Page 1

A1000

ORIGINAL OPERATING INSTRUCTIONS

Coffee machine: FCS4050 - Refrigeration unit: FCS4053

Read the Operating Instructions and the chapter "For your safety"

before operating the machine.

Keep the Operating Instructions with the machine and pass them

along to the next user if the machine is sold or transferred to a third

party.

Page 2

Page 3

Page 1

Congratulations on your purchase of an A1000. Thank you for your confidence in us.

The A1000 is a powerful and space-saving coffee machine that adapts to your needs perfectly.

The A1000 will enable you to offer high-quality coffee specialties rapidly and individually. Your

customers will be impressed.

We hope you enjoy your coffee machine and that it brings you many satisfied customers.

Sincerely, Franke Kaffeemaschinen AG

Dear Customer,

Page 4

Maintaining the a1000

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Cleaning and MaintenanCe plan

. . . . . . . . . . . . . . . . . . . . . . . . 36

Starting autoMatiC Cleaning of the a1000 and the

refrigeration unit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Cleaning the Milk Container, SuCtion line and reverSible adapter

38

Cleaning the SteaM wand

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning the aCCeSSorieS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning the bean hopper and powder Container

. . . . . . . . . . . . 40

rinSing the Coffee MaChine

. . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Starting Cleaning of the flavor Station

. . . . . . . . . . . . . . . . . 41

Cleaning the brewing unit (aS required)

. . . . . . . . . . . . . . . . . . 42

Cleaning the Monitor SCreen

. . . . . . . . . . . . . . . . . . . . . . . . . . 42

Configuring

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

introduCtion to prograMMing

. . . . . . . . . . . . . . . . . . . . . . . . . 43

"My SettingS" Menu tree

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

"Cleaning and MaintenanCe" Menu tree

. . . . . . . . . . . . . . . . . . . 44

My SettingS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

CounterS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

individualization and data tranSfer

. . . . . . . . . . . . . . . . . . . . . . . 53

overview

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

individualization and data tranSfer

. . . . . . . . . . . . . . . . . . . . . 54

individualization and data tranSfer Menu tree

. . . . . . . . . . . . . . 55

requireMentS for your own Media

. . . . . . . . . . . . . . . . . . . . . . 56

required folder StruCture on the uSb StiCk

. . . . . . . . . . . . . . 56

loading or deleting your own Media

. . . . . . . . . . . . . . . . . . . . . 57

uSing your own Media

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Saving/loading data

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

reStoring default valueS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

deCoMMiSSioning and diSpoSal

. . . . . . . . . . . . . . . . . . . . . . . . . . . 65

deCoMMiSSioning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

diSpoSal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

troubleShooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

eliMinating MaChine errorS

. . . . . . . . . . . . . . . . . . . . . . . . . . . 67

help with probleMS ConCerning produCt quality

. . . . . . . . . . . . 68

index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

for your Safety

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

proper uSe

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

general Safety ConCernS when uSing the a1000

. . . . . . . . . . . . 4

explanation of SyMbolS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SyMbolS froM the operating inStruCtionS

. . . . . . . . . . . . . . . . . 6

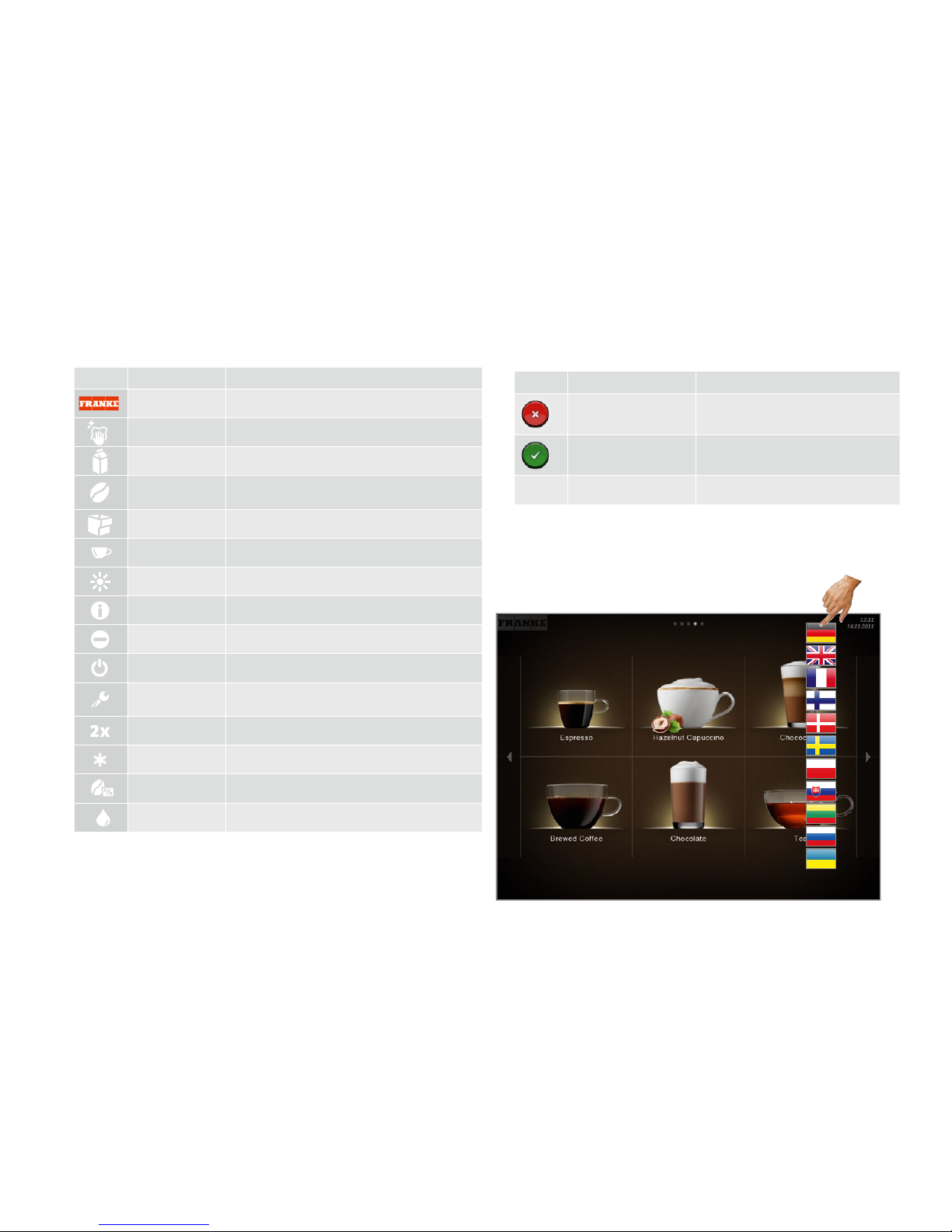

SyMbolS uSed in the Software

. . . . . . . . . . . . . . . . . . . . . . . . . . 7

depiCtion of error MeSSageS

. . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Color Code for error MeSSageS

. . . . . . . . . . . . . . . . . . . . . . . . 8

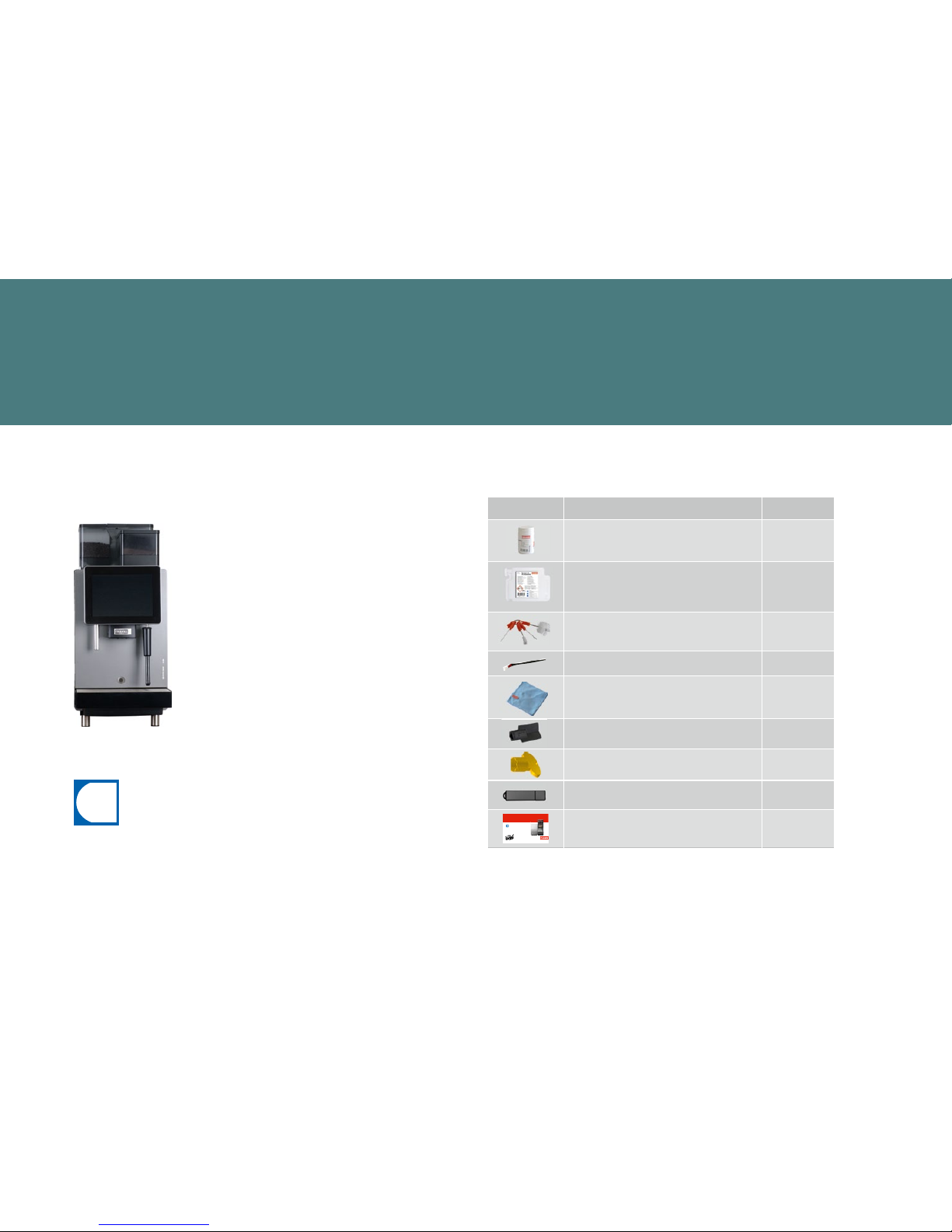

SCope of delivery and identifiCation

. . . . . . . . . . . . . . . . . . . . . . . . 9

SCope of delivery

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

identifiCation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

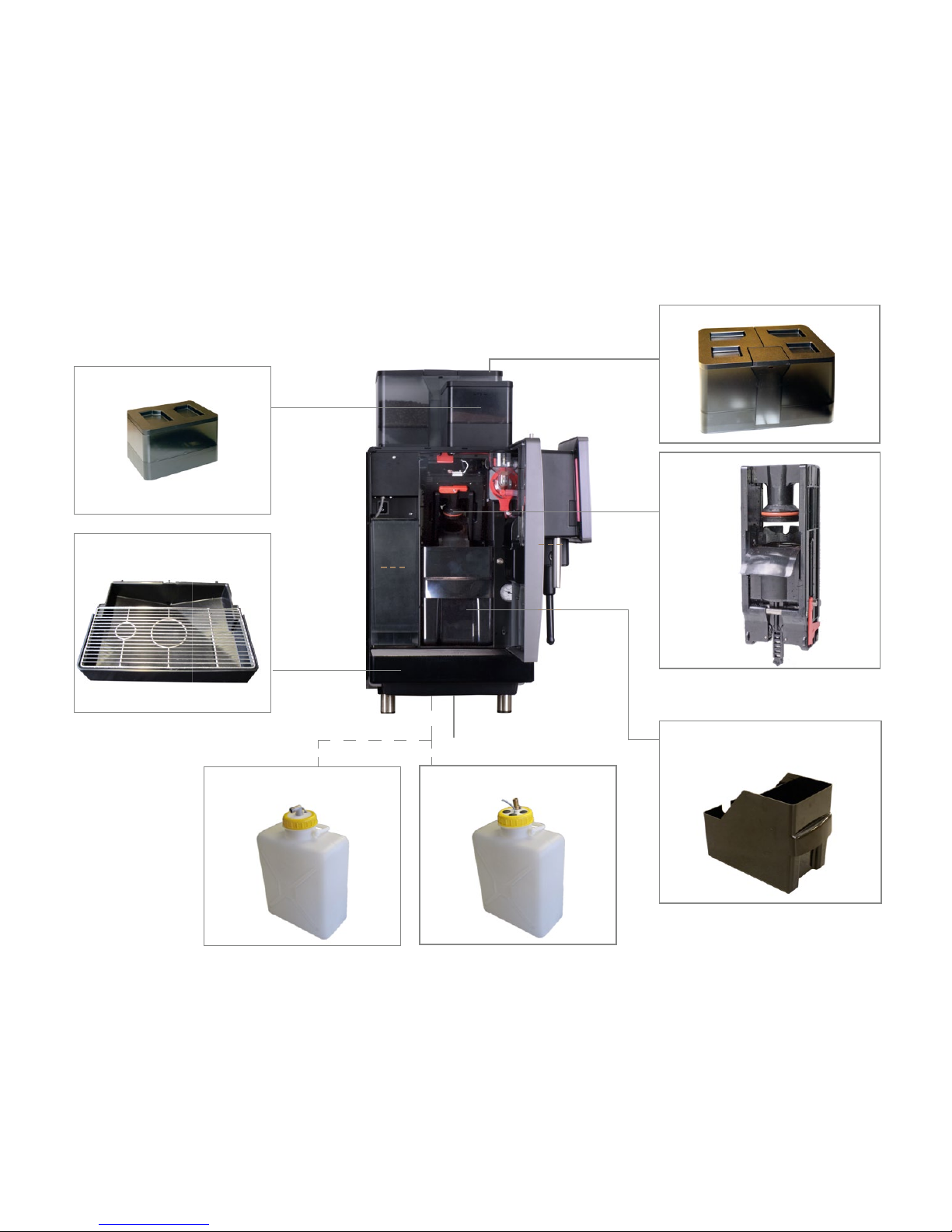

deSCription of the MaChine

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Coffee MaChine a1000

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CoMponentS of the a1000

. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CoMponentS of the refrigeration unit (Su12)

. . . . . . . . . . . . . . 13

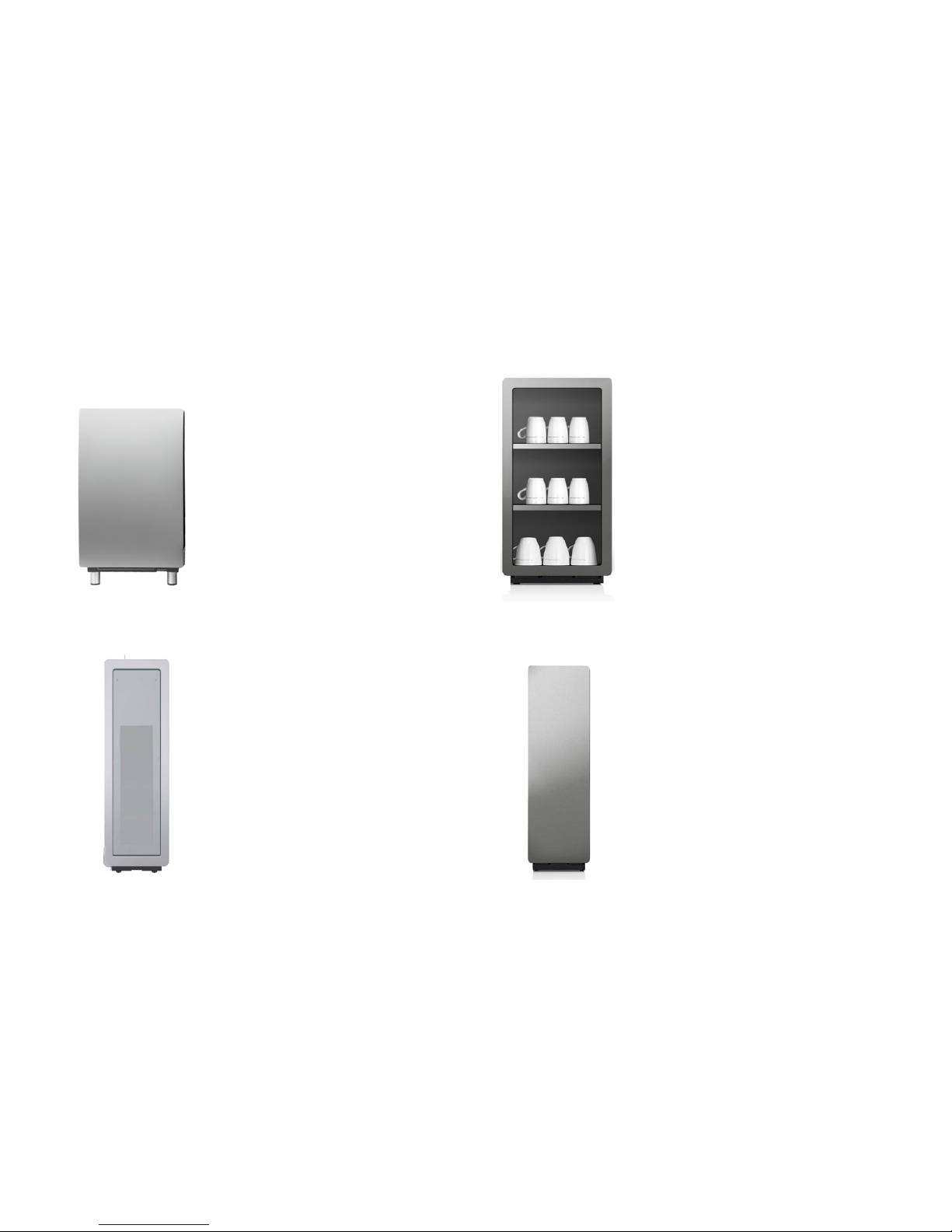

add-on unitS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

the operating interfaCe

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

overview of operating ModeS

. . . . . . . . . . . . . . . . . . . . . . . . . . 16

inStallation and teChniCal data

. . . . . . . . . . . . . . . . . . . . . . . . . . 18

CoMMiSSioning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

initial CoMMiSSioning of the a1000

. . . . . . . . . . . . . . . . . . . . . 21

daily CoMMiSSioning of the a1000

. . . . . . . . . . . . . . . . . . . . . 21

filling and eMptying

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

beanS, powder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Milk

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SyrupS (option)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

preparing drinkS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

preparing drinkS with quiCk SeleCt

. . . . . . . . . . . . . . . . . . . . . 29

preparing drinkS with CaSh regiSter

. . . . . . . . . . . . . . . . . . . . 30

preparing drinkS with inSpire Me

. . . . . . . . . . . . . . . . . . . . . . . 31

preparing drinkS with ground Coffee

. . . . . . . . . . . . . . . . . . . . 32

preparing water for tea

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SteaM diSpenSer (autoSteaM/autoSteaM pro)

. . . . . . . . . . . . . . 34

TABLE OF CONTENTS

Page 5

i

For your safety

Page 3

Cup warmer (optional)

The cup warmer is intended solely for preheating the coffee cups and glasses

that are required for preparing drinks.

The cup warmer is not designed to dry dish towels or other cloths. It is not necessary to cover the cups to warm them.

Flavor Station (optional)

The Flavor Station is intended exclusively for the automatic conveyance of syrups

and other liquid aromas for the preparation of drinks.

The Flavor Station is not designed to pump more viscous fluids such as sauces

(e.g. chocolate sauce).

Payment system (optional)

The payment system can be used for various methods of payment.

Examples: Payment with coins, cards, or mobile payment systems.

Do you have any questions that are not addressed in these instructions? Please do not hesitate to contact Customer Service or your

service technician.

A1000

The coffee machine is a commercial machine for preparing drinks and is intended for use in food services, offices and other similar environments.

The coffee machine is designed to process whole coffee beans, ground coffee,

powder that is suitable for automatic devices, and fresh milk.

The coffee machine is intended for the commercial preparation of drinks in

accordance with these instructions and the technical data.

The coffee machine is intended exclusively for operation in interior rooms.

The machine is not suitable for outdoor use or the storage of alcoholic or explosive substances.

Refrigeration unit

The refrigeration unit is used exclusively to keep milk cool while preparing coffee

drinks with a coffee machine.

Use only pre-cooled milk (2-5°C or 36-41°F).

Only use FRANKE Clean solution. Other cleaning agents may leave residues in

the milk system.

FOR YOUR SAFETY

Both you and the coffee machine are important to us. Therefore, we would like to provide

you with detailed safety information. For us, a high degree of safety goes without saying.

Protect yourself against residual risks arising from the functions of the machine.

Proper use

Page 6

!

For your safety

Page 4

Important

• Do not operate the coffee machine or addon units until you have completely read and

understood these instructions.

• Do not use the machine:

• If you are not familiar with its functions.

• If the machine or the connection lines

are damaged.

• If the machine has not been cleaned or

filled as intended.

• The A1000 is intended for use by trained

personnel. Each operator of the A1000

must have read and understood the instructions. This does not apply to its use in the

self-service sector. Self-service machines

must always be monitored to protect the

users.

• Children under the age of 8years are not

permitted to use the machine.

• Children or persons who are challenged

with respect to physical, sensory or mental

abilities are not permitted to use the machine except under supervision, nor should

they be permitted to play with the machine.

• Children are not permitted to carry out any

cleaning on the machine.

• Have the machine serviced at regular intervals. Regular maintenance will ensure the

safe operation and high performance of the

machine.

Risk of death by electrocution!

• Ensure that the power supply cable is not pinched and does not rub

against sharp edges.

• Ensure that the machine and power supply cable are not near any

hot surfaces such as gas or electric stoves or ovens!

• Never operate a machine that has been damaged or has a damaged

power supply cable!

• If the mains connection cable of the machine is damaged, it must be

replaced by a mains connection cable intended for that purpose.

• If the mains connection cable is not permanently attached, contact

the service technician.

• If the mains connection cable is not permanently attached, order and

use a new, original mains connection cable. (See section: Original

parts).

• If you suspect damage to the machine (for instance, a hot or burning

odor), unplug the machine from the outlet immediately and contact

your service technician!

• Never open or attempt to repair the machine yourself! The machine

contains electrically conductive parts.

• Do not make any modifications to the machine that are not described

in the Operating Instructions.

• Have repairs on electrical parts carried out by service technicians

using original spare parts.

• Have service work carried out by authorized persons only. Authorized

persons can demonstrate that they have corresponding qualifications.

DANGER

General safety concerns when using the A1000

Page 7

!

!

!

VORSICHT

WARNUNG

HINWEISE

!

!

!

For your safety

Page 5

CAUTION

CAUTION

Damage from water jets

The coffee machine is not protected against water jets.

•Avoid using water jets for cleaning and do not use high-pressure cleaners.

Damage to the coffee machine

•Set the machine up out of the reach of children.

•Do not expose the machine to the elements, such as rain, frost or direct sunlight.

Danger of tripping over the power supply cable

•Never let the power supply cable hang loose.

Blockage in the powder system caused by incorrect raw materials

•Ensure that the powder and beans are poured into the correct containers. Observe the machine

equipment.

NOTICES

WARNING

Risk of injury

Reaching into the machine may result in abrasions or crushing injuries from interior components.

•Open the machine only if daily work requires it (e.g. to clean the

powder system or to empty the grounds container).

•Exercise care and caution when working in an open machine.

•Only service technicians should open the machine for any other

reason.

Risk of injury, eye injury and damage to the machine

Objects in the bean hopper,powder containeror grinder may splinter

and be ejected, leading to damage to the machine or injury.

•Never introduce any objects into the bean hopper, powder

container or grinder.

Danger of burns

The coffee and milk dispensers, the hot water dispenser and the

steam dispenser become hot.

•Do not touch the outlets or nozzles.

The surfaces of the cup warmer are hot.

•Do not touch these surfaces.

Risk of scalding

During cleaning, hot water and steam are released repeatedly.

•Keep hands away from the outlets and nozzles during cleaning.

When drinks are dispensed, the products themselves pose a risk of

scalding.

•Always be careful with hot drinks.

Danger of irritation with cleaning agents

Descaler and Clean solution could lead to irritations.

•Observe the information enclosed with the cleaning agent.

•Observe the notes on the machine during the cleaning process.

•Avoid contact with skin or eyes.

•Wash your hands before your breaks and after you have completed your tasks.

Risk of spoiled food residue

If the machine is not cleaned regularly, milk and coffee residue may accumulate in the machine, clog the

outlets or find their way into drinks.

•Clean the coffee machine and add-on units at least once a day.

•Read the chapter "Care of the A1000".

Risk of contamination!

When the machine is not in use for extended periods, residue may accumulate.

•Rinse the coffee machine before initial use and when not in use for extended periods (more than

2 days).

Page 8

!

!

!

01

4

i

4

01

Steps on a colored background are

optional. They must be performed

depending on the model of your

machine.

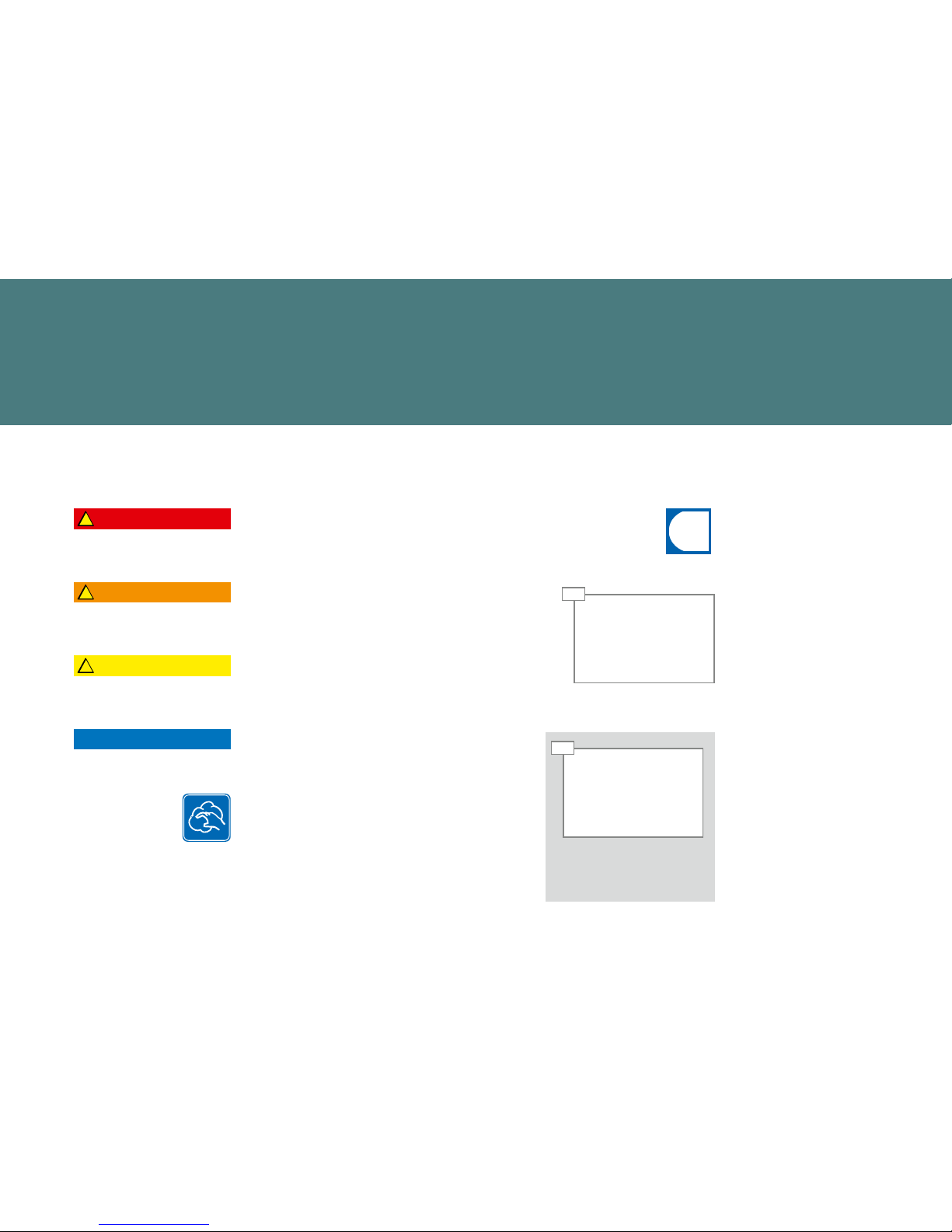

EXPLANATION OF SYMBOLS

So that you can get the most out of your A1000,we would like to familiarize you with the symbols used in the

Operating Instructions and software. For us, thorough information and open communication go without saying.

Symbols from the Operating Instructions

This symbol indicates tips, shortcuts and additional information.

Clean components with the five-step method (see

«Care of the A1000» on p. 35).

Describes and illustrates an operating step that you must perform.

DANGER

NOTICE

WARNING

CAUTION

NOTICE makes you aware of the risk of damaging

the machine.

DANGER indicates potentially life-threatening

danger or grave injury.

CAUTION directs your attention to a danger of

minor injuries.

WARNING indicates risk of injury.

Page 9

Explanation of symbols

Page 7

•Touch the fl ag

•Select the fl ag

The language is changed for the operating interface.

Switching language

Navigation

Symbol Name Description

Cancel button Cancel preparation

Start button Start preparation

Page backwards/forwards Scroll through menus with multiple pages.

Symbols used in the software

Symbols on the dashboard

Symbol Name Description

Franke Call up Maintenance level

Servicing/Cleaning Machine must be cleaned and/or serviced

Milk Milk container is empty or not installed correctly

Coff ee bean Bean hopper is empty or not installed correctly

Grounds container Grounds container must be emptied

Product

Brightness Set brightness

Info

Inactive

Standby Switch the machine to standby

Service/Confi gura-

tion/Administration

Double product Prepare double drink quantity (double dispensing)

Cold milk

Ground coff ee Selection button for ground coff ee

Extra Shot

Page 10

Schliessen

Tür off en

Personal informieren.

i

Explanation of symbols

Page 8

If the entire system is aff ected by an error, then the

error message will appear automatically.

Depiction of error messages

System has limited functionality.

System still fully functional.

Some or all resources are

locked.

Temporary interruption.

Color code for error messages

If a symbol is illuminated on the dashboard, tapping on the symbol will

display additional information and instructions.

If an error occurs, please refer to the «Troubleshooting» chapter for help.

Highlighted products cannot be prepared.

The banderole in the corner takes you to the error

message.

Highlighted products cannot be prepared.

The illuminated symbol on the dashboard takes you

to the error message.

Page 11

i

Scope of delivery and identifi cation

Page 9

The confi guration of your coff ee machine may diff er from that shown

in the instructions. Additional accessories may be obtained directly

from your retailer or from FRANKE Kaff eemaschinen AG in Aarburg,

Switzerland.

Designation Item no.

Cleaning tablets

(100 pcs.) BK328400

Cleaning agent for milk systems 1Z365033

Cleaning brushes 1L301376

Cleaning brush 1L301160

Microfi ber cloth 1H325974

Key for grind coarseness adjustment 1N330253

Key for Neoperl jet regulator 1H327863

USB stick (4 GB) 1H329064

Original Operating Instructions 1C345953

A1000

Scope of delivery

SCOPE OF DELIVERY AND IDENTIFICATION

The A1000 is a powerful coff ee machine. Its modern operating concept will help you keep your cool in any situation.

Listed below are ways to identify your machine and what is included in the standard scope of delivery.

Lesen Sie die Betriebsanleitung und das Kapitel

«Zu Ihrer Sicherheit», bevor Sie an der Maschine

arbeiten. Bewahren Sie die Betriebsanleitung bei

der Maschine auf.

Kaffeemaschine: FCS4043 - Kühleinheit: FCS4048Kaffeemaschine: FCS4043 - Kühleinheit: FCS4048

A600

ORIGINALBETRIEBSANLEITUNG

Page 12

Scope of delivery and identifi cation

Page 10

CW

The type plate for the cup warmer

is located on the inner side of the

device at the lower left.

Add-on unitsCoff ee machine A1000 (FCS4050)

SU12 Refrigeration unit with FoamMaster (cold and warm

milk, cold and warm milk foam)

CW Cup warmer

AC Payment device

FS Flavor Station

FS60A1000 SU12 FM

Type key

Position of type plates

Identifi cation

A1000 Coff ee machine (fully automatic device)

1 C 1M 1 coff ee machine, 1 milk type

3G Number of grinders (max. 3)

2P Number of powder containers (max. 2)

H1 Hot water

S1 Steam wand

S2 Autosteam

S3 Autosteam Pro

The type plate for the Flavor Station is located in the interior.

The type plate for the SU12 is

located in the cooling room.

The type plate is located to the

right of the grounds container

on the right interior wall of the

machine.

Page 13

Description of machine

Page 11

Cup sensor (optional)

Operator panel

Drip tray (permanently

attached) with drip grid

Steam wand

(optional)

Outlet with automatic height

adjustment

Bean hopper

Powder container

Lock and

Unlocking button

for the front door

Hot water outlet

Powder feed

Introduction

The A1000 coff ee machine has numerous options. To give you an

overview of your machine, a sample confi guration is illustrated below.

Please note that your coff ee machine may look diff erent from the

confi guration shown here.

Operating interface

•10.4-inch operator panel

•Multimedia compatible (audio/video)

•Audio output for powered speakers

•Nutritional value information for drinks

•Switching language

Options

•Two or three grinders with lockable bean hoppers

•One or two lockable powder dosing units

•Steam wand

•Autosteam function for automatically heating milk

•Autosteam Pro function for automatically foaming milk

•Coff ee ground chute

•Cup sensor

•Height-adjustable feet

•M2M/telemetry preparation

Coff ee machine A1000

Congratulations on selecting the A1000 for the single-serve coff ee experience you have been waiting for. Here

you will get to know the components of your coff ee machine and learn more about its functions and options.

DESCRIPTION OF MACHINE

Page 14

Description of machine

Page 12

Wastewater tank (optional)

Water connection

External water tank

(optional)

Drip tray (permanently attached)

with drip grid

Grounds container

Powder container

Brewing unit

Bean hopper

Components of the A1000

Page 15

Description of machine

Page 13

Door lock

Cup rack

(heatable)

Cleaning cartridge

Switch the heating element for the cup rack on

and off

Switch for alternating between milk delivery and

cleaning

Switch refrigeration unit on and off

Temperature display and

temperature control

Reversible adapter (milk delivery/

cleaning)

Milk container (2 x 4.5 l or 1 x 12 l)

Components of the refrigeration unit (SU12)

Page 16

Description of machine

Page 14

Payment system (optional)

For recording payment data.

Interfaces:

•VIP

Payment systems:

•Coin validator

•Coin changer

•Card readers

Refrigeration unit SU12 FM

•Automatic cleaning system

•Connection to the left and right of the machine possible

•Lockable

Models:

•SU12 with 12 l milk container

•SU12 with 2 x 4.5 l milk containers for the use of 2 milk

types

•SU12 Twin with 2 x 4.5 l milk containers for connecting 2

coff ee machines

•UT12 FM under-counter refrigeration unit with 12 l milk

container

•UT12 FM Twin under-counter refrigeration unit with 2 x

4.5 l milk containers for connecting 2 coff ee machines

•MUT (mounted under the counter)

Cup warmer (optional)

To enjoy coff ee at its best, you need pre-heated cups.

The cup warmer with four heatable shelves fi ts seamlessly

into your A1000.

Flavor Station FS60 (option)

Our Flavor Station is available to you as an option for unusual

creations.

You can use the Flavor Station to extend your range with up

to six diff erent fl avors.

Add-on units

Page 17

4

01 02

i

Description of machine

Page 15

Counters

Cleaning and maintenance

Individualization and data transfer

My settings

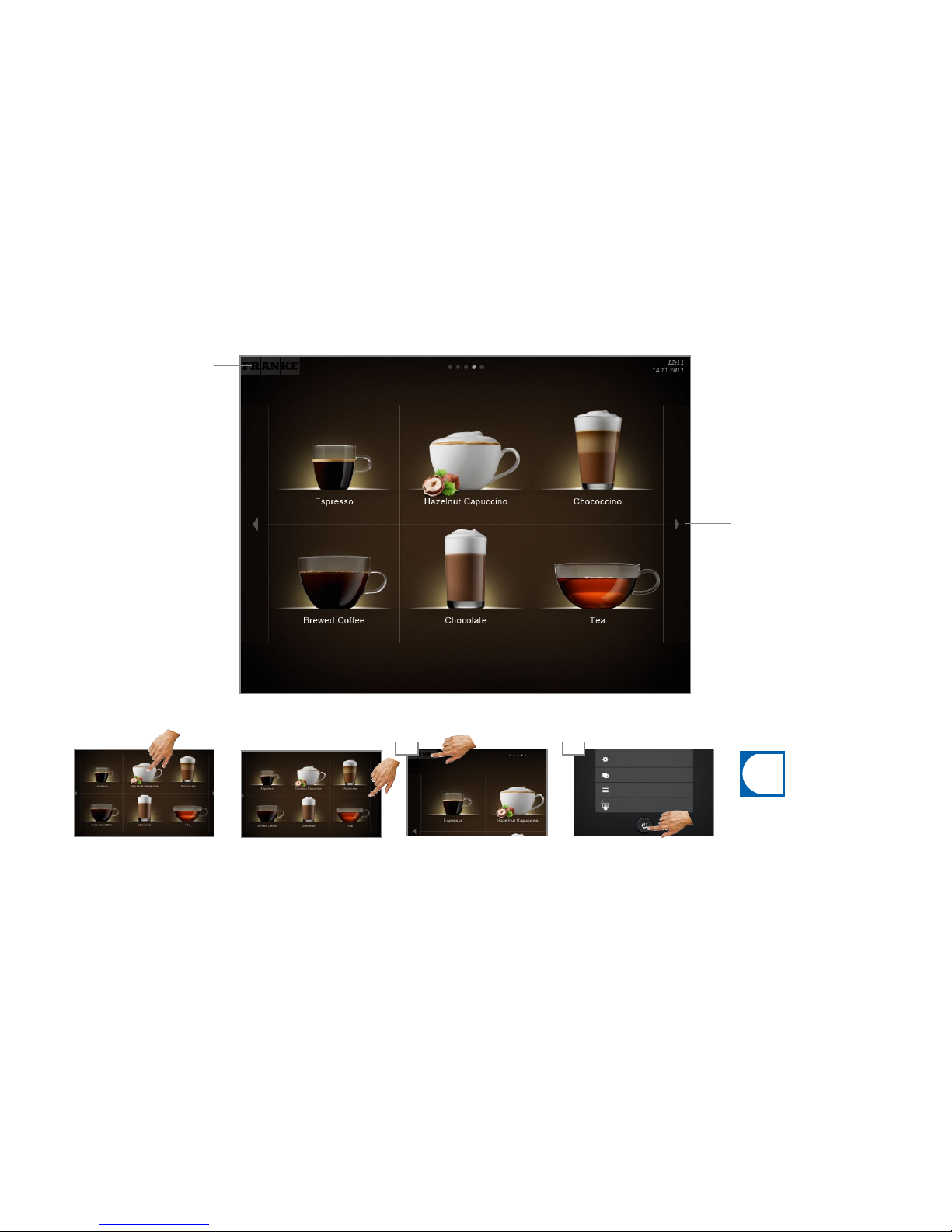

For scrolling, press the arrow

keys on the right-hand and lefthand sides of the screen.

The operating interface

Scroll forwards/backwards.

The FRANKE button is used to

switch between Maintenance

level and Product level.

To fi nish Energy saver mode,

tap on the operating interface.

Select Standby button and

confi rm.

Switch to Maintenance level.

Switching to Energy saver mode

To select an option, tap on the

respective fi eld.

Menu elements of the operating interface, using Quick Select as an example

Navigation

Page 18

Description of machine

Page 16

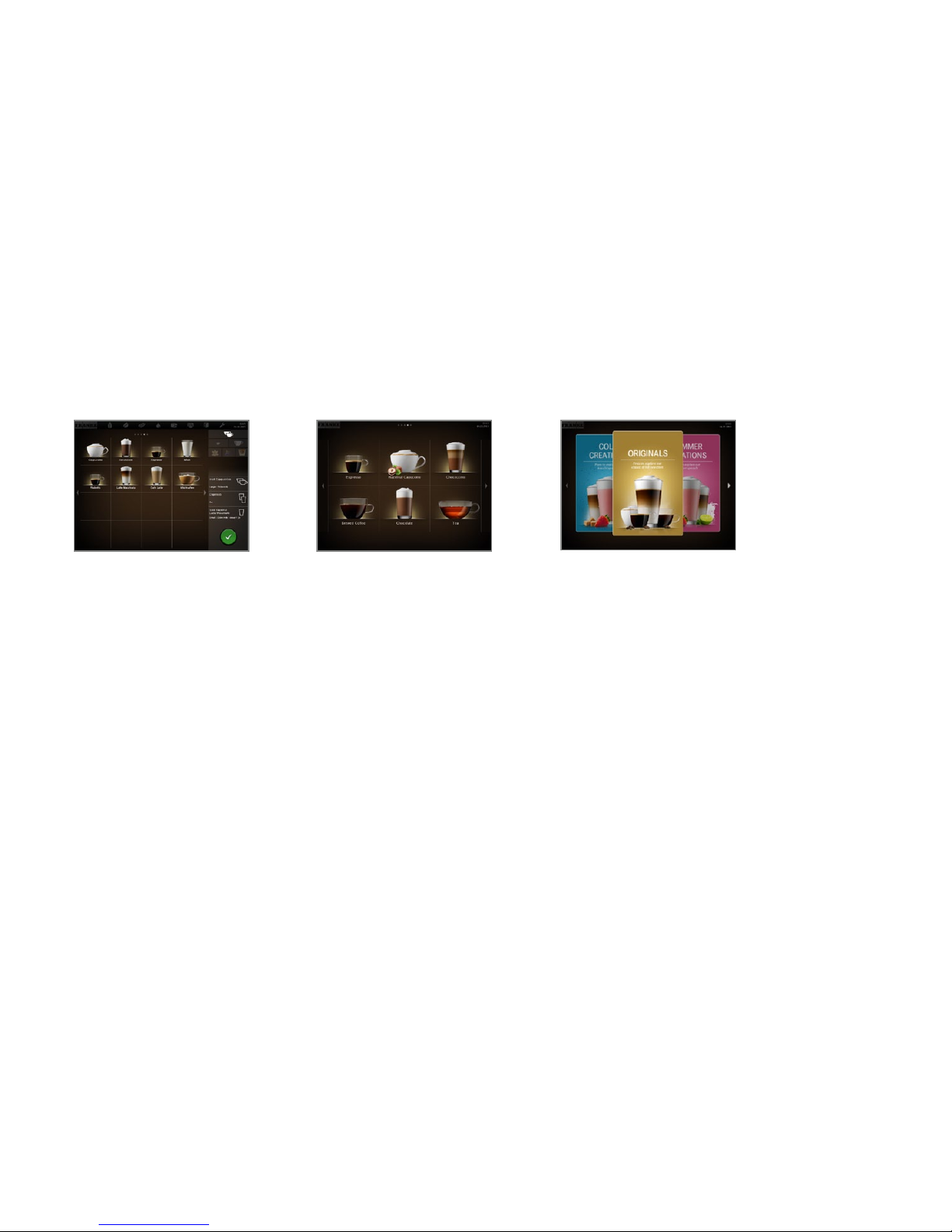

Individual adaptations:

•Customer-specifi c positioning of

beverages

Self-service

Structure of the operating interface:

•Level 1: Up to 6 menu cards with prefi ltered selection

•Level 2: up to 5 pages per menu card

•Level 3: 6 or 12 product keys per page

The Inspire Me operating mode is particularly suitable for self-service.

It inspires your customers to fi nd the

perfect drink for themselves.

Inspire Me

Self-service

Cash Register

Structure of the operating interface:

•Level 1: Product selection, up to 5

pages

•Level 2: Drink Selection status,

6, 12 or 20 product keys per page, select product options, start preparation

(if activated)

Structure of the operating interface:

•Level 1: Product selection, up to 5

pages. Column with the possible

options, the production status and the

waiting list

•Level 2: 4, 9 or 16 product keys per

page

Individual adaptations:

•Display: 2x2, 3x3 or 4x4 products per

page

•Depiction: photo-realistic, drawn

Individual adaptations:

•Display: 2x3, 3x4 or 4x5 products per

page

•Activate Credit Mode

•Customer-specifi c positioning of bever-

ages

The Quick Select operating mode is the

standard setting for self-service.

Once your customer has selected a drink,

he can adapt it in the second step if product options are activated.

Quick Select

(optional with Credit Mode)

Cash Register is the operating mode for

non-self-service utilization.

While your coff ee machine is preparing a

product, you can already add additional

orders.

Non-self-service

Overview of operating modes

Page 19

i

i

Description of machine

Page 17

Quick Select - product selection

The suitable operation mode is dependent on the utilization of your

coff ee machine, your product range and the preferences of your customers.

Operating modes for multimedia functions: Inspire Me, Quick Select

Operating modes without multimedia functions: Cash Register, Custom

Mode

Your Service technician will be happy to help you set the appropriate

operating mode.

Product selection

Status Drink Selection (if activated)

Inspire Me - Menu cards

Cash Register - product selection

Function:

•Product preview

•Display product options

•Start preparation

Credit: 6.00 CHF

Milk coff ee Vanilla

4.50 CHF

Macchiato Vanilla

5.50 CHF

Macchiato Caramel

5.50 CHF

Milk coff ee

4.00 CHF

Macchiato

5.00 CHF

Ristretto

3.00 CHF

•In the Drink Selection status, you cannot add any drink options with the Credit Mode

confi guration.

•You can activate the Credit Mode in the My Settings menu under 1 Set Machine, 1.5

Payment. Select Activate payment.

Credit Mode in the Quick Select operating mode

Display:

•Product prices

•Credit

•Missing credit

Page 20

Capacities (in accordance with DIN 18873-2)

Hourly capacity

Cups/h

Single prepa-

ration

Double prepara-

tion

Espresso 160 238

Coffee/café crème 109 141

Milk coffee 158 260

Cappuccino 149 200

Latte macchiato 114 200

Hot chocolate 129 -

Hot water 165 -

A1000 technical data (FCS4059)

Bean hopper 1.2kg per grinder

Powder container 1.2kg (may differ from this, depending on the powder used)

Grounds container 60—110 cakes, depending on the grind quantity (grounds ejection option)

Boiler Coffee: 0.9l; 2.5kW (at 230V); operating pressure 800kPa (8bar)

Hot water: 0.9l; 2.5kW (at 230V) operating pressure 800kPa (8bar)

Steam: 0.9l; 2.5kW (at 230V) operating pressure 100kPa (1bar)

Noise emission < 70dB

Weight Approx. 58kg without packaging; approx. 64kg with packaging

Water connection G 3/8" outside thread

Water pipeline pressure 0.8—8.0bar

Water shut-off With check valve and filter

Water hardness 4—8°dH (German total hardness)

7—14°fH (French total hardness)

70—140 ppm (mg/l)

Chlorine content <0.5mg/l

Acid content/ph value 6.5—7.5 pH

Funnel d = 50mm with siphon

Drain line dmin = 1"

Ambient conditions Humidity: max. 80%

Ambient temperature: 10—32° C

Energy loss/day

(incl. refrigeration unit SU12

FM)

3.165kW

Electrical connection

(see type plate)

CH/GB/EU 380—415 V/50 –60 Hz3L N PE6.3—7.5 kW

220—240 V/50 –60 Hz1L N PE2.6—3.0 kW

220—240 V/50 –60 Hz1L N PE4.4—5.0 kW

220 —240 V/50 –60 Hz3L PE5.6—7.9 kW

USA (UL) 220—240 V/60 Hz2L PE4.5—5.3 kW

JP 200—220 V / 50 –60 Hz2L PE4.5—6.3 kW

200—220 V / 50 –60 Hz3L PE6.8—8.1 kW

CN 380 V/50 Hz3L NPE6.3kW

Preparations

•The power connection for the coffee machine must be protected by a ground fault circuit interrupter (FI).

•Each terminal of the power supply must be able to be interrupted by a switch.

•The fixed water connection must have a water shut-off with a

check valve and filter that can be inspected and must meet

the requirements of the technical data.

•The fixed water connection to your coffee machine must be

done using the hose set that is supplied with it. Do not use

any other water hoses that happen to be present.

Installation

You must have completed these preparations before one of our

Service technicians can install the coffee machine for you.

Your Service technician will install your coffee machine and

carry out the initial commissioning. The technician will walk you

through the basic functions.

Your A1000 must be properly installed so that you can operate it correctly – your service technician will gladly do that for you.

You'll have to take care of a few things first. You'll find the requirements for problem-free enjoyment of your coffee machine here.

INSTALLATION AND TECHNICAL DATA

Page 21

340340

683

540 190

730

600

155

85 - 180

≥ 200

≥ 50

ii

Installation and technical data

Page 19

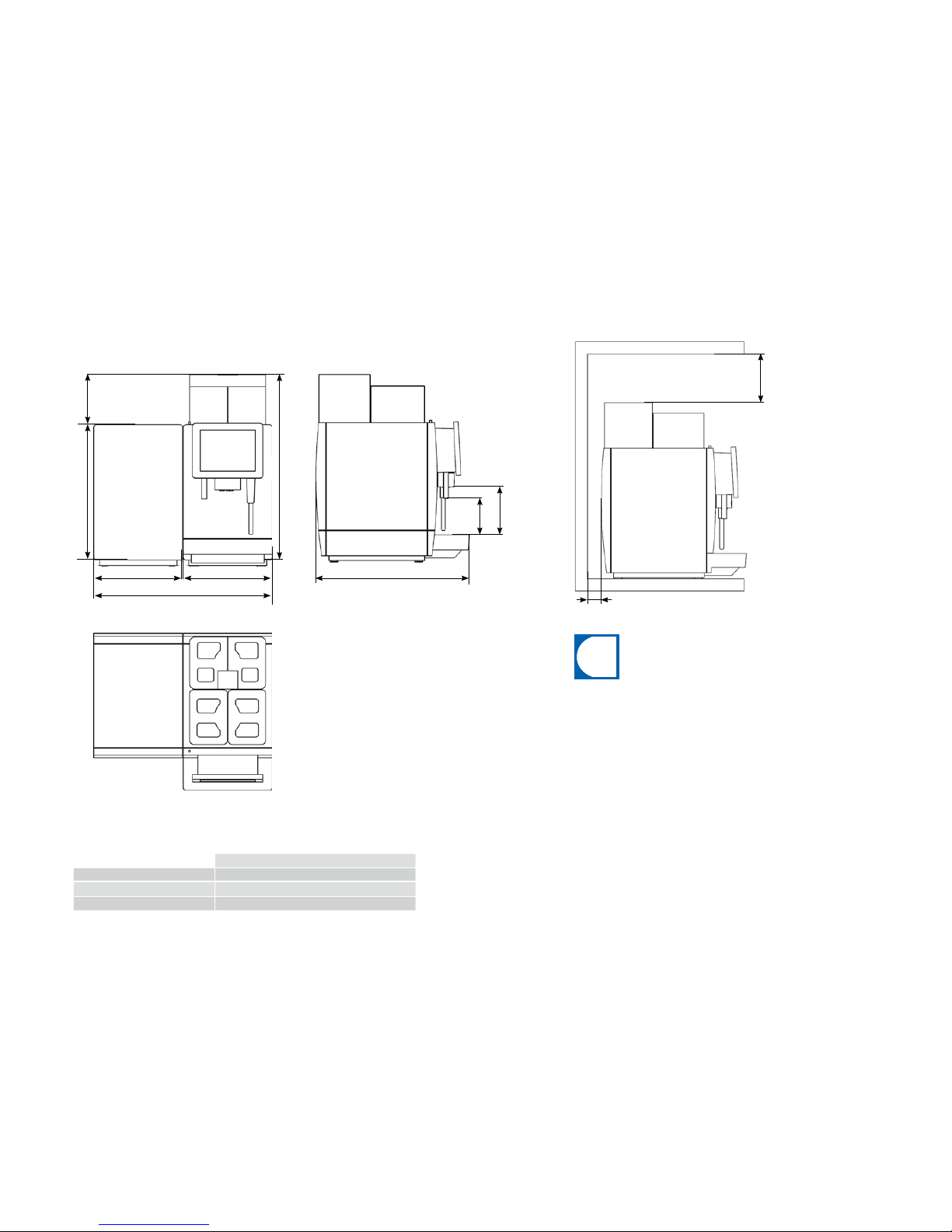

Total height

40 mm (standard) 730mm+40mm=770mm

70 mm (optional) 730mm + 70mm=800mm

(optional)

100mm (optional) 730mm + 100mm=830mm (optional)

Adjustable feet

The dimensions are specifi ed in mm.

Prepare a stable, ergonomic surface (min. load capacity: 150 kg or

330.7 lb). The operator panel should be at eye level.

Minimum clearances:

•To the rear wall: 50 mm

•Upwards: 200 mm (fi lling and removal of coff ee bean hopper)

Adjustable feet (optional) can be used to compensate for unevenness

or height diff erences.

Installation dimensions of the A1000 Dimensions of the A1000 with refrigeration unit SU12

Page 22

Installation and technical data

Page 20

Device type FCS4053

Milk container 12 l or 2 x 4.5 l

Electrical connection EU 220 – 240V1L N PE50/60Hz

SU12 FMCurrent consumption: 0.72A

Japan 100 V1L N PE50/60 Hz

SU12 FMCurrent consumption: 01.7 A

USA 100 – 127V1L N PE60 Hz

SU12 FM1.7 – 1.95 kW

SU12 FMCurrent consumption:

1.5 – 1.7 A

China 220V1L N PE50Hz

SU12 MSCurrent consumption: 0.8A

Electric cable 1800mm

Ambient conditions Humidity: max. 80%

Ambient temperature: 10 – 32°C

Coolant R134a/30 g

Climate class N (temperate climate)

Noise emission < 70dB (A)

Cooling temperature 2.0 - 5.0 °C

Empty weight (basic version) 25.7 kg

Width/Depth/Height 340mm/475mm/540mm

Under-counter refrigeration unit UT12 FM/UT12 FM Twin (optional) Payment system AC (option)

Flavor Station FS60 (option)

Weight 25.7 kg

Width/Depth/Height 320mm/467mm/547mm

Device type FCS4056

Electrical connection 85–264V1L N PE

Weight Approx. 18kg

Width/Depth/Height 200mm/451mm/542mm

Device type FCS4055

Capacity Up to 6 varieties of syrup

Bottle height Max. 330 mm

Electrical connection 230 V1L N PE50 W50/60 Hz

Fuse: 10A

Electric cable 1800mm

Ambient conditions Humidity: max. 80 %

Temperature: 10 - 32°C

Weight Approx. 25kg

Width/Depth/Height 200 mm/452 mm/545 mm (540 mm without

key)

Refrigeration unit SU12 FM/SU12 FM Twin (optional)

Device type FCS4054

Capacity Up to 120 cups (depending on cup size)

Electrical connection 220-240V1L N PE120W50/60Hz

Fuse: 10A

Weight Approx. 20kg

Width/Depth/Height 270 mm/475 mm/540 mm

Cup warmer CW (optional)

Page 23

02 03

4

i

44

01

i

!

Commissioning

Page 21

WARNING

The coff ee machine is ready for

operation.

If necessary, add coff ee beans,

suitable powder for automatic

machines, milk and syrup.

Also fi ll up the machine with water

for operation with the external

water tank.

The coff ee machine automatically vents the boiler system

and rinses while heating.

Your service technician will put your coff ee machine in operation

for the fi rst time and instruct you in its operation.

Later recommissioning will also be undertaken by your service

technician.

Initial commissioning of the A1000

Risk of scalding

The machine releases hot water

and hot steam.

•Do not touch the outlets or

the area beneath them.

Tap the operating interface.

In this chapter you will learn how to start up your A1000 coff ee machine for the fi rst time.

COMMISSIONING

Daily commissioning of the A1000

Page 24

01

02

03

4 4 4

i

!

4

04 05

Lift the powder container lid.

WARNING

Risk of injury, eye injury and damage to the machine

If objects fi nd their way into the bean hopperor grinder, splinters

may be ejected, leading to injuries or damage to the machine.

•Never place any objects in the bean hopper or grinder.

Fill the bean hopper with coff ee

beans.

Fill the powder container with

powder suitable for automatic

coff ee makers.

Add coff ee beans.

Attach the lid.

Attach the lid.Fill with powder suitable for

automatic coff ee makers.

Filling the bean hopper and powder container

Lift the bean hopper lid.

Ensure that all ingredients are always available. That way you will be able to off er your customers the

wide assortment of your product range at all times. Be prepared for a successful day.

FILLING AND EMPTYING

Beans, powder

Page 25

i

01

4

4

05

02

4

i

03

04

4

Filling and emptying

Page 23

Set the grind coarseness with

the grinder adjustment wrench.

NOTICE

If needed, the grind coarseness

can be set in stages for each

grinder.

+2 = Very coarse

0 = Normal

-2 = Very fi ne

For notes on cleaning the bean

hopper, see Chapter «Care of

the A1000», «Cleaning the bean

hopper and powder container»

on p. 36.

Impairment of function

If the bean hopper and powder container are not locked correctly,

this may impair both the function of the coff ee machine and the

product quality.

•Push the locking slide all the way in.

Attach the bean hopper.

Push the locking slide all the

way in.

Lift and remove the bean

hopper.

Empty, clean and dry the bean

hopper.

Pull the locking slide all the way

to the front.

Emptying the bean hopper, setting the grind coarseness

Page 26

!

Schliessen

Tür off en

Personal informieren.

i

01 02

4

01 03

04

4 44

4

03

02

Filling and emptying

Page 24

NOTICE

Impairment of function

If the bean hopper and powder container are not locked correctly,

this may impair both the function of the coff ee machine and the

product quality.

•Push the locking slide all the way in.

The message Door open

appears on the operating

interface.

Insert the grounds container

and close the door.

Empty, clean and dry the

grounds container.

Open the door and remove the

grounds container.

Formation of mildew

Coff ee residue can lead to the

formation of mildew.

•Empty and clean the

grounds container at least

once daily.

NOTICE

Emptying the grounds container

CAUTION

Attach the powder container.

Push the locking slide all the

way in.

Cutting injuries/crushing

The powder container's conveyor mechanism can cause cuts

or crushing injuries.

•Exercise care when cleaning the powder container.

Lift and remove the powder

container.

Empty the powder container.

Soiling

Powder may escape.

•Always transport the powder container closed in an

upright position.

NOTICE

Emptying the powder container

For notes on cleaning, see

Chapter «Care of the A1000».

Pull the locking slide all the way

to the front.

Page 27

04

01 02 03

4 4

4 4

4

4 4

05 06 07

i

i

Filling and emptying

Page 25

Milk

NOTICE

For notes on cleaning the milk

system, see Chapter «Care of

the A1000».

The milk system is prepared semi-automatically after a cleaning or a fi lling procedure.

Please observe the instructions in the error event messages.

Access to the error event messages is through the dashboard and requires no login.

Preparing the milk system

Filling the refrigeration unit

Drink quality

Incorrect handling of milk can lead to quality problems.

•Pour milk only into clean containers.

•Use only pre-cooled milk (2 - 5 °C or 36 - 41°F).

•Touch the inside of the milk container and the milk lid only after

sanitizing your hands, or wear disposable gloves.

Close the door.

Slide the milk container fully

into the cooling chamber.

Push the sliding cover to the

rear. Fill the milk container with

cooled milk.

Sliding cover

Pull out the milk container only

until the sliding cover of the

container lid is fully visible.

Switch the refrigeration unit on.

The current cooling chamber

temperature is displayed.

Open the door.

Page 28

03

!

4

4

4

4

04 05

4

01

02

06

Filling and emptying

Page 26

Switch off the refrigeration unit

if no longer required.

After switching off , do not close

the refrigeration unit door all

the way, but leave it slightly

open in order to prevent the

formation of odors.

Insert the milk container.Clean the milk container, the

parts that come into contact

with milk and the cooling

chamber.

CAUTION

Health risks due to spoiled milk

Milk residue could build up in the device as the result of insuffi cient

cleaning. This residue could clog outlets or make its way into the

products.

•Clean the milk system at least once a day using the automatic

cleaning program. Follow the instructions on the operating

interface.

•Clean the cooling chamber, the parts that come into contact

with milk and the milk container at least once a day using the

fi ve-step method.

NOTICE

Milk quality

The refrigeration unit is intended solely for keeping the milk cool

during use.

•Remove the milk and store it in a refrigerator when the coff ee

machine is not going to be used for a prolonged period, e.g.

overnight.

Store the milk in a refrigerator

or dispose of it, if necessary.

Emptying the refrigeration unit

Pull out the milk container.Open the door.

Page 29

01

i

02

03

05

06

07

08

4

04

4

4

4 4

4 4

1

2

3

4

5

6

10

4

09

4

Filling and emptying

Page 27

Push the hose connection into

the top of the bottle.

Close the Flavor Station.

Lift the bottle holders.

Slide the hose connection

upwards and onto the hose.

Insert the hose into the bottle.

Place the bottles in the Flavor

Station.

Pull the bottle holders down.

The hoses for Flavor 1 - 6 are

numbered. In the My settings

menu under 1.11 Flavor, each

type of syrup must be assigned to

the numbering accordingly.

Hoses for Flavor 1 - 6.

Use the key to unlock the Flavor Station.

Filling the Flavor Station

Syrups (Optional)

Switch on the Flavor Station

i

The switch is located

inside the Flavor Station, to the

left-hand side of the rear wall.

Open the Flavor Station.

Page 30

4

4

0201

4

i

03 04

Filling and emptying

Page 28

Clean the Flavor Station: see «Care of the A1000», «Starting cleaning of the Flavor Station» on p. 41.

After cleaning, do not re-insert the hoses into the bottles.

Remove the bottles from the Flavor Station.

Close the Flavor Station.

Prepare Flavor Station must

be executed:

•During the initial commissioning phase

•Every time a syrup bottle is

replaced

Counters

Cleaning and maintenance

Clean Flavor Station

Clean coff ee machine

Wipe protection

Prepare Flavor Station

Prepare milk system

Rinse coff ee machine

Error/Event log

Prepare Flavor Station

Cleaning and maintenance

Prepare Flavor 6

Start...

Prepare Flavor 5

Start...

Start...

Prepare Flavor 4

Prepare Flavor 3

Start...

Prepare Flavor 2

Clean Flavor Station

Clean coff ee machine

Start...

Start...

Prepare Flavor 1

Wipe protection

Prepare Flavor Station

Prepare milk system

Rinse coff ee machine

Error/Event log

Cleaning and maintenance

Individualization and data transfer

My settings

Preparing the Flavor Station

Switch to Maintenance level. Select Cleaning and mainte-

nance.

Select Prepare Flavor Station.

Select Start and confi rm.

The syrup type is prepared.

Observe instructions on the

operating interface.

Repeat this step for each

syrup bottle.

Emptying the Flavor Station

Page 31

4

4

02

06

04

4 4

4

4

03

!

05

01

Preparing drinks

Page 29

The Drink Selection product

preview appears.

Select product options.

Start preparation with the

green button.

Risk of scalding or burning!

The dispensers and drinks are hot.

•Do not touch the area under the outlets.

•In case of scalding or burns, immediately cool the aff ected area

and consult a doctor depending on the severity of the injury.

Product selection appears when

the drink is ready.

The outlet moves downwards.

Preparation begins.

Place the appropriate cup or

glass under the outlet.

Select product.

PREPARING DRINKS

Preparing drinks with Quick Select

You chose the A1000 because you love coff ee and want to off er your customers something special. In this section

you will fi nd information about drink preparation and the possible variations for your specialty drinks.

WARNING

Page 32

i

!

4

4

02

06

04

4

07

4

03

4

05

4

4

01

Preparing drinks

Page 30

Select product.

Preparation begins.

Product selection appears.

All products are ready.

Add more products to the

waiting list as needed.

The outlet moves downwards.

Next preparation begins.

Select product options.

Risk of scalding or burning!

The dispensers and drinks are hot.

•Do not touch the area under the outlets.

•In case of scalding or burns, immediately cool the aff ected area

and consult a doctor depending on the severity of the injury.

WARNING

Place the appropriate cup or

glass under the outlet.

When you prepare several products one after the other, be sure to observe the following:

•Have suffi cient glasses or cups ready to use.

•You can continuously add new products to the waiting list during the preparation.

•You can select and clear products from the waiting list.

Preparing drinks with Cash Register

Start preparation of each of

the products in the waiting

list by pressing the green

button.

Page 33

02

03

4

04

07

05

4

4

06

4

4

!

4

01

08

4

4

Preparing drinks

Page 31

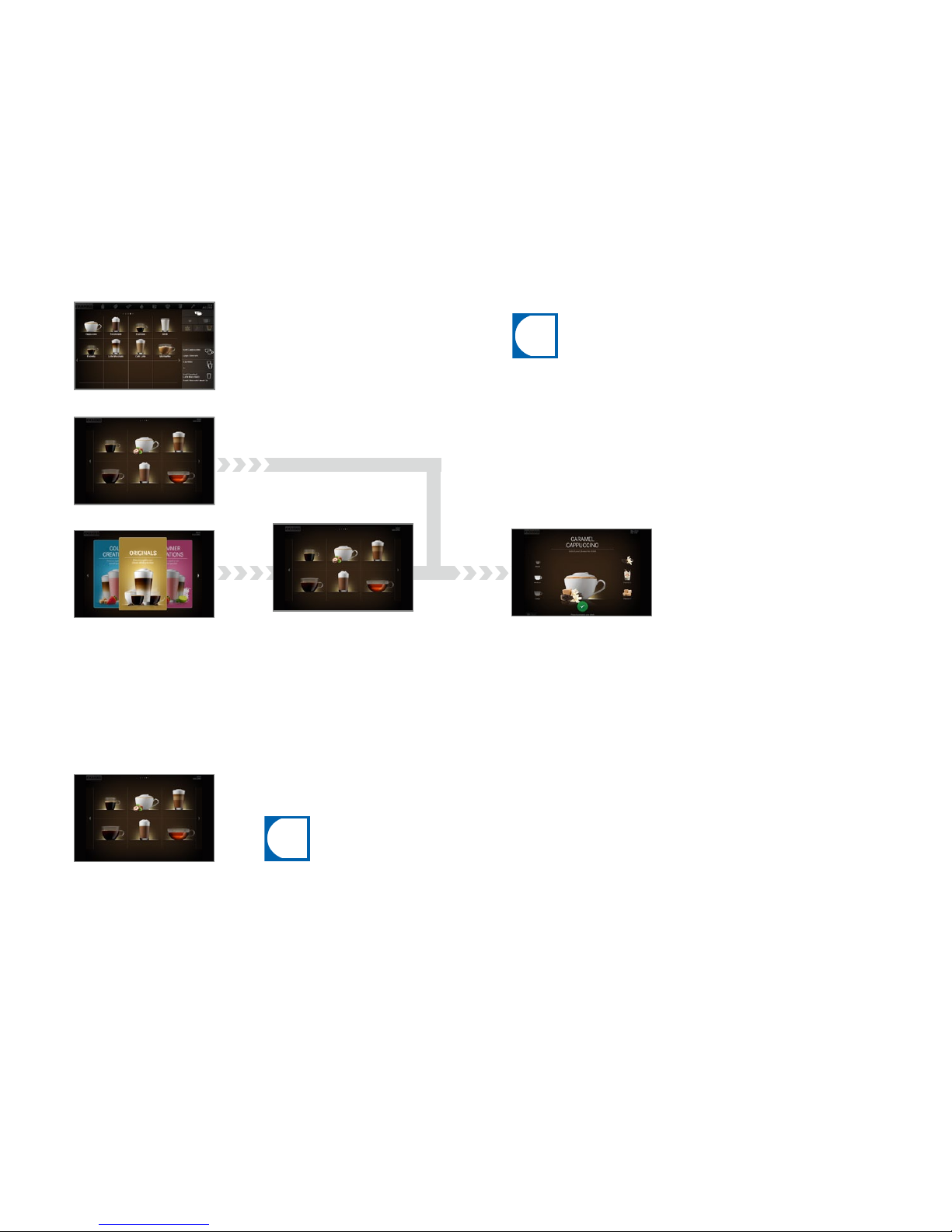

Menu cards appear.

The drink is ready.

The Drink Selection product

preview appears.

Select product options.

Start preparation with the

green button.

Risk of scalding or burning!

The dispensers and drinks are hot.

•Do not touch the area under the outlets.

•In case of scalding or burns, immediately cool the aff ected area

and consult a doctor depending on the severity of the injury.

WARNING

The outlet moves downwards.

Preparation begins.

Place an appropriate cup or

glass under the outlet.

Select product.

Tap on the desired menu card

with your fi nger.

The Drinks Overview appears.

Scroll through the menu cards.

Preparing drinks with Inspire Me

Page 34

!

4 4

02

03

06

4

08

09

01

4

4

4

4

05

07

i

4

4

04

Preparing drinks

Page 32

OK

OK

Only ground coff ee - decaff einated

or with caff eine - may be used.

Soluble instant coff ee made from

dried coff ee extract cannot be

used.

Example: Quick Select

You have selected a drink with

decaff einated coff ee.

Please open powder feed and add

decaff einated coff ee.

Message: Open powder feed

and add decaff einated coff ee.

Confi rm with OK.

Open the powder feed.

Product overview appears.

Product is ready.

The outlet moves downwards.

Preparation begins.

Add powder .

Close the powder feed.

Place an appropriate cup or

glass under the outlet.

The Decaff einated coff ee

selection key lights up.

Press the Decaff ein-

ated coff ee selection

key.

Risk of scalding or burning!

The dispensers and drinks are hot.

•Do not touch the area under the outlets.

•In case of scalding or burns, immediately cool the aff ec-

ted area and consult a doctor depending on the severity

of the injury.

WARNING

Preparing drinks with ground coff ee

You have selected a drink with

decaff einated coff ee.

Please open powder feed and add

decaff einated coff ee.

OK

OK

Page 35

4

02

!

01

i

4

03

4

05

04

4

Preparing drinks

Page 33

Water for tea

Select cup size.

Water for tea

Start preparation.

4

Water for tea

Example: Quick Select

You can stop the hot water dispenser at any time by pressing the

cancel button.

Risk of scalding or burning!

The dispensers and drinks are hot.

•Do not touch the area under the outlets.

•In case of scalding or burns, immediately cool the aff ected area

and consult a doctor depending on the severity of the injury.

WARNING

Preparing water for tea

Place an appropriate cup or

glass under the hot-water

outlet.

Select water for tea.

Page 36

4

02

03

4

04

05

4

i

!

01

i

Preparing drinks

Page 34

Example: Quick Select

Autosteam is suitable for the

manual heating and foaming

of milk and for the heating of

other drinks.

After each use:

•Wipe the steam outlet with

a damp cloth.

•Start the steam dispenser

briefl y to clean the nozzle.

The drink has reached the specifi ed temperature.

The Drinks Overview appears.

Depending on the model of the

steam wand, the steam dispenser

is automatically ended when your

drink has reached the specifi ed

temperature (Autosteam/Autosteam Pro) or the steam dispenser

cycle has ended (steam wand).

Independent of this, the steam

dispenser can be ended at any time

by pressing the cancel button.

Risk of scalding or burning!

The dispensers and drinks are hot.

•Do not touch the area under the outlets.

•In case of scalding or burns, immediately cool the aff ected area

and consult a doctor depending on the severity of the injury.

WARNING

Steam dispenser ( Autosteam/Autosteam Pro)

Hold a suitable container under

the steam outlet.

Select the steam dispenser.

The steam dispenser starts immediately.

Page 37

IV

4 4

III

4 4

II

V

i

I

Care of the A1000

Page 35

Accessories required:

•Cleaning tablets

•Microfi ber cloth

•Brush set

•Cleaning agent for milk systems

The perfect coff ee experience depends on a perfectly cleaned coff ee machine. Increase

the quality of your products!

Clean your coff ee machine at least once a day and more frequently if necessary.

Follow the 5-step method for all removable parts.

5-step method for removable parts

Dry the parts.Soak the parts in hot water

with a mild detergent. Clean all

parts of the suction line inside

with a brush.

Wash the parts.Remove coarse dirt with a

brush or paint brush.

Rinse the parts thoroughly.

Even a coff ee machine like the A1000 must be cared for. To ensure high-quality fl avor,

the A1000 must be cleaned at least once a day and serviced at regular intervals.

CARE OF THE A1000

Page 38

Care of the A1000

Page 36

Cleaning and maintenance plan

Frequency Task Information

Daily

Clean the A1000 and refrigeration unit See p. 37

Clean the steam wand See p. 39

Clean the external water tank/wastewater tank and connecting lines See p. 39

Clean the milk container, milk hoses and reversible adapter See p. 38

Weekly

Clean the interior, the inside of the door and the door seal in the refrigeration unit

Clean bean hopper See p. 40

Clean the powder container and powder chute See p. 40

If needed/prompted

Clean Flavor Station See p. 41

Cleaning the brewing unit See p. 42

Rinse the A1000 See p. 37

Descale the jet regulator for hot water See p. 39

Cleaning the monitor screen See p. 42

Every six months or every 80,000 products Maintenance by service technician Contact a Service technician

Page 39

!

4

4

4

01 02

04

4

05

03

4

06

4

i

4

i

4

Care of the A1000

Page 37

The machine automatically

switches to the cleaning mode.

Press Yes to start the cleaning

process.

•Slide the milk container all

the way in.

•Slide the cleaning lever to

the "Cleaning" position.

•Pull the reversible adapter

upwards from the suction

fi tting.

•Turn the reversible adapter

180°.

•Place the reversible adapter

on the suction fi tting.

Pull the milk container forwards.

Open the door.

The symbols indicate the correct position of the reversible

adapter for milk delivery and

cleaning.

After the cleaning cycle, the

machine switches back to

either the maintenance level or

to the energy saver mode.

Your service technician can set

the desired option for you.

Follow the instructions on the

operating interface and confi rm

with Continue.

The machine guides you to the

next step.

Starting automatic cleaning on the refrigeration unit

There are two ways of starting the automatic cleaning process:

1. On the refrigeration unit SU12 FM

2. Via the Cleaning and maintenance menu

WARNING

Starting automatic cleaning of the A1000 and the refrigeration unit

Risk of scalding!

During cleaning, hot water and

steam are released repeatedly.

• Do not touch the outlets or

the area beneath them.

Clean Coff ee Machine

Would you like to clean the coff ee

machine now?

No Yes

Continue

Page 40

01

04

06

08

05

02

07 09

03

03

4

04

4

4

01 02

i

4

4

4

44

4

4

44

4

4

4

08

01

06

04

02

0907

05

04

0201

Care of the A1000

Page 38

NOTICE

Impairment of function

Soiled accessories can have a

negative aff ect on the function

and quality of the drinks.

•Clean all parts using the

5-step method.

•All parts are dishwashersafe.

•The number of parts may

vary, depending on the

confi guration.

Close the door.Also clean the suction line and

reversible adapter inside with

a brush.

Assemble parts. Make sure the

suction fi tting engages in place.

Clean all of the parts.

Cleaning the milk container, suction line and reversible adapter

•Pull the suction line upwards.

•Remove the container lid.

Pull the reversible adapter upwards from the suction fi tting.

Turn the suction fi tting counterclockwise until it disengages.

•Pull the milk container

forwards.

•Remove the milk container

from the refrigeration unit.

Open the door.

After the cleaning cycle, the

machine switches back to

either the maintenance level or

to the energy saver mode.

Your service technician can set

the desired option for you.

Starting automatic cleaning on the operating interface

Counters

Clean Flavor Station

Wipe Protection

Prepare Flavor Station

Prepare milk system

Rinse Coff ee Machine

Error/event protocol

Individualization and data transfer

Cleaning and maintenance

Press Yes to start the cleaning

process. Follow the instructions

on the operating interface and

confi rm with Continue.

The machine guides you to the

next step.

Select and confi rm Clean Cof-

fee Machine.

Select Cleaning and mainte-

nance.

Switch to Maintenance level.

Authenticate with the PIN code

if necessary (default: 1111).

Clean Coff ee Machine

Clean Coff ee Machine

Would you like to clean the coff ee

machine now?

No Yes

Page 41

01 02

01

02

04

0503

4

4

4

4

4

4

Care of the A1000

Page 39

Remove the jet regulator for

hot water with the tool and

descale.

NOTICE

Impairment of function

Soiled accessories can have a

negative aff ect on the function

and quality of the drinks.

•Clean the accessories using

the 5-step method.

•Follow these instructions

for accessories.

Clean the water tank/wastewater tank and connecting lines.

Cleaning the accessories

Clean the steam wand

Empty the container

Wipe the steam wand with a

cloth.

Empty the container.

Fill the container with cold water and place under the steam

wand.

Select Autosteam/Steam.

The steam wand is being

rinsed.

Select Autosteam/Steam.

The steam wand is being

cleaned.

Fill container to approx. 5cm

with cold water and 30 ml of

Clean solution.

Place under the steam wand for

approx. 1 minute.

Page 42

4

4

01 02

4

03

04

05 06

07

10

!

09

4

4

4

4

4

4

4

4

4

4

11

08

4

Care of the A1000

Page 40

NOTICE

Impairment of function

If the bean hopper and powder

container are not locked correctly,

this may impair both the function

of the coff ee machine and the

product quality.

•Push the locking slide all the

way in.

Cutting injuries/crushing

The powder container's conveyor

mechanism can cause cuts or

crushing injuries.

•Exercise care when cleaning

the powder container.

Attach the powder container.

CAUTION

Clean the powder container

and rub it down with a dry

cloth.

Close the door.Push the locking slide all the

way in.

Lift the powder container up.

Empty the powder container.

Attach the bean hopper.

Clean the bean hopper and rub

it down with a dry cloth.

Lift up the bean hopper.

Empty the bean hopper.

NOTICE

Soiling, formation of mildew

The containers dry slowly and can still release moisture when they

are re-fi tted.

•Do not place the containers in direct contact with water.

•Only use a damp cloth for cleaning.

•Use detergent if necessary.

•Remove detergent residue.

Pull the locking slide all the way

to the front.

Open the door.

Cleaning the bean hopper and powder container

Pull the powder chute upwards

and clean it by using the 5-step

method.

Page 43

4 4

!

i

4

4

01 02

03

4

4

4

01 02 0403

4i4

03

4

0201

4

4

03

4

0201

4

4

Care of the A1000

Page 41

After the cleaning cycle, the

machine switches back to

either the maintenance level or

to the energy saver mode.

Your service technician can set

the desired option for you.

Starting cleaning of the Flavor Station

Counters

Clean Flavor Station

Wipe Protection

Prepare Flavor Station

Prepare milk system

Rinse Coff ee Machine

Error/event protocol

Individualization and data transfer

Cleaning and maintenance

Press Yes to start the cleaning

process. Follow the instructions

on the operating interface and

confi rm with Continue. The

machine guides you to the next

step.

Select and confi rm Clean Flavor

Station.

Select Cleaning and mainte-

nance.

Switch to Maintenance level.

Authenticate with the PIN code

if necessary (default: 1111).

Clean Coff ee Machine

Counters

Cleaning and maintenance

Individualization and data transfer

My Settings

Select Rinse coff ee machine

and confi rm.

A1000 is being rinsed.

•Rinsing is not a substitute for daily cleaning! Rinsing is

necessary to remove residue build-up in the coff ee and

milk systems.

•The A1000 automatically rinses after certain time intervals as well as when it is switched on or off .

WARNING

Danger of scalding!

Hot water is released during

rinsing.

• Do not touch the outlets or

the area beneath them.

•Do not place anything on

the drip grid.

Select Cleaning and mainte-

nance.

Switch to Maintenance level.

Rinse Coff ee Machine

Error/event protocol

Clean Coff ee Machine

Clean Flavor Station

Rinse Coff ee Machine

Prepare milk system

Prepare Flavor Station

Wipe Protection

Clean Flavor Station

Would you like to clean the Flavor

Station vnow?

No Yes

Page 44

4

4

4

01 02

4

03

04

4

4

4

4

05

06

i

4

4

4

4

04030201

Care of the A1000

Page 42

Counters

Counters

Cleaning and maintenance

Individualization and data transfer

My Settings

Clean the monitor screen.

Maintenance level appears.

Select Cleaning and mainte-

nance.

Select Wipe Protection.

The operating interface is

locked for 20 seconds.

You cannot cancel the locking

of the operating interface.

Locking lasts 20 seconds.

Switch to Maintenance level.

Cleaning the monitor screen

Clean Flavor Station

Wipe Protection

Prepare Flavor Station

Prepare milk system

Rinse Coff ee Machine

Error/event protocol

Clean Coff ee Machine

My Settings

Individualization and data transfer

Cleaning and maintenance

Lock the brewing unit in clockwise direction.

Insert the brewing unit.

Clean the brewing unit.Remove the brewing unit.Release the brewing unit lock in

counterclockwise direction.

Open the door.

Cleaning the brewing unit (as required)

Page 45

i

44

i

01

0302

Confi guring

Page 43

Counters

•All programming menu items are shown on the following pages. Some of these menu items may not be fea-

tured on your A1000, depending on the confi guration.

•Default PIN codes are assigned from the factory:

Owner Specialist Operator

Default PIN

1111 2222 7777

My PIN

•The PIN codes for key (secured) products and On/Off Machine can be viewed and changed with the owner

role in the My Settings/Access rights menu.

My Settings

Individualization and data transfer

Cleaning and maintenance

Your A1000 can be programmed individually — so that the coff ee machine is just as fl exible as you are.

We have kept the programming simple to make your job easier. Try it for yourself.

CONFIGURING

Introduction to programming

Confi rm each of the changes

with Save.

Authenticate with PIN. Select the menu.

Switch to Maintenance level.

Page 46

i

i

Configuring

Page 44

p. 50

4 Nutritional value information

4.1 Milk

4.2 Flavor

4.3 Powder

0.10 System information

0 Commissioning

1.3 Selection buttons

Additional information on

drink configuration, p. 45

p. 47

For additional information

on cleaning and maintenance, please refer to

the chapter «Care of the

A1000».

Rinse Coffee Machine

Prepare milk system

Prepare Flavor Station

Wipe Protection

Clean Coffee Machine

Cleaning and maintenance

Error/event protocol

«Cleaning and maintenance» menu tree

1.12 Accounting

1.14 Edge lighting

3.6 Timer 4

1.2 Operating mode

1.4 Cleaning

1.7 Temperatures

1.11 Flavor

6.7 On/Off machine

p. 51

p. 46

p. 42

1.1 Language

My Settings

3 Date and time

1 Configure machine

6 Access rights

6.2 Owner

6.3 Specialist

6.4 Operator

6.6 Key (secured) products

2 Set drinks

3.2 Date/Time

3.3 Timer 1

3.4 Timer 2

3.5 Timer 3

"My Settings" menu tree

Page 47

Configuring

Page 45

My Settings

1 Set Machine

1.1 Language

Parameters Value range Remarks

Operating mode:

Usage scenario

• Non-self-service

• Self-service

Operating mode • Quick Select

• Inspire Me

• Cash Register

• For the Self-service usage scenario, a selection can

be made between Quick Select and Inspire Me

• The only operating mode available in the non-self-

service usage scenario is Cash Register

Products per page • Cash Register: 4, 9, 16

• Quick Select/Inspire

Me: 6, 12, 20

• Number of products displayed simultaneously

• Default: 16 or 12

Adapt drinks Yes/No • Possibility for self-service customers to modify the

selected drink in accordance with the allocation of

the selection buttons

• Default: No

Custom images Yes/No • Activate customer-specific images

• For the Self-service usage scenario, Quick Select

and Inspire Me operating modes

• Default: No

Options:

Display the cancel button

Yes/No Display the button for canceling the product

• Default: No

Acoustic signal for drink

preparation

Yes/No

• Beeps when the product is ready

Acoustic signal for error

messages

Yes/No • Beeps in a 3-second cycle if a resource is missing

My Settings

Set machine

1.2 Operating mode

Parameters Value range Remarks

Select language de, en, fr, nl, da, fi, no, sv,

pl, cs, uk, ru, ...

• The language is switched immediately on the user

interface

• Default: de (German)

Page 48

Configuring

Page 46

Parameters Value range Remarks

Process behavior:

Buzzer

Yes/No • Acoustic prompts for actions during cleaning

• Default: No

1.4 Cleaning

1.3 Selection buttons

Parameters Value range Remarks

Product options • Small

• Medium

• Large

• 2x

• Decaf

• Flavor 1 - 6

• Extra Shot

• Iced

• Other milk type

• The maximum twelve selection buttons can be assigned with various pro-

duct options in the service menu. The product options appear in the Drink

Selection status

• With up to eight configured selection buttons, buttons 1-4 are displayed

on the left side; the rest on the right

• If more than eight selection buttons are configured, buttons 1-6 are

displayed on the left side and the rest of the buttons are displayed on the

right side

• Nine and more buttons are displayed at a reduced size

Text display • Function

• Free text

• No text

• Default: Function: Labeling corresponds to the name of the selected pro-

duct option.

• Free text: your own labeling of the selection buttons.

• No text: Labeling disabled.

Price • Amount

• Surcharge for the option.

• The total price is calculated by the machine.

PLU • PLU No. • PLU number for price calculation (if PLU numbers are used).

Set machine(continued)

Page 49

Configuring

Page 47

1.7 Temperatures

Parameters Value range Remarks

Coffee -20 ... +20 • The temperature in the coffee boiler is preset by the service technician

• The set temperature can be adjusted by percentages using the sliding

controller

Hot water/

steam

-20 ... +20 • The temperature in the hot water/steam boiler is preset by the service

technician

• The set temperature can be adjusted by percentages using the sliding

controller

Tea water -20 ... +20 • The temperature in the hot water boiler is preset by the service technician

• The set temperature can be adjusted by percentages using the sliding

controller

Parameters Value range Remarks

Flavor:

Counting is active

Yes/No Switching the counting of the Flavor products On/Off

Flavor 1 - 6 • [list of the syrup

varieties]

• User-defined

• Only the Flavor types stored here will be available later for the

drinks settings

• If User-defined is selected, the Flavor types can be named

according to preference

1.11 Flavor

Parameters Value range Remarks

Select lighting • Off

• Red, green, blue

Default: Color gradient

Error display on edge

lighting

Yes/No

Parameters Value range Remarks

Select payment type On/Off Switch Payment On/Off

Pay popup:

Show popup

Yes/No Activate/deactivate the display of the popup window

1.14 Edge lighting

1.12 Accounting

Set machine(continued)

Page 50

i

Configuring

Page 48

Select product

Select area

Confirm

variation

Preparing the test

product

Setting the

parameters

Button

Save

Select version

Test

Grind quantity

Brewing quantity

Grinder 2

Grinder 1

Water quantity

Back

Save

Coffee ...

General

Cold cappuccino

Task Menu item Information / Instruction Number

Selecting a product

Use the selection arrows to select the product to be defined, then select the

version to be edited

4, 1

Changing the product designation and product text

General

Enter the product designation and select the product text 2, 7

Determining the price (only available when payment is activated)

General

Determining PLU, prices and tokens; select the Free option 7

Adjusting the water quantity, grinders, pre-brewing and pressure

amounts

Coffee

Adapting the parameters 2, 7

Adjusting the milk quantity

Milk

Adjusting the milk quantity by percentages 2, 7

Adjusting the foam quantity

Foam

Adjusting the foam quantity by percentages 2, 7

Changing the powder options

Powder

Adjusting the water quantity of 1 and 2, powder quantity of 1 and 2 by percen-

tages

2, 7

Adding/deleting syrups

Flavor

Adjusting the syrup quantity of the various flavors by percentages 2, 7

Preparing the test product

Tes t

Use Tes t to prepare the selected product using the modified settings 6

Assigning drink variation that is to be prepared with this product selec-

tion

Select the version, then confirm with the checkmark 1, 5

Saving drink settings

Save

Use Save to save the drink configuration 3

1

3

2

4

5

6

7

•You can save each product in three user-specific versions. The

original cannot be changed.

•Only parameters that are relevant for the product are displayed.

•The percentage specifications are always based on the preset

value.

•Tips for configuring the parameters can be found in the "Help with

problems concerning product quality" chapter, p. 63.

Set drinks

Page 51

Configuring

Page 49

Date and Time

Parameters Value range Remarks

Display 12h/24h -

Day 0-31 Set the day

Month 0-12 Set the month

Year 0-63 Set the year

Hour 0-23/0-11 Configure hours

Minutes 0-59 Configure minutes

Time zone Set time zone

3.2 Date and time

3 Date and time

Parameters Value range Remarks

Active Mo, Tu, We, Th, Fr, Sa, Su Activate or deactivate days by tapping

On/Off hours 0-23/0-11 Switch-on time (hour)

On/Off minutes 0-59 Switch-on time (minute)

Monday - Sunday Yes/No Days on which the machine will switch on automatically

3.3 - 3.6 Timer 1 - 4

Page 52

Configuring

Page 50

Parameters Value range Remarks

Sugar (g) Number Enter value per 100 ml

Fat (%) Number Enter value per 100 ml

Protein (g) Number Enter value per 100 ml

Calories (kcal) Number Enter value per 100 ml

Ingredients Yes/No Default list of ingredients. Specify whether ingredient is contained

in the selected resource.

Special allergens

Characters

Enter ingredients or allergens that are not included in the list.

Parameters Value range Remarks

Sugar (g) Number Enter value per 100 ml

Fat (%) Number Enter value per 100 ml

Protein (g) Number Enter value per 100 ml

Calories (kcal) Number Enter value per 100 ml

Ingredients Yes/No Default list of ingredients. Specify whether ingredient is contained

in the selected resource.

Special allergens

Characters

Enter ingredients or allergens that are not included in the list.

4.3 Powder

Nutritional value information

Parameters Value range Remarks

Sugar (g) Number Enter value per 100 ml

Fat (%) Number Enter value per 100 ml

Protein (g) Number Enter value per 100 ml

Calories (kcal) Number Enter value per 100 ml

Ingredients Yes/No Default list of ingredients. Specify whether ingredient is contained

in the selected resource.

Special allergens

Characters

Enter ingredients or allergens that are not included in the list.

4.1 Milk

4 Nutritional value information

4.2 Flavor

Page 53

Configuring

Page 51

Parameters Value range Remarks

Set PIN 0-9 Authorization: Switch the coffee machine On/Off

Default PIN: 9999

Parameters Value range Remarks

Set PIN 0-9 Authorization: Lock and unlock key (secured) products

Default PIN: 8888

Parameters Value range Remarks

Set PIN 0-9 • Authorization: Call up the counter value of All pro-

ducts

• Default PIN: 7777

Parameters Value range Remarks

Set PIN 0-9 • Authorizations: Limited access to My Settings; call

up the counter values of All products

• Default PIN: 2222

6.7 On/Off Machine

6.3 Specialist

6.4 Operator

6.6 Key (secured) products

6 Access rights

Parameters Value range Remarks

Set PIN 0-9 • Authorizations: Access to My Settings; call up

counter values

• Default PIN: 1111

6 Access rights

6.2 Owner

Page 54

Configuring

Page 52

Owner menu items Specialist menu items Operator menu items

Without VIP system

(Standard)

4.1 Machine total - -

4.2 Cycles

4.3 Water filter - -

4.4 Grinders/dosing units

4.5 Cleanings - -

4.6 Coffee products - -

4.7 Milk products - -

4.9 Water products - -

4.10 Powder products - -

4.11 Flavor products - -

4.12 All products 4.12 All products 4.12 All products

4.13 Maintenance - -

With VIP system

4.3 Water filter - -

4.5 Cleanings - -

4.13 Maintenance - -

4.15 Product counters 4.15 Product counters 4.15 Product counters

4.16 Total product counters 4.16 Total product counters 4.16 Total product counters

4.17 List counters 4.17 List counters 4.17 List counters

4.18 List counters total 4.18 List counters total 4.18 List counters total

4.19 Sales 4.19 Sales 4.19 Sales

4.20 Exporting 4.20 Exporting 4.20 Exporting

4.21 Resetting 4.21 Resetting 4.21 Resetting

Counters

Page 55

i

4

i

01

02

Individualization and data transfer

Page 53

Cleaning and maintenance

My settings

Individualization and data transfer

Counters

• Use existing Franke media for drinks, screen savers or as advertising

media.

• Upload and view your own media objects on the machine.

• Use your own media for drinks, screen savers or as advertising media.

• Confi gure the behavior of the various operating modes or of the screen

savers.

• Saving settings.

• Create regular backups of your A1000 to a USB stick.

Multimedia functions

• Use image fi les or video fi les as an advertising medium.

• Use image fi les or video fi les as a screen saver.