FRANKE FDB10078IXS User Manual

Instructions for use and installation

Istruzioni per l’uso e l’installazione

Mode d’emploi et installation

Bedienungsanleitung und Einrichtung

Kullan

ım ve montaj talimatları

GB

IT

FR

DE

TR

Cooker Hood

Cappa

Hotte de Cuisine

Dunstabzugshaube

Davlumbaz

FDB 10078 I

FDB 14078 I

EN

Instructions Manual

INDEX

RECOMMENDATIONS AND SUGGESTIONS......................................................................................................................7

CHARACTERISTICS..............................................................................................................................................................8

INSTALLATION ....................................................................................................................................................................10

USE.......................................................................................................................................................................................14

MAINTENANCE....................................................................................................................................................................15

2

2

IT

Libretto di Istruzioni

INDICE

CONSIGLI E SUGGERIMENTI ............................................................................................................................................18

CARATTERISTICHE............................................................................................................................................................19

INSTALLAZIONE..................................................................................................................................................................21

USO......................................................................................................................................................................................25

MANUTENZIONE.................................................................................................................................................................26

3

3

FR

Manuel d’Instructions

SOMMAIRE

CONSEILS ET SUGGESTIONS ..........................................................................................................................................29

CARACTERISTIQUES.........................................................................................................................................................30

INSTALLATION ....................................................................................................................................................................32

UTILISATION........................................................................................................................................................................36

ENTRETIEN..........................................................................................................................................................................37

4

4

DE

Bedienungsanleitung

INHALTSVERZEICHNIS

EMPFEHLUNGEN UND HINWEISE....................................................................................................................................40

CHARAKTERISTIKEN..........................................................................................................................................................41

MONTAGE............................................................................................................................................................................43

BEDIENUNG.........................................................................................................................................................................47

WARTUNG............................................................................................................................................................................48

5

5

TR

Kullanim Kilavuku

IÇERIKLER

TAVSIYELER VE ÖNERILER ..............................................................................................................................................51

ÖZELLIKLER........................................................................................................................................................................52

MONTAJ...............................................................................................................................................................................54

KULLANIM............................................................................................................................................................................58

BAKIM...................................................................................................................................................................................59

6

6

EN

RECOMMENDATIONS AND SUGGESTIONS

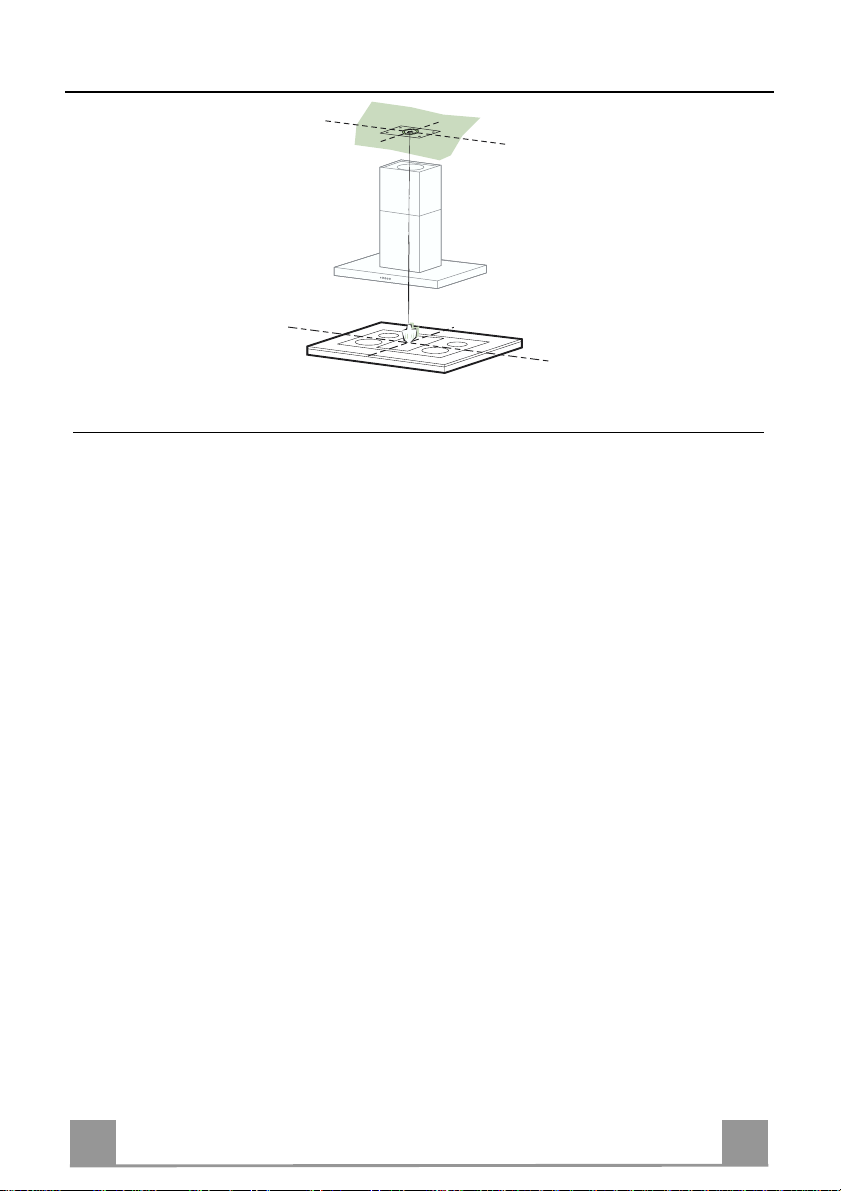

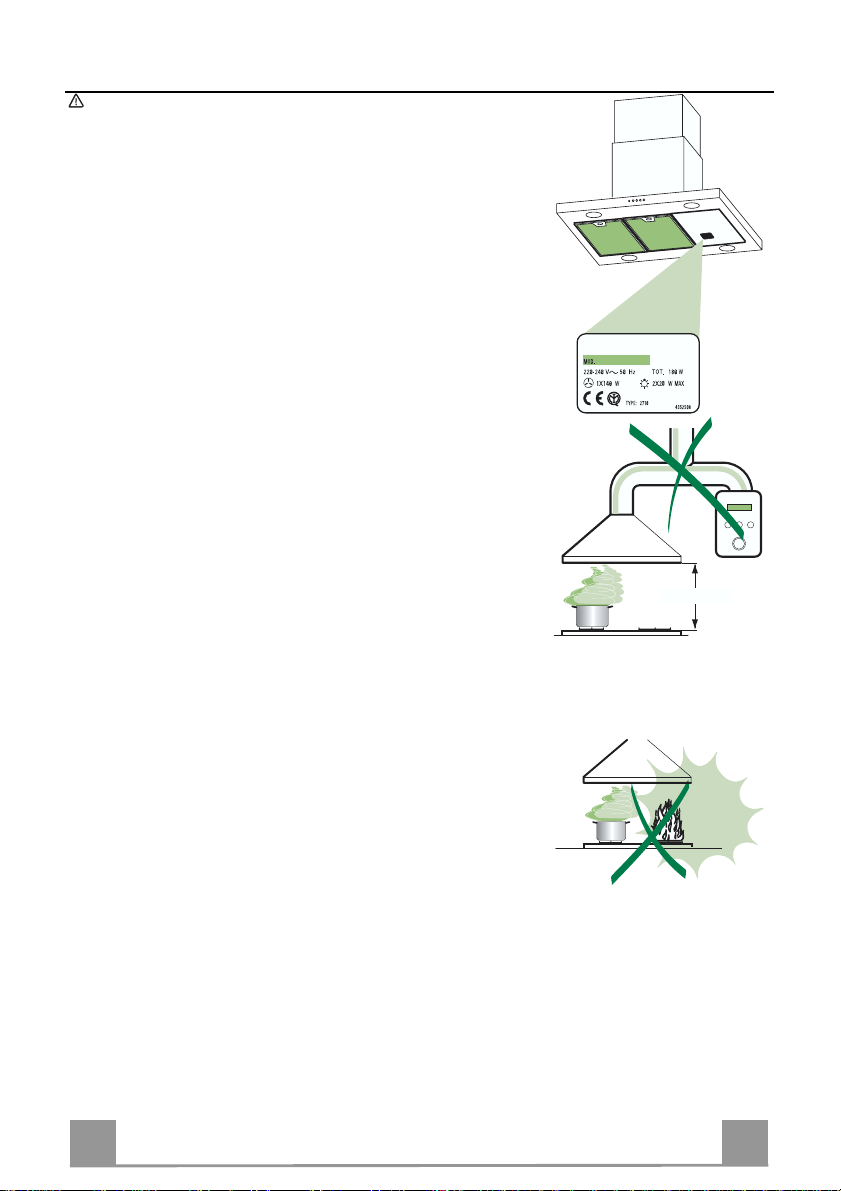

650 mm min.

The Instructions for Use apply to several versions of this appliance. Accord-

ingly, you may find descriptions of individual features that do not apply to your

specific appliance.

INSTALLATION

• The manufacturer will not be held liable for an y damages resulting fro m incorrect or impro per installation.

• The minimum safety distance between the cooker top and the extractor hood

is 650 mm.

• Check that the mains voltage corresponds to that indicated on the rating plate

fixed to the inside of the hood.

• For Class I appliances, check that the domestic power supply guarantees adequate earthing.

Connect the extractor to the exhaust flue through a pipe of minimum diameter

120 mm. The route of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carrying combustion fumes

(boilers, fi replaces, etc.).

• If the extractor is used in conjunction with non-electrical appliances (e.g. gas

burning appliances), a sufficient degree of aeration must be guaranteed in the

room in order to prevent the backflow of exhaust gas. The kitchen must have

an opening communicating directly with the open air in order to guarantee the

entry of clea n air.

USE

• The extractor hood has been designed exclusively for domestic use to eliminate kitchen smells.

• Never use the hood f or purposes other than for whi ch it has ben d esigned.

• Never leave high naked flames un der the hood when it is in operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only, making

sure that it does not engulf the sides.

• Deep fat fryers must be continuously monitored during use: overheated oil can

burst into flames.

• Do not flambè under the range hoo d; risk of fire

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the appliance.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before carrying out

any maintenance work.

• Clean and/or replace the Filters after the specified time period.

• Clean the hood using a damp cloth and a neutral l iquid detergent.

7

7

EN

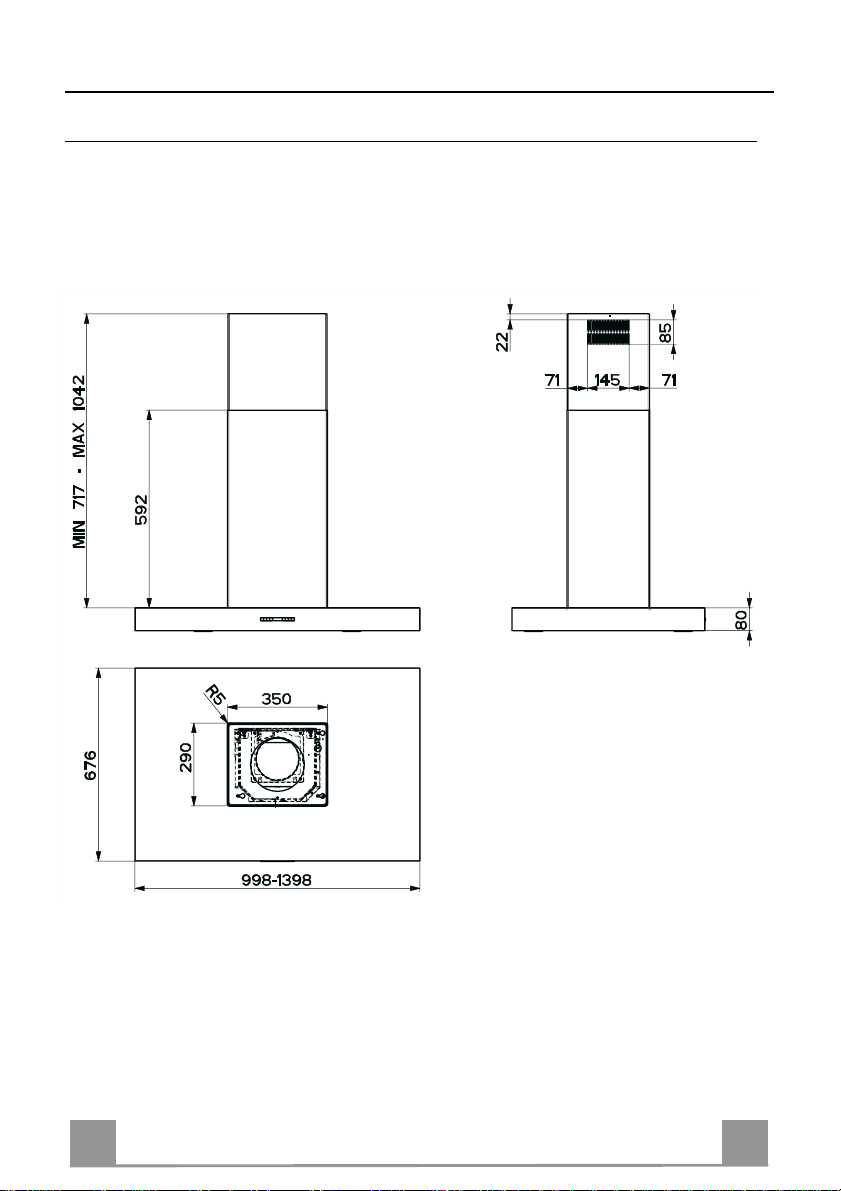

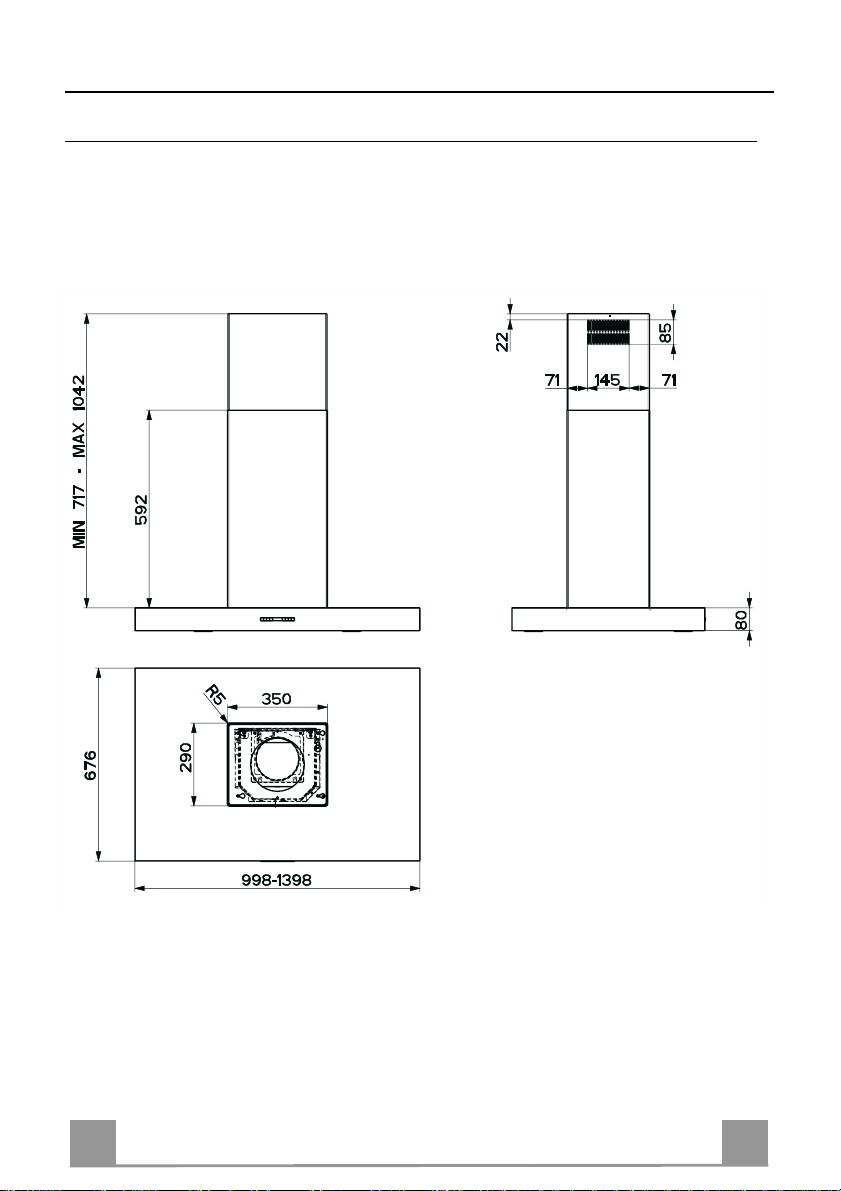

CHARACTERISTICS

Dimensions

8

8

EN

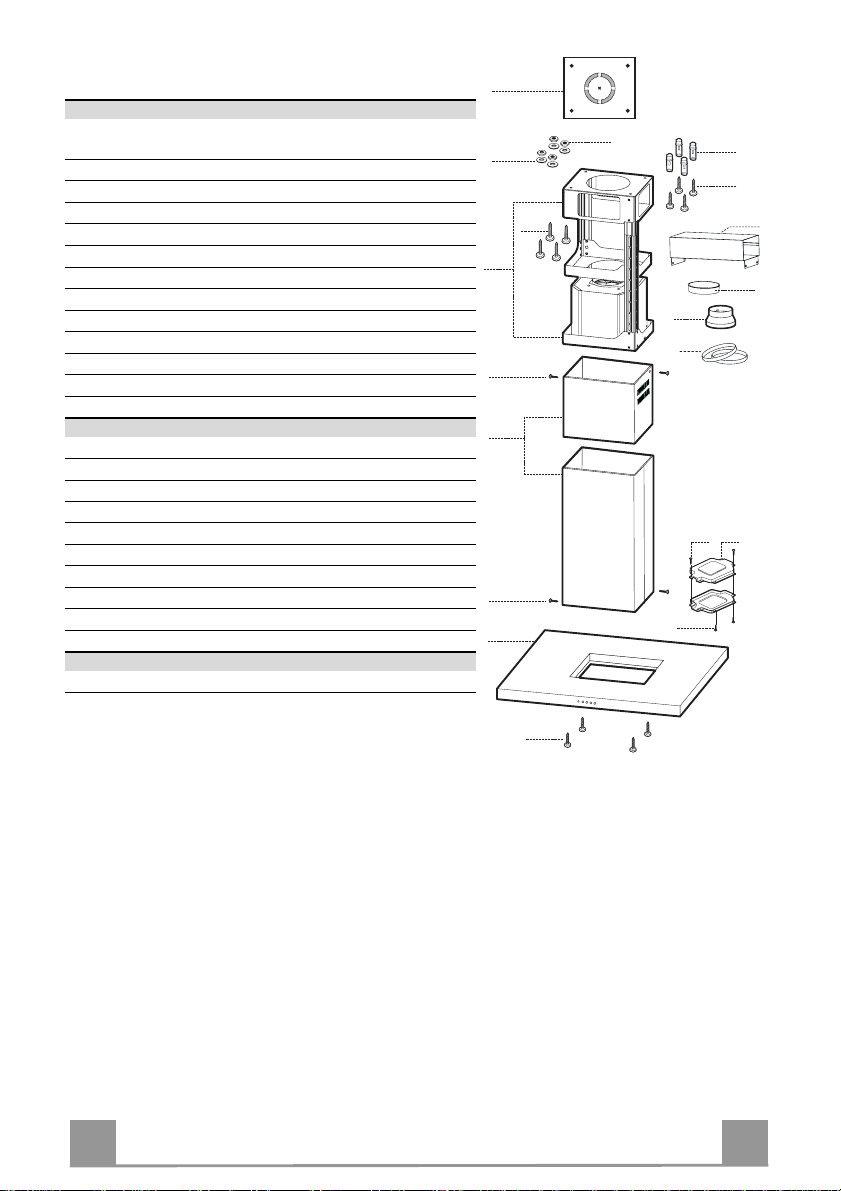

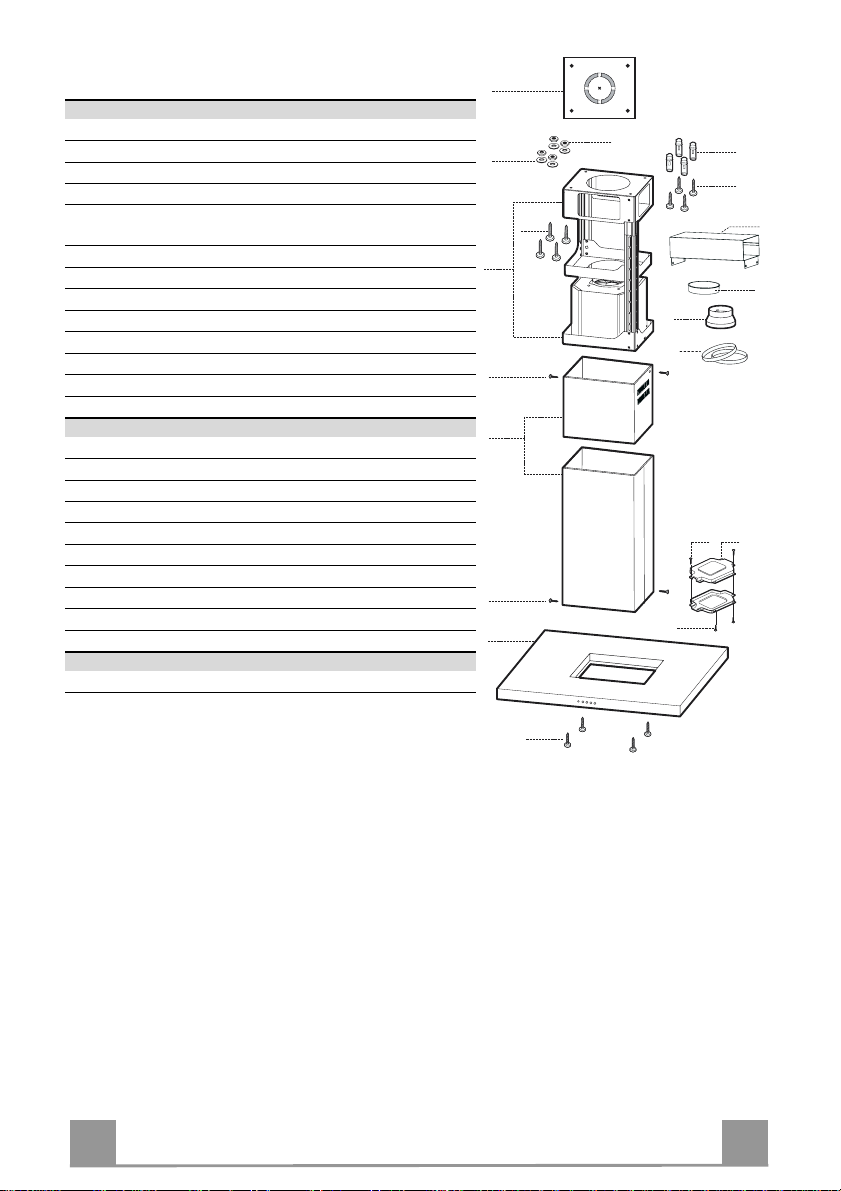

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light, Blower,

Filters

2 1 Telescopic Chimney comprising:

2.1 1 Upper Section

2.2 1 Lower Section

7.1 1 Telescopic f rame complet e with extract or, consisting of:

7.1a 1 Upper frame

7.1b 1 Lower frame

9 1 Reducer Flange ø 150-120 mm

10 1 Flange ø 150

15 1 Air Outlet Conn ection

24 1 Junction box

25 2 Pipe clamps

Ref. Q.ty Installation Components

11 4 Wall Plugs ø 10

12c 6 Screws 2,9 x 6, 5

12e 2 Screws 2,9 x 9, 5

12f 4 Screws M6 x 10

12g 4 Screws M6 x 80

12h 4 Screws 5,2 x 70

21 1 Drilling template

22 4 6.4 mm int. dia washers

23 4 M6 nuts

Q.ty Documentation

1 Instruction Manual

7.1

21

22

12c

2

12c

1

7.1a

12g

7.1b

2.1

2.2

12f

23

9

12c

11

12h

15

10

25

12e

24

9

9

EN 110

INSTALLATION

Drilling the Ceiling/shelf and fixing the frame

DRILLING THE CEILING/SHELF

• Use a plumb line to mark the centre of the hob on the ceiling/support shelf.

• Place the drilling template 21 provided on the ceiling/support shelf, making sure that the

template is in the correct position by lining up the axes of the template with those of the hob.

• Mark the centres of the holes in the template.

• Drill the holes at the points marked:

• For concrete ceilings, drill for plugs appropriate to the screw size.

• For hollow brick ceilings with wall thickness of 20 mm: drill ø 10 mm(immediately insert

the Dowels 11 supplied).

• For wooden beam ceilings, drill according to the wood screws used.

• For wooden shelf, drill ø 7 mm.

• For the power supply cable feed, drill ø 10 mm.

• For the air outlet (Ducted Versio n), drill according to t he diameter of the external air exhaust duct connection.

• Insert two screws of the following type, crossing them and leaving 4-5 mm from the ceiling:

• For concrete ceilings, use the appropriate plugs for the screw size (not provided).

• for Cavity ceiling with inner space, with wall thickness of approx. 20 mm, Screws 12h,

supplied.

• For wooden beam ceilings, use 4 wood screws (not provided).

• For wooden shelf, use 4 screws 12g with washers 22 and nuts 23, provided.

EN 111

Fixing the frame

2

2

1

1

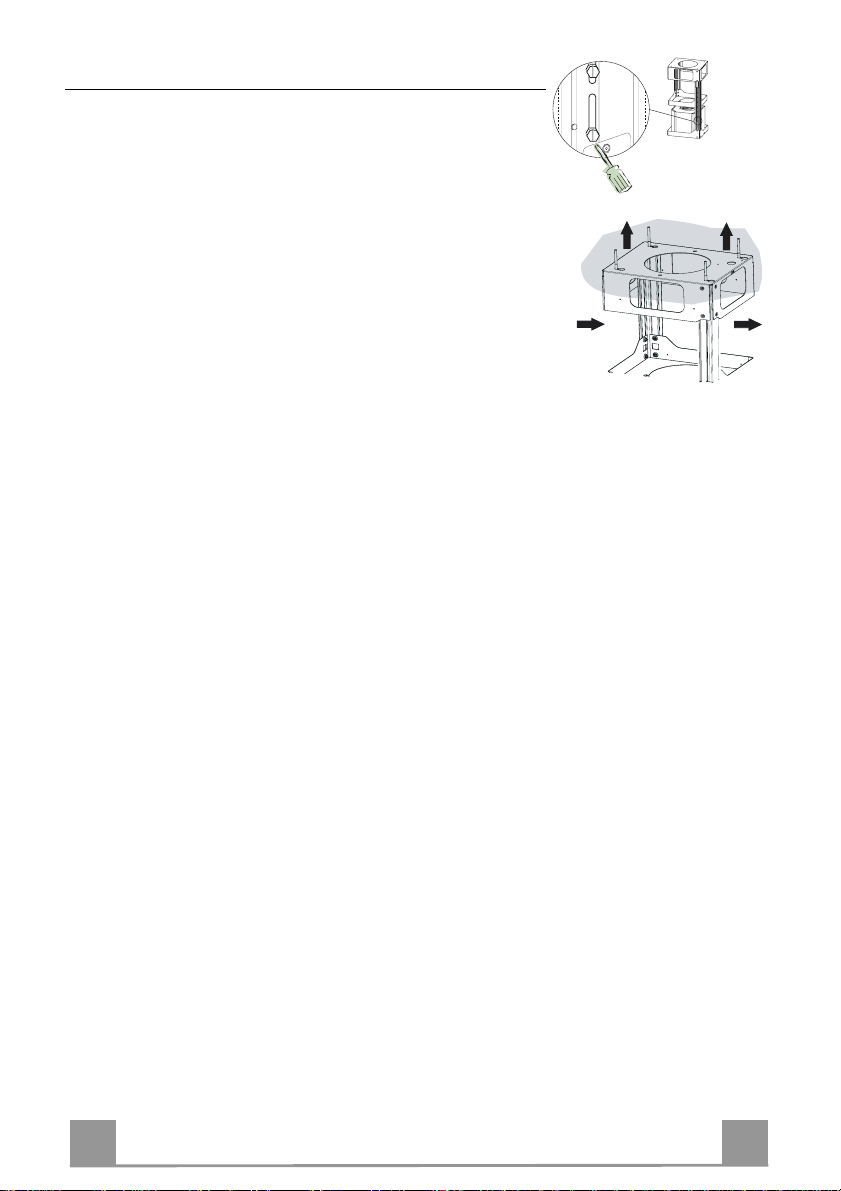

• Loosen the two screws fasten ing the lower chimney and remove this from the lower frame.

• Loosen the two screws fastening the upper chimney and remove this from the upper frame.

If you wish to adjust the height o f the frame, proceed as follows:

• Unfasten the eight metric screws joining the two columns, located at the sides of the frame.

• Adjust the frame to the h eight required, then replace all t he

screws removed as above.

• Insert the upper chimney stack from above, and leave it running free on the frame.

• Lift up the frame, fit the frame slots onto the screws up to the

slot end positions.

• Tighten the two screws and fasten the other two screws provided with the hood.

Before tightening the screws completely it is possible to adjust

the frame by turning it. Make sure that the screws do not come

out of their seats in the slotted holes.

• The frame mountings must be secure to withstand the weight

of the hood and any stresses caused by the occasional side

thrust applied to the device.

On completion, check th at the base is stable, even if the frame

is subjected to bending.

• In all cases where the ceiling is not strong enough at the suspension point, the installer must provide strengthening using

suitable plates and backing pieces anchored to the structurally

sound parts.

EN 112

Connections

9

ø 150

ø 120

25

25

15

10

12f

12c

12c

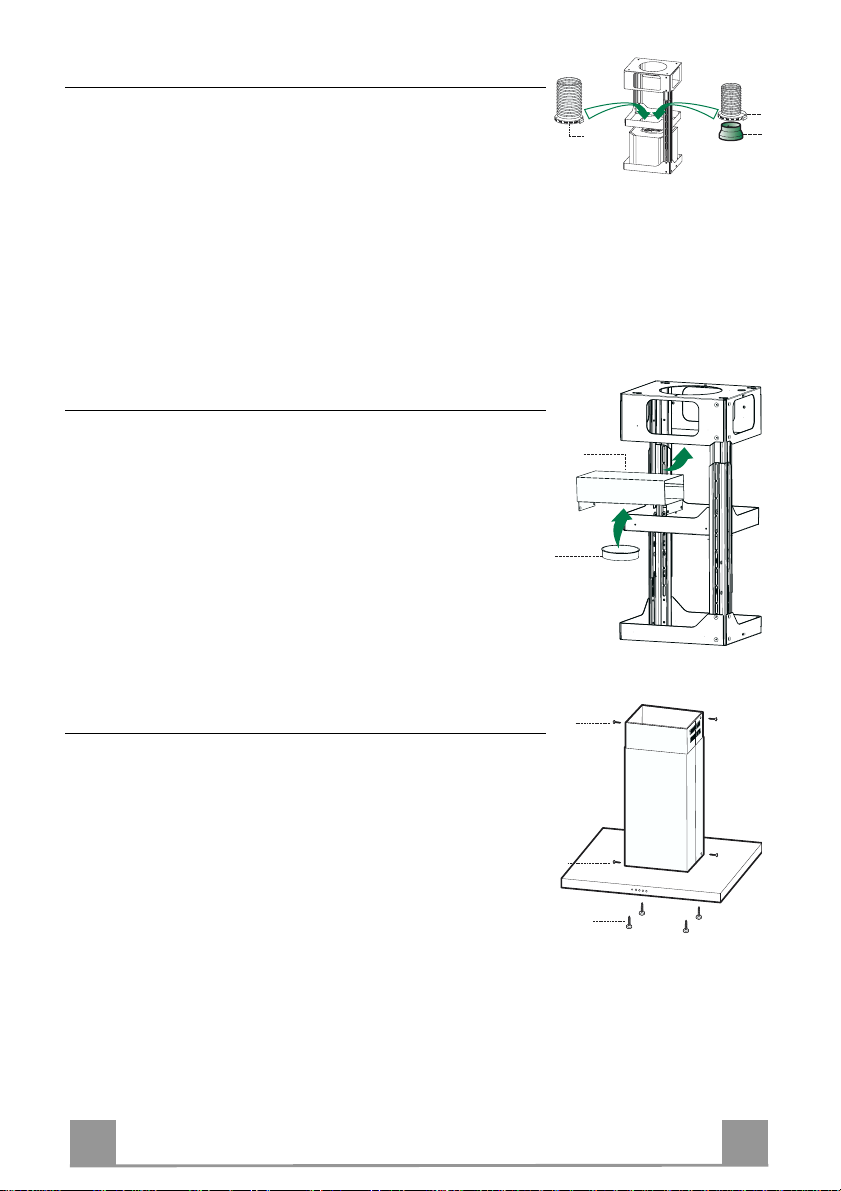

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the hood to the

chimney using either a flexible or rigid pipe ø 150 or 120 mm,

the choice of which is left to the installer.

• To install a ø 120 mm air exhaust connection, insert the reducer flange 9 on the hood body outlet.

• Fix the pipe in position using sufficient pipe clamps (not supplied).

• Remove any activated charco al filters.

Recirculation version air outlet

• Fix the connection 15 to the frame using the 4 screws provided.

• Fix the flange 10 to the lower opening of the connection 15.

• Connect the hood air outlet to the flange in the lower part of

the junction using a rigid or flexible ø 150 tube (by installer’s

choice).

Flue assembly - Mounting the hood body

• Position the upper chimney section and fix the upper part to the

frame using the 2 screws 12c (2,9 x 6,5) provided.

• Similarly, position the lower chimney section and fix the

lower part to the frame using the 2 screws 12c (2,9 x 6,5) provided.

Before fixing the hood body to the frame:

• Remove the grease filters from the hood body.

• Remove any activated charco al filters.

• From below, use the 4 screws 12f (M6 x 10)provided to fix the

hood body to the frame.

EN 113

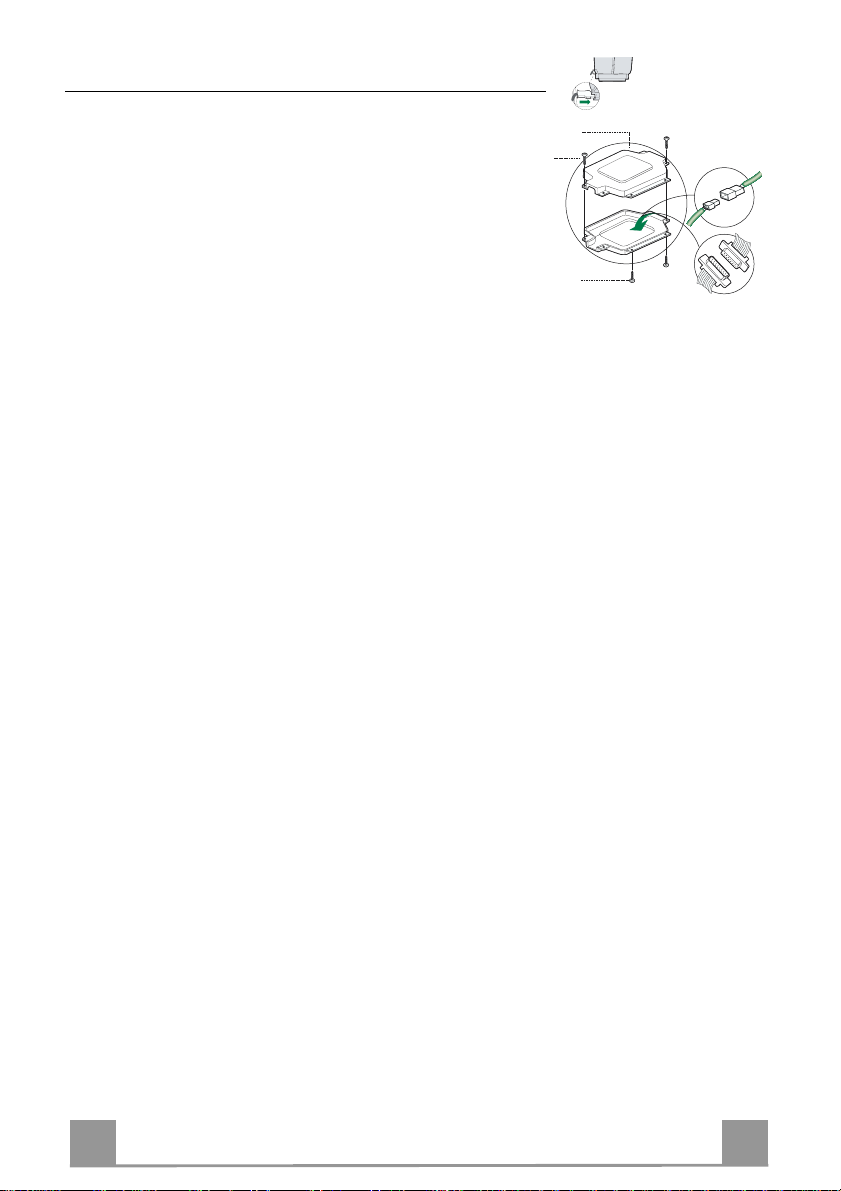

ELECTRICAL CONNECTION

24

12e

Cmd

12c

Lux

• Connect the hood to the mains through a two-pole switch having a contact gap of at least 3 mm.

• Re move the grease filters (see paragraph Maintenance) being

sure that the conn ector of the feeding cable is correctly inserted

in the socket placed on th e side of the fan.

• Connect the control co nnector Cmd.

• Connect the lights connector Lux.

• Place th e connectors in the junction box 24 and close it using

the 2 screws 12e (2,9 x 9,5) provided.

• Fix the junction box to the hood body using the 2 screws 12c

(2,9 x 6,5) provided.

• For the recirculation version, fit the activated carbon odour filter.

• Replace the grease filters.

EN 114

USE

By pressing this key it is possible to activate

selected speed. This function is suitable for

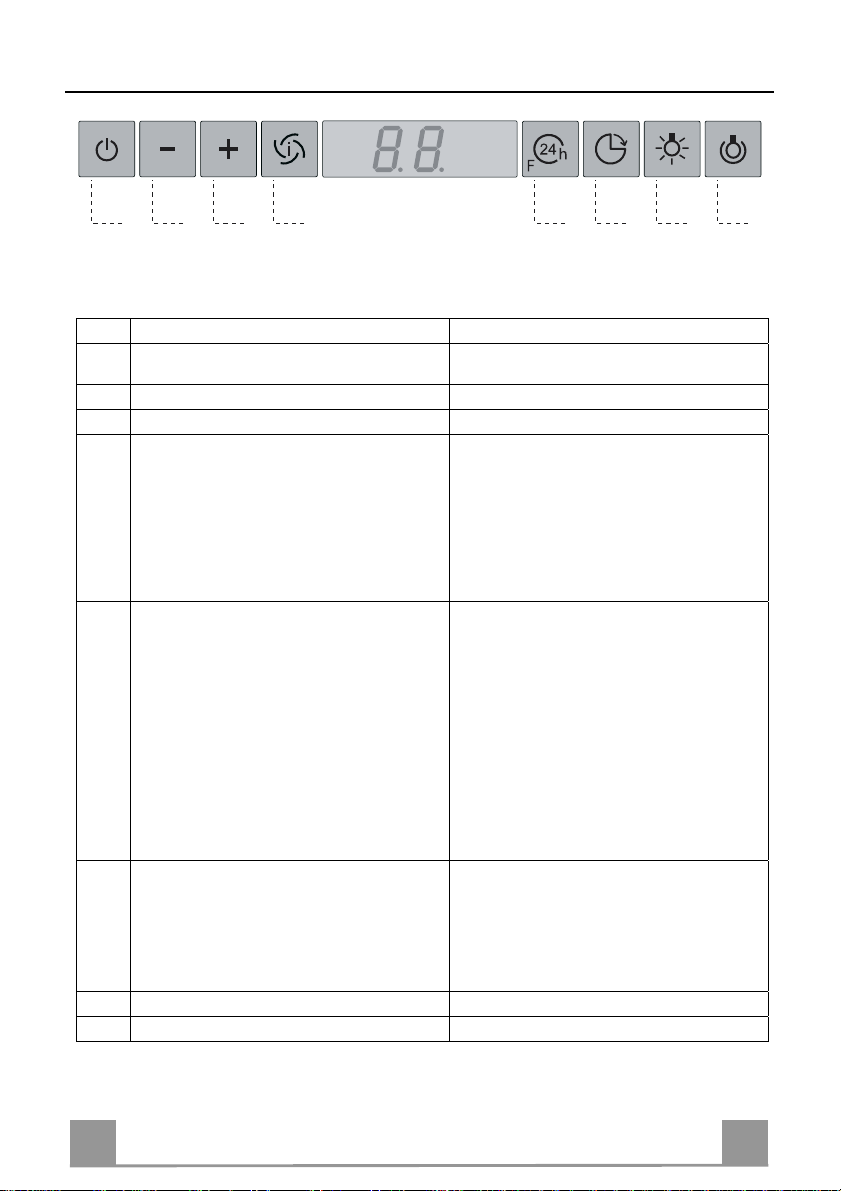

A B C D E F G H

Control board

Key Function Display

Switches the ext ractor motor on and off at the

A

latest selected speed

Decreases the suction speed.

B

Increases the suction speed.

C

D

the intensive speed from any previously selected speed . The intensiv e speed can be acti vated even when th e motor is O FF. Th is speed

has been timed at 10 minutes. After that time

the system activates automatically the latest

cooking conditions when vapours and smells

are of the utmost emission.

By pressing this key it is possible to set up the

E

motor to a suction speed at 100 m

minutes every hour. After this the motor

switches off automatically.

When the filter saturation is going on it is possible to reset the alarm by pressing this key for

about 3 seconds. The indication i s visible only

when the motor is off.

By pressing this key it is possible to set the

F

delayed shutdown of the appliance to 30 minutes. This function is suitable for a complete

elimination of the residual smells. It can be

activated at any position, and it is deactivated

by pressing the key again or by switching off

the motor.

Turns light on and off .

G

Turns light on and off a t reduced intensity.

H

3

/h lasting 10

Indicates the selected speed.

HI appears. The sp ot down on the right side

flashes once a second.

Indicates the 24-function. The spot down on

the right side flashes and the motor is on.

Once the process is finished the previous indication disappear s :

FF Indicates that the metal grease filters

saturation a larm has been t riggered, and

the filters need to be washed. Th e alarm

is triggered after 100 working hours.

EF Indicates that the charcoal filter satura-

tion alarm has been triggered, and the filter has to be replaced; the metal grease

filters must also be washed. The charcoal

filter is triggered after 200 working hours.

Indicates alternately the selected speed of the

hood and the tim e left before the hood shutdown. The sp ot down on the right side flashes.

EN 115

MAINTENANCE

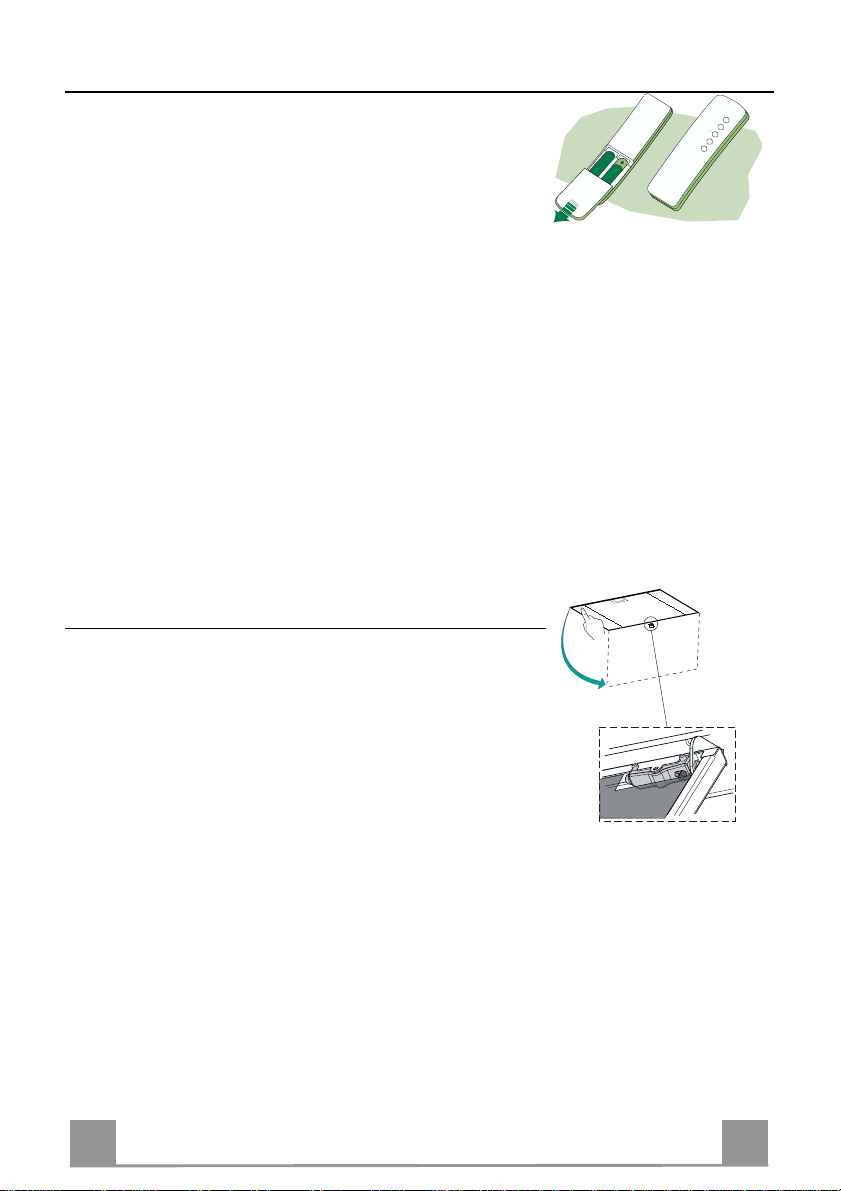

REMOTE CONTROL (OPTIONAL)

The appliance can be controlled using a remote control powered

by a 1.5 V carbon-zinc alkaline batteries of the standard LR03AAA type.

• Do not place the remote control near to heat sources.

• Used batteries must be disposed of in the proper manner.

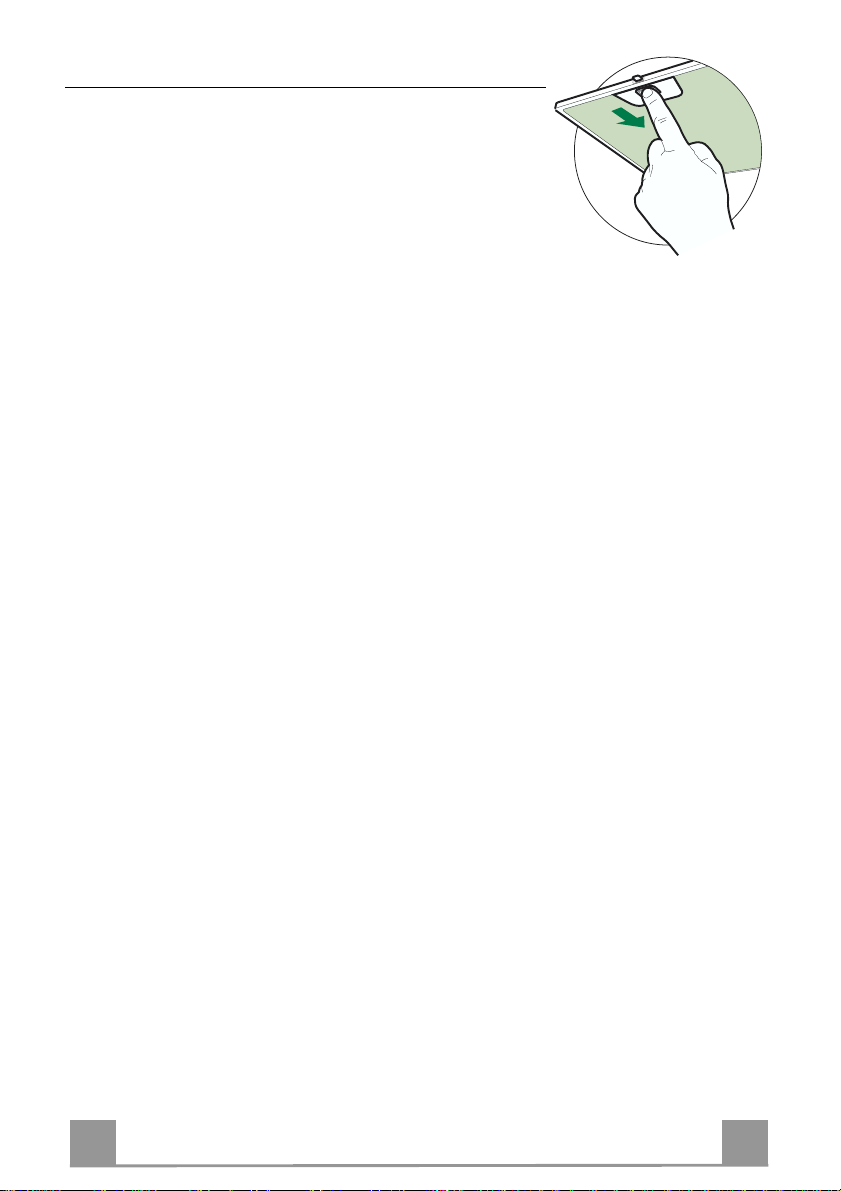

Cleaning the Comfort Panels

• Pull the Comfort Panel to open it.

• Disconnect the panel from the hood canopy by sliding the fixing pin lever.

• The comfort panel must never be washed in a dishwasher.

• Clean the outside using a damp cloth and neutral liquid detergent.

• Clean the inside as well using a damp cloth and neutral detergent; do not use wet cloths or sponges, or jets of water; do not

use abrasive substances.

• When the above operation has been completed, hook the panel

back to the hood canopy and close it by turning the knob in the

opposite direction.

EN 116

Metal grease filters

Filters can be washed in the dish machine. They need to be

washed when FF-sign appears on the display or in any case every

2 months, or even more frequently in case of particularly intensive use of the hood.

Alarm reset

• Switch off the hood and the lights. If the 24h-function has been

activated this has to be deactivated.

• Press the E-key till the display is unlit.

Cleaning the filters

• Pull the comfort panels to open them.

• Remove the filters one by one pushing them towards the back

side of the hood unit and simultaneously pulling downwards.

• Any kind of bending of the filters has to be avoided when

washing them. Before fitting them again into the hood make

sure that they are completely dry. (The colour of the filter surface may change throughout the time but this has no influence

to the filter efficiency).

• When fitting the filters into the hood pay attention that they are

mounted in correct position the handle facing outwards.

• Close the comfort panel.

EN 117

Charcoal filter (recycling version)

• This filter cannot be washed or regenerated. It must be replaced when the EF appears on the

display or at least once every 4 months.

Activation of the alarm signal

• In the recycling version hoods the filter saturation alarm must be activated during the installation or later.

• Switch off the hood and the lights.

• Disconnect the hood from the mains supply.

• When restoring the connection press and hold B-key.

• When releasing the key t wo rotating rectangles appear on the display.

• Within 3 seconds press the B-key until a flashing confirmation appears on the dispaly:

• 2 flashes with EF - charcoal filter saturation alarm ACTIVATED

• 1 flash with EF - charcoal filter saturation alarm DEACTIVATED.

REPLACING THE CHARCOAL FILTER

Reset of the alarm signal

• Switch off the hood and the lighting. If the 24h-function has

been activated this has to be deactivated.

• Press the E-key until the display is unlit.

Replacing of the filter

• Open the comfort panels pulling them downwards.

• Remove the metal grease filters.

• Remove the saturated charcoal filter by releasing the fixing

hooks

• Fit the new filter and fasten it in its correct position.

• Put the metal grease filters in their seats.

• Close the comfort panels.

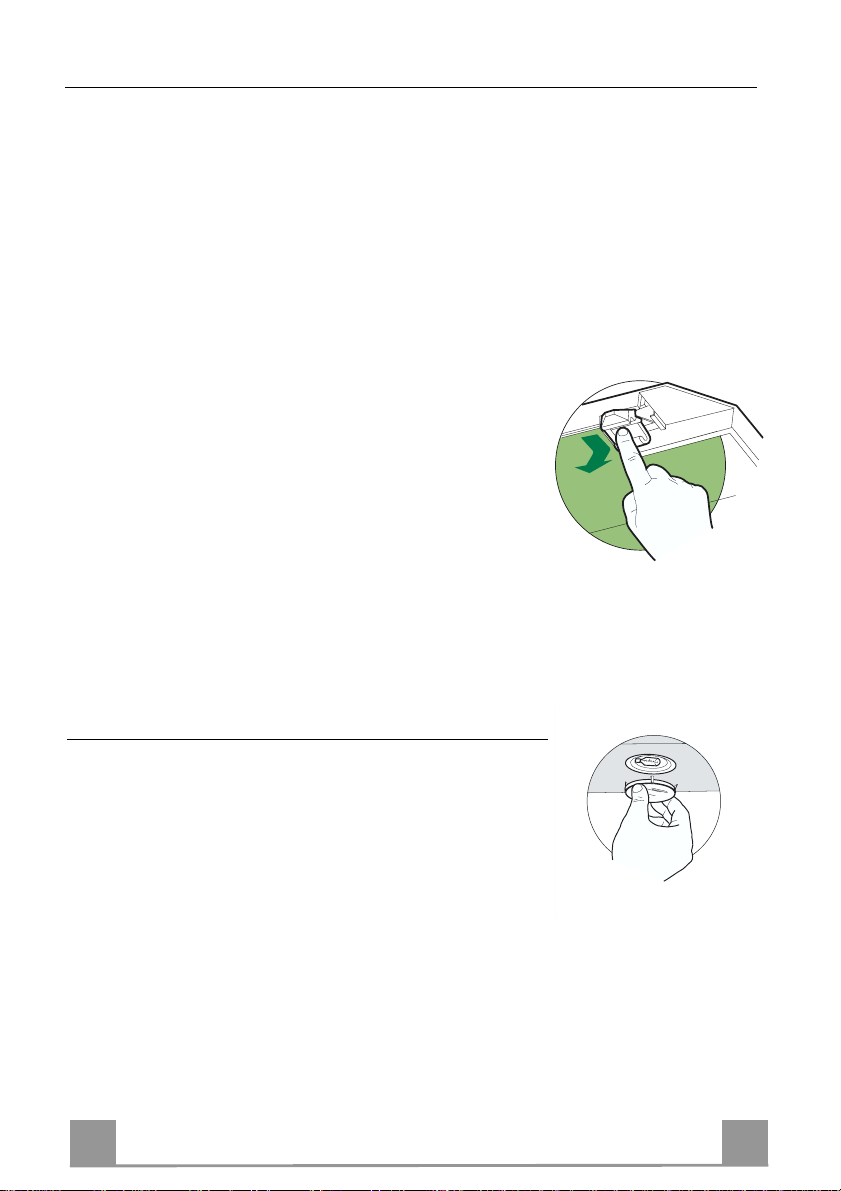

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the snap-on lamp cover by levering it from under the

metal ring, supporting it with one hand.

• Remove the halogen lamp from the lamp holder by pulling

gently.

• Replace the lamp with a new one of the same type, making

sure that you insert the two pins properly into the housings on

the lamp holder.

• Replace the snap-on lamp co ver.

IT 118

CONSIGLI E SUGGERIMENTI

650 mm min.

Questo libretto di istruzioni per l'uso è previsto per più versioni dell' apparec-

chio. É possibile che siano descritti singoli particolari della dotazione, che non

riguardano i l Vostro apparecchio.

INSTALLAZIONE

• Il produttore declina qualsiasi responsabilità per danni dovuti ad installazione

non corretta o non conforme alle regole dell’arte.

• La distanza minima di sicurezza tra il Piano di cottura e la Cappa deve essere

di 650 mm.

• Verificare che la tensione di rete corrisponda a quella riportata nella targhetta

posta all’interno della Cappa.

• Pe r Apparecchi in Classe Ia accertarsi ch e l’impianto elettrico domestico garantisca un corretto scarico a terra.

• Collegare la Cappa all’u scita dell’a ria aspirata con tuba zione di d iametro pari o

superiore a 120 mm. Il percorso della tubazione deve essere il più breve possibile.

• Non collegare la Cappa a condotti di scarico dei fumi prodotti da combustione

(caldaie, caminetti, ecc.).

• Nel caso in cui nella stanza venga no utilizzat i sia la Cappa che apparecchi non

azionati da energia elettrica (ad esempio apparecc hi utilizzatori di gas), si deve

provvedere ad una aerazione sufficiente dell’ambien te. Se la cucina ne fosse

sprovvista, praticare un’apertura che comunichi con l’esterno, per garantire il

richiamo d’ari a pulit a.

USO

• La Cappa è stata progettata esclusivamente per uso domestico, per abbattere

gli odori della cucina.

• Non fare mai uso improprio della Cappa.

• Non lasciare fiamme libere a forte intensità sotto la Cappa i n funzione.

• Regolare sempre le fiamme in modo da evitare una evidente fuoriuscita laterale delle stesse rispetto al fondo delle pe ntole.

• Controllare le friggitrici durante l’uso: l’olio surriscaldato potrebbe infiammarsi.

• Non preparare alimenti flambè sotto la cappa da cucina; peri colo d'incendio.

• Questo apparecchio non deve essere utilizzato da persone (bambini inclusi)

con ridotte capacità psichiche, sensoriali o mentali, oppure da persone senza

esperienza e conoscenza , a meno che non siano controllati o istruiti all’uso

dell’apparecchio da persone responsabili della loro sicurezza.

• I bambini devono essere supervisionati per assicurarsi che non giochino con

l’apparecchio.

MANUTENZIONE

• Prima di procedere a qualsiasi operazione di manutenzione, disinserire la

Cappa togliendo la spina elettrica o spegnendo l’interruttore generale.

• Effettuare una scrupolosa e tempestiva manutenzione dei Filtri secondo gli

intervalli consigliati.

• Per la pulizia delle supe rfici della Cappa è sufficiente utilizzare un pan no umido e detersivo liquido neut ro.

IT 119

CARATTERISTICHE

Ingombro

IT 220

Componenti

Rif. Q.tà Componenti di Prodotto

1 1 Corpo Cappa completo di: Comandi, Luce, Filtri

2 1 Camino telescopico formato da:

2.1 1 Camino superiore

2.2 1 Camino inferiore

7.1 1 Traliccio telescopico completo di Aspiratore, formato

da:

7.1a 1 Traliccio superiore

7.1b 1 Traliccio inferiore

9 1 Flangia di riduzione ø 150-120 mm

10 1 Flangia ø 150

15 1 Raccordo Uscita Aria

24 1 Scatola connessioni

25 2 Fascette stringitubo

Rif. Q.tà Componenti di Installazione

11 4 Tasselli ø 10

12c 6 Viti 2,9 x 6,5

12e 2 Viti 2,9 x 9,5

12f 4 Viti M6 x 10

12g 4 Viti M6 x 80

12h 4 Viti 5, 2 x 70

21 1 Dima di foratura

22 4 Rondelle øi 6,4

23 4 Dadi M6

Q.tà Documentazione

1 Libretto Istruzioni

7.1

21

22

12c

2

12c

1

7.1a

12g

7.1b

2.1

2.2

12f

23

9

12c

11

12h

15

10

25

12e

24

Loading...

Loading...