Page 1

Read the operating instructions and the chapter "For your safety"

before operating the machine.

Keep the operating instructions near the machine.

Coffee machine: FCS4039/FCS4039UL — Refrigeration unit: FCS4048

A200

ORIGINAL OPERATING INSTRUCTIONS

Page 2

Page 3

Page 1

With the A200/A200 FoamMaster, you have chosen a powerful

and space-saving coffee machine.

Thank you for your confidence in us.

The A200/A200 FoamMaster adapts to your needs perfectly.

Your customers will be impressed. You will be able to offer highquality coffee specialties rapidly and individually.

We hope you enjoy your coffee machine and that it will bring

you consistently happy customers.

Sincerely, Franke Kaffeemaschinen AG

DEAR CUSTOMER

Page 4

Dispensing hot water

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

steam Dispenser

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Care of the a200

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Cleaning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Cleaning the milk system (foammaster)

. . . . . . . . . . . . . . . . . . 34

rinsing the a200 manually

. . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DesCaling the a200

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Cleaning the water tank (for operation with a water tank)

. . . . . 37

replaCing the water filter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

emptying the system

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

maintenanCe plan

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Configuring

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

introDuCtion to programming

. . . . . . . . . . . . . . . . . . . . . . . . . 41

input

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

menu tree "Config"

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Config/aDministration–Configuration

. . . . . . . . . . . . . . . . . 44

Config/aDministration–rights management; Data transfer

. . . 45

Config/proDuCts 46

Config/inDiviDualization

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Config/information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

roles anD rights

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

DeCommissioning anD Disposal

. . . . . . . . . . . . . . . . . . . . . . . . . . . 53

DeCommissioning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Disposal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

help with maChine errors

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

help with problems ConCerning proDuCt quality

. . . . . . . . . . . . 56

inDex

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

for your safety

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

proper use

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

general safety ConCerns when using the a200

. . . . . . . . . . . . . . 4

explanation of symbols

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

symbols from the operating instruCtions

. . . . . . . . . . . . . . . . . . 6

symbols useD in the software

. . . . . . . . . . . . . . . . . . . . . . . . . . 7

navigation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

DepiCtion of error messages

. . . . . . . . . . . . . . . . . . . . . . . . . . . 8

sCope of Delivery anD iDentifiCation

. . . . . . . . . . . . . . . . . . . . . . . . 9

DesCription

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Coffee maChine a200/a200 foammaster

. . . . . . . . . . . . . . . . 11

Components of the a200

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Components foammaster

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

the operating interfaCe

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

installation anD teChniCal Data

. . . . . . . . . . . . . . . . . . . . . . . . . . 17

installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Commissioning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

initial Commissioning of the a200

. . . . . . . . . . . . . . . . . . . . . . 21

Daily Commissioning of the a200

. . . . . . . . . . . . . . . . . . . . . . 21

filling anD emptying

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

filling the Coffee maChine

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

emptying the Coffee maChine

. . . . . . . . . . . . . . . . . . . . . . . . . . 24

preparing Drinks

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

preparing a stanDarD Drink

. . . . . . . . . . . . . . . . . . . . . . . . . . . 26

preparing two Drinks at onCe

. . . . . . . . . . . . . . . . . . . . . . . . . 27

Drink preparation with grounD Coffee

. . . . . . . . . . . . . . . . . . . 28

Drink preparation with Capsule (optional)

. . . . . . . . . . . . . . . . . 29

TABLE OF CONTENTS

Page 5

i

For your safety

Page 3

Cup warmer (optional)

The cup warmer is an optional add-on unit for your coffee machine.

It is intended only for warming coffee cups and glasses used when

preparing drinks.

The cup warmer is not designed to dry dish towels or other cloths.

It is not necessary to cover the cups to warm them.

Refrigeration unit

A refrigeration unit is an optional add-on unit for your A200 that is

used exclusively for keeping milk cool for beverage preparation on

an A200 coffee machine.

Only use pre-cooled milk (2 - 5 °C or 36 - 41°F).

Only use FRANKE clean solution for cleaning the milk system. Other

cleaning agents may leave residue in the milk system.

FoamMaster

The FoamMaster is an add-on unit for your A200 FM, that is used

exclusively for keeping milk cool and for the foaming of milk on an

A200 FM coffee machine.

Only use pre-cooled milk (2 - 5 °C or 36 - 41°F).

Only use FRANKE clean solution for cleaning the FoamMaster.

Other cleaning agents may leave residue in the milk system.

Do you have any questions or

problems that are not addressed

in these instructions? Please do

not hesitate to contact Customer

Service or your Service technician.

A200

The A200 is a coffee machine for use in food service, offices and

similar environments. It is designed to process whole coffee beans,

ground coffee, capsules (optional) and fresh milk.

Your coffee machine is designed exclusively for preparing coffee

drinks, capsule drinks (optional) and hot water in accordance with

these instructions and the technical data.

FOR YOUR SAFETY

Both you and the coffee machine are important to us. Therefore, we would like to provide you with detailed safety information. For our products, a high degree of safety goes without saying. Protect yourself against residual risks arising from the functions of the machine.

Proper use

Page 6

!

For your safety

Page 4

Risk of death by electrocution!

•Never operate a machine that has been damaged or has a damaged power supply cable.

•If you suspect damage to the machine (for instance, a hot or

burning odor), unplug the machine from the outlet and contact

your Service technician.

•Ensure that the power supply cable is not pinched and does not

rub against sharp edges. The machine contains electrically conductive parts. Opening the machine can pose risk of death.

•Ensure that the machine and power supply cable are not near any

hot surfaces such as gas or electric stoves or ovens.

•If the power supply cable to this machine is damaged, it must be

replaced by a suitable power supply cable.

•If the power supply cable is permanently mounted to the machine: please contact your service partner.

•If the power supply cable is not permanently mounted to the

machine: order a new power supply cable (see p. 61 for the

item number).

•Never open or attempt to repair the machine yourself.

•Do not make any modifications to the machine that are not de-

scribed in the operating instructions.

•Repairs should only be made by Franke trained service technician

using original replacement and accessory parts.

Important

•Do not operate the coffee machine or add-on units until you

have completely read and understood these instructions.

•Keep these instructions near your coffee machine.

•Your coffee machine is intended for use by trained personnel.

Each operator of the coffee machine must have read and understood these instructions. This does not apply for self-service

customers. Self-service machines must always be monitored to

protect the users.

•The device is not suitable for children under the age of 8 years.

Children above the age of 8 or persons who are challenged

with respect to physical, sensory or mental abilities must never

approach the machine alone and must always be supervised.

Children are not allowed to play with the appliance. Children are

not permitted to perform any cleaning on the machine.

•The coffee machine is intended exclusively for operation in

interior rooms.

•Have the machine serviced at regular intervals. Regular maintenance will ensure the safe operation and high performance of

your coffee machine.

•If the machines are sold or transferred to a third party, give the

operating instructions to the next user.

•You will find statements regarding the conformity of your coffee

machine in the accompanying Declaration of conformity.

DANGER

General safety concerns when using the A200

Page 7

!

!

!

!

!

!

!

For your safety

Page 5

Risk of contamination

When the machine is not in use for extended periods, residue may accumulate.

•Rinse the coffee machine before initial use and when not in use for extended

periods (more than 2 days).

Risk of injury

Reaching into the machine may result in abrasions or crushing injuries from interior

components.

•Remove only the components of the machine intended for this purpose insofar

as required by daily work (grounds and capsule container, drip tray, water tank,

coffee bean hopper).

•Exercise care and caution when working in an open machine.

•Only Service technicians should open the machine for maintenance or repair.

Danger of tripping

Suspended cables or ones lying on the floor could cause people to trip.

•Do not let the power supply cable hang loose.

Damage to the coffee machine caused by adverse weather conditions

Adverse weather conditions could damage the machine and impair its functions.

•Do not expose the machine to the elements, such as rain, frost or direct sunlight.

CAUTION

CAUTION

Risk of scalding

During cleaning, hot water and steam are released repeatedly.

•Keep hands away from the outlets and nozzles during cleaning.

When drinks are dispensed, the products pose a risk of scalding.

•Always be careful with hot drinks.

Danger of burns

The combined outlet, the hot water outlet and the steam wand become hot.

•Do not touch the outlets or nozzles.

The surfaces of the cup warmer become hot.

•Do not touch these surfaces.

WARNING

WARNING

WARNING

Risk of injury, eye injury and damage to the machine

If objects find their way into the bean hopper, the capsule system, the powder feed or

the grinder, splinters may be ejected, leading to injuries or damage to the machine.

•Never put any objects into the coffee bean hopper, the capsule system, the powder feed or the grinder.

Damage from liquids

The coffee machine is not protected against spray water and can be damaged by the

effects of liquids.

•Avoid using water jets for cleaning and do not use high-pressure cleaners.

•Do not fill up any part of the machine with water except the water tank intended

for that purpose.

•Do not fill up any part of the machine with milk except the milk container intended for that purpose.

•Disconnect the machine from the power supply without delay if milk or water has

been filled in incorrectly and call your Service office.

NOTE

WARNING

Danger from spoiled food residue

If the machine is not cleaned regularly, milk and coffee residue may accumulate in

the machine or clog the outlets. Products could become contaminated as a result.

•Clean the coffee machine and add-on units at least once a day. See chapter "Care

of the A200", p. 32.

CAUTION

NOTE

Page 8

!

!

!

01

4

4

01

i

Clean components with the 5-step

method (p. 32).

WARNING indicates risk of injury.

CAUTION directs your attention to a

danger of minor injuries.

DANGER indicates potentially lifethreatening danger or grave injury.

NOTICE makes you aware of the risk

of damaging the machine.

Describes and illustrates a step

that you must perform.

Steps highlighted in color are

optional and must be performed

only on the corresponding

machine versions.

EXPLANATION OF SYMBOLS

So that you can get the most out of your A200, we would like to familiarize you with the symbols used in the operating

instructions and the software. For us, thorough information and open communication go without saying.

Symbols from the Operating instructions

This symbol indicates tips, shortcuts and additional information.

Thorough rinsing of removable

parts.

DANGER

NOTE

WARNING

CAUTION

Page 9

Explanation of symbols

Page 7

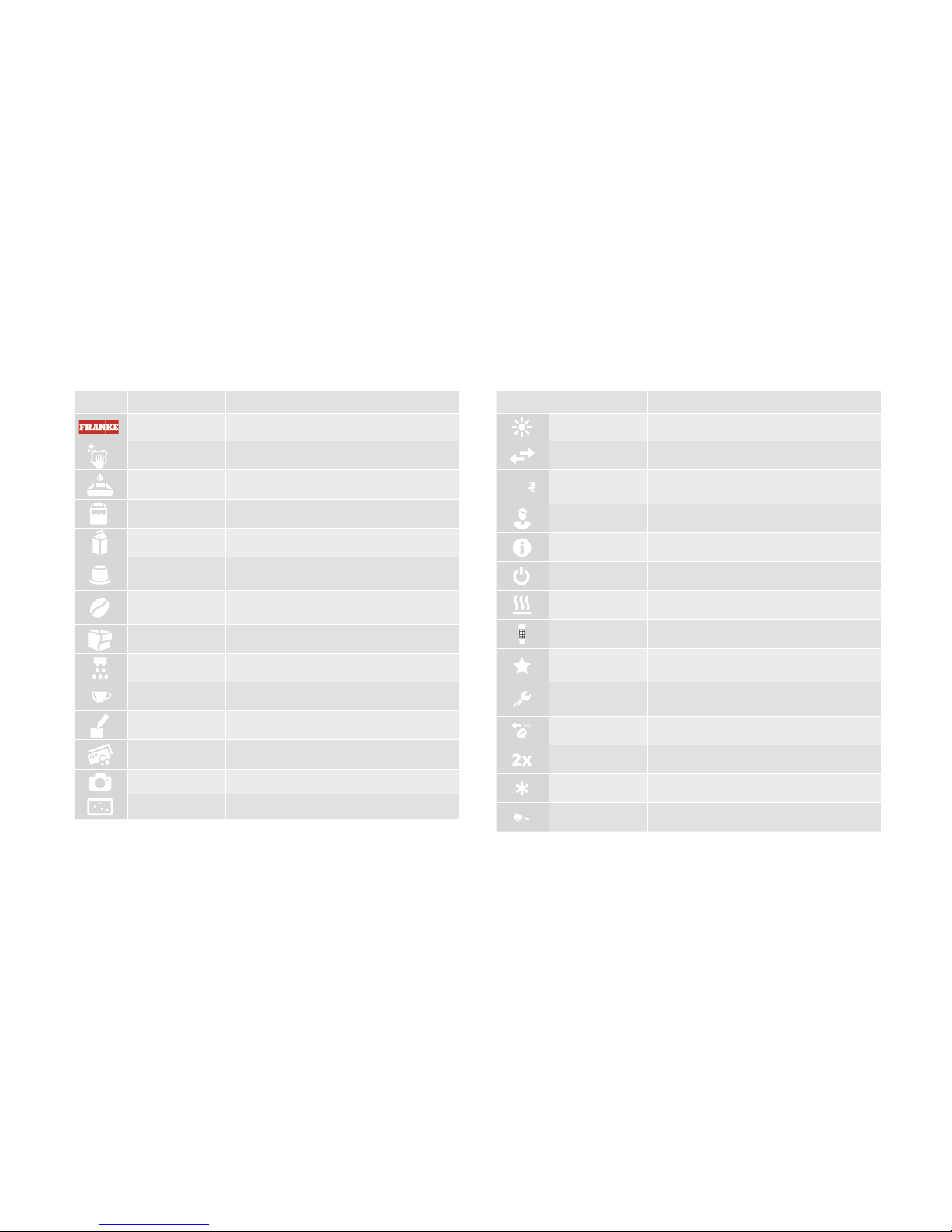

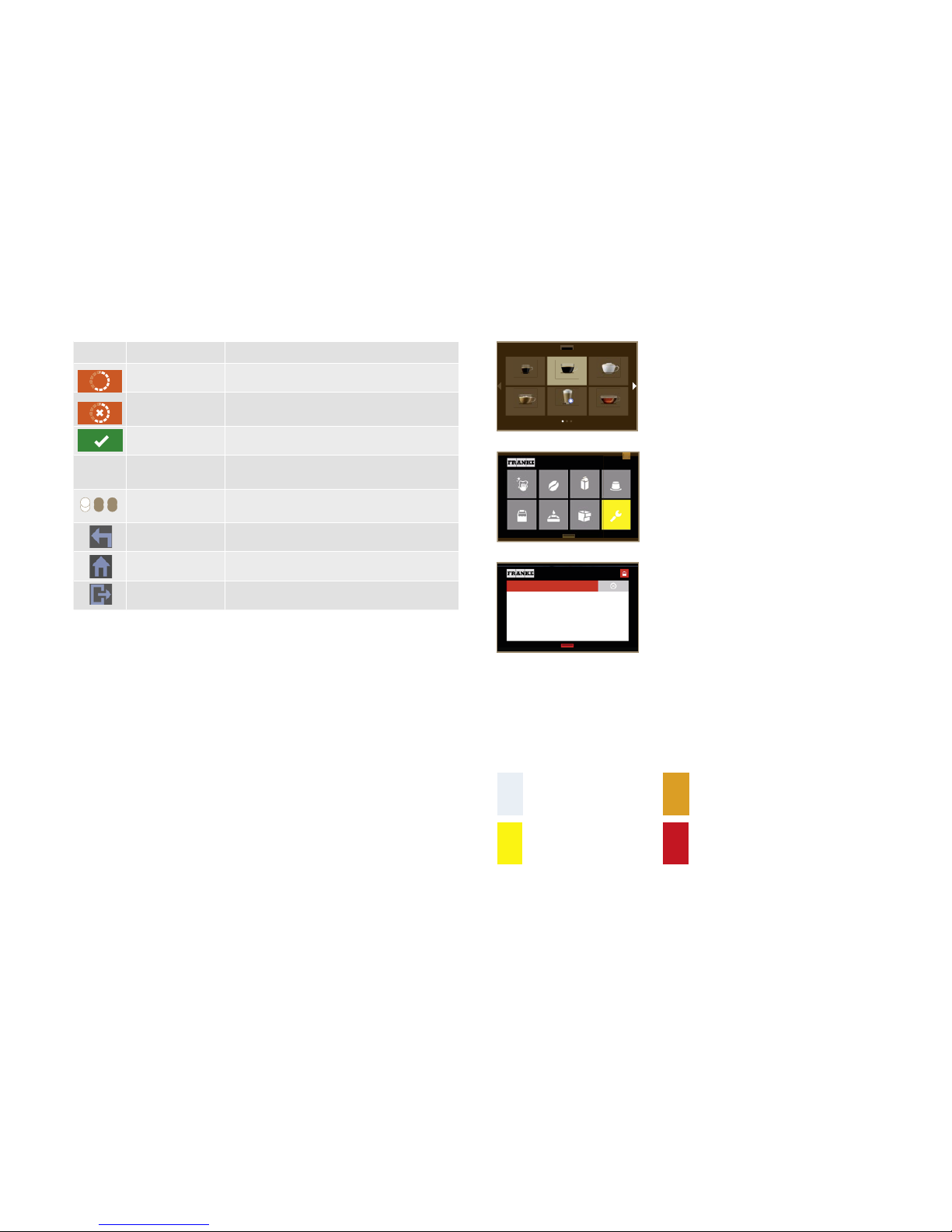

Symbols used in the software

Symbol Designation Description

Brightness Set brightness

Data transfer Data being transferred

Individual products

counter

Individualization

Info

Standby Machine switches to standby

Cup heater

Filter

Favorites

Favorites key, can be assigned to an often-used

function

Service/Confi gura-

tion/Administration

Bean left/right

Double product

Cold milk

Powder feed

00

Symbols in the dashboard, in the menu and for selection buttons

Symbol Designation Description

Franke Call up Maintenance level

Servicing/cleaning Machine must be cleaned and/or serviced

Drip tray Drip tray is full or not installed correctly

Water tank Water tank empty/missing

Milk Milk container is empty or not installed correctly

Capsule system

Capsule container missing or full

Capsule insert is open

Coff ee bean

Bean hopper is empty or not installed correctly

Powder feed is open or missing

Grounds container Grounds container must be emptied or is missing

Rinse Carry out rinsing

Product Set products

Descale Descaling required

Payment

Advertising images

Screen saver

Page 10

Explanation of symbols

Page 8

Symbol Designation Description

Progress display Displays the progress of the drink preparation

Progress display;

Cancel button

Cancel preparation

Start button Start preparation

Page backwards/

forwards

Scroll through menus with multiple pages

Number of monitor screen pages/active page

(white)

Return button Up one level/save confi guration

Home button Go to start screen

Exit menu Go to product overview

Symbol Designation Description

Progress display Displays the progress of the drink preparation

Progress display;

Cancel button

Cancel preparation

Start button Start preparation

Page backwards/

forwards

Scroll through menus with multiple pages

Number of monitor screen pages/active page

(white)

Return button Up one level/save confi guration

Home button Go to start screen

Exit menu Go to product overview

Temporary interruption

System not functioning.

System still fully

functional for the time

being.

System has limited

functionality.

Depiction of error messages

Color code for error messages

A colored symbol in the dashboard indicates

an error. Pressing the symbol will display further information and troubleshooting instructions.

Certain processes can be activated directly

from the error message (e.g. Cleaning).

Highlighted products cannot be prepared.

The dashboard can be called up with the

"roller shutter".

If the entire system is aff ected by an error,

then the error message will appear automatically.

Navigation

Symbol Designation Description

Progress display Displays the progress of the drink preparation

Progress display;

Cancel button

Cancel preparation

Start button Start preparation

Page backwards/

forwards

Scroll through menus with multiple pages

Number of monitor screen pages/active page

(white)

Return button Up one level/save confi guration

Home button Go to start screen

Exit menu Go to product overview

Page 11

i

Scope of delivery and identifi cation

Page 9

Item Designation Item no.

Filter cartridge

(Not for water connection option)

1P315694

Measuring strips

(to determine the water hardness)

1N330577

Grinder adjustment wrench 1N330253

USB stick

(optional) 1H329064

Kaffeemaschine: FCS4039 - Kühleinheit: FCS4048

A200

ORIGINALBETRIEBSANLEITUNG

Lesen Sie die Betriebsanleitung und das Kapitel «Zu Ihrer

Sicherheit», bevor Sie an der Maschine arbeiten.

Bewahren Sie die Betriebsanleitung beim Gerät auf.

Original Operating Instructions

Declaration of conformity

1A335001

1A335287

Keys (A200 FoamMaster) 1N330314

Milk suction hose with coupling

Milk suction hose

(FoamMaster)

1A335233

1B340144

Item Designation Item no.

Cleaning tablets (100 pcs.) BK328400

Clean solution MS1 1L301219

Clean solution for FoamMaster 1Z365033

Descaling agent 1P315430

Cleaning container

(A200 FoamMaster)

1B340220

Microfi ber cloth 1H325974

Dosing spoon 1N330799

Filter holder

1N330385

The scope of delivery may vary, depending on the device

confi guration. Please refer to your purchase agreement.

Additional accessories may be obtained directly from your

retailer or from FRANKE Kaff eemaschinen AG in Aarburg,

Switzerland.

A200 with MS1

A200FoamMaster

Scope of delivery

SCOPE OF DELIVERY AND IDENTIFICATION

The A200 is a powerful coff ee machine. Its modern operating concept will help you keep your cool in any situation.

Listed below are ways to identify your machine and what is included in the standard scope of delivery.

Page 12

Scope of delivery and identifi cation

Page 10

CW

The type plate for the cup

warmer is located on the inner

side of the device at the lower

left.

Add-on unitsCoff ee machine A200 (FCS4039)

SU05 Refrigeration unit (< 10 l)

MS1 Milk system without pump in SU05

MS2 Milk system with pump in SU05

FM1 FoamMaster (cold and hot milk, cold and hot milk

foam)

1 C 1M 1 coff ee machine, 1 milk type

CW Cup warmer

AC Payment device

SU05A200 KE200

Type key

Position of type plates

Identifi cation

A200 Coff ee machine (fully automatic device)

MS1 Milk system in accordance with the Venturi principle

(hot milk, hot milk foam)

2G Number of grinders

H1 Hot water

S1 Steam wand

FM1 FoamMaster (cold and hot milk, cold and hot milk

foam)

1 C Capsule system

W1 Fixed water connection

The type plate for the KE200 is

located in the cooling room.

The type plate for the SU05 is

located in the cooling room.

The type plate is located behind

the water tank.

Page 13

Description

Page 11

A200

Capsule container

Operator panel

(Touch Display)

Combined outlet

(coffee, milk, capsule products)

Hot water

Bean hopper

Steam wand

Powder feed

Capsule insert

(option)

Cup rack

On/Off switch

(on the rear)

Drip tray with drip grid

Water tank

Grounds container

Introduction

The coffee machine can be operated with water tank or with fixed water connection. A capsule system is available as an option. Depending

on your requirements, you can select further options and add-on units.

In order for you to obtain an overview of your machine, we are presenting here the standard version.

The configuration of your coffee machine may differ from that shown

in the instructions.

Coffee machine A200/A200 FoamMaster

You have chosen enjoyment of every single coffee with the A200. In this section you will learn more

about the functions and options of your coffee machine and where the controls are located.

DESCRIPTION

Page 14

Description

Page 12

Cup warmer

FoamMaster

A200 FoamMaster

Add-on units

Refrigeration unit

In many regions, milk is part of

a good cup of coff ee. You can

connect the refrigeration unit

directly to the A200 to make

sure the milk stays fresh (MS1).

Cup warmer

To enjoy coff ee at its best, you

need pre-heated cups. The cup

warmer fi ts perfectly on your A200.

Operator panel (Touch Display)

Combined outlet

(coff ee, milk, capsule products)

Hot water outlet

Bean hopper

Cup rack

On/Off switch (on the rear)

Water tank

Grounds container

Capsule container

Steam wand

Powder feed

Capsule insert

Drip tray with drip grid

Page 15

Description

Page 13

Water tank

Grounds container

Capsule container

Brewing unit

Drip tray

Components of the A200

Bean hopper

Page 16

Description

Page 14

Main switch

Temperature display

Clean solution

Cleaning container

Milk container

Components FoamMaster

Keys

Page 17

4

01 02 03

04

4 4

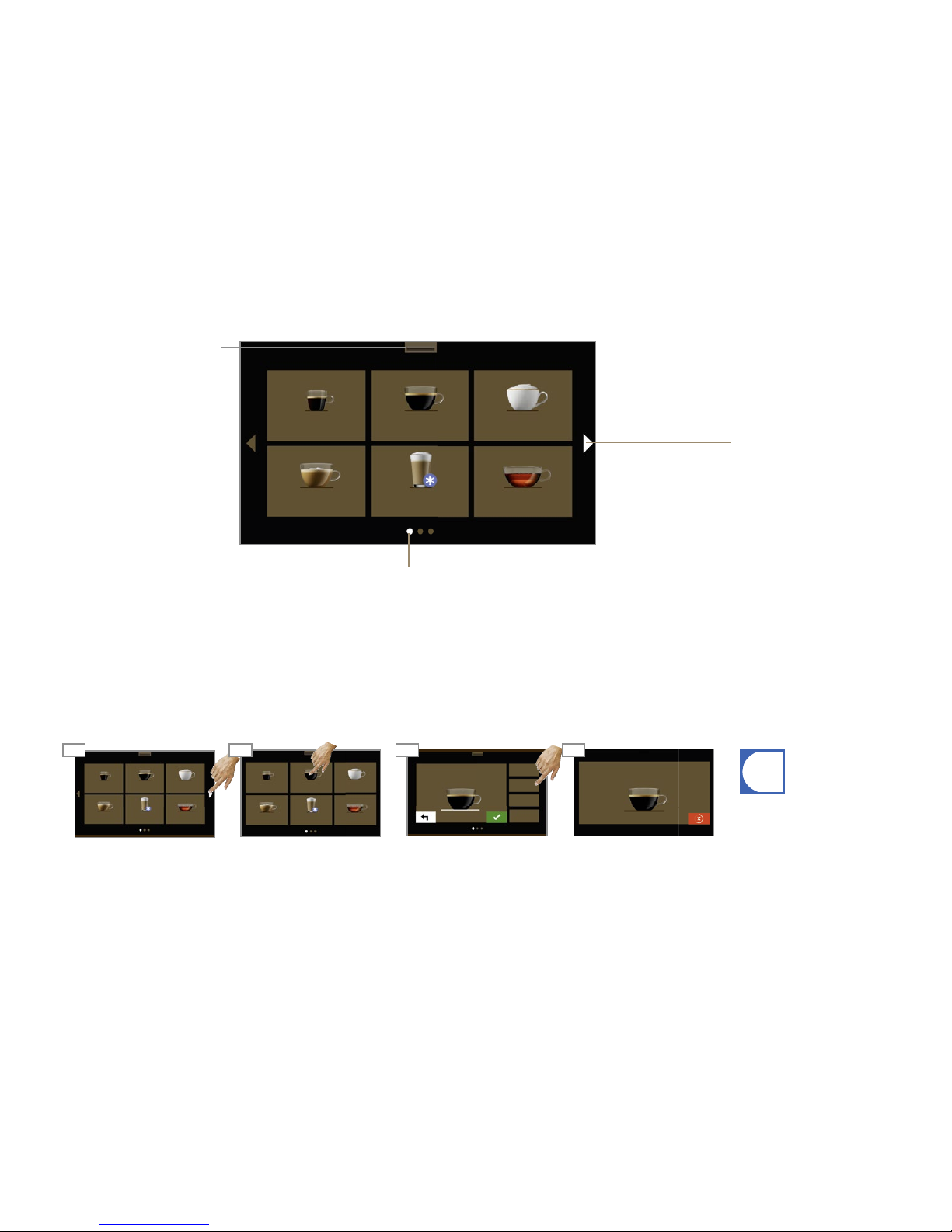

i

Description

Page 15

Cappuccino

TeaMilk coff ee Iced Latte Macc.

Café Crème

Espresso

Cappuccino

TeaMilk coff ee Iced Latte Macc.

Café Crème

Espresso

Additional information on the

preparation of drinks can be

found in the chapter "Preparing

drinks". See p. 26.

Tap the respective button to

select a drink.

Preparing drinks

In order to individualize the

beverage further, tap on selection button(s) (visible only if the

selection buttons are confi gured).

The drink is being prepared

The dashboard can be called up

with the "roller shutter".

See p. 16.

Scrolling forwards or backwards; the white arrow shows

that additional pages are present. If no more arrows appear,

then the active page is the last

one in this direction.

The operating interface

Press on the arrow to scroll.

The circles show the available

pages. The fi lled circle marks

the current position.

Cappuccino

TeaMilk coff ee

Iced Latte

macchiato

Café CrèmeEspresso

No return change Credit: 60.80

Café Crème

3.50

Page 18

i

01 02 03

04

i

i

44 4

4

4

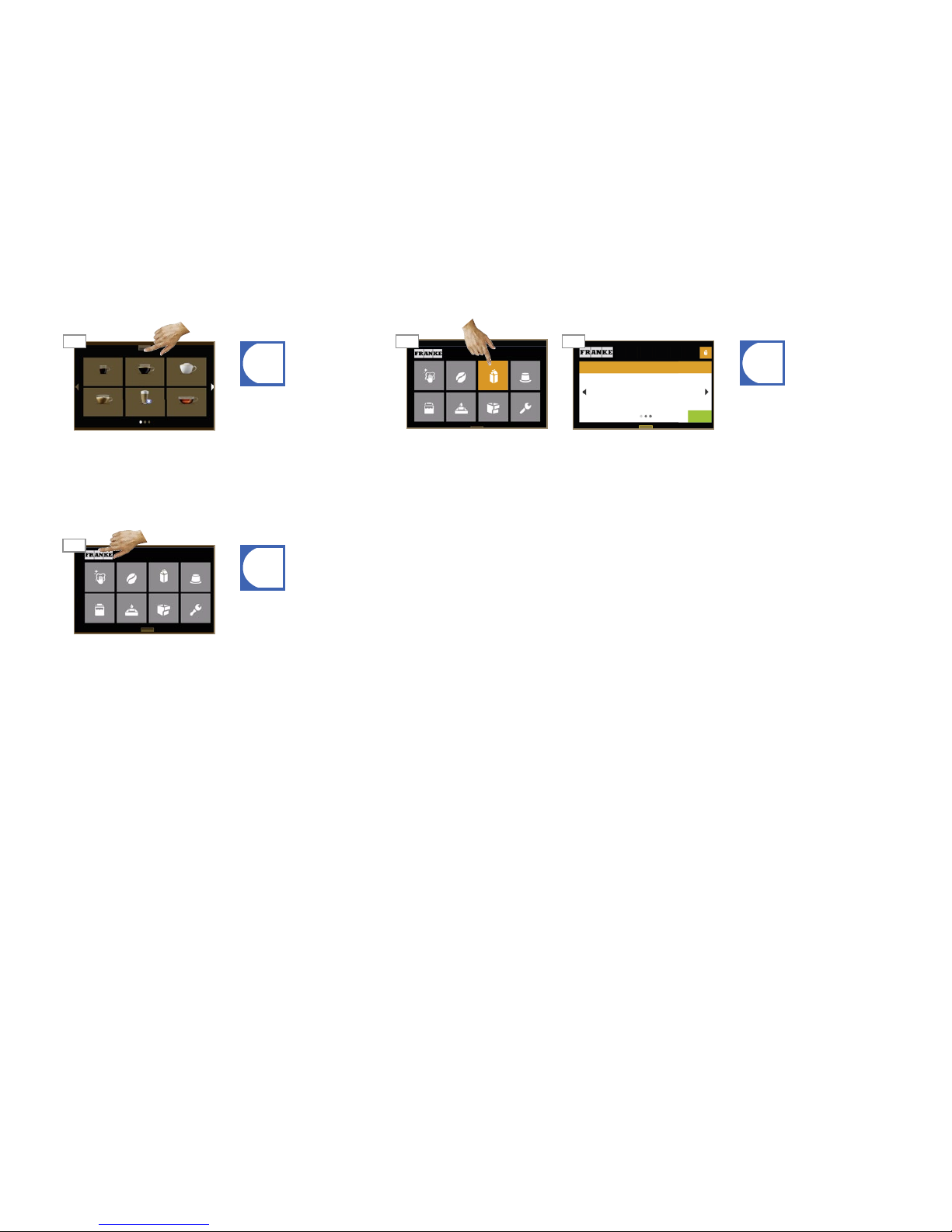

Description

Page 16

Cappuccino

TeaMilk coff ee Iced Latte Macc.

Café Crème

Espresso

09:26

Fr 2015-03-27

Additional information on administration, product settings,

individualization, care and machine information can be found

in the "Confi guration" chapter.

See p. 41.

Click on the Franke logo to

switch to programming mode.

The numerical pad appears for

entering the PIN.

Press the arrow to go to the

next error message.

To call up the more detailed

error message, press the corresponding symbol.

The error message is displayed.

Press the "roller shutter" to call

up the dashboard.

The dashboard appears.

The dashboard

OK

The milk in the FoamMaster is empty. No further

products can be produced with milk.

Please top up with fresh, pre-cooled milk.

E123 Milk empty

The symbols for the error

messages are displayed in the

dashboard.

Error messages contain the

error code, a key word, an

error description and handling

instructions for rectifying the

error.

Page 19

Installation and technical data

Page 17

Bean hopper 0.6 kg per hopper (optional: lockable)

Water tank 4.0 liters

Grounds container 40 cakes

Capsule container 10 empty capsules

Drip tray

(monitored) 2.5 liters

Electrical connection 220-240 V1LNPE2.4-2.75 kW50/60 HzFuse: 16A, without power management

220-240 V1LNPE1.2-1.50 kW50/60 HzFuse: 10A, with power management

100V2LPE1.30 kW50/60 HzFuse: 15A

120V2LPE1.45 kW60 HzFuse: 15A

Electric cable l = 1800 mm

Waste-water hose

(optional) Not permanently attached to the drain (vented), d = 14.5 mm, l = 2,000 mm

Noise emission < 70 dB (A)

Weight Approx. 20-25 kg

Width 340 mm

Depth 560 mm

Height 604 mm

Fixed water connection

(optional) Metal hose with union nut G 3/8", l = 1,500 mm (59")

Water supply line If possible on installation side: untreated water of drinking water quality (not from house-

hold decalcification system)

Water pressure 80-800 kPa (0.8-8.0 bar)

Water temperature < 25°C

Water shut-off With checkable check valve and filter

Water hardness max. 70 mg CaO/1 l water (7 dH, 13 °fH)

Chlorine content max. 0.1 mg/l(WHO recommendation: max. 0.5 mg/l)

Ideal pH value 7

Drain pipe dmin = 1"

Ambient conditions Humidity: max. 80 %

Ambient temperature: 10-32°C

Technical data of the A200/A200 FoamMasterRequirements

•The power connection for the coffee machine must be protected

by a ground fault circuit interrupter (GFCI).

•Each terminal of the power supply must be able to be interrupted

by a switch.

•For operation with a fixed water connection, this must have a

water shut-off with a check valve that can be inspected and a

filter. The fixed water connection must meet the requirements of

the technical data and of local regulations.

•The coffee machine must be connected to the water supply with

the hose set supplied. Do not use any other water hoses that happen to be present.

•The water for coffee preparation should always be fresh, oxygenated and rich in minerals.

Once the requirements are met, one of our service technicians will

install your coffee machine and put it into operation for the first time.

The technician will walk you through the basic functions.

Your coffee machine must be properly installed so that you can operate it correctly – your Service technician

will do that for you. You'll have to take care of a few things first. You'll find the preparations for problem-free

enjoyment of your coffee machine here.

INSTALLATION AND TECHNICAL DATA

Installation

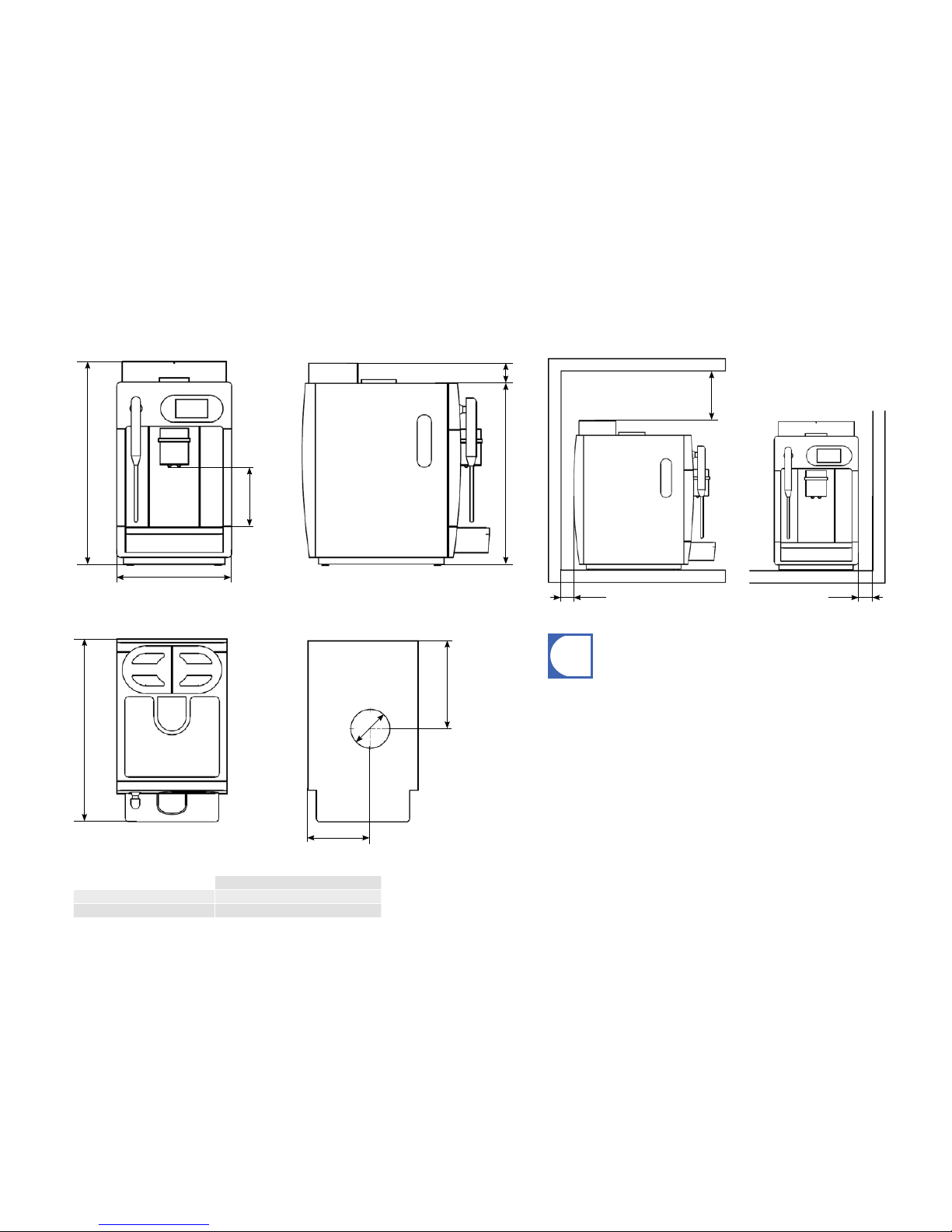

Page 20

604

340

193

∅120

560

272

540 60

70-180

i

Installation and technical data

Page 18

Prepare a stable, ergonomic surface (min. load capacity: 100 kg or 220 lb).

The operator panel should be no higher than at eye level.

Minimum clearances:

▪ To the rear wall: 50 mm

▪ Upwards: 200 mm (fi lling and removal of coff ee bean hopper)

▪ To the right: 60mm (for removal of the brewing unit)

▪ To the left: 60mm (for opening the refrigeration unit)

Adjustable feet (optional) can be used to compensate for unevenness or

height diff erences.

If optional add-on units are installed, up to an additional 330mm of width

may be required.

Buff et feed-through for grounds ejection

Installation dimensions of the A200 Dimensions of the A200

Total height

40 mm 600mm+40mm=640mm

100 mm 600mm + 100mm=700mm

Adjustable feet

≥ 50 ≥ 60

≥200

Page 21

560

≥200

≥ 60≥ 50

613

≥ 60

i

Installation and technical data

Page 19

Prepare a stable, ergonomic surface (min. load capacity: 100 kg or 220 lb).

The operator panel should be no higher than at eye level.

Minimum clearances:

▪ To the rear wall: 50 mm

▪ Upwards: 200 mm (filling and removal of coffee bean hopper)

▪ To the right: 60mm (for removal of the brewing unit)

▪ To the left: 60mm (for opening the refrigeration unit)

Adjustable feet (optional) can be used to compensate for unevenness or

height differences.

If optional add-on units are installed, up to an additional 330mm of width

may be required.

Total height

40 mm 600mm+40mm=640mm

100 mm 600mm + 100mm=700mm

Adjustable feet

Installation dimensions of the A200 FoamMasterDimensions of the A200 FoamMaster

60540

70-180

604

613

270 340

Page 22

Installation and technical data

Page 20

Device type FCS4048

Milk container 5 l

Electrical connection 220-240 V1LNPE1.95-2.3k W

50/60 Hz Fuse: 10 A

Electric cable 1800 mm

Ambient conditions Humidity: max. 80 %

Ambient temperature: 10 – 32 °C

Coolant R134a /40 g

Climate class N (temperate climate)

Noise emission < 70 dB (A)

Cooling temperature 2.0 - 5.0 °C

Weight Approx. 23kg

Width 270 mm

Depth 474 mm

Height 540 mm

Technical data FoamMaster (optional)

Device type KE200

Milk container 4 l

Electrical connection 220–240 V1LNPE82 W50/60 Hz

Fuse: 10 A

Electric cable 1800 mm

Ambient conditions Humidity: max. 80 %

Ambient temperature: 10 – 32 °C

Coolant R134a / 40 g

Climate class N (temperate climate)

Noise emission < 70 dB (A)

Cooling temperature 2.0 - 5.0 °C

Weight Approx. 13kg

Width 225 mm

Depth 468 mm

Height 337 mm

Technical data for the cup warmer (optional)Technical data KE200 (optional)

Device type FCS4054

Capacity Up to 120 cups (depending on cup size)

Electrical connection 220 – 240 V1L N PE120 W50/60 Hz

Fuse: 10 A

Electric cable 1800 mm

Weight Approx. 16 kg

Width 270 mm

Depth 453 mm

Height 544 mm (21¼")

Page 23

!

4

4

03

4

02

01

i

i

Commissioning

Page 21

Add coff ee beans and milk, if

necessary.

In addition to this, fi ll up with

water for operating with water

tank.

Your service technician will put your coff ee machine in operation for the

fi rst time and instruct you in its operation.

Later recommissioning will also be undertaken by your service technician.

Initial commissioning of the A200

The coff ee machine automatically vents and rinses after

heating.

In this chapter you will learn how to start up your coff ee machine for the fi rst time. In addition to the start-up

procedure, you will also learn about processes that take place automatically during daily commissioning.

The coff ee machine is ready for

operation.

WARNING

Risk of scalding

The machine releases hot water

and hot steam after being

switched on.

•Do not touch the machine

below the outlets or the

outlets themselves.

If necessary, switch machine

on at the power switch.

Tip on the operating interface.

The machine starts.

COMMISSIONING

Daily commissioning of the A200

Page 24

!

02

4 4 4

01

03

03

01 02

4 4 4

i

NOTE

Information regarding the insertion and

replacement of the water fi lter

can be found in the chapter

"Care of the A200", p. 32.

Machine damage

Incorrect fi lling of the machine

causes damage to the machine.

•Fill the water tank with water

only.

•Disconnect the machine

from the power supply if

there is milk in the FluidSystem

•Call Service

Adding coff ee beans

Replace water tank and slide

it into the machine until it hits

the stop.

Fill the water tank.

Use the lid to close the water tank.

Pull out the water tank.

Remove the lid.

Filling the water tank (optional)

Risk of injury, eye injury and damage to the machine

If objects fi nd their way into the bean hopperor grinder, splinters may

be ejected, leading to injuries or damage to the machine.

•Never put any objects in the coff ee bean hopper or grinder.

Ensure that all ingredients are always available. That way you will able to off er your customers

the wide assortment of your product range at all times. Get primed for a successful day.

FILLING AND EMPTYING

WARNING

Attach the bean hopper cover

and lock it (optional).

Add coff ee beans.Open the bean hopper.

Filling the coff ee machine

Page 25

08

04

4

02 03

4

4

01 02

01

03

4

4

4 4

4 4

4 4

4 4

05 06 07

Filling and emptying

Page 23

The quality of the milk may be impaired.

•Only clean containers should be fi lled with milk.

•Only use pre-cooled milk (2 - 5 °C or 36 - 41°F).

•Only touch the intake hose, the inside of the milk container and

the milk lid after sanitizing your hands, or wear disposable gloves.

•Place the container lid with the suction hose only on a surface

that is clean.

NOTE

Close the door.

Slide the milk container all the

way in.

Fit the container lid.

Fill the milk container with a

maximum of 5l of cooled milk.

Clean the milk container and

intake hose.

Remove milk container.The current cooling chamber

temperature is displayed.

Open the door and switch on

the FoamMaster.

Adding milk with FoamMaster (optional)

Slide in the milk container.

Insert the intake hose through

the opening in the cover.

Close the door.

Remove the lid.

Fill the milk container with milk

and seal it with the cover.

Open the door.

Pull intake hose out of the

machine.

Remove the milk container

towards the front.

Adding milk with MS1 (optional)

The quality of the milk may be impaired

•Only clean containers should be fi lled with milk.

•Only use pre-cooled milk (2 - 5 °C or 36 - 41°F).

•Only touch the intake hose after sanitizing your hands or wear

disposable gloves.

•Place the container lid with the suction hose only on a clean

surface.

NOTE

Page 26

!

01 02

4 4

4

07

4

4

44

4

0503

03

06

4 4

01 02

4

04

04

Filling and emptying

Page 24

Empty drip tray.

Emptying the drip tray, grounds container and capsule container

WARNING

Risk of scalding

The drip tray may contain hot water.

•Allow the water in the drip tray to cool down.

•Transport the drip tray carefully.

•Empty the drip tray slowly and carefully.

Formation of mildew

Coff ee residue can lead to

mildew formation.

•Empty and clean the

grounds container and the

drip tray at least once daily.

NOTE

Pull out the drip tray.

Emptying the coff ee machine

Pull out and empty the grounds

container.

Insert the capsule container

and grounds container.

Clean and dry the drip grid, drip

tray, grounds container and

capsule container.

Pull out the capsule container

and empty it.

Replace the drip tray.

Use the lid to close the water tank.Empty and clean the water tank.

Emptying the water tank

Replace water tank and slide it into

the machine until it hits the stop.

Pull out the water tank all the way.

Remove the lid.

Page 27

01 02 03

4

4

4 4

01 02

03

4

4

4

4

4

4

07 08

4

06

05

i

04

Filling and emptying

Page 25

If needed, the grind coarseness

can be set in stages for each

coff ee grinder.

NOTE

Emptying the bean hopper, changing the grind coarseness

Remove bean hopper by pulling

it out straight up.

Turn locking knob counterclockwise.

Open the two bean hopper covers (optional) and remove them.

Empty, clean and dry the bean

hopper.

Spoiled milk

Insuffi cient cooling or hygiene can cause milk to spoil.

•Do not use the refrigeration unit to store milk outside of

periods of operation.

•Store the milk in a refrigerator.

•Clean the coff ee machine and refrigeration unit once a day

(see p. 32).

Clean the milk container and

the refrigeration unit.

Store the milk in a refrigerator

or dispose of it, if necessary.

Open the door.

Remove the suction hose on

MNS1.

Remove the milk container

towards the front.

Emptying milk

Attach the bean hopper cover

and lock it (optional).

Turn locking knob clockwise.

Set the grind coarseness with the

grinder adjustment wrench.

•Finer grind: turn counterclockwise.

•Coarser grind: turn clockwise.

Insert the bean hopper.

Loss of coff ee quality

Moisture and cleaning agent

residue have a negative infl uence on coff ee quality.

•Dry the bean hopper well

after cleaning it. It must

not contain any moisture or

cleaning agent residue.

NOTE

Page 28

4

!

4

01 02

4

4

4

04 05 06

07

03

4

4

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

Tap the respective button to

select a drink.

The drink is being prepared.Press the arrow to scroll.

In order to individualize the

drink further, tap on selection

button(s) (visible only if the selection buttons are confi gured).

Preparation of the drink can

be canceled by pressing the

Cancel button.

Place an appropriate cup or

glass under the outlet.

Set the outlet height.

PREPARING DRINKS

Preparing a standard drink

You chose the A200 because you love coff ee and want to off er your customers something special. In this section

you will fi nd information about preparing drinks and the variations possible for your specialty drinks.

WARNING

Risk of scalding or burning

The dispensers and drinks are hot.

•Do not touch the area under the outlets.

•In case of scalding or burns, immediately cool the aff ected area

and, depending on the severity of the injury, consult a doctor.

Iced Latte

Macchiato

Page 29

!

i

4

4

4

01

4

4

4

4

04 05 06

07

03

02

Preparing drinks

Page 27

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

Tap the respective button to

select a drink.

Preparing two drinks at once

Risk of scalding or burning

The dispensers and drinks are hot.

•Do not touch the area under the outlets.

•In case of scalding or burns, immediately cool the aff ected area

and, depending on the severity of the injury, consult a doctor.

Place two appropriate cups or

glasses under the outlet.

Set the outlet height.

WARNING

The drink is being prepared.

In order to individualize the

drink further, tap on selection

button(s) (visible only if the selection buttons are confi gured).

Preparation of the drink can

be canceled by pressing the

Cancel button.

Press the arrow to scroll.

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

Page 30

!

03

04

4 4

44

i

4

4

06

05

07

08

4

01

02

i

4

4

Preparing drinks

Page 28

Café Crème

Fill powder and close powder lid.

Drink preparation with ground coff ee

Place an appropriate cup or

glass under the outlet.

Set the outlet height.

The drink is being prepared

Risk of scalding or burning

The dispensers and drinks are hot.

•Do not touch the area under the outlets.

•In case of scalding or burns, immediately cool the aff ected area

and, depending on the severity of the injury, consult a doctor.

For one cup, use approximately

7-9 g of ground coff ee.

Damage from foreign objects

Putting foreign objects through the powder lid can lead to damage to

the machine.

•Never insert any foreign objects.

•Never poke around in the powder lid with any object and never

insert anything except cleaning tablets or ground coff ee in the

powder lid.

NOTE

Fill in ground coff ee and close

powder lid.

Open powder lid.

WARNING

Preparation of the drink can

be canceled by pressing the

Cancel button.

Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Café Crème

Espresso

The prompt appears on the

display to add powder.

Tap the respective button to

select a drink.

Page 31

i

!

07

08

03

4

4

4

4

05

4

4

4

01

02

06

4

04

Preparing drinks

Page 29

Insert capsule and close the capsule cover.

Iced Latte Macchiato

Drink preparation with capsule (optional)

Place an appropriate cup or

glass under the outlet.

Set the outlet height.

Risk of scalding or burning

The dispensers and drinks are hot.

•Do not touch the area under the outlets.

•In case of scalding or burns, immediately cool the aff ected area

and, depending on the severity of the injury, consult a doctor.

WARNING

The drink is being prepared

Preparation of the drink can

be canceled by pressing the

Cancel button.

The prompt appears on the

display to insert the capsule.

Insert the capsule.

Close the capsule fl ap.

Open the capsule fl ap.

Select the desired product.

Damage from foreign objects

Putting foreign objects into the capsule system can cause damage to

the machine.

•Only use the designated capsules.

•Never insert any foreign objects in the capsule system.

NOTE

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

Page 32

!

4

01

03

4

4

i

4

04

05

4

02

Preparing drinks

Page 30

Set the outlet height.

▪ If the Simultaneous drink preparation function is not activated, all

other products are blocked during hot water dispensing.

▪ Hot water can be stored either as a permanent product or as an

individual product. In the case of permanent product, hot water

will continue to be dispensed for as long as the button is pressed.

In the case of an individual product, the quantity is defi ned.

These settings can be made only by a Service technician.

Risk of scalding or burning

The dispensers and drinks are hot.

•Do not touch the area under the outlets.

•In case of scalding or burns, immediately cool the aff ected area

and, depending on the severity of the injury, consult a doctor.

Place an appropriate cup or

glass under the hot-water

outlet.

Press the Tea product key.

WARNING

Hot water dispenser

The dispensing of hot water

begins.

Preparation of the drink can

be canceled by pressing the

Cancel button.

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

Page 33

4

01 02

4

02a

i

i

!

04

4

4

Preparing drinks

Page 31

Cancel preparation by pressing

the Cancel button.

03

Hot water

Steam

Steam

Permanent

2 Latte Mac-

chiato

Hot water

Permanent

Latte Macchiato

Steam is suitable for the

manual heating and foaming

of milk and for the heating of

other drinks.

Wipe the steam outlet with a

damp cloth after each use.

Select Steam continuous.

Preparation begins.

The steam dispensing takes

place until the Cancel button

is actuated or for the programmed time period, respectively.

Risk of scalding or burning!

The dispensers and drinks are hot.

•Do not touch the area under the outlets.

•In case of scalding or burns, immediately cool the aff ected area

and, depending on the severity of the injury, consult a doctor.

WARNING

Steam dispenser

Hold a suitable container under

the steam outlet.

Select Steam.

Preparation starts and will end

after the programmed output

time.

Hot water

Steam

Steam

Permanent

2 Latte Mac-

chiato

Hot water

Permanent

Latte Macchiato

Steam

Page 34

IV

4 4

III

4

4

4

II

V

i

I

CARE OF THE A200

Even a coff ee machine like the A200 must be cared for. To ensure high-quality fl avor,

the A200 must be cleaned at least once a day and serviced at regular intervals.

Cleaning

Rinse the parts thoroughly.Remove coarse dirt with a

brush or paint brush.

Wash the parts.Soak the par ts in water with a

mild detergent.

Dry the parts.

5-step method for removable parts

Your responsibility for the perfect coff ee experience

The perfect coff ee experience depends on a per fectly cleaned coff ee machine. Increase the quality

of your products!

Clean your coff ee machine at least once a day and more frequently if necessary.

Follow the 5-step method for all removable parts.

Accessories required:

•Cleaning tablets

•Microfi ber cloth

•Cleaning container

•Clean solution

Page 35

4

4

!

4

4

02

03

i

01

05

04

i

i

Care of the A200

Page 33

Menu

Fill the water tank

Cleaning (2/10)

Cleaning (1/10)

The automatic cleaning cycle

starts.

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

If you require a detailed guide

for a certain step, you can fi nd

this under the i symbol in

the bottom-right corner of the

screen.

Confi guration Standby

Select Clean and confi rm.

Click on the Franke logo to

switch to the Service Menu.

Click on the "roller shutter" to

call up the dashboard.

The dashboard appears.

Risk of scalding

During cleaning, hot water and

steam are released repeatedly.

• Do not touch the machine

below the outlets or the

outlets themselves.

Follow the instructions on

the display and confi rm with

Continue.

The machine guides you to the

next step.

This is how you start the automatic cleaningMy S ings

WARNING

Clean

For cleaning a coff ee machine

with MS1, you need an empty

container with a capacity of

1 l (0.264 liq.gal.) («Cleaning

container», not included in the

scope of delivery).

Follow the instructions during

automatic cleaning.

For coff ee machines with

FoamMaster, you can start

cleaning also directly on the

FoamMaster, see. p. 34).

Page 36

i

02

03

01

4

i

04

4 4

4

!

Espresso

Iced Latte

Macchiato

Milchkaff ee

Tee

Cappuccino

Café Crème

09

05

06

08

07

Care of the A200

Page 34

NoYes

Slide the milk container all the

way into the cooling chamber.

Close door.

Clean the milk container and

intake hose.

Clean and dry the interior

chamber, inner side of the door

and door seal.

Remove the cleaning container

from the cooling chamber when

prompted to do so.

Empty liquid residues into the

wastewater.

WARNING

Risk of scalding by hot

liquids

Hot liquid is discharged during

cleaning.

•Do not touch the area under

the outlet.

•Treat any injuries that occur

immediately.

Café Crème

Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

The machine is ready for

service.

If you require a detailed guide

for a certain step, you can fi nd

this under the

i

symbol in

the bottom-right corner of the

screen.

Follow the instructions on the

display.

Click Continue when a corresponding button appears.

The machine guides you to the

next step.

Confi rm cleaning by pressing

Yes .

Slide the empty cleaning

container all the way into the

cooling chamber.

A query window will appear on

the display.

Remove the milk container and

keep the milk cool.

The milk system must be

cleaned when prompted to do

so.

You can perform cleaning at

any time by pressing the cleaning button on the machine.

This is how you start the FoamMaster cleaning

Do you really want to start cleaning?

Start cleaning

Cleaning (1/10)

Page 37

4

!

i

4

4

4

4

01

02

07

03

06

04

05

4

04

4

Care of the A200

Page 35

Menu

Confi guration StandbyClean

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

The machine is ready for

service.

Confi guration

Descale

Emptying the system

In the menu Confi g.>Care,

select the menu item Rinsing.

Rinse

Info

Confi guration

Rinsing (1/3)

The rinsing starts.

Information

Products Individualization

Care

In the menu Confi guration,

select the menu item Care.

Administration

Tap on the Franke logo to

switch to the Service Menu.

Click on the "roller shutter" to

call up the dashboard.

The dashboard appears.

Rinsing the A200 manually

Risk of scalding

Hot water is released during

rinsing.

•Do not touch the machine below the outlets or the outlets

themselves.

•Do not place anything on the

drip grid.

WARNING

▪ Rinsing does not replace daily cleaning. Rinsing is necessary to

remove residue build-up in the coff ee and milk systems.

▪ The A200 automatically rinses after certain time intervals, as well

as when it is switched on or off . You can call up rinsing manually,

however.

Press Confi guration.

Page 38

4

!

i

!

4

4

4

4

4

01

02

4

03

08

04

05

4

07

Care of the A200

Page 36

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

Descale (1/8)

Confi g > Care

Descale

Emptying the system

In the menu Confi g.>Care,

select the menu item Descaling

and confi rm.

Rinse

Confi guration

Information

Products Individualization

Care

In the menu Confi guration,

select the menu item Care.

Descaling the A200

Descale (1/8)

Skin and eye irritation

The descaler can cause irritations upon contact with skin or

eyes.

•Observe the safety instructions on the packaging of

the descaler

•Wear protective gloves and

eye protection.

WARNING

Remove water fi lter from

the tank.

Fill water tank with 700 ml

of descaler.

Empty grounds container.

Empty drip tray.

Risk of scalding

During descaling, hot water and

steam are released repeatedly.

• Do not touch the machine

below the outlets or the

outlets themselves.

Follow the instructions on the

display.

Click Continue when a corresponding button appears.

The machine guides you to the

next step.

WARNING

If you require a detailed guide

for a certain step, you can fi nd

this under the i symbol in

the bottom-right corner of the

screen.

Descaling starts.

Tap on the Franke logo to

switch to the Service Menu.

Click on the "roller shutter" to

call up the dashboard.

The dashboard appears.

Press Confi guration.

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

The machine is ready for service.

Menu

Confi guration StandbyClean

0606

0707

Page 39

05

444

04

02

4

01 03

4

4

Care of the A200

Page 37

Turn the (optional) fi lter cartridge counterclockwise and

remove it.

Pull out the water tank.

Remove the lid.

Cleaning the water tank (optional for operation with a water tank)

Clean the water tank using the

5-step method.

Replace water tank and slide

it into the machine until it hits

the stop.

Insert the (optional) fi lter

cartridge in the fi lter holder and

turn clockwise until it hits the

stop.

Use the lid to close the water

tank.

Page 40

!

4

4

4

06

4

01

02

03 04

05

4

4

i

i

Care of the A200

Page 38

Menu

Confi guration Standby

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

The machine is ready for service.

Filter replacement (1/7)

Remove and empty the

water tank.

Follow the instructions on the

display.

Click Continue when a corresponding button appears.

The machine guides you to the

next step.

If you require a detailed guide

for a certain step, you can fi nd

this under the

i

symbol in

the bottom-right corner of the

screen.

Press Filter replacement.

Filter replacement

Confi g > Care

Descale

Emptying the system

Rinse

Confi guration

Information

Products

Individualization

Care

In the menu Confi guration,

select the menu item Care.

Administration

Tap on the Franke logo to

switch to the Service Menu.

Press Confi guration.

Health hazard

Contaminations could present a health hazard if the (optional) water

fi lter is used for too long.

•Replace the fi lter when prompted by the machine to do so.

•Do not use dried-out or used fi lter cartridges.

•Take care to ensure that the fi lter cartridge is mounted correctly.

CAUTION

The water fi lter ensures optimal

water quality. The (optional)

water fi lter must be replaced

on schedule in order to ensure

a long lifespan for the coff ee

machine.

Replacing the optional water fi lter

Page 41

4

4

4

4

4

4

i! i

01

04

05

02

03

0605

Care of the A200

Page 39

Remove and empty the

water tank.

Follow the instructions on the

display.

Click Continue when a corresponding button appears.

The machine guides you to the

next step.

If you require a detailed guide

for a certain step, you can fi nd

this under the

i

symbol in

the bottom-right corner of the

screen.

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

Confi guration

Descale

Emptying the system

In the menu Confi g.>Care,

select the menu item Empty

system and confi rm.

Rinse

Confi guration

Information

Products Individualization

In the menu Confi guration,

select the menu item Care.

Administration

Care

Emptying the system

Tap on the Franke logo to

switch to the Service Menu.

Click on the "roller shutter" to

call up the dashboard.

The dashboard appears.

Press Confi guration.

Emptying (1/3)

The system emptying process

begins.

After the emptying cycle, the

machine switches back into

energy saver mode.

Risk of scalding

While the system is emptying, hot water and steam are

released repeatedly.

• Do not touch the machine

below the outlets or the

outlets themselves.

WARNING

Emptying (1/3)

Menu

Confi guration StandbyClean

Page 42

Care of the A200

Page 40

Frequency Task Information

Daily Clean Coffee Machine p. 32

Weekly Clean water tank p. 37

When prompted by the machine Clean the brewing unit

Monthly Clean the coffee bean hopper p. 25

Every two months/as necessary Change water filter p. 38

As necessary Descale machine p. 36

Annually, after every 20,000 products, or as necessary Maintenance by Service technician Contact a Ser vice technician

Maintenance plan

Page 43

i

i

0201

03

4 4 4 4

04

Confi guring

Page 41

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

Confi guration

Information

Products IndividualizationAdministration

Care

Café Crème Cappuccino

Tea

Milk coff ee

Iced Latte

macchiato

Espresso

You can review and change the PIN codes with the

owner role in the menu Confi g/Administration/Rights

management, see p. 45.

Certain rights have been assigned to each PIN. The respective menu is displayed after the

authentication.

Authenticate with PIN.

The menu appears.

Click on the "roller shutter" to

call up the dashboard.

The dashboard appears.

Click on the Franke logo to

switch to programming mode.

The numerical pad appears for

entering the PIN.

Introduction to programming

CONFIGURING

Your A200 is individually programmable – so that the A200 is just as fl exible as you are. We have kept the

programming simple to make your job easier. Try it for yourself.

All programming menu items

are shown on the following

pages. Some of these menu

items may not feature on your

coff ee machine, depending on

the confi guration.

Page 44

02

01

i

44

Confi guring

Page 42

8 Cappuccino

Products>Milk settings

Milk temperature

Yes

Administration>Confi guration

Use water fi lter for tank (Claris)?

Change date

Individualization>Date/Time>Date

Date

Français

English

Individualization > Language

Deutsch

Select language

▪ Enter the desired value.

▪ Confi rm with OK.

▪ For confi guring relative

values.

▪ Steplessly confi gurable.

▪ Binary selection

▪ Click on desired Confi g

(Yes /No; On/O ff ).

▪ Press the return button (

)

to save the Confi g.

▪ Press the desired Confi g.

▪ Press the return button (

)

to save the Confi g.

Input

Select the input parameter that

is to be set by touching the

respective button.

Press confi gured date.

Window with numerical keypad

appears.

▪ On this page you will fi nd an overview of the various input options

for confi guring the machine.

▪ Information on the symbols and controls can be found in the

chapter "Explanation of symbols"», p. 7.

Confi g > Individualization

Depiction

Date and Time

Language

Page 45

i

Configuring

Page 43

▪ Start the maintenance processes in the Care menu. The mainte-

nance has to be performed in major time intervals.

▪ The Service technician can empty the system to be able to do

maintenance work.

Observe the information and data regarding filter replacement, descaling, and rinsing in the chapter "Care of the A200".

Assign Favorites

Acoustic signals

p. 52

p. 39

p. 36

p. 35

p. 38

p. 46

p. 49

p. 50

p. 48

p. 48

p. 45

p. 45

p. 45

p. 44

Payment

[Select product]

Configuration

Care

Filter replacement

Rinse

Descaling

Emptying the system

Products

Coffee

Milk

Capsule

Hot water

Steam

Prices

Information

Counter Individual

products

Product groups counter

Counters, other

Machine information

Individualization

Language

Panel setup

Load products

Clear products

Switch products

Depiction

Selection buttons

Advertising images

Screen saver

Backlight Brightness

Date and Time

Date

Time

Timer funct.

Timer

Administration

Configuration

Water supply

Milk foam

Rights management

Owner

Operator

Specialist

Data transfer

Backing up data

Load data backup

Cup heater

Menu tree "Config"

Page 46

Configuring

Page 44

Parameter Value range Remarks

Cup heater Yes/No Only with FoamMaster option

Cup heater

Parameter Value range Remarks

Set PIN 0-9 The PIN has a maximum length of 10 characters.

Owner

Rights management

Continued on next page

Parameter Value range Remarks

Signal tone before

rinsing

Yes/No -

Signal tone with

prompts

Yes/No -

Button tone Yes/No -

Acoustic signals

Parameter Value range Remarks

Solid foam Level 1-7 • Level 1: very liquid foam

• Level 7: very solid foam

Liquid foam Level 1-7 • Level 1: very liquid foam

• Level 7: very solid foam

Milk temperature

Milk foam

Parameter Value range Remarks

Water hardness Level 1-5 The levels correspond to those of the measuring strips.

Water filter Yes/No Claris water filter in the tank

Water tank Yes/No

Water supply

Configuration

Administration

Configuration

Config/Administration–Configuration

Page 47

Configuring

Page 45

Parameter Value range Remarks

Activate payment Yes/No • Ye s activates the payment. The price is displayed on

the monitor at the upper right during drink preparation. In the "Adapt drinks" monitor, the price is

displayed to the right of the product.

• No deactivates the payment. All product screens are

displayed without prices.

Payment

Parameter Value range Remarks

Load data backup - • A query appears as to whether the existing configu-

ration should be overwritten.

• If no USB stick is connected, the prompt will appear

"Insert USB stick".

• The successful data transfer is confirmed by a

message.

Parameter Value range Remarks

Backing up data - • The prompt appears "Inser t USB stick".

• The successful data transfer is confirmed by a

message.

Load data backup

Backing up data

Data transfer

Parameter Value range Remarks

Set PIN 0-9 The PIN has a maximum length of 10 characters.

Parameter Value range Remarks

Set PIN 0-9 The PIN has a maximum length of 10 characters.

Specialist

Operator

Config/Administration–Rights management; Data transfer

Page 48

Configuring

Page 46

Continued on next page

[Select product]

Milk

Coffee

Parameter Value range Remarks

Milk quantity 0-120s --

Milk temperature

(setting)

Relative value • To the right: higher milk temperature

• To the left: lower milk temperature

Foam quantity 0-120s -

Wait time after product 0-25s

Foam quality • Solid 100%

• Solid 50%, liquid 50%

• Liquid 100%

• Liquid 50%, solid 50%

Only with FoamMaster

Add steam with milk Yes/No Higher milk temperatures are made possible by adding

steam.

Parameter Value range Remarks

Water quantity 20-500ml -

Grind quantity Level 1-15 • To the right: larger grind quantity

• To the left: smaller grind quantity

Select grinder • Left

• Right

• Both

Select brew tempera-

ture

• Low

• Medium

• High

-

Pre-inject • No

• Short

• Medium

• Long

Pre-injection increases the brewing time and affects

product quality.

Configuration

Products

Config/Products

Page 49

Configuring

Page 47

Parameter Value range Remarks

PLU 1-999 The Service technician can select between two set-

tings:

• Permanently assigned PLU

• Variable PLU (click on the text box and use the

numerical keypad to enter the PLU)

Price list 0 (cash price) 0.10-999.99 Price input

Price list (Cashless 1) 0.10-999.99 Price input

Price list 2 (Cashless 2) 0.10-999.99 Price input

Free product Yes/No Product is free (Yes/No)

Token Yes/No Product can be paid for with token (Yes/No)

Price

Parameter Value range Remarks

Steam time 0-300s -

Steam

Parameter Value range Remarks

Water quantity 0-500ml -

Temperature • Low

• Medium

• High

-

Hot water

Parameter Value range Remarks

Water quantity 0-500ml -

Temperature • Low

• Medium

• High

-

Capsule

Config/Products (continued)

Page 50

Configuring

Page 48

Continued on next page

Assign Favorites

Parameter Value range Remarks

Assign a function to

favorite buttons 1-3

• No function

• Rinsing

• Descaling

• Advertising images

• Display brightn

• Product settings

• Water supply

• Individual products

counter

• Assign functions to the Favorites keys that you use

frequently.

Assign Favorites key:

• Click on the desired function in the selection menu.

• Exit the menu item, and confirm the configuration

change if necessary.

Parameter Value range Remarks

Select language 8 languages • The language is switched immediately

• For Asian languages, the English name of the langua-

ge appears in brackets

Parameter Value range Remarks

Assign product key - • 36 keys can be assigned on 6 pages

• When a button is touched, a selection list appears

with the available products (32)

Switch products

Panel setup

Clear products

Load products

Configuration

Individualization

Language

Config/Individualization

Parameter Value range Remarks

Clear product from key - -

Parameter Value range Remarks

Switch product keys - -

Page 51

Configuring

Page 49

Parameter Value range Remarks

Activate advertising

pictures

Yes/No • Load images from a USB stick to the machine if

necessary.

• Existing images can be activated/deactivated.

• If advertising images are activated, no simultaneous

drink preparation is possible.

Configure selection but-

tons

Parameter Value range Remarks

Double products Yes/No -

Switch grinders Yes/No Ye s: Two kinds of beans can be offered.

Instant coffee Yes/No Ye s: An additional coffee type can be offered in ground

form (e.g. decaffeinated coffee).

Activate selection but-

tons

Continued on next page

Parameter Value range Remarks

Select screen saver • No screen saver

• Franke screen saver

• Individual screen saver

For an individual screen saver, images must first be loa-

ded if there are not yet any available on the machine.

Set timeout 1-60min Wait time until the screen saver is switched on

Backlight Brightness

Screen saver

Advertising images

Config/Individualization(continued)

Parameter Value range Remarks

Set brightness Relative value Slider to the right: brighter display

Slider to the left: darker display

Depiction

Selection buttons

Parameter Value range Remarks

Activate selection

buttons

Yes/No -

Activate advertising

pictures

Page 52

Configuring

Page 50

Parameter Value range Remarks

Display mode 12h/24h -

Set time • Hours: 0-23/0-12

• Minutes: 0-59

• (a.m./p.m.)

Input via numerical keypad

Time

Date and Time

Parameter Value range Remarks

Set date • Days: 1-31

• Months: 1-12

• Years: 2013-9999

Input via numerical keypad

Date

Parameter Value range Remarks

Set time

(a.m./p.m.)

1-300min • Input via numerical keypad

• Switch on: press Activate button

A green checkmark appears next to the set time. The

timer is activated.

• Switch off: press Deactivate button

A red checkmark appears next to the set time. The

Timer is deactivated.

Parameter Value range Remarks

Activate days Mo, Tu, We, Th, Fr, Sa, Su Activate or deactivate days by clicking

Set switch-on time • Hours: 0-23/0-12

• Minutes: 0-59

• (a.m./p.m.)

• Input via numerical keypad

• Switch on: press Activate button

A green checkmark appears next to the set time. The

switch-on time is activated.

• Switch off: press Deactivate button

A red checkmark appears next to the set time. The

switch-on time is deactivated.

Set switch-off time • Hours: 0-23/0-12

• Minutes: 0-59

• (a.m./p.m.)

• Input via numerical keypad

• Switch On/Off as above

Timer

Timer funct.

Config/Individualization(continued)

Page 53

Configuring

Page 51

Parameter Value range Remarks

Software version

Serial number

Device type

1.0.0 ...

Parameter Remarks

Number of products since commissioning

Number of products until next maintenance

Cleanings performed

Remaining number of dispenses

Descalings performed

Remaining water quantity until next descaling

Remaining water qty for water filter in tank

Replace water filter in tank on: [dd.mm.yyyy]

Maintenance cycles performed

Product groups counter

Counters, other

Machine information

Parameter Value range Remarks

Coffee products - The product groups counters cannot be cleared.

Milk products -

Hot water products -

Capsule products -

Parameter Value range Remarks

[Product] - Clear Counters: all product counters are cleared.

Configuration

Information

Counter Individual

products

Config/Information

Page 54

Configuring

Page 52

Roles and rights

Menu items Owner Specialist

Operator

Administration

Configuration x x

-

Rights management x -

Data transfer x x -

Payment x x -

Products

[Select product] x x -

Individualizations

Language x x -

Panel setup x x -

Depiction x x -

Date and Time x x -

Care

Rinse filter x x x

Rinse x x x

Descaling x x x

Empty system x x -

Information

Counter Individual products x x -

Product groups counter x x -

Counters, other x x x (only reading rights)

Machine information x x -

Page 55

4

4

4

05

03

4

01 02 04

4

i

Decommissioning and disposal

Page 53

Please contact Service for recommissioning.

The coff ee machine must be serviced and cleaned before it is used

again. This is the only way to ensure that the coff ee machine functions properly and the products are of top quality.

Note the date of the decommissioning on the coff ee machine.

Care

Empty the machine. To do this,

open the menu Care and click

on Empty system, see p. 39.

Remove all food residue from

the machine after the system

has been emptied.

Empty and clean all containers.

Switch off the coff ee machine

and any add-on units.

Interrupt the electricity and

water supply.

Clean the coff ee machine and

its components, see p. 32.

Risk of damage to the machine

The coff ee machine will become damaged if it is not stored properly.

•Contact your FRANKE service team in the event of prolonged

decommissioning.

•Observe the storage conditions: Temperature: 5 °C to +50 °C,

humidity: max. 80%.

•Empty the coff ee machine.

NOTE

DECOMMISSIONING AND DISPOSAL

Do you want to shut down your coff ee machine for longer periods? Call your local Service. The used capsules,

all operating resources and the coff ee machine can be disposed of in an environmentally friendly manner.

Decommissioning

Decommissioning for longer periods, storage

Emptying the

system

Rinse

Descale

Clean

Confi guration

Information

Products Individualization

Care

Administration

Page 56

i

i

Decommissioning and disposal

Page 54

Dispose of plastic parts in accordance with their marking.

Disposal of the coffee machine and the FoamMaster

Disposal of the capsules and the operating resources

Dispose of electronic parts

separately.

The A200|A200FM coffee machine is in compliance with the European Directive 2002/96/EU regarding waste electrical and electronic equipment (WEEE) and may not be disposed of with domestic

refuse.