Page 1

Model FT3

®

Thermal Gas

Mass Flow Meter

and Temperature

Transmitter

For Industrial, Environmental,

Energy Monitoring and Process

Control Applications

FM / FMc

ATEX / IECEx

Precision Mass Flow Measurement

An ON

I

CON Brand

399 RESERVATION RD

MARINA, CA 93933

PHONE: 831-384-4300

FAX: 831-337-5786

sales@foxthermal.com

www.foxthermal.com

APPROVED!

Page 2

Smart, Real-Time Mass

Flow Measurement

The Fox Model FT3 measures two

important process variables with a

single instrument, providing isolated

4-20mA and pulse outputs for ow

rate, and a 4-20mA pulse output for

process gas temperature or a second

ow rate output.

Direct mass ow measurement,

exceptional low-ow sensitivity, fast

response, and low maintenance

requirements distinguish the Fox

Model FT3. Virtually immune to

changes in temperature and pressure,

the ow meter delivers repeatable,

accurate mass ow measurement

under varying loads. It’s rugged, no-

moving-parts design is also ideal for

high-vibration industrial environments,

and enhanced EMI immunity makes

it suitable for environments where

electric motors, ignitors or dirty power

may affect instrument performance.

Creative Solutions - Calibration

Validation with Fox Model FT3

Fox Thermal knows that customers

want creative and effective solutions

to some of their common process

problems. Downtime due to

equipment maintenance or calibration

costs money and wastes valuable time.

Calibration Validation of ow meters

in the eld provides assurance of the

functionality of the meter and avoids

the downtime associated with annual

calibrations.

Used in succession, Fox’s CAL-V™

and Zero CAL-CHECK® Tests can

give you the reassurance that your

meter is performing accurately in the

eld without the need to interrupt

ow or send the meter back to the

factory. The tests are quick and easy

to perform at any time and help with

CALIBRATION VALIDATION:

Typical Requirements of Competitive Models

Stop the ow*

Remove meter from pipe*

Disconnect wires from ow meter

Look up data on ow meter’s calibration certicate

Measure electrical characteristics with volt ohm meter

Perform calculations to evaluate ow meter performance

Set process pressure to manufacturer’s calibration pressure

Connect auxiliary test equipment and/or test gases to ow

meter

*When using a packing gland assembly for Zero CAL-CHECK®

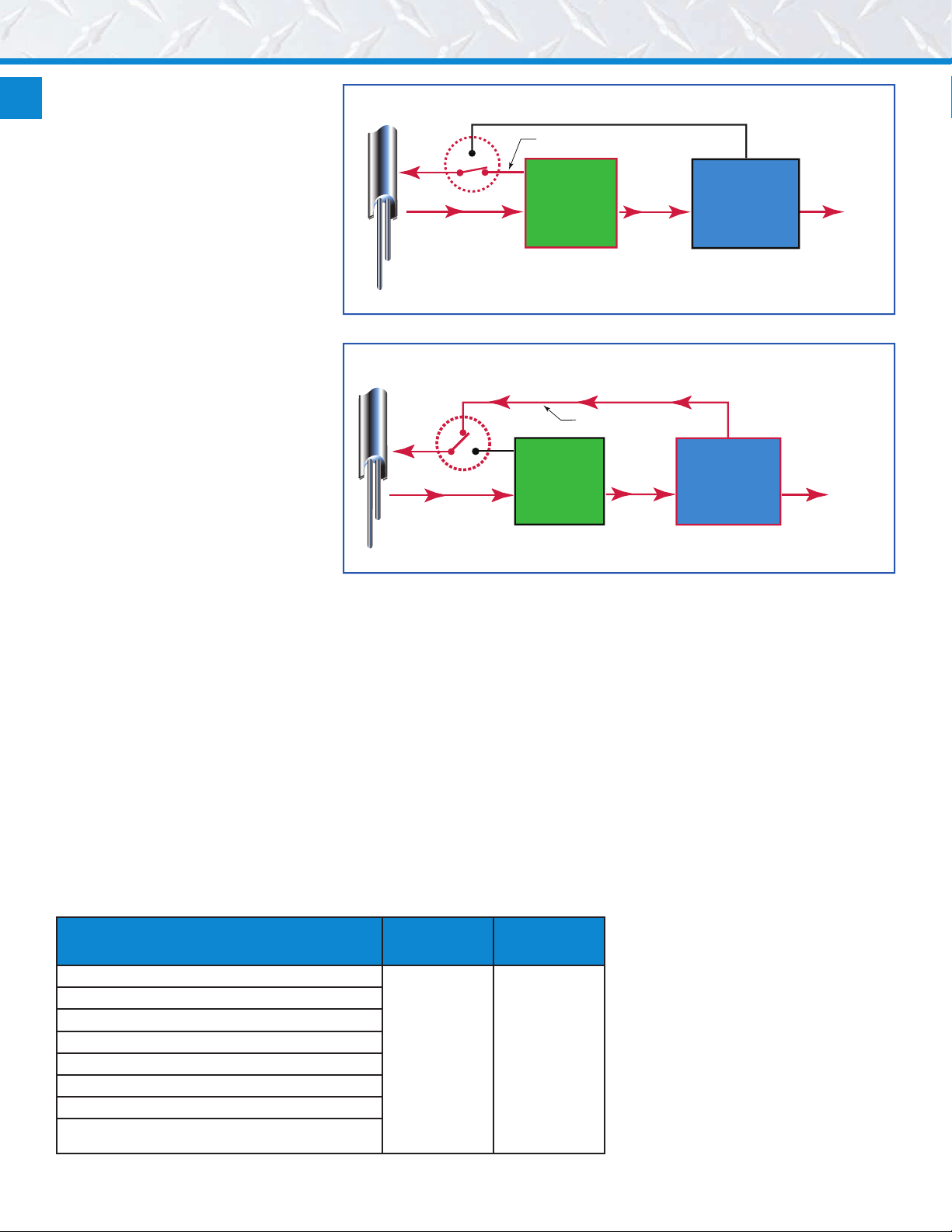

NORMAL MEASUREMENT MODE

Sensor Control Signal

SENSOR

SIGNAL

PROCESSING

ELECTRONICS

PowerPro™ Sensor

In normal measurement mode the signal processing electronics control the sensor.

CAL-V™ MODE

Sensor Control Signal

SENSOR

SIGNAL

PROCESSING

ELECTRONICS

PowerPro™ Sensor

In CAL-V™ mode, the microprocessor controls the sensor and determines the resulting electrical

characteristics.

the challenging requirements for

measuring the ow of air and gases.

look-up at any time.

CAL-V™ is an operator-initiated test

MICROPROCESSOR

MASS FLOW

MEASUREMENT

MICROPROCESSOR

CALIBRATION

VALIDATION

Calibration

Validation

PASS/FA IL

that can be performed at any ow rate,

CAL-V™

The CAL-V™ feature is an in-situ

calibration routine that validates the

ow meter’s calibration accuracy by

testing the functionality of the sensor

and its associated signal processing

circuitry. This innovative approach lets

you validate instrument calibration

in the pipe, at process conditions,

with just a push of a button. At the

conclusion of the test, the meter will

display a pass/fail message and the

CAL-V™ data is saved in the meter for

Other Thermal

Flow Meters

FT3 with CALV™ & Zero CALCHECK®

including zero, and is completed in just

three to four minutes. During the test,

the meter’s microprocessor adjusts

the signal to the sensor elements and

determines the resulting electrical

characteristics. These site-determined

characteristics are compared with the

data that was collected and stored in

the instrument electronics during the

original factory calibration. Matching

data within established tolerances

conrms the meter is measuring

accurately.

Zero CAL-CHECK® Tests

The Zero CAL-CHECK® tests are

used to ensure that the ow meter

still retains its original NIST-traceable

calibration at zero ow. The test can

be performed in one of two ways: In-

situ or Out-of-Pipe.

Required Not Required

In-situ Zero CAL-CHECK®

If zero ow can be established, the

sensor does not need to be removed

and the procedure can be done in

the pipe. If zero ow cannot be

established, a Fox Packing Gland

Assembly is used to remove the sensor

Outputs

Page 3

24VDC Input Power

85 to 264VAC Optional

Optional Display

and Configuration

The Model FT3 is a full-featured thermal mass ow meter with a conguration panel that comes

equipped with IR buttons for easy conguration of the meter’s settings.

Panel

from the gas stream to simulate a “no

ow” condition.

The test compares sensor

characteristics at zero ow with

customer-set zero ow baseline

and takes less than ve minutes to

complete after zero ow condition has

been established.

Out-of-Pipe Zero CAL-CHECK®

If zero ow cannot be established and

the meter must be removed from the

pipe, this test may be used. The test

will compare the sensor characteristics

at zero ow at ambient temperature

and atmospheric pressure with the

factory characteristics. This test can

also be performed in less than ve

minutes once the set up is complete.

Easy Accuracy Reporting

Both CAL-V™ and the Zero CALCHECK® Tests can be initiated from

the front panel, USB connection,

Modbus RTU (RS485) or HART. If

initiated by Fox’s FT3 View™ software

tool, CAL-V™ or Zero CAL-CHECK®

Calibration Validation Certicates can

be produced at the conclusion of the

tests.

This feature is of particular value

in environmental monitoring

applications, such as ares and vents,

where periodic calibration validation

is mandated. These tests help

operators comply with environmental

mandates and eliminates the cost

and inconvenience of annual factory

calibration. It can also be used

to streamline quality assurance,

improve process initiatives, and apply

Precision Mass Flow Measurement

An ON

I

CON Brand

Rugged, Reliable Performance

The Fox PowerPro™ sensor operates at

a higher power level than competitive

thermal ow sensors resulting in

improved response time and wider

turndown. The PowerPro™ sensor also

provides exceptional accuracy at high

velocities - up to 60,000 SFPM (280

NMPS).

The Model FT3 features a dualcompartment, explosion-proof

electronics enclosure. One

compartment houses the instrument

electronics and the second

compartment is accessible for wiring.

A waterproof seal between the

compartments helps prevent moisture

damage and maintain the integrity of

the instrument electronics.

An optional on-board 2 line x 16

character backlit display is available to

view ow rate, total ow, elapsed time,

process gas temperature and alarms.

The display is also used in conjunction

with the Conguration Panel for eld

conguration of ow meter settings

such as 4-20mA and pulse output

scaling, pipe area, zero ow cutoff,

ow ltering or damping, display

congurations, diagnostics and alarm

limits. Optically activated keys provide

interface to the ow meter without

removing the cover.

The Model FT3 features galvanically-

isolated outputs and enhanced

EMI immunity. A variety of meter

congurations, materials, process

connections and output options offer

improved design exibility, lower cost-

of-ownership and enhanced control

capabilities.

Standard I/O

4-20 mA Flow

4-20 mA Flow or Temperature

Frequency or Alarm

Contact Input

All Outputs are

Galvanically Isolated

Standard Digital Communication

USB (free FT3 View Software)

Optional Digital Communication

HART

Modbus RTU (RS485)

scheduled maintenance procedures.

The Model FT3 is available in both

insertion and inline models. The

insertion meter is easily installed with

a weld-o-let and compression tting.

The inline model is available in ¼-inch

to 6-inch sizes and includes built-in

ow conditioners that eliminate the

need for long, straight pipe runs.

Communications Options

A USB connection is standard on

the Model FT3, and Fox’s free FT3

View™ software provides complete

conguration and remote process

monitoring functions. FT3 View™

lets you adjust meter conguration,

evaluate transmitter alarm conditions,

collect process data, and view

measurements from your PC or

control station. HART and Modbus

RTU (RS485) are available options.

All digital communication is isolated

to provide immunity from electrical

interference.

NIST Traceable Factory Calibration

Fox calibrations are performed

with NIST traceable ow standards.

Whether you require a straightforward

air calibration or a complex mixed

gas calibration, our goal is to achieve

the highest accuracy and the fastest

turnaround time. The Fox Calibration

Lab employs a wide range of gases,

gas mixtures, temperatures, pressures

and line sizes to simulate actual uid

and process conditions. This realworld approach improves installed

accuracy and minimizes measurement

uncertainty.

Built-in ow conditioning improves

measurement accuracy in space-constrained

applications.

Precision Mass Flow Measurement

An ON

I

CON Brand

Page 4

Summary Specications

Performance Specs

Flow Accuracy:

Inline meter: ± 1% of reading ± 0.2% of full scale.

Insertion meter: ± 1% of reading ± 0.2% of full scale.

Straight, unobstructed pipe requirement:

Inline: 8 diameters upstream; 4 downstream.

Insertion: 15 diameters upstream; 10 downstream.

Insertion (¼” size): 6” (152mm) upstream & downstream

Flow Repeatability: ± 0.2% of full scale

Flow Response Time: 0.9 seconds (one time constant)

Temperature Accuracy:

± 1.8° F (± 1.0° C) -40 to 250° F (-40 to 121° C); ± 3.6° F (± 2.0° C), 250 to

650° F (121 to 343° C); 60 SFPM minimum.

Calibration:

Factory Calibration to NIST traceable standards

CAL-V™ & Zero CAL-CHECK

®: In situ, user-initiated calibration validation

Operating Specs

Units of Measurement (eld selectable):

SCFM, SCFH, NMPS, NM3/M, NM3/H, NM3/D, NLPS, NLPM, NLPH, MCFD,

MSCFD, SCFD, MMSCFD, MMSCFM, SMPS, SM3/D, SM3/H, SM3/M, LB/S,

LB/M, LB/H, LB/D, KG/S, KG/M, KG/H, SLPM, SFPM, MT/H

Flow Rates for Insertion Flow Meter:

15 to 60,000 SFPM (0.07 to 280 NMPS) - Air at 70°F (20°C) & 1 ATM

Turndown: up to 1000:1; 100:1 typical

Typical Flow Ranges for Insertion Flow Meters

Pipe size SCFM MSCFD NM³/HR

1.5” (40mm) 0 - 840 0 - 1,220 0 - 1,325

2” (50mm) 0 - 1,400 0 - 2,020 0 - 2,210

2.5”(63mm) 0 - 2,000 0 - 2,880 0 - 3,150

3” (80mm) 0 - 3,100 0 - 4,440 0 - 4,890

4” (100mm) 0 - 5,300 0 - 7,650 0 - 8,360

6” (150mm) 0 - 12,000 0 - 17,340 0 - 18,930

8” (200mm) 0 - 20,840 0 - 30,020 0 - 32,870

10” (250mm) 0 -32,800 0 - 47,250 0 - 51,740

12” (300mm) 0 - 46,600 0 - 67,180 0 - 73,500

Flow Ranges for Inline Flow Meters

Pipe size SCFM MSCFD NM³/HR

0.25” 0 - 7.5 0 - 10.8 0 - 11.8

0.5” 0 - 125 0 - 180 0 - 200

0.75” 0 - 220 0 - 320 0 - 350

1” 0 - 360 0 - 520 0 - 570

1.25” 0 - 625 0 - 900 0 - 990

1.5” 0 - 840 0 - 1,220 0 - 1,325

2” 0 - 1,400 0 - 2,020 0 - 2,210

2.5” 0 - 2,000 0 - 2,880 0 - 3,150

3” 0 - 3,100 0 - 4,440 0 - 4,890

4” 0 - 5,300 0 - 7,650 0 - 8,360

6” 0 - 12,000 0 - 17,340 0 - 18,930

Note: Standard conditions of air at 70°F and one atmosphere. Consult factory for other gases and for

ow ranges above those listed. Inline meters above 5,000 SCFM (7,900 NM3/H) air may require third

party Calibration. Contact Fox.

Gas Pressure (maximum):

Insertion: 500 psig (34.5 barg)

316 SS inline with NPT ends: 500 psig (34.5 barg)

316 SS inline with 150 lb. flanges: 230 psig (16 barg)

CS inline with NPT ends: 300 psig (20.1 barg)

CS inline with 150 lb. flanges: 285 psig (19.7 barg)

Retractor: 125 psig (8.6 barg)

High pressure retractor: NPT 600 psig (41.4 barg), ANSI 150lb flange &

ANSI 300lb flange, no valve supplied.

Notes:

• Check with factory for higher pressure options.

• With teflon ferrule option, gas pressure max: 60psig (4.1 barg)

• Pressure ratings stated for temperature of 100°F (38°C).

Relative Humidity: 90% RH maximum; non-condensing

Temperature (see Agency Approvals table to the right):

ST sensor: -40 to 250°F (-40 to 121°C)

HT Sensor: -40 to 650°F (-40 to 343°C)

Enclosure Ambient Temperature:

Without display or AC power supply: -40 to 158°F (-40 to 70°C)

With display and/or AC power supply: -4 to 158°F, (-20 to 70°C)

Remote sensor junction box: -40 to 212°F (-40 to 100˚C)

Input Power:

– – –

24 VDC

100 to 240VAC~(+10%/-15%), 50-60Hz, 0.2 Amps (with AC power option)

Note: Fluctuations of AC and DC power supply are not to exceed ±10% of rating.

Class I Equipment (Electrical Grounding Required for Safety).

Installation (Over-voltage) Category II for transient over-voltages.

Outputs:

Two isolated 4-20mA outputs (output one is for ow rate and output two is

programmable for ow rate or temperature); fault indication per NAMUR NE43.

Isolated pulse output 0 to 100Hz, 5 to 24 volts p/p for ow (the pulse output can

be used as an isolated solid state output for alarms); 10mA max.

Serial Communication:

USB communication port is standard. The free PC-based software tool - FT3

View™ - provides complete conguration, remote process monitoring, and data

logging functions.

Optional serial communication: HART and Modbus RTU (RS485).

4-20mA Loop Verication:

Simulation mode used to align 4-20mA output with the input to customer’s PLC/

DCS.

± 10%), 0.7 Amps (standard DC power)

—

(

Physical Specs

Sensor Material: 316 stainless steel standard; Hastelloy C276 optional

Enclosure: NEMA 4X (IP67), Aluminum, dual conduit entries with ¾” NPT or

optional M20 x 1.5mm.

Cabling to remote enclosure: 5-conductor, 18 AWG, twisted, shielded, 100 feet

maximum.

Insertion Flow Meter Installation:

Fox-supplied compression tting connects to customer-supplied 3/4” female

coupling welded to pipe.

Dimensions:

www.foxthermal.com/literature/

Agency Approvals

CE: Approved

EMC Directive; 2014/30/EU

Electrical Equipment for Measurement, Control and Lab Use: EN61326-1:2013

Low Voltage Directive (LVD): 2014/35/EU

Product Safety Testing: EN 61010-1: 2010

Pressure Equipment Directive: 2014/68/EU

Weld Testing: EN ISO 15614-1 and EN ISO 9606-1, ASME B31.3

FM/FMc: Approved

Class I, Div. 1, Gps B, C, D; Class II, Div. 1, Gps E, F, G; and Class III, Div. 1; T3C,

Ta = -40° to 70°C; Class I, Zone 1, AEx/Ex d IIB + H2 (T6, T4 or T1*); Ta = -20°C to

70°C; Type 4X, IP67.

ATEX (FM12ATEX0034X): Approved

II 2 G Ex d IIB + H2 (T6, T4 or T1*); Gb Ta = -20°C to 70°C; IP67

II 2 D Ex tb IIIC (T85°C, T135°C or T450°C*) Db Ta = -20°C to 70°C; IP67

IECEx (IECEx FMG 12.0010X): Approved

Ex d IIB + H2 (T6, T4 or T1*) Gb Ta = -20°C to 70°C; IP67

Ex tb IIIC (T85°C, T135°C or T450°C*) Db Ta = -20°C to 70°C; IP67**

Model Code Temp. Code (Gas) Temp. Code (Dust)

Encl. Sensor Mn. Encl. Remote Mn. Encl. Remote

E1 ST T4 N/A 135°C N/A

E2 ST T4 N/A 135°C N/A

E3 ST T6 T4 85°C 135°C**

E4 ST T6 T4 85°C 135°C**

E3 HT T6 T1 85°C 450°C**

E4 HT T6 T1 85°C 450°C**

*

Temperature code ratings for Zones are dependent on external process temperature factors and equipment

enclosure conguration. See table above for specic temperature code ratings.

**The IECEx dust rating does not apply to the Remote Enclosure.

FT3 Brochure Rev N

Loading...

Loading...