Page 1

Programming Instructions Typ G

Swiss Mambo

Softwareversions up from G 2.00; G3.01

Date: Mai 1998

Visum: BJC

Franke Kaffeemaschinen AG

CH-4663 Aarburg

Tel.: *41 (0)62 787 37 37

Fax: *41 (0)62 787 30 10

www.km.franke.ch

Page 2

Coffee-Machine G

CONTENTS

1. Programming keyboard

1.1 General view

1.2 Access into program parameters

1.3 Exit from the programming tree structure

1.4 Input key

2. Main groups in the programming tree

structure

2.1 Installation

2.1.1 Explanations of the installation main group

2.2 Service

2.2.1 Calibration of the Grinder

2.3 Program parameters

2.4 Counters

2.5 Set-up

3. Setting parameters in the programming tree

structure

4. Additional programming possiblities with the

Software G .301

5. Concise description of the special options

MANUAL 2/1

Page 3

Coffee-Machine G

1. Programming keyboard

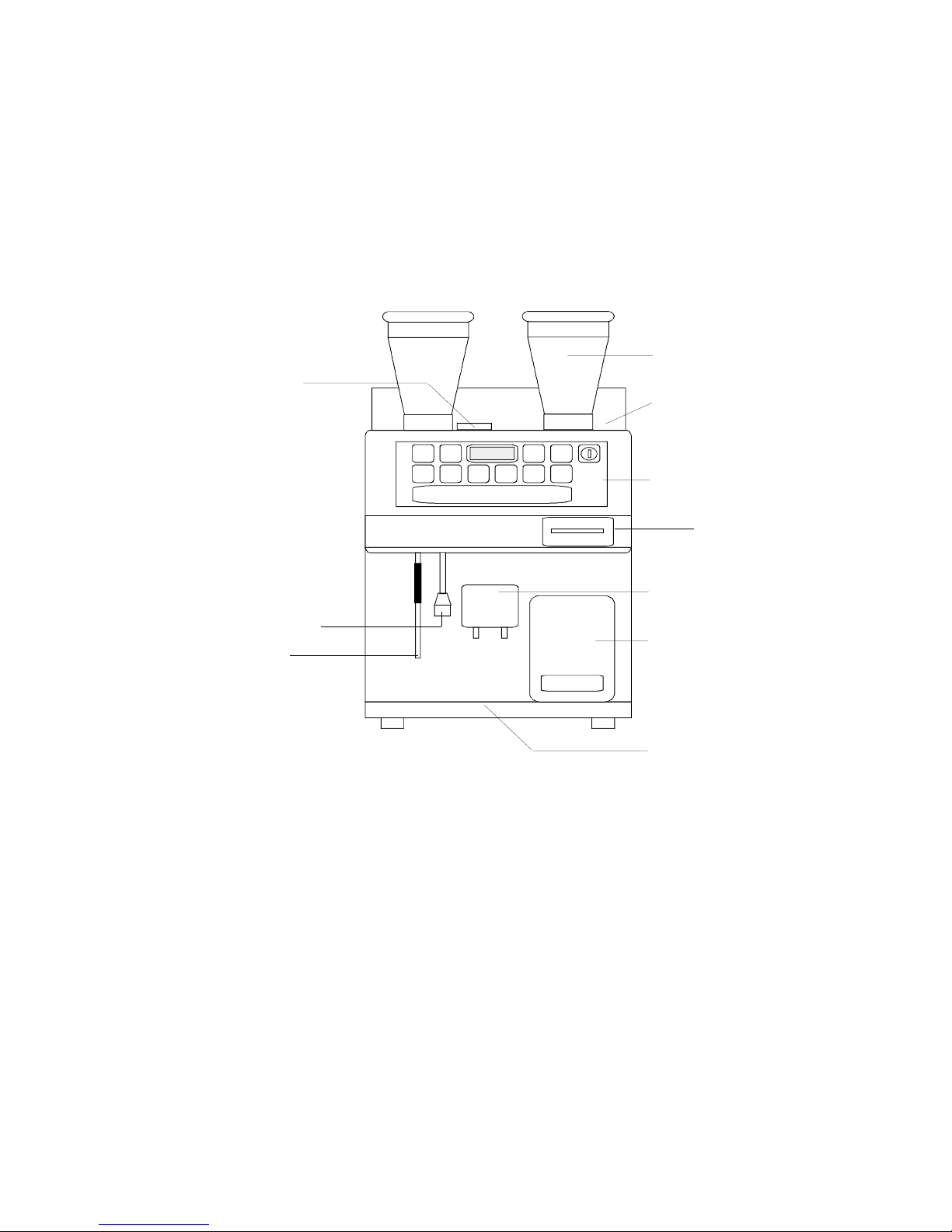

1.1 General view

MANUAL 2/2

Inlet f o r

ground coffee

Coffee beans container

Cup storage space

C o ntro l p anel

C offee outlet w ith

integrated Cappucinato

re

C o ff ee c a ke c o nta i ner

Grate

CLEAN

ON

OFF

678910

11 12

13

System C h ip ca r d

Ste am tu be

H

ot wa ter o utl et

Page 4

Coffee-Machine G

1.2 Access into program parameters

User:

The "Adjust-Card" allows fast and immediate access to adjust and optimize product

parameters, such as water quantity, grind quantity, steam-time and milk quantity for

Cappuccino, coffee brewing temperature and pricing for internal data central.

Procedure:

1. Insert "Adjust-Card"

2. Keep pressing button + until desired option is shown in digital display

3. Confirm desired option with button --

4. Press desired product button

5. Press button + to increase respectively button -- to decrease data

6. Remove "Adjust-Card", all data is stored

Service:

1. Plug in programming keypad on mainboard

2. Access programming mode by

- Turn coffee machine off with the ON/OFF button

- Press button "OK", keep it pressed

- Turn machine back on with the ON/OFF button

- Enter Service Code-No. 21 on keypad (Service Code)

3. Press button OK to access desired parameter

1.3 Exit of the programming tree structure

EN D Repeated actuation of the END key takes us back up the programming tree

until the programming mode is left and the normal operating mode started.

OFF Exit from the programming mode is also possible by switching off the whole

machine.

MANUAL 2/3

Page 5

Coffee-Machine G

MANUAL 2/4

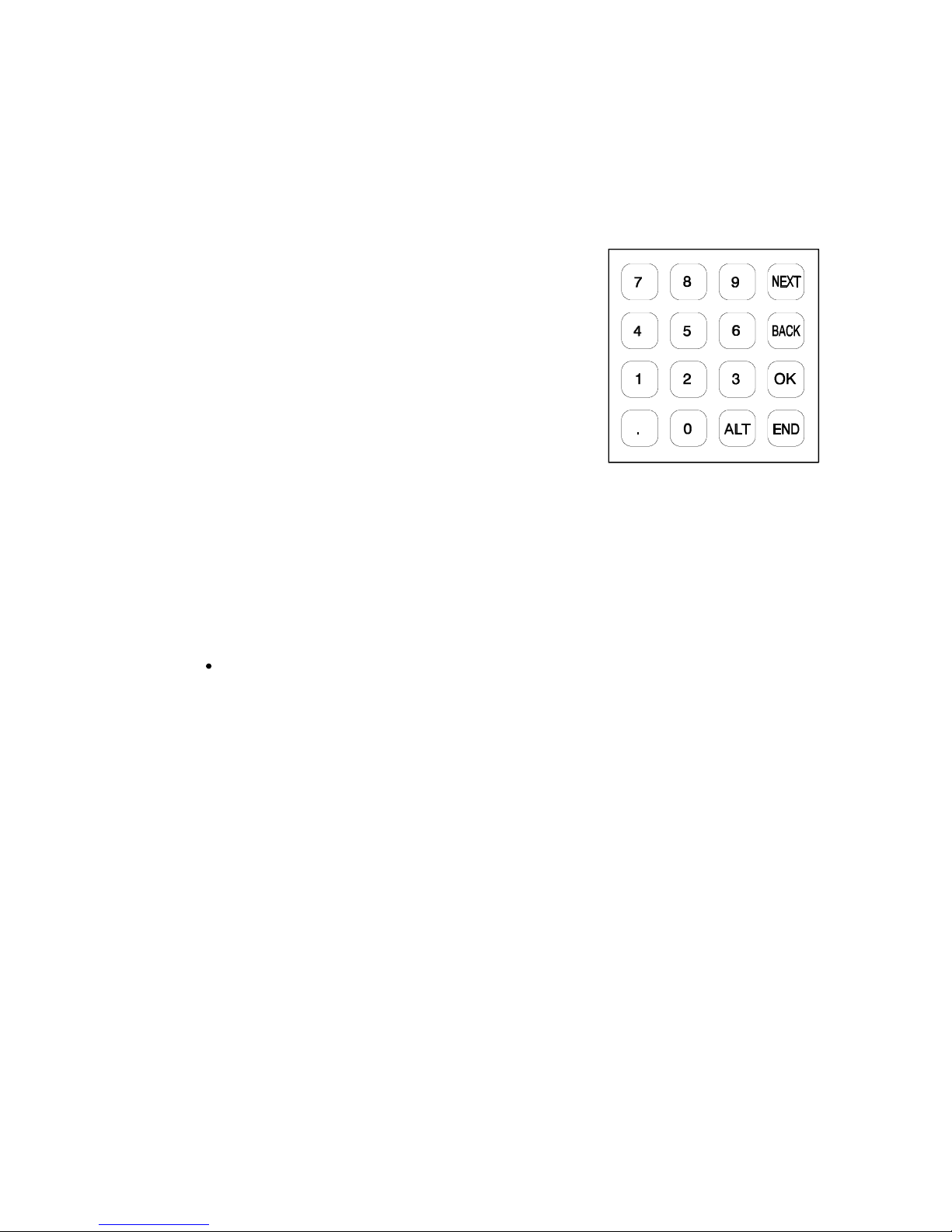

1.4 Input keys

NEXT When this key is actuated we

move on to the next programming step.

BACK Similar function to the NEXT

key to move back one step in

the programming tree structure.

OK This key is used to confirm an

input, to access a main group

of the programming tree structure or certain program steps to

start a procedure.

EN D Actuation of the END key exits from the current step. The program

indicator moves one main group higher.

A LT This key is used to display the old value again if a wrong input has

been made and the OK key has not been actuated. It also has various

functions in connexion with the definition of the waiters' keys and

clearing the counter tables.

. The dot key is used to input numerical values with decimal places,

when product names are to be selected from a table (program parameters) and when the counter readout are to be printed out on a

report printer.

Input of digit Enter a digit by means of the key board including the decimal point.

If the input is correct, confirm with the OK key.

If the input is incorrect, the BACK key can be used to move back one

place or the ALT key to recall the previous display content.

An input must therefore be terminated either by OK or by ALT before

we can move on further in the tree.

Page 6

Coffee-Machine G

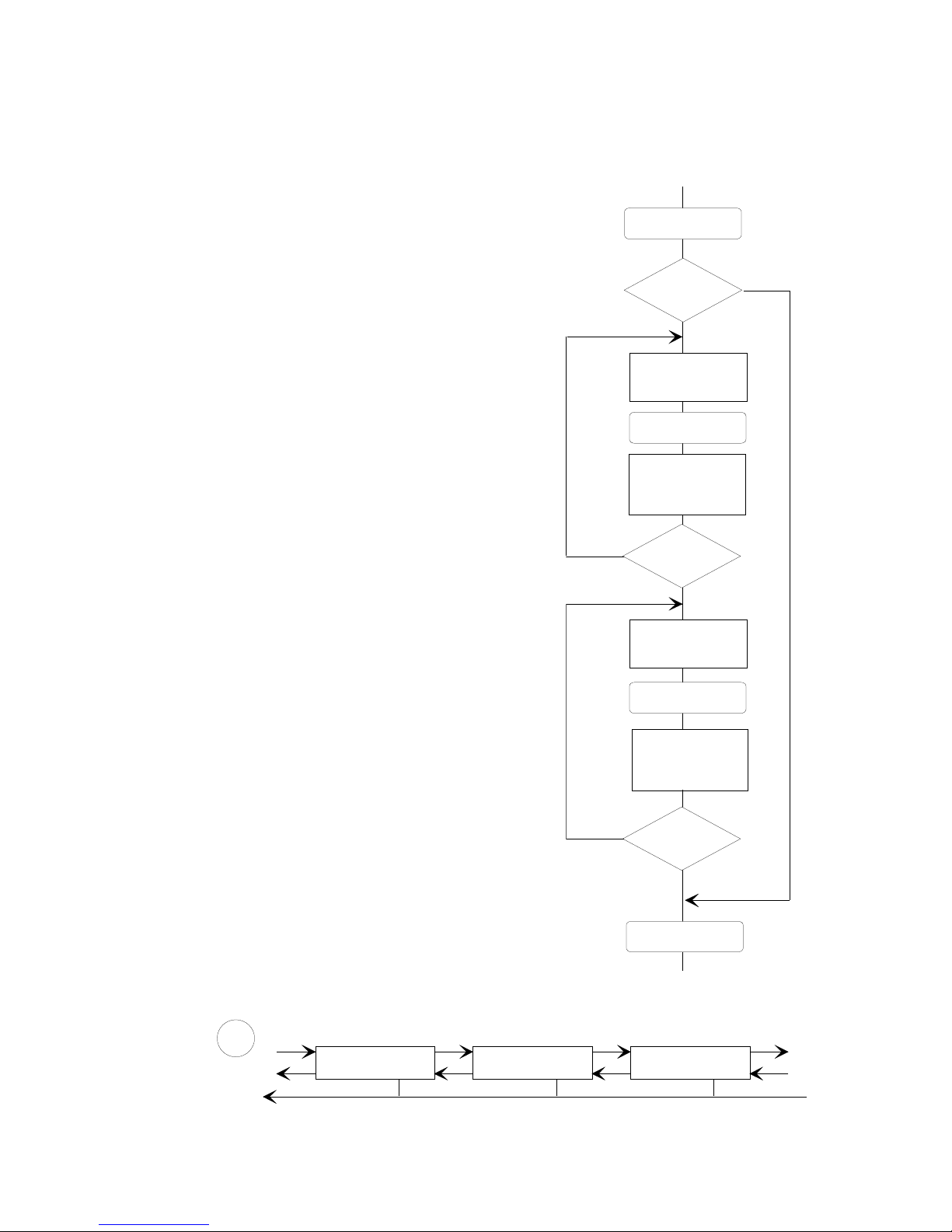

2.1 Installation

In this maingroup we

have the possibility to

activate all actuators

manually. In the display will appear a

small menu. By pressing the corresponding numeric pad the

desired actuator is

activated.

MANUAL 2/6

2.1.1 Explanations of the INSTALLATION main group

Scald head 1 : UP The piston moves up as long as the key is actuated. Switch-off is

not effected before the mechanical end stop is reached.

2 : DN The piston moves down as long as the key is actuated. Once

again, no switch-off is effected before the end stop is reached.

3 : INIT Actuation of the key 3 triggers a reference cycle. The piston runs

down to the lower end stop, changes its sense of rotation and

runs up to the top end stop.

end

ok

back

next

back

next

back

next

MOTORS

1: PU 2:ML 3:MR

TEA / STEAM 1:VT

2:VS 3:VW 4:HT

INSTALLATION

back

next

COFFEE 1

1:WD 2: VC 3: HC 4:ON

SLIDE

1:SL 2:SR

back

next

FILLING

1:COFFEE 2:TEA

OUTPUT 2

REL 1 - 7

back

next

SCALD HEA D

1:UP 2:D N 3:INIT

1: COFFEE TEMP 85.2

ok

end

back

next

OUTPUT 2

REL 8 - 14

CAPPUCCINO

1:VC 2:VR 3:VL

back

next

Page 7

Coffee-Machine G

MANUAL 2/7

It then travels to the basic position. This reference cycle enables

the piston itself to measure the geometry of the brewing assembly and set its top and bottom points, together with the position

of the stop switch.

Slide 1 : SL The left slide is activated (Y10) as long as the key is pressed.

2 : SR The right slide is activated (Y11) as long as the key is pressed.

Motors 1 : PU Activation of the pump motor (M2).

2 : ML Activation of the left grinding mill (M3).

3 : MR Activation of the right grinding mill (M4).

Coffee 1 : VC Activates the coffee valve (Y1).

2 : HC The relay on the output card and the power relay (K1) for the

heating system of the coffee heater (E1) are activated.

Cappuccino 1 : VC Valve Cappu (Y20) is actuated

2 : VR Valve Cappu (Y30) is actuated

3 : VL Valve Cappu Air (Y21) is actuated

Temp. display 1 : COFFEE TEMP Actual temperature displayed;

Operation of the key 1: Coffee heater on.

Tea/Steam 1 : VT Valve tea 1 (Y4) is actuated.

2 : VS The steam outlet valve (Y6) is actuated.

3 : VW Activation of the steam feed valve (Y5).

4 : HT The relay on the output card and the power relay (K2) for the

heating system of the tea heater (E2) are activated.

Filling 1 : COFFEE The pump (M2) and the coffee valves (Y1/Y2) are activa-

ted. This enables the system to be filled. 1. Operation of

the key 1: The piston is going down to the rinsing position.

2. Operation of the key 1: Filling.

2 : TEA The pump (M2), the steam valve (Y6) and the valve tea

(Y4) are activated.

Page 8

Coffee-Machine G

MANUAL 2/8

Output 2 Key 1: Y21 = Coffee outlet in front.

Key 2: Y22 = Common outlet.

Relay 1- 7: Key 1 = Relay 1

Key 7 = Relay 7

Relay 8-14: Key 1 = Relay 8

Key 7 = Relay 14

ok

SERVICE

SERVICE

DATE

DATE

28.02.91

ok

end

end

SERVICE

TELEFONE

ok

end

next

back

Maximal 20 digits

TELEFONE

062.43.31.31

ok

end

next

back

next

back

SERVICE

ERROR HISTORY

08 PROBE

Table with 20 places

02 CONTAINER FULL

ERROR H I STORY

clear it < ok> ?

old

ok

end

no Data erased

Data erased

SERVICE

CHECK

ok

end

next

back CHECK

20875 / 30000

SERVICE

CHIPCARD

DOWNLOAD=ok

back

ok

ok

DOWNLOADING

2.2 Service

This main group is considered as a help for the service engineer. It consist of the

following possibilities:

- Date of last service

- Telephone number of service center

- Service check number of piston movements ACTUAL NUMBERS / SETTING

- Error history of the last 20 failures

Page 9

Coffee-Machine G

Calibration of grinders

If in the main group "SETUP" under

"MILL OPTIONS" the "CL AFTER

CHECK" is set on 2, it is necessary to

calibrate the grinders prior to the

"MILLCHECK".

Each grinder has to be calibrated only

once!

Adjust degree of fineness of grind

before calibration to +/- 1/2 scale

setting. If a considerable adjustment is

made repeat calibration.

MANUAL 2/10

next

back

next

back

next

back

COFEE

MILL Q UANT 3.25

next

back

COFFEE

MILL C H E C K

COFFEE

CAL -> O K

A

Grinder is shorter

activated

WEIGHT _

Inp ut of weight of

ejected coffee cake.

Key O K

no

yes

Weight = 0 ?

Grinder is longer

activated

WEIGHT _

no

yes

Weight = 0 ?

Inp ut of weight of

ejected coffee cake.

Key O K

no

yes

Key O K ?

MILL CHECK

CAL -> O K

( N EXT )

press O K

Page 10

Coffee-Machine G

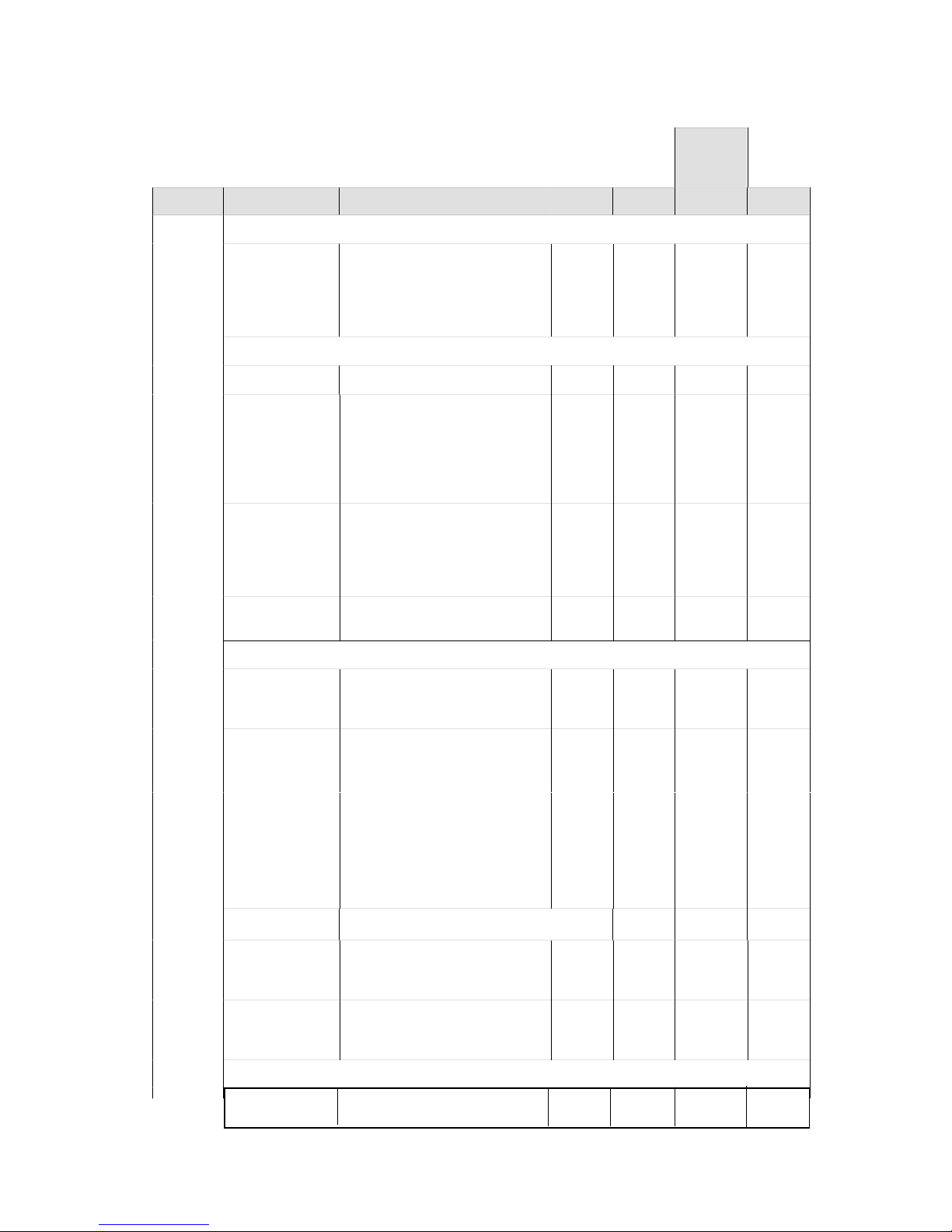

Defaultfacts

from

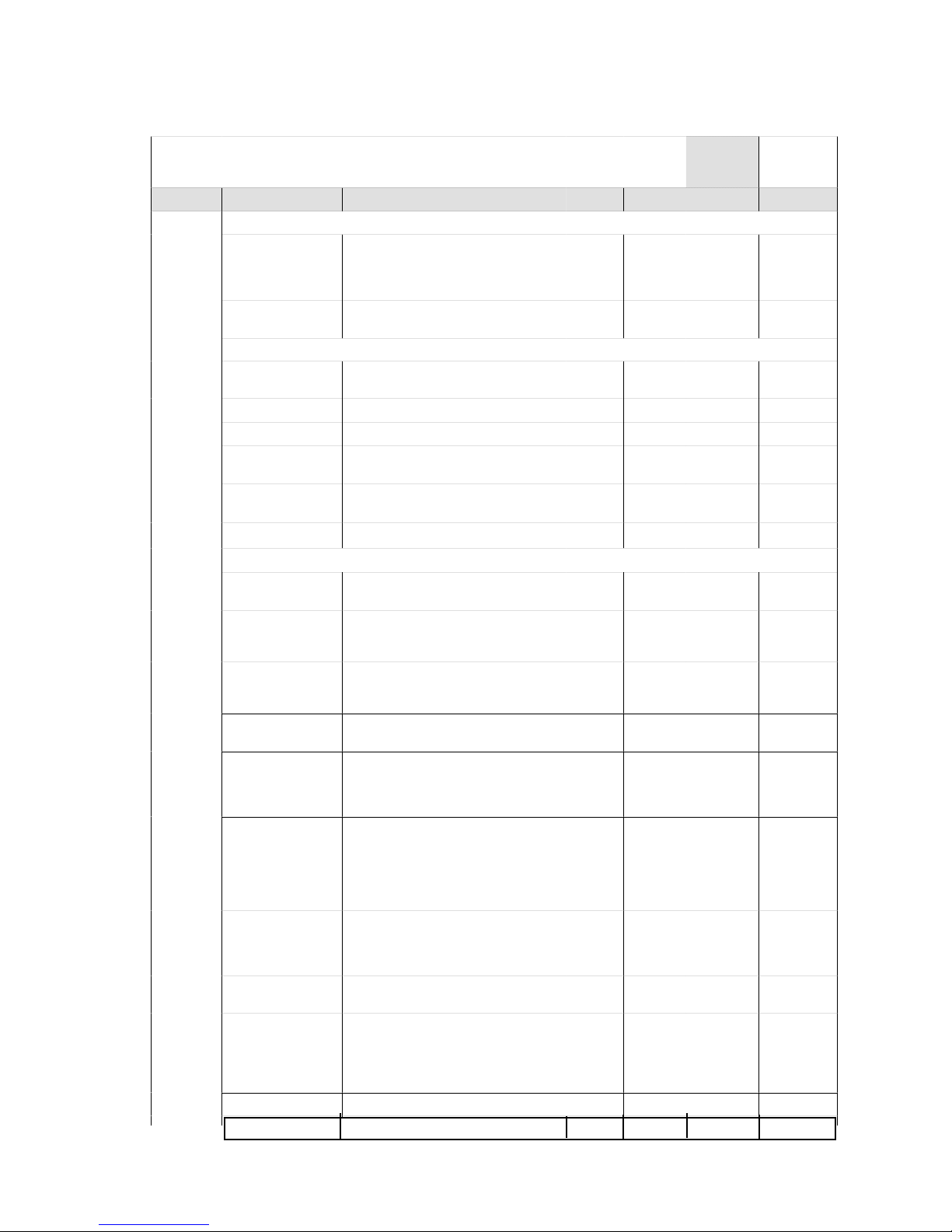

Tree Parameter Function Min Max E-prom Remarks

SERVIC DATE Date of last service

TELEPHONE Telephone no. of service

station

20 digits

00000.00.

00.00

99999.99.

99.99

SERVICE

CHECK

Automatically reminder to the

operator to call the service for

a check-up

0 30000 0

ERROR

HISTORY

List of errors with 20 places

(ring buffer)

CHIPCARD DOWNLOAD with card

Datas on card

PROGR

PARA

METER

Coffee

PRODUCT Group of product

0 = empty key 1 = COFFEE

0 to 2

NAME Select name of product out of

table with dot key

See

Man 3/3

CUPS Numbers of cups 1 99 1

PRICE Price unit per cup 0 9999.99 0

CYCLES Numbers of cycles 1 99 1

PREINFUSION Preinf usion

00 = OFF

35 (example)

3 = 3.0 sec. waiting

5 = 0.5 sec. water injection

0 1 0

PUMP Pump on/off for this key

0 = OFF 1 = ON

0 1 1 1 only

when free

in SETUP

PRESS 0 = Function off

Ground will be pressed

1 = Coffee ground will be

pressed first, then piston

automatically retracts

2 = Brew coffee

Piston stops in cleaning position

40 - 255 = OFF-set function

Piston stops before

pressing

0 255 0

CAPPU 0 = Without common outlet

(in front)

1 = With common outlet

steam

and coffee at the same

time

2 = With common outlet,

first coffee, then steam

3 = With common outlet,

first steam, then coffee

0 3 0

MILK Proportion milk to froth 0 100 10

CAPPU TIME Actuation time steam valve 0.1 99.9 1 seconds

MANUAL 2/14

3. Parameters in Programming Tree

Page 11

Coffee-Machine G

MANUAL 2/15

Defaultfacts

from

Tree Parameter Function Min Max E-prom Remarks

PROGR

PARA

METER

Coffee

MILLTIME OR

MILL QUANT

Mill time / Mill quantity 0 12 s

18 g

0.1 time (s)

weight (g)

MILLTIME 2 OR

MILL QUANT 2

Second milltime or quantity when

mixture

0 12 s

18 g

0 time (s)

weight (g)

MILL CHECK Quantity of Mill check press OK

key

WATER QUANT Quantity of water 0 500 10 ml

WATER CHECK Quantity of water check with

coffee

press OK

key

ENABLE Clearing price of SEND CODE 0 63 0 only when

SEND code

SEND CODE Code to be transmitted by

SEND CODE

0 99 0 to 12 only when

SEND code

PROGR

PARA

METER

Tea

PRODUCT Group of product

0 = empty key 2 = TEA

0 to 2

NAME Name of product from the table

with point-key

PORTION Mode of tea

0 = free flow 1 = dosed

0 1 0 to 1

CUPS Numbers of cups for price 0 99 1

PRICE Price unit per cup 0 9999.99 0

WATER QUANT Quantity of water 0 180 0 sec.

WATER CHECK Water quantity check press ok key

ENABLE 0 63 0 only when

SEND

SEND CODE Code to be transmitted by

SEND CODE

0 99 0 to 12 only when

SEND code

PROGR

PARA

METER

Steam/

Cappu

PRODUCT Group of product

0 = empty key 3 = STEAM

0 3 0 to 2

NAME Name of product with point-key

Price Price unit 0 9999.9 0

Milk permanent 0 = Start-Stop function

1 = Key funciton

0 1 0

Cappu 0 = Steam trough steam tube

1 = Steam trough Cappu

0 1 0

Time Time for steam 0 99.9 0

MILK 0 100 10

Enable Enable by send code 0 63 0

Send code Sending code by send code 0 99 0

Rinse

key

Cycles Number of cycles (Rinse) 1 99 1

Water Quantity of water 0 500 100 ml

Cycles Number of cycles (Cleaning) 3 9 3

Page 12

Coffee-Machine G

MANUAL 2/16

Defaultfacts

from

Tree Parameter Function Min Max E-prom Remark

SETUP LANGUAGE

LANGUAGE Dialogue language

0 = English

1 = German

2 = French

3 = Spanish

0 2 1

DEVICE

SELF 0 = NORMAL, 1 = SELF 0 1 0

LOCK LEVEL 0 = No locking of boilers

1 = Coffee, tea, steam

interlocked

2 = Heaters, grinders, pum p,

piston motor interlocked

3 = Coffee, grinder interlocked

0 3 1 see

Install

Instruction

page 2

CLIENT

(only for

machines

without

Chipcard)

Categorie of client

1 = Access authorization 0

2 = Access authorization 1

3 = Access authorization 2

1 3 1 SERVIC

without

chipcard

TRAIN 0 = Normal machine

1 = Train-machine

0

CONFIG

MILL Nu mbers of mills

1 = Mill left side

2 = Mill left side and right side

1 2 2

COFFEE Coffee

0 = Coffee OFF

1 = Coffee ON

0 1 1

TEA/STEA M Tea

0 = No tea

1 = Tea

2 = Steam

3 = Tea/Steam/Cold water

4 = Tea / Steam unlocked

0 4 2

PUMP

PUMP

COFFEE

Coffee

0 = Without pump

1 = With pump

0 1 1

PUMP

TEA/STEA M

Tea

0 = Without pump

1 = With pump

0 1 1

HEATER

Heater Temperature coffee boiler 60 99 86 ° C

Page 13

Coffee-Machine G

MANUAL 2/17

Defaultfacts

from

Tree Par ameter Function Min Max E-prom Remark s

SETUP MILL OPTIONS

CL AFTER

CHECK

Measuring of the coffee quantity

0 = No ejection after check

1 = Ejection after check

2 = Measuring with scald head in g

0 2 1

AUTO MILL 0 = without AUTO MILL

1 = with AUTO MILL

0 1 0

NUM PARAMS

PRESS TIME Dewatering time after brewing

process

0 9.9 1.0 sec.

ERROR WATER Minimum water quantity in 10 s 1 99 3 ml

WATER CREDIT Credit for water softener 1 99 99 6000

GROUNDS MAX Max. numbers of coffee cakes

0 = No monitoring

10 999 100

SC HEAD

MAX

Increment lowest position of piston

BK-init

800

SC HEAD MIN Position of ejection BK-init 200

COFFEE OPTIONS

CAPPU 0 = Without common outlet

1 = With common outlet

0 1 0

COFFEE

TIMEOUT

0 = OFF

0 - 255 = After XX seconds, the

extraction cycle will be terminated

0 255 0

MILL MIX Mill mix

0 = Without mill mix

1 = With mill mix

0 1 0

COVER FREE 0 = Related to buttons

1 = Not related to buttons

0 1 0

CLEAN

CYCLES

0 = OFF

0 - 9999 = After the desired

number, the display will show

"PLEASE CLEAN"

0 9999 0

BUZZER 0 = OFF

1 = Switch off the machine by key

switch. Now, the message

"PLEASE CLEAN" will appear on

the display if the function before

was not cleaning

0 1 0

AUTO CLEAN Automatical cleaning cycle

0 = No function

X = Single cycle of rinse after X

minutes

0 60 10

ADD RINSE 1 0 = Without rinse request

1 = Rinse request after start

0

SYSTEM

WARM UP

0 = OFF

1 = Piston warm up (after 3 min.)

2 = Only temperature increase

3 = Temperature increase and

piston warm-up

0 3 0

TEMP PLUS Input-possibility 1 - 10°C 1 10 1

Time Plus Input-possibility 1-30min 1 30 1

Page 14

Coffee-Machine G

MANUAL 2/18

Defaultfacts

from

Tree Parameter Function Min Max E-prom Remarks

SETUP

OTHER OPTIONS

SOFTENER Water soft ener system

0 = Without water so ftener system

1 = Water softener co nnected

0 1 0

PRINTER Tape printer

0 = Without printer

1 = With prin ter LF

2 = With printer CR LF

0 2 0

CYCLES

INC

Increment of product touc h

0 = Increment locked

1 = Increment possible

0 1 1

MONEY Numbers of figures after the

command

0 = without 1 = 0,0 2 = 0,00

0 2 2

ADD

STEAM

0000 = OFF

0410 (example)

04 = Number of seconds of time

delay between c appuccino

intervals

10 = 1 seconds incre ase of steam

time

OOOO 9999 O41O

EXTERNAL DEVICES (not used)

WAITER

SYSTEM Waiter accounti ng system

1 = Coin validator

(without Chipcard)

2 = CCI/CSI (without Chipcard)

3 = CCI/CSI + Coin validator

(without Chipcard)

4 = KAS + Chipca rd

5 = only Chipcard

0 63 0

WAITER

KEY

Waiter key

0 = No key for internal counter

1-63 = With waiter key

0 63 0

KEY X

(1 - 10)

Clear key X

0 = Key locked

0 255 0

Page 15

Coffee-Machine G

MANUAL 2/19

4. Additional programming possiblities with the Software G .301

Defaultfacts

from

Tree Parameter Function Min Max E-prom Remarks

SETUP FAST BREWING SYSTEM

FAST BREWING

SYSTEM

0 = Fast brewing system 0ff

1 = Fast brewing system On

0 1 0 Pregrinding

GRINDER 1 = Left grinder

2 = Right grinder

3 = Left and right grinder

1 3

OTHER OPTIONS

WATERTANK 0 = Control of alternate

Watertank OFF

1 = Control of W a te r t an k by

level switches ON

0 1 0 Reset of Water amount

1 Empty tank of refilling

1 Press Clean key

Automatic Water amount

counter no more possible if

"Watertank" = 1

PROGR

PARA

METER

Coffee

VALVE Y21 0 = Y21 switched off

1 = Y21 switched on

0 1 0 Breakfast

BREAKFAST Wateraddition max 80% 0 80 0

MILK

QUANTITY

in % 0 100 0 CT2-Version

0% = Foam

100% = Milk

SYSTEM 0 = Fast brewing system off

for this key

1 = Fast brewing system

with grinder of "set-up/fas t

brewing system/grinder"

2 = Fast brewing system

with grinder referin to ke y

programmation

0 2 0 Pregrinding

Page 16

Coffee-Machine G

MANUAL 2/20

5. Concise description of the special options

Grinding and When this option is selected, the quantity to be ground is requested

twice.

mixing While coffee production is in progress, the left and right mills are

activated for MILL QUANT 1 and 2.

Brewing The production of brewed coffee is effected in accordance with the

following cycle: the brewing piston stops at the topmost brewing

position and the ground coffee is not compressed. When the brewing

valve is opened the water circulates through the loose ground coffee;

the result is a coffee brew.

Increment The "Manual increment" option provides the following possibilities (for

(Repetition) coffee). If the product key is actuated repeatedly during production of

the corresponding beverage, these key actuations are memorized and

the product repeated accordingly. However, if the key is pressed more

than ten times, the machine switches over to continuous operation,

i.e. the selected product is repeated continuously (up to a maximumof

99 cups). Pressure on the CLEAN key terminates the cycle after the

current cup has been filled.

Self-service When the machine is programmed for "self-service", operation of the

cover on the filler opening triggers a cleaning cycle.

05.1998

1L 301'046

Loading...

Loading...