Page 1

MODEL FT2

THERMAL MASS FLOWMETER & TEMPERATURE TRANSMITTER

399 RESERVATION ROAD

MARINA, CA 93933

101364 Revision L

Page 2

Revision L ECO0762 08/17/11

Notice

This publication must be read in its entirety before performing any operation.

Failure to understand and follow these instructions could result in serious

personal injury and/or damage to the equipment. Should this equipment

require repair or adjustment beyond the procedures given herein, contact the

factory at:

FOX THERMAL INSTRUMENTS, INC.

399 RESERVATION ROAD

MARINA, CA 93933

TELEPHONE: 831-384-4300

FAX: 831-384-4312

EMAIL: SALES@FOXTHERMALINSTRUMENTS.COM

Download Technical Data Sheets from our website:

www.foxthermalinstruments.com

Fox Thermal Instruments believes that the information provided herein is

accurate however be advised that the information contained herein is NOT a

guarantee for satisfactory results. Specifically, this information is neither a

warranty nor guarantee, expressed or implied, regarding performance;

merchantability; fitness; or any other matter with respect to the products; nor

recommendation for the use of the product/process information in conflict

with any patent. Please note that Fox Thermal Instruments, Inc. reserves the

right to change and/or improve the product design and specification without

notice.

101364 Revision L

Page 3

TABLE OF CONTENTS

1. Introduction ..................................................................................................... 1

1.1. Scope ............................................................................................................................................................. 1

1.2. Product Description ....................................................................................................................................... 1

1.3. Block Diagram ................................ ................................ ................................................................ ............... 2

1.3.1. Menu Tree .............................................................................................................................................. 3

1.4. Analog 4-20 mA outputs................................................................................................................................ 5

1.5. Discrete I/O .................................................................................................................................................... 5

1.6. Frequency/Alarm Output ............................................................................................................................... 5

1.7. Local Display Options ................................................................................................................................... 5

1.8. Communication Features ............................................................................................................................... 5

1.9. Dimension Details ......................................................................................................................................... 5

2. Installation......................................................................................................10

2.1. Scope ........................................................................................................................................................... 10

2.2. Insertion Style .............................................................................................................................................. 10

2.2.1. Mounting – Insertion Style .................................................................................................................. 10

2.2.2. Installation Depth ................................................................................................................................. 11

2.2.3. Sensor Orientation ............................................................................................................................... 11

2.2.4. Flowmeter Placement - Insertion Style ................................ ................................................................ 13

2.2.5. Flowmeter Placement - Flow Body Style ............................................................................................ 14

2.2.6. Flow Body Orientation ........................................................................................................................ 15

3. Start Up ..........................................................................................................16

3.1. Scope ........................................................................................................................................................... 16

3.2. Wiring .......................................................................................................................................................... 16

3.2.1. Power Input Wiring and Grounding .................................................................................................... 17

3.2.2. 4 to 20 mA Output Wiring ................................................................................................ ................... 18

3.2.3. Frequency/Alarm Output Wiring ......................................................................................................... 19

3.2.4. RS485 Wiring ...................................................................................................................................... 20

3.2.5. Remote Switch Wiring ......................................................................................................................... 21

3.2.6. Local Sensor Wiring (4 wires) ............................................................................................................. 22

3.2.7. Local Sensor Wiring High Temperature (5 Wire) ............................................................................... 23

3.2.8. Remote Sensor Wiring Installation ...................................................................................................... 24

3.3. Start Up Sequence ........................................................................................................................................ 25

3.4. Measurement Mode ..................................................................................................................................... 25

3.5. 4 to 20 mA Outputs ...................................................................................................................................... 25

3.6. Frequency/Alarm Output ............................................................................................................................. 25

3.7. Local Display Screens ................................................................................................................................. 26

3.7.1. Display Screens ................................................................................................................................... 26

3.7.2. Engineering Screens ............................................................................................................................ 27

3.8. Resetting Total and Elapsed Time ............................................................................................................... 28

3.9. Alarm Indications ........................................................................................................................................ 28

4. Programming .................................................................................................29

4.1. Programming using the Local Display ........................................................................................................ 29

4.1.1. Data Entry using the local display module .......................................................................................... 29

4.1.2. Entering the Programming Mode ......................................................................................................... 30

4.1.3. Analog 4-20 mA Output ...................................................................................................................... 30

4.1.4. Frequency Output ................................................................................................................................ 31

4.1.5. Discrete Input/Output .......................................................................................................................... 33

4.1.6. RS485 Serial Communication Settings ................................................................................................ 34

4.1.7. Display Setup ....................................................................................................................................... 36

4.1.8. Password .............................................................................................................................................. 37

4.1.9. Units Settings ....................................................................................................................................... 38

4.1.10. Flow Parameters .................................................................................................................................. 40

4.1.11. Calibration Parameters ................................................................................................ ......................... 43

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page i

Page 4

TABLE OF CONTENTS … CONTINUED

4.1.12. Reset Total and Elapsed Time ............................................................................................................. 44

4.1.13. Restore Database ................................................................................................................................. 44

4.1.14. Reset CRC ........................................................................................................................................... 45

4.1.15. Simulation ............................................................................................................................................ 46

5. Preventative Maintenance ............................................................................48

5.1. Access to Electronics ................................................................................................................................... 48

5.2. Sensor Cleaning ........................................................................................................................................... 48

5.3. Broken or Damaged Probe ........................................................................................................................... 48

5.4. Calibration ................................................................................................................................................... 48

5.5. Fuse Replacement (Standard and NFP version) .......................................................................................... 48

6. Troubleshooting .............................................................................................49

6.1. Replacements Parts ...................................................................................................................................... 50

6.2. Return Procedure ......................................................................................................................................... 51

Warranty .................................................................................................................52

Glossary of Terms and Abbreviations .................................................................53

Index ........................................................................................................................54

Page ii Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 5

101364 Model FT2

1. Introduction

1.1. Scope

This Instruction Manual describes the electrical and mechanical considerations involved with installing

and maintaining the hardware associated with the Fox FT2 Thermal Mass Flowmeter and Temperature

Transmitter.

This manual is divided into the following sections:

Introduction:

Installation:

Start up:

Programming:

Preventive maintenance:

Troubleshooting:

1.2. Product Description

Theory of Operation

The Model FT2 is an advanced thermal mass flowmeter with temperature transmitter. It is

microprocessor-based and field programmable. The FT2 thermal sensor operates on the law that fluids

absorb heat. Therefore, a heated sensor placed in an air or gas stream transfers heat in proportion to

the stream’s mass velocity. There are two sensors in different legs of a balanced bridge circuit, one

sensor detects the fluid’s temperature and a second sensor is maintained at a constant temperature

(constant T) above the fluid’s temperature. The energy applied to the heated sensor to keep this

constant temperature difference is directly proportional to the mass of the flow velocity. The bridge

circuit maintains accurate flow measurement over a large temperature and pressure range.

Mass Flow

The Model FT2 measures mass flow, an advantage over most flowmeters, which measure volumetric

flow rate. Volumetric flow is incomplete because temperature and pressure are unknown and must be

measured separately. For example, the volume of a gas depends on its temperature and pressure. As

temperature and pressure changes, the gas volume changes but not it’s mass. Therefore a device

measuring mass flow is independent of temperature and pressure. By defining a Standard at 70° F and

1 Atmosphere (14.7 psia), 1 Standard cubic foot of gas equals the mass that is in 1 cubic foot of this

gas at 70° F and 1 Atmosphere.

The Model FT2 provides a direct measurement of Standard or Mass units with no additional

temperature and pressure measurements required.

I/O Description

The FT2 comes with two industry standard 4-20 mA isolated analog outputs, one isolated digital

output that can be used for frequency or alarm output, one programmable discrete input and a RS232

communication channel that can interface to a Palm™ handheld or a PC. The two 4 -20 mA outputs

are scalable for the 4 and 20 mA values and are assigned to flow rate and temperature. The frequency

output is programmable to represent flow rate and can be programmed using span/maximum

frequency, unit per pulse or pulse per units. The maximum frequency is 100 Hz. An optional Modbus

protocol is available in a configurable full or half duplex RS485 interface. In addition, a local display

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 1

Page 6

Model FT2 101364

and keypad for field programming the flowmeter and a serial communication channel for Profibus,

DeviceNet or Ethernet are also available as options.

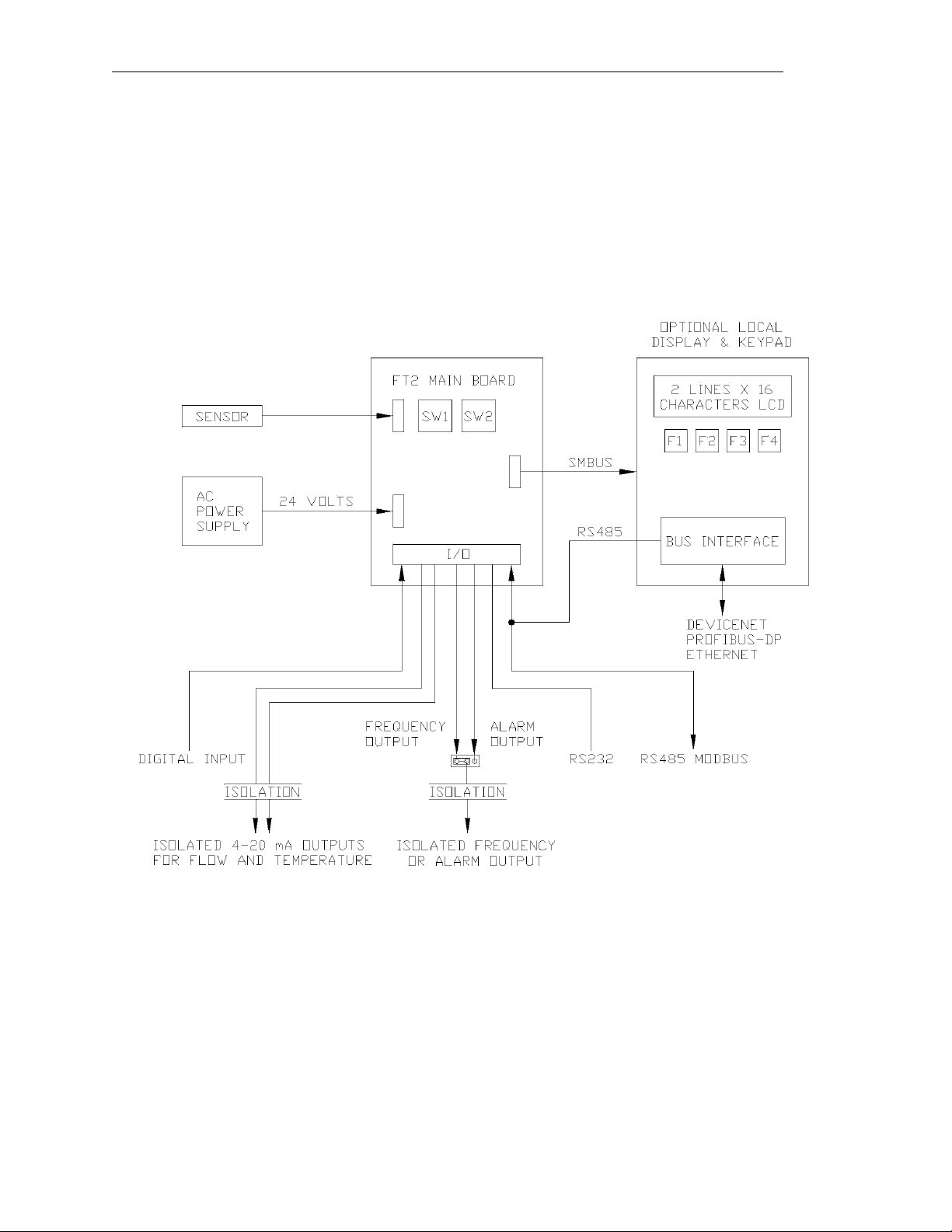

1.3. Block Diagram

The main parts of the FT2 Mass Flowmeter are: The FT2 main board, the sensor assembly, an

optional front panel, and an optional power supply. The two PCBs are mounted inside of the enclosure

and the sensor assembly is mounted external to the enclosure. The optional power supply is mounted

under the main PCB.

Figure 1-1 Block Diagram

Page 2 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 7

101364 Model FT2

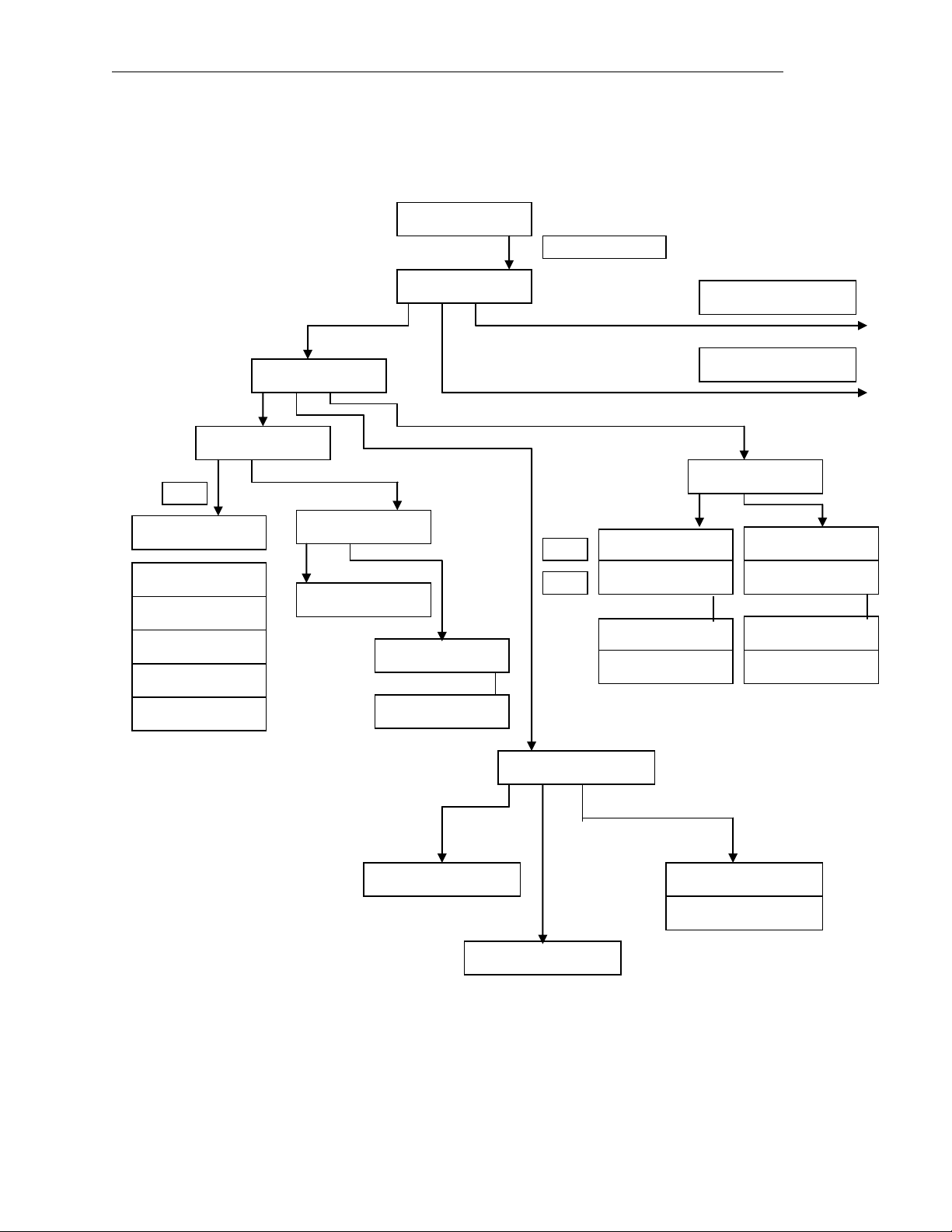

PASWD=

UP DN NXT OK

SET PARAMETERS

I/O FLO DSP EXIT

SET I/O

I/O FEQ 420 EXIT

SET I/O

COM CTC EXIT

Bus = Modbus

NXT OK

Baud = 9600

NXT OK

Parity = EVEN

NXT OK

Data Bits = 8

NXT OK

Stop Bits = 1

NXT OK

LoopID = 1

CHG OK

CONTACT

INP ALM EXIT

Inp = Not Used

NXT OK

ALM = HiFloAlm

NXT OK

FREQUENCY OUTPUT

P/U U/ P FEQ EXIT

PLS/UNT = 12.56

CHG OK

UNT/PLS=0.876

CHG OK

MAXFREQ=100 hz

CHG OK

MAXFLO= 100 SCFM

CHG OK

DISPLAY/PASSWORD

FLOW PARAMETERS

SET 4-20 MA

FLO TMP EXIT

20mACnt=4091

CHG OK

4mACnt=3

CHG OK

20 mA=3750 SCFM

CHG OK

4 ma=0 SCFM

CHG OK

Level2

Level2

If password is accepted

RS485

HiFloAlm=0 SCFM

CHG OK

20mACnt=4093

CHG OK

4mACnt=5

CHG OK

20 mA=112 °F

CHG OK

4 mA=10 °F

CHG OK

1.3.1. Menu Tree

*

*

*

*

*

* ONLY available for MODBUS

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 3

Page 8

Model FT2 101364

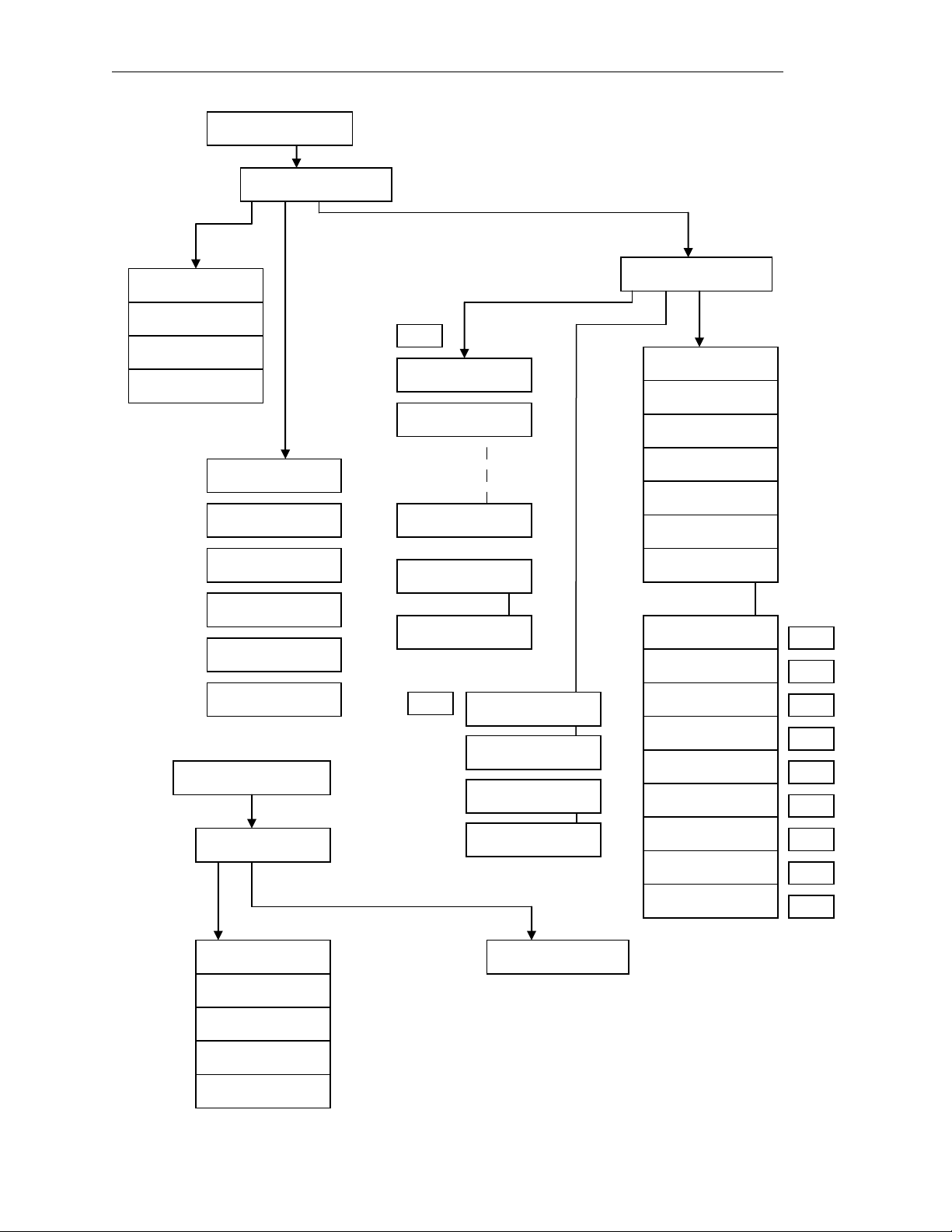

FLOW PARAMETER 1

SIM UNT PRM EXIT

FLOW PARAMETERS

FloSim=0 SCFM

CHG OK

TmpSim=0 °F

CHG OK

CsvSim=0 V

CHG OK

FLO UNT=SCFM

NXT OK

TMP UNT=°F

NXT OK

TmpRef= 60 °F

CHG OK

PRES UNT=mmHG

NXT OK

PresRef=760

CHG OK

DNS = 0.9234 Kg/M3

CHG OK

FLOW PARAMETER 2

CAL SPC PRM EXIT

Volt1=0.9345

CHG PRV NXT EXIT

Flo1=0.0

CHG PRV NXT EXIT

Volt20=1.245

CHG PRV NXT EXIT

Flo20=3756

CHG PRV NXT EXIT

CalDate= 12/7/03

CHG OK

RtdHiRes=282.4 Ohm

CHG OK

RtdHi_F=300 °F

CHG OK

RtdLoRes=192.1 Ohm

CHG OK

RtdLo_F=70 °F

CHG OK

AdcF=0.0005893

CHG OK

Rx= 49.9 Ohm

CHG OK

Restore Database?

Yes No

DISPLAY/PASSWORD

DSP1L1= Flo Rate

NXT OK

DSP1L2= Flo Total

NXT OK

DSP2L1= Temp

NXT OK

DSP2L2= Elps time

NXT OK

ALTERNATE=Off

NXT OK

DISPLAY/PASSWORD

DSP PSW EXIT

PASSWD=1234

CHG OK

Level2

Level 2

Level2

Level2

Level2

Level2

Level2

Level2

ShResOfst=0

CHG OK

Tsv_rt=0.197656

CHG OK

R20_value=2.5

CHG OK

Level2

Level2

Level2

ENABLE SIM ?

YES NO

Cutoff=1.0 SCFM

CHG OK

A2=0.0865 FT^2

CHG OK

Filter=0.5

CHG OK

HiFloAlm=0 SCFM

CHG OK

LoFloAlm=0 SCFM

CHG OK

HiTmpAlm=0 °F

CHG OK

LoTmpAlm=0 °F

CHG OK

Reset CRC?

Yes No

K fact = 0 %

CHG OK

MaxRTD9 = 16 Ohm

CHG OK

**

** ONLY for Kg/ and LB/

Page 4 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 9

101364 Model FT2

1.4. Analog 4-20 mA outputs

Two industry standard 4-20 mA isolated analog outputs are available to monitor flow rate and

temperature. Each output is scalable for the 4 and 20 mA values. See the programming section for

details.

1.5. Discrete I/O

One discrete input is available for remote resetting of the totalizer and elapsed time.

One isolated discrete output is available for generating an alarm for High or Low limits for temperature

or flow rate, if the output is not used for the pulse output.

1.6. Frequency/Alarm Output

One isolated frequency output is available to monitor flow rate and is typically used for totalization.

The maximum frequency output is 100 Hz. The output can be scaled by using the flow setting and

maximum frequency or using the pulse per unit or unit per pulse method of entry. The isolated digital

output can be used either as a frequency output or an alarm output but not both. The output type is

selected by JP1.

1.7. Local Display Options

An optional front panel with a LCD display and keypad is available to display measured data and

allow field programming of the flowmeter. The display is an easy to read, two-lines, 16 characters

backlit LCD and 4 function keys. The local display/keypad module is wired to the FT2 electronics

through connector TS6. TS6 is on the main board. Refer to the Programming section for a detailed

explanation of its usage.

1.8. Communication Features

The FT2 offers a RS232 serial link that communicates to a Palm™ PDA handheld or with a PC

application for data display and programming. Also, RS485 is available to connect to the optional

front panel with an interface to a specific bus converter (Profibus, DeviceNet or Ethernet). The RS485

can connect directly as an optional Modbus interface. Only one bus protocol is supported at one time.

1.9. Dimension Details

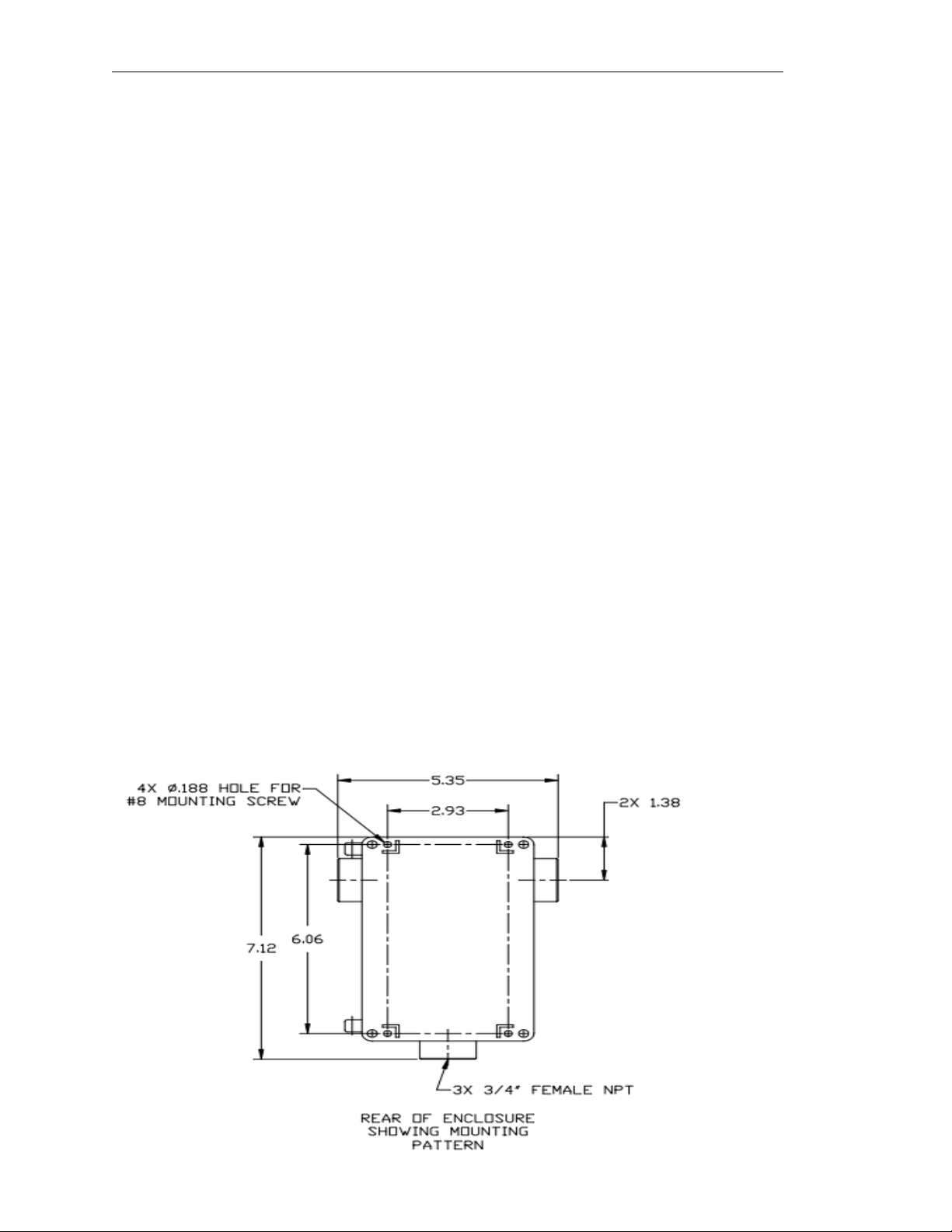

Figure 1-2 Enclosure Mounting Dimensions

Rear View of

enclosure without

sensor or conduit.

AC power enters on

one side, DC power

and signals enter on

the other side.

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 5

Page 10

Model FT2 101364

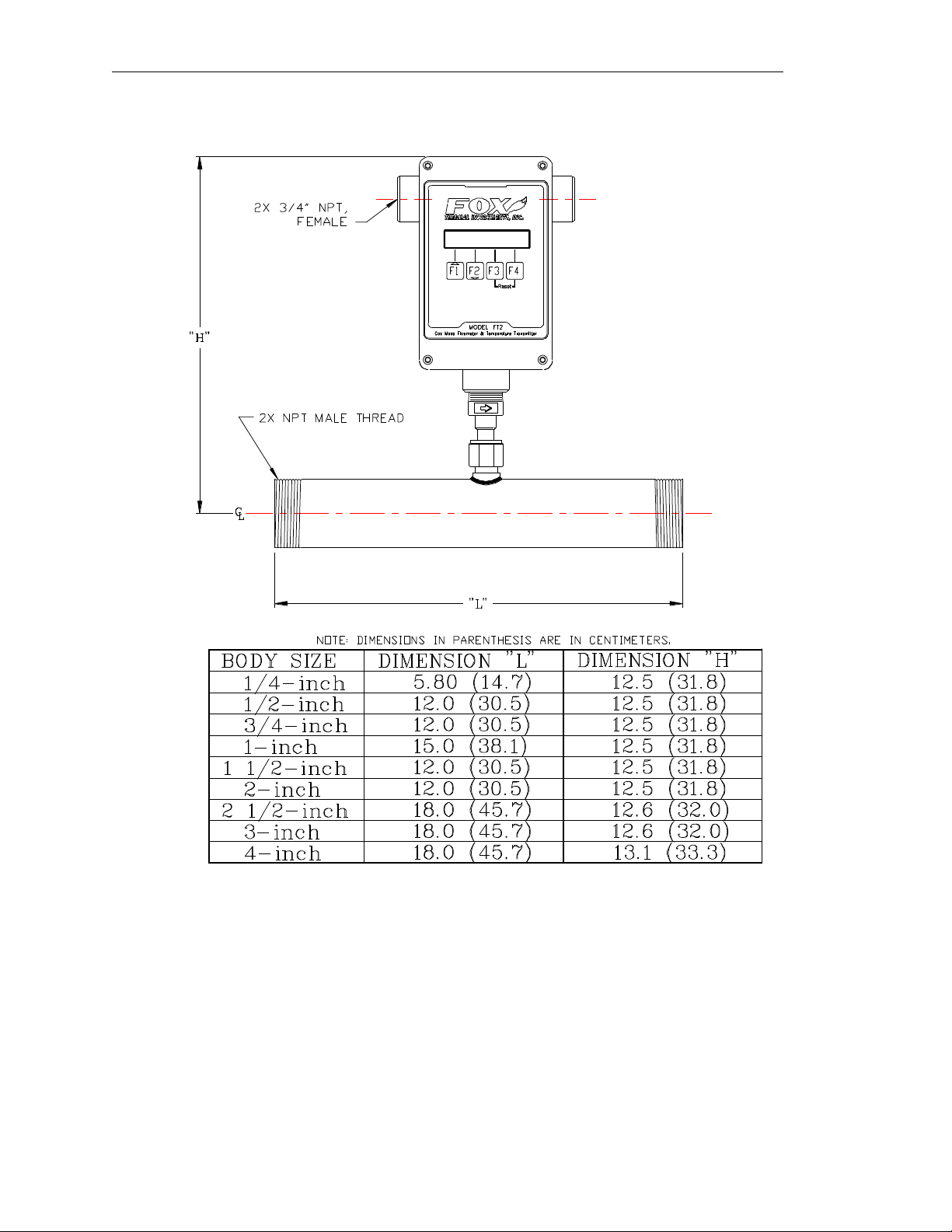

Figure 1-3 Dimensions for Flow Body Style with NPT Connections

Page 6 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 11

101364 Model FT2

Figure 1-4 Dimensions for Flow Body with Flange Connections

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 7

Page 12

Model FT2 101364

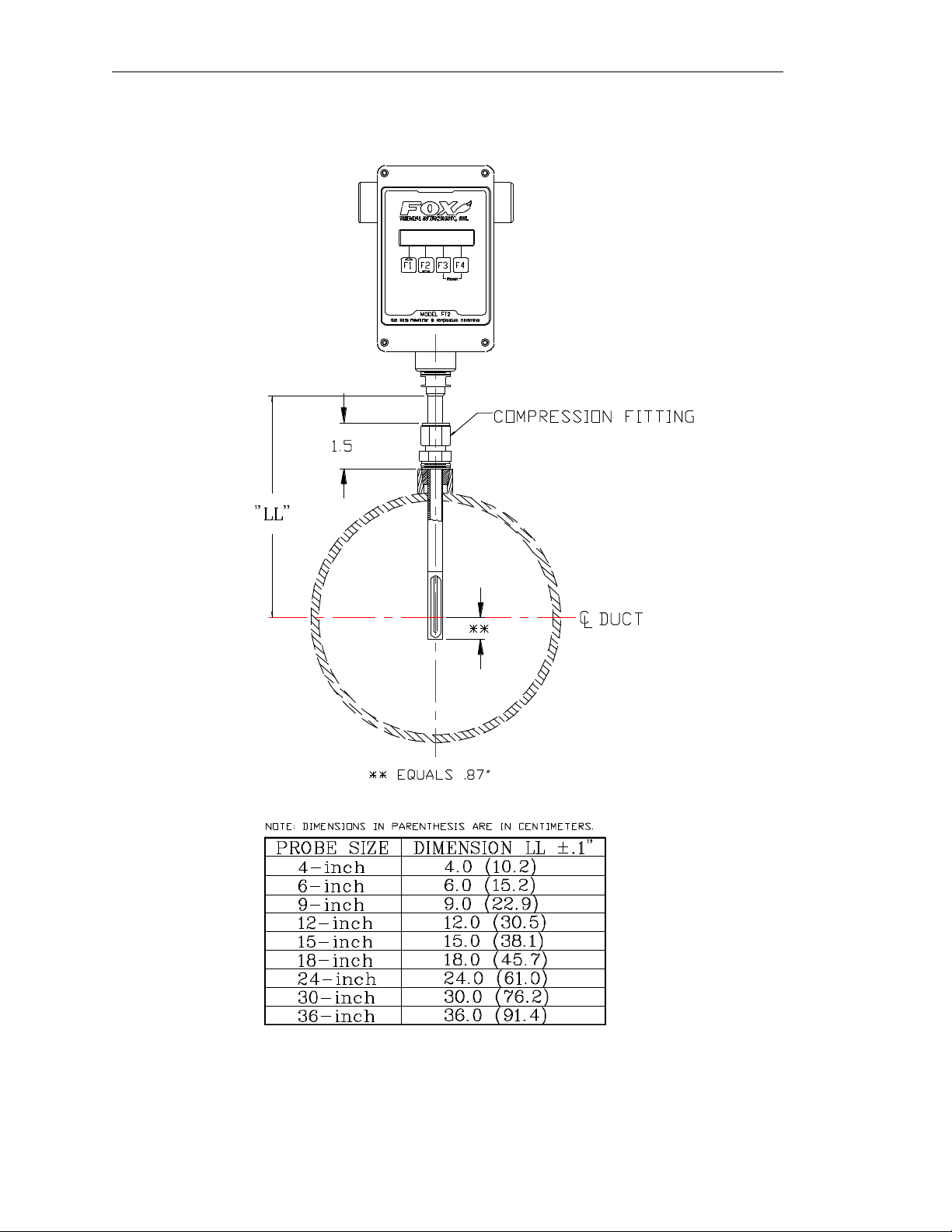

Figure 1-5 Dimensions for Insertion Style

Page 8 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 13

101364 Model FT2

Figure 1-6 Dimensions for Remote NEMA 4 Enclosure

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 9

Page 14

Model FT2 101364

2. Installation

2.1. Scope

This section describes how to install the FT2 flowmeter and how to get started.

The following, general precautions should be observed:

a. Exercise care during handling to avoid damaging the probe, sensor or enclosure.

b. The enclosure cover must be closed except during installation and programming.

c. Mounting FT2 in direct sunlight can cause the temperature inside the enclosure to increase

beyond design limits, resulting in failure of the LCD display and reduced component life. It

is recommended that a sunshade be installed to avoid direct sunlight.

d. Ensure that the arrow on the flow body is pointing in the direction of flow.

e. Do not install the FT2 enclosure near an igniter, igniter controller or switching equipment.

f. Do not install an external power supply in a cabinet containing an igniter controller or

switching equipment.

g. Do not power the power supply with an AC power source that is also used to power an igniter

or igniter controller.

2.2. Insertion Style

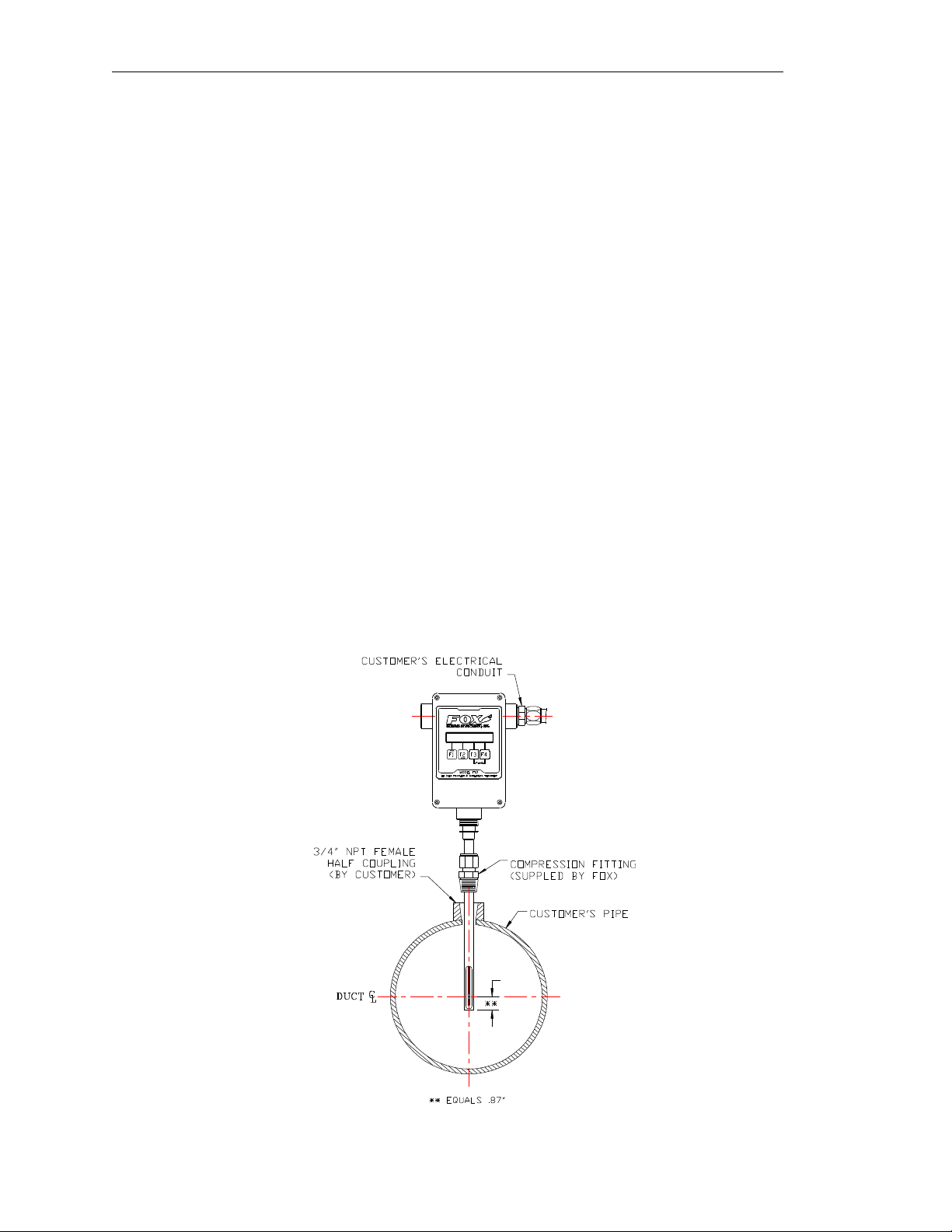

2.2.1. Mounting – Insertion Style

The Model FT2 is mounted through a ¾-inch hole and a ¾-inch female NPT half coupling

provided in the customer’s pipe. Installation procedures must be a combination of end user’s best

engineering practices, in compliance with local codes, and manufacturer’s recommendations.

Insertion style flowmeters are not recommended for pipes smaller than 1½”.

Figure 2-1 Insertion Style

Page 10 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 15

101364 Model FT2

2.2.2. Installation Depth

Note: Some flowmeters are shipped with sensors that have equal length elements (see Figure 2-2).

Others are shipped with the sensor elements that are offset (see Figure 2-3). The sensor type supplied

was selected at the factory to be the best suited for your application. Follow the appropriate sensor

orientation instructions below. (Refer to Figure 1-5)

a. Install the compression fitting into the ¾-inch female NPT half coupling.

b. When installing in a 2-inch pipe or larger, install the end of the probe 0.87-inch past the

centerline of the pipe and tighten the compression fitting nut. Refer to Figure 2-1.

c. When installing into a 1½-inch pipe carefully install the probe into the pipe until it touches the

opposite wall and pull back 0.1-inch. Tighten the compression fitting nut.

Caution: Once the compression fitting is locked onto the probe, the probe can be removed or

rotated, but the insertion depth is locked in place.

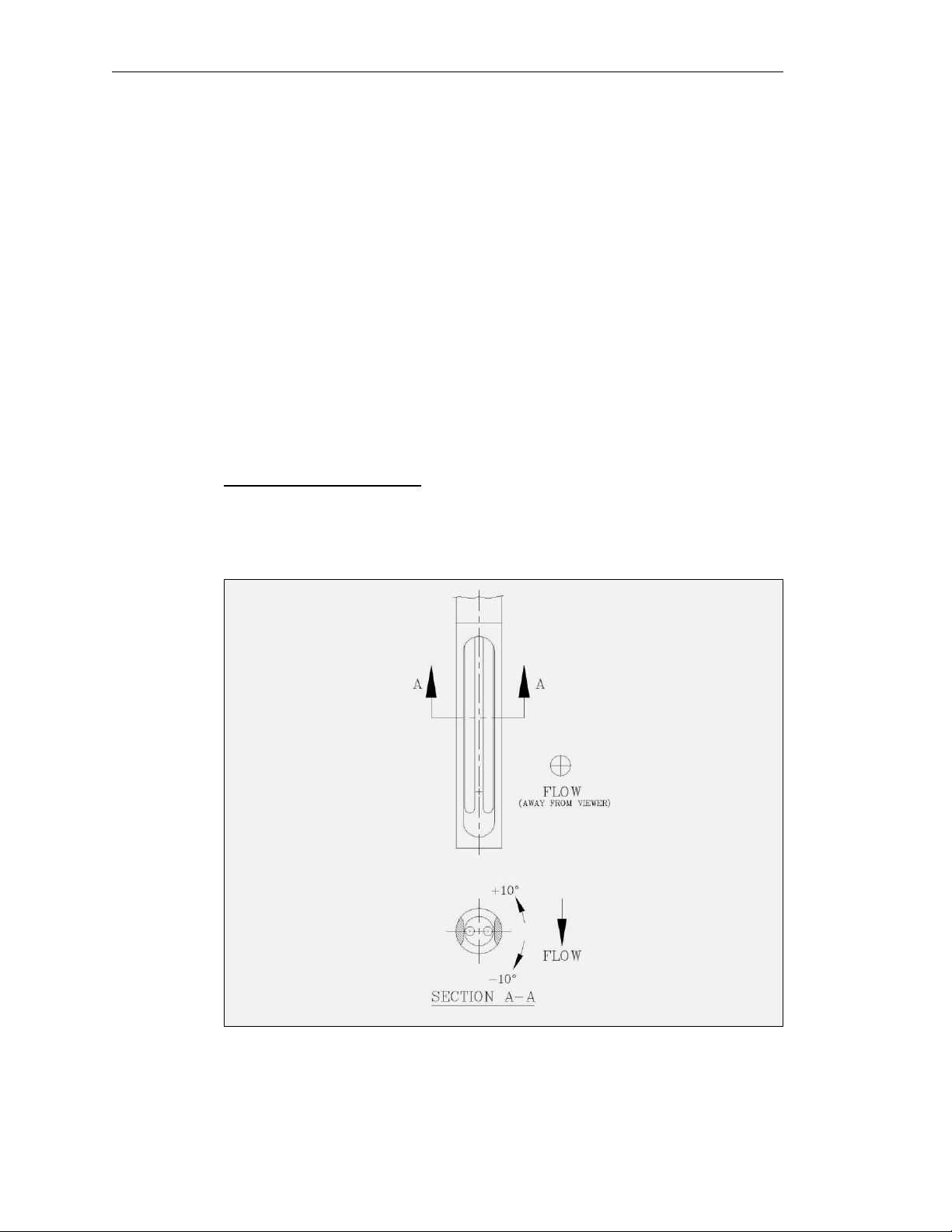

2.2.3. Sensor Orientation

Equal length sensor elements:

Install flowmeter with both sensor elements facing the flow stream within +/-10 degree.

Figure 2-2. Equal Length Sensor Elements.

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 11

Page 16

Model FT2 101364

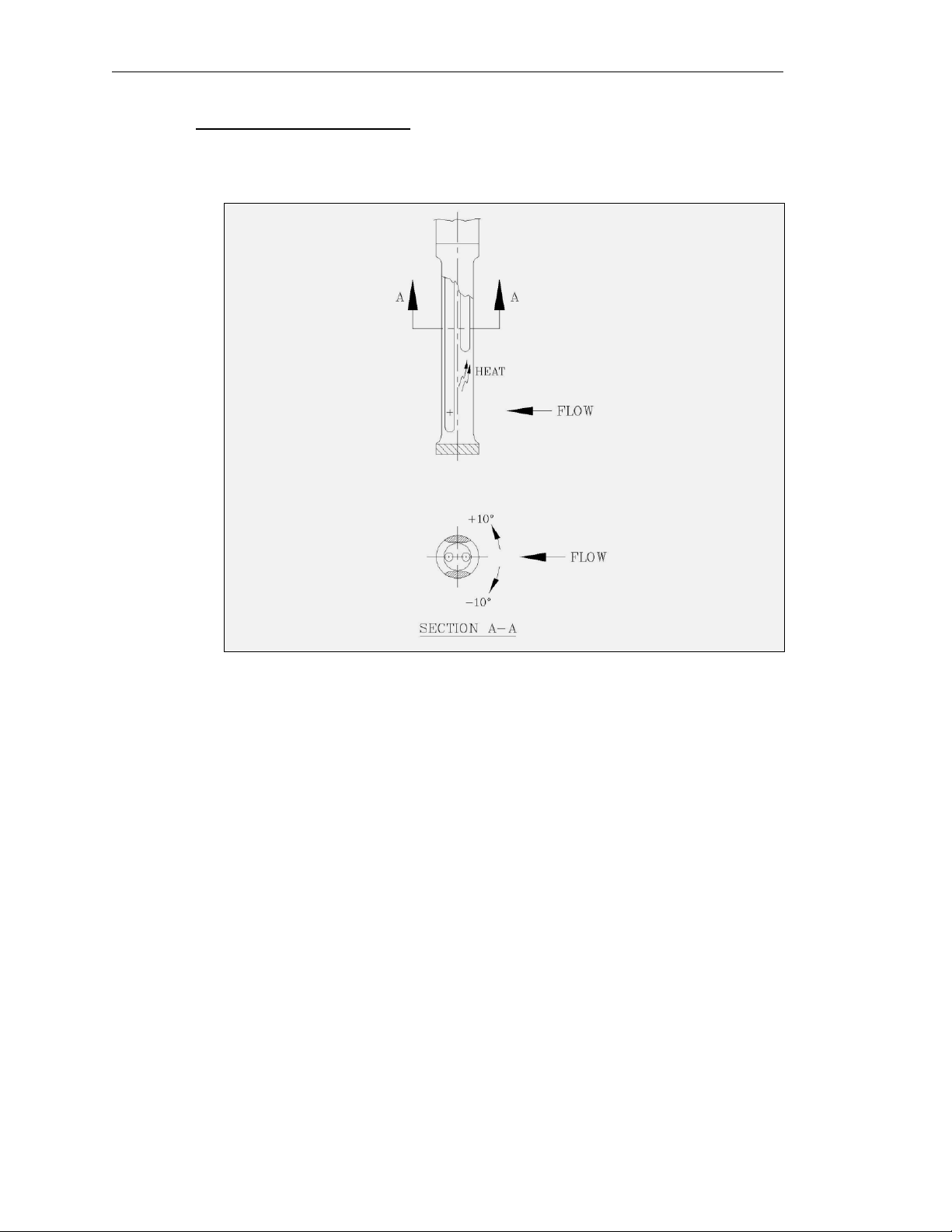

Unequal length sensor elements:

Install the shorter sensor element upstream from the longer one.

Figure 2-3 Unequal Length Sensor Element

Note: In extreme low flow measurements (below 30 standard feet per minute), convection heat

from the longer probe can affect the shorter probe. In these applications, chose a mounting that

prevents this from occurring (ex. Horizontal mounting).

Page 12 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 17

101364 Model FT2

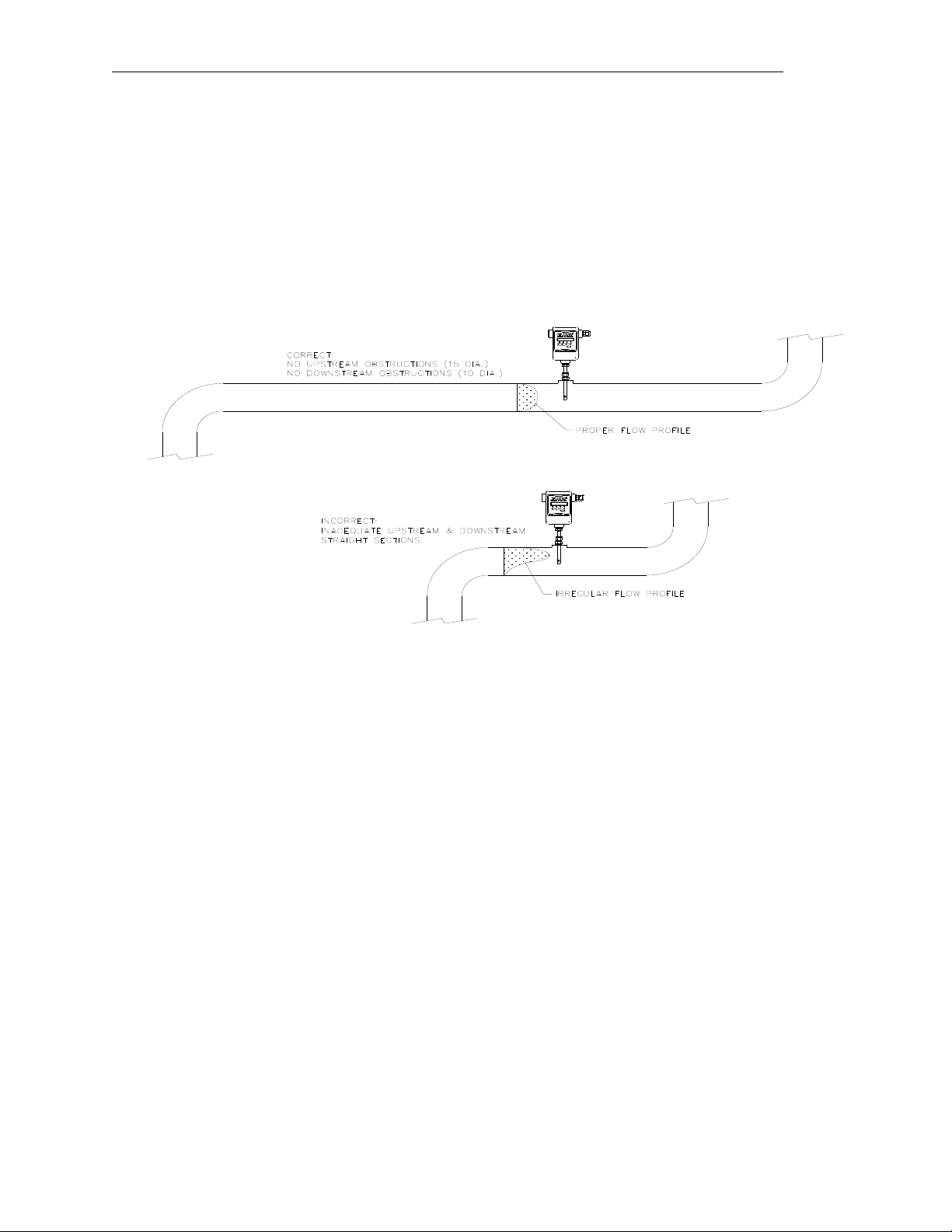

2.2.4. Flowmeter Placement - Insertion Style

Install the Model FT2 Insertion style flowmeter so that it is far enough away from bends in the

pipe, obstructions, or changes in line sizes to ensure a consistent flow profile. Fifteen diameters of

straight pipe upstream and ten downstream are recommended.

Figure 2-4 Flowmeter Placement – Insertion Style

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 13

Page 18

Model FT2 101364

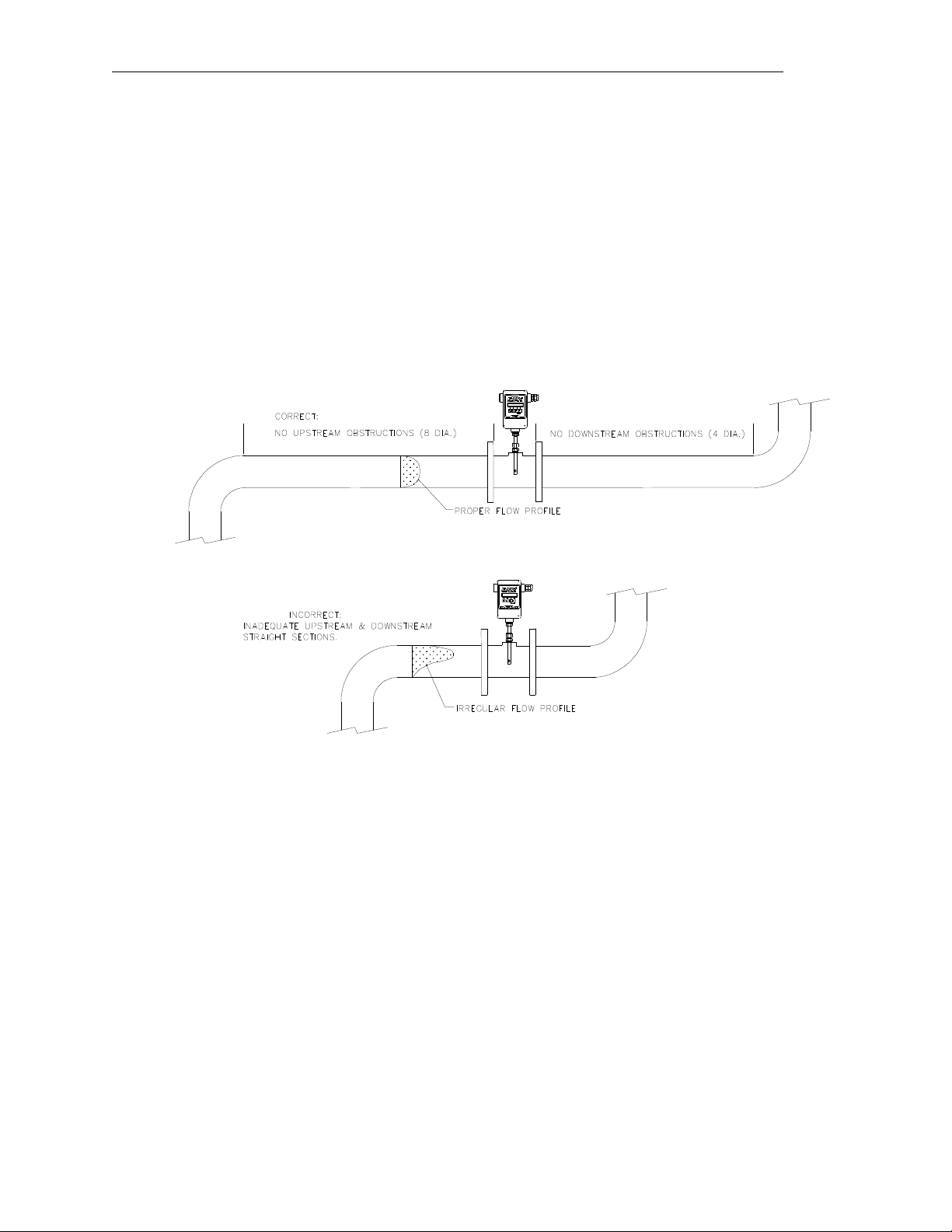

2.2.5. Flowmeter Placement - Flow Body Style

Install the Model FT2 Inline style flowmeter so that it is far enough away from bends in the pipe,

obstructions, or changes in line sizes to ensure a consistent flow profile. Eight diameters of

straight pipe upstream and four downstream are recommended.

The Model FT2 is welded, threaded or flanged to the customer’s pipe. Care should be taken to

ensure that the diameter of the mating pipe is the same diameter as the Model FT2 flow body or

errors in flow readings can occur. Installation procedure should be a combination of the end

user’s best engineering practices, in compliance with local codes, and the manufacturer’s

recommendations.

Figure 2-5 Flowmeter Placement - Flow Body Style

Page 14 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 19

101364 Model FT2

Figure 2-6 Flow Body Style

2.2.6. Flow Body Orientation

Install the flow body so that the arrow on the outside of the flow body is in the direction of flow.

This will ensure the correct sensor orientation.

Note: In extreme low flow measurements (below 30 standard feet per minute), convection heat

from the longer probe may affect the shorter probe (see Figure 2-3, View A-A). In these

applications, chose a mounting orientation that prevents this from occurring (ex. horizontal

mounting).

Figure 2-7 Flow Body Orientation

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 15

Page 20

Model FT2 101364

3. Start Up

3.1. Scope

This section describes the steps needed to get the FT2 Flowmeter running.

The enclosure has two separate conduit entries to maintain separation between AC input power and

output signal wiring. To eliminate the possibility of noise interference, use a separate cable entry for

AC power and signal lines.

Figure 3-1 Input Wiring

Note: All references to conduit orientation are from the Front Panel perspective.

3.2. Wiring

Warning! All installation procedures must be performed with power Off.

All plumbing and electrical installations of flow meters must be a combination of the end user’s best

engineering practices, in compliance with local codes, and the manufacturer’s recommendations.

Do not install the FT2 enclosure near an igniter, igniter controller or switching equipment.

Do not install an external power supply in a cabinet containing an igniter controller or switching

equipment.

Do not power the power supply with an AC power source that is also used to power an igniter or

igniter controller.

Wiring Installation

Warning! This flowmeter contains components that can be damaged by static electricity. You

must discharge yourself by touching a grounded steel pipe or other grounded steel material prior

to working inside this flowmeter.

Wiring is accomplished by loosing the 4 captive screws holding the cover of the enclosure to expose

the electronic circuit boards. Bring customer supplied wires into the enclosure through the conduit

access on the sides of the enclosure. Cut wires for a 2-inch service loop. Use stranded copper wire, no

larger than 16-gauge. If you are using the optional AC power supply, connect the two AC wires and

the safety ground to the TS7 connector marked as AC (bring AC wires in through the left-hand conduit

hub). If an external 24 VDC power source is used, it is recommended that a twisted shielded pair cable

be used. Connect the wires to connector TS1 being careful to connect with the correct polarity (bring

DC wires in through the right-hand conduit hub).

Page 16 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 21

101364 Model FT2

Signal Wires

Always use a separate shielded cable for each output signal, select the proper wire gauge. The

recommended wire gauge is 18 to 22 AWG. The cable shield should not be connected at the

flowmeter, the shield should be connected at the AC ground terminal at the power supply or

instrumentation AC ground terminal.

3.2.1. Power Input Wiring and Grounding

If the optional AC power supply is supplied by FOX, the input power can be 85 to 250 VAC. If the

customer supplies an external power supply, it must supply 24 VDC +/- 10 %, with a minimum of one

amp.

The enclosure must be properly grounded with a quality earth ground to protect the electronics from

static discharges. It is recommended that 16 gauge, stranded wire be used.

Figure 3-2 Power Input Wiring

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 17

Page 22

Model FT2 101364

Important note: The load

resister on the Fox

Flowmeter 4 to 20 mA

signal is typically 250

ohms and is located in or

at the customers PLC or

DCS. A 250 ohm resister

in the 4 to 20 mA line will

result in a 1 to 5 VDC

signal to the PLC or DCS.

Some PLC/DCS

equipment has the load

resister built into the unit;

please refer to the

PLC/DCS technical

manual. Do not exceed a

600 ohm load on the Fox

Flowmeter 4 to 20 mA

signal.

3.2.2. 4 to 20 mA Output Wiring

Bring the 4 to 20 mA wiring in through the right-hand conduit hub. Connect FLOW RATE 4 to 20

mA output to TS2, 1(+) & 2(-). Connect TEMPERATURE 4 to 20 mA output to TS2, 3(+) & 4(-).

Figure 3-3 Isolated Wiring for the 4-20mA Outputs

Page 18 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Figure 3-3A Non-Isolated Wiring for the 4-20mA Outputs

Page 23

101364 Model FT2

3.2.3. Frequency/Alarm Output Wiring

Bring frequency/alarm wiring in through the right-hand conduit hub. Connect to TS2, 5(+) & 6(-). The

frequency/alarm output is an open collector circuit capable of sinking a maximum of 10 mA of current.

The frequency output is selected when JP1 pins 1 & 2 are connected together using the shunt provided.

The alarm output is selected when JP1 pins 2 & 3 are connected together. Only one of the options can

be active at one time.

Figure 3-4 Frequency/Alarm Output Wiring

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 19

Page 24

Model FT2 101364

3.2.4. RS485 Wiring

W1 jumper is to terminate the bus with a 121ohm resistor and should only be installed on the last

instrument of the daisy chain. W3 and W4 are used for half duplex operation. (W3 connects TX+ &

RX+, W4 connects TX- & RX-).

Figure 3-5 RS485 Wiring and Configuration

Page 20 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 25

101364 Model FT2

3.2.5. Remote Switch Wiring

A remote switch can be used to reset the Totalizer and elapsed time, if enabled by the

programming mode. The switch contacts are de-bounced on the FT2 board. There is no polarity

requirement on these connections. Use TS2-12 and TS2-13.

When the 2 curve option is ordered the switch can be used to switch between curves.

Figure 3-6 Remote Switch Wiring

Note: Remote switch functionality needs to be enabled using the display front panel.

See programming section 4.1.5.1

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 21

Page 26

Model FT2 101364

3.2.6. Local Sensor Wiring (4 wires)

Note: Sensor terminations are performed at the factory except when Remote Electronics are provided.

Figure 3-7 Local Sensor Wiring (4 Wire)

Page 22 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 27

101364 Model FT2

3.2.7. Local Sensor Wiring High Temperature (5 Wire)

Note: Sensor terminations are performed at the factory except when Remote Electronics are provided.

Figure 3-8 Local Sensor Wiring High Temperature (5 Wire)

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 23

Page 28

Model FT2 101364

3.2.8. Remote Sensor Wiring Installation

Note: Remote wiring is only required when the Remote Electronics options is provided.

Five wire shielded cable required. The shielded cable should be ran through a separate grounded steel

conduit. (No other cables or wires in the conduit.)

Connect sensor wires as follows: Red wires to terminals # 1 and # 2, white wires to # 5 and # 6 and

yellow wire to # 3, cable shield to # 4 (see Figure 3-8).

Connect other end to connector TS8 (see Figure 3-7) on the main FT2 board as follows:

Red wires to TS8 pin 1 & 2, white wires to TS8 pins 5 & 6 and yellow wire to TS8 pin 3.

If you are using your own cable, make sure that the cable does not exceed 100 feet and has a wire

resistance that does not exceed one ohm (18 AWG recommended). Do not connect the shield at the

FT2 enclosure end. On the FT2 board, make sure that the jumper W2 is not across both pins when a

5-wire sensor is supplied (see Figure3-8).

Figure 3-9 Remote Sensor Wiring (5 wire) (see also Figure 1-6)

Page 24 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 29

101364 Model FT2

3.3. Start Up Sequence

The program automatically enters the Run/Measure mode after power up. If the Local display is

installed, the screen will show the software versions for the FT2 and the display module.

Refer to section 4.1 Programming using the Local Display. Programming of the flowmeter can also

be accomplished using a Palm™ handheld or a Windows-based PC program. The PC requires a null

modem connection.

The device used to program the unit must have FOX software installed, prior to beginning the

programming operation. FT2 View required for Windows.

3.4. Measurement Mode

In the measurement mode, there are 4 different display screens (display 1, 2, 3 and a prompt screen to

enter the programming mode), 2 display screens are user programmable (refer to section 4.1.7).

Scrolling through the display is accomplished by pressing the F1 or F2 key to view the next or

previous screen. Pressing the F1 and F2 keys at the same time enters the Engineering Menu screens

(display 10 through 22). Keys F1 and F2 are use to scroll through the different screens and key F4 to

EXIT to the normal menu screen.

Pressing the F3 & F4 keys at the same time brings up the Total Reset screen prompt.

3.5. 4 to 20 mA Outputs

The two isolated analog 4-20 mA outputs are available at connector TS2. Pins 1(+) & 2(-) are used for

the analog output associated with the flow rate. Pins 3(+) & 4(-) are used for the 4-20 mA output

associated with the temperature. Both require power for the loop to operate. Refer to Figure 3-3 for

wiring.

3.6. Frequency/Alarm Output

The frequency or alarm isolated output is available at connector TS2 pins 5(+) & 6(-). When using the

frequency output, it can be scaled to represent flow rate for totalizing or flow rate indication. Refer to

Figure 3-4 for wiring.

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 25

Page 30

Model FT2 101364

1456.5 SCFM

123456 SCF

Elp=14.6 HR

88.5 °F

Alarm=None

Elp=14.6 H

SET PARAMETER?

No Yes

F2

F1

F1

F1

F2

F2

F3

F4

F4

F2

F1

3.7. Local Display Screens

3.7.1. Display Screens

F1 key: Moves up one screen

F2 key: Moves down one screen

Display #1 (User programmable screen)

Enter “totalizer reset screen” when F3 & F4

are pressed at the same time.

Display #2 (User programmable screen)

Enter “engineering display screens” when

F1 & F2 are pressed at the same time

Display #3 (Fixed screen)

Prompt screen to enter programming mode

Display #4

Enter programming screen

Requires correct password. Default is 1234.

Note: CRC ERROR will flash on the display if a CRC Error is detected while reading the EEPROM.

Alarm Code 36 will be displayed in the Alarm Display. Refer to 4.1.14 RESET CRC.

Page 26 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 31

101364 Model FT2

Flo=1255 SCFM

Csv=0.45678 Volt

Csv=1456.5 cnt

Vel=123456 FT/H

CsvFlt=1456.2 cnt

Vel=23456.1 M/H

TsiAvr = 761.6 cnt

TsvAvr=932.6 cnt

Tsi=0.8765 Volt

Tsv=0.8675 Volt

Tsi=0.09827 Amp

Tsi=247.8 Ohm

RTD9 = 11.9 Ohm

GasTemp = 88.5 °F

Flo_420=4091 cnt

Tmp_420 = 2356 cnt

Feq = 2345 cnt

Alarm = None

FloHi = 1000 SCFM

FloLo = 0 SCFM

TmpHi = 100 °F

TmpLo = 50 °F

ELP = 11.77 HR

Stat(hex)=0000

Vers=FT2 V1.40

Display V1.22

Back to Display #10

Pwr_cyc=0

Err_tot=0

3.7.2. Engineering Screens

Pressing F1 and F2 keys at the same time in the normal mode, brings the engineering screens.

These screens display internal parameters of the FT2, which are used by Fox service personnel.

Display # 10 F1 key: Move up one screen

F2 key: Move down one screen.

F4 key: Exit engineering screen.

Display #11

Display #12

Display #13

Display #14

Display #15

Display #16

Display #17

Display #18

Display #19

Display #22

Display #20

Display #23

Display #21

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 27

Page 32

Model FT2 101364

Code

Description

12

Power up Initializing

13

Flow rate above high limit

14

Flow below low limit

15

Temperature above high limit

16

Temperature below low limit

22

Sensor out of range

23

Velocity out of calibration table range

24

Check settings

25

Simulation mode

26

Frequency output over range

32

4 to 20 mA for flow rate is out of range

33

4 to 20 mA for temperature is out of range

34

ANYBUS communication error

35

RTC Error

36

EEPROM CRC Error

37

Totalizer error detected

Reset Total ?

NO YES

F1

F2

F3

F4

PASWD:

UP DN NXT OK

F1

F2

F3

F4

3.8. Resetting Total and Elapsed Time

Pressing F3 and F4 at the same time in the normal running mode brings the prompt to reset the

totalizer and elapsed time:

If the password is active the program will prompt the user to enter the password:

If the password is correct, the reset will be performed, otherwise a “Wrong Password” message will be

displayed briefly before returning to the normal mode.

Note: To disable the programmable password set it to “0”.

3.9. Alarm Indications

Alarm indications are provided to indicate any malfunctions, out of range values or saturated analog

outputs.

The following list is a description of alarm codes:

Page 28 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 33

101364 Model FT2

VALUE = 0.91234

CHG OK

F1

F2

F3

F4

VALUE = 0.91234

UP DN NXT OK

F1

F2

F3

F4

FLO UNT = SCFM

NXT OK

F1

F2

F3

F4

4. Programming

4.1. Programming using the Local Display

4.1.1. Data Entry using the local display module

There are 2 basic types of menu entries: one for changing value or string and one for selecting

from a selection list.

4.1.1.1. To Change a Value or String :

Press CHG (F1) key to change the value, OK (F4) to accept the value.

Press the UP (F1) or DN (F2) key to select a new digit or character, the cursor points to

the selected digit. Press NXT (F3) to select the next digit and OK (F4) to accept the

entry.

Note: If the UP (F1) or DN (F2) key is held down for more the 1 second, the program

will progressively select new digits at increasing speed as time increases.

4.1.1.2. To Select from a List:

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 29

Press NXT (F1) key repeatedly until the correct selection is made and OK (F4) key to

accept the entry.

Page 34

Model FT2 101364

SET PARAMETERS ?

No Yes

F1

F2

F3

F4

PASWD:_

UP DN NXT OK

F1

F2

F3

F4

SET PARAMETERS

I/O FLO DSP EXIT

F1

F2

F3

F4

SET I/O

I/O FEQ 420 EXIT

F1

F2

F3

F4

4.1.2. Entering the Programming Mode

To enter the programming mode, press the F1 or F2 key repeatedly in the normal running mode

until the following screen is shown:

Press YES (F4) and the following screen will prompt the user to enter the password if it is active:

Enter the correct password, follow the instructions for changing a value as specified in section

4.1.1. The default Level 1 password is “1234”.

If the wrong password is entered, the message “Wrong Password” will be displayed for a few

seconds and then returns to the programming entry screen.

If the password is accepted, the following screen will be shown:

This is the base screen for the programming mode.

Press EXIT (F4) repeatedly until “Normal Mode” is seen briefly to exit the programming

mode.

4.1.3. Analog 4-20 mA Output

The following menu allows the scaling of the analog 4-20 mA outputs.

From the base screen, press I/O (F1) and then in the next screen press 420 (F3).

Page 30 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 35

101364 Model FT2

20 mA = 3751 SCFM

CHG OK

F1

F2

F3

F4

4 mA = 0 SCFM

CHG OK

F1

F2

F3

F4

FREQUENCY OUTPUT

P/U U/P FEQ EXIT

F1

F2

F3

F4

SET 4-20 MA

FLO TMP EXIT

F1

F2

F3

F4

Then select either FLO (F1) or TMP (F2) for flow rate or temperature channel.

Enter the value for the 20 mA and press OK (F4) key to accept setting.

Then the following screen will show:

Enter the value for the 4 mA and press OK (F4).

Note: 4 mA is normally set to 0.

Press EXIT (F4) repeatedly until “Normal Mode” is seen briefly to exit the programming mode.

Note: When the flow rate exceeds the programmed value for the 20 mA set point, the analog

output will stay at 20 mA and an alarm code will be generated.

4.1.4. Frequency Output

From the base screen, press I/O (F1) and then FEQ (F2)

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 31

The frequency output can be configured in three different ways: (1) specifying a maximum

frequency to a defined maximum value of flow rate, (2) specifying how many flow unit total per

pulse, U/P (i.e. 0.1 lb per pulse) or (3) specifying how many pulses per unit, P/U, of mass. All

these approaches are equivalent.

Use P/U (F1) to enter pulse per unit, U/P (F2) for Unit per pulse and FEQ (F3) to enter the flow

and maximum frequency to scale the frequency output.

Page 36

Model FT2 101364

PLS/UNT = 100

CHG OK

F1

F2

F3

F4

UNT/PLS = 0.01

CHG OK

F1

F2

F3

F4

MaxFreq=98.52 Hz

CHG OK

F1

F2

F3

F4

Maxflo=2000 SCFM

CHG OK

F1

F2

F3

F4

When data is entered with any of the 3 methods, the other values will be re-calculated according to

the settings.

4.1.4.1. Entering data in Pulse per Unit:

Press P/U (F1) and the following screen will show:

Press CHG (F1) to change the setting and then OK (F4) to accept entry.

The value entered is in pulse per selected flow unit total (i.e. 10 pulses per SCF)

4.1.4.2. Entering data in Unit per Pulse:

Press U/P (F2) and the following screen will show:

Press CHG (F1) to change the setting and then OK (F4) to accept entry.

The value entered is in unit per pulse (i.e. 0.01 flow unit total per pulse)

4.1.4.3. Entering data with flow and maximum frequency:

Press FEQ (F3) and the following screen will show:

Enter the maximum frequency and press OK (F4)

(Maximum frequency should not exceed 100 Hz)

The next screen will show:

Page 32 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 37

101364 Model FT2

SET I/O

I/O FEQ 420 EXIT

F1

F2

F3

F4

SET I/O

COM CTC EXIT

F1

F2

F3

F4

CONTACTS

INP ALM EXIT

F1

F2

F3

F4

INP = Not Used

NXT OK

F1

F2

F3

F4

Note: When the flow rate exceeds the maximum frequency set point, the output will stay at that

maximum frequency but the FT2 will issue an alarm code.

4.1.5. Discrete Input/Output

To program the discrete input or output, press I/O (F1) key from the base menu

Then press I/O (F1) again:

Then press CTC (F2) to select contact input/output

4.1.5.1. For Discrete Input Settings:

Press INP (F1) key to select input, then menu will display:

Press NXT (F1) repeatedly until the correct selection is shown and then press OK (F4) to

accept the setting.

Selections are: Not used

Tot Reset to reset the totalizer

Switch Crv Multi Curve Option Only

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 33

Page 38

Model FT2 101364

ALM = HiFloAlm

NXT OK

F1

F2

F3

F4

HiFloAlm = 1000 SCFM

CHG OK

F1

F2

F3

F4

SET I/O

I/O FEQ 420 EXIT

F1

F2

F3

F4

4.1.5.2. For Discrete Output Setting:

Press ALM (F2) key to select alarm output, then menu will display:

Press NXT (F1) repeatedly until the correct selection is shown and then press OK (F4) to

accept the setting.

Selections are: Not used

HiFloAlm for High Flow Alarm

LoFloAlm for Low Flow Alarm

HiTempAlm for High Temperature Alarm

LoTempAlm for Low Temperature Alarm

If a Limit type is selected, then the menu will display:

Enter the limit value to trigger the contact alarm output and then press OK (F4) to accept

the setting.

Press EXIT (F4) repeatedly until “Normal Mode” is seen briefly to exit the programming

mode.

The JP1 selection jumper needs to be installed between pin 2 & 3 on the main FT2

board to select the isolated digital output for the alarm.

4.1.6. RS485 Serial Communication Settings

To program the RS485 settings, press I/O (F1) key from the base menu

Then press I/O (F1) again:

Page 34 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 39

101364 Model FT2

SET I/O

COM CTC EXIT

F1

F2

F3

F4

Bus=Modbus

NXT OK

F1

F2

F3

F4

Baud=9600

NXT OK

F1

F2

F3

F4

Parity=None

NXT OK

F1

F2

F3

F4

Press COM (F1) to select RS485 communication bus type and then OK (F4)

Selections are: None

Modbus

Profibus

Ethernet

DeviceNet

Note: Special hardware is needed to use Profibus, DeviceNet and Ethernet

For Modbus selection only

Press NXT (F1) to select the baud rate and press OK (F4)

Selections are: 19200

9600

4800

2400

1200

For Modbus selection only

Press NXT (F1) to select the parity and press OK (F4)

Selections are: NONE

ODD

EVEN

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 35

Page 40

Model FT2 101364

DISPLAY/PASSWORD

DSP PSW EXIT

F1

F2

F3

F4

DSP1L1 = Flo Total

NXT OK

F1

F2

F3

F4

Data Bit=8

NXT OK

F1

F2

F3

F4

Stop Bit=1

NXT OK

F1

F2

F3

F4

Loop ID = 1

CHG OK

F1

F2

F3

F4

For Modbus selection only

Press NXT (F1) to select the data bit and press OK (F4)

Selections are: 7 or 8

For Modbus selection only

(Should always be 1)

Press NXT (F1) to select the stop bit and press OK (F4)

Selections are: 1 or 2

For Modbus selection only

Press CHG (F1) to change the Modbus address and then press OK (F4). To avoid conflicts on the

Modbus this must be a unique address.

NOTE: If any parameter for MODBUS is changed the unit requires a RESET or power cycle for

the new parameters to be loaded.

4.1.7. Display Setup

From the base programming menu press DSP (F3) to select the display menu:

4.1.7.1. To Program the Display:

Press DSP (F1) key. The display will show:

Page 36 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 41

101364 Model FT2

ALTERNATE = Off

NXT OK

F1

F2

F3

F4

DISPLAY/PASSWORD

DSP PSW EXIT

F1

F2

F3

F4

These are the selections for the display #1 line #1.

Selections are: Flo rate for Flow rate

Flo Total for Total mass

Elps time for elapsed time

Temp for temperature

Errors for error codes

When the selection is correct, press OK (F4) to accept it and then the display will go

through the same process for all 4 lines of the 2 programmable displays (DSP1L1,

DSP1L2, DSP2L1 and DSP2L2).

After the last line of display 2 is accepted, the display will show the following menu:

This menu allows you to alternate between menu display 1 and 2 every few seconds.

Selections are: On or Off

Press OK (F4) to accept selection.

Press EXIT (F4) repeatedly until “Normal Mode” is seen briefly to exit the programming

mode.

4.1.8. Password

There are 2 user level passwords, only Level 1 is programmable and gives access to all the normal

settings. The second one is used to allow access to calibration factors, that should normally never

be changed, and to set a new password in the event that the user forgets the Level 1 password.

Default Level 1 password is “1234”, and Level 2 password is “9111”.

The Level 1 programmable password can be disabled by setting it to “0”.

From the base programming menu press DSP (F3) to select the display menu:

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 37

Page 42

Model FT2 101364

PASSWD = 1234

CHG OK

F1

F2

F3

F4

SET PARAMETERS

I/O FLO DSP EXIT

F1

F2

F3

F4

FLOW PARAMETERS 1

SIM UNT PRM EXIT

F1

F2

F3

F4

FLO = SCFM

NXT OK

F1

F2

F3

F4

4.1.8.1. To Program the Password:

Press PSW (F2) key to select password.

This screen displays the current Level 1 password.

Press CHG (F1) key to change the password and enter new value accordingly to 4.1.1

description of entering data.

Press OK (F4) to accept new data and exit programming by pressing EXIT (F4) key

repeatedly until out of the programming mode.

Note: Password can be number or letter characters up to 4 digits.

4.1.9. Units Settings

This menu is used to set the units for mass flow, temperature, pressure reference and the settings

of reference temperature, reference pressure and density of gas when using Lbs/time or Kg/time.

These values will be set at FOX, using the Application Data Sheet values. If the customer changes

the application, these values can be changed to match the new application. Check with FOX

customer service before changing the application gas.

The unit setting is accessed from the base programming menu by pressing

FLO (F2) key:

Press UNT (F2) for Unit selection:

Press NXT (F1) key to change selection and OK (F4) to accept it

Page 38 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 43

101364 Model FT2

TMP UNT= Deg C

NXT OK

F1

F2

F3

F4

TmpRef = 60 C

CHG OK

F1

F2

F3

F4

Selections for Flow unit are: SCFM

SCFH

NM3/H

NM3/M

KG/HR

KG/M

KG/S

LBS/H

LBS/M

LBS/S

NLPH

NLPM

SMPS

NMPS

SFPM

MMSCFD

LBS/D

SLPM

NLPS

MSCFD

SM3/H

MT/H

NM3/D

MMSCFM

WARNING:

The FT2 re-calculates area, 4 & 20 ma values, Maximum flow for the frequency output and zero

flow cutoff when changing flow units, going to and from volumetric and mass flow. When going

to and from Velocity or velocity to velocity, the FT2 will not re-calculate these values and these

values must be re-entered manually.

After pressing OK (F4) to accept the Flow unit the display will prompt for the temperature unit

setting:

Press NXT (F1) key to change selection and OK (F4) to accept it.

Selections for Temperature unit are: DEG C

DEG F

After pressing OK (F4) to accept the temperature unit setting, the display will prompt for

temperature reference in selected unit.

Press CHG (F1) to change the reference and OK (F4) to accept it.

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 39

Page 44

Model FT2 101364

PRES UNT= mmHG

NXT OK

F1

F2

F3

F4

PresRef= 760

CHG OK

F1

F2

F3

F4

DNS = 0.988876 KG/m3

CHG OK

F1

F2

F3

F4

SET PARAMETERS

I/O FLO DSP EXIT

F1

F2

F3

F4

After pressing OK (F4) to accept the reference temperature, the display will prompt for the

pressure unit selection:

Press NXT (F1) to select next entry and OK (F4) to accept it.

Selections are: mmHG

Psia

bara

After the pressure unit selection is made, the display will show a menu to enter the pressure

reference:

Press CHG (F1) to change it and OK (F4) to accept.

After the pressure reference is accepted, the display will prompt for the gas density if LBS or KG

was selected for flow unit:

Press CHG (F1) to change and OK (F4) to accept.

Note: The density entry is only used when KG/time or LBS/time is selected for flow rate units.

Density conditions are referenced to 0 C° at 760 mmHg.

4.1.10. Flow Parameters

This is the menu used to set various flow parameter values. They are:

The menu is accessed from the base programming menu by pressing FLO (F2) key:

Page 40 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Flow cutoff, pipe area, filter, high and low alarm for flow and temperature.

Page 45

101364 Model FT2

FLOW PARAMETER 1

SIM UNT PRM EXIT

F1

F2

F3

F4

FLOW PARAMETER 2

CAL SPC PRM EXIT

F1

F2

F3

F4

CUTOFF = 2.0 SCFM

CHG OK

F1

F2

F3

F4

A^2 = 0.05672 Ft^2

CHG OK

F1

F2

F3

F4

FILTER = 0.8

CHG OK

F1

F2

F3

F4

Then press PRM (F3) key:

Note: The CAL and SPC function key will only appear and be accessible from a Level 2

password.

Then press PRM (F3) key:

Enter the value for the percent low flow cutoff and then press OK (F4) key.

When the flow rate falls below the zero flow cutoff, the flowmeter will display a flow value of

zero.

Enter the pipe area in square meters or square feet and then press OK (F4) key.

Use square meter for metric flow unit selection and square feet for English flow unit selection.

The filter value is also referred to as a dampening factor and is used to quiet the readings.

The filter value is an exponential filter that dampens the noise and is used as follows:

Flow Value = (FA * new value) + (FB * average) where

FA = filter value, FA + FB is equal to 1.0.

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 41

Page 46

Model FT2 101364

Filter

Response (sec)

(65% of target)

0.9

0.10

0.8

0.15

0.7

0.20

0.6

0.25

0.5

0.30

0.4

0.35

0.3

0.40

0.2

0.60

0.1

1.00

0.05

2.00

0.03

3.00

0.01

10.3

HiFloAlm = 1234 SCFM

CHG OK

F1

F2

F3

F4

LoFloAlm = 100 SCFM

CHG OK

F1

F2

F3

F4

HiTmpAlm = 230 C

CHG OK

F1

F2

F3

F4

For example if we enter a filter of 0.8, the weight ratio for new average is:

New average = (80% new sample) + (20% last average)

Filter range is 0.01 to 1.0, 0.01 being a high filter value and 1.0 = no filter.

Enter the filter value and then press OK (F4) key.

This is the upper flow limit alarm value that can be associated with a discrete output. An alarm

code is generated when the flow value exceeds this limit. If no checking is needed, this value

should be set to zero.

Press OK (F4) to accept the value.

This is the lower flow limit alarm value that can be associated with a discrete output. An alarm

code is generated when the flow value is below this limit. If no checking is needed, this value

should be set to zero.

Press OK (F4) to accept the value.

Page 42 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 47

101364 Model FT2

LoTmpAlm = 50 C

CHG OK

F1

F2

F3

F4

FLOW PARAMETER 2

CAL SPC PRM EXIT

F1

F2

F3

F4

Volt1 = 0.92367

CHG PRV NXT EXIT

F1

F2

F3

F4

Flo1 = 0

CHG PRV NXT EXIT

F1

F2

F3

F4

This is the upper temperature limit alarm value that can be associated with a discrete output. An

alarm code is generated when the temperature value exceeds this limit. If no checking is needed,

this value should be set to zero.

Press OK (F4) to accept the value.

This is the lower temperature limit alarm value that can be associated with a discrete output. An

alarm code is generated when the temperature value is below this limit. If no checking is needed,

this value should be set to zero.

Press OK (F4) to accept the value.

Note: If the programming menu was entered with a Level 2 password, then more menus will be

shown that deal with factory set parameters that should not be changed.

4.1.11. Calibration Parameters

This menu allows changing the factory calibrated setting of the flowmeter and is accessible with a

Level 2 password. Calibration parameters values are set for temperature and pressure at 0 degree

C and 760 mmHg.

These settings should normally never be changed except by Fox Thermal

Instrument personnel at the factory.

This menu is entered from the base menu and pressing FLO, PRM and CAL.

Press CAL (F1) then the display will show:

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 43

Page 48

Model FT2 101364

RESET TOTAL ?

NO YES

F1

F2

F3

F4

RESTORE DATABASE ?

YES NO

F1

F2

F3

F4

CalDate=2/24/03

CHG OK

F1

F2

F3

F4

Use the CHG (F1) key to change the entry, PRV (F2) to move to the previous entry, NXT (F3) to

move to the next entry and EXIT (F4) to return.

The calibration table can hold up to 20 data pair points. Each data point has a voltage and mass

velocity associated with it.

Pressing the NXT (F3) key will show the data point voltage and then mass velocity and then go to

the next data point. The number after Volt (ie.Volt1) or Flo (i.e. Flo1) indicated the data point

number.

Upon exiting the menu, the display will prompt for a calibration date as follows:

4.1.12. Reset Total and Elapsed Time

The resetting of the totalizer and elapsed time is accomplished by pressing the F3 and F4 keys at

the same time in the normal running mode.

Press YES (F4) to reset total and NO (F1) to cancel.

If you entered the programming menu with a Level 2 password,

The following menu Restore Database will be displayed:

4.1.13. Restore Database

Before restoring the factory default, please contact the Fox’s service department for advice.

Restoring the original factory settings is accomplished from the “Flow Parameter 2” menu

by entering a Level 2 password “9111” and pressing the SPC key (F2).

Page 44 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Press YES (F1) ONLY if you want to restore your database to the initial factory setting that the

meter was shipped with. All current user-entered settings will be overwritten.

The F1 key must be pressed while the push button S2 on the FT2 main board is pressed. The green

LP1 LED will flash at a faster pace until the recall is performed.

Page 49

101364 Model FT2

4.1.14. Reset CRC

If the EEPROM CRC check fails (Error Code 36), the EEPROM values will need to be verified

and corrected before clearing the error. Call FOX Customer Service if you need assistance.

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 45

Page 50

Model FT2 101364

FLOW PARAMETER 1

SIM UNT PRM EXIT

F1

F2

F3

F4

FloSim = 0 SCFM

CHG OK

F1

F2

F3

F4

TmpSim = 0 C

CHG OK

F1

F2

F3

F4

RESET CRC?

YES NO

F1

F2

F3

F4

Press YES (F1) ONLY if you want to reset the CRC and generate a new CRC value.

4.1.15. Simulation

This menu allows for the simulation of flow rate, temperature and flow input voltage. It should

only be used for testing and demonstration purposes.

Make sure to return all of these simulation values to zero, before returning to

the normal mode of operation.

Note: Simulated values are only enabled when not set to zero.

Caution:

If the 4 to 20 mA and/or the pulse outputs are connected to controllers, set the controllers to

“manual”. This will ensure that the simulated signals do not cause false controller action.

The menu is accessible from the main programming menu by pressing FLO, and SIM:

Pressing SIM (F1) will show:

Enter the value and then press OK (F4).

Note: Enter zero to disable this feature.

Enter the value and then press OK (F4).

Note: Enter zero to disable this feature.

Page 46 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 51

101364 Model FT2

CsvSim = 0 V

CHG OK

F1

F2

F3

F4

Enable SIM ?

YES NO

F1

F2

F3

F4

Enter the value and then press OK (F4).

Note: This value is used to simulate the Current Sense Voltage (CSV) and should be set to zero for

normal mode.

Press YES (F1) to start the simulation mode, NO (F4) otherwise.

Upon pressing either key, the program will return to the FLOW PARAMTER 1 menu.

NOTE: Simulation Mode will be cleared if the power is cycled.

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 47

Page 52

Model FT2 101364

5. Preventative Maintenance

Warning! Before attempting any maintenance, take the necessary safety precautions before removing the probe

from the duct (example: purge lines of toxic and/or explosive gas, depressurize, etc...)

Turn OFF input power before removing or installing a circuit board assembly from the enclosure.

5.1. Access to Electronics

After turning OFF the power, loosen the 4 captive screws from the cover plate to expose the circuit

boards. This should give access to the TS2 connector.

Caution needs to be exercised to not damage the cable connecting the LCD/Keypad board to the main

board.

5.2. Sensor Cleaning

Even though the sensor is insensitive to small amount of contamination, continued use in dirty

environments will necessitate periodic cleaning. Remove power before removing the unit from duct,

exposing the sensor elements. If they are visibly dirty, clean them with water or alcohol (ethanol)

using an artist’s brush until they appear clean again. Even though the sensor elements are rugged and

breakage resistant, avoid touching them with any solid object and use a light touch while cleaning

them.

5.3. Broken or Damaged Probe

If the sensor is broken or damaged, the probe and electronics must be returned to the factory.

A new sensor will be installed and calibrated. Refer to Section 6.2, Return Procedure.

5.4. Calibration

To insure continuing high accuracy of your Model FT2 Flow Meter, Fox Thermal Instruments Inc.

provides a full NIST traceable calibration. The minimum re-calibration interval is 2 years, unless

otherwise recommended by FOX.

5.5. Fuse Replacement (Standard and NFP version)

Warning! Turn input power OFF before removing or installing a circuit board assembly from

the enclosure and before removing or installing the fuse. Use only recommended fuse

replacements.

Verify the fuse is defective by measuring it with an Ohm Meter (Two replacement fuses are provided

with each unit).

To replace the fuse:

The fuse F1 is located on the edge of the main circuit board and can be removed by using a sharp

instrument or a small screwdriver (wrist watch type screwdriver).

Page 48 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 53

101364 Model FT2

Problem

Possible Cause

Action

Unit will not power-up

a) No power input

b) Bad fuse

c) Bad Power supply

a) Turn power on

b) Replace fuse. See section 5.5

c) Verify 24 VDC input power.

Velocity Measurement seems low

a) Probe not oriented properly

b) Sensor dirty

a) Orient probe per Section 2.2.3

b) Clean sensor. (Refer to section 5.2,

Preventative Maintenance)

Velocity measurement is erratic

or fluctuating

a) Very turbulent flow

b) Sensor dirty

c) Sensor broken

d) Probe not mounted securely

e) Malfunction in flow meter

f) Verify Installation guidelines

(see Figure 2-4).

a) Adjust dampening per section 4.1.10

b) Clean sensor (refer to section 5.2)

c) Return flow meter to Fox for repair

(refer to section 6.2 for shipping

instruction)

d) Probe must be mounted securely

without vibration

e) Return flow meter to Fox for repair

(refer to section 6.2 for shipping

instruction)

f) Install meter accordingly to

guidelines.

6. Troubleshooting

Caution! The electronics, sensor and sensor interconnect wires supplied by Fox are calibrated as a single

precision mass flowmeter. Interchanging sensors or sensor wiring will impair the accuracy of the flow meter.

If you experience any problem with your Model FT2 Flow Meter, call Fox’s Customer Service Department,

Technical Assistance at (831) 384-4300.

The following is a summary listing of problems occasionally encountered with the FT2 Thermal Mass Flowmeter

and it’s installation.

1. Inadequate power source.

For those models that are powered by 24VDC, a 24VDC 1VDC, 25-watt power supply is

recommended. If the voltage supplied is not within this range or if the power supply is not rated

for 25 watts minimum, a variety of problems can occur including inaccurate flow readings, dim

display and faulty programming action. The input voltage must be within the range of 23 to 25

VDC as measured at the power input terminals of the flowmeter electronics.

2. Improper wiring connections for power and/or 4-20mA output signal.

The FT2 requires a separate power source for the main board and the two 4-20mA output signals.

Two wires supply 24VDC power to the main board. Two wires are used for each of the 4-20 mA

output signals. Refer to Figure 3-2 and Figure 3-3.

3. Improper 4-20mA wiring.

The FT2 flowmeter can have the 4-20mA signal connected in an “isolated configuration” or “non-

isolated configuration”. In the isolated configuration, the customers signal receiving equipment

(PLC, DCS, etc.) powers the 4-20 mA loop. Refer to Figure 3-3.

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 49

Page 54

Model FT2 101364

In the non-isolated configuration, the 24 VDC power supplied to board power input connector

(TS1) can be connected to the 4-20 mA (+) input supply voltage. The 24 VDC return wire and the

(-) connection of the 4-20mA output must be connected back to the customer’s measuring device.

4. Improper sensor wiring

The FT2 monitors the sensor signals and will issue an Error Code 22 when a sensor is out of

range. If the temperature of the probe is excessive it will shut down the current to the sensor in

order to protect it. The display indicating flow may fluctuate on and off from 0 to some value

every ten seconds.

5. Flow measurement seems inaccurate.

Ensure that the flowmeter is installed so that the Flow Direction Arrow engraved on the flat

surface of the fitting below the electronics housing is properly pointing in the direction of flow.

Refer to Figure 2-6.

If you have a Fox Insertion Flowmeter, verify that the insertion depth of the sensor/probe is

correct. The end of the probe should be adjusted as per section 2.2.2. Refer to Figure 2-1.

Ensure there is a minimum of ten diameters of straight pipe upstream of the sensor and five

diameters downstream. If complex flow disturbances are upstream of the sensor, extension of the

straight pipe may be required. Contact Fox for assistance.

The internal cross sectional area of the pipe is programmed into the flowmeter through the front

panel (see section 4.1.10 Flow Parameters). This area is programmed in square feet or square

meters. The Calibration Certificate delivered with the flowmeter contains the area that was

programmed into the flowmeter at the Fox factory. Verify that this area was entered correctly.

6. Erratic flow reading especially a flow reading spiking high.

This is a symptom of moisture in the flow stream. Fox flowmeters are designed to work in

relatively dry gas applications only. Contact Fox to discuss resolutions to this problem.

7. The FT2 flowmeter is not responding to flow.

This problem could be caused by a number of items. First check to ensure adequate power is

supplied to the flowmeter as described above. If things appear to be correct, an easy functional test

can be performed. Carefully remove the probe and sensor from the pipe or flow body. Caution:

the sensor is HOT. For flowmeters with a display is reading zero, blow on the sensor to see if a

response occurs. If nothing happens, take a damp rag or sponge and place it in contact with the

sensor. A reading should occur. Contact Fox Customer Service with this information.

8. Display and/or 4-20mA signal reading above zero flow when no flow is occurring in the pipe.

If the reading is less than 5% of full scale, it is likely this is a normal condition caused by

convection flow created by the heated sensor. It does not mean that the zero of the instrument is

improperly set. The Fox sensor is extremely sensitive to gas flow and can even read the small

flow caused by convection. If this is an unacceptable condition, please contact Fox Customer

Service for alternatives.

6.1. Replacements Parts

F1 – Fuse. FOX Part Number 100045. Digi-Key Part Number F1142CT-ND.

Front Panel Display Module.

Page 50 Fox Thermal Instruments, Inc., 399 Reservation Road, Marina, CA 93933

Page 55

101364 Model FT2

6.2. Return Procedure

The Fox Thermal Instruments, Inc. Customer Service Department can be reached at (831) 384-4300.

Please have the model and serial number available when you call.

If it becomes necessary to return a Model FT2 Mass Flow Meter to Fox Thermal Instruments, obtain a

Return Material Authorization Number from Customer Service Department.

Unless specially instructed to do otherwise, the entire flow meter must be returned, including all

electronics.

Clean and decontaminate all wetted parts.

Please include information describing the difficulties experienced, purchase order number under which

the equipment was purchased, and a contact name and phone number.

Be sure to include complete return shipping instructions. We cannot deliver to post office boxes.

Ship to the following address:

Fox Thermal Instruments, Inc.

399 Reservation Road

Marina, CA 93933

Attn: Service Dept.

RMA Number

Fox Thermal Instruments Inc., 399 Reservation Road, Marina, CA 93933 Page 51

Page 56

Model FT2 101364

Warranty

a. FOX warrants that the products furnished under this Agreement will be free from defects

in material and workmanship for a period of one year from the date of shipment. The

customer shall provide notice of any defect to FOX, within one week after the Customer’s

discovery of such defect. The sole obligation and liability of FOX under this warranty

shall be to repair or replace, at its option, without cost to the Customer, the defective

product or part.

b. Upon request by FOX, the product or part claimed to be defective shall immediately be

returned at the Customer's expense to FOX. Replaced or repaired products or parts will be

shipped to the Customer at the expense of FOX. FOX shall have the right of final

determination as to the existence and cause of defect.

c. There shall be no warranty or liability for any products or parts that have been subject to

misuse, accident, negligence, failure of electric power or modification by the Customer

without the written approval of FOX. This warranty does not cover damage caused by

Customer’s exposure of the goods to corrosive or abrasive environments. Final

determination of warranty eligibility shall be made by FOX. If a warranty claim is

considered invalid for any reason, the Customer will be charged for services performed and

expenses incurred by FOX in handling and shipping the returned unit.

d. The liability of FOX shall be limited to replacing or repairing, at its option, any defective

parts which are returned. Labor and related expenses incurred by the Customer to install