Franke Foodservice FRGSF-18G2 18002746 Service Manual

FRGSF Service Manual Table of Contents/Section 1.1

Section No. Content/Service Operation Created/Updated

1.1 Table of Contents 6-3-09

1.2A Franke Warranty Statement 5-12-09

1.2B Franke Service Commitment 5-4-09

1.3 FRGSF Trouble Shooting Tables 5-12-09

1.4 FRGSF Parts List 5-29-09

1.5 FRGSF Electric Schematics& Components 5-29-09

1.6 Control Settings & OperatingCharacteristics 6-3-09

[General Part Replacement]

2.1 General Service Instructions &Warnings 5-4-09

2.2 Front Door Gasket Replacement 5-4-09

2.3 Rolling Lid Gasket Replacement 5-4-09

2.4 Rolling Lid Roller/Bearing Replacement 5-4-09

2.5 Grill Product [Pan] Trolley Flat Bearing Replacement 5-4-09

2.6 LED Remote [Front] Temperature Display Replace. 5-4-09

2.6A LED Temperature Display Cable Replacement 5-4-09

2.7 Controller/Thermostat [Danfoss ETC1H] Replace. 5-4-09

2.8 Temperature Sensors/Cable Replacement 5-15-09

2.9 High Temp. Cutoff Switch Replacement 5-4-09

2.10 Evaporator Defrost Heater Replacement 5-29-09

2.11 Top Cable Heater(s) Replacement 5-4-09

2.12 Caster Replacement 5-5-09

2.13 Door Hinge Replacement 5-12-09

2.14 Power Cord Replacement 5-5-09

[Part or Component Adjustments]

3.1 Reverse Door Hinges/Change Front Door Swing 5-5-09

3.2 Adjust Door/Gasket Fit 5-5-09

3.3 Thermostat Adjustment/Adjust Set Temperature 5-12-09

3.4 Change Temperature Display From °F to °C 6-3-09

[Refrigeration System Repair & Replacement]

4.1 Basic [Operator] Maintenance Procedures 5-5-09

4.2 Condenser Fan Motor Replacement 5-12-09

4.3 Evaporator Fan Motor Replacement 5-12-09

4.4 Evaporator Coil Assembly Replacement 5-5-09

4.5 Start Relay & Replace Start Capacitor Replacement 5-5-09

4.6 Check System[Refrigerant] Pressure/Leaks 5-5-09

4.7 Repair System [Refrigerant] Leak 5-5-09

4.8 Filter/Drier Replacement 5-12-09

4.9 Expansion Valve Replacement 5-5-09

4.10 Replace Condenser/Compressor Package 5-5-09

Rev. 6 6/3/09

For Technical Support, Call 800-537-2653. Copyright 2009Franke, Inc. All rights reserved.

FRGSF Service Manual Warranty/Section 1.2A

Franke New Equipment Limited Warranty

Franke Foodservice Systems (“Franke”)warrants new equipment manufactured in Franke’s own facilities and

installed in the United States and Canada to be free of defects dueto poor materials or workmanship for the

period of time listed below (following thedate of original installation):

Franke- Manufactured Equipment

Stainless Steel Surfaces – Life of the equipment

Compressor -- 5 Year Extended Warranty, as detailed below

All Other Components– 2 Years Parts and Labor

5-Year Extended Compressor Warranty

Two Years from Date of Installation – Parts & Labor

3rd through 5thYear from Date of Installation – Parts only

In accordance with the compressor manufacturer’s policy, the serialnumber plate affixed to the

compressor must be returnedwith the service invoice before reimbursement will be made.

Exclusions: Certain Franke parts that are expendable by nature and that need to be replacedfrequently may

not be covered. Franke is not liable under thesewarranties for repairs or damages due to improper operation,

attempted repairs or installation by unauthorizedpersons, alterations, waterquality, abuse, fire, flood, or acts

of God. Additionally, this warrantymay be voided in the case of:

Failure to follow Franke instructions for use, careor maintenance

Removal, alteration or defacingof the Franke-affixed serial number

This warranty isconditional upon Franke receiving noticeof any defect subject to this warranty withinthirty (30)

days of its original discoveryby the Buyer.

Other Equipment (Not Manufactured by Franke)

Equipment not manufactured by Franke (commonly known as “buyouts” or purchasedgoods) and

manufactured by other entities is coveredby the warranties, ifany, of such third-party manufacturers. Where

such third party manufacturers provide warrantieson any or all portions of said “buyouts,”Franke agrees to

transfer all such warranties to the Buyer.

Rev. 1 5/09

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

FRGSF Service Manual Service Commitment/Section 1.2B

The Franke Service Commitment

Franke Foodservice Systems’ TechnicalSupport Department and its third-partyService Network is committed

to meeting the unique service needs of restaurantoperators. Accordingly, we strive toprovide thefollowing

response times to service requestsfor Franke-manufactured equipment:

1. Provide contact with the customer…

– Within 30 minutes of requestfor service during normal business hours

– Within 90 minutes after normal business hours (includingweekends)

2. Perform service visit

– The same day for emergency service*

– Within 24 hours for standard service

3. Target a 90% “first call” fix rate

4. Provide 90-day warranty on serviceperformed

*For the purposesof thiswarranty, “emergency”is defined as an equipment operating condition that

poses an immediate risk to the safety of restaurantworkers or customers.

This response time breakdownapplies throughout the week and weekend. Due to varying customer locations,

and varying serviceagent locationsand schedules, response rates may occasionally be extended. In these

situations, Franke Technical Support will workdirectly with the customer to find mutually suitable options.

Franke reserves the right to use service agents outside of the stated Service Network.

Service Network

United States and Canada

Franke provides 24-hour, 7-day (24/7) response to customer service requests through itsown CallCenter.

Whenever possible, Franke selects service agents who belong to the Commercial Food Equipment Service

Association (CFESA). Thistrade association currently has more than 450 members representing the U.S.,

Canada, Mexico and Puerto Rico.

When Franke cannotselect a CFESA member, itnonetheless adheres to the CFESA standard for qualified

service agents in North America. Among them are:

• 24 Hour emergency service

• Factory authorized warranty service

• Factory trained and certified technicians

• OEM parts availability

• System for communication with field technicians

Performance of serviceagents, including their parts stocking abilities, call responsetime, service rates and

customer satisfaction are monitoredby the Franke Field Service Department via online, written and phone

surveys. This Service Network list is updated annuallyby Franke Technical Support.

Contact Information:

Franke Technical Services

1-800-5FRANKE (1-800-537-2653); select option 2

Tech.Support@Franke.com

Rev. 1 5/09

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

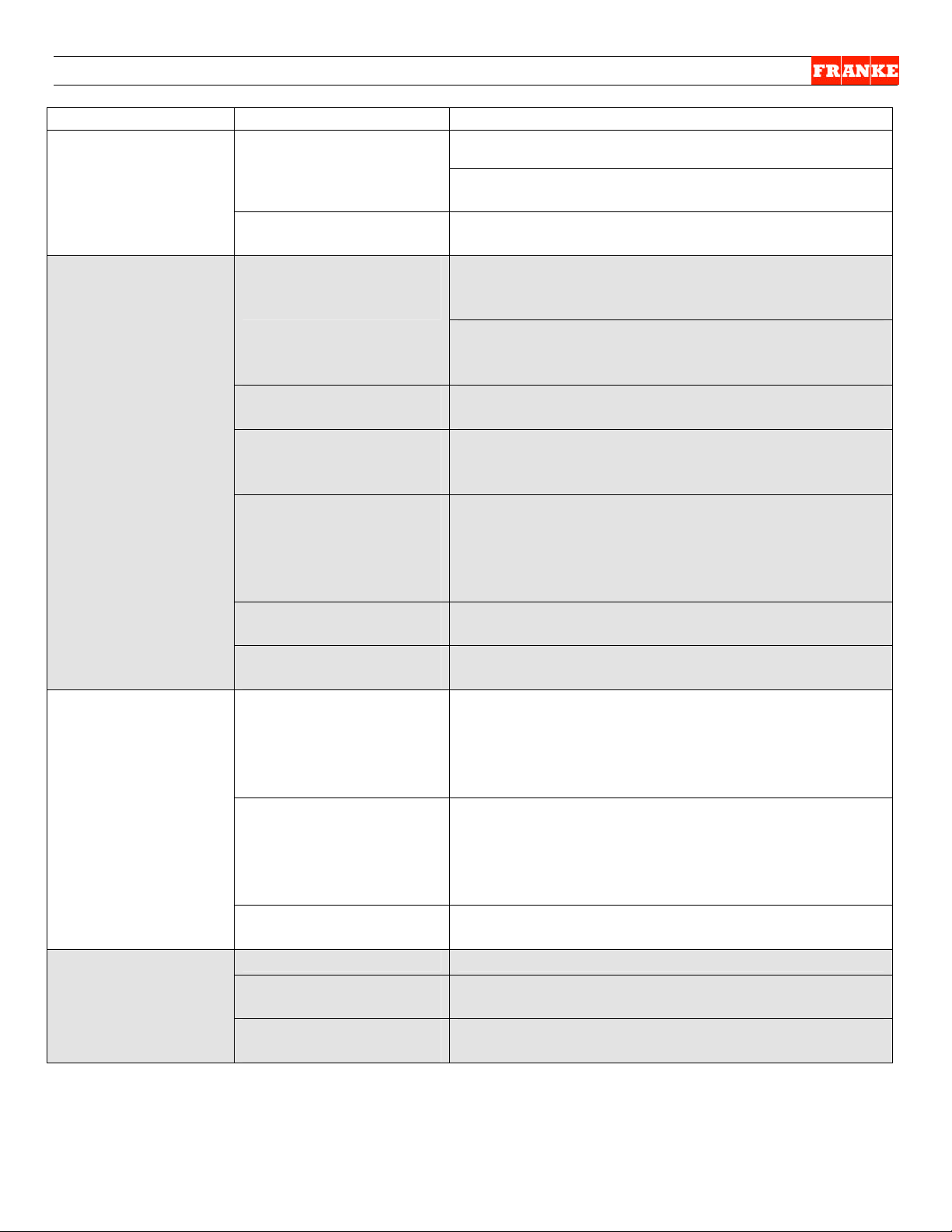

FRGSF Service Manual Advanced Troubleshooting Guide / Section 1.3

The Problem Possible Cause What To Check & Do

Breaker OK? Yes = Continue; No = Call electrician

Main Power Not

“ON”

Main Power “ON”

But Freezer Does

Not Run

Freezer Runs But

No Temperature Is

Displayed

Temperature

Display Reads

Temperature But

Freezer Does Not

Cool To 0° F

Power not available to

unit?

Receptacle OK? Yes = Continue; No = Call

electrician

Power cord OK? Yes = Continue; No = Replace power cord per

Section 2.14

Unplug Freezer power cord for 1 hour, then retry.

Compressor thermal

overload tripped?

If problem reoccurs, ensure condenser coil is clear

of debris and cleaned, per PM Service Instructions

Test condenser electric components for defects or

failure, including: start-capacitor, start relay,

condenser fan motor & compressor.

Power disconnected to

temperature controller

Temperature controller

disconnected from

Check input voltage to temperature controller.

Replace wiring harness if damaged.

Check output voltage at temperature controller.

Replace wiring harness to Condenser, if damaged

condensing unit

Sensor cable is

Connect or replace sensor cable per Section 2.8

disconnected or

damaged, from

controller to freezer

inner compartment

Condenser Package is

unplugged inside.

Temperature controller

Check Condenser Package plug through right

service access panel. Plug in if unplugged or loose.

Replace defective component per Section 2.7

is defective

Temperature sensor

cable is disconnected

Connect or replace temperature sensor & cable per

Section 2.8

or damaged, from

controller to freezer

inner compartment

Communications cable

disconnected or

Connect or replace display communications cable

per Section 2.6A

damaged from

controller to

temperature display

Temperature display is

Replace temperature display per Section 2.6

defective

Set point too high

Door and/or Rolling Lid

leaking cold air

Evaporator fan not

Adjust thermostat setting, per Section 3.3

Inspect door and lid gaskets for damage. If needed

replace per Section 2.2 [Door] and/or 2.3 [Lid]

Replace evaporator fan per Section 4.3

functioning

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

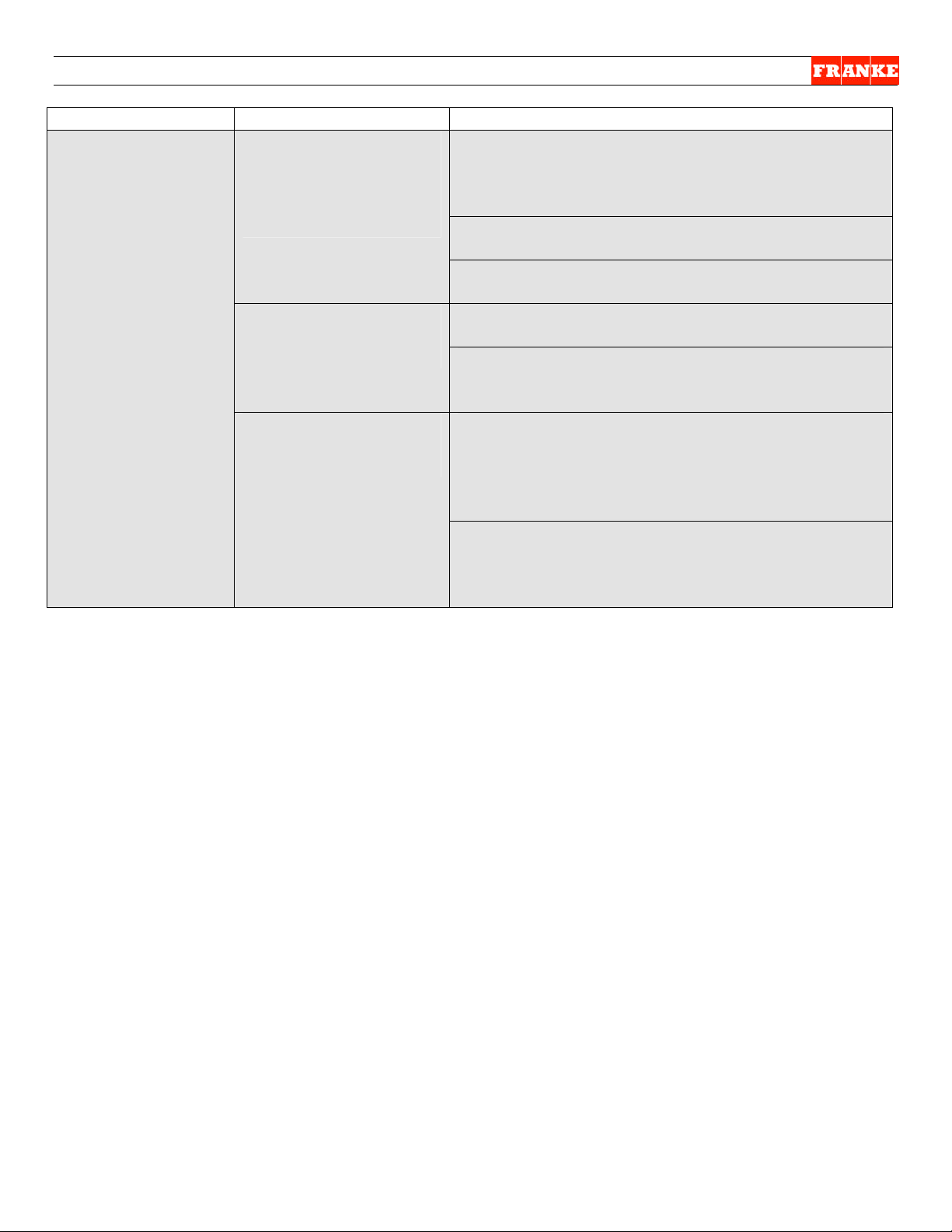

FRGSF Service Manual Advanced Troubleshooting Guide / Section 1.3

The Problem Possible Cause What To Check & Do

Check temperature controller circuit for defrost

heater. Does relay close when manual defrost is

initiated? If not, replace temperature controller per

Section 2.7

Check high temperature cutoff switch for proper

function. If needed, replace per Section 2.9

Check defrost heater integrity. If needed, replace

defrost heater per Section 2.10

Inspect service valves, lines, joints and

components for signs of leaks, kinks or restrictions.

Section 4.6. If leak is found, repair refrigeration

leak per Section 4.7

Ensure condenser coil is clean, unobstructed and

being cleaned every three months (or more

frequently, if needed) per FRGSF PMM Page

instructions. If dirty or obstructed, vacuum or brush

out condenser coiland notify unit manager.

Check condenser electrical components for defects

(start-capacitor, start-relay, condenser fan motor,

compressor, etc.) Replace if needed. (See Section

1.1 for specific section.)

Temperature

Display Reads

Temperature But

Freezer Does Not

Cool To 0° F

[Continued]

Evaporator coil blocked

with ice

Refrigerant charge is

not correct or system

has a leak. Check system pressure and check for leaks per

Condensing unit is not

starting properly or is

tripping on overload.

Rev. 1 5/09

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

FRGSF Service Manual Parts List & Component Diagrams / Section 1.4

Model FRGSF-30G2

shown

Basic Repair Parts List

[Also See Section 2.1 for a Truck Stock List]

For FRGSF-18 For FRGSF-30 Part Description Quantity

19001773 19001986 Front Door Gasket 1 ea.

19002064 19001992 Top Rolling Door Gasket 1 ea.

19001991 19001991 Top Rolling Door Roller-Bearings 4 ea.

19000574 19000574 Top Door Roller Guide, Outer 1 ea.

19000575 19000575 Top Door Roller Guide, Inner 1 ea.

19000471 19000471 Product Trolley Rollers 4 ea.

3587145 3587145 Door Hinge, Edge Mount, Adjustable 2 ea.

19000436 19000436 Remote Temperature Display 1 ea.

19001011 19001011 Display Guard Bezel 1 ea.

19001093 19001093 Danfoss Controller/Thermostat 1 ea.

19001171 19001171 Remote Temperature Display Cable (19”) 1 ea.

19000648 19000648 Air Temperature Sensor & Cable 1 ea.

3588590 3588590 High Temperature Cutoff Switch 1 ea.

19000470 19000470 Defrost Sensor & Cable 1 ea.

19001156 19001157 Defrost Heater (Evaporator Coil) 1 ea.

19001793 19001794 Heat Wire, Front & Top 2 ea.

19002529 19002529 Swivel Caster with Brake 4 ea.

19001253 19001253 Condenser Fan Motor 1 ea.

19000454 19000454 Evaporator Fan Motor 1 ea. [-18], 2 ea. [-30]

19002059 19002060 Evaporator Coil 1 ea.

18002767 18002768 Evaporator Assembly 1 ea.

19001084 3589843 Start Capacitor 1 ea.

19001081 3589841 Start Relay 1 ea.

19001189 19001190 Thermostatic Expansion Valve 1 ea.

19001941 19001941 High Pressure Control 1 ea.

19001809 19001809 Filter/Dryer 1 ea.

19002054 19000362 Condensing Unit 1 ea.

19001076 19001078 Compressor (only) Kit 1 ea.

19000282 19000282 Cord-set [8-feet] 1 ea.

Rev. 1 5/09

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

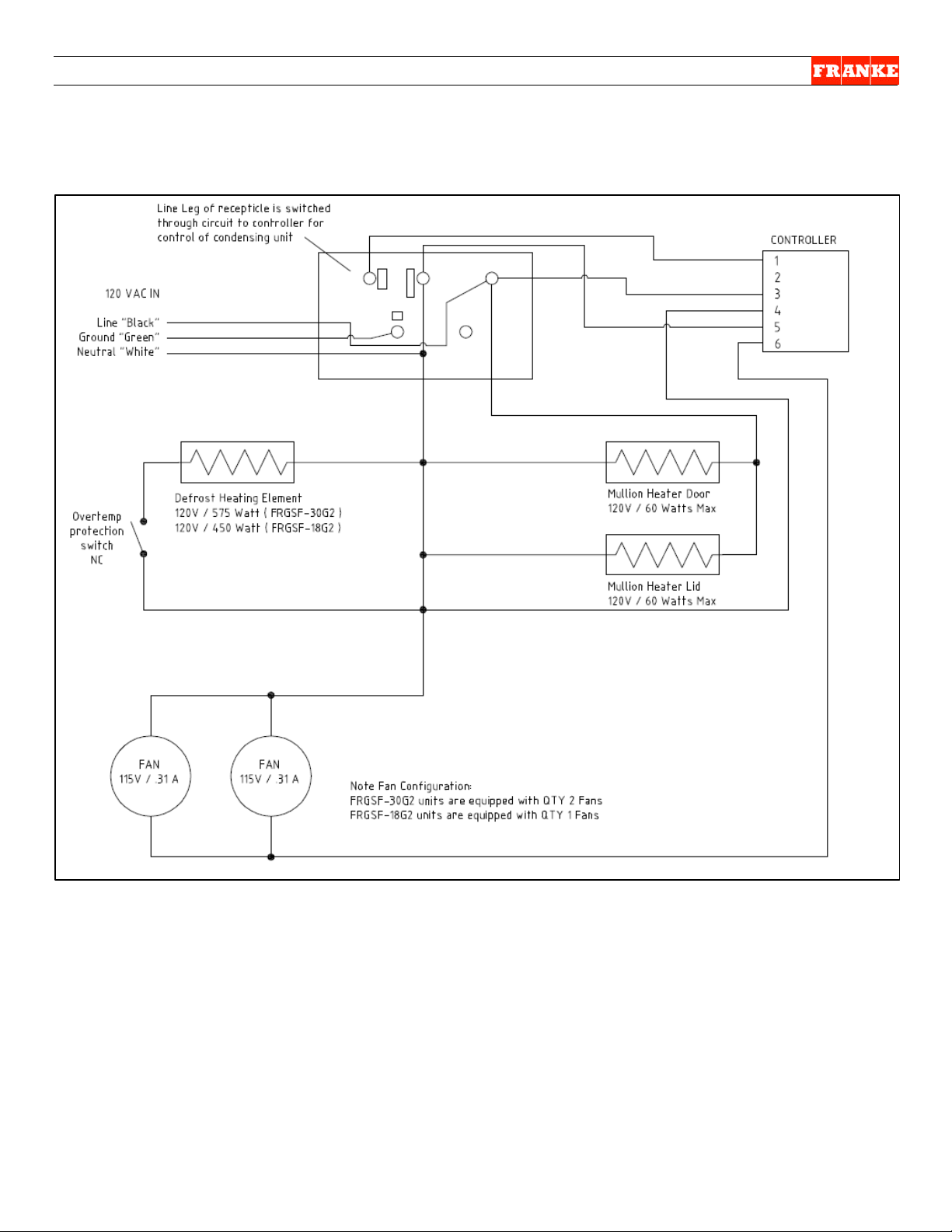

FRGSF Service Manual Electric Schematics / Section 1.5

FRGSF-18G2 & FRGSF-30G2 Wiring Harness

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

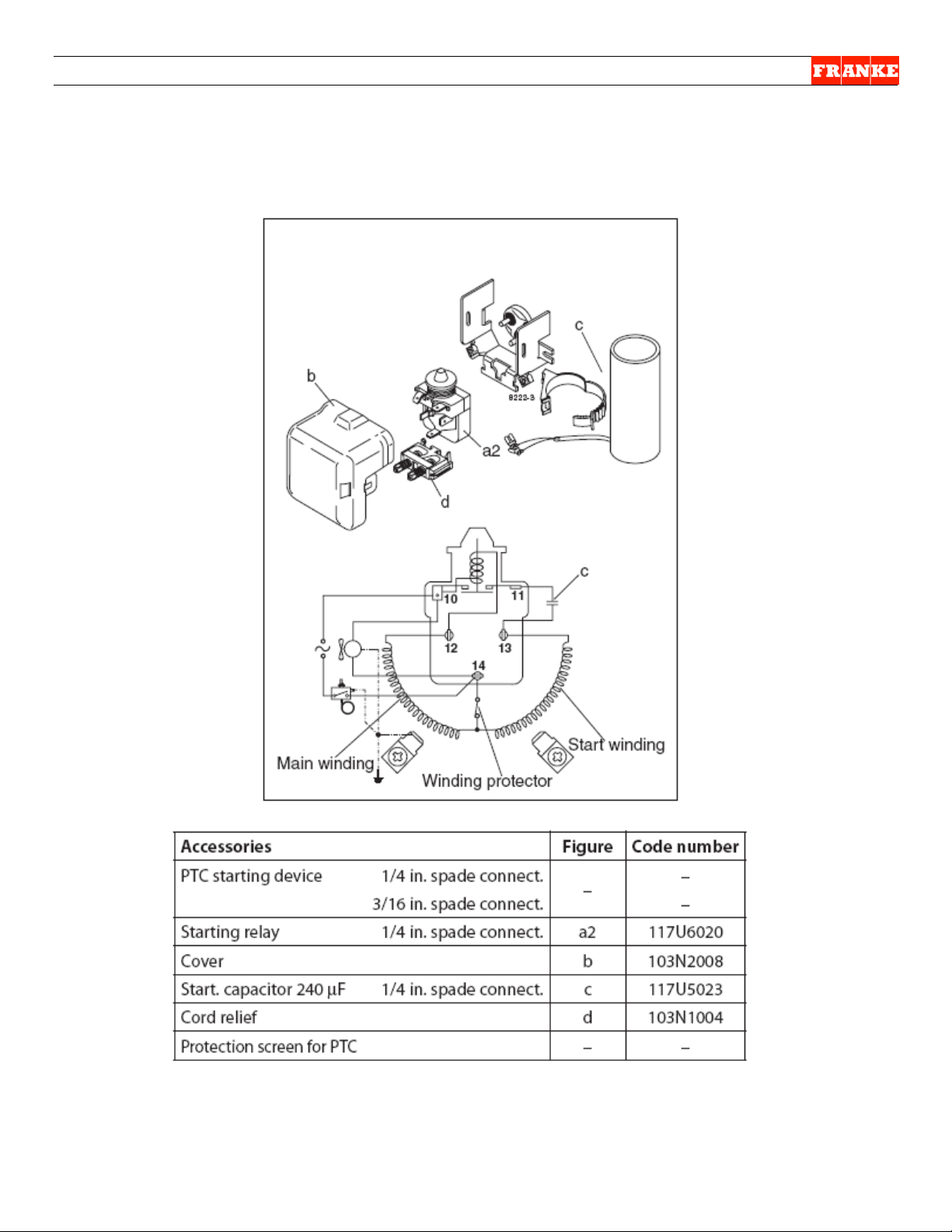

FRGSF Service Manual Electric Schematics / Section 1.5

Danfoss SC12CLX.2 Compressor

(For: Model FRGSF-30G2)

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

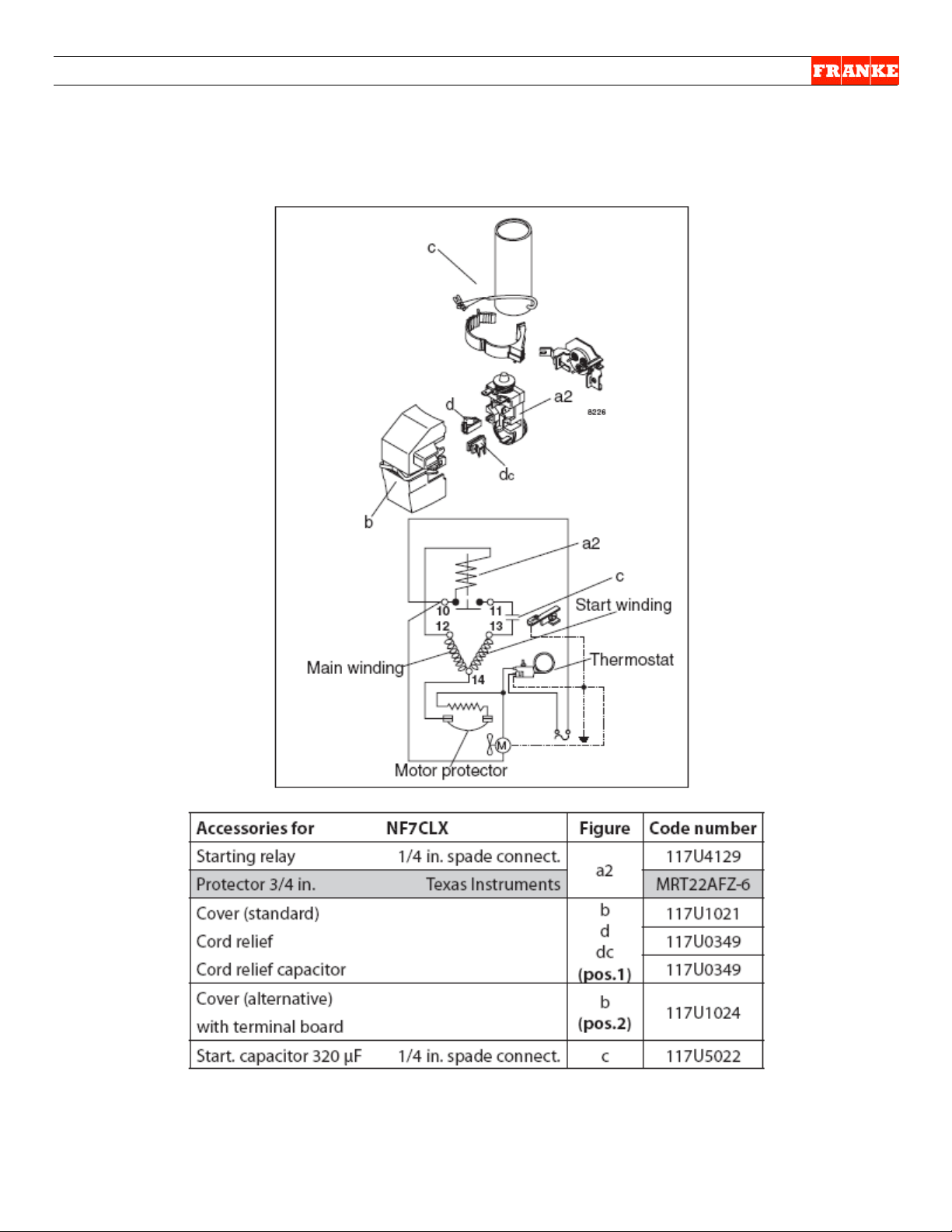

FRGSF Service Manual Electric Schematics / Section 1.5

Danfoss NF7CLX Compressor

(For: Model FRGSF-18G2)

Rev. 1 5/09

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

FRGSF Service Manual Control Settings-Characteristics / Section 1.6

Control Settings & Operating Characteristics

(For Trouble Shooting Reference)

Danfoss Temperature Controller For More Information

Temperature Range Adjustable

Coldest Set Point(midpoint) -12degrees F

Normal Cut Out -12 degrees F

Normal Set Point (midpoint) -7degrees F

Normal Cut In -2degrees F

Warmest Set Point (midpoint) -2degrees F

Compressor Protection Fixed

Minimum On Time 2 minutes

Minimum Off Time 2 minutes

Fail Safe Mode (if sensor fails) Fixed

Error On Time 10 minutes

Error Off Time 2.5 minutes

Defrost Settings Fixed

Termination Temp 60degreesF

Minimum Time Allowed 10 minutes

Maximum Time Allowed 90 minutes

Drip Time (heat off) 2 minutes

Defrost Based On Compressor On Time Fixed

Time Between Defrosts 3 hours

Fan Settings Fixed

During Defrost Off

Delay After Defrost 3 minutes

Start delay 1 minute

Display Features Adjustments

Select degrees F or C? Yes

Adjust Temperature from display? Yes See Section 3.3 to change

Initiate Defrost from display? Yes

Display During Defrost Cycle:

Display Update Frequency Every 10 seconds

dEF

See Section 3.3 of Service

Manual for Adjusting

Temperature

See Section 3.4 to change

See Section 4.1 to initiate

defrost cycle

Normal Operating Pressures Normal Operating Amps

High Side (85 air to condenser) 235 PSIG FRGSF-30G2 5 – 6 Amps

Low Side (-5 airinto coil) 13 PSIG FRGSF-18G2 8 – 9 Amps

High Pressure Safety Rated Operating Amps

Cut Out Setting 460 PSIG FRGSF-30G2 7 Amps

Differential 30 PSIG FRGSF-18G2 10 Amps

Defrost High Limit Safety

Cut Out Setting 155 degrees F

Differential 20degrees F

Rev. 1 6/09

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

FRGSF Service Manual Parts Replacement / Section 2.1

WARNING:

2.1 An Introduction To FRGSF Service Manual

The Basics:

1) Technicians should be authorized to work on Franke

Equipment and be EPA Certified and qualified to

diagnose and repair refrigeration equipment.

2) The Franke Grill-Side Freezer comes in two sizes, the

compact FRGSF-18 model and larger FRGSF-30 model.

3) Both FRGSF Models operate on 120-volt power and are

provided with a grounded plug and 8’ power cord.

Unplug unit from its120-volt power source whenever

servicing electrical components or removing the rear or

side service access panels. Failure to unplug unit may

result in electric shock, burns or death.

4) The FRGSF refrigeration system is charged with 18-20

ounces (.65 kg) of ozone-safe R404A refrigerant. See

unit Data Plate and use site glass provided, when filling.

5) Only use R404A refrigerant when recharging this unit.

6) Always verify proper unit cleaning before replacing or

repairing components. [See Section 4.1]

[Unit Model &Serial Number]

The FRGSF Unit Serial Number

is located below the Model

Number & Data sticker, which is

on the back of unit.

Suggested [On-Truck] Repair Parts:

We suggest the following to ensure a first-trip fix of FRGSF:

FRGSF-18 FRGSF-30 Description Qty.

19001773 19001986 Front Door Gasket 1 ea.

19002064 19001992 Top Rolling Door Gasket 1 ea.

19001991 19001991 Top Rolling Door Rollers 4 ea.

19000471 19000471 Product Trolley Rollers 4 ea.

19000436 19000436 Remote Temperature Display 1 ea.

19001093 19001093 Danfoss Controller/Therm. 1 ea.

19001171 19001171 Remote Temp. Display Cable 1 ea.

19000648 19000648 Temperature Sensor (Cable) 1 ea.

19001011 19001011 Display Guard Kit 1 ea.

19001157 19001159 Defrost Heater (Evaporator) 1 ea.

19000470 19000470 Defrost Sensor Cable 1 ea.

19002529 19002529 Swivel Caster w/Brake 4 ea.

19001253 19001253 Condenser Fan Motor 1 ea.

19000454 19000454 Evaporator Fan Motor 2 ea.

19001084 3589843 Start Capacitor 1 ea.

19001081 3589841 Start Relay 1 ea.

19001189 19001190 Thermostatic Expansion Valve1 ea.

19002054 19000362 Condensing Unit 1 ea.

19001076 19001078 Compressor Replacement Kit 1 ea.

19000282 19000282 PowerCord [8-foot] 1 ea.

3588590 3588590 High Temperature Cutoff 1 ea.

Tools Required:

[For Mechanical Systems Repair]

3/8” screwdriver

¼” screwdriver

1/16” “mini” screwdriver

1/8” Allen/hex wrench

3/16” Allen/hex wrench

5/32” Allen/hex wrench

5 mmAllen/hex wrench

13 mmAllen/hex wrench

7/16” box/socket wrench

Razor knife

Needle nose pliers

Small wire cutters

Rubber mallet

Plastic Wire Ties

[Also See Section 4.1]

Rev. 1 5/09

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

FRGSF Service Manual Parts Replacement / Section 2.2

Rubber mallet

2.2 Front Freezer Door Gasket Replacement

[Model FRGSF-18 use Part No. 19001778]

[Model FRGSF-30 use Part No. 19001986]

1) FRGSF Freezer should be unplugged and thefreezer

compartment fully defrosted before proceeding.

2) Open freezer door and inspect the one-piece magnetic

door gasket. If the gasket is torn or crushedso that it

doesn’t completely seal around the door perimeter, it

should be replaced.

3) Remove the three hinge-to-frame Phillips screws from

both door hinges using a power screwdriver with Phillips

bit or a Phillips screwdriver. Being careful not to drop the

door, place it on a non-mar surface, gasket side up.

4) Carefully remove the one-piece gasket from the slotted

plastic extrusion built into the back of the freezer door.

[Note: Plastic extrusion can be easily damaged. Using a

razor knife to separate the old gasket from its retaining

tailpiece may facilitate this procedure. Carefully remove

the separated tailpiece from the slot by pulling toward

each corner, using a small needle nose pliers. (See

Photos 2 and 3.)

5) Take the new gasket and insert the tailpiece into the

gasket-mounting slot. Align the corners and start at the

top of the door. Continue around the door perimeter until

completely seated. [Tip: Place the door on a cushioned

surface and carefully hammer the new gasket tailpiece

into the slot around the door perimeter. IMPORTANT:

Be careful not to break the rubber tailpiece.]

6) Re-install freezer door by replacing the three Phillips

screws in each hinge bracket.

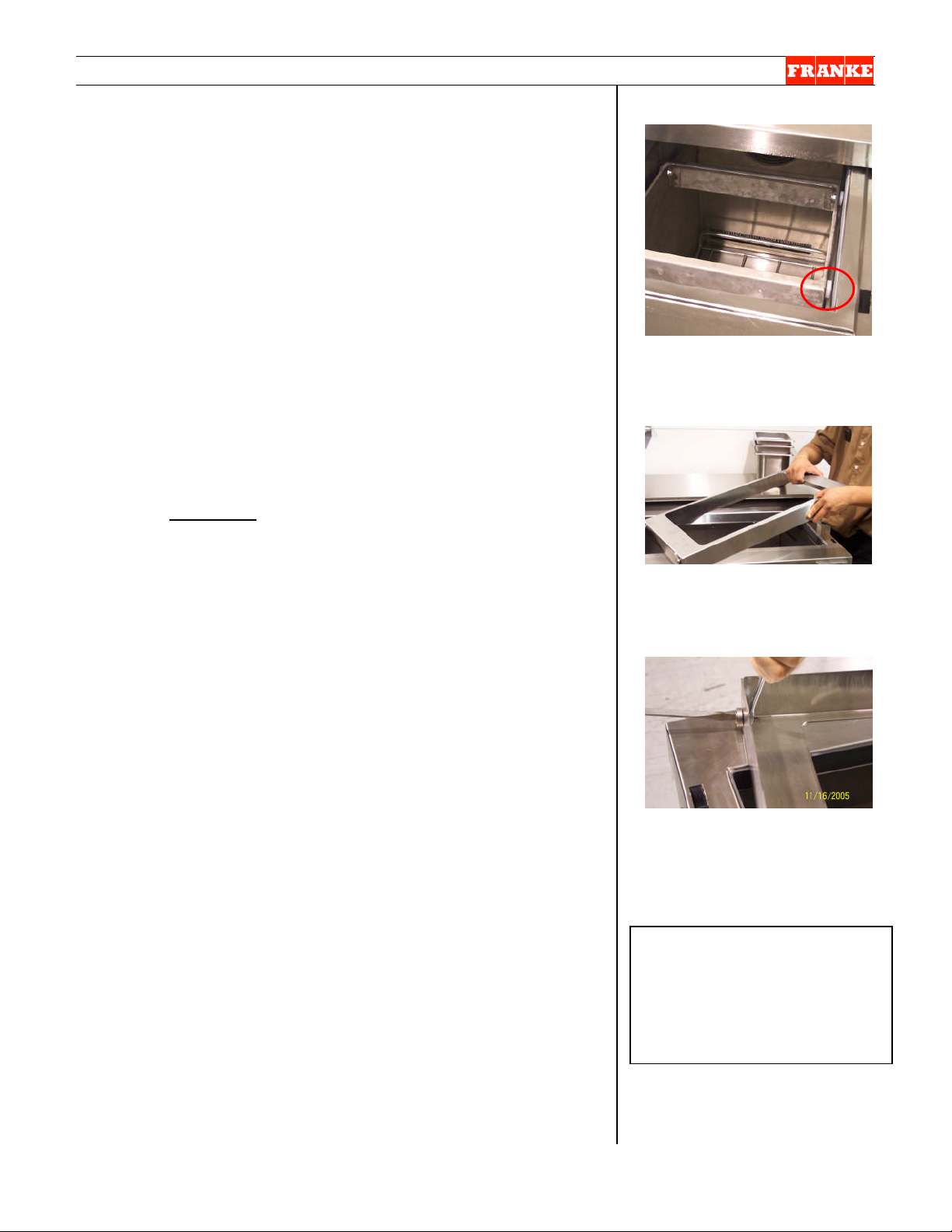

[Photo 1]

The GSF freezer door is

equipped with a one-piece

magnetic door seal.

[Photo 2]

To speed replacement, cut away

the old door gasket from its

tailpiece.

[Photo 3]

7) Test the replacement of the Freezer Door Gasket by:

8) Close the door and visually check the door seal and fit.

9) Plug power cord into 120-volt outlet. Allow compressor to

Power screwdriver w/PhillipsBit

Razor knife

Needle nose pliers

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

The gasket should expand slightly and seal completely

against door frame. (See Section 3.2 for adjusting door.)

draw down Freezer Compartmenttemperature. Check

with your hand around the full door perimeter for any

cold air leaks.

Tools Required:

Useneedle nose pliers to pull

the gasket tailpiece from slot.

[Photo 4]

Align gasket tailpiecewith door

slot and hammer carefully into

place around door perimeter.

Rev.1 5/09

RFGSF Service Manual Parts Replacement / Section 2.3

2.3 Top Roll-Back Door Gasket Replacement

[Model FRGSF-18 use Part No. 19002064]

[Model FRGSF-30 use Part No. 19001992]

1) FRGSF Freezer should be unplugged and the freezer

compartment fully defrosted before proceeding.

2) Roll back the top door, lift front edge and pull door clear

of roller STOP depressions in freezer top.

3) Turn over door to gasket side, place door on a non-mar

surface or the unit’s top, with the gasket side facing up.

4) Lift up inner edge of gasket material to expose the

plate/retainer screws. Use a large Phillips screwdriver to

remove all the screwsaround the perimeter of the door.

5) Lift retaining plate off gasket. It is OK to pry plate up with

a large flat blade screwdriver or dull putty knife.

6) Take new one-piece door gasket [P/N 190002064

(FRGSF-18) or 19001992 (FRGSF-30)] position and

align it inside the rolling lid door.

7) Take inner door/gasket retainer plate and insert it under

one side of gasket. Gently work around top, bottom and

other side of plate, pulling gasket up and around plate.

[IMPORTANT: Avoidusing sharp tools to lift or pry

gasket material around the retaining plate.]

8) Make sure gasket retaining plate holes all line up, then

insert and tighten all retaining screws.

9) Reposition the roll-back door on the freezer top with the

two large plastic roller stop/guides to the case front.

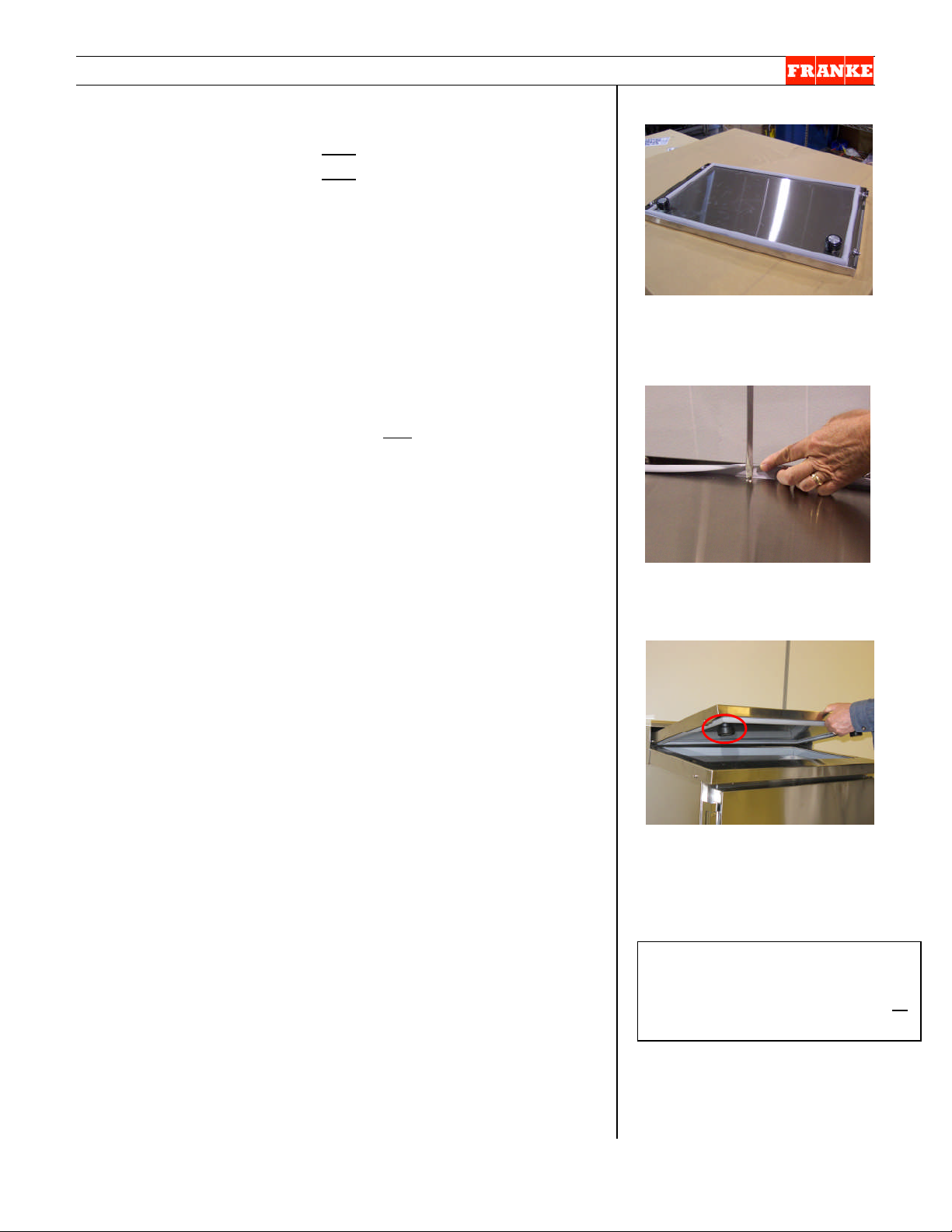

[Photo 1]

Lift roll-back doorup and off

FRGSF top and carefully place

up-side-down on freezer top.

[Photo 2]

Lift up gasket and remove all

gasket retaining plate screws.

[Photo 3]

Test the replacement of the Roll-Back Door Gasket by:

10) Roll back the door to see if it moves freely. Release the

door to see if it rolls forward unassisted and engages the

roller depressions or stops.

11) Plug power cord into 120-volt outlet. Allow compressor to

draw down Freezer Compartment temperature. Check

with your hand around the front and sides of the door

where it meets the top, for significant cold air leaks.

After replacing gasket, position

roll-back door with plasticroller

guides to unit front.

Tools Required:

Large Phillips screwdriver

Large flat blade screwdriver or

putty/utility knife

Rev. 1 5/09

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

FRGSF Service Manual Parts Replacement / Section 2.4

2.4 Rolling Lid Door Roller Replacement

[4-each Part No. 19001991]

1) FRGSF Freezer should be unplugged and the freezer

compartment fully defrosted before proceeding.

2) Roll back the top door, lift front edge and lift door clear of

roller STOP depressions in freezer top.

3) Turn over door to gasket side and place door on a flat,

non-mar surface, with the gasket side facing up.

4) Inspect each roller bearing to see if it is free of debris

and turns easily.

5) If one or more bearings are stiff or show minor corrosion,

lubricate with food-safevegetable-based oil.

6) If bearings are frozen [won’t rotate], badly corroded or

damaged, replace with Part No. 19001991 by:

7) Using a Phillips Screw Driver and ¼” [6 mm] wrench,

remove the M6-20 screw and matching acorn nut.

8) Position new bearing inside the door edge, insert new

M6-20 screw,apply some removable thread locking

compound then screw on the acorn nut and tighten.

[Repeat for each bearing that requires replacement.]

9) Reposition the roll-back door on the freezer top with the

plastic guide rollers to the front.

Test the replacement of the Roll-Back Door Bearings by:

10) Roll back the door to see if it moves freely. Release the

door to see if it rolls forward unassisted and engages the

roller depressions or stops.

11) Plug power cord into 120-volt outlet. Allow compressor to

draw down Freezer Compartment temperature. Check

the door seal with your hand around the front and sides

where it meets the top, for significant leaks of cold air.

[Photo 1] FRGSF-18 Model

The FRGSF top freezer door

rolls on four bearings that act as

rollers or wheels.

[Photo 2] FRGSF-30 Model

Inspect all four bearings for

foreign objects, corrosionand

damage.

[Photo 3]

Screw goes through door side,

then the bearing. Add locking

compound, screw on andtighten

the acorn nut to secure.

Tools Required:

Phillips Screw Driver

Adjustable or ¼” [6 mm] wrench

Removable thread locking

compound

Rev. 1 5/09

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

FRGSF Service Manual Parts Replacement / Section 2.5

2.5 Grill Product Trolley Roller Replacement

[4-each Part No. 19000471]

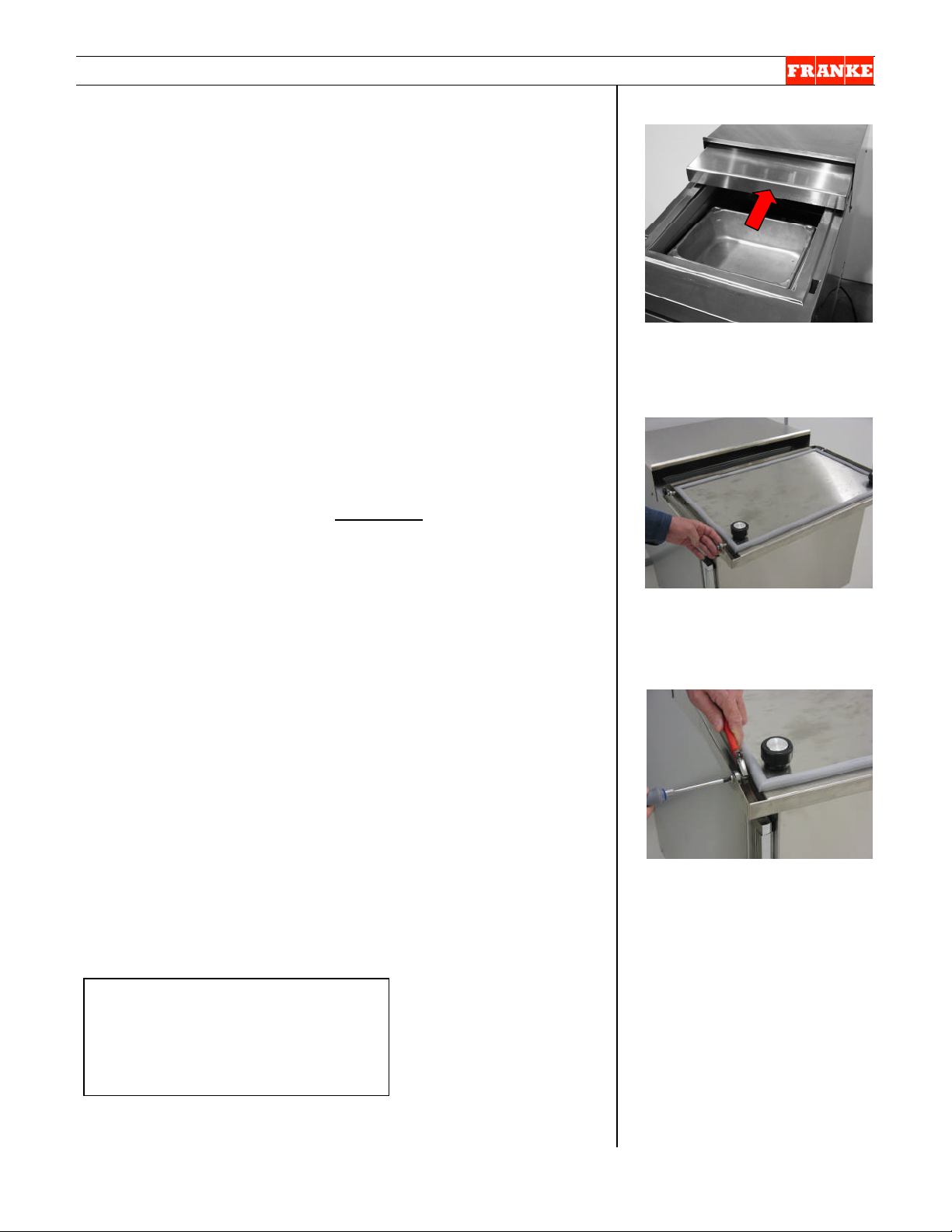

1) Roll back the top door, lift outinsert pan(s) and the

rectangular (Optional) Secondary Grill Product Trolley.

2) The Trolley rolls on four stainless steel rollers with

integrated bearings. Inspect each roller/bearing

assembly to see if it is free of debris and spins easily.

3) If one or more bearings are stiff or show minor corrosion,

lubricate with food-safevegetable-based oil. Wipe off

any excess oil with a paper towel.

4) If a bearing is frozen [won’t spin], badly corroded or the

wheel is damaged, replace with Part No. 19000471 by:

5) Using a flat blade screwdriver and ¼” [6 mm] wrench to

remove the 1/4-20 x 1/2” screw and matching acorn nut.

6) Position new bearing outside the trolley frame. Insert the

new screw from the bearing side, then through the trolley

frame.

7) Apply removable thread locking compound then screw

on the acorn nut and tighten. [Repeat for each bearing

that requires replacement.]

8) Reposition the Grill Product Trolley inside thefreezer.

Place the product pan(s) back into the trolley frame.

[Photo 1] – FRGSF-18 Model

The FRGSF Product Pan Trolley

rolls on four roller bearings that

serve as wheels.

[Photo 2]

Remove trolley and inspect all

four bearings for foreignobjects,

corrosion or rollerdamage.

Test the replacement of the Grill Product Trolley Bearings by:

9) While holding the Roll-Back Door open, pull the product

trolley forward, then release it. It should smoothly roll

back out-of-the-way,to provide unobstructed access to

frozen hamburger patties stored below the Secondary

Grilled Product.

[Photo 3]

Screw goes through the bearing,

then the trolley frame.Apply

thread locking compound to

threads then screw on & tighten

acorn nut to secure.

Tools Required:

Flat blade screwdriver

Pliers, ¼” [6 mm] socket or

wrench

Removable thread locking

compound

Rev. 1 5/09

For Technical Support, Call 800-537-2653. Copyright 2009 Franke, Inc. All rights reserved.

Loading...

Loading...