Page 1

Fox Thermal Instruments, Inc.

THERMAL MASS FLOW METER & TEMPERATURE TRANSMITTER

Model FT2A - Anybus:

Profibus/DeviceNet/Modbus TCP Ethernet

www.foxthermalinstruments.com | 399 Reservation Road Marina, CA. 93933

105436

Rev. A

Page 2

Anybus

Notice

This publication must be read in its entirety before performing any operation. Failure

to understand and follow these instructions could result in serious personal injury

and/or damage to the equipment. Should this equipment require repair or adjustment

beyond the procedures given herein, contact the factory at:

FOX THERMAL INSTRUMENTS, INC.

399 RESERVATION ROAD

MARINA, CA 93933

TELEPHONE: 831-384-4300

FAX: 831-337-5787

EMAIL: SERVICE@FOXTHERMALINSTRUMENTS.COM

Download Technical Data Sheets from our website:

www.foxthermalinstruments.com

Fox Thermal Instruments believes that the information provided herein is accurate

however be advised that the information contained herein is NOT a guarantee

FOX THERMAL INSTRUMENTS

for satisfactory results. Specifically, this information is neither a warranty nor

guarantee, expressed or implied, regarding performance; merchantability; fitness;

or any other matter with respect to the products; nor recommendation for the use

of the product/process information in conflict with any patent. Please note that Fox

Thermal Instruments, Inc. reserves the right to change and/or improve the product

design and specification without notice.

Fox FT2A Manuals:

• Model FT2A Instruction Manual

• Fox FT2A View™ Instruction Manual

• Fox FT2A Modbus and BACnet MS/TP Manual

2

Page 3

Table Of Contents

1. Introduction Page 4

a. Scope Page 4

b. Description Page 4

c. Related Documents Page 4

2. Data Organization Page 5

a. FT2A Registers Page 5

b. Status Bit Definitions Page 6

c. Control Page 6

3. Wiring and Configuration for Profibus/Devicenet/Ethernet Page 7

a. Profibus Page 7

b. DeviceNet Page 9

c. Ethernet Page 11

Anybus

TABLE OF CONTENTS

4. LED Indicators Page 14

5. Programming Page 15

a. Anybus Chip Programming Page 15

6. Appendices Page 16

a. Attachment A Page 16

b. Attachment B Page 19

7. Glossary of Terms and Abbreviations Page 22

8. Index Page 23

3

Page 4

Anybus

Introduction

Scope

Introduction

INTRODUCTION

Scope

Thank you for purchasing the Model FT2A Thermal Gas Mass Flow meter and

Temperature Transmitter from Fox Thermal Instruments. The Model FT2A is

one of the most technically advanced flow meters in the world. Extensive

engineering effort has been invested to deliver advanced features, accurate

measurement performance and outstanding reliability.

This document describes how to connect and use the Profibus/DeviceNet/

Modbus TCP Ethernet for the Model FT2A.

Description

The Model FT2A uses a pre-programmed Anybus-IC from HMS-Network to

interface to Profibus, DeviceNet or Modbus TCP Ethernet.

Related Documents

Documentation for the Anybus-IC is available on the HMS-Networks Website

at www.anybus.com/support. Select Anybus-IC to go to the support

documentation. Design guides are available under any single chip selection.

The following documents can be downloaded from the Anybus Website:

• Single chip for Profibus, Design Appendix

• Single chip for DeviceNet, Design Appendix

• Single chip for Ethernet/IP and Modbus TCP, Design Appendix

Other related documents:

• Fox FT2A Instruction Manual

• Fox FT2A View™ Manual

• Fox FT2A Modbus/BACnet MS/TP Manual

www.foxthermalinstruments.com

4

Page 5

Data Organization

Anybus

Data Organization

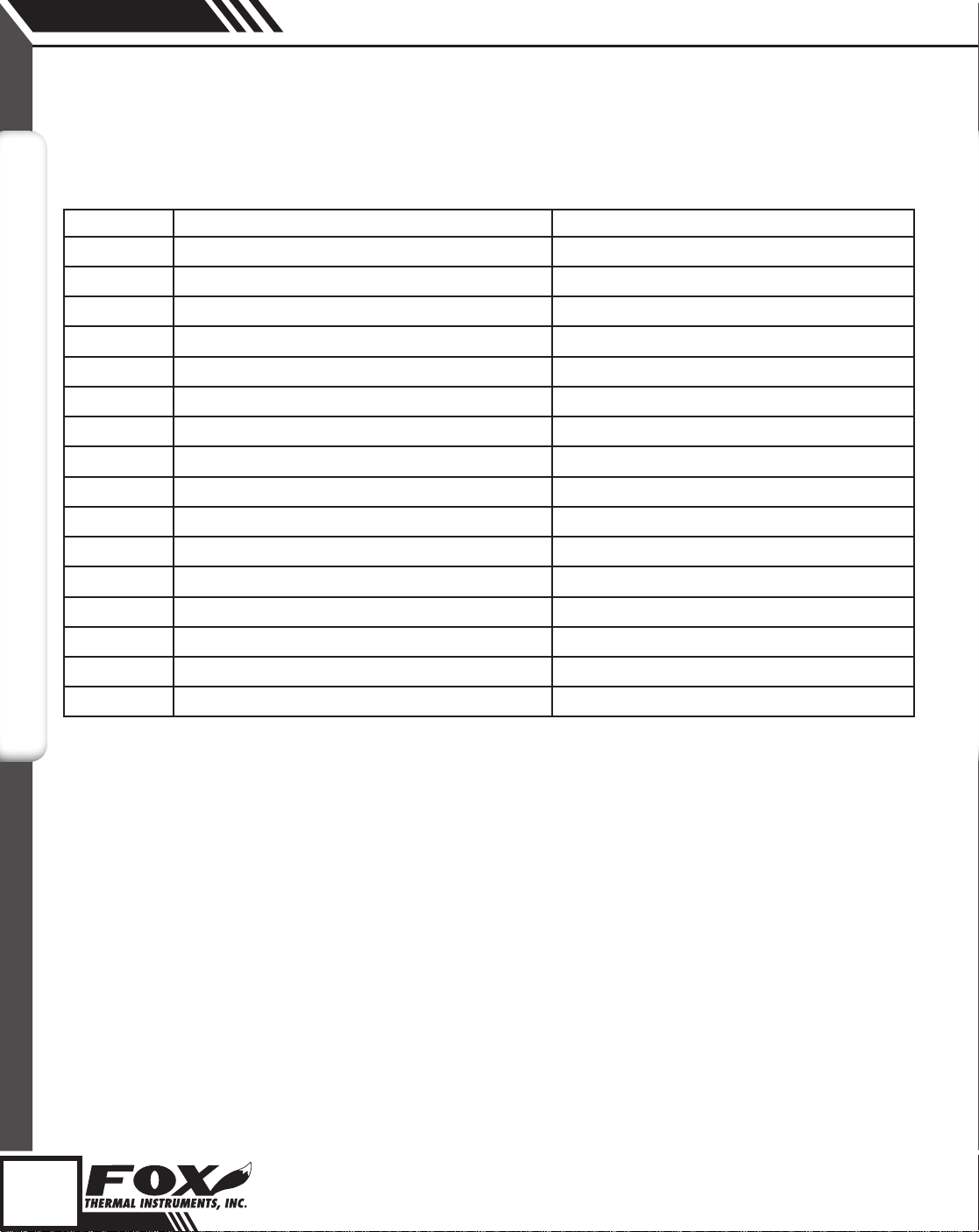

Byte Modbus

Address

00

30001

01

02

30002

03

04

30003

05

06

30004

07

08

30005

09

10

30006

11

12

30007

13

14

30008

15

16

30009

17

18

30010

19

202130011 Status (low register, MSB)

222330012 Flow *100 (low register, MSB)

242530013 Total *100 (low register, MSB)

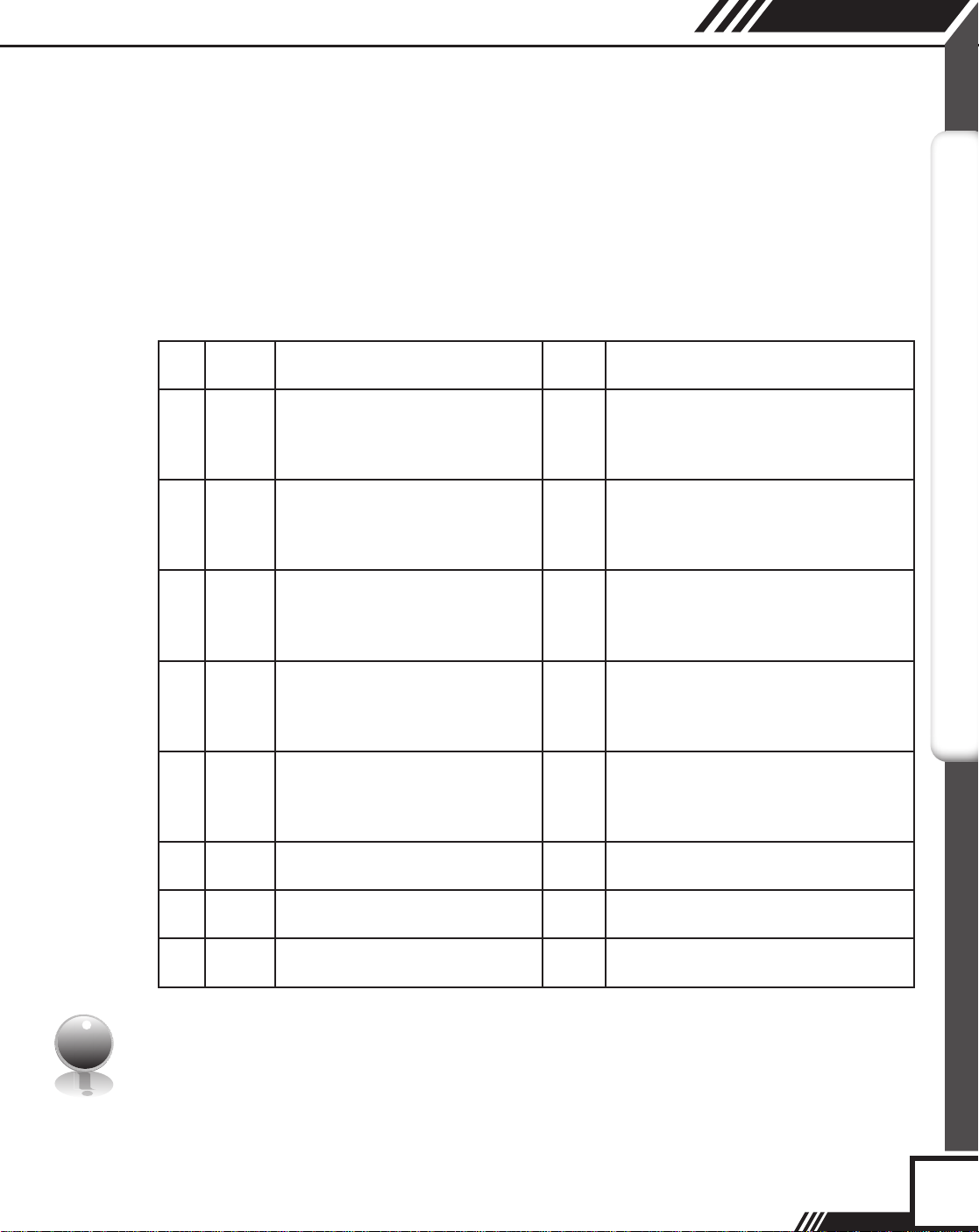

Data Organization

Data from the FT2A is updated into the Anybus IC every 300 ms. Data is

organized as a set of two 16 bit registers (32 bits) for data and one 16 bit

register for status. Table 2.1 defines the FT2A registers.

Table 2.1: FT2A Registers

Data Type Scaling Comment

Flow in Eng units (low register, MSB)

Flow in Eng units (low register, LSB)

Flow in Eng units (high register, MSB)

Flow in Eng units (high register, LSB)

Total (low register, MSB)

Total (low register, LSB)

Total (high register, MSB)

Total (high register, LSB)

Temperature (low register, MSB)

Temperature (low register, LSB)

Temperature (high register, MSB)

Temperature (high register, LSB)

Elapsed time (low register, MSB)

Elapsed time (low register, LSB)

Elapsed time (high register, MSB)

Elapsed time (high register, LSB)

Velocity (low register, MSB)

Velocity (low register, LSB)

Velocity (high register, MSB)

Velocity (high register, LSB)

Status (low register, LSB)

Flow *100 (low register, LSB)

Total *100 (low register, LSB)

No Mass flow in selected units

No Total in selected units

X 10 Temperature in selected units X 10 (Times

ten)

High register in not used

X 10 Elapsed time in hours X 10 (Times ten)

No Velocity in nm/hr

No Status/Alarm

X 100 Flow X 100

X 100 Total X 100

DATA ORGANIZATION

i

Note: Items 22/23 and 24/25 are only used for low flow and total to obtain more precision.

Velocity can be used to obtain flow rate in engineering units using pipe area and unit

conversion factor.

5

Page 6

Anybus

Data Organization

Status Bits

Table 2.2: Status Bits Definitions

Bit Definition Comment

0 Power up indication

1 Flow rate reached high limit threshold

2 Flow rate reached low limit threshold

3 Temperature reached high limit threshold

4 Temperature reached low limit threshold

5 Sensor reading is out of range

6 Velocity flow rate outside of calibration table

7 Incorrect Settings

8 In simulation mode

9 Frequency output is out of range

10 Analog 4-20 mA for flow is out of range

11 Analog 4-20 mA for temperature is out of range

12 Anybus error

13 Bridge Shut Down

DATA ORGANIZATION

14 EEPROM CRC error

15 Totalizer Error Detected

Reset when out of the power up sequence

Set limit to zero to disable

Set limit to zero to disable

Set limit to zero to disable

Set limit to zero to disable

Check sensor wiring

Check sensor wiring

Check settings

Set simulation value to 0 to disable

Check frequency output settings

Check analog output settings

Check analog output settings

Check wiring from RS485 to Anybus IC

Check sensor wiring

Check parameters and reset CRC

Reset the total

Control

One control register is used to reset the total and elapsed time. Data for that

register must be set to 0x02 to reset the total. Only a transition from a 0 to

2 will clear the total. Keeping that bit set will not continuously clear the total.

This register needs to be cleared after the reset operation.

6

Page 7

ETHERNET

RESET TOTAL

SWITCH

USB

COMMUNICATION

J1

S5

J4

Wiring: Profibus

Anybus

Probus Wiring

Profibus Wiring from Master

Wiring connections are made to terminal block TS3 for Profibus

communication. The following lists the wiring connections.

Display board Connector TS3:

FB1 A-Line

•

• FB2 B-Line

• FB3 RTS

• FB4 NC (NC = No Connection)

• FB5 GND BUS

• FB6 +5 V BUS

• FBPE PE

• SHIELD NC

Fig. 3.1: Profibus Wiring and Configuration

Inside Display/Cover

Profibus Master

PROFIBUS

TS3

1

2

3

4

5

6

7

8

OPTIONAL

COMMUNICATION

(DEVICENET

PROFIBUS)

FB1 - A-Line

FB2 - B-Line

FB3 - RTS

FB4 - No Connection

FB5 - GND Bus

FB6 - +5 V Bus

FBPE - PE

SHLD - SHLD

7

Page 8

Anybus

Configuration: Profibus

Model FT2A

Probus

Conguration

PROFIBUS

Baud Rate - Profibus

The Module supports all standard baud-rates from 9600 bps to 12 Mbps,

according to the Profibus specification. The Anybus-IC PDP supports

automatic baud rate detection, which means that the actual baud rate is only

configured in the Profibus Master.

Configuration File - Profibus

A GSD configuration file is needed by the master and is available from the

HMS-Networks Website under the AnyBus-IC/Profibus selection.

An example of the file is included for reference as Attachment A.

http://www.anybus.com/support/support.

asp?PID=88&ProductType=AnyBus-IC

Profibus Functions

The following functions are not supported with the Standard GSD-file:

User Parameter Data (Set_Prm).

Extended Diagnostic Data (Slave_Diag).

ID Number - Profibus

The Standard AnyBus-IC Profibus ID number is 1810h. This ID number is

related to the GSD file. If the AnyBus IC PDP is to be customized with other

functions or names, a new ID-number must be used (ordered from the

Profibus organization).

8

Page 9

ETHERNET

RESET TOTAL

SWITCH

USB

COMMUNICATION

J1S5J4

Wiring: DeviceNet

Anybus

DeviceNet Wiring

DeviceNet Wiring from Master

Wiring connections are made to terminal block TS3 for DeviceNet

communication. The following lists the wiring connections.

Display board Connector TS3:

• FB1 CAN_H

• FB2 CAN_L

• FB3 NC

• FB4 NC

• FB5 V- (GND)

• FB6 V+ (24 Volt DC)

• FBPE PE

• SHIELD SHIELD

CAN-H and CAN-L Termination Resistor

Connect a termination resistor across the receive/transmit signals of the

last device on the DeviceNet communication line. To connect the 120 ohm

termination resistor on the FT2A, set jumper W4 to the TERM position.

The termination resistor of the FT2A is disconnected by setting jumper W4 to

the NC (Not Connected) position.

DEVICENET

Fig. 3.2: DeviceNet Wiring from Master

Inside Display/Cover

W4

TERM NC

TS3

1

2

3

4

5

6

7

8

OPTIONAL

COMMUNICATION

(DEVICENET

PROFIBUS)

DeviceNet Master

FB1 - CAN_H

FB2 - CAN_L

FB3 - No Connection

FB4 - No Connection

FB5 - V -

FB6 - V+

FBPE - PE

SHLD - SHIELD

9

Page 10

Anybus

Configuration: DeviceNet

DeviceNet

Conguration

DEVICENET

Baud Rate - DeviceNet

Automatic baud rate detection is not supported. The baud rates that are

supported by the Anybus-IC DeviceNet are:

125 kbps

250 kbps

500 kbps

Configuration File - DeviceNet

Electronic Data Sheet (.EDS)

An EDS configuration file used by the master, it can be downloaded from the

HMS-Networks Website under the Anybus-IC and DeviceNet selection.

An example of the file is included for reference as Attachment B.

http://www.anybus.com/support/support.

asp?PID=88&ProductType=Anybus-IC or a quick Google search for AnybusIC.

10

Page 11

Inside Display/Cover

OPTIONAL

COMMUNICATION

(DEVICENET

PROFIBUS)

RESET TOTAL

SWITCH

USB

COMMUNICATION

1

2

3

4

5

6

7

8

TS3

S5

J4

W4

TERM

NC

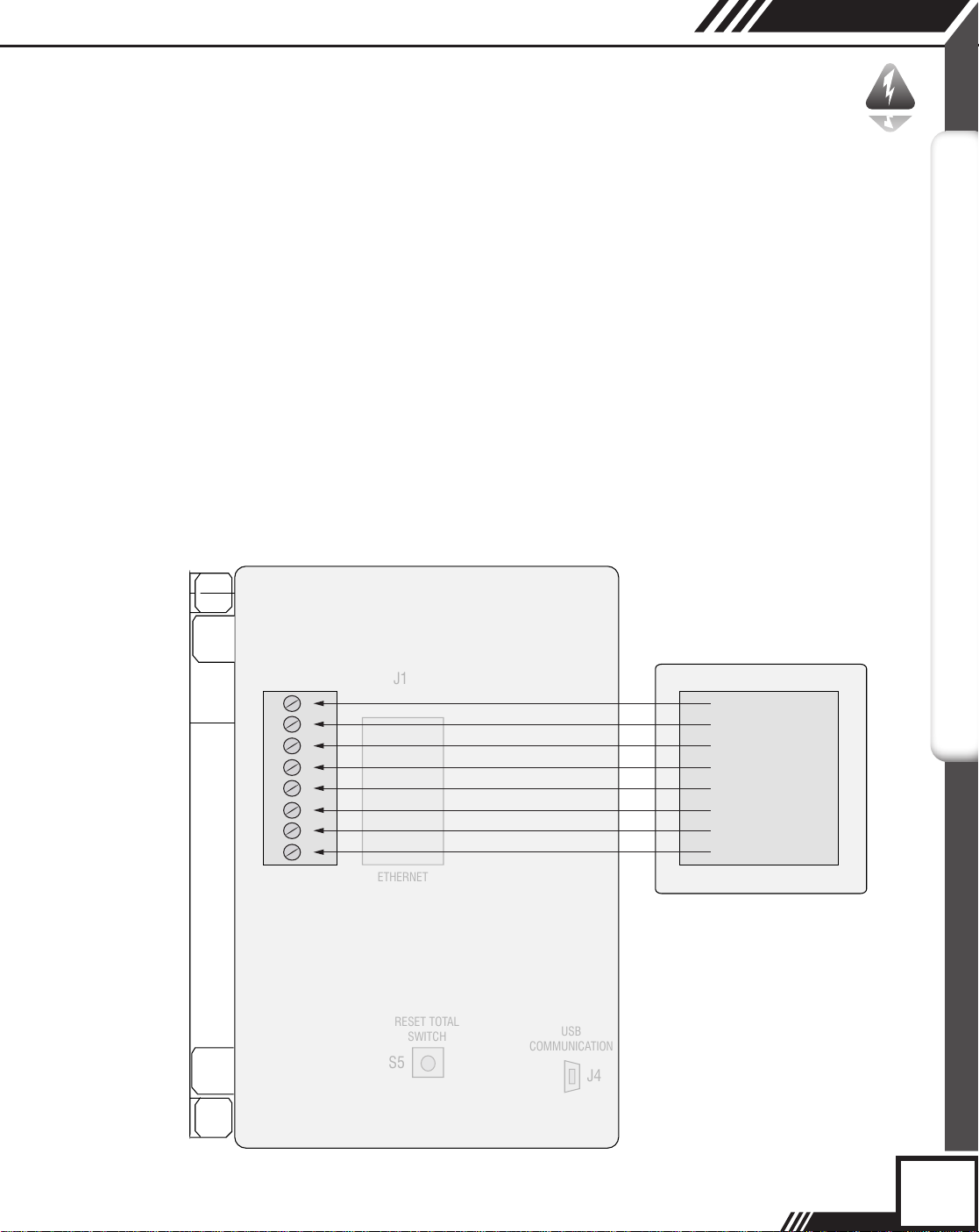

Wiring: Ethernet

Anybus

Ethernet Wiring

Ethernet Wiring

Connection to the network is accomplished by simply connecting to the

Ethernet connector mounted on the local display board (J1). If you are

connecting directly to a PC, you will need a crossover Ethernet cable.

Fig. 3.3: Ethernet Connector Location

ETHERNET

J1

ETHERNET

11

Page 12

Anybus

Configuration: Ethernet

Ethernet

Conguration

ETHERNET

Manual IP Address Configuration

Set the rotary switch setting to any desired position except zero. The IP

address will be set to 192.168.0.x, where x is the setting on the 2 digits of the

rotary switches.

Automatic IP Address Configuration

Set the rotary switches to zero. The Anybus chip has been programmed for

DHCP.

The control register for Ethernet is at address zero.

The Anybus-IC offers many other ways to operate. See the Anybus-IC Design

Guide. Programming of the Anybus-IC can be accomplished by connecting

a PC with a terminal emulator to the P2 connector on the local display with a

special Fox adapter board. The Anybus document can be downloaded from the

web at the following link :

http://www.anybus.com/support/support.asp?PID=88&ProductType=Anybus-IC or a

quick Google search for Anybus-IC.

Configuring the FT2A Ethernet IP with a Fixed Address

Set rotary IP address switches located on the local display board to an address

(i.e. 2, sw1=2, sw2=0)

Cycle the power and connect a cross-over Ethernet cable to a PC.

12

Note: Some PC/laptops can use a straight cable as they detect and switch the

lines automatically.

i

Open the web browser and enter 192.168.0.2 for the address and press enter.

The HMS Configurator should now be displayed. If not, check the cable and the

switch settings. (Addresses other than 2 may be used).

• Enter the IP address, Subnet mask and the gateway address in the HMS

Configurator.

• Uncheck “DHCP Enable” box.

• Click on “Save Configuration”.

• Reset the rotary IP switch address to 0 (sw1=0, sw2=0).

• Cycle the power and connect a straight Ethernet cable to the network.

• Ping the device with the IP address entered to verify the communication

link.

Page 13

Configuration: Ethernet

Anybus

Ethernet

Conguration

Protecting Access to FT2A HMS Configurator for Ethernet IP

Access to the HMS Configurator can be protected by creating a file containing

user names and passwords and storing it in the FT2A Anybus root directory as

specified in section 6-2 of the HMS Anybus Ethernet manual (see note below

for manual downloads). The file can be created using Notepad or any other

text editor.

For example:

User1:1234

User2:5678

Using Windows Explorer or any FTP program, transfer the file that you just

created into the FT2A Anybus root directory (See section 4-2 of the HMS

Ethernet manual). First connect to the FT2A by opening Windows Explorer and

replace the address with “FTP://xxx.xxx.xxx.xxx (where x is the IP address) and

press return. Windows explorer should now show the content of the specified

FT2A Anybus directory. Highlight the file that was created and drag it into the

folder that has the IP address.

Slave Address

The Slave Address is set using the two BCD rotary switches. Address can be

set from 0 to 99, for the Profibus/Modbus TCP Ethernet and from 0 to 63 for

the DeviceNet. Power needs to be cycled before the settings take effect. Rotary

switch SW1 controls the low digit address, SW2 the high digit address (ie

SW1=5, SW2=6, Address=65).

ETHERNET

i

Note: Links to HMS Manual Downloads

http://www.anybus.com/products/abic.shtml

Ethernet:

http://www.hms.se/upload/90-9118-ABIC-EIP_1_56_ROHS_SCM_1200_055.pdf

Ethernet

Profibus:

http://www.hms.se/upload/88-2310-Anybus-IC_PROFIBUS_2_00_SCM-1200-

022.pdf

DeviceNet:

http://www.hms.se/upload/89-7638-Anybus-IC_DeviceNet_user_manual.pdf

13

Page 14

J1

U2

J3

TS3

SW1

SW2

S6

Anybus

LED Indicators

LED Indicators

LED INDICATORS

LED’s

The local display board with the Anybus-IC option provides 3 LED’s with the

following functionality:

• LP1, Green LED: Flashes at 1 Hz indicating normal local display

operation

• LP2, Green LED: Showing green when Fieldbus communication/

connection is working properly

• LP3, Red LED: Showing red when Fieldbus communication/connection

is not working properly.

Fig. 4.1: LED Locations

LP2LP3

LP1

14

Page 15

Programming

Anybus

Anybus Chip

Programming

i

Anybus Chip Programming

The Anybus chip (U2) is shipped pre-programmed. If an AnyBus-IC PDP is

used in a customer-specific implementation, the Profibus ID-number and the

GSD-file must be changed to match the new implementation. This can be

accomplished using a terminal emulator (like "Hyperterminal") through a serial

or USB interface to connector P2 (see Fig. 5.1). A special cable is available

from FOX. HyperTerminal communication parameters should be set to 9600

Baud, 8 Bits, 1 Stop bit. Refer to the Anybus documentation for programming.

Note: After changing parameters for the Anybus Chip from the local display

(i.e baudrate, bus type) the FT2A needs to have the power cycled OFF and

back ON twice before the changes can take effect.

Fig. 5.1: Anybus Circuitry

PROGRAMMING

15

Page 16

Anybus

Appendices

Attachment A

APPENDICES

Attachment A

AnyBus_Profibus.gsd

;===================================

=========================

; Profibus Device Database of HMS Industrial Networks AB

; Model : ANYBUS-IC PDP

; Description : ANYBUS-IC Profibus DP slave

; Language : English

; Date : 30 September 2003

; Author : HMS Industrial Networks AB

;

; MODIFICATIONS:

; 30 September 2003:

; - 'MaxTsdr_xxx' for all baudrates have been optimized for the SPC3 ASIC.

; - 'Revision' upgrade

; - 'Hardware_Release' upgrade

; - 'Software_Release' upgrade

;===================================

=========================

#Profibus_DP

16

GSD_Revision = 2

; Device identification

Vendor_Name = "HMS Industrial Networks AB"

Model_Name = "AnyBus-IC PDP"

Revision = "Version 1.1"

Ident_Number = 0x1810

Protocol_Ident = 0 ; DP protocol

Station_Type = 0 ; Slave device

FMS_supp = 0 ; FMS not supported

Hardware_Release = "Version 1.1"

Software_Release = "Version 1.1"

;Used bitmap

Bitmap_Device = "ABIC_DE"

Bitmap_Diag = "ABIC_DI"

Bitmap_SF = "ABIC_SF"

Page 17

Appendices

Anybus

Attachment A

; Supported baudrates

9.6_supp = 1

19.2_supp = 1

45.45_supp = 1

93.75_supp = 1

187.5_supp = 1

500_supp = 1

1.5M_supp = 1

3M_supp = 1

6M_supp = 1

12M_supp = 1

; Maximum responder time for supported baudratesMaxTsdr_9.6 = 15

MaxTsdr_19.2 = 15

MaxTsdr_45.45 = 15

MaxTsdr_93.75 = 15

MaxTsdr_187.5 = 15

MaxTsdr_500 = 15

MaxTsdr_1.5M = 25

MaxTsdr_3M = 50

MaxTsdr_6M = 100

MaxTsdr_12M = 200

APPENDICES

; Supported hardware features

Redundancy = 0 ; not supported

Repeater_Ctrl_Sig = 2 ; TTL

24V_Pins = 0 ; not connected

Implementation_Type = "SPC3"

; Supported DP features

Freeze_Mode_supp = 1 ; supported

Sync_Mode_supp = 1 ; supported

Auto_Baud_supp = 1 ; supported

Set_Slave_Add_supp = 1 ; supported

; Maximum polling frequency

Min_Slave_Intervall = 1 ; 100 us

; Maximum supported sizes

Modular_Station = 1 ; modular

17

Page 18

Anybus

Appendices

Attachment A

APPENDICES

Max_Module = 24

Max_Input_Len = 48

Max_Output_Len = 48

Max_Data_Len = 96

Modul_Offset = 1

Fail_Safe = 1 ; Data telegram without data in state

CLEAR accepted

Slave_Family = 0

Max_Diag_Data_Len = 6

; Definition of modules

Module = "IN/OUT: 1 Byte" 0x30

EndModule

;

Module = "IN/OUT: 2 Byte ( 1 word)" 0x70

EndModule

;

Module = "IN/OUT: 4 Byte ( 2 word)" 0x71

EndModule

;

Module = "IN/OUT: 8 Byte ( 4 word)" 0x73

EndModule

;

Module = "IN/OUT: 16 Byte ( 8 word)" 0x77

EndModule

;

Module = "IN/OUT: 32 Byte (16 word)" 0x7F

EndModule

;

Module = "INPUT: 1 Byte" 0x10

EndModule

;

Module = "INPUT: 2 Byte ( 1 word)" 0x50

EndModule

;

Module = "INPUT: 4 Byte ( 2 word)" 0x51

EndModule

;

18

Page 19

Appendices

Anybus

Attachment A

Module = "INPUT: 8 Byte ( 4 word)" 0x53

EndModule

;

Module = "INPUT: 16 Byte ( 8 word)" 0x57

EndModule

;

Module = "INPUT: 32 Byte (16 word)" 0x5F

EndModule

;

Module = "OUTPUT: 1 Byte" 0x20

EndModule

;

Module = "OUTPUT: 2 Byte ( 1 word)" 0x60

EndModule

;

Module = "OUTPUT: 4 Byte ( 2 word)" 0x61

EndModule

;

Module = "OUTPUT: 8 Byte ( 4 word)" 0x63

EndModule

;

Module = "OUTPUT: 16 Byte ( 8 word)" 0x67

EndModule

;

Module = "OUTPUT: 32 Byte (16 word)" 0x6F

EndModule

APPENDICES

Attachment B

Attachment B

89-0754-EDS_ABIC_DEV_3_1.EDS

[File]

DescText = "HMS Anybus-IC DEV";

CreateDate = 11-22-2001;

CreateTime = 07:23:00;

ModDate = 03-14-2007;

ModTime = 14:30:00;

Revision = 3.1;

[Device]

VendCode = 90;

19

Page 20

Anybus

Appendices

Attachment B

APPENDICES

VendName = "HMS Networks";

ProdType = 12;

ProdTypeStr = "Communications Adapter";

ProdCode = 61;

MajRev = 3;

MinRev = 1;

ProdName = "Anybus-IC DeviceNet";

Catalog = "Anybus-IC DeviceNet";

DNetQC =

0x0001, $ Quick Connect supported at Powerup

265; $ 265 ms Powerup time

[IO_Info]

Default = 0x0001; $ Default IO Connection = Poll

PollInfo =

0x000F, $ Compatible IO type mask = All connections

1, $ Input1

1; $ Output1

StrobeInfo =

COSInfo =

CyclicInfo =

Input1 =

0x000F, $ Compatible IO type mask = All connections

1, $ Input1

1; $ Output1

0x0007, $ Compatible IO type mask = All connections

1, $ Input1

1; $ Output1

0x000B, $ Compatible IO type mask = All connections

1, $ Input1

1; $ Output1

1, $ 1 byte

0, $ All bits are significant

0x000F, $ Compatible IO type mask = All connections

20

Page 21

Appendices

Anybus

Attachment B

"ABIC Produce", $ Name

6, $ Path size

"20 04 24 64 30 03", $ Assembly object, Inst 100, Attr 3

"Data produced by the Anybus-IC";

Output1 =

1, $ 1 byte

0, $ All bits are significant

0x000F, $ Compatible IO type mask = All connections

"ABIC Consume", $ Name

6, $ Path size

"20 04 24 96 30 03", $ Assembly object, Inst 150, Attr 3

"Data consumed by the Anybus-IC ";

[ParamClass]

MaxInst = 0; $ Max Instances - total # configuration parameters

Descriptor = 0x0000; $ Parameter Class Descriptor - No parameters

CfgAssembly = 0; $ The config assembly is not supported.

APPENDICES

21

Page 22

Anybus

Definitions

Glossary of Terms

and Denitions

Aa

DEFINITIONS

EDS Electronic Data Sheet

IP Internet Protocol

PC Personal Computer

TERM Termination Resistor

22

Page 23

Index

Index

Anybus Chip Location, p. 15

Attachment A, p. 16

Attachment B, p. 19

CAN-H and CAN-L Termination Resistor, p. 9

Configuring Ethernet IP (Fixed Address), p. 12

Configuration

DeviceNet, p. 10

Ethernet, p. 12

Profibus, p. 8

Data Organization, p. 5

FT2A Registers, p. 5

Status Bits Definitions, p. 6

Control, p. 6

DeviceNet Baud Rate, p. 10

DeviceNet Configuration File, p. 10

Ethernet Automatic IP Address Configuration, p. 12

Ethernet Manual IP Address Configuration, p. 12

Introduction, p. 4

Scope, p. 4

LED Indicators, p. 14

Profibus Baud Rate, p. 8

Profibus Configuration File, p. 8

Profibus Functions, p. 8

Profibus ID File, p. 8

Programming, p. 15

Anybus, p. 15

Protecting Access (Ethernet), p. 13

Scope, p. 4

Slave Address, p. 13

Wiring

DeviceNet, p. 9

Ethernet, p. 11

Profibus, p. 7

Anybus

INDEX

23

Page 24

i

Information

Caution

Wiring

Aa

Definition of Terms

Troubleshooting Tips

Loading...

Loading...