Page 1

FF 1800 SERIES

Pull-Out Spout Faucet

Installation guide

Page 2

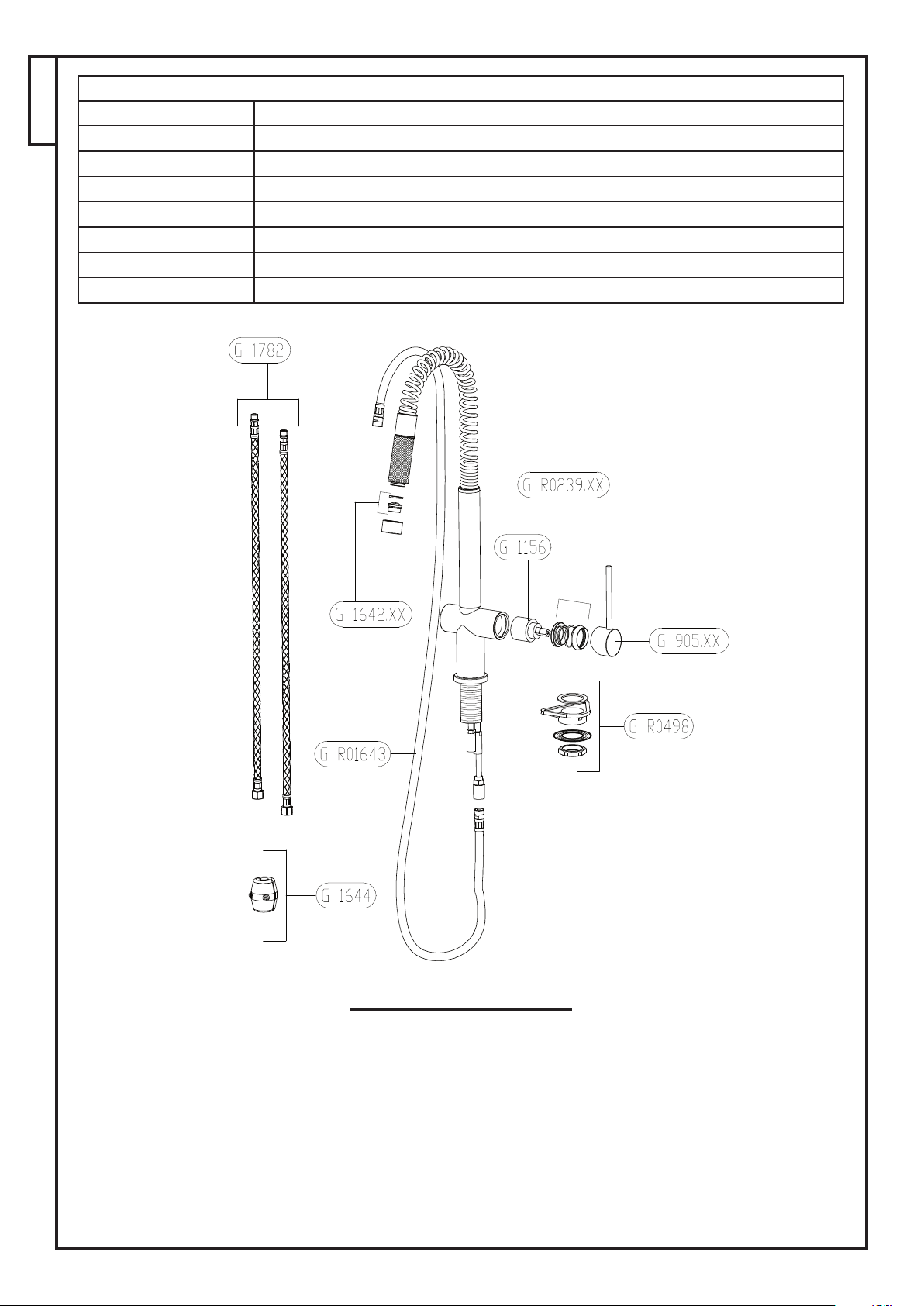

PARTS LIST

G 905.XX Handle

ENGLISH

G R0239.XX Ring cap kit

G 1156 Cartridge

G R0498 Fastening set (rubber washer, triangular flange, metal washer, threaded nut)

G R01643 Flexible hose

G 1644 Counter weight

G 1782 Supply flexible hoses

G 1642.XX Aerator

TECHNICAL DATA

Maximum water flow 2.2 gpm - 60 PSI

Recommended presure range 25-100 PSI - Over 100 PSI PRV required

Complies with Proposition 65, NSF 61, UPC and C-UPC requirements.

1/7

Page 3

Faucet installation

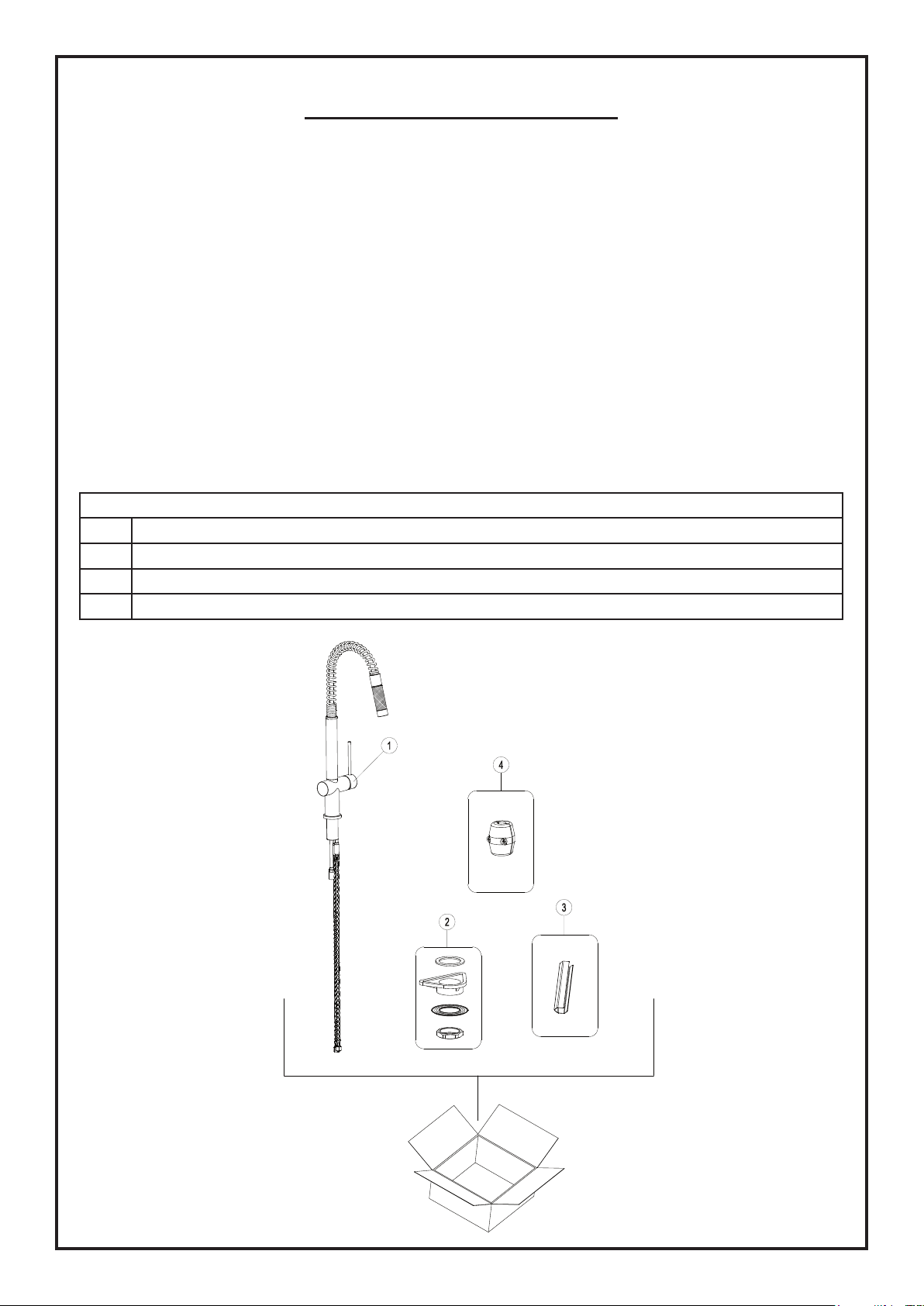

1. Remove all contents from the package and check for completeness (see itemized

table and picture).

NOTE:

Call us immediately if you see inconsistencies. (1-800-626-5771)

or visit

www.frankeksd.com

info.fks@franke.com

TABLE OF CONTENT

1 Faucet

2 Fastening set (rubber washer, triangular flange, metal washer, threaded nut)

3 Hexagonal wrench

4 Counter weight

2/7

Page 4

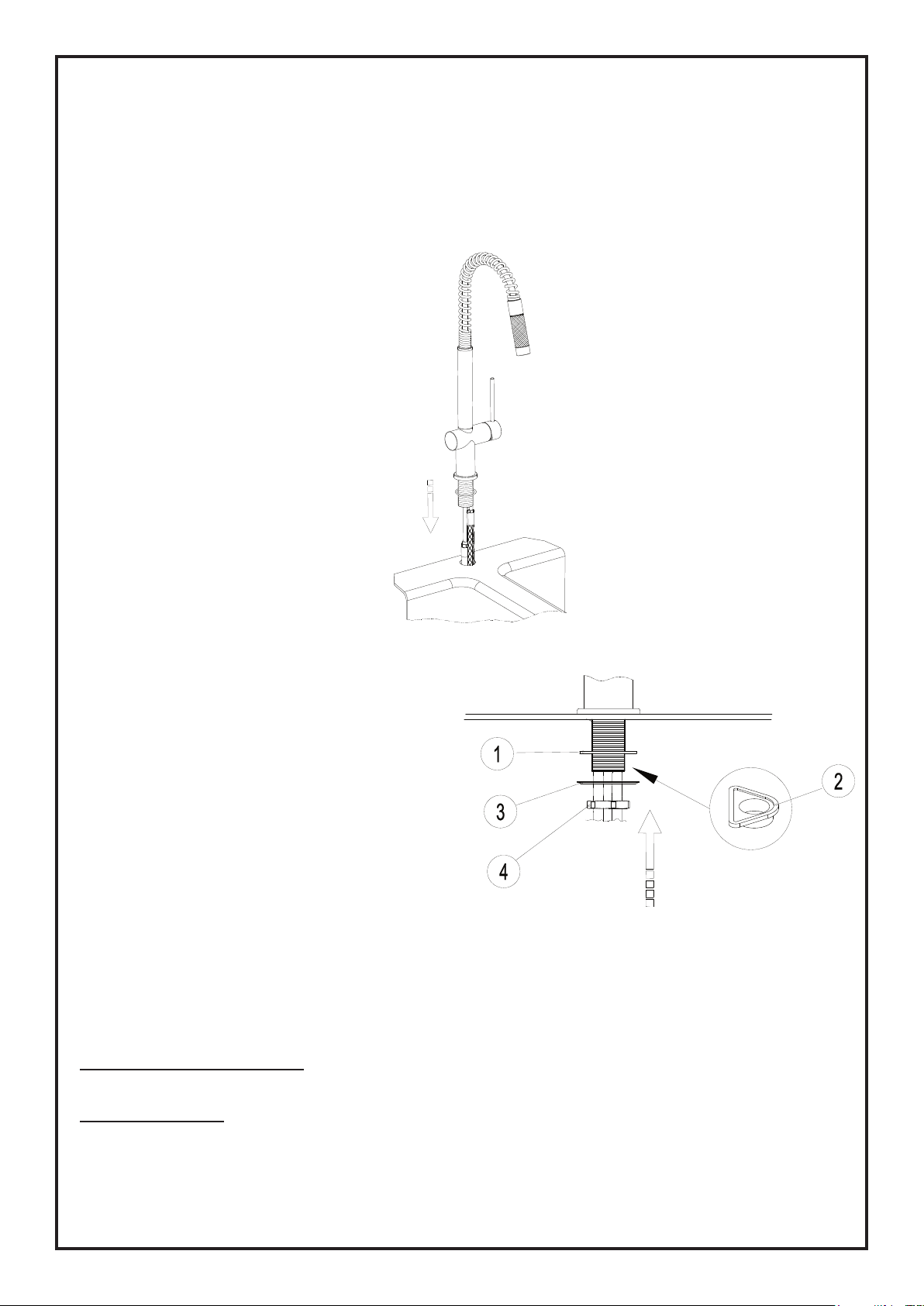

2. Remove all mounting hardware from protecting plastic bag.

3. Place the large O-ring over the faucet shank and place the faucet into the desired

location

NOTE:

the rubber O-ring should be sitting on top of the countertop and between the faucet

body. DO NOT use putty or other sealant at this location

4. Install the mounting hardware (GR0498) to the threaded shank in the following

sequence:

1 - round flat fiber washer

2 - triangular shaped plastic support

3 - flat metal washer

4 - thread brass nut

5. Assure that the handle and spout are properly aligned in forward position

6. Tighten the brass nut (4) with the provided wrench or use other professional

tools.

NOTE:

solid surface installation: The sub-countertop mounting surface needs to be flat and

free of debris; otherwise the faucet will not sit properly.

Tile installation: Avoid installations near or on top of grout lines. The faucet will not

sit secure when sitting on such.

3/7

Page 5

7. Flush the debris from the water lines and faucet.

1. Pull hose out of the faucet spout and point the open end towards the sink

drain.

2. Open faucet handle - cold side first - by turning handle to the right and moving it upward

3. Let the faucet run on cold for 15 to 30 seconds.

4. Open faucet handle - hot side second - by turning handle to the left and moving it upward.

5. Let the faucet run on cold for 15 to 30 seconds.

6. Turn faucet off.

7. Test for leaks under the cabinet.

4/7

Page 6

Standard maintenance and trouble shooting

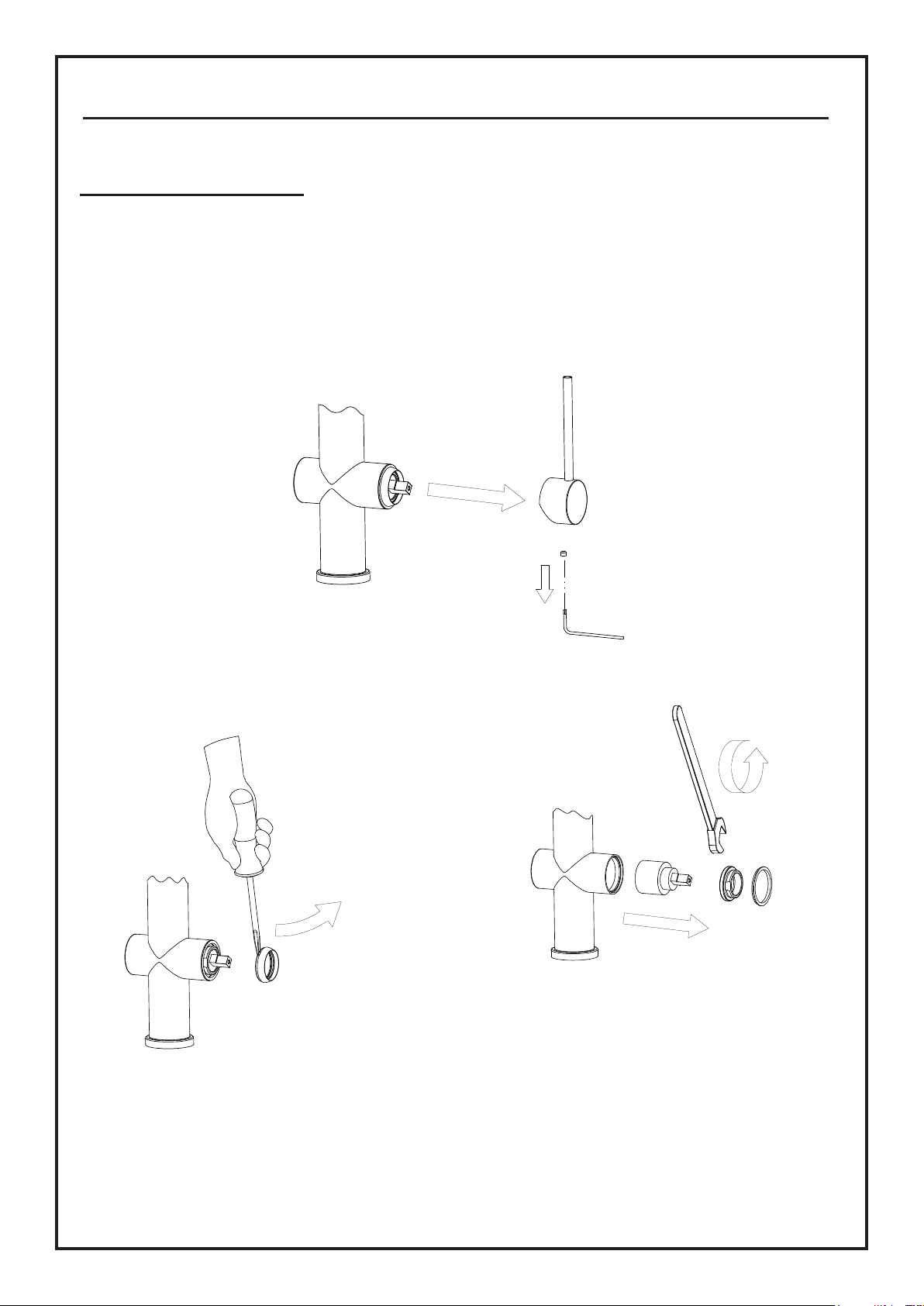

Replacing the Cartridge

1. Shut off the water supply to the faucet.

2. Open the faucet briefly to relief any pressure inside the faucet.

3. Move the faucet handle to the “OFF” position.

4. Use a the provided allen key to loosen the set screw which is accessible

from the back of the handle.

5. Lift the handle from the cartridge.

Key 2.5 mm

6. Find the small notch at the base of the chrome ring cap and carefully pry

up against this to remove the cap.

Key 28 mm

7. Remove the brass retaining ring.

8. Lift out the cartridge.

9. Ensure that the seats and O-rings are in good condition

10. Remove potential mineral deposits from inside the faucet body.

11. Install the new cartridge so that the central pivots fit into the corresponding

seats.

13. Re-assemble faucet in reverse order.

14. Test for leakage.

5/7

Page 7

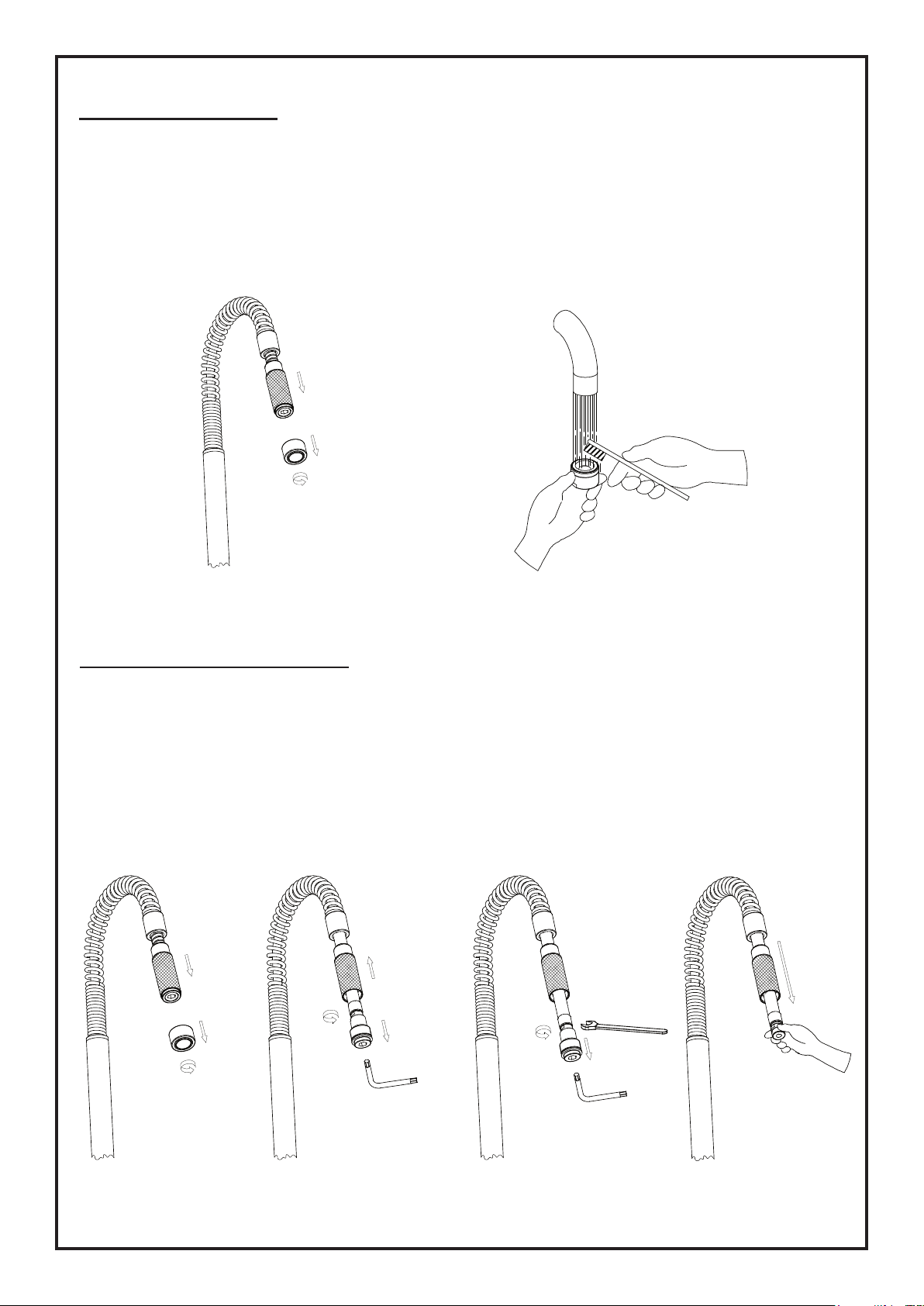

General maintenance

Clean aerator periodically.

Do not use harsh detergents, solvents, chemical agents, metallic sponges, etc. that could

harm the surface.

Clean only with a soft sponge and soapy water.

Clean and dry the faucet properly in case of hard water deposits which could damage the

surface.

Replacing the spray flex hose

1. Shut off the water supply to the faucet.

2. Pull the spout outwards from its place and unscrew the aerator .

3. Unscrew the hand shower from the flex hose by means of a 10mm key,

keeping the flex hose firm with a 13mm wrench.

4. Disassemble the joint and pull out the disassembled flex hose.

5. Reassemble following the directions in reverse.

Key 13 mm

Key 10 mm

Key 10 mm

6/7

Page 8

Limited lifetime warranty

Franke Consumer Products, Inc., Kitchen Systems Division extends the following warranty to the original purchaser of its faucets effective January 1, 2003.

All faucets installed in a private residence will carry a limited lifetime warranty on all mechanical

parts to be free of manufacturing defects in material and workmanship under normal usage. All chrome

finishes carry a limited lifetime warranty; all other finishes are warranted for five (5) years form the

original date of purchase.

Marine Installation: All products in a marine installation will carry a limited lifetime warranty on all

mechanical parts to be free of manufacturing defects in material and workmanship under normal usage.

All chrome products carry a limited lifetime warranty on the finish; all other finishes carry a three-year

(3) warranty from the original date of purchase.

This warranty applies only to the original owner, providing the product has been installed in accordance

with our installation instructions, used as recommended and in a normal residential application. In the

event of a warranty claim, the owner will be required to provide proof of purchase - save sales

receipt. This warranty covers all components which make the product operational. Franke, at its option,

may repair or replace the product or components necessary to restore the product to good working condition. Franke reserves the right to inspect the installation prior to the actual replacement of the product

or component part.

This warranty does not cover misuse or abuse, accidental damages, scuffs or scratches, improper installation, abnormal usage, negligence or damage caused by improper maintenance or cleaning. Normal

wear of parts is excluded from the warranty. Damage caused by impurities or acts beyond our control

are not covered. Any product or part which has been repaired or altered in any manner outside of Franke’s factory, unless previously authorized in writing by Franke, will void warranty. Any replacement

excludes transportation and any labor re-installation costs. This warranty does not allow recovery of

incidental or consequential damages such as loss of use, delay, property damage or other consequential

damage, and Franke accepts no liability for such damages.

The Franke warranty is limited to the above conditions and to the warranty period specified herein and is

exclusive. Franke DISCLAIMS all other warranties, expressed or implied, including IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR AS PARTICULAR PURPOSE. This

warranty gives you specific legal rights that may vary from state to state.

Further information

For any further information about our products, about the installation

of them or about the guarantee, please dial the number of the

customer service:

Phone number +1-215-822-6590

Or: 1-800-626-5771

Fax number + 1-215-822-5873

Franke Consumer Products Inc. - Kitchen Systems Division

3050 Campus Drive, Suite 500 Hatfield, PA 19440

7/7

Page 9

PARTS DE RECHANGE

G 905.XX Poignée

FRANÇAIS

G R0239.XX Anneau de fixage

G 1156 Cartouche

G R0498 Set de fixage (Anneau de caoutchouc, bride triangulaire , bride metallique, écrou fileté)

G R01643 Flexible pour la douchette

G 1644 Contrepoids en plomb

G 1782 Flexibles de aliméntation

G 1642.XX Brise-jet

DONNÉES TECHNIQUE

Consommation maximum d’eau : 2.2gpm 60PSI

Intervalle conseillé de pression : 25-100 PSI – au-delà de 100 PSI est recommendée un

reducteur de flux.

Conformée à Proposition 65, NSF 61, UPC et C-UPC conditions.

1/7

Page 10

Installation du mélangeur

1. Déballer tous les éléments et vérifier qu’ils soient tous présents (voir le tableau et

l’image spécifiés).

NOTE:

Communiquer immédiatement tout manque ou défaut.

(1-800-626-5771)

ou visite

www.frankeksd.com

TABLEAU DE CONTENU

1 Mélangeur

2 Set de fixage (Anneau de caoutchouc, bride triangulaire , bride metallique, écrou fileté)

3 Clé hexagonal

4 Contrepoids en plomb

2/7

Page 11

2. Retirer tous les éléments nécessaire pour le montage du sachet en plastique.

3. Insérer le grand joint dans le pied du mitigeur et placer le même

NOTE:

Le joint en caoutchouc doit être inséré entre le plan du lavabo et le corps du mitigeur.

N’UTILISEZ PAS de mastic, ou autre produit pour cette opération

4. Installer les éléments de montage ( GR0498) sur le pied, en les enfilant dans le

sens qui suit :

1-Rondelle plate en fibre

2-Support profilé triangulaire en plastique

3-Rondelle plate en métal

4-dé en laiton

5. Vérifier que la poignée et le bec soient alignés vers l’avant.

6. Serrer la rondelle en métal (4) avec la clé fournie ou utiliser des outils adéquats

NOTE:

INSTALLATION SUR UNE SURFACE SOLIDE : la partie au-dessous du plan doit

être plate et sans petits trous. Dans le cas contraire, le mitigeur ne peut-être placer

dans son emplacement.

INSTALLATION SUR DE LA FAÏENCE : Eviter l’installation à proximité ou sur

le bord de la vasque.

3/7

Page 12

7. Rinçage des débris du système hydraulique et du robinet.

1. Extraire le flexible du bec du robinet et diriger l’extrémité ouverte vers la

vidange du lavabo.

2. Ouvrir la poignée du robinet –le côté froid avant – en la tournant vers la

droite et en la déplaçant vers le haut.

3. Laisser l’eau froide couler pour 15 ou 30 secondes.

4. Ouvrir la poignée du robinet – côté droit – en la tournant vers la gauche en

la déplaçant vers le haut.

5. Laisser l’eau froide couler pour 15 ou 30 secondes.

6. Fermer le robinet.

7. Vérifier les pertes sous le meuble.

4/7

Page 13

Manipulation recommandée et solutions

aux problèmes

Remplacement de la cartouche

1. Fermer l’arrivée d’eau

2. Ouvrir le mitigeur un bref instant pour relâcher la pression

3. Tourner la poignée du mitigeur vers la position « OFF »

4. Utiliser la clé fournie pour desserrer les vis de fixation, lesquelles se trouvent sur la partie postérieure de la poignée

5. Soulever la poignée de la cartouche

Clé 2.5 mm

6. Trouver la petite encoche à la base du joint chromé et faire levier, en faisant attention pour enlever le joint.

Clé 28 mm

7. Enlever l’anneau de fixation en laiton

8. Extraire la cartouche

9. Vérifier que l’emplacement et les joints soient en bon état

10. Enlever les éventuels résidus de minéraux pouvant se trouver à l’intérieur du corps du

mitigeur

11. Installer la nouvelle cartouche de façon à ce que les axes centraux entrent dans les em-

placements correspondants

12.Remonter le mitigeur en suivant les étapes précédentes dans le sens inverse.

5/7

Page 14

Instructions générales

Nettoyer régulièrement l’aérateur.

N’utilisez pas de détergents, solvants, produits chimiques, éponges métalliques etc.…

qui risqueraient d’endommager la surface.

Nettoyer en utilisant seulement une éponge douce et d’eau savonneuse.

Nettoyer et essuyer soigneusement le mitigeur si l’eau est calcaire.

Remplacement du flexible de la douche

1. Fermée l’eau de la reseau hydrique.

2. Extraire la douchette dans la propre siège et dévisser l’ aérateur .

3. Dévisser la douchette en utilisant une clé de 10 mm en tenant fermemant le

flexible avec une clé de 13 mm.

4. Extraire complètement le flexible.

5. reassembler selon l’ ordre inverse.

Clé 13 mm

Clé 10 mm

Clé 10 mm

6/7

Page 15

Conditions de garanties à vie

Franke consumer Products. Inc. kitchen systems division étend la durée de sa garantie. A partir du 01

janvier 2003, le produit est garanti à vie ( en référence à la personne ayant acheté le produit.).

Installation dans habitations à titre privé :

Toutes les robinetteries installées dans une habitation à titre privé ont une garantie à vie pour les parties

mécaniques, et ceux pour une utilisation normale du produit.

Tous les produits chromés ont quant à eux une garantie à vie également pour les finitions. Pour les autres finitions, la garantie des finitions est de cinq (5) ans, à partir de la date d’achat.

La garantie se réfère à la personne ayant acquit le produit, à condition que ce dernier ait été installé

suivant la notice de montage fournie et utilisé conformément aux instructions requises. En cas de récla-

mation, l’acheteur devra fournir une preuve d’achat ou une facture. La garantie se réfère à tous

les éléments liés au bon fonctionnement du produit. Franke, se réserve le droit, de réparer ou substituer

le produit ou les éléments nécessaire à rétablir le bon fonctionnement de ce dernier. Franke se réserve

également de droit d’inspecter le produit avant de procéder à son remplacement ou à la substitution de

certaines parties.

La garantie ne fonctionne pas en cas de négligence ou d’utilisation abusive du produit, les dommages

accidentels, les rayures, l’installation inappropriée, la négligence ou les dommages résultant d’un mauvais entretien, ou d’une mauvaise utilisation.

La garantie ne couvre pas l’usure normale du produit. Toute réparation intervenue sur le produit ou un

de ses éléments, effectuée en dehors des établissements Franke, en sans autorisation de le part, conduira

à la cessation de la validité de la garantie. Sont exclus de la réparation, les coûts de transports et de

remontage.

La garantie ne prévoit pas le remboursement des dommages accidentels, ou provoqués par un manque

d’utilisation, le retard, les dommages à la propriété et autres dommages- Franke ne se retient aucune

responsabilité pour les dommages de ce type.

La garantie Franke est limitée aux conditions énumérées ci-dessus, pour la période indiquée et est

exclusive. Franke NE RECONNAÎT aucune autre garantie, explicite ou implicite, INCLUSES LES

GARANTIES IMPLICITES COMMERCIALES ET ADÉQUATES POUR UN CAS PARTICULIER.

Cette garantie prévoit des droits légaux spécifiques pouvant être modifiés selon les pays.

Information complémentaire :

Pour toute information complémentaire sur le produit, sur son installation ou sur sa garantie, vous pouvez contacter le service clientèle au numéro :

Phone number +1-215-822-6590

Or: 1-800-626-5771

Fax number + 1-215-822-5873

Phone number 877-6FRANKE

Fax number 866-527-5145

Franke Consumer Products Inc. - Kitchen Systems Division

3050 Campus Drive, Suite 500 Hatfield, PA 19440

Franke

1000 Kindred Road, Midland, Ontario, L4R4K9

7/7

Page 16

PIEZAS DE REPUESTO

G 905.XX Palanca compléta

ESPAÑOL

G R0239.XX Virola de fijación

G 1156 Cartucho

G R0498 Juego de fijaciòn (mondana de goma,arandola triangular,mondana de metal,turca de mon-

taje)

G R01643 Flexible de la ducha-teléfono

G 1644 Peso en plomo

G 1782 flexible de aliméntacion

G 1642.XX Aerador

DATOS TÉCNICOS

Consumo màximo de agua: 2.2 gpm ‘ 60 PSI

Intervalo aconsejado de presiòn: 25-100 PSI – Oltre 100 PSI es requesto PRV

Satisface los requisitos previstos por la Disposiciòn 65, NSF 61, UPC e C-UPC.

1/7

Page 17

Installation del mezclador

1. Remover l’embalaje de todos los elementos y averiguar que no hay partos faltantes ( se vean mesa y estallado correspondientes)

NOTA:

Comunicar enseguida cualquier falta o defecto

( 1-800-626-5771)

o visitar:

www.frankeksd.com

MESA SINOPTICA DE LOS CONTENIDOS

1 Mezclador

2 Juego de fijaciòn (mondana de goma,arandola triangular,mondana de metal,turca de montaje)

3 Llave hexagonal

4 Peso en plomo

2/7

Page 18

2. Sacar todos los elementos necesarios por el montaje de la bollita de plàstico

3. Insertar el O-ring grande en el tallo del mezclador y colocar el mezclador dònde

deseado

NOTA:

El O-ring de goma tiene que ser insertado entre el plan de montaje y el cuerpo del

mezclador. No utilices màstique, u otro sellador, en este punto.

4. Instalar a los miembros de montaje (GR0498) sobre el tallo fileteado en la secuencia aquiì bajo indicada:

1 – mondana plana rotonda en fibra Respaldo perfilado triangular de plàstico

2 – Respaldo perfilado triangular de plàstico

3 – Mondana plana en metal

4 – Dado fileteado de latòn

5. Averiguar que la palanca y la boca sean alineadas adecuadamente hacia adelante.

6. Apretar la mondana de latòn (4) con la llave dotada o utilizar los adecuados instrumentos.

NOTA:

INSTALACIÒN SOBRE SUPERFICIES SÒLIDAS: la parte de abajo al plan de

apoyo tiene que ser llana y falto de virutas; en caso contrario el mezclador no podrà

ser colocado adecuadamente en la misma sede.

INSTALACIÒN SOBRE BALDOSAS: Evitar l’ instalaciòn del mezclador cerca de

o sobre las fugas. El mezclador podrìa no resultar correctamente situado.

3/7

Page 19

7. Eliminación de las virutas del sistema hidráulico y del grifo.

1. Extraigan el flexible del caño del grifo y dirijan la extremidad abierta hacia

el desagüe del lavabo.

2. Abran la maneta del grifo – a partir del lado “frío” – girándola hacia la derecha y desplazándola hacia arriba.

3. Dejen fluir el agua fría por 15 - 30 segundos.

4. Abran la maneta del grifo – lado derecho – girándola hacia la izquierda y

desplazándola hacia arriba.

5. Dejen fluir el agua fría por 15 - 30 segundos.

6. Cierren el grifo.

7. Verifiquen si hay goteos debajo del mueble.

4/7

Page 20

Manutenciòn ordinaria e investiga averìas

Sostituciòn del cartucho

1. Cerrar l’ agua que va de la red hìdrica al mezclador.

2. Abrir el mezclador por un breve cansado de tempo para conceder la presiòn

a su interior

3. Girar la palanca del mezclador hacia la posiciòn “OFF”

4. Usar la llave a frugola dotado para aflojar la vid de fijado, al que se accede

de la parte de la posterior de la palanca

5. Levantar la palanca del cartucho

Llave 2.5 mm

6. Encontrar la pequena muesca a la base de la abrazadera cromada y hacer

palanca en este punto con atenciòn para remover la abrazadera misma .

Llave 28 mm

7. Remover l’ anillo de fijado de làton

8. Extraer el cartucho

9. Averiguar que las sedes y los O-ring estèn en buen estado

10. Remover los eventuales depòsitos minerales all interiores del cuerpo del mezcla-

dor

11. Instalar el nuevo cartucho de modo que los goznes centrales entren en las sedes

correspondientes.

12. Reensamblar el mezclador siguiendo l’ orden inverso de montaje

13. Controlar que no hay pèrdidas

5/7

Page 21

Manutenciòn general

Limpiar periodicamente l’ aerador.

No utilices detergentes agresivos, solvents, agents quìmicas esponjas metàlicas,ecc.

Què pueden perjudicar la superficie.

Limpiar sòlo utilizzando una esponga blanda y agua jabonadura.

Limpiar y secar bien el mezclador en presenzia de agua muy dura o calcarea que puede

depositare y perjudicar las superficies

Sustitución del flex de la duchita.

1. Cerrar el flujo de agua del grifo.

2. Soltar la duchita de su lugar y destornillar el aerador.

3. Destornillar la duchita del flex empleando una llave de 10mm, manteniendo

firme el flex mismo con una llave de 13mm.

4. Desarmar las guarniciones y soltar el flex que està desarmado.

5. Colocar el todo con el procedimiento opuesto.

Llave 13 mm

Llave 10 mm

Llave 10 mm

6/7

Page 22

Condiciones de garantìa limitada a vida

Franke Consumer Products. Inc. Kitchen Systems Division extiende la presente garantìa limitada al

comprador original de sus grifos a partir del 1 enero 2003.

Todos los grifos establecidos en casas privadas tendràn derecho a una garantìa limitada a vida por todas

las partes mecànicas que tèndran que estar faltos de defectos consiguientes de materiales o mano obra

durante su normal empleo. Todos los productos cromados tendràn derecho a una garantìa limitada a

vida sobre los perfeccionamientos. Todos los otros perfeccionamientos tendràn derecho a una garantìa

de 5 ( cinco ) anos de la fecha d’ adquiero.

Marine Installation: All products in a marine installation will carry a limited lifetime warranty on all

mechanical parts to be free of manufacturing defects in material and workmanship under normal usage.

All chrome products carry a limited lifetime warranty on the finish; all other finishes carry a three-year

(3) warranty from the original date of purchase.

Sòlo tendrà derecho a la presente garantìa el comprador original del produco, a condiciòn que èste haya

sido instalado siguiendo escrupulosamente las instrucciones d’ instalaciòn provista y le usado conforme

a cuanto enchufado, en un inmueble de tipo residencial. En caso de reclamaciòn el comprador tendrà

que proveer prueba dell’ adquiero o factura. La presente garantìa concierne todos los elementos atados a la funciòn del produco. Franke, a su jucio, podrà arreglar o reemplazar el produco o los miembros

necesarios a restablecer el buen funcionamiento del mismo. Franke se reserva el derecho a inspeccionar

el produco antes de la sustituciòn del mismo o sus partes.

La presente garantìa no se aplica a caso de empleo negligente o abuso de las instrumentaciones danos

accidentales, aranazos o abrasiones instalaciòn inadecuada, empleo impropria, negligencia o danos debidos a mala manutenciòn o limpieza. La normal usura de las partes es excluida por ella garantìa. Cualquiera reparaciòn o manumisiòn del producto, o sus partos efectuados a fuera de los establecimientos

Franke, si no previamente lìcito por escreto de Franke, causarà el decaimiento de la garantìa misma.

Son excluidos por las reparaciones los costes de transporte y reensamblaje. La presente garantìa no

preve el reembolso de danos accidentales o consiguientes cuàl el fallido empleo el retraso los danos a la

propiedad o a otros danos – Franke. No se creerà responsabile de danos de este tipo.

La garantìa Franke es limitada aquì a las condiciones sobre expuestas y al periodo indicado y es exclusiva. Franke No RECONOCERA otras garantìas expresaron o implicitas, includo LAS GARANTIAS

IMPLICITAS COMERCIALES Y O DE IDONEIDAD POR UN OBJECTIVO PARTICULAR. La

presente garantìa preve a especìficos rectos abogados que pueden variar segùn los Estados.

Ulteriores informaciones

Por ulteriores informaciones sobre el produco sobre l’ installaciòn o sobre la garantìa contactar los Departamentos de atenciòn al cliente autorizados al número:

Phone number +1-215-822-6590

Or: 1-800-626-5771

Fax number + 1-215-822-5873

Franke Consumer Products Inc. - Kitchen Systems Division

3050 Campus Drive, Suite 500 Hatfield, PA 19440

Phone number 877-6FRANKE

Fax number 866-527-5145

Franke

1000 Kindred Road, Midland, Ontario, L4R4K9

7/7

ET 38794 - R3

Loading...

Loading...