOOTCFG) that determine the boot location of the

MCU based at POR (Power On Reset). This is shown in the Table 4:

Table 4. BOOTCFG Control

J47 (FAB) J44 (ABS0) J46 (ABS2) Boot ID Boot Mode

1-2 2-3 2-3 — Serial Boot LinFlex

without autobaud

1-2 1-2 2-3 — Serial Boot FlexCAN

without autobaud

1-2 2-3 1-2 — Serial Boot via LinFlex

or FlexCAN in

autobaud

2-3 — — Valid SC (Single Chip)

2-3 — — Not Valid Safe Mode

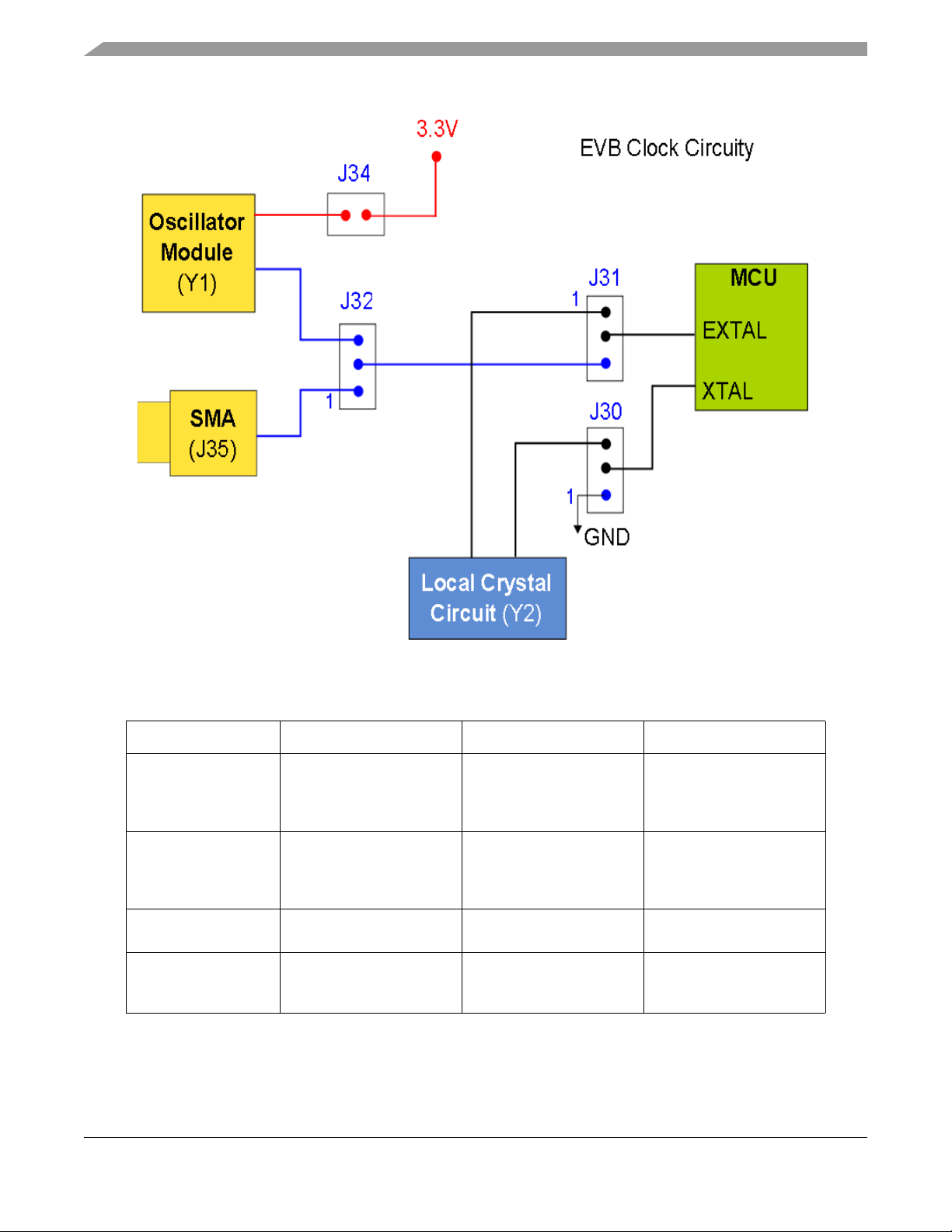

4.9 NEXUS

The EVB supports a standard JTAG cable with a 14-pin 0.1” walled header footprint.

4.9.1 Debug Connector Pinouts

The EVB is fitted with 14-pin JTAG connector. The following diagram shows the 14-pin JTAG connector

pin out (0.1” keyed header).

Figure 7. MPC5604E JTAG Connector

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 9

Configuration

NOTE

In order to preserve the ability to accurately measure power consumption of

the MCU pins, the JTAG connector reference voltages will be sourced

directly from the 3.3 V regulator.

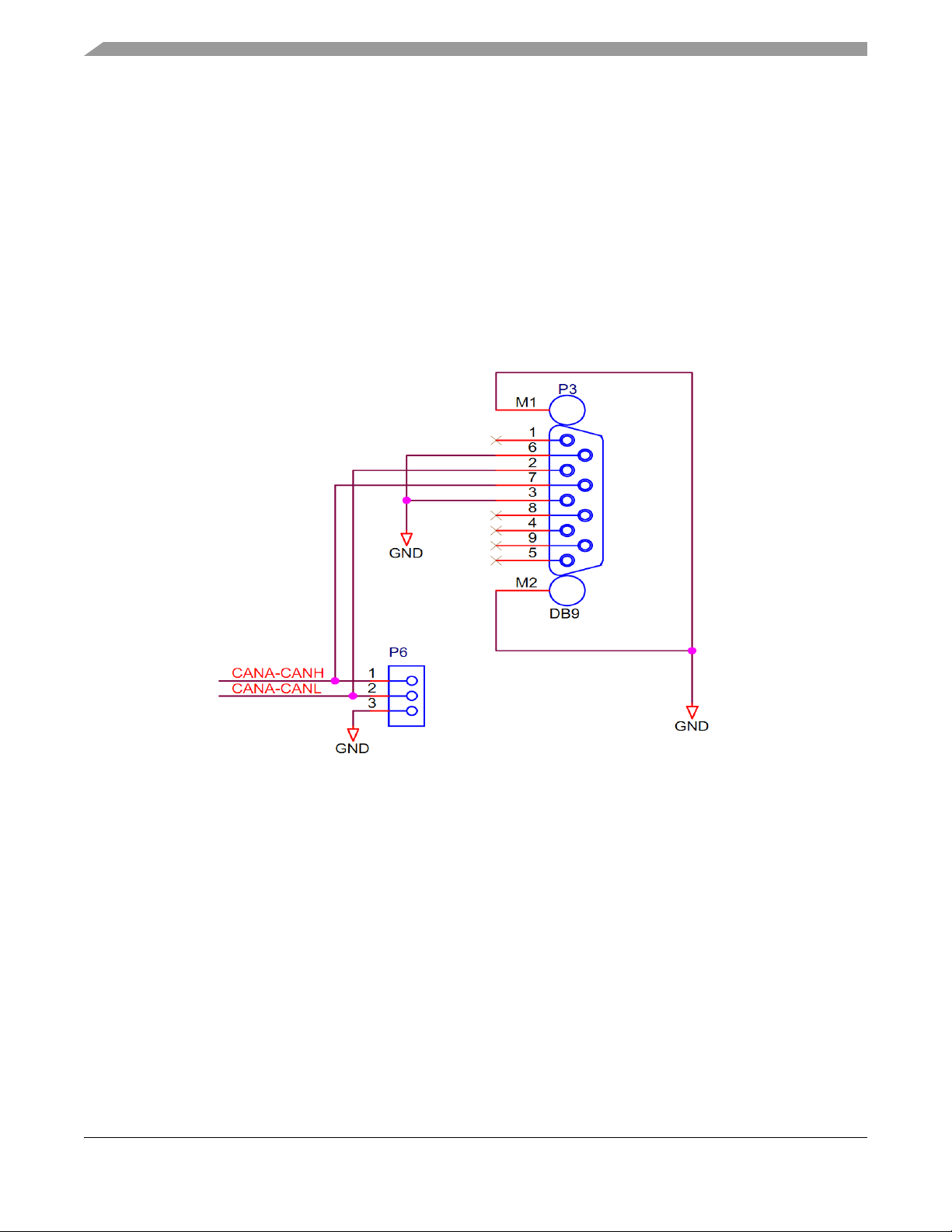

4.10 CAN Configuration (J10, J11, J12, J6, J9)

The EVB has one NXP TJA1041T high speed CAN transceiver on the MCU CAN channel. This can

operate with 3.3 V I/O from the MCU. For flexibility, the CAN transceiver I/O is connected to a standard

0.1” connector and DB9 connector at the top edge of the PCB. Connectors P6 and P3 provides the CAN

bus level signal interface for CAN-A. The pin out for these connectors is shown below.

Figure 8. CAN physical interface connector

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor10

Table 5. CAN Control Jumpers (J10, J11, J12, J6, J9)

Jumper Position PCB Legend Description

Configuration

J11 FITTED (D)

REMOVED

J12 FITTED (D)

REMOVED

J6 FITTED (D)

REMOVED

J10 FITTED (D)

REMOVED

J9

Position 1-2

J9

Position 3-4

J9

Position 5-6

FITTED (D)

REMOVED

FITTED (D)

REMOVED

FITTED (D)

REMOVED

• 5 V is applied to CAN

transceiver VCC

• No 5 V power is applied to

CAN transceiver

• 12 V Power is applied to

CAN transceiver VBAT

• No 12 V power is applied

to CAN transceiver

TX • MCU CAN_TXD is

connected to CAN

controller

• MCU CAN_TXD is NOT

routed to CAN controller.

RX • MCU CAN_RXD is

connected to CAN

controller

• MCU CAN_RXD is NOT

routed to CAN controller.

WAKE • CAN Transceiver WAKE

is connected to GND

• WAKE is not connected

and available on Pin 2

STB • CAN Transceiver STB is

connected to 5 V

• STB is not connected and

available on Pin 4

EN • CAN Transceiver is

Enabled

• EN is not connected and

available on Pin 6

Access to the Error and inhibit signals from the transceivers is provided on J14.

NOTE

You must do the fitting of the jumper headers carefully, as they can easily

be fitted in the incorrect orientation.

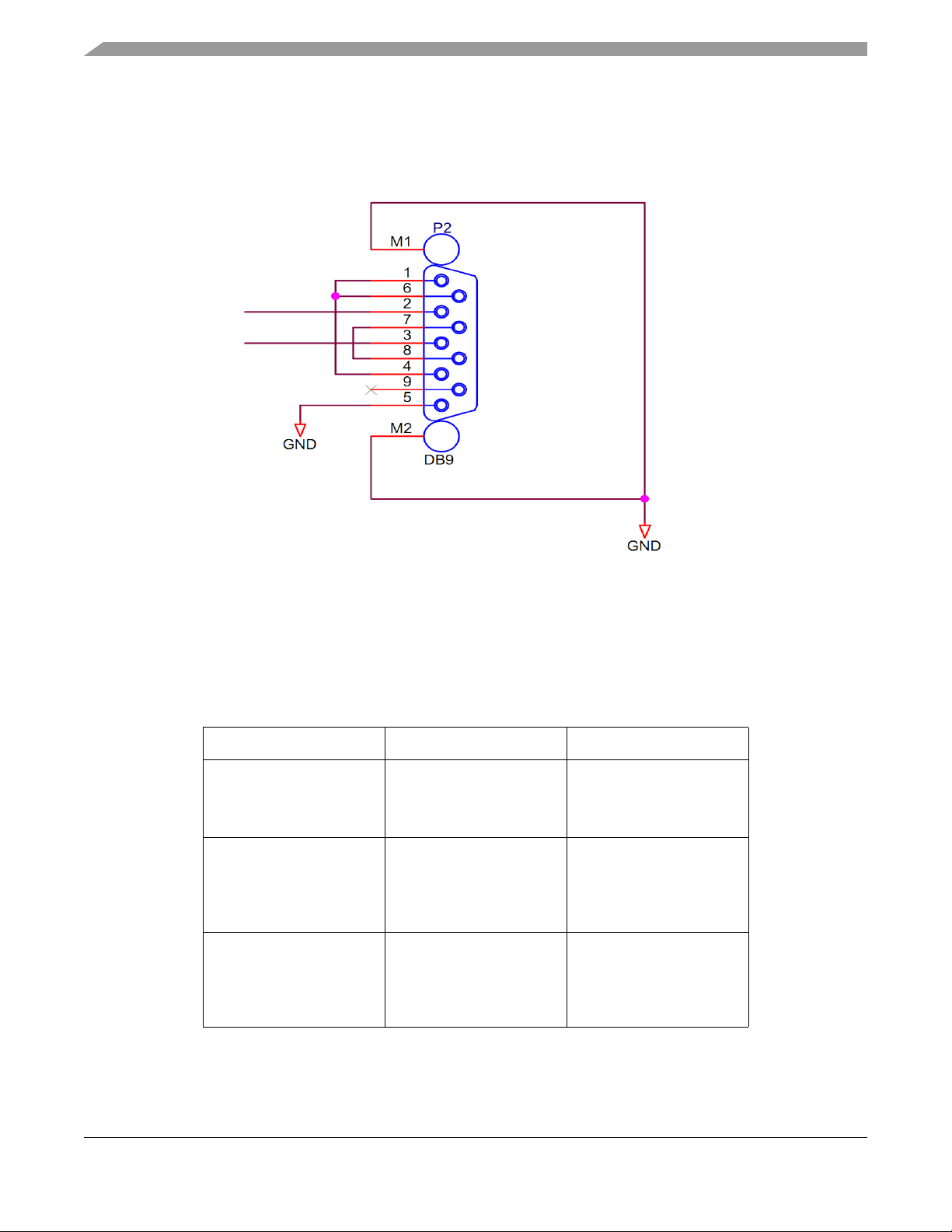

4.11 RS232 Configuration (J3, J7, J8)

The EVB has a single MAX3223 RS232 transceiver device, providing RS232 signal translation for the

MCU LINFlex channel.

The RS232 output from the MAX3223 device is connected to a DB9 connector, allowing a direct RS232

connection to a PC or terminal. Connector P2 provides the RS232 level interface for MCU SCI (LINFlex).

The connector pinout is detailed below.

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 11

Configuration

NOTE

The hardware flow control is not supported on this implementation.

Figure 9. RS232 Physical Notifies Connector

The MPC5604E LINFlex also provides hardware LIN master capability which is supported on the EVB

via LIN transceiver. Jumpers J7 and J8 are provided to isolate the MCU LINFlex signals from the RS232

interface as described below. There is also a global power jumper (J3) controlling the power to the RS232

transceiver.

Table 6. RS232 Control Jumpers

Jumper Position Description

J3

(SCI-PWR)

J7 2-3 (D)

J8 2-3 (D)

FITTED (D)

REMOVED

REMOVED

REMOVED

• Power is applied to the

MAX3223 transceiver

• No power is applied to the

MAX3223 transceiver

• MCU TXD is routed to

MAX3223

• MCU TXD signal is

disconnected from

RS232/LIN

• MCU RXD is routed to

MAX3223

• MCU RXD signal is

disconnected from

RS232/LIN

The default configuration enables SCI. RS232 compliant interfaces (with no hardware flow control) are

available at DB9 connector P2. If the MCU is configured such that SCI is set as a normal I/O port, then

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor12

Configuration

the relevant jumpers must be removed to avoid any conflicts occurring. If required, jumper J3 can be used

to completely disable the SCI transceiver.

4.12 LIN Configuration (J2, J5, J7, J8)

The EVB is fitted with one Freescale MCZ33661EF LIN transceiver. The LINFlex module incorporates a

UART mode, and as such, the LIN transceiver are connected to the TX and RX signals of SCI via UART.

For flexibility, the LIN transceiver is connected to a standard 0.1” connector (P7) and to one pin molex

connector (J1) at the top edge of the PCB as shown in the figure below.

For ease of use, the 12 V EVB supply is fed to pin1 of the P7 header and the LIN transceiver power input

to pin 2. This allows the LIN transceiver to be powered directly from the EVB supply by simply linking

pins 1 and 2 of header P7 using a 0.1” jumper shunt.

** Ensure P7 is added before running LIN as it is not the default on the EVB

Figure 10. LIN physical Interface Connector P7

Along with the MCU signal routing jumpers (J7 / J8), there is jumper (J5) to enable or disable the LIN

transceiver and jumper (J2) which determines if the LIN transceiver is operating in master or slave mode,

as defined in the table below.

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 13

Configuration

Table 7.

Jumper Position Description

J2 FITTED

REMOVED (D)

J5* FITTED (D)

REMOVED

J7 2-3 (D)

1-2

J8 2-3 (D)

1-2

• LIN transceiver is

configured for LIN Master

mode

• LIN transceiver is

configured for LIN Slave

mode

• The LIN transceiver is

enabled

• The LIN transceiver is

disabled

• MCU LIN_TXD is

connected to SCI TX

• MCU LIN0_TXD is

connected to LIN Physical

• MCU LIN_RXD is

connected to SCI TX

• MCU LIN_RXD is

connected to LIN Physical

NOTE

Jumper J5 do not route power to LIN transceivers, they only control an

enable line on the LIN device. Power to the LIN transceiver is supplied via

connector P7, Pin 2.

The Default LIN configuration is with the module enabled in master mode, LIN slave mode can be enabled

by removing jumper J2.

4.13 Ethernet

4.13.1 Ethernet Physical Interface (J22)

The EVB is fitted with a National Semiconductor DP83848C Ethernet physical interface (U10) and a RJ45

connector with integrated activity LEDs and magnetics (J24).

The National Semiconductor DP83848C physical interface is connected to the MII on the MPC5604E.

This is a fixed connection with no means of isolation. Pullups are also present on some of these signals.

These are detailed in the table below. Please be aware of this when using the related GPIOs.

Table 8. Pull up/Pull down resistors for Ethernet Physical

Port Pin Pull Direction Strength

FEC_CRS Down (GND) 2.2 k

FEC_RX_ER Down (GND) 2.2 k

FEC_RX_DV Down (GND) 2.2 k

FEC_RXD0 Down (GND) 2.2 k

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor14

Configuration

Table 8. Pull up/Pull down resistors for Ethernet Physical

Port Pin Pull Direction Strength

FEC_RXD1 Down (GND) 2.2 k

FEC_RXD2 Down (GND) 2.2 k

FEC_RXD3 Down (GND) 2.2 k

FEC_TX_EN Down (GND) 2.2 k

FEC_TXD0 Down (GND) 2.2 k

FEC_TXD1 Down (GND) 2.2 k

FEC_TXD2 Down (GND) 2.2 k

FEC_TXD3 Down (GND) 2.2 k

FEC_MDC_PHY Up (3.3 V) 1.5 k

FEC_MDIO_PHY Up (3.3 V) 1.5 k

The voltage domain that is used by the GPIO should be set to 3.3 V when power is applied to the physical

interface. Power can be removed from the physical interface via J22.

Table 9. Ethernet Physical Interface Power Supply Enabled (J22)

Jumper Position PCB legend Description

J22

(PHY PWR)

FITTED (D)

REMOVED

PHY PWR • The DP83848C Ethernet

Physical Interface is

powered from the 3.3 V

SR.

• The DP83848C Ethernet

Physical Interface is not

powered.

4.13.2 Ethernet MII connector (J49)

An universal 40-pin MII Connector is also provided on the board to provide possibility to connect

customer Ethernet Physical Interface to MPC5604E interface signals. Since this connector is normally

used by the Ethernet PHY daughter cards of standard PHY vendors, this provides a flexibility of

supporting validation with multiple PHY vendors.

Connector pin definition is located in the Section 6.1, “FEC (J33, J49) below.

Following resistors must be populated to enable connection between MPC5604E and MII connector on

board:

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 15

Configuration

Table 10. Resistor configuration for MPC5604E MII interface routed to MII connector

Resistor to be

populated

R62 0

R60 0

R58 0

R56 0

R54 0

R53 0

R82 0

R84 0

R86 0

R88 0

R90 0

R92 0

R94 0

FEC_TX_CLK routed to FEC_TX_CLK_CONN

FEC_TX_EN routed to FEC_TX_EN_CONN

FEC_TXD0 routed to FEC_TXD0_CONN

FEC_TXD1 routed to FEC_TXD1_CONN

FEC_TXD2 routed to FEC_TXD2_CONN

FEC_TXD3 routed to FEC_TXD3_CONN

FEC_RXD3 routed to FEC_RXD3_CONN

FEC_RXD2 routed to FEC_RXD2_CONN

FEC_RXD1 routed to FEC_RXD1_CONN

FEC_RXD0 routed to FEC_RXD0_CONN

FEC_RX_DV routed to FEC_RX_DV_CONN

FEC_RX_CLK routed to FEC_RX_CLK_CONN

FEC_MDIO routed to FEC_MDIO_CONN

Value Description

4.14 Video Connector (J45)

EVB has a possibility to connect Camera module to Video connector (J45). Camera signals are then routed

to the Video Encoder Wrapper module of MPC5604E. Video connector fits to standard connector used on

Omnivision camera evaluation boards.

Connector pin definition is located in the Section 6.4, “VIDEO (J45) below.

Following resistors and capacitors have to be populated to enable connection between MPC5604E and

Video connector on board:

Tab l e 11.

Resistor and

capacitor to be

populated

R33 10

R26 10

R35 10

R28 10

R37 10

L4 75

R39 10

R41 10

R43 10

PORT_A0 routed to CON_VID_DATA11

PORT_A1 routed to CON_VID_DATA10

PORT_A2 routed to CON_VID_DATA9

PORT_A3 routed to CON_VID_DATA8

PORT_A4 routed to CON_VID_DATA7

PORT_A5 routed to CON_VID_CLK

PORT_A6 routed to CON_VID_VSYNC

PORT_A7 routed to CON_VID_HSYNC

PORT_A8 routed to CON_VID_DATA6

Value Description

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor16

Tab l e 11.

Resistor and

capacitor to be

populated

R31 10 PORT_A9 routed to CON_VID_DATA5

R45 10

PORT_A10 routed to CON_VID_DATA4

Value Description

Configuration

R47 10

R49 10

R77 10

L6 75

PORT_A11 routed to CON_VID_DATA3

PORT_A12 routed to CON_VID_DATA2

PORT_A15 routed to VID_PWDN

PORT_C4 routed to MC_RGM_ABS0

Most of the Omnivision camera evaluation boards are configured via I2C interface. For this purpose J27,

J28, J39 and J37 should be connected correctly. For pin definitions see Section 6.8, “I2C clock selection

(J27, J28, J36, J37, J39, J40).

4.14.1 Audio Connector

EVB has a possibility to connect Sahara SGTL5000 daughter card to Audio connector J48. Audio signals

are routed to Serial Audio Interface module of MPC5604E.

Connector pin definition is located in the Section 6.3, “Audio (J48) below.

Following resistors and capacitors have to be populated to enable connection between MPC5604E and

Audio connector on board.

Table 12.

Resistor and

capacitor to be

populated

Value Description

R64 0 PORT_C3 routed to ETC1

R66 0

R32 0

R25 0

R34 0

R27 0

R36 0

R29 0

R38 0

R40 0

R42 0

R30 0

R44 0

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 17

PORT_C2 routed to ETC0

PORT_A0 routed to SAI0_DATA0

PORT_A1 routed to SAI0_DATA1

PORT_A2 routed to SAI0_DATA2

PORT_A3 routed to SAI0_DATA3

PORT_A4 routed to SAI0_SYNC

PORT_A5 routed to SAI1_SYNC

PORT_A6 routed to SAI2_SYNC

PORT_A7 routed to SAI0_BCLK

PORT_A8 routed to SAI2_DATA0

PORT_A9 routed to SAI2_BCLK

PORT_A10 routed to SAI2_MCLK

Default Jumper Summary Table

Resistor and

capacitor to be

populated

R70 0 PORT_B1 routed to SAI1_DATA0

R72 0

Table 12.

Value Description

PORT_B0 routed to SAI1_BCLK

R76 0

R78 0

PORT_A15 routed to SAI1_MCLK

PORT_C4 routed to SAI0_MCLK

Sahara SGTL5000 audio daughter card uses I2C interface for configuration. For this purpose J27, J28, J39

and J37 should be connected correctly. For pin definitions see Section 6.8, “I2C clock selection (J27, J28,

J36, J37, J39, J40).

5 Default Jumper Summary Table

Table 13. Default Jumper Positions

Jumper

Reference

J2 REMOVED 1 Master Mode Pullup disable

J3 1-2 1 Power on SCI is enabled

J4 1-2 1 Power for User switches is disabled

J5 1-2 1 Power on LIN is enabled

J6 1-2 1 CAN TXD is connected to MCU

J7 2-3 1 UART TXD is connected to MCU

J8 2-3 1 UART RXD is connected to MCU

Default Setting

Jump

Count

Description

J9 1-2

3-4

5-6

J10 1-2 1 CAN RXD is connected to MCU

J11 1-2 1 Power on CAN PHY is enabled

J12 1-2 1 Power on CAN PHY is enabled

J13 2-3 1 1.2 power supply switch is supplied from 12 V

J15 1-2 1 VPP_TEST should be grounded

J16 1-2 1 VDD_HV is enabled

J18 1-2 1 VDD_LV is enabled (external regulation

J19 2-3 1 VDD_BALAST is powered from 1.2 V

J20 2-3 1 VDD_BALAST_IN resistor is connected

J21 2-3 1 JTAG_RST is connected to Ethernet PHY

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

3 CAN control signals are on

mode)

(external regulation mode)

Freescale Semiconductor18

Table 13. Default Jumper Positions

User Connector Descriptions

Jumper

Reference

J22 1-2 1 Power on Ethernet PHY is enabled

J23 1-2 1 Power on VDD_HV_ADR is enabled

J30 2-3 1 Use on board 8.0 MHz crystal

J31 1-2 1 Use on board 8.0 MHz crystal

J32 2-3 1 Use on board 8.0 MHz crystal

J34 1-2 1 Use on board 8.0 MHz crystal

J41 1-2 1 3.3 V connected to FEC MII connector

J44 2-3 1 MC_RGM_ABS0 is tied to ground

J46 2-3 1 MC_RGM_ABS2 is tied to ground

J47 2-3 1 MC_RGM_FAB is tied to ground

Default Setting

Jump

Count

Description

6 User Connector Descriptions

This section details the pinout of the EVB user connectors. The connectors are 0.1 inch pitch turned pin

headers and are located at various locations on the EVB. They are grouped by port functionality and the

PCB legend shows the respective port number adjacent to each pin.

6.1 FEC (J33, J49)

Table 14. FEC Connector Pinout (J33)

Pin Function

1GND

2GND

3 FEC_TXD3

4 FEC_RXD2

5 FEC_TXD2

6 FEC_RXD3

7 FEC_TXD0

8 FEC_RXD1

9 FEC_TXD1

10 FEC_RXD0

11 FEC_TX_CLK

12 EC_RX_CLK

13 GND

14 GND

15 FEC_TX_EN

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 19

User Connector Descriptions

Table 14. FEC Connector Pinout (J33)

Pin Function

16 NC

17 NC

18 NC

19 GND

20 GND

21 FEC_MDC

22 NC

23 FEC_MDIO

24 FEC_RX_DV

25 GND

26 GND

Table 15. MII Connector Pinout (J49)

Pin Function

1 POWER_MII_CONN

2MDIO

3MDC

4RXD3

5RXD2

6RXD1

7RXD0

8RXDV

9RXCLK

10 RXER

11 TXER

12 TXCLK

13 TXEN

14 TXD0

15 TXD1

16 TXD2

17 TXD3

18 COL

19 CRS

20 POWER_MII_CONN

21 POWER_MII_CONN

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor20

Table 15. MII Connector Pinout (J49) (continued)

Pin Function

22 GND

23 GND

24 GND

25 GND

26 GND

27 GND

28 GND

29 GND

30 GND

31 GND

32 GND

33 GND

34 GND

35 GND

36 GND

37 GND

User Connector Descriptions

38 GND

39 GND

40 POWER_MII_CONN

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 21

User Connector Descriptions

6.2 ADC(J38)

6.3 Audio (J48)

Table 16. ADC Connector Pinout (J38)

Pin Function

1GND

2GND

3 ADC0_AN[11]

4 ADC0_AN[13]

5GND

6GND

7 ADC0_AN[12]

8 ADC0_AN[14]

9GND

10 GND

Table 17. Audio Connector Pinout (J48)

Pin Function

1 3.3 V

2GND

3 SAI0_DATA3

4GND

5 SAI0_DATA2

6GND

7 SAI0_DATA1

8GND

9 SAI0_DATA0

10 GND

11 SAI0_BCLK

12 GND

13 SAI0_SYNC

14 GND

15 SAI0_MCLK

16 GND

17 ETC2/AN14 (ADC signal)

18 GND

19 AUD_IIC1_CLK

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor22

Table 17. Audio Connector Pinout (J48) (continued)

Pin Function

20 GND

21 AUD_IIC1_DATA

22 GND

23 SAI1_D0

24 GND

25 SAI1_BCLK

26 GND

27 ETC1

28 GND

29 SAI1_SYNC

30 GND

31 SAI1_MCLK

32 GND

33 AUD_IIC0_CLK

34 GND

35 AUD_IIC0_DATA

User Connector Descriptions

36 GND

37 SAI2_DATA0

38 GND

39 SAI2_BCLK

40 GND

41 SAI2_SYNC

42 GND

43 SAI2_MCLK

44 GND

45 ETC0

46 GND

47 AN13(ADC signal)

48 GND

49 5V

50 GND

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 23

User Connector Descriptions

6.4 VIDEO (J45)

Table 18. Video Connector Pinout (J45)

Pin Function

1 CON_VID_DATA4

2 CON_VID_DATA5

3 CON_VID_DATA6

4 CON_VID_DATA7

5 CON_VID_DATA8

6 CON_VID_DATA9

7 CON_VID_DATA10

8 CON_VID_DATA11

9VID_PWDN

10 NC

11 VID_IIC_DATA

12 NC

13 VID_IIC_CLK

14 CON_VID_HSYNC

15 GND

16 CON_VID_VSYNC

17 GND

18 CON_VID_CLK

19 MC_RGM_ABS0

20 5 V

21 GND

22 5 V

23 CON_VID_DATA2

24 CON_VID_DATA3

25 NC

26 NC

27 NC

28 NC

29 NC

30 NC

31 GND

32 GND

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor24

6.5 NMI (J29)

6.6 LINFLEX (P7)

User Connector Descriptions

Table 19. NMI Connector Pinout (J29)

Pin Function

1GND

2NMI

3 3.3 V

Table 20. LINFLEX Connector Pinout (P7)

Pin Function

112 V

2 LINC-VSUP

3LINC-LIN

4GND

6.7 FlexCAN (P6)

Table 21. FLEXCAN Connector Pinout (P6)

Pin Function

1CANH

2CANL

3GND

6.8 I2C clock selection (J27, J28, J36, J37, J39, J40)

Table 22. Routing IIC0 to Video Connector – video usecase

Signal description Jumper Reference Configuration Description

IIC 0 clock J25 2-3 Port_C5 routed to J39 as

IIC0_CLK signal

J39 1-2 IIC0_CLK signal routed to

J28

J28 2-3 IIC0_CLK is selected for

Video IIC clock

IIC 0 data J26 2-3 Port_C6 routed to J40 as

IIC0_DATA signal

J40 1-2 IIC0_DATA signal routed to

J37

J37 2-3 IIC0_DATA is selected for

Video IIC data

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 25

Known Bugs List

Table 23. Routing IIC1 to Video Connector – video usecase

Signal description Jumper Reference Configuration Description

IIC 1 clock J27 1-2 Port_A13 routed to J28

J28 1-2 IIC1_CLK signal is selected

for Video IIC clock

IIC 1 data J36 1-2 Port_A14 routed to J37

J37 1-2 IIC1_DATA signal is

selected for Video IIC data

Table 24. Routing IIC0 to Audio Connector – audio usecase

Signal description Jumper Reference Configuration Description

IIC 0 clock J25 2-3 Port_C5 routed to J39 as

IIC0_CLK signal

J39 2-3 IIC0_CLK signal selected for

Audio IIC clock

IIC 0 data J26 2-3 Port_C6 routed to J40 as

IIC0_DATA signal

J40 2-3 IIC0_DATA signal selected

for Audio IIC data

Table 25. Routing IIC1 to Video Connector – audio usecase

Signal description Jumper Reference Configuration Description

IIC 0 clock J27 2-3 IIC1_CLK signal is selected

for audio IIC clock

IIC 0 data J36 2-3 IIC1_DATA signal is

selected for audio IIC data

7 Known Bugs List

None

8 Schematic Diagrams

This section shows the schematic diagram of the MPC5604EEVB64.

Following are the topics covered in the schematic:

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor26

Table 26. Schematic sections

Power section Sheet 2

Resistor MUX Sheet 3

Video & Audio section Sheet 4

MII Connector section Sheet 5

Debug Interface section Sheet 6

Reset & Clock section Sheet 7

Ethernet Physical

Interface and RJ45

CAN Physical Interface Sheet 9

LIN & SCI Physical

Interface

MPC5604E SoC Sheet 11

LED & Switch section Sheet 12

User I/O connectors Sheet 13

Sheet 8

Sheet 10

Schematic Diagrams

MPC5604EEVB64 Evaluation board User Manual, Rev. 0

Freescale Semiconductor 27

5

4

3

2

1

JP11

JP3

JP20

JP2

HDR 1X1

HDR 1X1

HDR 1X1

HDR 1X1

8

3

6

7

3.3V

1

1

1

1

JP21

JP5

JP6

JP18

HDR 1X1

HDR 1X1

HDR 1X1

HDR 1X1

Distribute Evenly over the board

D10

21

1N4148WS

C33

U12

2

BST

1

EPAD

0.1UF

SW

5

5VFB3V3_FB

FB

4

GND

2 1

IN

VCC

PG

EN/SYNC

9

MP2380

5.0V

1

1

1

1

L5

1 2

D15

B530C

4.7UH

HDR 1X1

1

JP4

HDR 1X1

1

JP24

HDR 1X1

1

JP1

HDR 1X1

1

JP19

GND

5.0V

R23

40.2K

TP7

C37

0.1UF

R22

7.68K

12

12

C39

C38

47UF

47UF

1.2V

HDR 1X1

1

C32

1.0 UF

JP7

JP10

JP8

JP9

HDR 1X1

HDR 1X1

HDR 1X1

1

1

1

R24 100K

R50

10.0K

Power supply input and filter

2.1mm Barrel

Connector

P4

1

P1

CON 2 TB

2

3

1

A

2

B

GND

D D

2 Lever

Connector

SW1

25136N

1 2 3

POWER SWITCH

F1

VSwitched VFused12V-IN

0.1UF

1 2

Fuse Holder

C509

C508

1000PF

D2 B130LB-13

2 1

Power Supply 3.3V

D7

1N4148WS

P12V

C C

C26

C28

C27

10UF

GND GND

10UF

0.1UF

C24

1.0 UF

R19 100K

10.0K

8

3

6

7

IN

VCC

PG

EN/SYNC

9

EPAD

MP2380

C25

U11

0.1UF

2

BST

1

3V3_L

SW

5

FB

4

GND

21

1 2

2 1

4.7UH

D8

B530C

+

L3

Main Power-In

L1

47UH

C3

68UF

TP6

P12V

+

C4

1000UF

GND

Power Supply 5.0 V

P12V

C34

10UF

GND GND

C36

C35

0.1UF

10UFR20

R18

40.2K

R17

13K

C29

0.1UF

3.3V

12

12

C31

C30

47UF

47UF

D9

LED GREEN

R21

100

5.0V

AC

4

D16

LED GREEN

R79

249

P12V

Power Supply 1.2V

J13

3

2

1

HDR TH 1X3

5.0V

VIN_VREG_1_2V

C12

10UF

C13

0.1UF

C11

10UF

GND GND

3

C9

1.0 UF

R7 100K

R8

10.0K

8

3

6

7

IN

VCC

PG

EN/SYNC

2

9

EPAD

MP2380

C10

U8

2

BST

1

SW

5

FB

4

GND

0.1UF

1 2

D6

B530C

2 1

4.7UH

L2

TP1

R6

162K

1.2VFB

C14

0.1UF

R5

324K

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

Drawing Title:

Drawing Title:

Drawing Title:

MPC5604-EVB

MPC5604-EVB

MPC5604-EVB

Page Title:

Page Title:

Page Title:

POWER SECTION

POWER SECTION

POWER SECTION

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

1.2V

12

12

C15

C16

47UF

47UF

X

X

___ ___

___ ___

___ ___

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

1

X

2 13

2 13

2 13

3.3V

AC

B B

GND GN D

A A

5

5

10

PORT_A0pg(11)

PORT_A1pg(11)

D D

PORT_A2pg(11)

PORT_A3pg(11)

PORT_A4pg(11)

C C

PORT_A5pg(11)

PORT_A6pg(11)

PORT_A7pg(11)

B B

A A

PORT_A8pg(11)

PORT_A9pg(11)

PORT_A10pg(11)

PORT_A11pg(11)

10

75 OHM

R32 0 DNP

R25 0 DNP

10

R34 0 DNP

10

R27 0 DNP

10

1 2

10

10

10

10

10

R33

R26

R35

R28

R37

R36 0 DNP

L4

R29 0 DNP

R39

R38 0 DNP

R41

R40 0 DNP

R43

R42 0 DNP

R31

R30 0 DNP

R45

R44 0 DNP

10

R47

R46 0 DNP

4

CON_VID_DATA11 pg(4)

SAI0_DATA0 pg(4)

CON_VID_DATA10 pg(4)

SAI0_DATA1 pg(4)

CON_VID_DATA9 pg(4)

SAI0_DATA2 pg(4)

CON_VID_DATA8 pg(4)

SAI0_DATA3 pg(4)

CON_VID_DATA7 pg(4)

SAI0_SYNC pg(4)

CON_VID_CLK pg(4)

SAI1_SYNC pg(4)

CON_VID_VSYNC pg(4)

SAI2_SYNC pg(4)

CON_VID_HSYNC pg(4)

SAI0_BCLK pg(4)

CON_VID_DATA6 pg(4)

SAI2_DATA0 pg(4)

CON_VID_DATA5 pg(4)

SAI2_BCLK pg(4)

CON_VID_DATA4 pg(4)

SAI2_MCLK pg(4)

CON_VID_DATA3 pg(4)

JP12

1

HDR 1X1

3

PORT_A15pg(11)

PORT_B0pg(11,13) CAN0_TXD pg(9)

PORT_B2pg(11,13)

PORT_C2pg(11)

PORT_C3pg(11)

2

R77 0

R76 0 DNP

R73 0

R72 0 DNP

R71 0

R70 0 DNP

R75 0

R74 0 DNP

R69 0

R68 0 DNP

R67 0

R66 0 DNP

R65 0

R64 0 DNP

75 OHM

1 2

L6

R78 0 DNP

VID_PWDN pg(4)

SAI1_MCLK pg(4)

SAI1_BCLK pg(4)

CAN0_RXD pg(9)PORT_B1pg(11,13)

SAI1_DATA0 pg(4)

LIN0_TXD pg(10)

AN13 pg(4)

LIN0_RXD pg(10)PORT_B3pg(11,13)

ETC2_AN14 pg(4)

JP25

1

HDR 1X1

ETC0 pg(4)

JP26

1

HDR 1X1

ETC1 pg(4)

MC_RGM_ABS0 pg(4,7)PORT_C4pg(11)

SAI0_MCLK pg(4)

1

10

R49

PORT_A12pg(11)

5

R48 0 DNP

4

CON_VID_DATA2 pg(4)

JP13

1

HDR 1X1

X

X

___ ___

___ ___

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

Drawing Title:

Drawing Title:

Drawing Title:

Page Title:

Page Title:

Page Title:

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

3

2

Wednesday, October 12, 2011

___ ___

MPC5604-EVB

MPC5604-EVB

MPC5604-EVB

RESISTOR MUX

RESISTOR MUX

RESISTOR MUX

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

1

X

3 13

3 13

3 13

5

4

3

2

1

IIC1_CLK

PORT_A13pg(11)

IIC1_DATA

PORT_A14pg(11)

IIC0_CLK

IIC0_CLKpg(4)

IIC0_DATA

IIC0_DATApg(4)

3.3V

SAI0_DATA3pg(3)

SAI0_DATA2pg(3)

SAI0_DATA1pg(3)

SAI0_DATA0pg(3)

SAI0_BCLKpg(3)

SAI0_SYNCpg(3)

SAI0_MCLKpg(3)

ETC2_AN14pg(3)

AUD_IIC1_CLKpg(4)

AUD_IIC1_DATApg(4)

SAI1_DATA0pg(3)

SAI1_BCLKpg(3)

ETC1pg(3)

SAI1_SYNCpg(3)

SAI1_MCLKpg(3)

AUD_IIC0_CLKpg(4)

AUD_IIC0_DATApg(4)

SAI2_DATA0pg(3)

SAI2_BCLKpg(3)

SAI2_SYNCpg(3)

SAI2_MCLKpg(3)

ETC0pg(3)

5.0V

AN13pg(3)

3.3V

IIC0_CLK

3.3V

IIC0_DATA

AUD_IIC1_CLK

AUD_IIC0_CLK

AUD_IIC0_DATA

1

2

3

1

2

3

R540

4.7K

R539

4.7K

DNP

J45

CON_VID_DATA5pg(3) CON_VID_DATA4 pg(3)

CON_VID_DATA7pg(3)

CON_VID_DATA9pg(3)

5.0V

D D

Pin Numbering on this Omnivision mating connector

is mirror image of the numbering on the Omnivision

Daughter Card.

C C

B B

CON_VID_DATA11pg(3)

CON_VID_HSYNCpg(3)

CON_VID_VSYNCpg(3)

CON_VID_CLKpg(3)

CON_VID_DATA3pg(3)

6 5

HDR_2X16

GND

12

34

78

910

1112

VID_IIC_DATA

1314

VID_IIC_CLK AUD_IIC1_DATA

1516

1718

1920

2122

2324

2526

2728

2930

3132

OMNIVISION VIDEO INTERFACE

CON_VID_DATA6 pg(3)

CON_VID_DATA8 pg(3)

CON_VID_DATA10 pg(3)

VID_PWDN pg(3)

VID_IIC_DATA pg(4)

VID_IIC_CLK pg(4)

MC_RGM_ABS0 pg(3,7)

CON_VID_DATA2 pg(3)

VIDEO INTERFACE

DNP as female part required on EVB

J27

HDR TH 1X3

J36

HDR TH 1X3

J39

1

2

3

HDR TH 1X3

J40

1

2

3

HDR TH 1X3

J48

1 2

3 4

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

41 42

43 44

45 46

47 48

49 50

HDR_2X25

3.3V

R532

4.7K

3.3V

R537

4.7K

65

3.3V

R529

4.7K

AUD_IIC1_CLK

AUD_IIC1_DATA

AUD_IIC0_CLK

AUD_IIC0_DATA

GND

AUD_IIC1_CLK pg(4)

AUD_IIC1_DATA pg(4)

AUD_IIC0_CLK pg(4)

AUD_IIC0_DATA pg(4)

AUDIO INTERFACE

3.3V

R535

4.7K

HDR TH 1X3

J37

HDR TH 1X3

J28

1

2

VID_IIC_CLK

3

1

2

VID_IIC_DATA

3

VID_IIC_CLK pg(4)

VID_IIC_DATA pg(4)

MC_RGM_ABS2 pg(7)

HDR TH 1X3

1

IIC0_CLK

IIC0_DATA

2

3

HDR TH 1X3

1

2

3

J25

IIC0_CLK pg(4)

J26

IIC0_DATA pg(4)

MC_RGM_FAB pg(7)

X

X

___ ___

___ ___

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

Drawing Title:

Drawing Title:

Drawing Title:

Page Title:

Page Title:

Page Title:

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

2

Wednesday, October 12, 2011

___ ___

MPC5604-EVB

MPC5604-EVB

MPC5604-EVB

VIDEO & AUDIO SECTION

VIDEO & AUDIO SECTION

VIDEO & AUDIO SECTION

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

1

X

4 13

4 13

4 13

PORT_C5pg(11)

A A

PORT_C6pg(11)

5

4

3

5

4

3

2

1

R52 0

FEC_TXD3pg(11)

R53 22

DNP

D D

FEC_TXD2pg(11)

FEC_TXD1pg(11)

FEC_TXD0pg(11)

C C

FEC_TX_ENpg(11)

FEC_TX_CLKpg(11)

FEC_MDCpg(11)

B B

5.0V

3

2

HDR TH 1X3

3.3V

A A

5

1

J41

R55 0

R54 22

DNP

R57 0

R56 22

DNP

R59 0

R58 22

DNP

R61 0

R60 22

DNP

R63 0

R62 22

DNP

R93 0

R80 22

DNP

FEC_MDIO_CONNpg(5)

FEC_MDC_CONNpg(5)

FEC_RXD3_CONNpg(5)

FEC_RXD2_CONNpg(5)

FEC_RXD1_CONNpg(5)

FEC_RXD0_CONNpg(5)

FEC_RX_DV_CONNpg(5)

FEC_RX_CLK_CONNpg(5)

FEC_TX_CLK_CONNpg(5)

FEC_TX_EN_CONNpg(5)

FEC_TXD0_CONNpg(5)

FEC_TXD1_CONNpg(5)

FEC_TXD2_CONNpg(5)

FEC_TXD3_CONNpg(5)

POWER_MII_CONN

4

GND

FEC_TXD2_PHY pg(8,13)

FEC_TXD2_CONN pg(5)

FEC_TXD1_PHY pg(8,13)

FEC_TXD1_CONN pg(5)

FEC_TXD0_PHY pg(8,13)

FEC_TXD0_CONN pg(5)

FEC_TX_EN_PHY pg(8,13)

FEC_TX_EN_CONN pg(5)

1

2

3

4

5

6

7

8

9

10

RX_ER

11

TX_ER

12

13

14

15

16

17

18

COL

19

CRS

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

SH1

SH2

FEC_TXD3_PHY pg(8,13)

FEC_RXD3pg(11)

FEC_TXD3_CONN pg(5)

FEC_RXD2pg(11)

FEC_RXD1pg(11)

FEC_RXD0pg(11)

FEC_RX_DVpg(11)

FEC_TX_CLK_PHY pg(8,13)

FEC_RX_CLKpg(11)

FEC_TX_CLK_CONN pg(5)

FEC_MDC_PHY pg(8,13)

FEC_MDIOpg(11)

FEC_MDC_CONN pg(5)

J49

5787170-4

3

R81 0

R82 0

DNP

R83 0

R84 0

DNP

R85 0

R86 0

DNP

R87 0

R88 0

DNP

R89 0

R90 0

DNP

R91 0

R92 0

DNP

R95 0

R94 22

DNP

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

Drawing Title:

Drawing Title:

Drawing Title:

Page Title:

Page Title:

Page Title:

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

2

Wednesday, October 12, 2011

FEC_RXD3_PHY pg(8,13)

FEC_RXD3_CONN pg(5)

FEC_RXD2_PHY pg(8,13)

FEC_RXD2_CONN pg(5)

FEC_RXD1_PHY pg(8,13)

FEC_RXD1_CONN pg(5)

FEC_RXD0_PHY pg(8,13)

FEC_RXD0_CONN pg(5)

FEC_RX_DV_PHY pg(8,13)

FEC_RX_DV_CONN pg(5)

FEC_RX_CLK_PHY pg(8,13)

FEC_RX_CLK_CONN pg(5)

FEC_MDIO_PHY pg(8,13)

FEC_MDIO_CONN pg(5)

___ ___

___ ___

___ ___

MPC5604-EVB

MPC5604-EVB

MPC5604-EVB

MII CONNECTOR SECTION

MII CONNECTOR SECTION

MII CONNECTOR SECTION

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

1

X

X

X

5 13

5 13

5 13

5

D D

4

3

2

1

Place CAPS as close to

connector pins as

possible but do NOT fit

caps at board assembly.

C506

3.3V

R507

10.0K

R506

10.0K R505

JCOMPpg(7)

TMSpg(11)

TDI

TDO

TCK

JTAG-RST_B

TDIpg(11)

C C

B B

TDOpg(11)

TCKpg(11)

JTAG-RST_Bpg(7,8,11)

JCOMP

TMS

10.0K

3.3V

R503

10.0K

DNP

47PF

C504

DNP

47PF

GND

JTAG Connector

11 12

13 14

P5

1 2

3 4

7 8

9 10

CON_2X7

65

JTAG INTERFACE

3.3V

(VSS)

(VSS)

(VSS)

(N/C)

TMS

(VSS)

JCOMP

GND

R500

10.0K

R501

10.0K

DNP

A A

X

X

___ ___

___ ___

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

Drawing Title:

Drawing Title:

Drawing Title:

Page Title:

Page Title:

Page Title:

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

5

4

3

2

Wednesday, October 12, 2011

___ ___

MPC5604-EVB

MPC5604-EVB

MPC5604-EVB

DEBUG INTERFACE

DEBUG INTERFACE

DEBUG INTERFACE

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

1

X

6 13

6 13

6 13

5

4

3

2

REMOVE XTAL jumper when driving EXTAL from

Oscillator Module or External Source

1

Power On Reset

D D

KS11R23CQD

1.2V

5.0V

R511

12K

R510

2K

C C

GND

Boot Config

B B

HDR TH 1X3

GND

J47

123

R544

4.7K

C8

0.1UF

SW2

3.3V

1

3

4 2

GND

C7

0.1UF

GND

3.3V

R543

4.7K

MC_RGM_FAB pg(4)

4

3

C5

0.1UF

SW3

KS11R23CQD

9 8

U4

VCC

MR

STM6315RDW13F

1

3

4 2

U6D

74LVC14AD

2

RST

1

VSS

3.3V

R3 10.0K

2

U7

STM6904TGEDS6F

3

V2IN

5

V3IN

VCC

6

V4IN

TRSEL

MR

VSS

4

U6E

11 10

74LVC14AD

3.3V

J44

123

R548

4.7K

RST

JCOMPpg(6)

R547

4.7K

MC_RGM_ABS0 pg(3,4)

7

1

C6

0.1UF

GND

HDR TH 1X3

GND

1

2

U2

3

BAS70

8

U3

2

BAS70

PW_ON_RESET_Bpg(8,11)

3

1

13 12

U6F

74LVC14AD

HDR TH 1X3

GND

3 4

JTAG-RST_B pg(6,8,11)

3.3V

J46

123

R546

4.7K

U6B

74LVC14AD

3.3V

147

U6A

VCC

1 2

GND

74LVC14AD

GND

J4

1

2

3

HDR TH 1X3

GND

U6C

5 6

74LVC14AD

R545

4.7K

MC_RGM_ABS2 pg(4)

R2

1.5K J31

AC

LED RED

D4

GND

R4

AC

1.5K

LED RED

D5

GND

R1

AC

1.5K

LED RED

D3

GND

Clock Circuit

C555

18pF

GND

Note - Internal

Pull-Up on Pin 1

SMA style

Connector

STRAIGHT SMA CONNECTOR ,PLACE NEAR TO SOC

Y2

25MHZ

1 2

C556

18pF

R536 0

GND

HDR TH 1X3

1

2

HDR TH 1X3

Y1

8MHz

4

R538 100

3

J30

1

2

3

GND

J34

OSC-MOD

EXTAL-SMA

EXTAL_J

R534

1.0M

XTAL_J

C554

0.01UF

1

E/D

GND2VCC

OUT

3

CON_1_SMA

2

3

1

4

5

J35

GND

EVB-EXTAL

(MCU Crystal Output)

(MCU Crystal Input)

HDR 1X2 TH

3.3V

1

2

HDR TH 1X3

EXTAL pg(11)

XTAL pg(11)

J32

123

EVB-EXTAL

A A

X

X

___ ___

___ ___

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

Drawing Title:

Drawing Title:

Drawing Title:

Page Title:

Page Title:

Page Title:

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

5

4

3

2

Wednesday, October 12, 2011

___ ___

MPC5604-EVB

MPC5604-EVB

MPC5604-EVB

RESET & CLOCK SECTION

RESET & CLOCK SECTION

RESET & CLOCK SECTION

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

1

X

7 13

7 13

7 13

5

D D

4

3

2

1

Ethernet Section

3.3V

C C

TX Resistors: Place Cose to PI

RX Resistors: Place Close to MCU

FEC_TXD3_PHYpg(5,13)

FEC_TXD2_PHYpg(5,13)

FEC_TXD1_PHYpg(5,13)

FEC_TXD0_PHYpg(5,13)

FEC_TX_EN_PHYpg(5,13)

FEC_TX_CLK_PHYpg(5,13)

FEC_RXD3_PHYpg(5,13)

FEC_RXD2_PHYpg(5,13)

FEC_RXD1_PHYpg(5,13)

FEC_RXD0_PHYpg(5,13)

FEC_RX_DV_PHYpg(5,13)

FEC_RX_ER

FEC_COL

FEC_CRS

B B

PW_ON_RESET_Bpg(7,11)

TP4

TP5

TP3

FEC_RX_CLK_PHYpg(5,13)

FEC_MDC_PHYpg(5,13)

FEC_MDIO_PHYpg(5,13)

JTAG-RST_Bpg(6,7,11)

HDR TH 1X3

J21

3

2

1

1 8

RN3A

3 6

22

RN3C

4 5

RN3D

22

R521 22

R515 22

1 8

22

R16 22

RN2A

22

2 7

RN3B

GND GND

2 7

RN2B

22

1 8

RN4A

22

R527

R526

2.2K

2.2K

J22

C17

33PF

3 6

2 7

RN4B

22

R528

2.2K

HDR 1X2 TH

1

2

QZ1

25MHZ

RN2C

22

3 6

RN4C

22

R525

2.2K

C19

33PF

21

4 5

RN2D

R14 22

4 5

RN4D

22

R524

2.2K

EP_3.3V

C532

R517

1.5K

22

22

R522

R523

2.2K

R13

2.2K

2.2K

0.1UF

R519

1.5K

GND

QZ1_X1

QZ1_X2

R520

R518

2.2K

R516

2.2K

2.2K

C536

+

C23

10UF

0.1UF

U10 10/100 single phy

32

22

34

X1

33

AVDD33

X2

6

TXD3_SNIMODE

5

TXD2

4

TXD1

3

TXD0

2

TXEN

1

TXCLK

46

RXD3_PHYAD3

45

RXD2_PHYAD2

44

RXD1_PHYAD1

43

RXD0_PHYAD1

39

RXDV_MIIMODE

41

RXER_MDIXEN

42

COL_PHYAD0

40

CRS_LEDCFG

38

RXCLK

31

MDC

30

MDIO

29

RESET

7

PWRDN_INT

R514

2.2K

GND GND

AGND_215AGND_1

36

19

R11

R10

2.2K

2.2K

20

RSVDPU221RSVDPU1

IOVDD33_248IOVDD33_1

25MHZ_OUT

dp83848c

LEDACTCOL_ANEN

LEDLINK_AN0

LEDSPEED_AN1

IOGND_247IOGND_135DGND

8

These are 100MHz all lines must be matched and as short as possible

18

RN1A

49.9

PFBOUT

PFBIN1

PFBIN2

RBIAS

TP2

25

17

TDP

16

TDN

14

RDP

13

RDN

28

26

27

23

18

37

24

RSVD512RSVD411RSVD310RSVD29RSVD1

GND

C531

R9

0.1UF

4.7K

GND

C533

0.1UF

EP_PF

C21

0.1UF

C22

+

10UF

RN1B

49.9

2 7

36

RN1C

49.9

RN1D

49.9

4 5

C520

0.1UF

GND

C18

C529

0.1UF

0.1UF

GND

GND GND

ETDP

ETDN

ERDP

ERDN

C20

0.1UF

3.3V

R12

249

3.3V

R15

249

J24

1

TD+

2

TD-

3

CT-T

6

CT-R

7

RD+

8

RD-

9

RLEDA

10

RLEDK

11

LLEDK

12

LLEDA

RJ45-8

SHIELD1

SHIELD2

4

GND

CG1

CG2

GND

To RJ45 Port

CHSGND25CHSGND1

A A

X

X

___ ___

___ ___

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

Drawing Title:

Drawing Title:

Drawing Title:

Page Title:

Page Title:

Page Title:

ETHERNET PHYSICAL INTERFACE AND RJ45

ETHERNET PHYSICAL INTERFACE AND RJ45

ETHERNET PHYSICAL INTERFACE AND RJ45

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

5

4

3

2

Wednesday, October 12, 2011

___ ___

MPC5604-EVB

MPC5604-EVB

MPC5604-EVB

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

1

X

8 13

8 13

8 13

5

D D

CAN interface

C C

4

J11

1

2

J12

3.3V

1

2

GND

HDR 1X2 TH

GND

HDR 1X2 TH

CAN-5V

C516

0.1UF

HDR 1X2 TH

J6

1

1

2

J10

CAN-12V

2

1 2

3 4

GND

C515

1000PF

J14 HDR 1X2 TH

J9

5.0V

P12V

HDR 1X2 TH

CAN0_RXDpg(3)

3.3V

C513

0.1UF

2

1

CANA-TX

CANA-RX

65

3

C511

C512

0.1UF

1000PF

GND

C514

1000PF

5

10

3

U5

7

VI/O

VCC

INH

8

VBAT

14

9

1

4

6

ERR

WAKE

TXD

RXD

STB

EN

TJA1041T

13

CANH

12

CANL

11

R508

SPLIT

GND

2

GND

60.4

CANA-CANH

CANA-CANL

R509

60.4

C510

0.01UF

GND

2

P3

M1

1

6

2

7

3

8

4

9

GND

P6

1

2

3

GND

5

M2

DB9

GNDCAN0_TXDpg(3)

1

B B

A A

X

X

___ ___

___ ___

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

Drawing Title:

Drawing Title:

Drawing Title:

Page Title:

Page Title:

Page Title:

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

5

4

3

2

Wednesday, October 12, 2011

___ ___

MPC5604-EVB

MPC5604-EVB

MPC5604-EVB

CAN PHYSICAL INTERFACE

CAN PHYSICAL INTERFACE

CAN PHYSICAL INTERFACE

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

1

X

9 13

9 13

9 13

5

4

3

2

1

LIN Interface

J7

D D

C C

HDR TH 1X3

3

2

1

J8

HDR TH 1X3

3

2

1

UART_A_TX

UART_A_RX

LIN0_TXD pg(3)

LIN0_RXD pg(3)

J5

1

2

R504 10.0K

HDR 1X2 TH

LINC-RX

LINC-TX

3.3V

U500

1

RXD

2

EN

3

WAKE

TXD4GND

MCZ33661EF

VSUP

INH

LIN

J2

1

C500

1000PF

2

GND

8

7

6

5

GNDGNDGND

Master Mode Pullup Enable

HDR 1X2 TH

D1

2 1

N16966294

GF1A

C501

0.1UF

R502 1.0K

LINC-VSUP

LINC-LIN

P12V

P7

1

4Pin Header

2

3

4

HDR_1X4

GND

J1

1

2

3

LIN Molex Connector

4

CON PLUG 4

GND

SCI Interface

J3

3.3V

B B

UART_A_TX

UART_A_RX

1

C2

0.1UF

C1

0.1UF

2

HDR 1X2 TH

C505

0.1UF

P2

C507

1000PF

GND

U1

19

2

VCC

C1+

4

C1-

5

C2+

6

C2-

13

T1IN

12

T2IN

15

R1OUT

10

R2OUT

1

EN

14

FORCEON

GND

GND

18

INVALID

FORCEOFF

MAX3223

T1OUT

T2OUT

C503

3

V+

0.1UF

17

GND

8

16

R1IN

9

R2IN

3.3V

11

20

7

V-

C502

0.1UF

GND

M1

1

6

2

7

3

8

4

9

5

M2

GND

DB9

GND

GND

A A

X

X

___ ___

___ ___

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

Drawing Title:

Drawing Title:

Drawing Title:

Page Title:

Page Title:

Page Title:

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

5

4

3

2

Wednesday, October 12, 2011

___ ___

MPC5604-EVB

MPC5604-EVB

MPC5604-EVB

LIN & SCI PHYSICAL INTERFACE

LIN & SCI PHYSICAL INTERFACE

LIN & SCI PHYSICAL INTERFACE

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

1

X

10 13

10 13

10 13

5

D D

4

3

C551

C550

0.1UF

C553

0.01UF

C552

1000PF

1000PF

GND GND GND

VDD_HV_ADR

C546

0.1UF

C549

0.01UF

C542

0.1UF

C548

1000PF

0.01UF

C547

C543

1000PF

C545

1000PF

2

VDD_HV

C544

1000PF

C517

0.1UF

C521

0.01UF

C519

1000PF

C518

1000PF

1

J16

HDR 1X2 TH

1

2

VDD_ADR

1

2

HDR 1X2 TH

J23

3.3V

VSSA

HDR 1X2 TH

1.2V

C C

B B

3.3V

R512 10.0K

PW_ON_RESET_Bpg(7,8)

J18

C534

C539

1000PF

C535

0.1UF

1000PF

JTAG-RST_B

PW_ON_RESET_B

NMI_B

0.1UF

C528

0.01UF

C537

C541

C538

1

2

0.1UF

0.1UF

3.3V

C540

0.01UF

GND GND GND

PORT_A0pg(3)

PORT_A1pg(3)

PORT_A2pg(3)

PORT_A3pg(3)

PORT_A4pg(3)

PORT_A5pg(3)

PORT_A6pg(3)

PORT_A7pg(3)

PORT_A8pg(3)

PORT_A9pg(3)

PORT_A10pg(3)

PORT_A11pg(3)

PORT_A12pg(3)

PORT_A13pg(4)

PORT_A14pg(4)

PORT_A15pg(3)

FEC_RXD3pg(5)

FEC_RX_CLKpg(5)

PORT_C2pg(3)

PORT_C3pg(3)

PORT_C4pg(3)

PORT_C5pg(4)

PORT_C6pg(4)

R531 10.0K

JTAG-RST_Bpg(6,7,8)

EXTALpg(7)

XTALpg(7)

TDOpg(6)

TCKpg(6)

TMSpg(6)

TDIpg(6)

NMI_Bpg(13)

C530

C522

1000PF

1000PF

U9

2

A[0]/VID_D[11]/DSPI1_SIN/EIRQ[0]/GPIO[0]/SAI0_D[0]

3

A[1]/VID_D[10]/EIRQ[1]/GPIO[1]/SAI0_D[1]/DSPI1_SOUT

4

A[2]/VID_D[9]/ETIMER0_ETC[5]/EIRQ[2]/GPIO[2]/SAI0_D[2]/DSPI1_SCK/SAI1_D[0]

5

A[3]/VID_D[8]/DSPI2_SIN/EIRQ[3]/GPIO[3]/SAI0_D[3]/SAI2_D[0]

8

A[4]/VID_D[7]/ETIMER0_ETC[3]/EIRQ[4]/GPIO[4]/SAI0_SYNC/DSPI2_SOUT

9

A[5]/VID_CLK/ETIMER0_ETC[4]/EIRQ[5]/GPIO[5]/SAI1_SYNC/DSPI2_SCK/SAI1_D[0]

10

A[6]/VID_D[0]/ETIMER0_ETC[1]/EIRQ[6]/GPIO[6]/SAI2_SYNC/DSPI2_CS0/VID_VSYNC

16

A[7]/VID_D[1]/ETIMER0_ETC[2]/EIRQ[7]/GPIO[7]/SAI0_BCLK/DSPI2_CS1/VID_HREF

24

A[8]/VID_D[6]/LIN1_RX/EIRQ[8]/GPIO[8]/SAI1_BCLK/DSPI1_CS0/SAI2_D[0]

25

A[9]/VID_D[5]/EIRQ[9]/GPIO[9]/SAI2_BCLK/DSPI1_CS1/LIN1_TX

26

A[10]/VID_D[4]/DSPI0_SIN/EIRQ[10]/GPIO[10]/SAI2_MCLK/ETIMER0_ETC[5]

27

A[11]/VID_D[3]/LIN0_RX/RX/GPIO[11]/CAN0_TX/DSPI0_CS1/DSPI1_CS0

28

A[12]/VID_D[2]/CAN0_RX/EIRQ[11]/GPIO[12]/LIN0_TX/DSPI0_CS0/LIN1_TX

29

A[13]/EIRQ[12]/GPIO[13]/IIC1_CLK/FCU0_F[0]/DSPI0_CS0

30

A[14]/DSPI0_SIN/EIRQ[13]/GPIO[14]/IIC1_DATA/FCU0_F[1]/DSPI0_CS1

61

A[15]/DSPI1_SCK/ETIMER0_ETC[0]/EIRQ[18]/GPIO[15]/DSPI0_SCK/CE_RTC_PPS3/SAI1_MCLK

53

C[0]/FEC_RX_D3/GPIO[32]

54

C[1]/FEC_RX_CLK/EIRQ[15]/GPIO[33]

57

C[2]/VID_D[0]/LIN0_RX/EIRQ[16]/GPIO[34]/ETIMER0_ETC[0]/CAN0_TX/CE_RTC_PPS1

60

C[3]/VID_D[1]/CAN0_RX/EIRQ[17]/GPIO[35]/ETIMER0_ETC[1]/LIN0_TX/SAI1_SYNC

62

C[4]/CE_RTC_TRIGGER1/MC_RGM_ABS[0]/EIRQ[19]/GPIO[36]/MC_CGL_MC_CGL/ETIME0_ETC[4]/SAI0_MCLK

63

C[5]/MC_RGM_ABS[2]/EIRQ[20]/GPIO[37]/IIC0_CLK/ETIMER0_ETC[3]/DSPI2_CS2

64

C[6]/MC_RGM_FAB/EIRQ[21]/GPIO[38]/IIC0_DATA/DSPI1_CS0/DSPI2_CS3

15

RESET

14

EXTAL

13

XTAL

43

TDO

42

TCK

41

TMS

40

TDI

31

POR

1

NMI

0.1UF

C523

C526

0.01UF

0.1UF

C525

C524

C527

1000PF

1000PF

VDD_LV

V_BALLAST_IN

7

21

35

58

VDD_LV_PLL0/VDD_LV_COR0_0

VDD_LV_COR0_1/VDD_LV_FLA1

VDD_LV_COR0_2/VDD_LV_FLA0

VSS_LV_PLL0/VSS_LV_COR0_0

6

23

38

47

55

11

VDD_HV_FLA0

VDD_HV_OSC0_REG0

B[2]/ADC0_AN[13]/CE_RTC_TRIGGER1/GPIO[18]/LIN0_TX/CE_RTC_PPS2/CE_RTC_ALARM1

B[3]/ADC0_AN[14]/LIN0_RX/EIRQ[14]/GPIO[19]/ETIMER0_ETC[2]/DSPI0_SOUT/CE_RTC_PPS1

VSS_LV_COR0_2

VSS_LV_COR0_1/VSS_LV_FLA1

59

36

VPP_TEST/TEST

VDD_HV_IO0_2/VDD_HV_FLA1

VDD_HV_ADR0/VDD_HV_ADV0

VDD_HV_S_BALLAST0/VDD_HV_S_BALLAST1

B[0]/ADC0_AN[11]/GPIO[16]/CAN0_TX/CE_RTC_ALARM2/SAI1_BCLK

B[1]/ADC0_AN[12]/CAN0_RX/TRIGGER2/GPIO[17]/SAI1_D[0]

VSS_HV_OSC0_REG0/VSS_HV_IO0_012VSS_HV_ADR0/VSS_HV_ADV022VSS_HV_IO0_2/VSS_HV_FLA1

VSS_HV_FLA0

37

56

V_BALLAST_IN_HDR

J19

1

2

3

HDR TH 1X3

1.2V

B[4]/FEC_RX_DV/GPIO[20]

B[5]/GPIO[21]/FEC_TX_D0/SSCM_DEBUG[0]

B[6]/GPIO[22]/FEC_TX_D1/SSCM_DEBUG[1]

B[7]/GPIO[23]/FEC_TX_D2/SSCM_DEBUG[2]

B[8]/GPIO[24]/FEC_TX_D3/SSCM_DEBUG[3]

B[9]/GPIO[25]/FEC_TX_EN/SSCM_DEBUG[4]

B[10]/GPIO[26]/FEC_MDC/SSCM_DEBUG[5]

B[11]/GPIO[27]/FEC_MDIO/SSCM_DEBUG[6]

B[12]/FEC_TX_CLK/GPIO[28]/SSCM_DEBUG[7]

B[13]/FEC_RX_D0/GPIO[29]

B[14]/FEC_RX_D1/GPIO[30]

B[15]/FEC_RX_D2/GPIO[31]

HDR TH 1X3

GND

17

18

19

20

32

33

34

39

44

45

46

48

49

50

51

52

J20

1

2

3

V_BALLAST_IN_RES

J15

123

HDR TH 1X3

3.3V

R513

2.55

PORT_B0 pg(3,13)

PORT_B1 pg(3,13)

PORT_B2 pg(3,13)

PORT_B3 pg(3,13)

FEC_RX_DV pg(5)

FEC_TXD0 pg(5)

FEC_TXD1 pg(5)

FEC_TXD2 pg(5)

FEC_TXD3 pg(5)

FEC_TX_EN pg(5)

FEC_MDC pg(5)

FEC_MDIO pg(5)

FEC_TX_CLK pg(5)

FEC_RXD0 pg(5)

FEC_RXD1 pg(5)

FEC_RXD2 pg(5)

3.3V

L501

600OHM

A A

5

GND VSSA

3.3V

VDD_ADR

L500600OHM

4

VSSA

GND

X

X

___ ___

___ ___

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

Drawing Title:

Drawing Title:

Drawing Title:

Page Title:

Page Title:

Page Title:

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

3

2

Wednesday, October 12, 2011

___ ___

MPC5604-EVB

MPC5604-EVB

MPC5604-EVB

SOC

SOC

SOC

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

1

X

11 13

11 13

11 13

5

4

3

2

1

HDR TH 1X3

J42

GND

3.3V

User switches

GND

123

R542

10.0K

SW4

1 3

SPST PB NO

42

3.3V

J43

3

2

1

HDR TH 1X3

GND

User LED's

HDR 1X1

JP14

D D

C C

HDR 1X1

HDR 1X1

HDR 1X1

JP15

JP16

JP17

YELLOW LED

1

1

1

1

AC

D11

YELLOW LED

AC

D12

YELLOW LED

AC

D13

YELLOW LED

AC

D14

LED's are SMD (1206) Yellow

RN5A

1 8

49.9

RN5C

3 6

49.9

1 8

RN6A 49.9

3 6

RN6C 49.9

3.3V

RN5B

2 7

49.9

RN5D

4 5

49.9

2 7

RN6B 49.9

4 5

RN6D 49.9

HDR 1X1

JP22

1

C557

0.1UF

B B

HDR 1X1

A A

5

4

R541

10.0K

1

JP23

C558

0.1UF

GND

SW5

1 3

SPST PB NO

42

X

X

___ ___

___ ___

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

Drawing Title:

Drawing Title:

Drawing Title:

Page Title:

Page Title:

Page Title:

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

3

2

Wednesday, October 12, 2011

___ ___

MPC5604-EVB

MPC5604-EVB

MPC5604-EVB

LED & SWITCH SECTION

LED & SWITCH SECTION

LED & SWITCH SECTION

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

1

X

12 13

12 13

12 13

5

4

3

2

1

1 x FEC

D D

GND GND

FEC_TXD3_PHYpg(5,8)

FEC_TXD2_PHYpg(5,8)

FEC_TXD0_PHYpg(5,8)

FEC_TXD1_PHYpg(5,8)

FEC_TX_CLK_PHYpg(5,8) FEC_RX_CLK_PHY pg(5,8)

FEC_TX_EN_PHYpg(5,8)

FEC_MDC_PHYpg(5,8)

FEC_MDIO_PHYpg(5,8)

J33

1 2

3 4

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

HDR_2X13

65

FEC_RXD2_PHY pg(5,8)

FEC_RXD3_PHY pg(5,8)

FEC_RXD1_PHY pg(5,8)

FEC_RXD0_PHY pg(5,8)

FEC_RX_DV_PHY pg(5,8)

ADC0

J38

1 2

PORT_B0pg(3,11)

PORT_B1pg(3,11)

C C

GND

3 4

65

7 8

9 10

HDR 2X5

R533

4.7K

J29

3

NMI_Bpg(11)

2

1

HDR TH 1X3

PORT_B2 pg(3,11)

PORT_B3 pg(3,11)

3.3V

GND

R530

4.7K

B B

A A

5

4

GND

X

X

___ ___

___ ___

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

ICAP Classification: FCP: FIUO: PU BI:

Drawing Title:

Drawing Title:

Drawing Title:

Page Title:

Page Title:

Page Title:

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

Wednesday, October 12, 2011

Date: Sheet of

3

2

Wednesday, October 12, 2011

___ ___

MPC5604-EVB

MPC5604-EVB

MPC5604-EVB

USER I/O CONNECTORS

USER I/O CONNECTORS

USER I/O CONNECTORS

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

SCH-27073 PDF: SPF-27073 A1

1

X

13 13

13 13

13 13

How to Reach Us:

Home Page:

www.freescale.com

Web Support:

http://www.freescale.com/support

USA/Europe or Locations Not Listed:

Freescale Semiconductor, Inc.

Technical Information Center, EL516

2100 East Elliot Road

Tempe, Arizona 85284

+1-800-521-6274 or +1-480-768-2130

www.freescale.com/support

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

www.freescale.com/support

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064

Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or 303-675-2140

Fax: 303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

Information in this document is provided solely to enable system and software

implementers to use Freescale Semiconductor products. There are no express or

implied copyright licenses granted hereunder to design or fabricate any integrated

circuits or integrated circuits based on the information in this document.

Freescale Semiconductor reserves the right to make changes without further notice to

any products herein. Freescale Semiconductor makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale Semiconductor assume any liability arising out of the application or use of any

product or circuit, and specifically disclaims any and all liability, including without

limitation consequential or incidental damages. “Typical” parameters that may be

provided in Freescale Semiconductor data sheets and/or specifications can and do vary

in different applications and actual performance may vary over time. All operating

parameters, including “Typicals”, must be validated for each customer application by

customer’s technical experts. Freescale Semiconductor does not convey any license

under its patent rights nor the rights of others. Freescale Semiconductor products are

not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life,

or for any other application in which the failure of the Freescale Semiconductor product

could create a situation where personal injury or death may occur. Should Buyer

purchase or use Freescale Semiconductor products for any such unintended or

unauthorized application, Buyer shall indemnify and hold Freescale Semiconductor and

its officers, employees, subsidiaries, affiliates, and distributors harmless against all

claims, costs, damages, and expenses, and reasonable attorney fees arising out of,

directly or indirectly, any claim of personal injury or death associated with such

unintended or unauthorized use, even if such claim alleges that Freescale