Page 1

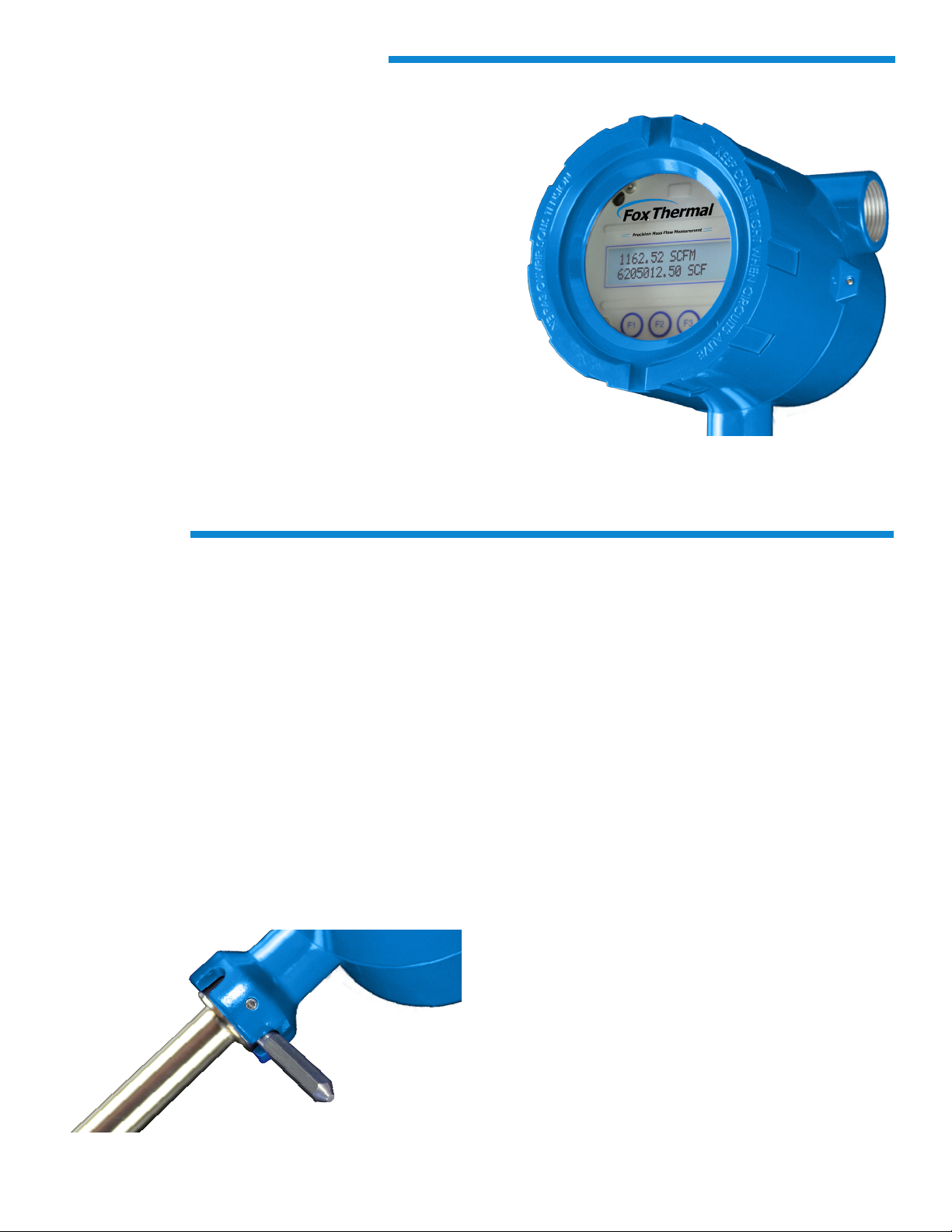

Model FT1 Gas Mass Flow Meter

Model

Thermal Mass

Flow Meter &

Temperature

Transmitter

Precision Mass Flow Measurement

An ON

I

CON Brand

For Industrial & Wastewater

Applications

• 2nd Generation DDC-Sensor™:

Robust, non-cantilevered design

• Gas-SelectX®: menu of field

selectable gas compositions

• CAL-V™ Calibration Validation

• Insertion and Inline styles

• Measures gas flow rate in SCFM,

MSCFD, KG/HR, & many more

• Wide measurement range: up to

1000:1 turndown; 100:1 typical

• 4-20mA for flow rate or temperature;

HART communication option

• Choice of second output: pulse

output for flow/total, Modbus RTU

(RS485), or BACnet MS/TP (RS485)

• USB port to connect to a PC, standard

• Free FT1 View™ Software available

• Welded, 316 SS sensor and flow body

construction, carbon steel flow body

optional

• Microprocessor based, fieldprogrammable electronics

• Optional on-board 2 line x 16

character, backlit display with

configuration panel

• NIST traceable calibration

• Low-end sensitivity for leak detection

• Negligible pressure drop

• FM (U.S.) & FMc (CANADA) approved

for Class I, Div 1; ATEX/IECEx

approved for Zone 1

• NEMA 4X and CE Mark

• 2015 Flow Control Innovation Award

Winner

• Processing’s 2015 Breakthrough

Product Award Winner

FOX THERMAL

399 RESERVATION ROAD

MARINA, CA 93933

PHONE: 831-384-4300

FAX: 831-337-5786

sales@foxthermal.com

www.foxthermal.com

F T 1

Innovation

2015

Innovation

2015

WINNER

WINNER

DDC-Sensor™ Technology

The Fox Thermal DDC-Sensor™ is a state-of-the-art sensor technology

used in the Fox Thermal Model FT1 Thermal Gas Flow Meter. The

DDC-Sensor™, a Direct Digitally Controlled sensor, is unlike other

thermal flow sensors available on the market. Instead of using

traditional analog circuitry, the DDC-Sensor™ is interfaced directly to

the FT1 microprocessor for more speed and programmability. The

DDC-Sensor™ accurately responds to changes in process variables

(gas flow rate, pressure, and temperature) to determine mass flow rate,

totalized flow, and temperature.

Fox Thermal’s DDC-Sensor™ provides a technology platform for

calculating accurate gas correlations. The FT1 correlation algorithms

allow the meter to be calibrated on a single gas in the factory while

providing the user the ability to select other gases in the Gas-SelectX®

menu. With its DDC-Sensor™ and advanced correlation algorithm, the

FT1 is a precision, multi-gas-capable thermal gas flow meter.

Gas-SelectX® Gas Selection Menu

Process Engineers need a fast solution to their monitoring needs. For

these cases, Fox Thermal has developed the Gas-SelectX® gas menu

feature for the Model FT1 flow meter. Gas-SelectX® allows the user

to choose from a menu of several common gases or gas mixtures for

their application. Available gases: Air, Argon, Butane, Carbon Dioxide,

Ethane, Methane, Natural Gas (NAESB composition), Nitrogen, Oxygen,

Helium, Hydrogen, Propane, & gas mix (any five gases in this list to

create a custom gas composition totalling 100%).

The meter’s proprietary algorithms allow the user to switch gases

or gas mixes in the field, as needed. This makes the FT1 ideal for

measurement of Digester Gas, Liquefied Petroleum Gas (LPG) and a

variety of other biogases. Whether you need to measure natural gas or

air, CO2 or digester gas, the FT1 brings these options and more to the

user with a push of a button.

Page 2

THERMAL MASS TECHNOLOGY

Fast and Flexible Gas Flow

Measurement

The Model FT1 thermal mass flow meter and temperature

transmitter can be used in a large variety of industrial and

commercial gas flow measurement applications. The FT1

offers the flexibility to monitor multiple gas types at the

push of a button, rotate the housing as needed for tight

installations, and configure meter settings from advanced

software.

Theory of Operation

Fox Thermal flow meters use a constant temperature

differential (constant Δ T) technology to measure the mass

flow rate of gases. The thermal mass flow sensor consists

of 2 Resistance Temperature Detectors (RTD’s).

The Reference RTD measures the gas temperature.

Meanwhile, the instrument electronics heat the mass flow

sensor, or heated element, to a constant temperature

differential (constant Δ T) above the gas temperature and

measures the cooling effect of the gas flow. The electrical

power required to maintain a constant temperature

differential is directly proportional to the mass flow rate of

the gas.

The Model FT1 flow meter and temperature transmitter is

approved for FM/FMc Class I, Division 1, ATEX/IECEx Zone 1.

CE Mark.

MODEL FT1

Fox Thermal Model FT1 Thermal Gas

Mass Flow Meter Features

The Fox Thermal Model FT1 measures gas ow rate in

standard units without the need for temperature or

pressure compensation. It provides an isolated 4-20mA

output (with a HART option) and a selection of pulse,

Modbus RTU (RS485), or BACnet MS/TP (RS485) for a

second output.

With an optional on-board 2-line x 16-character backlit

display, operators can view ow rate, total, elapsed time,

process gas temperature, and alarms. The display is also

used in conjunction with the Conguration Panel to access

ow meter settings, such as 4-20mA and pulse output

scaling, pipe diameter, zero ow cutoff, ow ltering

(damping), display options, and high or low alarm limits.

The Model FT1 is available in insertion and inline styles.

The insertion style FT1 has a robust stainless steel

probe and is easily installed by drilling a hole in the

pipe and welding on a 1” NPT coupling. A Fox Thermal-

supplied compression tting secures the probe in place.

It is supplied with 316 stainless steel wetted materials

standard. Inline styles of the FT1 are available in both

stainless steel and carbon steel with NPT and 150lb ange

options. See Specication section for details on sizing. A

USB port to connect to a computer or laptop is standard;

interface options include HART, Modbus RTU (RS485) and

BACnet MS/TP (RS485).

Fox Thermal has certied cleaning and bagging

procedures for ow meters to be used in oxygen

applications.

Advanced Features

Suitable for harsh and hazardous environments, the

instrument features:

• Robust DDC-Sensor™ Design

• Gas-SelectX® with a selection of pure gases or a

gas mix up to five gases

• CAL-V™ Calibration Validation

• Rotatable probe: allows ±180 degree swivel

• FM/FMc, ATEX, IECEx approvals. CE mark.

• 10-30VDC power input, standard

• NIST-traceable calibration

• Free FT1 View™ Software

• High and low alarm limits

• Wetted materials are all welded, 316 stainless steel

The DDC-Sensor™ allows the user to swivel the probe ±180°

into four positions.

Perfect for commercial and industrial applications, the

Model FT1 is a superior flow measurement instrument

with excellent accuracy!

Page 3

ADVANCED FEATURES

CAL-V™

For customers that need a quick and easy way to verify the

calibration of the meter in the field, the Model FT1 offers

the CAL-V™ feature. This feature can be initiated through

the meter’s optional display configuration panel or the FT1

View™ Software. The test takes fewer than 5 minutes to

run and produces a pass/fail result at the conclusion of the

test. A fail result may indicate either a dirty sensor or the

need to recalibrate.

If the CAL-V™ test is performed using the FT1 View™

software, a Calibration Validation Certificate can be

produced at the conclusion of the test. The certificate

will show the date and time of the test along with meter

data such as firmware version and meter serial number.

This in situ calibration validation helps operators comply

with environmental mandates and eliminates the cost and

inconvenience of annual factory calibration.

FT1 View™ Software

Fox Thermal has developed advanced software - FT1

View™ - a free PC-compatible application available for

download from the Fox Thermal website. Connect your

laptop, PC, or control station to the meter using the USB

port interface to access the meter’s data and configure the

meter’s settings.

FT1 View™ allows:

• Quick access to all configuration parameters with

pop-up windows and pull down menus

• Selection of measurement units, flow and

temperature ranges, alarm settings and more

• Print or save a CAL-V™ Calibration Validation

Certificate

• Set alarms; display alarm codes

• Storage of meter configurations to a file that can be

archived

• Simulation mode used to align 4-20mA output with

the input to customer’s PLC/DCS

• Raw data to be viewed in order to diagnose or

troubleshoot your meter

• Data logging to an Excel® spreadsheet

Approvals

CE Mark: Approved

EMC Directive: 2014/30/EU

Electrical Equipment for Measurement, Control, and Lab

Use: EN61326-1:2013

EU Directive: 2014/68/EU

Weld Testing: EN ISO 15614-1 and EN ISO 9606-1, ASME

B31.3

FM (FM16US0005X) & FMc (FM16CA0005X): Approved

Class I, Division 1, Groups B, C, D;

Class II, Division 1, Groups E, F, G;

Class III, Division 1; T4, Ta = -40˚ to 70˚C;

Class I, Zone 1, AEx/Ex db IIB + H2 T4; Gb Ta = -40˚C to

70˚C;

Type 4X, IP66/67

ATEX (FM16ATEX0013X): Approved

II 2 G Ex db IIB + H2 T4; Gb Ta = -40˚C to 70˚C; IP66/67

II 2 D Ex tb IIIC T135˚C; Db Ta = -40˚C to 70˚C; IP66/67

IECEx (IECEx FMG 16.0010X): Approved

Ex d IIB + H2 T4; Gb Ta = -40˚C to 70˚C; IP66/67

Ex tb IIIC T135˚C; Db Ta = -40˚C to 70˚C; IP66/67

APPROVALS & SPECIFICATIONS

Performance Specs

Flow Accuracy:

Air: ±1% of reading ±0.2% of full scale

Other gases: ±1.5% of reading ±0.5% of full scale

Accuracy specification applies to customer’s selected

flow range

Maximum range: 15 to 25,000 SFPM (0.07 to 120 NMPS)

Minimum range: 15 to 500 SFPM (0.07 to 2.4 NMPS)

Straight, unobstructed pipe requirement:

Insertion: 15 diameters upstream; 10 downstream.

Inline: 8 diameters upstream; 4 downstream.

Flow Repeatability: ±0.2% of full scale

Flow Response Time: 0.8 seconds (one time constant)

Temperature Accuracy: ±1° F (±0.6° C)

Calibration:

Factory Calibration to NIST traceable standards

CAL-V™: In-situ, operator-initiated calibration validation

ATEX and IECEx Standards:

EN 60079-0:2012 + A11:2013 IEC 60079-0:2011

EN 60079-1:2014 IEC 60079-1:2014

EN 60079-31:2014 IEC 60079-31:2013

EN 60529:1991 + A1:2000 IEC 60529:2001

Precision Mass Flow Measurement

An ON

I

CON Brand

Page 4

SPECIFICATIONS

Operating Specs

Gas-SelectX® Gas Selections:

Air, Argon, Butane, Carbon Dioxide, Ethane, Methane, Natural

Gas (NAESB gas composition), Nitrogen, Oxygen, Helium,

Hydrogen, Propane, 5-gas mix (any five gases in this list

equalling 100%). See the Fox Thermal website for more

information on current gases.

Gas Pressure (maximum; at 100°F):

Insertion: 740 psig (51 barg)

316 SS inline w/NPT ends: 500 psig (34 barg)

316 SS inline w/150lb flanges: 230 psig (16 barg)

CS inline w/NPT ends: 500 psig (34 barg)

CS inline w/150lb flanges: 285 psig (20 barg)

Retractor: 150 psig (10.3 barg)

Notes:

• Check with factory for higher pressure options.

• With Teflon Ferrule option (P/N 106415), maximum gas

pressure is 60 psig (4.1 barg).

• Pressure ratings for temperatures up to 100°F (38°C).

Temperature:

DDC-Sensor™: -40 to 250°F (-40 to 121°C)

Enclosure: -40 to 158°F (-40 to 70°C)**

**NOTE! Display dims below -4˚F (-20˚C); function returns once

temperature rises again.

Flow Velocity Range: 15 to 25,000 SFPM at 70°F (0.07 to 120

NMPS at 0°C)

Turndown: up to 1000:1; 100:1 typical

Flow Ranges - Insertion Meters

Pipe Diameter SCFM MSCFD NM3/H

1.5" (40mm) 0 - 354 0 - 510 0 - 558

2" (50mm) 0 - 583 0 - 840 0 - 920

2.5” (63mm) 0 - 830 0 - 1,310 0 - 1,200

3" (80mm) 0 - 1,280 0 - 1,840 0 - 2,020

4” (100mm) 0 - 2,210 0 - 3,180 0 - 3,480

6" (150mm) 0 - 5,010 0 - 7,210 0 - 7,910

8" (200mm) 0 - 8,680 0 - 12,500 0 - 13,700

10" (250mm) 0 - 13,600 0 - 19,600 0 - 21,450

12" (300mm) 0 - 19,400 0 - 27,900 0 - 30,600

NOTE! To determine if the FT1 will operate accurately in other pipe sizes,

divide the maximum ow rate by the pipe area. The application is acceptable

if the resulting velocity is within the velocity range above. Check Fox Thermal

website for velocity calculator.

Flow Ranges - Inline Meters

Pipe Diameter SCFM MSCFD NM3/H

0.75” 0 - 93 0 - 134 0 - 146

1” 0 - 150 0 - 216 0 - 237

1.25” 0 - 260 0 - 374 0 - 410

1.5" 0 - 354 0 - 510 0 - 558

2" 0 - 583 0 - 840 0 - 920

2.5” 0 - 830 0 - 1,310 0 - 1,200

3" 0 - 1,280 0 - 1,840 0 - 2,020

4” 0 - 2,210 0 - 3,180 0 - 3,480

6" 0 - 2,500 0 - 3,600 0 - 3,950

NOTE! Consult factory for ow ranges above those listed. Inline meters above

2,500 SCFM (3,950 NM3/H) may require third party calibration. Contact Fox

Thermal.

Relative Humidity: 90% RH maximum; non-condensing

Units of Measurement (field-selectable):

SCFM, SCFH, NM3/M, NM3/H, NM3/D, NLPS, NLPM, NLPH, MCFD,

MSCFD, SCFD, MMSCFD, MMSCFM, SM3/D, SM3/H, SM3/M, LB/S,

LB/M, LB/H, LB/D, KG/S, KG/M, KG/H, SLPM, MT/H

Input power: 12 to 28 VDC, 6 watts max.

Full input power range: 10 to 30 VDC.

A 20 Watt or greater power supply is recommended to power

the FT1

Outputs:

Channel 1: Standard isolated 4-20mA output for ow or

temperature; fault indication per NAMUR NE43; HART

communication option.

Channel 2: Option of a) pulse output or b) Serial

Communication (Modbus RTU (RS485) or BACnet MS/TP

(RS485))

Isolated pulse output: 5 to 24VDC, 20mA max., 0 to 100Hz

for ow (the pulse output can be used as an isolated solid

state output for alarms).

Serial Communication:

USB connector for connecting to a laptop or computer is

standard.

Optional isolated communication outputs: Modbus RTU

(RS485), BACnet MS/TP (RS485).

Free PC-based software tool - FT1 View™ - provides

complete conguration, remote process monitoring and

data logging functions.

4-20mA and Pulse Verication:

Simulation mode used to align 4-20mA output and pulse

output (if ordered) with the input to user’s PLC/DCS.

Physical Specs

Probe diameter: ¾”

Sensor Material: 316 stainless steel

Enclosure: NEMA 4X, aluminum, dual ¾” FNPT conduit entries.

Fox Thermal recommends the following probe lengths

(assuming no insulation around pipe):

Pipe Diameter Probe Length

1.5" (40mm) to 6" (150mm) 6-inch

8" (200mm) to 12" (300mm) 9-inch

14" (350mm) to 18" (450mm) 12-inch

Use equation below for selecting probe length of larger pipe sizes

Probe Lengths (LL*) in inches (cm) =

6.0 (15.2) 9.0 (22.9) 12.0 (30.5)

15.0 (38.1) 18.0 (45.7) 24.0 (61.0)

30.0 (76.2) 36.0 (91.4)

*See dimensional drawings on Fox Thermal website.

Dimensional

Refer to dimensional drawings on Fox Thermal website.

Equation for Selecting Probe Length

Probe length = ½ pipe ID (in inches) + 3” + thickness of

insulation (if any). Round up to the next standard probe length

available.

FT1 Rev. M

Loading...

Loading...