FRANK'S DDS Procedure Manual

Rev. A September 2014

Section No: 4.1.32 Page 1 of 14

Prepared By: J. Gaspard

QHSE Integrated Procedure Manual Approved By: QHSE Committee

OPS-P-4.1.32 DDS Connectors Installation

1.0 Purpose

To standardize the method by which DDS Pin and Box Connectors are installed.

2.0 Scope

This procedure outlines the requirements for the installation of DDS Pin and Box Connectors.

3.0 Definitions

None

4.0 Responsibility

4.1 Departmental Supervisor

4.1.1 The Departmental Supervisor shall be responsible for delegating technicians to

install DDS Pin and Box Connectors such that they meet the requirements of

this procedure.

4.1.2 The Departmental Supervisor shall ensure that any technician selected to

perform activities covered by this procedure is properly trained.

4.2 Connector Running Technician

4.2.1 The Connector Running Technician is responsible for obtaining and bringing

the proper work instructions for the type and size of connector being run to the

job site.

4.2.2 The Connector Running Technician is responsible for completing Equipment

Fault Reports on all nonconforming situations encountered during the course of

running the connector string.

5.0 Procedure

5.1 Pre-installation Instructions

5.1.1 Verify that box protectors are tight by inserting DDS protector spade breaker

bar (part# SOG199905100) into slot on the protector or by using DDS protector

breaker bar (part# SOG199905081) and turn the protector in a clockwise

motion (refer to Figure 1 and pages 14 and 15, respectively). Ensure that the

protector is visually shouldered to the connector.

Document may be uncontrolled if printed, verify current approved revision before use.

Rev. A September 2014

Section No: 4.1.32 Page 2 of 14

Prepared By: J. Gaspard

QHSE Integrated Procedure Manual Approved By: QHSE Committee

DDS Protector Breaker Bar

Part# SOG199905081

DDS Protector Spade Breaker Bar

Part# SOG199905100

Figure 1

5.1.2 Visually inspect the ID of the pipe to ensure that it is clean and free of debris.

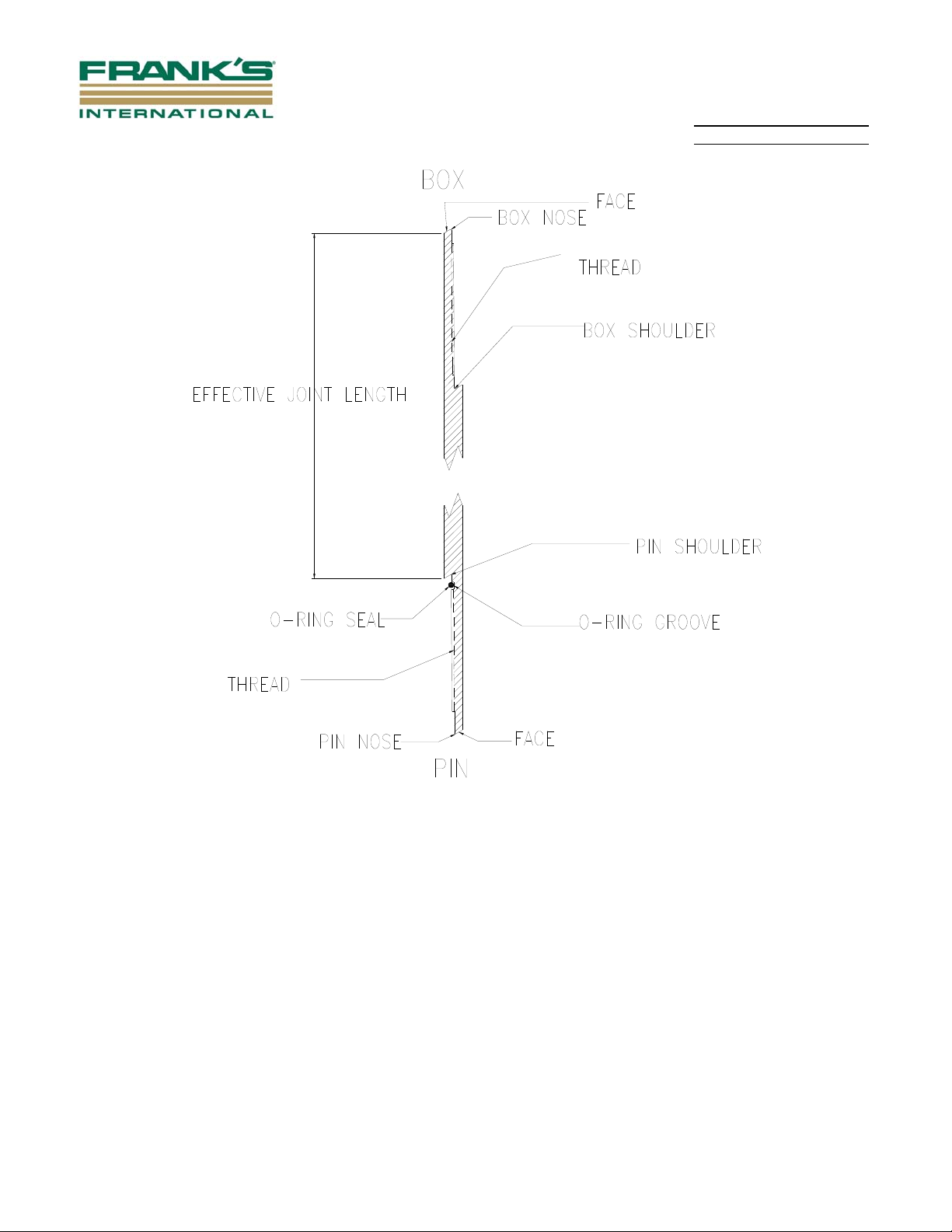

5.1.3 Tally pipe / connectors using locations as shown in Figure 2. Ensure that the

pipe is clearly identified and mark the effective joint length clearly on the pipe

surface.

NOTE: Ensure that the required pipe handling equipment is available.

Ensure that the correct spare parts running kit is available.

Document may be uncontrolled if printed, verify current approved revision before use.

Rev. A September 2014

Section No: 4.1.32 Page 3 of 14

Prepared By: J. Gaspard

QHSE Integrated Procedure Manual Approved By: QHSE Committee

Figure 2

5.2 Installation Instructions - DDS Connectors

5.2.1 A single joint of pipe is presented to the rig floor and held in a horizontal

position using slings. Depending on the rig, it may also arrive on a skate. The

bottom of the pipe shall be 1-1/2 to 2 feet above the rig floor, and the end of

the pipe containing the lift shoulder shall be 2 to 3 feet from the well bore.

5.2.2 Verify that box protectors are tight by inserting DDS protector spade breaker

bar (part# SOG199905100) into slot on the protector or by using DDS protector

breaker bar (part# SOG199905081) and turn the protector in a clockwise

motion (refer to Figure 1 and pages 14 and 15, respectively). Ensure that the

protector is visually shouldered to the connector.

Document may be uncontrolled if printed, verify current approved revision before use.

Rev. A September 2014

Section No: 4.1.32 Page 4 of 14

Prepared By: J. Gaspard

QHSE Integrated Procedure Manual Approved By: QHSE Committee

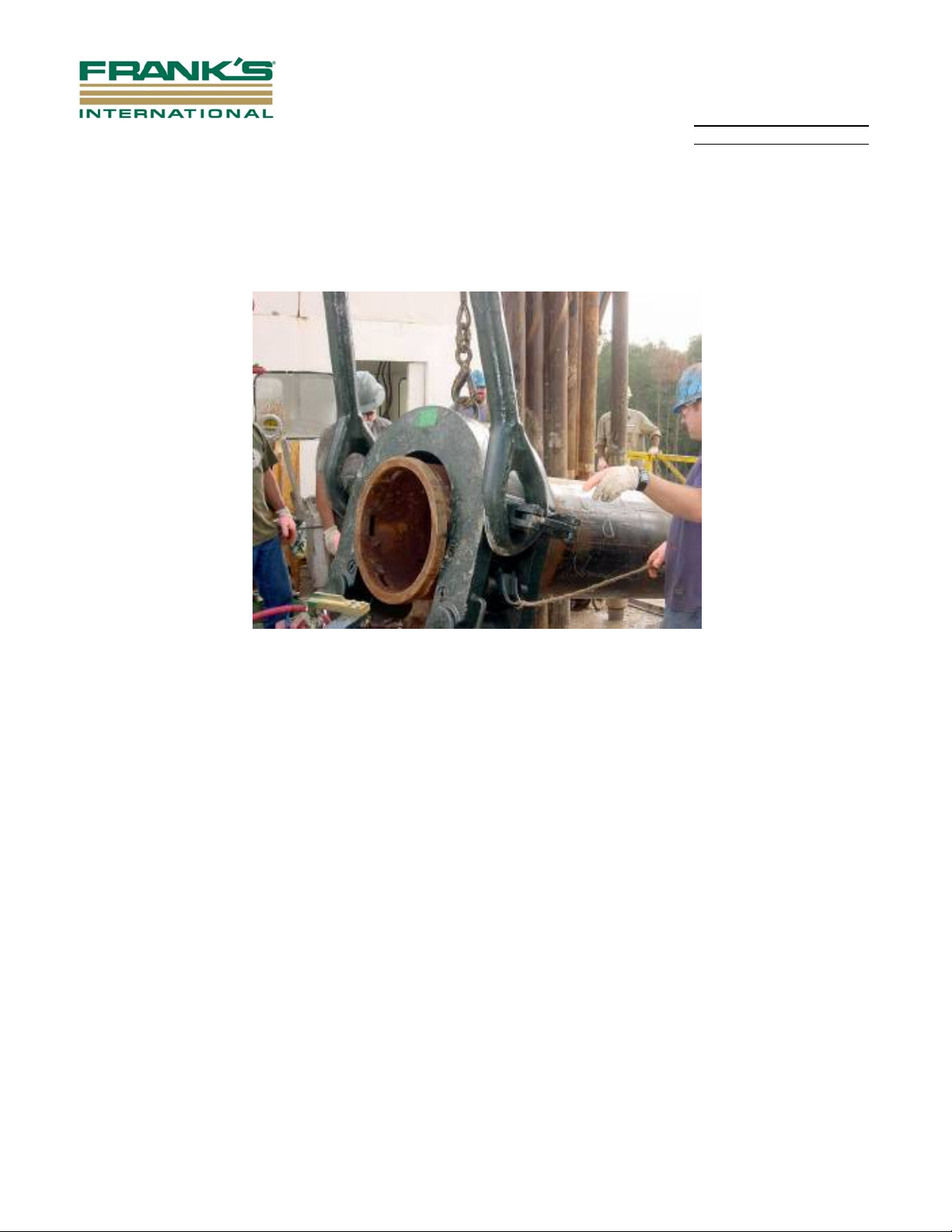

5.2.3 Attach an air winch line to the back of the elevator (refer to Figure 3). Once the

air winch line is attached, use it to pick up the back of the elevator. This will

rotate the elevator to a vertical position as well as position it above the end of

the pipe. Alternately, a top drive link tilt may be employed to push the bails out.

The elevator is then lowered onto the pipe and secured.

Figure 3

5.2.4 Remove the air winch line, pass it through the eye of the closest V-door post

and attach it to the post on the opposite side of the V-door. This catch line will

restrain the pipe from swinging when brought into a vertical position.

5.2.5 Clear all non-essential personnel from the rig floor.

5.2.6 Start lifting the elevator and pipe with slings still attached. Remove the sling

closest to the elevator first when it begins to show slack. Remove the second

sling when it too begins to show slack.

5.2.7 Elevate the pipe until the pin end of the joint clears the V-door with the air hoist

catch line restraining the pipe. Hold in place about 1 foot above the rig floor.

5.2.8 Pull a length of chain from the draw works, shackle the end of the chain to the

supplied Kevlar rope and hook with a swivel (part # 60191).

5.2.9 Insert the steel hook (1" to 1-1/4" part# SOG199905095 refer to page 16, or

1-1/2" to 2" part# SOG199905097 refer to page 17) into one of the rectangular

slots in the bottom of the pin protector and wrap the rope around the protector,

not less than two full turns.

Document may be uncontrolled if printed, verify current approved revision before use.

Rev. A September 2014

Section No: 4.1.32 Page 5 of 14

Prepared By: J. Gaspard

QHSE Integrated Procedure Manual Approved By: QHSE Committee

5.2.10 Pull slowly on the chain with the draw works to breakout the pin protector and

let it fall freely to the rig floor. Keep all personnel clear of the drop zone in order

to prevent the possibility of foot injuries.

5.2.11 Elevate the pipe and feed out the catch line so that the pipe joint becomes

nearly vertical, but not over the well bore, just slightly in front of the spider.

5.2.12 See Section 5.4 for repair procedure if indications such as burrs or light galling

are observed.

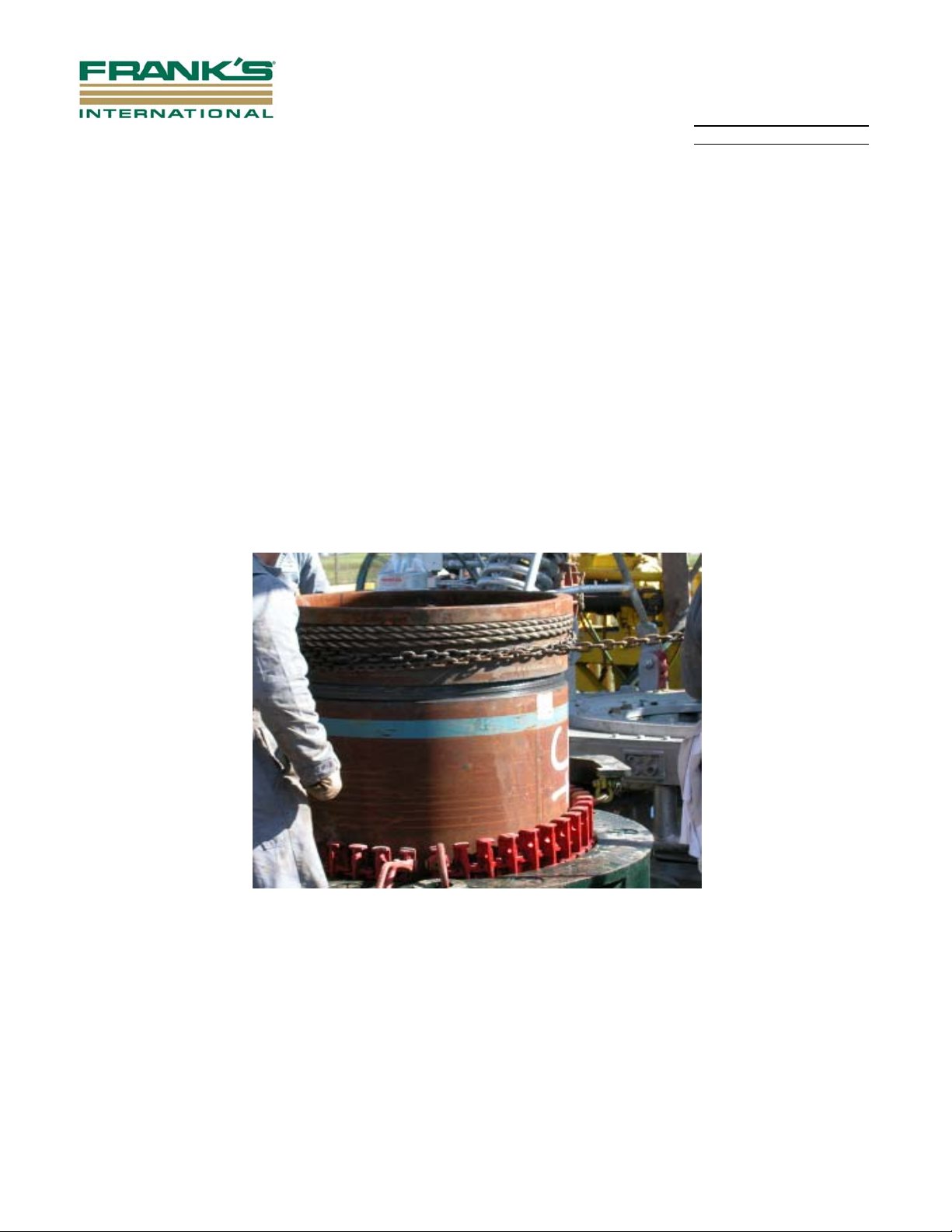

5.2.13 The box protector must be removed when a joint is being supported by the

spider. Pull a length of chain from the draw works and shackle the end of the

chain to the supplied Kevlar rope and hook using a swivel.

5.2.14 Insert the steel hook into one of the rectangular slots in the top of the box

protector and wrap the rope around the protector, not less than three full turns

(refer to Figure 4).

Figure 4

NOTE: Completely unscrewing the box protector with draw works will

damage the connector.

5.2.15 Pull slowly on the chain with the draw works to breakout the box protector, until

3 threads on the box protector are visible. Use the supplied DDS protector

spade breaker bar (part# SOG199905100) to finish backing out the protector

(refer to Figure 5).

Document may be uncontrolled if printed, verify current approved revision before use.

Loading...

Loading...