56F8356/56F8156

Data Sheet

Preliminary Technical Data

56F8300

16-bit Digital Signal Controllers

MC56F8356

Rev. 10.0

12/2005

freescale.com

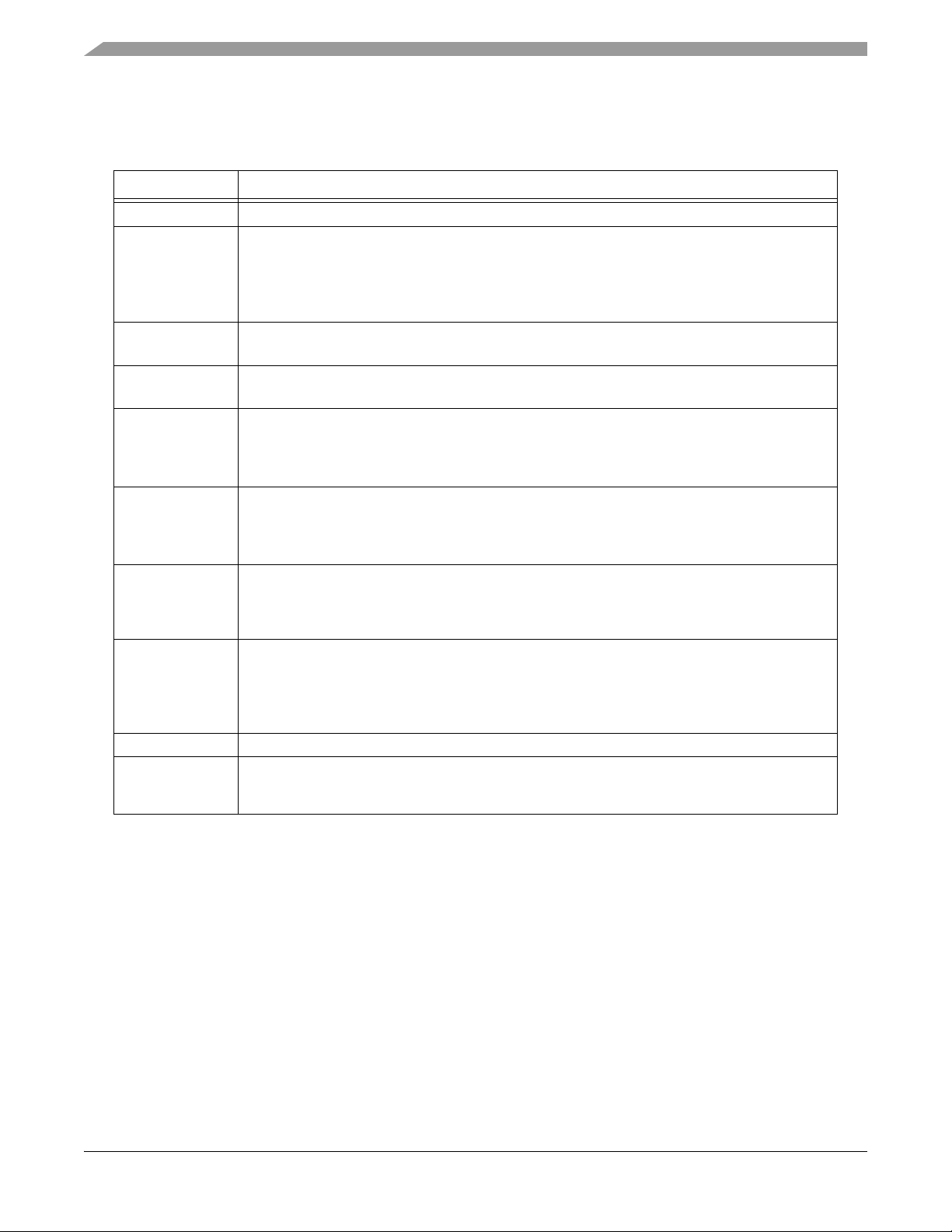

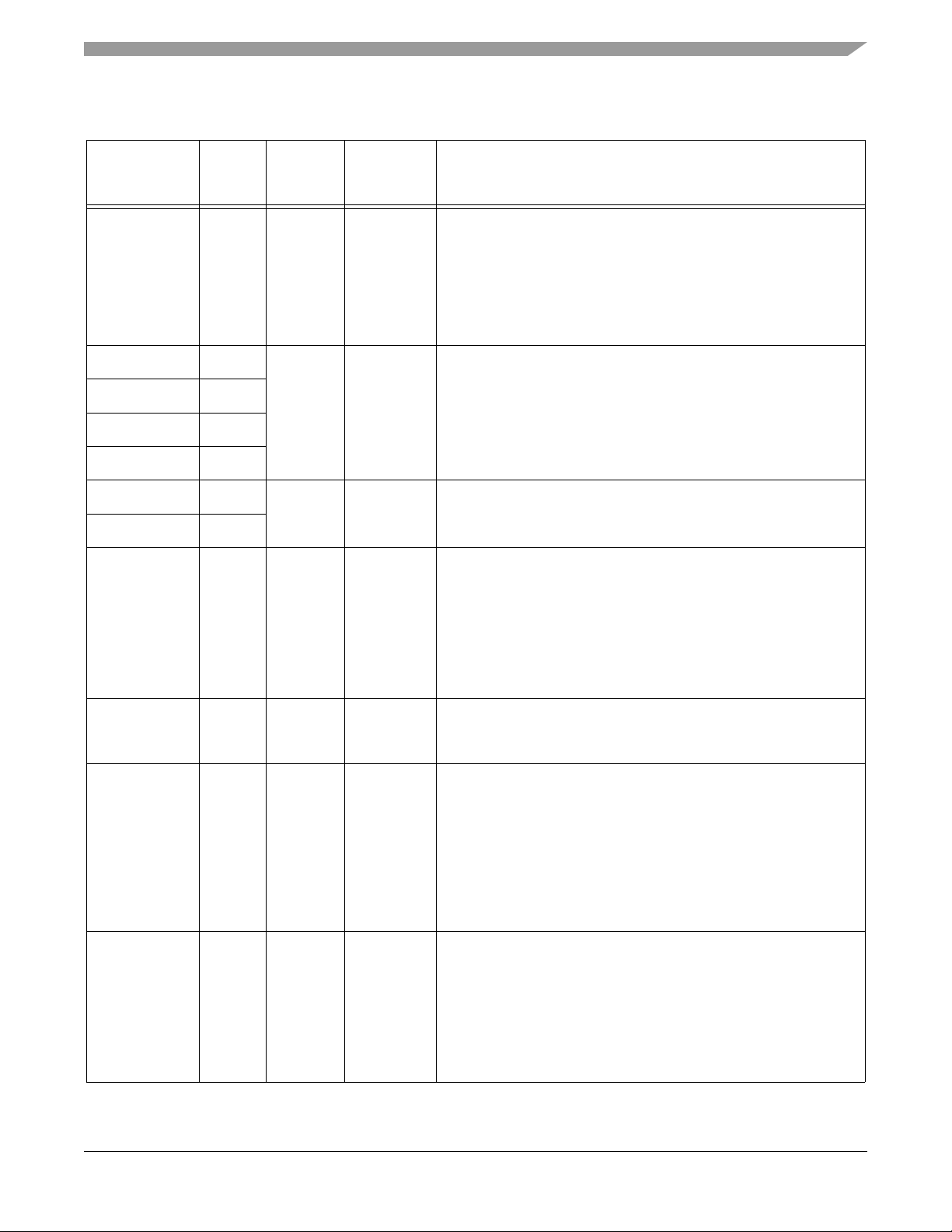

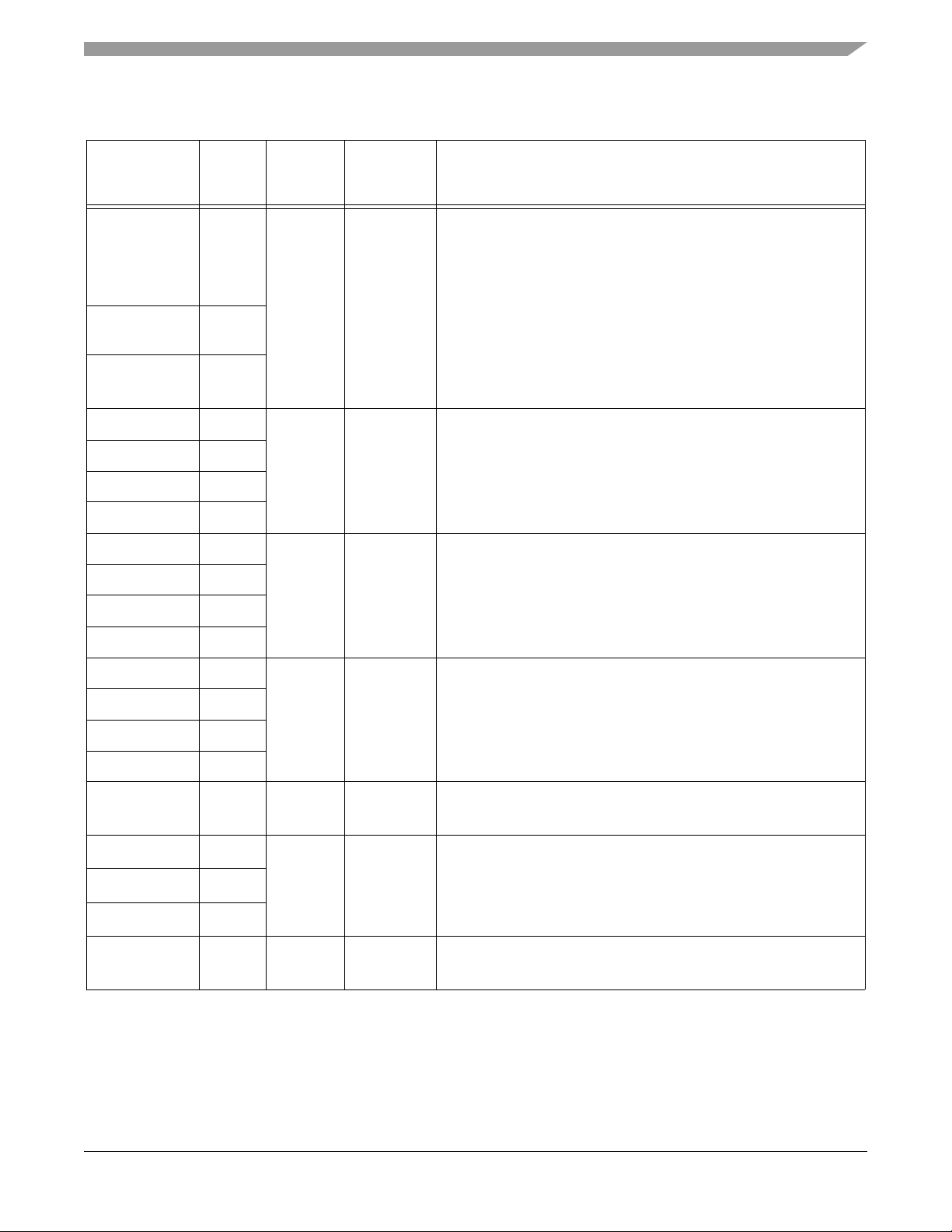

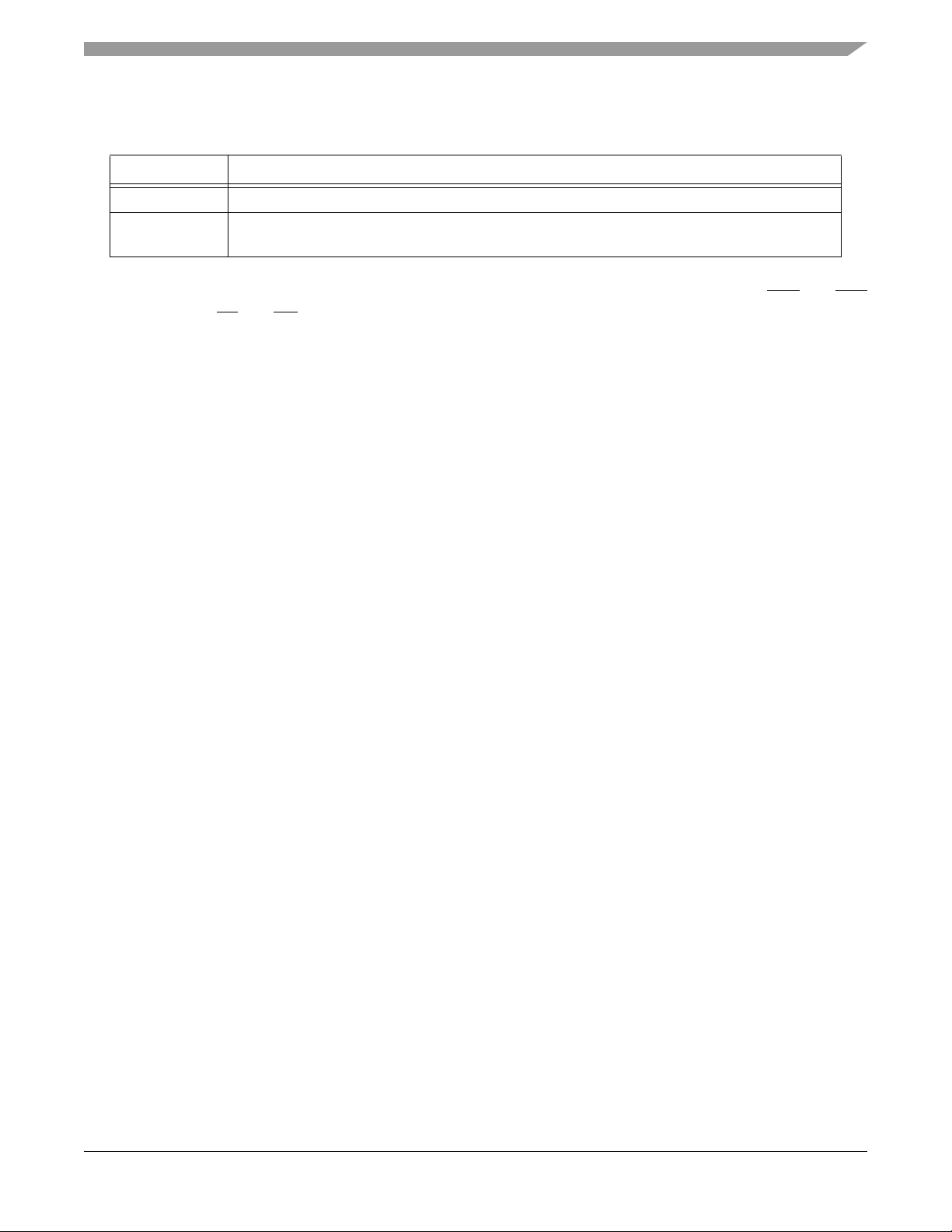

Document Revision History

Version History Description of Change

Rev 1.0

Rev 2.0

Rev 3.0

Rev 4.0

Rev 5.0

Rev 6.0

Rev 7.0 Added 56F8156 information; edited to indicate differences in 56F8356 and 56F8 156. Refor-

Rev 8.0 Added output voltage maximum value and note to clarify in Table 10-1; also removed overall

Rev 9.0 Updated Table 10-24 to reflect new value for maximum Uncalibrated Gain Error

Rev 10.0 Deleted RSTO from Pin Group 2 (listed after Table 10-1). Deleted formula for Max Ambient

Initial Public Release

Added Package Pins to GPIO Table in Part 8 General Purpose Input/Output (GPIO). Added

“Typical Min” values to Table 10-18. Editing grammar, spelling, consistency of language

throughout family. Updated values in Regulator Parameters Table 10-9, External Clock

Operation Timing Requirements Table 10-13, SPI Timing Table 10-18, ADC Parameters

Table 10-24, and IO Loading Coefficients at 10MHz Table 10-25.

Added Part 4.8, added the word “access” to FM Error Interrupt in Table 4-5, documenting only

Typ. numbers for LVI in Table 10-6, updated EMI numbers and writeup in Part 10.8.

Updated numbers in Table 10-7 and Table 10-8 with more recent data, Corrected typo in

Table 10-3 in Pd characteristics.

Replace any reference to Flash Interface Unit with Flash Memory Module; corrected thermal

numbers for 144 LQFP in Table 10-3; removed unneccessary notes in Table 10-12; corrected

temperature range in Table 10-14; added ADC calibration information to Table 10-24 and new

graphs in Figure 10-22

Adding/clarifing notes to Table 4-4 to help clarify independen t program flash blocks and other

Program Flash modes, clarification to Table 1 0-23, corrected Digital Input Current Low (pull-up

enabled) numbers in

Table 10-1.

matted for Freescale look and feel. Updated Temperature Sensor and ADC tables, then

updated balance of electrical tables for consistency throughout family. Clarified I/O power

description in Table 2-2, added note to Table 10-7 and clarified Section 12.3.

life expectancy note, since life expectancy is dependent on customer usage and must be

determined by reliability engineering. Clarified value and unit measure for Maximum allowed

in Table 10-3. Corrected note about average value for Flash Data Retention in Table 10-4.

P

D

Added new RoHS-compliant orderable part numbers in Table 13-1.

Operating Temperature (Automotive) and Max Ambient Operating Temperature (Industrial) in

Table 10-4. Added RoHS-compliance and “pb-free” language to back cover.

Table 10-5. Removed text and Table 10-2; replaced with note to

Please see http://www.freescale.com for the most current Data Sheet revision.

56F8356 Technical Data, Rev. 10.0

2 Freescale Semiconductor

Preliminary

56F8356/56F8156 General Description

Note: Features in italics are NOT available in the 56F8156 device.

• Up to 60 MIPS at 60MHz core frequency

• DSP and MCU functionality in a unified,

C-efficient architecture

• Access up to 1MB of off-chip program and data memory

• Chip Select Logic for glueless interface to ROM and

SRAM

• 256KB of Program Flash

• 4KB of Program RAM

• 8KB of Data Flash

• 16KB of Data RAM

• 16KB of Boot Flash

• Up to two 6-channel PWM modules

• Four 4-channel, 12-bit ADCs

EMI_MODE

6

3

3

6

3

4

4

4

5

4

4

TEMP_SENSE

4

4

1

2

2

PWM Outputs

Current Sense Inputs

or GPIOC

Fault Inputs

PWM Outputs

Current Sense Inputs

or GPIOD

Fault Inputs

AD0

ADCA

AD1

VREF

ADCB

Program Memory

128K x 16 Flash

Data Memory

4K x 16 Flash

8K x 16 RAM

Decoding

Peripherals

AD0

AD1

Quadrature

Decoder 0 or

Quad

Timer A or

GPIOC

Quadrature

Decoder 1 or

Quad

Timer B or

SPI1 or

GPIOC

Quad

Timer C o r

GPIOE

Quad

Timer D or

GPIOE

FlexCAN

PWMA

PWMB

Memory

2K x 16 RAM

8K x 16 Boot

Flash

SPI0 or

GPIOE

4

RSTO

Hardware Looping Unit

SCI1 or

GPIOD

2

EXTBOOT

RESET

Program Controller

and

XDB2

XAB1

XAB2

PAB

PDB

CDBR

CDBW

Peripheral

Device Selects

SCI0 or

GPIOE

2

5

JTAG/

EOnCE

Port

Address

Generation Unit

PAB

PDB

CDBR

CDBW

IPBus Bridge (IPBB)

RW

Control

COP/

Watchdog

IRQA

• Temperature Sensor

• Up to two Quadrature Decoders

• Optional on-chip regulator

• FlexCAN module

• Two Serial Communication Interfaces (SCIs)

• Up to two Serial Peripheral Interfaces (SPIs)

• Up to four general-purpose Quad Timers

• Computer Operating Properly (COP) / Watchdog

• JTAG/Enhanced On-Chip Emulation (OnCE™) for

unobtrusive, real-time debugging

• Up to 62 GPIO lines

• 144-pin LQFP Package

OCR_DIS

V

V

PP

2

56800E Core

IPAB IPWDB IPRDB

Interrupt

Controller

IRQB

V

CAP

DD

47

Digital Reg

16-Bit

Data ALU

16 x 16 + 36 -> 36-Bit MAC

Three 16-bit Input Registers

Four 36-bit Accumulators

System Bus

Control

System

Integration

Module

V

ss

5

Analog Reg

Low Voltage

Supervisor

R/W Control

Clock

resets

P

O

R

CLKO

V

DDA

2

Manipulation

Address Bus

External Data

Bus Switch

External Bus

Interface Unit

Bus Control

PLL

Clock

Generator

CLKMODE

V

SSA

Bit

Unit

External

Switch

O

S

C

6

2

8

7

9

2

XTAL

EXTAL

A0-5 or GPIOA8-13

A6-7 or GPIOE2-3

A8-15 or GPIOA0-7

GPIOB0 or A16

D0-6 or GPIOF9-15

D7-15 or GPIOF0-8

WR

RD

GPIOD0-1 or CS2-3

PS or CS0 or GPIOD8

or CS1 or GPIOD9

DS

56F8356 / 56F8156 Block Diagram

56F8356 Technical Data, Rev. 10.0

Freescale Semiconductor 3

Preliminary

Table of Contents

Part 1: Overview . . . . . . . . . . . . . . . . . . . . . . .5

1.1. 56F8356/56F8156 Features . . . . . . . . . . . . . 5

1.2. Device Description . . . . . . . . . . . . . . . . . . . . 7

1.3. Award-Winning Development Environment . 9

1.4. Architecture Block Diagram . . . . . . . . . . . . 10

1.5. Product Documentation . . . . . . . . . . . . . . . 14

1.6. Data Sheet Conventions . . . . . . . . . . . . . . 14

Part 2: Signal/Connection Descriptions . . .15

2.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2. Signal Pins . . . . . . . . . . . . . . . . . . . . . . . . . 18

Part 3: On-Chip Clock Synthesis (OCCS) . .37

3.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2. External Clock Operation . . . . . . . . . . . . . . 37

3.3. Registers . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Part 4: Memory Map . . . . . . . . . . . . . . . . . . .39

4.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2. Program Map . . . . . . . . . . . . . . . . . . . . . . . 40

4.3. Interrupt Vector Table . . . . . . . . . . . . . . . . . 42

4.4. Data Map . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.5. Flash Memory Map . . . . . . . . . . . . . . . . . . . 46

4.6. EOnCE Memory Map . . . . . . . . . . . . . . . . . 48

4.7. Peripheral Memory Mapped Registers . . . . 49

4.8. Factory Programmed Memory . . . . . . . . . . 76

Part 5: Interrupt Controller (ITCN) . . . . . . . .77

5.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.2. Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.3. Functional Description . . . . . . . . . . . . . . . . 77

5.4. Block Diagram . . . . . . . . . . . . . . . . . . . . . . 79

5.5. Operating Modes . . . . . . . . . . . . . . . . . . . . 79

5.6. Register Descriptions . . . . . . . . . . . . . . . . . 80

5.7. Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Part 6: System Integration Module (SIM) .107

6.1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.2. Features . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.3. Operating Modes . . . . . . . . . . . . . . . . . . . 108

6.4. Operating Mode Register . . . . . . . . . . . . . 108

6.5. Register Descriptions . . . . . . . . . . . . . . . . 109

6.6. Clock Generation Overview . . . . . . . . . . . 122

6.7. Power-Down Modes Overview . . . . . . . . . 123

6.8. Stop and Wait Mode Disable Func tion . . . 123

6.9. Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Part 8: General Purpose Input/Output

(GPIO) . . . . . . . . . . . . . . . . . . . . . . 127

8.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . .127

8.2. Memory Maps . . . . . . . . . . . . . . . . . . . . . .128

8.3. Configuration . . . . . . . . . . . . . . . . . . . . . . .128

Part 9: Joint Test Action Group (JTAG) . 133

9.1. 56F8356 Information . . . . . . . . . . . . . . . . .133

Part 10: Specifications . . . . . . . . . . . . . . . 134

10.1. General Characteristics . . . . . . . . . . . . . .134

10.2. DC Electrical Characteristics . . . . . . . . . .138

10.3. AC Electrical Characteristics . . . . . . . . . .142

10.4. Flash Memory Characteristics . . . . . . . . .142

10.5. External Clock Operation Timing . . . . . . .143

10.6. Phase Locked Loop Timing . . . . . . . . . . .143

10.7. Crystal Oscillator Timing . . . . . . . . . . . . .144

10.8. External Memory Interface Timing . . . . . .144

10.9. Reset, Stop, Wait, Mode Select, and

Interrupt Timing . . . . . . . . . . . . . .147

10.10. Serial Peripheral Interface (SPI) Timing .149

10.11. Quad Timer Timing . . . . . . . . . . . . . . . .153

10.12. Quadrature Decoder Timing . . . . . . . . . .153

10.13. Serial Communication Interface (SCI)

Timing . . . . . . . . . . . . . . . . . . . . .154

10.14. Controller Area Network (CAN) Timing .155

10.15. JTAG Timing . . . . . . . . . . . . . . . . . . . . .155

10.16. Analog-to-Digital Converter (ADC)

Parameters . . . . . . . . . . . . . . . . .157

10.17. Equivalent Circuit for ADC Inputs . . . . . .160

10.18. Power Consumption . . . . . . . . . . . . . . . .160

Part 11: Packaging . . . . . . . . . . . . . . . . . . 162

11.1. 56F8356 Package and Pin-Out

Information . . . . . . . . . . . . . . . . . .162

11.2. 56F8156 Package and Pin-Out

Information . . . . . . . . . . . . . . . . . .165

Part 12: Design Considerations . . . . . . . . 169

12.1. Thermal Design Considerations . . . . . . . .169

12.2. Electrical Design Considerations . . . . . . .170

12.3. Power Distribution and I/O Ring

Implementation . . . . . . . . . . . . . .171

Part 13: Ordering Information . . . . . . . . . 172

Part 7: Security Features . . . . . . . . . . . . . .124

7.1. Operat ion with Security Enabled . . . . . . . 124

7.2. Flash Access Blocking Mechanisms . . . . 125

56F8356 Technical Data, Rev. 10.0

4 Freescale Semiconductor

Preliminary

Part 1 Overview

1.1 56F8356/56F8156 Features

1.1.1 Core

• Efficient 16-bit 56800E family controller engine with dual Harvard architecture

• Up to 60 Million Instructions Per Second (MIPS) at 60MHz core frequency

• Single-cycle 16 × 16-bit parallel Multiplier-Accumulator (MAC)

• Four 36-bit accumulators, including extension bits

• Arithmetic and logic multi-bit shifter

• Parallel instruction set with unique DSP addressing modes

• Hardware DO and REP loops

• Three internal address buses

• Four internal data buses

• Instruction set supports both DSP and controller functions

• Controller style addressing modes and instructions for compact code

• Efficient C compiler and local variable support

• Software subroutine and interrupt stack with depth limited only by memory

• JTAG/EOnCE debug programming interface

56F8356/56F8156 Features

1.1.2 Differences Between Devices

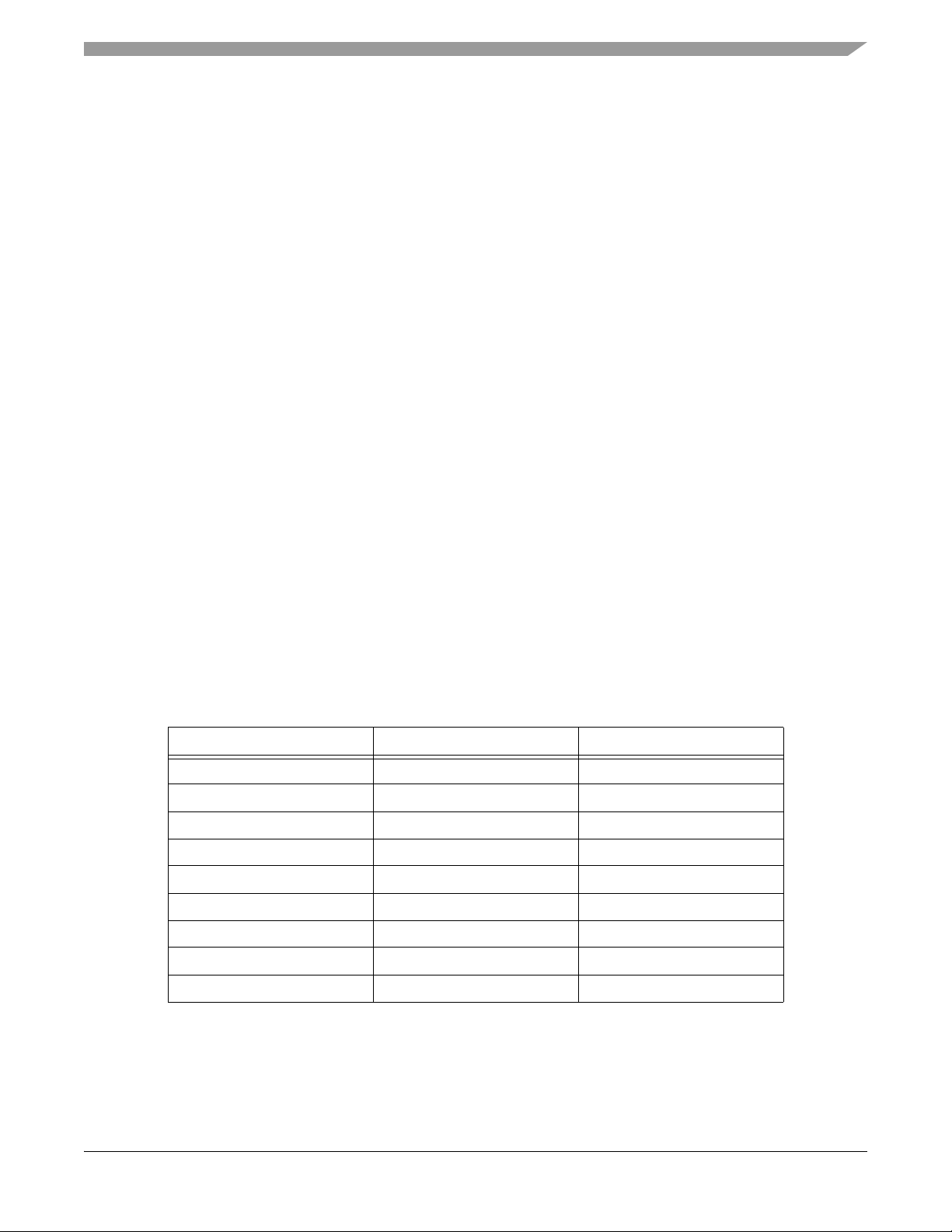

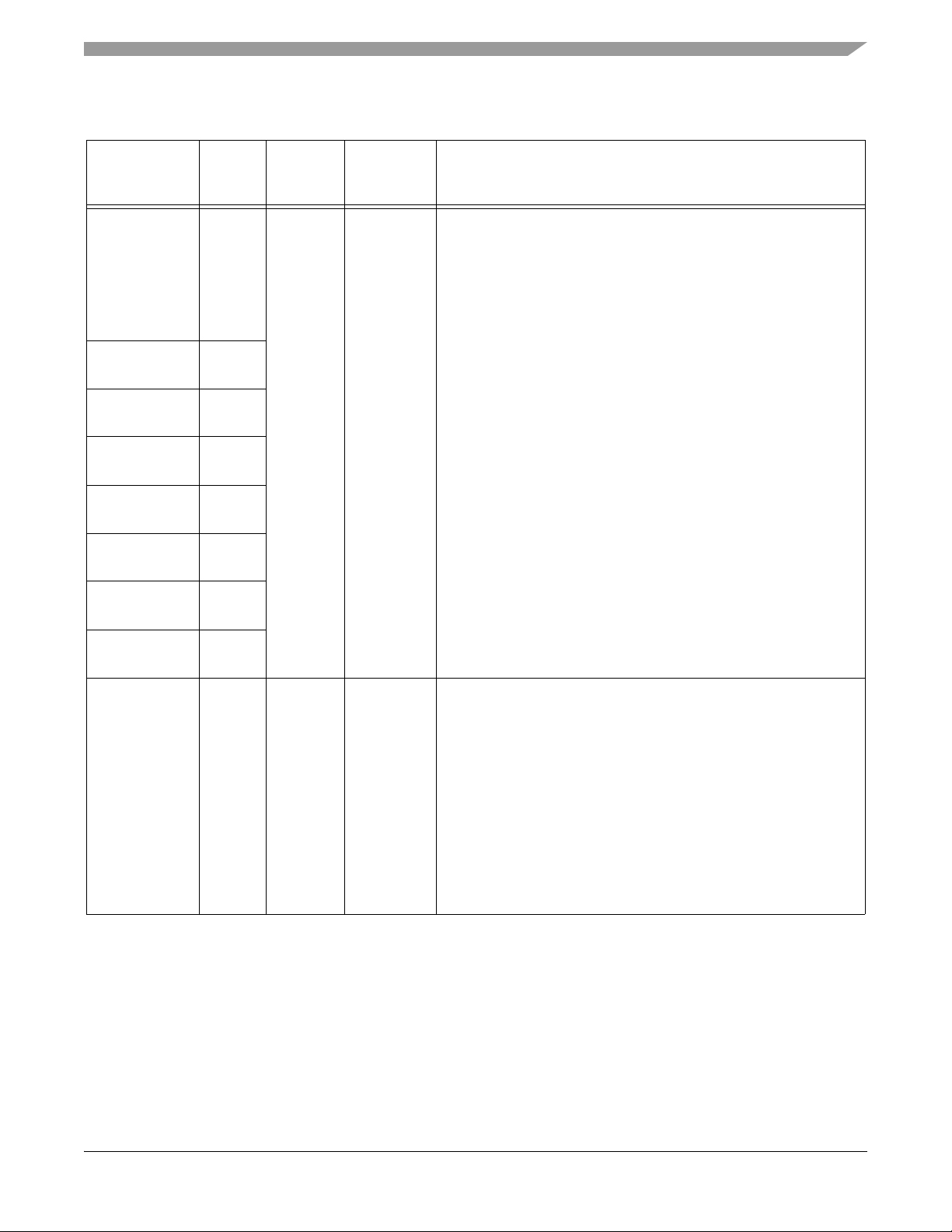

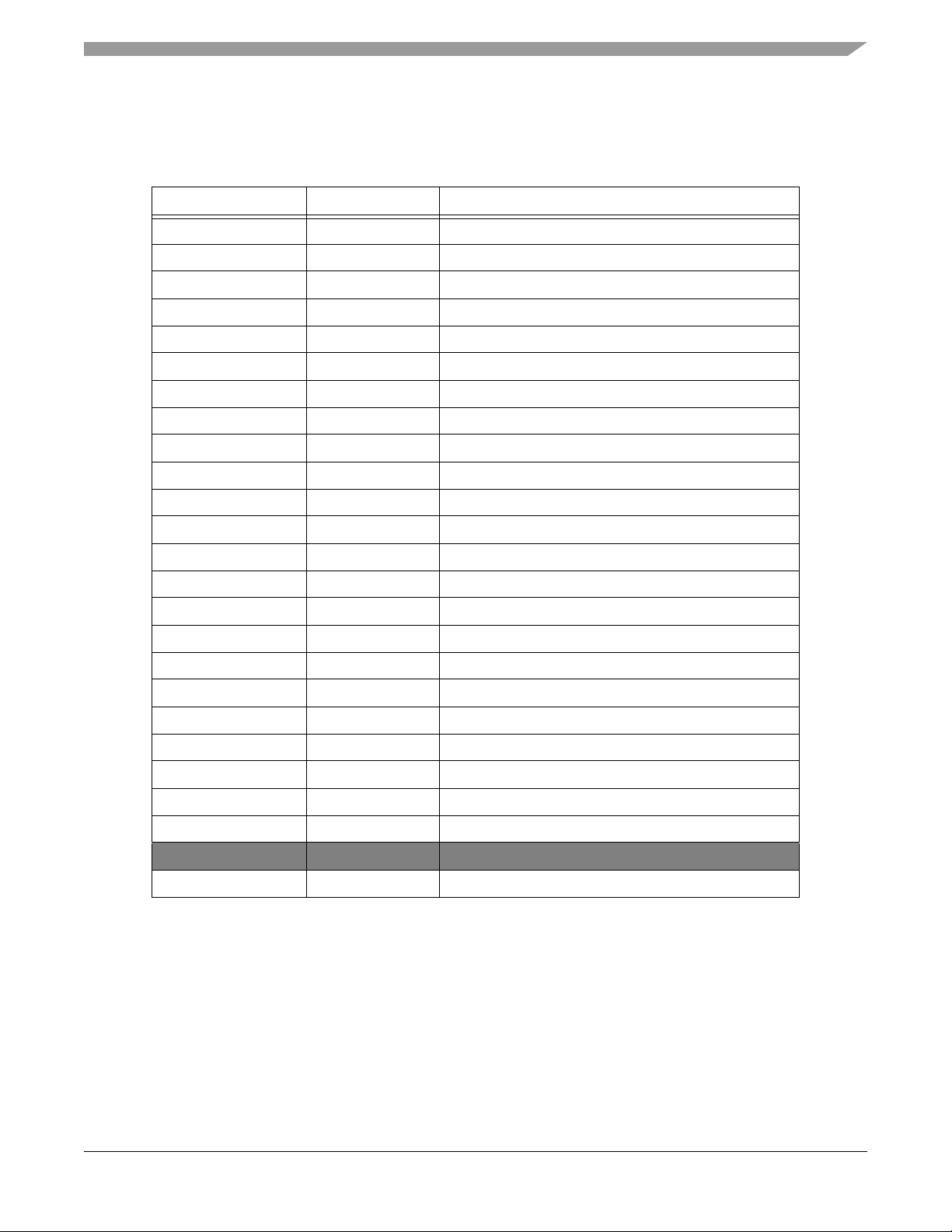

Table 1-1 outlines the key differences between the 56F8356 and 56F8156 devices.

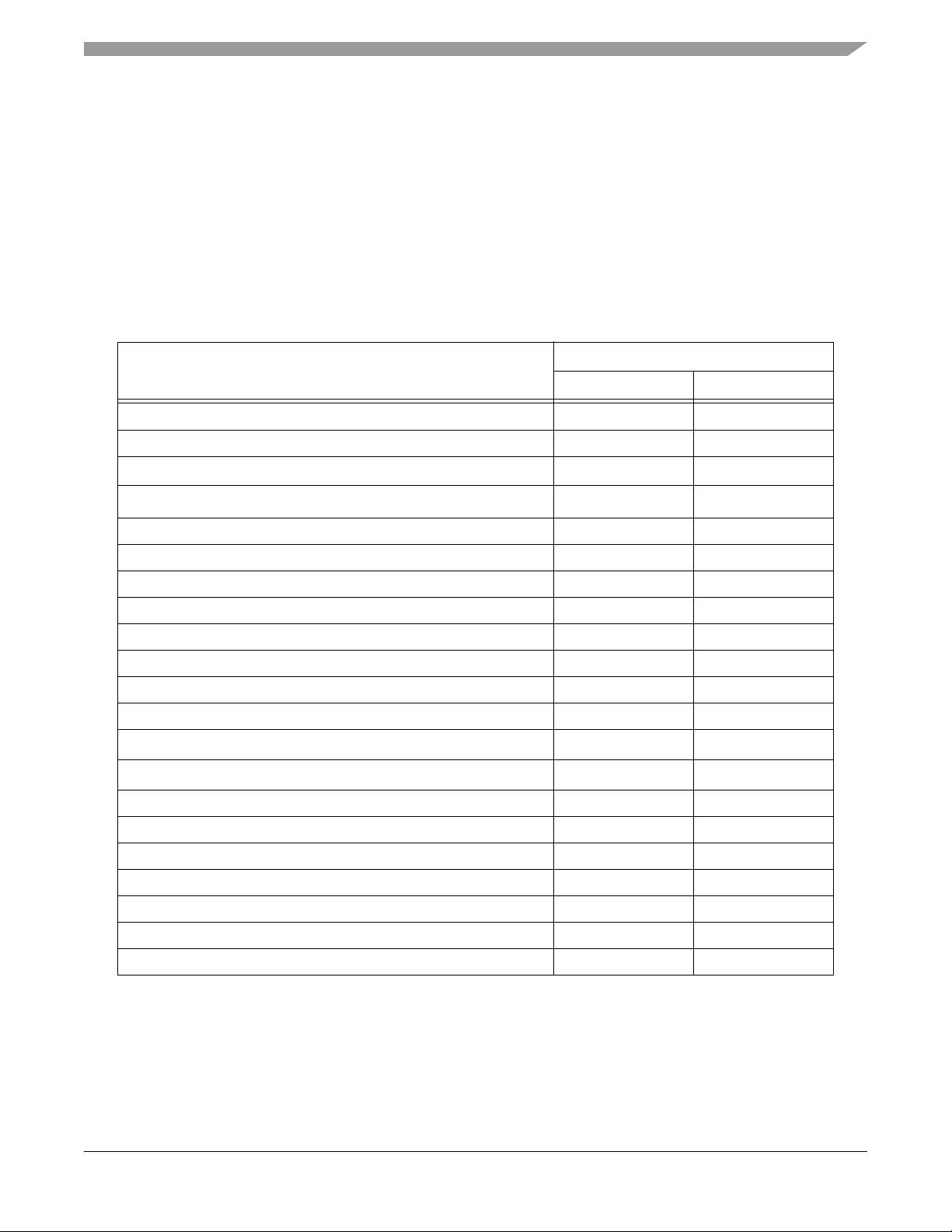

Table 1-1 Device Differences

Feature 56F8356 56F8156

Guaranteed Speed 60MHz/60 MIPS 40MHz/40 MIPS

Program RAM 4KB Not Available

Data Flash 8KB Not Available

PWM 2 x 6 1 x 6

CAN 1 Not Available

Quad Timer 4 2

Quadrature Decoder 2 x 4 1 x 4

Temperature Sensor 1 Not Available

Dedicated GPIO — 5

56F8356 Technical Data, Rev. 10.0

Freescale Semiconductor 5

Preliminary

1.1.3 Memory

Note: Features in italics ae NOT available in the 56F8156 device.

• Harvard architecture permits as many as three simultaneous accesses to program and data memory

• Flash security protection feature

• On-chip memory, including a low-cost, high-volume Flash solution

— 256KB of Program Flash

— 4KB of Program RAM

— 8KB of Data Flash

— 16KB of Data RAM

— 16KB of Boot Flash

• Off-chip memory expansion capabilities programmable for 0 - 30 wait states

— Access up to 1MB of program memory or 1MB of data memory

— Chip select logic for glueless interface to ROM and SRAM

• EEPROM emulation capability

1.1.4 Peripheral Circuits

Note: Features in italics are NOT available in the 56F8156 device.

• Pulse Width Modulator:

— In the 56F8356, two Pulse W idth Modulator mod ules, each with six PWM out puts, three Current Sense

inputs, and three Fault inputs; fault-tolerant design with dead time insertion; supports both

center-aligned and edge-aligned modes

— In the 56F8156, one Pulse Width Modulator module with six PWM outputs, three Current Sense inputs,

and three Fault inputs; fault-tolerant design with dead time insertion; supports both center-aligned and

edge-aligned modes

• Four 12-bit, Analog-to-Digital Converters (ADCs), which support four simultane ous conversions with

quad, 4-pin multiplexed inputs; ADC and PWM modules can be synchronized through Timer C, channels

2 and 3

• Quadrature Decoder:

— In the 56F8356, two four-input Quadrature Decoders or two additional Quad Timers

— In the 56F8156, one four-input Quadrature Decoder, which works in conjunction with Quad Timer A

• Temperature Sensor can be connected, on the board, to any of the ADC inputs to monitor the on-chip

temperature

•Quad Timer:

— In the 56F8356, four dedicated general-purpose Quad Timers totaling three dedicated pins: Timer C

with one pin and Timer D with two pins

— In the 56F8156, two Quad Timers; Timer A and Timer C both work in conjunction with GPIO

• Optional on-chip regulator

• FlexCAN (CAN Version 2.0 B-compliant ) module with 2-pin port for transmit and receive

56F8356 Technical Data, Rev. 10.0

6 Freescale Semiconductor

Preliminary

Device Description

• Two Serial Communication Interfaces (SCIs), each with two pins (or four additional GPIO lines)

• Up to two Serial Peripheral Interfaces (SPIs), both with configurable 4-pin port (or eight additional GPIO

lines)

— In the 56F8356, SPI1 can also be used as Quadrature Decoder 1 or Quad Timer B

— In the 56F8156, SPI1 can alternately be used only as GPIO

• Computer Operating Properly (COP) / Watchdog timer

• Two dedicated external interrupt pins

• 62 General Purpose I/O (GPIO) pins

• External reset input pin for hardware reset

• External reset output pin for system reset

• Integrated low-voltage interrupt module

• JTAG/Enhanced On-Ch ip Emulation (OnCE) for unobtrusive, processor speed-independent, real-time

debugging

• Software-programmable, Phase Lock Loop (PLL)-based frequency synthesizer for the core clock

1.1.5 Energy Information

• Fabricated in high-density CMOS with 5V-tolerant, TTL-compatible digital inputs

• On-board 3.3V down to 2.6V voltage regulator for powering internal logic and memories; can be disabled

• On-chip regulators for digital and analog circuitry to lower cost and reduce noise

• Wait and Stop modes available

• ADC smart power management

• Each peripheral can be individually disabled to save power

1.2 Device Description

The 56F8356 and 56F8156 are members of the 56800E core-based family of controllers. Each combines,

on a single chip, the processing power of a Digital Signal Processor (DSP) and the functionality of a

microcontroller with a flexible set of peripherals to create an extremely cost-effective solution. Because

of its low cost, configuration flexibility, and compact program code, the 56F8356 and 56F8156 are

well-suited for many applications. The devices include many peripherals that are especially useful for

motion control, smart appliances, steppers, encoders, tachometers, limit switches, power supply and

control, automotive control (56F8156 only), engine management, noise suppression, remote utility

metering, industrial control for power, lighting, and automation applications.

The 56800E core is based on a Harvard-style architecture consisting of three execution units operating in

parallel, allowing as many as six operations per instruction cycle. The MCU-style programming model and

optimized instruction set allow straightforward generation of efficient, compact DSP and control code.

The instruction set is also highly efficient for C/C++ Compilers to enable rapid development of optimized

control applications.

The 56F8356 and 56F8156 support program execution from either internal or external memories. Two

data operands can be accessed from the on-chip data RAM per instruction cycle. These devices also

provide two external dedicated interrupt lines and up to 62 General Purpose Input/Output (GPIO) lines,

depending on peripheral configuration.

56F8356 Technical Data, Rev. 10.0

Freescale Semiconductor 7

Preliminary

1.2.1 56F8356 Features

The 56F8356 controller includes 256KB of Program Flash and 8KB of Data Flash (each programmable

through the JTAG port) with 4KB of Program RAM and 16KB of Data RAM. It also supports program

execution from external memory.

A total of 16KB of Boot Flash is incorporated for easy customer inclusion of field-programmable software

routines that can be used to program the main Program and Data Flash memory areas. Both Program and

Data Flash memories can be independently bulk erased or erased in pages. Program Flash page erase size

is 1KB. Boot and Data Flash page erase size is 512 bytes. The Boot Flash memory can also be either bulk

or page erased.

A key application-specific feature of the 56F8356 is the inclusion of two Pulse Width Modulator (PWM)

modules. These modules each incorporate three complementary, individually programmable PWM signal

output pairs (each module is also capable of supporting six independent PWM functions, for a total of 12

PWM outputs) to enhance motor control functionality. Complementary operation permits programmable

dead time insertion, distortion correction via current sensing by software, and separate top and bottom

output polarity control. The up-counter value is programmable to support a continuously variable PWM

frequency. Edge-aligned and center-aligned synchronous pulse width control (0% to 100% modulation) is

supported. The device is capable of controlling most motor types: ACIM (AC Induction Motors); both

BDC and BLDC (Brush and Brushless DC motors); SRM and VRM (Switched and Variable Reluctance

Motors); and stepper motors. The PWMs incorporate fault protection and cycle-by-cycle current limiting

with sufficient output drive capability to directly drive standard optoisolators. A “smoke-inhibit”,

write-once protection feature for key parameters is also included. A patented PWM waveform distortion

correction circuit is also provided. Each PWM is double-buffered and includes interrupt controls to permit

integral reload rates to be programmable from 1 to 16. The PWM modules provide reference outputs to

synchronize the Analog-to-Digital Converters through two channels of Quad Timer C.

The 56F8356 incorporates two Quadrature Decoders capable of capturing all four transitions on the

two-phase inputs, permitting generation of a number proportional to actual position. Speed computation

capabilities accommodate both fast- and slow-moving shafts. An integrated watchdog timer in the

Quadrature Decoder can be programmed with a time-out value to alert when no shaft motion is detected.

Each input is filtered to ensure only true transitions are recorded.

This controller also provides a full set of standard programmable peripherals that include two Serial

Communications Interfaces (SCIs); two Serial Peripheral Interfaces (SPIs); and four Quad Timers. Any of

these interfaces can be used as General Purpose Input/Outputs (GPIOs) if that function is not required. A

Flex Controller Area Network (FlexCAN) interface (CAN Version 2.0 B-compliant) and an internal

interrupt controller are a part of the 56F8356.

1.2.2 56F8156 Features

The 56F8156 controller includes 256KB of Program Flash, programmable through the JTAG port, with

16KB of Data RAM. It also supports program execution from external memory.

A total of 16KB of Boot Flash is incorporated for easy customer inclusion of field-programmable software

routines that can be used to program the main Program Flash memory areas, which can be independently

bulk erased or erased in pages. Program Flash page erase size is 1KB. Boot Flash page erase size is 512

bytes. and the Boot Flash memory can also be either bulk or page erased.

56F8356 Technical Data, Rev. 10.0

8 Freescale Semiconductor

Preliminary

Award-Winning Development Environment

A key application-specific feature of the 56F8156 is the inclusion of one Pulse Width Modulator (PWM)

module. This module incorporates three complementary, individually programmable PWM signal output

pairs and can also support six independent PWM functions to enhance motor control functionality.

Complementary operation permits programmable dead time insertion, distortion correction via current

sensing by software, and separate top and bottom output polarity control. The up-counter value is

programmable to support a continuously variable PWM frequency. Edge-aligned and center-aligned

synchronous pulse width control (0% to 100% modulation) is supported. The device is capable of

controlling most motor types: ACIM (AC Induction Motors); both BDC and BLDC (Brush and Brushless

DC motors); SRM and VRM (Switched and Variable Reluctance Motors); and stepper motors. The PWM

incorporates fault protection and cycle-by-cycle current limiting with sufficient output drive capability to

directly drive standard optoisolators. A “smoke-inhibit”, write-once protection feature for key parameters

is also included. A patented PWM waveform distortion correction circuit is also provided. Each PWM is

double-buffered and includes interrupt controls to permit integral reload rates to be programmable from 1

to 16. The PWM module provides reference outputs to synchronize the Analog-to-Digital Converters

through two channels of Quad Timer C.

The 56F8156 incorporates a Quadrature Decoder capable of capturing all four transitions on the two-phase

inputs, permitting generation of a number proportional to actual position. Speed computation capabilities

accommodate both fast- and slow-moving shafts. An integrated watchdog timer in the Quadrature Decoder

can be programmed with a time-out value to alert when no shaft motion is detected. Each input is filtered

to ensure only true transitions are recorded.

This controller also provides a full set of standard programmable peripherals that include two Serial

Communications Interfaces (SCIs); two Serial Peripheral Interfaces (SPIs); and two Quad Timers. Any of

these interfaces can be used as General Purpose Input/Outputs (GPIOs) if that function is not required. An

internal interrupt controller are a part of the 56F8156.

1.3 Award-Winning Development Environment

Processor ExpertTM (PE) provides a Rapid Application Design (RAD) tool that combines easy-to-use

component-based software application creation with an expert knowledge system.

The CodeWarrior Integrated Development Environment is a sophisticated tool for code navigation,

compiling, and debugging. A complete set of evaluation modules (EVMs) and development system cards

will support concurrent engineering. Together, PE, CodeWarrior and EVMs create a complete, scalable

tools solution for easy, fast, and efficient development.

56F8356 Technical Data, Rev. 10.0

Freescale Semiconductor 9

Preliminary

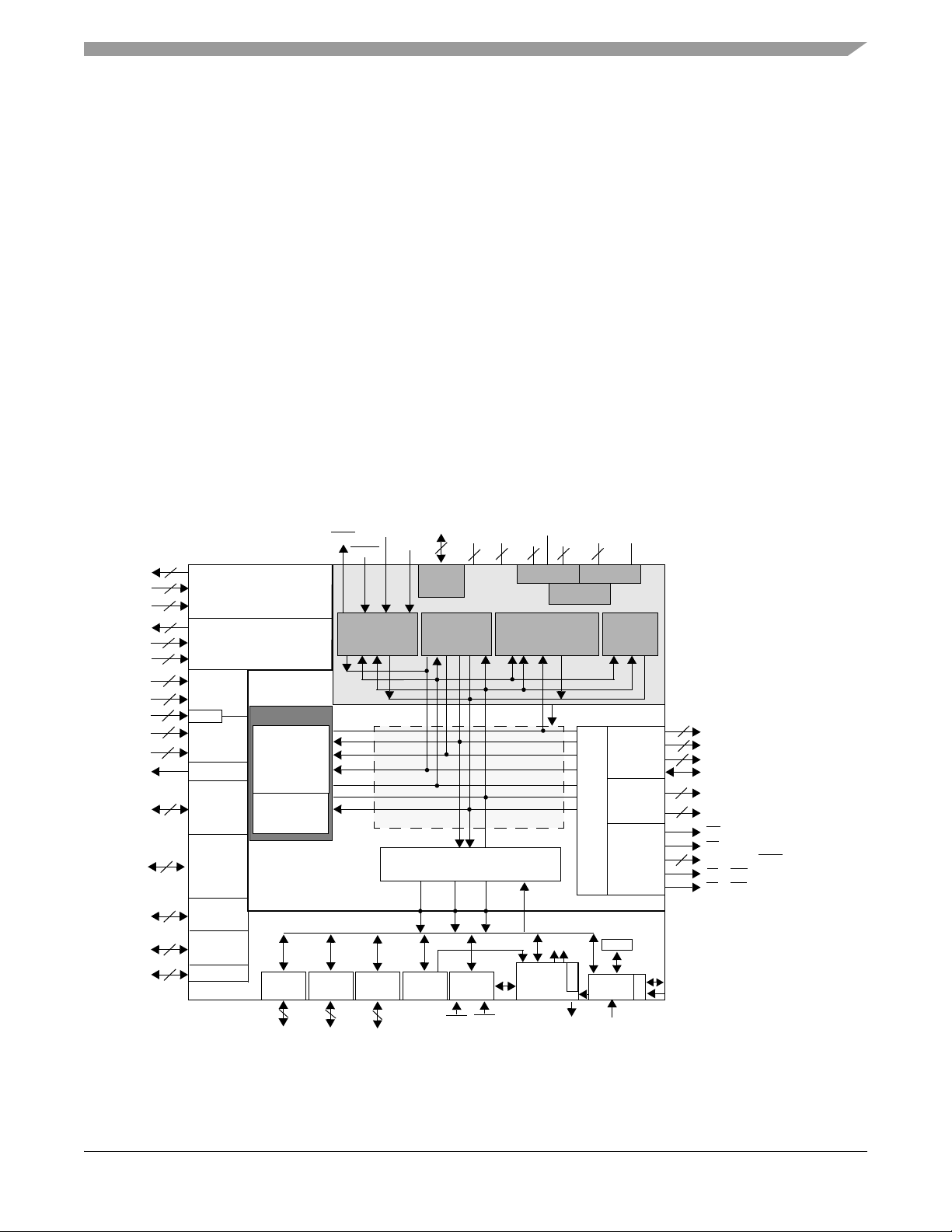

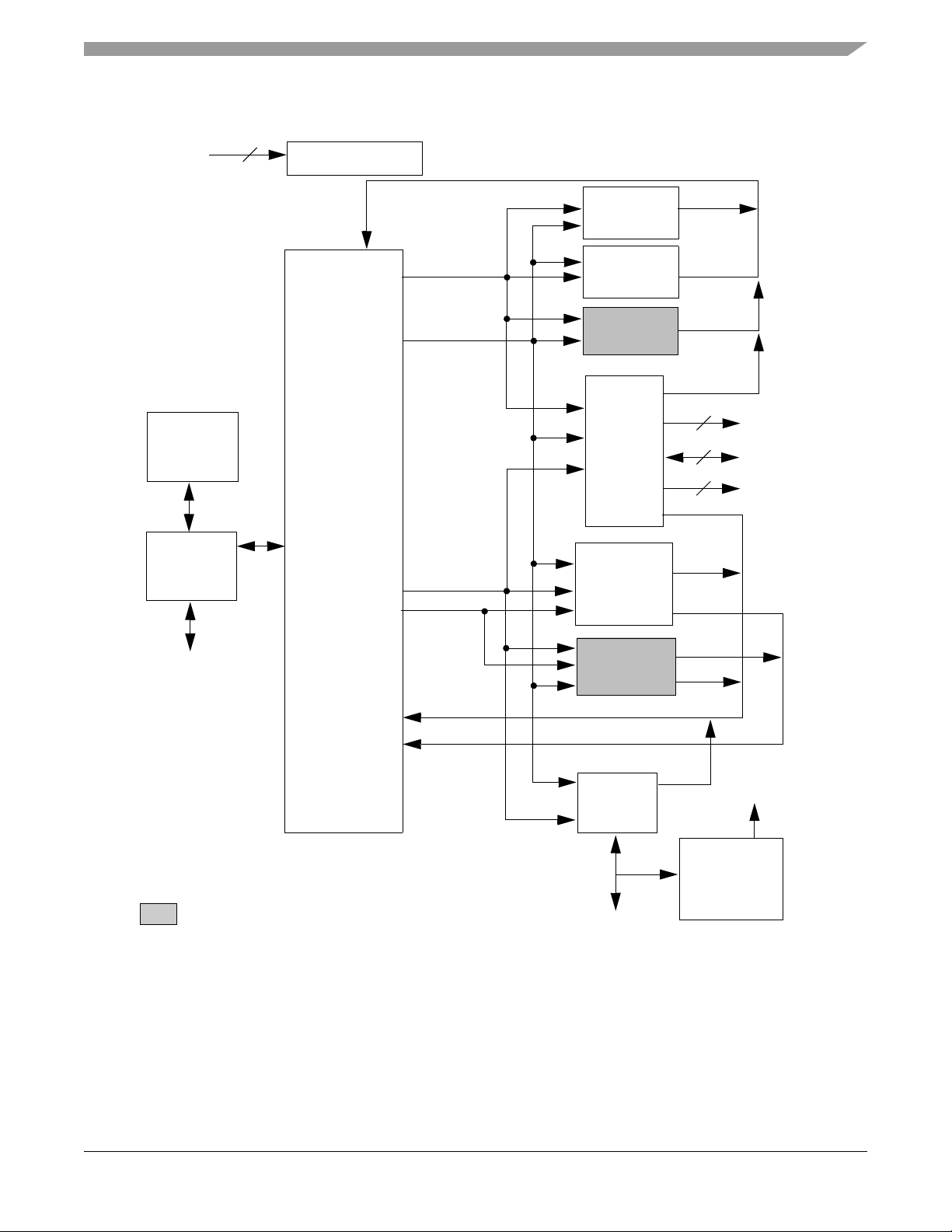

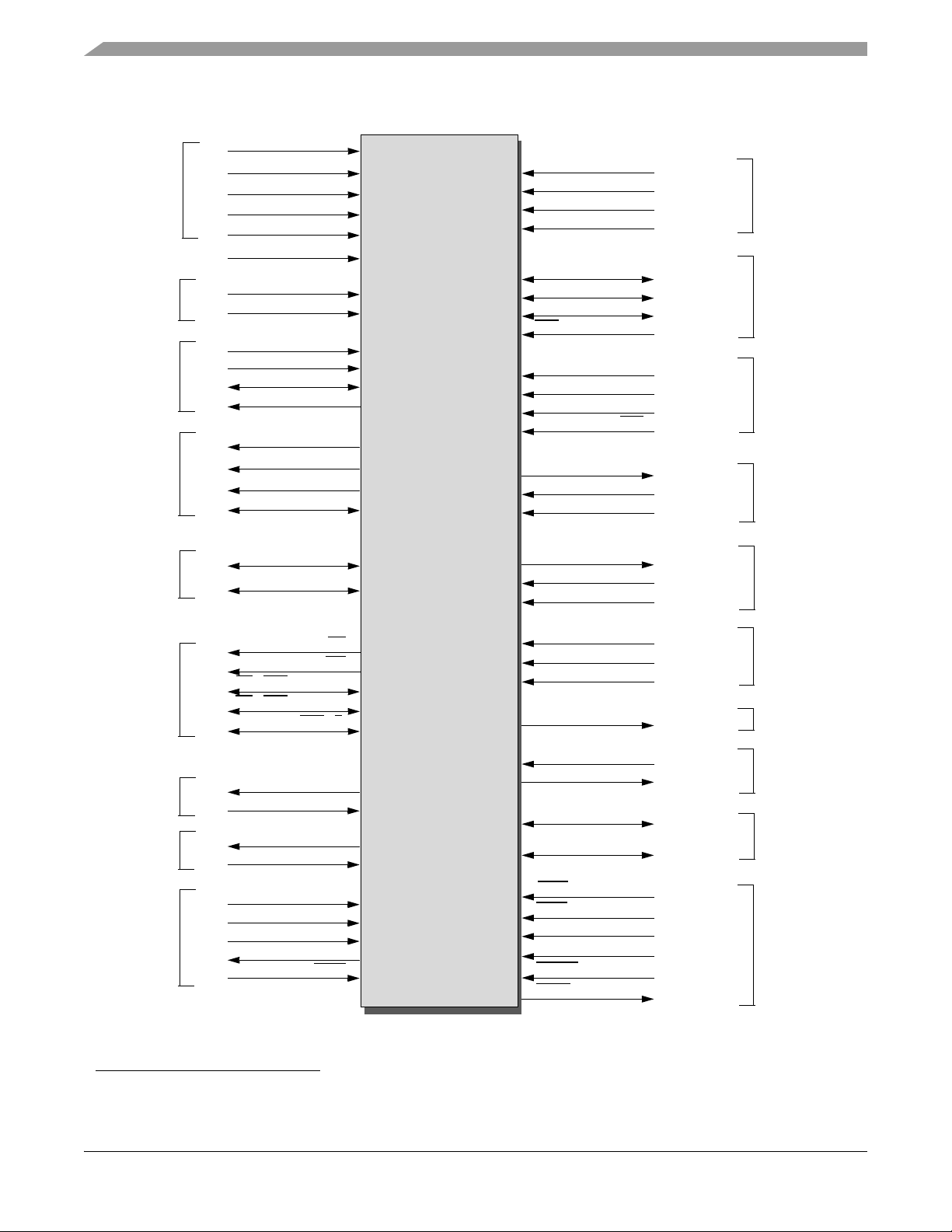

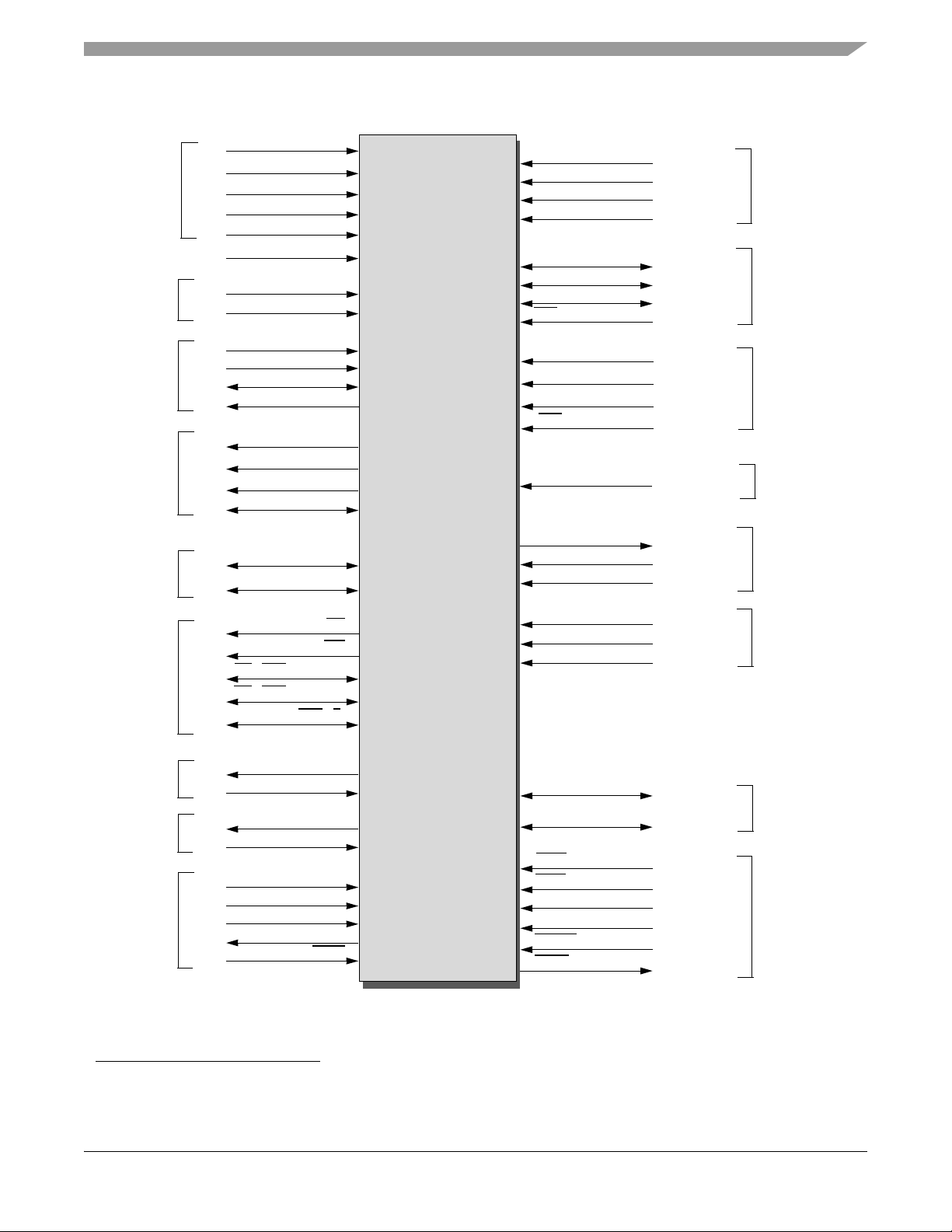

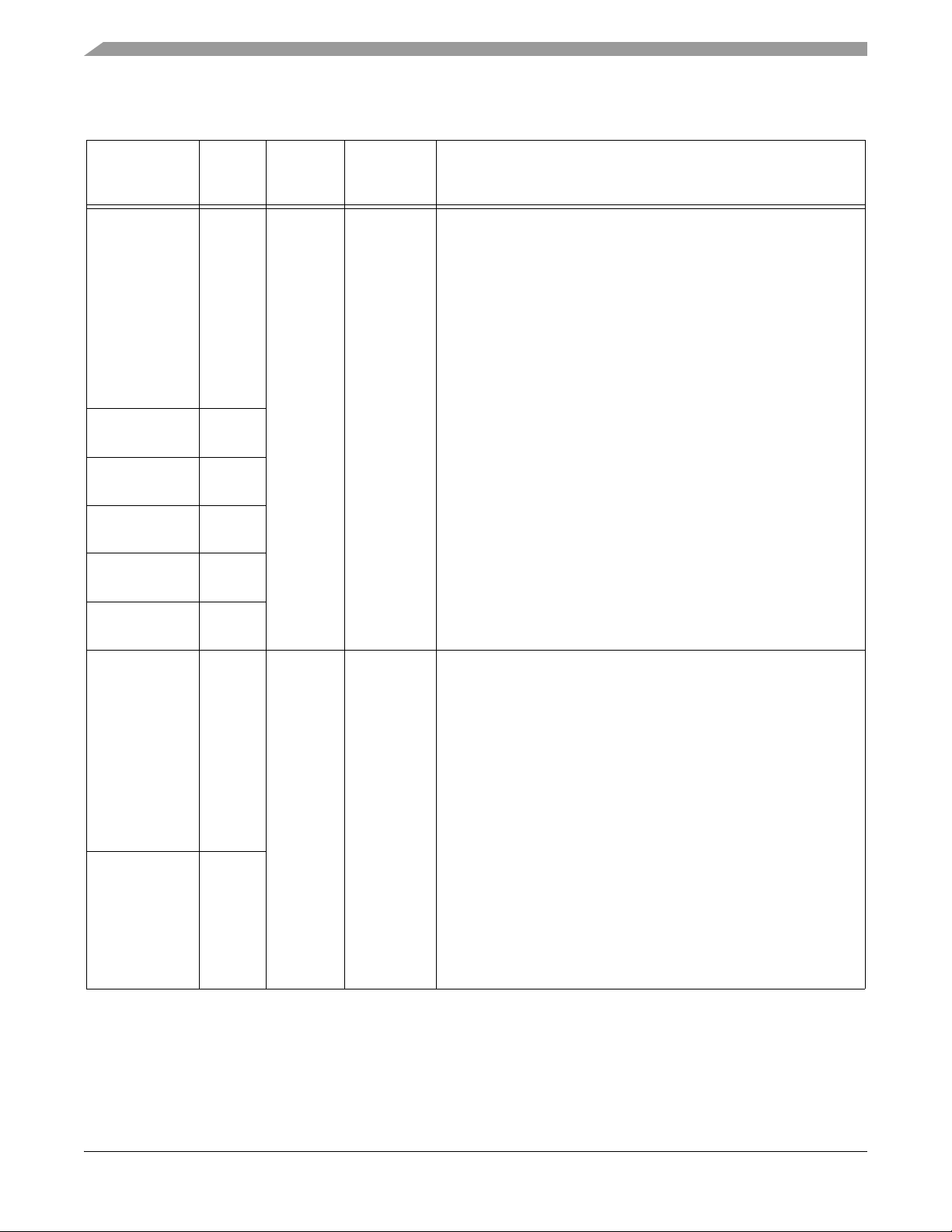

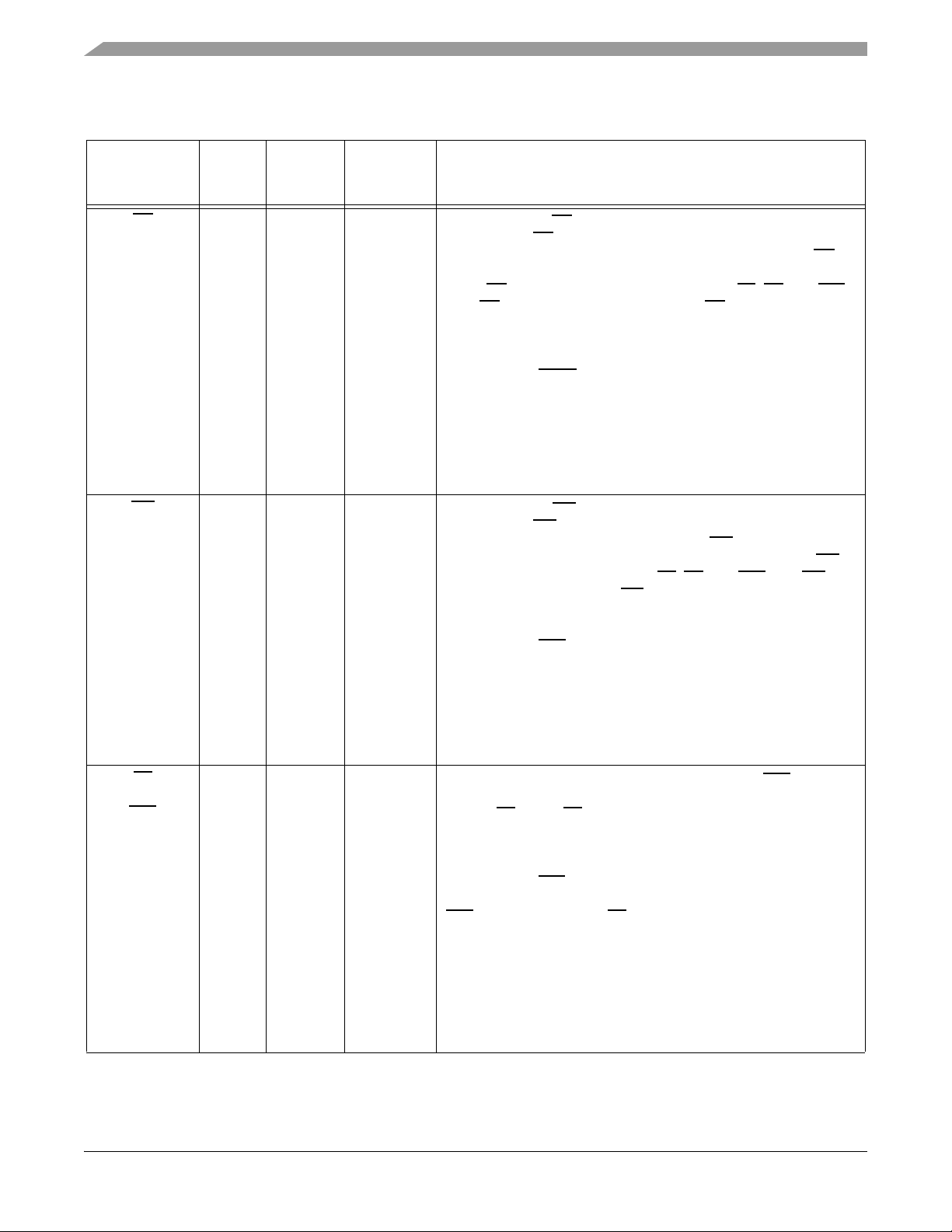

1.4 Architecture Block Diagram

Note: Features in italics are NOT available in the 56F8156 device and are shaded in the following figures.

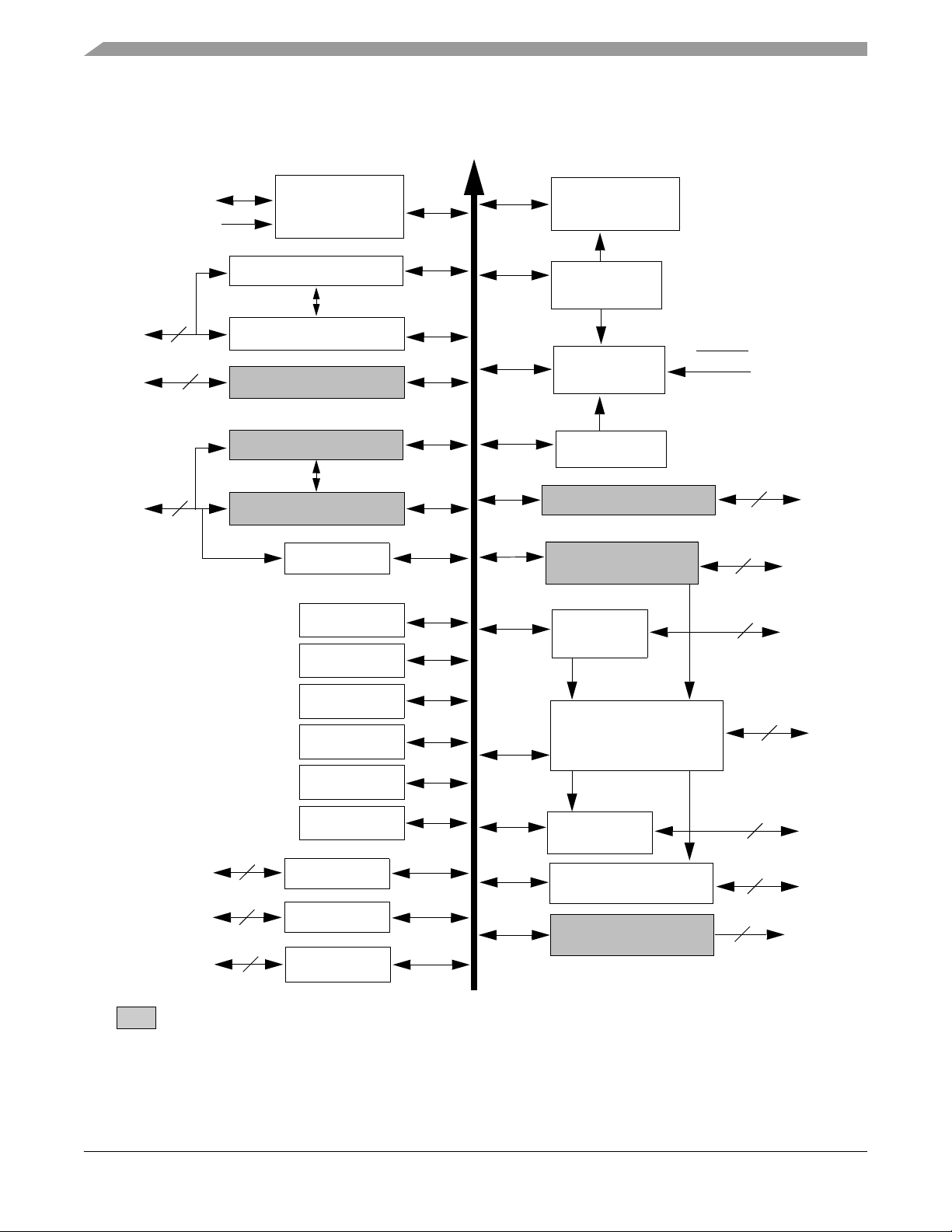

The 56F8356/56F8156 architecture is shown in Figure 1-1 and Figure 1-2. Figure 1-1 illustrates how the

56800E system buses communicate with internal memories, the external memory interface and the IPBus

Bridge. Table 1-2 lists the internal buses in the 56800E architecture and provides a brief description of

their function. Figure 1-2 shows the peripherals and control blocks connected to the IPBus Bridge. The

figures do not show the on-board regulator and power and ground signals. They also do not show the

multiplexing between peripherals or the dedicated GPIOs. Please see Part 2, Signal/Connection

Descriptions, to see which signals are multiplexed with those of other peripherals.

Also shown in Figure 1-2 are connections between the PWM, Timer C and ADC blocks. These

connections allow the PWM and/or Timer C to control the timing of the start of ADC conversions. The

Timer C channel indicated can generate periodic start (SYNC) signals to the ADC to start its conversions.

In another operating mode, the PWM load interrupt (SYNC output) signal is routed internally to the Timer

C input channel as indicated. The timer can then be used to introduce a controllable delay before

generating its output signal. The timer output then triggers the ADC. To fully understand this interaction,

please see the 56F8300 Peripheral User Manual for clarification on the operation of all three of these

peripherals.

56F8356 Technical Data, Rev. 10.0

10 Freescale Semiconductor

Preliminary

Architecture Block Diagram

CHIP

TAP

Controller

TAP

Linking

5

JTAG / EOnCE

pdb_m[15:0]

pab[20:0]

cdbw[31:0]

Boot

Flash

Program

Flash

Program

RAM

56800E

xab1[23:0]

xab2[23:0]

EMI

Data RAM

17

16

6

Address

Data

Control

External

JTAG

Port

cdbr_m[31:0]

xdb2_m[15:0]

Data Flash

IPBus

To Flash

Control Logic

Bridge

Flash

Module

NOT available on the 56F8156 device.

IPBus

Figure 1-1 System Bus Interfaces

Note: Flash memories are encapsulated within the Flash Module(FM). Flash control is accomplished by the

I/O to the FM over the peripheral bus, while reads and writes are completed between the core and the

Flash memories.

Note: The primary data RAM port is 32 bits wide. Other data ports are 16 bits.

56F8356 Technical Data, Rev. 10.0

Freescale Semiconductor 11

Preliminary

To/From IPBus Bridge

CLKGEN

(OSC/PLL)

Interrupt

Controller

Low Voltage Interrupt

Timer A

POR & LVI

4

2

Quadrature Decoder 0

Timer D

Timer B

4

Quadrature Decoder 1

SPI 1

GPIOA

System POR

SIM

COP Reset

COP

FlexCAN

PWMA

PWMB

RESET

2

12

SYNC Output

13

GPIOB

GPIOC

GPIOD

GPIOE

GPIOF

4

2

2

SPI0

SCI0

SCI1

NOT available on the 56F8156 device.

Figure 1-2 Peripheral Subsystem

IPBus

SYNC Output

ch3i

Timer C

ch3o

ch2i

1

ch2o

8

ADCB

, V

1

REFP

8

, V

REFMID

ADCA

TEMP_SENSE

Note: ADCA and ADCB use the same voltage

reference circuit with V

, and V

V

REFN

REFLO

REFH

pins.

,

56F8356 Technical Data, Rev. 10.0

12 Freescale Semiconductor

Preliminary

Architecture Block Diagram

Table 1-2 Bus Signal Names

Name Function

Program Memory Interface

pdb_m[15:0] Program data bus for instruction word fetches or read operations.

cdbw[15:0] Primary core data bus used for program memory writes. (Only these 16 bits of the cdbw[31:0] bus

are used for writes to program memory.)

pab[20:0] Program memory address bus. Data is returned on pdb_m bus.

Primary Data Memory Interface Bus

cdbr_m[31:0] Pri mar y core data bus for memory reads. Addressed via xab1 bus.

cdbw[31:0] Primary core data bus for memory writes. Addressed via xab1 bus.

xab1[23:0]

Primary data address bus. Capable of addressing bytes

on cdbw and returned on cdbr_m. Also used to access memory-mapped I/O.

Secondary Data Memory Interface

xdb2_m[15:0] Secondary data bus used for secondary data address bus xab2 in the dual memory reads.

xab2[23:0] Secondary data address bus used for the second of two simultaneous accesses. Capable of

addressing only words. Data is returned on xdb2_m.

Peripheral Interface Bus

IPBus [15:0] Peripheral bus accesses all on-chip peripherals registers. This bus operates at the same clock rate

as the Primary Data Memory and therefore generates no delays when accessing the processor.

Write data is obtained from cdbw. Read data is provided to cdbr_m.

1. Byte accesses can only occur in the bottom half of the memory address space. The MSB of the address will be forced

to 0.

1

, words, and long data types. Data is written

56F8356 Technical Data, Rev. 10.0

Freescale Semiconductor 13

Preliminary

1.5 Product Documentation

The documents in Table 1-3 are required for a complete description and proper design with the

56F8356/56F8156 devices. Documentation is available from local Freescale distributors, Freescale

semiconductor sales offices, Freescale Literature Distribution Centers, or online at

http://www.freescale.com.

Table 1-3 Chip Documentation

Topic Description Order Number

DSP56800E

Reference Manual

56F8300 Peripheral

User Manual

56F8300 SCI/CAN

Bootloader User

Manual

56F8356/56F8156

Technical Data Sheet

Errata Details any chip issues that might be present MC56F8356E

Detailed description of the 56800E family architecture,

and 16-bit controller core processor and the instruction

set

Detailed description of peripherals of the 56F8300

devices

Detailed description of the SCI/CAN Bootloaders

56F8300 family of devices

Electrical and timing specifications, pin descriptions,

and package descriptions (this document)

DSP56800ERM

MC56F8300UM

MC56F83xxBLUM

MC56F8356

MC56F8156E

1.6 Data Sheet Conventions

This data sheet uses the following conventions:

OVERBAR

“asserted” A high true (active high) signal is high or a low true (active low) signal is low.

This is used to indicate a signal that is active when pulled low. For example, the RESET pin is

active when low.

“deasserted” A high true (active high) signal is low or a low true (active low) signal is high.

Examples: Signal/Symbol Logic State Signal State

PIN True Asserted VIL/V

PIN False Deasserted VIH/V

PIN True Asserted VIH/V

PIN False Deasserted VIL/V

1. Values for VIL, VOL, VIH, and VOH are defined by individual product specifications.

56F8356 Technical Data, Rev. 10.0

14 Freescale Semiconductor

Voltage

1

OL

OH

OH

OL

Preliminary

Introduction

Part 2 Signal/Connection Descriptions

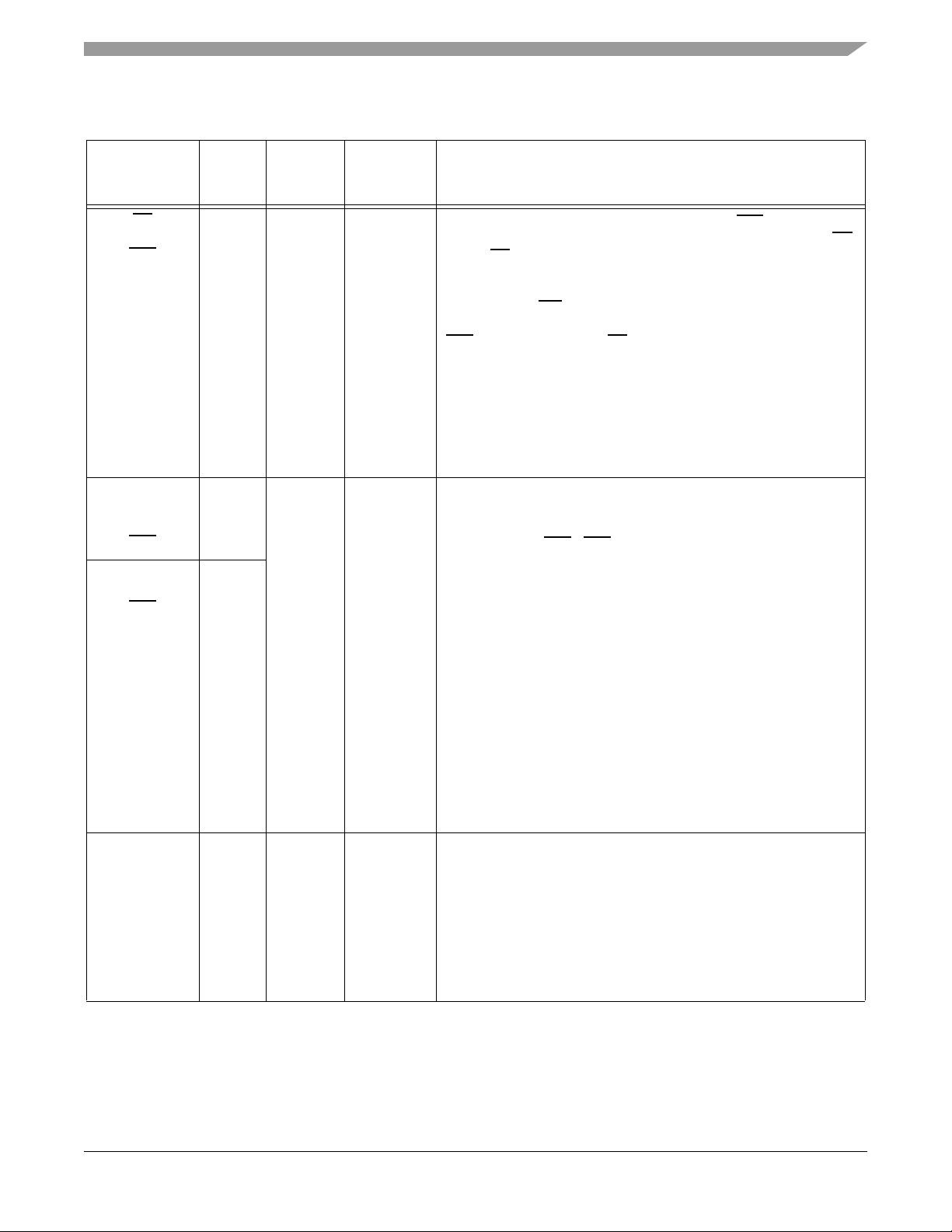

2.1 Introduction

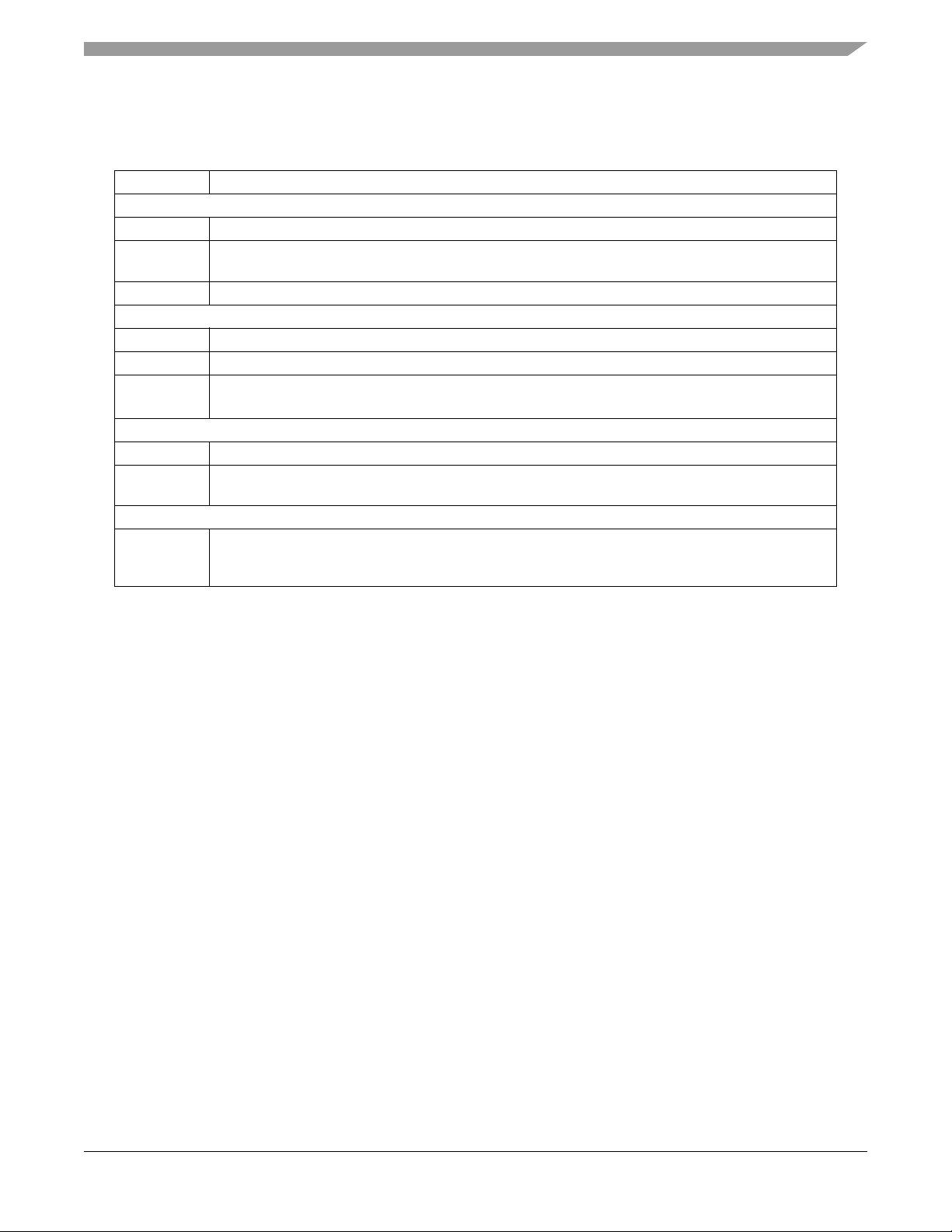

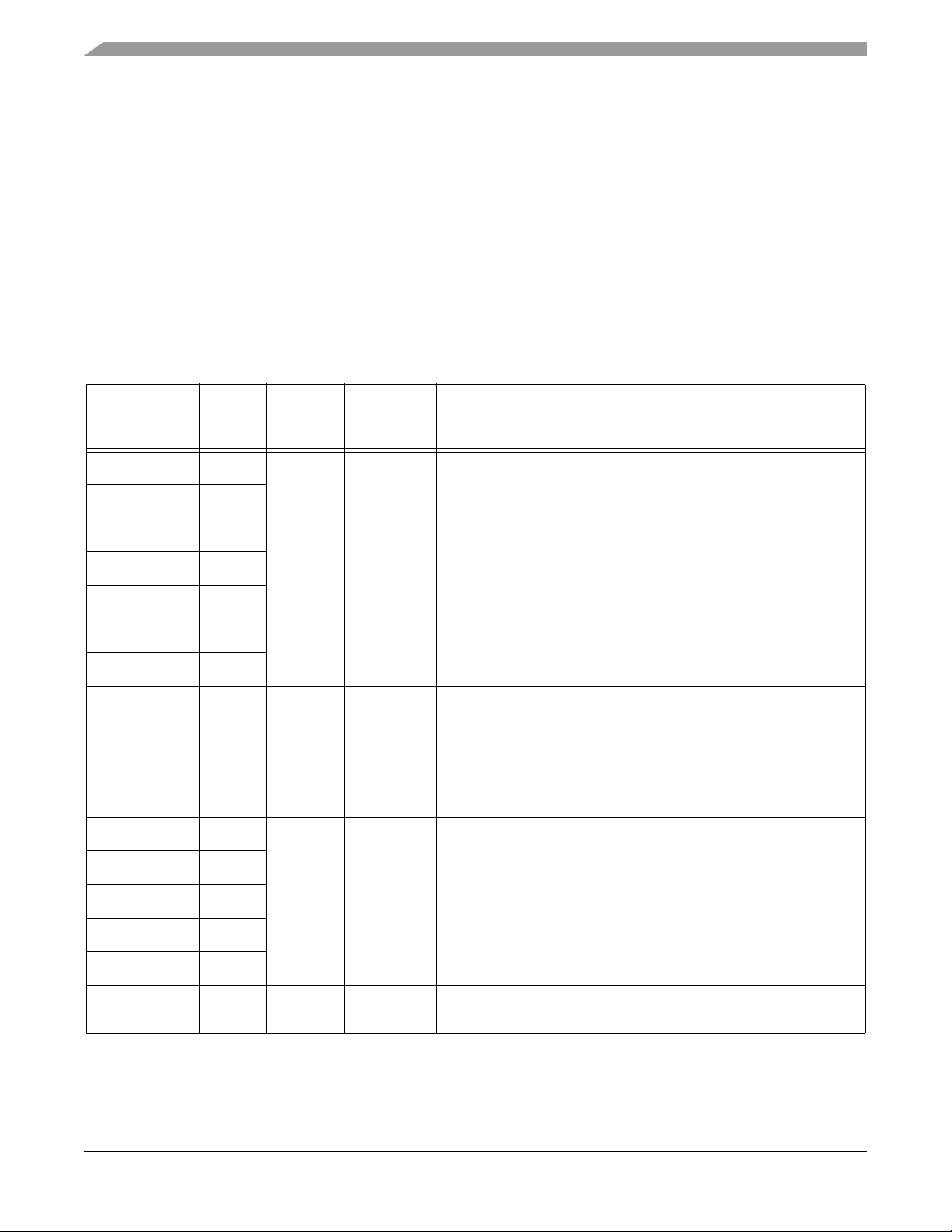

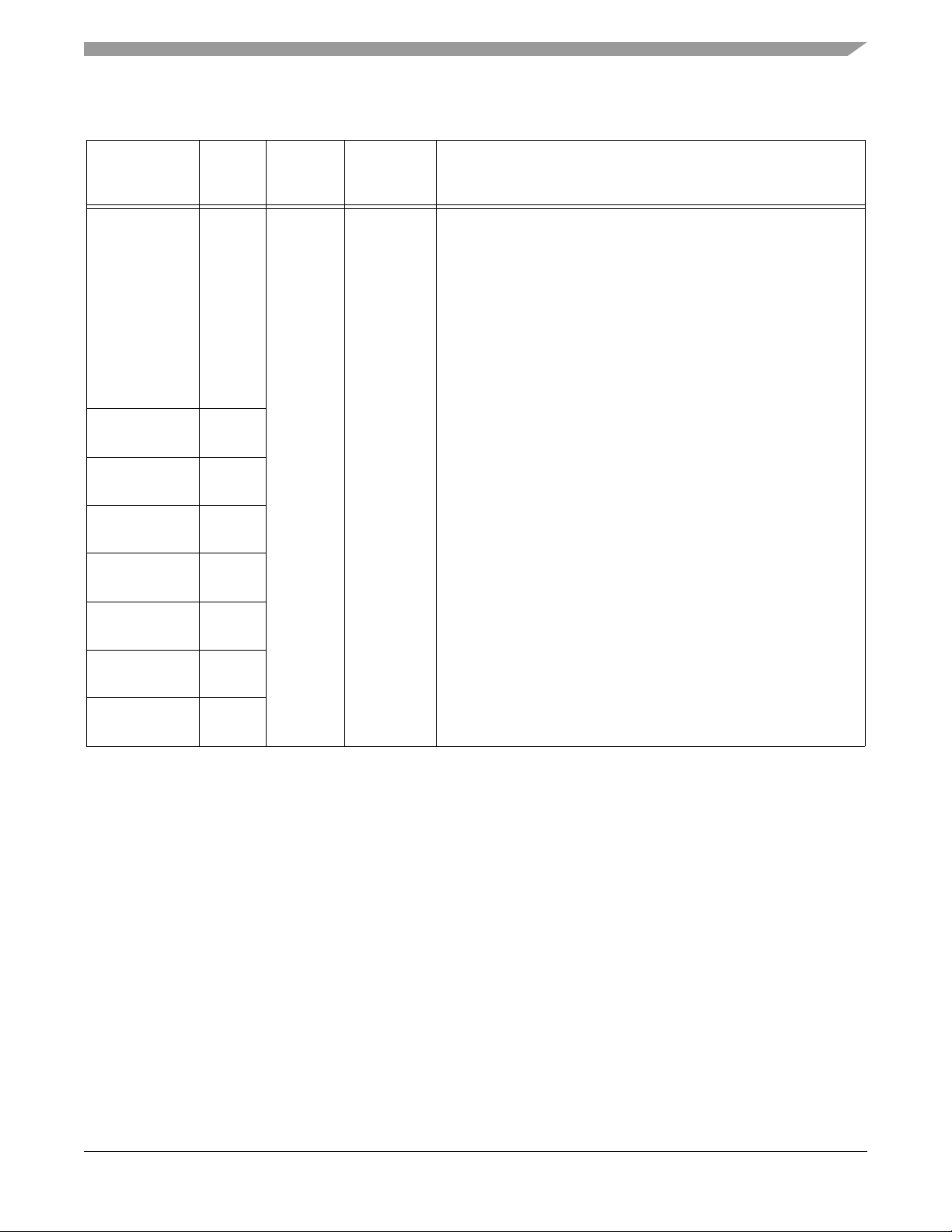

The input and output signals of the 56F8356 and 56F8156 are organized into functional groups, as detailed

in Table 2-1 and as illustrated in Figure 2-1. In Table 2-2, each table row describes the signal or signals

present on a pin.

Table 2-1 Functional Group Pin Allocations

Functional Group

Power (V

Power Option Control 1 1

Ground (VSS or V

Supply Capacitors1 & V

PLL and Clock 4 4

Address Bus 17 17

Data Bus 16 16

Bus Control 6 6

Interrupt and Program Control 6 6

Pulse Width Modulator (PWM) Ports 25 13

Serial Peripheral Interface (SPI) Port 0 4 4

Serial Peripheral Interface (SPI) Port 1 — 4

Quadrature Decoder Port 0

Quadrature Decoder Port 1

Serial Communications Interface (SCI) Ports 4 4

CAN Ports 2 —

Analog to Digital Converter (ADC) Ports 21 21

DD

or V

)99

DDA

)66

SSA

PP

2

3

Number of Pins in Package

56F8356 56F8156

66

44

4—

Quad Timer Module Ports 3 1

JTAG/Enhanced On-Chip Emulation (EOnCE) 5 5

Temperature Sense 1 —

Dedicated GPIO — 5

1. If the on-chip regulator is disabled, the V

2. Alternately, can function as Quad Timer pins or GPIO

3. Pins in this section can function as Quad Timer, SPI #1, or GPIO

Freescale Semiconductor 15

Preliminary

pins serve as 2.5V V

CAP

56F8356 Technical Data, Rev. 10.0

DD_CORE

power inputs

Power

Power

Power

Ground

Ground

Other

Supply

Ports

PLL

and

Clock

External

Address

Bus

or GPIO

V

DD_IO

V

DDA_ADC

V

DDA_OSC_PLL

V

SS

V

SSA_ADC

OCR_DIS

V

1 - V

CAP

CAP

V

1 & VPP2

PP

CLKMODE

EXTAL

XTAL

CLKO

A0 - A5 (GPIOA8 - 13)

A6 - A7 (GPIOE2 - 3)

A8 - A15 (GPIOA0 - 7)

GPIOB0 (A16)

7

PHASEA0 (TA0, GPIOC4)

1

1

5

1

1

56F8356

4

4

2

1

PHASEB0 (TA1, GPIOC5)

1

INDEX0 (TA2, GPIOC6)

1

HOME0 (TA3, GPIOC7)

1

SCLK0 (GPIOE4)

1

MOSI0 (GPIOE5)

1

MISO0 (GPIOE6)

1

1

SS0

(GPIOE7)

Quadrature

Decoder 0

or Quad

Timer A or

GPIO

SPI0 or

GPIO

1

1

1

1

PHASEA1(TB0, SCLK1, GPIOC0)

1

PHASEB1 (TB1, MOSI1, GPIOC1)

1

INDEX1 (TB2, MISO1, GPIOC2)

1

HOME1 (TB3, SS1

1

, GPIOC3)

Quadrature

Decoder 1 or

Quad Timer B

or SPI 1 or

GPIO

6

2

8

1

PWMA0 - 5

6

ISA0 - 2 (GPIOC8 - 10)

3

FAULTA0 - 2

3

PWMA or

GPIO

External

Data Bus

or GPIO

External

Bus

Control or

GPIO

SCI 0 or

GPIO

SCI 1

or GPIO

JTAG/

EOnCE

Port

D0 - D6 (GPIOF9 - 15)

D7 - D15 (GPIOF0 - 8)

RD

WR

PS / CS0 (GPIOD8)

DS / CS1 (GPIOD9)

GPIOD0 - 1 (CS2 - 3)

TXD0 (GPIOE0)

RXD0 (GPIOE1)

TXD1 (GPIOD6)

RXD1 (GPIOD7)

TCK

TMS

TDI

TDO

TRST

PWMB0 - 5

7

9

1

1

1

1

2

1

1

1

1

1

1

1

1

1

6

ISB0 - 2 (GPIOD10 - 12)

3

FAULTB0 - 3

4

ANA0 - 7

8

V

REF

5

ANB0 - 7

8

TEMP_SENSE

1

CAN_RX

1

CAN_TX

1

TC0 (GPIOE8)

1

TD0 - 1 (GPIOE10 - 11)

2

IRQA

1

IRQB

1

EXTBOOT

1

EMI_MODE

1

RESET

1

RSTO

1

PWMB or

GPIO

ADCA

ADCB

Temperature

Sensor

FlexCAN

QUAD

TIMER C and

D or GPIO

INTERRUPT/

PROGRAM

CONTROL

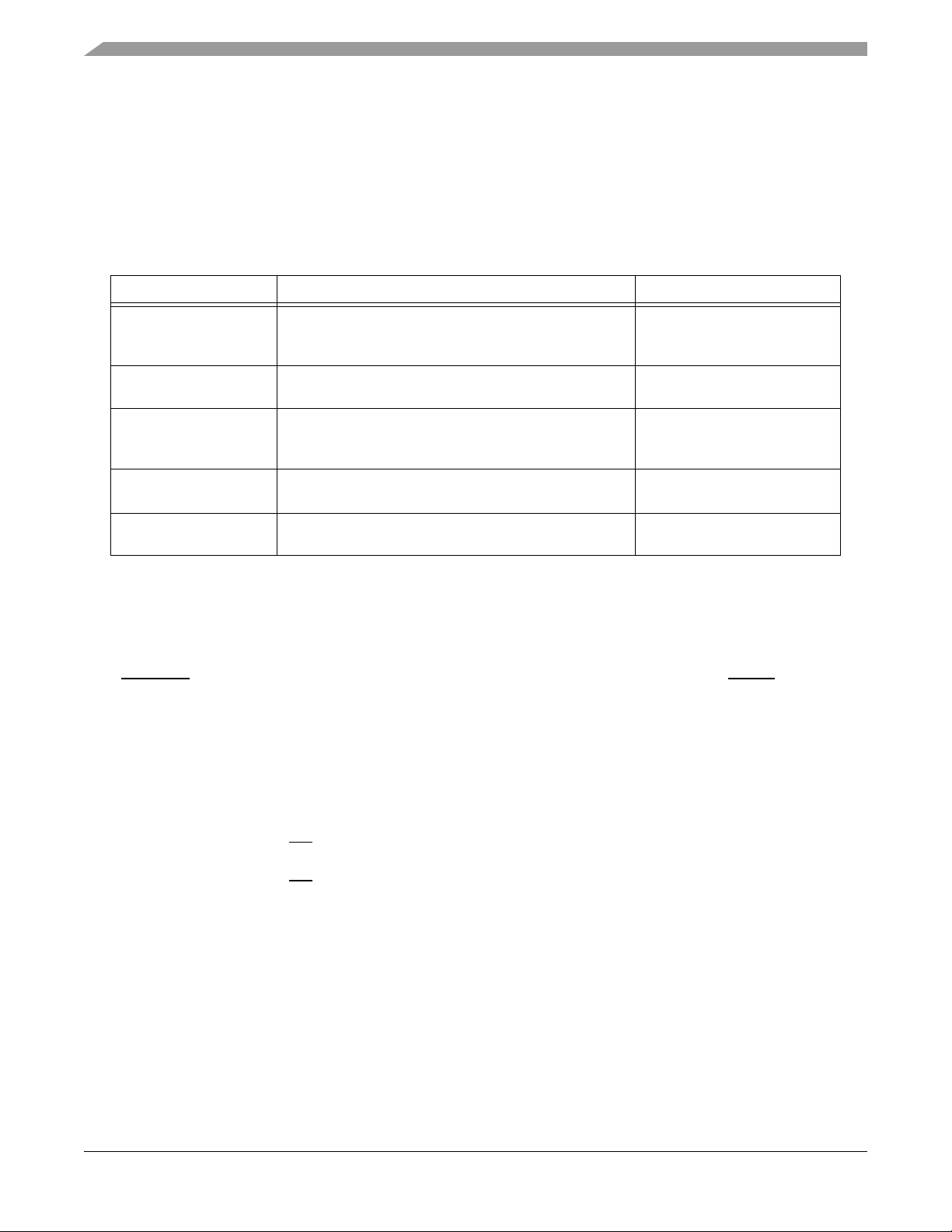

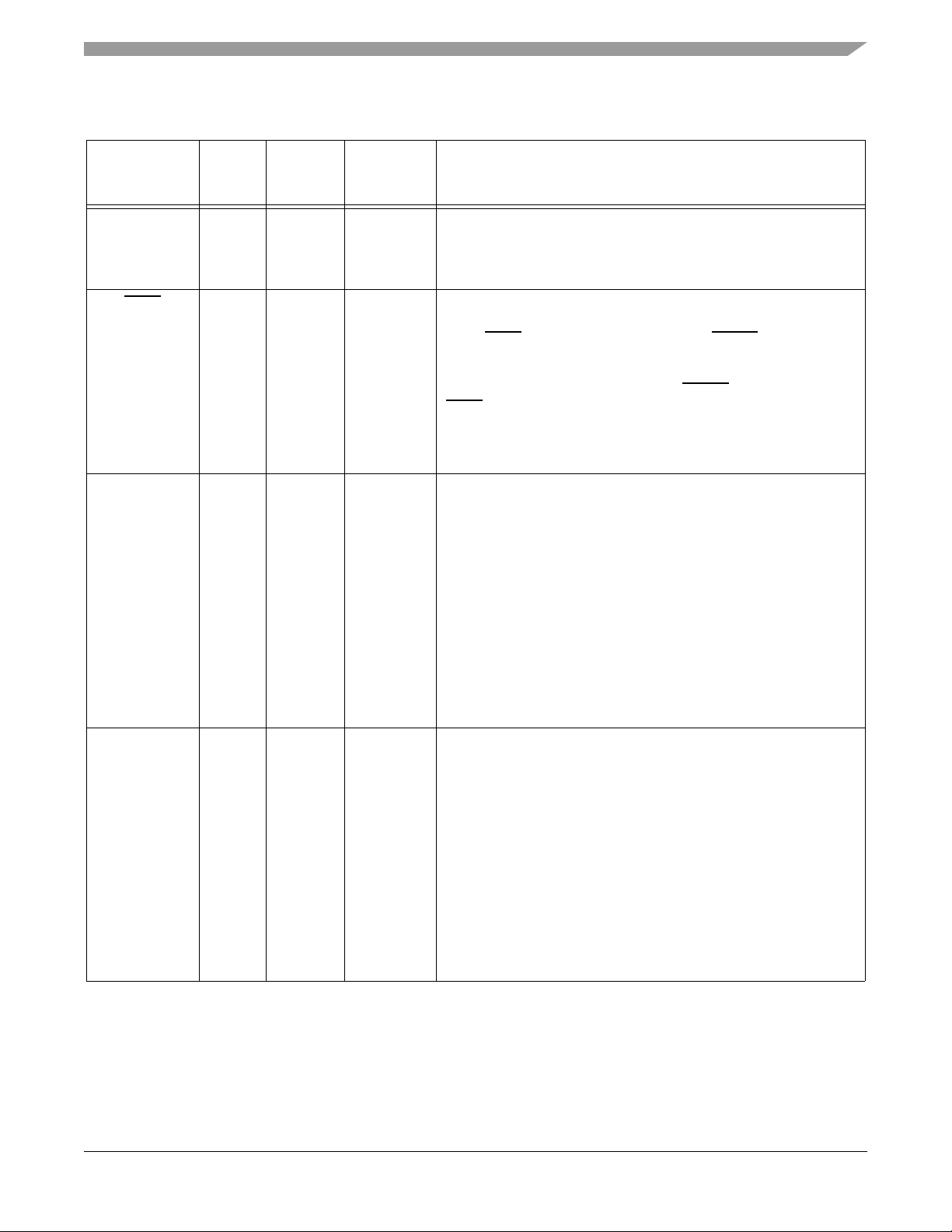

Figure 2-1 56F8356 Signals Identified by Functional Group1 (144-pin LQFP)

1. Alternate pin functionality is shown in parenthesis; pin direction/type shown is the default functionality.

56F8356 Technical Data, Rev. 10.0

16 Freescale Semiconductor

Preliminary

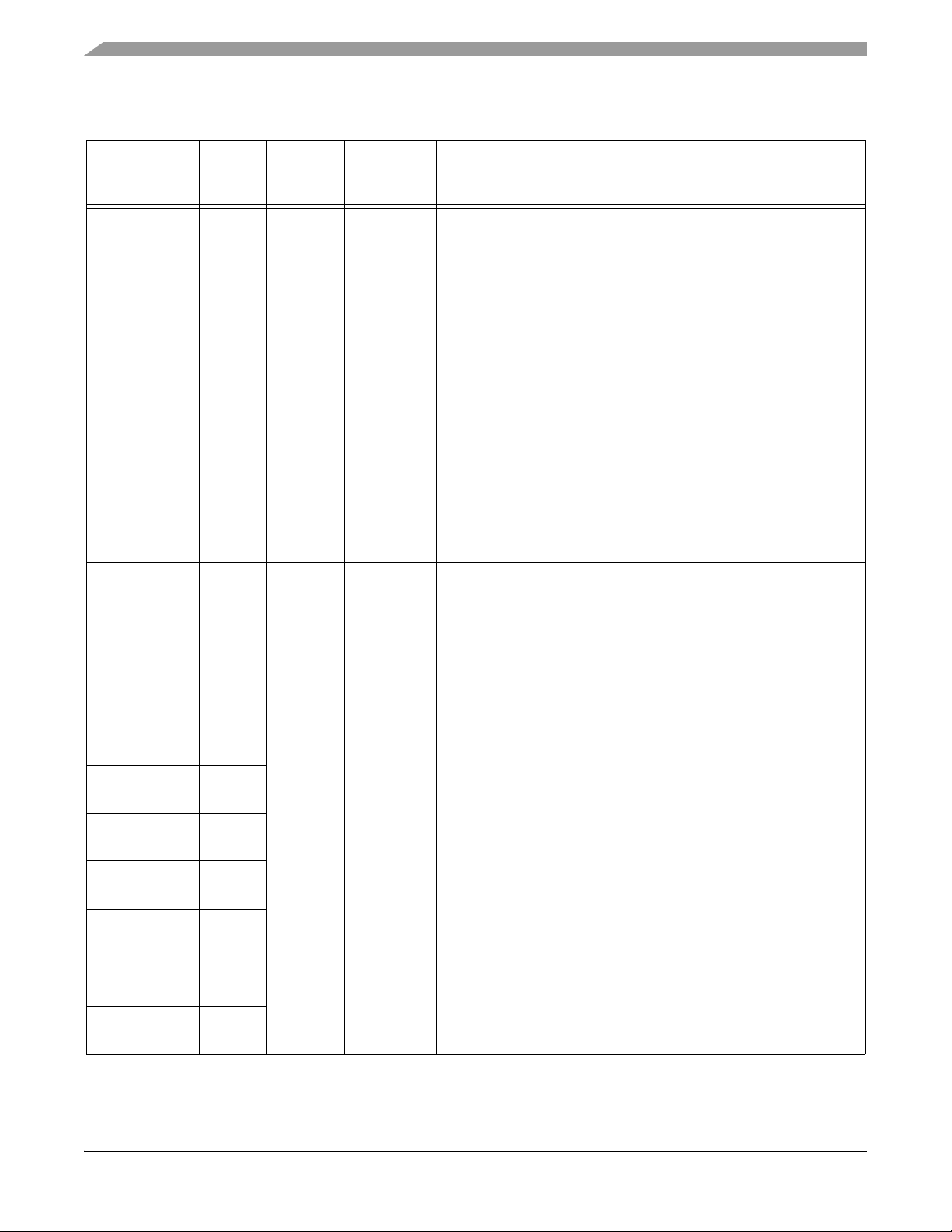

Power

Power

Power

Ground

Ground

Other

Supply

Ports

PLL

and

Clock

External

Address

Bus

or GPIO

V

DD_IO

V

DDA_ADC

V

DDA_OSC_PLL

V

SS

V

SSA_ADC

OCR_DIS

V

1 - V

CAP

V

PP

CAP

1 & VPP2

CLKMODE

EXTAL

XTAL

CLKO

A0 - A5 (GPIOA8 - 13)

A6 - A7 (GPIOE2 - 3)

A8 - A15 (GPIOA0 - 7)

GPIOB0 (A16)

Introduction

7

1

1

5

PHASEA0 (TA0, GPIOC4)

1

PHASEB0 (TA1, GPIOC5)

1

INDEX0 (TA2, GPIOC6)

1

HOME0 (TA3, GPIOC7)

1

Quadrature

Decoder 0

or Quad

Timer A or

GPIO

1

56F8356

1

4

4

2

1

1

1

1

SCLK0 (GPIOE4)

1

MOSI0 (GPIOE5)

1

MISO0 (GPIOE6)

1

SS0

1

(SCLK1, GPIOC0)

1

(MOSI1, GPIOC1)

1

(MISO1, GPIOC2)

1

(S

1

SPI0 or

GPIO

(GPIOE7)

SPI 1 or

GPIO

S1, GPIOC3)

6

2

8

3

(GPIOC8 - 10)

GPIO

1

External

Data Bus

or GPIO

External

Bus

Control or

GPIO

SCI 0 or

GPIO

SCI 1

or GPIO

JTAG/

EOnCE

Port

D0 - D6 (GPIOF9 - 15)

D7 - D15 (GPIOF0 - 8)

RD

WR

PS / CS0 (GPIOD8)

DS / CS1 (GPIOD9)

GPIOD0 - 1 (CS2 - 3)

TXD0 (GPIOE0)

RXD0 (GPIOE1)

TXD1 (GPIOD6)

RXD1 (GPIOD7)

TCK

TMS

TDI

TDO

TRST

PWMB0 - 5

6

ISB0 - 2 (GPIOD10 - 12)

7

9

1

1

3

4

8

5

8

FAULTB0 - 3

ANA0 - 7

V

REF

ANB0 - 7

PWMB or

GPIO

ADCA

ADCB

1

1

2

1

1

1

TC0 (GPIOE8)

1

TD0 - 1 (GPIOE10 - 11)

2

QUAD

TIMER C or

GPIO

1

IRQA

1

1

1

1

1

1

1

1

1

1

1

IRQB

EXTBOOT

EMI_MODE

RESET

RSTO

INTERRUPT/

PROGRAM

CONTROL

Figure 2-2 56F8156 Signals Identified by Functional Group1 (144-pin LQFP)

1. Alternate pin functionality is shown in parenthesis; pin direction/type shown is the default functionality.

56F8356 Technical Data, Rev. 10.0

Freescale Semiconductor 17

Preliminary

2.2 Signal Pins

After reset, each pin is configured for its primary function (listed first). Any alternate functionality must

be programmed.

If the “State During Reset” lists more than one state for a pin, the first state is the actual reset state. Other

states show the reset condition of the alternate function, which you get if the alternate pin function is

selected without changing the configuration of the alternate peripheral. For example, the A8/GPIOA0 pin

shows that it is tri-stated during reset. If the GPIOA_PER is changed to select the GPIO function of the

pin, it will become an input if no other registers are changed.

Table 2-2 Signal and Package Information for the 144-Pin LQFP

State

Signal Name Pin No. Type

During

Reset

Signal Description

V

DD_IO

V

DD_IO

V

DD_IO

V

DD_IO

V

DD_IO

V

DD_IO

V

DD_IO

V

DDA_ADC

V

DDA_OSC_PLL

V

SS

V

SS

V

SS

1 Supply I/O Power — This pin supplies 3.3V power to the chip I/O interface

and also the Processor core throught the on-chip voltage

16

31

38

66

84

119

102 Supply ADC Power — This pin supplies 3.3V power to the ADC modules.

80 Supply Oscillator and PLL Power — This pin supplies 3.3V power to the

27 Supply V

37

63

regulator, if it is enabled.

It must be connected to a clean analog power supply.

OSC and to the internal regulator that in turn supplies the Phase

Locked Loop. It must be connected to a clean analog power

supply.

— These pins provide ground for chip logic and I/O drivers.

SS

V

SS

V

SS

V

SSA_ADC

18 Freescale Semiconductor

69

144

103 Supply ADC Analog Ground — This pin supplies an analog ground to the

ADC modules.

56F8356 Technical Data, Rev. 10.0

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

State

Signal Name Pin No. Type

OCR_DIS 79 Input Input On-Chip Regulator Disab le —

During

Reset

Signal Description

Tie this pin to V

Tie this pin to V

to enable the on-chip regulator

SS

to disable the on-chip regulator

DD

This pin is intended to be a static DC signal from power-up to

shut down. Do not try to toggle this pin for power savings

during operation.

Signal Pins

1 51 Supply Supply V

V

CAP

1 - 4 — When OCR_DIS is tied to VSS (regulator enabled),

CAP

connect each pin to a 2.2µF or greater bypass capacitor in order to

2 128

V

CAP

3 83

V

CAP

4 15

V

CAP

1 125 Input Input VPP1 - 2 — These pins should be left unconnected as an open

V

PP

bypass the core logic voltage regulator, required for proper chip

operation. When OCR_DIS is tied to V

these pins become V

DD_CORE

and should be connected to a

(regulator disabled),

DD

regulated 2.5V power supply.

circuit for normal functionality.

VPP2 2

CLKMODE 87 Input Input Clock Input Mode Selection — This input determines the

function of the XTAL and EXTAL pins.

1 = External clock input on XTAL is used to directly drive the input

clock of the chip. The EXTAL pin should be grounded.

0 = A crystal or ceramic resonator should be connected between

XTAL and EXTAL.

EXTAL 82 Input Input External Crystal Oscillator Input — This input can be connected

to an 8MHz external crystal. Tie this pin low if XTAL is driven by an

external clock source.

XTAL 81 Input/

Output

Chip-driven Crystal Oscillator Output — This output connects the internal

crystal oscillator output to an external crystal.

If an external clock is used, XTAL must be used as the input and

EXTAL connected to GND.

The input clock can be selected to provide the clock directly to the

core. This input clock can also be selected as the input clock for

the on-chip PLL.

CLKO 3 Output Tri-Stated Clock Output — This pin outputs a buffered clock signal. Using

the SIM CLKO Select Register (SIM_CLKOSR), this pin can be

programmed as any of the following: disabled, CLK_MSTR

(system clock), IPBus clock, oscillator output, prescaler clock and

postscaler clock. Other signals are also available for test

purposes.

See Part 6.5.7 for details.

56F8356 Technical Data, Rev. 10.0

Freescale Semiconductor 19

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

Signal Name Pin No. Type

State

During

Reset

Signal Description

A0

(GPIOA8)

A1

(GPIOA9)

A2

(GPIOA10)

A3

(GPIOA11)

A4

(GPIOA12)

A5

(GPIOA13)

A6

138 Output

Input/

Output

10

11

12

13

14

17 Output

Tri-stated Address Bus — A0 - A5 specify six of the address lines for

external program or data memory accesses.

Depending upon the state of the DRV bit in the EMI bus control

register (BCR), A0 - A5 and EMI control signals are tri-stated when

the external bus is inactive.

Most designs will want to change the DRV state to DRV = 1 instead of

using the default setting.

Port A GPIO — These six GPIO pins can be individually

programmed as input or output pins.

After reset, the default state is Address Bus.

To deactivate the internal pull-up resistor, clear the appropriate

GPIO bit in the GPIOA_PUR register.

Example: GPIOA8, clear bit 8 in the GPIOA_PUR register.

Tri-stated

Address Bus — A6 - A7 specify two of the address lines for

external program or data memory accesses.

Depending upon the state of the DRV bit in the EMI bus control

register (BCR), A6 - A7 and EMI control signals are tri-stated when

the external bus is inactive.

Most designs will want to change the DRV state to DRV = 1 instead of

using the default setting.

(GPIOE2)

A7

(GPIOE3)

20 Freescale Semiconductor

18

Schmitt

Input/

Output

Input

56F8356 Technical Data, Rev. 10.0

Port E GPIO — These two GPIO pins can be individually

programmed as input or output pins.

After reset, the default state is Address Bus.

To deactivate the internal pull-up resistor, clear the appropriate

GPIO bit in the GPIOE_PUR register.

Example: GPIOE2, clear bit 2 in the GPIOE_PUR register.

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

Signal Name Pin No. Type

State

During

Reset

Signal Pins

Signal Description

A8

(GPIOA0)

A9

(GPIOA1)

A10

(GPIOA2)

A11

(GPIOA3)

A12

(GPIOA4)

A13

(GPIOA5)

A14

(GPIOA6)

19 Output

Schmitt

20

21

22

23

24

25

Input/

Output

Tri-stated

Input

Address Bus— A8 - A15 specify eight of the address lines for

external program or data memory accesses.

Depending upon the state of the DRV bit in the EMI bus control

register (BCR), A8 - A15 and EMI control signals are tri-stated when

the external bus is inactive.

Most designs will want to change the DRV state to DRV = 1 instead of

using the default setting.

Port A GPIO — These eight GPIO pins can be individually

programmed as input or output pins.

After reset, the default state is Address Bus.

To deactivate the internal pull-up resistor, clear the appropriate

GPIO bit in the GPIOA_PUR register.

Example: GPIOA0, clear bit 0 in the GPIOA_PUR register.

A15

(GPIOA7)

Freescale Semiconductor 21

Preliminary

26

56F8356 Technical Data, Rev. 10.0

Table 2-2 Signal and Package Information for the 144-Pin LQFP

Signal Name Pin No. Type

State

During

Reset

Signal Description

GPIOB0

(A16)

D0

33 Schmitt

Input/

Output

Output

59 Input/

Output

Input

Tri-stated

Tri-stated

Port B GPIO — This GPIO pin can be programmed as an input or

output pin.

Address Bus — A16 specifies one of the address lines for

external program or data memory accesses. Depending upon the

state of the DRV bit in the EMI bus control register (BCR), A16 and

EMI control signals are tri-stated when the external bus is inactive.

Most designs will want to change the DRV state to DRV = 1 instead of

using the default setting.

After reset, the start-up state of GPIOB0 (GPIO or address) is

determined as a function of EXTBOOT, EMI_MODE and the Flash

security setting. See Table 4-4 for further information on when this

pin is configured as an address pin at reset. In all cases, this state

may be changed by writing to GPIOB_PER.

To deactivate the internal pull-up resistor, clear bit 0 in the

GPIOB_PUR register.

Data Bus — D0 - D6 specify part of the data for external program or

data memory accesses.

Depending upon the state of the DRV bit in the EMI bus control

register (BCR), D0 - D6 are tri-stated when the external bus is

inactive.

(GPIOF9)

D1

(GPIOF10)

D2

(GPIOF11)

D3

(GPIOF12)

D4

(GPIOF13)

D5

(GPIOF14)

D6

(GPIOF15)

60

72

75

76

77

78

Input/

Output

Most designs will want to change the DRV state to DRV = 1 instead of

using the default setting.

Input

56F8356 Technical Data, Rev. 10.0

Port F GPIO — These seven GPIO pins can be individually

programmed as input or output pins.

At reset, these pins default to the EMI Data Bus function.

To deactivate the internal pull-up resistor, clear the appropriate

GPIO bit in the GPIOF_PUR register.

Example: GPIOF9, clear bit 9 in the GPIOF_PUR reg i ste r.

22 Freescale Semiconductor

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

Signal Name Pin No. Type

State

During

Reset

Signal Pins

Signal Description

D7

(GPIOF0)

D8

(GPIOF1)

D9

(GPIOF2)

D10

(GPIOF3)

D11

(GPIOF4)

D12

(GPIOF5)

D13

(GPIOF6)

D14

(GPIOF7)

28 Input/

Output

Input/

Output

29

30

32

133

134

135

136

Tri-stated

Input

Data Bus — D7 - D14 specify part of the data for external program

or data memory accesses.

Most designs will want to change the DRV state to DRV = 1 instead of

using the default setting.

Port F GPIO — These eight GPIO pins can be individually

programmed as input or output pins.

At reset, these pins default to Data Bus functionality.

To deactivate the internal pull-up resistor, clear the appropriate

GPIO bit in the GPIOF_PUR register.

Example: GPIOF0, clear bit 0 in the GPIOF_PUR reg i ste r.

D15

(GPIOF8)

137 Input/

Output

Input/

Output

Tri-stated

Input

56F8356 Technical Data, Rev. 10.0

Data Bus — D15 specifies part of the data for external program or

data memory accesses.

Most designs will want to change the DRV state to DRV = 1 instead of

using the default setting.

Port F GPIO — This GPIO pin can be individually programmed as

an input or output pin.

At reset, this pin defaults to the Data Bus function.

To deactivate the internal pull-up resistor, clear bit 8 in the

GPIOF_PUR register.

Freescale Semiconductor 23

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

State

Signal Name Pin No. Type

RD 45 Output Tri-stated Read Enable — RD is asserted during external memory read

During

Reset

Signal Description

cycles. When RD

and an external device is enabled onto the data bus. When RD

deasserted high, the external data is latched inside the device.

When RD is asserted, it qualifies the A0 - A16, PS, DS, and CSn

pins. RD

or ROM.

Depending upon the state of the DRV bit in the EMI bus control

register (BCR ) , RD is

Most designs will want to change the DRV state to DRV = 1 instead of

using the default setting.

To deactivate the internal pull-up resistor, set the CTRL bit in the

SIM_PUDR register.

can be connected directly to the OE pin of a Static RAM

is asserted low, pins D0 - D15 become inputs

tri-stated when the external bus is inactive.

is

WR

PS

(CS0)

44 Output Tri-stated Write Enable — WR is asserted during external memory write

is asserted low, pins D0 - D15 become outputs

, DS, and CSn pins. WR can

is tri-stated when the external bus is inactive.

in the

signal. PS is asserted low for external program

is tri-stated when the external bus is inactive.

46 Output

Tri-stated

cycles. When WR

and the device puts data on the bus. When WR is deasserted high,

the external data is latched inside the external device. When WR is

asserted, it qualifies the A0 - A16, PS

be connected directly to the WE pin of a static RAM.

Depending upon the state of the DRV bit in the EMI bus control

register (BCR), WR

Most designs will want to change the DRV state to DRV = 1 instead of

using the default setting.

To deactivate the internal pull-up resistor, set the CTRL bit in the

SIM_PUDR register.

Program Memory Select — This signal is actually CS0

EMI, which is programmed at reset for compatibility with the

56F80x PS

memory access.

Depending upon the state of the DRV bit in the EMI bus control

register (BCR), CS0

resets to provide the PS function as defined on the 56F80x

CS0

devices.

(GPIOD8)

24 Freescale Semiconductor

Input/

Output

Input

56F8356 Technical Data, Rev. 10.0

Port D GPIO — This GPIO pin can be individually programmed as

an input or output pin.

To deactivate the internal pull-up resistor, clear bit 8 in the

GPIOD_PUR register.

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

Signal Name Pin No. Type

State

During

Reset

Signal Pins

Signal Description

DS

(CS1)

(GPIOD9)

GPIOD0

)

(CS2

GPIOD1

)

(CS3

47 Output

Input/

Output

48 Input/

Output

Output

49

Tri-stated

Input

Input Port D GPIO — These two GPIO pins can be individually

Data Memory Select — This signal is actually CS1

which is programmed at reset for compatibility with the 56F80x DS

signal. DS

Depending upon the state of the DRV bit in the EMI bus control

register (BCR), DS

CS1 resets to provide the DS function as defined on the 56F80x

devices.

Port D GPIO — This GPIO pin can be individually programmed as

an input or output pin.

To deactivate the internal pull-up resistor, clear bit 9 in the

GPIOD_PUR register.

programmed as input or output pins.

Chip Select — CS2 - CS3 may be programmed within the EMI

module to act as chip selects for specific areas of the external

memory map.

Depending upon the state of the DRV bit in the EMI bus control

register (BCR), A0–A16 and EMI control signals are tri-stated when

the external bus is inactive.

is asserted low for external data memory access.

is tri-stated when the external bus is inactive.

in the EMI,

TXD0

(GPIOE0)

4 Output

Input/

Output

Tri-stated

Input

Most designs will want to change the DRV state to DRV = 1 instead of

using the default setting.

At reset, these pins are configured as GPIO.

To deactivate the internal pull-up resistor, clear the appropriate

GPIO bit in the GPIOD_PUR register.

Example: GPIOD0, clear bit 0 in the GPIOD_PUR register.

Transmit Data — SCI0 transmit data output

Port E GPIO — This GPIO pin can be individually programmed as

an input or output pin.

After reset, the default state is SCI output.

To deactivate the internal pull-up resistor, clear bit 0 in the

GPIOE_PUR register.

56F8356 Technical Data, Rev. 10.0

Freescale Semiconductor 25

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

Signal Name Pin No. Type

State

During

Reset

Signal Description

RXD0

(GPIOE1)

TXD1

(GPIOD6)

RXD1

(GPIOD7)

5 Input

Input/

Output

42 Output

Input/

Output

43 Input

Input/

Output

Input

Input

Tri-stated

Input

Input

Input

Receive Data — SCI0 receive data input

Port E GPIO — This GPIO pin can be individually programmed as

an input or output pin.

After reset, the default state is SCI output.

To deactivate the internal pull-up resistor, clear bit 1 in the

GPIOE_PUR register.

Transmit Data — SCI1 transmit data output

Port D GPIO — This GPIO pin can be individually programmed as

an input or output pin.

After reset, the default state is SCI output.

To deactivate the internal pull-up resistor, clear bit 6 in the

GPIOD_PUR register.

Receive Data — SCI1 receive data input

Port D GPIO — This GPIO pin can be individually programmed as

an input or output pin.

After reset, the default state is SCI input.

TCK 121 Schmitt

Input

TMS 122 Schmitt

Input

TDI 123 Schmitt

Input

Input,

pulled low

internally

Input,

pulled high

internally

Input,

pulled high

internally

To deactivate the internal pull-up resistor, clear bit 7 in the

GPIOD_PUR register.

Test Clock Input — This input pin provides a gated clock to

synchronize the test logic and shift serial data to the JTAG/EOnCE

port. The pin is connected internally to a pull-down resistor.

Test Mode Select Input — This input pin is used to sequence the

JTAG TAP controller’s state machine. It is sampled on the rising

edge of TCK and has an on-chip pull-up resistor.

To deactivate the internal pull-up resistor, set the JTAG bit in the

SIM_PUDR register.

Test Data Input — This input pin provides a serial input data

stream to the JTAG/EOnCE port. It is sampled on the rising edge

of TCK and has an on-chip pull-up resistor.

To deactivate the internal pull-up resistor, set the JTAG bit in the

SIM_PUDR register.

56F8356 Technical Data, Rev. 10.0

26 Freescale Semiconductor

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

State

Signal Name Pin No. Type

TDO 124 Output Tri-stated Test Data Output — This tri-stateable output pin provides a serial

During

Reset

Signal Description

output data stream from the JTAG/EOnCE port. It is driven in the

shift-IR and shift-DR controller states, and changes on the falling

edge of TCK.

Signal Pins

TRST

PHASEA0

(TA0)

(GPIOC4)

PHASEB0

120 Schmitt

Input

139 Schmitt

Input

Schmitt

Input/

Output

Schmitt

Input/

Output

140 Schmitt

Input

Input,

pulled high

internally

Input

Input

Input

Input

Test Reset — As an input, a low signal on this pin provides a reset

signal to the JTAG TAP controller. To ensure complete hardware

reset, TRST

The only exception occurs in a debugging environment when a

hardware device reset is required and the JTAG/EOnCE module

must not be reset. In this case, assert RESET

TRST.

To deactivate the internal pull-up resistor, set the JTAG bit in the

SIM_PUDR register.

Phase A — Quadrature Decoder 0, PHASEA input

TA0 — Timer A, Channel 0

Port C GPIO — This GPIO pin can be individually programmed as

an input or output pin.

After reset, the default state is PHASEA0.

To deactivate the internal pull-up resistor, clear bit 4 of the

GPIOC_PUR register.

Phase B — Quadrature Decoder 0, PHASEB input

should be asserted whenever RESET is asserted.

, but do not assert

(TA1)

(GPIOC5)

Freescale Semiconductor 27

Preliminary

Schmitt

Input/

Output

Schmitt

Input/

Output

Input

Input

56F8356 Technical Data, Rev. 10.0

TA1 — Timer A, Channel

Port C GPIO — This GPIO pin can be individually programmed as

an input or output pin.

After reset, the default state is PHASEB0.

To deactivate the internal pull-up resistor, clear bit 5 of the

GPIOC_PUR register.

Table 2-2 Signal and Package Information for the 144-Pin LQFP

Signal Name Pin No. Type

State

During

Reset

Signal Description

INDEX0

(TA2)

(GPOPC6)

HOME0

(TA3)

(GPIOC7)

141 Schmitt

Input

Schmitt

Input/

Output

Schmitt

Input/

Output

142 Schmitt

Input

Schmitt

Input/

Output

Schmitt

Input/

Output

Input

Input

Input

Input

Input

Input

Index — Quadrature Decoder 0, INDEX input

TA2 — Timer A, Channel 2

Port C GPIO — This GPIO pin can be individually programmed as

an input or output pin.

After reset, the default state is INDEX0.

To deactivate the internal pull-up resistor, clear bit 6 of the

GPIOC_PUR register.

Home — Quadrature Decoder 0, HOME input

TA3 — Timer A, Channel 3

Port C GPIO — This GPIO pin can be individually programmed as

an input or output pin.

After reset, the default state is HOME0.

SCLK0

(GPIOE4)

130 Schmitt

Input/

Output

Schmitt

Input/

Output

Input

Input

To deactivate the internal pull-up resistor, clear bit 7 of the

GPIOC_PUR register.

SPI 0 Serial Clock — In the master mode, this pin serves as an

output, clocking slaved listeners. In slave mode, this pin serves as

the data clock input.

Port E GPIO — This GPIO pin can be individually programmed as

an input or output pin.

After reset, the default state is SCLK0.

To deactivate the internal pull-up resistor, clear bit 4 in the

GPIOE_PUR register.

56F8356 Technical Data, Rev. 10.0

28 Freescale Semiconductor

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

Signal Name Pin No. Type

State

During

Reset

Signal Pins

Signal Description

MOSI0

(GPIOE5)

MISO0

(GPIOE6)

132 Input/

Output

Input/

Output

131 Input/

Output

Input/

Output

Tri-stated

Input

Input

Input

SPI 0 Master Out/Slave In — This serial data pin is an output from

a master device and an input to a slave device. The master device

places data on the MOSI line a half-cycle before the clock edge

the slave device uses to latch the data.

Port E GPIO — This GPIO pin can be individually programmed as

an input or output pin.

After reset, the default state is MOSI0.

To deactivate the internal pull-up resistor, clear bit 5 in the

GPIOE_PUR register.

SPI 0 Master In/Slave Out — This serial data pin is an input to a

master device and an output from a slave device. The MISO line of

a slave device is placed in the high-impedance state if the slave

device is not selected. The slave device places data on the MISO

line a half-cycle before the clock edge the master device uses to

latch the data.

Port E GPIO — This GPIO pin can be individually programmed as

an input or output pin.

After reset, the default state is MISO0.

To deactivate the internal pull-up resistor, clear bit 6 in the

GPIOE_PUR register.

SS0

(GPIOE7)

129 Input

Input/

Output

Input

Input

56F8356 Technical Data, Rev. 10.0

SPI 0 Slave Select — SS0

SPI module that the current transfer is to be received.

Port E GPIO — This GPIO pin can be individually programmed as

input or output pin.

After reset, the default state is SS0

To deactivate the internal pull-up resistor, clear bit 7 in the

GPIOE_PUR register.

is used in slave mode to indicate to the

.

Freescale Semiconductor 29

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

Signal Name Pin No. Type

State

During

Reset

Signal Description

PHASEA1

(TB0)

(SCLK1)

(GPIOC0)

PHASEB1

6Schmitt

Input

Schmitt

Input/

Output

Schmitt

Input/

Output

Schmitt

Input/

Output

7Schmitt

Input

Input

Input

Input

Input

Input

Phase A1 — Quadrature Decoder 1, PHASEA input for decoder 1.

TB0 — Timer B, Channel 0

SPI 1 Serial Clock — In the master mode, this pin serves as an

output, clocking slaved listeners. In slave mode, this pin serves as

the data clock input. To activate the SPI function, set the

PHSA_ALT bit in the SIM_GPS register. For details, see Part

6.5.8.

Port C GPIO — This GPIO pin can be individually programmed as

an input or output pin.

In the 56F8356, the default state after reset is PHASEA1.

In the 56F8156, the default state is not one of the functions offered

and must be reconfigured.

To deactivate the internal pull-up resistor, clear bit 0 in the

GPIOC_PUR register.

Phase B1 — Quadrature Decoder 1, PHASEB input for decoder 1.

(TB1)

(MOSI1)

(GPIOC1)

Schmitt

Input/

Output

Schmitt

Input/

Output

Schmitt

Input/

Output

Input

Tri-stated

Input

56F8356 Technical Data, Rev. 10.0

TB1 — Timer B, Channel 1

SPI 1 Master Out/Slave In — This serial data pin is an output from

a master device and an input to a slave device. The master device

places data on the MOSI line a half-cycle before the clock edge

the slave device uses to latch the data. To activate the SPI

function, set the PHSB_ALT bit in the SIM_GPS register. For

details, see Part 6.5.8.

Port C GPIO — This GPIO pin can be individually programmed as

an input or output pin.

In the 56F8356, the default state after reset is PHASEB1.

In the 56F8156, the default state is not one of the functions offered

and must be reconfigured.

To deactivate the internal pull-up resistor, clear bit 1 in the

GPIOC_PUR register.

30 Freescale Semiconductor

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

Signal Name Pin No. Type

State

During

Reset

Signal Pins

Signal Description

INDEX1

(TB2)

(MISO1)

(GPIOC2)

HOME1

8Schmitt

Input

Schmitt

Input/

Output

Schmitt

Input/

Output

Schmitt

Input/

Output

9Schmitt

Input

Input

Input

Input

Input

Input

Index1 — Quadrature Decoder 1, INDEX input

TB2 — Timer B, Channel 2

SPI 1 Master In/Slave Out — This serial data pin is an input to a

master device and an output from a slave device. The MISO line of

a slave device is placed in the high-impedance state if the slave

device is not selected. The slave device places data on the MISO

line a half-cycle before the clock edge the master device uses to

latch the data. To activate the SPI function, set the INDEX_ALT bit

in the SIM_GPS register. For details, see Part 6.5.8.

Port C GPIO — This GPIO pin can be individually programmed as

an input or output pin.

In the 56F8356, the default state after reset is INDEX1.

In the 56F8156, the default state is not one of the functions offered

and must be reconfigured.

To deactivate the internal pull-up resistor, clear bit 2 in the

GPIOC_PUR register.

Home — Quadrature Decoder 1, HOME input

(TB3)

)

(SS1

(GPIOC3)

Freescale Semiconductor 31

Preliminary

Schmitt

Input/

Output

Schmitt

Input

Schmitt

Input/

Output

Input

Input

Input

56F8356 Technical Data, Rev. 10.0

TB3 — Timer B, Channel 3

SPI 1 Slave Select — In the master mode, this pin is used to

arbitrate multiple masters. In slave mode, this pin is used to select

the slave. To activate the SPI function, set the HOME_ALT bit in

the SIM_GPS register. For details, see Part 6.5.8.

Port C GPIO — This GPIO pin can be individually programmed as

an input or output pin.

In the 56F8356, the default state after reset is HOME1.

In the 56F8156, the default state is not one of the functions offered

and must be reconfigured.

To deactivate the internal pull-up resistor, clear bit 3 in the

GPIOC_PUR register.

Table 2-2 Signal and Package Information for the 144-Pin LQFP

State

Signal Name Pin No. Type

PWMA0 62 Output Tri-State PWMA0 - 5 — These are six PWMA outputs.

PWMA1 64

PWMA2 65

PWMA3 67

PWMA4 68

PWMA5 70

During

Reset

Signal Description

ISA0

(GPIOC8)

ISA1

(GPIOC9)

ISA2

(GPIOC10)

FaultA0 71 Schmitt

FaultA1 73

FaultA2 74

PWMB0 34 Output Tri-State PWMB0 - 5 — Six PWMB output pins.

PWMB1 35

PWMB2 36

113 Schmitt

Input

Schmitt

114

115

Input/

Output

Input

Input

Input

Input FaultA0 - 2 — These three fault input pins are used for disabling

ISA0 - 2 — These three input current status pins are used for

top/bottom pulse width correction in complementary channel

operation for PWMA.

Port C GPIO — These GPIO pins can be individually programmed

as input or output pins.

In the 56F8356, these pins default to ISA functionality after reset.

In the 56F8156, the default state is not one of the functions offered

and must be reconfigured.

To deactivate the inte rnal pull-up resistor, clear the appropriate bit

of the GPIOC_PUR register. For details, see Part 6.5.8.

selected PWMA outputs in cases where fault conditions originate

off-chip.

To deactivate the internal pull-up resistor, set the PWMA0 bit in the

SIM_PUDR register. For details, see Part 6.5.8.

PWMB3 39

PWMB4 40

PWMB5 41

56F8356 Technical Data, Rev. 10.0

32 Freescale Semiconductor

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

Signal Name Pin No. Type

State

During

Reset

Signal Pins

Signal Description

ISB0

50 Schmitt

Input

Input

ISB0 - 2 — These three input current status pins are used for

top/bottom pulse width correction in complementary channel

operation for PWMB.

(GPIOD10)

ISB1

52

(GPIOD11)

ISB2

53

(GPIOD12)

FaultB0 56 Schmitt

FaultB1 57

FaultB2 58

FaultB3 61

Schmitt

Input/

Output

Input

Input

Port D GPIO — These GPIO pins can be individually programmed

as input or output pins.

At reset, these pins default to ISB functionality.

To deactivate the inte rnal pull-up resistor, clear the appropriate bit

of the GPIOD_PUR register. For details, see Part 6.5.8.

Input FaultB0 - 3 — These four fault input pins are used for disabling

selected PWMB outputs in cases where fault conditions originate

off-chip.

To deactivate the internal pull-up resistor, set the PWMB bit in the

SIM_PUDR register. For details, see Part 6.5.8.

ANA0 88 Input Input ANA0 - 3 — Analog inputs to ADC A, channel 0

ANA1 89

ANA2 90

ANA3 91

ANA4 92 Input Input ANA4 - 7 — Analog inputs to ADC A, channel 1

ANA5 93

ANA6 94

ANA7 95

V

REFH

V

REFP

V

REFMID

V

REFN

V

REFLO

101 Input Input V

100 Input/

Output

Input/

Output

99

98

97 Input Input V

56F8356 Technical Data, Rev. 10.0

— Analog Reference Voltage High. V

REFH

than or equal to

V

, V

REFP

REFMID

VDDA_ADC.

& V

REFN

— Internal pins for voltage reference

must be less

REFH

which are brought off-chip so they can be bypassed. Connect to a

0.1µF low ESR capacitor.

— Analog Reference Voltage Low. This should normally

REFLO

be connected to a low-noise V

SS

.

Freescale Semiconductor 33

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

State

Signal Name Pin No. Type

ANB0 104 Input Input ANB0 - 3 — Analog inputs to ADC B, channel 0

ANB1 105

ANB2 106

ANB3 107

ANB4 108 Input Input ANB4 - 7 — Analog inputs to ADC B, channel 1

ANB5 109

ANB6 110

ANB7 111

TEMP_SENSE 96 Output Output Temperature Sense Diode — This signal connects to an on-chip

During

Reset

Signal Description

diode that can be connected to one of the ADC inputs and used to

monitor the temperature of the die. Must be bypassed with a

0.01µF capacitor.

CAN_RX 127 Schmitt

Input

CAN_TX 126 Open

Drain

Output

TC0

(GPIOE8)

118 Schmitt

Input/

Output

Schmitt

Input/

Output

Input FlexCAN Receive Data — This is the CAN input. This pin has an

internal pull-up resistor.

To deactivate the internal pull-up resistor, set the CAN bit in the

SIM_PUDR register.

Open

Drain

Output

Input

Input

FlexCAN Transmit Data — CAN output

TC0 — Timer C, Channel 0

Port E GPIO — This GPIO pin can be individually programmed as

an input or output pin.

At reset, this pin defaults to timer functionality.

To deactivate the internal pull-up resistor, clear bit 8 of the

GPIOE_PUR register.

56F8356 Technical Data, Rev. 10.0

34 Freescale Semiconductor

Preliminary

Table 2-2 Signal and Package Information for the 144-Pin LQFP

Signal Name Pin No. Type

State

During

Reset

Signal Pins

Signal Description

TD0

(GPIOE10)

TD1

(GPIOE11)

IRQA

IRQB

RESET 86 Schmitt

116 Schmitt

Input/

Output

Schmitt

117

54 Schmitt

55

Input/

Output

Input

Input

Input

Input

Input External Interrupt Request A and B — The IRQA and IRQB

Input Reset — This input is a direct hardware reset on the processor.

TD0 - 1 — Timer D, Channels 0 and 1

Port E GPIO — These GPIO pins can be individually programmed

as input or output pins.

At reset, these pins default to Timer functionality.

To deactivate the inte rnal pull-up resistor, clear the appropriate bit

of the GPIOE_PUR register. See Part 6.5.6 for details.

inputs are asynchronous external interrupt requests during Stop

and Wait mode operation. During other operating modes, they are

synchronized external interrupt requests, which indicate an

external device is requesting service. They can be programmed to

be level-sensitive or negative-edge triggered.

To deactivate the internal pull-up resistor, set the IRQ bit in the

SIM_PUDR register. See Part 6.5.6 for details.

When RESET is asserted low, the device is initialized and placed