Franklin Electric SUBMERSIBLE PUMPS OWNER'S MANUAL

4” and 6”

CAUTION

DANGER

WARNING

CAUTION

WARNING

WARNING

WARNING

WARNING

SUBMERSIBLE PUMPS

OWNER'S MANUAL

READ AND FOLLOW SAFETY INSTRUCTIONS

This is the safety alert symbol. When you see

this symbol on your pump or in this manual, look

for one of the following signal words and be alert to the

potential for personal injury:

warns about hazards that will cause

serious personal injury, death or major property

damage if ignored.

warns about hazards that can cause

serious personal injury, death or major property

damage if ignored.

warns about hazards that will or can

cause minor personal injury or major property damage

if ignored.

The label NOTICE indicates special instructions, which

are important but not related to hazards.

BEFORE INSTALLING PUMP, BE SURE TO READ

THIS OWNER’S MANUAL CAREFULLY.

Fill pump with water before starting or

pump will be damaged. The motor on this pump is

guaranteed by the manufacturer. In event of failure

it must be returned to an authorized service station

for repairs. Motor warranty is void if repairs are not

made by an authorized repair station.

INSPECT THE SHIPMENT

Examine the pump when it is received to be sure there

has been no damage in shipping. Should any be evident,

report it immediately to the dealer from whom the pump

was purchased. Please check the pump package to see

that it includes pump, motor, and motor leads (if your

pump purchase includes a motor).

Carefully read and follow all safety instructions in

this manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

Wire motor

for correct voltage. See

“Electrical” section of

this manual and motor

nameplate.

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply. Disconnect

power before working

on pump, motor

or tank.

this manual when connecting motor to power lines.

before connecting to power

supply.

Electrical Code, Canadian

Electrical Code, and local

codes for all wiring.

Follow wiring instructions in

Ground motor

Meet National

106467101

Rev. 12

11.14

WARNING

IMPORTANT INFORMATION FOR

WARNING

INSTALLERS OF THIS EQUIPMENT!

THIS EQUIPMENT IS INTENDED FOR

INSTALLATION BY TECHNICALLY QUALIFIED

PERSONNEL. FAILURE TO INSTALL IT IN

COMPLIANCE WITH NATIONAL AND LOCAL

ELECTRICAL CODES, AND WITH FRANKLIN

ELECTRIC RECOMMENDATIONS, MAY RESULT

IN ELECTRICAL SHOCK OR FIRE HAZARD,

UNSATISFACTORY PERFORMANCE, AND

EQUIPMENT FAILURE. FRANKLIN INSTALLATION

INFORMATION IS AVAILABLE FROM PUMP

MANUFACTURERS AND DISTRIBUTORS, AND

DIRECTLY FROM FRANKLIN ELECTRIC. CALL

FRANKLIN TOLL FREE 800-348-2420 FOR

INFORMATION. RETAIN THIS INFORMATION

SHEET WITH THE EQUIPMENT FOR FUTURE

REFERENCE.

INSTALLATION RECORDS

It is good idea to keep an accurate record of your

installation. Be sure to record the data below:

Purchased From:

Date of Installation:

Pump Model No.*

Pump Date Code*

Well Inside Dia.(in/mm):

Depth of Well(ft/m):

Depth of Water(ft/m):

Pump Setting(ft/m):

Drop Pipe Size:

Wire Size(pump to control box):

Wire Size(control box to power source):

Horizontal Offset(between well & house):

Make of Motor*

Amps HP Volts Ph

Make of Control Box

HP Volts

SERIOUS OR FATAL ELECTRICAL SHOCK MAY

RESULT FROM FAILURE TO CONNECT THE MOTOR,

CONTROL ENCLOSURES, METAL PLUMBING, AND

ALL OTHER METAL NEAR THE MOTOR OR CABLE,

TO THE POWER SUPPLY GROUND TERMINAL

USING WIRE NO SMALLER THAN MOTOR CABLE

WIRES. TO REDUCE RISK OF ELECTRICAL SHOCK,

DISCONNECT POWER BEFORE WORKING ON

OR AROUND THE WATER SYSTEM. DO NOT USE

MOTOR IN SWIMMING AREAS.

Power Supply

Volts HZ

Pressure Switch (PSI)

Cut-in Cut-out

* This Information is on your pump or motor tag. It will

help us identify your pump in case of later inquiries.

TEST RUNNING

If test running pump before installation:

1. Insure that the power supply corresponds with that

shown on the nameplate of the motor and control

box. (if required).

2. Install pump and components appropriate for the

test as shown in Fig. 1.

3. Make sure power supply is turned off and circuit

breaker or disconnect switch is open. Make

electrical connections appropriate to your motor as

shown in Fig. 2, 3 or 4.

4. THREE-PHASE UNIT - A three-phase motor

requires a magnetic starter equipped with quick-trip,

ambient compensated heaters of correct size for the

horsepower of the motor. To insure correct rotation

of three-phase units, brace pump shell securely and

apply power momentarily by snapping line switch

quickly on and off.

2

If rotation is correct, reaction of the shell will be

clockwise when viewed from pump discharge

(that is, pump shaft will rotate counter clockwise).

Interchange any two leads at magnetic starter to

reverse rotation.

5. Run pump and motor unit for a few seconds to

ensure that it is in working order.

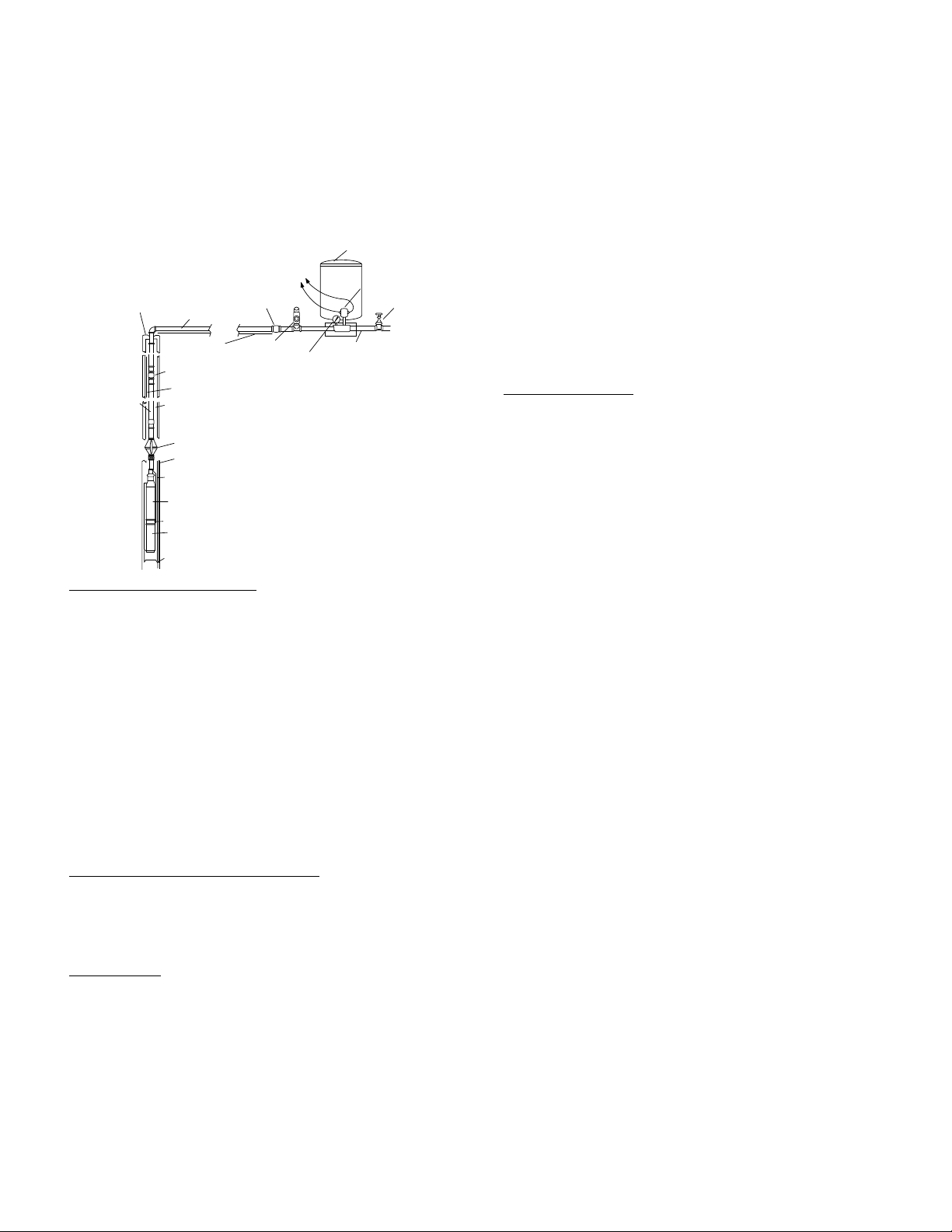

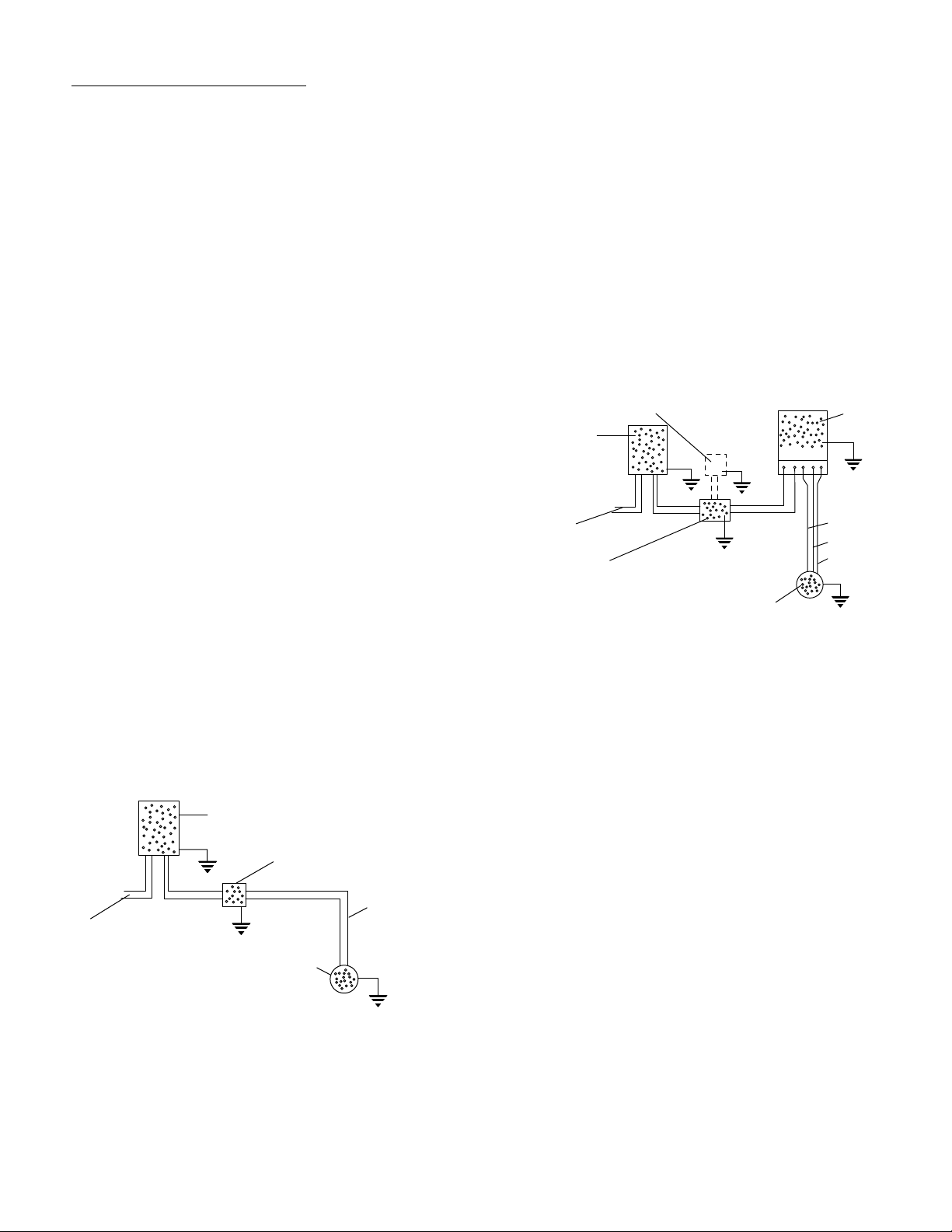

FIGURE 1 - Installation Diagram

Pressure Tank

Sanitary Well Seal

or Pitless Adapter

Drop Pipe

Discharge Pipe

Submersible Cable

Spring-Loaded

Check Valve

(Recommended every 100’/30m)

Safety Cable

Submersible Cable

(secured to drop

pipe with tape or

clamps every 10’/3m)

Torque Arrestor

Well Casing

Spring-Loaded

Check Valve

at Pump Discharge

Submersible

Pump Unit

Suction Screen

Motor

Well Screen or

Casing Perforations

See Wiring Diagrams

Spring-Loaded

Check Valve

Pressure Relief Valve

Pressure Gauge

Note: Keep pump at least 5’ from

bottom of well and above well screen

or casing perforations.

Pressure Switch

Gate Valve

Service Pipe

SUITABILITY OF WELL

Install the pump only in a well that has been properly

developed. Water from an undeveloped well often contains

an excessive amount of sand, dirt, and abrasives which

can damage the pump. Check that the well is large enough

to allow the pump to be set at the required depth. Do not

set the pump below the casing perforations or well screen

unless you make arrangements to ensure an adequate

flow of water over the motor for cooling purposes.

Determine the correct pump setting from the driller’s

record by taking into account the static water level and the

drawdown at the proposed pumping rate. Keep the pump

at least five feet from the bottom of a drilled well.

SPLICING THE POWER CABLE

Follow the instructions enclosed in the cable splicing

kit you purchase.

DROP PIPE

Drop pipe is recommended for suspending

submersible pumps into the well. Please refer to pipe

manufacturer for recommendations on depth and

pressure. Give special consideration to:

NOTICE: IT IS RECOMMENDED THAT STEEL CABLE

BE USED FOR THE PURPOSES OF SECURING THE

PUMP. 3/16" DIAMETER TO 1/4" DIAMETER BRAIDED

STEEL CABLE IS SUFFICIENT TO SUPPORT MOST

PUMP/MOTOR ASSEMBLIES. IT IS ALWAYS BEST

TO CONFIRM THAT THE PUMP/MOTOR ASSEMBLY

DOES NOT EXCEED THE MAXIMUM WEIGHT LIMIT

OF THE CABLE SELECTED.

2. Torque arrestor just above pump to prevent chafing

the cable when pump and pipe twist during the

starting and stopping cycle. (See Figure 1)

Take great care to keep pipes clean and free from

pebbles, scale and thread chips. Make sound, air-tight

connections at all fittings. Pipe sealant is recommended.

CHECK VALVES

It is recommended that one or more check valves

always be used in submersible pump installations. If

the pump does not have a built-in check valve, an inline

check valve should be installed in the discharge line

within 25 feet of the pump and below the draw down

level of the water supply. For deeper settings, check

valves should be installed per the manufacturer's

recommendations. More than one check valve is often

needed, but more than the recommended number of

check valves should not be used.

Swing type check valves are not acceptable and should

never be used with submersible motors/pumps. Swing

type check valves have a slower reaction time which

can cause water hammer (see next page). Internal

pump check valves or spring loaded check valves close

quickly and help eliminate water hammer.

NOTE: Only positive sealing check valves should be

used in submersible installations. Although drilling the

check valve or using drain-back check valves may

prevent back spinning, they create upthrust and water

hammer problems.

Check valves are used to hold pressure in the system

when the pump stops. They also prevent backspin,

water hammer and upthrust. Any of these can lead to

early pump or motor failure.

A. Backspin - With no check valve or a failed check

valve, the water in the drop pipe and the water in the

system can flow down the discharge pipe when the motor

stops. This can cause the pump to rotate in a reverse

direction. If the motor is started while it is backspinning,

1. A safety cable to prevent loss of pump if pipe

should break.

3

an excessive force is placed across the pump-motor

WARNING

assembly that can cause impeller damage, motor or

pump shaft breakage, excessive bearing wear, etc.

B. Upthrust - With no check valve, a leaking check

valve, or drilled check valve, the unit starts under a zero

head condition. This causes an uplifting or upthrust on

the impeller-shaft assembly in the pump. This upward

movement carries across the pump-motor coupling and

creates an upthrust condition in the motor. Repeated

upthrust can cause premature failure of both the pump

and the motor.

C. Water Hammer - If the lowest check valve is more than

30 feet above the standing (lowest static) water level, or a

lower check valve leaks and the check valve above holds,

a vacuum is created in the discharge piping. On the next

pump start, water moving at very high velocity fills the void

and strikes the closed check valve and the stationary water

in the pipe above it, causing a hydraulic shock. This shock

can split pipes, break joints and damage the pump and/

or motor. Water hammer can often be heard or felt. When

discovered, the system should be shut down and the pump

installer contacted to correct the problem.

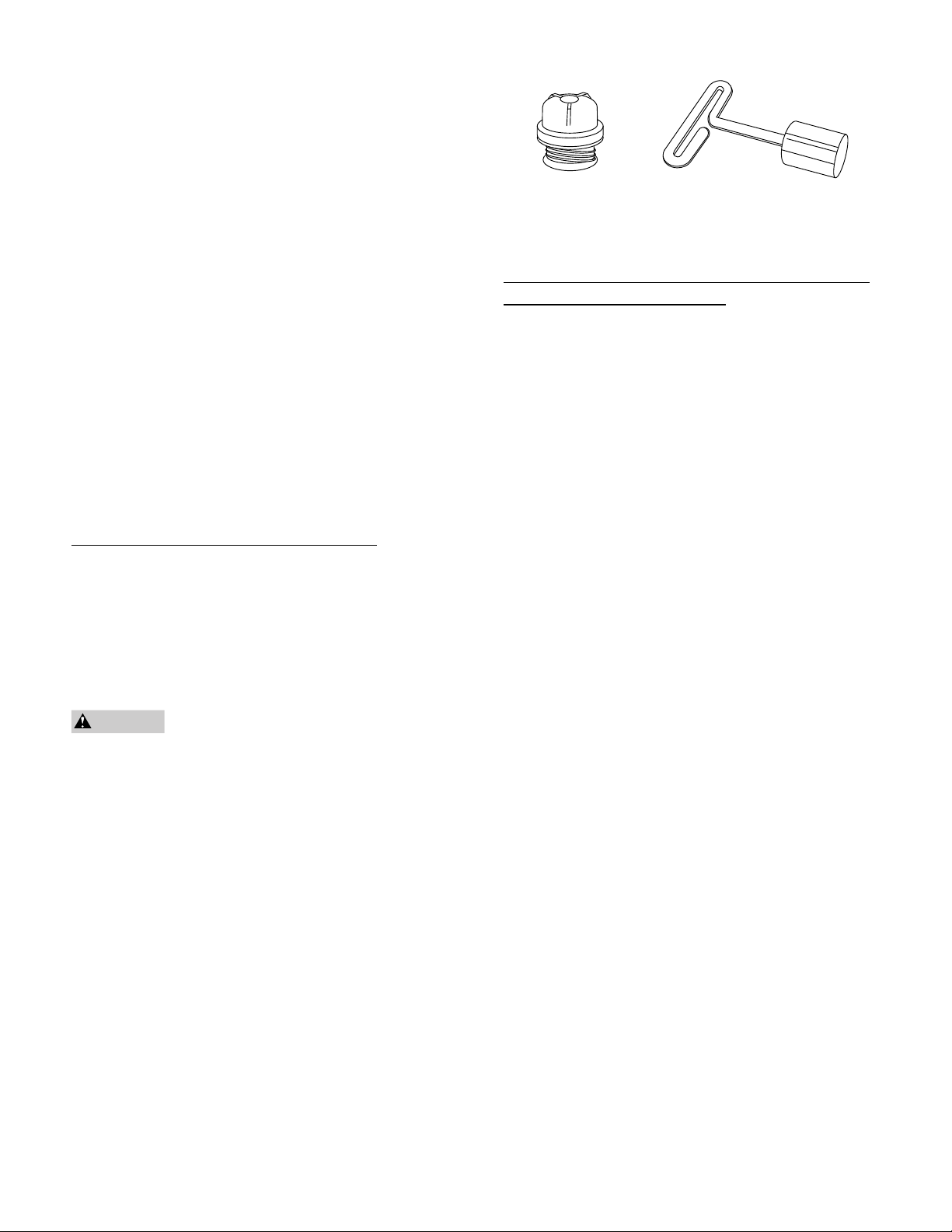

REMOVABLE POPPET CHECK VALVE

Some submersible pumps are supplied with a

REMOVABLE check valve assembly for applications

where the pump can become air locked. If the pump is

supplied without a check valve, or if the check valve is

removed, a spring-loaded inline check valve should be

installed roughly 10 to 20 feet (3 to 6.09 meters) above

the pump. This allows for the repriming of the pump

after the pump has run out of water.

Fluid draining back through the pump

can cause the pump to rotate backwards. If pump/

motor starts during this time; damage to the pump

can occur.

The check valve can be removed with the use of the

T-Handle Poppet Wrench (part no. 23498207), ordered

separately, or, with standard needle nose pliers. The

poppet assembly is left hand threaded and is removed

by turning CLOCKWISE.

If reinstalling a Popppet Check Valve assembly, the

assembly should be tightened to 15 inch-pounds.

Poppet Assembly

T-Handle Poppet Wrench

INSTALLATION OF PUMP, DROP PIPE, AND

ASSOCIATED EQUIPMENT

Fig. 1 illustrates a typical well installation showing inground components. Franklin recommends the following

procedure when installing the pump and drop pipe:

1. Prior to fastening the pump/motor assembly to

the drop pipe, confirm that the motor’s lead wires

are securely housed under lead guard which was

supplied with the pump. Fastening screws have been

provided for use during the lead guard’s installation.

2. Fasten the submersible cable to the drop pipe with

clamps or appropriate tape every 10 ft. (3m) to

prevent tangling and damage to the cable. The cable

must remain slack when using plastic drop pipe to

allow for stretching of pipe when installed in the well.

3. Take care not to scrape or pinch the submersible

cable against the well casing.

4. Use an ohmmeter or megger to make insulation and

continuity checks on the cable once the pump is

installed. This locates any fault in the cable.

5. Make sure system check valves are installed

properly. See previous sections of this manual for

further information on check valve placement, type,

and troubleshooting.

6. Install a torque arrestor just above the pump to

prevent chafing the cable when pump and pipe twist

during starting and stopping.

7. Attach a safety cable to pump to prevent loss of

pump if pipe should break.

NOTICE: IT IS RECOMMENDED THAT STEEL CABLE

BE USED FOR THE PURPOSES OF SECURING THE

PUMP. 3/16" DIAMETER TO 1/4" DIAMETER BRAIDED

STEEL CABLE IS SUFFICIENT TO SUPPORT MOST

PUMP/MOTOR SYSTEMS. IT IS ALWAYS BEST TO

CONFIRM THAT THE PUMP/MOTOR SYSTEM DOES NOT

EXCEED THE MAXIMUM WEIGHT LIMIT OF THE CABLE

SELECTED.

8. Place a sanitary well seal or pitless adapter with

an approved cover plate over top of well per

manufacturers recommendations.

9. Keep pump at least 5’ (1.5m) from bottom of well and

above well screen or casing perforations.

4

ELECTRICAL INFORMATION

1. Employ a licensed electrician to perform the

wiring. All wiring must be done in accordance with

applicable national and local electrical codes.

2. Check that the power supply corresponds with the

electrical rating of the submersible motor and the

control box(if required). Make sure that the control box

electrical rating matches the motor electrical rating.

3. Every installation requires a fused disconnect switch

or circuit breaker.

4. Every installation must be grounded. There must be

a reliable ground connection between the pump and

the distribution panel. The motor lead incorporates a

green grounding conductor.

5. Lightning arrestors are recommended for every

installation. All stainless steel, single phase motors

thru 5HP have built-in lightning arrestors. Any 6” motor

or 4”, 3-phase motor requires a separate lightning

arrestor installed as close to the wellhead as possible.

Install the arrestor in accordance with manufacturers

recommendations. A lightning arrestor provides

protection against induced voltage surges on

6. Mount the control box in an area protected from rain,

snow, direct sunlight or other high temperatures as

this may cause tripping of the overload protector.

Also protect the control box from extreme cold

(below 25oF/-32oC) as this may have adverse effects

on starting capacitor.

7. A two-wire pump does not require a motor control

box, since all electrical components are built inside

the motor. Fig. 2 shows a typical wiring diagram for

a two-wire installation.

8. A three-wire, single-phase pump requires a motor

control box incorporating overload relays. Fig. 3

shows a typical wiring diagram for a three-wire,

single-phase installation. Note that a magnetic

contactor must be used if the pressure switch

electrical rating is not sufficient to handle the

submersible motor electrical rating. The pressure

switch would then be incorporated into a pilot

circuit to control the magnetic contactor. Make

the connections at the control box in accordance

with the wiring diagram in the control box to avoid

damage to the motor.

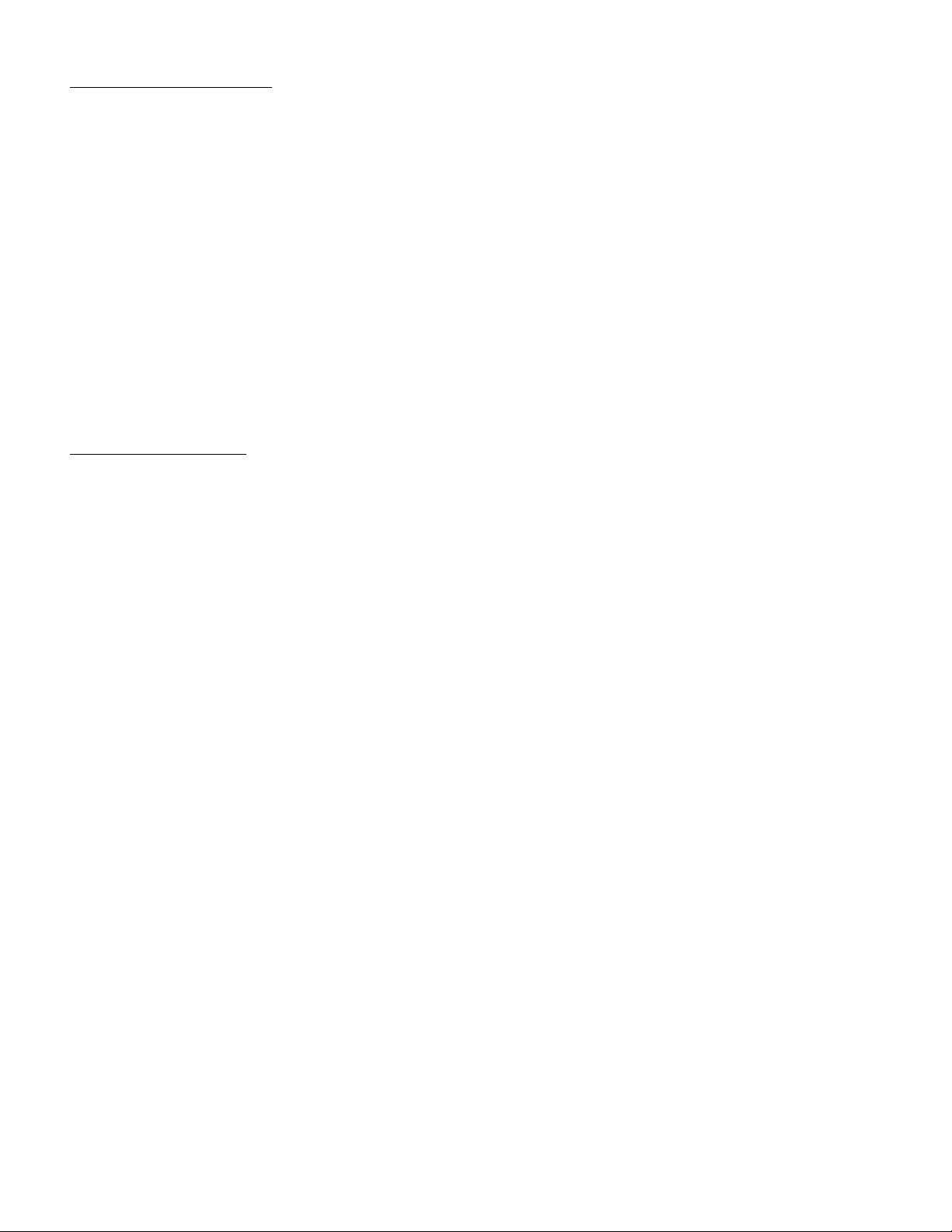

FIGURE 3 - 3-WIRE, 1-Phase, 1/2 thru 3 HP

Pump Wiring Diagram

Note: Order of red, yellow and black may

Pressure Switch (for pilot circuit)

If Magnetic Contactor is used

for starting.

Circuit Breaker

or Fused Disconnect Switch

Incoming 1 Phase Power

Switch or Timer (for direct switching) OR

Magnetic Contactor (w/ pilot circuit)

vary from control box to control box.

Always connect like colors.

L1

1-Phase Sumbersible Motor

L2 R

Y B

Single-Phase

Control Box

Red

Yellow

Black

FIGURE 2 - 2 WIRE, 1-Phase, 1/2 thru 1-1/2 HP

Pump Wiring Diagram

Circuit Breaker or

Fuse Disconnect Switch

Switch or Timer

Incoming 1-Phase Power

1-Phase Submersible Motor

Submersible Cable

5

CAUTION

9. A three-phase pump does not require a motor

control box . Fig. 4 shows a typical wiring diagram

for a 3-wire, three-phase installation. A magnetic

contractor with 3-leg protection having quick-trip

ambient compensated overload relays must be

used.

FIGURE 4 - 3-Wire, 3-Phase, 1-1/2 thru 50 HP

Pump Wiring Diagram

Circuit Breaker OR

Fused Disconnect Switch

Incoming 3-Phase Power

Pressure Switch

Magnetic Contactor w/

3-leg protection having

quick-trip ambient

conpensated overload relays

3-Phase Submersible Motor

10. Use an ohmeter to make continuity and insulation

checks after the installation is completed.

11. Place the additional motor label with the pump label

and place both in the disconnect switch or circuit

breaker box for future reference.

WELL TEST

Check the pump and well performance before making

the final connection to the discharge system.

1. Install a gate valve on the end of the pipe. Partially

open the valve.

2. Start the pump.

3. Open valve gradually to give full flow.

4. If the discharge is not clear, let the pump run until

water clears. If water does not clear in 30 minutes,

stop the pump and take the necessary steps to

correct the condition. After the water has appeared

clear, check for sand by discharging into a clean

bucket or suitable container.

5. Close valve until maximum required system flow

rate is obtained (this should correspond to the cut-in

pressure of the pressure switch). Ensure that the

output of the pump at this setting is not greater

than the yield of the well. This can be checked by

monitoring the well drawdown level and ensuring

that the level is stable at the maximum required

system flow rate.

Never run pump unless it is

completely submerged in water. If run without

water, the pump and motor could be damaged.

Note also that air drawn into the pump can cause

an airlock under certain conditions.

LOW-YIELDING WELL

A low-yielding well exists when the output from the

pump is greater than the yield of the well. It can

reduce the water level to the suction screen so that

a mixture of air and water enters the pump. Pumping

may stop since the pump cannot generate pressure

with insufficient water. In this case, the column of water

already in the drop pipe holds the check valve closed

and an airlock may develop inside the pump. Because

the conditions ensure neither adequate lubrication of

the pump nor proper cooling for the motor, damage

can result if power is not cut off quickly. Use one or

more of the following methods to correct and/or protect

this installation.

1. Install additional length of drop pipe to place pump

lower in well if possible.

2. Install a Franklin Pumptec or similar electronic

drawdown sensor.

3. Install a floatless liquid level control. This device

consists of an electrical relay activated by currents

flowing through the ground-return circuits of

electrodes hung in the well. The lower (STOP)

electrode, just above the pump, ensures that the

water level can never be pumped down to the

suction screen. The upper (START) electrode, just

below the lowest static water level, ensures that

the pump can start again as soon as the well has

recovered. A floatless liquid level control works

in series with the pressure switch. Refer to the

manufacturers instructions provided with control.

4. Install a flow control valve in the discharge line

upstream from the pressure switch. This restricts

the output from the pump without affecting the rate

that water can be drawn from the pressure tank.

Nevertheless, a heavy demand for water could

empty the pressure tank, so a tank with a bonded

diaphragm, air cell, or water bag is recommended.

5. Install a smaller pump to avoid over pumping the

well. Have dealer size pump to the well yield.

6. Install a low-pressure cut-off switch. A low pressure

cut off switch, or a pressure switch with such an

arrangement built in, protects a shallow-well pump

from losing its prime, but it does not always provide

satisfactory protection to a submersible pump from

the effects of over pumping the well. This is because

it responds to a loss of pressure at the surface,

which may occur after an air lock has formed inside

the pump. We recommend either a floatless liquid

level control or a flow control valve, in that order,

in preference to a low-pressure cutoff switch as

protection against over pumping.

6

DISCHARGE PLUMBING

Fig. 1 illustrates a typical well installation showing

above ground components. Adhere to the following

items when installing the discharge plumbing.

1. Install an above ground check valve upstream from

the pressure switch.

2. Always install a pressure relief valve in the system.

The relief valve should be capable of discharging the

flow rate of the pump at the rated working pressure

of the pressure tank. Locate the relief valve close to

the pressure tank.

3. Install a pressure switch between the check valve

and the pressure tank. Refer to Fig. 2, 3, or 4 for

proper wiring connections of pressure switch.

4. Install a pressure tank as close as possible to

the pressure switch. Refer to manufacturer’s

recommendations for installation.

TROUBLESHOOTING

1. PUMP FAILS TO START

a) Electrical trouble - call dealer or electrician.

b) Drawdown protection device has pump turned off.

c) Overload tripped.

d) Reset low pressure cutoff switch (if installed).

2. PUMP FAILS TO DELIVER WATER

a) Air lock in pump.

b) Clogged intake screen.

c) Insufficient well yield.

3. PUMP GIVES REDUCED OUTPUT

a) Insufficient well yield.

b) Worn pump.

c) Clogged intake screen.

d) Low voltage.

e) Incorrect rotation (3-phase only).

4. PUMP CYCLES TOO FREQUENTLY

a) Excessive pressure drop between pressure switch

and pressure tank.

b) “Cut-in” pressure at pressure tank too high.

c) “Cut-out” pressure at pressure tank too low.

d) Waterlogged pressure tank.

e) Start and stop electrodes of floatless liquid level

control set too close together.

f) Tank sized too small to meet system requirements.

5. OVERLOADS TRIP

a) Electrical trouble - call dealer or electrician.

6. PRESSURE SWITCH CYCLES RAPIDLY WHEN

PUMP STARTS

a) Pressure switch too far from pressure tank.

b) Adjust air charge of tank to manufacturer’s

recommendations.

7

LIMITED WARRANTY*

THIS WARRANTY SETS FORTH THE COMPANY’S SOLE OBLIGATION AND PURCHASER’S EXCLUSIVE

REMEDY FOR DEFECTIVE PRODUCT.

Franklin Electric Company, Inc. and its subsidiaries (hereafter “the Company”) warrants that the products accompanied by this

warranty are free from defects in material or workmanship of the Company.

The Company has the right to inspect any product returned under warranty to confirm that the product contains a defect in

material or workmanship. The Company shall have the sole right to choose whether to repair or replace defective equipment,

parts, or components.

The buyer must return the product to an authorized Franklin Electric Distribution outlet for warranty consideration. Returns to

the place of purchase will only be considered for warranty coverage if the place of purchase is an authorized Franklin Electric

Distributor at the time the claim is made. Subject to the terms and conditions listed below, the Company will repair or replace to

the buyer any portion of this product which proves defective due to materials or workmanship of the Company.

The Company will consider products for warranty for 12 months from the date of installation or for 24 months from the date of

manufacture, whichever occurs first.

The Company shall IN NO EVENT be responsible or liable for the cost of field labor or other charges incurred by any customer

in removing and/or affixing any product, part or component thereof.

The Company reserves the right to change or improve its products or any portions thereof without being obligated to provide

such change or improvement to previously sold products.

THIS WARRANTY DOES NOT APPLY TO products damaged by acts of God, including lightning, normal wear and tear,

normal maintenance services and the parts used in connection with such service, or any other conditions beyond the control

of the Company.

THIS WARRANTY WILL IMMEDIATELY VOID if any of the following conditions are found:

1. Product is used for purposes other than those for which it was designed and manufactured;

2. Product was not installed in accordance with applicable codes, ordinances and good trade practices;

3. Product was not installed by a Franklin Certified Contractor; or

4. Product was damaged as a result of negligence, abuse, accident, misapplication, tampering, alteration, improper

installation, operation, maintenance or storage, nor to an excess of recommended maximums as set forth in the

product instructions.

NEITHER SELLER NOR THE COMPANY SHALL BE LIABLE FOR ANY INJURY, LOSS OR DAMAGE, DIRECT, INCIDENTAL

OR CONSEQUENTIAL (INCLUDING, BUT NOT LIMITED TO, INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR LOST

PROFITS, LOST SALES, INJURY TO PERSON OR PROPERTY, OR ANY OTHER INCIDENTAL OR CONSEQUENTIAL

LOSS), ARISING OUT OF THE USE OR THE INABILITY TO USE THE PRODUCT, AND THE BUYER AGREES THAT NO

OTHER REMEDY SHALL BE AVAILABLE TO IT.

THE WARRANTY AND REMEDY DESCRIBED IN THIS LIMITED WARRANTY IS AN EXCLUSIVE WARRANTY AND REMEDY

AND IS IN LIEU OF ANY OTHER WARRANTY OR REMEDY, EXPRESS OR IMPLIED, WHICH OTHER WARRANTIES AND

REMEDIES ARE HEREBY EXPRESSLY EXCLUDED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, TO THE EXTENT EITHER APPLIES TO A PRODUCT

SHALL BE LIMITED IN DURATION TO THE PERIODS OF THE EXPRESSED WARRANTIES GIVEN ABOVE.

DISCLAIMER: Any oral statements about the product made by the seller, the Company, the representatives or any other parties,

do not constitute warranties, shall not be relied upon by the buyer, and are not part of the contract for sale. Seller’s and the

Company’s only obligation, and buyer’s only remedy, shall be the replacement and/or repair by the Company of the product as

described above. Before using, the user shall determine the suitability of the product for his intended use, and user assumes all

risk and liability whatsoever in connection therewith.

Some states and countries do not allow the exclusion or limitations on how long an implied warranty lasts or the exclusion or

limitation of incidental or consequential damages, so the above exclusion or limitations may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state and country to country.

Franklin Electric, in its sole discretion, may update this limited warranty from time to time. Any conflicting information relating

to warranty procedures, whether in a user manual or otherwise, is hereby superseded by this document. Nonetheless, all

references to the term, or length of a warranty term, will remain consistent with the warranty in place at the time of purchase.

*Contact Franklin Electric Co., Inc. Export Division for International Warranty.

Loading...

Loading...