Page 1

Instructions for use and installation

Asennu

s-, k

äyttö

-

ja hoito

-

opas

GB

DK

SE

NO

FI

Cooker Hood

Vejledning for installation brug og vedligeholdelse

Emhætte

Handbok för installation användning och underhăll

Köksfläkt

Håndbok for installasjon bruk og vedlikehold

Kjøkkenvifte

Liesituuletin

FDF 9044 I XS ECS

Page 2

EN

Instructions Manual

INDEX

RECOMMENDATIONS AND SUGGESTIONS......................................................................................................................7

CHARACTERISTICS..............................................................................................................................................................8

INSTALLATION ....................................................................................................................................................................10

USE.......................................................................................................................................................................................14

MAINTENANCE....................................................................................................................................................................15

EASY CLEANING TM...........................................................................................................................................................16

2

2

Page 3

DK

Brugsvejledning

INDHOLD

RÅD OG ANVISNINGER......................................................................................................................................................19

APPARATBESKRIVELSE....................................................................................................................................................20

INSTALLATION ....................................................................................................................................................................22

BRUG....................................................................................................................................................................................26

VEDLIGEHOLDELSE...........................................................................................................................................................27

EASY CLEANING TM...........................................................................................................................................................28

3

3

Page 4

SE

Bruksanvisning

INNEHÅLL

REKOMMENDATIONER OCH TIPS....................................................................................................................................31

EGENSKAPER.....................................................................................................................................................................32

INSTALLATION ....................................................................................................................................................................34

ANVÄNDING.........................................................................................................................................................................38

UNDERHÅLL........................................................................................................................................................................39

EASY CLEANING TM...........................................................................................................................................................40

4

4

Page 5

NO

Bruksanvisning

INNHOLD

ANBEFALINGER OG FORSLAG.........................................................................................................................................43

EGENSKAPER.....................................................................................................................................................................44

INSTALLASJON ...................................................................................................................................................................46

BRUK....................................................................................................................................................................................50

VEDLIKEHOLD.....................................................................................................................................................................51

EASY CLEANING TM...........................................................................................................................................................52

5

5

Page 6

FI

Käyttöopas

SISÄLTÖ

SUOSITUKSET JA EHDOTUKSET .....................................................................................................................................55

MITAT JA OSAT...................................................................................................................................................................56

ASENNUS.............................................................................................................................................................................58

KÄYTTÖ................................................................................................................................................................................62

HUOLTO...............................................................................................................................................................................63

EASY CLEANING TM...........................................................................................................................................................64

6

6

Page 7

EN

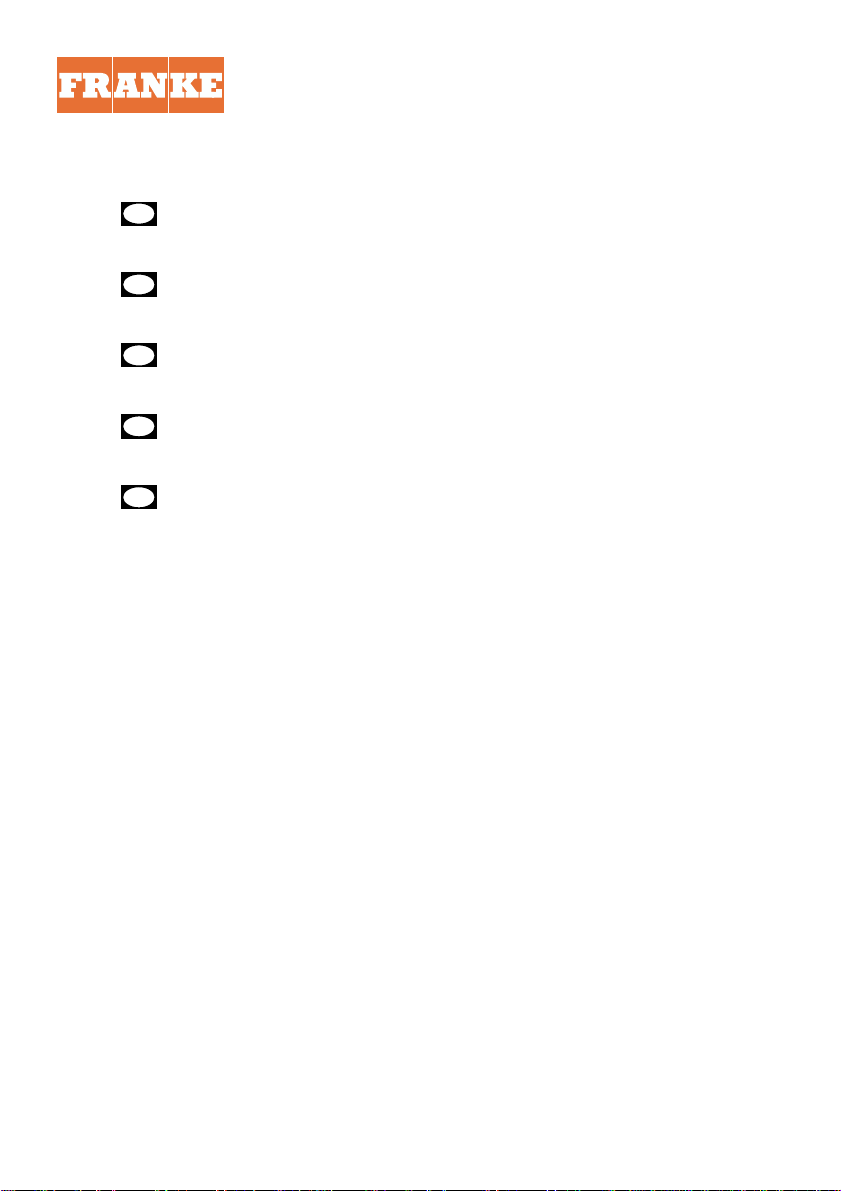

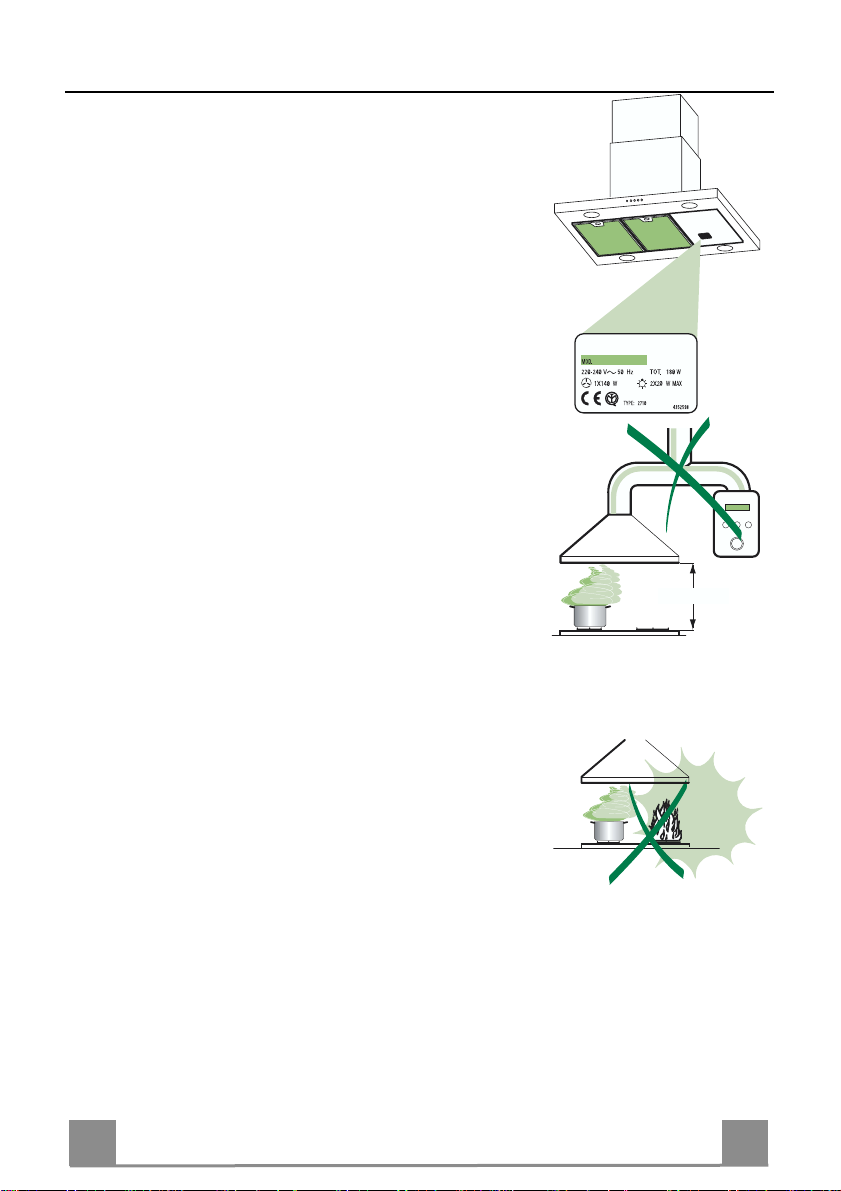

RECOMMENDATIONS AND SUGGESTIONS

INSTALLATION

• The manufacturer will not be held liable for any damages resulting

from incorrect or improper installation.

• The minimum safety distance between the cooker top and the extrac tor hood is 650 mm.

• Check that the mains voltage corresponds to that indicated on the

rating plate fixed to the inside of the hood.

• For Class I applianc es, c heck t hat th e domes tic po wer suppl y gua rantees adequate earthing.

Connect the extractor to the ex haust flue through a pi pe of minimum

diameter 120 mm. The route of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carryi ng combustion fumes (boilers, fireplaces, etc.).

• If the extractor is used in conj unction with non-electrical appliances

(e.g. gas burning appliances), a suffici ent degree of aeration must be

guaranteed in the room in order to prevent the backflow of exhaust

gas. The kitchen must have an opening communicating directl y with

the open air in order to guarantee the entry of clean air.

USE

• The extractor hood has been designe d ex cl usi vely for domesti c us e to

eliminate kitchen smells.

• Never use the hood for purposes ot her than for which it has ben designed.

• Never leave high naked flames under the hood when it is in operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only,

making sure that it does not engulf the sides.

• Deep fat fryers must be continuously monitored during use: overheated oil can burst into flames.

• Do not flambè under the range hood; risk of fire

• The hood should not be used by chil dren or persons not inst ructed in

its correct use.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before carrying out any maintenance work.

• Clean and/or replace the Filters after the specified time period.

• Clean the hood using a damp cloth and a neutral liquid detergent.

650 mm min.

7

7

Page 8

EN

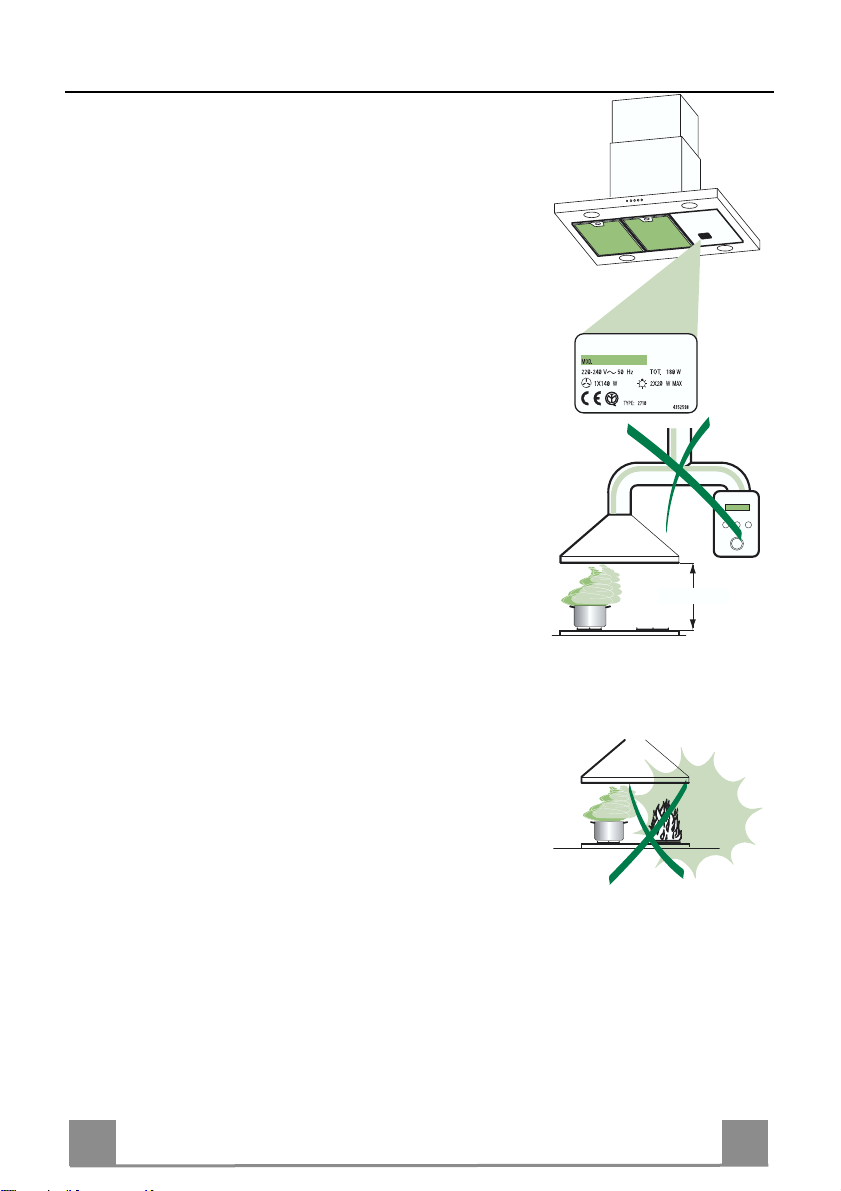

CHARACTERISTICS

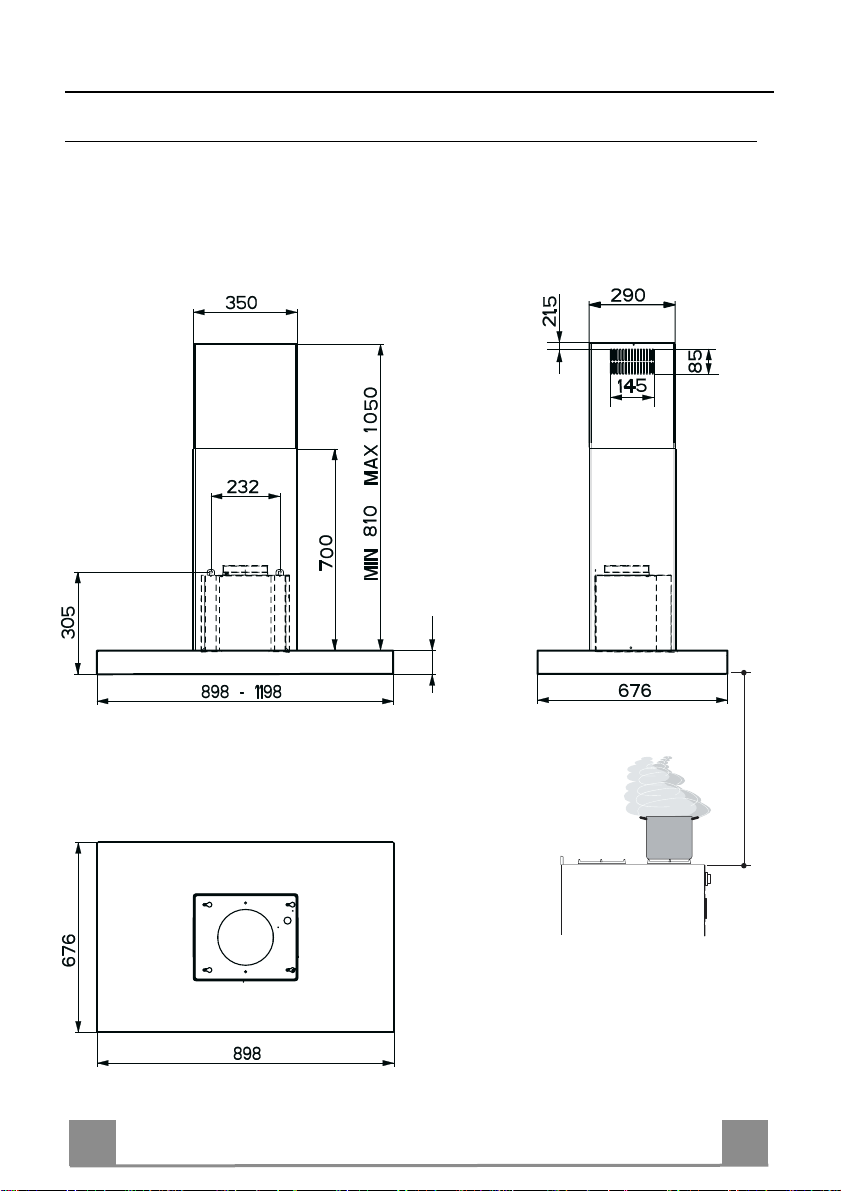

Dimensions

45

650 min.

8

8

Page 9

EN

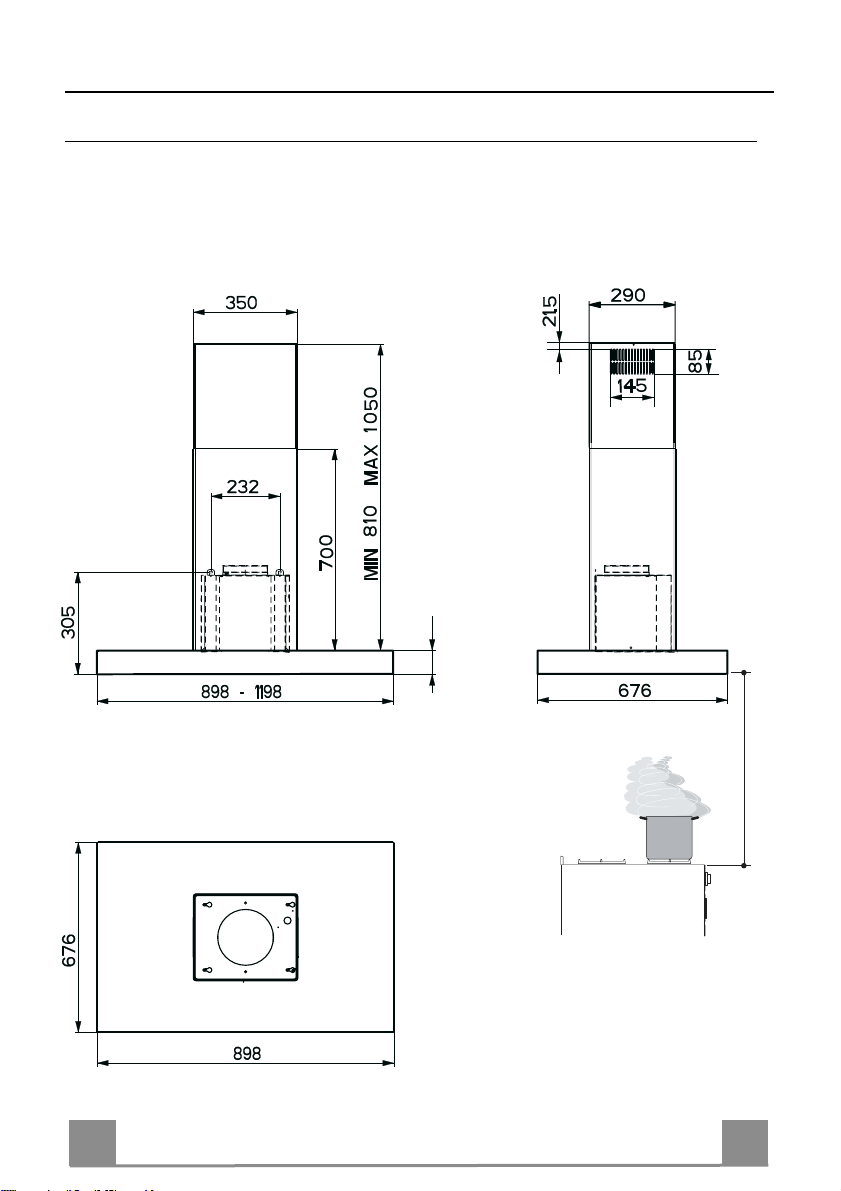

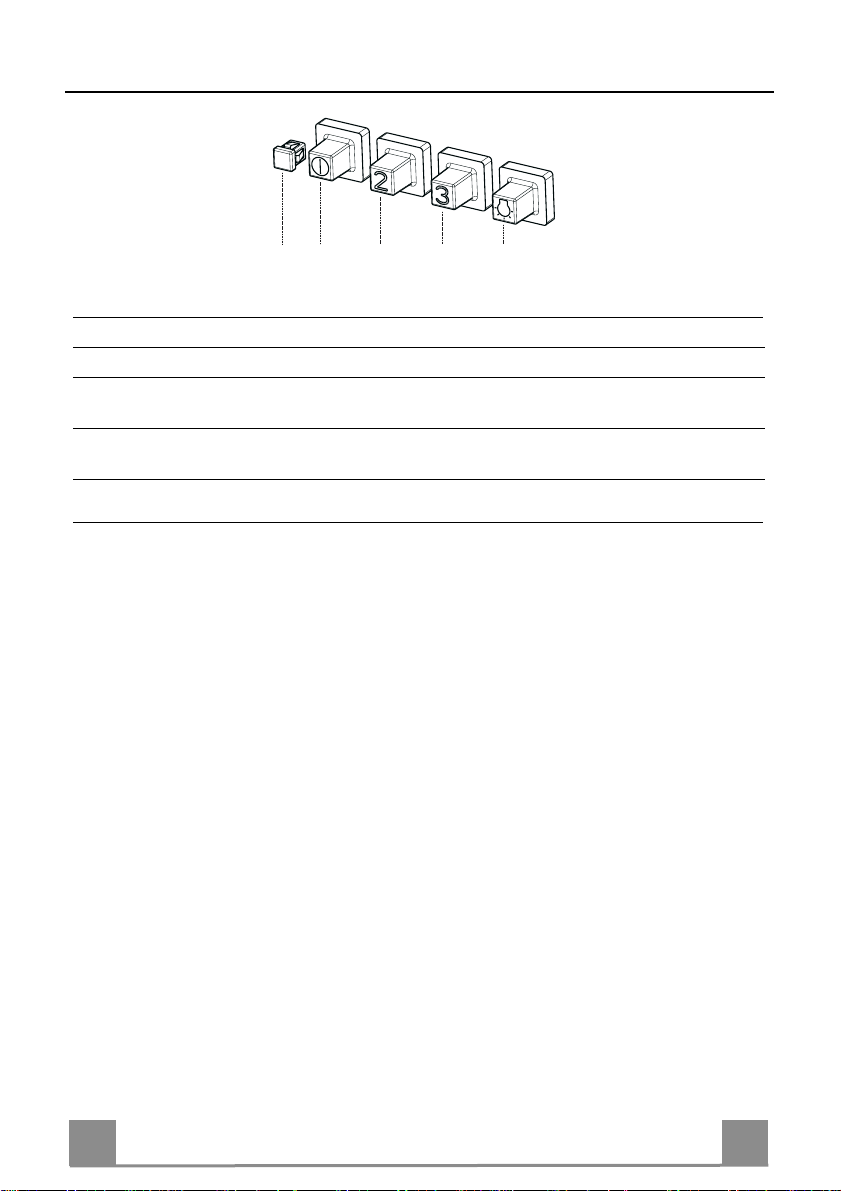

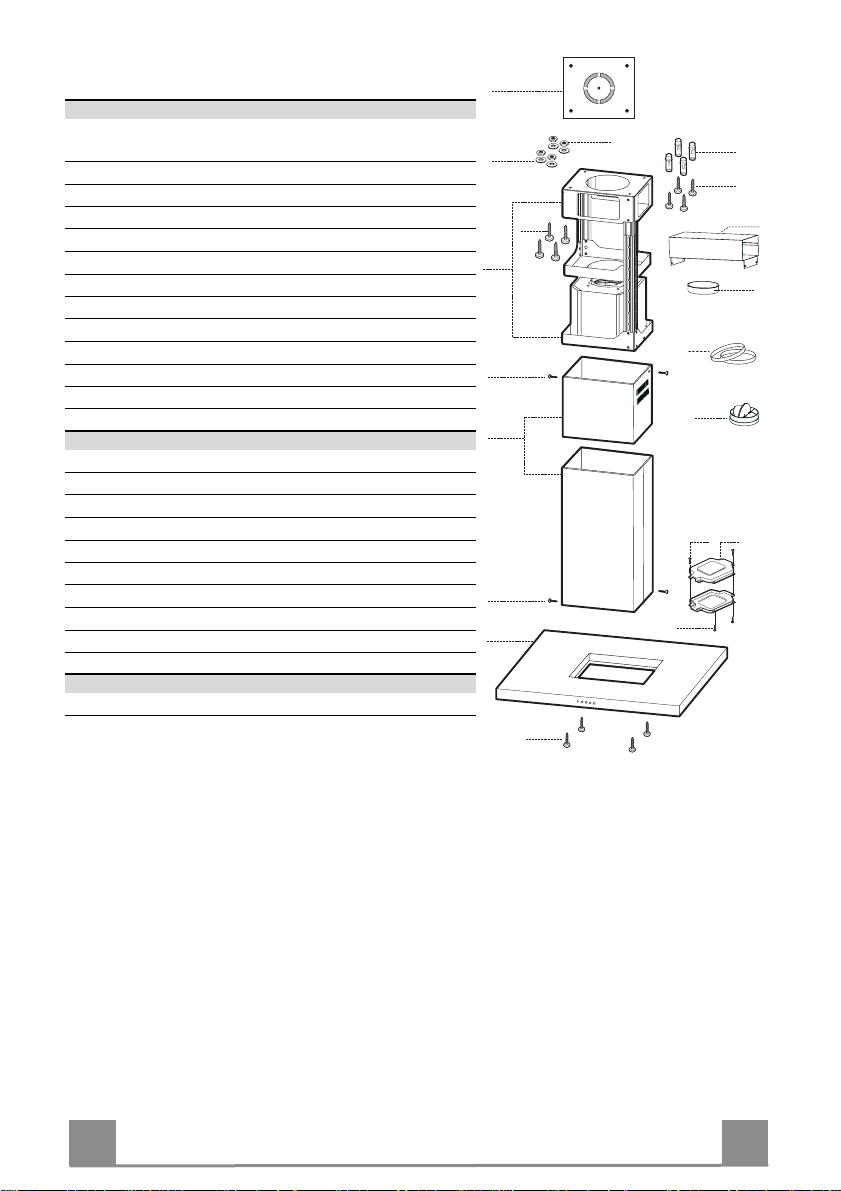

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light, Blower,

Filters

2 1 Telescopic Chimney comprising:

2.1 1 Upper Section

2.2 1 Lower Section

7.1 1 Telescopic frame complete wit h extractor, consisting of:

7.1a 1 Upper frame

7.1b 1 Lower frame

10 1 Flange ø 150

10a 1 Dumper ø 150mm

15 1 Air Outlet Connection

24 1 Junction box

25 2 Pipe clamps

Ref. Q.ty Installation Components

11 4 Wall Plugs ø 10

12c 6 Screws 2,9 x 6,5

12e 2 Screws 2,9 x 9,5

12f 4 Screws M6 x 10

12g 4 Screws M6 x 80

12h 4 Screws 5,2 x 70

21 1 Drilling template

22 4 6.4 mm int. dia washers

23 4 M6 nuts

Q.ty Documentation

1 Instruction Manual

7.1

21

22

12c

2

12c

1

7.1a

12g

7.1b

2.1

2.2

12f

23

12c

25

12e

11

12h

15

10

10a

24

9

9

Page 10

EN 110

INSTALLATION

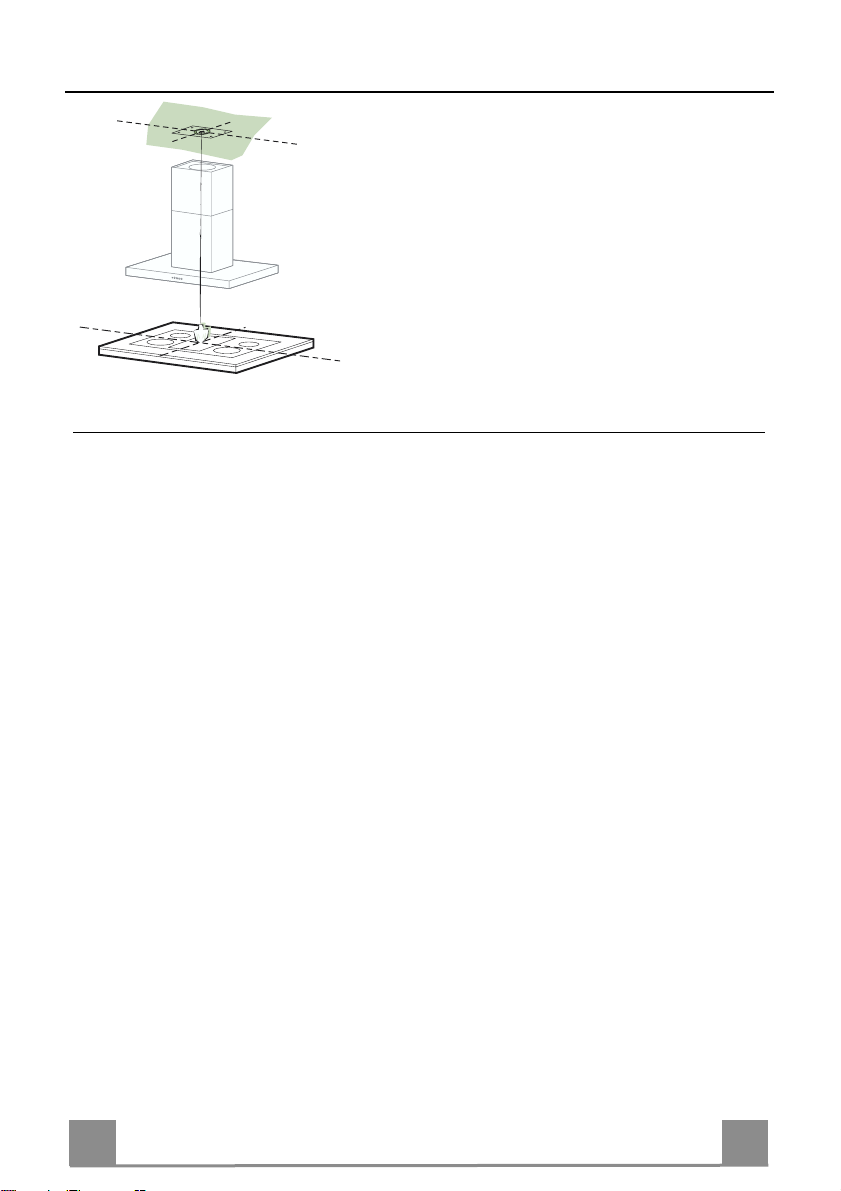

Drilling the Ceiling/shelf and fixing the frame

DRILLING THE CEILING/SHELF

• Use a plumb line to mark the centre of the hob on the ceiling/support shelf.

• Place the drilling template 21 provided on the ceiling/support shelf, making sure that the

template is in the correct position by lining up the axes of the template with those of the hob.

• Mark the centres of the holes in the template.

• Drill the holes at the points marked:

• For concrete ceilings, drill for plugs appropriate to the screw size.

• For hollow brick ceilings with wall thickness of 20 mm: drill ø 10 mm(immediately insert

the Dowels 11 supplied).

• For wooden beam ceilings, drill according to the wood screws used.

• For wooden shelf, drill ø 7 mm.

• For the power supply cable feed, drill ø 10 mm.

• For the air outlet (Ducted Versio n), drill according to t he diameter of the external air exhaust duct connection.

• Insert two screws of the following type, crossing them and leaving 4-5 mm from the ceiling:

• For concrete ceilings, use the appropriate plugs for the screw size (not provided).

• for Cavity ceiling with inner space, with wall thickness of approx. 20 mm, Screws 12h,

supplied.

• For wooden beam ceilings, use 4 wood screws (not provided).

• For wooden shelf, use 4 screws 12g with washers 22 and nuts 23, provided.

Page 11

EN 111

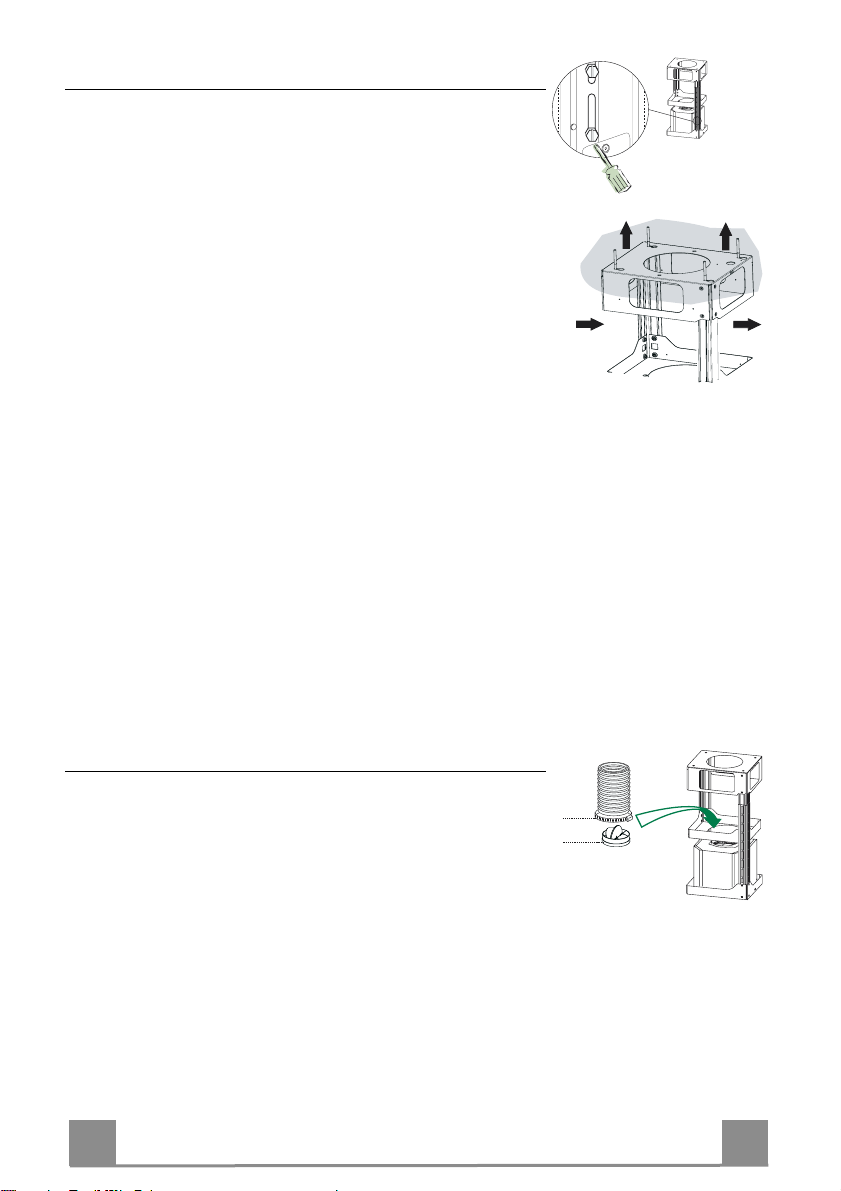

FIXING THE frame

2

2

1

1

10 a

ø 150

25

• Loosen the two scr ews fastening the lower chimney and remove this from the lower frame.

• Loosen the two screws fastening the upper chimney and remove this from the upper frame.

If you wish to adjust the height o f the frame, proceed as follows:

• Unfasten the eight metric screws joining the two columns, located at the sides of the frame.

• Adjust the frame to the height required, then replace all the

screws removed as above.

• Insert the upper chimney stack from above, and leave it running free on the frame.

• Lift up the frame, fit the frame slots onto the screws up to the

slot end positions.

• Tighten the two screws and fasten the other two screws provided with the hood.

Before tightening the screws completely it is possible to adjust

the frame by turning it. Make sure that the screws do not come

out of their seats in the slotted holes.

• The frame mountings must be secure to withstand the weight

of the hood and any stresses caused by the occasional side

thrust applied to the device.

On completion, check that t he base is stable, even i f the frame

is subjected to bending.

• In all cases where the ceiling is not strong enough at the suspension point, the installer must provide strengthening using

suitable plates and backing pieces anchored to the structurally

sound parts.

Connections

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the hood to the

chimney using either a flexib le or rigid pipe the choice o f which

is left to the installer.

To install a ø 150

• To install the dumper 10a ø 150.

• Fix the pipe in position using sufficient pipe clamps (not supplied).

• Remove any activated charcoal fil ters.

Page 12

EN 112

Recirculation version air outlet

• Fix the connection 15 to the frame using the 4

screws provided.

• Fix the flan ge 10 t o the lower openi ng of th e connection 15.

• Connect the hood air outlet to the flange in the lower

part of the junction using a rigid or flexible ø 150

tube (by installer’s choice).

15

10

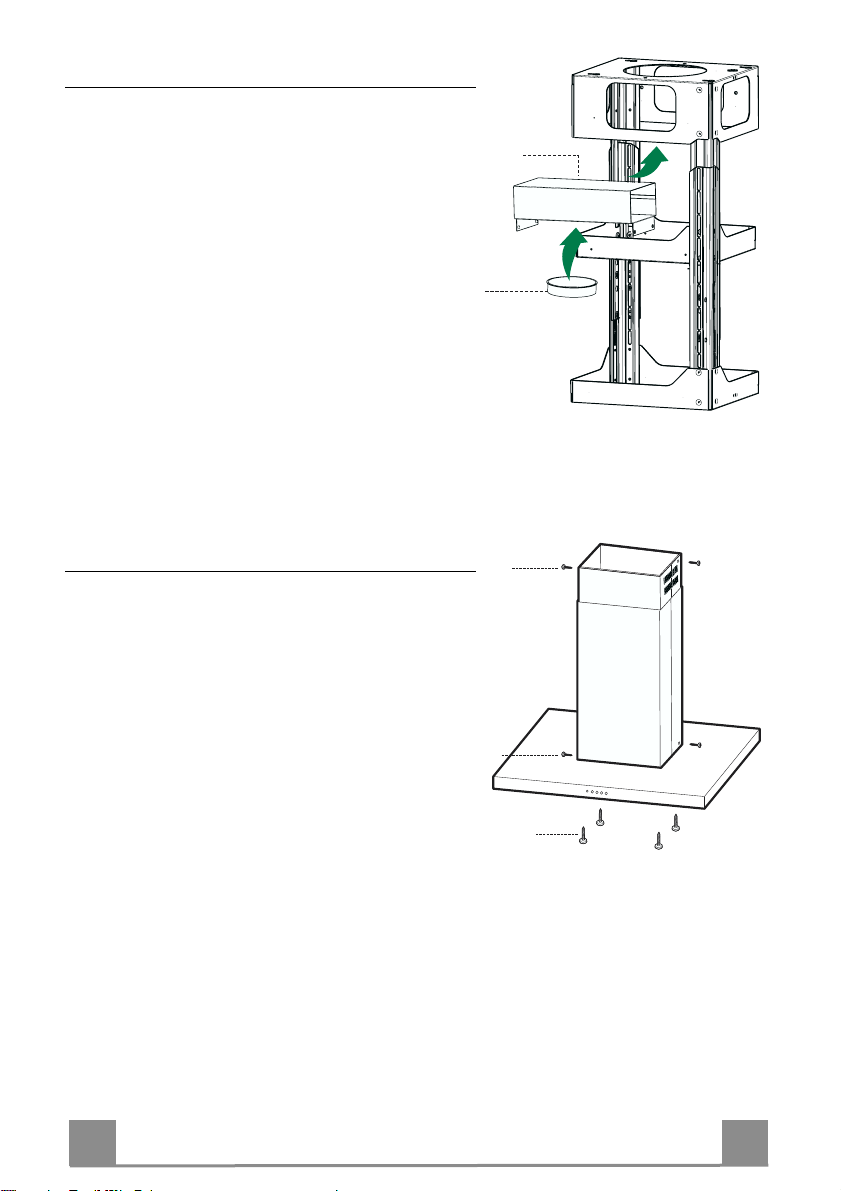

Flue assembly - Mounting the hood body

• Position the upper chimney section and fix the upper

part to the frame using the 2 screws 12c (2,9 x 6,5)

provided.

• Similarly, position the lower chimney section and

fix the lower part to the frame using the 2 screws 12c

(2,9 x 6,5) provided.

Before fixing the hood body to the frame:

• Remove the grease filters from the hood body.

• Remove any activated charcoal fil ters.

• From below, use the 4 screws 12f (M6 x

10)provided to fix the hood body to the frame.

12c

12c

12f

Page 13

EN 113

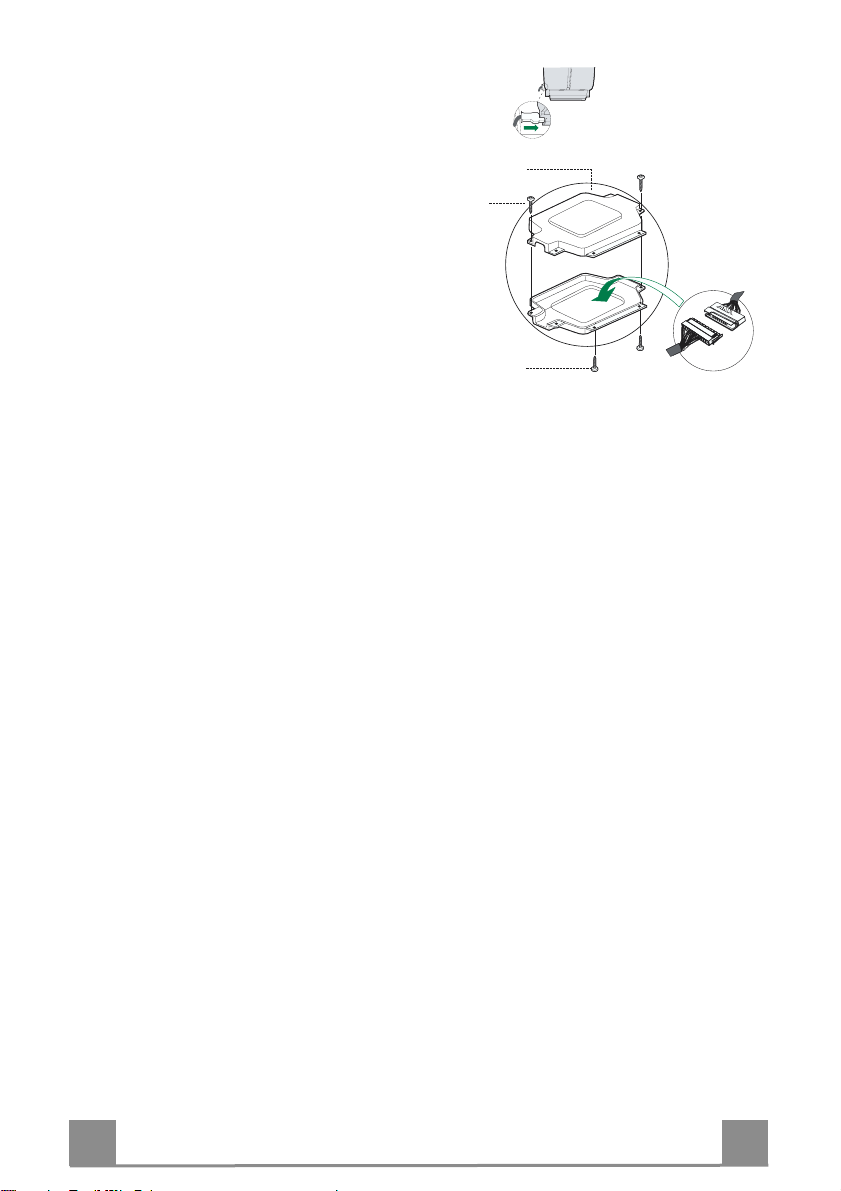

ELECTRICAL CONNECTION

• Connect the hood to the mains through a two-pole

switch having a contact gap of at least 3 mm.

• Remove the grease filters (see paragraph Maintenance) being sure that the connector of the feeding

cable is correctly inserted in the socket p laced on t he

24

12e

side of the fan.

• Connect the control connector Cmd.

• Place th e connect ors in the j unction box 24 and close

it using the 2 screws 12e (2,9 x 9,5) provided.

• Fix the junction box to the hood body using the 2

screws 12c (2,9 x 6,5) provided.

• For the recirculation version, fit the activated carbon

odour filter.

12c

Cmd

• Replace the grease filters.

Page 14

EN 114

USE

V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1

S

V2

V3

L

L Light Switches the lighting system on and off.

S Led Motor running led.

V1 Motor Switches the extractor motor on and off at low speed. Used to provide a

contin-uos and silent air change in the presence of light cooking vapours.

V2 Speed Medium speed, suitable for most operating conditions given the optimum

treated air flox/noise level ratio.

V3 Intensive Maximum speed, used for eliminating the highest cooking vapour e mission,

including long periods.

Page 15

EN 115

MAINTENANCE

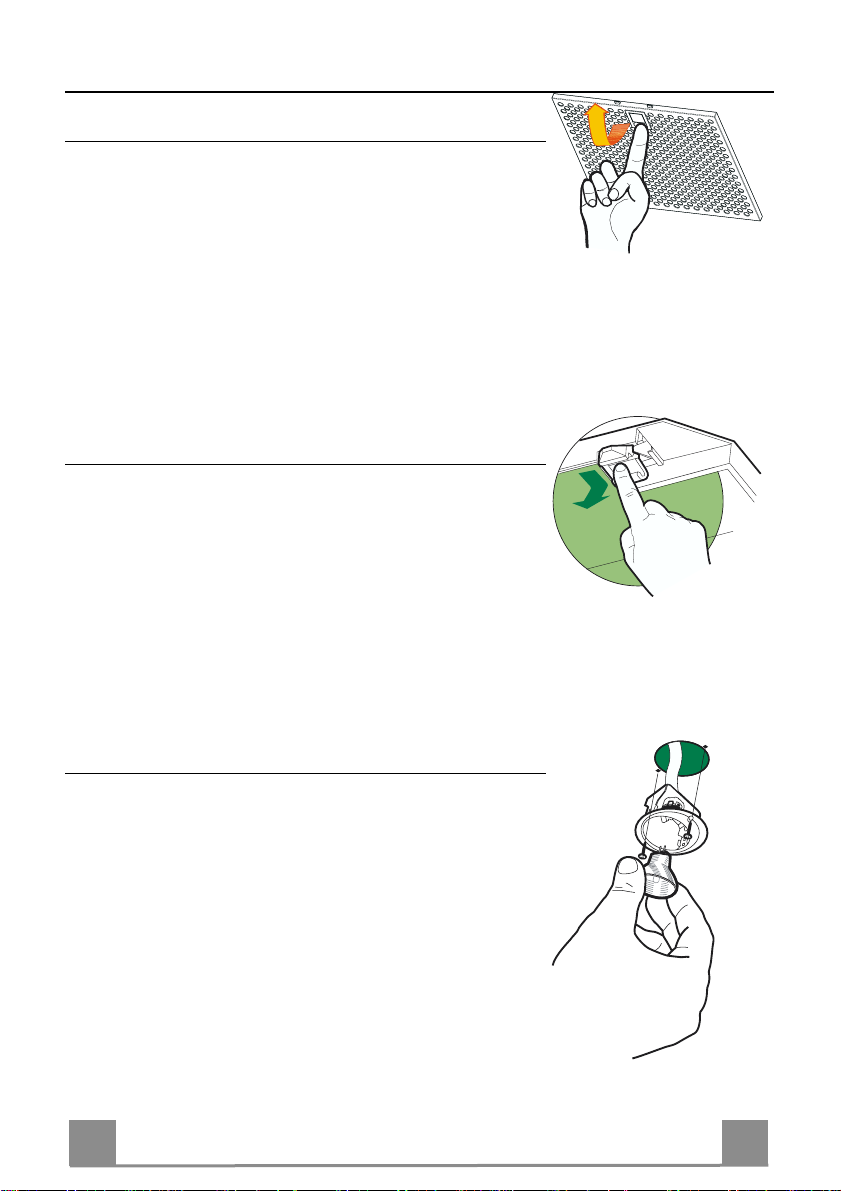

Grease filters

CLEANING META L SELF- SUPPO RTING GREASE FILTERS

• The filters must be cleaned every 2 months of operation, or

more frequently for particularly heavy usage, and can be

washed in a dishwasher.

• Remove the filters one at a time holding them up with one

hand and pulling the handle downwards with the other hand at

the same time.

• Wash the filters, taking care not to bend them. Allow them to

dry before refitting.

• When refitting the filters, make sure that the handle is visible

on the outside.

Activated charcoal filter (Recirculation version)

REPLACING THE ACTIVATED CHARCOAL FILTER

• The filter is not washable and cannot be regenerated, and

must be replaced approximately every 4 months of operation, or more frequently for particularly heavy usage.

• Remove the metal grease filters

• Remove the saturated activated carbon filter by releasing the

fixing hooks

• Fit the new filter by hooking it into its seating

• Replace the metal grease filters.

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the 2 screws fixing the Lighting support, and pull it

out of from the Hood.

• Extract the lamp from the Support.

• Replace with another of the same type, making sure that the

two pins are properly inserted in the lamp holder socket holes.

• Replace the Support, fixing it in place with the two screws removed as above.

Page 16

EN 116

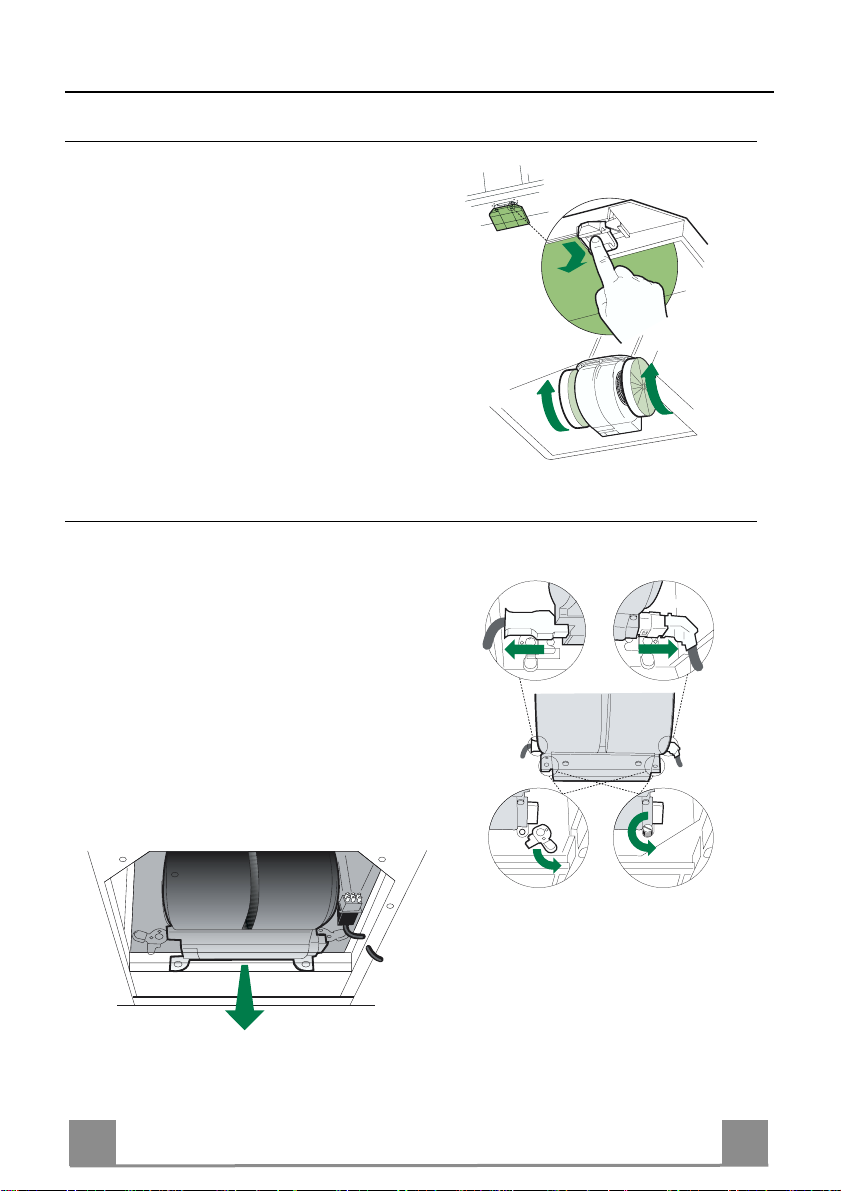

EASY CLEANING TM

Removing the Grease Filters

Before carrying out Maintenance on the EASY CLEANING Suction Unit:

• Disconnect the hood by switching off the

twopole switch on the mains power supply

line, or by switching off the main power

switch.

• Remove the grease filters from the hood.

• If the hood is of the recirculation type, remove the odour filters:

• For hoods with a flat cart ridge (A): turn the

fastening elements p rovided;

• For hoods with a bayonet cartridge (B):

turn as indicated and extract.

Disconnecting the EASY CLEANING Suction Unit

• Disconn ect t he po wer conn ecto r Ca and the

control and lighting connector Cmd on the

sides of the unit.

• For wall-mounted hoods and free-standing

hoods with square chimney, turn the levers

Lb locking the suction unit, so that they disconnect from the pins.

• For free-standing hoods with round chimney, unscrew the plugs Vb lockin g the suction unit.

• Pull the suction unit forwards so that it unhooks from the support pins, and remove it

downwards through the air outlet.

A

B

CmdCa

Lb

Vb

Page 17

EN 117

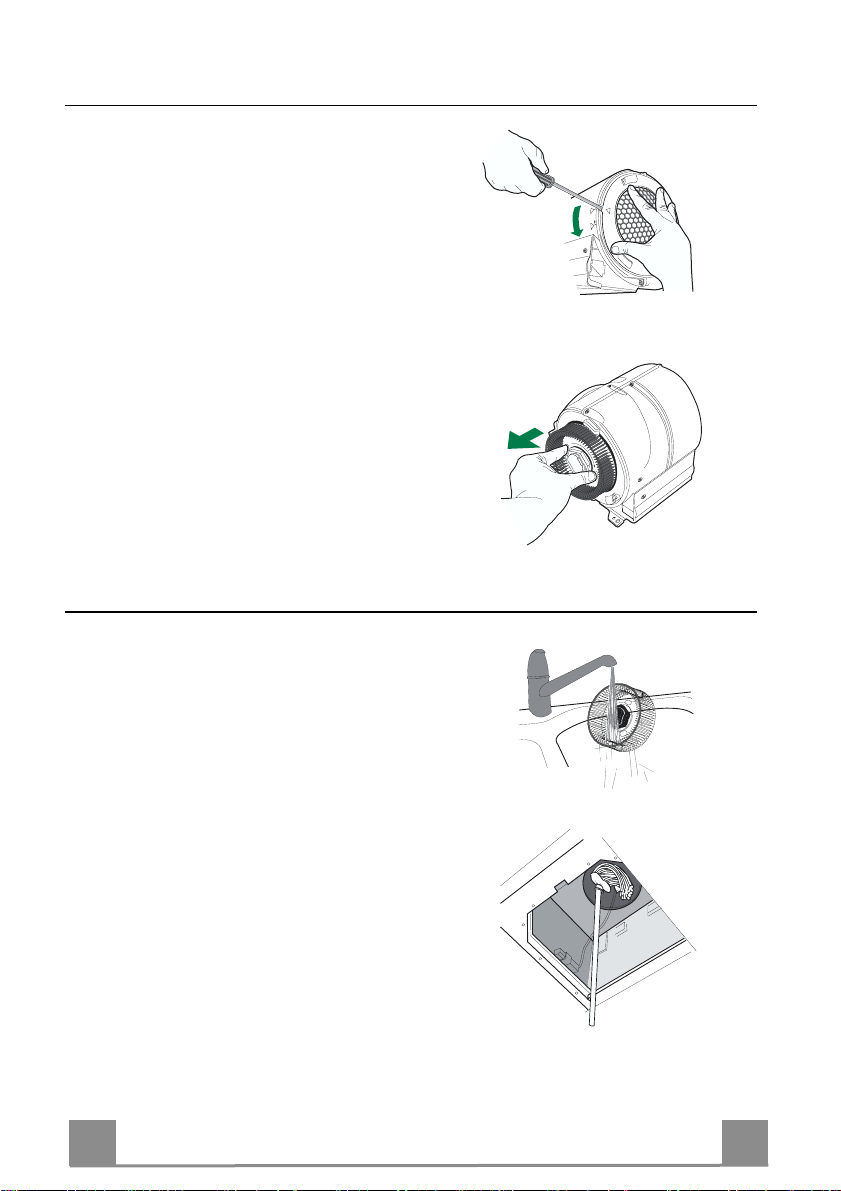

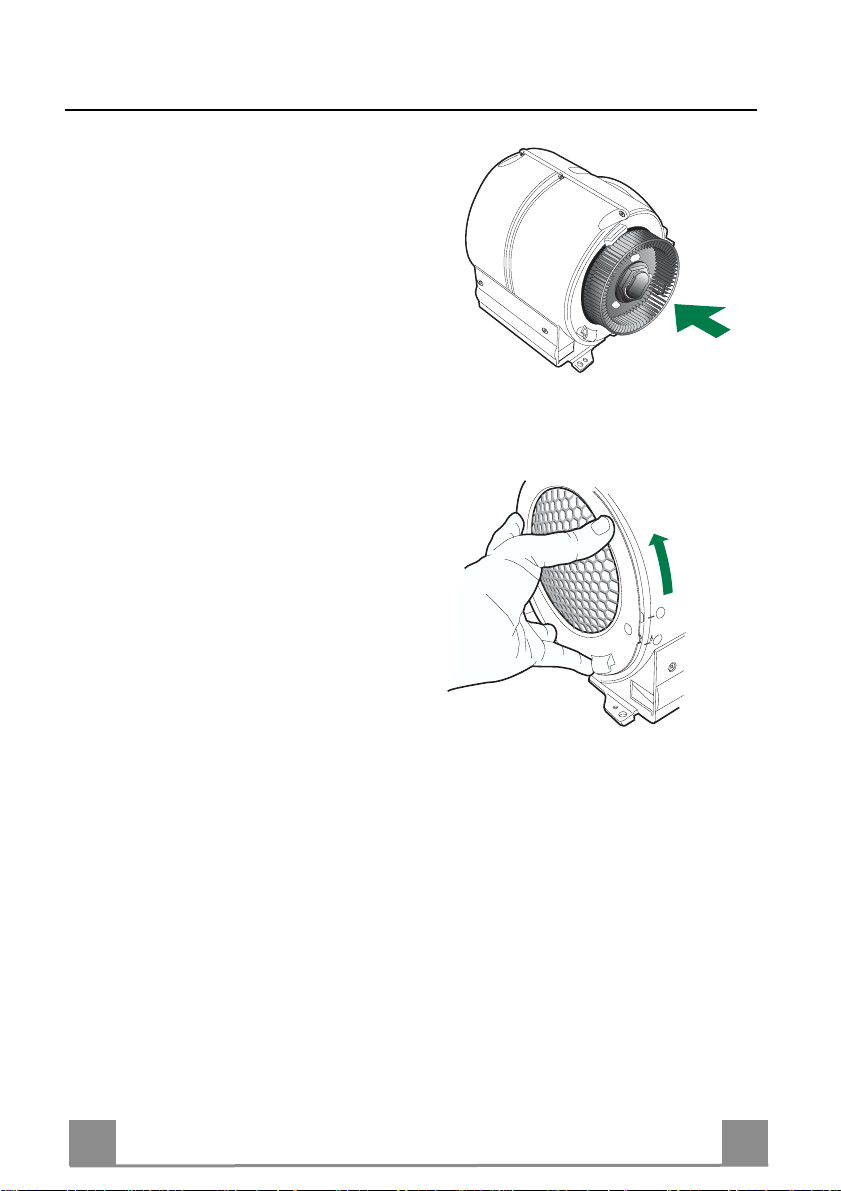

Dismantling Washable Parts

• To remove the side grilles protecting the

fans, lift up the stop tooth using a knife or

screwdriver and turn the grilles in the direction indicated by the arrow.

• Grasp the fans in the holes provided and

pull to extract.

CLEANING

• Wash the fans and the protection grilles,

using normal washing-up liquid. These elements can also be washed in the dishwasher.

• Using a damp cloth and a suitable detergent, clean the body of the suction device,

taking great care not to allow any water to

leak into the inside of the unit or into the

connector housings.

• Leave until completely dry bifore reassembling.

O

LOCK

P

E

N

E

E

FR

• Using a brush, clean the air outlet pipe as

far as you can reach.

Page 18

EN 118

REASSEMBLY

N.B. To avoid reassembling the wrong way

round, the two fans have different couplings.

• Reassemble the fans on the corresponding

pins, pressing them until they snap into

place.

• Fit the protection grilles so that the teeth

coincide in the “F REE” position and when

turned to “LOCK”.

• Replace the EASY CLEANING suction

unit on the hood, inserting it in position and

connecting it to the support pins.

• Turn the lock levers, or screw in the lock

plugs.

• Connect the power connector and the

command connector to the sockets on the

sides of the suction device.

• Replace any activated charcoal odour filters.

• Replace the grease filters.

• Co nnect the hood to the power su pply system, by turning the two-pole switch on the

mains power line to on, or by turning the

main switch on.

• Check that the hood is working properly,

by turning the motor and lighting on.

K

C

LO

O

P

E

N

FREE

Page 19

DK 119

RÅD OG ANVISNINGER

INSTALLATION

• Producenten kan ikke holdes ansvarlig for eventuelle skader, der

skyldes ukorrekt eller forkert installation.

• Den mindst tilladelige sikkerhedsafstand mellem komfurets top og

emhættens underside er 650 mm.

• Kontrollér, at lysnetspændingen er den samme som den spænding,

der er angivet mærkepladen, der sidder på inde i emhætten.

• For Klasse I apparater skal det også kontrolleres, at elforsy ningen er

forsynet med jord.

• Emhætten kobles til aftrækskanalen ved hjæl p af et rør med en min.diameter på 120 mm. Afstanden fra emhætten til kanalen skal være

så kort som mulig.

• Emhætten må ikke ti lsluttes en kanal, der fører forbræ ndingsgasser

ud i det fri (oliefyr, brændeovne etc.).

• Hvis emhætten skal anve ndes i f orbi ndelse med ik ke-elekt riske app arater (f.eks. gaskomfur, gaskogeblus), skal det sikres, a t lufttilgangen

til rummet er tilstrækkeli g, så aftræksgasserne ik ke slår tilbage. Køkkenet skal have en åbning, der har direkte forbi n del se ti l det fri , s å der

er sikret en tilstrækkelig mængde ren luft.

ANVENDELSE

• Emhætten er udelukkende beregnet til at fjerne em og lugte i kø kkener i private husholdninger.

• Emhætten må kun anvendes til det formål, hvortil den er konstrueret.

• Der må ikke forekomme høj åben ild under e mhætten, mens den anvendes.

• Justér brænderen, så flam merne er r ettet direkte m od bunden af p anden/gryden – de må ikke nå ud over kanten af bunden.

• Frituregryder skal under brug h oldes under konstant ops yn: kogende

varm olie kan sprøjte ind i flammerne.

• Emhætten må ikke anvendes af børn og personer, som ikke ved,

hvordan den betjenes.

• Apparatet er ikke beregnet til at s kulle anvendes af mi ndre børn eller

svækkede personer uden opsyn.

• Undlad at flambere retter under emhætten; de r opstår el lers brandfare.

• Mindre børn skal holdes under opsyn for at sikre, at de ikke leger med

apparatet.

VEDLIGEHOLDELSE

• Inden apparatet skal vedligeholdes eller rengøres, skal der slukkes for

det eller stikket skal tages ud af stikkontakten.

• Rengør og/eller udskift filtrene iht. det angivne tidinterval.

• Rengør emhætten ved hjælp af en fugtig klud og et neutralt flydende

rengøringsmiddel.

650 mm min.

Page 20

DK 220

APPARATBESKRIVELSE

Dimensioner

45

650 min.

Page 21

DK 221

Komponenter

Ref. Stk. Produktets komponenter

1 1 Emhættens hoveddel inkl.: Betjeningsanordninger, lys,

filtre

2 1 Teleskopaftræk bestående af:

2.1 1 Øverste aftræk

2.2 1 Nederste aftræk

7.1 1 Teleskopramme med udsugningsenhed bestående af:

7.1a 1 Øverste ramme

7.1b 1 Nederste ramme

10 1 Sidestykke ø 150

10a 1 Sidestykke med ventil ø 150 mm

15 1 Luftudstrømnings overgangsstykke

24 1 Forbindelseskasse

25 2 Rørklemmer

Ref. Stk. Installationsdele

11 4 Forankringer ø 10

12c 6 Skruer 2,9 x 6,5

12e 2 Skruer 2,9 x 9,5

12f 4 Sk ruer M6 x 10

12g 4 Skruer M6 x 80

12h 4 Skruer 5,2 x 70

21 1 Boreskabelon

22 4 Spændskiver int. ø 6,4

23 4 Møtrikker M6

Stk. Dokumentation

1 Brugerhåndbog

7.1

21

22

12c

2

12c

1

7.1a

12g

7.1b

2.1

2.2

12f

23

12c

25

12e

11

12h

15

10

10a

24

Page 22

DK 222

INSTALLATION

Boring i loftet/hylden og fastgørelse af rammen

BORING I LOFTET/H YLDEN

• Brug en lodlinie til at markere centrum af kogeplad en på loftet/støttehylden

• Placer den medfølgende boreskabelon 21 på loftet/støttehylden, idet du skal sikre dig, at

skabelonen er placeret korrekt ved at stille skabelonens akser på linie med kogepladens.

• Marker cen trum af hullerne i skabelo nen.

• Bor huller på de markerede punkter.

• Ved betonlofter skal der bores til plugs passende til skruestørrelsen.

• I hulstenslofter med en godstykkelse på 20 mm: bor ø 10 mm (isæt straks dyvlerne 11 der

er medleveret).

• I træbjælkelofter skal der bores passende til de anvendte træskruer.

• Til træhylden skal der bores ø 7 mm.

• For kraftkabeltilførslen skal der bores ø 10 mm.

• Til luftaftræk (afskærmet version) skal du bore i henhold til diameteren på den eksterne

kanalforbindelse til luftaftræk

• Isæt to skruer af følgende type, idet de krydses og sættes i 4-5 mm fra loftet:

• Ved betonlofter skal du bruge passende plugs til skruestørrelsen (medfølger ikke).

• til hulstensloft med hulrum, med en godstykkelse på ca. 20 mm, skruer 12h, medleveret.

• Til træbjælkelofter skal der bruges 4 træskruer (medfølger ikke).

• Til træhylde skal der bruges 4 skruer 12g med skiver 22 og møtrikker 23, medleveret.

Page 23

DK 223

Fastgørelse af rammen

2

2

1

1

10 a

ø 150

25

• Løsn de to skruer, der fastgør den nederste skorsten, og tag

denne væk fra den nederste ramme.

• Løsn de to skruer, der fastgør den øverste skorsten, og tag denne væk fra den øverste ramme.

Hvis du ønsker at justere rammens hø jde, skal du fortsætte som

følger:

• Løsn de 8 metriske skruer, der forbinder de to søjler, placeret

på rammens sider.

• Juster rammen til den krævede højde, og sæt så alle skruer, der

har været fjernet, på plads som ovenfor.

• Isæt den øverste skorstensskakt ovenfra og lad den løbe frit på

rammen.

• Løft rammen op, anbring rammens riller oven på skruerne op

til rillernes endepositioner.

• Stram de to skruer og fastgør de to andre skruer, der er leveret

med emhætten.

Inden skruerne strammes helt, er det muligt at justere rammen

ved at dreje den. Vær sikker på at skruerne ikke kommer ud af

deres lejer i de rillede huller.

• Rammebeslagene skal være sikre på at kunne modstå emhættens vægt og evt. påvirkninger forårsaget af det tilfældige sidetryk anvendt på apparatet.

Ved slutbearbejdning skal du kontrollere, at underkanten er

stabil, selv om rammen udsættes for bukning.

• I alle tilfælde hvor loftet ikke er stærkt nok på ophængningspunktet, skal installatøren sørge for forstærkning ved hjælp af

passende plader og underlagsstykker forankret til bygningsmæssige sunde dele.

Forbindelser

LUFTUDLEDNING PÅ VERSION MED UDSUGNING

Ved installation som version med udsugning forbindes emhætten

til udledningsrøret ved hjælp af et rør eller en flexslange, som det

påhviler installatøren at vælge.

Forbindelse af rør ø 150

• Sæt sidestykket med ventil 10a ø 150 på emhættens hoveddels

udledning.

• Fastgør røret med egnede rørklemmer. Det påkrævede materiale følger ikke med.

• Fjern lugtfiltrene med aktivt kul, såfremt de forefindes.

Page 24

DK 224

Luftudledning på Filtrerende version

• Fastgør overgangsstykket 15 til rammen ved hjælp af

de 4 medfølgende skruer.

• Før flangen 10 ind i det dertil beregnede, nederste hul

på overgangsstykket 15.

• Forbind emhættens luftudledning til flangen under

overgangsstykket ved hjælp af et rør eller en flexslange ø 150, som det påhviler installatøren at vælge.

15

10

Montering af aftræk og fastgøring af emhættens

hoveddel

• Placér det øverste a ftræk, og fastgør dets overdel til

rammen med de 2 medfølgende skruer 12c (2,9 x

6,5).

• Placér derefter det nederste aftræk, og fastgør dets

underside til rammen ved hjælp af de 2 medfølgende

skruer 12c (2,9 x 6,5 ).

Før emhættens hoveddel fastgøres til rammen:

• Fjern fedtfiltrene fra emhættens hoveddel;

• Fjern lugtfiltrene med aktivt kul, såfremt de forefindes.

• Fastgør derefter emhættens hoveddel til den installerede ramme, nedefra ved hjælp af de 4 medfølgende

skruer 12f (M6 x 10).

12c

12c

12f

Page 25

DK 225

ELEKTRISK TILSLUTNING

• Tilslut emhætten til strømmen via en topolet kontakt

med en kontaktafstand på mindst 3 mm.

• Tag fedtfiltrene af (se afsnittet Vedligeholdelse), idet

du skal sikre dig, at forbindelsesstykket for strømtilførselskablet er korrekt sat i stik dåsen placeret på si-

24

12e

den af ventilatoren.

• Tilslut kontrolforbindelsesstykket Cmd.

• Placer forbindelserne i tilslutningsdåsen 24 og luk

den ved hjælp af de 2 skruer 12e (2,9 x 9,5), der medfølger.

• Fastgør tilslutningsdåsen til emhætten ved hjælp af

de 2 skruer 12c (2,9 x 6,5), der medfølger.

• For recirkulationsudgaven skal du fastgøre de aktive

12c

Cmd

kullugtfiltre.

• Sæt fedtfiltrene på plads igen.

Page 26

DK 226

BRUG

V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1

S

V2

V3

L

L Lys Tænder og slukker for lyssystemet.

S Lysdiode Motorfungerende lysdiode.

VI Motor Tænder og slukker udsugningsmotoren på lav hastighed. Bruges til at give

en constant og lydløs luftudskiftning, hvis der er lette madlavningsdampe.

V2 Hastighed Middelhastighed, passende til de fleste driftbetingelser forudsat optimalt

forhold mellem behandlet luft/støjniveau.

V3 Intensiv Højeste hastighed, bruges til at fjerne de madlavningsdampe, der udsendes

på højeste varme, inklusive lange perioder.

Page 27

DK 227

VEDLIGEHOLDELSE

Fedtfiltre

RENGØRING AF SELVBÆRENDE FEDTFILTRE AF METAL

• De kan også vaskes i opvaskema skine, og de skal renses cirka

hver 2. måned ved almindelig anvendelse, helst oftere ved intensiv anvendelse.

• Fjern filtrene, ét ad gangen, og hold dem fast med den ene

hånd, mens grebet trækkes nedad med den anden.

• Skyl filtrene uden at bøje dem, og lad dem tørre, før de sættes

på plads igen.

• Sæt dem på plads igen, og sørg for, at håndtaget vender mod

den synlige yderside.

Aktivt kulfilter (recirkulationsudgave)

UDSKIFTNING AF DET AKTIVE KULFILTER

• Filteret kan ikke vaskes og kan ikke regenereres, og skal udskiftes omkring hver fjerde måned, eller oftere ved kraftig

brug.

• Tag fedtfiltrene af metal ud

• Tag det gennemvædede aktive kulfilter ud ved at løsne befæstelseskrogene.

• Fastgør det nye filter ved at hægte ind på plads

• Sæt metalfedtfiltrene på plads igen.

Belysning

UDSKIFTNING AF PÆRER

20W halogenpærer.

• Fjern de 2 skruer, som fastholder fatningen og tag den ud af

emhætten.

• Ta g pæren ud af fatningen.

• Skift den ud med en ny af samme slags, idet man sørger for at

indsætte de to spidser korrekt i fatningen.

• Montér fatningen igen ved hjælp af de to skruer.

Page 28

DK 228

EASY CLEANING TM

Udtagning af fedtfiltre

Før man går i gang med vedligeholdelsen af

EASY CLEANING udsugningsenheden:

• Frakobl emhætten ved at aktivere den topolede afbryder, der er installeret på netforsyningen, eller hovedafbryderen.

• Fjern fedtfiltrene fra emhætten.

• Fjern lugtfiltrene, hvis det drejer sig om

den filtrerende version af emhætten:

• Hvis emhætten er forsynet med flad indsats

(A): Indvirk på de dertil beregnede hager;

• Hvis emhætten er forsynet med bajonetindsats (B): Drej som vist på billedet, og tag

den ud.

Frakobling af EASY CLEANING udsugningsenheden

• Frakobl forsyningskonnektoren Ca og betjeningsanordningernes og belysningens

konnektor Cmd på enhedens sider.

• På vægmonterede emhætter og emhætter

over kogeøer med rektan gulært aftræk, skal

udsugningsenhedens spærregreb Lb drejes

og frakobles tappene.

• På emhætter over kogeøer med rundt aftræk, skal udsugningsenhedens spærhager

Vb løsnes.

• Træk udsugningsenheden frem, så den frakobles støttetappene, og tag den ud via

luftudgangen, i nedadgående retning.

A

B

CmdCa

Lb

Vb

Page 29

DK 229

Afmontering af de dele, der kan vaskes

• Sideristene, der beskytter rotorerne, fjernes

ved at hæve spærrehakkene med spidsen af

en skruetrækker eller en kn iv og dreje dem

i pilens retning.

• Tag fat i rotorerne i hullerne, og træk dem

ud.

RENGØRING

• Vask rotorerne og beskyttelsesristene med

et almindeligt opvaskemiddel. De kan også

vaskes i opvaskemaskine.

• Rens udsugningsanordningens hoveddel

med en fugtig klud og et egnet rengøringsmiddel; pas på, at der ikke trænger vand ind

i enheden og konnektorernes sæder.

• Lad den tørre godt, før den sættes på plads

igen.

• Rens luftudgangsrøret så langt ind som muligt med en gulvskrubbe.

O

CK

LO

P

E

N

FREE

Page 30

DK 330

GENMONTERING

OBS: For at undgå at bytte om på rotorerne,

når de sættes på plads igen, er deres tilkoblingssteder forskellige.

• Sæt rotorerne tilbage på de tilsvarende tappe, idet der presses, indtil der høres et klik.

• Montér beskyttelsesristene, idet hakkene i

positionen ”FREE” skal befinde sig ud for

hinanden, og drej dem over mod ”LOCK”.

• Sæt EASY CLEANING udsugningsenheden på emhætten igen ved at placere den og

koble den fast til støttetappene.

• Drej spærregrebene eller stram spærhagerne.

• Forbind forsyningens og betjeningsanordningernes konnektorer med tilkoblingsstederne på siderne af udsugningsanordningen.

• Sæt lugtfiltret med aktivt kul på igen, såfremt de t forefindes.

• Sæt fedtfiltrene på igen.

• Tilkobl emhætten netforsyningen ved at

aktivere den topolede afbryder, der er installeret på netforsyningen, eller hovedafbryderen.

• Kontrollér funktionen ved at tænde for motoren og lysene.

K

C

LO

O

P

E

N

FREE

Page 31

SE 331

REKOMMENDATIONER OCH TIPS

INSTALLATION

• Tillverkaren åtar sig i nget ansvar för fel som beror på felakti g eller

olämplig installation.

• Minsta tillåtna avstånd mellan spishäll och köksfläkt är 650 mm.

• Kontrollera att matningsnätets spänning motsvarar den som anges på

märkskylten inuti köksfläkten.

• F ör Klass I-apparater, kontrollera att matnings nätet ger effektiv jordning.

• Anslut fläkten till frånluftkanalen via ett rör med en diameter på minst

120 mm. Anslutningsröret skall hållas så kort som möjligt.

• Anslut inte köksfläkten till frånluftkanaler som leder förbränningsgaser

(från pannor, eldstäder etc.).

• Om fläkten används tillsammans med icke-elektriska spisar (t.ex.

gasspisar) måste tillräcklig ventilation garanteras i lokalen för att förhindra backflöde av förbränningsgaser. Köket måste ha ett tilluftdon

med direkt anslutning mot ytterluft för att garantera inflöde av friskluft.

ANVÄNDNING

• Köksfläkten är uteslutande avsedd för hemanvändning, för att eliminera köksos.

• Använd aldrig köksfläkten för andra ändamål än det avsedda.

• Undvik höga flammor under köksfläkten medan fläkten är i drift.

• Justera gas lågan så att flammorna e ndast berör kok kärlets unders ida

och inte tränger upp längs dess sidor.

• Fritöser mås te övervakas kontinuerli gt under användning: Överh ettad

olja kan fatta eld.

• Köksfläkten skall inte använd as av barn eller personer som inte ä r

insatta i korrekt användning.

• Apparaten är inte av sedd att användas av barn eller handi kappade

personer utan övervakning.

• Tillaga inga flamberade maträtte r under köksfläkten, då det fi nns risk

för eldsvåda

• Små barn sk all hållas under öv ervakning så att d e inte kan leka med

apparaten.

UNDERHÅLL

• Stäng av apparaten e ller skilj den från matningsnätet innan något un derhållsarbete utförs.

• Rengör och/eller byt filtren med angivet intervall.

• Rengör kök sfläkten med e n fuktig trasa oc h neutralt fly tande diskmedel.

650 mm min.

Page 32

SE 332

EGENSKAPER

Mått

45

650 min.

Page 33

SE 333

Komponenter

Ref. Antal Produktkomponenter

1 1 Köksfläktsstomme komplett med: R eglage, Belysning,

Filter

2 1 Teleskopisk skorsten bestående av:

2.1 1 Övre skorsten

2.2 1 Undre skorsten

7.1 1 Teleskopiskt stativ komplett med utsugningsanordning,

bestående av:

7.1a 1 Övre stativ

7.1b 1 Undre stativ

10 1 Fläns ø 150

10a 1 Fläns med ventil ø 150 mm

15 1 Anslutningsstycke för luftutsläpp

24 1 Anslutningsdosa

25 2 Slangklämmor

Ref. Antal Installationskomponenter

11 4 Expansionspluggar ø 10

12c 6 Skruvar 2,9 x 6,5

12e 2 Skruvar 2,9 x 9,5

12f 4 Skruvar M6 x 10

12g 4 Skruvar M6 x 80

12h 4 Skruvar 5,2 x 70

21 1 Borrmall

22 4 Brickor ø 6,4

23 4 Muttrar M6

Antal Dokumentation

1 Bruksanvisning

7.1

21

22

12c

2

12c

1

7.1a

12g

7.1b

2.1

2.2

12f

23

12c

25

12e

11

12h

15

10

10a

24

Page 34

SE 334

INSTALLATION

Borrning i vägg och fastsättning av konsoler

BORRNING I TAK/HYLLA

• Med hjälp av ett sänklod markera spishällens mittpunkt i taket/på hyllan.

• P lacera den medföljand e borrningsmallen 21 mot taket/hyllan, och låt dess mittpunkt sam-

manfalla med den projicerade mittpunkten och anpassa mallens axlar med spishällens axlar.

• Markera mallens hål.

• Borra följande hål:

• Innertak i betong: enligt använd expansionsplugg för betong.

• Innertak i tegelsten med luftrum, med en motståndskraftig tjocklek på 20 mm: ø 10 mm

(sätt omgående i de medföljande expansionspluggarna 11).

• Innertak i bjälklag: enligt använd träskruv.

• Hylla i trä: ø 7 mm.

• Passage för elkabel: ø 10 mm.

• Luftutsläpp (sugande version): enligt anslutningsdiametern till den externa avledningen.

• Skruva fast 2 skruvar i kors (diagonalt) och lämna 4-5 mm från innertaket:

• för betong, expansionsplugg för betong, medföljer inte.

• för tegelsten med luftrum, med en motståndskraftig tjocklek på cirka 20 mm, de med-

följande 12h skruvarna.

• för bjälklag, träskruv, medföljer inte.

• för hylla i trä, medföljande skruvar 12g med brickor 22 och muttrar 23.

Page 35

SE 335

FASTSÄTTNING AV STATIV

2

2

1

1

10 a

ø 150

25

• Lossa de två skruvarna som fäster den undre skorstenen och

dra ut den från stativet (från den undre delen)

• Lossa de två skruvarna som fäster den övre skorstenen och dra

ut den från stativet (från den övre delen)

Om du vill reglera höjden på stativet gå tillväga som följer:

• Skruva loss d e åtta metriska skruvarna som förenar de båda

kolonnerna, placerade på stativets sidor;

• Ställ in önskad höjd på stativet och skruva fast de tidigare

borttagna åtta skruvarna;

• Sätt i den övre skorstenen uppifrån och lämna den fri på stativet;

• Lyft upp stativet, haka i öglorna på skruvarna och låt det glida

ända tills stoppet;

• Skruva åt de två skruvarna och skruva fast de andra två medföljande;

Innan du slutligen dra åt skruvarna är det möjligt att utföra regleringar genom att vrida stativet men se till att skruvarna inte

går ut ur regleröglans säte.

• Fastsättningen av stativet måste vara säker i förhållande till

såväl kåpans vikt som tillfälliga tryck från sidan på monterad

apparat. Efter slutlig fastsättning kontrollera därför att basen är

stabil även om stativet utsätts för tryck från sidan.

• Hur som helst om innertaket inte är tillräckligt starkt i upphängningspunkten, ska installatören se till att förstärka den

med lämpliga plattor och motplattor förankrade i strukturmässigt motståndskraftiga delar.

Anslutningar

LUFTUTSLÄPP UTSUGANDE VERSION

För installation i utsugande version anslut köksfläkten till utsläppsrörledningen med en styv eller böjlig slang, valet lämnas åt

installatören.

Anslutning med slang ø 150

• För in flänsen med ventil 10a ø150 på köksfläktsstommens

utsläpp.

• Fäst slangen med lämpliga slangklämmor. Nödvändigt material

medföljer inte.

• Ta bort eventuella luktfilter med aktivt kol.

Page 36

SE 336

Luftutsläpp filtrerande version

• Fäst muff 15 på stativet med de medföljande 4 skru-

varna.

• Spänn fa st fläns 10 i det undre hålet på muff 15.

• Anslut kåpans luftutlopp med flänsen som sitter under muffen med ett styvt rör eller slang ø 150 mm ,

valet överlämnas till installatören

Montering av skorsten och fastsättning av köks-

fläktsstommen

• Placera den övre skorstenen o ch fäst den i överdelen

vid stativet med 2 medföljande 12c (2,9x 9,5) skru-

var.

• Placera den undre skorsten en på samma sätt och fäst

den i underdelen vid stativet med 2 medföljande 12c

(2,9 x 9,5) skruvar.

Innan du fäster köksfl äktsstom men på stativet:

• Avlägsna fettfiltren från köksfläktsstommen;

• Avlägsna eventuella luktfilter med aktivt kol.

• Fäst därefter köksfläktsstommen underifrån på det

förberedda stativet med de 4 medföljande skruvarna

12f (M6 x 10).

15

10

12c

12c

12f

Page 37

SE 337

ELEKTRISK ANSLUTNING

• Anslut fläktkåpan till eluttaget och installera en tvåpolig brytare med en öppning på minst 3 mm emellan

kontakterna.

• Avlägsna fettfiltren (se avsnitt “Underhåll”) och se

24

till att nätsladdens kontaktdon är rätt isatt i fläktens

uttag

12e

• Anslut kontaktdonet för kontrollerna Cmd.

• Lägg båda kontaktdonen i skyddsdosan 24 och skru-

va igen den med 2 medföljande 12e (2,9 x 9,5) skru -

var.

• Fäst skyddsdosan på köksfläktsstommen med 2 medföljande 12c (2,9 x 6,5) skruvar.

• För den filtrerande versionen montera luktfiltren med

aktivt kol.

12c

Cmd

• Montera fettfiltren på nytt.

Page 38

SE 338

ANVÄNDING

V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1

S

V2

V3

L

L Tänder och släcker belysningen

S Motor i drift

V1 Starta och stoppa motorn, samt startar en en tyst minimum gång

V2 Startar medium effekten, den bästa ljud och effekt nivå för matlagning

V3 Startar max effekten, som används vid kraftigt osande matframställning

Page 39

SE 339

UNDERHÅLL

Fettfilter

RENGÖRING AV SJÄLVBÄRANDE METALLFETTFILTER

• Dessa kan även diskas i diskmaskin, de ska diskas varannan

månad cirka eller oftare vid intensiv användning.

• Ta bort ett filter åt gången, genom att stödja dem med den ena

handen och dra spaken nedåt med den andra handen.

• Diska filtren utan att böja dem. Låt filtren torka före återmonteringen.

• Montera filtren på nytt. Se till att handtaget vänder mot den

synliga utsidan

Kolfilter

• byte av kolfilter:

• ta bort fettfiltren av metall

• ta bort de igensatta kolfiltren

• sätt tillbaka fettfiltren av metall

Belysning

BYTE AV LAMPOR

Halogenlampor, 20W

• Ta bort de två skruvarna som fäster lamphållaren och dra ut

den ur köksfläkten.

• Dra ut lampan ur hållaren.

• Byt ut lampan mot en ny med sa mma egenskaper. Sätt in d e

två piggarna korrekt i hållarens säte.

• Montera hållaren på nytt med de två skruvarna.

Page 40

SE 440

EASY CLEANING TM

Borttagning av fettfilter.

Innan du påbörjar underhållet av utsugningsenheten EASY CLEANING:

• Slå ifrån köksfläkten med den bipolära brytaren installerad på försörjningsnätet eller

med huvudströmbrytaren.

• Ta ut fettfiltren ur köksfläkten.

• Ta ut luktfiltren, vid köksfläkt i filtrerande

version:

• För köksfläktar med plan kassett (A): använd de speciella hakarna;

• För köksfläktar med bajonettkassetter (B):

vrid som visas på bilden och dra ut.

A

Friläggning av utsugningsenheten EASY CLEANING

• Koppla från starkströmskontakten Ca och

den för reglagen och belysningen Cmd som

sitter på enhetens sidor.

• För väggmonterade köksfläktar och de med

ö med skorsten med rektangulär sektion,

vrid låsningsspakarna Lb på utsugningsen-

heten, och haka av dem från stiften.

• På köksfläktarna med ö och rund skorstenssektion, skruva loss spärrhakarna Vb på utsugningsenheten.

• Dra utsugningsenheten framåt så att den

friläggs från stödstiften dra ut den nedåt

från luftutsläppet.

B

CmdCa

Lb

Vb

Page 41

SE 441

Demontering av de diskbara delarna

• För att avlägsna skyddsgallren på sidorna

av fläkthjulen, lyft upp låstanden med spetsen av en skruvmejsel eller kniv och vrid

dem i pilens riktning.

• Ta tag i fläkthjulen i de förberedda hålen

och dra ut dem.

RENGÖRING

• Diska fläkthjulen och skyddsgallren med

normalt diskmedel. De kan även diskas i

diskmaskin.

• Rengör utsugningsenheten med en fuktig

trasa och lämpligt rengöringsmedel, men ge

noga akt på att inte vatten kommer in i enheten och i kontakternas säten.

• Torka den väl innan du monterar tillbaka

den.

• Rengör luftutsläppskanalen så långt det är

möjligt med en borste.

O

K

LOC

P

E

N

EE

FR

Page 42

SE 442

ÅTERMONTERING

N.B. För att undvika omvända monteringar, har

fläkthjulen diff e rentie ra de koppli ng a r .

• Montera fläkthjulen på de motsvarande stiften och tryck tills du hör klicket för fasthakningen.

• Montera skyddsgallren och låt tänderna

sammanfalla i läge “FREE” och vrid dem

mot “LOCK”.

• Montera utsugningsenheten EASY CLEANING på köksfläkten, sätt i den i läge och

haka fast den på stödstiften.

• Vrid låssp akarna, eller skruva fast spärrhakarna.

• Anslut kraftförsörjningskontakten och den

för reglagen till uttagen som sitter på utsugningsenhetens sidor.

• Montera eventuella luktfilter med aktivt

kol.

• Montera fettfiltren på nytt.

• Slå på köksfläkten med den bipolära brytaren installerad på försörjningsnätet eller

med huvudströmbrytaren.

• Kontrollera funktionen genom att starta

motorn och tända belysningen.

K

C

LO

O

P

E

N

FREE

Page 43

NO 443

ANBEFALINGER OG FORSLAG

INSTALLASJON

• Produsenten skal i kke kunne holdes ansvarlig for eventuelle s kader

som oppstår som følge av feil eller ufullstendig montering.

• Minimum sikkerhetsavstand mellom komfyrtoppen og viftehetten er

650 mm.

• Kontroller at nettspenningen er i overensstemmelse med spen ningen

som er angitt på merkeplaten på innsiden av hetten.

• For utstyr i klasse I må det kontrolleres at strømforsy ningen garanterer tilstrekkelig jording.

• Koble sugeviften til avtrekkskanalen gjennom et rør med en minimumsdiameter på 120 mm. Trekkanalens rute må v ære så kort som

mulig.

• Ikke koble viftehetten til avtrekkskanaler med forbrenningsgasser (kjeler, ildsteder osv.).

• Hvis sugeviften brukes sammen m ed ikke-elek triske apparate r (f.eks.

gassapparater), må det sørges fo r tilstrekkelig lufting i rommet fo r å

hindre tilbakestrømning av avgass. Kjøkkenet må ha en direkte åpning til fri luft for å garantere tilførsel av ren luft.

BRUK

• Viftehetten er utviklet utelukkende for hjemmeb ruk for å motvirke lukter på kjøkkenet.

• Bruk aldri hetten til andre formål enn den er beregnet for.

• Tillat aldri høye, åpne flammer under hetten når den er i bruk.

• Juster flammestyrken sl ik at bare b un nen av gryten o ms l uttes, og i kk e

sidene.

• Frityrkokere må overvåkes kontinuer lig under bruk: overopphetet ol je

kan ta fyr.

• Hetten må ikke brukes av barn eller personer som ikke har fått opplæring i korrekt bruk.

• Utstyret er ikke beregnet for bruk av unge barn eller sykelige personer

uten tilsyn.

• Ikke flambér under kjøkkenviften pga. brannfaren.

• Unge barn må ha tilsyn slik at de ikke finner på å l eke med apparat et.

VEDLIKEHOLD

• Slå av eller koble apparatet fra strømnettet før det utføres vedlikeholdsarbeid.

• Rengjør og/eller skrift ut filtrene etter angitt tid.

• Rengjør hetten med en fukti g k lut og et nø ytral t, fl ytende rens e middel .

650 mm min.

Page 44

NO 444

EGENSKAPER

Dimensjoner

45

650 min.

Page 45

NO 445

Deler

Ref. Antall Produktets deler

1 1 Kjøkkenviftens hoveddel komplett med: Kontroller, lys,

filtre.

2 1 Uttrekkbart røkrør; består av:

2.1 1 Øverste røkrør

2.2 1 Nederste røkrør

7.1 1 Uttrekkbart beslag med sugesystem; består av:

7.1a 1 Øverste beslag

7.1b 1 Nederste beslag

10 1 Flens med en diameter på 150

10a 1 Flens med en diameter på 150 mm me d ventil

15 1 Luftutløpskopling

24 1 Tilkoplingsboks

25 2 Slangeklemmer

Ref. Antall Installasjonsdeler

11 4 Ekspansjonsplugger med en diameter på 10 mm

12c 6 Skruer 2,9 x 6,5

12e 2 Skruer 2,9 x 9,5

12f 4 Sk ruer M6 x 10

12g 4 Skruer M6 x 80

12h 4 Skruer 5,2 x 70

21 1 Boremal

22 4 Skiver med en innvendig diameter på 6,4 mm

23 4 Mutrer M6

Antall Dokumentasjon

1 Bruksveiledning

7.1

21

22

12c

2

12c

1

7.1a

12g

7.1b

2.1

2.2

12f

23

12c

25

12e

11

12h

15

10

10a

24

Page 46

NO 446

INSTALLASJON

Boring av hull i veggen og festing av konsollene

BORING AV HULL I TAKET/HYLLEN

• Ved hjelp av en blytråd må du merke av midten på platetoppen i taket/hyllen.

• Støtt boremalen 21 (følger med) til taket/hyllen. Midten på kjøkkenviften må passe sammen

med det avmerkete midtpunktet, og midtlinjen til boremalen må være på linje med midtlinjen til platetoppen.

• Merk av midten til hullene til boremalen.

• Bor hull i de følgende punktene:

• Betongtak: Alt etter hvilken type ekspansjonsplugger som brukes.

• Teglsteinstak med lufterom mellom (tykkelsen på bærelaget er 20 mm): 10 mm i diame-

ter. Før inn ekspansjonspluggene 11 (følger med) med en gang.

• Trebjelker: Alt etter hvilken type skruer til tre som brukes.

• Trehylle: 7 mm i diameter.

• Passasje for nettkabelen: 10 mm i diameter.

• Luftutløp (sugeversjon): Alt etter diameteren til tilkopling til det eksterne utløpsrøret.

• Skru inn to skruer på kryss og la dem stikke 4-5 mm ut fra taket:

• Betongtak: Ekspansjonsplugger til betong (følger ikke med).

• Teglsteinstak med lufterom mellom (tykkelsen på bærelaget er 20 mm): Skruer 12h (føl-

ger med).

• Trebjelker: Skruer til tre (følger ikke med).

• Trehylle: Skruer 12g med s kiver 22 og mutrer 23 (følger med).

Page 47

NO 447

FESTING AV BESLAGET

2

2

1

1

10 a

ø 150

25

• Skru løs de to skruene som fester det nederste røkrøret og trekk

det ut fra beslaget (underfra).

• Skru løs de to skruene som fester det øverste røkrøret og trekk

det ut fra beslaget (ovenfra).

Dersom du ønsker å justere høyden til beslaget må du gå frem

som følger:

• Skru løs de åtte metriske skruene som forener de to søylene

som er plassert på sidene til beslaget.

• Juster ønsket høyde til beslaget og skru til de åtte skruene

igjen.

• Før inn det øverste røkrøret ovenfra uten å feste det til beslaget.

• Løft beslaget, plasser festeåpningene inn på skruene og la det

gli helt inn.

• Stram de to skruene og skru inn de to andre skruene (følger

med).

Før du strammer skruene helt er det mulig å utføre justeringer

ved å flytte på beslaget. Pass på at skruene ikke glir ut av

festeåpningen.

• Beslaget må festes på en sikker måte i forhold til kjøkkenviftens vekt og eventuelle belastninger som følge av at du kan

komme tilfeldig borti kjøkkenviftens sider. Når du er ferdig

med å feste beslaget må du kontrollere at basen er stabil selv

om beslaget bøyes.

• I alle tilfeller hvor taket ikke er tilstrekkelig kraftig ved opphengingsstedet, må du sørge for å forsterke taket med egnede

plater og motplater festet til kraftige konstruksjonsdeler.

Tilkoplinger

LUFTUTLØP FOR SUGEVERSJON

For installasjon av kjøkkenviften i sugeversjon må du kople

kjøkkenviften til utløpsrøret med et rør eller en slange (etter eget

valg).

Tilkopling av rør med en diameter på 150 mm

• Før flensen med en diameter på 150 mm 10a med ventil inn på

utløpet fra kjøkkenviftens hoveddel.

• Fest røret med egnete slangeklemmer. Nødvendig materiale

følger ikke med.

• Fjern eventuelle aktive kullfiltre.

Page 48

NO 448

Luftutløp for filtreringsversjon

• Fest koplingen 15 til beslaget med de fire skruene

som føl ge r me d .

• Før flensen 10 i det nederste hullet på koplingen 15.

• Kople kjøkkenviftens luftutløp til flensen under koplingen med et rør eller en slange med en diameter på

150 mm (etter eget valg).

15

10

Montering av røkrøret og festing av kjøkkenviftens

hoveddel

• Plasser det øverste røkrøret og fest den øverste delen

til beslaget med de to skruene 12c (2,9 x 6,5) ( følger

med).

• På samme måte, plasser det nederste røkrøret og fest

den nederste delen til beslaget med de to skruene 12c

(2,9 x 6,5) (følger med).

Før du fester kjøkkenviftens hoveddel til beslaget:

• Ta ut fettfiltrene fra kjøkkenviftens hoveddel.

• Fjern eventuelle aktive kullfiltre.

• Fest deretter kjøkkenviftens hoveddel til beslaget underfra med de fire skruene 12f (M6 x 10) (følger

med).

12c

12c

12f

Page 49

NO 449

ELEKTRISK TILKOP LING

• Kople kjøkkenviften til strømnettet med en topolet

bryter med en kontaktåpning på minst 3 mm.

• Fjern fettfiltrene (se avsnittet Vedlikehold) og kontroller at koplingsstykket til nettkabelen er korrekt

innført i stikkontakten til sugesystemet.

• Kople koplingsstykket til kontrollene Cmd.

24

12e

• Plasser begge koplingsstykkene i beskyttelsesboksen

24 og lukk den igjen med de to skruene 12e (2,9 x

9,5) (følger med).

• Fest beskyttelsesboksen til kjøkkenviftens hoveddel

med de to skruene 12c (2,9 x 6,5) (følger med).

• For filtreringsversjonen må du montere det aktive

kullfilteret.

• Gjenmonter fettfiltrene.

12c

Cmd

Page 50

NO 550

BRUK

V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1

S

V2

V3

L

L Lys Tenner og slukker belysningen.

S Led Viser at motoren er slått på.

V1 Motor Tenner og slukker innsugningsmotoren ved min. hastighet. Denne hastigheten

er egnet til spesielt lydløs kontinuerlig luftsirkulasjon når det er lite matos.

V2 Hastighet Middels hastighet som er egnet til de fleste bruksforholdene. Forholdet luft-

strømning og lydnivå er ideelt.

V3 Hastighet Maks. hastighet som er egnet til forhold hvor det er mye matos også over leng-

re tid.

Page 51

NO 551

VEDLIKEHOLD

Fettfiltre

RENGJØRING AV DE SELV BÆ RE NDE ME TA LLI SK E FET TFI LT R EN E

• Filtrene kan vaskes også i oppvaskmaskinen. De må vaskes ca.

hver andre måned eller oftere avhengig av bruksforholdene.

• Fjern filtrene ett av gangen. Støtt dem med en hånd mens du

trekker spaken nedover med den andre hånden.

• Vask filtrene. Pass på at du ikke bøyer dem. La dem tørke før

du monterer dem igjen.

• Gjenmonter filtrene. Pass på at håndtaket er rettet mot den synlige utsiden.

Kullfilter, filtrerende versjon

UTSKIFTING AV KULLFILTERET

• Dette filteret kan ikke vaskes eller brukes om igjen. Det skal

skiftes ut minst hver fjerde måned eller oftere avhengig av

bruksforholdene.

• Fjern fettfiltrene av metall.

• Hekt av kullfilteret.

• Hekt det nye filteret på i dets sete.

• Monter fettfiltrene av metall igjen.

Belysning

BYTTE AV LYSPÆRENE

Halogenpærer på 20 W.

• Ta ut de to skruene som fester belysningsstøtten og trekk den

ut fra kjøkkenviften.

• Ta lyspæren ut fra støtten.

• Bytt lyspæren ut med en av samme type. Pass på at du fører de

to pluggene korrekt inn i stø ttens sete.

• Monter støtten igjen og fest den med de to skruene.

Page 52

NO 552

EASY CLEANING TM

Fjerning av fettfiltrene

Gjør som følger før du utfører vedlikehold på

sugesystemenheten EASY CLEANING:

• Frakople kjøkkenviften med den topolete

bryteren på strømnettet eller med hovedbryteren.

• Ta fettfiltrene ut av kjøkkenviften.

• Fjern de aktive kullfiltrene (filtreringsversjon):

• For kjøkkenvifter med flat patron (A): Grip

inn på de dertil bestemte krokene.

• For kjøkkenvifter med bajonettpatroner

(B): Drei som vist og trekk ut.

Avhekting av sugesystemenheten EASY CLEANING

• Frakople nettkabelens koplingsstykke Ca

og kontrollenes og belysningens koplingsstykke Cmd som er plassert på siden av

enheten.

• På kjøkkenvifter som monteres på veggen

og frittstående kjøkkenvifter med røkrør

med rektangulært tverrsnitt må du dreie

sperrespakene Lb til sugesystemenheten og

hekte dem av stiftene.

• På frittstående kjøkkenvifter med røkrør

med rundt tverrsnitt må du skru løs sperrehakene Vb til sugesystemenheten.

• Trekk sugesystemenheten fremover slik at

den kan hektes av støttestiftene og trekkes

nedover og ut fra luftutløpet.

A

B

CmdCa

Lb

Vb

Page 53

NO 553

Demontering av delene som kan vaskes

• For å fjerne beskyttelseristene på siden av

viftebladene må du løfte sperreanordningen

med spissen til et skrujern eller en kniv og

dreie dem i pilens retning.

• Ta tak i viftebladene i de bestemte hullene

og trekk dem ut.

RENGJØRING

• Rengjør viftebladene og beskyttelsesristene

med vanlig oppvaskmiddel. Delene kan

også vaskes i oppvaskmaskinen.

• Rengjør sugesystemenhetens hoveddel med

en fuktig klut og et egnet vaskemiddel. Pass

på at det ikke trenger vann inn i enheten og

koplingsstykkenes sete.

• La delene tørke skikkelig før du monterer

dem igjen.

• Bruk en kost og rengjør utløpsrøret så langt

opp s om mulig.

O

K

LOC

P

E

N

EE

FR

Page 54

NO 554

GJENMONTERING

NB.: For ikke å bytte om monteringsretningen har viftebladene ulike fester.

• Gjenmonter viftebladene på de tilhørende

stiftene. Trykk helt til de hektes på plass.

• Pass på at sperreanordningene står i posisjon “FREE” og monter beskyttelsesristene.

Drei deretter beskyttelsesristene mot

“LOCK”.

• Gjenmonter sugesystemenheten EASY

CLEANING på kjøkkenviften ved å plassere den i rett posisjon og så hekte den på

støttestiftene.

• Drei sperresp akene eller skru inn sperrehakene.

• Kople nettkabelens koplingsstykke og kontrollenes koplingsstykke til kontaktene på

siden av sugesystemet.

• Gjenmonter eventuelle aktive kullfiltre.

• Gjenmonter fettfiltrene.

• Kople kjøkkenviften til strømnettet med

den topolete bryteren på strømnettet eller

med hovedbryteren.

• Kontroller at alt fungerer ved å tenne motoren og belysningen.

K

C

LO

O

P

E

N

FREE

Page 55

FI 555

SUOSITUKSET JA EHDOTUKSET

ASENNUS

• Valmistaja ei vastaa virheellisestä tai huolimattomasta asennuksesta

aiheutuvista vahingoista

• Pienin sallittu turvaetäisyys liesitason ja liesikuvun välillä on 650 mm.

• Tarkista, että käytettävän sähköverkon jännite v astaa liesikuv un sisäpuolella olevaan arvokilpeen merkittyä jännitettä.

• Kytke laite vain maadoitettuun pistorasiaan.

• Yhdistä liesituuletin hormiin putkella, jonka halkaisija on vähintään

120 mm. Hormiin menevän putken on oltava mahdollisimman lyhyt.

• Älä yhdistä liesituuletinta savuhormiin (lämmityskattilat, tulisijat, jne.).

• Mikäli liesituuletinta käytetään muiden kuin sähkölaitteiden (esim.

kaasuhella) yhteydessä, on huolehdittava työskentelytilan riittävästä

tuuletuksesta, etteivät poistettavat k aasut pääse virtaamaan takaisin

työskentelytilaan. Keittiössä on ol tava ilmanvaihtoaukko puhdasta tuloilmaa varten.

KÄYTTÖ

• Liesituuletin on tarkoitettu vain kotitalouskäyttöön.

• Älä koskaan käytä liesituuletinta muuhun tarkoi tukseen kuin, mihi n se

on suunniteltu.

• Älä koskaan jätä av otulta liesituulettimen alle liesituulettimen ol lessa

käynnissä.

• Säädä liekin teho siten, että liekk i kohdistuu vain asti an pohjaan eikä

sen reunoille.

• Syvi ä paistinpannuja on paiston aikana kok o ajan pidettävä silmällä,

sillä ylikuumentunut öljy voi leimahtaa tuleen.

• Lapset tai henkilöt, joita ei ole opastettu laitteen oikeaan käyttöön,

eivät saa käyttää liesituuletinta.

• Liesikuvun alla ei saa valmistaa liekitettäviä ruokia: tulipalon vaara

• Lapset eivät saa leikkiä laitteella.

HUOLTO

• Sulje laite tai irrota sen pistoke pistorasiasta ennen hoitoa.

• Puhdista ja/tai vaihda suodattimet annetun ajan kuluttua.

• Puhdista liesituuletin kostealla kankaalla ja miedolla, nestemäisellä

pesuaineella.

650 mm min.

Page 56

FI 556

MITAT JA OSAT

Mitat

45

650 min.

Page 57

FI 557

Osat

Nro Lkm Tuotteen osat

1 1 Runko, johon kuuluvat: Kyt kimet, valo, s uodattimet

2 1 Teleskooppihormi, johon kuuluvat:

2.1 1 Ylempi hormi

2.2 1 Alempi hormi

7.1 1 Imulaitteella varustettu teleskooppinen kehikko, johon

kuuluvat:

7.1a 1 Ylempi kehikko

7.1b 1 Alempi kehikko

10 1 Laippa ø 150

10a 1 Laippa ø 150 suuntaisventtiilillä

15 1 Ilman ulostuloliitos

24 1 suojakoteloon

25 2 Putken pinne

Nro Lkm Asennusosat

11 4 Tulppa ø 10

12c 6 Ruuvi 2,9 x 9,5

12e 2 Ruuvi 2,9 x 6,5

12f 4 Ruuvi M6 x 10

12g 4 Ruuvi M6 x 80

12h 4 Ruuvi 5,2 x 70

21 1 Porausmalline

22 4 Välirengas ø 6,4

23 4 Mutteri M6

Lkm Asiakirjat

1 Käyttöopas

7.1

21

22

12c

2

12c

1

7.1a

12g

7.1b

2.1

2.2

12f

23

12c

25

12e

11

12h

15

10

10a

24

Page 58

FI 558

ASENNUS

Katon/hyllyn poraaminen ja kehikon kiinnitys

KATON/HYLLYN PORAAMINEN

• Merkitse luotilangan avulla keittotason keskipiste kattoon/hyllyyn.

• Aseta kattoon/hyllyyn toimitettu liesituulettimen malline 21 siten, että keskipiste tulee koh-

dalleen ja että keittotason ja mallineen sivut ovat samalla kohdalla.

• Merkitse mallineen reikien keskipisteet.

• Poraa reiät seuraavalla tavalla:

• Massiivibetonikatto: käytettyjen betonimuuriankkurien mukaan.

• Tiilinen välikatto, kestävä paksuus 20 mm: ø 10 mm (laita heti paikalleen toimitetut tulpat

11).

• Puupalkkikatto: käytettyjen puur uuvien mukaan.

• Puuhylly: ø 7 mm.

• Virtajohdon aukko: ø 10 mm.

• Ilman ulostulo (Imuversio): ulkopuolisen poistoputken halkaisijan mukaan.

• Ruuvaa kaksi ruuvia vastakkaisiin kulmiin ja jätä niiden kanta noin 4 - 5mm:n etäisyydelle

seinästä:

• Massiivibetoniin, betonimuuriankkurit, eivät kuulu toimitukseen.

• Tiiliseen välikattoon, kestävä paksuus noin 20 mm, toimitetut ruuvit 12h.

• Puupalkkikattoon, puuruuvit, eivät kuulu toimitukseen.

• Puuhyllyyn, toimitetut ruuvit 12g, välirenkaat 22 ja mutterit 23.

Page 59

FI 559

KEHIKON KIINNITYS

2

2

1

1

10 a

ø 150

25

• Ruuvaa auki kaksi ruuvia, jotka kiinnittävät alemman hormin

ja irrota se kehikosta (alakautta).

• Ruuvaa auki kaksi ruuvia, jotka kiinnittävät ylemmän hormin

ja irrota se kehikosta (yläkautta).

Jos haluat säätää kehikon korkeutta, toimi seuraavalla tavalla:

• Ruuvaa auki kehikon reunojen kahdeksan metriruuvia, jotka

kiinnittävät sivupalkit toisiinsa.

• Säädä haluamasi keh ikon korkeus j a ruuvaa kiin ni avaamasi

ruuvit.

• Työnnä ylempi hormi paikalleen yläkautta ja anna sen olla kehikon päällä vapaana.

• Nosta kehikkoa, kiinnitä aukot ruuveihin ja työnnä paikalleen.

• Kiristä kaksi ruuvia ja myös toiset kaksi toimitettua ruuvia.

Ennen ruuvien lopullista kiristämistä kehikkoa voidaan säätää

siirtämällä sitä. Varo kuitenkin, etteivät ruuvit tällöin irtoa aukoistaan.

• Kehikon kiinnityksen tulee olla varma, siinä on otettava huomioon sekä liesituulettimen paino että laitteeseen mahdollisesti

kohdistuvat sivurasitukset. Kun laite on kiinnitetty on tarkistettava, että pohja on tukeva vaikka kehikko olisi taivutusjännityksen alainen.

• Mikäli katto ei ole tarpeeksi vahva kiinnityskohdassa, asentajan täytyy vahvistaa sitä laatoilla ja vastalaatoilla, jotka kiinnitetään rakenteellisesti vahvoihin kohtiin.

Liitännät

IMUVERSION ILMAN ULOSTULO

Imuversio asennetaan liittämällä liesituuletin ilman ulostuloon

jäykällä tai taipuisalla putkella asentajan valinnan mukaan.

Putkiliitäntä ø 150

• Laita laippa 10a, ø 150, liesituulettimen rungon ulostuloon.

• Kiinnitä putki sopivilla puristimilla. Materiaali ei kuulu toimitukseen.

• Molemmissa tapauksissa mahdolliset aktiivihiilisuodattimet

täytyy poistaa.

Page 60

FI 660

Suodatusversion Ilmanpoisto

• Asenna ilman ulostuloliitos 15 teleskooppiseen kehikkoon. Käytä em. toiminpiteeseen 4 mukana tulevaa ruuvia.

• Sovita laippa 10 ilman ulostuloliitoksen 15 alempaan

aukkoon.

• Yhdistä tuulettimen ilman ulostuloaukko liitososan

alla olevaan laippaan asentajan valitsemalla joko jäykällä tai taipuisalla ø 150 mm:n putkella.

Hormin kokoaminen ja kiinnittäminen liesituuletti-

men runkoon

• Sijo it a ylempi ho rmi p aikal leen ja kii n ni tä se keh ikon

yläosaan kahdella toimitetulla ruuvilla 12c (2,9x

9,5).

• Sijoita sitten alempi hormi paikalleen ja kiinnitä se

kehikon alaosaan kahdella toimitetulla ruuvilla 12c

(2,9 x 9,5).

Ennen liesituulettimen rungon kiinnittämistä kehikkoon:

• Poista rasvasuodattimet rungosta.

• Poista mahdolliset aktiivihiilisuodattimet.

• Kiinnitä sitten liesituulettimen runko kehikkoon alakautta neljällä toimitetulla ruuvilla 12f (M6 x 10).

15

10

12c

12c

12f

Page 61

FI 661

SÄHKÖLIITÄNTÄ

• Liitä liesituuletin sähköverkkoon turvakytkimen

kautta, jonka koskettimien väli on ainakin 3 mm.

• Poista rasvasuodattimet (katso kappaletta “Huolto”) ja

varmista, että virtajohdon liitin on kunnolla kiinni

24

imulaitteessa.

• Liitä kytkimien liitin Cmd.

12e

• Vie molemmat liittimet suojakoteloon 24 ja sulje se

kahdella toimitetulla ruuvilla 12e (2,9 x 9,5).

• Kiinnitä suojakotelo liesituulettimen runkoon kahdella toimitetulla ruuvilla 12c (2,9 x 6,5).

• Suodatinversioon täytyy asentaa aktiivihiilihajusuodatin.

• Laita paikalleen rasvasuodattimet.

12c

Cmd

Page 62

FI 662

KÄYTTÖ

V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1

S

V2

V3

L

L Valot Sytyttää ja sammuttaa valaistuksen.

S Loistediodi Moottorin käynnistystä ilmaiseva loistediodi.

V1 Moottori Säätää moottorin tehon pienimmälle toimintanopeudelle. Jatkuva, hiljainen

tuuletus, joka soveltuu vähäistä höyrymäärää tuottavaan ruoanlaittoon.

V2 Nopeus Keskinopeus, joka soveltuu melkein jokaiseen ruoanlaittotilanteeseen. Paras

teho/melu -suhde.

V3 Nopeus Tehonopeus. Soveltuu tilanteeseen, jossa ruoanlaitosta aiheutuvat höyryt ja

käryt ovat suurimmillaan pidempiäkin aikoja.

Page 63

FI 663

HUOLTO

Rasvasuodattimet

METALLISTEN RASVASU ODA TTIMIEN PUHD ISTUS

• Suodattimet voidaan pestä myös astianpesukoneessa. On suositeltavaa pestä ne joka toinen kuukausi. Jos tuulettimen käyttö

on erikoisen runsasta, suositellaan suodattimien pesua useammin.

• Poista suodattimet yksi kerrallaan; kannata toisella kädellä

suodatinta ja samanaikaisesti vedä hakaa alaspäin toisella kädellä.

• Pese suodattimet. Vältä niiden taivutusta. Anna niiden kuivua

ennen uudelleen asennusta.

• Asenna suodattimet uudelleen paikoilleen. Varmista, että suodattimien poistokahva jää ulkopuolelle näkyviin .

Aktiivihiilisuodatin (Kiertoilmaversio)

AKTIIVIHIILISUODATTIMEN VAIHTO

• Aktiivihiilisuodatinta ei voi pestä. Se vaihdetaan neljän kuukauden väliajoin tai useimmin, mikäli tuulettimen käyttö on

erityisen runsasta.

• Poista metalliset rasvasuodattimet.

• Poista keittiöhajujen kyllästämä aktiivihiilisuodatin vetämällä

sen hakasista.

• Aseta uusi suodatin paikal leen.

• Aseta metalliset rasvasuodattimet uudelleen paikoilleen.

Valo

LAMPUN VAIHTAMINEN

Halogeenilamput, 20 W

• Irrota kaksi ruuvia, jotka pitävät kiinni valon tukea ja poista

tuki liesituulettimesta.

• Ota lamppu irti tuesta.

• Vaihda lamppu uuteen samanlaiseen lamppuun. Varmista, että

koskettimet ovat kunnolla kiinni tuessa.

• Laita tuki paikalleen ja kiinnitä se kahdella ruuvilla.

Page 64

FI 664

EASY CLEANING TM

Rasvasuodattimien irrottaminen

Ennen EASY CLEANING -imulaitteen huoltoa toimi seuraavasti:

• poista tuuletin sähköverkosta kytkemällä

päältä virransyöttöjohdon kaksinapainen

kytkin tai katkaisemalla virta päävirtakytkimestä

• poista rasvasuodattimet

• jos tuuletin toimii kiertoilmaversiolla, poista hiilisuodattimet

• litteäsalvalliset hiilisuodattimet (A): avaa

salvat

• kääntökytkimelliset hiilisuodattimet (B):

käännä kuvan osoittamalla tavalla ja vedä

hiilisuodatin ulos.

EASY CLEANING -imulaitteen irrottaminen

• Kytke irti virtaliitin Ca sekä ohjaus- ja valaistusliitin Cmd laitteen sivuilta.

• Seinälle asennettavat sekä vapaana riippuvat tuulettimet, joissa on poikkileikkaukseltaan nelikulmainen hormi: kierrä lukitussalpoja Lb niin, että ne irtoavat tapeista.

• Vapaana riippuvat tuulettimet, joissa on

poikkileikkaukseltaan pyöreä hormi: kierrä

imulaitteen lukitustapeista Vb.

• Vedä imulaitetta eteenpäin niin, että se irtoaa tukitapeista. Vedä se ulos alakautta ilmanpoistoaukon kautta.

A

B

CmdCa

Lb

Vb

Page 65

FI 665

Pestävien osien irrottaminen

• Puhaltimia suojaavien sivusäleikköjen poistamiseksi nosta lukitustappia ylöspäin veitsen tai ruuvimeisselin avulla. Käännä säleikköjä nuolen osoittamaan suuntaan.

• Vedä puhaltimet ulos.

PUHDISTUS

• Pese puhaltimet ja suojasäleiköt tavallisella

astianpesuaineella. Osat voidaan pestä

myös astianpesukoneessa.

• Pyyhi imulaitteen runko kostealla liinalla ja

sopivalla puhdistusaineella. Varo, ettei vettä pääse laitteen sisälle ja liitinkoteloihin.

• Jätä laite kuivumaan, kunnes se on täysin

kuiva.

• Puhdista harjan avulla ilmanpoistoaukkoa

niin pitkälle kuin mahdollista.

O

K

LOC

P

E

N

EE

FR

Page 66

FI 666

KOKOAMINEN

Huom. P uhaltimet on varustettu erilaisilla liittimillä niiden väärinpäin asentamisen estämiseksi.

• Asenna puhaltimet paikoilleen niitä vastaaviin tappeihin. Paina puhaltimia kevyesti,

kunnes ne naksahtavat paikoilleen.

• Asenna suojasäleiköt paikoilleen. Aseta

säleikön hammastus “FREE”-merkinnän

kohdalle ja kierrä säleikköjä “LOCK”merkinnän suuntaan.

• Asenna EASY CLEANING -imulaite tuulettimen sisälle omalle paikalleen. Varmista

kiinnitys tukitappien avulla.

• Kierrä lukituskytkimiä tai ruuvaa lukitustulpat kiinni.

• Kytke virtaliitin paikalleen ja ohjausliitin

imulaitteen sivuissa oleviin pistokkeisiin.

• Asenna mahdolliset aktiivihiilisuodattimet

paikoilleen.

• Asenna metallirasvasuodattimet paikoilleen.

• Liitä tuuletin sähköverkkoon virransyöttöjohdon kaksinapaisella kytkimellä tai kytkemällä virta päälle päävirtakytkimellä.

• Tarkista, että tuuletin toimii moitteettomasti

kytkemällä moottori ja valaistus päälle.

K

C

LO

O

P

E

N

FREE

Page 67

Page 68

Dir. 89/336/CEE

73/23/CEE

93/68/CEE

The symbol on the product or on i t s pac kaging indic a tes t ha t thi s pr o duct may not be treated as house hol d waste. Instead it shall

be handed over to the appl icable col lection p oint for t he recycli ng of electr ical and el ectronic equipment . By ensurin g this product is

disposed of correctly, you will help prevent potential negative consequences for the environment and human health, which could otherwise be caused by inap propr iat e wast e ha ndl ing of this pro duc t. For mor e det ail ed inf ormati o n about recy cli ng of this pro duc t, ple ase

contact your local city office, your household waste disposal service or the shop where you purchased the product.

Symbolet på prod uktet eller på p akken angiv er, at det te pr odukt ik ke m å beh andles som hush oldni ngsaff ald. D et sk al i stedet

overgives til en affaldsst ation for beh andling af elektrisk og elektroni sk udstyr. V ed at sørge f or at dette pr odukt bliv er bortskaffet på

den rette måde, hjælper du med til at forebygge eventuelle negative påvirkninger af miljøet og af personers helbred, der ellers kunne

forårsages af forkert bortskaffelse af dette produkt. Kontakt det lokale kommunekontor, affaldsselskab eller den forretning, hvor produkt

er købt, for yderligere oplysninger om genanvendelse af dette produkt.

Symbolen på produkten eller em ballaget anger att produkten i nte f år h an t eras som hushål l s av fa l l . Den sk al l i s täl let lämnas in på

uppsamlings pla ts f ör åt ervi nni ng av el - oc h el ektr onik k omp onen ter . Gen om at t säk er ställ a at t pr od ukt en ha nter as på rät t s ätt bidr ar du

till att förebygga eventuellt negativa miljö- och hälsoeffekter som kan uppstå om produkten kasseras som vanligt avfall. För ytterligare

upplysningar om återvinning bör du kontakta lokala myndigheter eller sophämtningstjänst eller affären där du köpte varan.

Symbolet på produktet ell er på emballasj e n v i ser at dette produkt et i k k e må behandl es s om h u s hol d ni n gs avfall. Det skal derimot

bringes til et mo ttak f or r esir kul eri ng av elek tris k og el ektro nis k utst yr . Ved å sør ge f or kor rek t a vhendi ng av a ppar atet , vi l du bi dr a til å

forebygge de negative konsekvenser for miljø og helse som gal håndtering kan medføre. For nærmere informasjon om resirkulering av

dette produktet, vennligst kontakt kommunen, renovasjonsselskapet eller forretningen der du anskaffet det.

Symboli , joka on merk itty tuott eese en tai s en pakk auksee n, osoi ttaa, e ttä tätä t uotet ta ei saa käsi tellä tal ousjä tteen ä. Tuote o n

sen sijaan luovutettava sopivaan sähkö- ja elektroniikkalaitteiden kierrätyksestä huolehtivaan keräyspisteeseen. Tämän tuotteen

asianmukaisen hävittämisen varmistamisella autetaan estämään sen mahdolliset ympäristöön ja terveyteen kohdistuvat haittavaikutukset, joita v oi aiheut ua muuss a tapauk sessa tämän tuo tteen ep äasianm ukaisest a jätek äsittel ystä. Tark empia ti etoja täm än tuot teen

kierrättämisestä saa paikallisesta kunnantoimistos ta, talousjätehuoltopalvelusta tai liikkeestä, josta tuote on ostettu.

436003489_ver1

Loading...

Loading...