Page 1

HP LTO Ultrium tape drives

technical reference manual

LTO4 FC, SCSI and SAS drives

volume 1: hardware integration

Edition 1, June 2007

HP restricted

Page 2

Legal and notice information

© Copyright 2005–2007 Hewlett-Packard Development Company, L.P.

Hewlett-Packard Company makes no warranty of any kind with regard to this material, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be liable for errors contained herein or

for incidental or consequential damages in connection with the furnishing, performance, or use of this material.

This document contains proprietary information, which is protected by copyright. No part of this document may be photocopied,

reproduced, or translated into another language without the prior written consent of Hewlett-Packard. The information is provided

“as is” without warranty of any kind and is subject to change without notice. The only warranties for HP products and services are

set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as

constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

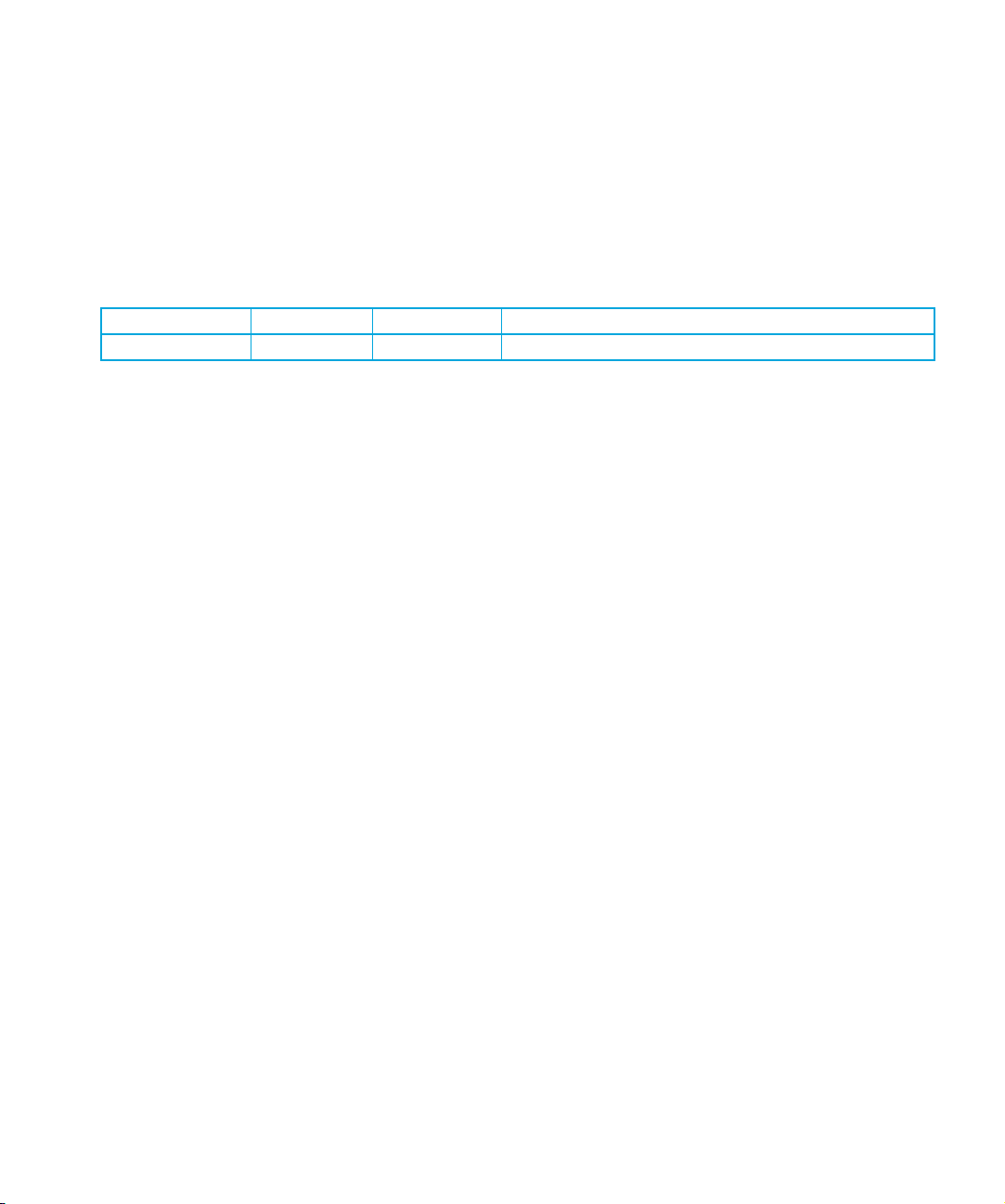

Revision history

Version Edition Date Changes

LTO 4 Edition 1 June 2007 LTO4 drives

This document is frequently revised and updated. To find out if there is a later version, please ask your HP OEM Representative.

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration

HP restricted

Page 3

Contents

Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Documentation map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Drives—general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Dealing with errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

LTO Ultrium features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General documents and standardization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1 LTO Ultrium drives in libraries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Backup software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Front panel for automation use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Front panel for use in autoloaders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Airflow requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Measuring internal drive temperatures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electrical fit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Rear panel and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fixing dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Bottom panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Side panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Operating drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Resetting drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Forced eject . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cleaning issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2 Using special features in libraries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Automation and drive interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Automation Control Interface (ACI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Automation/Drive Interface (ADI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configuring autoload and library-controlled loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cartridge positions during load and unload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 3

HP restricted

Page 4

Load scenarios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Load forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Using Cartridge Memory (LTO-CM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Use in libraries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Current libraries — barcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

More information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3 Drives in tape arrays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installing drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Identifying the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Modes of usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Attaching to Fibre Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Attaching to SCSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Attaching to SAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Appropriate HP rack-mount systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Airflow requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Setting the SCSI ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Inserting a drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Connecting to a Fibre Channel router or by SCSI/SAS to a server or router . . . . . . . . . . . . . . 35

Fibre Channel connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Server SCSI connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Server SAS connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Replacing a drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Removing a drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installing a new drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Operating the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Front panel features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Reset switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Loading a cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Unloading a cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cleaning the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Emergency unload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

General guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Problems with the host computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Problems with the drive and cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4 Internal drives in servers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Installing an internal drive into a server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Identifying the model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Standards and safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Mounting requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Airflow and cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Power requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4

HP restricted

Page 5

Server connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Fixing dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Bottom panel, full-height internal drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Side panel, full-height internal drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Connecting the drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Fibre Channel connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

SCSI connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

SAS connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Backup software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Operating the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Front panel features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Reset switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Loading a cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Unloading a cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Cleaning the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Emergency unload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

General guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Diagnosing the problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Problems with the host computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Problems with the drive and cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5 External standalone drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Identifying the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Connecting the drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

SCSI connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Setting the SCSI ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

SAS Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Moving drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Operating the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Front panel features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Reset switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Loading a cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Unloading a cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Rear panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Cleaning the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Emergency unload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

General guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Problems with the host computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Problems with the drive and cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 5

HP restricted

Page 6

6 Front panel and LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Usual meaning of LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Other LED patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

During firmware upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Replacing the front panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Parts needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Replacing the front panel on an full-height LTO Ultrium drive . . . . . . . . . . . . . . . . . . . . . . . . . 73

7 Rear panel LEDs, connectors and switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

LEDs (Fibre Channel drives only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Power-on self-test failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Port initialized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Port activity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Fibre Channel addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

SCSI connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Fibre Channel connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

SAS connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Automation Device/Interface (ADI) connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Connector pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8 Modes of usage and optimizing performance . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Modes of usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Direct Attach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Network Attach (LAN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Storage Area Network (SAN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Optimizing performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Dedicated SCSI bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

System performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Data transfer rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Performance checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9 Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Choosing cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Labeling cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Write-protecting cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Cartridge life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Caring for cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Avoiding condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Conditions in use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Conditions in storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Maximizing tape life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

LTO Cartridge Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

LTO Cartridge Memory issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

10Drive error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Generic module (from 0000h). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Automation Control Interface (from 0400h). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6

HP restricted

Page 7

Buffer manager (from 0800h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Diagnostic control (from 1800h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Drive control (from 1C00h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Drive monitor (from 2000h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

External interfaces (from 2400h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Front panel interface (from 2800h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Host interface (from 2C01h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Logical formatter (from 3000h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Logical media (from 3400h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Logical pipeline control (from 3800h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Mechanism control (from 3C00h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Non-volatile data manager (from 4000h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Operating system (from 4400h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Physical formatter (from 4C00h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Physical pipeline control (from 5000h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Physical side error recovery (from 5400h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Read/write control (from 5800h). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

System architecture (from 6400h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Tight integ (from 6800h). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Trace logger (from 6C00h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Mechanical interface (from 7400h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Exception handler (from 7800h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

SPI interface (from 7C01h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Cartridge Memory (from 8000h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Fault log manager section (from 8400h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Infrastructure section (from 8800h). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Critical section (from 8C00h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

SCSI module (from 9400h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Automation/Drive Interface (from 9800h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 7

HP restricted

Page 8

8

HP restricted

Page 9

Related documents

This is one of five volumes that document HP LTO Ultrium drives. This volume provides hardware

integration information for the following products:

• HP LTO Ultrium 4 full-height Fibre Channel tape drives

• HP LTO Ultrium 4 full-height SCSI tape drives

• HP LTO Ultrium 4 full-height SAS tape drives

The following documents provide additional information:

Related documents

Documents specific to HP LTO Ultrium drives

• Software Integration Guide, volume 2 of the HP LTO Ultrium Technical Reference Manual

• Host Interface Guide, volume 3 of the HP LTO Ultrium Technical Reference Manual

• Specifications, volume 4 of the HP LTO Ultrium Technical Reference Manual

• UNIX, Linux and OpenVMS Configuration Guide, volume 5 of the HP LTO Ultrium Technical

Reference Manual

Please contact your HP supplier for copies.

• The features and benefits of HP LTO Ultrium drives are discussed in the HP LTO Ultrium

Technology White Paper.

• For a general background to LTO technology and licensing, go to

http://www.lto-technology.com

.

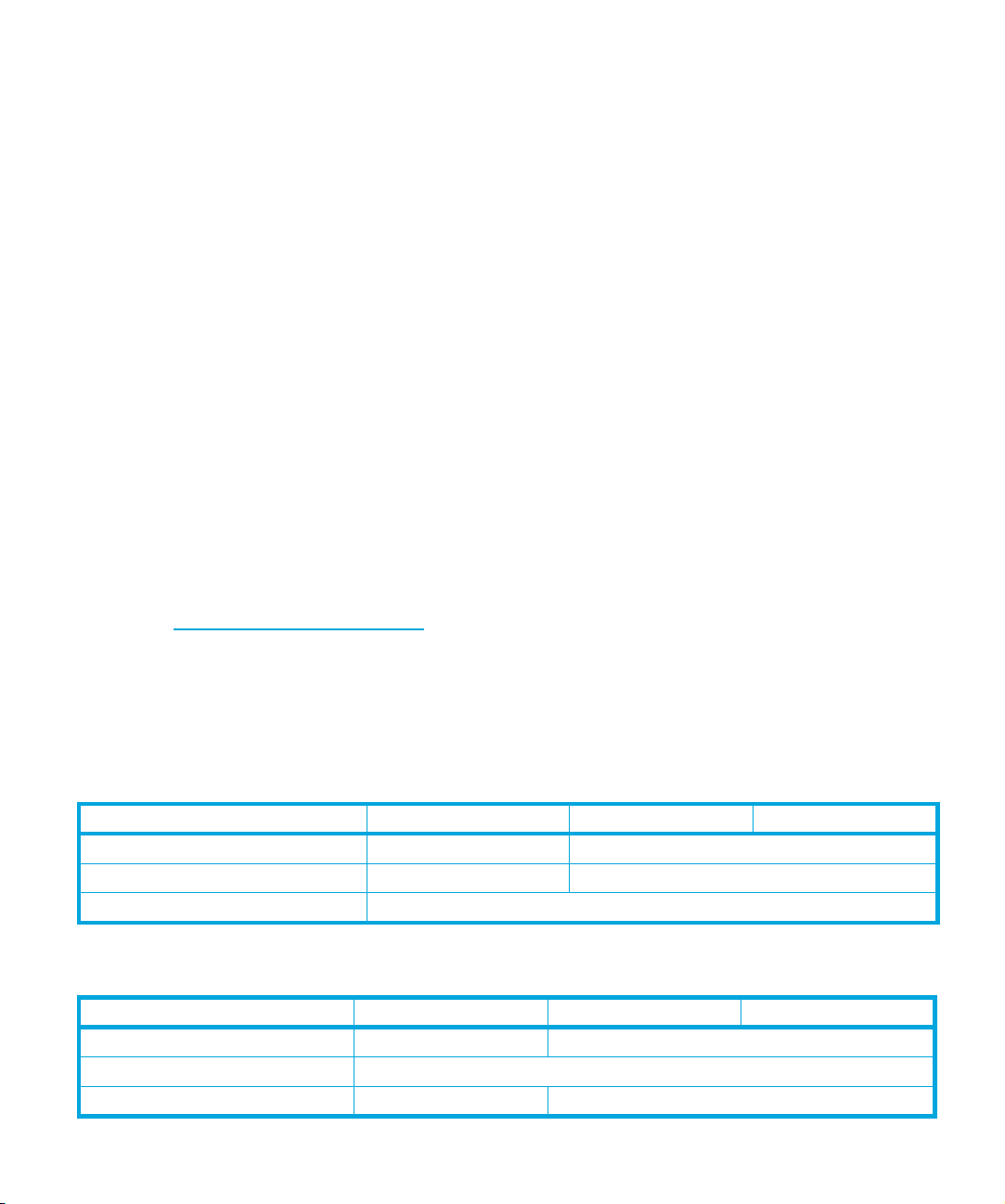

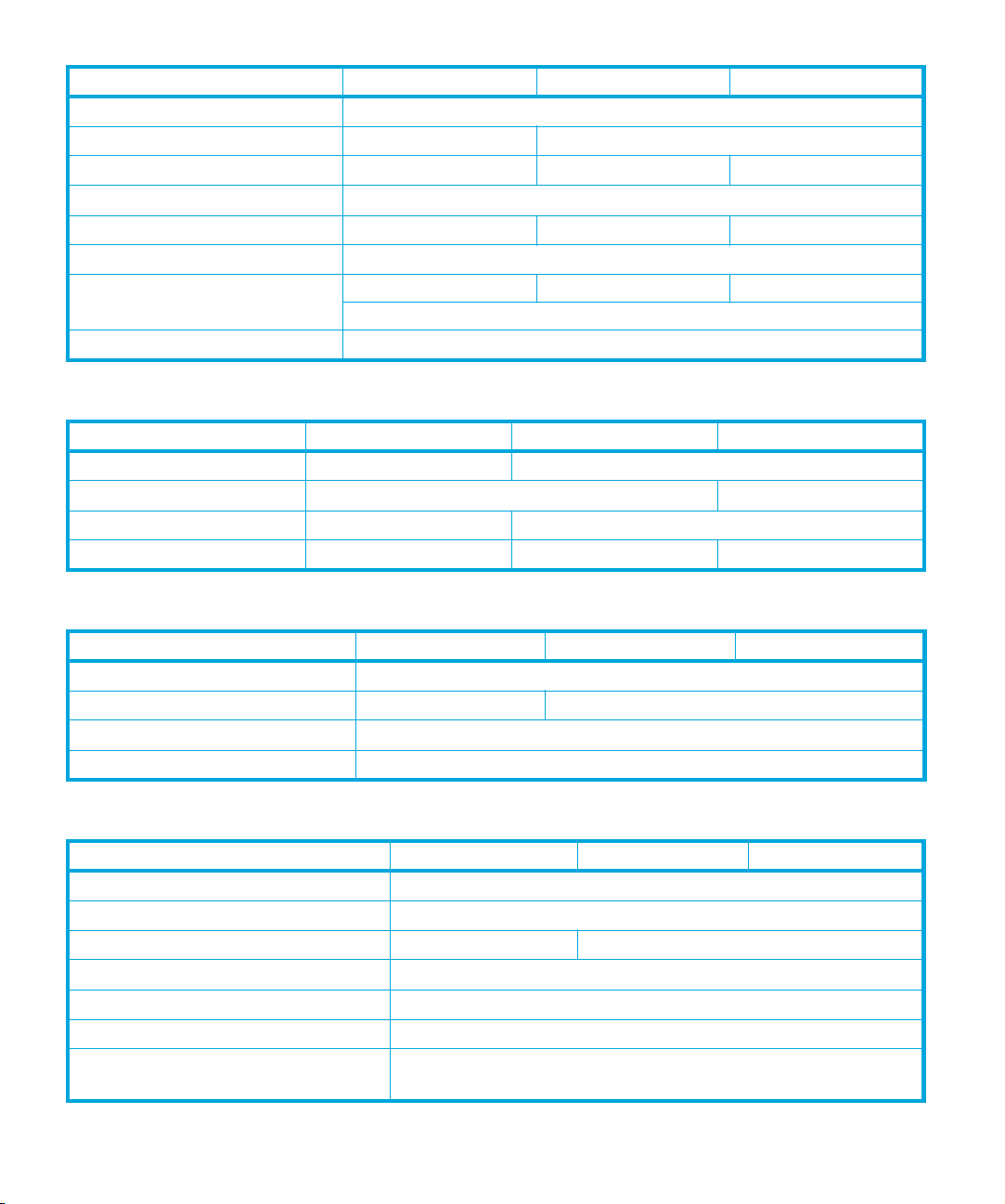

Documentation map

The following will help you locate information in the Technical Reference Manual. A reference like

“

1 HW Integration: ch. 7” means Volume 1, Hardware Integration Guide, of the HP LTO Ultrium

Technical Reference Manual, chapter 7.

Drives—general

Connectors

Front panel LEDs

Specifications

Installation and configuration

Connectors

Determining the configuration

External drives

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 9

FC Drives SCSI Drives SAS Drives

1 HW Integration: ch. 4 1 HW Integration: ch. 7

1 HW Integration: ch. 3 1 HW Integration: ch. 6

4 Specifications

FC Drives SCSI Drives SAS Drives

1 HW Integration: ch. 4 1 HW Integration: ch. 7

2 SW Integration: ch. 2

n/a 1 HW Integration: ch. 5

HP restricted

Page 10

In libraries

In servers

In tape arrays

Linux configuration

Modes of usage

OpenVMS configuration

Optimizing performance

UNIX configuration

Operation

External drives

In libraries

In servers

In tape arrays

Cartridges

FC Drives SCSI Drives SAS Drives

1 HW Integration: ch. 1

n/a 1 HW Integration: ch. 4

n/a 1 HW Integration: ch. 3 n/a

5 UNIX, Linux, OpenVMS Configuration

n/a 1 HW Integration: ch. 8 n/a

5 UNIX, Linux, OpenVMS Configuration

n/a 1 HW Integration: ch. 8 n/a

2 SW Integration: ch. 4

5 UNIX, Linux, OpenVMS Configuration

FC Drives SCSI Drives SAS Drives

n/a 1 HW Integration: ch. 5

1 HW Integration: ch. 1

n/a 1 HW Integration: ch. 4

n/a 1 HW Integration: ch. 3 n/a

Cartridge Memory (LTO-CM)

Cartridges

Managing the use of cartridges

Use of cartridges

Interface

FC, SCSI and SAS host interface guide

Commands

Error codes

Implementation

Interpreting sense data

Messages

Mode pages

—see the MODE SENSE command

10

FC Drives SCSI Drives SAS Drives

2 SW Integration: ch. 5

1 HW Integration: ch. 5 1 HW Integration: ch. 9

2 SW Integration: ch. 1

2 SW Integration: ch. 3

FC Drives SCSI Drives SAS Drives

3 Host Interface

3 Host Interface: ch. 5

1 HW Integration: ch. 6 1 HW Integration: ch. 10

3 Host Interface: ch. 1

2 SW Integration: ch. 3

3 Host Interface: ch. 2

3 Host Interface: ch. 5

HP restricted

Page 11

Pre-execution checks

Responding to sense keys and ASC/Q

Sense keys and ASC/Q

—see REQUEST SENSE command

Task management functions

Maintenance and troubleshooting

Cleaning

External drives

In libraries

In servers

In tape arrays

Monitoring drive and tape condition

Software troubleshooting techniques

Dealing with errors

FC Drives SCSI Drives SAS Drives

3 Host Interface: ch. 4

2 SW Integration: ch. 6

3 Host Interface: ch. 5

n/a 3 Host Interface: ch. 3

FC Drives SCSI Drives SAS Drives

2 SW Integration: ch. 5

2 SW Integration: ch. 7

n/a 1 HW Integration: ch. 5

1 HW Integration: ch. 1

n/a 1 HW Integration: ch. 4

n/a 1 HW Integration: ch. 3 n/a

2 SW Integration: ch. 7

2 SW Integration: ch. 1

Error codes

Handling errors

Logs—see the LOG SENSE command

Recovering from write and read errors

Software response to error correction

Software response to logs

TapeAlert log

LTO Ultrium features

Autoload

Automation Control Interface (ACI)

Cartridge Memory (LTO-CM)

Data compression, managing

OBDR and CD-ROM emulation

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 11

FC Drives SCSI Drives SAS Drives

1 HW Integration: ch. 6 1 HW Integration: ch. 10

2 SW Integration: ch. 5

3 Host Interface: ch. 4

2 SW Integration: ch. 7

2 SW Integration: ch. 3

2 SW Integration: ch. 3

2 SW Integration: ch. 7

FC Drives SCSI Drives SAS Drives

1 HW Integration: ch. 2

1 HW Integration: ch. 2

1 HW Integration: ch. 2

2 SW Integration: ch. 5

2 SW Integration: ch. 5

2 SW Integration: ch. 7

HP restricted

Page 12

FC Drives SCSI Drives SAS Drives

Performance optimization

n/a 1 HW Integration: ch. 8

Performance, factors affecting

Software design

Supporting LTO Ultrium features

General documents and standardization

See http://www.t10.org/t10_main.htm for INCITS SCSI Primary Commands—3 (SPC-3), SCSI

Streaming Commands (SSC-3) and other specifications

Copies of documents of other standards bodies can be obtained from:

2 SW Integration: ch. 1

2 SW Integration: ch. 4

2 SW Integration: ch. 1

2 SW Integration: ch. 5

INCITS

ISO

ECMA

Global Engineering

Documents

11 West 42nd Street

New York,

NY 10036-8002

USA

CP 56

CH-1211 Geneva 20

Switzerland

114 Rue du Rhône

CH-1204 Geneva

Switzerland

2805 McGaw

Irvine, CA 92714

USA

Tel: +41 22 849 6000

Web URL: http://www.ecma.ch

Tel: 800 854 7179 or 714 261 1455

12

HP restricted

Page 13

1 LTO Ultrium drives in libraries

Introduction

This chapter contains information that relates to placing an HP LTO Ultrium drive in an automated

device, such as an autochanger or a tape library:

• Drives for use in libraries have different front panels from drives mounted individually in servers

and standalone drives. There is also a special front panel for use in autoloaders. These are

described on page 14.

• For notes on the requirements and other details for the installation of drives into libraries, see

page 16.

• For notes on the operation of drives in libraries, see page 20.

• For troubleshooting information, see page 22.

Chapter 2 contains information about using special features of LTO Ultrium drives in libraries:

• The “Automation and drive interface” (ACI/ADI) allows the activities of the drive to be

coordinated within a library. See page 25 for details.

• “Configuring autoload and library-controlled loads” on page 27 allows you to configure

whether automatic or ACI-controlled loads and unloads occur.

• LTO Cartridge Memory (LTO-CM) or Cartridge Memory is EEPROM memory that is embedded in

every LTO Ultrium tape cartridge. It is non-volatile and is contactless in that it is read by RF

coupling rather than electrical contact.

• For suggestions of how to make use of cartridge memory in libraries, see “Using Cartridge

Memory (LTO-CM)” on page 30.

Backup software

You need backup application software that supports your LTO Ultrium drive and tape library.

Suitable backup applications will include driver software that establishes the interface between the

tape drive and the software. Applications usually recognize tape drives by their manufacturers’ ID

string rather than their model numbers, so check the following table for the appropriate reference.

Drive Model ID String

LTO 4 FC drive “HP Ultrium 4-SCSI”

LTO 4 SCSI drive “HP Ultrium 4-SCSI”

LTO 4 SAS drive “HP Ultrium 4-SCSI”

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 13

HP restricted

Page 14

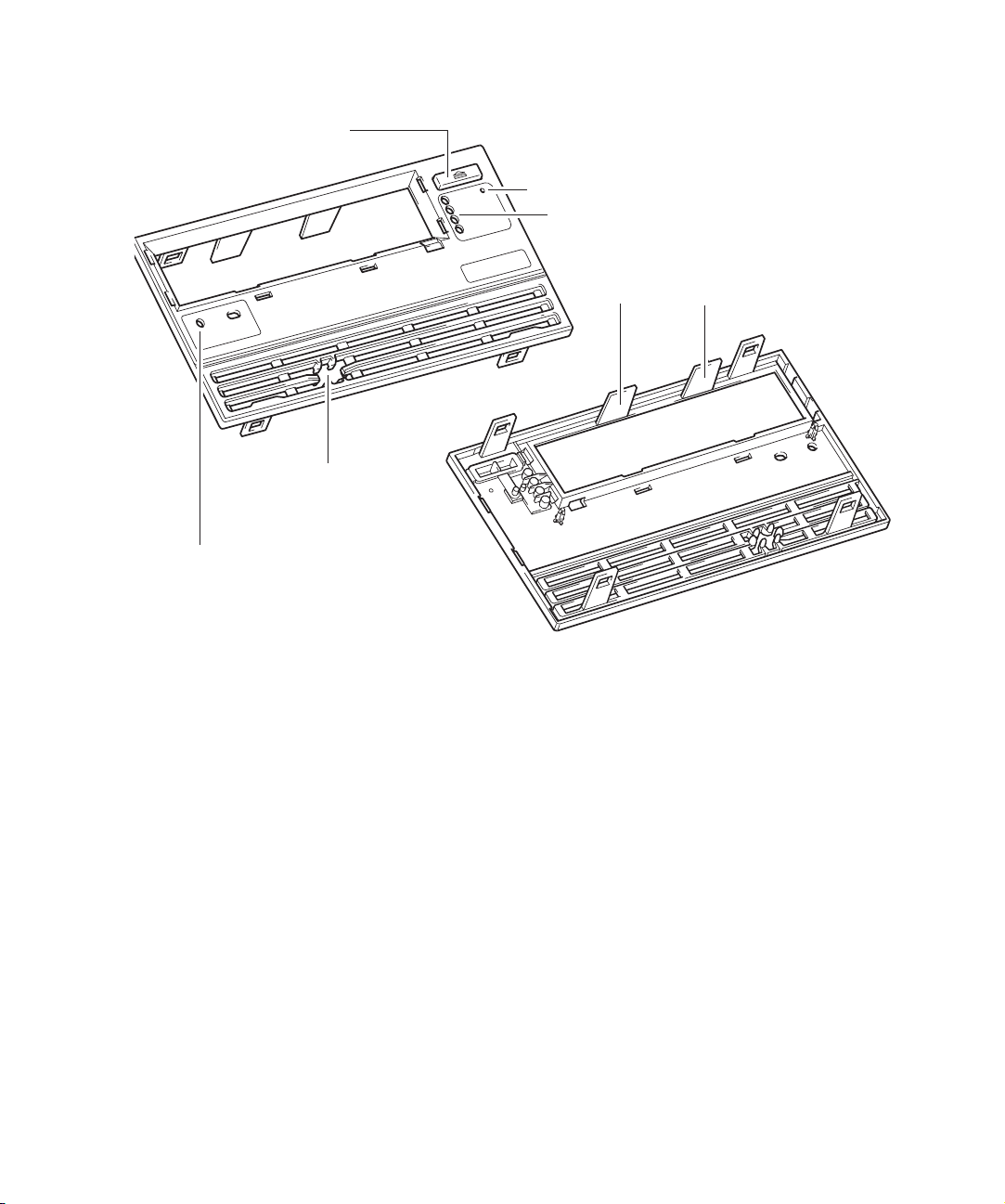

Front panel for automation use

eject button

diagnostic

port access

holestoactas

targets for optical

position sensors

access to emergency reset button

lights

guides to assist with loading

and unloading cartridge

The automation front panel has the following features:

• There is an eject button for manually ejecting a cartridge. Press this for approximately ten

seconds to start a “forced eject” for recovering a cartridge manually. See page 22 for details.

• Indicator LEDs provide a visible indicator of the state of health of the drive. See Chapter 6 on

page 69 for details.

• There is no door. Instead there are two fixed guides to guide the cartridge into the drive.

• There is access to a proprietary serial HP LTO diagnostics port. To access this port via RS232

requires an HP LTO Diagnostics Interface Card. Diagnostic information from the drive such as

power-on hours, tape-pulling hours, error codes, and firmware trace-logs can be accessed by

connecting to the serial communications port on a computer. Please contact HP for further details

on this diagnostics port.

• The indent for a label on the left just under the cartridge opening is left blank, exposing two

holes. These can be used to provide a target for the optical position sensor of a library picker.

• There are additional holes around the cartridge opening to allow a throat to be fitted if

necessary, to help the smooth loading of cartridges.

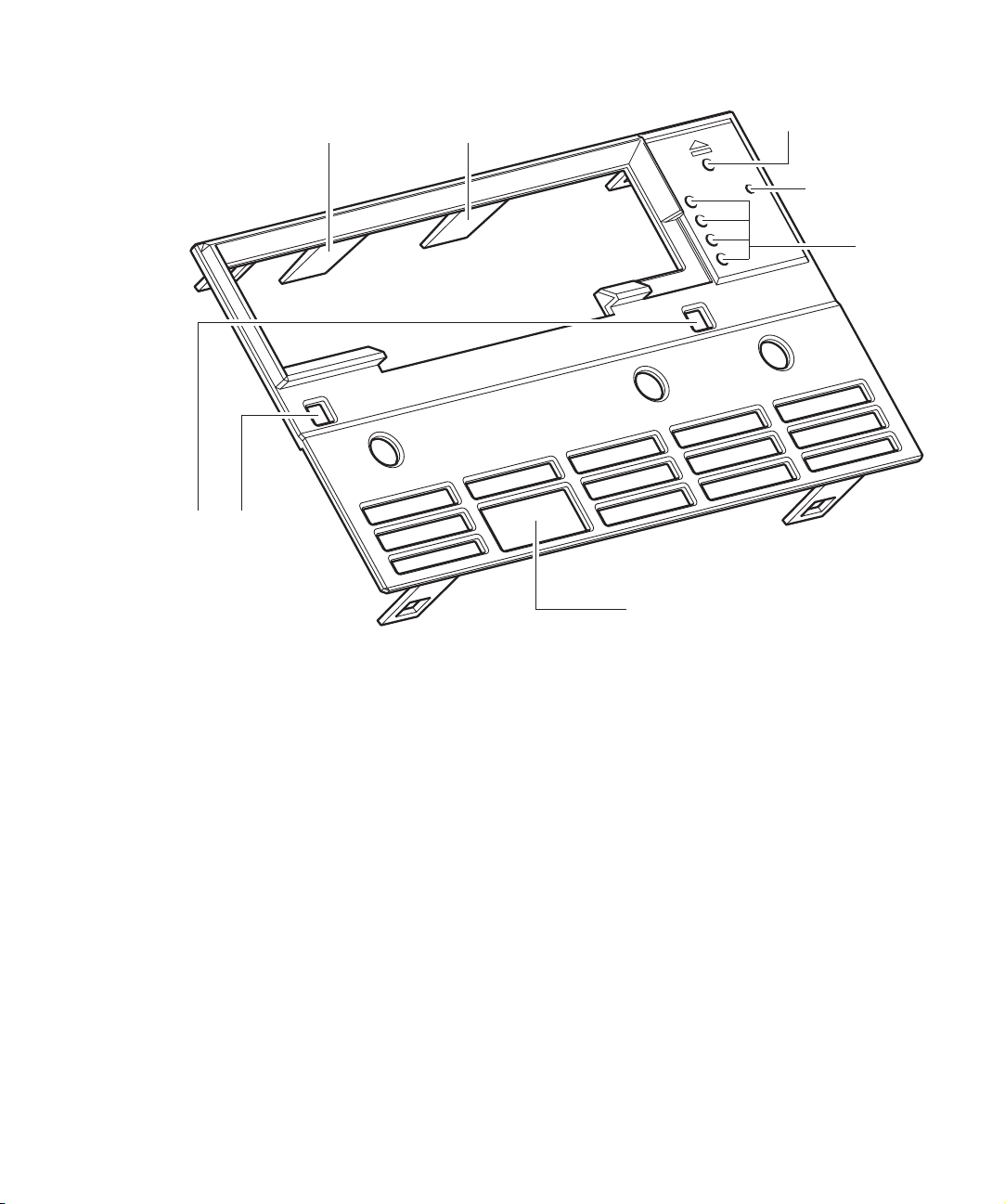

Front panel for use in autoloaders

A special front panel is available for autoloader applications where the autoloader conforms to a

2U product height. The front panel fits within the drive form factor in height and width:

LTO Ultrium drives in libraries14

HP restricted

Page 15

The autoloader front panel has the following features:

guides to assist with loading

and unloading cartridge

access to datum

surface on the front

of the drive

access to

eject switch

access to

emergency

reset button

lights

access to diagnostic port

• Simple one-piece plastic design

• Pinhole access to the eject switch on the drive for manually ejecting a cartridge. Press this for

approximately ten seconds to start a “forced eject” for recovering a cartridge manually. See

page 22 for details.

• Indicator LEDs provide a visible indicator of the state of health of the drive. See Chapter 6 for

details. The LEDs are viewed through holes in the autoloader front panel; no light pipes are

present.

• Access to a proprietary serial HP LTO diagnostics port. To access this port via RS232 requires an

HP LTO Diagnostics Interface Card. Diagnostic information from the drive such as power-on

hours, tape-pulling hours, error codes, and firmware trace-logs can be accessed by connecting

to the serial communications port on a computer. Please contact HP for further details.

• Clearance for picker finger access to the right-side cartridge-handling notch

• Two square holes through the panel to provide access to a datum surface on the front of the

drive

• Cartridge lead-in features to improve cartridge load and unload operations

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 15

HP restricted

Page 16

Installing drives

Airflow requirements

HP LTO Ultrium drives require forced airflow from front to back and, in the case of full-height drives,

from back to front provided it does not exceed critical temperatures.

The required flow depends on the ambient air temperature:

• 6 cfm for ambient air temperatures fluctuating in the range 10°C–35°C.

• 8 cfm for ambient air temperatures fluctuating in the range 10°C–40°C.

Measuring internal drive temperatures

FC and SCSI drives

The recommended method of measuring the temperature of critical components is to read the “Max

temperature since cartridge loaded” after exercising the drive by writing data at the maximum data

rate for a period of at least one hour. This temperature correlates closely with the temperature of the

most critical ICs.

If the airflow is adequate, the maximum temperature at the sensor should be no more than 20°C

above ambient.

The maximum temperature at the sensor should be:

• <31°C above ambient for 40°C maximum temperature ambient environment

• <36°C above ambient for 35°C maximum temperature ambient environment

This equates to:

• <71°C at 40°C ambient (8 cfm airflow)

• <71°C at 35°C ambient (6 cfm airflow)

Extracting internal temperature information

You can extract the “Max temperature since cartridge loaded” reading via the main interface or via

the ACI/ADI send_scsi command as follows:

1. Send a

1D 10 00 00 08 00

93 00 00 04 00 00 20 2A

2. Send a

1C 01 93 00 44 00

3. The “Max temperature since cartridge loaded” value is ASCII encoded in bytes 22–29 of the

incoming data.

Example SCSI trace:

SendDiagnostic |1D 11 00 00 08 00 |00008|00|00|

ReceiveDiagResults |1C 01 93 01 00 00 |0009C|00|00|

LTO Ultrium drives in libraries16

SEND DIAGNOSTICS command with the following data out:

RECEIVE DIAGNOSTICS command:

Data Out |93 00 00 04 00 00 20 2A |

Data In |93 00 00 98 30 30 30 30 31 41 31 32 20 30 30 30 |

Data In |30 31 41 31 32 20 30 30 30 30 31 41 37 34 20 30 |

HP restricted

Page 17

Data In |30 30 30 31 39 31 37 20 0D 0A 30 30 30 30 30 30 |

Data In |30 30 20 30 30 30 30 30 30 30 30 20 30 30 30 30 |

Data In |33 32 30 30 20 30 30 30 30 30 35 30 30 20 0D 0A |

Data In |46 46 46 46 38 30 30 30 20 46 46 46 46 38 30 30 |

Data In |30 20 46 46 46 46 38 30 30 30 20 46 46 46 46 38 |

Data In |30 30 30 20 0D 0A 46 46 46 46 38 30 30 30 20 46 |

Data In |46 46 46 38 30 30 30 20 30 30 30 30 30 35 30 30 |

Data In |20 30 30 30 30 30 35 30 30 20 0D 0A |

4. Translate each character received from ASCI to hex numbers.

For the example above: 30 30 30 30 31 41 37 34 = 00001A74h

5. Convert this number to decimal = 6772

6. Divide this number by 256 to give the temperature in °C = 26.45°C

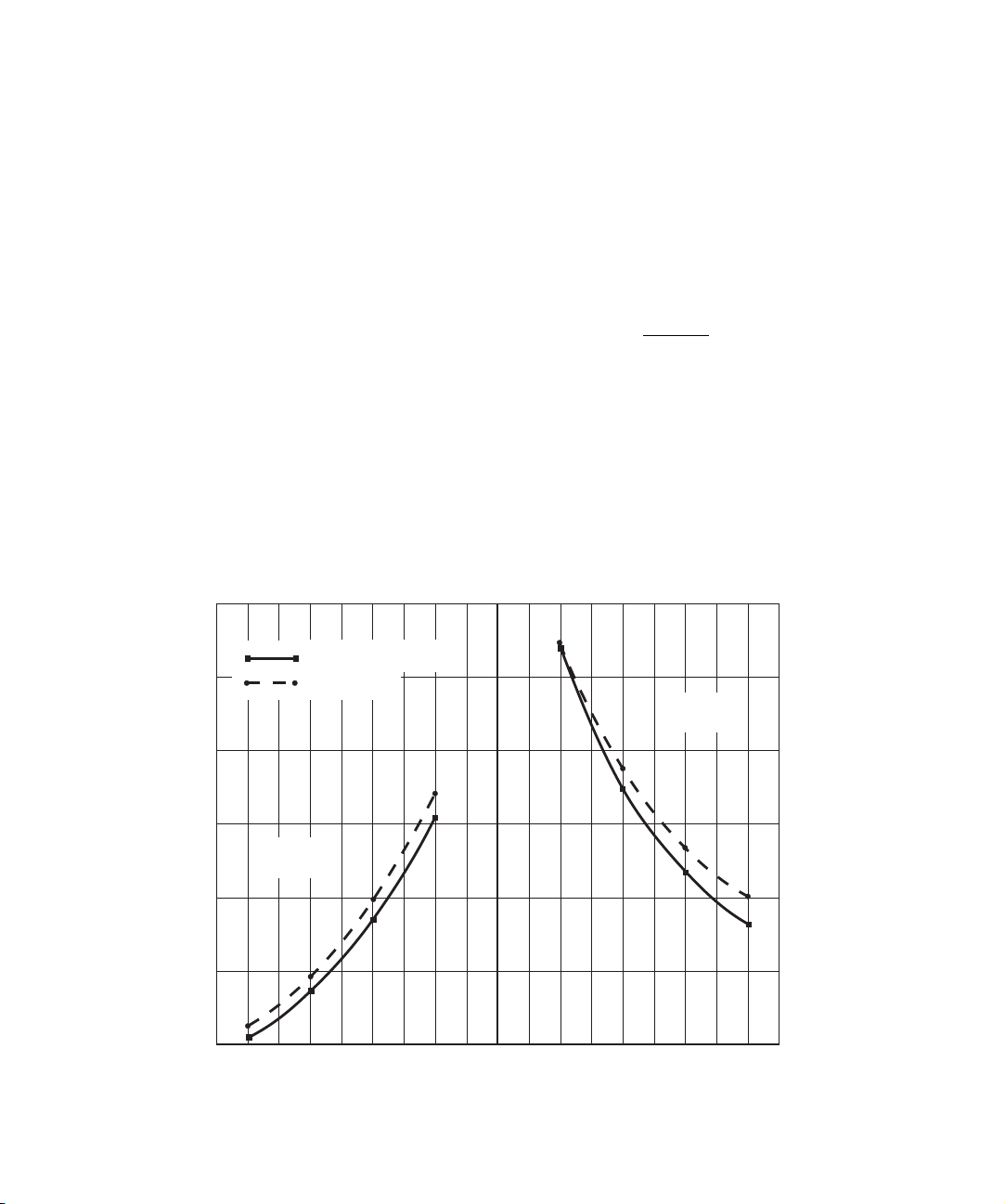

FC and SCSI drives

A method for approximating the air flow for LTO Ultrium drives is to use the drive’s Primary

Temperature Sensor (PTS).

1. Exercise the drive by writing data at the maximum data rate for a period of at least 45 minutes.

2. Find the PTS reading as in the previous section, ”Extracting internal temperature information”.

3. Subtract the ambient air temperature in which the drive was run from this PTS temperature.

4. Use this temperature rise above ambient to find the required air flow for the drive using the

following graph. Because of variations in the temperature sensor (PTS) reading between drives,

you are recommended to average readings from four different drives to obtain the best results.

50

45

SCSI drives

Airflow from

frontto back

Fibre Channel drives

40

35

Airflow from

backtofront

30

Temperature above ambient(ºC)

25

20

–9

–7

–8

–5

–6

–3

–4

–2 –1

0

12

3

5

4

678

9

Airflow(cfm)

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 17

HP restricted

Page 18

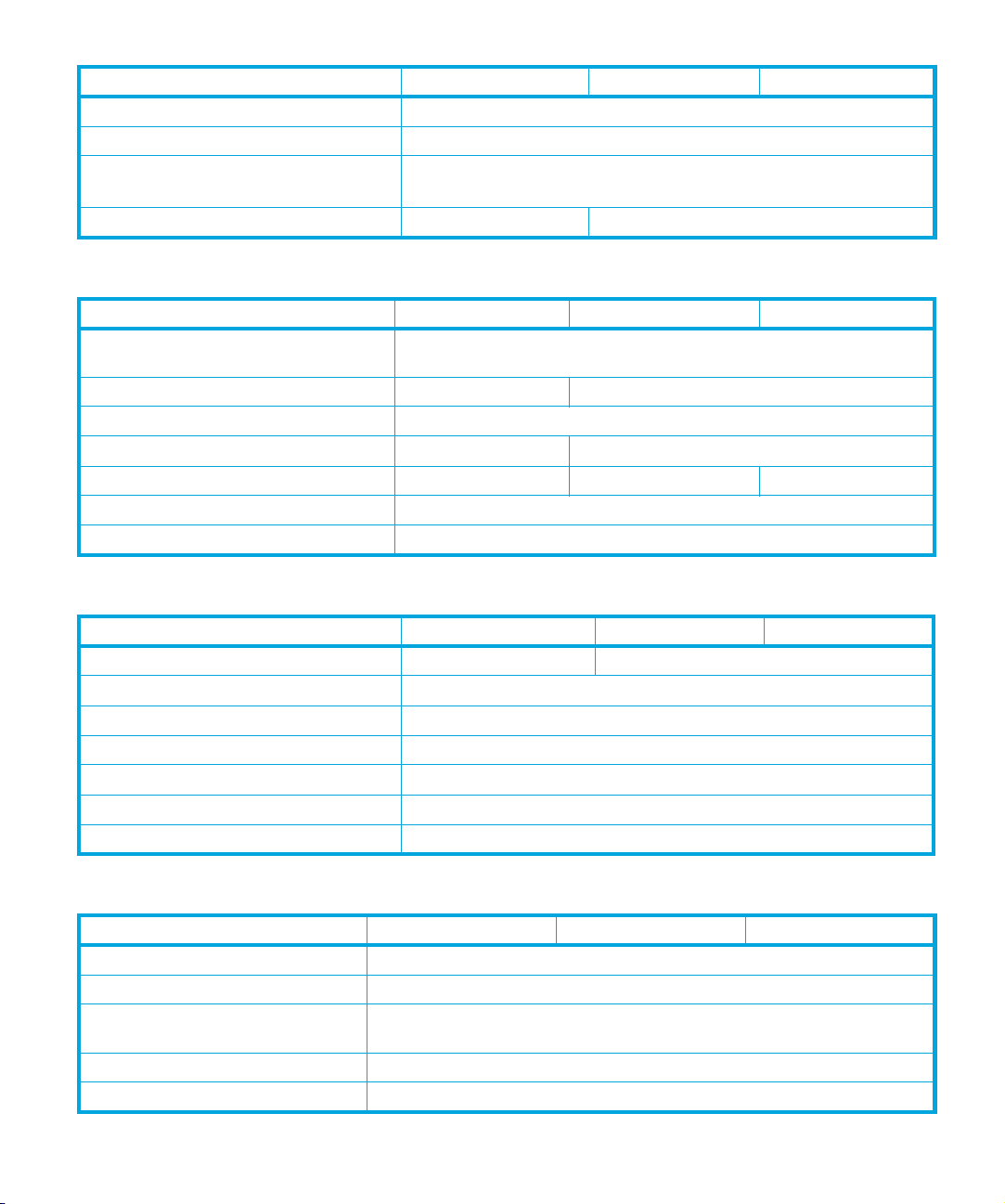

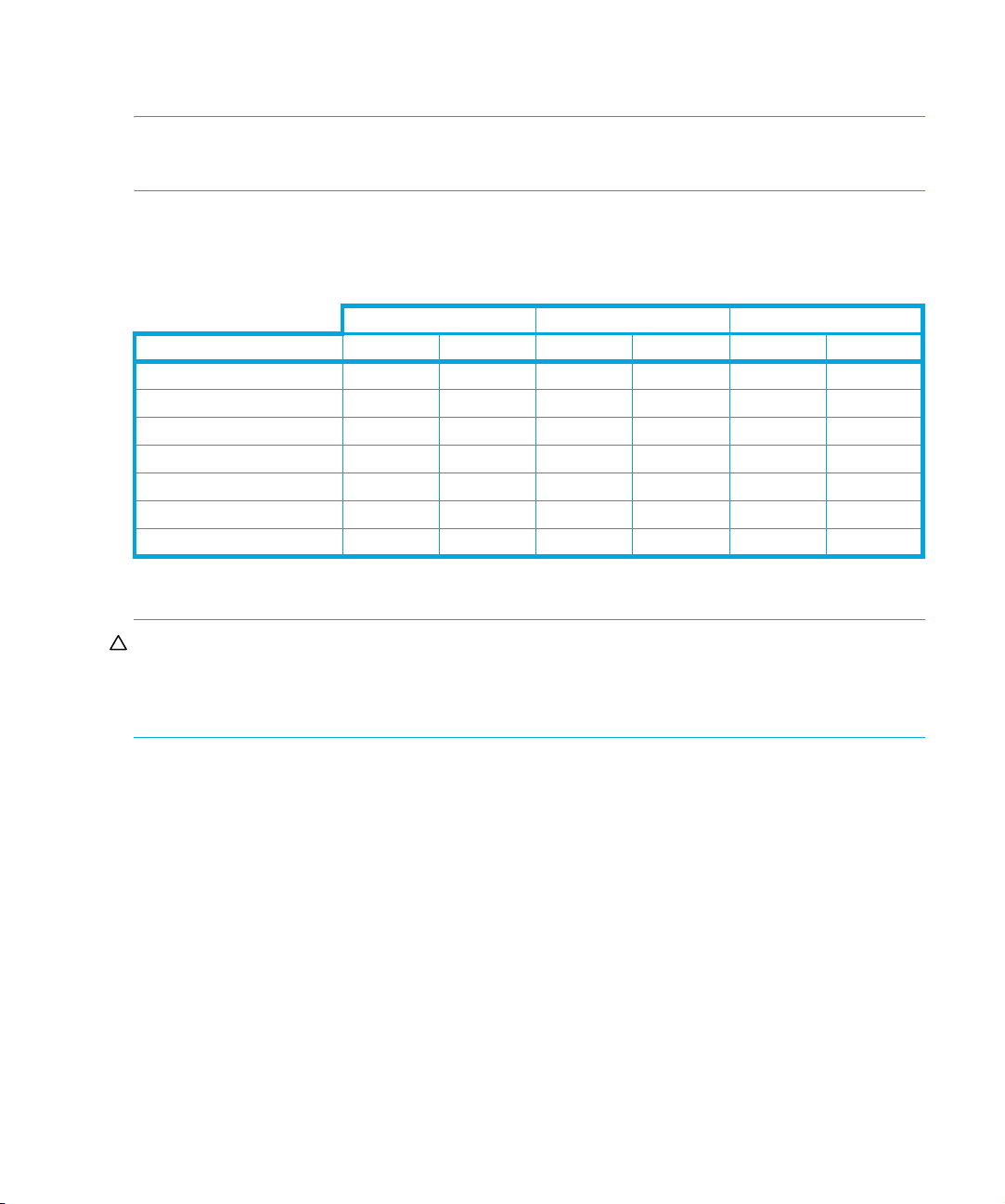

Electrical fit

NOTE: SAS drives should be powered from the normal rear panel connector, not through the

power part of the SAS connector.

The drive is specified to operate at 5V±5% and 12V±10%. Voltage and current requirement are as

follows:

Full-height drives

Specification 5V 12V 5V 12V 5V 12V

Max voltage 5.25V 13.2V 5.25V 13.2V 5.25V 13.2V

Min voltage 4.75V 10.8V 4.75V 10.8V 4.75V 10.8V

Max steady-state current 4.2A 0.75A TBD*A TBDA TBD*A TBDA

Max transient current 4.5A 2.5A TBD*A TBDA TBD*A TBDA

Max steady-state power 21W 9W TBDW TBDW TBDW TBDW

Max transient power 22.5W 30W TBDW TBDW TBDW TBDW

Max noise/ripple 150 mVpp 150 mVpp TBD mVpp TBD mVpp TBD mVpp TBD mVpp

Rear panel and connectors

FC Drives SCSI Drives SAS Drives

CAUTION: LTO Ultrium tape drives are not installable or replaceable by end-users, so the

attachment or removal of FC, SCSI, SAS, power and ADI cables between the tape drive and the

tape library should only be carried out be service-trained personnel authorized by the tape library

supplier. The connectors are not field upgradeable.

The rear panel contains the connectors that allow the tape drive to communicate with the tape

library and host computer system. The panel includes the following connectors:

On all drives:

• Power connector

A standard 4-pin power connector used to supply the 5V and 12V power the tape drive.

• ADI connector (for automation use)

For details of the ADI connector, see page 80. For details of the use of the ADI connector in

libraries see ”Automation/Drive Interface (ADI)” on page 26.

• Diagnostic Serial port connector

The proprietary serial HP LTO diagnostic port. To access this port via RS232 requires an HP LTO

Diagnostic Interface Card. Diagnostic information from the drive can be accessed by connecting

to the serial communications port on a computer. Contact HP for further details on this diagnostic

port and its function.

LTO Ultrium drives in libraries18

HP restricted

Page 19

On Fibre Channel drives:

• Fibre Channel connectors

Two Small Form Factor Pluggable (SFP) duplex-LC fibre channel transceivers. Depending on the

specific configuration, only one SFP FC transceiver may be installed. For details see page 80.

• AL_PA connector

A 2x7-pin auxiliary connector used to set a specific Arbitrated Loop Physical Address (AL_PA).

Two pairs of pins can also be used to power remote transceiver status LEDs. For details see

”Fibre Channel addressing” on page 78.

On SCSI drives:

• SCSI connector

A standard 68-pin high-density SCSI connector. The SCSI cables may be installed in a

daisy-chain configuration linking two or more LTO Ultrium tape drives on the same SCSI bus.

• SCSI address connector

A 12-pin auxiliary connector used to set the SCSI ID. Each device on the SCSI bus must have a

unique SCSI ID set by the SCSI address connector or by the tape library.

On SAS drives:

• A standard internal SAS connector

An HP LTO4 SAS tape drive should be powered from the normal power connector and not

through the power port of the SAS connector. The power port on the SAS connector is not

connected to the tape drive.

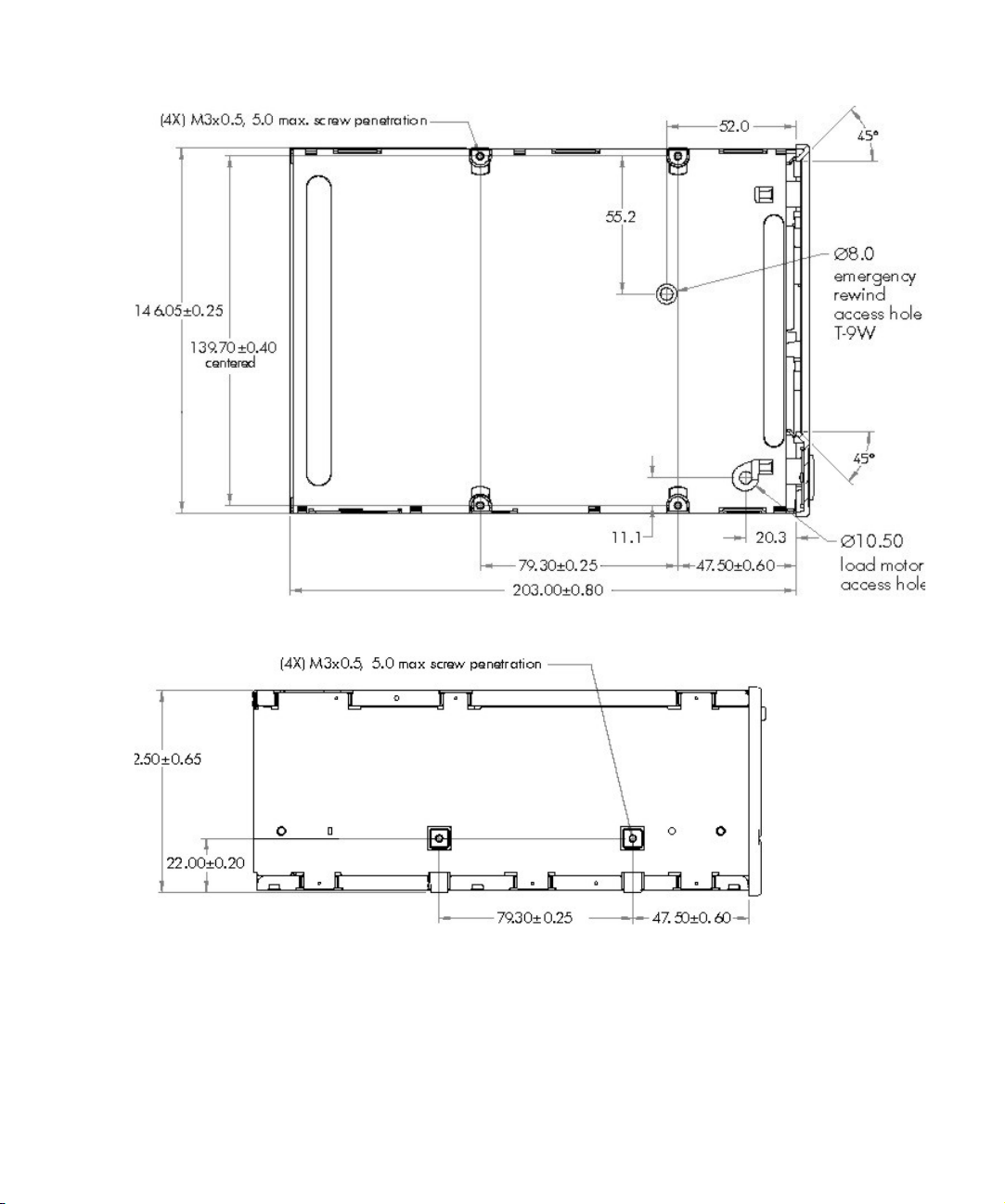

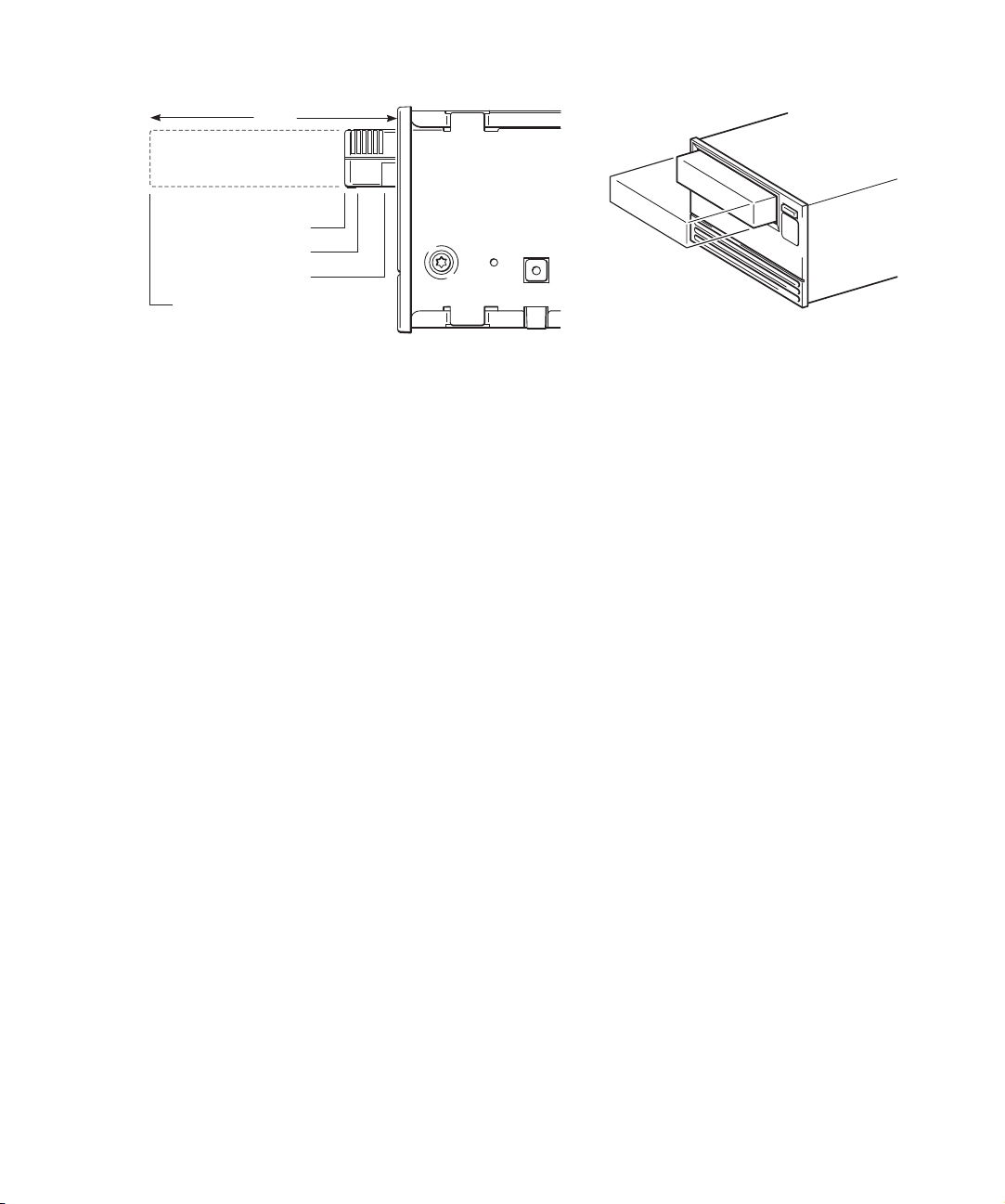

Fixing dimensions

The positions of fixing points are shown below.

The recommended screw length depends on the thickness of the rails or enclosure into which the

drive is mounted:

Server or Rail Thickness Recommended Screw Length

> 1.5 mm ≤ 2.0mm M3 x 6.0mm

> 1.0 mm ≤ 1.5 mm M3 x 6.0 mm

≤ 1.0mm M3 x 5.0mm

All screws should be M3 threaded. Do not use spring washers.

The recommended mounting torque is 6.0 ±0.5 in-lbs (60–70 N/cm).

HP recommends 0.3 mm mounting clearance around all covers for isolation mounting movement.

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 19

HP restricted

Page 20

Bottom panel

Side panel

Operating drives

Drives installed in a tape library are controlled through the tape library operator panel. Refer to the

tape library documentation for details.

LTO Ultrium drives in libraries20

HP restricted

Page 21

Cleaning

When the drive needs cleaning, the orange ‘Clean’ LED on the tape drive will flash. Only insert an

HP Ultrium Universal cleaning cartridge into the tape drive when the LED flashes.

The tape drive also tells the automation controller that a cleaning tape needs to be used via the ADI

connector.

See ”Automation and drive interface” on page 25 for details of ACI commands.

CAUTION: Only use LTO Ultrium Universal cleaning cartridges with HP LTO Ultrium tape drives. Do

not use swabs or other means of cleaning the heads.

To clean the heads:

NOTE: HP recommends that you use the HP LTO Ultrium Universal cleaning cartridge C7978A

(Orange).

LTO Ultrium Universal cleaning cartridges can be used up to 50 times.

1. Insert a cleaning cartridge into the drive. The tape drive automatically loads the cartridge and

2. Remove the cleaning cartridge from the drive.

cleans the heads.

If the cleaning cartridge ejects or returns to the ready-to-eject position immediately with the Tape

Error LED on, it has expired or it is not an LTO Ultrium Universal cleaning cartridge (or is an

older unsupported LTO Ultrium 1 cleaning cartridge). In this case, discard the cleaning cartridge

and repeat the operation with a new one.

The cleaning cycle can take up to 3 minutes, during which the orange ‘Clean’ LED will be on

steadily and the green ‘Ready’ LED will flash. When it has finished, the drive ejects the cartridge

or returns the cartridge to the ready-to-eject position.

Resetting drives

The tape drive can be reset by the automation controller via the ADI connector or by pulling the

ACI_RST_L line low (see page 80).

There are two levels of reset via the ADI connector:

• ACI reset—resets the ACI port and all Fibre Channel, SCSI or SAS ports

• Drive reset—equivalent to a power-on reset

Either reset method will interrupt the interface between the drive and host. A reset may result in no

End of Data mark being written. As a result, it is strongly recommended that a reset command is not

sent unless all other recovery methods have failed. Note that certain automation commands (Load,

Unload, Set Drive Configuration, Reset and Set Baud Rate) can be queued behind outstanding SCSI

commands giving the impression that the drive has stopped responding over the ADI connector. (All

command packages will be still be ack’ed even though the command will be queued.)

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 21

HP restricted

Page 22

Following a Reset command with reset control set to Drive Reset or after pulling the ACI_RST_L line

low, the drive will behave as if it has powered up and will go off bus and lose all ADI connector

configurations.

An FCP reset will not affect the ACI interface.

Note that following an upgrade of the drive firmware, the drive will be reset as if it had been

powered up.

Troubleshooting

If you experience problems when using your tape drive within an automation environment, you need

to isolate the cause of the problem. For example, if you have just installed a new SCSI host bus

adapter in your host system and your system will not start, the cause of the problem is likely to be the

adapter.

The first step in problem-solving is establishing whether the problem lies with the cartridge, the drive,

the tape library, the host computer and its connections, the operating system or backup application

on the host, or operator error.

Please refer to troubleshooting information provided with the tape library, the host or the backup

software if the problem seems to lie in one of these areas.

If none of the following advice helps you solve the problem, contact your tape library supplier.

Diagnostics

HP LTO Ultrium tape drives continuously monitor and gather information such as tape-pulling hours,

power-on hours, usage information on cartridges, firmware trace-logs, and error logs. These can be

used to aid health checks and diagnosis in cases of failure. Data can be extracted via:

• The main host interface

• The ADI connector

• The serial diagnostics port using a proprietary serial interface application.

Contact HP for a copy of the Diagnostics Extraction Guide on extracting and interpreting the

information.

Interpreting the LEDs on individual drives

HP LTO Ultrium tape drives have four LEDs on the front. See Chapter 6 on page 69.

Forced eject

If a cartridge fails to eject using the normal unload procedure, press and hold the Eject button for

10 seconds. This instructs the drive mechanics to perform an emergency unload. Wait for the

cartridge to be ejected. This may take up to 15 minutes (the maximum rewind time).

If the cartridge is still jammed, press the emergency reset button (see page 14) or perform an

emergency reset by pressing and holding the Eject button for 20 seconds. The drive will reset when

you release the button. Wait for the drive to reset and get back to the loaded position. This may take

up to 15 minutes. Again press and hold the Eject button for 10 seconds to perform a second forced

eject and emergency unload.

LTO Ultrium drives in libraries22

HP restricted

Page 23

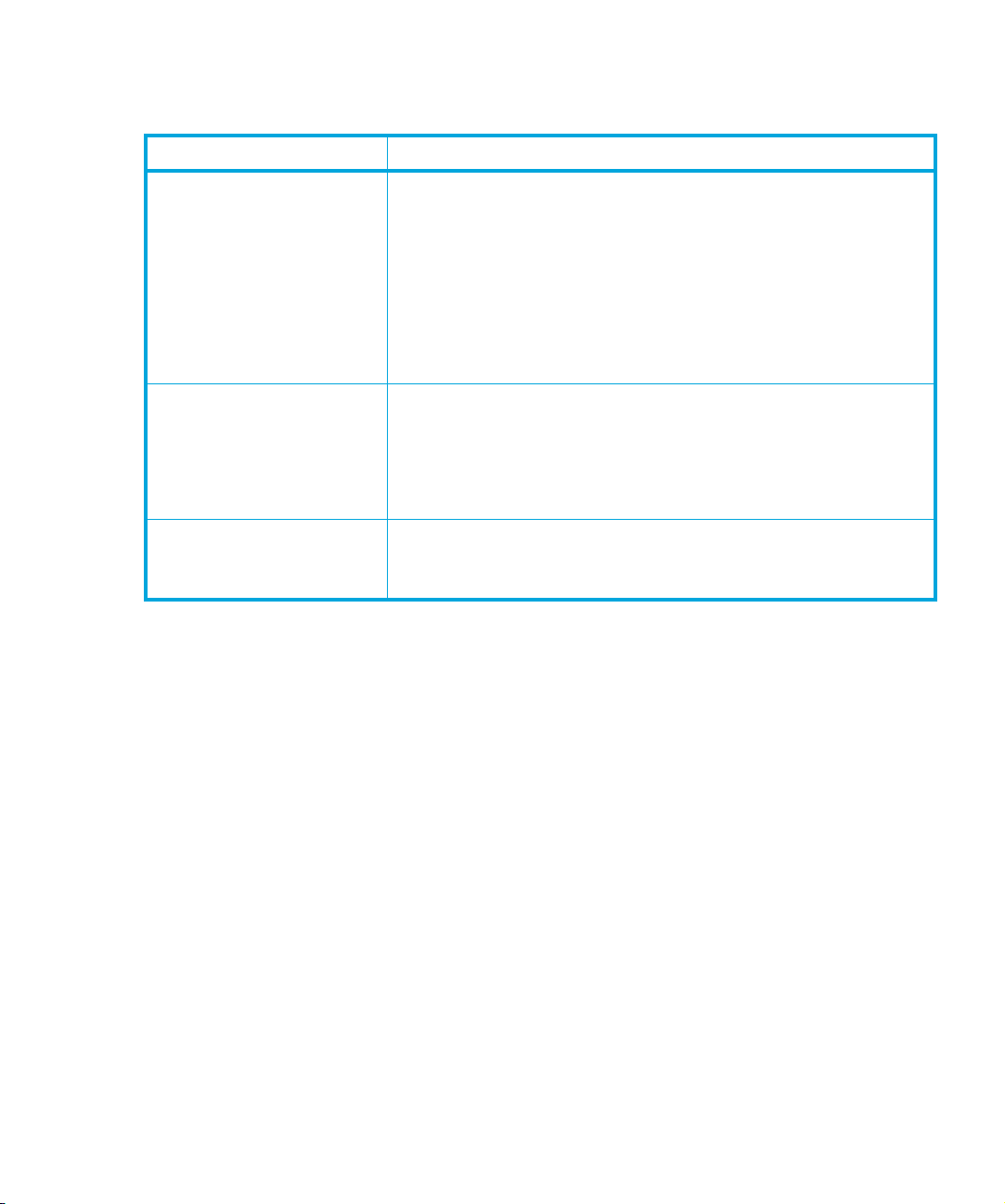

Cleaning issues

Use the following table to resolve cleaning problems:

Problem Solution

Recurring cleaning

message.

A brand new data cartridge

is used, and the library

operator panel indicates

that cleaning is required.

The cleaning cartridge is

ejected immediately after

loading.

Clean the drive with an LTO Universal Cleaning Cartridge as

instructed in the tape library documentation. If the message

reappears, replace the cleaning cartridge with a new one.

If the message reappears when a particular data cartridge is used,

verify that the data cartridge is readable by clearing the message

and reading the tape again.

If the data cartridge can be read, back up the data to another

cartridge and then discard the damaged one.

Clean the outside of the data cartridge with a barely damp, clean,

lint-free cloth. Clean the drive as instructed by your tape library

documentation.

If the operator panel indicates cleaning is required within a short

period of time, replace the data cartridge.

Make sure that you are using an approved LTO Ultrium Universal

cleaning cartridge and that the cleaning cartridge is not expired.

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 23

HP restricted

Page 24

LTO Ultrium drives in libraries24

HP restricted

Page 25

2 Using special features in libraries

Introduction

This chapter contains information that relates to placing an HP LTO Ultrium drive in an automated

device, such as an autochanger or a tape library.

• The “Automation and drive interface” described below allows the activities of the drive to be

coordinated within a library.

• “Configuring autoload and library-controlled loads” on page 27 tells you how to configure

whether automatic or library-controlled loads and unloads occur.

• “Using Cartridge Memory (LTO-CM)” on page 30 describes the EEPROM embedded in every

LTO Ultrium tape cartridge, part of which is available for use by applications.

Drives for inclusion in automated devices have different front panels from individual drives.

Automation and drive interface

The interface between the tape drive and the library will support both the Automation Control

Interface (ACI) and the Automation/Device Interface (ADI) standards. Typically the interface support

will be an OEM selection. For convenience, the connector is referred to as the ADI Connector in this

manual.

NOTE: ADI is covered by two T10 standards:

• For ADT: ANSI INCITS 406-2005

• For ADC: ANSI INCITS 403-2005

Automation Control Interface (ACI)

The Automation Control Interface (ACI) allows the activities of the drive to be coordinated within a

library. The protocol has been designed so that it can be made into a standard feature of tape

drives. It provides a rich and extensible functionality to allow automation manufactures to add value

in their application of it.

The interface is a serial bus with additional control lines, designed to connect the LTO Ultrium tape

drive to an automation controller in a tape library. Each tape drive position has a separate

automation controller. The ADI RS-422 serial port on the rear of the drive allows for ACI connection.

The ACI protocol provides the following fundamental functions:

• Coordinating the automation controller and the tape drive for Load and Unload operations

• Allowing the automation controller to retrieve information from the tape drive

• Setting tape drive configuration information

In addition, the following functions may be supported depending on the way that the tape library is

configured:

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 25

HP restricted

Page 26

• Providing upload and download of firmware images

• Providing access to the contents of the Cartridge Memory

• Providing a protocol for passing SCSI commands from the host to the tape drive

• Providing a protocol for passing SCSI commands from the host to the library (Surrogate SCSI)

NOTE: These notes refer to the “standard” automation drive variant.

For details of using ACI commands and the ACI protocol, see Chapter 5 of the Software Integration

Guide, volume 2 of the HP LTO Ultrium Technical Reference Manual.

Automation/Drive Interface (ADI)

The INCITS T10 (SCSI) committee has a working group devoted to the development of a common

Automation-Drive Interface (ADI). ADI consists of two standards:

• Automation/Drive Interface—Commands (ADC), ANSI INCITS 406-2005, which specifies the

SCSI command set used over ADI.

• Automation/Drive Interface—Transport Protocol (ADT), ANSI INCITS 403-2005, which specifies

a transport protocol for ADI.

The drive operates in either ACI or ADI mode. It is not possible to interleave ACI and ADI

commands because they are handled very differently. The drive defaults to ACI mode after a

power-on or hard reset. The Automation Controller can then instruct the tape drive to switch to ADI

mode by sending a Port Login frame under the following conditions:

1. No ACI commands are outstanding. This not only means that the tape drive must have received

acknowledgement for all responses to all ACI commands received, but also that all immediate

response commands have also finished. For example, if an Automation Controller initiates an

immediate response Load command (see section 5.3 of ACI specification), it cannot issue an

ADI command until the tape drive has finished physically loading the cartridge. If an ACI

command is outstanding when an ADI frame is received the drive will transmit an ACI <NAK>

character in response.

2. An Encoded ADI frame received when the tape drive is in ACI Mode must not exceed the

Receive Buffer size (see section 5.16 of the ACI Specification for details) and the frame must be

received within the ACI Transmission Period (see section 4.6.6.3.2 of the ACI Specification). If

either of these conditions is exceeded the tape drive will transmit a <NAK> character.

3. ADI frames received in ACI Mode must be Port Login frames otherwise the tape drive will revert

to ACI Mode after transmitting the appropriate ADI response.

4. The ADI protocol must be enabled; see the Set Drive Configuration command (section 5.6 of the

ACI Specification) for details. If the tape drive receives an ADI frame when the ADI protocol has

been disabled the drive will transmit a <NAK> character.

When the tape drive is in ADI Mode it will not acknowledge or respond to any ACI command until

the ADI port becomes logged out, either with an explicit Port Logout frame or an ADI Reset.

When the tape drive transitions from one mode to the other (ACI to ADI or ADI to ACI) it will not

implicitly change the drive’s configuration. However, Automation/Drive Interface [ADC] SCSI mode

Using special features in libraries26

HP restricted

Page 27

parameters only apply when the tape drive is in ADI Mode, so the tape drive behavior may change

after transitioning between the two modes.

HP recommends that the drive is used in either exclusively ACI or ADI modes of operation. Avoid

mixing operation of the two modes.

Configuring autoload and library-controlled loads

HP LTO Ultrium tape drives can be configured so that loads either occur automatically or under the

control of the library. A SCSI

is byte 5, bits 0–2 of the Control Mode page, 0Ah.

If the Autoload field = 0, Autoload is set and the drive automatically loads a cartridge when it is

inserted and threads the tape so that it is ready for use.

MODE SELECT command can set the Autoload field to do this. The field

If the Autoload field = 1 or 2, the drive pulls the cartridge into the drive but does

tape. In this position, the LTO-Cartridge Memory can be read. The drive requires a Load command

to thread the tape and make it ready for use.

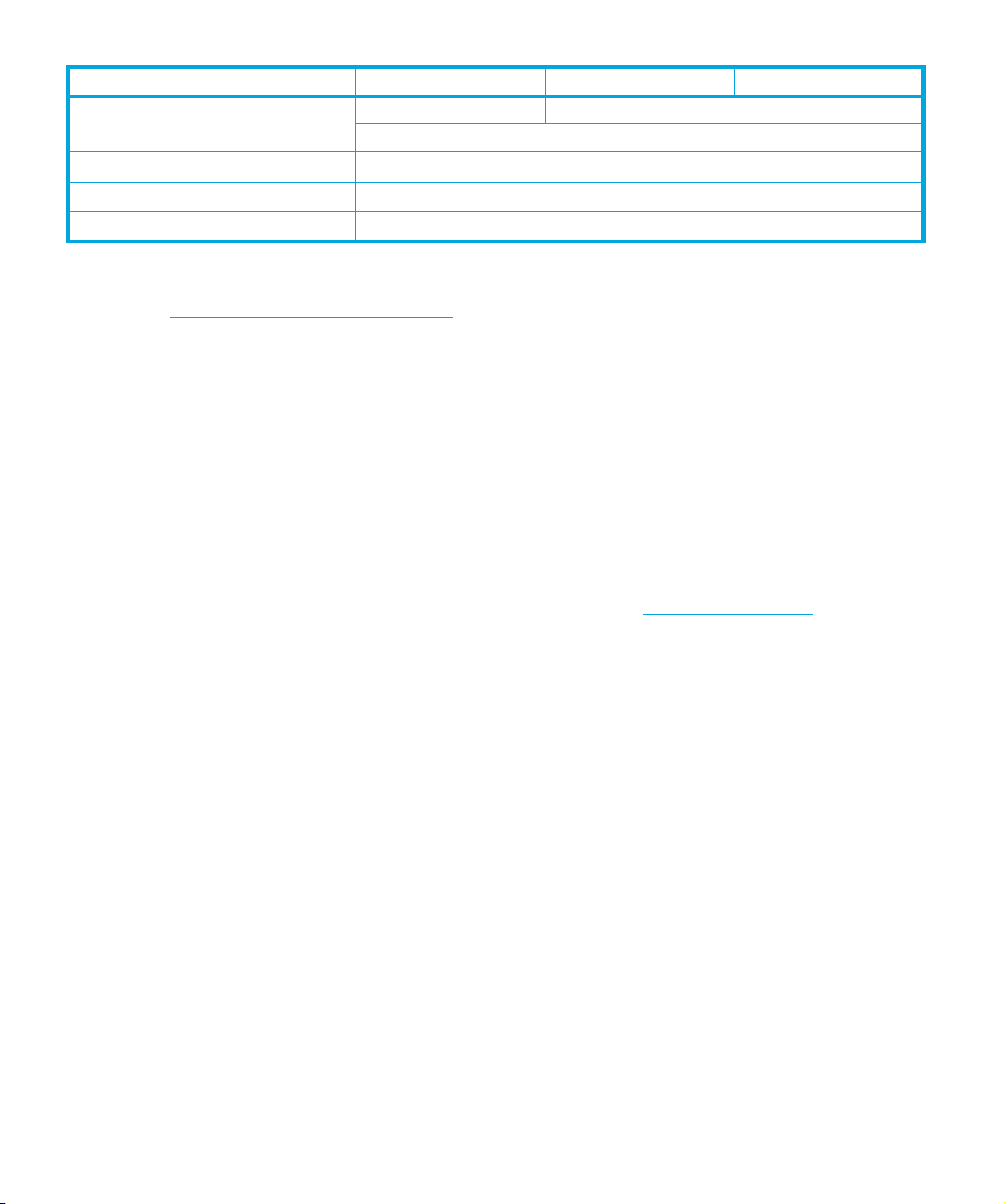

Cartridge positions during load and unload

The following diagrams show the positions of importance during load and unload.

not thread the

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 27

HP restricted

Page 28

Full-height drives

50 mm

5 mm

10 mm

5 mm

eject point

load point1

load point2

cartridge present point

SCALE 25%&50%

Eject Point Cartridges are ejected to this point. It is 20.9 mm beyond the front panel

and 26.1 mm beyond the front of the mechanism. The position tolerance is

±1 mm. The automation controller cannot configure the location of this

position.

Load Point 1 If Autoload is set (Autoload field = 0), the drive will start to load the

cartridge when it reaches this point.

If Autoload is not set (Autoload field = 1 or 2), the library must insert the

cartridge into the drive to a position between Load Point 1 and Load Point 2

and preferably closer to Load Point 1. The library can then issue a Load

command via the ADI connector to instruct the drive to load and thread the

cartridge.

Load Point 2 The maximum distance a cartridge can be inserted for optimal loading

There is one other point of note, the ready-to-eject position. If Auto-Eject is not set then when an

unload command is received by the drive, the tape will be rewound and unthreaded. The drive will

then wait at this point until it is commanded to eject the cartridge by the ACI Unload command.

Load scenarios

The following scenarios describe the operation during the various types of load.

Load scenario 1: Autoload

1. The library sends a Set Configuration command to enable Autoload. This is only necessary after

a drive power-on.

2. The host sends a Move Medium command to the robotics.

Using special features in libraries28

The maximum speed for inserting a cartridge into the drive is 80 mm/s.

Load Point 1 is the recommended minimum load point for commanded

loads. It is 15 mm beyond the front panel with a –2 mm tolerance.

performance, so that autoload or a Load command can load the cartridge. It

is 5 mm beyond the front panel. The automation controller cannot configure

the location of this position.

The maximum speed for inserting a cartridge into the drive is 80 mm/s.

HP restricted

Page 29

3. The picker gets a cartridge from a storage slot.

4. The picker inserts the cartridge into the drive aperture.

5. The picker pushes the cartridge to at least Load Point 1.

6. The drive automatically takes the cartridge, loads it and threads it.

Load scenario 2: Library controlled

1. The host sends a Move Medium command to the robotics.

2. The picker gets a cartridge from a storage slot.

3. The picker inserts the cartridge to between Load Point 1 and Load Point 2.

4. The picker lets go of the cartridge.

5. The library sends a Load command to the drive.

6. The drive takes the cartridge, then loads and threads it.

Unload scenario 1: Autoload

1. The library sends a Set Configuration command to enable Auto-Eject. This is only necessary after

a drive power-on.

2. The host sends an Unload command to the tape drive.

3. The drive rewinds, unthreads and ejects the cartridge to Eject Point.

4. The host sends a Move Medium command to the robotics.

5. The picker takes the cartridge from the tape drive and places it in its storage slot.

Unload scenario 2: Library controlled

1. The host sends an Unload command to the drive.

2. The drive rewinds and unthreads the tape. It then pauses with the cartridge at ready-to-eject

position.

3. The library sends an Unload command to eject the cartridge.

4. The drive ejects the tape to Eject Point.

5. The picker takes the cartridge from drive and places it in its storage slot.

Load forces

The unload force is 4.45N maximum; this is the force that an external mechanism must exert to

remove a fully ejected cartridge from the drive.

The load force varies according to the speed at which the cartridge is inserted into the drive. The

peak load force occurs when the cartridge begins to accelerate the drive carrier and only lasts for a

short time. The following graph plots examples of peak load force against load speed:

Figure 1 Peak load force versus load speed

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 29

HP restricted

Page 30

Using Cartridge Memory (LTO-CM)

Linear Tape Open—Cartridge Memory (LTO-CM) is an EEPROM that is embedded in every LTO

Ultrium tape cartridge. It is non-volatile and is contactless in that it is read by inductive coupling

rather than electrical contact.

The Cartridge Memory is used to store the tape directory and diagnostic and log information.

Because of the speed at which it can be read, load and unload times are reduced, information is

found on the tape more quickly and fewer tape passes are needed, increasing tape reliability.

The memory is primarily designed to speed up internal operations in the drive, but it also contains

free space that can be used by application software. This may be used to store “common”

information (shared by all software vendors) and “vendor-unique” information (specific to the

application).

Hosts can use this free space using the SCSI Write Attribute and Read Attribute commands. For

information on these commands, see Chapter 4 of Interface Guide, Volume 3 of this HP LTO Ultrium

Technical Reference Manual.

To support CM fully, software vendors should ensure that their company names are registered with

ANSI T10 or the National Committee for Information Technology Standards (NCITS) as they are

now known. The list of Vendor IDs is displayed at http://www.t10.org/lists/vid-alph.htm

also contains details of how to get a new name assigned.

Cartridge Memory adheres to the Media Auxiliary Memory (MAM) standard. “MAM” indicates

that the access method applies to all types of media, not just LTO Ultrium.

The MAM standard provides for the storage and access of information held as a set of pre-defined

and user-definable attributes that are divided into six main sections:

, which

• Media Common Section—hard-coded by the media manufacturer.

For example: manufacturer’s name, cartridge serial number, length, media type

Using special features in libraries30

HP restricted

Page 31

• Drive Common Section—updated by the drive every time it accesses the media.

For example: maximum and remaining tape capacity, TapeAlert flags

• Host Common Section—updated by the host’s software application every time it uses the media.

For example: software application vendor’s name and version, media text label, date last written

• Media Vendor Unique Section—optional information written by the media vendor for their own

purposes. Unique to the media vendor.

• Media Vendor Unique Section—optional information written by the media vendor for their own

purposes. Unique to the media vendor.

• Host Vendor Unique Section—space reserved for use by software applications for their own

purposes. Unique to the software vendor. Approximately 1 kilobyte.

For details of SCSI commands relating to Cartridge Memory or MAM, see Read Attributes (8Ch)

and Write Attributes (8Dh) in the Interface Guide.

Use in libraries

Cartridge memory offers possibilities for use in libraries as an adjunct to or replacement for

barcodes. The following diagram shows the architecture required. HP is working to provide a

standard module with this functionality via a third party.

Drive or Library Ultrium Cartridge

Controller

Demodulator/

Buffer

SPI

Interface

Host

Current libraries — barcodes

Many libraries use sticky labels with barcodes on cartridges to identify them. These are read by a

barcode reader attached to the picker arm. The application then needs to hold information as to the

contents of the tape to which it can relate the bar code.

Encoder/

Modulator

Decoder

LTO-CM

Reader IC

coupling

Tuning Circuit

RF

Demodulator/

Decoder

Encoder/

Modulator

LTO-CM

Transponder IC

Controller

4 KB EEPROM

(128x32 byte)

Cartridge Memory can be used as a substitute for these barcodes. No human interaction is needed

to fix barcode labels, reducing errors, though cartridges may still need labels that humans can read.

A cartridge can be identified by its serial number.

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 31

HP restricted

Page 32

However, because Cartridge Memory has space that can be written by applications, it can hold

details of the contents and nature of the tape. This obviates the need for this information to be held

by the application. HP is working with other industry leaders, both hardware and software, on an

Industry Common Implementation Guide.

More information

• The latest version of the specification is incorporated into SCSI SPC-3.

• The access specification can be found at http://www.t10.org/

.

Using special features in libraries32

HP restricted

Page 33

3 Drives in tape arrays

Installing drives

Identifying the drive

The model name is on the front panel and the product and serial numbers are on a label attached

to the drive.

Modes of usage

Tape arrays can be used in different system configurations; direct attach, network attach and

attached to a Storage Area Network (SAN). For details of these see page 83.

Attaching to Fibre Channel

When installing a SCSI drive on a fibre channel direct attach network or SAN configuration, you

need a fibre channel/SCSI router. Check www.hp.com

manual does not describe how to configure your fibre channel infrastructure or SAN network to use

the tape array. This is a complex area and users are advised to refer to their SAN documentation or

contact their SAN system administrator or supplier for technical support.

Attaching to SCSI

HP LTO Ultrium SCSI drives are high performance Ultra 3 SCSI devices designed to operate on a

low voltage differential SCSI bus (LVDS). They are installed in a tape array in a rack-mount system

and can be connected to a SCSI connection on a server or fibre channel/SCSI router. To get

optimum performance from your tape drive you need a SCSI bus that can transfer data at a rate that

supports the tape drive’s maximum transfer speed. We recommend an Ultra 3, 160 and 320 SCSI

bus.

for the latest ordering information. This

Attaching to SAS

HP LTO Ultrium SAS drives are high performance 3 GB SAS devices. When installed in a tape array

in a compatible rack mount system they can be connected to a SAS connection on a server or to an

expander as part of a larger SAS network. To get the optimum performance from your tape drive

you need a SAS topology that can transfer data at a rate that supports the tape drive's maximum

transfer speed.

Appropriate HP rack-mount systems

HP LTO Ultrium removable tape drives are used in conjunction with the HP StorageWorks Tape

Array 5300 system, which will hold up to two full-height drives.

The tape array is designed to be installed into any compatible 19” rack-mount systems. It must be

properly installed and configured. Refer to your tape array documentation for further details.

Airflow requirements

As long as the tape array is fully populated, it will provide adequate airflow for HP LTO Ultrium

drives.

HP LTO Ultrium 4 drives technical reference manual, volume 1: hardware integration 33

HP restricted

Page 34

If you have unused bays in the tape array, you must install the blanking plates provided with the

tape array. This ensures that there is adequate airflow to the drives. See the documentation with the

tape array for details on installing blanking plates.

You should ensure that ventilation is adequate at the front and rear of the tape array.

HP LTO Ultrium drives require forced airflow, either from front to back or from back to front.

The required flow depends on the ambient air temperature:

• 6 cfm for ambient air temperatures fluctuating in the range 10°C–35°C.

• 8 cfm for ambient air temperatures fluctuating in the range 10°C–40°C.

For details of how to test if the airflow is adequate, see “Airflow requirements” on page 16.

Setting the SCSI ID

For removable drives installed in an HP StorageWorks Tape Array 5300 rack enclosure, set the SCSI

ID at the appropriate switch on the rear of the tape array. Each drive should have a unique ID. The

number of address switches corresponds to the number of tape drives that can be inserted into the

tape array, so the HP StorageWorks Tape Array 5300 has four SCSI ID switches to enable the

installation of up to four half-height tape drives. When installing two HP LTO Ultrium full-height tape

drives, use the SCSI ID switches 1 and 2 only.

Termination

Both ends of a SCSI bus must be terminated.

Assuming that the host bus adapter is already correctly terminated, there are typically two

possibilities:

• The tape drive is being connected in a direct one-to-one configuration to the host

server—termination must be used.

• The tape drive is being daisy-chained with other tape devices onto the host server—only the last

device must be terminated.

The terminator can be plugged directly onto either of the two SCSI connectors on the rear of the

tape array. Terminators must be ordered separately.

Drives in tape arrays34

HP restricted

Page 35

Inserting a drive

1. Ensure that the extractor lever on the drive is in the

out position, as shown in the picture.

2. Lift the drive carefully.

3. Align the rear of the drive with the guides on the side

of the HP StorageWorks Tape Array 5300.

4. Slide the drive along the guides until the connectors

on the back mate with the connectors at the back of

the enclosure.

5. Push the extractor lever in until it locks the drive in

position.

Connecting to a Fibre Channel router or by SCSI/SAS to a server or router

Individual SCSI tape drives are connected to their host server or fibre channel router via the high

density LVD/SE SCSI connectors on the back of the tape array. They do not require any SCSI cables

to plug into the tape array. However, cabling and terminators are required to connect the tape array

with the SCSI host.

Individual SAS tape drives are connected to their hosts via the SAS connectors on the back of the

tape array. They do not require any SAS cables to plug into the array. However, cabling is required

to connect the tape array with the SAS host or expander.

Fibre Channel connection

If you are using your SCSI tape drive on a fibre channel (FC) network, you will need a FC/SCSI