Page 1

8VHU·V*XLGH8VHU·V*XLGH8VHU·V*XLGH8VHU·V*XLGH8VHU·V*XLGH

70

4XDQWXP6XSHU/RDGHU

4XDQWXP6XSHU/RDGHU70

6XSHU/RDGHU

70

2$

Page 2

Quantum SuperLoader 3 User’s Guide, 81-81317-02 A01, September 2005.

Quantum Corporation provides this publication “as is” without warranty of any kind, either express or

implied, including but not limited to the implied warranties of merchantability or fitness for a particular

purpose. Quantum Corporation may revise this publication from time to time without notice.

COPYRIGHT STATEMENT

Copyright 2005 by Quantum Corporation. All rights reserved.

Your right to copy this manual is limited by copyright law. Making copies or adaptations without prior

written authorization of Quantum Corporation is prohibited by law and constitutes a punishable violation of

the law.

TRADEMARK STATEMENT

Quantum, the Quantum logo, and SuperLoader 3 are trademarks of Quantum Corporation, registered in the

U.S.A. and other countries. DLTtape and Super DLTtape are registered trademarks of Quantum Corporation.

Products mentioned herein are for identification purposes only and may be trademarks or registered

trademarks of their respective companies. All other trademarks are the property of their respective owners.

Page 3

Contents

Preface xv

Chapter 1 Introduction 1

Overview............................................................................................................. 1

SuperLoader 3 LTO-2................................................................................. 2

SuperLoader 3 LTO-3................................................................................. 2

SuperLoader 3 VS160 ................................................................................. 3

SuperLoader 3 SDLT600 ............................................................................ 3

Chapter 2 Installation and Configuration 5

Installing the Autoloader.................................................................................. 5

Accessories..........................................................................................................8

Choosing a Location .......................................................................................... 9

Installation Overview.................................................................................6

Installation Preparation .............................................................................7

SCSI Bus Requirements.............................................................................. 7

SuperLoader 3 Autoloader User’s Guide iii

Page 4

Contents

UL Requirements..............................................................................................10

Elevated Operating Ambient Temperature...........................................10

Reduced Air Flow .....................................................................................10

Mechanical Loading..................................................................................10

Overloading the Circuit ...........................................................................10

Reliable Earthing (Grounding)................................................................10

Understanding Autoloader Features.............................................................11

General Features........................................................................................11

Bar Code Reader...............................................................................................11

Product Overview.....................................................................................12

Unpacking the Autoloader .............................................................................14

Identifying Product Components ..................................................................15

Accessories .................................................................................................15

Mounting the Rail Kit ......................................................................................16

Connecting the SCSI and Power Cables........................................................16

Attaching SCSI and Power Cables..........................................................17

Preparing the Host and Verifying the Connection......................................18

Installing the Device Drivers ..........................................................................19

Tape Drive Device Driver ........................................................................19

Autoloader Device Driver........................................................................20

Chapter 3 Operating the Autoloader 23

Operator's Panel Functionality.......................................................................24

Enter Passwords........................................................................................25

Logout.........................................................................................................25

Using Cartridges...............................................................................................26

Insert a Single Cartridge...........................................................................27

Moving a Single Cartridge.......................................................................28

Ejecting a Single Cartridge.......................................................................28

Using Magazines and Magazine Blanks .......................................................30

Ejecting a Magazine ..................................................................................31

Magazine Load/Unload Command.......................................................32

Installing a Magazine................................................................................32

Manually Operating the Magazine.........................................................33

Viewing Status Information............................................................................34

Viewing SuperLoader 3 Autoloader Status...........................................34

Viewing Firmware Version......................................................................35

Viewing Element Status ...........................................................................36

Viewing Tape Drive Status......................................................................37

Viewing Tape Drive Version ...................................................................37

Viewing Ethernet Information ................................................................38

iv SuperLoader 3 Autoloader User’s Guide

Page 5

Contents

Running an Inventory ..................................................................................... 38

Data Compression............................................................................................ 39

Chapter 4 On-board Remote Management 41

On-board Remote Management Overview.................................................. 41

Opening On-board Remote Management............................................. 42

Viewing Status Information .................................................................... 43

Default Username and Password........................................................... 43

Time Display ............................................................................................. 43

Feedback on Pages.................................................................................... 44

Configuration Page.......................................................................................... 44

System Operations Options..................................................................... 44

Updates Page.................................................................................................... 53

Diagnostics Page .............................................................................................. 54

Running Diagnostic Tests........................................................................ 54

Viewing Error or History Logs............................................................... 54

Diagnostics................................................................................................. 55

Identification.............................................................................................. 55

Performing a System Reset...................................................................... 55

Commands Page .............................................................................................. 56

Inventory.................................................................................................... 56

Set to Home ............................................................................................... 56

Sequential Operations.............................................................................. 57

Chapter 5 Administration 59

Administration of the Autoloader................................................................. 59

Configuring the Autoloader........................................................................... 60

Setting the Time................................................................................................ 66

Setting the SCSI ID.................................................................................... 62

Setting Ethernet.........................................................................................62

Setting the IP Address.............................................................................. 63

Setting the Subnet Mask .......................................................................... 64

Setting an IP Gateway .............................................................................. 64

Setting the SNMP Server ......................................................................... 65

Setting the Time Server............................................................................ 66

SuperLoader 3 Autoloader User’s Guide v

Page 6

Contents

Setting the Change Mode ................................................................................68

Sequential Mode Operations ...................................................................69

Setting Security..........................................................................................70

Setting Magazines .....................................................................................70

Setting Passwords .....................................................................................71

Getting Lost Passwords............................................................................72

Chapter 6 Diagnostics 73

POST...................................................................................................................74

Perform a POST.........................................................................................75

Interpret the POST Results ......................................................................75

Diagnostic Tests from the Front Panel ..........................................................75

Setting the Security ...................................................................................76

Stopping a Diagnostic Test ......................................................................76

Front Panel Diagnostic Tests ...................................................................77

On-board Remote Management Diagnostic Tests.......................................78

Diagnostics Using On-board Remote Management ............................79

Chapter 7 Customer Replaceable Units (CRUs) 81

Replacing a Magazine or Magazine Blank ...................................................82

Removing a Magazine..............................................................................82

Removing a Magazine Blank...................................................................83

Reinstalling a Magazine ...........................................................................83

Installing a magazine blank.....................................................................83

Changing the Orientation ........................................................................84

Rack Mounting the Autoloader......................................................................86

General Preparation for Rack Mount Installation................................88

Stationary Rack Mount Installation........................................................88

Installing and Removing the Optional V-Rail Kit .......................................95

Requirements.............................................................................................95

Accessory Pieces........................................................................................97

Installation in a .375 Square Hole Rack..................................................98

Installation in a .280 Diameter Thru Hole Rack....................................99

Installation in a 10-32 Threaded Hole Rack.........................................100

Chassis-Mounted Rails...........................................................................101

vi SuperLoader 3 Autoloader User’s Guide

Page 7

Contents

Chapter 8 Troubleshooting 107

Before Contacting Customer Support......................................................... 107

Returning the Autoloader for Service......................................................... 112

Preparing the Autoloader for Shipment.............................................. 112

Removing the Autoloader from a Rack............................................... 113

Packing the Autoloader ......................................................................... 114

Checking for Errors........................................................................................ 114

Hard Error Log Display.........................................................................123

Error Code Field Description................................................................ 125

Chapter 9 Basic Logs 137

Basic Information Logs.................................................................................. 137

Log Descriptions ............................................................................................138

Autoloader Logs ..................................................................................... 138

Error Codes..................................................................................................... 139

Soft Logs................................................................................................... 143

Update Logs............................................................................................. 143

Shadow Logs ...........................................................................................143

Boot Logs.................................................................................................. 144

OEM Logs ................................................................................................144

ID Logs ..................................................................................................... 144

Tape Drive Logs ............................................................................................. 145

Log Fields................................................................................................. 145

POST Failure Logs .........................................................................................146

Appendix A Specifications 147

Physical Specifications .................................................................................. 148

Autoloader Performance Specifications .....................................................149

Environmental Specifications.......................................................................151

Autoloader Power Specifications ................................................................ 152

Autoloader Vibration Specifications........................................................... 152

Autoloader Shock Specifications .................................................................153

SuperLoader 3 Autoloader User’s Guide vii

Page 8

Contents

Tape Drive Specifications..............................................................................153

LTO-2 Drive Specifications....................................................................153

Media Capacity........................................................................................154

Media Specifications ...............................................................................154

LTO-3 Drive Specifications....................................................................155

Media Capacity........................................................................................155

Media Specifications ...............................................................................155

VS160 Drive Specifications ....................................................................156

Media Capacity........................................................................................157

Media Specifications ...............................................................................157

SDLT600 Drive Specifications ...............................................................158

Media Capacity........................................................................................158

Media Specifications ...............................................................................159

Appendix B Drive Error Logs 161

Tape Drive Error Logs ...................................................................................161

Error Log Display....................................................................................161

SCSI Check Condition Error Logs ........................................................162

Bugcheck Error Logs (SDLT600 only) .........................................................166

Event Error Logs (SDLT600 only) ................................................................168

A500: Hard Read Error...........................................................................169

A501: SDLT Hard Write Error...............................................................171

A502: SDLT Loader Communication Error.........................................173

A503: SDLT Drive Servo Error..............................................................173

A507/A508: Directory Read Failure/Directory Write Failure .........179

Appendix C Regulatory Statements 187

Taiwan Statement...........................................................................................188

Japan Notice ....................................................................................................189

Canadian Notice (Avis Canadien) ...............................................................189

European Union Notice.................................................................................189

Product Safety Electrostatic Discharge .......................................................190

Grounding Methods ......................................................................................191

Disposal of Electrical and Electronic Equipment.......................................192

Glossary 193

viii SuperLoader 3 Autoloader User’s Guide

Page 9

Contents

Index 205

SuperLoader 3 Autoloader User’s Guide ix

Page 10

Contents

x SuperLoader 3 Autoloader User’s Guide

Page 11

Figures

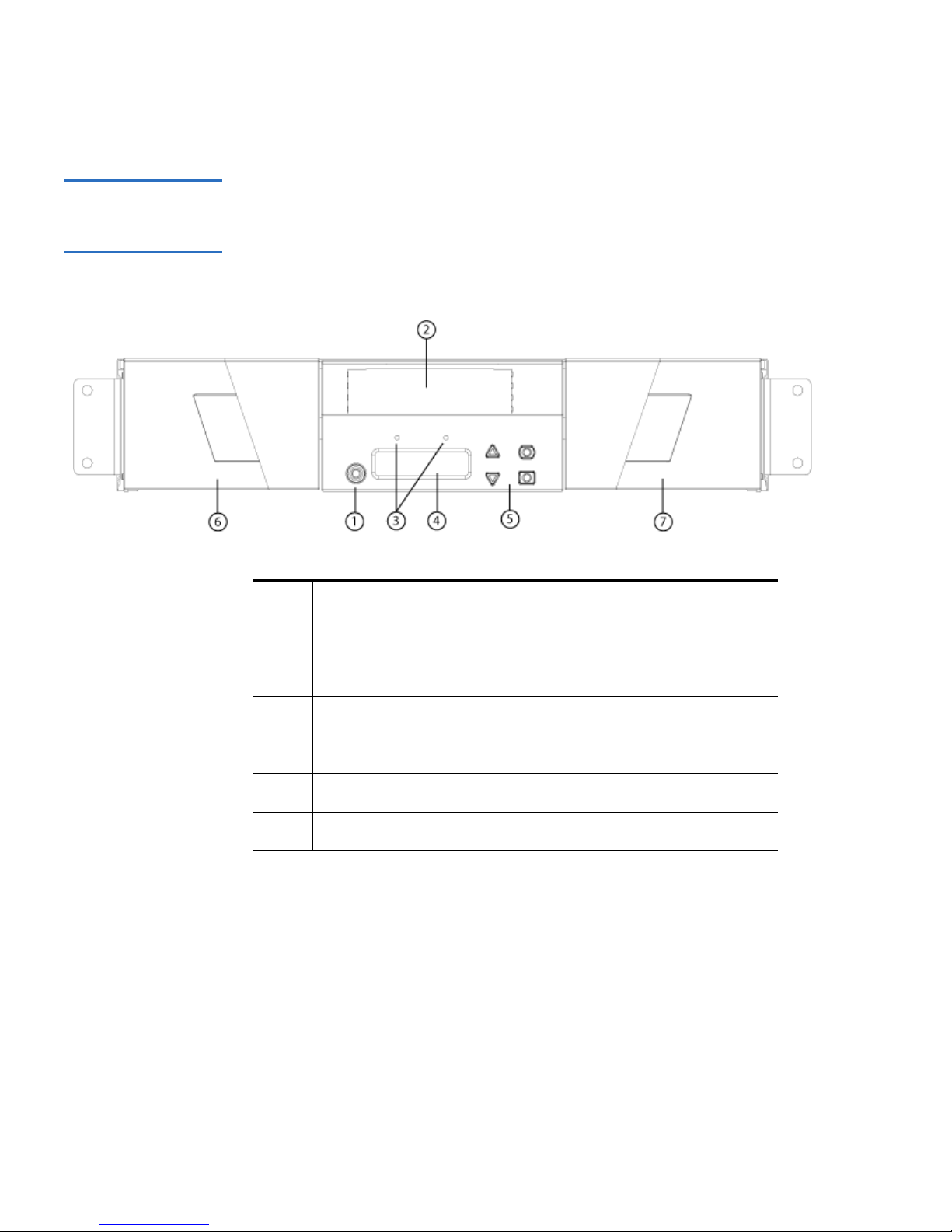

Figure 1 Front Panel Controls .................................................................. 12

Figure 2 Back Panel Overview ................................................................. 13

Figure 3 Accessories .................................................................................. 15

Figure 4 Attaching SCSI and Power Cables........................................... 17

Figure 5 Front Panel .................................................................................. 24

Figure 6 Left and Right Sides of a Magazine ......................................... 30

Figure 7 System Menu Tree...................................................................... 61

Figure 8 Magazine and Blank................................................................... 84

Figure 9 Removing the Screws from the Handle .................................. 85

Figure 10 Clearance Requirements for Rack Mounting .........................87

Figure 11 Required Parts for Installation ................................................. 89

Figure 12 Installing Two Clip Nuts...........................................................90

Figure 13 Attaching Autoloader Brackets................................................ 91

Figure 14 Attaching Support Brackets......................................................92

Figure 15 Sliding Autoloader into Rack ................................................... 93

Figure 16 Front Alignment ......................................................................... 94

Figure 17 Connecting Support Brackets ................................................... 94

SuperLoader 3 Autoloader User’s Guide xi

Page 12

Figures

Figure 18 Left Rail Assembly......................................................................96

Figure 19 Right Rail Assembly...................................................................96

Figure 20 Front Mount Features.................................................................97

Figure 21 Rear Mount Features..................................................................97

Figure 22 Front Cover Plate and 10-32 Nut Plates ..................................98

Figure 23 .375 Square Hole Rack Installation...........................................99

Figure 24 .280 Diameter Thru Hole Rack Installation...........................100

Figure 25 10-32 Threaded Hole Rack Installation..................................101

Figure 26 Chassis Rail Parts......................................................................102

Figure 27 Rail Installed on Chassis..........................................................102

Figure 28 Close up of Chassis Rail...........................................................103

Figure 29 Chassis Mounted in Rack ........................................................104

Figure 30 Back View of Mounted Chassis ..............................................104

Figure 31 Close Up of Back View Chassis ..............................................105

Figure 32 Back View of the Rail After Installation ................................105

Figure 33 Error Log Diagram ...................................................................116

Figure 34 Error Code Bit Descriptions ....................................................126

Figure 35 Error Code Field Descriptions ................................................126

Figure 36 Error Code Listing and Suggested Actions...........................128

Figure 37 Shadow Log Sample.................................................................144

Figure 38 Log Field Descriptions .............................................................145

Figure 39 POST Failures Event Log Sample...........................................146

Figure 40 Hard Read Error/Hard Write Error Block Descriptor........169

Figure 41 Hard Read Error/Hard Write Error Block Descriptor........171

Figure 42 Loader Communication Error Block Description ................173

Figure 43 Drive Servo Error Block Descriptor .......................................174

Figure 44 Directory Read Failure/Write Failure Block Descriptor.....179

xii SuperLoader 3 Autoloader User’s Guide

Page 13

Tables

Table 1 Location Criteria........................................................................... 9

Table 2 Autoloader Status....................................................................... 35

Table 3 Firmware Version Fields ........................................................... 35

Table 4 Drive Status Fields ..................................................................... 37

Table 5 Drive Version Fields .................................................................. 37

Table 6 Ethernet Information Fields...................................................... 38

Table 7 POST Descriptions ..................................................................... 74

Table 8 Probable Cause and Possible Solutions................................. 108

Table 9 Error Codes ............................................................................... 117

Table 10 Hard Error Log Field Descriptions........................................ 125

Table 11 Log Retrieval Methods ............................................................ 138

Table 12 Log Fields ..................................................................................139

Table 13 Error Code Fields ..................................................................... 140

Table 14 POST Failure Specific Fields ................................................... 146

Table 15 Error Log Display Field Descriptions.................................... 162

Table 16 SCSI Check Condition Error Log Field Descriptions.......... 163

Table 17 Sense Key Field Definitions .................................................... 163

SuperLoader 3 Autoloader User’s Guide xiii

Page 14

Tables

Table 18 ASC/ASCQ Field Descriptions ..............................................165

Table 19 Bugcheck Log Field Descriptions...........................................166

Table 20 Error Event Logs Field Descriptions......................................168

Table 21 Hard Read /Hard Write Error Field Descriptions...............169

Table 22 Hard Read Error/Hard Write Error Field Descriptions .....171

Table 23 Loader Communication Error Field Description.................173

Table 24 Drive Servo Error Field Descriptions.....................................174

Table 25 Directory Read/Write Failure Field Descriptions ...............180

xiv SuperLoader 3 Autoloader User’s Guide

Page 15

Preface

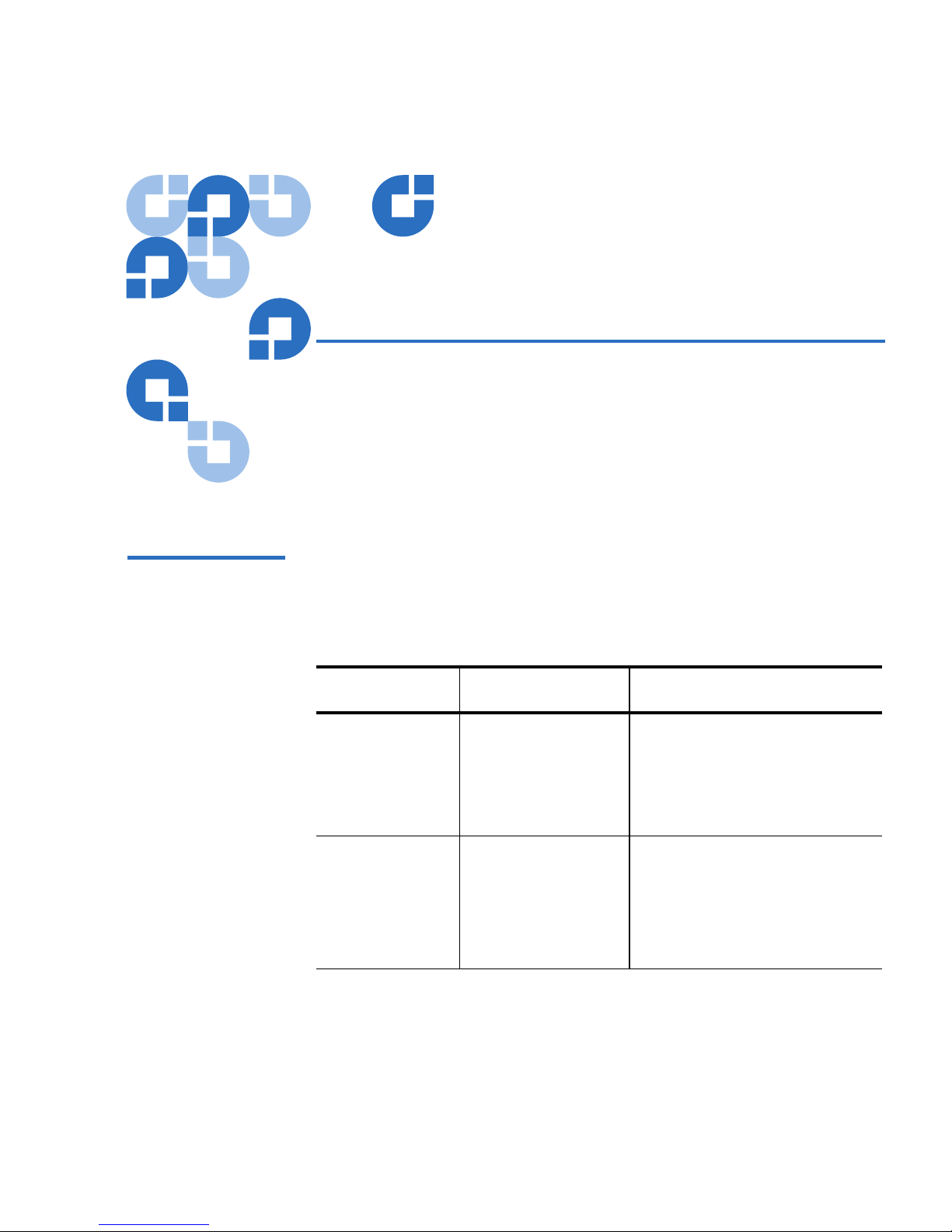

Related

Documentation

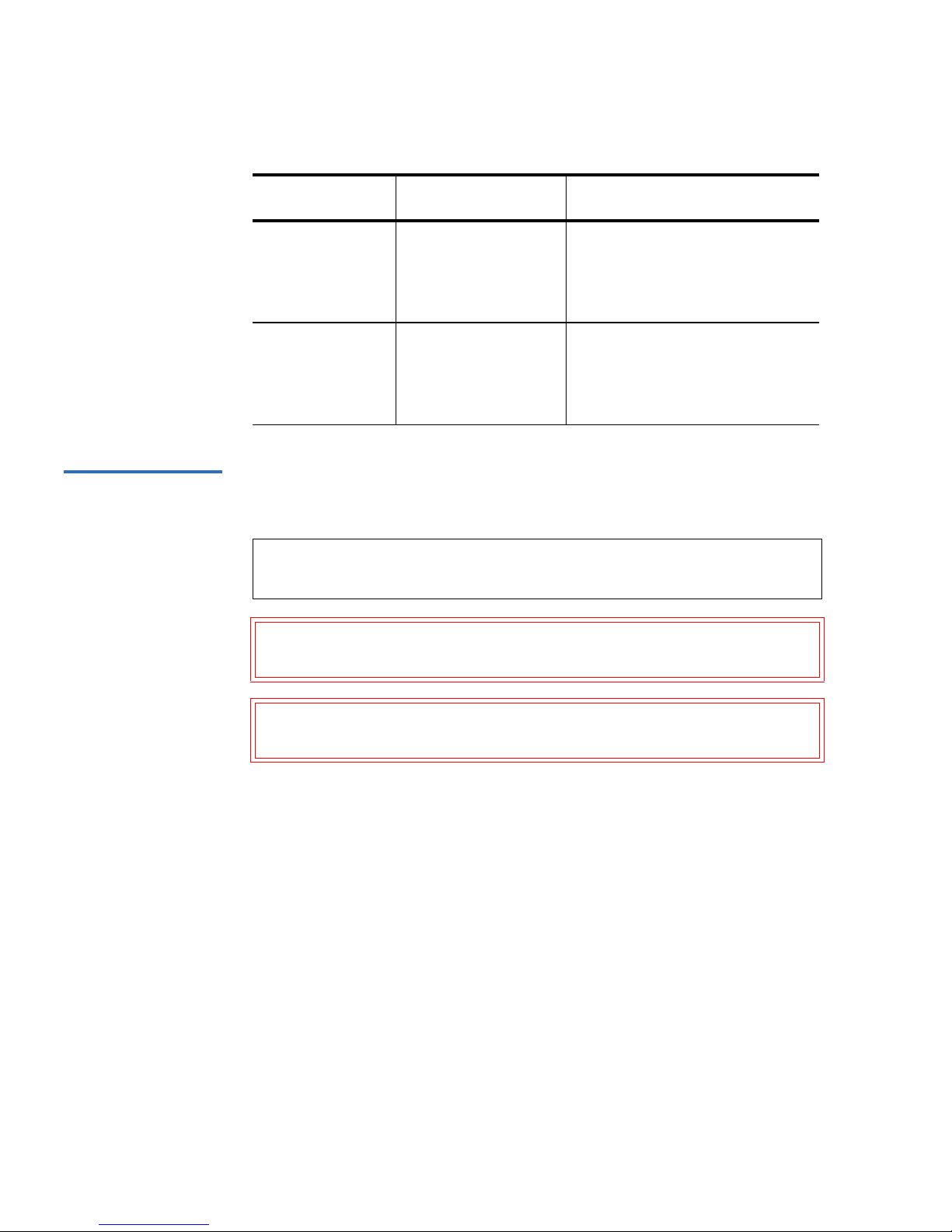

Documents related to the Quantum SuperLoader 3 are shown below:

Related Quantum Documentation

Document No. Document Title Document Description

81-81313

81-81314

Quantum

SuperLoader 3 Quick

Start Guide

Quantum

SuperLoader 3

Magazine and

Magazine Blank

Removal/

Replacement

This guide contains a

sequence of steps

recommended for unpacking,

installing, and setting up

your autoloader.

This guide contains a

sequence of steps

recommended for removal,

unpacking and installing a

magazine.

0

SuperLoader 3 Autoloader User’s Guide xv

Page 16

Preface

Document No. Document Title Document Description

Notational

Conventions

81-81316

81-81237

Quantum

SuperLoader 3 Rail

Installation Quick

Start Guide

How to Ship the

Quantum

SuperLoader

This guide contains a

sequence of steps

recommended for unpacking

and installing a rail kit.

This guide provides

information on the proper

packing for returning the

autoloader for repair.

This manual uses the following conventions to designate specific

elements:

Note: Notes emphasize important information related to the main

topic.

Caution: Cautions indicate potential hazards to equipment and are

included to prevent damage to equipment.

Warning: Warnings indicate potential hazards to personal safety

and are included to prevent injury.

xvi SuperLoader 3 Autoloader User’s Guide

Page 17

Contact Information

Quantum Corporate Headquarters 0

To order documentation for the Quantum SuperLoader 3 or other

products contact:

Quantum Corporation

141 Innovation

Irvine, CA 92617-3040

(949) 856-7800

(800) 284-5101

Technical Publications 0

Preface

To comment on existing documentation, send e-mail to:

doc-comments@quantum.com

Visit the Quantum home page at: 0

http://www.quantum.com

Quantum Frequently Asked Questions (FAQs) 0

Visit the Quantum Knowledge Base at:

http://www.quantum.com/am/service_support/faqs

SuperLoader 3 Autoloader User’s Guide xvii

Page 18

Preface

Customer Support 0

The Quantum Customer Support Department provides a 24-hour help

desk that can be reached at:

North/South America (949) 725-2100 or

(800) 284-5101

Asia/Pacific Rim (International Code)

+61 7 3839 0988

Europe/Middle East/Africa: (International Code)

+44 (0) 1256 848748

Send faxes for the Customer Support Department to:

North/South America (949) 725-2176

Asia/Pacific Rim (International Code)

+61 7 3839 0955

Europe/Middle East/Africa: (International Code)

+44 (0) 1256 848777

Send e-mail for the Customer Support Department to:

North/South America helpdesk@quantum.com

Asia/Pacific Rim apachelp@quantum.com

Europe/Middle East/Africa: eurohelp@quantum.com

xviii SuperLoader 3 Autoloader User’s Guide

Page 19

Chapter 1

1Introduction

Overview 1

Data backup is essential to protect irreplaceable information. Backing up

data to magnetic tape is an easy, cost-efficient method used by many

small and medium businesses. However, most enterprises have so much

data that a single backup tape is not enough; the information has to be

spread across numerous tapes. To avoid constantly changing tapes

manually, many tape backup systems include a Quantum SuperLoader 3

autoloader.

Each autoloader is a robot that includes a tape drive and one or two

magazines for tape cartridges. The user's application can automatically

load and unload tape cartridges as required for data backup or data

retrieval. Quantum SuperLoader 3 autoloaders provide a compact, high

capacity, but low cost method for simple, unattended data backup.

SuperLoader 3 Autoloader User’s Guide 1

Page 20

Chapter 1 Introduction

Overview

The Quantum SuperLoader 3 contains a Quantum LTO-2 half-height tape

drive, a Quantum LTO-3 tape drive, a Quantum VS160 tape drive, or a

Quantum SDLT600 tape drive, and one or two magazines containing up

to eight cartridges each. A single cartridge can be inserted directly via a

password-protected mailslot. From the mailslot, the cartridge can be

inserted into the tape drive provided there is no cartridge already in the

drive, or you can load the cartridge into a magazine slot provided there is

no cartridge already in the slot.

The front panel on the autoloader includes a liquid crystal display (LCD)

screen and four function keys. A scrolling menu on the LCD screen

allows you to obtain information from the autoloader and enter

commands. The front panel also includes two light emitting diodes

(LEDs) indicating the autoloader's ready status and error status.

The Quantum SuperLoader 3 connects to your host server via a SCSI

connection allowing the host to send data and commands automatically.

You can also connect to the autoloader using an Ethernet connection to

perform administrative functions and download system updates.

SuperLoader 3

LTO-2 1

SuperLoader 3

LTO-3 1

The autoloader is SCSI-3 compatible and operates as a single SCSI ID/

two LUN data storage device. The Quantum SuperLoader 3 LTO-2

autoloader is equipped with a Quantum LTO-2 half-height tape drive

and contains up to sixteen Ultrium 2 data cartridges when utilizing two

magazines, providing a compressed capacity of 6.4 Terabytes and a

sustained data transfer rate of 93.6 GB per hour (native) or as high as

187.2 GB per hour compressed (assuming 2:1 compression).

The autoloader is compatible with the most popular operating systems

and environments supporting a Ultra 160 SCSI-3 LVD interface but

requires direct support from the operating system or a compatible

backup application to take full advantage of its many features.

The autoloader is SCSI-3 compatible and operates as a single SCSI ID/

two LUN data storage device. The Quantum SuperLoader 3 LTO-2

autoloader is equipped with a Quantum LTO-3 tape drive and contains

up to sixteen Ultrium 3 data cartridges when utilizing two magazines,

providing a compressed capacity of 6.4 Terabytes and a sustained data

transfer rate of 245 GB per hour (native) or as high as 490 GB per hour

compressed (assuming 2:1 compression).

2 SuperLoader 3 Autoloader User’s Guide

Page 21

Chapter 1 Introduction

Overview

The autoloader is compatible with the most popular operating systems

and environments supporting a Ultra 160 SCSI-3 LVD interface but

requires direct support from the operating system or a compatible

backup application to take full advantage of its many features.

SuperLoader 3

VS160 1

SuperLoader 3

SDLT600 1

The autoloader is SCSI-3 compatible and operates as a single SCSI ID/

two LUN data storage device. The Quantum SuperLoader 3 VS160

autoloader is equipped with a Quantum VS160 tape drive and contains

up to sixteen Quantum VS1 data cartridges when utilizing two

magazines, providing a compressed capacity of 2560 GB and a sustained

data transfer rate of 28.8 GB per hour (native) or as high as 57.6 GB per

hour compressed (assuming 2:1 compression).

The autoloader is compatible with the most popular operating systems

and environments supporting a SCSI LVD interface but requires direct

support from the operating system or a compatible backup application to

take full advantage of its many features.

The autoloader is SCSI-3 compatible and operates as a single SCSI ID/

two LUN data storage device. The Quantum SuperLoader 3 SDLT600

autoloader is equipped with a Quantum SDLT600 tape drive and

contains up to sixteen SDLT II data cartridges when utilizing two

magazines, providing a compressed capacity of 9.4 Terabytes and a

sustained data transfer rate of 129.6 GB per hour (native) or as high as

259.2 GB per hour compressed (assuming 2:1 compression).

The autoloader is compatible with the most popular operating systems

and environments supporting a 16-bit Ultra 160 SCSI-3 LVD interface but

requires direct support from the operating system or a compatible

backup application to take full advantage of its many features.

SuperLoader 3 Autoloader User’s Guide 3

Page 22

Chapter 1 Introduction

Overview

4 SuperLoader 3 Autoloader User’s Guide

Page 23

Chapter 2

2Installation and Configuration

Installing the Autoloader 2

• Installation Overview

• Installation Preparation

• SCSI Bus Requirements

• Accessories

• Choosing a Location on page 9

• UL Requirements

• Understanding Autoloader Features

• Bar Code Reader

• Product Overview

• Identifying Product Components

SuperLoader 3 Autoloader User’s Guide 5

on page 10

on page 11

on page 12

on page 15

on page 11

Page 24

Chapter 2 Installation and Configuration

Installing the Autoloader

• Connecting the SCSI and Power Cables on page 16

Installation

Overview 2

• Preparing the Host and Verifying the Connection

• Installing the Device Drivers

on page 19

on page 18

Installing the autoloader consists of the following steps, which are

explained in more detail later in this section:

1 Prepare to install your new Quantum SuperLoader 3 autoloader (see

Installation Preparation

).

2 Identifying the proper SCSI bus types (see SCSI Bus Requirements

3 Identify the accessories that come with the autoloader (see

Accessories

on page 15).

4 Install the autoloader in a computer rack or select a table or desktop

near the host server. If installing a rack mount unit, refer to your rack

Installation Guide.

5 Shut down or turn off the server and all devices attached to the server

(see Connecting the SCSI and Power Cables

on page 16).

6 Attach the SCSI cable to the autoloader and server's SCSI host

adapter (see Connecting the SCSI and Power Cables

on page 16).

).

7 Attach the power cable to the autoloader and plug in the power cable

to the nearest power outlet (see Connecting the SCSI and Power

Cables on page 16). Power the autoloader on to ensure it passes the

Power-on Self Test (POST).

8 Set the SCSI ID for the autoloader (see Setting

page 62).

9 Set up the host and verify the connection (see Preparing the Host and

Verifying the Connection on page 18).

Warning: Whenever you power cycle the autoloader, allow 10

seconds before turning the power back on. The power

supply requires at least two to three seconds for the

capacitors to discharge. This ensures a complete system

reset on power down and may avoid system errors.

6 SuperLoader 3 Autoloader User’s Guide

the SCSI ID on

Page 25

Chapter 2 Installation and Configuration

Installing the Autoloader

Installation

Preparation 2

SCSI Bus

Requirements 2

Before you install your new Quantum SuperLoader 3 autoloader, unpack

it carefully and inspect it for any damage that might have occurred

during shipping. The

Quantum SuperLoader 3 Quick Start Guide included in

the packaging describes all the necessary information to unpack and

inspect your autoloader correctly.

Ensure that the work area is free from conditions that could cause

electrostatic discharge (ESD). Discharge static electricity from your body

by touching a known grounded surface, such as your computer's metal

chassis.

There are minor differences between the Quantum SuperLoader 3 LTO-2

and the Quantum SuperLoader 3 VS160/SDLT600 autoloaders.

SuperLoader 3 LTO-2 2

You must connect the Quantum SuperLoader 3 LTO-2 to one of the

following SCSI bus types:

• Ultra2 SCSI Low-voltage Differential (LVD), Single-ended (SE) SCSI

bus

Note: The autoloader is not compatible with a High-voltage

Differential (HVD) SCSI bus.

SuperLoader 3 LTO-3/VS160/SDLT600 2

You must connect the Quantum SuperLoader 3 LTO-3, VS160 or

SDLT600 autoloader to one of the following SCSI bus types:

• Ultra 320 SCSI-3, LVD SE SCSI bus

• Ultra 160 SCSI-3, LVD SE SCSI bus

SuperLoader 3 Autoloader User’s Guide 7

Page 26

Chapter 2 Installation and Configuration

Accessories

General Information 2

Your SCSI host adaptor card must also support the SCSI bus type used to

connect the autoloader. If you use a LVD SCSI bus, use a host adapter

card with a connection for a VHDCI cable.

Note: If you use a single-ended (SE) SCSI bus, the tape drive’s

performance is limited to the maximum data transfer speed of

the bus.

Note: The maximum number of autoloaders supported per SCSI bus

is four.

Note: The autoloader may not work with multiple SCSI LUNS when

attached to a RAID controller. The autoloader is not

recommended for use with a RAID controller. If this problem

occurs, it is recommended that the autoloader be attached to a

separate SCSI bus controller on the host or server.

Accessories 2

The following accessories are shipped with the Quantum SuperLoader 3

autoloader:

• Quantum SuperLoader 3 Quick Start Guide

• SCSI host cable

•SCSI terminator

• Hardware to rack mount the autoloader

• T8 and T10 TORX

• One magazine blank

•Power cable

8 SuperLoader 3 Autoloader User’s Guide

®

L-Key drivers

Page 27

Chapter 2 Installation and Configuration

Choosing a Location

• Documentation CD containing all of the documentation in Adobe®

Portable Document Format (PDF)

•Bar code labels

Choosing a Location 2

Choose a location that meets the following criteria (see table 1

autoloader uses standard rack mounting hardware.

Table 1 Location

Criteria

Criteria Description

Rack requirements Standard 19-inch rack with 2U of clearance.

Room temperature 10–35° C (50–95° F)

Power source AC power voltage: 100–127 VAC; 200–240 VAC

Line frequency: 50–60 Hz

Note: Locate the AC outlet near the autoloader. The AC

power cable is the product’s main disconnect

device and must be easily accessible at all times.

Weight 14.1 kg (31 lb.) unloaded

17.2 kg (38 lb.) loaded with 2 magazines, 16 cartridges

). The

Air Quality Minimize sources of particulate contamination. Avoid

areas near frequently used doors and walkways, cooling or

exhaust vents, stacks of supplies that collect dust, printers,

and smoke-filled rooms.

Caution: Excessive dust and debris can damage tapes

and tape drives.

SuperLoader 3 Autoloader User’s Guide 9

Page 28

Chapter 2 Installation and Configuration

UL Requirements

Criteria Description

Humidity 20–80% RH (non-condensing)

Clearance Back: Minimum of 43.2 cm (17 in.)

Front: Minimum of 68.6 cm (27 in.)

Sides: Minimum of 5.08 cm (2 in.)

UL Requirements 2

Elevated

Operating Ambient

Tempe rat u re 2

Reduced Air Flow 2 Installation of the equipment in a rack should be such that the amount of

Mechanical

Loading 2

Overloading the

Circuit 2

When installed in a closed multi-unit rack assembly, the operating

ambient temperature of the rack environment may be greater than the

room ambient. Therefore, consideration should be given to installing the

equipment in an environment compatible with the manufacturer’s

maximum recommended ambient temperature.

air flow required for safe operation of the equipment is not compromised.

Mounting of the equipment in a rack should be such that a hazardous

condition is not achieved due to uneven mechanical loading.

Consideration should be given to the connection of the equipment to the

supply circuit and the effect that overloading of circuits might have on

overcurrent protection and supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing the

concern.

Reliable Earthing

(Grounding) 2

10 SuperLoader 3 Autoloader User’s Guide

Reliable earthing of rack-mounted equipment should be maintained.

Particular attention should be given to supply connections other than

direct connections to the branch circuit, such as use of power strips.

Page 29

Chapter 2 Installation and Configuration

Understanding Autoloader Features

Understanding Autoloader Features 2

General Features 2 The autoloader is compatible with most operating systems and

environments that support the SCSI interface, but requires either direct

support from the operating system or a compatible backup application to

take full advantage of its many features.

Bar Code Reader 2

The bar code reader is enclosed within the body of the autoloader. The

bar code reader automatically scans each cartridge in the magazine upon

power up, after a reset, after an import or export, or when a re-inventory

command is issued (see Running an Inventory

there is no user interface with the bar code reader via the front panel

operator controls or LCD screen. The information from each label is

stored in memory and available through SCSI and On-board Remote

Management to the computer's operating system or backup application

upon request.

on page 38). Beyond that,

If utilizing the bar code reader, you must apply or slide the bar code

labels into the appropriate slot on the front of each cartridge. The labels

must conform to ANSI/AIM BC1 -1995 Uniform Symbology Specification

Code 39. A set of bar code labels is initially included with the autoloader.

Refer to

code labels.

www.quantum.com for information on obtaining additional bar

SuperLoader 3 Autoloader User’s Guide 11

Page 30

Chapter 2 Installation and Configuration

Bar Code Reader

Product Overview 2

Figure 1 Front Panel

Controls

1Power switch

2 Mailslot

3 Front panel LEDs

4 Front panel LCD screen

5 Function keys

6Left magazine (or blank)

7 Right magazine (or blank)

12 SuperLoader 3 Autoloader User’s Guide

Page 31

Figure 2 Back Panel

Overview

Chapter 2 Installation and Configuration

Bar Code Reader

1 VHDCI SCSI connectors

2Fan vent

3 Power connector

4 Ethernet connector

5Power switch

Note: If the cover must be taken off, there are 26 screws that need to

be removed.

SuperLoader 3 Autoloader User’s Guide 13

Page 32

Chapter 2 Installation and Configuration

Unpacking the Autoloader

Unpacking the Autoloader 2

Before you begin, clear a desk or table so that you can unpack the

autoloader. You also need to select an open 2U computer rack location

near the server that will host the autoloader.

Caution: If the room in which you are working differs from the

temperature in which the autoloader was shipped or

stored by 15° C (30° F) or more, let the autoloader

acclimate to the surrounding environment for at least 12

hours before opening the shipping carton.

Unpack and inspect the autoloader for shipping damage by doing the

following:

1 Clear a table or desk so that you have room to unpack the autoloader.

2 Inspect the shipping box for damage. If you notice any damage,

report it to the shipping company immediately.

3 Open the shipping box and remove the accessories package. Set the

accessories package aside for now.

4 Lift the autoloader and padding out of the box and place it on the

work surface, top facing up. Do not set the autoloader on either end or

sides.

5 Carefully remove the shipping padding from the left and right sides

of the autoloader. Then remove the bag from the autoloader. Save the

packing materials in case you need to move or ship the autoloader in the

future.

14 SuperLoader 3 Autoloader User’s Guide

Page 33

Chapter 2 Installation and Configuration

Identifying Product Components

Identifying Product Components 2

Accessories 2

Figure 3 Accessories

1 SCSI cable

2SCSI terminator

3Power cable

4 Quick Start Guide

5 CD (drivers and documentation)

6 Magazine blank

7Bar code labels

8 TORX T8 and T10 L-key drivers

SuperLoader 3 Autoloader User’s Guide 15

Page 34

Chapter 2 Installation and Configuration

Mounting the Rail Kit

Mounting the Rail Kit 2

For instruction on mounting the autoloader in a standard 19-inch rack,

see I

nstalling and Removing the Optional V-Rail Kit on page 95.

Connecting the SCSI and Power Cables 2

To connect the SCSI and power cables to the autoloader, follow these

steps:

1 Shut down and turn off the selected server. Turn off all attached

accessory devices, such as printers and other SCSI devices.

2 Attach one end of the SCSI cable (included in the accessory kit) to one

of the connectors on the back panel of the autoloader.

3 Attach the other end of the SCSI cable to the connector on the SCSI

host adapter or to the connector on the previous device on the SCSI

bus.

16 SuperLoader 3 Autoloader User’s Guide

Page 35

Attaching SCSI and

Power Cables 2

Figure 4 Attaching

SCSI and Power

Cables

Chapter 2 Installation and Configuration

Connecting the SCSI and Power Cables

3

1

2

1Ethernet cable

2 SCSI cable

3SCSI terminator

If the supplied SCSI cable does not fit the connector on your SCSI host

adapter, you either have an incompatible SCSI host adapter or you need

to purchase a cable adapter. Contact your service representative or your

SCSI host adapter manufacturer for information.

1 Attach the terminator to the remaining SCSI connector on the back

panel of the autoloader (if the autoloader is the last or only device on

the SCSI bus). Otherwise, attach the cable to the next device on the

SCSI bus. Make sure that the last device on the SCSI bus is properly

terminated.

2 Attach the female connector of the power cable to the power

connector on the back panel of the autoloader.

3 Plug in the power cable to the nearest properly grounded power

outlet.

4 Plug in the host server or workstation and all attached devices.

SuperLoader 3 Autoloader User’s Guide 17

Page 36

Chapter 2 Installation and Configuration

Preparing the Host and Verifying the Connection

5 Turn on the autoloader by setting the power switch on the front panel

to the

ON position. Turn on any other devices you turned off earlier.

Check the LCD screen to make sure the autoloader is receiving

power. If it is not, check the power connections and your power

source.

During the Power-on Self Test (POST), both LEDs are illuminated

briefly, followed by only the Ready/Activity LED flashing. When the

initialization sequence is complete, the LCD screen displays the

Home

screen.

6 Turn on the server.

Preparing the Host and Verifying the Connection 2

If necessary, install a SCSI host adapter, software, and compatible drivers.

Refer to the manuals for the host computer and SCSI host adapter for

detailed instructions. In addition, follow these general guidelines:

• When the host server is powered on, install software, and/or drivers

that are compatible with the autoloader (see Installing the Device

Drivers). Software compatibility information is available at

www.quantum.com. Most backup software packages require an

additional module to communicate with the autoloader robotics.

• If the host server is connected to a network, check with the system

administrator before turning off power.

• Use proper procedures to prevent electrostatic discharge (ESD). Use

wrist-grounding straps and anti-static mats when handling internal

components.

• Make sure that the host server has an open expansion slot.

• Make sure that your backup application supports the SCSI host

adapter.

• Depending on the server configuration, you may need to change the

SCSI ID of the autoloader (see Setting

the SCSI ID on page 62).

• Ensure the autoloader is properly terminated. If the autoloader is the

only SCSI device other than the SCSI host adapter on the selected

SCSI bus, it must be terminated. Likewise, if the autoloader is

physically the last SCSI device on the SCSI bus, it must be terminated.

18 SuperLoader 3 Autoloader User’s Guide

Page 37

Chapter 2 Installation and Configuration

Installing the Device Drivers

Only the devices physically at the beginning and end of the SCSI bus

should be terminated. If the host is located at the beginning of the

SCSI bus, the host should already have a terminator installed.

• Verify the connection between the autoloader and host by going to

Settings>Control Panel>System>Hardware>Device Manager>Tape

Drive

and/or Media Changer in Microsoft® Windows® 2000, Microsoft

Windows XP and Windows Server

®

2003. For more information on

verifying the connection of SCSI devices, consult the operating

system documentation.

Installing the Device Drivers 2

There are two device drivers associated with the SuperLoader 3

autoloader. One for the autoloader itself, and a second for the tape drive

within the autoloader.

Tape Drive Device

Driver 2

Note: Device drivers are required if you intend to use the Microsoft

Windows 2000 native backup application. Commercial backup

applications provide all necessary device driver support. Refer

to

www.quantum.com for a list of compatible backup

applications. Please note that Microsoft Windows NT

®

does

not include native support for autoloaders. A backup

application must be used if using the SuperLoader 3

autoloader under Microsoft Windows NT.

Microsoft Windows 2000:

1 Make sure that you are logged on to the host server with

administrator privileges.

2 Download the latest drivers from

service_support/downloads/default.htm. Save the drivers to your host

http://www.quantum.com/am/

computer.

SuperLoader 3 Autoloader User’s Guide 19

Page 38

Chapter 2 Installation and Configuration

Installing the Device Drivers

3 Open the device manager (please refer to your specific OS

documentation for instructions). For example, right-click the

Computer

Device Manager.

My

icon on the Windows desktop, click Manage, and then click

• The drive should be listed under the

QUANTUM [drive] SCSI Sequential Device.

4 Right-click the appropriate listing, click

? Other Devices item as

Uninstall, and then click OK

to confirm that you want to remove the device.

5 Click

Action in the upper-left corner of the Computer Management

dialog box.

6 Click

7 Right-click the appropriate listing and click

8 Select the

9 Click

Scan for Hardware Changes. Windows 2000 now scans for the

SuperLoader 3 drive. The drive appears under

Driver tab.

Update Driver.

? Other Devices again.

Properties.

10 When the Upgrade Device Driver Wizard appears, click

11 Click

12 Scroll down and click

Display a list... and then click Next.

Tape Drive, and then click Next.

13 Select the appropriate directory for your drive.

14 Click the

Quantum SuperLoader 3 [drive] entry, and then click Next.

Next.

Autoloader Device

Driver 2

15 Click

16 Click

17 Click the

Microsoft Windows 2000:

1 Make sure that you are logged on to the host server with

Next to install the driver.

Finish.

Device Properties dialog box.

The drive now appears in

Quantum SuperLoader 3 [drive] and is ready to use.

Device Manager under Tape Drives as a

administrator privileges.

2 Download the latest drivers from

service_support/downloads/default.htm. Save the drivers to your host

http://www.quantum.com/am/

computer.

20 SuperLoader 3 Autoloader User’s Guide

Page 39

Chapter 2 Installation and Configuration

Installing the Device Drivers

3 Right-click the My Computer icon on the Windows desktop, click

Manage, and then click Device Manager.

The autoloader should be listed under

Medium Changer Device

4 Right-click the

Uninstall, and then click OK to confirm that you want to remove the

Unknown Medium Changer Device listing, click

.

Medium Changers as Unknown

device.

5 Click

Action in the upper-left corner of the Computer Management

dialog box.

6 Click

Scan for Hardware Changes.

Windows 2000 now scans for the Quantum SuperLoader 3

Autoloader. The autoloader appears under

7 Right-click the

Properties.

8 Select the

Unknown Medium Changer Device listing and click

Driver tab.

9 When the Upgrade Device Driver Wizard appears, click

10 Click

Display a list... and then click Next.

Medium Changers again.

Next.

11 Browse to the location where the drivers were saved on the host

computer, and then click

OK.

12 Click the

13 Click

14 Click

15 Close the

Quantum SuperLoader 3 Autoloader entry and click Next.

Next again to install the driver.

Finish.

Device Properties dialog box.

The autoloader now appears in

Changers

as a Quantum SuperLoader 3 Autoloader, and is ready to

use.

SuperLoader 3 Autoloader User’s Guide 21

Device Manager under Medium

Page 40

Chapter 2 Installation and Configuration

Installing the Device Drivers

22 SuperLoader 3 Autoloader User’s Guide

Page 41

3Operating the Autoloader

• Operator's Panel Functionality

• Using Cartridges on page 26

Chapter 3

• Using Magazines and Magazine Blanks

• V

iewing Status Information on page 34

• Running an Inventory

• D

ata Compression on page 39

on page 38

on page 30

SuperLoader 3 Autoloader User’s Guide 23

Page 42

Chapter 3 Operating the Autoloader

Operator's Panel Functionality

Operator's Panel Functionality 3

Note: If security is enabled and you try to execute a command

without entering a password, the autoloader displays the

Enter Password screen until you enter a password. Once you

enter a password, the autoloader takes you back to the

command screen that you were at prior to entering the

password.

The Operator's Panel consists of two LEDs, four buttons, and a 2-line by

16-character LCD screen. The Operator's Panel provides everything you

need to monitor autoloader status and to control all of its functions.

Figure 5 Front Panel

1Power switch

2 Front panel LCD screen

3 Front panel LEDs

4 Scroll up button

24 SuperLoader 3 Autoloader User’s Guide

Page 43

Chapter 3 Operating the Autoloader

Operator's Panel Functionality

5 Scroll down button

6 Escape

7Enter

All the functionality accessed from the scrolling menu is passwordprotected. Two levels of security are built into the menu. The lower-level

security is the operator level and the higher-level security is the

administrator level. There is one password for each level.

The administrator password allows access to all the functionality

available. The operator password allows access to all the functionality in

the

Command and Status submenus.

Enter Passwords 3 Many functions on the autoloader may be password-protected to ensure

data integrity. To access the menu items necessary to execute these

functions, you must first enter your password (see Enter Passwords

on

page 25). All passwords are six numeric digits long.

When you enter a password, all password-protected functionality is

available until you close your browser session. If you do not use the front

panel for a period of time, the main screen reappears on the LCD. When

the main screen reappears, the autoloader has automatically logged you

out. You will have to re-enter your password again to access the menu

functionality.

Logout 3 To logout of the autoloader, use the following procedure.

1 From the main menu, scroll to

2 From the

Enter. Session Complete appears on the LCD.

Commands submenu, scroll to Log Out, and then press

Note: You can also press

Escape as required until the main screen appears.

Commands, and then press Enter.

Escape to log out. Continue pressing

SuperLoader 3 Autoloader User’s Guide 25

Page 44

Chapter 3 Operating the Autoloader

Using Cartridges

Using Cartridges 3

Typically, when you first install the autoloader, you load your cartridges

into the magazines and then load the magazines into the autoloader.

However, you can insert and eject cartridges individually using the

mailslot, or you can eject a magazine, manually load and unload

cartridges, then load the magazine back into the autoloader. The

autoloader automatically detects the presence of a cartridge in the

magazine slot.

Note: On the front panel menu, whenever you see

means the tape enters and leaves the autoloader through the

mailslot. Whenever you see

is loaded into or unloaded from the tape drive.

If you try to perform an illegal operation, the autoloader refuses to

perform the operation. For example, if you try to load a cartridge through

the mailslot to the drive but the drive already contains a cartridge, the

mailslot does not unlock. If you try to unload a cartridge from the drive

while the autoloader is writing to the tape, the command will not be

initiated until the write command is completed.

Caution: If a tape cartridge is holding the mailslot door open on

power up, the robot will not move. The system detects that

the mailslot door is open but cannot detect the presence of

the tape. If the mailslot door is open, the bar code scanner

laser light may shine out the door and potentially cause

physical injury.

With the mailslot door open, do not insert your hand

through the mailslot door. This is to prevent bodily injury

from the robot. Precautions are in place to prevent the

robotic mechanism functioning in this circumstance.

Load or Unload, it means the tape

Enter or Eject, it

26 SuperLoader 3 Autoloader User’s Guide

If the tape cartridge is holding the mailslot door open

during operation, the system keeps track of the tape

movement and continues robotic motion. This can occur if

the robot ejects the cartridge out through the mailslot

door.

Page 45

Chapter 3 Operating the Autoloader

Using Cartridges

Insert a Single

Cartridge 3

When you want to load a single cartridge into the autoloader, you can use

the mailslot. However, if the

Security option is turned on, you have to

enter a valid password to unlock the mailslot before you can load a

cartridge. When you insert a cartridge through the mailslot, you can load

it into the tape drive or store it in a magazine.

To insert a cartridge in the tape drive:

1 From the main menu, scroll to

2 From the

3 From the

Note: After

Commands submenu, scroll to Enter, and then press Enter.

Enter submenu, scroll to To D r ive, and then press Enter.

Load cartridge appears on the LCD, you have 20

Commands, and then press Enter.

seconds to load a cartridge through the mailslot before it

relocks.

Note: For the Quantum SuperLoader 3 autoloader, push in the

cartridge until you meet resistance. The cartridge will be

about 2 inches (5.0 cm) inside the mailslot, and only the

end of the cartridge will be visible through the mailslot.

4 Once you have inserted the cartridge, the prompt

appears. You have 20 seconds to press

Enter in response.

Enter to Continue

Note: If the insert cartridge function fails, the cartridge ejects and

you will have to perform steps 3

and 4 again.

To insert a cartridge in a magazine slot:

1 From the main menu, scroll to

2 From the

3 From the

Commands submenu, scroll to Enter, and then press Enter.

Enter submenu, scroll to To L o c ati o n , and then press Enter.

Commands, and then press Enter.

Scroll through the magazine slots and view their status until you find

the appropriate slot. Slots that are occupied by a data cartridge are

indicated by an asterisk (

*).

4 Scroll to the slot where you want to store the cartridge, and then

press

Enter.

SuperLoader 3 Autoloader User’s Guide 27

Page 46

Chapter 3 Operating the Autoloader

Using Cartridges

After Load cartridge appears on the LCD, you have 20 seconds to load

a cartridge through the mailslot before it relocks. The autoloader

automatically loads the cartridge into the selected slot.

Note: If the load cartridge function fails, the cartridge ejects and

you will have to perform steps 3

and 4 again.

Moving a Single

Cartridge 3

5 Once you have inserted the cartridge, the prompt

appears. You have 20 seconds to press

Enter in response.

Enter to Continue

You can easily move a single cartridge from one location to another

inside the autoloader.

1 From the main menu, scroll to

2 From the

The

Commands submenu, scroll to Move, and then press Enter.

Move screen appears under From:. Scroll to the current location of

Commands, and then press Enter.

the cartridge you want to move. Slots that are occupied by a data

cartridge are indicated by an asterisk (

*).

3 From To:, scroll to the location to which you want to move the

cartridge. Slots that are occupied by a data cartridge are indicated by

an asterisk (

4 Press

Enter.

If you select an empty location,

*). Press Enter.

No Source Element appears on the

LCD. Choose a different location.

If you select a location that is already occupied,

Destination Full

appears on the LCD. Choose a different location.

Ejecting a Single

Cartridge 3

When you want to remove a single cartridge from the autoloader, you

can specify the cartridge you want by bar code or location, or choose the

cartridge currently in the tape drive.

To eject a cartridge by bar code (if you have a bar code reader):

1 From the main menu, scroll to

2 From the

3 From the

press

28 SuperLoader 3 Autoloader User’s Guide

Commands, and then press Enter.

Commands submenu, scroll to Eject, and then press Enter.

Eject submenu, scroll to Tap e , scroll to Mailslot, and then

Enter.

Page 47

Chapter 3 Operating the Autoloader

Using Cartridges

4 Scroll to By Barcode.

A bar code label appears.

5 Scroll to the label that corresponds to the cartridge you want to eject.

Press

Enter.

To eject a cartridge by location:

1 From the main menu, scroll to

2 From the

3 From the

press

4 Scroll to

Commands submenu, scroll to Eject, and then press Enter.

Eject submenu, scroll to Tap e , scroll to Mailslot, and then

Enter.

By Location.

Commands, and then press Enter.

Slots that are occupied by a data cartridge are indicated by an asterisk

(

*). The slot that is occupied by a cleaning tape is indicated with an @

sign, if

Auto Clean is enabled. Scroll to the slot containing the

cartridge you want to eject.

5 Press

Enter.

The cartridge you want is ejected from the mailslot.

To eject a cartridge from the tape drive:

1 From the main menu, scroll to

2 From the

3 From the

4 Scroll to

Commands submenu, scroll to Eject, and then press Enter.

Eject submenu, scroll to Cartridge, and then press Enter.

From Drive, and then press Enter.

Commands, and then press Enter.

The cartridge you want is ejected from the mailslot.

SuperLoader 3 Autoloader User’s Guide 29

Page 48

Chapter 3 Operating the Autoloader

Using Magazines and Magazine Blanks

Using Magazines and Magazine Blanks 3

Figure 6 Left and

Right Sides of a

Magazine

30 SuperLoader 3 Autoloader User’s Guide

Page 49

Chapter 3 Operating the Autoloader

Using Magazines and Magazine Blanks

The autoloader will not run unless both magazine openings are properly

closed. One way that you can close the openings is to use two magazines.

If you use only one magazine, then you must fill the other magazine

opening with a magazine blank for the unit to become operational.

Note: Magazines, magazine blanks, and magazine handles are not

interchangeable between drives types. Please order the

appropriate part numbers when replacing these items.

Ejecting a

Magazine 3

When you want to remove several cartridges at once, eject the

magazine(s) first.

To eject a magazine:

1 From the main menu, scroll to

2 From the

3 On the

then press

Commands submenu, scroll to Eject, and then press Enter.

Eject submenu, scroll to Right Magazine or Left Magazine, and

Enter.

Commands, and then press Enter.

You will hear a distinctive popping sound as the appropriate

magazine is ejected from the autoloader.

ejected

or Right magazine has been ejected appears on the LCD.

Left magazine has been

Note: To prevent damage to the autoloader or the magazine, use

both hands when removing the magazine from the

autoloader supporting the entire length of the magazine.

4 Grasp the magazine by the handle with one hand and slide it out,

supporting it underneath with the other hand.

Note: Once you eject a magazine, you must fully remove it or

fully reinstall it before powering off the autoloader. Before

returning a magazine to the autoloader, manually turn the

wheels on the side of the magazine. If they move freely,

the cartridges are properly seated. If the wheels do not

turn freely, check the cartridges and remove and replace as

needed.

SuperLoader 3 Autoloader User’s Guide 31

Page 50

Chapter 3 Operating the Autoloader

Using Magazines and Magazine Blanks

Magazine Load/

Unload Command 3

Installing a

Magazine 3

When issuing a Load/Unload command to the autoloader, the system

automatically ejects the right-hand magazine. To remove the left-hand

magazine using the Load/Unload command, you must:

1 Remove the right magazine.

2 Replace the right magazine with a magazine blank.

3 Issue the Load/Unload command again. The system will then eject

the left magazine.

4 If you want to have the magazine in the right-hand bay, replace the

magazine blank in the right-hand bay with a cartridge magazine.

To install a magazine into the autoloader, use the following procedure.

1 Grasp the magazine by the handle with one hand and support it

underneath with the other hand.

2 Slide the magazine into the magazine bay until it clicks.

Make sure that you position the magazine correctly. It should slide

into the magazine bay smoothly. If you meet resistance, verify the

orientation of the magazine.

The magazine is correctly installed when you feel it click into place

and the front is flush with the front panel.

Mag Inserted

appears on the LCD. The autoloader automatically

Left Mag Inserted or Right

proceeds to run an inventory.

Note: Be careful not to turn the knob on the side of the magazine

while the magazine is partially inserted into the

autoloader. Doing so may cause damage to the magazine

or the autoloader.

32 SuperLoader 3 Autoloader User’s Guide

Page 51

Chapter 3 Operating the Autoloader

Using Magazines and Magazine Blanks

Manually

Operating the

Magazine 3

The following section describes how to operate a magazine.

There are two knobs located on each end of the magazine. You can move

the slots within the magazine by turning these two knobs and aligning a

slot with one of the two openings. You can use the openings in the

magazine to load and unload cartridges from the eight slots within each

magazine.

Note: It is recommended that you fully remove the magazine to load

and unload cartridges. If the magazine is not fully removed,

do not rotate the magazine.

To load cartridges into a fully ejected magazine:

1 To load cartridges into the magazine, center a slot within one of the

openings located on the side of the magazine.

2 Properly orient the cartridge.

Note: There is a keying feature in each slot that only allows you

to fully insert the cartridge one way.

3 Fully insert the cartridge into the slot.

When pushing the cartridge into the slot, you will feel a small

resistance (detente) until the cartridge is properly latched into the

slot. All forward progress stops when the cartridge is fully inserted.

You can remove a cartridge in the same manner as you insert it. Use the

knobs to center the desired slot(s) in the openings on the side of the

magazine. Using your thumb and index finger, pull out the cartridge.

You will feel a small resistance, but continue to pull the cartridge until it

comes free.

To unload cartridges from a fully ejected magazine:

1 Pull the ejected magazine until the large upper slot is accessible.

2 Rotate the desired slot into position (centered in the opening). Either

load or unload a cartridge to that location. Do not expose more than

the large upper opening when manually operating the magazine.

SuperLoader 3 Autoloader User’s Guide 33

Page 52

Chapter 3 Operating the Autoloader

Viewing Status Information

To identify a slot: 3

Each slot has an identification number that is exposed when the slots are

in the upper section of the magazine. With the magazine removed from

the autoloader, you can see the identification mark on the top side of the

magazine through one of two windows on the upper surface of the

magazine.

Each magazine has a unique identification number indicating whether it

is the right or left magazine. The left magazine will indicate the number 1

and the right magazine will indicate the number 9.

Viewing Status Information 3

From the scrolling menu on the LCD, you can view the autoloader status,

firmware version, element status, tape drive status, tape drive version,

and Ethernet information.

Viewing

SuperLoader 3

Autoloader Status 3

The autoloader status provides information about: whether a magazine is

installed or not, SCSI connection status, Ethernet connection status, and

whether a bar code reader is installed or not.

To view the autoloader status:

1 From the main menu, scroll to

2 From the

3 From the

Status submenu, scroll to Autoloader, and then press Enter.

Autoloader submenu, scroll to Status, and then press Enter.

Status, and then press Enter.

A list of messages similar to the following appears:

34 SuperLoader 3 Autoloader User’s Guide

Page 53

Chapter 3 Operating the Autoloader

Table 2 Autoloader

Status

Status Message Description

Magazines L=* The left magazine is present.

R=* The right magazine is present.

Viewing Status Information

SCSI ID A digit 0 through 7

The assigned SCSI ID for the autoloader.

(default 5)

Mode Random The change mode is set to Random.

SEQUENTIAL The change mode is set to Sequential.

BC Reader Yes or No A bar code reader is present.

Viewing Firmware

Version 3

To view the current firmware version, use the following procedure:

1 From the main menu, scroll to

2 From the

3 From the

Status submenu, scroll to Autoloader, and then press Enter.

Autoloader submenu, scroll to Version, and then press Enter.

Status, and then press Enter.

A list of messages appears on the LCD. The firmware version is listed

as

Firmware: VX.XX where X.XX is the current installed version of the

firmware.

Table 3 Firmware

Version Fields

Field Description

Firmware The number indicates the firmware version.

EDC The number indicates the Error Correction Code that

was generated when the firmware was installed. The

autoloader uses this number to verify that the

firmware and the memory holding the firmware are

good.

SuperLoader 3 Autoloader User’s Guide 35

Page 54

Chapter 3 Operating the Autoloader

Viewing Status Information

Field Description

HW Rev The number indicates the hardware version.

ME Rev The number indicates the mechanical version.

Viewing Element

Status 3

The element status reports the status of the magazine slots. The status